Page 1

REFRIGERATOR

Contents

1. Product Specification 2

2. Safety Warning & Caution 3

3. Specification of Electric Components 5

4. Circuit Diagram 7

5. Dimension & Part Name of Refrigerator 9

6. Freezing Cycle & Cold Air Circulation

Course in Refrigerator 15

7. Function & Operating Instruction of Refrigerator 17

8. Operating Principle of Circuit 26

9. Trouble Checkup & Repair Method 34

10. Operation Principle & Repair Method of ICE-MAKER 50

11. Reference 55

12. Disassembly Method of Freezer & Refrigerator 60

13. Method of Hinge up Assembly & Disassembly 63

14. Refrigerator Exploded view & List 64

15. Machine Room Assembly Specification 89

16. Disassembly & Assembly Method of Internal Part of

Electric Field Box 90

17. Installation Method of Water Supply Tube 91

18. Installation of the Water Dispenser Line 92

19. PCB Circuit Diagram and Service Components List 93

20. Specification of Principal Part of Circuit 94

Model :

SR-S2026C(D)SR-S2226C(D

)

SR-S2027C(D)SR-S2227C(D

)

SR-S2028C(D)SR-S2228C(D

)

SR-S2029C(D)SR-S2229C(D

)

SR-S2025C(D)

SR-S20NTC(D) SR-S22NTC(D)

SR-S20BTC(D) SR-S22BTC(D)

SR-S20DTC(D) SR-S22DTC(D)

SR-S20FTC(D) SR-S22FTC(D)

SR-S20YTC(D)

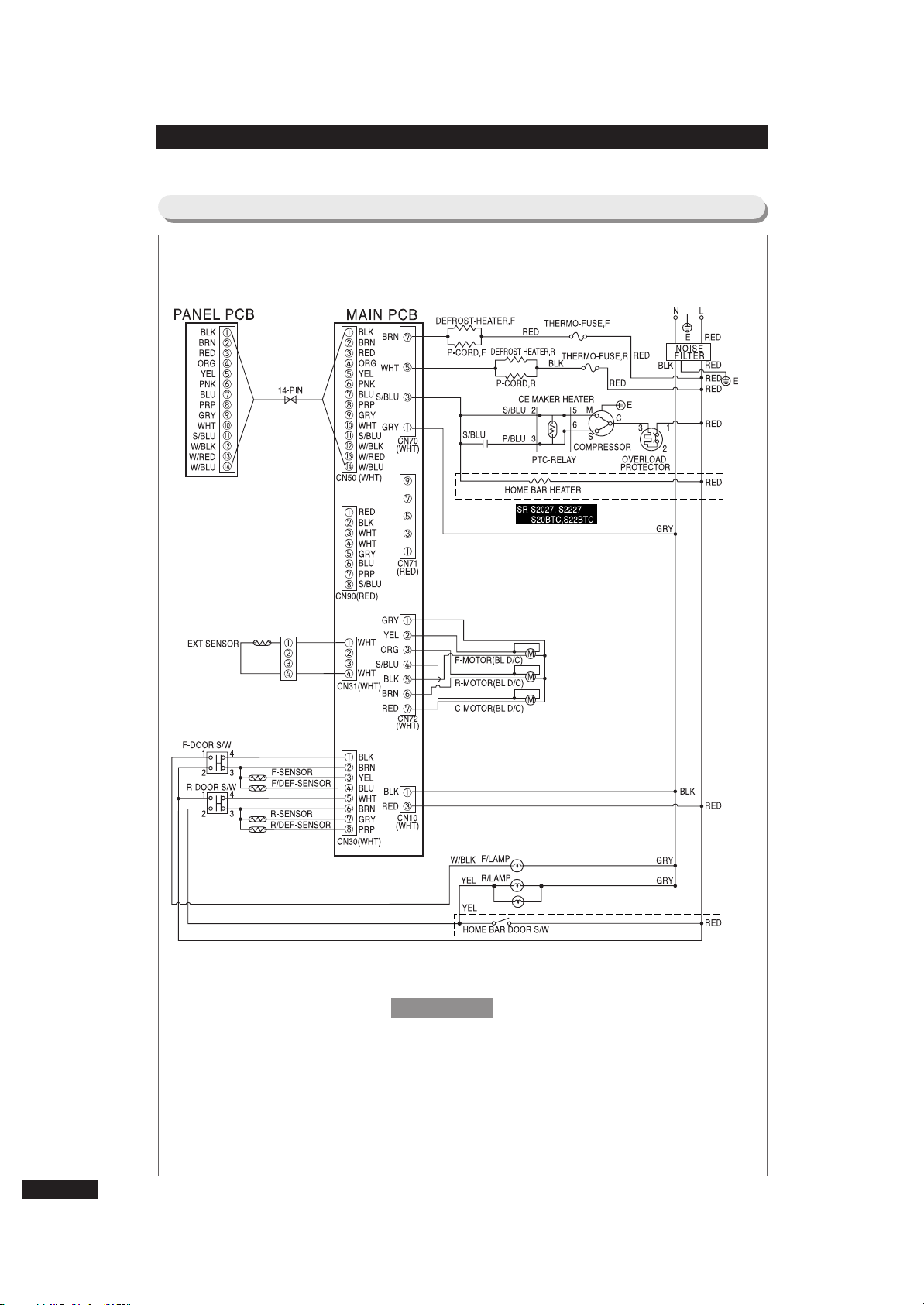

Page 2

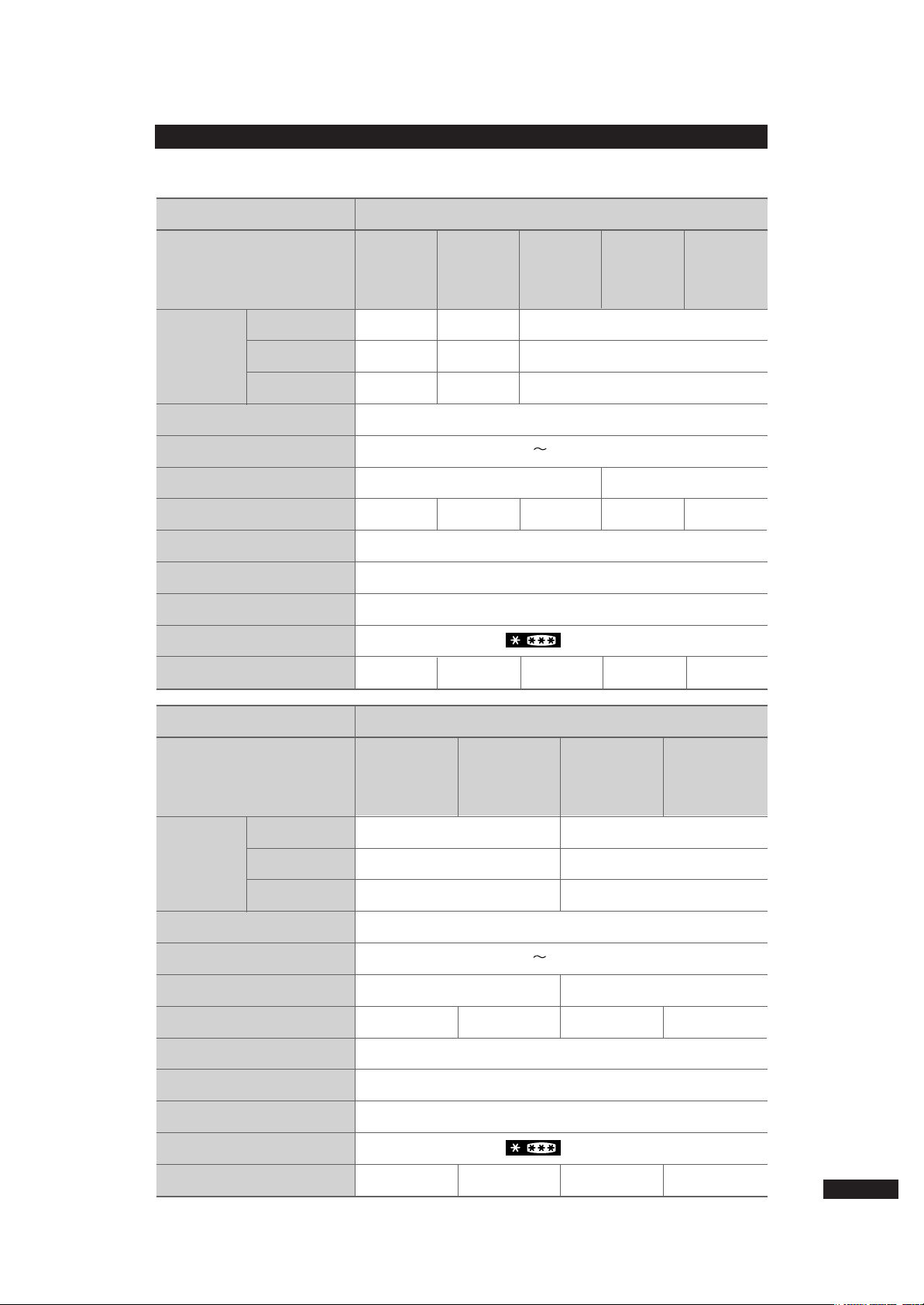

1. Product Specifications

2

562l

349l

213l

547l

336l

211l

540l

349l

191l

155W 160W

400W 410W 412W 412W 422W

111Kg 111Kg 117Kg 117Kg

Indirect Cooling Method Refrigerator

HFC-134a

190gr

(4-STAR)

908mm ✕719(724)mm ✕1760mm

230 240V/50Hz

SR-S2026C(D)

SR-S20NTC(D)

Basic

SR-S2025C(D)

SR-S20YTC(D)

Water Dispenser

SR-S2027C(D)

SR-S20BTC(D)

Basic

&

H/B

SR-S2028C(D)

SR-S20DTC(D)

Dispenser

SR-S2029C(D)

SR-S20FTC(D)

Dispenser & H/B

NNeett ddiimmeennssiioonn((WW××HH××DD))

Rated Frequency and Frequency

Motor Rated Consumption Power

Electric Heater Rated Consumption Power

Kind of Refrigerator

Refrigerant

Refrigerant Input Amount

Freezer Performance

Product Weight

Item

Specification

NNeett CCaappaacciittyy

TToottaall

RReeffrriiggeerraattoorr

FFrreeeezzeerr

MMooddeell

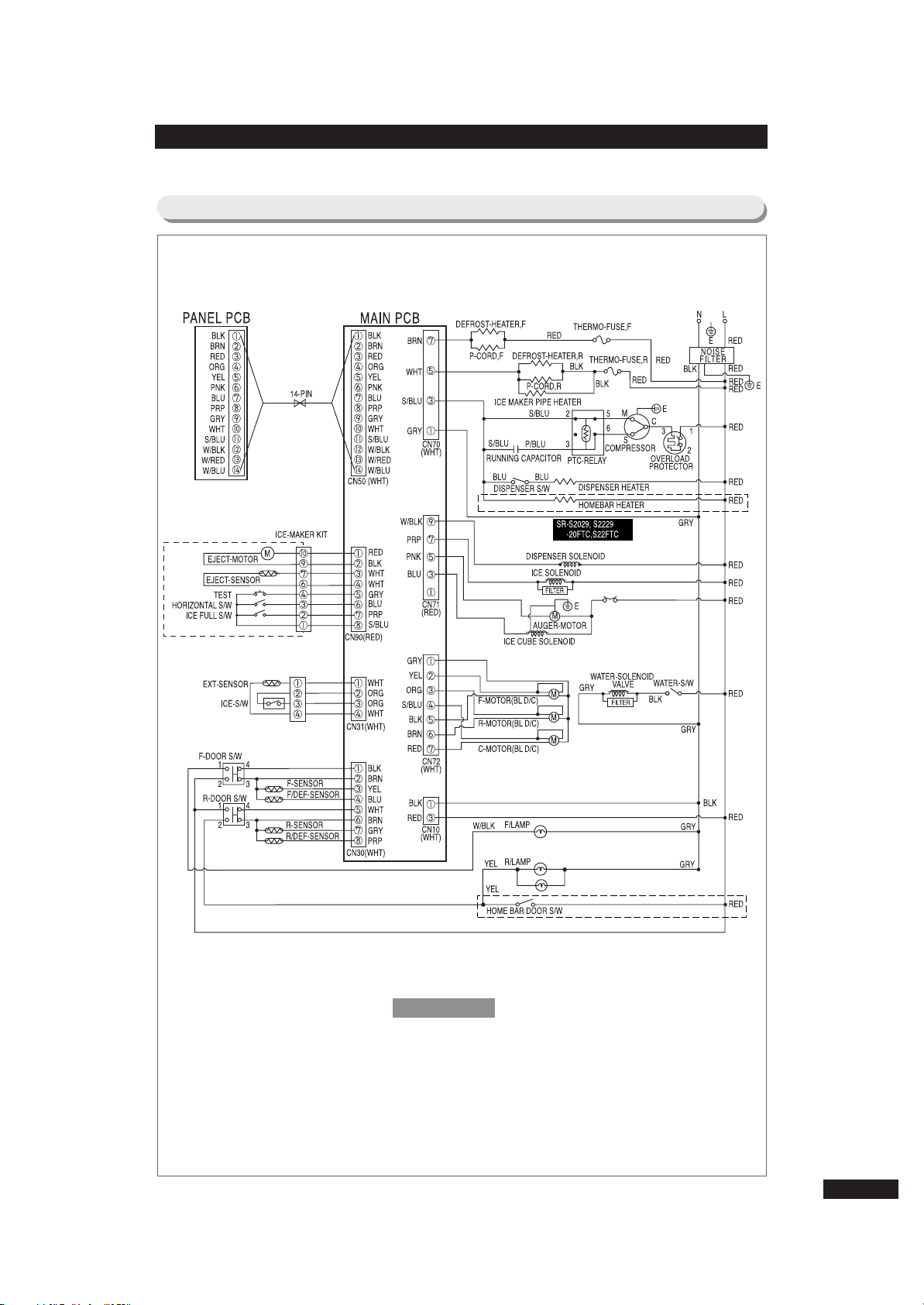

599l

227l

372l

569l

197l

372l

155W 160W

400W 410W 412W 422W

121Kg 121Kg 127Kg 127Kg

Indirect Cooling Method Refrigerator

HFC-134a

190gr

(4-STAR)

908mm ✕754(759)mm ✕1760mm

230 240V/50Hz

SR-S2226C(D)

SR-S22NTC(D)

Basic

SR-S2227C(D)

SR-S22BTC(D)

Basic

&

H/B

SR-S2228C(D)

SR-S22DTC(D)

Dispenser

SR-S2229C(D)

SR-S22FTC(D)

Dispenser & H/B

Outer Size (width ✕ depth ✕ height)

Rated Frequency and Frequency

Motor Rated Consumption Power

Electric Heater Rated Consumption Power

Kind of Refrigerator

Refrigerant

Refrigerant Input Amount

Freezer Performance

Product Weight

Item

Specification

Net Inside

Capacity

Total Inside Capacity

Freezer

Refrigerator

Model Name

Page 3

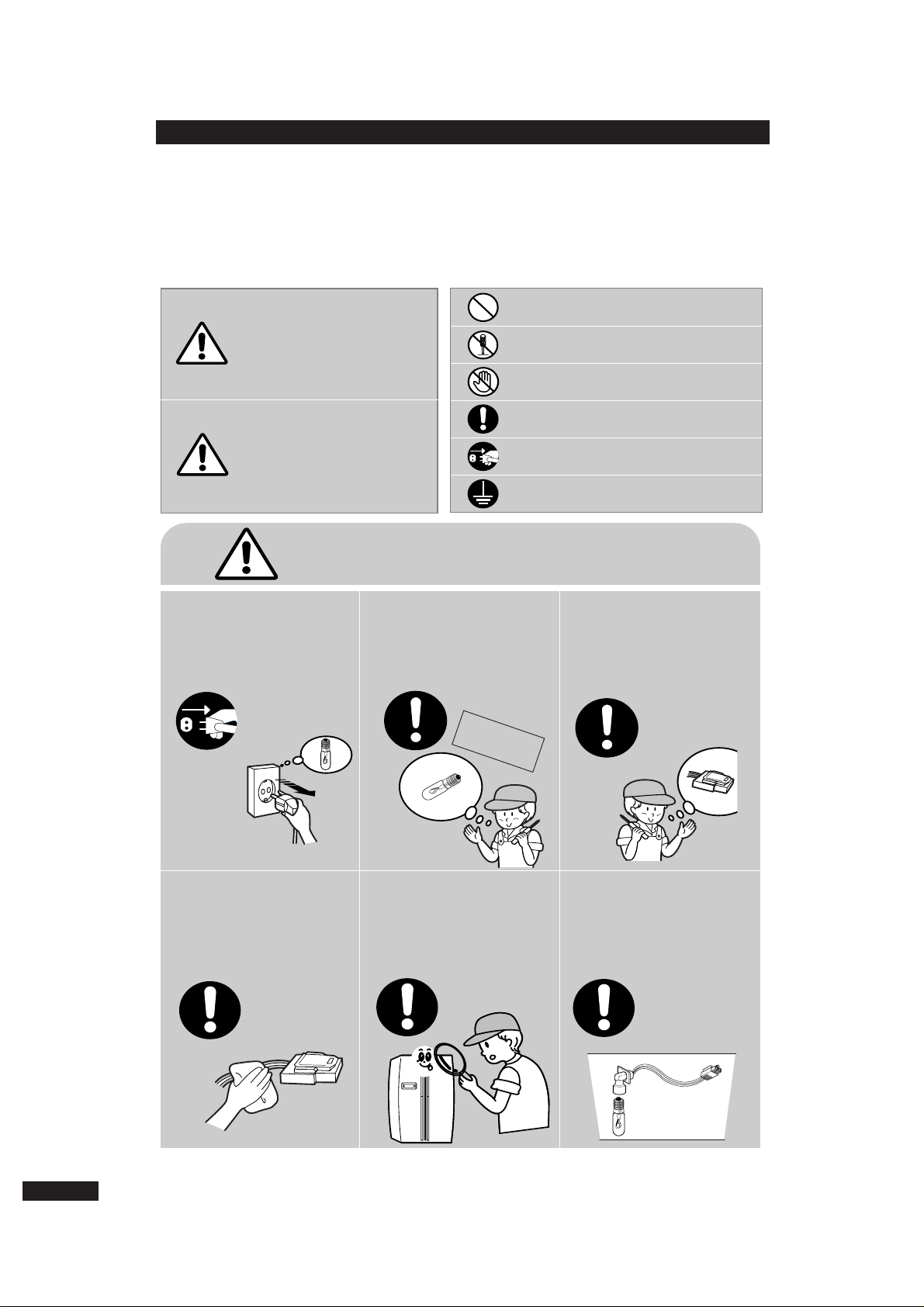

Read all instructions before using this product and keep to the instructions

in order to prevent danger or property damage.

2. SAFETY WARNINGS

CAUTION/WARNING SYMBOLS DISPLAYED

SYMBOLS

Indicates that a

danger of death

or serious injury

exists.

Indicates that a risk

of personal injury

or material damage

exists.

means “Prohibition”.

means “Do not disassemble”.

means “No contact”.

means ”The things to

be followed”.

means “Earth to prevent Electric

shock”.

means “Power cord should be

unplugged from the consent”

Pull the power plug out to

exchange the interior lamp

of the refrigerator.

●●

It may cause electric shock.

Use the rated components

on the replacement.

●●

Check the correct model,rated

voltage,rated current,operating

temperature and so on.

On repair,make sure that the

wires such as harness are

bundled tightly.

●●

Bundle tightly wires in order not to

be detached by the external force and

then not to be wetted.

On repair,remove completely

dust or other things of

housing parts,harness parts,

and check parts.

●●

Cleaning may prevent the possible

fire by tracking or short.

After repair,check the

assembled state of

components.

●

It must be in the same assembled

state when compared with the state

before disassembly.

Check if there is any trace

indicating the permeation

of water.

●●

If there is that kind of trace,change

the related components or do the

necessary treatment such

as taping using the

insulating tape.

Warning

Warning & Caution

Caution

Unplug

3

Rated

components

Page 4

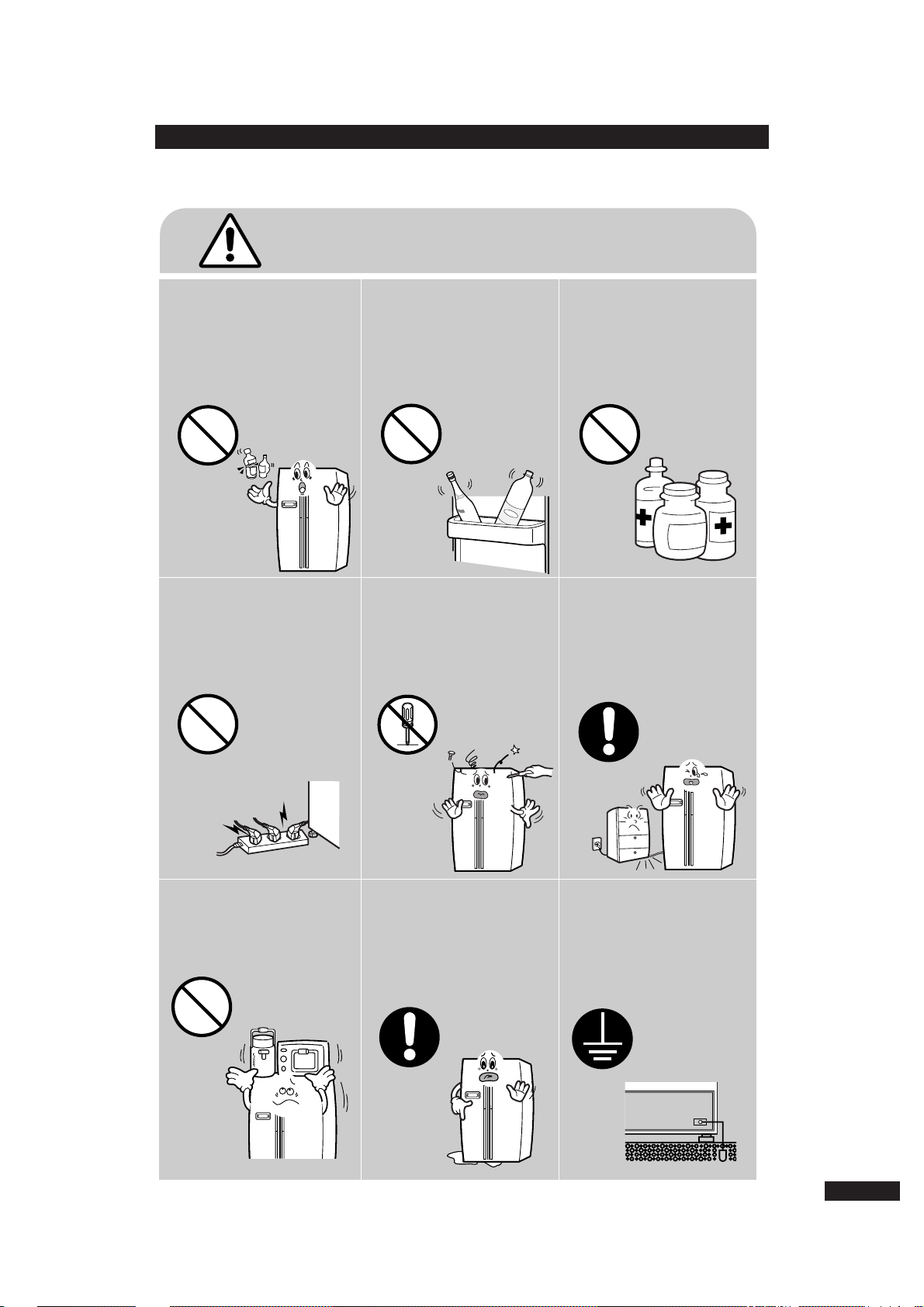

4

Do not allow users to put

bottles or kinds of glass in

the freezer.

●●

Freezing of the contents may inflict a

wound.

❈

Place let users know in detail.

Do not allow users to store

narrow and lengthy bottles

or foods in a small multipurpose room.

●●

It may hurt users when refrigerator

door is opened and closed resulting in

falling stuff down.

Do not allow users to store

pharmaceutical products,

scientific materials,

etc., in the refrigerator.

●●

The products which temperature

control should not be stored in the

refrigerator.

Do not allow users to insert

the power plugs for many

products at the same time.

●●

May cause abnormal generation of

heat or fire.

Do not allow users to

disassemble, repair or alter.

●●

It may cause fire or abnormal

operation which leads to injury.

Do not allow users to bend

the power cord with

excessive force or do not

have the power cord pressed

by heavy article.

●●

May cause fire.

Make sure of the earth.

●●

If earthing is not done, it will cause

breakdown and electric shock.

Do not allow users to install

the refrigerator in the wet

place or the place which

water splashes.

●●

Deterioration of insulation of

electric parts may cause electric

shock or fire.

Do not allow users to store

articles on the product.

●●

Opening or closing the door may

cause things to fall down, with may

inflict a wound.

Warning & Caution

Prohibition

Prohibition

Prohibition

Prohibition

Prohibition

Do not

disassemble

Earth

Page 5

THERMISTOR

(R-SENSOR)

502A T

Models

Freezing Capacity

Condenser

Dryer

Capillary tube

Refrigerant

SR-S20..∼SR-S22..

(4 STAR)

FREOL α- 15 (ESTER)

SPLIT FIN TYPE

SPLIT FIN TYPE

Forced and natural convection type

Molecular sieve XH-9

0.82×3000, 5.5 Kg/cm

2

HFC-134a

ON(℃) OFF(℃)

-25.0 -27.0

-19.0 -21.0

-13.0 -15.0

ON(℃) OFF(℃)

0.0 -2.0

4.0 2.0

8.0 6.0

4 hr ± 10 min

12 ~ 24 hr (vary according to the conditions used)

6 ~ 12 hr (vary according to the conditions used)

10 ± 2 min

THERMISTOR (502AT)

5.0㏀ at 25℃

THERMISTOR (502AT)

5.0㏀ at 25℃

AC 250V 10A

77 ± 4℃

Items Specification

Components for Freezer

Room Temperature Sensor Components

Freezer

Model

Temperature Selection

-26℃

-20℃

-14℃

THERMISTOR

(F-SENSOR)

502A T

Model

Temperature Selection

-1℃

3℃

7℃

Refrigerator

Defrost Cycle

Defrost Sensor

F Defrost-

Sensor

R Defrost-

Sensor

Thermal-Fuse

First Defrost Cycle (Concurrent defrost of F and R)

Defrost Cycle(FRE)

Defrost Cycle(REF)

Pause time

Model

SPEC

Model

SPEC

Rated

Operating temperature

Defrost Related Components

Compressor

Model

Starting type

Oil Charge

Evaporator

Freezer

Refrigerator

DK182Q-L2U

R.S.C.R

3. Specifications of Electric Components

5

Page 6

Electric Components

230 W

110 W

41 W

25 W

-

-

-

10W

5W

-

5W

10W

230 W

110 W

41 W

25 W

SR-S2029, S2229

SR-S20FTC,S22FTC

SR-S2028, S2228

SR-S20DTC,S22DTC

AC 250V 10A 72±4℃

Specifications

Items

Model

Conducting at F Defrosting

Conducting at R Defrosting

Conducting at F Defrosting

Conducting at R Defrosting

Interlock with F-FAN

Interlock with COMP

Defrost-Heater(FRE)

Defrost-Heater(REF)

DRAIN Heater(FRE)

DRAIN Heater(REF)

DISPENSER Heater

HOME-BAR Heater

Condenser for

COMP

(Package type)

Running

Starting

Model

Operation

Model

Temp. ON

Temp. OFF

Starting-Relay

Over-load Relay

MOTOR-BLDC(FRE)

MOTOR-BLDC(REF)

MOTOR-BLDC (Circuit)

Lamp(FRE)

Lamp(REF)

Door Switch

Door Switch (HOME-BAR)

Dispenser Switch

Power cord

Earth Screw

Thermal-Fuse for preventing

overheating of Freezer Defrost-Heater

DK182Q-L2U

350VAC-5μF

-

J531Q35E330M385-2

33Ω±20%

4TM265RFBYY-53

130 ±5℃

69 ±9℃

230V/50,60Hz

240V/50Hz UDQMOO2H4ASS

240V/50Hz UDQMOO2H4ASS

240V/50Hz UDQMOO2H4ASS

AC240V/25W

AC240V/25W×2

AC250V 0.5A×2

AC250V 0.5A

DECO 250VAC 6A

AC250V 12A

BSBN (BRASS SCREW)

Thermal-Fuse for preventing

overheating of Refrigerator Defrost-Heater

Compressor

Rated Voltage

6

SR-S2027, S2227

SR-S20BTC,S22BTC

SR-S2026, S2226

SR-S20NTC,S22NTC

SR-S20YTC,

SR-S2025

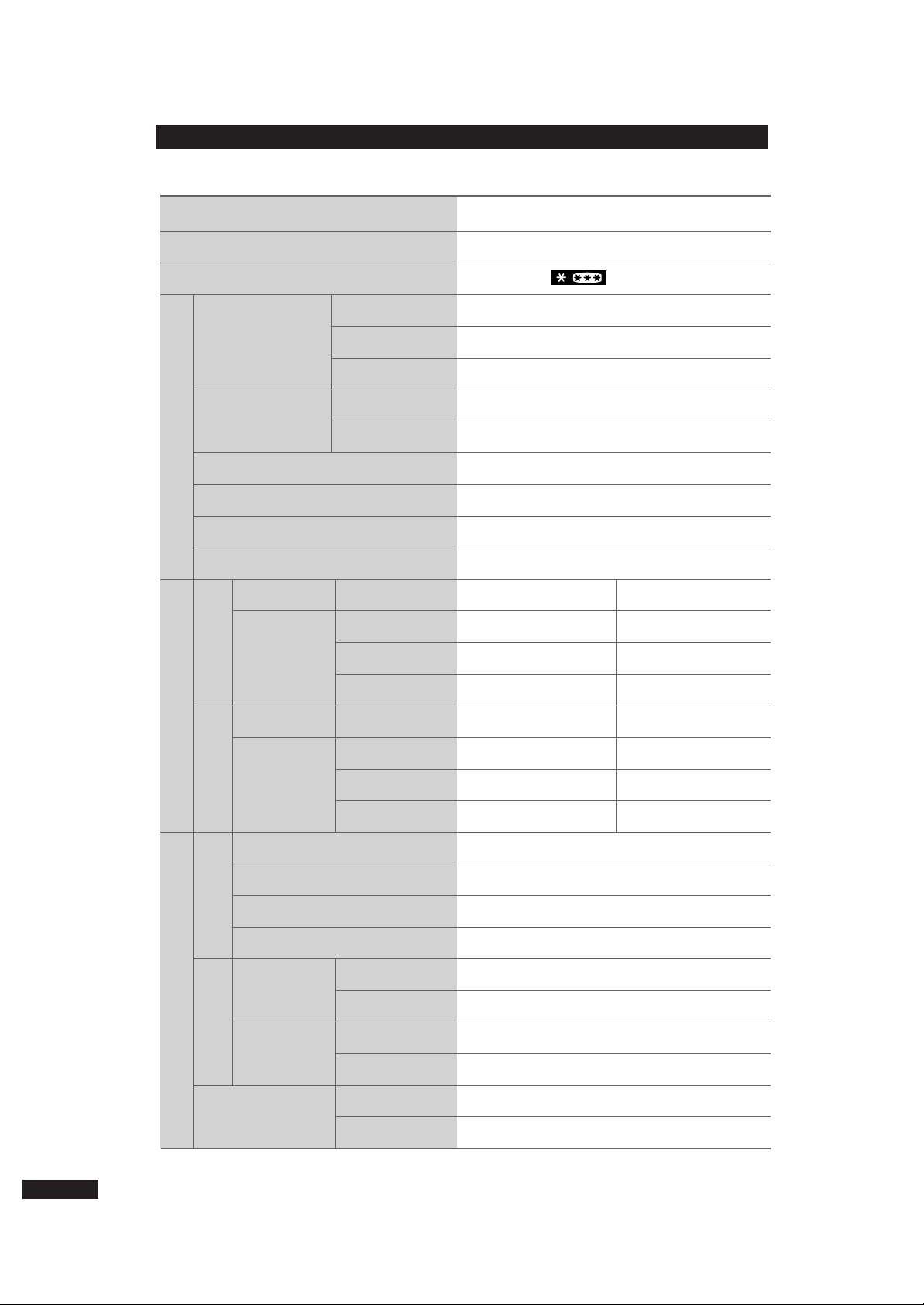

Page 7

4. Circuit Diagram

7

For Basic &&With Home Bar Models

(SR-S2025, S20YTC, S2026, S2027, S2226, S2227/S20NTC,S20BTC,S22NTC,S22BTC)

RED-RED

BLU-BLUE

ORG-ORANGE

P/BLU-PINK/BLUE

BRN-BROWN

PNK-PINK

GRY-GRAY

W/BLU-WHITE/BLUE

WHT-WHITE

YEL-YELLOW

BLK-BLACK

PRP-PURPLE

W/BLK-WHITE/BLACK

S/BLU-SKY/BLUE

E-EARTH

W/RED-WHITE/RED

Reference

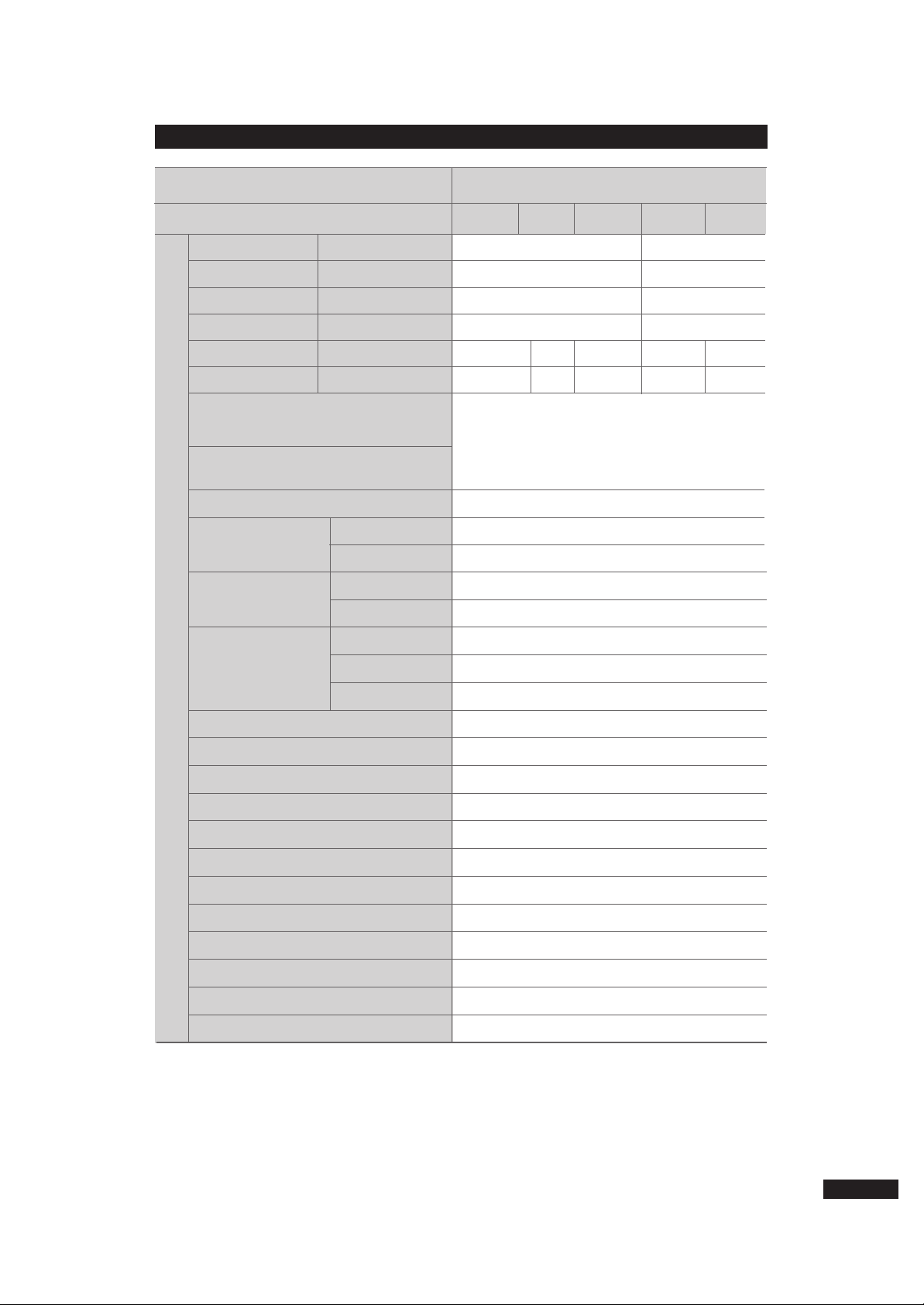

Page 8

For Dispenser &&With Home Bar Models

(SR-S2028, S2029 S2228, S2229/S20DTC, S20FTC,S22DTC,S22FTC)

8

RED-RED

BLU-BLUE

ORG-ORANGE

P/BLU-PINK/BLUE

BRN-BROWN

PNK-PINK

GRY-GRAY

W/BLU-WHITE/BLUE

WHT-WHITE

YEL-YELLOW

BLK-BLACK

PRP-PURPLE

W/BLK-WHITE/BLACK

S/BLU-SKY/BLUE

E-EARTH

W/RED-WHITE/RED

Reference

Page 9

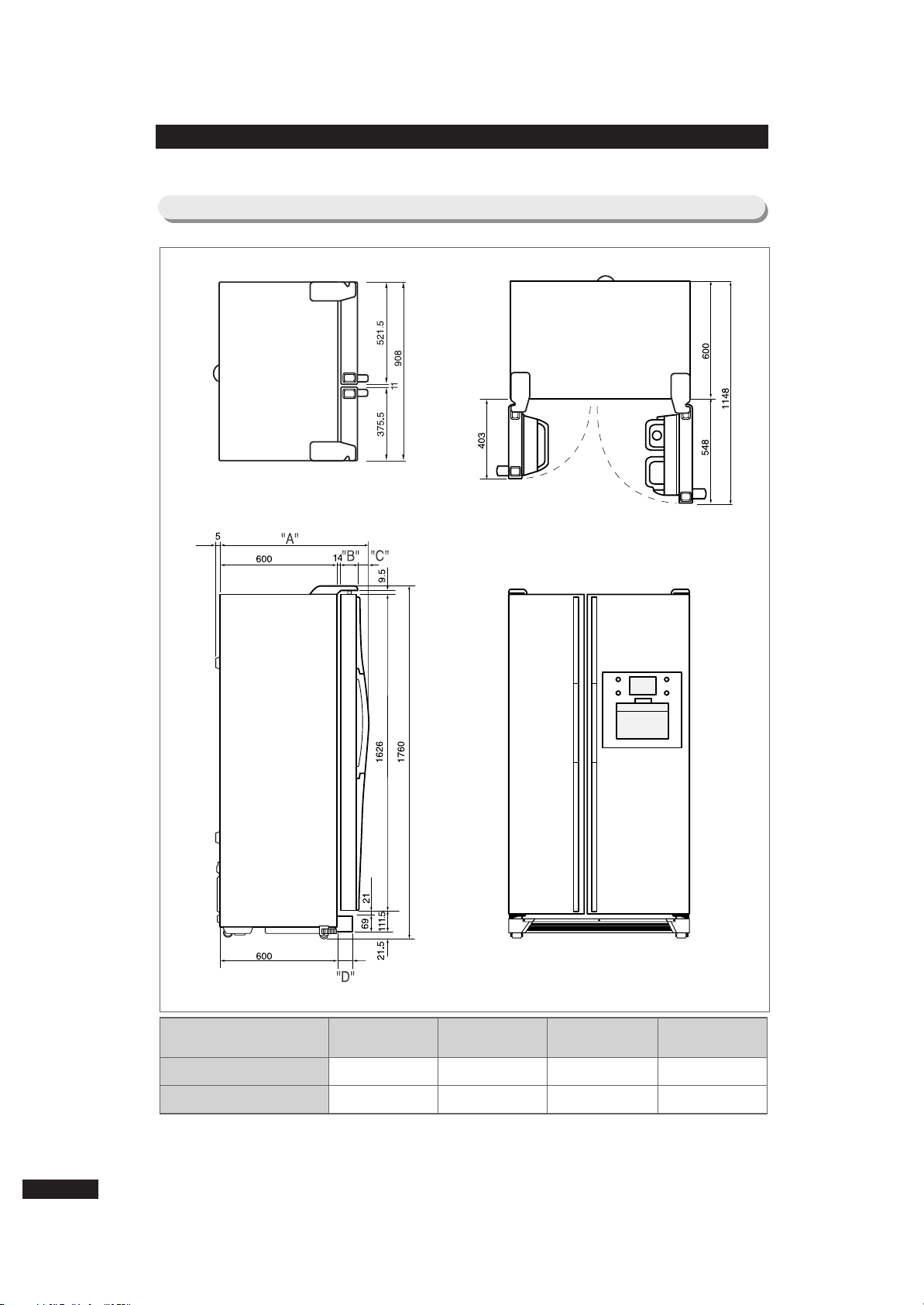

5-1) Product Dimension

(SR-S2025, S2-YTC)

(SR-S2025, S20YTC

MODEL

SR-S2025C, S20YTC

SR-S2025D, S20YTC

“A” “B” “C” “D”

719

714

50

50

55

50

54

54

5. Dimension &&part name of refrigerator

9

Page 10

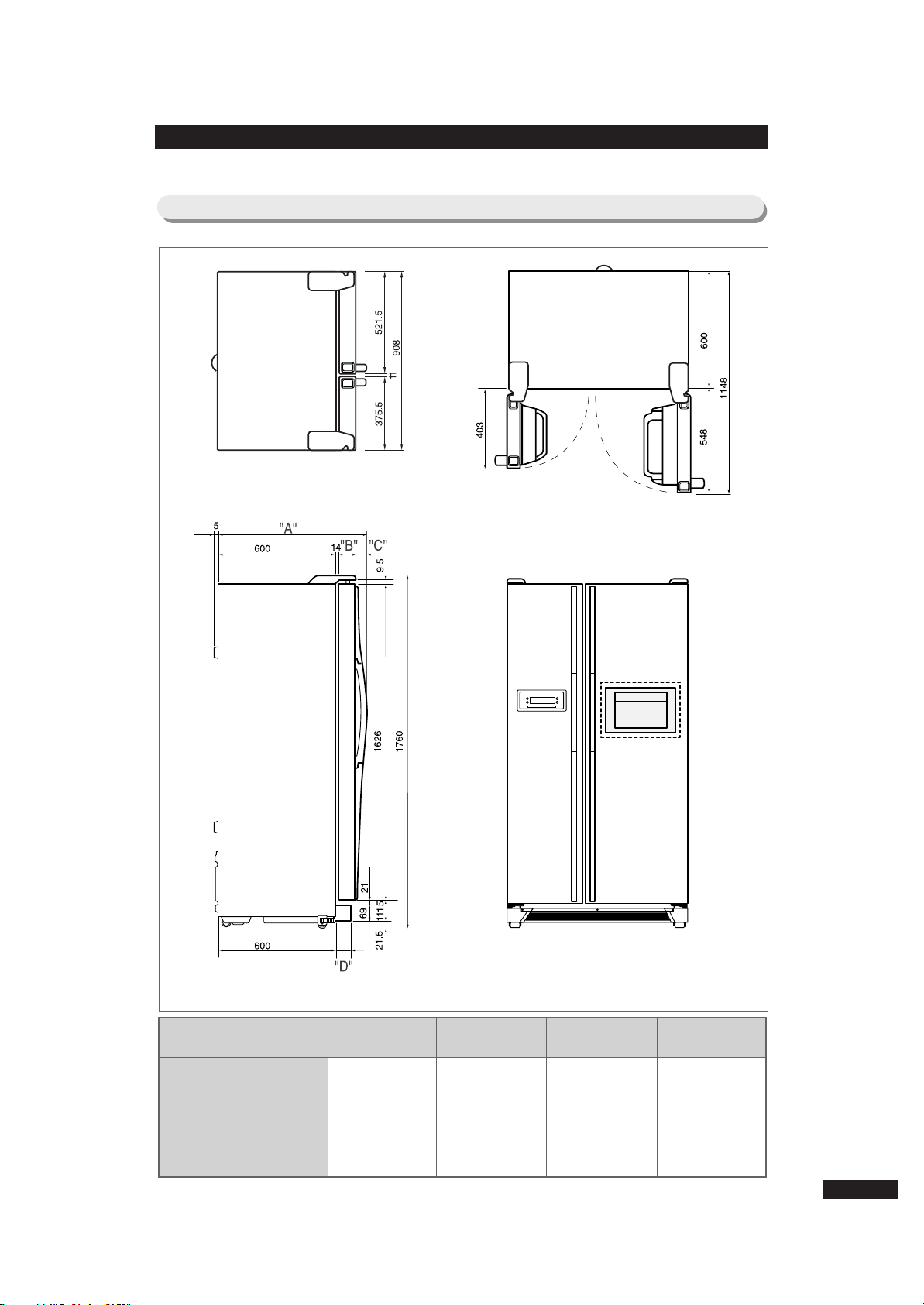

5-2) Product Dimension

(SR-S2026, S2027, S2226, S2227/S20NTC,S20BTC,S22NTC,S22BTC)

(SR-S2027, S2227)

-S20BTC,S22BTC

MODEL

SR-S2026C, S2027C/S20NTC,S20BTC(D)

SR-S2026D, S2027D/S20NTC(D),S20BTC(D)

SR-S2226C, S2227C/S22NTC,S22BTC(D)

SR-S2226D, S2227D/S22NTC(D),S22BTC(D)

“A” “B” “C” “D”

719

714

754

749

50

50

85

85

55

50

55

50

54

54

89

89

10

Page 11

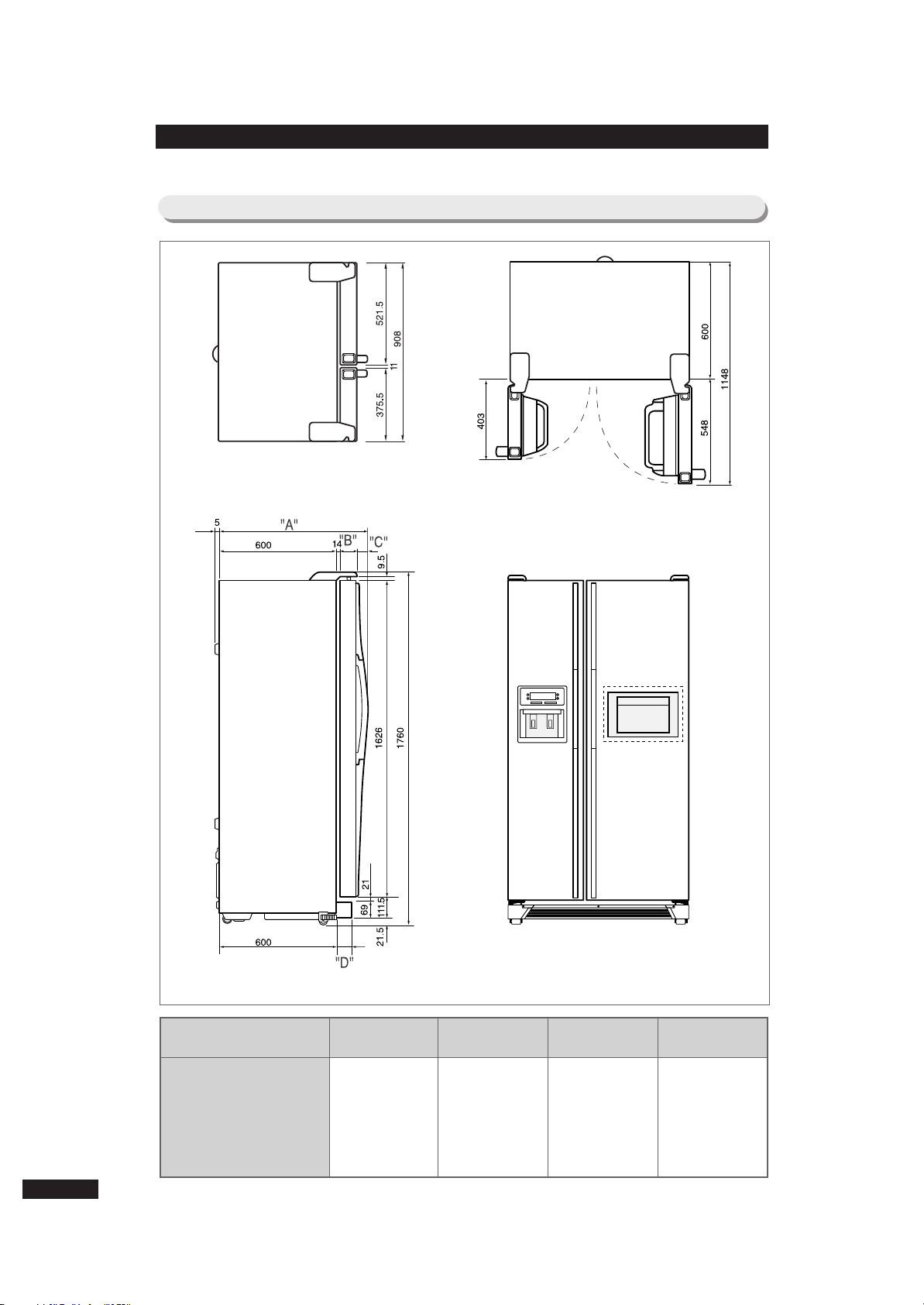

5-3) Product Dimension

(SR-S2028, S2029, S2228, S2229/S20DTC,S20FTC,S22DTC,S22FTC)

(SR-S2029, S2229)

-S20FTC,S22FTC

MODEL

SR-S2028C, S2029C/S20DTC,S20FTC(D)

SR-S2028D, S2029D/S20DTC(D),S20FTC(D)

SR-S2228C, S2229C/S22DTC,S22FTC(D)

SR-S2228D, S2229D/S22DTC(D),S22FTC(D)

“A” “B” “C” “D”

719

714

754

749

50

50

85

85

55

50

55

50

54

54

89

89

11

Page 12

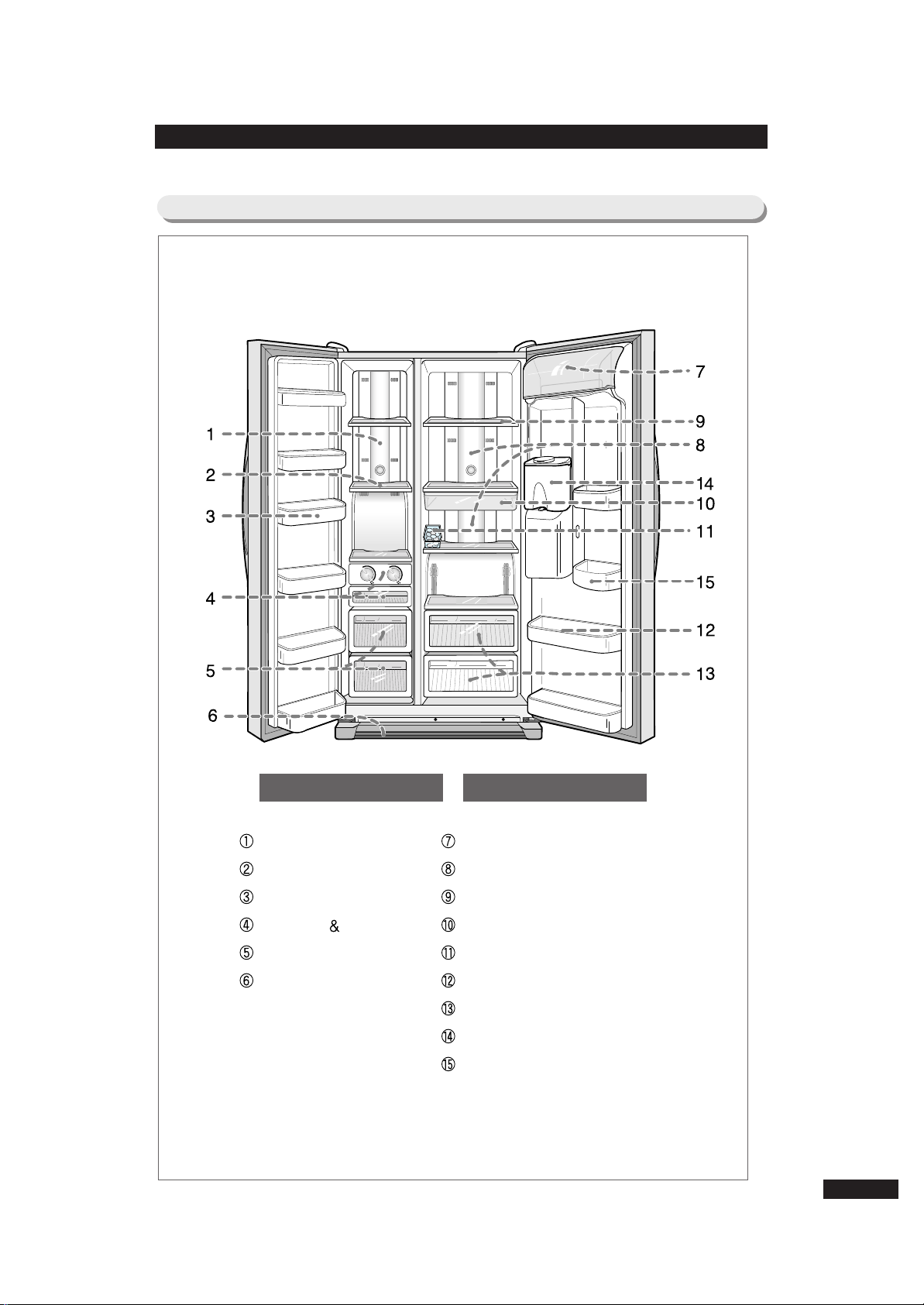

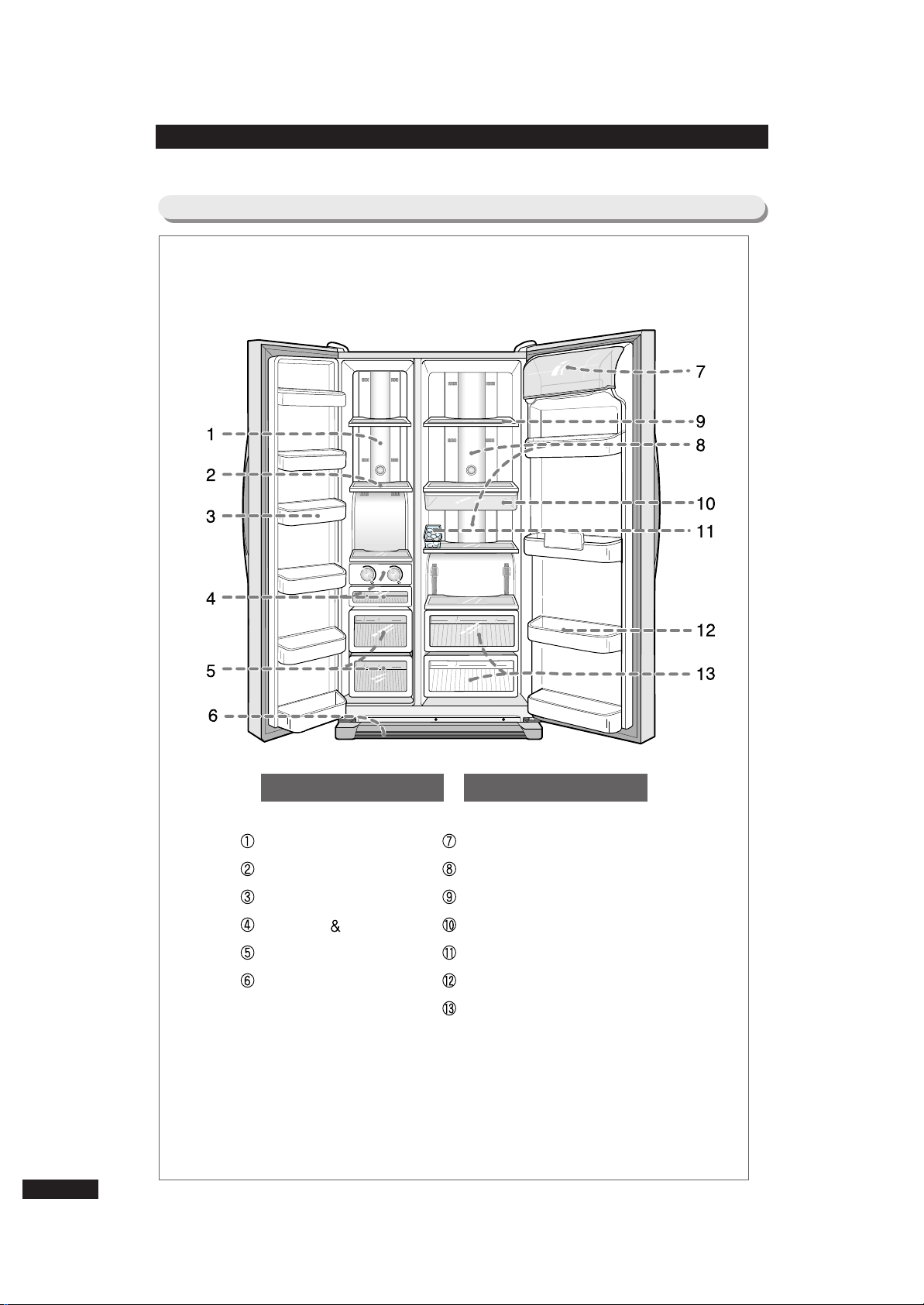

FFRREEEEZZEERR

LAMP-INCANDESCENT

SHELF

GUARD

TRAY-ICE ICE

CASE-BASKET

COVER-LEG, FRONT

RREEFFRRIIGGEERRAATTOORR

COVER-GUARD

LAMP-INCANDESCENT

SHELF

TRAY-CHILLED ROOM

TRAY-EGG

GUARD

CASE-VEGETABLE

TANK-WATER ASS’Y

GUARD-VARIETY

5-4) Part Name (SR-S2025 / SR-S20YTC)

12

Page 13

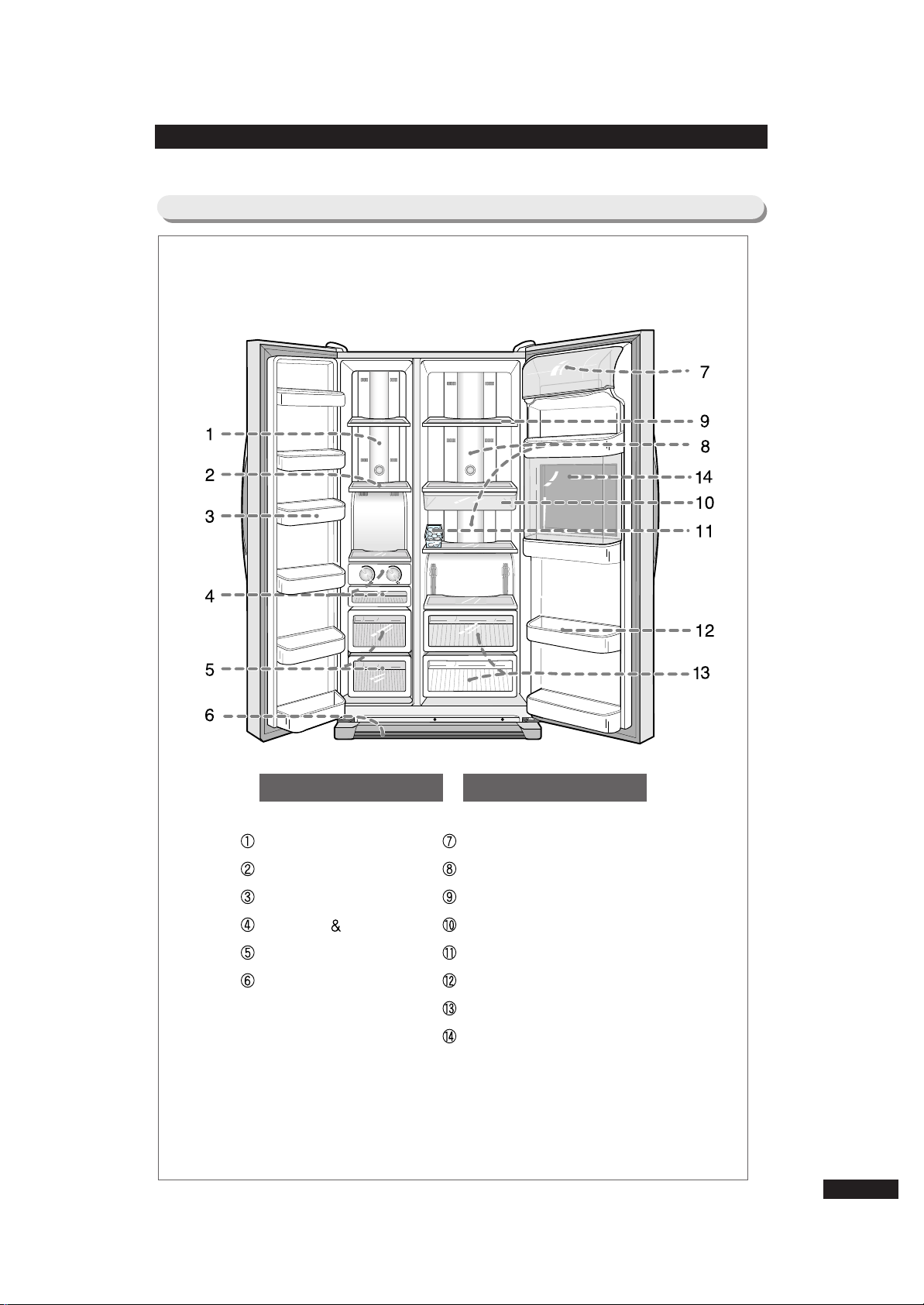

FFRREEEEZZEERR

LAMP-INCANDESCENT

SHELF

GUARD

TRAY-ICE ICE

CASE-BASKET

COVER-LEG, FRONT

RREEFFRRIIGGEERRAATTOORR

COVER-GUARD

LAMP-INCANDESCENT

SHELF

TRAY-CHILLED ROOM

TRAY-EGG

GUARD

CASE-VEGETABLE

5-5) Part Name (SR-S2026, S2226/S20NTC,S22NTC)

13

Page 14

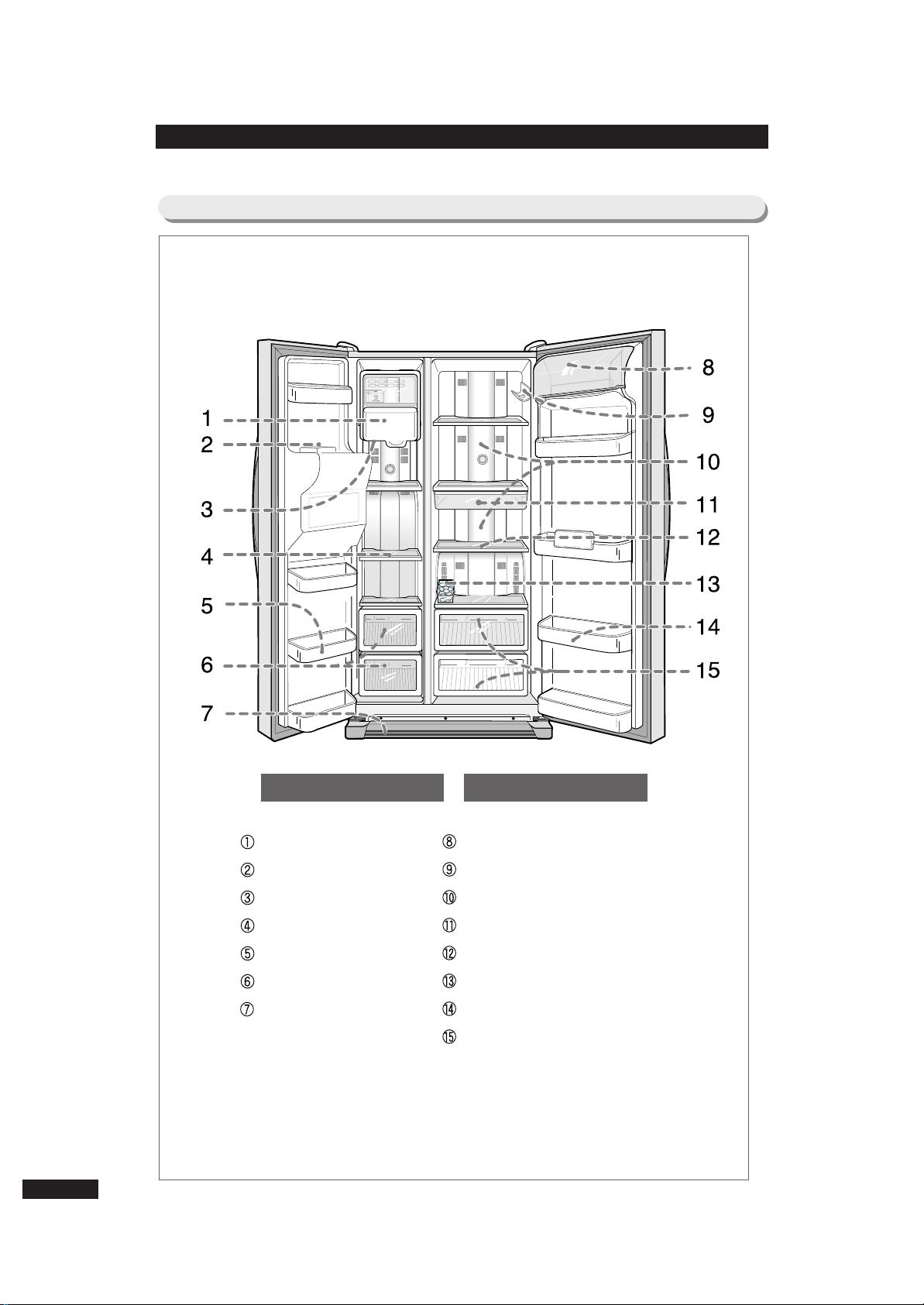

FFRREEEEZZEERR

LAMP-INCANDESCENT

SHELF

GUARD

TRAY-ICE ICE

CASE-BASKET

COVER-LEG, FRONT

RREEFFRRIIGGEERRAATTOORR

COVER-GUARD

LAMP-INCANDESCENT

SHELF

TRAY-CHILLED ROOM

TRAY-EGG

GUARD

CASE-VEGETABLE

HOME-BAR

5-6) Part Name (SR-S2027, S2227/S20BTC,S22BTC)

14

Page 15

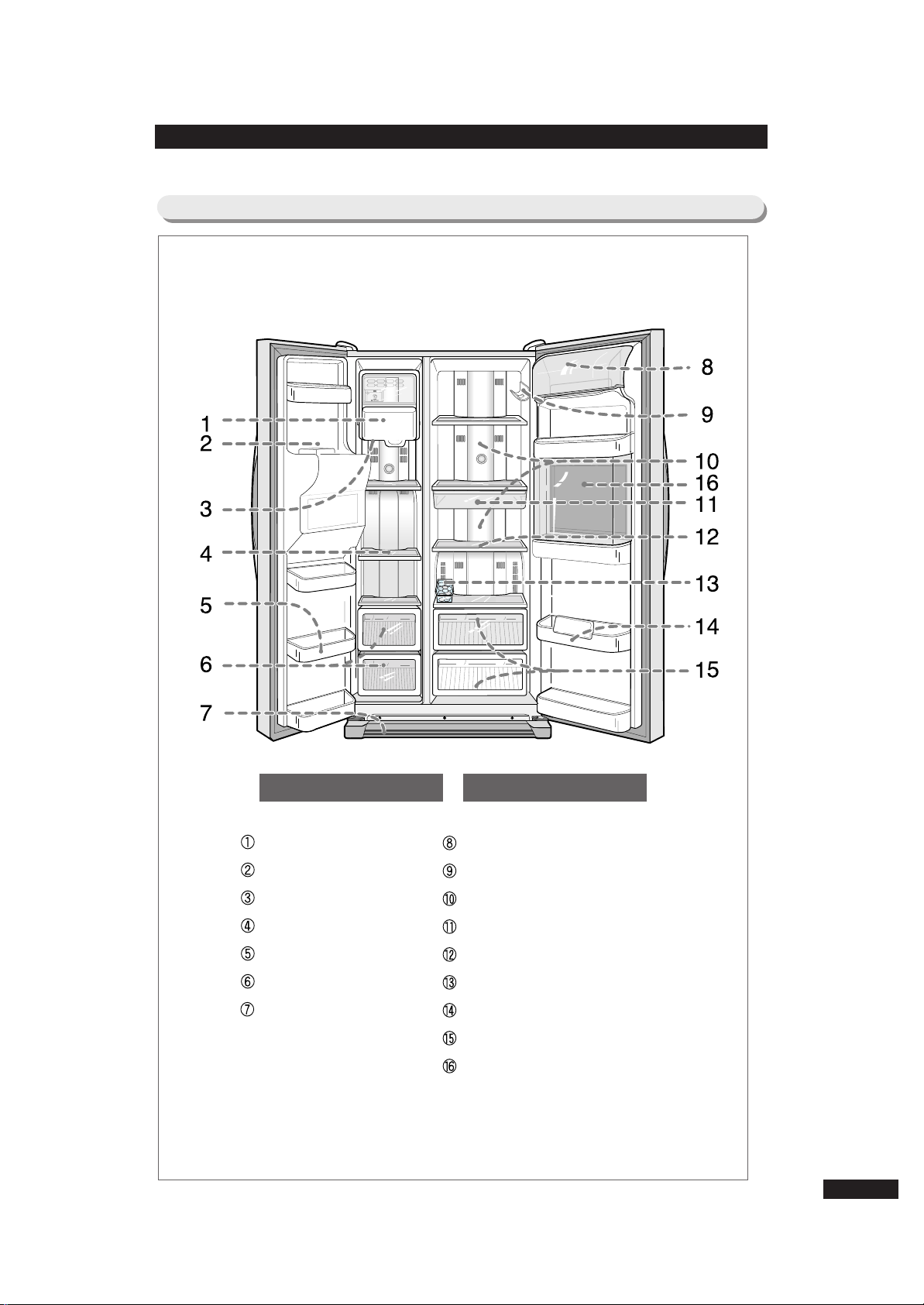

FFRREEEEZZEERR

ICE-MAKER

ICE-CHUTE

LAMP-INCANDESCENT

SHELF

GUARD

CASE-BASKET

COVER-LEG, FRONT

RREEFFRRIIGGEERRAATTOORR

COVER-GUARD

SHELF-WINE

LAMP-INCANDESCENT

TRAY-CHILLED ROOM

SHELF

TRAY-EGG

GUARD

CASE-VEGETABLE

5-7) Part Name (SR-S2028, S2228/S20DTC,S22DTC)

15

Page 16

16

FFRREEEEZZEERR

ICE-MAKER

ICE-CHUTE

LAMP-INCANDESCENT

SHELF

GUARD

CASE-BASKET

COVER-LEG, FRONT

RREEFFRRIIGGEERRAATTOORR

COVER-GUARD

SHELF-WINE

LAMP-INCANDESCENT

TRAY-CHILLED ROOM

SHELF

TRAY-EGG

GUARD

CASE-VEGETABLE

HOME-BAR

5-8) Part Name (SR-S2029, S2229/S20FTC,S22FTC)

Page 17

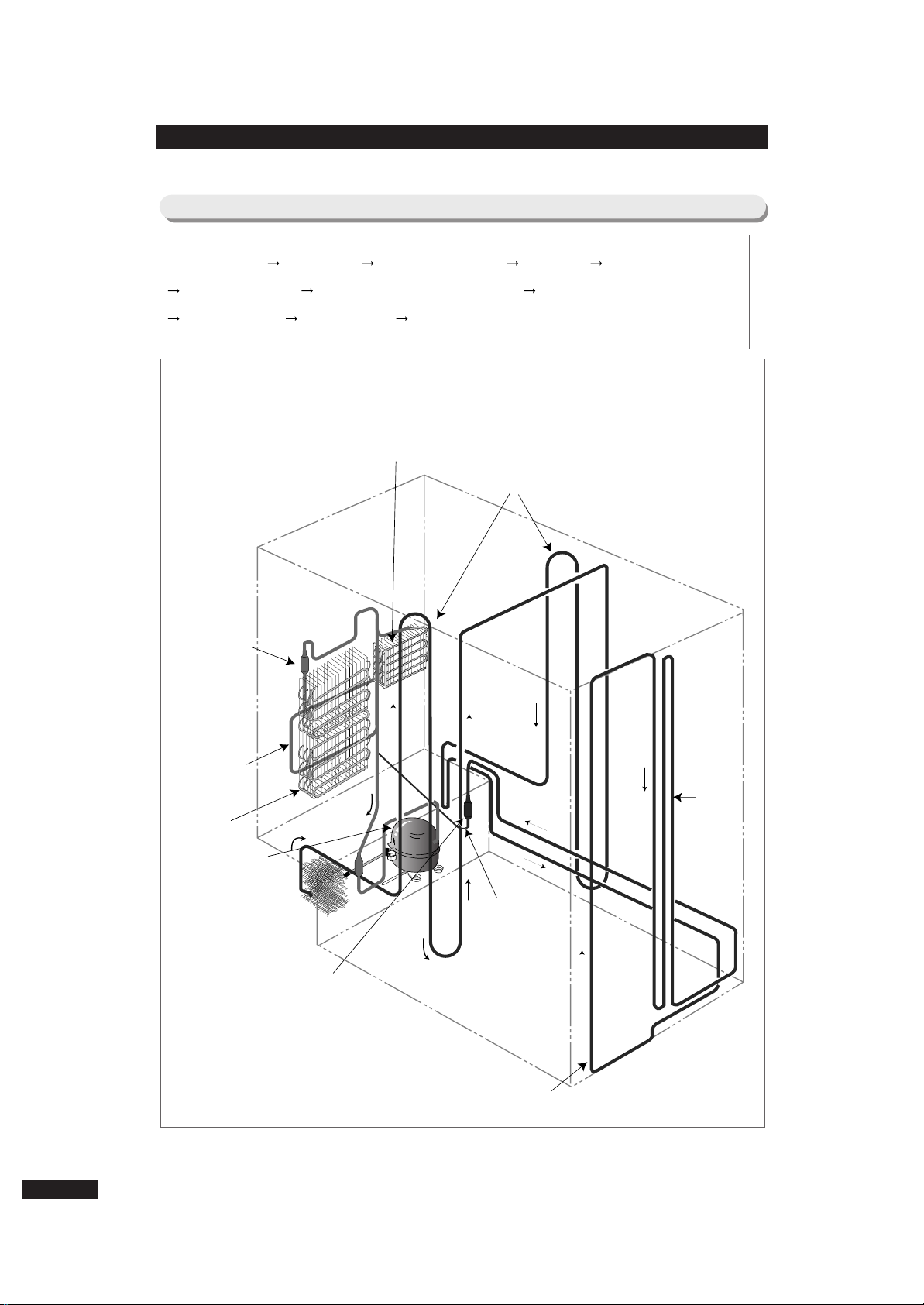

6. Freezing Cycle & Cold Air Circulation Course in Refrigerator

COMPRESSOR WIRE-COND SIDE CLUSTER PIPE HOT PIPE DRYER

CAPILLARY TUBE REFRIGERATOR EVAPORATOR FREEZER EVAPORATOR

ACCUMULA TOR SUCTION PIPE COMPRESSOR

6-1) Freezing Cycle

REFRIGERATOR EVAPORATOR

CAPILLARY TUBE

ACCUMULATOR

FREEZER

EVAPORATOR

SUCTION PIPE

DRYER

WIRE-CONDENSER

HOT-PIPE

HOT-PIPE

COMPRESSOR

SIDE CLUSTER PIPE

17

Page 18

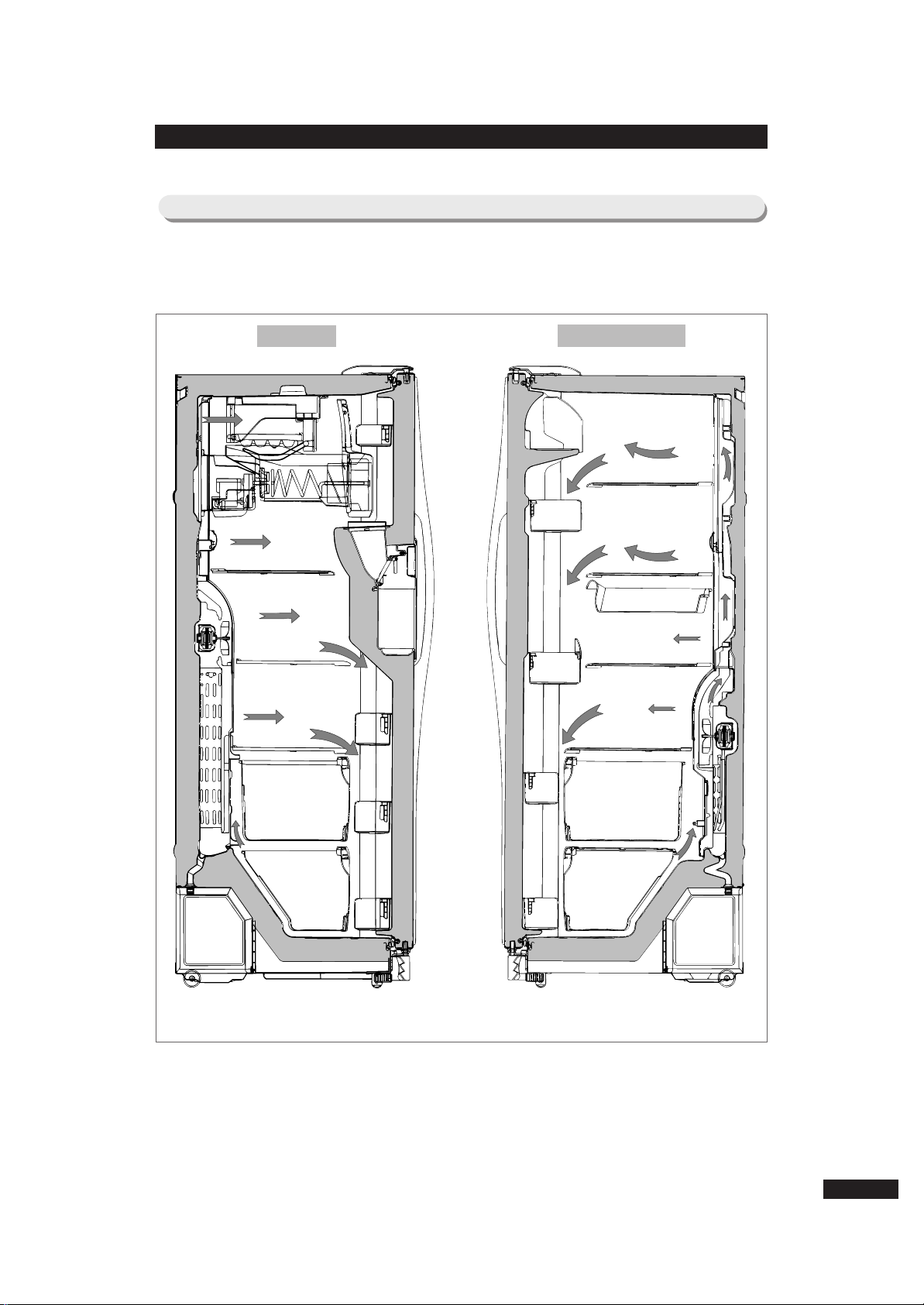

6-2) Cold Air Circulation Course in Refrigerator (Cold Air Passage Circulation Course)

FFRREEEEZZEERR

RREEFFRRIIGGEERRAATTOORR

18

Page 19

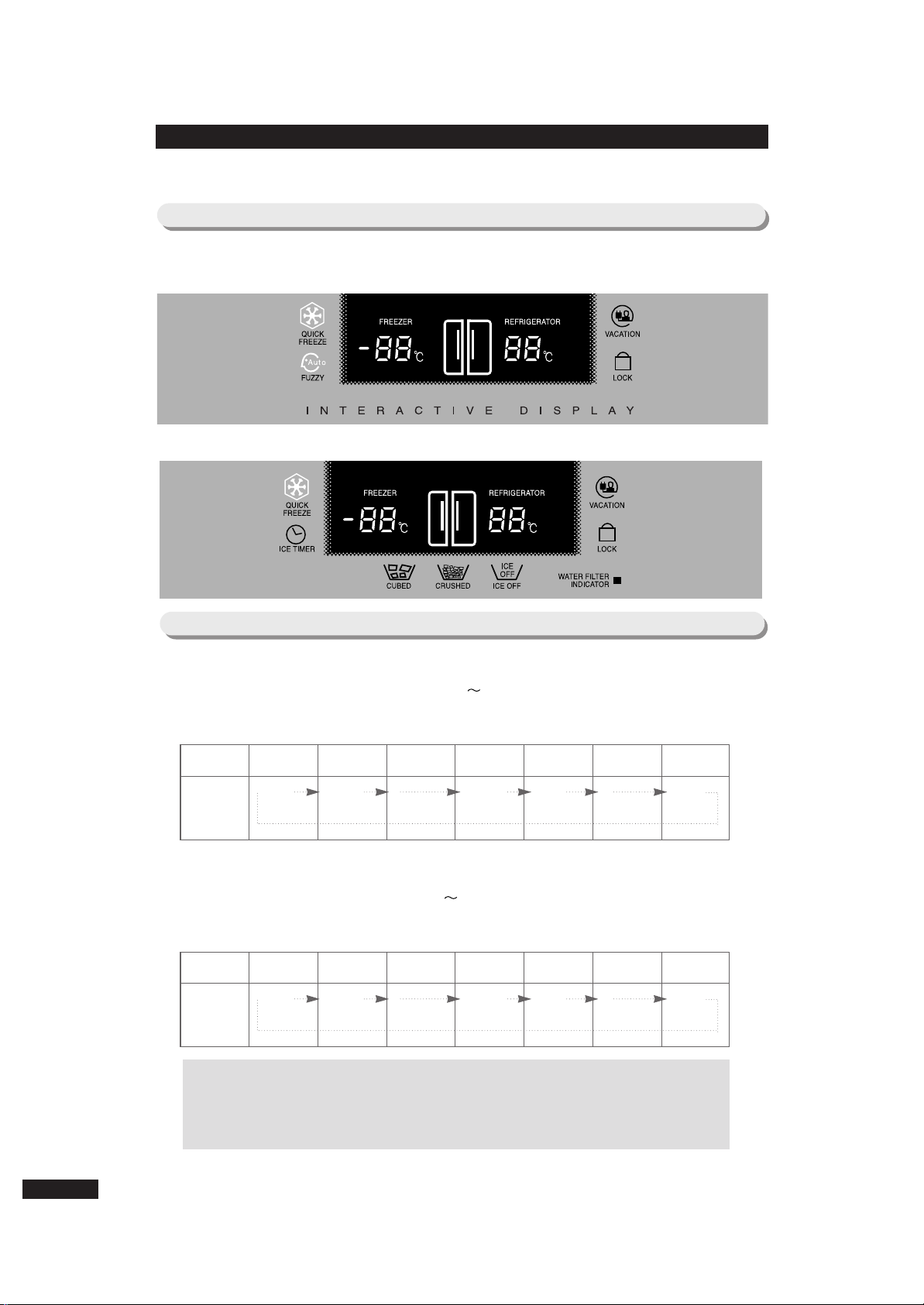

7. Function & Operating Instruction of Refrigerator

7-1) Temperature Control Function

11)) BBaassiicc aanndd wwiitthh HHoommee BBaarr MMooddeellss

22)) DDiissppeennsseerr aanndd wwiitthh HHoommee BBaarr MMooddeellss

7-2) Temperature Control Function

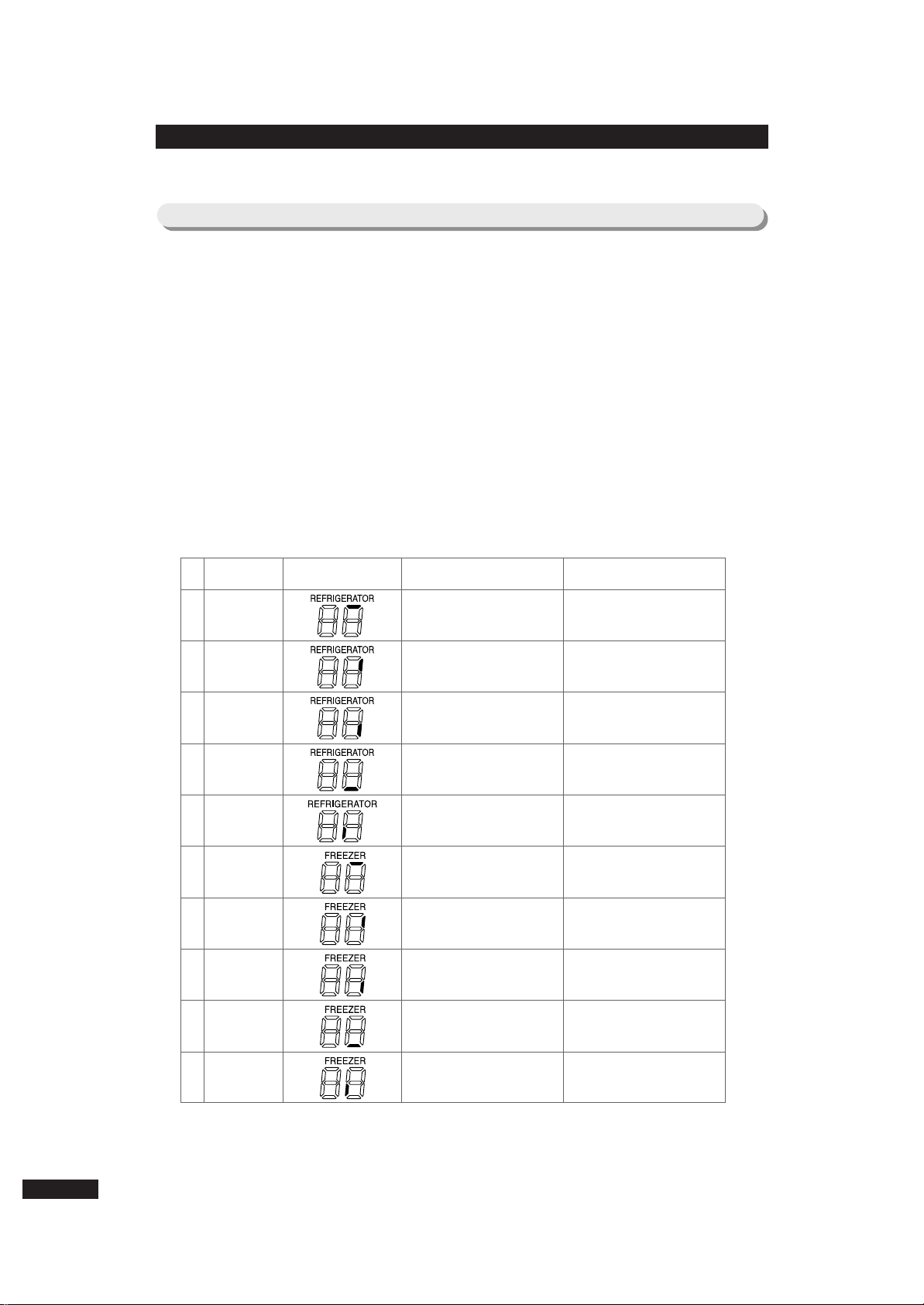

① Temperature selecting function of freezer

1) At initial Power On, -20˚C is selected automatically.

2) Select one button for 13 levels of -14˚C -26˚C.

3) 1˚C drops per each pressing of temperature selection button of freezer.

➁ Temperature selecting function of Refrigerator

1) At initial Power On, 3˚C is selected automatically.

2) Select one button for 9 levels of 7˚C -1˚C.

3) 1˚C drops per each pressing of temperature selection button of Refrigerator.

Division

At Initial Power On

One Time Press

● ● ●

6 Times Press

7 TimesPress

● ● ●

12 TimesPress

Display

Change

Division

At Initial Power On

One Time Press

● ● ●

4 Times Press

5 TimesPress

● ● ●

8 TimesPress

Display

Change

4

˚C

❋ Reference (terms explanation)

1)F Room: freezer 2) R Room: Refrigerator 3) F-FAN: fan motor in

freezer 4) R-FAN: fan motor in Refrigerator 5) COMP: compressor

19

7

˚C

-1

˚C

2

˚C

3

˚C

-19

˚C

-14

˚C

-26

˚C

-21

˚C

-20

˚C

Page 20

● Select extra Quick Freeze & Vacation button.

● Whenever Quick Freeze & Vacation button is pressed, selection/ cancellation

(corresponding lamp On/Off) is repeated.

● When Quick Freeze & Vacation is selected, temperature setup of freezer and

Refrigerator does not change.

● At state of selecting Quick Freeze & Vacation, change of temperature setup of freezer

and Refrigerator is possible.

① Quick Freeze Function

1) When Quick Freeze function is selected, COMP and F-FAN operates

continuously for 2 and half hours.

2) While Quick Freeze function is working, Refrigerator operates under

present setup condition.

3) When Quick Freeze function is completed (after continuous operation of

COMP, F-FAN for 2 and half hours), Quick Freeze lamp lights out

automatically and operates according to setup temperature of freezer.

➁ Vacation Function

1) When Vacation is selected, Refrigerator fan is turned off.

2) Though Vacation function is selected, Refrigerator fan does not turned off

but turned on for initial 5 minutes.

3) When Vacation function is selected and Ice Timer is set, Vacation function

completes automatically when Ice Maker works by Ice Timer function.

Then Refrigerator fan operates according to temperature setup of

Refrigerator. (explained in detail at Ice Timer function)

4) Vacation function is selected/ canceled by Vacation button. It can be

canceled by temperature control button of Refrigerator while Vacation function

is selected.

5) While Vacation function is working, Vacation lamp is ON, and temperature

display of Refrigerator is OFF.

7-3) Function of Quick Freeze & Vacation

20

Reference

Temperature of table on previous page is temperature of center part of

1/3 height of Refrigerator/Freezer compartments. It is temperature data at

unload state. When actually used, temperature may differ according to

surrounding condition and use frequency. The table displays general

characteristic of temperature.

❋ Reference

If Quick Freeze function is selected when freezer temperature is over -10˚C

and Refrigerator temperature is over +10˚C like the condition of initial

Power ON, Refrigerator Fan becomes OFF until freezer temperature

drops under certain temperature. When freezer temperature becomes

under certain temperature, Refrigerator Fan operates.

Page 21

7-4) Alarm Function

① Button Touch Sound (“Ding-Dong” Sound)

1) Input confirmation sound of “Ding-Dong” sounds when each button of

Control Panel is pressed.

2) “Ding-Dong” doesn’t sound if more than two keys are pressed at the

same time or buttons are wrongly operated.

➁ Door-Open Alarm Sound (“Ding-Dong” Sound)

1) If door of freezer or Refrigerator remains open over 2 minutes, alarm

sounds ten times.

2) If door remains open continually afterward, alarm repeats ten times per one minute

cycle.

3) Alarm stops immediately when door of freezer or Refrigerator is closed.

➂ Forced Operation & Forced Defrost Alarm Sound (“Beep” Sound)

1) If forced operation or forced defrost is selected, “Beep” sound occurs.

2) If forced operation is selected, alarm sound occurs until automatic

cancellation (after 24 hour’s forced operation) or cancellation function is

selected.

3) Also in case of forced defrost, alarm sound occurs until defrost is

completed (including pause) or cancellation function is selected.

7-5) Defrost Function

① At time of initial Power On, defrost function works for both freezer and Refrigerator at

the same time, when integrating time of Comp On is over 4 hours.

➁ Afterward defrost cycle is changeable according to use condition or surrounding

environment from 6 hrs. to 38 hrs..

➂ After completing the initial defrost, PRE-COOL function works for 20 min. to minimize

temperature increase by defrost work. However, PRE-COOL function is determined

according to temperature in Refrigerator at the point of defrost time.

➃ If F-room temperature is over -21˚C, PRE-COOL function works for F-room. If F room

temperature is below -21˚C, PRE-COOL function does not work.

21

Page 22

7-6) Test Function

● Test function is for test, process inspection and SVC of PCB and product.

● After selecting test S/W and confirming function of product, turn on power switch

again to operate self-inspection function.

● If you press Quick Freezer Key on Display Panel and temperature control Key in

R-room for more than 8 seconds, all Displays will be turned off and continue

operating in Test Mode. At this moment, if any key is pressed among freezer

temperature control key, Refrigerator temperature control key, quick freeze key or

vacation key, it operates as the test button.

❈ F-room : Freezer, R room : Refrigerator

① Forced Operating Function

1) In the state where display panel was converted into test mode, if test button

is selected once, COMP will operate immediately without 5 minute

delay function. Therefore, forced operation is conducted at the very moment

of COMP OFF, over load may be caused. Please be careful.

2) If forced operation is selected, freezer and Refrigerator is set to automatic,

and the temperature of freezer is set to “-26˚C”and Refrigerator is set to

“1˚C”, Comp and F-fan operates continuously, and R-fan in Refrigerator is

controlled by “1˚C”setup.

3) Forced operation is valid for 24hrs. That is, if 24hours. pass after

selecting forced operation, simultaneous defrost in both Refrigerator and

freezer is automatically carried out. And normal operation is carried out

by present setup of Refrigerator and freezer.

4) Cancellation of forced operation in the middle of working is possible by

turning on Power after turning it off (resetting), or by selecting test cancel

mode shown in the item 3 below.

5) When forced operation works, alarm sound will continue until forced

operation is completed. There is no alarm cancel function.

➁ Forced Defrost Function

1) In the state of forced operation, if display panel is converted into test mode and

press the test button once more, forced operation is cancelled immediately,

and evaporator defrost function of Refrigerator operates.

2) At this time, beep alarm sounds for 3sec. at the point of defrost, and

0.75sec. ON/0.25sec. off sound occurs during forced defrost function

of Refrigerator works.

3) If above defrost function of Refrigerator is maintained, it operates normally

after defrost is completed.

4) While forced defrost function of Refrigerator operates, pressing the test

button once more enables simultaneous defrost for both freezer and

Refrigerator.

5) At this time, beep alarm also sounds for 3sec. at the point of defrost, and

0.75sec. ON/ 0.25sec. off sound occurs continually until simultaneous

defrost of F and R is completed.

➂ Test Cancel Mode

1) In the state of simultaneous defrost of freezer and Refrigerator, if display panel

is converted into test mode, and test button is pressed once more, defrost

of both freezer and Refrigeration is cancelled immediately and resumes

normal operation .

22

❈ Reference

It works step by step in test function. It does not change from 1 step

(forced operation) to 4 step (test cancel mode) directly. It operates

corresponding function only after it goes through the previous step. While

test function works, it is most desirable to turn off main power and then turn it on.

Page 23

7-7) Self-diagnosis Function

① Self-diagnosis Function at the time of initial power is on.

1) When the initial power is applied to Refrigerator, all lamps light and conduct

self-diagnosis function internally.

2) If result shows no fault, display will go into the initial normal lighting state.

3) If result shows any fault, corresponding led is turned on and off and alarm

sounds.

4) Error sign of self-diagnosis continues until all defects of parts are repaired

or self-checkup function is cancelled.

5) If all corresponding parts are repaired completely, display will go into the

normal mode state.

6) After repairing Refrigerator, turn on switch again after turning it off to

make it sure if Refrigerator is properly repaired.

7) Therefore, in case open & short related problem of sensor needs to be

confirmed during A/S, turn off the power of Refrigerator and turned it on

again to operate self-Diagnosis function. Then sensor function can be

checked.

8) When any defect occurs, corresponding display signs are shown as in the

following chart.

NO Items Corresponding LED Defect Content Remark

01

02

03

04

05

06

07

08

09

10

ICE-MAKER

SENSOR

Defect of wire connecting system due to

badness of Open/Short related aspect of

Sensor which is equipped at the

beneath of ice-making bowl

When temperature sensing of Rsensor is more than +50℃ and less

than -50℃.

Refrigerator

R-sensor

Missing sensor housing of R-room,

contact defects, disconnection of wires,

defect of short-circuit sensor itself, etc.

Defect is indicated when temperature

sensing of R-sensor is more than +50

℃ and less than -50℃.

Defect is indicated when temperature

sensing of R-sensor is more than +50℃

and less than -50℃.

Refrigerator

defrost sensor

Missing sensor housing of R-room,

contact defects, disconnection of wires,

defect of short-circuit sensor itself, etc.

When normal operation is not done until iceisolating motion is attempted 3 times (only

ice-making function model corresponds).

R-fan motor

Error

F-fan motor

Error

C-fan motor

Error

Interference of Fan due to frost, etc.,

un-insertion of connector,

disconnection, etc.

Occurrence of the case where Fan Motor of

inner refrigerator room becomes to operate

under about 600rpm at the normal operation

condition or stops driving.

Interference of Fan due to frost, etc.,

un-insertion of connector,

disconnection, etc.

Un-insertion of connector,

disconnection, etc.

Defect of micro S/W in Gear box,

motor, gear and other defect in wire

system

Badness is indicated when temperature sensing

of Outside Air Sensor is more than +50℃ and

less than -50℃.

ICE-MAKER

KIT

Outside Air

Sensor

Freezer

F-sensor

Freezer

defrost-sensor

Missing of outside air sensor housing inside of PCB

base of top part of Refrigerator, contact defect,

disconnection of wires, defect of short-circuit sensor

itself, etc.

Missing sensor housing in F-room,

contact defects, disconnection of wires,

defect of short-circuit sensor itself, etc.

Missing defrost-sensor housing in evaporator of

F- room, contact defects, disconnection of wires,

defect of short-circuit sensor itself, etc

Defect is indicated when temperature

sensing of F-sensor is more than +50℃

and less than -50℃.

Defect is indicated when temperature

sensing of F-sensor is more than +50℃

and less than -50℃.

Occurrence of the case where Fan Motor of inner freezer

room becomes to operate under about 600rpm at the

normal operation condition or stops driving.

Occurrence of the case where Comp Cooling Fan

Motor becomes to operate under about 600rpm at

the normal operation condition or stops driving.

Note) This self-Diagnosis works only when the open/short related aspect of sensor is bad. Minute

feature change of sensor is not judged as defect if it does not get rid of the extent of temperature

sensor described in Remark so that it is indicated as normal.

23

Page 24

➁ Self-Diagnosis Function in Normal Operation

1) Under normal operation of Refrigerator, if you press “Quick freeze”and

“Vacation”button at the same time for 6sec., temperature setup display

will proceed On/Off blink of all for 2sec. at 0.5sec. interval.

If you press “Quick freeze”and “Vacation”button continuously at the

same time for about 8sec. including 2sec. of repetition of LED’s On/Off,

self-Diagnosis function is selected.

2) At this moment, it goes into self-Diagnosis function with“Ding-dong”

buzzer sound.

3) When Error occurs, it is restored to normal state regardless of defect

repairing after signal lasts for 30sec. (“Ding-dong”buzzer sound).

4) While it is operating self-Diagnosis function, it does not accept input of

button.

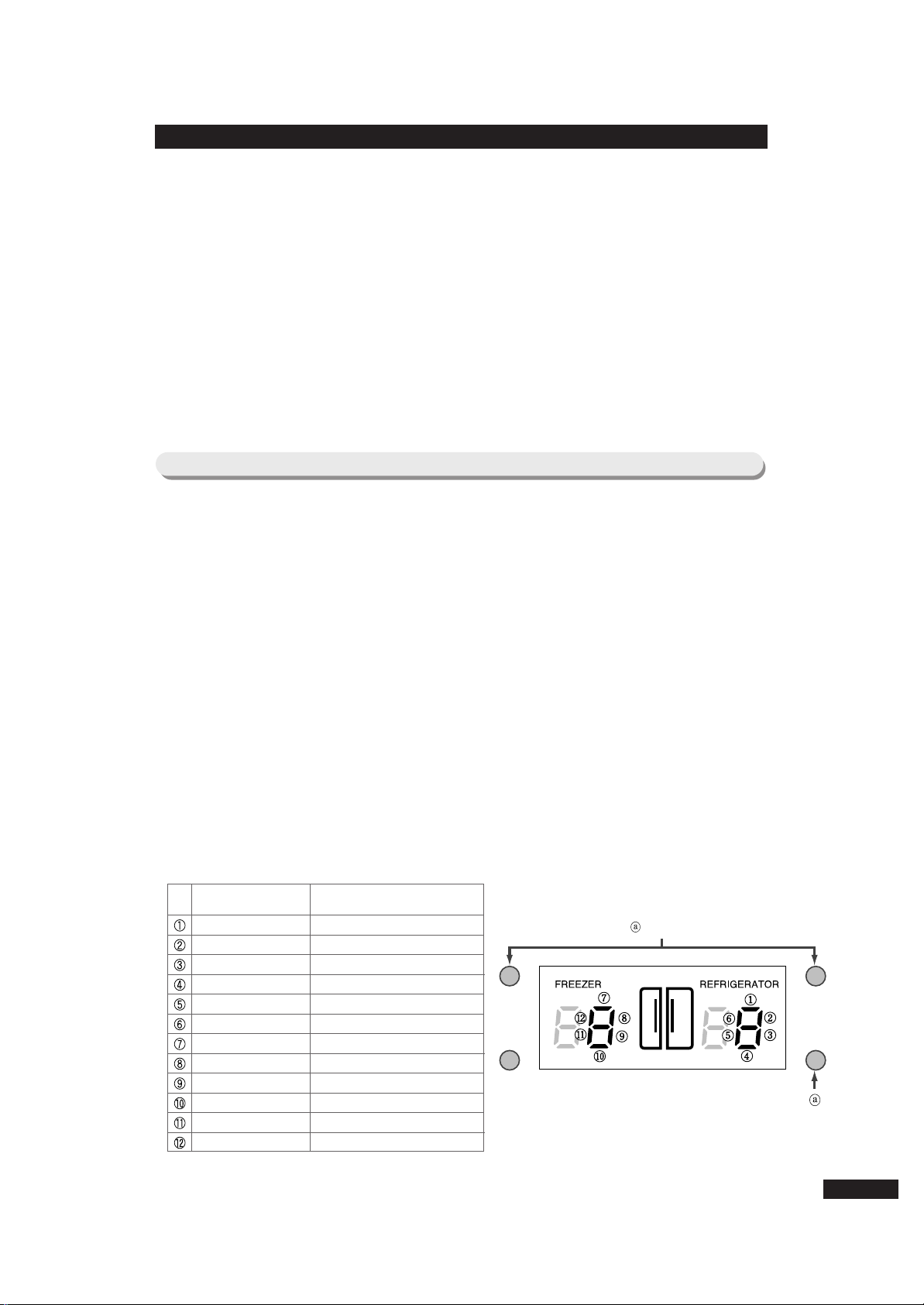

7-8) Load Condition Indicating Function

① In normal operation, if you press “Quick freeze”and “Vacation”button

at the same time for 6 sec., all setup display of freezer and Refrigerator

are turned on. If you hand off from the button at this moment, temperature

setup display of freezer and Refrigerator will proceed On/Off blink of all for

2sec. at 0.5sec. interval. While On/Off blink is processing, if you press the

temperature setup button, it goes into load condition indicating function

(with ding-dong buzzer sound).

➁ Load condition indicating mode shows from which load Micom signal

outputs at present. However, it only shows that micom signal is outputted

and does not confirm whether load is actually operating or not. That is,

even if load is displayed as it is operating, load may not operate because

of actual defect of load or defect of relay on PCB. During A/S, you can

use this function by applying the main function.

➂ Time required to indicate is 30 sec.. After 30sec., it is automatically

restored to the setup state before its function.

➃ Corresponding display indication about load condition is shown as in the

following table.

NO Display Content Operation Content

R-fan high

R-fan low

R-Def-Heater

Start Mode

Overload Mode

Low-temperature Mode

Comp

F-fan high

F-fan low

F-Def-Heater

C-fan high

C-fan low

R-fan high speed operation indication

R-fan low speed operation indication

R room defrost-heater operation indication

indication operation stage (Not important)

when ambient temperature is more than 34℃

when ambient temperature is less than 17℃

Comp operation indication

F-fan high-speed operation indication

F-fan low-speed operation indication

F room defrost-heater operation indication

C-fan high-speed rotation operation indication

C-fan low-speed rotation operation indication

Load Mode Check List

Press both buttons 6 sec, simultaneously, all LED lights are

turned on and off twice.

At this time press button .

For load under operation, corresponding LED lights on.

24

Page 25

● This function only applies to a model equipped with ice-maker.

● This function is limited to a model from which ice and water can be taken out

from outside without opening door.

① Cube Ice / Crushed Ice/ Stop (Off) Function

1) At the time of intial power on, when inside temperature of freezer is more than 5℃,

Cube Ice LED light on display is lit on, and Crushed Ice LED light keeps light-off

state. But when power is turned on, if inside temperature of freezer is less than 5℃,

Micom recalls form of ice which was set up before power off so that it displays the

memorized ice form.

2) “Cube”→“ Crushed”→“ Ice Off”is selected in turn by ice selecting Key.

3) In case of selecting “Crushed”mode, it operates Gear Motor to eject crushed ice

to outside when ice lever operates as ice is made in the bowl of ice machine.

4) In case of selecting “Cube”mode, Gear Motor and ice solenoid operate to eject

cube ice to the outside when ice lever operates as ice is made in the vessel of

ice machine.

5) If “Ice Off”is selected, it stops only ice-making function of ice-maker so

that ice is not made.

◆ At the moment of selecting “Ice Off”, ice-making function stops. But, if it is in

the process of ice-isolating, returning to horizontal state and supplying

water, it maintains stoppage state after water supply is completed.

◆ Even when “Ice-Off”function is operating, ice eject lever operates normally.

This is not a defect. Therefore, remained ice in the ice container can be used

normally.

② Ice Timer Function

1) If you press ice timer button, it is automatically set to Ice-Off mode regardless of

present setup condition of ice mode (Cube / Crushed / Ice Off), and ice lamp is

turned on. And time is set to 3 days on temperature control display of freezer at first.

And each time you press the ice button, the number increases one by one. And if it

reaches 30 days, it resumes from 3 days.

2) Among ice timer functions, if you press ice selecting key, ice timer function

is cancelled.

3) If reservation is made by ice timer button, setup temperature of freezer returns to

temperature display of freezer after 5sec.. At this moment, if ice timer button is

pressed again, it displays the previous reserved date again.1-2 days before the

reserved date is completed, ice maker starts operating. And when the reserved date

is completed, more than half of ice bucket is filled.

4) If ice timer is reserved and vacation function operates, vacation function

ends at the same time when ice timer function ends.

7-9) Function of Ice/Water Dispenser when they are equipped.

25

Page 26

5) The following are examples for use.

◆In case of selecting vacation function only

If you press “vacation”button, Refrigerator will not operate and freezer will operate

only. In case you select this function, take out all foods in the Refrigerator. And “Ice

Off”is automatically selected among ice modes, so ice bucket should be empty and

water supply valve should be turned off.

◆In case of selecting ice timer function only

In case you press “Ice Timer”button to select date as explained above, and not

selecting “Vacation”function so that Refrigerator continues to operate, ice mode is

selected as “Ice Off”and ice is stored in the bucket when you return. Therefore, do

not lock the water supply valve.

◆In case of selecting both vacation and ice timer function

In case you press “Ice Timer”button and “Ice Timer”button to select date to select

date as explained above, or if you press “Ice Timer”button to select date and press

“Vacation”button afterward, Refrigerator does not operate but freezer operates only,

and ice mode is automatically selected as “Ice Off”. So you must take out all foods in

Refrigerator, empty ice in the ice bucket, check water leakage on valves, other hoses

and connection parts without locking water supply valve. When “Vacation”function is

cancelled, Refrigerator resumes its operation.

③ Ice Dispenser Function (Cover Ice Route Solenoid Valve)

1) After 8sec. from initial power on, solenoid of ice exit operates once. This is the

function to prevent interruption of electric service when ice exit is open. So this is not

a defect.

2) With turning the dispenser S/W from on to off and ice ejecting is

completed, 5sec. after turning off S/W, ice exit is closed because cover ice

route solenoid of ice dispenser operates.

④ Water Dispenser Function

1) This function is a system of direct connection with water supply. When water lever is

pressed, water solenoid valve which is equipped at the right side of machine room

opens so as to operate to eject water. However, it has no function to control on

Micom PCB. Therefore, if there happens any defect at water eject function, check

and repair solenoid itself, wire connecting connector, connecting tube and state of

water supply.

⑤ Water Filter Indicator Function

1) After the initial power on, indication lamp is displayed in green light. After 5 months

passed, it is displayed in orange light, and 1 month after this, it is displayed in red

light. This is memorized by EEPROM in Micom PCB, so it counts the passed time

continually though the power is turned on again after it was turned off.

2) If you press ice selecting button and ice-making stop button at the same time for

25sec. continuously, indication lamp lights in green color. And it becomes orange

after 5 months from this moment. And it displays red after 1 month from the

moment.

3) If you press ice selecting button and ice-making stop button at the same time for 5

sec., indication lamp is turned off and water filter indicator function stops. At this

moment, passed time is not counted.

4) At the state where the function is stopped, if you press ice selecting button and icemaking stop button at the same time for 25sec. continuously, “Green”light is turned

on and water filter indicator function will resume. And it becomes orange light after 5

months from this moment. And it displays red light after 1 month from the moment.

26

Page 27

27

1) In case power is applied to prevent customer from nonsense call about

initialization of freezer and Refrigerator at -20℃ and 3℃ respectively when

a momentary power stoppage (not a long-term power stoppage) occurs

while Refrigerator is operating, it operates in two ways. The first one is

initialization by judging the temperature of inside of freezer, and the second

one is restoration of operation state.

2) At the initial power on, in case temperature of the inside of freezer is

judged as about less than +5℃, it is regarded as momentary power

stoppage during operation. Therefore, functions related with panel display

such as Quick Freeze, Vacation, Freezer setup, Refrigerator setup, Ice

timer, Form of ice, etc. are restored.

3) At the initial power on, in case temperature of the inside of freezer is about

more than +5℃, it is regarded as long-term power stoppage. In this case,

panel display is initialized (Quick off, Vacation off, Freezer is set to -20℃,

Refrigerator is set to 3℃, Ice timer off, Cube selecting).

4) Ice timer function and water filter indication function are not initialized in

case of power stoppage. But during power stoppage, time count does not

progress because Micom in PCB does not operate because power source is

not supplied.

7-10) Restoring Function of Operation State in case of Power Stoppage

Page 28

8. Operation Principle of Circuit

Terminal Oscillation Frequency

Xin(#30)

Xout(#31)

4MHz

4MHz

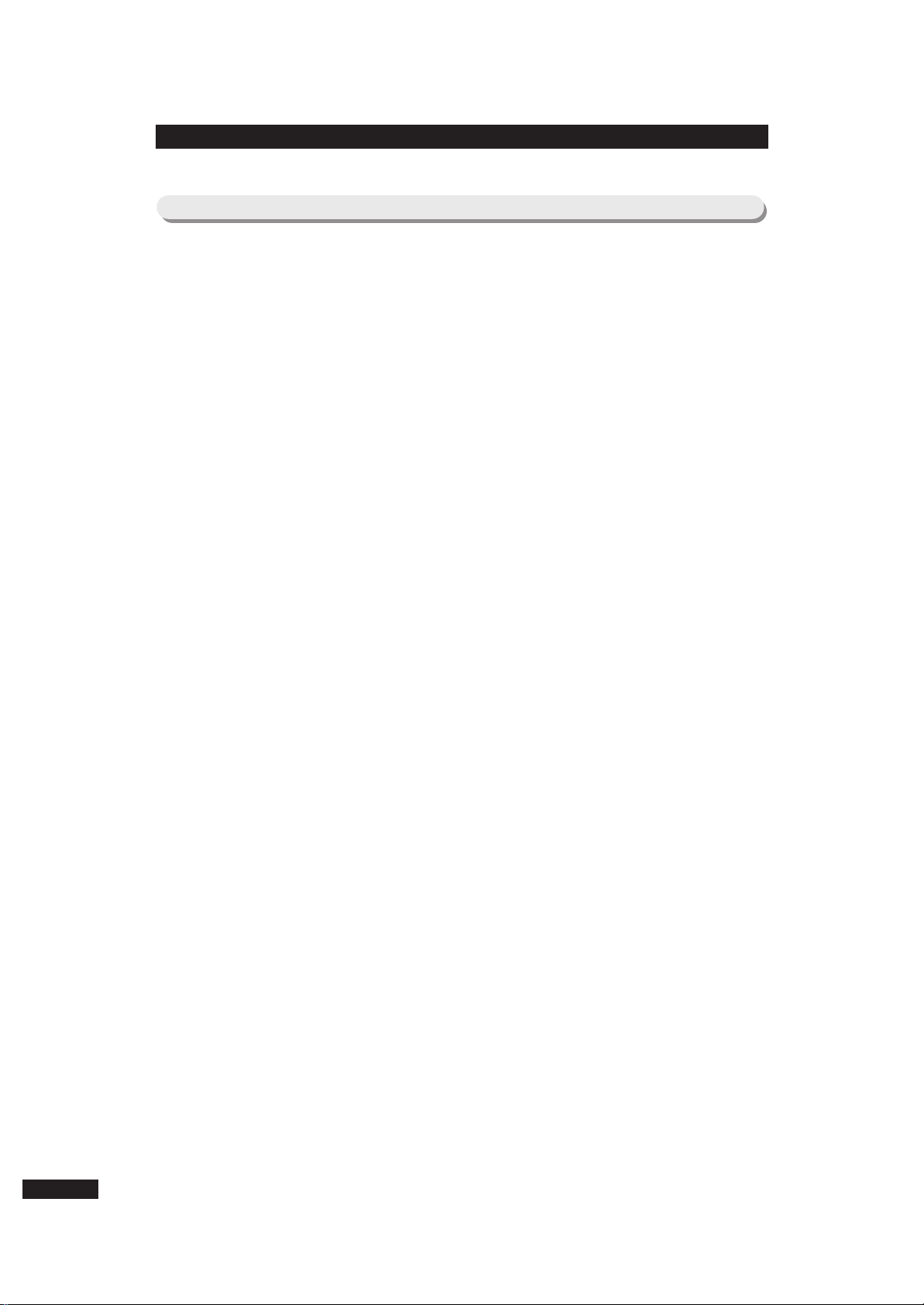

8-1) Power Source Part

When power is supplied, electric wave is rectified through BD1 to generate voltage of

about DC 300V.Top S/W is automatically switched to the optimum condition according to

load condition of the second part.

When electricity flows between D and S of the top S/W, electricity is generated inside

the trans, and when the power between D and S is turned off, electricity which is

deserted at trans is transmitted to the second part.

This process is repeated to maintain the fixed voltage of 12V by C102 of the second

part. This power supplies electricity to power source of 5V, relay and display, and it

allows operation of main PCB possible.

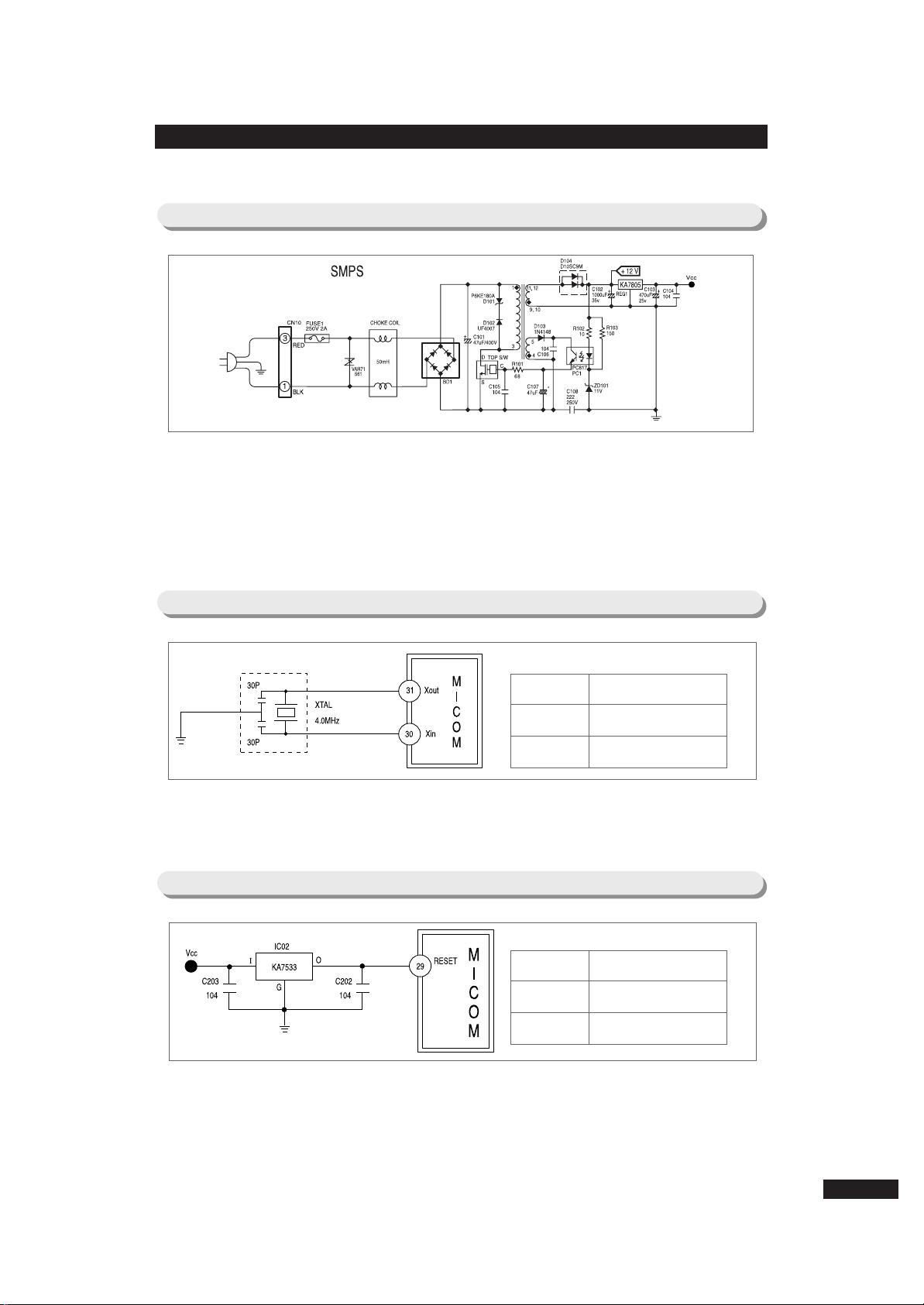

8-2) Oscillation Circuit Part

It is oscillation circuit for synchronism clock generation and time calculation on

information sending/receiving of internal elements. It does not carry out its normal

function because timing system of MICOM alters in case the specification of resonator

changes.

8-3) Reset Circuit Part

Reset circuit is a circuit which allows the whole program operate on an initial

position by initializing several parts such as RAM inside of MICOM when power is

applied to MICOM. When power is supplied, the reset terminal voltage becomes

several tens ㎲“LOW”state compared with Vcc voltage (DC 5V) of MICOM, and it

maintains “HIGH”(Vcc voltage) state in normal operation condition.

Terminal Voltage

Vcc

RESET

DC 5V

DC 5V

28

Page 29

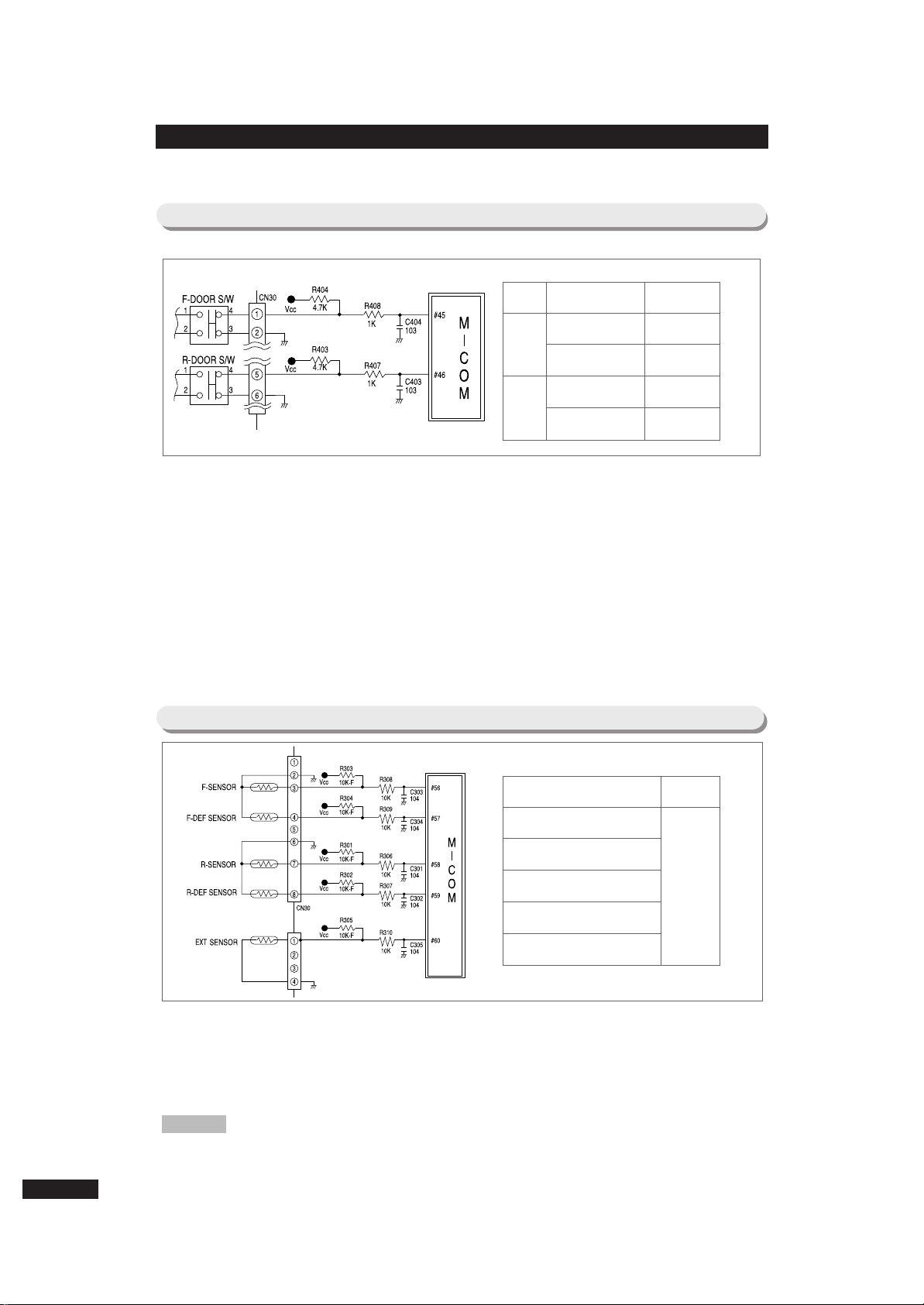

8-4) Door S/W Sensing Circuit

For door open sensing of F room, ② of CN30 is connected to the ground. For ①, Vcc(DC

5V) is supplied through resistance R404(4.7㏀), and “LOW”(0V)/”HIGH(5V) is applied to

MICOM by open/close of the F room door so that it can sense open/close of the F room

door. For door open sensing of R room, ⑥ of CN30 is connected to the ground. For ⑤,

Vcc(DC 5V) is supplied through resistance R403(4.7㏀), and “LOW”(0V)/”HIGH(5V) is

applied to MICOM by open/close of the R room door so that it can sense open/close of

the R room door. At this time, if there is any defect at the door S/W, the corresponding

fan inside the Refrigerator does not work or alarming function works. Therefore, the door

S/W must be checked in case of A/S. That is, if door opens, the corresponding fan inside

the Refrigerator stops without fail. When connection point of S/W has defect, MICOM

judges that door is open so that it stops the fan though the door is closed.

8-5) Temperature Sensing Circuit Part

Terminal

Voltage

MICOM

F-Room

DOOR CLOSE

DOOR OPEN

5V (HIGH)

0V (LOW)

R-Room

DOOR CLOSE

DOOR OPEN

0V (LOW)

5V (HIGH)

MICOM terminal Voltage

PIN #56 (F-SENSOR)

PIN #57 (F-DEF-SENSOR)

PIN #58 (R-SENSOR)

PIN #59 (R-DEF-SENSOR)

PIN #60 (EXT-SENSOR)

MICOM

terminal

voltage

changes in

accordance

with

temperature.

29

Sensor uses thermistor which has temperature coefficient of negative resistance. When

temperature rises, resistance value gets smaller, and when temperature falls, resistance

value gets larger. R306~R310, C301~C305 are parts for noise prevention, which are not

related to temperature sensing characteristic. In case of F-SENSOR, if setup voltage

inputted to MICOM Referred to as Vf, Vf= (Rth*Vcc)/(R303+Rth). Here, Rth is

resistance value of thermistor corresponding to temperature. See conversion table of

“Refer 6”of this manual on resistance and voltage of sensor about temperature for

Reference. As terminal voltage of MICOM corresponding to temperature is also

designated, Refer to it at A/S time.

Page 30

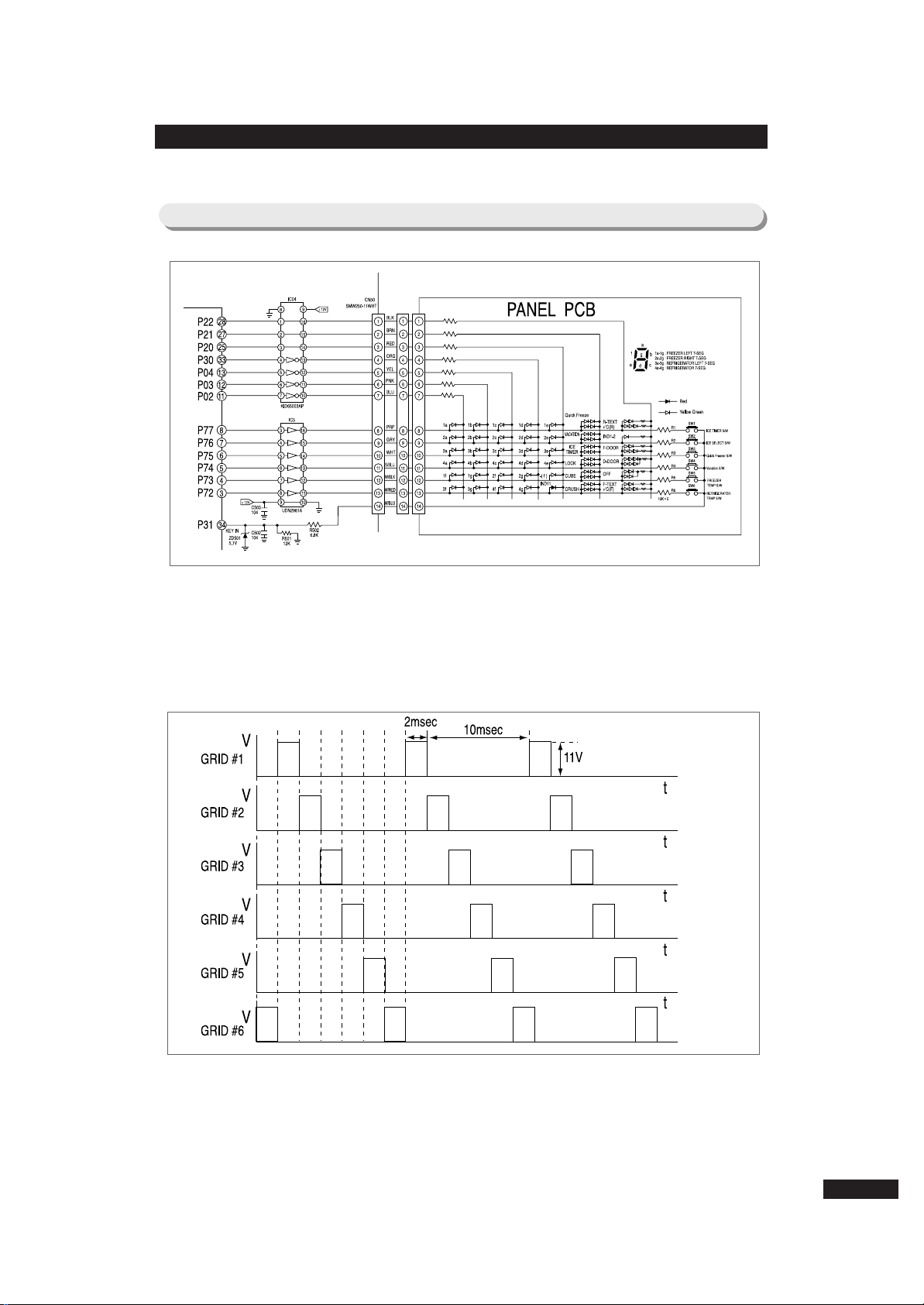

8-6) Key Scan & Display Circuit Part

① Key Scan and Display Operation

As is seen on each wave form of the following, send “HIGH”output in an

order of MICOM PIN NO #3→#4→#5→#6→#7→#8 for 2msec in a cycle

of 12msec using six terminals of MICOM NO #3, 4, 5, 6, 7, 8. This signal

appears onto output terminal through input terminal of IC05(UDN2981 or

KID65783AP). At this time, peak-to-peak voltage of the spherical wave is

about 11V(DC RMS1.5), and form of output wave form is like the drawing 1.

② Key Scan

When the wave form of GRID#2 is outputted, this signal is provided to SW6 button

through the resistance of 10㏀. When SW6 is pressed at this time, signal gets smaller

by R501(12㏀), and about 4.5V of peak-to-peak voltage is applied to MICOM.

MICOM judges that the wave form of GRID#1 is inputted, and changes function

corresponding to SW6 KEY. In this way, each wave form of GRID is recognized.

30

Page 31

8-7) Load Operation Circuit Part

When “HIGH”signal is applied to INPUT terminal of IC03(KID65003AP) from MICOM

PIN NO #16(P07), IC is turned on. At this time, V12(DC12V) which is applied to the one

terminal of coil of COMP relay flows to ground through output of IC03. Then core

generates magnetic field to turn on the connection point, and it applies voltage of 230V

to COMP load to turn on COMP. When MICOM PIN NO #16 changes to “LOW”state,

electricity cannot flow to COMP relay coil because IC is turned off. So relay connection

point becomes to OFF state and stops COMP.

① COMP & F,R Defrost Heater Inter-operation Explanation

Like the above block diagram, operation of F, R defrost heater is determined according

to the operation of relay for COMP. When COMP relay is connected to NO terminal,

COMP operates. However, in case of F, R defrost heater, electricity does not pass

through the heater though relay works. But, if COMP relay is connected to MC terminal,

COMP does not operate and heater gets electricity according to operation of F, R

defrost relay.

※ Purpose of application of above circuit: It aims to interrupt electricity passage through

F, R defrost heater even though F, R defrost relay is bad while COMP is operating.

31

Page 32

8-8) BLDC Motor Operation Circuit Part

■ In case Fan Motor is locked, therefore, when Fan Motor is constrained to less than

about 600rpm in order to prevent over-current to the power source group, PIN #39,

#38 and #37 sense it so that they can stop Fan Motor operation.

If Fan Motor operation is stopped by this function, it becomes to re-operate every 10

second. If Motor Connector is separated under the state where the power source is

applied during service, Micom recognizes it as Fan Motor is constrained so that

Micom can stop Motor. Then Motor resumes to operate after 10 seconds.

However, there are a part of products which re-operate every about 5 minute among

the products which were manufactured in February and March.

Therefore, when the product is completely repaired, confirm the repaired state with

power-ON again after power-OFF if possible.

32

Page 33

8-9) Various Option Function

■When pressing the temperature control s/w of freezer and vacation s/w for 12 sec.

continuously at the same time, display is converted into option setup mode.

■When display is converted into option setup mode, every display except for

temperature display of freezer and Refrigerator turns off like the following.

■On display like the above, temperature display of Refrigerator indicates items of

option, and temperature display of freezer indicates setup value for each

item.For the temperature display of Refrigerator, when temperature control s/w is

pressed, option items increase, and when vacation s/w is pressed, option items

decrease. For the temperature display of freezer, when temperature control s/w

is pressed, option setup value increases, and when vacation s/w is pressed,

option setup value decreases. If waiting for 20sec. after changing option by

controlling s/w, option setup value is saved to EEPROM, and option setup mode

is canceled automatically and restored normal display. For example, if you want

to shift temperature of Refrigerator by -3℃ by controlling option, follow the

processes of below.

1) Press temperature control s/w and vacation s/w of freezer for more than

12 sec. simultaneously : all displays become off except temperature

display of freezer and Refrigerator.

2) Pressing temperature control s/w of Refrigerator for one time, “1”is

indicated on Refrigerator display : If indication “1”is displayed on

Refrigerator display, it shows temperature setup of Refrigerator, and

current temperature setup value of Refrigerator is indicated on

temperature display of freezer.

3) If temperature display of freezer indicates “9”this time, check value

which is set at present from the table in the next page. In this case,

you can see that temperature is changed to +1.0℃ compared to the

standard temperature according to the table : Here, in order to change

by -3.0℃, (+1.0℃) + (-3℃) = -2.0℃ is calculated.

4) Now Refer to the table on the next page to change temperature to

-2℃. Press temperature s/w and quick freeze s/w of freezer for

temperature control display to indicate “4”: Waiting for 20sec. after

setup, MICOM saves setup value to EEPROM and returns to the

normal display and cancel option setup mode.

33

Caution

When product is delivered, option function is set to EEPROM from the plant,

therefore, Refrain from intentional change except for special case. Option

function setup is completed only after it is returned to the normal display after

20sec.. So do not turn power off before display returns to the normal state.

Page 34

■

Freezer Temperature Change Table

●Example

- When set to -2.5℃, compared with the standard

temperature of freezer

Temperature change Temperature change

Set item Refrigerator display

“0”

Freezer temperature

change mode

0

- 0.5℃

- 1.0℃

- 1.5℃

- 2.0℃

- 2.5℃

- 3.0℃

- 3.5℃

+ 0.5℃

+ 1.0℃

+ 1.5℃

+ 2.0℃

+ 2.5℃

+ 3.0℃

+ 3.5℃

+ 4.0℃

“0”

“1”

“2”

“3”

“4”

“5”

“6”

“7”

“8”

“9”

“10”

“11”

“12”

“13”

“14”

“15”

Freezer display Freezer display

Temperature change Temperature change

0

- 0.5℃

- 1.0℃

- 1.5℃

- 2.0℃

- 2.5℃

- 3.0℃

- 3.5℃

+ 0.5℃

+ 1.0℃

+ 1.5℃

+ 2.0℃

+ 2.5℃

+ 3.0℃

+ 3.5℃

+ 4.0℃

“0”

“1”

“2”

“3”

“4”

“5”

“6”

“7”

“8”

“9”

“10”

“11”

“12”

“13”

“14”

“15”

Freezer display Freezer display

Set item Refrigerator display

“1”

Refrigerator temperature

change mode

■ Refrigerator Temperature Change Table(●: corresponding lamp is on,

●: corresponding lamp is off)

8-10) Option Related to Temperature

34

●Example

- When set to +2.5℃, compared with the

standard temperature of Refrigerator

Page 35

8-11) Option Related with Ice Maker

■

Following options are applied only for models which are equipped with ice maker.

■

It is water supply time option that operates

when the flow sensor for time control

function of water-supply for ice maker is out

of order (identical with DIP s/w of existent

ZIPEL).

■

When Refrigerator temperature display indicates “2”,

the data indicated on the freezer temperature display is

the function which is not used in this model so that

additional adjustment is not necessary.

■

If Refrigerator temperature display is not selected

more than “2”during option function is setting among

models which are equipped with dispenser and icemaker, replace the main PCB assembly.

■

It is the temperature of ice making sensor

which checks whether the ice of ice-maker of

temperature change of ice making sensor

freezes completely.

Set item

Ice maker water supply time

Water supply time

“ 3 ”

5sec

4sec

3sec

6sec

7sec

8sec

9sec

10sec

12sec

13sec

15sec

17sec

19sec

21sec

23sec

25sec

“ 0 ”

“ 1 ”

“ 2 ”

“ 3 ”

“ 4 ”

“ 5 ”

“ 6 ”

“ 7 ”

“ 8 ”

“ 9 ”

“ 10 ”

“ 11 ”

“ 12 ”

“ 13 ”

“ 14 ”

“ 15 ”

Refrigerator display

Freezer display

Set item

Ice making temperature

Temperature change

“ 4 ”

- 7℃

- 6℃

- 8℃

- 9℃

- 10℃

- 11℃

- 12℃

- 13℃

“ 0 ”

“ 1 ”

“ 2 ”

“ 3 ”

“ 4 ”

“ 5 ”

“ 6 ”

“ 7 ”

Refrigerator display

Freezer display

35

●Example

- When ice making sensor is set to -10℃

●Example

- When water supply time is set to 9sec.

Note: If Refrigerator temperature control s/w and vacation s/w are used, several other options except the

above functions are set. However, those points are omitted because they are not necessary part at the

A/S time as they are items related with Refrigerator control function (Do not set options other than the

above A/S manual contents).

Page 36

9. Trouble Diagnosis & Repair Method

1. Check whether power cord is normally connected before repairs.

2. Practice checkup on the basis of Reference in the next page.

230V AC FUSE

Disconnection?

Start

Replace FUSE

power cord terminal connection

As high pressure current more

than DC300Vgenerates on the

power part of main PCB, take

great care in case of checkup

and measurement.

※

Caution

Is power 230V

applied to both terminals

of CM10?

Check cord assembly

connection.

Is voltage about

DC 320V applied to both

BD1+terminals ?

Replace PCB pattern

and BD1.

Is voltage DC5.8V

applied between top s/w

223Y ‘C-S’?

Replace PCB

assembly.

Is voltage 12V

applied to both terminals

of C102?

Replace D104(D105)

(S3L20U)(D10SC9M)

Is voltage 5V

applied to both terminals

of C103?

Replace REG1 (7805).

※

lead wire cable, door (connect

at HINGE-UP part)

Does panel PCB

operate normally?

① Check cord assembly

and repair

② Replace panel PCB

Does load of relay

and so forth operate

normally?

① Replace the

corresponding relay

② Check connection of

lead wire

Normal

Y

N

N

Y

N

Y

N

Y

N

Y

N

Y

N

Y

N

Y

Pre-checkup

9-1) When power is not supplied

36

Page 37

1. When power is applied initially, COMP works after 3~6 sec.. However, when COMP turns off during

its operation, COMP doesn’t work for 5min..

2. COMP doesn’t work during defrost

3. If freezer sensor is not connected, it is sensed as low temperature and COMP doesn’t work.

Reference 4

9-2) When COMP doesn

’’

t work

Passed 5min. after COMP off?

Start

Check after 5 min.

Reference 7

(Does alarm sound due to forced operation?)

Replace MICOM and PCB

Replace IC03 and repair

Does COMP

drive at forced

operation?

Is MICOM #1601

HIGH applied?(5V)

Repair open and

connection state

Repair sensing part

and replace PCB

Is IC03 #14 LOW

applied?(0V)

Control cord and repair

connection state

Replace COMP relay

and repair

Replace COMP RELAY

Reference 2

Is contact state of

Connector CN70, CN71

is normal?

Complete insertion of

Connector

Is COMP assembly normal?

Replace COMP ASS’Y

and repair

Cord Assembly and Connection State

N

Y

Y

N

N

Y

N

Y

Y

Y

N

Y

N

Y

N

Y

Is freezer sensor

normal?

Is temperature

sensor of main PCB is

normal?

Pre-checkup

37

Page 38

9-3) Defrost function does not work

1. At the initial power on, cooling operation is normally carried out. However, after a certain time

passes (when defrost time comes), badness occurs on Refrigerating and freezing work. It is

a case where there is defect on defrost part. Checkout whether there is defect on defrost

system by Referring this trouble diagnosis.

Judgment Condition

1. If each EVA-SENSOR of F room and R room has open or short-related defect, electricity

does not flow to defrost heater and it returns to normal operation after pause time passes.

Therefore, if the period when defrost heater does not work accumulates, Refrigerating and

freezing badness results.

2. If temperature fuse which is a safety device is turned off, or defrost heater has wire

disconnection, or relay on PCB is bad, defrost is done by natural temperature rise. In this

case, period of COMP off according to defrost becomes very long so that badness on

Refrigerating and freezing function results.

Reference

Is F, R defrost

sensor normal by

self-diagnosis?

Start

Replace and repair the

corresponding sensor

Refer to load defect checkup on

this manual Ref 3.

Refer to 7-7 self-diagnosis

function of main function.

Judge in accordance with Ref 4

and Ref 8 on this manual.

Refer to 7-6) test function of the

main function.

Is F, R defrost

heater normal by

self-diagnosis?

Check temperature fuse, heater

itself, cord disconnection, cord

contact state

Is temperature

of corresponding defrost sensor

below -5℃?

Forced operation for certain

time

Perform forced defrost for F and R

simultaneously.

Is power applied

to each defrost heater?

A

B

N

N

Y

Y

N

Y

N

Y

38

Page 39

Does it return to

cold operation after heating for

certain time?

When temperature of F, R

defrost sensor reach more than +5℃

and +15℃ by heating, terminate

heating and convert into cooling

operation after pause.

Normal

Repair connection terminal

Refer to load operation circuit

part and checkup method on

relay defect on Ref 2

N

Y

A

Recheck troubles of corresponding

sensor that does not return.

Is connection terminal

of MAIN-PCB part normal?

Check troubles on corresponding

defrost heater relay, badness of PCB,

and defect on normal/close terminal

connection of COMP RELAY.

Replace and repair bad relay or

replace PCB ASS’Y

N

Y

B

39

Page 40

9-4) Self-diagnosis Abnormality Occurs

① When abnormality on outer temperature sensor occurs

Is insertion of

main PCB connecter(CN31)

normal?

Start

Repair badness on

connector contact or

omission

Is outer temperature

sensor forging normal?

Replace temperature

sensor

Is voltage input of

MICOM PIN #60 normal?

Check main-PCB cold

lead or short

No defect on PCB and temperature

sensor. Recheck connector contact

badness

N

N

Y

Y

N

Y

② When abnormality of temperature sensor of Refrigerator occurs

Is outer temperature

sensor forging normal?

Start

Replace temperature

sensor.

Is insertion of

MAIN-PCB connector(CN30)

normal?

Badness on connector

contact. Re-insert.

Is connection cord

between main-PCB connector

(CN30) sensors?

Disconnection of wire

between connector and

sensor.

No defect on PCB and temperature

sensor. Recheck connector contact

badness

N

N

Y

Y

N

Check cold lead, short,

lead touch.

N

Y

Is input voltage of

MICOM PIN #58 normal?

Y

Reference 4

Reference 4

40

Page 41

③ When abnormality on defrost sensor of Refrigerator occurs.

Is insertion of

MAIN-PCB connector(CN30)

normal?

Start

Repair contact badness on

connector(CN30) and un-

inserted part

Replace temperature sensor

Repair the un-inserted

Connecter or contact badness.

Is defrost sensor

forging normal?

Is connection

between defrost sensor and

connector normal?

No defect on PCB and temperature

sensor. Recheck connector contact

badness

N

N

Y

Y

N

Y

Check cold lead, short and

lead touch

Is voltage input of

MICOM PIN#59 normal?

N

Y

④ When abnormality on temperature sensor of freezer occurs

Is insertion of main-PCB

connector(CN30) normal?

Start

Repair contact badness on

connector(CN30) and un-

inserted part.

Is defrost sensor

forging normal?

Replace temperature sensor

Is connection

between defrost sensor and

connector normal?

Repair the un-inserted

Connecter or contact badness.

No defect on PCB and temperature

sensor. Recheck connector contact

badness

N

N

Y

Y

N

Check cold lead, short and

lead touch

N

Y

Is voltage input of

MICOM PIN#56 normal?

Y

41

Reference 4

Reference 4

Page 42

⑤ When abnormality on defrost sensor of freezer occurs

Is insertion of

MAIN-PCB connector(CN30)

normal?

Start

Repair contact badness on

connector(CN30) and un-

inserted part.

Is defrost sensor

forging normal?

Replace temperature sensor

Is connection

between defrost sensor and

connector normal?

Repair the un-inserted

Connecter or contact badness.

No defect on PCB and temperature sensor.

Recheck connector contact badness

N

N

Y

Y

N

Check cold lead, short and

lead touch

N

Y

Is voltage input of

MICOM PIN#57 normal?

Y

Reference 4

9-5) When alarm is continuously ringing

·Alarm for freezer/Refrigerator door open continues for 10sec. at the initial door open. After 2 min. of

initial opening, it alarms for 10sec. by the 1min.

cycle when door remains open (10 times of Ding-Dong sound).

Reference

① When Ding-Dong sound continuously occurs

Is there any

penetration of moisture to

door s/w?

Start

Replace DOOR S/W

Do input voltages

of MICOM PIN #45, #46

change?

Repair cord disconnection and

badness DOOR S/W

Is insertion of

MAIN-PCB connector(CN30)

normal?

Repair the un-inserted

Connecter or contact badness.

MAIN-PCB and DOOR S/W are

normal

N

N

(DOOR OPEN/CLOSE)

Y

Y

N

Replace DOOR S/W

N

Y

Is DOOR S/W itself normal?

Y

42

Page 43

② When “Beep-Beep”sound continuously occurs

Isn’t forced

operation or defrost

selected?

Start

Cancel forced operation or

defrost.

Does buzzer

sound occurs if power

is reset?

MAIN-PCB is normal

Check dirt insertion and short on test

jumper part inside of the MAIN-PCB

N

N

Y

Y

Sound of “Beep-Beep”does not occur except abnormalities due to forced operation, defrost or

self-diagnosis abnormality.

In case of self-diagnosis abnormality, it is easy to check because it is indicated on panel-display.

If “Beep-Beep”sound continues to ring though panel display is normal, it is considered that

forced operation or defrost is selected.

Reference

③ In case PANEL-DISPLAY is not lit

Is connector

insertion of HINGE-UP cover

normal?

Start

Re-insert connector, repair

badness on contact

Is insertion of MAIN-PCB

connector(CN50) normal?

Re-insert connector inside

of the MAIN-PCB.

Is connector

insertion of the panel dispenser

part normal?

Re-insert connector, repair

badness on contact.

Replace PANEL-DISPLAY

N

N

Y

Y

N

Y

43

Page 44

④ When key selection of PANEL-DISPLAY is not available

Is connector insertion

of HINGE-UP 14PIN of freezer

normal?

Start

Re-insert connector.

Repair contact badness

Repair on the basis of

connection diagram of electric

wire assembly cabinet-door of

Reference 1.

Is connector(CN50)

insertion on the MAIN-PCB

normal?

Re-insert CN50 connector,

correct and repair.

Is connector insertion

of the PANEL-PCB part

normal?

Re-insert connector,

correct and repair.

Is there any case

that more than one key are pressed

in a series?

Reassemble PCB base,

resolve pressed part.

Continuous operation is

impossible

Is it badness of

ZD501 or short-related defect on the

MAIN-PCB

Replace and repair

ZD501.

Is GRID signal

inputted to MICOM PORT

#34?

Replace and repair the

MAIN-PCB ASS’Y

Check if corresponding GRID

signal is inputted when PANEL-PCB

S/W button is pressed.

Repair corresponding button of

PANEL-PCB, or replace PANEL ASS’

Y PCB

N

N

Y

Y

N

Y

N

Y

Y

N

N

Y

44

Page 45

Check sensing circuit on PCB related

with F-DOOR S/W. Replace and repair.

Judge on the basis of

abnormality of DOOR S/W in

“check item”of this manual Ref 5.

Check only at the condition where

Refrigerator door is closed.

Refer to checkup method of relay

badness on Ref 2.

9-6) When FAN does not work

“Check cooling fan only at the condition of selecting forced operation necessarily.”

1. When COMP is turned off, cooling fan of freezer(F-FAN), cooling fan of Refrigerator(R-FAN),

COMP, and cooling fan of COMP mostly retains “off”state. However, in case of R-FAN, it can

operate for some period of time by natural defrost function if COMP is turned off.(It operates

depending on temperature condition of Refrigerator)

2. Evenat forced operation condition, R-FAN is not always turned on (including normal operation),

and retains “off”state if temperature of Refrigerator room is reached the set temperature.

3. When the door of freezer and Refrigerator is closed after opening, each fan has its delay time. That

is, fan stops immediately when door is opened during its operation, and operates again after

delay of about 10sec. or 1min. (when outer temperature is over 35℃) when the door is closed.

Reference

① When FAN of freezer(F-FAN) does not work (when COMP operates normally by temperature).

Is COMP in “off”state?

Start

Allow forced operation.

Open freezer door

Is F-FAN turned off?

Replace and repair MAIN-PCB ASS’Y.

Y

N

N

F-FAN is normal.

Y

Y

When pressing

F-DOOR S/W, does FAN operate after

delay time?

N

Badness of fan itself. Replace

and repair

Y

Is voltage of

DC7~11V applied to both terminals

of fan?

N

Re-insert connector and

repair.

N

Is contact of CN72 on

PCB normal?

Y

45

Page 46

Check sensing circuit on PCB

related with R-DOOR S/W. Replace

and repair.

Judge on the basis of

abnormality of DOOR S/W in

“check item”of this manual Ref 5.

Is COMP in “off”state?

Start

Let forced operation.

Open refrigerator door to raise

temperature inside of refrigerator

Is R-FAN turned off?

Replace and repair the MAIN-PCB

ASS’Y

Y

N

N

R-FAN is normal

Y

Y

With pressing

R-DOOR S/W, does fan operate after

delay time?

N

Badness on fan itself. Replace

and repair.

Y

Is voltage of

DC7~11V applied to the both terminals

of FAN?

N

Re-insert connector and repair.

N

Is contact

of CN72 on the PCB

normal?

Y

② When Refrigerator fan (R-FAN) does not work (when temperature sensing function in

Refrigerator room is normal).

46

Page 47

9-7) When lamp inside of Refrigerator is not lit.

There exists the risk of electric shock when replacing the lamp inside of

Refrigerator. Replace and repair at only “power off”state.

Is connector contact

inside of Refrigerator

normal?

Start

Re-insert connector and

repair.

Is filament of LAMP broken?

Replace LAMP in the

Refrigerator.

Is there any

abnormality on connection point of

R-DOOR S/W?

Check if voltage of 230V is applied

to socket of R-LAMP and repair.

N

Y

Y

N

N

Y

Inside of cover of Refrigerator LAMP

※

Check on the basis of

abnormality checking method for

DOOR S/W of Ref 5.

Check and repair R-DOOR S/W.

Caution

47

Page 48

9-8) When lamp inside of freezer is not lit.

There exists the risk of electric shock when replacing the lamp inside of freezer room. Replace and repair

at only “power off” state.

Caution

Is connector

contact inside of freezer

normal?

Start

Re-insert connector and

repair.

Is filament of LAMP broken?

Replace LAMP in the

freezer.

Is there any

abnormality on connection point of

F-DOOR S/W?

Check if voltage of 230V is applied

to socket of F-LAMP and repair.

N

Y

Y

N

N

Y

※

Inside of cover of FREEZER-LAMP

※

Check on the basis of abnormality

checking method for DOOR S/W of Ref 5.

Check and repair F-DOOR S/W.

48

Page 49

9-9) Abnormality diagnosis method for ICE-MAKER

Is DC electricity

(5V, 12V) normally outputted?

Is ICE-MAKER

dish horizontal?

Badness of power

resource terminal

Replace the

MAIN-PCB

Power Resource

Terminal Check

Disconnect

connector like

Ref. 8

Kit Check (CN90

Terminal WIRE

HARNESS)

Sensor Check

(Ref. 4)

Motion Check

Is resistance between

both ends (between ① and ②) of ice-eject motor within

range of 18~22Ω?

N

N

N

Y

Y

Y

Badness on

motor

Is TEST S/W(both ends

of ⑤ and ⑧) open?

N

Y

Badness on

TEST S/W

Is horizontal S/W(both

ends of ⑥ and ⑧) open?

N

Y

Badness on

MICRO S/W

Is ice-check S/W (both ends

of ⑦ and ⑧) open?

N

Y

Badness on

MICRO S/W

Is ice-eject sensor

(both ends of ③ and ④) within range written on

table of Ref. 8?

N

N

Y

Y

Badness on ice-

eject sensor

Pressing test s/w for more than

1.5sec., does it normally perform ice-eject and horizontal

restoration and generate sound of “Ding-Dong”

for one time?

Badness on kit

ASS’Y

Replace kit

ASS’Y

Normal

49

Page 50

① When cube ice does not come out when cold cube ice is selected.

When cube ice is

selected, does cube ice

come out?

Start

Isn’t freezer door open? Close

the door if it is open.

When ice lever is

operating, does cube ice

come out?

Normal

N

Y

Y

Replace and repair MAIN-PCB

ASS’Y

N

N

Is micro port #20 on

MAIN-PCB “HIGH”?

Y

Replace and repair relay RY76.

N

Is relay K76 turned on?

Y

Check lead wire and repair

defected part

N

Re-check the water supply

point.

N

Does drill motor

solenoid inside of freezer operate

normally?

Is tap water normally supplied?

Y

Y

When motion system is normal, however, if there is no ice in the ice container, ice does not come

out. Please ensure whether there is ice in the ice container.

Reference

9-10) When cube and crushed ice are not normally operated.

50

Page 51

Does S/V operate for

0.3 sec. when 8 sec. are passed after initial

power on?

Start

Check and repair

devices such as

stopper lever &

support, etc

No defect on S/V control PCB ASS’Y

and wire system

When ice lever is

pressed, does it maintain

open state?

Replace MAIN-

PCB ASS’Y

Badness of IC03.

Exchange

Utilize checkup

method for SSR

defection of Ref. 2

At door-closed state,

does ice conveying motor operate if ICE S/W is

turned on?

Is cover closed

after about 5sec. by S/V

operation?

No defect on cover ice-route control

system

N

Y

N

N

N

N

Y

N

Y

Y

Y

N

Y

MICOM control port is normal

After 8sec. from the point

of initial power on, does IC03 #12 indicate “LOW”

state for 0.3sec.?

Check ICE S/W.

Check and repair

wire connection

system

With the initial power on,

does MICOM #18 on PCB indicate “HIGH”

state for 0.3sec.?

9-11) When solenoid which is cover ice-route delay device does not work

1. Check whether solenoid automatically operates for 0.3sec. regardless of open/close of cover

ice-route 8 sec. after initial power on.

2. Check whether Hinge-up connector contact is normal.

Pre-checkup

51

Exchange defected parts

after checking SSR71 or

replace PCB ASS’Y.

S/V is abbreviation of Solenoid Valve

Reference

Page 52

Performance of motion to retain horizontal level

of ice-making dish for initial power apply or for

restoration from stoppage of electric current.

Performance of ice-separation regardless of

water supply to ice-making dish by waiting for 1

cycle.

After ice-making is finished, motion of iceseparation from ice on dish into storage

container. Ice-separation is performed by

checking the horizontal s/w, and the signal

change of ice-inspection s/w and the changed

time. They should be checked together in parallel.

After ice-making is finished, motion to supply icemaking water to ice-tray using water valve.

Is it horizontal?

Start

ice-eject motor

stop

Wait for 1 cycle

(under -7℃)

Ice-eject step

Water supply

step

This step means the period from when water

supply is finished to when it is judged that water

turned into ice completely. This is judged by

parallel checkup of temperature and time.

Ice-making step

Function for cases which are needed for forced

operation for the purpose of operation test, A/S,

and cleaning.Ice-separation motion and water

supply motion are conducted continually and this

step should have priority than any other

operations.

Test step

Y

N

Reverse-

rotation of ice-

eject motor

10. Operation Principle & Repair Method of ICE-MAKER

10-1) Operation Principle of ICE-MAKER

52

Page 53

10-2) Ice-maker Test Function

5. Test Function

●It is function for the case which needs forced motion for the purpose of cleaning and

so on at the time of operation test and A/S. This function is performed when the test

s/w which is equipped with the body of automatic ice-maker itself, is pressed for

more than 1.5 sec..

1) Test button does not go into test function during ice-eject, levelling for horizontal

position and water supply. It operates in the horizontal state. It does not operate at

the state where ice is fully filled. Only after ice full mode is cancelled and ice-check

s/w is off, test function operates.

2) When test button is pressed in the horizontal state for more than 1.5sec., ice-eject