Samsung SR-61KTC, SR-65NMC, SR-69NMC, SR-65KTC, SR-61NMC Service Manual

REFRIGERATOR CONTENTS

1. Product Specifications 1

2. Safety Warning & Caution 2

3. Electrical part specifications & standard 4

4. Electric diagram 6

5. Air Circulation route 7

6. Function & Vsing method 8

7. Temperature control & other Functions 11

8. Circuit Operating theory 21

9. Failure diagnosis & repairment 36

10. Dissembie & Assemble drowing and part LIST 53

11. Disassemble & Assemble Method 88

12. Packing 84

13. Main componets specification 86

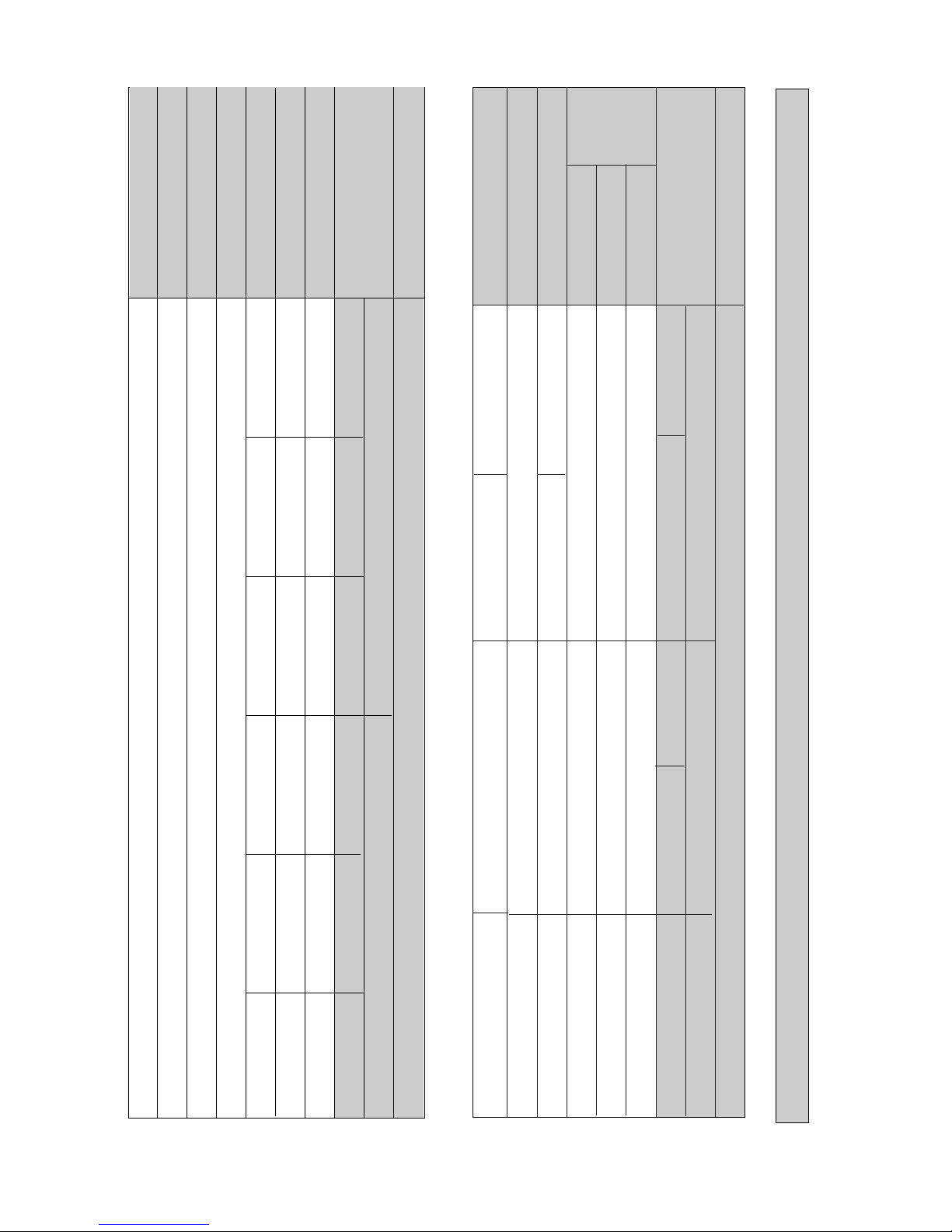

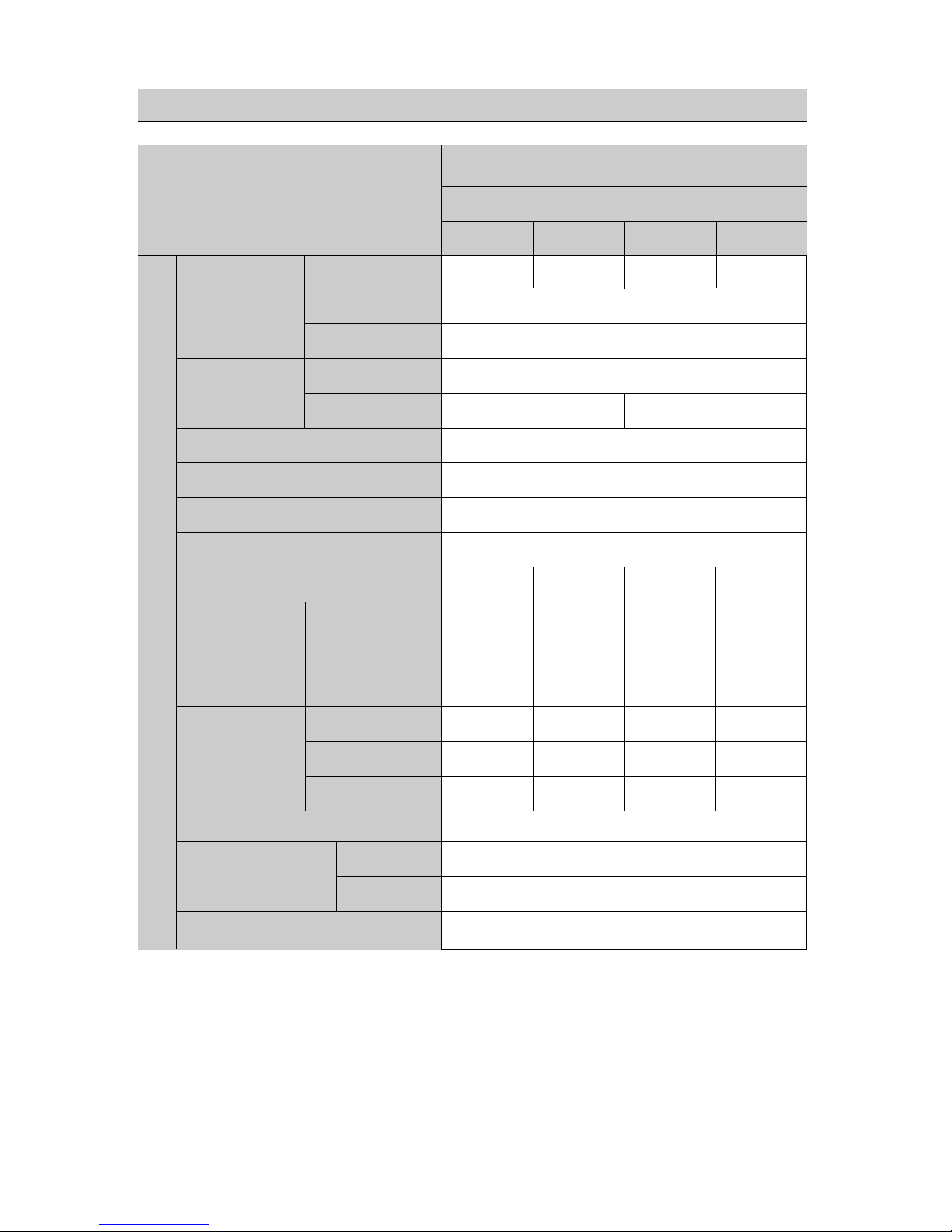

Model: SR-61KTC/SR-61NMC

SR-65KTC/SR-65NMC

SR-69NMC

ITEM.

MODEL NAME

NET DIMENSION

NET WEIGHT

ELECTRIC HEATING EQUIPMENT

POWER

- 2-

1. Product specifications.

●Classification by Capacity

NET

CAPACITY

TOTAL

FREEZER

REFRIGERATOR

STANDARD

510 MODEL

550 MODEL

590 MODEL

SR69-NMC

SR-61KTC

SR-61MNC

SR-65KTC

SR-65NMC

514LT

153LT

361LT

554LT

165LT

389LT

589LT

165LT

424LT

840*761.5*1755.5

840*761.5*1760.5

840*761.5*1810.5

840*761.5*1854.5

96 KG

97 KG

98 KG

388W

378W

388W

378W

●Classification by Electric power

ITEM.

MODEL NAME

REGULAR FREQUENCY

REGULAR VOLTAGE

ELECTRIC MOTOR REGULAR POWER

SORT OF REFRIGERATOR

COOLING MASS

COOLING MASS SEALED QUANTITY

FREEZER PERFORMANCE

STANDARD

SR-61KTC, 65KTC

SR-61NMC, 65NMC, 69NMC

AC127V / 60Hz

60Hz

AC 127V

AC127V / 60Hz

60Hz

AC 127V

OCCASSIONAL COOLING TYPE REFRIGERATOR

HFC-134α

150 G

4 STAR

AC220V / 50~60HZ

50~60Hz

AC 220V

AC240V / 50HZ

50Hz

AC 240V

AC220V / 50~60HZ

50~60Hz

AC 220V

AC240V / 50HZ

50Hz

AC 240V

- 3-

2.Safety precautions and warnings

xRead all instructions before using this product and keep to the instructions

in order to prevent danger or property damage.

25cm

Warning

W arning

Caution

Description of symbolsWarning/Caution

Indicates that a

danger of death

or serious injury

exists.

Indicates that a risk

of personal injury

or material damage

exists.

IN DICATES PROHIBITION

DO NOT DISASSEMBLE

DO NOT CONTANT

ADHERE THE INSTRUCTION STRICTLY

ONPLUP FROM THE ELECTRICAL

AVOLD

EARTH THE APPLIANCE TO AVOID THE

RISK OF AN ELECTRIC SHOCC

Do not insert the power cables.

●

May cause abnormal

generation of heat or fire.

Do not disassemble to

repair or alter.

●

It may cause fire or abnormal

operation which leads to injury.

Do not bend the power cable with

excessive force or do not have the

power cord pressed by heavy article.

●

May cause fire.

Check the operating environment.

●

Deterioration of electric parts insulation

may cause electric shock or fire.

Make sure of the earth.

●

If power doesn’t ground, it will

cause breakdown and electric shock.

Pull the power plug out to exchange

the interior lampof the refrigerator.

●

It may cause electric shock.

Prohibition

Do not

disassemble

Earth

Unplug

- 4-

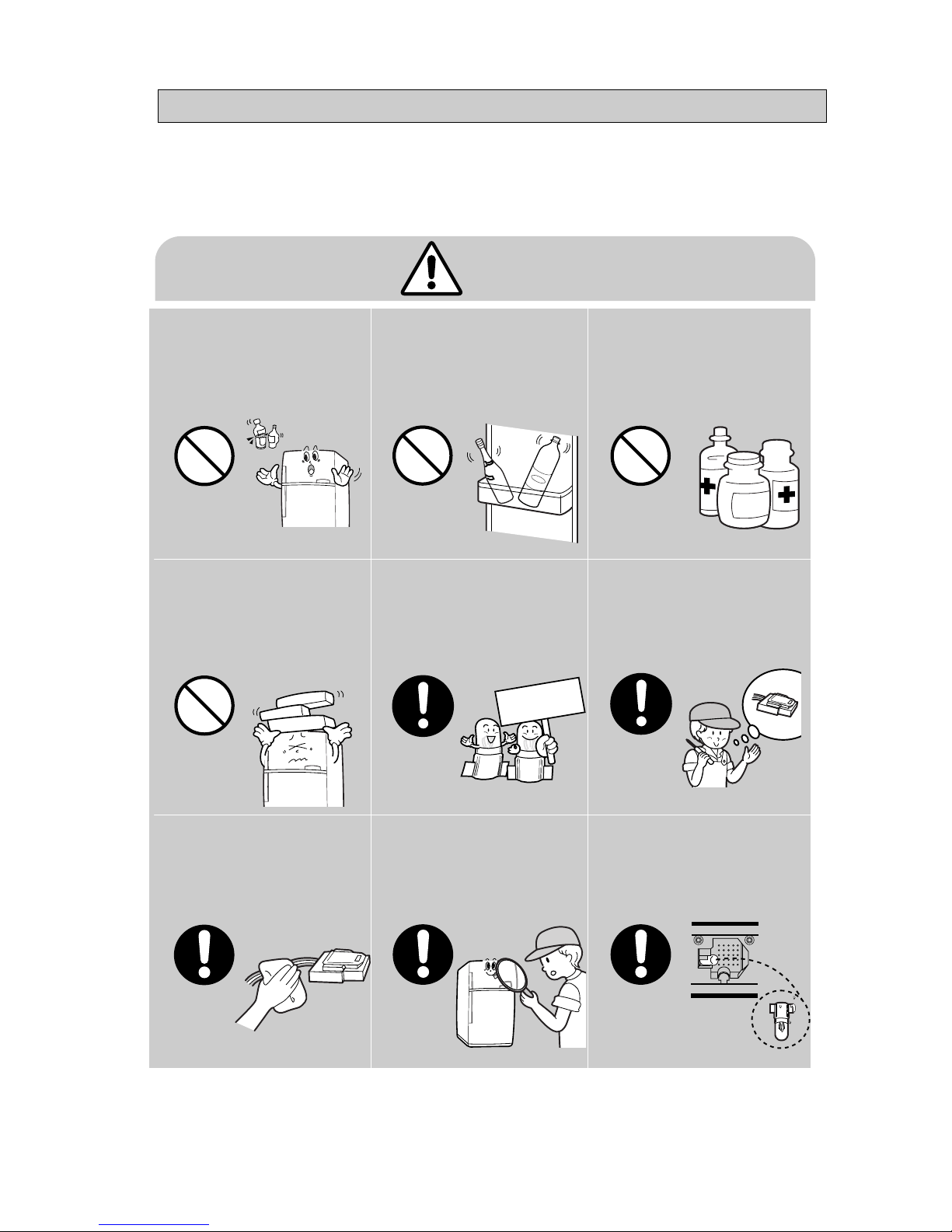

Caution

Do not put bottles or kinds of

glass in the freezer.

●

Freezing of the contents may inflict a

wound.

Do not store narrow and lengthy

bottles or foods in a small multipurpose room.

●

It may hurt you when refrigerator door

open and close.

Do not store pharmaceutical

products, scientific materials,

etc., in the refrigerator.

●

The products which temperature control

should not be stored in the refrigerator.

Do not store articles on the

Refrigeration.

●

Opening or closing the door may

cause things to fall down, wihch

may inflict a wound.

When replacing electric

comporents, be sure to use rates

comporents.

●

Check the model, rated voltage, rated

current, operating temperature etc. of

the component.

On repair, make sure that the wires

such as harness are tightly

bundled.

●

Tghtly bundle wires in order not

to be detached by the external

force and to be wetted.

On repair, remove completely dust or

other things of housing parts,

harness parts, and check parts.

●

Cleaning may prevent the possible fire by

tracking or short.

After repair, check the assembled

state of components.

●

It must be in the same assembled state

when compared with the state before

disassembly.

Check the electrical parts for the

trace of moisture.

●

When the trace of moisture penetration is

detected, replace the patt or try insulation

tapping.

Prohibition

Prohibition

Prohibition

Prohibition

Reted

components

RSCR

Freol α-15(ESTER)

SPLIT FIN TYPE

FORCED AND NATUAL CONUECTION TYPE

MOLECULAR SIEVE XH-9

0.82X2500 4.26Kg/cm

2

HFC-134a

- 5-

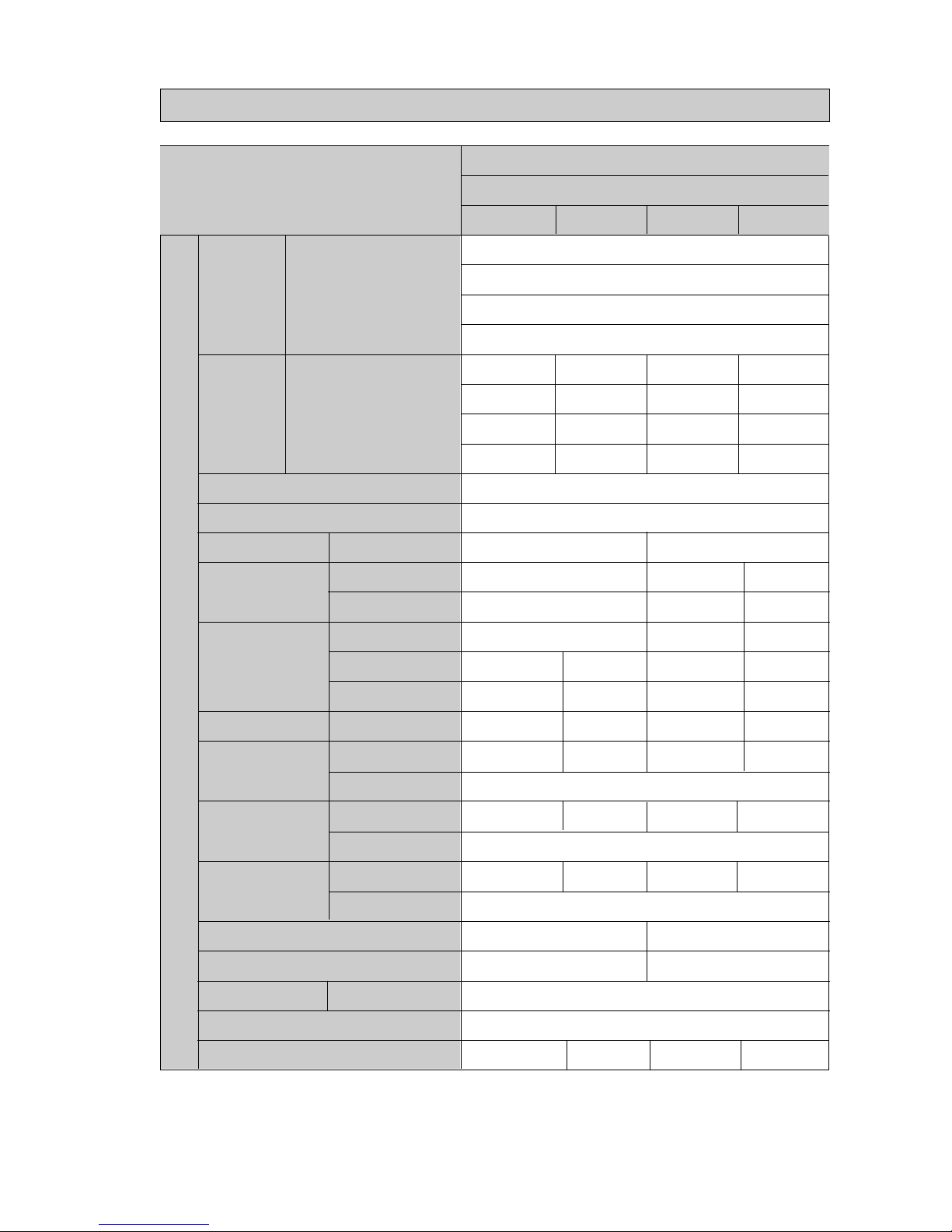

3. ELECTRIC PARTS STANDARD

ITEM

STANDARD

DEFROST

TEMPERA TURE

REFRIGERA TION PAR TS

COMPRESSOR

COOLER

MODEL

STARTING TYPE

OIL CHARGE

FREEZER

REFRIIGERATOR

4hours±10minute

10minute±2minute

CONDENSER

DRYER

CAPILLARY TUBE

REFRIGERANT

FREEZER

REFRIGERATOR

HIGH

MID

LOW

HIGH

MID

LOW

FIRST CYCLE

PAUSE TIME

ON(℃)

-21℃

-18℃

-15℃

-0.5℃

3.5℃

6.5℃

OFF(℃)

-23℃

-20℃

-17℃

-1.5℃

2.5℃

5.5℃

ON(℃)

-22℃

-18℃

-15℃

-0.5℃

2.5℃

5.5℃

OFF(℃)

-24℃

-20℃

-17℃

-1.5℃

1.5℃

4.5℃

REFRIGERATOR

FREEZER

CYCLE

SR-61/65/69NMC / SR-61/65KTC

DK172C-L2U

110~115V/60Hz

127V/60Hz

220V/50~60Hz

230~240V/50Hz

DK172P-L2U

SK190H-L2U DK190Q-L2U

SPLIT FIN TYPE & TUBE TYPE

SPLIT FIN TYPE

10hours

20hours

- 6-

ITEM

SENSOR

F-SENSOR

R-SENSOR

F-DEF SENSOR

R-DEF SENSOR

DRAIN HEATER

F DEF HEATER

R DEF HEATER

DID HEATER

F DEF FUSE

R DEF FUSE

CONDENSER

STARTING RELAY

O/L-PROTELTOR

SR-61/65/69NMC

SR-61/65/69NMC

SR-61 / 65KTC

SR-61 / 65KTC

SR-61 / 65KTC

F-LAMP

R-LAMP

DID DOOR-S/W SR-61 / 65KTC

DOOR-S/W

Power cord

SR-61/65/69NMC

SR-61/65/69NMC

DC TRANS

F-COOLER FAN MOTOR

R-COOLER FAN MOTOR

CYCLE FAN MOTOR

502 AT

〃

〃

〃

HEATER

250V 0.7A

250V/0.7A

12V, DC - BLDC , SENSORLESS

12V, DC - BLDC , SENSORLESS

12V, DC - BLDC , SENSORLESS

110 / 130V 15W

130V 30W

240V 15W

240V 25W

SR-61/65/69NMC / SR-61/65KTC

110~115V/60Hz

127V/60Hz

220V/50~60Hz

230~240V/50Hz

12㎌ / 250VAC

J531QE100M2002

10Ω±20%(

SURROUNDING TEM

25℃)

250V 10A 72

±4℃

250V 10A 72

±4℃

5㎌ / 350VAC

13W / 110V

235W / 220V

120W / 110V

10W / 110V

13W / 127V

235W / 127V

120W / 127V

10W / 127V

13W / 220V

235W / 220V

120W / 220V

10W / 220V

13W / 240V

235W / 240V

120W / 240V

10W / 240V

69

℃

130

℃

115V 50/60Hz

110V 60Hz

69

℃

125

℃

127V 50/60Hz

127V 60Hz

69

℃

130

℃

220V 50/60Hz

220V 50/60Hz

J531Q34E100M350-2

220Ω±20%

(

SURROUNDING TEM

25℃)

4TM314RHBYY-53

61

℃

130

℃

240V 50/60Hz

240V 50Hz

110V 60Hz

127V 60Hz 220V 50~60Hz 230~240v 50Hz

110V 60Hz

127V 60Hz 220V 50~60Hz 230~240v 50Hz

J531Q35E330M385-2

330Ω±20%

(

SURROUNDING TEM

25℃)

4TM265RHBYY-53

4TM437RHBYY-53

EP-2,127V/7A

SPT-3,125V/7A VCP-2,250V/10A BF-3,250V/10A

OPERATION

MODEL

START

MADEL

ON TEM

OFF TEM

ELECTRIC P AR TS

-7-

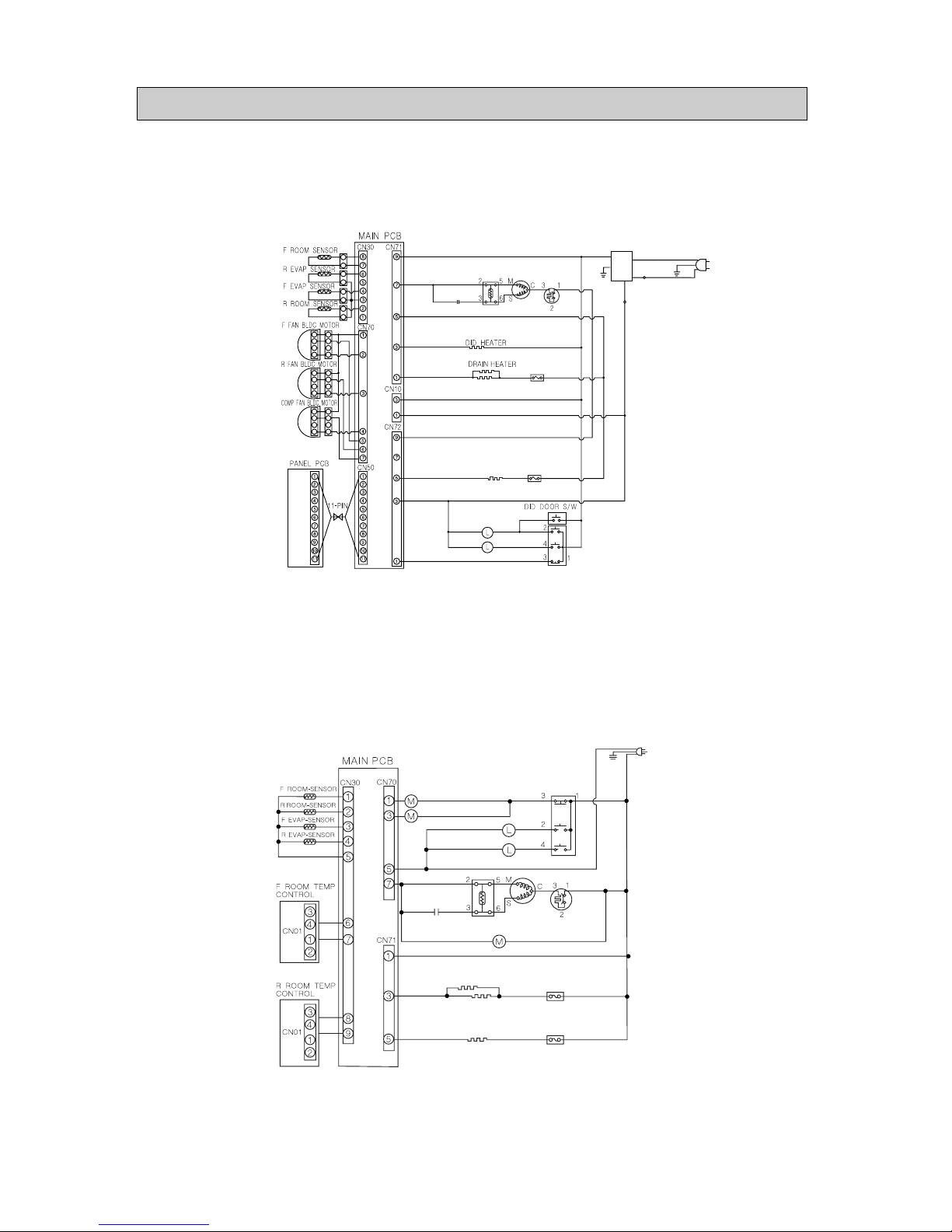

4. Electric diagram

ORG

ORG

YEL

YEL

YEL

BLU

VLT

BLK

BRN

BRN

BRN

GRY

GRY

GRY

GRY

RED

RED

RED

PIK

PIK,BLU

RED

RED

RED

RED

RED

RED

RED

RED

RED

F DEFROST-NEATER

R DEFROST-NEATER

RED

R ERM FUSE

F ERM FUSE

COMP RELAY

COMPRTSSOR COOLER MOTOR

OPERATING CONDENSER

WHT

WHT

WHT

WHT

WHT,BLK

SIBLU

SIBLU

SIBLU

SIBLU

SIBLU

EARTHED

CIRCUIT

FREEZER FAN MOTOR

DOOR SWITCH

FREEZER FAN MOTOR

REFRIGERATOR LAMP

FREEZER LAMP

4-2) SEMI BASIC (SR-61NMC, 65NMC, 69NMC)

4-1. Electronic mode(SR-61KTC,65KTCT)

BLU

BLU

VLT

VLT

VLT

VLTVLT

BLK

BLK

BLK

BLK

BLK

BLK

BLK

EARTHED

CIRCUIT

EARTHED

CIRCUIT

BLK

BLK

BLK

BLK

W / B

W / B

BRN

BRN BRN

BRN

RED

RED

RED

RED

RED

GRN

EMI

FILTER

WHT

GRN

RED

REDRED

RED

F-DEFROST-HEATER

R-DEFROST-HEATER

REFRIGERATOR

FREEZER LAMP

RED

RED

WHT

ORG

ORG

ORG

ORG

PNK

BLU

VLT

GRY

GRY

GRY

GRYGRY

GRY

GRY

GRY

WHT

WHT

WHT

YEL

YEL

YEL

SIBLU

SIBLU

SIBLU

SIBLU

P .T.C RELAY

COMPERESSOR

COMP RELAY

OPERATING

CONDENSER

SIBLU

SIBLU

BLK

BRN

RED

RED

ORG

PNK

PNK

BLU

VLT

GRY

WHT

SIBLU

SIBLU

GRY

F-TEM FUSE

R-TEM FUSE

-8-

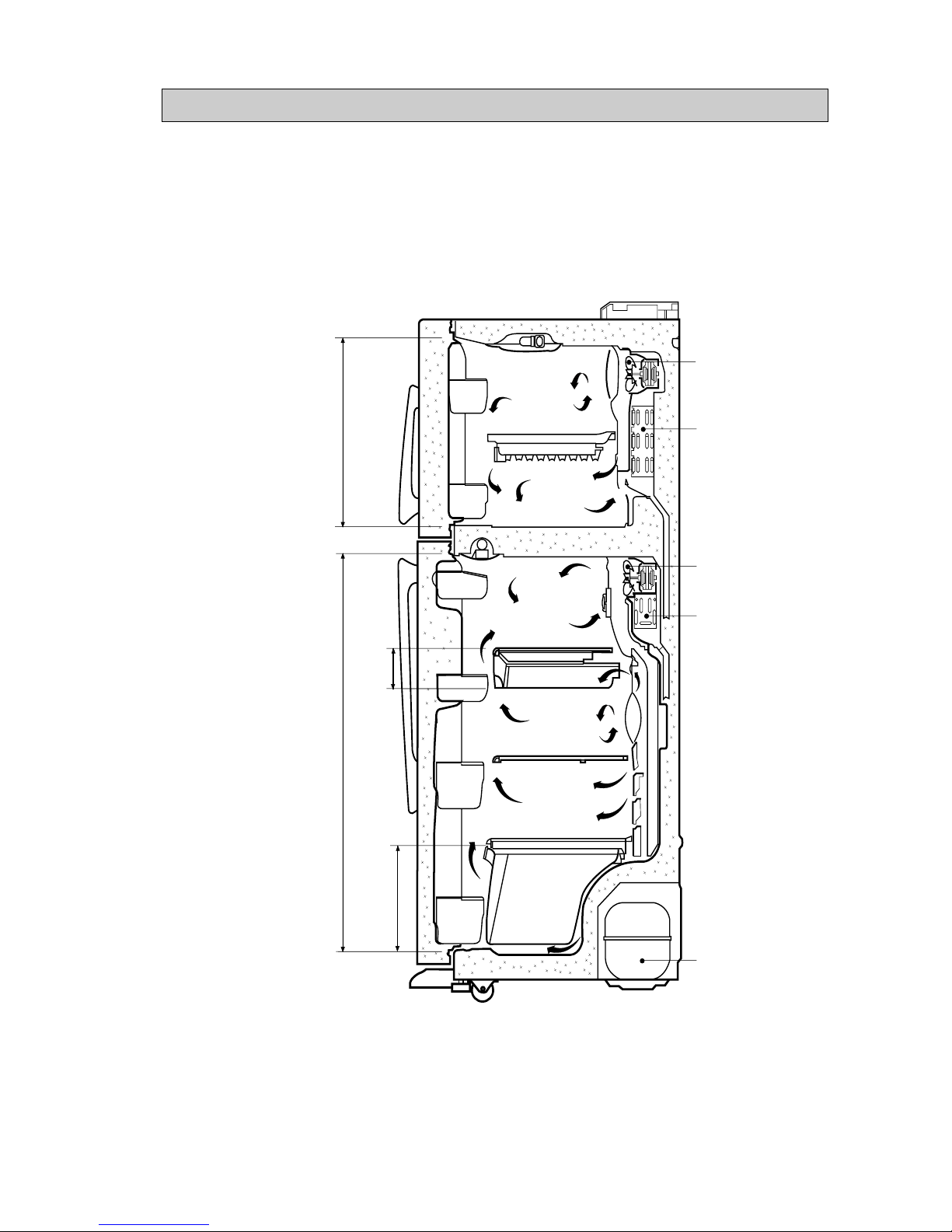

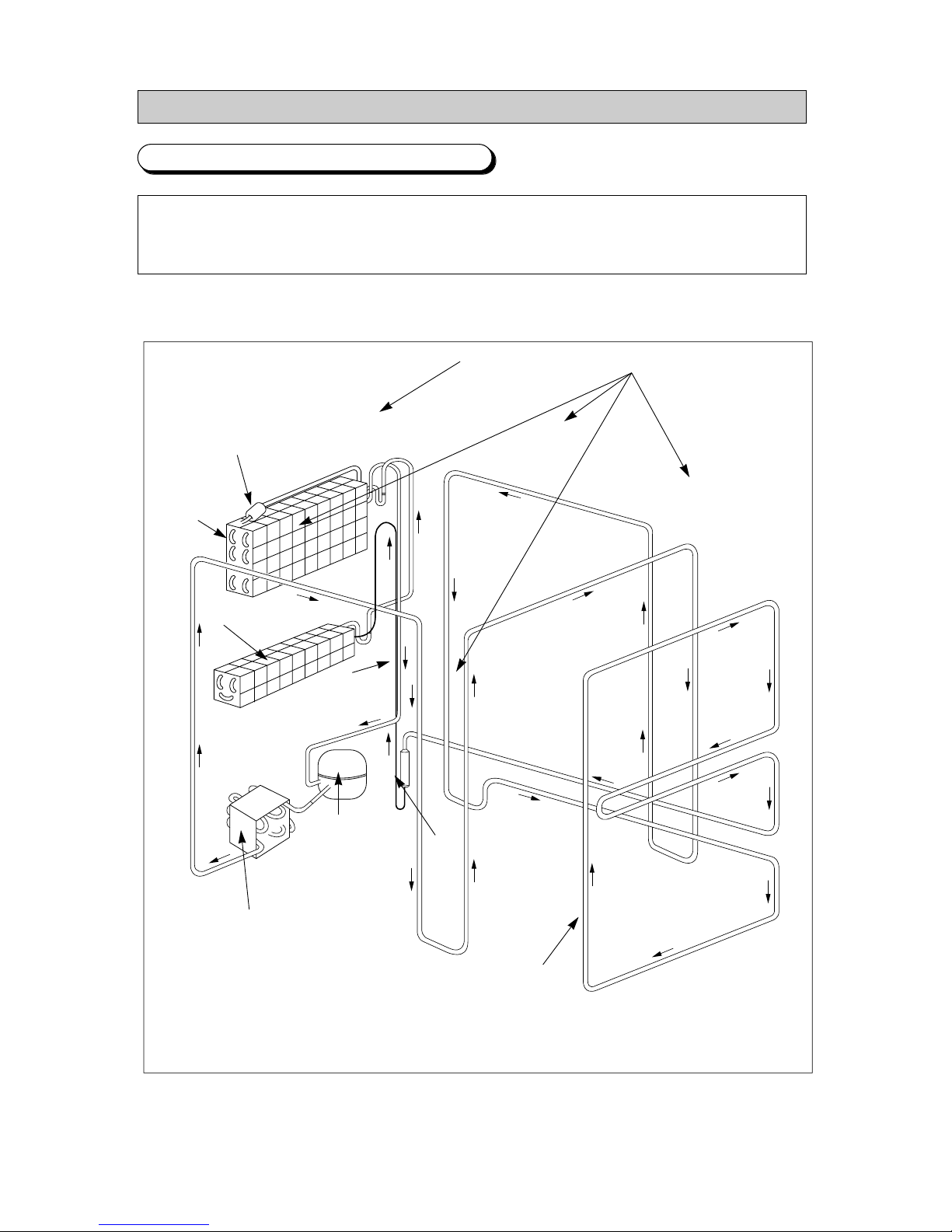

5. Cool Air Circulation

Freezer

Refrigerator

Case of Re

frigerator

Vegetabele

part

Compressor

Cooler of

Refrigerator

Cooling fan of

Refrigerator

Cooler of

Freezer

Cooling fan of

Freezer

-9-

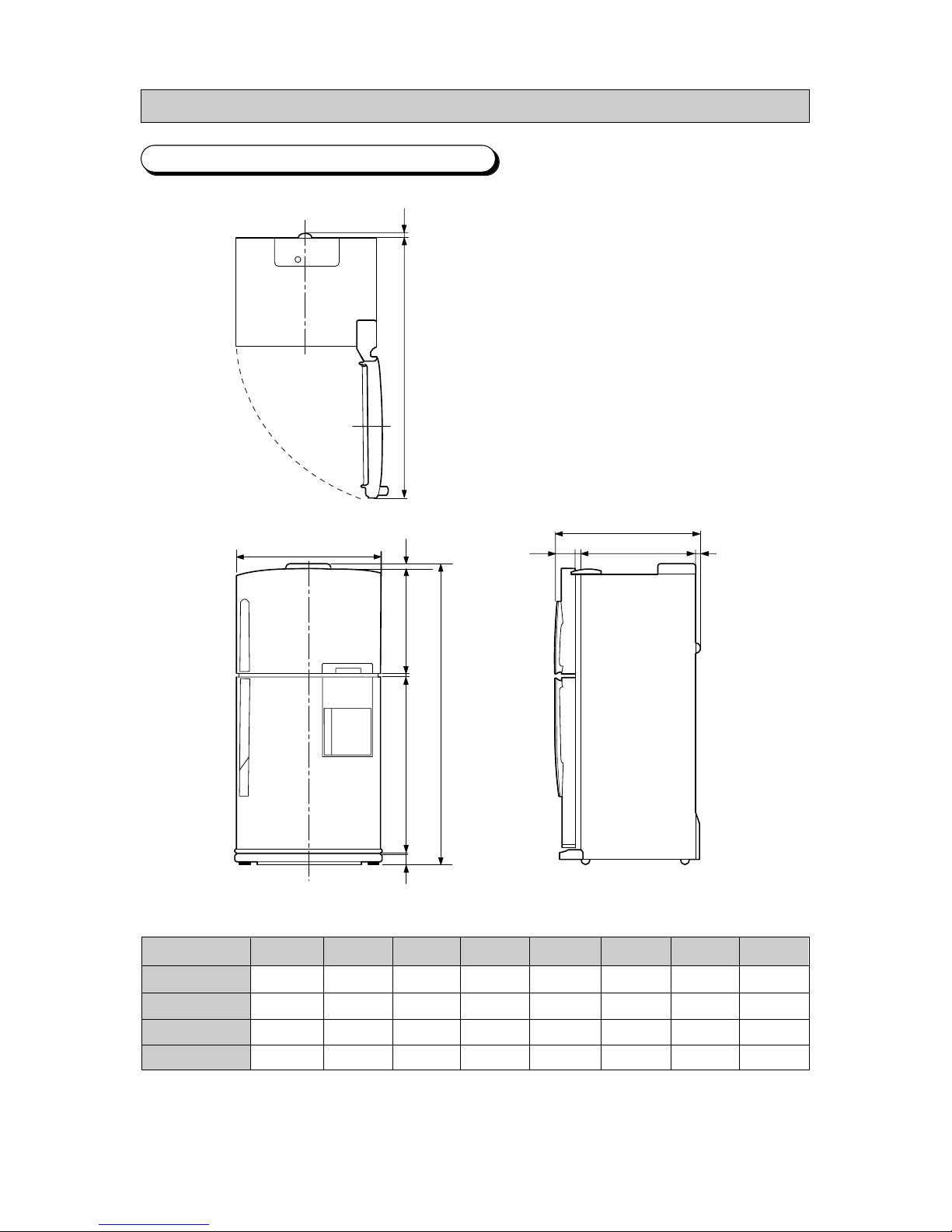

6-1. THE OUTER SIZE

6. FUNCTIONS AND DIRECTIONS

MODEL

SR-61KTC

SR-61NMC

SR-65KTC/NMC

SR-69NMC

A

1066.5

1066.5

1096.5

1140.5

B

580

580

600

600

C

1755.5

1760.5

1810.5

1854.5

D

761.5

761.5

761.5

761.5

E

617.5

617.5

617.5

617.5

F

1479

1479

1479

1479

G

123

123

123

123

F

17

A

C

B

9.5

9

71.5

840

D

EG

11

10

10

-10-

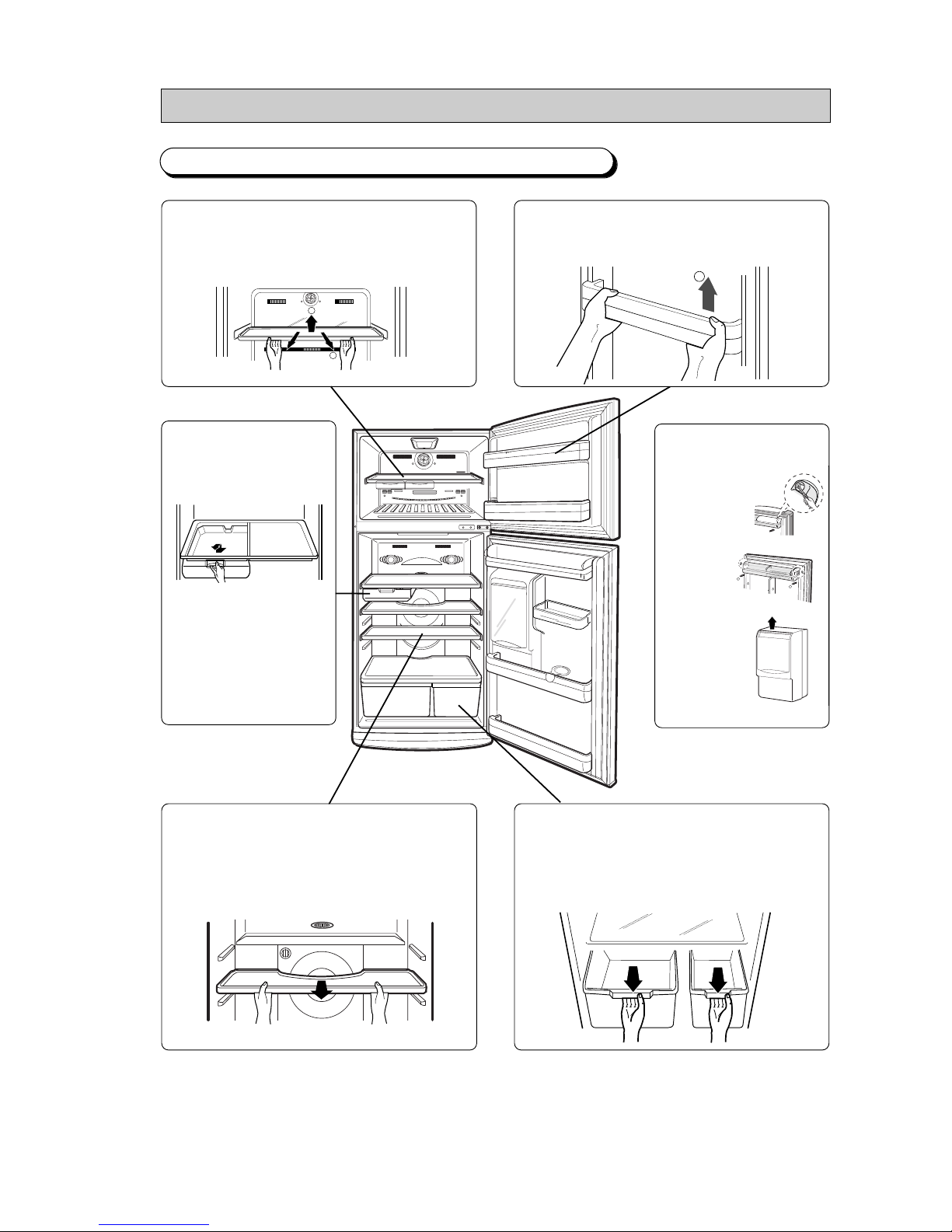

6-2. THE NAME OF EACH PARTS AND DISASSEMBLE METHOD

●

Pull with both hands as showed

●

The height can be adjusted according to the stored bowls.

2

●

Push to direction ②

●

Up the front of shelf to direction ①then pull and

apart to direction②.

2

1

FREEZER SHELF

DOOR GUARD

TEMPERRD GLASS TRAY

CHILLED ROOM SHELF

DID CASE

●

Upthe cover and apart then pull out the vegetable//salad

compartment cover and case at the mid-point and up

and pull to apart.

VEGETABLE/SALAD COVER AND CASE

●

Pull to the arrow direction

then up and apart at the

locking point.

1

2

●

Pull and apart

display part of

door guard.

●

Up and apart

as showed.

-11-

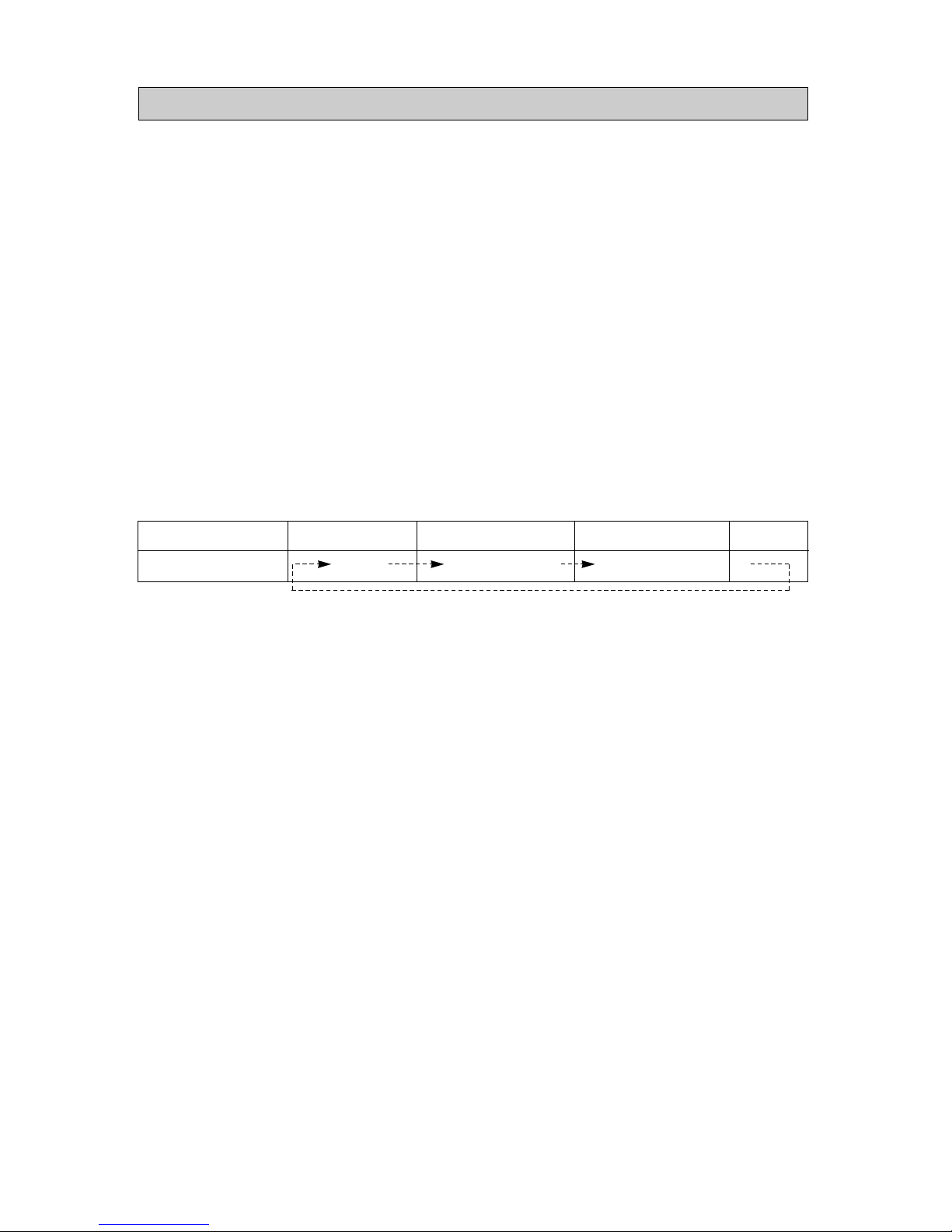

6-3. CYCLE OF FREEZING

COMPRESSOR → SUB CONDENSER → CLUSTER PIPE → HOT PIPE → DRYER → CAPILLARY TUBE

→ EVAPORATOR OF REFRIGERATOR → EVAPORATOR OF FREEZER → ACCUMULATOR →

SUCTION PIPE → COMPRESSOR

ACCUMULATOR

SUCTION PIPE

CLUSTER PIPE

HOT PIPE

DRYER

COMPRESSOR

CAPILLARY

TUBE

SUB CONDENSER

EVAPORATOR OF

REFRIGERATOR

EVAPORATOR OF

FREEZER

-12-

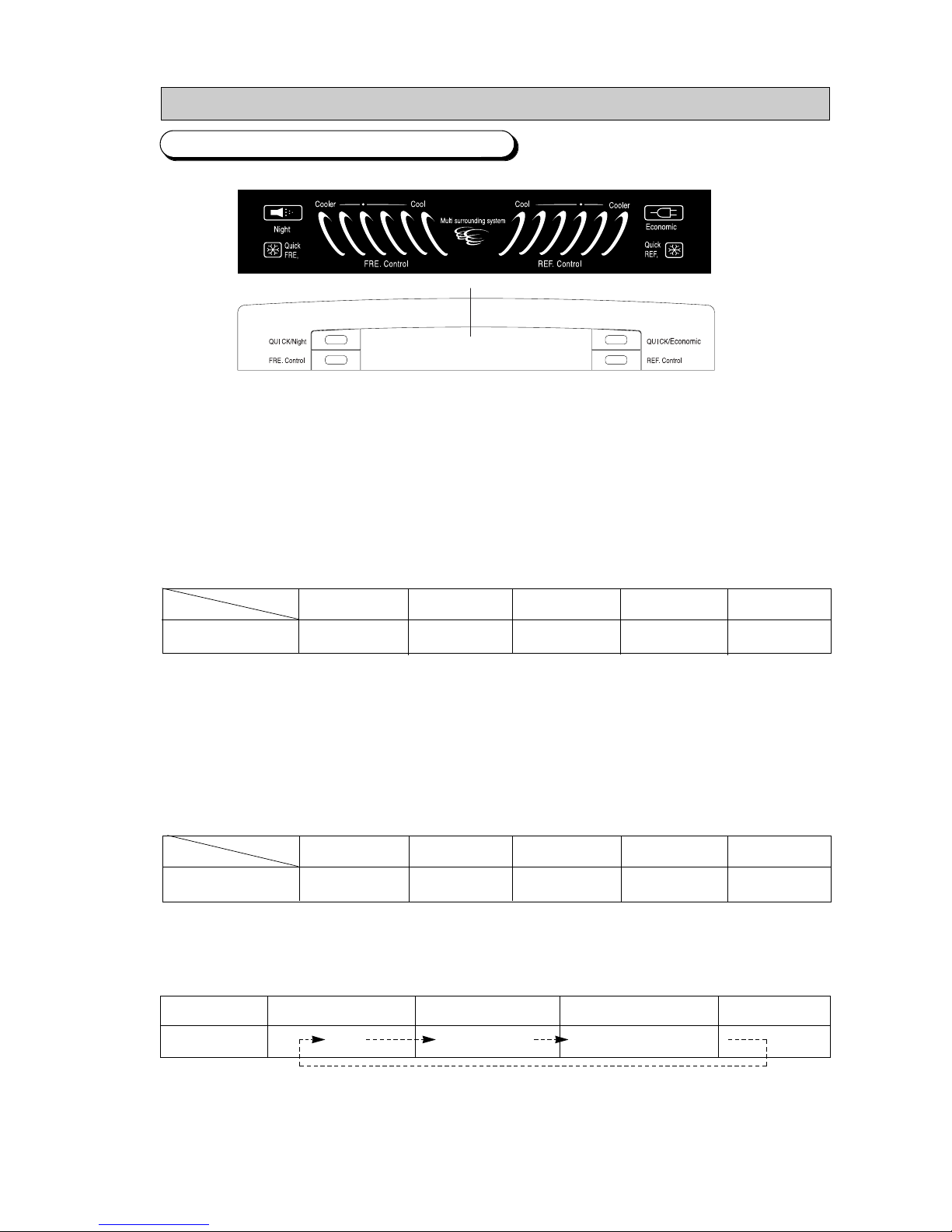

7. TEMPERATURE CONTROL AND THE OTHERS

1) Freezer temperatur control

1-1)

It consists of five steps as follows and selected by one button.

MID →MID,HIGH →NIGH →LOW →LOW,MID

1-2)

setting up turn on a light in order by system of freezer cholce button.

( MID →MID,HIGH →NIGH →LOW →LOW,MID →MID...)

1-3) It set up “

MID”

automaticature during power on.

1-4) There is standard temperatically list of each notch part. (1/3H standard)

1-5) When inputting freezer key, display of LED change at once but actual operating start in 10 seconds

2) Refrigerator temperature control

2-1)

It consists of five steps as follows and selected by one button.

MID →MID,HIGH →NIGH →LOW →LOW,MID

2-2)

setting up turn on a light in order by system of freezer cholce button.

( MID →MID,HIGH →NIGH →LOW →LOW,MID →MID...)

2-3) It set up “

MID”

automaticature during power on.

2-4) There is standard temperatically list of each notch part. (1/3H standard)

2-5) When inputting freezer key, display of LED change at once but actual operating start in 10 seconds

3) Ppwer freezering / Regular condition /9in bed)

1) It select just power freezer / Regular condition.

2) If you press power freezing / regular freezing → Power freezing → Regular condition.

3) When first power on, lamp does appear.

TEMPERATURE

ITEM

NOTCH

LOW

-16.0℃

⊙

-17.5℃

MID

-19.0℃

⊙

-20.5℃

HIGH

-22.0℃

CLASSIFICATION

LAMP CHANGE

First POWER ON

OFF

Pressed once

POWER freezing

Pressed twice

Regular condition operating

TEMPERATURE

ITEM

NOTCH

LOW

+6.0℃

⊙

+4.5℃

MID

+3.0℃

⊙

+1.0℃

HIGH

-1.0℃

1. DISPLAY DESIGN

2. Temperature control function

7-1. ELECTRONIC MODE

-13-

3-1) Power freeze function

A. Input power freeze/regular condetion key. When power freeze startes, LED signal change at once.

(Comp and F-fan runs continuously for two and a half hours when quick freeze sekected.)

B. During quick freezing the refrigerator controlled by setted notch.

3-2) Regular condition function

A. Judge the temp. of F/R room, F room is over comp on of “LOW”NOTCH or R room is over comp on of “LOW”NOTCH.

If so regular condition function isn’t performed and LED is OFF below 0.5 seconds.

B. Input the function, judge temp. of F room or R room, F room is less than comp on of “LOW”NOTCH and R room is less than

comp on of “LOW”NOTCH. If so regular condition function is operate and comp F,R-FAN is off without state of operation in recently.

C. When state the operation of regular condition, judge the temp. of F/R room, F room is over comp on of “LOW”NOTCH or R room is

over comp on of “LOW”NOTCH. If son regular condition function is the end and it is returned before.

4) Power refrigerator/Power saving function

1) Select power refrigerator/power saving button

2) Press POWER/SAVING BUTTON at once. And it is selected “OFF”“Power refrigerator”“Saving operation”.

3) Initial power on isn’t signal.

4-1) Power refrigerator function

A. Input power refrigerator/saving key. When power refrigerator started, LED signal change at once.

(Comp. and R-fan runs until the temperature of refrigerator reaches -4℃ when quick refrigeration selected.)

B. During power refrigerator the freezing controlled by setted notch.

4-2) Saving operation function.

A. Input saving operation button, F/R room temp. operate 0.8℃ rising. (When situation about NOTCH, rised 0.8℃)

B. When input power freezer or power refrigerator, saving function stop to the end of power function and saving operation is

performed after the end of power function.

※ When power freeze and refrigeration selected at the same time

- Each function applied at the same time Power freeze runs Comp. and F-fan for two and half hours and power refrigeration runs

Comp. and R-fan for -4℃ and power refrigeration runs.

3. Alarming

1) Button touch(“Ding-Dong”sound)

1-1) Everytime the button pushed, the input confirmation, “Ding-Dong”sound.

1-2) Not sounds, if two keys are pushed at the same time or wrongly handled

2) Door-Open Warning

2-1) Two minutes after door opened, alarming sounds.

2-2) If door opened continuously, ten times of alarming sounds with one minute cycle.

2-3) Alarming stopped just after door closed.

CLASSIFICATION

CHANGE OF SIGNAL LAMP

INITIAL POWER ON

OFF

PRESS ONE

POWER REFRIGERATOR

PRESS T ONE

SAVING OPERATION NOTES

NOTES

-14-

3) Forced operating and defrosting (“Beep”sound)

3-1) If forced function selected the “Beep”sounds.

3-2) Alarming sounds until the forced operating canceled by automatically(24Hr) or manualy.

3-3) Alarming sounds until the forced defrosting canceled by automatiically(24Hr) or manualy.

4) Defrosting

1-1) From the first power on, defrosting started after 4 hours of total Comp on time.

1-2) After that defrosting cycle can be varied from 6 hours to 24 hours.(Comp on time)

5) Testing

◆ Testing is for PCB, product, function and service.

◆ After testing, turn the power on to start self diagmosis.

1) Fored operating

1-1) As the button on PCB pushed once, Comp starts immediately.

1-2) If fored operating selected the notch of freezer and refrigerator fixed to “HIGH”and “MID-HIGH”. Then comp and

F-fan is controlled to pull down and R-fan is controlled to “MID-HIGH”notch.

1-3) Pull-down maintained just for 24 hours during forced operating, after that automatically defrost freezer and refrigerator

and then stares nomal operating.

1-4) Turn the power off or select test cancel mode to cancel the forced operating.

1-5) Alarming (0.25 secon/0.75 sec off) continues until the forced operating finished. It continues without any relations

to alarming key selection or cancel.

2) Forced defrosting

2-1) Push the test button one more time to run the forced defrosting of refrigerator.

2-2) One more push in the above status will run defrosting of freeaer and refrigerator simult a neously.

2-3) Forced operating cancelled automatically by starting forced defrosting and return to normal operating

after campletion of defrosting.

3) Test cancel mode

3-1) One more push in the status of forced defrosting of F/R wiill run normal operating.

3-2) Alarming stopped in the test cancel mode.

4). Initial function of first POWER ON.

1) If power is impressed, it begins to make a self diagnosis and light all LED for 2 second if normal condition is confirmed.

2) After first self diagnosis find unstable sensor among temp. sensor. And LED is on and off 5 second periods.

3) During 2 second turn on all LED. AND F/R LED display “MID-MID”

4) Early state R-EVA and F-EVA sensor is all below 15℃.

And R defrosting HEATER and F defrosting HEATER is perform per 0.5 second turn on.

5) After early state R-EVA sensor temp. or F-EVA sensor is over 15℃ and F/R defrosting is end per 3 second,

COMP and F-FAN, R-FAN is turn on per 0.5 second and operated per 5 minutes without temp. condition.

6) Input TEST S/W among 4) and 5) movemen 5 it is the end and perform TEST function.

-15-

1) SELF DIAGNOSIS AT FIRST POWER ON

1-1) As the power applied to the refrigerator first time, all dispays show operating and run the self diagnosis.

1-2) If no problem foundes, display returns to normal mode

1-3) If probiem foundes, on and off the related display lamp and start alarming.

1-4) Lamp displayed until the problem solved or seif diagnosis cancelled.

1-5) After problem solved the display mode return to nomal.

1-6) After refrigerator repaired, sure to power off and on to run self diagnosis.

1-7) Refer to belows for problem and related displays.

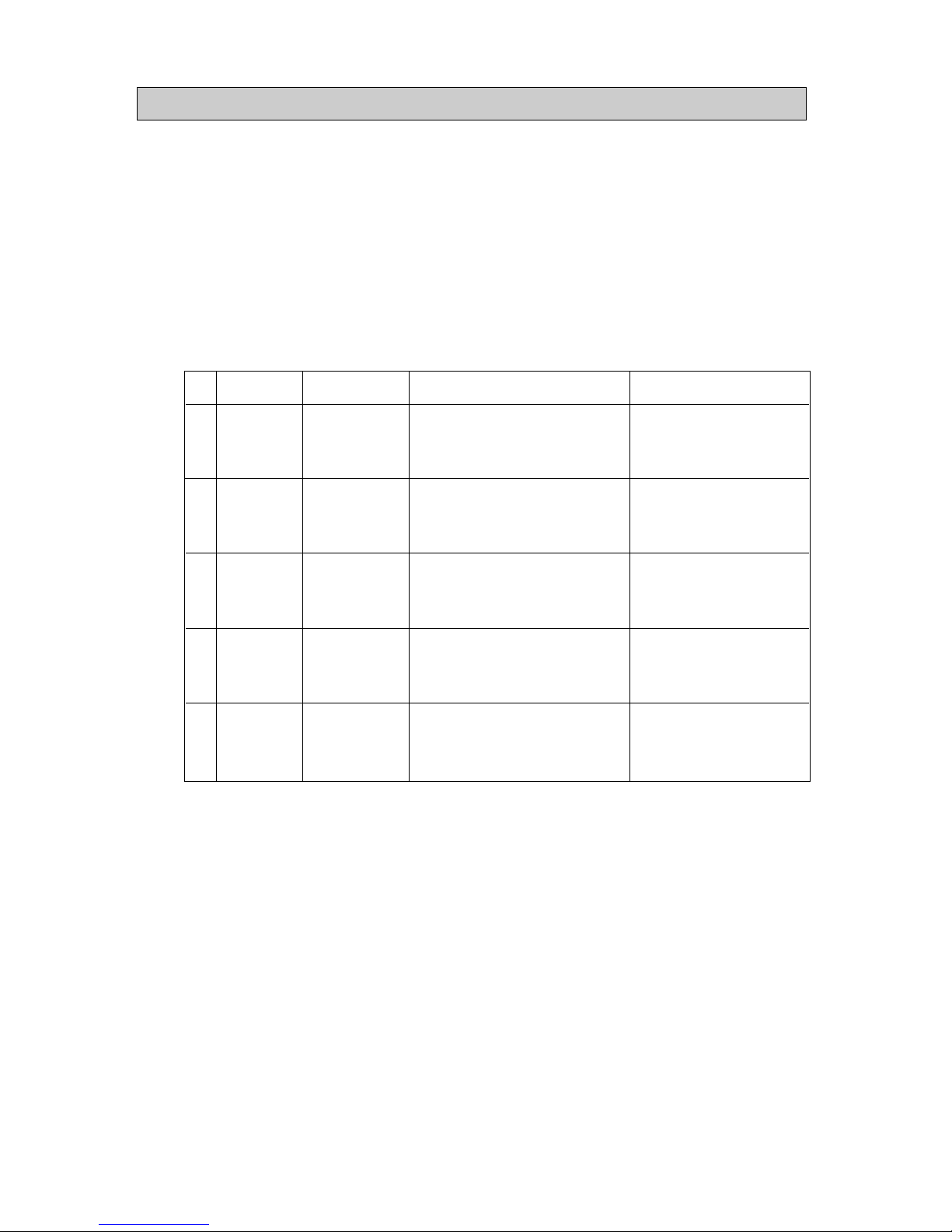

NO

1

2

3

4

5

SYMPTOM

Refrigerator sensor houslng disconnection

Faulty connection

Wire open or short

Faulty sensor

Refrigerator defrost sensor houslng

disconnection

Faulty connection

Wire open or short

Faulty sensor

Room-Temp senser LEAD disconnection

Faulty connection(PCB MAIN)

Wire open or short

Faulty sensor

Freezer defrost sensor houslng

disconnection

Faulty connection

Wire open or short

Faulty sensor

Freezer defrost sensor houslng

disconnection

Faulty connection

Wire open or short

Faulty sensor

REMARK

R-SENSOR temperature is over

+50℃ or below -50℃

RD-SENSOR temperature is over

+50℃ or below -50℃

Room-Temp sensor temperature

is over +50℃ or below -50℃

ZF-SENSOR temperature is over

+50℃ or below -50℃

FD-SENSOR temperature is over

+50℃ or below -50℃

ITEM

R-SENSOR

RD-SENSOR

ROOM-TEMP

SENSOR

F-SENSOR

FD-SENSOR

DISPLAY LED

Refrigerator

“LOW”

Refrigerator“MID”

Freezer“LoW”

Freezer“LOW,MID”

Freezer“MID”

( SELF-DIAGNOSIS DISPLAY TABLE) )

5. SELF DIAGNOSIS

-16-

NO

1

2

3

4

5

6

7

8

MODE DISPLAY

REFRIGERATOR SUBORDINATE

FREEZER SUBORDINATE

(LOAD STATUS DISPIAY TABLE)

1) Press power freezing / regular conditing and power refrigerating / power saving key for five seconds then

press temperature control key in the refrigerator after temperature display lamps on and off three times

2) This mode shows which lamps is being sourced signal from MICOM currently. This doesn’t mean the load is

operate due to the open wire or relay missing though the display shows the compressor operating.

3) Load status display return to normal mode after sixty seconds.

4) Follows are load status and related dispay.

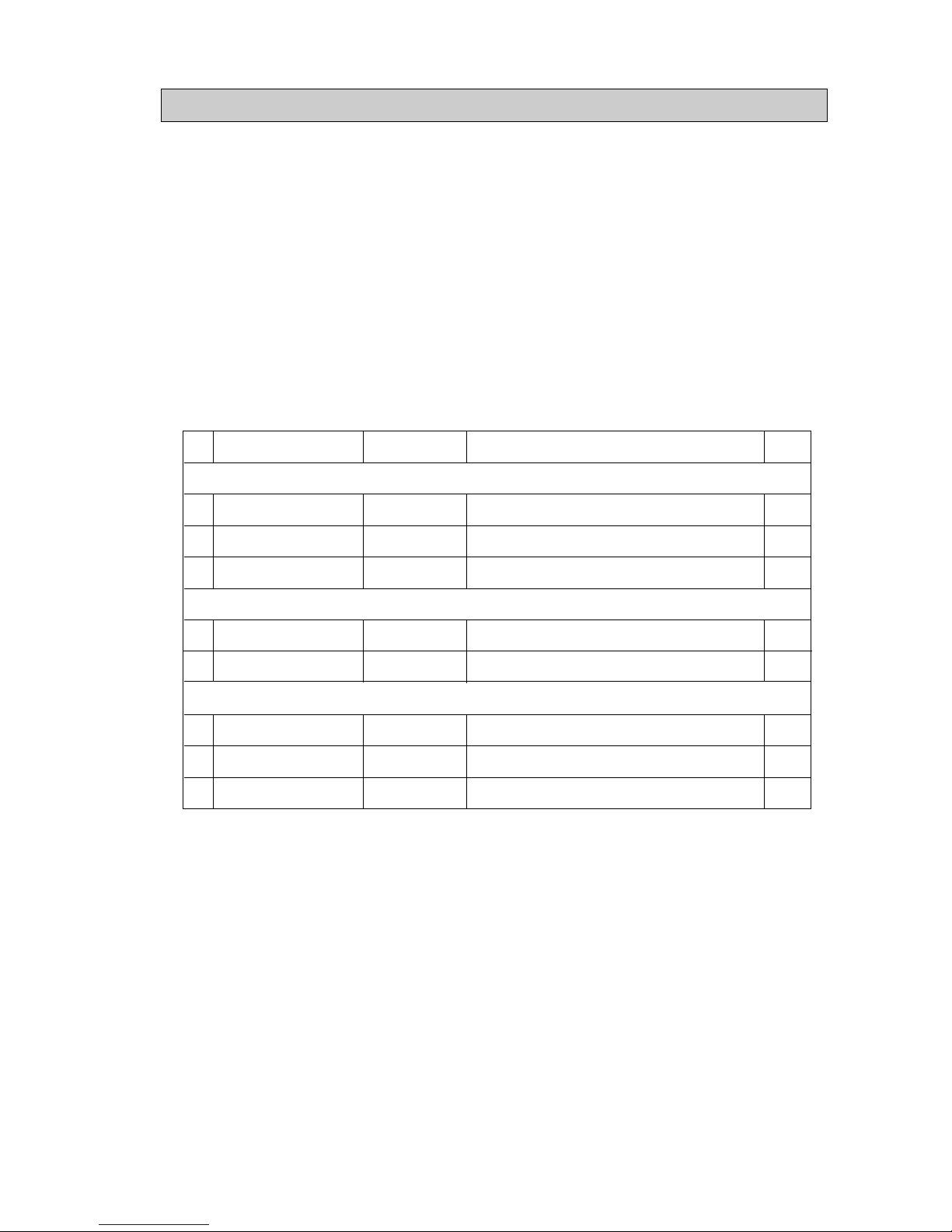

6. LOAD STATUS DISPLAY

ITEM

COMP

F-FAN

FREEZER DEFROST HEATER

R-FAN, S-FAN

REFRIGERATOR DEFROST HEATER

INITIAL MODE

OVERLOAD

LOW TEMP MODE

DISPLAY LED

FREEZER ”LOW”

FREEZER ”LOW,MID”

FREEZER ”MID”

REFRIGERATOR ”LOW”

REFRIGERATOR ”MID”

POWER FREEZER

POWER REFRGERATOR

POWER SAVING

DISPLAY

RELEVANT LED ON DURING COMPRESSOR OPERATION

RELEVANT LED ON DURING F-FAN OPERATION

RELEVANT LED ON DURING FREEZER DEFROST HEATER ON.

RELEVANT LED ON DURING S-FAN AND F-FAN OPERATION

RELEVANT LED ON DURING REFRIGERATOR DEFROST

RELEVANT LED ON QITH INITIAL POWER INPUT.

RELEVANT LED ON QHEN ROOM-TEMP. IS OVER 35℃

RELEVANT LED ON QHEN ROOM-TEMP. IS BELOW 15℃

-17-

7. operating of fan motor

8. OPTION TABLE

1) FAN MOTORoperates BLDC MOTOR by dc power.

2) After first starting power, it operates “HIGH”rpm to off dot of fan and then operates “LOW”rpm

3) if binding motor or not sensing regular freguency of motor to pcb, motor will stop operating.

(After stopping, reoerating start in 10 seconds.)

※ F, R, C-FAN operate equal.

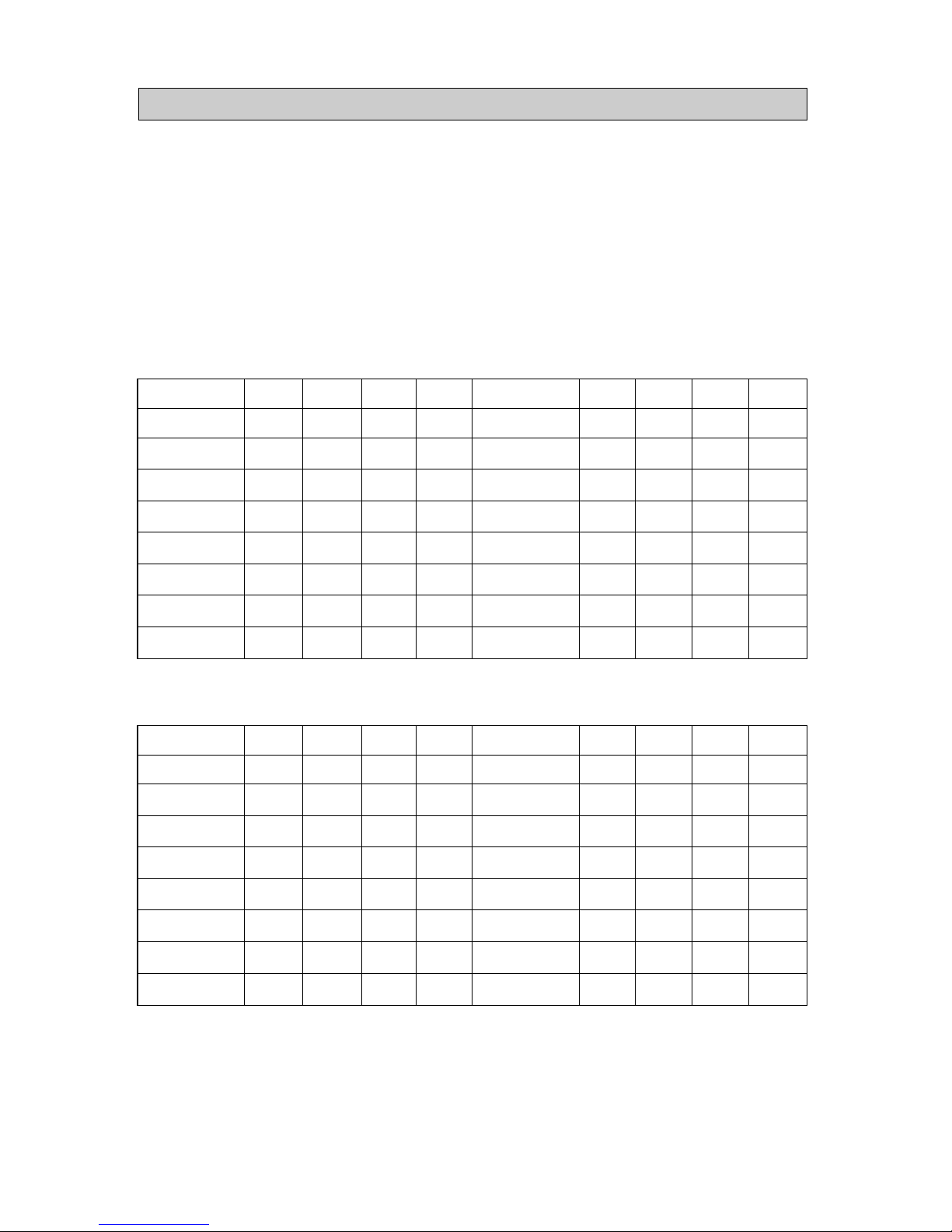

1) Temperature change TABLE of Freezer ( ● : Pertinent DIODE )

SHIFT

STANDARD TEMPERATURE

-0.5

-1.0

-1.5

-2.0

-2.5

-3.0

-3.5

SHIFT

+0.5

+1.0

+1.5

+2.0

+2.5

+3.0

+3.5

+4.0

4

4

●

●

●

●

●

●

●

●

3

●

●

●

●

3

●

●

●

●

2

●

●

●

●

2

●

●

●

●

1

●

●

●

●

1

●

●

●

●

2 ) Temperature change TABLE of refrigerator ( ● : Pertinent DIODE )

SHIFT

STANDARD TEMPERATURE

-0.5

-1.0

-1.5

-2.0

-2.5

-3.0

-3.5

SHIFT

+0.5

+1.0

+1.5

+2.0

+2.5

+3.0

+3.5

+4.0

8

8

●

●

●

●

●

●

●

●

7

●

●

●

●

7

●

●

●

●

6

●

●

●

●

6

●

●

●

●

5

●

●

●

●

5

●

●

●

●

-18-

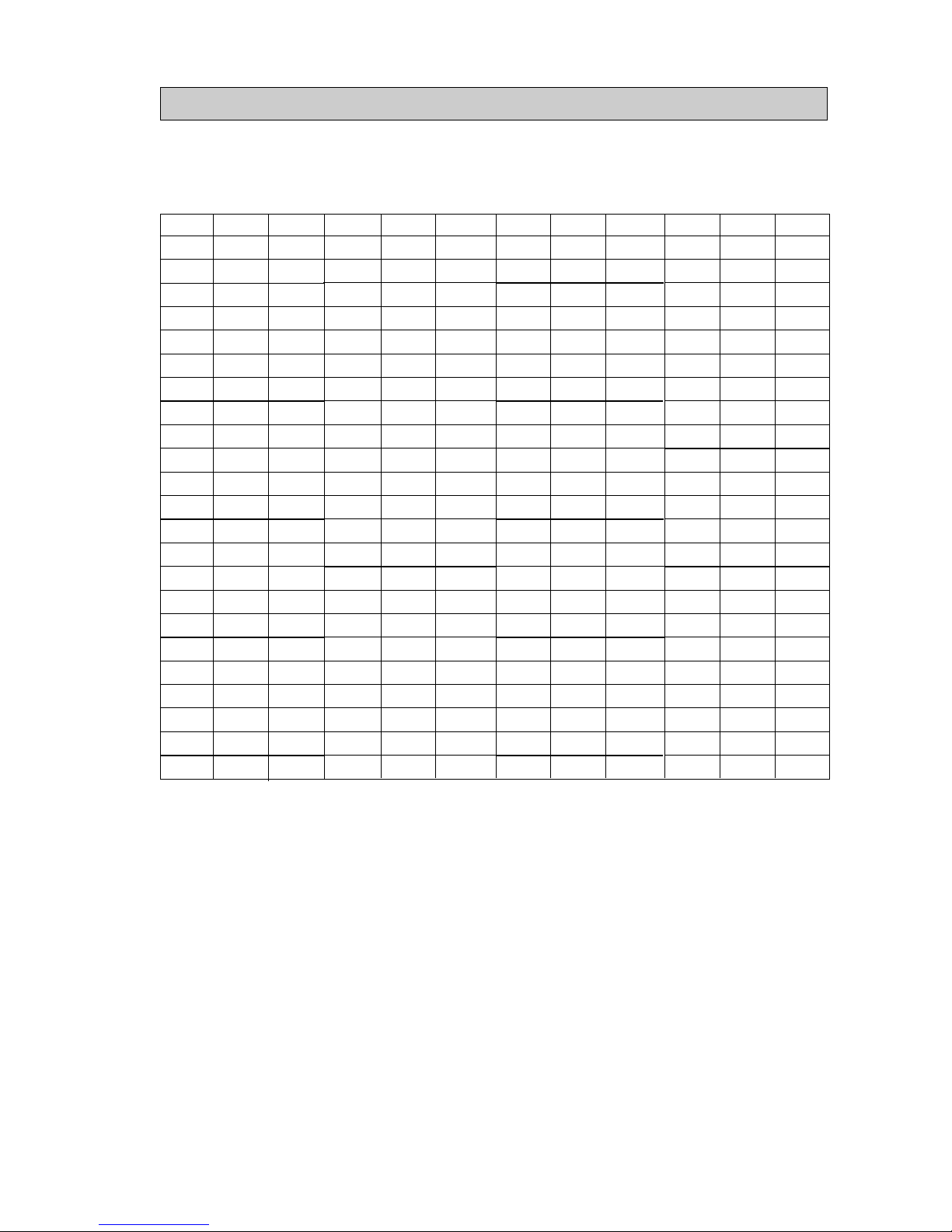

※ Personal Informatin

Micomport Voltage and Resisting force of sensor by Temperature.

TEMPERATURE (℃)

-42

-41

-40

-39

-38

-37

-36

-35

-34

-33

-32

-31

-30

-29

-28

-27

-26

-25

-24

-23

-22

-21

-20

RESISTANCE

98870

93700

88850

84150

79800

75670

71800

68150

64710

61480

58430

55550

52840

50230

47770

45450

43260

41190

39240

37390

35650

33990

32430

VOLTAGE (V)

4.541

4.518

4.494

4.469

4.443

4.416

4.389

4.360

4.331

4.301

4.269

4.237

4.204

4.170

4.134

4.098

4.061

4.023

3.985

3.945

3.905

3.863

3.822

TEMPERATURE (℃)

-19

-18

-17

-16

-15

-14

-13

-12

-11

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

0

1

2

3

RESISTANCE

30920

29500

28140

26870

25650

24510

23420

22390

21410

20480

19580

18730

17920

17160

16430

15740

15080

14450

13860

13290

12740

12220

11720

VOLTAGE (V)

3.778

3.734

3.689

3.644

3.597

3.551

3.504

3.456

3.408

3.360

3.310

3.260

3.209

3.159

3.108

3.057

3.006

2.955

2.904

2.853

2.801

2.750

2.698

TEMPERATURE (℃)

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

RESISTANCE

11250

10800

10370

9959

9569

9195

8839

8494

8166

7852

7552

7266

6992

6731

6481

6242

6013

5792

5581

5379

5185

5000

4821

VOLTAGE (V)

2.647

2.596

2.545

2.495

2.445

2.395

2.346

2.296

2.248

2.199

2.151

2.104

2.057

2.012

1.966

1.922

1.878

1.834

1.791

1.749

1.707

1.667

1.626

TEMPERATURE(℃)

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

RESISTANCE

4650

4487

4329

4179

4033

3894

3760

3631

3508

3390

3276

3167

3062

2962

2864

2770

2680

2593

2510

2429

2352

2278

2206

VOLTAGE (V)

1.587

1.549

1.511

1.474

1.437

1.104

1.366

1.322

1.298

1.266

1.234

1.203

1.172

1.143

1.113

1.085

1.057

1.030

1.003

0.977

0.952

0.928

0.904

-19-

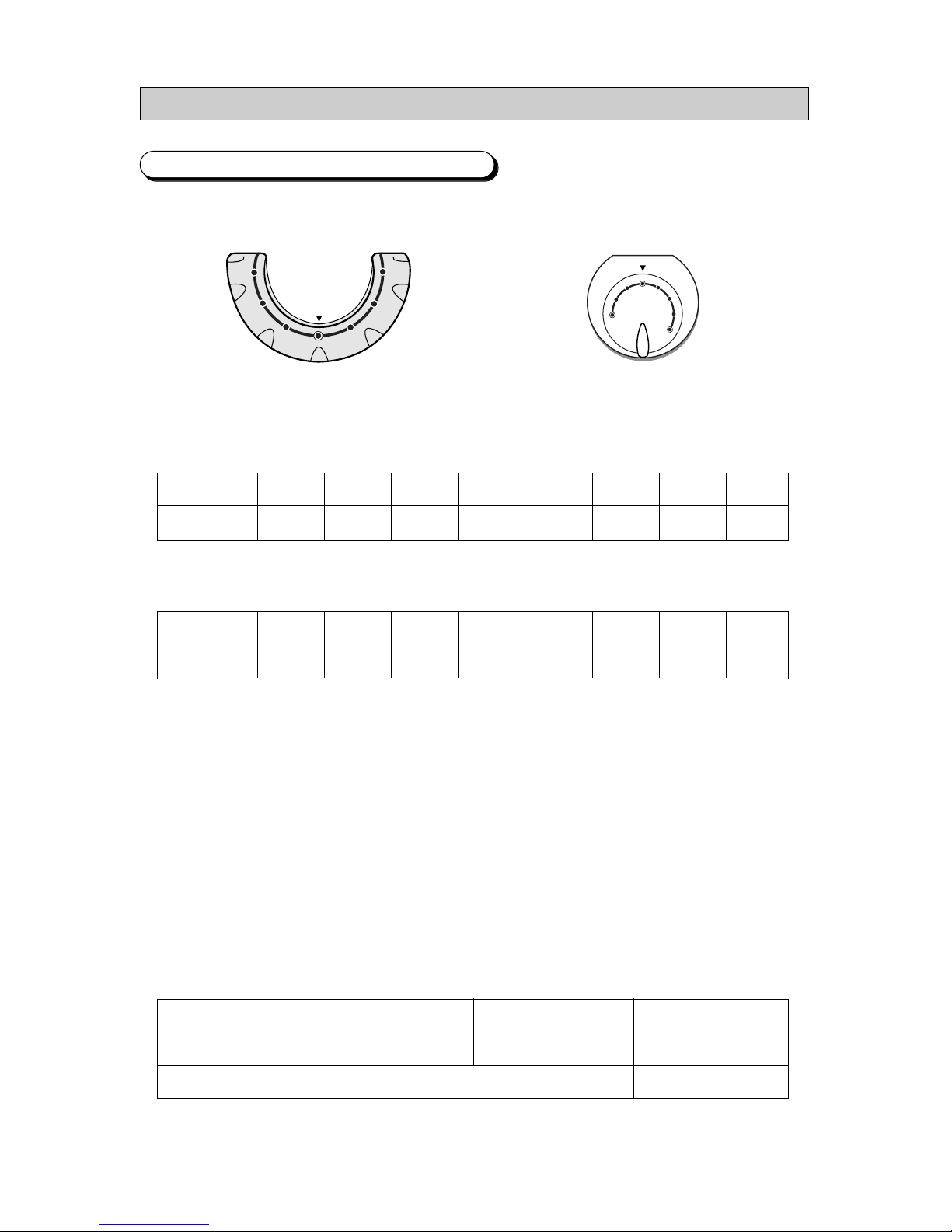

7-2, SEMI ELECTRONIC MODE

A. Temperature control part design

B. Temperature control function

1) Tempera ture choice of freezer

·You can choose to ⑧ From ①

·Follows are control temperature by KNOB position.

Freezer temperature control refrigerator temperature control

KNOB position

control temperature

①

-16.0

②

-17.0

③

-18.0

④

-19.0

⑤

-20.0

⑥

-21.0

⑦

-22.0

⑧

-23.0

2) Temperature choice of refrigerator

·You can choose to ⑧ From ①

·Follows are control temperature by KNOB position.

NOTE) Temperature contol of freezer and refrigerator is position control by ROTRAY S/W, if it get out of

position it control NOTCH

C. Defrost function

1) Defrost set up by time of COMP ON.

2) Defrost tun Heating → Rest time

3) When initial power on, initial defrost run defrost of freezer and refriger ator in 4 hours of COMP

ON. Since initial

(R →R, F →R →R, F ... Cycle operating))

4) ON/OFF of defrost - heater control by EVA-SENSOR If EVA-SENSOR is problem (short 10 pen),

it run just rest time and then finishes defrost function without heating.

5) During defrosting it maintain COMP and FAN state and after finish defrost-heating rest time

is 10 minutes.

6) Follows are defrost heating ON point and OFF point that operate by EVA-SENSOR.

KNOB position

control temperature

①

5.0

②

4.0

③

3.0

④

2.0

⑤

1.0

⑥

0

⑦

-1.0

⑧

-1.0

HEATER ON dot

HEATER OFF dot

REFRIGERATOR

BEIOW+10℃

FREEZER

BEIOW -5℃

REMARK

17℃

TEMP, FRE

TEMP, REF

-20-

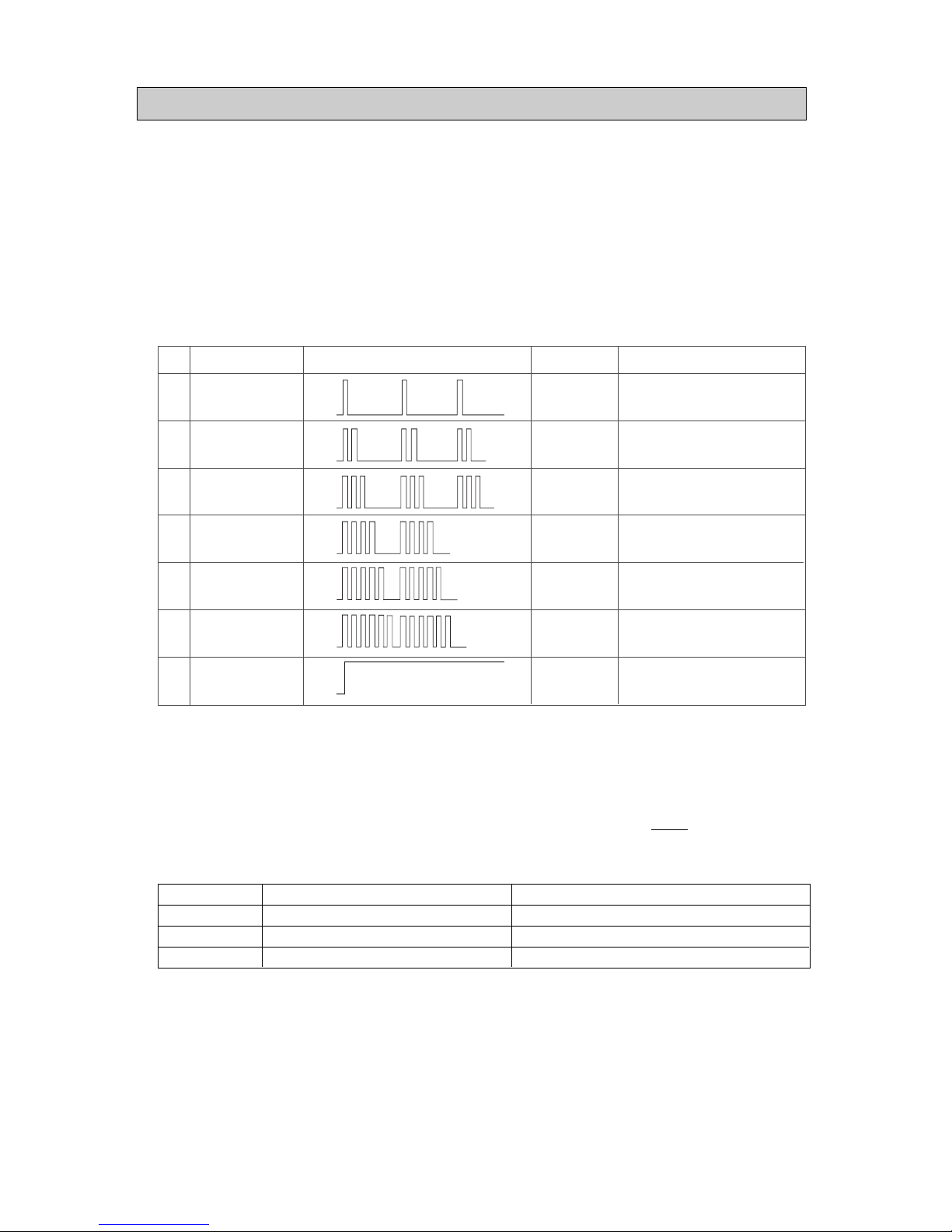

D. TEST FUNCTION

▶ TEST function is function for test,SVC and fair test of PCB and product.

▶ TEST S/W choose and confirm function of product and then POWER ON to run self diagnosis.

1) FORCED OPERATING FUNCTION

● Pressed once TEST S/W on MAIN PCB. If so COMP and F-FAN run at once. Thus be careful because

occur COMP over load.

(Refrigerator FAN control ON/OFF by temperature)

● Since it set up forced operating function, it always run COMP and F-FAN and display lamp on MAIN

PCB with ON/OFF 0.1 second periodically.

(Refrigerator FAN control ON/OFF by temperature)

● In 24 hours forced operating function of freezer and refrigerator operate and finish then run normal mode

by KNOB position of temperature setting up.

● During forced operating function if you want to stop it first power OFF and then power on or choose

TEST cancellation mode.

2) Forced defrost function

● For forced operating pressed once TEST S/W button, it cancel forced operating at once and refrigerator

forced defrst function with display forced defrost position ON/OFF lamp on MAIN PCB 0.5 secoonds

periodically. If press one more TEST S/W bueeon display refrigerator and freezer defrosting.

● If forced defrost choose, COMP and FAN power OFF and defrost heater on at once, At this time,

if sensing temperature of EVA-SENSOR over 12℃ defost heater power off and operate rest time normal mode.

● After heating finish it need 10 minal mode

3) TEST FUNCTION CANNCELLATION MODE

● Duting refrigerator and freezer run forced defrost function press one more TEST S/W button if so forced

defrost cancel and rest in 10 minutes and then turn normal mode.

OPERA TING

OPERA TING BEFORE OPEN STEP

“HIGH”

OPERA TING BEFORE SETTING UP STEP

-21-

E. self diagnosis function

1) Power on refrigerator and it run seif diagnosis function about 2 seconds at the inner part.

2) If no preblem it turns normal mode.

3) If find prebiem display lamp of PCB show errw position like lower list and everything don’t operate until repair

error position.

4) After refrigerator power off and then power on for confirming conditiom.

5) Thus if you want to know OPEN/SHORT of temperature sensor on SVC, power off and on if it run self

diagnosis function.

6) When error occur LAMP display method.(Lamp on time : 0.3 seconds ( ON/OFF) Lamp off time : 2 seconds)

● In case of many problems find it display error position in order.

<Example of error display>

① When problem R-ROOM SENSOR display lamp operating.

(0.3 seconds ; ON/OFF) Four times →2 seconds OFF - REPEAT -

② When problem R-ROOM SENSOR and F-ROOM sensor at the same time display method.

(0.3 seconds ; ON/OFF) Three times →2 seconds OFF - REPEAT -

※ Tem perature contre control operating by ROTRAY SWITCH

F. Quick heating operating

1) If freezer heating sensor OPEN/SHORT error at freezer heating it runs just rest time without heating..

2) If refrigerator heating sensor OPEN/SHORT error at refrigerator heating it runs jest time without heating.

1

2

3

4

5

6

7

F DEFROST

SENSOR

R DEFROST

SENSOR

F SENSOR

R SENSOR

F Rotary S/W

R Rotary S/W

NORMAL MODE

-.OPEN ERROR

-.SHORT ERROR

-.OPEN ERROR

-.SHORT ERROR

-.OPEN ERROR

-.SHORT ERROR

-.OPEN ERROR

-.SHORT ERROR

-.OPEN ERROR

-.OPEN ERROR

-. SENSOR IS BELOW -50℃

-. SENSOR IS BELOW +50℃

-. SENSOR IS BELOW - 50℃

-. SENSOR IS BELOW +50℃

-. SENSOR IS BELOW - 50℃

-. SENSOR IS BELOW +50℃

-. SENSOR IS BELOW - 50℃

-. SENSOR IS BELOW +50℃

Vntil operating initial 5minutes

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

On

Off

No.

ITEM

Led Display

Remark Problem

OPEN ERROR

SHORT ERROR

SECTION

INITIAL SEIF DIAGNOSIS(OFF/ON)

STOP ERROR DISPLA Y OPERA TING

“HIGH”

“MID”

-21-

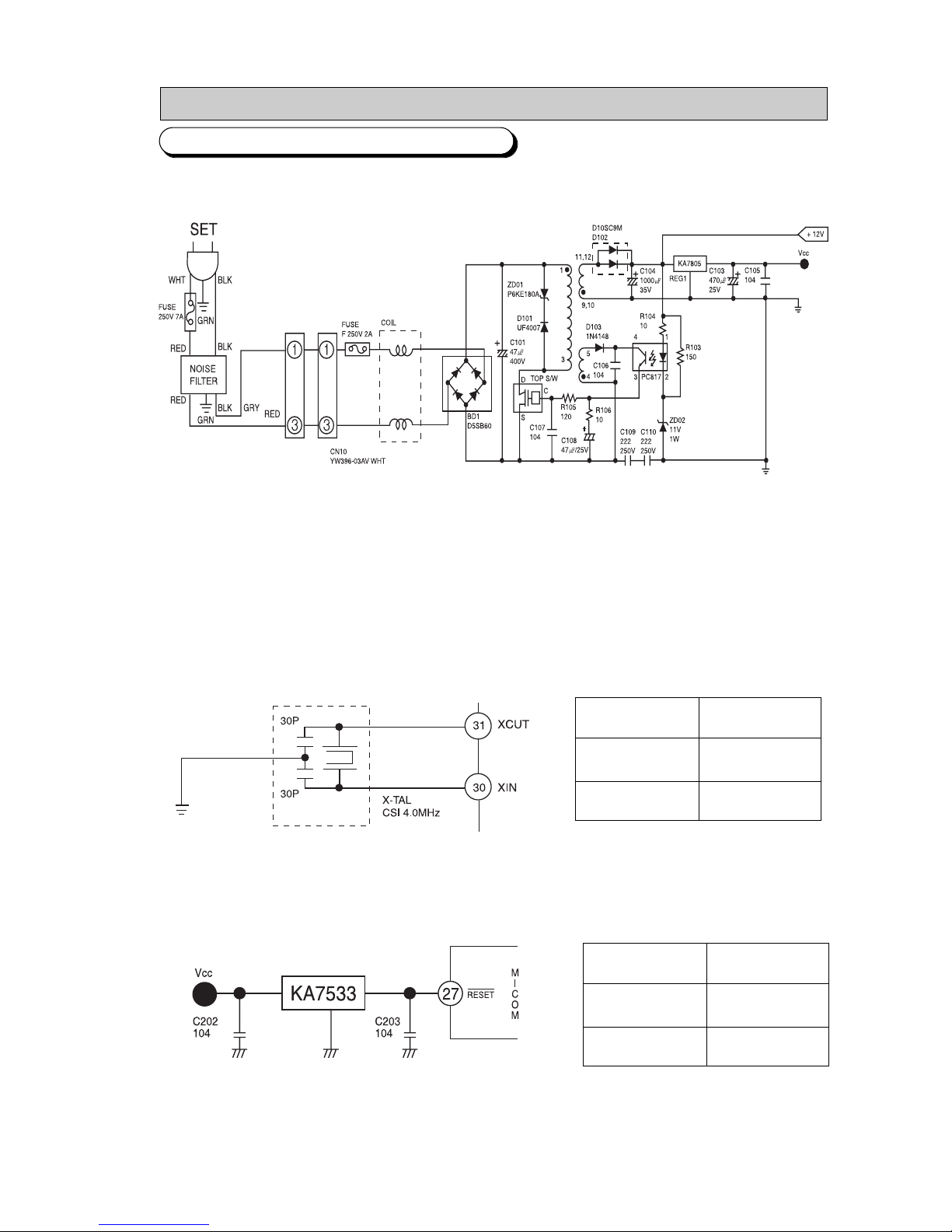

8. CIRCUIT OPERATING THEORY

1) Power is on and makes about DC 300V through BD1.

2) TOP S/W is switching the best condition automatically.

Electric current run between D and S of TOP S/W and occur electric current in TRANS and when power of D-s is

off storing electric current of TRANS pass to secondary voltage.

3) Voltage main 12V. This is applied to display, relay and 5V power of sourcr and Main PCB

1) Tish needs function for CLOCK occurrence and time calculation.

In case of SPEC of RESONATOR change abnormal mode run because of changing Timming system of MICOM.

1. Power suooly part

2. OSCILLATOR

3. RESET PART

TERMINAL

Xin(#30)

Xout(#31)

FREQUENCY

4MHz

4MHz

TERMINAL

Vcc

RESET

VOL TAGE

DC 5V

DC 5V

8-1. ELECTRONIC MODE

-22-

1) RESET part is intialize RAM of MICOM and others when power is on or power is inferruoted for some time It will make

whole program runs from the first status. When power is supplied, reset voltage is “LOW”status for a few seconds and

turn into “HIGH”(Vcc Voltage) status in the normal opweating.

1) DOOR S/W sensing part doesn,t sense Door of Fand R room on each micom.

2) Lamp control door is opened, door S/W pin NO 3 opened and voltage no touching No1 of CN 27 and MICOM input Then the

door-open is sensed.

3) When the door is opened, Door S/W pin No 3 opened and voltage no touching No 1 of CN No 27 and MICOM input.

Then the door-open is sensed.

→ It makes door alarm after 2 minutes

This time F,R DOOR must close at the same time for stopping Door alarm.

4) DID DOOR S/Whave no each sensing parts and control lamp ON/OFF by contact dot of DOOR.

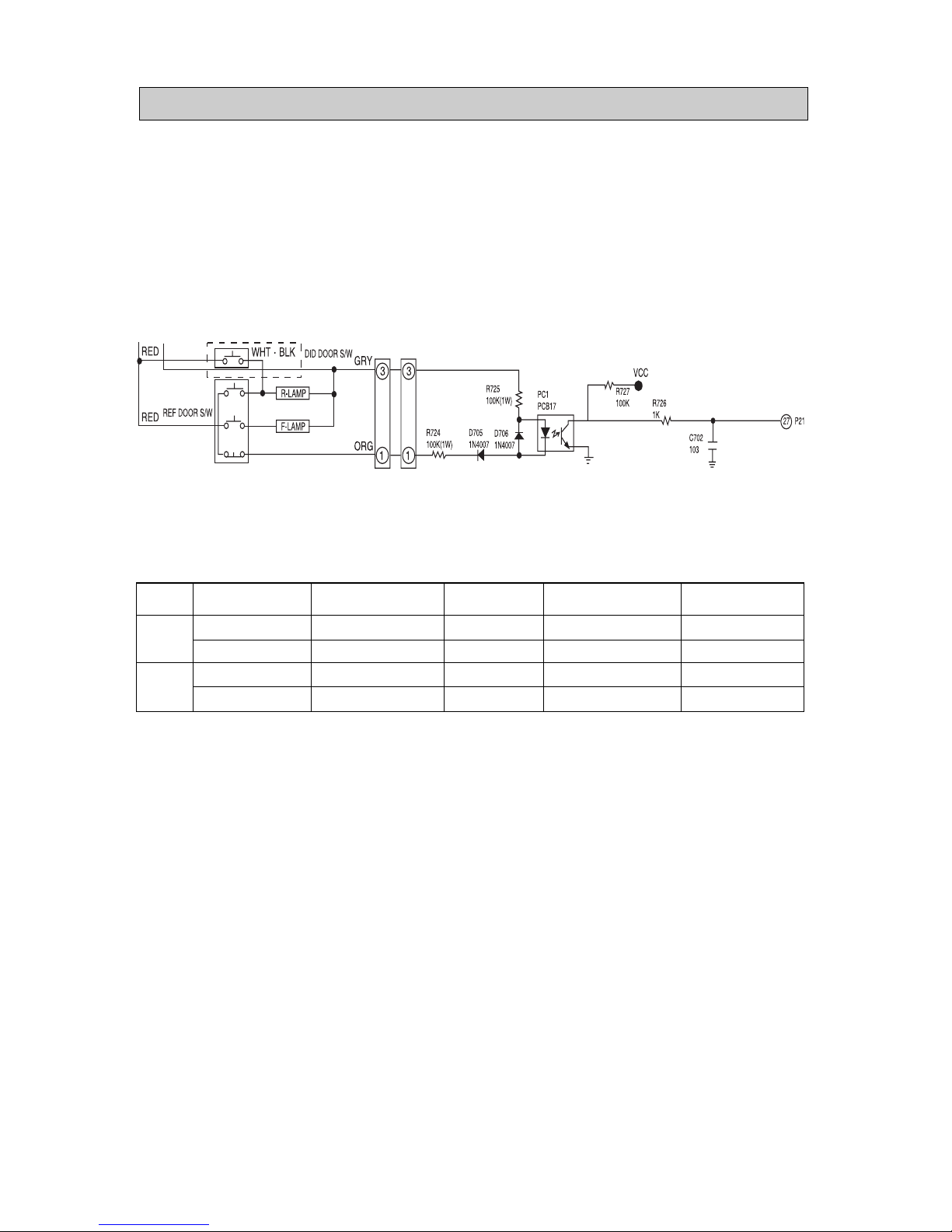

4. DOOR S/W SENSING PART

ITEM

F

R

DOOR CONDITIONS

CLOSE

OPEN

CLOSE

OPEN

DOOR S/W CONTACT

OPEN

CLOSE

OPEN

CLOSE

LAMP

OFF

ON

OFF

ON

MICOM INPUT VOLTAGE

OUTMODE

5V

OUTMODE

5V

CN72PIN NO1 CONTACT

ON

OFF

ON

OFF

-23-

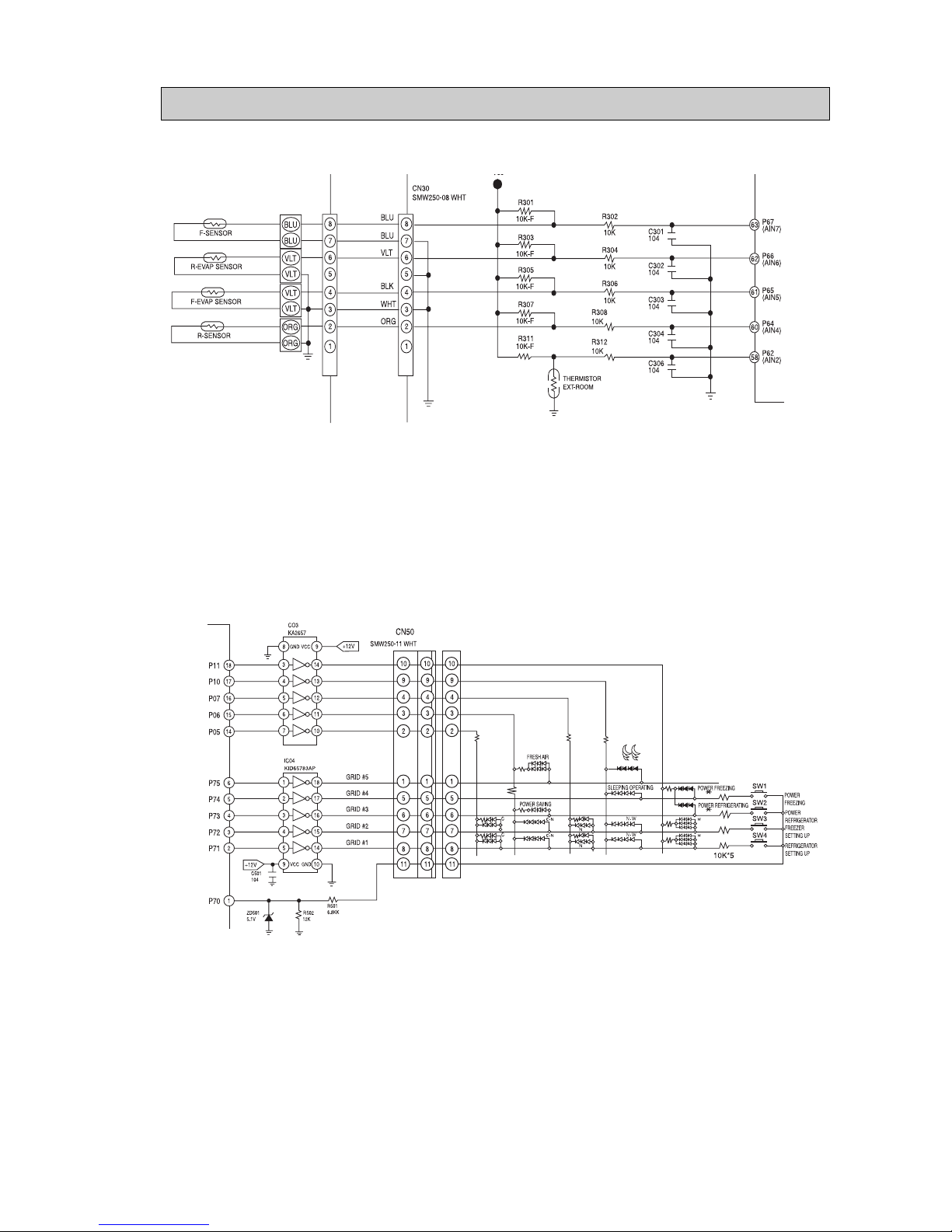

1) Thermistor is used for sensing which has negative resistance coffiecient to the temperature.

R 302, 4, 6, 8, 12, C301~C306 are pares for preventing noise.

2) MICOM input voltage, Vf of sensor is Vf=(R+hx x Vcc)/(R301+Rth) (Rth : sensor resistance)

1) KEY SCAN and display operating

It is used for No 5 of MICoM NO #2, 3, 4, 5, 6,

It operates “high”10 msec periodically for 2 msec cycle : MICOM pin No : #2

→ #3 → #4 → #5 → #6

This signal pass by IC 04 (UDN 2981 or KID 65783AP) from Input dot to Dotput dot.

Voltage of peak to peak is about 11V (DC RMS 1.5V)

5. TEMP·SENSING PART

6. KEY SCAN AND DISPLAY PARTS

Loading...

Loading...