Page 1

R E F R I G E R A

Model : SR-608EV

Model :

SR-648EV

SR-688EV

M a n u a l

S E R V I C E

TO R

R E F R I G E R A T O R C O N T E N T S

1. Safety Precautions And Warnings

2. Product Specifications

3. Electrical Part Specifications & Standard

4. Electric Diagram

5. Outer Package Specification

6. Air Circulation Route

7. Functions And Directions

8. Circuit Operating Theory

"A"

9. Failure Diagnosis And Repairment

10. Disassemble & Assemble Drawing And

Part Lists

11. Disassemble & Assemble Method

“A”: WITH DISPENSER

S R - 6 0 8 E V

S R - 6 4 8 E V

S R - 6 8 8 E V

WITHOUT DISPENSER

SR-606EV

SR-646EV

SR-686EV

12. Packing Method

13. PCB Diagram

14. PCB Specifications

15. Main Components Specifacations

Page 2

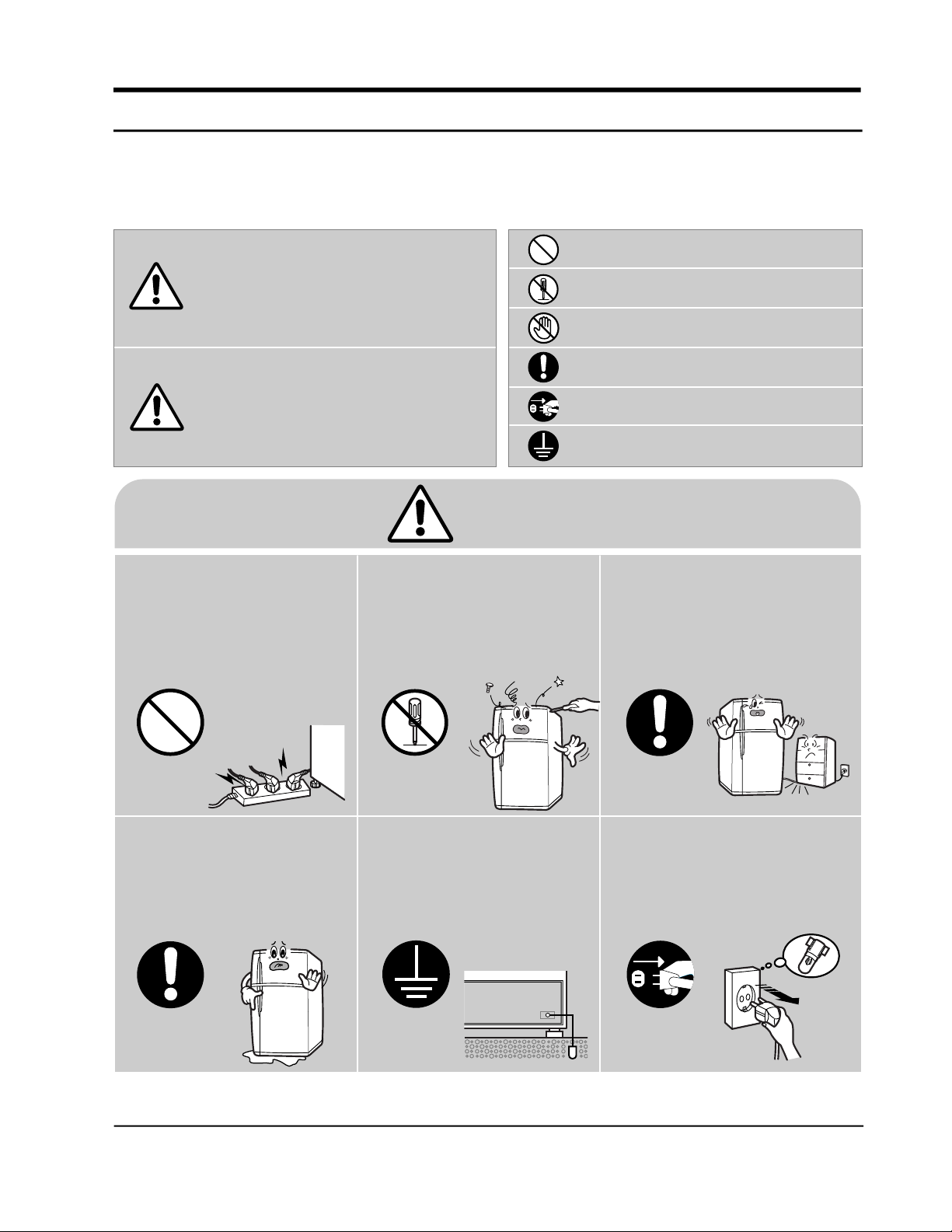

1. Safety precautions and warnings

Read all instructions before using this appliance in order to aboid risk of accident or possible damage.

Warning/Caution Description of symbols

Indicates prohibition

This symbol is intended to

W a r n i n g

C a u t i o n

alert the user to the

possible death or injury.

This symbol is intended to

alart the user to the

possible injury or damage.

Do not disassemble

Do not contant

Adhere the instruction strictly

Unplug from the electrical outlet

Earth the appliance to avoid the

risk of an electric shock

Warning

Do not plug multiple

electrical appliances into

the same outlet.

• This may cause abnormal

heating or a fire hazard.

Prohibition Do not disassemble

Check the operating

environment.

• Do not install the refrigerator in a

hurnid (with condensation) location

or on an unstable surface.

Do not attempt to make

repairs yourself.

•

This could lead to fire hazard or

abnormal operation causing

severe personal injury.

Do not attempt to make

repairs yourself.

•

This could lead to fire hazard or

abnormal operation causing

severe personal injury.

Make sure the power cord is

not crushed or damaged.

•

Repair immediately all power cords or

outlets that have become frayed or

otherwise damaged.

Make sure the power cord is

not crushed or damaged.

• Repair immediately all power cords or

outlets that have become frayed or

otherwise damaged.

Earth Unplug

Samsung Electronics 1

Page 3

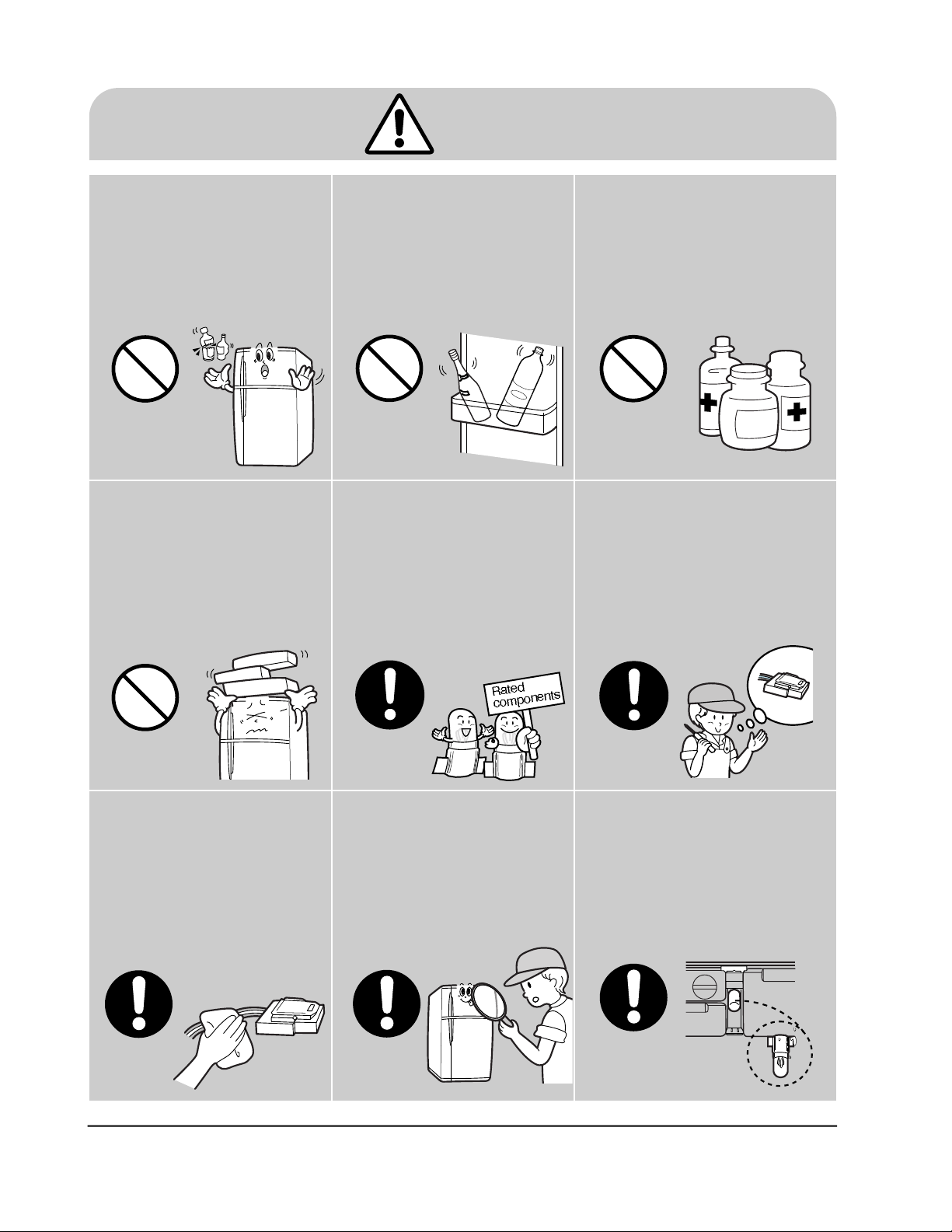

Caution

Do not store bottled food

or drinks in the freezer

compartment.

• Bottles may explode

causing personal injury.

Prohibition

Do not put anything on top

of the refrigerator.

• Opening or closing the door

may trigger loose items to

slip and cause injury.

Do not store food in an

unstable manner.

• Opening the door may

trigger loose items to slip

and cause injury.

Do not store anything other

than food in the refrigerator.

• Medical supplies which need

to be under strict temperature

control should not be stored in

the refrigerator.

Prohibition Prohibition

When replacing electric

components, be sure to

use rated components.

• Check the model, rated

voltage, rated current,

operating temperature etc.

of the component.

When servicing the refrigerator,

completely remove dust or

foreign substances from the

housing, electric connections

and etc.

• This can protect against the risk of fire hazard

caused by tracking and short circuit.

Prohibition

When servicing the refrigerator,

completely remove dust or foreign

substances from the housing,

electric connections and etc.

• This can protect against the risk

of fire hazard caused by

tracking and short circuit.

2 Samsung Electronics

After servicing the refrigerator,

be sure to check the

components are reassembled

in a correct manner.

•

The serviced unit should be

reassembled and returned to its original

assembly state.

Check the electrical parts for the

trace of moisture penetration.

• When the trace of moisture

penetration is detected, replace

the part or try insulation tapping.

Page 4

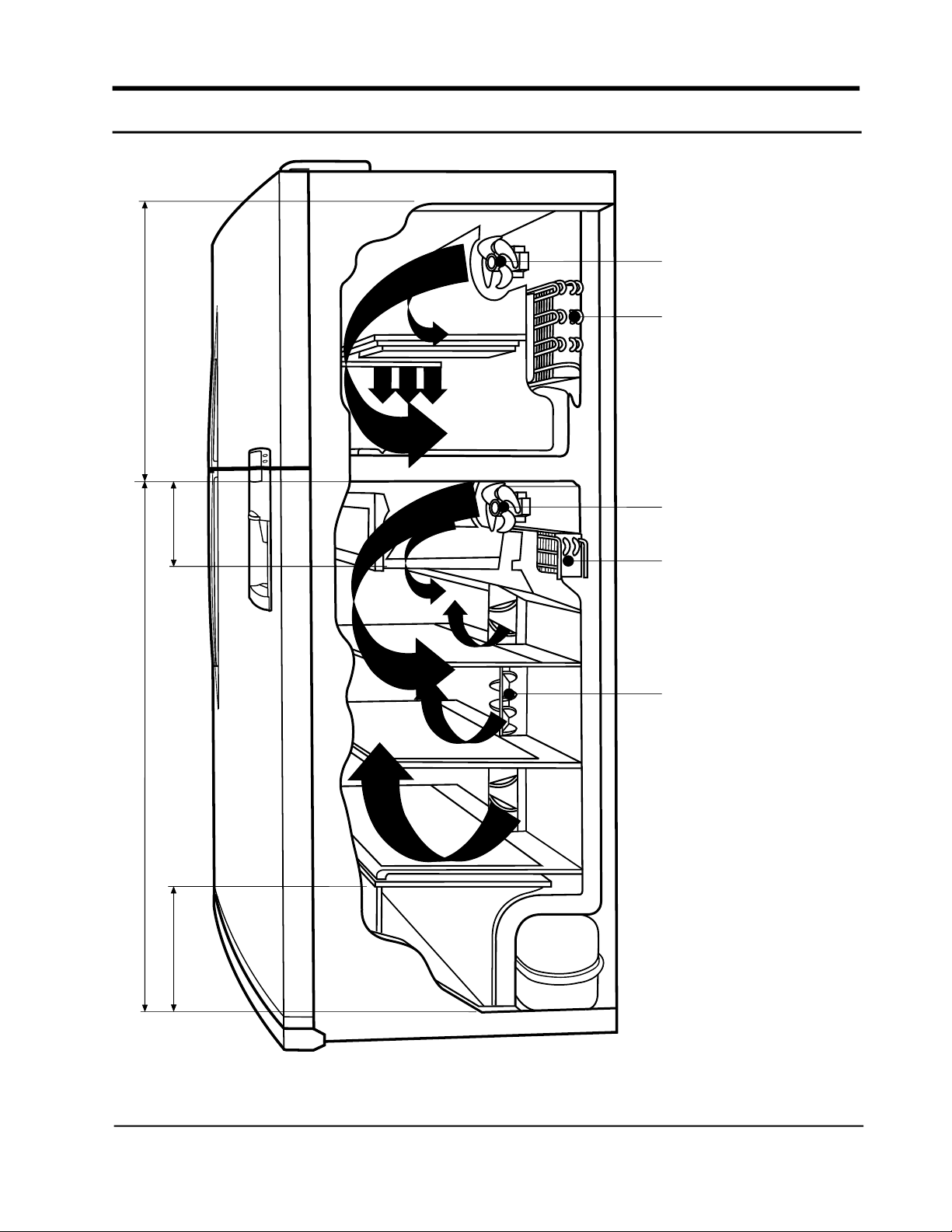

6. Air circulation route

Freezer

Freezer cooling fan

Freezer cooling device

Refrigerator cooling fan

Special

Refrigerator

Vegetable

Refrigerator cooling device

Swing fan

Samsung Electronics 7

Page 5

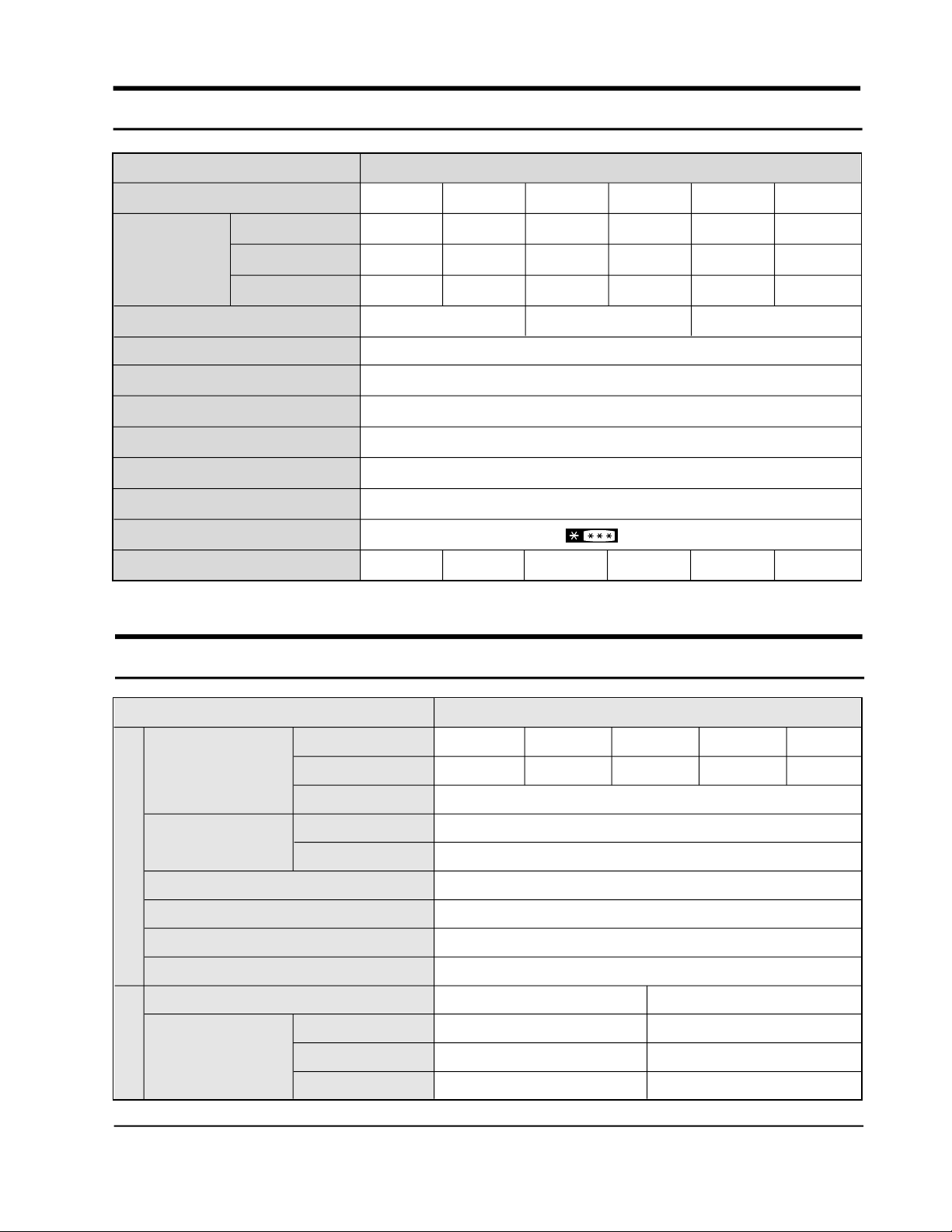

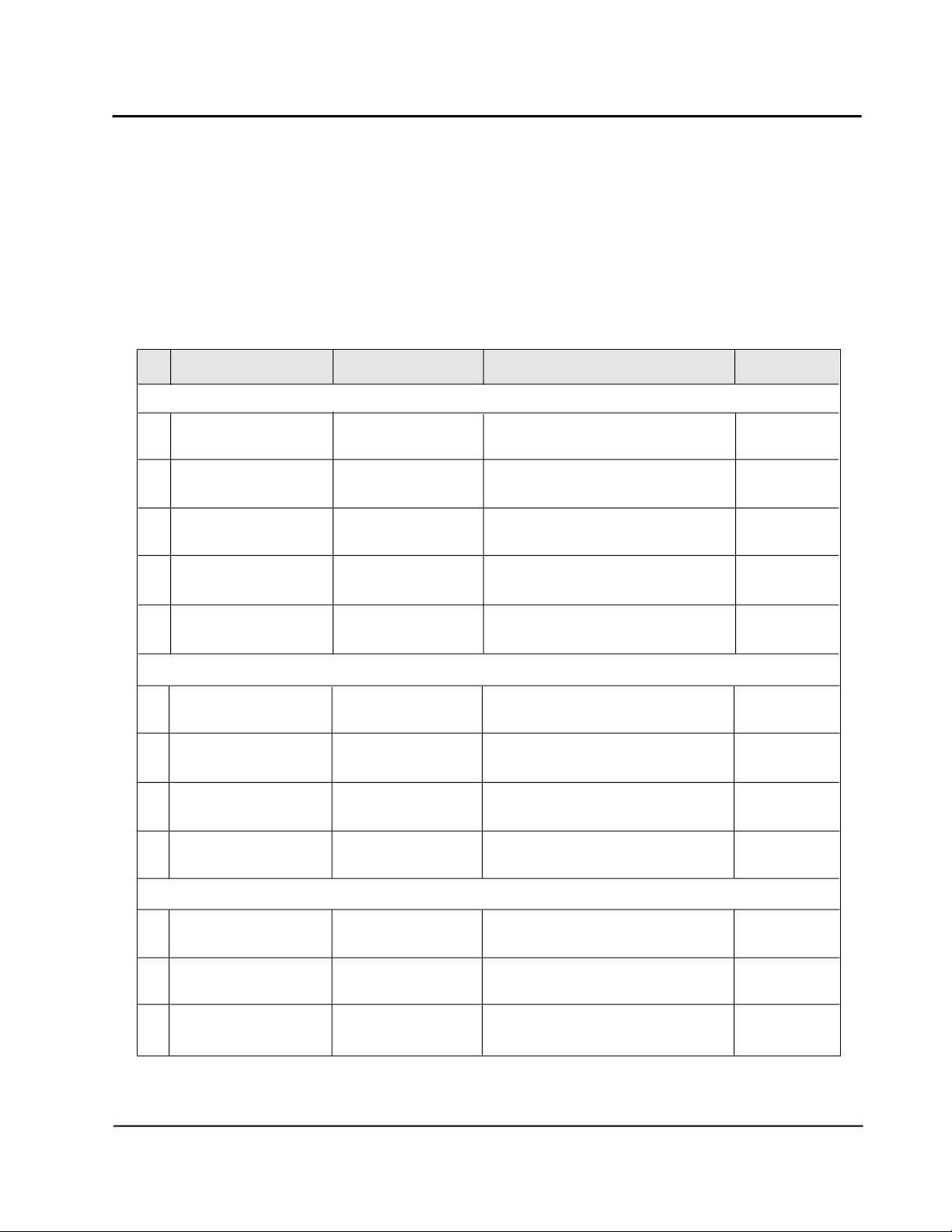

2. Product Specifications

ITEM

Model Name

Total

Net Capacity

Freezer

(l/CU.FT)

Refrigerator

Net dimension (WxHxD )

Regular Frequency

Electric Metor Regular Power

Electric Heating Equipment power

Sort of Refrigerator

Cooling Mass

Cooling Mass Sealed Quanlty

Freezer performance

Net weight

STANDARD

S R - 6 0 6 E V

5 0 4

1 5 3

3 5 1

840X726X1753.5

105kg 106kg 106kg 107kg 108kg 109kg

S R - 6 0 8 E V

4 9 9

1 5 3

3 4 6

115/60, 127/60, 240/50. 220/50,60

Occassional cooling type refrigerator

S R - 6 4 6 E V

5 4 4

1 6 5

3 7 9

840X726X1803.5 840X726X1847.5

S R - 6 4 8 E V

5 3 8

1 6 5

3 7 3

165W

378W

HFC-134a

155gr

(4 STAR)

S R - 6 8 6 E V

5 8 1

1 6 5

4 1 6

S R - 6 8 8 E V

5 7 5

1 6 5

4 1 0

3. Electrical part specifications & standard

ITEM

Compressor

Evaporator

Condenser

Dryer

Capilary tube

Refrigerant

Type

Freezer

Temperature Refrigeration Cycle

Model

Starting type

Oil charge

Freezer

Refrigerator

High

Mid

Low

S K 1 8 2 C - L 2 W

C S R

S K 1 8 2 P - L 2 W

Forced & Natural Convection Type

ON(˚C)

–20˚C

–17˚C

–14˚C

C S R

Freol α-15C(ESTER)/265CC

STANDARD

S K 1 9 0 H - L 2 U

R S C R

Split Fin Type

Split Fin Type

Molecular Sieve XH-9

0.82 X 2500 4.26kg/cm

HFC-134a/155gr

S K 1 9 0 Q - L 2 U

R S C R

2

OFF(˚C)

–22˚C

–19.0˚C

–16˚C

Samsung Electronics 3

Page 6

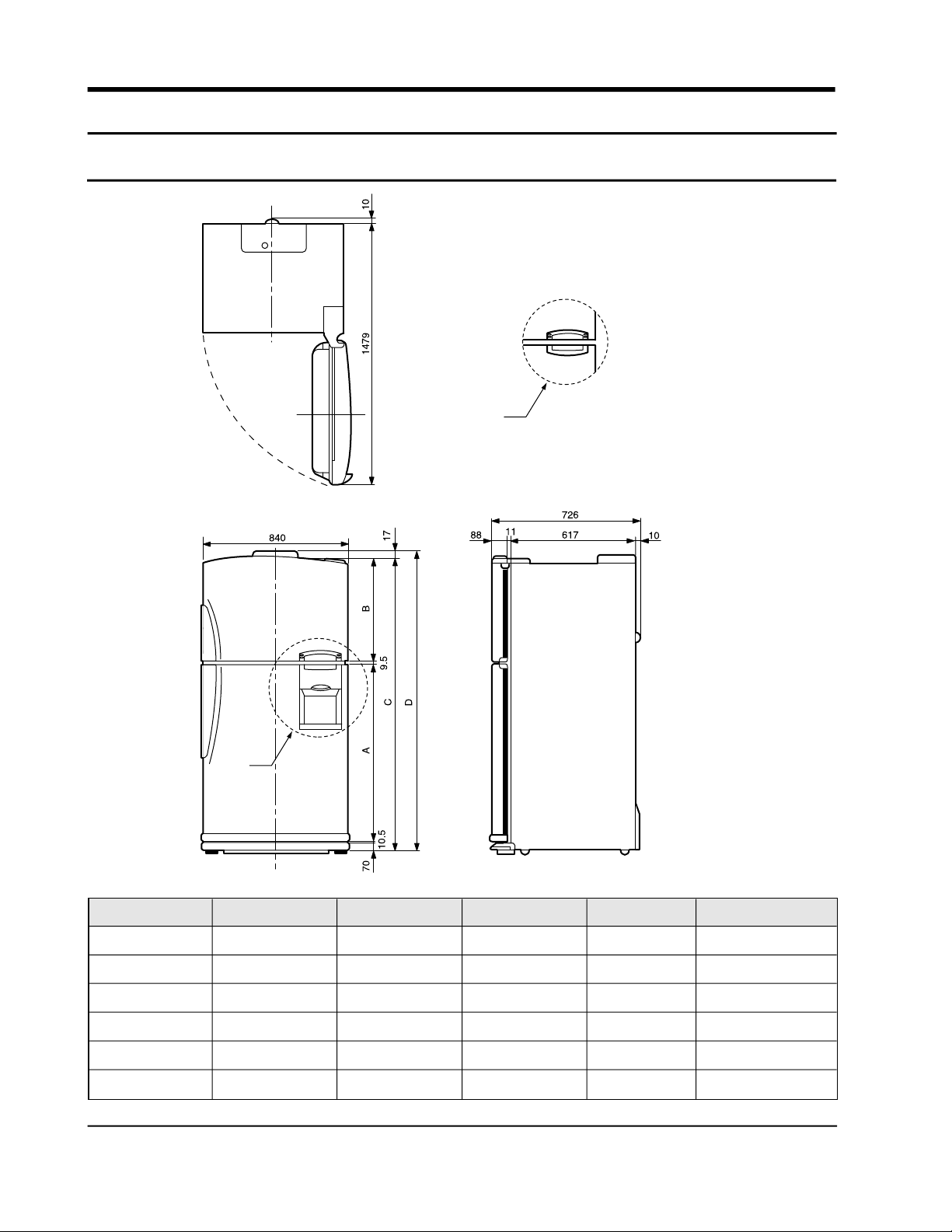

7. Function and Directions

7-1 The outer size

a

b

Model A B C D Remark

SR-606EA 1066.5 580 1736.5 1753.5 ‘a’ applied

SR-608EA 1066.5 580 1736.5 1753.5 ‘b’ applied

SR-646EA 1096.5 600 1766.5 1803.5 ‘a’ applied

SR-648EA 1096.5 600 1766.5 1803.5 ‘b’ applied

SR-686EA 1140.5 600 1810.5 1847.5 ‘a’ applied

SR-688EA 1140.5 600 1810.5 1847.5 ‘b’ applied

8 Samsung Electronics

Page 7

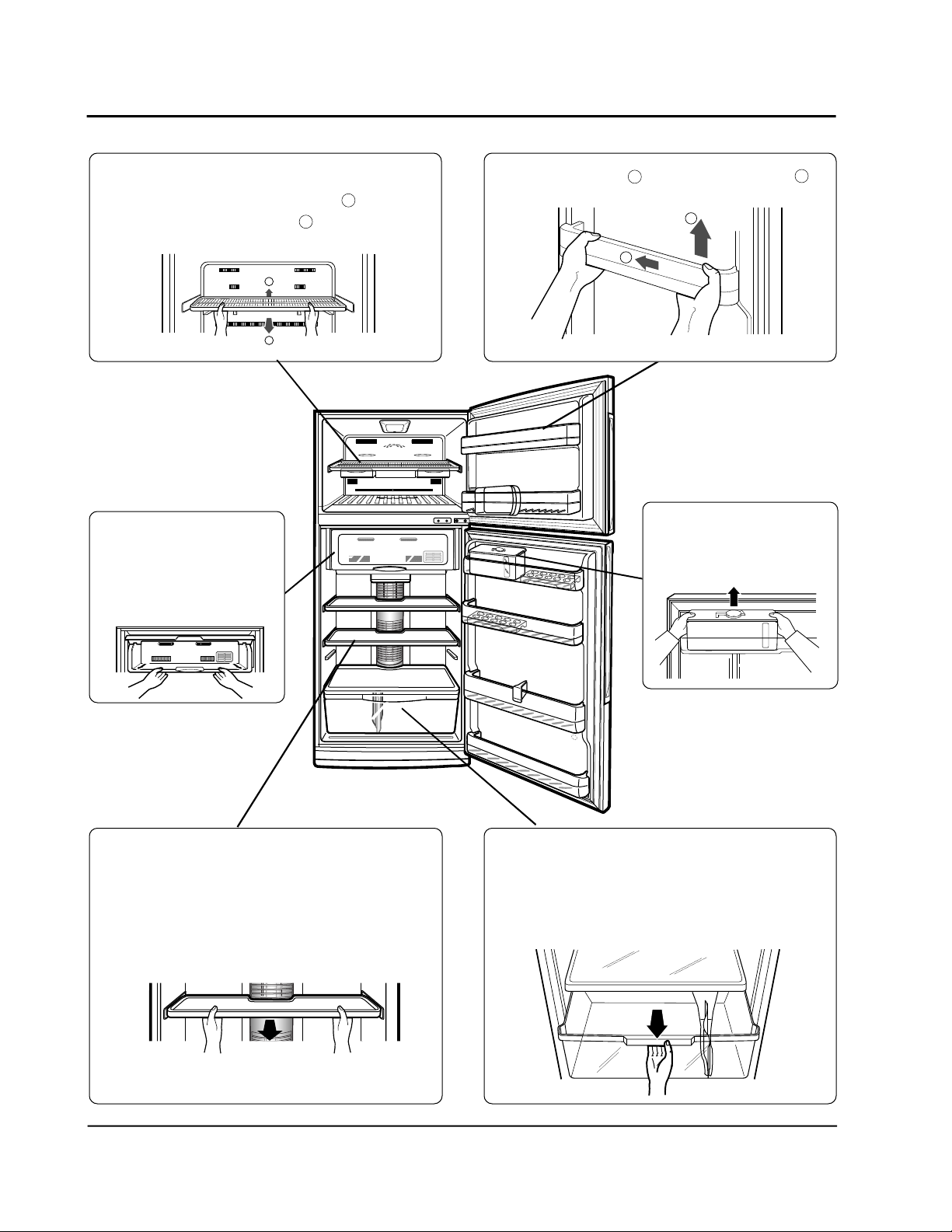

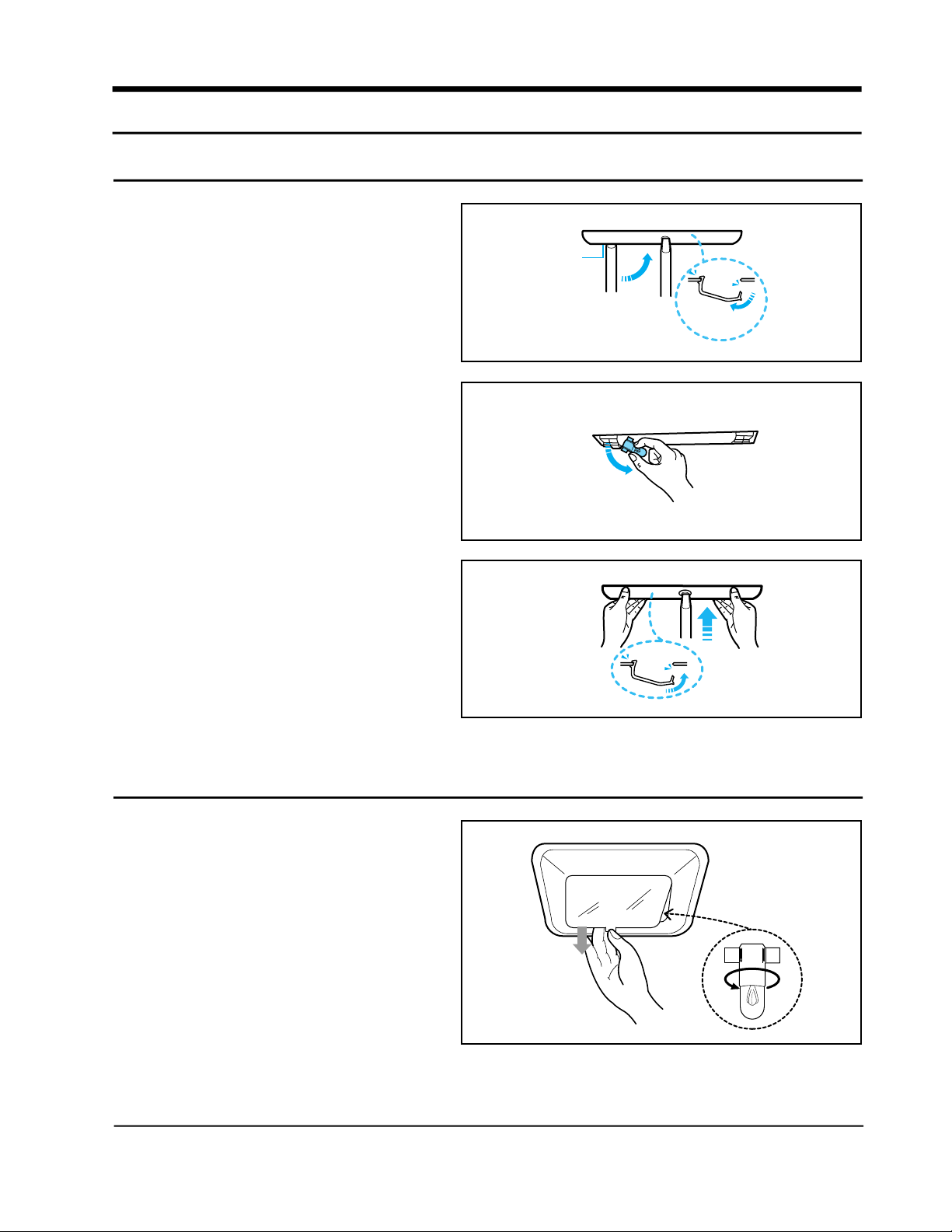

7-2 The name of each parts and disassemble method

Freezer shelf

• Up the front of shelf to direction then

pull and apart to direction .

1

2

1

2

Chilled room shelf

• Pull to the arrow direction

then up and apart at the

locking point.

• Push to direction and apart to direction .

1

2

1

2

• Up and apart as showed.

(concerned model : SR-

5066/5466/5866)

Shelf REF.

• Pull with both hands as showed.

• The height can be adjusted according to the

stored bowls.

Vegetable box and cover

• Up the cover and apart then pull out the

vegetable box at the mid-point and up and

and pull to apart.

Samsung Electronics 9

Page 8

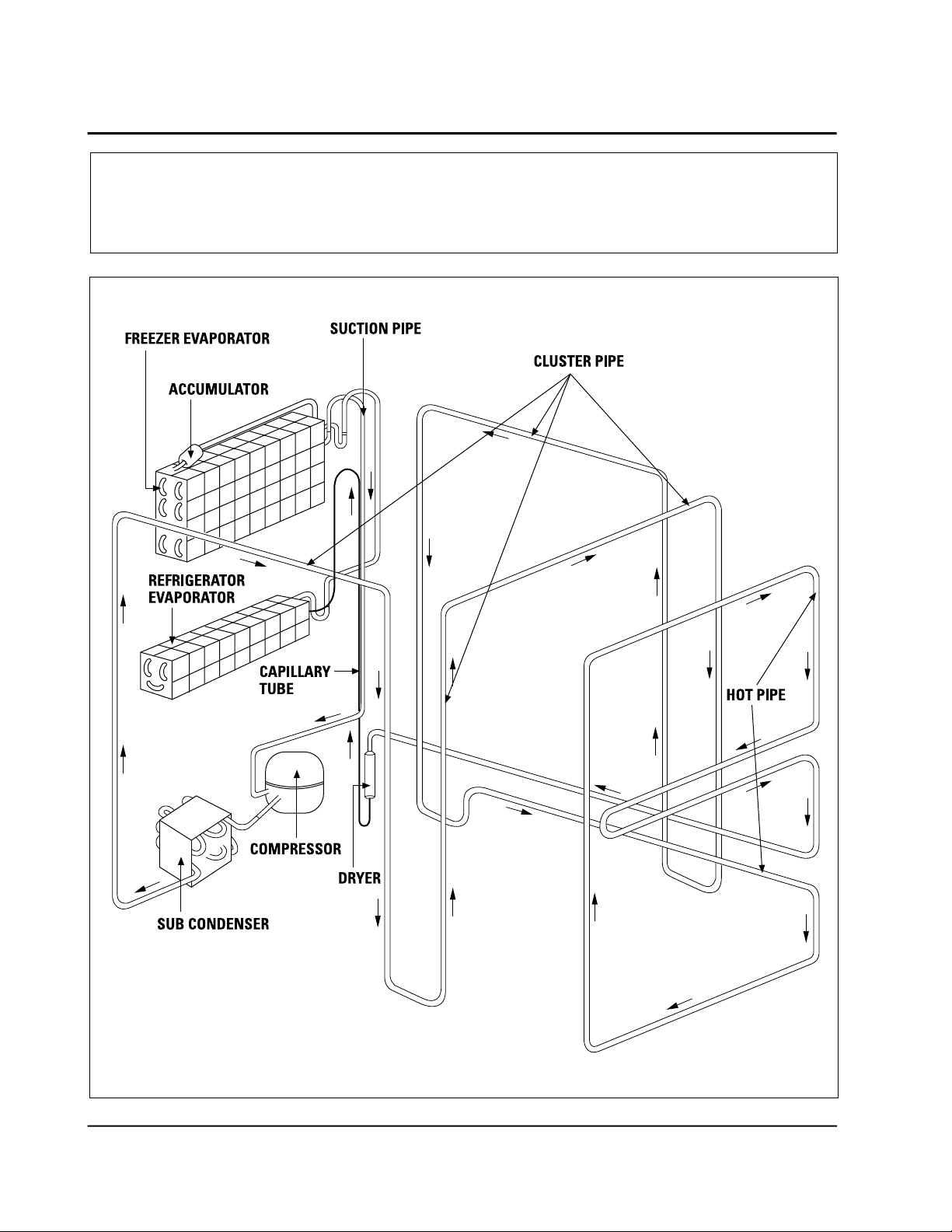

7-3 Freezing cycle

COMPRESSOR → SUB CONDENSER → CLUSTER PIPE → HOT PIPE → DRYER →CAPILLARY

TUBE →REFRIGERATOR EVAPORATOR → FREEZER EVAPORATOR → A C C U M U L A T O R

→SUCTION PIPE → COMPRESSOR

10 Samsung Electronics

Page 9

7-4 PANEL display

QUICK REF.

FRE

CONTROL

DOOR

ALARM

DOOR

FREE

QUICK

FRE.

FRE, CONTROL

LO

HI

LO

HI

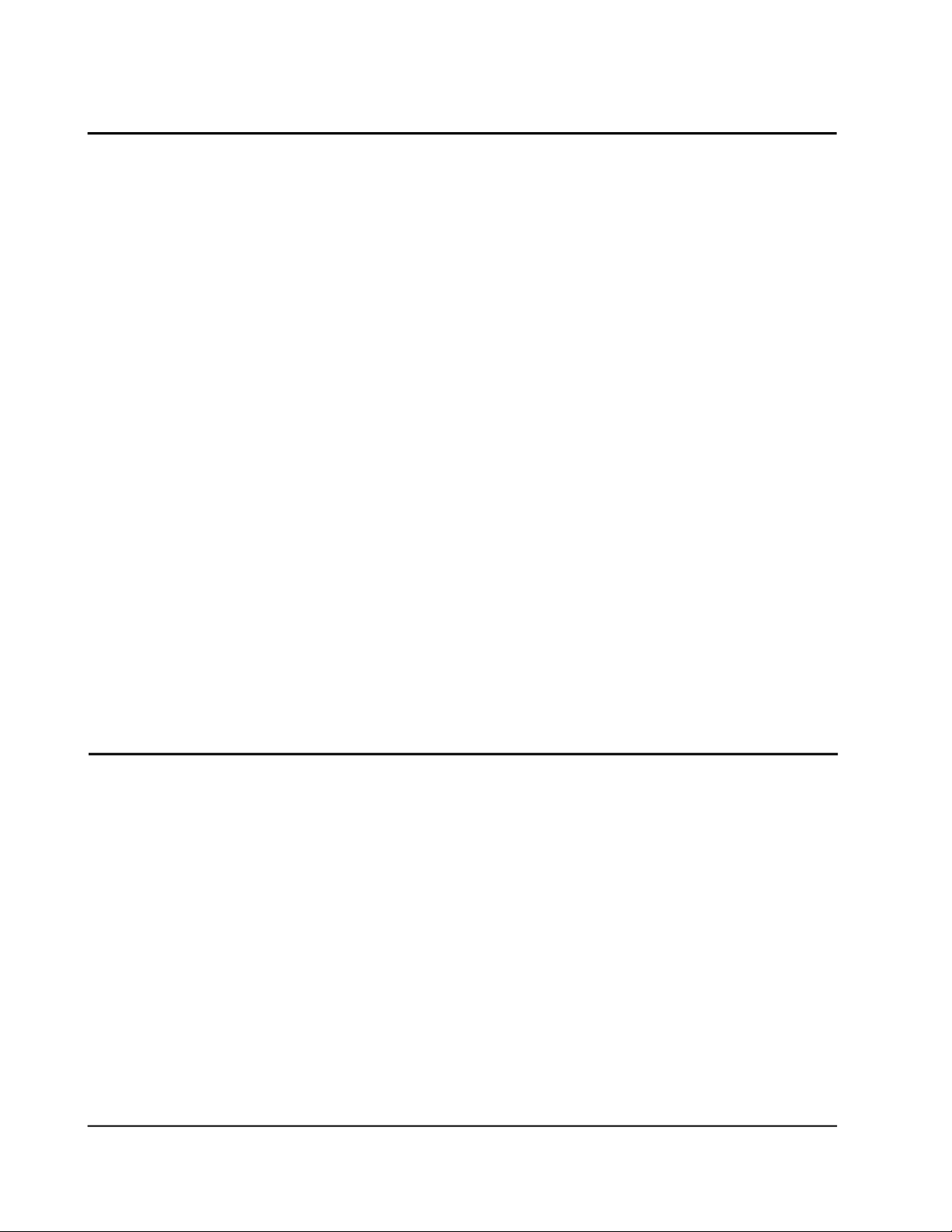

7-5 Temperature control

1) Freezer temperature control

1. It consists of five steps as follows and selected by one button.

Mid Æ Mid.High Æ High Æ Low Æ Low.Mid

2. It is circulated and displayed one by one by pressing the button.

3. At first power on it is selected ”Mid”

Category

Indicator Lamp

Initial power on

Mid

Pressed once

Mid·High

Pressed twice

High

QUICK

FRE.

Pressed 3 times

Low

HI-MOISTURE

Pressed 4 times

Low·Mid

QUICK REF.

REF.

CONTROL

Remark

Reference Temp.

–18˚C –19.5˚C

–21˚C

–15˚C

–16.5˚C

2) Temperature control in the refrigerating compartment

1) Select the 5 stages of ‘Mid’–‘Mid · High’–‘High’–‘Low’–‘Low · Mid’ with a button.

2) Whenever the temperature control button of refrigerator is pressed, it continues of light from

‘Mid’–‘Mid · High’–‘High’–‘Low’–‘Low · Mid’.

3) When power turns on “Mid” is automatically selected.

Category

Indicator Lamp

Reference Temp.

Initial power on

Mid

3˚C 1˚C

Pressed once

Mid·High

Pressed twice

High

–1˚C

Pressed 3 times

Low

6˚C

Pressed 4 times

Low·Mid

4.5˚C

Remark

Samsung Electronics 11

Page 10

7-6. Power freeze and Power

• Selected by additional quick freeze & refrigeration button.

• The lamp of quick freeze and refrigeration circulated ever ytime it pushed.

• No change of setting temperature occured during quick free ze and refrigeration selected.

• Te m p e r a t u re of freezer and r e f r i g e r a t o r can be re-setted while quick freeze and refrigeration opera tes.

1) Quick freeze

(1)Comp. and F-fan runs continuously for two and a half hour s when quick freeze selected. ( one

minute after selection )

(2) During quick freezing the refrigerator controlled by se tted notch.

2) Quick refrigeration

(1) Comp. and R-fan runs until the temperature of refrigerat or reaches -4 ˚C when quick refrigeration

selected.

(2) After the temperature reaches -4 ˚C the ’HIGH’ notch runs for an hour and finish quick

refrigeration.

(3) Unless the temperature of refrigerator reaches -4 ˚C within two and a half hours quick

refrigeration stopped.

3) When quick freeze and refrigeration selected at the same time

(1) Each function applied at the same time. Quick freeze ru ns Comp. and F-fan for two and a half

hours and quick refrigeration runs Comp. and R-fan for two a nd a half hours with no relation of

each other.

7-7 Alarming

1) Button touch ( ”Ding-Dong ” sound)

(1)Everytime the button pushed, the input confirmation, ”Ding-Dong ”, sounds.

(2) Not sounds, if two keys are pushed at the same time or w rongly handled.

2) Door-Open warning ( ”Ding-Dong ” sound)

(1)Two minutes after door opened, ten times of alarming soun ds.

(2) If door opened continuously, ten times of alarming sound s with one minute cycle.

(3)Alarming stopped just after door closed.

3) Forced operating and defrosting ( ”Beep” sound)

(1) If forced function selected the ”beep” sounds.

(2) Alarming sounds untill the forced operating canceled by automatically ( 24Hr ) or manualy.

(3) Alarming sounds untill the forced defrosting canceled by automatically ( 24Hr ) or manualy.

12 Samsung Electronics

Page 11

7-8 Defrosting

1) From the first power on, defrosting started after 4 hours of total Comp on time.

2) After that defrosting cycle can be varied from 6 hours to 32hours. (Comp on time)

7-9 Testing

• Testing is for PCB, product, function and service.

• After testing, turn the power on to start self diagnosis.

1) Forced operating

(1) As the button on PCB pushed once, Comp starts immediately without 5 minutes delay.

(2)If forced operating selected the notch of freezer and refrigerator fixed to ”HIGH” and ”MID-

HIGH”. Then Comp and F-fan is controlled to pull-down and R-fan is controlled to ”MID-HIGH”

notch.

(3) Pull-down maintained just for 24 hours during forced operating, after that automatically defrost

freezer and refrigerator and then starts normal operating.

(4) Turn the power off or select test cancel mode to cancel the forced operating.

(5)Alarming (0.25 sec on/0.75 sec off) continues until the forced operating finished. It continues

without any relations to alarming key selection or cancel.

2) Forced defrosting

(1) Push the test button one more time to run the forced defrosting of refrigerator.

(2) One more push in the above status will run defrosting of freezer and refrigerator simultaneously.

(3) Forced operating cancelled automatically by starting foced defrosting and return to normal

operating after completion of defrosting.

3) Test cancel mode

(1) One more push in the status of forced defrosting of F/R will run normal operating.

(2) Alarming stopped in the test cancel mode.

7-10 Self diagnosis

1) Self diagnosis at first power on

(1) As the power applied to the refrigerator first time, all displays show and run the self diagnosis.

(2) If no problems founded display returns to normal model.

(3) If problem is founded, on and off the related display lamp and start alarming.

(4) Lamp displayed until the problem solved or self diagnosis cancelled.

(5) After problem solved the display mode return to normal.

Samsung Electronics 13

Page 12

(6) When refrigerator repaired, sure to power off and on to run self diagnosis.

(7) Refer to belows for problems and related displays.

No

1

R1-Sensor

2

R2-Sensor

3

RD-Sensor

4

Room-Temp.

Sensor

Item

Display LED

Refrigerator “Low”

Refrigerator

“Low · Mid”

Refrigerator “Mid”

Freezer “Low”

Symptom

• R-room left sensor housing

disconnection.

• Faulty connection.

• Wire open or short.

• Faulty sensor.

• R-room left right sensor

housing disconnection.

• Faulty connection.

• Wire open or short.

• Faulty sensor.

• R-room defrost sensor

housing disconnection.

• Faulty connection.

• Wire open or short.

• Faulty sensor.

• Room-Temp sensor housing

disconnection.

• Faulty connection.

• Wire open or short.

• Faulty sensor.

Remark

R1-Sensor temperature is

over +50˚C or below –50˚C.

R2-Sensor temperature is

over +50˚C or below –50˚C.

RD-Sensor temperature is

over +50˚C or below –50˚C.

Room-Temp Sensor

temperature is over +50˚C

or below –50˚C.

5

F-Sensor

6

FD-Sensor

7

GearedMotor

Freezer “Low”

Freezer “Mid”

Refrigerator “High”

(Self-diagnosis Display Table)

• F-room sensor housing

disconnection.

• Faulty connection

• Wire open or short.

• Faulty sensor.

• R-room defrost sensor

housing disconnection.

• Faulty connection.

• Wire open or short.

• Faulty sensor.

• Faulty geared-motor

• Faulty reed-switch

housing disconnection.

• Faulty connection.

F-Sensor temperature is

over +50˚C or below –50˚C.

F-Sensor temperature is

over +50˚C or below –50˚C.

Square wave not detected

by reed-S/W.

14 Samsung Electronics

Page 13

7-11 Load status display

1) Press power F/R key for five seconds then press temperature control key in the refrigerator after

temperature display lamps on and off three times.

2) This mode shows which load is being sourced signal from MICOM currently. This doesn’ t mean

the load is operating but just show MICOM signal output. The Compressor may not operate due

to the open wire or relay missing though the display shows the Compressor operating.

3) Load status display return to normal mode after sixty seconds.

4) Follows are load status and related display.

No

Freezer Subordinate

1

COMP

2

F-FAN

3

Freezer defrost Heater

4

Freezer bulb

5

COMP. Cooling Fan

Refrigerator Subordinate

6

R-FAN

Refrigerator defrost

7

Heater

8

Refrigerator bulb

Item

Display LED

Freezer “Low”

Freezer “Low · Mid”

Freezer “Mid”

Freezer “Mid · High”

Freezer “High”

Refrigerator

“Low · Mid”

Refrigerator “Mid”

Refrigerator

“Mid · High”

Display

Relevant LED ON during

Compressor operation

Relevant LED ON during F-FAN

operation

Relevant LED ON during freezer

defrost heater on

Relevant LED ON during freezer

bulb ON

Relevant LED ON during

Compressor Cooling Fan oeration

Relevant LED ON during F-FAN

operation

Relevant LED ON during

refrigerator defrost

Relevant LED ON during

refrigerator bulb ON

Remark

9

GEARED-Motor

Mode Display

10

Initial Mode

11

Overload

12

Low temp.

Samsung Electronics 15

Refrigerator “High”

Quick Freezing

Quick Refrigeration

High humidity

refrigeration

(Load Status Display Table)

Relevant LED ON during

refrigerator brade rotation

Relevant LED ON with initial

power input

Relevant LED ON when ROOM

temperature is over 35˚C

Relevant LED On when ROOM

temperature is below 20˚C

Page 14

11. Disassemble and assemble method

11-1 Refrigerator inside lamp replacement

1) Remove the screw with (+) driver and

push the cover to the arrow direction and

apart.

2) Remove out the lamp to the arrow direction

and replace with new one. ( Left & Right )

3) Insert the front of the cover first and screw

it.

11-2 Freezer inside lamp replacement

• Grab the the salient part of cover and pull

it down to apart. Replace the 220V/15W

lamp and insert front of cover first and

then fix it.

Samsung Electronics 41

Page 15

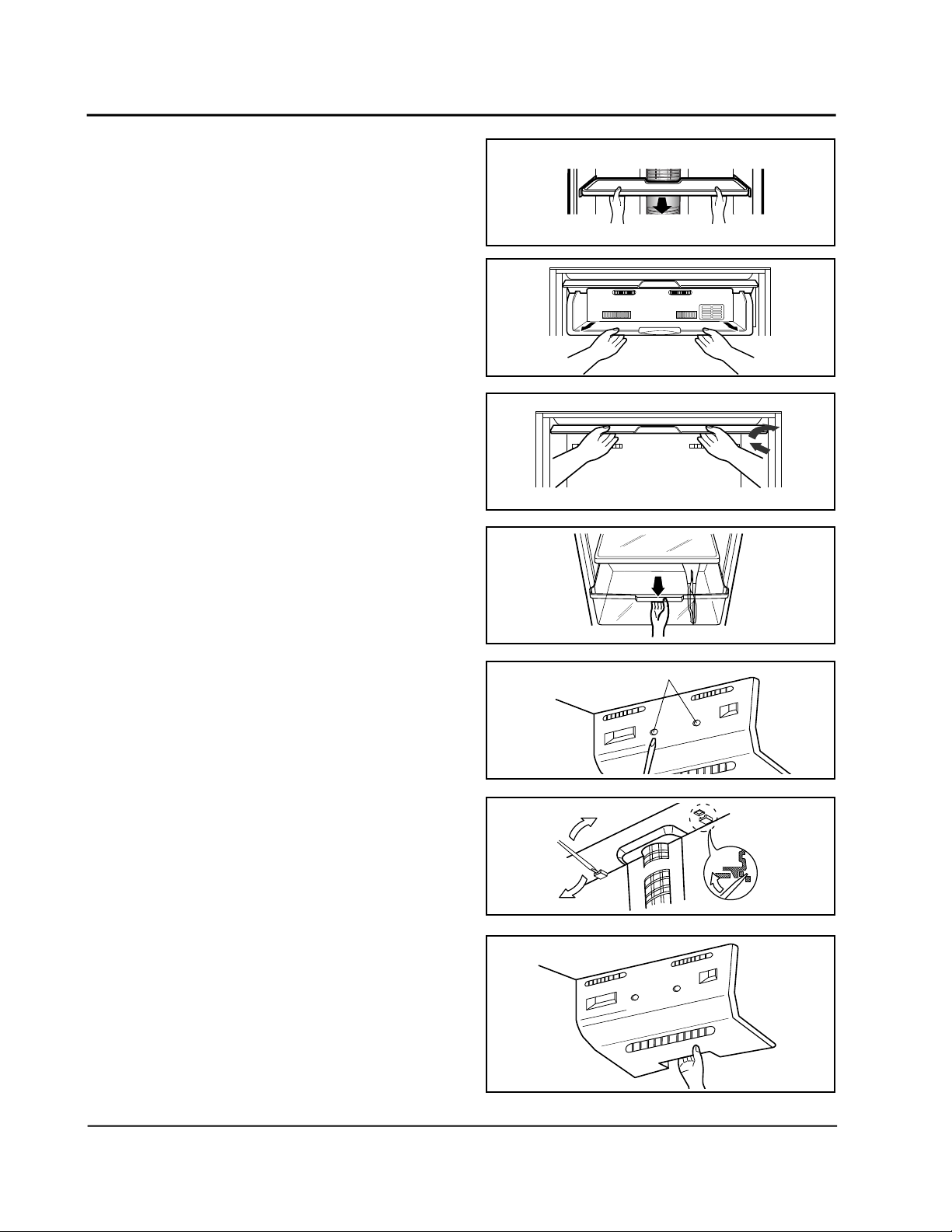

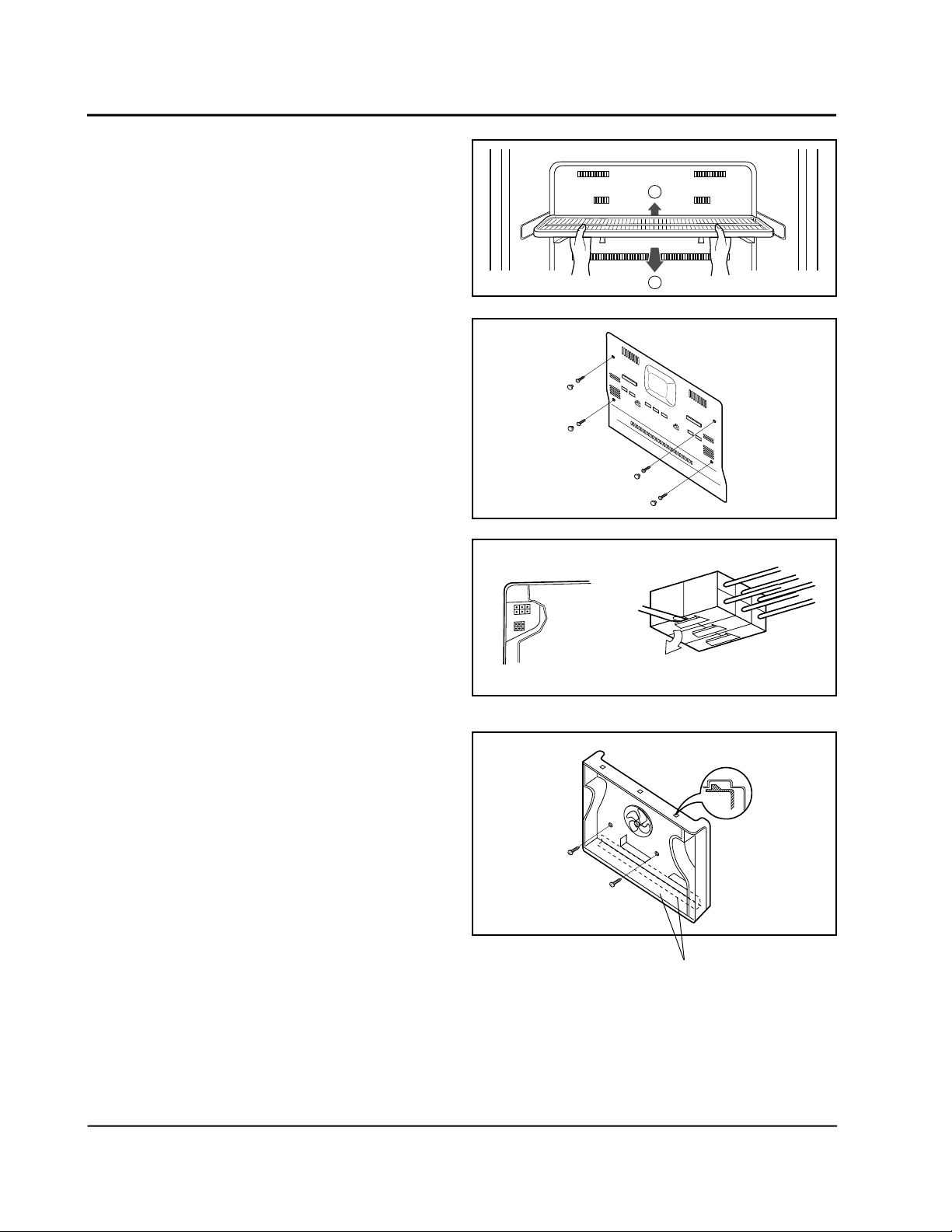

11-3 Disassemble of refrigerator cooling part

1) Remove foods and shelves inside the

refrigerator.

2) Pull out the chilled room box to the arrow

direction and pul it up to apart at the locking

point.

3) Push the right arrow part of the chilled room

inside and apart the chilled room cover.

4) Up the cover of vegetable box and pull apart

then pull it out.

5) Remove the screws with (-) driver.

6) Release the locking part using (-) driver as

shown.

7) Pull out the cover front part.

2 screws

42 Samsung Electronics

Page 16

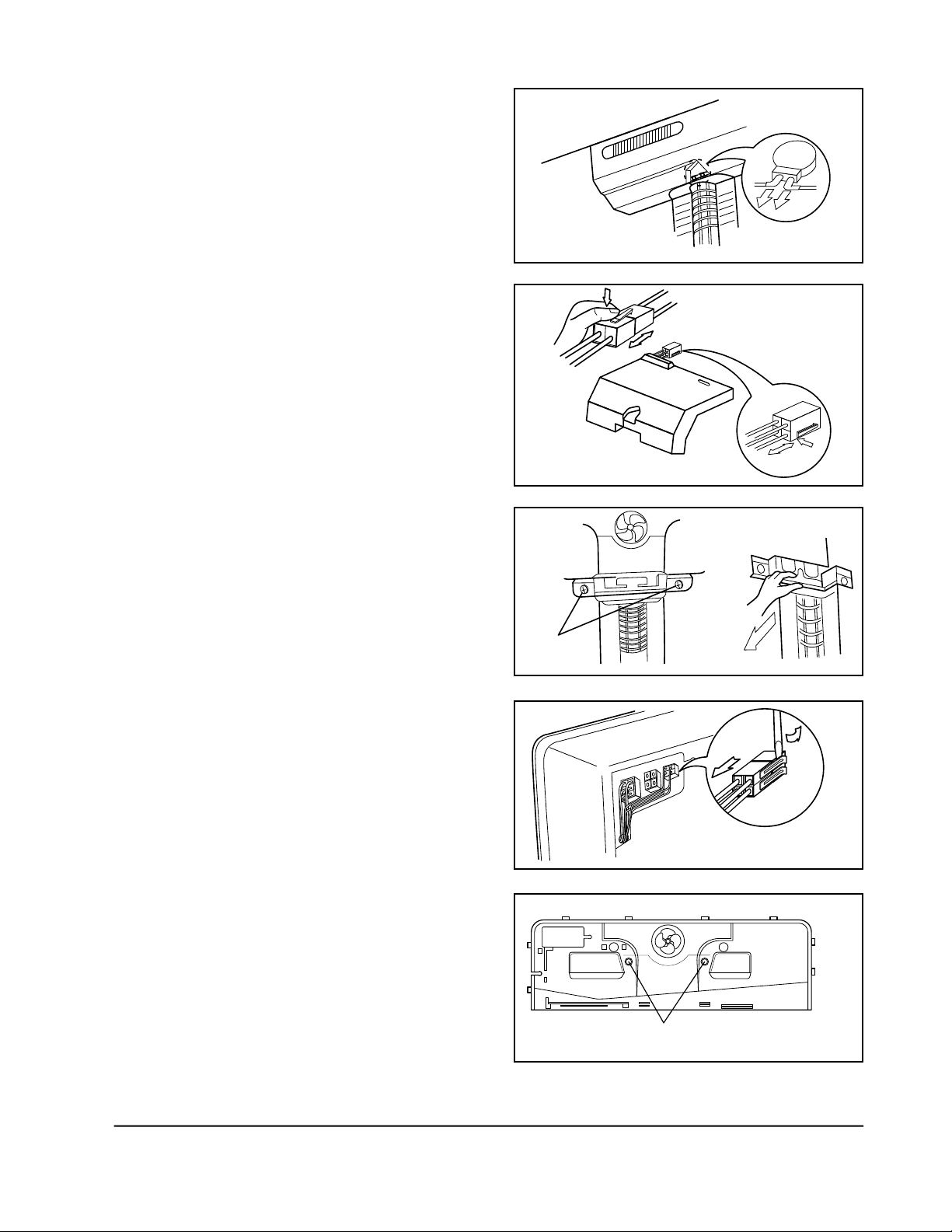

8) Disassemble the wire housing of motor in the

center.

9) Pull the housing part and disassemble the wire

terminal.

10) Remove screws of duct and pull apart.

11) Release wire terminal on top of the left.

12) Remove screws of evap. Cover rear and release

the locking part of both left and right using (-)

driver.

Remove 2

screws

latch

Remove 2 screws

Samsung Electronics 43

Page 17

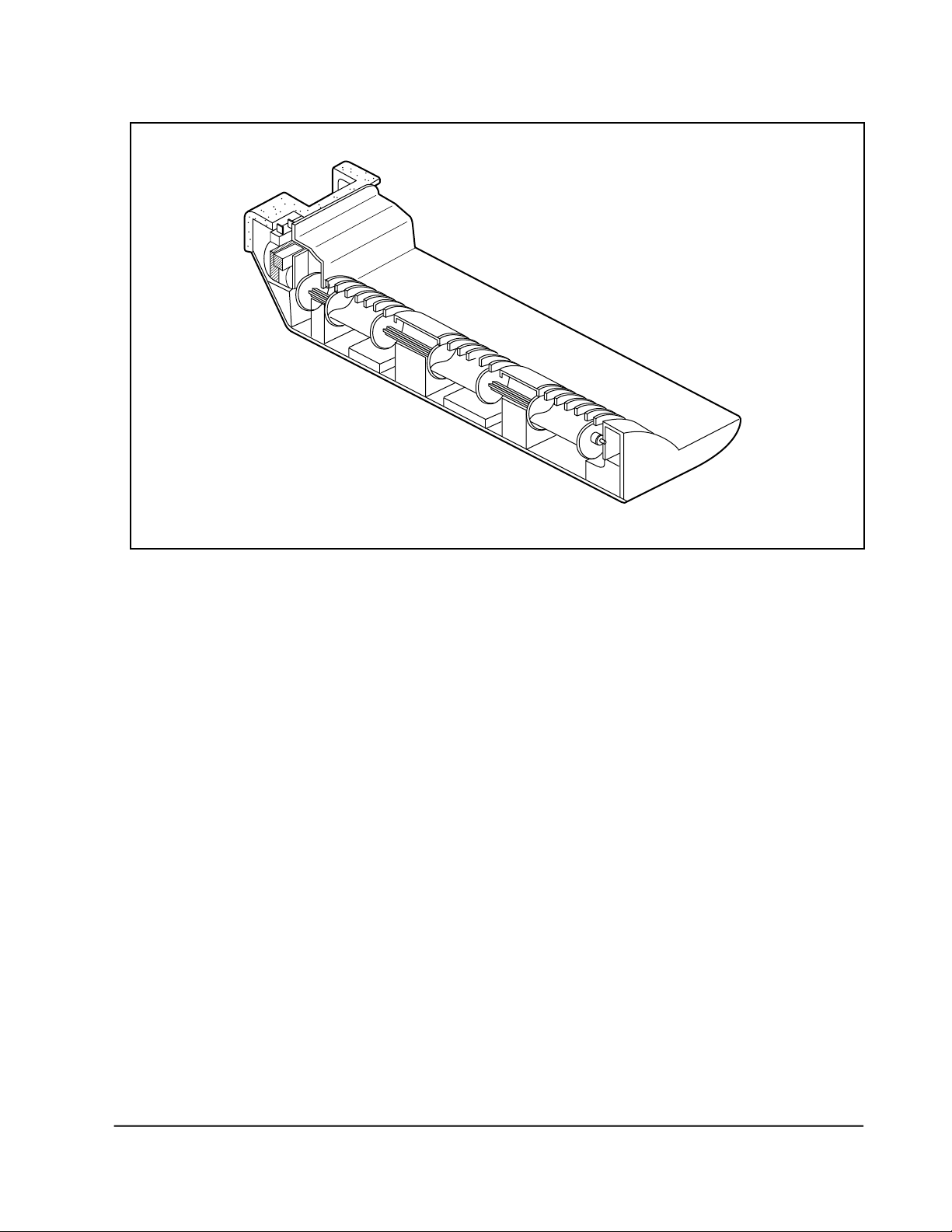

♦ Cooling cycle unit assembly in the refrigerating compartment

♦ Cooling cycle unit cover assembly in the refrigerating compartment

(Groove for preventing

small ice when

defrosting)

44 Samsung Electronics

Page 18

♦ Rotating duct assembly in the refrigerating compartment

Samsung Electronics 45

Page 19

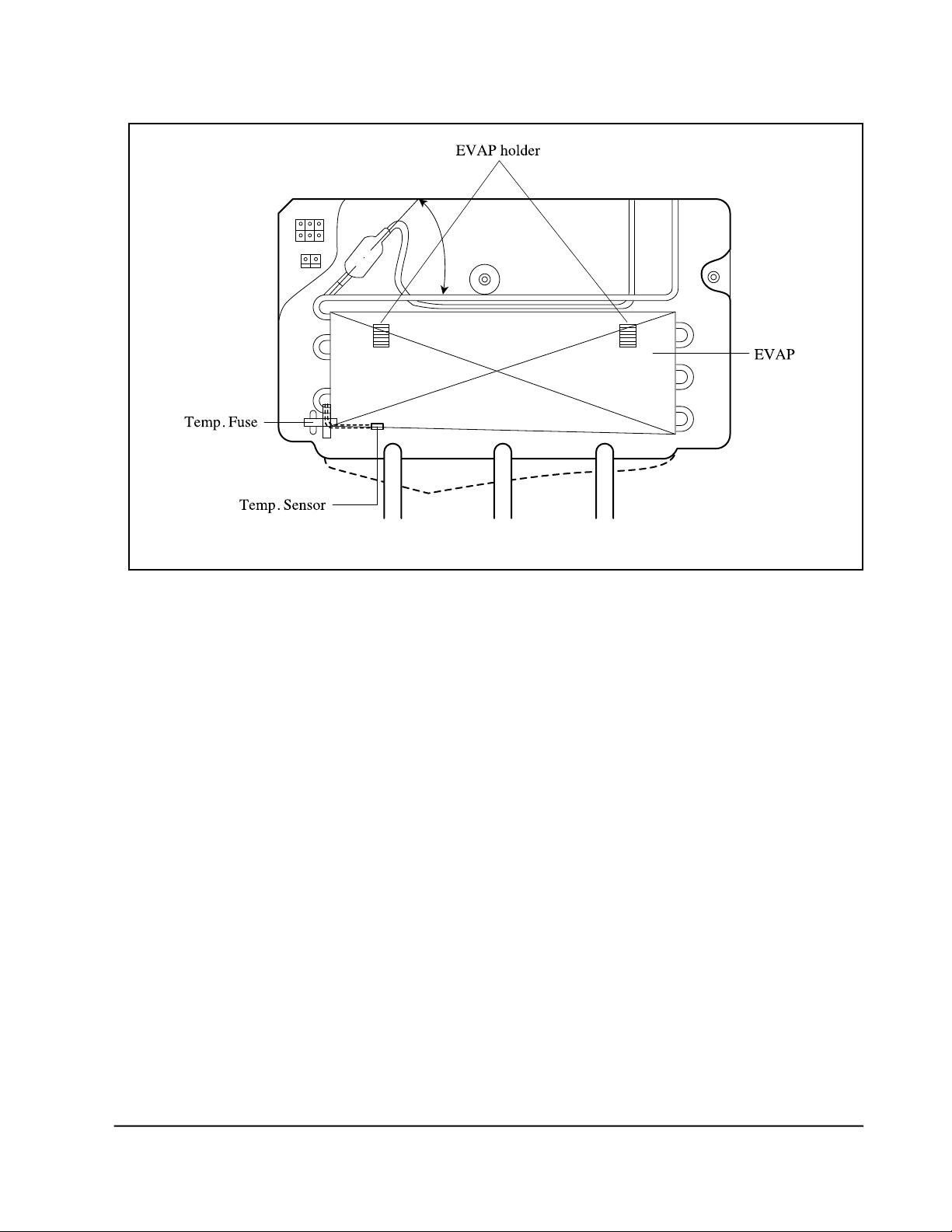

11-4 Disassemble of cooling part in the freezing room

1) Pull out the shelf.

1

2

2) Remove screws of evap cover and pull apart.

3) Disconnect the each terminal of wire housing

on top of the left side.

4) Remove screws of evap. Cover rear and

release the locking point using (-) driver.

Residual spread preventer

46 Samsung Electronics

Page 20

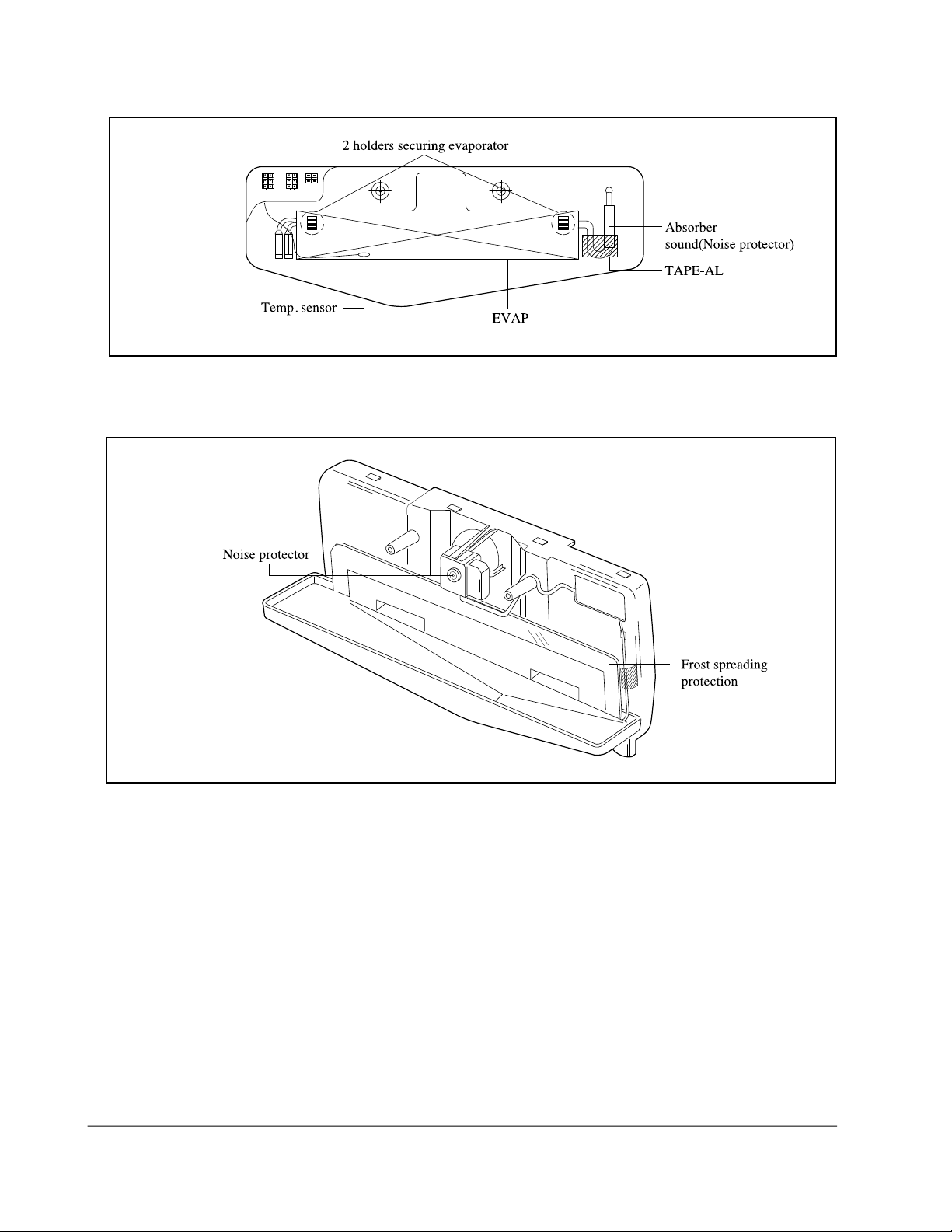

♦ Assembly of the cooling cycle unit in the freezer

Maintains 45˚

(Coolant & noise

reduction)

Samsung Electronics 47

Page 21

11-5 Assembling specifications of machinery room

1. remove screws of compressor cover

2. Assembling specifications of machinery room

Noise & Vibration

reduction rubber

48 Samsung Electronics

Page 22

11-6 Assembling specifications of power supply part

1. Turn off the power of

refrigerator.

2. Remove the cover using (-) driver.

3. Assembling specifications of power supply part

TEST S/W

Condenser

D/C Trans

Samsung Electronics 49

Page 23

11-7 Disassembling method and order of water dispenser

1. Disassembling method and order of cock part

1-1. Open the door and detach the water tank. Throw away waters in the tank.

1-2. Turn the cock on the bottom of the water tank to counterclockwise and apart.

1-3. Push part 6 to arrow direction and apart part 2 then part 5,6 automatically aparted. Puch the

locking point to arrow direcion to apart part 3.

1) Be careful not to damage the parts 1,2,5,7 ( It may cause a leak of water. )

2) Assembling is reverse of the disassembling order.

part 5

part 6

part 2

part 3

part 7

part 1

part 4

2. Disassembling method and order of lever

2-1. Close the door and turn the screw of the bottom of cover dispenser to counterclockwise using (+)

driver and pull out to arrow direction and apart the cover.

2-2. Release locking point of lever dispensor using (-) driver to the arrow direction and apart spring

and lever dispenser.

2-3. Push locking point using (-) driver and pull out key-lock to upside then apart dispenser locking

device.

2-4. Assembling is reverse of the disassembling order after inserting the spring to lever shaft.

50 Samsung Electronics

Page 24

11-8 The operating theory and order of water dispenser

1. Push the knob lever(1-1) to the arrow direction.

2. Lever dispenser(1-2) rotates around spring-lever(1-

3) to the counterclockwise and push guide pin(2-1)

and press the spring dispenser(2-2) vertically.

3. O-ring(big)(2-4) inserted in guide-push(2-3) moves

vertically and aparts from cock-dispenser(2-5) then

water flows through path of guide-pin(2-1) to the

cup.

4. O-ring(small)(2-6) inserted in guide-pin(2-1) also

aparts from guide-push(2-3) to let air go through

that helps water flowing.

5. Stop pushing knob lever(1-1) when water filled to

certain point.

6. Lever-dispenser returns by expansive force of

spring-dispenser(2-2) and spring-lever(1-3) .

7. Guide-push(2-2), guide-pin(2-1), o-ring(small)(2-6)

and o-ring(big)(2-4) also retun and contact cockdispenser(2-5) then return to initial state.

W A T E R - D I S P E N S E R

2-7

Samsung Electronics 51

Page 25

11-9 Dispenser unit list

NO CODE-NO PART

1

1 - 1

1 - 2

1 - 3

1 - 4

1 - 5

2

2 - 1

2 - 2

2 - 3

2 - 4

2 - 5

2 - 6

2 - 7

2 - 8

2 - 9

2 - 1 0

2 - 1 1

2 - 1 2

2 - 1 3

2 - 1 4

3

3 - 1

3 - 2

3 - 3

3 - 4

3 - 5

4

5

6

7

8

DA63-10905C

DA64-40173B

DA32-10105G

DA61-20146A

DA64-90138B

DA64-10896B

DA64-90136A

DA71-70158A

DA61-20147A

DA71-70159A

DA60-90103B

DA67-10402A

DA60-90103A

DA74-40142A

DA71-20159A

DA67-30214A

DA74-90115B

DA63-30011A

DA63-10383A

DA65-20004A

DA67-30005A

DA67-10403B

DA71-20264A

DA74-40144A

DA02-10143A

DA02-10142A

DA02-10014A

DA63-10010A

DA67-40295B

DA67-40294B

DA63-20158C

6002-000213

ASS’Y-COVER DISPENSER

KNOB(LEVER)

LEVER-DISPENSER

SPRING(LEVER)

KEY(LEVER)

COVER-DISPENSER

TANK-WATER ASS’Y

GUIDE-PIN

SPRING-DISPENSER

GUIDE-PUSH

RING-O

COCK-DISPENSER

RING-O

VALVE(WATER-TANK)

FIXER-FILTER

CAP-TANK UPP

TANK-WATER

GASKET-COMP V/PLATE

COVER TANK

CLAMP-TANK

CAP

CASE-DISPENSER

FIXER-CASE

VALVE(FIXER-CASE)

TAPE-AL, FOIL(B)

TAPE-AL, FOIL(A)

TAPE-AL

COVER-DISPENSER, B

TRAY-DISPENSER, A

TRAY-DISPENSER, B

GUARD-VARIETY, A

SCREW-TAP

SPEC. Q’TY REMARK

M-PROJECT

ABS

POM(TP-20)

STS-304(WPB)

ABS(HG-0760)

ABS(HG-0760)

M-PROJECT

PC

STS-304(WPB)

PC

SILICON(TSE-221)

PC-ABS

SILICON(TSE-221)

SILICON(TSE-221)

PE(HARD)

PE(SEMI-HARD)

ABS(INSERT)

SILICON(TSE-221)

ABS, WHT

PC ABS

ABS

ABS

ABS

SILICON(TSE-221)

AL(T=0.075)

AL(T=0.075)

TAPE AL, T0.05, W50, 1RL

ABS

ABS

ABS

GPPS

TH1 4X12 FZ-FZY

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

0.32MT

1

1

1

1

2

PART USED INSTEAD

OF WATER TANK

A/S IMPOSSIBLE

A/S IMPOSSIBLE

A/S IMPOSSIBLE

A/S IMPOSSIBLE

A/S IMPOSSIBLE

A/S IMPOSSIBLE

52 Samsung Electronics

Page 26

11-10 General diagnosis of water dispenser

No water or too little water flow out

Check the water in the water tank

Normal

Normal

Check the fixed state of water tank

Normal

Water falls continueously

Check the contact state of o-ring ( burr, eveness, etc)

Normal

Fill in the water tank

( If the fixed state is bad the guide-pin doesn’ t work due to the

wrongly positioned cock-ass’ y)

Fix the water tank correctly ( Check guide-variety )

(It acn cause a leak of water.)

If gasket is missed or wrongly assembled, then fix the problem.

Check the gasket between cock-ass’ y and water tank

(Misse valve(water tank) cause a leak of water between cock-ass’ y and

water tank. )

If valve(water tank) is missed or wrongly assembled,

Normal

Change all the parts

Normal

Change refrigerator door

Samsung Electronics 53

then fix the problem.

Page 27

8. Circuit operating theory

8-1 Power supply part

Voltage

(DC 12V)

Vcc (DC 5V)

V12 (DC 12V)

Secondary voltage output of DC trans is sourced 1~3 and 5~7 about 15V. On the ’a’ part, input is

rectified and regulated by MC 7812 and is about DC12V. This voltage is applied for relay running and

regulated again by 7805 to transformer. DC 5V is applied to display part after rectified and regulated by

MC7812.

Relay Operation

Power around MICOM & Sensor Detector

LED Display & S/W Detector

Circuit used

8-2 Resetpart

Reset part is intialize RAM of MICOM and others when

KA7533 RESET

+

29

power is on or power is interrupted for some time. It

will make whole program runs from the first status.

When power is supplied, reset voltage is ”low” status

for a few seconds and turn into ”High” status in the

normal operating.

16 Samsung Electronics

Page 28

8-3 Door S/W sensing part

DOOR

F

R

Door Conditions

CLOSE

OPEN

CLOSE

OPEN

Door S/W Contact

CLOSE

OPEN

CLOSE

OPEN

CON06

PIN NO

1

3

Micom Input Voltage

1) When the door is opened, the door S/W closed and MICOM input is ‘Low’.

Then the door-open is sensed.

2) When the door is closed, the door S/W is opened and MICOM input is ‘high’.

Then the door closed is sensed.

8-4 “V” motor, location sensing part ( Reed S/W)

“HIGH”

“LOW”

“HIGH”

“LOW”

1) “V” motor’s location sensing which is for G.A. fuzzy control is done by reed S/W.

2) There occure a “high” to “Low” and “Low” to “High” conversion period on con02 pin6 by the

motion of swing fan. “V” motor’s location is detected by it

Samsung Electronics 17

Page 29

8-5. Temp. sensing part

(Room Temp Sensor)

When Sensor is opened

MICOM input “HIGH”

1) Thermistor is used for sensing which has negative resistance coffiecient to the temperature.

2) MICOM input voltage, VF of sensor is ( Vcc: 5V, Rth : Sensor resistance )

3) Refer to conversion table for VF and RTH according to temperature.

VF= xVcc

RTH

RTH + R24

When sensor is cut off

MICOM input “LOW”

18 Samsung Electronics

Page 30

8-6 Comp and defrosting heater operating

As it is seen above block diagram, 220V line is connected to the commons of Comp relay, Ry78 and

defrosting heater relay, Ry77, Ry71. When those relays are off state Comp and defrosting heater are also

off. As Comp relay moves to on and AC 220V applied to Comp load it starts operating. On the other

hand defrost heater runs if defrost heater relay moves to on. There is no chance that both Comp and

defrost heater runs together so it’s useful for safety aspect.

COMP

ON

ON

ON

ON

RELAY

Defrost H

OFF

OFF

OFF

OFF

Load

Comp Operation

Comp off, Defrost-Heater Off

Defrost-Heater On

Comp Off, Defrost-Heater Off

Remark

Defrost-Heater Power Off

Comp Power Off

Samsung Electronics 19

Page 31

9. Failure diagnosis and repairment

Main PCB check

• Turn the power off and on again for self diagnosis check.

• Refer to belows for error code table

♦ Error code table

Item

Refrigerator

Freezer

CONTROL BOX

Display “LOW”

Room Temp s

F Sensor

F Defro. Sensor

R1 Sensor

R Defro. Sensor

R1 sensor

e n s o r

Room TEMP-Sensor

R2 Sensor

“LOW.Mid”

R2 sensor

F sensor

Freezer

Refrigerator

♦ Table for Vf and Rth according to temperature

T(˚C)

-35

-34

-33

-32

-31

-30

-29

-28

-27

-26

-25

-24

-23

-22

-21

-20

-19

R(ohm)

68648

65011

61595

58384

55366

52526

49854

47337

44967

42733

40626

38640

36765

34995

33323

31743

30250

V(v)

4.364

4.333

4.301

4.268

4.235

4.200

4.164

4.127

4.090

4.051

4.012

3.972

3.930

3.888

3.845

3.802

3.757

T(˚C)

-18

-17

-16

-15

-14

-13

-12

-11

-10

-9

-8

-7

-6

-5

-4

-3

-2

R(ohm)

28838

27502

26237

25040

23906

22832

21814

20848

19932

19062

18237

17453

16709

16001

15328

14688

14080

V(v)

3.712

3.666

3.620

3.573

3.525

3.477

3.428

3.379

3.329

3.279

3.229

3.178

3.127

3.076

3.025

2.974

2.923

“Mid”

R Defro.

s e n s o r

F Defro. sensor

T(˚C)

R(ohm)

-1

14051

0

12949

1

12424

2

11924

3

11447

4

10993

5

10559

6

10146

7

9752

8

9375

9

9016

10

8673

11

8345

12

8032

13

7732

14

7446

15

7172

“ M i d . H I G H ”

–

–

V(v)

2.872

2.821

2.770

2.719

2.668

2.618

2.567

2.518

2.468

2.419

2.370

2.322

2.274

2.227

2.180

2.134

2.088

T(˚C)

“LOW”

Swing fan motor

–

R(ohm)

16

6910

17

6659

18

6420

19

6190

20

5970

21

5759

22

5557

23

5363

24

5178

25

5000

26

4829

27

4665

28

4508

29

4357

30

4212

V(v)

2.043

1.998

1.954

1.911

1.869

1.828

1.786

1.745

1.705

1.666

1.628

1.590

1.553

1.517

1.481

20 Samsung Electronics

Page 32

Check in advance

1. Check the power of consent and power code.

2. Check it based on the “References” on the next pages.

9-1 No Input Power

N

Y

Y

N

N

Y

Y

N

N

Y

Y

Y

Samsung Electronics 21

Page 33

9-2 Self diagnosis failure

1) Outer temperature sensor failure

Start

Is main PCB connection

(CON 5) O.K. ?

Y

Is outertemp sensor O.K.

Y

Is input vltg of CON 05

pin2 O.K.

Change main PCB ass’ y

N

N

N

2) R1, R2, refrigerator temp. sensor failure

Start

Is temp. sensor O.K. ?

N

Connection failure

Change sensor

Wire open

Y

Is main PCB connection

(CON02) O.K. ?

Y

Is input vltg of CON 02

pin1,2 O.K.

Y

Is input vltg of CON 02

pin1,2 O.K.

Y

Change main PCB ass’ y

N

N

N

Change sensor

Connection failure

Connection between sensors open

Wire open

22 Samsung Electronics

Page 34

3) Refrigerator’ s defrosting sensor failure

Start

Is main PCB connection

(CON 5) O.K. ?

Y

Is defrosting sensor O.K.

Y

Is connection of defrosting

sensor O.K.

Y

Is input vltg of CON 03

pin4 O.K.

Y

Change main PCB ass’ y

4) F1, Freezer temp. sensor failure

N

Connection failure

N

Change sensor

N

Connection failure

N

Wire open

Start

Is main PCB connection

(CON03) O.K. ?

Y

Is temp. sensor O.K.

Y

Is connection of temp.

sensor O.K.

Y

Is input vltg of CON 03

pin1 O.K.

Y

Change main PCB ass’ y

N

Connection failure

N

Change sensor

N

Connection failure

N

Wire open

Samsung Electronics 23

Page 35

5) Freezer’ s defrosting sensor failure

Start

Is main PCB connection

(CON03) O.K. ?

Y

Is defrosting sensor O.K.

Y

Is connection

of defrosting sensor

O . K .

Y

Is input vltg of CON 03

pin5 O.K.

Y

Change main PCB ass’ y

N

Connection failure

N

Change sensor

N

Connection failure

N

Wire open

24 Samsung Electronics

Page 36

9-3 In case of continuous alarming

references

• F/R door open alarms for ten seconds after 2 minutes later. If door opens continuously, door

open alarms for ten seconds with one minute cycle. ( ten times of “Ding-Dong”)

• If there is moisture in door S/W, it is shorted and alarms due to the MICOM’s misjudgement.

In this case the inside lamps of freezer and refrigerator turns off so the lamp do not turns on

though you open the door.

• If the door S/W is rusted, the signal of door open do not reach to MICOM and no alarms and

lamps turned off continuously.

1) In case of “Ding-Dong” alarming

Start

Is main PCB connection

(CON03) O.K. ?

Y

Is the door S/W O.K.

Y

Is main PCB connection

(CON06) O.K.

Y

Does the vltg of CON06

Pin 1,3 change?

Y

Change main PCB ass’ y

N

Connection failure

N

Change sensor

N

Connection failure

N

Wire open, Change door S/W

Samsung Electronics 25

Page 37

2) In case of “Beep-Beep” alarming

Start

Is forced operating /

frosting selected ?

Y

Is it the same when

power on again?

Y

CON04 shorted. or touched

N

Cancel forced oper./defro.

N

Main PCB O.K.

references

• There is no “beep-beep” alarming except the forced deforst or sensing trouble during self

diagnosis.

• If self diagnosis sensed trouble, it is displayed on the panel PCB, so easy to check. If not , the

forced deforst or forced operation is selected the notch status are “High”-“Mid.High” at that

time.

3) In case of no panel PCB display

Start

Is the connection of

cover O.K. ?

Y

Is main PCB connection

(CON07) O.K. ?

Y

Is panel PCB

connection O.K. ?

Change panel PCB

N

Connection failure

N

Re-connection

N

Connection failure

26 Samsung Electronics

Page 38

4) In case of the panel PCB key selection is impossible

Start

Is the connection of

cover O.K. ?

Y

Is main PCB connection

(CON07) O.K. ?

Y

Is panel PCB connection

O.K. ?

Y

Are there any keys

already pressed ?

Y

Change panel PCB

9-4 In case of fan do not run

N

Connection failure

N

Re-connection

N

Connection failure

N

Re-assemble panel PCB

references

‘Be sure to check cooling fan under forced operation. ’

1. F-fan, R-fan and Comp cooling fan are off when Comp is of f.

2. Though the Comp is on, the R-fan is not always on because the fan is off when the temperature

was reached to the set point.

3. There is delaying time to run the fan after door open (Co mp on state) . The delay time varys

from ten seconds to one minute. (Forced operation included)

Samsung Electronics 27

Page 39

9-5 In case of swing fan in the refrigerator doesn’ trun.

Start

references

Does it run for

30 seconds when the

door open?

N

Is the door S/W O.K. ?

Y

Is the connection of

CON09 O.K. ?

Y

Is the vltg of both ends of

motor 220V

N

Change main PCB ass’ y

Y

Swing fan O.K.

N

Change door S/W

N

Connection failure

Y

Motor failure

1. Swing fan doesn’ t run at the off state of R-fan. ( door closed)

2. Swing fan runs for 30 seconds when the door is open but from then it doesn’ t work as the door

opened continuously. It’ s just runs for 30 seconds from the time the door is opened.

28 Samsung Electronics

Page 40

1) In case of F-fan doesn’ t run

Start

Is it forced operation ?

Y

Does it run 1 min

after the door S/W pressed?

N

Is the connection of

CON10 O.K. ?

Y

Is the vltg of both ends of

F-fan 220Vac

N

Does the door S/W

works normally

Y

Change main PCB ass’ y

Forced operation

Y

F-fan O.K.

N

Re-connection

Y

F-fan failure

N

Change door S/W

Samsung Electronics 29

Page 41

2) In case of R-fan doesn’ trun

Start

Select forced operation.

Does it run

1 min after the door S/W

p r e s s e d ?

N

Does the door S/W

works normally

Y

Is the connection of

CON09 O.K. ?

Y

Is the vltg of both ends of

F-fan 220Vac

N

Change main PCB ass’ y

Y

R-fan O.K.

N

Change door S/W

N

Re-connection

Y

F-fan failure

30 Samsung Electronics

Page 42

10. Disassemble & assemble drawing and part list

10-1 Freezing Compartment

Samsung Electronics 31

Page 43

NO CODE-NO ITEM SPECIFICATIONS Q’TY

R E M A R K

1

1-1

1-2

1-3

1-4

1-5

2

2-1

2-2

2-3

3

3-1

3-2

4

4-1

4-2

5

5-1

5-2

5-3

5-4

5-5

5-6

5-7

5-8

6

7

8

9

DA63-11041B

DA63-11041C

DA32-10109A

DA63-11030A

DA47-40112R

4713-000213

4713-001035

6002-000215

DA67-20163N

DA67-20135D

DA67-40299A

DA64-20194A

DA63-10403C

DA63-10338A

DA67-10205D

DA59-40245B, C, A, D

DA47-10148D

DA32-10105G

DA63-11044C, D, F, E

DA63-11035A

DA63-10364A

DA31-20103A

DA31-10109D

DA31-10109W

DA31-10109B

DA31-10109F

DA63-40119A

DA61-20128A

DA72-60042A

6002-000224

6002-000215

DA67-30266D

DA63-10402K

DA47-20208G

DA47-20208H

DA47-20208F

DA47-20208J

COVER LAMP FRE ASSY

COVER LAMP FRE ASSY

SENSOR FRE

COVER LAMP FRE

LAMP HOLDER

LAMP-INCANDESCENT

LAMP-INCANDESCENT

SCREW TAP TH

SHELF FRE ASSY

SHELF FRE

TRAY ICE

TRIM SHELF

CASE ICE

COVER CASE ICE

CASE ICE CUBE

EVAP-FRE ASSY

THERMO FUSE

SENSOR-REF

COVER-EVAP REAR(FRE)ASSY

COVER-EVAP REAR

COVER MOTOR FAN

FAN

MOTOR-FAN

MOTOR-FAN

MOTOR-FAN

MOTOR-FAN

GROMMET FAN MOTOR

SPRING FAN

BUMPON-MOTOR

SCREW TAP TH

SCREW TAP TH

CAP-SCREW

COVER-EVAP FR(FRE)ASSY

HEATER DRAIN

HEATER DRAIN

HEATER DRAIN

HEATER DRAIN

220V, 240V

110V, 127V

5 0 2 A T

M I P S

P B T

2 2 0 V ~ 2 4 0 V / 1 5 W

1 1 0 V ~ 1 2 7 V / 1 5 W

1-4X16FE, FXY

G P P S

G P P S

P P

P E

G P P S

H I P S

110V, 127V, 220V, 240V

250V, 10A

250V, 10.5A

110V, 127V, 220V, 240V

P P

P P

ABS, 120µ

110V, 2650RPM

127V, 2650RPM

220V, 2650RPM

240V, 2650RPM

N B R

S U S 2 7 W R

N B R

2S 4X16FE, FZY

1-4X16FE, FZY

P P

P P

1 1 0 V / 1 3 W

1 2 7 V / 1 3 W

2 2 0 V / 1 3 W

2 4 0 V / 1 3 W

1

1

1

1

1

1

1

2

1

1

2

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

6

4

1

1

1

1

1

32 Samsung Electronics

Page 44

10-2 Refrizerating Compartment

Samsung Electronics 33

Page 45

NO CODE-NO ITEM SPECIFICATIONS Q’TY

R E M A R K

1

1-1

1-2

1-3

2

2-1

2-2

2-3

2-4

3

4

5

5-1

5-2

5-3

5-4

6

7

8

9

9-1

9-2

9-3

9-4

9-5

9-6

9-7

9-8

10

11

11-1

12

13

14

15

16

17

17-1

17-2

17-3

17-4

17-5

DA59-40238C, E, A, B

DA47-10148D

DA32-10105G

DA63-40001A

DA63-11040D, C

DA63-11031A

4713-000213

4713-001035

DA47-40112T

DA61-70266A

DA02-90106E

DA63-11036A

DA67-40300D

DA66-10104A

DA71-20145A

DA64-20205A

DA64-20204A

DA63-11020D

DA63-10467A

DA32-10105B

DA63-10534L, R, J, K

DA63-10216A

DA63-10364A

DA31-20103A

DA31-0109D, W, B, F

DA61-20128A

DA72-60042A

6002-000224

DA63-40119A

6002-000215

DA72-40484A

DA39-20122E

DA63-10235F

DA67-30266D

6002-000215

DA67-20172B

DA63-10384G

DA63-10237J

DA63-10237E

DA63-10237L

DA63-10237F

DA63-10897E

DA31-20133B

DA31-20135B

DA72-30193A

DA72-60158C

EVAP-REF ASSY

THERMO FUSE

SENSOR-DEF

GROMMET EVAP

COVER-LAMP REF ASSY

COVER LAMP REF

LAMP-INCANDESCENT

LAMP-INCANDESCENT

HOLDER LAMP

SUPT LAMP

CATALYST-LTC

COVER-PURIFIER

TRAY-CHILL ROOM ASSY

ROLLER-FREE

FIXER ROLLER

TRIM TRAY, R

TRIM TRAY, L

COVER-CHILLED ASSY

COVER-SENSOR REF

SENSOR-ASSY

COVER EVAP REAR REF ASSY

COVER EVAP RE, (R)

COVER MOTOR FAN

FAN

FAN-MOTOR

SPRING FAN

BUMPON MOTOR

SCREW TAP TH

GROMMET FAN MOTOR

SCREW TAP TH

INS, COVER EVAP FR

WIRE HARNESS GEARED

COVER EVAP FRONT(REF)

CAP SCREW

SCREW-TAP TH

SHELF-REF ASSY

COVER-VEG ASSY

COVER-DUCT ASSY

COVER-DUCT ASSY

COVER-DUCT ASSY

COVER-DUCT ASSY

COVER-DUCT REF

BLADE AIR LOW

BLADE AIR UPP

SPACER DUCT, REF

SEAL DUCT, REAR

110V, 127V, 220V, 240V

250V, 10A

250B, 10.5A

NR

110~127V, 220~240V

SAN

220V~240V/15W

110V~127V/15W

PBT

STS

T15, W40, L70

PP

POM

NY-66

PE

PE

HIPS

502AT

110V, 127V, 220V, 240V

PP

PP

ABS

110V, 127V, 220V, 240V

SUS27WR

NBR

2S 4X12FE, FZY

NBR

1-4X16FE, FZY

PP,WHT

1-4X16FE, FZY

110V~127V

220V~240V

110V~127V

220V~240V

HIPS

ABS

ABS

FOAM-PS

FOAM-PE

1

1

1

1

1

1

2

2

2

2

1

1

1

2

2

1

1

1

2

2

1

1

1

1

1

1

1

1

2

2

1

1

1

2

2

2

1

1

SR-606(8)EV

1

SR-606(8)EV

1

S R - 6 4 6 ( 8 ) E V S R - 6 8 6 ( 8 ) E V

1

S R - 6 4 6 ( 8 ) E V S R - 6 8 6 ( 8 ) E V

1

1

1

1

1

34 Samsung Electronics

Page 46

NO CODE-NO DESCRIPTION SPECIFICATIONS Q’TY

R E M A R K

17-6

17-7

17-8

17-9

17-10

17-11

17-12

18

18-1

18-2

18-3

DA72-60161D

DA31-10107D

DA31-10107E

DA60-40104A

DA31-20132A

DA63-40133A

DA31-20132A

DA63-11024A

DA67-10227F

DA67-10228A

DA66-10104A

DA71-20145A

SEAL DUCT, AIR

GEARD MOTOR

GEARD MOTOR

WASHER

BLADE-AIR GUIDE

GROMMET MOTOR

BLADE CONNECTING

COVER DUCT, FR

CASE-VEG ASSY

CASE VEG

ROLLER-FRE

FIXER ROLLER

PVC-FOAM

AC220V~240V

AC110V~127V

ID 04, T0.5

PP

NBR

HIPS

GPPS

POM

NY-66(PA)

1

1

1

1

7

1

1

1

1

1

4

4

Samsung Electronics 35

Page 47

10-3 Cabinet and Unit Compartment

36 Samsung Electronics

Page 48

NO CODE-NO

ITEM SPECIFICATIONS Q’TY

R E M A R K

1 0

1 1

1 2

1 3

1 4

1 5

1 6

1 7

1 8

1 9

2 0

2 1

2 2

2 3

2 4

2 5

2 6

2 7

2 8

2 9

3 0

3 1

3 2

3 3

3 4

1

2

3

4

5

6

7

8

9

DA90-10230P

DA61-40115B

DA61-10145D

DA61-30127B

DA59-50021A

DA59-50033A

DA59-50014A

DA59-50015A

DA34-10003P

DA34-10003P

DA34-10003W

DA34-10003G

DA35-10003H

DA35-10003H

DA35-10003L

DA35-10003N

DA63-10352A

DA32-10105F

DA65-20101A

DA63-40234C

DA34-10122D

DA73-30102A

DA60-10104B

DA60-10110A

DA62-20001C

DA63-40171B

DA67-30218P

DA39-10123

6002-000216

DA71-60123F

DA60-90101A

DA61-40101C

DA66-20112A

DA60-10107A

DA67-40176C

DA31-10110G

DA31-10110L

DA31-10110F

DA31-10110H

DA31-20102A

DA61-20128A

6002-000215

DA73-10314C

2501-001091

2401-000511

2501-000423

DA26-30112A

DA26-30112B

DA26-30110C

DA26-30110A

DA63-10243A

ASSY-CABI FOAM

CASTER-FRONT

HINGE-LOW

FOOT-ASSY

COMPRESSOR

COMPRESSOR

COMPRESSOR

COMPRESSOR

O/L PROTECTOR

O/L PROTECTOR

O/L PROTECTOR

O/L PROTECTOR

PTC

PTC

PTC

PTC

COVER-RELAY

SENSOR-ASSY(EXIT)

CLAMP-COMP

GROMMET-COMP

DOOR SWITCH

DRYER

SCREW TAP TITE

SCREW SPECIAL, C

TUBE-PVC

GROMMET-COMP

CAP-SCREW

POWER-CORD

SCREW TAP TITE

CHASSIS COMP ASSY

RIVET CASTER

CASTER REAR

SHAFT COMP

SCREW EARTH

TRAY DRAIN WATER ASSY

MOTOR-CIRCUIT

MOTOR-CIRCUIT

MOTOR-CIRCUIT

MOTOR-CIRCUIT

FAN-SIRRCOO

SPRING-FAN

SCREW TAPPING

PIPE SUB COND ASSY

CAPACITOR

CAPACITOR

CAPACITOR

TRANS-DC

TRANS-DC

TRANS-DC

TRANS-DC

COVER-COMP ASSY

PP

SCP1

PP

SK182C-L2W

SK182P-L2W

SK190H-L2U

SK190Q-L2U

4TM444NHBYY-53

4TM444NHBYY-53

4TM314RHBYY-53

4TM232SHBYY-53

PTHAS-T100M200B

PTHAS-T100M200B

PTHAR-T220M350D

PTHAS-T330M385D

PP

STC5, TO.6

NBR, BLK

WHT

CU. OD18.85, L119

SNC3

M5, STS

PVC

NBR

PP

L2500(OPTION)

PH1-4X20

MSWR10, ZPC

PP, NTR

SUM24,ZPC2(YEL)

BSBN, M4X10

110V

127V

220V

240V

ABS, P/120

STS27

TH1-4X16

TO.7, OD4.76, L969

5µF, 350VAC

12µF, 250VAC

125µF, 125VAC

105V/50,60HZ

127V

220V

240V

SECC1

1

2

1

2

1

1

1

1

2

4

1

1

1

3

2

4

1

1

2

1

2

2

2

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

Samsung Electronics 37

Page 49

NO CODE-NO ITEM SPECIFICATIONS Q’TY REMAR

3 5

3 6

3 7

3 8

3 9

4 0

4 1

4 2

4 3

4 4

4 5

DA72-60019A

6002-000213

DA63-11029A

DA67-10105G

DA63-10212H

DA41-20146A

DA41-20105F

DA41-20146B

DA41-20105G

DA61-10205A

DA63-10920G

DA63-50145A

DA61-10146C

DA63-50146A

SEAL PAM ABSORB

SCREW TAPPING

COVER LEG, FRONT

CASE CONTROL BASE

COVER-PCB PANEL

ASSY-MAIN PCB

ASSY-MAIN PCB

ASSY-MAIN PCB

ASSY-MAIN PCB

HINGE-UPP

COVER-HINGE UPP

SHIM-HINGE UPP

HINGE-MID ASSY

SHIM-HINGE, LOW

T10, W170, L170

TH 4X12FR, FZY

PP

PP-VO

PP

SR-606(8)EV

SR-606(8)EV

SR-646(8), 680(8)EV

SR-646(8), 686(8)EV

SHP1, T3.2

PP

RD-PVC T1.0

SHP1 T4.0

RD-PVC T1.0

1

3

1

1

1

1SET

1SET

1SET

1SET

1

1

1

1

1

38 Samsung Electronics

Page 50

10-4 Door Parts

Samsung Electronics 39

Page 51

NO CODE-NO DESCRIPTION SPECIFICATION Q’TY

1

2

3

4

5

6

7

8

9

1 0

1 1

1 2

1 3

1 4

1 5

1 6

1 6 - 1

1 6 - 2

1 6 - 3

1 6 - 4

1 6 - 5

1 6 - 6

1 7

1 8

1 9

2 0

2 1

2 2

2 3

24

2 5

2 6

27

2 8

( 1 ) ( 2 ) ( 3 ) ( 4 )

DA91-10258L, M, N, P

( 1 ) ( 2 ) ( 3 ) ( 4 )

DA91-10258Q, R, S, T

DA91-10259M, N, P, Q

DA91-10260H, J, K, L

DA91-10259R, S, T, U

DA91-10260M, N, P, Q

DA91-10259V, W, X, Y

DA91-10259R, S, T, U

D A 6 3 - 3 0 1 7 8 N

D A 6 3 - 3 0 1 7 8 P

D A 6 3 - 2 0 1 6 0 B

D A 6 3 - 2 0 1 5 8 A

D A 6 3 - 2 0 1 5 9 B

D A 6 3 - 2 0 1 6 2 C

D A 6 3 - 2 0 1 6 1 C

D A 7 1 - 4 0 1 3 5 A

D A 6 3 - 4 0 1 1 8 A

D A 6 5 - 9 0 1 1 1 H

D A 7 1 - 4 0 1 6 9 A

D A 6 3 - 1 0 8 9 4 B

D A 6 3 - 1 0 9 8 4 B

D A 6 7 - 1 0 4 0 1 C

D A 6 4 - 4 0 1 3 5 C ( L )

D A 6 4 - 4 0 1 3 5 C ( R )

6 0 0 2 - 0 0 0 4 6 6

D A 6 3 - 1 0 8 9 4 A

6 0 0 2 - 0 0 0 4 5 3

D A 4 1 - 2 0 1 5 6 B

D A 7 1 - 1 0 2 7 2 B

D A 7 4 - 9 0 1 3 6 B

D A 7 1 - 1 0 2 7 2 A

D A 6 7 - 4 0 2 9 7 A

D A 6 7 - 4 0 2 9 8 A

D A 6 7 - 4 0 2 9 4 B

D A 6 7 - 4 0 2 9 5 A

D A 6 3 - 1 0 9 0 5 E

6 0 0 2 - 0 0 0 2 1 3

6 0 0 2 - 0 0 0 2 1 3

-

6 0 0 2 - 0 0 0 2 1 5

ASS ’Y FOAM DOOR FRE

ASS ’Y FOAM DOOR FRE

ASS ’Y FOAM DOOR FRE

ASS ’Y FOAM DOOR FRE

ASS ’Y FOAM DOOR FRE

ASS ’Y FOAM DOOR FRE

ASS ’Y FOAM DOOR FRE

ASS ’Y FOAM DOOR FRE

ASS ’Y FOAM DOOR FRE

ASS ’Y FOAM DOOR FRE

ASS ’Y FOAM DOOR FRE

GASKET DOOR FRE ASS ’Y

GASKET DOOR FRE ASS ’Y

GUARD FRE

GUARD VARIETY ,A

GUARD VARIETY ,B

GUARD BOTTLE

GUARD REF LOW

STOPPER MID

GROMMET HINGE MID

ASS ’Y AUTO CLOSE

STOPPER DOOR MID

STOPPER DOOR,C

SCREW TAP PH

CASE-PCB ASS ’Y

CASE-PCB

KNOB TOUTH

KNOB TOUTH

SCREW TAP PH

COVER PCB PANEL

SCREW TAP FH

PCB PANEL ASS ’Y

REINF HINGE.REF

TANK-WATER ASS ’Y

GUIDE BOTTLE

TRAY EGG,A

TRAY EGG,B

TRAY DISPENSER,B

TRAY DISPENSER,A

COVER DISPENSER ASS ’Y

SCREW TAP

SCREW TAP TH

SCREW-PH

SCREW TAP TH

( W I T H D I S P E N S E R )

( W I T H D I S P E N S E R )

( W I T H D I S P E N S E R )

SR-606, 608V

SR-646, 648EV, SR-686, 688EV

SR-606EV

SR-608EV

SR-646EV

SR-648EV

SR-686EV

SR-688EV

SR-606, 608EV

SR-606, 608EV

GPPS

GPPS SR-608, 648, 688EV

GPPS SR-608, 648, 688EV

GPPS

GPPS

STS304

POM

SR-60, 64, 68

SR-60, 64, 68

SR-60, 64, 68

M4X14 FE FZY

EXP ALL

EXP ALL

ABS MP-0160

ABS MP-0160

2S 3X8 FE, FZY

GPPS

FH1 4X12 STS304

EXP ALL

SHP1 T3.0

WITH DISPENSER

PP

GPPS

GPPS

ABS

ABS

WITH DISPENSER

TH1 4X12 FE FZY

1-4X12 FE, FZY

MAX25, FE, FZY

1-4X14 FE, FZY

1SET

1SET

1SET

1SET

1SET

1SET

1SET

1SET

1

1

2

1

1

1

1

1

1

1

1

1

2

1SET

1

2

2

2

1

3

1SET

1

1SET

1

1

1

1

1

1SET

1

1

1

2

R E M A R K

( 1 ) NOBLE-BEIG

( 2 ) MMD GRAY

( 3 )

MILKY WHITE

( 4 ) LIGHT GREEN

Indicated part is for eclectrical safety components

40 Samsung Electronics

Page 52

12. Packaging method

♦ Packaging specifications of door and inside of cab

Tape:W50X100(2EA)

♦ C o m p l e t e d

p a c k a g i n g

s p e c i f i c a t i o n

PAD-PACKING IN:

SR-50:W520XL750

SR-54:W660XL779

SR-58:W660XL823

FOAM-PE:T17XW50X175

Tape:W50X150

♦ Packaging specifications of rear and front

HIGH CUSHION:3EA

Tape:W50XL150(1EA)

PriamentTape:W50XL100

FOAM-PS:T15x500xl500

P.E BAG:1EA

Tape : W50XL200(1EA)

Tape : W50xL300(2EA)

T10XW80XL180(2EA)

EPS:

Low CUSHION(R,L)

:846X145X160(2EA)

T15X60X825(2EA)

Corrugated cadrboard

box881X796X140(1EA)

54 Samsung Electronics

Page 53

14. PCB Specification

14-1 Parts for service

N O

1

2

3

4

5

6

PART

D A 2 6 - 3 0 1 1 0 B

D A 2 6 - 3 0 1 1 2 A

D A 2 6 - 3 0 1 1 2 B

D A 2 6 - 3 0 1 1 0 C

D A 2 6 - 3 0 1 1 0 A

D A 3 2 - 1 0 1 0 5 B

D A 3 2 - 1 0 1 0 5 G

D A 3 2 - 1 0 1 0 5 F

D A 4 1 - 2 0 1 4 9 A

D A 4 1 - 2 0 1 0 5 F

S P E C .

T R A N S - D C

T R A N S - D C

T R A N S - D C

T R A N S - D C

T R A N S - D C

R, R2, F-SENSOR COMMON USE

R, F DEF-SENSOR

E X T - S E N S O R

PCB PANEL

PCB MAIN

SPEC.

1 0 5 V / 5 0 , 6 0 H Z

1 0 5 V / 5 0 , 6 0 H Z

1 2 7 V / 5 0 , 6 0 H Z

2 2 0 V / 5 0 , 6 0 H Z

2 4 0 V / 5 0 H Z

502 AT

502 AT

502 AT

SR-60, 64, 68

SR-60, 64, 68

VENOR

Y O U K Y U N G

S E G 1

D O N G K W A N G

D O N G K W A N G

D O N G K W A N G

SEOUL SEMI-CONDUCTOR

KWANGJU ELECTRONICS

Q’TY

1

3

2

1

1

1

REMARK

DISP NO

TOSHBA MICOM

58 Samsung Electronics

Page 54

13 PCB Diagram circuit

Samsung Electronics 55

Page 55

13-2 Part list

N O CODE-NOPART SPEC.

1

I C - M C U ( O T P )

2

R E S O N A T O R

3

R E L A Y

4

R E L A Y

5

I C - D R I V E R

6

I C - D R I V E R

7

P C B - M A I N

8

V O L T A G E - R E G

9

V O L T A G E - R E G

1 0

HEAT-SINK “S1”

1 1

F U S E - C L I P

1 2

F U S E

1 3

I C - R E S E T

1 4

R C - N E T W O R K

1 5

R C - N E T W O R K

1 6

B U Z Z E R

1 7

T A C T - S W

1 8

Z E R N E R - D I O D E

1 9

J U M P - W I R E

2 0

T R A N S I S T O R

2 1

OP-AMP IC

2 2

C O I L

2 3

S C R E W

2 4

D I O D E - R E C

2 5

C - E L E C

2 6

C - E L E C

2 7

C - E L E C

2 8

C - E L E C

2 9

C - E L E C

3 0

C - C E R A M I C

3 1

R - M E T A L

3 2

R - M E T A L

3 3

R - M E T A L

3 4

R - C A R B O N

3 5

R - C A R B O N

3 6

R - C A R B O N

T M P 8 7 P H 4 0 A N

C S T 4 . 0 0 M G W T F 0 1

V S B - 1 2 T B

JZ1 a FS - 1 2 V

U L N 2 9 8 1 A

U D N 2 0 0 3 A

1 3 5*197 FR-1

M C 7 8 1 2 C T

K I A 7 8 0 5 P I

AL L30

F H - 5 1 H

5 0 0mA / 2 5 0 V

K A 7 5 3 3

R C N - 1 0

S Q 1 2 0 1

C B E 2 2 2 0 B A

SKHV 10910A

UZ 5.1B, 5.1V

T A 0 . 6 P I / 5 2m m

K S R 1 0 0 5

L M 3 2 4

7 5mH / 1 0 %

PH-2S 3*8

1 N 4 0 0 4

2 2 0 0uF 35V

1 0 0 0uF 35V

1uF 50V

4 7 0uF 25V

3 3uF 25V

1 0 4 Z

3.9K-F 1/4W

1.0K-F 1/4W

10K-F 1/4W

1K-J 1/4W

1.2K-J 1/4W

4.7K-J 1/4W

4 B 4 0 0 2 - 0 5 9 5

4 B 1 2 8 3 - 0 0 5 3

4 B 3 0 6 8 - 0 0 0 4

4 B 3 0 6 8 - 0 0 7 2

4 2 1 0 9 - 1 0 1 - 0 2 1

4 2 2 1 9 - 7 0 1 - 0 0 8

4 6 0 2 9 - 0 0 3 4

4 A 4 0 0 8 - 0 1 7 8

4 1 1 2 9 - 6 0 2 - 0 2 2

4 1 1 2 4 - 0 0 4 3 - 0 0

4 A 3 0 6 4 - 0 0 2 1

4 A 3 0 6 5 - 0 1 5 6

4 A 4 0 0 8 - 0 7 5 4

4 A 1 1 1 4 - 0 0 0 6

4 A 1 1 1 4 - 0 0 0 7

4 A 1 3 0 5 - 0 0 1 2

4 A 3 0 1 8 - 0 0 4 7

4 A 4 1 0 6 - 0 0 4 8

4 0 5 0 9 - 4 0 0 - 1 0 8

4 A 4 0 6 8 - 0 0 0 8

4 A 4 0 0 8 - 0 7 7 4

4 A 1 1 3 0 - 0 0 8 5

4 7 0 0 8 - 1 3 0 - 0 8 1

4 A 4 1 0 4 - 0 1 0 9

4 A 1 1 0 4 - 0 0 8 7

4 A 1 1 0 4 - 0 6 4 1

4 A 1 1 0 4 - 0 5 0 0

4 A 1 1 0 4 - 0 0 5 7

4 A 1 1 0 4 - 0 0 2 5

4 A 1 1 0 0 - 0 3 4 0

4 A 1 0 0 0 - 0 4 0 9

4 1 0 1 8 - 2 7 5 - 1 0 2

4 1 0 1 8 - 2 7 5 - 1 0 3

4 A 1 0 0 0 - 0 1 5 1

4 A 1 0 0 0 - 0 0 0 5

4 A 1 0 0 0 - 0 1 7 4

Q ’ T Y U N I T REMARK

1

E A

1

E A

2

E A

6

E A

1

E A

2

E A

1

E A

2

E A

1

E A

2

E A

1

E A

1

E A

1

E A

1

E A

3

E A

1

E A

1

E A

1

E A

1 9

E A

3

E A

1

E A

1

E A

2

E A

9

E A

1

E A

2

E A

1

E A

2

E A

1

E A

1 8

E A

2

E A

4

E A

6

E A

8

E A

1

E A

7

E A

VENOR PART NO.

T O S H I B A

M U R A T A

T A K A M I S W A

M A T S U S H I T A

A L L E G R O

A L L E G R O

CHUNGJU ELECTRONICS

SAMSUNG SEMMI-CONDUCTOR

SAMSUNG SEMMI-CONDUCTOR

SHINDANG INDUSTRY

YUNHO ELECTRONICS

SAMJU ELECTRONICS

SAMSUNG SEMMI-CONDUCTOR

DOOSHIN ACCURACY

KEUMKANG ELECTRONICS

BUJUN ELECTRONICS PARTS

KYUNGIN ELECTRONICS

PYUNGCHANG TRADE

WON CONSTRUCTION

SAMSUNG SEMMI-CONDUCTOR

SAMSUNG SEMMI-CONDUCTOR

BUJUN INDUSTRY

TAIYANG METAL

PYUNGCHANG TRADE

SAMHWA ELECTRIC

SAMHWA ELECTRIC

SAMHWA ELECTRIC

SAMHWA ELECTRIC

SAMHWA ELECTRIC

DANGYANG HEREDITY

ABCO, HANRYUK

ABCO, HANRYUK

ABCO, HANRYUK

I C 0 1

X - T A L

RY77, RY78

R Y 7 1 - R Y 7 6

I C 0 5

IC02, IC04

P C B

R G 1 0 1 , R G 1 0 2

R G 1 0 3

R G 1 0 1 , R G 1 0 2

F U S E 2

F U S E 2

I C 0 3

A C 7 0 1

S P 7 1 - 7 3

B Z

T E S T - S W

Z D 5 0 1

J 0 1 - J 2 0

Q 8 0 1 , Q 8 0 2 , Q 8 0 3

I C 0 6

L 8 0 1

F U S E

D 1 0 1 - 1 0 8 , 6 0 1

C 1 0 3

C 1 0 4 , 1 0 5

C 2 0 3

C 1 0 6 , C 1 0 7

C 8 0 1

R 3 1 4

R 3 1 5 , 3 1 6 , 3 1 7 , 3 2 0

R301,303,305,

R 3 0 7 , 3 0 9 , 3 1 1

ABCO, HANRYUK

R 2 0 1 , 5 0 3 , 6 0 1 , 6 0 2 , R 6 0 3

, 6 0 4 , 6 0 5 , 9 0 4

ABCO, HANRYUK

ABCO, HANRYUK

R 5 0 2

R 4 0 1 , 4 0 3 , 4 0 5 , 5 0 4 , R 8 0 1

N E W ( P G M )

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

N E W

N E W

N E W

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

N E W

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

N E W

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

N E W

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

N E W

N E W

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

N E W

ACE COMMON USE

, 8 0 3 , 9 0 5

56 Samsung Electronics

Page 56

N O CODE-NOPART SPEC.

Q ’ T Y U N I T REMARK

VENOR PART NO.

3 7

R - C A R B O N

3 8

R - C A R B O N

3 9

R - C A R B O N

4 0

R - C A R B O N

4 1

C O N N E C T O R

4 2

C O N N E C T O R

4 3

C O N N E C T O R

4 4

C O N N E C T O R

4 5

C O N N E C T O R

4 6

C O N N E C T O R

4 7

C O N N E C T O R

4 8

C O N N E C T O R

4 9

C O N N E C T O R

5 0

C O N N E C T O R

5 1

I C - M C U ( M S K )

10K-J 1/4W

12K-J 1/4W

47K-J 1/4W

4.7-J 1/4W

Y W 3 9 6 - 0 9 A V ( W H T )

Y W 3 9 6 - 0 9 A V ( R E D )

Y W 3 9 6 - 0 5 A V ( W H T )

S M W 2 5 0 - 0 7 ( W H T )

S M W 2 5 0 - 0 3 ( W H T )

S M W 2 5 0 - 0 7 ( Y E L )

S M W 2 5 0 - 0 6 ( W H T )

S M W 2 5 0 - 1 1 ( W H T )

S M W 2 5 0 - 0 2 ( W H T )

S M W 2 5 0 - 0 2 ( B L U )

T M P 8 7 P H 4 0 A N - X X X X

4 1 0 1 8 - 2 2 7 - 1 0 3

4 1 0 1 8 - 2 2 7 - 1 2 3

4 1 0 1 8 - 2 7 7 - 4 7 3

4 A 1 0 0 0 - 0 2 6 1

4 A 6 0 1 0 - 0 5 3 0

4 A 6 0 1 0 - 0 5 4 6

4 A 6 0 1 0 - 0 4 7 0

4 A 6 0 1 0 - 1 4 0 7

4 A 6 0 1 0 - 1 3 8 7

4 A 6 0 1 0 - 1 4 0 9

4 A 6 0 1 0 - 1 4 0 2

4 A 6 0 1 0 - 1 4 2 7

4 A 6 0 1 0 - 1 3 8 2

4 A 6 0 1 0 - 1 3 8 5

4 B 4 0 0 2 - 0 8 2 5

1 6

1

8

1

1

1

1

1

1

1

1

1

1

1

1

E A

ABCO, HANRYUK

E A

ABCO, HANRYUK

E A

ABCO, HANRYUK

E A

ABCO, HANRYUK

E A

YUNHO ELECTRONICS

E A

YUNHO ELECTRONICS

E A

YUNHO ELECTRONICS

E A

YUNHO ELECTRONICS

E A

YUNHO ELECTRONICS

E A

YUNHO ELECTRONICS

E A

YUNHO ELECTRONICS

E A

YUNHO ELECTRONICS

E A

YUNHO ELECTRONICS

E A

YUNHO ELECTRONICS

E A

T O S H I B A

R 2 0 2 , 3 0 2 , 3 0 4 , 3 0 6 ,

ACE COMMON USE

R 3 0 8 , 3 1 0 , 3 1 2 , 3 1 3 ,

R 3 1 8 , 4 0 2 , 4 0 4 , 4 0 6 ,

R 7 0 1 , 9 0 1 , 9 0 2 , 9 0 3

R 8 0 4

R 6 0 6 - 6 1 3

R 8 0 4

C O N 1 0

C O N 0 9

C O N 0 8

C O N 0 1

C O N 0 6

C O N 0 2

C O N 0 3

C O N 0 7

C O N 0 5

C O N 0 4

I C 0 1

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

ACE COMMON USE

N E W P G M )

Samsung Electronics 57

Page 57

4. Electric Diagram

1. 110~115V/60Hz, 127V/60Hz, 220V/50Hz, 240V/50Hz

CIRCUIT-DIAGTAM

“A-1”:220-240V/50,60Hz

“A-2”:110-127V/60Hz

“B-1”, “C-1”:WITHOUT EARTH

“B-2”, “C-2”:WITH EARTH

RED-RED WHT-WHITE

BLUE-BLUE YEL-YELLOW

ORG-ORANGE BLK-BLACK

BRN-BROWN PRP-PURPLE

PINK-PINK W/BLK-WHITE/BLACK

GRY-GRAY S/BLU-SKY BLUE

P/BLUE-PINK/BLUE

Samsung Electronics 5

Page 58

5. Out Package Specification

Model A B C D Remark

S R - 6 0 6 E V 8 1 4 8 9 9 1 8 0 6 5 0 –

S R - 6 0 8 E V 8 1 4 8 9 9 1 8 0 6 5 0 Dispenser applied

S R - 6 4 6 E V 8 9 9 1 8 5 8 5 0 S R - 6 4 8 E V 8 1 4 8 9 9 1 8 5 8 5 0 Dispenser applied

S R - 6 8 6 E V 8 1 4 899 1 9 0 2 5 0 –

S R - 6 8 8 E V 8 1 4 8 9 9 1 9 0 2 5 0 Dispenser applied

6 Samsung Electronics

Page 59

15. Main components specifications

1) REGULATOR

3-TERMINAL 1A POSITIVE VOLTAGE GRGULATORS

The MC78XX/MC78XXA series of three-terminal positive regulators are available in

the TO-220 package and with several fixed output voltaes, making it useful in a

wide range of applicationes. These regulaators can provide local oncard regulation,

eliminating the distribution problems assciated with single point regulation. Each

type employs internal current limiting, thermal shut-down and safe area protection,

making it essentially indestructible. If adequate heat sinking is provided, they can

delive over aA output corrent. Although designed primarily as fixed voltage

regulators, these devices can be used with external components to obtain

adjustable voltages and currents. MC78XXI is characterized for operation from -40°

°Cto +125°c, and MC78XXC from 0°c to +125°c

TO-220 1 2 3 1 : Input 2 : GND 3 : Output

FEATURES

• UOutput Current up to 1.5A

• UOutput voltages of 5;6;8;9;10;11;12;15;18;24V

• UThermal Overload Protection

• UShort Circuit Protection

• UOutput Transistor SOA Protection

• UNo external components required

• UOutput current in excess of 1A

• UIndustrial and commercial temperature range

BLOCK DIAGRAM

ORDERING INFORMATION

Device

Device

MC78XXCT

MC78XXCT

MC78XXACT

MC78XXACT

MC78XXT

MC78XXT

Package

TO-220

TO-220

TO-220

Operating Temperature

0~+125°C

-40~+125°C

ABSOLUTE MAXIMUM RATINGS

Characteristic

Input Voltage (for Vo = 5V to 18V)

(for Vo = 24V)

Thermal Resistance Junction - Cases

Thermal Resistance Junction - Air

Operating Temperature Range MC78XXC/AC

MC78XXI

Storage Temperature Range

Symbol

VIN

VIN

θJC

θ♣JA

Topr

Tstg

Rating

35

40

5

65

0 ~ +125

-40 ~ +125

-65 ~ +150

Unit

V

V

°C/W

θ/W

°C

°C

°C

Samsung Electronics 59

Page 60

2) REGULATOR(MC7812C)

ELECTRICAL CHARACTERISTICS MC7812

(Refer to test circuit, Tmin < Ti < Tmax, Vi = 500mA, Vi = 19V, Ci = 0.33µF, Co = 1.0µFunless otherwise specified)

Characteristic

Output Voltage

Line Regulation

Load Regulation

Quiescent Current

Quiescent Current Change

Output Voltage Drift

Output Noise Boltage

Ripple

Rejection

Dropout Voltage

Output Resistance

Short Circuit Current

Peak Current

Symbol

Vo

∆Vo

∆Vo

Id

∆Id

∆Vo/∆T

Vn

RR

VD

RO

ISC

Ipeak

Ti = 25°C

Ti = 25°C

Test Conditions

Ti = 25°C

5.0mA≤Io≤1.0A, P≤15W

Vin = 14.5V to 27V

Vi = 15.5V to 27V

Vi = 14.5V to 30V

Vi = 16V to 22V

Io = 5.0mA to 1.5V

Io = 250mA to 750mA

Ti = 25°C

Io = 5mA to 1.0A

Vi = 14.5V to 30V

Vi = 15V to 30V

Io = 5mA

f = 10Hz to 100KHz Ti = 25°C

fF = 120Hz

Vi = 15 to 25V

Io = 1A, Ti = 25°C

f = 1KHz

Vi = 35V, Ti = 25°C

Ti = 25°C

Min

11.5

11.4

55

MC7805C

Typ

12

12

10

3.0

12

4.0

5.1

-1

75

71

2

18

250

2.2

Max

12.5

12.6

240

120

240

120

8

0.5

1.0

Unit

V

mV

mV

mA

mA

mV/°C

µ/V

dB

V

mΩ

mA

A

* Tmin < Ti < Tmax

MC78XXI : Tmin = -40°C, Tmax = 125C

MC78XXC, Tmin = 0°C, Tmax = 125°C

* Load and line regulation are specified at constant junction temperature. Changes in Vo due to heating effects must be taken into

account separately. Pulse testint with low duty is used.

60 Samsung Electronics

Page 61

MC 7805 AC(T)

ELECTRICAL CHARACTERISTICS MC7805

(Refer to test circuit, Tmin < Ti < Tmax, Io = 500mA, Vi = 10V, Ci = 0.33ßfi, unless otherwise specified)

Characteristic

Output Voltage

Line Regulation

Load Regulation

Quiescent Current

Quiescent Current Change

Output Voltage Drift

Output Noise Boltage

Ripple

Rejection

Dropout Voltage

Output Resistance

Short Circuit Current

Peak Current

Symbol

Vo

∆Vo

∆Vo

Id

∆‚Id

∆Vo/∆T

Vn

RR

VD

RO

ISC

Ipeak

Ti = 25°C

Ti = 25°C

Test Conditions

Ti = 25°C

5.0mA ≤ Io ≤ 1.0A, Po ≤ 15W

Vi = 7V to 20V

Vi = 8V to 20V

Vi = 7V to 25V

Vi = 8V to 12V

Io = 5.0mA to 1.5V

Io = 250mA to 750mA

˚C

Ti = 25

Io = 5mA to 1.0A

Vi = 7V to 25V

Vi = 8V to 25V

Io = 5mA

f = 10Hz to 100KHz Ti = 25

F = 120Hz

Vi = 8 to 18V

Io = 1A, Ti = 25

f = 1KHz

Vi = 35V, Ti = 25

Ti = 25

˚C

˚C

˚C

˚C

Min

4.8

4.75

62

MC7805C

Typ

5.0

5.0

5.0

1.5

9

3

5.0

-0.8

40

78

2

17

250

2.2

Max

5.2

5.25

100

50

100

50

8

0.5

1.3

U n i t

V

m V

m V

m A

m A

m V / ° C

µ / V

d B

V

mΩ

m A

A

* Tmin < Ti < Tmax

MC78XXI : Tmin = -40˚C, Tmax = 125

MC78XXC, Tmin = 0˚C, Tmax = 125

* Load and line regulation are specified at constant junction temperature. Changes in Vo due to heating effects must be taken into

account separately. Pulse testint with low duty is used.

˚C

˚C

Samsung Electronics 61

Page 62

HIGH-VOLTAGE, HIGH-CURRENT

SOURCE DRIVERS

Series UDS2980H and UDS2980R hermetically sealed source

drivers link standard low-power digital logic and relays, solenoids,

magnetic print hammers, stepping motors, LEDs, and lamps in

applications requiring separate logic and load grounds, load supply

voltages to +80V, and load currents to 500 mA.

Types UDS2981H/R and UDS2983H/R are intended for use

with 5v logic systems(TTL, Schottky TTL. DTL and 5V CMOS).

UDS2982H/R and UDS2984H/R integrated circuits are intended for

MOS interface (PMOS and CMOS) operating from supply voltages

of from 6 to 16V.

Types UDS2981H/R and UDS2982H/R will withstand an output

OFF voltage of 50 V. UDS2983H/R and UDS2984H/R drivers will

withstand a maximum output OFF voltage of 80V.

Under normal operating conditions, the devices will sustain 50

mA continuously on each of the eight outputs at an ambient

temperature of +85°c and with a supply voltage of 15V. All types

include input current-limiting resistors and output transientsuppression diodes. In all cases, outputs are swiched ON by an

active high input level.

Note that the maximum current rating may not be obtained at 55°c because of reduced beta, or at +125°c because of package

power limitations.

Dwg No A 10243

ABSOLUTE MAXIMUM RATINGS

at +25°c Free-Air Temperature

Cutput Voltage Range, VCE

(UDS298t and

UDS2982H/R).......................................5V to 50V

(UDS2983 and

UDS2984H/R).....................................35V to 80V

Input Voltage, Vin

(UDS2981 and

UDS2983H/R).................................................15V

(UDS2982 and

UDS2984H/R).................................................30V

Output Current, Iout-........................................500 mA

Ground Terminal Current,

IGND........................................................................................................3.0A

Power Dissipation. PD

(any one driver).............................................1.1W

(total package).....................................See Graph

Operating Temperature Range,

TA.............................................................................-55˚Cto + 125

Storage Temperature Range,

Ts............................................................................-65˚Cto + 150

˚C

˚C

Series UDS2980H drivers are furnished in 18-pin

ceramic/metal(side-brazed) hermetic dual in-line packages. Series

UDS2980R drivers are supplied in ceramic/glass(cer-DIP) hermetic