Samsung SP0411N, SP0311N, SP0221N Service Manual

PANGO(PL40) Series

Model:

SP0221N

SP0311N

SP0411N

HARD DISK DRIVE service manual

Hard Disk Drive

Contents

1. Specification summary

2. Block Diagram of HDD

3. Connector & Jumper Pin Assignments

4. Exploded View

5. Maintenance Cylinder Configuration

6. How to use LEO Program

7. How to progress Burn-In Test

8. Caution

Attachment

related HDD

Attachment

Attachment

1. The basic information

2. HDD related terms

3. Q&A

SAMSUNG HARD DISK DRIVE

1. Specification Summary

Items Specification Remarks

Voltage Requirement DC +12V/±10%, DC +5V/±5%

Interface ATA - 6

SP0221N - 20.0GB (1CH)

Capacity

Disk / Head

Features

Seek Time

(RD/WT typical)

RPM 7,200 ± 0.35 % RPM

Temperature

(Operating)

Track to Track : 1.0 / 1.2 ms

Average : 10.0 / 12.0 ms

Full Stroke : 17.5 / 19.0 ms

SP0311N - 30.0GB (1CH)

SP0411N - 40.0GB (1CH)

SP0221N - 1/1(disk/head)

SP0311N - 1/1(disk/head)

SP0411N - 1/1(disk/head)

S.M.A.R.T Compliant

Buffer size 2 Mbytes

MTBF(POH) 500,000 hours

5~55°C

UDMA133supporting

MA100 Default)

(UD

Humidity

(Operating)

Temperature

(Non-operating)

Humidity

(Non-operating)

Linear Shock

(Operating)

Linear Shock

(Non-operating)

PANGO(PL40)

5~90%

-40~+70°C

5~95%

63 G @2.0ms Linear Shock

350 G (2ms linear shock)

Non-condensing

2

SAMSUNG HARD DISK DRIVE

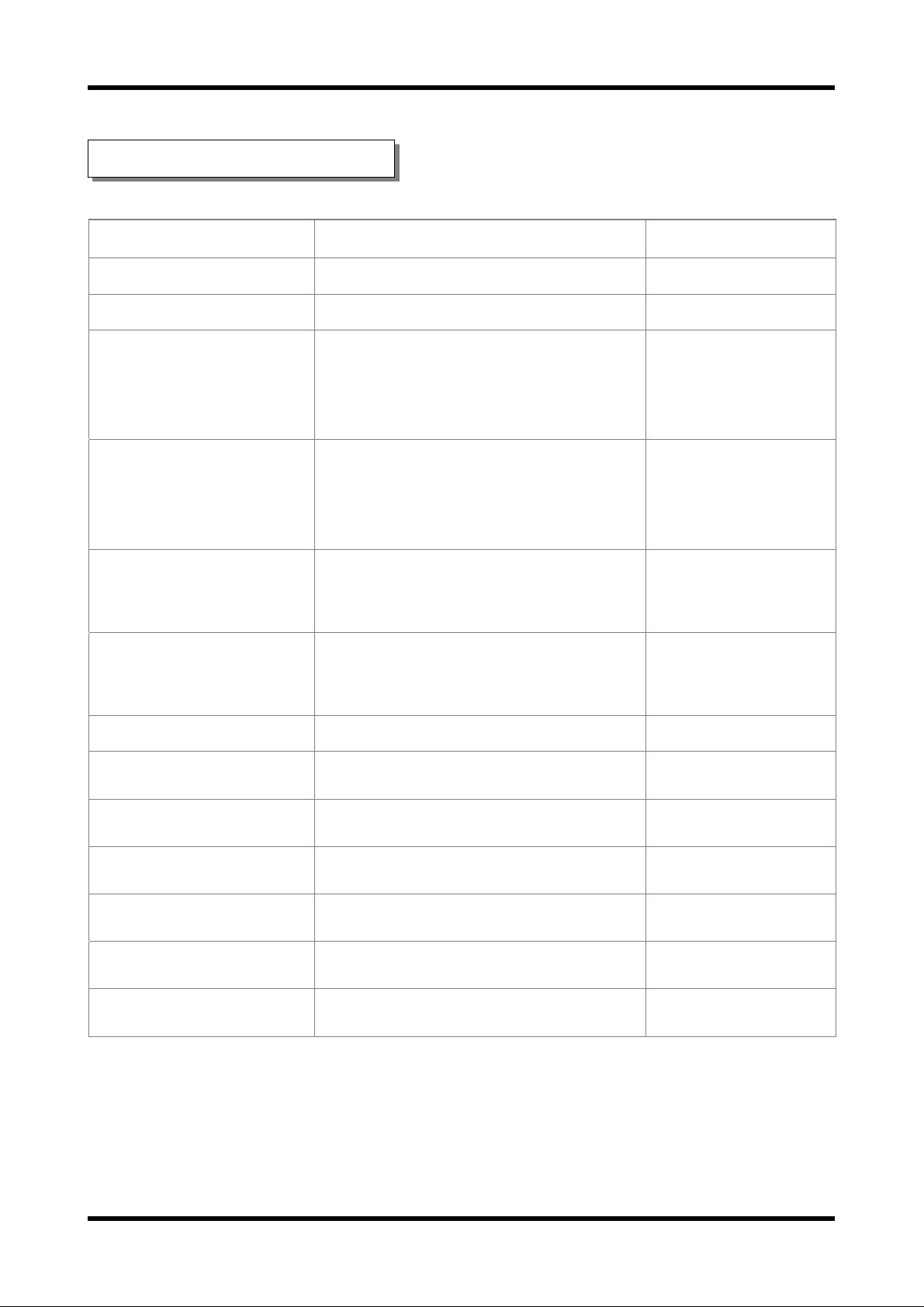

2. Block Diagram of HDD

PREAMP &

WRITE DRIVER

Marvell

81G5122

HDA

SPINDLE MOTOR &

ACTUATOR COMBO

DRIVER

HA13627

HDD

Flash 1Mbit

M29F102BB

AT Controller

R/W Channel

Servo Controller

Dual-DSP

88I6522

Buffer 16Mbit

EM636165TS-6

A

T

A

B

U

S

HDA (HEAD DISK ASSEMBLY)

-HEAD

-DISK

- VCM (Voice Coil Motor)

- SPM (Spindle Motor)

PANGO(PL40)

PCBA (PCB ASSEMBLY)

-PCBA

3

SAMSUNG HARD DISK DRIVE

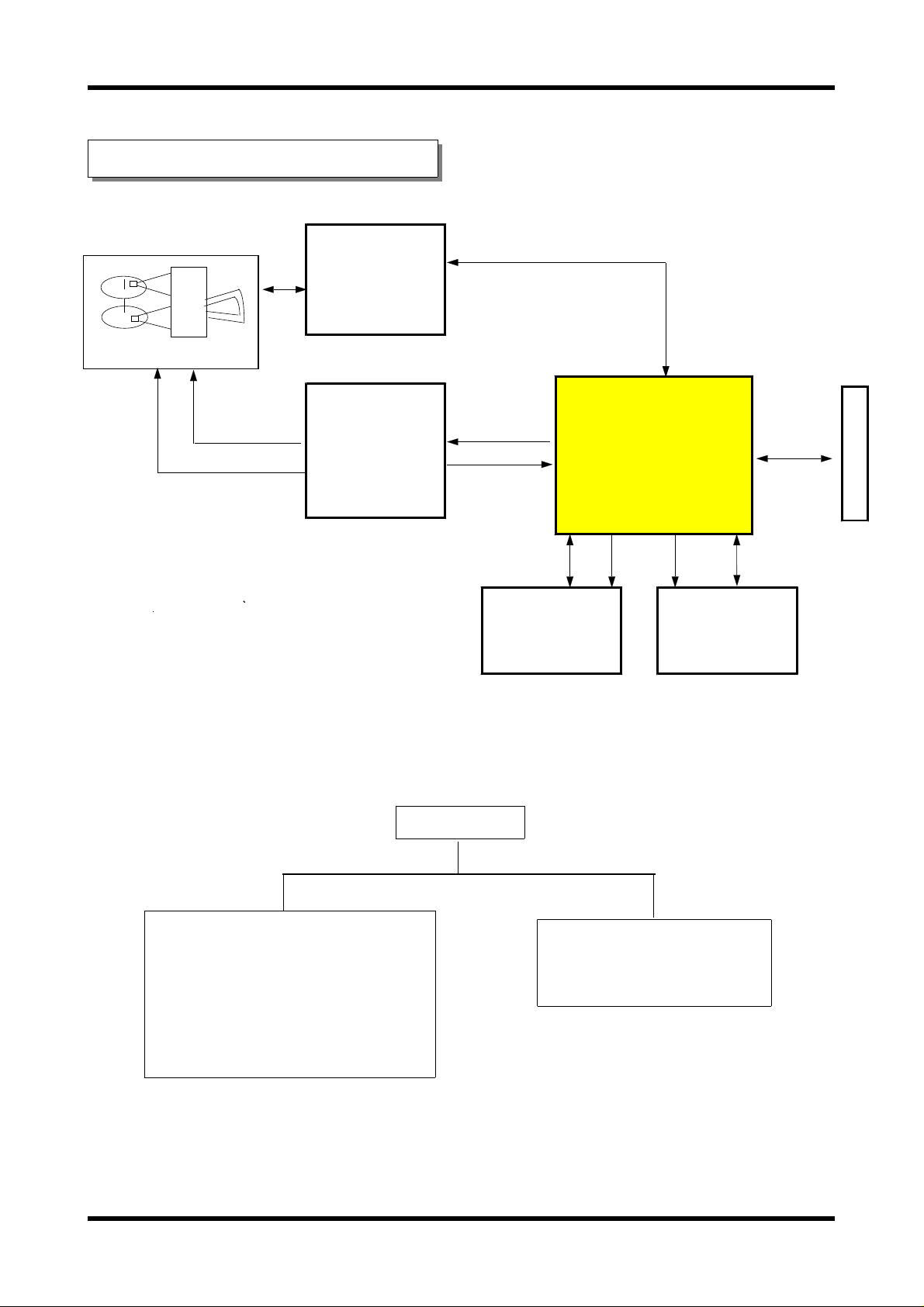

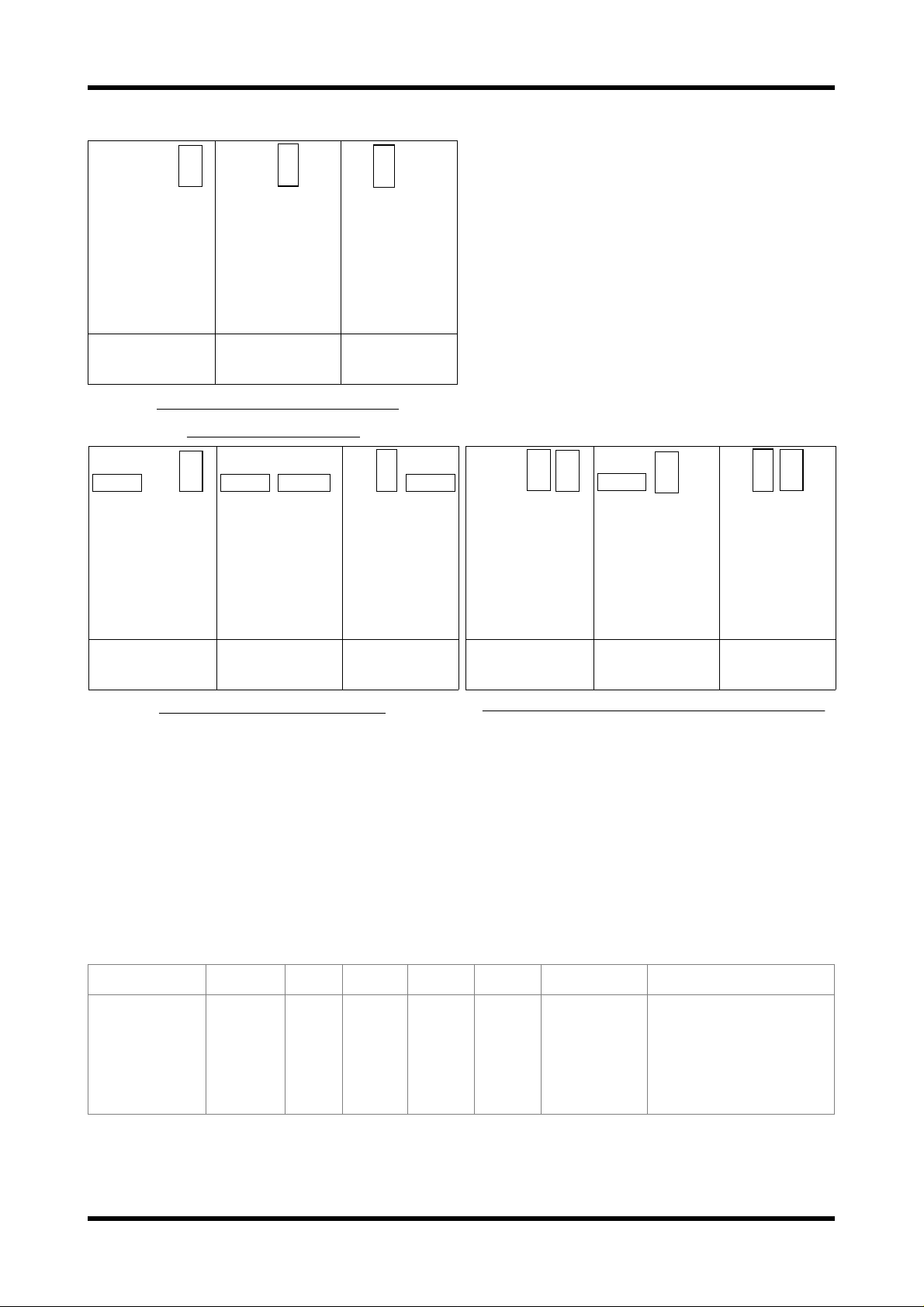

3. Connector / Jumper Pin Assignment

●

40 Pin I/O Connector Interface Signals

Number Signal Number Signal Remarks

1 RESET- 2 GND

3 DD7 4 DD8

5 DD6 6 DB9

7 DD5 8 DB10

9 DD4 10 DB11

11 DD3 12 DB12

13 DD2 14 DB13

15 DD1 16 DB14

17 DD0 18 DB15

19 GND 20 Key Pin

21 DMARQ 22 GND

23 DIOW - : STOP 24 GND

25 DIOR - : HDMARDY

27 IORDY : DDMARDY

29 DMACK 30 GND

31 INTRQ 32 IOCS16

33 DA1 34 PDIAG - : CBLID 35 DA0 36 DA2

37 CS0- 38 CS139 DASP- 40 GND

●

Jumper Pin Assignment

+GG+

12NN5

VDDV

JUMPER PIN

26 GND

: HSTROBE

28 CSEL

:HSTROBE

PCBA components side

oooo

PANGO(PL40)

2468

1357

246810121416182022242628303234363840

13579111315171921232527293133353739

HDA BASE

4

SAMSUNG HARD DISK DRIVE

②④⑥⑧

①③⑤⑦

M

S

C

S

A

L

S

T

S

A

E

T

V

L

E

E

R

MASTER

(1DRIVE)

< Jumper Pin Setting for

SP0221n,SP0311N>

②④⑥⑧

①③⑤⑦

M

S

C

S

A

L

S

T

S

A

E

T

V

L

E

E

R

MASTER

(1DRIVE)

②④⑥⑧

①③⑤⑦

S

C

S

S

T

E

L

SLAVE

②④⑥⑧

①③⑤⑦

C

S

S

T

E

L

SLAVE

M

L

A

A

S

V

T

E

E

R

S

M

L

A

A

S

V

T

E

E

R

②④⑥⑧

①③⑤⑦

M

S

C

S

A

L

S

T

S

A

E

T

V

L

E

E

R

CABLE

SELECT

②④⑥⑧

①③⑤⑦

M

S

C

S

A

L

S

T

S

A

E

T

V

L

E

E

R

CABLE

SELECT

②④⑥⑧

①③⑤⑦

M

S

C

S

A

L

S

T

S

A

E

T

V

L

E

E

R

MASTER

(1DRIVE)

②④⑥⑧

①③⑤⑦

S

C

S

T

S

E

L

SLAVE

M

L

A

A

S

V

T

E

E

R

②④⑥⑧

①③⑤⑦

M

S

C

S

A

L

S

T

S

A

E

T

V

L

E

E

R

CABLE

SELECT

< Setting for SP0411N >

●

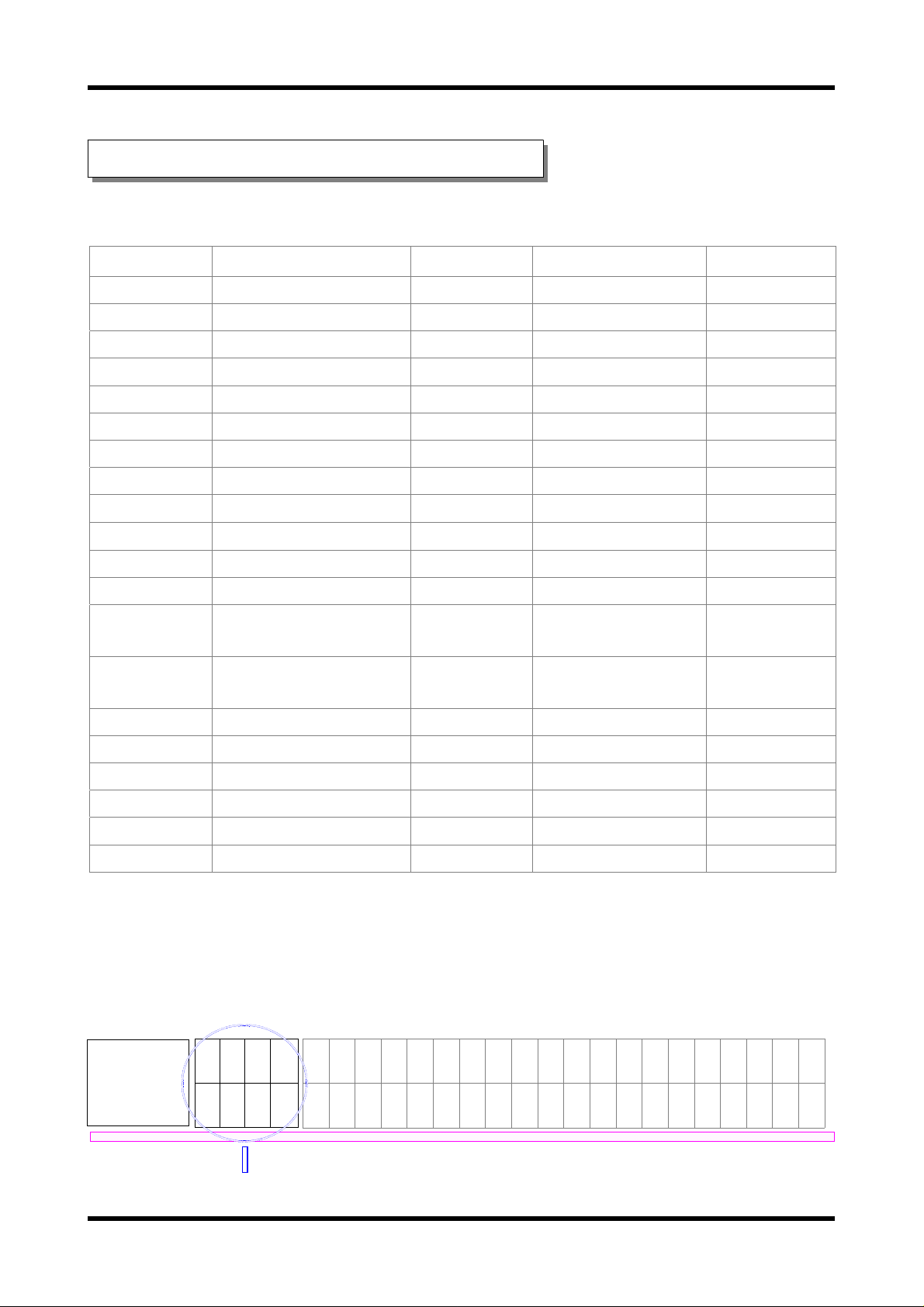

BIOS Setup Parameter

모델구분

SP0221N

SP0311N

SP0411N

CYL HD PRE LZ SEC SIZE

38,870

58,246

77,622

16

16

16

< 32GB Capacity Limit of PC/BIOS >

비고

X

X

X

X

X

X

63

63

63

20.0 GB

30.0 GB

40.0 GB

39,180,960

58,711,968

78,242,976

PANGO(PL40)

5

SAMSUNG HARD DISK DRIVE

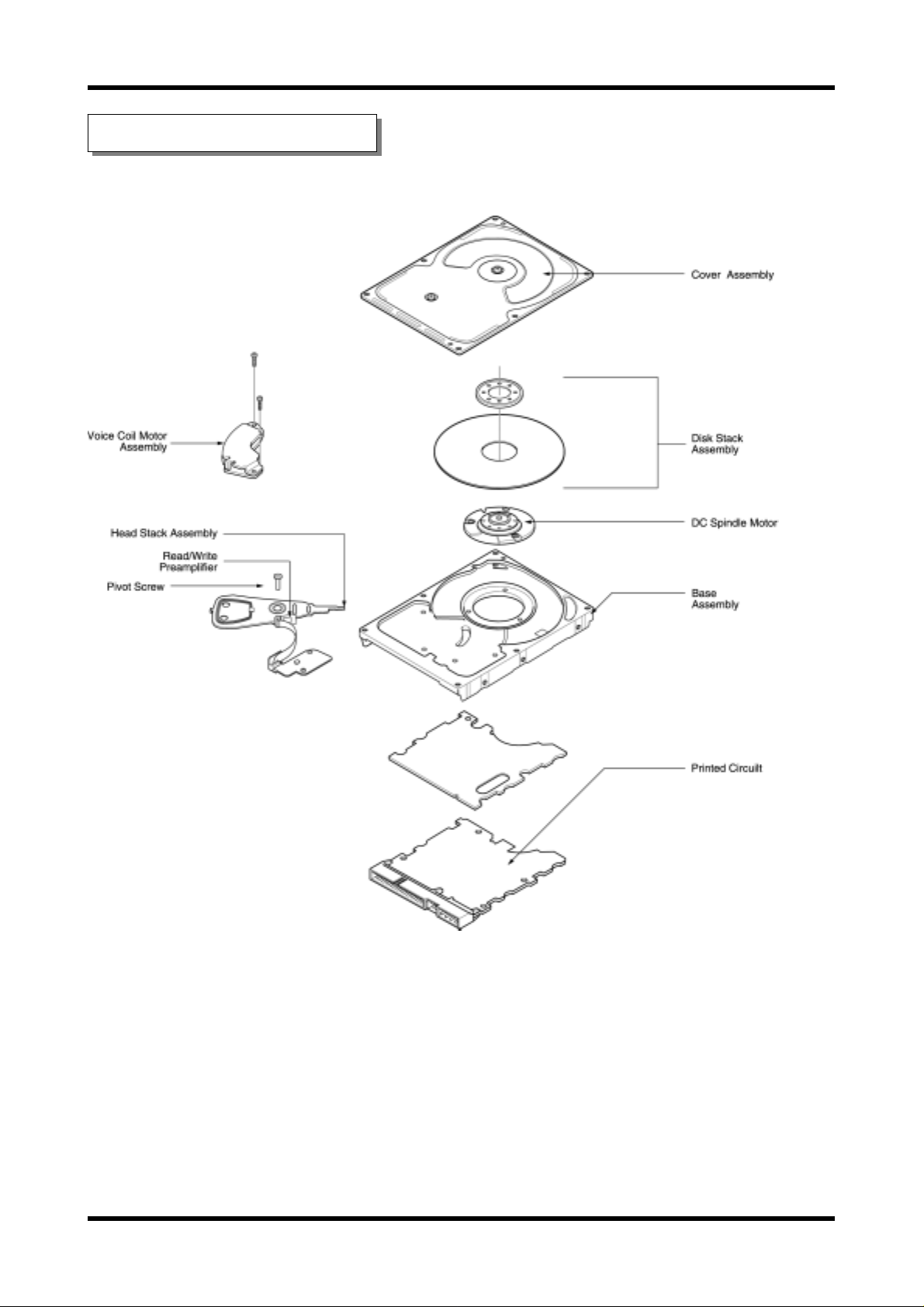

4. Exploded View

PANGO(PL40)

6

SAMSUNG HARD DISK DRIVE

<< Major components of HDD >>

HDD is formed by major components as follows: Base, Cover, ARM(E-Block), Latch, Crash Stop,

Pivot Bearing, Breather Filter, Window Clock, Window Push Pin, Jump Pin, Spindle Motor,

Actuator, Magnetic Head, Magnetic Disk, PCBA

① Base

Base could be a basic frames for HDD assembly. Spindle motor, ARM, VCM, cover and PCBA

are assembled on it, and other components are sub-assembled on those configuration.

ARM and Spindle motor assembled to Head and Disk each in advance,then those are assembled

on Base. If base could be effected by external and internal vibration (spindle motor

& actuator's fake vibration), relative displacement occurred between head and disk so to

reduce this effect to PES(Position Error Signal) and data signal, shape design concerned

mode shaping should be needed.

② Cover

Cover protect HDD components from the exterior impact and play role of sealing to cut off

particle and moisture which could be a fatal factor to head and disk. Cover is also designed

in consideration of noise and vibration effect.

③ ARM (E-block)

ARM is assembled HGA and VCM coil back and forth and it is connected to pivot axis pivot

bearing. When VCM coil generate torque due to electromagnetic force of VCM, ARM swing around

pivot and play a role of carriage so as head may access to information side of disk.

Inertia

reach to the proper point on of HDD efficiency, is minimizing ARM's weight to decrease inertia.

And then to decrease weight of ARM, it'll be composed low density materials and reduce ARM's

size within safety allowed when designed.

Unbalance

unbalance occur and it caused ARM to torque.

And acceleration might affect on unbalance mass in condition impact or vibration are given

from the exterior. In case of magnetic latch, this unbalance could be a reason that latch

released. Therefore shape simulation of ARM should be designed lest the center of gravity

should go off center of revolving.

④ Latch

When power HDD off, spindle motor stop spinning and park at parking zone automatically

according to the order systemized. By that time if head is given any impact or vibration

from the exterior, head invade data zone clung to disk. And then data damaged consequently,

Latch solve the problem above as maintain the regular distance of ARM.

: It is the best way to shorten data access time that shows how fast head can

: If the center of gravity for ARM isn't the same with that of pivot center,

PANGO(PL40)

7

SAMSUNG HARD DISK DRIVE

⑤ Crash Stop

Crash stop is made of elastic material and weaken a impact of actuator in emergency condition,

head getting out of data zone when it move to parking zone or seek.

⑥ Pivot Bearing

Pivot bearing is a roll bearing fixed the center of gyration of ARM. Inner Race is fixed by

screw after being connected to Base pivot and outer Race is fixed by retaining ring after

being connected by ARM's hole and make the ARM's revolving movement actively.

⑦ Breather Filter

In the interior of HDD, air flow is formed by the spinning disk in high speed and pressure

distribution occurred. This pressure is lower than atmospheric pressure of the exterior of

HDD and due to this, the outside air inflow into the interior caused contamination.

Breather filter fixed in inflow plug induce clean air and help air circulation.

⑧ Window Clock

Head must know the data's location information to access data on disk. Servo write is

a process of recording information disk. To record information, we make hole that head

for servo write can enter the interior of HDD and this hole is window clock.

This hole is closed with sealing label after done servo writing, be careful not to be

occurred inner contamination due to label's injury.

⑨ Window Push Pin

Head should be controlled to move on disk at a regular track pitch interval rate during

servo writing. ARM is torqued by VCM continuously and was controlled each track's moving

using push pin. Window push pin is a hole for this, the pin could enter interiorofHDA

and be careful contamination caused by label's injury because this hole is closed by sealing

label after done servo writing.

⑩ Jump Pin

During installing, HDD need setting of pin organization in the next according to

the drive running mode: master drive in single system, master drive in dual system,

slave drive in dual system.

⑪ Spindle Motor

Spindle motor is a sort of small motor which can change electric energy to mechanical energy

utilizing for magnetic field. When the current of stator's coil formed by electromagnet

is on, magnetic power occur between stator and rotator. (repeal occur between same pole and

attract occur in case of different pole) This power can make rotator revolve and we should

keep on changing the magnetic pole of the stator to maintain rotate at regular speed.

To progress this function, we deduct rotation speed and circuit for controlling needed.

It is possible to control the current flow and time interval with Hall element and MR

PANGO(PL40)

8

SAMSUNG HARD DISK DRIVE

element (these are sensitive to voltage change). The magnetic disk of hard disk is running

by DC Brushless direct drive motor directly. Brush has long life and high reliability

because it doesn't have belt. Recently we use flat motor to be adopted to the request of

minimizing. The rotation bearing is supported by Fluid Dynamic Bearing(FDB), this is not

keeping high speed spinning but also reducing resistance even eliminating and this make the

acceleration better.

The life of hard disk is up to the durability of this bearing supporting revolving axis.

Spindle motor rotate a disk media at regular speed.This device start to rotate as soon as

put power on and no matter what HDD read or write data,spindle motor always revolve.

Besides accurate reading from the media point of view is possible when maintain the constant

speed within 0.1%,rotation error. The control circuit of spindle motor receive the index data

from the spindle motor or media at every spin and check whether constant speed persists or not

then revise the speed. Spindle motor is applied to DC brushless motor.

⑫ Actuator

Hard disk has 2 disks so it has 4 written sides, and each side needs each written replay

device, 8 heads needed. This 4 heads can't work independently. Each head is connected with

one carriage and set as running altogether. For example, one head move at tenth track and

then the rest come to move at the same track. Retrieval(information searching) is a moving

the head to track properly. The faster searching speed, the better for a quick access.

It is profitable to use voice coil motor for a fast searching speed. Making narrow

the width and interval of track is for HDD capacity improvement so we can build more tracks

on written side so searching movements in head become subtle. Therefore servo control the

decision of HDD location. Magnetic disk is put standard signal for location marking from the

manufacturing step. Head read this to find the relative difference then run motor mediate

the head's location.

⑬ Magnetic Head

Magnetic field is formed around the conduct on passing electric current to conductor and

the direction and size of magnetic field are decided by those of an electric current.

Magnetic head build a minute gap in core (formed by ring) and pass an electric current then

strong magnetic leakage are occurred around gap thus magnetic particles of media vary the

direction according to the that of current: this is called recording. On the contrary, a

process induce magnetic signal to electric signal is called reading(decipherment).

⑭ Magnetic Disk

Recording carrier become a permanent magnet according to applying magnetic material to the

surface and change the magnetization direction of a electromagnet and it is possible to

store information during long term.

⑮ PCBA

PCBA is a circuit element concerning about HDD running and constructed in

engine IC,COMBO IC,read/write IC,ROM ,and sort of chip etc.

- Engine IC: contained RAM&Interface IC and exchange information to computer.

- COMBO IC: Controlling spindle motor & VCM running when HDD power on.

- Read/Write IC: read/write of HDD

PANGO(PL40)

9

SAMSUNG HARD DISK DRIVE

- ROM: Checking HDD basic function and management basic spec.

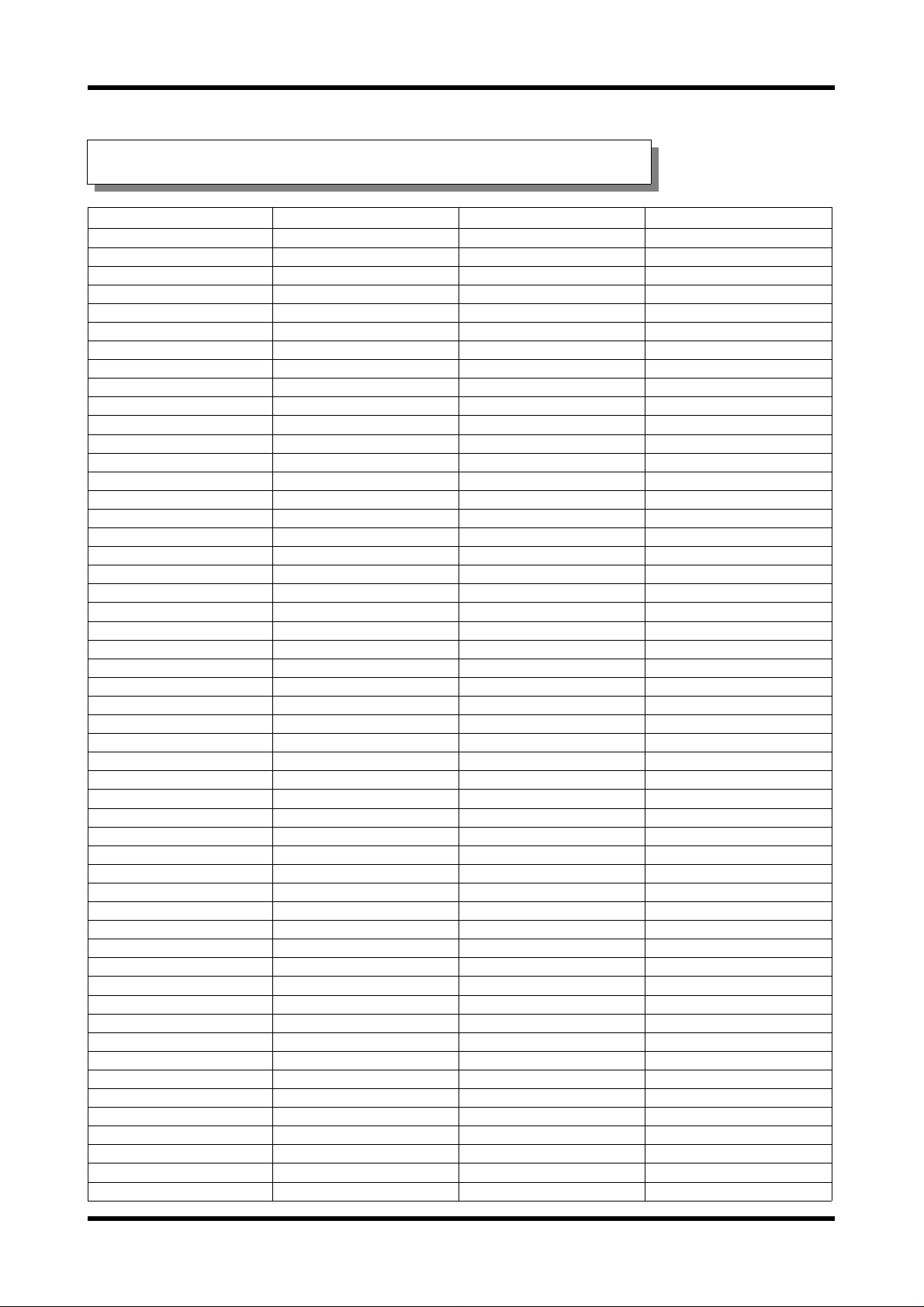

5.Maintenance Cylinder Configuration

Contents Disk Location sector size Header

CTBL 4, 0, 131 8 CHN_TB3

IDFY 0, 0, 1 1

IDFY 0, 0, 1 3

MLIST 0, 0, 6 1 MLIST

SRVTBL 0, 0, 7 3 SV_TBL

CONFIG 1, 0, 1 2 CONFIG

SNTBL 1, 0, 3 2

BISPT 1, 0, 5 4

BRSLT 1, 0, 10 1

FINALTST 1, 0, 12 8

FINALTST 1, 0, 19 8

CTBL 1, 0, 30 8 CHN_TBL

VLISTHDR 1, 0, 78 1 VLIST_H

VLIST 1, 0, 79 16

SLISTHDR 1, 0, 111 1 SLIST_H

SLIST 1, 0, 112 128

TLIST 1, 0, 368 4 TLIST

ALIST 1, 0, 372 8 RLIST

TMPRTR 1, 0, 395 2 TMPRTURE

MRTUNE 1, 0, 383 3 SV_TBL2

ARCOTBL2 1, 0, 387 8 CHN_TB2

LATCHFRC 4, 0, 4 1 LATCH_FC

BTIME 4, 0, 91 2 BI_TIME

ERRTRK 4, 0, 56 1 BER

ERRZN 4, 0, 57 1 BER1

ERRDRV 4, 0, 58 1 BER2

SRTDATA 4, 0, 59 1 ER_CNT

SRTSRVO 4, 0, 60 1 SV_ERCNT

PARAM 4, 0, 62 10

TSTPI 4, 0, 82 4 TPI_WRW

MRTUNEMT 4, 0, 86 5 MR_TUNE

DLIST 3, 0, 1 768

BPI 4, 0, 521 8 AZL_BPI

BPICSM 4, 0, 513 8 AZL_CSM

CURGEO 4, 0, 512 1 CUR_BPI

SMART 11, 0, 1 8 SMARTMEM

SEL 11, 0, 2 4

ELOG 12, 0, 1 768

RCOHDR 5, 0, 1 2 RCOHDR

RCODATA 5, 0, 1 256 RCODATA

SKEW 0, 0, 2 1 SKEW

CRITERIA 0, 0, 11 1

MRSKEW 0, 0, 189 1 MRSKEW

SMTBL 0,0,192 1 SM

UNITABLE 0, 0, 197 2 UNITABLE

SETMAX 0, 0, 233 1 SETMAX

D_CSM 3, 0, 2 252

WB_RLT 0, 1, 5 1 WB_RLT

GAIN 0, 0, 691 1 GAIN

WKHEAD 4, 0, 72 4 WK_HEAD

NPV 4, 0, 77 4

HIT 4,0,533 4

PANGO(PL40)

10

SAMSUNG HARD DISK DRIVE

7. How to use HUTIL Program

1) Before you start

HUTIL support from Voyager11P to VERNA series.(HUTIL 1.09 version)

(HUTIL has been upgrading constantly whenever new model comes out.)

- Preparation before use

Diskette or HDD containing HUTIL.EXE should be boot-up to MS-DOS mode,that is,

should be contained IO.SYS, MSDOS.SYS,COMMAND.COM (IO.SYS, MSDOS.SYS: hidden file).

And also HUTIL.CFG is required.

2) Explanation of each menu

OPTION - ABOUT HUTIL : Version of HUTIL.

OPTION - DOS SHELL : Execute DOS Shell. If you want back to HUTIL, input EXIT.

EXIT TO DOS : End HUTIL program.

OPTION - DRIVE INFORMATION : Open the information window about the target HDD.

Press ESC to close.

TEST - READ ALL: Display error list when error is occurred after reading whole cylinder.

Message will be appeared if the test time delay is over 20 seconds compared

with other normal HDD. In this case, HDD may have problem. (Progress

sequential read test from cyl. #0 to the last cylinder. No Defect Free.

- Refer to attachment below.)

TEST - READ FROM : Read from the designated cylinder and head to the last cylinder.

Press ESC to stop in the middle.

TEST - WRITE ALL: Write 00h on all cylinder except maintenance cylinder.

All data will be removed. (Even partition table, boot sector & FAT)

TEST - WRITE FROM : Write from the designate cylinder and head to the last cylinder.

INFORMATION - NEW DEFECT LIST : View the error list in memory.

TEST - BURN IN : Download burn-In script to HDD.

TEST - DEFECT FREE : Progress after Read Drive command.

Defect free operation for the defects in the error list.

TEST - SHORT TEST : Menu for random read test, no defect free test.

TEST - LONG TEST : Read test from the first cylinder to the last in order,

no defect free test.

TEST - LONG TEST & DF : Current auto test.Check defect and defect free during read test and

examine defect free again.

INFORMATION - NEW DEFECT MAP : Show defect on drive in graphic mode. These defects are invisible

because of done then these are added after defect free done

B/I & Read test or Auto test separately.

INFORMATION - GROWN DEFECT MAP : Show the defects in graphic mode during HUTIL program.

Moving along cursor with up/down arrow key, these keys

are indicated the location of defects in the right list

on disk. This location is agreed with the real location

because skew was concerned in that already.

The color of an arrow is agreed with those of head in

PANGO(PL40)

11

Loading...

Loading...