Samsung SMH9151S, SMH9151BE, SMH9151BE/XAA, SMH9151STE Service Manual

BASIC: SMH9151S

MODEL: SMH9151BE

MODEL CODE: SMH9151BE/XAA

1. Precaution

2. ProductSpecication

3. Disassembly and Reassembly

4. Troubleshooting

5. Exploded Views and Part List

6. PCB Diagrams

7. Wiring Diagrams

8. Schematic Diagrams

•Contents

1. Precaution ..............................................................................3

1-1 Safety precautions .....................................................................4

1-2 Special High Voltage Precautions .........................................................5

2.Specications ...........................................................................6

2-1 Features .............................................................................6

2-2 Accessory ............................................................................6

2-3 Table of Specications ..................................................................7

3. Disassembly and Reassembly ..............................................................8

3-1 Replacement of High Voltage Transformer ..................................................8

3-2 Replacement of Magnetron .............................................................10

3-3 Replacement of Door Assembly ..........................................................11

3-4 Replacement of Fuse ..................................................................13

3-5 Replacement of Drive Motor ............................................................13

3-6 Removal of stirrer .....................................................................14

3-7 Replacement of Control Circuit Board .....................................................15

3-8 Replacement of Cooktop lamp ...........................................................16

3-9 Replacement of Oven Light .............................................................17

4. Troubleshooting ........................................................................18

4-1 Parts checking method .................................................................18

4-2 Error Code Numbering Rule .............................................................19

4-3 Error Code List .......................................................................19

4-4 Electrical Malfunction ..................................................................21

5. Exploded Views and Parts List ............................................................38

5-1 Exploded Views ......................................................................38

5-2 Main Parts List .......................................................................39

5-3 Door Parts List .......................................................................41

5-4 Control Parts List .....................................................................42

5-5 Standard Parts List ....................................................................43

6. PCB Diagrams ..........................................................................44

6-1 PCB Diagrams .......................................................................44

6-2 PCB Diagrams .......................................................................45

7. Wiring Diagrams ........................................................................46

7-1 Wiring Diagrams ......................................................................46

8. Schematic Diagrams .....................................................................48

8-1 Schematic Diagram ...................................................................48

2

1. Precaution

3

1. Precaution

Follow these special safety precautions. Although the microwave oven is completely safe during ordinary use,

repair work can be extremely hazardous due to possible exposure to microwave radiation, as well as potentially

lethal high voltages and currents.

1-1 Safety precautions ( )

1. All repairs should be done in accordance with the

procedures described in this manual. This product

complies with Federal Performance Standard 21

CFR

2. Microwave emission check should be performed to

prior to servicing if the oven is operative.

3. If the oven operates with the door open :Instruct

the user not to operate the oven and contact

the manufacturer and the center for devices and

radiological health immediately.

4. Notify the Central Service Center if the microwave

leakage exceeds 5 mW/cm2.

5. Check all grounds.

6. Do not power the MWO from a “2-prong” AC cord.

Be sure that all of the built-in protective devices are

replaced. Restore any missing protective shields.

7. When reinstalling the chassis and its assemblies,

be sure to restore all protective devices, including:

nonmetallic control knobs and compartment covers.

8. Make sure that there are no cabinet openings

through which people --particularly children--might

insert objects and contact dangerous voltages.

Examples: Lamp hole,ventilation slots.

9. Inform the manufacturer of any oven foundto have

emission in excess of 5 mW/cm2 ,Make repairs to

bring the unit into compliance at no cost to owner

and try to determine cause. Instruct owner not to use

oven until it has been brought into compliance.

CENTRAL SERVICE CENTER

10. Service technicians should remove their watches

while repairing an MWO.

11. To avoid any possible radiation hazard,replace parts

in accordance with the wiring diagram. Also, use

only the exact replacements for the following parts:

Primary and secondary interlock switches, interlock

monitor switch.

12. If the fuse is blown by the Interlock Monitor Switch:

Replace all of the following at the same time:

Primary, door sensing switch and power relay, as

well as the Interlock Monitor Switch. The correct

adjustment of these switches is described elsewhere

in this manual. Make sure that the fuse has the

correct rating for the particular model being repaired.

13. Design Alteration Warning: Use exact replacement

parts only, i.e.,only those that are specied in

thedrawings and parts lists of this manual. This

is especially important for the Interlock switches,

described above. Never alter or add to the

mechanical or electrical design of the MWO.

Any design changes or additions will void the

manufacturer’s warranty. Always unplug the unit’s

AC power cord from the AC power source before

attempting to remove or reinstall any component or

assembly.

14. Never defeat any of the B+ voltage interlocks. Do not

apply AC power to the unit (or any of its assemblies)

unless all solid-state heat sinks are correctly

installed.

15. Some semiconductor (“solid state”) devices

are easily damaged by static electricity. Such

components are called Electrostatically Sensitive

Devices (ESDs). Examples include integrated

circuits and eld-effect transistors. Immediately

before handling any semiconductor components or

assemblies, drain the electrostatic charge from your

body by touching a known earth ground.

16. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting the

positive lead; always remove the instrument’s ground

lead last.

17. When checking the continuity of the witches or

transformer, always make sure that the power is

OFF, and one of the lead wires is disconnected.

18. Components that are critical for safety are indicated

in the circuit diagram by shading, or .

19. Use replacement components that have the same

ratings, especially for ame resistance and dielectric

strength specications. A replacement part that does

not have the same safety characteristics as the

original might create shock, re or other hazards.

NOTE : Connect the oven to a 20A. When

connecting the oven to a 15A,make sure that circuit

breaker can operate.

4

1. Precaution

H. V. Diode

Short

H. V. Capacitor

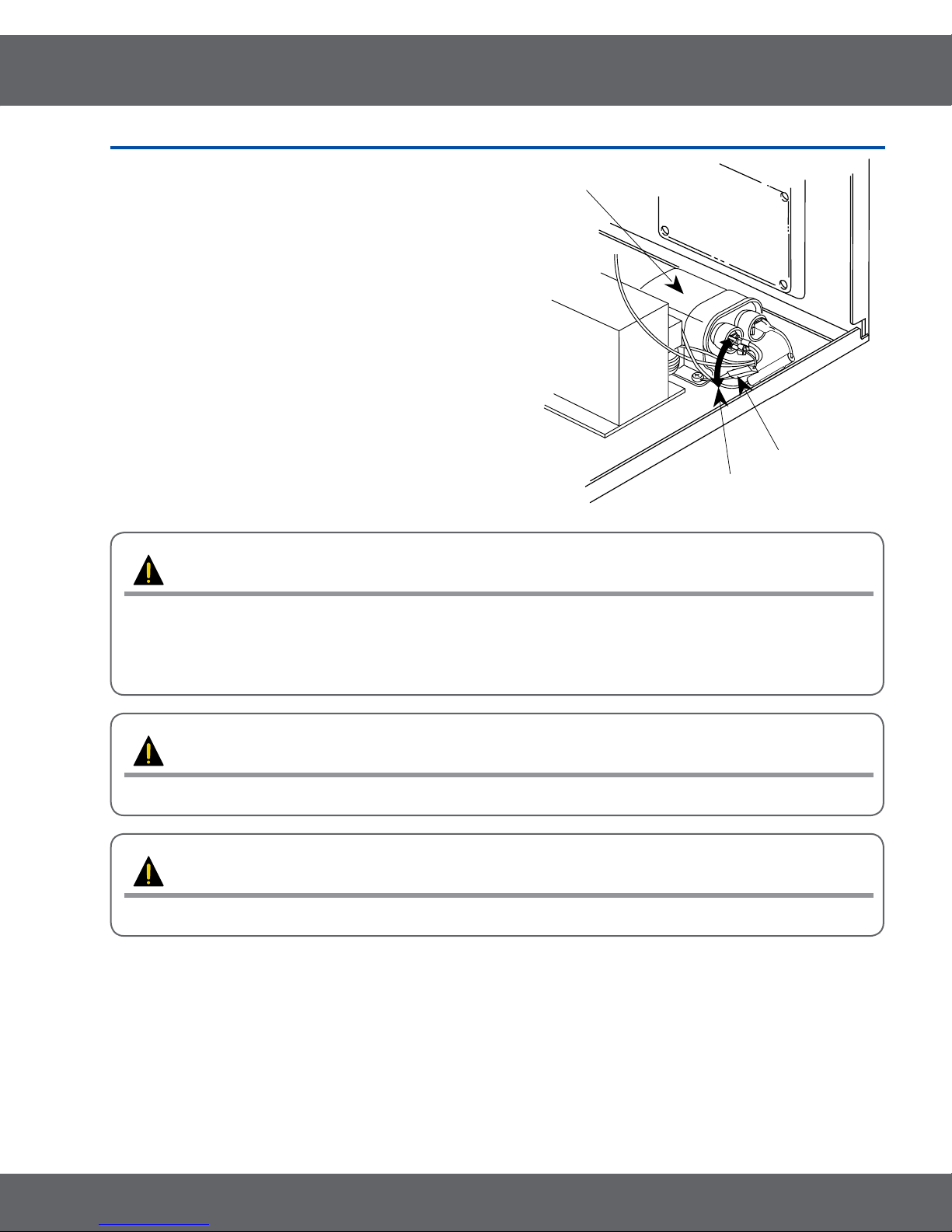

1-2 Special High Voltage Precautions

1. High Voltage Warning Do not attempt to measure any of

the high voltages --this includes the lament voltage of the

magnetron. High voltage is present during any cook cycle.

Before touching any components or wiring, always unplug

the oven and discharge the high voltage capacitor (See

Figure 1-1)

2. The high-voltage capacitor remains charged about 30

seconds after disconnection. Short the negative terminal

of the high-voltage capacitor to to the oven chassis. (Use a

screwdriver.)

3. High voltage is maintained within specied limits by close-

tolerance, safety-related components and adjustments. If

the high voltage exceeds the specied limits, check each

of the special components.

PRECAUTION

There exists HIGH VOLTAGE ELECTRICITY with high current capabilities in the circuits of the HIGH

VOLTAGE TRANSFORMER secondary and lament terminals. It is extremely dangerous to work on or

near these circuits with the oven energized.

DO NOT measure the voltage in the high voltage circuit including lament voltage of magnetron.

PRECAUTION

Servicemen should remove their watches whenever working close to or replacing the magnetron.

PRECAUTION

Never touch any circuit wiring with your hand nor with uninsulated tool during operation.

5

2.Specications

2-1 Features

Product Features

•StirrerandTurntable Continually rotates food to ensure even cooking.

•InstantCook Instant On Controls - Allow quick, one touch cooking and reheating.

•VentingSystem

2-2 Accessory

Item Description Code No. Q’ty

Two speed, 300CFM venting system - Quickly removes smokr and

steam from cook top

TRAY-COOKING DE63-00536A 1

ASSY-GUIDE ROLLER DE92-90495C 1

ASSY-HOOD DAMPER DE92-90242D 1

ASSY-HARD WARE DE92-90505G 1

FILTER-AIR DE63-00196A 1

FILTER-CHARCOAL DE63-00367E 1

6

2.Specications

2-3TableofSpecications

Items

Cavity Size (cu.ft.) 1.6 1.6

Power

Power Source 120 V / 60 Hz 120 V / 60 Hz

Output Power (Watts) 1000 1000

Power Consumption (Watts/Amp) 1580/13.5 1580/13.5

Characteristics

Control Method Touch Touch

Display LED LED

Sensor No No

Cooking Timer 99 min. 99 sec. 99 min. 99 sec.

Power Level 10 10

Auto Defrost Yes Yes

Auto Reheat Yes Yes

One Touch Instant Cook Pads Yes Yes

Soften/Melt Yes Yes

More/Less Yes Yes

Cooking Stages 2 2

Add 30 sec No No

One Minute Yes Yes

Clock Yes Yes

Kitchen Timer Yes Yes

Weight Option Oz Oz

Reminder End Signal On/Off No No

Child Safety Lock Yes Yes

Clock System Option (12 hrs / 24 hrs) 12 hrs 12 hrs

Demonstration Mode No No

Numeric Pads 0-9 0-9

Turntable Distribution Stirrer + Turntable Stirrer + Turntable

Turntable On/Off No No

End Signal Sound Yes Yes

Vent Fan CFM 220 220

Vent Orientation Vertical Vertical

Vent Fan Control Hi/Lo/Off Hi/Lo/Off

Cooktop Lighting Hi/Lo/Off Hi/Lo/Off

Cabinet Colour STSS/Black/White/Silver STSS/Black/White/Silver

Cavity Interior Epoxy Epoxy

Cabinet Dimensions W x H x D (inches) 29 7/8 x 16 1/2 x 15 1/16 29 7/8 x 16 1/2 x 15 1/16

Net Weight (lb)

Shipping Properties

Shipping Dimensions W x H x D (inches) 33 3/8 x 19 15/16 x 19 13/32 33 3/8 x 19 15/16 x 19 13/32

Loading Q’ty (sets / 40ft) 330 (Jumbo) 330 (Jumbo)

Shipping Weight (lb)

STSS: 45.9 lbs / Plastic: 44.5

STSS: 53.4 lbs / Plastic: 52.0

Basic Model New Model

SMH9151S SMH9151BE

lbs

lbs

STSS: 45.9 lbs / Plastic: 44.5 lbs

STSS: 53.4 lbs / Plastic: 52.0 lbs

7

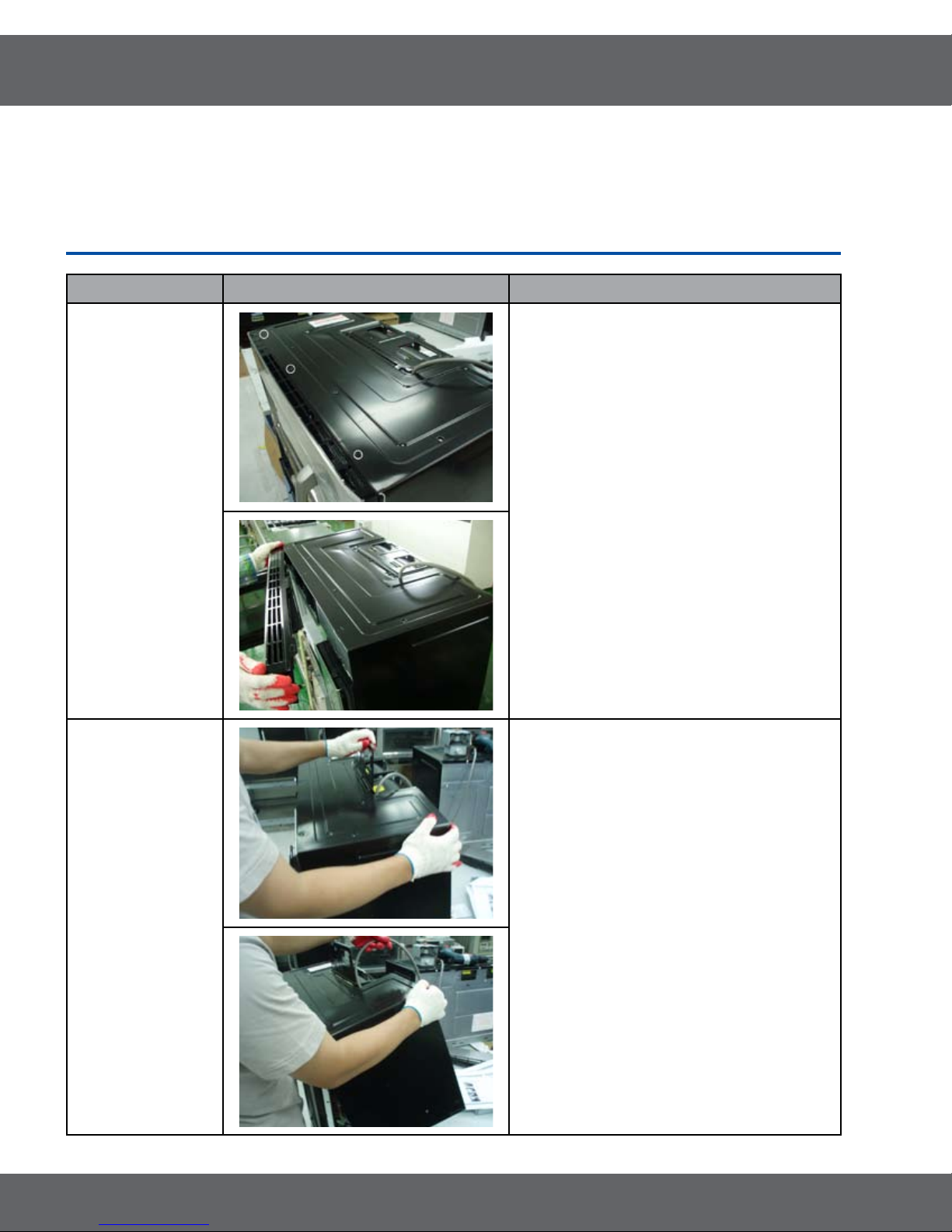

3. Disassembly and Reassembly

MAGNETRON, MOTOR ASSEMBLY, VENT BLOWER AND HIGH VOLTAGE TRANSFORMER

Oven must be removed from wall.

REMOVING OVEN FROM WALL (2 PEOPLE REQUIRED)

Oven is hooked on metal tabs at bottom of wall mounting plate and to cabinet by (3) top cabinet bolts.

3-1 Replacement of High Voltage Transformer

Parts Explaination Photo Explaination

1. Disconnect oven power.

Grille

Panel Outer

2. Remove Grille.

1) Remove 2 screws

2) Slide the Grille to the left, then pull it

straght out.

3. Remove Panel Outer.

8

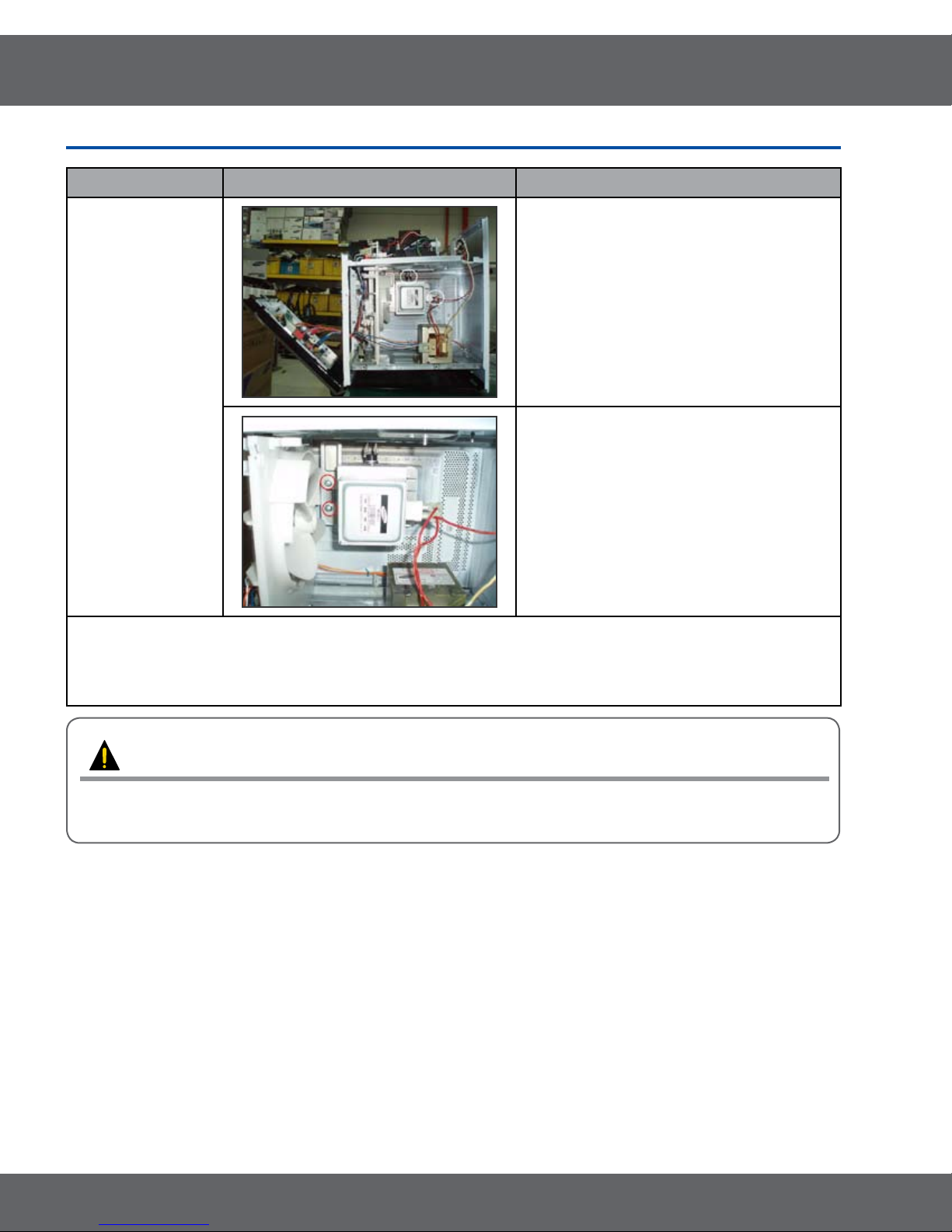

3. Disassembly and Reassembly

3-1 Replacement of High Voltage Transformer

Parts Explaination Photo Explaination

4. Discharge the High voltage capacitor.

High

voltage

capacitor

5. Disconnect all the leads.

Base

Bottom

HV Trans

6. Remove Base

bottom.

7. Take out the HV Trans.

9

3. Disassembly and Reassembly

3-2 Replacement of Magnetron

Parts Explaination Photo Explaination

Magnetron

Remove the magnetron including the shield

case, permanent magnet, choke coils and

capacitors (all of which are contained in one

assembly).

1. Disconnect all lead wires from the

magnetron.

2. Remove nuts (4) securing the magnetron

to the wave guide.

3. Take out the magnetron very carefully.

NOTE1: When removing the magnetron, make sure that it antenna does not hit any adjacentparts, or it may be

damaged.

NOTE2: When replacing the magnetron, be sure to remount the magnetron gasket in the correct position and make

sure the gasket is in good condition.

PRECAUTION

During replacement, be certain R.F. anode gasket is in place around anode stub.

PERFORM MICROWAVE LEAKAGE TEST

10

3. Disassembly and Reassembly

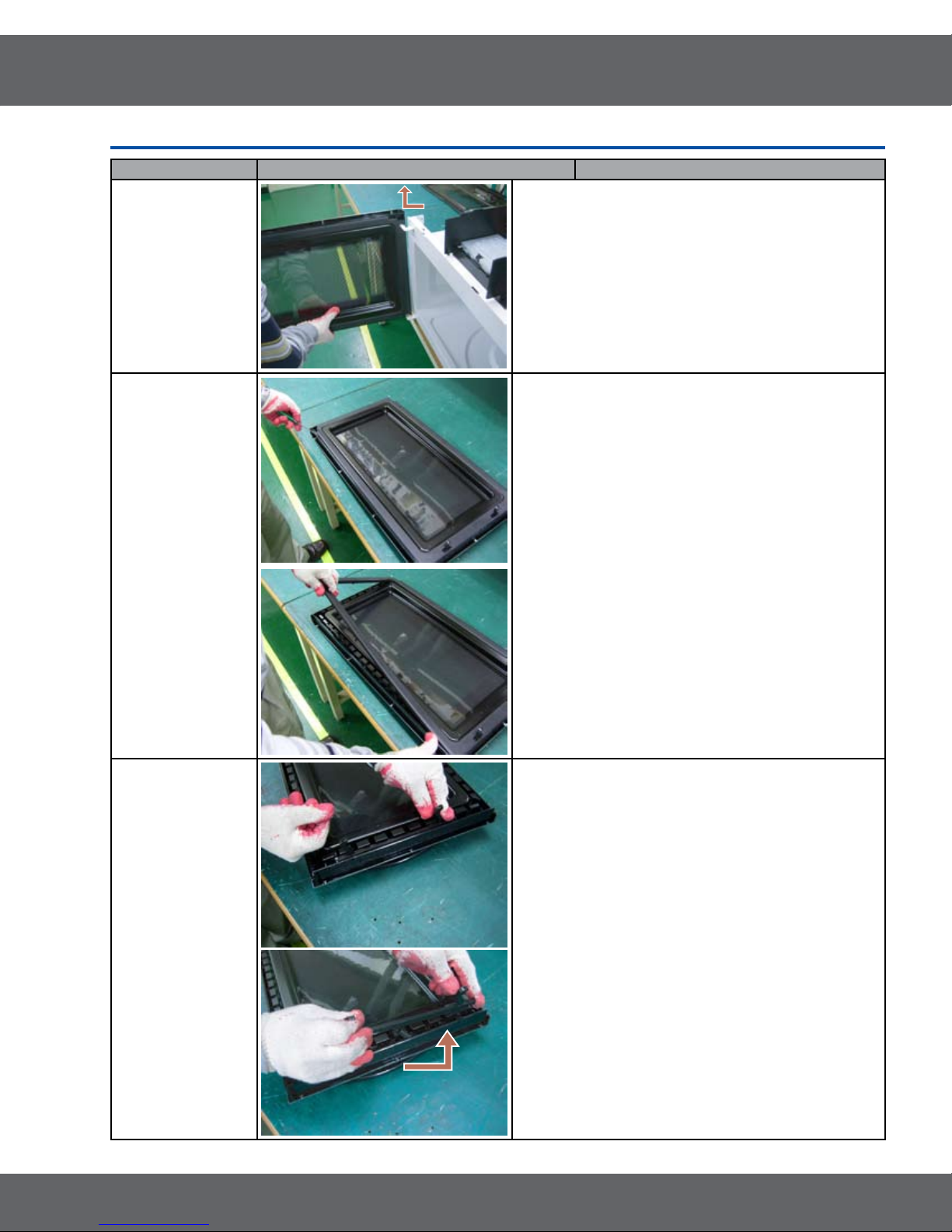

3-3 Replacement of Door Assembly

Parts Disassembly Photo Explaination

Removal of

Door Assembly

1. Insert at screwdriver into the gap between Door

“A” and Door “C” to remove Door “C”. Be careful

when handling Door “C” because it is fragile.Then

remove the door assembly.

Removal of

Door C

Removal of Key

Door & Spring

2. Insert at screwdriver into the gap between Door

“A” and Door “C” to remove Door “C”.

•Becareful when handling Door “C” because it is

fragile.

3. Detach the spring and key door from Door.

11

3. Disassembly and Reassembly

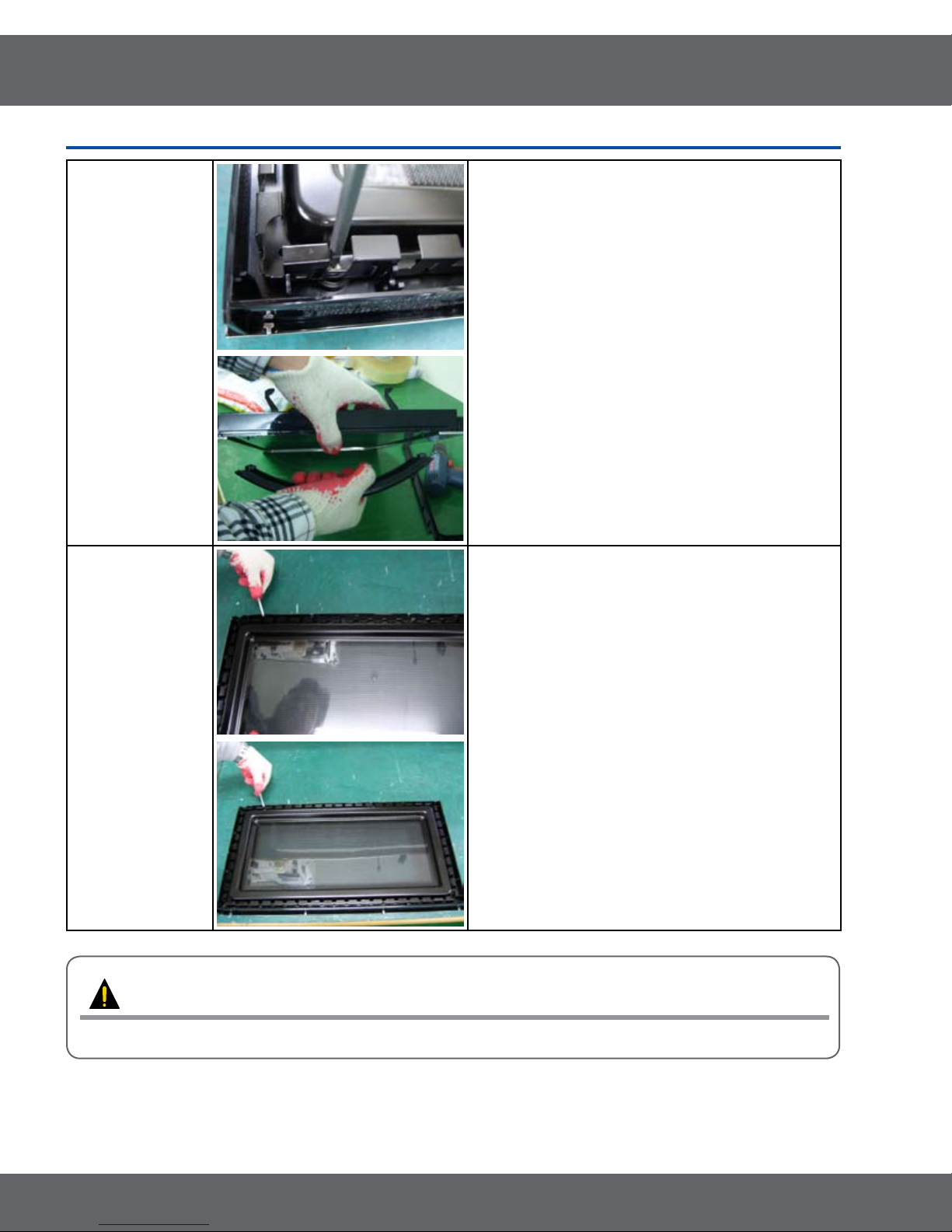

3-3 Replacement of Door Assembly

Removal of

Handle

Removal of

Door “E”

4. Remove 2 screws, then handle is detached from

Door “A”.

5. Following the procedure as shown in the gure,

insert and bend a thin metal plate between Door

“E” and Door “A” until you hear the ‘tick’ sound.

•Insertion depth of the thin metal plate should be

0.5mm or less.

PRECAUTION

PERFORM MICROWAVE LEAKAGE TEST

12

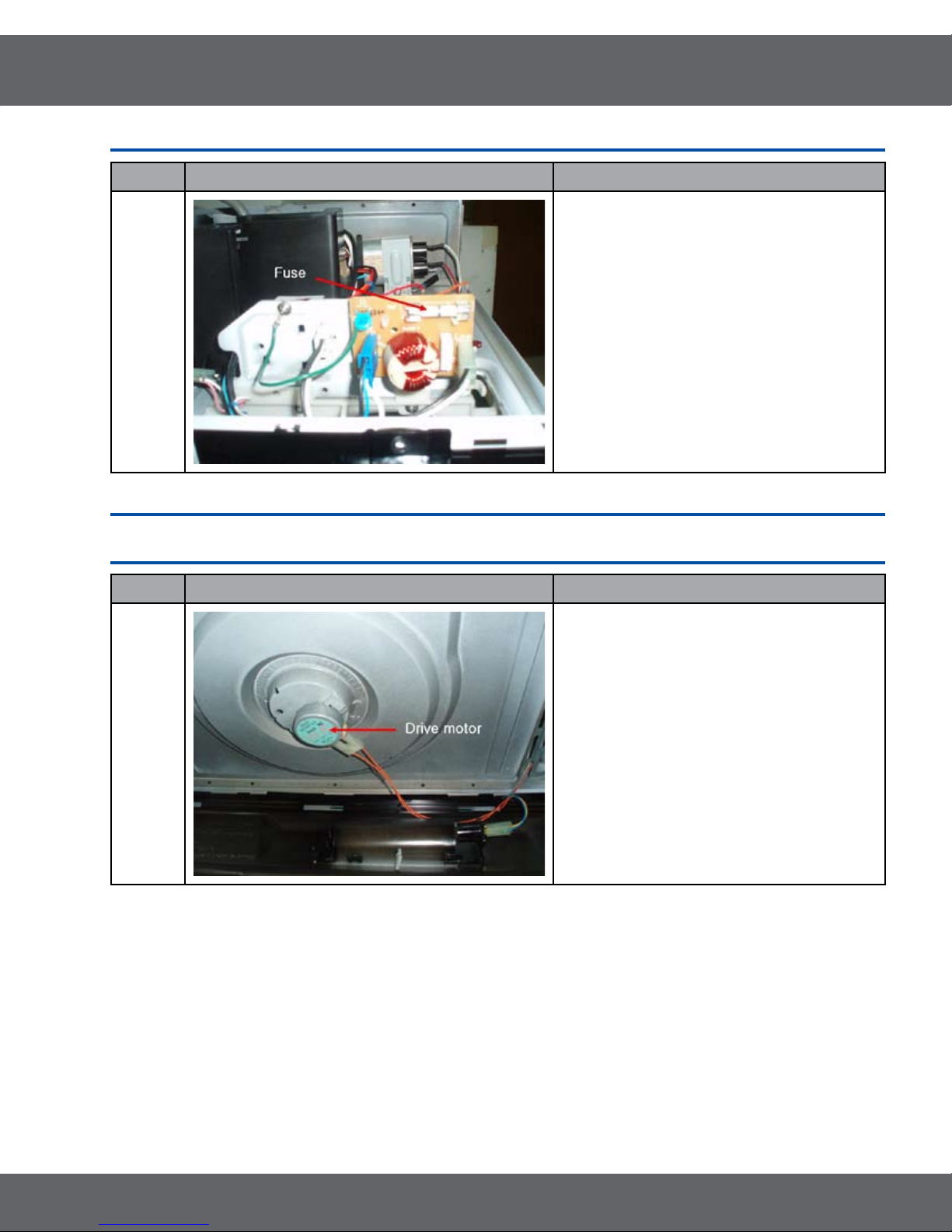

3. Disassembly and Reassembly

3-4 Replacement of Fuse

Parts Explaination Photo Explaination

The fuse is located on the noise lter.

1. Disconnect power and remove grille.

2. Replace the fuse.

3. When 20A fuse blows out by the operation

of interlock monitor switch failure, replace

Fuse

the primary interlock switch, secondary

interlock switch, door sensing switch,

interlock monitor switch and power relay.

4. When the above four switches operate

properly, check if any other part such as the

control circuit board, blower motor or high

voltage transformer is defective.

3-5 Replacement of Drive Motor

Parts Explaination Photo Explaination

1. Disconnect power and remove bottom plate

screws(5).

2. Remove bottom plate and disconnect the

turntable motor drive.

Drive

Motor

3. Remove turntable motor screws(1) and pull

the turntable motor out.

4. When replacing the drive motor, be sure to

remount it in the correct position with the

coupler.

5. Connect all the leads to the drive motor.

13

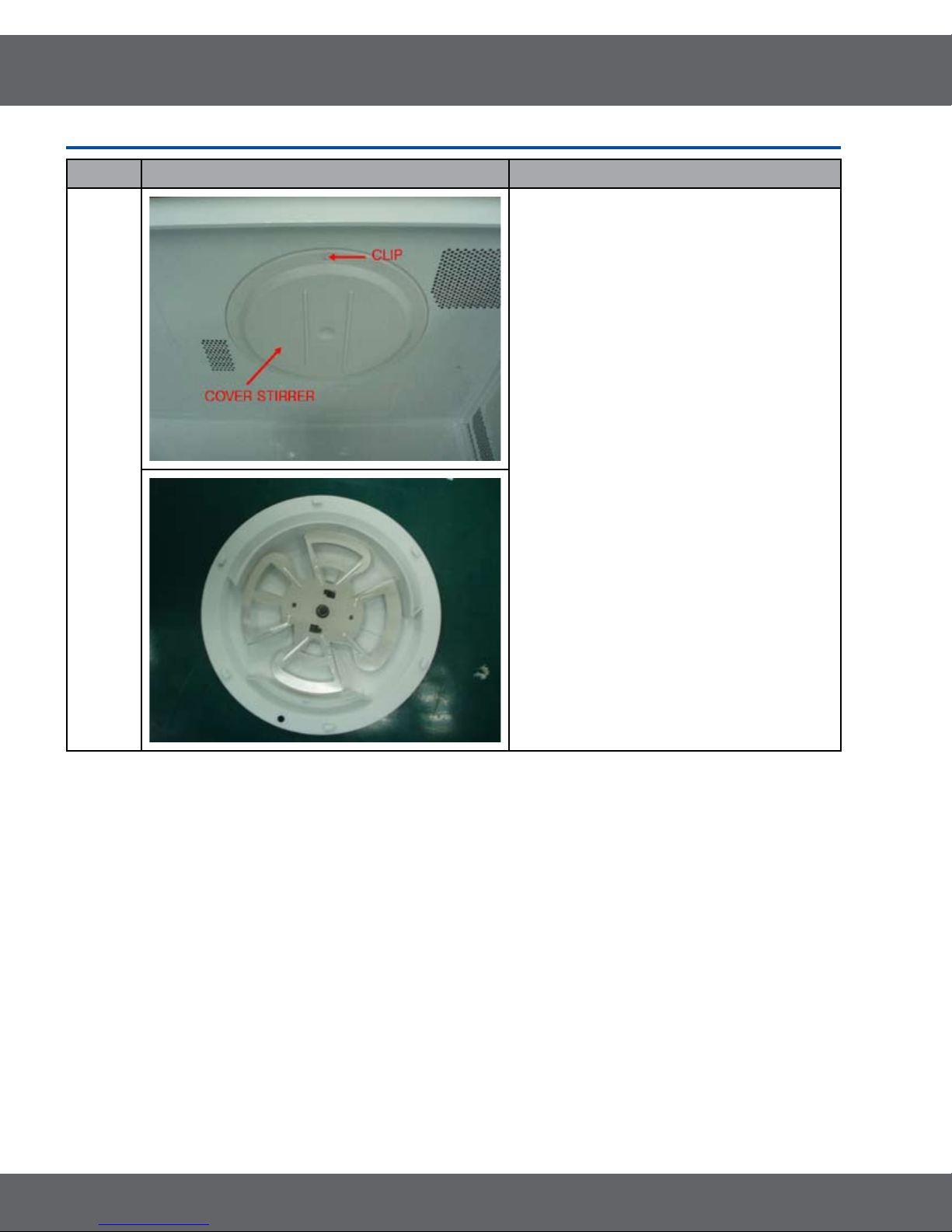

3. Disassembly and Reassembly

3-6 Removal of stirrer

Parts Explaination Photo Explaination

The stirrer is motor driver and located on the

upper side of the cavity. The oven uses a top

feed wave guide.

The stirrer is located in the wave guide and

the motor is located on the wave guide.

Stirrer

1. Disconnect power and open the door.

2. Remove the clip and turn the stirrer cover

left.

3. Remove stirrer cover and the stirrer will

come with it.

14

3. Disassembly and Reassembly

3-7 Replacement of Control Circuit Board

Parts Explaination Photo Explaination

Removal of

Control Box

Assembly

1. Disconnect power and remove grille.

2. Be sure to ground any static electric charge in

your body and never touch the control circuit.

3. Remove a screw securing the control box

assembly.

4. Disconnect the connectors from the control

circuit board.

Removal of

P.C.B Assembly

1. Pull the lever end of the plastic fastener and

remove the Flexible Printed Circuit(FPC) of

membrane panel.

2. Remove screws (4) securing the control circuit

board.

3. Lift up the control circuit board from the Ass’y

control box.

4. When reconnecting the FPC connector, make

sure that the holes on the connector are

properly engaged with the hooks on the Plastic

Fastener.

15

Loading...

Loading...