SAMSUNG SDR_430E.10029.1.15 Service Manual

DVD-ROM DRIVE

SD R-430

DVD-ROM Service

Manual

D V D - R O M D R I V E

C O N T E N T S

1. Precautions

2. Specifications

3. General information

3-1. External part name

3-2. Cricuit description

3-3. Troubleshooting

3-4. IC internal block and IC pin option

4. Disassembly and assembly

5. Alignment and adjustment

6. Exploded views and prats

7. Cricuit Part list

8. Block diagram

9. Electrical board

10. Schematic diagrams

ELEC TRONICS

¨Ï Samsung Electronics Co., Ltd.October.1998

Pr inted in Korea

1. Precaution s

1-1. General items

1) Be careful not to have eyes or a part of

body touch with laser diode at repair because

this product uses laser diode.

2) Do not disassemble Pick-up at repair.

If the laser diode is bad, replace the

entire Pick-up.

3) Keep away from TV or other electrical units

at repair to prevent a influence from

surrounding units.

4) If you want to replace the parts during

repair, be sure to plug off power cable

before replacement.

5) If you insert a disc into CD player, beg

sure to load it correctly.

1-2. Electricity sensing device

Some semiconductor units may be damaged easily by

electricity. These elements are called as electricity

sensing device(ESD) in general. For example,

integrated circuit, field effect transister,

semiconduct chip.

The following methods have to be used to reduce the

accident of element damage generated by electricity.

1) Emit all electric charges in your body through

contact with earthing materail at once before

handling a semiconductor factor or device

including it.

In other way, make use of commercial wristlet

against electRIC1ty. It shall be detached before

power impression to the unit on testing because

of shock.

2) After detaching an electrical device including

ESD, it shall be placed on conductive urface such

as aluminium to prevent the charge acummulation

and unit exposure.

3) Utilize only the soldering iron with earthed end

for ESD soldering or release.

4) Make use of only anti-static soldering release

unit. A soldering release unit not to be

classified as anti-static may generate the enough

charge to damage ESD unit.

5) Never use a Freon-propelling chemical product.

It may generate the enough charge to damage ESD.

6) Because this unit can't be used by itself, surely

mount it on PC(pentium or more) and check the

operations in use of private device drive floppy

diskettd. Refer to Instruction manual.

7) This unit has many parts with features related to

safety and especially, for essential parts, the

importance is indicated on circuit diagram and part

list. Be certain to use the parts with same

specifications at replacing these parts.

6) Untill installing ESD unit for replacement, never

it from protection package.(Most of ESD unit for

replacement have lead composed of package shorted

electrically by conductive foam, aluminium or

similar conductive material.

7) Contact with shassis including ESD or protection

material in circuit parts hust before detaching the

protection meterial from lead of ESD unit for

replacement.

NOTE: Be sure to avoid the power impression

to the shassis or circuit and observe the safey

instruction

8) Minimize the body action at handling an unpacked

ESD unit for replacement.

(Otherwise, an unconscious action, so to speak,

friction between clothes or foot lifting from

carpet floor may generate the enough charge to

damage ESD unit.)

Samsung Electronics

1-1

1-3. Safety instructions

1) Read all safety and operational manuals before

operating this product.

2) Keep the safety and operational manuals for future

reference.

3) Observe all precations and operational instuctions

in or on the suface of this product.

4) Follow all operation and maintenance cautions.

5) Be sure to plug off the power cable before cleaning. Use a dry cloh to clean a dusty cover of

cabinet instead of Instead of liquid or aersol

cleaner.

6) Never use a attachment not to be recommended

by this company. It may result in danger and

damage.

7) Never use this product around water such as

bathtub, washbasin, laundry machine, swimming

pool or lakeside.

8) Never place this product on bed, sofa or around

radiator and heater.

9) Power : Utilize the only power displayed on lebel

If the power type can't be checked, call to dealer of Korea Electricity, Co, Ltd. Refer to operate this product by battery or other power.

10)Lightning : Plug off the power cable for product

protection during thunder and lightning flashes or

this product is unused for a long time.

11) Overload: Be careful that the wall outlet and

expanded cord is overloaded due to danger of

fire and electric shock.

12) Never insert a substance or liquid into this

prouct. It may cause fire or shorck by contact

with voltage point or short.

13) Part replacement : The service engineer has to

use the parts of same specification at replacement. Otherwire, Otherwire, fire, shock or other

dangers may be occurred.

14) Safety check : Be sure to perform the safety

check at service or repair completion.

Im portance

:

This product includes special impotrant

parts on safety. These parts are indicated

by on schematic diagram.

At replacement of these parts, use the

parts of same specification due to shock,

fire or other dangers.

Never transform the original design

without permission of this company.

1-4. Earthing cautions at handling Pick-up

Because the laser diode in optical Pick-up is subject

to get out of order due to the potential difference

occurring by electricity load charged in clothes or

bodies, observe the following eathing items at

handling.

1) Body earthing at repair : Be sure to wear a wrist

strip with one side earthed.(Impedance : Below

4

10§Ù). It removes the electicity formed in body.

2) Wire table earthing : Put the earthed conductive

Plate(Impedance : Below 10§Ù)such as copper plate

on work table.

4

3) Cautions for clothes : Do not have any clothes is

destroyed easily.

4) FPCB operation be careful to handle FPCB because

it may be damaged easily.

1-2

Samsung Electronics

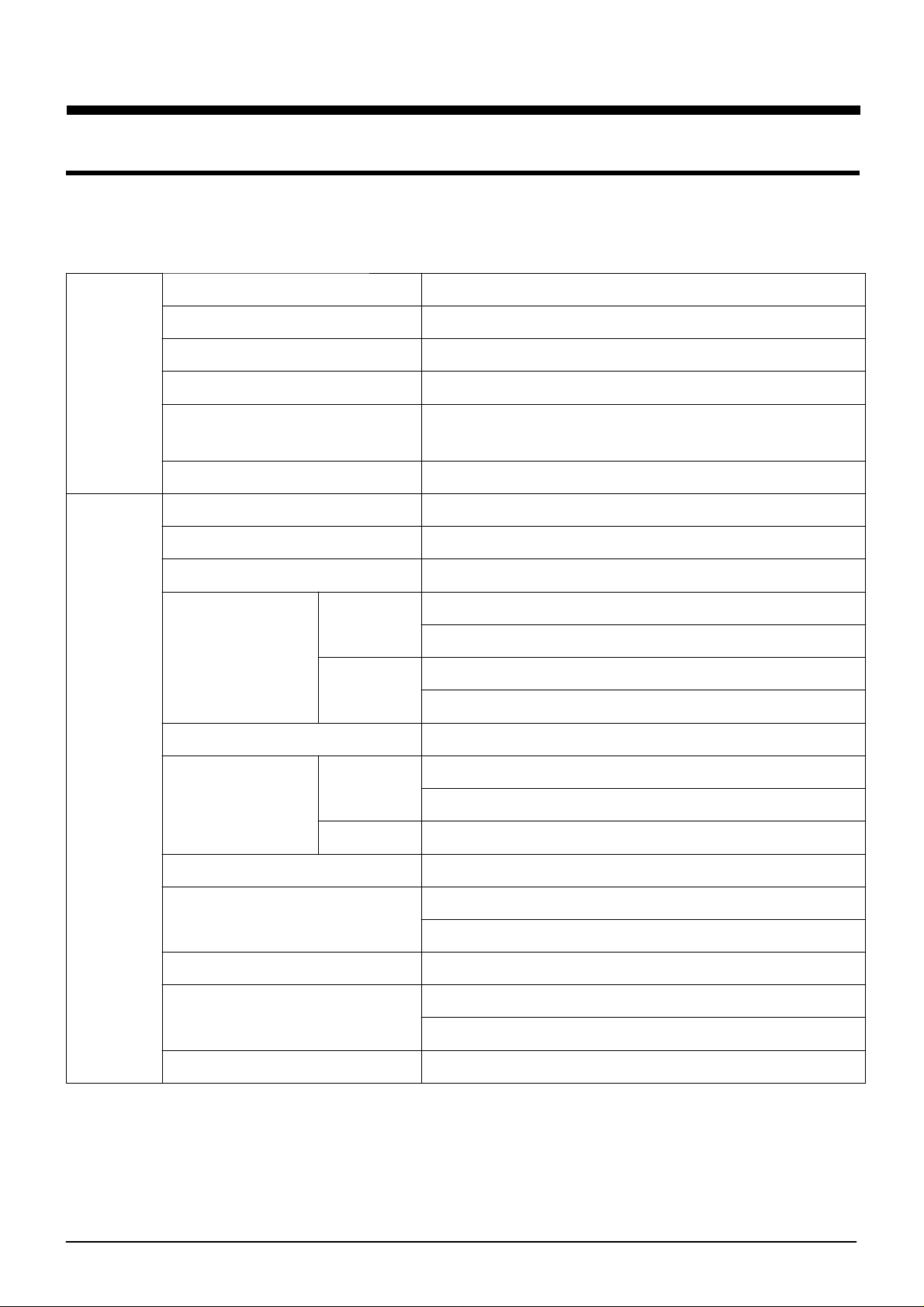

2. Specifications

The specification and design may be altered without previous notice and the below weight and dimensions

are approximate values.

Drive type Computer built-in

Power consumption Dc + 5V, 1A DC + 12V, 1.5A(MAX)

General

option

Electrical

feature

Weight 930g

Dimension 149mm(W)¡¿200mm(D)¡¿415mm(H)

Allowable operational

temperature

+5¡É ~ +45¡É

Allowable operational humidity: 8% ~ 80%

Standard mode CD-ROM Mode 1,2

Interface ATAPI BUS (IDE)

Data transfer rate CD-ROM:4,800Kbyte/sec,DVD-ROM:6,480Kbyte/sec

ACCESS

TIME

CD-ROM

1/3 stoke Below : 110ms

full stoke Below : 200ms

1/3 stoke Below : 130ms

CD-ROM

full stoke Below : 200ms

Buffer capacity 512KB

-12

-9

Error ratio

Mode 1 : Below 10

CD-ROM

Mode 1 : Below 10

DVD-ROM Below 10

-15

Frequency response 20Hz to 2KHz : Below ¡¾ 3dB

Sign al to noise ratio

Distortion factor Below 0.15% (1KHz)

Signal output level

Lase Semiconductor laser

Samsung Electronics

LINE OUT over : 75dB

H/PHONE over : 65dB

LINE OUT : 0.7Vrms ¡¾ 20%

H/PHONE : 0.6Vrms ¡¾ 20%

2-1

4. Disassembly and assembly

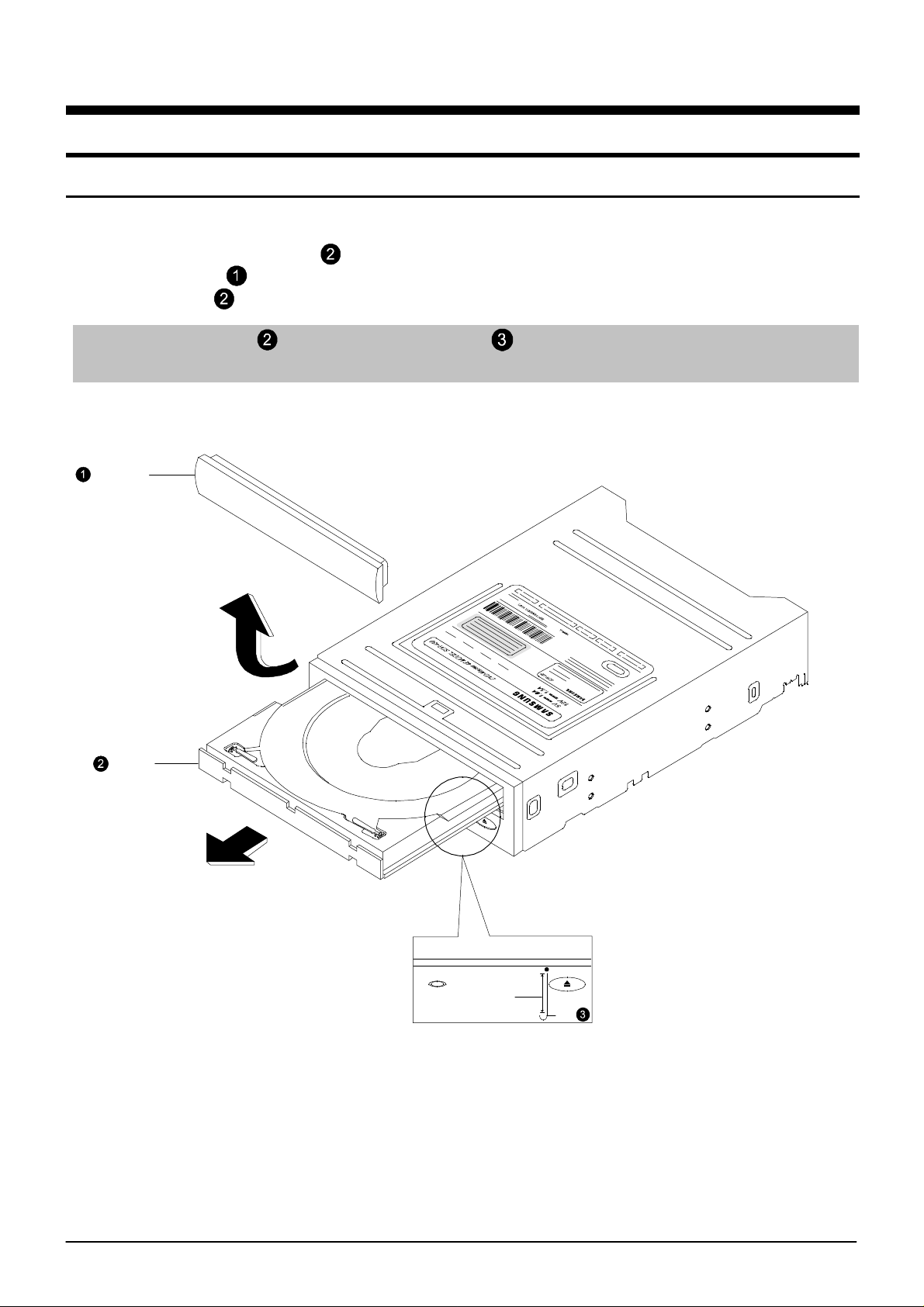

4-1. Exterior and PCB disass embly

4-1-1 Door-tray

1) Supply power to open the tray in direction of arrow "A"

2) Lift up the door in direction of arrow "B"

3) Close the tray and power off.

Reference: If the tray doesn't open, push the clip into specified hole shown in detailed figure

to open it compulsorily.

DOOR

¡°B¡±

TRAY

¡°A¡±

BYSY

70mm

CLIP

Figure 4-1 Door tray

4-1

Samsung Electronics

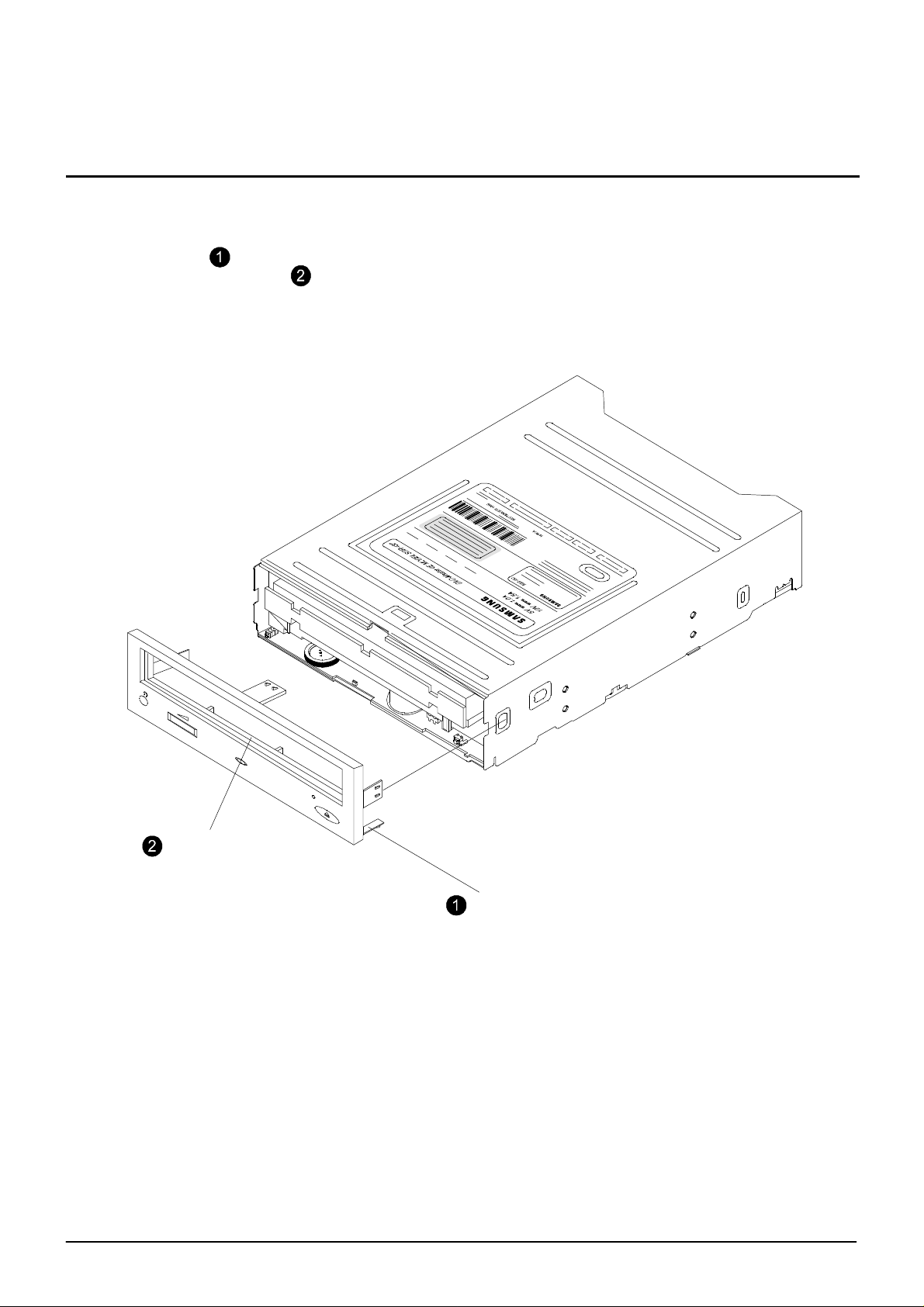

4-1-2 Panel front

1) Remove 5 hooks

2) Take out the panel-front forward.

Disassembly and assembly

Panel-front

Samsung Electronics

5 Hooks

Figure 4-2 Panel-front

4-2

Disassembly and assembly

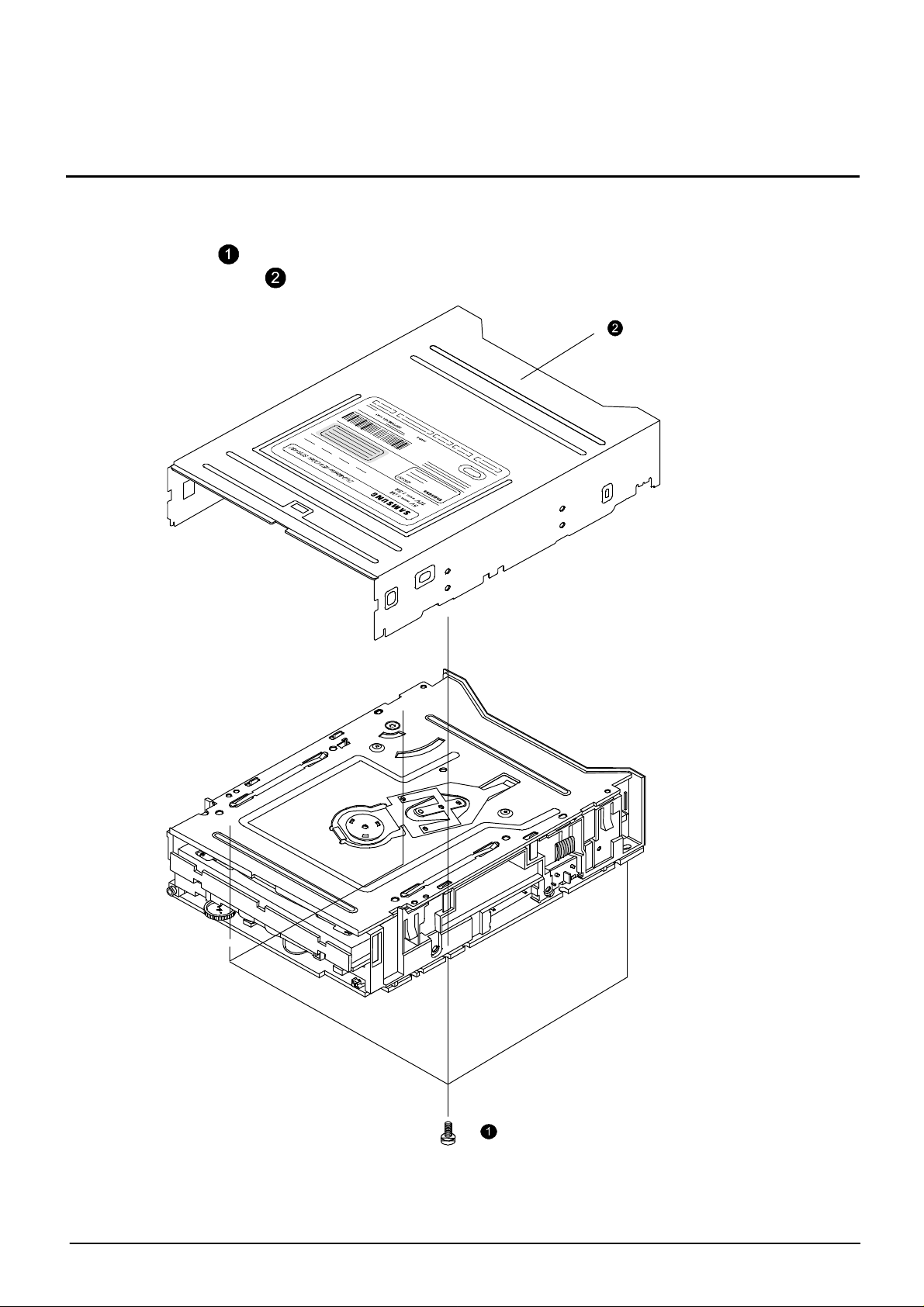

4-1-3 Top-cabinet

1) Remove 4 screws in the bottom

2) Lift up the top-cabinet

Top-cabinet

4-3

4 Screws

Figure 4-3 Top-cabinet

Samsung Electronics

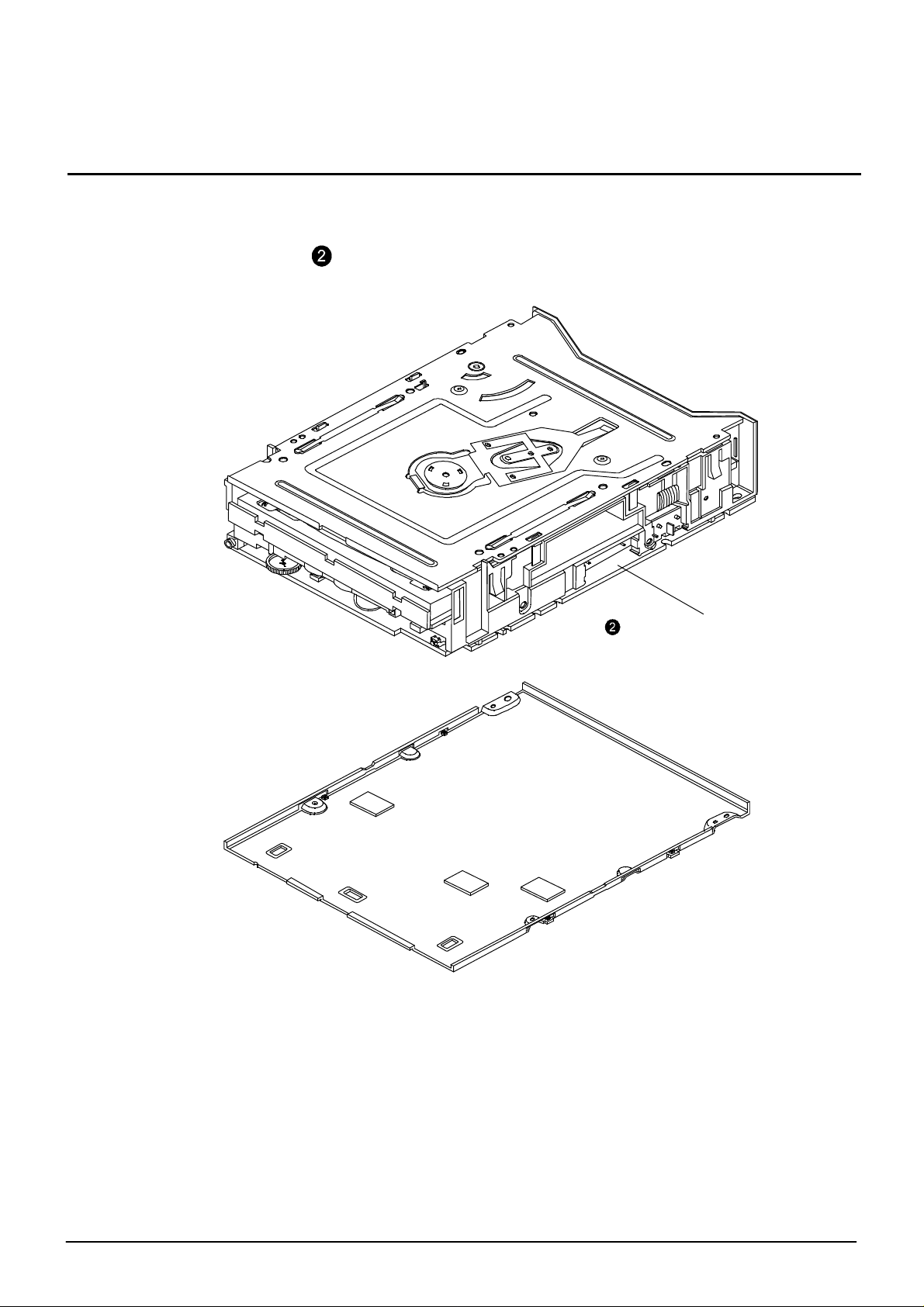

4-1-4 Ass'y-frame Low

1) Lift up the ass'y frame low

Disassembly and assembly

Ass'y frame Low

Samsung Electronics

Figure 4-4 Ass'y-frame Low

4-4

Disassembly and assembly

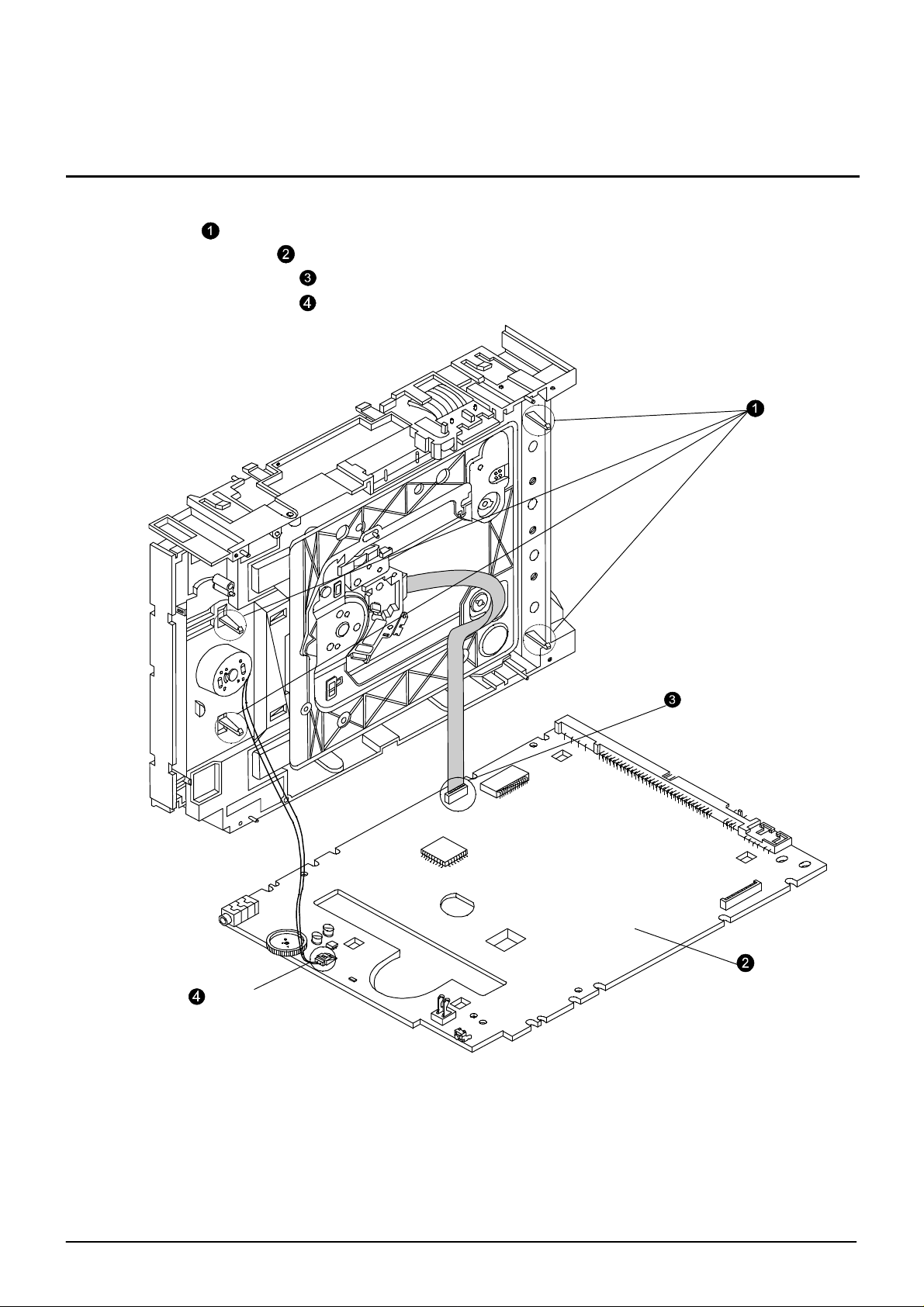

4-1-5 MAIN-PCB

1) Remove 4 hooks for PCB fixing in deck.

2) Disassemble the MAIN-PCB

3) Disassemble the pick up FPC in PCB.

4) Disassemble the motor wire in PCB.

4 hooks

MOTOR Wire

Pick up FPC

PCB-MAIN

4- 5

Figure 4-5 Disassembly connector

Samsung Electronics

4-3. Deck disassembly

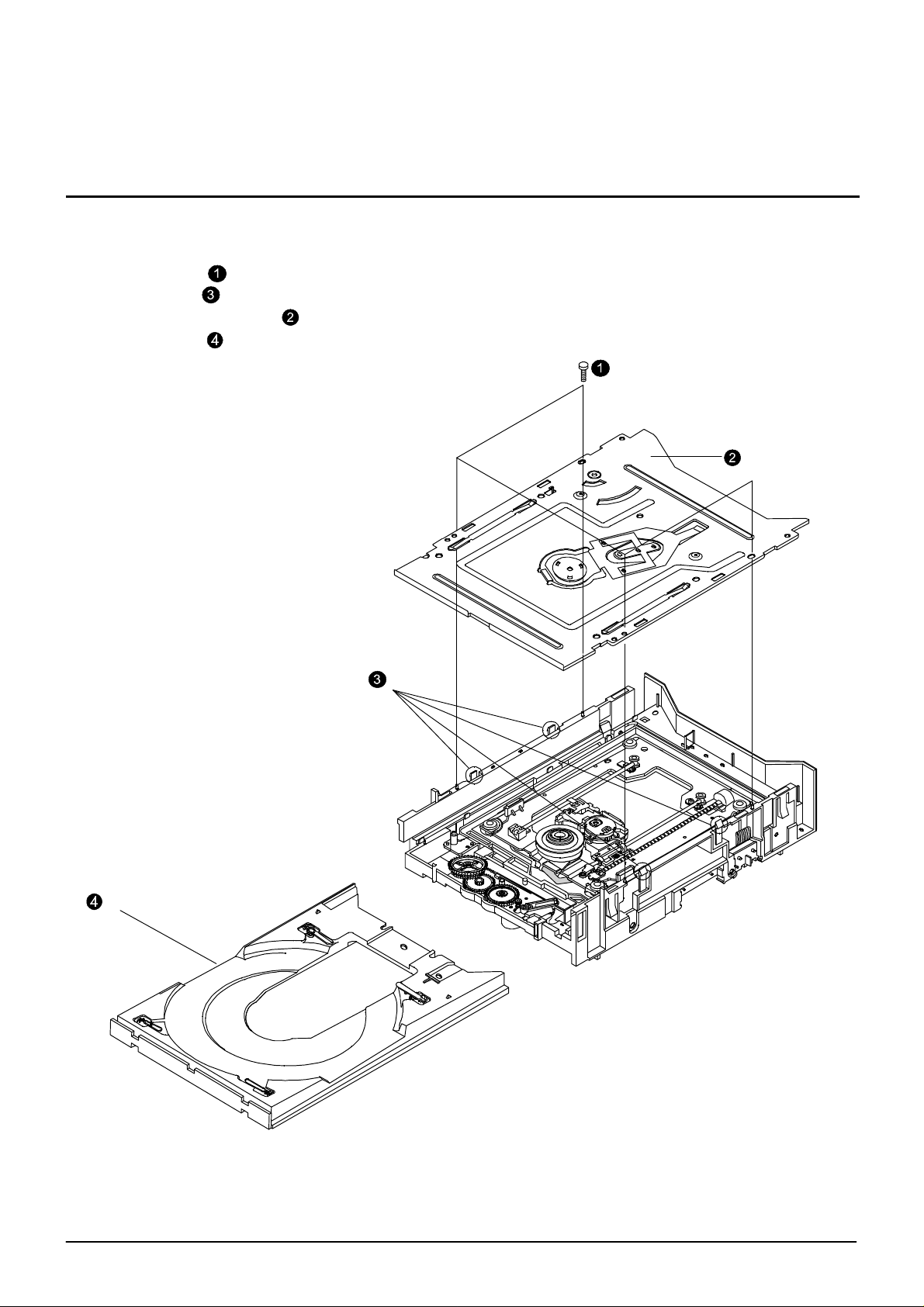

4-3-1 Tray, Clamper

1) Remove 4 screws

2) Remove 4 hooks

3) Lift up the ass'y clamper

4) Lit up the tray

4 screws

Ass'y clamper

Tray

4 hooks

Samsung Electronics

Figure 4-6 Tray

4- 6

Disassembly and assembly

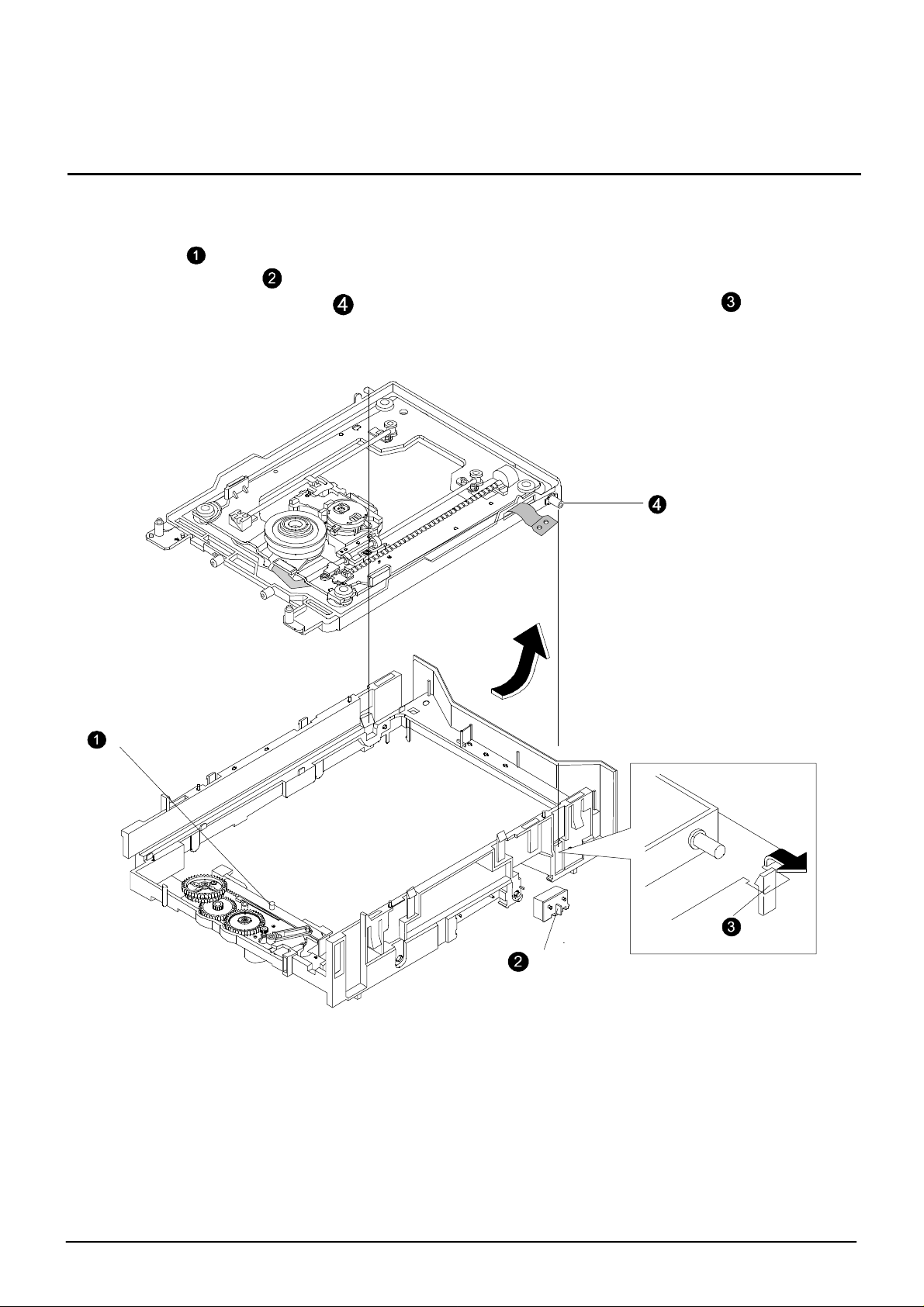

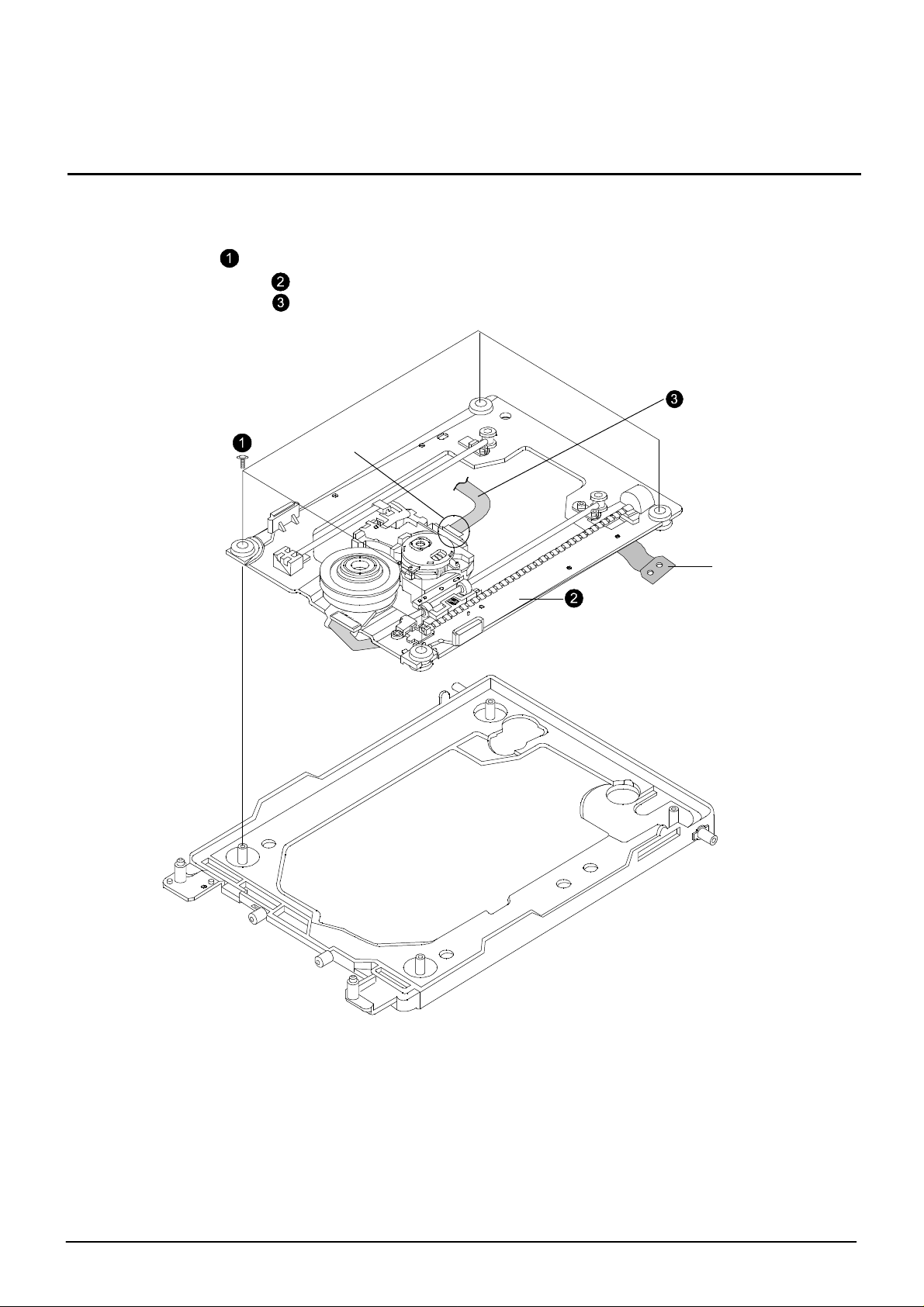

4-3-2 Ass'y-Deck DVD

1) Move the slide cam in left direction.

2) Remove the HOLDER FPC and disassemble the DECK FPC.

3) Disassemble the ass'y-deck DVD in arrow "B" direction with pushing the 2hooks in direction

of arrow "A"

Ass'y-Deck DVD

Slide cam

"B"

HOLDER FPC

¡°A¡±

hook

<Detailed figure>

4-7

Figure 4-7 Ass'y-Deck DVD

Samsung Electronics

Disassembly and assembly

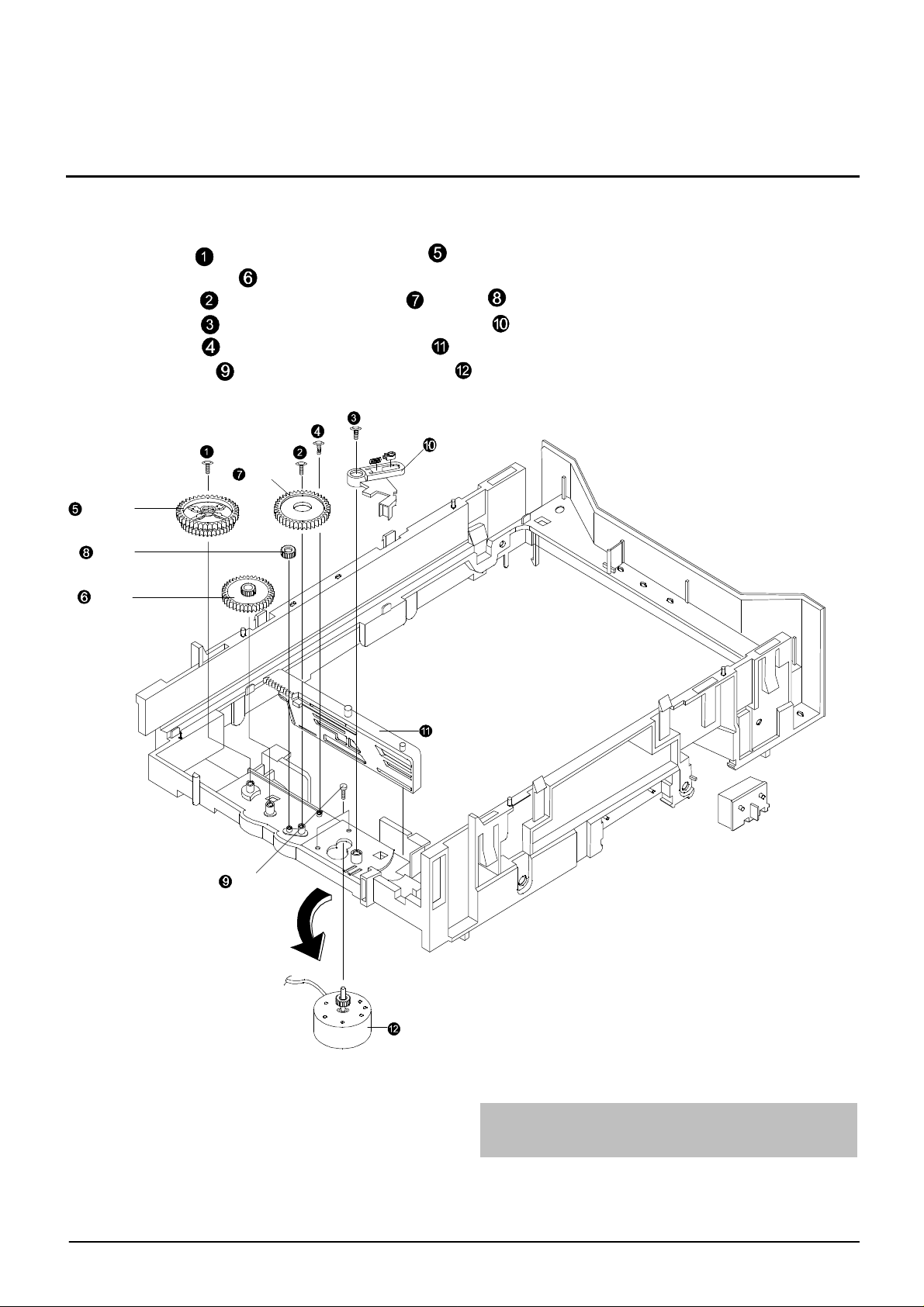

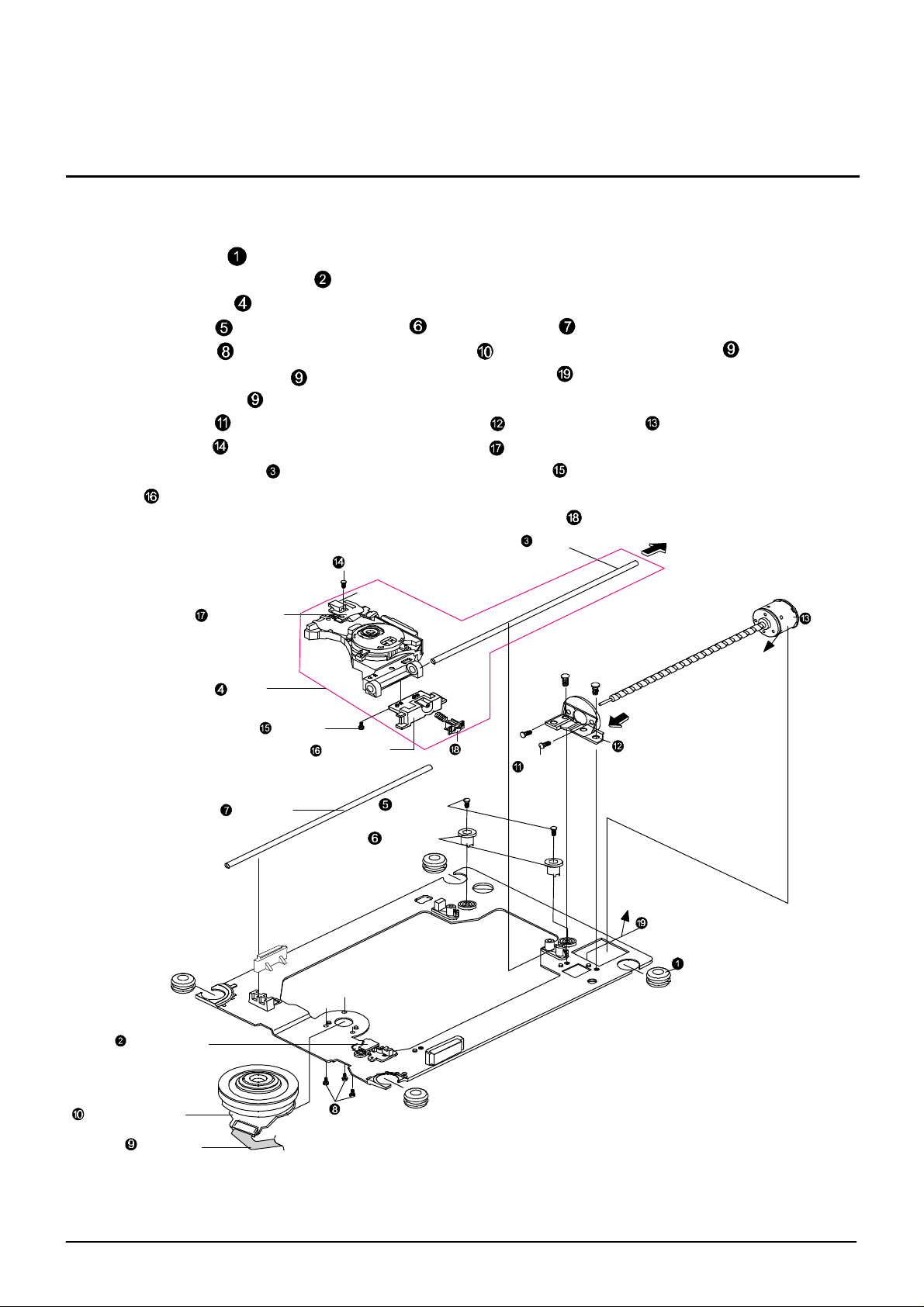

4-3-3 Chassis-main individual materials

1) Remove screw , and lift up the GEAR TRAY

2) Lift up the GEAR B

3) Remove screw , and lift up the GEAR A , GEAR D

4) Remove screw , and lift up the ASSS'Y OPEN LEVER

5) Remove screw , and lift up the SLIDE CAM

6) Remove 2 screws , and remove the MOTOR ASS'Y in "A" direction

ASS'Y OPEN LEVER

GEAR A

GEAR TRAY

GEAR D

GEAR B

2Screws

¡°A¡±

SLIDE CAM

MOTOR ASS'Y

¢Ä Assemblingthe motor and pulley: The height of

pulley shall be same as the endd of motor shaft.

Samsung Electronics

Figure 4-8 Chassis-main individual materials

4- 8

4-3-4 Ass'y-deck

1) Remove 4 screws

2) Lift up the ass'y-deck

3) Remove the pick-up FPC in "A"

Disassembly and assembly

Pick up FPC

¡°A¡±

DECK FPC

Ass'y-deck

4-9

Figure 4-9 Ass'y-deck

Samsung Electronics

Disassembly and assembly

4-3-5 Ass'y-deck individual materials

1) Remove 4 dampers

2) Rotate 180¡£ the SHAFT COVER in CCW direction.

3) Lift up the ass'y

4) Remove 2 screws , and remove the 2 CAMs , and lift up P/U

5) Remove 3 screws , and removev the MOTOR SPINDLE , and disassemble the DECK-FPC

6) Remove soldering "A",¡°B¡± in deck-FPC, and remove the S?W

7) Remove the DECK FPC

8) Remove 4 screws , and disassemble the HOLDER MOTOR in the STEP MOTOR in "C" direction

9) Remove 1 screw , and disassemble the spring plate

10) Remove the shaft P/U in "D"direction, and remove 1 screw ,and disassemble the ass'y slide

step

11) Remove 2 hooks in ASS'Y SLIDE STEP, and remove the slide step

SHAFT P/U

1 screw

¡°D¡±

SHAFT COVER

SPRING PLATE

ASS'Y

SHAFT P/U

1 screw

SLIDE STEP

³ª»ç 2°³

2 CAMs

SLIDE

STEP

¡°A¡±

¡°C¡±

HOLDER MOTOR

4screws

¡°B¡±

S/W

4 dampers

MOTOR SPINDLE

DECK FPC

3 screw

Figure 4-10 Ass'y-deck individual materials

4- 10Samsung electronics

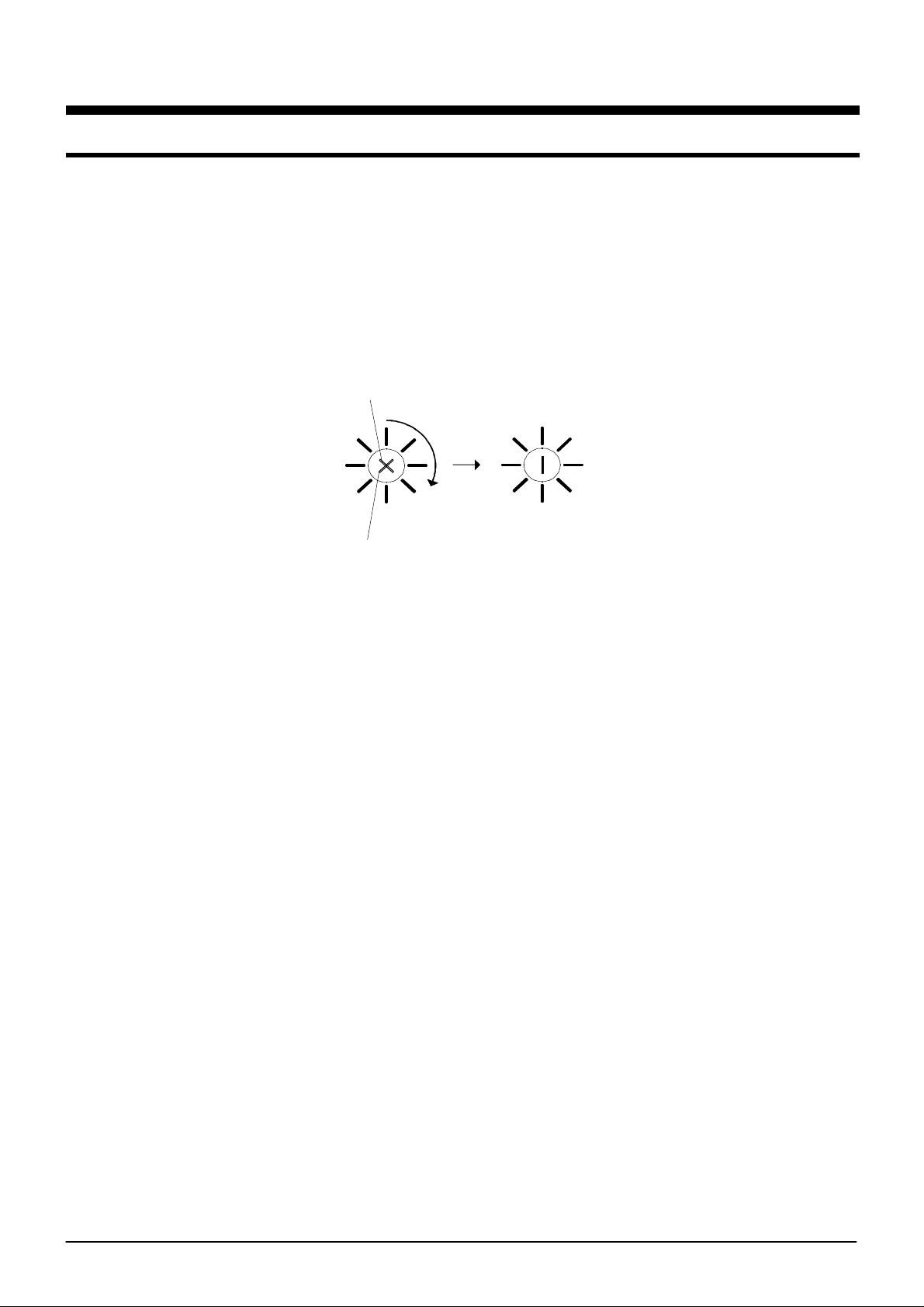

5. PLL ADJUSTMENT

5-1. PLL adjustment( FOR DVD)

1) Insert DVD disk, make it full stroke on CDT. Making use of SVR1, and then turn it CW with athe

controller. Next turn VR CCW at the point ¨Í of stoping stroke. Again check up the point ¨Î of stoping

stroke VR ¨Î located between point ¨Í and ¨Î. VR is lied halfway between two point.

ex)

¨Íposition

ccw

<After adjustment position>

¨Îposition

<M AIN-PCB:operational position diagram>

5-1

Samsung electronics

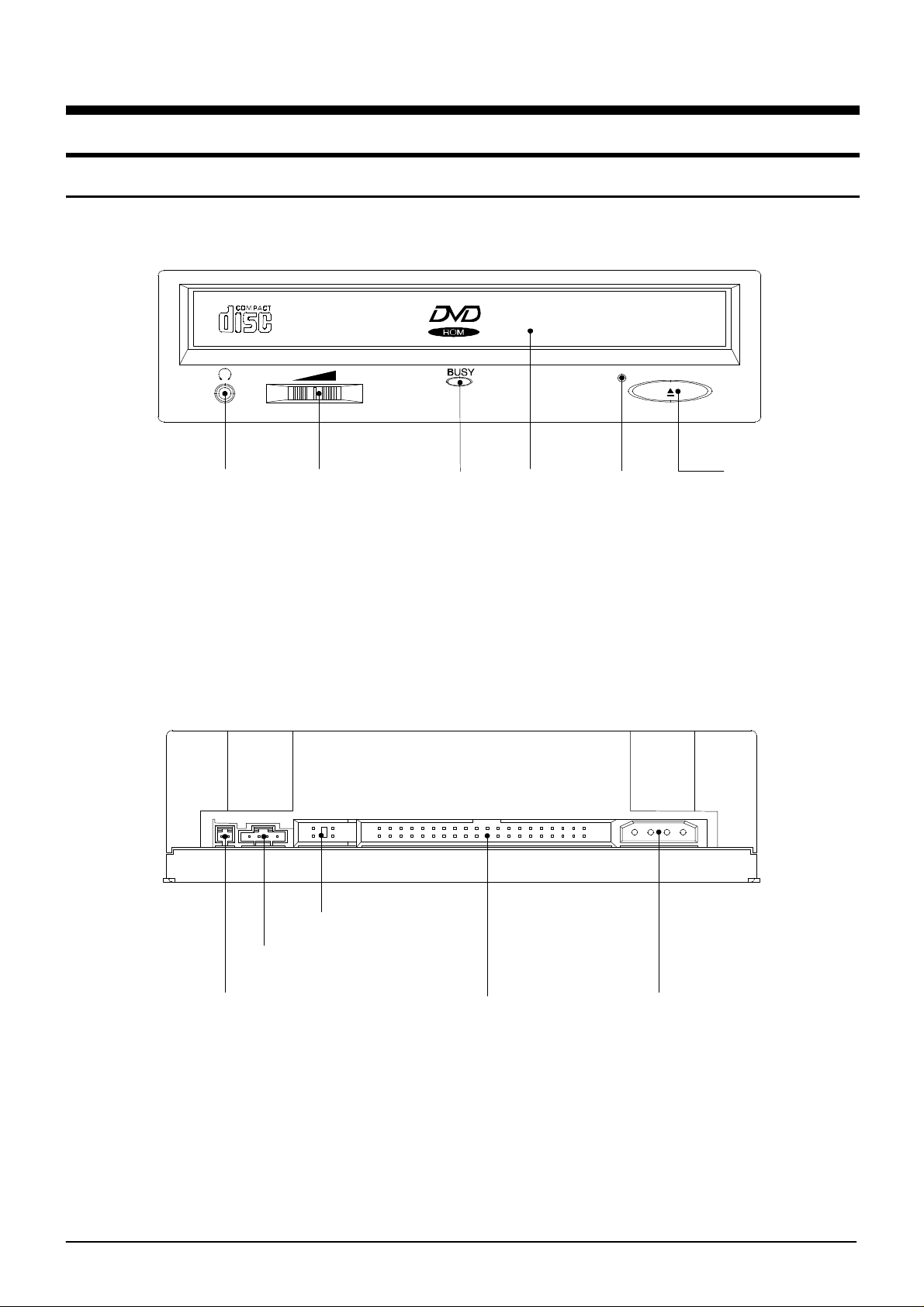

3. General information

3-1. Circuit descr iption

3-1-1. Front

3-1-2. Rear

Earphone

jack

Up/Down

Volume

LED Disc tray Emergency

Figure 3-1

Stop/ Open

button

HOLE

Digital output

terminal

(Optional)

Samsung Electronics

Sound output

terminal

Master/Slave

select pin

Interface terminal

Figure 3-2

Power terminal

3-1

3-2. Circuit descr iption

3-2-1. RF

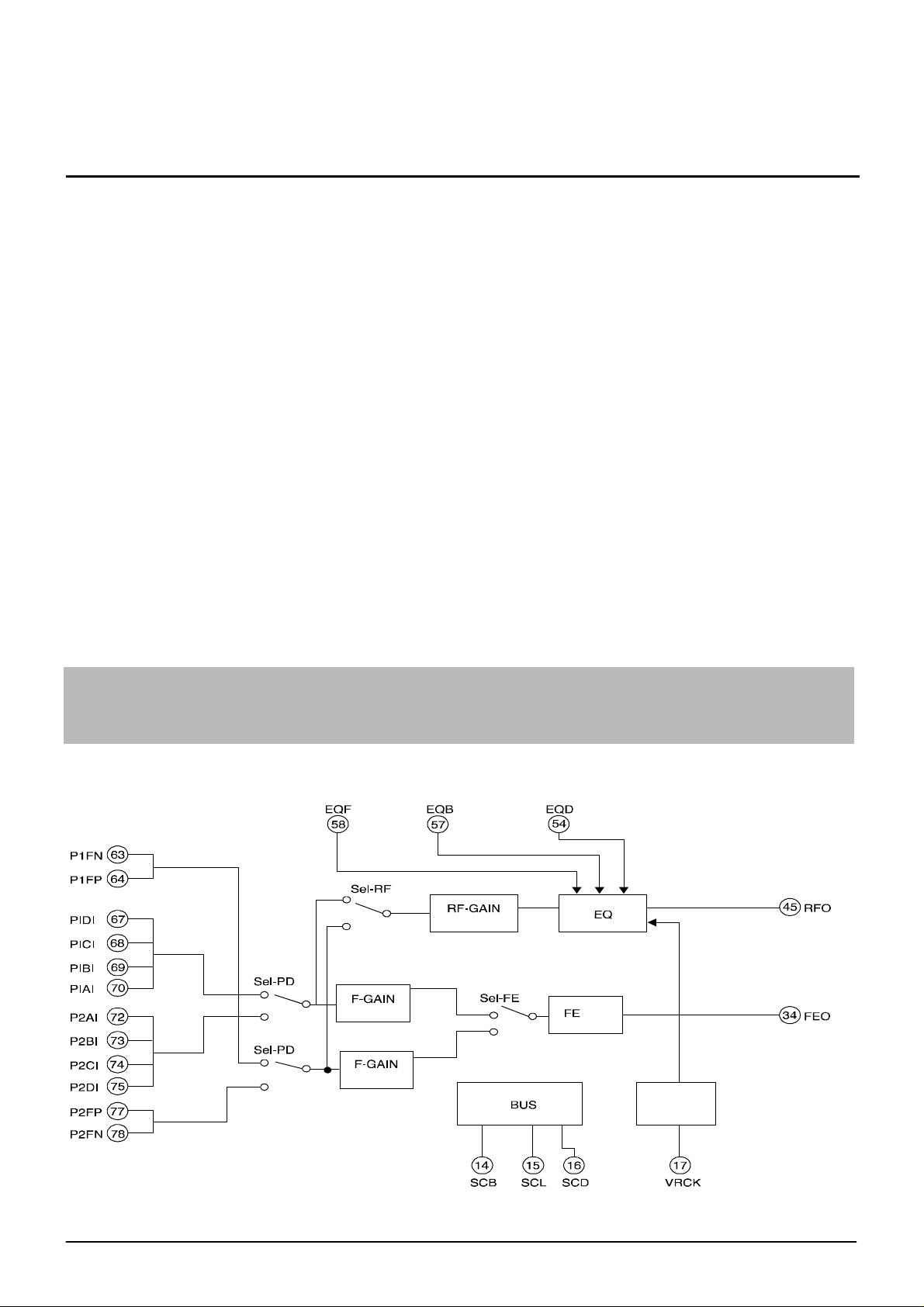

3-2-1(A) RIC1(TA1293F)

RIC1(TA1293F)is used in combination with TC 9453F as bipolar IC developed for CD/DVD RF signal

system. In main, it receives the pick-up output converted into I/V and performs DVD waveform equalization(EQ), CD equalization(EQ), astigmatic focus error signal generation, 1-beam tracking error

signal generation(by DPD method), 3-beam tracking error signal generation FE TE RF GAIN adjutment and laser power control, etc.

1) Reference potentiometer

RIC1 selects a single power method and from pick-up input singnal terminl works on the basis

VrA of 2.1.V.

2) CD/DVD-RF signal system : RICL(TA1293F)

Figure 3-3 shows the flow of RF signal generated in pick-up.

¡Ü EQ control parameter

1. EGF(58pin) : Change the peak frequency with EQ frequency features.

(Convert PWM signal, (C9453F(168-pin) into DC via low-pass fiter and supply it.)

2. EGF(57pin) : Change the boost of EQ frequency features.

3. VRCK(17pin) : Input the base clock and link the peak frequency witt it.

4. EQD(24pin) : Change the group delay characteristics with EQ frequency features.

CD/DVD play signal is equalized according to the above control parameter setting and output to

RFD(45pin) and this signal is transferred to TC9453F and detected as digital signal.

3-2

Figure 3-3

Samsung Electronics

Circuit description

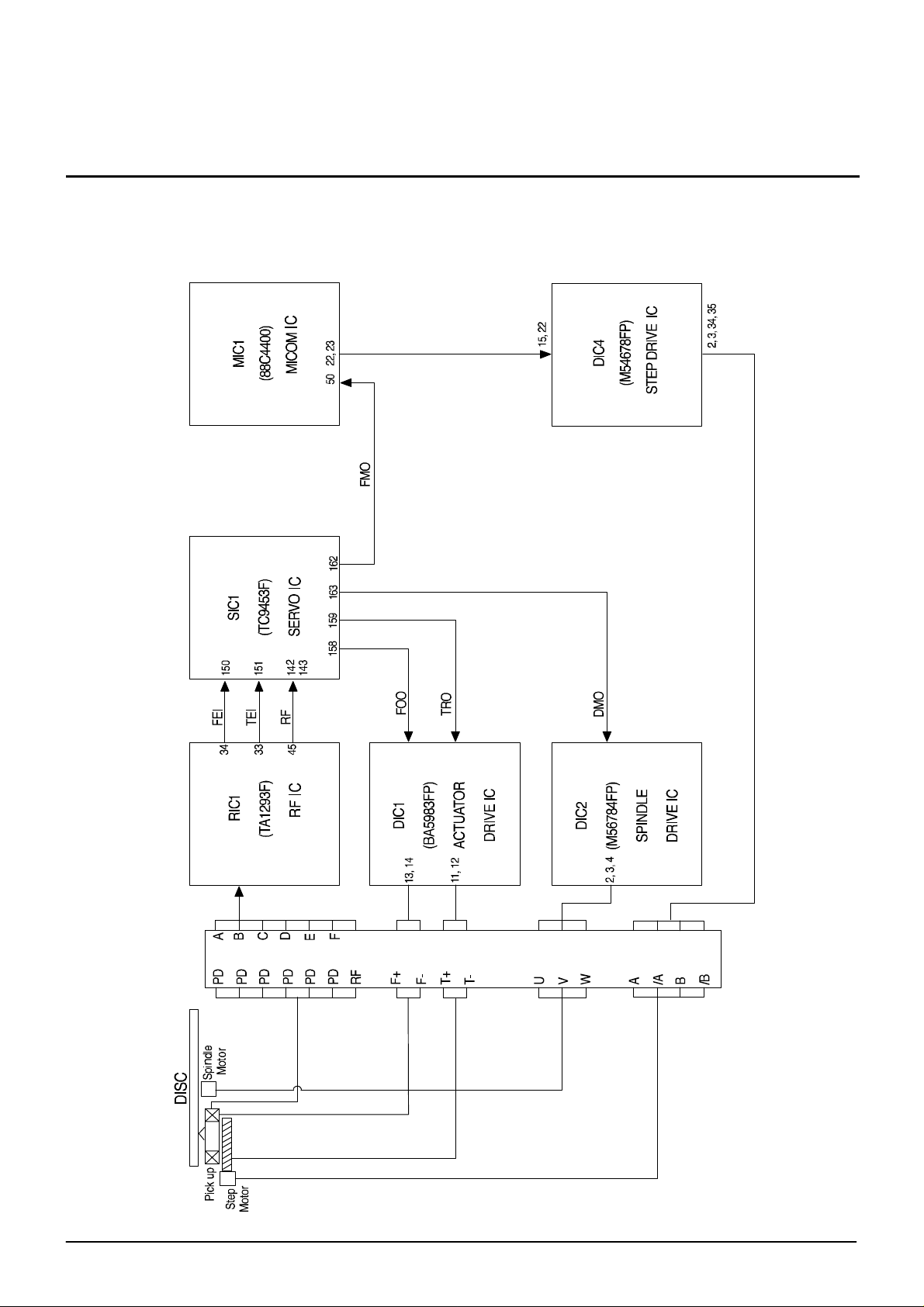

3-3-3. SERVO circuit descrip tion

3-2-2(A) Outline

SERVO system of DVD is divided into FOCUS SERVO, TRACKING SERVO, STEP MOTOR LINKED SERVO

and SPINDLE MOTOR CONTROL SERVO.

1) FOCUS SERVO

Focus the optical spot outputted from object lens on disc surface correctly by maintaining a regular distance beween object lens of Pick-up and disc for surface vibration of disc.

2) TRACKING SERVO

Make the object lens follow the disc track in use of tracking error signal created from Pick-up.

3) STEP MOTOR LINKED SERVO

When the tracking actuator inclines to outer as the object lens follow the track at play, move

STEP motor a little. and prevent it from leaning.

4) SPINDLE MOTOR CONTROL SERVO

Control the disc motor to maintain a constant angular velocity in use of FG signal outted in Drive

IC.

Samsung Electronics

3-3

Circuit description

3-2-2(B) SERVO SYSTEM BLOCK DIAGRAM

3-4

Figure 3-4

Samsung Electronics

Circuit description

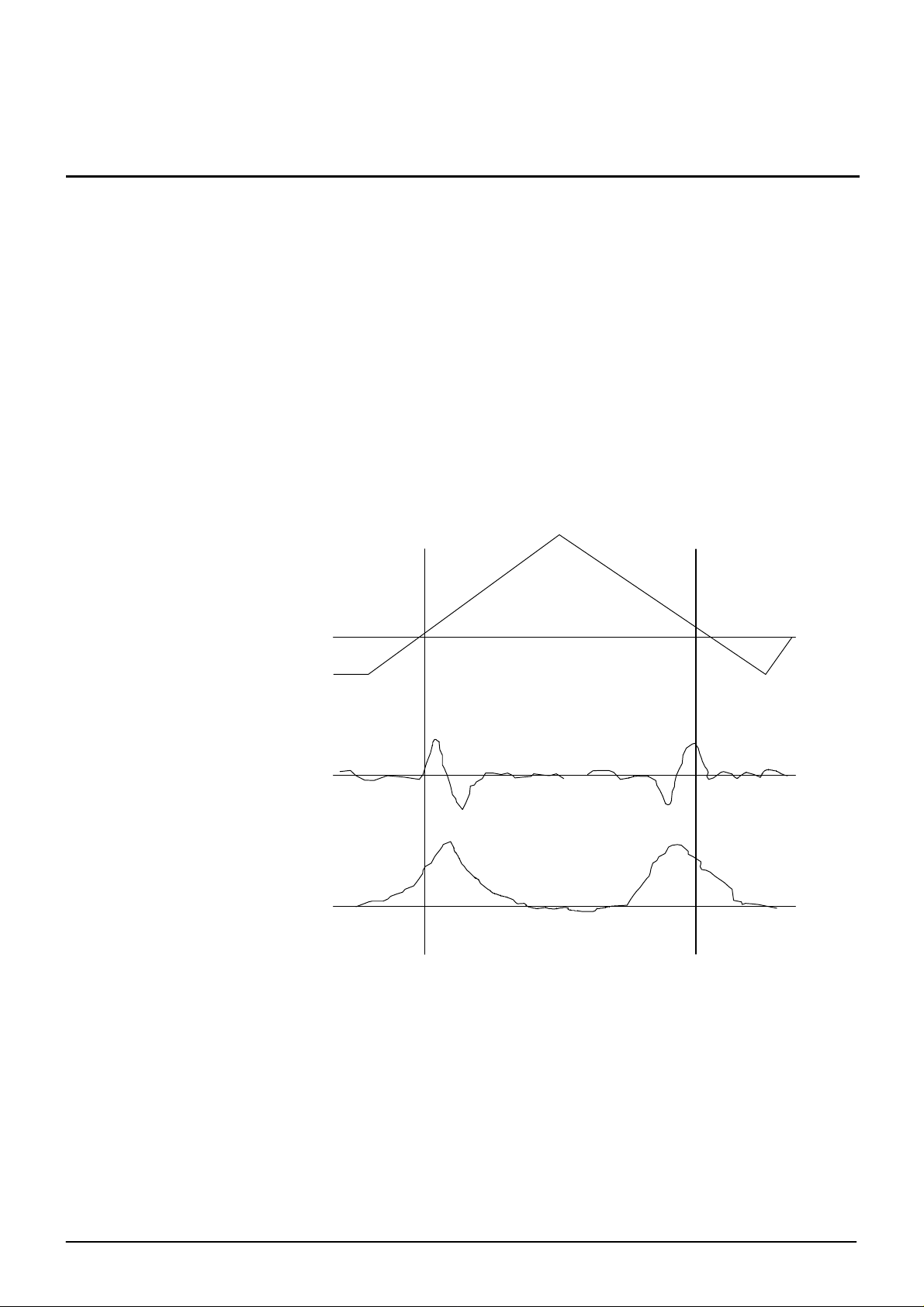

3-2-2(C) Operation descriptions

1) Focusing SERVO

(1)Focus input

The focus loop is changed from open loop to close loop. The triangular waveform moves the object lens up and down in 158pin terminal of SIC1 at Focus SERVO ON. At that time, S curve is

inputted to 150 pin terminal of SIC1. SBAD (152pin terminal of SIC1) signal, summing signal of

PD A, B, C, D, is gernerated at occurrence of S curve and zero cross(1.7V)point is found by S

curve and focused on when SBAD signal exceeds a regular value. The focus loop is changed into

close loop and the object lens follows the moving of disc, maintaining a regular distance with disc.

While, this operations are same in CD and DVD.

158pin terminal of SIC1(FOO)

150pin terminal of SIC1(FEI)

152pin terminal of SIC1(SBAD)

Figure 3-5

(2)Play

When focus loop gets to close loop at focus servo on, both 150pin and 158pin terminal of SIC1

are contolled by Vref voltage(approx.1.7V)and focus on cascade on the disc up and down.

Ve rf

Ve rf

1V

Samsung Electronics

3-5

Loading...

Loading...