SAMSUNG SDC33 Service Manual

DIGITAL STILL CAMERA

SDC-30

SDC-33

SERVICE

POWER

MODE

TIMER

DELETE

1. Precautions

2. Reference Information

3. Product Specifications

4. Disassembly and Reassembly

5. Alignment and Adjustment

6. Troubleshooting

7. Exploded View and Parts List

8. Electrical Parts List

9. Block Diagram

10. PCB Diagrams

11. Schematic Diagrams

Manual

DIGITAL STILL CAMERA CONTENTS

© Samsung Electronics Co., Ltd. JUN. 1997 AD68-20286A / AD68-20289A

1. Precautions

1. Be sure that all of the built-in protective devices are

replaced. Restore any missing protective shields.

2. When reinstalling the chassis and its assemblies, be

sure to restore all pretective devices, including :

control knobs and compartment covers.

3. Make sure that there are no cabinet openings

through which people--particularly children

--might insert fingers and contact dangerous

voltages. Such openings include the spacing

between the picture tube and the cabinet mask,

excessively wide cabinet ventilation slots, and

improperly fitted back covers.

If the measured resistance is less than 1.0 megohm

or greater than 5.2 megohms, an abnormality exists

that must be corrected before the unit is returned

to the customer.

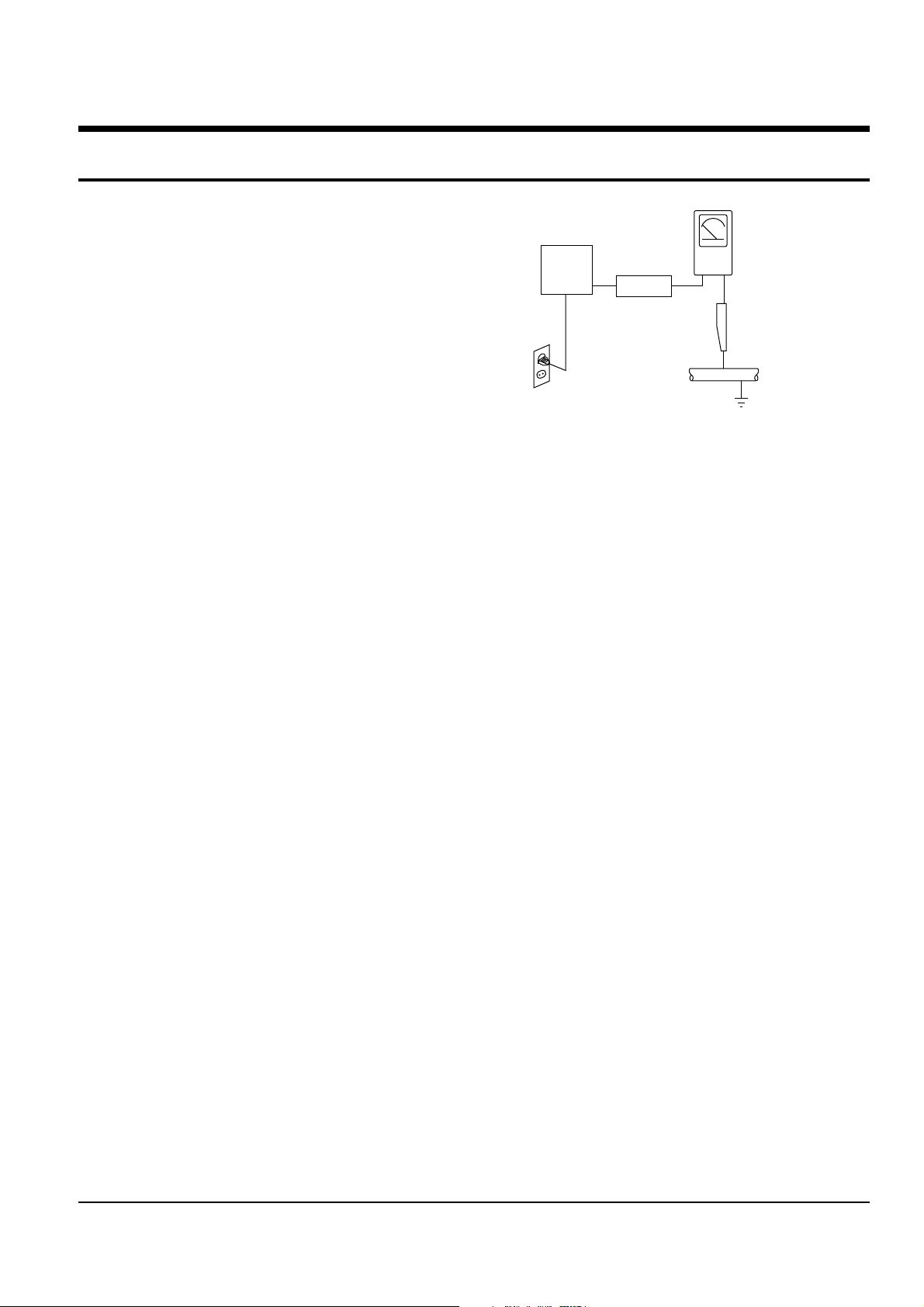

4. Leakage Current Hot Check (See Fig. 1) :

Warning : Do not use an isolation transformer

during this test. Use a leakage current tester or a

metering system that complies with American

National Standards Institute (ANSI C101.1,

Leakage Current for Appliances), and Underwriters

Laboratories (UL Publication UL1410, 59.7).

(Reading should

not be above

Device

Under

Test

Test all

exposed metal

surfaces

2-Wire Cord

Also test with

plug reversed

(using AC adapter

plug as required)

0.5mA)

Leakage

Currant

Tester

Earth

Ground

Fig. 1 AC Leakage Test

7. Antenna Cold Check :

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across the

two AC prongs. Connect one lead of the ohmmeter

to an AC prong.

Connect the other lead to the coaxial connector.

8. High Voltage Limit :

High voltage must be measured each time

servicing is done on the B+, horizontal deflection

or high voltage circuits.

5. With the unit completely reassembled, plug the AC

line cord directly the power outlet. With the unit’s

AC switch first in the ON position and then OFF,

measure the current between a known erath

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including : antennas, handle

brackets, metal cabinets, screwheads and control

shafts. The current measured should not exceed

0.5 milliamp. Reverse the power-plug prongs in the

AC outlet and repeat the test.

6. X-ray Limits :

The picture tube is designed to prohibit X-ray

emissions. To ensure continued X-ray protection,

replace the picture tube only with one that is the

same type as the original.

Heed the high voltage limits. These include the

X-ray protection Specifications Label, and the

Product Safety and X-ray Warning Note on the

service data schematic.

9. Some semiconductor (“solid state”) devices are

easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect transistors.

The following techniques will reduce the

occurrence of component damage caused by static

electricity.

10. Immediately before handling sny semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known

earth ground. Alternatively, wear a discharging

Wrist-strap device. (Be sure to remove it prior to

applying power--this is an electric shock

precaution.)

Samsung Electronics 1-1

Precautions

11. High voltage is maintained within specified limits

by close-tolerance, safety-related components and

adjustments. If the high voltage exceeds the

specified limits, check each of the special

components.

12. Design Alteration Warning :

Never alter or add to the mechanical or electrical

design of this unit. Example : Do not add

auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also, any

design changes or additions will void the

manufacturer’s warranty.

13. Hot Chassis Warning :

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only if

the AC power plug is inserted so that the chassis

is connected to the ground side of the AC source.

To confirm that the AC power plug is inserted

correctly, do the following : Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the reading

is greater than 1.0V, remove the AC power plug,

reverse its polarity and reinsert. Re-measure the

voltage between the chassis and ground.

14. Some TV chassis are designed to operate with 85

volts AC between chassis and ground, regardless

of the AC plug polarity. These units can be safely

serviced only if an isolation transformer inserted

between the receiver and the power source.

18. Picture Tube Implosion Warning :

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure that

the replacement picture tube is the same as the

original.

19. Do not remove, install or handle the picture tube

without first putting on shatterproof goggles

equipped with side shields. Never handle the

picture tube by its neck. Some “in-line” picture

tubes are equipped with a permanently attached

deflection yoke; do not try to remove such

“permanently attached” yokes from the picture

tube.

20. Product Safety Notice :

Some electrical and mechanical parts have special

safety-related characteristics which might not be

obvious from visual inspection. These safety

features and the protection they give might be

lost if the replacement component differs from the

original--even if the replacement is rated for

higher voltage, wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( or ).

Use replacement components that have the same

ratings, especially for flame resistance and

dielectric strength specifications. A replacement

part that does not have the same safety

characteristics as the original might create shock,

fire or other hazards.

15. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of its

assemblies) unless all solid-state heat sinks are

correctly installed.

16. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrument’s

ground lead last.

17. Observe the original lead dress, especially near

the following areas : Antenna wiring, sharp

edges, and especially the AC and high voltage

power supplies. Always inspect for pinched, outof-place, or frayed wiring. Do not change the

spacing between components and the printed

circuit board. Check the AC power cord for

damage. Make sure that leads and components

do not touch thermally hot parts.

1-2 Samsung Electronics

2. Reference Information

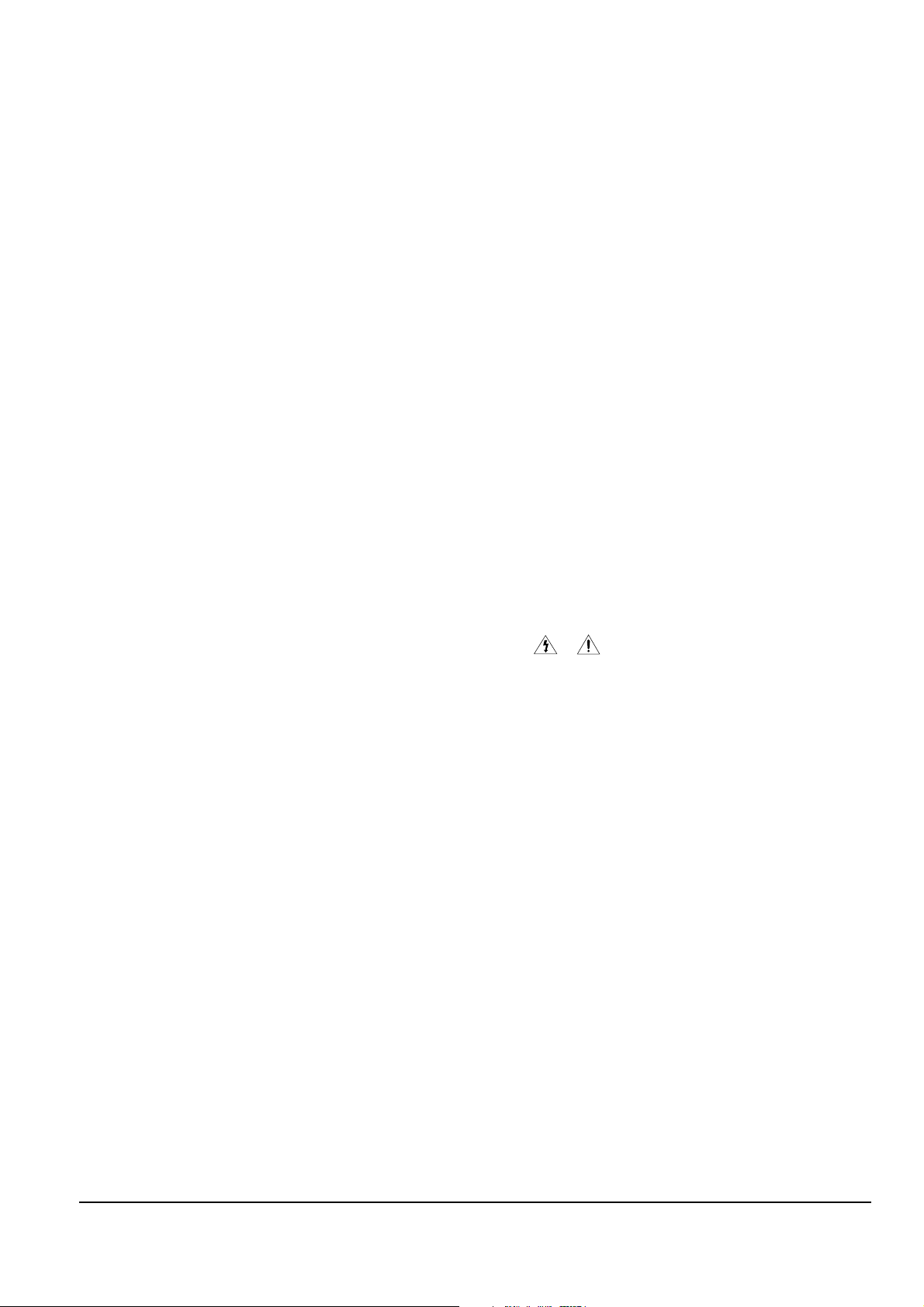

2-1 Circuit description

2-1-1 DSC

Digital camera(SDC-30/33), is an image-input device that connects to a PC. It’s small and light welght, supplies

high quality images and has a large capacity (4MB/2MB). The digital camera consists of 3 sections: Camera,

signal processing and storage.

1. Camera

The camera is similar to a camcorder but adapts a scanning method of 525/30 (which can read an entire image of

in one frame, whereas the camcorder’s scanning method is 525/60.

Photo-exposure is controlled by the electronic shutter through timing generator and CCD driver IC (where as a

camcorder controls the exposure using an IRIS).

Main function of this part is to control the photo-exposure in accordance with the brightness, and to store the

image in DRAM.

2. Digital Signal Processing

Image information of 1 frame is temporarily stored in DRAM. Image information stored in DRAM is the

digitalized CCD signal from the camera. It needs additional image signal processing by the 32-bit microprocessor.

The image signal processing done by the microprocessor includes white balance, shape adjustment and Y/C

signal conversion.

3. Storage

After image signal processing, an image signal compression technique allows more image to be stored in the

limited memory. In the case of SDC-30/33, 10:1 compression is normally executed for standard JPEG specification.

After compression, the image information is stored in the nonvolatile flash memory : Max. 45/22 frame for

VGA(640*480), and max 180/90 frame for QVGA(320*240).

The image can be stored, edited, and printed by the PC image editing program that is supplied with the camera.

2-1-2 Power

LCD MICOM generates the control signal that turns on the system (5V). When the power is on, the signal turns

on IC140 PWM IC which outputs 5V through T141.

When shot key is pressed, the signal for output is generated from MICOM, which turns on IC120 PWM IC and

outputs 5V, -7V, and 15V through T121. After the shot, the camera control signal turns off the power supply within. 5sec (through T121).

2-1-3 DC/DC block operation description

2-1-3(A) DC/DC BLOCK CONSISTS OF THREE COMPONENTS AS BELOW.

1. EVER5V

EVER5V consists of S8420 (IC100) IC and the assocciat battery circuitry (CN101 Pin2) is input to

IC100 (S8420). Pin 8 and 5V voltage are generated internally and are output to pins 1 and 7. EVER5V power

(Pin 1) is input to the function board for LCD MICOM (IC601) drive, POWER S/W (LED01) driving power, and

PULL-UPvoltage. RESET output of IC100 Pin 5, which changes from low to high at the power input, is connected

to LCD MICOM RESET PIN (and resets LCD MICOM).

Samsung Electronics 2-1

Reference Information

2. Camera power

Camera power block consists of IC120 (PWM IC MB3800), Q121 (INVERTER TR DTC144EU), Q122 (SWITCHING TR KSD1621), and rectifier circuit.

When CAM5V control pin of LCD MICOM 10PIN is high, it is converted at Q121 and IC 120. Pin 4 becomes low;

then IC120 Pin 7 starts oscillating and the PWM output from IC120 Pin 5 switches Q122. Pin 6 generates the 15V

output by a switching pulse and this output is rectified by D121, L123, C127, and C128 to generate 15V power for

the drive of CCD (IC201) and V DRIVE IC (MN3112SA).

The pulse for -7V (which is generated at T121 pin 10), is rectified by D121, C129, L124, C130 and becomes -7V

power for the drive of CCD and V DRIVE IC.

The pulse for 5V power, which is output from T121 pin 7, becomes CAMERA 5V power by D122, C133, L127, and

C134. The 5V power is divided by D5V for the drive of IC204(MN5246) and IC202(MN3112SA) and A5V for the

drive of IC203, IC205, and IC206 through L125.

3. SYS 5V

Using the same technique as with camera 5V (L141, IC140, Q142, and T141), the SYS 5V power drives IC301,

IC302, IC303, IC304 and IC307, and is generated by SYS 5V CONT from the LCD micom.

EVER5V power is always output when battery and adapter are connected; SYS 5V power is output only when

power is turned on. CAM power is output for 0.5 second (only during shot operation).

2-1-4 Camera

1/3" 35

CCD

LENS

V-Drive

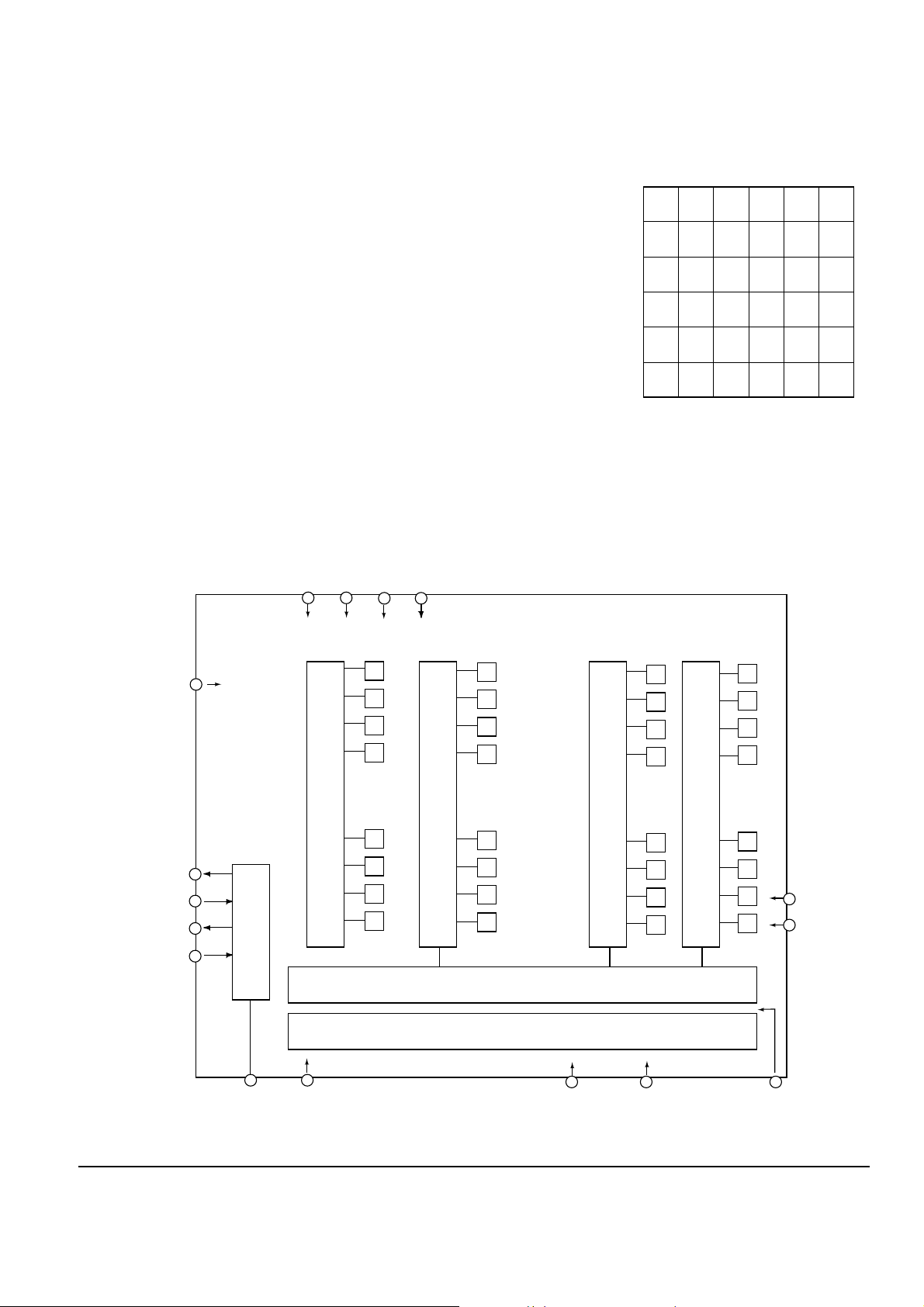

1. Camera operation

V1~V4

VSUB

CDS out

Vout Vout

R

H1

H2

Timing

AGC IN

CDS

AGC

SMD

SHP

Gen

A/D

(8bit)

D Data, DCLK

HD, VD

Fig. 2-1

D7~D0

Data 8

8-16 CONV.

DRAM CTRL

Camera

Ctrl

D15~D0

Data 16

16

DRAM

4Mb

Address

A9~A1

S/W

DSCP

RISC Chip

The image from the lens is converted to an electrical signal by the photoelectric conversion component, CCD

(MN3776PE). Each pulse used to extract CCD signal is generated by the timing geneartor IC(MN5246),

converted to actual driving voltage by V Drive IC(MN3112SA), and supplied to CCD. After noise elimination

(CDS) and amplification (AGC) at analog process IC(NN2038FAQ), CCD output signal is converted to a digital

signal by A/D converter. The 8-bit digital data is changed to 16-bit by DRAM control IC(SMA9606), and stored in

the DRAM.

2-2 Samsung Electronics

Reference Information

2. Lens

SDC-30/33 lens uses a fixed focus method, and can take a photograph clearly at over 1 meter distance (optimal

quality is between 1.5 and 3 meters).

3. Color Filter

Color filter, which remove, the color information on CCD, adapts RGB method

for best color characteristics and Bayer method for best.

RGRG – –

GBGB – –

RGRG – –

4. CCD(MN3776PE) and V Driver(MN3112SA)

GBGB – –

CCD converts the optical image to an electrical signal and is similar to an

existing camcorder (except for the scanning method). The camcorder method

––––––

uses interlace scanning, which outputs a field image every 1/60 second. (First

field consists of odd lines, the second field consists of even line, and a complete

––––––

picture consists of two fields. However, SDC-30/33 uses a the progressive

scanning method, which outputs a frame every 1/30 second (and has excellent vertical resolution).

The image is output at Pin 1 of CCD, and is input to Pin39 of analog signal process IC (IC203) through TR (Q201).

V Driver IC (MN3112SA) mixes each CCD driving pulse from Timing Generator IC, and converts it to

the required voltage.

Effective Pixel

325,546=659(H)X494(V)

ØV1~ØV4: Vertical Shift Clock

ØH1~ØH2:

Horizontal Shift Clock

V01: Video output

Ø

V

1

15 13

<BLOCK>

Ø

Ø

Ø

Ø

V

V

V

V

3

2

4

14 12

P W

V O 1

(Bias) L G

V O 2

O D

16

1

2

5

4

3

V

e

r

t

i

c

a

l

S

h

i

f

t

R

e

g

i

s

t

e

r

9

S U B

11

P T

Horizontal Shift Register 1

Horizontal Shift Register 2

6

O GØ R

7810

S GØ H 2Ø H 1

Fig. 2-2

Samsung Electronics 2-3

Reference Information

5. Timing Generator (MN5246)

A timing generator generates each clock, synchronized signal, and CCD driving pulse for the system. Also, it

receives the shutter speed information for the photo-exposure control (from the microprocessor).

Signal

process

CLK

VDO,HDO

CSYNC

Image signal

H1

H2

bias

CCD

ØV2

ØV1

V1RV2V3V4

ØV3

ØV4

SUB

ØSUB

CH1

CDS

ØSG

DS1,DS2

SG

MN 5246

VDLIDE

2fck=24.5Mhz

Fig. 2-3

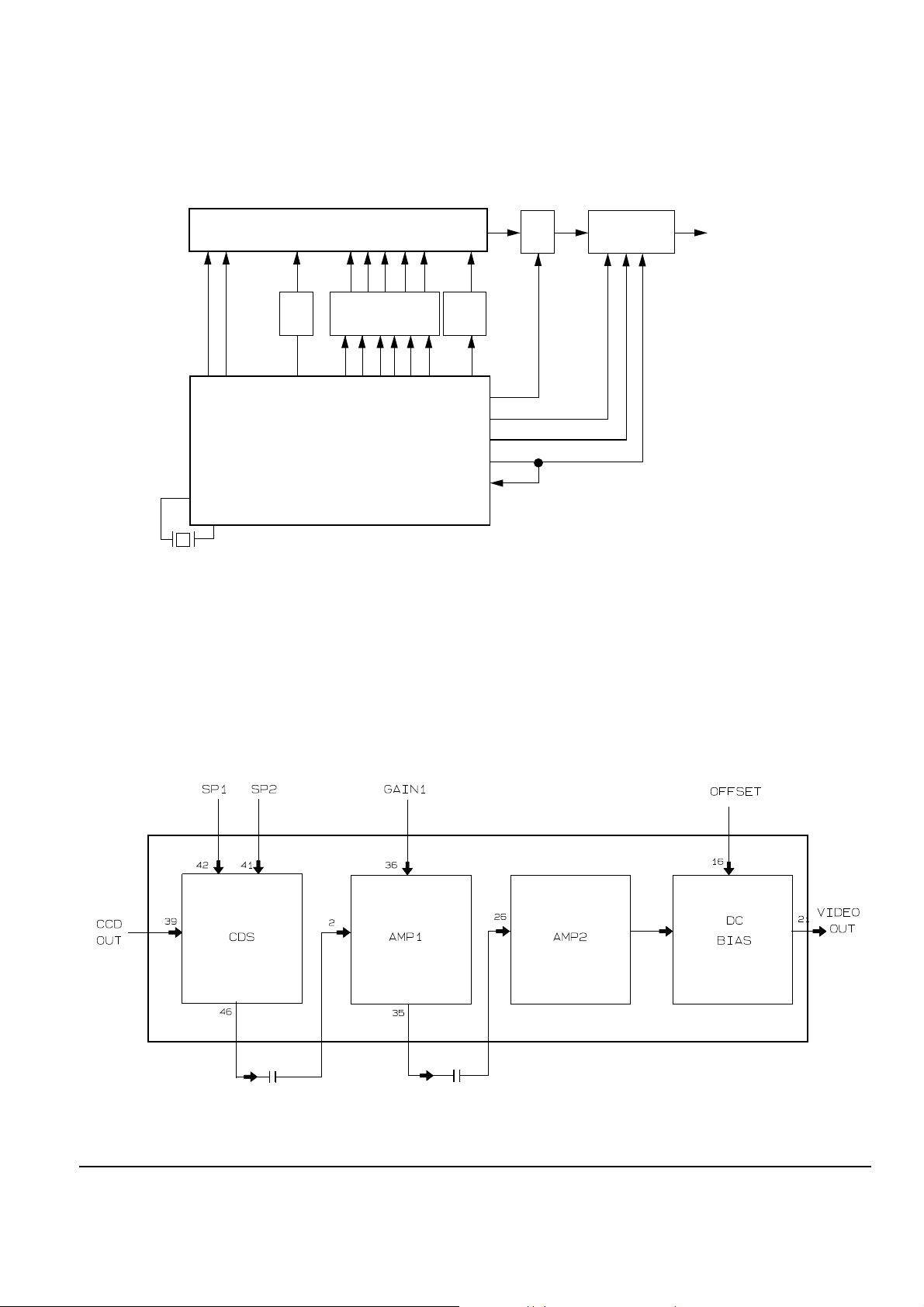

6. Analog processing IC (MN2038FAQ)

After eliminating the noise (CDS) from the CCD output signal (which is input to Pin39, to DS1/DS2 signal

of TG), Analog processing IC outputs it to Pin 46, and then it is input to pin 2 through C232 (for Row Clip and

primary amplificationAGC). Then it is output to Pin 35 and Pin 37 of EVR (IC206), which is input to pin 36,

which controls AGC. Pin 35 output signal is input to Pin 26 through C218, and is amplified second time at the

main amplifier. The offset adjust (pin 16 input) is activated by EVR output signal (Pin 4) and the output (Pin 21)

is sent to A/D converter.

Fig. 2-4

2-4 Samsung Electronics

Reference Information

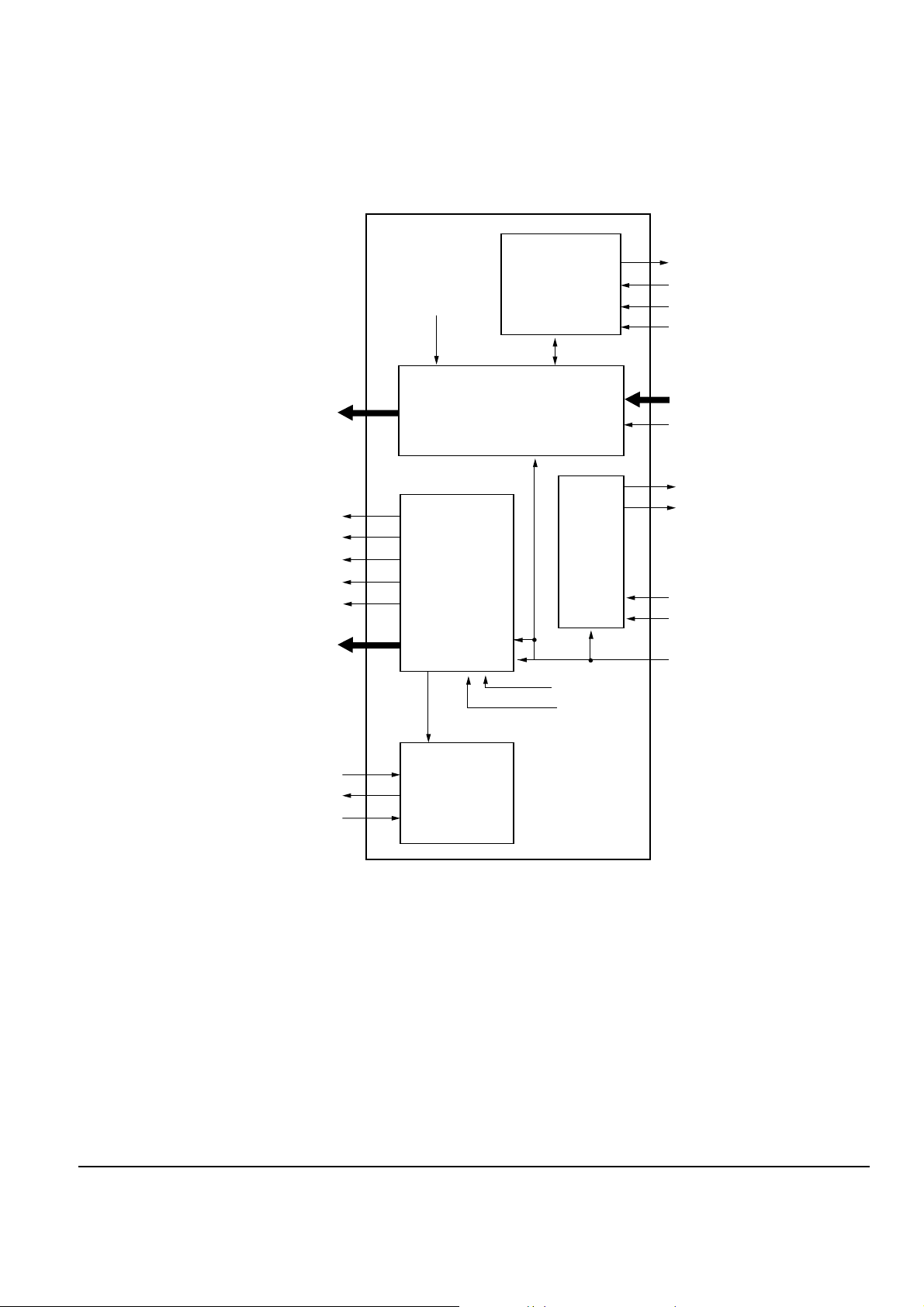

7. A/D converter (KAD0228) and DRAM Controller (SMA9606)

A/D converter converts the analog signal which is output from Analog processing IC to the 8-bit digital signal

(24.54Mhz). DRAM Controller is synchronized with Vsync, converts the 8-bit data which is output from A/D

converter to 16-bit data, and stores it in DRAM (controlled by the 32-bit microprocessor).

TRI

STATE

OUTPUT

(High Z

when

Power Off)

D_OUT(15:0)

–

RAS

CASU

CASL

WR

OE

A–OUT(9:1)

SO

SCK

SI

MODE

Data Register

&

SIO

SCS

AE Data Detect.

2 & Knee,

8bit to 16bit Convert

AD_IN(9:0)

–

ADCK IN(12.27MHz)

WND1 OUT

–

WND2 OUT

–

–

–

–

DRAM

Address

Generator

VD/HD

GEN

EXT VD IN

EXT HD IN

CLK IN(24.54MHz)

EOC

–

H ADJ

V ADJ

R/B

–

BREQ

–

BACK

–

Samsung Electronics 2-5

ADDR/DATA

BUS

CONTROL

Fig. 2-5

OE

–

Reference Information

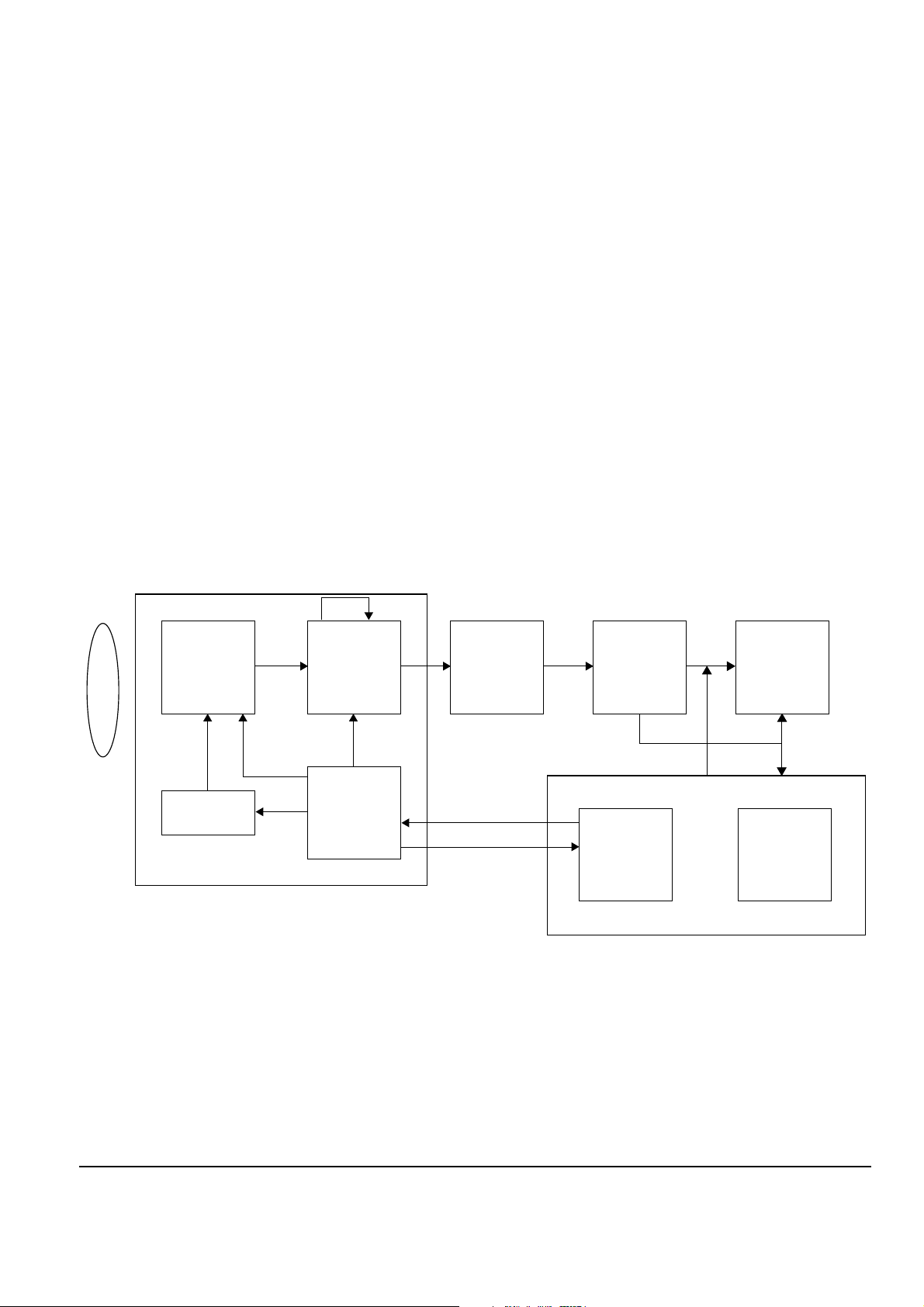

2-1-5 Digital Section

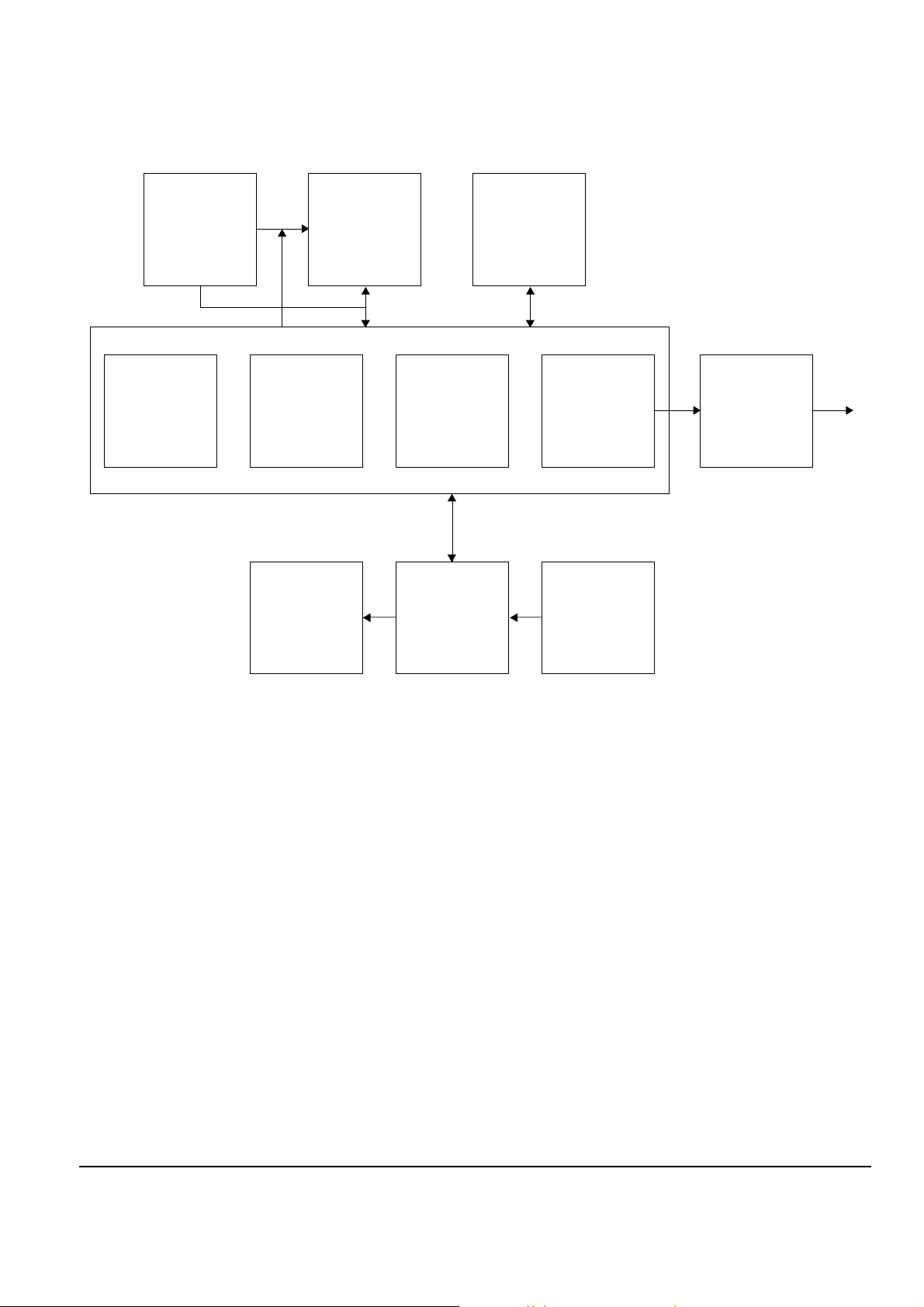

1. Overview

8-6 CONV

DRAM CTRL

Camera

Ctrl

S/W

DSCP

DRAM

4Mb

32bit RISC MICROPROCESSOR

Power

Control

S/W

JPEG

LCD

Micom

Flash

Memory

16Mb/32Mb

Memory

Pannel

Ctrl

PC I/F

LCD

Fig. 2-6

2. DRAM (KM416C256BLT) and flash memory (TC5832FT/TC5816FT)

DRAM stores the image signal temporarily and enables the microprocessor to process the signal. Flash memory

(nonvolatile) records various system information and the compressed image.

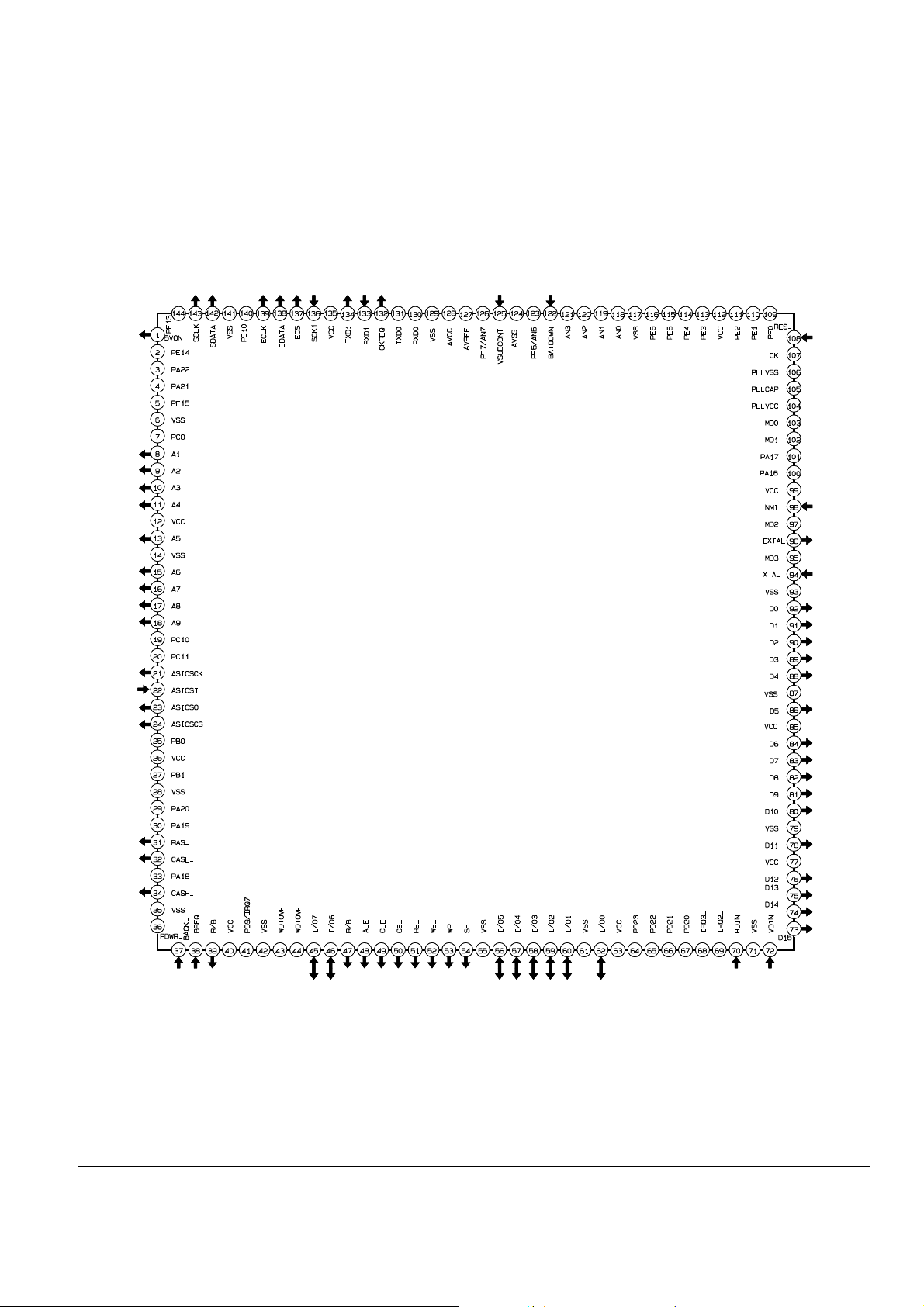

3. 32-bit RISC microprocessor (HD6477043F28)

This microprocessor is the core of the system and handles the camera control, image signal processing, image

compression, flash memory control, communication with PC, and communication with LCD control MICOM.

(Refer to 2-1-6 “System Control” for details.)

2-6 Samsung Electronics

Reference Information

2-1-6 Sytem control

Dual controller (MICOM) is located in DSC : A RISC chip controls the signal processing, and is the 4-bit MICOM

controls the LCD, timer, and switch.

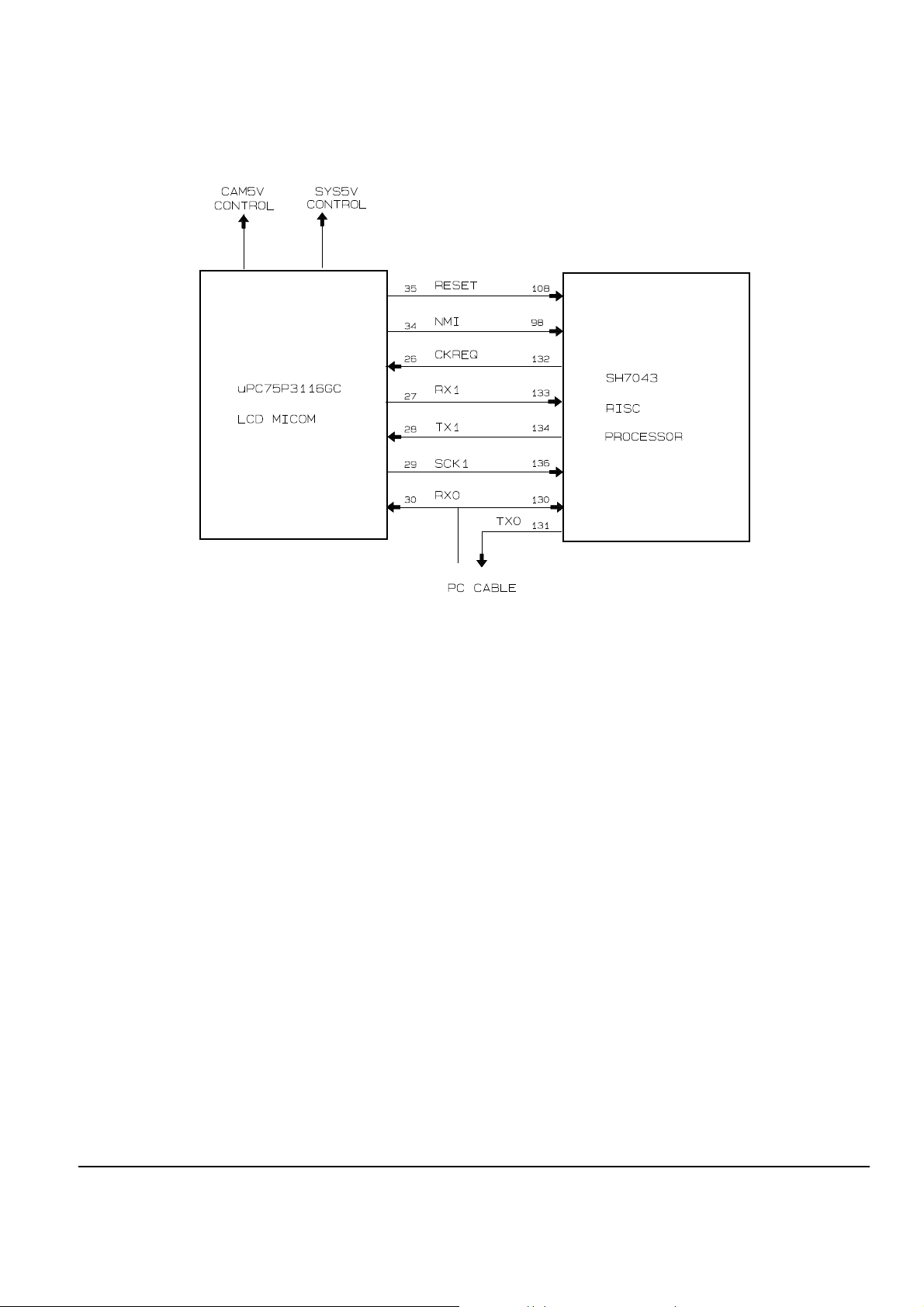

Fig. 2-7

1. 4-bit MICOM; Functions and connections

1) PIN connection status

- RISC is connected to the 4-bit MICOM (total 7 lines).

- Pins 98, 130, and 108 and SCI No. 1 are used.

- Pins 132, 133, 134, and 136 are used for communication with 4-bit MICOM.

- Synchronized communication is used with 4-bit MICOM.

2) Function

- RISC is usally in the standby mode (low-power) because it consumes so much current when it operates.

- 4-bit MICOM acknowledges the starting time (for example, when the user pushes the shot key) and sends the

NMI pin signal to RISC, so that the standby mode can be changed to the operation mode. The information is

sent to RISC through communication port. After RISC executes the appropriate program, it returns to the

standby mode.

2. Main function of 4-bit MICOM

- Power ON/OFF: 4-bit MICOM turns the PC (main body) on, and turns on the RISC.

- Execution of shot: When the shot is executed by the PC key (or main body), 4-bit MICOM signals the shot

execution to RISC. When the shot is finished (system 5V and head power 5V), 4-bit MICOM changes the RISC

mode to standby mode.

- Delay shot: When the delay shot is executed by the PC key (or main body), 4-bit MICOM signals the RISC and

supplies the system 5V and head power 5V. Then, the RISC changes to standby mode.

Samsung Electronics 2-7

Reference Information

- Mode change: When the mode is input by the PC key (or main body), 4-bit MICOM signals the RISC. When

the mode is changed, 4-bit MICOM displays it on LCD, and changes the RISC to standby mode.

- Delete execution: When the delete instruction is input by the PC key (or main body), 4-bit MICOM signal the

RISC and changes the RISC to standby mode.

- LCD display: DSC status is displayed.

- Error handling: When an error occurs, (or RISC) the error message is displayed on LCD. If the RISC cannot

operate, the power is automatically off.

- Battery operation: The capacity of battery is classified as "Full", "Half", "Low", or "Battery replacement". For the

"Battery replacement" status, only the power on/off function is available, and other functions cannot operate.

- Auto power OFF: When any operation has not been executed (three minutes for main body operation, or

10 minutes for PC operation) the power automatically turns off.

3. Main functions of RISC processor

- Communication with 4-bit MICOM: RISC operation is completely controlled by the 4-bit MICOM.

A synchronization method is adapted for communication between 4-bit MICOM and RISC (with 8-bit*11 byte

communication).

- DRAM control: RISC processor includes internal BSC. BSC helps RISC to control the DRAM. RISC uses DRAM

as though it were internal RAM (with the help of BSC). BSC generates all DRAM control signals by itself. RISC

uses DRAM for the image buffer, temp memory for the calculation, and an area that manages the flash

memory and FAT(File Allocation Table).

- Camera Head control: RISC handles the control of the camera head during the shot. RISC controls the timing

generator, ASIC, etc. so that the image data from CCD can be transferred.

- Signal processing: RISC executes the signaling processing internally with CCD image data stored in DRAM.

After RISC separates CCD data into RGB, and processes detail and gamma, it creates a YUV signal, and

executes JPEG compression. The compressed JPEG data will be stored in DRAM again.

- Flash memory control: The compressed data (in DRAM) is stored in the flash memory. The file management

program is recorded in RISC, and manages the files in the flash memory (file location, file size, etc).

- PC communication: RISC processor receives the signal from PC (4-bit MICOM) and activates up RISC.

Then, RISC processor sets the flag for the request input from PC, and transfers the flag to RISC. The RISC

communicates with PC through the serial port. (PC always requests the PC communication to DSC, but RISC

does not request it from the PC.)

- Battery level checking: Battery indicator, which is displayed in LCD of 4-bit MICOM, accepts the data from

RISC. Battery level checking is executed when the camera head and main board are on. When new battery is

inserted, it outputs 6.2V; but the actual voltage drops below 6V after supplying power to the camera head and

main board.

2-8 Samsung Electronics

2-2 IC Blocks

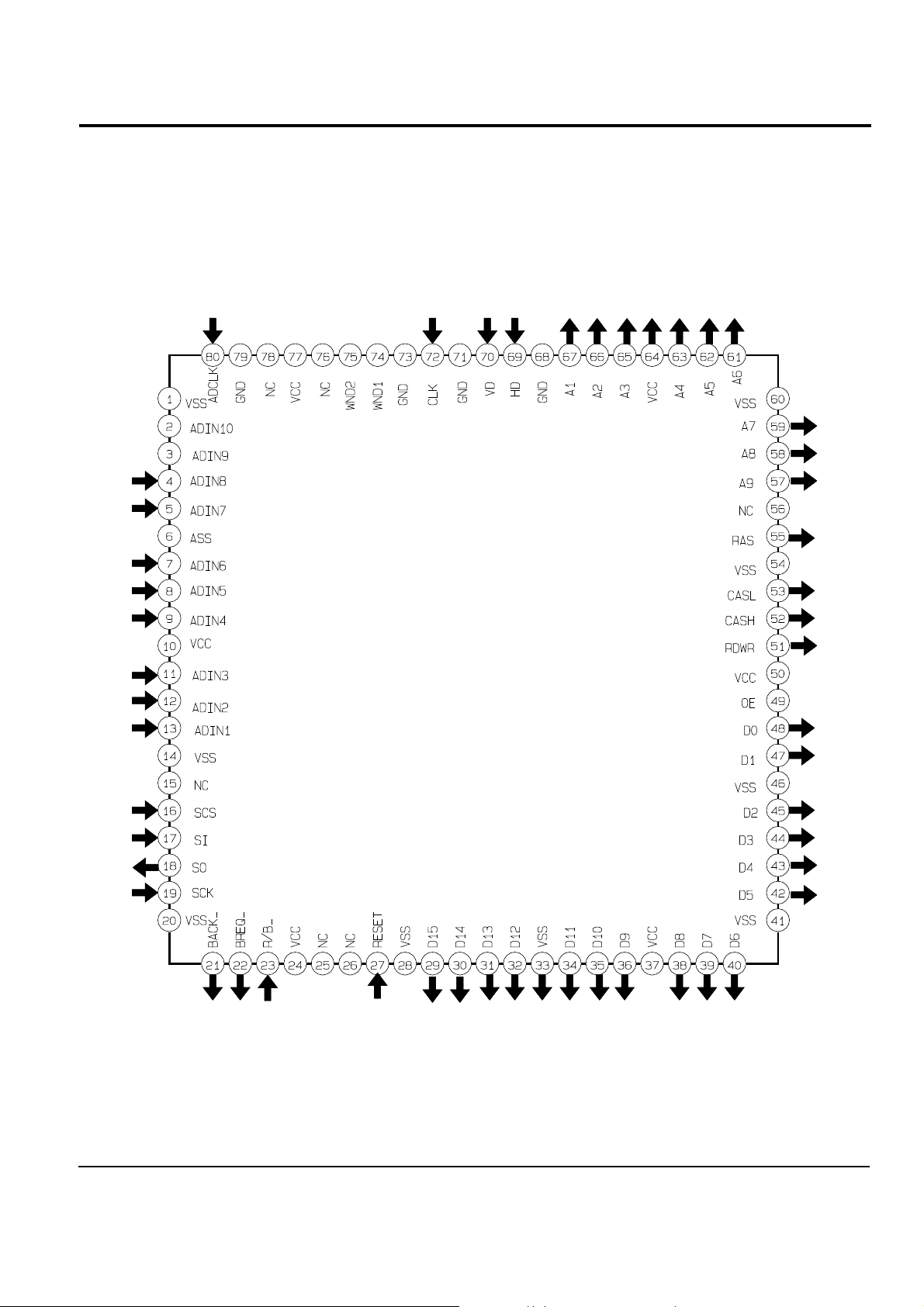

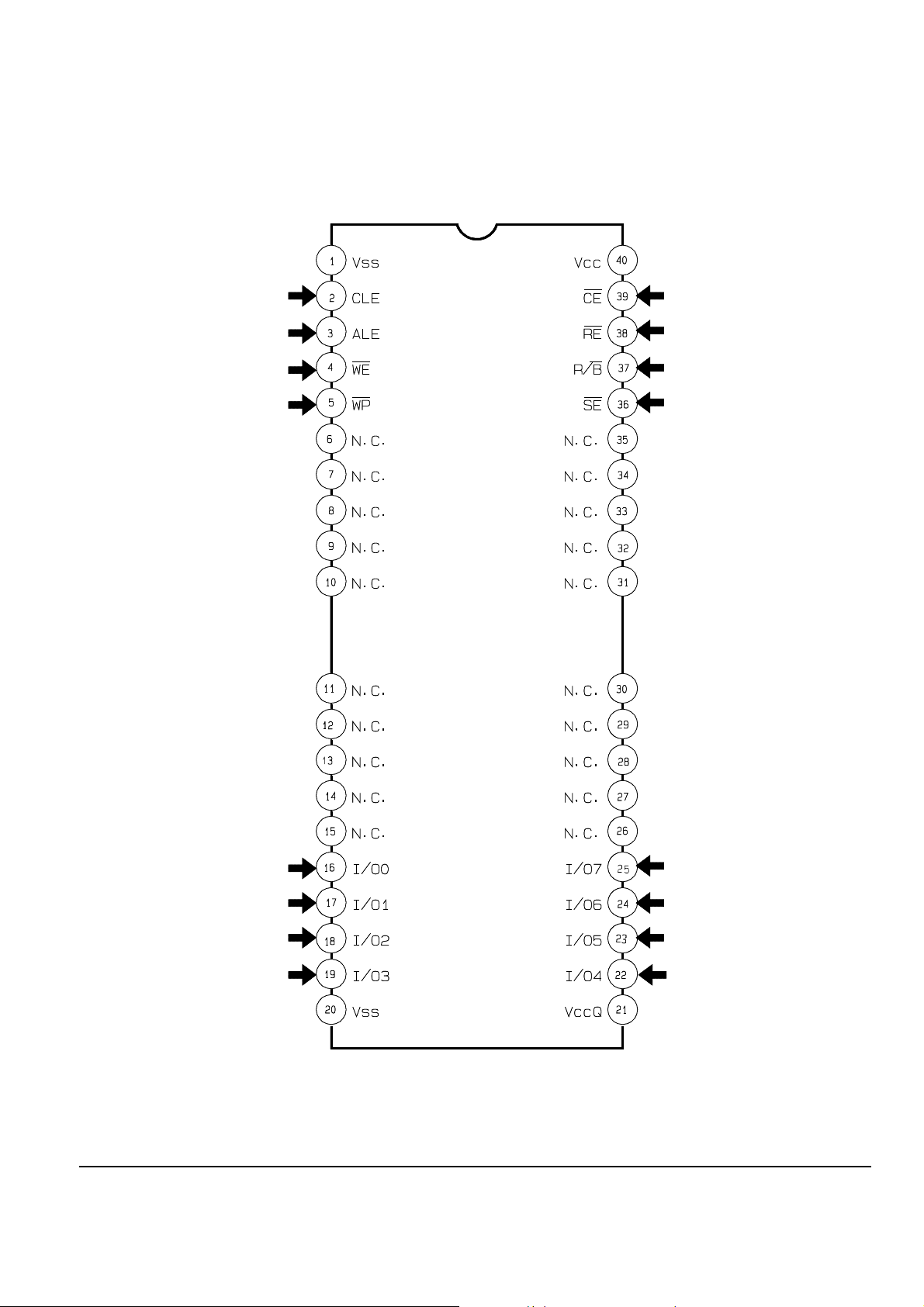

2-2-1 IC301 (SMA9606)

Reference Information

Samsung Electronics 2-9

Reference Information

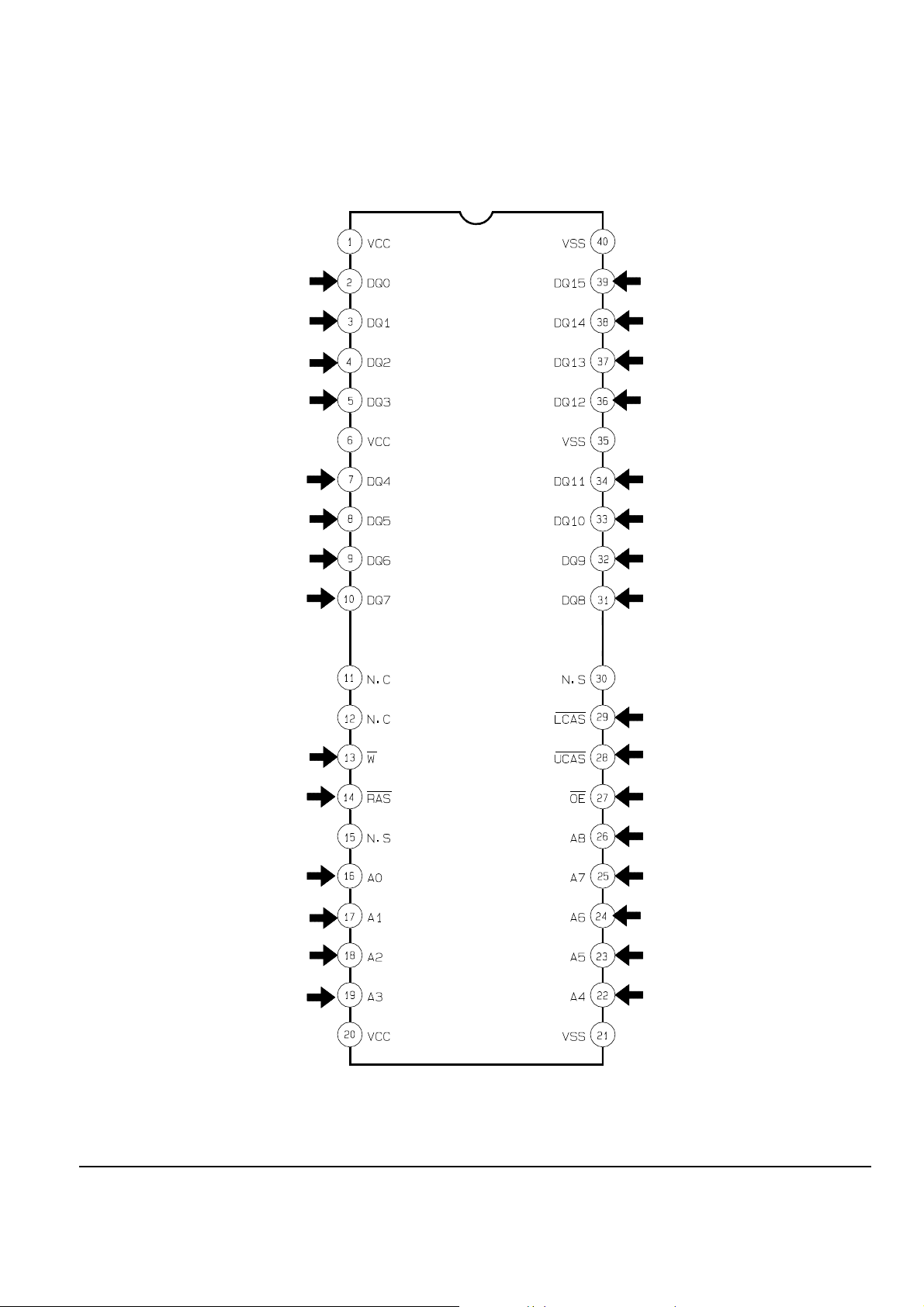

2-2-2 IC302 (KM416C256BLT)

2-10 Samsung Electronics

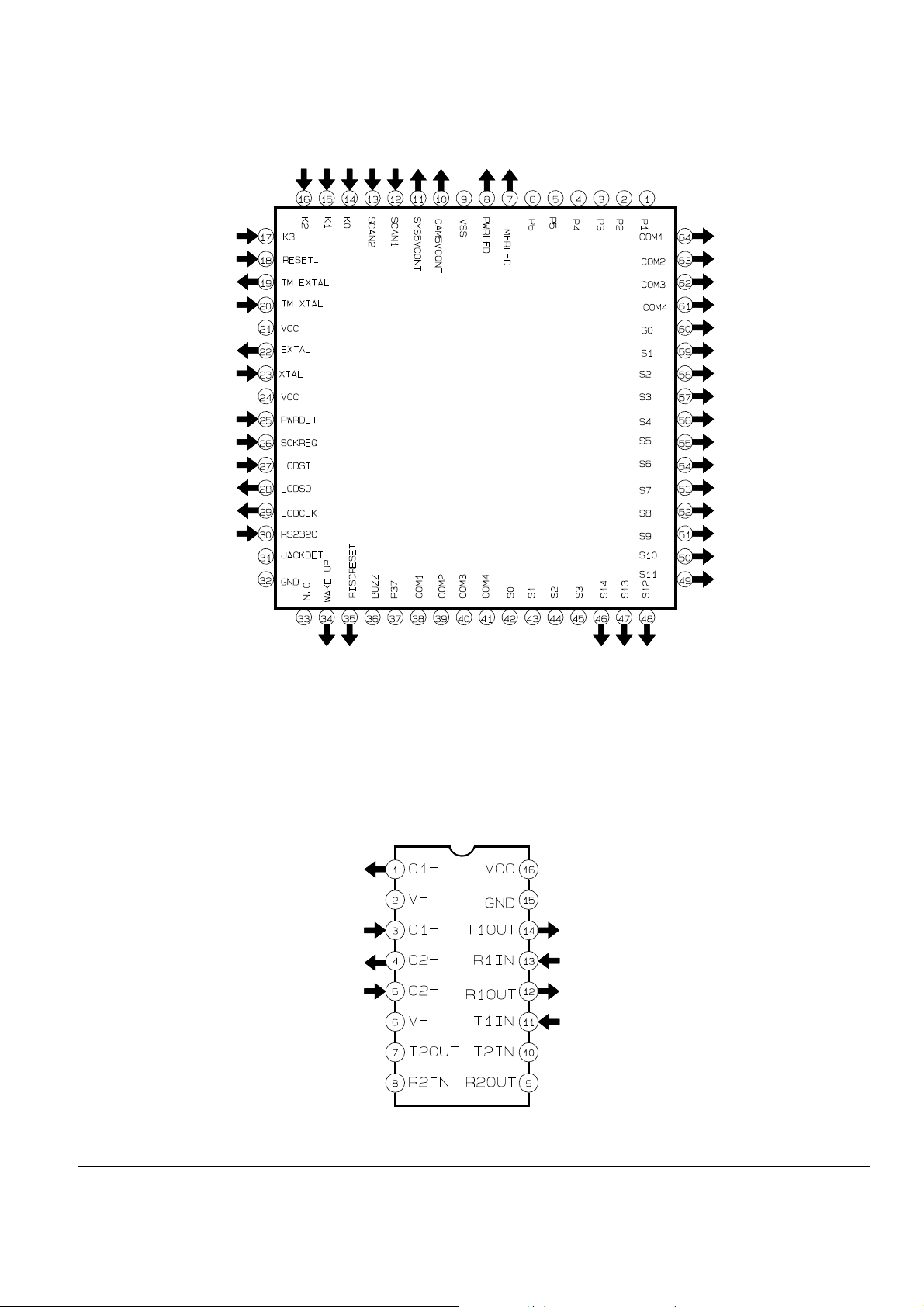

2-2-3 IC304 (HD6477043)

Reference Information

Samsung Electronics 2-11

Reference Information

2-2-4 IC307 (TC5832FT)

2-12 Samsung Electronics

2-2-5 IC601 (UPD75P3116GC)

Reference Information

2-2-6 IC501 (MAX232C)

Samsung Electronics 2-13

Reference Information

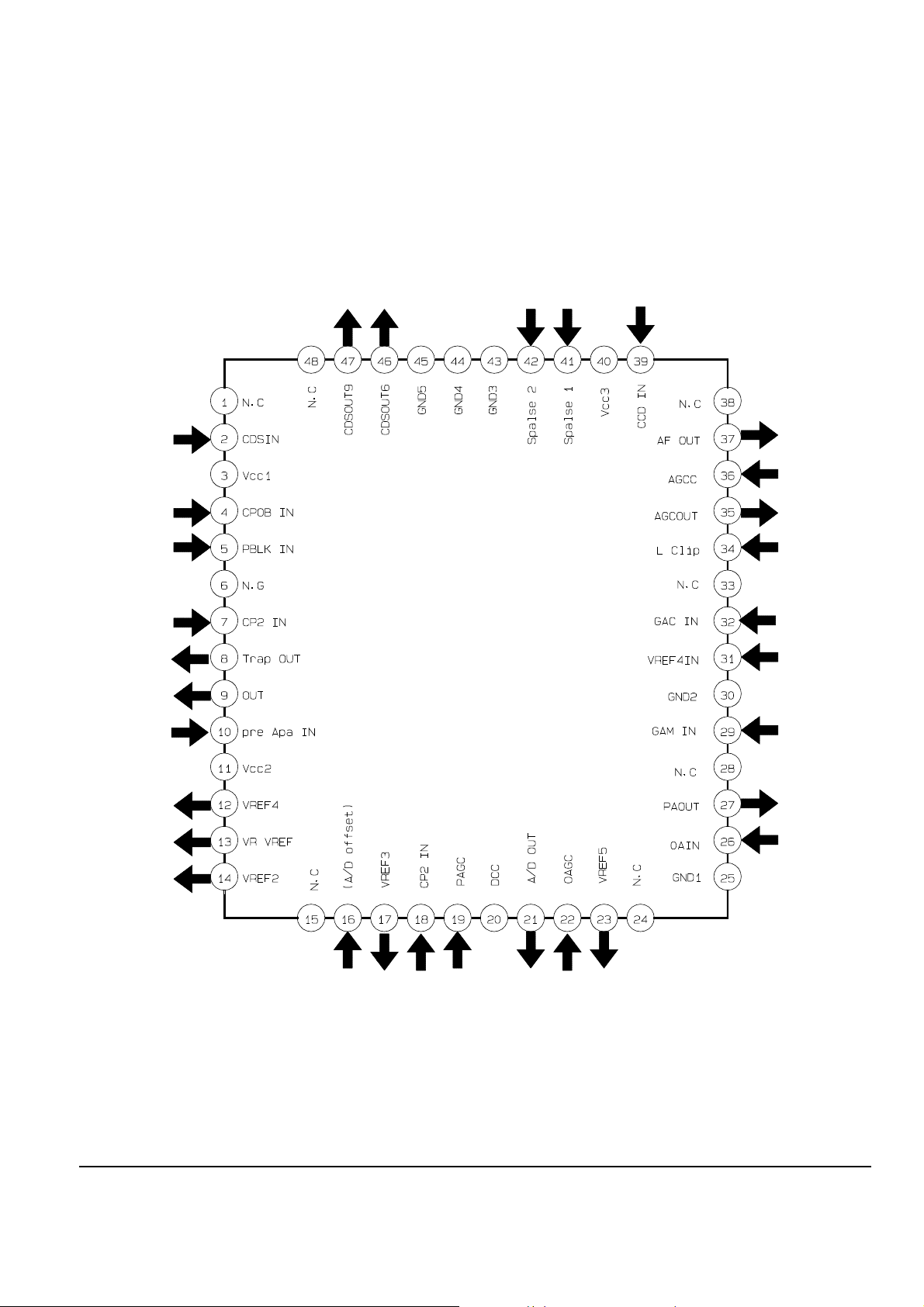

2-2-7 IC203 (NN2038FAQ)

2-14 Samsung Electronics

2-2-8 IC204 (NN5248)

Reference Information

Samsung Electronics 2-15

Reference Information

MEMO

2-16 Samsung Electronics

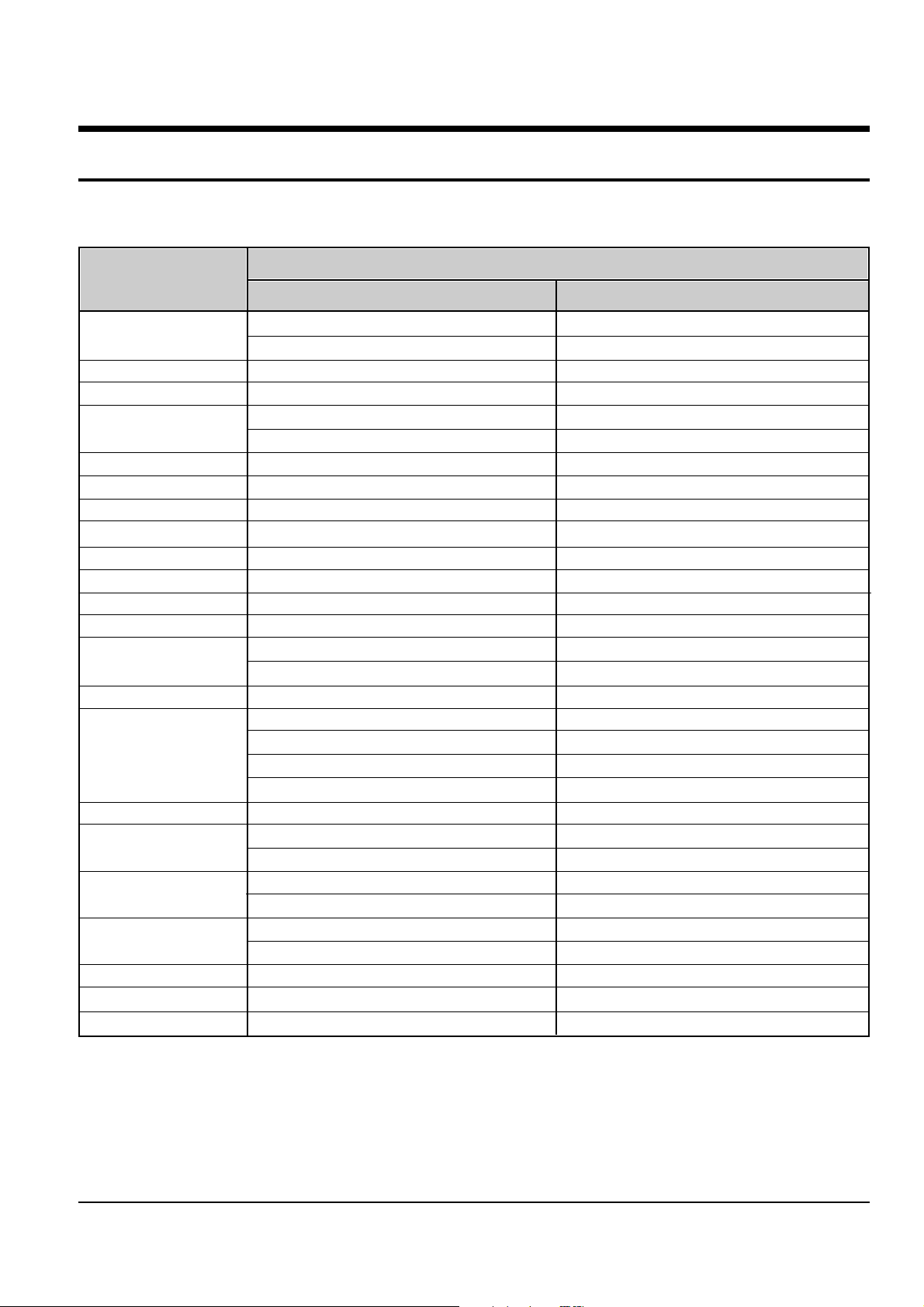

3. Product Specifications

Design and specifications are subject to change without notice.

Operation

SDC-30 SDC-33

Descriptions

Image sensor

Color depth

Memory

Image capacity

Compression

Lens

Range

Viewfinder

Shutter

Exposure system

Color balance

Sensitivity

Picture formats

Supported OS

PC

requirements

PC lnterface

Image transfer

time (speed)

Power

Power

consumption

Battery life

Dimensions

Net weight

350,000 pixel CCD

(STD) :640 X 480 pixels (ECO)20 X 240 pixels

24 bit true color (16million colors)

2MB internal flash memory

Standard (STD) : 22 images

Economical (ECO) : 88 images

Standard JPEG

Fixed focusing

100 cm (3.3 feet) - infinity

Separate optical

Auto electronic (1/4 ~ 1/8000 seccond)

Auto exposure

Automatic White Balance (AWB)

ISO 100

BMP, JPG, PCX, PNG

PSD, TGA, TIF, TPL

Windows 3.1 or higher (Including Windows 95)

RAM : 8MB or more

HDD : 30MB or more (free space)

CPU : 486DX or higher (IBM PC based)

CD- ROM drive (recommended)

Standard RS-232C (9600 -115200bps)

(STD) Standard images : 7~8 sec. (at 115Kbps)

(ECO) Economy images : Under 2 sec. (at 115Kbps)

4AA TYPE alkaline batteries

6V DC in using AC adaptor (not supplied)

At power on : below 500mA

At power off : below 500uA

More than 200 images using new alkaline batteries

115(W) X 75(H) X 38(D)mm

140g (without batteries)

350,000 pixel CCD

(STD) :640 X 480 pixels (ECO) : 320 X 240 pixels

24 bit true color (16million colors)

4MB internal flash memory

Standard (STD) : 45 images

Economical (ECO) : 180 images

Standard JPEG

Fixed focusing

100 cm (3.3 feet) - infinity

Sparate optical

Auto electronic (1/4 ~1/8000 seccond)

Auto exposure

Automatic White Balance (AWB)

ISO 100

BMP, JPG, PCX, PNG

PSD, TGA, TIF, TPL

Windows 3.1 or higher (Including Windows 95)

RAM : 8MB or more

HDD : 30MB or more (free space)

CPU : 486DX or higher (IBM PC based)

CD- ROM drive (recommended)

Standard RS -232C (9600 -115200bps)

(STD) Standard images : 7~8 sec. (at 115Kbps)

(ECO) Economy images : Under 2 sec. (at 115Kbps)

4AA TYPE allaline batteries

6V DC in using AC adaptor (not supplied)

At power on : below 500mA

At power off : below 500uA

More than 200 images using new alkaline batteries

115(W) X 75(H) X 38(D)mm

140g (without batteries)

Samsung Electronics 3-1

Product Specifications

MEMO

3-2 Samsung Electronics

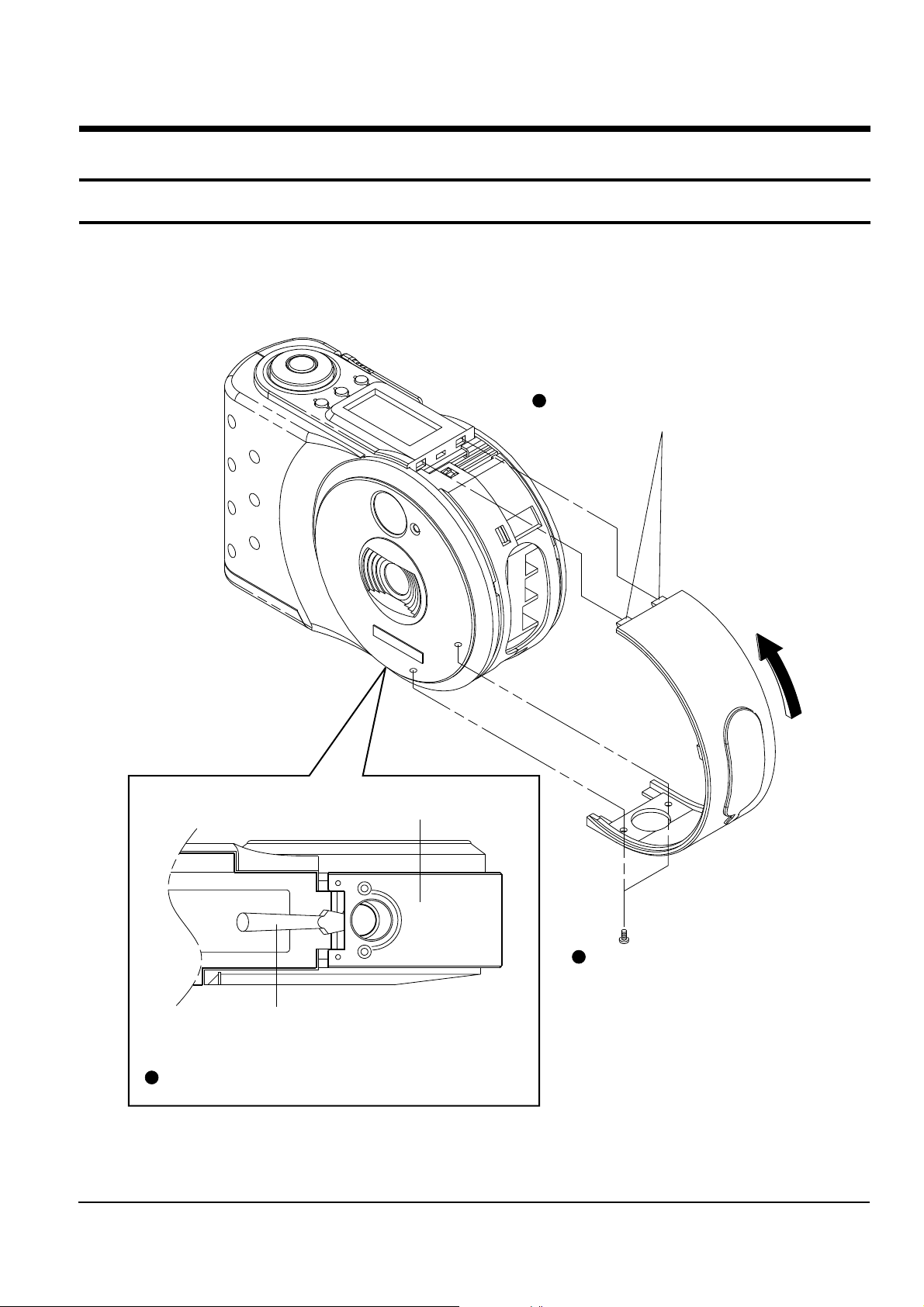

4. Disassembly and Reassembly

4-1 Cabinet and PCB

Disassemble in the order shown.

(Reassemble in reverse order.)

4-1-1 Case-Side Removal

3

Disconnect 2 tabs while lifting

up the case-side to the arrow direction.

Bottom Side

1

Remove 2 screws.

Precision screw Driver

2

Lift up the case-side using the precision screw driver.

<BOTTOM SIDE>

Fig. 1

Samsung Electronics 4-1

Loading...

Loading...