Page 1

Troubleshooting

Service Manual

7-1

Samsung Electronics

7

7

7. Troubleshooting

7.1 Scanner

7.1.1 COPY

White copy • Check the Scan-Cover open. • Room light can transit a thin original.

• Check shading profile. • Remake shading profile in the tech mode.

Black copy • Check the CCD problem in Main PBA. • Check the CCD harness contact.

• Check shading profile. • Remake shading profile in the tech mode.

Defective image quality • Check shading profile. • Remake shading profile in the tech mode.

• Check the gap between original and scanner. • The gap above 0.5mm can cause a

glass blurred image.

• Check printing quality. • See “Print” troubleshooting.

Abnormal noise • Check the Scanner Motor and any mechanical • Check the right position of the Scanner

disturbance. Motor, and check the any mechanical dis

turbance in the CCD carriaging part.

• Check the Motor Driver in Driver PBA. • If any driver is defective, replace it.

PROBLEM ITEMS TO BE CHECKED. HOW TO SOLVE

Page 2

Service Manual

Troubleshooting

7-2

Samsung Electronics

7.1.2 PC-Scan

Scanning Error • Check the printer cable installed. • Check correct installation, and use standard

IEEE1284 cable.

• Check how TWAIN driver is installed. • Remove any other scanner driver.

• Reboot after reinstallation of the TWAIN

driver.

• Check the printer port(Parallel). • Check the parallel-port-related items in the

CMOS Setup.

As a printer port, Select ECP among

SPP(Normal), ECP, and EPP

modes(increase print-ing speed)

• Check harness contact. • Check CN12 contact in Main PBA

• Check the IEEE1284 signal level. • If any signal level is defective, replace

Driver PBA.

Main PBA = 0.8V to 2.4V TTLsignal.

• Otherwise, replace Main PBA.

• Check the USB signal level. • If USB signal level is defective, replace

Main PBA.

Defective image • Check shading profile. • Remake shading profile in the tech mode.

Quality • Check the gap between original and scanner glass. • The gap above 0.5mm can cause a

blurred image.

Abnormal noise • Check the Scanner Motor and any mechanical • Check the right position of the Scanner

disturbance. Motor, and check the any mechanical

disturbance in the CCD carriaging part.

• Check the motor driver in Driver PBA. • If any driver is defective, replace it.

PROBLEM ITEMS TO BE CHECKED. HOW TO SOLVE

Page 3

Troubleshooting

Service Manual

7-3

Samsung Electronics

7.2 FAX (only SCX-6320F)

7.2.1 FAX/TELEPHONE Precautions

TEL LINE CANNOT BE

ENGAGED

(NO DIAL TONE)

Cannot MF dial

MF dial is possible but

not DP dial.

Defective fax

transmission

Defective automatic fax

reception

• When you press “ OHD” key:

a) Check line cord connection.

b) Check MAIN LIU harness, and CN1

(LIU PBA).

• Check MAIN-LIU harness.

• Check DP control signal of MAIN PBA and Liu

PBA.

• Check MAIN LIU harness.

• Is the external phone hooked off?

• Check ‘hook off’ : Refer to ‘TEL LINE CANNOT

BE ENGAGED’ above.

• Check transmission path and reception path of

the LIU PBA.

• Is the ring checked?

• Refer to ‘Defective Transmission.’

a) insert it correctly into the connection jack

called “line”.

b) Replace defective parts.

• Replace defective parts.

• Replace LIU PBA.

• Replace defective parts.

• Replace LIU PBA if low.

• Refer to ‘TEL LINE CANNOT BE

ENGAGED’ above.

• Replace main PBA, if abnormal.

• Replace LIU PBA.

Replace main PBA.

• Replace LIU PBA if it cannot be checked.

• Refer to ‘Defective Transmission’.

PROBLEM ITEMS TO BE CHECKED. HOW TO SOLVE

Page 4

Service Manual

Troubleshooting

7-4

Samsung Electronics

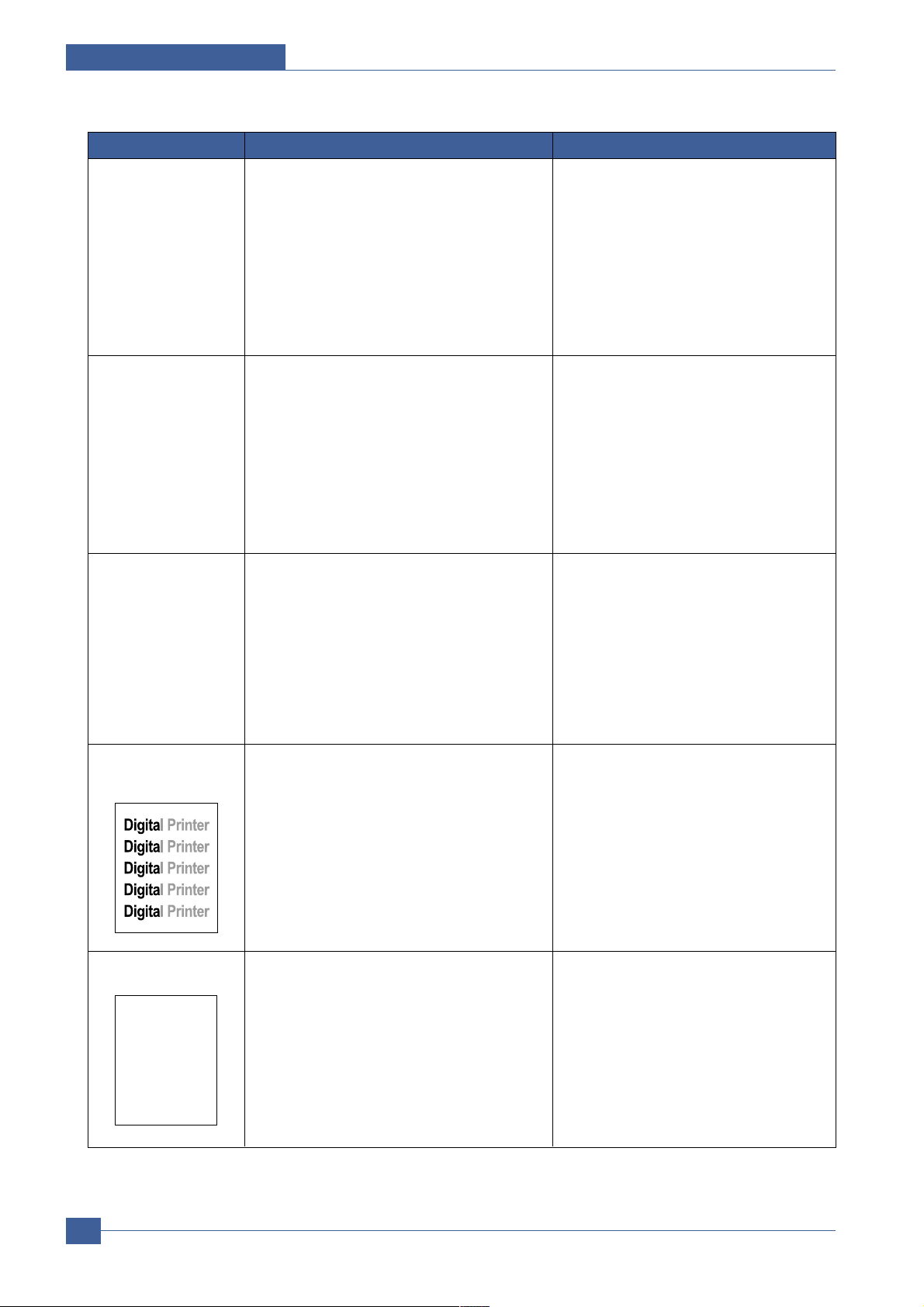

7.3 Print Quality

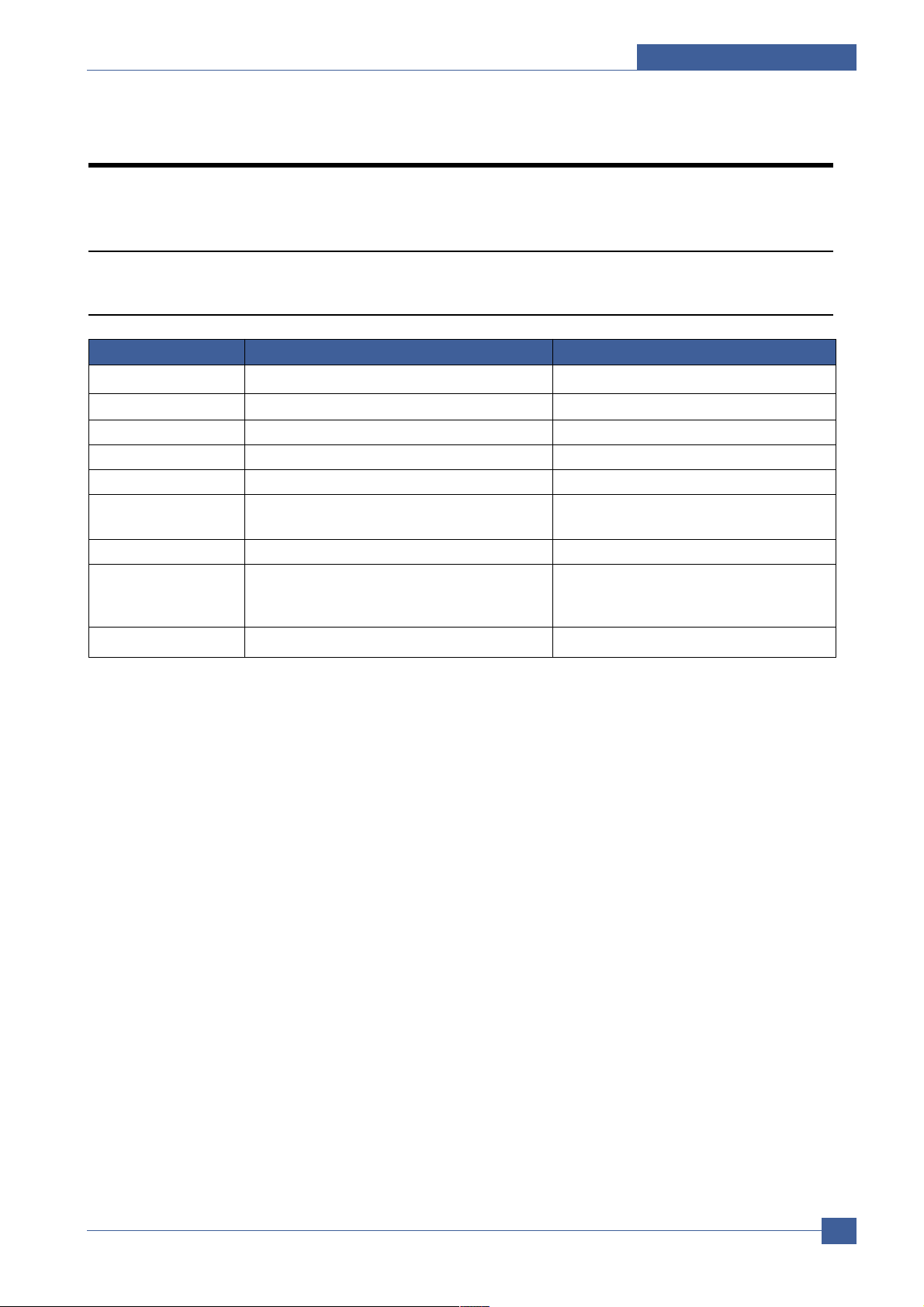

Vertical black line and

band

1. Bad blade of Toner cartridge

2. LSU

3. Bad cleaning blade of drum cartridge.

1. Change Toner cartridge

2. Replace LSU

3. Replace drum cartridge.

Error Status Check Solution

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Vertical white line 1. LSU window contamination

2. Toner cartridge

1. Clean LSU window

2. If not LSU, change Toner cartridge.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

No image 1. GND OPC is well grounded?

2. LSU running well?

3. Biss voltage is normal?

4. Lower toner?

5. Is there video data from Main PBA

1. Measure the resistance between frame

ground and the ground spring attached frame.

Confirm stable ground. Unless bad ground,

detach cabinet, check where is bad point

2.Adjust LSU or replace it

3. Normal Dev bias = -450V

4. Shake toner cartridge and print.If a like

good, toner is empty

5. Test engine test pattern , replace Main PBA

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Light image 1. LSU light power normal?

2. Enough toner?

3. High charger voltage?

4. Lower bias voltage

5. Contamination of high voltage contact.

6. Transfer volatge and roller.

1. LSU light power check is difficult.

Compare with new one and check.

2. Check toner and the toner cartridge counter

3~4. Measure all high voltage output.

5. Leakage toner cause bad contact and

increase contact resistance. Clean contaminated area.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 5

Troubleshooting

Service Manual

7-5

Samsung Electronics

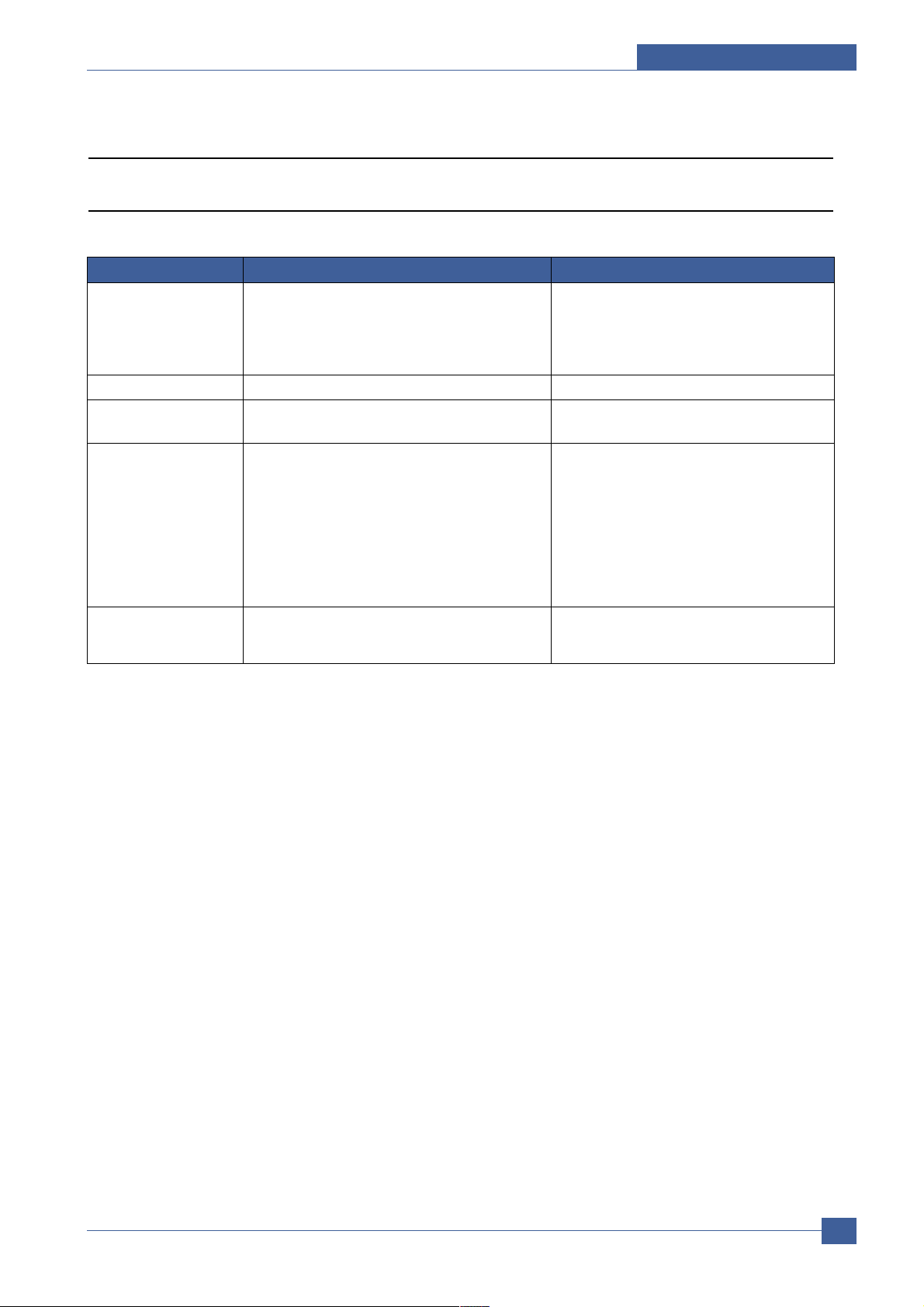

Dark image 1. LSU light power normal?

2. Bias voltage output is high?

3. Video data is always supplied?

4. Bad high charge voltage contact.

1. Check the rated level and replace.

2. Set to power rating.

3. Replace defected board.

4. Check the charge voltage or change the

drum cartridge.

Error Status Check Solution

Digital Printer

Digital Printer

Background 1. High voltage output is normal?

2. C/R of drum cartridge is contaminated?

1. Adjust to the rated status.

2. Replace drum cartridge.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Ghost 1. High voltage output.

2. Pre-Transfer Lamp.

3. Bad high voltage contact.

1. Check every high voltage.

2. Check the turn-on PTL, LED crash.

3. Clean the inside machine or replace drum

cartridge.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Stains on back of

paper

1. Contamination of transfer roller.

2. Stains of paper path.

3. Pressure roller’s contamination.

1. Clean the transfer roller with vacuum cleaner.

2. Clean the area of paper path with cloth or

air cleaner.

3. Remove fuser and replace it.

Page 6

Service Manual

Troubleshooting

7-6

Samsung Electronics

Poor Fusing 1. Use recommended paper?

2. Check fusing temperature.

3. The machine was under the low tempera ture

for a long time?

1. Should use recommended paper.

2. Check engine controller board. If you have

not thermometer, measure the thermistor

voltage to CPU, If 2.3V±5% in printing CPU

works well. Then, disassemble fuser and

check the thermistor contact and thermistor.

3. Re-check after putting the machine in the

warm place for certain period.

Error Status Check Solution

Partial blank image

(not periodic)

1. Toner is low?

2. The toner cartridge is out of position?

1. Replace Toner cartridge.

2. Checkand adjust.

Partial blank image

(periodic)

1. Develop roller scar or particle.

2. Scar or particle. (94.3 mm)

3. Transfer roller scar or particle. (56.6 mm)

1. Replace toner cartridge.

2. Replace drum cartridge.

3. Replace transfer roller.

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Different image density

(left and right)

1. Charge roller’s pressure force unbalance

2. Dev. roller and OPC or Dev. roller and blade’s

pressure force unbalance

3. Transfer roller’s pressure force unbalance of

each side

1. Replace drum cartridge.

2. Replace toner cartridge and drum cartridge.

3. Check left and right spring of transfer roller

and the spring pressing the toner cartridge

inside the machine

Horizonral band 1. Unstable high voltage contact

2. Charge roller’s contamination

3. Contamination of heat roller

4. Malfunction of LSU

1. Clean each contact and check good contact

2. Clean charge roller

3. Replace fuser unit

4. Check Main PBA.

Page 7

Troubleshooting

Service Manual

7-7

Samsung Electronics

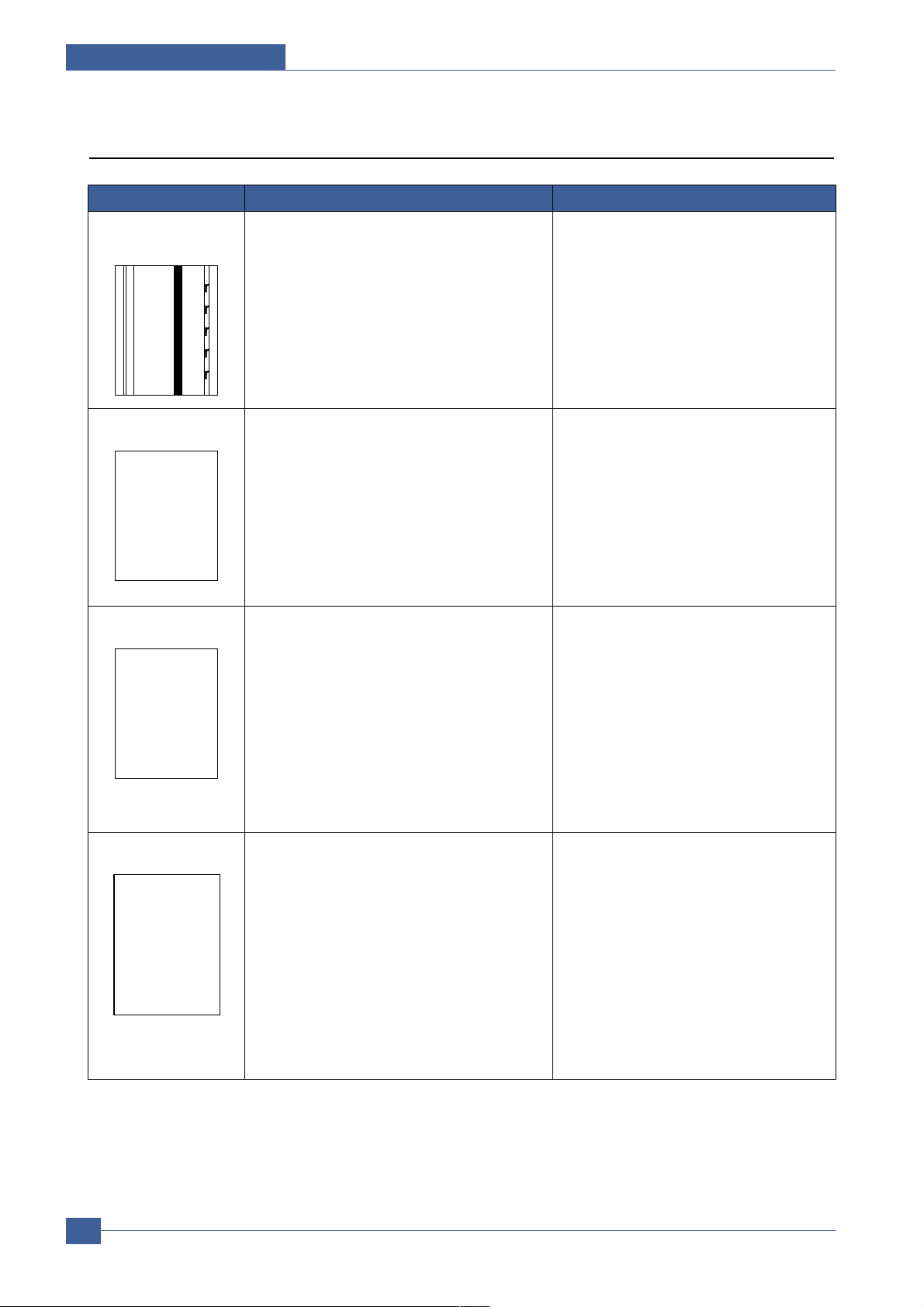

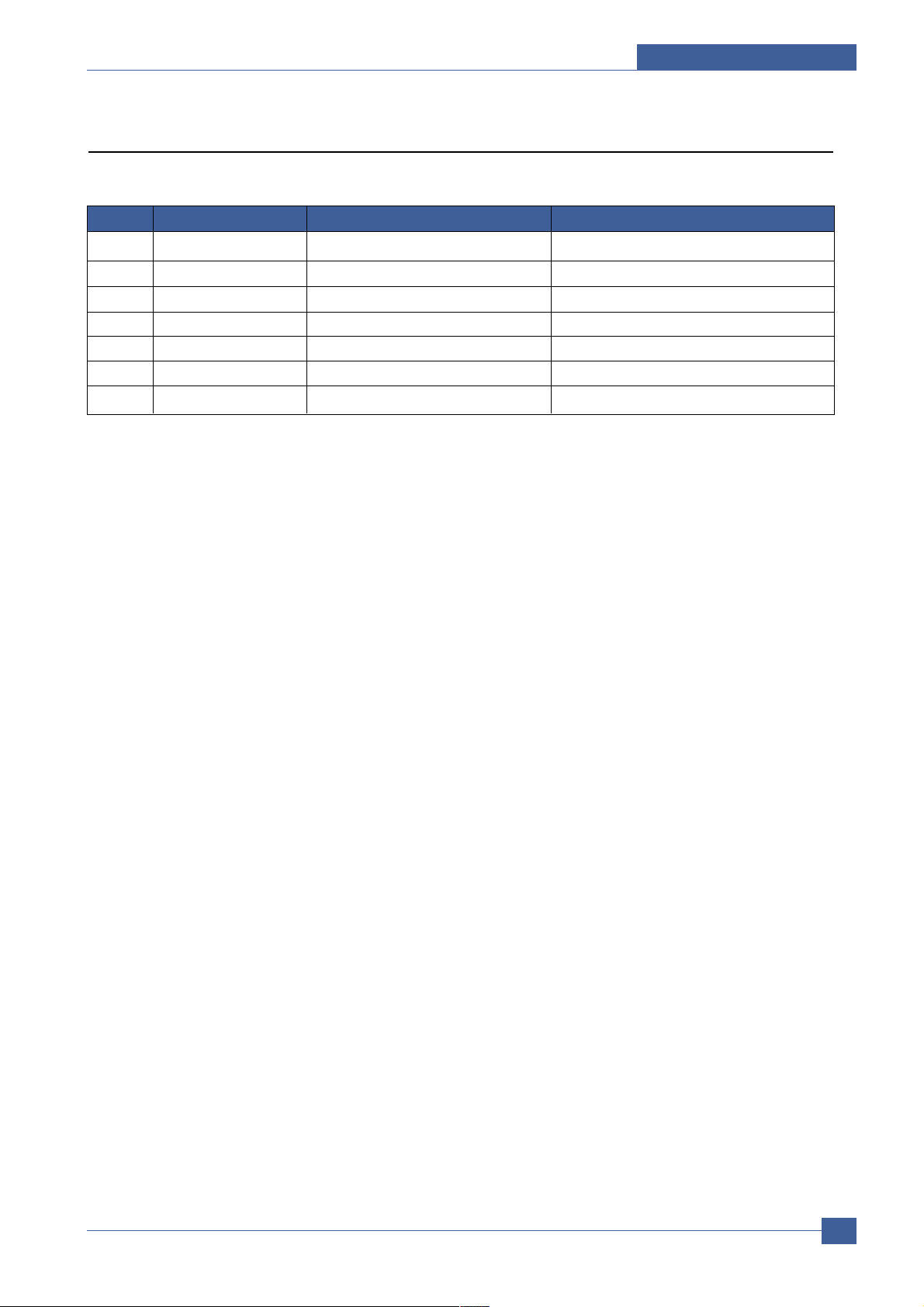

Abnormal Image Printing and Defective Roller

If abnormal image prints periodically, check the parts shown below.

1 OPC Drum 94.3 mm White spot. Black spot

2 Charge Roller 38.3 mm White spot. Black spot

3 Supply Roller 43.8 mm Horizontal dark band

4 Develope Roller 54.3 mm Horizontal dark band

5 Transfer Roller 56.6 mm Black side contamination/transfer fault

6 Heat Roller 83.6 mm Black spot, White spot

7 Pressure Roller 91.0 mm Black side contamination

NO Roller Abnormal image period Kind of abnormal image

Page 8

Service Manual

Troubleshooting

7-8

Samsung Electronics

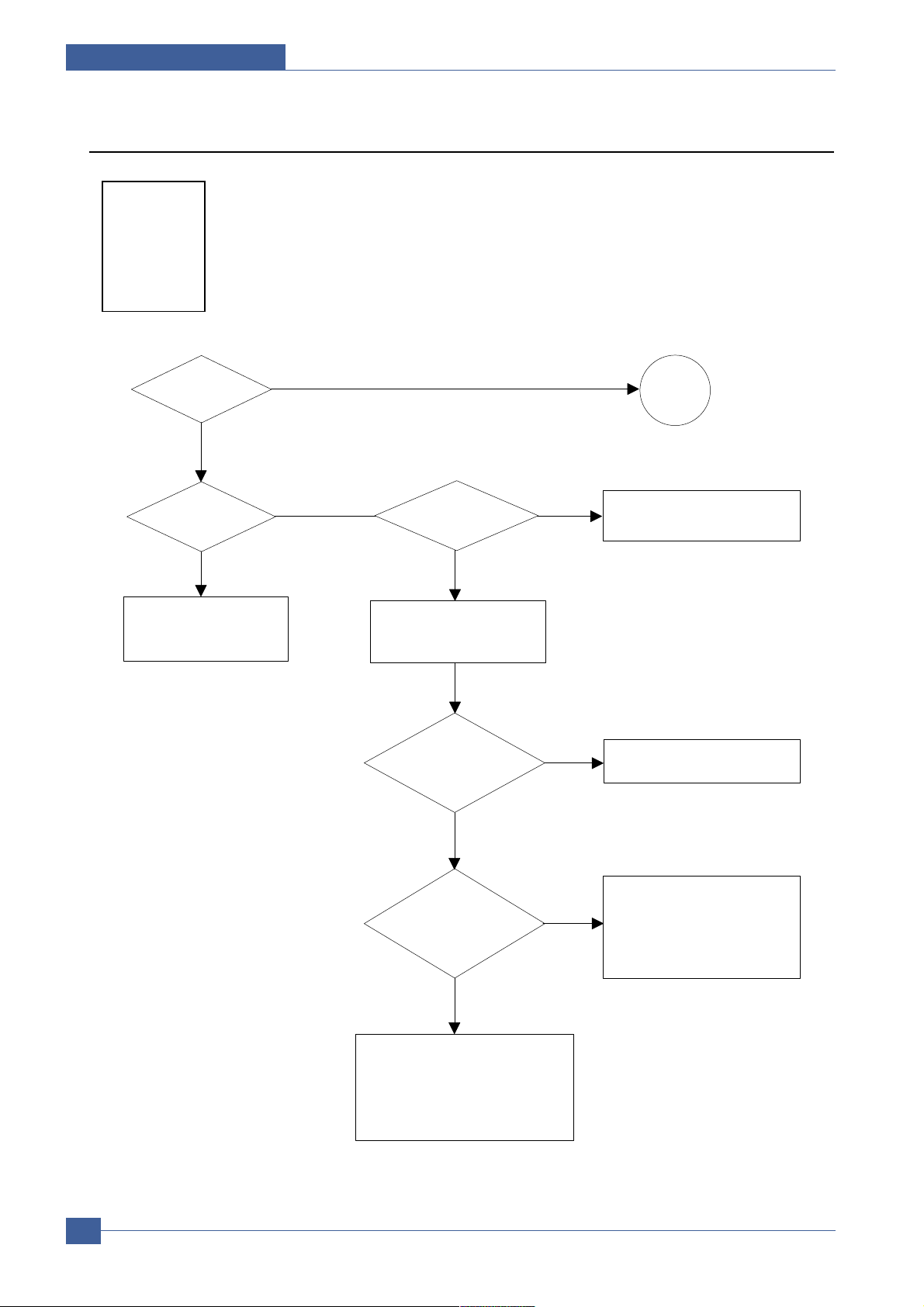

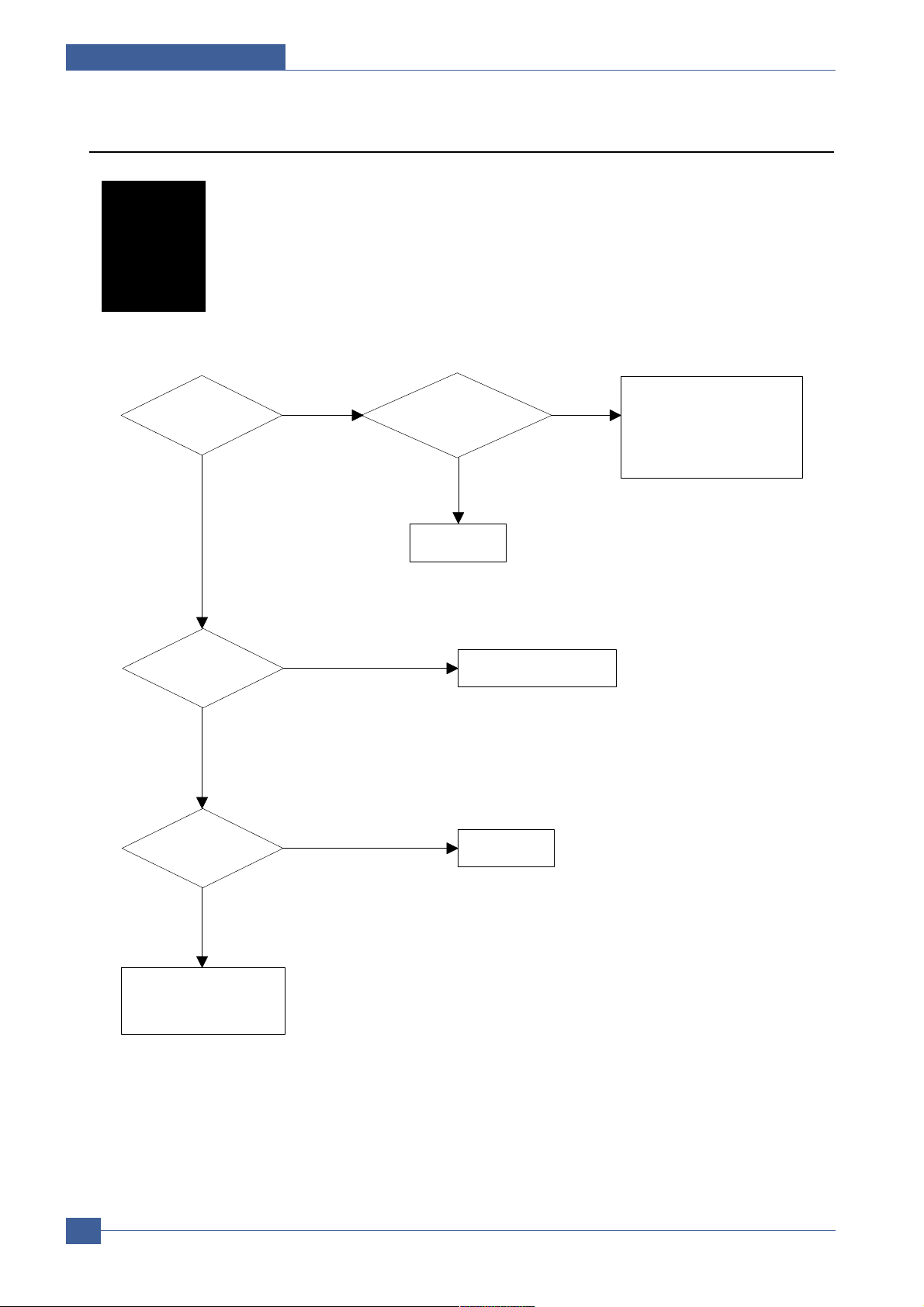

No Image

Check connection to

computer or replace

controller

Take out the cartridge

and prepare the tester

for electronic connection

Repair or replace the GND

terminal

Check the path between

Main board

and HVPS. Repair or replace

the defective component

or board

The mirror in LSU might be

misplaced so the light path to the

OPC deviates ->Repair or replace

LSU or remove any defective

matters in the machine

Self test

pattern prints?

No image?

Self testing

is possible ?

Is the OPC

terminal of machine

is well-connected

to Frame?

Does the

video data line to

LSU transit to High/Low

when printing?

Retest after replacing the

connector or controller board

A on

next page

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 9

Troubleshooting

Service Manual

7-9

Samsung Electronics

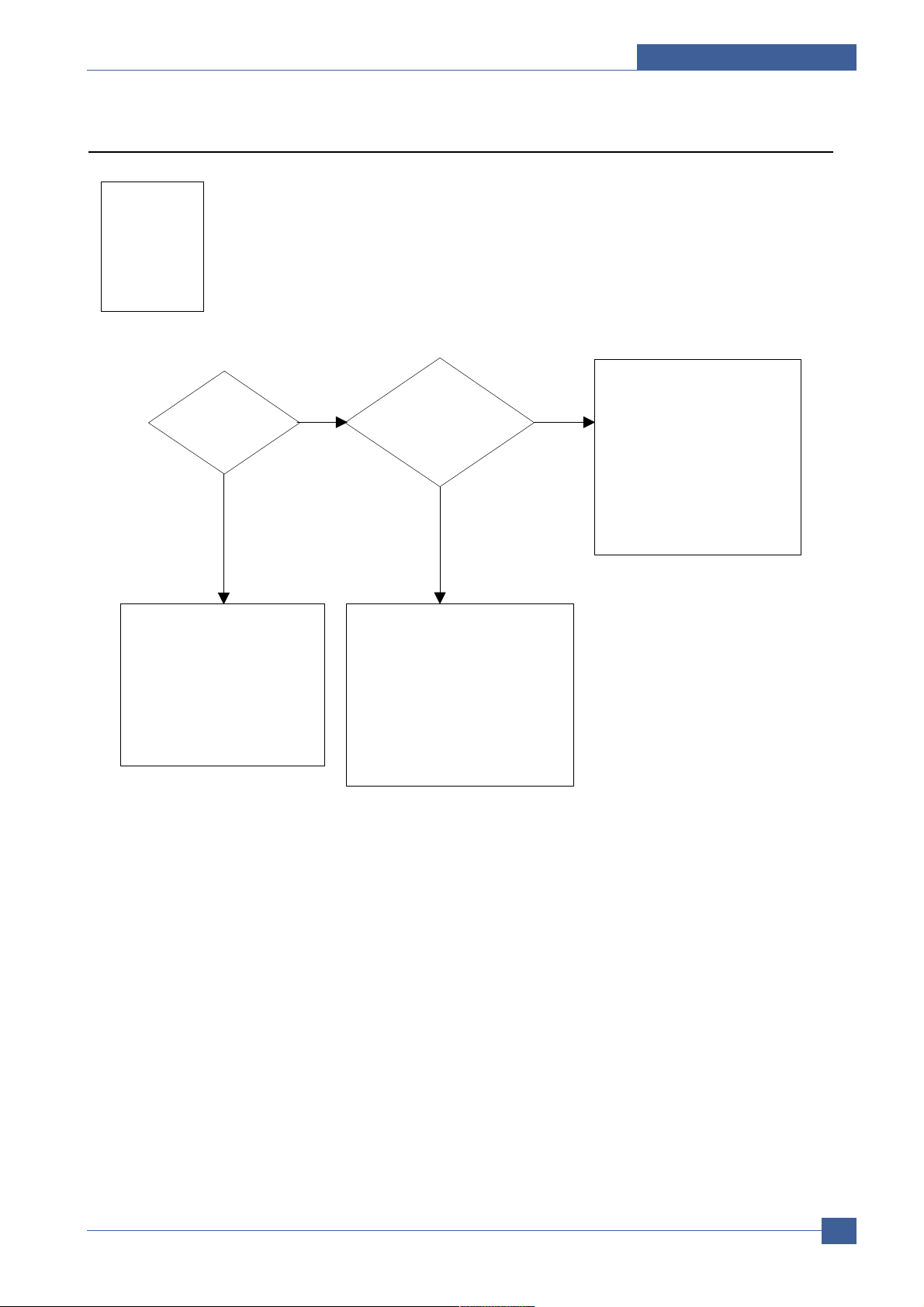

Transfer roller might be out of its location

-> Locate the roller into its place

This could occurs when he power of LSU is low or

the density is low due to the obstacles on the window

-> Replace LSU or clean the window

A

Transfer

voltage OK? (on the

transfer roller

shaft)

Are the

connection terminal

and connection

correct?

Repair or replace terminal

Replace HVPS or repair defective component

Is the connection

terminal OK?

Replace HVPS or repair

defective component

Repair or replace terminal

Developing

(-450V) and supplying

(-600V) voltage

are OK?

Does the

counter indicate over

the toner’s guaranty

life

Replace the toner cartridge

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

Page 10

Service Manual

Troubleshooting

7-10

Samsung Electronics

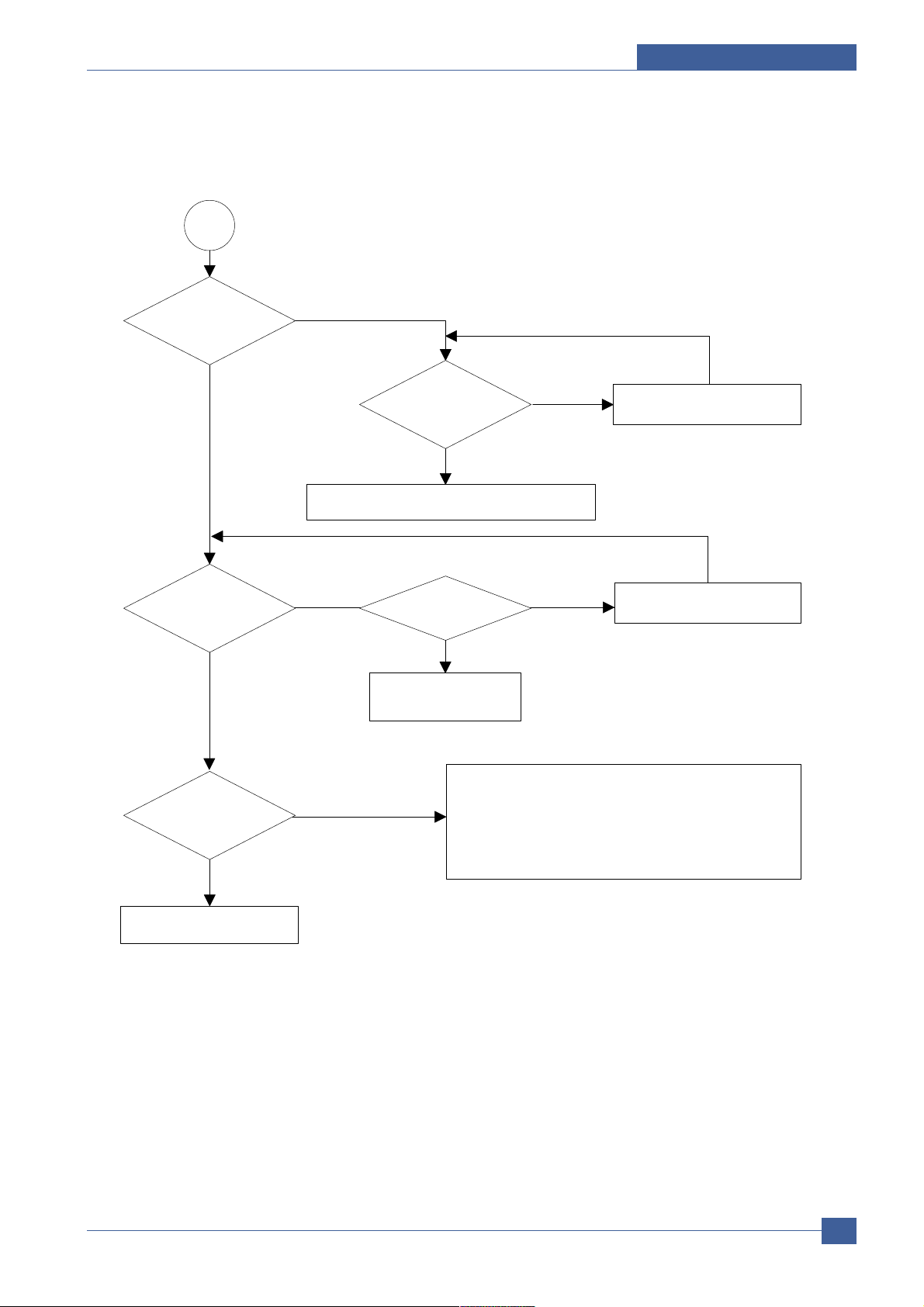

All Black

All black in

printing area?

Is charge

voltage supplied

from HVPS?

Is the

Hsync signal received

in LSU?

Charge part’s contact

is bad -> Repair or

replace the drum cartridge

Does the

video data line to LSU

transit to High/Low when

printing?

Replace LSU

Check the path among video

controller, engine board,

HVPS, LSU for the shortage

or open -> Repair or replace

the boards

Repair or replace HVPS

Replace LSU

NO

NO

NO

NO

YES

YES

YES

YES

Digital Printer

Digital Printer

Page 11

Troubleshooting

Service Manual

7-11

Samsung Electronics

Vertical White Line (Band)

White line

missing definitely?

Dirt of dust stuck onto the

window of internal lens of LSU

-> Clean it or replace LSU

Preventive obstacles through

the path between OPC of

toner cartridge and LSU prevent the

path -> Remove the obstacles

Check if the

printout is still has the

same problem even right after

passed through the

transfer roller

Toner material might be stuck to

blade in the developer inside and it

prevents toner supply -> Replace

the toner cartridge

Check both if the toner cartridge’s

counter is over its guaranty and

amount of the toner material

-> Replace the toner cartridge

The ribs in fuser or toner on the

roller may invoke the image

problem -> Replace the fuser

cover or the defective part

The image is originally black or the

black part is far close to the top

-> Use the pattern which has the

image below bigger than 10mm

from the top

NO

NO

YES

YES

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 12

Service Manual

Troubleshooting

7-12

Samsung Electronics

Dark Image

Dark selected

via RCP?

Change to

Normal and test

Works correctly

with -450V of Bias

voltage?

Works

correctly after

replaced LSU?

Repair or replace the defective

component

The power of LSU is set

high or internal problem

-> Replace LSU or adjust

volume

Same at Normal?

END

NO

NO

NO

Toner over supply due to the

adjustment fault of metering

blade in toner cartridge

-> Replace toner cartridge

NO

YES

YES

YES

YES

Digital Printer

Digital Printer

Page 13

Troubleshooting

Service Manual

7-13

Samsung Electronics

Barkground

Recommended

paper used?

Transfer,

charge and developing

voltage are OK?

Operating/

storage atmosphere is

too high temperature

/humidity?

Solve the problem under

the recommended condition

(10-32 degree Centigrade)

Dirty or

dust around the

charge roller?

Clean the charge roller

or replace step-up device

/terminal after check

Work OK?

Internal blade or supplying

part of the toner cartridge

is defective

-> Replace the toner

cartridge

Check Terminals or contacts and "transfer roller springs"

are misplaced

-> Repair or replace transfer roller etc.

Check if the LED of PTL in front of the transfer roller

is on when it presses the top cover switch on purpose

-> If not, replace PTL

Print 20 to 30 pages using

the recommended paper

Same problem

occurs?

- Adjust voltage or

replace HVPS

- Repair or replace

after

checking the

terminals’ contacts

END

Replace the

toner cartridge

NO

NO

NO NO

NO

NO

YES

YES

YES

YES

YES

YES

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 14

Service Manual

Troubleshooting

7-14

Samsung Electronics

Ghost

YES

Is it regular

interval of 94.3mm?

PTL lamp

works OK?

Transfer

voltage is set to

standard?

Is it regular

interval of 54.3mm?

Is it regular

interval of 56.6mm?

(as transfer roller

interval)

Developing

/supplying voltage

normal? (-450V/

-600V)

Check HVPS

contacts and

HVPS’s selfoutput

-> If failed,

repair/replace

HVPS

Replace PTL

assembly

Irregularity of NIP

between rollers in

toner cartridge

-> Replace toner cartridge

- Repair or replace HVPS

- Check and Repair or

replace the terminal

contacts

A specific part of the transfer

roller has ruined or its

resistance value is changed

-> Replace transfer roller

Transfer roller cannot force

regularly due to the gears

eccentricity of transfer roller

-> Replace the defective

component

Bias voltage

is OK? (-450V)

Operating/storage

temperature is too low or

not recommended

paper used?

Adjust the Bias voltage

or replace HVPS

There may be a problem in toner

layer control in toner cartridge

-> Replace the toner cartridge

Use the machine with

recommended paper and

at condition

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 15

Troubleshooting

Service Manual

7-15

Samsung Electronics

Black Spot

Is it regular

interval of 38.3mm?

The problem occured

since the obstacles

stuck to charge roller

-> Clean the Charge Roller

and then reprint.

When taking

out the toner cartridge,

toner leaks?

Toner leaks and much

toner material dropped

onto the paper ->

Replace the toner cartridge

Bad image

removes by

scratching?

Check toner is stuck onto

the P/R or H/R in fuser

-> Clean it or replace

The problem

randomly occurred

due to the toner

fallen -> Clean the

machine

NO NO NO

YES

YES

YES

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 16

Service Manual

Troubleshooting

7-16

Samsung Electronics

Horzontal Band

NO

Black band?

The black

band has regular

interval?

Black band

is far about 94.3mm from

white band?

Problem of internal

contacts in OPC

-> Replace the drum

cartridge

The OPC is damaged under the

direct sunlight for around 5

minutes -> If the same problem

persists in 10 hours, replace

the drum cartridge

This occurs when no

Hsync/ at LSU

-> Replace LSU

94.3mm interval?

Heat roller is ruined

-> Replace the roller

The OPC is damaged due to

the irregular transfer voltage

of HVPS

-> Repair/replace HVPS

-> If the same problem persists,

replace the drum cartridge

Does it appear

at every 83.6mm at

specific place?

Problems of terminal contact,

transfer voltage supplying,

and transfer roller’s due to the

charge roller is ruined (38.3mm)

-> Repair/replace HVPS,

drum cartridge

NO

NO NO

NO

YES

YES

YES

YES

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 17

Troubleshooting

Service Manual

7-17

Samsung Electronics

Irregular Density

OK after

taking out and

rocking the toner

cartridge?

It is over the guaranty

life of toner cartridge

(Check the counter

and replace it)

When gray

pattern printing,

irregular density

persists?

PTL lamp

works OK?

Any obstacles

on the PTL lamp?

transfer/

charge/developing

voltage drops while

printing?

Defective agitator in

the toner supplying part

of the

toner cartridge

->Replace the

toner cartridge

Check if the ’guide deve

spring’ works OK and

repair/repalce

Check high voltage

output and repair/

replace terminals, HVPS

Replace lamp

Clean the window of PTL

Bad images

around the no image

area?

Irregularity of toner

supply from the

toner cartridge

-> Replace the

toner cartridge

Light distortion due to

the mirror ruined or

LSU’s diffused reflection

-> Replace LSU

NO

NO NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

Page 18

Service Manual

Troubleshooting

7-18

Samsung Electronics

White Spot

Is it regular

interval of 94.3mm?

Obstacles stuck on OPC’s

surface

-> Clean the OPC and

machine or replace

toner cartridge

When putting in/out the

drum cartridge

, scratch is made

-> Replace the

drum cartridge

Transfer

voltage is normal?

D/R in the

toner cartridge

unit has the defect

-> Replace the

toner cartridge

Too high voltage supplied

due to the setting error of

transfer voltage

-> Adjust/replace HVPS

NO

NO

YES

YES

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 19

Troubleshooting

Service Manual

7-19

Samsung Electronics

Trembling at the End When OHP Printing

Recommended

OHP film used?

Inserted over

than 10 films into

the MPF?

When multi-page OHP printng,

less than 10 films are

guranteed. (Reduce the

number of films and re-insert

after paper check LED if off)

Use the recommended film

When OHP

printing, does the fan

temporarily stops

and revolves?

Use the recommended film

Other parts are touching the

fan and prevents it from

revolution

-> Check and repair

NO

NO NO

YES

YES

YES

Page 20

Service Manual

Troubleshooting

7-20

Samsung Electronics

Poor Fusing Grade

After printing

completed, any error

related fuser?

Both ends

of thermostat

open?

Replace thermostat

and re-test

Replace the control

component on Main

PBA

Check any contact

problem in thermistor

and repair

The machine

placed under the

severe low tempera

ture for a long

time?

Place the machine

at normal

temperature and

re-test

While printing,

the voltage of pin 60

of U36 (CPU) on Main

PBA is 2.1V

- 2.6V?

Thermistor’s

contact is OK?

Open the top

cover. When black

printing, is the fuser NIP

width is 3.0-

3.5mm?

The paper used is too

thick or contains too

much cotton in it

-> Re-test with the

recommended paper

Check if the hardness of

P/R, and spring force is OK?

(hardness: 24 degree,

spring’s force: 3 Kg)

Re-assemble

thermistor

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

Page 21

Troubleshooting

Service Manual

7-21

Samsung Electronics

7.4 Malfunction

No power

Fuser Error

Cover open

Jam 0

Jam 1

1. Check power is supplying

2. Check fuse F1 open

1. Thermostat open

2. AC wire open

3. Thermistor wire open

4. Main PBA

1. When close Side cover, check the lever is

pressed

2. Micro switch’s contact

3. CPU and related circuit

Check where Jam 0 happens

1. Paper is not picked up

2. Paper is located in feed sensor

3. Happened when inserting specific papers such

as envelope into the MPF (Multipurpose Paper

Feeder)?

4. Happened when inserting specific papers such

as envelope into the Manual Feeder?

5. Is the Stacker Extender is folded out?

6. Does not the Guide Adjust distort the papers

Paper is stopped in just after of fuser unit.

1. If supplying power differs from machine’s

power rating, replace the machine.

2. Replace it.

1. Detach AC connector and measure the

resistane between pin 1 and 2. If it is

megohm, thermostat is open, Replace it.

2. Check bad connector contact or wire is cut.

3. Check thermistor wire and its connection.

4. Replace Main PBA

1. Open Side cover and press the lever with

pen. If Controller detects cover close, there

is some mechanical trouble in Side cover

and lever’s assembly. If not so there is electrical problem.

1. Check whether solenoid is working or not

by using Engine test mode

2. Check feed sensor malfunction.

3. Re-try inserting a fewer papers.

•fan the papers and align

•take out the loaded papers and insert

them reverse direction

4. Take out the loaded papers and insert them

reverse direction

•inserted papers as recommended for

Manual Feeding?

•When loading, tap the papers until paper

detect sensor senses loading

5. When using long papers, use the Stacker

Extender

6. Adjust Guide to fit the paper width

1. It is mostly resulted from double feeding.

Check paper is well stocked in feeder.

2. Check feed actuator position and actuator’s

operating. There may be stiff movind or

double reflection. If not so, check the operation of feed sensor by Engine test mode.

3. Check exit lever operation. Remore jam

and check actuator moving by hand. If actuator is too stiff, paper is wrapped around the

heat roller. Remove obstacles or replace.

Error Status Check Solution

Page 22

Service Manual

Troubleshooting

7-22

Samsung Electronics

Jam 2

Jam 2 at face-down

tray

Clutch error

High voltage error

Feeding obstacles

Skew

Stacking

Engine Error

Document Jam

Check where Jam 2 happens

1. Paper is curled and cannot exit.

2. Paper is curled in the exit cover?.

1. Then paper is not drawn in because of the

stack of papers in the Out tray.

2. Does it curl while coming out?

1. Check the spring of solenoid

2. Check the armature assembly/cushion

3. Electrical check

1. Check the terminal output voltage

2. Check HVPS

Does the Plate-knockup prevent the paper

loading?

Is the Guide adjust set to the paper width?

1. Took out the Stacker extender to support long

papers?

2. Stacked too many papers more than Stacker

can hold?

Check CBF Harness_CN7.(Main PBA to LSU)

Document is not picked up(in ADF).

Document is stopped after it has fed into the ADF.

Does it curl while coming out?

1. Remove paper using pinset or some tool

and watch if separate claws have any troble.

Clean around fuser.

2. Check locking works wells. Watch whether

the ribs of exit cover hace any burr or resisitive

edge. If they do, remove obstacles or replace.

1. Load recommended quantity of papers

2. Open the Cover Front and check whether

roller or spring, which are related to paper

out, is not out of position. If so, re-locate or

replace.

1. Check whether the spring is expanded or not.

2. Check armature is well installed. It may be

unstable assemble.

3. Remove the Main PBA.

1. Remove the Toner cartridge and open the

cover and press cover open switch lever

and measure the voltage with high voltage

probe and sending printing data. If the voltage is normal, change the toner cartridge.

2. Disassemble the left side cover, and check

HV of the solder side of HVPS and change it.

MPF :

Turn the power off and on. Open and close

the Side cover to return to the original state.

Cassette :

Adjust Guide to fit the paper width.

Fit the paper width using the Guide adjust.

1. Use extender as per the paper length.

2. The Face-up stacker normally can hold 100

pages when using 75g/m2, however, stacking capacity can be lowered depending on

the type of papers.

Refer to troubleshooring “ENGINE ERROR”.

1. Check document is well stocked in ADF.

2. Check whether document was been fastened together by staple or clip.

3. Load recommended quantity of papers.

1. Check whether the Reg. sensor is working

or not.

2. Check whether the Feed Roller is working

or not.

1. Check the Open Cover whether there are

bosses.

2. Check the ADF ass'y is well assemble.

Error Status Check Solution

Page 23

Troubleshooting

Service Manual

7-23

Samsung Electronics

No Power (LCD NO display LED Off)

Plug in the

power cord?

The power

voltage supplying is

the same as

rating?

The fan

revolves when

powered on?

LEDs blink

once when

powered on?

Shortage on

the OPE panel

board?

Repair/replace the

board

Check the voltage first and plug

the power cord

Supply the power as the rating

Connections

on board are OK?

Re-connect firmly

and re-test

The connection

error between

controller board

and panel board

or malfunction

of boards.

-> Replace the

boards

Fuse of SMPS

if open?

Shortage

between 5V and

GND, or between

24V and

GND?

Replace the fuse

Toner cartridge

is in the set?

Detect failure due to the

board which detects side

cover open or switch error

-> Replace the board or switch

Put in the

cartridge

Remove the shortage

or replace the board

NO

NO

NO

NO

NO

NO

NO NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

Page 24

Service Manual

Troubleshooting

7-24

Samsung Electronics

Fuser Error

Less than 10W?

AC is being supplied?

The voltage

of pin #60 of U36

(CPU) on the Main PBA

is about 2.65V when

printing?

END

Thermostat is open due to the heat etc.

-> Replace the thermostat

The voltage of pin #6 of U5

on the Main PBA is about

3.2V?

If not check the

CN4 on the power board.

Measure the resistance

at the both ends of AC

Line with covers open

Remove the covers

Re-assemble the top

cover and close it

Thermistor, connecting point or engine

board defect -> Repair/replace the

component/board

NO

NO

NO

YES

YES

YES

Page 25

Troubleshooting

Service Manual

7-25

Samsung Electronics

Paper Jam (Mis-Feeding)

Sounds the

solenoid on when starts

print?

Does the

paper move?

Does the

paper move more than

100mm?

The Main PBA board defected

-> Replace boards

The solenoid defected

-> Replace it

The pick-up unit is

assembled wrong

-> Re-assemble or replace

the unit

Feeder

sensor is assembled

reverse?

Switch them

The sensor and

Main PBA defected

-> Repair/replace

Too many

papers in the

feeder?

Paper guides

fit the paper width?

Paper end curled?

Does the

extender pulled out?

<Recommendation>

Use the MPF for the thick

paper such as envelope

and cardstock

Reduce the amount

and re-test

Take out the paper

and re-insert

Use the recommended

and quality paper

Pull out the

extender

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES YES

Page 26

Service Manual

Troubleshooting

7-26

Samsung Electronics

Paper Jam (Jam 1)

Paper

stopped before

the OPC?

Check the LSU and

if it has the defect

replace it

Paper

stopped before

the fuser?

Severe skew

when feeding?

Adjust the paper guides to fit the

paper width

The force of springs pressing the

developer is weak

-> Check guide-DEVE

The paper

came out through

between fuser and

developer?

Too thin

or sensitive paper to

static electricity?

Use the recommended

paper

Check guide transfer

is grounded Check

the shutter prevents

feeding

Check the input path

to the fuser (such as

mis-assembly)

The

actuator of

paper exit sensor

works OK?

Check the actuator exists and its

operation and around the Main PBA

-> Replace

Is the paper

rolled around the

presseure

roller?

Remove the fuser, remove

the paper and replace the

pressure roller, if necessary

Feeds

multiple pages?

Remove any factors

Check the roller

and ribs of fuser

are in place, and

remove burrs, if

any

-> Remove the

factors of jam

NO NO NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

Page 27

Troubleshooting

Service Manual

7-27

Samsung Electronics

Engine Error

Check

CBF Harness-CN7

(Main B’D to

LSU)

Check

Main B’D CN7-9,

P_MOTOR Signal

( )

Check

Main B’D CN7-8,

LREADY Signal

( )

END

Try again to connector or

Replace connector

Replace Main PBA

Replace LSU

Replace Main PBA

Replace LSU

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

Check

Main B’D CN7-4,

LDON Signal

( )

Check

Main B’D CN7-1,

HSYNC Signal

( )

Page 28

Service Manual

Troubleshooting

7-28

Samsung Electronics

7.5 Toner Cartridge and Drum Cartridge Service

It is not guaranteed for the default caused by using other toner and the drum cartridge other than the cartridge supplied by the Samsung Electronic or caused by non-licensed refill production.

Precautions on Safe-keeping of the Drum Cartridge

Excessive exposure to direct light more than a few minutes may cause damage to the drum cartridge.

Service for the Life of Toner Cartridge

If the printed image is light due to the life of the toner, you can temporarily improve the print quality by

redistributing the toner(Shake the toner cartridge), however, you should replace the toner cartridge to solve

the problem thoroughly.

Service for Judgement of Inferior Expendables and the Standard of Guarantee

Please refer to User's Manual or Instructions on Fax/Printer Expendables SVC for the judgement of inferior

expendables and the standard of guarantee besides this service manual.

Page 29

Troubleshooting

Service Manual

7-29

Samsung Electronics

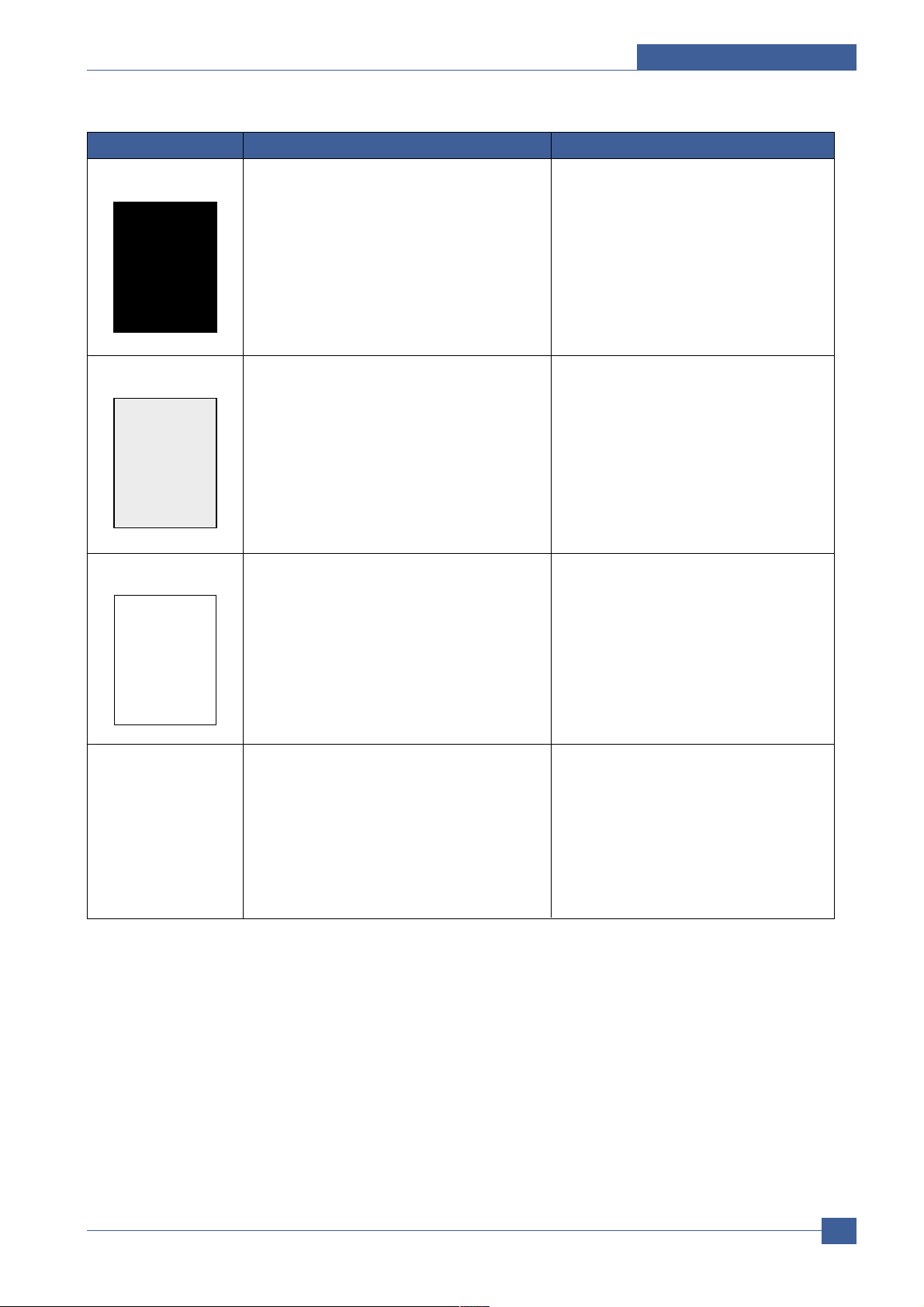

7.5.1 Signs and Measures at Poor toner cartridge

Light image and

partially blank

image

(The life is ended.)

• The printed image is light

or unclean and untidy.

• Some part of the image is

not printed.

• Periodically a noise as

"tick tick" occurs.

1. If the image is light or unclean

and untidy printed image Shake the toner cartridge and

then recheck.

(1)NG: Check the weight of the

toner cartridge

(2)OK: Lack of toner, so the life

is nearly closed.

2. Some part of image is not printed

- Shake the toner cartridge and

then recheck.

(1)NG: Check the weight of the

toner cartridge and clean

the LSU window with a

cotton swab, then recheck.

(2)OK: Lack of toner, so the life

is nearly closed.

3. Periodically a noise as "tick tick"

occurs - Measure the cycle and

the weight of the toner cartridge.

4. White vertical stripes on the

whole screen or partly :

Check the weight of the toner

cartridge.

1. All of 1, 2, 3 aboveIf it become better by shaking,

replace with a new toner cartridge

after 50-100 sheets in the closing

state of the life span.

2. In case of 2If it becomes better after cleaning

the LSU window, then the

toner cartridge is normal.

(Because of foreign substance

on the LSU window, the image

has not been printed partly.)

3. In case of 3If the cycle of noise is about 2

seconds, the toner inside the

toner cartridge has been nearly

exhausted. (Purchase and

replace with a new toner cartridge

after using about 200 sheets at

the point of occurrence)

4. In case of 3This is a phenomenon caused

by lack of toner, so replace with

a new toner cartridge.

Toner

Contamination

• Toner is fallen on the

papers periodically.

• Contaminated with toner

on prints partly or over the

whole surface.

1. Toner is fallen on the paper

periodically .

(1)Check the cycle of the falling

of the toner.

(2)Check the appearance of both

ends of the toner cartridge

and the drum cartridge.

2.The center of the printed matter

is contaminated with toner.

(1)Check whether foreign

substances or toner are stuck

to the terminal (contact point)

of the toner cartridge and the

drum cartridge.

(2)Check whether the state of the

terminal assembly is normal.

1. If both ends of the OPC drum

are contaminated with toner:

Check the life of the toner

cartridge and the drum cartridge.

2. Check whether it could be

recycled.

Fault Signs Cause & Check Solution

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 30

Service Manual

Troubleshooting

7-30

Samsung Electronics

White or Black

spot

• Light or dark black dots on

the image occur

periodically .

• White spots occur in the

image periodically.

1. If light or dark periodical black

dots occur, this is because the

deve rollers are contaminated

with foreign substance or paper

particles.

(1)38.3mm interval :

Charged roller

(2)94.3mm interval :

OPC cycle

2. If white spots occur in a black

image at intervals of 94.3 mm,

or black spots occur elsewhere,

the OPC drum is damaged or

foreign substance is stuck to the

surface.

3. If a black and white or graphic

image is partially broken at irregular intervals, the transfer roller's life

has been expired or the transfer

voltage is abnormal.

1. In case of 1 above Run OPC Cleaning Mode Print

4-5 times repeatedly to remove.

Especially check foreign substance on the OPC surface, then

remove them with a clean gauze

moistened with IPA(Isopropyl

Alcohol) not to damage OPC if

necessary .

Caution : Never use usual alcohol.

2. In case of 2 If they are not disappeared by

running OPC Cleaning Mode

Print 4-5 times.

: at intervals of 94.3mm -

Replace the OPC Drum.

: at intervals of 38.3mm -

Remove foreign substance,

Clean the Charged Roller

: Broken image -

Replace the toner cartridge

according to carelessness.

3. In case of 3 - Exchange the

transfer roller because the life of

the transfer roller in use has

been expired. (Check the transfer

voltage and readjust if different.)

Recycled product • Poor appearance of the

toner cartridge and the

drum cartridge.

• Unclean and rough

printouts.

• Bad background in the

image.

1. Poor appearance of the toner

cartridge and the drum cartridge.

(1)Check the damage to label

and whether different materials

are used.

(2)Check the appearance of

parts of the toner cartridge

and the drum cartridge, such

as frame, hopper.

2. Unclean and rough printouts.

(1)Check whether foreign sub-

stance or toner are stuck to

the terminal (contact point) of

the toner cartridge and the

drum cartridge.

(2)Check whether the state of the

terminal assembly is normal.

1. In case of 1 (1)If there is an evidence of dis-

assembling the toner cartridge.

(2)If materials other than normal

parts of the toner cartridge are

added or substituted.

2. In case of 2 - If there are any

abnormals in connection with the

situation of 1.

(1)It occurs when the toner cartridge

is recycled over 2 times.

(2)If toner nearly being expired

are collected to use, it is judged

as the recycled toner cartridge.

Fault Signs Cause & Check Solution

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Digital Printer

Page 31

Troubleshooting

Service Manual

7-31

Samsung Electronics

Ghost & Image

Contamination

• The printed image is too

light or dark, or partially

contaminated black.

• Totally contaminatedblack.

(Black image printed out)

1. The printed image is too light or

dark, or partially contaminated

black.

(1)Check whether foreign sub

stance or toner are stuck to

the terminal(point of contact)

of the toner cartridge.

(2)Check whether the terminal

assembly is normal.

2. Totally contaminated black.

(Black image printed out)

(1)Check whether foreign sub

stances are stuck to the terminal

(point of contact) of the toner

cartridge and the drum cartridge

and the state of assembly.

(Especially check the charged

roller terminal.)

1. All of 1, 2, 3 above

(1)Remove toner and foreign

substances adhered to the

contact point of the toner

cartridge.

(2)The contact point of the unit

facing that of the toner cartridge

also must be cleaned.

(3)If the terminal assembly is

unsafe:

• Fully stick the terminal to or

reassemble it after disassembling.

• Disassemble the side plate and

push the terminal to be stuck,

then reassemble it.

2. In case of 2

It is a phenomenon when the

OPC drum of the drum cartridge

is not electrically charged. Clean

the terminals of the charged

roller, then recheck it.

Fault Signs Cause & Check Solution

Page 32

Service Manual

Troubleshooting

7-32

Samsung Electronics

7.6 The cause and solutions of bad environment of the software

7.6.1 The printer is not working (1)

1. Check if the PC and the printer is properly connected and the toner cartridge installed.

2. Printing is nor working in the Windows.

3. Check if the printer cable is directly connected to

peripheral devices

1. Replace the printer cable. If the problems not solved even after the

cable replaced, check the amount of the remaining tone.

2. Check if the connection between PC and printer port is proper. If

you use windows, check if the printer driver in the controller is set

up. If the printer driver is properly set up, check in which program

the printing is not working. The best way to find out is to open the

memo pad to check the function of printing. If it is not working in a

certain program, adjust the setup the program requires.

Sometimes, the printout is normal within the Windows basic programs, but it's not working in a particular program. In such case,

install the new driver again. If not working in the Windows basic

program, Check the setup of the port of CMOS is on ECP. And

check the address of IRQ 7 and 378

3. If the scanner needs to be connected to the printer, first the

remove the scanner from the PC to see if the printer is properly

working alone.

Check and Cause Solution

• Description : While Power turned on, the printer is not working in the printing mode.

1. Secure more space of the hard disk.

2. Printing error occurs even if there is enough

space in the hard disk.

3. Check the parallel-port-related items in the CMOS

Setup.

4. Reboot the system to print.

1. Not working with the message 'insufficient printer memory' means

hard disk space problem rather than the RAM problem. In this

case, provide more space for the hard disk. Secure more space

using the disk utilities program.

2. The connection of the cable and printer port is not proper. Check if

the connection is properly done and if the parallel port in CMOS is

rightly set up.

3. As a printer port, Select ECPor SPP among SPP(Normal), ECP,

and EPP modes(increase printing speed) SPP normal mode support 8-bit data transfer, while ECPMode transfer the 12-bit data.

4. If the regular font is not printing, the cable or the printer driver may

be defective. Turn the PC and printer off, and reboot the system to

print again. If not solved, double-click the printer in my computer If

the regular fonts are not printed this time again. the cable must be

defective so replace the cable with new one.

Check and Cause Solution

• Description : After receiving the printing order, no response at all or the low speed of printing occurs due to wrong

setup of the environment rather than malfunction of the printer itself.

7.6.2 The printer is not working (2)

Page 33

Troubleshooting

Service Manual

7-33

Samsung Electronics

1. Set up the parallel port in the CMOS SETUP.

2. Printer Driver Error.

3. Error message from insufficient memory.

(The printing job sometimes stops or due to

insufficient virtual memory, but it actually comes

from the insufficient space of the hard disk.)

1. Select SPP(Normal) or ECP LPT Port the among ECP, EPP or

SPP in the CMOS Setup.

2. Check the printer in My Computer.(to see if the printer driver is

compatible to the present driver or delete the old driver, if defective

and reinstall the new driver)

3. Delete the unnecessary files to secure enough space of the hard

disk and start printing job again.

Check and Cause Solution

• Description : The printing is not working properly even when the cable has no problem. (even after the cable is

replaced) If the printer won't work at all or the strange fonts are repeated, the printer driver may be

defective or wrong setup in the CMOS Setup.

How to delete the data in the spool manager.

7.6.3 Abnormal Printing

1. Insufficient space of the hard disk in the directory

assigned for the basic spool.

2. If the previous printing error not solved.

3. When expected to collide with other program.

4. When an application program or the printer driver

is damaged.

5. When some files related to OS are damaged or

virus infected.

6. Memory is less than suggested one.

1. Delete the unnecessary files to provide more space to start printing

job.

2. If there are some files with the extension name of ****.jnl, Delete

them and Reboot the Windows to restart printing job.

3. Shut down all other programs except the current one, if possible.

4. Delete the printer driver completely and reinstall it.

5 After rebooting the computer, check for viruses, restore the dam-

aged files and reinstall the program to do the printing job.

6. Add up enough memory to the PC.

Check and Cause Solution

• Description : To spool which stands for "simultaneous peripheral operations online" a computer document or task

list (or "job") is to read it in and store it, usually on a hard disk or larger storage medium so that it can

be printed or otherwise processed at a more convenient time (for example, when a printer is finished

printing its current document).

7.6.4 SPOOL Error

In the spool manager, the installed drivers and the list of the documents waiting to be printed are shown.

Select the document to be deleted and check the delete menu.

If you intend to delete the current document being printed, the data being transferred to the printer will be put out and

then the document is removed. Before choosing the document, the menu is still inactive.

Or put the document out of the list and repeat the routine as in the above or finish the spool manager.

Page 34

Service Manual

Troubleshooting

7-34

Samsung Electronics

Loading...

Loading...