Page 1

Service Manual

■ 33 ppm(A4) Network-ready MFP

■ Toner cartridge

: Initial : 4K / Sales : 4K,10K

■ Paper handling

: 500 sheets Standard cassette

: 500 sheets Optional cassette

: 50 sheets DADF

The keynote of Product

DIGITAL LASER MFP

SCX-5835NX_5935NX Series

■ 160GB HDD

■ High Performance CCDM

■ Easy to install ( CRU & Option )

■ Color Graphic Touch-Screen LCD (7”)

■ Low Cost per Page

■ Direct USB

Page 2

GSPN (Global Service Partner Network)

North America : service.samsungportal.com

Latin America : latin.samsungportal.com

CIS : cis.samsungportal.com

Europe : europe.samsungportal.com

China : china.samsungportal.com

Asia : asia.samsungportal.com

Mideast & Africa : mea.samsungportal.com

ⓒ

Samsung Electronics Co.,Ltd. June. 2010

Printed in Korea.

VERSION NO. : 1.00 CODE : 5835-N0000E

Page 3

chapter 1 Precautions

1.1 Safety Warning …………………………………………………… 1-1

1.2 Caution for safety ………………………………………………… 1-2

1.3 ESD Precautions ………………………………………………… 1-5

1.4 Super Capacitor or Lithium Battery Precautions ……………… 1-5

chapter 2 Product Overview

2.1 Product Overview ………………………………………………… 2-1

2.1.1 Product Summary …………………………………………… 5-1

Contents

2.1.2 Specications ………………………………………………… 2-2

2.1.3 Model Comparison ………………………………………… 2-11

2.2 System Overview ………………………………………………… 2-14

2.2.1 System Conguration ……………………………………… 2-15

2.2.2 Hardware Conguration …………………………………… 2-15

2.2.3 Mechanic Conguration …………………………………… 2-22

chapter 3 Disassembly and Reassembly

3.1 Disassembly and Reassemblyons on Disassembly ………… 3-1

3.2 Maintenance Parts ……………………………………………… 3-2

3.3 General Disassembly …………………………………………… 3-3

3.3.1 Fuser Unit …………………………………………………… 3-3

3.3.2 DADF Pick up unit and rubber pad ……………………… 3-3

3.3.3 Pick up roller ………………………………………………… 3-4

3.3.4 Transfer roller ……………………………………………… 3-4

3.3.5 Cover ………………………………………………………… 3-5

3.3.6 DADF Board ………………………………………………… 3-7

3.3.7 Scan Assy …………………………………………………… 3-8

3.3.8 Middle Cover ………………………………………………… 3-10

Page 4

3.3.9 HDD/ Main PBA/ Fax board ……………………………… 3-11

3.3.10 SMPS board ……………………………………………… 3-12

3.3.11 Main Drive unit ……………………………………………… 3-12

3.3.12 HVPS board ………………………………………………… 3-13

3.3.13 LSU Unit …………………………………………………… 3-13

chapter 4 Alignment and Troubleshooting

4.1 Alignment and Adjustments ……………………………………… 4-1

4.1.1 Paper path …………………………………………………… 4-1

4.1.2 Clearing Paper Jams ……………………………………… 4-2

Contents

4.1.3 Abnormal Image Printing and Defective Roller …………… 4-13

4.1.4 Control Panel overview …………………………………… 4-15

4.1.5 Understanding The Status LED …………………………… 4-18

4.1.6 Menu overview ……………………………………………… 4-19

4.1.7 Firmware Upgrade ………………………………………… 4-31

4.1.8 Diagnostics …………………………………………………… 4-35

4.2 Troubleshooting…………………………………………………… 4-59

4.2.1 Procedure of Checking the Symptoms …………………… 4-59

4.2.2 Error Message ……………………………………………… 4-60

4.2.3 Solution ……………………………………………………… 4-64

chapter 5 System Diagram

5.1 Block Diagram …………………………………………………… 5-1

5.2 Connection Diagram……………………………………………… 5-3

chapter 6 Reference Information

6.1 Tool for Troubleshooting ………………………………………… 6-1

6.2 Acronyms and Abbreviations …………………………………… 6-2

Page 5

6.2.1 Acronyms …………………………………………………… 6-2

6.2.2 Service Parts ………………………………………………… 6-4

6.3 The Sample Pattern for the Test ………………………………… 6-8

6.4 Selecting a location ……………………………………………… 6-9

attached Exploded Views & Parts List

Contents

Page 6

Precautions

1. Precautions

In order to prevent accidents and damages to the equipment please read the precautions listed below

carefully before servicing the product and follow them closely.

1.1 Safety warning

(1) Only to be serviced by a factory trained service technician.

High voltages and lasers inside this product are dangerous. This product should only be serviced by a

factory trained service technician.

(2) Use only Samsung replacement parts.

There are no user serviceable parts inside the product. Do not make any unauthorized changes or

additions to the product as these could cause the product to malfunctions and create an electric shocks

or re hazards.

(3) Laser Safety Statement

The product is certied in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1

Subchapter J for Class 1(1) laser products, and elsewhere, it is certied as a Class I laser product conforming to the requirements of IEC 825. Class I laser products are not considered to be hazardous. The

laser system and product are designed so there is never any human access to laser radiation above a

Class I level during normal operation, user maintenance, or prescribed service condition.

Warning >> Never operate or service the product with the protective cover removed from Laser/Scanner

assembly. The reected beam, although invisible, can damage your eyes.

When using this product, these basic safety pre-cautions should always be followed to reduce

risk of re, electric shock, and personal injury.

Service Manual

1-1

Samsung Electronics

Page 7

Precautions

Service Manual

1-2

Samsung Electronics

1.2 Caution for safety

1.2.1 Toxic material

This product contains toxic materials that could cause illness if ingested.

(1) If the LCD control panel is damaged, it is possible for the liquid inside to leak. This liquid is toxic.

Contact with the skin should be avoided. Wash any splashes from eyes or skin immediately and contact

your doctor. If the liquid gets into the mouth or is swallowed, see a doctor immediately.

(2) Please keep imaging unit and toner cartridge away from children. The toner powder contained in the

imaging unit and toner cartridge may be harmful, and if swallowed, you should contact a doctor.

1.2.2 Electric shock and re safety precautions

Failure to follow the following instructions could cause electric shock or potentially cause a re.

(1) Use only the correct voltage, failure to do so could damage the product and potentially cause a re or

electric shock.

(2) Use only the power cable supplied with the product. Use of an incorrectly specied cable could cause the

cable to overheat and potentially cause a re.

(3) Do not overload the power socket, this could lead to overheating of the cables inside the wall and could

lead to a re, and/or cause your ceiling or lamp lights to icker.

(4) Do not allow water or other liquids to spill into the product, this can cause electric shock. Do not allow

paper clips, pins or other foreign objects to fall into the product, these could cause a short circuit leading

to an electric shock or re hazard.

(5) Never touch the plugs on either end of the power cable with wet hands, this can cause electric shock.

When servicing the product, remove the power plug from the wall socket.

(6) Use caution when inserting or removing the power connector. When removing the power connector, grip it

rmly and pull. The power connector must be inserted completely, otherwise a poor contact could cause

overheating possibly leading to a re.

(7) Take care of the power cable. Do not allow it to become twisted, bent sharply around corners or wise

damaged. Do not place objects on top of the power cable. If the power cable is damaged it could overheat

and cause a re. Exposed cables could cause an electric shock. Replace the damaged power cable

immediately, do not reuse or repair the damaged cable. Some chemicals can attack the coating on the

power cable, weakening the cover or exposing cables causing re and shock risks.

(8) Ensure that the power sockets and plugs are not cracked or broken in any way. Any such defects should

be repaired immediately. Take care not to cut or damage the power cable or plugs when moving the

machine.

(9) Use caution during thunder or lightning storms. Samsung recommends that this machine be disconnected

from the power source when such weather conditions are expected. Do not touch the machine or the

power cord if it is still connected to the wall socket in these weather conditions.

(10) Avoid damp or dusty areas, install the product in a clean well ventilated location. Do not position the

machine near a humidier or in front of an air conditioner. Moisture and dust built up inside the machine

can lead to overheating and cause a re or cause parts to rust.

(11) Do not position the product in direct sunlight. This will cause the temperature inside the product to rise

possibly leading to the product failing to work properly and in extreme conditions could lead to a re.

(12) Do not insert any metal objects into the machine through the ventilator fan or other part of the casing, it

could make contact with a high voltage conductor inside the machine and cause an electric shock.

Page 8

Precautions

Service Manual

1-3

Samsung Electronics

1.2.3 Handling precautions

The following instructions are for your own personal safety to avoid injury and so as not to damage the

product.

(1) Ensure the product is installed on a level surface, capable of supporting its weight. Failure to do so could

cause copy quality problems, and/or the product to tip or fall.

(2) The product contains many rollers, gears and fans. Take great care to ensure that you do not catch your

ngers, hair or clothing in any of these rotating devices.

(3) Do not place any small metal objects, containers of water, chemicals or other liquids close to the product

which if spilled could get into the machine and cause damage or a shock or re hazard.

(4) Do not install the machine in areas with high dust or moisture levels, beside on open window or close to a

humidier or heater. Damage could be caused to the product in such areas.

(5) Do not place candles, burning cigarettes, etc on the product, These could cause a re.

1.2.4 Assembly / Disassembly precautions

Replace parts carefully and always use Samsung parts. Take care to note the exact location of parts and also

cable routing before dismantling any part of the machine. Ensure all parts and cables are replaced correctly.

Please carry out the following procedures before dismantling the product or replacing any parts.

(1) Check the contents of the machine memory and make a note of any user settings. These will be erased if

the main board or network card is replaced.

(2) Ensure that power is disconnected before servicing or replacing any electrical parts.

(3) Disconnect interface cables and power cables.

(4) Only use approved spare parts. Ensure that part number, product name, any voltage, current or

temperature rating are correct.

(5) When removing or re-tting any parts do not use excessive force, especially when tting screws into

plastic.

(6) Take care not to drop any small parts into the machine.

(7) Handling of the OPC Drum

- The OPC Drum can be irreparably damaged if it exposed to light.

Take care not to expose the OPC Drum either to direct sunlight or to uorescent or incandescent room

lighting. Exposure for as little as 5 minutes can damage the surface of the photoconductive properties

and will result in print quality degradation. Take extra care when servicing the product. Remove the OPC

Drum and store it in a black bag or other lightproof container. Take care when working with the Covers

(especially the top cover) open as light is admitted to the OPC area and can damage the OPC Drum.

- Take care not to scratch the green surface of OPC Drum Unit.

If the green surface of the Drum Cartridge is scratched or touched the print quality will be compromised.

Page 9

Precautions

Service Manual

1-4

Samsung Electronics

1.2.5 Disregarding this warning may cause bodily injury

(1) Be careful with the high temperature part.

The fuser unit works at a high temperature. Use caution when working on the printer. Wait for the fuser to

cool down before disassembly.

(2) Do not put nger or hair into the rotating parts.

When operating a printer, do not put hand or hair into the rotating parts (Paper feeding entrance, motor,

fan, etc.). If do, you can get harm.

(3) When you move the printer

- When transporting/installing the equipment be sure to hold the positions as shown in the reference

chapter.

The equipment is quite heavy and weighs approximately 23.1Kg (including consumables), therefore pay

full attention when handling it.

- Be sure not to hold the movable parts or units (e.g. the control panel, DADF) when transporting the

equipment.

- Be sure to use a dedicated outlet with 110V/220Vpower input.

- The equipment must be grounded for safety.

- Select a suitable place for installation. Avoid excessive heat, high humidity, dust, vibration and direct

sunlight.

- Provide proper ventilation since the equipment emits a slight amount of ozone.

- To insure adequate working space for the copying operation, keep a minimum clearance of 10cm (3.9”

on the left, 10 cm (3.9”) on the right and 10 cm (3.9”) on the rear.

- The equipment shall be installed near the socket outlet and shall be accessible.

- Be sure to x and plug in the power cable securely after the installation so that no one trips over it.

Page 10

Precautions

Service Manual

1-5

Samsung Electronics

1.3 ESD precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly

called “Electrostatically Sensitive (ES) Devices” or ESDs. Examples of typical ESDs are: integrated

circuits,some eld effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component damage

caused by static electricity.

Caution >>Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

1. Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a known earth ground. Alternatively, employ a

commercially available wrist strap device, which should be removed for your personal safety reasons prior

to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESDs, place the assembly on a conductive surface,

such as aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity

of the assembly.

3. Use only a grounded tip soldering iron to solder or desolder ESDs.

4. Use only an “anti-static” solder removal device. Some solder removal devices not classied as “anti-static”

can generate electrical charges sufcient to damage ESDs.

5. Do not use Freon-propelled chemicals. When sprayed, these can generate electrical charges sufcient to

damage ESDs.

6. Do not remove a replacement ESD from its protective packaging until immediately before installing it.

Most replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil,

or a comparable conductive material.

7. Immediately before removing the protective shorting material from the leads of a replacement ESD, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

8. Maintain continuous electrical contact between the ESD and the assembly into which it will be installed,

until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as

the brushing together of clothing fabric and lifting one’s foot from a carpeted oor, can generate static

electricity sufcient to damage an ESD.

1.4 Super Capacitor or Lithium Battery Precautions

1. Exercise caution when replacing a super capacitor or Lithium battery. There could be a danger of explosion

and subsequent operator injury and/or equipment damage if incorrectly installed.

2. Be sure to replace the battery with the same or equivalent type recommended by the manufacturer.

3. Super capacitor or Lithium batteries contain toxic substances and should not be opened, crushed, or

burned for disposal.

4. Dispose of used batteries according to the manufacture? instructions.

Page 11

Product spec and feature

2. Product spec and feature

2.1 Product Overview

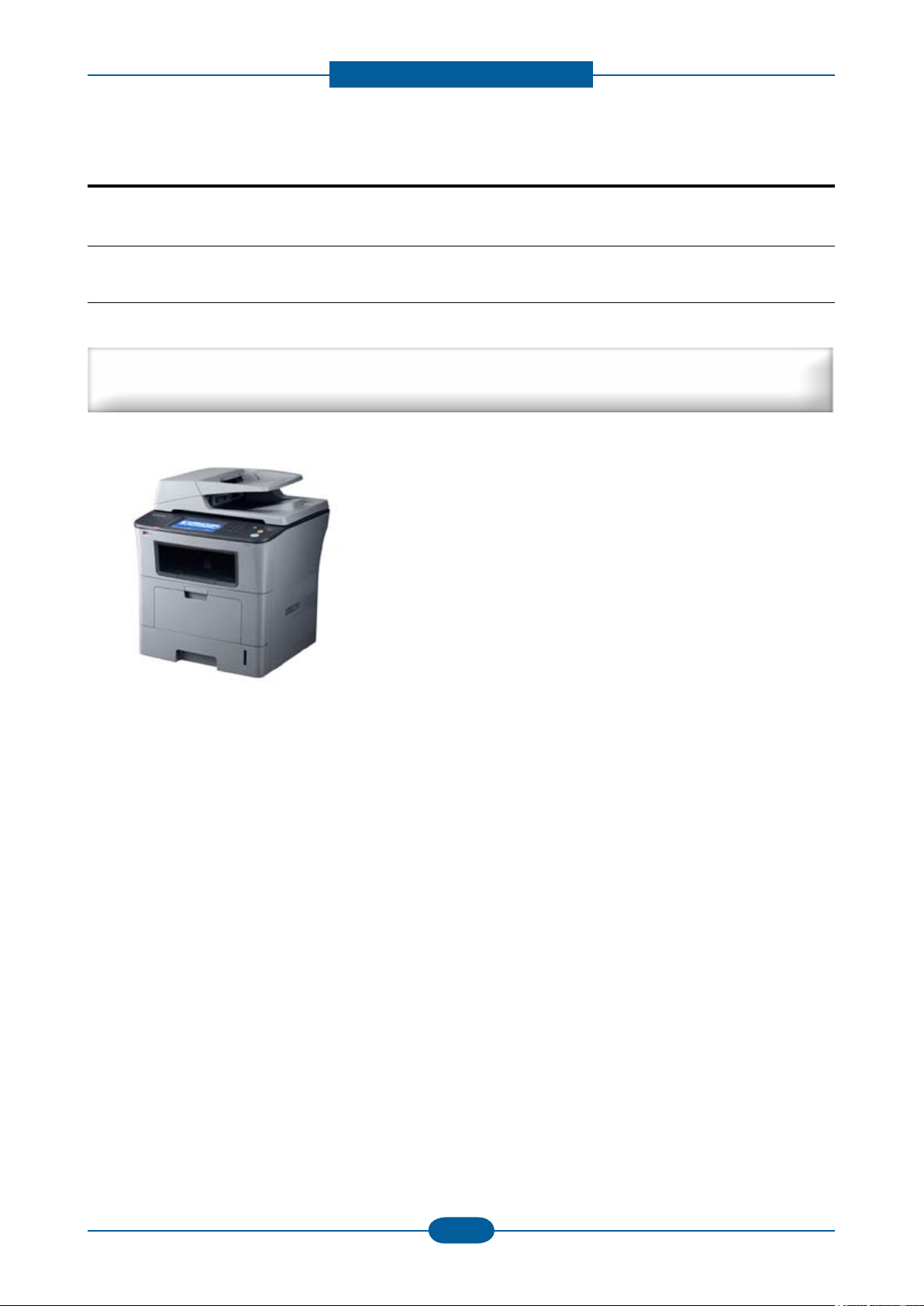

2.1.1 Product Summary

Premium LMFP with High Reliability and Quality

Target user : 10 Persons N/W Small Workgroup

■ 33 ppm(A4) Network-ready MFP

■ Toner cartridge

: Initial : 4K / Sales : 4K,10K

■ Paper handling

: 500 sheets Standard cassette

: 500 sheets Optional cassette

: 50 sheets DADF

■ 160GB HDD

■ High Performance CCDM

■ Easy to install ( CRU & Option )

■ Color Graphic Touch-Screen LCD (7”)

■ Low Cost per Page

■ Direct USB

Service Manual

2-1

Samsung Electronics

Page 12

Product spec and feature

Service Manual

2-2

Samsung Electronics

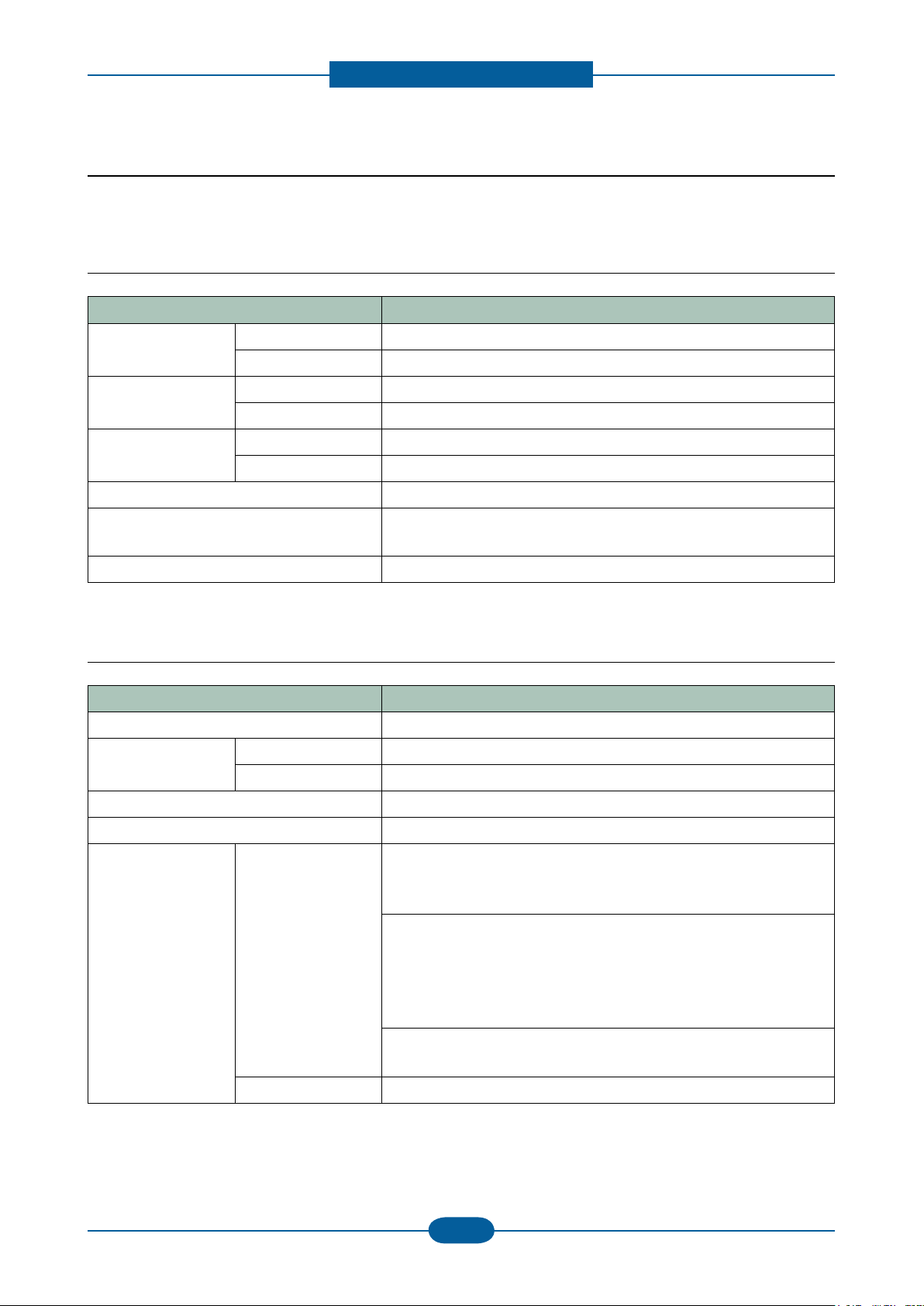

2.1.2 Specications

• Product Specications are subject to change without notice. See below for product specications.

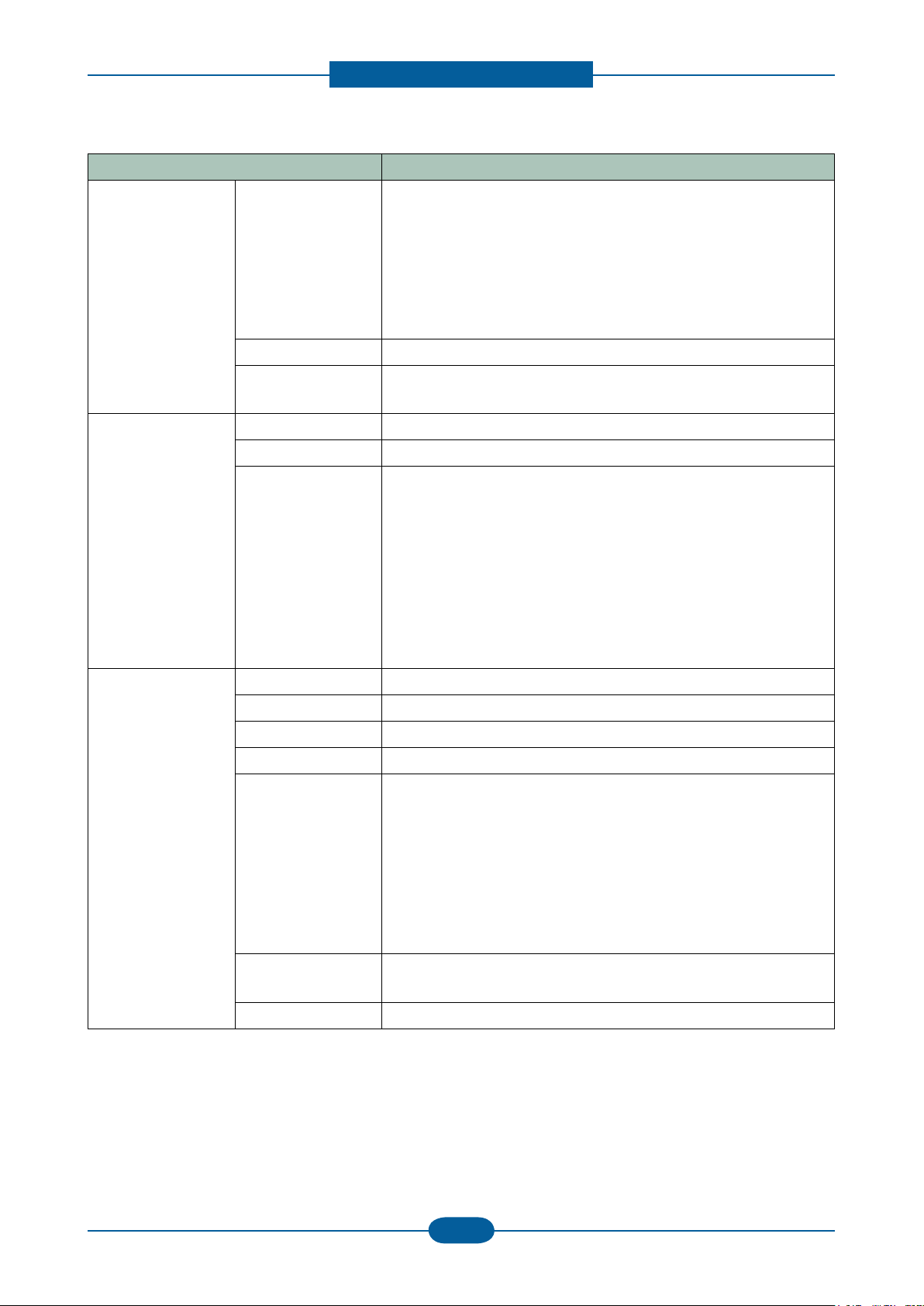

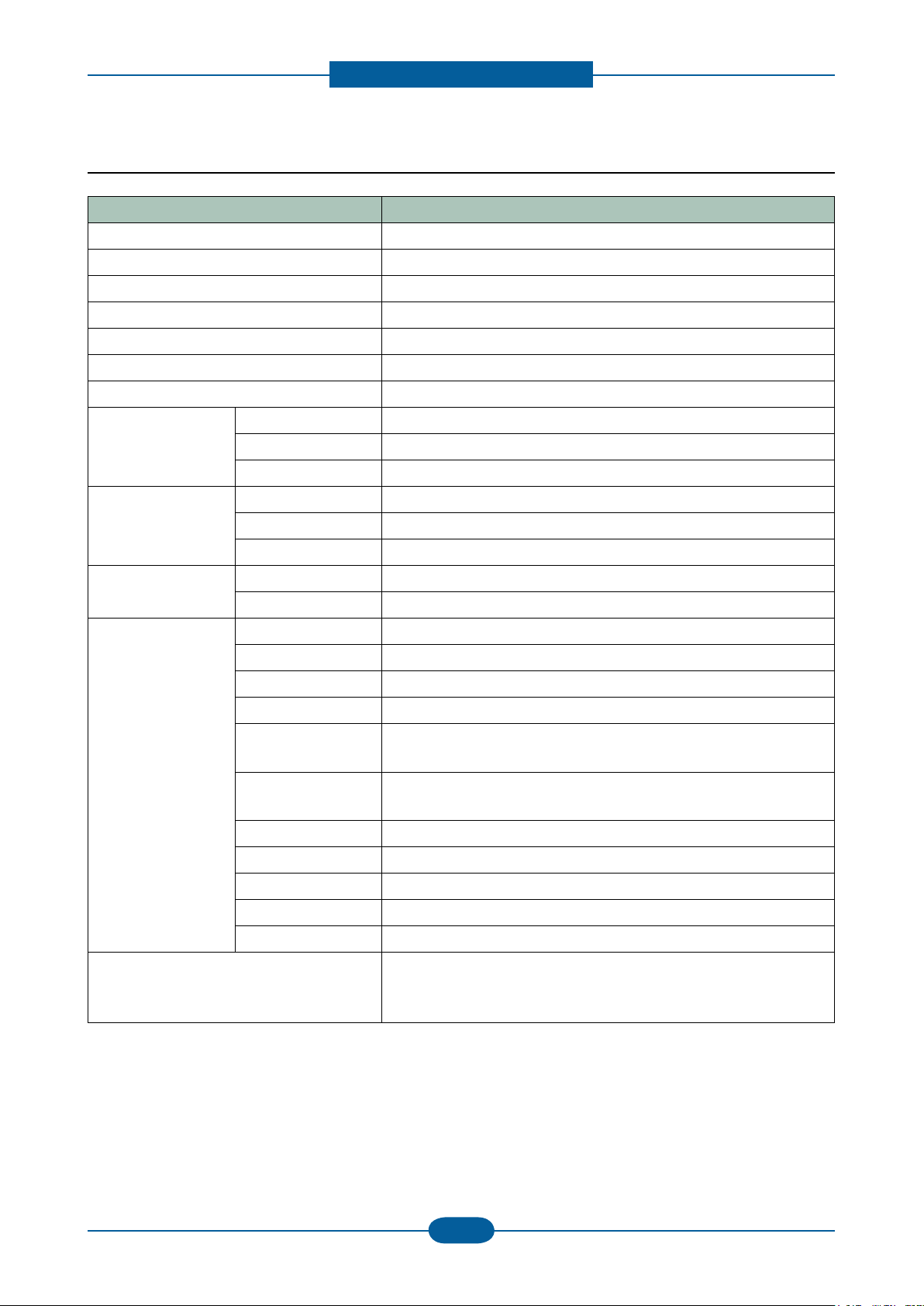

2.1.2.1 General Print Engine

Item Description

Engine Speed Simplex Up to 33 ppm in A4 (35 ppm in Letter)

Duplex Up to 17 ipm in A4 (18 ipm in Letter)

FPOT From Ready Less than 8.5 sec

From Power Save Less than 25 sec

Resolution Optical 600 x 600 dpi

Enhanced Addressible 1200 dpi

Printer Languages PCL6, PostScript3, PDF 1.4, TIFF, EPSON/IBM Pro (Israel only)

Fonts PCL:93 scalable, 1 bitmap, PS:136, OCR Font(OCR-A, OCR-B),

barcode, 2-D barcode

Downloadable Fonts Yes (PCL & PS3 S/W Font)

2.1.2.2 Controller & S/W

Item Description

Processor Chorus3 360Mhz

DRAM Std. 256 MB

Max. 512 MB

Memory Expansion 1 DDR1 SODIMM Slots(Option Memory: 256MB DDR1)

Storage(Std.) 80GB HDD

Printer driver Supporting OS [Windows]

- Windows 2000/XP(32/64bit)/2003(32/64bit)/Vista(32/64bit)/

2008(32/64bit)

[Linux]

- RedHat 8.0 ~ 9.0

- Fedora Core 1~4

- Madrake 9.2 ~ 10.1

- SuSE 8.2 ~ 9.2

[Mac]

- Mac OS X 10.3~10.5

Default Driver PCL6 (For Windows), PS (for Mac, Linux)

Page 13

Product spec and feature

Service Manual

2-3

Samsung Electronics

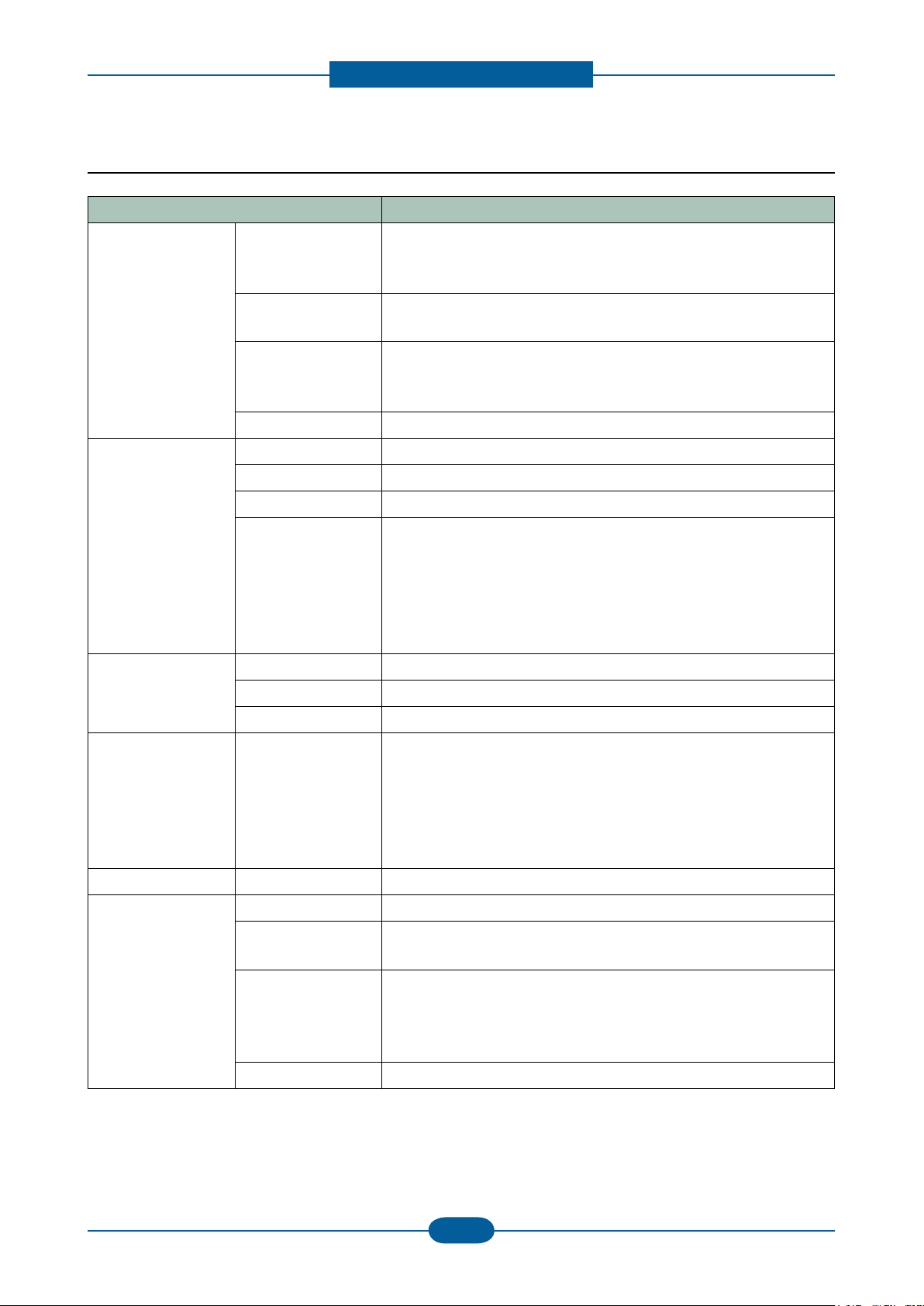

Item Description

Printer driver

(Continue..)

Driver feature [Windows]

- Watermark, Overlay, N-up printing, Poster printing

- Duplex, Quality, Color mode (Color, Gray scale)

- Support Color spec., Device color, color management

[Mac/Linux]

- N-up printing, Duplex, Quality

- Color mode (Color, Gray scale)

WHQL Windows 2000/XP(include 64bit)/2003/Vista

Language

Localization

English, French, German, Italian, Spanish, Korean, Russian,

Brazilian Portuguese

Scan driver TWAIN Yes (N/W and USB)

WIA Yes (USB Only)

Supporting OS [Windows]

- Windows 2000/XP(32/64bit)/2003/Vista(32/64bit)

[Linux]

- RedHat 8 ~ 9

- Fedora Core 1~4

- Madrake 9.2 ~ 10.1

- SuSE 8.2 ~ 9.2

[Mac]

- Mac OS 10.3~10.5

Application PC-FAX Yes

NW-FAX Yes (Supported through SmarThru Ofce)

OCR ReadIRIS

Smart Panel Yes (Install default: Windows, Linux, Mac)

Network

Management

Set IP, SWAS 4.0 & SWS

SWAS Plug-In

- Job Accounting, Storage management, Cloning, Remote Install

* Supported Web Browser:

- IE 5.5 or higher

- FireFox 1.5 or higher

- Safari 1.3 or higher

HDD File

N/A

Management S/W

SmarThru Smarthru Ofce v2.0, SmarThru WorkFlow v2.0 (Optional)

Page 14

Product spec and feature

Service Manual

2-4

Samsung Electronics

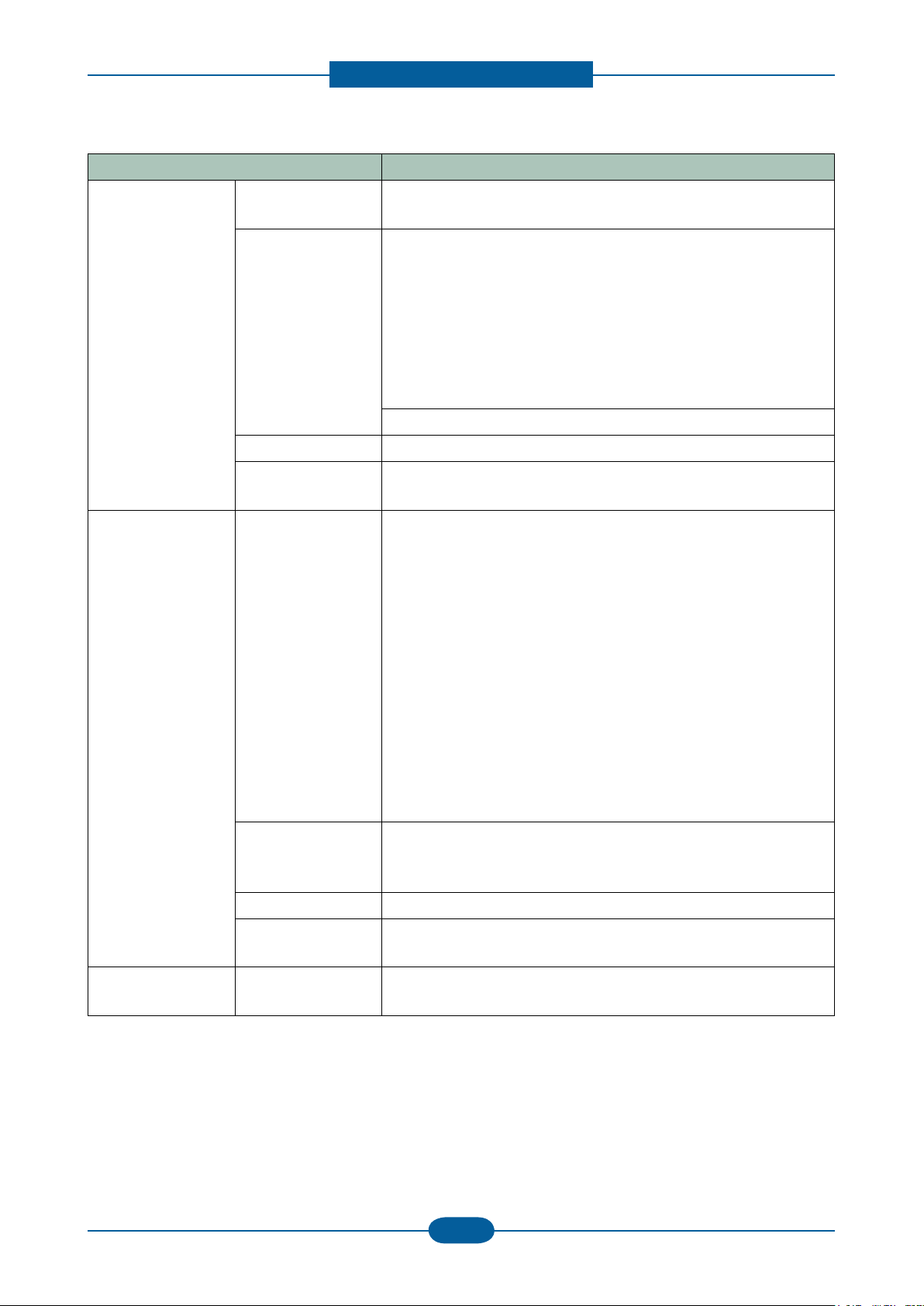

Item Description

Interface Parallel

(IEEE 1284)

USB Hi-Speed USB 2.0 Host (2 channel)

Wired LAN Ethernet 10/100/1000 Base TX

Foreign Device

Interface (FDI)

Network

Network OS [Windows]

Interface

No

* Use:

• Front

- Scan to USB

- USB direct printing

- F/W down load for system upgrade

• Rear

- Card Reader w/ Jscribe

Hi-Speed USB 2.0 Peripheral (1Channel)

Optional

- Microsoft Windows

2000/XP(32/64bits)/2003(32/64bits)/Vista(32/64bits)

[Mac]

- Mac OS 10.3~10.5

[Linux]

- RedHat 8 ~ 9

- Fedora Core 1~4

- Madrake 9.2 ~ 10.1

- SuSE 8.2 ~ 9.2

[Novell]

- Netware 5.x, 6.x(TCP/IP Only)

[Others]

- Unix(HP-UX,Solaris,SunOS, SCO)

Protocol * TCP/IP :

TCP/IPv4, HTTP, SNMPv1/v2c/V3, LDAP, SMTP, SSL/TLS,

IPSec

IP Addressing Static IP, Auto IP, BOOTP, DHCP

SNMP/MIB Access Host Resource MIB(RFC 2790), Printer MIB(RFC 3805)

Finisher MIB(RFC(3806), Samsung private MIB, SNMP Trap

User Interface LCD 800 x 480 7 WVGA Color graphic LCD with Touch-Screen, 16bit

color

Page 15

Product spec and feature

Service Manual

2-5

Samsung Electronics

2.1.2.3 Scan

Item Description

Scan method Color CCDM

Compatibility TWAIN(USB & N/W), WIA(Only for USB)

Color Mode Mono / Gray / Color

Scan Speed Color/Mono. Gray 0.73msec/line @600*600dpi

Mono Binary 0.365msec/line @300*300dpi

Resolution Optical 600 x 600ppi

Enhanced 4,800 x 4,800ppi

Gray Scale 256 levels

Scan Size Max. Document

Max.216mm(8.5)

Width

Efective Scan

Max 208mm(8.2inch)

Width

Max. Document

Max.356mm (Legal)

Length

Scan Depth Color Internal : 36 bits

External : 24 bits

Mono - 1bit for Linearity & Halftone

- 8Bits for Gray scale

Image Compression PDF,JPEG,BMP,TIFF

Page 16

Product spec and feature

Service Manual

2-6

Samsung Electronics

2.1.2.4 Copy

Item Description

Copy Speed

(DADF)

SDMC

(Single Document

Multiple Copy)

MDSC

(Multiple Document

Single Copy)

FCOT From Ready Platen : Less than 9.5 sec

Zoom Range 25% ~ 400% in 1% increments (Platen)

Multi Copy 1~999

Original Type Text Platen: Scan 600x600dpi , Printing 600x600dpi

Simplex: up to 33 cpm in A4 (35 cpm in Letter)

Duplex : up to 17 cpm in A4 (18 cpm in Letter)

Simplex: up to 29 cpm in A4 (30 cpm in Letter)

Duplex : up to 12 cpm in A4 (13 cpm in Letter)

DADF : Less than 11.5 sec

25% ~ 200% in 1% increments (DADF)

DADF: Scan 300x300dpi, Printing 600x600dpi

Text/Photo Platen: Scan 600x600dpi, Printing 600x600dpi

DADF: Scan 300x300dpi, Printing 600x600dpi

Photo Platen: Scan 600x600dpi, Printing 1200x1200dpi

DADF: Scan 300x300dpi, Printing 600x600dpi

Reduce & Enlarge * Zoom Range : 25% to 400% in Platen, 25% to 200% in ADF

* Preset

[Original(100%)]

[Auto Fit]

[A4 → A5(71%)]

[LGL→LTR(78%)]

[LGL→A4(83%)]

[A4→LTR(94%)]

[EXE→LTR(104%)]

[A5 → A4(141%)]

25%, 50%,150%, 200%, 400%

[Custom:25-400%)]

Duplex Copy Using Platen

- 1 → 1Sided

- 1 → 2Sided

Using DADF

- 1 → 1Sided

- 1 → 2Sided Short,

- 1 → 2Sided Long,

- 2 → 1Sided

- 2 → 1Sided, Rotate Side2

- 2 → 2Sided Short

- 2 → 2Sided Long

Page 17

Product spec and feature

Service Manual

2-7

Samsung Electronics

2.1.2.5 Fax

Item Description

Compatibility ITU-T G3

Communication System PSTN/PABX

Modem Speed 33.6Kbps

TX Speed 3sec (Mono/Standard/ECM-MMR, ITU-T G3 No.1 Chart)

Compression MH/MR/MMR/JBIG/JPEG

Color Fax Yes (TX only)

ECM Yes

Resolution

(Mono)

Std 203*98dpi

Fine 203*196dpi

S.Fine 300*300dpi

Resolution

(Color)

Std 200*200dpi (TX Only)

Fine 200*200dpi (TX Only)

S.Fine 200*200dpi (TX Only)

Scan speed Platen 0.365msec/line at 300*300dpi

DADF 0.365msec/line at 300*300dpi

Telephone

Features

Speed Dial 200 Locations

One touch dial NONE

Chain Dial NONE

Manual Dial Yes

Last Number

Yes

Redial

Automatic Redial

Yes

Transmission

Pause Yes

Flash No

Handset & Cradle NONE

Ringer Volume OFF. LOW, MEDIUM, HIGH

Tone/Pulse Select Selectable in Tech Mode

VoIP Support Yes. ( The communication in VoIP network is supported, but

the fax quality may be fallen. Beacause the purpose of VoIP

network is not fax but Internet network for voice. )

Page 18

Product spec and feature

Service Manual

2-8

Samsung Electronics

2.1.2.6 Paper Handling

Item Description

Bypass Tray Capacity Plain paper : 50 sheets

Transparency : 5 sheets

Envelopes : 5 sheets

Media sizes 76.2x127 mm(3x5) ~ 215.9x355.6mm (8.5x14.0)

Banner Size Printing : 216mm x 900mm

Media type Printer Default, Plain Paper, Thick Paper, Thin Paper, Bond

Paper, Color Paper, CardStock, Labels, Transparency,

Envelope, Preprinted, Cotton, Recycled Paper, Archive

Media weight 16~43lb (60 to 163g/m²)

Standard

Cassette

Tray

Capacity 500 sheets @ 20lb (80g/m²)

Media sizes Letter, Legal, Ocio, Folio, A4, JIS B5, ISO B5, Executive, A5

Media types Plain Paper, Thin Paper, Pre-Printed, Recycled, Thick, Archive

Media weight Plain Paper : 75~90 g/m²

Thin Paper : 60~70 g/m²

Thick Paper : 90~105 g/m²

Pre-Printed : 75~90 g/m²

Recycled : 60~90 g/m²

Duplex : 75~90 g/m²

Optional

Cassette

Tray(SCF)

Optional

Cassette

Tray(SCF)

(Continue..)

Capacity 500 sheets @ 20lb (80g/m²), drawer type

Media sizes Letter, Legal, Ocio, Folio, A4, JIS B5, ISO B5, Executive, A5

Media types Plain Paper, Thin Paper, Pre-Printed, Recycled, Thick, Archive

Media weight Plain Paper : 75~90 g/m²

Thin Paper : 60~70 g/m²

Thick Paper : 90~105 g/m²

Pre-Printed : 75~90 g/m²

Recycled : 60~90 g/m²

Duplex : 75~90 g/m²

Output Stacking 250 sheets @ 20lb (80g/m²)

DADF Capacity 50 sheets ( 20lb, 80g/m²)

2-sided Document

Yes (Reversing)

Scanning

Document Size Width: 145 ~ 216mm (5.7~8.5)

Length : 145 ~ 356mm (5.7 ~ 14.0) for Single page scan

145 ~ 400mm (5.7 ~ 15.7) for Multi pages scan

Bank Check Scan : 69.6mm x 152.4mm

Document Weight 12.5~28lb

Page 19

Product spec and feature

Service Manual

2-9

Samsung Electronics

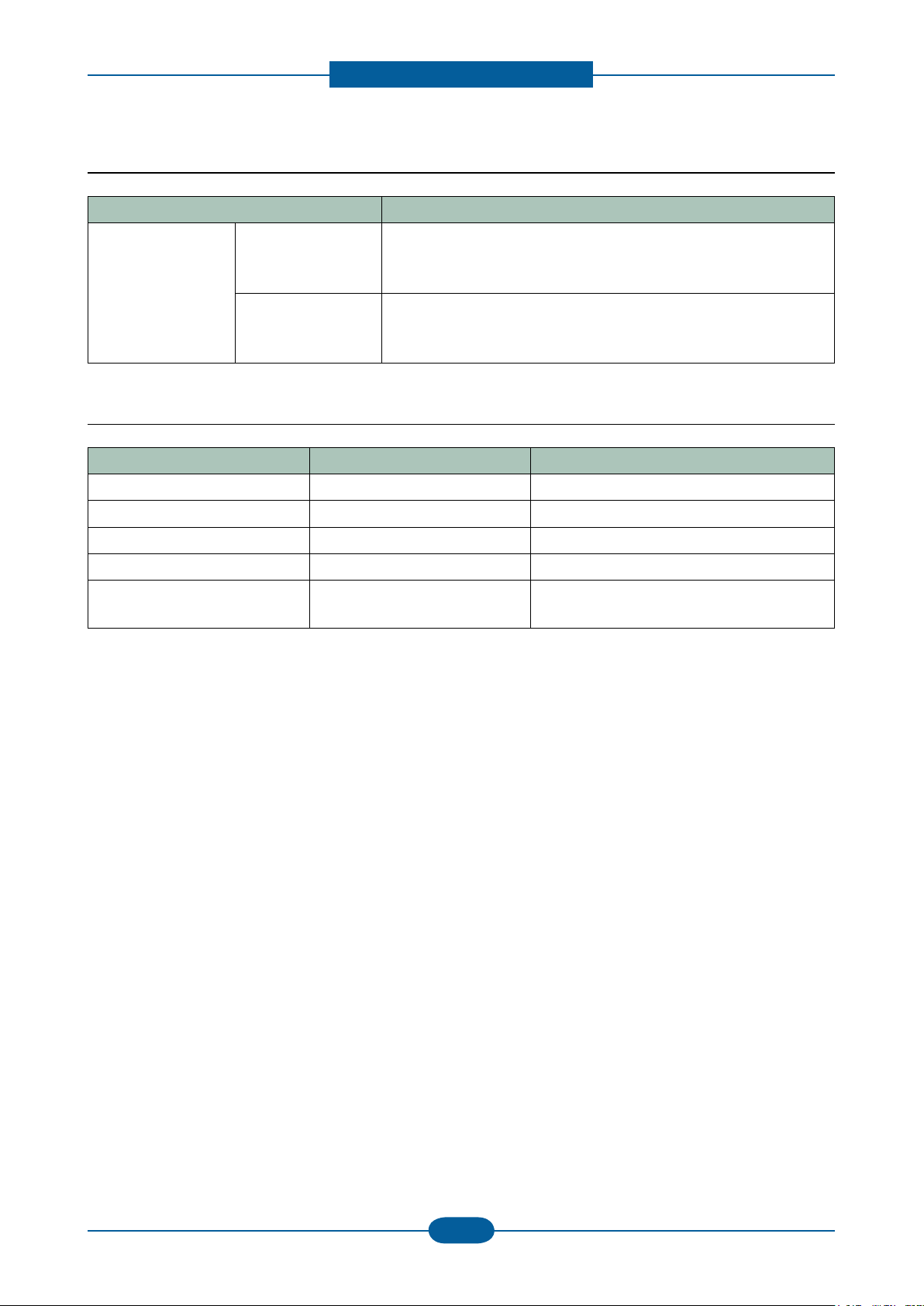

2.1.2.7 Consumables (CRU)

Item Description

Toner Cartridge MLT-D206S Average Continuous Black Cartridge Yield: 4,000* standard

pages

* Declared yield value in accordance with ISO/IEC 19752

MLT-D206L Average Continuous Black Cartridge Yield: 10,000* standard

pages

* Declared yield value in accordance with ISO/IEC 19752

2.1.2.8 Consumables (FRU)

Item Item Description

DADF Rubber Pad JC97-03069A 50,000 feeds

DADF Pick-up Assembly JC97-03070A 100,000 feeds

Pick up roller JC97-02441C 150,000 feeds

Transfer Roller JC66-01181A 100,000 images

Fuser Unit JC96-05064A(220V)

JC96-05063A(110V)

100,000 images

Page 20

Product spec and feature

Service Manual

2-10

Samsung Electronics

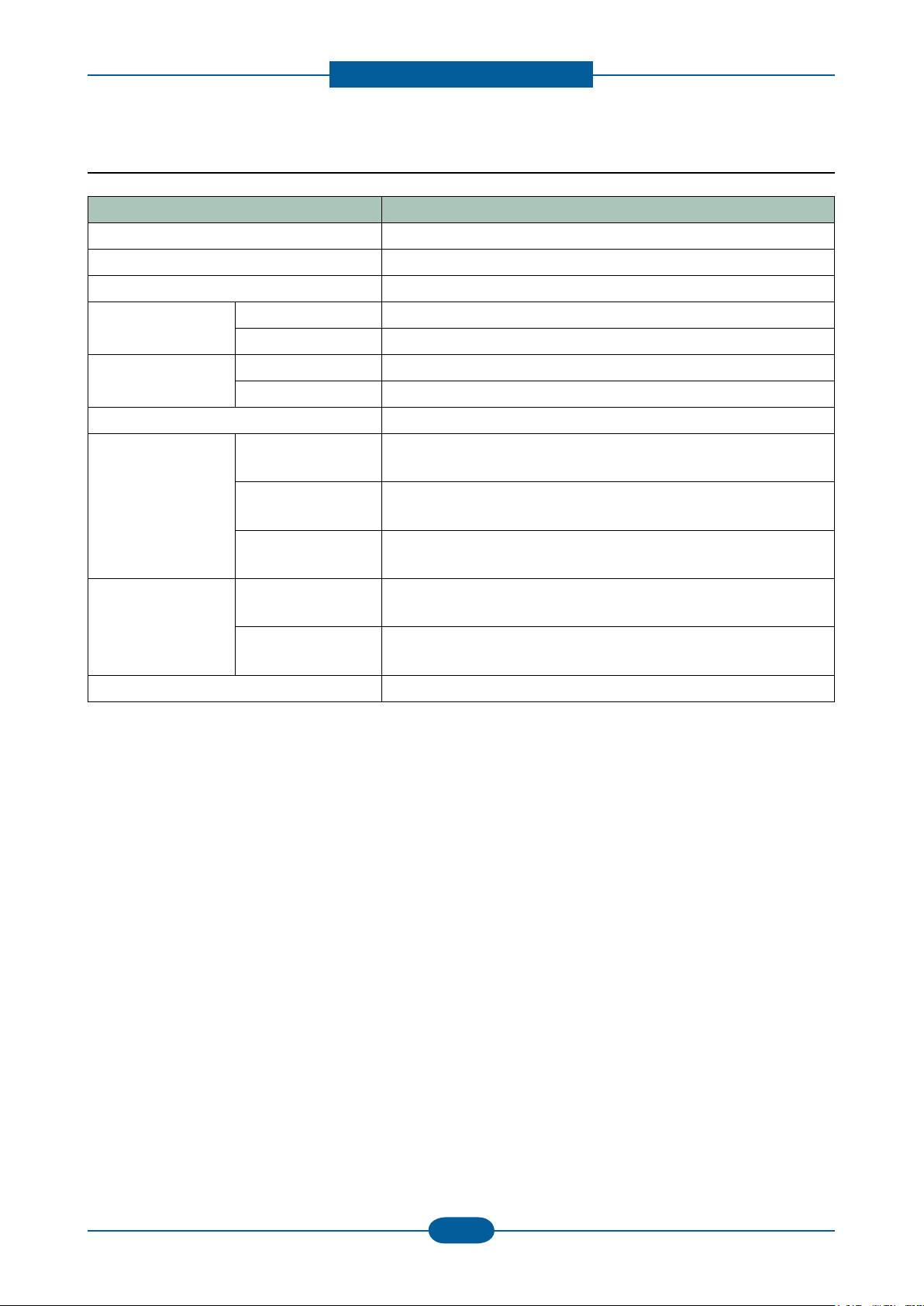

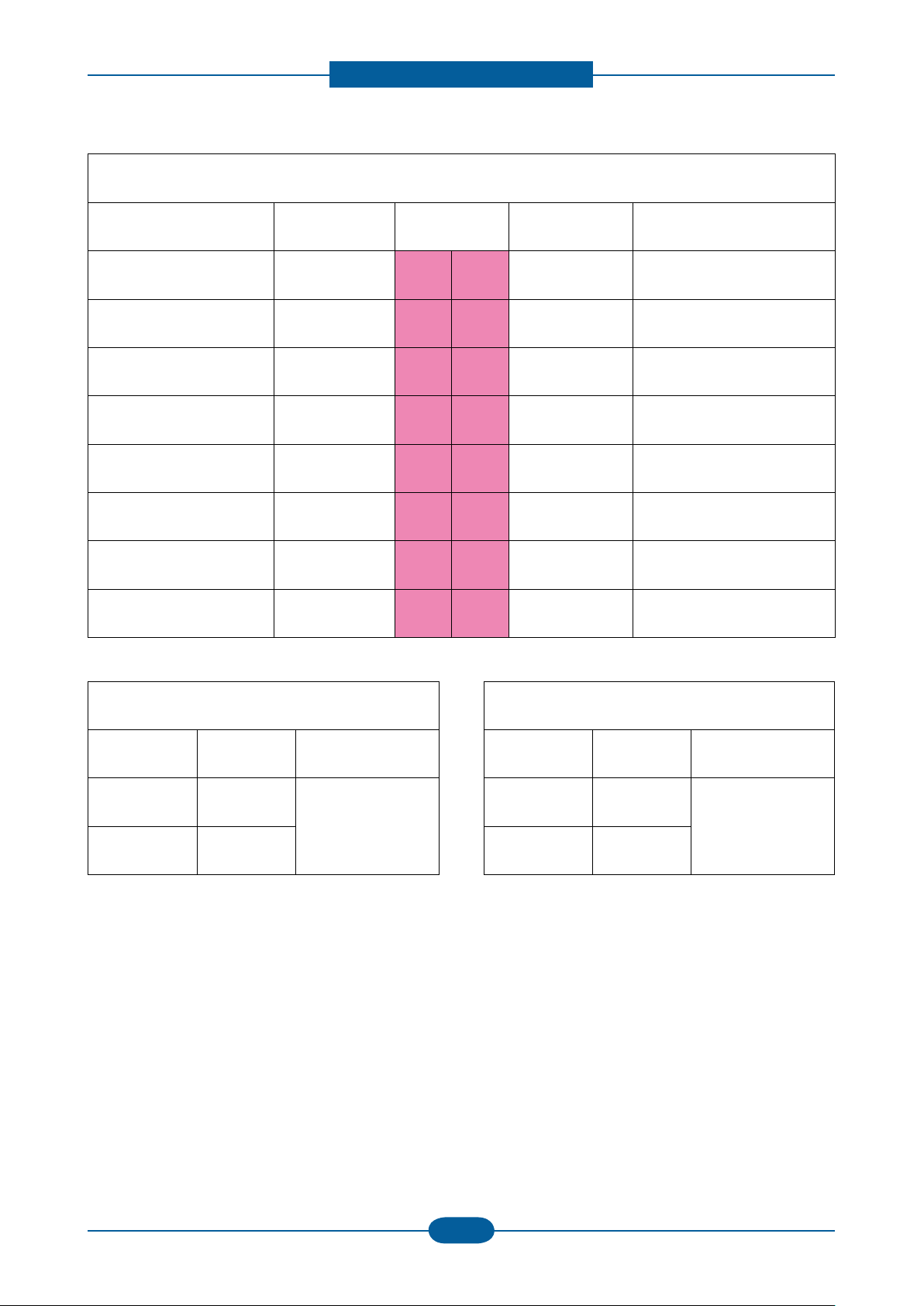

2.1.2.9 Service & Environment

Item

AMPV

Max Monthly Duty

MPBF ( Mean Page Between Failure)

MTTR (mean time to repari)

Temperature

Humidity

Input Voltage

Noise

Power Consumption

Dimensions (WxDxH)

Weight (with consumables)

Operating 10℃ ~ 32℃

Storage 20℃ ~ 40℃

Operating 20~80% RH

Storage 10~90% RH

Printing

Simplex / Duplex

Copying

Simplex / Duplex

Standby 39 dB

Ready Less than 100W

AVG. Less than 750W

Power save Less than 25W

Power off 0W

Description

2500 pages/month (A4 size, IDC 5% coverage)

75,000 pages/month (A4 size, IDC 5% coverage)

50,000 pages

30 minutes

AC 110-127V or AC 220-240V

52 dB

54 dB

500x465x547 mm

23.1Kg

Item Description

Optional Tray (SCF) SCX-S5835A 500 sheets feeder

Memory CLP-MEM202 256 MB

Jscribe SCX-KIT10J JScribe Related S/W Enabler

Page 21

Product spec and feature

Service Manual

2-11

Samsung Electronics

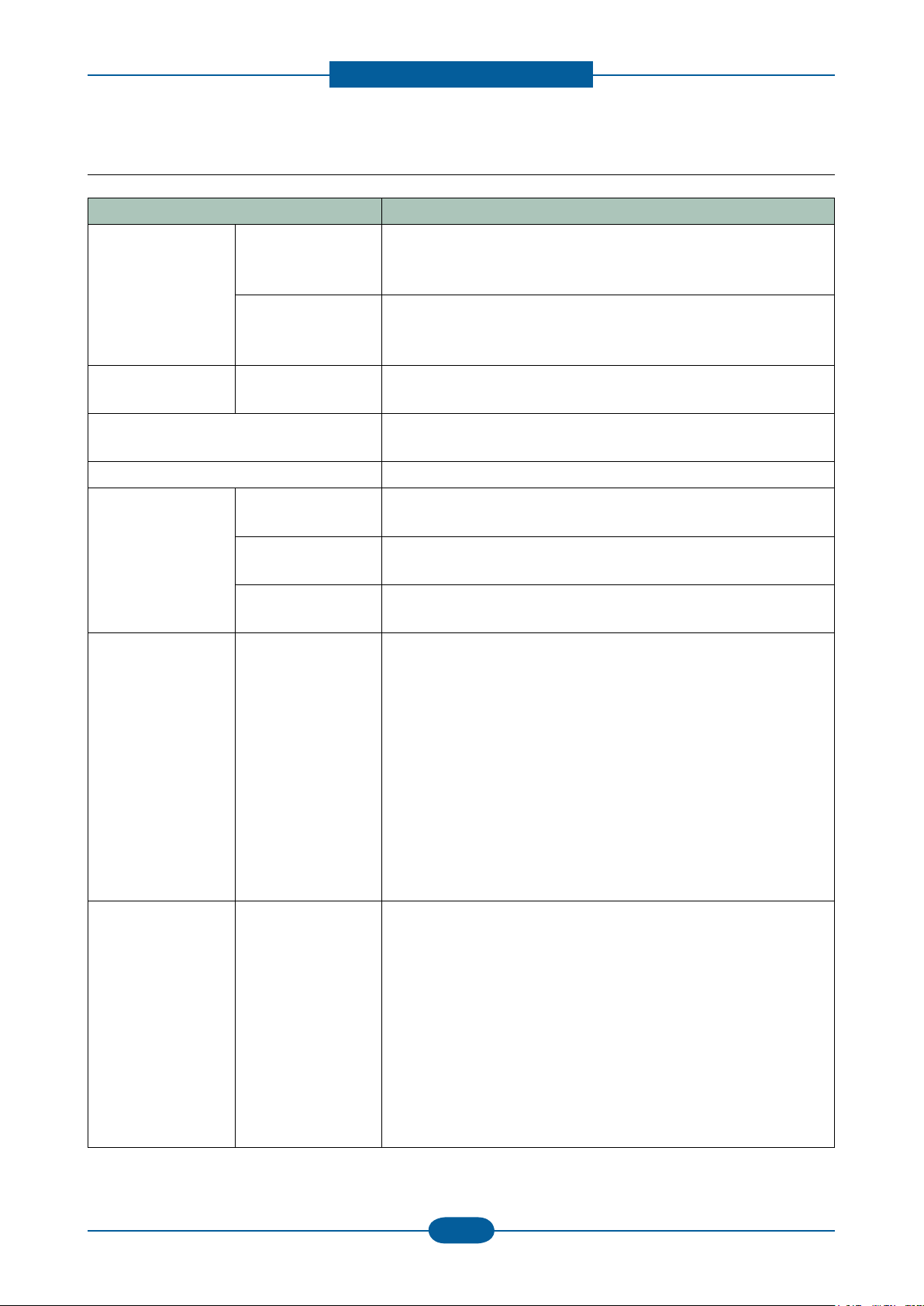

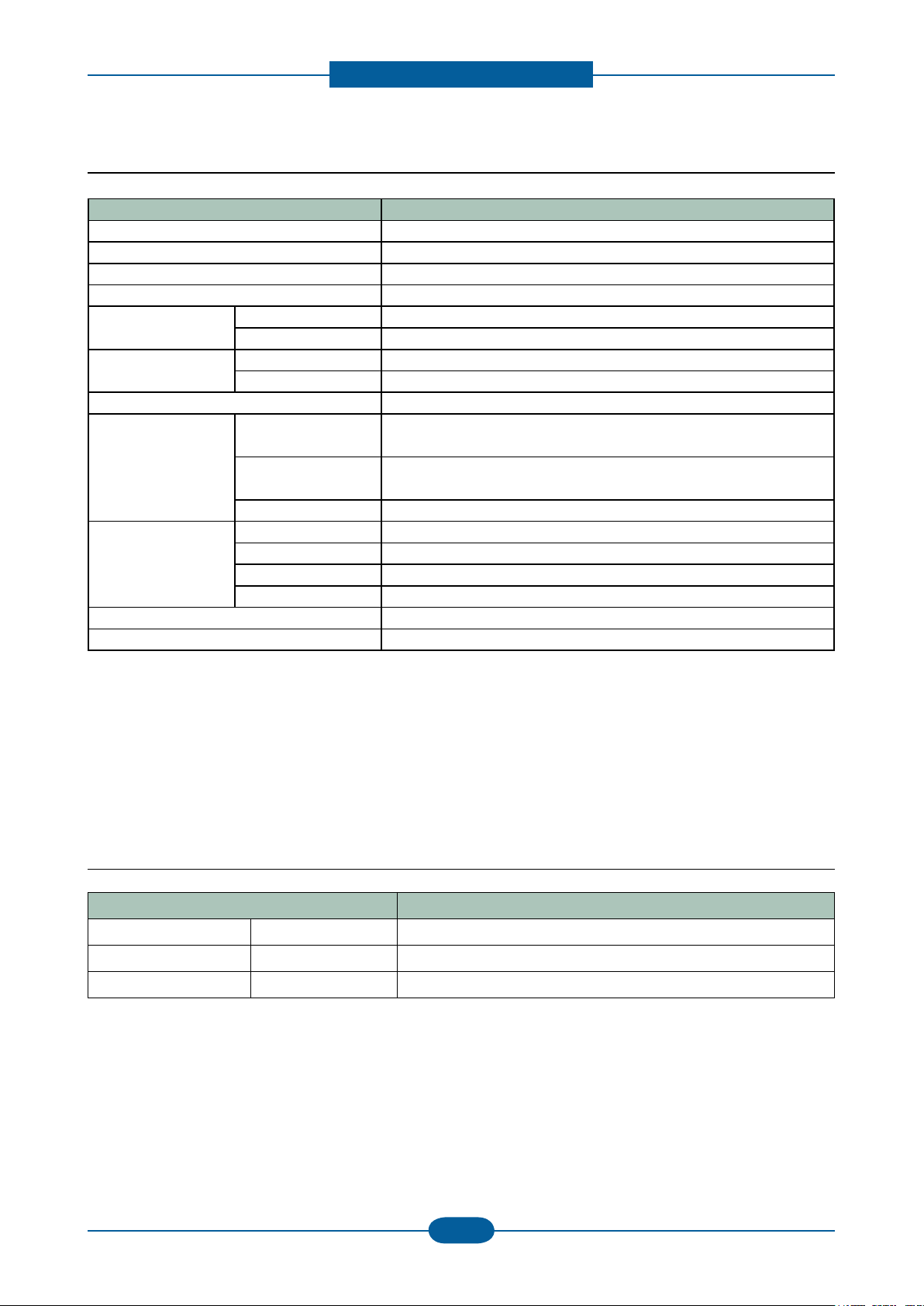

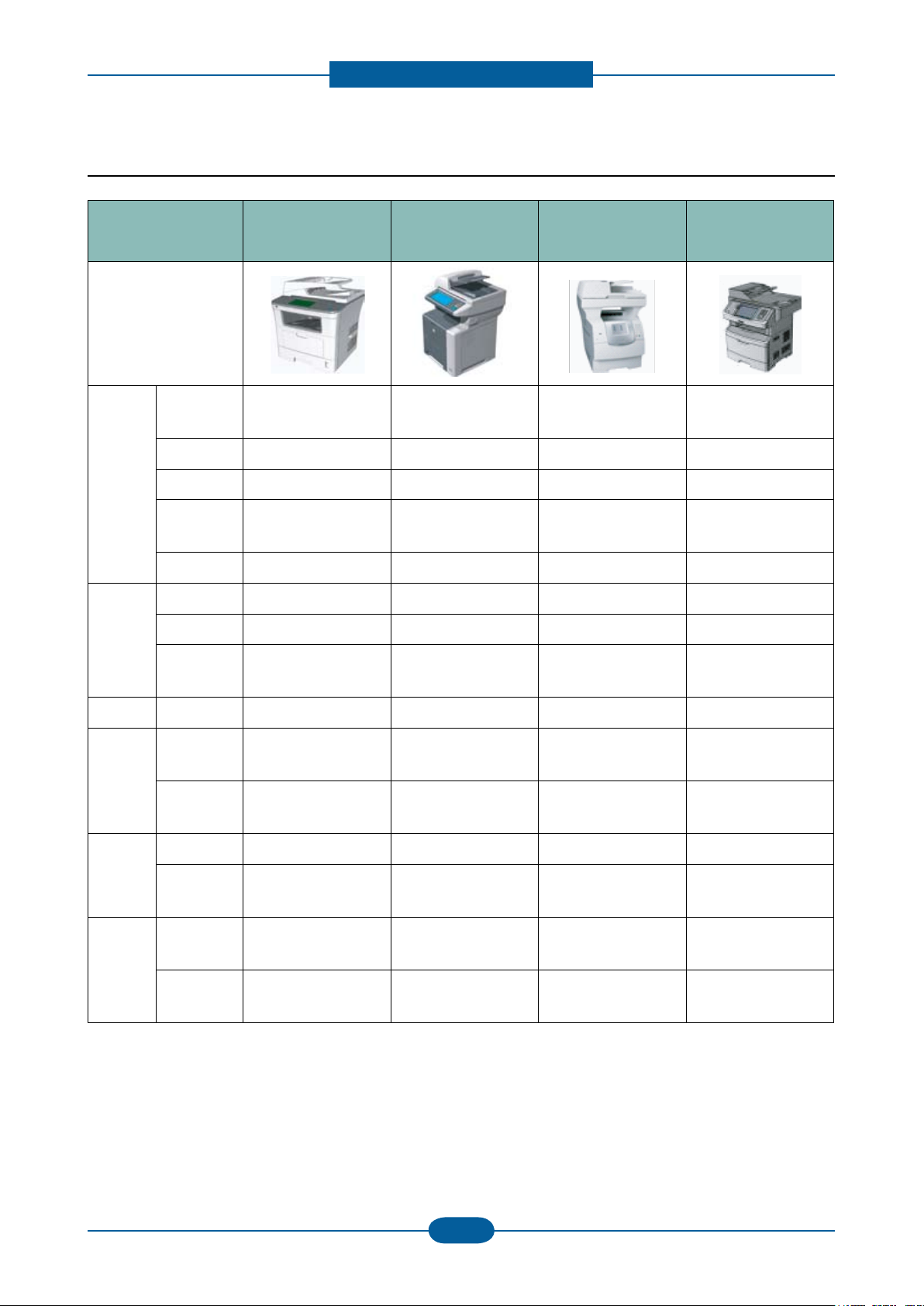

2.1.3 Model Comparison

Printer

Copy

SAMSUNG

SCX-5835NX

SCX-5935NX

Image

Speed

(A4/Ltr.)

Copy size A4 A4 Legal Legal

Resolution 1,200 x 1,200 dpi 1,200 x 1,200 dpi 1,200 x 1,200 dpi 1,200 x 1,200 dpi

Emulation

Duplex Print Standard Standard Option Standard

Speed 35cpm 35cpm 35cpm 35cpm (Estimated)

Resolution 600dpi 600 dpi 600 dpi 600 dpi (Estimated)

Zoom 25 – 400% 25 – 400% 25 – 400%

33ppm/35ppm 33ppm/35ppm 43ppm/45ppm 38ppm/40ppm

PCL5e, PCL6, PS,

PDF1.5

HP

LJ M3035

PCL5, PCL6, PS,

PDF1.5

Lexmark

X642e

PCL5, PCL6, PS,

PDF1.5

Lexmark

New 4dte

PCL5, PCL6, PS,

PDF1.5

25 – 400%

(Estimated)

Scan Resolution 600dpi 600dpi 600dpi 600dpi (Estimated)

Fax

Paper

Handling

General

Modem

Speed

Memory HDD Backup

DADF 50sh. 50 sh 50sh. 50sh.

Input

Tray(Std.)

Memory

Std.(Max)

Toner 4K, 10K

33.6 Kbps LJ-M3035xs Only 33.6 Kbps 33.6 Kbps

HDD Backup

(LJ-M3035xs Only)

500 sh. Tray

50 sh. MP

256MB(512MB) 128MB(640MB) 256MB(?)

500 sh. Tray

100 sh. MP

Q7551x

(13,000 sh.)

- HDD Backup

500 sh. Tray

100 sh. MP

10K, 21K 9K, 15K

2 x 250 sh. Tray

50 sh. MP

Page 22

Product spec and feature

Service Manual

2-12

Samsung Electronics

2.2 System Overview

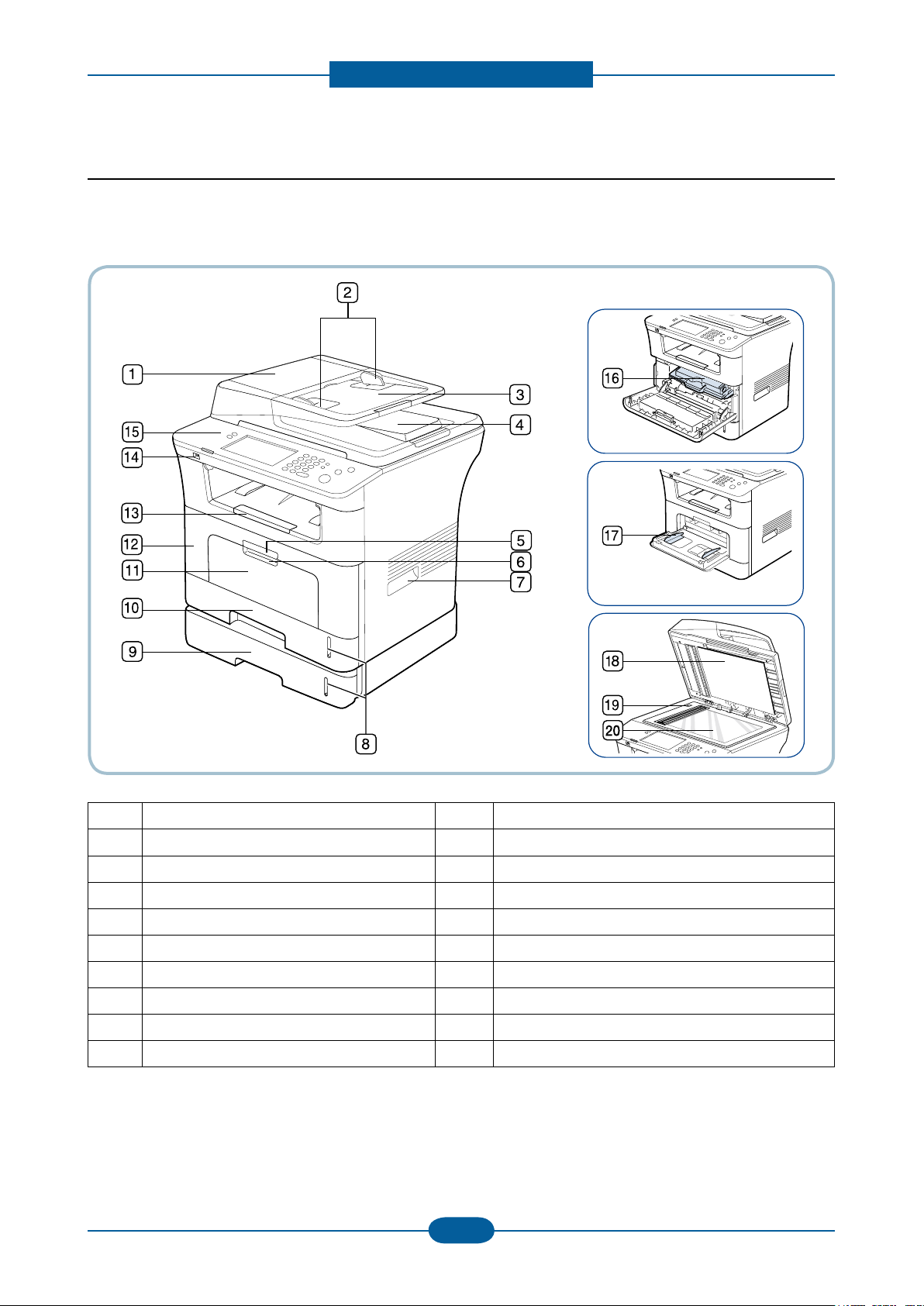

■ Front View

1 Document feeder cover 11 Multi-purpose tray

2 Document feeder width guides 12 Front cover

3 Document feeder input tray 13 Document output tray

4 Document feeder output tray 14 USB memory port

5 Front cover handle 15 Control panel

6 Multi-purpose tray handle 16 Toner cartridge

7 Handle 17 Multi-purpose tray paper width guides

8 Paper level indicator 18 Scanner lid

9 Optional tray 2

10 Tray 1 20 Scanner glass

[a] Optional device.

[a]

19 Scanner lock switch

Page 23

Product spec and feature

Service Manual

2-13

Samsung Electronics

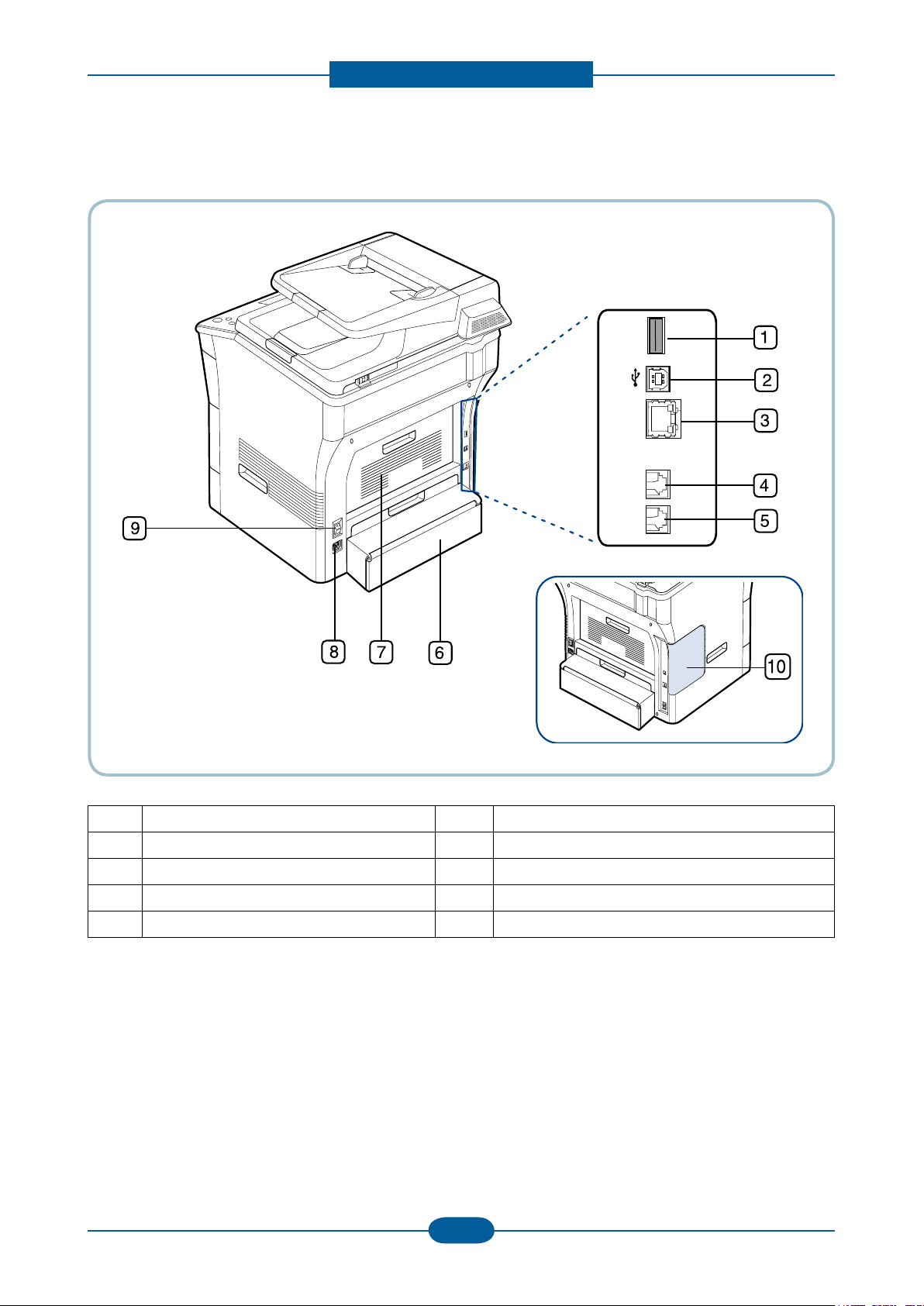

■ Rear View

1 USB host port 6 Duplex unit

2 USB port 7 Rear cover

3 Network port 8 Power receptacle

4 Telephone line socket 9 Power-switch

5 Extension telephone socket (EXT) 10 Control board cover

Page 24

Product spec and feature

Service Manual

2-14

Samsung Electronics

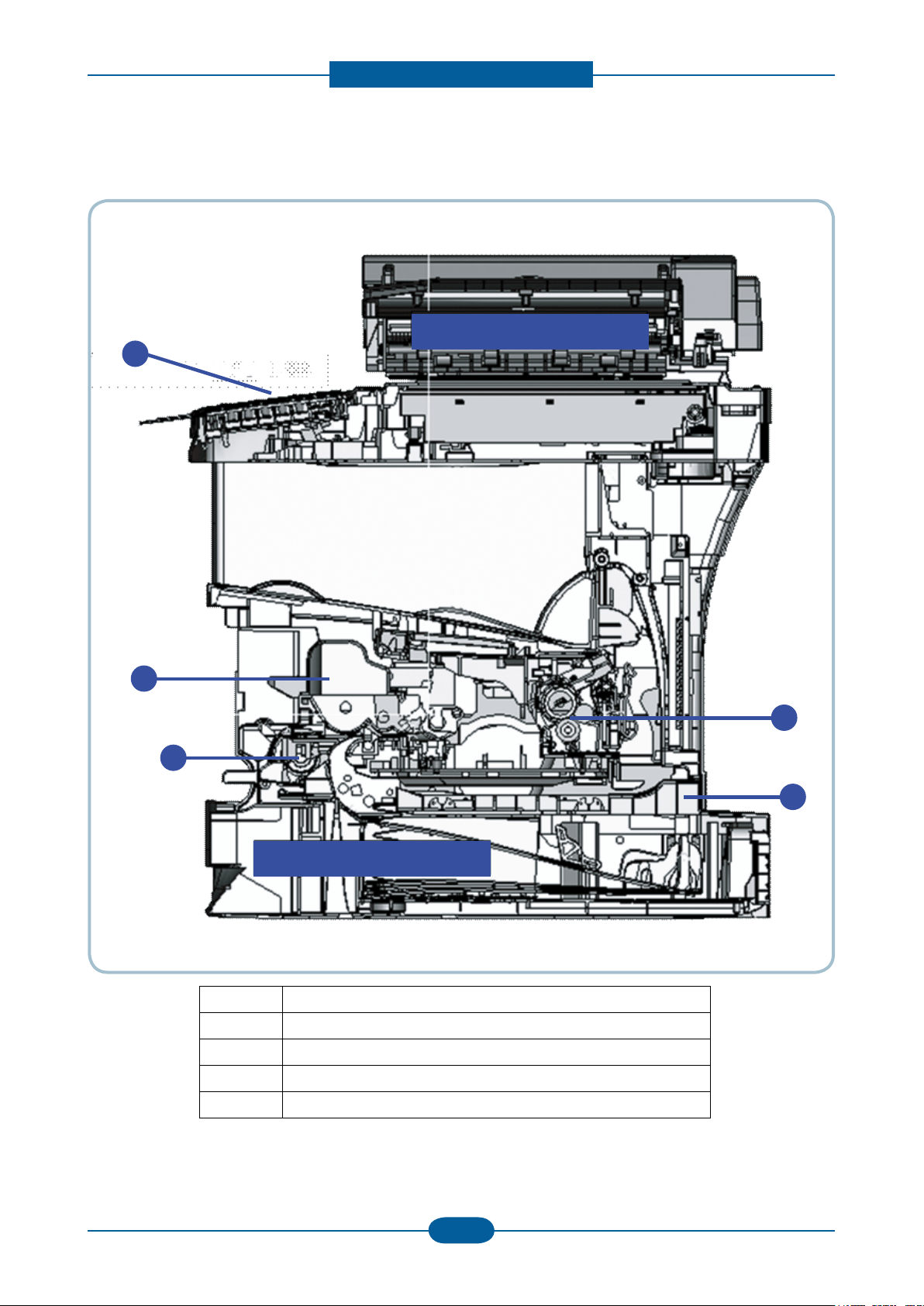

■ System Layout

520 sh. Cassette

Scanner / DADF

5

4

3

2

1

500 sh. Cassette

Scanner / DADF

5

4

3

2

1

1 OP Panel / 7 “ LCD Touch Screen

2 Toner Cartridge

3 MP Roller

4 Fuser Unit

5 Duplex Unit

Page 25

Product spec and feature

Service Manual

2-15

Samsung Electronics

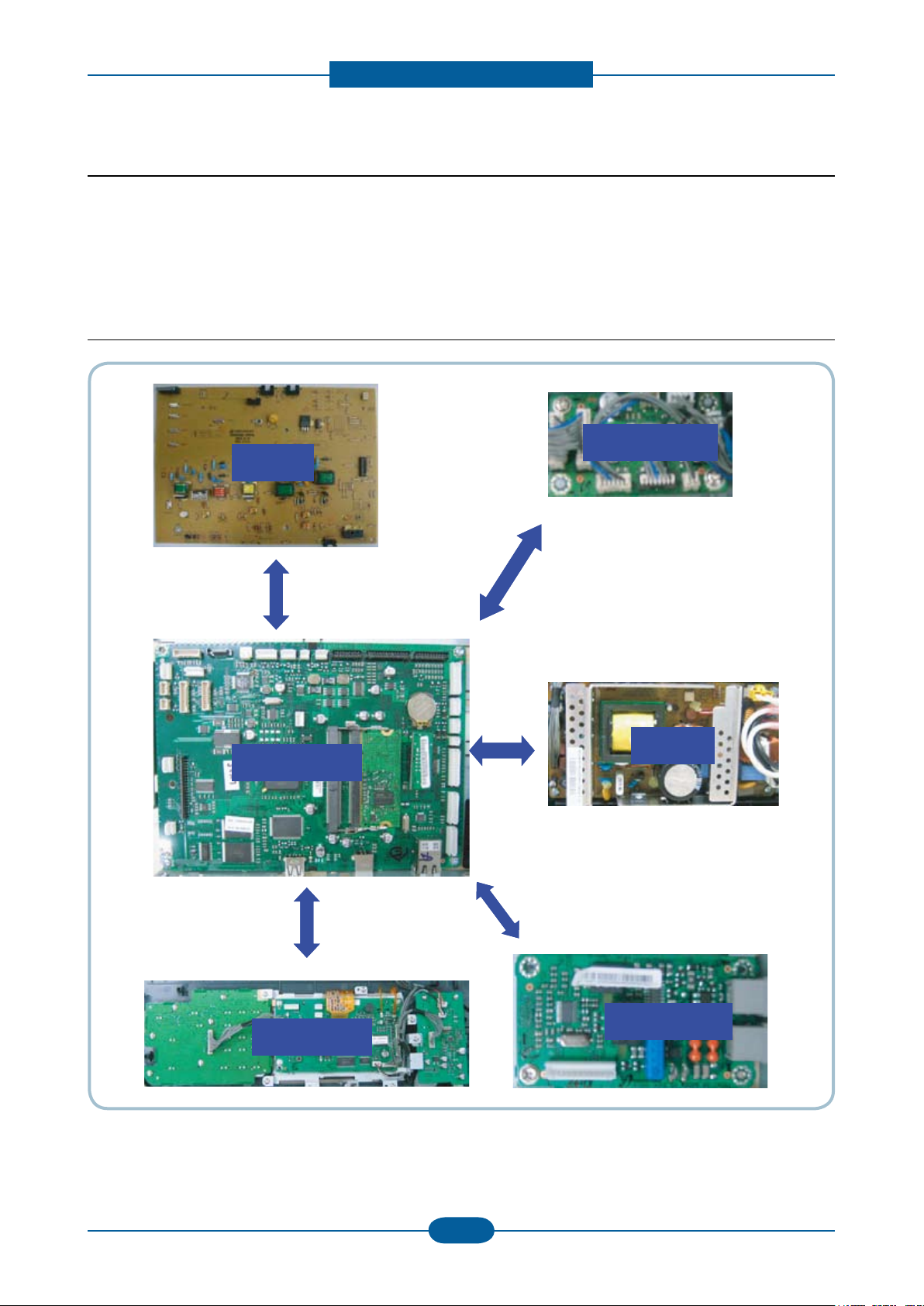

HVPS

MAIN PBA

OPE PBA

DADF PBA

SMPS

Fax Board

HVPS

MAIN PBAMAIN PBA

OPE PBA

DADF PBA

SMPSSMPS

Fax Board

2.2.1 System Conguration

SCX-5835NX_5935NX Series consist of Main Control Part, Operation Panel Part, Scanner Part, Line

Interface Part ,Power Part and Optional DIMM(Dual-In-Memory Module) for Scan-To-Email.

Main Controller is commonly applied in all products, SCX-5835NX_5935NX Series, and in case of necessary

a part of components or Module is selectively adopted in accordance with required feature of each model.

2.2.2 Hardware Conguration

Page 26

Product spec and feature

Service Manual

2-16

Samsung Electronics

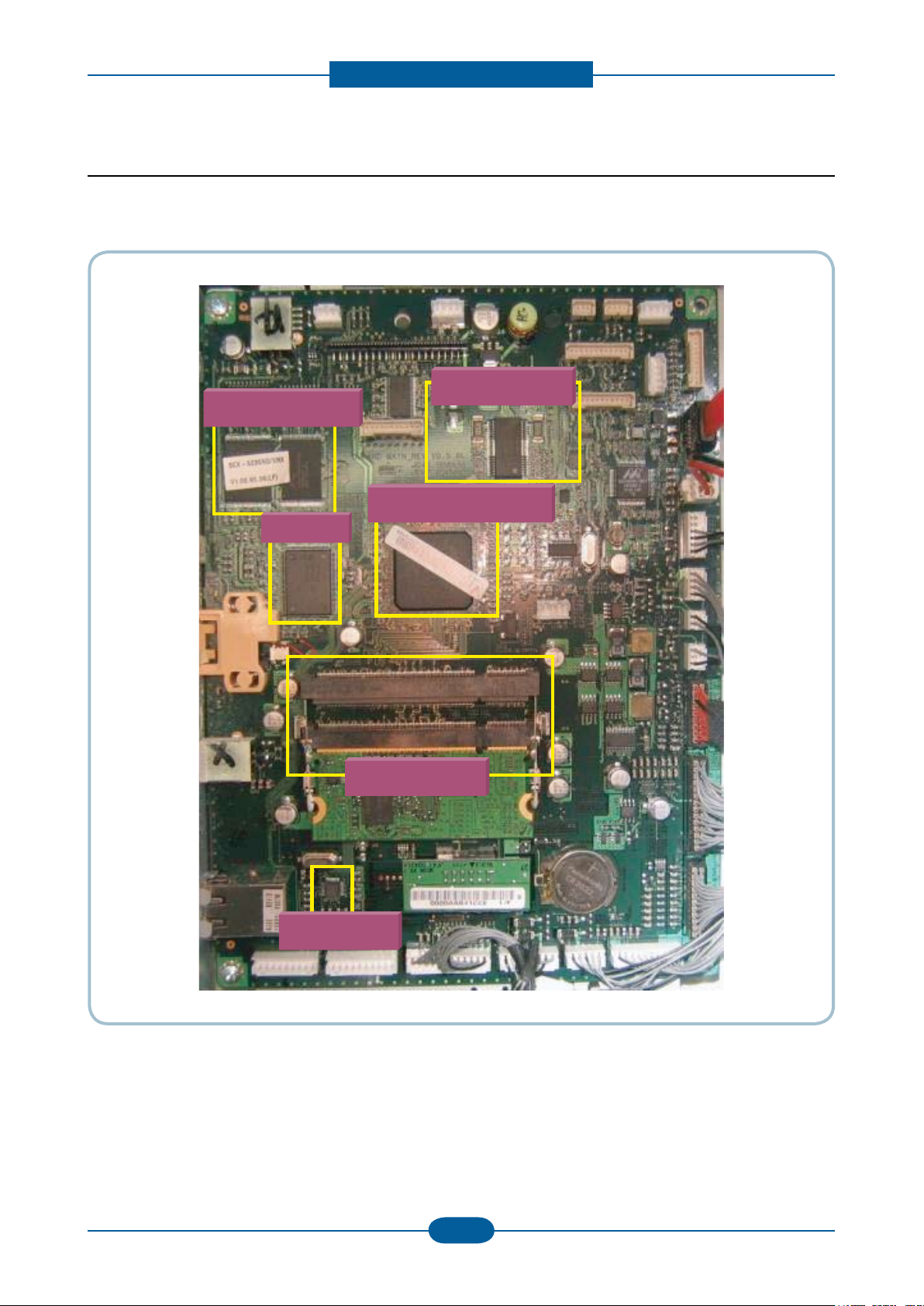

4-1. Main Board

Scan MOTIC

CHORUS3(ASIC)

Flash Memory

USB IC

DDR2 DIMM

Network IC

4-1. Main Board

Scan MOTIC

CHORUS3(ASIC)

Flash Memory

USB IC

DDR2 DIMM

Network IC

2.2.2.1 Main Controller

The Main Control Part comprises 1 CPU and 1 B’D by adopting the dedicated Controller for Fax & LBP. The

Scanner Part comprises DADF& CCD and connected with Main board through Harness.

Page 27

Product spec and feature

Service Manual

2-17

Samsung Electronics

CPU (CHORUS3)

It uses the ARM 926EJS, 32Bit RISC Processor, which is dedicated Controller for Printer & Fax function and

drives the each internal Operation Block by system program of Flash Memory and thereby controlling the

whole System.

- Main Function Block : Completely Integrated System for Embedded Applications,

▶ 32 Bit RISC Architecture, Efcient and Powerful ARM 926EJS Core.

▶ LSU Interface Module for Interfacing PVC or HPVC with LSU

▶ Dual Memory Bus Architecture

- Operation Frequency : AHB Bus: 133MHz, Internal System Bus: 120MHz

- Operation Power : 3.3V / 1.0V(core)

Flash Memory

It stores system program, Fonts data(PCL, PS/3), and can download the system program through PC

Interface or Network.

- Capacity: 32M Byte

- Access Time : 80 nsec

System Memory (DDR2)

It is used as Swatch Buffer for Printing, Scan Buffer for Scanning and System Working Memory Area.

- System memory: 256MB Capacity

- Max Frequency: 120 MHz

System Data Memory (EEPROM + Flash Memory)

This memory, which is for storing the operation variable & the setting parameter of Elbert2, keeps the

information.

Optional Memory (DIMM)

SCX-5835NX_5935NX Series provide one (1) Extension Slot for extending Memory. The RAM Extension

Slot can be used for:

General Memory Extension

256 MB Optional Memory is available.

Page 28

Product spec and feature

Service Manual

2-18

Samsung Electronics

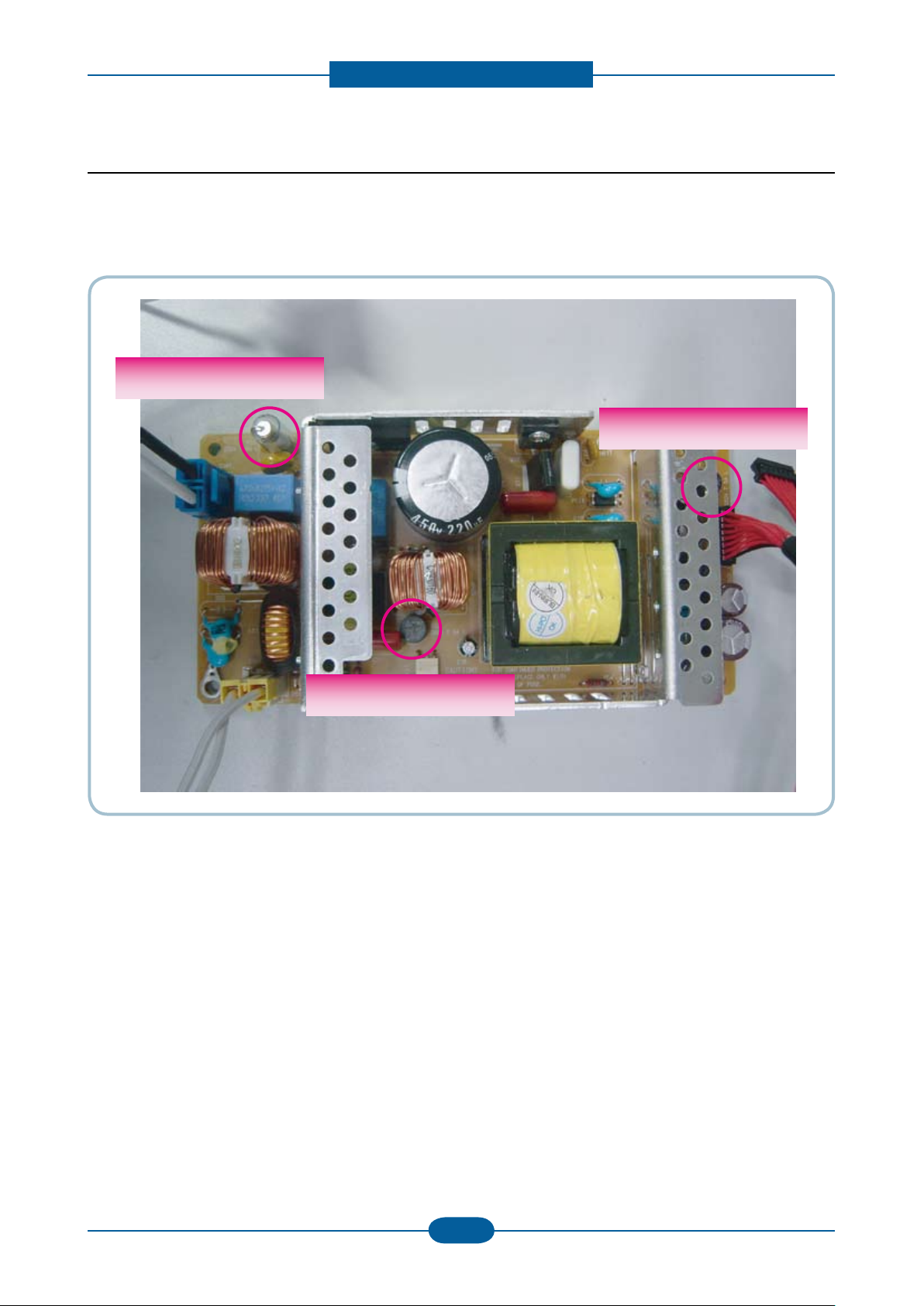

Fuse 5V

Fuse 5V

Fuse 24V

Fuse 24V

Fuse 5V

Fuse 5V

Fuse 5V

Fuse 5V

Fuse 24V

Fuse 24V

Fuse 5V

Fuse 5V

2.2.2.2 SMPS board

SMPS( Switching Mode Power Supply ) Board supplies electric power to a Main Board and other boards

through a Main Controller by +5V,+24V from 110V/220V power input. It has safety protection modes for over

current and load.

Page 29

Product spec and feature

Service Manual

2-19

Samsung Electronics

DC Output Connector( CON3 )

Description PIN NO PIN ASSIGN PIN NO Description

Fuser ON

(Active High)

Fuser_On 1 2 24VS

Power

(Photo Triac Bias)

Power +24V 3 4 GND +24V Ground

Power +24V 5 6 GND +24V Ground

Power +24V 7 8 GND +24V Ground

Power +24V 9 10 GND +24V Ground

Power +5V 11 12 GND +5V Ground

Power +5V 13 14 GND +5V Ground

Relay On Relay_On 15 16 OFF/SINK +24V On/OFF

AC Input Connector( CON1 )

SMPS → Heater Controller( CON2 )

PIN ASSIGN PIN NO Description

1 AC_L

AC Input

2 AC_N

PIN ASSIGN PIN NO Description

1 AC_L

AC Output

for Heater

2 AC_N

Page 30

Product spec and feature

Service Manual

2-20

Samsung Electronics

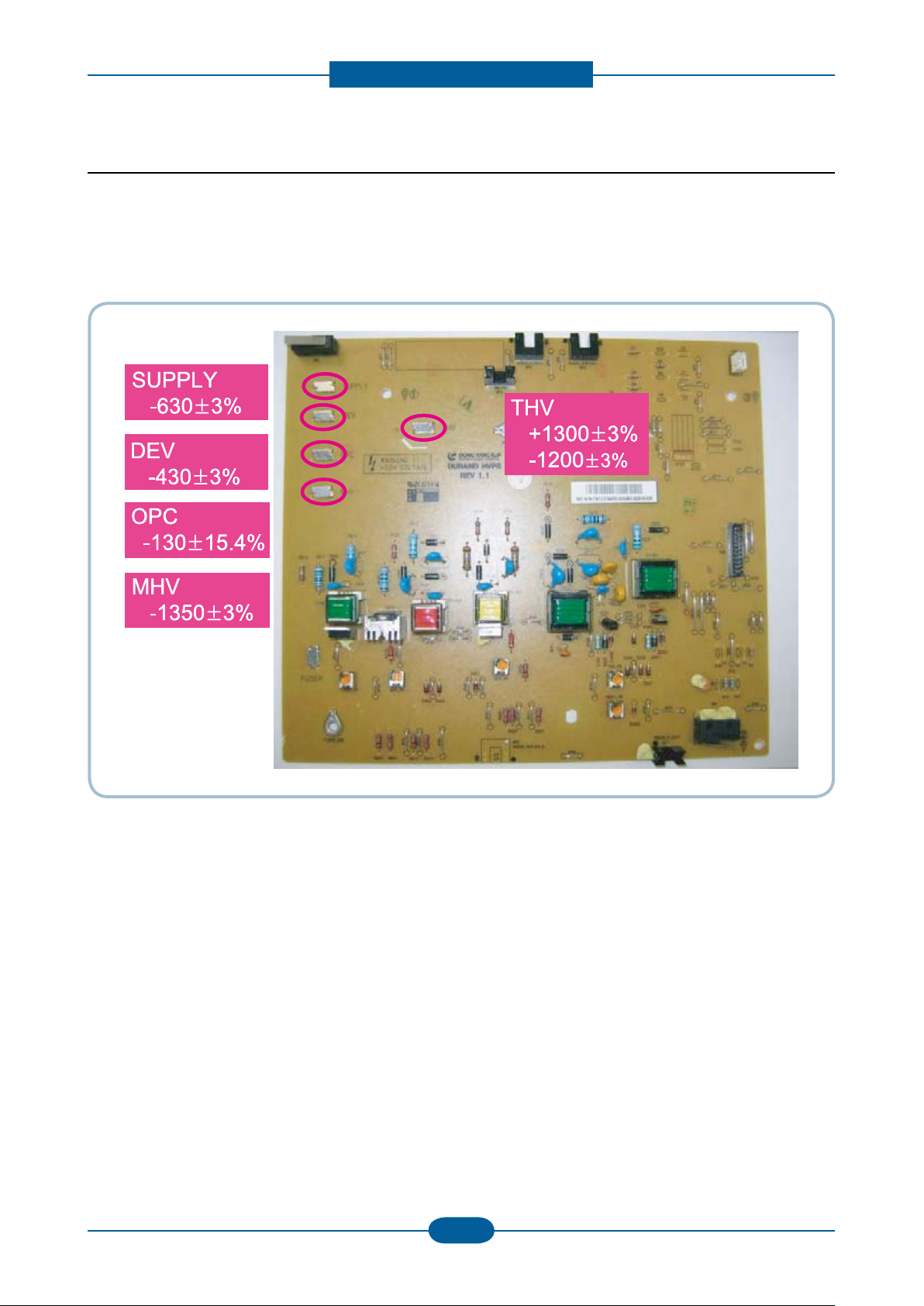

2.2.2.3 HVPS board

HVPS(High Voltage Power Supply)

HVPS Part outputs the generated high voltage for THV/MHV/BIAS/DETACH/FUSER BIAS by inputting 24V,

and the output high voltage is provided into OPC Cartridge and Transfer Roller.

Page 31

Product spec and feature

Service Manual

2-21

Samsung Electronics

2.2.2.4 FAX Board

Specications

• LINE CONNECTION: PSTN or PABX (RJ-11)

• Compatibility: ITU-T G3, Super G3

• Communication System: PSTN/PABX

• Modem Speed: 33.6Kbps

• TX Speed: 3 sec

* Standard Resolution, MMR, 33,6Kbps

* Phase “C” by ITU-T No.1 Chart in Memory transmission with ECM

• Scan Speed

Platen -> 2 sec / A4

ADF -> 5.5 sec / A4

* Scan time: 2 sec/A4 @ 203x98dpi * Scan setup time : 3.5 sec

• Receive Mode: Fax, TEL, ANS/FAX

• Compression: MH/MR/MMR/JBIG/JPEG

• ECM: Yes

• Resolution Std: 203*98dpi

Fine: 203*196dpi

S.Fine: 300*300dpi

• Contrast: Adsustable 5 levels

• Fax Memory: 32MB (in HDD)

Page 32

Product spec and feature

Service Manual

2-22

Samsung Electronics

2.2.3 Mechanic Conguration

2.2.3.1 Feeding Section

1) Cassette

It stores and automatically feeds print paper.

Pick-up Roller picks up paper, controls drive, feeds paper, removes static electricity, and so on.

> Spec.

* Feeding Method : Cassette Type

* Feeding Standard : Center Loading

* Feeding Capacity : Cassette 500 Sheets

(80g/ , 20lb Paper Standard)

* Paper Detecting Sensor : Photo Sensor

(Empty, Registration, Exit)

* Paper Size Sensor : None

2) MPF

> Spec.

* Capacity : Plain paper : 50 sheets

Transparency : 5 sheets

Envelopes : 5 sheets

* Media sizes : 76.2x127mm(3”x5”)

~215.9x355.6mm(8.5”x14.0”)

* Media weight : 16~43lb(60 to 163 g/m²)

Page 33

Product spec and feature

Service Manual

2-23

Samsung Electronics

2.2.3.2 Drive Unit

Drive Unit is used for image process.

Main Drive Unit is for Paper path(Pick up, Feeding, Registration).

Fuser Drive unit is for Fuser Driving, Exit roller

Duplex Drive unit is for Duplex feeding.

[ Main Drive Unit ]

[ Duplex Drive Unit ]

[ Fuser ]

Page 34

Product spec and feature

Service Manual

2-24

Samsung Electronics

OPC Drum

Photo Diode

LD Driver circit

Protector panel

LD(Laser Diode)

Polygon Mirror

Polygon Motor

Motor Driver

2.2.3.3 LSU ( Laser scanning unit )

LSU consists of LD(Laser Diode) and polygon motor control. For realizing Color Image, it is controled by 4

LD. When the controller generate the printing signal, LD will turn on and Polygon motor starts.If the receiving

part in LSU detect the beam , Hsync is generated. When the rotation of polygon motor is steady, it is time of

LSU ready status for printing. If either of two condition is not satised, LSU error is expected.

Page 35

Product spec and feature

Service Manual

2-25

Samsung Electronics

2.2.3.4 Fuser Unit

This unit consists of IH-HEAT ROLLER, Thermostats and a Thermistor. It melts and fuses the toner,

transferred by the transfer roller onto the paper, by applying pressure and high temperature to complete

printing job.

- Fusing type : Thermal xing with a couple of one heat roller and two pressure rollers

- Hear roller : ø28.3, Anodized, singel halogen lamp, thick brown color coating

- Pressure roller 1 : ø16.0 : PFA tube, Electrically conductive

- Pressure roller 2 : ø20.0 : LSR+PFA, Electrically conductive

- Single thermistor and a pair of thermostat

- A ball bearing at each end of heat roller (total amount; two)

- Jam removal lever / Fuser door open for jam removal

- Life span : 80,000 pages

① Thermostat

When a heat lamp is overheated, a Thermostat cuts off the main power to prevent over-heating.

- Non-Cotact type Thermostat

② Heat roller

The heat roller transfers the heat from the lamp to apply a heat on the paper. The surface of a heat roller

is coated with Teon, so toner does not stick to the surface.

③ Pressure roller

A pressure roller mounted under a heat roller is made of a silicon resin, and the surface also is coated with

Teon. When a paper passes between a heat roller and a pressure roller, toner adheres to the surface of

a paper permanently.

Trouble Temperature Control concept

Open Heat Error 85˚C below for 20 sec after power on

Over Heat Error

(Fuser High Error)

Low Heat Error

(Fuser Low Error)

- 220˚C over for 20sec

- 230˚C over for 3sec

10˚C below than target Temp. for 10 sec. At Warm up

20˚C below than target Temp. for 10 sec. At Printing

20˚C below than target Temp. for 10 sce. At stand-by

16˚C below than target Temp. for 10 sce. At pick up

Page 36

Product spec and feature

2.2.3.5 Scanner Section

1) Optical System: Lens Reduction type All-In-One (Scanning Lamp + Lens + CCD Image sensor).

2) Light Source: White LED(Light Emitting Diode)

3) Scanning method:

- Platen: Optical Moving

- DADF: Document Moving

* Scanning Area

Maximum Document Width: 216mm

Effective Scanning Width: 208mm

* Source Document Specication (DADF)

1) DADF capacity : 50 sheets of 20lbs /80gsm paper

2) Specication

Item Specication Item Specication

Length 145~356mm Weight 12.5lb ~ 28lb

Width 142~216mm Thickness 0.075mm ~ 0.13mm

Curl Below 5mm - This machine must be able to

feed the documents in Normal

Environment / Standard Paper

(20lb/80gsm)

Service Manual

2-26

Samsung Electronics

Page 37

Disassembly and Reassembly

3. Disassembly and Reassembly

3.1 General Precautions on Disassembly

When you disassemble and reassemble

components, you must use extreme caution. The

close proximity of cables to moving parts makes

proper routing a must.

If components are removed, any cables disturbed

by the procedure must be restored as close as

possible to their original positions. Before removing

any component from the machine, note the cable

routing that will be affected.

Whenever servicing the machine, you

must perform as follows:

1. Check to verify that documents are not stored in

memory.

2. Be sure to remove the toner cartridge before you

disassemble parts.

3. Unplug the power cord.

4. Use a at and clean surface.

5. Replace only with authorized components.

Releasing Plastic Latches

Many of the parts are held in place with plastic

latches. The latches break easily; release them

carefully.

To remove such parts, press the hook end of the

latch away from the part to which it is latched.

6. Do not force plastic-material components.

7. Make sure all components are in their proper

position.

Service Manual

3-1

Samsung Electronics

Page 38

Disassembly and Reassembly

Service Manual

3-2

Samsung Electronics

3.2 Maintenance Parts

Sec_Code Description Life Image

JC97-02441C MEA-ROLLER PICK UP 150K

JC66-01181A ROLLER-TRANSFER 100K

JC96-05064A(220V) ELA UNIT-FUSER 100K

JC97-03070A MEA UNIT-PICK UP DADF 100K

JC97-03069A MEA UNIT-DADF RUBBER 50K

JC97-03249A MEA UNIT-HOLDER PAD

(Cassette friction pad)

100K

Page 39

Disassembly and Reassembly

Service Manual

3-3

Samsung Electronics

Spring

Hook

Spring

Hook

Spring

Hook

Spring

Hook

3.3 General Disassembly

3.3.1 Fuser Unit

1. Open the Rear Cover. 2. Remove the Fuser unit after remove the

4 screws.

3.3.2 DADF Pick up unit and rubber pad

1. Open the DADF Cover. Remove the DADF

rubber pad by removing both side hook.

2. Remove the DADF pick up unit by removing the

spring.

Page 40

Disassembly and Reassembly

Service Manual

3-4

Samsung Electronics

TrasferrollerTrasferroller

3.3.3 Pick up roller

1. Remove the Cassette. 2. Pull the Pick up roller to the direction of arrow

from the bottom of SET.

3.3.4 Transfer roller

1. Open the front cover and remove the toner cartrdige. To remove the Tranfer roller, Push the lever to the

direction of arrow.

Page 41

Disassembly and Reassembly

Service Manual

3-5

Samsung Electronics

3.3.5 Cover

1. Remove the Cassette.

2. Remove the Duplex Unit from the rear.

3. Open the DADF back. And Lift it up after remove

the connector.

4. Remove the 4 screws from the rear.

Page 42

Disassembly and Reassembly

Service Manual

3-6

Samsung Electronics

5. Open the Front cover. And remove the 4 screws.

6. Remove the Left Side Cover.

7. Remove the Right Side Cover.

Page 43

Disassembly and Reassembly

Service Manual

3-7

Samsung Electronics

3.3.6 DADF Board

1. Open the DADF back. And Lift it up after remove

the connector.

2. Remove the 5 screws from the bottom of DADF.

4. Remove the 3 screws from the bottom of DADF.

And remove the COVER-DADF-FRONT/REAR.

5. Disassemble the Stacker.

3. Remove the Sponge.

6. Remove all harness and 2 screws.

Page 44

Disassembly and Reassembly

Service Manual

3-8

Samsung Electronics

3.3.7 Scan Assy

1. Remove the COVER-DECO UPPER.

2. Remove the 1 screw.

3. Turn up the OPE unit. And remove the 8 screws.

4. Remove the 2 screws from the rear.

Page 45

Disassembly and Reassembly

Service Manual

3-9

Samsung Electronics

5. Remove the 1 screw.

6. Remove all harness connecting the Scan Assy.

8. Remove the Scan Upper from the Scan Lower.

9. Remove the at cable.

7. Lift the Scan Assy up.

10. Remove the CCDM module after remove the

belt unit.

Page 46

Disassembly and Reassembly

Service Manual

3-10

Samsung Electronics

3.3.8 Middle Cover

1. Remove the 2 screws.

2. Remove all harness.

3. Remove the 5 screws and all harness.

4. Remove the 1 screw.

Page 47

Disassembly and Reassembly

Service Manual

3-11

Samsung Electronics

3.3.9 HDD/ Main PBA/ Fax board

1. Remove the 4 screws and harness. Remove the

HDD Assy.

2. Remove all harness and 5 screws.

3. Remove the fax board cover after remove the

2 screws.

4. Remove the 1 screw.

Page 48

Disassembly and Reassembly

Service Manual

3-12

Samsung Electronics

3.3.10 SMPS board

1. Remove the Cover-SMPS. 2. Remove the SMPS Shield after remove the

2 screws.

3.3.11 Main Drive unit

1. Remove the Drive unit after remove the

6 screws.

Page 49

Disassembly and Reassembly

Service Manual

3-13

Samsung Electronics

3.3.12 HVPS board

LSU-UnitLSU-Unit

1. Separate the HVPS Shield after remove the

8 screws.

3.3.13 LSU Unit

Caution

When disassembling and assembling the HVPS

Shield, be careful the harness of the Cassette

Sensor.

1. Remove the LSU unit after the 2 harness and

4 screws.

Page 50

3.3.14 USB port

Disassembly and Reassembly

1. Remove the COVER-DECO UPPER

2. Remove the 1 SCREW.

3. Turn up the OPE unit

4. Remove the 5 screw, 3 harness.

Service Manual

3-14

Samsung Electronics

Page 51

Alignment & Troubleshooting

Scanner Part

Engine Part

Roller-Heat

Roller-Exit

Roller-Transfer

Roller-Pickup

Roller-Feed

Roller-MP

Roller-Pressure

Roller-REGI

OPC

Duplex

Duplex

Roller-REGI

OPC

FEED

SENSOR

SCAN

SENSOR

PAPER EMPTY

SENSOR

4. Alignment & Troubleshooting

This chapter describes some of the main service procedures including;

- Clearing paper jams

- Using the Diagnostic mode

- How to rmware upgrade

- Troubleshooting. etc.

4.1 Alignment and Adjustments

4.1.1 Paper path

Service Manual

4-1

Samsung Electronics

Page 52

Alignment & Troubleshooting

Service Manual

4-2

Samsung Electronics

FEED SENSOR

SCAN SENSOR

EXIT SENSOR

DUPLEX SENSOR

(1)

(2)

(3)

(4)

(5)

(1)JAM-0 : Paper empty sensor ~ Feed sensor

(2)JAM-1 : Feed sensor ~ Exit sensor

(3)JAM-2 : Exit sensor ~

(4)Duplex Jam-1 : ~ Duplex sensor

(5)Duplex Jam-0 : Duplex sensor ~ Feed sensor

PAPER EMPTY

SENSOR

FEED SENSOR

SCAN SENSOR

EXIT SENSOR

DUPLEX SENSOR

(1)

(2)

(3)

(4)

(5)

JAM-

PAPER EMPTY

SENSOR

4.1.2 Clearing Paper Jams

Occasionally, paper can be jammed during a print job. Some of the causes include:

• The tray is loaded improperly or overlled.

• The tray has been pulled out during a print job.

• The front cover has been opened during a print job.

• Paper was used that does not meet paper specications.

• Paper that is outside of the supported size range was used.

If a paper jam occurs, LCD window will show it’s speeds. Find and remove the jammed paper. If you don’t

see the paper, open the covers.

Do not use a pinset or a sharp metal tool when removing a jam.

The covering of a metal part can be removed which can cause an electric leakage.

■ Description of ENGINE JAM type (Layout)

Page 53

Alignment & Troubleshooting

Service Manual

4-3

Samsung Electronics

■ Description of ENGINE JAM type (Simplex)

Type Case Jam Removal Jam Layout

Leading edge of media does

Jam 0

not arrive at registration within a

certain time after pick-up(If fails

at a time,it tries pick-up again)

1. Pull out cassette

2. Remove jammed paper

1. Open front cover

2. Pull out toner cartridge

3. Remove jammed paper

Jam 1

Leading edge of media does not

arrive at Exit Sensor within a

certain time after registration

1. Open rear cover

2. Pull down jam lever on fuser

unit and open fuser cover)

3. Remove jammed paper from

Jam 2

Trailing edge of media does not

leave Exit Sensor within a certain

time after touching registration

exit

■ Description of ENGINE JAM type (Duplex)

Type Case Jam Removal Jam Layout

1. Open rear cover

2. Remove jammed paper

OR

1. Pull out duplex unit

2. Remove jammed paper from

duplex unit

Duplex

Jam 1

Trailing edge of media leaves

Exit Sensor, and does not arrive

at Duplex Sensor

Leading edge of media does

Duplex

Jam 0

not arrive at registration within

a certain time after touching

Duplex Sensor

1. Open rear cover

2. Remove jammed paper

OR

1. Pull out duplex unit

2. Remove jammed paper from

duplex unit

Page 54

Alignment & Troubleshooting

Service Manual

4-4

Samsung Electronics

■ Description of DADF JAM type

FEED

SENSOR

SCAN

SENSOR

PAPER EMPTY

SENSOR

FEED

SENSOR

SCAN

SENSOR

PAPER EMPTY

SENSOR

Type Case Jam Removal

Document Jam All case of DADF Jam

1. Open DADF open cover

2. Remove jammed paper

OR

1. Open DADF open cover and Lift up DADF middle

cover

2. Remove jammed paper

Page 55

Alignment & Troubleshooting

Service Manual

4-5

Samsung Electronics

4.1.2.1 Tips for avoiding paper jams

By selecting the correct media types, most paper jams can be avoided. When a paper jam occurs, follow the

steps outlined on page 98.

• Ensure that the adjustable guides are positioned correctly.

Do not overload the tray. Ensure that the paper level is below the paper capacity mark on the inside of the

tray.

• Do not remove paper from the tray while your machine is printing.

• Flex, fan, and straighten paper before loading.

• Do not use creased, damp, or highly curled paper.

• Do not mix paper types in a tray.

• Use only recommended print media.

• Ensure that the recommended side of the print media is facing down in the tray, or facing down in the multi-

purpose tray.

• If paper jams occur frequently when you print on A5/B5-sized paper: Load the paper into the tray with the

long edge facing the front of the tray. If load the paper this way, printing both sides of the paper (Duplex) is

not supported.

In the Printer Preferences window, set the page orientation to be rotated 90 degrees.

Page 56

Alignment & Troubleshooting

Service Manual

4-6

Samsung Electronics

4.1.2.2 Clearing Original Document Jams

When an original jams while passing through the document feeder, a warming message appears on the

display screen.

1. Remove any remaining pages from the

document feeder.

2. Seize the misfeed paper, and remove the paper

from the document output tray by carefully

pulling it to the right using both hands.

If you see no paper in this area, go to the next

step.

3. Open the document feeder cover.

4. Gently remove the jammed paper from the

document feeder.

If you see no paper in this area, go to the next

step.

5. Open the document feeder cover. Gently remove

the jammed paper.

Page 57

Alignment & Troubleshooting

Service Manual

4-7

Samsung Electronics

6. Close the document feeder cover. Reload the

pages you removed, if any, in the document

feeder.

7. Open the scanner lid.

8. Grasp the misfeed paper and, using both hands,

remove the paper from the feed area by carefully

pulling it to the right.

9. Close the scanner lid. Load the removed pages

back into the document feeder.

Page 58

Alignment & Troubleshooting

Service Manual

4-8

Samsung Electronics

4.1.2.3 Clearing paper jams

When a paper jam occurs, a warming message appears on the display screen. Refer to the table below to

locate and clear the paper jam.

In tray 1

1. Open and close the front cover. The jammed

paper is automatically ejected from the machine.

If the paper does not exit, go to the next step.

2. Pull out tray 1.

3. Remove the jammed paper by gently pulling it

straight out.

In optional tray 2

1. Pull out optional tray 2 open.

2. Remove the jammed paper from the machine.

If the paper does not move when you pull or if

you do not see the paper in this area, stop and

go to step

If the paper does not move when you pull, or if

you do not see the paper in this area, check the

fuser area around the toner cartridge.

4. Insert tray 1 back into the machine until it snaps

into place. Printing automatically resumes.

3. Pull tray 1 half-way out.

4. Pull the paper straight up and out.

5. Insert the trays back into the machine. Printing

automatically resumes.

Page 59

Alignment & Troubleshooting

Service Manual

4-9

Samsung Electronics

In the multi-purpose tray

1. If the paper is not feeding properly, pull the

paper out of the machine.

2. Open and close the front cover to resume

printing.

Inside the machine

1. Open the front cover and pull the toner cartridge

out, lightly pushing it down.

2. Remove the jammed paper by gently pulling it

straight out.

3. Replace the toner cartridge and close the front

cover. Printing automatically resumes.

Page 60

Alignment & Troubleshooting

Service Manual

4-10

Samsung Electronics

In exit area

1. Open and close the front cover. The jammed

paper is automatically ejected from the machine.

2. Gently pull the paper out of the output tray.

If you do not see the jammed paper or if there is

any resistance when you pull, stop and go to the

next step.

5. Release the white strip, the rear cover stopper,

and fully open the rear cover, as shown.

6. Unfold the duplex guide fully.

3. Open the rear cover.

4. If you see the jammed paper, push the pressure

lever on each side up and remove the paper.

Skip to step 9.

If you still do not see the paper, go to the next

step.

7. While pushing the fuser lever to the right, open

the fuser door.

Page 61

Alignment & Troubleshooting

Service Manual

4-11

Samsung Electronics

8. Pull the jammed paper out.If the jammed paper

does not move when you pull, push the pressure

lever on each side up to loosen the paper, and

then remove it.

9. Return the lever, door, stopper, and guide to

their original position.

10. Close the rear cover. Printing automatically

resumes.

In the duplex unit area

If the duplex unit is not inserted correctly, a paper

jam may occur. Make sure that the duplex unit is

inserted correctly.

1. Pull the duplex unit out of the machine.

2. Remove the jammed paper from the duplex unit.

If the paper does not come out with the duplex

unit, remove the paper from the bottom of the

machine.

If you still do not see the paper, go to the next

step.

Page 62

Alignment & Troubleshooting

Service Manual

4-12

Samsung Electronics

3. Open the rear cover.

4. Unfold the duplex guide fully.

5. Pull the jammed paper out.

Page 63

Alignment & Troubleshooting

Service Manual

4-13

Samsung Electronics

1

2

3

4

OPC Drum

Charge Roller

Supply Roller

Developing Roller

5

6

7

Transfer Roller

Heat Roller

Pressure Roller1

8

Pressure Roller2

1

2

3

4

5

6

7

8

4.1.3 Abnormal Image Printing and Defective Roller

If abnormal image prints periodically, check the parts shown below.

No Roller Abnormal image period Kind of abnormal image

1 OPC Drum 75.5mm White spot, Block spot

2 Charge Roller 37.7mm Black spot

3 Supply Roller 44.9mm Horizontal density band

4 Develop Roller 35.2mm Horizontal density band

5 Transfer Roller 47.1mm Black side contamination/transfer fault

6 Heat Roller 77.8mm Black spot and fuser ghost

7 Pressure Roller1 62.8mm Black side contamination

8 Pressure Roller2 50.2mm Black side contamination

Page 64

Alignment & Troubleshooting

Service Manual

4-14

Samsung Electronics

Start line

OPC Drum

Pressure Roller1

Pressure Roller2

Heat Roller

Charge Roller

Develop Roller

Supply Roller

Transfer Roller

■ Repetitive defect Image check page

Print this page. Align the this page and the printed defect image and nd the defective roller.

Page 65

Alignment & Troubleshooting

Service Manual

4-15

Samsung Electronics

4.1.4 Control Panel overview

1 Machine Setup Guides you to the machine setup and advanced settings.

2 Job Status Shows jobs currently running, queued jobs and completed.

3 Status Shows the status of your machine.

4 Display screen Displays machine’s current status and prompts during an operation.

Set menus easily using the touch screen.

5 Numeric keypad Dials fax number, and enters the number value for document copies or other

options.

6 Clear: Deletes characters in the edit area.

7 Redial/Pause In standby mode, redials the last number; or in edit mode, inserts a pause into

a fax number.

8 On Hook Dial Engages the telephone line.

9 Interrupt Stops a job in process to do an urgent copy job.

10 Clear All Reverts the current settings to default values.

11 Power Saver Sends the machine into power saver mode. You can also turn the power on

and off with this button.

12 Stop Stops an operation at any time. The pop-up window appears on the screen

showing the current job that the user can stop or resume.

13 Start Starts a job.

Page 66

Alignment & Troubleshooting

Service Manual

4-16

Samsung Electronics

4.1.4.1 Introducing the touch screen and useful buttons

Touch screen

The touch screen allows for user-friendly operation

of the machine. Once you press the home icon

(

) on the screen, it shows the Main screen.

: Shows Help. You can nd the explanation by

•

feature contents.

• Copy: Enters the Copy menu.

• Fax: Enters the Fax menu. (Optional)

• Scan: Enters Scan to Email, NetScan, Scan to

Server menu.

• Stored Documents: Enters the Stored Documents

menu.

• USB: When USB memory is inserted into the USB

memory port on your machine, USB icon shows

on the display screen.

• SmarThru Workow: Enters the SmarThru

Workow menu.

(Optional)

• Toner Info.: Shows amount of toner used.

• LCD Brightness: Adjusts the brightness of the

touch screen.

•

: You can change the display language.

•

: Guides you to remove the USB memory

devices from the machine. Follow the instruction

on the LCD. This icon appears only when you

connect an USB memory module.

• Logout: Logs out from the currently logged in

account.

Machine Setup button

When you press Machine Setup button, you

can browse current machine settings or change

machine values.

• This button allows you to move to Copy, Fax,

Scan, Stored Documents menu directly.

• Machine Status: Shows the current status of the

machine.

• Admin Setting: Allows an administrator to set up

the machine.

• Usage Page Report:You can print the report on

the amount of printouts depending on the paper

size and type.

Page 67

Alignment & Troubleshooting

Service Manual

4-17

Samsung Electronics

Job Status button

When you press Job Status button, the screen

shows the lists of currently running jobs, queued

jobs and completed jobs.

• Current Job tab: Shows the list of jobs in progress

and pending.

• Completed Job tab: Provides the list of completed

jobs.

• Active Notice tab: Displays any error codes that

have occurred.

• No.: Gives the order of jobs.

• Job Name: Shows job information like name and

type.

• Status: Gives the current status of each job.

• User: Provides user name, mainly computer

name.

• Job Type: Displays details of the active job, such

as job type, recipient phone number and other

information.

• Detail: Shows the detailed information of the

selected option on the Current Job, Completed

Job and Active Notice list.

• Delete: Removes the selected job from the list.

• Delete All: Removes all the jobs from the list.

• Close: Closes the job status window and switches

to previous view.

Power Saver button

When the machine is not in use, save electricity

with the provided power save mode. Pressing this

button puts the machine into power save mode.

If you press Power Saver button for more than two

seconds, a window appears, requesting that you

turn the power off. If you choose Yes, the power is

turned off.

This button can also be used to turn the button on.

Status Description

Off • The machine is not in the power

save mode.

• The machine is in the low power

save mode.

Blue On machine is in the power save mode.

Blink The machine is in the ready power

save mode.

Interrupt button

When you press Interrupt button, the machine goes

into interrupt mode which means it stops a printing

job for urgent copy job. When the urgent copy job

completes, the previous printing job continues.

Status Description

Off The machine is not in interrupt

printing mode.

Blue On The machine is in interrupt printing

mode.

Page 68

Alignment & Troubleshooting

Service Manual

4-18

Samsung Electronics

4.1.5 Understanding The Status LED

The color of the Status LED indicates the machine’s current status.

Status Description

Off • The machine is powered off-line.

• The machine is in power save mode. When data is received, or any

button is pressed, it switches to on-line automatically.

Green Blinking • When the backlight slowly blinks, the machine is receiving data from the

computer.

• When the backlight blinks rapidly, the machine is printing data.

On • The machine is powered on and can be used.

Red Blinking • A minor error has occurred and the machine is waiting for the error to be

cleared. Check the display message. When the problem is cleared, the

machine resumes.

• The toner cartridge is near the end of its life. Order a new toner cartridge.

You can temporarily improve print quality by redistributing the toner.

On • The toner cartridge is totally empty. Remove the old toner cartridge and

install a new one.

• A paper jam has occurred.

• The cover is opened. Close the cover.

• There is no paper in the tray. Load paper in the tray.

• The machine has stopped due to a major error. Check the display

message.

Page 69

Alignment & Troubleshooting

Service Manual

4-19

Samsung Electronics

Basic

Address

Duplex

Resolution

Advanced

Original Size

Delay Send

Priority Send

Polling

Mail Box

Image

Original Type

Darkness

Erase Background

Color Mode

Basic

Address

Duplex

Resolution

Basic

Address

Duplex

Resolution

Advanced

Original Size

Delay Send

Priority Send

Polling

Mail Box

Advanced

Original Size

Delay Send

Priority Send

Polling

Mail Box

Image

Original Type

Darkness

Erase Background

Color Mode

Basic

Original Size

Reduce & Enlarge

Duplex

Output

Original Type

Darkness

Paper Supply

Advanced

ID copy

N-Up

Poster Copy

Clone copy

Book Copy

Booklet

Covers

Transparencies

Image

Edge Erase

Off

Border Erase

Small Original

Hole Punch Erase

Book Center and Edge Erase

Erase Background

Off

Auto

Enhance

Erase

Margin Shift

Off

Auto Center

Custom Margin

Scan Enhance

Basic

Original Size

Reduce & Enlarge

Duplex

Output

Original Type

Darkness

Paper Supply

Basic

Original Size

Reduce & Enlarge

Duplex

Output

Original Type

Darkness

Paper Supply

Advanced

ID copy

N-Up

Poster Copy

Clone copy

Book Copy

Booklet

Covers

Transparencies

Image

Edge Erase

Off

Border Erase

Small Original

Hole Punch Erase

Book Center and Edge Erase

Erase Background

Off

Auto

Enhance

Erase

Margin Shift

Off

Auto Center

Custom Margin

Scan Enhance

4.1.6 Menu overview

4.1.6.1 Menu Map

The control panel provides access to various menus to set up the machine or use the machine’s functions.

These menus can be accessed by pressing Machine Setup, Job Status, or touching menus on the display

screen. Refer to the following table.

NOTE - Some menus may not appear in the display depending on options or models. If so, it is not applicable

to your machine.

Main screen

The main screen is shown on the display screen on the control panel. Some menus are grayed out

depending on your model.

Copy Menu Map

Fax Menu Map

Page 70

Alignment & Troubleshooting

Service Manual

4-20

Samsung Electronics

Scan Menu Map

Scan to PC

No.

Application

Select

Scan to Server

Basic

SMB Server List

FTP Server List

Duplex

Resolution

Advanced

Original Size

Image

Original Type

Color Mode

Darkness

Erase Background

Sacn to Edge

Output

Quality

Scan Preset

File Format

Scan to Email

Basic

Address

Duplex

Resolution

Advanced

Original Size

Image

Original Type

Color Mode

Darkness

Erase Background

Scan to Edge

Output

Quality

File Format

Scan Preset

Scan to PC

No.

Application

Select

Scan to Server

Basic

SMB Server List

FTP Server List

Duplex

Resolution

Advanced

Original Size

Image

Original Type

Color Mode

Darkness

Erase Background

Sacn to Edge

Output

Quality

Scan Preset

File Format

Scan to Email

Basic

Address

Duplex

Resolution

Advanced

Original Size

Image

Original Type

Color Mode

Darkness

Erase Background

Scan to Edge

Output

Quality

File Format

Scan Preset

Public

Detail

Edit

Delete

Delete All

Print

Secured

Detail

Edit

Delete

Print

Public

Detail

Edit

Delete

Delete All

Print

Secured

Detail

Edit

Delete

Print

USB

USB Format

USB Print

Scan to USB

Basic

Advanced

Image

Output

USB

USB Format

USB Print

Scan to USB

Basic

Advanced

Image

Output

Stored Documents Menu Map

USB Menu Map

Page 71

Alignment & Troubleshooting

Service Manual

4-21

Samsung Electronics

Machine Setup button

Machine Status

Supplies Life

Toner Cartridge-C

Fuser Kit

Feed Roller Kit-Tray 1

Feed Roller Kit-Tray 2

Feed Roller Kit-Bypass Tray

BTR Kit

Machine Info

Machine Details

Tray Status

Print/Report

Usage Counters

Admin setting

General

Device Info

Date&Time

Default Settings

Measurements

Timers

Language

Power Saver

Tray Management

Altitude Adjustment

Contention Management

SoundSuppliesManagement

Machine Test

On Demand Overwrite

HDD Spooling

Stored Job File Policy

Country

Setup

Copy Setup

Fax Setup

Network Setup

Authentication

Optional Service

Print/Report

Print

Accounting Reports

Report

Usage Page Report

Are you sure you want to print it?

Machine Status

Supplies Life

Toner Cartridge-C

Fuser Kit

Feed Roller Kit-Tray 1

Feed Roller Kit-Tray 2

Feed Roller Kit-Bypass Tray

BTR Kit

Machine Info

Machine Details

Tray Status

Print/Report

Usage Counters

Machine Status

Supplies Life

Toner Cartridge

Fuser Kit

Feed Roller Kit-Tray 1

Feed Roller Kit-Tray 2

Feed Roller Kit-Bypass Tray

BTR Kit

Machine Info

Machine Details

Tray Status

Print/Report

Usage Counters

Admin setting

General

Device Info

Date&Time

Default Settings

Measurements

Timers

Language

Power Saver

Tray Management

Altitude Adjustment

Contention Management

SoundSuppliesManagement

Machine Test

On Demand Overwrite

HDD Spooling

Stored Job File Policy

Country

Setup

Copy Setup

Fax Setup

Network Setup

Authentication

Optional Service

Print/Report

Print

Accounting Reports

Report

Admin setting

General

Device Info

Date&Time

Default Settings

Measurements

Timers

Language

Power Saver

Tray Management

Altitude Adjustment

Contention Management

SoundSuppliesManagement

Machine Test

On Demand Overwrite

HDD Spooling

Stored Job File Policy

Country

Setup

Copy Setup

Fax Setup

Network Setup

Authentication

Optional Service

Print/Report

Print

Accounting Reports

Report

Usage Page Report

Are you sure you want to print it?

Current Job

Detail

Delete

Delete All

Close

Completed Job

Detail

Close

Active Notice

Detail

Close

Current Job

Detail

Delete

Delete All

Close

Completed Job

Detail

Close

Active Notice

Detail

Close

When you press the Machine Setup button on the control panel, the screen displays two menus. Machine

Status shows the supplies life, billing, counters and reports. Admin Setting lets you set the advanced setup to

use your machine in depth and conveniently. Usage Page Report prints a report on the number of printouts

based on the paper size and type.

Job Status button

This menu shows the job in process, jobs waiting and, in completed, and error messages.

Page 72

Alignment & Troubleshooting

Service Manual

4-22

Samsung Electronics

4.1.6.2 Understanding the Copy screen

When you press Copy on the Main screen, the Copy screen appears which has several tabs and lost of

copying options. All the options are grouped by features so that you can congure your selections easily. If

the screen displays an other menu, press Home button to go to the Main screen. If you want to know more

information for copy screen, please consult the user manual.

Basic Tab

• Original Size : Selects the size of the originals.

• Reduce/Enlarge : Reduces or enlarges the size of a copied image.

• Duplex : Sets the machine to print copies on both sides of the paper.

• Output : Selects Collated or Uncollated copy options.

• Original Type : Improves the copy quality by selecting the document type for the current copy job.

• Light, Dark : Adjusts the brightness level to make a copy that is easier to read, when the original contains

faint markings and dark images.

• Paper Supply : Selects the paper supply tray.

• Erase Edge : Allows you to erase punch holes, staple marks, and fold creases along any of the four

documents edges.

Page 73

Alignment & Troubleshooting

Service Manual

4-23

Samsung Electronics

Advanced Tab

• ID Copy: Prints 2-sided originals on one sheet of paper. This feature is helpful for copying a small-sized

item, such as a business card.

• N-Up: Prints 2 or 4 original images, reduced to t onto one sheet of paper.

• Poster Copy: Prints a large image into divided 9 pages.

• Clone Copy: Prints multiple image copies from the original document on a single page.

• Book Copy: Allows you to copy an entire book.

• Booklet: Creates booklets from a sequential set of either 1-sided or 2-sided originals.

• Covers: Automatically adds covers to your copied set using stock taken from a different tray.

• Transparencies: Adds a blank or printed divider between transparencies within a set.

Image Tab

• Erase Edge: Allows you to erase punch holes, staple marks, and fold creases along any of the four

documents edges.

• Erase Background: Prints an image with no background.

• Margin Shift: Creates a binding edge for the document.

Page 74

Alignment & Troubleshooting

Service Manual

4-24

Samsung Electronics

4.1.6.3 Understanding the FAX screen