Service Manual

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Speed

• SCX-483x series : 31 ppm in A4 / 33 ppm in Letter

• SCX-5x3x series : 35 ppm in A4 / 37 ppm in Letter

2. Processor

• SCX-483xFD : 360 MHz

• SCX-483xFR / SCX-5x3x series : 600 MHz

3. Printer Languages

• PCL6, PS3

The keynote of Product

4. Memory (Std / Max)

• SCX-483xFD : 128 MB/ 384 MB

MONO LASER MFP

SCX-483x/563x/573x Series

SCX-483xFR/FD/HD

SCX-563xFR/HR, SCX-573xFW

• SCX-483xFR / SCX-5x3x series : 256 MB/ 768 MB

5. Interfaces

• High Speed USB 2.0

• 10/100 BaseTX network connector (SCX-483xFD)

• 10/100/1000 BaseTX network connector

(SCX-483xFR/ SCX-5x3x series)

• 802.11b/g/n wireless LAN (SCX-573xFW)

6. Toner cartridge (Initial / Sales)

• SCX-483x series : 2K / 2K, 5K

• SCX-5x3x series : 5K / 2K, 5K, 10K

GSPN (Global Service Partner Network)

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

North America : service.samsungportal.com

Latin America : latin.samsungportal.com

CIS : cis.samsungportal.com

Europe : europe.samsungportal.com

China : china.samsungportal.com

Asia : asia.samsungportal.com

Mideast & Africa : mea.samsungportal.com

ⓒ

Samsung Electronics Co.,Ltd. November. 2010

Printed in Korea.

VERSION NO. : 1.00 CODE : 5737-00000E

chapter 1 Precautions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1.1 Safety Warning …………………………………………………… 1-1

1.2 Caution for safety ………………………………………………… 1-2

1.2.1 Toxic material ………………………………………………… 1-2

1.2.2 Electric Shock and Fire Safety Precautions ……………… 1-2

1.2.3 Handling Precautions ……………………………………… 1-3

1.2.4 Assembly / Disassembly Precautions …………………… 1-3

1.2.5 Disregarding this warning may cause bodily injury ……… 1-4

1.3 ESD Precautions ………………………………………………… 1-5

Contents

chapter 2 Product specifi cations and descriptions

2.1 Speci cations …………………………………………………… 2-1

2.1.1 Product Overview …………………………………………… 2-1

2.1.2 Features by models ………………………………………… 2-2

2.1.3 Speci cations ………………………………………………… 2-3

2.1.4 Model Comparison Table …………………………………… 2-11

2.2 Product Description ……………………………………………… 2-12

2.2.1 Front View …………………………………………………… 2-12

2.2.2 Rear View …………………………………………………… 2-13

2.2.3 Paper Path …………………………………………………… 2-14

2.2.4 System layout ……………………………………………… 2-15

2.2.5 Hardware con guration …………………………………… 2-22

2.2.6 Engine F/W Control Algorithm ……………………………… 2-41

2.2.7 S/W Descriptions …………………………………………… 2-44

chapter 3 Disassembly and Reassembly

3.1 General precautions on disassembly ………………………… 3-1

3.2 Screws used in the printer ……………………………………… 3-2

Contents

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

3.3 Disassembly procedure ………………………………………… 3-3

3.3.1 Cover ………………………………………………………… 3-3

3.3.2 Scanner Assy ………………………………………………… 3-5

3.3.2.1 OPE board ……………………………………………… 3-6

3.3.2.2 CIS Unit ………………………………………………… 3-7

3.3.2.3 Scan Motor ……………………………………………… 3-8

3.3.2.4 Home Position Sensor ………………………………… 3-8

3.3.3 DADF Unit (SCX-563xFR / 563xHR / 573xFW) ………… 3-9

3.3.3.1 DADF Pick up unit ……………………………………… 3-9

3.3.3.2 DADF board …………………………………………… 3-10

3.3.3.3 DADF Motor …………………………………………… 3-11

3.3.4 ADF Unit (SCX-483xFR/FD/HD)) ………………………… 3-13

3.3.4.1 Tray Input ……………………………………………… 3-13

3.3.4.2 Front / Rear cover ……………………………………… 3-14

3.3.4.3 Paper Path Assy ……………………………………… 3-14

3.3.4.4 ADF Pick up unit ……………………………………… 3-15

3.3.4.5 ADF Motor ……………………………………………… 3-15

3.3.5 Middle Cover ………………………………………………… 3-16

3.3.6 Main board …………………………………………………… 3-17

3.3.7 HVPS board ………………………………………………… 3-17

3.3.8 SMPS board ………………………………………………… 3-18

3.3.9 Laser Scanning Unit (LSU) ………………………………… 3-18

3.3.10 Fuser unit …………………………………………………… 3-19

3.3.11 Main drive unit ……………………………………………… 3-20

3.3.12 Feed drive unit ……………………………………………… 3-21

3.3.13 Pick up/ Regi/ MP clutch ………………………………… 3-21

3.3.14 Pick up roller ……………………………………………… 3-22

3.3.15 Transfer roller ……………………………………………… 3-22

3.3.16 MP unit ……………………………………………………… 3-23

3.3.17 Bin-full sensor ……………………………………………… 3-23

3.3.18 Regi. / Feed / Empty sensor ……………………………… 3-24

3.3.19 Cassette roller (Retard roller) …………………………… 3-25

chapter 4 Alignment and Troubleshooting

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

4.1 Alignment and Adjustments ……………………………………… 4-1

4.1.1 Control Panel ………………………………………………… 4-1

4.1.2 Understanding The Status LED …………………………… 4-6

4.1.3 JAM Removal ……………………………………………… 4-7

4.1.4 Useful menu item for service ……………………………… 4-15

4.1.5 Periodic Defective Image …………………………………… 4-17

Contents

4.1.6

4.1.7 Updating Firmware ………………………………………… 4-20

4.1.8 Tech Mode …………………………………………………… 4-23

4.2 Troubleshooting…………………………………………………… 4-28

4.2.1 Procedure of Checking the Symptoms …………………… 4-28

4.2.2 Error Message and Troubleshooting ……………………… 4-31

4.2.3 Image Quality problem ……………………………………… 4-49

4.2.4 Other errors ………………………………………………… 4-61

4.2.5 Network problems …………………………………………… 4-63

Using the Easy Printer Manager program and smart panel

chapter 5 System Diagram

5.1 Block Diagram …………………………………………………… 5-1

5.2 Connection Diagram……………………………………………… 5-3

… 4-18

chapter 6 Reference Information

attached Parts Catalog (Exploded Views & Parts List)

6.1 Tool for Troubleshooting ………………………………………… 6-1

6.2 Acronyms and Abbreviations …………………………………… 6-2

6.3 A4 ISO 19752 Standard Pattern ………………………………… 6-8

6.4 Selecting a location ……………………………………………… 6-9

1. Precautions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1. Precautions

In order to prevent accidents and to prevent damage to the equipment please read the precautions listed

below carefully before servicing the printer and follow them closely.

1.1 Safety Warning

(1) Only to be serviced by appropriately quali ed service engineers.

High voltages and lasers inside this product are dangerous. This printer should only be serviced by a

suitably trained and quali ed service engineer.

(2) Use only Samsung replacement parts

There are no user serviceable parts inside the printer. Do not make any unauthorized changes or

additions to the printer, these could cause the printer to malfunction and create electric shock or re hazards.

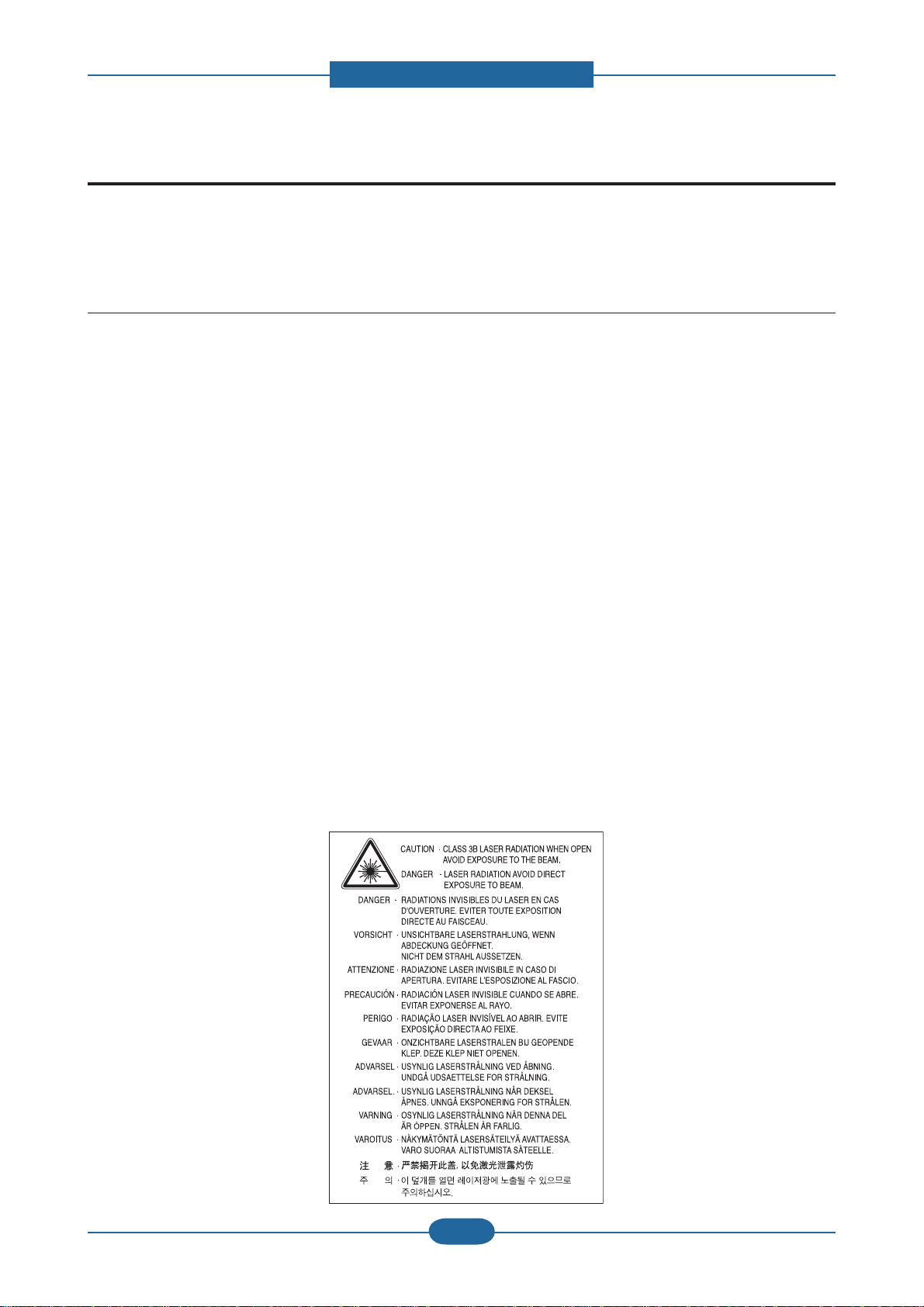

(3) Laser Safety Statement

The printer is certi ed in the U.S. to conform to the requirements of DHHS 21 CFR, chapter 1 Subchapter

J for Class I(1) laser products, and elsewhere is certi ed as a Class I laser product conforming to the

requirements of IEC 60825-1:1993 + A1:1997 + A2:2001. Class I laser products are not considered to

be hazardous. The laser system and printer are designed so there is never any human access to laser

radiation above a Class I level during normal operation, user maintenance or prescribed service condition.

• Wavelength: 800 nm

• Beam divergence

- Paraller: 12 degrees

- Perpendicular: 35 degrees

• Maximum power or energy output: 15 mW

WARNING

Never operate or service the printer with the protective cover removed from Laser/Scanner assembly. The

fl ected beam, although invisible, can damage your eyes. When using this product, these basic safety

re

precautions should always be followed to reduce risk of fi re, electric shock, and injury to persons:

Service Manual

SCX-483x/5x3x series

1-1

Samsung Electronics

1. Precautions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1.2 Caution for safety

1.2.1 Toxic material

This product contains toxic materials that could cause illness if ingested.

(1) If the LCD control panel is damaged it is possible for the liquid inside to leak. This liquid is toxic. Contact

with the skin should be avoided, wash any splashes from eyes or skin immediately and contact your

doctor. If the liquid gets into the mouth or is swallowed see a doctor immediately.

(2) Please keep Drum cartridge and Toner Cartridge away from children. The toner powder contained in the

Drum cartridge and Toner Cartridge may be harmful and if swallowed you should contact a doctor.

1.2.2 Electric Shock and Fire Safety Precautions

Failure to follow the following instructions could cause electric shock or potentially cause a re.

(1) Use only the correct voltage, failure to do so could damage the printer and potentially cause a re or

electric shock.

(2) Use only the power cable supplied with the printer. Use of an incorrectly speci ed cable could cause the

cable to overheat and potentially cause a re.

(3) Do not overload the power socket, this could lead to overheating of the cables inside the wall and could

lead to a re.

(4) Do not allow water or other liquids to spill into the printer, this can cause electric shock. Do not allow

paper clips, pins or other foreign objects to fall into the printer these could cause a short circuit leading to

an electric shock or re hazard.

(5) Never touch the plugs on either end of the power cable with wet hands, this can cause electric shock.

When servicing the printer remove the power plug from the wall socket.

(6) Use caution when inserting or removing the power connector. The power connector must be inserted

completely otherwise a poor contact could cause overheating possibly leading to a re. When removing

the power connector grip it rmly and pull.

(7) Take care of the power cable. Do not allow it to become twisted, bent sharply round corners or other

wise damaged. Do not place objects on top of the power cable. If the power cable is damaged it could

overheat and cause a re or exposed cables could cause an electric shock. Replace a damaged power

cable immediately, do not reuse or repair the damaged cable. Some chemicals can attack the coating on

the power cable, weakening the cover or exposing cables causing re and shock risks.

(8) Ensure that the power sockets and plugs are not cracked or broken in any way. Any such defects should

be repaired immediately. Take care not to cut or damage the power cable or plugs when moving the

machine.

(9) Use caution during thunder or lightening storms. Samsung recommend that this machine be disconnected

from the power source when such weather conditions are expected. Do not touch the machine or the

power cord if it is still connected to the wall socket in these weather conditions.

(10) Avoid damp or dusty areas, install the printer in a clean well ventilated location. Do not position the

machine near a humidi er. Damp and dust build up inside the machine can lead to overheating and

cause a re.

(11) Do not position the printer in direct sunlight. This will cause the temperature inside the printer to rise

possibly leading to the printer failing to work properly and in extreme conditions could lead to a re.

(12) Do not insert any metal objects into the machine through the ventilator fan or other part of the casing, it

could make contact with a high voltage conductor inside the machine and cause an electric shock.

Service Manual

SCX-483x/5x3x series

1-2

Samsung Electronics

1. Precautions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1.2.3 Handling Precautions

The following instructions are for your own personal safety, to avoid injury and so as not to damage the

printer

(1) Ensure the printer is installed on a level surface, capable of supporting its weight. Failure to do so could

cause the printer to tip or fall.

(2) The printer contains many rollers, gears and fans. Take great care to ensure that you do not catch your

ngers, hair or clothing in any of these rotating devices.

(3) Do not place any small metal objects, containers of water, chemicals or other liquids close to the printer

which if spilled could get into the machine and cause damage or a shock or re hazard.

(4) Do not install the machine in areas with high dust or moisture levels, beside on open window or close to a

humidi er or heater. Damage could be caused to the printer in such areas.

(5) Do not place candles, burning cigarettes, etc on the printer, These could cause a re.

1.2.4 Assembly / Disassembly Precautions

Replace parts carefully, always use Samsung parts. Take care to note the exact location of parts and also

cable routing before dismantling any part of the machine. Ensure all parts and cables are replaced correctly.

Please carry out the following procedures before dismantling the printer or replacing any parts.

(1) Check the contents of the machine memory and make a note of any user settings. These will be erased if

the mainboard or network card is replaced.

(2) Ensure that power is disconnected before servicing or replacing any electrical parts.

(3) Disconnect printer interface cables and power cables.

(4) Only use approved spare parts. Ensure that part number, product name, any voltage, current or

temperature rating are correct.

(5) When removing or re- tting any parts do not use excessive force, especially when tting screws into

plastic.

(6) Take care not to drop any small parts into the machine.

(7) Handling of the OPC Drum

- The OPC Drum can be irreparably damaged if it exposed to light.

Take care not to expose the OPC Drum either to direct sunlight or to uorescent or incandescent

room lighting. Exposure for as little as 5 mins can damage the surface? photoconductive properties

and will result in print quality degradation. Take extra care when servicing the printer. Remove the

OPC Drum and store it in a black bag or other lightproof container. Take care when working with the

covers(especially the top cover) open as light is admitted to the OPC area and can damage the OPC

Drum.

- Take care not to scratch the green surface of OPC Drum Unit.

If the green surface of the Drum Cartridge is scratched or touched the print quality will be compromised.

Service Manual

SCX-483x/5x3x series

1-3

Samsung Electronics

1. Precautions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1.2.5 Disregarding this warning may cause bodily injury

(1) Be careful with the high temperature part.

The fuser unit works at a high temperature. Use caution when working on the printer. Wait for the fuser to

cool down before disassembly.

(2) Do not put nger or hair into the rotating parts.

When operating a printer, do not put hand or hair into the rotating parts (Paper feeding entrance, motor,

fan, etc.). If do, you can get harm.

(3) When you move the printer.

This printer weighs approx. 16 kg (35.27 lbs) including toner cartridge and cassette. Use safe lifting and

handling techniques. Use the lifting handles located on each side of the machine. Back injury could be

caused if you do not lift carefully.

(4) Ensure the printer is installed safely.

The printer weighs approx. 16 kg (35.27 lbs), ensure the printer is installed on a level surface, capable of

supporting its weight. Failure to do so could cause the printer to tip or fall possibly causing personal injury

or damaging the printer.

(5) Do not install the printer on a sloping or unstable surface. After installation, double check that the printer

is stable.

Service Manual

SCX-483x/5x3x series

1-4

Samsung Electronics

1. Precautions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1.3 ESD Precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly

called “Electrostatically Sensitive (ES) Devices” or ESDs. Examples of typical ESDs are: integrated circuits,

some eld effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help reduce the incidence of component damage

caused by static electricity.

Caution >>Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

1. Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a known earth ground. Alternatively, employ a

commercially available wrist strap device, which should be removed for your personal safety reasons prior

to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESDs, place the assembly on a conductive surface,

such as aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity

of the assembly.

3. Use only a grounded tip soldering iron to solder or desolder ESDs.

4. Use only an “anti-static” solder removal device. Some solder removal devices not classi ed as “anti-static”

can generate electrical charges suf cient to damage ESDs.

5. Do not use Freon-propelled chemicals. When sprayed, these can generate electrical charges suf cient to

damage ESDs.

6. Do not remove a replacement ESD from its protective packaging until immediately before installing it. Most

replacement ESDs are packaged with all leads shorted together by conductive foam, aluminum foil, or a

comparable conductive material.

7. Immediately before removing the protective shorting material from the leads of a replacement ESD, touch

the protective material to the chassis or circuit assembly into which the device will be installed.

8. Maintain continuous electrical contact between the ESD and the assembly into which it will be installed,

until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as

the brushing together of clothing fabric and lifting one’s foot from a carpeted oor, can generate static

electricity suf cient to damage an ESD.

Service Manual

SCX-483x/5x3x series

1-5

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

2. Product specifi cations and descriptions

2.1 Specifi cations

2.1.1 Product Overview

1. Speed

• SCX-483x series : 31 ppm in A4 / 33 ppm in Letter

• SCX-5x3x series : 35 ppm in A4 / 37 ppm in Letter

2. Processor

• SCX-483xFD/HD : 360 MHz

• SCX-483xFR / SCX-5x3x series : 600 MHz

3. Printer Languages

• PCL6, PS3

4. Memory (Std / Max)

• SCX-483xFD/HD : 128 MB / 384 MB

• SCX-483xFR / SCX-5x3x series : 256MB / 768 MB

5. Interfaces

• High Speed USB 2.0

• 10/100 BaseTX network connector (SCX-483xFD/HD)

• 10/100/1000 BaseTX network connector

(SCX-483xFR / SCX-5x3x series)

• 802.11b/g/n wireless LAN (SCX-573xFW)

6. ADF (SCX-483xFD/HD) /

RADF (SCX-483xFR/ SCX-5x3x series)

7. Toner cartridge (Initial / Sales)

• SCX-483x series : 2K / 2K, 5K

• SCX-5x3x series : 5K / 2K, 5K, 10K

Service Manual

SCX-483x/5x3x series

2-1

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

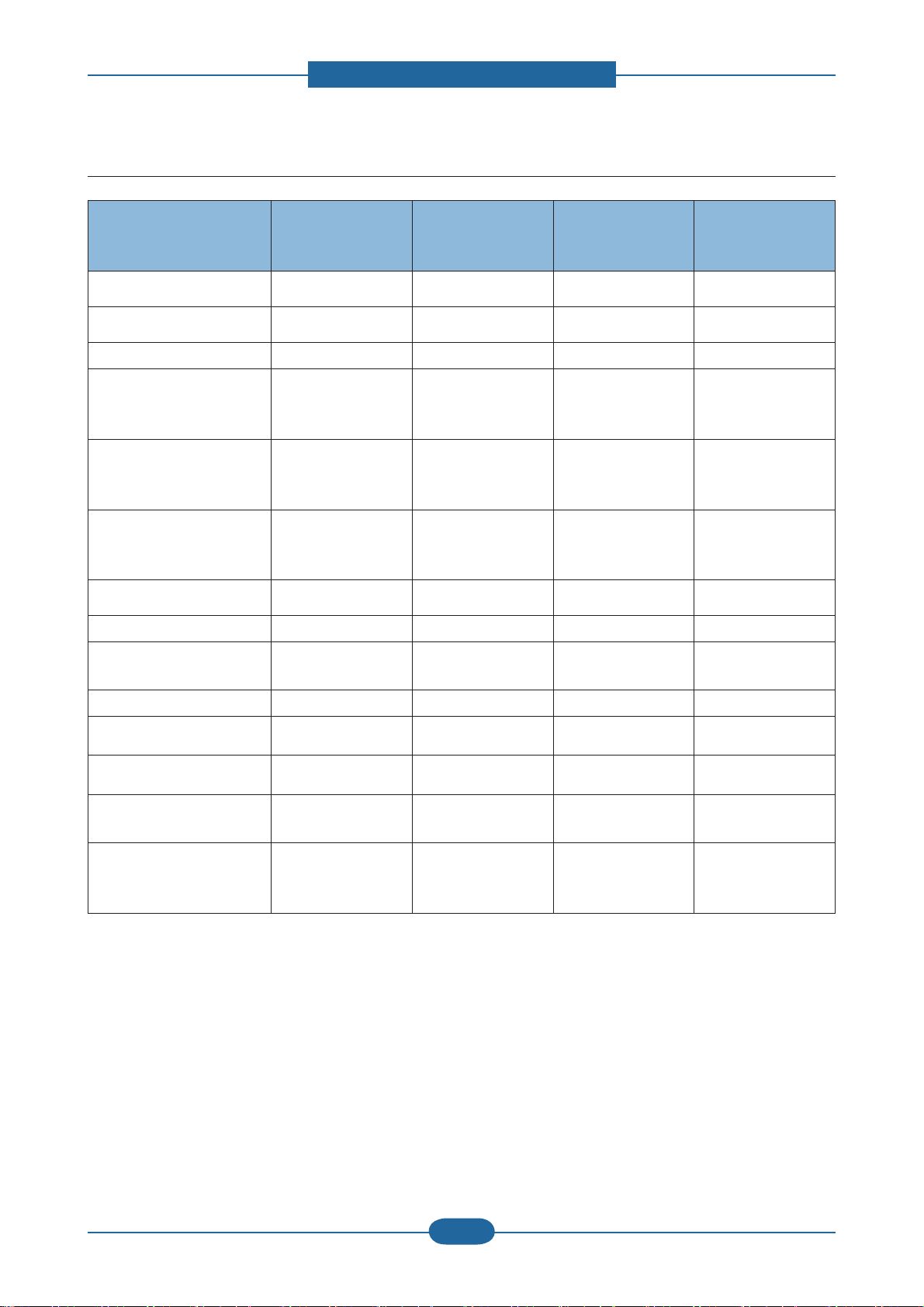

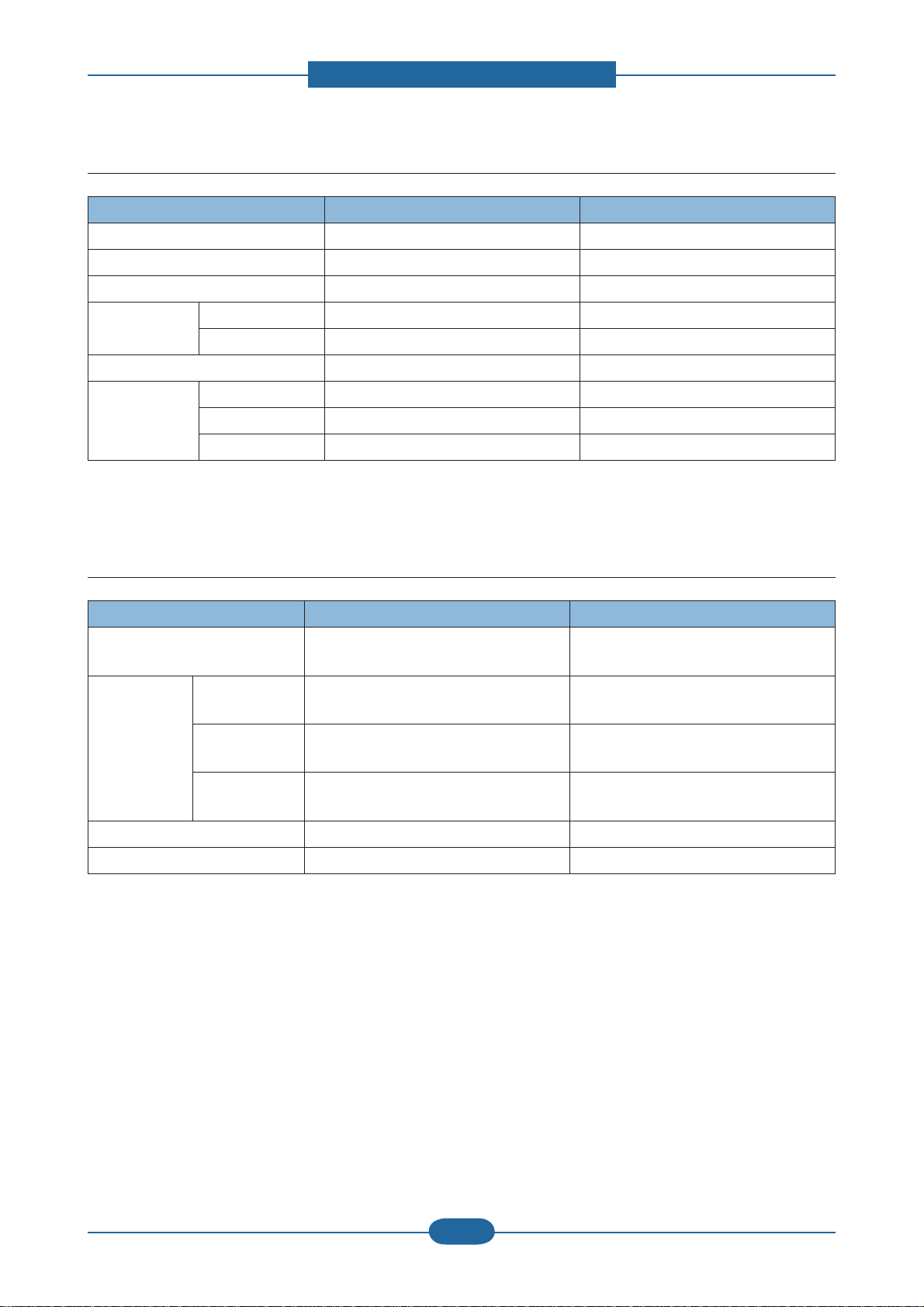

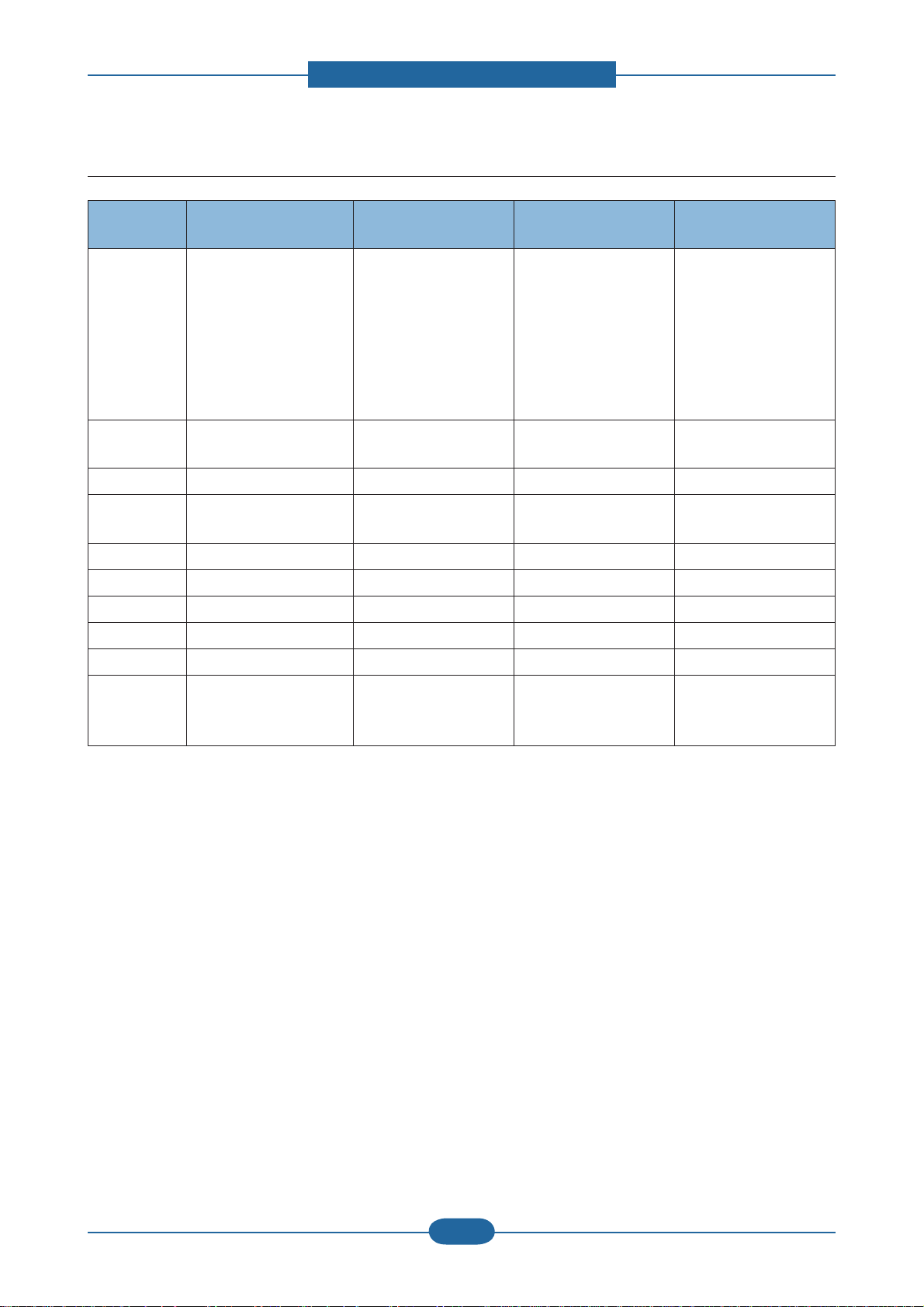

2.1.2 Features by models

SCX-4833FD

Features

Print, Copy, Scan, Fax ● ● ● ●

Hi-Speed USB 2.0 ● ● ● ●

IEEE 1284 Parallel ○ ○ ○ ○

Network Interface

Ethernet 10/100 Base

TX wired LAN

Network Interface

Ethernet 10/100/1000

Base TX wired LAN

Network Interface

802.11b/g/n wireless

LAN

Eco printing ● ● ● ●

Duplex (2-sided) printing ● ● ● ●

Samsung Easy Printer

Manager

SCX-4835FD

SCX-4833HD

●

● ● ● ●

SCX-4833FR

SCX-4835FR

● ● ●

SCX-5637FR

SCX-5639FR

SCX-5637HR

SCX-5737FW

SCX-5739FW

●

Memory ○ ○ ○ ○

Tray 2 (520 sheets) ○ ○ ○ ○

SyncThru Web Service " ● ● ● ●

Automatic Document

Feeder (ADF)

Reversed Automatic

Document Feeder

(RADF)

( ●: Included, ○: Optional, Blank: Not available)

●

● ● ●

Service Manual

SCX-483x/5x3x series

2-2

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

2.1.3 Specifi cations

• Product Specifi cations are subject to change without notice. See below for product specifi cations.

2.1.3.1 General Print Engine

Item SCX-483x series SCX-5x3x series

Engine Speed Simplex Up to 31 ppm in A4 (33 ppm in Letter) Up to 35 ppm in A4 (37 ppm in Letter)

Duplex Up to 15 ipm in A4 (16 ipm in Letter) Up to 17 ipm in A4 (18 ipm in Letter)

Warmup time From Sleep 15 sec 15 sec

FPOT From Ready As fast as 8 sec As fast as 8 sec

From Sleep As fast as 15.5 sec As fast as 15.5 sec

Resolution - Up to 1,200 x 1,200 dpi effective output Up to 1,200 x 1,200 dpi effective output

2.1.3.2 Copier specifi cation

Item SCX-483x series SCX-5x3x series

Copy Speed SDMC

(SDMC: Single

Document Multiple

Copy)

MDMC

(MDMC: Multiple

Document Multiple

Copy)

FCOT From Ready @

platen

From Sleep @

platen

- Simplex to Simplex (1-1) : 30 sec

- Simplex to Duplex (1-2) : 15 sec

- Duplex to Simplex (2-1) : 30 sec (only

483xFR)

- Duplex to Duplex (2-2) : 15 sec (only

483xFR)

- Simplex to Simplex (1-1) : 20 sec

(483xFD/HD) / 24 sec (483xFR)

- Simplex to Duplex (1-2) : 24 sec

(483xFD/HD) / 17 sec (483xFR)

- Duplex to Simplex (2-1) : 10 sec (only

483xFR)

- Duplex to Duplex (2-2) : 10 sec (only

483xFR)

As fast as 15 sec As fast as 12 sec

As fast as 23 sec As fast as 20 sec

- Simplex to Simplex (1-1) : 30 sec

- Simplex to Duplex (1-2) : 15 sec

- Duplex to Simplex (2-1) : 30 sec

- Duplex to Duplex (2-2) : 15 sec

- Simplex to Simplex (1-1) : 24 sec

- Simplex to Duplex (1-2) : 17 sec

- Duplex to Simplex (2-1) : 10 sec

- Duplex to Duplex (2-2) : 10 sec

Service Manual

SCX-483x/5x3x series

2-3

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

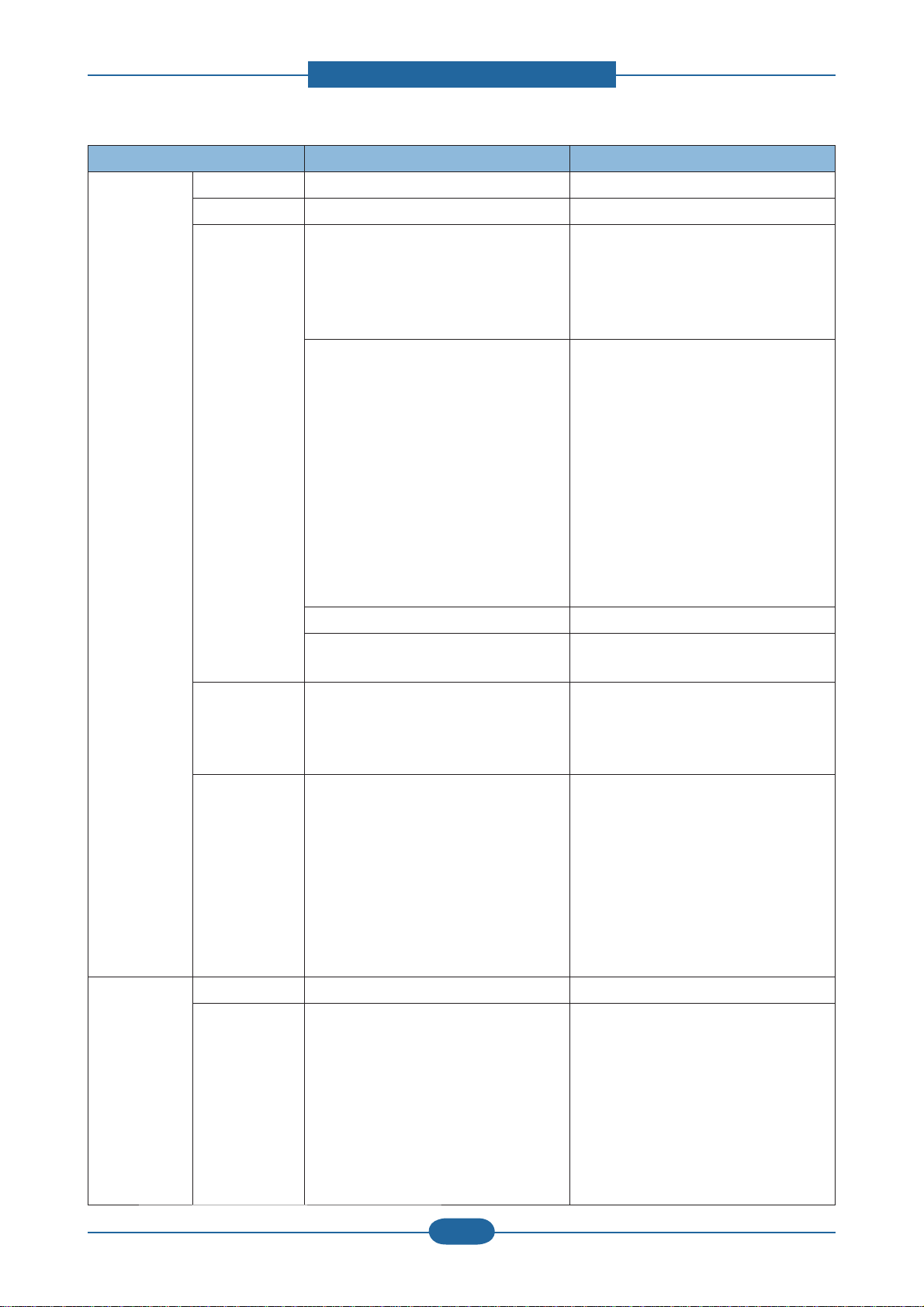

Item SCX-483x series SCX-5x3x series

Resolution Text

Text and Photo

Contrast Level 1 1 levels 1 1 levels

Darkness Level 1 1 levels 1 1 levels

Multicopy Max 99 copies Max 99 copies

- Scan

300x300 dpi @ ADF

600x300 dpi @ DADF

600x600 dpi @ Platen

- Print

600x600 dpi

- Scan

600x300 dpi @ DADF

600x600 dpi @ Platen

- Print

600x600 dpi

2.1.3.3 Scanner Specifi cation

Item SCX-483x series SCX-5x3x series

Scan Method CIS CIS

Scan Speed Black 20 ipm @ 300 dpi (483xFD)

24 ipm @ 300 dpi (483xFR)

Gray 20 ipm @ 300 dpi (483xFD)

24 ipm @ 300 dpi (483xFR)

Color 6 ipm @ 300 dpi (483xFD)

8 ipm @ 300 dpi (483xFR)

Resolution Optical 1,200 x 1,200 dpi 1,200 x 1,200 dpi

Scanning Size ADF/DADF Max. Document Width : 216 mm

Effective Scan Width : 208 mm

Max. Document Length : 356 mm

Effective Scan Lenght : 348 mm

Platen Max. Document Width : 216 mm

Effective Scan Width : 208 mm

Max. Document Length : 297 mm

Effective Scan Lenght : 289 mm

Scan Format PDF, TIFF, TIFF uncompress, Multi-

TIFF, Multi-TIFF-uncompress, JPEG

24 ipm @ 300 dpi

24 ipm @ 300 dpi

8 ipm @ 300 dpi

Max. Document Width : 216 mm

Effective Scan Width : 208 mm

Max. Document Length : 356 mm

Effective Scan Lenght : 348 mm

Max. Document Width : 216 mm

Effective Scan Width : 208 mm

Max. Document Length : 297 mm

Effective Scan Lenght : 289 mm

PDF, TIFF, TIFF uncompress, MultiTIFF, Multi-TIFF-uncompress, JPEG

Service Manual

SCX-483x/5x3x series

2-4

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

2.1.3.4 Fax Specifi cation

Item SCX-483x series SCX-5x3x series

Compression Method MH/MR/MMR, JBIG, JPEG MH/MR/MMR, JBIG, JPEG

Modem Speed 33.6 Kbps 33.6 Kbps

Transmission Speed Approx. 3 sec Approx. 3 sec

TX Resolution Normal 98 x 203 dpi 98 x 203 dpi

Fine 196 x 203 dpi 196 x 203 dpi

Gray Scale / Halftones 256 levels 256 levels

Fax Memory Type USB Memory stick USB Memory stick

Std 6 MB 50 MB

Page Capacity 480 pages 4000 pages

2.1.3.5 Controller & S/W

Item SCX-483x series SCX-5x3x series

Processor - SCX-483xFD/HD : 360 MHz

- SCX-483xFR : 600 MHz

Memory Std. - SCX-483xFD/HD : 128 MB

- SCX-483xFR : 256 MB

Max. - SCX-483xFD/HD : 384 MB

- SCX-483xFR : 768 MB

Flash - SCX-483xFD/HD : 16 MB

- SCX-483xFR : 32 MB

Printer Languages PCL, PS3 PCL, PS3

Fonts 93 scalable, 1 bitmap 93 scalable, 1 bitmap

600 MHz

256 MB

768MB

32 MB

Service Manual

SCX-483x/5x3x series

2-5

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

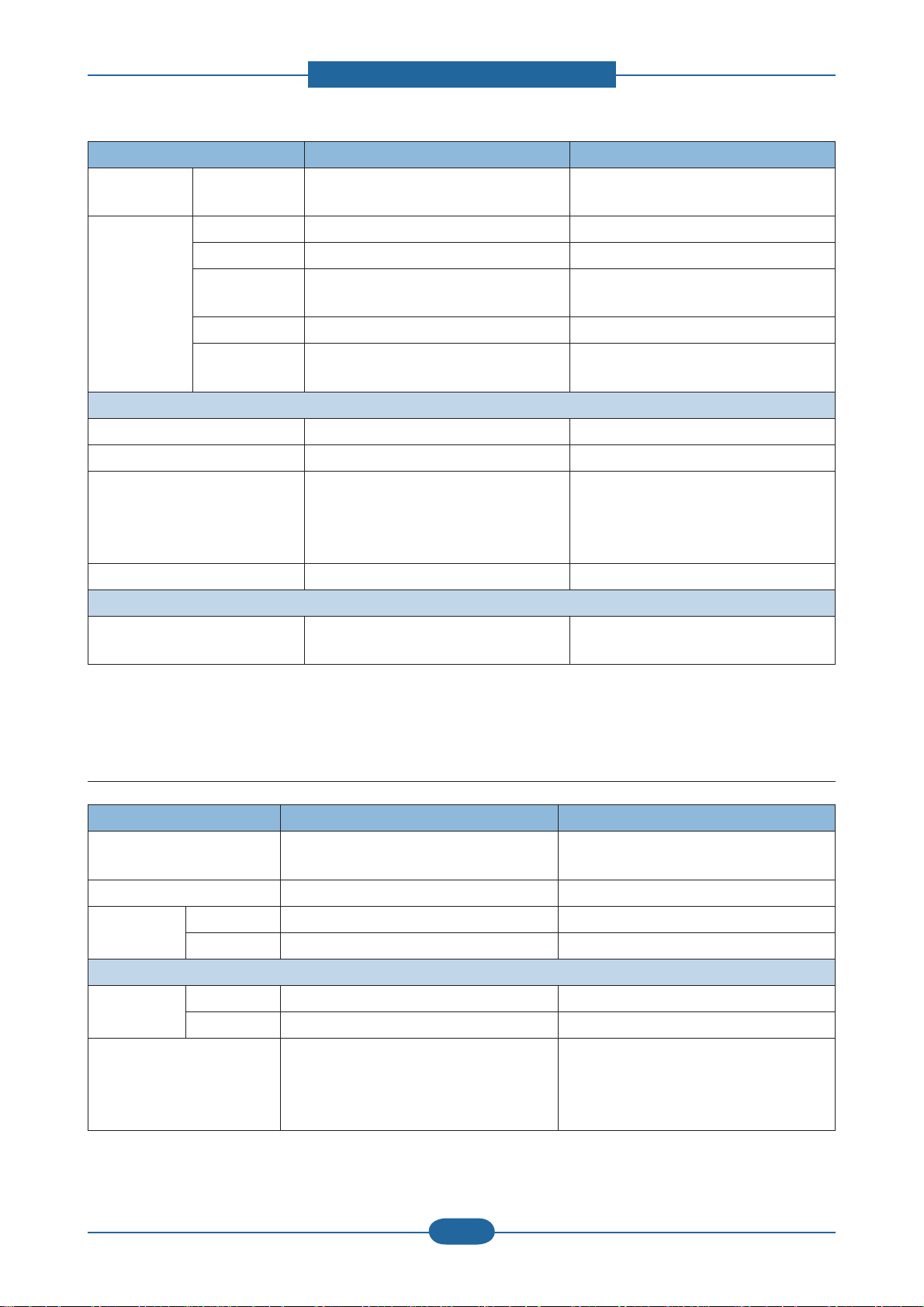

Item SCX-483x series SCX-5x3x series

Driver Default Driver PCL PCL

Install PCL6 / PS3 PCL6 / PS3

Supporting OS Windows 2000/XP (32/64 bits) /

Vista (32/64 bits) /

2003 Server (32/64 bits) /

2008 Server(32/64 bits) /

7 (32/64 bits) /2008 Server R2

V arious Linux OS:

Fedora Core 4, 5, 6

Fedora 7, 8, 9, 10, 1 1, 12

RedHat Enterprise Linux WS 4, 5

SuSE 10.0, 10.1

openSuSE 10.2, 10.3, 1 1.0, 11.1, 11.2

SuSE Linux Enterprise Desktop 10, 1 1

Debian 4.0, 5.0

Ubuntu 5.04, 5.10, 6.04, 6.10, 7.04, 7.10,

8.04, 8.10, 9.04, 9.10

Mandriva 2005LE, 2006, 2007, 2007.1,

2008, 2008.1, 2009, 2009.1

Mac OS 10.3 ~ 10.6 Mac OS 10.3 ~ 10.6

Windows 2000/XP (32/64 bits) /

Vista (32/64 bits) /

2003 Server (32/64 bits) /

2008 Server(32/64 bits) /

7 (32/64 bits) /2008 Server R2

V arious Linux OS:

Fedora Core 4, 5, 6

Fedora 7, 8, 9, 10, 1 1, 12

RedHat Enterprise Linux WS 4, 5

SuSE 10.0, 10.1

openSuSE 10.2, 10.3, 1 1.0, 11.1, 11.2

SuSE Linux Enterprise Desktop 10, 1 1

Debian 4.0, 5.0

Ubuntu 5.04, 5.10, 6.04, 6.10, 7.04, 7.10,

8.04, 8.10, 9.04, 9.10

Mandriva 2005LE, 2006, 2007, 2007.1,

2008, 2008.1, 2009, 2009.1

Citrix Presentation Server

Windows Terminal Services

WHQL Windows 2000/XP(32/64bits)/

Vista(32/64bits)/2003

Server(32/64bits)/2008 Server(32/64bits)/

7(32/64bit)/2008 Server R2(64bits)

Compatibility SPL & PCL6: Win 2000/

XP(32/64bits)/2003 Server(32/64bits)/

Vista(32/64bits)/2008

Server(32/64bits)/7(32/64bits)

PS3: Win 2000/XP(32/64bits)/

Vista(32/64bits)/2003

server(32/64bits)/2008

Server(32/64bits)/7 (32/64bits) PPD,

Mac PPD, Linux PPD

Wired Network Protocol TCP/IP, Ethertalk, SNMP , HTTP 1.1 TCP/IP, Ethertalk, SNMP , HTTP 1.1

Supporting OS Windows 2000/XP(32/64bits)/2003

Server(32/64bits)/Vista(32/64bits)/2008

Server(32/64bits)

Mac OS 8.6~9.2, 10.1~10.5

V arious Linux OS including Red Hat 8~9,

Fedora Core 1~4, Mandrake 9.2~10.1,

and SuSE 8.2~9.2

NetWare 5.x, 6.x (TCP/IP Only)

Unix HP-UX

Citrix Presentation Server

Windows Terminal Services

Windows 2000/XP(32/64bits)/

Vista(32/64bits)/2003

Server(32/64bits)/2008 Server(32/64bits)/

7(32/64bit)/2008 Server R2(64bits)

SPL & PCL6: Win 2000/

XP(32/64bits)/2003 Server(32/64bits)/

Vista(32/64bits)/2008

Server(32/64bits)/7(32/64bits)

PS3: Win 2000/XP(32/64bits)/

Vista(32/64bits)/2003

server(32/64bits)/2008

Server(32/64bits)/7 (32/64bits) PPD,

Mac PPD, Linux PPD

Windows 2000/XP(32/64bits)/2003

Server(32/64bits)/Vista(32/64bits)/2008

Server(32/64bits)

Mac OS 8.6~9.2, 10.1~10.5

V arious Linux OS including Red Hat 8~9,

Fedora Core 1~4, Mandrake 9.2~10.1,

and SuSE 8.2~9.2

NetWare 5.x, 6.x (TCP/IP Only)

Unix HP-UX

Service Manual

SCX-483x/5x3x series

2-6

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Item SCX-483x series SCX-5x3x series

Wireless

Network

Application Smart Panel SmartPanel for Macintosh/LINUX SmartPanel for Macintosh/LINUX

Interface

IEEE 1284 Parallel Optional Optional

USB Hi-Speed USB 2.0 Hi-Speed USB 2.0

Wired Network - 483xFD/HD :Ethernet 10/100 Base TX

Wireless Network N/A Only SCX-573xFW : 802.11n

User Interface

LCD - 483xFD/HD : 2-Line

Protocol N/A Only SCX-573xFW : 802.1 1n

Printer Setting PSU for Macintosh/LINUX PSU for Macintosh/LINUX

Network

Management

IP Setting SetIP SetIP

Others Easy Printer Manager (Windows Only),

SyncThru Web Admin Service 5.0 SyncThru Web Admin Service 5.0

Easy Printer Manager (Windows Only),

SmarThru Offi ce , DPU, PC fax

(Internal)

- 483xFR : Ethernet 10/100/1000 Base

TX (Internal)

- 483xFR : 4-Line

SmarThru Offi ce , DPU, PC fax

Ethernet 10/100/1000 Base TX (Internal)

- 563x series : 4- Line

- 573x series : 4.3 inch Touch Screen

2.1.3.6 Paper Handling

Item SCX-483x series SCX-5x3x series

Standard Capacity 250-sheet Cassette Tray, 50-sheet Multi

Purpose Tray @80g/㎡

Max. Capacity 820 sheets @ 80g/㎡ 820 sheets @ 80g/㎡

Printing Max. Size 216 x 356 mm (8.5" x 14") 216 x 356 mm (8.5" x 14")

Min. Size 76 x 127 mm (3.0" x 5.0") 76 x 127 mm (3.0" x 5.0")

Multi-purpose tray

Capacity Plain Paper 50 sheets @ 80g/㎡ 50 sheets @ 80g/㎡

Envelop 5 sheets 5 sheets

Media sizes A4, A5, A6, Letter, Legal, Folio, Ofi cio,

Executive, ISO B5, JIS B5, 3"x5",

Envelope(Monarch, No.10, DL, C5, C6),

Custom

250-sheet Cassette Tray, 50-sheet Multi

Purpose Tray @80g/㎡

A4, A5, A6, Letter, Legal, Folio, Ofi cio,

Executive, ISO B5, JIS B5, 3"x5",

Envelope(Monarch, No.10, DL, C5, C6),

Custom

Service Manual

SCX-483x/5x3x series

2-7

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

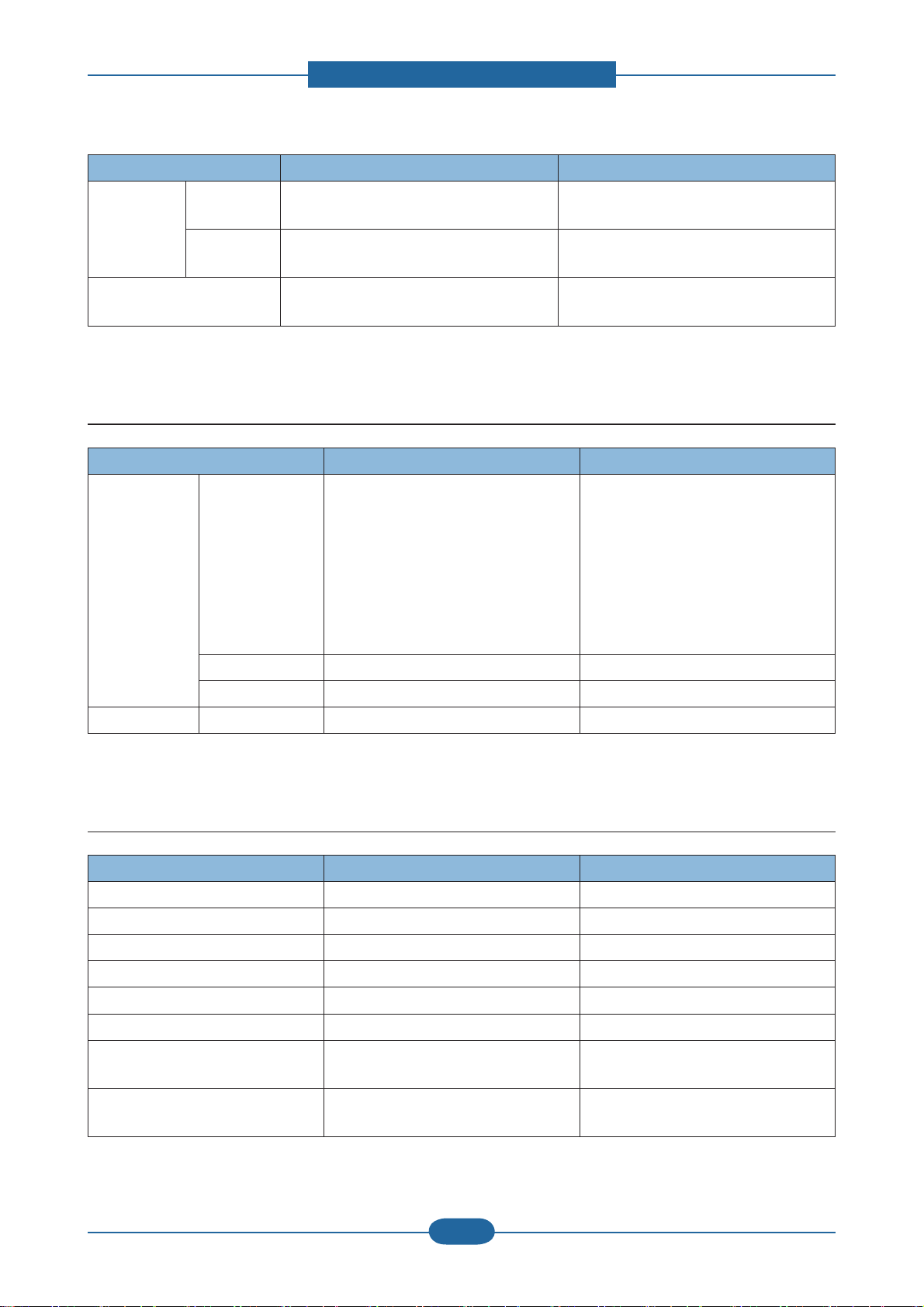

Item SCX-483x series SCX-5x3x series

Media type Plain, Thin, Thick, Thicker, Cotton, Colored,

Envelope, Transparency, Pre-Printed,

Recycled, Labels, Bond, Card stock,

Archive

Media weight 16~58lb (60 to 220g/㎡) 16~58lb (60 to 220g/㎡)

Sensing Paper Empty Paper Empty

Standard Cassette Tray

Capacity 250 sheets @ 80g/㎡ 250 sheets @ 80g/㎡

Media sizes A4, A5, A6, Letter, Legal, Folio, Ofi cio,

Executive, ISO B5, JIS B5, Custom

Media types Plain Paper, Thin, Thick, Recycled, Bond,

Cardstock, Archive

Media weight 16~43lb (60 to 163g/㎡) 16~43lb (60 to 163g/㎡)

Sensing Paper Empty Paper Empty

Optional Cassette Tray

Capacity 520 sheets @ 80g/㎡ 520 sheets @ 80g/㎡

Media sizes A4, A5, A6, Letter, Legal, Folio, Ofi cio,

Executive, ISO B5, JIS B5

Media types Plain Paper, Thin, Thick, Recycled, Bond,

Cardstock, Archive

Plain, Thin, Thick, Thicker, Cotton, Colored,

Envelope, Transparency, Pre-Printed,

Recycled, Labels, Bond, Card stock,

Archive

A4, A5, A6, Letter, Legal, Folio, Ofi cio,

Executive, ISO B5, JIS B5, Custom

Plain Paper, Thin, Thick, Recycled, Bond,

Cardstock, Archive

A4, A5, A6, Letter, Legal, Folio, Ofi cio,

Executive, ISO B5, JIS B5

Plain Paper, Thin, Thick, Recycled, Bond,

Cardstock, Archive

Media weight 16~43lb (60 to 163g/㎡) 16~43lb (60 to 163g/㎡)

Sensing Paper Empty Paper Empty

Output Stacking

Capacity Face-Down 150 sheets @ 80g/㎡ 150 sheets @ 80g/㎡

Face-Up 1 sheet 1 sheet

Output Full sensing Yes Yes

Duplex

Supporting Built-in Built-in

Media sizes A4, Letter, Ofi cio, Folio, Legal A4, Letter, Ofi cio, Folio, Legal

Media types Plain Paper, Thin, Thick, Recycled, Bond Plain Paper, Thin, Thick, Recycled, Bond

Media weight 16~32lb (60 to 120g/㎡) 16~32lb (60 to 120g/㎡)

Document Thickness

Non-Printable

Area

RADF/ADF

Type - 483xFD/HD : ADF

Envelop 10mm(0.4") from edge(Top, Bottom, Left,

Right)

Other Media 4mm(0.16") from edge(Top, Bottom, Left,

Right)

- 483xFR : RADF

10mm(0.4") from edge(Top, Bottom, Left,

Right)

4mm(0.16") from edge(Top, Bottom, Left,

Right)

RADF

Capacity 50 sheets @ 20lb 50 sheets @ 20lb

Service Manual

SCX-483x/5x3x series

2-8

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

Item SCX-483x series SCX-5x3x series

Document

Size

Paper Weight - ADF : 16~28lb

Width - ADF : 142~216mm

- RADF : 145~216mm

Length - ADF : 148~356mm

- RADF : 145~356mm

- RADF : 12.5~28lb

2.1.3.7 Consumables

Item SCX-483x series SCX-5x3x series

Toner Black - Standard: Average Cartridge Yield 2K

standard pages.

- High Yield: A verage cartridge Yield 5K

standard pages.

Declared cartridge yield in accordance

with ISO/IEC 19752.

145~216mm

145~356mm

12.5~ 28 lb

- Standard: Average Cartridge Yield 2K

standard pages.

- High Yield: A verage cartridge Yield 5K

standard pages.

- Extra High Yield: Average cartridge

Yield 10K standard pages.

Declared cartridge yield in accordance

with ISO/IEC 19752.

Key Electronic key(CRUM) Only Electronic key(CRUM) Only

Life detect Toner gauge sensor by dot count T oner gauge sensor by dot count

Drum Yield N/A N/A

2.1.3.8 Reliability & Service

Item SCX-483x series SCX-5x3x series

Recommanded AMPV 1000 sheets/month 1500 sheets/month

Max AMPV 2500 sheets/month 3500 sheets/month

Max. Monthly Duty 50,000 sheets/month 80,000 sheets/month

MPBF 35,000 sheets 45,000 sheets

MTBF 35 months 35 months

MTTR 30 min. 30 min.

ADF / RADF Unit life - ADF : 20,000 sheets

- DADF : 80,000 sheets

SET Life Cycle 170,000 sheets or 5 years (whichever

comes fi rst)

- DADF : 80,000 sheets

220,000 sheets or 5 years (whichever

comes fi rst)

Service Manual

SCX-483x/5x3x series

2-9

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

2.1.3.9 Maintenance part

Item Part Code Life

Transfer roller JC66-02842A Approx. 100,000 Pages

Fuser Unit JC91-01023A (110V)

JC91-01024A (220V)

Pick-up Roller JC73-00340A Approx. 90,000 Pages

Retard Roller JC90-01032A Approx. 60,000 Pages

RADF rubber pad JC97-03069A Approx. 20,000 pages

Approx. 90,000 Pages

2.1.3.10 Environment

Item SCX-483x series SCX-5x3x series

Operating Environment Temperature 10C to 32C 10C to 32C

Humidity 20% to 80% 20% to 80%

Acoustic Noise

Level(Sound Power/

Pressure)

Power Consumption Ready Less than 50W - 563xFR/HR : Less than 50W

Printing 51dBA 52dBA

Standby 26 dBA 26 dBA

Sleep Back Ground Level Back Ground Level

- 573xFW : Less than 65W

A VG. Less than 600W Less than 650W

Power Save Less than 8W - 563xFR/HR : Less than 8W

Dimension (W x D x H) SET - 483xFD : 407 x 424 x 382 mm

- 483xFR : 447 x 469 x 438 mm

Weight SET - 483xFD : 14 Kg

- 483xFR : 16 Kg

2.1.3.11 Options

Item SCX-483x series SCX-5x3x series

Memory * 483xFD/HD

- CLP-MEM202 : 256MB

* 483xFR

- ML-MEM170: 512 MB

Second Cassette 520-sheet Cassette Tray

(ML-S3710A)

- 573xFW : Less than 10W

447 x 469 x 438 mm

16 Kg

- ML-MEM170: 512 MB

520-sheet Cassette Tray

(ML-S3710A)

Service Manual

SCX-483x/5x3x series

2-10

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

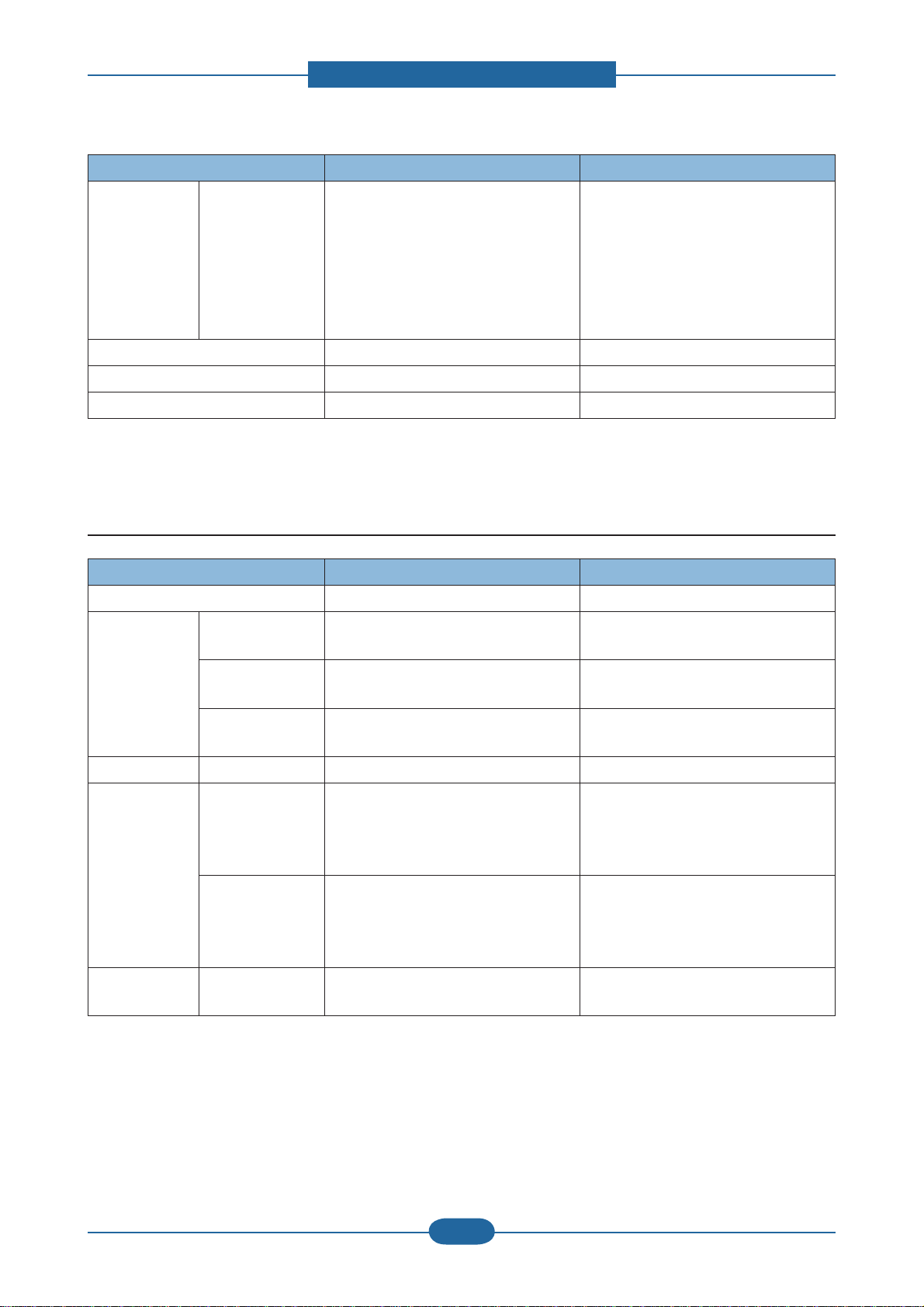

2.1.4 Model Comparison Table

Samsung

SCX-563xFR

Image

Speed

Processor 600 MHz 360 MHz - 266 MHz

Memory

(Std/Max)

Emulation PCL6/PS3 PCL6/PS3 PCL6 PCL6/PS3

MP/Cassette 50 / 250 50 / 250 50 / 250 1 / 250

SCF 520 sheets 520 sheets 250 sheets 250 / 550 sheets

Duplex Std. Std. Std. Std.

Toner Yield 2K/ 5K / 10K 2K / 5K 3K/ 8K 3.5K / 9K

Interface

35 ppm (A4)

37 ppm (Letter)

256 / 768 MB 128 / 384 MB 64 / 576 MB 64 / 64 MB

- High speed USB 2.0

- Ethernet 10/100/1000

Base TX)

Samsung

SCX-483xFD

31 ppm (A4)

33 ppm (Letter)

- High speed USB 2.0

- Ethernet 10/100 Base

TX

Brother

MFC-8890DW

30 ppm (A4) 28 ppm (A4)

- High speed USB 2.0

- Ethernet 10/100 Base

TX

- High speed USB 2.0

- Ethernet 10/100 Base

TX

Lexmark

X264DN

Service Manual

SCX-483x/5x3x series

2-11

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

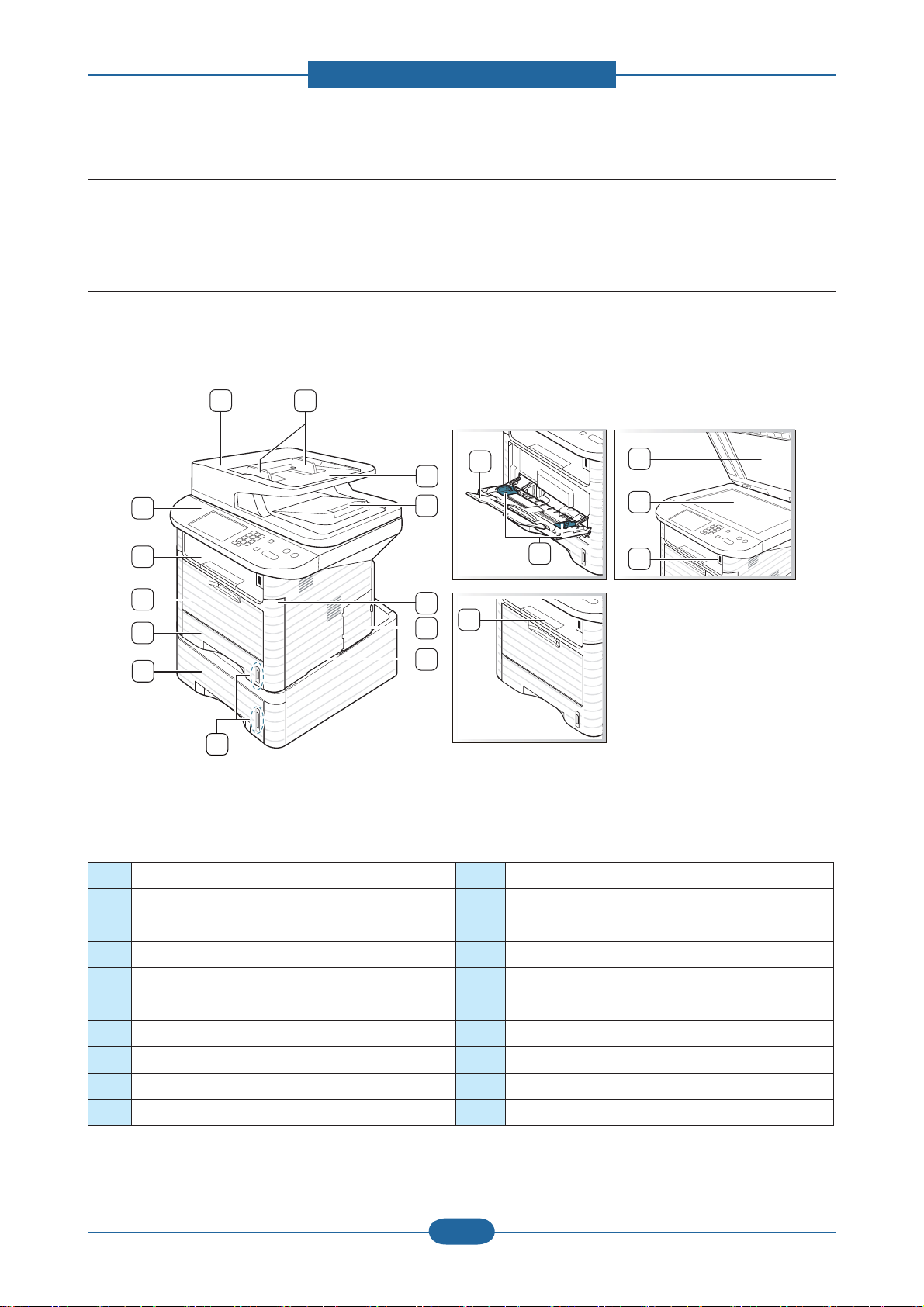

2.2 Product Description

This chapter describes the functions and operating principal of the main component.

2.2.1 Front View

X

XZ

XY

XX

XW

`

_

Y

Z

[

\

]

^

X[

X\

X]

X^

X_

X`

NOTE

• This illustration may differ from your machine depending on its model.

• Some features and optional goods may not be available depending on model or country.

1 Document feeder cover 11 Multi-purpose tray

2 Document feeder width guide 12 Output tray

3 Document feeder input tray 13 Control panel

4 Document feeder output tray 14 Multi-purpose tray paper extension

5 Front cover 15 Paper width guides on a multi-purpose tray

6 Control board cover 16 Output support

7 Handle 17 Scanner lid

8 Paper level indicator 18 Scanner glass

9 Tray2 (optional) 19 USB port

10 Tray1 20 Handset

Service Manual

SCX-483x/5x3x series

2-12

Samsung Electronics

2.2.2 Rear View

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

X

Y

Z

[

\

]

2. Product specifi cations and descriptions

XX

XW

`

^ _

NOTE

• This illustration may differ from your machine depending on its model.

• Some features and optional goods may not be available depending on model or country.

1 EDI port 7 Duplex Unit

2 Network port 8 Rear cover

3 USB port 9 Tray back cover

4 IEEE 1284 parallel connector (optional) 10 Telephone line socket

5 Power-switch 11 Extension telephone socket (EXT)

6 Power receptacle

Service Manual

SCX-483x/5x3x series

2-13

Samsung Electronics

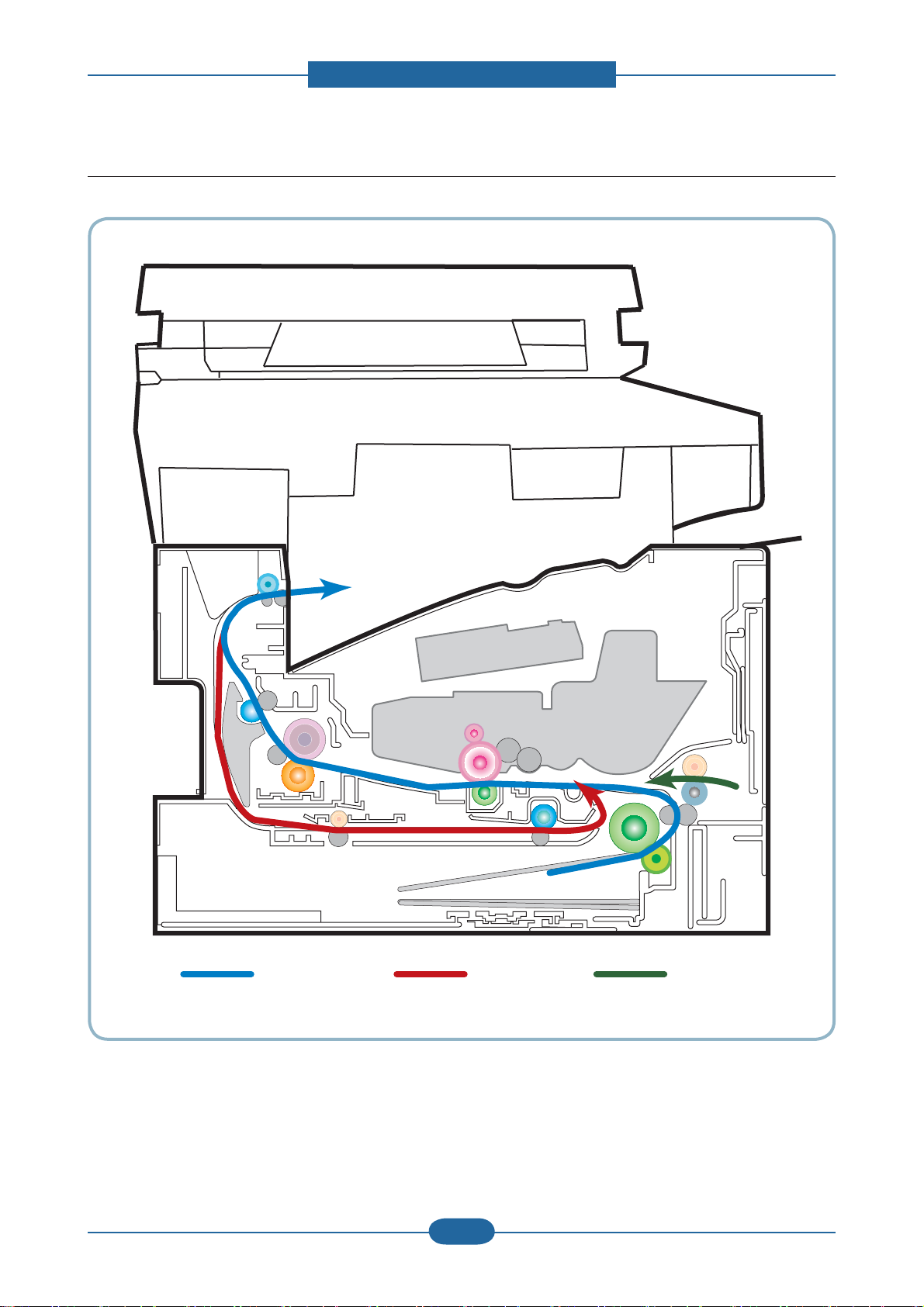

2.2.3 Paper Path

[1] Simplex [2] Duplex [3] MP

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

2. Product specifi cations and descriptions

Service Manual

SCX-483x/5x3x series

2-14

Samsung Electronics

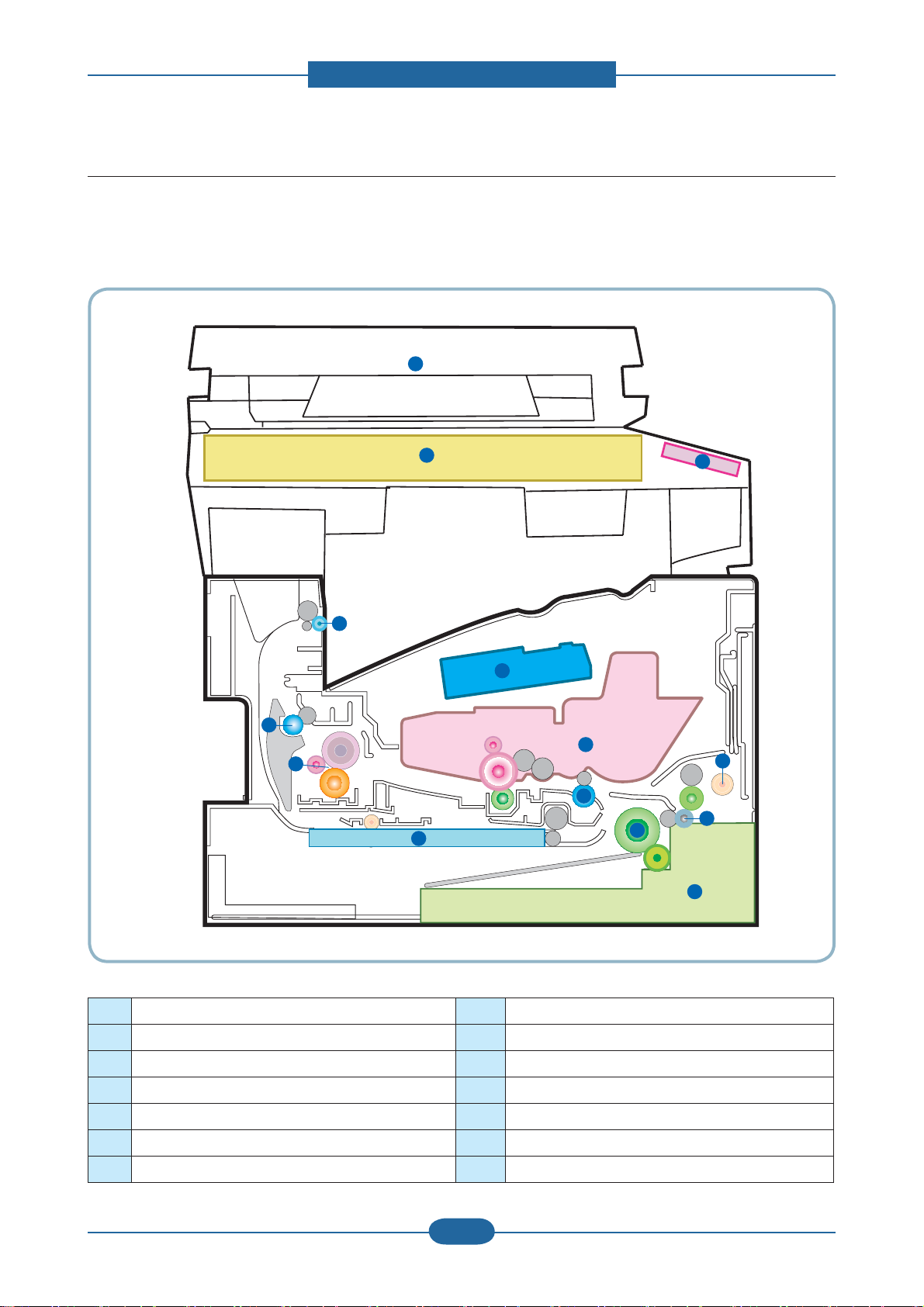

2. Product specifi cations and descriptions

1

2

3

4

7

6

8

5

11

10

9

12

14

132

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

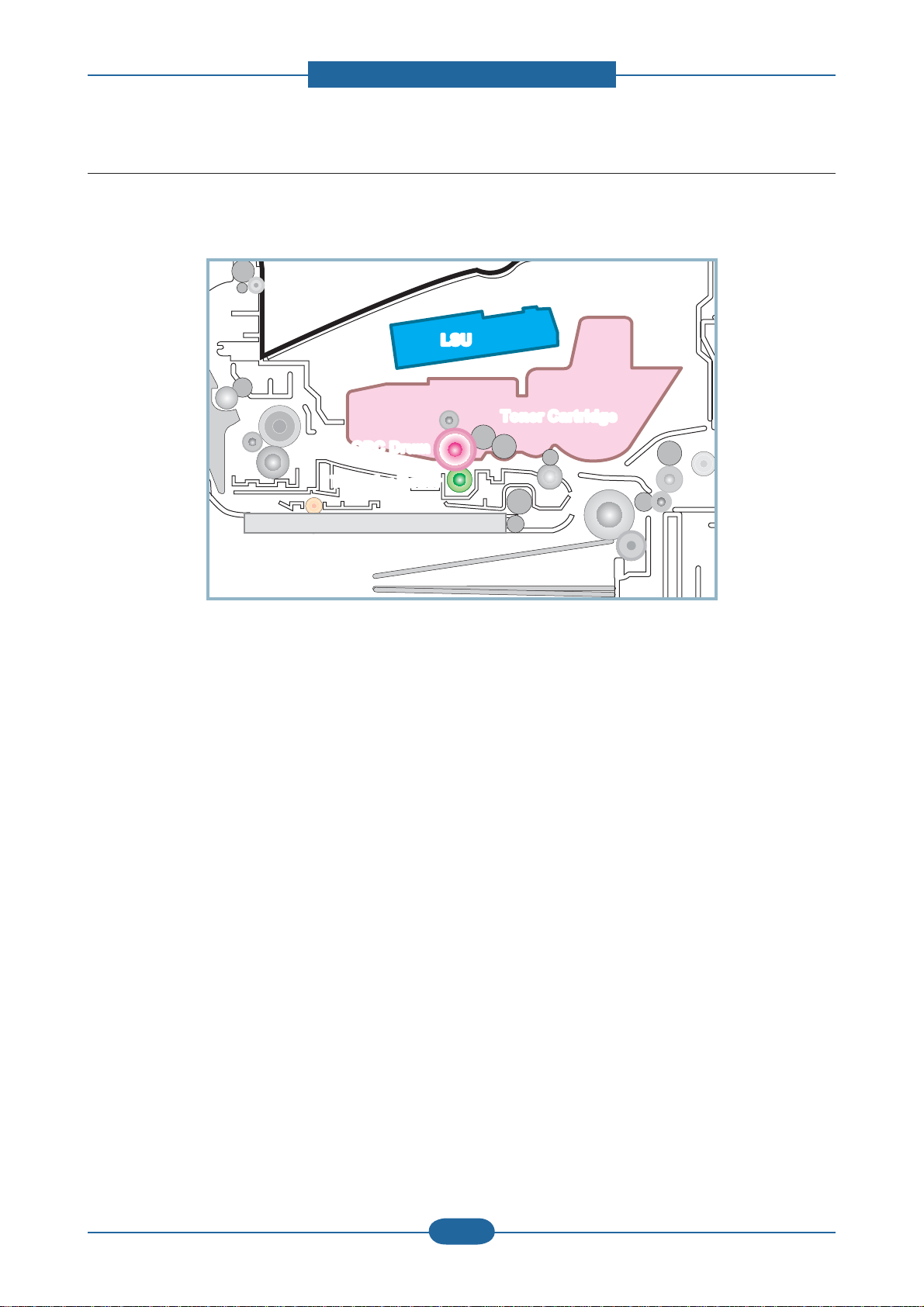

2.2.4 System layout

This model is consisted of the Engine parts and F/W. The engine parts is consisted of the mechanical

parts comprising Frame, Feeding, Developing, Driving, Transferring, Fusing, Cassette and H/W comprising

the main control board, power board, operation panel, PC Interface.

1 LSU 8 Duplex

2 Cartridge 9 Fuser

3 Regi roller 10 Exit roller1

4 MP 11 Exit roller2

5 Feed roller 12 Scanner (Platen)

6 Pick up roller 13 DADF/ADF

7 Cassette 14 OPE

Service Manual

SCX-483x/5x3x series

2-15

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

2.2.4.1 Feeding Part

It is consists of a basic cassette, an MP tray for supplying different types of media (envelope, label, special

paper) and parts related to paper transferring.

1) Tray

The basic tray is located on front side of the machine and allows feeding of common paper. Paper size is set

using the Size Guides in each tray. Adjust the Paper length/width guides to match the paper size.

3

1

LGL

A4

LTR

2

1 Paper length guide

2

Support guide

3

Paper width guide

2) Pick up / Retard Roller

When pickup takes place, the pickup roller rotates to separate and transport the paper.

The pickup roller rotates when the pickup clutch is activated. The retard roller serve to make sure

that a single sheet of paper is moved to the paper path, and the paper is moved as far as the registration

roller by the work of the feed roller. The following is a diagram of the pickup section:

Pickup Roller

Pickup Roller

Service Manual

SCX-483x/5x3x series

Feed Roller

Feed Roller

Retard Roller

Retard Roller

2-16

Regi. Roller

Regi. Roller

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

3) Registration roller

It has a paper arranging function, paper transferring function, paper detecting function, jam removing

function, and so on.

4) MP tray

The multi-purpose tray can hold special sizes and types of print material, such as postcards, note cards, and

envelopes. It is useful for single page printing on letterhead or colored paper. It uses 3 rollers feeding method

to feed 50 sheets of general papers.

5) Duplex unit

It has paper transferring function, paper guide function, jam removing function.

It is designed for basic attachment, and the duplex feeding takes a side feeding method. Usable

papers are A4, letter, and legal size paper. For removing a jam occurred in a front part, it is designed to open

a cassette and a guide.It is designed to open a rear cover to remove a jam in a rear part. If a face up tray is

open, the duplex option cannot be used.

6) SCF (Second Cassette Feeder)

It is the same method with the main cassette, and the capacity is 520 sheets.

It has a separate driving mechanism. It is designed for a common use with a main cassette.

Service Manual

SCX-483x/5x3x series

2-17

Samsung Electronics

2.2.4.2 Imaging unit

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

1) Printing process overview

2. Product specifi cations and descriptions

LSU

LSU

Toner Cartridge

Toner Cartridge

OPC Drum

OPC Drum

Transfer Roller

Transfer Roller

This mono printing system includes the LSU with a laser beams, a toner cartridge and transfer roller.

This machine uses single toner cartridge and dual laser beams for mono printing. The toner cartridge

consists of Drum unit and Development unit. The Drum unit has an OPC drum, cleaning blade.

The OPC drum is charged with a negative voltage by the scorotron and is exposed by the light from the LSU

(Laser Scanning unit). The light produced by a laser creates a latent image by discharging on the surface

of the OPC drum. The negatively charged toners are attracted to the latent image due to and electric fi led.

The toners(real image) on the OPC drum are moved to the transfer media by the positive bias applied to the

transfer roller.

1. Charging the OPC drum: The scorotron gives the drum negative charges.

2. Laser exposure: Light produced by a laser diode irradiates the charged OPC through the lens and mirrors.

3. Development: This machine uses a dual-component development system . The magnetic roller carries negatively

charged toner to the latent image on the drum surface.

4. Transfer: The transfer rollers opposite the OPC drums transfer toner from the drums to the transfer media (e.g.

paper, OHP fi lm, etc).

5. Cleaning for OPC drum: The cleaning blade removes remaining toners on the drum surface after image transfer

to the paper.

Service Manual

SCX-483x/5x3x series

2-18

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

2) Toner cartridge

By using the electronic photo process, it creates a visual image. In the toner cartridge, the OPC unit and the

developing unit are in a body. The OPC unit has OPC drum and charging roller, and the toner cartridge unit

has toner, supply roller, developing roller, and blade (Doctor blade)

• Operation condition : Temp 10~30℃, Humidity 20~85% RH

• Developing Method : Non magnetic 1 element contacting method

• Toner : Non magnetic 1 element shatter type toner

• The life span of toner (ISO 19752 pattern / A4 standard)

→ Initial toner : 2K (483x series) / 5K (5x3x series)

→ Sales toner : 2K / 5K / 10K(only 5x3x series)

• Toner Residual Sensor : Dot count with CRUM(CRU Monitor)

• OPC Cleaning : Collect the toner by using cleaning blade

• Handling of wasted toner : Collect the wasted toner in the cleaning frame by using cleaning blade

• OPC Drum Protecting Shutter : None

• Classifying device for toner cartridge: ID is classifi ed by CRUM.

ⓐ Charge Roller ⓕ Supply Roller

ⓑ Drum OPC ⓖ Charge Cleaning Roller

ⓒ Cleaning Blade ⓗ Agitator 1

ⓓ Doctor Blade ⓘ Agitator 2

ⓔ Developer Roller

Service Manual

SCX-483x/5x3x series

2-19

Samsung Electronics

2. Product specifi cations and descriptions

CÓPIA NÃO CONTROLADA

CÓPIA NÃO CONTROLADA

2.2.4.3 Fuser unit

It is consisted of a halogen lamp, heat roller, pressure roller, thermistor and thermostat. It sticks the toner on

a paper by heat and pressure to complete the printing job.

Thermistor

Thermostat

Heat Roller

Pressure Roller2

Pressure Roller

Halogen Lamp

1) Thermostat

When a heat lamp is overheated, a Thermostat cuts off the main power to prevent over- heating.

- Thermostat Type : Non- Contact type THERMOSTAT

- Control Temperature : 170℃ ± 5℃

2) Thermistor

It is a temperatrue detecting sensor.

- Temperature Resistance : 7㏀ (180℃ )

3) Heat roller

The heat roller transfers the heat from the lamp to apply a heat on the paper.

The surface of a heat roller is coated with Tefl on, so toner does not stick to the surface.

4) Pressure roller

A pressure roller mounted under a heat roller is made of a silicon resin, and the surface also is coated with

Tefl on. When a paper passes between a heat roller and a pressure roller, toner adheres to the surface of a

paper permanently.

5) Halogen Lamp

- Voltage 120 V : 115 ± 5 %

220 V : 230 ± 5 %

- Capacity : 850 Watt ± 25 W

Service Manual

SCX-483x/5x3x series

2-20

Samsung Electronics

Loading...

Loading...