Page 1

Alignment and Adjustmens

Samsung Electronics

Service Manual

4-1

4

4

4. Alignment and Adjustments

This chapter describes some of the main service procedures including:

Using the EDC mode; Clearing paper jam and test patterns.

Much of this chapter is also included in the user's guide.

4.1 Engine Test Mode

The Engine Tests Mode supplies useful functions to check the condition of the engine. It tests the condition of

each device and displays the result of the test on the LCD. It is classified into 5 functions (0~4), and are shown

below.

4.1.1 To enter the Engine Test Mode

To enter the Engine Test mode

Press “ Menu -> Copies -> -> Menu -> ” in sequence, and the LCD briefly displays

'Engine Test [Diagnostic]', the machine has entered Engine Test Mode.

• To enter a lower menu (Sub menu) Press the Start/Enter key.

• To exit into an upper menu Press the Menu/Exit key.

• To return to the user menu Press the Menu/Exit key.

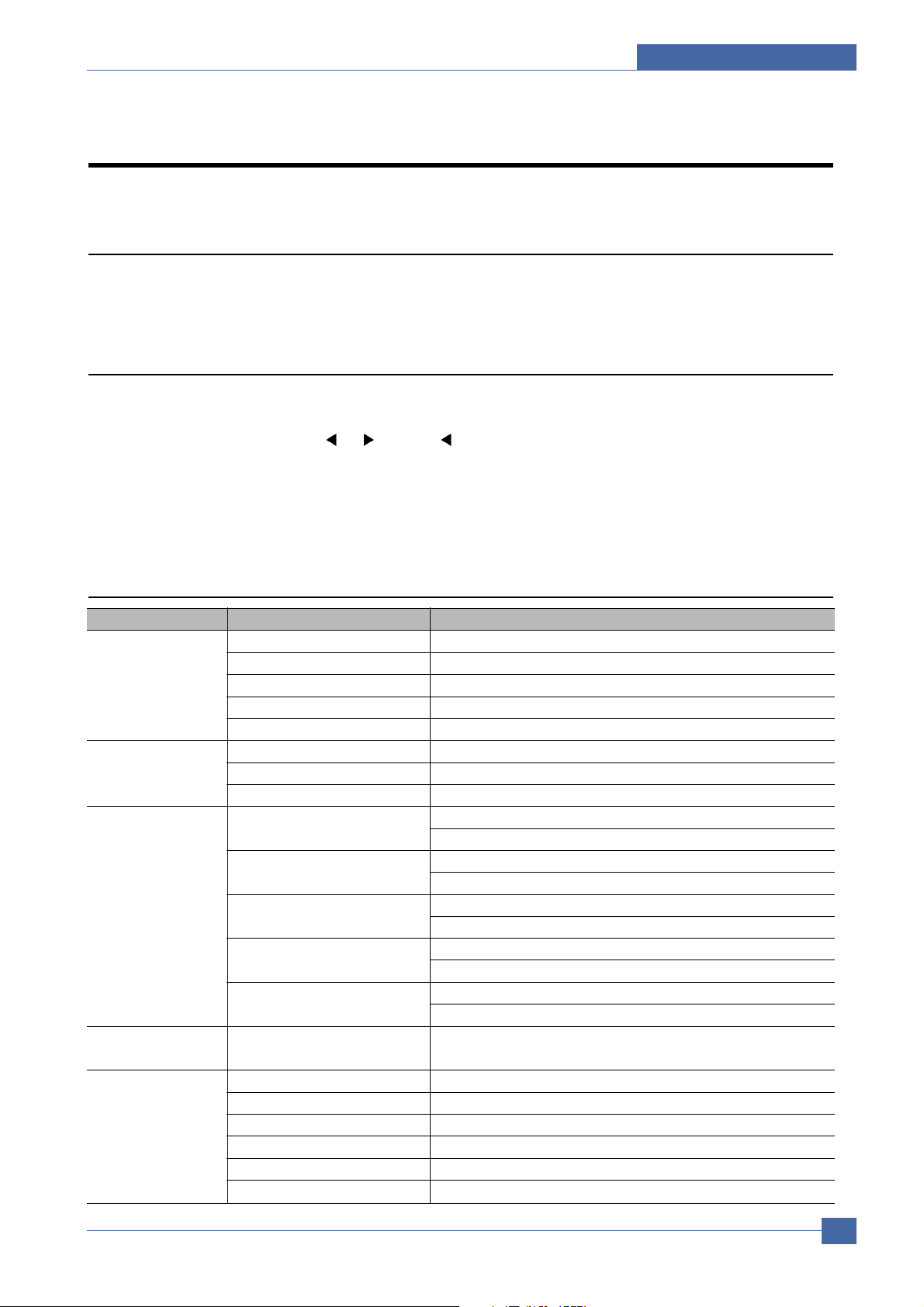

4.1.2 Diagnostic

Main Menu Engine test Remark

ENGINE TEST Motor Test 1 : On, 2 : Off

MTR FAN SOLETC PickUp Test 1 : On, 2 : Off

Fan Test 1 : On, 2 : Off

Manual Clt Test 1 : On, 2 : Off

PTL Test 1 : On, 2 : Off

ENGINE TEST LSU Motor Test 1 : On, 2 : Off

LSU TEST LSU Hsync Test 1 : On, 2 : Off

LD Test 1 : On, 2 : Off

ENGINE TEST Feed Sen Test Check : Check Start

SENSOR TEST Next : Next Sensor Check

Exit Sen Test Check : Check Start

Next : Next Sensor Check

Cover Sen Test Check : Check Start

Next : Next Sensor Check

Empty Sen Test Check : Check Start

Next : Next Sensor Check

Manual Sen Text Check : Check Start

Next : Next Sensor Check

ENGINE TEST Therm ADC 220~85 1 : On, 2 : Off (maintain the fusing temp. 65C~230C)

HEA TTEST

ENGINE TEST MHV Test 1 : On, 2 : Off (-1550V ± 50V)

HVPS TEST Dev Bias Test 1 : On, 2 : Off (-430V ± 20V)

THV EN/NEG Test 1 : On, 2 : Off (-1000V +300V/-150V)

THV ON (1300V) 1 : On, 2 : Off (+1300V ± 20V)

THV ADC 1300V 1 : On, 2 : Off

THV ADC 600V~3550V 1 : On, 2 : Off (Compare each ADC Value)

Page 2

Samsung Electronics

Service Manual

Alignment and Adjustmens

4-2

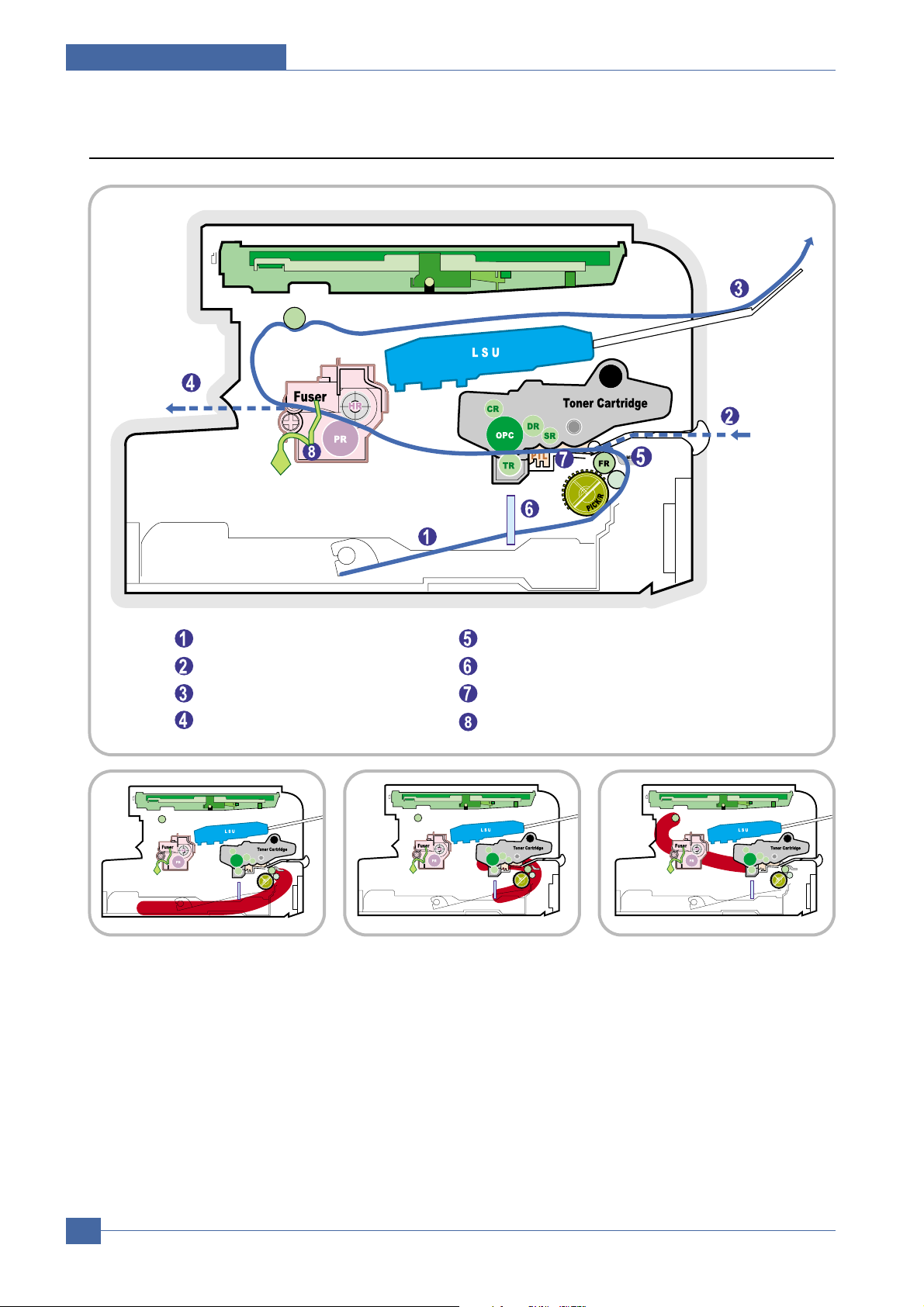

4.2 Paper Path

SCAN PART

Paper Input (Cassette)

Paper Input (Manual Feeder)

Paper Out (Face Down)

Paper Empty Sensor (Manual)

Paper Empty Sensor (Cassette)

Paper Feeding Sensor

Paper Exit SensorPaper Out (Face Up)

SCAN PART

SCAN PART

SCAN PART

1) After receiving a print command, the printer feeds paper from the main cassette or manual feeder as required.

2) The paper being fed passes the paper feed sensor. (Jam 0 occurs if the sensor is not operated within a certain

time)

3) Having passed the paper feed sensor the paper moves to the paper exit sensor via printing process. (Jam 1

occurs if the sensor is not operated within a certain time)

4) The paper then passes through the paper exit sensor and out of the set. (Jam 2 occurs if the trailing edge of the

paper does not pass the exit sensor within a certain time of the paper leading edge activating the exit sensor)

<Jam0> <Jam1> <Jam2>

Page 3

Alignment and Adjustmens

Samsung Electronics

Service Manual

4-3

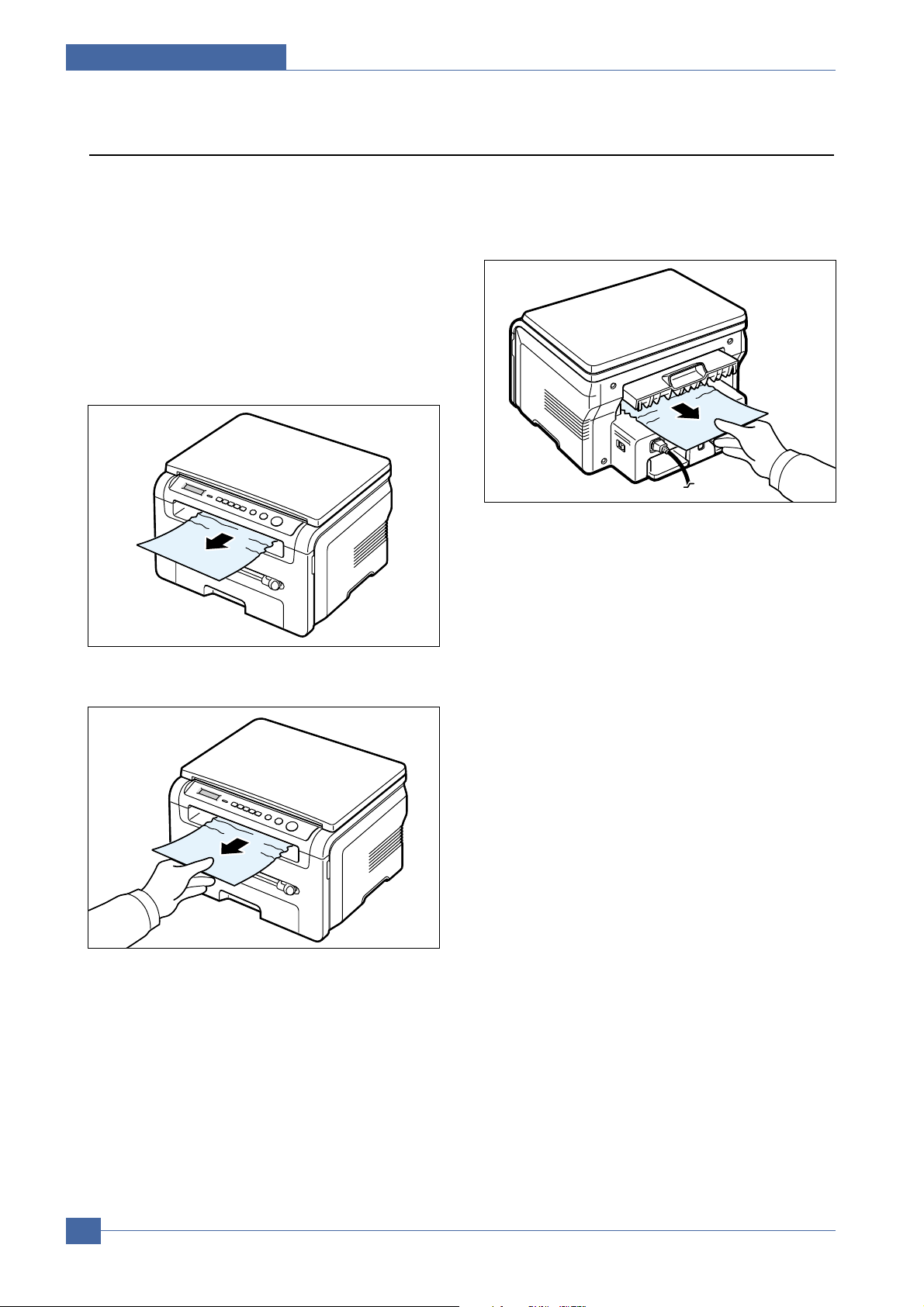

4.3 Clearing Paper Jams

When a paper jam occurs, "Paper Jam" appears on the display . Refer to the table below to locate and clear the paper jam.

To avoid tearing the paper, pull the jammed paper out gently and slowly. Follow the steps on the next pages to clear the jam.

Message Location of Jam

PAPER JAM 0 OPEN/CLOSE DOOR In the paper tray

PAPER JAM 1 OPEN/CLOSE DOOR In the paper exit area

PAPER JAM 2 CHECK INSIDE In the fuser area or around the toner cartridge

BYPASS JAM In the manual feeder

1 Open and close the front cover. The jammed paper

is automatically ejected from the machine. If the

paper is not ejected continue to step 2.

2 Pull the paper tray open.

3 Remove the jammed paper by gently pulling it

straight out.

If there is any resistance and the paper does not

move when you pull or if you cannot see the paper

in this area, skip to the fuser area around the toner

cartridge. See page 6-5

4 Insert the paper tray into the machine until it snaps

into place.

5 Open and close the front cover to resume printing.

4.3.1 In the Paper Tray

Page 4

Samsung Electronics

Service Manual

Alignment and Adjustmens

4-4

1 Open and close the front cover. The jammed paper

is automatically ejected from the machine. If the

paper is not ejected continue to step 2.

2 Gently pull the paper out of the front output tray.

Skip to step 9.

If you cannot see the jammed paper in the front

output tray, continue to step 3.

3 Open the jam cover by lifting the front edge of the

scanner unit. The support lever will automatically

pop up.

4 Pull the paper out gently.

5 Close the jam cover by pushing the support tab to

the left and hold it down whilst lowering the cover

carefully until the cover fully down, this will hold

down the tab.

If there is any resistance and the paper does not

move when you pull or if you cannot see the paper

in the jam cover, continue to step 6.

6 Open the rear cover.

7 Remove the jammed paper by gently pulling it

straight out.

8 Close the rear cover.

9 Open and close the front cover to resume printing.

4.3.2 In the Paper Exit Area

Page 5

Alignment and Adjustmens

Samsung Electronics

Service Manual

4-5

NOTE: The fuser area is hot. T ake care when removing

paper from the machine.

1 Open the front cover and lightly push down on the

cartridge then pull to take it out.

2 Remove the jammed paper by gently pulling it

straight out.

3 Replace the toner cartridge and close the front

cover.

Printing automatically resumes.

4.3.3 In the Fuser Area or Around the Toner Cartridge

“Bypass Jam” appears on the display when you try to

print using the manual feeder and the machine does

not detect paper, due to no paper or improper paper

loading.

The error message may also occur when the paper is

not properly fed into the machine through the manual

feeder.

In that case, pull the paper out of the machine.

4.3.4 In the Manual Feeder

Page 6

Samsung Electronics

Service Manual

Alignment and Adjustmens

4-6

4.4 Printing the System Data List

Your machine can print the system data report which shows the status of the user-selectable options. You may print this

list to confirm your changes after changing any settings.

To print the system data list:

1 Press Menu until "Report" appears on the top line of the display.

"System Data" appears on the bottom line.

2 Press Start

The system data list prints out.

4.5 Clearing the Memory

You can selectively clear information stored in your machine’s memory.

1 Press Menu on the control panel until "Maintenance" appears on the top line of the display.

2 Press the scroll button ( < or > ) until you see "Clear Settings" on the bottom line and press Start

The first available menu item, “Paper Setting” displays on the bottom line.

3 Press the scroll button ( < or > ) until you see the item you want to clear.

• Paper Setting: Restores all of the Paper Setting options to the factory default.

• Copy Setup: Restores all of the Copy Setup options to the factory default.

• All Settings: Resets all of your settings to the factory default.

• Machine Setup: Resets all of the system settings, such as the display language and save modes, to the factory

default.

4 Press Start/Enter. The selected memory is cleared and the display asks you to continue clearing the next item.

5 To clear another item, press Start/Enter and repeat steps 3 and 4. Or, to return to Standby mode, press Stop/Clear.

4.6 Clearing the Drum

If there are streaks or spots on your print, the OPC drum of the cartridge may require cleaning.

1 Before carrying out the cleaning procedure, make sure that paper is loaded in the machine.

2 Press Menu on the control panel until "Maintenance" appears on the top line of the display.

The first available menu item, "Clean Drum", displays on the bottom line.

3 Press Start

4 When the display asks you to confirm your selection, press Start

The machine prints a cleaning page. Toner particles on the drum surface are affixed to the paper.

5 If the problem remains, repeat steps 1 through 4.

Page 7

Alignment and Adjustmens

Samsung Electronics

Service Manual

4-7

COMPONENT REPLACEMENT CYCLE

Pick-up Roller 50,000 Pages

Paepr Feeding Roller(Friction Pad) 50,000 Pages

Transfer Roller 50,000 Pages

Fuser 50,000 Pages

Toner Cartridge Original 1,000 Pages Replacement 3,000 Pages

4.7 Consumables and Replacement Parts

The cycle period outlined below is a general guideline for maintenance.

The example list is for an average usage of 50 transmitted and received documents per day.

Environmental conditions and actual use will vary these factors.

The cycle period given below is for reference only.

LCD Meaning Solutions

Door Open

[JAM 1] or

[No Cartridge]

Low Heat Error

Open Heat Error

[Over Heat]

[LSU Error]

No Paper

[Add Paper]

Paper Jam 0

Open/Close Door

Paper Jam 1

Open/Close Door

Paper Jam 2

Check Inside

The front or rear cover is not securely

latched.

The toner cartrige is not installed.

There is a problem in the fuser unit.

A problem has occurred in the LSU

(Laser Scanning Unit).

The paper tray has run out of paper.

Paper has jammed in the feeding area of

the paper tray.

• Paper has jammed in the fuser area.

• Apaper jam has occurred in the manual

feeder or the machine detects nonfeeding from the manual feeder.

Paper has jammed in the paper exit area.

Close the cover until it locks into place.

Install the toner cartridge.

Unplug the power cord and plug it back in.

(Tech Mode Reference)

Unplug the power cord and plug it back in.

(Tech Mode Reference)

Load paper in the paper tray.

Clear the jam.

• Clear the jam.

• Clear the jam.

Clear the jam.

4.8 The LCD Status Display by Each Error

Page 8

Samsung Electronics

Service Manual

Alignment and Adjustmens

4-8

4.9 Periodic Defective Image

If a mark or other printing defect occurs at regular intervals down the page it may be caused by a damaged or

contaminated roller. Measure the repetition interval and refer to the table below to identify the roller concerned.

No Roller Defective image Typical defect

1 OPC Drum 75.5mm white spot on black image or black spot

2 Charge Roller 37.8mm black spot

3 Supply Roller 44.9mm light or dark horizontal image band

4 Developing Roller 35.2mm horizontal image band

5 Transfer Roller 45.3mm image ghost

6 Heat Roller 64.0mm Black spot and image ghost

7 Pressure Roller 75.3mm black spot on the backside

SCAN PART

PTL

1

3

7

5

MP Sensor

1

2

3

4

OPC Drum

Charge Roller

Supply Roller

Developing Roller

5

6

7

Tramsfer Roller

Heat Roller

Pressure Roller

<Rollers Layout>

Page 9

Alignment and Adjustmens

Samsung Electronics

Service Manual

4-9

4.10 Error Message

Display Meaning Suggested solutions

Door Open The front cover is not securely latched. Close the cover until it locks into place.

Hsync Error A problem has occurred in the LSU

(Laser Scanning Unit).

Unplug the power cord and plug it back in. If the

problem persists, please call for service.

[Invalid

Cartridge]

There is invalid foner install. Installed authorized toner cartridge.

Low Heat Error There is a problem in the fuser unit. Unplug the power cord and plug it back in. If the

problem persists, please call for service.

[LSU Error] A problem has occurred in the LSU

(Laser Scanning Unit).

Unplug the power cord and plug it back in. If the

problem persists, please call for service.

[No Paper]

Add Paperr

The paper in the paper input tray has run

out.

Load paper in the paper input tray.

Open Heat Error There is a problem in the fuser unit. Unplug the power cord and plug it back in. If the

problem persists, please call for service.

[Over Heat] There is a problem in the fuser unit. Unplug the power cord and plug it back in. If the

problem persists, please call for service.

[Paper Jam 0]

Open/Close

Door

Paper has jammed in the feeding area

of the paper input tray.

Clear the jam.

[Paper Jam 1]

Open/Close

Door

Paper has jammed in the fuser area or

in the manual feeder.

Clear the jam.

[Paper Jam 2]

Check Inside

Paper has jammed in the paper exit area. Clear the jam.

Power Failure Power has turned off then on and the

machine’s memory has not been back up.

The job which you were trying to do before the

power failure must be completely re-done.

Scanner Error There is a problem in the scanner unit. Unplug the power cord and plug it back in. If the

problem persists, please call for service.

Page 10

g

g

t

,

A4(

)

p

[

]

o

f

g

p

y

p

1st level

Upper Level -- Upper Level

Left/Ri

ht &&

Enter

Menu 1.Reduce/Enlarge

2.Darkness

3.Original Type

4.Special Copy

5.Toner Save

6.Paper Setting

7.Copy Setup

8.Report 1

9.Machine Setup

0.Maintenance

Tech Mode

2nd level 3rd level 4th level Default Value Descriptions

Enter

ht

LTR,LGL, A4, EXE, Folio, A5,

B5, A6

LTR,LGL, A4, EXE, Folio, A5,

B5

A6

Light/Normal/Dark

Text, Text/Photo,Photo

[Original(100%)]

[A4ױLTR(94%)]

[EXEױLTR(104%)]

50%

150%

200%

[Custom:50-200%]

1-99

Total Pa

e CNT

FLT Scan CNT

Local

Remote

100%

* Default

LTR(US)

A4(EU/AP)

LTR(US)

EU/AP

Normal

Text

1

English Portuguese ( European)

--ඖ 16 Character

Original(100%)

A4ױLTR(94%)

EXEױLTR(104%)

50%

1

150%

200%

Custom:50-200%

Normal

1

Dark

2

Light

3

1Text * Defaul

2 Text/Photo

3Photo

1Off * Default

2Clone

3 Auto Fit

4 2 Sides in 1 pg ID Copy

52 UP

6 Poster

1

On

Off

2

Paper Size

1

Paper Type

2

Default-Change

1

Timeout

2

System Data

Language

1

Power Save

2

USB Mode

3

1

Clean Drum

Clear Settings

2

Data Setup

1

Machine Test

2

3

Re

ort

Left/Ri

Tray Paper

Manual Feed

Plain Paper, Bond,

Transparency, Card Stock,

Labels, Preprinted, Colored,

Envelope,Thick, Thin

Darkness

Original Type

Reduce/Enlarge 100%

Co

ies

15,30,60,180 sec, Off 30 sec

[English/French/Spanish/P

rtuguese/German/Italian/D

utch/Russian/Swedish]- 9

countries

On 5, 10, 15, 30, 45 5 min

Of

Fast, Slow Fast

Paper Setting

Copy Setup

All Settings

Machine Setup

Clear All Mem.

Clear Count

Flash Upgrade

Switch Test

Dram Test

Rom Test

Pattern Test

Shading Test

stem Data

S

DIRECT KEY

Copies

Menu

Start

Sto

ڪڦ

ඔ/ඖ

Service Manual

4-10

1-99 * Default : 1

This is to be used to enter the Menu.

This key is used to activate the job.

This key is used to stop the job being done or to exit from the Menu. And clear value of 5 copy keys..

This key is used to select the right item what customer wants from several items.

Left/Right Arrow Key

Samsung Electronics

Page 11

;ΒΔΙΚΟΖͺ͵ͽͶΕΤΚΡΝΒΪ

͵ͺͶʹ΅ͼͶΊ

ڭڠڜڟڴ

ٻٻٻڌڋڋڀٻٻٻٻٻٻٻٻٻګډڌ

ڌډڞڪګڴٻڟڤڭڠڞگٻڦڠڴ

notice

ڤۉٻۀڼھۃٻڧڞڟٻڿۄێۋۇڼ۔ٻ ڞڪګڴٻٻٻٻٻٻٻٻٻٻٻٻڌڊڌڋ

ڤہٻېێۀۍٻۋۍۀێێٻڮۏڼۍۏڊڠۉۏۀۍٻۆۀ۔ ٻٻٻٻٻٻٻٻٻٻٻٻٻٻٻٻٻګډڌ

;ΒΔΙΚΟΖΤΥΒΣΥΤΔΠΡΪ

ڤۉٻۀڼھۃٻڧڞڟٻڿۄێۋۇڼ۔ٻ Ready

ڤہٻېێۀۍٻۋۍۀێێٻڮۏۊۋڊڞۇۀڼۍ 100% P.1

ڇڨڼھۃۄۉۀٻێۏۊۋێٻھۊۋ۔

ڞۊۋۄۀێ ڞۊۋۄۀێ ڞۊۋۄۀێ

LCD Display

ڶڌڈڔڔڸڙں 3*4KEY ڶڌڈڔڔڸڙڌڋں ENTER 100% P.10

ڍډڞڪڨڨڪکٻڟڤڭڠڞگٻڦڠڴ

ڮگڪګ Ready

notice

Menu

Start

Stop

ڪڦ

ඔ/ඖ

100% P.1 ΄΅ʹͽͶͲ

ګۇۀڼێۀٻڲڼۄۏ೨

ڞۇۀڼۍٻڦۀ۔ٻڱڼۇېۀ

ͺΞΒΘΖʹΠΟΥΣΒΤΥͿΠΗʹΠΡΚΖΤΖΕΦΔΖͶΟΝΒΣΘΖ΄ΡΖΔΚΒΝ

ΖΥΦΣΟΕΖΗΒΦΝΥΧΒΝΦΖΠΗΒΝΝΔΠΡΪΜΖΪΤ

This is to be used to enter the Menu.

This key is used to activate the job.

This key is used to stop the job being done or to exit from the Menu. And clear value of 5 copy keys..

This key is used to select the right item what customer wants from several items.

Left/Right Arrow Key

ڎډڮۏڼۏېێٻڧڠڟ

ͺΕΝΖ͵ΚΤΡΝΒΪ Ready

LED Color LED Status

ΗΗ ΗΗ

Green

Ο

ͳΝΚΟΜ

ΖΕ

Ο

ͳΝΚΟΜ

ΠΨΖΣΗΗ΄ΝΖΖΡ;ΠΕΖ

Discription

ΖΒΕΪ

ΈΙΖΟΥΙΖΛΠΓΚΤΚΟΡΣΠΘΣΖΤΤ

ͳΝΚΟΜ΄ΝΠΨΝΪΣΚΟΥΖΣ͵ΒΥΒʹΠΞΞ

ͳΝΚΟΜͷΒΤΥΣΚΟΥΚΟΘ

ͳΝΚΟΜͿΠΣΞΒΝΝΪʹΠΡΪ΄ΔΒΟ

ΖΩ΅ΠΟΖΣͶΞΡΥΪΒΡΖΣͻΒΞΒΡΖΣͶΞΡΥΪʹΠΧΖΣ

ΠΡΖΟ

ͺΟΔΒΤΖΠΗΣΖΔΠΧΖΣΒΓΝΖͶΣΣΠΣ

ΖΩΒΡΖΣ;ΚΤΞΒΥΔΙΚΟΘ

ͺΟΔΒΤΖΠΗΈΒΣΞΚΟΘΦΡΤΥΒΥΖ

ΖΩΖΡΝΒΔΖ΅ΠΟΖΣ

Samsung Electronics

Service Manual

4-11

Loading...

Loading...