Page 1

Agenda

Agenda

Ⅰ. Introduction

Ⅱ. Main PBA

Ⅲ. OPE PBA

Ⅳ. SMPS PBA

Page 2

Objectives

Objectives

I. To make you aware of the

key specification points

II. To show you how SCX-4200

series are different

Page 3

1-1. Overview

Panel Board

OPC

SMPS + HVPS

Main Board

Page 4

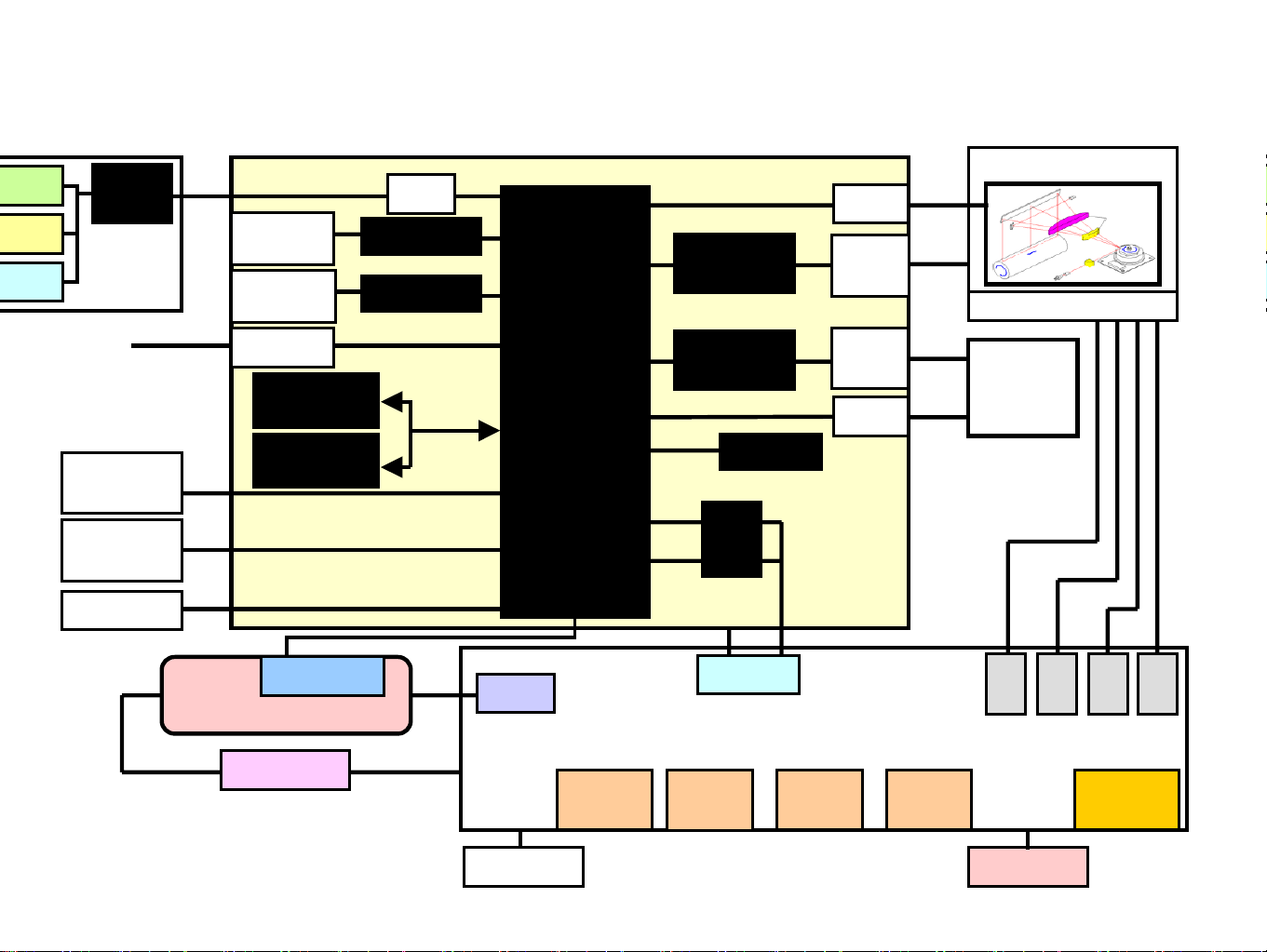

1-2. Block Diagram

LCD

KEY

LED

HC

48C50

OPE

Pickup

Solenoid

MP

Solenoid

Main CLK

10.00MHz

Video CLK

16.59MHz

USB2.0

FLASHROM

29LV800

SDRAM

8MB

UART

CY25811

CY25814

A(1:20)

D(0:15)

Chrous2

Main Board

Motor Drv.

A3977

Motor Drv.

A3977

3.3V

1.8V

3.3V

RESET IC

REG

REG

LSU

Main

Motor

Scan

Motor

CIS

Engine

Frame

Developer

Unit

Scanner

LSU

FAN 2

Thermistor

Fuser

Thermostat

TRIAC

FAN 1

P/Empty

Sensor

24V/5V

MP

Sensor

5V

SMPS

HVPS

Exit

Sensor

Feed

Sensor

T

R

CDRH S/W

S

R

D

R

Cover

Open S/W

C

R

Page 5

1-3. Connection Diagram

Page 6

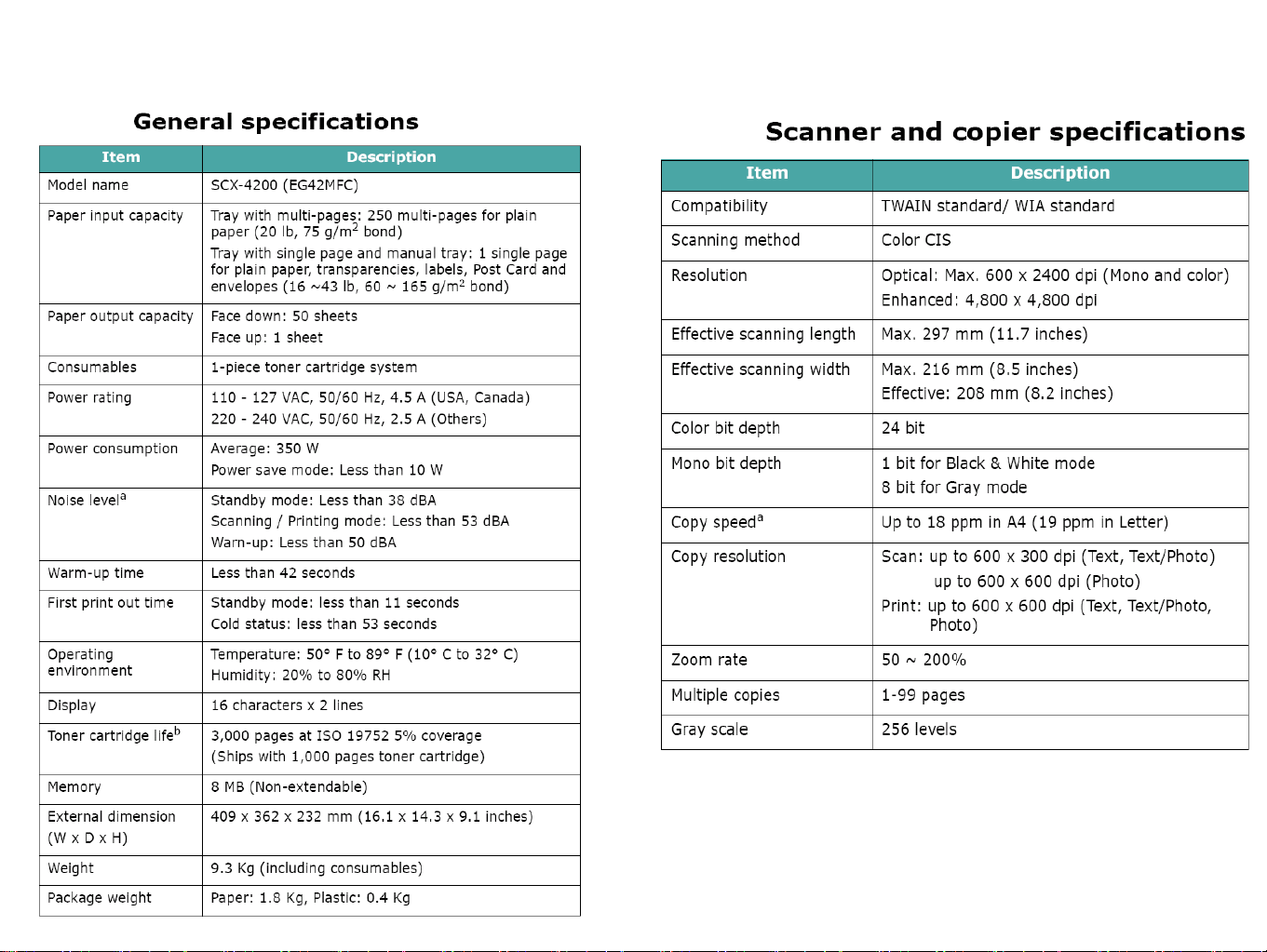

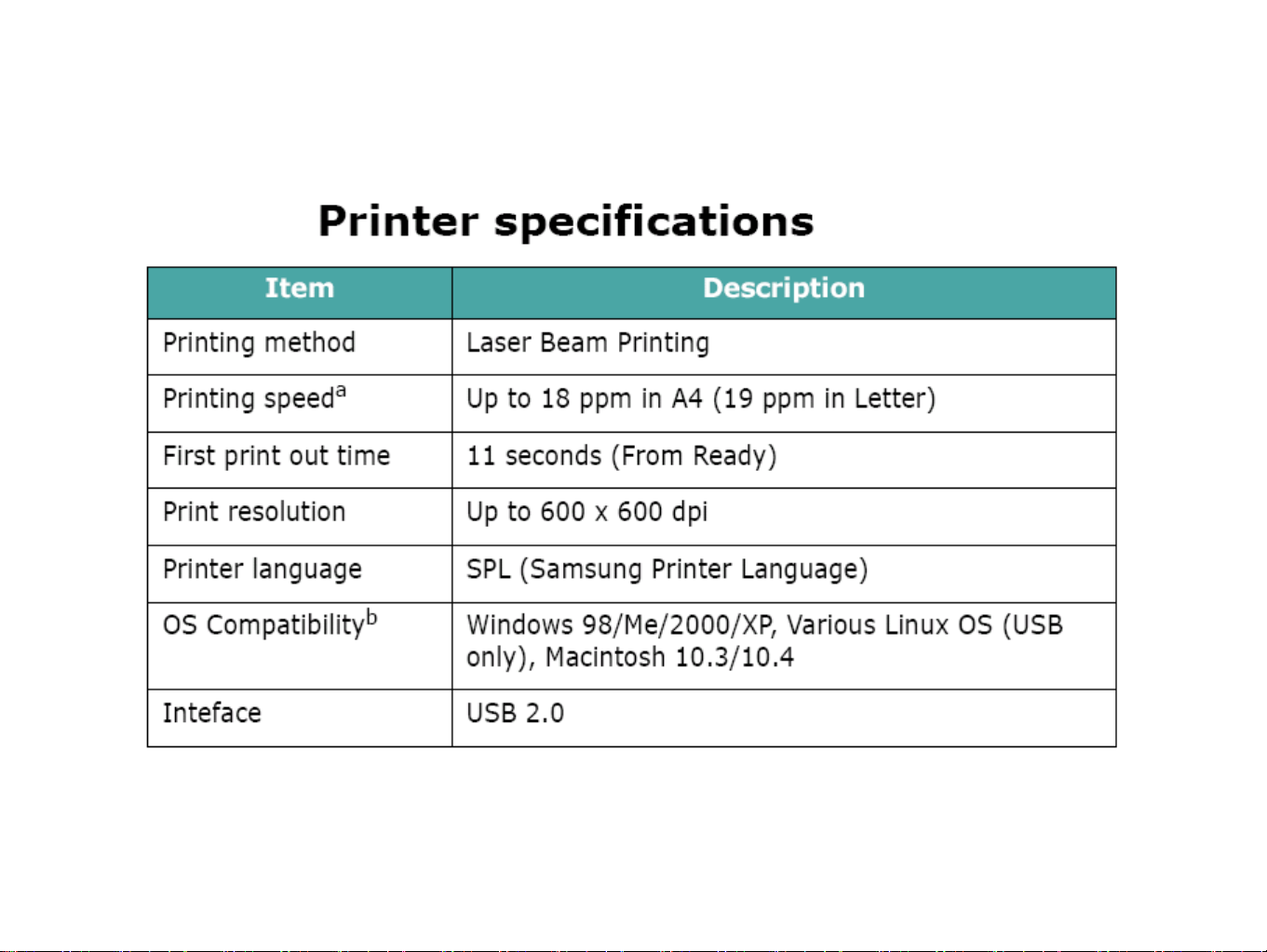

1-4. General Spec.

Page 7

1-4. General Spec.

Page 8

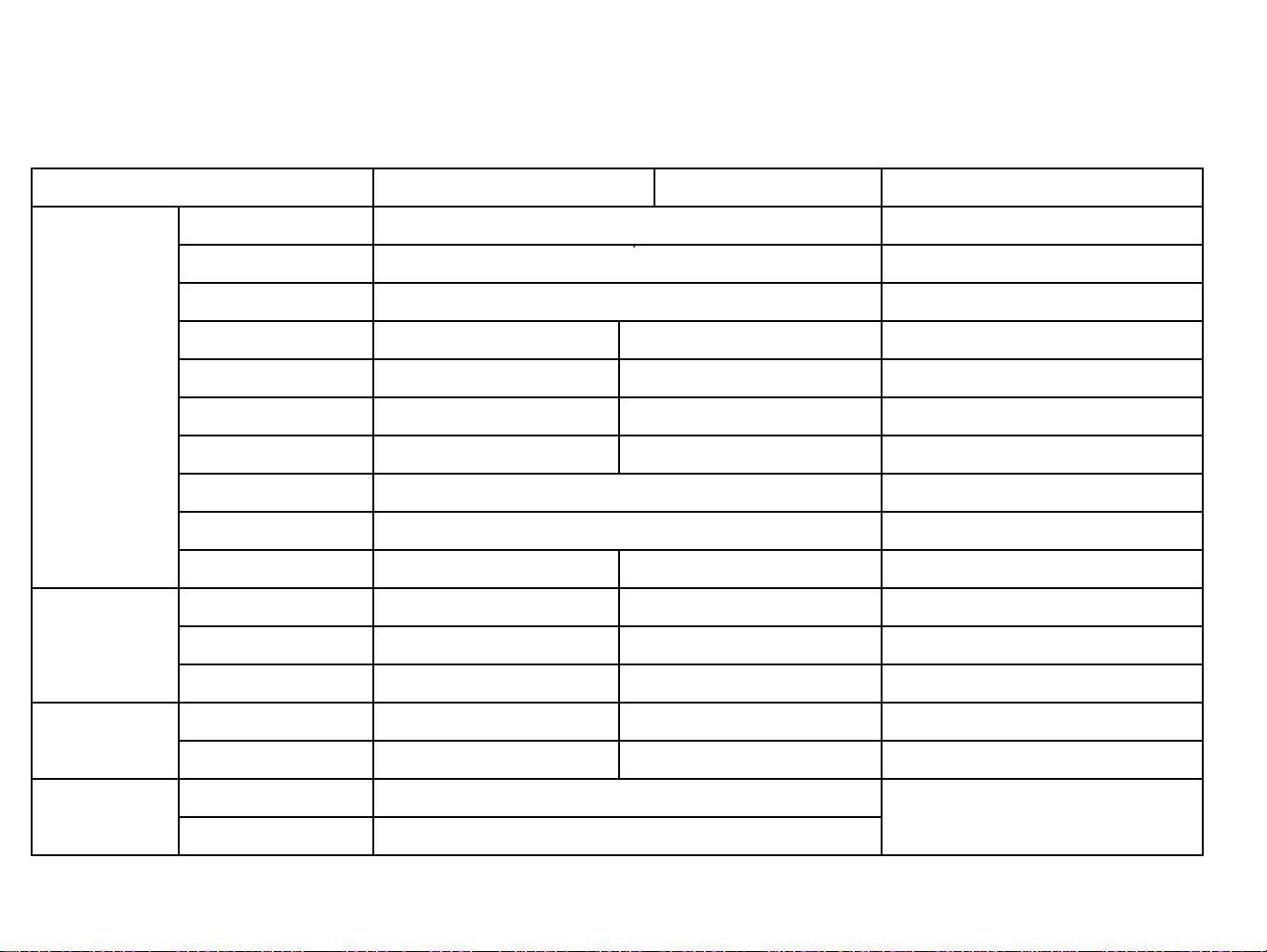

1-5. Comparison Between SCX-4100 and SCX-4200

Same (Chorus 2)CPU

Same (1MB)ROM

Same (8MB)RAM

16.59MHz12.99MHzVideo Clock

USB 2.0USB 1.1USB

Main

2NK (Bi-polar)2K (Bi-Polar)Main-Motor

A3977AN44060Motor-IC

Same (600W)Heat-Lamp

SameLSU

Main(1) + Sub(1)Main(1)Fan

LITEON 600dpiCanon 600dpiCIS

ETCSCX-4200SCX-4100Item

Scan

Panel

SMPS

/HVPS

Bi-Polar(35Φ)Uni-Polar(35Φ)Scan-Motor

A3977 (Bi-polar)STA403A(Uni-Polar)Motor-IC

2*16 , 8Keys , 1LED2*16 , 7Keys LCD

48C05(Holtec)9228(SEC)ASIC

SameSMPS

SameHVPS

SMPS/HVPS on 1 Board

->Heat Sink Added

Page 9

Objectives

Objectives

I. To show you the structure

and key elements of Main

PBA in SCX-4200

Page 10

2-1. General description

Main PBA employs Chorus2 as an ASIC, which is developed for LBP Printer

1 32 4 15 67 8

20 219 7

10 11 12 135 17 18 191416

Page 11

2-1. General description

MAIN CLUTCH CONNECTOR3 (CN2)12LSU CONNECTOR (CN5)1

MAIN MOTOR DRIVER IC –A3977(U12)

2

SCAN MOTOR DRIVER IC –A3977 (U6)

5

MP CLUTCH CONNECTOR (CN3)11

FLASH ROM-29LV800 (U4)13

SDRAM -K4S641623H-TL75 (U2)14MAIN MOTOR CONNECOR (CN10)3

CIS CONNECTOR (CN8)15PTL CONNECTOR (CN9)4

GRAPHIC PROCESSOR ASIC-CHORUS2 (U5)16

MAIN CLOCK CRYSTAL-10.00 MHz (OSC3)17SCAN MOTOR CONNECTOR (CN13)6

VIDEO CLOCK CRYSTAL -16.59MHz (OSC2)18THERMISTOR CONNECTOR (CN12)7

19USB 2.0 (CN6)8

USB CLOCK CRYSTAL –12MHz (OSC1)

OPE CONNECTOR (CN14)20CRUM CONNECTOR (CN11)9

FAN2 (CN7)21ENGINE CONNECTOER (CN4)10

Page 12

2-2. LBP CPU Serises

CPU Core Clock Bus Package features

Jupiter 4e

SPGPm

SPGPv3

Chorus 2

Chorus m

PPC 266

RM7000Se

ARM 9 150㎒ 16 bit QFP Internal Flash 0.5MB

ARM 9 166㎒ 16 bit BGA RAM 32bit Control

ARM 10 400㎒ 32 bit BGA DDR Memory supporting

ARM 7 66㎒ 16 bit QFP Internal CIP

ARM 9 300㎒ 32 bit BGA Internal CIP

PPC 266㎒ 32 bit QFP CPU

MIPS 460㎒~ 64 bit BGA CPU

Page 13

2-3. Chorus2

Samsung's S3C46Q0X 16/32-bit RISC micro controller is designed to provide a cost-effective, low

power, small die size and high performance micro-controller solution for inkjet, laser beam printer and

MFP.

The S3C46Q0X is developed using ARM7TDMI core, 0.18m CMOS standard cell, and memory cell.

The integrated on-chip functions are as follows:

- 1.8V internal, 3.3V external (I/O boundary) microprocessor with 4KByte Cache

- Image Processor

- On-chip clock generator with PLL

- Memory & External Bank Control

- DMA Control (5-channel)

- Interrupt Control

- 2-port USB Host /1- port USB Device (ver 2.0) Interface Control

- UART (2 Channel)

- Synchronous Serial Interface Control

-Timer (4 Channel)

- Watch Dog Timer

- Power control: Normal, Slow, Idle, Stop and SL_IDLE mode

- A/D Converter (10-bit, 2 Channel)

- General I/O Port Control

- Print Head Control

- Carrier Motor Control

- Paper Motor Control

- Tone Generator

- RTC with calendar function

- S/W Assistant function( Rotator )

Page 14

Ⅱ. Main PBA

2-3. CPU (Chorus2)

Boundary Scan

JTAG

ARM7TDM

Clock Generator

(MPLL)

Clock Generator

(UPLL)

Clock Generator

(PPLL)

Controller

AIN[3:0]

I

TAP

10bit ADC

Watchdog Timer

(Real Time Clock)

Block diagram

CPU Unit

Write

Buffer

ARM7TDMI

CPU Core

Cache

4K Byte

System Bus Bridge & Arbitration /

Rotator

RTC

SSB

BDMA (2-Ch.)

Bus Arbiter

Memory I/F ROM/

SRAM

DRAM/SDRAM

PRT_TOP

Interrupt

Controller

General DMA

(2-CH)

I

P_TOP

USB v1.1

GPIO

Controller

System Timer

(4-ch)

UART (2-ch)

HP SIO

Tone Generator

CRCON

LFCON

CRFIRE

LSU I/F

Parallel Port

(P1284)

General Purpose I/O

Page 15

2-4 Flash Memory (as ROM) : AM29LV800

Storing the systems

program and downloading

the system program

through the PC interface.

Capacity : 1 Mega Byte.

AM29LV800

Access Time : 70 nsec

Circuit Diagram of Flash Memory

Page 16

2-5. SDRAM

Circuit Diagram of SDRAM

Page 17

2-6. Main motor Driver

Using A3977 as Motor Drive

By gearing the main motor drives the rollers such as feeding roller, developing roller,

fuser roller, and distributing roller. The step motor is controlled for the sections,

acceleration section and fixed speed section. In the initial stage of the motor run, appoint

the acceleration section to prevent the isolation of the motor. It is controlled by the

AN44060 motor drive IC. The step signal and the enable signal are sent to make the

phase for driving the motor in CPU.

Page 18

2-7. USB INTERFACE

Uses PHILIPS ISP1582BS IC

■ Complies fully with:

- Universal Serial Bus Specification Rev. 2.0

- Most Device Class specifications

- ACP, OnNow and USB power management requirements.

■ Supports data transfer at high-speed (480 Mbit/s) and full-speed (12 Mbit/s)

■ High performance USB peripheral controller with integrated Serial Interface Engine (SIE),

Parallel Interface Engine (PIE), FIFO memory and data transceiver

■ Automatic Hi-Speed USB mode detection and Original USB fall-back mode

■ Supports sharing mode

■ Supports I/O voltage range of 1.65 V to 3.6 V

■ Supports VBUS sensing

■ High-speed DMA interface

■ Fully autonomous and multi-configuration DMA operation

■ 7 IN endpoints, 7 OUT endpoints and a fixed control IN/OUT endpoint

■ Integrated physical 8 kbytes of multiconfiguration FIFO memory

■ Endpoints with double buffering to increase throughput and ease real-time data transfer

■ Bus-independent interface with most microcontrollers and microprocessors

■ 12 MHz crystal oscillator with integrated PLL for low EMI

■ Software-controlled connection to the USB bus (SoftConnect)

■ Low-power consumption in operation and power-down modes; suitable for use in buspowered USB devices

Page 19

2-8. CIS

CIS Module radiates the light by LED to the document, then according to LED,

the reflection signals are divided with R,G,B data. The RGB data (analog signal)

convert into digital signal through ADC ,then the digital signal is transmitted to

Chorus2 Image Processor Block.

Page 20

Image Scanning Process

Light Source

Object

Structure of CIS

Image Sensing

Image Sensor

Signal Receiving

Transfer

Processing…

Display

Printing

Etc

Page 21

Circuits

Rod Lens

Rod Lens

Vout

Vout

Timing Diagram

N

N

Shift Register

Shift Register

Page 22

Page 23

LED Timing for Color Reading

LED Timing for Mono Chrome Reading

1. Per 3 Color per Storage Time

2. Only Green LED ON

Page 24

3-1. General description

OPE board is consisted of various function keys and LCD to display an operation of key.

OP micom(48C05) is 8-bit micro controller device designed for multiple I/O control. It creates a panel

circuit with LCD and other devices. A communication method with a CPU of a main board is UART( TXDtransmit, RXD-receive).

Menu ◀ OK ▶ Back Copies Stop Start

Menu

Copies

OK

Start

Back

This is to be used to enter the Menu

1-99

This key is used to select the right item what customer wants from several items.

This key is used to activate the job

This key is used to stop the job being done or to exit from the Menu.Stop

This key is used to move previous menu – upper level

Left/Right Arrow Key◀/▶

Page 25

3-2. UART

■ OPE and main board exchange information by UART.

The band rate is 9600bps, and uses 7.37 MHz resonator as oscillating element.

It engages in communication with 8 bit data without parity bit. UART has two

lines for Tx and Rx. The default level is in the 'high' state. For communication,

the start bit (low level) is transmitted before the data. When the data transmission

is completed, the high state is maintained as the stop bit is transmitted.

■ UART TX format :Codes for change of keys are transmitted in single code,

and OK or error message to check if communication is performed properly are

also transmitted in single code.

■ UART RX format: : Data being received will be arranged to be received as

according to the following specified format to know what data they are.

Page 26

1. The Role of SMPS & HVPS

Main

Controller

Micro

Processor

FUSER

Supply

Dev.

Cha.

OPC

Clean

LSU

HVPS

SMPS (Switched Mode Power Supply)

To Supply Constant & Stable DC Power

To Supply DC Bias Voltage

To Control Total System Operation

INTERFACE

AC to DC and then

DC to DC Conversion

Page 27

4-2. SMPS & HVPS Spec.

SMPS is the power source of entire system. It is assem bled by an independent module and completely common use

with SCX-4200 and it is same characteristic with SCX-4100. It is mounted at the bottom of the set.

The SMPS supplies the DC power for driving the system, and the AC heater control part, which supplies the power to fuser.

it has two output channels. Which are +5V and +24V.

HVPS creates the high voltage of THV/MHV/Supply/Dev and supplies it to the developer part for making

best condition to display the image. The HVPS part takes the 24V and outputs the high voltage for THV/MHV/BIAS,

and the outputted high voltage is supplied to the toner, OPC cartridge, and transfer roller.

SMPS( Switching Mode Power Supply ) HVPS (High Voltage Power Supply )

Page 28

4-3. SMPS & HVPS Spec.

1) Transfer High Voltage(THV+)

- Input Voltage: 24 V DC ±15%

- Output Voltage: MAX +5.0KV ± 5%(Duty Variable, no loading)

-1.0KV ± 15%(when clearing, 200Mohm)

- Output Voltage Trigger :6.5 µA

- Input contrast of the Voltage stability degree under ± 5%(fluctuating input 21.6V~26.4V)

Loading contrast : ±5% or less

- Output Voltage Rise Time : 100ms Max

- Output Voltage Fall Time : 100ms Max

- Transfer voltage range as environment variable :+650V(Duty 90%) ~5KV(Duty 10%)

- Environment Recognition Control Method :The THV-PWM ACTIVE transfers active

signal. It detects the resistance by recognizing the voltage value, F/B, while

permits the environmental recognition voltage.

- Output Voltage Control Method :Transfer Output Voltage is output and controlled by

changing the Duty cycle of the THV PWM Signal. 90% Duty:+650V, 10% Duty:+5KV ± 5%

2) Charge Voltage(MHV)

- Input Voltage: 24 V DC ±15%

- Output Voltage: -1.3KV ~ -1.8KV DC ±50V

- Output Voltage Rise Time : 50ms Max

Page 29

4-4. SMPS & HVPS Spec.

- Output Voltage Fall Time : 50ms Max

- Output Loading Range : 30M ohm ~1000M ohm

- Output Control Signal(MHV-PWM):CPU is HV output when PWM is LOW

3) Clearing Voltage(THV-)

- The(+) Transfer Voltage is not output because the THV PWM is controlled with high.

- The(-) Transfer Voltage is output because the THV –Enable Signal is controlled with

low.

- The output fluctuation range is big because there is no Feedback control.

4) Developing Voltage(DEV)

- Input Voltage: 24 V DC ±15%

- Output Voltage: - 200V~600V DC ±20V

- Output Voltage Fluctuation range: PWM Control

- Input contrast of the output stability degree ± 5% or less

Loading contrast : ±5% or less

- Output Voltage Rise Time : 50ms Max

- Output Voltage Fall Time : 50ms Max

- Output Loading range : 10M ohm ~1000M ohm

- Output Control Signal(BIAS-PWM): the CPU output is HV output when PWM is low.

5) Supply

- Output Voltage: -400V ~ 800V DC±50V(ZENER using, DEV)

- Input contrast of the output stability degree under ±5%

Loading...

Loading...