Page 1

©

Samsung Electronics Co., Ltd. Aug. 1996. Code No. AH68-20126A

MUSIC CENTER

1. Precautions

2. Specifications

3. Disassembly and Reassembly

4. Alignment and Adjustments

5. Special Circuit Descriptions

6. Troubleshooting

7. Exploded Views and Parts List

8. Electrical Parts List

9. Block Diagrams

10. PCB Diagrams

11. Wiring Diagram

12. Schematic Diagrams

MONO/ST

CLOCK

TIMER

TUNING

TUNER

TAPE

CD

PHONO

VOLUME

BAND

PRESET/MANUAL

MEMORY

CLASSIC POPS ROCK

EQ PRESET

PLAY/PAUSE

STOP/CLEAR

HI-SPEED DUBBING

OPEN/CLOSE

DISPLAY

INTRO

SKIP

SEARCH

REPEAT

RANDOM

ON/STANORY

POWER

DECK 1

REC/PLAY

PLAYBACK

DECK 2

HIGH SPEED DUBBING CONTINUOUS PLAY

PHONES

REC PLAY REW STOP/EJ PAUSEF.FWD PLAY REW F.FWD STOP/EJ PAUSE

SERVICE

Manual

MUSIC CENTER

SCM-6700

CONTENTS

Page 2

1. Precautions

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential hazards

such as electrical shock and X-rays.

1-1 Safety Precautions

1. Be sure that all of the built-in protective

devices are replaced.

(Reading should

2. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including control knobs and

compartment covers.

3. Make sure that there are no cabinet

openings through which people-particularly children--might insert fingers

and contact dangerous voltages. Such

openings include the spacing between the

picture tube and the cabinet mask,

excessively wide cabinet ventilation slots,

and improperly fitted back covers.

Device

Under

Test

Test all

exposed metal

surfaces

2-Wire Cord

Also test with

plug reversed

(using AC adapter

plug as required)

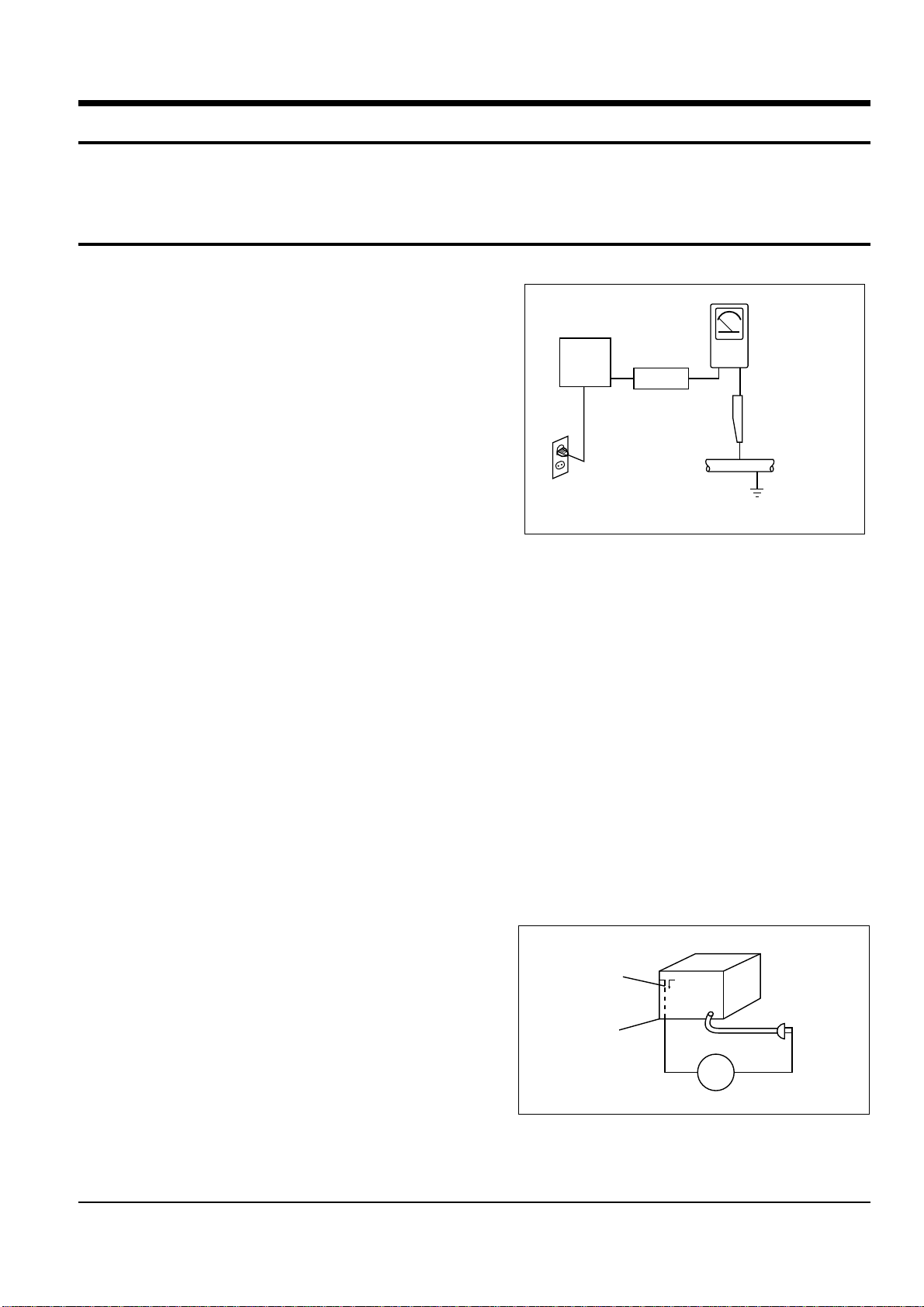

Fig. 1-1 AC Leakage Test

not be above

0.5mA)

Leakage

Currant

Tester

Earth

Ground

4. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of the unit. Example: Do

not add auxiliary audio or video connectors. Such alterations might create a safety

hazard. Also, any design changes or additions will void the manufacturer's warranty.

5. Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANSI C101.1, Leakage Current for

Appliances), and Underwriters Laboratories

(UL Publication UL1410, 59.7).

With the unit completely reassembled, plug

the AC line cord directly into a 120V AC

outlet. With the unit's AC switch first in

the ON position and then OFF, measure the

current between a known earth ground

(metal water pipe, etc.) and all exposed

metal parts. Examples: Handle brackets,

metal cabinets, screwheads and control

shafts. The current measured should not

exceed 0.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat.

6. Insulation Resistance Cold Check:

(1) With the unit's AC plug disconnected

from the AC source, connect an electrical

jumper across the two AC prongs. (2) Set

the power switch to ON. (3) Measure the

resistance between the shorted AC plug and

any exposed metallic parts. Example:

Screwheads, antenna, control shafts or

handle brackets.

If any of the exposed metallic parts has a

return path to the chassis, the measured

resistance should be between 1 and 5.2

megohms. If there is no return path, the

measured resistance should be "infinite." If

the resistance is outside these limits, a shock

hazard might exist. See Figure 1-2

Antenna

Terminal

Exposed

Metal Part

ohm

Ohmmeter

Fig. 1-2 Insulation Resistance Test

Samsung Electronics 1-1

Page 3

Precautions

1-1 Safety Precautions (Continued)

7. Components, parts and wiring that appear

to have overheated or that are otherwise

damaged should be replaced with parts

that meet the original specifications.

Always determine the cause of damage or

overheating, and correct any potential

hazards

8. Observe the original lead dress, especially

near the following areas: Antenna

wiring, sharp edges, and especially the

AC and high voltage power supplies.

Always inspect for pinched, out-of-place,

or frayed wiring. Do not change the

spacing between components and the

printed circuit board. Check the AC

power cord for damage. Make sure that

no wires or components touch thermally

hot parts.

1-2 Servicing Precautions

9. Product Safety Notice:

Some electrical and mechanical parts

have special safety-related characteristics

which might not be obvious from visual

inspection. These safety features and the

protection they give might be lost if the

replacement component differs from the

original--even if the replacement is rated

for higher voltage, wattage, etc.

10 Components that are critical for safety are

indicated in the circuit diagram by

shading, or . Use replacement

components that have the same ratings,

especially for flame resistance and

dielectric strength specifications. A

replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

Warning1: First read the "Safety Precautions" section of this manual. If some unforeseen circumstance creates a conflict

between the servicing and safety precautions, always follow the safety precautions.

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit's AC power cord

from the AC power source before

attempting to: (a) Remove or reinstall any

component or assembly, (b) Disconnect an

electrical plug or connector, (c) Connect a

test component in parallel with an

electrolytic capacitor.

3. Some components are raised above the

printed circuit board for safety. An

insulation tube or tape is sometimes used.

The internal wiring may be clamped to

prevent contact with thermally hot

components. Reinstall all such elements to

their original position.

4. After servicing, always check that the

screws, components and wiring have been

correctly reinstalled. Make sure that the

portion around the serviced part has not

been damaged.

5. Check the insulation between the blades of

the AC plug and accessible conductive parts

(examples: metal panels, input terminals

and earphone jacks).

6. Insulation Checking Procedure: Disconnect

the power cord from the AC source and

turn the power switch ON. Connect an

insulation resistance meter (500V) to the

blades of the AC plug.

The insulation resistance between each

blade of the AC plug and accessible

conductive parts (see above) should be

greater than 1 megohm.

7. Never defeat any of the B+ voltage

interlocks. Do not apply AC power to the

unit (or any of its assemblies) unless all

solid-state heat sinks are correctly installed.

8. Always connect a test instrument's ground

lead to the instrument chassis ground

before connecting the positive lead; always

remove the instrument's ground lead last.

Samsung Electronics1-2

Page 4

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

Precautions

1. Some semiconductor ("solid state") devices

are easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs). Examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component

damage caused by static electricity.

2. Immediately before handling any

semiconductor components or assemblies,

drain the electrostatic charge from your

body by touching a known earth ground.

Alternatively, wear a discharging

wrist-strap device. (Be sure to remove it

prior to applying power--this is an electric

shock precaution.)

3. After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4. Do not use freon-propelled chemicals.

These can generate electrical charges that

damage ESDs.

5. Use only a grounded-tip soldering iron

when soldering or unsoldering ESDs.

6. Use only an anti-static solder removal

device. Many solder removal devices are

not rated as "anti-static" (these can

accumulate sufficient electrical charge to

damage ESDs).

7. Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive

materials.

8. Immediately before removing the protective

material from the leads of a replacement

ESD, touch the protective material to the

chassis or circuit assembly into which the

device will be installed.

9. Minimize body motions when handing

unpackaged replacement ESDs. Motions

such as brushing clothes together, or lifting

a foot from a carpeted floor can generate

enough static electricity to damage an ESD.

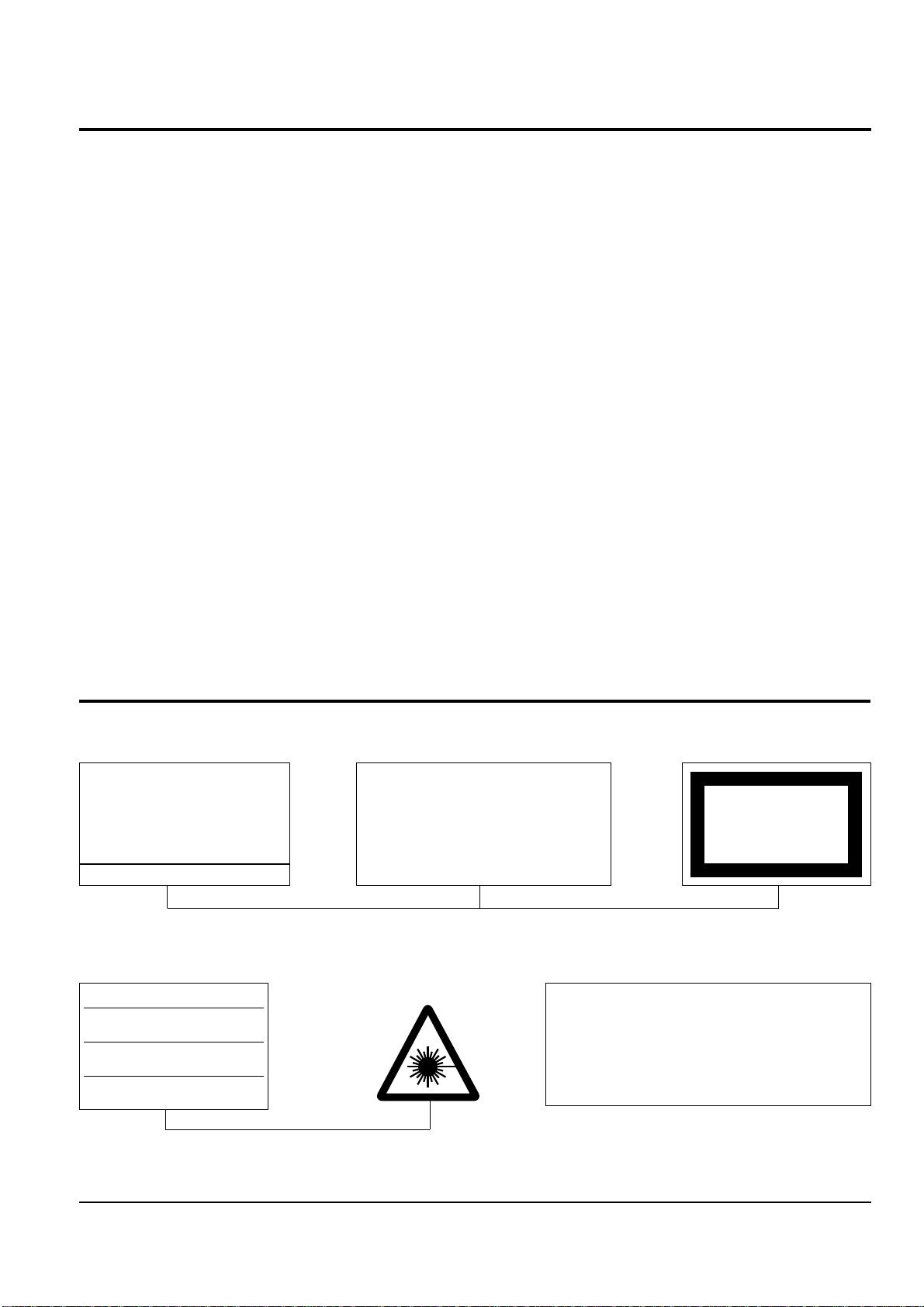

1-4 Special Precautions and Warning Labels for Laser Products

(UL)

This Product Complies with

DHHS Rules 21CFR, Sub

chapter J.At date of Manufacture

(SCAN)

CAUTION : INVISIBLE LASER RADIATION WHEN OPEN

AND INTERLOCKS DEFEATEO AVOIDEXPOSURE TO BEAM

ADVARSEL:USYNLIG LASERSTRÅLING VED ABNING

NÅR SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION

UNDGA UDSAETTELSE FOR STRALING

VARO:AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALTTINA NAKYMATTÖMALLE LASERSATEILYLLE ALA

KATSO SATEESEEN!

VARNING:OSYNLIG LASERSTRÅLNING NAR DENNA DEL

AR OPPNAD OCH SPARREN AR URKOPPLAD BETRAKTA

EJSTRÅLEN!

CERTIFIED ONLY TO CANADIAN

ELECTRICAL CODE.

CERTIFIE EN VERTU DU CODE

CANADIAN DE LELETRICITE

SEULEMENT

Fig. 1-3 Warning Labels (Location: Enclosure Block)

(EU)

(CSA)

UL : Manufactured for U.S.A. Market.

CSA : Manufactured for Canadian Market.

EU : Manufactured for European Market.

SCAN : Manufactured for Scandinavian

Market.

(EU)

CLASS 1

LASER PRODUCT

Fig. 1-4 Warning Labels (Location: Disc Clamper, Inner Side of Unit Door or Nearby Unit Chassis )

Samsung Electronics 1-3

Page 5

Precautions

1-4 Special Precautions and Warning Labels for Laser Products (Continued)

1-4-1 Warnings

1. When servicing, do not approach the LASER

exit with the eye too closely. In case it is

necessary to confirm LASER beam emission,

be sure to observe from a distance of more

than 30 cm from the surface of the objective

lens on the optical pick-up block.

2. Do not attempt to handle the objective lens

when the DISC is not on the tray.

1-4-2 Laser Diode Specifications

Material: GaAs+ GaAlAs

Wavelength: 760-800 nm

Emission Duration: Continuous

Laser Output: 0.2 mw (measured at a

1.6 mm distance from the objective lens

surface on the optical pick-up block.)

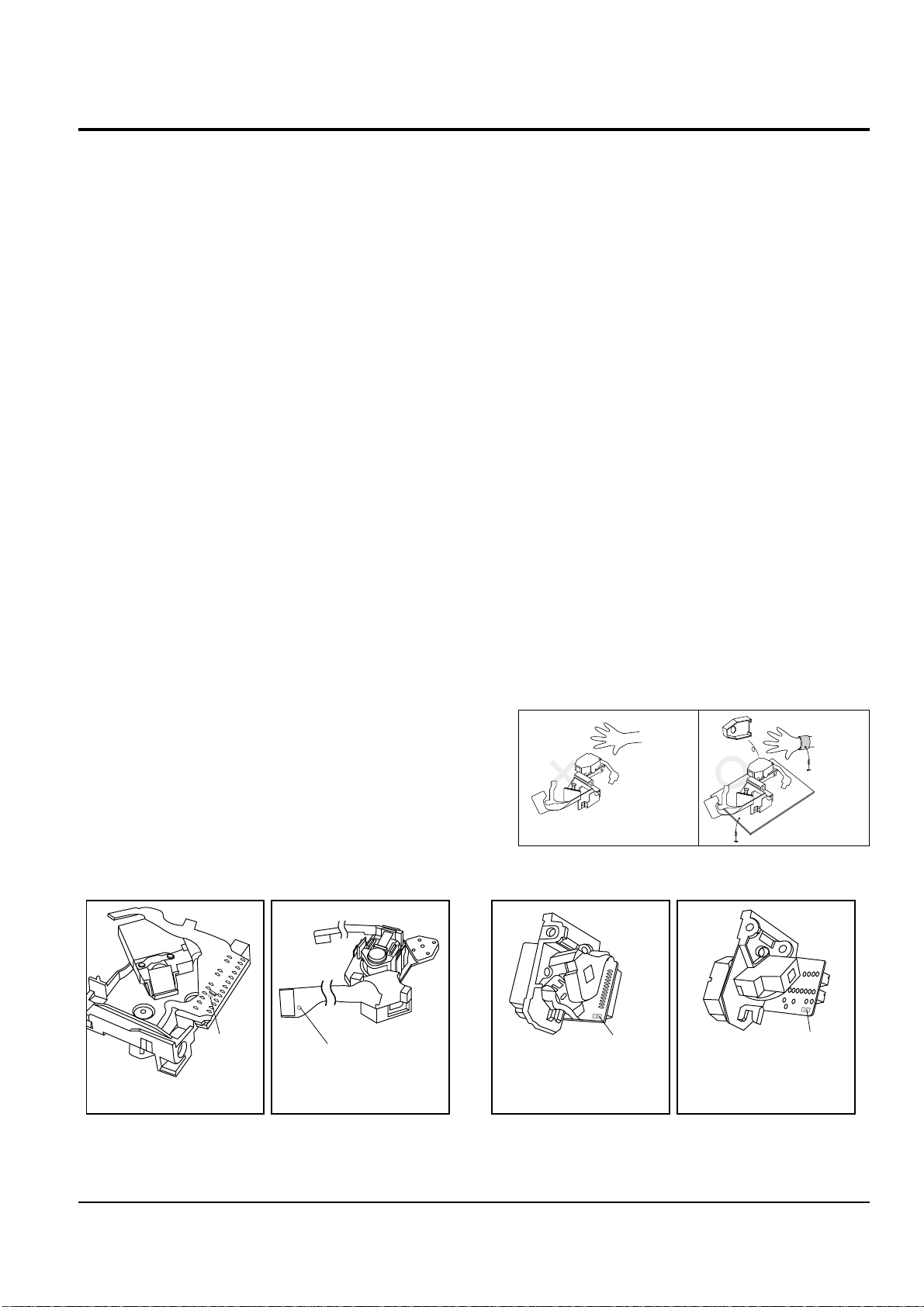

1-4-3 Handling the Optical Pick-up

1. Static electricity from clothing or the body

may cause electrostatic breakdown of the

laser diode in the Optical Pickup. Follow

this procedure:

2. Place a conductive sheet on the work bench

(i.e., the black sheet used for wrapping

repair parts.) Note: The surface of the work

bench should be covered by a copper

ground plane, which is grounded.

3. The repair technician must wear a wrist

strap which is grounded to the copper sheet.

4. To remove the Optical Pickup block:

Place the set on the conductive sheet, and

momentarily touch the conductive sheet

with both hands. (While working, do not

allow any electrostatic sources--such as

clothes--to touch the unit.)

5. Ground the "Short Terminal" (located on the

PCB, inside the Pickup Assembly) before

replacing the Pickup. This terminal should

be shorted whenever the Pickup Assembly

is lifted or moved.

short

terminal

SOH91VI(LDP)

short terminal

SOH91CI(CAR,walkman)

6. After replacing the Pickup, reopen the Short

Terminal. See diagrams below:

1M

THE UNIT

(1) WRIST-STRAP

FOR GROUNDING

short

terminal

SOH-A1

(CMS-V10,CMS-V30)

1M

SOH94T4N

(CMS-V10,CMS-V30)

CONDUCTIVE SHEET

short

terminal

Samsung Electronics1-4

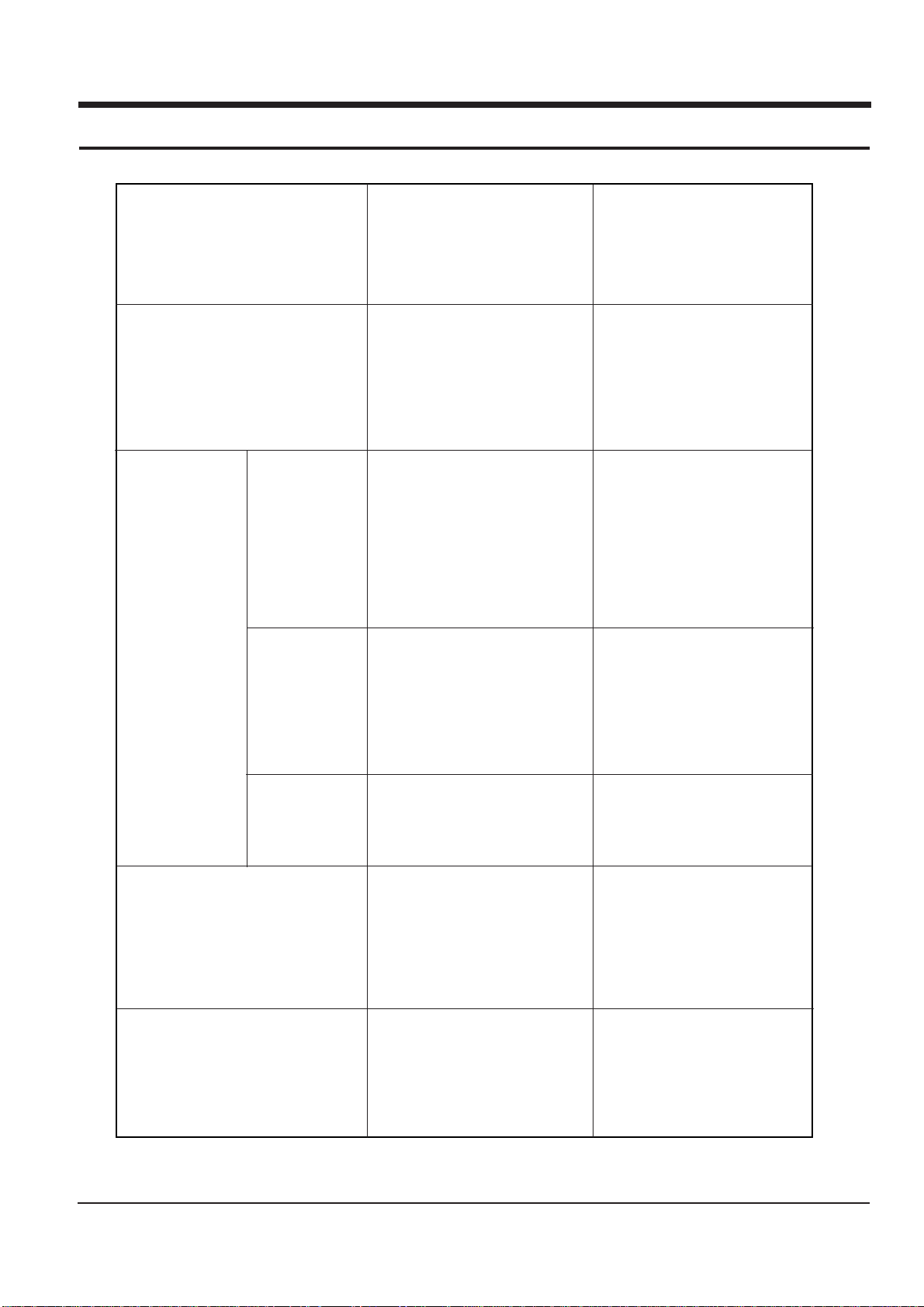

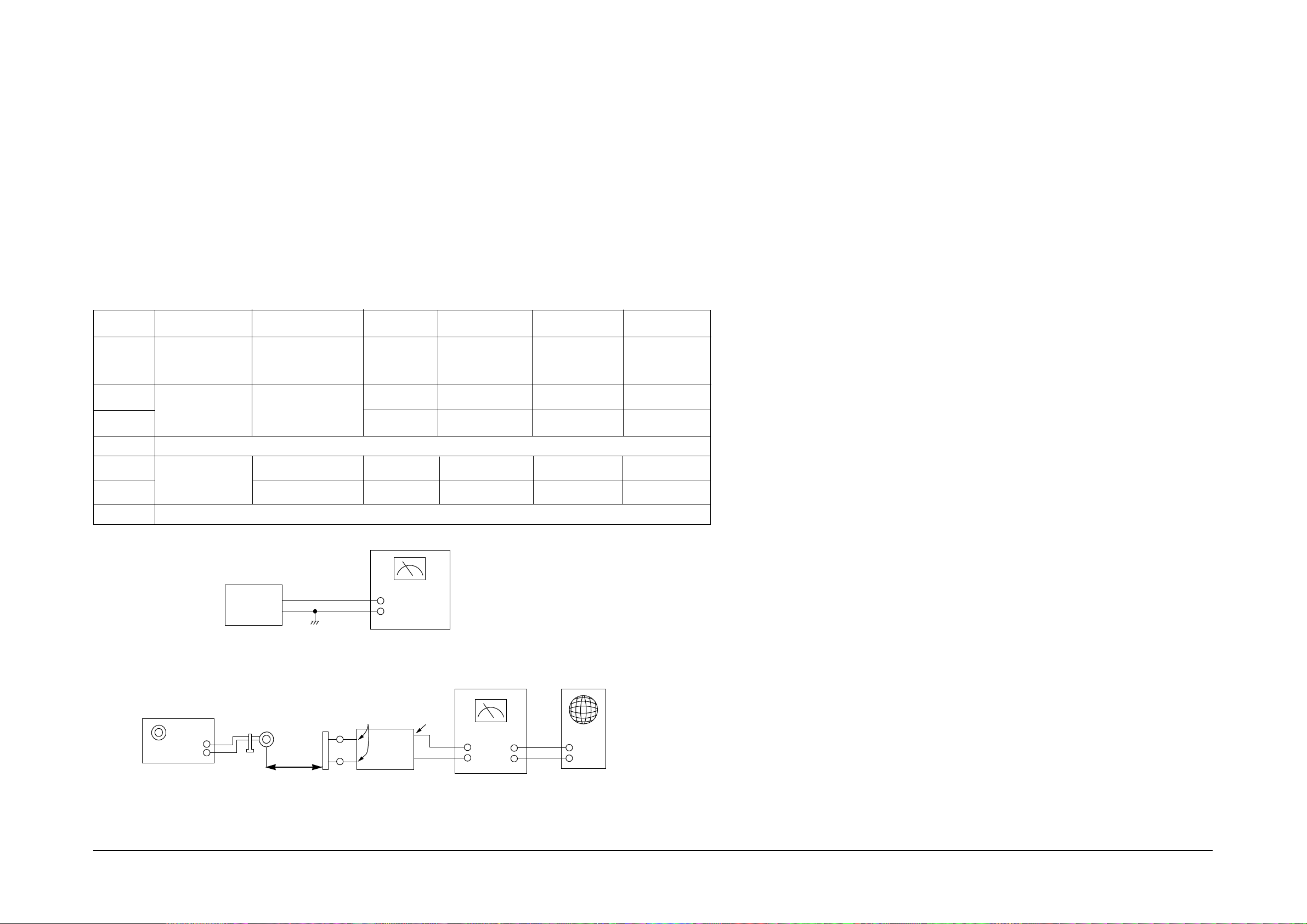

Page 6

Power source

Power consumption

Dimensions (mm)

AC 115/230V 50/60Hz

(Option)

30W

350(W)x328(H)x316(D)

Power output

Total harmonic distortion

Frequency range

Signal to noise ratio

Channel separation

Frequency range

Usable sensitivity

Signal to noise ratio

IF rejection ratio

Total harmonic distoration

Separation (Stereo)

Frequency range

Usable sensitivity

Signal to noise ratio

IF rejection ratio

Total harmonic distoration

Frequency range

Usable sensivity

Signal to noise ratio

Frequecny range

WOW FLUTTER

Erasing effect

Signal to noise ratio

Total harmonic distortion

Frequency response

Signal to noise ratio

Channel separation

Total harmonic distortion

87.5 ~ 108MHz

6µV

55dB

60dB

0.5%

25dB

522 ~ 1611KHz

600µV

40dB

30dB

1%

146 ~ 290KHz

1200µV

35dB

125Hz ~ 12.5KHz

0.15%

50dB

40dB

2.5%

20Hz ~ 20KHz(¡ 1dB)

85dB(1kHz 0dB)

75dB(1kHz 0dB)

0.1%(1kHz 0dB)

5W/CH

0.5%

50Hz ~ 17kHz

60dB

45dB

General

Amp

Tuner

Cassette

Compact Disc

FM

MW

LW

Samsung Electronics 2-1

* Specifications are subject to change without notice.

2. Specifications

Page 7

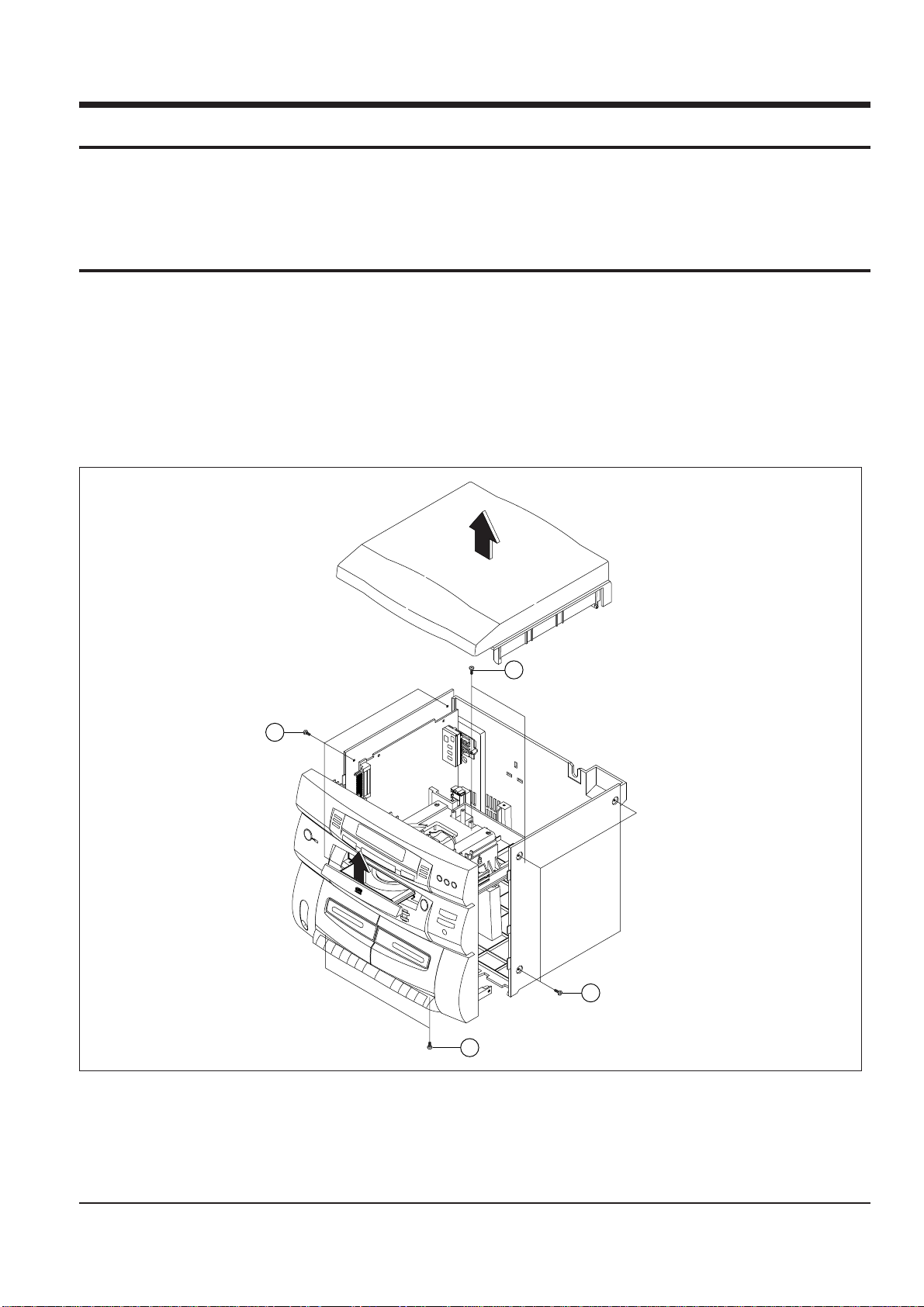

3. Disassembly and Reassembly

3-1 Turn-Table, Cabinet-Front, Cabinet-Bottom

1. Remove Door-CD (Direction A).

2. Release 6 screws !.

3. Remove Turn-Table (Direction B).

4. Release 2 screws @.

5. Release 2 screws #.

6. Remove Front-Cabinet.

45

33

2

1

1

B

3

A

Samsung Electronics 3-1

Figure 3-1

Page 8

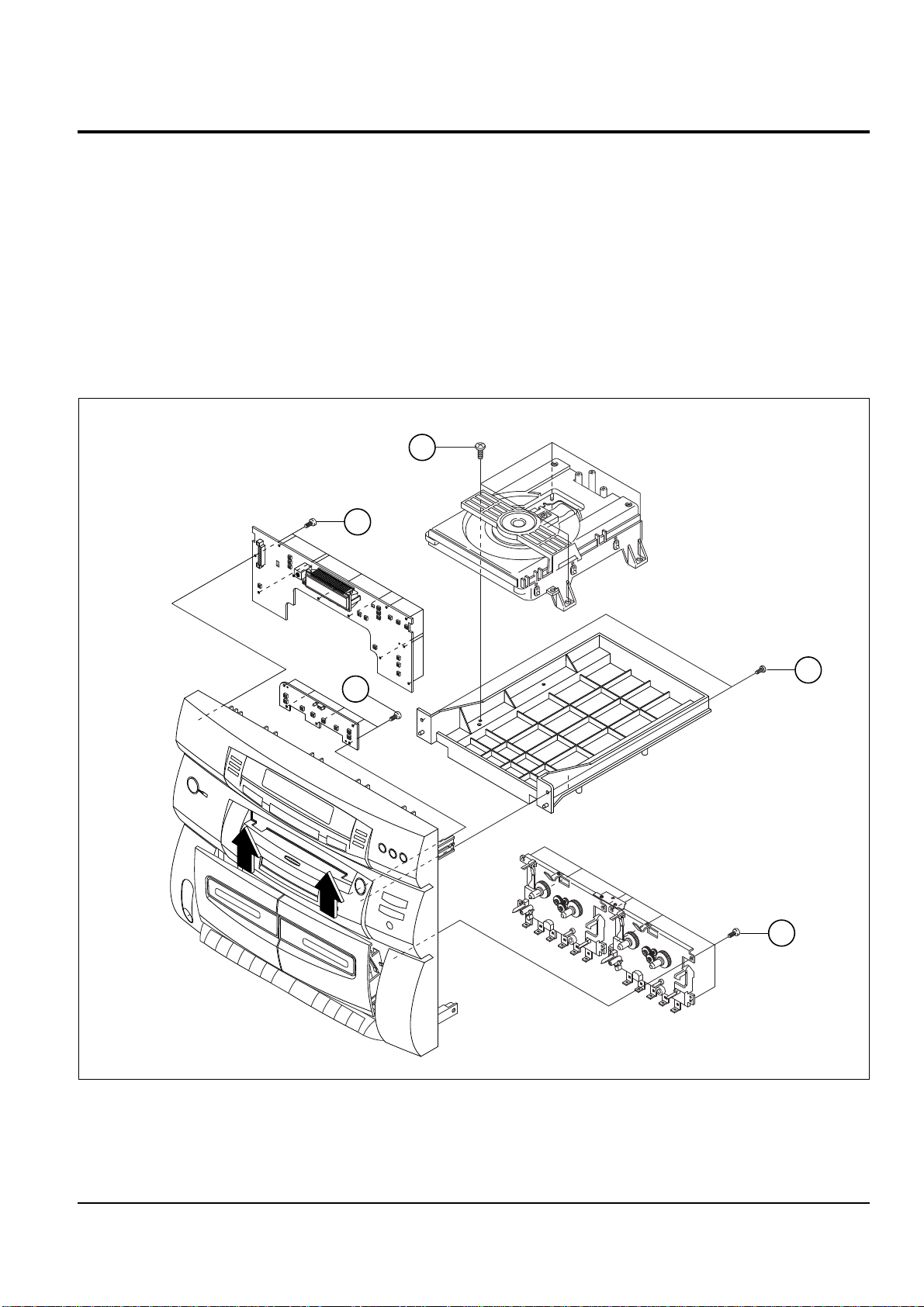

3-2 Deck-CD, Front-PCB, Cassette-Deck, Door-Cassette

1. Release 2 screws !.

2. Remove Deck-CD ASSÕY.

3. Release 4 screws @.

4. Remove Deck-CD.

5. Release 17 screws #.

6. Remove Front-PCB, SUB-PCB.

7. Release 7 screws $.

8. Remove Cassette-Deck.

3-2 Samsung Electronics

2

3

3

1

4

A

A

Figure 3-2

Disassembly and Reassembly

Page 9

3-3 Cabinet-Bottom and Main-PCB

1. Release 3 screws !.

2. Remove Main-PCB.

1

Samsung Electronics 3-3

Figure 3-3

Disassembly and Reassembly

Page 10

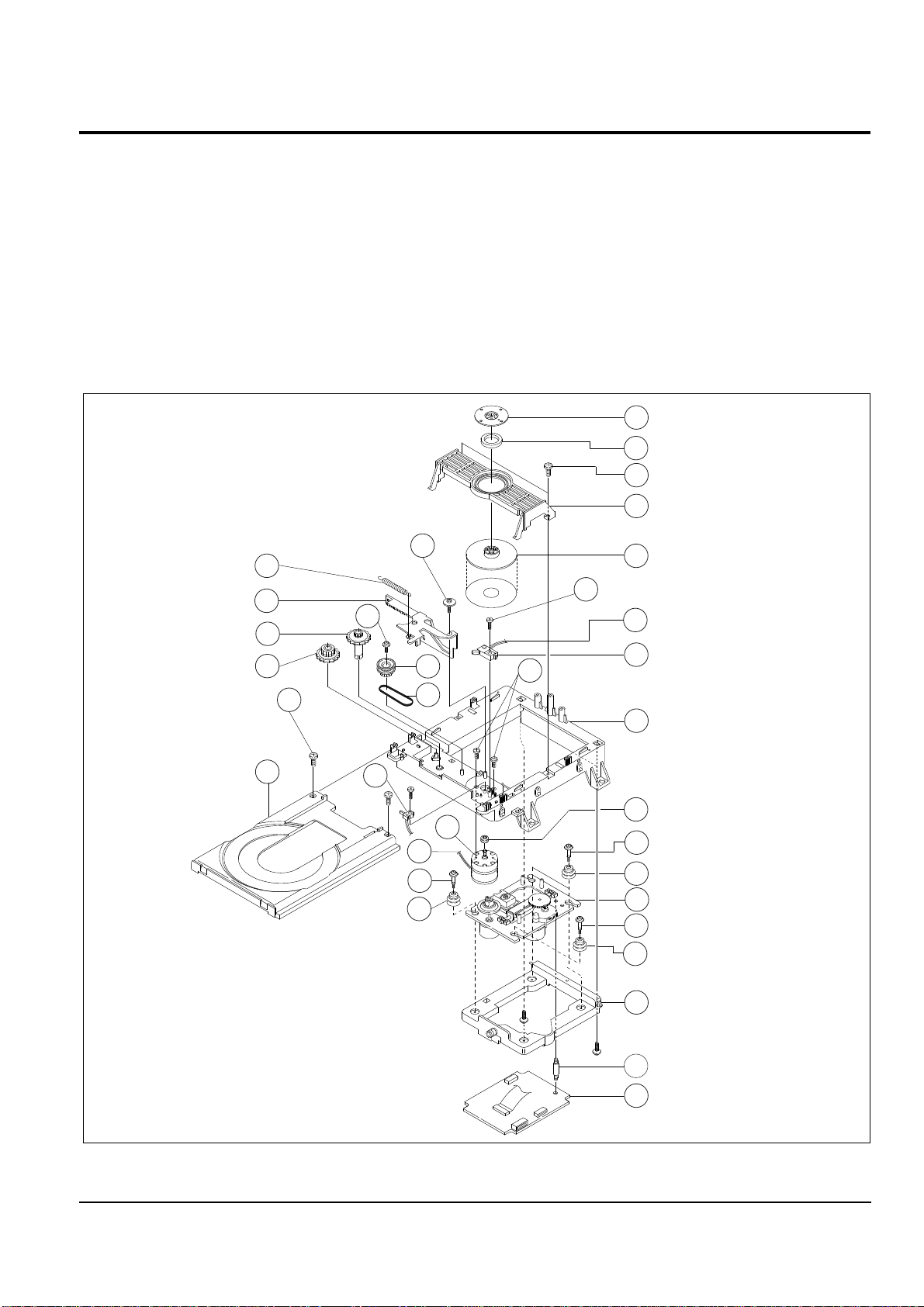

3-4 CD Pack

1. Undo 2 screws (A), and remove the Chuck-Bracket @, the Ferrite-Magnet 5, Chuck Union-Table $ and

Chuck-Holder &.

2. Undo 2 screws (B), pull the Tray-M1 1 forward to remove.

3. Undo 1 screw (C), and remove the Cam-Spring 8 and the Cam #.

4. Undo 1 screw (D), and remove the Gear-Pulley (, the Belt-Pulley @, the Gear-A % and the Gear-B ^.

5. Undo 2 screws (E), and remove the Motor-Pulley ) and the Dc-Motor 0 .

6. Undo 2 screws (F), and remove the Leaf-Switch 9 and the Detector-Switch “.

Disconnect the Lead- Connector assÕy 4 with soldering iron.

7. Remove the AssÕy PCB 3 with soldering iron and remove the PCB-Holder + .

8. Undo 4 screws from the CD-Shaft 7, and remove the CD-Rubber 6 and the CD-Deck ‘

3-4 Samsung Electronics

Figure 3-4

1 1

3 3

5 5

6 6

8 8

9 9

1010

1717

1818

1919

2020

1414

2121

1111

1212

1313

1414

1717

1616

1717

1616

1616

2222

2323

2 2

4 4

7 7

1515

AA

FF

CC

DD

EE

BB

Disassembly and Reassembly

Page 11

3-5 CD Deck

1. Remove the Shaft ! .

2. Lift the P/U @ .

Note : Take extreme care not to touch the surface of lens.

3. Lift the Center-ring # .

4. Remove the Spring-T/Table $ .

5. Remove the Turn-Table (M) % .

6. Remove 2 screw ^ and then remove the Motor-Spindle & .

7. Remove the Gear-Cover * by pushing the hook.

8. Remove the Gear(c) ( by pushing the hook.

9. Lift the Gear(b) ) .

10. Remove the Gear(a) 1 .

11. Remove 2 screws 2 and then remove the Feed-Motor 3 .

12. Remove the Deck(M)-Chassis 4.

3

4

5

6

12

2

1

8

9

10

11

13

14

7

Samsung Electronics 3-5

Figure 3-5

Disassembly and Reassembly

Page 12

4. Alignment and Adjustments

4-1 Tuner

CSVR801

CCON801

ISVR2

ISVR1

IT2

OT1

OT2

OCT2

OCT4

OCT3

OL2

OL1

TCON1

OCT1

IT1

KT431

FM T.H.D Adjustment

SSG FREQ. 98MHz

Adjustment

point FM DETECTOR COIL

(IT1)

Minumum output(Figure 4-1)

FM Search Level Adjustment

SSG FREQ. 98MHz

Adjustment

point SEMI-VR(50KB)

(ISVR1)

"TUNED" is shown on LCD(Figure 4-2)

FM

Antenna

Terminal

Speaker

Terminal

Input

Input

Figure 4-1 IF CENTER and T.H.D Adjustment

Figure 4-2 FM Auto Search Level Adjustment

Output

Distortion Meter

Oscilloscope

Oscilloscope

FM antenna

FM SSG

FM SSG

GND

30dB

75Ω

Dummy

50Ω

Dummy

FM IN

FM Antenna

SET

50 kB

SET

Output

GND

FM Stereo Adjustment

SSG FREQ. 98MHz

Adjustment

point SEMI-VR(5KB)

(ISVR2)

L-CH/R-CH : Maximum(Figure 4-3)

Figure 4-3 FM Stereo Separation Adjustment

EXT

FM

SSG

Stereo

Modulator

(Pilot 10%)

Speaker

terminal

SET

GND

OUT

VTVM

5KB

4-1Samsung Electronics

Page 13

Step

Item

Connection SSG.FREQ.

FREQ. Setting

Adjust. Point

Remark

Maximum

output

Maximum output

Maximum output

1

Intermediate

frequency (IF)

adjustment

AM frequency

coverage

adjustment

Figure 4-5

Figure 4-4

Connect DC

voltmeter to TCON1

and GND(TP1)

522 KHZ

522 KHZ IT 2

OT 1

OCT 2

OL 1

OCT 1

9V

0.9V

522 KHZ

594 KHZ

1404 KHZ

1611 KHZ

594 KHZ

1404 KHZ

Figure 4-5

_

_

_

Repeat step 2 and 3 serveral times

Repeat step 5 and 6 several times

AM tracking

adjustment

Figure 4-4 AM Frequecny Coverage Adjustment

Figure 4-5 AM Tracking Adjustment

SET

TP2

DC Voltmeter

Input

TP1

AM Signal

Generator

Test Loop

Antenna

AM

Loop Antenna

Jack

Speaker

terminal

GND

Oscilloscope

VTVM

IN

OUT

SET

60 cm

Samsung Electronics4-2

Alignment and Adjustments

2

3

4

5

6

7

4-1-1 Test Equipment

1. AM Standard Signal Generator (S.S.G) : 400Hz, 30% MOD

2. Oscilloscope

3. VTVM

4. Frequency counter

5. Loop antenna

6. Dummy load (4½)

7. DC voltmeter

4-1-2 Pre-Adjustment

1. Check the source voltage.

2. Set function and band switches to the band to be aligned.

3. Set the equalizer, volume and balance controls to mid position.

4-1-3 AM Adjustment

Page 14

Alignment and Adjustments

Figure 4-6

Figure 4-7

Figure 4-8

4-2 Cassette Deck

4-2-1 Additional Test Equipment : Testing Tape

1. MTT-111 (or equivalent) : Test tape on which 3 KHz signal is recorded (Tape speed adjustment).

2. MTT-114 (or equivalent) : Test tape on which 10 KHz signal is recorded (Azimuth adjustment).

4-2-2 Recording Bias Adjustment

1. Connect frequency counter KC434 and press the REC button.

2. Adjust KT431(BIAS OSC COIL) until frequency counter reads 85¡ 0.2KHz.

Item

Connection

Preparation

Tape speed

(normal speed)

adjustment

Figure 4-6

Figure 4-8

3 KHz

CSVR801

AZIMUTH

(DECK A,B)

adjustment

Maximum

output and

identical

phase of L,R

channel.

Set the screw

after adjustment.

Insert MTT-111 to

Deck A or B.

Press PLAY button.

Insert MTT-114 to

Deck A and Deck B.

Press PLAY button.

CSVR801

CCON801

ISVR2

ISVR1

IT2

OT1

OT2

OCT2

OCT4

OCT3

OL2

OL1

TCON1

OCT1

IT1

KT431

Figure 4-7

AZIMUTH Adjustment

screw

REC PB Head

Oscilloscope

IN

OUT

INSET

Frequency

Counter

Speaker

Terminal

Speaker

Terminal

Remark

Adjustment point

SET

(GND)

VTVM

V H

4-3Samsung Electronics

Page 15

Samsung Electronics4-4

4-3 CD

TP2

TP1

Vref

NVR1704

NVR1703 NVR1702

NVR1701

TE CENTER

FE CENTER

E.F BAL

F.BIAS

0V

A

B

A=B

---100mV

---0V

---250mV

---0 V

---100mV

---0 V

---0 V

---0 V

---0 V

4-3-1 To Adjust FOCUS BIAS(STOP mode)

4-3-3 To Adjust Focus Gain (PLAY mode)

4-3-2 To Adjust Tracking Gain (PLAY mode)

4-3-4 To Adjust E/F Balance (PLAY mode)

1. Set Volt/Div of the oscilloscope to DC 100mV.

2. Ground the scope input and set the waveform to 0V, DC range.

3. Connect the GND terminal of the oscilloscope to

Vref, and (+) terminal to center of TP1.

4. Set NVR1701 to 0mV.

1. Connect the GND terminal of the oscilloscope to Vref and (+) terminal to TP2.

2. Load and play the disc

3. While the disc is running adjust the gain with NVR1704 as shown below.

1. Connect the GND terminal of the oscilloscope to Vref and (+) terminal to TP1.

2. Load and play the disc

3. While the disc is running adjust the gain with NVR1703 as shown in the following figure.

VOLT/DIV : 0.2V

TIME/DIV : 2mS

Normal frequency

Normal frequency

Low frequency

High frequency

Low frequency

High frequency

VOLT/DIV : 0.1V

TIME/DIV : 2mS

VOLT/DIV : 0.1V

TIME/DIV : 2mS

VOLT/DIV : 0.1V

TIME/DIV : 2mS

VOLT/DIV : 0.2V

TIME/DIV : 2mS

VOLT/DIV : 0.2V

TIME/DIV : 2mS

1. Set TIME/DIV of the oscilloscope to 2mS.

2. Set Volt/DIV of the oscilloscope to 0.5V.

3. Ground the scope input and set to DC

and then set the DC range.

4. Connect the GND terminal of the oscilloscope to Vref

and (+) terminal to center to TP2.

5. Load and play the disc.

6. Turn NVR1704 counterclockwise to the minimum value.

7. Raise NVR1702 and adjust the waveform so that its middle

comes to GND of the oscilloscope (or until the upper half

of waveform becomes symmetrical to the bottom half, A=B)

8. Adjust NVR1704 (arrow) for normal sound.

Alignment and Adjustments

Page 16

6. Troubleshooting

6-1 Main

6-1-1 Power Malfunction

Samsung Electronics 6-1

Yes

No

Yes

No

Yes

No

No

Yes

LCD lamp is ON

Power Transistor &

fuse normal

Pins 73,31 of

UIC1(LC72362)

is at 5V

Connection

and soldering

of SCON1-FCW2

are normal

Check Voltage at RIC1

Voltages at RQ1,RQ2 and

RFR1 are normal

Replae RQ701

Voltages at

RQ702,RQ703

are normal

Voltage at

RQ701 is normal

Page 17

6-2 Samsung Electronics

Troubleshooting

Yes

No

Yes

No

No

6-1-2 FM No Sound

6-1-3 AM No Sound

Voltages at

IIC1(LC1851N) and semi

conductors tuner section

are normal

Voltage at power supply

section

Check pump charge circuitry(OQ5)

connection or soldering of SCON1FCW2,FCON1 soldering of pin 77 of

LC72362

TCON1 is at

1.5V¡ 0.5 on low coverage

7.5V ¡ 0.5 on high

coverage

Replace FET

Voltage at FET are

normal

Yes

No

No

Check pump charge circuitry

(OQ5) connection of SCON1,

FCW2, FCON1 soldering of pin77

of LC72362N

Yes

Voltage

at LC1851N(IIC1) and tuner

semi conductors are normal

(Refer to Schematic Diagram)

Voltage between

TCON1: AM(MW)

Low coverage 0.9V 0.5

High coverage 9V 0.5

LW Low coverage 0.7V 0.5

High coverage

4.5V 0.5

Check loop antenna soldering and

connection of OL1, OL2, OT1,OT2, IT2

Check voltage at power

supply section

Page 18

Samsung Electronics 6-3

Troubleshooting

Yes

No

Yes

No

Yes

No

Connection and soldering of head

wire normal

Replace JIC1 (KA22291)

Voltage at

JIC1(KA22291) are normal

(Refer to Schematic

Diagram)

Check power supply circuitry

Noise occurs at

pin3,22 or pin4,21 with volume

control at mid position

Noise occurs at pins1,24

Check function selector

section

6-1-4 Tape Not Playing

6-1-5 Audio Output Problem

No

Yes

Yes

Yes

No

Speaker connections are normal

all pins of AIC1(TA8207)

are normal (Refer to Schematic

Diagram)

Voltage at base of AQ601,

AQ651(C945) is

less than

0.6V

Pattern & Speaker Jack normal

Check power supply section

Check Muting circuitry

Voltages to

Page 19

6-4 Samsung Electronics

Troubleshooting

Check CLOSE S/W voltage.

CLOSE condition : 0V

Is Focus Search done properly ?

Check oscillation of NXF100

(16.9344MHz).

Does Laser function during

Focus Search ?

Replace PICK-UP.

Check NIC9282 pin73 voltage

Replace NIC9282.

Yes

POWER ON

Check CLOSE MOTOR driving

Replace NIC9220 or NIC9258.

element and CLOSE S/W.

during Focus Search : 5V

Yes

Yes

No

No

No

No

Yes

Yes

6-2 CD

6-2-1 Malfunction of DISC Revolution

Page 20

Samsung Electronics 6-5

Troubleshooting

Check voltage of NIC05

Check waveform of NIC9282

No

Check NIC9282 soldring conditon

Check waveform of NIC9270

pins 9,12

Check waveform of NIC9270

Replace NIC05

Check Amp. operation

Malfunction of Audio output

pins 19,20

Replace NIC9270

Check NIC9270 soldering condition

Replace NIC9270

Check NIC9270 soldering condition

Yes

Yes

Yes

Yes

Yes

No

No

No

pins 2,19

6-2-2 Malfunction of Audio output

Page 21

7-1Samsung Electronics

2

3

4

5

6

9

10

20

21

22

23

2425

11

12

15

1

8

13

14

16

17

18

19

2

3

4

5

7

9

10

20

22

24

25

11

12

13

16

17

18

19

No. New Part No. Description Specification Old Part No.

1

2

3

4

5

6

7

8

9

10

11

12

AH59-20004F

AH81-10026X

AH81-10026C

AH81-10025B

AH81-10025D

AH81-10025E

AH81-10025F

AH81-10025G

AH81-10021T

AH81-10025J

AH81-10025K

AH81-10025T

AH81-10025M

DECK-CASSETTE

LEVEL-SYNCHRO

SPRING PACK

TAKE UP REEL ASS’Y

PINCH ARM ASS’Y

IDLER ARM ASS’Y

FLYWHEEL GEAR S ASS’Y

FLYWHEEL GEAR D ASS’Y

MOTOR

FR ARM ASS’Y

REEL GEAR ASS’Y

ARM-SENSOR

PAUSE LOCK CAM

ADR2040FW

11134-01280AA

51299-02506XC

ADR28-010

ADR26-001

ADR02-042

ADR15-021

ADR15-022

EG530YD2B

ADR22-012

11128-00045AA

11102-00530AA

11116-00011A

10000-607-186

10000-607-146

10000-607-101

10000-607-103

10000-607-104

10000-607-105

10000-607-106

10000-502-020

10000-607-108

10000-607-109

10000-607-117

10000-607-111

No. New Part No. Description Specification Old Part No.

13

14

15

16

17

18

19

20

21

22

23

24

25

AH81-10025P

AH81-10026B

AH81-10026W

AH81-10026M

AH81-10025Q

AH81-10025R

AH81-10025S

AH81-10026T

AH81-10026U

AH81-10022E

AH81-10026P

AH81-10026L

AH81-10026H

HEAD BASE M

LEVER REC SAFETY

LEVER RELEASE

LEVER EJECT(F)

CAM GEAR

F.F GEAR

PAUSE CAP

LEAF SW (MAIN)

LEAF SW (REC)

R/P HEAD

MGARM ASS’Y

BELT MAIN

BELT SUB

11105-00031AA

11134-01000A

11134-01240AA

11134-01220AA

11128-00393AA

11128-00055AA

11116-00011AA

MSW1541 X ACV

MSW 1716CV

MS15R-AA2N1

11102-00520AA

59.7 PI X 1.0T

34.7 PI X 1.0T

10000-607-113

10000-607-145

10000-607-184

10000-607-160

10000-607-114

10000-607-115

10000-607-116

10000-607-178

10000-607-179

10000-523-008

10000-607-162

10000-607-159

10000-607-128

7. Exploded Views and Parts List

7-1 Cassette View and Parts List

Page 22

45

33

1

2

3

4

5

6

7

8

9

8

9

10

20

31

32

33

34

34-1

30

21

22

23

24

25

26

27

24

25

26

27

28

29

11

12

13

14

15

16

17

18

19

FRONT – PCB

SUB – PCB

CASS - DECK ASS'Y

MAIN – PCB

LCD

POWER - CORD

POWER - PCB

36

EQ PRESET MUTE

MONO/ST

PHONO

POWER

PLAY/PAUSE

VOLUME

TUNING

TUNING

INTRO

MEMORY BAND

SLEEP PRESET/MANUAL

CLOCK TIMER

TUNER

SKIP/SEARCH STOP

REPEATDISPLAYPROGRAM

TAPE CD

VOLUME

35

Exploded Views and Parts List

7-2 Main Exploded View and Parts List

Page 23

7-3Samsung Electronics

Exploded Views and Parts List

7-2-1 Main Parts List

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

34-1

35

36

AH64-30337B

AH64-50188B

AH64-50189B

AH64-40338A

AH64-40339A

AH64-50190B

AH64-40335B

AH61-60241E

AH61-80030A

AH64-10869A

AH64-10887B

AH67-10094A

AH64-10871B

AH67-40024A

AH61-20335A

AH67-10097A

AH64-10872B

AH64-10870A

AH64-10886A

AH64-10890B

AH64-10873B

AH64-10875B

AH64-10876B

AH64-10876D

AH64-10876C

AH64-10876E

AH64-10880B

AH64-10874B

AH61-10573A

AH61-10576A

AH62-30107A

AH64-30338A

AH61-10683A

AH59-90012W

AH63-30005A

AH59-10080C

G3A8-1/C

14074-0310-00

14074-0311-00

14083-0877-00

14083-0878-00

14083-0880-00

13014-0378-00

12201-0174-00

12000-0341-00

-,MIPS,94HB,T2.5,-,BL

-,ABS,94HB,T2.5,-,BLK,-

-,ABS,94HB,T2.5,-,BLK,PC,-,T0.7,BLK,-,BLK,PC,-,T0.7,BLK,-,

ABS,94HB,T2.5,-,BLK,-

-,ACRYL,-,-,CLR,-,

-,TS,STS304,PI0.9,OD8.6,-,SCM6700

-,POM,M0.8,GI30,BLK,-,

ABS,94HB,BLK,T1.5,

-,ABS,94HB,BLK,-,SCM6700

PMMA,-,-,-,MILKEY,SCM6700

-,ABS,94HB,BLK,-,SCM6700

PC,T0.5,-,-,-,-,WHT,SCM6700

ABS,94HB,WHT,T1.5,SCM6700

PMMA,-,-,-,MILKEY,SCM6700

-,ABS,94HB,BLK,-,SCM6700

ABS,94HB,BLK,T1.5,SCM6700

ABS,94HB,BLK,T1.5,SCM6700

-,ABS,94HB,BLK,-,SCM6700

-,ABS,94HB,BLK,-,SCM6700

-,ABS,94HB,BLK,-,SCM6700

-,ABS,94HB,BLK,-,SCM6700

-,ABS,94HB,BLK,-,SCM6700

-,ABS,94HB,BLK,-,SCM6700

-,ABS,94HB,BLK,-,SCM6700

-,ABS,94HB,BLK,-,SCM6700

-,ABS,94HB,BLK,-,SCM6700

SECC,-,T0.8,-,-,SCM6700

ABS,94HB,-,BLK,-,SCM6700

-,AL,-,T6.0,-,WHT,-,SCM6700

MIPS,94HB,T3,-,BLK,-

-,SECC,-,T1.0,NTR,-,SCM6700

SCM6500

GP150,94HB,T3.0,D/BLU

-,-,-,60,SCM6700

1-CD G3A8 CKD

CABINET-FRONT

DOOR-CASS,A

DOOR-CASS,B

WINDOW-DOOR(A)

WINDOW-DOOR(B)

DOOR-CD

WINDOW-TUNER

SPRING-DOOR

DAMPER-ASSY

KNOB-TUNER(A)

KNOB-POWER

LENS-POWER

KNOB-FUNCTION

FILTER-LCD

HOLDER-CD

LENS-PLAY(CD)

KNOB-SKIP

KNOB-TUNER(B)

KNOB-EQ

KNOB-OP/CL

KNOB-PLAY,CD

KNOB-DECK,REC

KNOB-PLAY,S

KNOB-REW

KNOB-DECK,FF

KNOB-DECK,SJ/EJ

KNOB-DECK,PAUSE

KNOB-PLAY,L

BRACKET-DECK

CHASSIS-MECHA

HEAT-SINK

CABINET-BOTTOM

BRACKET-P/T

ASS’Y-T/T

COVER-DUST

REMOCON-ASS’Y

ASS’Y -CD PACK

No. New Code No. Description Specification Old Code No.

Page 24

7-3-1 CD Pack Exploded View (G3A8-1/C)

1 1

3 3

5 5

6 6

8 8

9 9

1010

1717

1818

1919

2020

1414

2121

1111

1212

1313

1414

1717

1616

1717

1616

1616

2222

2323

2 2

4 4

7 7

1515

No. New Code No. Description Specification Old Code No.

7-3 CD Pack Parts List

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

CMSP3M6T

AH61-20004A

AH61-10241A

AH66-50004A

AH66-90053A

AH66-20007A

AH66-20008A

AH61-20245A

AH66-30001B

AH66-10001A

AH66-10002A

AH66-90009B

AH66-60001A

AH90-10346A

AH39-20001F

3302-000158

AH73-10012A

AH61-50182B

AH61-60010A

3409-000135

AH31-10021A

3409-000175

CMS-P30NM6

AH61-20227A

DECK-CD MINI MECHA

BASE-MAIN

BRACKET-CHUCK

CAM

TABLE-CHUCK UNION

GEAR-A

GEAR-B

HOLDER-CHUCK

LEVER-LIFTER DECK(P)

PULLEY-GEAR

PULLEY-MOTOR

TRAY-M1

BELT-PULLEY

ASSY-PCB

LEAD-CONNECTOR ASS'Y

MAGNET-FERRITE

RUBBER-CD

SHAFT-CD

SPRING-CAM

SWITCH-LEAF

MOTOR-DC

SWITCH-DETECTOR

DECK-CD

HOLDER-PCB

BASIC

ABS, -, BLK, -, CMS-M1

SBHG, -, T0.8 WHT,-,CMS-CR1

PC, -, BLK,-, CMS-M1

-, ABS. -, BLK,-, CMSA3

NYLON12,M0.5/M0.5,Z17/45,-, -,

POM,M0.5/M0.8, Z19/Z46, -, -,

ABS,94HB,BLK,-,CMS-M1

PC, -, -, -, CMSP3

POM,BLK,CMS-M1

POM,BLK,CMS-M1

ABS,-,BLK,-,CMS-M1

NEOPLENE,T1.5, 2%,L78.8,BLK

G3A8

51004,-,6P,300MM, 1007#28

AC,-,3500-3800G,2.6-3.2MG0E,30

SI RUBBER, -, CMS-M5M6C,BLU

FE,D2.6,L10.5, -, -,

ES,STS-W,PI0.2,OD3.2,-,CMS-M1

16V,1A,70GF,SPST

RF-500TB,9VDC/130MA

30VDC,100MA,SPST

CMS-P30NM6

NYLON66,-,NTR,DAHP-18N,M

12201-0013-00

13014-0119-00

11583-0001-00

12223-0015-00

11474-0006-00

11474-0007-00

13329-0013-00

11532-0004-01

11504-0001-00

11504-0002-00

13602-0001-01

11494-0001-00

19129-0357-03

13070-046-125

14014-500-600

16174-503-411

15104-531-710

12724-0010-00

B3022-0004

B3070-0002

13573-901-050

13324-0209-00

Exploded Views and Parts List

Samsung Electronics7-4

Page 25

CMSP30NM6

AH61-10022C

AH63-30048A

AH66-20016A

AH66-20017A

AH66-20018A

AH71-50036A

15253-503-011

AH66-90018A

AJ30-200013B

AH61-60055A

AH31-10009A

AH31-10002B

AH60-10014A

12001-0052-02

13313-0057-00

11474-0017-00

11474-0018-00

11474-0019-00

11404-0041-00

15253-503-011

12223-0003-00

*SOH-AP

12724-0062-00

16829-0004-00

14769-057-250

17008-120-032

DECK -CD

CHASSIS-DECK(M)

COVER-GEAR

GEAR(A)

GEAR(B)

GEAR(C)

SHAFT-PU

CENTER-RING

TURN-TABLE(M)

PICK-UP CDP

SPRING-T/TABLE

MOTOR-SPINDLE

MOTOR-FEED

SCREW-PH(+M2*3)

BASIC

CMSA30 POM M90-44

CMS-V30 BLK ABS

CMS-V30 M0.3 Z13 SP POM

CMS-V30 M0.3 Z13 SP POM

CMS-V30 M0.3 Z16/Z90 SP POM

CMS-V30 D3 L79 SUS420J2

ABS+GS 20% CMS-V10N

ABS+GS 20% CMS-V10N

P/U SOH-A1 ROW V-P/J

CS STS-W PI0.4 D5.7 L9.3 CMS-V10N

RF-310T-11400 43L 25V 85mA

RF-310TA 30MM NDM4RA3ETL 11.0MM

+M2X3 FE FZY W700

1

2

3

4

5

6

7

8

9

10

11

12

13

No. New Code No. Description Specification Old Code No.

7-4 CD DECK ASS'Y Parts List

7-4-1 CD DECK Exploded View

Exploded Views and Parts List

7-5Samsung Electronics

Page 26

AH59-90012W

AH81-10019S

AH81-10019T

AH81-10019U

AH63-30005A

AH81-10019W

AH81-10019X

AH81-10019Y

AH81-10019Z

AH81-10020A

AH81-10020B

AH81-10020C

AH81-10020D

AH81-10020E

AH81-10021F

AH81-10020G

AH81-10020H

AH81-10020J

AH81-10020K

AH81-10020L

AH81-10020M

AH81-10020N

AH81-10020Q

15029-502-970

10000-451-001

10000-451-003

10000-451-004

13311-0070-00

10000-451-006

10000-451-007

10000-451-008

10000-451-009

10000-451-010

10000-451-012

10000-451-013

10000-451-014

10000-451-015

10000-451-017

10000-451-019

10000-451-020

10000-451-022

10000-451-023

10000-451-024

10000-451-025

10000-451-026

10000-451-027

10000-451-028

10000-451-029

ASS’Y-T/T

CABINET-TOP

LOCKER ARM

HINGE ASS’Y

COVER-DUST

PLATE CLUTCH

GUIDE CLUTCH

LINK-ACTUATING

SPRING-ADJUST

LEVER S/W

CARTRIDGE

TONE ARM ASS’Y

HOLDER-ARM

FEED ARM

SWITCH-LEAF

PULLEY-MOTOR

MOTOR

ADAPTER EP

SPACER

BELT DRIVING

PLATTER

E-RING

CONNECTOR-5P

SLIDE SWITCH

STYLUS

SCM6550

PM00010, M13000 TV

PM40230,ACETAL

PA40091

PM20370, M13000 TV

PM40211, ACETAL

PM40221, ACETAL

PZ40171,STS

PZ40162,STS

PM40051,ACETAL

CP-405-30

PM20101, ABS

PM40730,ACETAL

PM30151,ACETAL

LSB61123A3

PL40170, MBSBDI

SHR2R6I

PM40030,ABS

ø7.2 X ø15 X T0.5, PE

PP4029, RC-WRT

PM20110, M13000TV

E-6

SC25-05HG

DSS-1123

CP- 385 -10

1

3

4

5

6

7

8

9

10

12

13

14

15

17

19

20

22

23

24

25

26

27

28

29

No. New Code No. Description Specification Old Code No.

7-5 Turn Table ASS'Y Parts List

7-5-1 Turn Table Exploded View

Exploded Views and Parts List

Samsung Electronics7-6

Page 27

AH90-10632A ASSY-PCB MAIN;SCM6700TE,EXP

AH90-30473A ASSY-COM PCB MAIN;SCM6700TE,EXP

FD1,2,OD1,2,ID1,2 0401-000101 DIODE-SWITCHING;1N4148,100V,200MA,5

CD801,802,803,804,805,806

CD807,808,809,810,811,812 0401-000101 DIODE-SWITCHING;1N4148,100V,200MA,5

KD401,402,403,ED1,2

RD701 0402-000450 DIODE-BRIDGE;PBL403,200V,4.0A,DIP-4 12169-219-330

RZD704 0403-000358 DIODE-ZENER;UZ5.6BSB,5.6V,5.46-5.7V 12169-404-790

RZD701,702 0403-000379 DIODE-ZENER;UZP12B,12V,11.4-12.6V,1 12169-403-910

UZD901,RZD703 0403-000399 DIODE-ZENER;UZP9.1B,9.1V,8.5-9.6V,1 12169-403-340

OVD1 0405-000138 DIODE-VARACTOR;KV1236,20V,100NA,TO- 12169-501-005

RQ703,UQ903,JQ301,302, 0501-000010 TR-SMALL SIGNAL;KSC1008-Y,NPN,80V,6 12149-301-050

JQ351,352,CQ806

CQ805,808,RQ706 0501-000294 TR-SMALL SIGNAL;KSA708-Y,PNP,-80V,- 12149-101-560

IQ2,CQ801,802,OQ4 0501-000303 TR-SMALL SIGNAL;KSA733,PNP,-60V,-50 12149-101-520

PQ1L,1R 0501-000337 TR-SMALL SIGNAL;KSC1222,NPN,50V,45V 12149-301-820

IQ1 0501-000392 TR-SMALL SIGNAL;KSC838,NPN,35V,30V, 12149-301-860

KQ431,PQ1 0501-000394 TR-SMALL SIGNAL;KSC900,NPN,30V,25V, 12149-301-840

UQ904,954,AQ601,651,603 0501-000398 TR-SMALL SIGNAL;KSC945,NPN,60V,50V, 12149-301-900

CQ803,KQ401,451

RQ702,UQ902 0501-000610 TR-SMALL SIGNAL;KSA928A,PNP,-30V,-3

UQ901 0502-000299 TR-POWER;KSD73,NPN,100V,60V,5A,30W, 12149-401-070

RQ701,704 0502-000303 TR-POWER;KSD882,NPN,40V,30V,3A,1W,T 12149-101-900

RQ705 0502-000407 TR-POWER;KTC4369-Y,NPN,30V,30V,3A,1 A4050-0037

IQ4 0504-000118 TR-DIGITAL;KSR1003,NPN,300MW,22K-22 12159-301-780

KQ403,453,402,452,JQ304, 0504-000121 TR-DIGITAL;KSR1007,NPN,300MW,22K-47 12159-301-800

JQ354,IQ3,JQ303,AQ602

CQ809,KQ404 0504-001003 TR-DIGITAL;KSR2003,PNP,300MW,22K-22

OQ5 0505-000236 FET-SILICIN;2SK583,N,50V,200MA,20OH 12139-601-450

AIC601 1201-000334 IC-POWER AMP;8207,SIP,12P,-,DUAL,-, 12119-101-290

JIC1 1201-000358 IC-PREAMP;22291,DIP,24P,-,DUAL,-,PL A4012-0070

RIC1 1203-000276 IC-POSI.FIXED REG.;7805,TO-220,3P,- 12119-601-770

QIC1 1204-001031 IC-VOLUME CONTROL;LC75394E,QFP,64P,

RD704,705,706,707,UD901 12169-201-080 DIODE-RECTIFIER;1N 4001,TAPE

RR23,7244 13954-100-310 CERAMIC-PIPE;PI1.4 15MM WHT

IR3 2001-000003 R-CARBON;330OHM,5%,1/8W,AA,TP,1.8X3 11018-877-331

IR2 2001-000005 R-CARBON;390OHM,5%,1/8W,AA,TP,1.8X3 11018-877-391

AR602,652 2001-000008 R-CARBON;15KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-153

KR407,457 2001-000010 R-CARBON;68KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-683

KR435 2001-000034 R-CARBON;220OHM,5%,1/4W,AA,TP,2.4X6 11018-277-221

UR903 2001-000042 R-CARBON;1KOHM,5%,1/4W,AA,TP,2.4X6. 11018-277-102

OR1,2,QR505,555 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,1.8X 11018-877-104

PR5L,5R,QR503,KR412, 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3 11018-877-101

JR32,KR413,409

IR11,OR9,IR12,JR312 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-103

CR821,822,823,824,816

CR826,JR321,371

PR6R,ZR151

AR603,653 2001-000325 R-CARBON;120OHM,5%,1/8W,AA,TP,1.8X3 11018-877-121

OR6,KR432 2001-000331 R-CARBON;12KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-123

JR314 2001-000362 R-CARBON;150OHM,5%,1/8W,AA,TP,1.8X3 11018-877-151

Loc No. New Part No. Description Specification Old Part No.

8. Electrical Parts List

Samsung Electronics 8-1

Page 28

PR3L,3R 2001-000397 R-CARBON;180KOHM,5%,1/8W,AA,TP,1.8X 11018-877-181

ZR102,152,KR408,458 2001-000411 R-CARBON;18KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-183

IR8,JR303,304,353,354 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3. 11018-877-102

JR310,CR802

IR1,OR10,IR22,CR827,828 2001-000449 R-CARBON;2.2KOHM,5%,1/8W,AA,TP,1.8X 11018-877-222

AR601,651,605,UR904,954

QR504,554,PR1,UR907,957

IR19,20,23,CR825 2001-000449 R-CARBON;2.2KOHM,5%,1/8W,AA,TP,1.8X 11018-877-222

KR402,452,QR502,552 2001-000472 R-CARBON;2.7KOHM,5%,1/8W,AA,TP,1.8X 11018-877-272

JR306,356,323,373 2001-000508 R-CARBON;220KOHM,5%,1/8W,AA,TP,1.8X 11018-877-224

IR5 2001-000515 R-CARBON;220OHM,5%,1/8W,AA,TP,1.8X3 11018-877-221

JR313,UR906,956 2001-000522 R-CARBON;22KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-223

JR315,CR817,818,819

RR706,UR908

AR607,IR31 2001-000525 R-CARBON;22OHM,5%,1/4W,AA,TP,2.4X6. 11018-277-220

KR433 2001-000527 R-CARBON;22OHM,5%,1/8W,AA,TP,1.8X3. 11018-877-220

IR21,OR7 2001-000548 R-CARBON;270KOHM,5%,1/8W,AA,TP,1.8X 11018-877-274

AR606,656 2001-000552 R-CARBON;270OHM,5%,1/4W,AA,TP,2.4X6 11018-277-271

IR13,14,17,18 2001-000563 R-CARBON;27KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-273

IR9,JR309,359 2001-000591 R-CARBON;3.3KOHM,5%,1/8W,AA,TP,1.8X 11018-877-332

RR722 2001-000611 R-CARBON;3.9KOHM,5%,1/4W,AA,TP,2.4X 11018-277-392

JR308,358,322 2001-000613 R-CARBON;3.9KOHM,5%,1/8W,AA,TP,1.8X 11018-877-392

IR4 2001-000666 R-CARBON;33OHM,5%,1/8W,AA,TP,1.8X3. 11018-877-330

CR804 2001-000689 R-CARBON;390KOHM,5%,1/8W,AA,TP,1.8X 11018-877-394

PR4L,4R,CR829,SR205,255 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X 11018-877-472

SR202,252,UR905,JR311

RR720,721,718,JR372

IR15,16

KR410 2001-000773 R-CARBON;470KOHM,5%,1/8W,AA,TP,1.8X 11018-877-474

PR2 2001-000780 R-CARBON;470OHM,5%,1/8W,AA,TP,1.8X3 11018-877-471

KR404,454 2001-000786 R-CARBON;47KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-473

JR307,357 2001-000793 R-CARBON;47OHM,5%,1/8W,AA,TP,1.8X3. 11018-877-470

IR10,25,26 2001-000812 R-CARBON;5.6KOHM,5%,1/8W,AA,TP,1.8X 11018-877-562

FR6,CR803,805

JR301,302,351,352,KR401,451 2001-000812 R-CARBON;5.6KOHM,5%,1/8W,AA,TP,1.8X 11018-877-562

KR406,456,IR27,7

FR5 2001-000817 R-CARBON;5.6OHM,5%,1/8W,AA,TP,1.8X3 11018-877-569

QR501,551,CR801 2001-000857 R-CARBON;560OHM,5%,1/8W,AA,TP,1.8X3 11018-877-561

JR305,355,KR411,PR2L,2R 2001-000890 R-CARBON;6.8KOHM,5%,1/8W,AA,TP,1.8X 11018-877-682

AR654,604,RR719

KR405,455,IR30,CR831 2001-000977 R-CARBON;8.2KOHM,5%,1/8W,AA,TP,1.8X 11018-877-822

PR1L,1R 2001-000989 R-CARBON;820KOHM,5%,1/8W,AA,TP,1.8X 11018-877-824

KR403,453 2001-001006 R-CARBON;82OHM,5%,1/8W,AA,TP,1.8X3. 11018-877-820

RR705 2001-001050 R-CARBON(S);1.5KOHM,5%,1/2W,AA,TP,2 11018-377-152

RR709,704 2001-001138 R-CARBON(S);390OHM,5%,1/2W,AA,TP,2. 11018-377-391

RR723,724 2003-000650 R-METAL OXIDE(S);330OHM,5%,2W,AA,TP 11048-577-331

RR710,UR901 2003-000669 R-METAL OXIDE(S);390OHM,5%,1W,AA,TP 11048-477-391

RR711 2008-000127 R-FUSIBLE;10OHM,5%,2W,AA,TP,6.5X17M 11058-577-100

RR701,702,703,707 2008-000157 R-FUSIBLE;4.7OHM,5%,1/4W,AA,TP,2.6X 11058-277-479

ISVR1 2103-000461 VR-SEMI;50KOHM,30%,1/10W,TOP 11249-102-064

CSVR801,ISVR2 2103-000492 VR-SEMI;5KOHM,30%,1/10W,TOP 11249-102-024

FC3 2201-000146 C-CERAMIC,DISC;100PF,5%,50V,SL,5X3. 11407-017-101

QC507,557 2201-000377 C-CERAMIC,DISC;220PF,5%,50V,UJ,8.0* 11407-067-221

OC5 2201-000557 C-CERAMIC,DISC;470PF,10%,50V,SL,10. 11407-018-471

8-2 Samsung Electronics

Loc No. New Part No. Description Specification Old Part No.

Electrical Parts List

Page 29

IC3,14,OC8,10,CC801 2201-000565 C-CERAMIC,DISC;47NF,20%,50V,Y5V,12. 11417-344-473

FC1,2,RC714,715,716,717

IC8,10,19,22,23 2202-000781 C-CERAMIC,MLC-AXIAL;100PF,10%,50V,Y 11449-518-101

JC304,354,305,355,KC401,451

UC902,952,QC519,569

KC404,454,JC312 2202-000785 C-CERAMIC,MLC-AXIAL;10NF,20%,16V,Y5 11447-910-103

FTZ5,6 2202-000796 C-CERAMIC,MLC-AXIAL;1NF,10%,50V,Y5P 11449-518-102

KC436,437,ZC101,151 2202-000806 C-CERAMIC,MLC-AXIAL;220PF,10%,50V,Y 11449-518-221

IC1,20,21,KC409 2202-000807 C-CERAMIC,MLC-AXIAL;22NF,+80-20%,25 11448-010-223

JC309,359 2202-000809 C-CERAMIC,MLC-AXIAL;3.3NF,20%,16V,Y 11447-619-332

QC566,516 2202-000825 C-CERAMIC,MLC-AXIAL;680PF,10%,50V,Y 11449-518-681

KC407,457,JC301,351,302 2202-000847 C-CERAMIC,MLC-AXIAL;1,8NF,0.3,50V,Y

JC352

AC602,652 2202-000848 C-CERAMIC,MLC-AXIAL;1.5NF,0.3,50V,Y

QC514,564 2202-000850 C-CERAMIC,MLC-AXIAL;2.2NF,0.3,16V,Y

JC307,357 2202-000853 C-CERAMIC,MLC-AXIAL;4.7NF,0.3,16V,Y

IC2,28,OC2,IC33,FC4 2202-000854 C-CERAMIC,MLC-AXIAL;47NF,0.3,50V,Y5

QC512,562 2202-000855 C-CERAMIC,MLC-AXIAL;6.8NF,0.3,16V,Y

SC201,251 2203-002208 C-CERAMIC,CHIP;330PF,0.1,50V,Y5P,20

KC432,433 2301-000379 C-FILM,PEF;10NF,10%,50V,6X7X3.2MM,5

QC511,561,AC606,656 2301-000387 C-FILM,PEF;150NF,10%,50V,12.5X15X7. 11505-714-154

QC515,565,IC24,25 2301-000390 C-FILM,PEF;15NF,10%,50V,6.5X9X3.5MM

IC7,JC306,356 2301-000393 C-FILM,PEF;18NF,10%,50V,6.5X12.5X3.

KC434 2301-000400 C-FILM,PEF;1NF,10%,50V,5X7X2.8MM,5M

QC510,560,517,567 2301-000412 C-FILM,PEF;22NF,10%,50V,6.5X10.5X4M

OC11 2301-000419 C-FILM,PEF;27NF,10%,50V,7.5X10.5X4M

IC6 2301-000422 C-FILM,PEF;3.3NF,10%,50V,5.5X7X3MM,

JC308,358 2301-000433 C-FILM,PEF;33NF,5%,50V,7.5X11X4MM,5

QC513,563 2301-000456 C-FILM,PEF;56NF,10%,50V,8X12X4.5MM,

KC405,455 2301-000476 C-FILM,PEF;82NF,10%,50V,10.5X12.5X6 11505-714-823

AC607,657 2401-000129 C-AL;1000UF,20%,16V,GP,10X16MM,-, 11609-103-102

AC605,655,608,3 2401-000303 C-AL;100UF,20%,25V,GP,6.3*11,2.5MM, 11608-104-104

RC703,707 2401-000303 C-AL;100UF,20%,25V,GP,6.3*11,2.5MM, 11608-104-104

IC9,18,QC506,556 2401-000419 C-AL;10UF,20%,16V,GP,5X11,2.5MM,

RC713,IC15

RC712 2401-000438 C-AL;10UF,20%,25V,GP,5*11,2MM, 11608-104-103

RC706 2401-000778 C-AL;220UF,20%,10V,GP,6.3X11,2.5MM, 11608-102-224

JC313,PC3 2401-000795 C-AL;220UF,20%,16V,GP,8X11.5,3.5MM,

UC903,RC709 2401-000830 C-AL;220UF,20%,25V,GP,8*11.5,3.5MM, 11608-104-221

IC12,KC402,452,406,456 2401-001022 C-AL;3.3UF,20%,50V,GP,5*11,2MM, 11608-106-332

JC310,360,QC508,558,505,555

RC701 2401-001052 C-AL;3300UF,20%,25V,GP,16*31.5,7.5M 11609-154-332

UC901 2401-001102 C-AL;330UF,20%,16V,GP,8X11,-,

JC311 2401-001364 C-AL;470UF,20%,16V,GP,10X12MM,5MM,T 11608-103-471

RC711 2401-001552 C-AL;47UF,20%,35V,GP,6.3*11,2.5MM, 11608-105-470

IC17,29,QC518,568,522 2401-001895 C-AL;100UF,20%,16V,GP,6.3X11MM,2.5M

QC523,RC705,704,710,UC904

IC34,RC706,UC905,AC604,654

IC11,13,27,26,5,OC12 2401-001912 C-AL;1UF,20%,50V,GP,5X11MM,2MM,BK

QC501,551,502,552,503,553

QC504,554,521,571

PC1L,1R,2L,2R,AC603,653

QC520,570,RC708,PC1,CC805

KC410

Loc No. New Part No. Description Specification Old Part No.

Electrical Parts List

Samsung Electronics 8-3

Page 30

AC609 2401-001925 C-AL;2200UF,20%,25V,GP,16X25MM,7.5M 11607-104-222

CC802,803,804 2401-001938 C-AL;22UF,20%,25V,GP,5X11MM,2MM,BK

QC509,559 2401-001968 C-AL;470NF,20%,50V,GP,5X11MM,2MM,BK

JC303,353,KC403,453 2401-001975 C-AL;47UF,20%,16V,GP,5X11MM,2MM,BK

CC806,KC431

OTC1,2 2502-000127 C-CERAMIC TRIMMER;20-4.6PF,+50-0%,1 11829-512-030

AL602,652,603,JW64 2701-000114 INDUCTOR-AXIAL;10UH,10%,2.5X3.4MM 12429-411-100

IL1 2701-000116 INDUCTOR-AXIAL;10UH,10%,4.2X9.8MM 12429-508-100

ICF4 2802-000215 RESONATOR-CERAMIC;19KHZ,+-38HZ,-,7. 14539-504-100

ICF1,3 2903-000105 FILTER-CERAMIC;BP,10.7MHZ+-25KHZ 14529-301-753

ICF5 2903-000148 FILTER-CERAMIC;BP,450KHZ+-1KHZ A1243-0049

CCON801 3711-000588 CONNECTOR-HEADER;BOX,10P,1R,2.5MM,S 13349-103-103

FCON1 3711-000820 CONNECTOR-HEADER;BOX,2P,1R,2.5MM,ST 13349-512-561

JCON301,TCON1 3711-000903 CONNECTOR-HEADER;BOX,3P,1R,2.5MM,ST 13349-527-502

PCON1 3711-001011 CONNECTOR-HEADER;BOX,5P,1R,2.5MM,ST 13349-103-053

SCON1 3711-003080 CONNECTOR-HEADER;NOWALL,28P,1R,1.25

JCON302 3711-003110 CONNECTOR-HEADER;BOX,4P,1R,2.5MM,ST

FJ1 3716-000201 TERMINAL-BLOCK;NON SOLDER,4P,4MM,-, A3059-0006

AJ1 3716-000209 TERMINAL-BLOCK;,-,-,60V,7A 13303-500-620

AJ2 3722-000143 JACK-PHONE;1P,3.4MM,MBAG,BLACK,- 13339-101-590

IR6 61048-177-333 R-CARBON;RD 1/8 T 333-J

IIC1 AH14-10002D IC;LA1851N,-,

IT1 AH26-10001C TRANS-IF;KS940228-10,FM,-,7.6X12.0, 12619-020-067

IT2 AH26-10001E TRANS-IF;KS940228-09,-,-,7.6X12.0,- 12619-030-005

OT1 AH26-10001K TRANS-IF;KS940228-02,-,110UH,7.6X12 12619-047-203

KT431 AH26-10002G TRANS-IF;IODT-N5002,BIAS-OSC,3.7MH, 12619-573-071

KLF401,451 AH26-10002Y COIL-TRAP;FB875-85A,BIAS-TRAP,35DB, 12429-306-113

OL1 AH26-10003A COIL-TRAP;KS940228-13,MW-ANT,250UH, 12619-561-000

RCW1 AH39-20008Y LEAD-CONNECTOR ASS’Y;5264,5395,3P,2 13078-473-125

UCW901 AH39-20022G LEAD-CONNECTOR ASS’Y;51004,5295,8P, 16439-0204-00

FEP1 AH40-10001U TUNER;FE337-A05,-,75OHM B1290-0002

AH62-30061A HEAT SINK-S;AL,WHT,-,-,H40,AV330R,- 15684-507-510

AH62-30107A HEAT SINK;-,AL,-,T6.0,-,WHT,-,SCM-6

AH90-10636A ASSY-PCB FRONT;SCM6700,EXP

AH90-30476A ASSY-COM PCB FRONT;SCM6700,EXP

UD4,7,9,11,12 0401-000101 DIODE-SWITCHING;1N4148,100V,200MA,5

UQ2 0501-000303 TR-SMALL SIGNAL;KSA733,PNP,-60V,-50 12149-101-520

UQ1 0501-000398 TR-SMALL SIGNAL;KSC945,NPN,60V,50V, 12149-301-900

LED1,2,3 0601-000141 LED;ROUND,GRN,3.1MM,555NM A4150-0290

UIC2 1003-001029 IC-LCD DRIVER;LC75823E,QFP,64P,17.2

UD10 12169-201-080 DIODE-RECTIFIER;1N 4001,TAPE

UR49 2001-000005 R-CARBON;390OHM,5%,1/8W,AA,TP,1.8X3 11018-877-391

UR12 2001-000010 R-CARBON;68KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-683

UR50,51,52,55 2001-000273 R-CARBON;100KOHM,5%,1/8W,AA,TP,1.8X 11018-877-104

UR24,11,30,17,43,47 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-103

UR25,31,18 2001-000331 R-CARBON;12KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-123

UR33,34,35,38,39,40 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3. 11018-877-102

UR44,57,58,59,60 2001-000449 R-CARBON;2.2KOHM,5%,1/8W,AA,TP,1.8X 11018-877-222

UR45 2001-000515 R-CARBON;220OHM,5%,1/8W,AA,TP,1.8X3 11018-877-221

UR19,32 2001-000522 R-CARBON;22KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-223

UR36,37 2001-000702 R-CARBON;39KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-393

Loc No. New Part No. Description Specification Old Part No.

Electrical Parts List

8-4 Samsung Electronics

Page 31

UR20,21,13,14,6,7 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X 11018-877-472

UR26,27,56,54,53

UR1,2,3,4,5,48 2001-000786 R-CARBON;47KOHM,5%,1/8W,AA,TP,1.8X3 11018-877-473

UR46 2001-000793 R-CARBON;47OHM,5%,1/8W,AA,TP,1.8X3. 11018-877-470

UR8,15,22,28 2001-000890 R-CARBON;6.8KOHM,5%,1/8W,AA,TP,1.8X 11018-877-682

UR9,16,23,29 2001-000977 R-CARBON;8.2KOHM,5%,1/8W,AA,TP,1.8X 11018-877-822

UC13,14 2201-000273 C-CERAMIC,DISC;18PF,5%,50V,NPO,5.0* 11407-057-180

PC1,2 2201-000520 C-CERAMIC,DISC;4.7NF,+80-20%,400VAC 11469-501-070

UC7,4,18 2201-000565 C-CERAMIC,DISC;47NF,20%,50V,Y5V,12. 11417-344-473

UC1,2,5,10 2202-000796 C-CERAMIC,MLC-AXIAL;1NF,10%,50V,Y5P 11449-518-102

UC3,6,8,11,12,17,19 2202-000854 C-CERAMIC,MLC-AXIAL;47NF,0.3,50V,Y5

UC16 2401-000419 C-AL;10UF,20%,16V,GP,5X11,2.5MM,

UC9 2401-001465 C-AL;47UF,20%,10V,GP,5*11,2MM, 11608-102-473

UC15 2409-000123 C-EDL;47000UF,4UA,5.5V,-,-,5MM,BK B1104-0540

UX1 2801-001398 CRYSTAL-UNIT;4.5MHZ,50PPM,28-AAM,12 14539-003-010

FU1,2 3602-000147 FUSE-CLIP;250V,7.5A,30MOHM 13164-101-913

FCW5 3708-000451 CONNECTOR-FPC/FC/PIC;16P,1.25MM,STR B6010-1549

FCW2 3710-001036 CONNECTOR-SOCKET;28P,1R,1.25MM,STRA

PCW1 3711-000190 CONNECTOR-HEADER;1WALL,2P,1R,7.92MM 13349-156-020

PCW2 3711-000898 CONNECTOR-HEADER;BOX,3P,1R,2.5MM,AN 13349-102-030

FCW4 3711-001011 CONNECTOR-HEADER;BOX,5P,1R,2.5MM,ST 13349-103-053

FCW5 3809-000200 CABLE-FLAT;30V,80C,300MM,16P,1.25MM B6032-0070

LAMP1,2,3,4 4713-000158 LAMP-NEON;9V,75MA,0.7W,TRP,3X5.3MM, B4158-0043

LCD1 AH07-10035C LCD-PANNEL;-,LE-0727AP,SCM6700,-

UIC1 AH09-10060Y IC-MCU;LC72362N-9257,80P,QFP,-

PL1,2 AH27-10001F COIL-CHOKE;27UH,K,Q30,-,-,DR(6.5*7. 12429-010-330

FCW3 AH39-20548A LEAD CONNECTOR-ASSY;-,5264,51088,5P

FCW1 AH39-30010A CABLE-IF;-,5264/51088-02,300MM,1365

EYE1 AH59-60001G MODULE-REMOCON;RC-38S2L,38KHZ,-,-,- A1294-0041

LCD1 AH61-20335A HOLDER-CD;ABS,94HB,WHT,T1.5,SCM6700 13323-0263-00

AH67-40024A FILTER-LCD;PC,T0.5,-,-,-,-,WHT,SCM6 10874-0014-00

LAMP1,2,3,4 AH73-10007A RUBBER-CAP;SILICON,-,RCD-1650,GRN

AH90-40355A ASSY-OPT PCB FRONT;SCM6700TCE,SEA

2001-001095 R-CARBON(S);2.2MOHM,5%,1/2W,AA,TP,2 11018-377-225

6202-000111 TUBE-VINYL;-,ID5.2,T0.43,-,CLR,PVC, 10659-413-041

AH26-80140H TRANS-POWER;EI60X30,115/230V,60/50H

AH39-10001S POWER-CORD;EP2,SPT#2/18,2M,SOLDERIN 13059-808-301

AH61-40022A STUD-TAP;SPC1,T0.5,BT2,-,-, 13124-100-710

Loc No. New Code No. Description Specification Old Code No.

Electrical Parts List

Samsung Electronics 8-5

Page 32

G3A8-1/C ASSY-CD PACK;1-CD G3A8 CKD

AH90-10346D ASSY-PCB,CD;G3A8, 19129-0357-03

0202-000152 SOLDER-WIRE FLUX;SV92-8SA,S92,,92SN 10849-740-121

0202-000155 SOLDER-WIRE FLUX;KR19-RMA S60A,S60A A0074-0003

0204-000203 CH-ISOPROPHYL ALCOHO;,C2H50H,99% 10849-405-021

ND200,201,202,203 0401-000101 DIODE-SWITCHING;1N4148,100V,200MA,5

NZD101 0403-000358 DIODE-ZENER;UZ5.6BSB,5.6V,5.46-5.7V 12169-404-790

NQ1502 0501-000323 TR-SMALL SIGNAL;KSB564Y,PNP,-30V,-2 12149-202-050

NQ1501 0501-000610 TR-SMALL SIGNAL;KSA928A,PNP,-30V,-3

NIC9282 0904-000157 IC-DSP;9282,-,QFP,80P,-,16.9344MHZ, A4012-0291

NIC9258 1003-000179 IC-MOTOR DRIVER;KA9258D,SOP,28P,-,S

NIC1641 1003-000298 IC-MOTOR DRIVER;LB1641,SIP,10P,-,-,

NIC9270 1204-000110 IC-AUDIO FILTER;KA9270,SOP,20P,-,PL A4012-0089

NIC9220 1204-000230 IC-SSP;KA9220C,QFP,80P,-,PLASTIC,6V A4012-0290

NR605 2007-000001 R-CHIP;68KOHM,5%,1/10W,DA,TP,2012 11119-101-683

NR606,611,608,609,610 2007-000029 R-CHIP;0OHM,5%,1/10W,DA,TP,2012 11119-101-000

NR47L,47R,104,203,NRD 2007-000282 R-CHIP;100KOHM,5%,1/10W,DA,TP,2012 11119-101-104

NR106,107 2007-000338 R-CHIP;120KOHM,5%,1/10W,DA,TP,2012 11119-101-124

NR41L,41R,204,191,100 2007-000355 R-CHIP;12KOHM,5%,1/10W,DA,TP,2012 11119-101-123

NR190

NR103,119 2007-000395 R-CHIP;150KOHM,5%,1/10W,DA,TP,2012 11119-101-154

NR110 2007-000409 R-CHIP;15KOHM,5%,1/10W,DA,TP,2012 11119-101-153

NR115 2007-000444 R-CHIP;180KOHM,5%,1/10W,DA,TP,2012 11119-101-184

NR102,109,205,45L,45R 2007-000468 R-CHIP;1KOHM,5%,1/10W,DA,TP,2012 11119-101-102

NR42L,42R,114 2007-000477 R-CHIP;1MOHM,5%,1/10W,DA,TP,2012 11119-101-105

NR40L,40R 2007-000586 R-CHIP;22KOHM,5%,1/10W,DA,TP,2012 11119-101-223

NR101 2007-000593 R-CHIP;22OHM,5%,1/10W,DA,TP,2012 11119-101-220

NR43L,43R,200 2007-000653 R-CHIP;27KOHM,5%,1/10W,DA,TP,2012 11119-101-273

NR201,202 2007-000686 R-CHIP;3.3KOHM,5%,1/10W,DA,TP,2012 11119-101-332

NR105 2007-000830 R-CHIP;39KOHM,5%,1/10W,DA,TP,2012 11119-101-393

NR44L,44R,46L,46R 2007-000872 R-CHIP;4.7KOHM,5%,1/10W,DA,TP,2012 11119-101-472

NR117 2007-000898 R-CHIP;430KOHM,5%,1/10W,DA,TP,2012 11119-101-434

NR111,108 2007-000941 R-CHIP;47KOHM,5%,1/10W,DA,TP,2012 11119-101-473

NR112 2007-001039 R-CHIP;56KOHM,5%,1/10W,DA,TP,2012 11119-101-563

NR113 2007-001177 R-CHIP;8.2KOHM,5%,1/10W,DA,TP,2012 11119-101-822

NR116 2007-001195 R-CHIP;820KOHM,5%,1/10W,DA,TP,2012 11119-101-824

NR118 2007-001213 R-CHIP;82OHM,1%,1/10W,DA,TP,2012 11119-102-820

NR555 2008-000141 R-FUSIBLE;2.2OHM,5%,1/4W,AA,TP,2.6X 11058-277-229

NVR1701 2103-000007 VR-SEMI;50KOHM,30%,1/10W,SIDE 11249-102-063

NVR1702,1703,1704 2103-000291 VR-SEMI;20KOHM,30%,1/10W,SIDE 11249-102-043

NC119,120,121,107,108 2203-000199 C-CERAMIC,CHIP;100NF,+80-20%,50V,Z5

NC603

NC205,110,116,102,103 2203-000260 C-CERAMIC,CHIP;10NF,10%,50V,X7R,201 11129-004-103

43R,44L,500,600,601,602

NC700,701

NC1000,1001 2203-000361 C-CERAMIC,CHIP;150PF,5%,50V,NPO,201

NC112 2203-000495 C-CERAMIC,CHIP;2.2NF,10%,50V,X7R,20 11129-004-222

NC118 2203-000787 C-CERAMIC,CHIP;330PF,5%,50V,NPO,201

NC113,125,101 2203-000802 C-CERAMIC,CHIP;33NF,10%,50V,X7R,201 11129-001-333

NC100 2203-000892 C-CERAMIC,CHIP;4.7NF,10%,50V,X7R,20

NC204,124 2203-000925 C-CERAMIC,CHIP;470NF,+80-20%,50V,Y5 11128-018-474

NC200 2203-000979 C-CERAMIC,CHIP;47NF,10%,50V,X7R,201

NC2000 2203-001026 C-CERAMIC,CHIP;4PF,0.25PF,50V,SL,20

Loc No. New Part No. Description Specification Old Part No.

Electrical Parts List

8-6 Samsung Electronics

Page 33

NC45R,46L 2203-001058 C-CERAMIC,CHIP;560PF,5%,50V,NPO,201 11129-019-561

NC111 2203-001105 C-CERAMIC,CHIP;6.8NF,10%,50V,X7R,20 11129-004-682

NC115 2203-001137 C-CERAMIC,CHIP;68NF,+80-20%,50V,Y5V 11129-004-683

NC190 2203-001256 C-CERAMIC,CHIP;8PF,0.25PF,50V,NPO,2

NC109,104,42R,43L 2203-001537 C-CERAMIC,CHIP;1NF,10%,50V,X7R,2012

NC41L,41R 2203-001550 C-CERAMIC,CHIP;1.2NF,10%,50V,X7R,20

NC201 2203-001551 C-CERAMIC,CHIP;1.5NF,10%,50V,X7R,20

NC202,203 2203-001619 C-CERAMIC,CHIP;27PF,5%,50V,NPO,2012

NC702,105 2401-000243 C-AL;100UF,20%,10V,GP,6.3*5,2.5MM,T 11608-152-101

NC114 2401-000419 C-AL;10UF,20%,16V,GP,5X11,2.5MM,

NC703 2401-000778 C-AL;220UF,20%,10V,GP,6.3X11,2.5MM, 11608-102-224

NC700,701 2401-000868 C-AL;220UF,20%,4V,GP,6.3*5,2.5MM,TP 11608-171-221

NC45L,44R,40L,40R,122 2401-001238 C-AL;4.7UF,20%,25V,GP,3*5,1MM,TP 11608-154-479

NC42L 2401-001502 C-AL;47UF,20%,16V,GP,6.3*5,2.5MM,TP 11608-153-470

NC117 2401-001968 C-AL;470NF,20%,50V,GP,5X11MM,2MM,BK

NL100 2703-000002 INDUCTOR-SMD;100UH,10%,2.5X3.2X2MM 11176-600-040

NXF100 2802-000211 RESONATOR-CERAMIC;16.93MHZ,0.5%,TP, 14539-503-083

NS100 3409-000174 SWITCH-LEAF;16VDC,500MA,10GF,SPST 13564-601-100

NCW100 3708-000177 CONNECTOR-FPC/FC/PIC;16P,1.0MM,ANGL A6010-1523

NCW103 3708-000413 CONNECTOR-FPC/FC/PIC;16P,1.25MM,ANG A6010-1525

NCW104 3711-001061 CONNECTOR-HEADER;BOX,6P,1R,2MM,ANGL 13349-139-061

NCW101 3711-001136 CONNECTOR-HEADER;BOX,8P,1R,2MM,ANGL 13349-139-080

3809-000202 CABLE-FLAT;30V,80C,82MM,16P,1MM,UL2 A6032-0066

3811-000130 WIRE-PVC CU;BCWA,300V,60MM,7/0.16MM 13049-011-106

3811-000389 WIRE-NO SHEATH CU;SPCW,300V,52.4MM,

A0074-0004 SOLDER-BAR;DONG YANG S63A 30X400

NIC05 AC14-12001G IC;KA78L05,T,-

AH62-30047A HEAT SINK;ETHD,-,T0.5,-,-,-,MAX-555 11124-0061-00

AH63-40017A SHIELD-PLATE;SPTE,T0.3,-,MM-77,-, 12074-0024-00

Loc No. New Part No. Description Specification Old Part No.

Electrical Parts List

Samsung Electronics 8-7

Page 34

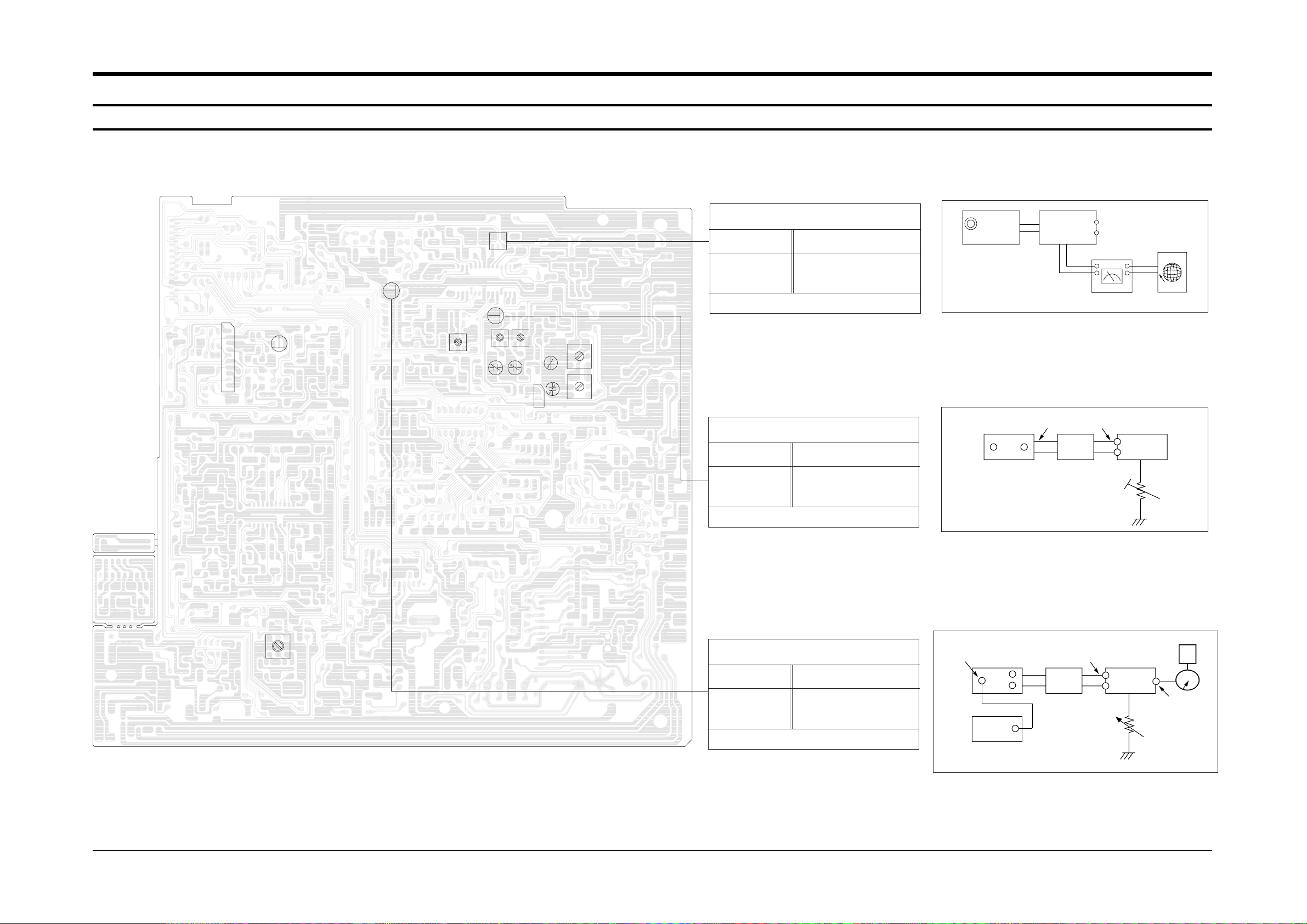

Samsung Electronics 9-1

IIC1

UIC1

JIC1

AIC1

UIC2

LC72362

PLL/CD MICOM

9. Block Diagrams

9-1 Main

Page 35

SLED

MOTOR

SPINDLE

MOTOR

PICK - UP

TRACKING

ACTUATOR

FOCUSING

ACTUATOR

A.B.C.D.E.F

LD.PD

DISC

SP+

SP-

TRK+ TRK-

FCS-

17

18

11 12 26 27 1

2

+5V

19

10

25 3

40

44

48

46

68.69 P/U IN

LIMIT S/W

OPEN/CLOSE MOTOR

2

10

DM- DM+

MOTOR DRIVER

OPEN/CLOSE S/W

8

70.71

74.75

76.77

32.38

11.12.13

25.31

33

27.28.29

30

60

69

52.53 57.56

63

61.62

NVR1704

TE GAIN

NVR1703

FE GAIN

NVR1701

FE-BIAS

NVR1702

EF BAL

MOTOR CONTROL

S/W SENSOR

FOK

MAIN PCB MAIN PCB

MICOM CTRL LINE

POWER / AUDIO LINE

10

1

11

2 19

19

R

G

L

21

20

36.37.38

68

25.26.30

29

10.70.72

73.75.76

27

MCK. MDATA. MLT

ISTAT

SQDT. LKFS. SOS1

SQCK

A. GND

R-CH

L-CH

GND

B+

LD ON

RESET

LOCK.SMEF.WDCH.SMON.SMSD

SL IN

SP IN

TE IN

EF IN

VREF

SL-

SL+

MOTOR/ACTUATOR DRIVER

KA9258

6

NIC 9258

ASSP

KA9220

NIC 9220

NCW103/SCW2

NCW101/SCW1/SCW3

KA9270

NIC9270

KS9282

NIC9282

SIC1,SIC2,SIC3

DIGITAL SIGNAL PROCESSOR

16.9344MHz

65.69

8

EFM.TRCNT

LB1641/BA6209

NCW104

9-2 CD

9-2 Samsung Electronics

Block Diagrams

Page 36

9-3 IC & TR Internal Diagrams

9-3-1 Main

KA22291 : JIC1

LC75823E : UIC2

Samsung Electronics 9-3

23 22 21 8 20 19 18 15

24

16

17

9

1

2 3 4 5 7 6 10

11

12

13

14

PB

NF(2)

PR IN(2)

R/PSWMUTE

SW

MUTE

(IN2)

ALC RECOUT(2)

100K

PRE

RECORD

LREF

PLAYBACK

LREF

PRE

NF

100K

INPUT

PB.BIAS

REC.BIAS

INPUT

N.F

MODE CONTROL

/BIAS CIRCUIT

PU

NF(1)

PB IN(1) A/BSWPB GND MUTE

IN(1)

REC

OUT(1)

PB OUT(1)

REC GND

Vcc

Vcc

PBOUT(2)

100K

PRE

INPUT

N.F

ALC

DET

PRE

N.F

INPUT

REC NF(2)

REC IN(2)

REC IN(1)

REC IN(1)

100K

ALC TIME CONSTANT

R/P SW

A-IN

B-IN

A/B SELECT S/W

A-IN

B-IN

64 63 62 61 60 59 58 57 56 55 54 53 52 51 50 49

DICLCE

OSC

Vss

V

DD 2VDD 1

INH

VDD

COM 3

COM 2

COM 1

S 52

S 51

S 50

S 49

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

S 17

S 18

S 19

S 20

S 21

S 22

S 23

S 24

S 25

S 26

S 27

S 28

S 29

S 30

S 31

S 32

S 1 1

S 2 2

S 3 3

S 4 4

S 5 5

S 6 6

S 7 7

S 8 8

S 9 9

S 10 10

S 11 11

S 12 12

S 13 13

S 14 14

S 15 15

S 16 16

S 48

S 47

S 46

S 45

S 44

S 43

S 42

S 41

S 40

S 39

S 38

S 37

S 36

S 35

S 34

S 33

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

Block Diagrams

Page 37

LC72362N : UIC1

LC75394E : QIC1

9-4 Samsung Electronics

XIN 1

TEST 2 2

SI 0/PG 3 3

SO 0/PG 2 4

SCK 0/PG 1 5

PG 0 6

SI 1/PF 3 7

S0 1/PF 2 8

SCK 1/PF 1 9

PF 0 10

SI 2/PE 3 11

SO 2/PE 2 12

SCK 2/PE 1 13

PE 0 14

PD 3 15

PD 2 16

PD 1 17

PD 0 18

PC 3 19

PC 2 20

PC 1 21

PC 0 22

PB 3 23

PB 2 24

64 PH 2/ADI 2/

63 PH 3/ADI 3

62 PI 0/ADI 4

61 PI 1/ADI 5

60 PJ 0

59 PJ 1

58 PJ 2

57 PJ 3

56 PK 0/INT 0

55 PK 1/INT 1

54 PK 2

53 PK 3

52 PL 0

51 PL 1

50 PL 2

49 PL 3

48 PM 0

47 PM 1

46 PM 2

45 PM 3

44 PN 0/BEEP

43 PN 1

42 PN 2

41 PN 3

PB 1

PB 0

PA 3

PA 2

PA 1

PA 0

Vdd

PQ 0

PP 3

PP 2

PP 1

PP 0

P 03

P 02

P 01

P 00

25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

XOUT

TEST 1

EO 1

EO 2

Vss

FMIN

AMIN

Vdd

SUBPD

EO 3

HCTR

LCTR

SNS

HOLD

PH 0/ADI 0

PH 1/ADI 1

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65

LC72362N

(QIP80E)

I/0

I/0

I/0

0

0

0

I I/0 0 0

0

I/0

I/0

I/0

0

I

I

49RF 3

50RVref

51RINVIN 2

52RTOUT

53RVRIN

54NC

55RVROUT

56Vref

57VDD

58LVROUT

59NC

60LVRIN

61LTOUT

62LINVIN 2

63LVref

64LF 5

1

LF 4C32LF 4C23LF 4C14LF 3C35LF 3C26LF 3C17LF 2C38LF 2C29LF 2C110LF 1C311LF 1C212LF 1C1

13

LTIN

14

LSEL 0

15

LINVIN 1

16

L 4

32 R3

31 NC

30 R 2

29 NC

28 R 1

27 AVss

26 Vss

25 CE

24 DI

23 CL

22 Vss

21 L 1

20 NC

19 L 2

18 NC

17 L 3

48

RF 4C347RF 4C246RF 4C145RF 3C344RF 3C243RF 3C142RF 2C341RF 2C240RF 2C139RF 1C338RF 1C237RF 1C136RTIN35RSEL 034RINVIN 1

33

R 4

LC75394E

Block Diagrams

Page 38

ONON OFFOFF SLEEPSLEEP REP.1REP.1 TUNEDTUNED MONOMONO STEREOSTEREO

1 2 3 4

5 6 7 8

9 10 11 12

13

A-BA-B

AUTOAUTO

KHzKHz

MHz MUTEMHz MUTE

CLASSICCLASSIC POPSPOPS ROCKROCK PROGRAMPROGRAM INTROINTRO RANDOMRANDOM SYNCSYNC HI-DUBBHI-DUBB

OVEROVER

VOLUMEVOLUME

VOLUMEVOLUME

TRACKTRACK

COM 1

COM 2

COM 3

COM 1

COM 2

COM 2

/

/

5a

5b

5c

1

22

/

/

MONO

/

2

23

/

/

6f

6e

COL

3

24

P

6g

6d

4

25

CLASSIC

6a

6b

6c

5

26

7f

7e

PROGRAM

6

27

1f

1i

1e

INTRO

7g

7d

7

28

1h

1g

1d

7a

7b

7c

8

29

1a

1b

1c

/

STEREO

/

9

30

2f

AUTO

KHz

MHz

10

31

2h

2g

2d

MUTE

RANDOM

11

32

2a

2b

2c

12

33

3f

3e

2j

13

34

3h

3g

3d

14

35

3a

3b

3c

15

36

SLEEP

1

REP

SYNC

HI-DUBB

OVER

16

37

4f

4e

3j

S1

S2

S3

17

38

4g

4d

S4

S5

18

39

4a

4b

4c

S6

S7

S8

19

40

5f

5e

4hj

S9

S10

A-B

20

41

5j

5g

5d

21

TUNEDTUNED

ONON

OFFOFF

TRACK

POPS

2e

4

3

2

7

6

1

5 10

9

8

12

13

11

ROCK

VOLUME

com1

com3

com2

LCD : LCD1

Samsung Electronics 9-5

Block Diagrams

Page 39

3 2

OUT1 OUT2

VCC2

8 10 9 7

P1 P2 VCC1

4

V2

6

IN2IN1

GND

5

1

LB1641

Input logic circuit

Predriver

LB1641/BA6209

1 2 3 4 5

6 7

8

9

10

12 1113

14

15

16

17

1819

2 0

LPF

OUTPUT2

LPF28 V

REF

RIPPLE

DE-EMPHA

CTL

DE-EMPHA

OUT2

DE-EMPHA

IN2

BUFFER

OUT2

INPUT2

LPF2

LPF1

GND LPF

OUTPUT1

LPF1B MUTE

CONTROL

INPUT

DE-EMPHA

CONTROL

INPUT

DE-EMPHA

CTL

DE-EMPHA

OUT1

DE-EMPHA

IN1

BUFFER

OUT1

INPUT1

1/2Vcc-AMP

Vcc

DE-AMP2

DE-AMP1

BUFFER2

BUFFER1

MUTE

SW

DE-EM

SW

28 27 26 25 24 23 22 21 20 19 18 17 16 15

1 2 3 4 5 6 7 8 9 10 11 12 13 14

LEVEL

SHIFT

LEVEL

SHIFT

BUY

10K

10K

REGULATOR

10K

MUTE

50K

50K

10K

LEVEL

SHIFT

LEVEL

SHIFT

10K

BUY

T S D

10K

BUY

LB1641/BA6209(MOTOR DRIVER) : NIC1641

KA9270 : NIC9270

KA9258 : NIC9258

TR 1 2 3

KSR1003 E C B

A928

* NOTE : KSB564 ='EBC' TYPE

1

2

3

9-6 Samsung Electronics

Block Diagrams

9-3-2 CD

Page 40

Block Diagrams

22 35 28 38 37 84 27 28 20 30 9 32 34 6 33 7 3 2 5 8 41 40 39 42

24

21

23

36

14

31

12

13

25

55

43

44

11

59

4

60

65 66 67 78 70 71 75 74 69 73 74 76 62 61 68 79 80 1 33 57 56 19 18 17

10

54

47

48

72

15

16

50

51

52

53

49

20

58

45

46

– +

– +

– +

– +

– +

FVC

VREOI

VREO

FBM

N/C

LOCK

SMPD

SMON

SMEF

DVCC (S)

SPDI

SPDLO

WDCH

FOK

N/C

LDON

AVCC (S)

TDFCT

TKEI

TKEO

AVCC(RF)

TGSW

RTG

ATS

TZC

TE2

TE1

N/C

FSCH

FDFCT

FCE

FSEO

TEST2

SLEN

SLEO

SLEI

SLSTP

N/C

CPH

CBH

PFSET

ISTAT

N/C

AVEE (S)

TRCNT

DIRC

RESET

MDAT

MLT

MCK

DVEE (S)

AASC

EFMO

BPF

APDI

ISET

LFR

FSW

HF GO

FE2

FE1

FBIAS

AVEE (RF)

DCC1

DCC2

RV

EI

EO

F

E

N/C

CV

PD2

PD1

PD

LD

P/N

RF

RFO

RFI

LOQP

FILTER

EFM

COMPARATOR

VREO & VIC

VCO

1-TIME

VCO

2-TIMES

TTL TO COMS

COMS

TO

TTL

CLV

LPF

MICOM TO SERVO CONTROL

AUTO SEQUENCER

FS1 TG4

TG1 TG2

FM1 TG7

PS1 TG2

DEFECT AMP

& COMPARATOR

DEFECT AMP

& COMPARATOR

ARC AMP

RF AMP

FOCUS

ERROR AMP

FOCUS

PHASE

COMPENSATION

TRACKING

ERROR AMP

WINDOW

COMPARATOR

TRACKING

PHASE

COMPENSATION

MIROR

AMP

&

COMPA

-RATOR

KA9220(ASSP) : NIC9220

Samsung Electronics 9-7

Page 41

Block Diagrams

68

69

37

36

9

8

70

76

75

73

72

2

4

3

5

80

78

67

66

26 32 33

7 19 206564636261

16

17

22

23

31

30

EFMI

APDO

VCOI1

VCOI2

CNTVOL

DPFIN

DPF OUT

DPDO

SMEF

SMON

SMDP

SMSD

LOCK

XIN

XOUT

MLT

MDAT

MCK

38

TRCNT

/ISTAT

SQDT

SQOK

VREFH2

VREFH1

VREFL1

VREFL1

LCHOUT

RCHOUT

DATX

TEST

SEL4

SEL3

SEL2

SEL1

SOS1

SBCK

SDAT

SUBCODE

SYNC

DETECTOR

SUBCODE

OUTPUT

SUBCODE Q

REGISTER

EFM

MODULATOR

23 BITS

SHIFT

REGISTER

EFM

PHASE

DETECTOR

DPLL

C L V

SERVO

E C C

10K SRAM

3RAM

ADDRESS

GENERATOR

DIGITAL

FILTER (BFS)

D A C

DIGITAL

OUTPUT

X' TAL