Samsung SCC-B2335 - Super High-Resolution WDR Day/Night Camera, SCC-B2033P(N), SCC-B2035P(N), SCC-B2333P(N), SCC-B2335P(N) Service Manual

CCTV CAMERA

SERVICE

1. Precautions

2. Product Specification

3. Disassembly and Reassembly

4. Trouble Shooting

5. Exploded View and Parts List

6. PCB Diagrams

7. Schematic Diagrams

Manual

CCTV CAMERA Contents

SERVICE MANUAL SCC-B2033, SCC-B2035, SCC-B2333, SCC-B2335

© Samsung Electronics Co., Ltd. MAR.2009

Printed in Korea

This Service Manual is a property of Samsung Electronics Co .,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

BASIC : SCC-B2335

Application Model

: SCC-B2033P(N)

SCC-B2035P(N)

SCC-B2333P(N)

SCC-B2335P(N)

Application Area

:

ARG, BEN, BOK, CHN, CZC, DRA, DSC,

ESP, GAR, GBR, GVI, JPK, JPN, KOD,

LAT, LOT, MOC, RUS, SAP, SAU, TRK,

UMG, XAA, XAX, XEC, XEF, XEG, XEO,

XET, XEV

If you want to know additional information which is not includ-

ed on this Service Manual, Please refer to the SKP(Samsung

Knowledge Portal) web site.

Area Web Site

North America URL ; http://service.samsungportal.com

Latin America URL ; http://latin.samsungportal.com

CIS URL ; http://cis.samsungportal.com

Europe URL ; http://europe.samsungportal.com

China URL ; http://china.samsungportal.com

Asia URL ; http://asia.samsungportal.com

Mideast & Africa URL ; http://mea.samsungportal.com

1. Precautions 1-1 ~ 1-4

1-1 Safety Precautions (1-1)

1-2 Servicing Precautions (1-3)

1-3 ESD Precautions (1-4)

2. Product Specication 2-1 ~ 2-10

2-1 Product Specication (2-1)

2-2 Chassis Product Specication (2-7)

2-4 Option Product Specication (2-9)

3. Disassembly and Reassembly 3-1 ~ 3-6

3-1 Cabinet and PCB (3-1)

4. Trouble Shooting 4-1 ~ 4-16

4-1 Trouble Shooting (4-2)

4-2 Alignment & Adjustment (4-9)

4-2 Software Update (4-13)

5. Exploded View and Parts List 5-1 ~ 5-6

5-1 Cabinet Assembly (5-2)

5-2 Electrical Parts List (5-4)

6. PCB Diagrams 6-1 ~ 6-10

6-1 Wiring Diagram (6-2)

6-2 CCD PCB (6-4)

6-3 REAR PCB (6-6)

6-4 POWER 24 PCB (6-8)

7. Schematic Diagrams 7-1 ~ 7-22

7-1 All block Diagram (7-2)

7-2 Power Distribution Diagram (7-3)

7-3 Power (Power PCB) (7-4)

7-4 A1 DSP (CCD PCB) (7-5)

7-5 CCD (CCD PCB) (7-6)

7-6 CDS_AGC_A/D (CCD PCB) (7-7)

7-7 Day_Night (CCD PCB) (7-8)

7-8 EEPROM (CCD PCB) (7-9)

7-9 H-Drive (CCD PCB) (7-10)

7-10 I/O (CCD PCB) (7-11)

7-11 IRIS Control (CCD PCB) (7-12)

7-12 Motor Drive (CCD PCB) (7-13)

7-13 Regulator (CCD PCB) (7-14)

7-14 Reset (CCD PCB) (7-15)

7-15 RS-485 (CCD PCB) (7-16)

7-16 UTP (CCD PCB) (7-17)

7-17 V-Drive (CCD PCB) (7-18)

7-18 Video (CCD PCB) (7-19)

7-19 Video Communication (CCD PCB)) (7-20)

7-20 UTP 1/1 (REAR PCB) (7-21)

7-21 UTP 1/2 (REAR PCB) (7-22)

CONTENTS CONTENTS

1. Precautions

1-1 Safety Precautions

Samsung electronics 1-1

1) Before returning an instrument to the customer,

always

make a safety check of the entire instrument,

including, but not limited to, the following items:

(1) Be sure that no built-in protective devices are

defective or have been defeated during servicing.

(1)Protective shields are provided to protect both

the technician and the customer. Correctly replace

all missing protective shields, including any

removed for servicing convenience.

(2)When reinstalling the chassis and/or other

assembly in the cabinet, be sure to put back in place

all protective devices, including, but not limited to,

nonmetallic control knobs, insulating fish papers,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not operate

this instrument or permit it to be operated without

all protective devices correctly installed and

functioning.

(2) Be sure that there are no cabinet openings through

which adults or children might be able to insert

their fingers and contact a hazardous voltage. Such

openings include, but are not limited to, excessively

wide cabinet ventilation slots, and an improperly

fitted and/or incorrectly secured cabinet back

cover.

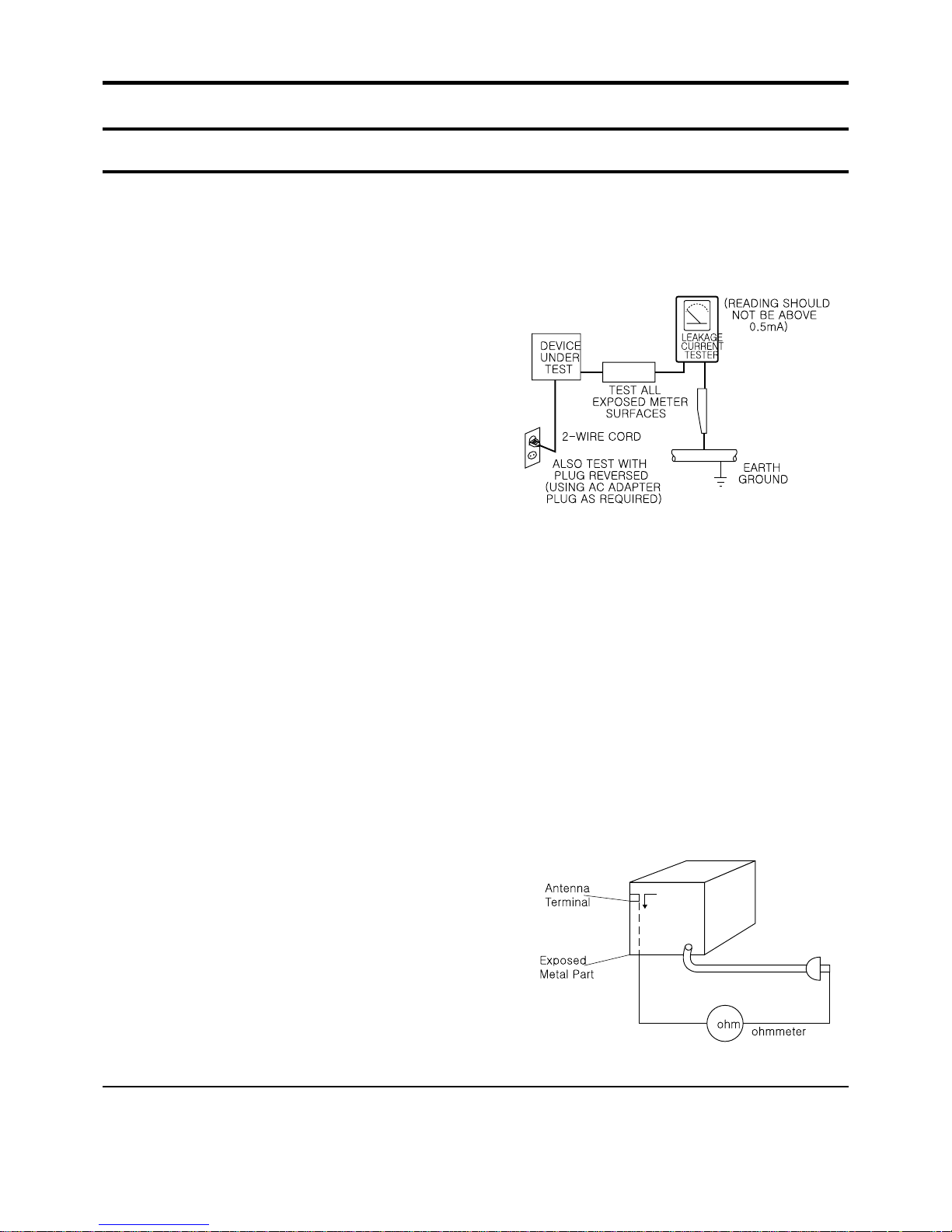

(3) Leakage Current Hot Check-With the instrument

completely reassembled, plug the AC line cord

directly into a 230V(220V ~ 240V) AC outlet. (Do

not use an isolation transformer during this test.)

Use a leakage current tester or a metering system

that complies with American National Standardsp

institute (ANSI) C101.1 Leakage Current for

Appliances and Underwriters Laboratories (UL)

1270 (40.7). With the instrument’s AC switch first in

the ON position and then in the OFF position,

measure from a known earth ground

(metal water pipe,

conduit, etc.) to all exposed metal parts of the

instrument (antennas, handle brackets, metal

cabinets,

screwheads, metallic overlays, control shafts,

etc.), especially any exposed metal parts that offer

an electrical return path to the chassis.

Any current measured must not exceed 0.5mA.

Reverse the instrument power cord plug in the outlet

and repeat the test. See Fig. 1-1.

Any measurements not within the limits specified

herein indicate a potential shock hazard that must

be eliminated before returning the instrument to

the customer.

Fig. 1-1 AC Leakage Test

(4) Insulation Resistance Test Cold Check-(1) Unplug

the power supply cord and connect a jumper wire

between the two prongs of the plug. (2) Turn on the

power switch of the instrument. (3) Measure the

resistance with an ohmmeter between the

jumpered AC plug and all exposed metallic cabinet

parts on the instrument, such as screwheads,

antenna, control shafts, handle brackets, etc. When

an exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2

megohm. When there is no return path to the chassis,

the reading must be infinite. If the reading is

not within the limits specified, there is the possibility

of a shock hazard, and the instrument must be

repaired and rechecked before it is returned to the

customer. See Fig. 1-2.

Fig. 1-2 Insulation Resistance Test

Precautions

1-2 Samsung Electronics

2) Read and comply with all caution and safety related

notes on or inside the cabinet, or on the chassis.

3) Design Alteration Warning-Do not alter or add to

the mechanical or electrical design of this

instrument.

Design alterations and additions, including

butnotlimitedto,circuitmodicationsandthe

addition of items such as auxiliary audio output

connections, might alter the safety characteristics of

this instrument and create a hazard to the user. Any

design alterations or additions will make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

4) Observe original lead dress. Take extra care to

assure correct lead dress in the following areas:

(1) near sharp edges, (2) near thermally hot parts (be

sure that leads and components do not touch

thermally

hot parts), (3) the AC supply, (4) high voltage,

and (5) antenna wiring. Always inspect in all areas

for pinched, out-of-place, or frayed wiring, Do not

change spacing between a component and the

printed-circuit board. Check the AC power cord for

damage.

5) Components, parts, and/or wiring that appear to

have overheated or that are otherwise damaged

should be replaced with components, parts and/ or

wiringthatmeetoriginalspecications.

Additionally, determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

6) Product Safety Notice-Some electrical and mechanical

parts have special safety-related characteristics

which are often not evident from visual inspection,

nor can the protection they give necessarily be

obtained by replacing them with components rated

for higher voltage, wattage, etc. Parts that have

specialsafetycharacteristicsareidentiedby

shading,

an ( )or a ( )on schematics and parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacementpartmightcreateshock,reand/or

other hazards. Product safety is under review

continuously and new instructions are issued

whenever appropriate.

Samsung Electronics 1-3

Precautions

1-2 Servicing Precautions

CAUTION : Before servicing units covered by this

service manual and its supplements, read and follow

the Safety Precautions section of this manual.

Note:Ifunforseencircumstancescreateconict

between the following servicing precautions and any

of the safety precautions, always follow the safety precautions.

Remember: Safety First.

1-2-1 General Servicing Precautions

(1) a. Always unplug the instrument’s AC powercord

from the AC power source before (1) re-moving

or reinstalling any component, circuit board,

module or any other instrument assembly, (2)

disconnecting any instrument electrical plug or

other electrical connection, (3) connecting a test

substitute in parallel with an electrolytic ca

pacitor in the instrument.

b. Do not defeat any plug/socket B+ voltage

interlocks with which instruments covered by

this service manual might be equipped.

c. Do not apply AC power to this instrument and

/or any of its electrical assemblies unless all

solid-state device heat sinks are correctly installed.

d. Always connect a test instrument’s ground lead

to the instrument chassis ground before connecting

the test instrument positive lead. Always

remove the test instrument ground lead last.

Note : Refer to the Safety Precautions section ground

lead last.

(2) The service precautions are indicated or printed on

the cabinet, chassis or components. When servicing,

follow the printed or indicated service precautions

and service materials.

(3)Thecomponentsusedintheunithaveaspecied

ameresistanceanddielectricstrength.

When replacing components, use components

whichhavethesameratings.Componentsidentied

by shading, by( ) or by ( ) in the circuit diagram

are important for safety or for the characteristics

of the unit. Always replace them with the exact

replacement components.

(4) An insulation tube or tape is sometimes used and

some components are raised above the printed

wiring board for safety. The internal wiring is

sometimes clamped to prevent contact with heating

components. Install such elements as they

were.

(5) After servicing, always check that the removed

screws, components, and wiring have been installed

correctly and that the portion around the

serviced part has not been damaged and so on.

Further, check the insulation between the blades of

the attachment plug and accessible conductive

parts.

1-2-2 Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet

and turn the power ON. Connect the insulation resistance meter (500V) to the blades of the attachment

plug. The insulation resistance between each blade of

the attachment plug and accessible conductive

parts(see note) should be more than 1 Megohm.

Note : Accessible conductive parts include metal panels,

input terminals, earphone jacks, etc.

Precautions

1-4 Samsung Electronics

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damagedeasily by static electricity.

Such components commonly are called Electrostatically Sensitive Devices(ESD). Examples of typical ESD

devicesareintegratedcircuitsandsomeeld-effect

transistors and semiconductor chip components. The

following techniques should be used to help reduce

the incidence of component damage caused by static

electricity.

(1) Immediately before handling any semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic charge on your body by

touching a known earth ground. Alternatively,

obtain and wear a commercially available

discharging wrist strap device, which should be

removed for potential shock reasons prior to

applying power to the unit under test.

(2) After removing an electrical assembly equipped

with ESD devices, place the assembly on a

conductive surface such as aluminum foil, to

prevent electrostatic

charge buildup or exposure of the assembly.

(3) Use only a grounded-tip soldering iron to solder or

unsolder ESD devices.

(4) Use only an anti-static solder removal devices.

Somesolderremovaldevicesnotclassiedas

“anti-static”cangenerateelectricalchargessuf

cient to damage ESD devices.

(5) Do not use freon-propelled chemicals. These can

generateelectricalchargessufcienttodamage

ESD devices.

(6) Do not remove a replacement ESD device from its

protective package until immediately before your

are ready to install it.(Most replacement ESD

devices are packaged with leads electrically shorted

together by conductive foam, aluminum foil or

comparable conductive materials).

(7) Immediately before removing the protective

materials from the leads of a replacement ESD

device, touch the protective material to the

chassis or circuit assembly into which the device

will be installed.

CAUTION : Be sure no power is applied to the chassis

or circuit, and observe all other safety precautions.

(8) Minimize bodily motions when handling

unpackaged replacement ESD devices.

(Otherwise harmless

motion such as the brushing together of your

clothes fabric or the lifting of your foot from a

carpetedoorcangeneratestaticelectricity

sufcienttodamageanESDdevice).

1-3 ESD Precautions

2. Product Specication

2-1 Product Specication

Samsung Electronics 2-1

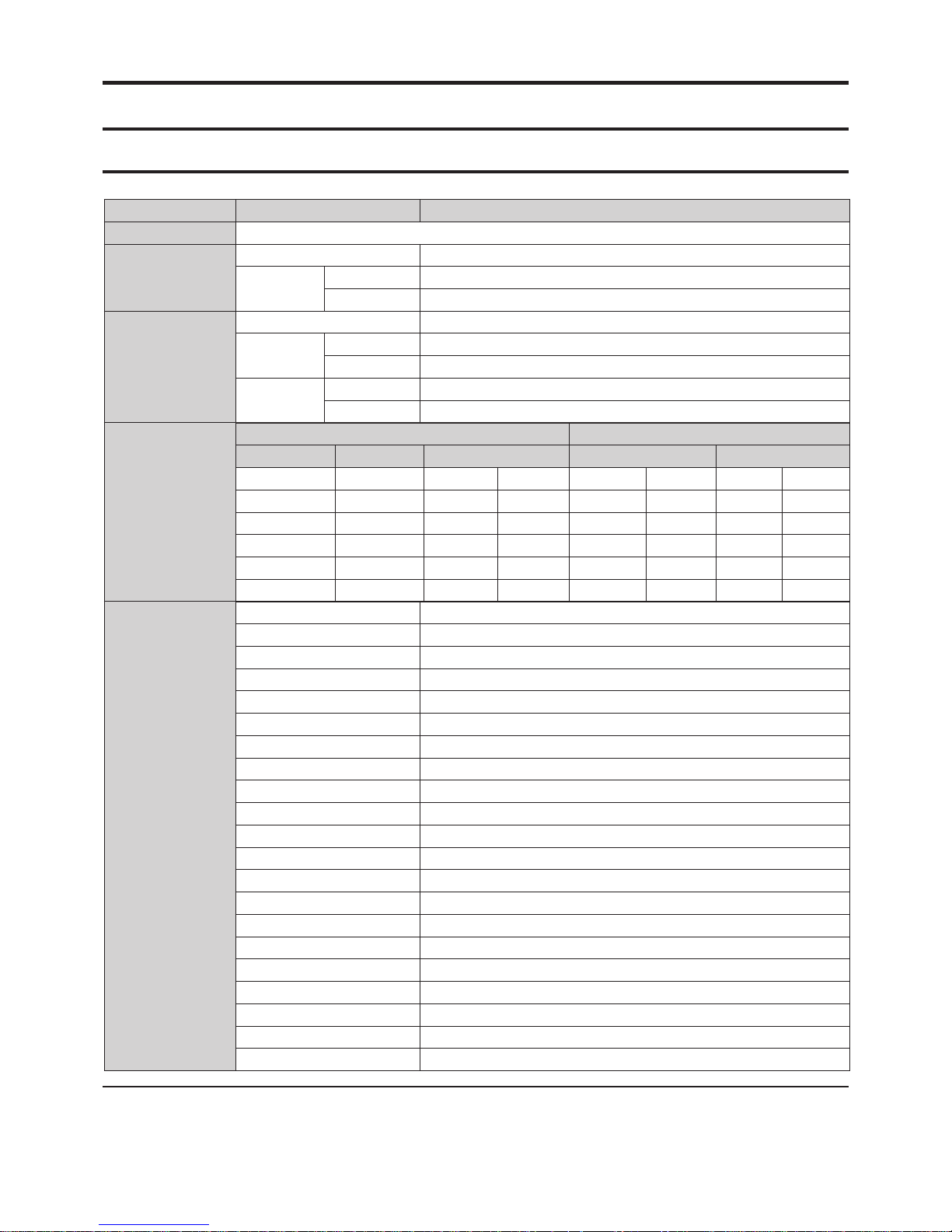

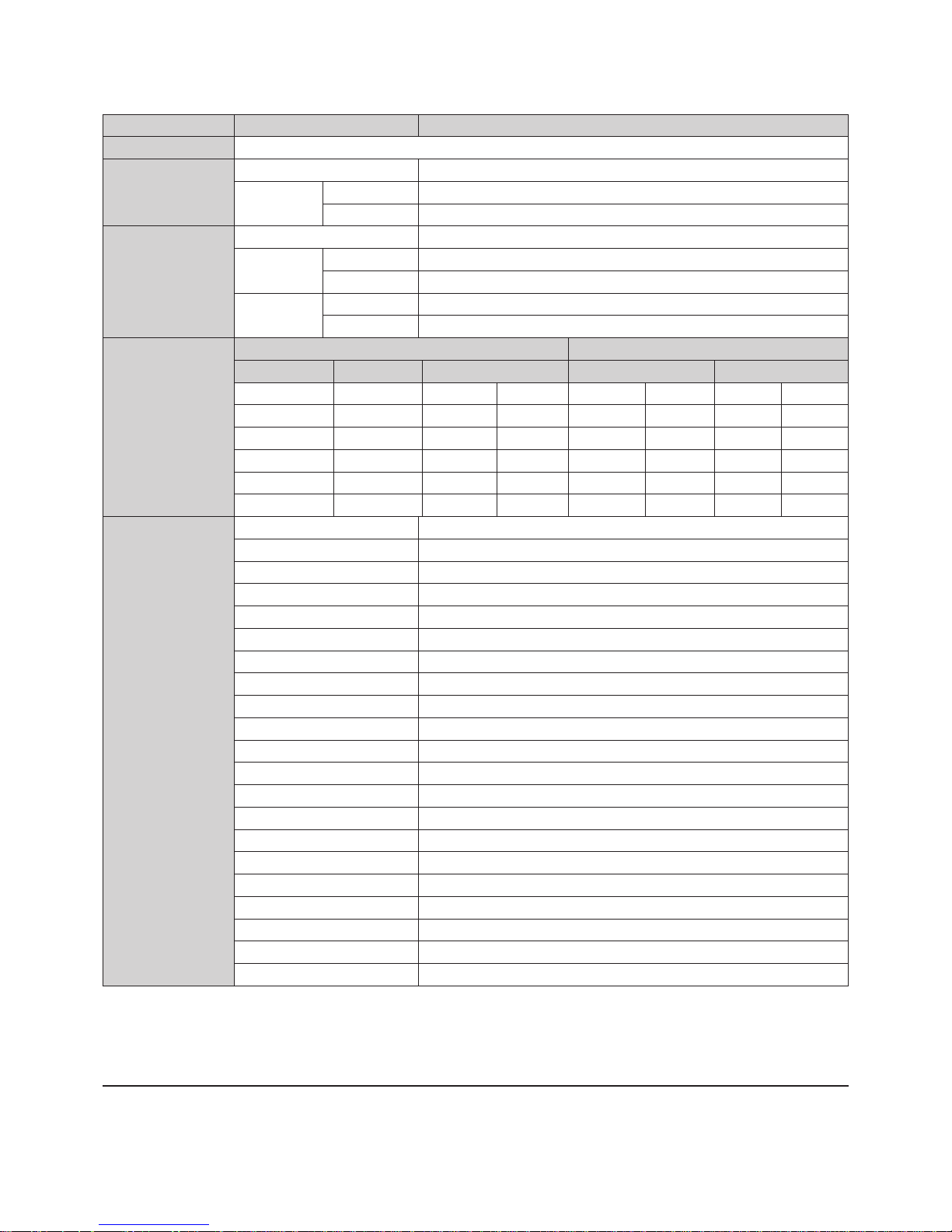

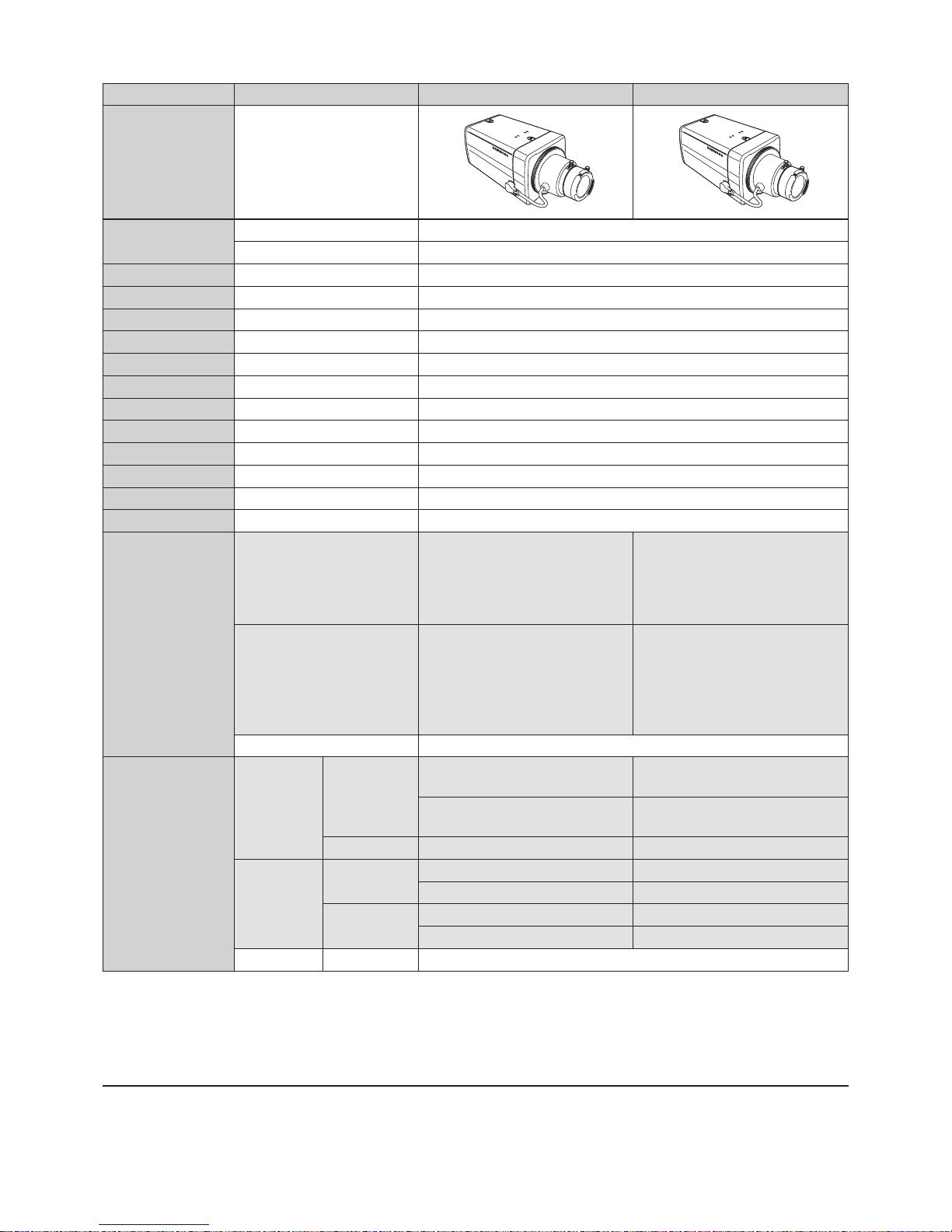

Item Sub-items SCC-B2333P / SCC-B2033P

Camera Type CCTV Camera (DAY/NIGHT)

Image

Device 1/3” Super-HAD IT CCD

Pixels

Total 795 x 596

Effective 752 x 582

Scanning

System

Interlace

Horizontal

Frequency

Internal Mode 15,625 Hz

Line-lock Mode 15,625 Hz

Vertical

Frequency

Internal Mode 50 Hz

Line-lock Mode 50 Hz

Min. Scene

Illumination

Functions

Number of Privacy Zone 12 (Polygonal Method)

Day/Night DAY/NIGHT/AUTO/EXT

Motion Detection OFF/Tracking/Detection

eXtended Dynamic Range(XDR) Off/On (Level Setting)

Wide Dynamic Range(WDR) Off/On (x160)

Virtual Progressive Scan(VPS) Off/On

D-Zoom Max. x16

PIP Off/On

High Speed Shutter 1/50 ~ 1/10Ksec (OSD/External Control)

Flickerless Off/On

Sens-Up x2 ~ x512

BLC Off/On (Area Setting)

AGC Off/On (Max.Level Setting)

ELC Off/On ( ~ 1/200K sec)

Line Lock Off/On (Phase Control)

Camera ID Off/On (Max.54ea/2Line)

White Balance ATW1/ATW2/AWC/3200K/5600K

Digital Noise Reduction(DNR) Off/On (Adaptive 3D+2D)

Digital Image Stabilization(DIS) Off/On

Intelligent Video Fixed/Moved, Fence

Etc. Function Detail, Reverse(H/V), Posi/Nega

2-1-1 SCC-B2033/B2333

Condition Min. Scene illumination

Sens-up F No. Level DAY NIGHT

OFF 1.2 50 IRE 0.4 Lux 0.4 Lux

OFF 1.2 30 IRE 0.24 Lux 0.24 Lux

OFF 1.2 15 IRE 0.12 Lux 0.12 Lux

512 times 1.2 50 IRE 0.0008 Lux 0.0008 Lux

512 times 1.2 30 IRE 0.00047 Lux 0.00047 Lux

512 times 1.2 15 IRE 0.00023 Lux 0.00023 Lux

Product Specication

2-2 Samsung Electronics

Resolution

Horizontal 600 TV Lines

Vertical 350 TV Lines

Video Output - VBS 1.0Vp-p, 75 Ω

S/N Ratio S/N Ratio Approx. 52dB

Lens

Lens Drive Type MANUAL/AI(VIDEO/DC)

Mount Type CS/C

Alarm

Input N/A

Output 1 Output

Remote

Control

Coaxitron (Data On Coax cable) Yes (with SCX-RD100)

RS-485 Yes (Multi Protocol, 8ea)

Environmental Operating Temperature -10°C ~ +50°C

Conditions Humidity Less than 90%

Power

Power Requirement

SCC-B2333P : AC24V ± 10%(50Hz±0.3Hz)

DC12V ± 10%

SCC-B2033P : AC220V ± 10%(50Hz±0.3Hz)

Power Consumption

(With DC Lens)

In Normal operation :

SCC-B2333P : 2.3W

SCC-B2033P : 2.9W

In switching the DAY/NIGHT fi lter :

SCC-B2333P :2.8W

SCC-B2033P : 3.4W

LED Indicator Yes

Physical

Specifi cation

Dimensions

(WxHxD)

Net

SCC-B2333P : 64(W) x 58(H) x 109.2(D) mm

SCC-B2033P : 64(W) x 58(H) x 129.2(D) mm

Package 173(W) x 99(H) x 115(D) mm

Weight

Net

SCC-B2333P : Approx. 305g

SCC-B2033P : Approx. 395g

Package

SCC-B2333P : Approx. 530g

SCC-B2033P : Approx. 620g

Color Body Silver

Samsung Electronics 2-3

Product Specication

2-1-2 Key Feature

q High Resolution

This camera has realized high resolution of 600 lines using the top-notch full digital image processing and

special algorithm technologies.

q Intelligent Motion Detection & Tracking

This is an intelligent function that automatically detects a motion of an object. You can set a virtual fence so it

sounds an alert if an object passes / enters /exits the virtual fence or virtual area.

q XDR (eXtended Dynamic Range)

Actively controls the gamma compensation in the way it operates the ambient luminance contrast in a certain pixel unit to

determine the optimal visibility.

q DAY/NIGHT

This function can make the IR Cut ltering function inactive under the illumination below the normal value.

q High Sensitivity

It implements images of high sensitivity using the up-to-date SONY Super-HAD IT CCD..

q Low Illumination

It uses the digital signal technologies such as low illumination and Day/Night functions that make your camera identify

objects even in the worst environment.

q Superior Backlight Adjustment

When an object has a bright illumination or sunlight behind it, this camera automatically improves the shaded

object picture quality.

q Digital Power Synchronization

The full digital Line Lock function directly adjusts the vertical camera synchronization to enhance the operationability and

reliability of this camera.

q Output Signal Setting

You can set the following Video output signals: Image reversion (Horizontal, Vertical, or both), Privacy,

Horizontal/Vertical pro ling, and digital zooming.

q OSD(On Screen Display) Menu

OSD menu is provided to display the status of camera and to con gure the functions interactively.

q Coaxial Cable Communication

This is a remote control function that overlaps the coaxial cable (for a transfer of the video signal) with the

control signal. In installation or repair, this helps you control the communication controller (optional) without additional cabling.

Product Specication

2-4 Samsung Electronics

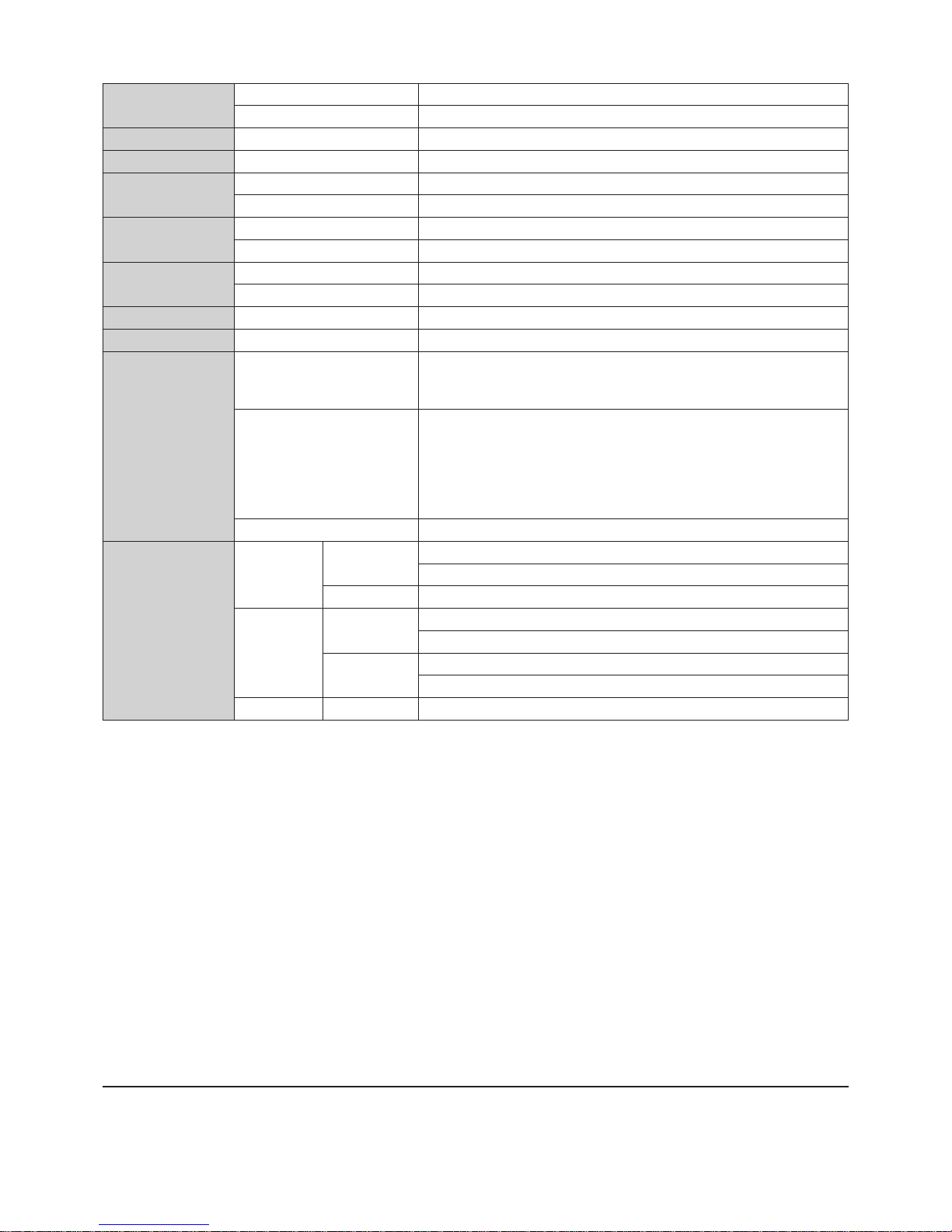

2-1-3 SCC-B2035/B2335

Item Sub-items SCC-B2035P / SCC-B2335P

Camera Type CCTV Camera (WDR & DAY/NIGHT)

Image

Device 1/3” Super-HAD IT CCD

Pixels

Total 795 x 596

Effective 752 x 582

Scanning

System

Interlace/Progressive

Horizontal

Frequency

Internal Mode 15,625 Hz

Line-lock Mode 15,625 Hz

Vertical

Frequency

Internal Mode 50 Hz

Line-lock Mode 50 Hz

Min. Scene

Illumination

Functions

Number of Privacy Zone 12 (Polygonal Method)

Day/Night DAY/NIGHT/AUTO/EXT

Motion Detection OFF/Tracking/Detection

eXtended Dynamic Range(XDR) Off/On (Level Setting)

Wide Dynamic Range(WDR) Off/On (x160)

Virtual Progressive Scan(VPS) Off/On

D-Zoom Max. x16

PIP Off/On

High Speed Shutter 1/50 ~ 1/10Ksec (OSD/External Control)

Flickerless Off/On

Sens-Up x2 ~ x512

BLC Off/On (Area Setting)

AGC Off/On (Max.Level Setting)

ELC Off/On ( ~ 1/200K sec)

Line Lock Off/On (Phase Control)

Camera ID Off/On (Max.54ea/2Line)

White Balance ATW1/ATW2/AWC/3200K/5600K

Digital Noise Reduction(DNR) Off/On (Adaptive 3D+2D)

Digital Image Stabilization(DIS) Off/On

Intelligent Video Fixed/Moved, Fence

Etc. Function Detail, Reverse(H/V), Posi/Nega

Condition Min. Scene illumination

Sens-up F No. Level DAY NIGHT

OFF 1.2 50 IRE 0.4 Lux 0.4 Lux

OFF 1.2 30 IRE 0.24 Lux 0.24 Lux

OFF 1.2 15 IRE 0.12 Lux 0.12 Lux

512 times 1.2 50 IRE 0.0008 Lux 0.0008 Lux

512 times 1.2 30 IRE 0.00047 Lux 0.00047 Lux

512 times 1.2 15 IRE 0.00023 Lux 0.00023 Lux

Samsung Electronics 2-5

Product Specication

Resolution

Horizontal 600 TV Lines

Vertical 350 TV Lines

Video Output - VBS 1.0Vp-p, 75 Ω

S/N Ratio S/N Ratio Approx. 52dB

Lens

Lens Drive Type MANUAL/AI(VIDEO/DC)

Mount Type CS/C

Alarm

Input N/A

Output 1 Output

Remote

Control

Coaxitron (Data On Coax cable) Yes (with SCX-RD100)

RS-485 Yes (Multi Protocol, 8ea)

Environmental Operating Temperature -10°C ~ +50°C

Conditions Humidity Less than 90%

Power

Power Requirement

SCC-B2335P : AC24V ± 10%(50Hz±0.3Hz)

DC12V ± 10%

SCC-B2035P : AC220V ± 10%(50Hz±0.3Hz)

Power Consumption

(With DC Lens)

In Normal operation :

SCC-B2335P : 2.6W

SCC-B2035P : 3.3W

In switching the DAY/NIGHT fi lter :

SCC-B2335P :3 .2W

SCC-B2035P : 3.8W

LED Indicator Yes

Physical

Specifi cation

Dimensions

(WxHxD)

Net

SCC-B2335P : 64(W) x 58(H) x 109.2(D) mm

SCC-B2035P : 64(W) x 58(H) x 129.2(D) mm

Package 173(W) x 99(H) x 115(D) mm

Weight

Net

SCC-B2335P : Approx. 305g

SCC-B2035P : Approx. 395g

Package

SCC-B2335P : Approx. 530g

SCC-B2035P : Approx. 620g

Color Body Silver

Product Specication

2-6 Samsung Electronics

2-1-4 Key Feature

q High Resolution

This camera has realized high resolution of 600 lines using the top-notch full digital image processing and

special algorithm technologies.

q VPS(Virtual Progressive Scan)

This is an advanced technology that reproduces a sharp progressive image. This is appropriate to high

quality recording and le transfer via the Internet.

q Intelligent Motion Detection & Tracking

This is an intelligent function that automatically detects a motion of an object. You can set a virtual fence so it

sounds an alert if an object passes / enters /exits the virtual fence or virtual area.

q WDR

WDR extends the contrast range as it takes a picture of each of dark and bright areas before compositing

the two, which is useful if you take a picture of windows inside a building. Namely, it improves the picture

quality of the outdoor scenery as well as indoor.

q XDR (eXtended Dynamic Range)

Actively controls the gamma compensation in the way it operates the ambient luminance contrast in a

certain pixel unit to determine the optimal visibility.

q DAY/NIGHT

This function can make the IR Cut ltering function inactive under the illumination below the normal value.

q High Sensitivity

It implements images of high sensitivity using the up-to-date SONY Super-HAD Progressive CCD.

q Low Illumination

It uses the digital signal technologies such as low illumination and Day/Night functions that make your camera

identify objects even in the worst environment.

q Superior Backlight Adjustment

When an object has a bright illumination or sunlight behind it, this camera automatically improves the

shaded object picture quality.

q Digital Power Synchronization

The full digital Line Lock function directly adjusts the vertical camera synchronization to enhance the

operationability and reliability of this camera.

q Output Signal Setting

You can set the following Video output signals: Image reversion (Horizontal, Vertical, or both), Privacy,

Horizontal/Vertical pro ling, and digital zooming.

q OSD(On Screen Display) Menu

OSD menu is provided to display the status of camera and to con gure the functions interactively.

q Coaxial Cable Communication

This is a remote control function that overlaps the coaxial cable (for a transfer of the video signal) with the

control signal. In installation or repair, this helps you control the communication controller (optional) without

additional cabling.

Samsung Electronics 2-7

Product Specication

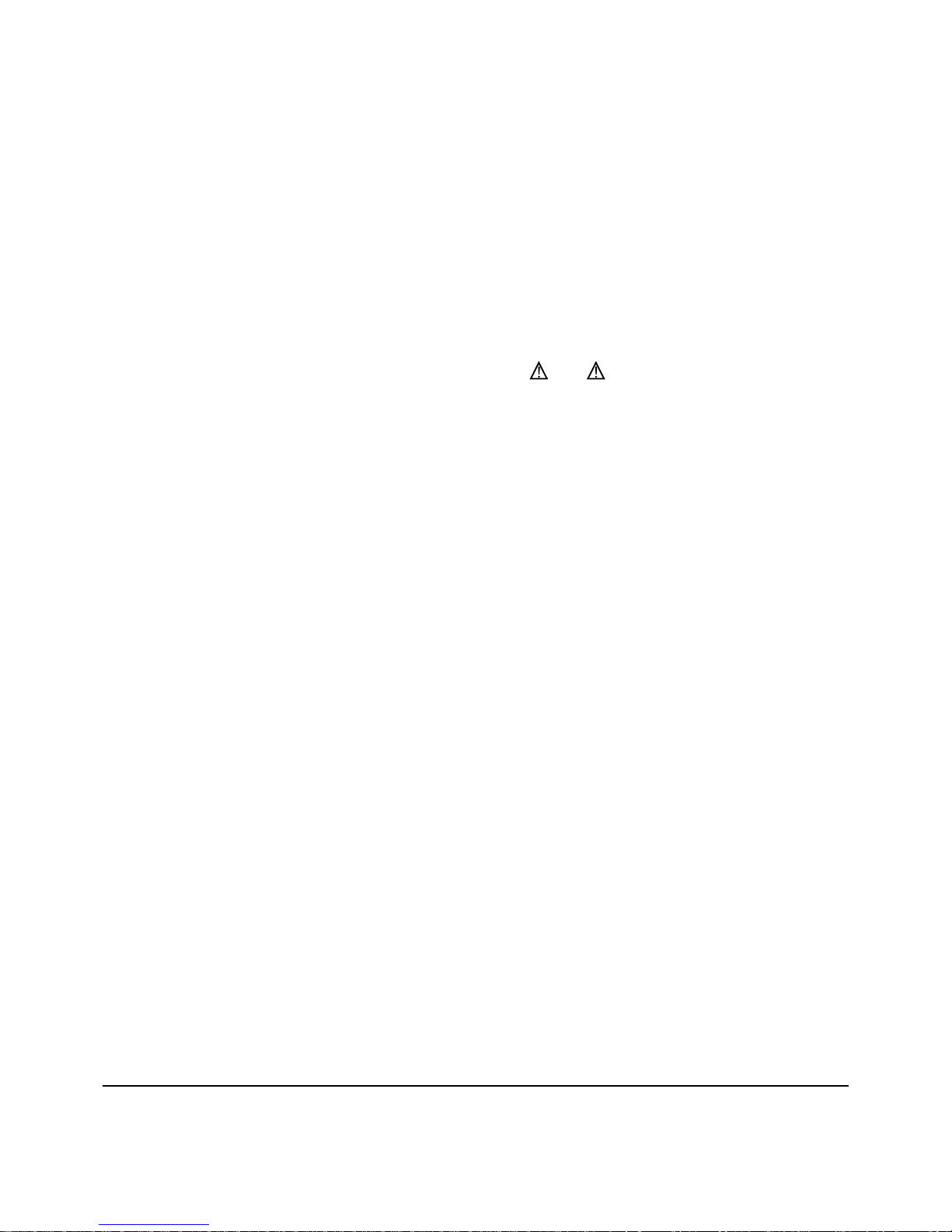

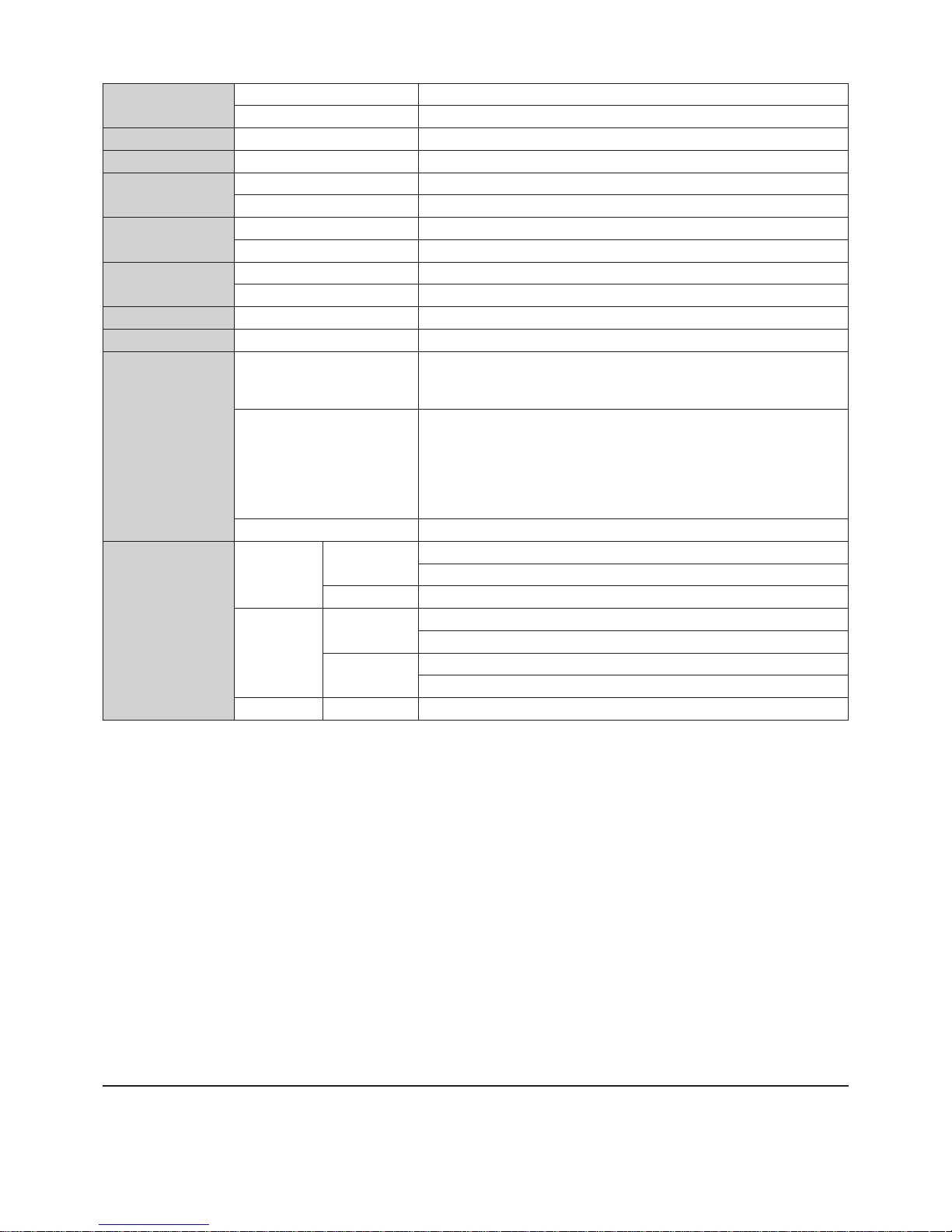

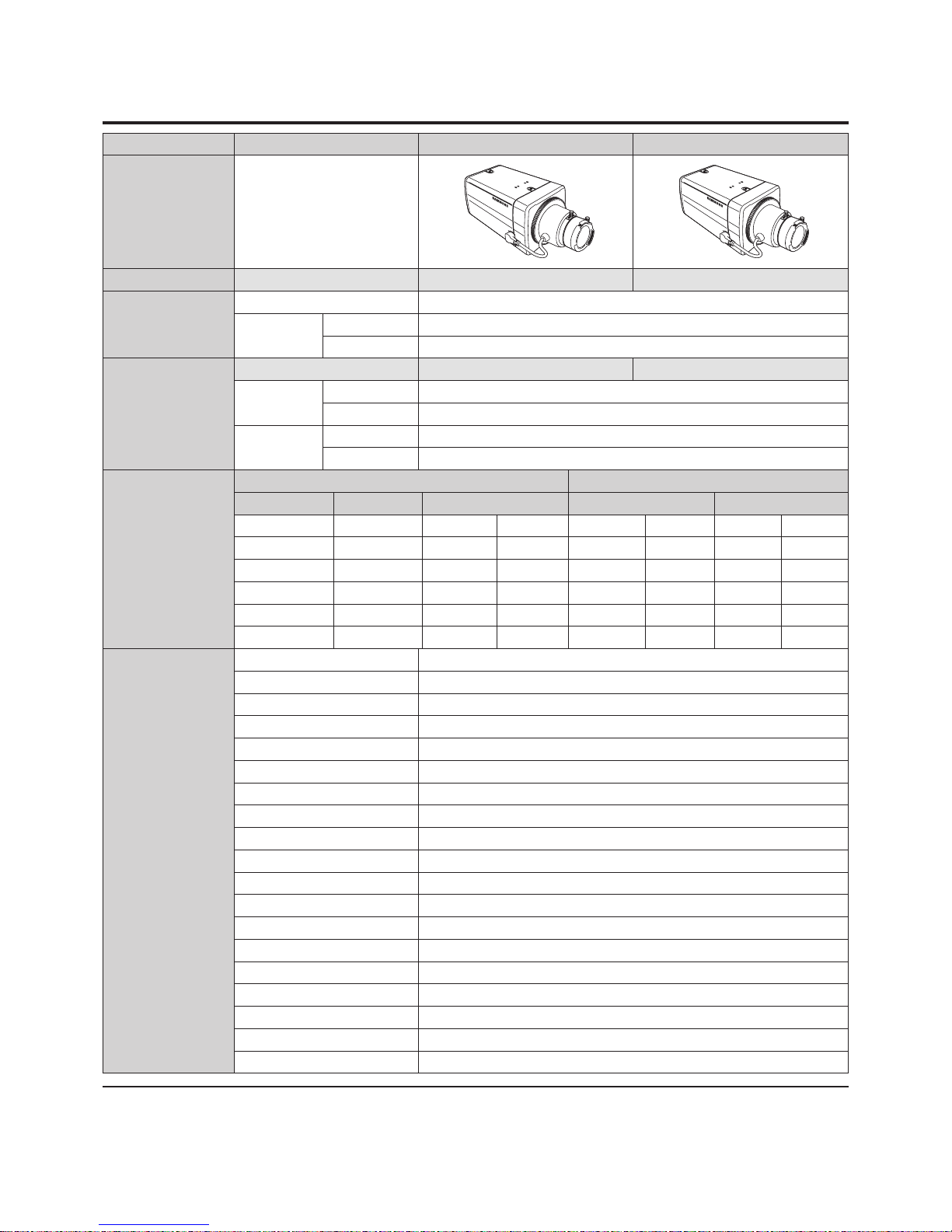

2-2 Chassis Product Specification

Item Sub-items SCC-B2333P / SCC-B2033P SCC-B2035P / SCC-B2335P

Model Model Image

Camera Type CCTV Camera (DAY/NIGHT) CCTV Camera (WDR & DAY/NIGHT)

Image

Device 1/3” Super-HAD IT CCD

Pixels

Total 795 x 596

Effective 752 x 582

Scanning

System

Interlace Interlace/Progressive

Horizontal

Frequency

Internal Mode 15,625 Hz

Line-lock Mode 15,625 Hz

Vertical

Frequency

Internal Mode 50 Hz

Line-lock Mode 50 Hz

Min. Scene

Illumination

Functions

Number of Privacy Zone 12 (Polygonal Method)

Day/Night DAY/NIGHT/AUTO/EXT

Motion Detection OFF/Tracking/Detection

eXtended Dynamic Range(XDR) Off/On (Level Setting)

Wide Dynamic Range(WDR) Off/On (x160)

Virtual Progressive Scan(VPS) Off/On

D-Zoom Max. x16

PIP Off/On

High Speed Shutter 1/50 ~ 1/10Ksec (OSD/External Control)

Flickerless Off/On

Sens-Up x2 ~ x512

BLC Off/On (Area Setting)

AGC Off/On (Max.Level Setting)

ELC Off/On ( ~ 1/200K sec)

Line Lock Off/On (Phase Control)

Camera ID Off/On (Max.54ea/2Line)

White Balance ATW1/ATW2/AWC/3200K/5600K

Digital Noise Reduction(DNR) Off/On (Adaptive 3D+2D)

Digital Image Stabilization(DIS) Off/On

Condition Min. Scene illumination

Sens-up F No. Level DAY NIGHT

OFF 1.2 50 IRE 0.4 Lux 0.4 Lux

OFF 1.2 30 IRE 0.24 Lux 0.24 Lux

OFF 1.2 15 IRE 0.12 Lux 0.12 Lux

512 times 1.2 50 IRE 0.0008 Lux 0.0008 Lux

512 times 1.2 30 IRE 0.00047 Lux 0.00047 Lux

512 times 1.2 15 IRE 0.00023 Lux 0.00023 Lux

Product Specication

2-8 Samsung Electronics

Functions

Intelligent Video Fixed/Moved, Fence

Etc. Function Detail, Reverse(H/V), Posi/Nega

Resolution Horizontal 600 TV Lines

S/N Ratio Vertical 350 TV Lines

Video Output - VBS 1.0Vp-p, 75 Ω

S/N Ratio S/N Ratio Approx. 52dB

Lens Lens Drive Type MANUAL/AI(VIDEO/DC)

Mount Type CS/C

Alarm Input N/A

Output 1 Output

Remote Coaxitron (Data On Coax cable) Yes (with SCX-RD100)

Control RS-485 Yes (Multi Protocol, 8ea)

Environmental Operating Temperature -10°C ~ +50°C

Conditions Humidity Less than 90%

Power

Power Requirement

SCC-B2333P : AC24V ±

10%(50Hz±0.3Hz)

DC12V ± 10%

SCC-B2033P : AC220V ±

10%(50Hz±0.3Hz)

SCC-B2335P : AC24V ±

10%(50Hz±0.3Hz)

DC12V ± 10%

SCC-B2035P : AC220V ±

10%(50Hz±0.3Hz)

Power Consumption

(With DC Lens)

In Normal operation :

SCC-B2333P : 2.3W

SCC-B2033P : 2.9W

In switching the DAY/NIGHT fi lter :

SCC-B2333P :2.8W

SCC-B2033P : 3.4W

In Normal operation :

SCC-B2335P : 2.6W

SCC-B2035P : 3.3W

In switching the DAY/NIGHT fi lter :

SCC-B2335P :3 .2W

SCC-B2035P : 3.8W

LED Indicator Yes

Physical

Specifi cation

Dimensions

(WxHxD)

Net

SCC-B2333P : 64(W) x 58(H) x

109.2(D) mm

SCC-B2335P : 64(W) x 58(H) x

109.2(D) mm

SCC-B2033P : 64(W) x 58(H) x

129.2(D) mm

SCC-B2035P : 64(W) x 58(H) x

129.2(D) mm

Package 173(W) x 99(H) x 115(D) mm 173(W) x 99(H) x 115(D) mm

Weight

Net

SCC-B2333P : Approx. 305g SCC-B2335P : Approx. 305g

SCC-B2033P : Approx. 395g SCC-B2035P : Approx. 395g

Package

SCC-B2333P : Approx. 530g SCC-B2335P : Approx. 530g

SCC-B2033P : Approx. 620g SCC-B2035P : Approx. 620g

Color Body Silver

Item Sub-items SCC-B2333P / SCC-B2033P SCC-B2035P / SCC-B2335P

Model Model Image

Samsung Electronics 2-9

Product Specication

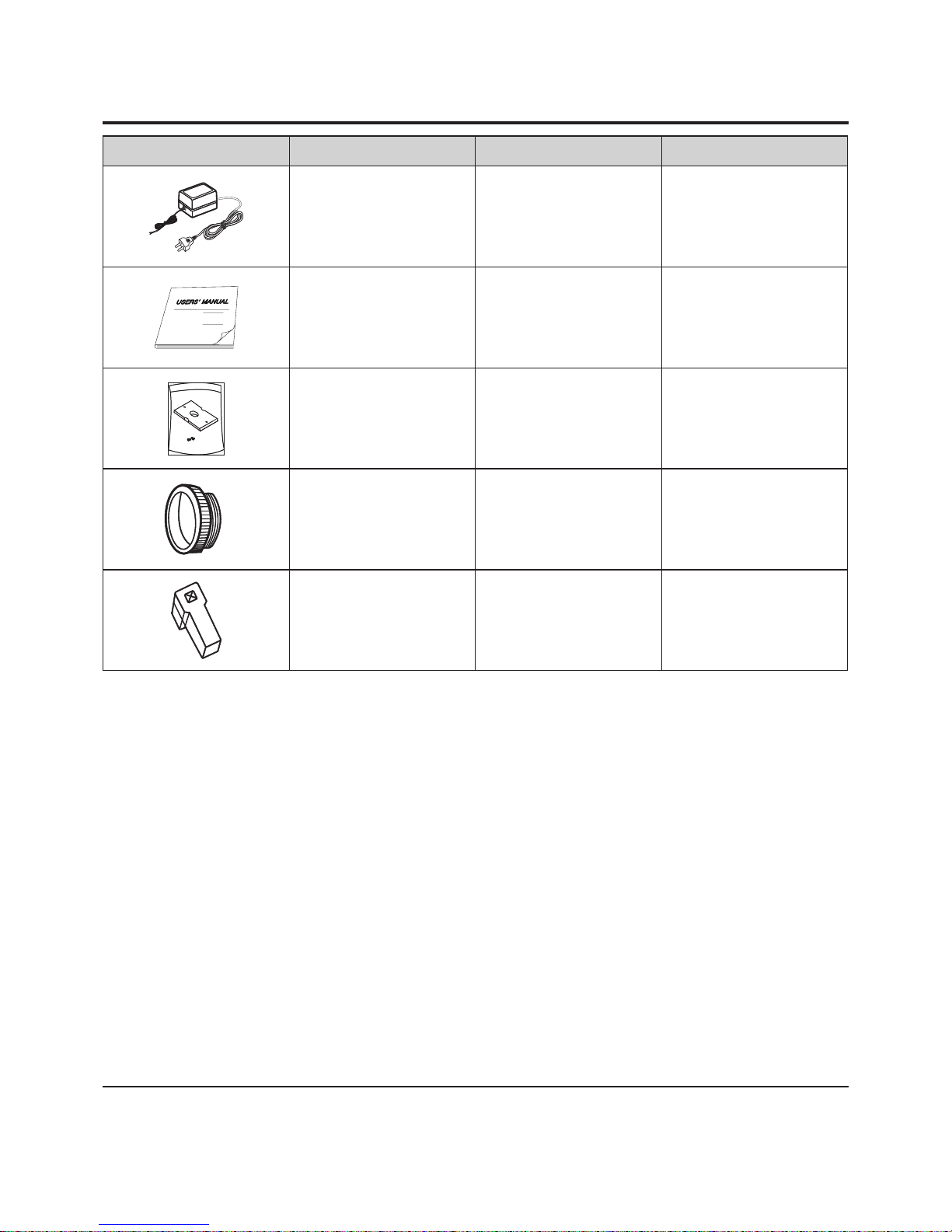

Description Fig Description Parts No Remark

AC Adapter AB44-00047A

Model Standad

of SCC-B2333P

User manual

AB68-00786A : SCC-B2333

AB68-00779A : SCC-B2335

Camera Holder(Mount) AB61-00516A

Model Standad

of SCC-B2333P

C Mount Adapter AB61-00516A

Model Standad

of SCC-B2333P

Auto Iris

Lens Connector

3721-001017

Model Standad

of SCC-B2333P

2-3 Option Product Specification

Product Specication

2-10 Samsung Electronics

M E M O

3. Disassembly and Reassembly

3-1 Cabinet and PCB

Samsung Electronics 3-1

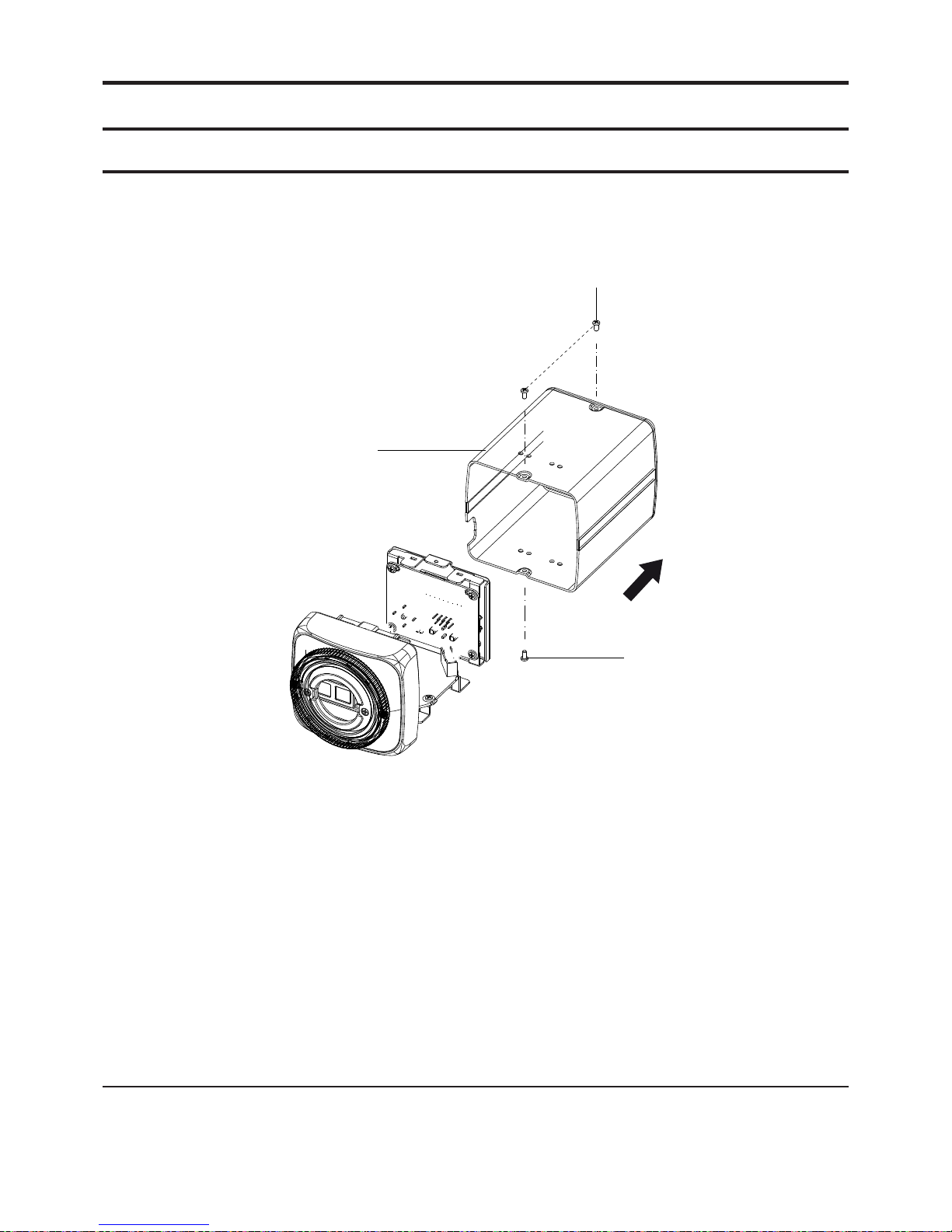

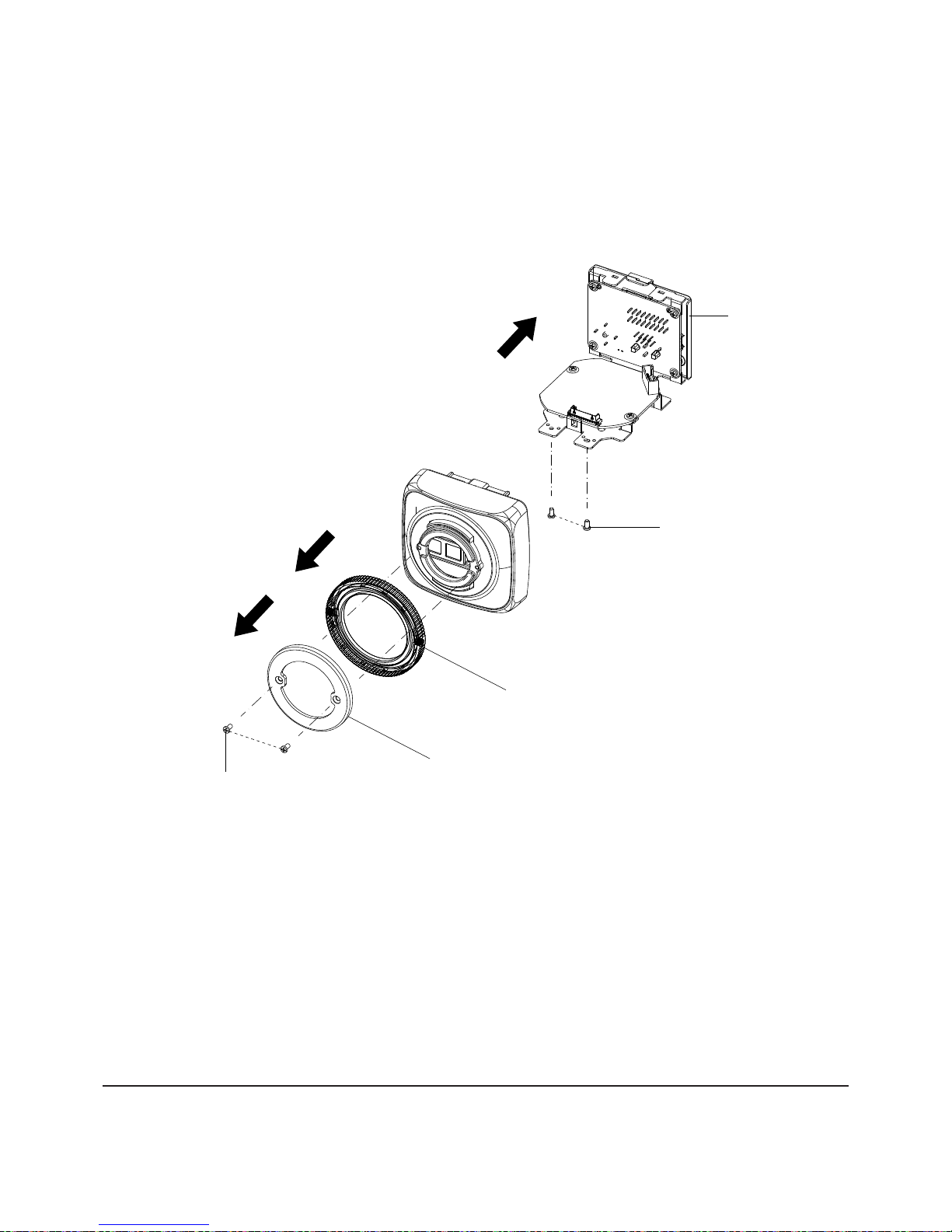

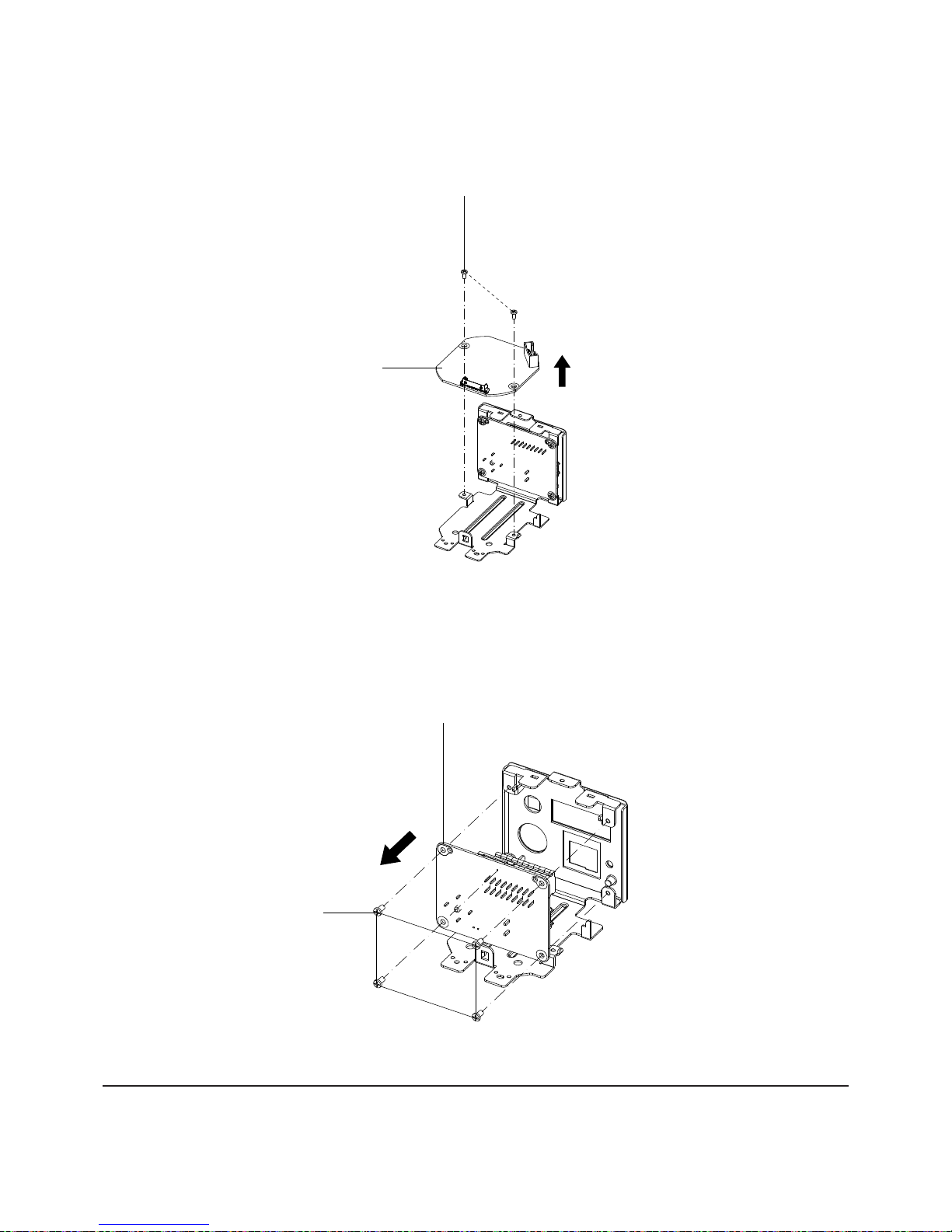

3-1-1 Ass'y Body Removal

1) Remove 3 screw q, w.

2) Remove Ass'y Body e.

Fig 3-1 Ass'y Body Removal

q 4 SCREW

(2X4 W)

q 4 SCREW

(2X4 W)

w ASS'Y BODY

Disassembly and Reassembly

3-2 Samsung Electronics

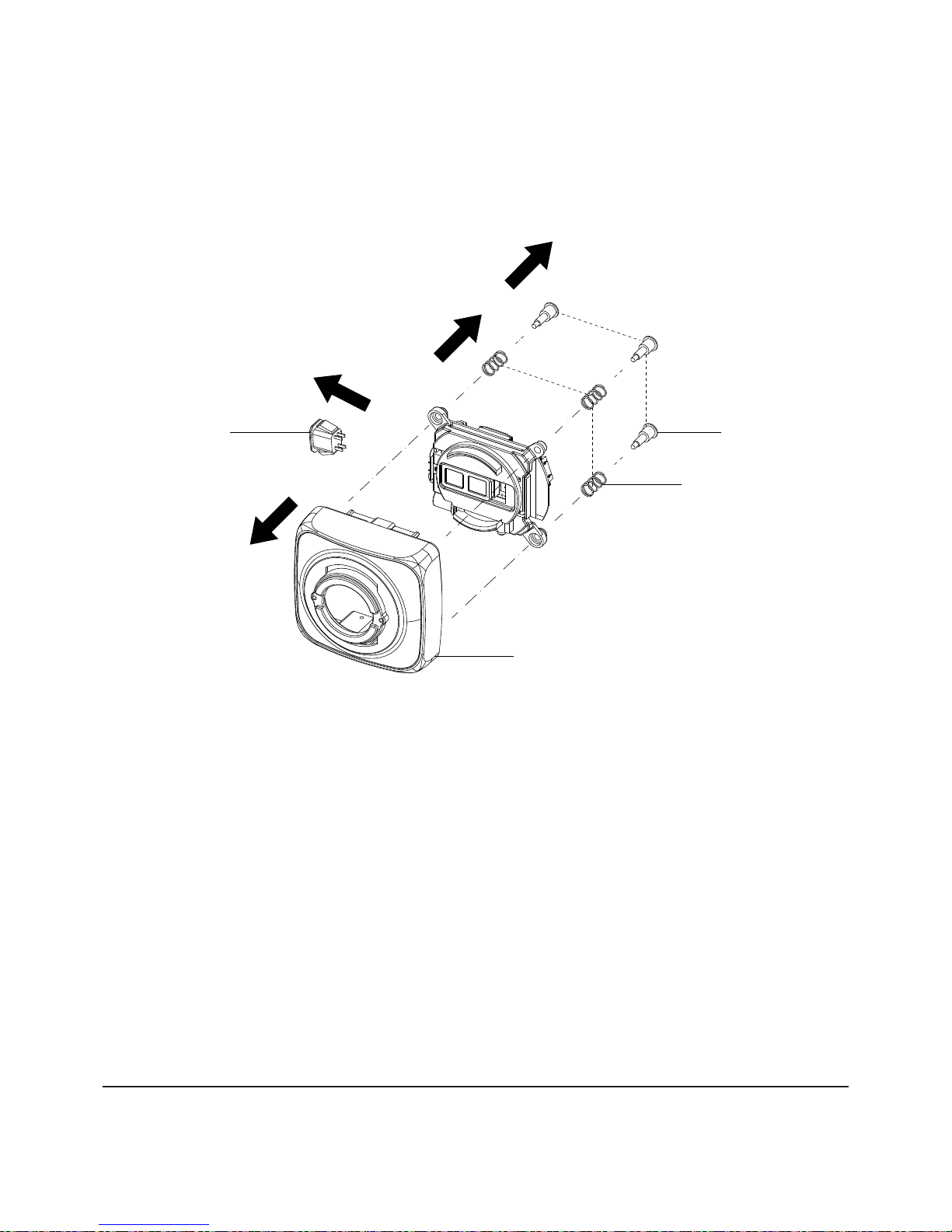

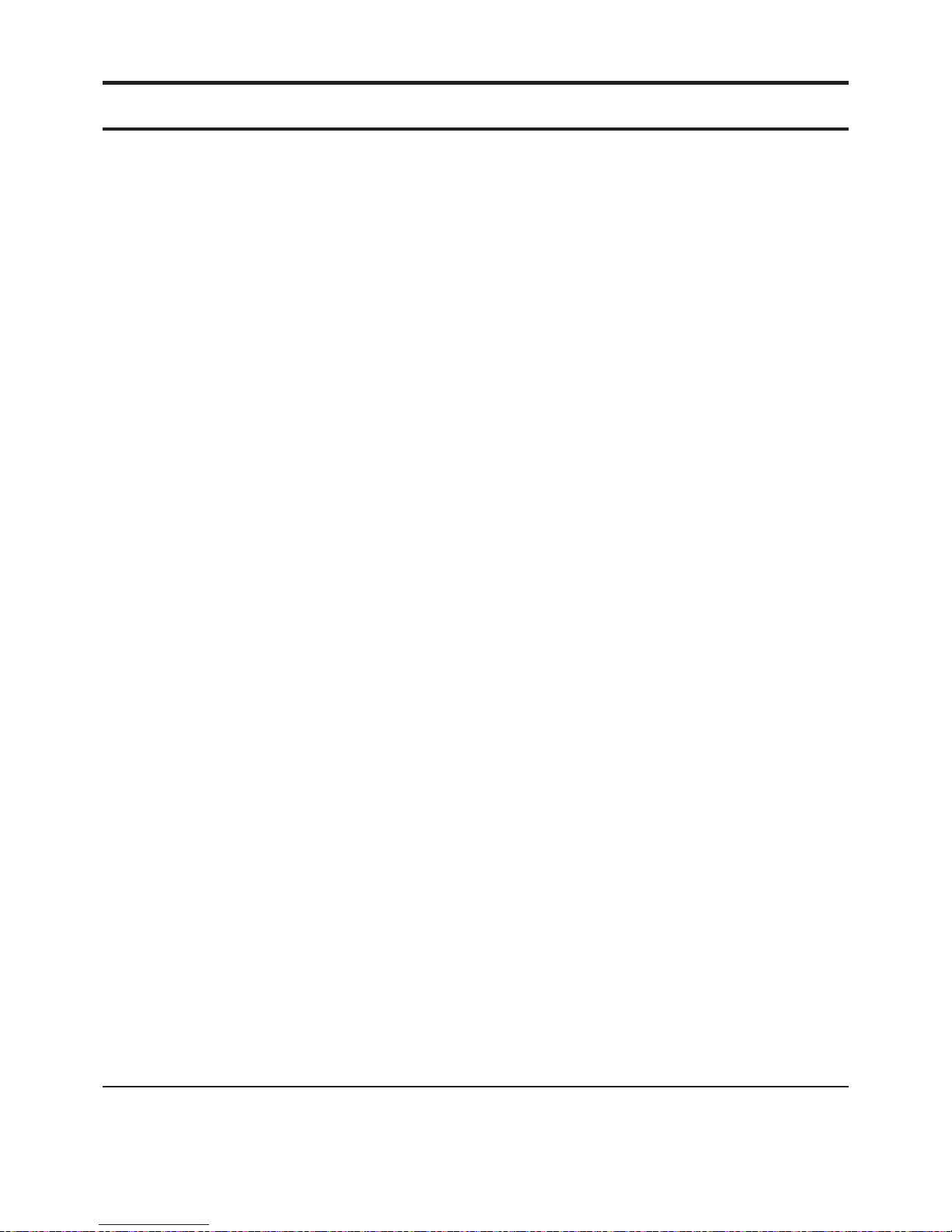

3-1-2 Ass'y Rear & Ass'y Front Removal

1) Remove 2 screws q.

2) Remove Ass'y Rear w.

3) Remove 2 screws e.

4) Remove Cover Guide r.

5) Remove Guide Slider t.

Fig 3-2 Ass'y Rear & Ass'y Front Removal

q 2 SCREWS

(2X4 B)

e 2 SCREWS

(2X4 B)

w ASS'Y REAR

t GUIDE SLIDER

r COVER GUIDE

Samsung Electronics 3-3

Disassembly and Reassembly

3-1-3 Front Case Removal

1) Remove Harness AI q.

2) Remove 2 Guide Pins w.

3) Remove 2 Spring Pins e.

4) Remove Front Case r.

q

HARNESS AI

Fig 3-3 Front Case Removal

r FRONT CASE

e 2 SPRING PINS

w 2 GUIDE PINS

Disassembly and Reassembly

3-4 Samsung Electronics

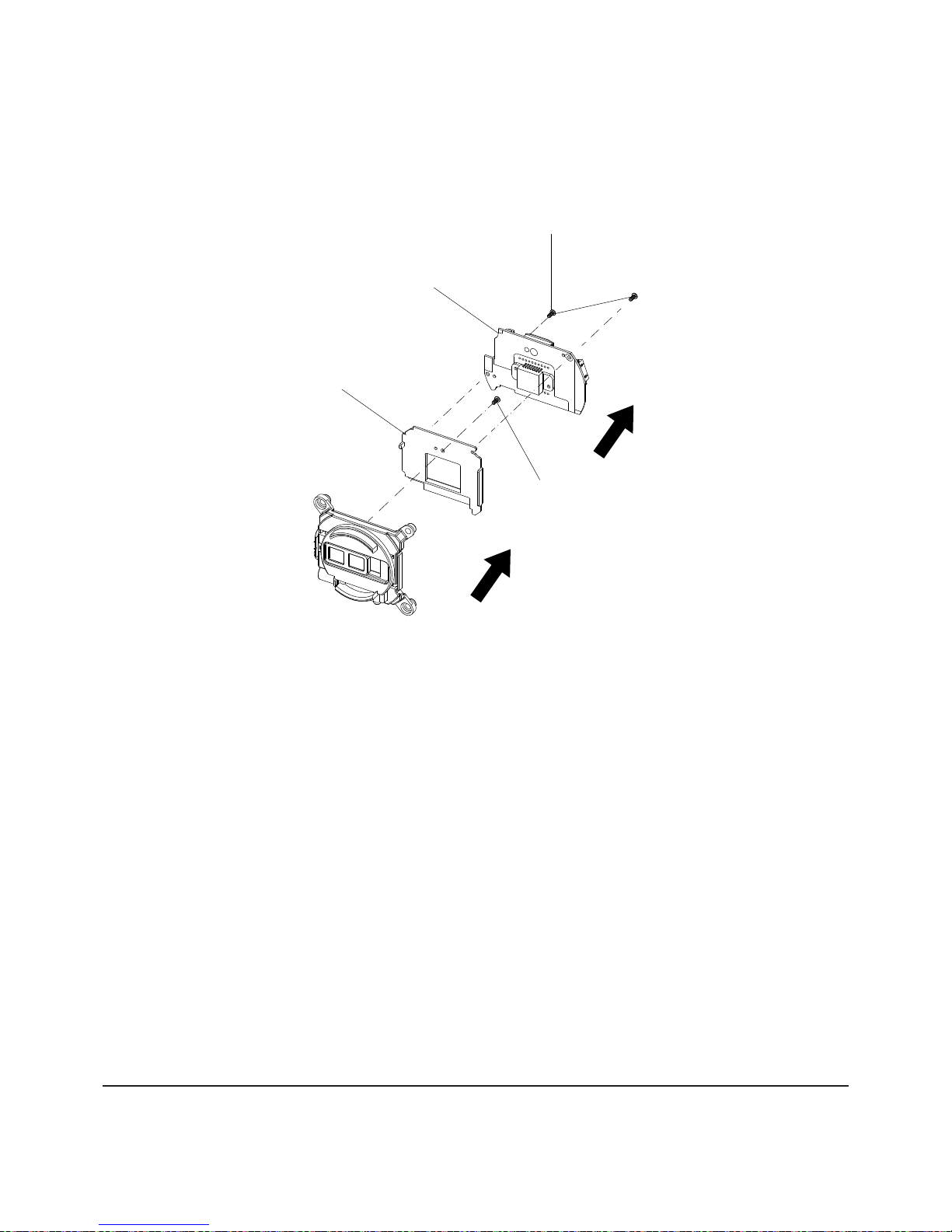

3-1-4 Ass'y CCD PCB Removal

1) Remove 2 Screws q.

2) Remove Ass'y CCD PCB w.

3) Remove 1 Screw e.

4) Remove Cover Filter r.

e

1 SCREW

(7X4 B)

q 2 SCREWS

(7X4 B)

r COVER FILTER

w ASS'Y CCD PCB

Fig 3-4 Ass'y CCD PCB Removal

Samsung Electronics 3-5

Disassembly and Reassembly

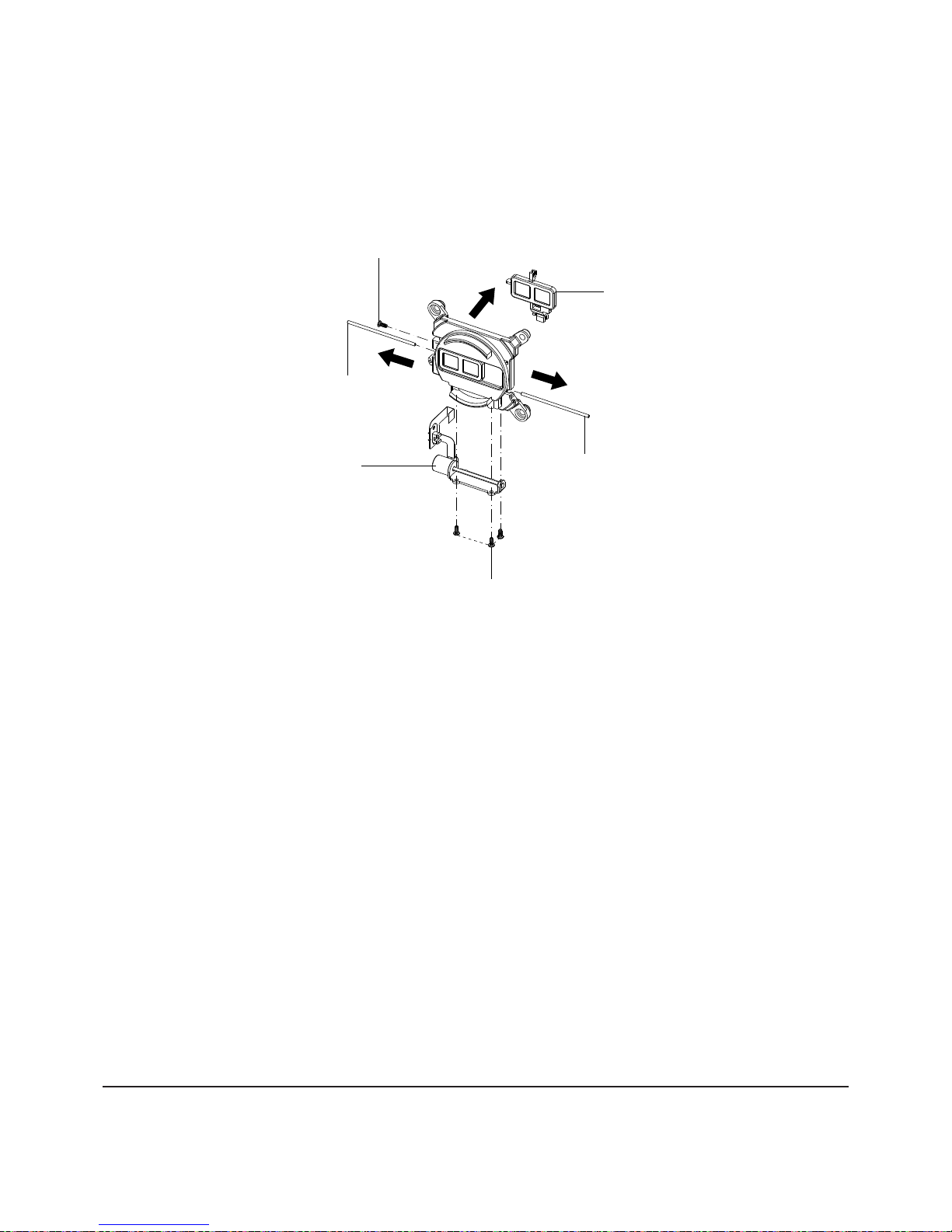

3-1-5 Ass'y Motor & Ass'y OLPF Removal

1) Remove 4 screws q,w.

2) Remove Ass'y Motor e.

3) Remove 2 Guide Filters r,t.

4) Remove Ass'y OLPF y.

w

3 SCREWS

(7X4 B)

q 1 SCREW

(7X4 B)

t 1 GUIDE FILTER

r 1 GUIDE FILTER

Fig 3-5 Ass'y Motor & Ass'y OLPF Removal

e ASS'Y MOTOR

y ASS'T OLPF

Disassembly and Reassembly

3-6 Samsung Electronics

3-1-6 ACDC PCB Removal

1) Remove 2 Screws q.

2) Remove ACDC PCB w.

q

2 SCREWS

(2X4 B)

w ACDC PCB

Fig 3-6 ACDC PCB Removal

3-1-7 Ass'y Rear PCB Removal

1) Remove 4 Screws q.

2) Remove Ass'y PCB w.

Fig 3-7 Ass'y Rear PCB Removal

q 2 SCREWS

(2X4 B)

w ASS'Y REAR PCB

4. Trouble Shooting

Samsung Electronics 4-1

4-1 Trouble Shooting -------------------------------------------------------------------------------- 4-2

4-2 Alignment & Adjustment -------------------------------------------------------------------- 4-9

4-2 Software Update -------------------------------------------------------------------------------4-13

Loading...

Loading...