Samsung S5L9250B01-Q0R0 Datasheet

DATA SHEET S5L9250B

INTRODUCTION

The CD-ROM 48X 1 chip receives the input signal read from the CD-DA/VIDEO-CD/CD-ROM disc after handling

by the RF amplifier. The signal is input into the digital servo block which has a built-in DSP core, and goes

through focus and tracking adjustments. The RF signal input into a data path goes through the data slicer, PLL,

EFM demodulator, C1/C2 ECC and the audio handling block. In the case of a CD-DA, the signal is output through

the 1-bit DAC. In the case of a CD-ROM, the signal is input into an external CD-ROM controller for handling, then

transmitted to the host through the ATAPI I/F. Also, if you operate the CD-DA in audio buffering mode while

already in CAV mode, the signal is stored in the CD-ROM controller DRAM at high speed, then output at 1x from

the CD-ROM controller, after passing through the 1-bit DAC built-in to the S5L9250B.

FEATURES

• Main Features

Digital servo, CD-DSP, 1-bit DAC.

33.8688MHz crystal.

Supports CLV 4X and 8X.

Supports CAV MAX 16X, 20X, 24X, 32X, 40X, and 48X.

Interrupt (SINTB)

MICOM interface

• Digital Servo Block

Automatic adjusting feature (focus/tracking loop offset, balance, loop gain)

Built-in AGC feature that adapts to work optimally with various disc types

Built-in search algorithm for speed control

Servo monitor signal generation (FOK, MIRROR, TZC, ANTI-SHOCK)

Various loop filter coefficient selection by MICOM

Built-in algorithm for handling defects/shocks

Disc discriminating data out (FEpk, SBADpk)

RF IC and serial interface

Built-in 10-bit DAC (Focus/Tracking/SLD)

OAK DSP core

• CD Digital Signal Processing Block

Wide capture range analog PLL

Data Slicer using duty feedback method

EFM demodulation

Sync detection, protection, insertion

CLV, CAV disc spindle motor control

C1/C2 ECC

Built-in 16 K SRAM for ECC

Subcode P - W handling feature

CD-DA Audio handling feature

SUB-Q De-interleaving & CRC check

High speed data transmission support by CD-ROM decoder block for audio buffering (sync mode

selection between subcode sync and CD-DA data)

Digital audio out block

Subcode sync. Insertion, Protection

1

S5L9250B DATA SHEET

• 1-Bit DAC

16-bit ∑ ∆ digital-to-analog converter

On-chip analog postfilter

Filtered line-level outputs, linear phase filtering

90dB SNR

Sampling rate: 44.1kHz

Input rate 1Fs or 2Fs by normal mode/ double mode selection

Digital volume control by MICOM interface

On-chip voltage reference

Digital de-emphasis on/off, digital attenuation

Low clock jitter sensitivity

• Technology & Gate Density

0.35um mixed mode CMOS technology

3.3V power supply (internal core & analog)

5.0V power supply (digital I/O)

Current used: 300mA

Package: 128QFP.

Core used: OAK DSP; ADC for servo use; DAC, 1-bit DAC; 16K SRAM.

Clock used:

1) 33.8688MHz & PLL clock (4.3218MHz * speed coeff.) → DP part.

2) 33.8688MHz or 40MHz synthesized frequency → servo part.

3) 16.9344MHz → 1-bit DAC part.

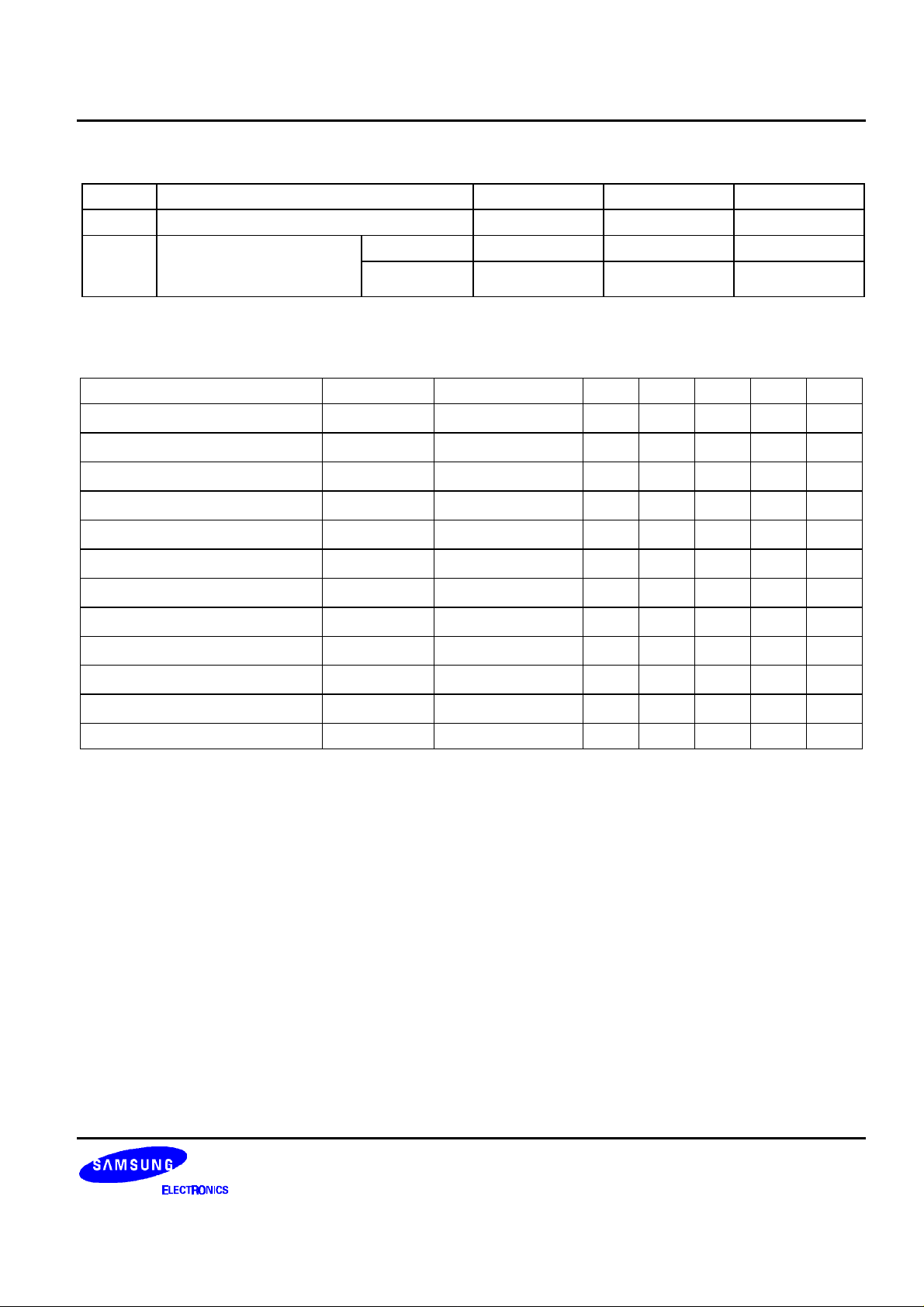

ORDERING INFORMATION

Device Package Operating Temperature

S5L9250B01-Q0R0 128-QFP-1420C -20°C - +75°C

2

DATA SHEET S5L9250B

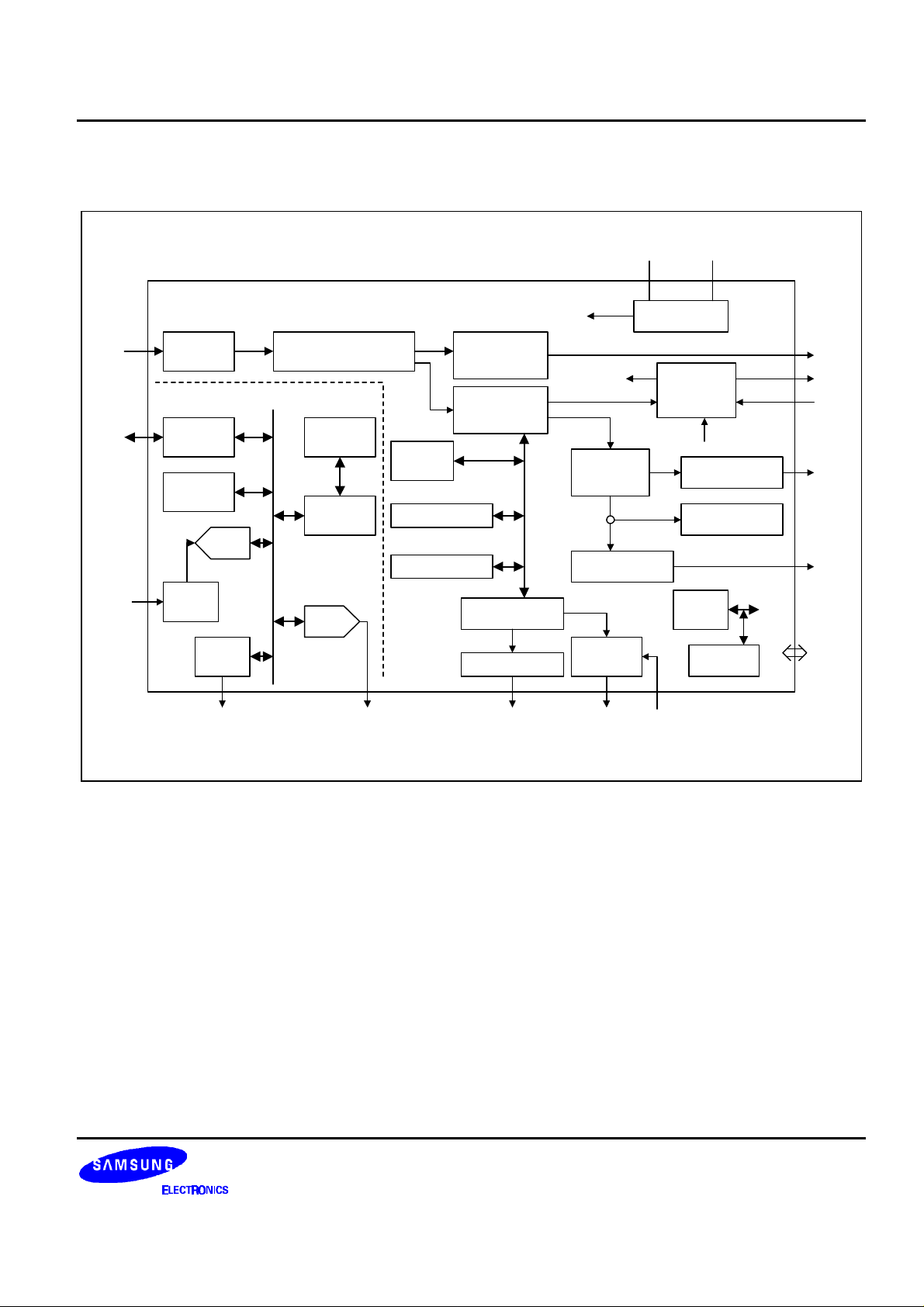

CD-ROM 48X 1 CHIP (DSP+SERVO+1-BIT DAC) BLOCK DIAGRAM

XI XO

33.8688MHz

Timing

RF

Signal

I/O

Signal

Various

Error

Signals

From RF

Data

Slicer

Servo Part

Glue

Logic

Data RAM

512 * 16*2

Analog

Block

10-bit

ADC

PWM

Block

TPWM 1

(bit clock regenerator)

PLL

ROM 8K

Word

OAK Core

10-bit

DAC*4

FOD

Sled 0

TRD

Sled 1

Memory

Control

SRAM for ECC

C1/C2 ECC

CD-DSP Part

EQ Control

Voltage

Generator

EFM

Demodulator

Sync Detector

Audio Processing

Block

DSP I/F

To Servo

Subcode

Processing

Block

Subcode I/F

D/Filter &

1-bit DAC

Analog

Audio

Generator

Spindle

Control

Sub-Q Handling

PSC

CMD

From Servo

D/Audio Out

Block

Micom

I/F

nX-to-1X

CD-DA

Signal

EQ CTL

To Motor

FG

Digital

Audio

Subcode

I/F

Micom

I/F

3

S5L9250B DATA SHEET

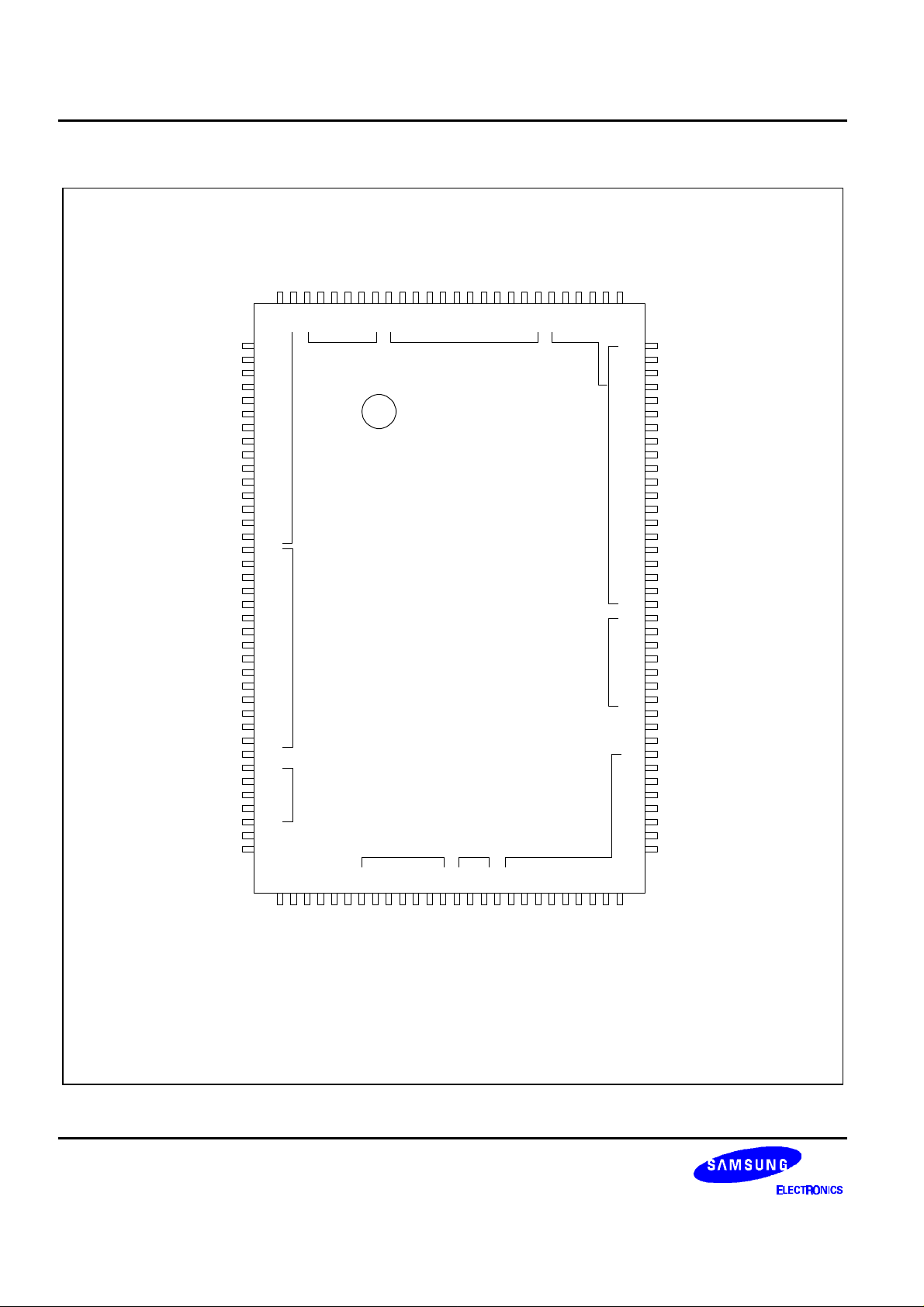

PIN CONFIGURATION

EQCTL

VCCA1(VCCA)

RFI

LPF0

LPF1

VCCA7(VCCA)

EFMCOMP

VSSA7(VSSA)

RISS

VALGC

VCCA6(VSSA)

RVCO

RDAC

VSSA6(VSSA)

VCTRL

VCCA5(VCCA)

VBG

PWMI

PWMO

VSSA5(VSSA)

VHALF

VREF

VCCA4(VCCA)

AOUTR

AOUTL

VSSA4(VSSA)

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

104

103

102

VSSA1-VSSA

VREFI

VSSA2-VSSA

RFRP

RFCT

SBAD

CEI

TZCA

TE

TELPF

FE

FELPF

VCCA2-VCCA

AOUT

PPUMP

VSSA3-VSSA

TRD

FOD

SLED0

SLED1

SPINDLE

VREFO

VCCA3-VCCA

SMON

DVSS1-VSSOP

GPIO0

SSTOP/GPIO1

PS1/GPIO2

FG

DIRROT

DVDD2-VDD3I

RFEN

RFDATA

RFCLK

DVSS2-VSSI

DFCTI

TEST1

DVDD1-VDD5OP

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Data Slicer

Part

From RF

RF Interface

Motor IFRF IF

PLL Part

KS9250

S5L9050B

EVT3

EVT3

PIN DIAGRAM

PIN DIAGRAM

Micom IF X'tal

i-Bit

DAC

Part

Monitor Part CD-ROM Decoder IF

Micom

IF

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

LRCKI

SDATAI

VDDD1-VDD3I

BCKI

VSSD1-VSSI

SCORO

DVSS12-VSSOP

CK50M

DVDD11-VDD3I

WFCKO

SBSO

DBDD11-VDD5OP

EXCK

DAOUT

DVSS11-VSSOP

BCKO

C2PO

DVSS10-VSSI

LRCKO

SDATAO

GFS

EFML/SL

DVSS9-VSSOP

CLVLOCK

PLCK/EMPH

PLOCK

DVDD8-VDD3I

SCANEN

DVSS8-VSSI

AD0

AD1

AD2

AD3

AD4

AD5

AD6

DVDD7-VDD5OP

AD7

39404142434445464748495051525354555657585960616263

XI

CKO

TEST2

TEST3

TEST4

MIRR/GPIO5

TZCO/GPIO4

TPWM1/GPIO3

NOTES:

1. P1 - P23: Analog

2. P24 - P102: Digital

3. P103 - P128: Digital

DVDD2A(VDD3I)

PHOLD/GPIO6

FOKB/GPIO8

COUT/GPIO7

DVSS4(VSSI)

XO

SENSE

DVSS5(VSSOP)

DVDD3(VDD5OP)

ZRST

SINTB

RDB/DSB

WRB/RWB

DVDD4(VDD3I)

64

CSB

ALE/RSB

DVSS6(VSSI)

DVSS7(VSSOP)

4

DATA SHEET S5L9250B

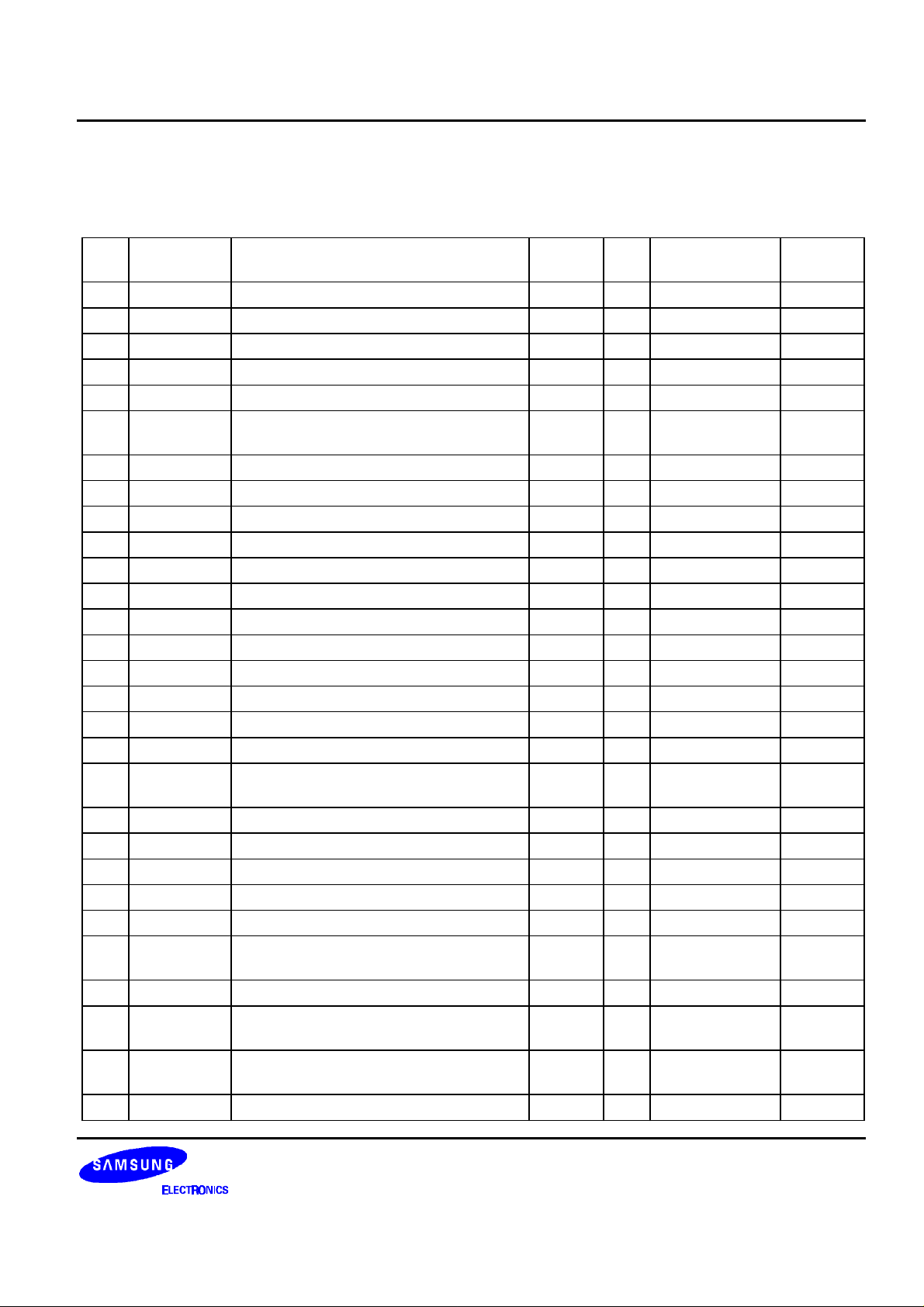

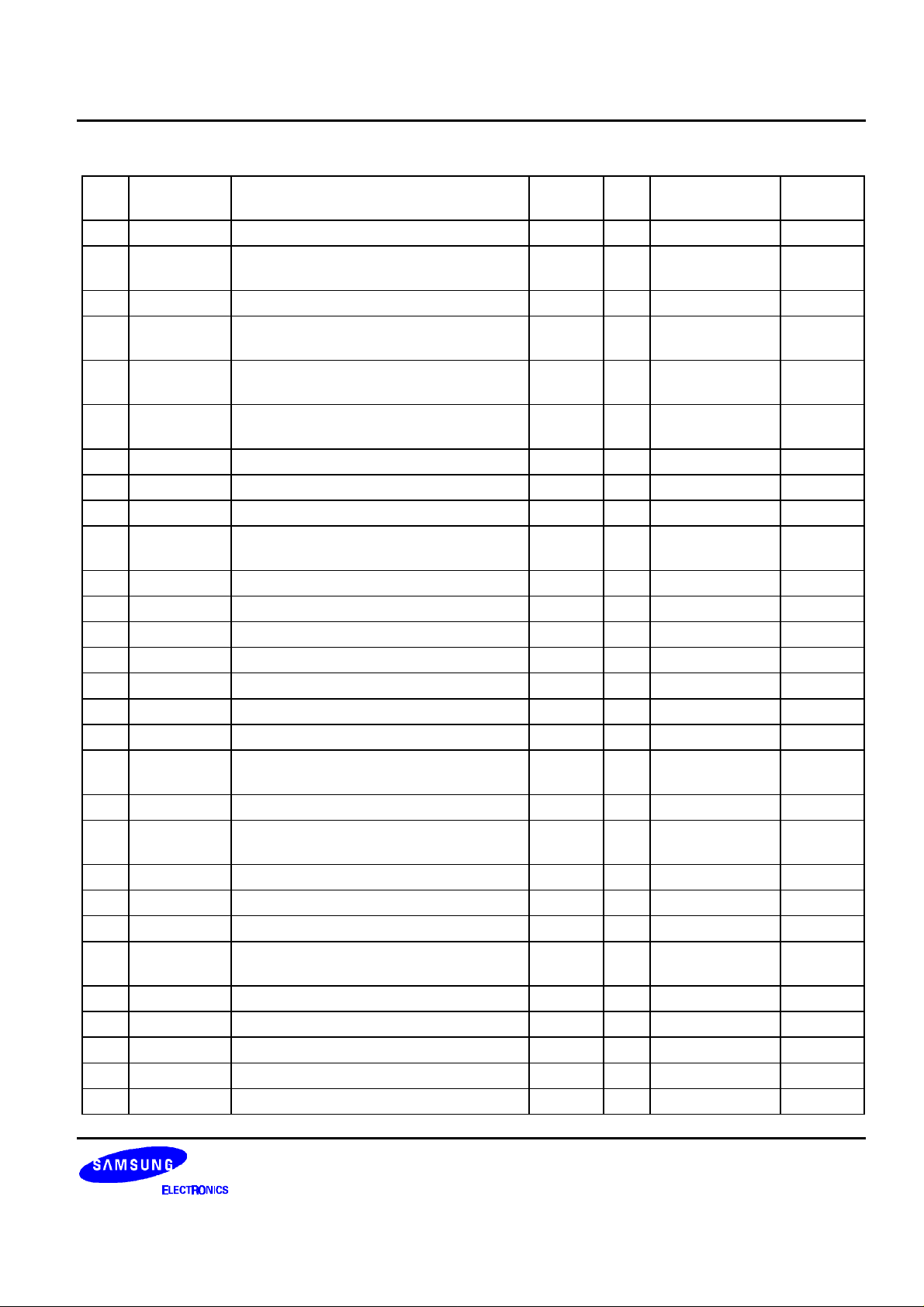

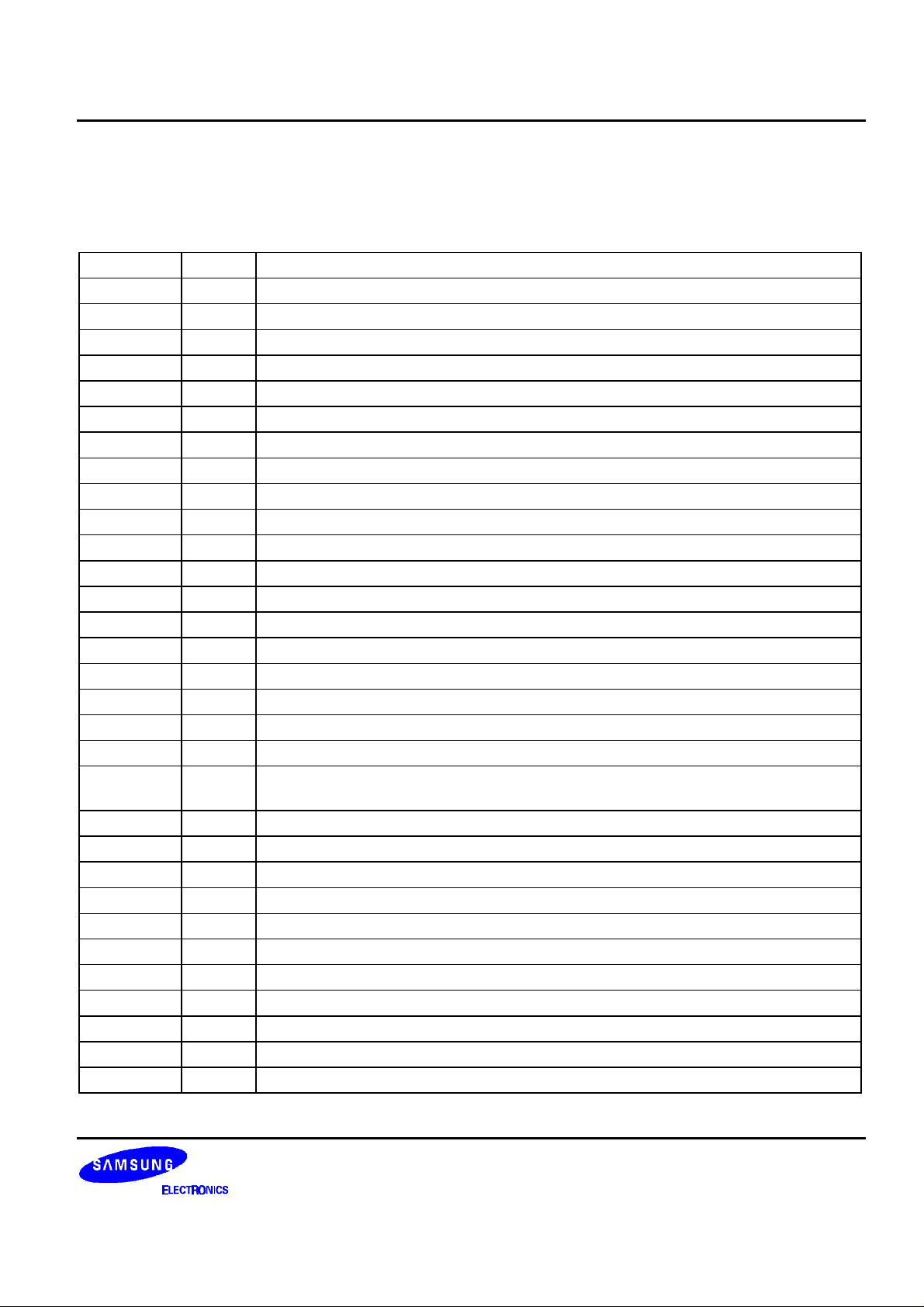

PIN DESCRIPTION

Table 1. Pin Description

No Name Description Related

Block

1 VSSA1 Analog ground (EQ controller) - P VSSA 2 VREFI VREF input SERVO I PICA RF

3 VSSA2 Analog ground (for servo ADC use) - P VSSA 4 RFRP RF envelope signal SERVO I PICA RF

5 RFCT RF envelope's center detection signal SERVO I PICA RF

6 SBAD FOK, DFCT generating SUB-BEAM ADD

signal (E+F)

7 CEI ERROR signal for center servo use SERVO I PICA RF

8 TZCA TZC signal generating signal (=TE) SERVO I PICA RF

9 TE Tracking error signal SERVO I PICA RF

10 TELPF TE defect holding pin SERVO I PICA 11 FE Focusing error signal SERVO I PICA RF

12 FELPF FE defect holding pin SERVO I PICA 13 VCCA2 Analog 3.3V power (for servo ADC use) - P VCCA 14 AOUT Analog out SERVO O POBA MONI

15 PPUMP Pump out for PLL use (filter) SERVO O POBA 16 VSSA3 Analog ground (for servo DAC use) - P VSSA 17 TRD Tracking drive signal (10-bit DAC) SERVO O POBA DRV

18 FOD Focusing drive signal (10-bit DAC) SERVO O POBA DRV

19 SLED0 Stepping control signal 0/DC motor

control signal

20 SLED1 Stepping control signal 1 SERVO O POBA DRV

21 SPINDLE Spindle controlling PWM output CLV O POBA 22 VREFO VREF out for driver IC SERVO O POBA SLED

23 VCCA3 Analog 3.3V power (for DAC use) - P VCCA 24 SMON Spindle motor on/off CLV O PHOB4 MOTOR

25 DVSS1 Digital GND

(for output PAD + PRE driver)

26 GPIO0 General purpose I/O 0 B PHBCT4

27 STOP/GPIO LIMIT switch/sled position sensor

PS0/general purpose I/O

28 PS1/GPIO Sled position sensor signal 1/general

purpose I/O

29 FG Frequency generator signal (for CAV) CLV I PHIC MOTOR

SERVO I PICA RF

SERVO O POBA DRV

- P VSSOP -

SERVO B PHBCT4 -

SERVO B PHBCT4 -

I/O Pad Type To/From

5

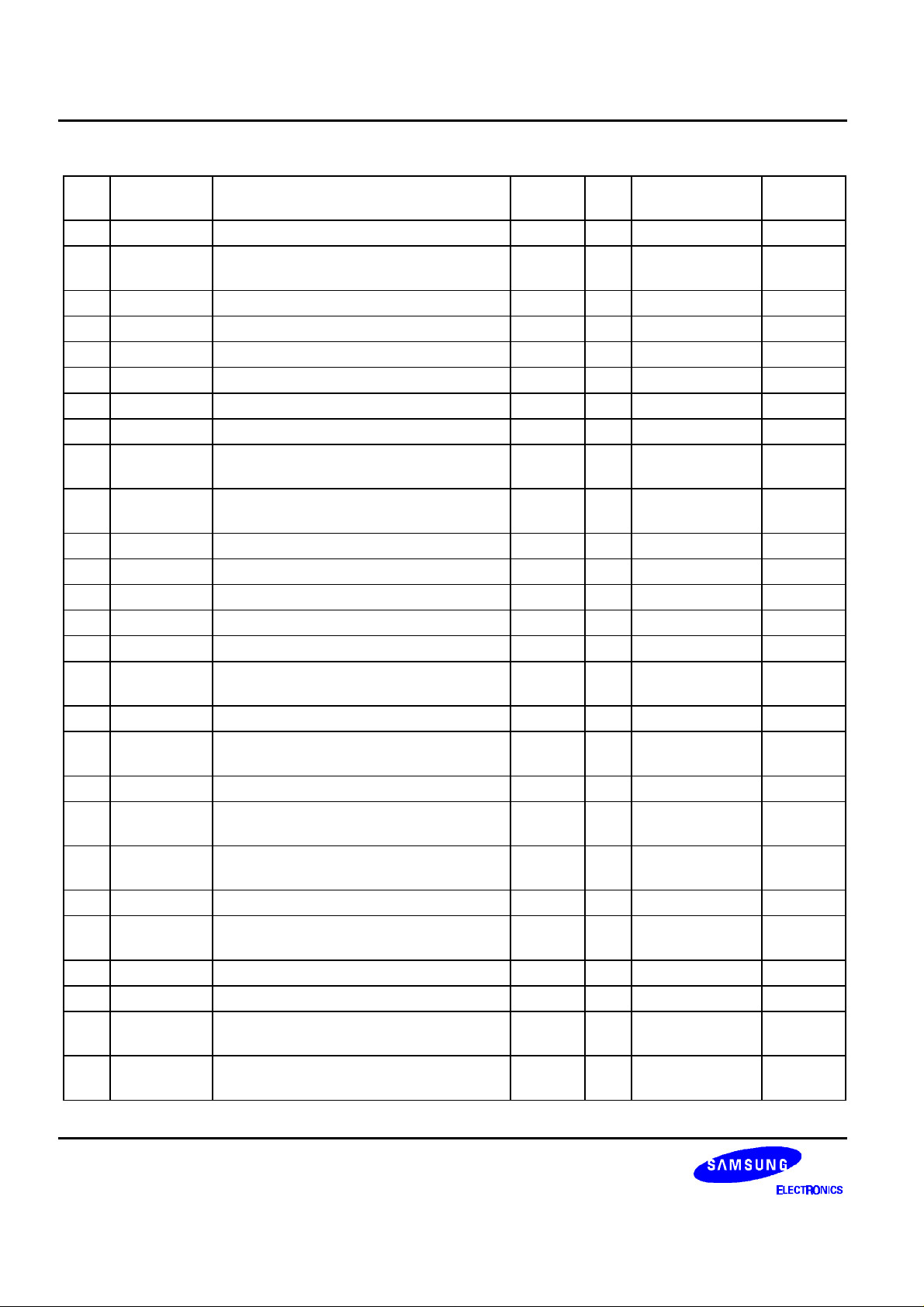

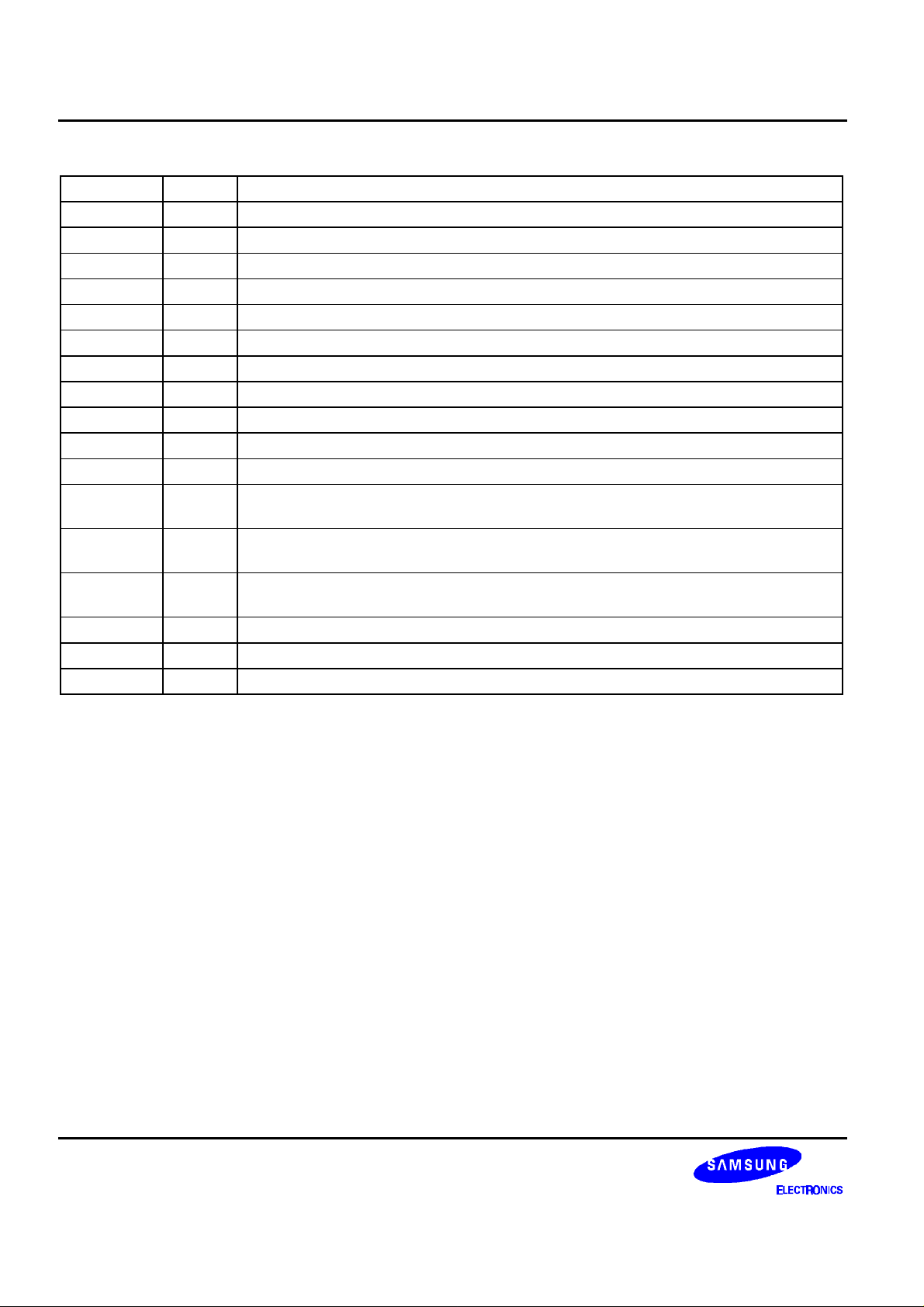

S5L9250B DATA SHEET

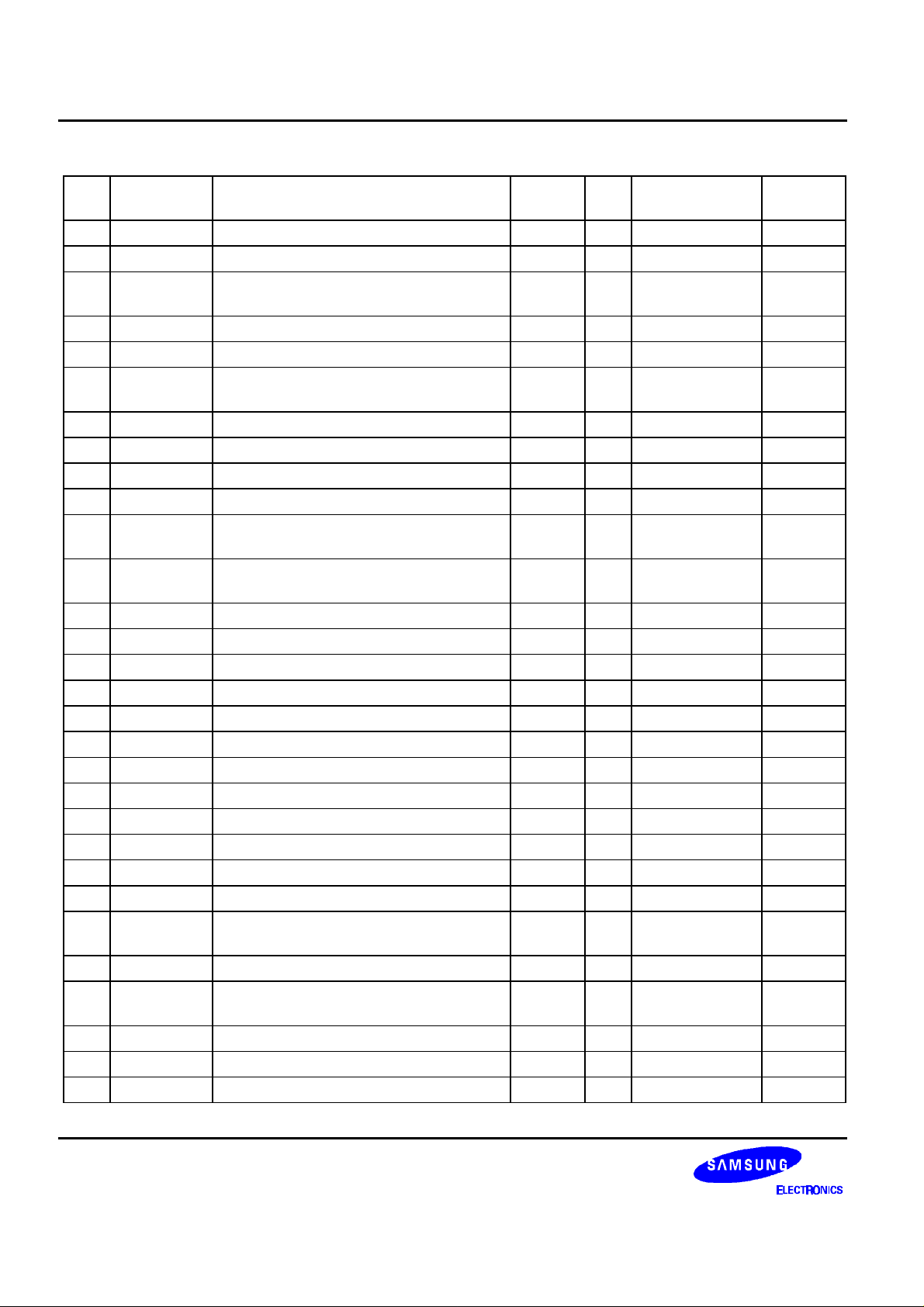

Table 1. Pin Description (Continued)

No Name Description Related

I/O Pad Type To/From

Block

30 DIRROT Spindle disc rotation direction CLV I PHIC MOTOR

31 DVDD2 Digital 3.3 V power (for internal logic

- P VDD3I -

use)

32 RFEN RF data enable SERVO O PHOB4 RF

33 RFDATA RF serial data SERVO O PHOB4 RF

34 RFCLK RF Interface clock SERVO O PHOB4 RF

35 DVSS2 Digital ground (for internal logic use) - P VSSI 36 DFCTI Defect detection signal SERVO I PHIS RF

37 TEST1 Test mode select TEST I PHICD50 38 DVDD1 Digital 5.0V power

- P VDD5OP -

(for output PAD + PRE driver)

39 PWM1/

GPIO

PWM (TPWM1) output

(sled monitor)/general purpose I/O 3

SERVO B PHBCT4

40 CKO 33.8688MHz CK out O PHOB8SM

41 TEST2 Test mode select TEST I PHICD50 42 TEST3 Test mode select TEST I PHICD50 43 DVDD2A Digital 3.3V power (for servo SRAM use) - P VDD3I 44 TEST4 Test mode select TEST I PHICD50 45 TZCO/GPIO Track zero cross signal/general purpose

SERVO B PHBCT4 MONI

I/O

46 MIRR/GPIO MIRROR signal/general purpose I/O SERVO B PHBCT4 MONI

47 PHOLD/

GPIO

ATSC+DFCT+KICK signal/general

purpose I/O

SERVO B PHBCT4 MONI

48 DVSS4 Digital ground (for servo SRAM use) - P VSSI 49 COUT/GPIO COUT signal/L_MIRR signal/general

SERVO B PHBCT4 MONI

purpose I/O

50 FOKB/ GPIO FOCUSING ok signal/general purpose

SERVO B PHBCT4 MICOM

I/O

51 SENSE Servo processor's status monitor signal SERVO O PHOD4U MICOM

52 DVDD3 Digital 5.0V power

- P VDD5OP -

(for output PAD + PRE driver)

53 XI System clock signal input pin CLK I PHSOSCHF OSC

54 XO System clock signal output pin CLK O PHSOSCHF OSC

55 DVSS5 Digital ground

- P VSSOP -

(for output PAD + PRE driver)

56 SINTB Microprocessor disc interrupt

MICOM O PHOB4 MICOM

(data processor)

6

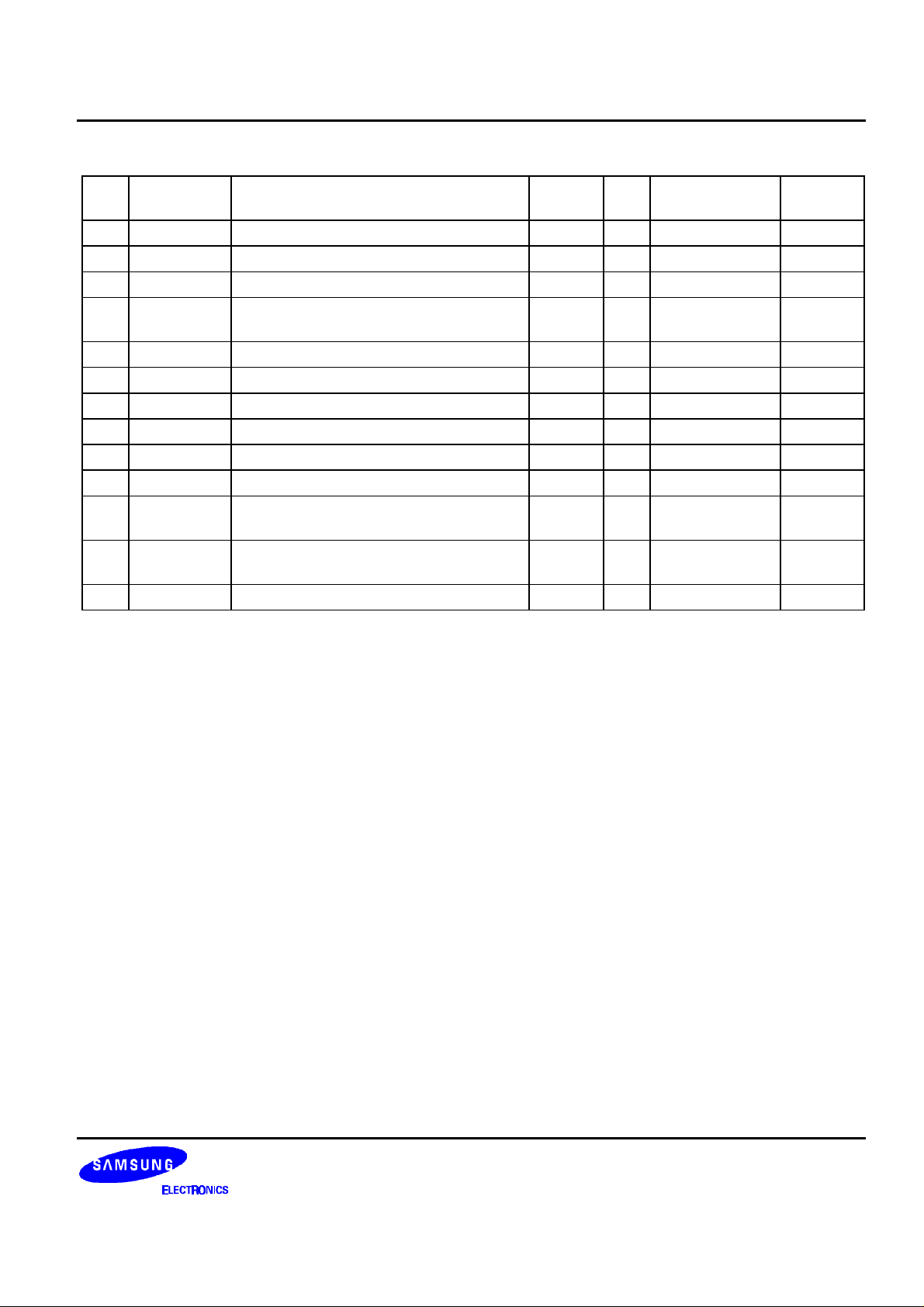

DATA SHEET S5L9250B

Table 1. Pin Description (Continued)

No Name Description Related

I/O Pad Type To/From

Block

57 ZRST System reset MICOM I PHIS MICOM

58 WRB/RWB Microprocessor write strobe (INTEL)/

MICOM I PHISU50 MICOM

read-write strobe (MOTOROLA)

59 DVDD4 Digital 3.3V power (for internal logic use) - P VDD3I 60 RDB/DSB Microprocessor read strobe (INTEL)/

MICOM I PHISU50 MICOM

data strobe signal (MOTOROLA)

61 ALE/RSB Microprocessor address latch enable/

MICOM I PHISU50 MICOM

address register select in indirect mod

62 DVSS7 Digital ground

- P VSSOP -

(for output PAD + PRE driver)

63 CSB Chip select MICOM I PHISU50 MICOM

64 DVSS6 Digital ground (for internal logic use) - P VSSI 65 AD7 Microprocessor address[7]/DATA BUS[7] MICOM B PHBCT4 MICOM

66 DVDD5 Digital 5.0V power

- P VDD5OP -

(for output PAD + PRE drive)

67 AD6 Microprocessor address[6]/DATA BUS[6] MICOM B PHBCT4 MICOM

68 AD5 Microprocessor address[5]/DATA BUS[5] MICOM B PHBCT4 MICOM

69 AD4 Microprocessor address[4]/DATA BUS[4] MICOM B PHBCT4 MICOM

70 AD3 Microprocessor address[3]/DATA BUS[3] MICOM B PHBCT4 MICOM

71 AD2 Microprocessor Address[2]/DATA BUS[2] MICOM B PHBCT4 MICOM

72 AD1 Microprocessor Address[1]/DATA BUS[1] MICOM B PHBCT4 MICOM

73 AD0 Microprocessor Address[0]/DATA BUS[0] MICOM B PHBCT4 MICOM

74 DVSS8 Digital ground (for internal SRAM: SRAM

- P VSSI -

for DP ECC use)

75 SCANEN Enable pin during scan mode test TEST I PHICD50 76 DVDD8 Digital 3.3V power (for internal SRAM

- P VDD3I -

use: SRAM for DP ECC)

77 PLOCK PLL lock indicator with HYSTERISIS PLL O PHBCT4 MONI

78 PLCK Channel bit clock(O)/EMPH(I) PLL B PHBCT12SM MONI

79 CLVLOCK CLV lock output CLV O PHOB4 MONI

80 DVSS9 Digital ground

- P VSSOP -

(for output PAD + PRE drive)

81 EFML/SL Latched EFM signal(O) PLL O PHOB8SM MONI

82 GFS Good frame sync detection flag EFM O PHOB4 MONI

83 SDATAO Serial data output AUDIO O PHOB12SM ATAPI

84 LRCKO Sample rate clock AUDIO O PHOB4 ATAPI

85 DVSS10 Digital ground (for internal logic use) - P VSSI -

7

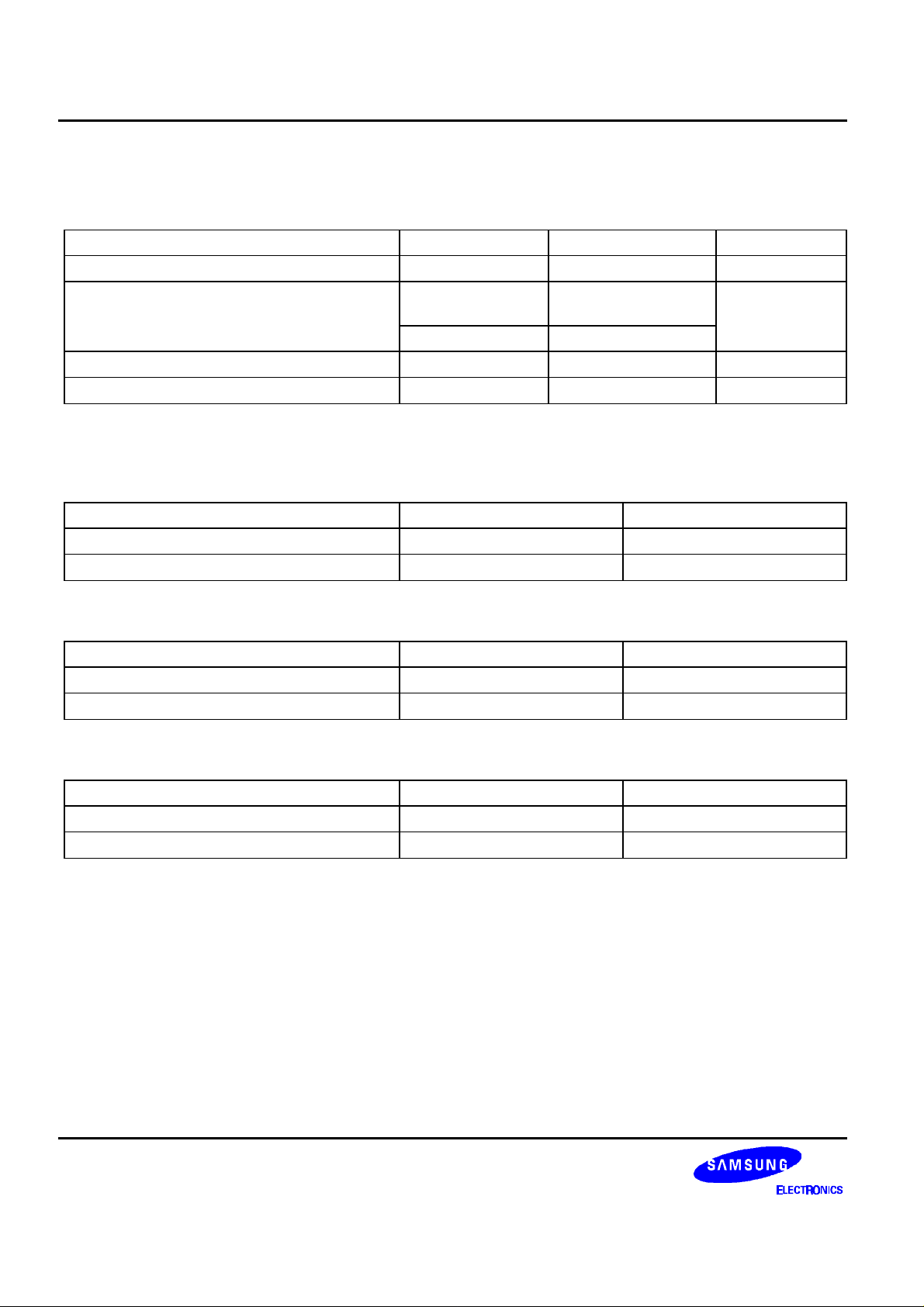

S5L9250B DATA SHEET

Table 1. Pin Description (Continued)

No Name Description Related

I/O Pad Type To/From

Block

86 C2PO C2 error pointer AUDIO O PHOB4 ATAPI

87 BCKO Bit clock AUDIO O PHOB12SM ATAPI

88 DVSS11 Digital ground

- P VSSOP -

(for output PAD + PRE drive)

89 DAOUT Digital audio out D/AUDIO O PHOT8 90 EXCK Subcode data readout clock SUB I PHIC ATAPI

91 DVDD11 Digital 5.0V power

- P VDD5OP -

(for output PAD + PRE drive)

92 SBSO Subcode P TO W serial output SUB O PHOB4 ATAPI

93 WFCKO Delayed WFCK (write frame clock) SUB O PHOB4 94 DVDD11 Digital 3.3V power (for internal logic use) - P VDD3I 95 CK50M 1-BIT DAC system clock from KS9246 DAC I PHIC ATAPI

96 DVSS12 Digital ground

- P VSSOP -

(for output PAD + PRE drive)

97 SCORO When either S0 or S1 is detected,

SUB O PHOB4 ATAPI

SCORO is high (subcode block sync)

98 VSSD1 Digital ground (1-bit DAC) DAC P VSSI 99 BCKI Bit clock input DAC I PHIC ATAPI

100 VDDD1 Digital 3.3V power (1-bit DAC) DAC P VDD3I 101 SDATAI Serial digital Input data DAC I PHIC ATAPI

102 LRCKI Sample rate clock input DAC I PHIC ATAPI

103 VSSA4 Analog ground (1-bit DAC) DAC P VSSA 104 AOUTL Analog output for L-CH DAC O POBA SPEAKER

105 AOUTR Analog output for R-CH DAC O POBA SPEAKER

106 VCCA4 Analog 3.3V power (1-bit DAC) DAC P VCCA 107 VREF Reference voltage output for bypass DAC O POBA 108 VHALF Reference voltage output for bypass DAC O POBA 109 VSSA5 Analog ground (PLL_L) PLL P VSSA 110 PWMO ALGC carrier frequency controlling

PLL O POBA -

output

111 PWMI ALGC carrier frequency controlling input PLL I PICA 112 VBG PLL band gap reference monitoring

PLL O POBA -

output

113 VCCA5 Analog 3.3V power (PLL_L) PLL P VCCA 114 VCTRL VCO control voltage PLL I PICA 115 VSSA6 Analog ground (PLL_S) PLL P VSSA -

8

DATA SHEET S5L9250B

Table 1. Pin Description (Continued)

No Name Description Related

I/O Pad Type To/From

Block

116 RDAC Biasing resistor for IDAC at charge pump PLL I PICA 117 RVCO VCO V/I converting resistor PLL I PICA 118 VCCA6 Analog 3.3V power (PLL_S) PLL P VCCA 119 VALGC ALGC PWM LPF output

PLL I PICA -

(external, DC voltage, analog level)

120 RISS VCO bias resistance PLL O POBA 121 VSSA7 Analog ground (data slicer) SLICER P VSSA 122 EFMCOMP Duty feedback slicer output SLICER O POBA MONI

123 VCCA7 Analog 3.3V power (data slicer) SLICER P VCCA 124 LPF1 LPF input (CD X20, X40) SLICER I PICA 125 LFP0 LPF input (CD X1, X2, X4, X8) SLICER I PICA 126 RFI Eye pattern from RF SLICER I PICA_25_

RF

S5L9250B

127 VCCA1 Analog 3.3V power

- P VCCA -

(EQ controller + motor I/F (P1-5))

128 EQCTL EQ output voltage EQCTL O POBA RF

9

S5L9250B DATA SHEET

ELECTRICAL CHARACTERISTICS

ABSOLUTE MAXIMUM RATINGS

Item Symbol Spec. Unit

DC supply voltage VDDmax -0.3 to +7.0 V

DC input voltage: 3.3V (internal)

: 5.0V I/O

DC input current Iin

Storage Temperature Tstg -40 to 125

ELECTROSTATIC CHARACTERISTICS

Human Body Mode

Item Spec. Note

VDD positive/negative

VSS positive/negative

Vin3 -0.3 to 3.6 V

Vin5 -0.3 to 5.5

± 10

± 2000V

± 2000V

mA

°C

MM (Machine Model) Mode

Item Spec. Note

VDD positive/negative

VSS positive/negative

CDM Method

Item Spec. Note

VDD positive/negative

VSS positive/negative

± 300V

± 300V

±800V

±800V

10

DATA SHEET S5L9250B

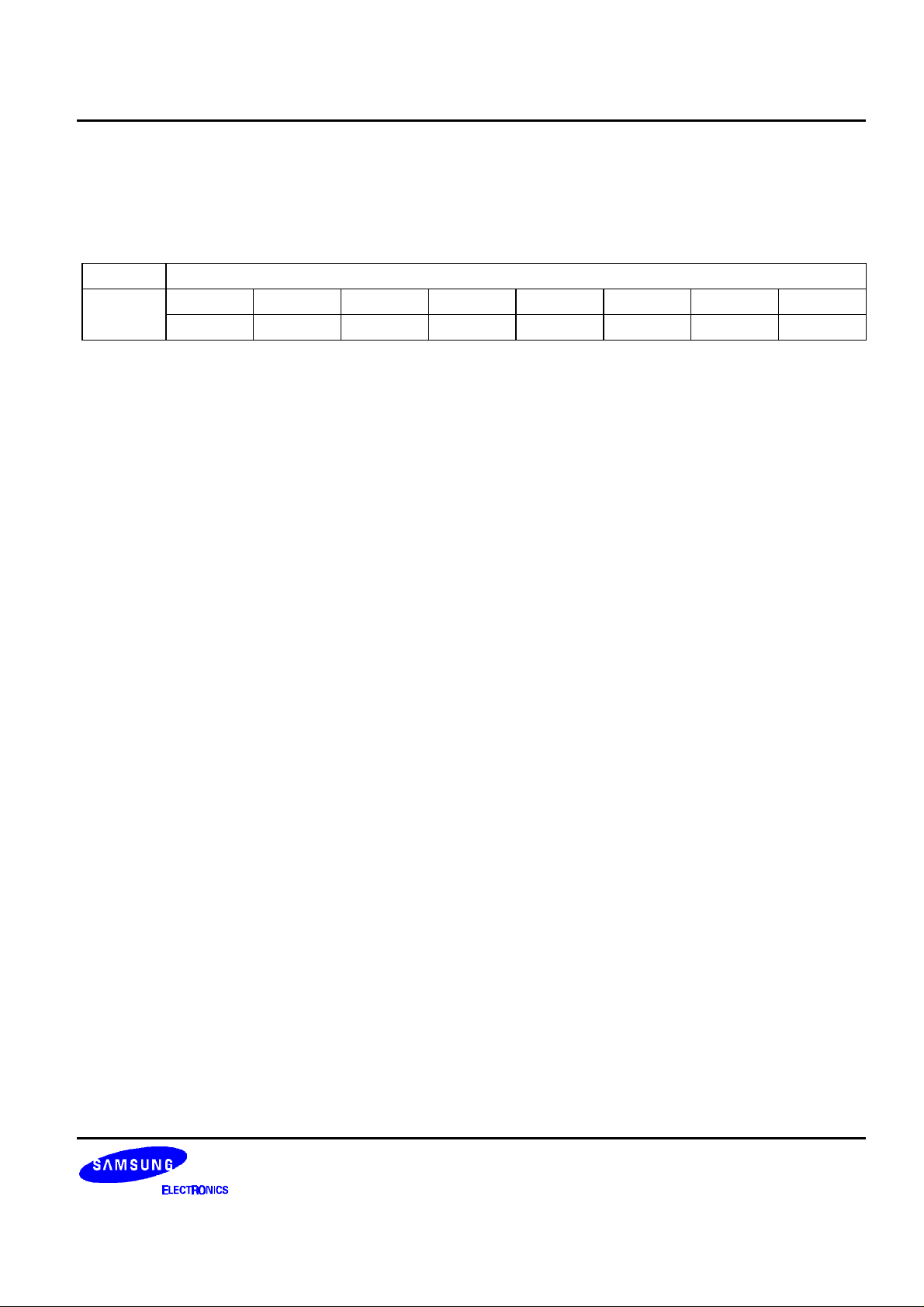

RECOMMENDED OPERATING CONDITIONS

No Item Symbol Spec. Unit

1 Operating temperature Topr 0 - 70

°C

2 DC supply voltage 3.3V VDD3 3.0 - 3.6 V

5.0V VDD5 4.75 5.25 V

DC CHARACTERISTICS: (VDD = 5V, VSS= 0V, Ta = 25°C)

ITEM Symbol Test Condition MIN TYP MAX Unit Note

'H' input voltage1

'L' input voltage1

'H' input voltage2

'L' input voltage2

'H' input current1

'L' input current1

'H' input current2

'L' input current2

'H' output voltage1

'L' output voltage1

Tri-state output leakage current

V

V

V

V

I

IH(1)

I

I

IH(2)

I

V

OH(1)

V

OL(1)

I

IH(1)

IL(1)

IH(2)

IL(2)

IL(1)

IL(2)

OZ

3.5 - - V

- - 1.5 V

2.0 - V

- 0.8- V

Vin = VDD -10 10 uA

Vin = VSS -10 10 uA

Vin = VDD 10 100 200 uA

Vin = VSS -200 -100 -10 uA

IOH = -2/-4/-8mA

IOL = 2/4/8mA

2.4 - - V

- - 0.4 V

Vout = VSS or VDD -10 - 10 uA

(1)

(1)

(2)

(2)

(3)

(3)

(4)

(5)

(6)

(6)

(7)

Quiescent supply current IDS Vin = VSS 100 uA

NOTES:

1. Related pins: All CMOS interface input terminals (PHIC)

All tri-state bi-directional pad's input terminals (PHBCT4)

2. Related pins: All CMOS schmitt trigger input terminals (PHIS, PHISU)

3. Related pins: All input terminals, bi-directional pad's input mode terminals.

4. Related pins: All input buffers with pull-down.

5. Related pins: All input buffers with pull-up.

6. Related pins: All output terminals.

7. Related pins: Tri-state output buffer (PHBCT4)

11

S5L9250B DATA SHEET

AC CHARACTERISTICS

DATA SLICER

Item Symbol Spec. Conditions

Min Typ Max Unit

RF input size Vrf 0.5 1.0 1.5 V

Input resistance Rin0 1.05 1.5 1.95 Kohm RES[2:0] = 0H

Rin1 1.4 2 2.6 Kohm RES[2:0] = 1H

Rin2 1.75 2.5 3.25 Kohm RES[2:0] = 2H

Rin3 2.1 3 3.9 Kohm RES[2:0] = 3H

Rin4 3.5 5 6.5 Kohm RES[2:0] = 4H

Rin5 4.55 6.5 8.45 Kohm RES[2:0] = 5H

Rin6 7 10 13 Kohm RES[2:0] = 6H

Rin7 28 40 52 Kohm RES[2:0] = 7H

Gain input resistance Ra1 8 10 12 Kohm

AMP offset Vosa -10 0 10 mV

Comparator open

Loop duty error DTe -2 0 2 %

COMP output resistance Roc 0 - 100 ohm

Switch on resistance Ron 0 - 100 ohm

Slice level fix

Output rang 1.24V - 2.04V

AMP gain Ra0 - 0 - Kohm INLG[2:0] = 0H

Ra1 4 5 6 Kohm INLG[2:0] = 1H

Ra2 8 10 12 Kohm INLG[2:0] = 2H

Ra3 32 40 48 Kohm INLG[2:0] = 3H

Ra4 72 90 108 Kohm INLG[2:0] = 4H

Ra5 150 190 228 Kohm INLG[2:0] = 5H

Ra6 232 290 348 Kohm INLG[2:0] = 6H

Ra7 392 490 588 Kohm INLG[2:0] = 7H

Output current = ±1m

Output current = ±1m

Vref ±15 Ls

12

DATA SHEET S5L9250B

EQUALIZER CONTROL

Item Symbol Spec. Conditions

MIN TYP MAX Unit

F/V gain Kfv 15.35 16.5 17.66 mV/%

F/V linearity FVlin -7 - 7 %

DAC resolution

∆VLS

26 mV DAC output range:

0.25 × VDD - 0.75 × VDD

DAC linearity

∆Li

-2 - 2 LSB

DAC velocity Ts 2.17 - 14.76 uS

Manual control voltage Output range: 0V - 3.3V

PLL

Item Symbol Spec Conditions

Min Typ Max Unit

Pump UP current absolute value IPU 2.1 2.3 2.5 mA

Pump DN current absolute value IPD -2.5 -2.3 -2.1 mA

Pump UP/DN current matching 1 IP1 - 5 10 %

Pump UP/DN current matching 2 IP2 - 5 10 %

VCO oscillating frequency high OSCH 200 - 250 MHz

VCO oscillating frequency low OSCL 20 - 50 MHz

Frequency division ratio 1 f40 - 45 - MHz

Frequency division ratio 2 f32 - 45 - MHz

Frequency division ratio 3 f28 - 30 - MHz

Frequency division ratio 4 f24 - 30 - MHz

Frequency division ratio 5 f20 - 22.5 - MHz

Frequency division ratio 6 f16 - 22.5 - MHz

Frequency division ratio 7 f8 - 15 - MHz

Frequency division ratio 8 f4 - 7.5 - MHz

Frequency division ratio 9 f1 - 1.875 MHz

CD lock check CDOK 2.8 3.8 - V

13

S5L9250B DATA SHEET

ARCHITECTURE DESCRIPTION

DIGITAL SERVO

Characteristics

• CD-ROM MAX 48X:

CLV: 4X, 8X

CAV: MAX 12X, 16X, 20X, 24X, 32X, 40X, 48X.

• Servo automatic adjustment:

F/T/SBAD offset, tracking balance, focus bias, F/T loop gain

• F/T input AGC feature that adapts to work with various disc types at an optimum level

• Track search algorithm using speed control method

• Algorithm for handling defects and shocks

• Generates various servo monitor signals: FOK, MIRR, TZC, and ATSC.

• Built-in 10-bit ADC (8ch division):

Samples FE/TE/various channels (1/16int.handling) three times at each fs.

• Built-in 4ch 10-bit DAC (for fod/trd/sled0, sled1 use)

• Disc discriminating data out (FEpk, SBADpk)

• Built-in 16-bit H/W track counter

• MICOM I/F feature: 8-bit parallel interface

• Serial interface with serial interface

Various automatic adjusting control signals, LD on/off, etc.

• Each loop filter's coefficient selection possible through MICOM:

focus normal/down, tracking normal/up, sled filter, various average value filter, BPF for ATSC use, BPF for

loop gain automatic adjustment, etc.

• Sampling frequency: 176.4kHz

• System clock: 33.8688MHz

• 3.3V & 5.0V dual power

14

DATA SHEET S5L9250B

Block Diagram

RFRP

RFCT

GPIO5/MIRR

SBAD

VREFI

CEI

PPUMP

XI

GPIO6/PHOLD

GPIO8/FOKB

DFCTI

ZRSTB

LOCK

SMONFGDIRROT

GPIO2/PS1

GPIO1/SSTOP

FELPF

TELPF

TZCA

GPIO4/TZCO

VREFO

TE

FE

AOUT

GPIO7/COUT

FOD

TRD

SLED0

SLED1

GPIO3/TPWM1

Analog & 10-bit

ADC

(bw1217l_cd)

Interface Block

Track Counter

10-bit DAC

(bw1244d)

Converter Block

PWM Generator

PLL

(al2002la)

Timing

Generator

DSP Core

SSP 1820

(OAKCORE)

ROM 8K

VROM_8192X16m32b2

I/O Interface BLock

RF Interface

Block

Micom Interface

Block

(Intel/Motorola)

RFDATA

RFCLK

RFEN

SENSE

WRB/RWB

RDB/DSB

ALE/RSB

CSB

AD[7:0]

15

S5L9250B DATA SHEET

Block Description

• Analog (A/D) interface block:

This block receives servo errors such as focus and tracking errors, and carries out input gain control

functions such as A/D conversion in order to heighten the rate of ADC deconstruction. It also has a TZC, a

MIRR comparator feature, a VREF generating feature, and a built-in 8ch dividing MUX.

• Timing generator:

The timing generator generates various timings used within the servo utilizing the external crystal

33.8688MHz. It also uses the built-in PLL's 40MHz as the basic signal for timing generation.

• I/O interface block:

This block accepts externally generated signals such as lock and SSTOP, and outputs internally generated

signals. It outputs various monitor signals such as ATSC and FOKB.

• RF interface block:

This block transmits various automatic adjustment outputs and data needed by the RF, such as

focus/tracking offset, TBAL output, AGC output, LD on/off, MICOM data, etc.

• MICOM interface block:

This block relays data between MICOM and 8-bit parallel.

• Track counter:

The track counter has a built-in 16-bit up/down counter to act as an accurate counter during jump.

It is 16-bit, allowing for full stroke counting.

• DA converter block:

This block uses a 10-bit DAC (R-string) to control the focus/tracking/sled0/sled1 at high resolution.

• Spindle PWM output:

This output is a 1-channel PWM output for spindle control (possible with sled)

• ROM:

This ROM is a servo program ROM with a built-in servo control program.

• DSP core for digital servo:

This block is central to the servo. It digitally handles various emergencies such as focus/tracking loop filter

handling, tracking jump, and sled move.

16

DATA SHEET S5L9250B

Register MAP and Bit Description

40x Servo Command Set for CD-ROM

Table 2. Register MAP and Bit Description

Name Code Description

STPcmd 00 Stop command: Stops jump or other auto adjustment-related actions.

DDTcmd 01 Disc detect command: Detects disc presence and carries out focus search.

FONcmd 02 Focus on command: Turns focus on through focus pull-in motion.

TONcmd 03 Track on command: Turns tracking on or off.

SLDcmd 04 Sled command: Controls the sled motor.

TRJcmd 05 Track jump command: Carries out track jump using the track counter.

SMVcmd 06 Sled move command: Carries out sled move using the track counter.

RPTcmd 07 Repeat jump command: Carries out interval jump using the track counter.

- 08 (Reserved).

- 09 (Reserved).

- 0A (Reserved).

CJNCcmd 0B CD jump number common command: Designates track number.

FGAcmd 0C Focus gain adjustment command: Automatically adjusts focus gain.

TGAcmd 0D Tracking gain adjustment command: Automatically adjusts tracking gain.

OFAcmd 0E Offset adjustment command: Automatically adjusts offset of TE/FE/SBAD.

TBAcmd 0F Tracking balance adjustment command: Automatically adjusts tracking balance.

HWofst 10 HWOFST (for center point control) adjustment command.

FBAcmd 11 Focus balance (= bias) adjustment command: Automatically adjusts focus balance.

ADScmd 12 Address setting command: Carries out upper address setting of RAM inside D-servo.

ADS1cmd 13 Address setting1 command: Sets and prepares to read lower address of RAM inside

D-servo.

DScmd 14 Data setting command: Decides address status after RAM write within D-servo.

DS1cmd 15 Data setting1 command: Upper data write in RAM within D-servo.

DS2cmd 16 Data setting2 command: Lower data write in RAM within D-servo.

JMDcmd 17 Jump mode select command: Designate jump-related initial value.

JMD1cmd 18 Jump mode1 select command: Designate jump-related initial value.

JMD2cmd 19 Jump mode2 select command: Designate jump-related initial value.

JMD3cmd 1A Jump mode3 select command: Designate jump-related initial value.

JMD4cmd 1B Jump mode4 select command: Designate jump-related initial value.

- 1C (Reserved).

EMEcmd 1D Emergency command: Various emergency-related setting command.

SenLcmd 1E If servo is active, sense is forcibly set to "L".

17

S5L9250B DATA SHEET

Table 2. Register MAP and Bit Description (Continued)

Name Code Description

CEoncmd 1F Center point servo controlling command

RFcmd 20 RF command set: Transmits RF address to send serial data to the RF IC.

RF1cmd 21 RF1 command set: Transmits RF data to send serial data to the RF IC.

HWCcmd 22 Hardware control command: Controls D-servo's H/W.

HWC1cmd 23 Hardware control1 command: Controls D-servo's H/W.

- 24 (Reserved).

- 25 (Reserved).

- 26 (Reserved).

- 27 (Reserved).

- 28 (Reserved).

ECOcmd 29 Eccentricity counter command: Counters eccentricity when off track.

ECScmd 2A Eccentricity compensation select command: Selects eccentricity compensation

method when off track.

ECCcmd 2B Eccentricity compensation control command: Controls eccentricity compensation

on/off.

FTSTcmd 2C Focus/tracking servo filter test command: Used for measuring the digital servo's

filter characteristics.

DPRWcmd 2D Direct port read/write command: Controls input/output of H/W inside D-servo.

DPWcmd 2E Direct port write command: Writes upper 8-bit data on the H/W inside D-servo.

DPW1cmd 2F Direct port write1 command: Writes lower 8-bit data on the H/W inside D-servo.

18

DATA SHEET S5L9250B

DETAILED BLOCK CHARACTERISTICS

Stop Command (STPcmd)

This command stops jump or auto adjustment-related servo activities, or enters into stop mode. The check

priority is RST>STOP>ABRT. LDON and IDLE have the same priority.

Code 1'st byte

00 D7 D6 D5 D4 D3 D2 D1 D0

RST STOP ABRT LDON 0 0 0 0

RST

0: Maintain current status.

1: Reset S/W (usually used during tray off).

STOP

0: Maintain current status.

1: Stop (automatically adjusted value does not change).

ABRT

0: Maintain current status.

1: Stop jump or adjustment-related servo activities.

LDON: Laser diode on/off bit (works only in stop mode).

0: Laser diode off.

1: Laser diode on.

D3-0: (Reserved). Must be set to "L".

19

S5L9250B DATA SHEET

Disc Detect Command (DDTcmd)

Laser diode is automatically turned on.

To detect if a disc is present, the focus actuator searches at the designated speed using the data RAM's

FSSPD(0x20) and FSDELTA(0x21). After this command, the Fepk (S-curve/2) data and SBpk (SBAD/2)'s

information are stored in the buffer so that SYSCON can read it.

Code 1'st byte

01 D7 D6 D5 D4 D3 D2 D1 D0

RPT DTM1, 0 0 FPKU 0 0 0

RPT: Repeat focus search motion (only possible when DTM1, 0 = 0, 0).

0: Carry out focus search motion only once.

1: Continue focus search motion until RPT = 0, or when STOPcmd's abort bit = 1 is accepted

(maintain sense = "L").

DTM1 -DTM0:

0: Carry out focus search once (auto).

01: Move the focus actuator to Vref position.

10: Raise focus actuator.

11: Lower focus actuator.

FPKU: S-curve detect location (set to 0 in manual mode).

0: Detect when down.

1: Detect when up.

• Search speed can be adjusted using the RAM's FSSPD(0x20), FSDELTA(0x21), FCNTmax(0x28), and

FCNTmin(0x29).

Search speed (1 period) = (FCNTmax-FCNTmin)*2*FSSPD/FSDELTA/Fs

• FE peak can be read through the MICOM interface after one search.

• The following are the data that MICOM can refer to after DDTcmd:

- FEpk: FE peak data (S-curve/2).

- SBpk: SBAD peak data (SBAD/2).

D15 D8 D7 D0

Fepk SBpk

20

DATA SHEET S5L9250B

Focus On Command (FONcmd)

This command carries out focus pull-in. The laser diode is turned on automatically. If focus is already on when

this command is received, no further actions are taken.

Code 1'st byte

02 D7 D6 D5 D4 D3 D2 D1 D0

0 FONU 0 0 PIM 0 0 0

FONU: Focus pull-in location.

0: After actuator up, pull-in when down.

1: After actuator down, pull-in when up.

PIM: Pull-in method.

0: Recognize FE. Use pull-in level's absolute value.

1: Recognize FE. Use pull-in level's FEPK percentage (can be set freely using kFEok(0xfe3e) and

kFEpi(0xfe3f)).

• Adjust search speed using the RAM's FSSPD(0x20), FSDELTA(0x21), FCNTmax(0x28), and FCNTmin

(0x29).

Search speed (1 period) = (FCNTmax-FCNTmin) * 2 * FSSPD/FSDELTA/Fs

• If FONcmd is accepted again during play (TRon), the tracking/sled is turned off.

21

S5L9250B DATA SHEET

Tracking On Command (TONcmd)

TONcmd is a tracking pull-in command.

If tracking is already on when this command is accepted, no further actions are taken.

Code 1'st byte

03 D7 D6 D5 D4 D3 D2 D1 D0

0 TON SLDX TFSB TOLB1-0 0 KICK

TON: Track on/off.

0: Off.

1: On.

SLDX : Sled servo on/off.

0: Sled off.

1: Turn sled servo on after a certain time interval from tracking on.

TFSB: Eccentricity compensation pull-in control bit during track pull-in.

0: Normal pull-in.

1: Eccentricity compensation pull-in (count between the edges of TZC and pull-in where

the frequency is low).

TOLB1-0: Lens brake during track pull-in and T/F gain control enable/disable.

Used for pull-in after jump using stepping motor.

0X: Off.

10: On (during normal pull-in, use the lens kick value for the lens brake time).

11: On (pull-in after the stepping motor feed kick).

KICK: KICK signal control (for stepping motor sled movement).

0: Set KICK signal to "L".

1: Set KICK signal to "H".

22

DATA SHEET S5L9250B

Sled On Command (SLDcmd)

SLDcmd is a sled motor control command. Bit check starts from the home bit.

Code 1'st byte

04 D7 D6 D5 D4 D3 D2 D1 D0

HOME SMOV SPLY 0 0 0 0 0

HOME: SLED HOME_IN mode select

0: Normal sled control mode.

1: Auto sled HOME_IN control mode.

When this bit is set, the sled motor moves backwards until it detects the LIMIT S/W. From then on, it moves

forward for the time designated by tSLDhomein.

SMOV, SPLY: Sled on/off and sled move control bit.

00: Sled off

01: Sled on

10: Sled forward move

11: Sled backward move

D4 to 0: Reserved. Must be set to "L".

When HOME = 1 (auto sled control mode), the SENSE is as shown below.

SENSE

LIMIT S/W

RVS

innermost

ON OFF

FWD

All limit sensor data when not in auto mode are output when focus is off while the sled is moving in either

direction. The limit sensor choice is made at JMD1cmd's JLIM1-0. It is "L" early in the command, but

becomes

"H" when it reaches either the innermost or outermost circumference.

23

S5L9250B DATA SHEET

Track Jump Command (TRJcmd)

TRJcmd is a track jump command used for track kick/brake jump and track speed control jump.

Code 1'st byte

05 D7 D6 D5 D4 D3 D2 D1 D0

DIR NUMS

DIR: Direction you want to move in using the track counter (TC).

0: Outward movement.

1: Inward movement.

NUMS: Number of upper tracks you want to move (0x00 - 0x7F).

• The lower jump track number is designated by CJNCcmd (0B).

24

DATA SHEET S5L9250B

Sled Move Command (SMVcmd)

SMVcmd is a sled move command that is used for sled kick/brake movement and sled speed control movement.

Code 1'st byte

06 D7 D6 D5 D4 D3 D2 D1 D0

DIR NUMS

DIR: The direction you want to move in using the track counter (TC).

0: Outward movement.

1: Inward movement.

NUMS: Number of upper tracks you want to move (0x00 - 0x7F).

• The lower Jump track number is designated by CJNCcmd (0B).

1. Repeat Jump Command (RPTcmd): (Reserved).

RPTcmd is an Interval track jump command that is used during a repeating jump.

Code 1'st byte

07 D7 D6 D5 D4 D3 D2 D1 D0

DIR NUMS

DIR: Direction you want to move in using the track counter (TC).

0: Outward movement.

1: Inward movement.

DIR: Direction you want to move in using the track counter (TC).

0: Outward movement.

1: Inward movement.

NUMS: Number of upper tracks you want to move (0x00 - 0x7F).

• The lower Jump track number is designated by CJNCcmd (0B).

• The interval frequency is designated by MICOM as 16 bit (0xfeef). interval freq.= sampling freq (fs)/MICOM

data

Example) If MICOM data is h'4000, 176 kHz (fs)/h'4000 (d'16384) = 9.2 Hz

25

S5L9250B DATA SHEET

CD Jump Number Common Command (CJNCcmd)

CJNCcmd is a command that designates the track number of TRJcmd, RPTcmd (reserved), and the lower track

number of SMVcmd.

Code 1'st byte

08 D7 D6 D5 D4 D3 D2 D1 D0

NUMS

NUMS: The number of lower tracks you want to move (0x01 - 0xFF).

Command input method for CD when executing sled move using SMVcmd.

: Input in the order, 06xx → 0Bxx.

Focusing Gain Adjustment Command (FGAcmd)

FGAcmd is a command that adjusts the auto focus gain. Use when focus servo is on, and tracking servo on or

off.

Code 1'st byte

0C D7 D6 D5 D4 D3 D2 D1 D0

FGud 0 0 0 0 0 0 TFGA

FGud: Auto focus gain update

0: No update

1: When changing Kfo, Kfuo after automatic adjustment, update according to the rate of change

during the automatic adjustment.

TFGA: Test mode for FGA

0: Normal FGA

1: Change focus gain once without regard to focus gain ok, then change back to the previous mode.

26

DATA SHEET S5L9250B

Tracking Gain Adjustment Command (TGAcmd)

TGAcmd is an auto tracking gain adjustment command.

Use while both focus servo and tracking servo are on.

Code 1'st byte

0D D7 D6 D5 D4 D3 D2 D1 D0

TGud 0 0 0 0 0 0 TFGA

TGud: Auto tracking gain update

0: No update

1: When changing Kto, Ktuo after automatic adjustment, update according to the rate of change during the

automatic adjustment.

TTGA : Test mode for TGA

0: Normal TGA

1: Change tracking gain once without regard to tracking gain ok, then change back to the previous mode.

27

S5L9250B DATA SHEET

Offset Adjustment Command (OFAcmd)

OFAcmd is an auto focus/tracking/SBAD offset Adjust command that measures and adjusts focus error, tracking

error, and SBAD signal. Lens location is selected by DDTcmd's DTM1-0.

Code 1'st byte

0E D7 D6 D5 D4 D3 D2 D1 D0

VREN RFRP SBEN TRD0 FOD0 CEIEN TEN FEN

VREN: VREF offset measurement enable bit.

0: Do not measure VREF offset.

1: Measure VREF offset.

RFRP: RFRP offset measurement enable bit.

0: Do not measure RFRP offset.

1: Measure RFRP offset.

SBEN: SBAD offset measurement enable bit.

0: Do not measure SBAD offset.

1: Measure SBAD offset.

TRDO: Tracking DAC offset adjustment.

0: Do not adjust.

1: Adjust.

FODO: Focus DAC offset adjustment.

0: Do not adjust.

1: Adjust.

CEIEN: Center error offset adjustment enable bit for center point servo.

0: Do not adjust offset.

1: Adjust offset.

TEN: Tracking offset adjustment enable bit.

0: Do not adjust tracking offset.

1: Adjust tracking offset.

FEN: Focus offset adjustment enable bit.

0: Do not adjust focus offset.

1: Adjust focus offset.

• After offset measurement, subtract the Vref offset from TRD and FOD.

28

DATA SHEET S5L9250B

Tracking Balance Adjustment Command (TBAcmd)

TBAcmd averages the MAX and MIN values of TE using eccentricity while the focus is on and tracking is off.

Always use before going into play (tracking on).

Code 1'st byte

0F D7 D6 D5 D4 D3 D2 D1 D0

0 0 0 0 0 0 0 TTBA

TTBA: Test mode for TBA

0: Normal TBA

1: Change tracking balance once without regard to tracking balance ok, then change back to

previous mode.

Hardware Offset Adjust Command (HWOFSTcmd)

HWOFSTcmd is the offset adjustment command for CEI, an input signal for center point control.

Code 1'st byte

10 D7 D6 D5 D4 D3 D2 D1 D0

0 0 0 0 0 0 0 THW0

Adjust the offset of RF's CEI output when HWOFSTcmd is accepted.

THWO: Test mode for HW offset.

0 : Normal HW offset

1: Carry out HW offset adjustment once without regard to HW offset OK, then change back to the previous

mode.

29

S5L9250B DATA SHEET

Focus Balance Adjustment Command (FBAcmd)

FBAcmd uses the RF envelop signal to end focus balance adjust when the RF signal is at its maximum. Always

use after focus pull-in.

Code 1'st byte

11 D7 D6 D5 D4 D3 D2 D1 D0

0 0 0 0 0 0 0 TFBA

TFBA: Test mode for FBA.

0 : Normal FBA.

1: Carry out focus balance once without regard to focus balance ok, then change back to the

previous mode.

Address Setting Command (ADScmd)

ADScmd directly accesses SRAM within the digital servo and sets the upper address during read/write. The lower

address is designated by ADS1cmd.

Code 1'st byte

12 D15 D14 D13 D12 D11 D10 D9 D8

ADDRESS

ADDRESS: Designates upper address of X,Y data memory.

• This command is used together with ADS1cmd that designates the lower address, and is thus always used as

2 bytes (ADScmd,ADS1cmd).

Address Setting1 Command (ADS1cmd)

ADS1cmd directly accesses SRAM within the digital servo and sets the lower address during read/write. It is

always used after ADScmd.

Code 1'st byte

13 D7 D6 D5 D4 D3 D2 D1 D0

ADDRESS

ADDRESS: Designates the lower address of X,Y data memory.

30

Loading...

Loading...