Page 1

Global LCD Panel Exchange Center

G

G

G

mvyGtlzzyza

GGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGGkh{laGq|sGX[SGYWXWG

www.panelook.com

TOP

CUSTOMER’S SPECIFICATIONS

106.68cm (42 Inch) Wide Plasma Display Module

MODEL:S42AX-YD13(M3)

(NTSC/PAL)

* This specification will be approved by both TOP and Samsung SDI Co.,Ltd.

* Please return one of this specification with your signature for approval.

Proposed by: Approved by:

Signature

Signature

G/Manager. ChangSub, Son

PDP Development Team, PDP Business

Division, Samsung SDI Co., Ltd

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

SAMSUNG SDI Corporation Plasma Display Panel

www.panelook.com

Revision History

No Date Description Of Changes Rev. no Approval

1 DEC 22, 09 Tentetive SPEC for customer application R0.0

1)30% L/R :

2 JAN 12, 10

z Typical 190cd/້ -> 165cd/້

z Minimum 160 cd/້ -> 155 cd/້

Page 7

SAMSUNG SDI - 2/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

㡺⮮

㺛Ṟ䞒Ṗ 㩫㦮♮㠊 㧞㰖 㞠㔋┞┺

㡺⮮! 㺛Ṟ䞒Ṗ 㩫㦮♮㠊 㧞㰖 㞠㔋┞┺

㡺⮮! 㺛Ṟ䞒Ṗ 㩫㦮♮㠊 㧞㰖 㞠㔋┞┺

㡺⮮! 㺛Ṟ䞒Ṗ 㩫㦮♮㠊 㧞㰖 㞠㔋┞┺

㡺⮮! 㺛Ṟ䞒Ṗ 㩫㦮♮㠊 㧞㰖 㞠㔋┞┺

㡺⮮! 㺛Ṟ䞒Ṗ 㩫㦮♮㠊 㧞㰖 㞠㔋┞┺

㡺⮮! 㺛Ṟ䞒Ṗ 㩫㦮♮㠊 㧞㰖 㞠㔋┞┺

㡺⮮! 㺛Ṟ䞒Ṗ 㩫㦮♮㠊 㧞㰖 㞠㔋┞┺

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

TABLE OF CONTENTS

TU1. DESCRIPTIONUT ......................................................................................................................... 5

TU2. FEATURESUT ............................................................................................................................... 5

TU3. PRODUCT NAME AND MODEL NUMBERUT ....................................................................... 5

TU4. FUNCTION OUTLINEUT ............................................................................................................ 5

TU5. BLOCK DIAGRAMUT ................................................................................................................. 6

TU6. DISPLAY CHARACTERISTICSUT ........................................................................................... 7

TU6.1 DISPLAY PERFORMANCEUT ........................................................................................................ 7

TU6.2 DISPLAY CELL ARRANGEMENTUT .............................................................................................. 8

TU6.3 LUMINANCE MEASUREMENT CONDITIONUT............................................................................... 9

TU6.4 CONTRAST MEASUREMENT CONDITIONUT ............................................................................... 10

TU6.5 DISPLAY CELL DEFECT SPECIFICATIONUT ............................................................................... 11

TU6.6 UNIFORMITY SPECIFICATIONSUT .............................................................................................. 12

TU6.7 POWER CONSUMPTIONUT.......................................................................................................... 13

TU6.8 GAMMA CHARACTERISTICSUT .................................................................................................. 17T

TU

6.9 FILM FILTERUT ......................................................................................................................... 19

TU6.10 WHITE BLANCEUT.................................................................................................................. 21

TU7. SOUND PRESSURE LEVEL SPECIFICATIONUT .............................................................. 19

TU7.1 MEASURING CONDITIONUT ...................................................................................................... 22

TU7.2 SOUND PRESSURE LEVELUT ..................................................................................................... 22

TU8. MECHANICAL CHARACTERISTICSUT............................................................................... 23

TU8.1 MECHANICAL SPECIFICATIONSUT ............................................................................................ 23

TU8.2 MECHANICAL CHARACTERISTICSUT......................................................................................... 23

TU9. ENVIRONMENTAL CONDITIONSUT ................................................................................... 24

TU9.1 OPERATIONAL ENVIRONMENTAL CONDITIONUT ...................................................................... 24

TU9.2 STORAGE ENVIRONMENTAL CONDITION *1UT ......................................................................... 24

TU9.3 PANEL SURFACE CONDITIONUT ............................................................................................... 25

TU10. INTERFACE SIGNAL SPECIFICATIONSUT...................................................................... 26

TU10.1 CONFIGURATION CONTEXTUT ................................................................................................ 26

TU10.2 INTERFACE FUNCTION SPECIFICATIONS (INPUT DATA AND DISPLAY PROCESSING)UT ........

.

TU10.3 INPUT SIGNAL DEFINITIONUT ...............................

TU10.4 LVDS SIGNAL DEFINITION AND FUNCTIONUT .....

TU10.5 LVDS SIGNAL PIN ASSIGNMENTUT .....................

TU10.6 VIDEO SIGNAL DEFINITION AND FUNCTIONUT ....................................................................... 30

TU10.7 ELECTRICAL CONDITION OF INTERFACE SIGNALUT

TU10.8 VIDEO SIGNAL INTERFACE TIMING CONDITIONSUT

TU10.9 LVDS INTERFACE TIMING CONDITIONSUT ..........

TU10.10 LVDS CONNECTION SPECIFICATIONSUT ............

SAMSUNG SDI - 3/64 - Rev.01 31/12/0

!

.

.

.

.

.

.

.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

㡺⮮! 㺛Ṟ䞒Ṗ 㩫㦮♮㠊 㧞㰖 㞠㔋┞┺

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

TU10.11 I2C INTERFACE CONDITIONSUT..........................

TU11.ADDRESS MAPUT ................................................... 㡺⮮! 㺛Ṟ䞒Ṗ 㩫㦮♮㠊 㧞㰖 㞠㔋┞┺.

TU12.UT TUPOWER SUPPLY UNIT SPECIFICATIONUT ..................................................................... 42

TU12.1UT TUINPUT REQUIREMENTSUT ................................................................................................... 42

TU12.2 TUELECTRICAL CHARACTERISTIC OVERVIEWUT .................................................................... 43UT

TU

12.3 TUOUT DIMENSION FOR REFERENCEUT .................................................................................. 43UT

12.4 TUPOWER APPLYING SEQUENCEUT ........................................................................................ 44UT

TU

12.6 TUMECHANICAL OUT DRAWINGUT ........................................................................................ 46UT

TU

TU

13. MECHANICAL DIMENSION DRAWINGUT....................................................................... 49

TU13.1 FRONT SIDEUT........................................................................................................................ 49

TU13.2 REAR SIDEUT ......................................................................................................................... 49

TU13.2 REAR SIDEUT ......................................................................................................................... 50

TU14. LABELUT ................................................................................................................................... 51

TU14.1 LABEL TYPEUT ....................................................................................................................... 51

TU14.2 LABEL LOCATIONUT ............................................................................................................... 52

TU15. PACKINGUT.............................................................................................................................. 53

TU15.1 PACKING DIMENSION AND PARTS LISTUT .............................................................................. 53

TU15.2 PACKING ASSEMBLY DRAWINGUT ......................................................................................... 53

.

TU16. RELIABLITYUT ....................................................................................................................... 54

TU16.1 EXPECTED SERVICE LIFEUT ................................................................................................... 54

TU16.1.1DefinitionUT .................................................................................................................... 54

TU16.1.2 Test condition and life timeUT........................................................................................ 54

TU16.2 DISCLAIMERUT ...................................................................................................................... 54

TU16.4 CERTIFICATEUT ...................................................................................................................... 54

TU17. WARNING CAUTION / NOTICEUT..................................................................................... 55

TU17.1 WARNINGUT........................................................................................................................... 55

TU17.2 CAUTIONUT ............................................................................................................................ 57

TU17.3 NOTICEUT............................................................................................................................... 58

SAMSUNG SDI - 4/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

SAMSUNG SDI Corporation Plasma Display Panel

www.panelook.com

1. DESCRIPTION

The S42AX-YB09(M1) and S42AX-YD13 are a 42-inch wide full color plasma display

Module with a resolution of 1024(H) Ý 768(V) pixels. The display module includes the

Plasma Display Panel, the Panel Driving Electronics, the Logic Control Board.

2. FEATURES

x Wide aspect ratio(16:9) 42 inch diagonal display screen. The display area is 933.89mm

wide and 532.22mm high.

x Slim and light weight. The display Module is 45.2mm in depth and weight only

approx. 11.9kg.

x 1073.7 million colors(10Bit), or 16.77 million colors(8Bit) combination of R,G and B

digital data.(According to LVDS input selection)

x High Luminance, High contrast, Wide viewing angle. The screen has a white peak

Luminance of typical 500 cd

contrast of typical 10,000:1(NTSC/PAL).

And a viewing angle of greater than 160¶ comparable to that achieved

/້(In Film transmissivity 45.0%, NTSC/PAL),

3. PRODUCT NAME AND MODEL NUMBER

x Product name : 42 inch Full Color Plasma Display Module

(abbreviation : PDP Module)

x Model number : S42AX-YD13(M3) (Project name : U2P)

4. FUNCTION OUTLINE

x The plasma display module has an APC(Automatic Power Control) function which

restricts power consumption within the certain value with regard to each display load

ratio.

x The plasma display module is operated by following digital video signals; Vertical

synchronous signal, Horizontal synchronous signal, Enable signal and 8~12bit data

signals of each R, G and B color. All signals are based on LVDS level.

x The plasma display module is operated at 50Hz60Hz frame rate. An external frame rate

conversion is required in order to display the other formats.

x The plasma display module requires several types of input power voltages ; voltage for

logic IC, voltage for Gate Driver, voltage for Sustain and voltage for Address.

x The plasma display module is operated at progressive signal only.

An external progressive scan conversion is required in order to display the other formats.

SAMSUNG SDI - 5/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

5. BLOCK DIAGRAM

LVDS SIGNAL

ULOGIC CONTROLLERU

LVDS I/F CONTROLLER

DATA PROCESSOR

DISPLAY DATA

U U

SCAN PULSE

DRIVER

PDP

1024Ý768 Pixels

DATA DRIVER

DRIVING VOLTAGE

SUSTAIN PULSE

DRIVER

POWER SUPPLY UNIT

Figure-1. Block Diagram of PDP module

SAMSUNG SDI - 6/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

6. DISPLAY CHARACTERISTICS

6.1 Display Performance

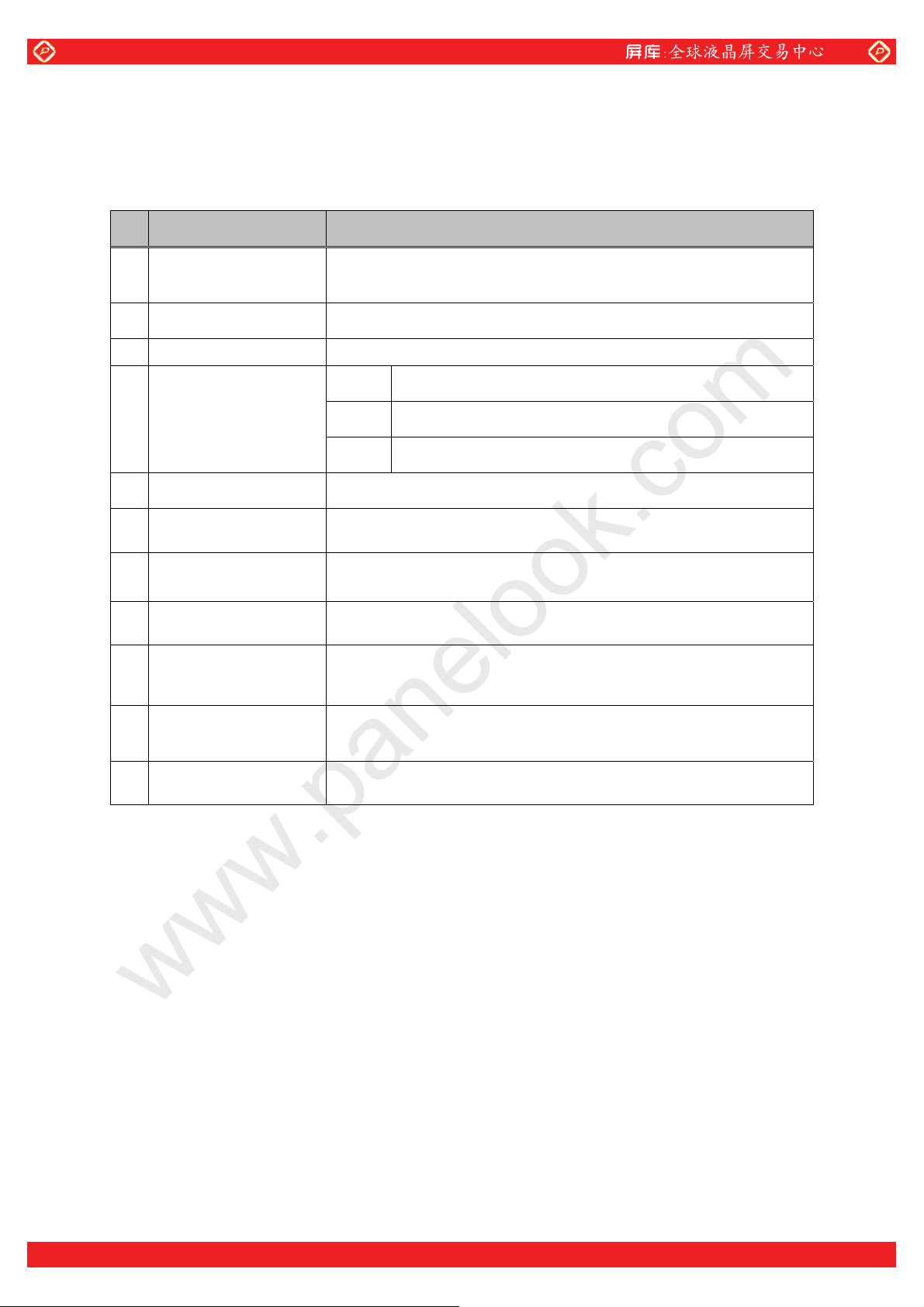

No Item Rating

1 Display Pixels

Horizontal 1024 ൴Vertical 768 pixels

(1 pixel = 1 R,G,B cells)

2 Display Cells Horizontal 3,072 ൴Vertical 768 cells

3 Pixel Pitch

Horizontal 912༁൴Vertical 693༁

R Horizontal 304༁൴Vertical 693༁

4 Cell Size

G Horizontal 304༁൴Vertical 693༁

B Horizontal 304༁൴Vertical 693༁

5 Pixel Type R, G, B Non stripe (refer to Figure-2)

6

Effective Display

Size

7 Number of color

Peak Luminance *1

8

(peak algorithm on)

Horizontal 933.89༂൴Vertical 532.22༂

[ 36.77 inch ൴ 20.95 inch ]

1073.7 million colors (10Bit)

16.77 million colors ( 8Bit)

Typical 500 cd/້ , Minimum 400 cd/້

Contrast Ratio *2

9

10

(in dark room,

peak algorithm on)

Brightness

(Full white Brightness)

1,000,000:1

Typical 60cd/້ , Minimum 50 cd/້

* 30% L/R : Typical 165cd/້ , Minimum 155 cd/້

11 Viewing Angle *3 Over 160

(Note)

* 1. Luminance and Color Coordinates are the values that were measured with Full load

ratio white pattern. The condition for measurement is shown in Figure-3.

* 2. Contrast Ratio is calculated from the display Luminance and the non-display

Luminance value. Display condition is shown in Figure-4.

* 3. Viewing angle is a critical angle at which the Luminance is reduced to 50% to the

Luminance perpendicular to the PDP Module. The Luminance is measured by a noncontact luminance meter MINOLTA CA-100Plus.

SAMSUNG SDI - 7/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

6.2 Display Cell Arrangement

1st

Pixel

Row

2nd

Pixel

Row

767th

Pixel

Row

1st

Pixel

Column

Pixel Pitch (Width): 0.912 mm

Pixel

Pitch

2nd

Pixel

Column

ڭڢڝ ڭڢڝ ڭڢڝ

ڭڢڝ ڭڢڝ ڭڢڝ

WUZ W[G

WUZW[G

WUZ W[G

ڭڢڝ ڭڢڝ ڭڢڝ

3rd

Pixel

Column

ڞۀۇۇ

ګۄۏھۃ ڣۀۄۂۃۏ

ڃڋډڑڔڎ ۈۈڄ

1022th 1023th 1024th

Pixel Pixel Pixel

Column Column

ڭڢڝ ڭڢڝ ڭڢڝ

ڭڢڝ ڭڢڝ ڭڢڝ

ڭڢڝ ڭڢڝ ڭڢڝ

Column

768th

Pixel

Row

ڭڢڝ ڭڢڝ ڭڢڝ

Figure-2.Display Cell Arrangement

ڭڢڝ ڭڢڝ ڭڢڝ

SAMSUNG SDI - 8/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

g

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

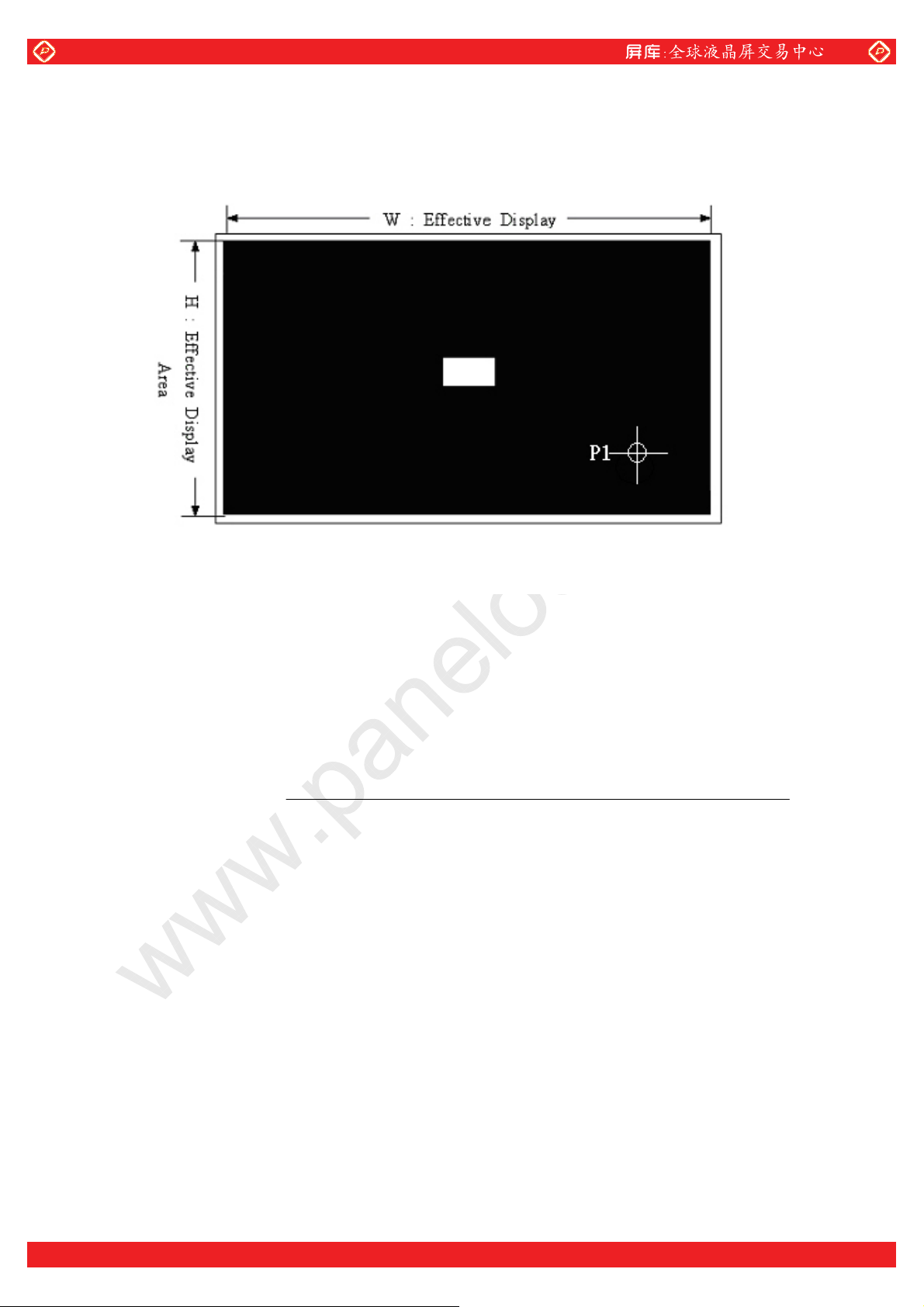

6.3 Luminance Measurement Condition

(1) Display Pattern

Effective Display Area

Effective Dis play Area

460 104 460

Unit : Pixels(=lines)

marked area : White display area by maximum gradation setting

marked area : Black color (non-dis play area)

ure-3. DisplayPattern forBrightness & Contrast Ratio Measurement

Fi

345

78

345

(2) Display Area ratio : 1% white window

(3) Vsync : 16.7ms

(4) Measuring equipment : MINOLTA CA-100Plus

Pattern Generator(VG-828, LVDS Output).

(5) Ambient Temperature : Room Temperature

(6) Ambient Luminance : Dark Room (<2 lux)

[ Note]

1. Measurement is done within 30 seconds after Power On. The temperature of panel

before measurement is room temperature (25ଇ).

2. Measurement is done within 3 seconds after Display Pattern(

mTZPGvG

SAMSUNG SDI - 9/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

6.4 Contrast Measurement Condition

(1) Measuring point

Figure-4. Measurement point

(2) Vsync : 16.7 ms

(3) Measuring Equipment : MINOLTA CA-100Plus

Pattern Generator(VG-828, LVDS Output).

(4) Contrast Calculation formula

Luminance of 1% white window Area at the center of the screen

Contrast ratio =

Luminance of Black Area *1

ૺ Note ૻ

1. For mass production test purposes, it is recommended to measure just 1 point, P1 of

Figure 4 on display pattern of Figure 3.

2. Measuring point _P1 is that minimum luminance point from among effective display

area

(5) Ambient Light : Dark Room (<2 lux)

SAMSUNG SDI - 10/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

~G

oV[G

GiG

GhG

oV[G

oVYG

oG

~V[G ~VYG ~V[G

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

6.5 Display Cell Defect Specification

In some cases, a panel may have defective cells that cannot be controlled.

These defective cells can be categorized into three types;

(1) Non-lighting cell defect : defect in which the cell is always off

(2) Non-extinguishing cell defect : defect in which the cell is always on.

(3) Flickering cell defect : defect in which the cell is flickering.

(4) High intensity cell defect : defect in which the cell is brighter than other cells

(5) Test Pattern : Full White, Full Red, Full Green and Full Blue with 1024 gray level.

The display cell defect specifications define the allowed limits for display cell defects

and

are used as the criteria in determining whether a panel should be shipped.

Item

Non-lighting cell 3 and less 10 and less

Non-extinguishing cell 1 and less 2 and less

Flickering cell

(the W/R/G/B screen)

Flickering cell

(the other pattern)

High Intensity Cell 1 and less 2 and less

Figure-5. Measurement Area

Number of cell defects

A Zone B Zone

2 and less 3 and less

1 and less 2 and less

Remark

Regardless of A and B Zone,

Maximum 1 Cell Defect

in an area of 20*20mm

is allowed.

Continuous Cell 1 and less 2 and less

Total defect 14 and less

SAMSUNG SDI - 11/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

x

x

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

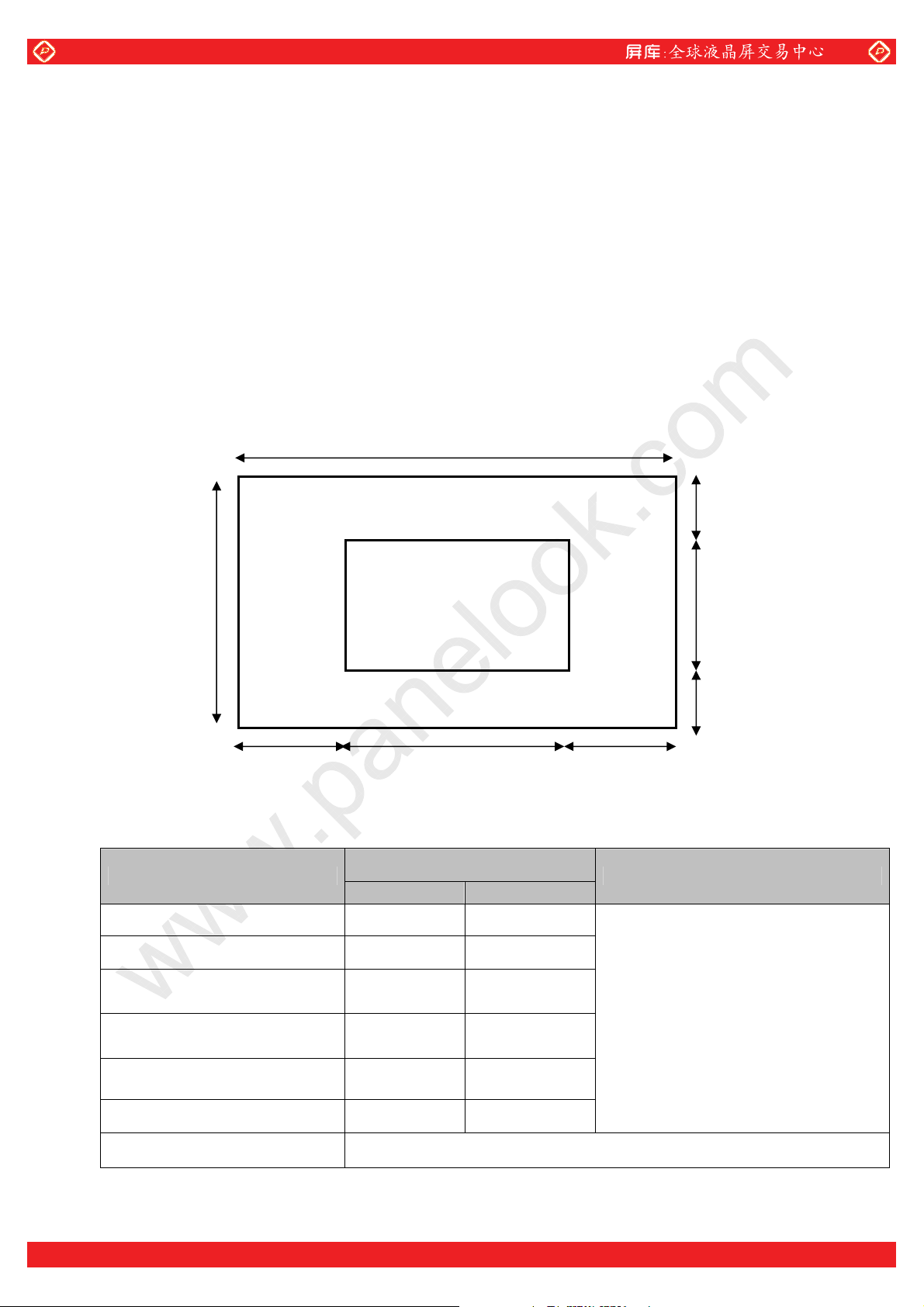

6.6 Uniformity Specifications

The color-PDP uses ultraviolet light produced by gas discharge to illuminate phosphor.

Uneven phosphor coating and inconsistent discharge characteristics cause slight difference

in brightness among the sections in a panel.

Item

Full white

brightness

variation

Equation

Definition

The brightness is measured at 9 points (A1~A9 of

Fig-6) on full white pattern.

The full white brightness variation as then calculated

from the following equations.

Max x

x Min

u 100%

Specification

15% and less

u 100%

&

The brightness variation specifications define the allowed limits for brightness differences

and the criteria in determining whether a panel is shipped.

W : Effective Display Area

H : Effective Display Area

A1 A2 A3

A4

A7

W*0.1 W*0.1

Figure-6. Measuringareas

A5 A6

A8 A9

H* 0.1

H* 0.1

SAMSUNG SDI - 12/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

(

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

6.7 Power consumption

6.7.1 APC (Automatic Power Control) Function

The PDP has an APC (Automatic Power Control) function for the panel driver power source.

When the total display load ratio exceeds approximately 10%, total power consumption is

limited within a specified level (=Lower Power Limit) by APC function.

The operation behavior of APC function is called as SLOW-APC. When the display loadratio changes from low to high value, the power-consumption rises instantly to “Upper

Power Limit” and gradually decreases until it reaches to the “Lower Power Limit.”

[Note] Number of steps may Power vary as a function of the load ratio.

Power

Upper Power

Limit

Power

Load-ratio

Time for transition between 2 setps = 8 frames

Lower Power

Limit

This could be controlled by R HOLD TIME)

t

Figure 7. Slow APC Behavior

6.7.2 Brightness and Power Mode Control

This PDP module offsers two methods for Brightness and Power mode control.

One is APCO(APC Offset) for Peak-Brightness control, and the others are PUG and

PLG

for power mode control. APCO, PUG and PLG are registers controllable through I2C

communication from image B’d. For a detailed address and data bits of these registers ,

refer to the Chapter 11. Address Map.

(1) Peak-Brightness Control( APCO)

- controls the max.sustain number

- APCO variable range : 0010h~01FFh (cf. 00C8h~01F4h @3D Mode)

Sustain

number

Max. Sustain

Normal Bright Mode (APCO=0000h)

2/3 Peak-bright Mode (APCO=00F0h)

1/3 Peak-bright Mode (APCO=1A4h)

Min. Sustain

SAMSUNG SDI

0

C

max

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

load ratio

- 13/64 100%

Figure-8. APCO Behavior

www.panelook.com

Page 14

Global LCD Panel Exchange Center

@

)

N

r

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

(2) ASLG ( Power-Mode Control using ASL gain function)

- ASLG variable range : 80~FFh

- Maximum available power decrease by increasing ASLG above 80h(NTSC)

Sustain

number

Max. Sustain

Min. Sustain

ASLG < ASLG’

ASLG’ = 60h

ASLG > ASLG’

load at F/W pattern

NTSC(50h@PAL

High-Power Mode

Powe

Saturated at Min. Sustain

0

Load-ratio

100%

-

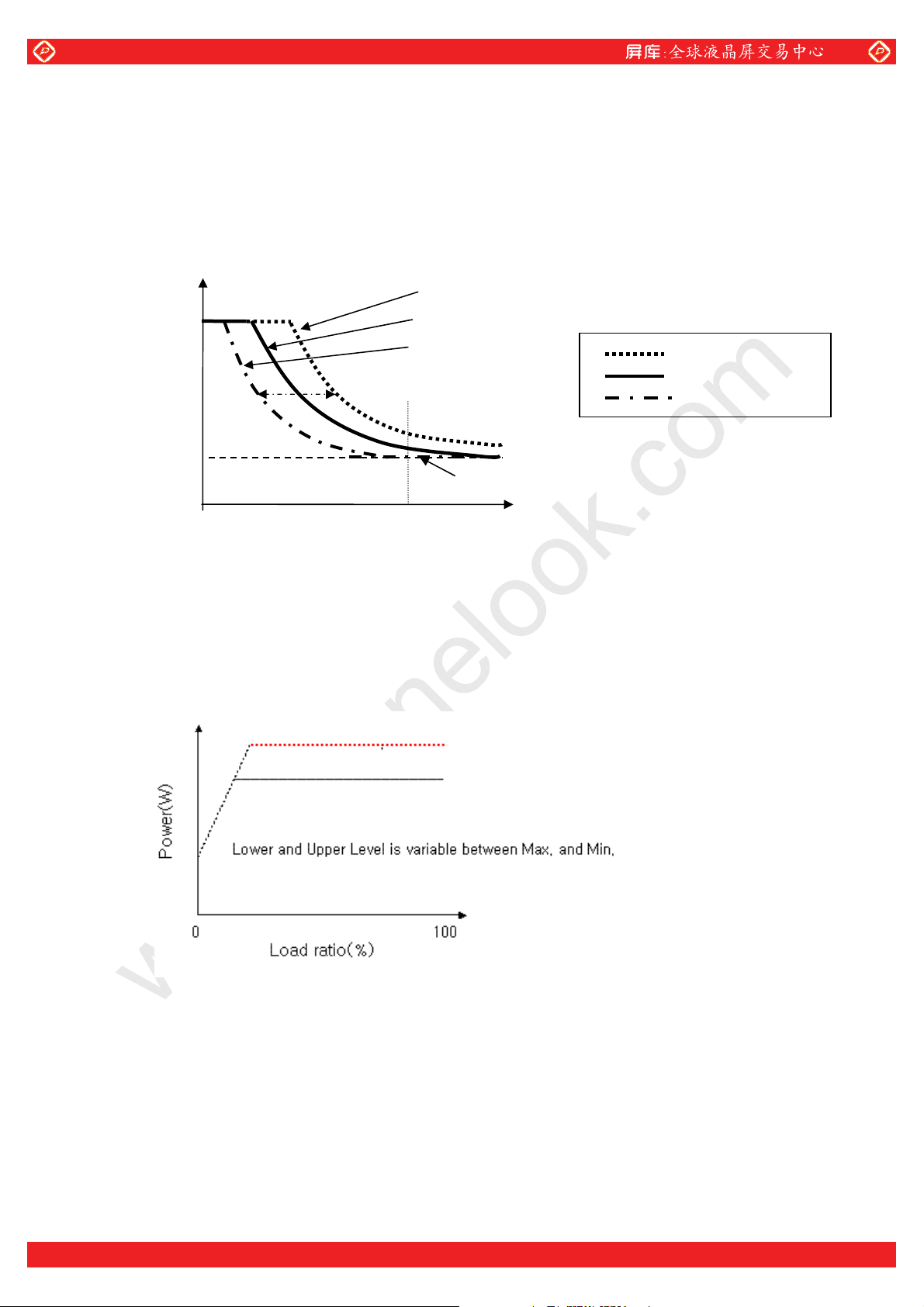

(3) Power-Mode Control (PLG)

- PLG(Power Lower Gain control register)

- Variable range : 00h ~ FFh(Tentative) , Default Value : 80h

- PLG is for lower power level.

- PLG value : smaller than the default in order to make less power consumption.

ormal Mode

-Save Mode

Max(Guarantee Stress) : 215W

Typical : 175W

Figure-10. APCL Behavior(PLG Adjust)

SAMSUNG SDI - 14/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

(4)Power- Consumption Ratio( BY ASLG, PLG)

PLG ASLG ASLG_SW Power- Consumption Ratio

80 128 80 128 OFF 100%

70 112 80 128 OFF 90%

69 105 88 136 ON 80%

60 96 93 147 ON 70%

ૺ Note ૻCondition By Moving Picture(30% Window Size)

ΠΨΖΣΈ

Figure 11. Power- Consumption Ratio ByWindowsize(Load)

; ΠΕΖ

; ΠΕΖ

; ΠΕΖ

; ΠΕΖ

ΈΚ Ο ΕΠΨ ΄Κ Ϋ Ζ

SAMSUNG SDI - 15/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

(

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

(5) SAPC_Timer

The module is equipped with the APC Timer function to reduce the amount of image

retention. If the input image is not varying for at least one minutes, the fuction starts to

operate and reduce the intial APC level one step down to a predefined target level in

every three seconds. The fuction is immediately turned off when the input image starts

varying.

(1Minute)

APC350)

SAMSUNG SDI - 16/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

6.8 Gamma characteristics

6.8.1 Basis of Gamma Curve

This PDP module is normally applied to the 2.2 gamma curve (refer to Figure-12)

But this specification could be modified on the request of the customer

Figure-12. Default Gamma Curve

SAMSUNG SDI - 17/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

SAMSUNG SDI - 18/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

SAMSUNG SDI Corporation Plasma Display Panel

www.panelook.com

6.9 Film filter

6.9.1 Structure of the PDP FF

Hard coating layer

Color PSA

Film transmissivity 45%

6.9.2 Characteristics of the PDP FF

(1) Attached with a Hard coating film on the View side.

(2) Attached with a Near Infrared (NIR) cut off function in the Color PSA to shield them.

6.9.3 Dimension Specifications

SAMSUNG SDI - 19/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

༂

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

6.9.4 Film Filter Defect specifications

Items Specification

Allow Defects

Point Defects Size (mm)

Area A Area B

<0.5

Point

Defects

Linear Defects Size (mm) Allow Defects

Width Length Area A Area B

0.1W<0.15

Linear

Defects

0.05W<0.1

0.05W<0.1

W<0.05

W<0.05

* Distance between defect 㻢30

unlimited

0.5<1.0

1.01.5 1 2

1.5< ø

10<L20

10<L20

1 5

3 5

none

L<10

10 20

10<L20

L

<10

35

SAMSUNG SDI - 20/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

SAMSUNG SDI Corporation Plasma Display Panel

www.panelook.com

6.10 White Blance

(1) Measuring pattern

179Gray 51Gray

Figure. Measurement pattern(30% Window)

(2) Measuring condition : After 1hour aging , 50

(3) Measuring Equipment : MINOLTA CA-100Plus

Pattern Generator(VG-828, LVDS Output).

(4) Ambient Light : Dark Room (<2 lux)

(5) Default data

X Y

51Gray 0.278 0.288 8.5

179Gray 0.278 0.288 115

ଇG

Luminance

SAMSUNG SDI - 21/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

7. SOUND PRESSURE LEVEL SPECIFICATION

7.1 Measuring Condition

(1) Background noise level : less than 20dBA under anechoic chamber environment

(2) Pattern : Full White

(3) Equipment : FFT Analyzer

z PULSE Analyzer Type 3560C made by B&K or,

z PAK System v5.3 above made by MÜLLER-BBM

(4) Distance : 1 m from the center of rear side of PDP Module (M3)

(5) Bandwidth : octave band, Weighting Filter : A-weighting

7.2 Sound Pressure Level

7.2.1 Level Ground (Land)

- Measuring Condition : 0 m

- Sound Pressure Level is overall level calculated from the individual band levels of

250Hz ~ 8kHz.

- Specification : 31.xx dB max.

7.2.2 High Ground

-. Measuring Condition : 1,600 meter

-. Sound Pressure Level is overall level calculated from the individual band levels of

4 kHz ~ 12.5 kHz.

TUGzGaGY_UGiGUG

ૺ Note ૻ

[ Note ]

1. SDI recommends that the back cabinet of a TV has the ventilation holes of less

than 2.7 mm in diameter.

2. Audible noise is guaranteed till the altitude of 1,600 meter.

3. In order to guarantee audible noise at higher altitude than 1,600 meter, a special

module has to be used.

ଖ Overall value is calculated as follows,

Overall(dB) 10log

Figure-13. Measuring Point

dB

@250Hz

§

10

¨

dB

10

10

¨

©¹

20log

@Freq.

10

§

·

P

¨

¸

¨

P

©

where, P

¸

0

¹

10

dB

@315Hz

10

10

20 u106Pa

0

dB

@8kHz

·

10

¸

¸

SAMSUNG SDI - 22/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

8. MECHANICAL CHARACTERISTICS

8.1 Mechanical Specifications

No Item Rating

Outer

1

Dimension

2 Weight Approximatly 11.9 kg

Width 1002.4

(include FPC and TCP)

*see Appendix : Mechanical Dimension Drawing

±1 mm Ý Height 597.5±1 mm Ý Thickness 49±2mm

8.2 Mechanical Characteristics

No Item Rating

Frequency : 10 ~ 55 Hz

1 Vibration

2 Shock

* Notes: ( Test condition ) Non-Packaging, Operational (only for Vibration)

* Test time of Vibration Test is 30 minutes every direction(x,y,z)

* The number of times for shock test is 6 times every direction(x,y,z).

Sweep Rate : 1 Octave/min

Stroke : X, Y direction : 0.35 mm

Z direction : 0.175 mm

Acceleration : less than 20 G (X, Y direction)

less than 10 G (Z direction)

Duration Time : 11 ms

SAMSUNG SDI - 23/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

Global LCD Panel Exchange Center

ć

ć

ć

ć

ଇG

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

9. ENVIRONMENTAL CONDITIONS

9.1 Operational Environmental Condition

Ratings

ITEM

Recommended Absolute maximum

Temperature 5

HumidityTPF

i

FPT 20 ~ 70% RH 20 ~ 80% RH

~ 45

0

~ 50

[NOTE]

1. Functional Operation means that the PDP module is operated only its electrical function.

2. Display Operation means that the PDP module is operated in its full specifications.

3. Panel Surface Temperature means the surface temperature of panel that is just increased

due to the loss of power inside Panel during the image display at a normal display mode

and a ambient temprature defined in this table.

The judgement of display defects (e.g. weak discharge, missing discharge) should be done

when the panel is operated at a ambient temperature defined in this table.

4. Sound Noise is guaranteed till 1,600m

9.2 Storage Environmental Condition *1

Ratings

ITEM

Recommended Absolute maximum

Temperature

1

HumidityP

P

Air Pressure

-5ଇ ~ 45ଇ -20ଇ ~ 70

20 ~ 80% RH 5 ~ 85% RH

633 ~ 760 Torr

0 ~ 1,500 m

230 ~ 760 Torr

0 ~ 10,000m

[NOTE]

1. Storage means the short term period. (e.g. transportation, relocation and so on)

SAMSUNG SDI - 24/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

SAMSUNG SDI Corporation Plasma Display Panel

www.panelook.com

9.3 Panel Surface Condition

9.3.1. Panel surface temperature specification

The panel surface temperature should be kept as below in order to get stable display of

image.

- Tp= below 120

- Tp= below 85

If the temperature exceeds above level, it may cause the defects of display image like dot

missing, line missing and/or poor image. As the surface temperature of panel has tendency

to rise with deduction of display rate, the relation with temperature can be describe as

below :

85

ଇ (display load rate is high : large area ) ~ 120ଇ (display load rate is low : small area)

ଇ (Absolute Maximum Rating); when small size of image is displayed

ଇ; when Full White is displayed.

Surface

Temperature

120

85ଇG

15~20% 100%

Displayed

Figure-14. Surface Temperature Vs Displayed Area

It is strongly recommended that the panel surface temperature should be kept as low as

possible, eventhought its maximium rating is descreibed as above.

9.3.2. Panel Surface Temperature for Breaking

The temperature uniformity across panel should be maintained below 20ଇ/ not to

occure panel breaking by temperature difference.

This breaking temperature is not absolute temperature, because it depends on condition

of panel production and panel scratch. Please take this value as a reference.

SAMSUNG SDI - 25/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

U30U<#

J30J<#

E30E<#

VGD#

VFO#

SGSbJR#

W{#

U{#

VWDUWbRSW#

6GbV\QF#

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10. INTERFACE SIGNAL SPECIFICATIONS

10.1 Configuration Context

U

U

U

Yv|qf#

Kv|qf#

HQDEOH#

GFON#

Image scaler b’d

G#

Q

L

H#

W{2U{3㘢#

W{2U{4㘢#

W{2U{5㘢#

W{2U{6㘢#

W{2U{7㘢#

W{2U{FON㘢#

PDP Module

SPS-HI13

UU30U<#

UJ30J<#

O#

Y#

G#

V

P#

l

f#

r#

p#

UE30E<#

Yv|qf#

Kv|qf#

HQDEOH#

GFON#

Figure-14. Interface Block Diagram

SAMSUNG SDI - 26/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10.2 Interface Function Specifications (input data and display processing)

- 1024x768-dot data signals are inputted to this product to display data.

- The Video signal and control signal input section uses a low voltage differential

signaling (LVDS) interface.

- An I2C bus serial data interface is used for the communication between MPU of FTV

side and the CLU (Control LOGIC Unit) of this PDP Module.

- PDP_GO signal is used that software upgrading using broadcasting signal.

(1 : PDP module’s operation is stop, 0 : Normal Operating mode)

10.3 Input Signal Definition

No Item Signal name Q I/O Method Definition

1 Displa

y

Video

Signal

Signal

Rx_IN0±

Rx_IN1±

Rx_IN2±

Rx_IN3±

Rx_IN4±

Input LVDS

2

2

Differentials

2

2

2

Differential serial data signal.

Input video and timing

signals after differential serial

conversation using a

dedicated transceiver. The

serial data signal is

transmitted seven times faster

than the base signal.

2 MPU

Comm

unicat

ion

Dot

Clock

Comm

unicat

ion

Rx_CLKIN± 2 Input LVDS

Differential

SDA

SCL

PDP_GO

Rx

Tx

3D_SYNC

START_OPT

1

1

1

1

1

1

1

Input

Input

Input

Input

Output

Output

Input

LVTTL(I2C)

LVTTL(I2C)

LVTTL

UART

UART

LVTTL

LVTTL

Differential clock signal.

Input the clock signal after

differential conversation

using a dedicated transceiver.

The clock signal is

transmitted at the same speed

as the base signal.

I2C bus serial data/Uart bus

serial data communication

signal. Communication with

the CLU (Control Logic Unit)

of this product is enabled.

*3D_SYNC : 3D Mode

Control

*START_OPT : PDP Power

Down

SAMSUNG SDI - 27/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 28

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10.4 LVDS Signal Definition and Function

A video signal (display data signal and control signal) is converted from parallel data to serial

data with the LVDS transmitter and further converted into four sets of differential signals before

inputted to this PDP Module. These signals are transmitted seven times faster than the dot clock

signals. The dot clock signal is converted into one set of differential signals.

The LVDS signal definitions and functions are described as follows: (LVDS Default is 10Bit)

10.4.2 10 BIT Application

Table 2. Input signal definition and pin assignments of LVDS Receiver (10 Bit)

Signal I/O Function Remarks

Rx_IN0- I Display Data Signal:

Rx_IN0+ I

Rx_IN1- I Display Data Signal:

Rx_IN1+ I

Rx_IN2- I Display Data Signal:

Rx_IN2+ I

Rx_IN3- I Display Data Signal:

Rx_IN3+ I

Rx_IN4- I Display Data Signal:

Rx_IN4+ I

Rx_CLKIN- I Dot Clock Signal:

Rx_CLKIN+ I

R2, R3, R4, R5, R6, R7, G2

G3, G4, G5, G6, G7, B2, B3

B4, B5, B6, B7, Hsync, Vsync, DEN

R8, R9, G8, G9, B8, B9,reserved

R0, R1, G0, G1, B0, B1,N/C

CLK

10.4.3 8 BIT Application

Table 3. Input signal definition and pin assignments of LVDS Receiver (8 Bit)

Signal I/O Function Remarks

Rx_IN0- I Display Data Signal:

Rx_IN0+ I

R0, R1, R2, R3, R4, R5, G0

Rx_IN1- I Display Data Signal:

Rx_IN1+ I

G1, G2, G3, G4, G5, B0, B1

Rx_IN2- I Display Data Signal:

Rx_IN2+ I

B2, B3, B4, B5, Hsync, Vsync, DEN

Rx_IN3- I Display Data Signal:

Rx_IN3+ I

R6, R7, G6, G7, B6, B7,reserved

Rx_CLKIN- I Dot Clock Signal:

Rx_CLKIN+ I

CLK

SAMSUNG SDI - 28/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 29

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10.5 LVDS Signal Pin Assignment

The table below indicates pin assignment of the LVDS IC(Transmitter & Receiver).

In the 10bit input mode, for other input bit mode, refer to technical references

Table 4. Pin assignment of receiver

PIN No PIN NAME PIN No PIN NAME PIN No PIN NAME

1 GND 11 RxIN2- 21 GND

2 GND 12 RxIN2+ 22 3D_SYNC

3 RxIN4- 13 GND 23 GND

4 RxIN4+ 14 RxCLKIN- 24 UART Tx

5 RxIN0- 15 RxCLKIN+ 25 GND

6 RxIN0+ 16 GND 26 UART Rx

7 GND 17 RxIN3- 27 GND

8 RxIN1- 18 RxIN3+ 28 SCL

9 RxIN1+ 19 GND 29 GND

10 GND 20 PDP_GO 30 SDA

uUZWG

YEONHO (C-NET) LVDS Connector (Top View)

uUZWG uUXG

YEONHO (C-NET) LVDS Connector (Top View)

uUXG

SAMSUNG SDI - 29/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 30

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10.6 Video Signal Definition and Function

The table below indicates the definitions and functions of input video signals before

LVDS conversion.

Interfaces Signal Functions

Symbol Function Remarks

UR9(7)U to R0 U10(8)U bits red video signal (note 1)

UG9(7)U to G0

UB9(7)U to B0 U10(8)U bits blue video signal (note 1)

U10(8)U bits green video signal (note

1)

Hsync Horizontal synchronous signal

Display data signal:

UR9(7):U MSB*, R0: LSB**

Display data signal:

UG9(7):U MSB*, G0: LSB**

Display data signal:

UB9(7):U MSB*, B0: LSB**

This signal specifies the data period for

one horizontal line. Control of the next

line begins at the rising edge of Hsync.

Timing signal that controls the start of the

Vsync Vertical synchronous signal

screen. Control of the next screen begins

at the rising edge of Vsync.

DEN Data Enable Valid data enable signal

DCLK Clock for video signal Latch the video signal at falling edge.

* MSB: Most Significant Bit

**LSB: Least Significant Bit

Note 1: The RGB signal may be compensated with Inverse J circuit [Halftoning Algorithm

(Error Diffusion, Dither) must be included] before inputted to the PDP Module. In

order to obtain good characteristic of low level’s gray scale, inverse J correction

and E/D process are advisory to be performed after inputted to the PDP Module.

SAMSUNG SDI - 30/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 31

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10.7 Electrical Condition of Interface Signal

10.7. 1. Maximum Ratings

Common conditions : Ta = 25ଇ, Vcc = 3.3V

Absolute Ratings

Item Parameter Symbol Ratings Module

Input

Signals

LVDS

3.3V

CMOS

Rx0-/+,Rx1-/+,Rx2-/+,

Rx3-/+, Rx4/+, Rx5-/+

CLKin-/+

SDA, SCL Input Voltage Vi

UInput VoltageU UViU U-0.3~ UVU

U3.6U

U

Input CurrentU UIiU U-10~10U

U-0.5~3.5U

UInput CurrentU UIUi U8U

U

V

U

U

U

10.7. 2. Electrical Characteristics

Common conditions : Ta = 25ଇ, Vcc = 3.3V

Electrical Characteristics

Signal Item Symbol Conditions Min. Typ. Max. Module

Differential

LVDS

I2C

Vs_On

3D_SYNC

input high threshold V

voltage

Differential

input low threshold

voltage

Input current I

Input Voltage

Input Capacitance V

Output Voltage

Output Current I

High level input

voltage

Low level input

voltage

th VCM=1.2V - - 100 ໜ

V

tl VCM=1.2V -100 - - ໜ

VIN =

in +2.4V/0V - - ·20.0

Vcc = 3.6V

V

ih 0.7*Vcc - 3.5 V

V

il -0.5 - 0.8 V

in ---8

V

oh

V

ol - - - 0.8 V

ol ---8

V

ol - 2.4 - - V

I

ol - - - 0.3*Vcc V

Ioh = 8

2.4 - - V

PS_ON

PDP_GO

START_

OPT

High level input

voltage

Low level input

voltage

High level input

voltage

Low level input

voltage

V

ih - 2.5 - 3.5 V

I

il - -0.5 - 0.3*Vcc V

V

ih - 2.4 - 3.5 V

I

il - -0.5 - 0.3*Vcc V

SAMSUNG SDI - 31/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 32

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10.8 Video Signal Interface Timing Conditions

The table below indicates the conditions of input video signal before LVDS conversion.

These conditions must be satisfied. Refer to the figure of the timing chart.

HSYNC must be risen up within 1 clock after the rising edge of VSYNC.

U8 bits LVDS ~10 bit LVDS belong to one timing table below.

Video Input Signal Timing (NTSC/PAL)

ITEM SYMBOL Min Typ Max Units Remarks

DCLK

Hsync

Vsync

Data

Enable

* Hsync period :

- Min : 20.0 us (1480Tclk @DCLK 74MHz)

- Typ : 20.32 us (1504 Tclk @DCLK 74MHz)

* Vsync Period :

- Min : 794/947 (@Hsync Period : Typ value)

- Typ : 820/984 (@Hsync Period : Typ value)

- Max : 895/1094(@Hsync Period : Typ value)

Tvsync :

- PAL Long Mode : Below 48Hz

- PAL Normal Mode : 48~52Hz

- PAL LB Mode : 52~55Hz

- NTSC Long Mode : 55 ~ 58 Hz

- NTSC Normal Mode : 58 ~ 62 Hz

- NTSC LB Mode : 62 ~ 65 Hz

- NTSC Mask Mode : above 65 Hz

* LB Mode(=Low Brightness Mode) : By decreasing sustain period on the Tvsync shorter

than normal, brightness is reduced.

*

1`Mask(or Flicker) Mode : Masks abnormally short Vsync, and displays at the frame

* Long Mode : mode change is not occurred in this period, the display is normally operation

Period TB

B 14.08 13.50 12.82 ns

clk

Frequency 71.2 74 78 MHz

Period 20.0 20.32 - us

Frequency F

Width T

Period TB

Frequency F

Width T

Horizontal Valid TB

Horizontal Back Porch TB

Horizontal Front Porch TB

Vertical Valid TB

Vertical Back Porch TB

Vertical Front Porch TB

B

B 50.25 49.26 - KHz

h

B

B 6 10 - TB

wh

B 794/947* 820/984* 895/1094* TBhpB NTSC/PAL

vp

B

B 62/52 60/50 55/45 Hz NTSC/PAL

v

B

B 2 6 10 TB

wv

B 1365 1365 1365 TB

hv

B 56 76 - TB

hbp

B -- -TB

hfp

B 768 768 768 TB

vv

B 20 30 - TB

vbp

B 8 - - TBhpB NTSC/PAL

vfp

clk

hp

clk

clk

clk

hp

hp

B

B

B

B

B

B

B

period twice as input Vsync period.

by increasing the Vsync period.

SAMSUNG SDI - 32/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 33

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10.9 LVDS Interface Timing Conditions

This PDP Module uses an LVDS interface for the signal input

VSYNC

HSYNC

DE

VALID DATA

VSYNC

T

HSYNC

DE

VALID DATA

HSYNC

WV

VSYNC

T

1 2 3 1024

1 2 3

1 2 3

VH

T

1

HSYNC

T

WH

T

1024

2

VSYNC

T

HSYNC

T

1024

HV

T

3

1024

CH

DE

VALID DATA

HC

T

Valid Data Period

Valid Data

CLK

T

T

DCLK

DATA_R

DATA_G

Invalid

WCLK1

t

SUD

t

Invalid Invalid

WCLK2

t

HD

t

D1 D2 D3

D

1023 D 1024

InvalidInvalid Invalid Invalid

DATA_B

Figure 16. Video Input Signal Timing Chart

SAMSUNG SDI - 33/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 34

Global LCD Panel Exchange Center

pthnlG svnpjG

hzpjG

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10.10 LVDS Connection Specifications

The following Figure shows the connection specifications and signal assignments of the

LVDS interface IC. Do not connect or disconnect the connector when the system power in

on. Otherwise, the LVDS interface IC could be damaged.

ULVDS Interface Connection

yG

100

nG

iG

}G

oG

kG

lG

yGGXWG

nGGXWG

iGGXWG

}G

oG

kG

lG

kjsrG

kjsrG

100˟G

Figure-17. LVDS Interface Connection

SAMSUNG SDI - 34/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 35

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10.11 I2C Interface Conditions

10. 11. 1 Basic Specifications

This PDP Module has the I2C bus serial data communication function.

The customer may use this function to make settings for PDP Module characteristics of

several items.

No

1

URecommendedU Transfer Rate U100 kbpsU

Parameter

Specifications

2 Device Status Slave Receiver

3 Slave Address CC(Write), CD(Read)

10. 11. 2 Data Validity

Amount of data that is transferred is 1-Bit per 1 SCL cycle. Data is valid when SCL is

high and recognized as to state of SDA.

10. 11. 3 Start & Stop Condition

Start /Stop condition is generated by Master (=Image B’D). Before start condition or after

stop condition, a SDA cannot be recognized as valid data.

UStart conditionU ൯ SCL high & SDA transition from H to L

UStop conditionU ൯ SCL high & SDA transition from L to H

SAMSUNG SDI - 35/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 36

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10. 11. 4. Acknowledge

When Master (=Image B’D) needs to stop reading data, the master should give NO ACK

signal to slave by SDA. Slave (=PDP Module) gives ACK whenever 8-bit transfer is

done.

10. 11. 5. 7-Bit Addressing for Device address(with example of CC or CD)

Master could choose slave by 7-bit slave address and decide what procedure is by R/W

bit (H=Read procedure, L=Write procedure).

START

R/W ACKSlave Address

10. 11. 6. 16-Bit Mode

The basic I2C format (8-bit (Byte)) is expanded by 16-bit (Word). Therefore this PDP

Module’s I2C architecture consists of 7-bit slave addressing, 16-bit base addressing and

16-bit data (Refer to ‘Write & Read Operation’).

10. 11. 7 . Data Transfer Sequence (Write)

The basic I2C format (8-bit (Byte)) is expanded by 16-bit (Word). Therefore this PDP

module’s I2C architecture consists of 7-bit slave addressing, 16-bit base addressing and

16-bit data (Refer to ‘Write & Read Operation’).

Note 1: Black letters mean master (=Image B’D )’s bus occupation.

Note 2: Blue letters mean slave (=PDP module)’s bus occupation.

Note 3: Option Bit = 01: ROM , 10: RAM , 11: both Memory(ROM and RAM)

If ROM mode is very slow, it is impossible to use normal I2C

communication

S0 S1 S2 S3 S4 S5 S6 W ACK

Slave Address

U. The image board can only use RAM mode.U

S0 S1 S2 S3 S4 S5 S6 S7 ACK

Base Address (Upper Byte)

S0 S1 S2 S3 S4 S5 S6 S7Receive Data (Upper Byte) ACK

S0 S1 S2 S3 S4 S5 S6 S7Base Address (Lower Byte)

S0 S1 S2 S3 S4 S5 S6 S7Receive Data (Lower Byte) ACK

ACK

SAMSUNG SDI - 36/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

STOP S0 S1 S2 S3 S4 S5 S6 S7Receive Data (Lower Byte) [2N + 1] ACKS0 S1 S2 S3 S4 S5 S6 S7Receive Data (Upper Byte) [2N] ACK

www.panelook.com

Page 37

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10.11. 8. Data Transfer Sequence (Read)

The basic I2C format (8-bit (Byte)) is expanded by 16-bit (Word). Therefore this

PDP Module’s I2C architecture consists of 7-bit slave addressing, 16-bit base

addressing and 16-bit data (Refer to ‘Write & Read Operation’).

Note 1: In advance, master should initialize writing sequence by giving base address

and stop condition.

Note 2: After start condition and slave addressing, master could receive data from

slave.

Note 3: Master should give acknowledge whenever 8-bit data is received.

Note 4: ‘No acknowledge’ could make master give stop condition on bus. Therefore,

NACK is used for master to stop receiving data from slave.

Note 5: Black letters mean master (=Image B’D)’s bus occupation.

Note 6: Blue letters mean slave (=PDP Module)’s bus occupation.

Note 7

: Option Bit = 11: both memory, 01: ROM (FLASH), 10: RAM (in UASICU)

S0 S1 S2 S3 S4 S5 S6 WSlave Address START

S0 S1 S2 S3 S4 S5 S6 S7 ACK Base Address (Upper Byte) S0 S1 S2 S3 S4 S5 S6 S7Base Address (Lower Byte) ACK STOP

S0 S1 S2 S3 S4 S5 S6 R ACK Slave Address START

ACK

S0 S1 S2 S3 S4 S5 S6 S7

Request Data (Lower Byte) ACK S0 S1 S2 S3 S4 S5 S6 S7Request Data (Upper Byte) ACK

10.11.9. I2C Interface Circuit

D3.3V

33 k: X 2ea

STOPS0 S1 S2 S3 S4 S5 S6 S7Request Data (Lower Byte) [2N + 1] NACK S0 S1 S2 S3 S4 S5 S6 S7Request Data (Upper Byte) [2N] ACK

CN2004

47: X 2ea

SAMSUNG SDI - 37/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 38

Global LCD Panel Exchange Center

SAMSUNG SDI Corporation Plasma Display Panel

www.panelook.com

10. 11. 11. I2C Bus Timing Specifications

* Refer to the following data merely as sample data.

No Item Symbol

1 SCL Input Frequency

2 SCL Input “HIGH” Period

3 SCL Input “Low” Period

4 Start Condition Set Up

Time

5 Start Condition Hold Time

6 Data Input Set Up Time

7 Data Input Hold Time

8 Stop Condition Set Up

Time

9 Data Output Delay Time

10 Data Output Hold Time

11 SDA Bus Free Time

12 SCL, SDA Input Rising

Time

13 SCL, SDA Input Falling

Time

14 SCL, SDA Line Capacitor

fSCL

tHIGH

tLOW

tSU.STA

tHD.STA

tSU.DAT

tHD.DAT

tSU.STO

tPD

tDH

tBUF

tR

tF

Cb

Min. Typ. Max. Module

5 100 200

2.5 - -

2.5 - -

3.0 - -

2.3 - -

0.2 - -

0.1 - 3.45

2.3 - -

0.1 - -

0.1 - -

4.0 - -

- - 1.0

- - 0.3

- - 400

Standard

໗

໗

໗

໗

໗

໗

໗

໗

໗

໗

໗

໗

SAMSUNG SDI - 38/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 39

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10.12 Connector Specifications

Connector

Name

CN2004

Pin

#

1 GND

2 GND

3 LVDS RxIN44 LVDS_RxIN4+

5 LVDS_RxIN06 LVDS_RxIN0+

7 GND

8 LVDS_RxIN1-

9 LVDS_RxIN1+

10 GND

11 LVDS_RxIN212 LVDS_RxIN2+

13 GND

14 LVDS_RxCLKIN15 LVDS_RxCLKIN+

16 GND

17 LVDS_RxIN318 LVDS_RxIN3+

19 GND

20 PDP_GO

21 GND

22 3D_SYNC

23 GND

24 Tx

25 GND

26 Rx

27 GND

28 SCL

29 GND

30 SDA

Signal Name

NOTES:

1. CN2004 connector is located in Logic Board.

2. Pin to Pin pitch of connector CN2004 is 1 ༂.

3. The length of mating cable is recommended to be not longer than 25.0 ༃.

4. Pin numbering order :

right to left view from component side of Logic Board.

5. All the other pins are GND.

6. Reserved for factory use only. This pin should be disconnected in case of customer's use.

7. This pin is output pin. In case of fan failure, this signal becomes high.

If not use, this pin should be N.C.

SAMSUNG SDI - 39/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 40

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

10.13.Mode change

10.13.1. Mode

It has three kinds of mode that is divied NT and PAL by input sync.

Mode NT PAL

Normal Normal_NT Normal_PAL

Cinema Cinema_NT Cinema_PAL

10.13.2. Mode Control Register

.

Sub

Address

8079 0 CINEMA_ON

ଖ Vsync cause fluctuations in 40msec interval I2C communication, you can not be longer than 40msec interval.

Data

Bit

Symbol Item / Function

CINEMA_MODE : ON=1, OFF=0 (Default)

ଖ I2C communication can not enter commands during the 40ms

Figure . I2C communication between Disabled

10.13.3.Mode Change

NT, PAL, including the conversion of 4 different Mode is available to each other.

SAMSUNG SDI - 40/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 41

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

11.ADDRESS MAP

I2C Slave Address ൯ Write: CC (hex), Read: CD (hex)

Setting [hex]

Sub

Address

8114(NT)

A114(PAL)

89DA(NT)

A9DA(PAL ) 0~7 PLG

Data

Symbol Item / Function

Bit

Pattern Select

൯ Patterns below are valid when IE

(Internal clk or External clk) is set to ‘1’.

00: Full Window (Black)

01~04: Full Window (White,Red,Green,Blue)

05 : 1 point Box(White, Windows size)

0B: Color Bar

0C : Half Gray

0D: Cross Hatch

0E : Dot Array

0F : 30% Window

10~13 : Gray Bar (Horizontal, Vertical)

14~16: Horizontal Ramp Pattern (Stay, Scroll)

17~19: Vertical Ramp Pattern (Stay, Scroll)

1A : Horizontal Gray Color Bar

1B : Dot Array, 1C : IRE, 1D : Scroll,

1E : Half Gray, 1F : Moving Scroll

Power Lower Gain Control

൯ Control the power lower level of PDP module.

0~5

R_PAT

T_SEL

Initial

Range

NT PAL

00~1E 00 00 *(a)

00~FF 80 80 *(c)

Note

89C6(NT)

A9C6(PAL)

89C6(NT)

A9C6(PAL)

89C0(NT)

A9C0(PAL)

8~15 ASLG

ASLG_

0

0~8 APCO

ASL Constant Gain

൯ Control the ASL Gain of PDP module.

ASL Constant Operation on/off S/W

SW

൯ ‘1’ = On, ‘0’ = Off

APC Offset Level

൯ Adjusts peak luminance for customer’s specifications.

80~FF 80 80 *(c)

0/1 00 00 *(c)

10~1FF 00 00 *(c)

[Note]

1. Only sub-addresses shown in above table are allowable for access. An access to the

any other address than shown in above sub-address table may lead to an abnormal

system down or permanent damage.

2. Above table contain the option bits of memory access, MSB and MSB-1 bit in Base

address(Upper byte)

*(a) Please access these address for test use only.

For ordinary operating conditions, values of these address should be set to initial

values.

Patterns that From 06 to 0A and 0F are activated by setting the value to 0001 of

address 4F0Ch

*(b) Customers can set these values considering their specifications.

*(c) APCO , ASLG, PLG is used for control the “Brightness and Power Mode” of PDP

Module. For a detailed behavior and variable range, refer to the Chapter 6.7 Power

Consumption

.

SAMSUNG SDI - 41/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 42

Global LCD Panel Exchange Center

y

g

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

12. POWER SUPPLY UNIT SPECIFICATION

12.1 Input Requirements

AC Input Min. Nominal (rated) Max.

Frequency

Voltage

Phase / PFC

Inrush Current

ON/OFF frequency of AC power

Leakage Current

Lightning Surge Test

Hi-Pot Test

Standby Energy Consumption

47Hz 50 / 60Hz 63Hz

90V 100V to 240V 264V

Single-Phase / Including Power Factor Correction

60 amps or less (Cold start & Hot start)

Power Supply must operate at any AC power ON/OFF combination.

Less 0.45 mA @ 132Vac,60Hz

·6kV(Common/Normal Mode) : No Components damaged

AC3.0kV/DC4.24kV, Cut-off Current 10mA, Test Time 60sec.(Safety spec)

STBY 5V Load 0.040A

Pin (Watt)

0.9 watt ˨G

Parameter Remarks

Model

Output Power

Efficienc

Coolin

85% @ Vin=110Vac

Natural Convection (No FAN)

# of Output

Hold-up Time

Line Drop out Immunity

PDP must keep display ON, It must not be malfunction and function change, and

there must not be Latch Up and breakdown, while AC line 1.5 cycle full-dip testing,

min. 40mSec. @90Vac/47Hz, M3

U2 STD 42HD

280 watt max.

5ea

SAMSUNG SDI - 42/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 43

Global LCD Panel Exchange Center

tUG uUG tG

r

r

r

r

r

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

12.2 Electrical Characteristic Overview

Output

Name

VS +211V 0.0A 0.8A 1.2A

VA +54V 0.0A 0.45A 1.0A

D5.3V +5.2V 0.1A 3.5A 4.5A

D15V +15V 0.1A 1.5A 3.0A

STBY +5.2V 0.0A 0.1A 0.5A

Nominal

Voltage(V

)

Average output current (*1)Load

Regulation

(%)

1.5

(*2)Variable

Remark

Range(V)

200V~215V

2

5

5

5

Fixed

Fixed

Fixed

Fixed

Sustain voltage

Address voltage

Logic, Drive,

Image Board

Image Board

Image Board

*1. This means nominal voltage stability when current is changed from min to max.

*2. The output voltages for VS,VA could be varied within variable range by feedback

variable resistors.

Above voltage levels are norminal value. They are adjustable to drive Panel.

12.3 Out Dimension for reference

Length(mm) Width(mm) Height(mm) Remark

245mm 245mm Max. 27mm From PCB top

SAMSUNG SDI - 43/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 44

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

12.4 Power Applying Sequence

more than 35ms

Maintain Display on

W/O

Having any flicker

during

1.5cycle dip time.

SAMSUNG SDI - 44/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 45

Global LCD Panel Exchange Center

ڧۊھڼۏۄۊۉٻ ڞکړڋڋڮٻ ڞکړڋڌٻ ڞکړڋڍٻ ڞکړڋڎٻڅڌٻ ڞکړڋڏٻ

ڱۀۉڿۊۍٻ

ڴۀۊۉۃۊٻ ڴۀۊۉۃۊٻ ڴۀۊۉۃۊٻ ڴۀۊۉۃۊٻ ڴۀۊۉۃۊٻ

ڰێڼۂۀٻ ڜڞٻڤۉۋېۏٻ ڤ

ۈڼۂۀٻ ڧۊۂۄھٻ ڳڈڿۍۄۑۀٻ ڴڈڿۍۄۑۀٻ

ګڼۍۏٻکېۈڽۀۍٻ

ڴڲڎڔڑڈ

ڋڎڜڝٻ

ڮڨڲڍڋڋڈڍڏڞڢڝٻ ڍڐڋڎړڲڮڈڋڑڜٻ ڴڲڎڔڑڈڋڐڝٻ ڴڲڎڔڑڈڋڑڝٻ

ګۄۉٻ

ۉې

ۈڽۀۍٻ

ګۄۉٻ

ۉېۈڽۀۍٻ

ګۄۉٻکڼۈۀٻ ګۄۉٻکڼۈۀٻ ګۄۉٻکڼۈۀٻ ګۄۉٻکڼۈۀٻ ګۄۉٻکڼۈۀٻ

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

12.5 Pin assignment of connectors for Power Supply

ڌٻ ڌٻ ڍٻ ڜڞٻڧۄۑۀٻ

ڍٻ ڎٻ ڏٻ کڊڞٻ ڮگڝڴٻ ڢکڟٻ ڟڐډڎڱٻ ڱڮٻ ڱڮٻ

ڎٻ ڐٻ ڑٻ

ڏٻ ڒٻ ړٻ ڟڌڐڱٻ ڟڌڐڱٻ ڢکڟٻ ڢکڟٻ ڟڌڐڱٻ

ڐٻ ڔٻ ڌڋٻ ڢکڟٻ ڢکڟٻ

ڑٻ ڌڌٻ ڌڍٻ ڢکڟٻ ڢکڟٻ

ڒٻ ڌڎٻ ڌڏٻ ڟڐډڎڱٻ ڟڐډڎڱٻ

ړٻ ڌڐٻ ڌڑٻ ڟڐډڎڱٻ ڟڐډڎڱٻ

ڔٻ ڌڒٻ ڌړٻ ڢکڟٻ ڢکڟٻ

ڜڞٻ

کۀېۏۍڼۇٻ

ګڮںڪک

*3

ڢکڟٻ ڢکڟٻ ڢکڟٻ ڢکڟٻ ڢکڟٻ

کډڞٻ ڟڐډڎڱٻ ڱڮٻ ڱڮٻ

ګڮںڪک

ڱڮںڪک

*3

*2

ڟڌڐڱٻ ڢکڟٻ

ڱڜٻ

ڌڋٻ ڌڔٻ ڍڋٻ ڟڌڐڱٻ ڢکڟٻ

ڌڌٻ ڍڌٻ ڍڍٻ ڟڌڐڱٻ ڟڌڐڱٻ

ڌڍٻ ڍڎٻ ڍڏٻ کډڞٻ کډڞٻ

*1. CN803 is removed.

*2. This is a signal from Logic main to PSU. (High : 3.3V, Low : 0V)

This is marked at Power Applying Sequence.

*3. PS_ON is the signal for remote ON/OFF control. (High : 2.7 ~ 3.3V, Low : 0 ~ 1.0V)

Outputs (except STBY) shall be enabled with an active low,

TTL compatible signal (PS_ON).

We strongly recommend That there are no resisters(pull up,pull down and damping)

connected PS_ON signal in Image board.

SAMSUNG SDI - 45/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 46

Global LCD Panel Exchange Center

jjuu__WWY

Y

\\UUZZ}}SSwwzzvvu

u

}}z

z

vvu

u

hhj

jG

jjuu__WW[

[

}}

S

S

}}

S

S

jjuu__W

W

jjuu__WWX

X

wwzzvvuuSSzz{{ii

\\UUZZ}

}

S

S

XX\\}

}

S

S

XX\\}}

kk

pp

ss

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

12.6 Mechanical Out Drawing

245m

132.5m

5m

245m

35m

5m

SAMSUNG SDI - 46/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 47

Global LCD Panel Exchange Center

൘

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

Logic Start Sequence – Controlled by Vsync

AC on, Relay on

R P

ARM

CFG

S0 S2 S3 S4 S5 S6

*1. ASIC config “R”, “P” is initialization for ASIC.

*2. ASIC config “ARM CFG” is initialization for arm processor.

*3. States that from s0 to s6 are setions of power on after system operation.

*4. ARM_call is measured by cpu counter.

SAMSUNG SDI - 47/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 48

Global LCD Panel Exchange Center

൘

൘

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

Timing description.

Parameter Description Min Typ Max Unit

a. IO-Core time delay Delay time to io from core 0.1 1.24 – ms

b. System reset Reset time for chip 10 53 – ms

c. boot configuration Boot configuration time – 273 – ms

d. configuration Glogic configuration time – 563 – ms

e. asic nreset Glogic Reset time to System reset – 835 – ms

f. external device set External device setting time – 6.4 – ms

g. data loading Data loading time 7.2 – ms

h. power sequence1 – – – ms

i. power sequence2 – – – ms

j. initial end System setup end time – 53 – ms

State description.

Stat

Description

S0

S2 Data loading period from External flash memory to ASIC sram

S3

S4

S5 Temperature mode setting, holding data restoration, FRC mode setting, etc.

S6 Normal operation(Internal/External switchover, 50/60Hz detect)

Register(PLL, MEM Ctrl, I/O spec, Etc) setting period for chip after system reset or

configuration

VS_ON output activating after S2

Power ON Sequence. Ypn bootstrap capacitor charging and Startup discharge

stabilization

SAMSUNG SDI - 48/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 49

Global LCD Panel Exchange Center

SAMSUNG SDI Corporation Plasma Display Panel

www.panelook.com

13. MECHANICAL DIMENSION DRAWING

13.1 Front Side

Appendix A1

SAMSUNG SDI - 49/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 50

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

13.2 Rear Side

Appendix A2

SAMSUNG SDI - 50/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 51

Global LCD Panel Exchange Center

ڟۄۂۄۏٻ ڞۊۉۏۀۉۏێٻ

ڞۊېۉۏۍ۔ٻڞۊڿۀٻ ڍٻ

ڰکڤگٻڤڟٻ ڍٻ

hGsG ڌٻ

~GzG XG

ڨۊڿېۇۀٻڞۊڿۀٻ _G

ڨڡڢٻڤڊڟٻ ڏٻ

ڟڼۏۀٻ ڎٻ

ڮۀیډٻکۊٻ ڏٻ

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

14. LABEL

14.1 Label Type

(1) Integrated Label for the PDP Module

(2) Label for PANEL Serial Number

ڞکڍڋڡڜڏڍڜڡڋڒڋڜڟڏڧڳڮڞڔڌڍڎڏٻ

ڦڭٻڕٻڦۊۍۀڼڇٻڣڰٻڕٻڣېۉۂۍ۔ڇٻڨڳٻڕٻڨۀۓۄھۊڇٻڞکٻڕٻڞۃۄۉڼٻ

ګڟګٻڨۊڿېۇۀٻڕٻڍڋٻ

ڜۙڣٻڧۄۉۀٻ

ڜڕڟڼ۔ڇٻڝڕڜہۏۀۍۉۊۊۉڇٻڞڕکۄۂۃۏٻ

ڡڼھۏۊۍ۔ٻڞۊڿۀٻ

ڃٻ㡞ٻڕٻګګڏڍڜڡڋڒڒڜٻٻڏڍڜڡڋڒڒڜڄ

ڱڠکڟڠڭٻڞڪڟڠٻ

ڟڟڌڋٻڕٻڦۊۍۀڼڃڝېێڼۉڄڇٻڟڟڋڔٻڕٻڦۊۍۀڼڃڮېےۊۉڄڇٻڤڋڋڑٻڕٻڦۊۍۀڼڃڞۃۀۊۉڼۉڄٻ

ڝڨڭڵٻڕٻڣېۉۂۍ۔ڇٻڝڍڧڜٻڕٻڨۀۓۄھۊڇٻڟڏڧڳٻڕٻڞۃۄۉڼٻ

ڴۀڼۍٻڕٻڍڋڋړڬڇٻڍڋڋڔڮڇٻڍڋڌڋڵڇٻಪډډٻ

ڨۊۉۏۃٻڕٻڌڇٻڍڇٻڎڇٻڏڇٻڐڇٻڑڇٻڒڇٻړڇٻڔڇٻڜڇٻڝڇٻڞٻ

ڟڼۏۀٻڕٻڌڇٻڍڇٻڎڇٻڏڇٻڐڇٻڑڇٻڒڇٻړڇٻڔڇٻڜڇٻڝڇٻڞڇٻڟڇٻڠڇٻڡڇٻڢڇٻڣڇٻڤڇٻڥڇٻڦڇٻڧڇٻڨڇٻکډډډډٻ

ڋڋڋڌٻۙٻڔڔڔڔٻٻڌۙٻڔڇڔڔڔٻ

ڜڋڋڌٻۙٻڜڔڔڔٻٻڌڋڇڋڋڋٻۙٻڌڋڇڔڔڔٻ

ڝڋڋڌٻۙٻڝڔڔڔٻٻڌڌڇڋڋڋٻۙٻڌڌڇڔڔڔٻ

SAMSUNG SDI - 51/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 52

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

14.2 Label location

NOTE sGXGGwGzGuG

sGYGGwVjV}G

SAMSUNG SDI - 52/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 53

Global LCD Panel Exchange Center

www.panelook.com

SAMSUNG SDI Corporation Plasma Display Panel

15. PACKING

15.1 Packing Dimension and Parts List

- Number of Module in 1 package: 26Modules

- Packing dimensions (W*L*H): 1460*1140* 1085 (mm) (Including Pallet :125mm)

- Weight: 350

· 10 kg(26ea)

NO Item NO Item

1 PACKING BOX-TOP 7 BAG-PE

2 CUSHION-TOP 8 TAPE-ACETATE

3 CUSHION-MIDDLE 9 CHEMICALS

4 CUSHION-BOTTOM 10 BAND-PP

5 TAPE-FILAMENT 11 LABEL-INSPECTION

6 PALLET

15.2 Packing Assembly Drawing

SAMSUNG SDI - 53/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 54

Global LCD Panel Exchange Center

SAMSUNG SDI Corporation Plasma Display Panel

www.panelook.com

16. RELIABLITY

16.1 Expected Service Life

16.1.1Definition

The expected service life is defined by the following two categories.

And the life time is defined by either (1) or (2), whichever occurs first.

(1) The white color Luminance level becomes half (50%) of its initial value, which is

determined by the phosphor characteristics.

(2) The number of display cell defects increases to double the specification value,

which is depending on the discharge characteristics.

16.1.2 Test condition and life time

The expected service life time varies depending on the display conditions set forth

below.

(1) Test Condition : 8Hr/Day on full white pattern

(2) Life Time : 70,000 hrs

16.2 Disclaimer

This Specification stipulates the final and comprehensive requirements for the respective

products hereof. Beyond this Specification, it is the responsibility of the customer to

explicitly disclose any additional requirements, information or reservations regarding these

requirements to Samsung SDI prior to implementation, where any and all disclosures of the

customer shall be with an authorized representative of Samsung SDI in writing. Samsung

SDI shall not be responsible for safety, performance, functionality or compatibility of the

system with which the Samsung SDI-supplied components are integrated unless such

features have been expressly communicated and described in the

Specification. SAMSUNG SDI MAKES NO GUARANTY OR WARRANTY, EXPRESS

OR IMPLIED, INCLUDING BUT NOT LIMITED TO MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, TO ANY PARTY. Moreover, any party

should do their own due diligence regarding these requirements prior to implementation

16.4 Certificate

We verify that we never use or include the restricted substances, for example RoHS and Pb

in parts and components, subsidiary material, materials used for unit parts, and packing

materials or substances added during manufacturing process

SAMSUNG SDI - 54/64 - Rev.01 31/12/0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

except PANEL.

www.panelook.com

Page 55

Global LCD Panel Exchange Center

SAMSUNG SDI Corporation Plasma Display Panel

www.panelook.com

17. WARNING CAUTION / NOTICE

{vG wyl}lu{G wvzzpislG khunlySG khthnlSG hukG ivkpsG ohytSG

wslhzlG jvuzpklyG hukG vizly}lG hssG ~hyupunzG hukG jh|{pvuzG

jvu{hpulkGpuG{opzGwhyhnyhwoUG

17.1 Warning

pGGGGGGGSGGGGGGGG

G

(1) The Module is controlled by high voltage about 350V. If you need to handle the Module

during operation or just after power-off, you must take proper precautions against

electric shock and must not touch the drive circuit portion and metallic part of Module

within 5 minutes. The capacitors in the drive circuit portion remain temporarily charged

even after the power is turned off. After turning off the power, you must be sure to wait

at least one minute before touching the Module. If the remain voltage is strong enough, it

could result in electric shock.

(2) Do not use any other power supply voltage other than the voltage specified in this

product specifications. If you use power voltage deviated from the specifications, it

could result in product failure.

(3) Do not operate or install under the deviated surroundings from the environmental

specification set for the below; in moisture, rain or near water-for example, bath tub,

laundry tub, kitchen sink; in a wet basement; or near a swimming pool; and also near fire

or heater - for example, near or over radiator or heat resistor; or where it is exposed to

direct sunlight; or somewhere like that. If you use the Module in places mentioned above,

it could result in electric shock, fire hazard or product failure.

(4) If any foreign objects (e.g. water, liquid and metallic chip or dust) entered the Module,

the power supply voltage to the Module must be turned off immediately. Also, never

push objects of any kind into the Module as they may touch dangerous voltage point or

make short circuits that could result in fire hazard or electric shock.

(5) If smoke, offensive smell or unusual noise should come from the Module, the power

supply voltage to the Module must be turned off immediately. Also, when the screen

fails to display any picture after the power-on or during operation, the power supply

must be turned off immediately. Do not continue to operate the Module under these

conditions.