Page 1

S3P8245

ARM Blood Pressure Monitor

A

A

p

p

pllii

p

c

c

attii

a

o

o

n

n

N

N

ott

o

e

e

Revision 0.00

July 2010

© 2010 Samsung Electronics Co., Ltd. All rights reserved.

Page 2

Important Notice

The information in this publication has been carefully

checked and is believed to be entirely accurate at the

time of publication. Samsung assumes no

responsibility, however, for possible errors or

omissions, or for any consequences resulting from the

use of the information contained herein.

Samsung reserves the right to make changes in its

products or product specifications with the intent to

improve function or design at any time and without

notice and is not required to update this

documentation to reflect such changes.

This publication does not convey to a purchaser of

semiconductor devices described herein any license

under the patent rights of Samsung or others.

Samsung makes no warranty, representation, or

guarantee regarding the suitability of its products for

any particular purpose, nor does Samsung assume

any liability arising out of the application or use of any

product or circuit and specifically disclaims any and all

liability, including without limitation any consequential

or incidental damages.

"Typical" parameters can and do vary in different

applications. All operating parameters, including

"Typicals" must be validated for each customer

application by the customer's technical experts.

Samsung products are not designed, intended, or

authorized for use as components in systems intended

for surgical implant into the body, for other

applications intended to support or sustain life, or for

any other application in which the failure of the

Samsung product could create a situation where

personal injury or death may occur.

Should the Buyer purchase or use a Samsung product

for any such unintended or unauthorized application,

the Buyer shall indemnify and hold Samsung and its

officers, employees, subsidiaries, affiliates, and

distributors harmless against all claims, costs,

damages, expenses, and reasonable attorney fees

arising out of, either directly or indirectly, any claim of

personal injury or death that may be associated with

such unintended or unauthorized use, even if such

claim alleges that Samsung was negligent regarding

the design or manufacture of said product.

Copyright © 2010 Samsung Electronics Co., Ltd.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in

any form or by any means, electric or mechanical, by photocopying, recording, or otherwise, without the prior

written consent of Samsung Electronics.

Samsung Electronics Co., Ltd.

San #24 Nongseo-Dong, Giheung-Gu

Yongin-City, Gyeonggi-Do, Korea 446-711

Contact Us: younghee46.won@samsung.com

TEL: (82)-(31)-209-3865

FAX: (82)-(31)-209-6494

Home Page: http://www.samsungsemi.com

Page 3

Revision History

Revision No. Date Description Author(s)

0.00 June 17, 2010 - Initial draft Xu Hui

Page 4

Table of Contents

1 OVERVIEW OF ARM BLOOD PRESSURE MONITOR...................................8

1.1 KEY Features of ARM Blood Pressure Monitor...........................................................................................9

1.2 System Block Diagram...............................................................................................................................10

1.3 Principles of Electronic Blood Pressure Monitor........................................................................................10

1.4 Process of Blood Measurement in Blood Pressure Monitor ......................................................................11

2 HARDWARE IMPLEMENTATION.................................................................13

2.1 Analog Signal Processing ..........................................................................................................................13

2.1.1 Introduction to MPS-3117 Pressure Sensor.......................................................................................14

2.1.2 Constant Current Driver Circuit ..........................................................................................................14

2.1.3 Differential amplifier circuit .................................................................................................................15

2.1.4 High Pass Filter Circult: 0.8Hz............................................................................................................16

2.1.5 Amplifier Circuit: 11x...........................................................................................................................17

2.1.6 Low-Pass Filter Circuit: 38Hz .............................................................................................................18

2.1.7 Pulse Rate Trigger Circuit ..................................................................................................................19

2.1.8 Interface between Analog Board and Main Board..............................................................................20

2.2 Microcontroller............................................................................................................................................21

2.2.1 Key Features of S3P8245 ..................................................................................................................22

2.2.2 Resource Assignment ........................................................................................................................23

2.2.3 LCD.....................................................................................................................................................24

2.2.4 Battery Voltage Detect........................................................................................................................24

2.2.5 I2C Device: EEPROM and Real Time Clock......................................................................................25

2.3 Pump Motor Driver Circuit..........................................................................................................................26

2.4 Valve Motor Driver circuit...........................................................................................................................27

2.5 Buzzer Enable and Driver Circuit...............................................................................................................28

2.6 Power Supply Circuit..................................................................................................................................29

3 SOFTWARE IMPLEMENTATION..................................................................30

3.1 Initialization ................................................................................................................................................31

3.2 Battery Voltage Detect ...............................................................................................................................31

3.3 Blood Pressure Monitor .............................................................................................................................33

3.3.1 Overview of Blood Pressure Monitor ..................................................................................................33

3.3.2 Monitor DC and AC Signals of Blood Pressure..................................................................................35

3.3.3 Analysis ..............................................................................................................................................36

3.4 EEPROM Write and Read Operations.......................................................................................................37

3.5 Interrupt Service Subroutine ......................................................................................................................38

3.5.1 Pulse Rate Input ISR ..........................................................................................................................38

3.5.2 User Button (Power On/Off) ISR ........................................................................................................39

3.5.3 User Button (Start, Up/Down, Delete, Save) ISR ...............................................................................40

Page 5

4 SCHEMATIC ..................................................................................................42

5 PCB LAYOUT ................................................................................................44

6 MEASUREMENT............................................................................................48

6.1 Test Environment.......................................................................................................................................48

6.2 Final Measurement Environment Setting...................................................................................................49

6.3 Test Result .................................................................................................................................................50

7 APPENDIX 1: BILL OF MATERIALS ............................................................51

8 APPENDIX 2: SOURCE CODE......................................................................54

Page 6

List of Figures

Figure Title Page

Number Number

Figure 1-1 Types of Blood Pressure Equipments ..................................................................................................9

Figure 1-2 System Block Diagram .......................................................................................................................10

Figure 1-3 DC and AC Components of Blood Pressure Signal and SBP/DBP Position......................................12

Figure 2-1 Analog Board (Driver, Diff-amp, 0.8Hz HPF, 11x Amp, 38Hz LPF, and Comparator) Circuit............13

Figure 2-2 MPS-3117 Pressure Sensor Appearance and Pin Assignment .........................................................14

Figure 2-3 Constant Current Driver and Pressure Sensor...................................................................................14

Figure 2-4 Diff-amplifier Circuit ............................................................................................................................15

Figure 2-5 High Pass Filter Circuit : 0.8Hz...........................................................................................................16

Figure 2-6 Amplifier Circuit : 11x..........................................................................................................................17

Figure 2-7 Low-Pass Filter Circuit : 38Hz ............................................................................................................18

Figure 2-8 Pulse Rate Trigger Circuit...................................................................................................................19

Figure 2-9 Interface between Analog Board and Main Board..............................................................................20

Figure 2-10 Microcontroller Circuit .......................................................................................................................21

Figure 2-11 LCD Function Diagram and External Driving Circuit ........................................................................24

Figure 2-12 Battery Voltage Detect Circuit...........................................................................................................24

Figure 2-13 EEPROM Circuit and Real-time Clock Circuit ..................................................................................25

Figure 2-14 Pump Motor Driver Circuit ................................................................................................................26

Figure 2-15 Valve Motor Driver Circuit.................................................................................................................27

Figure 2-16 Buzzer Enable and Driver Circuit......................................................................................................28

Figure 2-17 Power Supply Circuit ........................................................................................................................29

Figure 3-1 System Flow Chart .............................................................................................................................30

Figure 3-2 Battery Voltage Detect Flow Chart .....................................................................................................32

Figure 3-3 Blood Pressure Monitor Flow Chart....................................................................................................34

Figure 3-4 Monitor DC and AC of BP Flow Chart ................................................................................................35

Figure 3-5 Analysis Flow Chart ............................................................................................................................36

Figure 3-6 EEPROM Write and Read Operation Flow Chart...............................................................................37

Figure 3-7 Pulse Rate Input (External INT0) ISR Flow Chart ..............................................................................38

Figure 3-8 User Button (Power ON/OFF, External INT2) ISR Flow Chart...........................................................39

Figure 3-9 User Button (Start, Up/Down, Delete, Unit, Save, External INT4-7) ISR Flow Chart.........................41

Figure 4-1 Schematic of Analog Board ................................................................................................................42

Figure 4-2 Schematic of Main Board....................................................................................................................43

Figure 5-1 Main Board and Analog Board PCB Assembly (Top Layer)...............................................................44

Figure 5-2 Main Board and Analog Board PCB Assembly (Bottom Layer) .........................................................45

Figure 5-3 Main Board and Analog Board PCB (Top Layer) ...............................................................................45

Figure 5-4 Main Board PCB (Bottom Layer) ........................................................................................................46

Figure 5-5 Final Implementation of Blood Pressure Monitor (Main Board)..........................................................47

Figure 5-6 Final Implementation of Blood Pressure Monitor (Analog Board) ......................................................47

Figure 6-1 Final Measurement Environment Setting ...........................................................................................49

Figure 6-2 Blood Pressure Signals Measurement Waveform..............................................................................50

Page 7

List of Tables

Table Title Page

Number Number

Table 2-1 Microcontroller Resource Assignment .................................................................................................23

Table 7-1 Bill of Main Board Materials .................................................................................................................51

Table 7-2 Bill of Analog Board Materials..............................................................................................................53

Page 8

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

1 OVERVIEW OF ARM BLOOD PRESSURE

MONITOR

This application note describes an arm blood pressure monitor (BPM) based on Samsung's S3P8245

microcontroller. The reference design is intended for novices, who are not familiar with blood pressure monitor

system design. You can modify the design to build more complicated applications.

With rising living standards and increase in ageing among people, medical testing equipments have become

necessity for families. For instance, home blood pressure equipments have become increasingly popular with the

Chinese families.

Usually, these equipments are of two types:

• First is the Mercury sphygmomanometer. The main advantage of such equipment lies in its numerical stability.

However, the disadvantages include: patients cannot measure themselves if they are alone; the equipment

must be operated by healthcare professionals. This equipment can also result in significant visual observation

error. The measurement results can be different, depending on the doctor's experience and criterion, so it can

lead to subjectivity. The Mercury sphygmomanometer is bulky and not easy to carry (not portable).

• Second is the electronic Blood Pressure Monitor (BPM). The main advantage of such equipment include:

ease of use; patients without any professional training can also use this equipment. It is easy to record the

measured values with this equipment. Besides, it is lightweight and portable. Due to its advantages, more

families are using this equipment. From 2007 to 2010 alone, China's annual demand for electronic blood

pressure monitor grew to 350 million units.

Electronic blood pressure monitor are of two types:

• Wrist blood pressure monitor

• Arm blood pressure monitor

8

Page 9

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

Figure 1-1 shows all the above-mentioned blood pressure equipments.

a. Mercury Sphygmomanometer b. Wrist Blood Pressure Monitor c. Arm Blood Pressure Monitor

Figure 1-1 Types of Blood Pressure Equipments

1.1 KEY Features of ARM Blood Pressure Monitor

The key features of arm blood pressure monitor based on Samsung's S3P8245 microcontroller include:

• Measurement: Arm-type

• Measuring range: Pressure: 0 ~ 299mmHg (0 ~ 39.9kPa), Pulse: 40 ~ 180 beats/minute

• Accuracy: Pressure: ±4mmHg (±0.5kPa), Pulse: ±5%

• Pump method: Inflatable pump automatic inflate

• Deflate method: Release valve automatic deflate

• Measurement method: Oscillographic determination method

• Functions:

− User button: Power On/Off, Start, Up/Down, Delete, Save, and Unit

− Records up to 35 blood pressure monitoring records

− No user button operation; automatic shutdown after 30 seconds

• Power: 4x AA batteries or 6V DC power supply

• Battery life: 200 times measurement

• Operation temperature and humidity: +10℃ ~ +40℃; 30%RH ~ 85%RH

9

Page 10

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

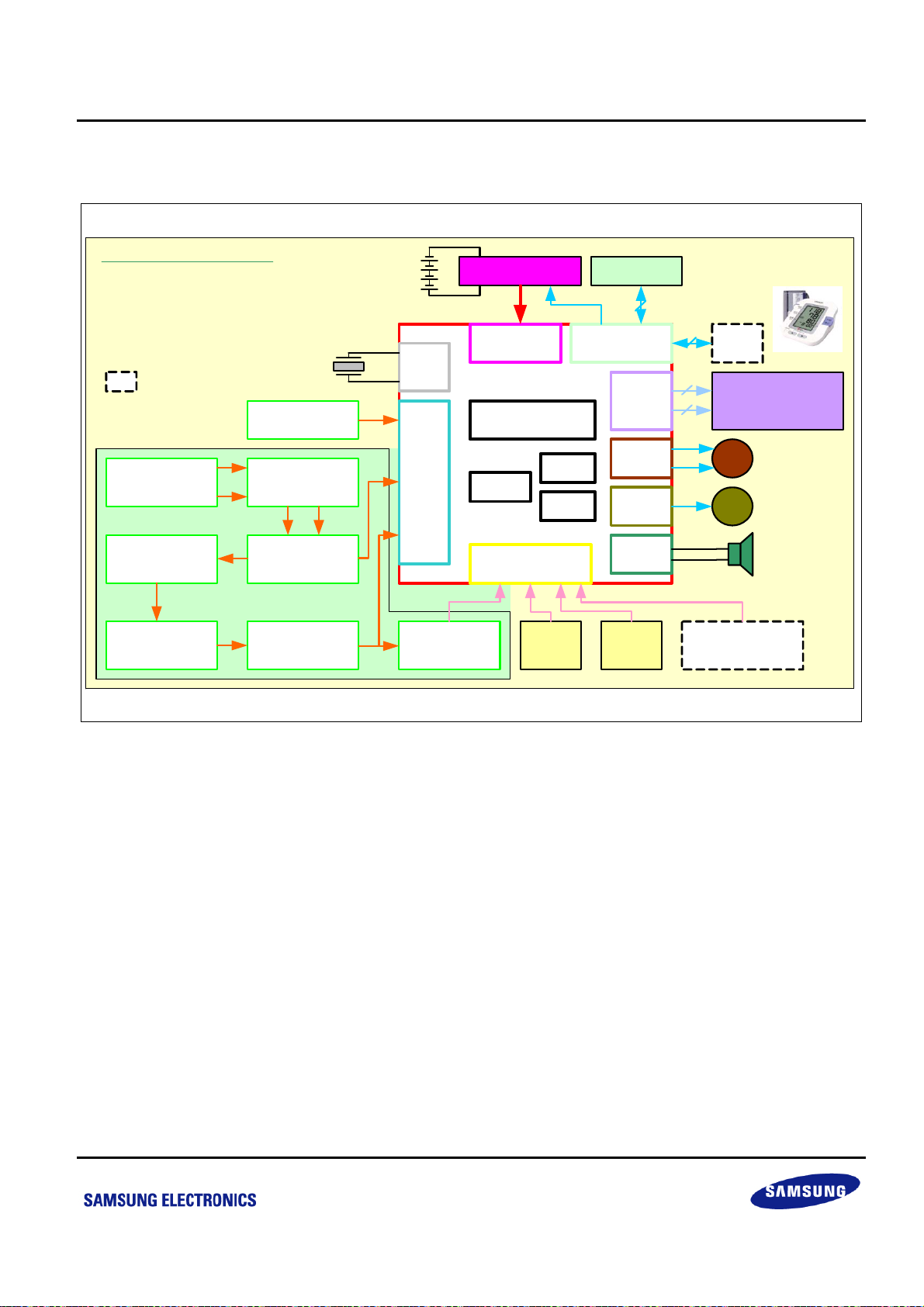

1.2 System Block Diagram

Note of BPM System Block

BT +6V : Battery +6 V

Power Mana. : Power Management

Cons. Cur. Driver : Constant Current Driver

Start But. : User Button

Power But. : User Button

RTC :

Real Timer Clock

: Not used

Cons. Cur .

Driver

2nd Order

HPF : 0 .8Hz

Amplifier

11 x

(Start)

(Power ON/OFF)

10 MHz

32. 768 KHz

Battery Vol . CPU

Pressure

Sensor

V+ V-

Diff - Amp

Analog Board V 1 . 0

2 nd Order

LPF : 38Hz

ADC2

ADC0

ADC1

BT

+6V

OSC

ADC

INT0

Pulse Rate

Trigger

Power Mana .

+5V

S3P8245

ROM

SIO

RAM

Ext. INT

INT1 INT2

Start

But .

EEPROM

3

I/OPWR

LCD

T1

TB

BUZ

INT4-INT7

Power

But .

Main Board V 2 .1

2

RTC

4

19 SEG * 4 COM

19

M

M

Other

User Button

LCD Screen

Pump

Motor

Valve

Motor

Figure 1-2 System Block Diagram

1.3 Principles of Electronic Blood Pressure Monitor

Typically, blood pressure can be described as systolic blood pressure (SBP) and diastolic blood pressure (DBP).

• Systolic blood pressure (SBP): The blood pressure is measured at the time of heart contraction, that is, when

blood hits the blood vessels.

• Diastolic blood pressure (DBP): The blood pressure is measured when the heart does not contract. If the cuff

pressure is equal to the blood pressure, blood begins to flow and produces a "cuff" sound. The blood pressure

is measured at this point (SBP). Once the cuff sound weakens, it gradually disappears. The blood pressure is

measured again at this point (DBP).

10

Page 11

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

1.4 Process of Blood Measurement in Blood Pressure Monitor

• The process of blood pressure measurement in the blood pressure monitor is described as follows:

• When the patient presses the Start button, the microcontroller opens the inflatable pump motor.

• The BPM system inflates up to 200mmHg. After reaching this value, it slowly deflates with the speed of

5mmHg per second.

• The pressure sensor outputs a signal through differential amplifier.

− One part of signal goes to the ADC0 channel to monitor the DC component of blood pressure signal.

− Other part goes to 0.8Hz second order high-pass filter to remove the DC component.

− Rest of the AC component of 11x amplification is inputted to the 38Hz second order low-pass filter (to filter

power and skin friction with the cuff of high-frequency noise and frequency interference, and to adjust the

signal in the range of 0 to 5V).

− One part of the filtered AC signal is sent to the pulse rate trigger circuit for generating trigger pulses that

starts the ADC module operation.

− Other part is sent to the ADC1 channel for calculating the amplitude of AC signal.

• Find the maximum peak-to-peak amplitude. Mark this point as MAP point.

• Before MAP point, determine the value that is the closest to 0.54*MAP. The corresponding DC component

value of this transient position specifies the systolic blood pressure (SBP) value.

• After MAP point, determine the point whose value is closest to 0.72*MAP. The corresponding DC component

value specifies the diastolic blood pressure (DBP) value.

• By using the internal timer to measure the interval between every two adjacent pulses, the system easily

obtains the pulse rate (PR) value.

• All the measurement results will be showed on the LCD screen.

11

Page 12

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

Figure 1-3 shows the system operation process, blood pressure, systolic and diastolic blood pressure signals, and

their position.

Pump Deflate

DC . BP

MAP

DBP

SBP

AC . BP

Figure 1-3 DC and AC Components of Blood Pressure Signal and SBP/DBP Position

12

Page 13

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

2 HARDWARE IMPLEMENTATION

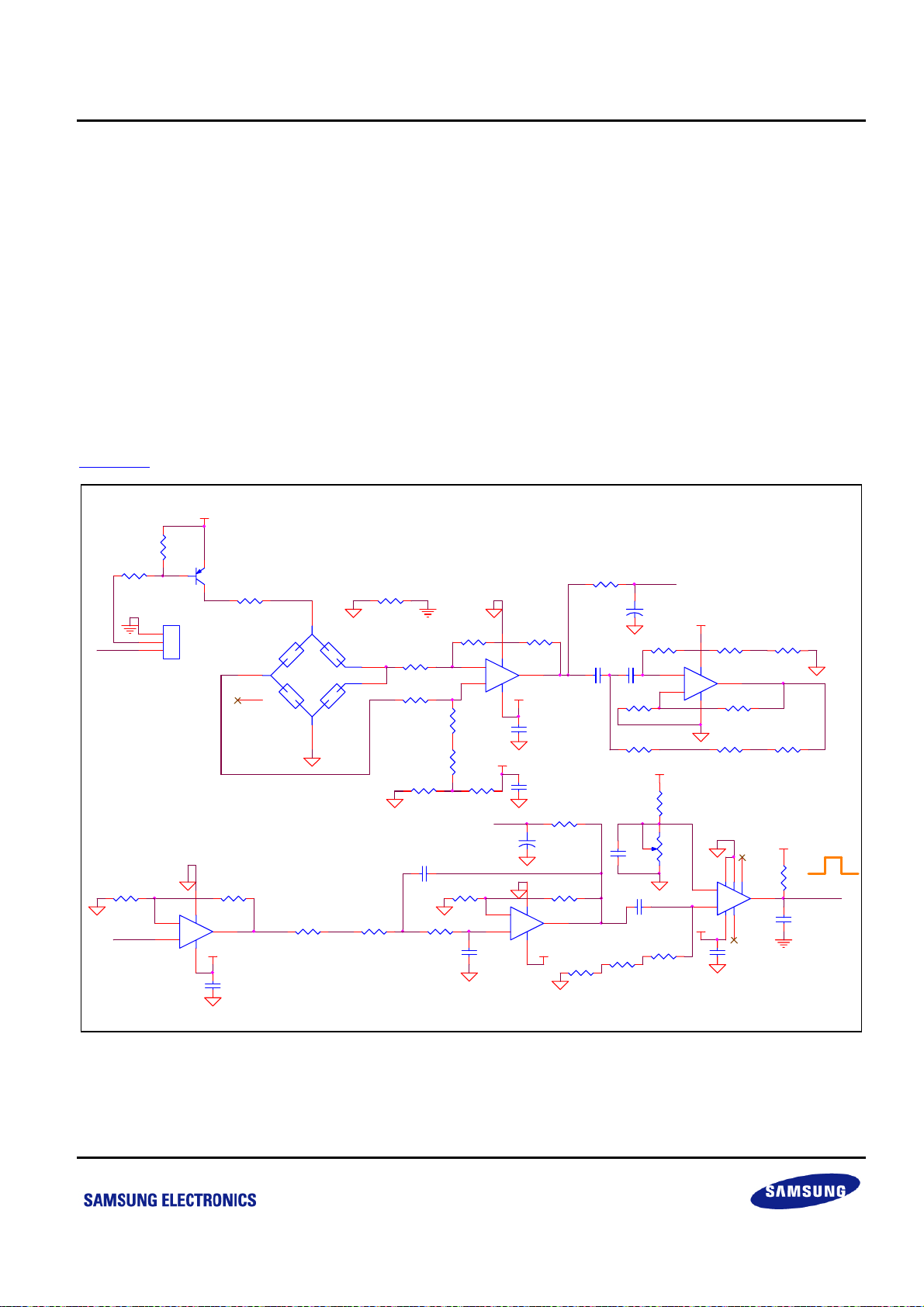

2.1 Analog Signal Processing

The blood pressure monitor system needs a filter and an amplify circuit for the purpose of processing weak analog

signals and recognizing pulse signals. Such system is made of a single PCB board called the Analog Board. The

board provides a constant current driver (for pressure sensor), pre-amplifier (for pressure sensor's output weak

signal), high-pass filter, intermediate amplifier, low-pass filter, and pulse signal (which is sent to the MCU).

Figure 2-1

R2

4.7K ohm

P1.2/T1PWM

VHPF

shows a schematic diagram of the Analog Board.

VCC_+5V

R1

4.7K ohm

Q1

9012

J4

1

2

3

CON3

2

3

Amplifier: 11x

-

+

U4A

LM358

VCC_+5V

8 4

R28 10K ohm 1%R27 1K ohm 1%

R4

1.2K ohm

3

3

4

4

MPS-3117-006G_6_SOP

Pressure Sensor

VMAG

1

C13

104

2

U1

2

5

5

R31 49.9K ohm 1%

R5 0 ohm

AGND

R11 30K ohm 1%

1

1

6

6

R12 30K ohm 1%

R32 10K ohm 1%

GND

R6 1M ohm 1%

R20

2.4K ohm

AC Signal of BP

C8

104

R29 30K ohm 1%

2nd Order LPF: 38Hz

-

2

+

3

R13

1M ohm 1%

R16

1.3M ohm 1%

VCC_+5V

R21

182K ohm

P2.1/ADC1

C11

104

R7 1.3M ohm 1%

U2A

LM358

1

VCC_+5V

8 4

C4

104

C5

104

+

-

6

+

5

8 4

VDIF F

VDIF F

R23 100 ohm 1%

C6

10uF

R30 1K ohm 1%R25 1K ohm 1 %

7

LM358

U4B

VCC_+5V

R35 1M ohm 1%

R3 100 ohm 1%

C2

104

P2.0/ADC0

+

C3

104

R14 1K ohm 1%

R17 1M ohm 1% R18 1.5M ohm 1% R19 360K ohm 1%

C7

104

C9

VLPF

104

R33 5. 1M ohm 1%

DC Signal of Blood Pressure (BP)

C1

10uF

VCC_+5V

R8 1M ohm 1%

VCC_+5V

R34 10M ohm 1%

84

5

+

6

-

R22

100K ohm 1%

R24

50K ohm

VCC_+5V

R9 200K ohm 1%

U2B

LM358

R15 1K ohm 1%

2nd Order HPF: 0.8Hz

3

2

Pulse Rate Detector

7

641

-

LM311

7

+

U3

5

8

C12

104

R10 200K ohm 1%

VHPF

VCC_+5V

R26

10K ohm

P0.0/INT0

C10

Pulse Rate

104

Figure 2-1 Analog Board (Driver, Diff-amp, 0.8Hz HPF, 11x Amp, 38Hz LPF, and Comparator)

Circuit

13

Page 14

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

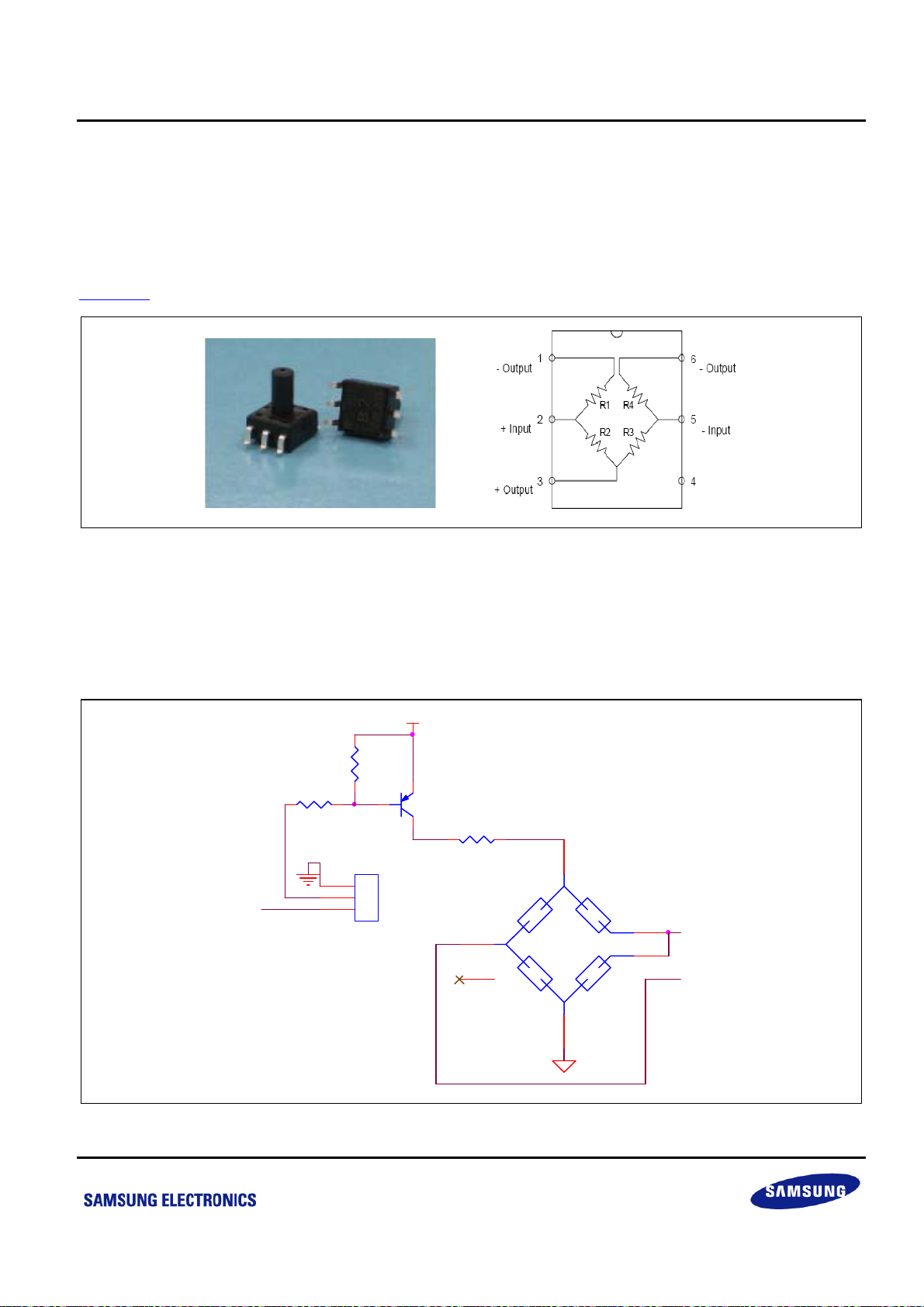

2.1.1 Introduction to MPS-3117 Pressure Sensor

MPS-3117 is a pressure sensor for blood pressure monitor from Taiwan Metrodyne Microsystem Corp. Its

dimension is 7mm×7mm×10mm, and its measurable pressure ranges from -299.95mmHg to +299.95mmHg.

MPS-3117 uses a constant source to drive the Wien Bridge. It sends the double-ended output differential signals

according to the pressure.

Figure 2-2

shows the appearance and pin assignment of MPS-3117 pressure sensor.

Figure 2-2 MPS-3117 Pressure Sensor Appearance and Pin Assignment

2.1.2 Constant Current Driver Circuit

The BPM system requires a constant current source to drive pressure sensor. The typical value of drive current is

1mA while the maximum value of drive current is 3mA.

VCC_+5V

R1

1

2

3

J4

CON3

4.7K ohm

Q1

9012

R4

1.2K ohm

3

3

4

4

MPS-3117-006G_6_SOP

U1

2

2

1

1

6

6

5

5

R2

4.7K ohm

P1.2/T1PWM

Figure 2-3 Constant Current Driver and Pressure Sensor

14

Page 15

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

+

2.1.3 Differential amplifier circuit

In the BPM system, the differential amplifier plays the role of amplifying weak signal output from pressure sensor.

One way to do that is directly to the microcontroller as a DC signal of blood pressure. The other signal is provided

to the back analog circuits for filtering and amplification processing.

The diff-amplifier circuit output can be calculates as follows:

RR

+

67

VVV VVVV

( ) ( ) ( ) ( ) 76.667 ( )

=×−= ×−≈×−

DIFF IN IN IN IN IN IN

Rk

11

+− +− +−

11.3

MM

30

R7 1.3M ohm 1%

U2A

-

LM358

+

VCC_+5V

8 4

VCC_+5V

1

C4

104

C5

104

VDI FFVDI FF

R11 30K ohm 1%

R12 30K ohm 1%

R20

2.4K ohm

R6 1M ohm 1%

2

3

R13

1M ohm 1%

R16

1.3M ohm 1%

R21

182K ohm

Figure 2-4 Diff-amplifier Circuit

R3 100 ohm 1%

P2.0/ADC0

+

C1

10uF

15

Page 16

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

R

R

+

R

2.1.4 High Pass Filter Circult: 0.8Hz

The analog board of the BPM system uses 2nd order Butterworth high-pass filter circuit, whose transfer function is

calculated as follows:

2

()

HS

HPF

=

CC

2

SS

()

++

()()( )

8 9 10 2 3 8 9 10 17 18 19 2 3

+

23

R R CC R R R R R R CC

++ ++ + +

S

1

5

6

VCC_+5V

84

+

-

U2B

LM358

R15 1K ohm 1%R14 1K ohm 1%

7

VHPF

VDI FF

R8 1M ohm 1% R 9 200K ohm 1% R10 200K ohm 1%

C2

C3

104

104

R17 1M ohm 1% R18 1.5M ohm 1% R19 360K ohm 1%

Figure 2-5 High Pass Filter Circuit : 0.8Hz

Suppose the network coefficient a11 of 2nd order Butterworth is 1.414 and the angular frequency is 0.8x2π, while

the value of both C2 and C3 is 0.1uF. So, the values of R8+R9+R10 and R17+R18+R19 can be calculated as

follows:

CC

+

RR M

++ = = = Ω

8910

23

αω π

CC

2311

0.1 0.1 1.414 0.8 2

c

0.1 0.1

×× ××

1.41

RR M

++= = = Ω

17 18 19

( ) 1.41 0.1 0.1 (0.8 2 )

RRRCC M

++ Ω××× ×

891023

11

22

ωπ

c

2.86

16

Page 17

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

2.1.5 Amplifier Circuit: 11x

The signal coming from high-pass filter is weak and needs to amplify. Therefore, the system uses an 11x

magnification amplifier circuit.

R28 10K ohm 1%R27 1K ohm 1%

U4A

-

VHPF

2

3

+

8 4

LM358

1

VCC_+5V

C13

104

VMAG

Figure 2-6 Amplifier Circuit : 11x

17

Page 18

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

R

R

α

R

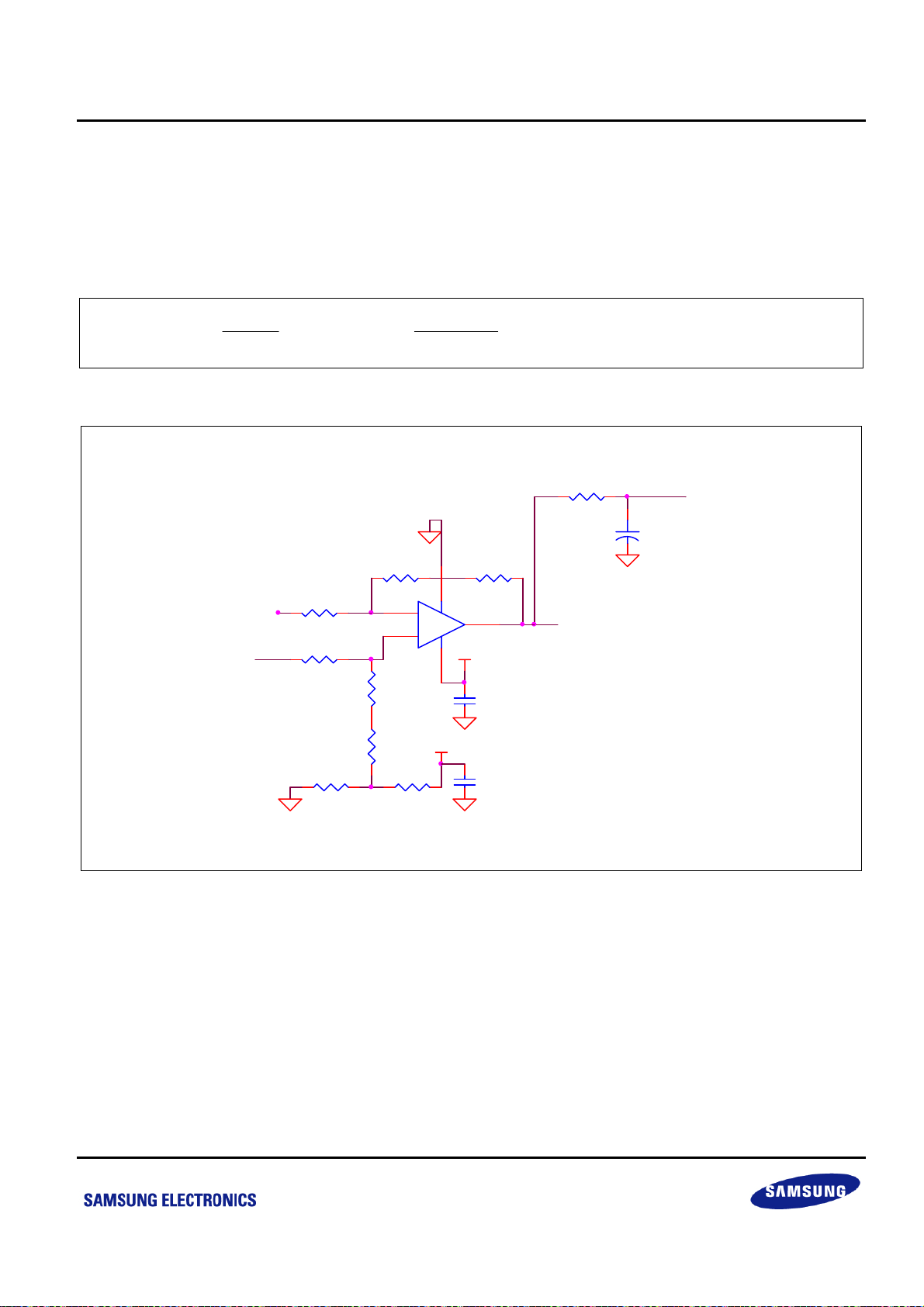

2.1.6 Low-Pass Filter Circuit: 38Hz

System uses 2nd order Butterworth low-pass filter circuit, whose transfer function is calculated as follows:

1

RRRCC

()

+

HS

()

LPF

=

2

SS

RRR

()

++

() ()

31 32 29 11 31 32 29 8 11

Suppose the network coefficient a11 of 2nd order Butterworth is 1.414 and the angular frequency is 38x2π, while

the value of both C2 and C3 is 0.1uF. So, the values of R31+R32 and R29 can be calculated as follows:

31 32 29 8 11

++

31 32 29

RRC R RRCC

++

1

Rk

+= = = Ω

31 32

== =Ω

29

( ) 59.3 0.1 0.1 (38 2 )

RRCC

11

+××××

31 32 8 11

11

CF

ωπμ

c

8

22

ωπ

c

1.414

38 2 0.1

××

59.3

29.3

k

C8

104

R31 49. 9K ohm 1%

VMAG

R32 10K ohm 1% R29 30K ohm 1%

C11

104

P2.1/ADC1

6

5

R23 100 ohm 1%

+

C6

10uF

R30 1K ohm 1%R25 1K ohm 1%

-

+

LM358

U4B

8 4

VCC _+5V

7

VLPF

Figure 2-7 Low-Pass Filter Circuit : 38Hz

18

Page 19

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

R

2.1.7 Pulse Rate Trigger Circuit

System uses a single, high-speed voltage differential comparator as the pulse rate trigger circuit. The signal,

which goes through the RC low-pass filter, will input to the positive side of comparator LM311. More reference

voltage is put on the negative side. When the signal is greater than the reference voltage, LM311 will be output

high. Otherwise, it holds the low level. Figure 2-8

shows the pulse rate trigger circuit.

R35 1M ohm 1%

VLPF

R33 5. 1M ohm 1%

VCC_+5V

C7

104

C9

104

R34 10M ohm 1%

R22

100K ohm 1%

R24

50K ohm

Figure 2-8 Pulse Rate Trigger Circuit

The reference voltage value is calculated as follows:

3

2

VCC _+5V

-

+

8

C12

104

VCC_+5V

641

LM311

7

U3

5

R26

10K ohm

P0.0/INT0

C10

104

RR

VV V

CMPREF DD

=× =×

24 24

++

22 24 24

5

RkR

100

By adjusting the potentiometer R24 value, you can select the appropriate reference voltage for pulse rate trigger

circuit. The actual value of R24 in this BPM system is 0.745V.

19

Page 20

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

2.1.8 Interface between Analog Board and Main Board

There are two interfaces (J8 and J9) between analog board and main board in the BPM system. One is called J9

that includes DC and AC signals of blood pressure and pulse rate trigger signal. Also, J9 provides +5V power,

both analog and digital ground. Both analog ground and digital ground is shorted by a 0Ω resistor. The other

interface is called J8 that controls the pressure sensor operation status. When P1.2 outputs low level, the sensor

turns on, else it turns off.

1

2

3

4

5

6

J9

CON6

P1.2/T1PWM

Pressure P1.2

ON 0

OFF 1

J8

1

2

3

CON3

R82 0 ohm

AGND

GND

VCC_+5V

P2.0/ADC0

P2.1/ADC1

AGND

P0.0/INT0

Figure 2-9 Interface between Analog Board and Main Board

20

Page 21

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

2.2 Microcontroller

In the reference design, Samsung’s S3P8245 is used as the microcontroller. The main function of this

microcontroller is to control both pump motor and valve motor, acquire and process both DC and AC of analog

signal, respond the pulse trigger and user button, and then display on the LCD screen.

The second function of this microcontroller is power management, record monitored results, and alarm patients

via buzzer.

P0.4/IN T4

P0.5/IN T5

P0.6/IN T6

P0.7/IN T7

C7 33pF

C11 33pF

C15 33pF

C16 33pF

J4

1

2

3

4

CON4

Y2

10MHz

Y3

32.768KHz

C10

100uFC8104

P0.1/I NT1

C17

104

VCC_+5V

+

1 2SW 5 SW KEY -SPST

VCC_+5V

R23

10K ohm

C18

0.1uF

VCC_+5V

R24

10K ohm

SEG9

SEG8

SEG7

SEG6P2.4/AD C4

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

P4.1/SEG17

P4.2/SEG18

P4.3/SEG19

P4.4/SEG20

P4.5/SEG21

P5.0/SEG24

P5.1/SEG25

P4.6/SEG22

SW6

KEY2

P5.2/SEG26

P5.3/SEG27

P5.4/SEG28

P5.5/SEG29

P5.6/SEG30

P5.7/SEG31

P3.0/TBPWM

P3.1

P3.2

P3.3

P3.4

VDD

GND

XOU T

XIN

TEST

XTI N

XTOU T

RESET

P0.0/I NT0

U4

1

SEG26/P5.2

2

SEG27/P5.3

3

SEG28/P5.4

4

SEG29/P5.5

5

SEG30/P5.6

6

SEG31/P5.7

7

P3.0/TBPWM

8

P3.1/TAOUT/ TAPWM

9

P3.2/TACLK

10

P3.3/TACAP/ SDAT

11

P3.4/SC LK

12

VDD

13

VSS

14

XOU T

15

XI N

16

TEST

17

XTI N

18

XTO U T

19

RESET

20

P0.0/I NT0

S3P8245_80_TQFP

80

P0.1/I NT1

P4.7/SEG23

79

SEG25/P5.1

P0.1/INT 121P0.2/INT 222P0.3/INT 323P0.4/INT 4

P0.2/I NT2

P0.3/I NT3

P4.0/SEG16

64

70

SEG1065SEG1166SEG1267SEG1368SEG1469SEG15

SEG16/P4.071SEG17/P4.172SEG18/P4.273SEG19/P4.374SEG20/P4.475SEG21/P4.576SEG22/P4.677SEG23/P4.778SEG24/P5.0

S3P8245

(80-TQFP-1212)

P0.5/INT 525P0.6/INT 626P0.7/INT 727P1.0/T1CAP28P1.1/T1CLK29P1.2/T1OUT/T1PWM30P1.331P1.4/BUZ32P1.5/SO33P1.6/SCK34P1.7/SI35P2.0/ADC036P2.1/ADC137P2.2/ADC238P2.3/ADC339P2.4/ADC4

24

P0.5/I NT5

P0.6/I NT6

P0.7/I NT7

P1.0

P1.1

P1.2/T 1PWM

P1.3

P1.4/BU Z

P1.5/SO

P1.6/SC K

P1.7/SI

P2.0/AD C0

P0.4/I NT4

P2.1/AD C1

SEG661SEG762SEG863SEG9

AVREF

P2.7/AD C7/VVLDR EF

P2.6/ADC6

P2.5/ADC5

40

P2.2/AD C2

P2.3/AD C3

Figure 2-10 Microcontroller Circuit

SEG5

SEG4

SEG3

SEG2

SEG1

SEG0

COM3

COM2

COM1

COM0

VLC2

VLC1

VLC0

AVSS

SEG4

SEG5

SEG6

SEG7

SEG0

SEG1

SEG[0...18]

SEG5

60

SEG4

59

SEG3

58

SEG2

SEG1

SEG0

COM3

COM2

COM1

COM0

VLC2

VLC1

VLC0

CA

CB

AVSS

AVREF

P2.7

P2.6

P2.5

VCC_+5V

R10

100K ohm

C12 0.1uF

R13

100K ohm

R14

100K ohm

R15 100K ohm

R17 0 ohm

R16 50 ohm

57

56

55

54

53

52

51

50

49

48

47

CA

46

CB

45

44

43

42

41

U2

BPMLCD_00598

C14

GND

+

103

11223344556677889

23

C13

10uF

VCC_+5V

SEG8

SEG2

COM3

SEG9

SEG3

COM2

COM1

SEG10

SEG11

9

12

1010111112

高压

低压

KPammHg

心

率

次/分

131314141515161617171818191920202121222223

P4.0/SEG16

SEG15

SEG14

SEG13

COM0

SEG12

P4.2/SEG18

P4.1/SEG17

21

Page 22

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

2.2.1 Key Features of S3P8245

The key features of S3P8245 include:

• Memory

− 16Kbytes One-time-program (OTP) ROM

− 544 bytes of data memory (RAM)

• 45 I/O (Sharing with LCD signal outputs)

• Interrupts

− 6 level, 8 vector, 8 internal interrupts

− 2 level, 8 vector, 8 external interrupts

• Timer

− Watch Timer for real-time and interval time measurement, clock generation for LCD and buzzer.

− 8-bit Timer/Counter A/B, Timer B can generate the carrier frequency

− 16-bit Timer/Counter 0/1

• 32 seg * 8 com LCD Controller/Driver

• 10-bit Analog to Digital Converter * 8 channels

• SIO * 1 channel

• Operating Temperature Range: -25℃ to 85℃

• Operating Voltage Range: 1.8V to 5.5V

• Package Type : 80-QFP-1420C, 80-TQFP-1212

22

Page 23

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

2.2.2 Resource Assignment

Table 2-1 Microcontroller Resource Assignment

No. Function Module Assignment Pin Note

DC & AC Signal of

1

Blood Pressure

Detector

ADC

One channel ADC for DC signal of

BP; Other channel for AC signal of

BP

P2.0/ADC0 (#36),

P2.1/ADC1 (#37)

2

channel

2

Pulse Rate

Detector

Interrupt

Rising edge trigger, calculate PR

@ ISR

3 LCD display LCD 4COM * 19 SEG

Timer Timer 0 generates 5ms interval - -

Rising edge trigger, ON/OFF @

ISR

Output high level to enable

GM6155-5.0

Updates the over-time counter

every 5ms. If the system is waiting

for over-time, no button is

4

Power

Management

Interrupt

I/O

Timer

pressed.

Falling edge trigger, execute

5 User Button Interrupt

function (Start, Up/Down,

Delete, Unit, Save) @ ISR

Timer

6 Pump Motor

I/O

Timer 1 is set in the PWM mode to

control the pump speed

Motor control 0-1, support

function:

Start/ Forward/ Reverse/ Stop

P0.0/INT0 (#20) -

COM0-3(#51-54),

SEG0-18(#55-73)

P0.2/INT2 (#22) -

P0.3 (#23) -

- -

P0.1/INT1 (#21),

P0.4/INT4 ~

P0.7/INT7 (#24-27)

Up to 5

channels

- -

P1.0-P1.1 (#28-29) -

-

7 Valve Motor Timer

8 EEPROM I/O

Timer B is set in repeating mode

to control the valve speed

One I/O for power control; Other

two I/O for I2C clock and data

P3.0/TBPWM (#7) -

P2.5-P2.7 (#41-43) -

9 RTC I/O Two I/O for I2C clock and data P3.3-P3.4 (#10-11) Not used

Generates the carrier frequency of

buzzer

Timer A is set in the PWM mode to

control the buzzer output time

One ADC channel for battery

voltage

P1.4/Buz (#32) -

- -

P2.2/ADC2 (#38) -

10 Buzzer

11

Battery Vol.

Detector

23

Buz

I/O Enables the buzzer output P1.3 (#31) -

Timer

ADC

Page 24

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

2.2.3 LCD

The internal LCD module in S3P8245 can directly drive up to 128-dot (32 segments × 4 commons) LCD panel.

The internal resistor bias can provide 1/2 bias, 1/3 bias, and 1/4 bias, without any bias pin or off chip resistor.

S3P8245 supports two kinds of LCD voltage driving circuit, that is, internal and external. This solution uses

external LCD voltage driving circuit.

The LCD panel used can display systolic blood pressure (SBP), diastolic blood pressure (DBP), pulse rate (PR),

diagnose result, and other system status (such as battery under-voltage). The drive method is +5V, 1/4 duty, and

1/3 bias.

Figure 2-11 LCD Function Diagram and External Driving Circuit

2.2.4 Battery Voltage Detect

Battery voltage is measured through R30 and R29 to ground. The relationship between voltage of P0.2/ADC2 port

and battery voltage is as follows:

R

VV V V

=× =× ≈×

ADC BAT BAT BAT

2

29

RR k k

++

29 30

k

10

10 5.1

0.662

When the battery voltage drops to 4.8V, the voltage of ADC2 input is about 3.179V. After battery voltage resumes

to 5.1V, the voltage of ADC2 increases to 3.377V.

C20 104

R29 10K ohm

P2.2/ADC2

R30 5.1K ohm VC C_+6V

Figure 2-12 Battery Voltage Detect Circuit

24

Page 25

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

2.2.5 I2C Device: EEPROM and Real Time Clock

The system uses a two-wire EEPROM 24C01 as blood pressure monitored data memory unit. Three I/O ports

(P2.5 ~ P2.7) are used to control this device. One is used to control the power supply when EEPROM is not used

during the main software process. Other two ports are the serial data and clock line between the MCU and

EEPROM interfaces.

Even though the final system does not use the RTC, this interface is used for hardware and software upgrades.

The system remains real-time clock circuit for high-resolution time and date application. The PCF8563 is a CMOS

real-time clock/calendar optimized for low power consumption. A programmable clock output, interrupt output, and

voltage-low detector are also provided. All addresses and data are transferred serially via a two-line bidirectional

I2C bus. Its maximum bus speed is 400 kbit/s. The built-in word address register is incremented automatically

after each written or read data byte.

1

2

3

VCC_+5V

U5

A0

VCC

A1

WP

A2

SCL

VSS4SDA

24C01_8_D IP

9012

8

7

6

5

R18 10K ohmQ2

R20 100 ohm

R21

R22

20K ohm

20K ohm

P2.5

P2.6

P2.7

Y1

32.768KH z

C9 CAP

C5

CAP VR

U3

1

OSCI

2

OSCO

3

INT

4

VSS

PCF 8563_8_DI P

VDD

CLKOUT

SCL

SDA

VCC_+5V

C6

104

8

7

6

5

R7

R11

20K ohm

20K ohm

P3.3

P3.4

Figure 2-13 EEPROM Circuit and Real-time Clock Circuit

25

Page 26

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

2.3 Pump Motor Driver Circuit

The BPM system has a 6V DC motor for cuff inflation. The scope of internal air pressure is restricted to measure

blood pressure (170 ~ 200mmHg). This driver circuit uses symmetry bridge type to support three motor modes,

including start, stop, forward, and reverse modes.

VCC_+6V

R35

Q5

9012

1K ohm

R39

Q8

9013

1K ohm

R32

1K ohm

R33

1K ohm

R34

1K ohm

Q6

9013

R31

1K ohm

R38

1K ohm

Q4

9012

MG1

1 2

MOTO R AC

Q7

9013

D1

1N4007

D2

1N4007

R36

1K ohm

Q9

9013

P1.0

P1.1

+

C23

10uF

C25

104

Figure 2-14 Pump Motor Driver Circuit

26

Page 27

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

2.4 Valve Motor Driver circuit

The BPM system uses a 6V DC motor for cuff deflation called valve motor. Use the timer B PWM output waveform

to control the speed of deflation.

P3.0/TBPWM

C26 104

R42

R45

1K ohm

10K ohm

VCC_+6V

12

Q10

9013

MG2

MOTO R

D3

1N4007

R43

0 ohm

Figure 2-15 Valve Motor Driver Circuit

27

Page 28

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

2.5 Buzzer Enable and Driver Circuit

When the User button is pressed (or system error occurs during measurement), the system will generate a buzzer

sound to grab the patient's attention. S3P8245 supports four kinds of frequencies for buzzer output. Therefore,

one I/O port connected through the buzzer module is used to control the buzzer frequency. The other I/O port is

used to enable or disable the buzzer output.

P1.4/BUZ

P1.3

1

2

R25

10K ohm

J3

CON2

R27

0 ohm

VCC_+5V

R19

1K ohm

Q3

9012

R26

1K ohm

R28

1K ohm

C19

+

47uF

LS1

Buzzer

Figure 2-16 Buzzer Enable and Driver Circuit

28

Page 29

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

2.6 Power Supply Circuit

GM6155-5.0 is an efficient linear voltage regulator with ultra low noise output, extremely low dropout voltage, and

extremely low ground current. The EN pin (#3) in this regulator controls the VOUT pin (#5), which supplies power

to the MCU.

When EN is low, VOUT has no output. On the contrary, when EN is high, VOUT outputs +5V power. After

pressing Key1 (Power ON/OFF user button), the +6V battery voltage is sent to ground through R37, SW7, D4,

and R46. The voltage of R46 is about 3.97V. When EN is high, VOUT will start to output +5V power to the

microcontroller. During the system initialization process, after the microcontroller starts operation, P0.3 outputs

high level. Then regardless of whether Key1 continues to be pressed or released, the EN pin will always be high

and the system will work properly. After that, if you press the Key1 again, the +6V battery voltage is sent to ground

through R37, SW7, and R40. The voltage of R40 will quickly rise to 3.97V and the diode D4 is off, leading to a

rising edge on the external interrupt input port P0.2/INT2.

After the MCU responds to this interrupt, P0.3 output low level, diode D6 is off and EN will be directly shorted to

ground through R46. As a result, VOUT will stop the output power supply to microcontroller. The system will enter

the power-down mode.

Figure 2-17

P0.2/ INT2

shows the power supply circuit of this blood pressure monitor system.

R41 100 ohm

C21

104

10K ohm

P0.3/ INT3

R40

D6

1N4007

R37

5.1K ohm

SW7

KEY1

D4

1N4007

R46

10K ohm

C22

+

470uF

VCC _+6V

C24

1

104

2

GM6155-5.0ST25R_5_SOT-25

VCC_+6V

U8

VIN

VOUT

GND

EN3BY P

1

2

1

2

J6

CON2

J7

CON2

5

4

VCC_+5V

Figure 2-17 Power Supply Circuit

C27

104

J5

1

2

CON2

VCC _+5V

C28

+

100uF

D5 LED

C29

104

R44

330 ohm

29

Page 30

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

3 SOFTWARE IMPLEMENTATION

Figure 3-1 shows the system flow chart with sequence of events in the software. After the microcontroller and

system initializes, if the Start button is pressed, the software enters the main loop. Battery voltage detect is used

for monitoring the battery voltage. The Blood Pressure Monitor starts a new blood pressure measurement for the

patient. After that, the software will respond to external user button operation, and execute the corresponding

function. When the system is waiting for User button out of time, the software will automatically shut down the

power supply.

Start

System Initialization

(MCU, Variable, LCD)

Start Button is

pressed?

Y

Battery Voltage Detect

Y

Y

Battery Vol. is

Under- voltage?

Blood Pressure Monitor

(SBP, DBP, PR)

System is

Over-time?

User Button Service

(Up/Down, Delete, Save)

Start Button

is pressed?

Switch off System Power

N

N

N

N

Y

End

Figure 3-1 System Flow Chart

30

Page 31

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

3.1 Initialization

Initialization involves three parts:

• First, initialize the microcontroller. All the function modules and control registers should be set to their proper

values.

• Second, initialize the system variables.

• Third, initialize the LCD, clear the display RAM area, and initialize all the LCD variables. Additionally, the

record data stored in the EEPROM should be read out before it is displayed on the LCD screen.

3.2 Battery Voltage Detect

After the Start button is pressed, the system will enter in the main routine.

• First, execute the battery voltage detector. The ADC channel #2 in S3P8245 is configured for battery voltage

detection.

• If the voltage value is lower than 4.9V, the software will set under-voltage flag (nSysFlag.6) and toggle the low

battery voltage label "

• Even if the voltage value is below 4.8V, the system will immediately turn off the power.

• On the other hand, if the battery voltage is up to 5.1V or more, the software will automatically clear the under-

voltage flag (nSysFlag.6) and turn off the corresponding label on the LCD screen.

" on the LCD screen.

31

Page 32

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

Start

Enanle ADC2 for

Battery Vol Sampling

N

Battery Vol.ls

= 4.9V?

Y

N

Battery Vol.ls

= 5.1V?

Y

Set Under-voltage flag

nSysFlag.6

Clear Under-voltage flag

nSysFlag.6

Turn OFF Low Bat. Vol.

label on LCD Screen

Toggle Low Bat Vol.

label on LCD Screen

N

Battery Vol.ls

= 4.8V?

Y

Switch off System power

End

Figure 3-2 Battery Voltage Detect Flow Chart

32

Page 33

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

3.3 Blood Pressure Monitor

This subroutine will complete a blood pressure measurement process for patient.

3.3.1 Overview of Blood Pressure Monitor

After initialization, the software inflates the pressure value to 200mmHg. The release valve remains closed during

this time. It then starts to exhaust the gas. Two seconds later, the external interrupt port 0 is enabled in order to

respond to the pulse signal.

In the ensuing process, the system monitors both DC signal and AC signals of blood pressure. As soon as the

software deflates the pressure value to 50mmHg, the system will end deflation. The pulse signal triggers the ADC

start operation. The software receives the effective DC and AC values of current cycle, that is, an effective pulse

signal. It can record up to 40 times of this effective pulse signal.

The software analyzes and diagnoses all monitored data. The final results are displayed on the LCD screen.

33

Page 34

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

Start Pump & OFF Valve

N

Stop Pump & Start Valve

input interrupt (INT0)

N

Start

Initialization

Pressure is

= 200mmHg

Y

Delay 2s

Enable Pulse Rate

Enable ADC0/1

(nSysFlag.0)?

Stop Valve

System is

Over-time?

N

Delay 400ms

Y

Y

Monitor DC & AC of BP

Pressure is

Y

= 50mmHg?

N

Monitor Time is

= 40?

Y

N

Analysis Monitor Results

Diagnose

Display SBP,DBP & PR

value on LCD

End

Figure 3-3 Blood Pressure Monitor Flow Chart

34

Page 35

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

3.3.2 Monitor DC and AC Signals of Blood Pressure

The subroutine monitors both DC and AC signals of blood pressure. Calculate the AC signal's peak-to-peak value

between two adjacent effective pulses. Determine the maximum and minimum values, and calculate the difference

between the two peaks. At the same time, the software will calculate the average DC signal value during the two

pulses.

Monitor ADC0(DC Of

BP) & ADC1(AC of BP)

Enable ADC0/1

N

(nSysFlag.0)?

Monitor DC & AC of BP

Amplitude-limit Filter for

Update Max. /Min./Sum.

DC value of BP

Update Max. / Min.

AC value of BP

Update DC/AC

Sampling Time

Start

Y

DC of BP

Sampling Time

is Over-time?

Y

Save to AC S tring Buffer

Save to DC String Buffer

Set ADC0/ADC1 enable

flag (nSysFlag.0)

Set Cur. Moni tor R esult

valid flag (nSysFlag.2)

End

N

Figure 3-4 Monitor DC and AC of BP Flow Chart

35

Page 36

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

3.3.3 Analysis

The subroutine analyzes the obtained DC and AC values of blood pressure to determine the SBP and DBP points.

• First, find the largest peak-to-peak value in AC data buffer. Mark this point as MAP point.

• Second, search the point whose value is the closest to 0.54*MAP. This point is located in front of the MAP

point. The corresponding average value in DC data buffer specifies the systolic blood pressure (SBP) value.

• Search the point whose value is the closest to 0.72*MAP. This point is located behind the MAP point. The

corresponding average value of DC data specifies the diastolic blood pressure (DBP) value.

• Finally, the PR value for patient can be determined by analyzing the entire pulse rate (PR) data.

Start

Find Max. AC of BP

Calculate

0.54*Max. AC of BP

Find preceding point which is

close to 0 .54*Max . AC

Calculate Practical SBP

Calculate

0.72*Max. AC of BP

Find subsequent point which

is close to 0.72*Max. AC

Calculate Practical DBP

Calculate Practical PR

End

Figure 3-5 Analysis Flow Chart

36

Page 37

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

3.4 EEPROM Write and Read Operations

The system uses two wires EEPROM 24C01(1K, 128*8) as storage unit, which can record up to 35 blood

pressure monitor results, including SBP, DBP, and PR values. 24C01 is an EEPROM chip with I2C interface.

Read and write operations on the bytes have a special definition, as follows:

Write Start

Varibles Initialization

Send START Signal

Send C ontrol Byte

(1010xxx0B)

Receive ACK

N

Signal?

Y

Send Word Address

(0xxxxxxxB)

Receive ACK

N

Signal?

Y

Send Data to EEPROM

(xxxxxxxxB)

Read Start

Varibles Initialization

Send START Signal

Send Control Byte

(1010xxx0B)

Receive ACK

N

Signal?

Y

Send Word Address

(0xxxxxxxB)

Receive ACK

N

Signal?

Y

Re-send START Signal

Receive ACK

N

Signal?

Send STOP Signal

Delay 5ms

Write End

Figure 3-6 EEPROM Write and Read Operation Flow Chart

37

Send Control Byte

(1010xxx1B)

Y

Receive ACK

N

Signal?

Send STOP Signal

Delay 5ms

Y

Read Data from

EEPROM

Read End

Page 38

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

3.5 Interrupt Service Subroutine

The BPM software has several important interrupt service subroutines (ISR), including pulse rate input ISR and

user button ISR.

3.5.1 Pulse Rate Input ISR

The subroutine can calculate the pulse rate and set (or clear) ADC0/ADC1 enable flag corresponding to different

conditions. Figure 3-7

shows the flow chart of this interrupt service routine.

N

N

ISR Enter

Clear Ext. INT0

pending bit

Delay 2ms

(for S/W debounce)

P0.0/IN T0 is

high level?

Y

Clear Timer 0 Counter

Calculate PR &

Save to PR B uffe r

First Time

Enter E xt .INT0?

Y

N

Toggle ADC0/ADC1 En.

Flag (nSysFlag.0)

Monitor Process

is Start?

Y

Clear ADC0/ADC1 En.

Flag (nSysFlag.0)

Clear Over-time Counter

ISR Return

N

Set Monitor Process

Start Flag (nSysFlag.1)

Set ADC0/ADC1 En.

Flag (nSysFlag.0)

Figure 3-7 Pulse Rate Input (External INT0) ISR Flow Chart

38

Page 39

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

3.5.2 User Button (Power On/Off) ISR

If the user power on/off button is pressed, the software will execute this subroutine. Only when the P0.2 remains

high level for more than 40ms, the system will be able to determine if this is a valid key. Then you can turn off the

power. The goal is to remove noise interference on P0.2. This way the system cannot be misused.

ISR Enter

Clear Ext.INT2

pending bit

Delay 20ms

(for S/W debounce)

N

P0.2 is

high level?

Y

Update User Button

Valid Counter (nkeyflag)

Re-read P0.2

N

Time = 3?

Y

Button Valid

N

Time is = 2?

Y

Set User Button

Pres sed Flag (nKey Info.0)

Toggle Special User Button

Pres sed Flag (nKey Info.2)

Enable Timer A &

Start Buzzer Output

Clear Us er Button

Pressed Flag (nKeyInfo.0 )

Switch off System Power

ISR Return

Figure 3-8 User Button (Power ON/OFF, External INT2) ISR Flow Chart

39

Page 40

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

3.5.3 User Button (Start, Up/Down, Delete, Save) ISR

There are up to five user buttons in this system, namely, start, up/down, delete, unit, and save. Determine whether

a valid button is pressed.

• Using the Start button, you can start or stop the monitoring process during measurement.

• Using the up/down button, you can view the prior monitoring values recorded in the EEPROM.

• Using the Delete button, you can delete the currently displayed records.

• Using the Unit button, you can choose the correct pressure unit such as mmHg or kPa.

• Using the Save button, you can save the latest "valid" monitor results.

40

Page 41

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

Note:

n: 1,4 ~ 7

ISR Enter

Clear Ext.INTn

pending bit

Delay 20ms

(for S/W debounce)

N

P0.n is

low level?

Y

Update User Button

Valid Counter (nkeyflag)

Re-read P0.n

N

Time = 3?

Y

Button Valid

N

Time is = 2?

Y

Set U ser Button

Press ed Flag (nKeyInfo.0)

Set S pecial User Button

Press ed Flag (nKey Info.n)

Enable Timer A &

Start Buzzer Output

Clear U ser B utton

Press ed Flag (nKey Info.0)

Clear Over-time Counter

ISR Return

Figure 3-9 User Button (Start, Up/Down, Delete, Unit, Save, External INT4-7) ISR Flow Chart

41

Page 42

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

4 SCHEMATIC

Figure 4-1 Schematic of Analog Board

42

Page 43

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

Figure 4-2 Schematic of Main Board

43

Page 44

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

5 PCB LAYOUT

Figure 5-1 Main Board and Analog Board PCB Assembly (Top Layer)

44

Page 45

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

Figure 5-2 Main Board and Analog Board PCB Assembly (Bottom Layer)

Figure 5-3 Main Board and Analog Board PCB (Top Layer)

45

Page 46

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

Figure 5-4 Main Board PCB (Bottom Layer)

46

Page 47

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

Layout Guide

1. ADC0 and ADC1 are extremely sensitive signals in the BPM system. Therefore, they should be protected by

using ground lines.

LCD Screen

Buzzer

EEPROM

Valve

Motor

MCU

GND

S3P8245

Pump

Motor

BPM Main Board

V2.1

User Button

Analog Board

Inferface

Managment

+6V

Power

Figure 5-5 Final Implementation of Blood Pressure Monitor (Main Board)

Analog Board Interface

BPM AB V1.0

CCS PS PRTDiff-AMPHPF AMP LPF

Note:

CCS: Constant Current Source; PS: Pressure Sensor

Diff-AMP: Differential Amplifier; AMP: 11x Amplifier

HPF: 0.8Hz High-pass Filter;

LPF: 38Hz Low-pass Filter; PRT: Pulse Rate Trigger

Figure 5-6 Final Implementation of Blood Pressure Monitor (Analog Board)

47

Page 48

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

6 MEASUREMENT

6.1 Test Environment

The test environment comprises the following:

• Power supply: +6V DC power or 4x AA batteries

• Temperature: 25℃

• Equipments:

− Agilent E3648A DC Power Supply (Optional)

− Tektronix TDS3034B Digital Phosphor Oscilloscope

48

Page 49

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

6.2 Final Measurement Environment Setting

Figure 6-1 shows the final measurement environment setting of the BPM reference solution.

Cuff for Patient

Patient’s Arm

6V DC Valve Motor

6V DC Pump Motor

Main Board of BPM

Analog Board of BPM

4x AA Battery Power

Figure 6-1 Final Measurement Environment Setting

49

Page 50

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

6.3 Test Result

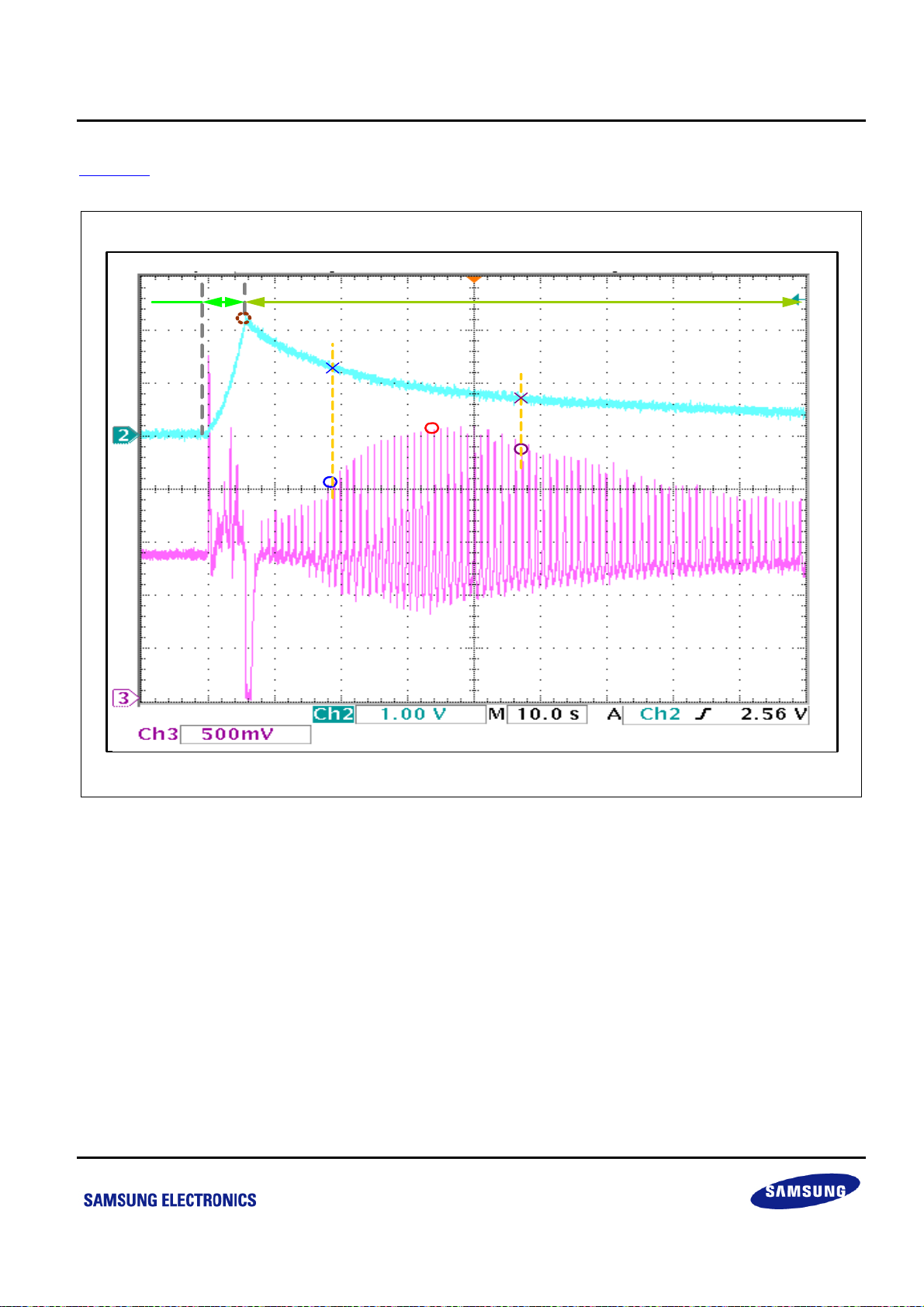

Figure 6-2 shows the real measurement of blood pressure waveform by using this BPM reference solution.

Pump Deflate

MAP

DBP

DC . BP

AC . BP

PR

SBP

Figure 6-2 Blood Pressure Signals Measurement Waveform

50

Page 51

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

7 APPENDIX 1: BILL OF MATERIALS

Table 7-1 Bill of Main Board Materials

Item Quantity Reference Value Comments

1 1 U2 4COM×19SEG LCD

2 1 U3 PCF8563 RTC, 8-SOP

3 1 U4 S3P8245 80-TQFP

4 1 U5 24C01 EEPROM, 8-SOP

5 1 U8 GM6155-5.0 SMD SOT-25

6 1 MG1 - 6V Pump Motor, 2-SIP

7 1 MG2 - 6V Valve Motor, 2-SIP

8 2 Y1, Y3 32.768 KHz Quartz crystal

9 1 Y2 10 MHz Quartz crystal

10 4 Q2, Q3, Q4, Q5 9012 SMD SOT-23

11 5 Q6, Q7, Q8, Q9, Q10 9013 SMD SOT-23

12 5 D1, D2, D3, D4, D6 1N4007 SMD DO-214AC

13 1 D5 LED SMD 1206

14 2 SW6, SW7 Button -

15 1 LS1 Buzzer -

16 1 J3 CON2 2-SIP

17 3 J5, J6, J7 CON2 Power Connector

18 1 J4 CON4 4-SIP

19 1 J8 CON3 3-SIP

20 1 J9 CON6 6-SIP

21 1 C5 Variable CAP 2-DIP

22 12

23 4 C7, C11, C15, C16 33pF SMD 0805

24 1 C9 CAP 2-DIP

25 2 C10, C28 100uF/10V SMD Tantalum Capacitor

26 2 C13, C23 10uF/10V SMD Tantalum Capacitor

27 1 C14 0.01uF SMD 0805

28 1 C19 47uF/10V SMD Tantalum Capacitor

29 1 C22 470uF/16V Aluminum Capacitor

C6, C8, C12, C17, C18, C20, C21,

C24, C25, C26, C27, C29

0.1uF SMD 0805

51

Page 52

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

30 4 R7, R11, R21, R22 20 KΩ SMD 0805

31 4 R10, R13, R14, R15 100 KΩ SMD 0805, 1%, 1/16 W, 50 V

32 1 R16 50 Ω SMD 0805, 1%, 1/16 W, 50 V

33 2 R17, R82 0 Ω SMD 0805, 1%, 1/16 W, 50 V

34 7

35 12

R18, R23, R24, R25, R40, R45,

R46

R19, R26, R28, R31, R32, R33,

R34, R35, R36, R38, R39, R42

10 KΩ SMD 0805

1 KΩ SMD 0805

36 2 R20, R41 100 Ω SMD 0805

37 2 R27, R43 0 Ω SMD 0805

38 1 R29 10 KΩ SMD 0805, 1%, 1/16 W, 50 V

39 1 R30 5.1 KΩ SMD 0805, 1%, 1/16 W, 50 V

40 1 R37 5.1 KΩ SMD 0805

52

Page 53

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

Table 7-2 Bill of Analog Board Materials

Item Quantity Reference Value Comments

1 1 U1

MPS-3117-

006G

Pressure Sensor, 6-SOP

2 2 U2, U4 LM358 8-SOP

3 1 U3 LM311 8-SOP

4 1 Q1 9012 SMD SOT-23

5 2 J1, J2 CON2 2-SIP

6 1 J3 CON6 6-SIP

7 1 J4 CON3 3-SIP

8 2 C1, C6 10uF/16V SMD Tantalum Capacitor

9 10

C2, C3, C4, C5, C7, C8, C9, C10,

C11, C12

0.1uF SMD 0805

10 2 R1, R2 4.7 KΩ SMD 0805

11 2 R3, R23 100 Ω SMD 0805, 1%, 1/16 W, 50 V

12 1 R4 1.2 KΩ SMD 0805, 1%, 1/16 W, 50 V

13 1 R5 0 KΩ SMD 0805, 1%, 1/16 W, 50 V

14 5 R6, R8, R13, R17, R35 1 MΩ SMD 0805, 1%, 1/16 W, 50 V

15 2 R7, R16 1.3 MΩ SMD 0805, 1%, 1/16 W, 50 V

16 2 R9, R10 200 KΩ SMD 0805, 1%, 1/16 W, 50 V

17 3 R11, R12, R29 30 KΩ SMD 0805, 1%, 1/16 W, 50 V

18 5 R14, R15, R25, R27, R30 1 KΩ SMD 0805, 1%, 1/16 W, 50 V

19 1 R18 1.5 MΩ SMD 0805, 1%, 1/16 W, 50 V

20 1 R19 360 KΩ SMD 0805, 1%, 1/16 W, 50 V

21 1 R20 2.4 KΩ SMD 0805, 1%, 1/16 W, 50 V

22 1 R21 182 KΩ SMD 0805, 1%, 1/16 W, 50 V

23 1 R22 100 KΩ SMD 0805, 1%, 1/16 W, 50 V

24 1 R24 50 KΩ

BOURNS3362 Single-Turn

Cermet Trimmers

25 1 R26 10 KΩ SMD 0805

26 2 R28, R32 10 KΩ SMD 0805, 1%, 1/16 W, 50 V

27 1 R31 49.9 KΩ SMD 0805, 1%, 1/16 W, 50 V

28 1 R33 5.1 MΩ SMD 0805, 1%, 1/16 W, 50 V

29 1 R34 10 MΩ SMD 0805, 1%, 1/16 W, 50 V

53

Page 54

S3P8245_ARM BLOOD PRESSURE MONITOR_AN_REV 0.00 错误!未定义样式。 错误!未定义样式。

8 APPENDIX 2: SOURCE CODE

For details on the source code, refer to the Arm_Blood_Pressure_Monitor_S3P8245_V1.2.rar.

54

Loading...

Loading...