7. General Error Function

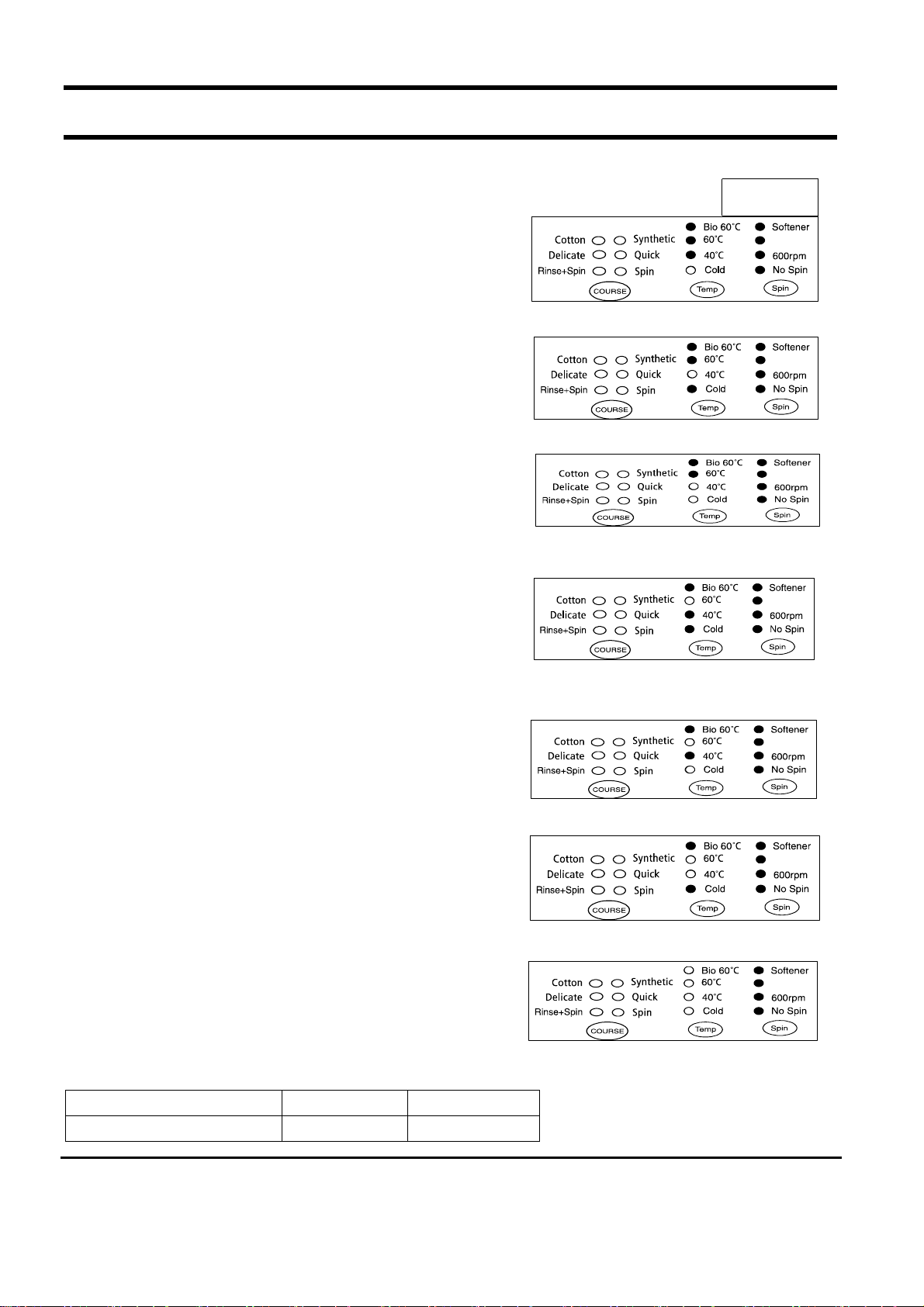

When an error occurs, this function starts to keep generating error melody sounds and displays error indicators as

shown in the followings per corresponding error by blinking in 0.5sec interval until the error status is completely cleared out.

In this case, all the driving devices are turned off until the error is cleared out.

1. WATER SUPPLY ERROR

- Display shows such as fig. 1

- Water Supply Error occurs when water level frequency does not show

changes more than 100Hz or water is not supplied

up to the water level presetting for 20 min or more at the time of initial

water supply.

-The error status can be cleared by turning POWER S/W OFF and

resuming the POWER ON initial status.

fig. 1

○ :Lighton

● :Lightoff

1000rpm

2. WATER DRAIN ERROR

- Display shows such as fig.2

- In case the water level frequency is 24.5KHz or less in the initial phase

of UNB-detecting cycle.

- Water Drain error can be cleared by turning POWER S/W OFF and

resuming the POWER ON initial status.

3. OVER-FLOW ERROR

- Display shows such as fig.3

- Over-Flow error occurs when the water level is in abnormal operation.

ItcanbeclearedbyturningPOWERS/WOFF.

Water is drained prior to POWER S/W OFF and it is forced to be drained

for 2 min if a frequency of more than 24.5 KHz is detected.

4. UNBALANCE ERROR

- Display shows such as fig4.

- Laundry load is unbalanced; loosen any tangled laundry.

- If only one item of clothing needs washing, such as a bathrobe or jeans,

the final spin result might be unsatisfactory and an error message will be

shown in the display panel such as fig 4..

- Unbalance error is cleared by POWER S/W OFF and by resuming the

POWER ON initial status.

5.WATERHEATERERROR

- Display shows such as fig.5 or fig.6

- In case the water temperature rises by 7∞C or more in 1 min. or by 2∞C

less in 10 min after heating is started.

- It can be cleared by turning POWER S/W OFF.

1000rpm

fig. 2

1000rpm

fig. 3

1000rpm

fig. 4

1000rpm

6 DOOR OPEN ERROR

- Display shows such as fig.7

- Door Open error can be cleared by closing the door.

7. ASSí Y PRESSURE S/W ERROR

* Generated Frequency Signal of WATER LEVEL(W/L) S/W (KHz)

Level Low Level High Level

Abnormal W/L Frequency 30.00 KHz 15.00 KHz

- 12 -

fig. 5

1000rpm

fig. 6

1000rpm

fig. 7

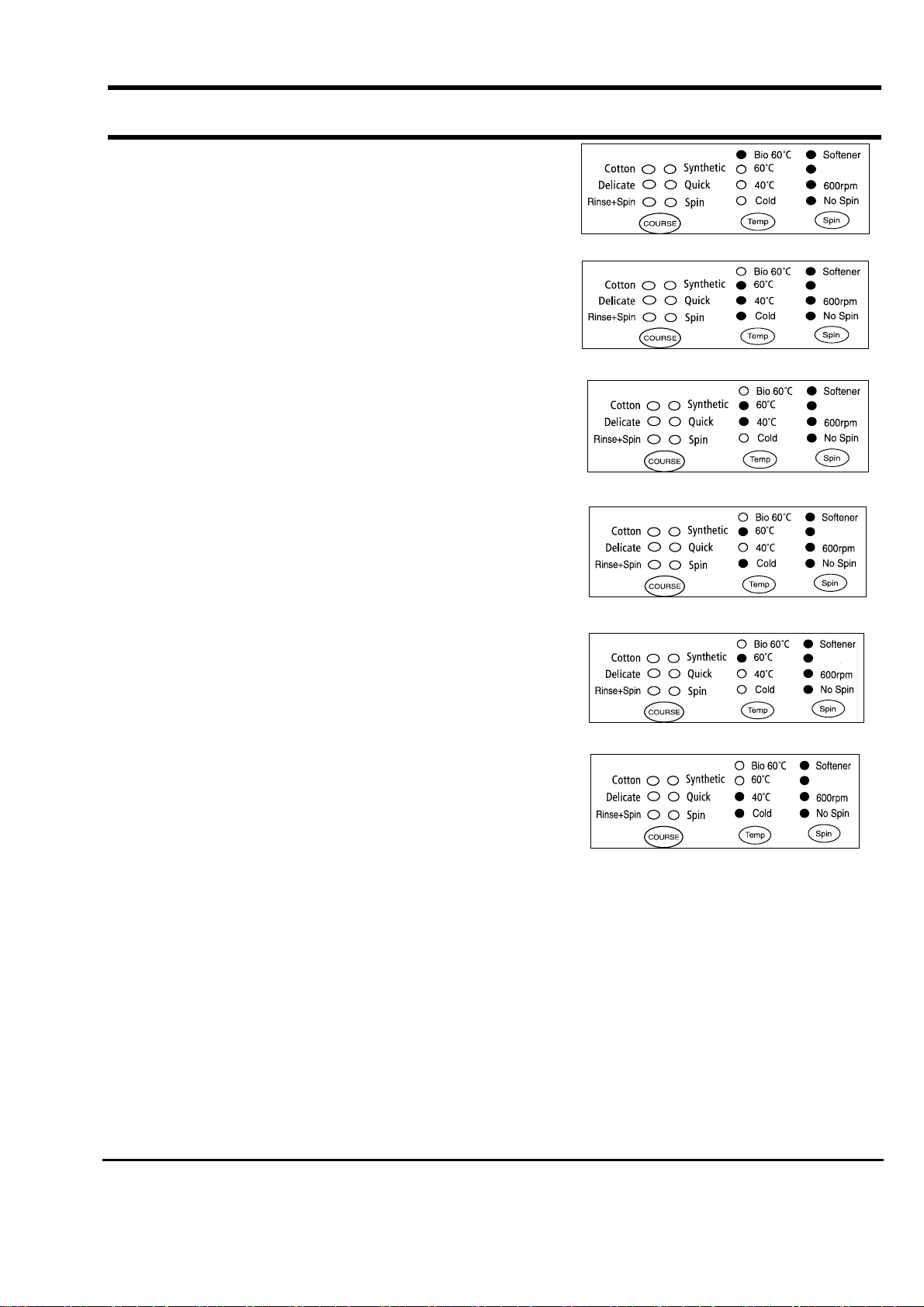

7. General Error Function

- If the same signal as the above table is detected for more than

5 seconds, it is a PRESSURE S/W Error.

- When the error occurs, water drain pump will operate for 3 min. and

then turn off the water drain pump.

Then the display shows fig. 8 indicating a pressure s/w error indicator.

1000rpm

8. ABNORMAL WATER TEMPERATURE ERROR

- In case the water temperature is 50∞C or more in Delicate and Wool

course.

- At the time of initial water supply, if the water temperature is not

appropriate, water starts to be drained and it is forced to be drained

for 2 min when the abnormal frequency of 24.5KHz is detected.

- Display shows fig. 9

- This error can be cleared by POWER S/W OFF.

9. WATER LEAKAGE ERROR (E9)

- Water Leakage error occures when water is drained naturally after

washing program starts.

10. Tacho Error

- This error occurs in case motor thaco is out of order or tacho siganals

inputted are fewer than 2

- Display shows fig. 11

- This error can be cleared by power s/w off

11. Motor Triac short Error

- This error occurs in case over 300 per 1 sec tacho signals are inputted

power S/w should be off.

-fig. 12 is diplayed.

- This error can be cleared by power s/w off

fig. 8

1000rpm

fig. 9

1000rpm

fig. 10

1000rpm

fig. 11

1000rpm

fig. 12

12. Thermistor error

- This error occurs, when Thermistor circuit is abnormal or the detected

electrical volt is 0.2v below or 4.5v over

- fig. 13 is displayed

- This error can be cleared by power s/w off

- 13 -

1000rpm

fig. 13

8. Trouble Diagnosis

- As the micom wash machine is configured of the complicate structure, there might be the service call.

Below information is prepared for exact trouble diagnosis and suitable repair guide.

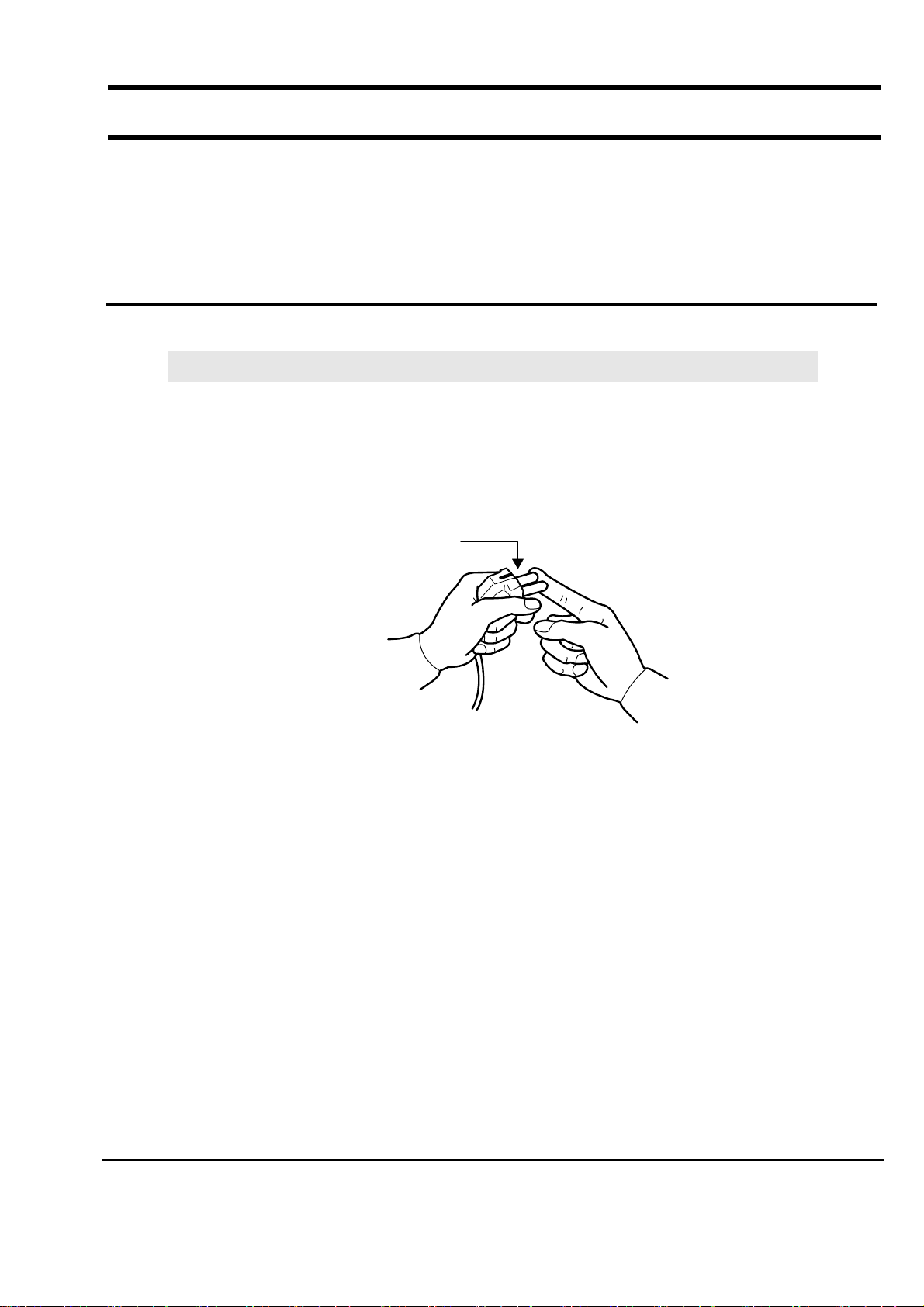

Caution for the Repair and Replacement

Please follow below instruction for the trouble diagnosis and parts replacement.

1) As some electronic components are damaged by the charged static electricity from the resin part of wash

machine or the human body, prepare the human body earth or remove the potential difference of the

human body and wash machine by contacting the power supply plug when the work contacting to PCB is

executed.

POWER SUPPLY PLUG

2) Since AC220~240V is applied to the triac T1 and T2 on P.C.B, the electric shock may occur by touching

and be careful that the strong and weak electricity are mixed.

3) As the P.C.B assembly is designed for no trouble, do not replace the P.C.B assembly by the wrong

diagnosis and follow the procedure of the trouble diagnosis when the micom is not operated normally.

- 14 -

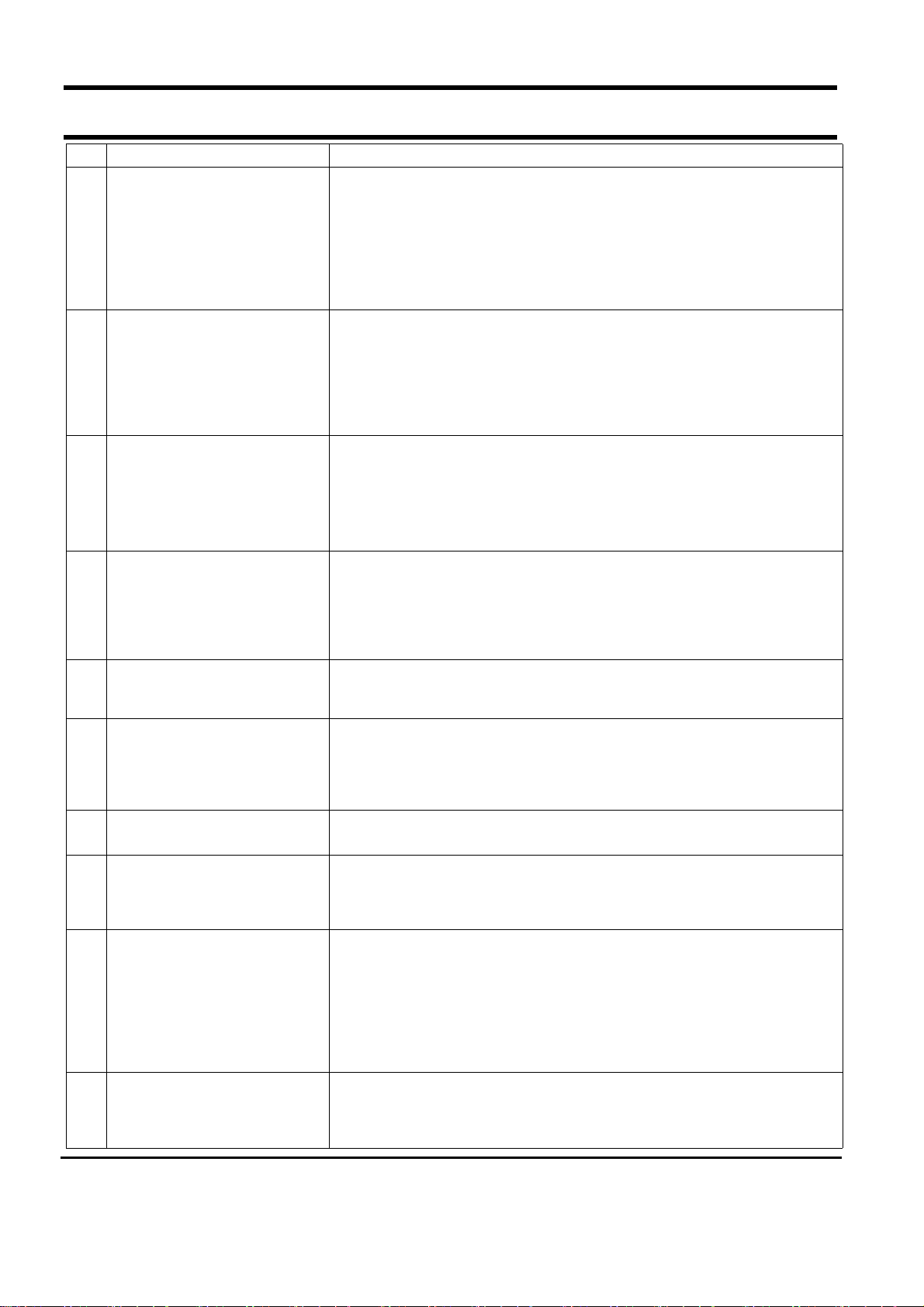

8-1. Trouble Diagnosis

No Item Cause and treatment

- Is the PCB connector connected well?

- Is the voltage normal?

- Is the power supply plug connected well?

1 The power is not supplied

2 The water is not supplied.

The wash does not start though

3

the water supply is stopped.

- Is the noise filter connected well?

- Is the secondary output of the power supply transformation normal?

- Is the fuse disconnected? (option)

ï If above points are not found, the PCB assembly is out of order.

Replace it.

- Is the knob open?

- Did you push START/PAUSE button after selecting the course?

- Is the water supply valve connected well?

- Is the winding of the water supply valve continuous?

- Is the connection and operation of the pressure switch normal?

ï If above points are not found, the PCB assembly is out of order.

Replace it.

- Is the connection and operation of the pressure switch normal?

- Is the pressure switch hose damaged so that the air is leaked?

- Is the pressure switch hose bent?

- Check the operation of the water level switch.

ï If above points are not found, the PCB assembly is out of order.

Replace it.

The drum does not rotate during

4

washing.

The drum rotates by one direction

5

during washing. (The drum rotates

to one direction for SPIN.)

6 Drainage problem.

7 Dehydration problem.

8 Abnormal noise during SPIN.

Leak breaker or current/leak

9

breaker is down during washing.

10 The heating is not executed.

- Is the belt connected well?

- Is the winding of the motor continuous?

(Rotor winding, stator winding, generator)

- Is the motor protector normal?

ï If above points are not found, the PCB assembly is out of order.

Replace it.

- The PCB assembly is out of order. Replace it.

(Inversion relay open trouble)

- Is the drainage hose bent?

- Is the winding of the drainage pump continuous?

- Is the drain filter clogged by the waste?

ï If above points are not found, the PCB assembly is out of order.

Replace it.

- The unbalance is detected.

- Put in the laundry uniformly and start again.

- Is the pulley nut loosen?

- Is the transport safety device removed?

- Is the product installed on the level and stable place?

(Little noise may be generated during the high-speed SPIN.)

<When the leak breaker and current breaker is installed separately>

- When the leak breaker is down, check and make the earth of the outlet.

- When the current is down, the current is leaked.

<Is the breaker down when the leak/current breaker is combined?>

- Check the rated capacity of the current and leak breaker.

The current breaker may be down due to the lack of the current when the

wash machine and other apparatus are used.

In this case, execute the cold water wash to check whether the current capacity is lack.

- Is the wash heater terminal unplugged?

- Is the wash heater normal?

- If above points are not found, the PCB assembly is out of order.

Replace it.

- 15 -

Loading...

Loading...