Samsung RF32FMQDBSR/AA, RF34H9950SR/AA, RF34H9950S4/AA, RF24J9960S4/AA, RF34H9960S4/AA Service Manual

REFRIGERATOR

CONTENTS

1. Precautions (Safety Warnings) .........5

2.

Product Features and Specifications

...9

3. Disassembly and Reassembly ....... 23

4. Troubleshooting ..........................69

5. PCB Diagram ............................ 108

6. Wiring Diagram .......................... 112

7. Block Diagram............................ 114

8. References ................................ 116

FRENCH DOOR REFRIGERATOR

REFRIGERATOR

Basic Model code: RF32FMQDBSR/AA

New Model code: RF34H9950S4/AA,

RF34H9950SR/AA,

RF34H9960S4/AA,

RF24J9960S4/AA

IMPORTANT SAFETY NOTICE

The service guide is for service technicians with sufficient

background in electrical, electronic and mechanical engineering.

Any attempt to repair the appliance yourself may result in personal

injury and property damage.

The manufacturer or dealer will not be held responsible for the

interpretation of this information.

SAMSUNG ELECTRONICS AMERICA, INC.

Technical Service Guide

Copyright ©2014

All rights reserved. This service guide may not be reproduced in whole or in part in

any form without written permission from the SAMSUNG ELECTRONICS Company.

WARNING

3

CONTENTS

1. Precautions (Safety Warnings) ...................................................................5

2. Product Features and Specifications ..........................................................9

2-1. Compartment Features by Model ................................................................................................................10

2-2. Basic Product Specifications (inch/mm) ......................................................................................................11

2-3. Comparison of Specifications (inch, mm) ................................................................................................... 12

2-4. Specifications ................................................................................................................................................. 16

2-5. Dimensions ....................................................................................................................................................18

2-6. ICE-MAKER Function .................................................................................................................................. 20

2-7. Material Specification ....................................................................................................................................22

3. Disassembly and Reassembly ................................................................. 23

3-1. Precautions ................................................................................................................................................... 23

3-2. Disassembling the Refrigerator Door ......................................................................................................... 24

3-3. Disassembling the Fridge Doors (RF24J* only) ........................................................................................ 26

3-4. Assembing the Fridge Doors (RF24J* only) ............................................................................................. 28

3-5. Assy Auto Hinge .......................................................................................................................................... 29

3-6. Braket (RF24J* only) .................................................................................................................................... 30

3-7. Door Soft Damper (RF24J* only) ................................................................................................................. 31

3-8. Disassembling the Freezer Doors .............................................................................................................. 32

3-9. Assembling the Freezer Doors................................................................................................................... 33

3-10. Disassembling the Display ........................................................................................................................ 34

3-11. Disassembling the Main PCB and Inverter PCB ...................................................................................... 35

3-12 Dispenser ..................................................................................................................................................... 36

3-13. Case Water Filter .........................................................................................................................................37

3-14. Water Filter (Assembly & Disassembly) ................................................................................................... 38

3-15. Disassembling the REF EVAP Cover ....................................................................................................... 39

3-16. Disassembling the FRE EVAP Cover ....................................................................................................... 40

3-17. Disassembling the Machine Compartment Motor Fan ............................................................................. 41

3-18. Disassembling the Relay Protector O/L ................................................................................................... 42

3-19. Disassembling the Step Valve .................................................................................................................. 43

3-20. Disassembling the Fridge Internal Lamp ................................................................................................. 44

3-21. Disassembling the Freezer Internal Lamp ............................................................................................... 44

3-22. Disassembling the Tempered Glass Shelf .............................................................................................. 45

3-23. Vegetable shelf .......................................................................................................................................... 45

3-24. CHEF PANTRY ........................................................................................................................................... 46

3-25. Disassembling the French .........................................................................................................................47

3-26. REF Evaporator .......................................................................................................................................... 48

3-27. FRE/Cool Select Room Evaporator .......................................................................................................... 48

3-28. ASSY RAIL .................................................................................................................................................. 49

3-29. Ice-Maker ................................................................................................................................................... 50

3-30. Auger Motor Fan ....................................................................................................................................... 52

3-31. ASSY GUARD DISPENSER ........................................................................................................................ 53

3-32. Assy Sparking Kit ...................................................................................................................................... 54

3-33. ASSY GUARD UTILITY ............................................................................................................................... 55

3-34.

Descriptions of CO2 Cylinder Installation and Sparkling Water Functions

(only for RF33H9960S4)

...................56

3-35. USING THE MAIN CONTROL PANEL ....................................................................................................... 62

4

CONTENTS

4. Troubleshooting ....................................................................................69

4-1. Functions for failure diagnosis .................................................................................................................... 69

4-1-1. Test mode (manual operating / manual defrosting function) ...................................................... 69

4-1-2. Display function of Communication error ....................................................................................... 71

4-1-3. Self-diagnostic function ..................................................................................................................72

4-1-4. Display function of Load condition .................................................................................................77

4-1-5. Display function of Load condition (Sparkling water model) .......................................................79

4-1-6. Cooling Off Mode setting function ................................................................................................. 80

4-1-7.

AP Mode Function and E-Smart Icon ................................................................................................... 80

4-1-8. Option setting function ..................................................................................................................... 81

4-1-9. Option TABLE .................................................................................................................................. 83

4-2. Troubleshooting by symptom ..................................................................................................................... 88

4-2-1. When there is no power at Inverter PCB (F/R Room Inverter) .................................................. 88

4-2-2.

The LED blinking frequency depending on the protection functions (F/R Room Inverter PCB)

........... 90

4-2-3.

When a "1E","2E", "4E", "5E", "6E", "7E", ''9E, "11E", "13E", "24E", "29E" error occures(defrosting failure)

.........91

4-2-4. When occur the cooling defect by a lot of frosting on the Fridge compartment ........................ 92

4-2-5. When an error occurs in self diagnostic mode (in case of a sensor error) ............................ 93

4-2-6. When the Fan does now operate(F, R, CV, C-FAN) ................................................................. 94

4-2-7. When the Fan does now operate (ICE ROOM - FAN) .............................................................. 95

4-2-8. When the ICE MAKER does not operate ..................................................................................... 96

4-2-9. When water does not supply at Ice Maker ..................................................................................97

4-2-10. When Cubed or Crushed ice does not dispense properly ..................................................... 98

4-2-11. When COVER ICE ROUTE MOTOR (GEARED MOTOR) does not work properly ................... 99

4-2-12. When the alarm is heard continuously (buzzer sound) ...........................................................100

4-2-13. When the DISPENSER Panel PBA does not work properly ....................................................102

4-2-14. When the MAIN Panel PBA does not work properly ...............................................................103

4-2-15. When the Micro Hole Panel PBA does not work properly ......................................................104

4-2-16.

When the internal LED Lamp of the F-Room or R-Room or Cool select-room is not turned on

.............105

5. PCB Diagram ...................................................................................... 108

5-1. PCB Layout with part positions (Main Board) ...........................................................................................108

5-2. Inverter PCB Layout positions ...................................................................................................................109

5-3. Connector Layout with part positions (Main Board) ................................................................................ 110

5-4. Connector Layout with part positions ........................................................................................................ 111

6. Wiring Diagram ....................................................................................112

6-1. Sparkling/Dispenser Model .........................................................................................................................112

6-2. Dispenser Display+SODA PBA .................................................................................................................113

7. BLOCK DIAGRAM .................................................................................114

7-1. Dispenser + Sparkling + MHD ....................................................................................................................114

7-2. Whole block diagram (ISB-LC5) ................................................................................................................115

8. References .......................................................................................... 116

8-1. Glossary .........................................................................................................................................................116

8-2. French Heater Control Using a Humidity Sensor .....................................................................................118

8-3. Model Numbering Convention ....................................................................................................................119

8-4. Troubleshooting. Check the following before calling the service centre .............................................120

8-5. Optimum Operating Environment for Sparkling water ............................................................................126

5

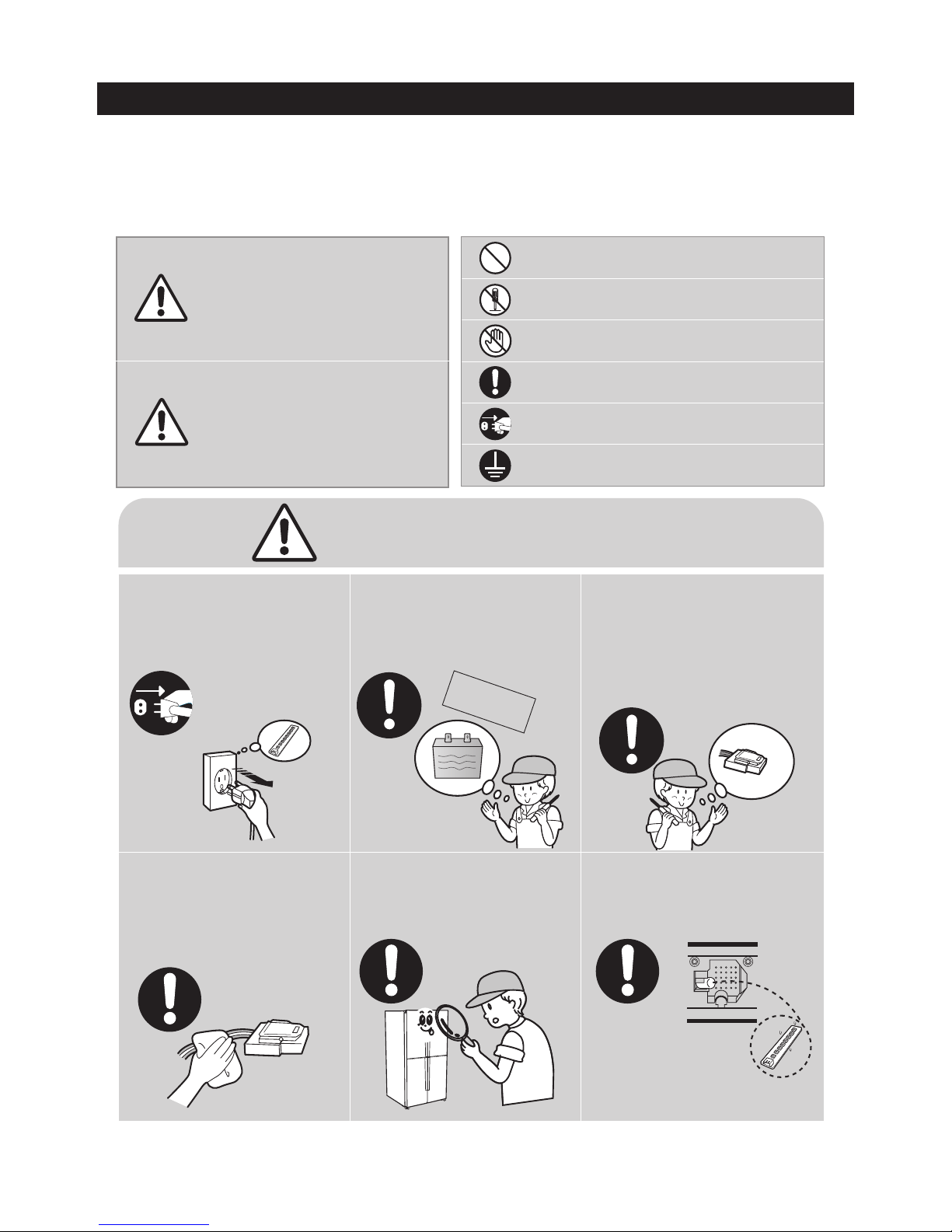

1. PRECAUTIONS (SAFETY WARNINGS)

● Unplug the appliance before replacing or repairing electrical parts.

⇒ Be careful to avoid electric shock.

● Always use only the correct replacement parts.

⇒ Check the model name, rating voltage, rating current, running temperature

symbols.

● When troubleshooting, verify that wiring harnesses are connected securely.

⇒ Make sure the connectors are not separated when power is supplied.

● Check for visible traces of water on electrical parts.

⇒ Replace or secure any part that may have come in contact with water.

● Check the status of parts after replacement or troubleshooting.

⇒ All parts must be reinstalled properly.

● Check the location where the refrigerator will be used.

⇒ If the refrigerator will be used in a damp or wet space, or if installation will be

unstable, the unit should be relocated.

● The refrigerator must be grounded properly.

⇒ An earth ground should be used if there is a risk of high humidity or wetness.

● The refrigerator should be plugged into a dedicated outlet.

⇒ Make sure the power cord is not damaged, crushed, squeezed or burned. If

the plug is damaged it should be replaced.

⇒ If the socket is damaged, it should not be used.

● Consumers must not try to repair the refrigerator.

● Nothing should be stored in the refrigerator except food.

⇒ Drugs requiring precise temperatures should not be stored in the refrigerator.

⇒ Flammable substances (alcohol, benzene, ether, LP gas, etc.) carry risk of

explosion and should not be stored in the refrigerator.

6

PRECAUTIONS(SAFETY WARNINGS)

Read all instructions before repairing the product and follow the instructions

in order to prevent danger or property damage.

Plug out and remove all the items in regrigerator prior to repair.

CAUTION/WARNING SYMBOLS DISPLAYED

SYMBOLS

Indicates that a

danger of death

or serious injury

exists.

Indicates that a risk

of personal injury

or material damage

exists.

means "Prohibited".

means "Do not disassemble".

means "No contact".

means "Warning or Caution".

means "Earth or Ground".

means "Unplug the unit before

preforming service"

Unplug to exchange the interior

lamp.

• It may cause electric shock.

Warning

Warning & Caution

Caution

Unplug

Use the rated components

on the replacement.

• Check the correct model, rated

voltage, rated current, operating

temperature and so on.

On repair, make sure that the

all wiring harnesses are

reconnected.

• Wiring harnesses should be connected

tightly and kept dry.

• Bundle tightly wires in order not to be

detached by the external force and then

not to be wetted.

Check for visible traces of water on

electrical parts.

• Replace or secure any part that may have

come in contact with water.

Check the status of parts after

replacement or troubleshooting.

•

All parts must be reinstalled properly.

On repair, Make sure that all parts

and wires are free of dust and

debris.

• Cleaning parts could help prevent fire or

shorting.

Rated

components

7

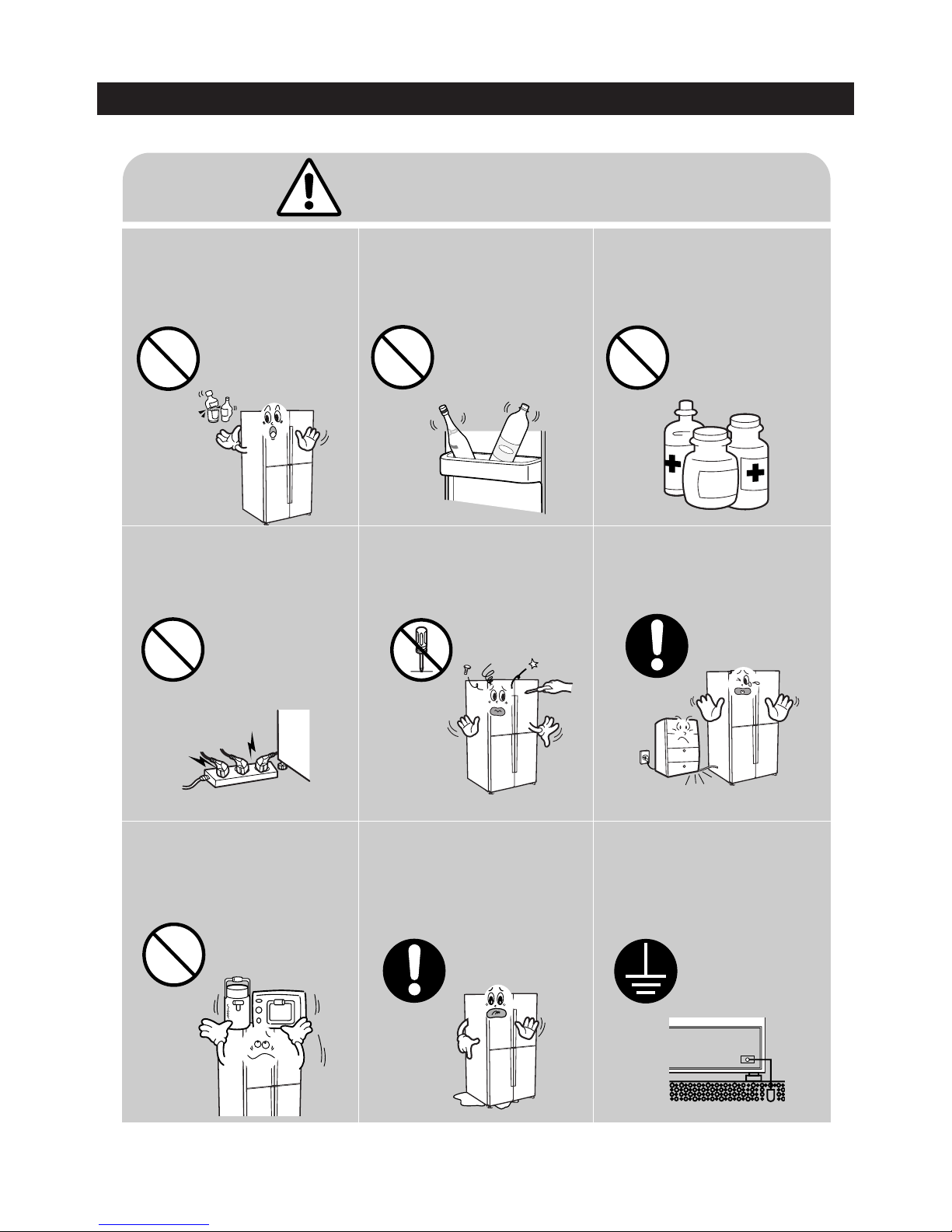

PRECAUTIONS(SAFETY WARNINGS)

❈ Please let users know following warnings & cautions in detail.

Customers should not store glass

bottles of liquid in the freezer section.

Frozen bottles could explode and

cause injury.

Customers should not store narrow

or long bottles or food in a small

door shelf.

• These items could fall when the door is

opened, causing injury tot he customer.

Drugs requiring precise

temperatures should not be stored

in the refrigerator.

Articles on the product.

• Opening or closing the door may cause

things to fall down, which may cause

injury.

Prohibition

Warning & Caution

Consumers must not try to

repair the refrigerator.

• Electrical and mechanical parts could

injure the consumer.

Do not

disassemble

The refrigerator should be

plugged into a dedicated outlet.

• Multiple plugs in the outlet could cause

excessive heat or fire.

Prohibited

Make sure the power cord is not

damaged or crushed.

• A damaged cord could cause excessive

heat or fire.

Check the location where the

refrigerator will be used.

• If the refrigerator will be used in a

damp or wet space, or if installation will

be unstable, the unit should be

relocated.

The refrigerator must be

grounded properly.

• An earth ground should be used if

there is a risk of high humidity or

wetness.

Earth

8

PRECAUTIONS(SAFETY WARNINGS)

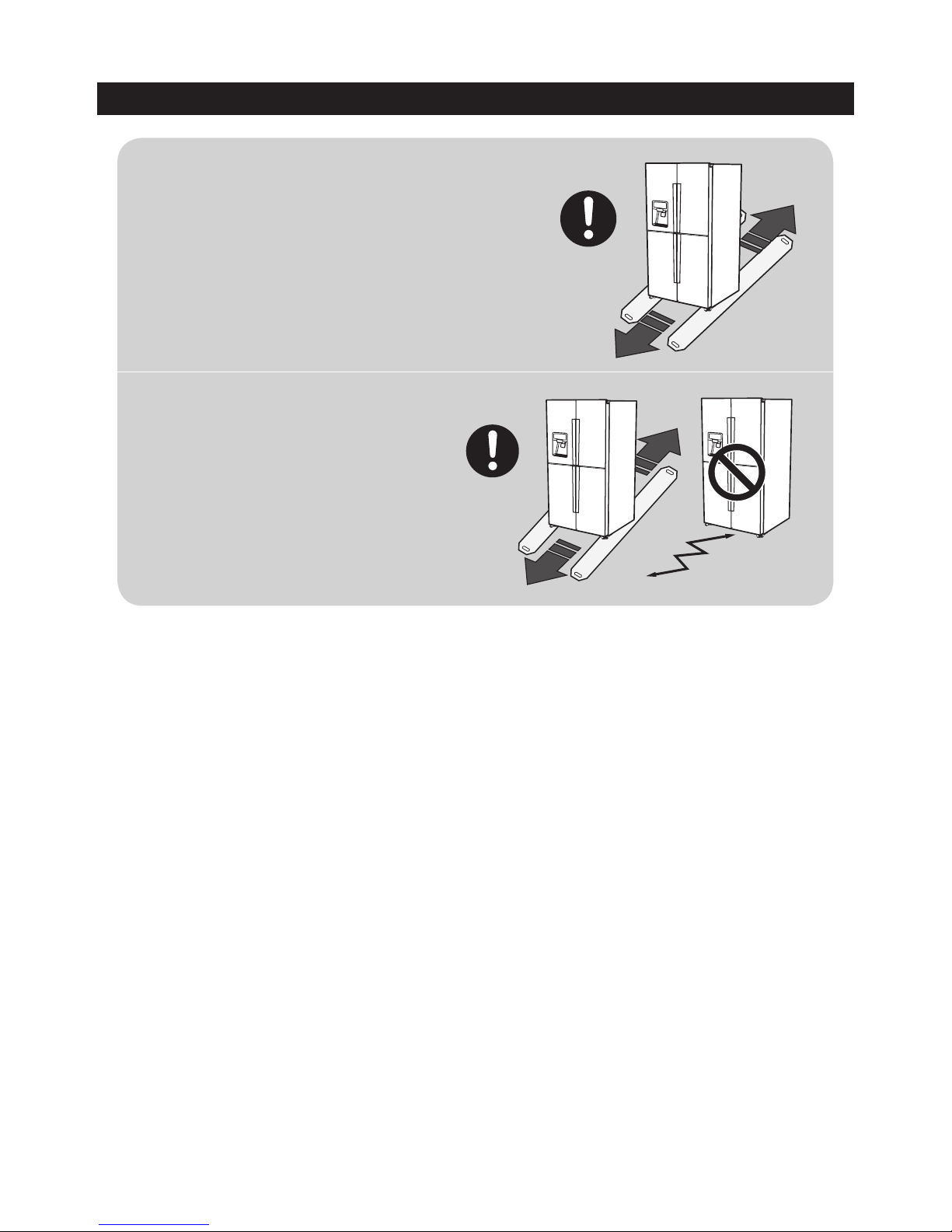

For proper installation, this refrigerator must be

placed on a level surface of hard material that is the

same height as the rest of the flooring. This surface

should be strong enough to support a fully loaded

refrigerator, or approximately 660 lb (299kg).

FLOORING

Protect the finish of the flooring. Cut a large

section of the cardboard carton and place

under the refrigerator where you are working.

When moving, be sure to pull the unit straight

out and push back in straight.

MOVING

9

2. PRODUCT FEATURES AND SPECIFICATIONS

Product Features

Cool Select Room ▶ You can store various foods by selecting a mode from among

'Freezer,' 'Soft Freezer,' 'Chill,' and 'Cool' modes. You can set it to

be a fridge compartment if you have more foods for refrigeration

and to be a freezer compartment if you have more foods to be

frozen.

Chef Mode ▶ It controls the temperature minutely by letting the temperature

sensor inside the refrigerator sense the temperature more

frequently. It makes a fresh storage environment by minimizing

the changes of foods by temperature changes.

Chef Pantry ▶ You can store meat or fish fresh, and can store foods of size up

to a pizza box of 13" (48 cm).

Moisture Care Technology

and Triple Independent

Cooling Method

▶ It maintains the taste and flavor of foods' own by the triple

independent cooling method, which is an upgraded version of

the moisture care technology of Zipel's own, and keeps foods

fresh for a long time by maintaining the humidity inside the fridge

compartment at around 70%.

10

PRODUCT FEATURES AND SPECIFICATIONS

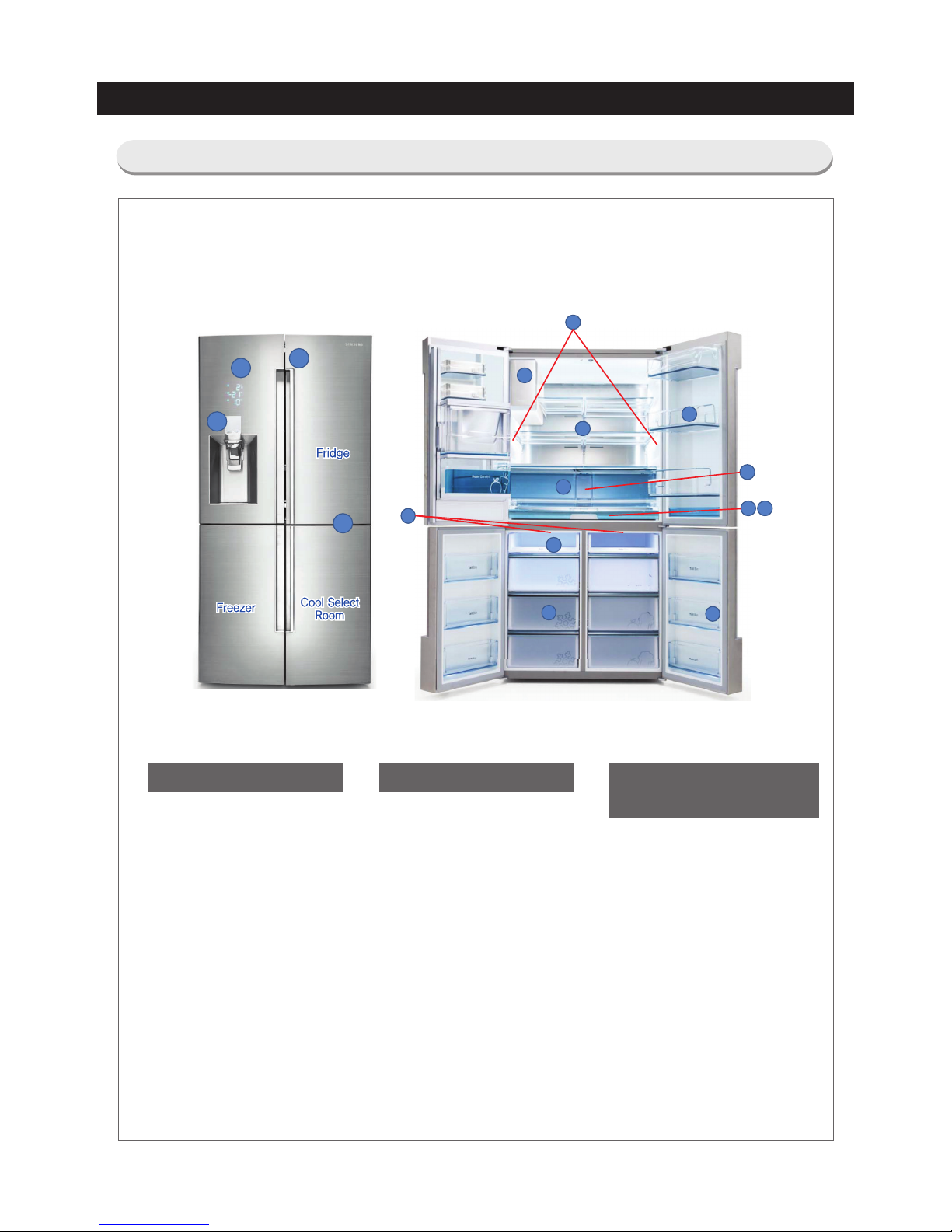

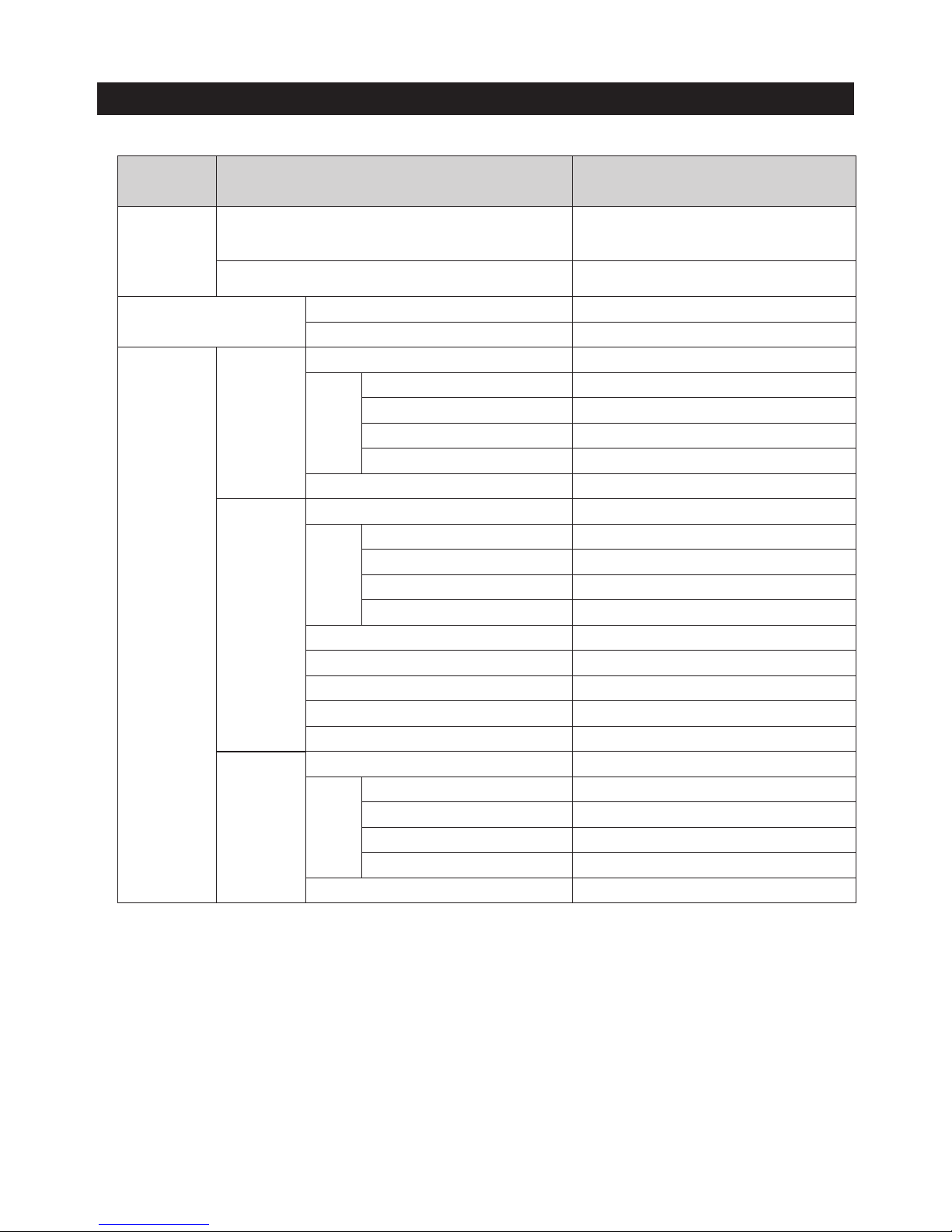

2-1. Compartment Features by Model

Appearance

A) Handle

B) Buttons

C) Indicators

Freezer Compartment /

Cool Select Room

7) Freezer lamps

8) Freezer shelf

(only for RF34H99*)

9) Freezer drawer

10) Freezer door bins

* Egg trays

Fridge Compartment

1) Refrigerator lamps

2) Refrigerator shelf

3) Refrigerator drawer

4) Refrigerator door bins

5) Water filter

6) Auto ice maker

11) Chef pan

12) Chef panty

A

B

C

B

1

2

3

4

5

6

7

8

9

10

11 12

Water Dispenser model :

RF34H99*, RF24J99*

11

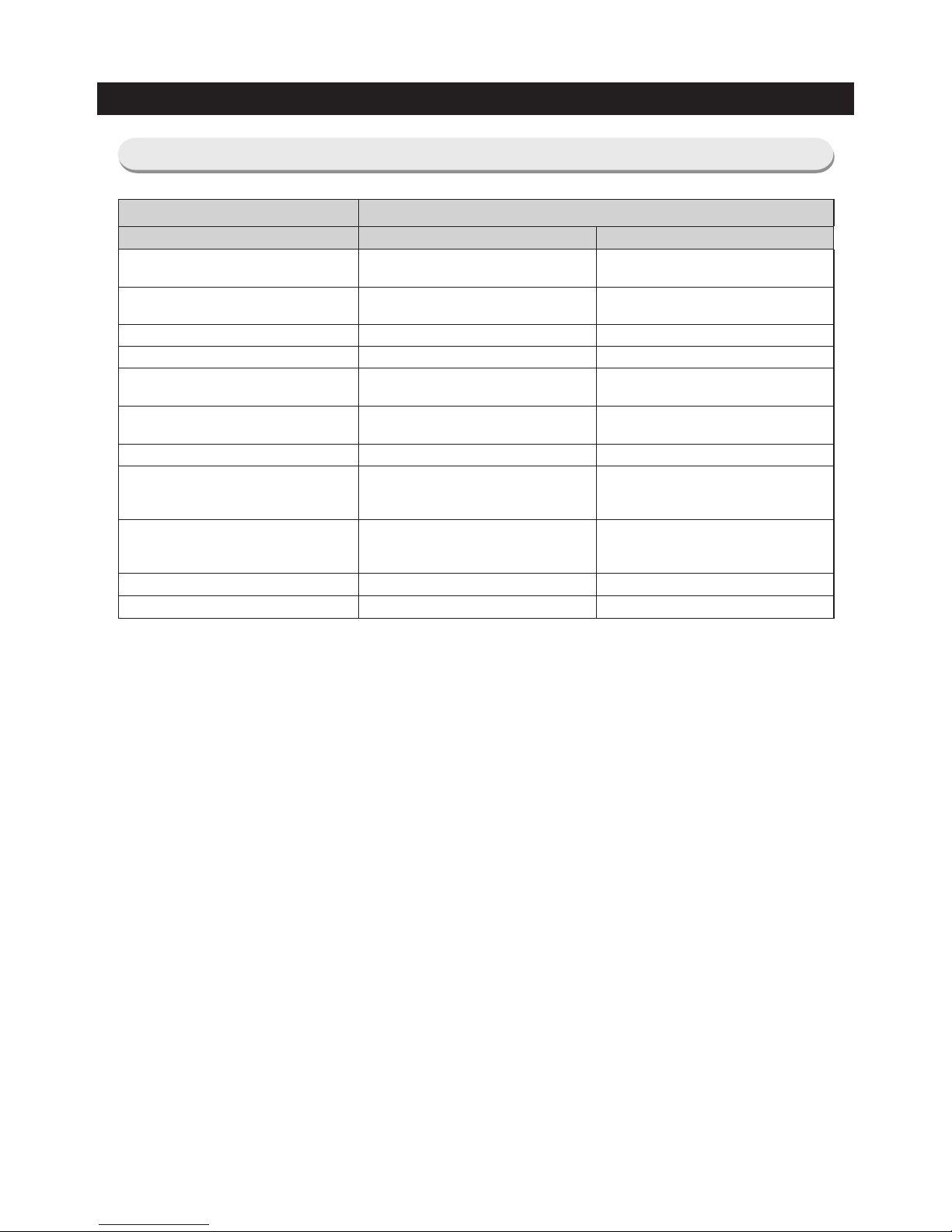

PRODUCT FEATURES AND SPECIFICATIONS

2-2. Basic Product Specifications (inch/mm)

Item Specifications

Model no.

RF34H99*

RF24J99*

External dimensions

(width x depth x height)

35 3/4” X 35 3/4” X 72 7/8”

(908 X 906 X 1850)

35 6/8” X 28 7/8” X 68 7/8”

(908 X 733 X 1777 mm)

Packing dimensions

(width x depth x height)

38 1/4” X 38 1/4” X 79 3/8”

(972 X 972 X 2018)

38 1/4” X 31 1/4” X 76 1/8”

(972 X 795 X 1934 mm)

Rated power frequency (HZ) 60 60

Rated power (V) 115 115

Rated power consumption of the

electric motor (W)

145 145

Rated power consumption of the

electric heater (W)

370 370

Refrigerator type Indirect cooling type refrigerator Indirect cooling type refrigerator

Refrigerant

Freezer / Cool Select Room / Ice

Room : R-134a

Fridge : R-134a

Freezer / Cool Select Room / Ice

Room : R-134a

Fridge : R-134a

Amount of sealed refrigerant

Freezer / Cool Select Room / Ice

Room : 6.00 oz(170 g)

Fridge : 3.53 oz(100 g)

Freezer / Cool Select Room / Ice

Room : 6.00 oz(170 g)

Fridge : 3.53 oz(100 g)

Weight (kg)

533.51 lb (242 kg) 438.72 lb (199kg)

Packing weight (kg)

559.97 lb (254 kg) 461.65 lb (209.4kg)

12

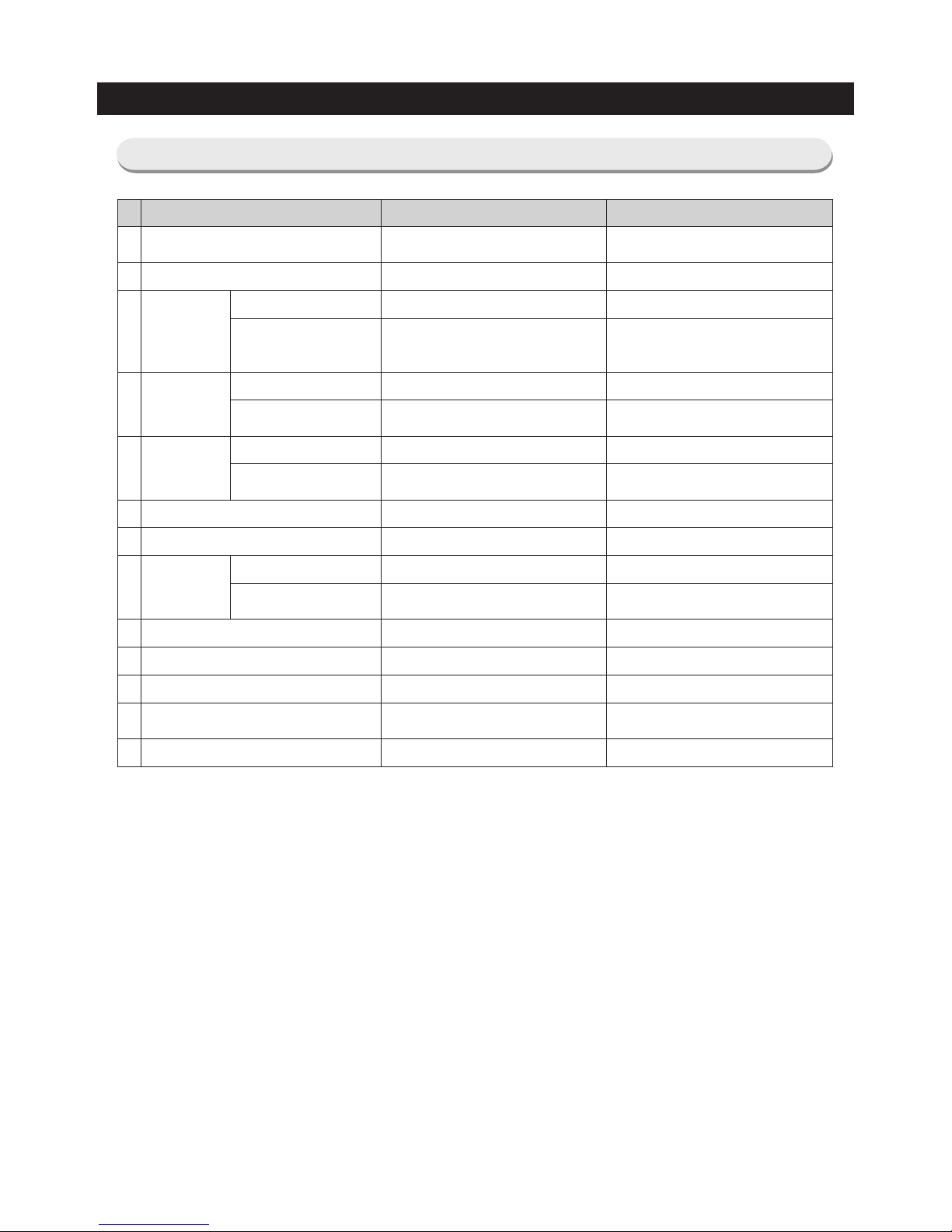

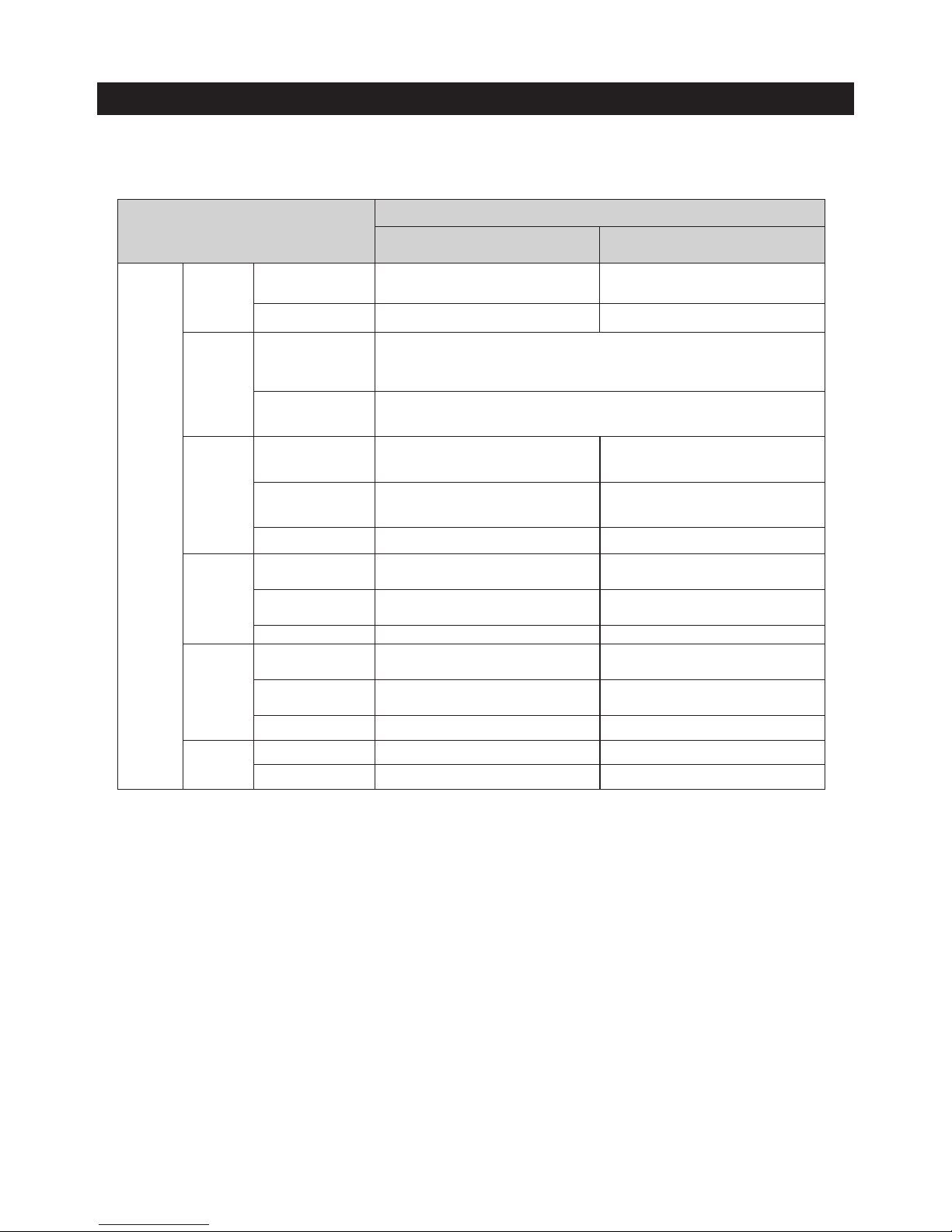

PRODUCT FEATURES AND SPECIFICATIONS

No. Module RF34H99* RF24J99*

1 Dimensions

35 3/4” X 35 3/4” X 72 7/8”

(908 X 906 X 1850)

35 6/8” X 28 7/8” X 68 7/8”

(908 X 733 X 1777 mm)

2 Door SWING 4 Door/ STS ←

3 Lighting

Fridge SIDE: 4 PILLAR LAMP ←

Freezer/

Cool Select

TOP: 1 LED (1EA, High-luminance LED

Lamp), FRIDGE DOOR BOTTOM:

1 LED(1EA, High-luminance LED Lamp)

←

4 Shelf

Fridge Slide, FIX/ AL Foil-Trim ←

Freezer/

Cool Select

Tray Shelf / AL Foil-Trim -

5 Box

Fridge 3 Pieces / AL Foil-Trim ←

Freezer/

Cool Select

3 Pieces / AL Foil-Trim ←

6 Cool Select Room modes Freezer / Soft Freezing / Chill / Cool ←

7 Ice Maker Direct cooling system Auto I/M ←

8

Guard

Fridge Transparent 2 piece

←

Freezer/

Cool Select

Transparent 2 piece ←

9 Egg tray Transparent 1 piece ←

10 Handle Hidden handle ←

11 Display LED ←

12 VIP

VIP 9 sheets (cabi side/rear/up,

liner bottom, door ref/fre)

←

13 Back cluster Applied ←

2-3. Comparison of Specifications (inch, mm)

13

PRODUCT FEATURES AND SPECIFICATIONS

Item

Item RF34H99*, RF24J99*

Specifications

Cycle, Refrigerant

Dual Comp.

F/CV/Ice Room: R134a (6.00 oz(170 g))

R Room: R134a (3.53 oz(100 g))

Compressor

F/CV/Ice Room: MKV190CL2B/E01

R Room: NC1MV43AMP

Ice-making performance

Normal 0.056oz(1.6kg)/day↑

Worst 0.035oz(1.0kg)/day↑

Notch

(Freezer/Cool

Select/Fridge)

* Detailed

information table

appended,

C-C-C

Freezer 1/3H -8±2.7℉(-23±1.5℃)

Cool

Select

1/3H

Freezer -8±2.7℉(-23±1.5℃)

Soft Freezing 23±3.6℉(-5±2.0℃)

Chill 30±3.6℉(-1±2.0℃)

Cool 41±3.6℉(5.0±2.0℃)

Fridge 1/3H 34℉±2 7℉(1±1 5℃)

N-N-N

Freezer 1/3H 0±2.7℉(-18±1.5℃)

Cool

Select

1/3H

Freezer 0±2.7℉(-18±1.5℃)

Soft Freezing 23±3.6℉(-5±2.0 ℃)

Chill 30±3.6℉(-1±2.0 ℃)

Cool 41±3.6℉(5.0±2.0 ℃)

Fridge 1/3H 37±2.7℉(3±1.5℃)

Freezer temperature distribution 36℉↓(20℃)

Cool Select temperature distribution 36℉↓(2.0℃)

Fridge temperature distribution 3.6℉↓(2.0℃)

Operating ratio 100% ↓

W-W-W

Freezer 1/3H 5±2.7℉(-15±1.5℃)

Cool

Select

1/3H

Freezer 5±2.7℉(-15±1.5℃)

Soft Freezing 23±3.6℉(-5±2.0 ℃)

Chill 30±3.6℉(-1±2.0 ℃)

Cool 41±3.6℉(5.0±2.0 ℃)

Fridge 1/3H 44±2.7℉(7±1.5℃)

14

PRODUCT FEATURES AND SPECIFICATIONS

Item

RF34H99*, RF24J99*

Freezer, Cool select, Ice room

cycle (parallel)

Fridge cycle

Cycle

Specifications

Compressor

Model no. MKV190CL2B/E01 NC1MV43AMP

Amount of refrigerant R134a (6.00oz(170g)) R134a (3.53oz(100g))

Evaporator

Freezer/

Cool Select Room

3 rows 2 layer, Depth 70mm

Fridge Compartment 3 rows 2 layer, Depth 70mm

Condenser

Condenser

SFC (Serpentine Flow Condenser) 3

rows

SFC (Serpentine Flow Condenser) 2rows

Cluster pipe -

Side Cluster: Not applied

Back Cluster: OD4.0(t 0.7), 4.94m

Hot pipe OD4.0(t 0.7), 11.4m

-

Suction

Cool select -

Freezer Pipe

OD7.94(t 0.5), 0.785m

-

Freezer - Ice Maker

connection Pipe

OD7.0(t 0.5), 2.5m

-

Suction pipe OD7.94(t 0.5), 2.5m OD7.94(t 0.5), 3.0m

Capillary

Tube

Freezer capillary

Tube

OD2.05, ID0.82, 3500mm

-

Cool Select capillary

Tube

OD1.9, ID0.82, 3300mm -

Fridge capillary tube - OD1.9, ID0.82, 3500mm

Other

Dryer Step valve Single Dryer

Valve Step valve (3 way) -

15

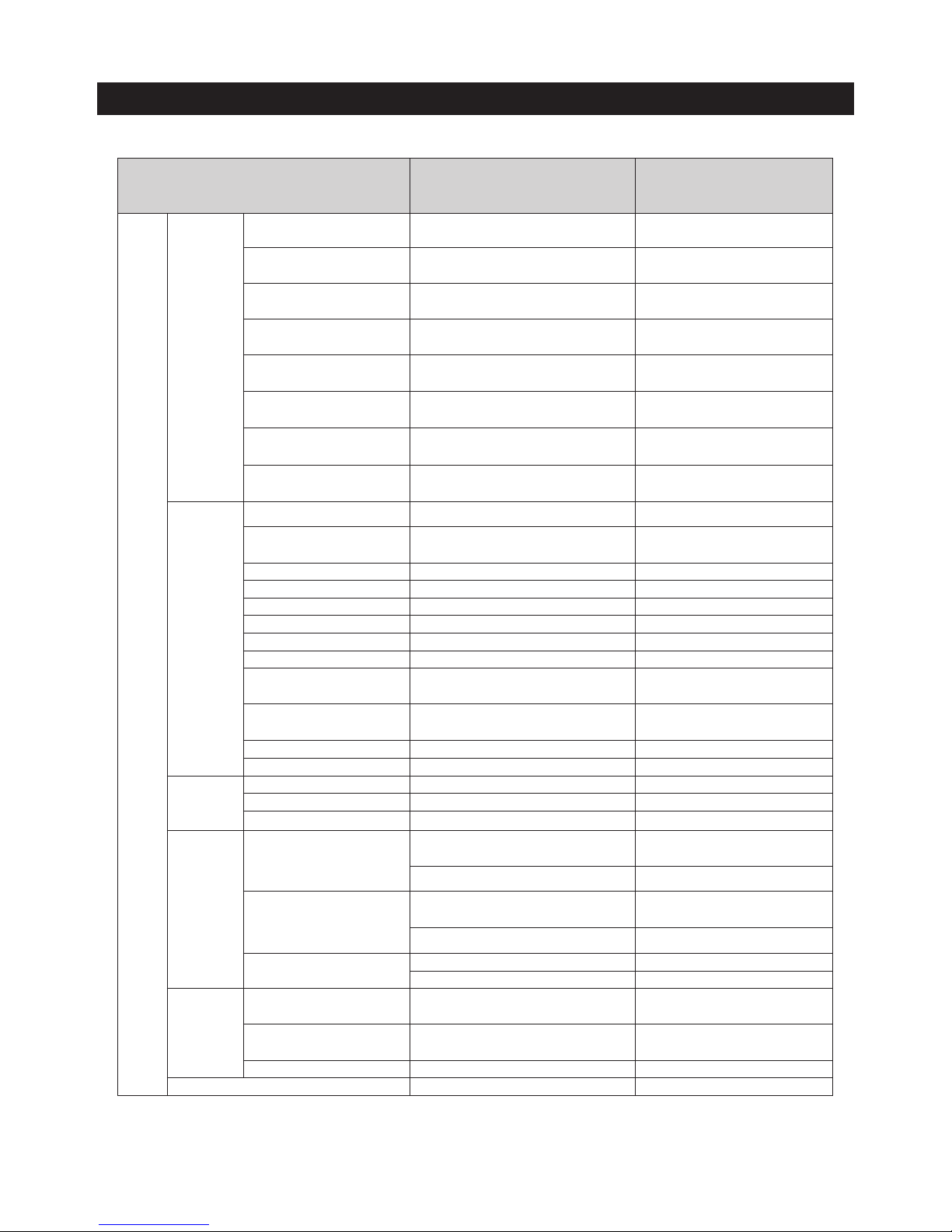

PRODUCT FEATURES AND SPECIFICATIONS

Classification RF34H99*, RF24J99*

Remarks

Electrical

parts

Motor

&

Fan

Freezer

BLDC(ARES2120RA), ø120 11Wing,

DC12V, 2.5W, 1870rpm

AIO Q7

Cool Select Room

BLDC(ARES2120RA), ø120 11Wing,

DC12V, 2.5W, 1870rpm

AIO Q7

Fridge

BLDC(ARES2120RA), ø120 11Wing,

DC12V, 2.5W, 1870rpm

AIO Q7

Machine compartment

BLDC(DRCP8020LA), ø160 3Wing,

CCW 12VDC 1.7W, 1120rpm

AIO 160

PANTRY

BLDC(U92C12MS1B3-52K09), 92*92*32,

3Wing, DC12V, 0.16A, 3350rpm

BOX FAN

ICE ROOM

BLDC(2606JL-04W-S39), 66*66*15,

9Wing,DC12V, 1.2W, 3600rpm

BOX FAN

AUGER

AC 120V/60Hz, LONG SHAFT, CCW,

18 RPM

GEARED

DISPENSER

AC 120V/60Hz, Syncronous, CCW, 18

RPM

GEARED

Heater

F-Evap. AC120V 121(Sheath Heater)

CV-Evap. AC120V 121(Sheath Heater)

Common to both the F and CV

compartments

R-Evap. Not applied.

French

AC120V 10W(Cord Heater)

Door F DC12V 2.5W(Cord Heater)

Door CV DC12V 2.5W(Cord Heater)

Door R Not applied.

Dispenser AC120V 2.5W

Water pipe

DC12V 2.3W

(Cord Heater)

ICE Room

DC12V 2W

(Cord Heater)

ICE Maker AC120V 120W

Damper Not applied.

Comp

electrical

parts

OLP 4TM445PHBYY-82

PTC Relay Not applied.

Capacitor Not applied.

Over

Heater

Protector

Freezer

Bimetal

[Off : 140°F (60°C) / On : 104°F (40°C)]

Thermal Fuse [Cut-off 230℉ (110℃)]

Cool Select Room

Bimetal

[Off : 140°F (60°C) / On : 104°F (40°C)]

Thermal Fuse [Cut-off 230℉ (110℃)]

Fridge

Not applied.

Not applied.

Internal lamp

Freezer

TOP: 1 LED(1EA) / FRIDGE DOOR

BOTTOM: 1 LED(1EA)

Cool Select Room

TOP: 1 LED(1EA) / FRIDGE DOOR

BOTTOM: 1 LED(1EA)

Fridge SIDE: 12 LEDs(4EA)

3 Way Valve Stepping Motor (NSCEV01TA*)

16

PRODUCT FEATURES AND SPECIFICATIONS

2-4. Specifications

Item

Dimensions

Temperature sensors inside Compartment

Freezer

Thermistor

(F-Sensor)

Temp. Selection

Threshold that turns the

sensor output on

Thresholds that turns the sensor

output off

-8℉

-5℉(-21℃) -11℉(-24℃)

0℉

3℉(-16℃) -3℉(-19℃)

5(℉)

8℉(-14℃) 2℉(-17℃)

Cool Select Room

Thermistor

(R-Sensor)

Freezer Same as Freezer compartment Same as Freezer compartment

Soft Freezing

27℉(-3℃) 19℉(-7℃)

Chill

33℉(1℃) 26℉(-3℃)

Cool

45℉(7℃) 37℉(3℃)

Fridge

Thermistor

(R-Sensor)

34℉

37℉( 3℃) 31℉( 0℃)

37℉

40℉(4℃) 34℉(1℃)

44(℉)

47℉(8℃) 41℉(5℃)

Defrosting Parts

Defrosting sensor

F defrosting - sensor

Model no.

THERMISTOR (DTN-C502)

Specifications

5.0 ㏀ at 77℉ (25℃)

R defrosting - sensor

Model no.

THERMISTOR (DTN-C502)

Specifications

5.0 ㏀ at 77℉ (25℃)

Bimetal (Freezer)

Model no.

BIMETAL THERMOSTAT (BT-121-M)

Operating temperature

Off : 140°F (60°C) / On : 104°F (40°C)

Bimetal (Cool select)

Model no.

BIMETAL THERMOSTAT (BT-121-M)

Operating temperature

Off : 140°F (60°C) / On : 104°F (40°C)

17

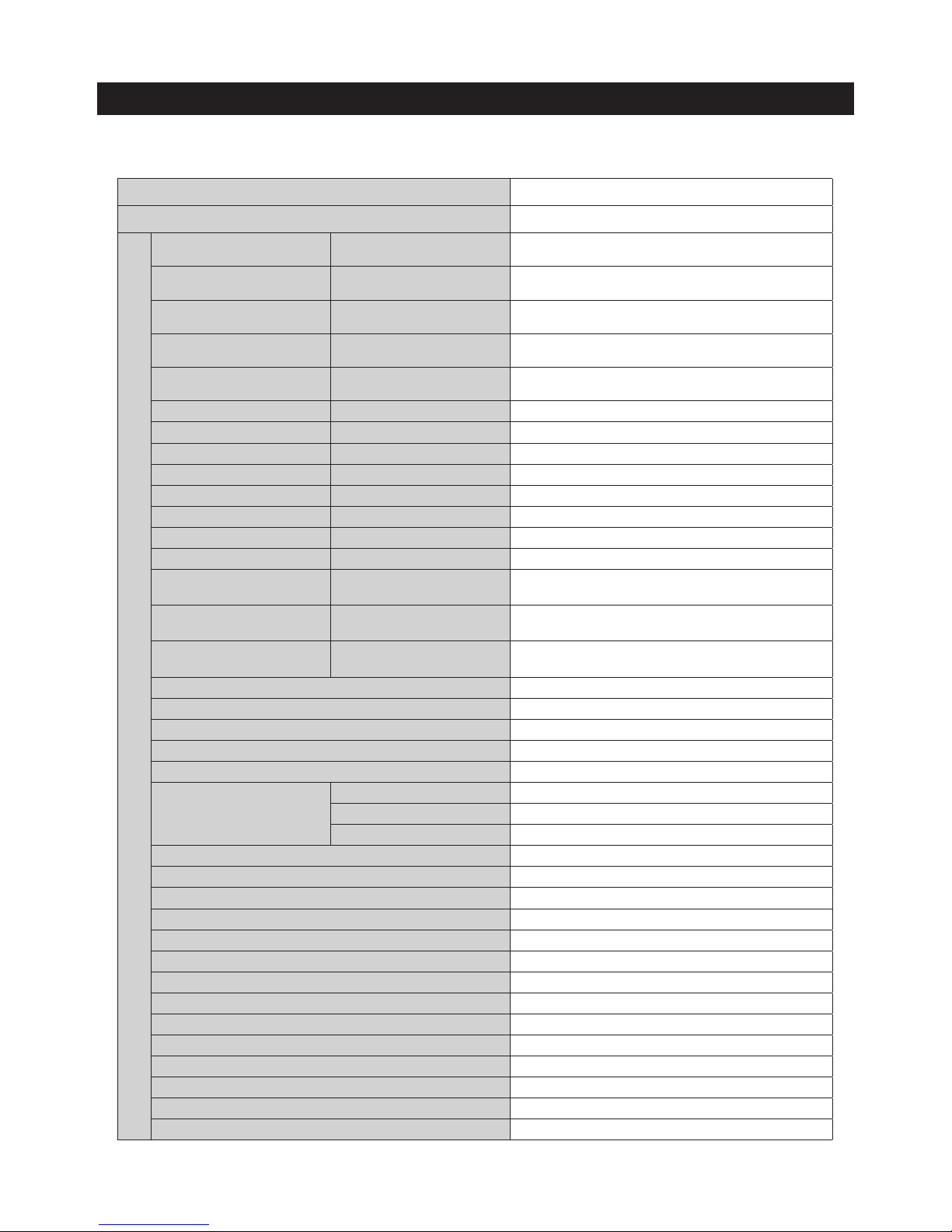

PRODUCT FEATURES AND SPECIFICATIONS

Item Dimensions

Model

RF34H99*, RF24J99*

Electrical parts

Freezer compartment defrosting

heater

Current flows when F defrosting is

conducted.

AC120V 121W

Cool Select compartment defrosting

heater

Current flows when CV defrosting is

conducted.

AC120V 121W

Fridge compartment defrosting heater

Current flows when R defrosting is

conducted.

-

Cool Select compartment drain

heater

Current flows when CV defrosting is

conducted.

-

French heater

According to external humidity ,

Heater is operated

AC120V 10W

Water tank heater -

-

Dispenser heater -

AC120V 2.5W

Cap door heater (R compartment) -

-

Display heater (F compartment) -

-

Ice water supply pipe heater -

-

Ice water drain pipe heater -

DC12V 2.3W

ICE Room Heater -

DC12V 2W

Damper heater

-

-

Freezer compartment door heater

The heater is operated by the

external humidity sensor.

DC 12 V 2.3 W

Cool Select compartment door heater

The heater is operated by the

external humidity sensor.

DC 12 V 2.3 W

Fridge compartment door heater

The heater is operated by the

external humidity sensor.

-

Freezer compartment defrosting heater overheating prevention bimetal

Off: 140℉(60℃) / On: 104℉(40℃)

Freezer compartment defrosting heater overheating prevention fuse

230℉ (110℃), 120V/15A

Cool Select compartment defrosting heater overheating prevention bimetal

Off: 140℉(60℃) / On: 104℉(40℃)

Cool Select compartment defrosting heater overheating prevention fuse

230℉ (110℃), 120V/15A

Noise filter

20 mH, 80*60*1.6 t

OLP

Model no.

4TM445PHBYY-82

Temperature at which it turns on

156.2°F (69°C)

Temperature at which it turns off

257°F (125°C)

Freezer compartment cooling fan motor

DC 12V BLDC(ARES2120RA)

Cool Select compartment cooling fan motor

DC 12V BLDC(ARES2120RA)

Fridge compartment cooling fan motor

DC 12V BLDC(ARES2120RA)

Comp. cooling fan motor

DC12V BLDC(DRCP8020LA)

PANTRY

DC 12V BLDC(U92C12MS1B3-52K09)

ICE ROOM

DC 12V BLDC(2606JL-04W-S39)

AUGER

AC 120V/60Hz, Shading pole(ISG-3240SSJ)

DISPENSER

AC 120V/60Hz, Syncronous(MVCD18AR19)

Motor step valve

DC 14 V / 0.7 A

Freezer / Cool Select Room interior lamps

TOP: 1 LED(1EA), FRIDGE DOOR BOTTOM: 1 LED(1EA)

Fridge interior lamps

SIDE: 12 LEDs(4EA)

Door reed switch

DC 200 V / 0.5 A

Power cord

125V/15A

Grounding screw

BSBN (brass screw)

18

PRODUCT FEATURES AND SPECIFICATIONS

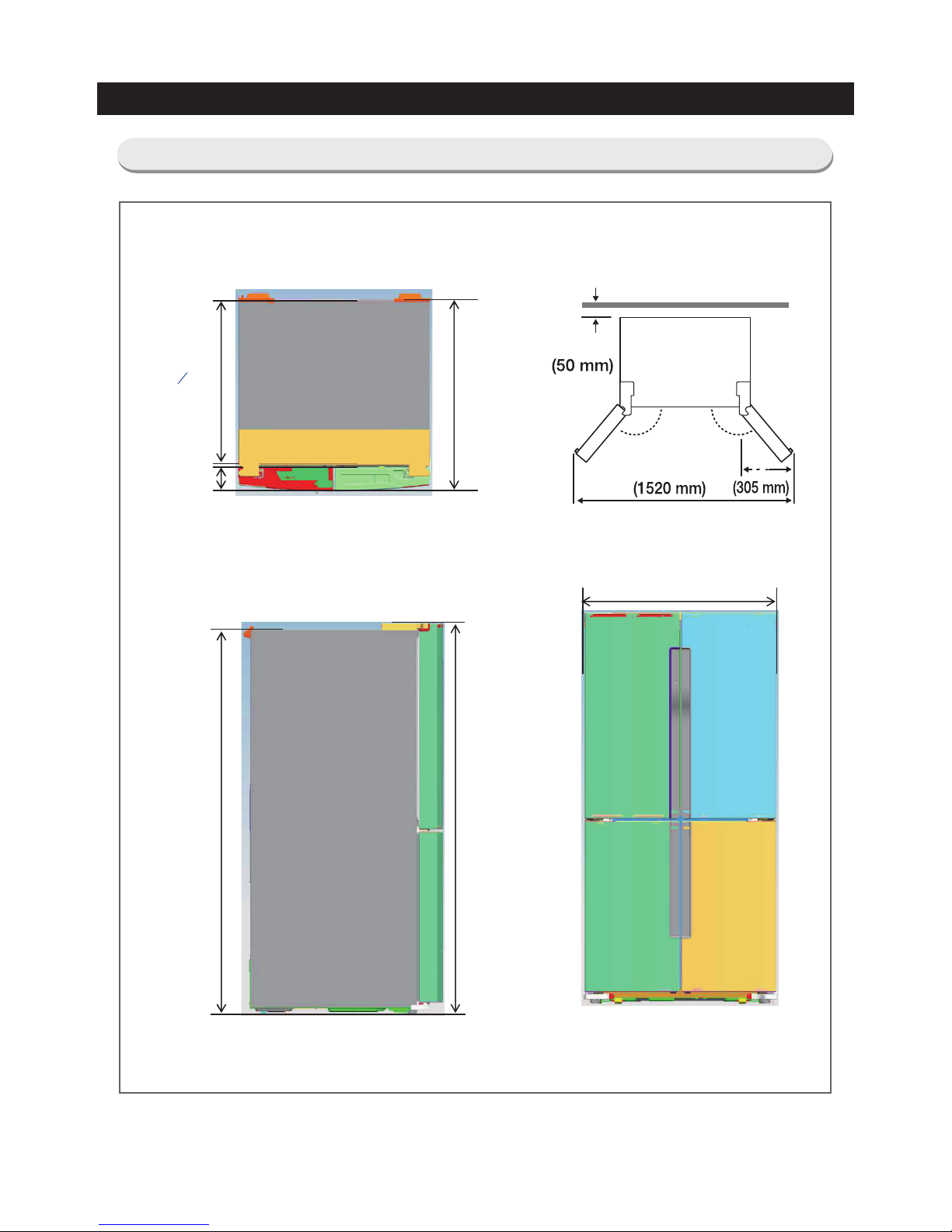

2-5. Dimensions

35 3/4"

(908 mm)

35 ¾” (908 mm)

72 ⅞”

(1850 mm)

71 ¾”

(1822 mm)

30

15

16

”

(785 mm)

4 ⅜"

(112mm)

59 3/4”

12”

123° 123°

2”

RF34H99*

19

PRODUCT FEATURES AND SPECIFICATIONS

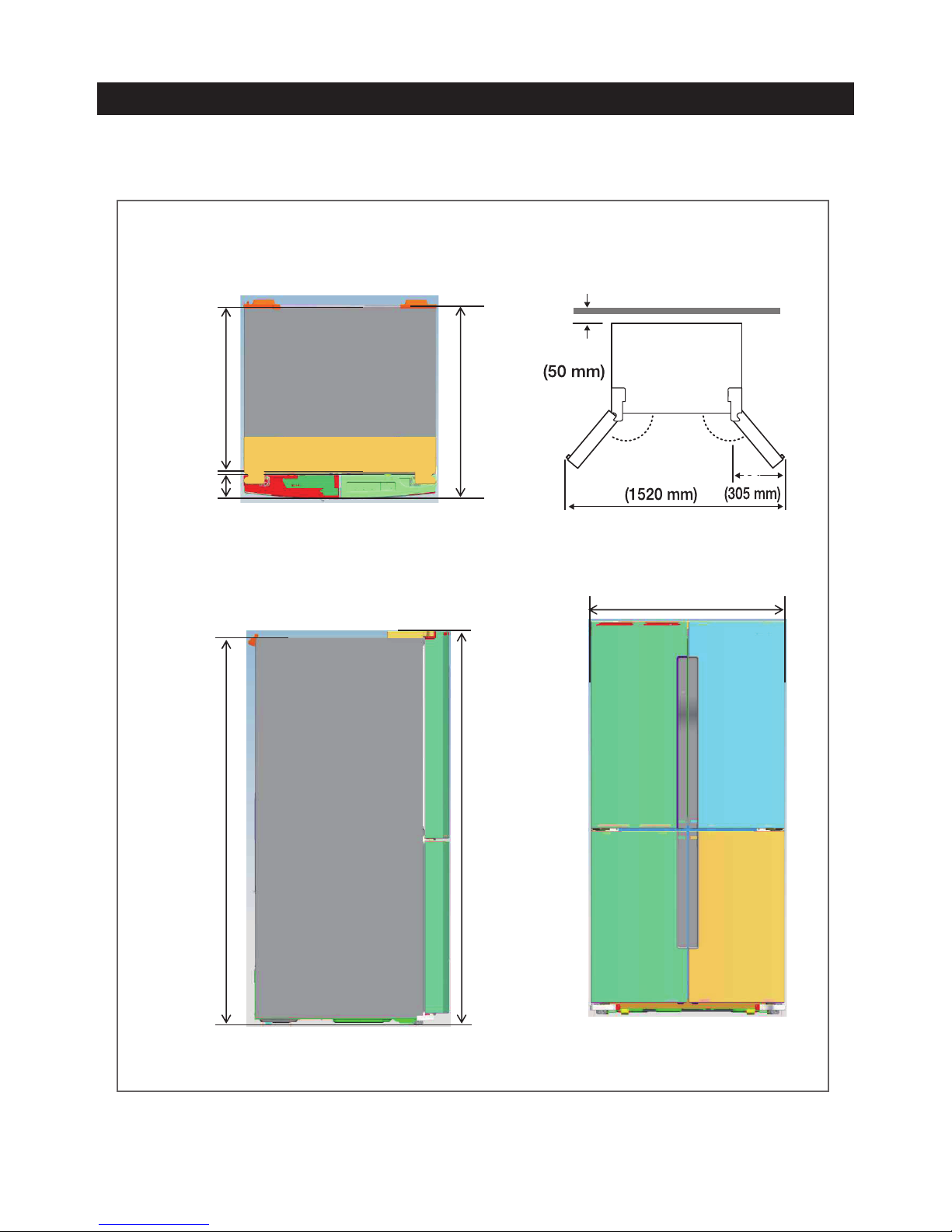

28 7/8"

(733mm)

35 ¾” (908 mm)

70"

(1777m)

68 7/8"

(1749mm)

24"

(610mm)

4 ⅜"

(112mm)

59 3/4”

12”

123° 123°

2”

RF24J99*

20

PRODUCT FEATURES AND SPECIFICATIONS

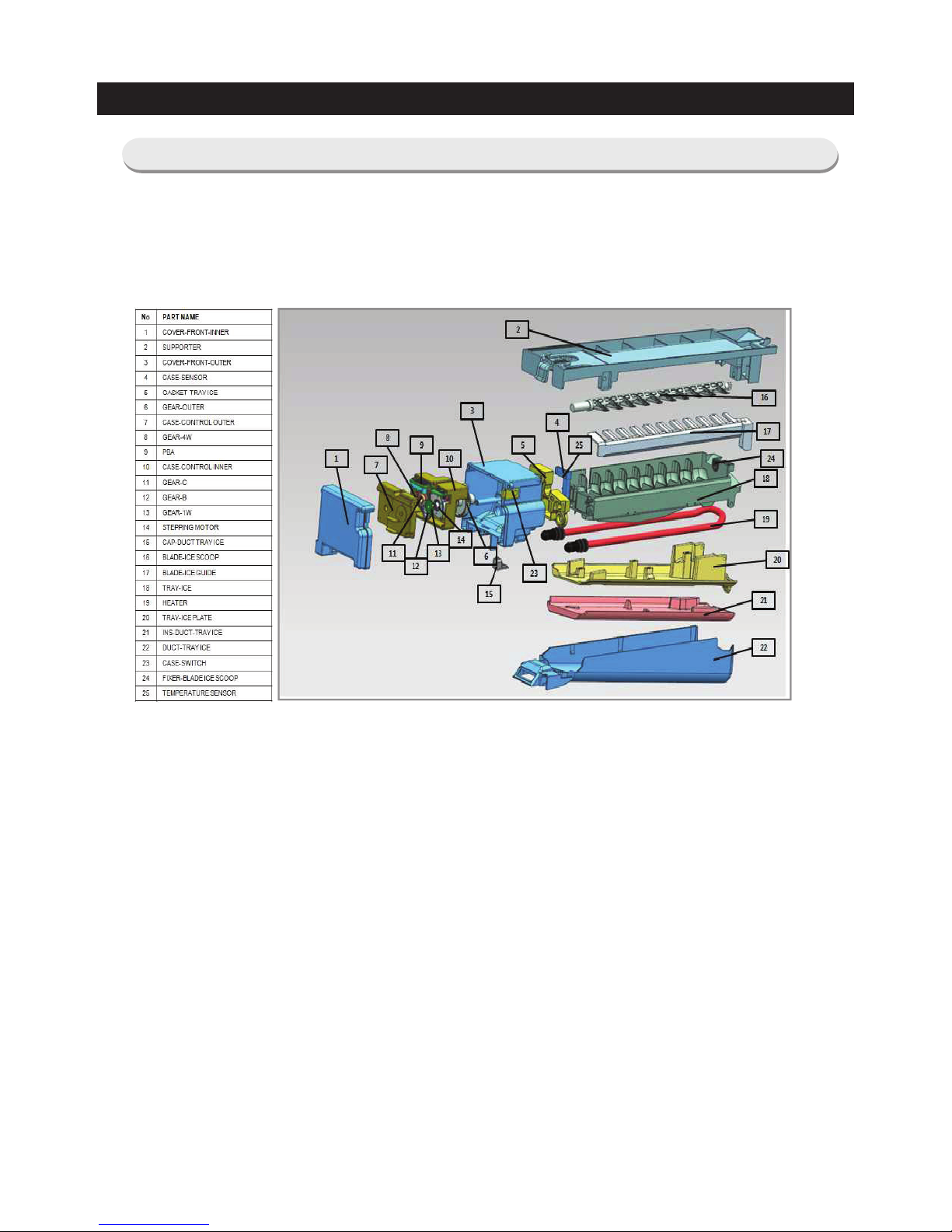

2-6. ICE-MAKER Function

- The ICE-MAKER function is an option and the following explains the function of these models.

- The ICE-MAKER is a kit that supplies water on its own, freezes water into ice and stores the ice cubes in the Ice

Container with the capability of making ice automatically without manual controlling

1) ICE-MAKER Components

2) Initial Operations

1. When the power is on, it checks the temperature of the Ice Maker Sensor. If the Ice Maker Sensor

temperature is lower than 0℃, the Ice Maker Heater will be on for 4 minutes. After that, it will run the Initial

Test Mode. If the Ice Maker Sensor temperature is higher than 0℃, it will run the Initial Test Mode right

away.

2. During the Initial Test Mode, it carries out the operation of the Ice Maker Motor and its Heater turns on for

30 seconds.

3. If the Ice Maker Sensor temperature is over 0℃ upon the initial power on, the Water Valve will work for a

second while its Heater is on.

4. The Ice Maker Motor rotates both clockwise and counter clockwise repeatedly. And, when it is sensed as

being at the parallel position (Home) within 6 minutes after the Motor starts operating, its initial operation will

stop and its normal ice making will begin.

5. When it does not sense the parallel position (Home) within 6 minutes after the Motor starts operating, it will

be considered as the Ice Maker defect and its initial operation will stop.

※ Operation upon Ice Maker Defect during the Initialization.

1) Upon the termination of the Initialization due to the Ice Maker Defect, it runs the Initialization again. And, when

the defect is detected during all the set number of times (ex. 3 times), it will stop the Initialization of the Ice Maker.

2) When it is sensed as defect 3 times in a row during the initialization, the Ice Maker does not operate for the

set duration (ex. 3 hours) and it runs the initialization again after a set time period.

21

PRODUCT FEATURES AND SPECIFICATIONS

3) General Operation

•

Water Supply > Stand-by Time for Ice Making > Temperature Checking for Ice Maker Sensor > Ice Removing

Water Supply Ice Making Ice Removing

1. After supplying water, it stands by for 14 minutes before starting the ice making. After that, it checks the Ice Maker

Temperature.

2. When the Ice Maker Sensor temperature is measured lower than -13℃ for more than 5 seconds, its ice making

is completed.

3. When the ice making is completed, the Ice Maker Heater and Motor operates and the ice cubes are to be

removed from the Ice Maker. At this time, its heater thaws out the outer surface of the ice cubes allowing them to

be removed from the Ice Maker easily. And, its motor turns both clockwise and counter clockwise to remove the

ice cubes from the Ice Maker.

4. The Ice Maker repeats the operation of the (1) ~ (3) until ice cubes build up in the Ice Bucket triggering the Full-

Ice Detect Sensor on. At this time, the Ice Maker stops producing ice cubes.

4) Ice Off (Stopping Ice Making) Function

1. When turning on the Ice Off function at the preference setting, the Ice Maker function will be off.

2. When the Ice Maker is off, it does not supply water to the Ice Tray.

3. When turning off the Ice Off function, the Ice Off function will be cancelled. When the Ice Off is cancelled, it starts

from ice making and the operation of the Ice Maker resumes.

5) TEST Function

- It is a function to be used when it needs the forced operation for the purpose of repairs or cleaning.

1. When pressing the Test Button for 1.5 seconds, the Test Function will start.

2. The Test Function works as follows.

Start (Alarm Sound) → Motor On (Rotating Counter Clockwise) → Motor On (Rotating Clockwise) → Heater On →

Motor On (Rotating Clockwise) → Home Location → Water Supply → Completed (Alarm Sound)

※ The Ice Maker Heater will be On / Off

The Ice Maker Heater will be On and Off according to the temperature conditions of the Ice Maker Sensor when

the Ice Maker Motor rotates clockwise.

3. When the entire operation is to be completed within 6 minutes after the motor starts operating upon pressing the

Test button, it sends out alarm sound. And, after this, it does normal ice making.

4. When the entire operation does not complete normally (ex. Not reaching at the Home location) within 6 minutes

after the motor starts operating upon pressing the Test button, it will be considered as the Ice Maker defect and

the entire loads (Motor, Heater, etc) will be off. (No alarm sound)

After this, it performs an operation checking whether the Ice Maker operates normally according to the set time

cycle (ex. 3 hour).

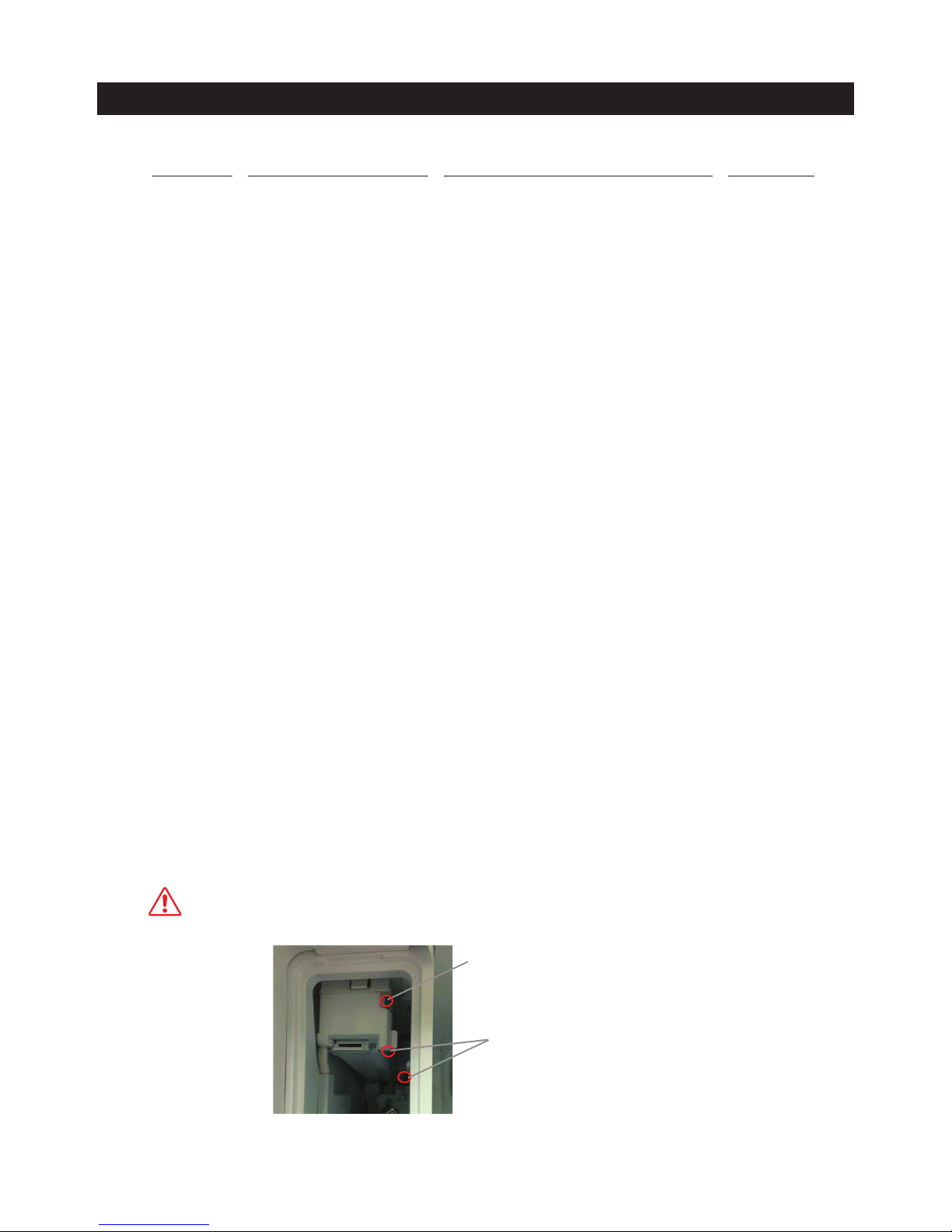

Ice Level Checking IR Sensor

Ice maker test switch

Caution

When the Ice Maker Heater is on, it may cause personal injury. So, take extra care

22

PRODUCT FEATURES AND SPECIFICATIONS

2-7. Material Specification

Photograph Part Name Part Code AMOUNT

FILTER WATER-ASSY DA29-00019B 1

23

3.

DISASSEMBLY AND REASSEMBLY

3-1. Precautions

• Before replacing or repairing an electrical part, be sure to unplug the product's power cord.

- Failing to do so may result in electric shock.

• Be sure to replace any electrical parts with rated parts.

- Be sure to check the model no, rated power voltage, operating temperature etc. printed on the product.

• When repairing a product, connect the harnesses firmly so that no water enters the product.

- They should not become separated if a certain amount of force is applied.

• When repairing the product, completely remove all dust or foreign substances from the housing, connectors and

terminals.

- Prevents fire due to tracking or short-circuits.

• Check if there are any marks of moisture having entered the electric parts.

- If it appears that moisture has penetrated the part, take countermeasures such as replacing the part or wrapping

the part with insulation tape.

• After fixing a problem, check the assembly status of the parts.

- The status must be the same as before repairing the product.

• Check the operating environment of the refrigerator.

- If the refrigerator is exposed to moisture or is installed near water or on an unstable surface, relocate the

refrigerator.

• Ground the refrigerator if necessary.

- In particular, if there is a danger of electric leakage due to moisture or water, be sure to ground the refrigerator.

• Do not share a power strip with other appliances.

• Check if the power plug or electrical outlet is damaged, deformed or old.

- If the power plug or outlet is damaged or out of order, repair it immediately.

- Take care when you move the product so that the power cord is not damaged, cut or becomes trapped.

• Do not store food in an unstable manner in the refrigerator or store bottles in the freezer.

• Do not let customers repair the product by themselves.

• Do not let customers store items other than food in the refrigerator.

- Medicine or chemicals: A precise temperature cannot be maintained by the refrigerator for home use.

- Inflammable materials (alcohol, benzene, ether, LP gas, butane gas, etc.): There is a danger of explosion.

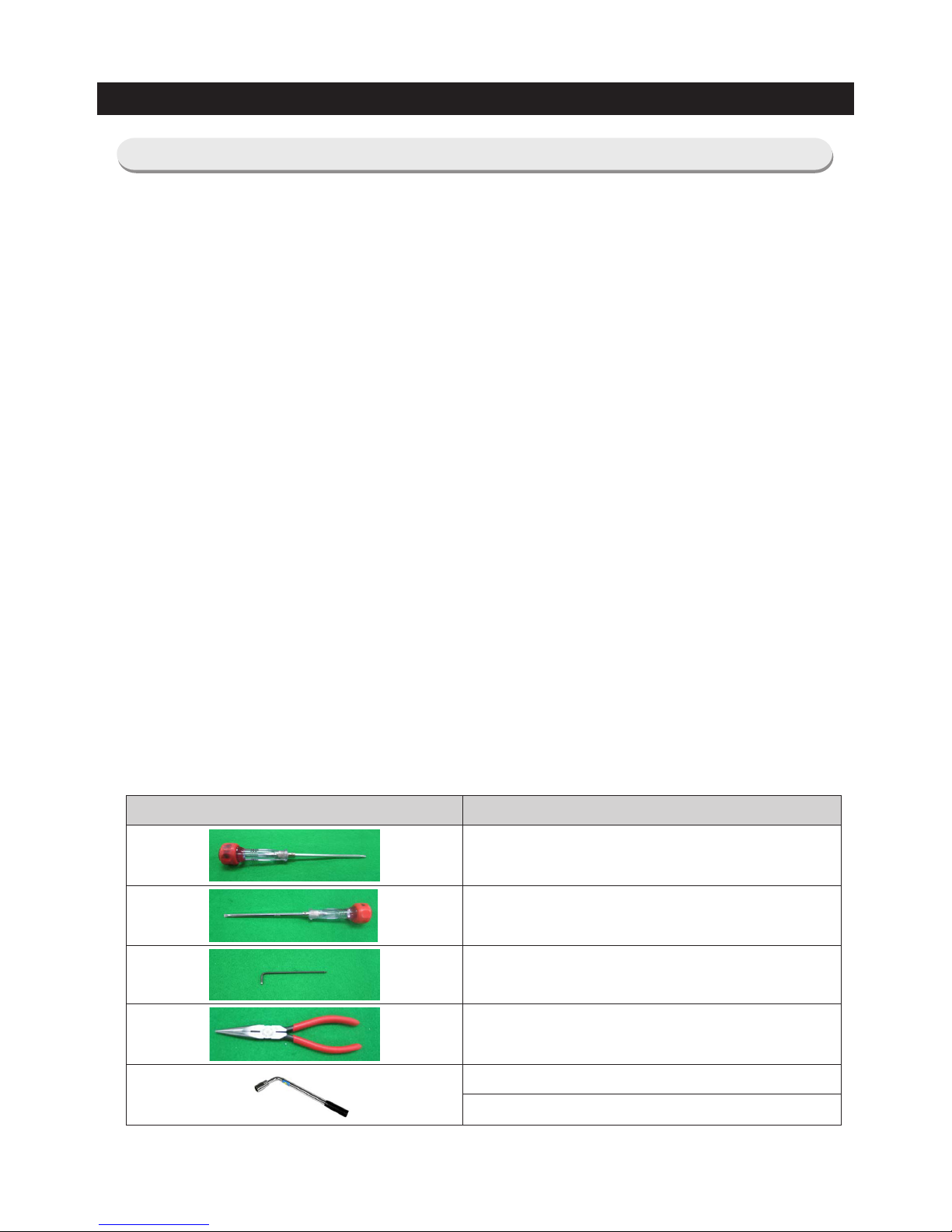

Required Tools

Image Item

(+) screw driver

(-) screw driver

Hexagon wrench (2 mm diameter)

Long nose pliers

Box wrench (12 mm) - To disassemble the compressor

Box wrench (10 mm) - To disassemble the hinge Lower

24

DISASSEMBLY AND REASSEMBLY

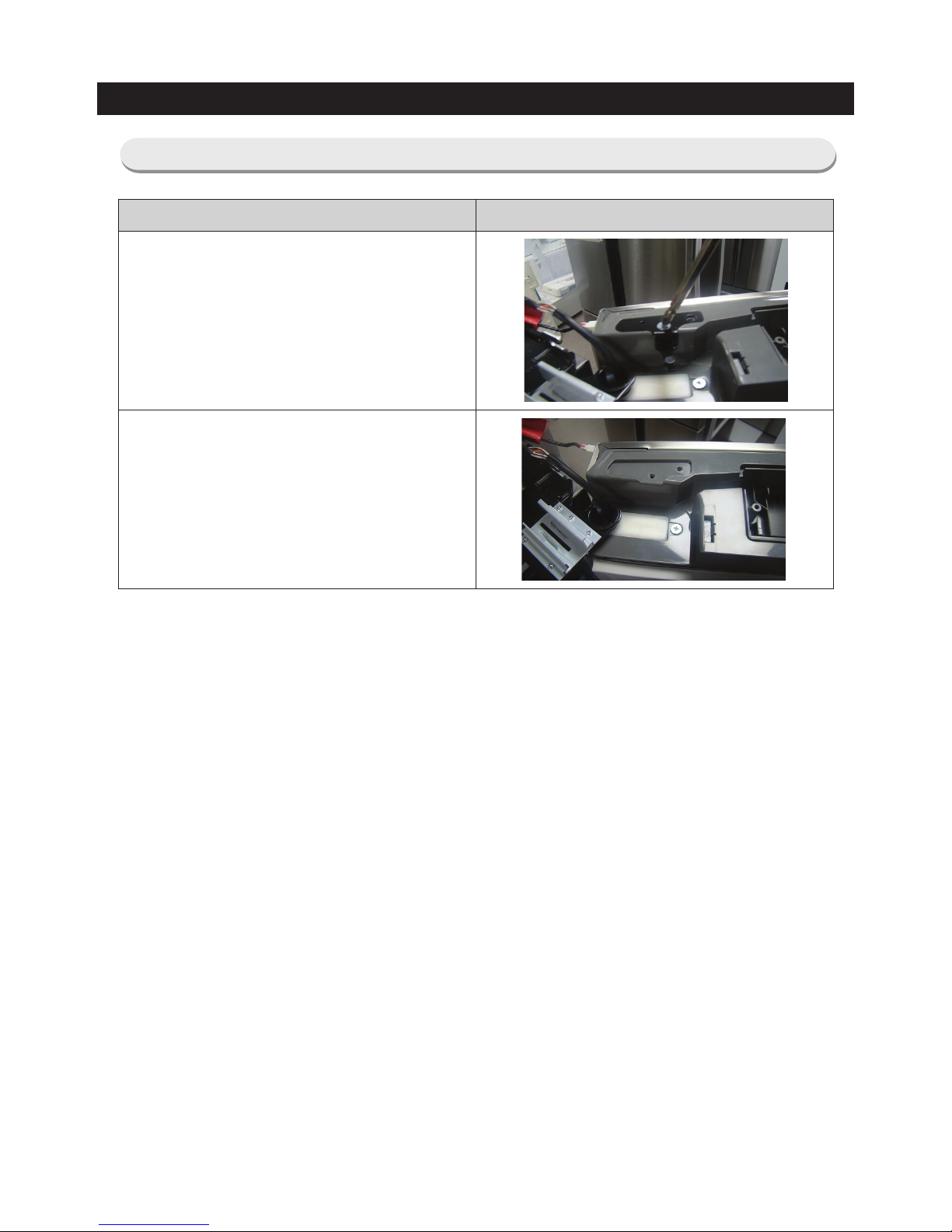

3-2. Disassembling the Refrigerator Door

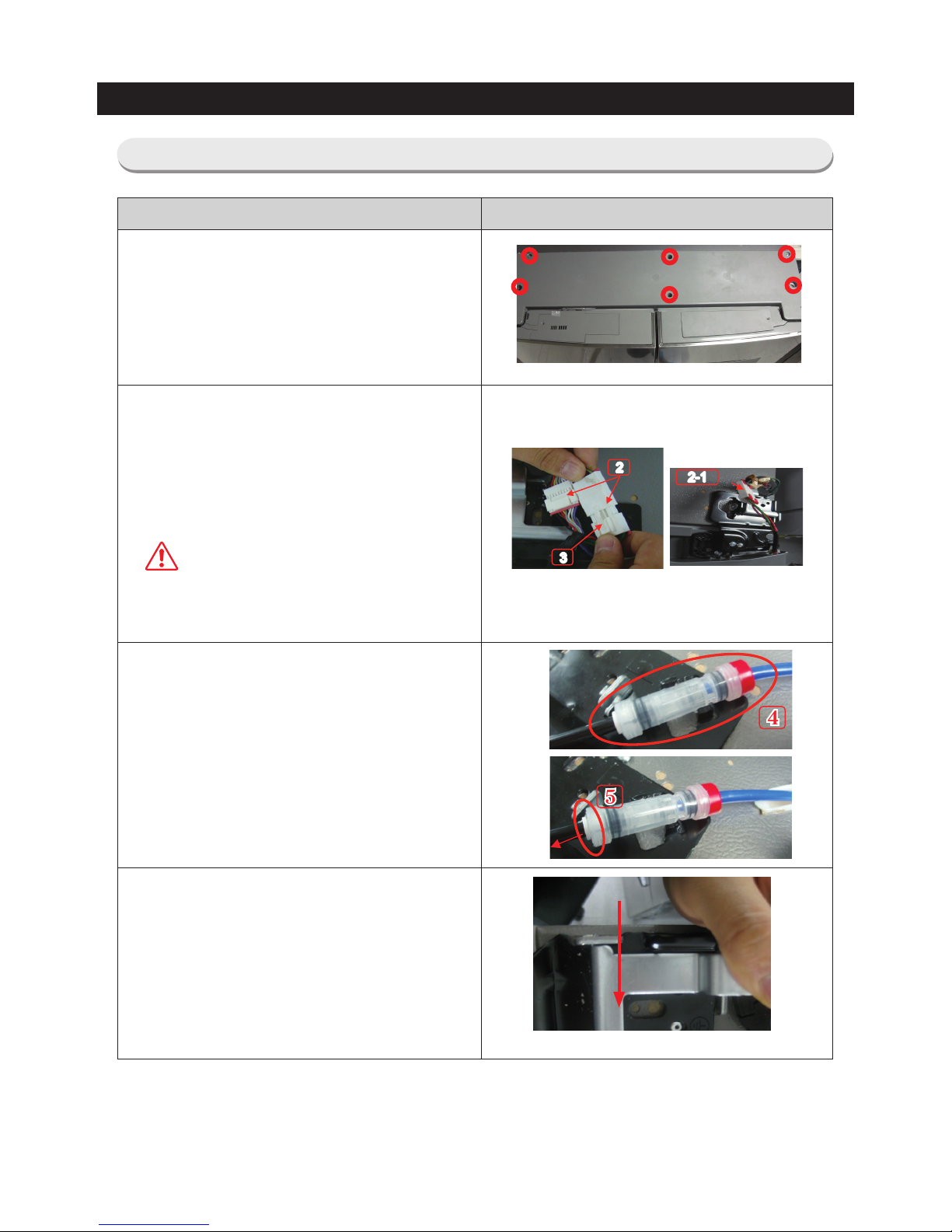

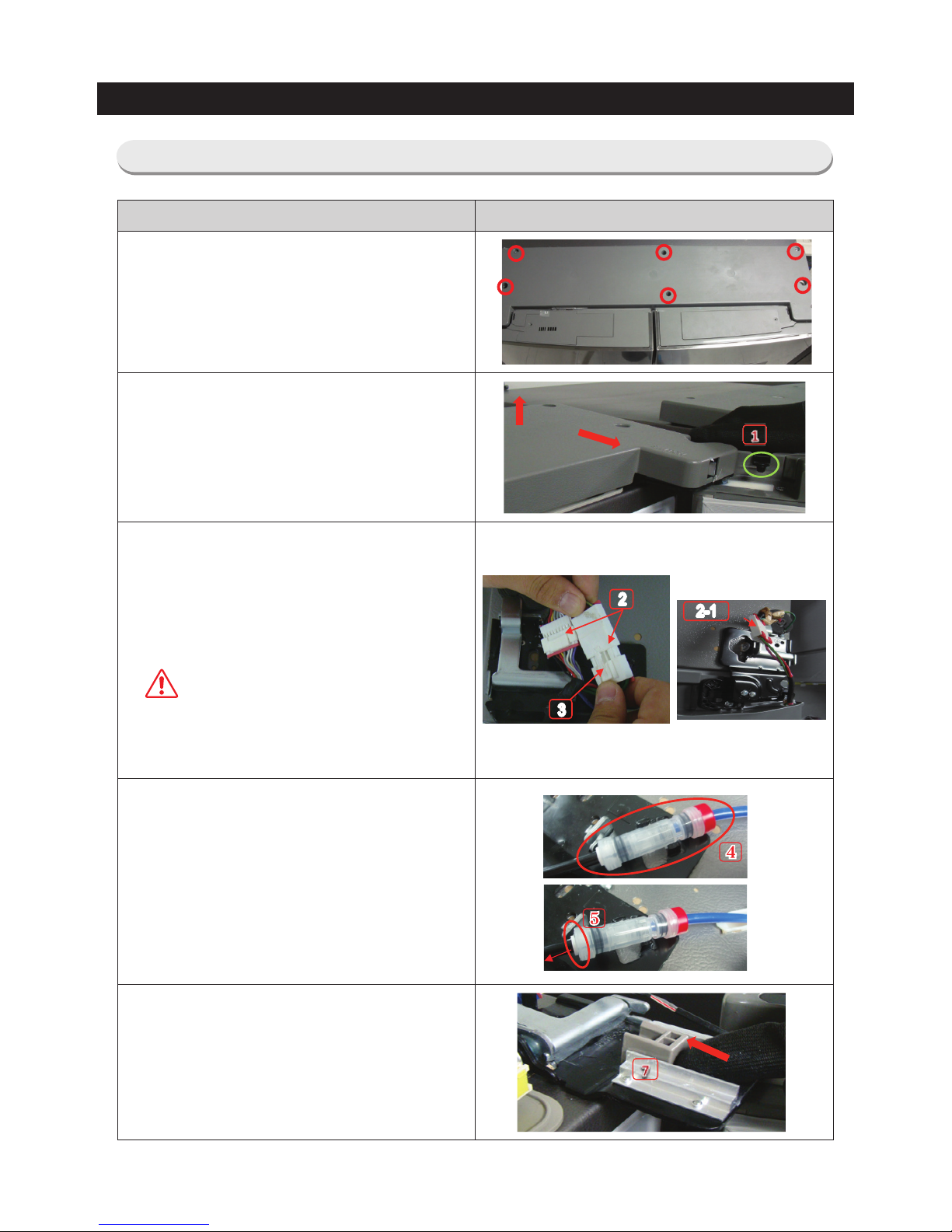

How To Do Descriptive Picture

1. Remove the 6 screws fixing the Top Table and

separate the Top Table (①).

2. Separate the 2 housing connectors (②) from the

hinge at the top left of the fridge compartment

door and the 1 housing connector (②-1) from

the hinge at the top right of the door.

To separate the housing connectors more

easily, pull the connector while holding down

the fixing hook (③).

Caution

Make sure to unplug the power cord

before performing the procedures above.

Note. The number of housing units may differ

depending on the model.

3

2

2-1

3

2

2-1

3. As shown in the picture, Remove water tube

from hinge (4) by holding at the both sides of

the Tube Fitting and pulling it out. And, remove

the Tube Fitting (5) by pulling the water hose

after pushing in the locking ring tab at the end

of the Tube Fitting.

4. After pulling the Hinge Lever, remove the

Hinge.

25

DISASSEMBLY AND REASSEMBLY

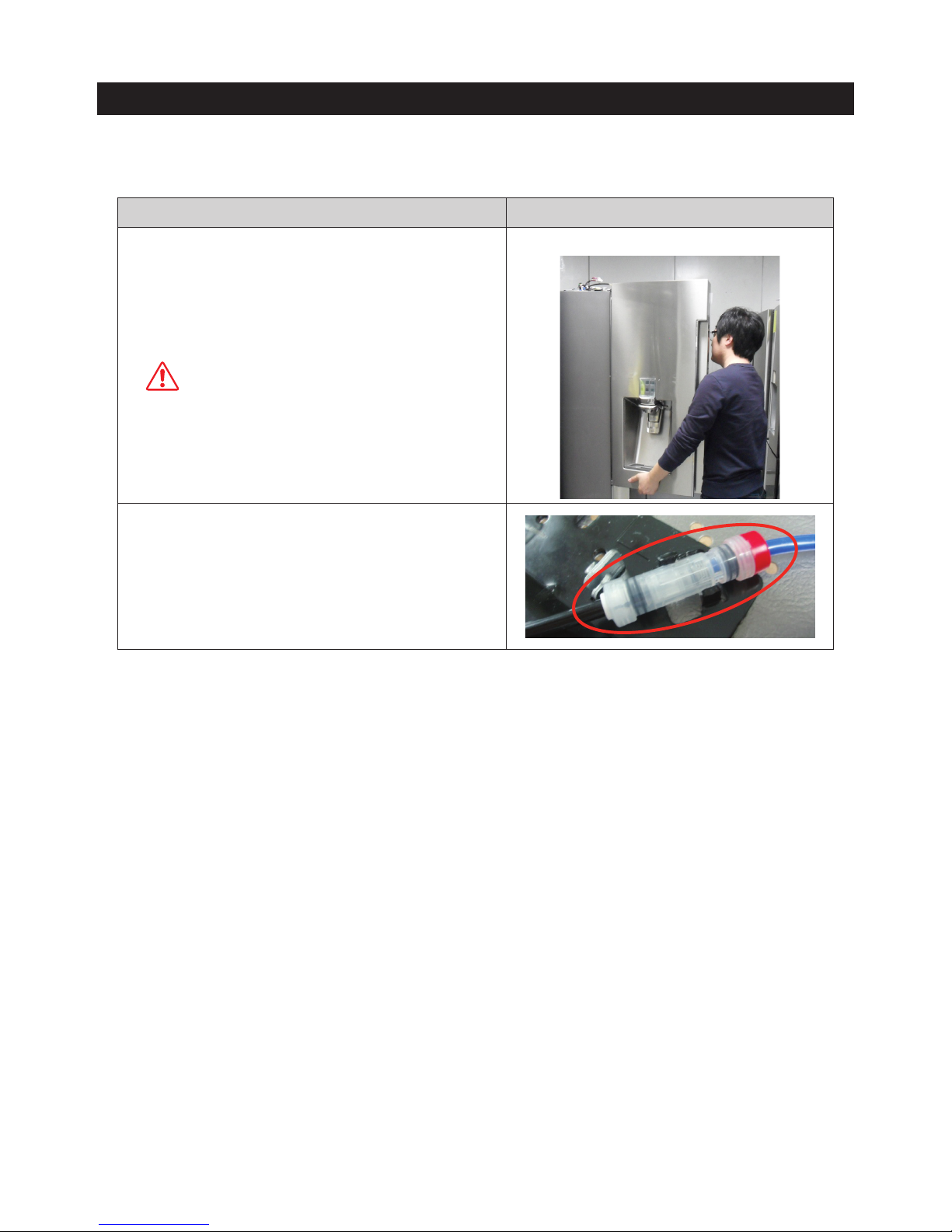

How To Do Descriptive Picture

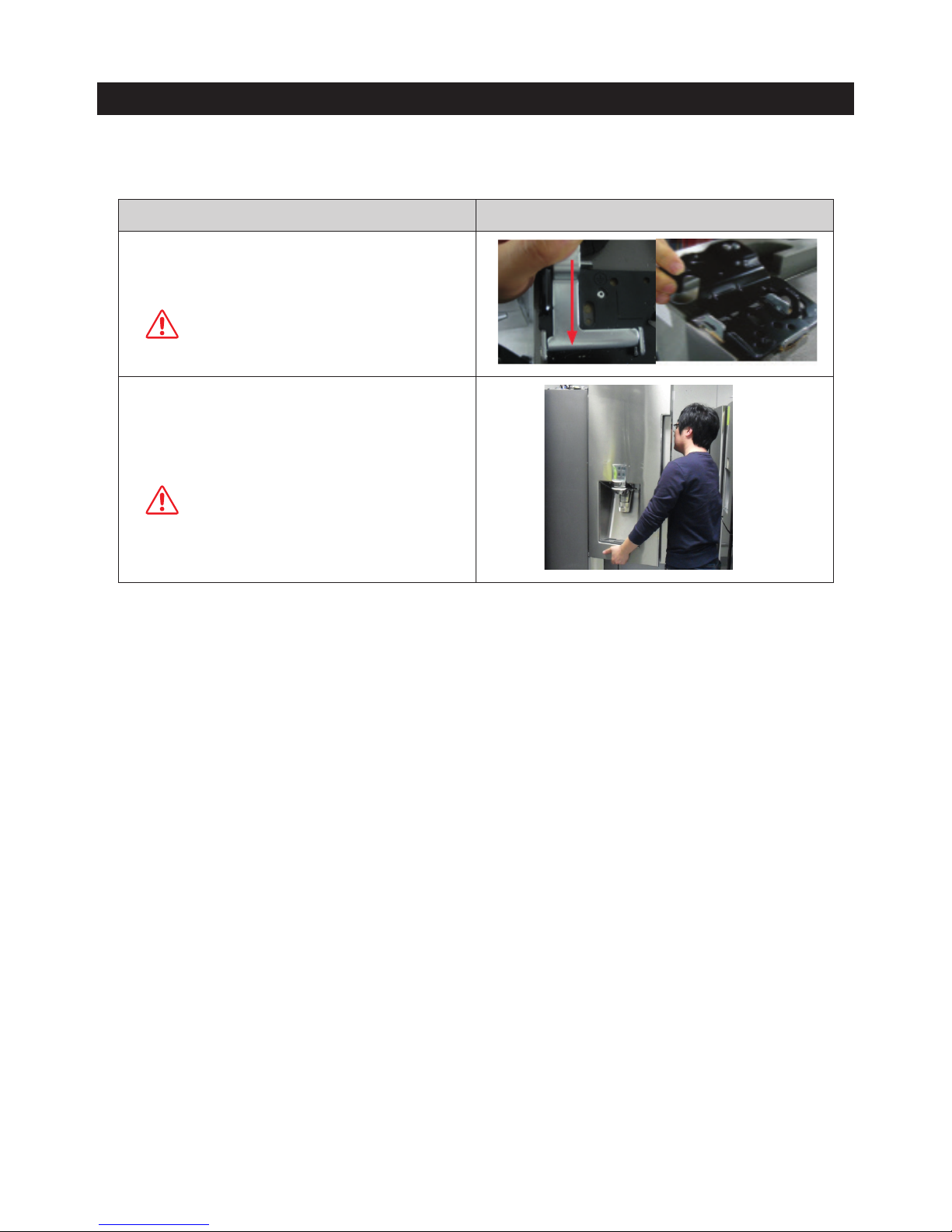

5. Lift the door straight up to remove while opening

it more than 90°.

CAUTION

Be careful not to drop the door.

6. Assemble the door in the reverse order of

disassembly; reconnect the fitting; connect the water

supply; check if water comes out from the dispenser;

and check if water leaks for one minute or longer. (You

can check the water with bare eyes at the transparent

fitting. If it is hard to observe with bare eyes, you can

also check it against a piece of toilet paper)

26

DISASSEMBLY AND REASSEMBLY

3-3. Disassembling the Fridge Doors (RF24J* only)

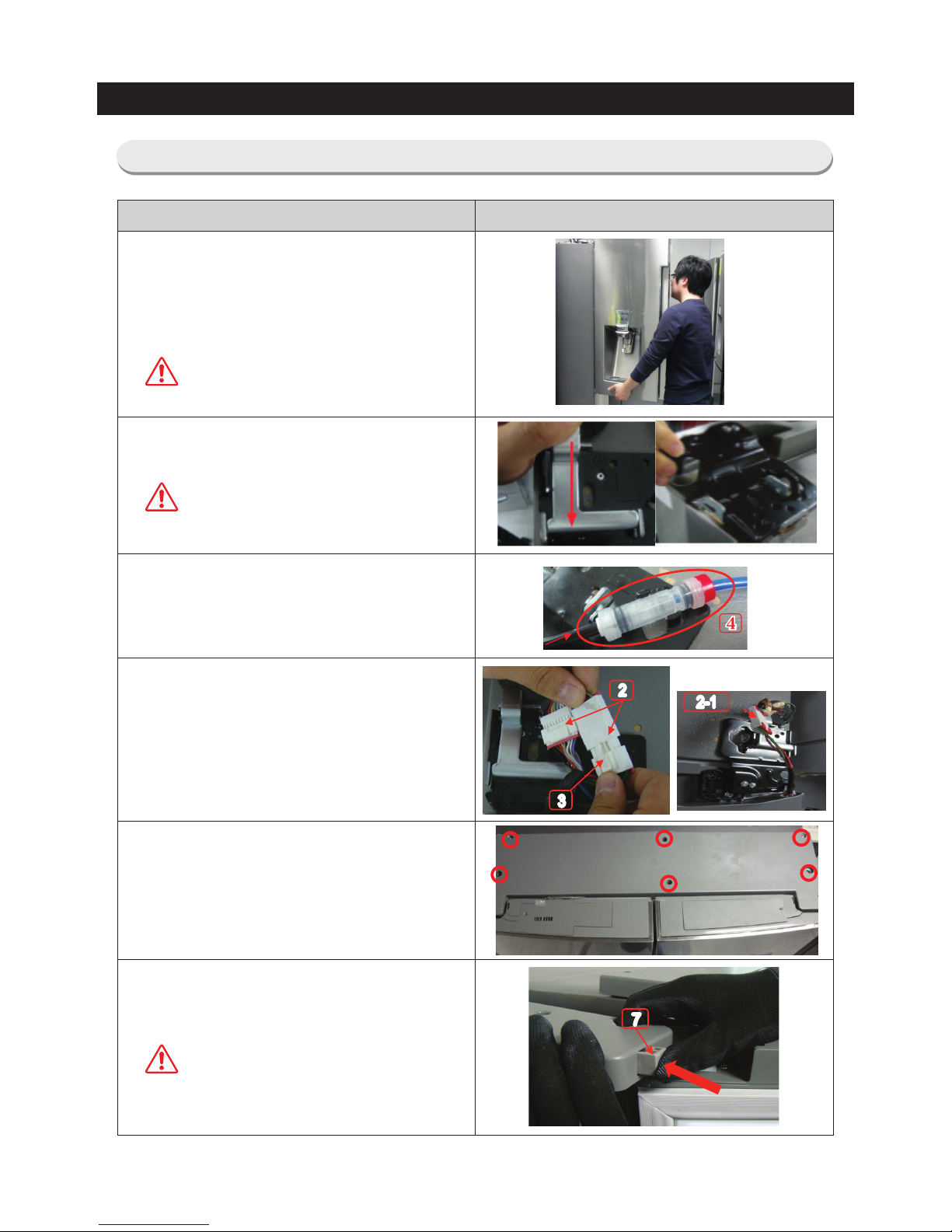

How To Do Descriptive Picture

1. Remove the 6 screws fixing the Top Table.

2. Open the right door of the fridge compartment

so that it does not interfere with the Bracket (②)

and the Top Table.

Lift the back side of the Top Table and pull it to

the front to disassemble.

3. Separate the 2 housing connectors (②) from the

hinge at the top left of the fridge compartment

door and the 1 housing connector (②-1) from

the hinge at the top right of the door.

To separate the housing connectors more easily,

pull the connector while holding down the fixing

hook (③).

Caution

Make sure to unplug the power cord

before performing the procedures

above.

[Note] The number of housing units may differ

depending on the model.

3

2

2-1

3

2

2-1

4. As shown in the picture, Remove the water

tube from hinge by holding at the both sides of

the Tube Fitting (④) and pulling it out. After that,

remove the Tube Fitting by pulling the water

hose after pushing in the locking ring (⑤).

[Note] For Dispenser model only

5. Push the Pusher (⑦) in the direction of the

arrow at the right hinge to disassemble.

27

DISASSEMBLY AND REASSEMBLY

How To Do Descriptive Picture

6. Pull the fixer from the hinge in the direction of

the arrow to separate, and then lift the hinge to

separate.

Caution

If the hinge is separated, the door may

fall down and hurt you, so hold the door

with both hands to disassemble.

7. Lift the door straight up to remove while opening

it by more than 90°. Disassemble the left door in

the order of 4 and 5.

Caution

Be careful not to drop the door.

28

DISASSEMBLY AND REASSEMBLY

3-4. Assembing the Fridge Doors (RF24J* only)

How To Do Descriptive Picture

1. Assemble the door to the middle hinge at the

position of 90 degrees.

(Fix the position for the shaft at the bottom of the

door to go into the groove of the middle hinge by

making the angle the same as the door's angle

during disassembly.)

Caution

Be careful not to drop the door.

2. After assembling the upper hinge, make sure to

fix it firmly by pressing the fixer.

Caution

While assembling the hinge, hold the

door with both hands to prevent the

door from falling down.

3. Completely insert the hose of the door part into

the Tube Fitting, and fix the Tube Fitting at the

hinge as in the picture.

4. Connect the 2 housing connectors (②) from the

hinge at the top left of the fridge compartment

door and the 1 housing connector (②-1) from

the hinge at the top right of the door.

[Note] The number of housing units may differ

depending on the model.

3

2

2-1

3

2

2-1

5. Assemble the Top Table (①), and lock the six

screws for fixing the Top Table.

6. Push the Pusher (⑦) in the direction of the

arrow to combine.

Caution

Completely insert the Pusher (⑦) for its

front side not to protrude.

7

7

29

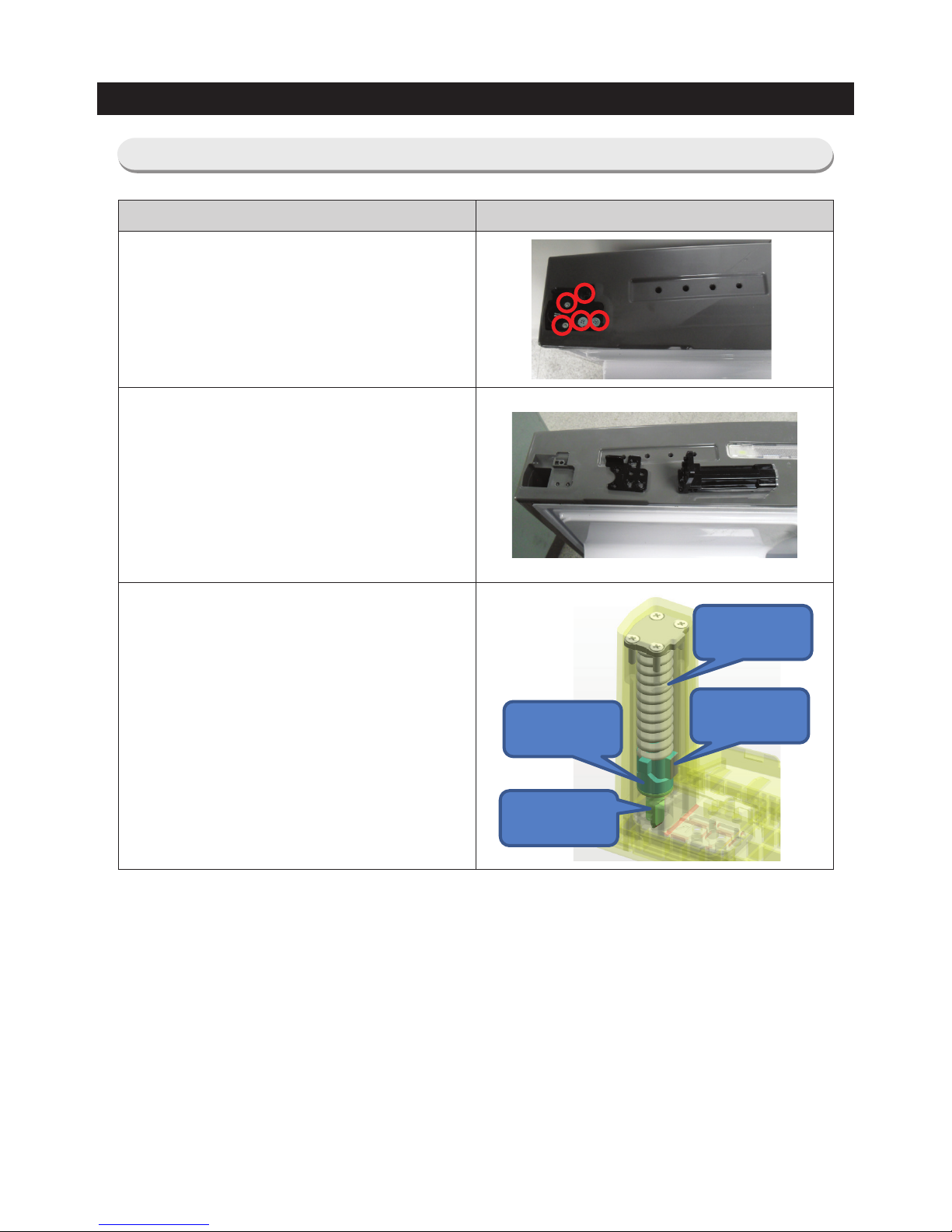

DISASSEMBLY AND REASSEMBLY

3-5. Assy Auto Hinge

How To Do Descriptive Picture

1. Remove the SCREW at 5 point under the

Refrigerator Door.

2. Lift up the stopper and auto hinge.

※ The working principle of the hinge.

Auto hinge make to work the door by torsion of

the spring.

Spring auto

close

Cam auto

close upper

Cam auto

close lower

Shaft auto

close lower

30

DISASSEMBLY AND REASSEMBLY

3-6. Braket (RF24J* only)

How To Do Descriptive Picture

1. Remove the Screw.

2. Remove the Bracket.

Loading...

Loading...