Page 1

Troubleshooting

Samsung Electronics 6-1

6. Troubleshooting

6-1 No Raster(Board Change in PDP Monitor)

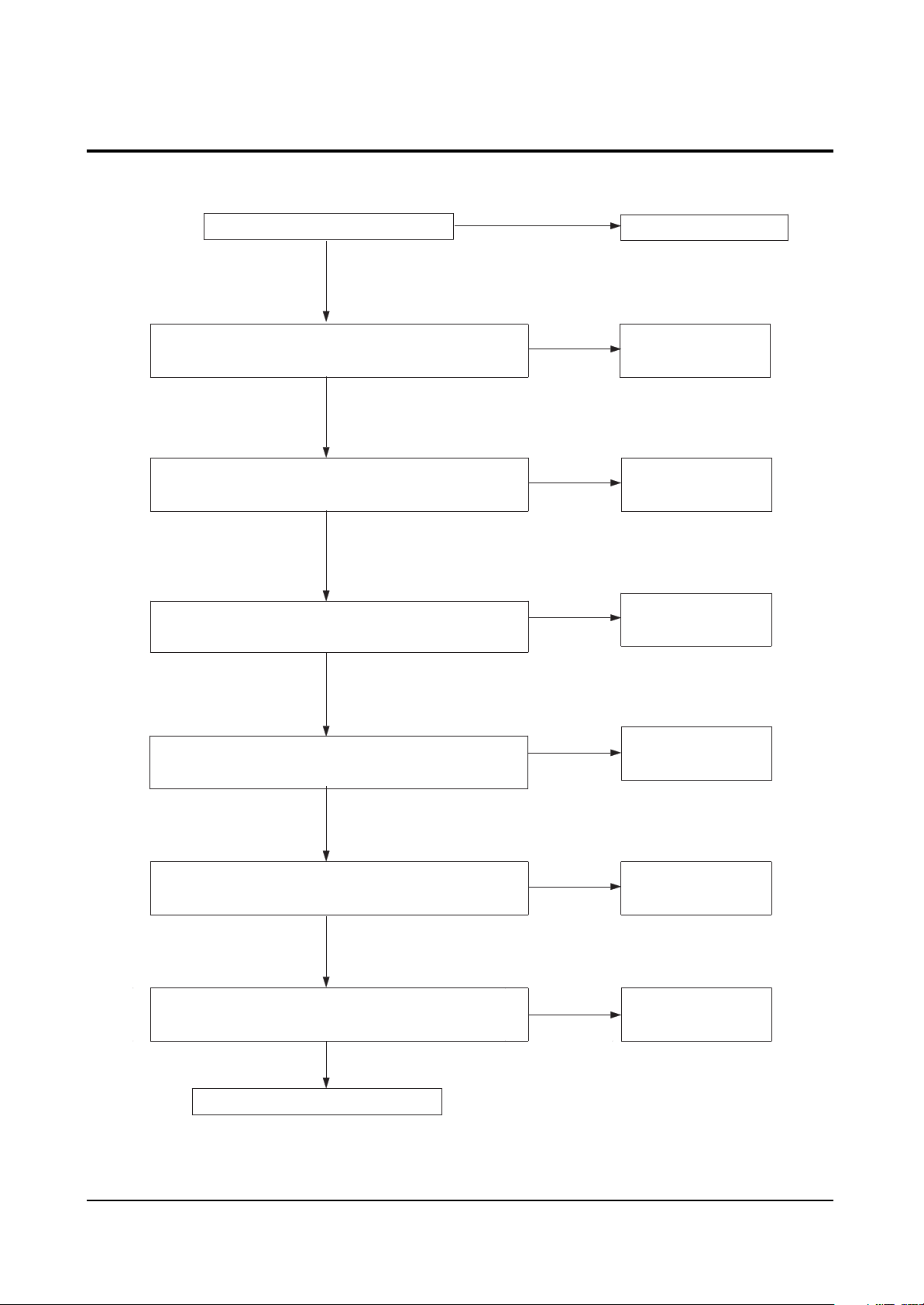

ST- BY Mode(LED:RED)

Pow er On

8J1

Repl ace scal er B ’d

(LED:GREEN)

Output

or Go to Page 7- 2

SM PS

AC

Output Voltage

Input

Logic Connect Pow er Replace SMPS

LED Light- on

(Power,Sink)

X- B’d Connect Power

X- B’d

Output

Y- B’d Connect Power

Y- B’d

Output

Rep l ace Panel

ST 5V

normal

normal

Abnormal

normal

Change Fuse

normal

Abnormal Abnormal

normal

normal

Replace Logic B’d

Abnormal

normal

Replace X- B’d

Abnormal

Replace X- B’d

normal

Abnormal

Abnormal

Page 2

6-2 Samsung Electronics

Alignment and Adjustments

6-2 No Raster in Scaler Board

Normal

Abnormal

Abnormal

Normal

Abnormal

Normal

Abnormal

Normal

Abnormal

Abnormal

Normal

Normal

Check Input Signal of U38 uPD64082

Pin 88(CVBSin)

CHECK

UPD64082

CHECK INPU T SIGINA L

Check Input Signal of 3U1 VPC3230

Pin 75(Y IN)

Check Output Signal of 3U3 SDA9280

Pin 47(Yout),

Check Input Signal of 1U1 AD9884

R,G,B IN A ND H,V IN

Normal

Check Output Signal of 1U1 AD9884

Pin 115(CLK), 85(G7), 105(R7),65(B7)

Check Input Signal of 5U1 LV DS IC

Pin 2 7(L H S),28(L V S),32(CL K )

Check Output Data of 5J1

Check 3U1,

3U2 OR3U3

CHECK 2U2

CXA 2101

CHECK 1U1

AD9884

CHECK

PW364

Check 5U1

LVDS IC

Check Logic B’d

Page 3

Troubleshooting

Samsung Electronics 6-3

6-3 Checking the Board (Unit)

Page 4

Troubleshooting

6-4 Samsung Electronics

6-4 50” HD D1.0 Logic Main Board T/S

If the PDP unit and the logic board operates properly, the operation LED of Figure 1 would blink at about

1 second interval.

If the unit is out of order, check the status of the operation LED through eye-inspection first.

If the behavior of the operation LED is different from that of normal state, you have to replace the board.

To check the trouble on the board, complete the following logic board test procedures described below.

Required testing equipment : - Oscilloscope (digital 400 MHz with more than 3 channels)

- Multi-meter

Other equipment : - DC power supply (5V: 1EA)

- Sub-PCB ASS'Y for JIG: 1 EA

① First, perform eye-inspection and short-circuit inspection for the power stage of the target logic

board. Then, perform the following tests on the board in sequence if no problem has been found.

② Replace the (Serial EEPROM) on the logic board with the Test EERPOM.

Change the clock setting of the logic board to internal.

(Refer to the configuration procedures in the next page)

If the Test EEPROM is not available, perform the tests by installing key scan and set the address

number 9F to 00.

➂ Implement 5V to the LD1, and check if the LED on the left-top of the board blinks at about one

second intervals.

➃ If the LED blinks too fast or the LED is not turned on, it means that the LOGIC board is not operating

properly.

➄ If no problem is found in the above step, connect sub-PCB to check the logic output. Then measure

the output waveform of the sub-PCB, and compare it with the appended waveform in normal state.

Record the test result (OK or NG).

➅ Check drive Y s/w , drive X s/w , and address signals in that order.

⑦ Set probe 1 of the oscilloscope to the trigger signal, and connect it to TP105 on the logic board.

➇ Set the oscilloscope to 2ms/div. After adjusting probe 2 to 5V/div, check the output signal.

⑨ After T/S, turn off the power supply, and disconnect the connector.

➉ Record the test result on the test sheet.

Page 5

Troubleshooting

Samsung Electronics 6-5

6-4-1 Data : No6~15 at LE2001, LE2002, LE2003, LG2001, LG2002, LG2003

: No28~33 at LG2003

: No35~40 at LE2003

6-4-2 POL : No25 at LE2001, LE2002, LE2003, LG2001, LG2002, LG2003

Page 6

Troubleshooting

6-6 Samsung Electronics

6-4-3 STB: No24 at LE2001, LE2002, LE2003, KG2001, KG2002, LG2003

6-4-4 CLK : No12,22 at LE2001, LE2002, LE2003, LG2001, LG2002, LG2003

Page 7

Troubleshooting

Samsung Electronics 6-7

6-4-5 Y5

6-4-6 Y7

Page 8

Troubleshooting

6-8 Samsung Electronics

6-4-7 Y9

6-4-8 Y11

Page 9

Troubleshooting

Samsung Electronics 6-9

6-4-9 Y13

6-4-10 Y15

Page 10

Troubleshooting

6-10 Samsung Electronics

6-4-11 Y17

6-4-12 Y19

Page 11

Troubleshooting

Samsung Electronics 6-11

6-4-13 Y21

6-4-14 Y23

Page 12

Troubleshooting

6-12 Samsung Electronics

6-4-15 Y25

6-4-16 Y28

Page 13

Troubleshooting

Samsung Electronics 6-13

6-4-17 Y30

6-4-18 Y32

Page 14

Troubleshooting

6-14 Samsung Electronics

6-4-19 Y34

6-4-20 X2

Page 15

Troubleshooting

Samsung Electronics 6-15

6-4-21 X4

6-4-22 X6

Page 16

Troubleshooting

6-16 Samsung Electronics

6-4-23 X8

6-4-24 X10

Page 17

Troubleshooting

Samsung Electronics 6-17

6-5 50” HD Logic Buffer Board T/S

Required testing equipment : - Oscilloscope (digital 400 MHz with more than 2 channels)

Other equipment : - DC power supply (5V: 1EA)

- Multi-meter

- Logic board: 1EA

- Sub-PCB ASS'Y for JIG: 1 EA

! First perform eye-inspection and short-circuit inspection for the power stage of the logic board to

test. Then, perform the following tests on the board in sequence if no problem has been found.

@ If no problem was found in step ! connect the buffer board as [Figure2.3] shows. Then connect

the sub-PCB to check COF data and replace the serial EEPROM with the Test EEPROM so the

output pattern of the logic board becomes a full-white pattern.

# If the Test EEPROM is not available, then perform the tests by installing key scan, and setting

the address number 9F to 00.

$ Supply 5V to the logic board, and check that the LED on the left-top of the board blinks at about

1 second intervals. If no problem is found, measure the output waveform of the sub-PCB, and

compare it with the appended waveform of normal state.

% Checking order; ECN3001, ECN3002, ECN3003, FCN3104, FCN3105, FCN3106,FCN3107, FCN3108,

GCN3209, GCN3210, GCN3211, HCN3312, HCN3313, HCN3314, ICN3415, ICN3416, ICN3417,

ICN3418, ICN3419, JCN3520, JCN3521, and JCN3522. You can also check only the doubtable

waveforms selectively.

^ Set probe 1 of the oscilloscope to trigger signal, and connect it to the TP105 of the logic board.

Set the oscilloscope to 2ms/div. You can magnify the important points to check in details.

After adjusting probe 2 to 5V/div, check the output signal.

& The appended waveform is when a full-white input pattern is implemented.

* After T/S, turn off the power supply and disconnect the connector. Then record the result on the

examination sheet.

Page 18

Troubleshooting

6-18 Samsung Electronics

LOGIC MAIN BOARD & LOGIC BUFFER BOARD(E,F,G) CONNECTION

LOGIC MAIN BOARD & LOGIC BUFFER BOARD(H,I,J) CONNECTION

Page 19

Troubleshooting

Samsung Electronics 6-19

6-5-1 DATA-IG No(13~18, 49~45)

6-5-2 POL Signal-Jig No(20, 27, 56, 63)

Page 20

Troubleshooting

6-20 Samsung Electronics

6-5-3 Magnified POL(Magnifying the Above Signal)

6-5-4 STB-Jig No(25, 32, 61, 68)

Page 21

Troubleshooting

Samsung Electronics 6-21

6-5-5 Magnified STB(Magnifying the Above Signal)

6-5-6 CLK-Jig No(24, 31, 60, 67)

Page 22

Troubleshooting

6-22 Samsung Electronics

6-5-7 Magnified CLK

Page 23

Troubleshooting

Samsung Electronics 6-23

6-6 Driver Board T/S

6-6-1 Main X Board Layout and T/S TP point

CN4007

CN4006

R4031

TP5

R4001 T P1

R4015

TP3

400

R4035

TP4

R4044

TP2

210

Page 24

Troubleshooting

6-24 Samsung Electronics

6-6-2 Main y Board Layout and T/S TP point

TPOUT1

TPSI

TPPOL

TPBLK

TPSTB

TPCLK

CN5008

TPSI

TPPOL

TPBLK

TPSTB

TPCLK

M5014

TP7

M5037

TP8

ZD5002

TP6

R5029

TP1

R5001

TP3

400

R5035

TP5

300

R5077

TP9

R5052

TP2

R5083

TP4

260

60

Page 25

Troubleshooting

Samsung Electronics 6-25

6-6-3 Input Power

Pin#

1

2

3

4

5

6

7

8

9

10

11

12

Voltage Source

Vcc1=5V

GND

Vcc2=17V

GND

Ve=0V

GND

NC

GND

GND

Vs=168V

Vs=168V

Vs=168V

CN4007

Pin#

1

2

3

4

5

6

7

8

9

10

11

12

13

Voltage Source

Vcc1=5V

GND

Vcc2=17V

GND

Vscan=70V

GND

Vset=210V

NC

GND

GND

Vs=168V

Vs=168V

Vs=168V

CN5008

Page 26

Troubleshooting

6-26 Samsung Electronics

6-6-4 Drive Board Troubleshooting

:The following measures are troubleshooting procedures in case of SET troubles, due to the drive board

problem.

l If SMPS shutdown is blocked.

- Find out which board is faulty by connecting the power ports of the X/Y board one by one.

: Check the resistance between the drain and the source of the FET on the faulty board.

In case of a short, replace the corresponding FET.

: Check for a short between the input voltage ports (CN4007 and CN5008) and the GND of the

faulty board.

l If the discharge screen is in trouble (Discharge trouble):

- Check that the Scan output voltage of the power output port is between 70V and 85V.

- Check the resistance between the drain and the source of the FET (M5014) on the Y board.

If they are short, replace the FET.

- Checking the operation of the drive buffer board:

: Check the resistance between the Test Points [OUT_L ~ OUT_H]. In case of a short, replace the

buffer board.

- Checking the connectors:

: Check CN5002 (Y board), and CN4008 (X board) to ensure if they are connected properly.

l When driving screen, horizontally adjacent 2 lines are emitting.

- Check if there is extraneous substance or inappropriate soldering, which may occur a short

around the IC output lines in question on the drive buffer board.

l When the drive board does not operate

(The LED of the logic board blinks, but nothing appears on the screen):

- Check that the drive board input stage is installed in the connector properly.

- Check if the fuses (F4001, F4002, F5001, and F5002) are blown.

Page 27

Troubleshooting

Samsung Electronics 6-27

6-7 Troubleshooting when the SMPS is out of order

1. Check that auxiliary power (5VSB) is detected.

1.1 If auxiliary power is not detected, check if BRD101S is a short.

2. If it is in shutdown state;

2.1 Check that each output is a short.

2.2 Check if the protection circuit has a problem.

3. If output voltage (except auxiliary power) is not detected, check as follows.

3.1. If VS voltage is not detected

3.1.1 When the FUSE is blown --> Check that FET (Q5S and Q6S) is a short.

Check that FET (Q308 ~ Q311) is a short.

Check that BRD1S is a short.

3.1.2 If DC5V RELAY (RL1S, RL2S) does not operate, check that auxiliary power (5VSB) is detected.

3.1.3 If DC24V RELAY (RL3S) does not operate, check if F1 is blown.

3.2 In case of +5V (D), check if D305 is short.

3.3 In case of VSAMP, check if D509 is short.

3.4 In case of VA, check if D303 is short.

3.5 In case of VSET, VE, and VSCAN, check if VS voltage is detected and if F501 is blown.

Page 28

Troubleshooting

6-28 Samsung Electronics

6-8 No audio is sounded and video is displayed properly

Check the voltage of pin3(9V)

and the voltage between pin 6 and

7(12V) of CN602.

Normal

Supply noise to C668

or C669(+) terminal.

Normal

Check the circuitry

around IC601.

Abnormal

Check the output voltage

of SMPS Ass’y.

Abnormal

Check the circuitry

around IC602 and

the connectivity between

the speakers and

the jacks of the unit.

Loading...

Loading...