Page 1

Circuit Operation Description

Samsung Electronics 5-1

5. Circuit Description

5-1 Power supply

5-1-1 Outline(PDP SMPS)

Considering various related conditions, the switching regulator with good efficiency and allowing for its

small size and light weight was used as the power supply for PDP 50inch, VS requiring high power consumption used forward converter and 12VSAMP used the simple flyback converter and other high voltage

(VSCAN,VSET,VE)used DC/DC converter. To comply with the international harmonics standards and

improve the power factor, active PFC(Power Factor Correction) was used to rectify AC input into +400V

DC output, which in turns used as input to the switching regulator.

5-1-2 50" SMPS Specification

5-1-2(A) INPUT

The power supply shall be capable of supplying full rated output power over free voltage ranges that

are rated 100 VAC - 240 VAC RMS nominal. Operating voltage : 90 VAC - 264 VAC.

The power supply must be able to start up under peak loading at 90V AC. The power supply shall

automatically recover from AC power loss. (Note that nominal voltages for test purposes are considered

to be with +/- 1.0V of nominal).

+5VSB is a SELV standby voltage that is always present when AC mains voltage present.

5-1-2(B) OUTPUT

This power supply is 13output switching power supply for PDP 50inch. The output voltage, and current

requirements for continuous operation are stated below. (Table1.)

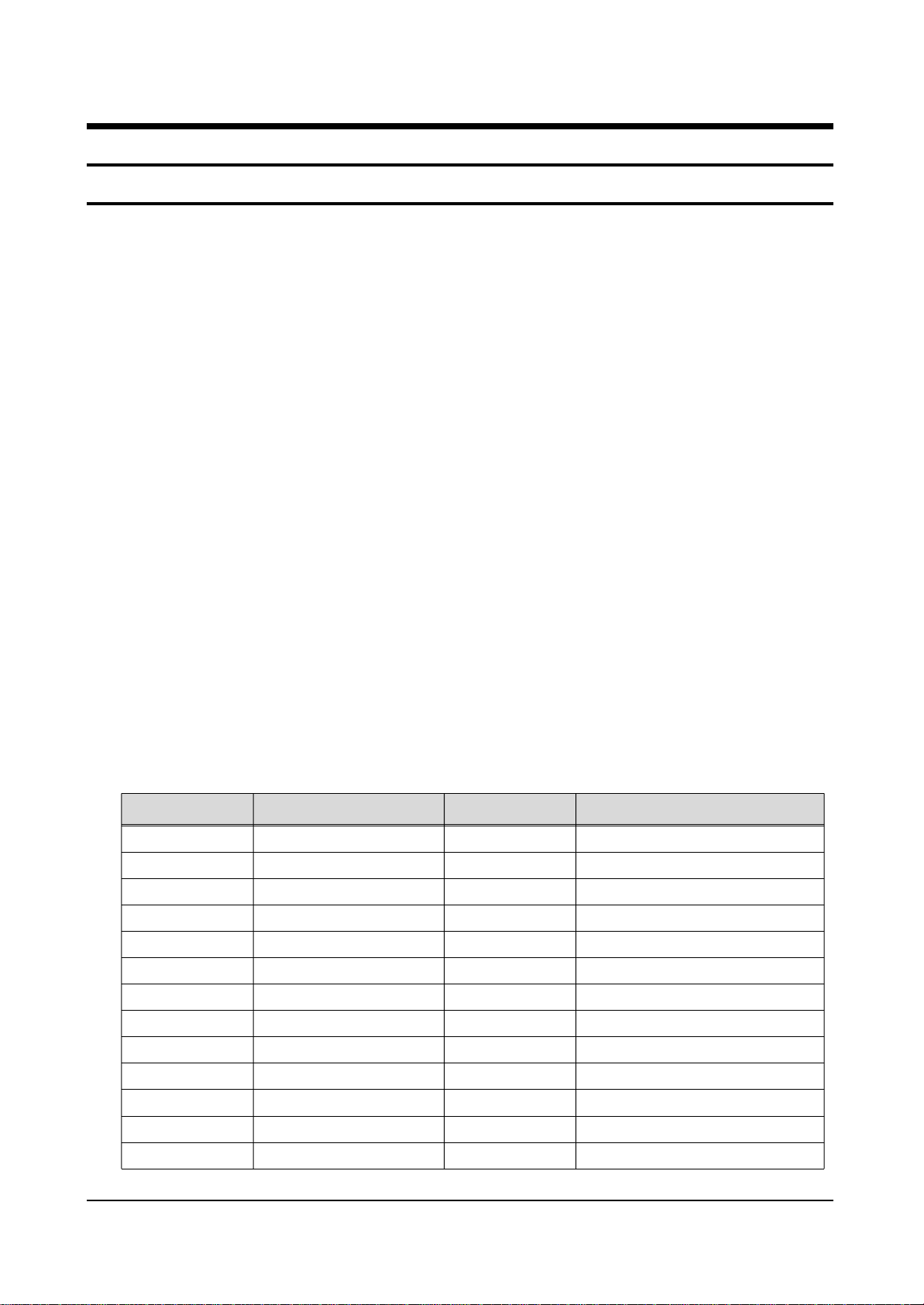

Table1. Specifications of Output Power Supplies for PDP SMPS

Output Name

Vsustain

Vaddress

Vscan

Vset

Ve

Vg

Vfan

V9

V6

V5(D)

Vsb

V12

Vsamp

Output Voltage

+165V ~ 200V(165V)

+58V ~ 73V(65V)

+60V ~ 78V(70V)

+195V ~ 230V(215V)

+180V ~ 210V(185V)

+1V ~ 20V(18.4V)

+10V ~ 12V(11V)

+1V ~ 10V(9.0V)

+1V ~ 8V(6.0V)

+5.1V ~ 5.9V(5.4V)

+4.8V ~ 5.4V(5.2V)

+10V ~ 12V(11V)

+10V ~ 13V(12V)

Output Current

1.8A

0.5A

0.05A

0.05A

0.05A

0.3A

0.8A

0.3A

1.0A

3.5A

0.4A

1.2A

1.5A

Using in PDP driving

Sustain Voltage of Drive Board

Address Voltage of Drive Board

Driving Voltage of Fet

Driving Voltage of Fan

IC Driving Voltage of Logic Board

Stand-by for Remote Control

AMP Voltage of Audio Board

Page 2

Circuit Operation Description

5-2 Samsung Electronics

Table 2. Over voltage Protection.

5-1-2(C) Over voltage Protection

The over voltage sense circuitry and reference shall reside in package that are separate and distinct from

the regulator control circuitry and reference. No single point fault shall be able to cause a sustained over

voltage condition on any of all outputs. The supply shall provide latch-mode Over Voltage Protection as

defined below. (Table2.)

Table 3. Over Current Protection.

Parameter

VS(169V)

VA(65V)

5V(D)

Min

3.0 ~

2.0 ~

10 ~

Unit

A

A

A

Parameter

VS(169V)

VA(65V)

5V(D)

Min

195 ~

90 ~

5.5 ~

Unit

V

V

V

5-1-2(D) Short Circuit and Over current Protection.

An output short circuit is defined as output impedance of less than 300mohms. The power supply shall

shutdown and latch off for shorting VS DC rails to return or any other rail. Shorts between main output

rails and 5VSB shall not cause any damages to the power supply. The power supply shall either shutdown and latch off for shorting is removed, the P/S shall recover. The power supply shall be capable of

withstanding a continuous shot-circuit to the output without damage or over stress to the unit (components, PCB traces, connectors,etc.) under the input conditions specified in Section2 above.

Current Protection as defined below. (Table3.)

5-1-2(E) Function of Board

① REMOTE CONTROL

Using a 250V/10A relay, the board makes remote control available.

➁ FREE VOLTAGE

The board is designed so that the input voltage can be used within 90VAC to 264VAC.

➂ Improvement of power factor

The board is designed using the active PFC circuit so that the Power Factor can be over 9.0.

➃ Protection

The OCP(Over current Protection), OVP(Over voltage Protection), Short Circuit Protection

functions are added against system malfunction.

Page 3

Circuit Operation Description

Samsung Electronics 5-3

5-1-2(F) Part Block Diagram and Part Function.

(1) AC-DC Converter

The Power supply output +400V DC from the common AC power supply using the active PFC

booster converter. This converter is designed for improving the power factor and preventing the

noise with high frequency and finally becomes the input power system for the switching regulator on the output side.

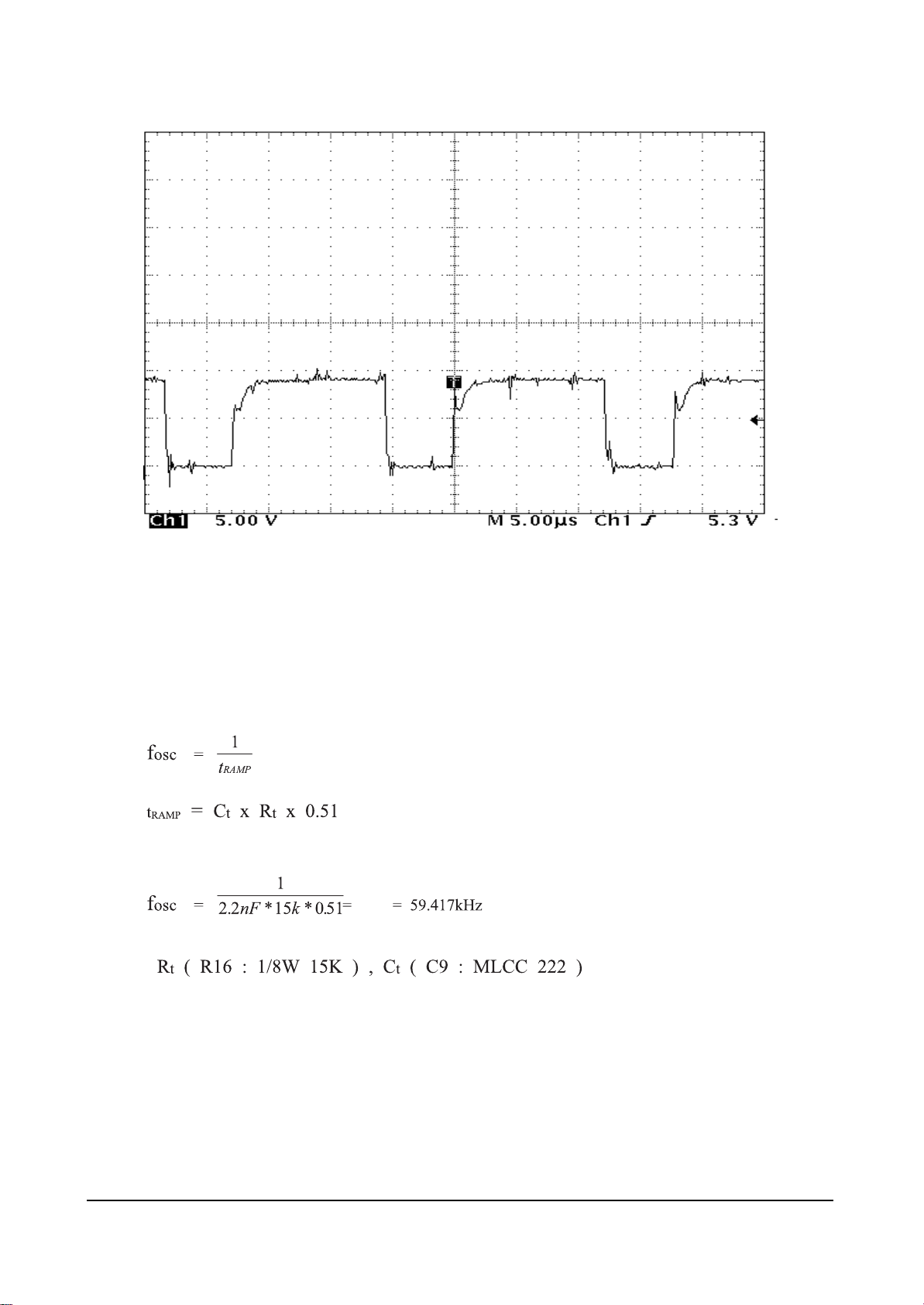

Picture1. PFC Drive FET(2SK2372) Drain pulse

Page 4

Circuit Operation Description

5-4 Samsung Electronics

- Oscillator Frequency

Oscillator Frequency is determined by the values of Rt and Ct, which determine the ramp and

off-time of the oscillator output clock

Oscillator Frequency is derived from the following equation

For the circuit shown in the PDP50, with the oscillator running at

Picture2. PFC Drive FET(2SK2372) Gate pulse

Page 5

Circuit Operation Description

Samsung Electronics 5-5

(2) AC-DC Converter

Auxiliary Power Supply

The auxiliary power supply is a block generated power of micom for remote controlling. Once

the power plug is inserted, this block always comes into operation, causing micom to get into the

standby state for the output. Thus, this output is called the standby voltage. And with the relay

ON signal inputted through the remote controller, this block turns the mechanical switch of relay

to ON for driving the main power supply.

Picture3. Standby flyback Pulse.

Page 6

Circuit Operation Description

5-6 Samsung Electronics

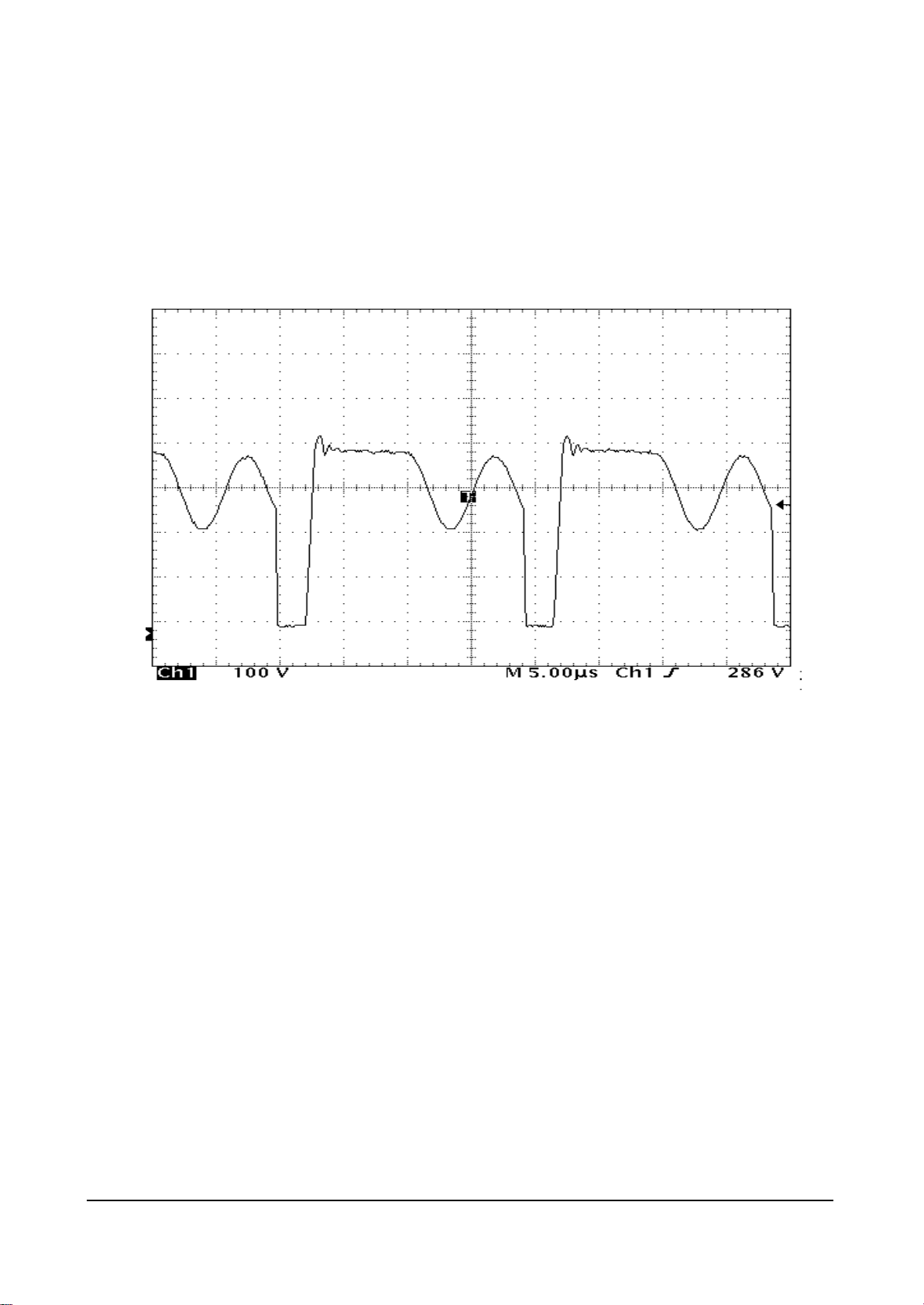

(3) Implementation of Sustain Voltage

As the main part of a SMPS for PDP, sustain voltage must supply a high power, 180V/1.8A.

To comply with the specification, the forward method was basically used. At the output stage two

90V converters are connected serially for high efficiency and reduction of system size against a

single 180V converter.

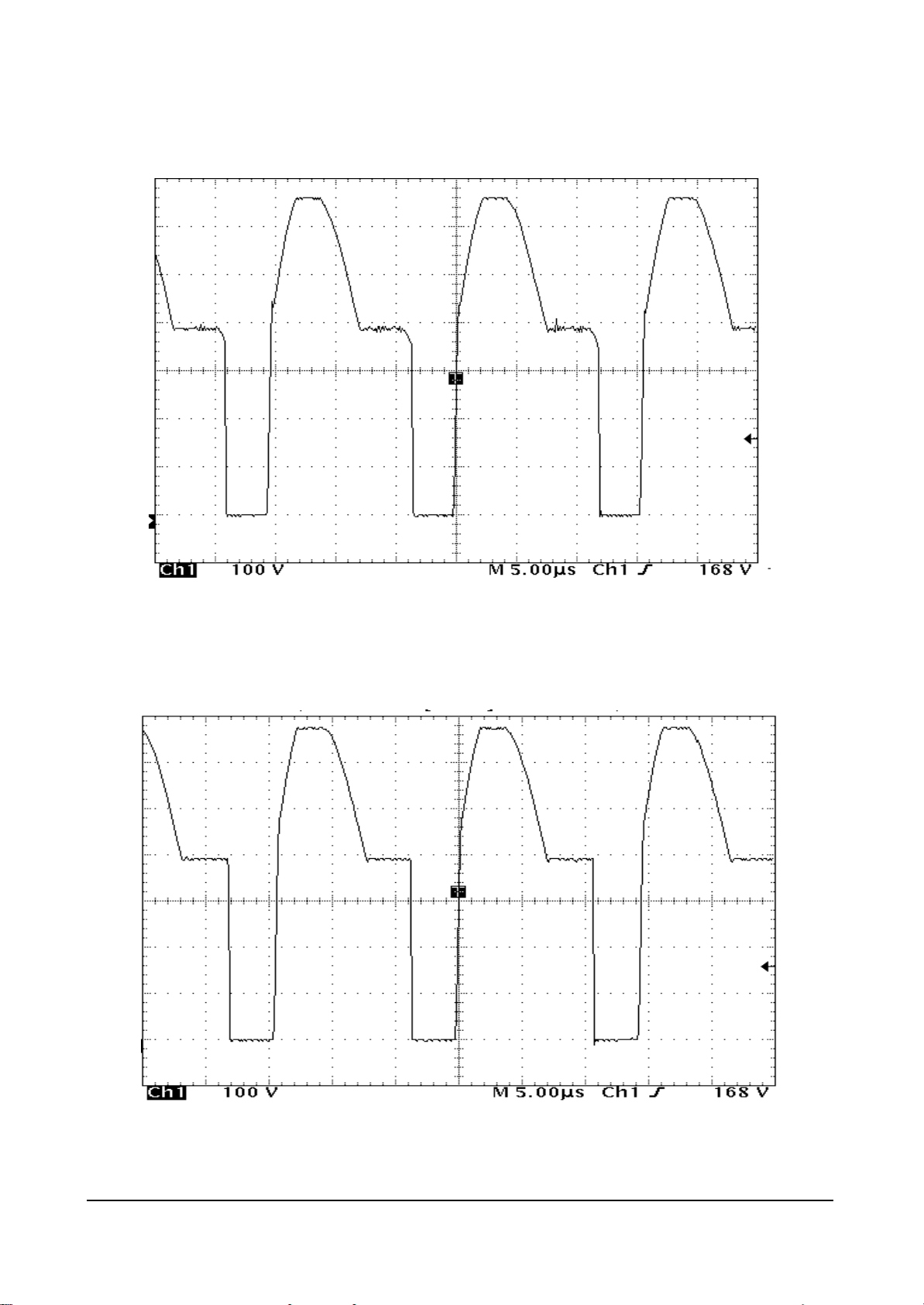

Picture4. VS Driving FET(2SK2968) drain pulse.

Picture5. VS Driving FET(2SK2968) gate pulse.

Page 7

Circuit Operation Description

Samsung Electronics 5-7

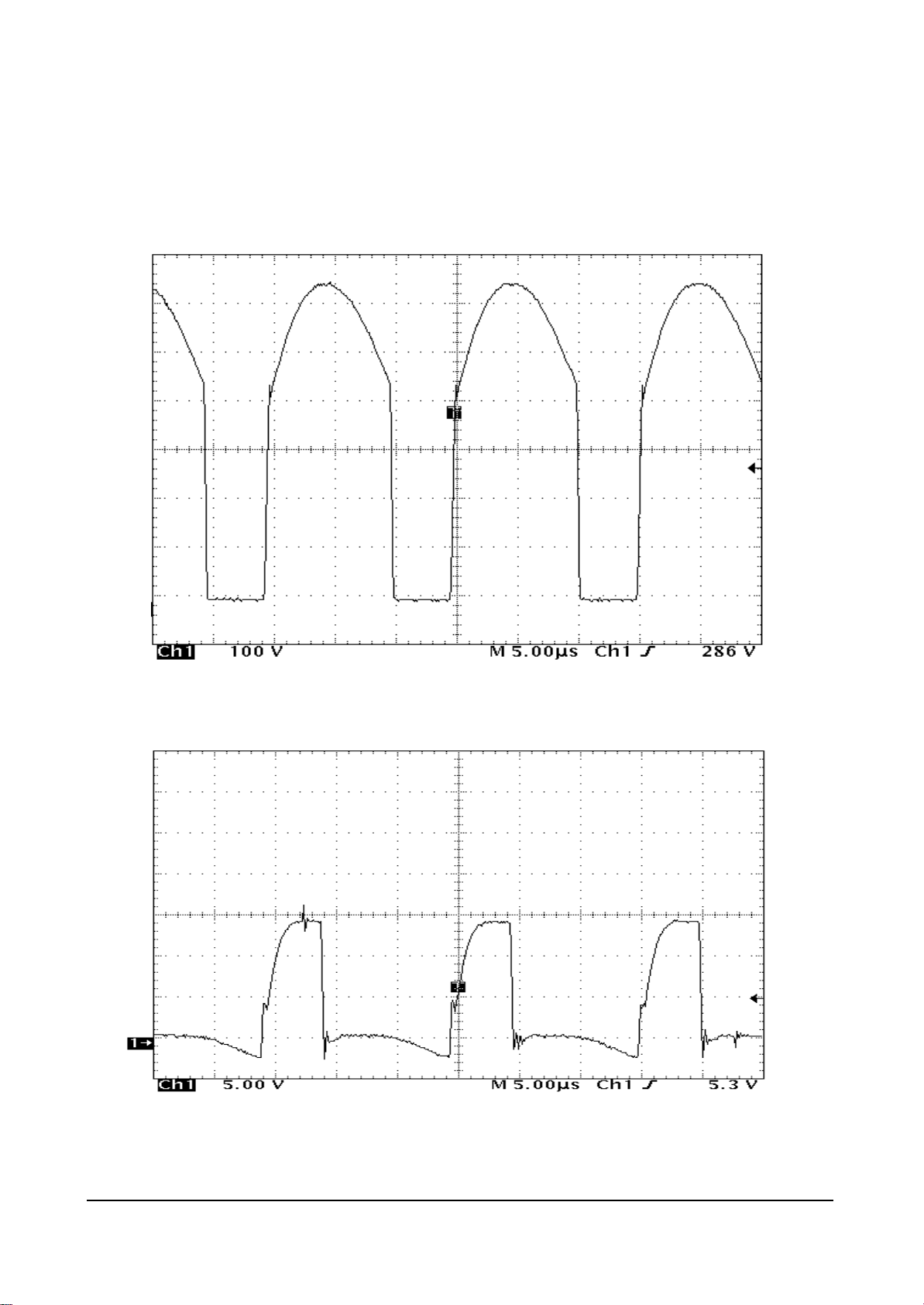

❏ PWM SECTION ( Pulse Width Modulator )

PDP SMPS use PWM IC ( KA3844 ) in PWM section. KA3844 is fixed frequency current-mode

PWM controller. They are specially designed for Off-Line and DC-to-DC converter applications

with minimum external components. These integrated circuits featurea trimmed oscillator for

precise dutycycle control, a temperature compensated reference, high gain error amplifier.

Current sensing comparator, and a high current totempole output Ideally suited for driving a

power MOSFET. Protection circuity Includes built in under -voltage lockout and current limiting.

This IC can operate with 50% duty cycle.

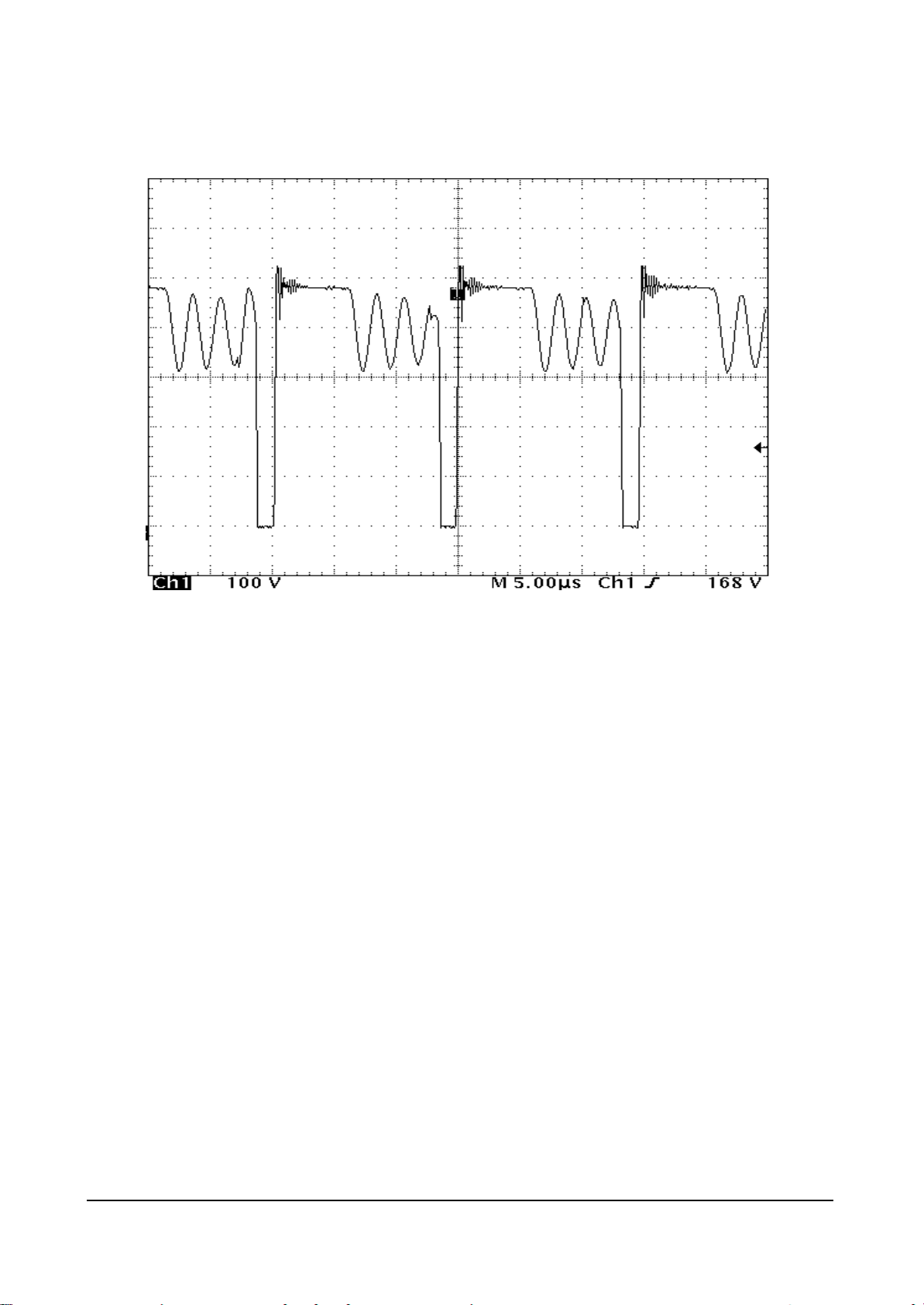

Picture6. KA3844 Oscillating Frequency pulse.

Oscillator timing capacitor (Ct) is charged by Vref through Rt and discharged by an internal

current source. During the discharge time, the internal clock signal blanks the output to the low

state. Selection of Rt and Ct therefore determines both oscillator frequency and maximum duty

cycle. Charge and discharge times are determined by the formula.

Page 8

Circuit Operation Description

5-8 Samsung Electronics

(4) DC-DC Converter

Input of VSCAN, VSET, VE is Sustain Voltage. This circuit use MA2820.

Maximum output wattage of MA2820 is 60W.

Picture7. MA series Block Diagram

Picture8. MA2820 main pulse.

Page 9

Circuit Operation Description

Samsung Electronics 5-9

(5) Output (VA,5V,12VSAMP) Pulse

Picture9. VA main pulse.

Picture10. 5V main pulse.

Page 10

Circuit Operation Description

5-10 Samsung Electronics

Picture11. 12VSAMP main pulse.

Page 11

Circuit Operation Description

Samsung Electronics 5-11

5-1-3 Block Diagram

Picture9. VA main pulse.

Page 12

Circuit Operation Description

5-12 Samsung Electronics

5-1-4 Connector Pin Assignment

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

OUTPUT

+5.3V

SYM

VSB

User specification

RELAY

(INPUT)

5V/0.3A

MAX

User specification

NO

1

2

3

4

5

6

7

8

9

10

11

12

13

OUTPUT

+5.3V

GND

+18.3V

GND

80V

GND

205V

N.C

GND

GND

163V

163V

163V

SYM

Vcc

Vdd

Vscan

Vset

Vs

Vs

Vs

OUTPUT

+5.3V

GND

+18.3V

GND

190V

GND

80V

GND

GND

163V

163V

163V

SYM

Vcc

Vdd

Ve

Vscan

Vs

Vs

Vs

NO

1

2

3

4

5

6

7

8

9

10

11

12

NO

1

2

3

4

5

6

7

8

9

OUTPUT

+6.0V

GND(A)

+9V

+12V

GND(A)

+12V

+12V

GND(AMP)

GND(AMP)

SYM

+6V(A)

V9

V12

VSAMP

VSAMP

NO

1

2

3

4

OUTPUT

+5.3V

GND(D)

+5.3V

GND(D)

SYM

Vcc

Vcc

SA(Image Board) SY(Drive) SX(Drive)

Speaker SL(Logic)

NO

1

2

3

OUTPUT

AC

AC

AC

SYM

-

-

-

NO

1

2

3

OUTPUT

+12V

GND

SYM

VFAN

AC(INPUT) FAN(4EA)

NO

1

2

3

4

OUTPUT

+70V

+70V

GND

GND

SYM

Va

Va

BUFFER

FAN SIGNAL

Page 13

Circuit Operation Description

Samsung Electronics 5-13

5-1-5 Power Supply Systematic Diagram & Wiring Diagram

355

Xboard

Buffer

55

PDP 50Inch

PSA- 521B(

330

PSPD521901A

(

Logic Boar d

YBoard

INLET

FAN

Image Board

Spea ke r

Page 14

Circuit Operation Description

5-14 Samsung Electronics

5-1-6 Power Supply Layout

T306

BUFFER

VSET

H/S 1

SX

SY

SL

SPEAKER

T307

T308

VE

VSCAN

H/S 5

T303

T305

VA

12V

SAMP

H/S 6

T301

T301

VS

H/S 7

XF(FAN)1

X

F(FAN)2

X

F(FAN)3

X

F(FAN)4

X

F(FAN)5

S

A

H/S 4

T101

T304

5VSB

5V(D) , 12V

6V(A) , VG

9V

H/S 3

H/S 2

AC

INPUT

Pri mary

Secondary

Page 15

Circuit Operation Description

Samsung Electronics 5-15

5-2 Drive Circuit

5-2-1 Drive Circuit Overview

5-2-1(A) WHAT IS THE DRIVER CIRCUIT

It is a circuit generating an appropriate pulse (High voltage pulse) and then driving the panel to

implement images in the external terminals (X electrode group, Y electrode group and address electrode), and this high voltage switching pulse is generated by a combination of MOSFETs.

5-1-2(B) PANEL DRIVING PRINCIPLES AND TYPES OF DISCHARGE BY DRIVE PULSE

In PDP, images are implemented by impressing voltage on the X electrode, Y electrode and address

electrode, components of each pixel on the panel, under appropriate conditions. Currently, ADS

(Address & Display Separate: Driving is made by separating address and sustaining sections) is

most widely used to generate the drive pulse. Discharges conducted within PDP pixels using this

method can largely be

classified into 3 types, as follows:

① Address discharge: This functions to generate wall voltage within pixels to be lighted by

addressing information to them (i.e., impressing data voltage)

➁ Sustaining discharge: This means a display section where only pixels with wall voltage by the

address discharge display self-sustaining discharge by the support of such wall voltage.

(Optic outputs realizing images are generated.)

➂ Ramp reset discharge: To have address discharge occur selectively in pixels, all pixels in the panel

must have the same conditions (i.e., the same state of wall and space electric discharges).

The ramp reset discharge section, therefore, is important to secure the drive margin, and methods

most widely used to date include wall voltage controlling by ramp pulse.

Page 16

Circuit Operation Description

5-16 Samsung Electronics

5-1-2(C) Discharge of Drive

① Sustaining discharge

1(C). Kinds and detailed descriptions of driving discharge

Sustaining discharge means a self-sustaining discharge generated by the total of the sustaining

pulse voltage (usually, 160~180V) alternately given to X and Y electrodes during the sustaining

period and the wall voltage which varies depending upon pixels' previous discharge status. It is

operated by the memory function (through this, the current status is defined by previous operation conditions) AC PDP basically possesses. That is, when there is existing wall voltage in pixels

(in other words, when pixels remain ON), the total of wall voltage and a sustaining voltage to be

impressed subsequently impresses a voltage equal to or above the discharge start voltage, thereby

generating discharge again, but when there is no existing wall voltage in pixels (in other words,

when pixels remain OFF), the sustaining voltage only does not reach the discharge start voltage,

thus causing no discharge. The sustaining discharge is a section generating actual optic outputs

used in displaying images.

➁ Address discharge

This means a discharge type generated by the difference between positive voltage of the address

electrode (usually, 60~70V) and GND of the Y electrode. The address discharge serves to generate

wall voltage in pixels where images are to be displayed (that is, discharge is to be generated) prior

to the sustaining discharge section. Namely, pixels with wall voltage by the address discharge will

generate sustaining discharge by the following sustaining pulses.

➂ Weak erasing discharge

The purpose of resetting discharge is to make even wall voltage in all pixels on the panel.

Wall voltage which may vary depending upon the previous sustaining discharge status must be

made even. That is, wall voltage generated by the sustaining discharge must surely be removed,

by making discharges and then supplying ions or electrons. Wall voltage can be removed by making discharges and then setting a limitation on time for opposite polarity charging of the wall voltage or generating weak discharge (Low voltage erasing) to supply an appropriate quantity of ions

or

electrons and keep polarities from being charged oppositely. The weak discharge (Low voltage

erasing) methods which have been known to date can largely be into two types:

1) the log pulse adopted by most companies including F Company, and

2) the ramp pulse adopted by Matsushita.

In both two methods, impression is made with a slow rising slope of the erasing pulse. Because

the total of the existing wall voltage and a voltage on the rising pulse must be at least the drive

start voltage to generate discharges, external impressed voltage is adjusted based on the difference

in wall voltage between pixels.

And, weak discharge is generated because of a small impressed voltage.

Page 17

Circuit Operation Description

Samsung Electronics 5-17

5-1-2(D) Pulse of Reset, Address and Sustain period and optic output

Page 18

Circuit Operation Description

5-18 Samsung Electronics

5-2-2 Drive pulse and functions (ADS-driven method)

Page 19

Circuit Operation Description

Samsung Electronics 5-19

5-2-2(A) FUNCTIONS OF PULSES

① Narrow-width erasing pulse

X Narrow-width erasing pulse

Pulses in the sustaining section always begin with Y electrode pulse and end with X electrode

pulse.

Especially, the last of the X electrode has a narrow width, which serves as erasing discharge to

remove the wall electric charge on electrodes by setting a limitation on time for generating such

electric charge, as explained above. This method removes wall voltage on pixels which remained

ON in the sustaining section, thereby making even all pixels.

➁ Ramp rising pulse

The purpose of ramp rising pulse is to make wall voltage to some level for low voltage address

drive (includig low level sustain) in all pixels on the panel.

➂ Ramp falling pulse and X Ve level

Ramp falling pulse and Ve pulse are using to keep the wall charges safely which were generater

by ramp rising pulse to next steps

➃ scan pulse

This is called the scan pulse, selecting each of Y electrodes on a one-line-at-a-time basis. In this

case, Vscan means the scan bias voltage, functioning to lower switching voltage of the drive IC

(by switching Vscan into ground). Ground is impressed on electrode lines with ground impressed

on, and 75V (Vscac) is impressed on other lines, so that only pixels with data voltage (usually,

65V) impressed on electrodes have the discharge start voltage (65V) or higher for address discharge. Thus, because scan pulse and data pulse are impressed line by line, very long time is taken

for PDP addressing.

➄ 1st sustaining pulse

The sustaining pulse always begins with the Y electrode. This is because when address discharge

[positive (+) voltage on ADD electrode and negative (-) voltage on Y electrode] is generated,

positive (+) wall voltage is generated on the Y electrodes. Because wall electric charge generated

by address discharge is generally smaller than wall voltage generated by sustaining discharge,

initial discharges have small discharge strength, and stabilization is usually obtained after 5~6

times discharges, subject to variations depending on the structure and environment of electrodes.

The purpose of impressing the initial sustaining pulses long is to obtain stable initial discharges

and generate wall electric charges as much as possible.

Page 20

Circuit Operation Description

5-20 Samsung Electronics

5-2-3 Configuration and operation principles of driver circuit

YA

YB

H

Y-Board

- Sustian pulse

- Energy recovery

- Reset ramp pulse

- Vscan pulse

13pin - 250mm

I

4pin

(SMPS - Y : 13pin - 510 mm)

LOGIC

( SMPS - Logic : 4 - 550 mm)

2pin

speaker(9pin

¿»(13pin)

Fan (3pin)

SMPS

AC line filter

Y(13pin)

Logic(4pin)

)

Ground Connection

J

(SMPS-ADDRESS : 4pin - 220mm)

( SMPS - X : 12pin - 210mm )

Addres(4pin)

)

X(12pin

(SMPS - - 550mm)

12pin - 250mm

X-Board

-Sustain pulse

-Energy recovery

ADDRESS : 4pin

12pin - 200mm

13pin - 200mm

4pin power

E

F

(Logic - X : 13 + 12- 800mm)

G

4pin power

Page 21

Circuit Operation Description

Samsung Electronics 5-21

5-2-3(A) DESCRIPTIONS OF EACH BOARD'S FUNCTIONS

① X-Bd

Main PCB

Connected to the panel's X terminal, generating sustaining voltage pulse (including ERC), and

whole erasing pulse.

➁ Y-Bd

Main PCB

Connected to the panel's Y terminal, generating sustaining voltage pulse (including ERC), and log

erasing pulse.

➂ Y-buffer

Upper part + lower part

Board impressing scan pulse on Y terminals, consisting of the upper and lower sub-boards.

With wide VGA, one board is equipped with 4 scan driver ICs (SN755858: 64 outputs).

➃ COF

Upper part + lower part

Impresses Va pulse on address electrodes in the address section and generates address discharge

based on a difference between such Va pulse and scan pulse impressed on Y electrodes.

Page 22

Circuit Operation Description

5-22 Samsung Electronics

5-2-3(B) DRIVING BOARD'S BLOCK DIAGRAM

❏ Components of driving board's operations

1. Power supply

(1) Supplied from the power supply board

- For sustaining discharge: 155V ~ 170V

- For Ramp rising voltage,Vset: 200V ~ 235V

- For X Ve level: 185V ~ 195V

- For scan: 85V;

- For addressing discharge: 63V ~ 73V

- For logic signaling buffer: 5V

- For gate driver IC: 15V.

2. Logic signal

(1) Supplied from the logic board

- Gate signals for FETs.

LOGIC SIGNAL INPUT

LOGIC SIGNAL BUFFER

FET GAT E DRIVER

REC O V ERY

SWITC HING

RECOVERY C IRC UIT

(Recovery Cap)

MAIN

S WITCHING

165V

5V

18V

VSET

S WITCHING

POWER

205V 190V

VE

SWIT CHING

80V

VSCAN

S WITCHING

Page 23

Circuit Operation Description

Samsung Electronics 5-23

5-2-3(C) PRINCIPLES OF FET'S OPERATION AND HIGH VOLTAGE SWITCHING

❏ FET’s operation principles

❏ FET’s high voltage switching principles

(1) With signal impressed on the gate(Positive voltage), FET

gets short-circuited (a conducting wire of zero (0) resistance); and

(2) With no signal impressed on the gate (GND), FET gets

open-circuited (a non-conducting wire of ∞ resistance).

(1) With signal impressed on the gate(Positive

voltage), FET gets short-circuited (a conducting wire of zero (0) resistance); and

(2) With no signal impressed on the gate

(GND), FET gets open-circuited (a non-conducting wire of ∞ resistance).

Page 24

Circuit Operation Description

5-24 Samsung Electronics

5-2-3(D) DRIVER CIRCUIT DIAGRAM

Cp

2

1

3 2

1

3

Vs

Yr

D_YVsC

D_Yr

LY

C_Yerc D_YGC

D_Yf

Yf

0 0 00

Ys

Yg

Ramp

Rset

Dset

Cset

Yfr

Yrr

Ramp

Yp

+5V

D_fVdd

C_fVdd

VscanVset

C_Ysink

floating 5V

Ysc

Ysp

Dscan

D_Ysink

Ramp

Xrr

VsVe

C_Xsink

D_Xsink

Xs

Xg

0

D_Xs

LX

Xr

D_YVsC

D_Xr

C_Xerc

D_YGC

D_Xf

Xf

0 0

Page 25

Circuit Operation Description

Samsung Electronics 5-25

5-2-3(E) X BOARD TEST: ASSEMBLE LOGIC AND POWER INPUT JACK.

5-2-3(E)-1 Gate Signal Test

Condition) Connect 5V, GND, 17V to power connectors 1, 2, 3, respectively and then check each

TP shows like figures below.

① R4001 ② R4004

➂ R4015 ④ R4035

➄ R4031

Page 26

Circuit Operation Description

5-26 Samsung Electronics

5-2-3(E)-2 X Output Waveform Test

Condition) After applying 5V, 17V, 168V, 190V successively, use a probe to check #6 (connector),

and then check the following waveform shows at an oscilloscope.

➅ R4001

Page 27

Circuit Operation Description

Samsung Electronics 5-27

5-2-3(F) Y BOARD TEST: CONNECT A CABLE TO Y BUFFER AND ASSEMBLE A LOGIC AND POWER INPUT JACK.

5-2-3(F)-1 Gate Signal Test

Condition) Connect 5V, GND, 17V to Y power connectors 1, 2, 3, respectively and then check each

TP shows like figures below.

① R5029 ② R5052

➂ R5001 ④ R5083

➄ R5035 ➅ ZD5002

Page 28

Circuit Operation Description

5-28 Samsung Electronics

➆ M5014 ➇ M5037

⑨ R5077 ⑩ TPSI

1 TPPOL 2 TPBLK

Page 29

Circuit Operation Description

Samsung Electronics 5-29

5-2-3(F) Y BOARD TEST: CONNECT A CABLE TO Y BUFFER AND ASSEMBLE A LOGIC AND POWER INPUT JACK.

5-2-3(F)-2 Y Output Waveform Test

Condition) After applying 5V, 17V, 168V, 70V, 210V successively, use a probe to check #15

(TPOUT1), and then check the following waveform shows at an oscilloscope.

3 TPSTB 4 TPCLK

5 TPOUT1

Page 30

Circuit Operation Description

5-30 Samsung Electronics

5-3 Logic Part

5-3-1 Front Block

5-3-1(A) FRONT BLOCK DIAGRAM

Page 31

Circuit Operation Description

Samsung Electronics 5-31

5-3-2 The Description of the Logic Board

5-3-2(A) THE DESCRIPTION OF THE LOGIC BOARD

The logic board consists of the logic main board and the buffer board. The logic main board

processes the video signal, and generates the output address driver output signal, as well as XY

drive signal.

The buffer board stores the address driver output signal, and sends the signal to the address driver IC (COF module).

LOGIC BOARD

LOGIC MAIN

FUNCTION

-. Video signal processign (W/L, Error diffusion, APC)

-. Output address driver control adn data signal.

-. Outputs XY drive board control signal.

Sends data and control signals to three COFs at the left bottom part.

Sends data and control signals to five COFs at the middle bottom part.

Sends data and control signals to three COFs at the right bottom part.

Sends data and control signals to three COFs at the left top part.

Sends data and control signals to three COFs at the middle top part.

Sends data and control signals to three COFs at the right top part.

LOGIC

BUFFER

BOARD

E Buffer Board

F Buffer Board

G Buffer Board

H Buffer Board

I Buffer Board

J Buffer Board

Page 32

Circuit Operation Description

5-32 Samsung Electronics

NO

1

2

3

4

5

6

7

8

9

10

NAME

LVDS Connector

Operation LED

Key Scan Connector

24C16(128APC)

Y Connector

X Connector

LE01, LE02 and LE03

(Address Buffer Connector)

LG01, LG02 and LG03

(Address Buffer Connector)

Power Fuse

Power Connector

FUNCTION

An input connector that receives LVDS encoded RGB, H, V DATAEN and

DCLK signals from the video board.

Indicates if the logic board properly receives Sync and clock signal.

In normal state, it flickers every on second.

A connector that connects to the Key Scan board in order to check and

adjust 24C16 data.

An EEPROM for saving the gamma table, the APC table, the drive signal

timing and other options.

A connector that connects to the output address data, and control signals

to the E F and G buffer board.

A connector that connects to the output address data, and control signals

to the E F and G buffer board.

A fuse connector to the power source(5V) line of the logic board.

A connector to supply power(5V) to the logic board.

A connector that connects to the Y output drive board control signal.

A connector that connects to the X output drive board control signal.

5-3-2(B) THE NAME AND DESCRIPTION OF THE MAJOR COMPONENTS OF THE LOGIC BOARD

Page 33

1. External/Internal Input Mode Selection Features of 50”HD Multi Logic

Input selection features are provided. The Dip Switch and Logic circuits are designed to allow inspection

of NTSC and PAL internal patterns in the M3 module while in production or upon shipment.

External Mode Selection

1. When the NTSC mode is being selected, enter PAGE00/ When the PAL mode is being selected, enter

PAGE40.

2. Set the address value of Register 2E at 01.

3. Adjust the Dip Switch as shown in the above figure.

(UP : PIN_NUMBER 6,5,3,2,1 / DOWN : PIN_NUMBER 4)

Circuit Operation Description

Samsung Electronics 5-33

REGISTER

ADDRESS

2E

2E

PAGE

00

40

MODE

NTSC

PAL

EXTERNAL

MODE VALUE

01

01

DIP SWITCH STATE

EXTERNAL MODE

External Mode Selection

1. When the NTSC mode is being selected, enter PAGE00/ When the PAL mode is being selected, enter

PAGE40.

2. Set the address value of Register 2E at 00.

3. Adjust the Dip Switch as shown in the above figure.

(UP : PIN_NUMBER 6,5,4,3,2 / DOWN : PIN_NUMBER 1)

REGISTER

ADDRESS

2E

2E

PAGE

00

40

MODE

NTSC

PAL

EXTERNAL

MODE VALUE

00

00

DIP SWITCH STATE

EXTERNAL MODE

External Mode Selection

1. When the NTSC mode is being selected, enter PAGE00/ When the PAL mode is being selected, enter

PAGE40.

2. Set the address value of Register 2E at 00.

3. Adjust the Dip Switch as shown in the above figure.

(UP : PIN_NUMBER 6,5,4,2 / DOWN : PIN_NUMBER 3,1)

REGISTER

ADDRESS

2E

2E

PAGE

00

40

MODE

NTSC

PAL

EXTERNAL

MODE VALUE

00

00

DIP SWITCH STATE

EXTERNAL MODE

3456

2

1

6

4

5

3

2

1

6

4

5

3

2

1

Page 34

Circuit Operation Description

5-34 Samsung Electronics

LD2010

LD2002

LD2001

..

..

..

..

CN2000

..

..

..

..

..

..

..

..

U2050

F3

U2049

F2

EP20K400EBC652 - 1

LA2000

U2034

ALETRA

APEX

U2001

F1

TM

CN2001

U2048

67.4

X2007

U2033

1 40 1 40 1 40

LG2001 LG2002 LG2003

U2011~U2021

U2002

SAMSUNG

K4G323222A

U2005

SPLS - HMEM

SAMSUNG

K4G323222A

U2006

FU102

CN2002

1

LY1

40

FU2101

D2002

D2001

FU2102

L2004

L2005

U2040

U2041

50

REGIST

U2035

U2039

U2052

U2051

U2038

U2043 U2042 U2044

U2047

U2037

U2036

51.0

X2006

IC108

IC123

U2003

SPLS - HMEM

U2004

SPLS - HMEM

SAMSUNG

K4G323211A

U2007

SAMSUNG

K4G323222A

U2008

SAMSUNG

K4G323222A

U2009

SAMSUNG

K4G323222A

U2010

U2046

SW2000

U2045

CN2003

1 13 40 1 40 1 40 1

LE1 LE2 LE3

U2022~U2032

Page 35

Circuit Operation Description

Samsung Electronics 5-35

5-4 Scaler Board Block Diagram & Description

5-4-1 General Signal Process B/D

Mai n CVBS

S-Vi deo(Y/C)

Scar t Jac k

Component I nput Jac k

DVD YPbPr

( 480P, 480i )

Component I nput Jac k

DTV YPbPr

( 480P, 720P, 10800i )

PC I nput( 15Pi n D-s ub)

VGA To SXGA

( Hf : 31 TO 80KHz )

( Vf : 56 TO 75Hz)

480i

DVD-Y/ SCT_G

DVD- P b / SC T- B

DVD-P r /SCT _R

480P

9VA

SDA/SCL

DTV Y/Pb/ Pr

PC_R/ G/B, H/ V- SYNC

HD_PC_SW(PW364)

DDC I C

( 24LC21-I C506)

3D_Comb

Mai n CVBS

Mai n Y/ C

SCT_F B/SCT _CVBS

I VVS/ I VHS

Multi Component Pr ocess or

( CXA2101- I C402)

( YPbPr ➞ RGB)

R/ G/ B _OUT

HS_OUT 2 / V S_OUT 1

Analog Switc h

( BA7657F - I C501)

PC_DET

CAPT_CVBS

PC_V- SYNC

Main Vi deo Decoder

( VPC3230- I C201)

RESET Q

SDA/SCL

5V_A, 3. 3V_D

TTX_F B/ R/G/ B

V-YPbPr

HS/ V S_OUT 1

SCP

R/ G/ B _OUT

HS_OUT 1

AD_R_ OUT

AD_G_OUT

AD_B_ OUT

LLC1 : 13. 5MHz

CLK2 : 2 7MHz

Y/ UV 8Bi t

H1/ V 1_ OUT

CLK2 0

Sandcast l e Pul e Gen

(M4LV-32 - I C401)

3. 3VA

SDA/SCL

A/ D C on v e r t er Wi t h P L L / Ga i n Am p

VS_OUT1

A/ D C on v e r t er Wi t h P L L / Ga i n Am p

3. 3V_A

SEL_[ 0~2]

( AD9884 - I C801)

( AD9884 - I C101)

5V

VFI ELD

RESET Q

SDA/SCL

3. 3V_D

I nter l ace To Pr ogr ess i ve

( SDA9400 - I C202)

YI N/ UVI N[0~7]

3CH. DA Conver t er

( SDA9280 - I C703)

RESET Q

SDA/SCL

5V_A

EEPROM

( 24C16 - I C302)

SCL1 /SDA1

R/G/B [ 0~7]

VHS/VCL K

I VCL K/I VPEN

I VHS/ I VVS

SR[0~23]

SQ[ 0~23]

SOG/ M HS/ P CL K

CKI NV/ CL AMP

MHSYNC

MC OAST

RXD/T XD

MAX232- I C603

Ser i a l

Interface

M_RSTR

M_RE

M_OE

LLC1

Sub Video Decoder ( PI P)

Y_[0~7]

C[ 0~7]

I VVS

IVHS

( I CT003- 4S641632)

EEPROM

SDA/SCL

(PW364 - I C301)

FAN_DET

PC_DET

TH_DET

PROTECT

Megat ext SDA6000

SDRAM

CAPT_CVBS

( 24C16 - I C302)

Image Pr ocessor ( Image Scal i ng,

OSD Mi x e r , F r a me Ra t e

Conver si on With CPU)

MCKEXT: 130MHz

DCKEXT: 2 6MHz

OSC

MAIN_CVBS

MAIN_Y/C

D

VD_Pb/ SCT_B

DVD_Y/SCT_G

DVD_Pr /SCT _R

( VPC3230- I CP01)

Y[ 0~7]

C[ 0~7]

( 81V04160-I CP02)

SDA3/SCL 3

3. 3 V_D, 2. 5V_t t x

LEDRED/GRN

I RRCVR/ I RRCVR1

KEY[1~4]

R/ G/B 8 Bi t

LVS/ L HS/

LENG

A[1~19]

D[0~15]

ROMWEn

ROMOEn

A[0~18]

D[0~15]

RAMWEn

RAMOEn

BHENn

SCT_CVBS

SCT_F /B

RESET Q

SDA/SCL

3. 3V_D

5V_A

3. 3V_D

RESET Q

A[0~20]

D[0~15]

EPROM

( I CT002- M27V160)

I R Modul e

Ent ernal Keypad

LVDS( DS90C385 - I C503)

Fl ash Memory

29LV160 - OTP01

Sr am

616V1000 - I C602

Page 36

Circuit Operation Description

5-36 Samsung Electronics

5-4-2 Description in Signal Process Block

VPC3230 : This functions as a video decoder, which can receive all of the YC, YUV, CVBS inputs.

In addition, this converts Y/C into YUV after receiving 3D Comb Output Y/C, S-Vido Y/C, and DVD YUV.

VIDEO DOUBLER : Usually, the current video image adopts the INTERLACE Scanning system and it has poor video because of

Flicking on the screen. Using the SDA9400 , INTERLACE is converted into PROGRESSIVE in order to

improve the quality of video.

VIDEO PROCESSOR : Since the HD modes like 1920*1080I have higher video bandwidth than the existing video signals, the

ordinary decoder like VPC3230 can't handle those modes. PC has higher bandwidth of video signal than

TV and the RGB video format.

Therefore, if the HD signal can be converted into the RGB signals, the TV video signal can have the same

processing as the PC VIDEO signal. CXA2101 developed by SONY is used to convert YPbPr into RGB.

CXA2101 converts both DTV signals and all the SD signals processed in the sequence of SDA9400 then

SDA9280 into RGB.

This processor performs some user control functions, such as tint, color, and sharpness.

Also, it controls high light gains low light offsets when doing white balance adjustments.

ANALOG SWITCH : The video decoder like VPC3230 has a built-in video switch that assigns one signal out of various

received inputs, though most of ICs for PC are designed so that they support only one source because of

less necessity of simultaneously processing the multi inputs. To process the input source of MULTI

(PC&HD), therefore, a function of selecting an input should be externally added; as is performed by

ROHM's BA7657F. PW364 transmits a signal determining which input is selected.

ADC : A device that converts the input RGB signals into the 8bit DIGITAL RGB signals.

In case of white balance adjustments, this device sets the color temperature by controlling R/B gains and

R/B offsets.

PW364 : PW364 is a multi-functional scaler which one chip has video signal scaling, 8086 CPU, 4M BYTE VIDEO

MEMORY functions. The PC and Video input signals are received from GRAPHIC PORT and VIDEO PORT,

respectively.Its main functions include UP/DOWN SCALING, PIP, ZOOM, GAMMA CORRECTION,

Compensation of GEOMETRIC DISTORTION, powerful GRAPHIC OSD.

FIRMWARE : Mounted is a software that is used for system control by operating 8086 built in PW364. A 4MBIT FLASH

ROM is mainly used, but one up to 8MBIT can be used according to PROGRAM and capacity of OSD

DATA.

The system is easy to maintain because programming can be re-done at any yime using the FLASH ROM.

Page 37

Circuit Operation Description

Samsung Electronics 5-37

5-4 Main I/O signal pules and voltages

5-4-1 Signal Pulses of Image Board(Input Signal Conditions : 7 Color bar)

Page 38

Circuit Operation Description

5-38 Samsung Electronics

Page 39

Circuit Operation Description

Samsung Electronics 5-39

Page 40

Circuit Operation Description

5-40 Samsung Electronics

MEMO

Loading...

Loading...