Page 1

IMPORTANT SAFETY INSTRUCTIONS

NX58H5650WS

115

180

WARNING

The following information is intended for use by

persons possessing adequate electrical, electronics,

and mechanical backgrounds and experience. Lack

of proper background and experience during any

repair of a major appliance could result in death,

personal injury, and/or property damage. The

manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume

any liability in connection with its use.

• Disconnect the electrical power to the appliance

before servicing.

• Shut o the gas supply to the appliance before

servicing.

• Reconnecting all grounding devices before

reconnecting the electrical power and opening the

gas supply to the appliance.

• All electrical components in this appliance are

grounded. All grounding wires, screws, straps,

nuts, and/or washers must be replaced to their

original position and properly fastened.

LP conversion must be performed by a qualified

•

installer or gas supplier in accordance with the

manufacturer’s instructions and all codes and

requirements of the authority having jurisdiction.

Failure to follow ALL instructions could result

in serious injury or property damage. The

qualified agency performing this work assumes

responsibility for the conversion.

• Know the location of the gas shut-o valve and

how to shut it o if necessary.

• Do not operate the cooktop surface burners or

oven burners of this range when using LP gas

before converting the pressure regulator and

burner orifices for LP gas use. Failure to do so

could cause high flames and toxic fumes which

can result in serious injury.

• Do not mix up or substitute LP gas burner

orifices during the conversion process. Improper

orifice placement will aect burner and cooking

performance and could result in personal injury

and/or product damage.

LP GAS (PROPANE) CONVERSION

1. Converting the pressure regulator

The regulator is located in the lower, left-hand rear corner

of the bottom drawer opening.

A. Remove the warming drawer or the storage drawer.

B. Locate the pressure regulator in the rear of the drawer

opening. The pressure regulator can be seen and

accessed through the square hole in the rear wall as

viewed from the front.

C. Using your fingers, turn the red plastic cap and the

dual-purpose orifice spud counterclockwise to remove

them from the pressure regulator.

D. Completely remove the cap from the spud and the

threads and reinstall it on the opposite side of the spud.

Shut-O

Lever

Dual-Purpose

Orifice

Flip Orifice

to change

application

size.

E. Reinstall the spud in the pressure regulator so the large,

open LP gas end is exposed. Tighten the spud until it

is finger-tight. Do not overtighten. Replace the plastic

cap over the exposed spud threads.

F. Make sure the gas shut-o lever on the side of the

pressure regulator is in the open position.

G. Replace the warming drawer or the storage drawer.

Pressure

Regulator

Plastic Cap

2. Converting the surface burners

The range comes with low-altitude LP conversion kits.

The kit contains 7 burner orifices. Five of these 7 orifices

are sized and color-coded for surface burner use. The

remaining 2 orifices are for the bake and broil oven burners.

Use the following charts to properly size and replace the

orifices:

BURNER ORIFICE SIZES AND OUTPUT RATINGS

(LP Gas [Propane] 10 in WCP)

Burner location BTU Rate Orifice size [mm]

¹Model NX58H5650WS ²Model NX58H5600SS

BURNER ORIFICE SIZES AND OUTPUT RATINGS

Burner location BTU Rate Orifice size [mm]

¹Model NX58H5650WS ²Model NX58H5600SS

1

RF

2

RF

1

LF

2

LF

RR 4,000 0.62

LR 7,500 0.83

CTR 7,500 0.83

BAKE 15,000 1.15

BROIL 11,500 1.02

(Natural Gas 5 in WCP)

1

RF

2

RF

LF 15,000 1.78

RR 5,000 1.01

LR 9,500 1.40

CTR 9,500 1.38

BAKE 18,000 1.90

BROIL 13,500 1.64

14,500 1.12

12,500 1.06

11,500 1.04

10,000 0.98

Orifice markings:

115 – Denotes 1.15 mm orifice size

opening.

18,000 1.92

17,000 1.92

Orifice Markings:

180 – Denotes 1.80 mm orifice size

opening.

A. Remove the surface burner grates.

B. Lift o the surface burner caps and the surface burner

heads from the surface burner manifold cups.

C. Using a 9/32˝ or 7 mm nut driver, remove the burner

orifice from the bottom of each manifold cup.

NOTE: Keep these orifices and note their positions for

future conversion back to natural gas.

White

Yellow

White

Red

Orange

NX58H5650WS

White

Yellow

White

Blue

NX58H5600SS

D. Identify the proper orifice by orifice size and color

code for each of the surface burners.

E. Install the proper orifices in each of the burner manifold

cups as shown above. Tighten with a 9/32˝ or 7 mm nut

driver. Do not overtighten.

NOTE: Any other placement of orifices could result in

dangerous operating conditions and/or poor

cooking results.

F. Replace the surface burner heads and caps in the

same location from which they were removed. The

burner heads should be flat on top of the manifold cups

and the caps should be flat on top of the burner heads

to ensure proper, safe operation.

None

3. Converting the oven burners

WARNING

The following adjustments must be made before

turning on the gas to the oven burners. Failure to

do so could result in death and/or serious personal

injury due to high flames and toxic fumes.

The oven has a bake (lower) and a broil (upper) oven

burner. Both burners require the orifices to be changed.

See the charts in column 2 for the proper orifice usage.

To replace the bake (lower) burner orifice:

A. Remove the two screws from the back of the cavity

floor. Lift back to clear the front edge and lift out the

cavity floor.

B. Remove two screws from the front of the bracket bake-

spreader.

C. Lift front the bracket bake spreader and lift out the

bracket-bake spreader.

D. Lift up the burner bake from the holder-bake burner on

the bottom of the drawer.

E. Using a 9/32˝ or 7mm nut driver and an adjustable

wrench, hold the gas fitting with the wrench and

remove the bake oven burner orifice from the center of

the lower gas fitting.

F. Install a properly sized burner orifice for the lower oven

burner using LP gas.

To replace the broil (upper) burner orifice:

G. Remove 1 screw of bracket HSI-wire

H. Remove 4 screw of bracket-broil spreader to top of

oven.

I. Support the burner-broil with one hand, remove 2 screw

supporting the burner-broil to the front and the rear of

the oven.

J. To replace the nozzle broil-burner, remove the gas

nozzle with a 9/32˝ nut driver.

K. Install a properly sized burner orifice for the upper oven

burner, using LP gas.

L. Position end of upper oven burner over the burner

orifice and secure it in place with the front screw.

4. Adjusting the air shutter settings on the

oven burners

NOTE: To ensure proper flame characteristics, install and

close the oven door before checking the oven burner

flames.

A. Install and close the oven door.

B. Open the gas shut-o valve to the range.

C. Plug in the power cord or connect the power supply to

the range.

D. Program the oven to BAKE and press START.

E. Visually check the flame characteristics through the

oven window.

• The inner cone of the flames should be

approximately 1/2˝ to 3/4˝ long.

• The visual appearance of the flame will denote the

flame combustion quality.

Soft blue flames are

normal for natural gas

operation.

Yellow tips on outer

cones are normal for

LP gas operation.

Yellow flames are

abnormal for any gas

operation. Further

adjustment required.

Orange flames occur

from foreign particles

in the gas line. The

particles will burn o

and the orange flames

will disappear.

WARNING

Use caution when measuring the flames and

adjusting the air shutter. The burner flames could

burn you or ignite your clothes causing personal

injury and/or death.

Locking Screw

F. Loosen the locking screw and adjust the oven burner

air shutter. Clockwise rotation will open the air shutter

and increase airflow. Counterclockwise rotation will

close the air shutter and decrease airflow.

NOTES:

• If the flames are yellow, the air shutter on the burner

needs to be opened further.

• If the flames flutter or blow away, the air shutter on

the burner needs to be closed further.

• We highly recommend that the air shutter be fully

opened in case of using LP gas.

G. After flames are adjusted, tighten the locking screw.

H. Program the oven to BROIL and press START. Repeat

Steps E~G.

I. Turn o the oven, install the oven bottom, and replace

the oven racks.

Locking Screw

5. Adjusting low flame settings on surface

burners

All surface burner flames should be checked and adjusted

at their lowest setting.

NOTE: Low setting adjustments should always be made

with 2 or more burners operating at the same time.

A. Turn on 2 or more surface burners and set them HI.

B. Quickly turn one of the control knobs counterclockwise

to the lowest setting. The flame should stay lit. If the

flame flutters or goes out, adjust the bypass valve in

the base of the valve stem for that control knob.

C. Pull the control knob for that burner straight o.

Small Screwdriver

Valve Stem

D. Insert a small flat-blade screwdriver into the valve stem.

While holding the valve stem in place, turn the bypass

valve adjusting screw counterclockwise to increase the

flame size.

E. Replace the control knob and repeat Steps A and B.

F. Repeat Steps A~E to check and adjust the remaining

surface burners.

Additional low flame check

Quickly open the oven door while a surface burner is set

on LO. If the flame is extinguished, increase the low flame

setting and repeat the test until the flame is stable.

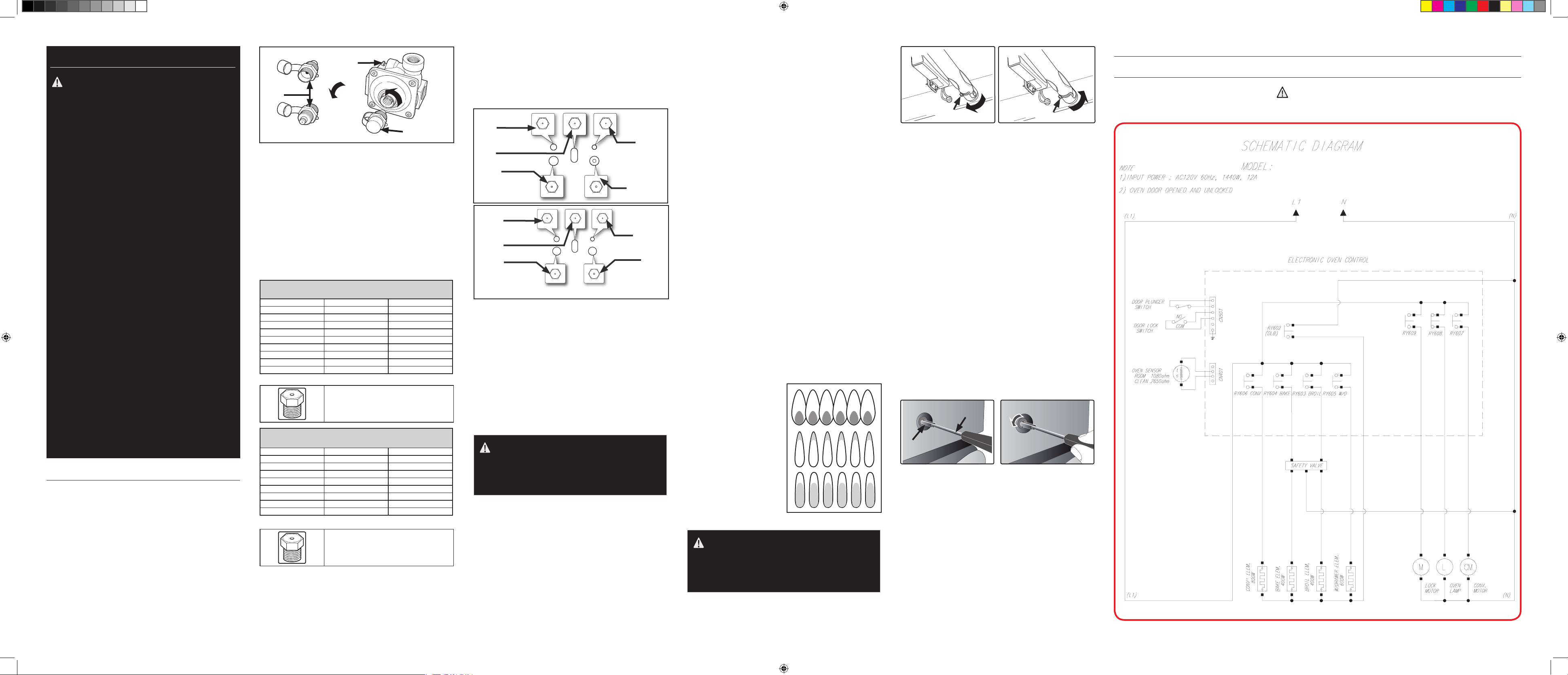

WIRING DIAGRAMS

Model NX58H5650WS

WARNING

POWER MUST BE DISCONNECTED BEFORE SERVICING THIS APPLIANCE.

Mini-Manual_NX58H56_DG68-00528A_EN+MES+CFR.indb 1 06/02/2014 14:12:59

Page 2

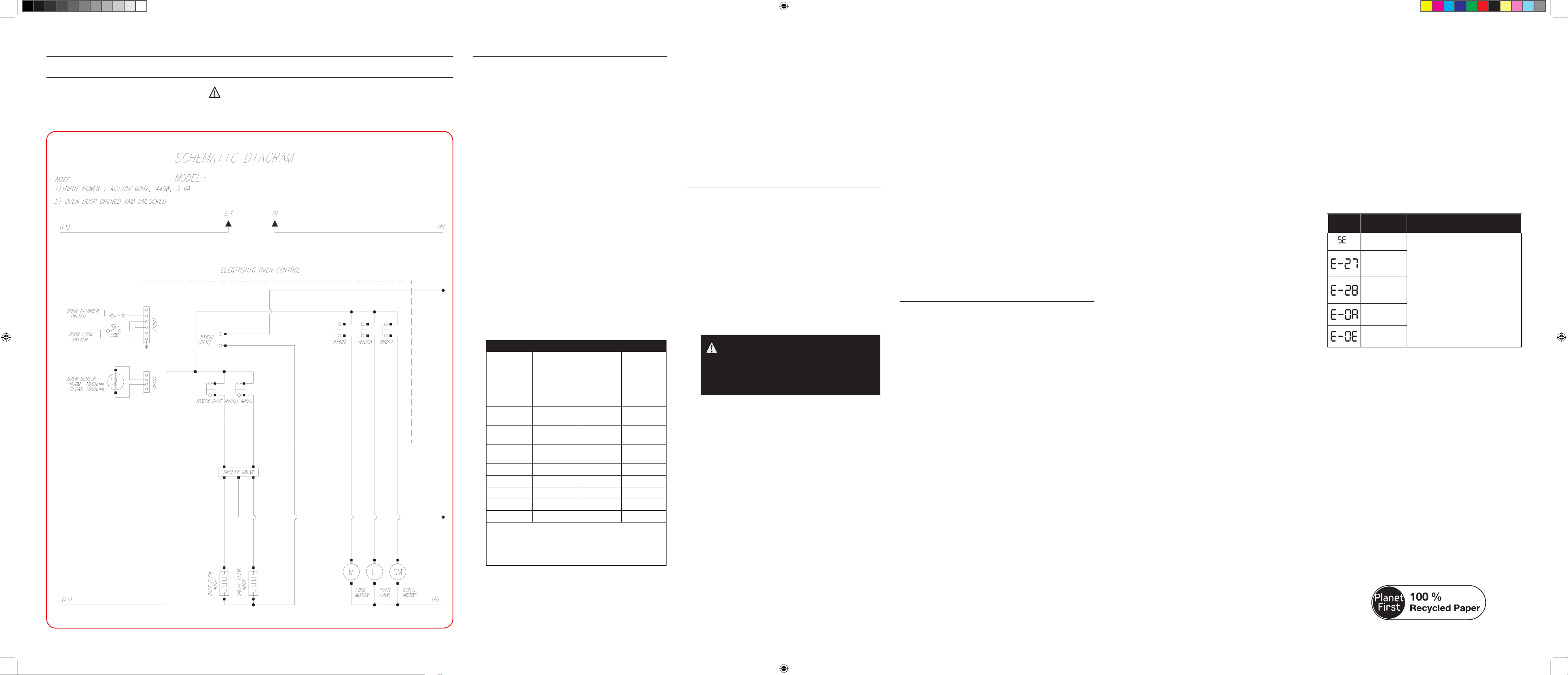

WIRING DIAGRAMS (CONT.)

NX58H5600SS

Model NX58H5600SS

POWER MUST BE DISCONNECTED BEFORE SERVICING THIS APPLIANCE.

WARNING

GAS RANGE CONTROLS

1. Calibrating the oven temperature

The oven temperature can be calibrated to meet your

cooking needs and/or match your previous oven

temperature settings.

A. Remove the warming drawer or the storage drawer.

B. Locate the pressure regulator in the left-rear of the

drawer opening.

C. Using your fingers, turn the red cap and the dual-

purpose orifice counterclockwise to remove them from

the pressure regulator.

D. Remove the cap from the orifice and reinstall it on the

opposite side of the orifice.

E. Reinstall the orifice in the pressure regulator so the

large open LP gas end is exposed. Tighten the orifice

until it is finger-tight. Do not overtighten. Make sure

the red cap is secured over the end of the orifice.

F. Make sure the gas shut-o lever on the side of the

pressure regulator is in the open position.

G. Replace the warming drawer or the storage drawer.

2. Accessing the oven control panel

A. Disconnect or turn o the electrical supply to the range.

B. Shut o the gas shut-o valve to the range.

C. Carefully pull range away from back wall to access the

cover-back guard Wire.

D. Remove the upper rear cover panel.

3. Testing the printed circuit board (PCB)

A. Carefully reconnect the electrical power and perform

the following checks.

B. After checks have been made, disconnect the power to

the range.

RELAY CONTACT OPERATION TEST

RELAY TERMINALS

Convection

bake

Convection

roast

Warming

drawer*

Favorite

Cook

Self-clean

Bake Bake to N 120 VAC** 0 VAC

Broil Broil to N 120 VAC** 0 VAC

Keep Warm Warm to N 120 VAC 0 VAC

Bread Proof Proof to N 120 VAC 0 VAC

Oven light Light to L1 120 VAC 0 VAC

**Be sure to select a temperature or setting.

Remaining circuits are deactivated until Sabbath

Conv. Bake

to N

Conv. Roast

to N

Warming

Dwr to N

Cooking

Cycle to N

Self-Clean

to N

*NX58H5650WS only

**120 VAC to Bake and Cook Time only.

circuit is deactivated.

VOLTAGE IN

COOK MODE

120 VAC** 0 VAC

120 VAC** 0 VAC

0 VAC (in

Self-Clean)

120 VAC 0 VAC

120 VAC 0 VAC

4. Replacing the PCB

A. Mark and disconnect the wires going to the PCB.

B. Remove 17 screws and cover wire LT/RT, cover-

back guard wire, cover-back main wire, and coverconvection.

VOLTAGE IN

OFF

120 VAC

C. Remove 2 screws from the Holder-PCB.

D. Replace the PCB and secure with 2 screws.

E. Reconnect all wires from where they were removed.

5. Spark module replacement

The spark module is located behind the upper rear cover

panel on the lower-right side.

A. Mark and disconnect the wires going to the spark

module.

B. Remove 2 screws and the spark module from the

backguard.

C. Install new spark module in the backguard and secure

with 2 screws.

D. Reconnect wires from where they were removed.

COOKTOP SERVICING

1. Removing the cooktop

A. Disconnect electrical power to the range.

B. Shut o the gas shut-o valve in the gas supply line to

the range.

C. Open the door or remove it.

D. Pull burner control knobs straight o to remove them

from the valve shafts.

E. Remove 2 screws from the top, 2 screws from the front

and 4 screws from the bottom of the chassis manifold

panel.

F. Remove the chassis manifold panel from the front of

the range.

G. Place a finger behind each side of the switch ignition

and pull it straight out to release it from the control

shaft. Repeat for each switch.

H. Disconnect the wires at the connectors.

WARNING

Do not bend the aluminum tubing to the surface

burner cups. Bending can damage the tubing or

fittings resulting in death, personal injury, fire,

and/or product damage.

2. Door latch replacement

A. Remove the oven door and the cooktop frame as

described above.

B. Remove the control knob and the chassis manifold.

C. Remove the Assy’ tube-manifold with a wrench.

D. Remove 2 screws from the Bracket-Latch sub to the

rear of the range.

E. Disconnect wires of the door latch to the rear of the

range and remove it.

F. Remove 2 screws holding the Assy bracket-latch rear

to the rear of the range.

G. Remove the latch-rod from the Assy bracket-latch front.

H. Remove 2 screws holding the Assy bracket-latch front

to the front of cavity.

I. After replacement, reverse the order to install the ASSY

DOOR LATCH.

3. Electrode/harness replacement

A. Remove cooktop as described above.

B.

Remove the cover wire LT/RT and cover-back guard wire.

C.

Carefully remove electrode locking clips from the bottom

of the electrodes on the burner cups. Lift and slide the

electrode wire out of the slot on the burner cup.

D. Trace electrode wire back to the starter module and

disconnect the wire from the spark module.

E. Connect new electrode harness to the spark module

in the same location from where the old harness was

removed.

F. Insert electrode in the slot in the burner cup and secure

it in place with the locking clip.

4. Ignition switch harness replacement

A. Disconnect electrical power to the range.

B. Shut o the gas shut-o valve in the gas supply line to

the range.

C. Open the door or remove it.

D. Pull burner control knobs straight o to remove them

from the valve shafts.

E. Remove 2 screws from the top, 2 screws from the front

and 4 screws from the bottom of the chassis manifold

panel.

F. Remove the chassis manifold panel from the front of

the range.

G. Place a finger behind each side of the switch ignition

and pull it straight out to release it from the control

shaft. Repeat for each switch.

H. Disconnect the wires at the connectors.

I. Connect the new ignition switch harness to the wire

connectors from where the old harness was removed

and install the new harness in reverse order.

OVEN SERVICING

1. Oven temperature sensor replacement

A. Disconnect electrical power to the range.

B. Open the oven door and remove the oven racks.

C. Disconnect connector of the sensor thermister to the

rear of the range.

D. Remove 2 screws securing the oven temperature

sensor to the upper left-hand corner of the rear wall.

E. Carefully pull out the sensor wire leads until the wire

connectors appear. NOTE: If the wire connectors

cannot be accessed from inside the oven, remove the

upper rear cover panel, mark the wires, and disconnect

them from behind the oven.

F. Reverse the order to install a new oven temperature

sensor.

2. Lower burner replacement (bake)

A. Turn o the electrical supply going to the range.

B. Shut o the gas shut-o valve in the gas supply line to

the range.

C. Open the oven door and remove the racks from inside

the oven.

D. Pull on the wires or the connector until the wire

connector appears from the back wall of the warming

drawer opening.

E. Disconnect the connector of HSI of the burner bake.

F. Remove the two screws from the back of the cavity

floor. Lift back to clear the front edge and lift out the

cavity floor.

G. Remove 2 screws from the front of the bracket bake-

spreader.

H. Lift front the bracket bake-spreader and lift out the

bracket-bake spreader.

I. Lift up the burner bake from the holder-bake burner on

the bottom of the drawer.

J. Reverse the order to install a new bake burner.

3. Upper burner replacement (broil)

A. Disconnect electrical power to the range.

B. Shut o the gas shut-o valve to the range.

C. Open the oven door and remove the racks

D. Remove cover-back main wire to the rear of the oven.

E. Disconnect the wires or the connector of the HSI.

F. Remove 1 screw of bracket HSI-wire and remove 4

screws of bracket-broil spreader to top of oven.

G. Support the burner-broil with one hand, remove 2

screw supporting the burner-broil to the front and the

rear of the oven.

H. Pull the upper Assy-burner broil spreader to disconnect

it from the holder nozzle-broil on the rear wall of the

oven.

I. Carefully remove Assy-burner broil spreader.

J. Reverse the order to install a new bake burner.

4. Glow bar ignitor replacement (hot surface

ignitor)

A. Disconnect electrical power to the range.

B. Shut o the gas supply to the range.

C. Open the oven door and remove the oven racks.

D. Remove the oven burner closest to the faulty ignitor.

(See burner replacement instructions.)

E. Remove 2 screws securing the glow bar ignitor.

F. Carefully pull the wire leads until the wire connectors

appear.

G. Reconnect new ignitor and reassemble the oven in

reverse order.

5. Assy safety valve (with pressure regulator)

A. Disconnect electrical powe to the range.

B. Shut o the gas supply to the range.

C. Remove the regulator support bracket from the rear of

the range

D. Carefully identify and mark the wires going to the ASSY

VALVE SAFETY. Disconnect the 4 wires.

WARNING

Cross-wiring the wires to the ASSY VALVE SAFETY creates

an explosion hazard that can result in death, personal injury,

and/or property and product damage.

E. Disconnect the 3 gas lines from the ASSY VALVE

SAFETY. Do not bend or crimp gas lines during

removal.

F. Remove gas fittings from the ASSY VALVE SAFETY.

G. Remove 4 screws and the ASSY VALVE SAFETY from

the back wall of the warming drawer opening.

H. Install the new ASSY VALVE SAFETY from the back

wall of the warming drawer with 4 screws.

I. Reconnect gas lines to the ASSY VALVE SAFETY.

J. Reconnect wire connectors in their original positions.

NOTE: Check all gas lines and fittings for leaks before

operation.

WARNING

Cross-wiring the wires to the gas control valve creates an

explosion hazard that can result in death, personal injury, and/

or property and product damage.

WARMING DRAWER SERVICING

(Model NX58H5650WS)

1. Warming drawer element replacement

A. Disconnect the electrical power to the range.

B. Shut o the gas supply to the range.

C. Pull out the warming drawer. Press down the left glide

lever, lift up on the right glide lever, and then remove

the drawer from the drawer opening.

D. Disconnect the connector from the back wall of the

warming drawer opening.

E. Remove the bottom screw and the heater-warming

drawer from the back wall of the warming drawer

opening.

F. Reverse the order to install and connect the new heater

warming drawer.

FAILURE CODE CHART

FAILURE

CODE

CAUSE SOLUTION

Shorted Key.

Oven sensor

opened

problem.

Oven sensor

shorted

problem.

Oven

overheating.

Door locking

error.

This manual is made with 100 % recycled paper.

Press the OFF/CLEAR pad and restart

the oven.

If the problem persists, disconnect

all power to the range for at least 30

seconds and then reconnect the power.

If this does not solve the problem, call

for service. See bottom of this chart.

DG68-00528A-00

Mini-Manual_NX58H56_DG68-00528A_EN+MES+CFR.indb 2 06/02/2014 14:13:01

Page 3

INSTRUCCIONES DE SEGURIDAD

NX58H5650WS

115

180

IMPORTANTES

La siguiente información está destinada al uso por parte

personas que tienen el conocimiento y la experiencia

adecuada sobre electricidad, electrónica y mecánica. La falta

de conocimiento y experiencia durante cualquier reparación

de un electrodoméstico puede ocasionar muerte, lesión física

o daños materiales. El fabricante o vendedor no se hace

responsable por la interpretación de esta información, ni

asume responsabilidad alguna en relación con su uso.

• Desconecte la alimentación eléctrica del electrodoméstico

• Cierre el suministro de gas del electrodoméstico antes de

• Cómo volver a conectar todos los dispositivos de

• Todos los componentes eléctricos de este

•

• Debe conocer la ubicación de la válvula de cierre del gas y

• No haga funcionar los quemadores exteriores ni los

• No mezclar o sustituir los orificios del quemador de gas

CONVERSIÓN A GAS LP (PROPANO)

1. Cómo convertir el regulador de presión

El regulador está ubicado en la esquina inferior izquierda

posterior de la abertura del cajón inferior.

A. Retire el cajón de calentamiento o el cajón de

almacenamiento.

B. Localice el regulador de presión en la parte posterior

del hueco del cajón. El regulador de presión se puede

ver y acceder a través del orificio rectangular en la

pared posterior vista desde el frente.

C. Con los dedos, gire la tapa de plástico roja y el orificio

de acoplamiento de doble uso hacia la izquierda para

retirarlos del regulador de presión.

D. Retire completamente la tapa del acoplamiento y de

las roscas y vuelva a instalarla en el lado opuesto del

acoplamiento.

ADVERTENCIA

antes de realizar tareas de mantenimiento o reparación.

realizar tareas de mantenimiento o reparación.

conexión a tierra antes de reconectar la alimentación

eléctrica y abrir el suministro de gas del electrodoméstico.

electrodoméstico están conectados a tierra. Todos los

cables, tornillos, cintas, tuercas y/o arandelas de conexión

a tierra deben volver a colocarse en su posición original y

se deben ajustar adecuadamente.

La conversión a LP debe ser realizada por un instalador

o un proveedor de gas calificado de acuerdo con las

instrucciones del fabricante y con todos los códigos y

requisitos de la autoridad competente. No seguir TODAS

las instrucciones puede ocasionar graves lesiones o

daños materiales. La agencia cualificada que realice este

trabajo asume toda la responsabilidad de la conversión.

cómo cortar éste si es necesario.

del horno cuando utilice gas LP antes de convertir el

regulador de presión y los orificios para utilizar gas LP. Se

podrían producir llamas altas y humos tóxicos con riesgo

de lesiones personales graves.

LP durante el proceso de conversión. La colocación

inadecuada de los orificios afecta el rendimiento de los

quemadores y de la cocción y puede ocasionar lesiones

físicas y/o daños materiales al producto.

Palanca

de cierre

Orificio de

doble uso

Voltear el

orificio para

cambiar el

tamaño de

aplicación.

E. Reinstale el acoplamiento en el regulador de presión de modo

que el extremo grande, abierto del gas LP quede expuesto.

Ajuste el acoplamiento hasta que quede como ajustado con

los dedos. No los ajuste demasiado. Vuelva a colocar la tapa

de plástico sobre las roscas expuestas del acoplamiento.

F. Asegúrese de que la palanca de cierre de gas del lado del

regulador de presión esté en posición abierta.

G. Coloque nuevamente el cajón de calentamiento o el cajón de

almacenamiento.

Regulador

de presión

Tapa de plástico

2. Conversión de los quemadores superiores

La estufa cuenta con kits de conversión de LP de baja altitud. El kit contiene 7

orificios de quemador, Cinco de estos siete orificios tienen el tamaño y código

de color para el uso de los quemadores superiores. Los dos orificios restantes

pertenecen a los quemadores para hornear y para asar. Utilice los siguientes

cuadros para medir y colocar adecuadamente los orificios:

TAMAÑOS DE LOS ORIFICIOS DEL QUEMADOR Y

POTENCIAS DE SALIDA (Gas LP [Propano] 10 en WCP)

Ubicación del

quemador

1

FD

2

FD

1

FI

2

FI

DD 4,000 0.62

DI 7,500 0.83

CEN 7,500 0.83

HORNEAR 15,000 1.15

ASAR 11,500 1.02

1

Modelo NX58H5650WS

TAMAÑOS DE LOS ORIFICIOS DEL QUEMADOR Y

POTENCIAS DE SALIDA (Gas natural 5 en WCP)

Ubicación del

quemador

1

FD

2

FD

FI 15,000 1.78

DD 5,000 1.01

DI 9,500 1.40

CEN 9,500 1.38

HORNEAR 18,000 1.90

ASAR 13,500 1.64

1

Modelo NX58H5650WS

Potencia BTU

14,500 1.12

12,500 1.06

11,500 1.04

10,000 0.98

2

Modelo NX58H5600SS

Marcas del orificio:

115 – Indica un tamaño de abertura del

orificio de 1.15 mm.

Potencia BTU

18,000 1.92

17,000 1.92

2

Modelo NX58H5600SS

Marcas del orificio:

180 – Indica un tamaño de abertura del

orificio de 1.80 mm.

Tamaño orificio

[mm]

Tamaño orificio

[mm]

A. Retire las parrilas del quemador superior.

B. Levante y quite las tapas y las cabezas del quemador superior de

las tazas distribuidoras del quemador superior.

C. Utilizando una llave para tuercas de 9/32˝ o de 7mm, retire el orificio

del quemador de la parte inferior de cada taza distribuidora.

NOTA: Mantenga estos orificios y anote las posiciones para una

futura conversión a gas natural.

Blanco

Amarillo

Blanco

Rojo

Ninguno

NX58H5650WS

Blanco

Amarillo

Blanco

Azul

D. Identifique el orificio adecuado por tamaño y código de color para

cada uno de los quemadores superiores.

E. Instale los orificios adecuados en cada una de las tazas

distribuidoras del quemador como se muestra más arriba. Ajuste

con una llave para tuercas de 9/32˝ o de 7mm. No los ajuste

demasiado.

NOTA: Cualquier otra ubicación de los orificios podría resultar

en condiciones de funcionamiento peligrosas o en malos

resultados de cocción.

F. Vuelva a colocar las cabezas y las tapas del quemador superior

en la misma ubicación de donde fueron retiradas. Las cabezas

del quemador deben estar planas en la parte superior de las tazas

distribuidoras y las tapas deben estar planas en la parte superior

de las cabezas del quemador para garantizar un funcionamiento

adecuado y seguro.

Ninguno

NX58H5600SS

3. Conversión de los quemadores del horno

ADVERTENCIA

Los siguientes ajustes se deben hacer antes de abrir el

gas. No hacerlo puede provocar la muerte o lesiones

personales graves por las llamas o los humos tó.

El horno cuenta con quemadores para hornear (inferior) y para asar

(superior). Ambos quemadores requieren que se cambien los orificios.

Consulte los cuadros en la columna 2 para ver el uso adecuado de los

orificios.

Para volver a colocar el orificio del quemador para hornear (inferior):

A. Retire los dos tornillos de la parte posterior del suelo de la cavidad.

Levante para liberar el borde frontal y extraiga el suelo de la

cavidad.

B. Retire los dos tornillos de la parte delantera de la ménsula del

distribuidor de horneado.

C. Levante el frontal del soporte del quemador y retírelo.

D. Levante el quemador para hornear del soporte en la parte inferior

del cajón.

E. Utilizando una llave para tuercas de 9/32˝ o de 7mm y una

llave ajustable, sostenga la conexión de gas con la llave

ajustable y retire el orificio del quemador para hornear del

centro de la conexión de gas inferior.

F. Monte un orificio adecuado al tamaño del quemador inferior

del horno que sirva para gas LP.

Para volver a colocar el orificio del quemador para asar (superior):

G. Retire 1 tornillo del cable HSI del soporte.

H. Retire 4 tornillos de la ménsula del distribuidor para asar en la

parte superior del horno.

I. Sostenga el quemador para asar con una mano, retire los

dos tornillos que sostienen el quemador para asar en la parte

delantera y posterior del horno.

J. Para volver a colocar la boquilla del quemador para asar, retire

la boquilla de gas con una llave para tuercas de 9/32˝.

K. Instale un orificio del quemador del tamaño adecuado para el

quemador superior usando gas LP.

L. Coloque el extremo del quemador superior del horno sobre el

orificio y asegúrelo en su lugar con el tornillo frontal.

4. Ajuste de la configuración de los obturadores

de aire en los quemadores del horno

NOTA: Para asegurarse de que las llamas tengan las

características adecuadas, instale y cierre la puerta

del horno antes de verificar las llamas de los

quemadores del horno.

A. Instale y cierre la puerta del horno.

B. Abra la válvula de cierre de gas de la estufa.

C. Enchufe el cable de alimentación o conecte el

suministro eléctrico a la estufa.

D. Programe el horno para BAKE (hornear) y presione

START (inicio).

E. Verifique las características de las llamas a través de la

ventana del horno.

• El cono interior de las llamas debe tener

aproximadamente 1/2˝ a 3/4˝ de largo.

• El aspecto visual de la llama indicará la calidad de la

combustión.

Las llamas de

color azul claro son

normales para el

funcionamiento con

gas natural.

Las puntas amarillas

del cono exterior

son normales para el

funcionamiento con

gas LP.

Las llamas amarillas

no son normales para

ningún tipo de gas.

Se requieren más

ajustes.

Las llamas naranjas se producen a causa de

partículas extrañas en el conducto de gas. Las

partículas se quemarán y desaparecerán las llamas

naranjas.

ADVERTENCIA

Tenga cuidado al medir las llamas y ajustar el obturador de

aire. Las llamas del quemador podrían quemarlo o prender

fuego a su ropa lo que provocaría lesiones físicas o la muerte.

Tornillo de bloqueo

F. Afloje el tornillo de bloqueo y ajuste el obturador de aire del

quemador del horno. La rotación hacia la derecha abre el

obturador de aire y aumenta el flujo de aire. La rotación hacia

la izquierda cierra el obturador de aire y reduce el flujo de aire.

NOTAS:

• Si las llamas son amarillas, será necesario abrir más el

obturador de aire en el quemador.

• Si las llamas son inestables o se apagan, será necesario

cerrar más el obturador de aire en el quemador.

• Se recomienda abrir completamente el obturador de aire en

caso de utilizar gas LP.

G. Luego de regular las llamas, ajuste el tornillo de bloqueo.

H. Programe el horno para BROIL (asar) y presione START

(inicio). Repita los pasos E~G.

I. Apague el horno, instale la parte inferior del horno, y vuelva a

colocar los estantes.

Tornillo de bloqueo

5. Ajuste de la configuración de la llama baja

en los quemadores superiores

Todas las llamas del quemador superior deben verificarse y

regularse en su configuración más baja.

NOTA: Los ajustes de la configuración de la llama baja deben

realizarse siempre con 2 quemadores o más funcionando

al mismo tiempo.

A. Encienda 2 o más quemadores superiores y ajústelos en HI.

B. Gire rápidamente una de las perillas de control en sentido

contrario a las agujas del reloj para el ajuste más bajo. La

llama debe quedar encendida. Si la llama es inestable o

se apaga, ajuste la válvula de paso en la parte inferior del

vástago de la válvula para esa perilla de control.

C. Hale la perilla de control de este quemador para retirarla.

Destornillador

pequeño

Vástago de

válvula

D. Inserte un destornillador pequeño de cabeza plana en el

E. Vuelva a colocar la perilla de control y repita los pasos A y B.

F. Repita los pasos A~E para verificar y ajustar el resto de los

Verificación adicional de la llama baja

Abra rápidamente la puerta del horno mientras uno de los

quemadores superiores está en LO. Si la llama se apaga, aumente

la configuración de la llama baja y repita la prueba hasta que la

llama permanezca estable.

la

vástago de la válvula. Mientras mantiene el vástago de la

válvula en su lugar, gire la válvula de paso ajustando el

tornillo hacia la izquierda para aumentar el tamaño de la

llama.

quemadores superiores.

DIAGRAMAS DE CABLEADO

Modelo NX58H5650WS

ADVERTENCIA

SE DEBE DESCONECTAR LA ALIMENTACIÓN ANTES DE REALIZAR TAREAS DE MANTENIMIENTO O

REPARACIÓN EN ESTE ELECTRODOMÉSTICO.

Mini-Manual_NX58H56_DG68-00528A_EN+MES+CFR.indb 1 06/02/2014 14:13:03

Page 4

DIAGRAMAS DE CABLEADO (CONT.)

NX58H5600SS

Modelo NX58H5600SS

ADVERTENCIA

SE DEBE DESCONECTAR LA ALIMENTACIÓN ANTES DE REALIZAR TAREAS DE MANTENIMIENTO O

REPARACIÓN EN ESTE ELECTRODOMÉSTICO.

CONTROLES DE LA ESTUFA DE GAS

1. Cómo calibrar la temperatura del horno

La temperatura del horno puede calibrarse para satisfacer sus

necesidades a la hora de cocinar y/o adecuarse a las configuraciones

previas de temperatura del horno.

A. Retire el cajón de calentamiento o el cajón de almacenamiento.

B. Ubique el regulador de presión en la parte posterior izquierda de la

abertura del cajón.

C. Con los dedos, gire la tapa roja y el orificio de doble uso hacia la

izquierda para retirarlos del regulador de presión.

D. Retire la tapa del orificio y vuelva a instalarla en el lado opuesto del

orificio.

E. Reinstale el orificio en el regulador de presión de modo que el

extremo grande, abierto del gas LP quede expuesto. Ajuste el

orificio hasta que quede como ajustado con los dedos. No los

ajuste demasiado. Asegúrese de que la tapa roja esté bien sujeta al

extremo del orificio.

F. Asegúrese de que la palanca de cierre de gas del lado del regulador

de presión esté en posición abierta.

G. Coloque nuevamente el cajón de calentamiento o el cajón de

almacenamiento.

2. Acceso al panel de control del horno

A. Desconecte o corte la energía eléctrica que alimenta a la estufa.

B. Cierre la válvula de cierre de gas de la estufa.

C. Con cuidado, aleje la estufa de la pared posterior para acceder al

cable de seguridad de la cubierta.

D. Retire la cubierta superior trasera del panel.

3. Prueba de la placa de circuito impreso (PCB)

A. Con cuidado, vuelva a conectar la alimentación eléctrica y realice las

siguientes verificaciones.

B. Luego de las verificaciones, desconecte la alimentación de la estufa.

PRUEBA DEL FUNCIONEMIENTO DE CONTACTO DEL RELÉ

VOLTAGE EN

RELÉ TERMINALES

Convection

bake

(Hornear por

convección)

Convection

roast (Asar

al horno por

convección)

Cajón de

calentamiento*

Favorite cook

(Cocción

personalizada)

Auto-limpieza

Bake (Hornear) Hornear a N 120 VCA** 0 VCA

Broil (Asar a la

parrilla)

Tibio Calentar a N 120 VCA 0 VCA

Bread Proof

(Entibiar para

leudado)

Luz del horno Luz a L1 120 VCA 0 VCA

**Asegúrese de seleccionar una temperatura o configuración.

Los circuitos restantes se desactivan hasta que el circuito

"Conv.

Hornear a N

"Conv. Asar al

horno a N

Cajón de

calentamiento

a N

Ciclo de

cocción a N

Auto-limpieza

a N

Asar a N 120 VCA** 0 VCA

Entibiar para

leudado a N

*NX58H5650WS solamente

**120 VCA para Bake (hornear) y

Cook Time (Tiempo de cocción) solamente.

Shabat esté desactivado.

MODO DE

COCCIÓN

120 VCA** 0 VCA

120 VCA** 0 VCA

0 VCA (en

auto-limpieza)

120 VCA 0 VCA

120 VCA 0 VCA

120 VCA 0 VCA

VOLTAGE EN

OFF (APAGADO)

120 VCA

4. Reemplazo del PCB

A. Marque y desconecte los cables que van al PCB.

B. Retire los 17 tornillos y el cable de la cubierta LT/RT, el cable de

seguridad de la cubierta, el cable principal de la cubierta y la cubierta

de convección

C. Retire los 2 tornillos del soporte del PCB.

D. Vuelva a colocar el PCB y ajústelo con los 2 tornillos.

E. Vuelva a conectar todos los cables de donde fueron retirados.

5. Reemplazo del módulo de encendido

El módulo de encendido está ubicado detrás de la cubierta superior

trasera del panel del lado inferior derecho.

A. Marque y desconecte los cables que van al módulo de encendido.

B. Retire los 2 tornillos y el módulo de encendido del protector posterior.

C. Instale el nuevo módulo de encendido en el protector posterior y

ajústelo con los 2 tornillos.

D. Vuelva a conectar los cables de donde fueron retirados.

TAREAS DE MANTENIMIENTO Y

REPARACIÓN DE LA CUBIERTA

1. Cómo retirar la cubierta

A. Desconecte la alimentación eléctrica de la estufa.

B. Cierre la válvula de cierre de gas del conducto de suministro de gas

que alimenta la estufa.

C. Abra la puerta o retírela.

D. Tire de las perillas de control del quemador hacia afuera para

retirarlas del eje de la válvula.

E. Retire 2 tornillos de la parte superior, 2 tornillos de la parte delantera

y 4 tornillos de la parte inferior del chasis del panel de distribución.

F. Retire el chasis del panel de distribución de la parte delantera de la

estufa.

G. Coloque un dedo detrás de cada lado del interruptor de encendido y

tire de él para extraerlo del eje de control. Repita los pasos para cada

interruptor.

H. Desconecte los cables de los conectores.

ADVERTENCIA

No doble la tubería de aluminio de las tazas del quemador

superior.Si la dobla puede dañar la tubería o los

accesorios, lo que podría ocasionar la muerte, lesiones

físicas, incendio y/o daños materiales al producto.

2. Reemplazo de la traba de la puerta

A. Retire la puerta del horno y el marco de la cubierta como se describe

más arriba.

B. Retire la perilla de control y el distribuidor del chasis.

C. Retire el tubo de distribución de montaje con una llave.

D. Retire los 2 tornillos de la traba de la ménsula de la parte posterior de

la estufa.

E. Desconecte los cables la traba de la puerta de la parte posterior de la

estufa y retírela.

F. Retire los 2 tornillos que sostienen la traba de la ménsula de montaje

de la parte posterior de la estufa.

G. Retire la varilla de la traba frontal de la ménsula de montaje.

H. Retire los 2 tornillos que sostienen la traba frontal de la ménsula de

montaje del frontal de la cavidad.

I. Tras el reemplazo, siga el orden inverso para instalar la TRABA DE LA

PUERTA DE MONTAJE.

3. Reemplazo del electrodo/arnés

A. Retire la cubierta como se muestra más arriba.

B. Retire el cable de la cubierta LT/RT y el cable de seguridad de la

cubierta.

C. Retire cuidadosamente los sujetadores de bloqueo de electrodos de

la parte inferior de los electrodos en las tazas de los quemadores.

Levante y deslice el cable del electrodo hacia afuera de la ranura en

la taza del quemador.

D. Ubique el cable del electrodo del módulo de arranque y desconecte

el cable del módulo de encendido.

E. Conecte el arnés del nuevo electrodo al módulo de encendido en el

mismo lugar del que se retiró el antiguo arnés.

F. Inserte el electrodo en la ranura de la taza del quemador y ajústelo

con el sujetador de bloqueo.

4. Reemplazo del interruptor de encendido

A. Desconecte la alimentación eléctrica de la estufa.

B. Cierre la válvula de cierre de gas del conducto de suministro de gas

que alimenta la estufa.

C. Abra la puerta o retírela.

D. Tire de las perillas de control del quemador hacia afuera para

retirarlas del eje de la válvula.

E. Retire 2 tornillos de la parte superior, 2 tornillos de la parte delantera

y 4 tornillos de la parte inferior del chasis del panel de distribución.

F. Retire el chasis del panel de distribución de la parte delantera de la

estufa.

G. Coloque un dedo detrás de cada lado del interruptor de encendido y

tire de él para extraerlo del eje de control. Repita los pasos para cada

interruptor.

H. Desconecte los cables de los conectores.

I. Conecte el arnés del nuevo interruptor de encendido a los cables de

conexión de donde se retiró el antiguo arnés e instale el nuevo arnés

en el orden inverso.

TAREAS DE MANTENIMIENTO Y

REPARACIÓN DEL HORNO

1. Reemplazo del sensor de temperatura del horno

A. Desconecte la alimentación eléctrica de la estufa.

B. Abra la puerta del horno y retire los estantes.

C. Desconecte el conector del termistor de la parte posterior de la

estufa.

D. Retire los 2 tornillos que sujetan el sensor de temperatura del horno a

la esquina superior izquierda de la pared posterior.

E. Tire cuidadosamente de los cables de alimentación del sensor hasta

que aparezcan los conectores del cable. NOTA:Si no se puede

acceder a los conectores del cable desde el interior del horno,

retire la cubierta superior trasera del panel, marque los cables, y

desconéctelos de la parte posterior del horno.

F. Revierta el orden de los pasos para instalar el nuevo sensor de

temperatura del horno.

2. Reemplazo del quemador inferior (hornear)

A. Corte la energía eléctrica que alimenta a la estufa.

B. Cierre la válvula de cierre de gas del conducto de suministro de gas

que alimenta la estufa.

C. Abra la puerta del horno y retire los estantes.

D. Tire de los cables o del conector hasta que aparezca el cable

de conexión de la pared posterior de la abertura del cajón de

calentamiento.

E. Desconecte el conector de HSI del quemador para hornear.

F. Retire los dos tornillos de la parte posterior del suelo de la cavidad.

Levante para liberar el borde frontal y extraiga el suelo de la cavidad.

G. Retire los 2 tornillos de frontal del soporte del quemador.

H. Levante el frontal del soporte del quemador y retírelo.

I. Levante el quemador para hornear del soporte en la parte inferior del

cajón.

J. Revierta el orden de los pasos para instalar el nuevo quemador para

hornear.

3. Reemplazo del quemador superior (asar)

A. Desconecte la alimentación eléctrica de la estufa.

B. Cierre la válvula de cierre de gas de la estufa.

C. Abra la puerta del horno y retire los estantes.

D. Retire el cable principal de la parte posterior del horno.

E. Desconecte los cables o el conector del HSI.

F. Retire 1 tornillo de la ménsula del cable HSI y retire 4 tornillos de la

ménsula del distribuidor para asar en la parte superior del horno.

G. Sostenga el quemador para asar con una mano, retire los dos

tornillos que sostienen el quemador para asar en la parte delantera y

posterior del horno.

H. Tire del distribuidor para asar del montaje del quemador superior

para desconectarlo del soporte de la boquilla para asar en la pared

posterior del horno.

I. Retire cuidadosamente el distribuidor para asar del montaje del

quemador.

J. Revierta el orden de los pasos para instalar el nuevo quemador para

hornear.

4. Reemplazo de la barra de luz del dispositivo de

encendido(dispositivo de encendido de superficie

caliente)

A. Desconecte la alimentación eléctrica de la estufa.

B. Cierre el suministro de gas de la estufa.

C. Abra la puerta del horno y retire los estantes.

D. Retire el quemador del horno que se encuentra más cerca del

dispositivo de encendido que presenta fallas. (Consulte las

instrucciones de reemplazo del quemador.)

E. Retire los 2 tornillos que sujetan la barra de luz del dispositivo de

encendido.

F. Tire cuidadosamente de los cables de alimentación hasta que

aparezcan los conectores del cable.

G. Vuelva a conectar el nuevo dispositivo de encendido y realice el

montaje del horno en el orden inverso.

5. Válvula de seguridad de montaje

(con regulador de presión)

A. Desconecte la alimentación eléctrica de la estufa.

B. Cierre el suministro de gas de la estufa.

C. Retire la ménsula del soporte del regulador de la parte posterior de la

estufa.

D. Identifique y marque cuidadosamente los cables de la VÁLVULA DE

SEGURIDAD DE MONTAJE. Desconecte los 4 cables.

ADVERTENCIA

El cableado cruzado de los cables de la VÁLVULA DE SEGURIDAD DE

MONTAJE crea el riesgo de explosión que puede ocasionar muerte, lesión

física o daños materiales al producto.

E. Desconecte los tres conductos de gas de la VÁLVULA DE

SEGURIDAD DE MONTAJE. No doble ni aplaste los conductos de

gas durante la extracción.

E. Retire las conexiones de gas de la VÁLVULA DE SEGURIDAD DE

MONTAJE.

G. Retire los 4 tornillos y la VÁLVULA DE SEGURIDAD DE MONTAJE de

la pared posterior de la abertura del cajón de calentamiento.

H. Instale la nueva VÁLVULA DE SEGURIDAD DE MONTAJE de la pared

posterior del cajón de calentamiento con los 4 tornillos.

I. Vuelva a conectar los conductos de gas a la VÁLVULA DE

SEGURIDAD DE MONTAJE.

J. Vuelva a conectar los conectores del cable en su posición original.

NOTA:Verifique que no haya pérdidas en los conductos y en

las conexiones de gas antes de poner el electrodoméstico en

funcionamiento.

ADVERTENCIA

El cableado cruzado de los cables de la válvula de control de gas crea el

riesgo de explosión que puede ocasionar muerte, lesión física o daños

materiales al producto.

TAREAS DE MANTENIMIENTO

O REPARACIÓN DEL CAJÓN DE

CALENTAMIENTO

(Modelo NX58H5650WS)

1. Reemplazo del elemento del cajón de calentamiento

A. Desconecte la alimentación eléctrica de la estufa.

B. Cierre el suministro de gas de la estufa.

C. Quite el cajón de calentamiento. Presione la palanca de deslizamiento

izquierda, levante la palanca de deslizamiento derecha y luego retire

el cajón de la abertura.

D. Desconecte el conector de la pared posterior de la abertura del cajón

de calentamiento.

E. Retire el tornillo inferior y el cajón de calentamiento de la pared

posterior de la abertura del cajón de calentamiento.

F. Revierta el orden para instalar y conectar el nuevo cajón de

calentamiento.

CUADRO DE CÓDIGO DE FALLA

CÓDIGO DE

FALLA

CAUSA SOLUCIÓN

Tecla en

cortocircuito.

Problema de

sensor del horno

abierto.

Problema

de sensor

del horno en

cortocircuitos.

Recalentamiento

del horno.

Error de la traba

de la puerta.

Presione la almohadilla OFF/ CLEAR y encienda

nuevamente el horno. Si el problema persiste,

desconecte toda alimentación eléctrica a la estufa

durante por lo menos 30 segundos y luego reconecte

la alimentación eléctrica. Si esto no soluciona el

problema, llame al servicio de reparaciones. Consulte

la parte inferior de este cuadro.

Ce manuel est en papier recyclé à 100 %.

DG68-00528A-00

Mini-Manual_NX58H56_DG68-00528A_EN+MES+CFR.indb 2 06/02/2014 14:13:04

Page 5

CONSIGNES DE SÉCURITÉ

NX58H5650WS

115

180

IMPORTANTES

AVERTISSEMENT

Les informations suivantes sont destinées aux personnes

possédant une connaissance et une expérience

adéquates dans le domaine électrique, électronique

et mécanique. Le manque de connaissance et

d'expérience lors de toute réparation d'un gros appareil

électroménager est susceptible d'entraîner la mort,

des blessures et/ou des dégâts matériels. Le fabricant

ou le vendeur ne peut pas être tenu pour responsable

de l'interprétation de ces informations et rejette toute

responsabilité en relation avec leur utilisation.

• Déconnectez l'alimentation électrique de l'appareil

avant toute réparation.

• Fermez l'arrivée de gaz de l'appareil avant toute

réparation.

• Raccordez tous les dispositifs de mise à la terre

avant de reconnecter l'alimentation électrique et

d'ouvrir l'arrivée de gaz de l'appareil.

• Tous les composants de cet appareil sont reliés à

la terre. Tous les fils de mise à la terre, vis, liaisons,

écrous et/ou rondelles doivent être replacés sur

leur position d'origine et correctement serrés.

La conversion au GPL doit être réalisée par un

•

installateur qualifié ou un fournisseur de gaz en

accord avec les instructions du fabricant et de tous

les codes et exigences des autorités compétentes.

Le non respect de TOUTES ces instructions est

susceptible d'entraîner des blessures graves ou

des dégâts matériels. L’agence qualifiée eectuant

ces travaux assume la responsabilité de la

conversion.

• Repérez la vanne de coupure de gaz et la façon de

la fermer si nécessaire.

• Ne faites pas fonctionner les brûleurs de la surface

de cuisson ou du four de cette cuisinière en cas de

fonctionnement au GPL avant d'avoir converti le

régulateur de pression et les orifices des brûleurs

pour le fonctionnement au GPL. Le non-respect de

cette consigne est susceptible de provoquer des

flammes hautes et des fumées toxiques pouvant

entraîner de graves blessures.

• Ne mélangez pas ou ne remplacez pas les orifices

de brûleur pour fonctionnement au GPL pendant

l'opération de conversion. Le placement incorrect

d'un orifice aectera le brûleur et les performances

de cuisson et est susceptibles d'entraîner des

blessures corporelles et/ou des dégâts matériels.

CONVERSION GPL (PROPANE)

1. Conversion du régulateur de pression

Le régulateur de pression est situé dans le coin inférieur

gauche, à l'arrière de l'ouverture du tiroir du bas.

A. Retirez le tiroir chaue-plat ou le tiroir de rangement.

B. Localisez le régulateur de pression à l'arrière de l'ouverture

du tiroir. Le régulateur de pression est visible et accessible

depuis l'avant à travers le trou carré de la paroi arrière.

C. A l'aide de vos doigts, tournez le bouchon en plastique

rouge et le raccord de l'orifice à double usage en sens antihoraire pour les retirer du régulateur de pression.

D. Retirez complètement le bouchon du raccord et les filets et

réinstallez-le du côté opposé du raccord.

Levier de

coupure

Orifice double

eet

Faites basculer

l'orifice pour

changer

de taille

d'application.

E. Réinstallez la tige dans le régulateur de pression de façon à ce

que l'extrémité GPL large et ouverte soit exposée. Serrez la tige

jusqu'à son blocage à la main. Ne serrez pas trop. Replacez le

bouchon en plastique sur les filets exposés de la tige.

F. Vérifiez que le levier de coupure de gaz situé sur le côté du

régulateur de pression est en position ouverte.

G. Replacez le tiroir chaue-plat ou le tiroir de rangement.

Bouchon en plastique

Régulateur

de pression

2. Conversion des brûleurs de la surface de cuisson

L'appareil est livré avec des kits de conversion GPL basse altitude.

Le kit contient 7 orifices de brûleur. Cinq de ces 7 orifices ont une

dimension et un code couleur pour une utilisation sur la surface

de cuisson. Les 2 orifices restants sont destinés aux brûleurs de

cuisson et du gril du four. Utilisez les schémas suivants pour la

dimension et l'emplacement corrects des orifices:

TAILLES DES ORIFICES DES BRÛLEURS ET PUISSANCE

(GPL [Propane] 10 dans WCP)

Emplacement du brûleur Taux BTU

CUISSON TRADITIONNELLE

1

Modèle NX58H5650WS

TAILLES DES ORIFICES DES BRÛLEURS ET PUISSANCE

Emplacement du brûleur Taux BTU

CUISSON TRADITIONNELLE

1

Modèle NX58H5650WS

1

AvD

2

AvD

1

AvG

2

AvG

ArD 4,000 0.62

ArG 7,500 0.83

CTR 7,500 0.83

GRIL 11,500 1.02

Repères des orifices:

115 – Indique une ouverture de

1.15mm de l'orifice.

(Gaz naturel 5 dans WCP)

1

AvD

2

AvD

AvG 15,000 1.78

ArD 5,000 1.01

ArG 9,500 1.40

CTR 9,500 1.38

GRIL 13,500 1.64

Repères des orifices:

180 – Indique une ouverture de

1.80mm de l'orifice.

14,500 1.12

12,500 1.06

11,500 1.04

10,000 0.98

15,000 1.15

2

Modèle NX58H5600SS

18,000 1.92

17,000 1.92

18,000 1.90

2

Modèle NX58H5600SS

Taille de l'orifice [mm]

Taille de l'orifice [mm]

A. Retirez les grilles situées sur les brûleurs de la surface de

cuisson.

B. Soulevez les chapeaux et les têtes de brûleur des cuvettes

de répartition des brûleurs.

C. A l'aide d'un tournevis à douille de 9/32˝ ou de 7mm, retirez

l'orifice du brûleur du bas de chaque cuvette de répartition.

REMARQUE: Conservez ces orifices et notez leurs positions

pour une conversion ultérieure au gaz naturel.

Blanc

jaune

Blanc

Rouge

Orange

NX58H5650WS

Blanc

Blanc

Bleu

jaune

Argent

NX58H5600SS

D. Identifiez l'orifice approprié par sa taille et son code

couleur pour chacun des brûleurs de la surface de cuisson.

E. Installez les orifices appropriés dans chacune des cuvettes

de répartition comme indiqué ci-dessus. Serrez à l'aide d'un

tournevis à douille de 9/32˝ ou de 7mm. Ne serrez pas trop.

REMARQUE: Tout autre positionnement des orifices peut

produire des conditions d'utilisation dangereuses

et/ou de mauvais résultats de cuisson.

F. Replacez les têtes et les cuvettes de brûleur au mêmes

emplacements que ceux occupés avant le démontage.

Les têtes de brûleur doivent être à plat sur les cuvettes

de répartition et les coupelles doivent être à plat sur

les têtes de brûleur pour assurer un fonctionnement

approprié et en toute sécurité.

AVERTISSEMENT

Les ajustements suivants doivent être eectués avant

d'ouvrir le gaz des brûleurs du four. Le non respect peut

provoquer la mort et/ou de graves blessures coporelles

dues aux flammes hautes et aux fumées toxiques.

3. Conversion des brûleurs du four

Le four comporte un brûleur de cuisson (inférieur) et un

brûleur de gril (supérieur) Il est nécessaire de remplacer les

orifices des deux brûleurs. Reportez-vous aux tableaux de

la colonne2 pour une utilisation appropriée des orifices.

Pour remplacer l'orifice du brûleur de cuisson (inférieur):

A. Retirez les deux vis à l'arrière de la sole du four. Soulevez

vers l'arrière pour libérer le bord avant et retirez la sole.

B. Retirez les deux vis situées à l'avant du support du

diuseur de chaleur.

C. Soulevez vers l'avant le support du diuseur et retirez-le.

D. Retirez le brûleur du porte-brûleur situé sur le fond du tiroir.

E. A l'aide d'un tournevis à douille de 9/32" ou de 7mm et

d'une clé à molette, maintenez la fixation du gaz à l'aide

de la clé à molette et retirez l'orifice du brûleur du four

situé au centre de la fixation de gaz inférieure.

F. Installez un orifice de brûleur de taille appropriée pour

le brûleur inférieur du four fonctionnant au GPL.

Pour remplacer l'orifice du brûleur de gril (supérieur):

G. Retirez 1 vis du support métallique HSI.

H. Retirez 4 vis du support du diuseur de gril dans la

partie supérieure du four.

I. Soutenez le brûleur du gril d'une main puis retirez les 2

vis le soutenant à l'avant et à l'arrière du four.

J. Pour remplacer le gicleur du brûleur du gril, retirez le

gicleur à gaz à l'aide d'un tournevis à douille de 9/32".

K. Installez un orifice de brûleur de taille appropriée pour le

brûleur supérieur du four fonctionnant au GPL.

L. Positionnez l'extrémité du brûleur supérieur sur l'orifice

et fixez-le à l'aide de la vis avant.

4. Ajustement des réglages du volet d'air des brûleurs

REMARQUE: Pour assurer des caractéristiques de flamme

appropriées, installez et fermez la porte du

four avant de vérifier les flammes du brûleur.

A. Installez et fermez la porte du four.

B. Ouvrez la vanne de coupure du gaz de la cuisinière.

C. Branchez le cordon d'alimentation ou connectez

l'alimentation à la cuisinière.

D. Programmez le four sur BAKE (CUISSON

TRADITIONNELLE) et appuyez sur START (ALLUMAGE).

E. Vérifiez visuellement les caractéristiques de la flamme à

travers la vitre du four.

• Le dard des flammes doit mesurer environ 1/2"à

3/4" de long.

• L'apparence visuelle de la flamme dénote sa qualité

de combustion.

Des flammes

bleu clair sont

normales pour un

fonctionnement au

gaz naturel.

Des pointes jaunes

à l'extrémité

des dards sont

normales pour un

fonctionnement au

GPL.

Des flammes jaunes

sont anormales pour

un fonctionnement

avec tous types de

gaz. Un ajustement de plus est nécessaire.

Des flammes orange proviennent de la présence

de corps étrangers dans le tuyau de gaz. Les

particules brûleront et les flammes orange

disparaîtront.

AVERTISSEMENT

Soyez prudent lorsque vous mesurez les flammes et

ajustez le volet d'air. Les flammes sont susceptibles de

vous brûler ou de mettre le feu vos habits entraînant

ainsi des blessures corporelles voire la mort.

Vis de verrouillage

F. Desserrez la vis de verrouillage et ajustez le volet d'air

du brûleur. Une rotation en sens horaire ouvre le volet

et augmente le débit d'air. Une rotation en sens antihoraire ferme le volet et diminue le débit d'air.

REMARQUES:

• Si les flammes sont jaunes, le volet d'air du brûleur

doit être plus ouvert.

• Si les flammes tremblent ou explosent, le volet d'air

du brûleur doit être plus fermé.

• L'ouverture complète du volet d'air est fortement

recommandée en cas de fonctionnement au GPL.

G. Lorsque les flammes sont ajustées, serrez la vis de

verrouillage.

H. Programmez le four sur BROIL (GRIL) et appuyez sur

START (ALLUMAGE). Répétez les étapes E à G.

I. Eteignez le four, installez la sole et remettez en place

les grilles du four.

Vis de verrouillage

5. Ajustement des réglages de flamme faible

des brûleurs de la surface de cuisson

Toutes les flammes des brûleurs de la surface de cuisson

doivent être vérifiées et ajustées sur leur réglage de plus

faible.

REMARQUE: Les réglages de flammes faible doivent

toujours être eectués avec deux brûleurs

minimum fonctionnant simultanément.

A. Allumez deux brûleurs minimum et réglez-les sur HI

(FORT).

B. Tournez rapidement l'un des boutons en sens anti-

horaire sur le réglage le plus faible. La flamme doit

rester allumée. Si la flamme tremble ou s'éteint, ajustez

la vanne de dérivation située à la base de la tige de la

vanne pour ce bouton.

C. Tirez vers vous le bouton de ce brûleur.

Petit tournevis

Tige de

vanne

D. Insérez un petit tournevis à lame plate dans la tige de la

vanne. Tout en maintenant la tige de la vanne en place,

tournez la vis d'ajustement de la vanne de dérivation en

sens anti-horaire pour augmenter la taille de la flamme.

E. Replacez le bouton et répétez les étapes A et B.

F. Répétez les étapes A à E pour vérifier et ajuster les

brûleurs restants.

Vérification complémentaire de flamme faible

Ouvrez rapidement la porte du four lorsque le brûleur est

réglé sur LO (FAIBLE). Si la flamme s'éteint, augmentez le

réglage de flamme faible et répétez le test jusqu'à ce que la

flamme se stabilise.

SCHÉMAS DE CÂBLAGE

Modèle NX58H5650WS

AVERTISSEMENT

L'ALIMENTATION DOIT ETRE DÉBRANCHÉE AVANT TOUTE RÉPARATION DE CET APPAREIL.

Mini-Manual_NX58H56_DG68-00528A_EN+MES+CFR.indb 1 06/02/2014 14:13:06

Page 6

SCHÉMAS DE CÂBLAGE (SUITE)

NX58H5600SS

Modèle NX58H5600SS

AVERTISSEMENT

L'ALIMENTATION DOIT ETRE DÉBRANCHÉE AVANT TOUTE RÉPARATION DE CET APPAREIL.

COMMANDES DE LA CUISINIÈRE À GAZ

1. Réglage de la température du four

La température du four peut être réglée pour répondre à vos besoins

de cuisson et/ou correspondre aux réglages précédents de votre four.

A. Retirez le tiroir chaue-plat ou le tiroir de rangement.

B. Localisez le régulateur de pression dans la partie arrière gauche

de l'ouverture du tiroir.

C. A l'aide de vos doigts, tournez le bouchon rouge et l'orifice à

double usage en sens anti-horaire pour les retirer du régulateur

de pression.

D. Retirez le bouchon de l'orifice et réinstallez-le du côté opposé de

l'orifice.

E. Réinstallez l'orifice dans le régulateur de pression de façon à ce

que l'extrémité GPL large et ouverte soit exposée. Serrez l'orifice

jusqu'à son blocage à la main. Ne serrez pas trop. Assurez-vous

que le bouchon rouge est correctement fixé sur l'extrémité de

l'orifice.

F. Vérifiez que le levier de coupure de gaz situé sur le côté du

régulateur de pression est en position ouverte.

G. Replacez le tiroir chaue-plat ou le tiroir de rangement.

2. Accès au tableau de commande du four

A. Débranchez ou coupez l'alimentation électrique de la cuisinière.

B. Fermez la vanne de coupure du gaz de la cuisinière.

C. Éloignez avec précaution la cuisinière du mur pour accéder à la

protection arrière du câblage protecteur.

D. Retirez le panneau de protection supérieur arrière.

3. Test de la carte du circuit imprimé (PCB)

A. Reconnectez l'alimentation électrique avec précaution et

eectuez les vérifications suivantes.

B. Une fois les vérifications terminées, débranchez

l'alimentation.

TEST DE FONCTIONNEMENT DU CONTACT DU RELAIS

RELAIS BORNES

Cuisson par

convection

Rôtissage par

convection

Tiroir chaue-

plat*

Cuisson

personnalisée

Auto-

nettoyage

Cuisson

traditionnelle

Gril Gril sur N 120VCA** 0VCA

Chaud Chaud sur N 120VCA 0VCA

Levée Levée sur N 120VCA 0VCA

Éclairage du

four

**Veillez à sélectionner une température ou un réglage.

**120VCA sur Cuisson et Temps de cuisson uniquement.

Les circuits restants sont désactivés jusqu'à ce que le circuit

L'indication

Conv. Cuisson

sur N

L'indication

Conv.

Rôtissage

sur N

Tiroir chaue-

plat sur N

Cycle de

cuisson sur N

Auto-

nettoyage

sur N

Cuisson sur N 120VCA** 0VCA

Éclairage sur

L1

*Modèle NX58H5650WS uniquement.

Shabbat soit désactivé.

TENSION EN

MODE CUISSON

120VCA** 0VCA

120VCA** 0VCA

0VCA

(en auto-

nettoyage)

120VCA 0VCA

120VCA 0VCA

120VCA 0VCA

COUPURE DE

LA TENSION

D'ENTRÉE

120VCA

4. Remplacement de la carte de circuit

imprimé

A. Repérez et déconnectez les fils reliés à la carte de circuit

imprimé.

B. Retirez les 17 vis et la protection du câblage LT/RT, la

protection arrière du câblage protecteur, la protection arrière

du câblage principal et le couvercle de convection.

C. Retirez les 2 vis du support de la carte de circuit imprimé.

D.

Remplacez la carte de circuit imprimé et fixez-la à l'aide de 2vis.

E. Reconnectez tous les fils aux emplacements où ils se

trouvaient avant le démontage.

5. Remplacement du module d'étincelle

Le module d'étincelle est situé à l'arrière du panneau arrière

supérieur du côté inférieur droit.

A. Repérez et déconnectez les fils reliés au module d'étincelle.

B. Retirez les 2 vis et le module d'étincelle du dosseret.

C. Installez un nouveau module d'étincelle dans le dosseret et

fixez-le à l'aide de 2vis.

D. Reconnectez les fils aux emplacements où ils se trouvaient

avant le démontage.

RÉPARATION DE LA SURFACE DE CUISSON

1. Démontage de la surface de cuisson

A. Débranchez l'alimentation électrique de la cuisinière.

B. Fermez la vanne de coupure du circuit d'alimentation en gaz

de la cuisinière.

C. Ouvrez la porte ou retirez-la.

D. Tirez les boutons vers vous afin de les retirer des axes de la

vanne.

E. Retirez les 2 vis de la partie supérieure, les 2 vis de la partie

avant et les 4 vis de la partie inférieure du panneau répartiteur

du châssis.

F. Retirez le panneau répartiteur du châssis de la partie avant de

la cuisinière.

G. Placez un doigt derrière chaque côté du commutateur

d'allumage et tirez-le tout vers vous pour le libérer de l'axe de

commande. Répétez l'opération pour chaque commutateur.

H. Déconnectez les fils des connecteurs.

AVERTISSEMENT

Ne pliez pas le tube en aluminium des cuvettes des

brûleurs.Le contraire est susceptible d'endommager le tube

ou la fixation et entraîner la mort, des blessures corporelles,

un incendie et/ou des dommages sur le produit.

2. Remplacement du loquet de la porte

A. Retirez la porte du four et le cadre de la surface de cuisson

comme décrit ci-dessus.

B. Retirez le bouton et le répartiteur du châssis.

C. Retirez l'ensemble tube-répartiteur à l'aide d'une clé.

D. Retirez les 2 vis du support-loquet auxiliaire à l’arrière de la

cuisinière.

E. Déconnectez les fils du loquet de la porte à l’arrière de la

cuisinière et retirez-les.

F. Retirez les 2 vis maintenant l’ensemble support-loquet arrière

à l’arrière de la cuisinière.

G. Retirez le loquet-axe de l’ensemble support-loquet avant.

H. Retirez les 2 vis maintenant l’ensemble support-loquet avant

à l’avant de l’enceinte du four.

I. Après remplacement, inverser l’ordre pour installer

l’ENSEMBLE LOQUET PORTE.

3. Remplacement de l'électrode/fils couplés

A. Retirez la surface de cuisson comme indiqué ci-dessus.

B. Retirez la protection du câblage LT/RT et la protection arrière

du câblage protecteur.

C. Retirez soigneusement les épingles de verrouillage de la

partie inférieure des électrodes dans les cuvettes de brûleur.

Soulevez et glissez le fil d'électrode hors de la fente dans la

cuvette de brûleur.

D. Suivez le fil d'électrode jusqu'au module de démarrage et

déconnectez le fil du module d'étincelle.

E. Connectez de nouveaux fils couplés d'électrode au module

d'étincelle au même emplacement que ceux qui ont été

retirés.

F. Insérez l'électrode dans la fente de la cuvette de brûleur et

fixez-le à l'aide des épingles de verrouillage.

4. Remplacement de fils couplés du

commutateur d'allumage

A. Débranchez l'alimentation électrique de la cuisinière.

B. Fermez la vanne de coupure du circuit d'alimentation en gaz

de la cuisinière.

C. Ouvrez la porte ou retirez-la.

D. Tirez les boutons vers vous afin de les retirer des axes de la

vanne.

E. Retirez les 2 vis de la partie supérieure, les 2 vis de la partie

avant et les 4 vis de la partie inférieure du panneau répartiteur

du châssis.

F. Retirez le panneau répartiteur du châssis de la partie avant de

la cuisinière.

G. Placez un doigt derrière chaque côté du commutateur

d'allumage et tirez-le tout vers vous pour le libérer de l'axe de

commande. Répétez l'opération pour chaque commutateur.

H. Déconnectez les fils des connecteurs.

I. Connectez les nouveaux fils couplés du commutateur

d'allumage aux connecteurs où se trouvaient les anciens fils

et installez les nouveaux fils couplés dans l'ordre inverse.

RÉPARATION DU FOUR

1. Remplacement du capteur de température

du four

A. Débranchez l'alimentation électrique de la cuisinière.

B. Ouvrez la porte du four et retirez les grilles.

C. Débranchez le connecteur de la thermistance du capteur

située à l'arrière de la cuisinière.

D. Retirez 2 vis fixant le capteur de température du four situé

dans le coin supérieur gauche de la paroi arrière.

E. Tirez soigneusement les fils du capteur jusqu'à ce que les

connecteurs du fil apparaissent.

REMARQUE: Si les connecteurs du fil ne sont pas

accessibles depuis l'intérieur du four, retirez le panneau de

protection supérieur arrière, repérez les fils et déconnectezles depuis l'arrière du four.

F. Installez un nouveau capteur de température du four dans

l'ordre inverse.

2.

Remplacement

A. Coupez l'alimentation électrique de la cuisinière.

B. Fermez la vanne de coupure du circuit d'alimentation en gaz

de la cuisinière.

C. Ouvrez la porte du four et retirez les grilles situées à l'intérieur.

D. Tirez sur les fils ou le connecteur jusqu'à ce que le

connecteur du fil soit visible depuis la paroi arrière du

logement du tiroir chaue-plat.

E. Débranchez le connecteur du HSI du brûleur de cuisson.

F. Retirez les deux vis à l'arrière de la sole du four. Soulevez

vers l'arrière pour libérer le bord avant et retirez la sole.

G. Retirez les deux vis situées à l'avant du support du diuseur

de chaleur.

du brûleur inférieur (cuisson)

H. Soulevez vers l'avant le support du diuseur et retirez-le.

I. Retirez le brûleur du porte-brûleur situé sur le fond du tiroir.

J. Installez un nouveau brûleur de cuisson dans l'ordre inverse.

3. Remplacement du brûleur supérieur (gril)

A. Débranchez l'alimentation électrique de la cuisinière.

B. Fermez la vanne de coupure du gaz de la cuisinière.

C. Ouvrez la porte du four et retirez les grilles.

D. Retirez la protection arrière du câblage principal situé à

l'arrière du four.

E. Débranchez les fils ou le connecteur du HSI.

F. Retirez une vis du support de fil HSI et retirez 4 vis du

récupérateur du support de gril situé dans la partie supérieure

du four.

G. Soutenez le brûleur du gril d'une main puis retirez les 2 vis le

soutenant à l'avant et à l'arrière du four.

H. Tirez l'ensemble diuseur du brûleur de gril pour le

déconnecter du porte-gicleur de gril situé sur la paroi arrière

du four.

I. Retirez soigneusement l'ensemble diuseur du brûleur de gril.

J. Installez un nouveau brûleur de cuisson dans l'ordre inverse.

4. Remplacement de la barre du dispositif

d'allumage à éclat

(dispositif d'allumage de surface chaude)

A. Débranchez l'alimentation électrique de la cuisinière.

B. Fermez l'arrivée de gaz de la cuisinière.

C. Ouvrez la porte du four et retirez les grilles.

D. Retirez le brûler de four proche du dispositif d'allumage

défaillant. (Reportez-vous aux instructions de remplacement

du brûleur)

E. Retirez 2 vis fixant la barre du dispositif d'allumage à éclat.

F. Tirez soigneusement les fils jusqu'à ce que les connecteurs

de fil apparaissent.

G. Reconnectez un nouveau dispositif d'allumage et

réassemblez le four dans l'ordre inverse.

5. Ensemble de vanne de sécurité

(avec régulateur de pression)

A. Débranchez l'alimentation électrique de la cuisinière.

B. Fermez l'arrivée de gaz de la cuisinière.

C. Retirez le support du régulateur de l'arrière de la cuisinière.

D. Identifiez et repérez soigneusement les fils allant à la VANNE

DE SÉCURITÉ. Déconnectez les 4 fils.

AVERTISSEMENT

Le croisement transversal des fils de la VANNE DE SÉCURITÉ

provoque un risque d'explosion susceptible d'entraîner la mort,

des blessures corporelles et/ou des dégâts sur le produit.

E. Débranchez les 3 conduites de gaz de la VANNE DE

SÉCURITÉ. Ne pliez pas ou ne sertissez pas les conduites de

gaz durant leur retrait.

F. Retirez les raccords de gaz de la VANNE DE SÉCURITÉ.

G. Retirez 4 vis et la VANNE DE SÉCURITÉ de la paroi arrière du

compartiment du tiroir chaue-plat.

H. Fixez la nouvelle VANNE DE SÉCURITÉ à la paroi arrière du

tiroir chaue-plat à l'aide des 4 vis.

I. Rebranchez les conduites de gaz sur la VANNE DE

SÉCURITÉ.

J.

Reconnectez les connecteurs de fil dans leurs positions d'origine.

REMARQUE: Vérifiez l'absence de fuites au niveau des

conduites et raccords avant toute utilisation.

AVERTISSEMENT

Le croisement transversal des fils de la vanne de commande

du gaz provoque un risque d'explosion susceptible d'entraîner

la mort, des blessures corporelles et/ou des dégâts sur le

produit.

RÉPARATION DU TIROIR CHAUFFE-PLAT

(Modèle NX58H5650WS)

1. Remplacement de l'élément du tiroir

chaue-plat

A. Débranchez l'alimentation électrique de la cuisinière.

B. Fermez l'arrivée de gaz de la cuisinière.

C. Retirez le tiroir chaue-plat. Appuyez sur le levier de