Samsung Msys 730 Service Manual

SERVICE

SAMSUNG FACSIMILE

Msys 730

Manual

SAMSUNG FACSIMILE CONTENTS

1. Precautions

2. Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. Exploded Views and Parts List

6. Block Diagram

7. Connection Diagram

ELECTRONICS

© Samsung Electronics Co.,Ltd. MAY

2002

Printed in Korea.

VERSION NO. : 1.00 CODE : JC-0073A

This service manual is also provided on the web,

the ITSELF system Samsung Electronics Co., Ltd.

“http://itself.sec.samsung.co.kr”

This manual is stated and

provided for service description.

All rights reserved. Any parts of the

information in this manual are prohibited

from free duplication, use or translation

without prior written approval except in

cases allowed by the Copyright Act.

Specifications are subject to change without

prior notice.

Copyright (c) 2002. 5.

Samsung Electronics Digital Printing CS Group

1-1

Samsung Electronics

1. Precautions

Please read the following carefully to prevent any accidents and not to damage the unit during service.

1-1 Safety Precautions

1-2 Precautions on Disassembly and Reassembly

1. Safety Precautions

There are some electric or machinery parts with safety

related property. If the parts replaced are different from

the original, the safety may not function. Even if the part

could allow higher voltage than that of the part used, do

not replace it and use a regular product clarified in specifications.

2. Be careful not to leave a switch, a cover or a safety device

out when reinstalling or assembling the product after

repair.

3. Replacing Precautions

Do not change or add parts as you like. You cannot benefit from such a remodeled product at your will during the

term of guarantee.

4. You must replace overheated or damaged parts or cords

with regular products. Please solve the problem causing

any damage or overheating and troubles beforehand.

Especially mind the safety on the part with this

mark.

You must use regular parts described in specifications for the parts inflammable and where the current can be flown. Otherwise any hazard such as

an electric shock or a fire could occur.

LASER STATEMENT (LASERTURVALLISUUS)

WARNING : NEVER OPERATE AND SERVICE THE PRINTER

WITH THE PROTECTIVE COVER REMOVED

FROM LASER/SCANNER ASSEMBLY. THE

REFLECTIVE BEAM, ALTHOUGH INVISIBLE, CAN

DAMAGE YOUR EYES.

Class 1 laser product

Luokan 1 laserlaite

Klass 1 laser apparat

Allonpituus 770-795nm

Teho 0.3mW±0.03mW

CAUTION

VORSICHT

ATTENTION

ATTENZIONE

PRECAUCION

CAUTION : Avoid exposure to invisible laser radiation when the

development unit is not installed.

INVISIBLE LASER RADIATION WHEN

THIS COVER OPEN. DO NOT OPEN

THIS COVER.

UNSICHTBARE LASERSTRAHLUNG,

WENN ABDECKUNG GEOFFNET.

NIGHT DEM STRAHLAUSSETZEN.

REYONNEMENT LASER INVISIBLE EN CAS

D’OUVERTURE. EXPOSITION DANGERUSE AU

FAISCEAU.

RADIAZIONE LASER INVISIBLE IN CASO DI

APERTURA. EVITARE L’ESPOSIZONE LA FASCIO.

REDIACION LASER INVISIBLE CUANDO SE

ABRE. EVITAR EXPONERSE AL RAYO.

Very careful precautions should be taken when replacing

parts. Before replacing, please check cables because you

cannot put the cables that you removed for replacing parts

into the proper place if you would not make sure of where

they were connected and in which condition.

Please do the following before disassembling

for a repair or replacement of parts.

1. Pull out paper cassette, printer cartridge installed.

Especially careful not to be scratched by the surface of

developer or not to expose them to light.

2. Turn the power switch off.

3. Take out the power plug, printer cable from the printer.

4. Use only the same type of part as original when replacing

parts.

5. Do not force to open or fasten plastic material components.

6. Be careful that small parts such as screws should not get

in the printer.

7. When disassembling, assembling, also observe small

components are located in place.

8. If you uncover and turn the machine over to replace some

parts, toner or paper particles may contaminate the LSU

window. Protect the LSU window with clean paper.

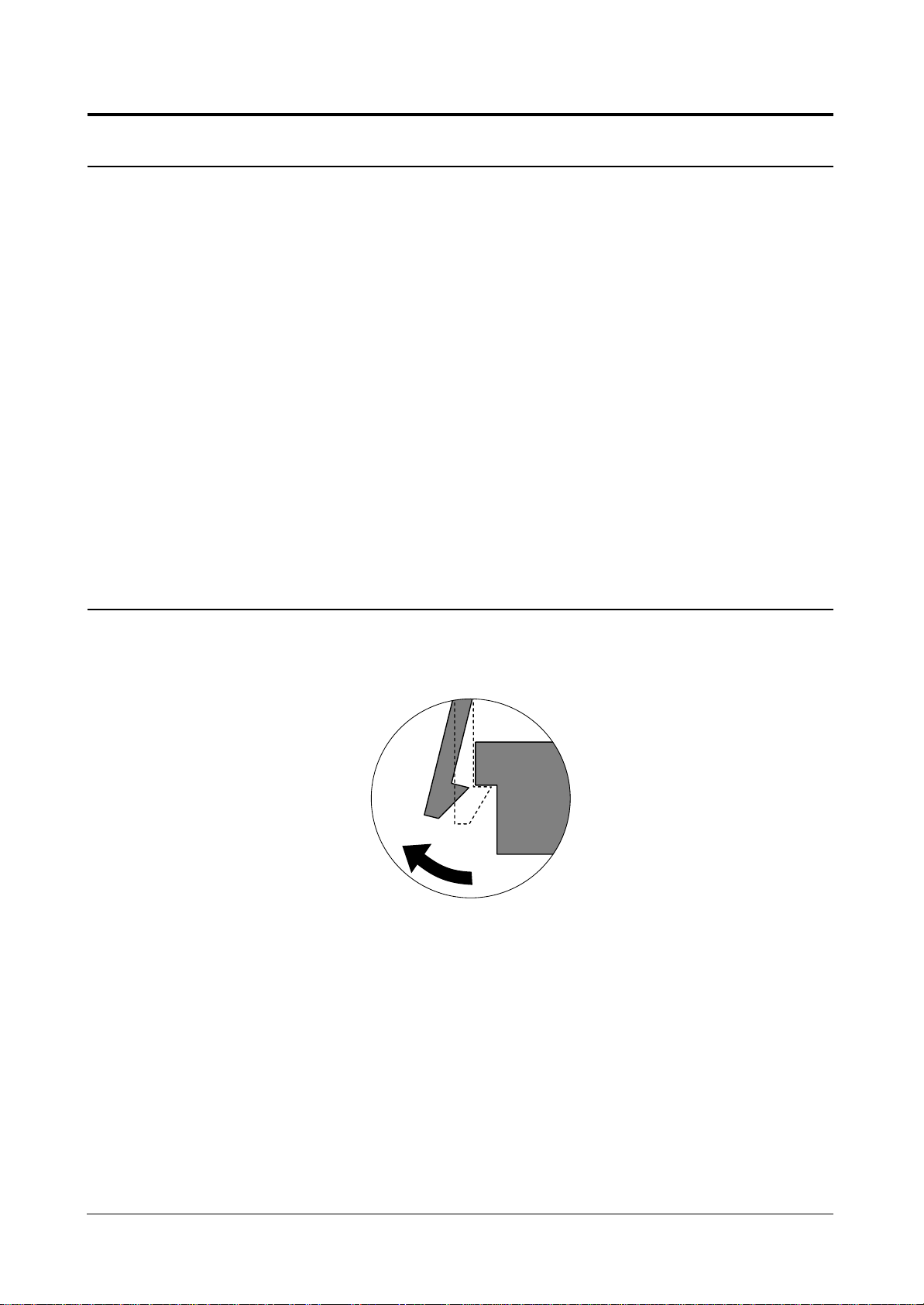

Releasing Plastic Latches

Many of parts are held in

place with plastic latches.

The latches break easily :

release them carefully.

To remove such parts,

press the hook end of the

latch away from the part to

which it is latched.

Certain semiconductor devices can be easily damaged by

static electricity. Such components are commonly called

“Electrostatically Sensitive (ES) Devices”, or ESDs.

Examples of typical ESDs are: integrated circuits, some field

effect transistors, and semiconductor “chip” components.

The techniques outlined below should be followed to help

reduce the incidence of component damage caused by static electricity.

1. Immediately before handling a semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, employ a commercially available wrist strap device, which should be removed for your

personal safety reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with

ESDs, place the assembly on a conductive surface, such

as aluminum or copper foil, or conductive foam, to prevent electrostatic charge buildup in the vicinity of the

assembly .

3. Use only a grounded tip soldering iron to solder or desolder ESDs.

4. Use only an “anti-static” solder removal device. Some solder removal devices not classified as “anti-static” can

generate electrical charges sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When sprayed,

these can generate electrical charges sufficient to damage ESDs.

6. Do not remove a replacement ESD from its protective

packaging until immediately before installing it. Most

replacement ESDs are packaged with all leads shorted

together by conductive foam, aluminum foil, or a comparable conductive material.

7. Immediately before removing the protective shorting

material from the leads of a replacement ESD, touch the

protective material to the chassis or circuit assembly into

which the device will be installed.

8. Maintain continuous electrical contact between the ESD

and the assembly into which it will be installed, until completely plugged or soldered into the circuit.

9. Minimize bodily motions when handling unpackaged

replacement ESDs. Normal motions, such as the brushing together of clothing fabric and lifting one’s foot from a

carpeted floor, can generate static electricity sufficient to

damage an ESD.

1-3 ESD Precautions

Precautions

1-2

Samsung Electronics

CAUTION:

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

Precautions

1-3

Samsung Electronics

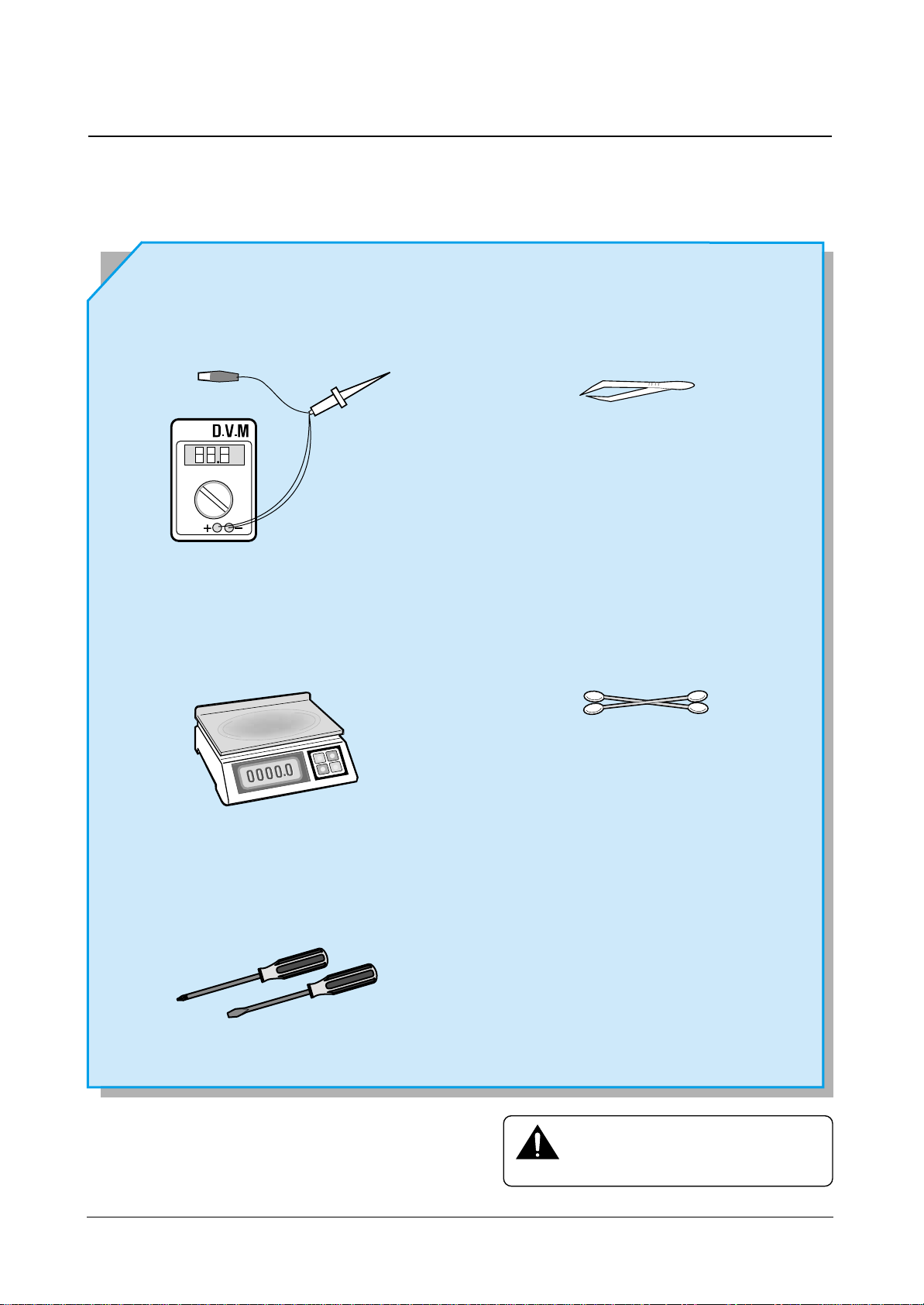

1-4 Tools for Troubleshooting

The following tools are recommended for safe and smooth troubleshooting described in this service manual.

DVM(Digital Volt Meter)

Standard : Indicates more than 3 digits.

Electronic Scale

Standard : Equipment to check the weight of con-

sumables(toner cartridge) . (The gram unit

can be measured.)

Driver

Standard: "-" type, "+" type (M3 long, M3 short, M2

long, M2 short)

Pinset

Standard : For general home use, small type.

Cotton Swab

Standard : For general home use, for medical ser-

vice.

Cleaning Equipments a IPA(Isopropyl

Alcohol) dry cloth or a soft stuff neutral

detergent.

Mind your hands not to be touched when

you disassemble and reassemble PBAASS'Y,

such as the main board, SMPS, HVPS.

Note

2. Specification

2-1 Facsimile

Machine type Desk Top

Applicable line Public Switched Telephone Network (PSTN) or behind PABX

Compatibility CCITT Group 3

Data coding MH/MR/MMR

Modem speed

33600/31200/28800/26400/24000/21600/19200/16800/

14400/12000/9600/7200/4800/2400 bps

Transmission speed Approx. 6 sec.(14.4K,ECM,4% Letter)

Effective scanning width 8.2 inches (208 mm)

Effective printing width 8.2 inches (208 mm : LTR)

Scanning method Sheet-fed scanning using a Contact Image Sensor (CIS)

Memory 5 MByte

Halftone 256 levels

Printing speed 8 PPM (Letter size)

Automatic document feeder 50 pages (75g/m2, 20lb : 0.09 ~ 0.10 mm thickness)

Documents size

Width 5.8 to 8.5 inches (148 to 216 mm)

Length Single page : 5 to 59 inches (128 to 1,500 mm)

Multi pages : 8.3 to 11.7 inches (279 to 297 mm)

Weight Single page : 12.5 to 32 lb (50 to 100g/m

2

) (0.07 to 0.15 mm)

(thickness) 20 pages: 12.5 to 28 lb (50 to 90g/m

2

) (0.07 to 0.13 mm), Uncoated paper

50 pages : 20 lb (75g/m

2

) (max 0.1 mm), Uncoated paper

One-touch dial :

Registration for 38 numbers

Speed dialing Registration for 150 numbers

LCD : 16 characters x 2 lines

2-2 SCANNER

Scanning Method : Sheet-fed scanning by CIS and feeding of the document by a

stepping motor

Resolution Horizontal 11.8 lines/mm (300 dpi)

Vertical STANDARD : 3.85 lines/mm (98 Lpi)

FINE : 7.7 lines/mm (196 Lpi)

SUPER FINE : 11.8 lines /mm (300 Lpi)

Gray Scale : 256 shades

Scanning period : STANDARD : 2.5 ms/line

FINE : 2.5 ms/line

SUPER FINE : 2.5 ms/line

Samsung Electronics 2-1

2-2 Samsung Electronics

2-3 Printer

Print Speed 8 PPM (A4 Size, 5% Charcter Pattern) : At Copy Mode

Resolution 600 X 600 DPI

Source of Light Laser Diode(LSU)

Print Method Non-impact Electrophotography, Laser Beam

Feed Method Multi-Purpose Feeder and Manual

Feed Reference Side Reference Loading

Paper Size Cassette Type Normal Paper : A4,Letter,Legal,B5,Executive

A5 (for manual)

Length 148 ~ 356mm

Width 98 ~ 216mm

Paper Weight For MPF 60 ~ 90g/m

2

For Manual 60 ~120g/m

2

Paper Capacity MPF 250 Sheets (based on 75g/m2)

Manual Slot 1 Sheet

Paper Stacker Capacity Face up : 150 Sheets (75g/m2,20 lb)

Warming up Time About 20 sec

First Printing Time Stand-By About 25 sec

Power Save Mode About 40 sec

Power Rating AC 110V ~127V ± 15% 50/60Hz ± 3Hz,

AC 220V ~ 240V ± 15% 50/60Hz ± 3Hz

Power Consumption Max. 210Wh

Stand-by 50Wh

Avg. 13Wh

Power Saving Consumption Sleeping Mode

Certification & Compliance FCC, cUL, CE, CB, IC CS-03

Acoustic Noise Standby Less than 36dB

Operating Less than 50dB

Toner Cartridge One-Cartridge type

Expected Life Span 100,000 Sheets

Operating Environment Temperature : 10 ~ 30°C , Humidity : 30 ~ 80%RH

Storage Environment Temperature : 0 ~ 35°C , Humidity : 20 ~ 95%RH

Weight SET Net : 9 kg Gross : 14.3 kg

SCF Net : 4.8 kg Gross : 6.0 kg

External Dimension 386(W) X 405(D) x 270(H)mm

Developer Life Span 5% Pattern,Min. 6,000 Sheets

Developing Non-magnetic Contact Developing

Charging Conductive Roller Charging

Density Adjustment Dark, Medium

Toner Supply Method Exchanging Toner Cartridge

New Developer Checkable YES

Transfer System Pre-transfer By LED & Conductive Roller Transfer

Fusing System Temperature & Pressure

OZONE Emission Max. 0.1 PPM(8 Hours)

Specification

Samsung Electronics 2-3

Specification

2-4 Quality

Conditions

Paper Normal Paper , 75g/m

2

Environment Temperature : 20 ~ 25°C

Humidity : 40 ~ 60%

Print Quality Image Density Min. 1.3

Min. 1.0(Temperature : 10 ~ 15°C) ,Samsung Paper

Background Max. 0.2

Uniformity Max. 0.2(Including Continuous Print)

Fusing Min. 75% (All Black)

Start Position Top : 4.23mm ± 2, Side : 4mm ± 2 From Left

Skew Top : Max. ± 1.5mm/200mm

Side : Max. ± 2.0mm/250mm

Orthogonality ± 1.0mm

Horizontal Scan ± 0.6mm/200mm

(Bowed Line Skew : Pattern 1)

Special Paper Exception Image Density : Min 1.0 (Envelope)

Fusing : Min. 70% (All Black)

(Envelope/OHP/Postcard)

Paper Jam Less than 1/1,000(75g/m

2

Paper)

Paper Curl First : Less than 16mm (10 Sheets, 75g/m2Paper)

After Cooling : Less than 16mm (10 Sheets, 75g/m2Paper)

Reliability Insulation Resistance Less than 10 MΩ (at DC 500V)

Dielectric Strength AC 1000V (DC 1420V), 10mA

Ground Continuous Less than 0.1Ω

Voltage DIP Rated Voltage ± 15%

AC Impulse Noise AC 1000V 10, 100, 200, 400, 1000ns Rated Power

Leakage Current Less than 3.5mA

Surge 6 KV, 500A

OZONE Emission Less than 0.1 ppm (8 Hours)

Top Cover Open Isolating the input power of the LSU,

High Voltage Part, and Fuser

Overcurrent Protect Fuse inside the Engine Controller

Fusing System Trouble Sensing .The temperature doesn’t rise to the specific

temperature in the specific time.

.The temperature is too high.

Overheat Sensing 240 ~ 250°C (The thermostat cuts off the Fuser from the

power.)

Thermistor Open Sensing : Without the initial temperature

change of the Fuser

2-4 Samsung Electronics

Specification

2-5 SMPS (Switching Mode Power Supply)

Input (AC) AC Input Voltage American

Minimum 90V

Typical 120V

Maximum 135V

Max. AC Input Currents 3Amps

Max. Inrush Current) 40 Ap-p (at 25°C)

Output (DC) Line Regulation 24V ± 10%

12V ± 5%

Road Regulation -12V ± 5%

5V ± 5%

Ripple Noise 24V : Peak 500mVp-p

12V : Peak 500mVp-p

-12V : Peak 500mVp-p

5V : Peak 300mVp-p

Over Current Protect 24V : 2.7A ± 10% (by Circuit)

5V : 3A ± 10% (by Circuit)

Over Voltage Protect 24V : 33V

5V : 5.6V

Disassembly and Reassembly

3-1

Samsung Electronics

3. Disassembly and Reassembly

3-1 General Precautions on Disassembly

When you disassemble and reassemble components, you must use extreme caution. The close proximity of cables to

moving parts makes proper routing a must.

If components are removed, any cables disturbed by the procedure must be restored as close as possible to their original positions. Before removing any component from the machine, note the cable routing that will be affected.

Whenever servicing the machine, you must perform as follows:

1. Check to verify that documents are not stored in memory.

2. Be sure to remove the toner cartridge before you disassemble parts.

3. Unplug the power cord.

4. Use a flat and clean surface.

5. Replace only with authorized components.

6. Do not force plastic-material components.

7. Make sure all components are in their proper position.

3-2 Releasing Plastic Latches

Many of the parts are held in place with plastic latches. The latches break easily; release them carefully.

To remove such parts, press the hook end of the latch away from the part to which it is latched.

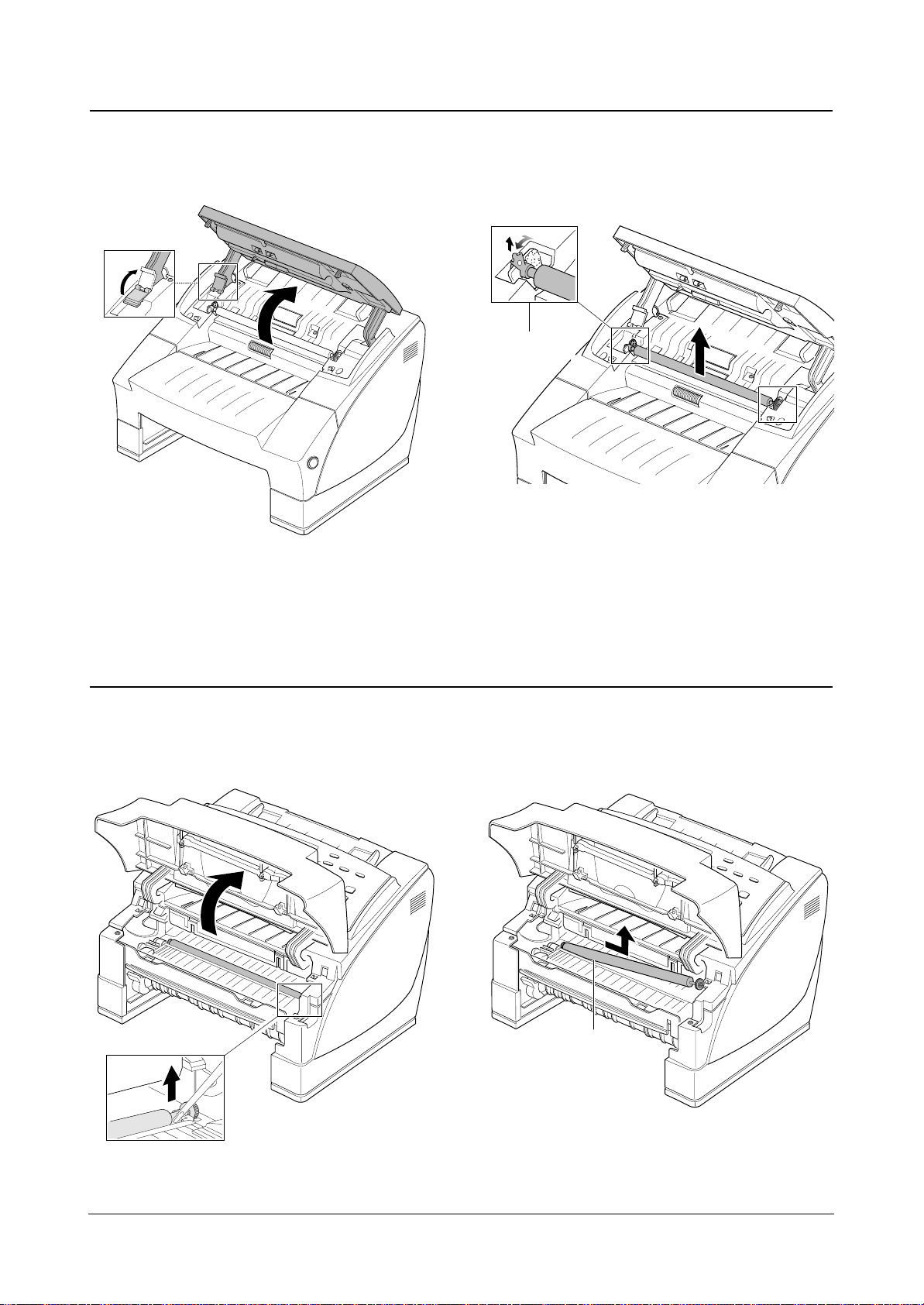

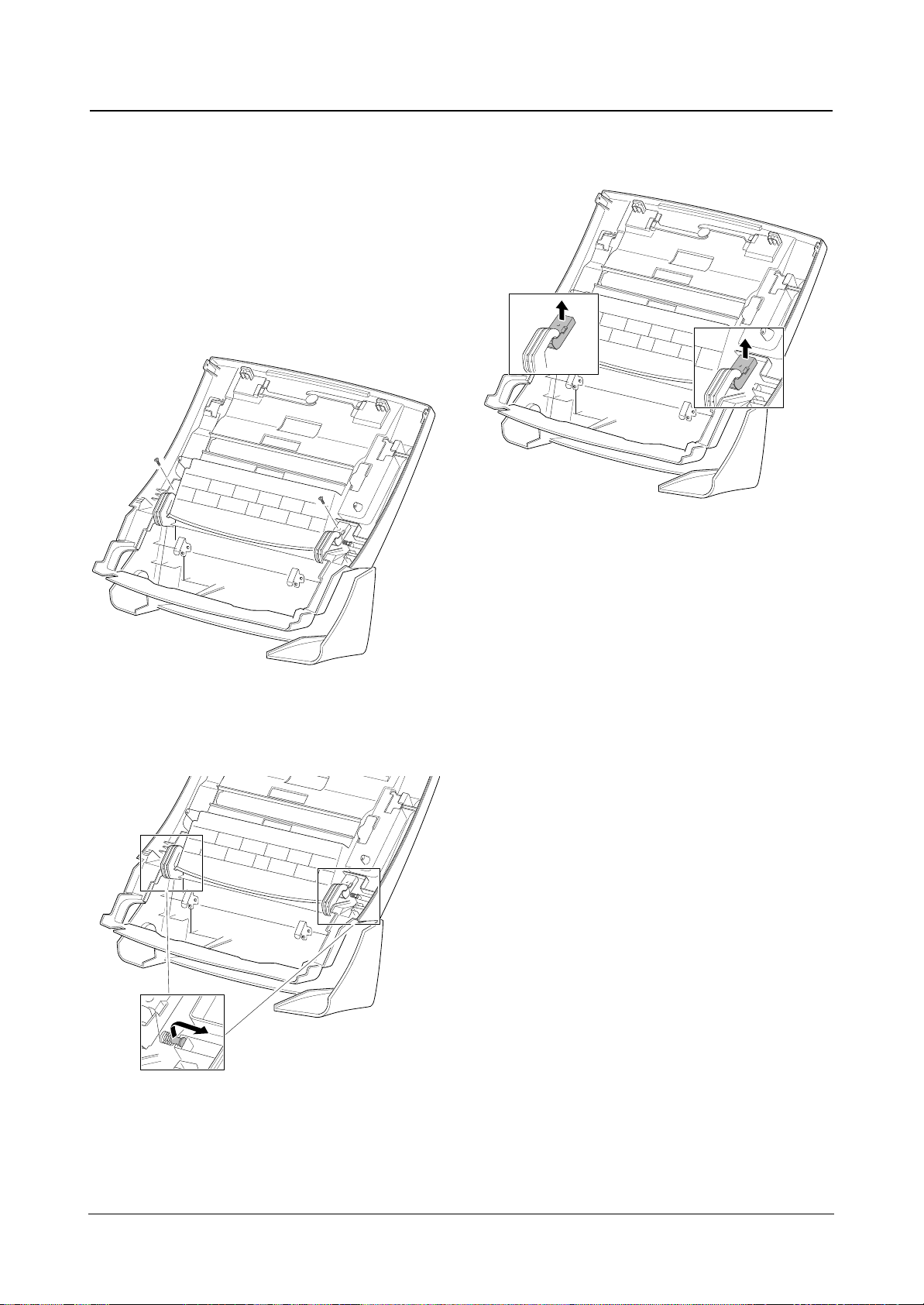

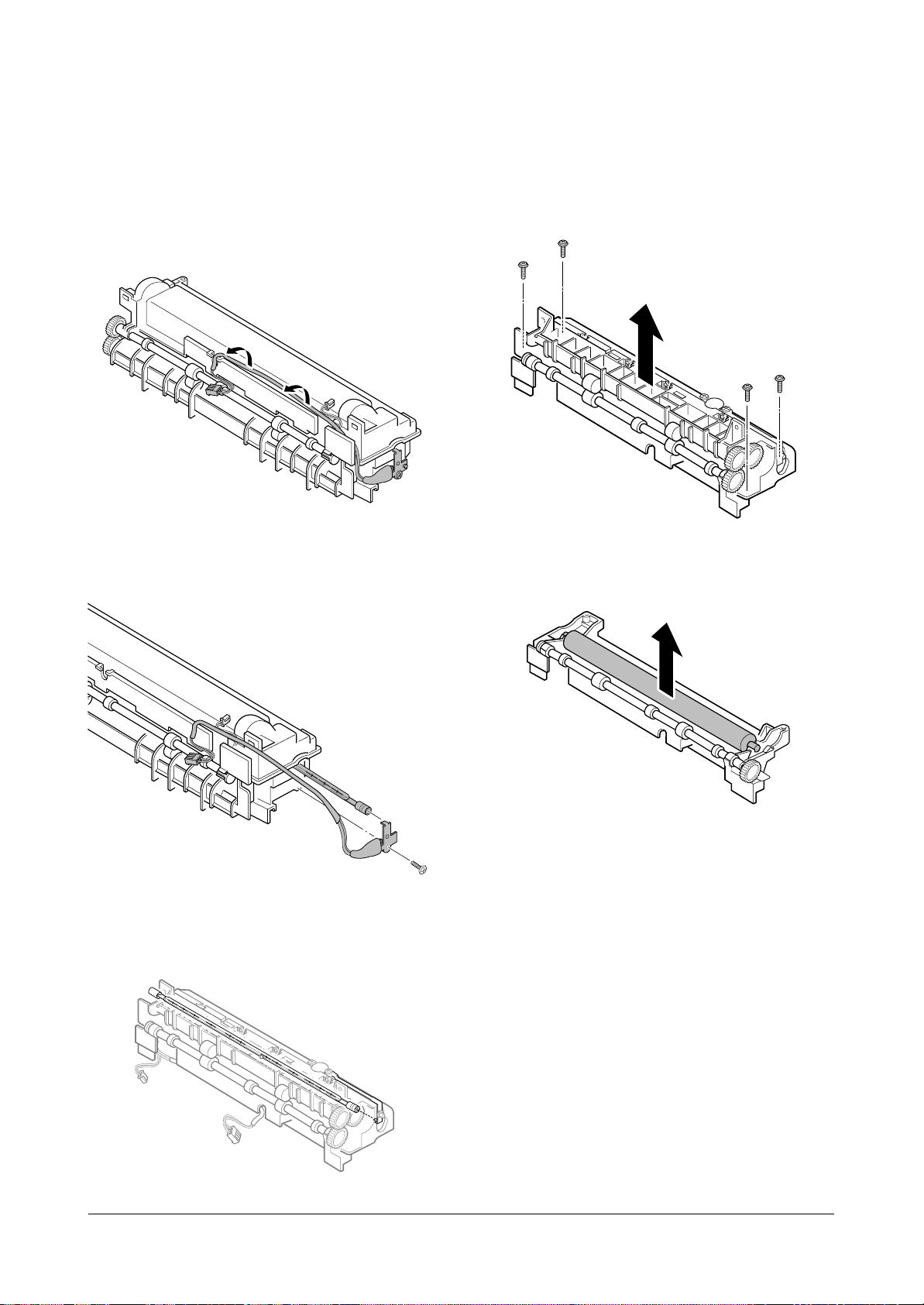

1. Open the OPE panel, then set the support-OPE to

the OPE panel.

2. Push the bushing on the both ends of the roller

slightly inward, then rotate it until it reaches the slot.

Then lift the roller out.

Note: Check the roller for any dirt. If dirty, wipe it off with

soft cloth dampened with water. If the roller is heavily worn, replace it with a new one.

1. Open the front cover, and release one end of the

roller using a proper tool as shown in the square.

2. Pull the other end of the roller slightly inward, then lift

it up.

Disassembly and Reassembly

3-2

Samsung Electronics

3-3 White Roller

Bushing

Transfer roller

3-4 Transfer Roller

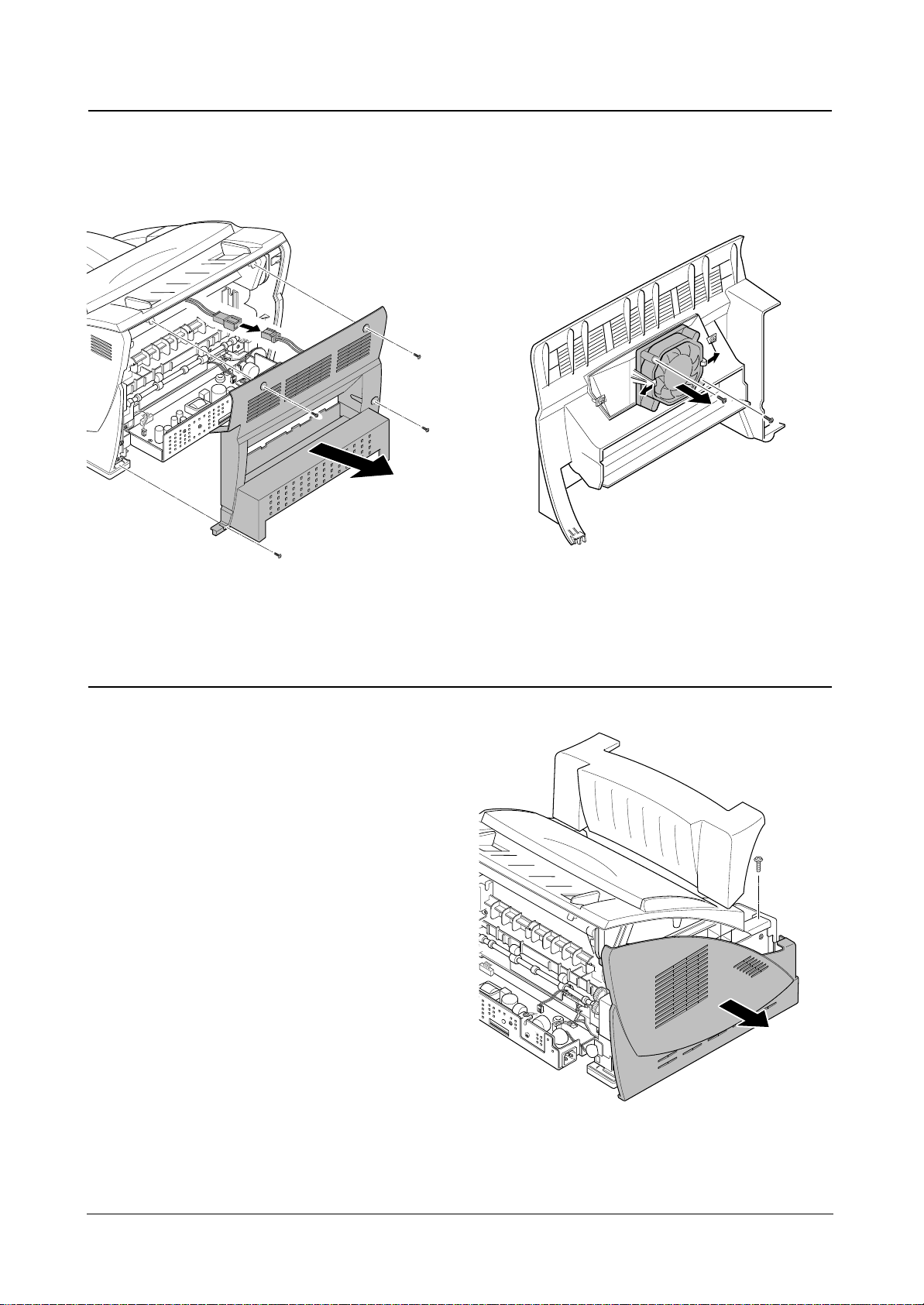

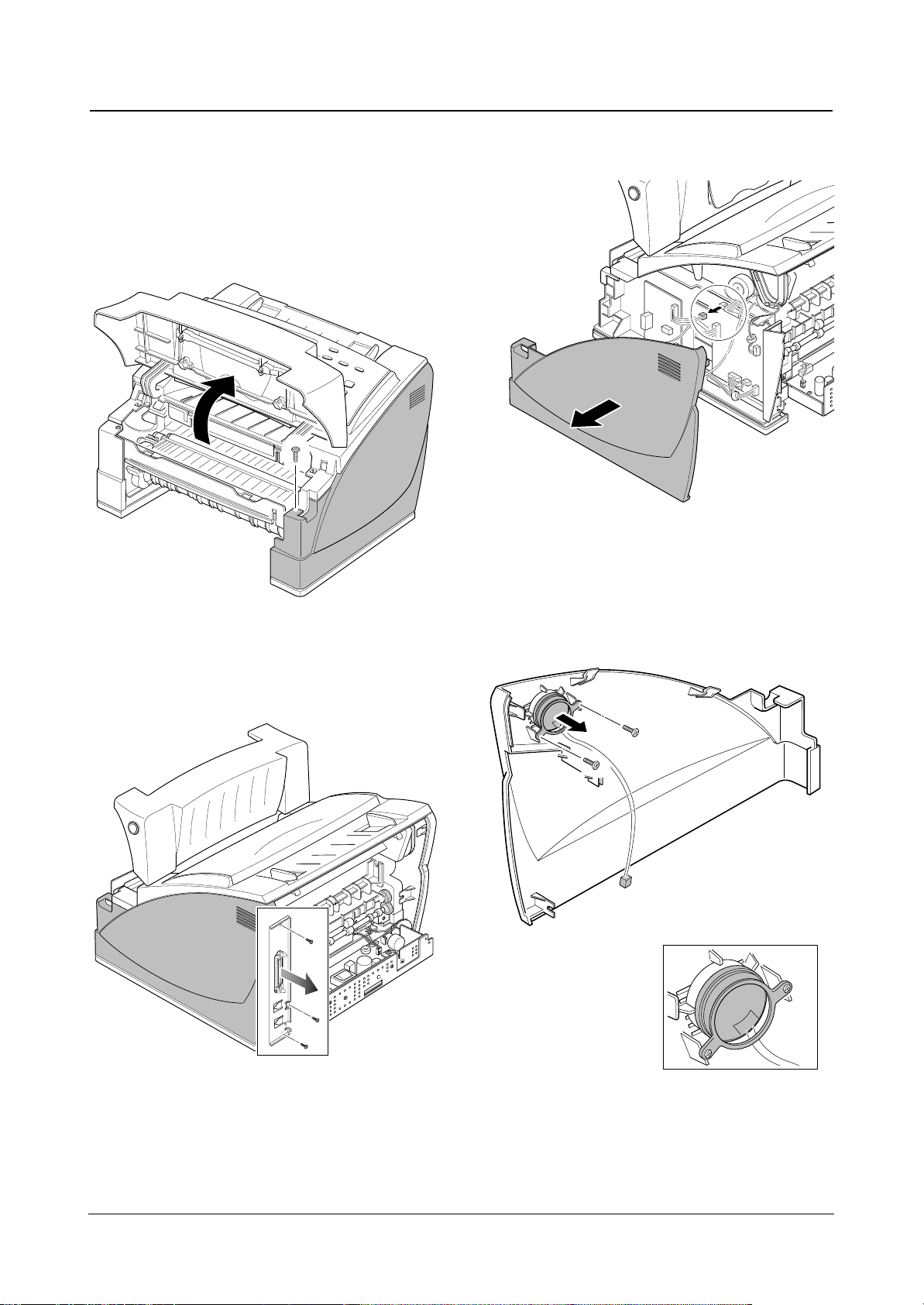

1. Remove four screws, unplug one harness, then

remove the rear cover.

2. If you want to remove the dummy fan from the rear

cover, remove two screws and release two latches,

then take it out.

1. Before you remove the cover, you should remove:

– Rear cover (see page above)

2. Open the front cover, remove one screw, then

remove the left side cover.

Disassembly and Reassembly

3-3

Samsung Electronics

3-5 Rear Cover

3-6 Left Side Cover

1. Before you remove the cover, you should remove:

– Rear cover (see page 3-3)

2. Open the front cover, and remove one screw.

3. Remove three screws, then pull the plate slightly

toward you to release the side cover.

4. Unplug the speaker harness from the main board,

then remove the right side cover.

5. If you remove the fan from the side cover, remove

two screws, then take it out.

Disassembly and Reassembly

3-4

Samsung Electronics

When you reassemble

the fan, make sure

that the fan is placed

correctly.

3-7 Right Side Cover

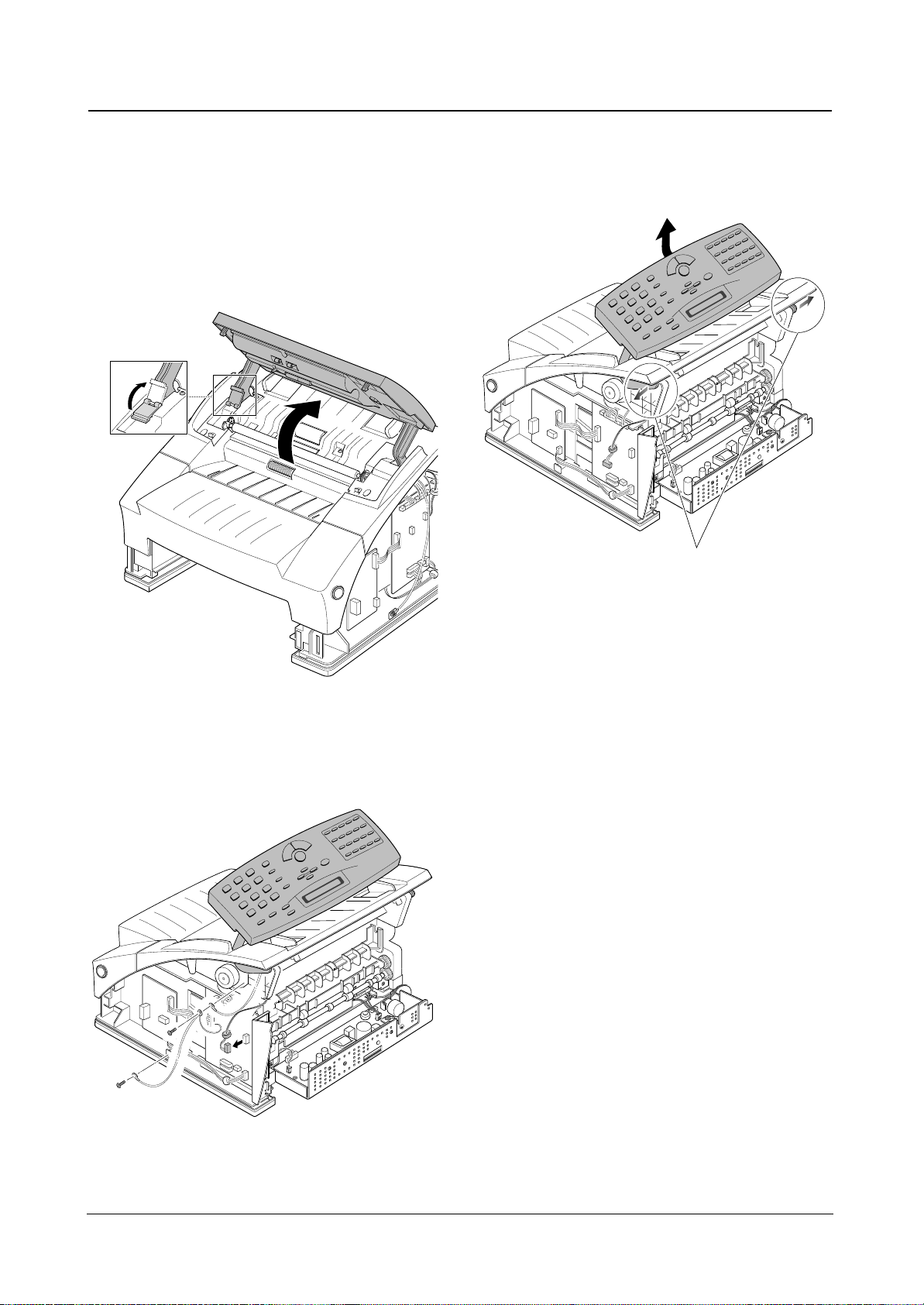

1. Before you remove the cover, you should remove:

– Rear cover (see page 3-3)

– Left/Right side covers (see page 3-3, 3-4)

2. Open the OPE panel, then set the support-OPE to

the OPE panel.

3. From the right side of the main body, remove two

ground screws and unplug one OPE harness. .

4. To unlatch the OPE ass’y, spread the both ends of

the OPE ass’y shown in circles in the figure below,

then remove the OPE ass’y.

Disassembly and Reassembly

3-5

Samsung Electronics

3-8 OPE Assembly

Spread the both ends of the OPE ass’y.

Disassembly and Reassembly

3-6

Samsung Electronics

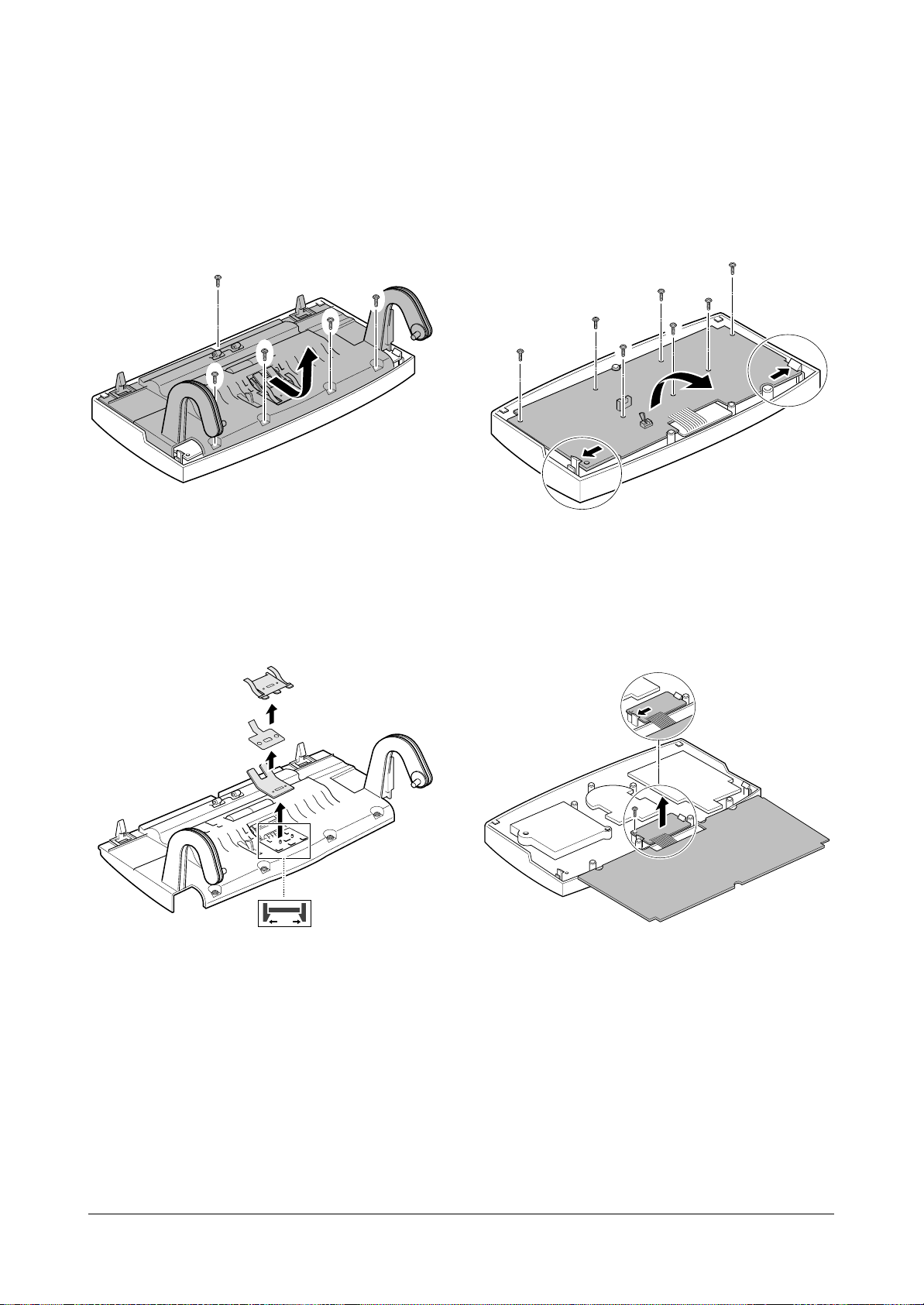

ADF Rubber on the OPE Ass’y

1. Remove five screws, then remove the scan upper

frame.

2. To unlatch the ADF rubber, push the plastic latches

on the ADF rubber from the bottom of the OPE ass’y.

Then remove the ADF rubber..

OPE PBA on the OPE Ass’y

1. Remove seven screws, release the plastic latches

securing the board, then turn the board upside down.

2. Remove a screw and release one of the latches

securing the LCD board, then remove the OPE

board with the LCD board.

Lever Sensor on the OPE Ass’y

Squeeze the both ends of the lever sensor and lift it up.

Spring on the OPE Ass’y

Release one end of the spring and take it out from the

OPE ass’y.

Pinch Spring on the OPE Ass’y

Remove three screws securing the pinch spring then

take it out.

Pinch on the OPE Ass’y

Remove the pinch from the OPE ass’y.

Disassembly and Reassembly

3-7

Samsung Electronics

Disassembly and Reassembly

3-8

Samsung Electronics

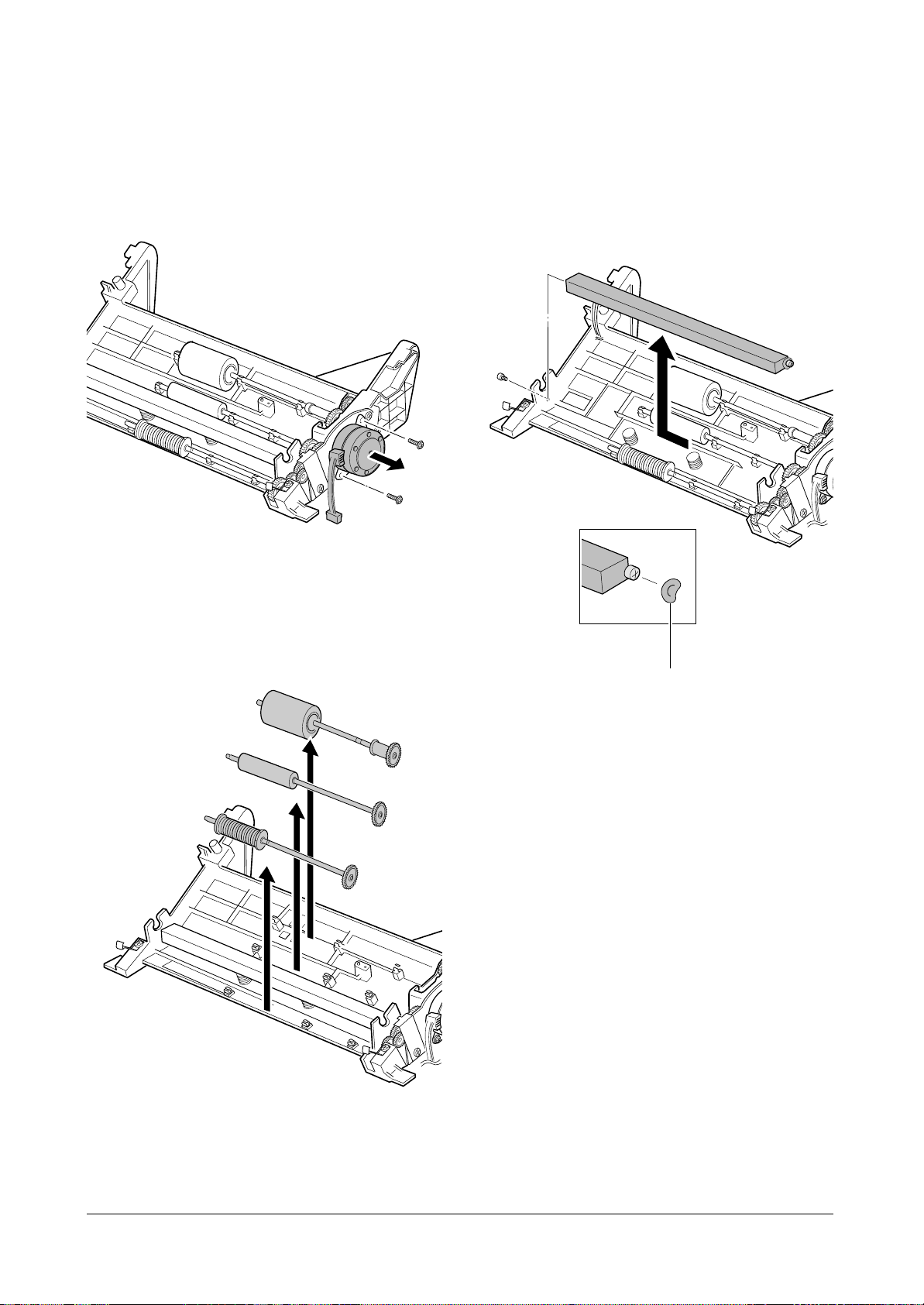

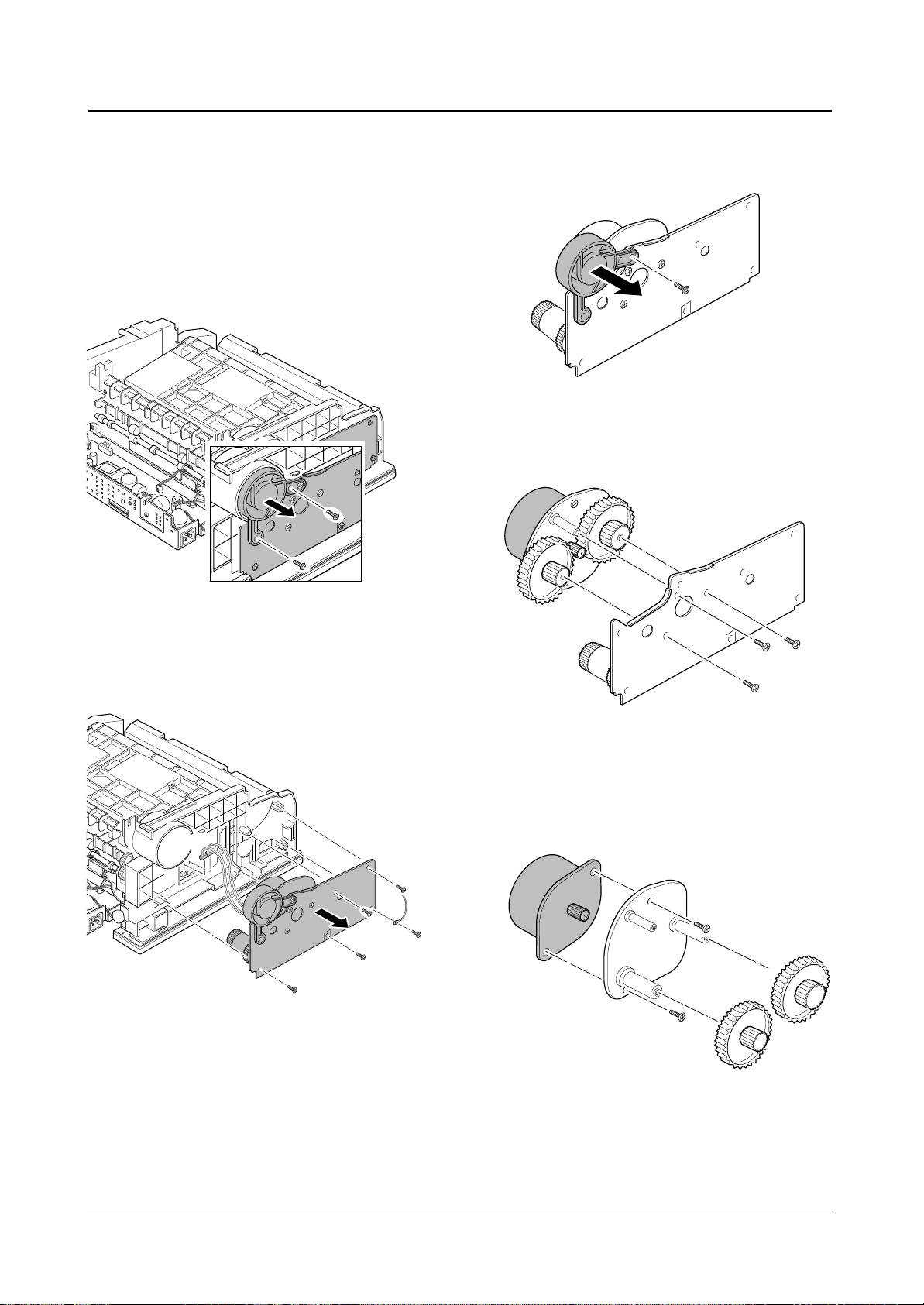

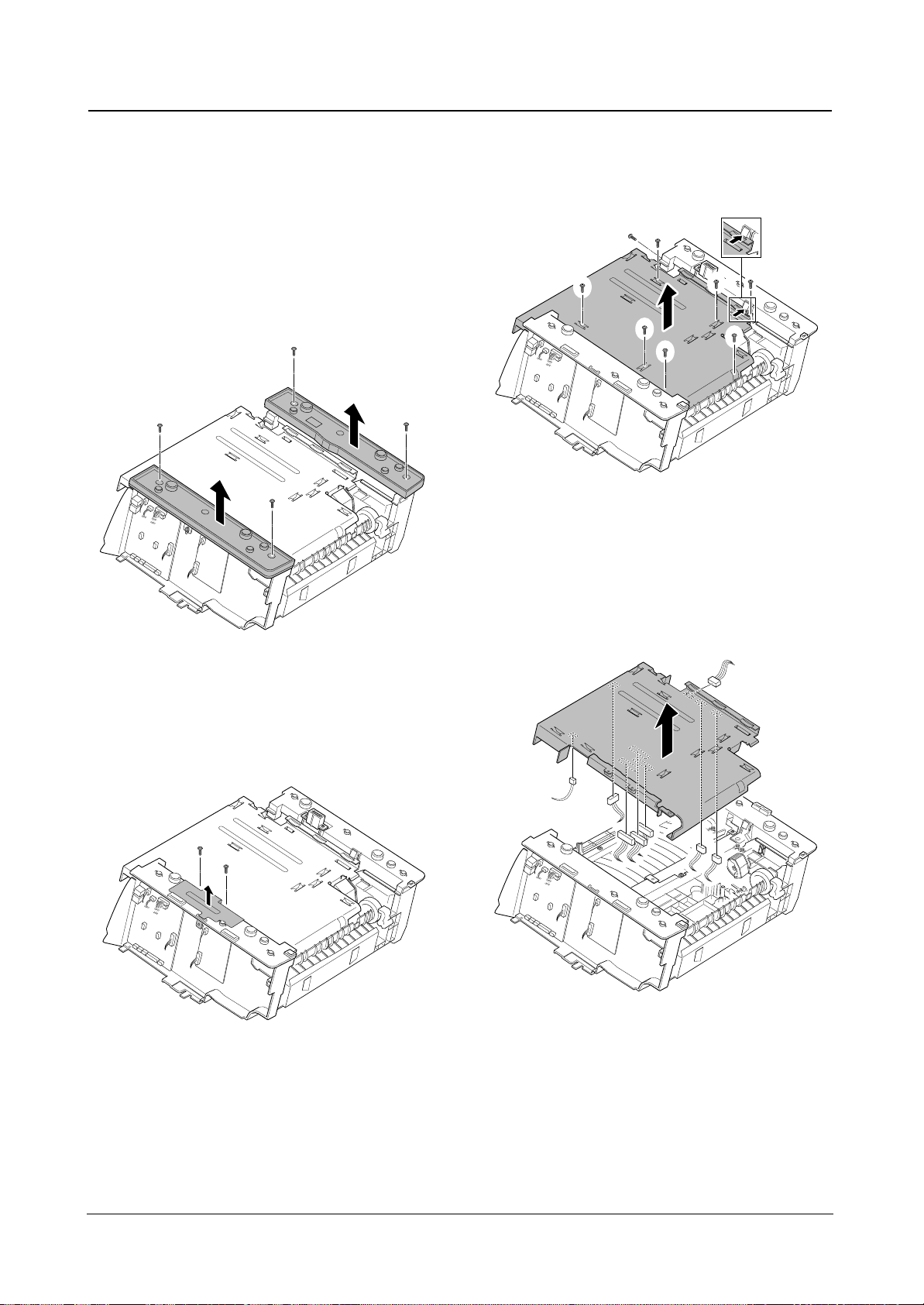

1. Before you remove the scan lower frame, you should

remove:

– Rear cover (see page 3-3)

– Left/Right side covers (see page 3-3, 3-4)

– Top Assembly (see page above)

2. Remove four screws and remove the scan lower

frame.

3-10 Scan Lower Frame

3-9 Top Assembly

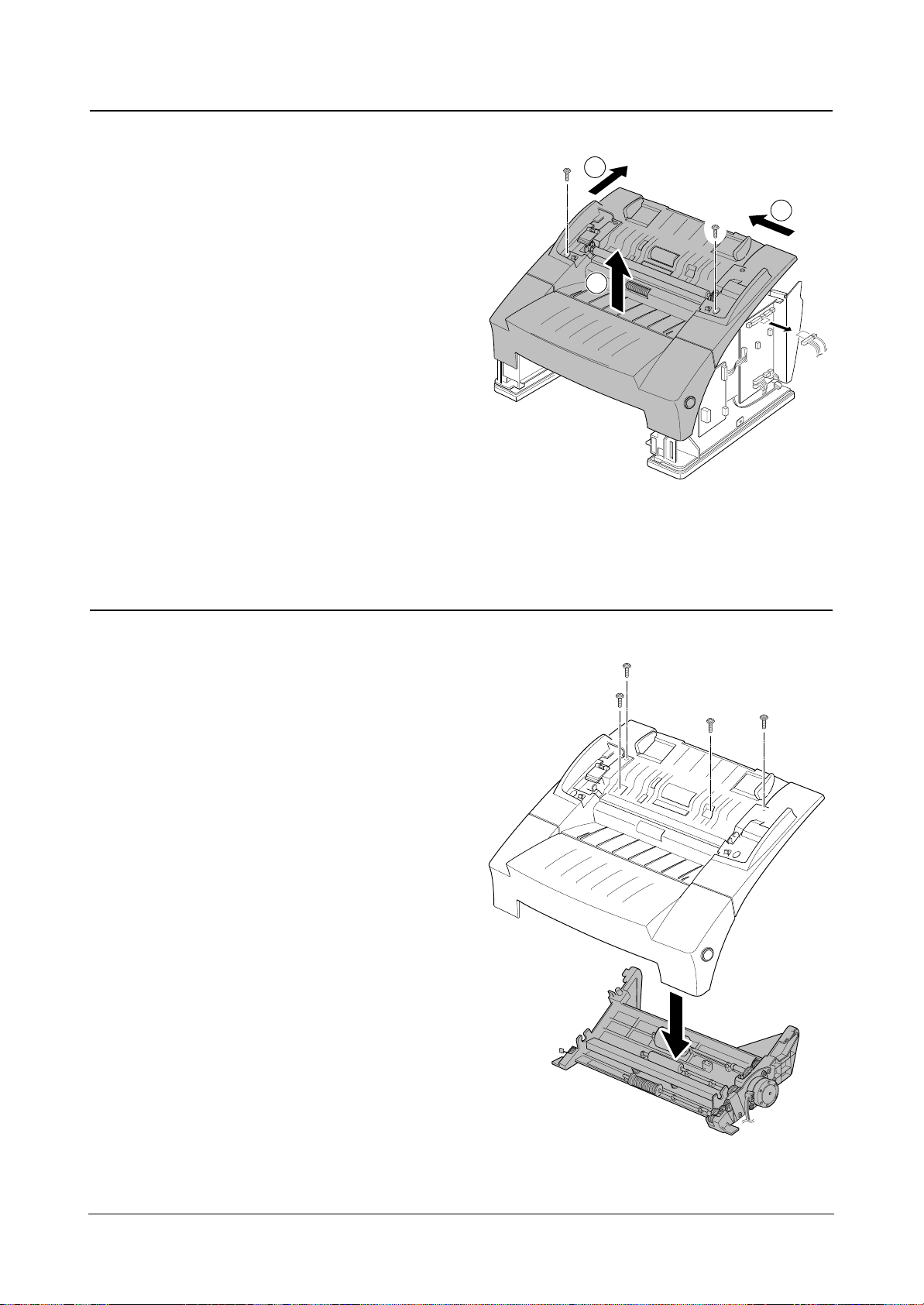

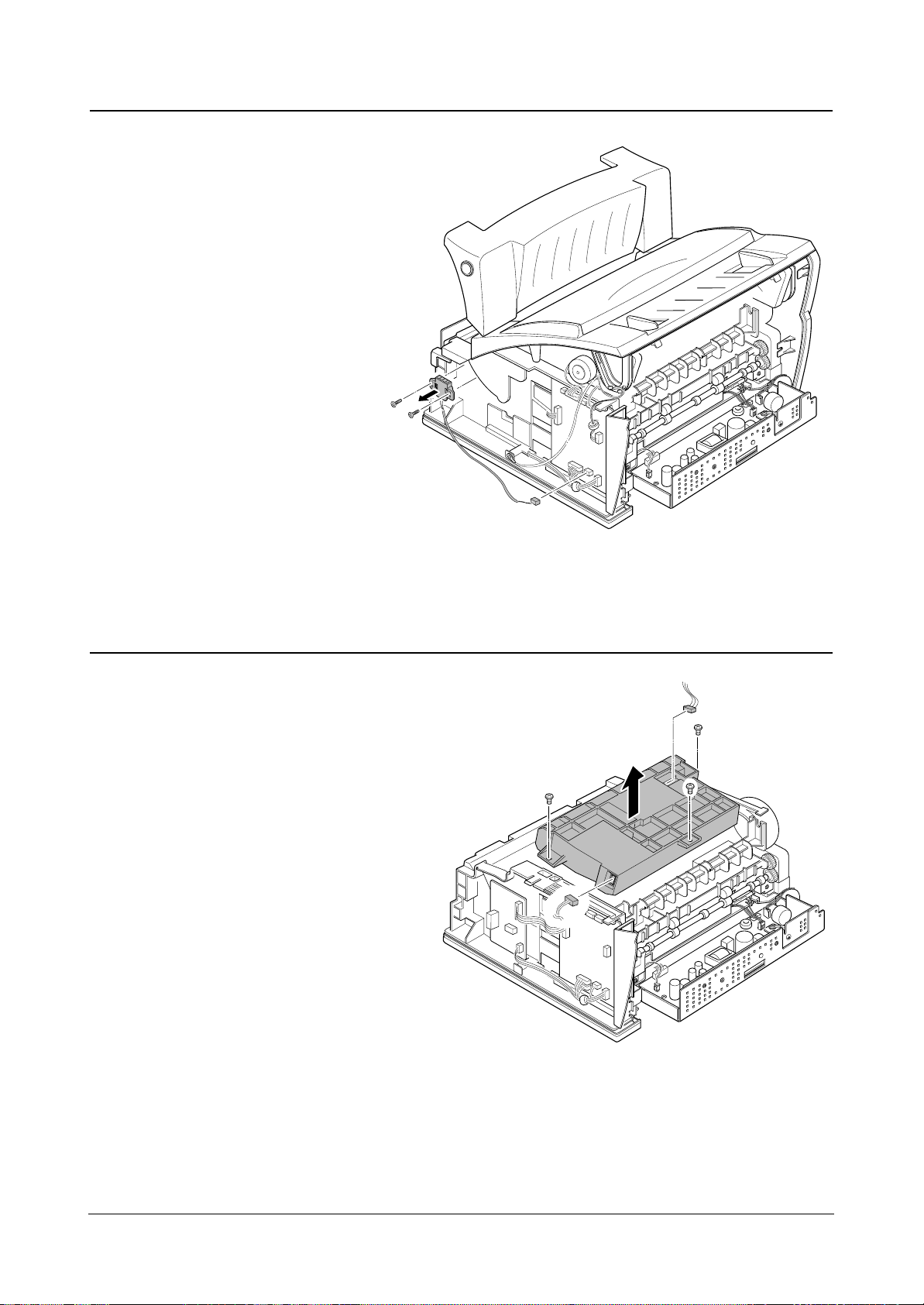

1. Before you remove the cover, you should remove:

– Rear cover (see page 3-3)

– Left/Right side covers (see page 3-3, 3-4)

– OPE ass’y (see page 4-8)

2. Remove two screws and unplug two connectors from

the main board, then remove the Top ass’y pushing

in the direction of the arrows in order.

1

2

3

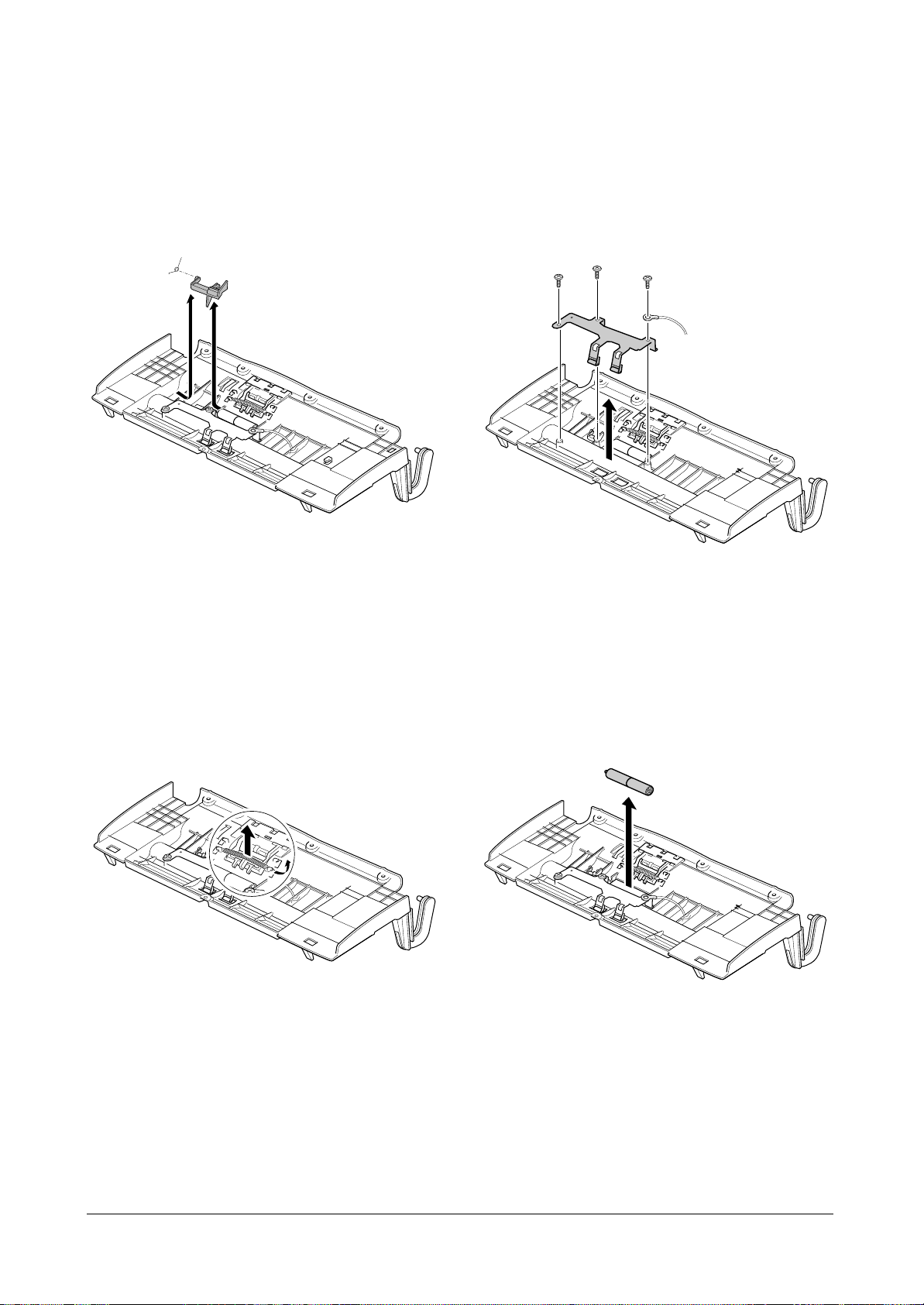

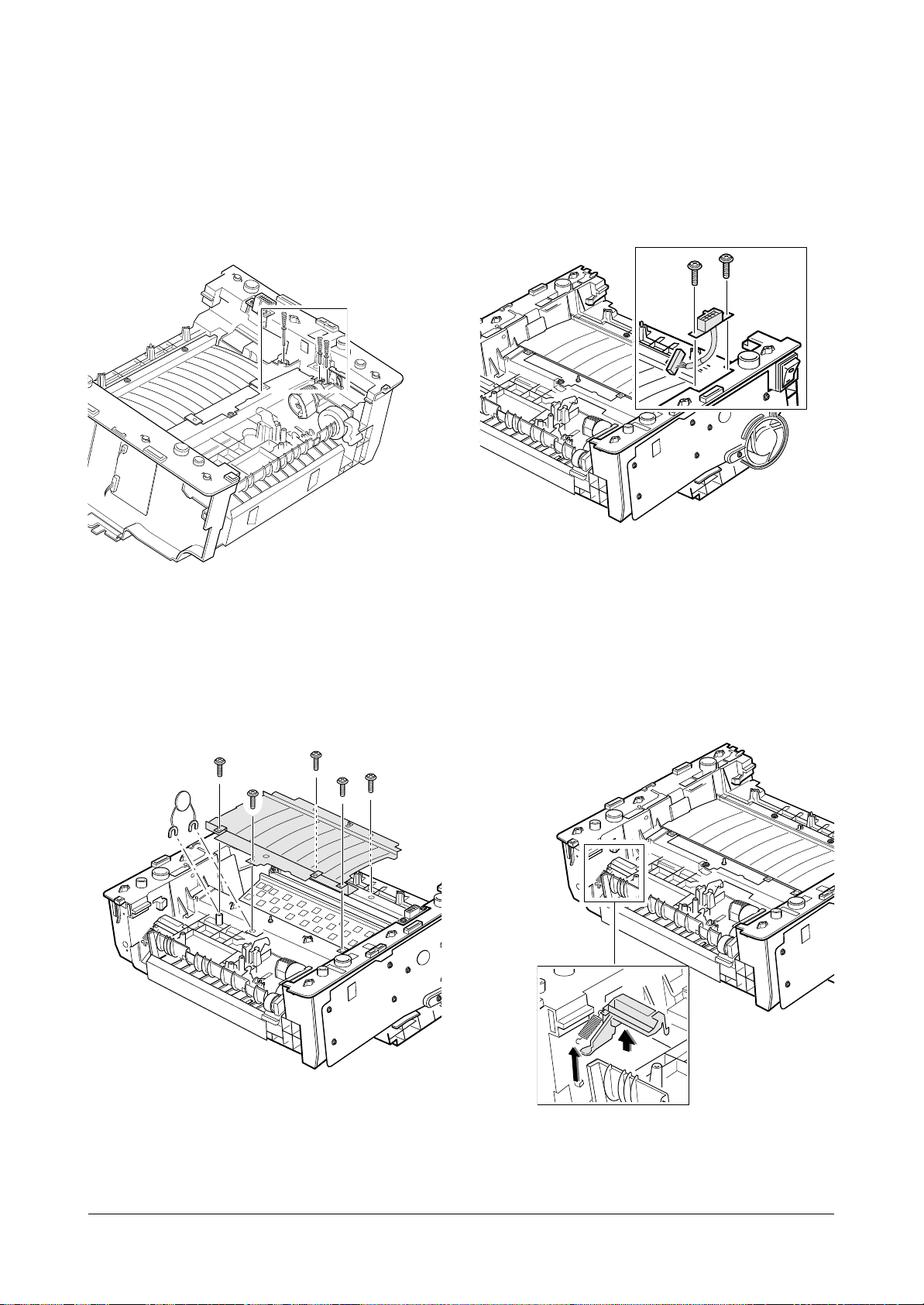

Scan Motor on the Scan Lower Frame

Remove two screws, and remove the scan motor.

Rollers on the Scan Lower Frame

Remove rollers.

CIS on the Scan Lower Frame

Remove one screw, slide the CIS slightly in the direction

of arrow, then lift it up.

Disassembly and Reassembly

3-9

Samsung Electronics

When you reassemble the CIS,

be careful for the direction of

this part.

1. Before you remove the covers, you should remove:

– Rear cover (see page 3-3)

– Left/Right side covers (see page 3-3, 3-4)

– OPE assembly (see page 3-5)

– Top assembly (see page 3-8)

– Scan lower frame (see page 3-8)

2. Remove two screws.

3. Remove shafts and springs connecting the two cov-

ers.

4. Remove the left and right hinge shafts. Now the two

covers can be separated.

Disassembly and Reassembly

3-10

Samsung Electronics

3-11 Main Cover and Front Cover

Disassembly and Reassembly

3-11

Samsung Electronics

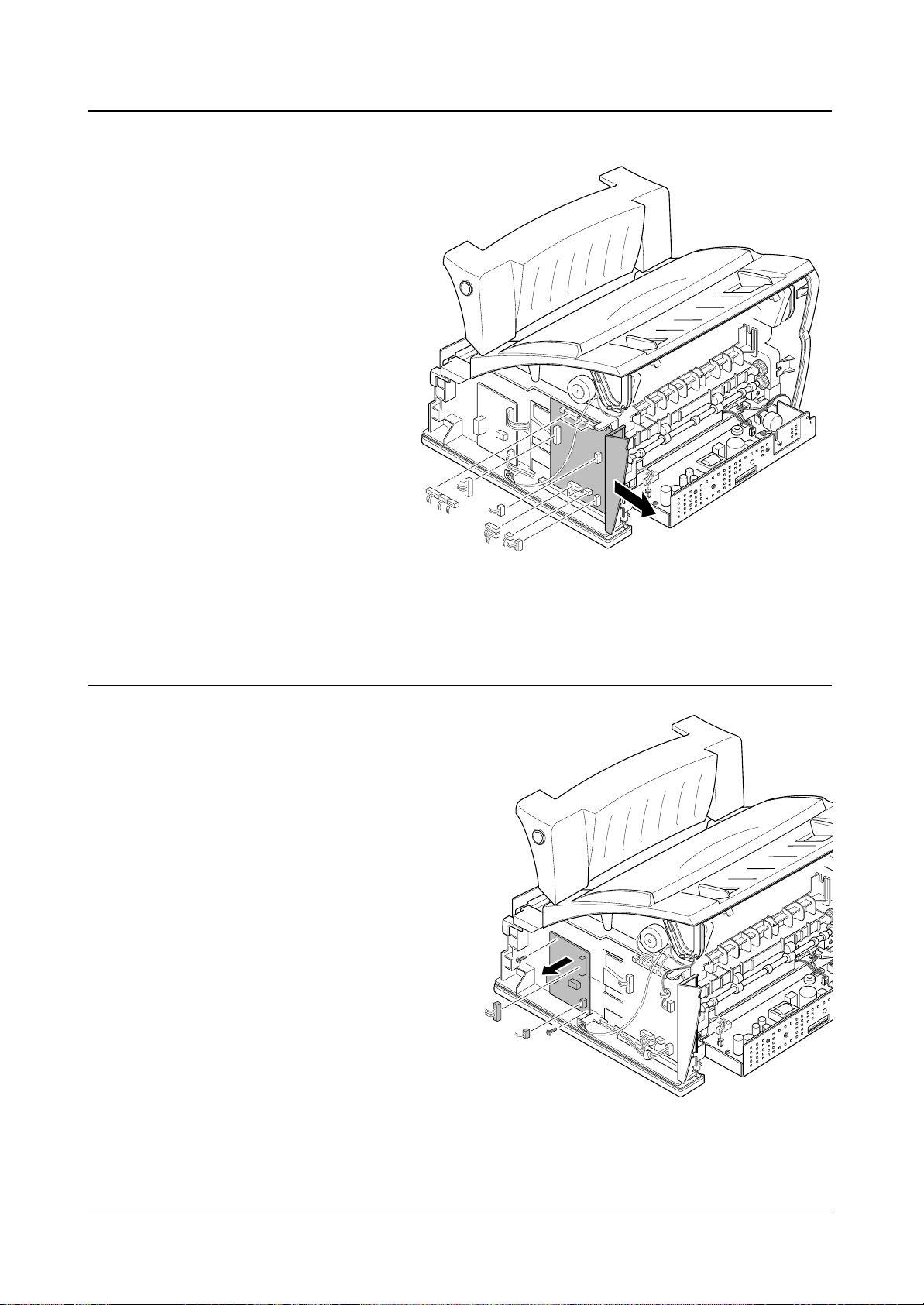

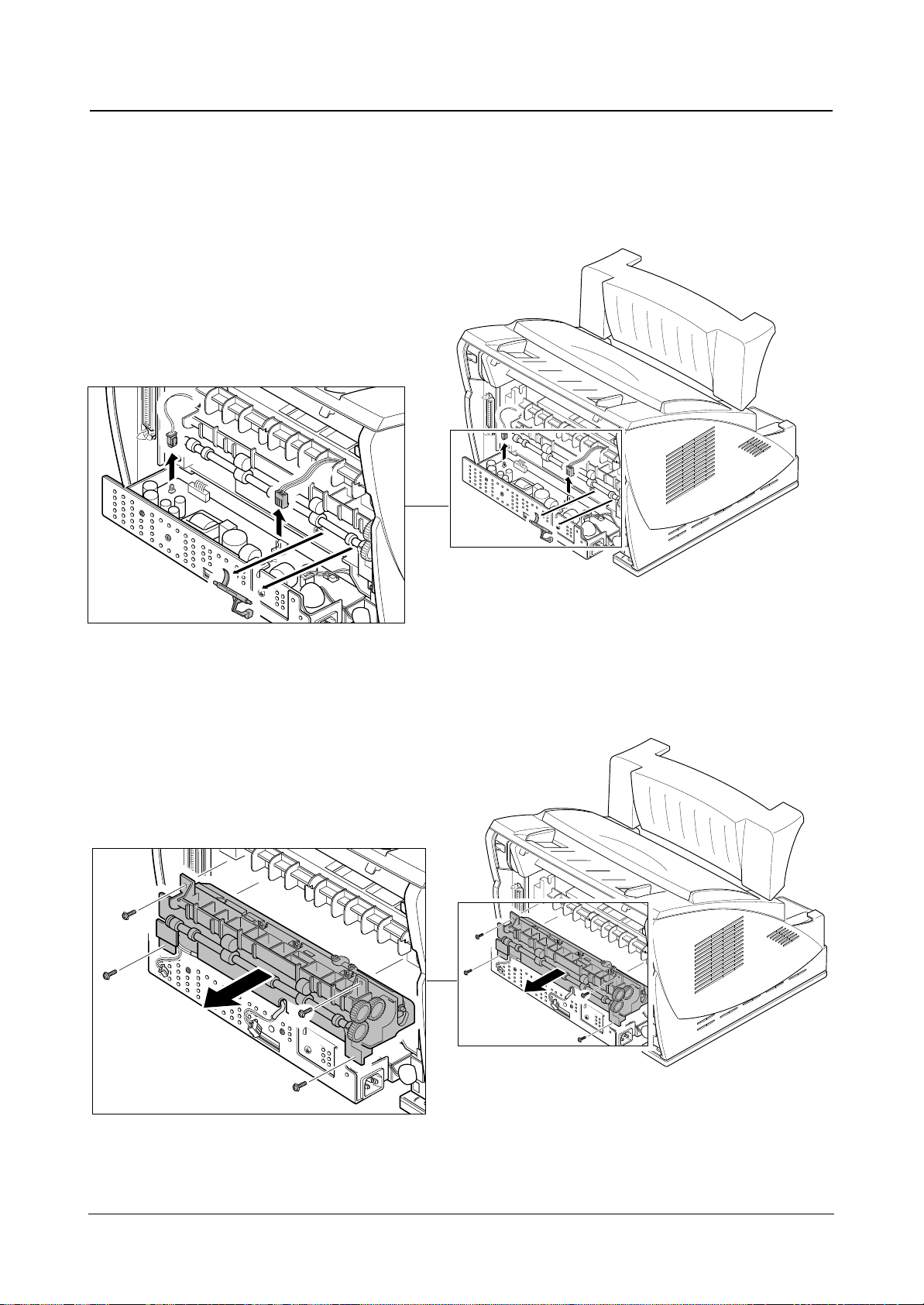

3-12 Main Board

1. Before you remove the main board, you should

remove:

– Rear cover (see page 3-3)

– Right side cover (see page 3-4)

2. Unplug all connectors from the main board, then

remove the board.

3-13 LIU Board

1. Before you remove the LIU board, you should

remove:

– Rear cover (see page 3-3)

– Right side cover (see page 3-4)

2. Remove two screws, then unplug all connectors from

the LIU board, then remove the board.

Disassembly and Reassembly

3-12

Samsung Electronics

1. Before you remove the assembly, you should

remove:

– Rear cover (see page 3-3)

– Right side cover (see page 3-4)

– LIU board (see page 3-11)

2. Remove two screws, and unplug one connector from

the main board, then remove the socket contact

ass’y.

3-14 Socket Contact Assembly

1. Before you remove the LSU, you should remove:

– Rear cover (see page 3-3)

– Left/Right side covers (see page 3-3, 3-4)

– Top assembly (see page 3-8 )

2. Remove three screws, unplug two connectors, then

remove the LSU.

3-15 LSU

Disassembly and Reassembly

3-13

Samsung Electronics

3-16 Motor Assembly and Fan

1. Before you remove the motor assembly, you should

remove:

– Rear cover (see page 3-3)

– Left/Right side covers (see page 3-3, 3-4)

– Top assembly (see page 3-8)

2. Remove two screws securing the fan.

3. Remove five screws, unplug two connectors, then

remove the motor assembly.

4. Remove a screw securing the fan and remove the

fan.

5. Remove three screws from the motor assembly.

6. Remove two screws from the motor bracket and

remove the motor.

Disassembly and Reassembly

3-14

Samsung Electronics

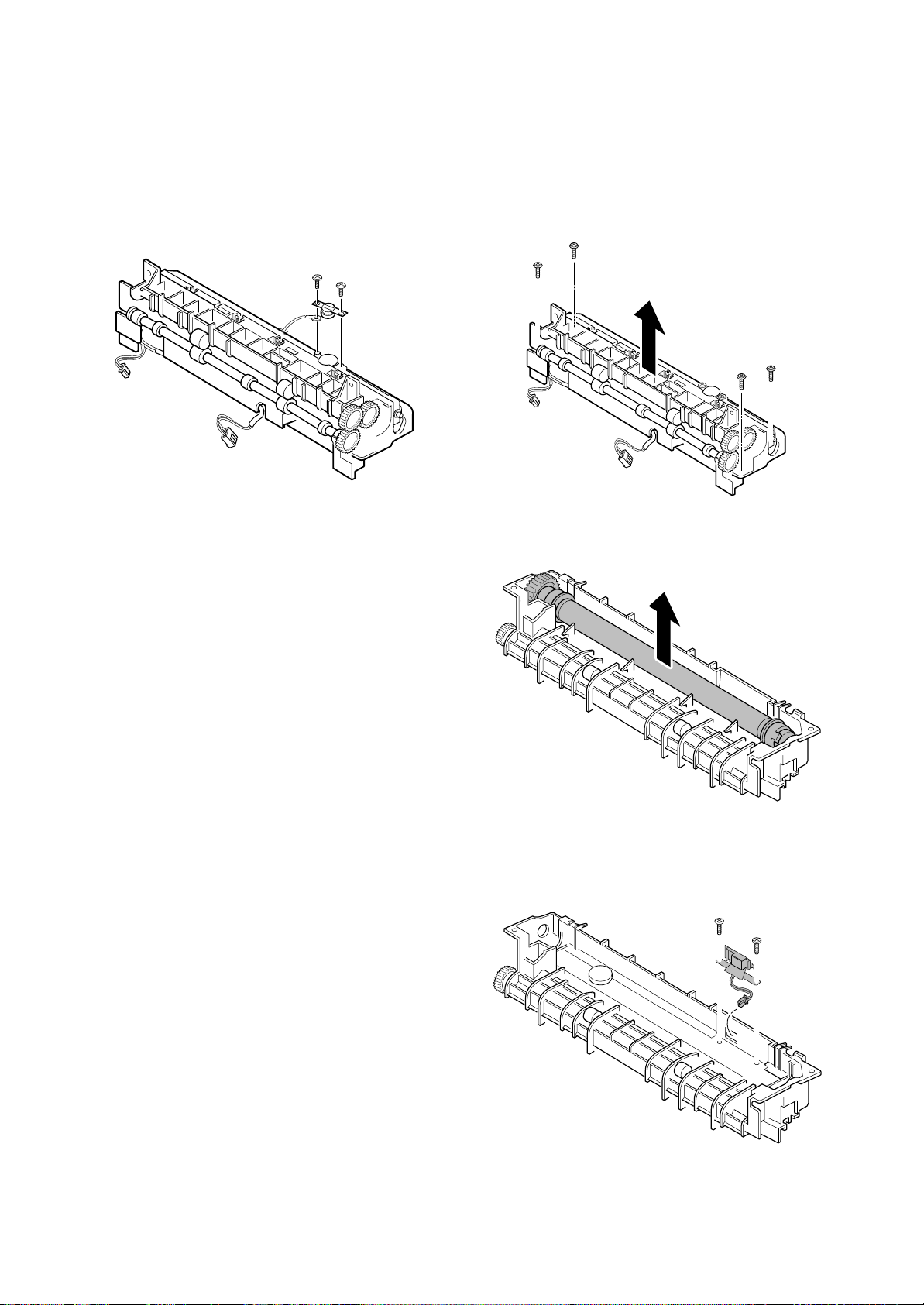

1. Before you remove the fuser, you should remove:

– Rear cover (see page 3-3)

2. Remove the exit actuator and unplug two connectors.

3. Remove four screws, then remove the fuser.

3-17 Fuser

Thermostat on the Fuser

Remove two screws securing the thermostat and take it

out.

Thermistor on the Fuser

1. Remove four screws and remove the upper cover.

2. Remove the heat roller.

3. Remove two screws securing the thermistor, then

take it out.

Disassembly and Reassembly

3-15

Samsung Electronics

Disassembly and Reassembly

3-16

Samsung Electronics

Halogen Lamp on the Fuser

1. Release the connector cable from its recessed channel.

2. Remove one screw and remove the halogen lamp.

Note: When you reassemble the lamp, make sure that

the halogen lamp is inserted in place.

Roller on the Fuser

1. Remove four screws and remove the upper cover.

2. Remove the roller.

Disassembly and Reassembly

3-17

Samsung Electronics

1. Before you remove the engine board, you should

remove:

– Rear cover (see page 3-3)

– Left/Right side covers (see page 3-3, 3-4)

– Top assembly (see page 3-8)

2. Remove four screws and remove the right and left

base brackets.

3. Remove two screws and remove the ICU ground.

4. Remove seven screws, and release the latch securing the PCU shield.

5. Unplug all connectors and remove PCU shield.

3-18 Engine Board and Others

Disassembly and Reassembly

3-18

Samsung Electronics

HV Terminals

Remove HV terminals. When you reassemble the terminals, make sure that the terminals are inserted in place.

Transfer Guide

Remove five screws and remove the transfer guide.

SCF Connector

Remove two screws and remove the connector.

Cover Open Sensor

Remove the spring and remove the sensor.

Loading...

Loading...