SAMSUNG Ml85 Service Manual

2-4 Recommended Test Equipment

Samsung recommends the following equipment when servicing the Laser Printer.

Digital Multimeter A digital multimeter with attached LED or LCD 4-digit Panel.

Oscilloscope A digitizing oscilloscope which can measure more than

High Voltage probe

DCU (Diagnostic Control Unit) DCU can be supplied from Samsung which can easily shows the engine’s

A high voltage probe which can measure about less than

Error status

Table 2-4-l Equipment List

QUIDCK

REFERANCE

+

0

STATUS

+

0

MAGNOSTIC

DIAGNOSTIC CONTROL

5PPM

LASER BEAM PRINTER

+

cl

ON OFF

UNIC

1OOMHz

1OKV

UP

DOWN SHIFT

Figure 241 DCU

28

ENTER

STOP

2-5 DCU Control

2-5-l DCU Setup

The DCU is used to diagnose Printer malfunctions.

The DCU harness wire(lOpin-todpin) is connected to the Printer engine via:

1) Engine Board connector, CN2 (4pins)

2) (Video) Controller Board connector, 56 (4pins)

Open the Printer’s side cover(=SIMM Cover) and remove the shield cover and connect the DCU

to connector 56 on the Controller Board.

2-5-2 DCU Error messages (LED Display)

If an error occurs, connect the DCU to the Printer. DCU messages will indicates malfunctioning

areas of the machine.

(Consult Service Manual for detailed troubleshooting information)

Display

60

62

64

68

70

71

72

73

95

Error messages

OPEN FUSER ERROR

LOW HEAT ERROR

COVER OPEN ERROR

OVERHEAT ERROR

NO PAPER OR CASSETTE

PAPER

JAM1 (REGISTER SENSOR TO EXIT SENSOR)

JAM2 (EXIT SENSOR TO FUSER)

LSU NOT READY

JAM0

(CASSETTE PICK-UP TO REGISTER SENSOR)

29

2-5-3 DCU diagnostic messages (LED display)

After receiving an error message, use the DCU to locate malfunction unit.

Displav

0

1

2

3

4

5

6

I

8

9

10

11

12

13

14

Error messaee

MAIN MOTOR OPERATING SYSTEM

MAIN HIGH VOLTAGE ON (- 14KV)

TRANSFER HIGH VOLTAGE

THV

(+)

REFERENCE VOLTAGE

DEVSUPPLY HIGH VOLTAGE ON

LSU OPERATING TEST

PICKUP CLUTCH ON

PAPER EMPTY SENSOR TEST

FEED & EXIT SENSOR TEST

COVER OPEN SENSOR TEST

FUSER TEST

HOT BURN TEST

CLEAN (MESSAGE) PRINT

THV TRIGGER & THV ON DUTY

THV PLUS DUTY

(-)

ON

(+9OOV)

2-5-4 DCU Diagnostic Mode

1) Connect DCU to Controller or Engine Board

2) To apply power, simultaneously press tand hold ‘DOWN’, ‘SHIFT’, and ‘STOP’ keys. 78 will display

3) After 2-3 seconds, release the keys. 00 will display

4) Press ‘UP’ or ‘SHIFT+DOWN’ keys until the desired number is displayed in the DCU display.

5) Press ‘ENTER’ to begin operating.

30

6) Example

Select numbers 13 and 14 to adjust the electrophotography trigger voltage.

1: Turn power on by simultaneously pressing ‘DOWN’, ‘SHIFT’, and ‘STOP’ for 2-3 seconds.

2: Press

‘SHIFT+DOWN’

until diagnostic cocde

#14

is displayed.

4: Press ‘SHIFT’ and ‘STOP’ to exit routine.

5: Press ‘SHIFT’ and ‘DOWN’ to display diagnostic code

#13.

6: Display will antemate between electronc photography trigger voltage and On duty voltage.

7: To end operation, press ‘SHIFT’ and ‘STOP’ keys.

7) DCU Error Message

a) Error messgae

Error message

Error message

‘60’,

‘THERMISTOR OPEN ERROR’

‘62’,

‘LOW TEMPERAURE ERROR’

‘68’,

‘OVERHEAT ERROR’

Action:

1) Measure Fuser’s Thermistor resistance

Normal Thermistor resistance is 2-3 ohms (1

lOV),

6-10 ohms (220V)

2) Confirm Fuser Lamp operation

3) Measure Engine Board resistances at QlOl (Triac Thyrister)

4) Replace Engine Board Q 10 1

5) Replace Engine Board Q3 (KSC 1008-Y)

6) Replace Engine Board PC 15 1 (Triac Photo Coupler)

b) Error message

‘70’,

‘PAPER EMPTY’

Action:

1) Check for paper in cassete tray

2) Replace 0P2 Sensor (Photo Interrupter)

3) Confirm Feed Clutch operation (mode ‘06’)

4) Replace Feed Clutch or Engine Board’s 44 (KSC 1008-Y)

c) Error message ‘7

1’)

‘PAPER JAM- 1’

Action:

1) Check for paper in cassette tray

2) Check for Pick-up unit wear

3) Replace OP 1 sensor (Photo Intermpter)

31

d) Error message

Error message

‘72’,

‘PAPER JAM-2’

‘73’,

‘PAPER JAM-3’

Action:

1) Confirm that normal paper is being used

2) Check for Paper Jam in Fuser

3) Replace sensor ‘SW 1’ on Engine Board

4) Check for Fuser Roller contamination

8) Error message

‘95’,

‘LSU READY ERROR’

a) Confirm normal readings at Engine Boards, QS

b) Replace LSU

(KSC1008-Y)

32

3. Product Information

3-1 Specifications

3-l -1 Engine(ML-80)

Specifications are correct at the time of printing. Product specifications are subject to change without notice.

I

1. Engme

3. Print Speed

Resolution

Source Of

Print Method

Feed Method

Feed Stde

Paper Handling (input)

I.

Paper Handling (output)

1 I

Feed

112.

Warm-up Time

113. Ftrst

114.

Print Time

Power

15. Power Consumption

Item

Ltght

Capactty

Rating

r

16.

Power Saving Consumption

r---

1 I7

Power Swatch

18.

Certification & Compliance

19.

Acoustic Standby

Noise

Operating

Specification & Description

VlL-80

Desktop Page Printer

I

ppm(page per minute)

A4 Size, 5% Character Pattern)

frue

600 X 600 dpi(dot per inch)

,aser

Diode (LSU: Laser Scanner

\Jon-impact

3assette & Manual

side

L

Size

0

0

Electrophotography

Loading

Standard : A4, Letter, Legal, B5, Executive

Envelope : manual feed only

Untt)

)I

0

Universal type

Length : 150 - 356 mm

Width:

k

Weight : For Cassette, 60 - 90

t

Recommended Paper

90-216mm

For Manual, 60 -

120

g/in’

g/m’

USA: X420, X4024, NEKOSA, BOISE CASCADE

EC: REFLEX, ADAGIO

Transparancies:

Label: AVERY 53XX series

:ace

Down :

Tace

Up : lsheet

3M (CG3300 or 3360)

150sheets

50-sheet Tray

!50-sheet Tray and one opttonal 250-sheet Drawer

3etween 25seconds

setween 25seconds

\C

100-I

2OV/220-240V (*

15%) 50Hz/60Hz (+ 3%)

‘eak: 720W

luring

Printing :

luring

Sleeping

,ess

than 28W during I hour at first

Vane

3E,

TUV, SEMKO, NEMKO, DEMKO, C-tick,

FCC, UL,

Less than 29dB

Less than 47dB

l50WH

(Average)

:

Max 1 SW

CSA, CDRH, CB,

MEEI

CClB

Remarks

Small Footprint

At Copy Mode

Left Adjust

ML-84/85G

ML-84/85G plus

ML-85, ML-85 plus

For EPA

Class B for EMC

33

item

3. Reliability

1.

Toner Supply

2. Expected Life Span

3. Operating Environment

4.

Storage Environment

5. Weight

5. External Dimension

7. Print Cartridge

8. Packing

MPBJ

MPBF

MTBF

Main Kit

Specification & Description

2,500 pages/75g Paper

30,000 pages

2,250 hours

(MTBF =

Print Cartridge

100,OOOsheets

Temperature : 10 - 30

Humidity : 30 - 80 %RH

Temperature : 0 - 35

Humidity : IO - 90 %RH

Net : Max 9.3kg

Gross : Max

ML-84/85G, QwikLaser 84/856

ML-85, QwikLaser 85

Ml-84

ML-85 plus

Life Span : 5,000 pages, 5% Pattern and 50% Duty

Developing : Non-magnetic Contact Developing

Charging : Conductive Roller Charging

Density Adjustment : 3steps (Light, Medium, Dark)

Toner Supply Method Exchanging The Developer

Toner Checking Sensor : None

Transfer System: Conductive Roller Transfer

Fusing System : Temperature & Pressure

Erasing Method: Light Using LED

Ozone Emission : Less than

Printer

Cassette

Developer Cartridge1 Piece

Guide Manual and Diskettes

Power Cord

7.5hours

10.5Kg

pIus/85G

X 20days X MPBF /Monthly Use)

“C

“C

360(W) X 367(D) X 176(H)

360(W) X 367(D) X 188(H)

plus

I

Set

1

Piece

1

Piece

360(W) X 375(D) X 176(H)

360(W) X 367(D) X 188(H)

O.IPPM

Remarks

Jam Rate

For machine

Normal:22 “C 65%

mm

mm’

mm’

mm’

Negative(-)

PWM Control

Quenching Lamp

33-l

3-l-2 ML-84, ML-84 plus or

Specifications are correct at the time of printing. Product specifications are subject to change without notice,

And ML-84 plus has the new front cover.

QwikLaser

84

Item

Interface Engine

Resolution

Emulation

Including the driver

Font

CPU

RAM MEMORY

ROM

EEPROM

Front Control Panel

0. Interface

Specification & Description

SAMSUNG ML-SO

WPS : 600 X 600 dpi

PCL4.5 : 300 X 300 dpi

PCL4.5 (Compatible with HP LaserJet IIP)

Mtcrosoft W

7 bitmaps

Motorola MC68322-20MHz

Standard : IM or

Optional SIMM Module

* These SIMMs are compatible with the Computer’s,

1

Mbyte (Font + Program)

5 12bytes

4LEDs

Bidirectional Parallel Standard

-

IEEE1284 COMPATIBLE MODE

-

IEEE1284 NIBBLE MODE

-

IEEE1284 BYTE MODE

-

IEEE1284 ECP WITHOUT RLE

-

IEEE1284 ECP WITH RLE

PS(W

indows Printing System)

1.5M

bytes

:

For IM Standard : 4, I6 Mbytes

For

1.5M

Standard : 4, 16 Mbytes

&

1

key

Remarks

NVRAM

Centronics

Use ECP cable

I. Copy Capacity

2. Interface Switching

3. Interface Time Out

4. Jam Recovery

5 AEP

6. Engine Interface Error

7. Status Monitor

8. PRS Buffer

9. Top Margin

Serial Interface Optional

-

300,600,

57600, I1 5200 bps

-

XON/XOFF, DTR/DSR Protocol

-

Robust XON for XON/XOFF

Enable up to 999

Automatic (Serial & Parallel)

1 step is I second from 20 seconds to 5 minutes.

(Zero is disable)

Jam 0, 1, 2 according to the Jam position

The recopy of Jam 0, 1 is default.

The recopy of Jam2 is optional.

(Don’t use Jam2 recovery under WPS status.)

Emulation switching according to Emulation code.

All LEDs blink when communication is error

Bidirectional Status Feedback

Animation for printing

755Kbytes

4.23 f 2.0 mm

1200,2400,4800,9600,

19200,38400,

33-2

RS232C

WPS only

PC L Pattern

3-l-3 ML-85, ML-85 plus or

Specifications are correct at the time of printing. Product specifications are subject to change without notice

And ML-85 plus has the new front cover.

QwikLaser

85

Item

Interface Engine

Resolution

Emulation

Including the driver

4

Font

5

CPU

RAM MEMORY

6

ROM

EEPROM

Front Control Panel

0. Interface

I

SAMSUNG ML-80

WPS : 600 X 600 dpi

PCL5e (Compatible with HP LaserJet

Microsoft WPS(W indows Printing System)

1

bitmap

45 scalable (35 intelligent, 10 truetype)

Motorola MC68322-20MHz

Standard : 2Mbytes

Option SIMM Module : 2, 4, 8, 16 Mbytes

* These SIMMs are compatible with the Computer’s,

2Mbyte (Font + Program)

5 12bytes

4LEDs &

Bidirectional Parallel Standard

-

IEEE1284 COMPATIBLE MODE

-

IEEE1284 NIBBLE MODE

-

IEEE1284 BYTE MODE

-

IEEE1284 ECP WITHOUT RLE

-

IEEE1284 ECP WITH RLE

Specification & Description

SP)

lkey

1

Remarks

NVRAM

Centronics

Use ECP cable

1.

Copy Capacity

2. Interface Switching

3. Interface Time Out

4. Jam Recovery

5. AEP

6. Engine Interface Error

7. Status Monitor

8. PRS Buffer

9. Top Margin

Serial Interface Optional

-

300, 600,

57600, 115200 bps

-

XON/XOFF, DTR/DSR Protocol

-

Robust XON for XON/XOFF

Enable up to 999

Automatic (Serial & Parallel)

1 step is 1 second from 20 seconds to 5 minutes.

(Zero is disable)

Jam 0, 1, 2 according to the Jam position

The recopy of Jam 0, 1 is default.

The recopy of Jam2 is optional.

(Don’t use Jam2 recovery under W PS status.)

Emulation switching according to Emulation code.

All LEDs blink when communication is error

Bidirectional Status Feedback

Animation for printing

755Kbytes

1

4.23 * 2.0 mm

1200,2400,4800,9600,

19200, 38400,

RS-232C

WPS only

1

PCL Pattern

33-3

3-l-4 ML-85G, ML-85G plus or QwikLaser 85G

Specifications are correct at the time of printing. Product specifications are subject to change without notice.

And ML-S% plus has the new front cover.

Item

1.

Interface Engine

2. Resolution

3 Emulation

Including the

4. Font

5. CPU

6. RAM MEMORY

7 ROM

8

EEPROM(=NVRAM)

9 Front Control Panel

IO. Interface

I I

Copy Capacity

12.

Jam Recovery

13.

Engine Interface Error

14. Status Monitor

115.

PRS Buffer

drover

Specification & Description

SAMSUNG ML-SO

WPS : 600 X 600 dpi

Computer 16Mbytes RAM : 300 X 300 dpi

PCL4

(Compatible with HP LaserJet II)

Microsoft WPS(Windows Printing System)

HP LaserJet II Internal fonts

None (ASIC dependent on host computer)

Standard :

None

ML-85G, ML-85G

QwikLaser 85G

ML-85G,

ML-85G

Bidirectional Parallel Standard

-

IEEE1284 COMPATIBLE MODE

-

IEEE1284 NIBBLE MODE

-

IEEE1284 BYTE MODE

-

IEEE1284 ECP WITHOUT RLE

-

IEEE

Serial Interface : None

Enable up to 999

Jam 0, I, 2 according to the Jam position

The recopy of Jam 0, I is default.

The recopy of Jam2 is optional.

(Don’t use Jam2 recovery under WPS status.)

All

Bidirectional Status Feedback

Animation for printing

755Kbvtes

O.SMbytes

plus

QwikLaser 85G

plus

1284

ECP WITH RLE

LEDs

blink when communication is error

None

X24COl

5

4

LEDs

LEDs

P

only

only

Remarks

S/W Driver

No option memory

POWER LED

READY LED ON

Centronics

Use ECP cable

WPS only

33-4

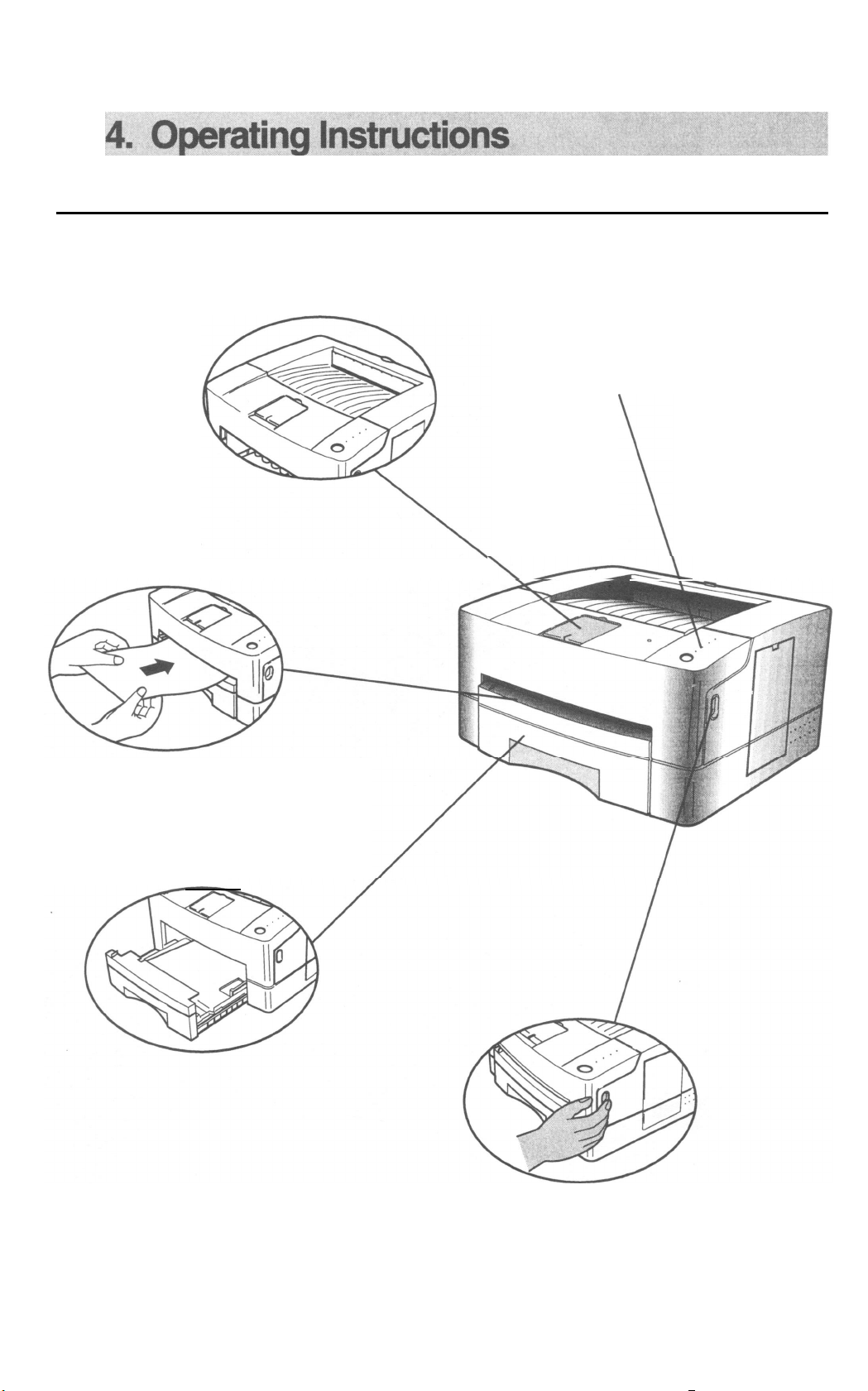

4-1. External Views and Functions

Face Down Tray

Control Panel

Each LED indicates printer status.

Manual Feeder

Cassette

\

\-

35

Cover Open Button

Parallel Connector

It connects

parallel port

Computer

Facu

up Tray

Open Face up Tray and it will

stacks one page.

Air Flow hole

Emits internal

thermal air

5. Disassembly

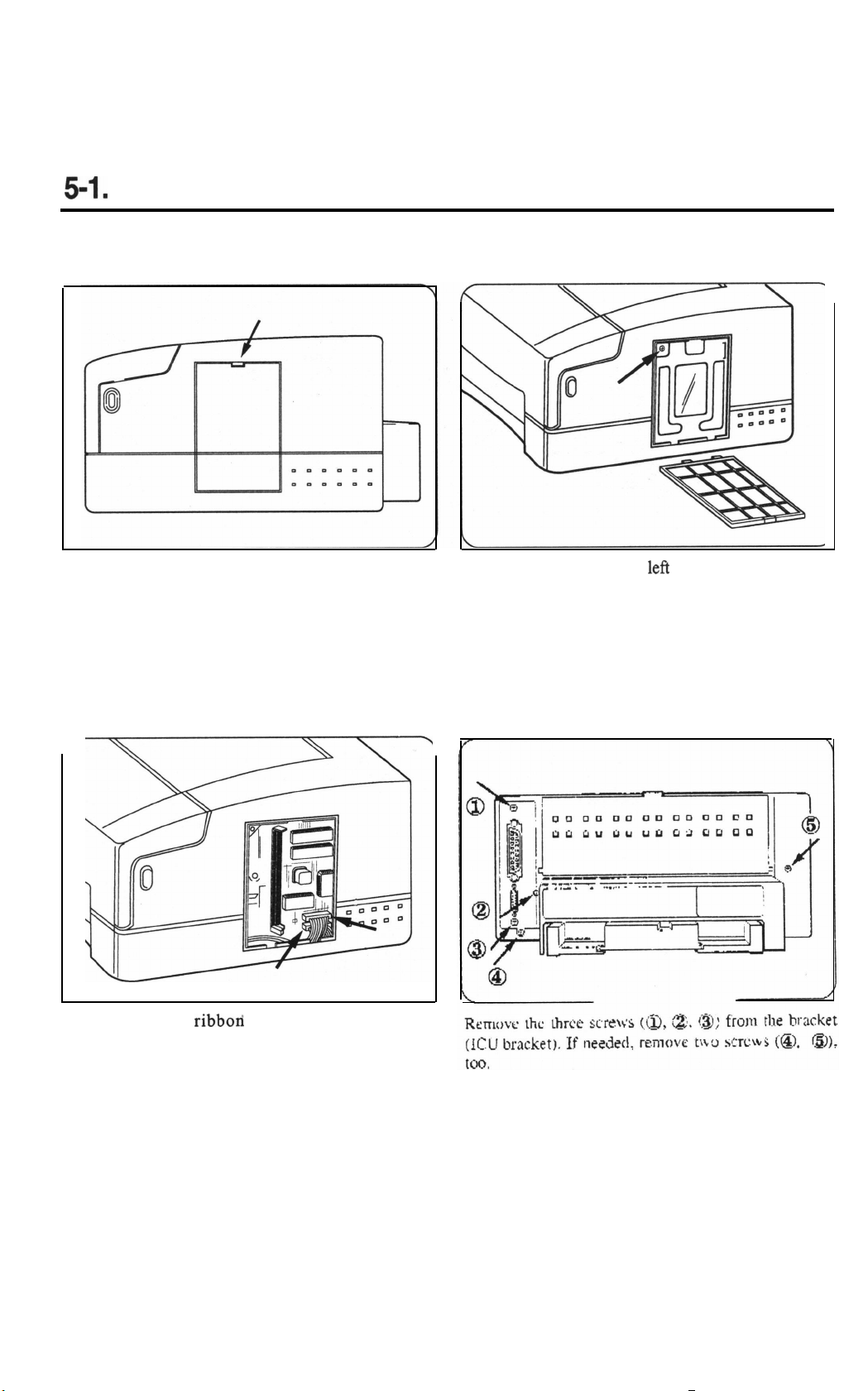

5-l.

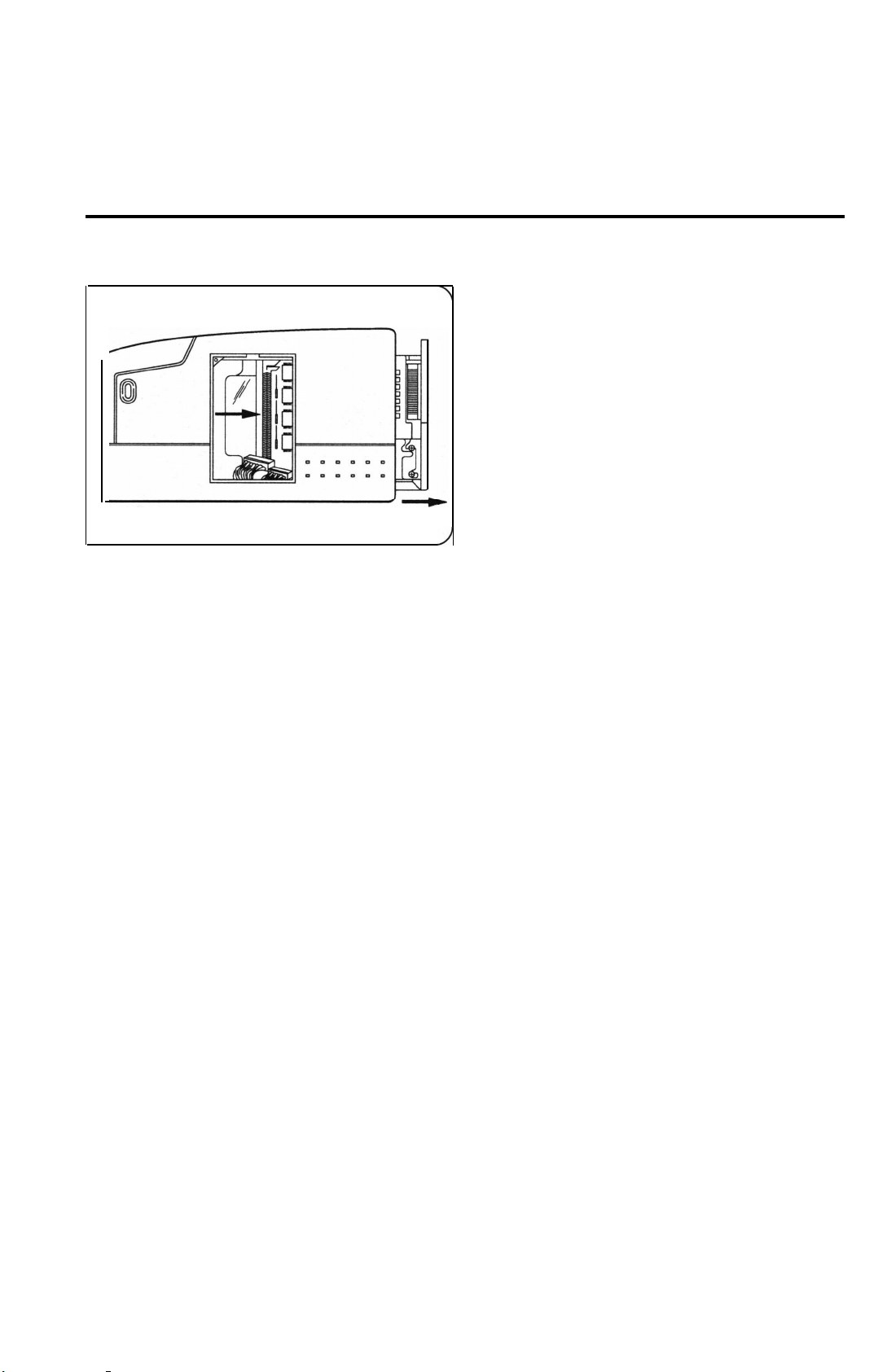

Controller Disassembly

Remove the SIMM cover.

Push the tab down and pull the SIMM cover away from

the printer.

Remove the two

controller board.

ribboa

connectors on the video

Remove the screw in upper

panel, then remove the panel to expose the video

controller board.

left

comer of the metal

37

c

/

Pull the rear metal panel out and slowly slide the video

controller out of the LBP and put it on a flat surface.

38

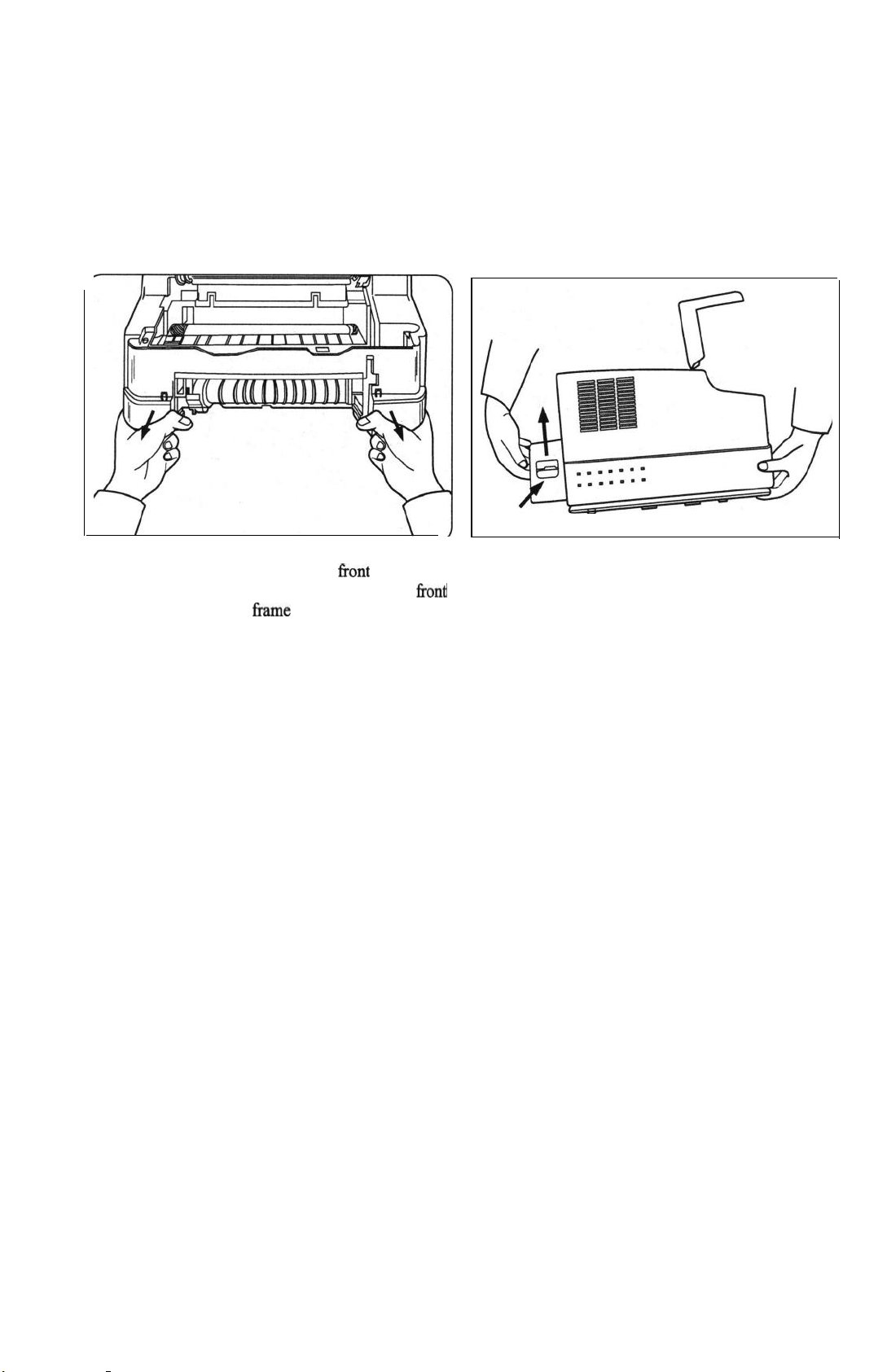

5-2.

Cover Housing Disassembly

Remove the Drum unit, and place it in a place isolated from direct sunlight.

wire

panel

Locate and remove the two screws along the rear side

of the printer.

Turn the printer’s front to you then lift the door and

remove the two screws. If the printer has the Cleaning

roller, there should be a connection between OUT of

Cleaning board and IN of Cleaning roller.

From underneath the door, using your thumb, as shown,

pull the hook to the left and then pull out the cap wire

panel.

Remove the Panel PBA harness and locate it not to

prevent you from working.

39

To remove the entire cabinet, release the hook that is

near the bottom and towards the right front side of the

cabinet. To do this, use both hands to elevate the front

of the printer, push the frame lock inward while you

The cabinet also has a lock on the inlet side. Push the

inlet inward and pull the cabinet upward. Gently pull

the cabinet outward to release the lock as shown in the

diagram.

pull the cabinet outward.

40

53. Fuser Disassembly

If you have not already done so, remove the printer

Disconnect the thermistor wire and the heater wire.

cabinet.

Remove the two screws holding the SMPS Shield and

lift the shield up and away from the SMPS.

,

AC wire

\ thermistor wire

Remove the four screws holding the fkser assembly and

pull it away from the printer.

41

Fuser Assembly.

Release the lock holding the actuator and lift one end of

the actuator and then the other end up and away from

Remove the screw at the end of the f&er assembly and

pull the right electrode off the fuser assembly.

the fuser assembly.

Gently, pull the lamp out of the heat roller.

Remove the two screws around the thermostat as

shown in the diagram.

Lift the thermostat out of the f&er assembly and left

electrode.

42

Upper Fuser Frame

Lower Fuser Frame

Remove the four screws holding the upper and lower

fuser frame together.

Gear Exit-Laud

Pull the upper and lower

fker

frames apart.

Pull off and reserve the gear exit-land the CS ring.

Pull the heat roller up and out of the upper fuser

43

fkame.

Remove the

firser

gear from the right end and the

bearings from each end of the heat roller.

Gently lift the spring lock point to release the

thermistor assembly Corn the underside of the upper

fuser frame.

Locate the two exit rollers on the underside of the

Locate and remove the three guide claws and springs.

upper Iuser Came. Gently lift the sprint lock points and

remove the exit rollers.

44

Pressure Roller

Lift the pressure roller up and out of the lower

fi-ame

assembly.

fuser

Remove the two pressure roller bearings and their

springs.

Remove the gear exit from the end of the pressure

roller.

Remove the left bearing exit Roller and right bearing

exit roller.

45

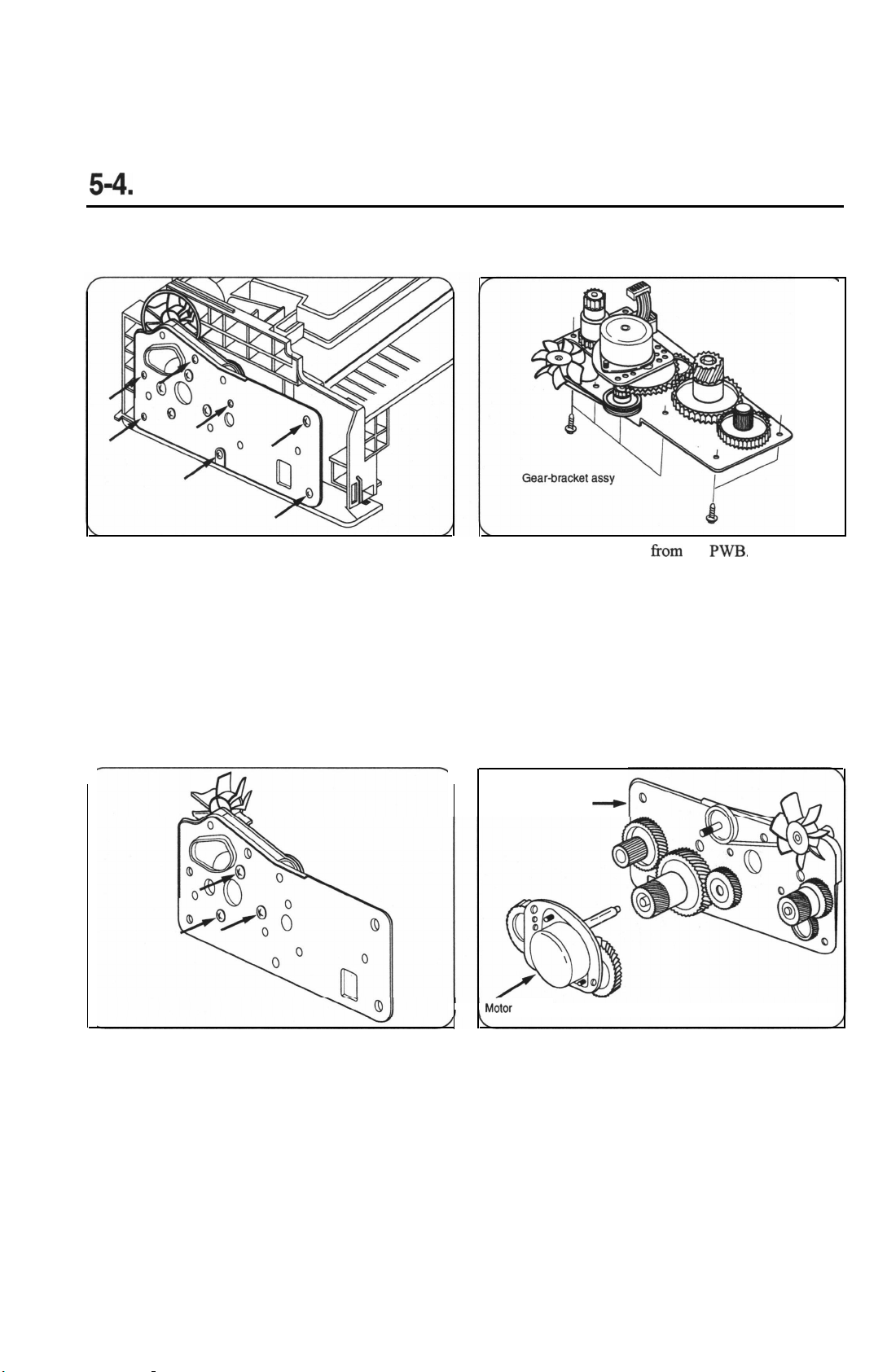

5-4.

Gear Bracket Disassembly

Along the power inlet side of the printer, locate and

remove the seven screws which hold the gear bracket

assembly on the printer.

Detach the motor harness from the

Gear Bracket Assy

M&or Bracket

-_)

PM.

Remove the three screws holding the motor bracket to

the gear bracket assembly and pull the motor away.

Pull up on the gears individually to remove them.

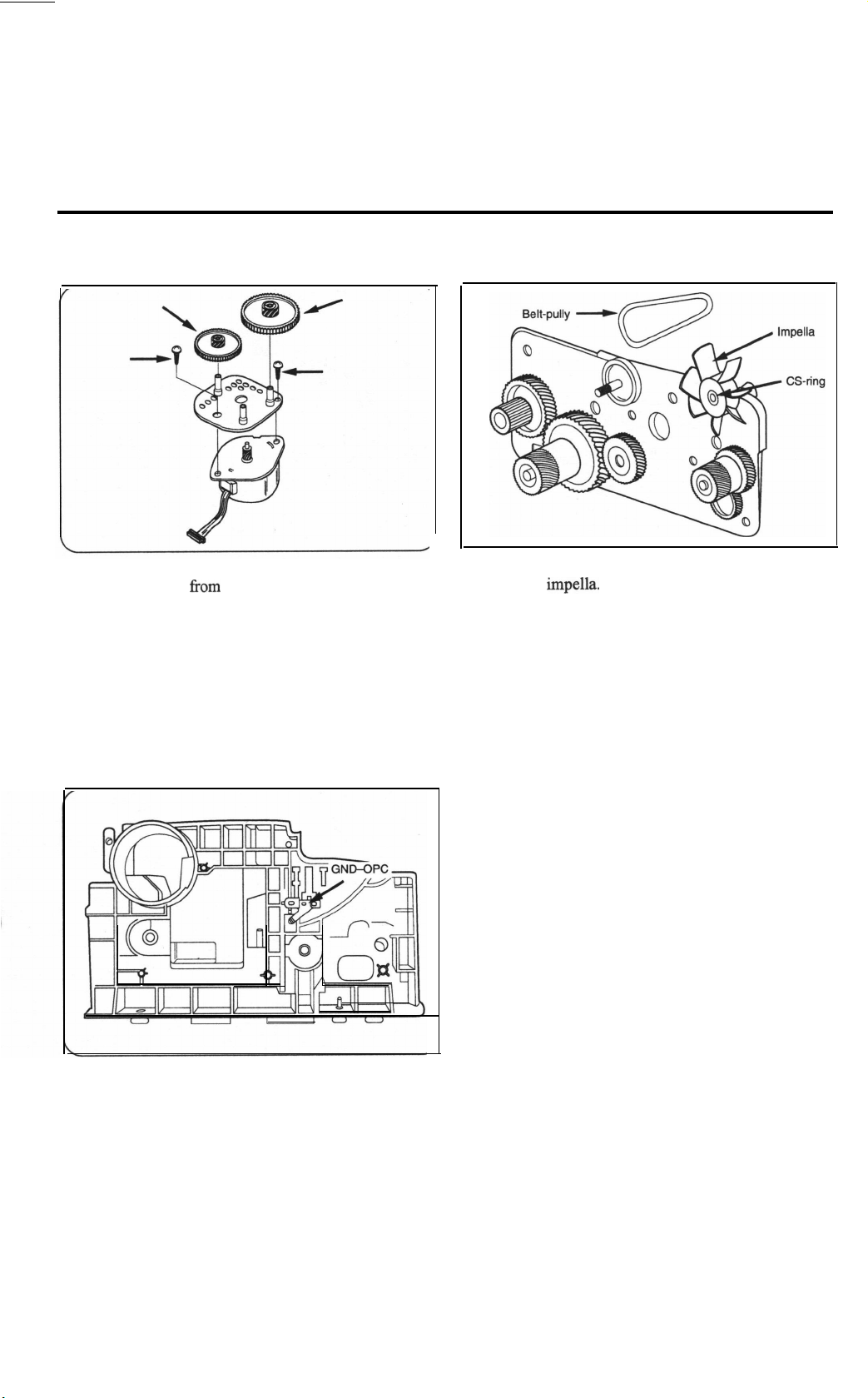

46

Remove the two screws on the motor bracket to

separate the motor

from

the motor bracket.

On the gear train, remove the belt pulley and CS ring to

remove the

impella.

Other gears on the gear train have

permanently welded gear locks.

The OPC Ground can be removed after taking off the

gear bracket.

47

5-5. LSU Disassemblv

Remove the three screws holding the LSU in the lower

part of the printer.

Detach the 5-pin scanner motor wire then

while you detach the 6-pin LD wire.

lift

the LSU

48

5-6.

Shaft-Exit Disassembly

If you have not already done so, remove the ICU

Shield.

Release

the exit bearing on both sides of the exit shaft.

Roller

Holder exit face down

exht

\

Lift the exit shaft up and away from the printer.

Locate and remove the face down exit spring, face

down exit holder and exit roller.

49

5-7. Top Cover Disassembly

If you have not already done so, remove the printer

cabinet and cap wire panel.

Working on the underside of the top cover, release the

spring hook lever and remove the hook lever.

C/O

B&on

To remove the top cover from the cabinet, remove the

four screws holding the two spring-C/OS.

Pull out the C/O shaft and separate the top cover Tom

the cabinet.

Remove the C/O button by pressing in the hook and

pulling the button and its spring out of the cabinet.

50

Loading...

Loading...