SAMSUNG ML7000XEG Service Manual

ML-7000 Series

1. Precautions

2. Reference Information

3. Product Information

4. Disassembly

5. Trouble Shooting

6. Exploded Views & Parts List

7. Block Diagrams

8. PCB Diagrams

9. Port Thru

(Network Printer Card)

ML-7000P

ML-7000N

QwikLaser 7000

QwikLaser 7000P

QwikLaser 7000N

SERVICE

Manual

Laser printer Contents

ELECTRONICS

© Samsung Electronics Co., Ltd. Sep. 1998

Printed in Korea

P/N. JC68-00034A Rev 1.00

List of Contents

1. Precautions

1-1 Safety Precautions

1-2 Laser Safety Statement

2. Reference Information

2-1 Abbreviations and Acronyms

2-2 Diagnostic Control Unit

3. Product Information

4. Disassembly

4-1 Front View

4-2 Rear View

4-3 Cabinet disassembly

4-4 Video Controller Board & Joint Board

4-5 Fuser Ass’y

4-6 Bracket Motor Ass’y & Cover Open

Switch Unit

6. Exploded Views & Parts List

6-1 Cover Ass’y

6-2 Frame Ass’y

6-3 Cassette Ass’y

6-4 MP Tray Ass’y

6-5 Pick Up Ass’y

6-6 Fuser Ass’y

6-7 Shield Ass’y

6-8 Bracket Duplex Ass’y

6-9 Bracket Motor Ass’y

6-10 Frame SCF Ass’y

6-11 Cassette SCF Ass’y

6-12 Miscellaneous Items

7. Block Diagrams

7-1 Wiring Diagrams

7-2 Engine Controller

7-3 Video Controller

4-7 Pickup Ass’y

4-8 Laser Scanner Unit

4-9 Multi Purpose Tray

4-10 Control Panel

4-11 Engine Controller Board

4-12 SMPS & Bracket Duplex Ass’y

4-13 Transfer Roller Ass’y

5. Troubleshooting

5-1 Print Quality

5-2 HVPS OUTPUT Spec

5-3 Malfunction

5-4 Connector Pin Assignment

5-5 Trouble shooting of Video Controller.

8. PCB Diagrams

8-1 Engine Controller Board & Joint Board

8-2 Cassette Sensor Board

8-3 Video Contoller Board

8-4 Panel & LCD Board

8-5 PTL (Pre Transfer Lamp) Board

8-6 SCF (Second Cassette Feeder) Board

8-7 InfraRed Adaptor Board

8-8 Flash SIMM Board

8-9 Postscript Board

8-10 Local Talk & Serial Board

9. Port Thru (Network Printer Cord) :

Option

1. Precautions

1-1 Safety precautions

Read each caution carefully

1. Do not use the pinter near water or when exposed to inclement weather.

2. Do not place this printer on an unstable cart, stand or table, the product may fall, causing

serious damage to the product.

3. Slots and openings on the cabinet are provided for ventilation. To ensure reliable operation

and to protect the printer from overheation, do not block or cover any of these openings. Do

not place the printer in an enclosure unless the enclosure providesadequate ventilation.

4. Never push any kind of objects into the printer through the cabinet ventilaition slots as they

may touch dangerous hihg voltage points, create short circuits, cause a fire, or produce an

electrical shock. Never spill any kind of liquid on the printer.

5. Do not place the printer in a lacation where someone may trip on the cord.

6. Select a work surface that is lartge enough to hold the printer.

7. Operate this printer using the power source (110V, 220V, etc) indicated on the marking label.

If you are not sure of the type of power source available, consult your dealer or local power

company.

8. If you need to use an extension power cord with this printer, make sure that is uses a threewire grounded cord and that the total ampere ratings for all of the products using the

extension, do not exceed the extension cord ampere ration.

9. Do not allow anything to rest on th power cord or data communications cable.

10. Unplug this printer from the wall outlet before cleaning. Do not use liquid cleaners or aerosol

sprays. Use a damp cloth for cleaning.

11. Do not touch the surface of the photo-sensitive drum as marks ro scratches may impair print

quality.

12. Do not expose the drum unit to direct light for prolonged periods.

13. Use only standard papers, OHP films and approved envelopes.

1-2 Laser Safety Statement

Caution: Never operate and service the printer with the protective cover removed from Laser Scanner

Assembly. The reflective beam, although invisible, can damage your eyes

The printer is certified in the U.S to conform to the requirement of DHHS 21CFR Subchapter J for Class I(1) laser

product, and elsewhere is certified as a class I laser product conforming to the requirement of IEC 825.

Class I laser product are not considered to be hazardous. The laser system and printer are designed so there is never

any human assess to laser radiation above a Class I level during normal operation, user maintenance, or prescribed

service condition

CAUTION - INVISIBLE LASER RADIATION WHEN THIS COVER OPEN.

DO NOT OPEN COVER

VORSICHT- UNSICHTBARE SASERSTRAHLUNG, WENN ABDECKUNG GEÖFFNET.

ATTENTION - RAYONNEMENT LASER INVISIBLE EN CAS D’OUVERTURE, EXPOSITION DANGEREUSE AU

ATTENZIONE - RADIAZIONE LASER INVISIBLE IN CASO DI APETURA, EVITARE L’ESPOSIZIONE AL FASCIO.

PRECAUCION - RADIACION LASER IVISIBLE CUANDO SE ABRE, EVITAR EXPONERSE ALRAYO.

ADVARSEL - USTNLIG LASERSTRÄLNING VED ÄBNING, NÄR SIKKERHEDSBRYDERE ER UDE AF

ADVARSEL - USYNLIG LASERSTRÄLNING NÄR DEKSEL ÄPNES, STIRR IKKE INN I STRÄLEN, UNNGÄ

VARNING -OSYNLIG LASERSTRÄLNING NÄR DENNA DELÄR ÖPPNADOCH SPÄRREN ÄR URKOPPLAD,

VARO! - AVATTAESSA JA SUOJALUKITUS OHITEETTAESSA OLET ALTTINA NÄKYMÄTTÖMÄLLE

¡÷ ¿« - ¿Ãµ§∞≥∏¶ø≠∏È∑π¿Ã¡Æ±§ø°≥Î√‚µ…ºˆ¿÷¿∏π«∑Œ¡÷¿««œΩ Ω√ø¿.

NICHT DEM STRAHL AUSSETZEN.

FAISCEAU.

FUNKTION, UNDGÄ UDSAETTELSE FOR STRÄLNING.

EKSPONERING FOR STRALEN.

BETRAKTA EJ STRÄLEN, STRÄLEN ÄR FARLIG.

LASER SÄTELYLLE ÄLÄ KATSO SÄTEESEEN.

LSU caution label is located on the LSU top side

CLASS 1 LASER PRODUCT

LASER KLASSE 1

LUOKAN 1 LASERLAITE

APPAREIL A LASER DE CLASSE 1

TO IEC 825

2. Reference Information

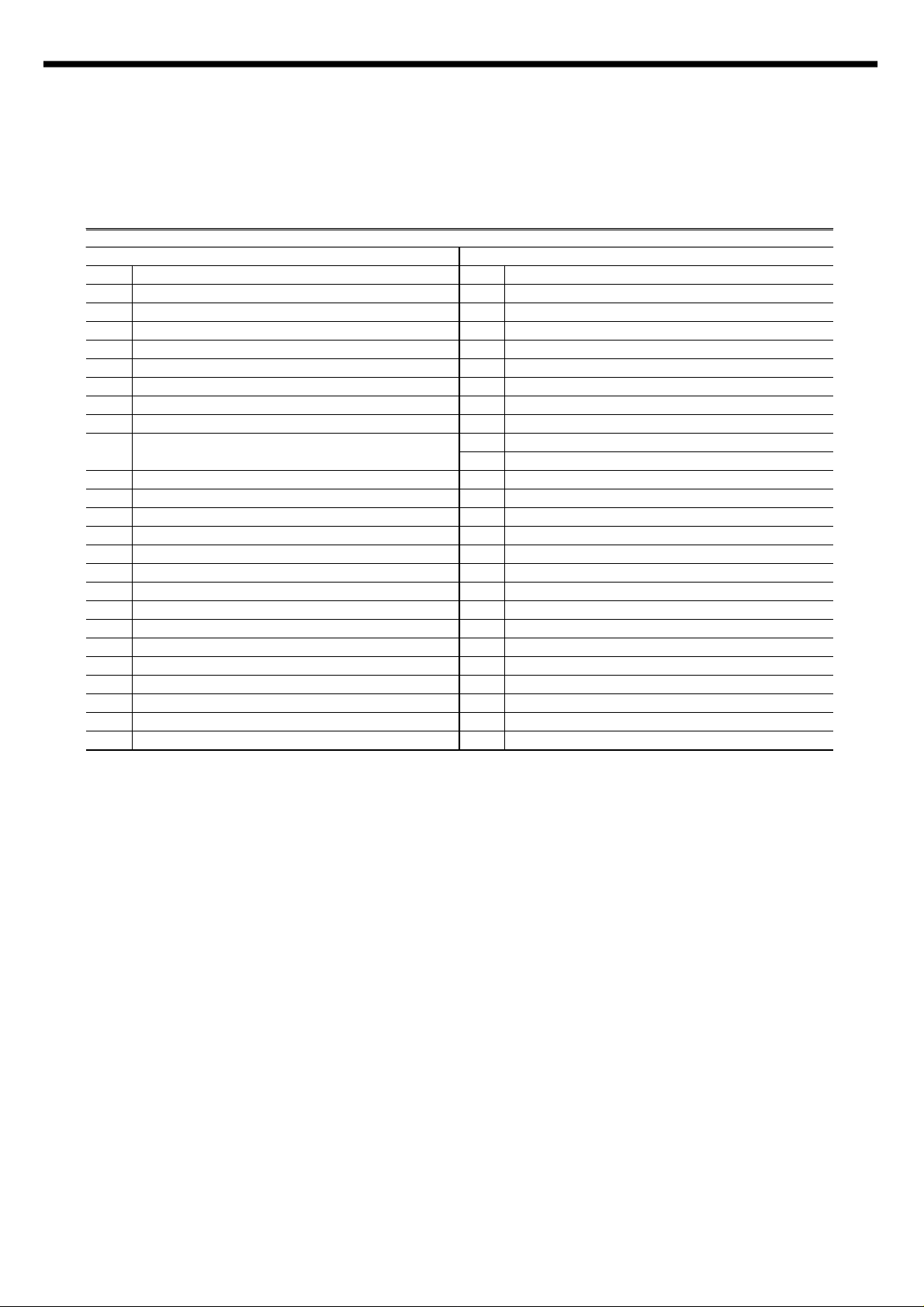

2-1 Abbreviations and Acronyms

Tables 2-1 and 2-2 List abbreviations and acronyms which may be found in this sevice manual.

Table 2-1. Abbreviations

Abbv Definition Abbv Definition

amps amperes lb pound(s)

lin linearity

ass’y assembly lock bus lock

badac bad assess mm millimeter(s)

neg negative

bps bits per second od open drain

clk clock OSC oscillator

cm centimeter(s) OUT output

CON connector PIC picture

GND ground pos positive or position

HLDA hold acknowledge pot potential

HLDAR hold acknowledge received psynrq page synchronizaton request

HLDR hold request pwr power

HOR horizontal qty quantity

in inch(es) or input sw switch

INTA interrupt Acknowledge sync synchronous or

synchronization

INT Interrupt tach tachometer

INTR Interrupt request Vcc collector supply valtage(dc)

I/O Input and Output vert vertical

mpx multiplex Vp-p peak-to-peak voltage

VR variable resistor

Table 2-2. Acronyms

Acronym Definition Acronym Definition

ABL Automatic Blanking Limiter IDE Intelligent Drive electronics or

Imbedded Drive Electronics

ACC Automatic Color Control IF Intermediate Frequency

ADC Analog to Digital Converter IPM Images Per Minute

ADS Address/Data Status ISA Industry Standard Architecture

ALE Address-Latch Enable KBC Keyboard Controller

ASCII American Standard Code for LAD Local Address/Data Bus

Information interchange

BIOS Basic Input/Output System LCD Liquid Crystal Display

BPF Band Pass Second LED Light Emitting Diode

BPS Bits Per Second MCA Micro Channel Architecture

CCFT Cold Cathode Fluorescent Tube MDA Monochrome Display Adapter

CGA Color Graphics Adapter NC No Connection

CMOS Complementary Metal Oxide NF Noise Fiqure or Noise Factor

Semiconductor

CPU Central Processing Unit PA Power Amplifier

CRT Cathode Ray Tube PBA Printed Board Assembly

CRU Customer Replacement Unit

DMA Direct Memory Access or PBM Primary Bus master

Dynamic Memory Address

DMAC Direct Memory Access PCB Printd Circuit Board

Controller

DVM Digital Voltmeter PCMCIA Personal Computer Memory

Card International Association

EEPROM Electronically Erasable Pro- PLCC Plastic Leaded Chip Carrier

grammable read Only Memory

EGA Enhanced Graphics Adapter PMS Power Management System

EISA Extended Industry Standard POST Power On Self Test

Architecture

ESDI Enhanced Small Device PPM Pages Per Minute

Interface

FDC Floppy Disk Controller PQFP Plastic Quad Flat Package

FDD Floppy Disk Drive QFP Quad Flat Package

FL Fluorescent Light(Lamp) RAM Random Access Memory

HDD Hard Disk Drive ROM Read Only Memory

HPF High Pass Filter RTC Real-Time Clock

SCSI Small Computer Systems SBM Secondary Bus Master

Interface

SIO Serial Input/Output Controller TSTN Triple Super Twisted Nematic

SOP Small Outline Package UHF Ultrahigh Frequency

SSOP Shrink Small Outline Package VCO Voltage Controlled Oscillator

STN Super Twisted Nematic VESA Video Electronics Standard

Association

SCC Serial Communications VGA Video Graphics Array

Controller

TFT Thin Film Transistor VHF Very High Frequency

TS Tri-State XO Crystal Oscillator

TSOP Thin Small Outline Package

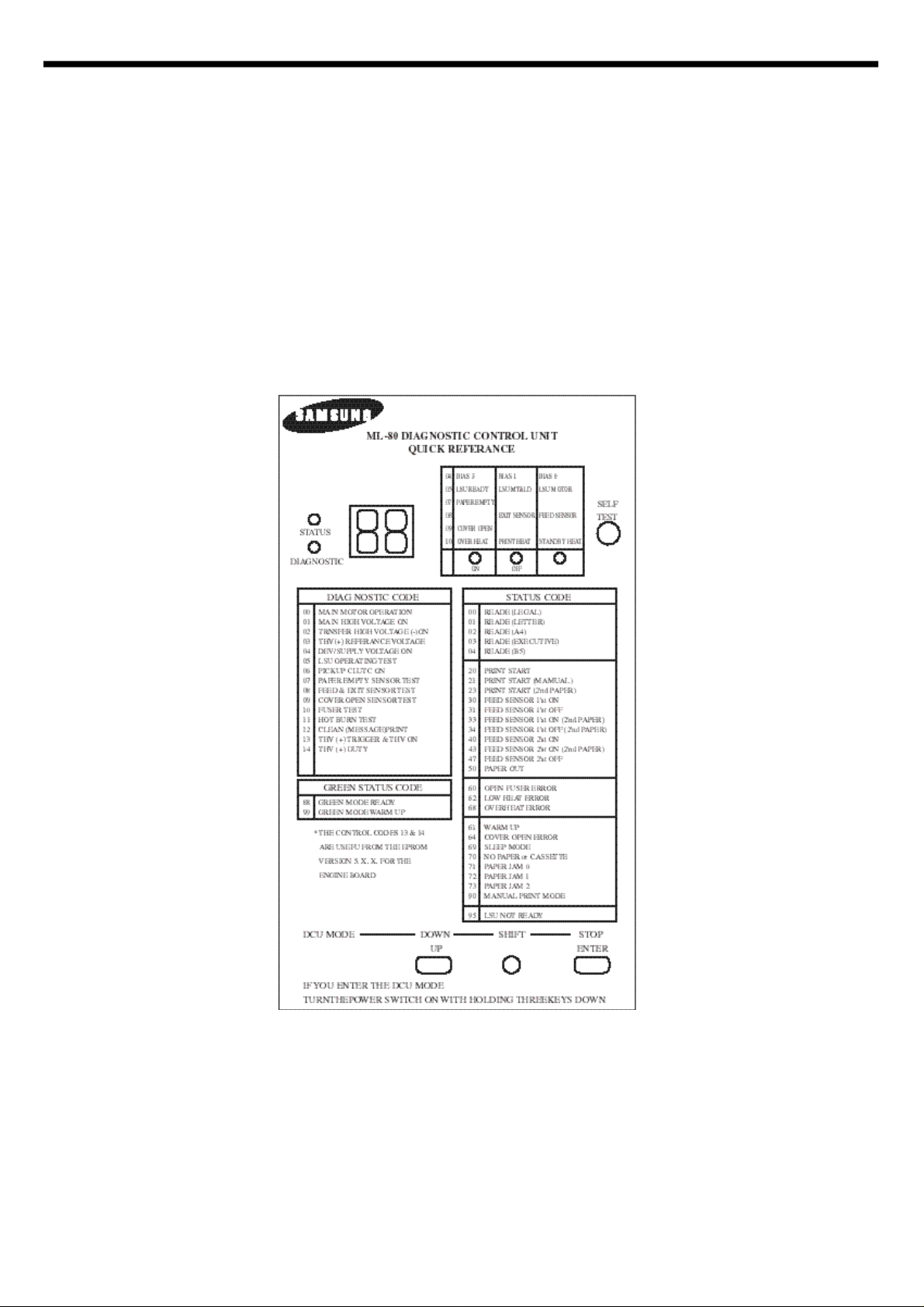

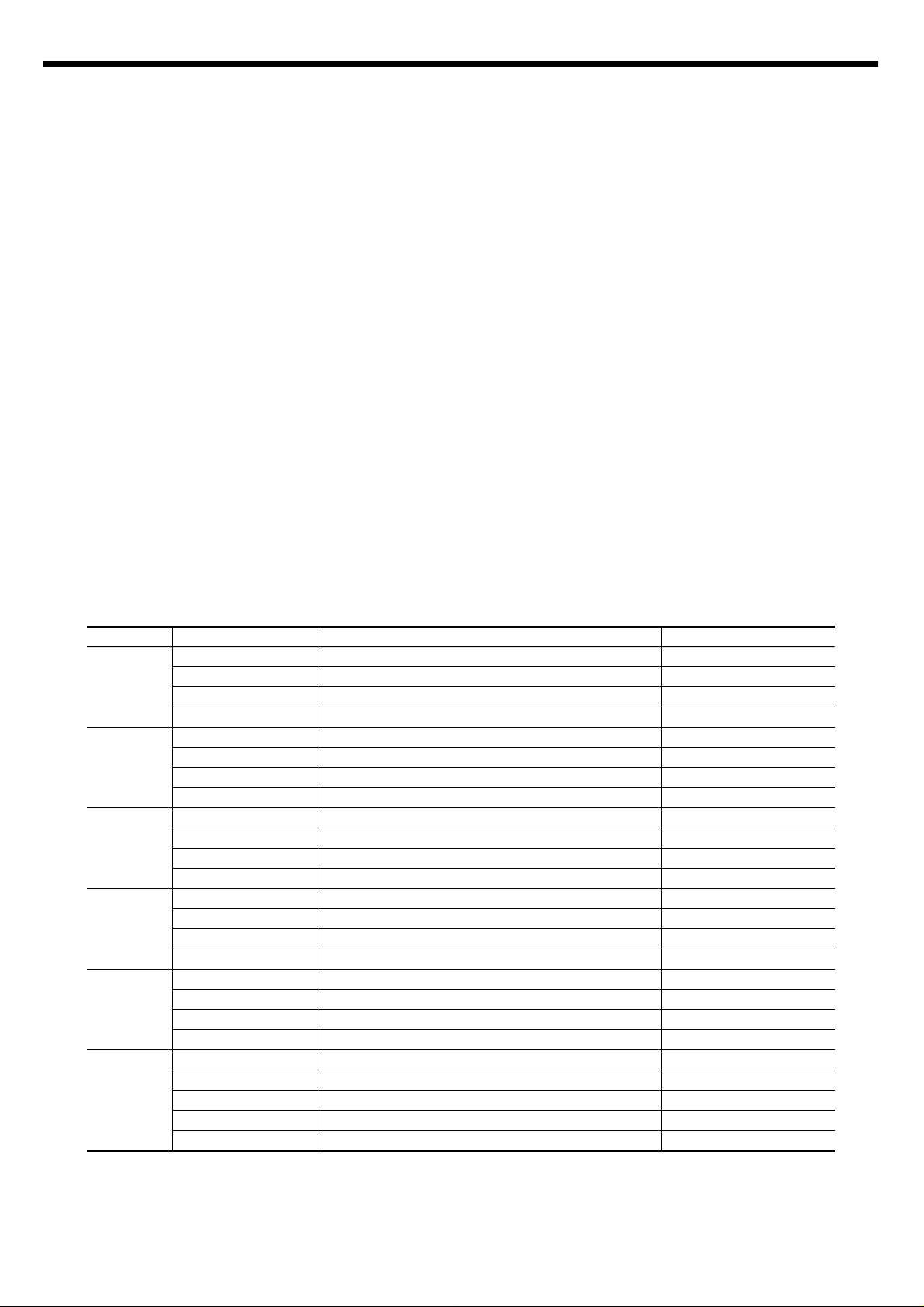

2-2. Diagnostic Control Unit

2-2-1. Abstract

The diagnostic Control Unit(DCU) is useful for troubleshooting the Laser beam printer ML Series engines,

and for checking printer status.

The DCU can be used in common for ML series, but each model has several different code description.

Refer to the code description for ML-7000 in next page.

< Fig 1-1. ML-80 DCU >

2-2-2. List of code description

Code Description

1. DIAGNOSTIC CODE 2.STATUS CODE

00 MAIN MOTOR OPERATING 78 SYSTEM ERROR

01 MAIN HIGH VOLT ON / OFF TEST 00 Ready to print from LEGAL paper tray

02 THV (- ) ON / OFF TEST 01 Ready to print form LETTER paper tray

03 THV (+) ON / OFF TEST 02 Ready to print form A4 paper tray

04 DEV, SUPPLY ON / OFF TEST 03 Ready to print form EXEC paper tray

05 LSU OPERATING TEST 04 Ready to print from B5 paper tray

06 PICK UP CLUTCH ON 05 Ready to print from FOLIO paper tray

07 PE, DS1, DS2 SENSOR TEST 20 PRINT START (1st CASSETTE)

08 MP, EXIT, FEED SENSOR TEST 21 PRINT START (MULTI PURPOSE)

09 TOP & REAR COVER OPEN, 22 PRINT START (2’nd CASSETTE)

OUT BIN SENSOR TEST 23 PRINT START (DUPLEX)

10 FUSER TEST 50 PAPER OUT

11 HOT BURN TEST 60 OPEN FUSER ERROR

12 DUPLEX CLUTCH TEST 62 LOW HEATER ERROR

13 MULTI PURPOSE CLUTCH TEST 68 OVER HESTER ERROR

14 THERMISTER 2 TEST 61 WARM-UP

15 PAPER SIZE SENSOR TEST 64 COVER OPEN ERROR

69 SLEEP MODE

70 NO PAPER or CASSETTE

71 PAPER JAM “0”

72 PAPER JAM “1”

73 PAPER JAM “2”

74 DUPLEX JAM “1”

75 DUPLEX JAM “2”

76 OUT BIN FULL

95 LSU NOT READY

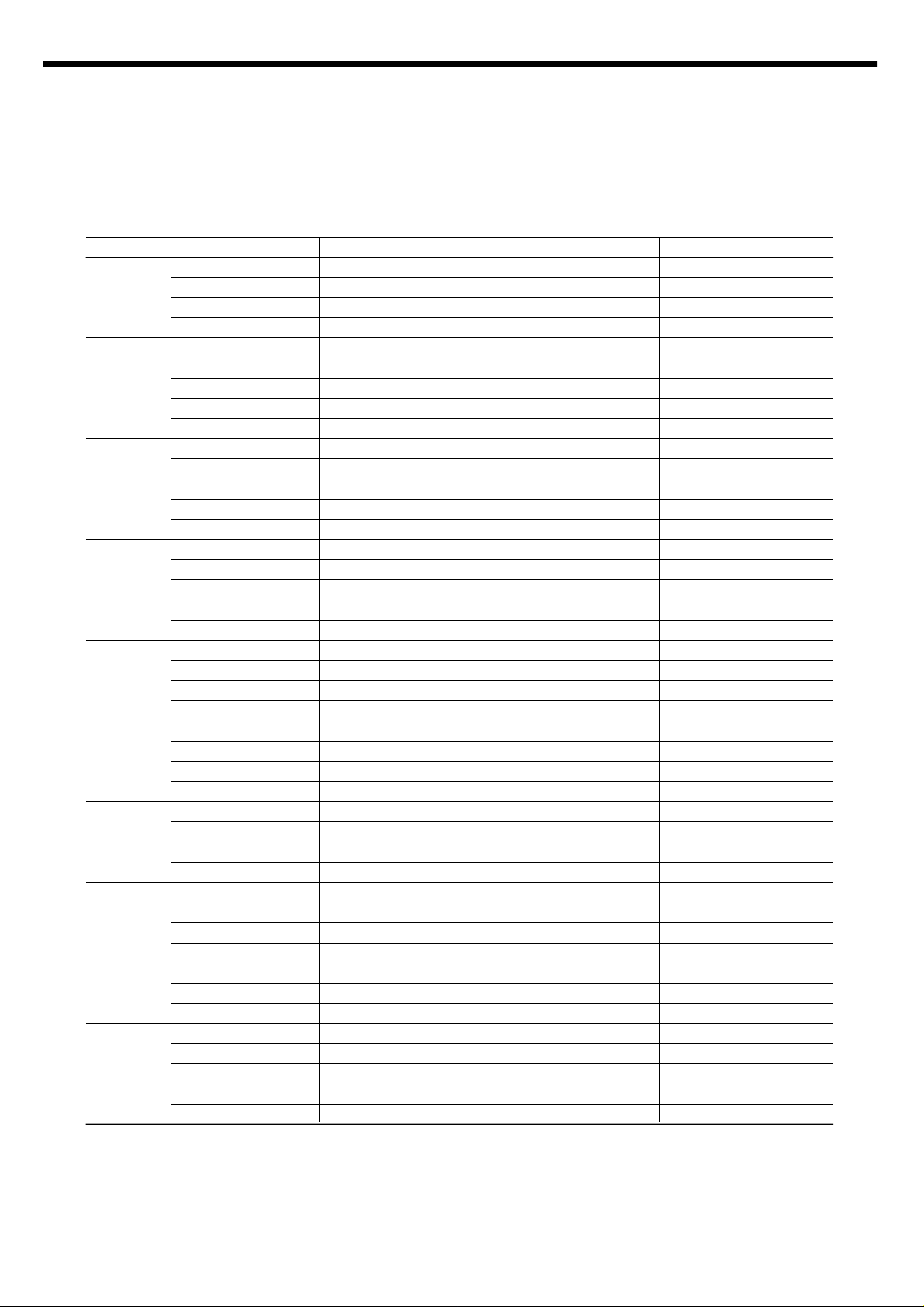

2-2-3. The Diagnostic Control Unit (DCU) Operating Guide

¶°Display the engine status and error status code. Refer to List of Code Description.

2) Self-Test mode.

¶°When the engine is ready, this button starts printing a streak pattern.

3) Green mode

¶°Transfer high Voltage adjustment mode

With the power off, hold down the Self-Test button and turn on the pinter. Continue holding down the button

for 5 seconds to start Green mode.

4) Diagnostic Control mode.

¶°With the power off, hold down the 3 button (up/down, shift, stop/enter) and turn on the printer

Continue holding down the button for 5 seconds to start Diagnostic Control mode on the engine.

¶°The DCU has three diagnostic control buttons.

UP : Steps the function of the other two buttons:

SHIFT : Controls the function of the other two buttons:

SHIFT+UP means step down and SHIFT+START means stop.

START : Stasrts or stops the current diagnostic test.

Code Key Operation LED Display

00 ENTER Run Main Motor Lighten ON LED

SHIFT+STOP Stop Main Motor Lighten OFF LED

UP Increment DCU Code No. (01, MHV)

SHIFT+DOWN Decrement DCU code No. (13, MP)

01 ENTER MHV ON Lighten ON LED

SHIFT+STOP MHV OFF Lighten OFF LED

UP Increment DCU Code No. (02, THV Negative)

SHIFT+DOWN Decrement DCU code No. (00, Main Motor)

02 ENTER THV Negative ON Lighten ON LED

SHIFT+STOP THV Negative OFF Lighten OFF LED

UP Increment DCU Code No. (03, THV)

SHIFT+DOWN Decrement DCU code No. (02, MHV)

03 ENTER THV ON Lighten ON LED

SHIFT+STOP THV OFF Lighten OFF LED

UP Increment DCU Code No. (04, Dev)

SHIFT+DOWN Decrement DCU code No. (02, THV Negative)

04 ENTER DEV, SUPPLY ON Lighten ON LED

SHIFT+STOP DEV, SUPPLY ON Lighten OFF LED

UP Increment DCU Code No. (05, LSU)

SHIFT+DOWN Decrement DCU code No. (03, THV)

05 ENTER LSU Motor On Lighten 3rd LED

UP LSU Leady and LD On Lighten 1, 2nd LED

SHIFT+STOP LSU Motor OFF

UP Increment DCU Code No. (06, Pickup Clutch)

SHIFT+DOWN Decrement DCU code No. (04, Dev)

The DCU has functions as follows:

1) Engine Status and Error Code Display mode

Code Key Operation LED Display

ßZ15°…1st LED ON

No Action 15°…¶ZTemperature ¶Z30°…2nd LED ON

No Action Temperature ß[30°…3nd LED ON

No Action Thermister 2 Open All LED ON

No Action Thermister 2 Short All LED OFF

UP Increment DCU code No.

(15, Cassette sensor TEST)

SHIFT + DOWN Decrement DCU Code No. (13, MP Clutch TEST)

15 No Action Cassette Sensor 1 ON/OFF 1st LED ON/OFF

No Action Cassette Sensor 2 ON/OFF 2nd LED ON/OFF

No Action Cassette Sensor 3 ON/OFF 3nd LED ON/OFF

UP Increment DCU Code No. (00, Main Motor)

SHIFT + DOWN Decrement DCU Code No. (14, Thermister 2 Test)

06 ENTER Pickup Clutch ON Lighten ON LED

SHIFT+STOP Pickup Clutch OFF Lighten OFF LED

UP Increment DCU Code No. (07, Sensor TEST)

SHIFT+DOWN Decrement DCU code No. (06, Pickup Clutch)

07 No Action Paper Empty Sensor ON/OFF 1st LED ON/OFF

No Action Duplex 1 Sensor ON/OFF 2nd LED ON/OFF

No Action Duplex 2 Sensor ON/OFF 3rd LED ON/OFF

UP Increment DCU Code No. (08, Sensor TEST)

SHIFT+DOWN Decrement DCU Code No. (06, Pickup Clutch)

08 No Action Multi Purpose Sensor ON/OFF 1st LED ON/OFF

No Action Exit Sensor ON/OFF 2nd LED ON/OFF

No Action Feed Sensor ON/OFF 3rd LED ON/OFF

UP Increment DCU Code No. (09, Sensor TEST)

SHIFT+DOWN Decrement DCU Code No. (07, Sensor TEST)

09 No Action Cover Open Sensor ON/OFF 1st LED ON/OFF

No Action Cover Open Sensor ON/OFF 2nd LED ON/OFF

No Action Out Bin Sensor ON/OFF 3rd LED ON/OFF

UP Increment DCU Code No. (10, Fuser TEST)

SHIFT+DOWN Decrement DCU Code No. (08, Sensor Clutch)

10 ENTER Fuser ON Lighten ON LED

SHIFT+STOP Fuser OFF Lighten OFF LED

UP Increment DCU Code No. (04, Dev)

SHIFT+DOWN Decrement DCU code No. (02, THV Negative)

12 ENTER Duplex Clutch ON Lighten ON LED

SHIFT+STOP Duplex Clutch OFF Lighten OFF LED

UP Increment DCU Code No. (13, MP Cluth)

SHIFT+DOWN Decrement DCU code No. (11, Self-Test)

13 ENTER Multi Purpose Clutch ON Lighten ON LED

SHIFT+STOP Multi Purpose Clutch OFF Lighten OFF LED

UP Increment DCU Code No. (14,Thermister 2 Test)

SHIFT+DOWN Decrement DCU code No. (12, Duplex Clutch)

14 No Action Temperature

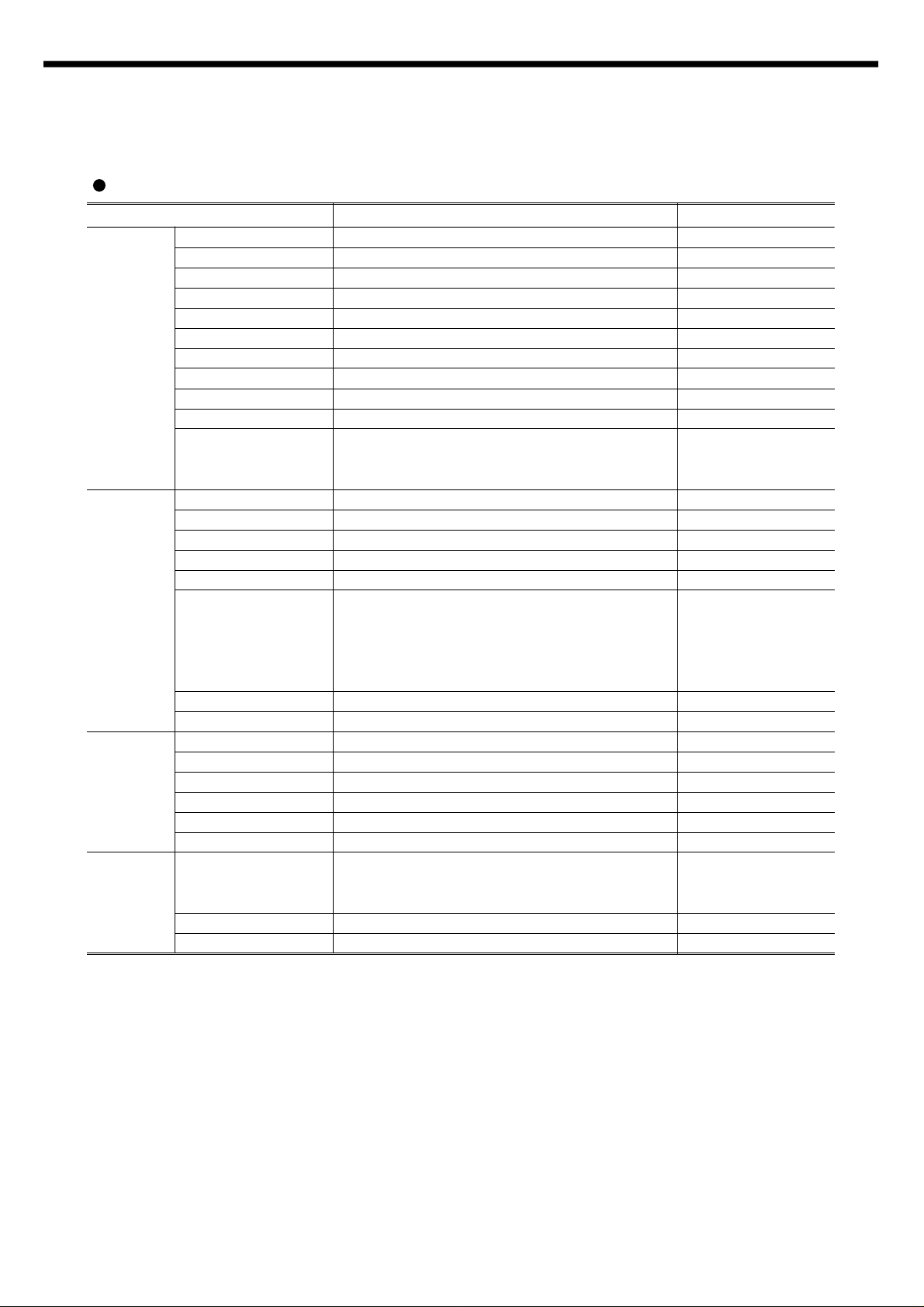

3. Product Information

°ø442 °ø301mm

Weight Less than 16.5Kg (36.4lb) not packaged

Power Consumption 340W Avg/ 34W Sleep

Printing : °¬50dB

Noise Level Standby : °¬36dB

Sleep : Background noise Blow Fan off

Input Capacity 500 sheets Universal

Optional Input 500 sheets (40 envelopes)

Output Capacity 250 sheets Facedown No faceup mode

MP Tray 100 sheets (10 envelopes)

Envelop Feeder

supported by Multi-Purpose tray, optional cassette

Paper °§Cassette : A4, LTR, FO, LEG, EXE, ISO B5

Handling Type of Media °§MP Tray : Legal~A6, OHP, LABEL

COM-10, MON, DL, C5, C6

°§Optional Cassette : A4, LTR, FO, LEG

COM-10, MONARCH, DL, C5

Duplexing Paper : A4, LTR, FO, LEG

Paper Sensor Yes

CRU type Single cartridge Replacement

CRU Life 8,000 pages at 5% coverage

Imaging Cleaning System Mechanical Cleaning

Catridge Charging/Transfer Contact Charging & Transfer

Toner Sensor Yes

Toner saving Yes

°§8°ø2 LCD

Control Panel °§LCD Display angle adjusting

Others °§Backlighting

Paper Level Indicator Visible Mechanism

Power Switch Front & Left side, Push botton

Engine Specifiation

Item Descriptions Remarks

Speed 17 PPM Letter

Resolution 600 DPI +RET

Imaging Eletrophotography

Toning/Fusing Non-mag monocomponent/contact

WarmUp time Less than 60 secs N/N condition

FPOT Less than 13 secs standby mode

Engine Duty Cycle Maximum 50,000 pages per month

Size(WDH) 427

Controller Specification

°§Default : PCL6

°§Option : Postscript Level 2

°§4MB Standard

°§Max up to 68MB

°§Speed : 60nS

°ÿDRAM Module’s Features

°§Refresh Time : 2048 Cycles/32mS

Memory

°§Fast Page Mode with Extended data out

°§CAS-before-RAS refresh capability

°§TTL compatible inputs and outputs

°§Single +5V °æ10% power supply

°§2, 4MB Flash memory option

°§Postscript : 12MB Standart P.S Simm Module

°§IEEE 1284 B type

Option :

Interface Serial RS 232C

Controller InfraRed Adaptor connector

Local Talk,

Internal Network

AIS/AES Y/Y

Font 35 Intellifont, 10 True Type, 1Bit Map

°§Ethernet TCP/IP, SPX/IPX

Port Thru

°§10 base T Apple Talk,

(Network Printer Card)

°§SNMP in MIB NetBEUI/NetBios

°§TCP/IP

°§Netware, Windows, OS/2, Unix, Mac

Device Driver PCL : Windows 3.1/95/NT, DOS

Item Descriptions Remarks

CPU Power PC, 100MHZ

Emulation

4. Disassembly

°‹

°‹

°‹

°‹

°‹

°‹

°‹

°‹

°‹

Controller

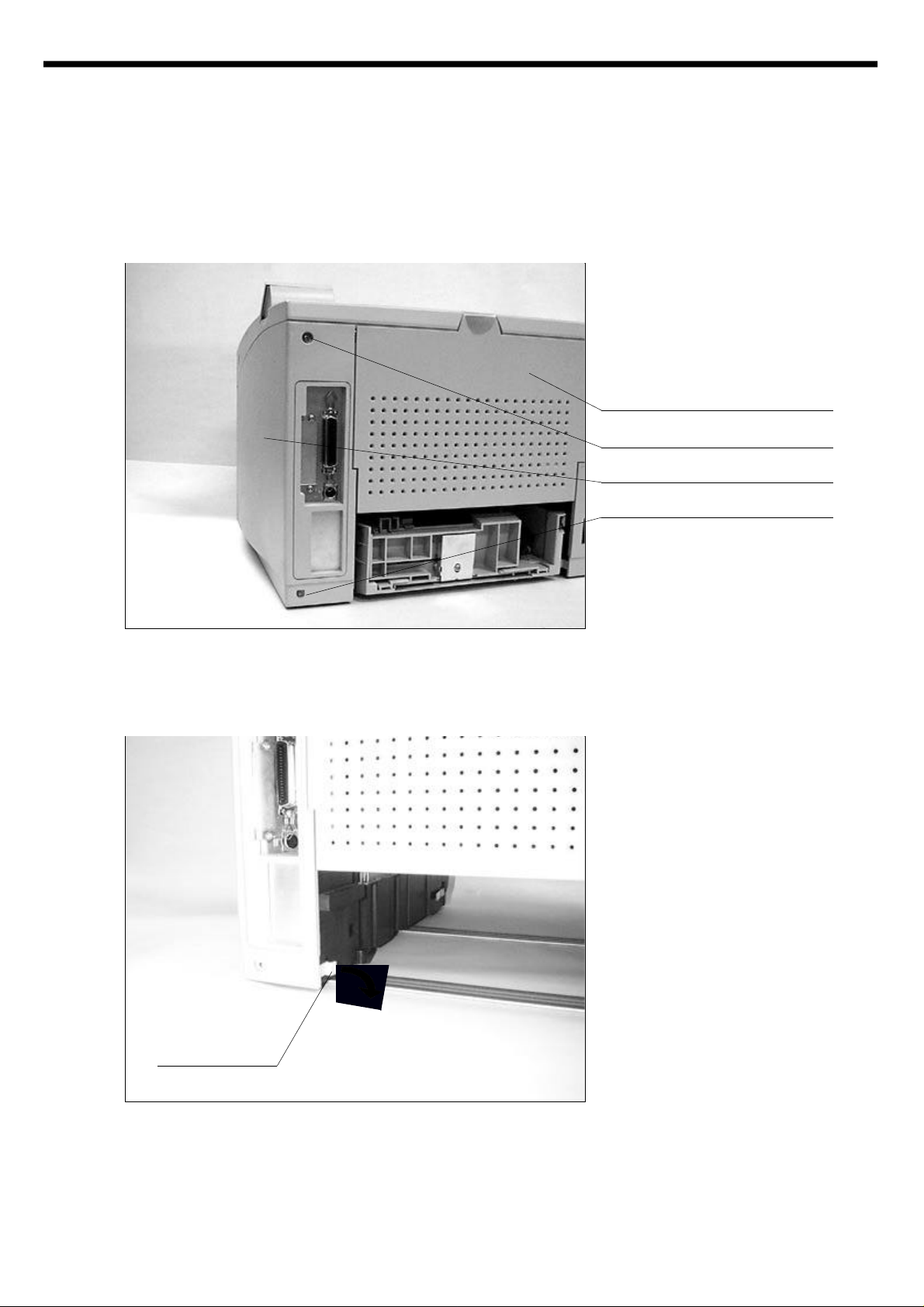

Cassette

Power Inlet

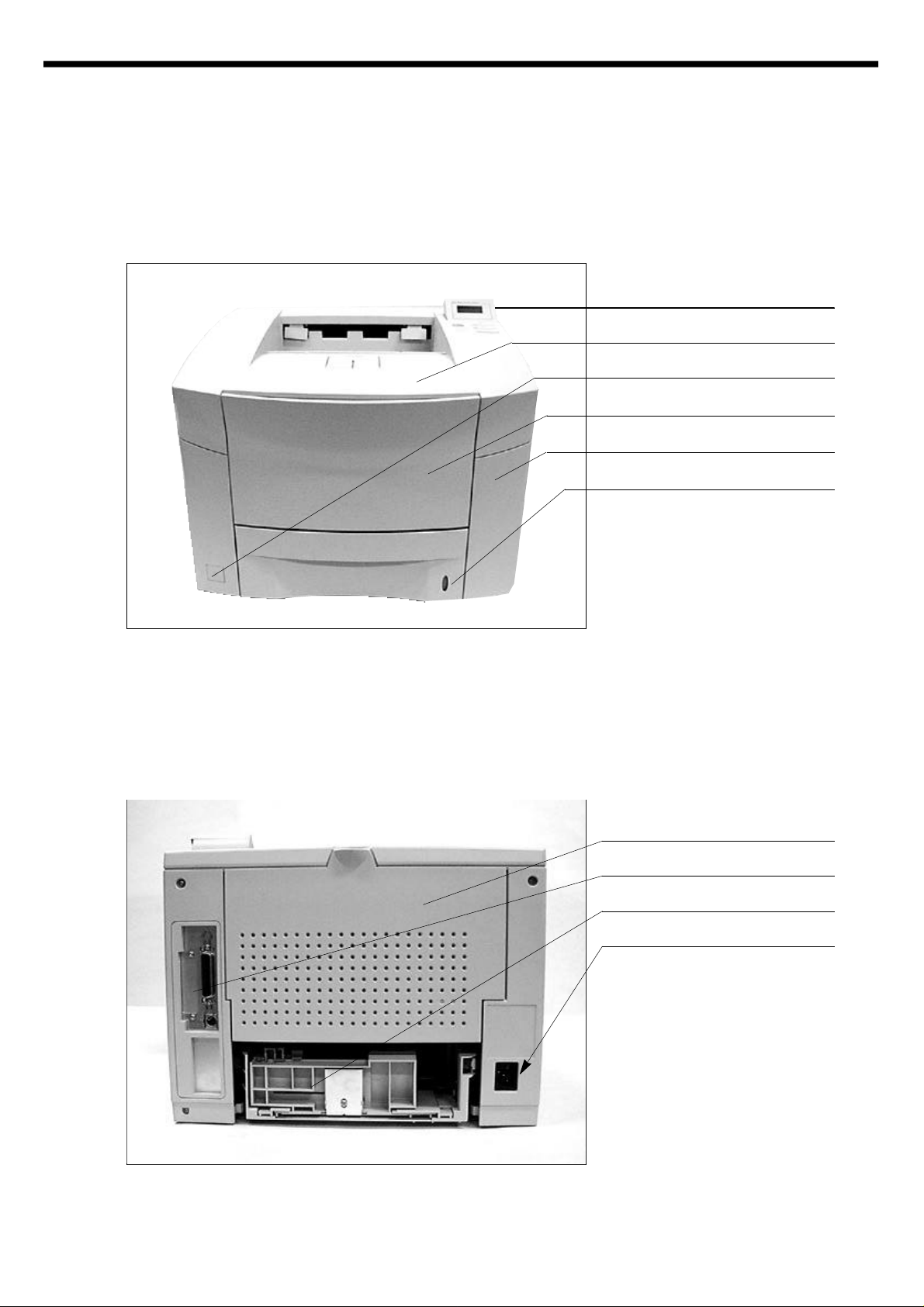

4-1 Front View

Control Panel

Cover Open

Power Switch

Cover Tray

Cover Front

Paper Level Indicator

4-2 Rear View

Cover Rear

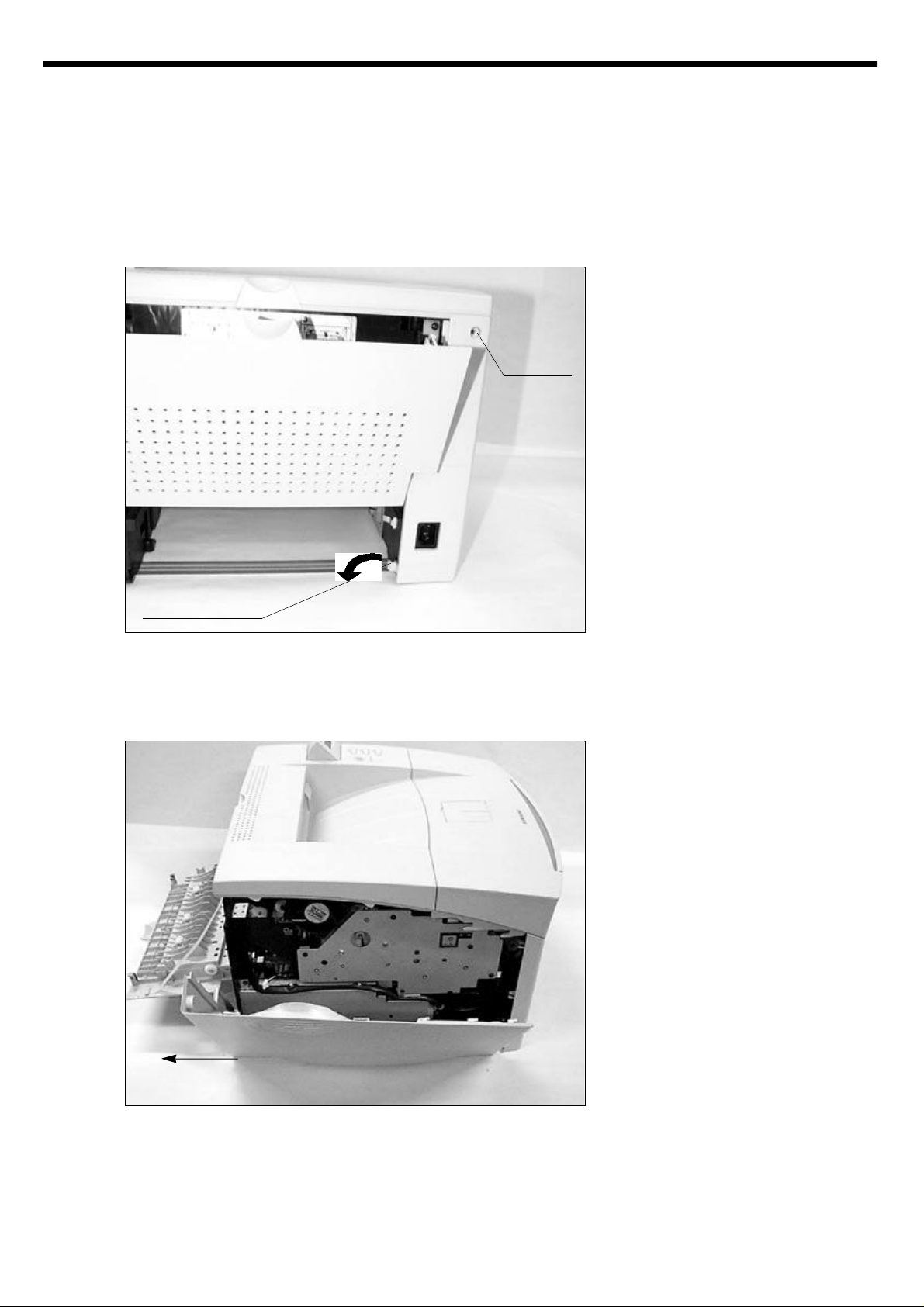

4-3 Cabinet Disassembly

°‹

°‹

Screw

Cover Rear

Cover Right

Screw

Hook

4-3-1. Cover Right

Remove the screws and open the

Cover Rear.

In order to remove the Cover Right.

Please see the hook which locks

the cabinet to the frame, right hand

should first grab the hook and pull it

out for releasing the hook from the

frame.

The left hand should slide the

Cover Right to the backward.

4-3-2. Cover Left

Hook

Hook

Screw

Remove screw and open the Cover

Rear.

Please see the hook of the Cover

Left. Pull the Hook and release it

from the frame.

Pull

Slide the Cover Left to the

backward with pulling the hook out.

The Cover Left can be easily

removed.

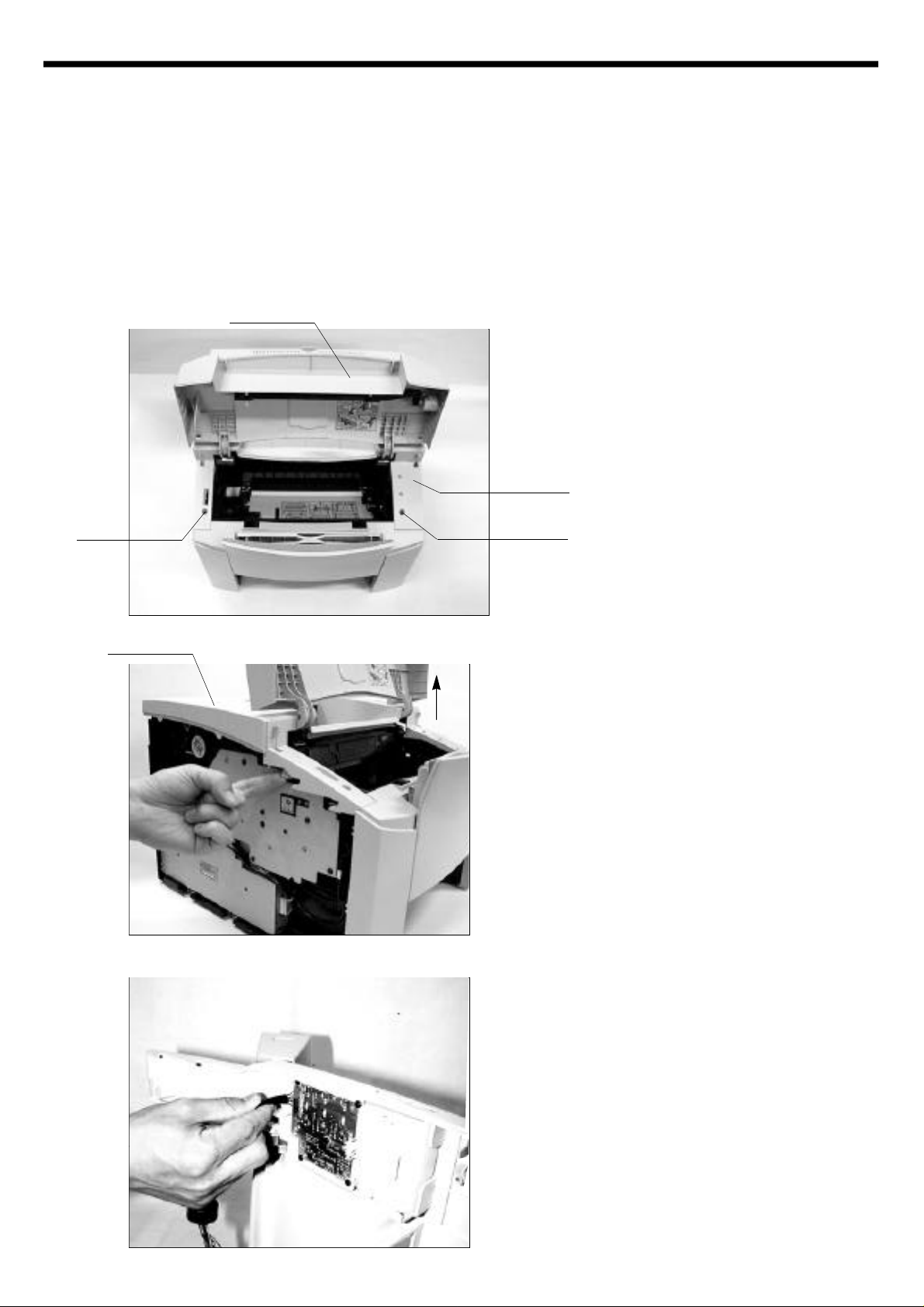

4-3-3. Cover Front

Please see the MP tray disassembly. (4-9)

4-3-4. Cover Main

Cover Open

Open the Cover Open.

Remove two screws.

Cover Top

Screw

Cover Main

Up

Screw

See the hooks.

Push the hooks up and pull them

upward.

With holding Cover Main, remove

the panel wire.

Loading...

Loading...