SAMSUNG ML5100AXEU Service Manual

SERVICE

LASER PRINTER

ML-5100A

Manual

LASER PRINTER CONTENTS

1. Precautions

2. Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. Exploded Views and Parts List

6. Electrical Parts List

7. Schematic Diagrams

ELECTRONICS

P/N. JC68-00073A Rev. 1.00

Samsung Electronics 1-1

1. Precautions

1-1 Safety Precautions

Read each caution carefully:

1. Do not use this printer near water or when

exposed to inclement weather.

2. Do not place this printer on an unstable cart, stand

or table; the product may fall, causing serious

damage to the product.

3. Slots and openings in the cabinet are provided for

ventilation. To ensure reliable operation and to

protect the printer from everheating, do not block

or cover any of these openings. Do not place the

printer in an enclosure unless the enclosure

provides adequate ventilation.

4. Never push objects of any kind into the printer

through the cabinet ventilation slots as they may

touch dangerous high voltage points, create short

circuits, cause a fire, or produce an electrical shock.

Never spill liquid of any kind on the printer.

5. Do not place the printer in a location where

someone may trip on the cords.

6. Select a work surface that is large enough to hold

the printer.

7. Position the printer within six feet of the computer

and within five feet of an electrical outlet.

8. Operate this printer using the power source (110V,

220V, etc) indicated on the marking label. If you are

not sure of the type of power source available,

consult your dealer or local power company.

9. If you need to use an extension power cord with

this printer, make sure that it uses a three-wire

grounded cord and that the total ampere ratings

for all of the products using the extension do not

exceed the extension cord ampere rating. Also,

make sure that the total of all products plugged

into the wall outlet does not exceed 15 amperes.

10. Do not allow anything to rest on the power cord

or data communications cable.

11. Unplug this printer from the wall outlet before

cleaning. Do not use liquid cleaners or aerosol

sprays. Use a damp cloth for cleaning.

12. Do not touch the surface of the photo-sensitive

drum as marks or scratches may impair print

quality.

13. Do not expose the drum unit to direct light for

prolonged periods.

14. Use only standard papers, OHP films, and

approved envelopes. Feed OHP films though the

manual feed slot only. See specifications for

approved papers and envelopes.

15. Other than replacing consumables such as paper

and toner, refer all questions to qualified service

personnel.

WARNING :

NEVER OPERATE AND SERVICE THE PRINTER WITH THE

PROTECTIVE COVER REMOVED FROM LASER/SCANNER

ASSEMBLY. THE REFLECTIVE BEAM, ALTHOUGH INVISIBLE,

CAN DAMAGE YOUR EYES.

Note :

Requirements for AC power are described on the label

affixed to the rear of the printer. Check the AC voltage

rating requirement before use.

1. Before disassembly, pull the power plug from the AC

power connector.

2. To avoid spilling toner inside the machine, do not

turn the printer over or on its side before removing

the developer cartridge.

3. Faulty installation of DRAMs may cause permanent

damage to the Laser Printer.

4. Use only+5V power for video controller-related

circuitry.

5. When replacing parts, use only the same type of part

as the original. Replacing components with a second

vendorÕs part may cause faulty operation.

6. Check the insulation between the blades of the AC

plug and accessible conductive parts (examples :

metal panels and input ports).

7. Insulation Checking Procedure:

Disconnect the power cord from the AC power

source. Connect an insulation resistance meter (500V)

to the blades of the AC plug.

The insulation resistance between each blade of the

AC plug and accessible conductive parts (see left)

should be greater than 1 megaohm.

8. Never defeat any of the B+ voltage interlocks. Do not

apply AC power to the unit (or any of its assemblies)

unless all solid-state heat sinks are correctly installed.

9. Always connect a test instrumentÕs ground lead to the

instrument chassis ground before connecting the

positive lead; always remove the instrumentÕs ground

lead last.

1-2 Samsung Electronics

Precautions

1-2 Servicing Precautions

CAUTION : Be sure the power is off to the

chassis or circuit board, and

observe all other safety precautions

1. Immediately before handling any semiconductor

components assemblies, drain the electrostatic charge

from your body by touching a known earth ground.

Alternatively, wear a discharging wrist strap device.

(Be sure to remove the strap before applying power to

the unit under test to avoid potential shock.)

2. After removing ESD-equipped assembly, place it on a

conductive surface such as aluminum foil to prevent

accumulation of an electrostatic charge.

3. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ESDs.

4. Use only a ground-tip soldering iron when soldering

or desoldering ESDs.

5. Use only anti-static solder removal device. Some

solder removal devices are not rated as Òantistatic;Óthese can accumulate sufficient electrical

charge to damage ESDs.

6. Do not remove a replacement ESD from its protective

package until you are ready to install it. Most

replacement ESDs are package with leads that are

electrically shorted together by conductive foam,

aluminum foil or other conductive materials.

7. Immediately before removing the protective material

from the leads of a replacement ESD, touch the

protective material to the chassis or circuit assembly

into which the device will be installed.

8. Minimize body motions when handling unpackaged

replacement ESDs. Motion such as your clothes

brushing together, or lifting a foot from a carpeted

floor can generate enough static electricity to damage

an ESC.

9. Handle ICs and EPROMs carefully to avoid bending a

pin.

10. Pay attention to the direction of parts when mounting

or inserting them on a PCB.

11. Components can be permanently damaged if heated

for longer than necessary while welding. All

components are susceptible to heat damage.

1-3 ESD Precautions

Some semiconductor (Òsolid stateÓ) devices are easily damaged from static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESDs); examples include integrated circuits (ICs),

Large-Scale Integrated circuits (LSIs), some field-effect transistors, and semiconductor chip components. The

following techniques will reduce the occurrence of component damage caused by static electricity:

Emulation PCL5e,PCL6

Interface Centronics IEEE- P1284 compatible bi-directional (Nibble, Byte, ECP)

USB (Universal Serial Bus)

Print Speed 8 PPM (A4 Size, 5 % Character Pattern)

Print Method Non-impact Electrophotography, Laser Beam

Resolution 600 X 600 DPI

Memory Standard: 4 Mb

Expandable up to 36 Mb

Operating Environment Temperature : 5 ~ 32.5 oC,

Humidity: 20 ~ 85 % RH

Storage Environment Temperature : -20 ~ 40 oC,

Humidity: 10 ~ 95 % RH

Weight Net : 7.5 kg (max.),

Gross : 10 kg (max.)

Dimension 345 (W) X 365 (D) x 224 (H) mm

Certification & Compliance CE, TUV, SEMKO, NEMKO, DEMKO, C-tick

FCC, UL, CSA, CDRH, CB, EPA

2. Specifications

2-1 General

Samsung Electronics 2-1

2-2 Samsung Electronics

Specifications

Input Voltage USA : AC 100~127 V , 50/60 Hz ± 3 Hz (Normal : 115V)

EUROPE : AC 200~240 V , 50/60 Hz ± 3 Hz (Normal : 230V)

DC Output Voltage

Line Regulation 24 V ± 3 %

5 V ± 2 %

Load Regulation 24 V - 3 %/+10 %

5 V ± 3 %

Ripple Noise 24 V : 120 mV (Peak 400 mV)

5 V : 50 mV (Peak 100 mV)

Over Current Protect 24 V : 2.7 A ± 10 % (by C't )

5 V : 1.5 A ± 10 % (by C't )

Power Consumption Max. 450 W Everage: 200 W

Power Save Mode: Less than 15W

Warming Up Time 20 seconds or less

First Print Time Idle mode : 17 seconds or less

Power Save mode : 30 seconds or less

Acoustic Noise Standby : 33 dB or less

Sleep Mode: Background level

Operating : 50 dB or less

Reliability

Insulation Resistance 10 Mohm or less (at DC 500 V)

Dielectric Strength AC 1500 V (DC 2100 V), 10 mA

Ground Continuous 0.1 ohm or less

Voltage DIP Rated voltage ± 15 %

AC Impulse Noise AC 1000 V 10, 100, 200, 400, 1000 ns

Leakage Current 3.5 mA or less

Surge 0.5 ~ 4 kV, 0.25 ~ 2 kA

Ozone Emission 0.1 ppm or less (8 hours)

Top Cover Open Isolating the input power of the LSU, high voltage part, and fuser

Overcurrent Protect Fuse inside the Engine Controller

Fusing System

Trouble Sensing The temperature doesn't rise to the specific temperature within a

specific time. Fuser error occurs if the temperature is too high.

Overheat Sensing 240 ~ 250 oC (The thermostat cuts off the Fuser from the power.)

Thermistor Open Sensing Without the initial temperature change of the Fuser

Source of Light Laser Diode (LSU)

Developer

Developing Non-magnetic contact developing

Charging Conductive roller charging

Density Adjustment Dark, Medium

Transfer System Pre-transfer by LED & conductive roller

Fusing System Temperature & Pressure

Ozone Emission 0.02 PPM or less (8 hours)

2-2 Electrical

Samsung Electronics 2-3

Specifications

Conditions

Paper Normal paper (75 g/m2)

Environment Temperature : 20 ~ 25 oC, Humidity : 40 ~ 60 % RH

Print Quality

Image Density min. 1.3

Background max. 1.0

Uniformity max. 0.2 (including continuous print)

Fusing min. 80 % (all black)

Start Position Top : x ± 3 mm, Side : y ± 3 mm (from left)

Skew Top : max. ± 1.5 mm/200 mm

Side : max. ± 1.5 mm/250 mm

Orthogonality ± 1.0 mm

Horizontal Scan ± 0.5 mm/208 mm

(Bowed Line Skew : S600,0909 pattern)

Special Paper Exception Image Density : min. 1.0 (envelope)

Fusing : min. 70 % (all black, envelope/OHP/postcard)

Paper Jam 1/2,000 or less

Paper Curl First : 16 mm or less (10 sheets)

After Cooling: 12 mm or less (10 sheets)

2-3 Print Quality

Toner Cartridge

Type One-cartridge type

Life Span Built-in toner cartridge : 5,000 pages at 5 % coverage

Optional toner cartridge: 5,000 pages at 5 % coverage

Note: Its duration may last longer under Econo mode.

Memory (ML-5100A only) Memory RAM: 4,8, 16, 32 Mb (memory is expandable to 36 Mb)

2-4 Option

2-4 Samsung Electronics

Specifications

Input Paper Size

Paper Type Size Feeding Source

A4 210 x 297 mm Paper Tray or Manual feeder

Letter 216 x 279 mm Paper Tray or Manual feeder

B5 (ISO) 176 x 250 mm Paper Tray or Manual feeder

Executive 184 x 267 mm Paper Tray or Manual feeder

Folio 216 x 330 mm Paper Tray or Manual feeder

Legal 216 x 356 mm Paper Tray or Manual feeder

Com-10 Envelope 105 x 241 mm Manual feeder only

Monarch Envelope 98 x 191 mm Manual feeder only

DL Envelope 110 x 220 mm Manual feeder only

C5 Envelope 162 x 229 mm Manual feeder only

C6 Envelope 114 x 162 mm Manual feeder only

A5 Envelope 148 x 210 mm Manual feeder only

Transparency A4 or Letter Manual feeder only

Label paper A4 or Letter Manual feeder only

*Others Width: 75-216 mm, Length: 125-356 mm Paper Tray or Manual feeder

Feeding Source Paper tray and manual feeder

Paper Weight 60 ~ 163 g/m2(16 ~ 28) , Cardstock/other : 24 ~ 43 lb

Input Paper Capacity Paper tray: 150 sheets, Manual feeder : 1 sheet at a time

Paper Stacker Capacity Face down : 100 sheets, Face up : 1 sheet

Paper Limitations -Adhesive label sheets specifically designed for laser printers

-Transparencies specifically designed for laser printers

-Envelopes with peel-off adhesive strips or more than one fold-over flap

to seal must have adhesive compatible with the heat and pressure of the

printerÕs fusing process.

Unacceptable Papers -Paper with embossed lettering, perforations, or rough texture

-Paper with which color was added after the paper was made

-Paper forms whose ink is not for laser printing

2-5 Paper

3. Disassembly and Reassembly

3-1 Removal Procedures

Cautions:

¥Be sure to unplug the power cord whenever you are working on the printer with one of the covers

removed.

¥Be sure to remove the toner cartridge before you repair parts.

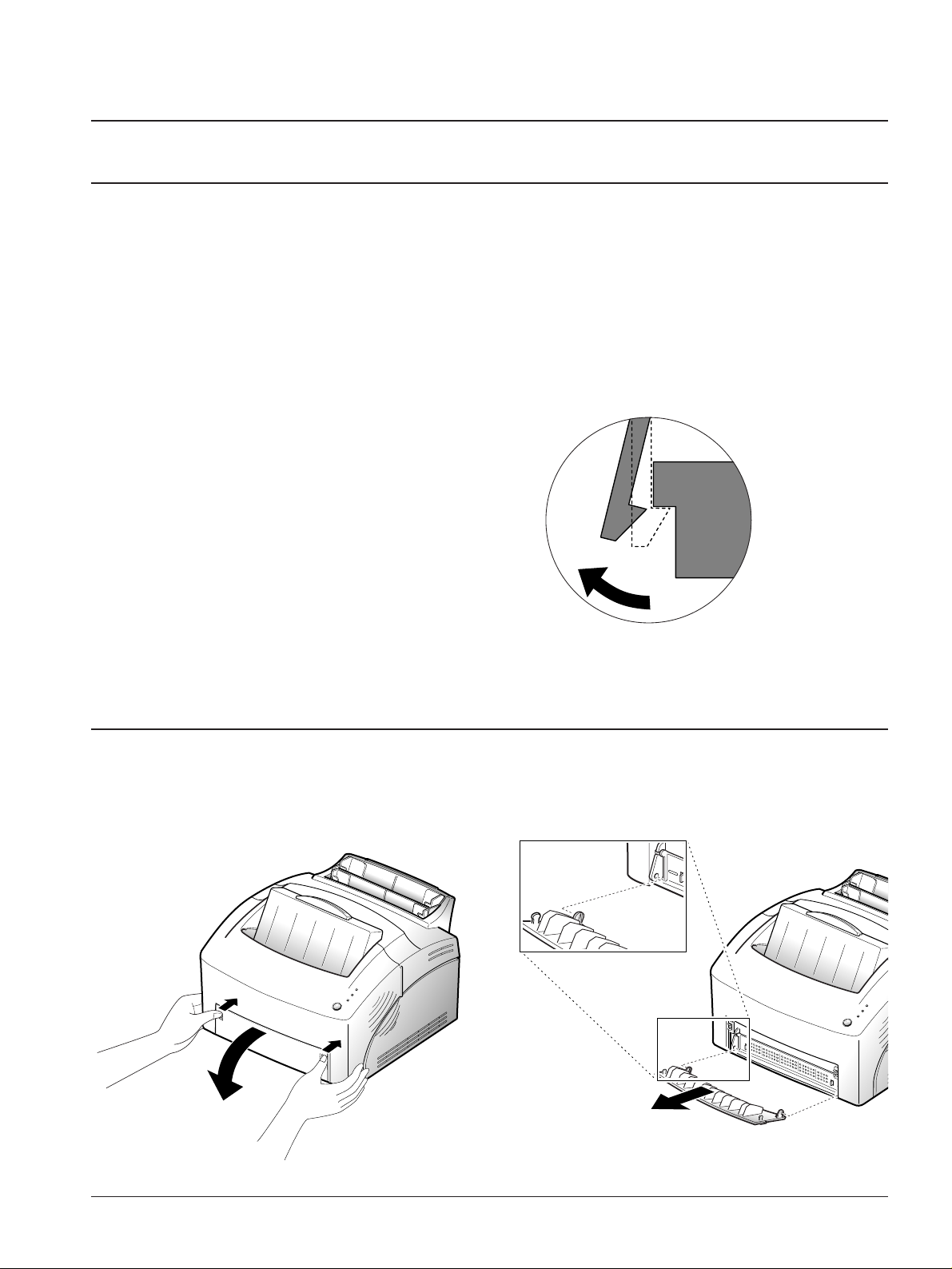

Releasing Plastic Latches

Samsung Electronics 3-1

Many of the parts are held in places with plastic

latches. The latches break easily; release them

carefully. To remove such parts, press the hook

end of the latch away from the part to which it is

latched.

3-2 Face-Up Cover and Front Cover

1. Place your fingers on both sides of the face-up

cover, push the cover, and pull it down.

2. Bend the cover slightly to release the tabs at the

end, then remove the cover.

3-2 Samsung Electronics

Disassembly and Reassembly

3. Open the front cover with hand. 5. Unlatch the front cover, then remove the front

cover.

4. Remove a screw securing the front cover to the

main frame.

3-3

Samsung Electronics

Disassembly and Reassembly

3-3 Panel Board and Board Cover

1. Before you remove these parts, you should

remove:

-Face up cover and Front cover

(see page 3-1)

2. From the front cover, remove two screws,

then remove the board cover.

3-4 Transfer Roller

1. Open the front cover with hand.

2. Remove the transfer roller cap.

3. To remove the transfer roller, pull up the tab to

release the roller, then take it out.

Cap

Panel board

Board cover

3-4 Samsung Electronics

Disassembly and Reassembly

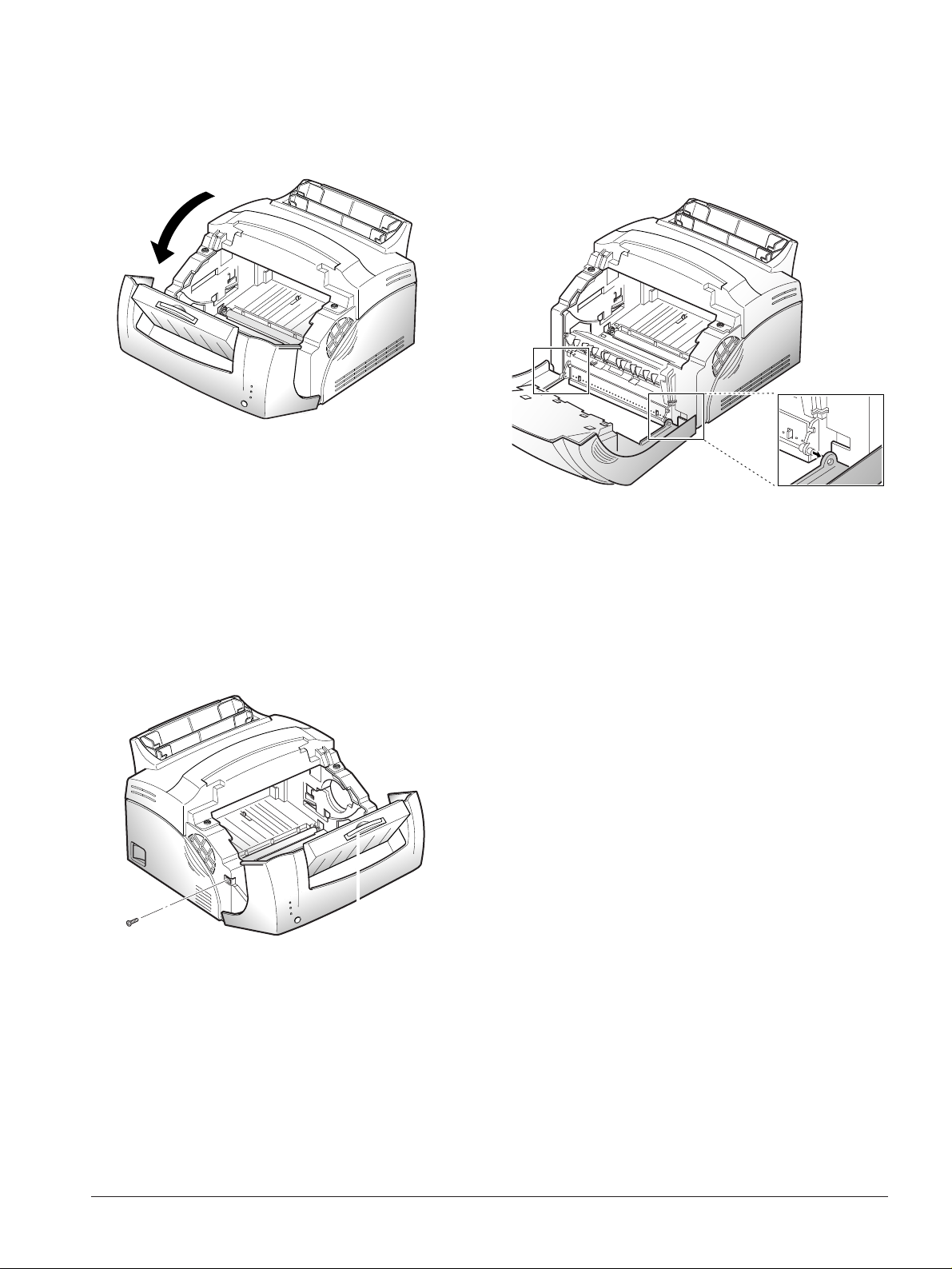

3-5 Top Cover and Rear Cover

1. Before you remove these covers, you should

remove:

-Face up cover and Front cover (see page 3-1)

2. Remove three screws.

3. Unlatch the tabs on the left and right side end of

the cover, then take out the rear cover.

4. Remove two screws, and remove the top cover.

Unlatch the tabs at both

sides to remove the cover.

3-6 Side Covers (Left, Right)

1. Before you remove these side covers, you should

remove:

-Face up cover and Front cover (see page 3-1)

-Top cover and Rear cover (see page 3-4)

2. Remove two screws on the back of the covers.

3. Unlatch the left and right side covers, and

remove them.

3-5Samsung Electronics

Disassembly and Reassembly

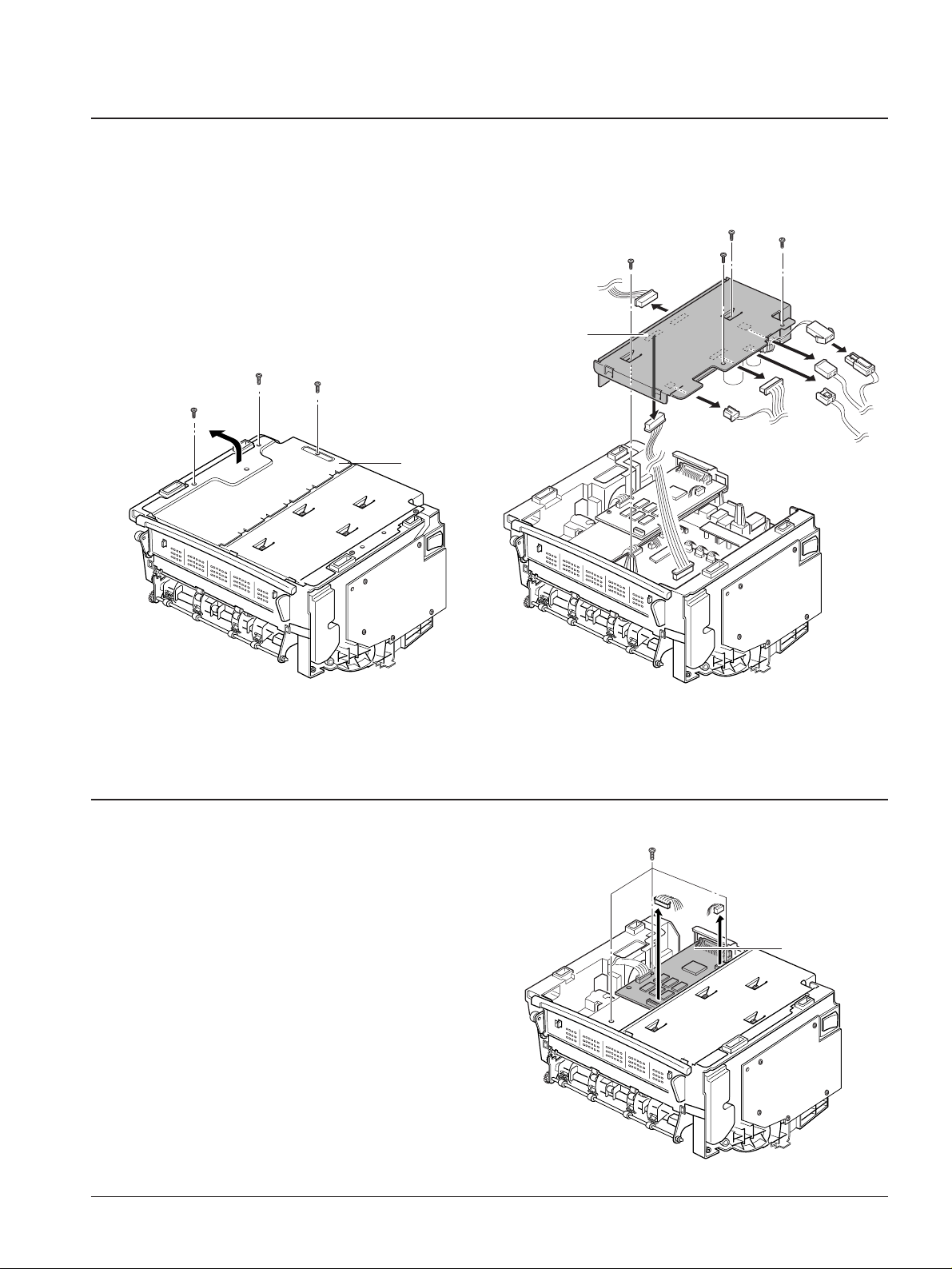

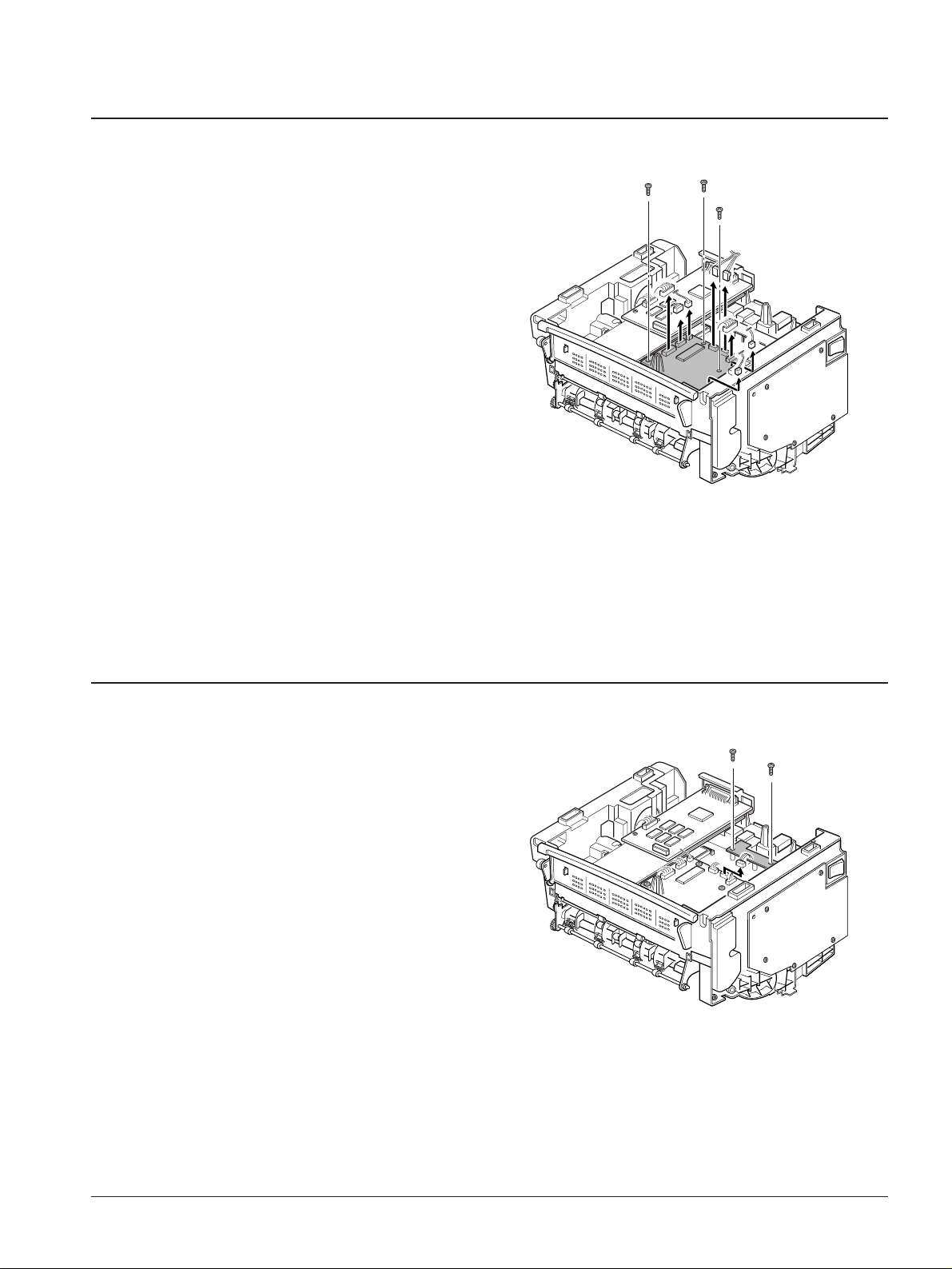

3-7 SMPS/Engine Control Board

1. Before you remove the board, you should

remove:

-All covers (see pages 3-1, 3-4)

2. Turn the printer upside down.

3. Remove three screws securing the shield, then

remove the shield.

4. Unplug all the connectors from the SMPS, then

take out the SMPS and the engine board.

3-8 Control Board

1. Before you remove the control board, you should

remove:

-All covers (see pages 3-1, 3-4)

2. Unplug all the connectors from the control board,

remove three screws, and take out the control

board.

Shield

SMPS and

Engine board

Control Board

3-6 Samsung Electronics

Disassembly and Reassembly

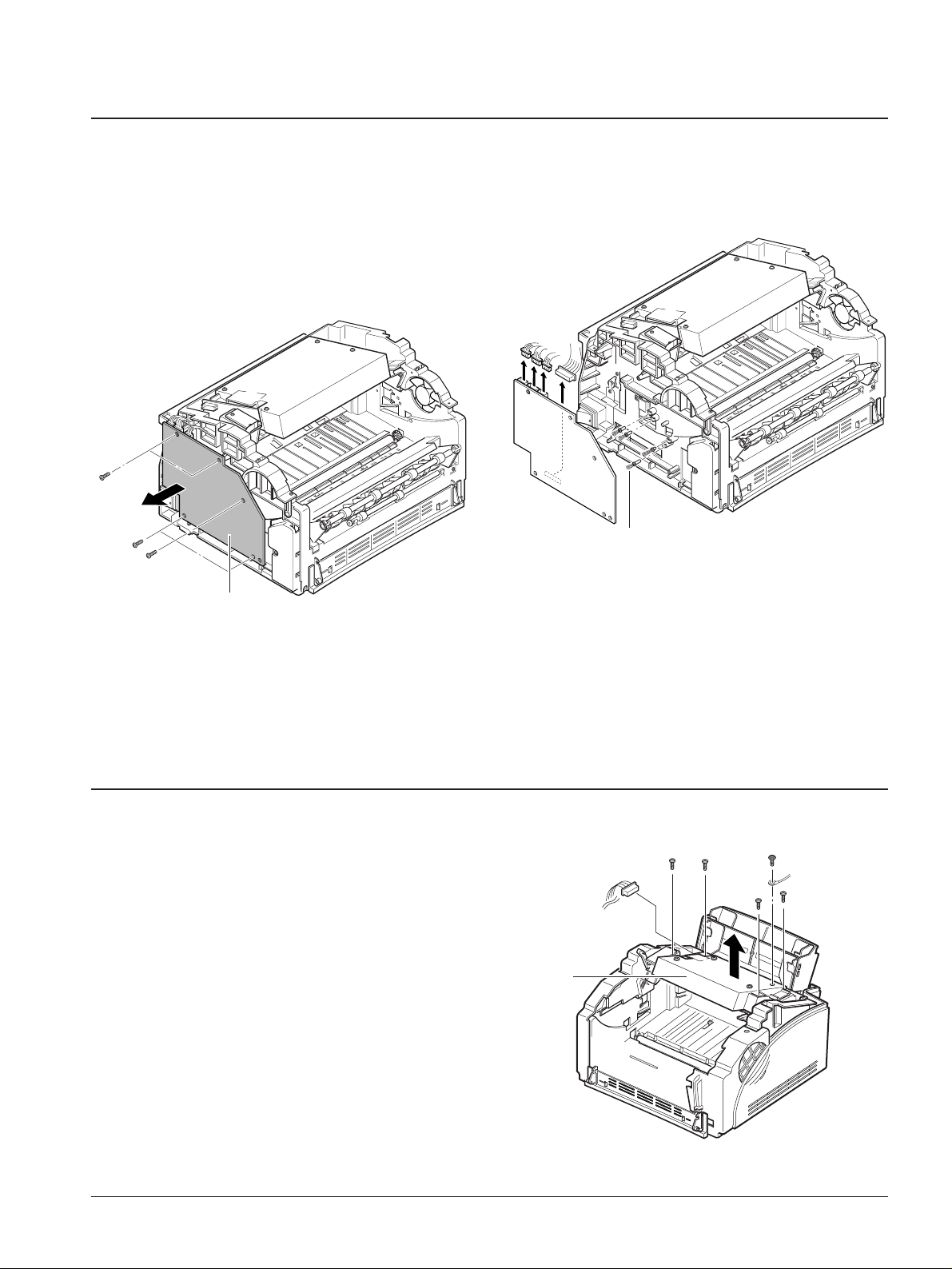

3-9 Joint Board

1. Before you remove the joint board, you should

remove:

-All covers (see pages 3-1, 3-4)

-SMPS (see page 3-5)

2. Unplug all connectors from the joint board,

remove three screws, then remove the joint

board.

3-10 Sensor Board

1. Before you remove the sensor board, you should

remove:

-All covers (see pages 3-1, 3-4)

-SMPS (see page 3-5)

2. Remove two screws, unplug all connectors from

the sensor board, then remove the board.

3-7Samsung Electronics

Disassembly and Reassembly

3-11 Gear Bracket

1. Before you remove the gear bracket, you should

remove:

-All covers (see pages 3-1, 3-4)

2. Remove six screws securing the gear bracket,

unplug the connector from the motor, then

remove the gear bracket.

3-12 Motor

1. Before you remove the motor, you should

remove:

-All covers (see pages 3-1, 3-4)

-Gear bracket (see page 3-14)

2. Remove three screws, then remove the motor.

Motor

Gear bracket

3-8 Samsung Electronics

Disassembly and Reassembly

3-13 HVPS Board

1. Before you remove the HVPS board, you should

remove:

-All covers (see pages 3-1, 3-4)

2. Remove five screws from the HVPS board.

3. Unplug the connector from the HVPS board,

then remove the board.

Note: When you reassemble the HVPS board, make

sure that the high voltage electrodes are

placed correctly.

3-14 LSU

1. Before you remove the LSU, you should remove:

-All covers (see pages 3-1, 3-4)

2. Unplug two connectors, remove five screws, then

take out the LSU.

HVPS board

High voltage electrodes

LSU

3-9Samsung Electronics

Disassembly and Reassembly

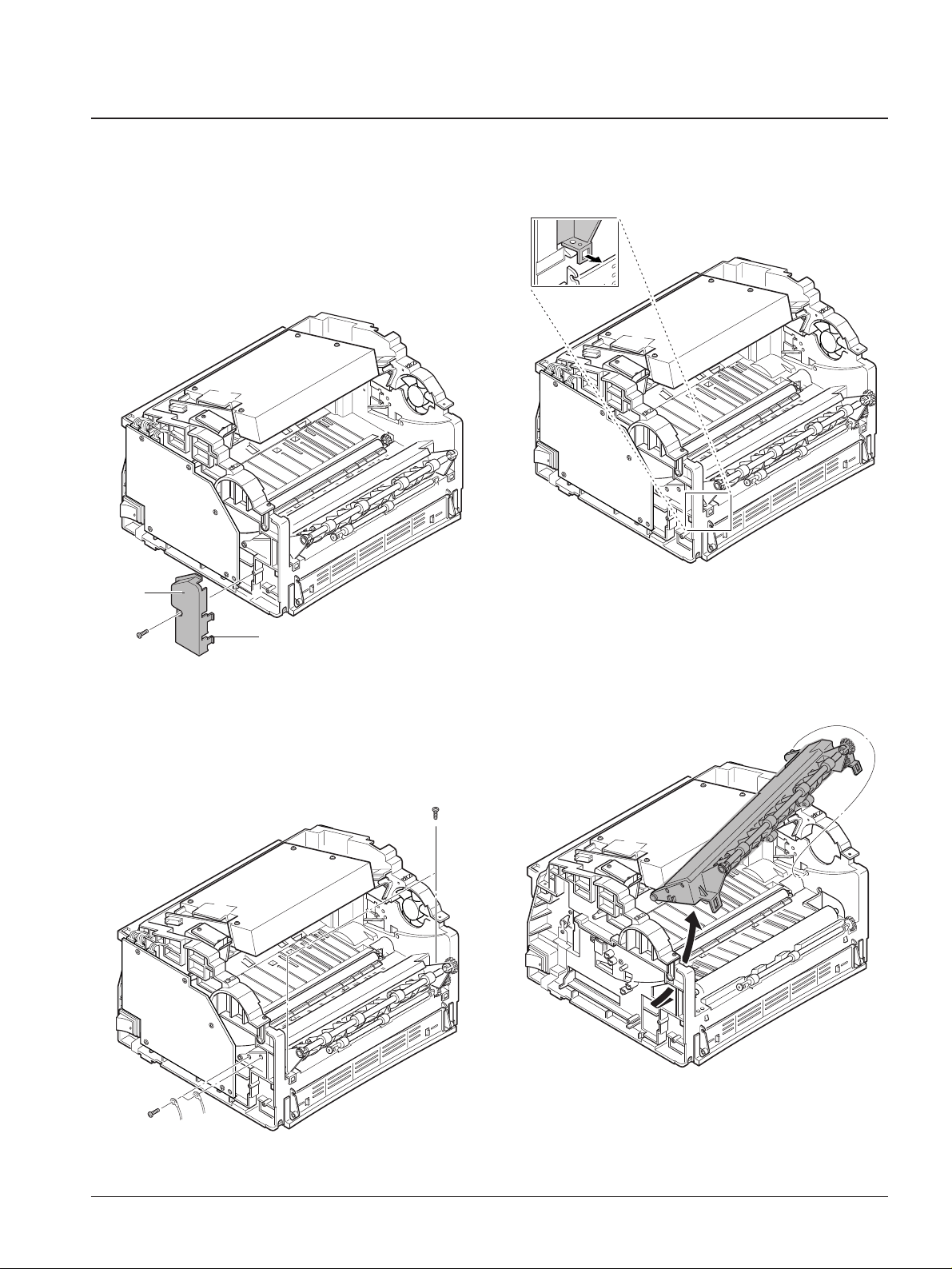

3-15 Fuser

1. Before you remove the fuser, you should remove:

-All covers (see pages 3-1, 3-4)

2. Remove one screw securing the wire cap at the

left side of the frame, unlatch the cap, then

remove the cap.

4. Unlatch the tabs using a proper tool.

5. Slide the fuser in the direction of arrow and take

it out.

3. Remove four screws.

Wire cap

Unlatch these tabs.

3-10 Samsung Electronics

Disassembly and Reassembly

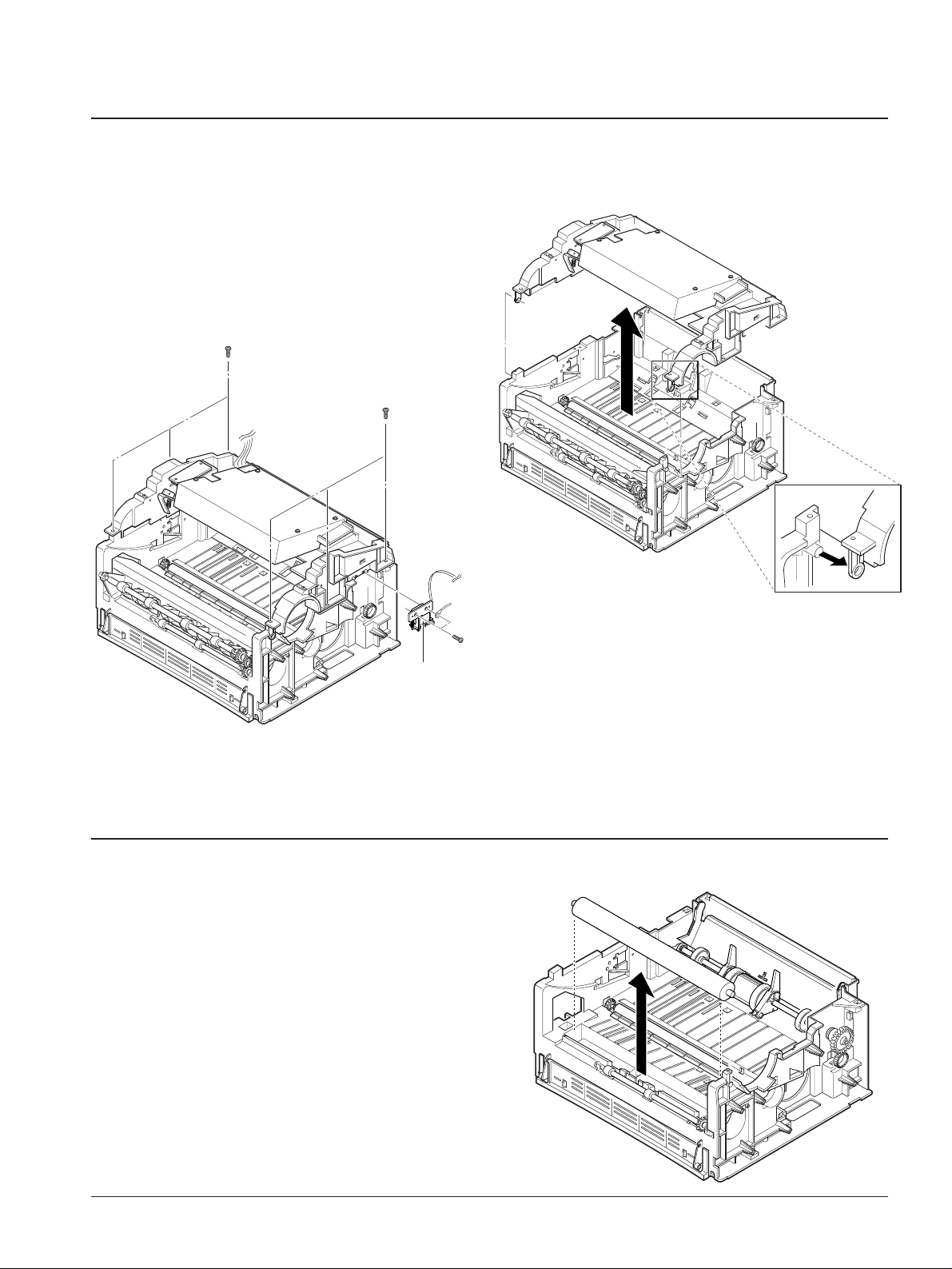

3-16 Upper Frame

1. Before you remove the upper frame, you should

remove:

-All covers (see pages 3-1, 3-4)

-Gear bracket (see page 3-14)

-HVPS board (see page 3-16)

2. Remove six screws, then remove two screws

securing the solenoid.

3. Unlatch the front end of the frame, then lift it up.

3-17 Pressure Roller

1. Before you remove the roller, you should

remove:

-All covers (see pages 3-1, 3-4)

-All boards (see pages 3-3, 3-5, 3-6, 3-8)

-Upper frame (see page 3-10)

-Fuser (see page 3-9)

2. Remove the roller.

Solenoid

Samsung Electronics 3-11

Disassembly and Reassembly

3-18 Pickup Roller

1. Before you remove the pickup roller, you should

remove:

-All covers (see pages 3-1, 3-4)

-All boards (see pages 3-3, 3-5, 3-6, 3-8)

-Upper frame (see page 3-9)

2. Remove one screw, pull the pick-up bushing

slightly toward you, then rotate it clock-wise.

3. Remove the E-ring at the right end of the roller.

4. Remove a pin passing through a shaft to take out

the pick-up roller, then push the roller shaft to

the right. Lift the left side of the roller, then take

it out.

3-19 Installing SIMM

1. Before you install SIMM, make sure that printer

power is off, all cables are unpluged. The toner

cartridge is also to be removed.

2. Turn the printer upside down, and remove all

screws securing the shield cover, then remove

the shield cover.

3-12 Samsung Electronics

Disassembly and Reassembly

5. Push it firmly until it snaps into place.

Make sure both metal clips on the connector are

fastened and the two pins on the connector are

pushed through the holes on the SIMM.

Note: When you disassemble the SIMM, push

out on the metal clips at each end of the

connector and pull it toward you.

6. Reassemble the shield cover.

3. Locate the SIMM connector on the control board.

4. Hold the SIMM with the connection points and

insert the SIMM all the way into the connector at

30oangle .

4. Troubleshooting

4-1 Abnormal Image Printing and Defective Roller

If abnormal image prints periodically, check the parts shown below.

Samsung Electronics 4-1

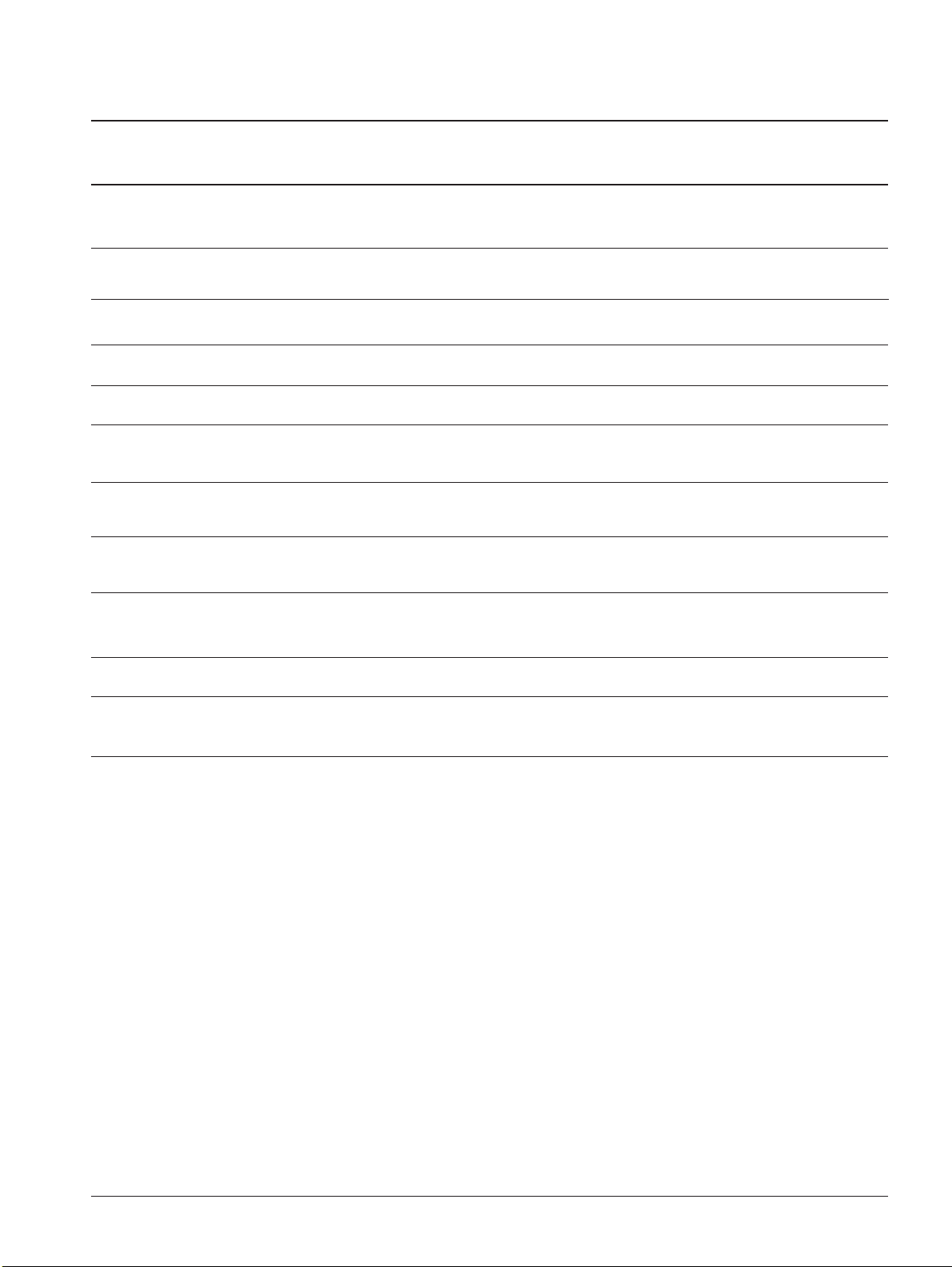

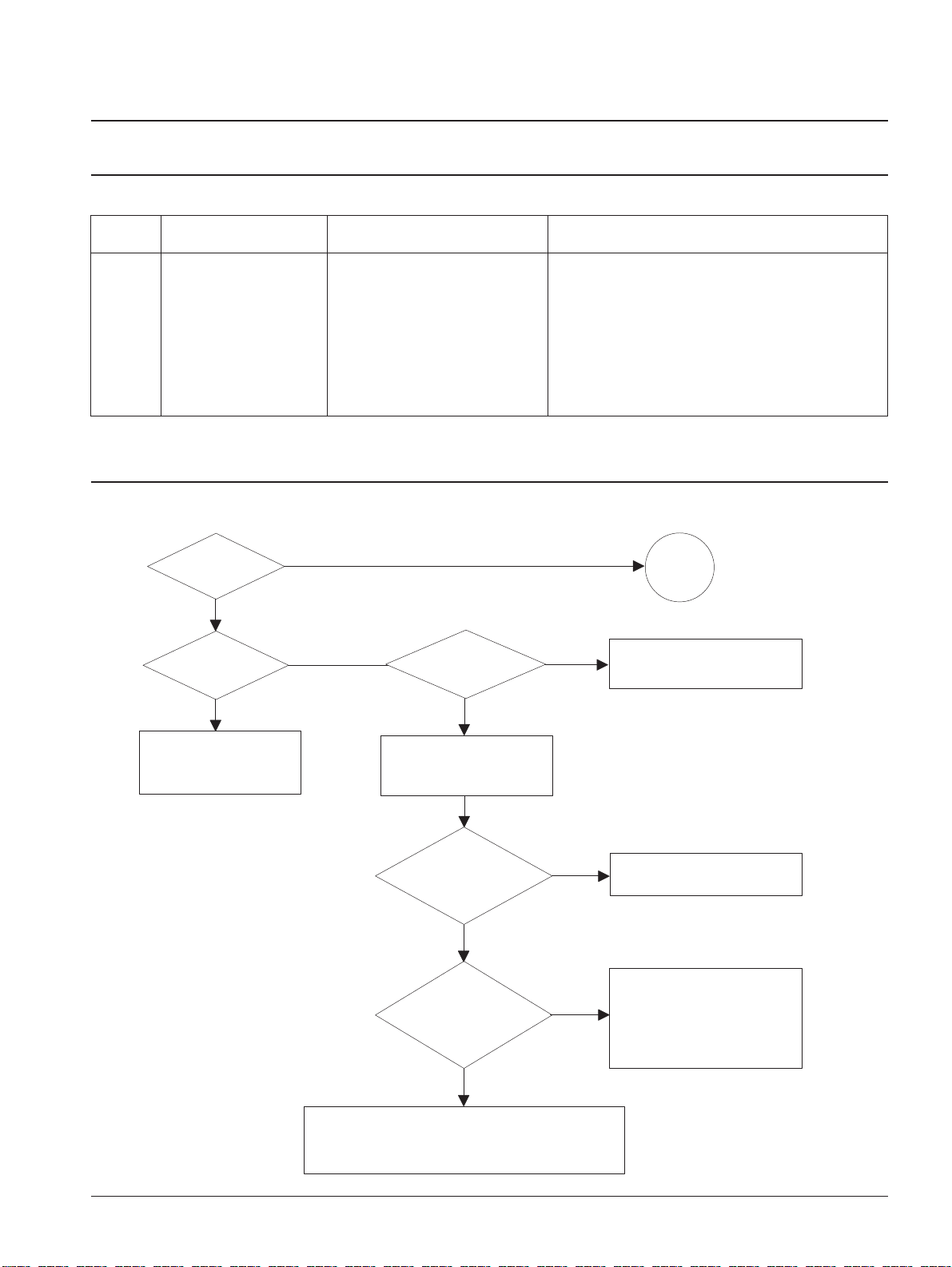

No Roller Abnormal image period Kind of abnormal image

1 OPC Drum 94.3mm White spot

2 Charge Roller 37.7mm Black spot

3 Supply Roller 40.0mm Horizontal density band

4 Develop Roller 46.1mm Horizontal density band

5 Transfer Roller 47.1mm Black side contamination/transfer fault

6 Heat Roller 56.1mm Black spot and fuser ghost

7 Pressure Roller 56.2mm Black side contamination

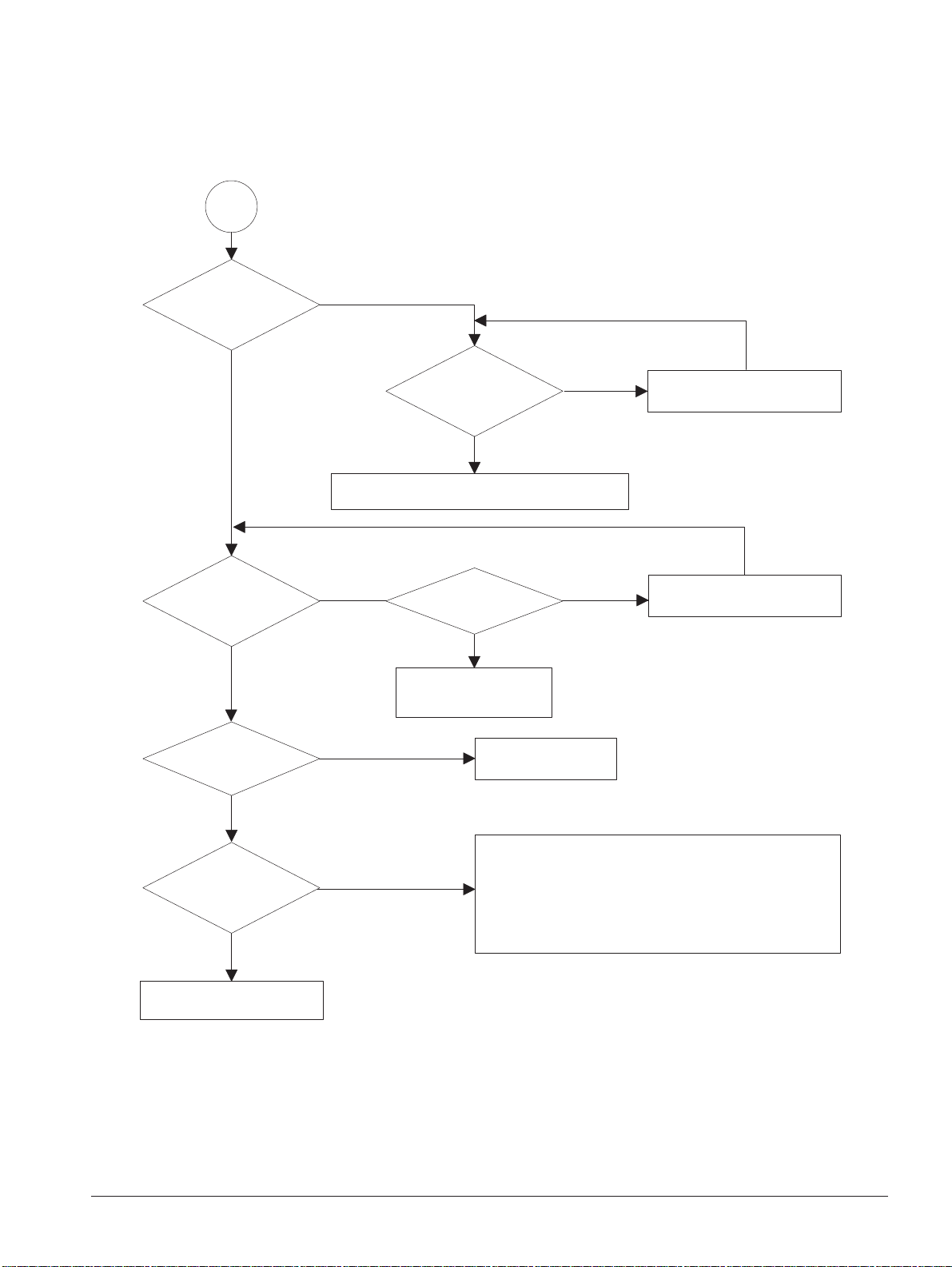

Check connection to

computer or replace

controller.

Take out the cartridge

and prepare the tester

for electronic connection.

Repair or replace the GND

terminal.

Check the path between

video controller, engine board

and HVPS. Repair or replace

the defective component

or board.

The mirror in LSU might be misplaced so the light

path to the OPC deviates ->Repair or replace LSU

or remove any defective matters in the machine.

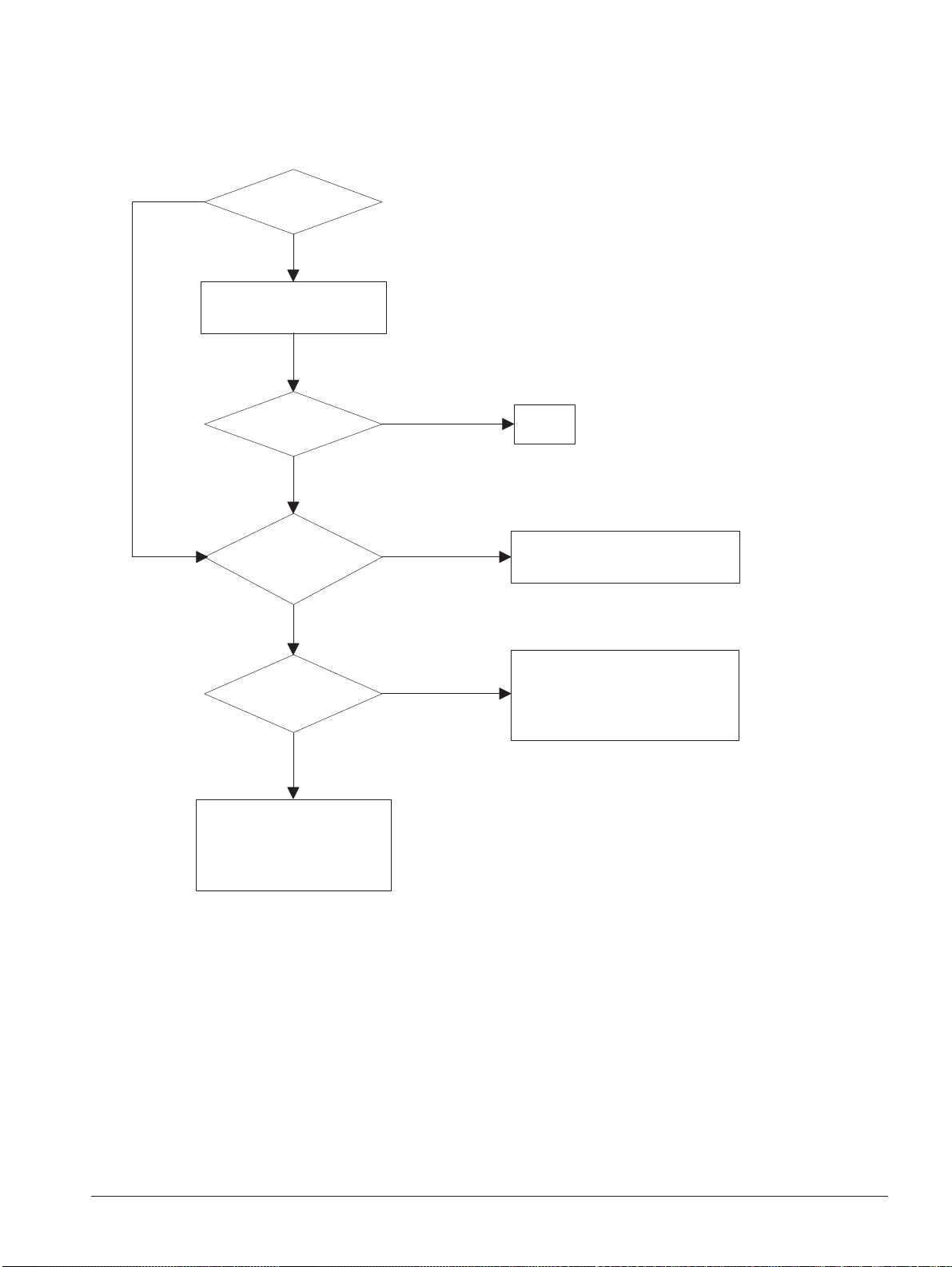

Self test

pattern prints?

No image?

Self testing

is possible via

DCU?

Is the OPC

terminal of machine

well-connected

to Frame?

Does the

video data line to

LSU transit to High/Low

when printing?

Re-test after replacing the

conector or controller board.

A on

next page

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

4-2 Print Quality

4-2-1 No Image

4-2 Samsung Electronics

Troubleshooting

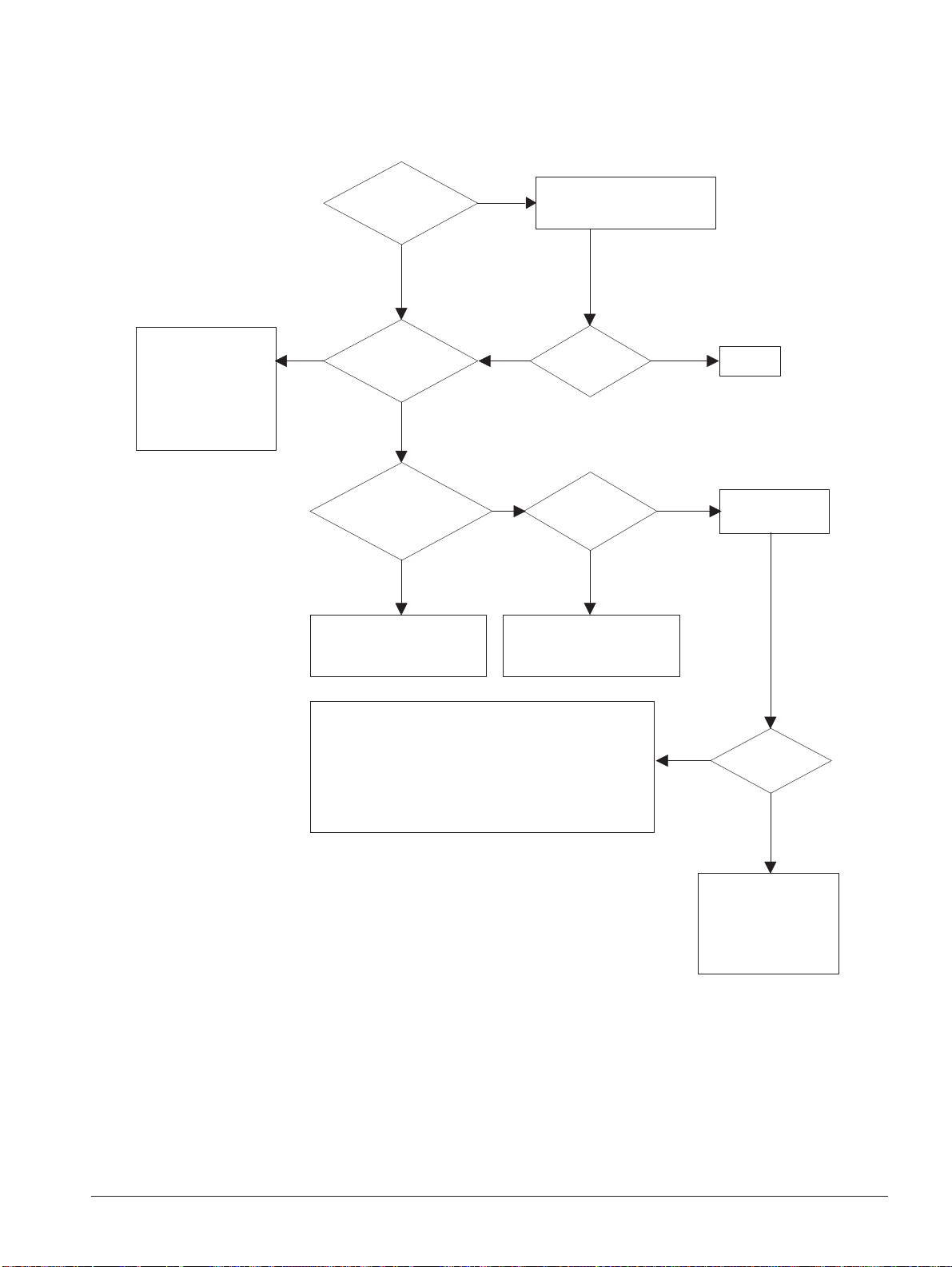

Transfer roller might be out of its location.

-> Locate the roller into its place.

This could occurrs when the power of LSU is low or

the density is low due to the obstacles on the window

-> Replace LSU or clean the window.

A

Transfer

voltage OK? (on the

transfer roller

shaft)

Are the

connection terminal

and connection

correct?

Repair or replace terminal.

Sealing tape

is removed from the

cartridge?

Replace HVPS or repair defective component.

Is the connection

terminal OK?

Replace HVPS or repair

defective component.

Repair or replace terminal.

Remove the tape.

Developing

(-300V) and supplying

(-500V) voltage

are OK?

Does the

counter indicate over

the toner's guarranty

life?

Replace the toner cartridge.

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

4-3

Samsung Electronics

Troubleshooting

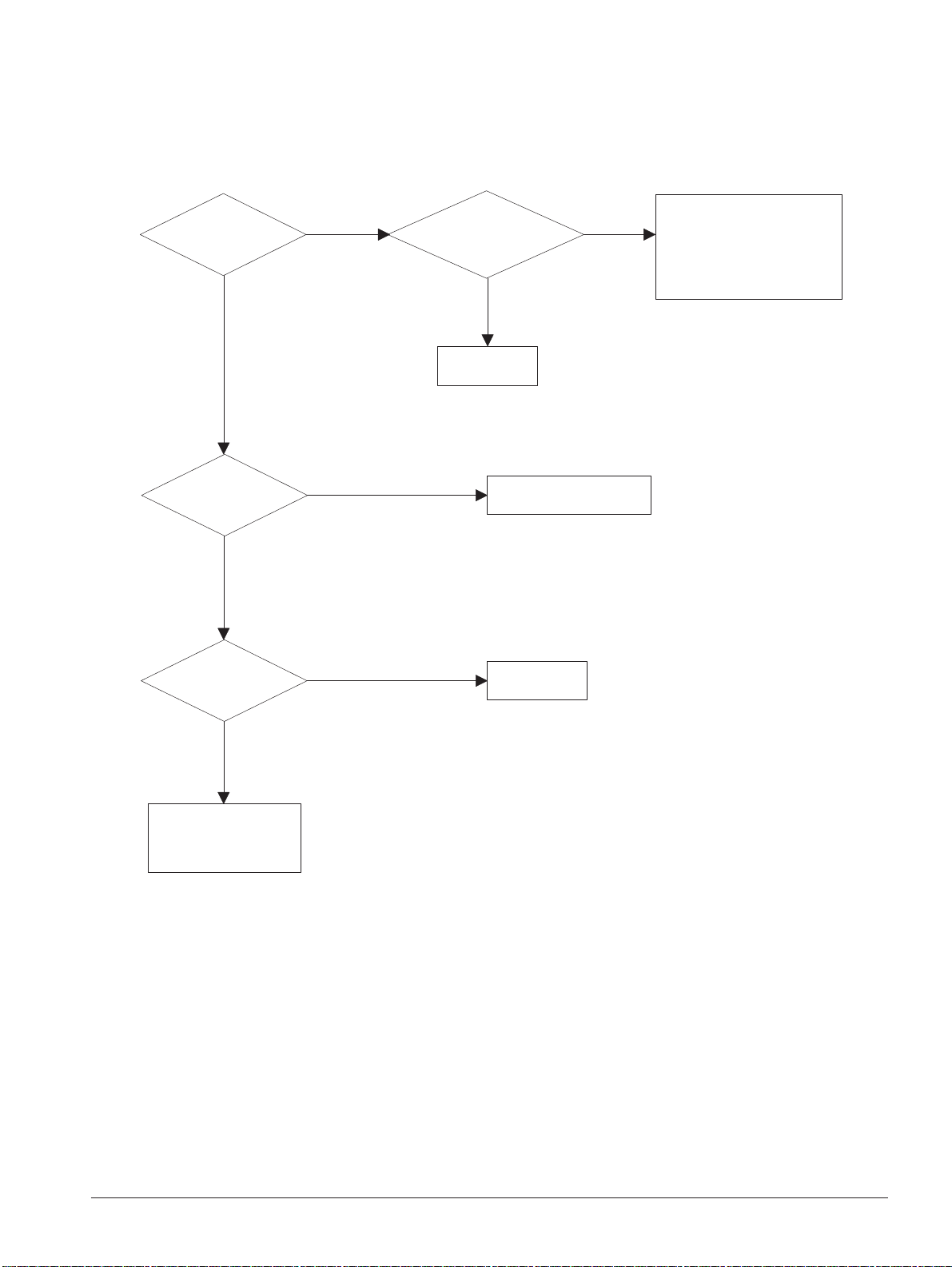

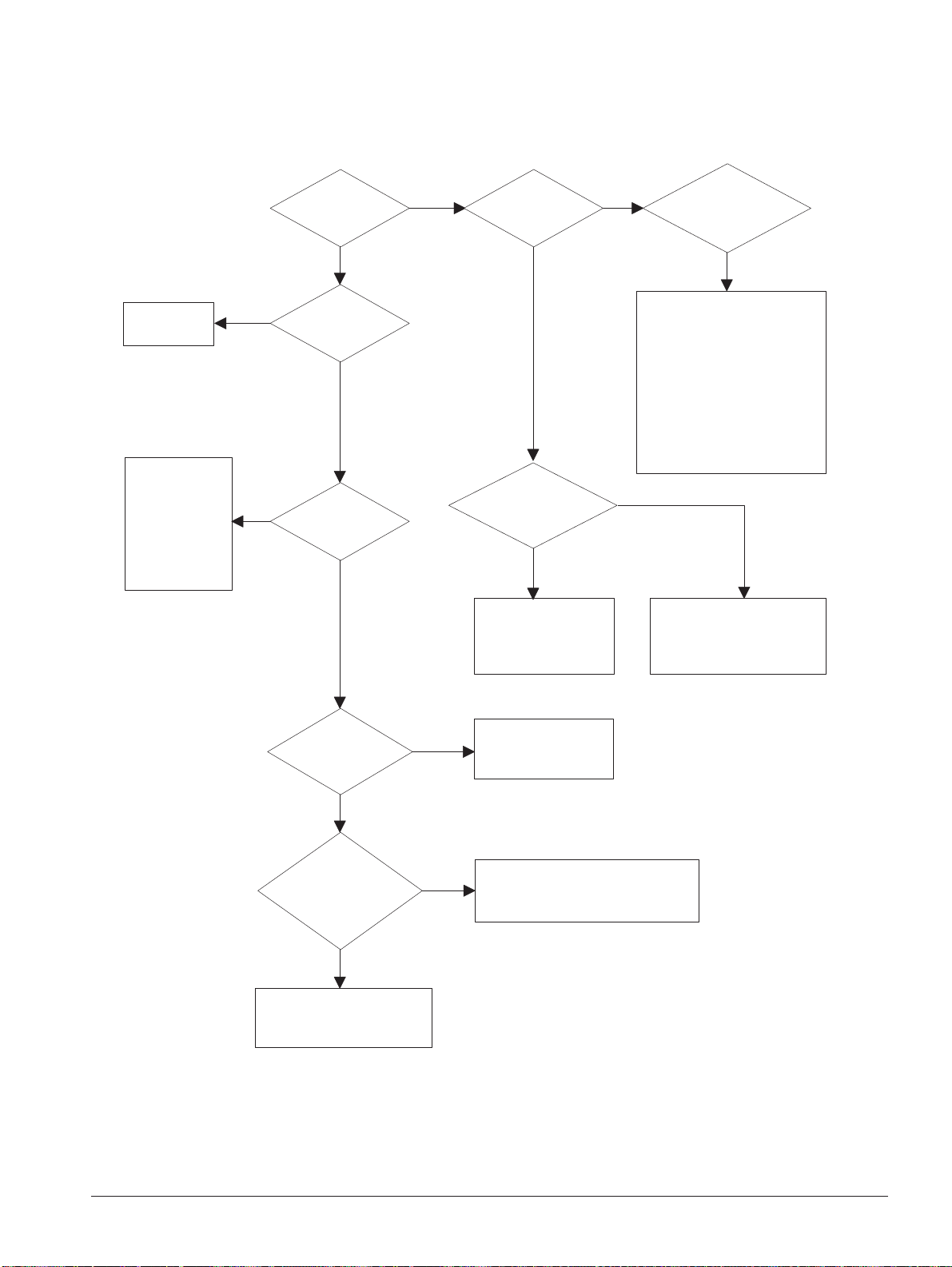

All black in

printing area?

Is transfer

voltage supplied

from HVPS?

Is the

Hsync/ signal received

in LSU?

Transfer part's contact

is bad. -> Repair or

replace toner cartridge.

Does the

video data line to LSU

transit to High/ Low when

printing?

Replace LSU.

Check the path among video

controller, engine board,

HVPS, LSU for the shortage

or open. -> Repair or replace

the boards.

Repair or replace HVPS.

Replace LSU.

NO

NO

NO

NO

YES

YES

YES

YES

4-2-2 All Black

4-4 Samsung Electronics

Troubleshooting

White line

missing definitely?

Dirt of dust stuck onto the

window of internal lens of LSU

-> Clean it or replace LSU.

Preventive obstacles through

the path between OPC of

developer and LSU prevent the

path -> Remove the obstacles.

Check if the

printout is still has the

same problem even right after

passed through the

transfer roller.

Toner material might be stuck to

blade in the developer inside and it

prevents toner supply -> Replace

the developer.

Check both if the toner cartridge's

counter is over its guaranty and

amount of the toner material.

-> Replace the toner cartridge.

The ribs in fuser or toner on the

roller may invoke the image

problem. -> Replace the fuser

cover or the defective part.

The image is originally black or the

black part is far close to the top.

-> Use the pattern which has the

image below bigger than 10mm

from the top.

NO

NO

YES

YES

4-2-3 Vertical White Line (Band)

4-5Samsung Electronics

Troubleshooting

'Dark' selected

via RCP?

Change to

'Normal' and test.

Works

correctly with

-300V of Bias

voltage?

Works

correctly after

replaced LSU?

Repair or replace the defective

component.

The power of LSU is set

high or internal problem.

-> Replace LSU or adjust

volume.

Same at 'Normal'?

END

NO

NO

NO

Toner over supply due to the

adjustment fault of metering

blade in developer.

-> Replace developer.

NO

YES

YES

YES

YES

4-2-4 Dark Image

4-6 Samsung Electronics

Troubleshooting

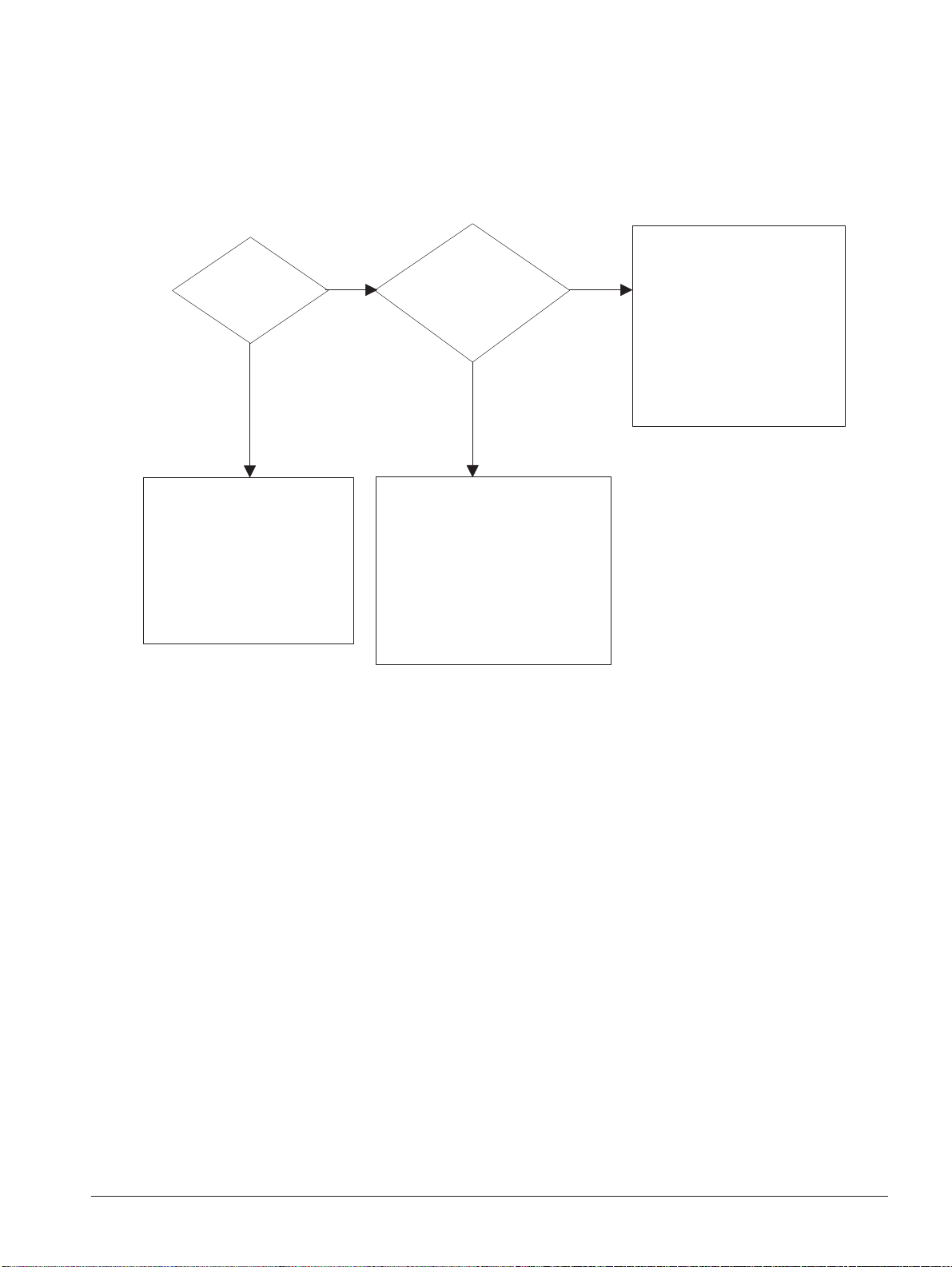

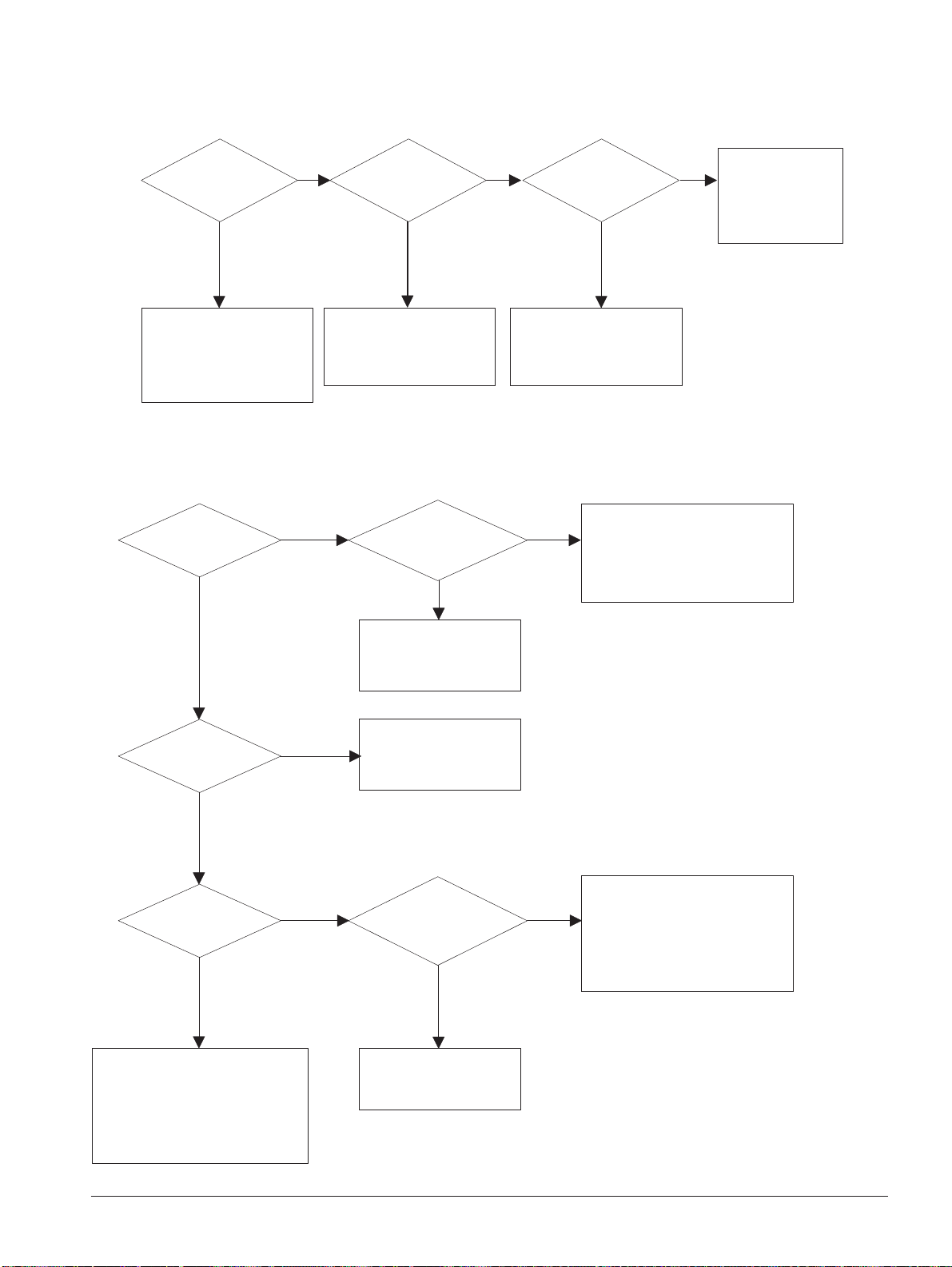

Recommended

paper used?

Transfer,

charge and developing

voltage are OK?

Operating/

storage atmosphere is

too high temperature

/humidity?

Solve the problem under

the recommended condition

(10-32 degree Centigrade).

Dirt or

dust around the

charge roller?

Clean the charge roller

or replace step-up device

/terminal after check.

Work OK?

Internal blade or

suppying part of the

developer is defective.

-> Replace the toner

cartridge.

Check terminals or contacts and 'Guide-Deve Spring'

are misplaced.

-> Repair or replace transfer roller etc.

Check if the LED of PTL in front of the transfer roller

is on when it presses the top cover switch on purpose.

-> If not, replace PTL.

Print 20 to 30 pages using

the recommended paper.

Same problem

occurs?

- Adjust voltage or

replace HVPS.

- Repair or replace

after checking the

terminals' contacts.

END

Replace the

toner cartridge.

NO

NO

NO NO

NO

NO

YES

YES

YES

YES

YES

YES

4-2-5 Background

4-7Samsung Electronics

Troubleshooting

YES

Is it regular

interval of 94mm?

PTL lamp

works OK?

Transfer

voltage is set to

standard?

Is it regular

interval of 46mm?

Is it regular

interval of 47mm?

(as transfer roller

interval)

Developing

/suppying voltage

normal? (-300V/

-500V)

Check HVPS

contacts and

HVPS's selfoutput.

-> If failed,

repair/replace

HVPS.

Replace PTL

assembly.

Irregularity of NIP

between rollers in

developer.

-> Replace developer.

- Repair or replace HVPS .

- Check and repair or

replace the terminal

contacts.

A specific part of the transfer

roller has ruined or its

resistance value is changed.

-> Replace transfer roller.

Transfer roller cannot force

regularly due to the gears

eccentricity of transfer roller.

-> Replace the defective

component.

Bias voltage

is OK? (-300V)

Operating/storage

temperature is too low or

not recommended

paper used?

Adjust the Bias

voltage or replace

HVPS.

There may be a problem in toner

layer control in toner cartridge.

-> Replace the developer.

Use the machine with

recommended paper and

at normal condition.

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

4-2-6 Ghost

4-8 Samsung Electronics

Troubleshooting

Is it regular

interval of 38mm?

The problem occured

since the obstacles

stuck to charge roller.

-> Replace developer

and C/R.

When taking

out the cartridge,

toner leaks?

Toner leaks and toner

material dropped onto

the paper. -> Replace the

developer.

Bad image

removes by

scratching?

Check toner is stuck onto

the P/R or H/R in fuser.

-> Clean it or replace.

The problem

randomly occured

due to the toner

fallen. -> Clean the

machine.

NO NO NO

YES

YES

YES

4-2-7 Black Dot

NO

Black band?

The black

band has regular

interval?

Black band

is far about 10mm from

white band?

Problem of internal

contacts in OPC.

-> Replace developer.

The OPC is damaged under the

direct sunlight for around 5

minutes. -> If the same problem

persists in 10 hours, replace

the developer.

This occurs when no

Hsync/ at LSU.

-> Replace LSU.

94mm interval?

Heat roller is ruined.

-> Replace the roller.

The OPC is damaged due to

the irregular transfer voltage

of HVPS.

-> Repair/replace HVPS.

-> If the same problem persists,

replace the developer.

Does it appear

at every 56.1mm at

specific place?

Problems of terminal contact,

transfer voltage supplying,

and transfer roller's due to the

charge roller is ruined (38mm).

-> Repair/replace HVPS,

developer.

NO

NO NO

NO

YES

YES

YES

YES

4-2-8 Horizontal Band

Loading...

Loading...