Samsung ME11A7710DG, ME11A7510DS, ME11A7710DS, ME11A7510DG INSTALLATION INSTRUCTIONS AND OPERATION MANUAL

Page 1

Microwave Oven

Installation manual

ME11A7510** / ME11A7710**

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 1Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 1 2021-06-16 �� 11:00:482021-06-16 �� 11:00:48

Page 2

Before you beginContents

Before you begin

Before you begin

Before you begin 2

General information 3

Important safety instructions 3

Electrical requirements 3

Hood exhaust 4

Damage - Shipment/Installation 6

Parts included 6

Tools you will need 7

Mounting space 7

Step-by-step installation guide 9

Step 1. Placement of the mounting plate 9

Step 2. Ventilation types (choose a, b or c) 12

Step 3. Installation 15

Step 4. Before you use your microwave 19

ABOUT THIS MANUAL

READ THESE INSTRUCTIONS COMPLETELY AND CAREFULLY.

Important

• Save these instructions for local inspector’s use.

• Observe all governing codes and ordinances.

Important note to the installer

Be sure to leave these instructions with the Consumer.

Important note to the consumer

Keep these instructions with your user manual for future reference.

Skill level

Installation of this appliance requires basic mechanical and electrical skills.

Proper installation is the responsibility of the installer

Product failure due to improper installation is not covered under

the Warranty

2 English

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 2Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 2 2021-06-16 �� 11:00:482021-06-16 �� 11:00:48

Page 3

General information

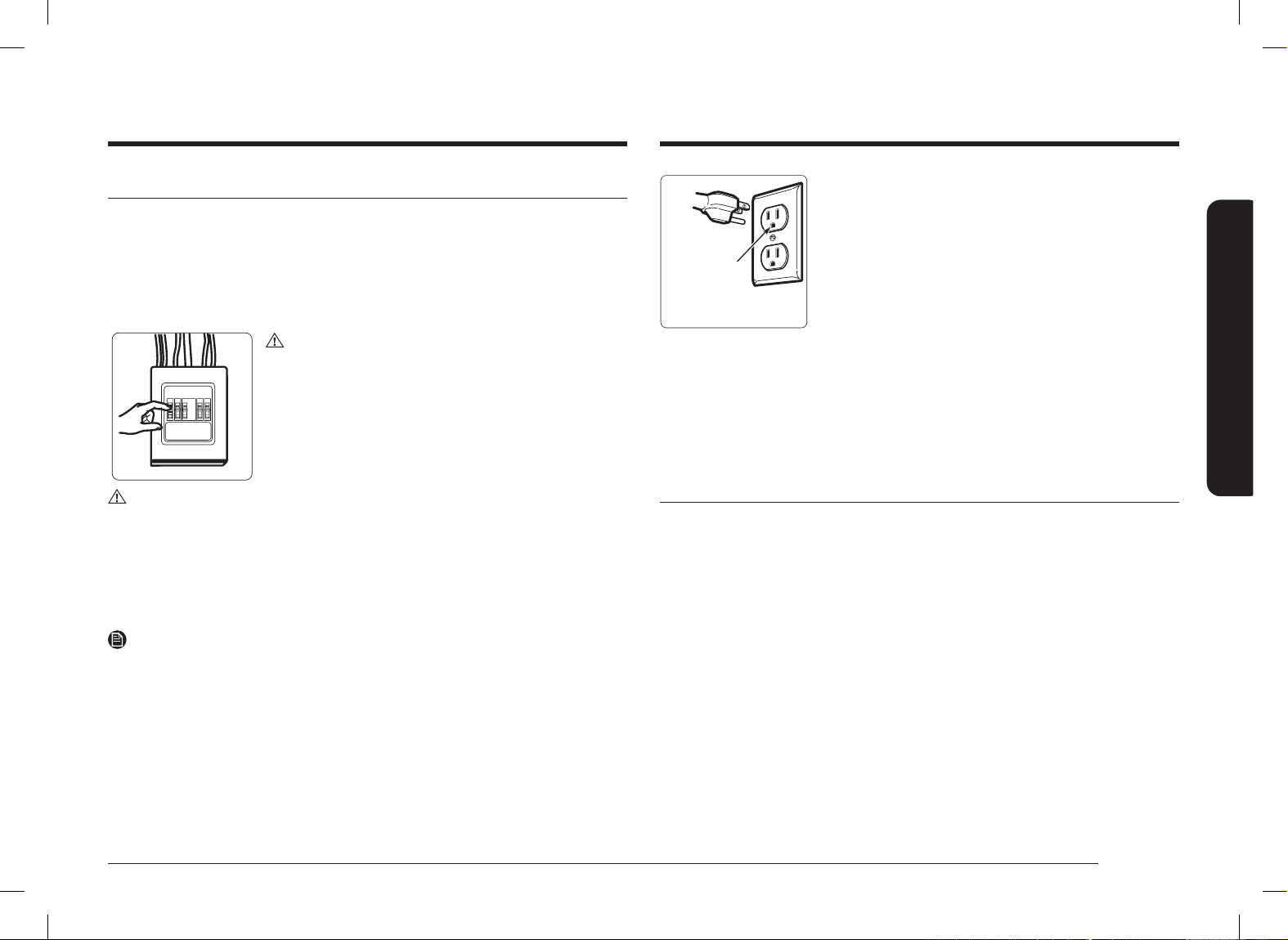

IMPORTANT SAFETY INSTRUCTIONS

This product requires a three-prong grounded outlet. The installer must perform a

ground continuity check on the power outlet box before beginning the installation

to ensure that the outlet box is properly grounded. If not properly grounded, or

if the outlet box does not meet electrical requirements noted (under ELECTRICAL

REQUIREMENTS), a qualied electrician should be employed to correct any

deciencies.

CAUTION

For personal safety, remove the house fuse or open the

circuit breaker before beginning the installation to avoid

severe or fatal shock injury.

CAUTION

• For personal safety, the mounting surface must be capable of supporting the

cabinet load in addition to the added weight of this 69 pound product, plus

additional oven loads of up to 50 pounds or a total weight of 119 pounds.

• For personal safety, do not install this product in cabinetry congured as an

island or a peninsula. The microwave oven must be mounted to BOTH a top

cabinet AND a wall.

NOTE

For easier installation and personal safety, we recommend that two people install

this product.

The power cord of this appliance is equipped with

a three-prong (grounding) plug which mates with a

standard three-prong (grounding) wall receptacle to

minimize the possibility of electric shock hazard from

this appliance.

Insure proper

ground exists

before use.

You should have the wall receptacle and circuit checked by a qualied electrician

to make sure the receptacle is properly grounded.

If you have a standard two-prong wall receptacle, it is very important to have

it replaced with a properly grounded three-prong wall receptacle, installed by a

qualied electrician.

DO NOT, UNDER ANY CIRCUMSTANCES, CUT, DEFORM OR REMOVE ANY OF THE

PRONGS FROM THE POWER CORD. DO NOT USE WITH AN EXTENSION CORD.

ELECTRICAL REQUIREMENTS

Product rating is 120 volts AC, 60 Hertz, 14.5 amps and 1.7 kilowatts. This product

must be connected to a supply circuit of the proper voltage and frequency. Wire

size must conform to the requirements of the National Electrical Code or the

prevailing local code for this kilowatt rating. The power supply cord and plug

should be brought to a separate branch circuit single grounded outlet of at least

15 A and max of 20 A. The outlet box should be located in the cabinet above

the microwave oven. The outlet box and supply circuit should be installed by a

qualied electrician and conform to the National Electrical Code or the prevailing

local code.

General information

IMPORTANT – PLEASE READ CAREFULLY. FOR PERSONAL SAFETY,

THIS APPLIANCE MUST BE PROPERLY GROUNDED TO AVOID SEVERE

OR FATAL SHOCK.

English 3

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 3Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 3 2021-06-16 �� 11:00:482021-06-16 �� 11:00:48

Page 4

General information

General information

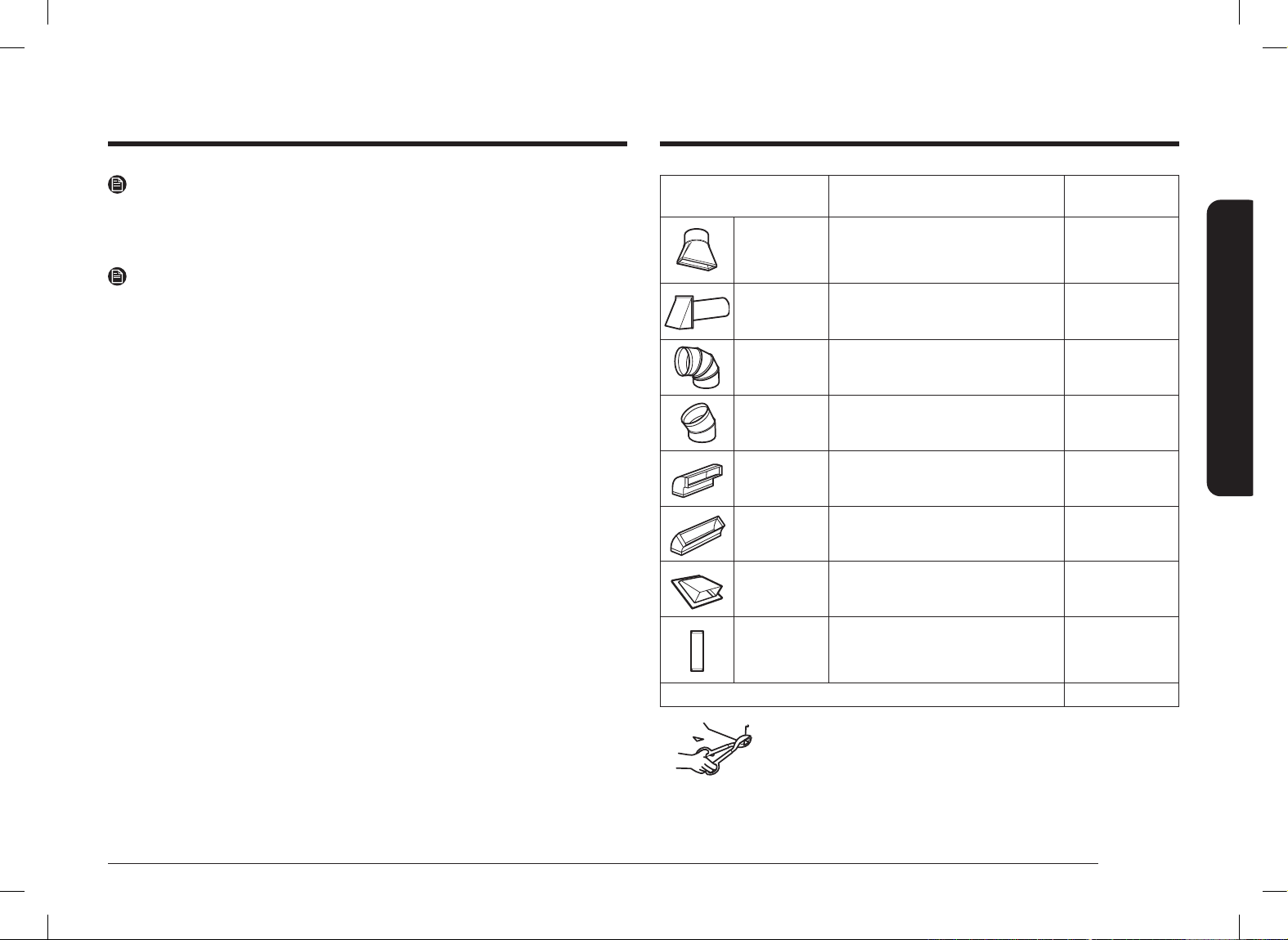

HOOD EXHAUST

NOTE

Read these next two pages only if you plan to vent your exhaust to the outside. If

you plan to recirculate the air back into the room, proceed to page 12.

OUTSIDE TOP EXHAUST (EXAMPLE ONLY)

The following chart contains an example of one possible ductwork installation.

DUCT PIECES

Roof Cap 24 ft. x (1) = 24 ft.

12 Ft.

Straight Duct

(6˝ Round)

Rectangularto-Round

Transition

Adaptor*

Equivalent lengths of duct pieces

are based on actual tests and reect

requirements for good venting

performance with any vent hood.

EQUIVALENT

LENGTH

12 ft. x (1) = 12 ft.

5 ft. x (1) = 5 ft.

NUMBER

x

USED

Total Length = 41 ft.

EQUIVALENT

=

LENGTH

OUTSIDE BACK EXHAUST (EXAMPLE ONLY)

The following chart contains an example of one possible ductwork installation.

DUCT PIECES

Wall Cap 40 ft. x (1) = 40 ft.

3 Ft. Straight

Duct

(3 ¼˝ x 10˝

Rectangular)

90° Elbow 10 ft. x (2) = 20 ft.

Equivalent lengths of duct pieces

are based on actual tests and reect

requirements for good venting

performance with any vent hood.

NOTE

For back exhaust, care should be taken to align the exhaust with the space

between studs, or the wall should be prepared at the time it is constructed by

leaving enough space between the wall studs to accommodate exhaust.

EQUIVALENT

LENGTH

3 ft. x (1) = 3 ft.

x

NUMBER

USED

Total

Length

EQUIVALENT

=

LENGTH

= 63 ft.

IMPORTANT:

If a rectangular-to-round transition adaptor is used, the bottom corners of the

damper will have to be cut to t, using the tin snips, in order to allow free

movement of the damper.

4 English

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 4Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 4 2021-06-16 �� 11:00:482021-06-16 �� 11:00:48

Page 5

NOTE

If you need to install ducts, note that the total duct length of 3 ¼˝ x 10˝

rectangular or 6˝ diameter round duct should not exceed 140 equivalent feet.

Outside ventilation requires a HOOD EXHAUST DUCT. Read the following carefully.

NOTE

It is important that venting be installed using the most direct route and with as

few elbows as possible. This ensures clear venting of exhaust and helps prevent

blockages. Also, make sure dampers swing freely and nothing is blocking the

ducts.

Exhaust connection:

The hood exhaust has been designed to mate with a standard 3 ¼˝ x 10˝

rectangular duct.

If a round duct is required, a rectangular-to-round transition adaptor must be used.

Do not use less than a 6˝ diameter duct.

Maximum duct length:

For satisfactory air movement, the total duct length of 3 ¼˝ x 10˝ rectangular or 6˝

diameter round duct should not exceed 140 equivalent feet.

DUCT PIECES

Rectangularto-Round

Transition

Adaptor*

Wall Cap

90 ° Elbow

45 ° Elbow

90 ° Elbow

45 ° Elbow

EQUIVALENT

LENGTH

x

NUMBER

USED

EQUIVALENT

=

5 ft. x ( ) = ft.

40 ft. x ( ) = ft.

10 ft. x ( ) = ft.

5 ft. x ( ) = ft.

25 ft. x ( ) = ft.

5 ft. x ( ) = ft.

LENGTH

General information

Elbows, transitions, wall and roof caps, etc. present additional resistance to airow

and are equivalent to a section of straight duct which is longer than their actual

physical size. When calculating the total duct length, add the equivalent lengths of

all transitions and adaptors plus the length of all straight duct sections. The chart

below shows you how to calculate total equivalent ductwork length using the

equivalent length in feet of some typical ducts.

Roof Cap

Straight Duct

6˝ Round or

3 ¼˝ x 10˝

Rectangular

24 ft. x ( ) = ft.

1 ft. x ( ) = ft.

Total Ductwork = ft.

*IMPORTANT : If a rectangular-to-round transition adaptor is

used, the bottom corners of the damper will

have to be cut to t, using tin snips, to allow free

movement of the damper.

Equivalent lengths of duct pieces are based on

actual tests and reect the requirements for good

venting performance with any vent hood.

English 5

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 5Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 5 2021-06-16 �� 11:00:482021-06-16 �� 11:00:48

Page 6

General information

TOP CABINET TEMPLATE

Template

INSTALLATION

INSTRUCTIONS

General information

DAMAGE SHIPMENT/INSTALLATION

• If the unit is damaged in shipment, return the unit to the store in which it was

bought for repair or replacement.

• If the unit is damaged by the customer, repair or replacement is the

responsibility of the customer.

• If the unit is damaged by the installer (if other than the customer), repair

or replacement must be made by arrangement between the customer and

installer.

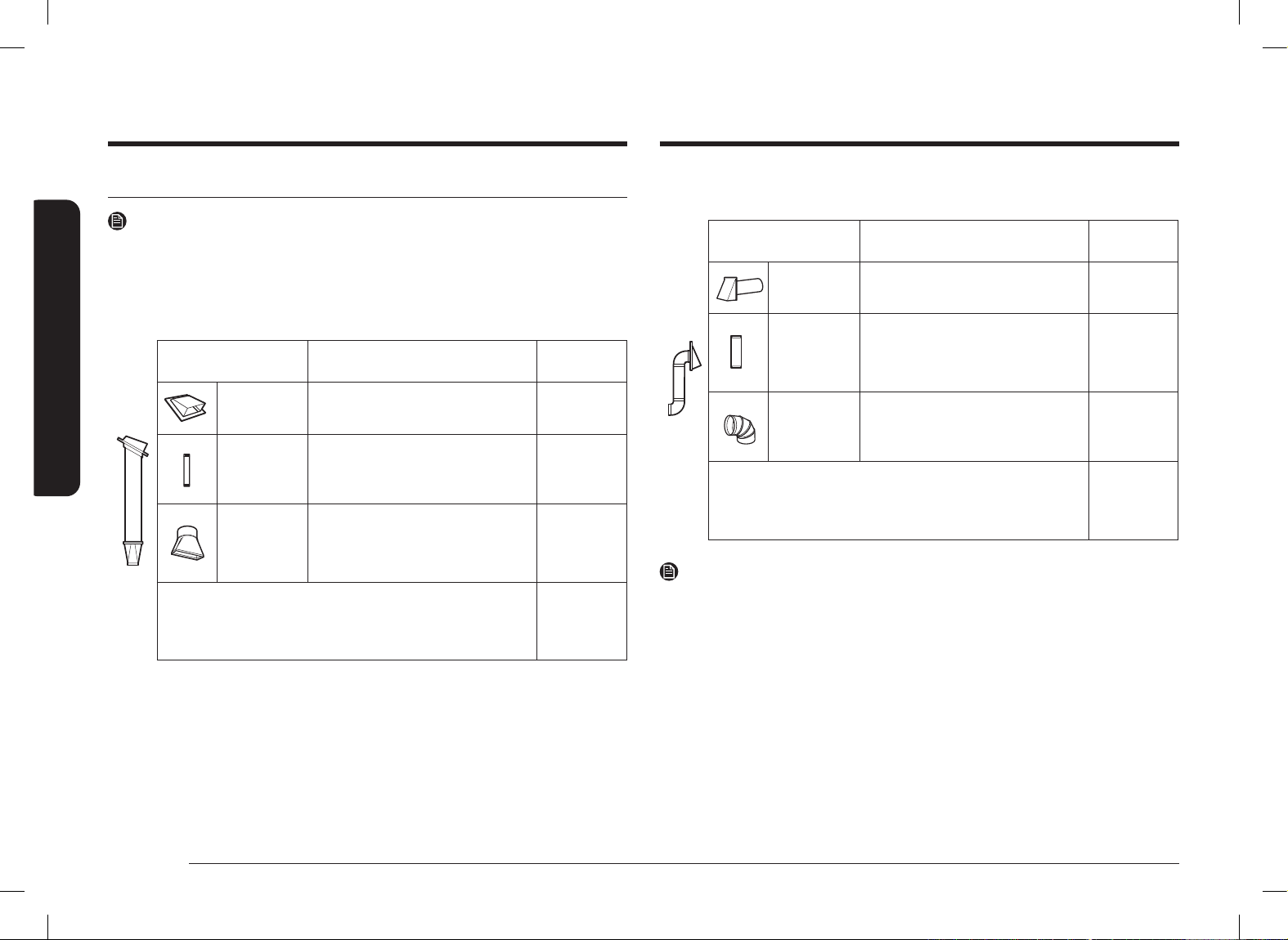

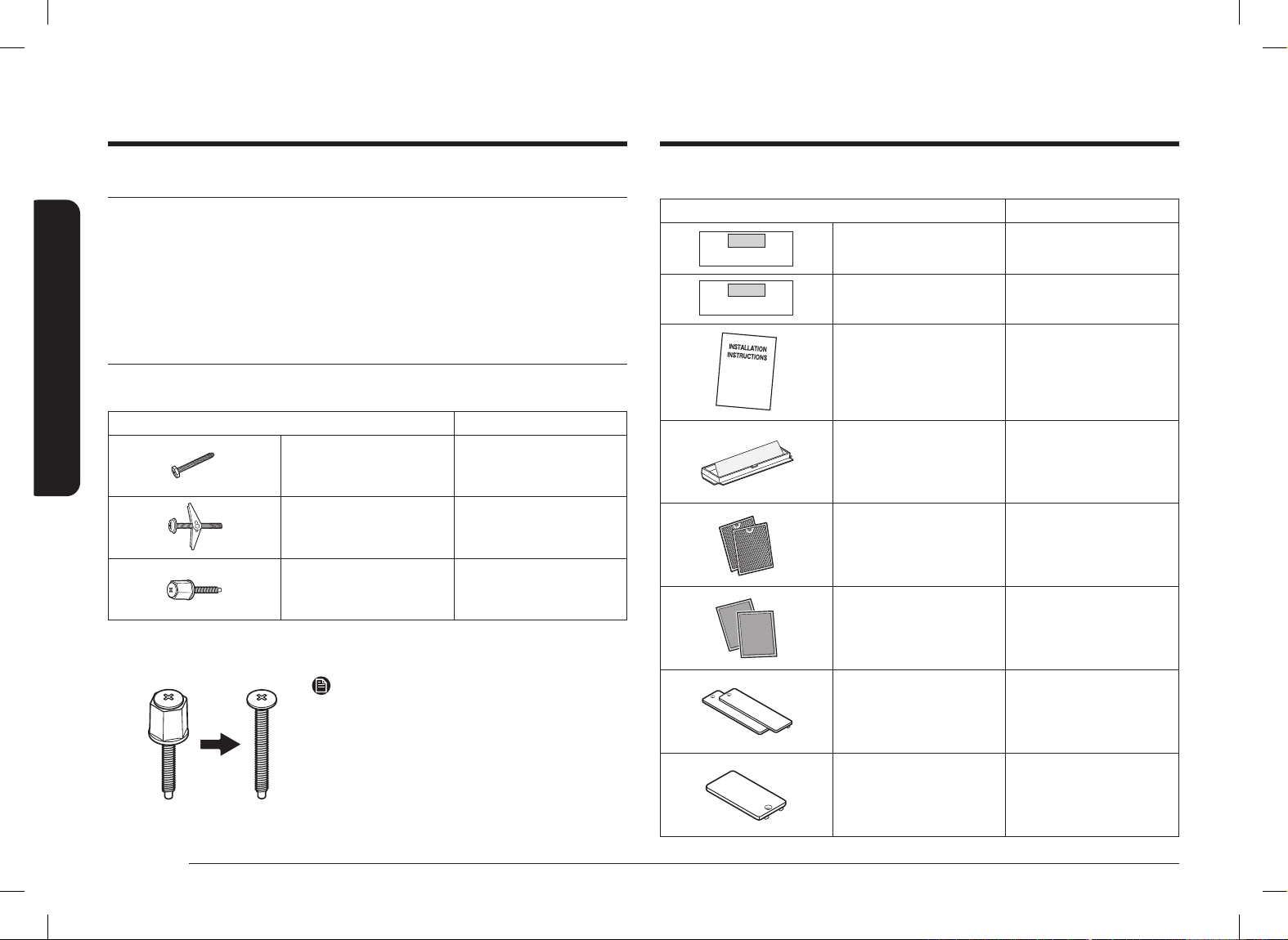

PARTS INCLUDED

HARDWARE PACKET

PART QUANTITY

Wood Screws 1

Toggle Bolts

(and wing nuts)

Self-aligning

Machine Screws

With Supporter

You will nd the installation hardware contained in a packet with the unit. Check to

make sure you have all these parts.

NOTE

If Cabinet Thickness is over 1 ˝, Remove

Supporter.

2

2

ADDITIONAL PARTS

TOP CABINET TEMPLATE

REAR WALL TEMPLATE

PART QUANTITY

Top Cabinet Template 1

Rear Wall Template 1

Installation Instructions 1

Exhaust Adaptor 1

Separately Packed

Grease Filters

Separately Packed

Charcoal Filters

2

2

Cover Air-Right 2

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 6Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 6 2021-06-16 �� 11:00:492021-06-16 �� 11:00:49

Cover Air-Left 1

6 English

Page 7

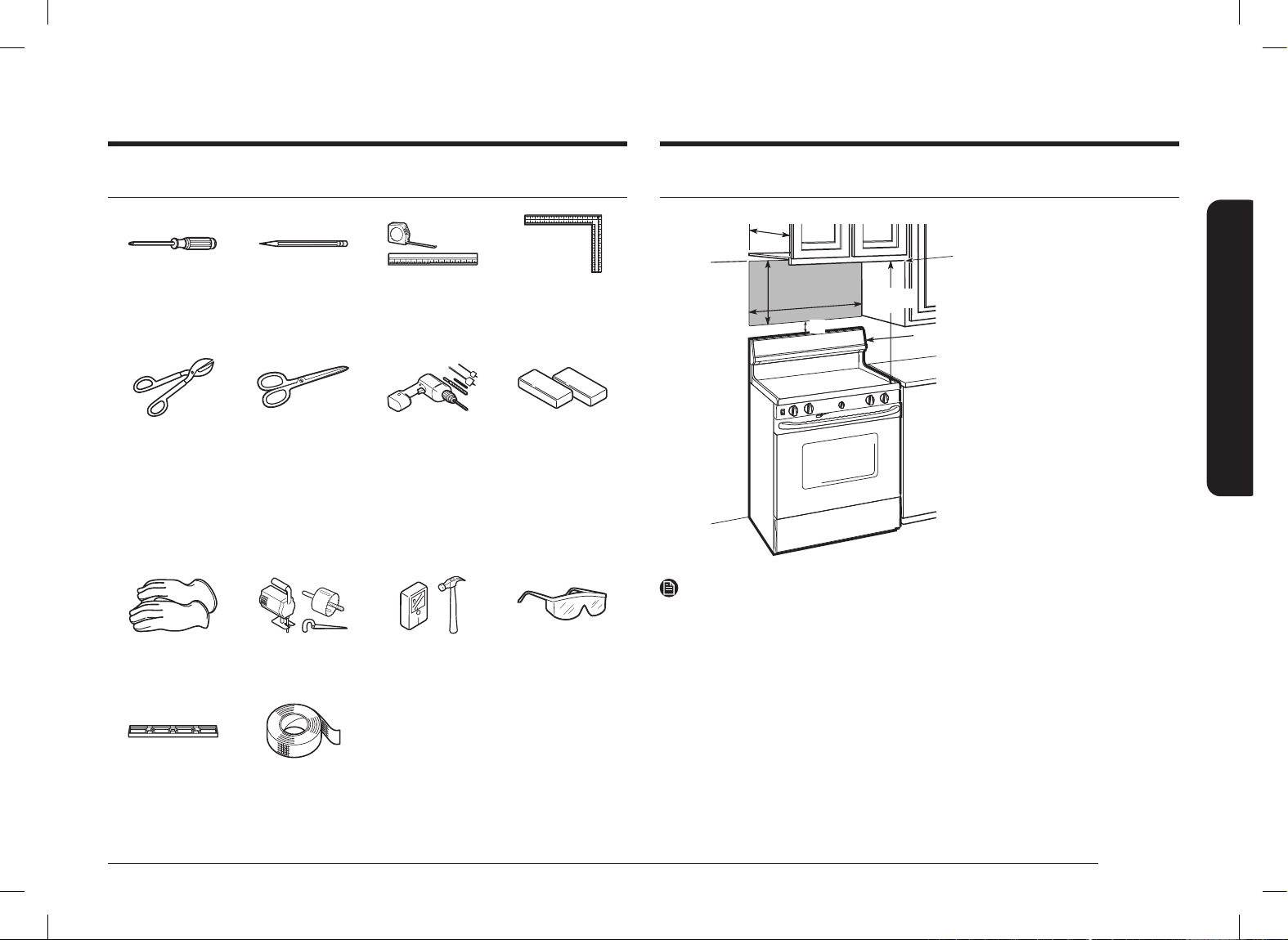

TOOLS YOU WILL NEED

MOUNTING SPACE

#1 and #2 Phillips

screwdriver

Tin snips (for cutting

Scissors (to cut

damper, if required)

Gloves Saw (saber, hole or

Level Duct and masking

Pencil Ruler or tape

measure and

straight edge

Electric drill with

template, if

necessary)

3

/16˝, 1/2˝ and 5/8˝

drill bits

Stud nder or

keyhole)

Hammer (optional)

tape

Carpenter square

(optional)

Filler blocks or

scrap wood pieces,

if needed for top

cabinet spacing

(used on recessed

bottom cabinet

installations only)

Safety goggles

12˝ max.

Bottom edge of the cabinet

needs to be 24

1

/5˝ or more

from the cooking surface.

1

24

30˝

5˝

/5˝

Backsplash

NOTE

• The space between the cabinets must be 30˝ wide and free of obstructions.

• This microwave oven is for installation over ranges up to 36˝ wide.

• If you are going to vent your microwave oven to the outside, see the Hood

Exhaust Section for exhaust duct preparation.

• If installing the microwave oven beneath smooth at cabinets, be careful to

follow the instructions on the top cabinet template for power cord clearance.

• Maximum cabinet depth above and beside the unit is 12˝.

• The dimensions provided are the minimum required for mounting the

microwave oven. Local codes and the practical use of the range will likely

require you to provide more than the 13.5˝ shown between the range and the

bottom of the microwave.

General information

English 7

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 7Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 7 2021-06-16 �� 11:00:492021-06-16 �� 11:00:49

Page 8

General information

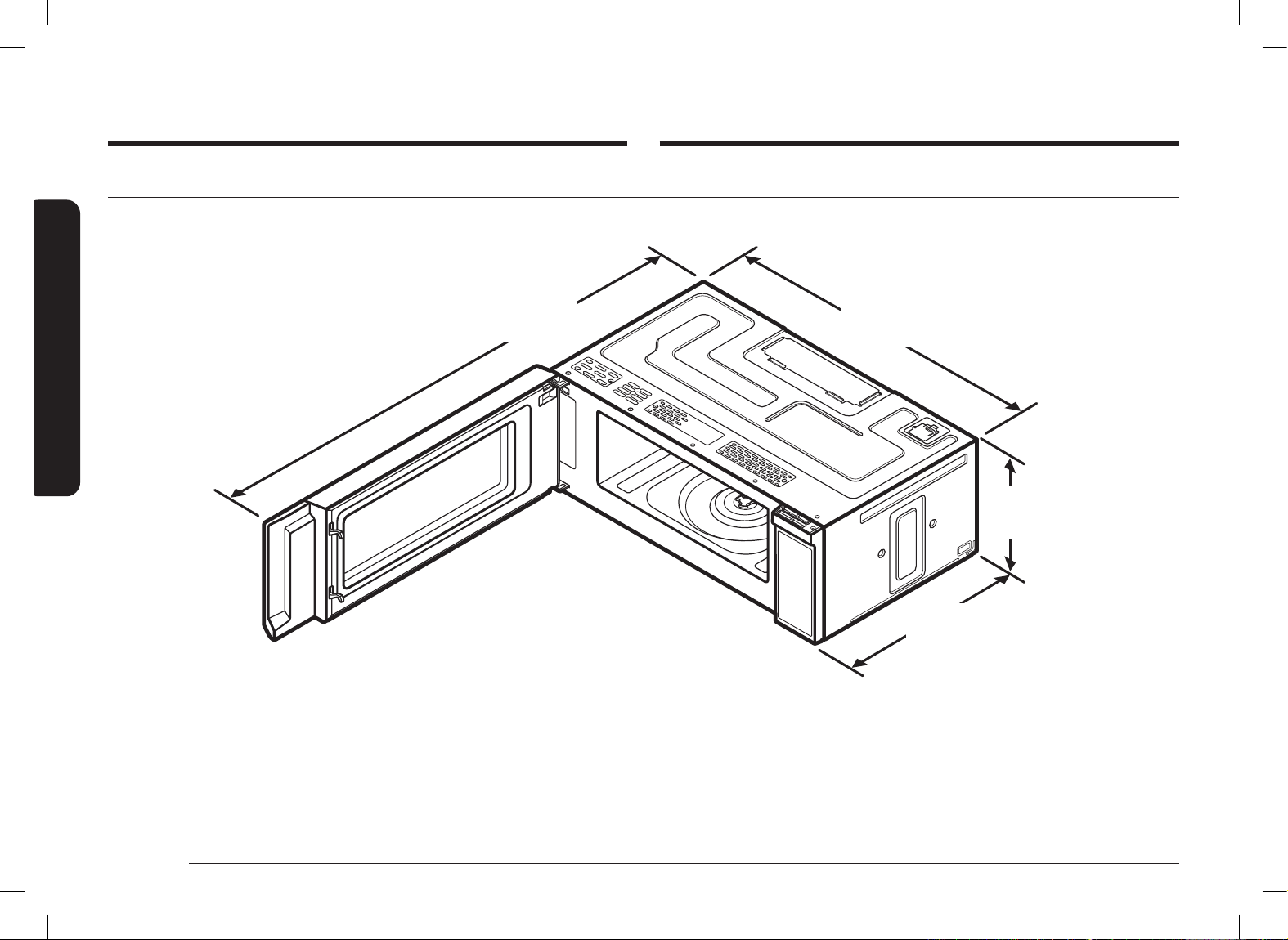

DIMENSION OF PRODUCT

General information

46 11/16˝

(1185.9mm)

With Plate mounting

29 7/8˝

(758.8mm)

10 11/16˝

(272.0mm)

19 3/16˝

(486.7mm)

With Plate

mounting

8 English

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 8Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 8 2021-06-16 �� 11:00:502021-06-16 �� 11:00:50

Page 9

Step-by-step installation guide

Step 1. Placement of the mounting plate

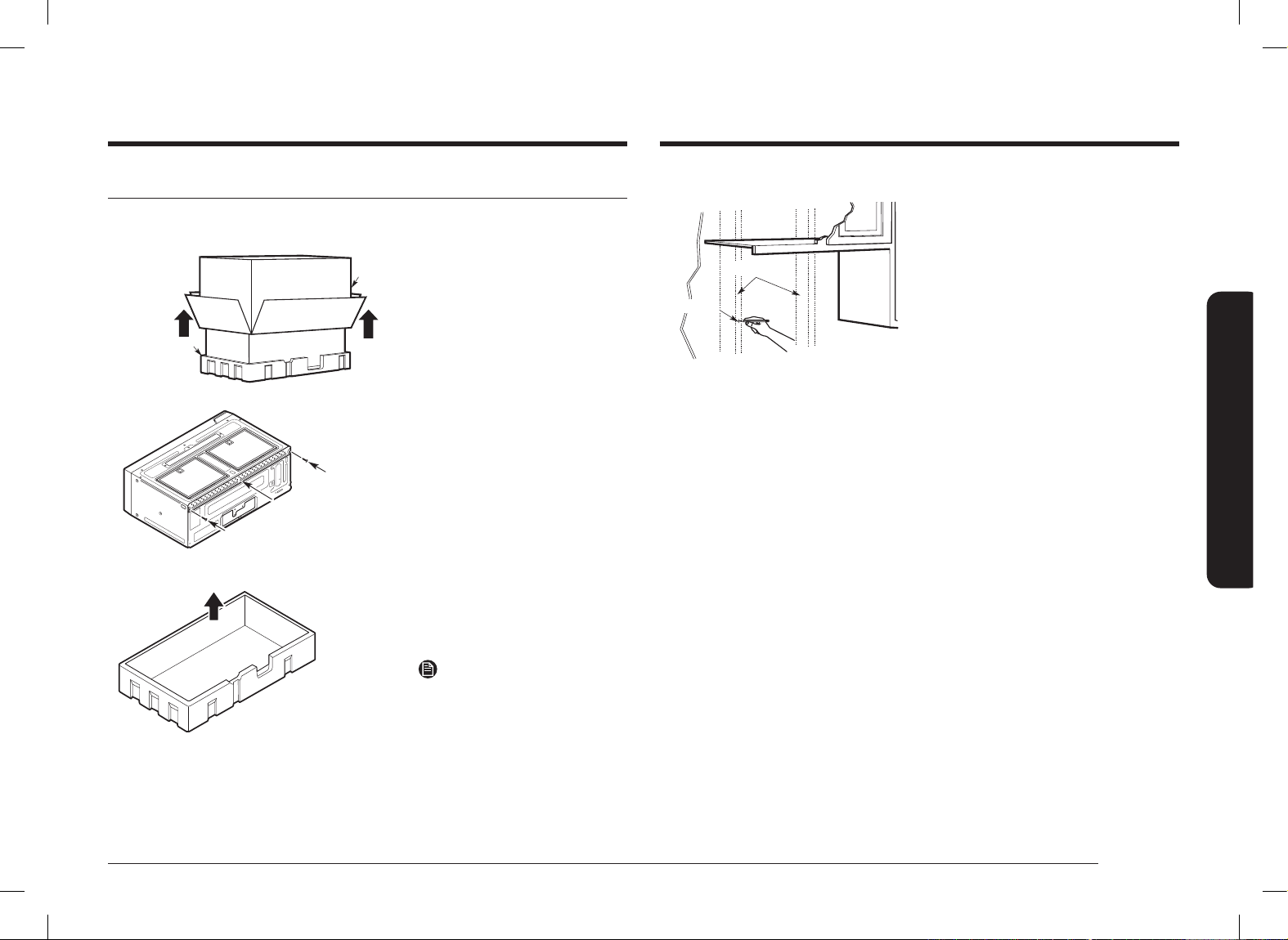

A. Removing the microwave oven from the carton/Removing the mounting plate

Carton

Styrofoam

Screws

Mounting Plate

Screws

1. Remove the installation

instructions, Exhaust

Adaptor, lters, glass tray,

and the small hardware

bag. Do not remove the

Styrofoam protecting the

front of the oven.

2. Fold back all 4 carton aps

fully against carton sides.

Then carefully roll the oven

and carton over onto the

top side. The oven should be

resting in the Styrofoam.

3. Pull the carton up and off

the oven.

4. Remove and properly

discard plastic bags.

5. Remove the 2 screws from

the mounting plate. This

plate will be used as the

rear wall template and for

mounting.

B. Finding the wall studs

1. Find the studs using one of the

following methods:

A. With a stud nder – a magnetic

Wall Studs

Center

2. After locating the stud(s), locate the

3. Draw a line down the center of the

THE MICROWAVE MUST BE CONNECTED TO AT LEAST ONE WALL STUD.

device which locates nails.

OR

B. Use a hammer to tap lightly

across the mounting surface until

you hear a solid sound. This will

indicate a stud location.

stud’s center by probing the wall

with a small nail to nd the edges of

the stud. Then, place a mark halfway

between the edges. The center of

any adjacent studs should be 16˝ or

24˝ from this mark.

studs.

Step-by-step installation guide

NOTE

Retain the two screws. You will

need to re-insert the screws in

their original locations after you

have removed the mounting

plate.

English 9

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 9Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 9 2021-06-16 �� 11:00:502021-06-16 �� 11:00:50

Page 10

Step-by-step installation guide

C

L

`

i

Plate position – beneath recessed bottom

cabinet with front overhang

Step-by-step installation guide

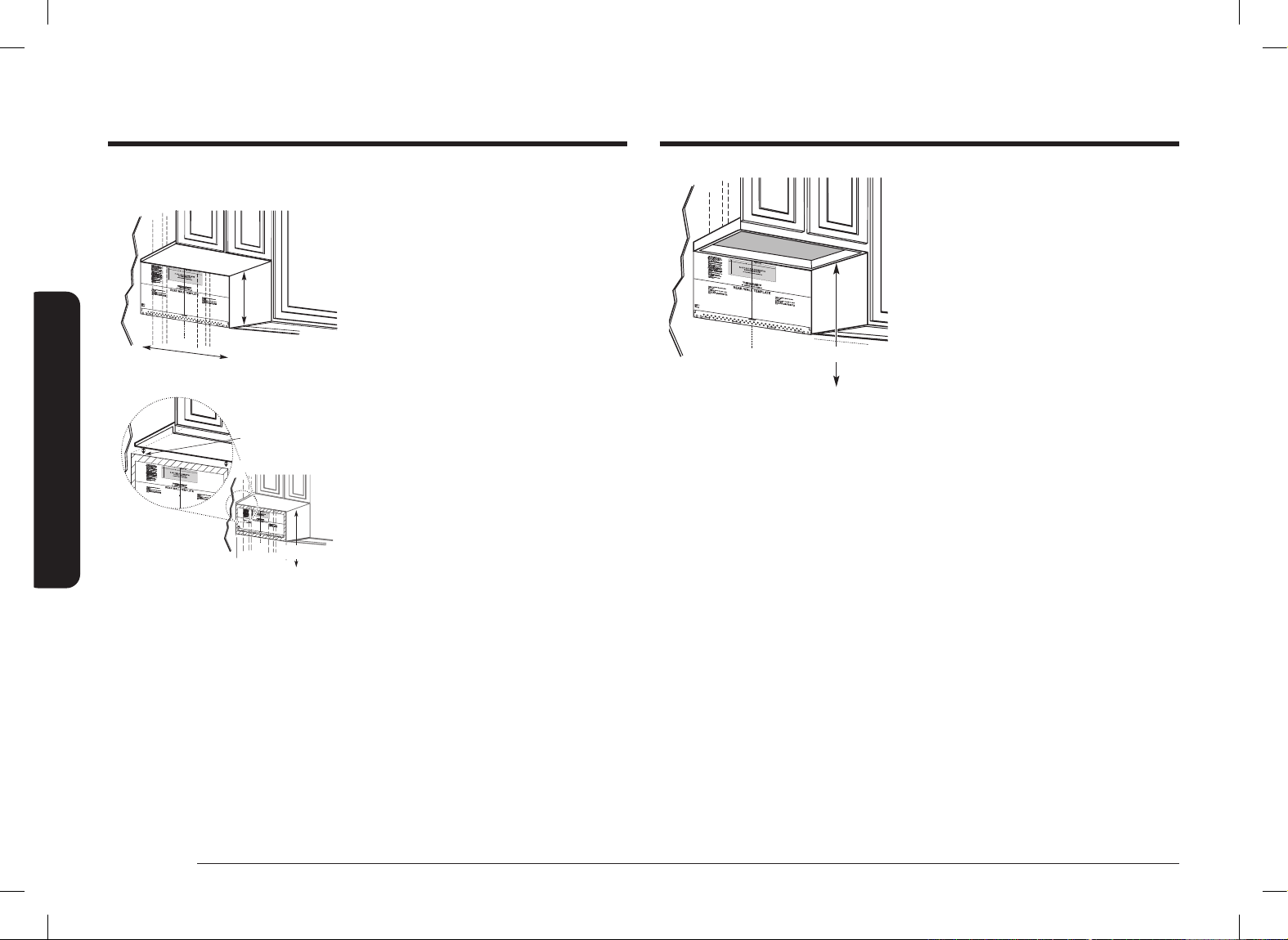

C. Determining wall plate location under your cabinet

Plate position – beneath a at bottom

cabinet.

Draw a vertical line on the wall at the

center of the 30˝ wide space. Tape the Rear

Wall Template onto the wall so that the top

of the template touches the bottom of the

cabinet and the centerline on the template

lines up with the line you drew on the wall.

At least 30˝

Draw a horizontal

line to mark how

far the inside of

the front overhang

descends below

the cabinet.

Plate position – beneath a recessed bottom

cabinet with a front overhang.

Draw a vertical line on the wall at the

center of the 30˝ wide space. Draw a

second, horizontal line on the wall below

the cabinet to mark how far the inside of

the front overhang descends below the

cabinet. Tape the Rear Wall Template onto

24 1/5˝

the wall so that the top of the template

touches the bottom of the horizontal line

and the centerline on the template lines up

with the vertical line.

Plate position – beneath a framed recessed

cabinet bottom.

Draw a vertical line on the wall at the

center of the 30˝ wide space. Tape the Rear

Wall Template onto the wall so that the top

of the template touches the bottom of the

cabinet frame and the centerline on the

template lines up with the line you drew

on the wall.

C

L

24 1/5˝

Your cabinets may have decorative trim that interferes with the microwave

installation. Remove the decorative trim to install the microwave properly and to

make it level.

THE MICROWAVE MUST BE LEVEL.

Use a level to make sure the cabinet bottom is level.

10 English

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 10Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 10 2021-06-16 �� 11:00:502021-06-16 �� 11:00:50

Page 11

D. Aligning the wall plate

NOTE: IT IS VERY IMPORTANT TO

READ AND FOLLOW THE DIRECTIONS

IN THE INSTALLATION INSTRUCTIONS

BEFORE PROCEEDING WITH THIS

REAR WALL TEMPLATE.

This Rear Wall Template serves to position the bottom

mounting plate and to locate the horizontal exhaust outlet

Horizontal Line

1. Use a level to check that the template is positioned accurately.

2. Locate and mark at least one stud on the left or right side of the centerline.

NOTE:

It is important to use at least one wood screw mounted rmly in a stud to support

the weight of the microwave. Mark two additional, evenly spaced locations for

the supplied toggle bolts.

3. Drill holes in the marked locations. Where there is a stud, drill a 3/16” hole for wood screws,

for holes that do not line up with a stud, drill 5/8” holes for toggle bolts

NOTE:

DO NOT INSTALL THE MOUNTING PLATE AT THIS TIME.

4. Remove the template from the rear wall.

5. Review the Installation Instruction book for your installation situation.

Français au verso.

Locate and mark holes to align with holes in the mounting plate.

IMPORTANT:

LOCATE AT LEAST ONE STUD ON EITHER SIDE OF THE CENTERLINE.

MARK THE LOCATION FOR 2 ADDITIONAL, EVENLY SPACED TOGGLE

BOLTS IN THE MOUNTING PLATE AREA.

IT IS RECOMMENDED TO INSTALL BOLTS IN A, B, AND C HOLES. THE LOCATION

MAY BE SUBJECT TO CHANGE ACCORDING TO CIRCUMSTANCES BUT IT IS

RECOMMENDABLE TO INSTALL THEM NEAR THE THREE HOLES MENTIONED.

Trim the rear wall template along the dotted line.

Printed in Malaysia

DE68-04707B-00

Hole A

Area E

F. CUT OUT FOR HORIZONTAL

OUTSIDE EXHAUSE

CUT HOLE THROUGH REAR WALL FOR EXHAUST ADAPTOR

CAUTION - IF EXHAUST ADAPTOR IS POSITIONED OUTSIDE

RECOMMENDED DIMENSION, GREASE-LADEN AIR WILL

30" MINIMUM WIDTH REQUIRED

REAR WALL TEMPLATE

Centerline

notches

CAUTION

Wear gloves to avoid cutting ngers on sharp edges.

1. Draw a horizontal line on the wall at the bottom of the “Rear Wall Template”.

2. Drill 5/8˝ holes for toggle bolts in 2 locations (Hole A, Hole B) as shown in the

illustration above. If the location of a hole lines up with a stud, drill a

3

/16˝ hole

for a wood screw. You cannot use a toggle bolt to attach the wall plate to a

stud.

NOTE

DO NOT MOUNT THE PLATE AT THIS TIME.

3/8" TO EDGE

Trim the rear wall template along the dotted line.

Draw a vertical line on the

wall to mark the center of

DISCHARGE INTO HOUSE STRUCTURE.

Hole C

the cabinet above.

Locate and mark holes to align with holes in the mounting plate.

IMPORTANT:

LOCATE AT LEAST ONE STUD ON EITHER SIDE OF THE CENTERLINE.

MARK THE LOCATION FOR 2 ADDITIONAL, EVENLY SPACED TOGGLE

BOLTS IN THE MOUNTING PLATE AREA.

IT IS RECOMMENDED TO INSTALL BOLTS IN A, B, AND C HOLES. THE LOCATION

MAY BE SUBJECT TO CHANGE ACCORDING TO CIRCUMSTANCES BUT IT IS

RECOMMENDABLE TO INSTALL THEM NEAR THE THREE HOLES MENTIONED.

Hole B

Draw a horizontal line on the wall along the

bottom of the “Rear Wall Template”.

3. Holes A and B are inside area E. If none of these holes line up with a stud,

nd a stud in area E that lines up with a hole circle in Area E, and then drill

3

a

/16˝ hole into it for a wood screw. You must have at least one wood screw

mounted rmly into a stud to support the weight of the microwave. Set the

mounting plate aside.

Step-by-step installation guide

Horizontal Line

English 11

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 11Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 11 2021-06-16 �� 11:00:512021-06-16 �� 11:00:51

Page 12

Step-by-step installation guide

Step-by-step installation guide

Step 2. Ventilation types (choose A, B or C)

This microwave oven is compatible with the following three types of ventilation:

A. Outside top exhaust

(vertical duct)

Bracket

C. Outside back exhaust

(horizontal duct)

B. Recirculating

(non-vented ductless)

A. Outside top exhaust (vertical duct)

A1. ADAPTING THE COVER PANEL FOR THE EXHAUST ADAPTOR

Cover

Panel

Back

Panel

1. Remove 1 screw from Cover Panel

and take off Cover Panel.

2. Remove 1 screw from Back Panel.

3. Assemble the Cover Panel as sliding

from top to bottom and the screw

that was removed from Back Panel.

NOTE

This microwave is shipped assembled for Recirculating. An Exhaust Adaptor is

shipped assembled and attached to the ller-upper. Select the type of ventilation

required for your installation and proceed to that section.

12 English

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 12Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 12 2021-06-16 �� 11:00:512021-06-16 �� 11:00:51

Page 13

A2. INSTALLATION DAMPER

Damper

1. Remove the tape securing the

Damper.

2. Assemble the Damper as sliding from

back to front until stopped.

Bracket

NOTE

You must check bracket picture according

to ventilation type at page 12.

Step-by-step installation guide

House Duct

House Duct

NOTE

Make sure Dampers swing freely.

NOTE

• You must attach the House Duct to

the Exhaust Adaptor after installation

is complete.

• You must seal Exhaust Duct joints

using Duct Tape.

The marked Brackets should not

have Vent holes.

NOTE

Apply A1 and A2 equally.

B. Recirculating (non-vented ductless)

B1. Adapting the COVER PANEL for recirculation

Cover

Panel

Back

Panel

1. Make sure the Cover Panel is

assembled properly. (Top assembly)

English 13

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 13Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 13 2021-06-16 �� 11:00:512021-06-16 �� 11:00:51

Page 14

Step-by-step installation guide

Step-by-step installation guide

NOTE

• The Exhaust Adaptor with

the Damper is not needed for

recirculating type. You may want to

save them for possible future use.

• You must check bracket picture

according to ventilation type at page

12.

The marked Brackets should have

Vent holes.

C. Outside back exhaust (horizontal duct)

C1. Adapting the COVER PANEL for outside back exhaust

1. Make sure the Cover Panel is

assembled properly. (Top assembly)

2. Cut 8 area to remove plates using

nipper.

Plate

8EA

After removing Plates

NOTE

You must check bracket picture according

to ventilation type at page 12.

The marked Brackets should not

have Vent holes.

14 English

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 14Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 14 2021-06-16 �� 11:00:512021-06-16 �� 11:00:51

Page 15

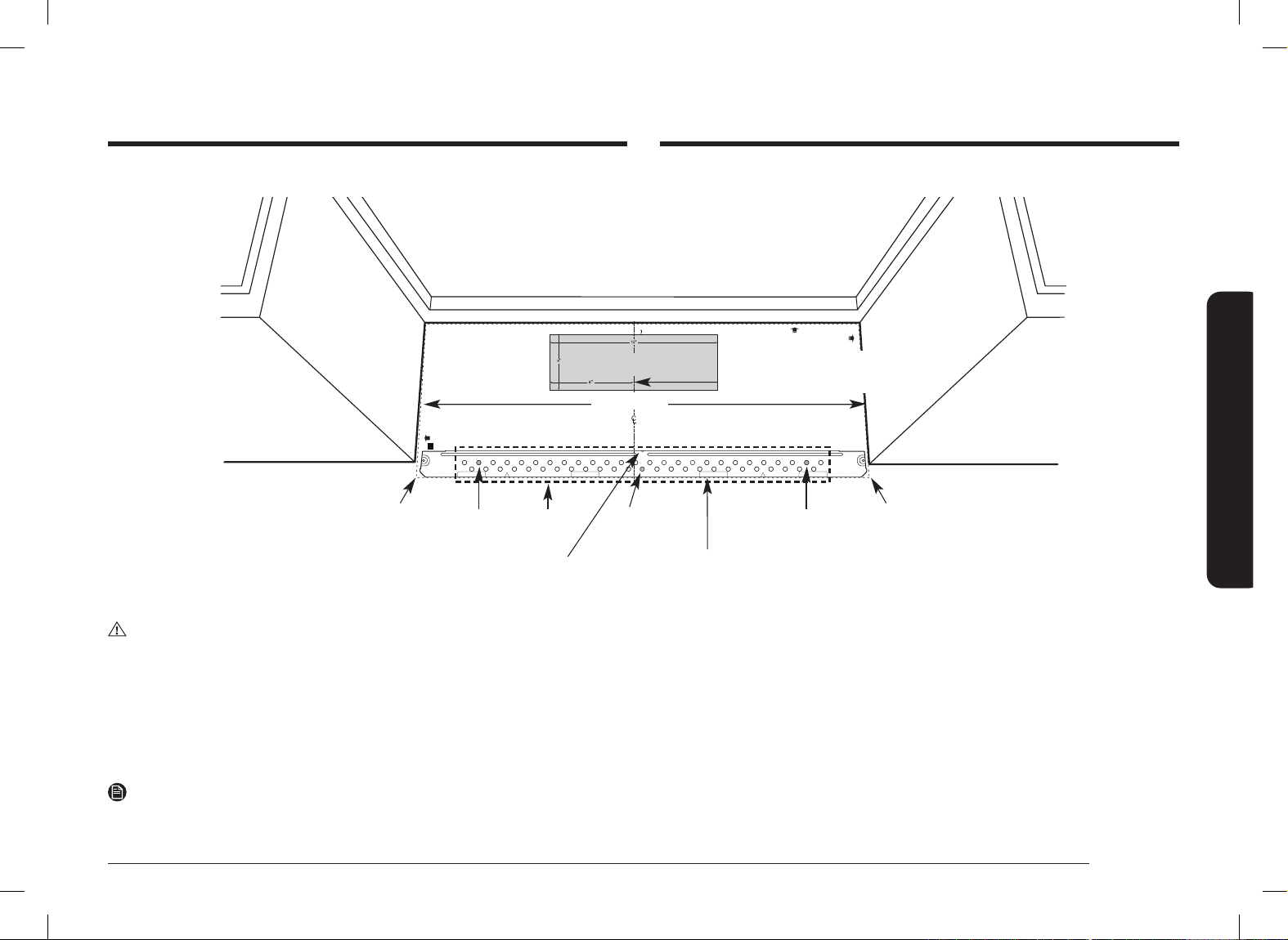

Step 3. Installation

INSTALLATION OVERVIEW

F. CUT OUT FOR HORIZONTAL

OUTSIDE EXHAUSE

REAR WALL TEMPLATE

3. Remove the tape securing the

Damper.

4. Assemble the Damper as sliding from

top to bottom until stopped.

NOTE

Make sure Dampers swing freely.

A. Prepare the Rear Wall (for outside

back exhaust/horizontal duct only)

B. Attach the Mounting Plate to the

Wall

C. Prepare the Cabinet above

D. Mount the Microwave Oven

E. Connect the Ductwork (for outside

top exhaust/vertical duct only)

Dim. Comparison

1

2

1

9

4

(235mm)

DE68-04708A-00

1 27/32˝

(47mm)

3

13

32

(332.4mm)

1

9

4

1

6

4

13

1

6

2

After assembling the screws in the D and E holes,

31

31

6

6

64

64

(164.5mm)

(164.5mm)

check the dimensions.

3

5

4

NOTE

11

(290.75mm)

3

13

32

(332.4mm)

Screw exposure length

(Cabinet bottom to End of bolt)

when using the Supporter.

30

28

~

1

32

32

(49mm) (22mm)

Screw exposure length

(Cabinet bottom to End of bolt)

without the Supporter.

26

28

~

1

32

32

(46mm) (22mm)

7

16

(235mm)

1

2

1

9

4

CUT OUT SLOT

CUT OUT SLOT

FOR SMOOTH

FOR SMOOTH

FLAT BOTTOM

FLAT BOTTOM

CABINETS ONLY

1

(37.3mm)

CABINETS ONLY

3

3

4

4

4

4

1

1

2

POWER

CORD

15

32

Step-by-step installation guide

3 1/2˝

(88.7mm)

9 1/4˝

1 15/32˝

(235mm)

(37.3mm)

26 3/16˝

(664.8mm)

1 27/32˝

(47mm)

English 15

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 15Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 15 2021-06-16 �� 11:00:522021-06-16 �� 11:00:52

Page 16

Step-by-step installation guide

Step-by-step installation guide

A. Prepare the rear wall for outside back exhaust

You need to cut an opening in the rear wall for outside exhaust.

• Read the instructions for outside

back exhaust on the REAR WALL

TEMPLATE.

• Tape the REAR WALL TEMPLATE to

the rear wall.

• Cut the opening, following the

instructions on the REAR WALL

TEMPLATE.

CAUTION

Do not cut an opening in the rear wall

C

L

if you are installing the microwave with

vertical duct or non-vented ductless

ventilation.

B. Attach the mounting plate to the wall

Attach the plate to the wall using toggle

bolts. At least one wood screw must be

used to attach the plate to a wall stud.

1. Remove the toggle wings from the

bolts.

2. Insert the bolts into the mounting

plate through the holes designated

to go into drywall, and then reattach

the toggle wings so that ¾˝ of the

bolt protrudes beyond the wing.

3. Place the mounting plate against

the wall, pinch the wings of each

Plate

Toggle Wings

Toggle

Bolt

toggle together, and then insert the

toggle wings of each toggle into and

Mounting

through the holes in the wall.

Wall

Bolt End

NOTE

Before tightening the toggle bolts and

wood screw, make sure the bottom

of the Mounting plate runs along the

bottom Horizontal line of the “Rear wall

Template” and the Mounting plate is

properly centered under the cabinet.

CAUTION

Be careful to avoid pinching your ngers

between the back of the mounting plate

and the wall.

4. Tighten all bolts. Pull the plate away

from the wall to help tighten the

bolts. Tighten the screw.

C. Use the top cabinet template to prepare the cabinet above

You need to drill holes for the top support screws and a hole large enough for the

power cord to t through.

• Read the instructions on the TOP

CABINET TEMPLATE.

• Tape it underneath the top cabinet.

• Drill the holes, following the

instructions on the TOP CABINET

TEMPLATE.

CAUTION

Wear safety goggles when drilling holes

in the cabinet bottom.

16 English

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 16Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 16 2021-06-16 �� 11:00:522021-06-16 �� 11:00:52

Page 17

D. Mount the microwave oven

FOR EASIER INSTALLATION AND

PERSONAL SAFETY, WE RECOMMEND

THAT TWO PEOPLE INSTALL THIS

MICROWAVE OVEN.

IMPORTANT: Do not grip or use the

handle during installation.

NOTE

• If your cabinet is metal, use the

nylon grommet in the power cord

hole to prevent the cord from being

cut.

• Filler blocks are required when

mounting this unit under any cabinet

with a recessed bottom or front

overhang. (See page 10.)

IMPORTANT: The case damage that will

occur from over tightening

screws if you do not use

ller blocks is not covered

under warranty.

IMPORTANT: Be careful not to damage

the lower Lamp Glass during

handling.

Cabinet Front

Cabinet Bottom Shelf

Microwave Oven Top

Supporter

Filler Block

Equivalent

to Depth

of Cabinet

Recess

Self-Aligning

Screw

Thickness of cabinet

1. Lift the microwave, tilt it forward,

and hook the slots at the back

bottom edge onto the four lower

tabs of the mounting plate.

2. Rotate the front of the oven up

against the cabinet bottom.

3. Insert a self-aligning screw

through the top center cabinet

hole. Temporarily secure the oven

by turning the screw at least two

full turns after the threads have

engaged. (It will be completely

tightened later.) Be sure to keep

the power cord tight. Be careful not

to pinch the cord, especially when

mounting ush to the bottom of

cabinet.

NOTE

If Cabinet Thickness is

Under 1 ˝, Use Supporter.

1

15

/16

/16 ˝

~

Step-by-step installation guide

NOTE

When mounting the microwave oven, thread the power cord through hole in the

bottom of the top cabinet. Keep it tight throughout Steps 1–3. Do not pinch the

cord or lift the oven by pulling cord.

1~2˝

NOTE

If Cabinet Thickness

is over 1 ˝, Remove

Supporter from the SelfAligning Screw.

NOTE

The self-aligning screw can be installed up to 1

15

/16 ˝ (49mm).

English 17

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 17Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 17 2021-06-16 �� 11:00:532021-06-16 �� 11:00:53

Page 18

Step-by-step installation guide

Step-by-step installation guide

4. Attach the microwave oven to the

top cabinet.

5. Insert the 2 self-aligning screws

through the cabinet bottom shelf and

ller block into the outer top cabinet

of the unit. Continue to support the

unit until both screws are inserted

and engaged at least two full turns,

then fully tighten all screws until the

unit is secure.

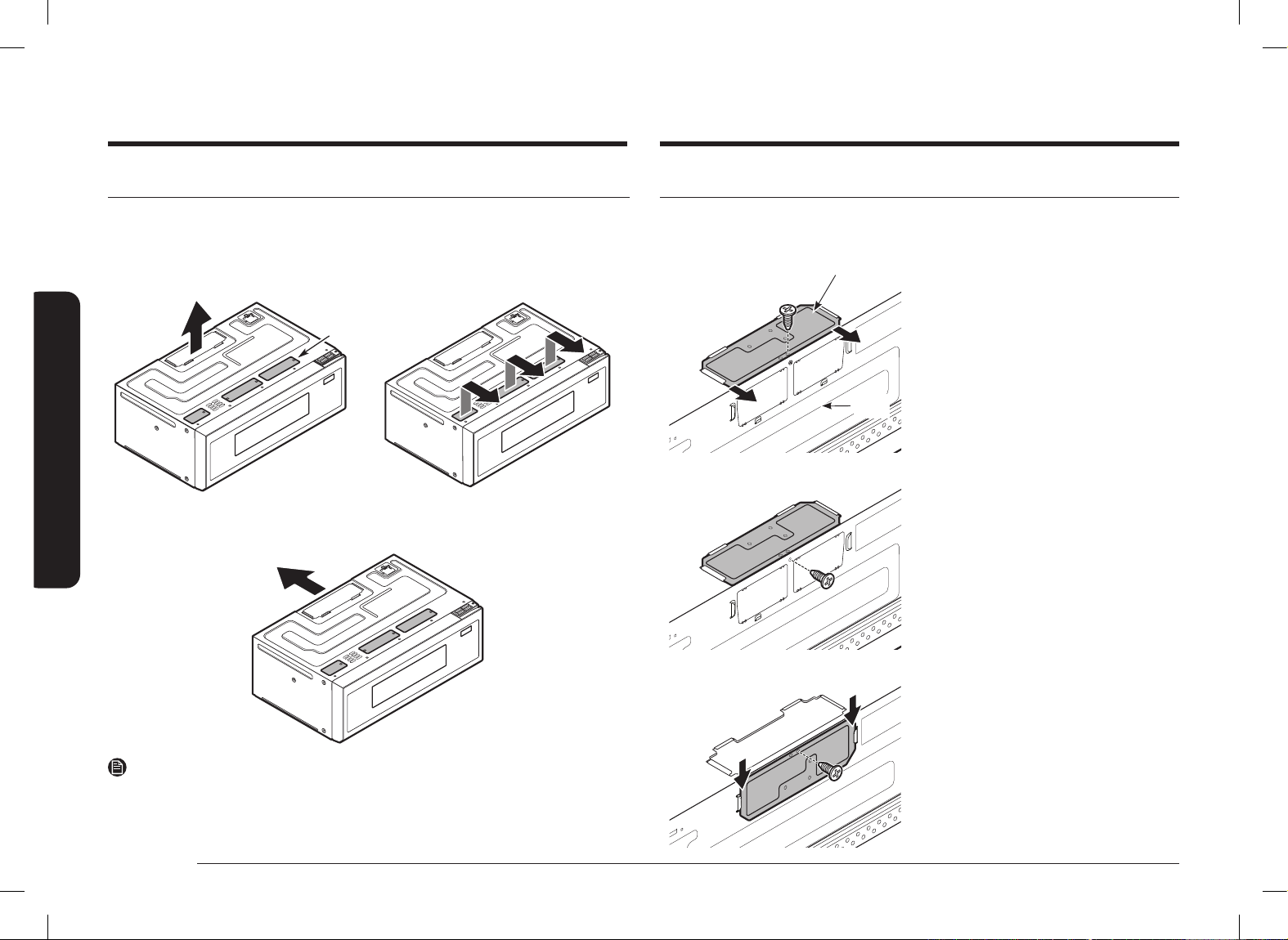

E. Installing the charcoal lters and Grease Filters

E1. Charcoal Filter assembly method

1. Insert the Charcoal Filter from the

back.

2. Raise the front of the Charcoal Filter

until it is at with the bottom, and

then pull it forward to lock it in

place.

E2. Grease Filter assembly method

1. Push the Grease Filter backward and

insert the Grease Filter until atness

with bottom surface of products.

F. Connect the ductwork for outside top exhaust

House Duct

House Duct

1. Extend the House Duct down to

connect to the Exhaust Adaptor.

2. Seal the exhaust duct joints using

duct tape.

18 English

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 18Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 18 2021-06-16 �� 11:00:532021-06-16 �� 11:00:53

Page 19

Step 4. Before you use your microwave

1. Make sure the microwave oven

has been installed according to

instructions.

2. Remove all packing material from the

microwave oven.

3. Install the turntable and ring in the

cavity.

4. Replace the house fuse or turn the

breaker back on.

5. Plug the power cord into a dedicated

15 amp electrical outlet.

Insure proper

ground exists

before use.

7. Keep installation instructions for the

local inspector’s use.

Step-by-step installation guide

6. Read the Owner’s Manual.

English 19

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 19Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 19 2021-06-16 �� 11:00:532021-06-16 �� 11:00:53

Page 20

Scan the QR code* or visit

www.samsung.com/spsn

to view our helpful

How-to Videos and Live Shows

* Requires reader to be installed on your

smartphone

Please be advised that the Samsung warranty does NOT cover service calls to explain product operation, correct improper installation, or perform normal cleaning or

maintenance.

QUESTIONS OR COMMENTS?

COUNTRY CALL OR VISIT US ONLINE AT

U.S.A

Consumer Electronics

CANADA 1-800-SAMSUNG (726-7864)

1-800-SAMSUNG (726-7864) www.samsung.com/us/support

www.samsung.com/ca/support (English)

www.samsung.com/ca_fr/support (French)

DE68-04709B-00

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 20Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 20 2021-06-16 �� 11:00:532021-06-16 �� 11:00:53

Page 21

Four à micro-ondes

Manuel d'installation

ME11A7510** / ME11A7710**

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 1Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 1 2021-06-16 �� 11:00:542021-06-16 �� 11:00:54

Page 22

AVANT DE COMMENCER

Table des matières

AVANT DE COMMENCER

AVANT DE COMMENCER

AVANT DE COMMENCER 2

Informations générales 3

Consignes de sécurité importantes 3

Exigences électriques 3

Échappement de hotte 4

Dommages - Expédition/Installation 6

Pièces incluses avec le produit 6

Outils nécessaires 7

Espace de montage 7

Guide d'installation étape par étape 9

Étape 1 : Emplacement de la plaque de xation 9

Étape 2 : Types de ventilation (sélectionnez A, B ou C) 12

Étape 3 : Installation 15

Étape 4 : Avant d’utiliser votre four micro-ondes 19

À PROPOS DE CE MANUEL

LISEZ ENTIÈREMENT ET ATTENTIVEMENT CES INSTRUCTIONS.

Important

• Conservez ces instructions d’installation an que la personne chargée du

contrôle local puisse s’y reporter.

• Conservez précieusement ce manuel en vue du passage éventuel d'un technicien

en cas de réparation.

Remarque importante destinée à l'installateur

Assurez-vous de laisser ces instructions à l'utilisateur.

Remarque importante destinée à l'utilisateur

Conservez ces instructions avec votre manuel d’utilisation pour référence future.

Niveau de compétences

L'installation de cet appareil nécessite des connaissances mécaniques et électriques

de base.

L'installateur est responsable de toute mauvaise installation

La défaillance du produit due à une mauvaise installation n’est pas

couverte par la garantie

2 Français

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 2Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 2 2021-06-16 �� 11:00:542021-06-16 �� 11:00:54

Page 23

Informations générales

CONSIGNES DE SÉCURITÉ IMPORTANTES

Cet appareil nécessite une prise tripolaire reliée à la terre. L’installateur doit

effectuer un contrôle de continuité de terre sur le boîtier de prise de courant avant

de commencer l’installation pour s’assurer que le boîtier de prise est correctement

mis à la terre. Si ce n'est pas le cas, ou si la prise ne répond pas aux exigences

indiquées en matière de raccordement électrique (dans la section EXIGENCES EN

MATIÈRE DE RACCORDEMENT ÉLECTRIQUE), faites appel à un électricien qualié

pour corriger les défaillances.

ATTENTION

Pour votre sécurité personnelle, retirez le fusible de la

maison ou ouvrez le disjoncteur avant de commencer

l’installation pour éviter des blessures graves ou

mortelles par électrocution.

ATTENTION

• pour votre sécurité, la surface de xation doit être capable de le poids du

meuble, en plus des 69 livres de l'appareil et des charges pouvant aller jusqu'à

50 livres, soit un poids total de 119 livres.

• Pour des raisons de sécurité personnelle, n’installez pas ce produit dans des

armoires congurées en îlot ou en péninsule. Le four à micro-ondes doit être

monté À LA FOIS sur une armoire supérieure ET sur un mur.

REMARQUE

Pour une installation plus facile et pour des raisons de sécurité personnelle, nous

recommandons que l’installation de ce produit se fasse à deux.

Le cordon d'alimentation de cet appareil est équipé d'une

prise tripolaire (mise à la terre) correspondant à la prise

murale tripolaire standard (mise à la terre) an de réduire

le risque d'électrocution.

Assurez-vous

que le four est

correctement

mis à la terre

avant de

l'utiliser.

Faites vérier la prise murale et le circuit par un électricien qualié an de vous

assurer que la prise est correctement mise à la terre.

Si vous possédez une prise murale standard à deux broches, il est très important de

la faire remplacer par une prise murale à trois broches correctement mise à la terre,

installée par un électricien qualié.

NE COUPEZ, NE DÉFORMEZ NI NE RETIREZ JAMAIS LES BROCHES DE LA PRISE DU

CORDON D'ALIMENTATION. N'UTILISEZ PAS DE RALLONGE.

EXIGENCES ÉLECTRIQUES

La valeur nominale du produit est de 120 volts CA, 60 Hertz, 14,5 ampères et

1,7 kilowatt. Cet appareil doit être relié à un circuit d'alimentation doté de la tension

et de la fréquence appropriées. La taille des ls doit être conforme aux exigences

du Code électrique national ou du code local en vigueur pour le régime nominal en

kilowatts. Le cordon d’alimentation et la che doivent être reliés à une prise simple

séparée reliée à la terre à circuit de dérivation entre 15 et 20 A. La prise doit être

placée dans le meuble situé au dessus du four à micro-ondes. La prise et le circuit

d'alimentation doivent être installés par un électricien qualié et conformément au

Code électrique national ou au code local en vigueur.

Informations générales

IMPORTANT – LISEZ ATTENTIVEMENT CE MANUEL. POUR VOTRE

SÉCURITÉ, CETAPPAREIL DOIT ÊTRE CORRECTEMENT MISÀ LA

TERRE AFIN D'ÉVITER TOUT RISQUED'ÉLECTROCUTION

Français 3

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 3Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 3 2021-06-16 �� 11:00:552021-06-16 �� 11:00:55

Page 24

Informations générales

ÉCHAPPEMENT DE HOTTE

SYSTÈME D'ÉVACUATION PAR L'ARRIÈRE (EXEMPLE UNIQUEMENT)

Le tableau suivant contient un type d'installation de conduits possible.

REMARQUE

les deux prochaines pages ne vous concernent que si vous souhaitez utiliser un

Informations générales

système d'évacuation de l'air. Si vous souhaitez que la circulation de l'air se fasse en

circuit fermé, passez à la page 12.

SYSTÈME D'ÉVACUATION PAR LE HAUT (EXEMPLE UNIQUEMENT)

Le tableau suivant contient un type d'installation de conduits possible.

COMPOSANTS DE

L'ÉVACUATION

Chaperon de

toit

12 pi. Conduit

droit

(6 po rond)

Adaptateur

rectangulaire

circulaire*

Les longueurs équivalentes des composants du

système d'évacuation sont basées sur des essais

réels et reètent les exigences en matière de

performance de ventilation avec n'importe quel

type de hotte.

LONGUEUR

ÉQUIVALENTE

24 pi. x (1) = 24 t.

12 pi. x (1) = 12 pi.

5 pi. x (1) = 5 pi.

x

NOMBRE

UTILISÉ

Longueur

totale

=

= 41 pi.

LONGUEUR

ÉQUIVALENTE

REMARQUE

Pour l'évacuation par l'arrière, veillez à aligner l'évacuation sur l'espace situé entre

les montants ou préparez le mur lors de sa construction en ménageant un espace

entre les montants du mur an de disposer l'évacuation.

COMPOSANTS DE

L'ÉVACUATION

Chaperon

mural

3 pi. Conduit

droit

(3¼ x 10 po

rectangulaire)

Coude de 90° 10 pi. x (2) = 20 pi.

Les longueurs équivalentes des composants du

système d'évacuation sont basées sur des essais

réels et reètent les exigences en matière de

performance de ventilation avec n'importe quel

type de hotte.

LONGUEUR

ÉQUIVALENTE

40 pi. x (1) = 40 pi.

3 pi. x (1) = 3 pi.

x

NOMBRE

UTILISÉ

Longueur

totale

LONGUEUR

=

ÉQUIVALENTE

= 63 pi.

IMPORTANT :

si un adaptateur rectangulaire-circulaire est utilisé, les coins inférieurs du registre

devront être coupés à l'aide de cisailles an de le xer et de permettre au registre

de bouger librement.

4 Français

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 4Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 4 2021-06-16 �� 11:00:552021-06-16 �� 11:00:55

Page 25

REMARQUE

Si vous devez installer des conduits, notez que la longueur totale des conduits

rectangulaires de 3¼ x 10po ou ronds de 6po de diamètre ne doit pas dépasser

140pi équivalents.

La ventilation extérieure nécessite un SYSTÈME D'ÉVACUATION DE LA HOTTE. Lisez

attentivement ce qui suit.

REMARQUE

Il est important que la ventilation soit installée en utilisant le chemin le plus

direct et avec le moins de coudes possible. Cela garantit une ventilation dégagée

de l’échappement et aide à prévenir les blocages. Assurez-vous également que

les registres oscillent librement et que rien ne bloque les conduits.

COMPOSANTS DE

L'ÉVACUATION

Adaptateur

rectangulaire

circulaire*

Chaperon

mural

Coude de 90 ° 10 pi. x ( ) = pi.

LONGUEUR

ÉQUIVALENTE

5 pi. x ( ) = pi.

40 pi. x ( ) = pi.

x

NOMBRE

UTILISÉ

=

LONGUEUR

ÉQUIVALENTE

Informations générales

Raccord d’échappement :

L’évacuation de la hotte a été conçue pour s’accoupler avec un conduit rectangulaire

standard de 3¼ x 10 po.

Si un conduit rond est requis, un adaptateur de transition rectangulaire à rond doit

être utilisé. N’utilisez pas un conduit de moins de 6 po de diamètre.

Longueur maximale du conduit :

Pour une circulation d’air satisfaisante, la longueur totale du conduit rectangulaire de

3¼ x 10 po ou rond de 6 po de diamètre ne doit pas dépasser 140 pi équivalents.

Les coudes, transitions, chapeaux de mur et de toit, etc. présentent une résistance

supplémentaire au ux d’air et sont équivalents à une section de conduit droit qui

est plus longue que leur taille physique réelle. Lors du calcul de la longueur totale du

conduit, ajoutez les longueurs équivalentes de toutes les transitions et adaptateurs

plus la longueur de toutes les sections de conduit droites. Le tableau ci-dessous vous

montre comment calculer la longueur équivalente totale des conduits en utilisant la

longueur équivalente en pieds de certains conduits typiques.

Coude de 45 ° 5 pi. x ( ) = pi.

Coude de 90 ° 25 pi. x ( ) = pi.

Coude de 45 ° 5 pi. x ( ) = pi.

Chaperon de

toit

Conduit droit

6 rond ou

3¼ x 10 po

rectangulaire

24 pi. x ( ) = pi.

1 pi. x ( ) = pi.

Total des conduits = pi.

*IMPORTANT: si un adaptateur rectangulaire-circulaire est utilisé, les

coins inférieurs du registre devront être coupés à l'aide

de cisailles an de le xer et de permettre au registre

de bouger librement.

Les longueurs équivalentes des composants du système

d'évacuation sont basées sur des essais réels et reètent

les exigences en matière de performance de ventilation

avec n'importe quel type de hotte.

Français 5

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 5Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 5 2021-06-16 �� 11:00:552021-06-16 �� 11:00:55

Page 26

Informations générales

TOP CABINET TEMPLATE

Template

INSTALLATION

INSTRUCTIONS

DOMMAGES EXPÉDITION/INSTALLATION

• Si l'appareil est endommagé lors du transport, retournez-le au magasin dans

PIÈCES SUPPLÉMENTAIRES

PIÈCE QUANTITÉ

lequel il a été acheté an qu'il soit réparé ou remplacé.

• Si l'appareil est endommagé par l'utilisateur, sa réparation ou son remplacement

Informations générales

lui incombe.

• Si l'appareil est endommagé par l'installateur (autre que l'utilisateur), un accord

devra être trouvé entre l'utilisateur et l'installateur en vue d'une réparation ou

TOP CABINET TEMPLATE

REAR WALL TEMPLATE

Gabarit du meuble haut 1

Gabarit pour mur arrière 1

d'un remplacement.

PIÈCES INCLUSES AVEC LE PRODUIT

Instructions d’installation 1

MATÉRIEL

PIÈCE QUANTITÉ

Vis à bois 1

Boulons à ailettes

(et écrous à oreilles)

2

Autoalignement

Vis à métal|

2

Avec supporter

L'appareil est livré avec un sachet contenant le matériel d'installation. Vériez que

vous disposez de toutes ces pièces.

REMARQUE

Si l’épaisseur du meuble est supérieure à 1 po,

retirez le supporter.

Adaptateur du système

d'évacuation

Emballé séparément

Filtres à graisse

Emballé séparément

Filtres au charbon

Couvercle d’aération - Droit 2

1

2

2

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 6Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 6 2021-06-16 �� 11:00:562021-06-16 �� 11:00:56

Couvercle d’aération - Gauche 1

6 Français

Page 27

OUTILS NÉCESSAIRES

5 po

Tournevis cruciforme

n°1 et n°2

Crayon Règle ou mètre à

ruban et règle plate

Équerre de

charpentier

(facultatif)

ESPACE DE MONTAGE

12 po max.

11

10

/16 po

30 po

5 po

24

1

/5 po

Le bord inférieur de

l’armoire doit être à

1

24

/

5

po ou plus de la

surface de cuisson.

Dosseret

Informations générales

Cisailles (pour la

coupe du registre si

nécessaire)

Gants Scie (scie sauteuse,

Niveau Ruban adhésif en

Ciseaux (pour la

coupe du gabarit si

nécessaire)

scie-cloche ou scie à

toile et ruban-cache

guichet)

Perceuse électrique

avec mèches de

3

/16 po, 1/2 po et

5

/8 po

Détecteur de

montant ou marteau

(facultatif)

Cales ou morceaux

de bois, pour

l'espacement du

meuble haut si

nécessaire (utilisé

pour l'installation

de meubles

bas encastrés

uniquement)

Lunettes de

protection

REMARQUE

• L’espace entre les armoires doit être de 30 po de large et libre d’obstructions.

• Ce four à micro-ondes est conçu pour une installation sur des cuisinières jusqu’à

36 po de large.

• Si vous souhaitez utiliser un système de ventilation pour le four micro-ondes,

reportez-vous à la partie Système d'évacuation de la hotte pour la préparation

du conduit d'évacuation.

• Lors de l'installation du four micro-ondes sous un meuble plat et lisse, respectez

les instructions gurant sur le gabarit du meuble haut pour la distance

d'isolement du cordon d'alimentation.

• La profondeur maximale du meuble au-dessus et à côté de l’unité est de 12 po.

• Les dimensions indiquées sont celles minimales nécessaires pour le montage

du four micro-ondes. Les codes locaux et l'utilisation pratique de la cuisinière

peuvent nécessiter un espace supérieur aux 13,5 po indiqués entre la cuisinière

et la partie inférieure du four micro-ondes.

Français 7

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 7Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 7 2021-06-16 �� 11:00:562021-06-16 �� 11:00:56

Page 28

Informations générales

DIMENSIONS DU PRODUIT

Informations générales

avec plaque de support

46 11/16 po

(1185,9 mm)

29 7/8 po

(758,8 mm)

10 11/16 po

(272,0 mm)

19 3/16 po

(486,7 mm)

avec plaque de

support

8 Français

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 8Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 8 2021-06-16 �� 11:00:572021-06-16 �� 11:00:57

Page 29

Guide d'installation étape par étape

Étape 1 : Emplacement de la plaque de xation

A. Retrait du four micro-ondes du carton/retrait de la plaque de xation

Carton

Polystyrène

Vis

Plaque de xation

Vis

1. Retirez les consignes

d'installation, l'adaptateur

du système d'évacuation,

les ltres, le plateau en

verre et le sachet contenant

le matériel. Ne retirez pas

la mousse de polystyrène

protégeant l'avant du four.

2. Pliez les 4 rabats du carton

contre ses côtés. Retournez

avec précaution le four

et le carton. Le four doit

reposer sur la mousse de

polystyrène.

3. Tirez le carton vers le haut.

4. Retirez et jetez les sacs

en plastique de manière

appropriée.

5. Retirez les 2 vis de la plaque

de xation. Cette plaque

est utilisée comme gabarit

du mur du fond et pour le

montage.

B. Détection des montants

1. Recherchez les montants en utilisant

l'une des méthodes suivantes :

A. À l’aide d’un détecteur de clous

Montants

Centre

2. Après avoir localisé le ou les

3. Tracez un trait vertical à partir du

LE FOUR MICRO-ONDES DOIT ÊTRE FIXÉ À AU MOINS UN DES MONTANTS.

– un appareil magnétique qui

localise les clous.

OU

B. Utilisez un marteau pour taper

légèrement sur la surface de

montage jusqu’à ce que vous

entendiez un son solide. Cela

indique l'emplacement d'un

montant.

montants, localisez le centre du

montant en sondant le mur avec un

petit clou pour trouver les bords du

montant. Puis tracez un repère au

centre entre des arêtes. Le centre des

montants adjacents doit être situé à

16 ou 24 po de ce repère.

centre des montants.

Guide d'installation étape par étape

REMARQUE

Conservez les deux vis. Vous

devrez réinsérer les vis dans

leurs emplacements d’origine

après avoir retiré la plaque de

montage.

Français 9

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 9Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 9 2021-06-16 �� 11:00:572021-06-16 �� 11:00:57

Page 30

Guide d'installation étape par étapeGuide d'installation étape par étape

C

L

`

i

Plate position – beneath recessed bottom

cabinet with front overhang

Guide d'installation étape par étape

C. Détermination de l’emplacement de la plaque murale sous le meuble

Position de la plaque – sous une armoire à

fond plat.

Tracez un trait vertical sur le mur du fond,

au centre de l’espace de 30 po de large.

Fixez le gabarit du fond au mur an que

la partie supérieure du gabarit touche la

partie inférieure du meuble et que le trait

central du gabarit soit aligné avec la ligne

que vous avez tracée sur le mur.

Au moins 30 po

Tracez une ligne

horizontale an

de marquer la

distance dont la

partie intérieure

du débord frontal

descend sous le

meuble.

Position de la plaque - sous une armoire

inférieure encastrée avec un surplomb

avant.

Tracez un trait vertical sur le mur du fond,

au centre de l’espace de 30 po de large.

Tracez une deuxième ligne horizontale sur

le mur situé sous le meuble an de marquer

la distance dont la partie intérieure du

débord frontal descend sous le meuble.

24 1/5 po

Fixez le gabarit du fond au mur an que la

partie supérieure du gabarit touche le bas

de la ligne horizontale et que le trait central

du gabarit soit aligné avec la ligne verticale.

Position de la plaque - sous un fond

d’armoire encastré encadré.

Tracez un trait vertical sur le mur du fond,

au centre de l’espace de 30 po de large.

Fixez le gabarit du fond au mur an que

la partie supérieure du gabarit touche la

partie inférieure du cadre du meuble et que

le trait central du gabarit soit aligné avec la

ligne que vous avez tracée sur le mur.

C

L

24 1/5 po

Si le meuble sur lequel vous souhaitez xer l’appareil comporte des ornements

décoratifs, ces derniers risquent de gêner l’installation. Retirez ces ornements pour

assurer une installation et une mise à niveau correctes du four.

IL EST TRÈS IMPORTANT QUE LE FOUR MICROONDES SOIT À NIVEAU.

Utilisez un niveau pour vous assurer que le plancher du meuble est bien à

horizontale.

10 Français

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 10Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 10 2021-06-16 �� 11:00:572021-06-16 �� 11:00:57

Page 31

D. Alignement de la plaque murale

REMARQUE: IL EST TRÈS IMPORTANT DE

LIRE ET DE SUIVRE LES DIRECTIVES

D’INSTALLATION AVANT D’UTILISER CE

GABARIT POUR MUR ARRIÈRE.

Ce modèle de paroi arrière permet de placer la plaque

de fixation inférieure et de localiser la sortie d’air horizontale.

1. Utilisez un niveau pour vous assurer que le modèle est correctement positionné.

2. Localisez et marquez d’un repère au moins un goujon à droite ou à gauche de l’axe médian.

REMARQUE:

Utilisez au moins une vis à bois et

Trait horizontal

fixez-la solidement dans un goujon afin que le montage

ainsi formé supporte le poids du micro-ondes. Localisez

deux emplacements supplémentaires situés à égale

distance en vue de la pose des boulons à ailettes fournis

avec l’appareil.

3. Precez des trous aux emplacements signalés.

Arrivé au goujon, percez un trou de 3/16” en vue de la pose des vis à bois.

Pour les trous non alignés sur un goujon, percez-en d’autres de 5/8” en vue de

la pose des boulons à ailettes.

REMARQUE:

NE POSEZ PAS LA PLAQUE DE FIXATION A CETTE ETAPE DU MONTAGE.

4. Enlevez le gabarit du mur arrière.

5. Reportez-vous aux consignes d’installation afin de connaître vos conditions d’installation.

Turn over for English.

Localisez et marquez d’un repère l’emplacement des trous afin que

ceux-ci soient alignés sur les trous de la plaque de fixation.

IMPORTANT:

LOCALISEZ AU MOINS UN GOUJON DE CHAQUE COTE DE L’AXE MEDIAN.

MARQUEZ L’EMPLACEMENT DE DEUX BOULONS A AILETTES

SUPPLEMENTAIRES SITURS A EGALE DISTANCE DANS LA

ZONE DE LA PLAQUE DE FIXATION.

IL EST RECOMMANDÉ D’INSTALLER LES BOULONS DANS LES TROUS A, B ET C.

L’EMPLACEMENT PEUT ÊTRE MODIFIÉ EN FONCTION DES CIRCONSTANCES MAIS

IL EST RECOMMANDÉ DE LES INSTALLER À PROXIMITÉ DES TROIS TROUS MENTIONNÉS.

Ebarbez le modele de parol arriere en suivant les pointilles.

Imprimé en Malaisie

DE68-04707B-00

Trou A

Zone E

F. DÉCOUPE D’ÉVACUATION

HORIZONTALE

DÉCOUPEZ UN TROU DANS LE MUR APPIÈRE POUR L’ADAPTATEUR D’ÉVACUATION

MISE EN GARDE - SI L’ADAPTATEUR D’ÉVACUATION EST PLACÉ À L’EXTÉEIRUR

DES DIMENSIONS RECOMMANDÉES, L’AIR CHARGÉ DE GRAISSE

SERA RELÂCHÉ DANS LA STRUCTURE DE LA MAISON

LARGEUR MINIMALE DE 30 PO REQUISE

GABARIT POUR MUR ARRIÈRE

Trou C

Encoches sur

le trait central

ATTENTION

portez des gants car les bords de la plaque sont très tranchants.

1. Tracez ensuite une ligne horizontale juste en dessous du gabarit du mur.

2. Percez des trous de 5/8 po pour les boulons à ailettes à 2 emplacements (trou A,

trou B) comme indiqué sur l’illustration ci-dessus. Si l’emplacement d’un trou est

aligné sur un montant, percez un trou de 3/16 po en vue de la pose d’une vis à

bois. Les boulons à ailettes ne peuvent être utilisés pour xer la plaque murale

à un montant.

Ebarbez le modele de parol arriere en suivant les pointilles.

Tracez un trait vertical sur le mur

du fond, au centre de l’espace de le

armoire situé au dessus.

Localisez et marquez d’un repère l’emplacement des trous afin que

ceux-ci soient alignés sur les trous de la plaque de fixation.

IMPORTANT:

LOCALISEZ AU MOINS UN GOUJON DE CHAQUE COTE DE L’AXE MEDIAN.

MARQUEZ L’EMPLACEMENT DE DEUX BOULONS A AILETTES

SUPPLEMENTAIRES SITURS A EGALE DISTANCE DANS LA

ZONE DE LA PLAQUE DE FIXATION.

IL EST RECOMMANDÉ D’INSTALLER LES BOULONS DANS LES TROUS A, B ET C.

L’EMPLACEMENT PEUT ÊTRE MODIFIÉ EN FONCTION DES CIRCONSTANCES MAIS

IL EST RECOMMANDÉ DE LES INSTALLER À PROXIMITÉ DES TROIS TROUS MENTIONNÉS.

Trou B

Trait horizontal

Tracez ensuite un trait horizontal juste en

dessous du gabarit du mur.

3. Les trous A et B sont à l’intérieur de la zone E. Si aucun de ces trous ne s’aligne

avec un montant, trouvez un montant dans la zone E qui s’aligne avec un cercle

de trous dans la zone E, puis percez un trou de 3/16 po pour vis à bois. Vous

devez utiliser au moins une vis à bois et la xer solidement dans un montant

an que le montage ainsi formé supporte le poids du four à micro-ondes.

Mettez la plaque de montage de côté.

Guide d'installation étape par étape

REMARQUE

NE POSEZ PAS ENCORE LA PLAQUE À CETTE ÉTAPE DU MONTAGE.

Français 11

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 11Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 11 2021-06-16 �� 11:00:582021-06-16 �� 11:00:58

Page 32

Guide d'installation étape par étapeGuide d'installation étape par étape

Guide d'installation étape par étape

Étape 2 : Types de ventilation (sélectionnez A, B ou C)

Ce four à micro-ondes est compatible avec les trois systèmes de ventilation suivants :

A. Système d'évacuation par le haut

(conduit vertical)

Support

C. Système d'évacuation par l'arrière

(conduit horizontal)

B. Circulation de l'air en circuit fermé

(sans conduit et sans évents)

A. Système d'évacuation par le haut (conduit vertical)

A1. ADAPTATION DU PANNEAU DE PROTECTION POUR L’ADAPTATEUR

D’ÉCHAPPEMENT

Panneau de couverture

Panneau

arrière

1. Retirez 1 vis du panneau de

couverture et retirez le panneau de

couverture.

2. Retirez 1 vis du panneau arrière.

3. Assemblez le panneau de couverture

en le glissant de haut en bas et la vis

qui a été retirée du panneau arrière.

REMARQUE

Ce micro-ondes est expédié assemblé pour la recirculation. Un adaptateur du

système d'évacuation est livré assemblé et xé à la cale supérieure. Sélectionnez

le système de ventilation adapté à votre installation et reportez-vous à la section

correspondante.

12 Français

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 12Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 12 2021-06-16 �� 11:00:582021-06-16 �� 11:00:58

Page 33

A2. MONTAGE DU REGISTRE

Registre

1. Retirez le ruban xant le registre.

2. Assemblez le registre en le glissant de

l’arrière vers l’avant jusqu’à l’arrêt.

Support

REMARQUE

Vous devez vérier l’image du support en

fonction du type de ventilation à la page

12.

Guide d'installation étape par étape

Conduit de maison

House Duct

REMARQUE

Assurez-vous que les registres oscillent

librement.

REMARQUE

• Vous devez xer le conduit de

l'habitation à l'adaptateur du système

d'évacuation après avoir terminé

l'installation.

• Vous devez sceller les joints du

conduit d’échappement à l’aide de

ruban adhésif.

Les supports marqués ne doivent pas

avoir de trous d’aération.

REMARQUE

Appliquer A1 et A2 de manière égale.

B. Circulation de l’air en circuit fermé (sans conduit et sans évents)

B1. Adaptation du PANNEAU DE COUVERTURE pour la recirculation

Panneau de couverture

1. Assurez-vous que le panneau

de couverture est assemblé

correctement. (Assemblage supérieur)

Panneau

arrière

Français 13

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 13Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 13 2021-06-16 �� 11:00:582021-06-16 �� 11:00:58

Page 34

Guide d'installation étape par étape

Guide d'installation étape par étape

REMARQUE

• L’adaptateur d’échappement avec le

registre n’est pas nécessaire pour

le type à recirculation. Vous pouvez

toutefois les conserver en vue d'une

utilisation ultérieure éventuelle.

• Vous devez vérier l'image du

support en fonction du type de

ventilation à la page 12.

Les supports marqués doivent avoir

des trous d’aération.

C. Système d'évacuation par l'arrière (conduit horizontal)

C1. Adaptation du PANNEAU DE COUVERTURE pour échappement arrière extérieur

1. Assurez-vous que le panneau

de couverture est assemblé

correctement. (Assemblage supérieur)

2. Coupez 8 zones pour retirer les

plaquettes à l’aide d’une pince.

Plaque

8EA

Après avoir retiré les plaques

REMARQUE

Vous devez vérier l'image du support en

fonction du type de ventilation à la page

12.

Les supports marqués ne doivent pas

avoir de trous d'aération.

14 Français

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 14Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 14 2021-06-16 �� 11:00:582021-06-16 �� 11:00:58

Page 35

Étape 3 : Installation

PRÉSENTATION DE L'INSTALLATION

F. CUT OUT FOR HORIZONTAL

OUTSIDE EXHAUSE

REAR WALL TEMPLATE

3. Retirez le ruban xant le registre.

4. Assemblez le registre en glissant du

haut vers le bas jusqu’à l’arrêt.

REMARQUE

Assurez-vous que les registres oscillent

librement.

A. Préparez le mur arrière (pour

l’évacuation arrière extérieure/

conduit horizontal uniquement)

B. Fixation de la plaque murale

C. Préparez l’armoire du dessus

D. Montage du four micro-ondes

E. Raccordez les conduits (pour

l’évacuation supérieure extérieure/

conduit vertical uniquement)

Dim. Comparaison

1

2

Il faut maintenir

une distance de

1

9

4

(235mm)

jusqu'au mur arrière.

Côté gauche

DE68-04708B-00

1 27/32 po

(47 mm)

arrière

3

13

32

(332.4mm)

Gabarit pour placard supérieur

Il faut maintenir

une distance de

1

9

4

(235mm)

jusqu'au mur arrière.

IMPORTANT : Lire les instructions d'installation fournies avec

l'ensemble four à micro-ondes/hotte. Suivre les

instructions dans la section "Préparation du

placard supérieur" des instructions d'installation.

Installations pour décharge à travers le toit

1

6

4

Mur

Axe central

Découper cette partie du fond du placard supérieur

si la décharge se fait à travers le toit.

13

1

6

2

Après avoir placé les vis dans les trous D et E,

vériez les dimensions.

31

6

64

(164.5mm)

3

13

32

(332.4mm)

Vissez la longueur d’exposition

(du fond du placard à l’extrémité du boulon)

lorsque vous utilisez l’option Supporter.

30

28

~

1

32

32

(49mm) (22mm)

Vissez la longueur d’exposition

(du fond du placard à l’extrémité du boulon)

sans l'option de Supporter.

REMARQUE

3

5

4

11

(290.75mm)

26

28

~

1

32

32

(46mm) (22mm)

7

16

jusqu'au mur arrière.

Il faut maintenir

une distance de

9

(235mm)

1

2

1

4

4

15

1

32

(37.3mm)

FENTE DE DÉCOUPE

POUR LES CABINETS

À FOND PLAT LISSE

UNIQUEMENT

3

4

Trou pour cordon

d'alimentation

1

1

2

Découpez d’abord ce trou

avant de découper l’ouverture

de la ventilation du toit

REMARQUE :

Installer une bague pour

cordon d'alimentation,

autour du trou percé dans

un placard en métal.

CORDON

D'ALIMENTATION

arrière

Côté droit

Guide d'installation étape par étape

Mur

3 1/2 po

(88,7 mm)

9 1/4 po

(235 mm)

1 15/32 po

(37,3 mm)

26 3/16 po

(664,8 mm)

1 27/32 po

(47 mm)

Français 15

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 15Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 15 2021-06-16 �� 11:00:592021-06-16 �� 11:00:59

Page 36

Guide d'installation étape par étape

Guide d'installation étape par étape

A. Préparez la paroi arrière pour l’échappement arrière extérieur

Vous devez pratiquer une ouverture dans le mur du fond pour installer le système

d'évacuation.

• Lisez les instructions relatives au

système d'évacuation par l'arrière

gurant sur le GABARIT DU MUR DU

FOND.

• Fixez le GABARIT DU MUR DU FOND

au mur arrière.

• Pratiquez l'ouverture en respectant

les instructions gurant sur le

GABARIT DU MUR DU FOND.

ATTENTION

C

L

Ne pratiquez pas une ouverture dans le

mur du fond si vous souhaitez installer

le four micro-ondes avec une ventilation

sans conduit et sans évents ou à conduit

vertical.

B. Fixation de la plaque murale

Fixez la plaque au mur à l'aide de boulons

à ailettes. Au moins une vis à bois est

nécessaire pour xer la plaque à un

goujon.

1. Retirez les ailettes des boulons.

2. Insérez les boulons dans la plaque

de xation via les trous pour cloison

sèche, puis remettez les ailettes

de telle sorte que ¾ po du boulon

dépasse l'ailette.

16 Français

3. Placez la plaque de montage contre

Plaque de

xation

Ailettes

Boulon à

ailettes

le mur, pincez les ailes de chaque

bascule ensemble, puis insérez les

ailes à bascule de chaque bascule

dans et à travers les trous du mur.

Mur

Extrémité du boulon

REMARQUE

avant de serrer les boulons à ailettes et

la vis à bois, assurez-vous que la partie

inférieure de la plaque de xation est

alignée sur le trait horizontal inférieur

du gabarit du mur du fond ; assurez-vous

également que la plaque est correctement

centrée sous le meuble.

ATTENTION

veillez à ne pas vous pincer les doigts

entre l’arrière de la plaque et le mur.

4. Serrez tous les boulons. Retirez

la plaque du mur pour faciliter

l’opération. Serrez la vis.

C. Utilisez le gabarit de l’armoire supérieure pour préparer

l’armoire du dessus

Vous devez percer des trous pour les vis de xation supérieure et un trou de

diamètre sufsamment important pour y faire passer le cordon d’alimentation.

• Lisez les instructions gurant sur le

GABARIT DU MEUBLE HAUT.

• Collez-le sous le plancher du meuble

haut.

• Percez les trous en respectant les

instructions gurant sur le GABARIT

DU MEUBLE HAUT.

ATTENTION

portez des lunettes de sécurité pendant

cette dernière opération.

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 16Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 16 2021-06-16 �� 11:00:592021-06-16 �� 11:00:59

Page 37

D. Montage du four micro-ondes

POUR PLUS DE FACILITÉ ET DE SÉCURITÉ

LORS DE L’INSTALLATION DE L’APPAREIL,

DEUX PERSONNES SONT NÉCESSAIRES.

IMPORTANT: évitez de saisir ou

d’accrocher la poignée du

four pendant l’installation.

REMARQUE

• si votre meuble est en métal, placez

la rondelle en nylon dans le trou du

cordon d’alimentation an d’éviter de

couper ce dernier.

• des cales sont nécessaires pour le

montage de cette unité sous un

meuble encastré ou avec débord

frontal. (Voir page 10.)

IMPORTANT: les dommages causés à

l’habillage du meuble qui

pourraient survenir à cause

du serrage excessif des

vis provoqué par la nonutilisation de cales n’est pas

couvert par la garantie.

IMPORTANT: Veillez à ne pas endommager

le verre de la lampe

inférieure pendant la

manipulation.

REMARQUE

lors du montage du four, faites passer le cordon d’alimentation dans le trou pratiqué

dans le plancher du meuble haut. Gardez-le bien serré tout au long des étapes 1 à 3.

Ne pincez pas le cordon et ne soulevez pas le four en tirant sur le cordon.

1. Soulevez le microondes, inclinez-le

vers l'avant et faites correspondre les

encoches situées à l'arrière et en bas

avec les quatre pattes inférieures de

la plaque de xation.

2. Faites pivoter la partie frontale du

four vers le haut contre le dessous du

meuble.

3. Insérez une vis autocentreuse dans

Avant du meuble

Étagère inférieure d’armoire

Bloc de remplissage

Vis

autocentreuse

Haut du four micro-ondes

Équivalent à la

profondeur de

l’évidement de

l’armoire

le trou central du meuble haut. Fixez

temporairement le four en faisant

effectuer à la vis au moins deux tours

complets après l’engagement des

lets. (Elle sera complètement serrée

ultérieurement.) Assurez-vous de

conserver le cordon d’alimentation

correctement connecté. Attention à ne

pas coincer le cordon, en particulier

au moment où vous montez le four à

eur contre le plancher du meuble.

Épaisseur de l’armoire

REMARQUE

Si l’épaisseur de l’armoire

Supporter

1

/16

est inférieure à 1 po,

utilisez un supporter.

~15/16 po

REMARQUE

Si l’épaisseur du meuble

1~2 po

est supérieure à 1 po,

retirez le supporter de la

vis d’autoalignement.

REMARQUE

La vis autocentreuse peut être installée jusqu’à une profondeur de 1 15/16 po (49 mm).

Guide d'installation étape par étape

Français 17

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 17Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 17 2021-06-16 �� 11:01:002021-06-16 �� 11:01:00

Page 38

Guide d'installation étape par étape

Guide d'installation étape par étape

4. Fixez le four micro-ondes sur le

meuble haut.

5. Insérez 2 vis autocentreuses à travers

le fond du meuble et des cales dans

les trous extérieurs du meuble haut

de l’unité. Continuez le soutien l’unité

jusqu’à ce que les deux vis soient

insérées et engagées d’au moins

deux tours complets, puis serrez

complètement toutes les vis jusqu’à ce

que l’unité soit sécurisée.

E. Installation des ltres à charbon et des ltres à graisse

E1. Méthode d’assemblage du ltre à charbon

1. Insérez le ltre à charbon par

l’arrière.

E2. Méthode d’assemblage du ltre à graisse

1. Poussez le ltre à graisse vers

l’arrière et insérez le ltre à graisse

jusqu’à ce qu’il soit plat avec la

surface inférieure des produits.

F. Connectez le réseau de conduits pour l’échappement supérieur

extérieur

House Duct

Conduit de maison

1. Tirez le conduit de la cuisine vers le

bas pour le relier à l’adaptateur du

système d’évacuation.

2. Scellez les joints du conduit du

système d’évacuation à l’aide d’un

ruban adhésif en toile.

2. Soulevez l’avant du ltre à charbon

jusqu’à ce qu’il repose à plat sur le

fond, puis tirez-le vers l’avant pour

l’immobiliser.

18 Français

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 18Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 18 2021-06-16 �� 11:01:002021-06-16 �� 11:01:00

Page 39

Étape 4 : Avant d’utiliser votre four micro-ondes

1. Assurez-vous que le four micro-ondes

a été installé conformément aux

instructions.

2. Retirez tout élément d'emballage du

four micro-ondes.

3. Installez le plateau tournant et la bague

dans la cavité.

4. Remplacez le fusible ou remettez le

disjoncteur sous tension.

5. Branchez le cordon d'alimentation sur

une prise dédiée de 15 A.

Assurez-vous

que le four est

correctement mis

à la terre avant de

l'utiliser.

7. Conservez précieusement ces

instructions d'installation an que la

personne chargée du contrôle local

puisse s'y reporter.

Guide d'installation étape par étape

6. Lisez le manuel d'utilisation.

Français 19

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 19Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 19 2021-06-16 �� 11:01:002021-06-16 �� 11:01:00

Page 40

Scannez le code QR* ou rendez-vous sur le site

www.samsung.com/spsn pour voir nos

vidéos et démonstrations en direct

d’utilisation.

* Requiert l’installation d’un lecteur sur votre smartphone

Veuillez noter que la garantie Samsung n'inclut pas les déplacements du service après-vente pour expliquer le fonctionnement de l'appareil, corriger une installation non correcte

ou exécuter des travaux de nettoyage ou d'entretien réguliers.

UNE QUESTION ? UN COMMENTAIRE ?

PAYS N° DE TÉLÉPHONE SITE INTERNET

U.S.A

Consumer Electronics

CANADA 1-800-SAMSUNG (726-7864)

1-800-SAMSUNG (726-7864) www.samsung.com/us/support

www.samsung.com/ca/support (English)

www.samsung.com/ca_fr/support (French)

DE68-04709B-00

Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 20Install_ME11A7510DG_AC_DE68-04709B-00_EN+CFR.indb 20 2021-06-16 �� 11:01:002021-06-16 �� 11:01:00

Loading...

Loading...