Page 1

Global LCD Panel Exchange Center

G

2

EXTENSION CODE

ARPPROVED BY

7 / Jan / ’13 Alan Choi

PREPARED BY

7 / Jan / ’13 Kevin Park

www.panelook.com

PRODUCT SPECIFICATION

( √ ) PRODUCT INFORMATION G

( ) APPROVAL SPECIFICATION

This is Product Information is subject to change after 3 months of issuing date

CUSTOMER

PROGRAM

General

-

CUSTOMER APPROVAL & FEEDBACK

MODEL LTM240CL0

N02

Application Engineering Group

Samsung Display Co., Ltd.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 2

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

2/34

SAMSUNG DISPLAY

Ver.M07

P0.0

www.panelook.com

Contents

Revision History ----------------------------------------------------------------------------------- (3) G

1. General Description -------------------------------------------------------------------------------- (4) G

2. Absolute Maximum Ratings ----------------------------------------------------------------------- (5) G

3. Optical Characteristics ----------------------------------------------------------------------------- (7) G

4. Block Diagram ------------------------------------------------------------------------------------ (11)G

5. Electrical Characteristics -------------------------------------------------------------------------- (12)G

5.1 TFT LCD ModuleG

5.2 Back Light UnitG

5.3 LVDS Input CharacteristicsG

5.4 Timing Parameters G

5.5 Input Signals, Basic Display Colors and Gray Scale of Each ColorG

5.6 Power ON/OFF SequenceG

5.7 Input Terminal Pin AssignmentG

6. Outline Dimension ------------------------------------------------------------------------------- (25) G

7. Packing ------------------------------------------------------------------------------------------- (27)

8. General Precautions ------------------------------------------------------------------------------ (29)

8.1 Handling Precautions G

8.2 Storage Precautions G

8.3 Operation Precaution

8.4 Design Guide for System

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

3/34

SAMSUNG DISPLAY

Ver.M07

P0.0

Version

Page

P0.0

7. Jan., 2013

All

Product information

Revision History

www.panelook.com

Date

Description

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

4/34

SAMSUNG DISPLAY

Ver.M07

P0.0

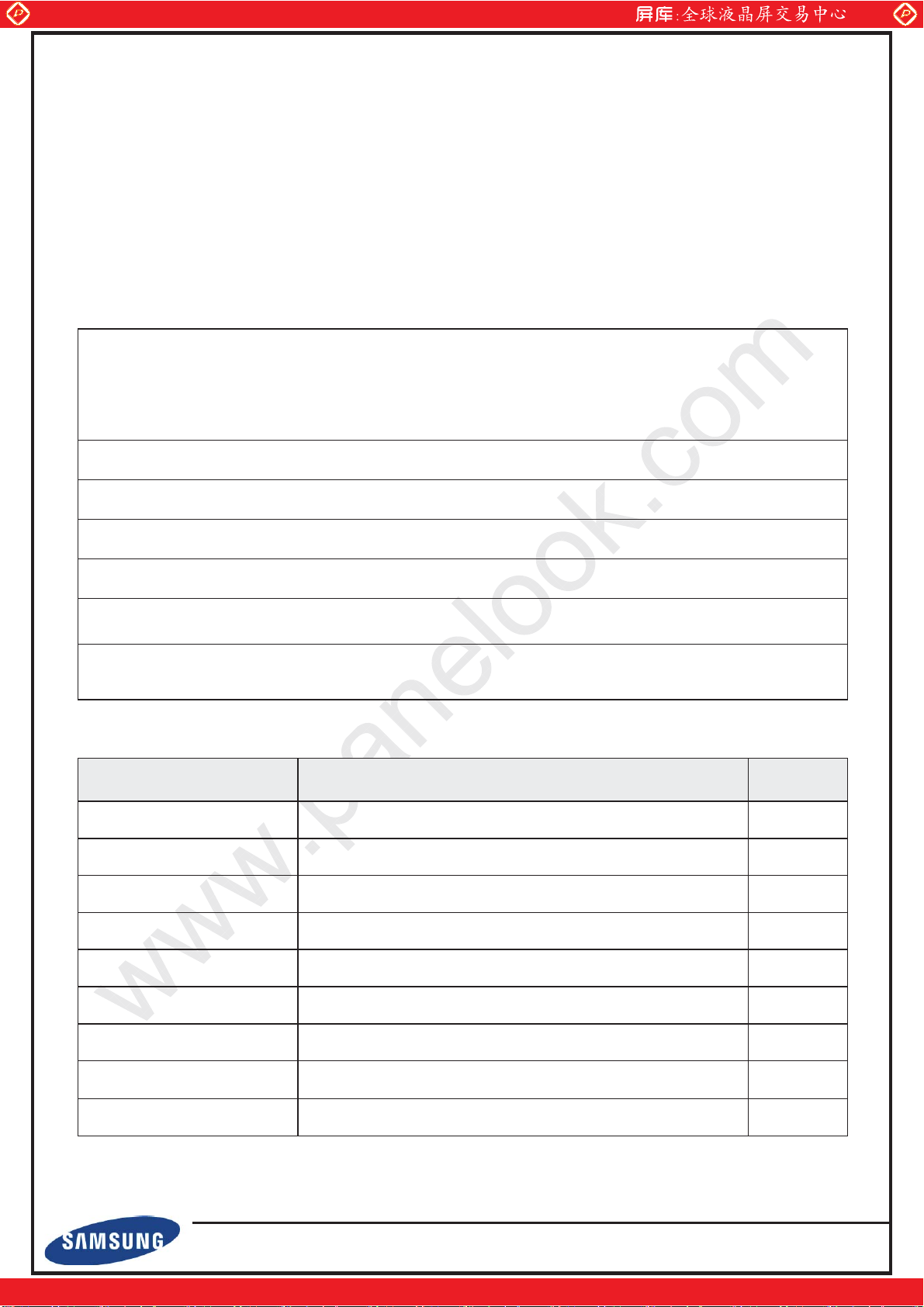

Application

- Monitors for Industrial machine

DE (Data Enable) only mode

LVDS (Low Voltage Differential Signaling) interface (2pixel/clock)

RoHS, Halogen Free

LED 2-side Edge Backlight

TCO

Interlace enable

Items

Specification

Unit

Pixel Pitch

0.270 (H) x 0.270(W)

mm

Active Display Area

518.4(H) x 324.0(V)

mm

Surface Treatment

AG type, Haze 35% , Hard coating (3H)

-

Display Colors

16.7M (True 8bit)

colors

Number of Pixels

1,920 x 1,200

pixel

Pixel Arrangement

RGB vertical stripe

-

Display Mode

Normally Black

-

Luminance of White

300 (Typ.)

cd/້

Power Consumption

Total 48W (Typ.) ( Panel 6W / BLU 42W)

W

www.panelook.com

1. General DescriptionG

Overview G

LTM240CL02 is a color active matrix liquid crystal display (LCD) that uses amorphous

silicon TFT (Thin Film Transistor) as switching components. This model is composed of a

TFT LCD panel, a driver circuit and a back light unit. The resolution of a 24.0” is 1920 x

1200 (WUXGA) and this model can display up to 16.7 million colors.

Features

- Workstation & Desktop monitors

- Display terminals for AV Products

6.0 compliance

General Information

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

5/34

SAMSUNG DISPLAY

Ver.M07

P0.0

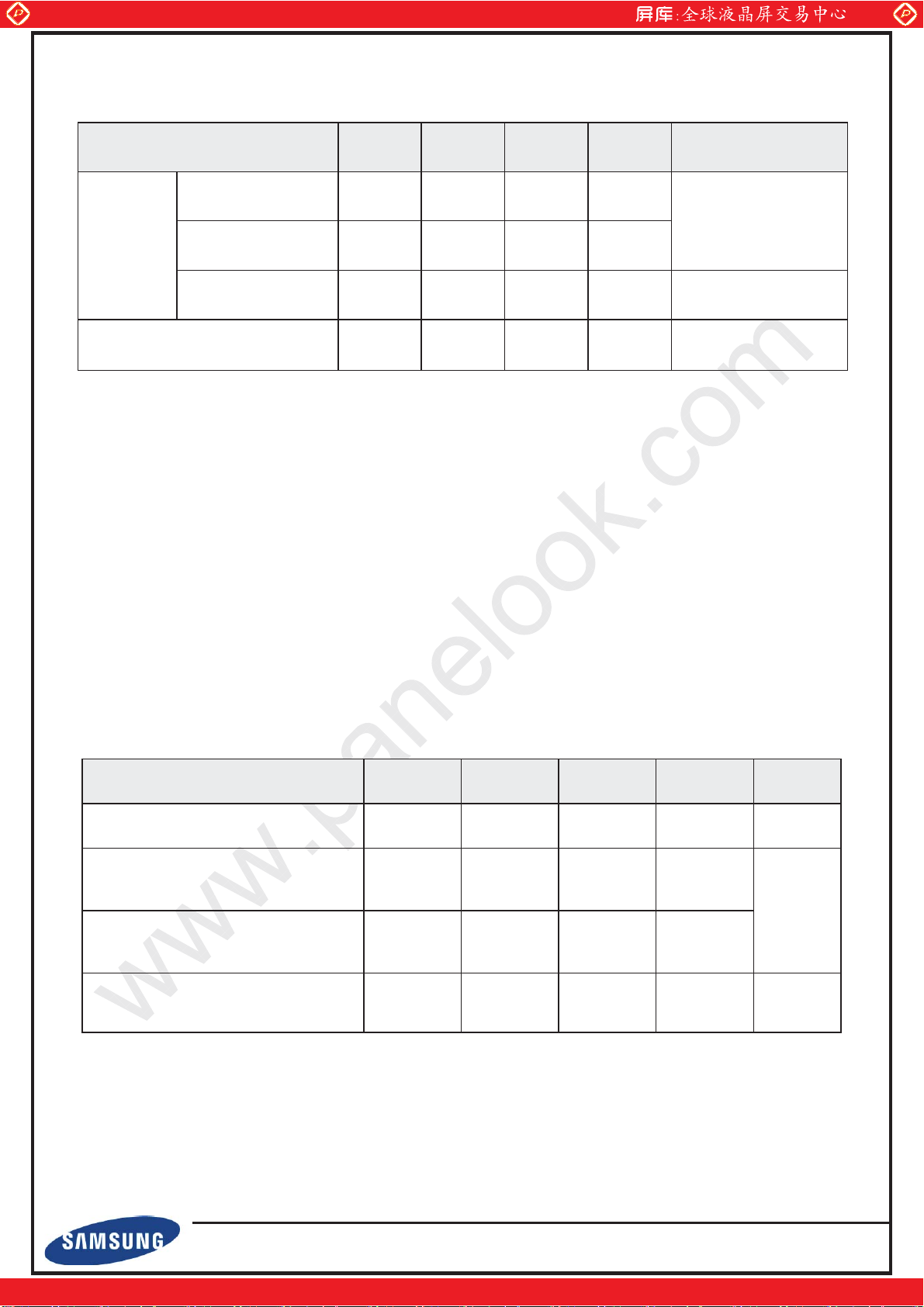

Min.

Typ.

Max.

Unit

Module

Horizontal (H)

562.8

563.3

563.8

Vertical (V)

364.4

364.9

365.4

050

LCD module only

Symbol

Max.

Note

V

DD

GND

0.5

V

50

60

Glass surface temperature

(Operation)

65

Mechanical Information

www.panelook.com

Item

mm

size

Depth (D) - - 17.9 mm -

Weight - - 3,

Note (1) Mechanical tolerance is ± 0.5mm unless there is a special comment.G

mm

g

Note

-

2. Absolute Maximum Ratings

If the condition exceeds maximum ratings, it can cause malfunction or unrecoverable damage

to the device.

G

Power Supply Voltage

Operating Temperature

Storage temperature

Note (1) Ta= 25 ± 2 °C

Item

T

T

T

OPR

STG

SUF

Min.

-

0

-20

0

6.5

Unit

(1)

(2)

(3)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

6/34

SAMSUNG DISPLAY

Ver.M07

P0.0

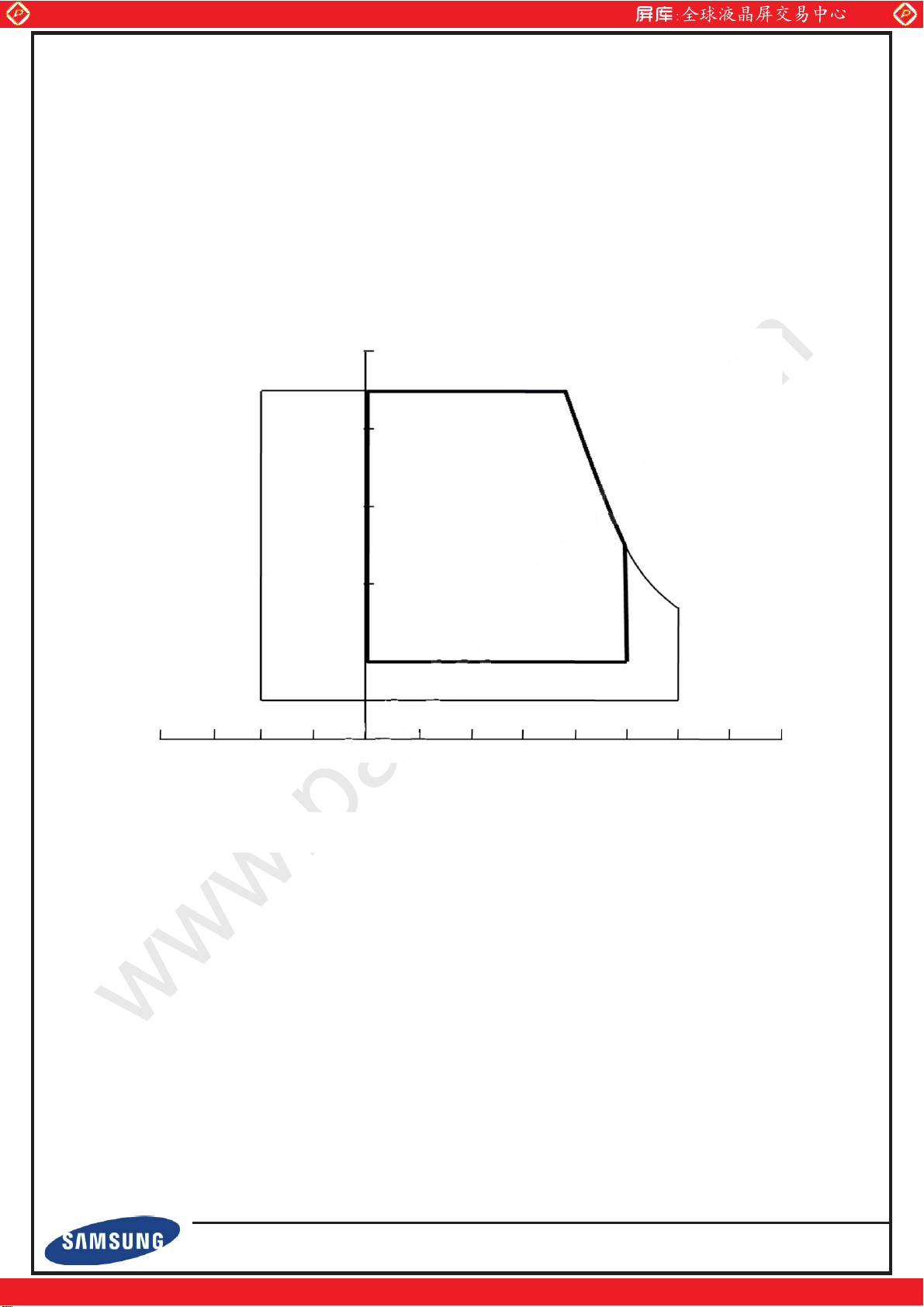

Fig. Temperature and Relative Humidity range

Operating Range

Storage Range

Temperature (°C )

Relative Humidity (% RH)

(39, 90)

(50, 50.4)

(60, 27.7)

(60, 27.7)

(-20, 10)

100

90

80

60

40

20

10

-40

-20

0

20

40

60

80

(2) Temperature and relative humidity range are shown in the figure below.

a. 90 % RH Max. (Ta ≤ 39 °C)

b. Maximum wet-bulb temperature at 39 °C or less. (Ta ≤ 39 °C)

c. No condensation.

(3) The maximum operating temperature of LCD module is defined with surface

temperature of active area. Under any condition, the maximum ambient operating

temperature should be keeping the surface of active area not any higher than 65 °C

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

7/34

SAMSUNG DISPLAY

Ver.M07

P0.0

Symbol

Condition

Min.

Typ.

Max.

Unit

Note

Contrast Ratio

(Center of screen)

C/R

1000

(3)

SR-3

Response Time

G to G

Normal

=0

=0

Viewing

msec

(5)

RD

80S

2

(6)

3

Brightness Uniformity

(9 Points)

uni

(4)

SR-3

Chromaticity

Red

- 0.030

0.680

+0.030

(7),(8)

3

Ry

0.308

Green

Gx

0.207

Gy

0.683

Blue

Bx

0.148

0.051

White

Wx

0.313

Wy

0.329

Chromaticity

Red

Ru'

510

Rv'

Green

Gu'

077

Gv'

Blue

Bu'

Bv'

White

Wu'

0.198

Wv'

0.468

www.panelook.com

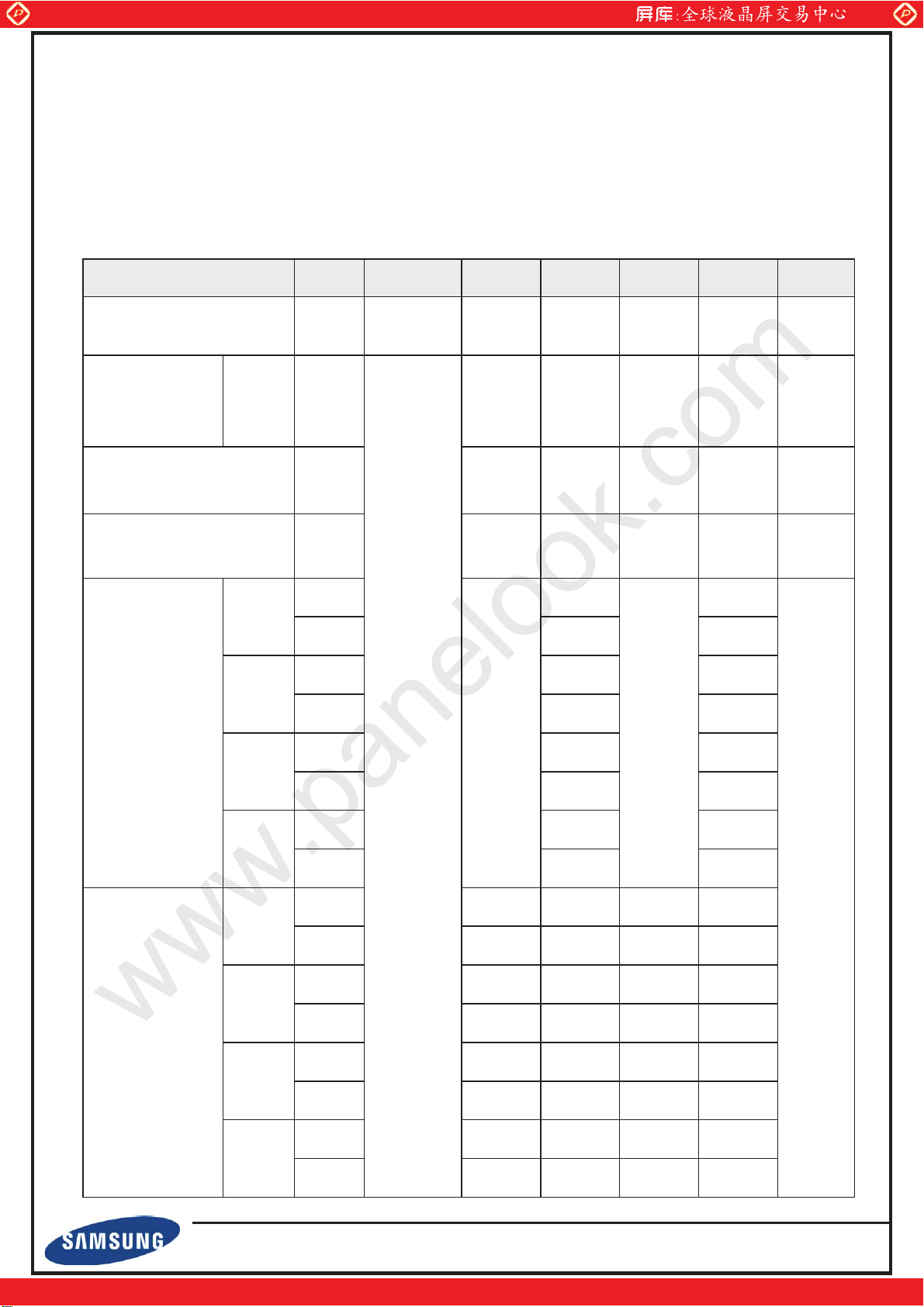

3. Optical Characteristics

The optical characteristics should be measured in a dark room or equivalent.

Measuring equipment : SR-3, RD-80S (TOPCON), EZ-Contrast (Eldim)

(Ta = 25 ± 2°C, VDD=5V, fv= 60Hz, f

Item

=77MHz, If=Magenta 174 mA, Green 225 mA)G

DCLK

Luminance of White

(Center of screen)

Color

(CIE 1931)

TGTG

Y

L

B

Rx

By

600

-1225

250 300 -

--25%

θ

L,R

θ

U,D

-

-

cd/m

SR-

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Color

(CIE 1976)

Angle

-0.

-0.519-

-0.

-0.570-

-0.179-

-0.138-

-

-

-

-

-

-

SR-

www.panelook.com

Page 8

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

8/34

SAMSUNG DISPLAY

Ver.M07

P0.0

Symbol

Condition

Min.

Typ.

Max.

Unit

Note

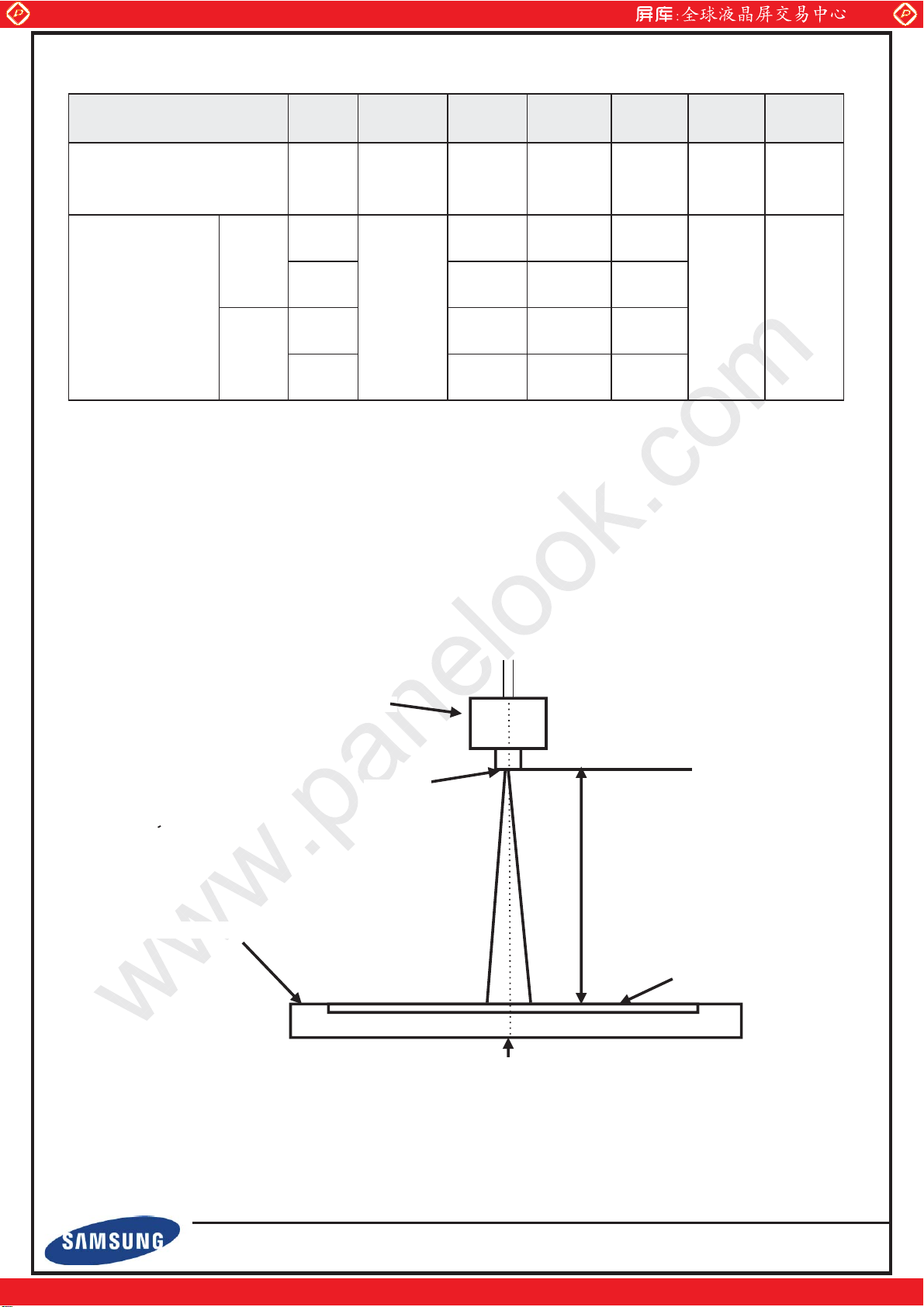

6500

Hor.

L

CR≥10

Degrees

-

Contrast

R

Ver.

U

D

Photo

detector

LCD Panel

TFT - LCD

Module

The center of the

screen

SR-3 : 50༃

RD-80S : 50༃

Field

2°

Item

www.panelook.com

Color Temperature - -

θ

Viewing

Angle

Note (1) Test Equipment Setup

The measurement should be executed in a stable, windless and dark room between

30min after lighting the back light at the given temperature for stabilization of the

back light. This should be measured in the center of screen.

LED Forward current : If = Magenta 174mA, Green 225mA

θ

θ

θ

Environment condition : Ta = 25 ± 2 °C

80 89 -

80 89 -

80 89 -

80 89 -

-K

(8)

EZ

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

9/34

SAMSUNG DISPLAY

Ver.M07

P0.0

192

960

1728

Active Area

120

600

1080

B

max

- B

min

B

max

B

uni

= 100 x

G

max

G

min

CR =

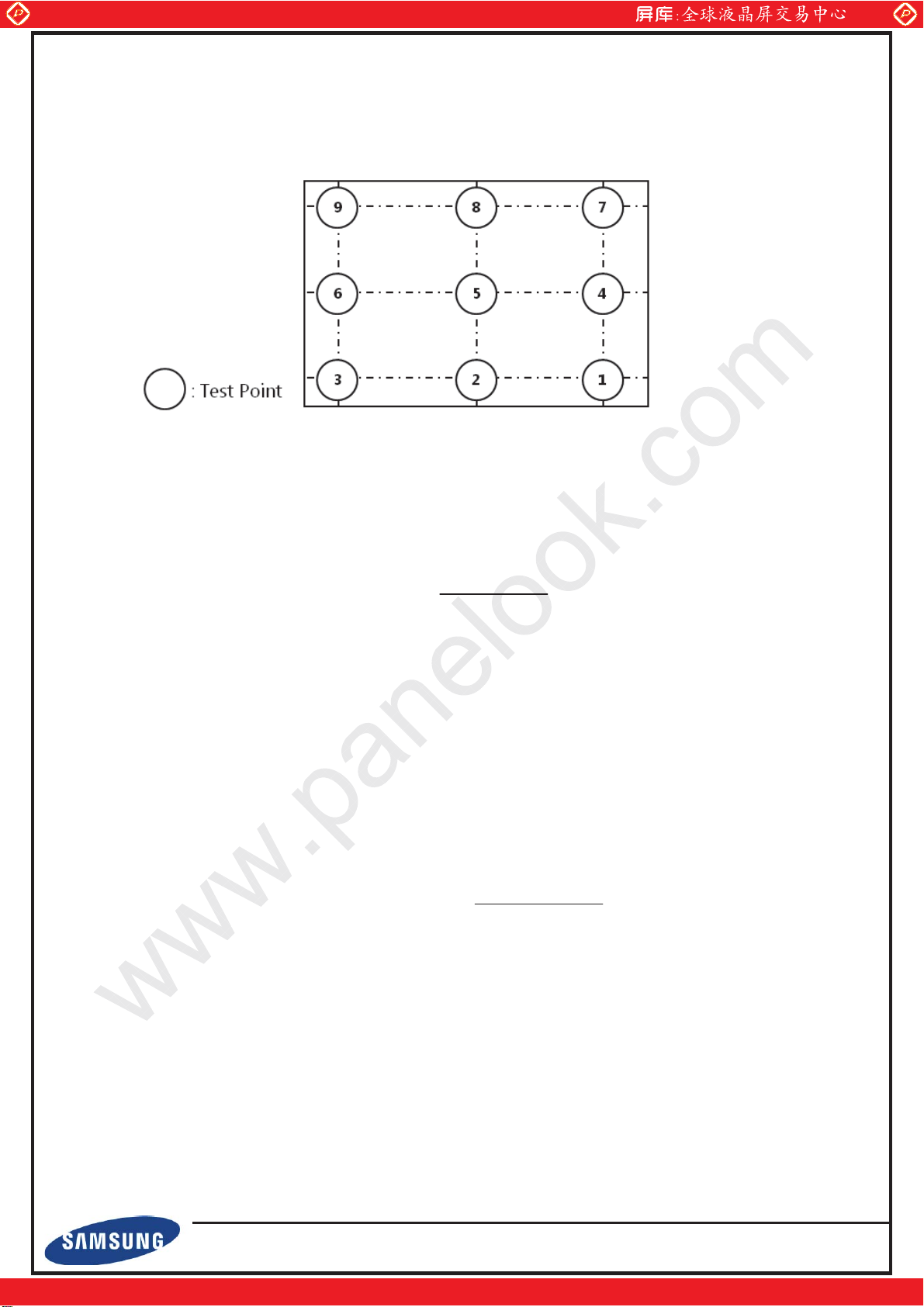

(2) Definition of test point

(3) Definition of Contrast Ratio (CR)

: Ratio of gray max (G

www.panelook.com

) & gray min (G

max

: Luminance with all pixels white

G

max

: Luminance with all pixels black

G

min

) at the center pointྜྷ of the panel

min

(4) Definition of 9 points brightness uniformity

B

: Maximum brightnessG

max

B

: Minimum brightness

min

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

10/34

SAMSUNG DISPLAY

Ver.M07

P0.0

(5) Definition of Response time

GtoG : The time for transitions between specific gray levels

- 31 Æ 63, 63 Æ 95, 95 Æ 127, 127 Æ 159, 159 Æ 191 , 191 Æ 223 grays and vice

versa

- G to G typ. : Average time at rising and falling for gray transition except the

transition

(6) Definition of Luminance of White : Luminance of white at center point (5)

(7) Definition of Color Chromaticity (CIE 1931, CIE1976)

Color coordinate of Red, Green, Blue & White at center point (5)

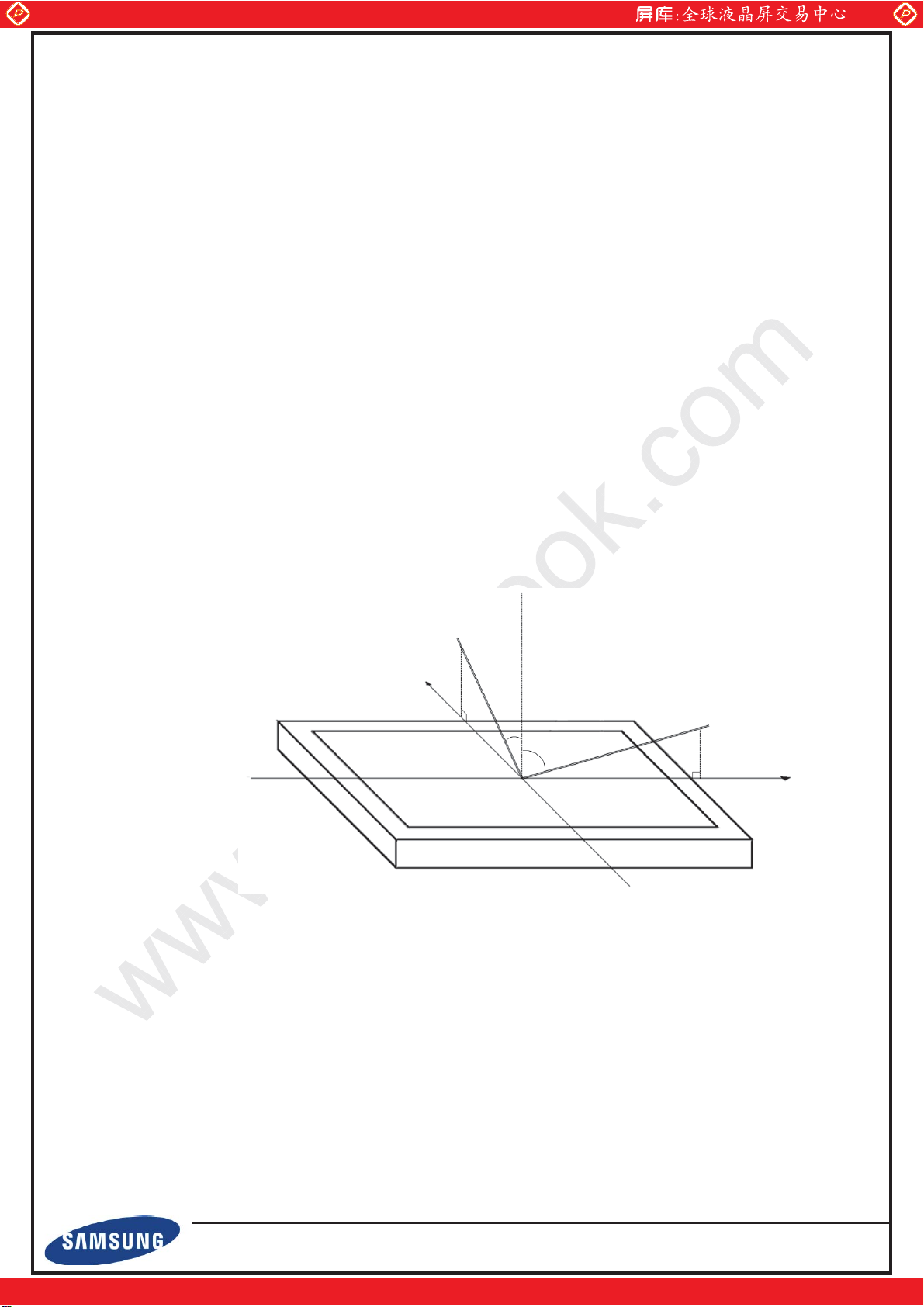

(8) Definition of Viewing Angle

: Viewing angle range (CR ≥ 10)

www.panelook.com

ƟL = 90°0

ƟU = 90°0

Normal

Ɵ

= ƟD= ƟL= ƟR = 0°

U

Y

Ɵ

U

Ɵ

R

X

= 90°0

Ɵ

R

ƟD = 90°0

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

11/34

SAMSUNG DISPLAY

Ver.M07

P0.0

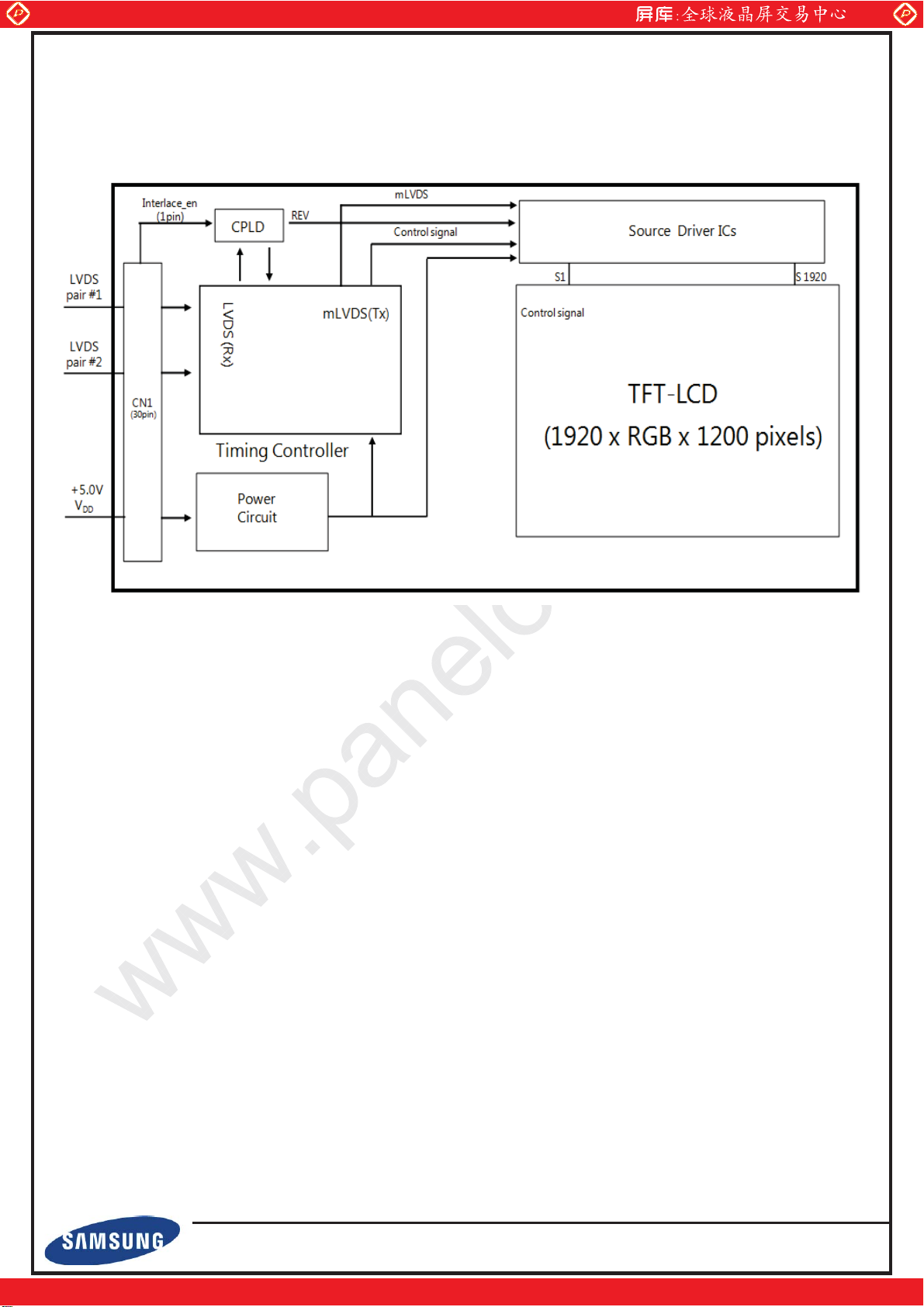

4. Block Diagram

www.panelook.com

Fig. Function Block Diagram

Note (1) The connector for display data & timing signal should be connected

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

12/34

SAMSUNG DISPLAY

Ver.M07

P0.0

Symbol

Min.

Typ.

Max.

Unit

Note

5.0

msec

Current of

1400- mA

(3),(4)

900

mA

1200

mA

(d) Dot

-

1200

-

mA

6.0-Watt

(4),(5)

4.5V ≤ VDD ≤ 5.5V

5. Electrical Characteristics

5.1 TFT LCD ModuleG

The connector for display data & timing signal should be connected.

Item

Voltage of Power Supply

Power Dip Condition

www.panelook.com

V

V

DD

CC

Td

4.5

4.0 -

0-20

Ta=25 ± 2C

5.5 V (1)

V

DD

V

(2)

-

-

-

-

--5.0A(6)

Power

Supply

(c) Mosaic -

Power Consumption

Rush Current

(a) White

(b) Black -

I

DD

P

LCD

I

RUSH

Note (1) The ripple voltage should be controlled under 10% of VDD

(2) Definition of V

Power Dip

DD

- The above conditions are for the glitch of the input voltage. G

- For stable operation of an LCD Module power, please follow them.

V

DD

T

d

90%

80%

V

CC

GND

If V

(Typ.) x 80% ≤ VCC ≤ VDD(Typ.) x 90%G

DD

G

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

13/34

SAMSUNG DISPLAY

Ver.M07

P0.0

www.panelook.com

(3) fV=60Hz, f

= 77MHz, VDD = 5.0V, DC Current.

DCLK

(4) Power dissipation mosaic pattern (LCD Module only)

(5) The power consumption is specified whereas mosaic pattern is displayed

at f

=60Hz, f

V

= 77MHz, VDD = 5.0V

DCLK

(6) Measurement Condition

Rush Current I

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

can be measured when T

RUSH

. is 470โ

RUSH

www.panelook.com

Page 14

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

14/34

SAMSUNG DISPLAY

Ver.M07

P0.0

Item

Symbol

Min.

Typ.

Max.

Unit

Note

LED Forward Current

I

F

-

Magenta : 174

Green : 225

-

mA

(1),(2)

LED Array Voltage

V

P

-

Magenta : 70

Green : 38

-

V

(1)

Power Consumption

P

BLU

-

42W -

Watt

(3)

Operating Life Time

Hr

30,000

-

-

Hour

(4)

5.2 Backlight Unit

The characteristics of LED bar Ta=25 ± 2¶C.

www.panelook.com

Note (1) The above specification is not for the converter output, but for the LED bar.

- LED bar : 2 ea ( 2 side Edge )

- The LED bar consists of Magenta 36 LED packages (3 parallel X 12 serial) &

Green 36 LED packages (3 parallel X 12 serial)

- LED current is defined at 100% duty ratio of LED driver

(2) The LED Forward current for single LED channel is Typ.58mA ( Magenta )

& Typ.75mA ( Green )

- The output current of converter in the system should be transmitted to the LED

bar constantly.

- It is recommended to control the returned signal respectively for even

distribution of current to each channel of LED bar

(3) The power consumption is specified at typical current 174mA ( Magenta ) &

225mA ( Green ) with 100% duty ratio

- It does not include power loss of external LED driver circuit block

- Typical power consumption

P

= 2*[ Green(IF (Typ.) x VP (Typ.))+ Magenta(IF (Typ.) x VP (Typ.))]

BLU

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

15/34

SAMSUNG DISPLAY

Ver.M07

P0.0

Item

Symbol

Min.

Typ.

Max.

Unit

Note

Differential Input

Voltage for LVDS

receiver threshold

High

-

-

+100

mV

(1)

Low

-100

- -

mV

LVDS skew

t

SKEW

-30

0

-

300

ps

(2)

Differential input

voltage

lVidl

100

-

600

mV

(3)

Input voltage

range(single ended)

V

in

0.7

-

1.7

V

(3)

Common mode

voltage

V

cm

1.0 1.2

1.4

V

(3)

5.3 LVDS Characteristics

5.3.1. LVDS Input Characteristics Ta=25 ± 2C G

www.panelook.com

Note (1) Differential receiver voltage definitions and propagation delay and transition time

test circuit

b. C

a. All input pulses have frequency = 10MHz, t

Input

V

= (VIA+ V

IC

includes all probe and fixture capacitance G

L

R

IN+

R

IN-

) / 2

IB

V

IA

V

= VIA-V

D

V

IB

or tF =1nsG

R

IB

C

L

R

out

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

16/34

SAMSUNG DISPLAY

Ver.M07

P0.0

(2) LVDS Receiver DC parameters are measured under static and steady conditions

which may not be reflective of its performance in the end application.

www.panelook.com

T

LVDS Clk

V

= 0V

DIFF

LVDS Data

RX +/-

t

SKEW

where t

T : 1 period time of LVDS clock

cf. (-/+) of 300psec means LVDS data goes before or after LVDS clock

(3) Definition of V

V

DD

: skew between LVDS clock & LVDS data,

SKEW

and V

ID

using single-end signals

CM

V

= 0V

DIFF

Differential

Differential

VCM=1.4V

VCM=1.2V

VCM=1.0

V

SS

|VID| = 100mV

|VID| = 100mV

VCMrange with Min |VID|

VCM=1.4V

VCM=1.0

VCMrange with Max |VID|

|VID| = 600mV

|VID| = 600mV

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

17/34

SAMSUNG DISPLAY

Ver.M07

P0.0

5.3.2. LVDS Data Format

Timing Diagrams of LVDS For Transmitting

- LVDS Receiver : Integrated T-CON

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 18

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

18/34

SAMSUNG DISPLAY

Ver.M07

P0.0

SIGNAL ITEM

SYMBOL

Min.

Typ.

Max.

Unit

Note

Clock

Frequency

1/T

C

68 77 81

MHz

-

Hsync

F

H

65 74 78 kHz -

Vsync

F

V

53 60 63 Hz -

Vertical

Display Term

Active

Display

Period

T

VD

1,2

00

1,2

00

1,2

00

Lines

-

Vertical

Tot al

T

V

1,2

09

1,235

1245

Lines

-

Horizontal

Display Term

Active

Display

Period

T

HD

96

0

960

960

Clocks

2pixel/clock

Horizontal

Tot al

T

H

9

93

1,0

40

1

,075

clocks

2pixel/clock

5.4 Interface Timing Specification

5.4.1. Timing ParametersG

www.panelook.com

Note (1) DE only mode

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

- While operation, DE signal should be have the same cycle. G

(2) Best operation clock frequency is 77MHz (60Hz)

(3) Max, Min variation range is at main clock typical value (77MHz)

(4) Main frequency Max is 84.0MHz without spread spectrum

www.panelook.com

Page 19

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

19/34

SAMSUNG DISPLAY

Ver.M07

P0.0

DATA

SIGNALS

DE

D

CLK

DE

0.5 V

CC

T

C

DE

DISPLAY

DATA

0.5 V

CC

0.5 V

CC

T

CH

T

CL

T

DS

T

DH

T

ES

T

H

T

HD

T

V

T

VD

T

VB

T

C

D

CLK

5.4.2. Timing diagrams of interface signal ( DE only mode )G

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

20/34

SAMSUNG DISPLAY

Ver.M07

P0.0

COLOR

DISPLAY

(8bit)

DATA SIGNAL

GRAY

SCALE

LEVEL

RED

GREEN

BLUE

R0R1R2R3R4R5R6R7G0G1G2G3G4G5G6G7B0B1B2B3B4B5B6

B7

BASIC

COLOR

BLACK

000000000000000000000000-

BLUE

000000000000000011111111-

GREEN

000000001111111100000000-

CYAN

000000001111111111111111-

RED

111111110000000000000000-

MAGENTA

111111110000000011111111-

YELLOW

111111111111111100000000-

WHITE

111111111111111111111111-

GRAY

SCALE

OF

RED

BLACK

000000000000000000000000R0

DARK

↑

↓

LIGHT

100000000000000000000000R1010000000000000000000000

R2

:::::: :::::: ::::::

.

.

.

101111110000000000000000R253

011111110000000000000000R254

RED

111111110000000000000000R255

GRAY SCALE

OF GREEN

BLACK

000000000000000000000000G0

DARK

↑

↓

LIGHT

000000001000000000000000G1

000000000100000000000000G2

:::::: :::::: ::::::

.

.

.000000001011111100000000

G253

000000000111111100000000G254

GREEN

000000001111111100000000G255

GRAY

SCALE

OF BLUE

BLACK

000000000000000000000000B0

DARK

↑

↓

LIGHT

000000000000000010000000B1000000000000000001000000

B2

:::::: :::::: ::::::

.

.

.

000000000000000010111111B253

000000000000000001111111B254

BLUE

000000000000000011111111B255

www.panelook.com

5.5 Input Signals, Basic Display Colors and Gray Scale of Each Color

Note (1) Definition of Gray

- Rn : Red Gray, Gn : Green Gray, Bn : Blue Gray (n = Gray level)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

Input Signal : 0 = Low level voltage, 1 = High level voltage

www.panelook.com

Page 21

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

21/34

SAMSUNG DISPLAY

Ver.M07

P0.0

SYMBOL

Min.

Typ.

Max.

Unit

Description

T

1

0.5 - 10

ms

V

DD

rising time from 10% to 90%

T

2

0.01 - 50

ms

The time from V

DD

to valid data at power ON

T

3

0.01 - 50

ms

The time from valid data off to V

DD

off at power Off

T

4

1

-

-

s

V

DD

off time for Windows restart

T

5

500 - -

ms

The time from valid data to B/L enable at power ON

T

6

100 - -

ms

The time from valid data off to B/L disable at power Off

Power Supply (VDD)

www.panelook.com

5.6 Power ON/OFF Sequence

To prevent a latch-up or DC operation of the LCD Module, the power on/off

sequence should be as the diagram below.

0.9 V

DD

0.1 V

0 V

DD

T

1

T

2

0.9 V

DD

0.1 V

DD

T

3

T

4

Signals

Power On

T

5

VALID

50% 50%

Power Off

T

6

Note (1) The supply voltage of the external system for the Module input should be

the same as the definition of VDD.

(2) Apply the BLU power within the LCD operation range. When the back light

turns on before the LCD operation or the LCD turns off before the back light

turns off, the display may momentarily show abnormal screen.

(3) In case of V

= off level,

DD

please keep the level of input signals low or keep a high impedance.

(4) T4 should be measured after the Module has been fully discharged between

power off and on period.

(5) Interface signal should not be kept at high impedance when the power is on.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

22/34

SAMSUNG DISPLAY

Ver.M07

P0.0

Pin No.

Symbol

Function

1

RXO0N

Negative LVDS differential data output

2

RXO0P

Positive LVDS differential data output

3

RXO1N

Negative LVDS differential data output

4

RXO1P

Positive LVDS differential data output

5

RXO2N

Negative LVDS differential data output

6

RXO2P

Positive LVDS differential data output

7

GND

High speed ground

8

RXOC-

Negative Sampling Clock (ODD data)

9

RXOC+

Positive Sampling Clock (ODD data)

10

RXO3N

Negative LVDS differential data output

11

RXO3P

Positive LVDS differential data output

12

RXE0N

Negative LVDS differential data output

13

RXE0P

Positive LVDS differential data output

14

GND

High speed ground

15

RXE1N

Negative LVDS differential data output

16

RXE1P

Positive LVDS differential data output

17

GND

High speed ground

18

RXE2N

Negative LVDS differential data output

19

RXE2P

Positive LVDS differential data output

20

RXEC-

Negative Sampling Clock (EVEN data)

21

RXEC+

Positive Sampling Clock (EVEN data)

22

RXE3N

Negative LVDS differential data output

23

RXE3P

Positive LVDS differential data output

24

GND

LCD logic and driver ground

25

NC

* Reserved for LCD manufacturer's use (CE_DVR)

26

NC

* Reserved for LCD manufacturer's use (CTL_DVR)

27

NC

No Connection

28

VDD

Power Supply : +5V

29

VDD

30

VDD

5.7 Input Terminal Pin Assignment

5.7.1. Input signal & Power Pin Assignment

Connector : UJU IS100-L30B-C23 or equivalent

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

23/34

SAMSUNG DISPLAY

Ver.M07

P0.0

Pin No. 1 Pin No. 30

UJU IS100-L30B-C23 or equivalent

#1 #30

#1 #30

UJU IS100-L30B-C23 or equivalent

Fig. Connector diagramG

Note (1) If the system already uses the 25, 26pins, it should keep under GND level

The voltage applied to those pins should not exceed -200mV.

(2) Pin number starts from Left side

www.panelook.com

PCB

Ɂ

Ɂ

(3) All GND pins should be connected together and also be connected

to the LCD’s metal chassis.

(4) All power input pins should be connected together.

(5) All NC pins should be separated from other signal or power

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

24/34

SAMSUNG DISPLAY

Ver.M07

P0.0

Pin No.

Symbol

Function

G 0DJHQWD/('G 0DJHQWDUHWXUQFKDQQHOG

G *UHHQ/('G *UHHQUHWXUQFKDQQHOG

G 0DJHQWD/('G 0DJHQWDUHWXUQFKDQQHOG

G *UHHQ/('G *UHHQUHWXUQFKDQQHOG

G 0DJHQWD/('G 0DJHQWDUHWXUQFKDQQHOG

G *UHHQ/('G *UHHQUHWXUQFKDQQHOG

G *UHHQ/('G /('*UHHQSRZHULQSXWG

G 0DJHQWD/('G /('0DJHQWDSRZHULQSXWG

5.7.2. LED Connector Pin assignment

Connector :

1507WR-H08G, Yeon Ho Electronics Co.Ltd.

www.panelook.com

Note (1) Pin number starts from Left side

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

25/34

SAMSUNG DISPLAY

Ver.M07

P0.0

6. Outline Dimension

[ Refer to the next page ]G

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

27/34

SAMSUNG DISPLAY

Ver.M07

P0.0

-

Packing case

8

-

-

1

-

-

-

-

LTM240CL02 Module

PACKING-Case

Pallet Plastic

Packing Pallet box

7. Packing

7.1 Carton

Item Packing form Specification

www.panelook.com

Weight

Pallet box

Pallet

-

panels in a case

16 cases in a box

28 panels in a box

-

Total Weight ( Including Pallet ) : Approx. 420Kg

Packing Case Size : W273 x L615 x H408

Material : Paper (SW, DW)

Packing Pallet Box Size : W1112 x L1250 x H808

Material : Paper (SW,DW)

Pallet Size : W1270 x L1150 x H122

Material : Wood

( 8 EA )

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 28

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

28/34

SAMSUNG DISPLAY

Ver.M07

P0.0

Cell Position No. (In the Glass)

Glass No. (In the one Lot)

Lot No. (Glass)

Month

Year

Product code

LineG

LTM240CL02

www.panelook.com

7.2 Marking

A nameplate bearing followed by is affixed to a shipped product at the specified location

on each product.

(1) Parts number : LTM240CL02G

(2) Revision: Three lettersG

(3) Lot number : X X X X XXX XX XG

G

G

G

G

G

G

(4) Nameplate Indication

(5) Packing box attach

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 29

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

29/34

SAMSUNG DISPLAY

Ver.M07

P0.0

www.panelook.com

8. General Precautions

8.1 Handling Precautions

A. When assembling LCD module into its system, using all the mounting holes is

strongly suggested.

B. Keep LCD module from any external shock or force which can cause physical damage

to LCD module. It may cause improper operation or damage to LCD module.

C. Polarizer films are very fragile. It could be damaged easily. Do not press or scratch

the surface harder than a HB pencil lead.

D. Wipe off water droplets or oil immediately. Water drops or oils can cause permanent

stain or discoloration.

E. To clean LCD module, please use IPA (Isopropyl Alcohol) or Hexane.

F. Do not use ketone type material (ex. Acetone), ethyl alcohol, toluene, ethyl acid or

methyl chloride. Using these could cause permanent polarizer damage to the LCD

module.

G. If the liquid crystal leaks from LCD module, keep it away from human eyes or mouth.

In case of contact with human body or clothes, it should be washed with soap thoroughly.

H. Protect LCD module from static discharge.

I. To keep the LCD module clean, make sure to wear fabric gloves and finger coats when

you are inspecting and/or assembling the unit.

J. Do not disassemble LCD module.

K. Protection film on LCD module display area should be slowly peeled off just before

assembly to prevent static discharge.

L. Pins of the Interface connector should not be touched directly with bare hands.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 30

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

30/34

SAMSUNG DISPLAY

Ver.M07

P0.0

Storage

Tem per at ure

5 40

Storage

Humidity

35 75

Storage life

Condition

- The storage room should provide good ventilation and temperature

-

-

-

-

humidity of 50% for 24 hours.

8.2 Storage Precautions

It is highly recommended to comply with the criteria in the table below

www.panelook.com

Item

Storage

Unit

()

(%rH)

Control

.

Products should not be placed on the floor, but on the Pallet away

from a wall

.

Prevent products from direct sunlight, moisture nor water;

Be cautious of a build up of condensation.

Avoid other hazardous environment while storing goods.

Min.

12 months

Max.

If products delivered or kept in conditions of over the storage period

of 3 months, the recommended temperature or humidity range,

it is recommended to leave them at a temperature of 20 and a

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 31

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

31/34

SAMSUNG DISPLAY

Ver.M07

P0.0

www.panelook.com

8.3 Operating Precautions

A. If the module is used to other applications besides the recommendation on General

Description, please contact SAMSUNG for application engineering device in advance

B. Do not connect or disconnect the LCD module when it is set to the “Power On”

condition.

C. Input power should always follow ‘5.6 Power on/off sequence’

D. Polarizer films are very fragile. It could be damaged easily. Do not press or scratch the

Polarizer films

E. LCD module contains electrical circuits that operate in high frequencies. To minimize

electromagnetic interference, be sure to sufficiently ground and shield the LCD module and

system.

F. If LCD module containing system is out of SAMSUNG ’s operating condition,

SAMSUNG can not guarantee LCD module operating properly.

G. If the product will be used in extreme conditions such as high temperature, humidity,

display patterns, operation time, etc., it is strongly recommended to contact SAMSUNG for

application engineering device. Otherwise, the reliability and function

of the module may not be guaranteed. Extreme conditions are commonly found at

airports, transit stations, banks, stocks, markets, and controlling systems.

H. Ultra-violet ray filter is necessary for outdoor operation.

I. If the module keeps displaying the same pattern for a long period of time, the image

maybe burned in to the screen. To avoid image retention, it is recommended to use a

screen saver.

J. This module has its PCB’s circuitry on the rear side and should be handled carefully in

order to avoid stress.

K. Please contact SAMSUNG beforehand, if you plan to display the same pattern for a

long period of time.

L. Any foreign materials brought into an LCD module by external forced-airflow are not

guaranteed by SAMSUNG .

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 32

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

32/34

SAMSUNG DISPLAY

Ver.M07

P0.0

www.panelook.com

8.4 Design Guide for System

A. The LED driver should be designed in compliance with the specifications of LED bar strictly

to make the LED in LCD module perform as expected.

B. It is recommended that you locate the rib on the front or rear cover not to be placed on the

spot where D-IC is located on the upper or left of LCD module

( See ‘6. Outline Dimension ’ for the exact location of driver ICs )

C. It is recommended that assemble the bracket which has two sides with holes for assembly.

D. It is recommended that you design the bracket with the structure which covers the sides of

module when designing the bracket for customer.

E. It is recommended that you design the bracket not to be interfered with the SET at the area

where the PBA of module is located.

F. D. It is recommended that more than 0.3 mm is allowable as a gap between the metal case

and the rear of module

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 33

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

33/34

SAMSUNG DISPLAY

Ver.M07

P0.0

G. It is recommended that structure to support the module shall be far away 10mm from the

edge of border.

H. It is recommended that metal case (or board) shall be affixed to the rear case at the spot

where is far away 10mm from the edge of border.

www.panelook.com

I. When applying the measures described below to reduce the level of EMI which occurs

between the metal cover and the rear of module.

J. If you use Finger, less than 0.3mm is allowable for overlap.

The thickness of EMI gasket should be less than 1.1 times (110%) of the gap between

System metal case and LCD module.

K. It is recommended that more than 0.3mm gap between the front case (or cover) and the

panel glass is allowable.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 34

Global LCD Panel Exchange Center

LTM240CL02

7 Jan. 2013

34/34

SAMSUNG DISPLAY

Ver.M07

P0.0

L. It is recommended that more than 0.05mm gap between the front case and the top chassis

is allowable.

M. It is recommended that insert the screws into user holes from the ones on the parts, which

the light comes out to ones in the corresponding parts.

www.panelook.com

N. It is recommended that design the metal frame and the top chassis to be in parallel with

having no gap after inserting the side screw.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...