Page 1

Global LCD Panel Exchange Center

• ••• • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

Customer : DATE : 28.Nov.2005

www.panelook.com

Product Information

Product Information

SAMSUNG TFT--

SAMSUNG TFT

SAMSUNG TFT-LCD

MODEL

MODEL

MODEL : LTA230W2-L01

Any Modification of Specification is not allowed without SEC's Permission.

NOTE :

Customer’’

Customer

LCD

LCD

: LTA230W2--

: LTA230W2

s Approval

s Approval

L01

L01

••••• •••••••••••••••••••

DATE

28.Nov.2005

••• •••••••••••••••

DATE

•••••••• ••••••••••••••

Jeong-Geun Han

28.Nov.2005

DATE

LCD Application Engineering 3, TCS Team

Samsung Electronics Co . , LTD.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

•

www.panelook.com

Page 2

Global LCD Panel Exchange Center

• ••• • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

www.panelook.com

Contents

Revision History -------------------------------------------------------------------------------------------- (3)

General Description --------------------------------------------------------------------------------------- (4)

General Information --------------------------------------------------------------------------------------- (4)

1. Absolute Maximum Ratings -------------------------------------------------------------------------- (5)

2. Optical Characteristics --------------------------------------------------------------------------------- (7)

3. Electrical Characteristics ----------------------------------------------------------------------------- (10)

3.1 TFT LCD Module

3.2 Back Light Unit

3.3 Inverter Input & Specification

4. Block Diagram ------------------------------------------------------------------------------------------- (13)

5. Input Terminal Pin Assignment --------------------------------------------------------------------- (14)

5.1 Input Signal & Power

5.2 Inverter Input Pin Configuration

5.3 Inverter Input Power Sequence

5.4 LVDS Interface

5.5 Input Signals, Basic Display Colors and Gray Scale of Each Color

6. Interface Timing ---------------------------------------------------------------------------------------- (19)

6.1 Timing Parameters (DE only mode)

6.2 Timing Diagrams of interface Signal (DE only mode)

6.3 Power ON/OFF Sequence

7. Outline Dimension -------------------------------------------------------------------------------------- (22)

8. Packing --------------------------------------------------------------------------------------------------- (25)

9. Marking & Others --------------------------------------------------------------------------------------- (25)

10. Inspection Criteria ------------------------------------------------------------------------------------- (26)

11. General Precaution ----------------------------------------------------------------------------------- (27)

11.1 Handling

11.2 Storage

11.3 Operation

11.4 Operation Condition Guide

11.5 Others

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 3

Global LCD Panel Exchange Center

• ••• • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

• •

Æ

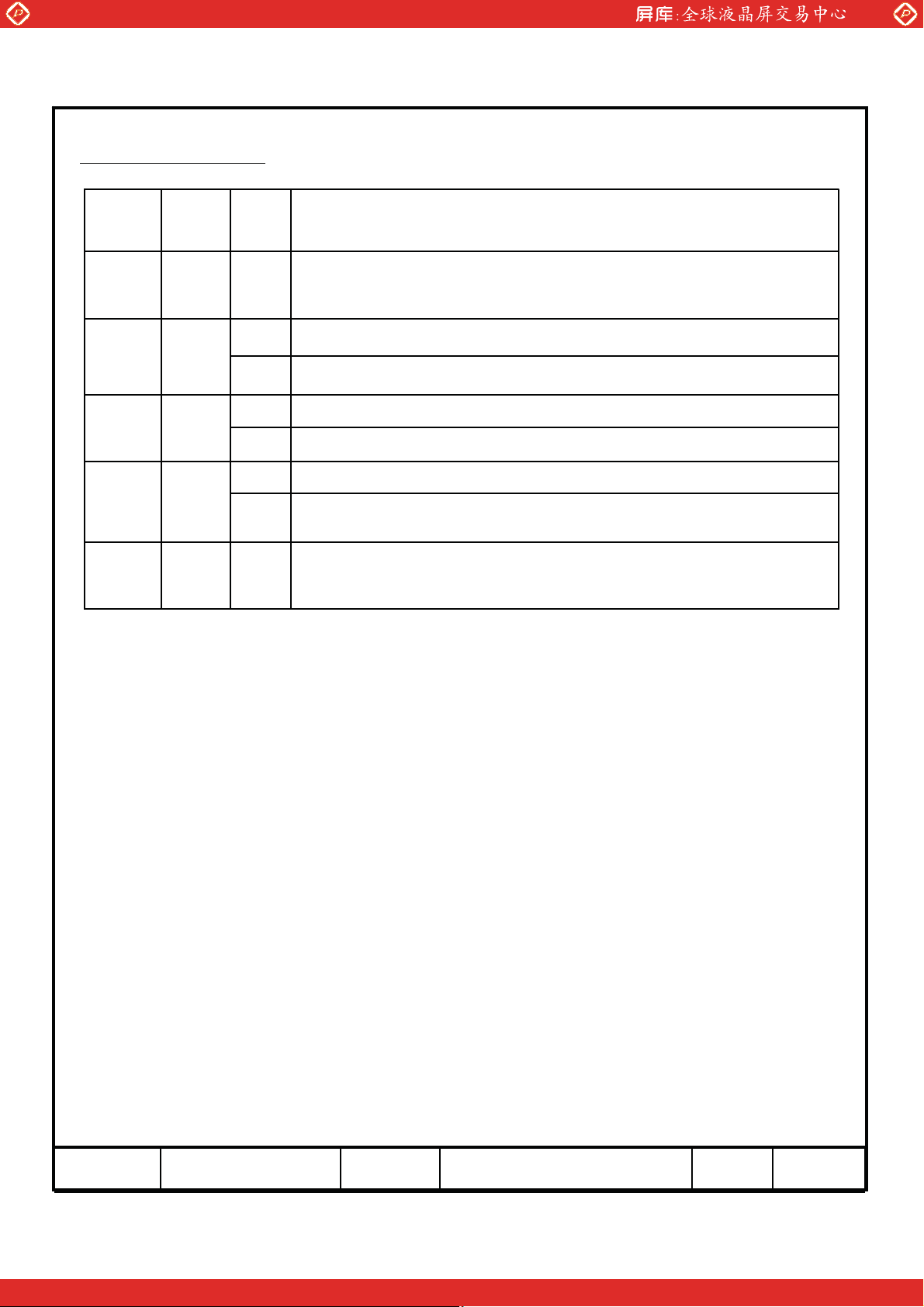

* Revision History

www.panelook.com

Date

July

21,

2005

Aug

11,

2005

Sep

05,

2005

Sep

29,

2005

Oct

05,

2005

Rev.

No

001

002

003

10,19

19

SummaryPage

First issuedall000

Response Time G-to-G : 8 msec7

Input Signal & Power : Connector FI-E30S (JAE)14

Color Chromaticity of R, G, B Updated7

Input Signal & Power Pin No. 20 : No Connection

f

Module Main Frequency

Vertical Total Min / Typ / Max : 773 / 806 / 1000

Horizon Total Min / Typ / Max : 1420 / 1688 / 1750

Note) LVDS Option : HIGH

Max : 82MHz Æ84MHz

DCLK

HIGH (3.3 V) or OPEN14003

GND14

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 4

Global LCD Panel Exchange Center

• ••• • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

General Description

Description

LTA230W2-L01 is a color active matrix liquid crystal display (LCD) that uses amorphous

silicon TFT(Thin Film Transistor) as switching components. This model is composed of a

TFT LCD panel, a driver circuit and a back light unit. The resolution of a 23.0“ is

1366 x 768 and this model can display up to 16.7 million colors with wide viewing angle of

89••or higher in all directions. This panel is intended to support applications to provide a

excellent performance for Flat Panel Display such as Home-alone Multimedia TFT-LCD

TV, Display terminals for AV application products, and High Definition TV (HDTV).

Features

RoHS compliance (Pb-free)

High contrast ratio, high aperture ratio, fast response time

PVA(Patterned Vertical Align) mode

Wide viewing angle (• •178••)

High speed response

WXGA (1366 x 768 pixels) resolution (16:9)

Low Power consumption

U - Type 6 CCFTs (Cold Cathode Fluorescent Tube)

DE(Data Enable) mode

LVDS (Low Voltage Differential Signaling) interface (1pixel/clock)

www.panelook.com

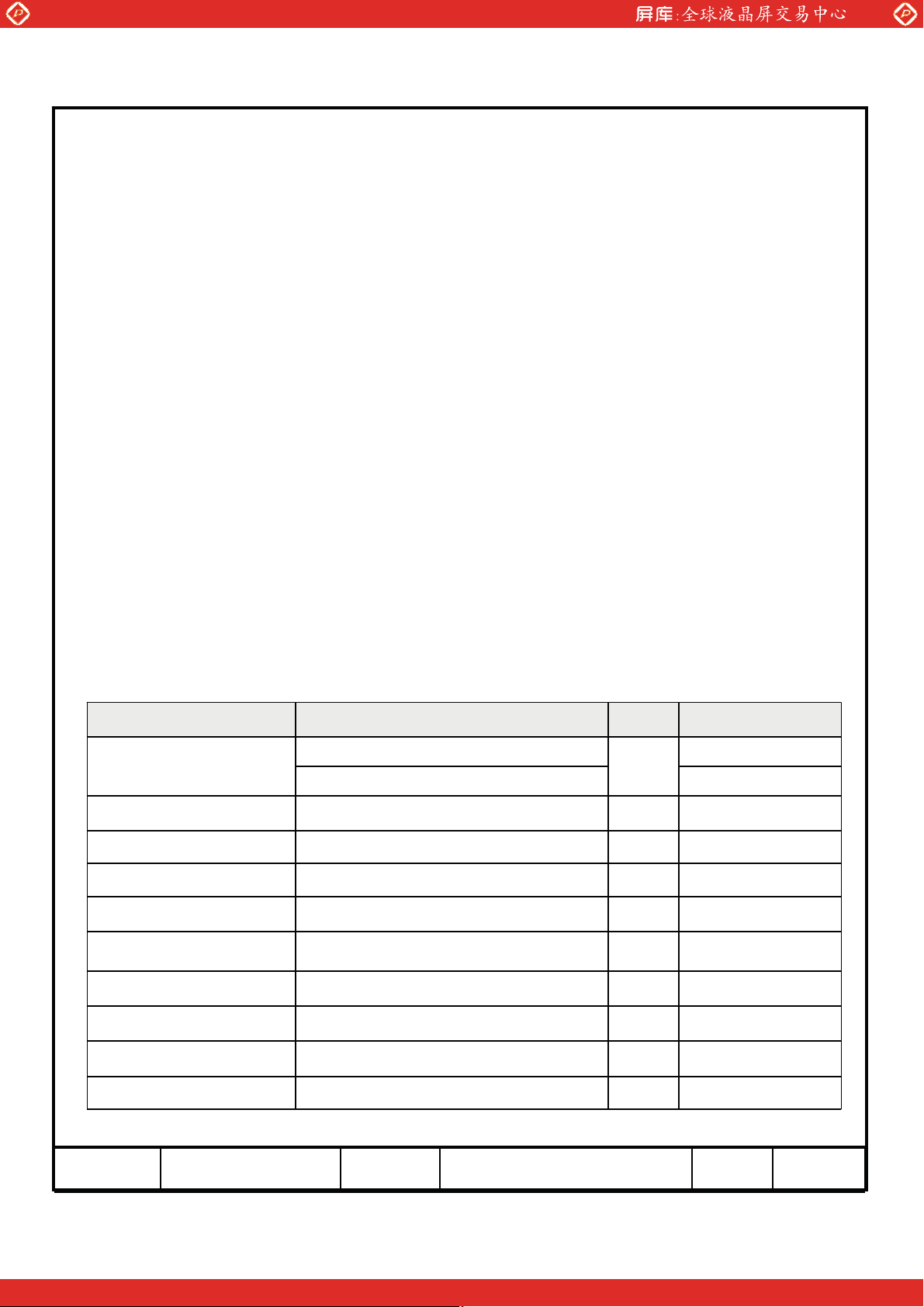

General Information

Module Size

546.0(H

Haze 44% , Hard-coating (3H)Surface Treatment

RGB vertical stripePixel Arrangement

TYP

47.3(D

Normally BlackDisplay Mode

450 (Typ.)Luminance of White

) x 318.3(V

)

MAX

TYP

UnitSpecificationItems

)

mm

g3,000(Max)Weight

mm0.372(H) x 0.124(W)*3Pixel Pitch

mm508.125(H) x 285.696(V)Active Display Area

colors8 bit - 16.7MDisplay Colors

pixel1366 x 768Number of Pixels

cd/m

2

Note

••1.0mm

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 5

Global LCD Panel Exchange Center

• ••• • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

1. Absolute Maximum Ratings

If the condition exceeds maximum ratings, it can cause malfunction or unrecoverable

damage to the device.

www.panelook.com

NoteUnitMax.Min.SymbolItem

Power Supply Voltage

Storage temperature

Glass surface

Center

DD

STG

OPR

temperature

(Operation)

T. Uniformity

Shock ( non - operating )

Vibration ( non - operating )

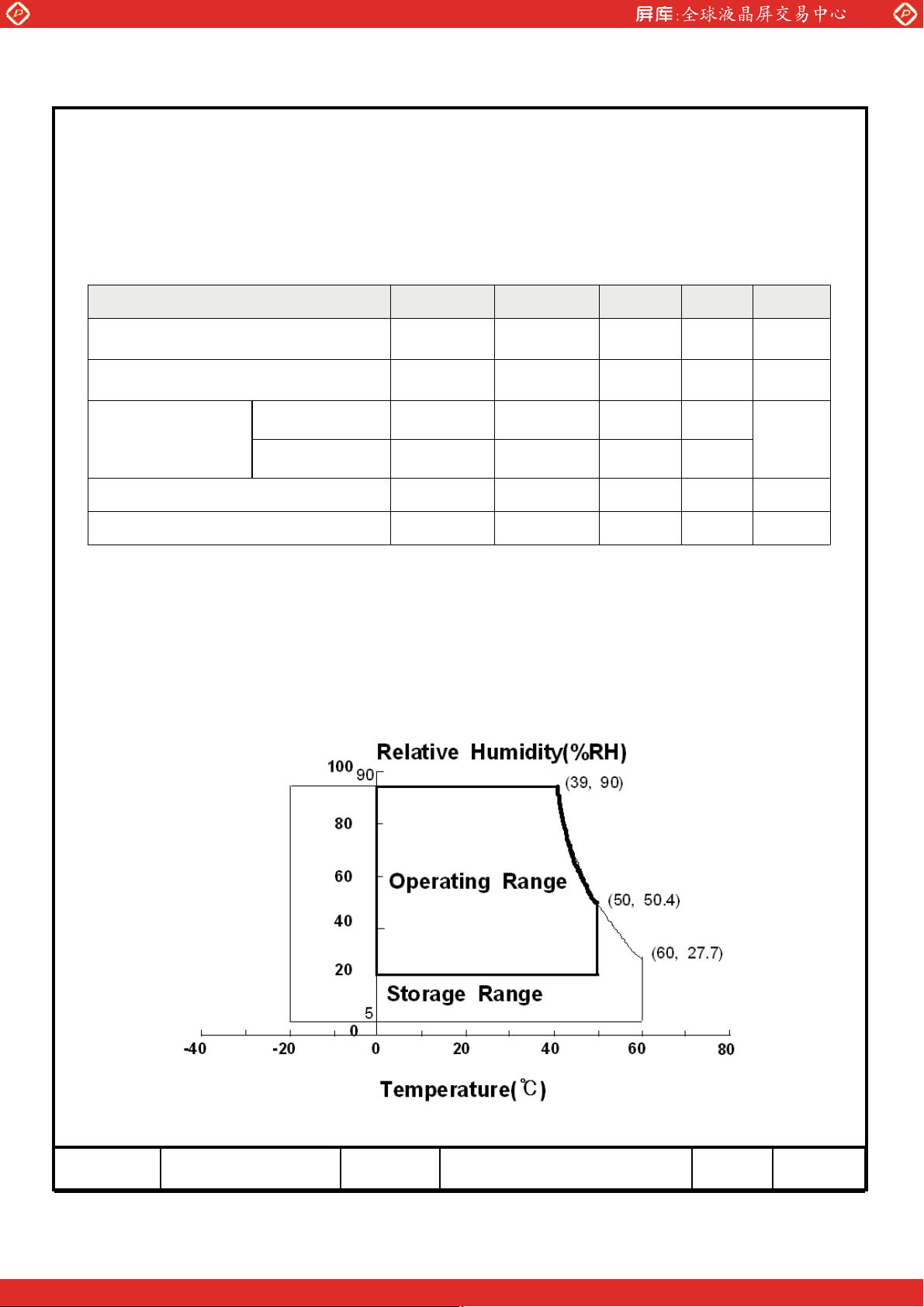

Note (1) Ta= 25 • •2 ••C

(2) Temperature and relative humidity range are shown in the figure below.

a. 90 % RH Max. (Ta • •39 ••C)

b. Maximum wet-bulb temperature at 39 ••C or less. (Ta • •39 ••C)

c. No condensation

(3) 11ms, sine wave, one time for • •X, • •Y, • •Z axis

(4) 10-300 Hz, Sweep rate 10min, 30min for X,Y,Z axis

••T

nop

nop

60-20T

500T

10-

50

••

••

••

(1)V6.5GND-0.5V

(2)

(2),(5)

(3)G-S

(4)G1.5-V

Fig. Temperature and Relative humidity range

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 6

Global LCD Panel Exchange Center

• ••• • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

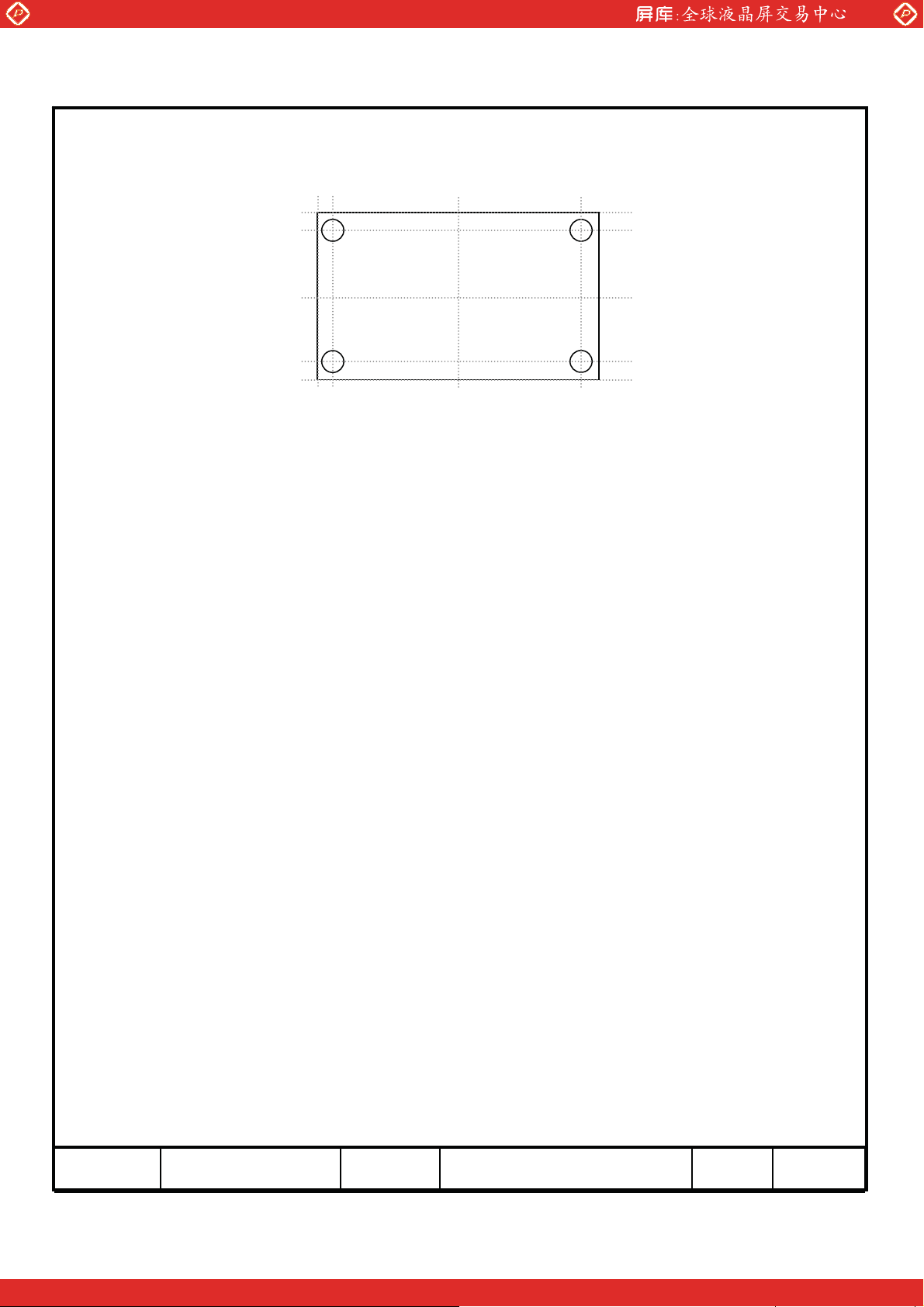

(5) Definition of test point

www.panelook.com

5mm

5mm

12

5

••

LCD Module (Active)

3

••

••T should be less than 10

T

: Temperature of the center of the glass surface (Test point 5)

OPR

(ƸT = | T

OPR–TMAX

T1~ T4 : Temperature of each edge of the glass surface

: The highest temperature of the glass surface

T

MAX

4

| )

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 7

Global LCD Panel Exchange Center

• ••• • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

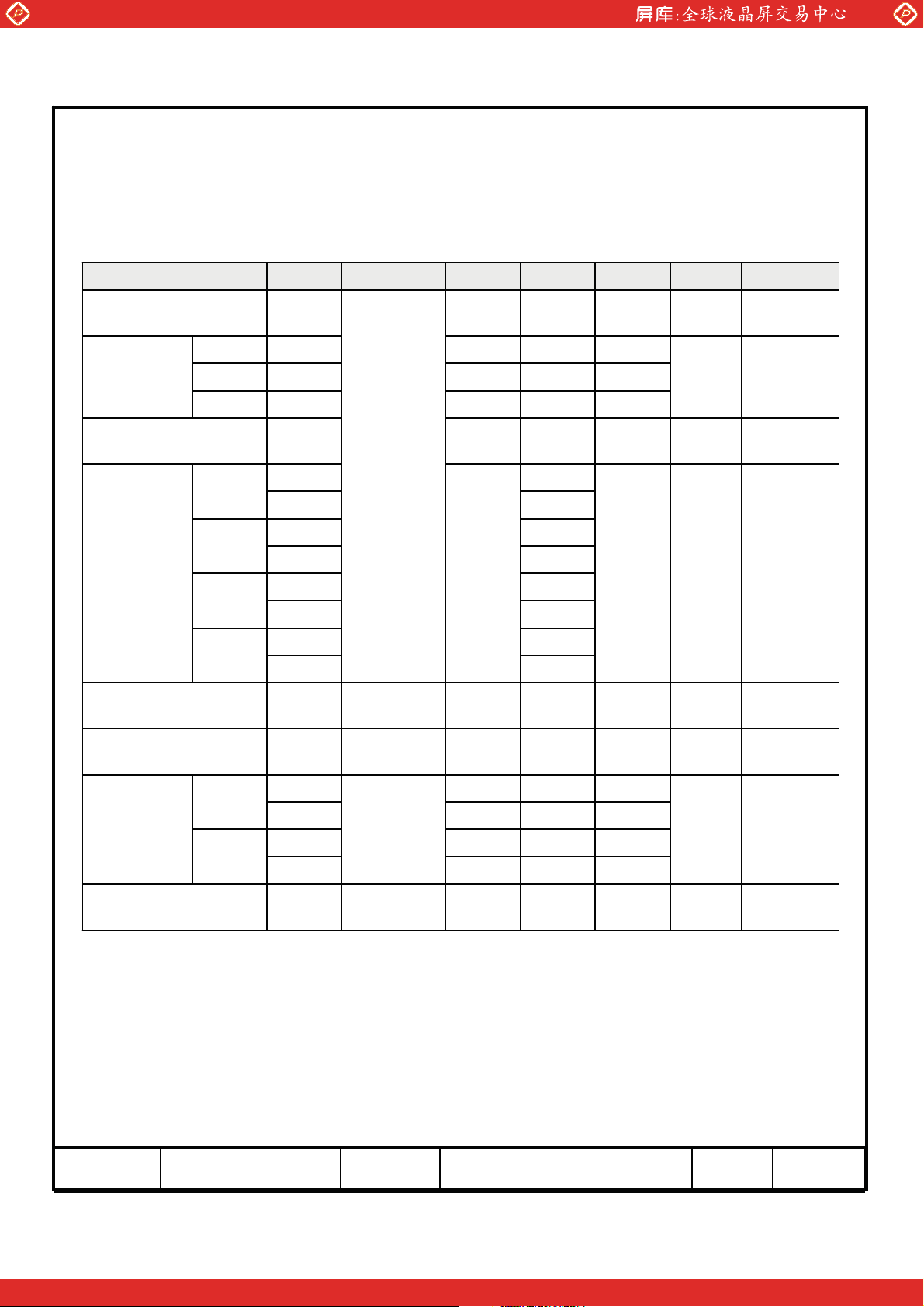

2. Optical Characteristics

The optical characteristics should be measured in a dark room or equivalent.

Measuring equipment : TOPCON BM-7,SPECTRORADIOMETER SR-3

www.panelook.com

Contrast Ratio

(Center of screen)

Response

Time

Luminance of White

(Center of screen)

Color

Chromaticity

(CIE 1931)

Rising

Falling

Red

Green

Blue

White

(Ta = 25 • •2••C, VDD=5V, fv= 60Hz, f

TgG-to-G

L

Rx

Normal

TL,R=0

TU,D=0

Viewing

Angle

TYP.

-0.03

0.643

0.329Ry

0.286Gx

0.591Gy

0.144Bx

0.063By

0.280Wx

0.290Wy

=75MHz, IL= 6.0mArms)

DCLK

-1200800C/R

2116-Tr

129-Tf

msec

-8-

-450400Y

cd/m

2

TYP.

+0.03

NoteUnitMax.Typ.Min.ConditionSymbolItem

(3)

SR-3

(5)

BM-7

(6)

SR-3

(7),(8)

SR-3

-8975

-8975T

Degree

-8975T

-8975T

Viewing

Angle

Hor.

Ver.

T

L

R

U

D

C/R• •10

Brightness Uniformity

(9 Points)

uni

Note (1) Test Equipment Setup

The measurement should be executed in a stable, windless and dark room between

40min and 60min after lighting the back light at the given temperature for stabilization

of the back light. This should be measured in the center of screen.

Single lamp current : 6.0mA

Environment condition : Ta = 25 • •2 ••C

%-72--Color Gamut

K-10000--Color Temperature

(7)

SR-3

(7)

SR-3

(8)

SR-3

%25--B

(4)

SR-3

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 8

Global LCD Panel Exchange Center

• ••• • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

• •• •• •

• •

• •

• •

• • • •

• •

www.panelook.com

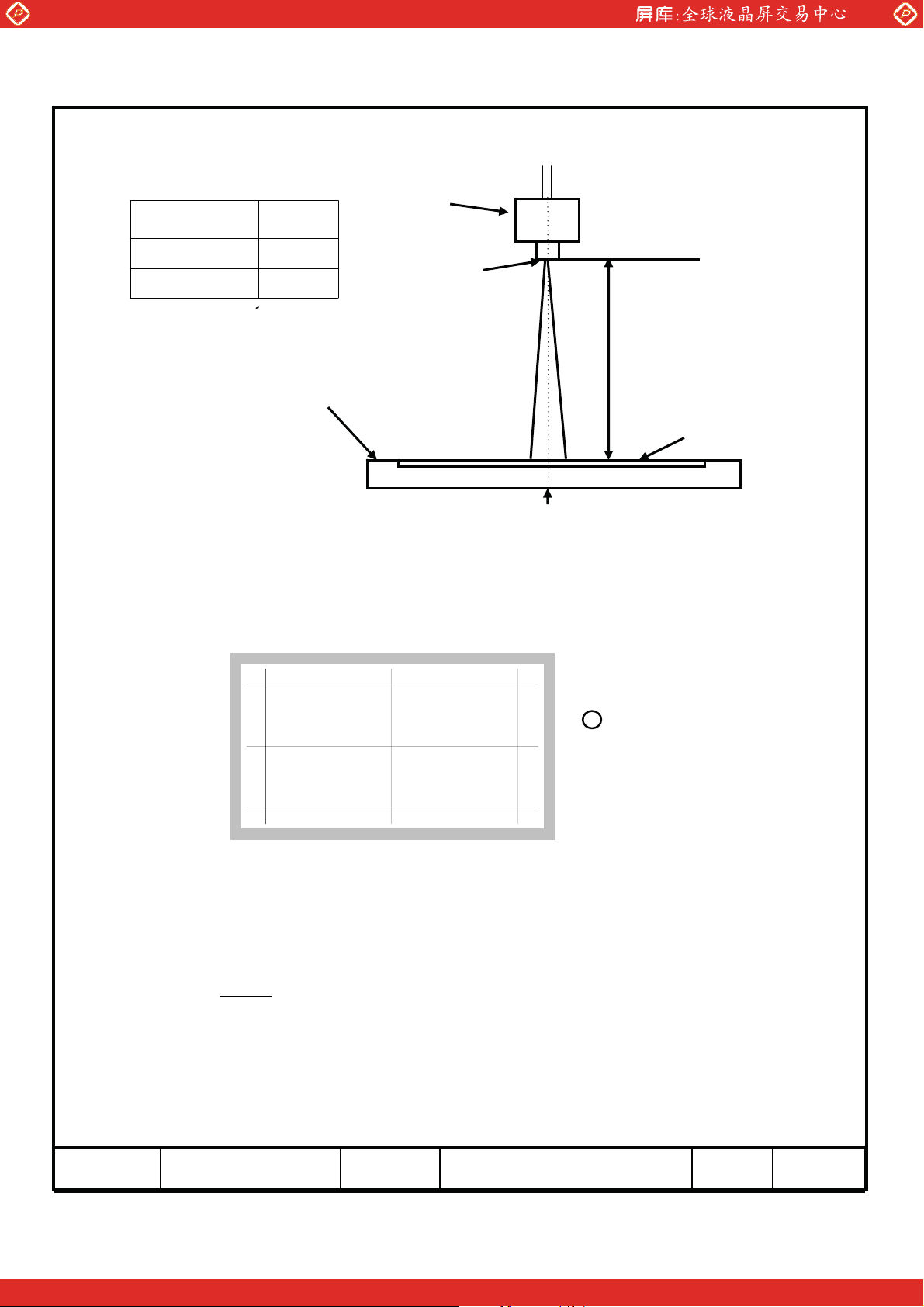

Field Photo detector

1• •SR-3

2• •BM-7

TFT - LCD Module

Note (2) Definition of test point

228 683 1138

Photo detector

Field

SR-3 : 50• •

BM-7 : 50• •

LCD Panel

The center of the screen

128

384

640

Note (3) Definition of Contrast Ratio (C/R)

: Ratio of gray max (Gmax) & gray min (Gmin) at the center point • •of the panel

CR

/

G

max

G

min

Gmax : Luminance with all pixels white

Gmin : Luminance with all pixels black

Active Area

Test Point

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 9

Global LCD Panel Exchange Center

• ••• • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

Note (4) Definition of 9 points brightness uniformity

www.panelook.com

BB

Buni

Bmax : Maximum brightness

Bmin : Minimum brightness

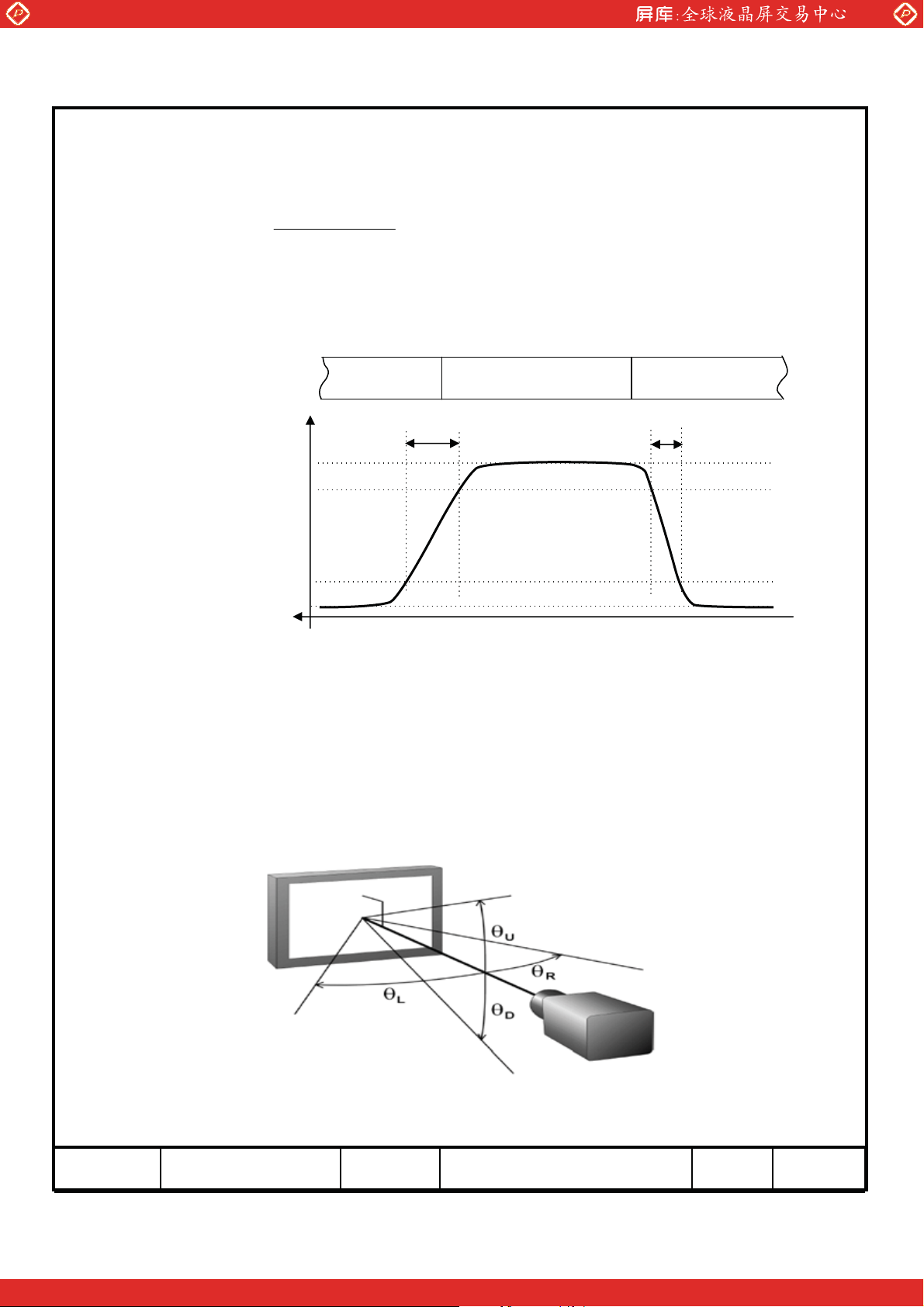

Note (5) Definition of Response time : Sum of Tr, Tf

Display data

Optical Instruments

Response

(max min)

100

100%

90%

10%

0%

B

max

Black (data off)

White (data on)

T

R

White (data off)

T

F

TIME

Note (6) Definition of Luminance of White : Luminance of white at center point • •

Note (7) Definition of Color Chromaticity (CIE 1931)

Color coordinate of Red, Green, Blue & White at center point • •

Note (8) Definition of Viewing Angle

: Viewing angle range (C/R ı10)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 10

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

3. Electrical Characteristics

3.1 TFT LCD Module

The connector for display data & timing signal should be connected.

www.panelook.com

Ta = 25••C• •2••C

NoteUnitMax.Typ.Min.SymbolItem

Voltage of Power Supply

Current

(a) Black

of Power

DD

I

DD

Supply

Vsync Frequency

Hsync Frequency

Main Frequency

Rush Current

V

H

DCLK

RUSH

Note (1) The ripple voltage should be controlled under 10% of VDD.

V=60Hz, fDCLK = 75MHz, V

(2) f

= 5.0V, DC Current.

DD

(3) Power dissipation check pattern (LCD Module only)

a) Black Pattern b) White Pattern c) N-Pattern

(1)V5.55.04.5V

mA-750-

mA-1160-(b) White

(2),(3)

mA13901260-(c) N-Pattern

Hz-60-f

kHz534844f

MHz847565f

(4)A5--I

(4) Measurement Conditions

100%

90%

10%

GND

Rush Current I

can be measured when T

RUSH

T

RUSH

=470• •

. is 470• •.

RUSH

V

DD

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 11

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

www.panelook.com

3.2 Back Light Unit

The back light unit contains 6 U-type CCFTs ( Cold Cathode Fluorescent Tube ). The

characteristics of lamps are shown in the following tables.

Ta=25 • •2••C

NoteUnitMax.Typ.Min.SymbolItem

Lamp Current

Lamp Voltage

L

L

mArms5.0-4.0I

Vrms-1760-V

Note (1) It is defined as the time to take until the brightness reduces to 50% of its original value.

[Operating condition : Ta = 25• •2• •, IL = 6.0mArms(typ.), For single lamp only. ]

Inverter

Inverter

HOT 1

HOT 2

HOT 3

HOT 4

CCFT 1

CCFT 2

LCD

Module

HOT 11

HOT 12

CCFT 6

(1)Hour--50,000HrOperating Life Time

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 12

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

3.2.1 Inverter Input Condition & Specification

ConditionsSymbolItems

www.panelook.com

Specifications

NoteUnit

Max.Typ.Min.

Input

Voltage

Input

Current

Lamp

Current

Frequency

Backlight

On/Off

Dimming

Control

I

RUSH

LAMP

V

O

DIM

Vin=24.0V

Vdim=3.3V

Ta=25• • ••••••••V26.42421.6-Vin

Initial Turn-onA5--

mArms7.06.56.0Vdim=3.3 VI

kHz656055Vin=24.0 VF

-

-

5.25-2.4Vin=24.0 VON

-V

0.8-0Vin=24.0 VOFF

--3.3Max Lum

-V

0--Min. Lum

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 13

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

4. Block Diagram

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 14

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

5. Input Terminal Pin Assignment

5.1. Input Signal & Power Connector : FI-E30S (JAE)

www.panelook.com

DescriptionPIN No.DescriptionPIN No.

GND16No Connection1

RxIN3-17No Connection2

RxIN3+18No Connection3

GND19GND4

GND20RxIN0-5

LVDS OPTION (Note 1)21RxIN0+6

No Connection22GND7

GND23RxIN1-8

Note) No Connection: This PINS are only used for SAMSUNG internal using.

(1) LVDS OPTION : If this PIN : HIGH (3.3 V) or OPEN • • Normal LVDS format

: LOW (GND) • • JEIDA LVDS format

SEQUENCE : On = V

OFF = Interface Signal(T3) • •LVDS Option • •V

DD(T1) • •LVDS Option • •Interface Signal(T2)

DD

GND24RxIN1+9

GND25GND10

Vin26RxIN2-11

Vin27RxIN2+12

Vin28GND13

Vin29RxCLK-14

Vin30RxCLK+15

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 15

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

Note(1) Pin number starts from Right side

www.panelook.com

PCB

••

Pin No. 1 Pin No. 30

#1

connect name

#1

#30

#30

Fig. Connector diagram

a. All GND pins should be connected together and also be connected to the LCD’s

metal chassis.

b. All power input pins should be connected together.

c. All NC pins should be separated from other signal or power.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 16

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

5.2. Inverter Input Pin Configuration

www.panelook.com

Connector : S14B-PH-SM3-TB(JST)

Pin Configuration(FUNCTION)Pin No.

24 V1

24 V2

24 V3

24 V4

24 V5

GND6

GND7

GND8

GND9

GND10

11

* ERROR DETECTION (NORMAL : GND / ABNORMAL : 5V)

Backlight On /Off [ON:2.4 - 5.25 V, OFF: 0 - 0.8 V]12

Dimming Control [0V:Min, 3.3V:Max]13

External PWM Signal - Note (1)14

No Connection

Note (1) When use Ext PWM Signal : Pin 13 must fix at 3.3V

When do not use Ext PWM Signal : Pin 14 must No Connection.

High-duty = On/(On+Off) * 100

On

Off

5.3. Inverter Input Power Sequence

0.95 Vin

Vin (24V)

Dimming Control

( 0 ~ 3.3 V )

20msec [Min]

0.1 Vin

1.1sec [Min]

On Off

0.5sec [Min]

0.5sec [Min]

Back Light On/Off

0.5sec [Min]

2.4 V

0.1sec [Min]

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 17

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

5.4 LVDS Interface

- LVDS Receiver : Tcon (merged)

- Data Format (JEIDA & Normal)

www.panelook.com

VESA -DATAJEIDA -DATALVDS pin

R0R2TxIN/RxOUT0

R1R3TxIN/RxOUT1

R2R4TxIN/RxOUT2

TxOUT/RxIN0

TxOUT/RxIN1

TxOUT/RxIN2

R3R5TxIN/RxOUT3

R4R6TxIN/RxOUT4

R5R7TxIN/RxOUT6

G0G2TxIN/RxOUT7

G1G3TxIN/RxOUT8

G2G4TxIN/RxOUT9

G3G5TxIN/RxOUT12

G4G6TxIN/RxOUT13

G5G7TxIN/RxOUT14

B0B2TxIN/RxOUT15

B1B3TxIN/RxOUT18

B2B4TxIN/RxOUT19

B3B5TxIN/RxOUT20

B4B6TxIN/RxOUT21

B5B7TxIN/RxOUT22

HSYNCHSYNCTxIN/RxOUT24

VSYNCVSYNCTxIN/RxOUT25

TxOUT/RxIN3

RESERVEDRESERVEDTxIN/RxOUT23

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

DENDENTxIN/RxOUT26

R6R0TxIN/RxOUT27

R7R1TxIN/RxOUT5

G6G0TxIN/RxOUT10

G7G1TxIN/RxOUT11

B6B0TxIN/RxOUT16

B7B1TxIN/RxOUT17

www.panelook.com

Page 18

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

www.panelook.com

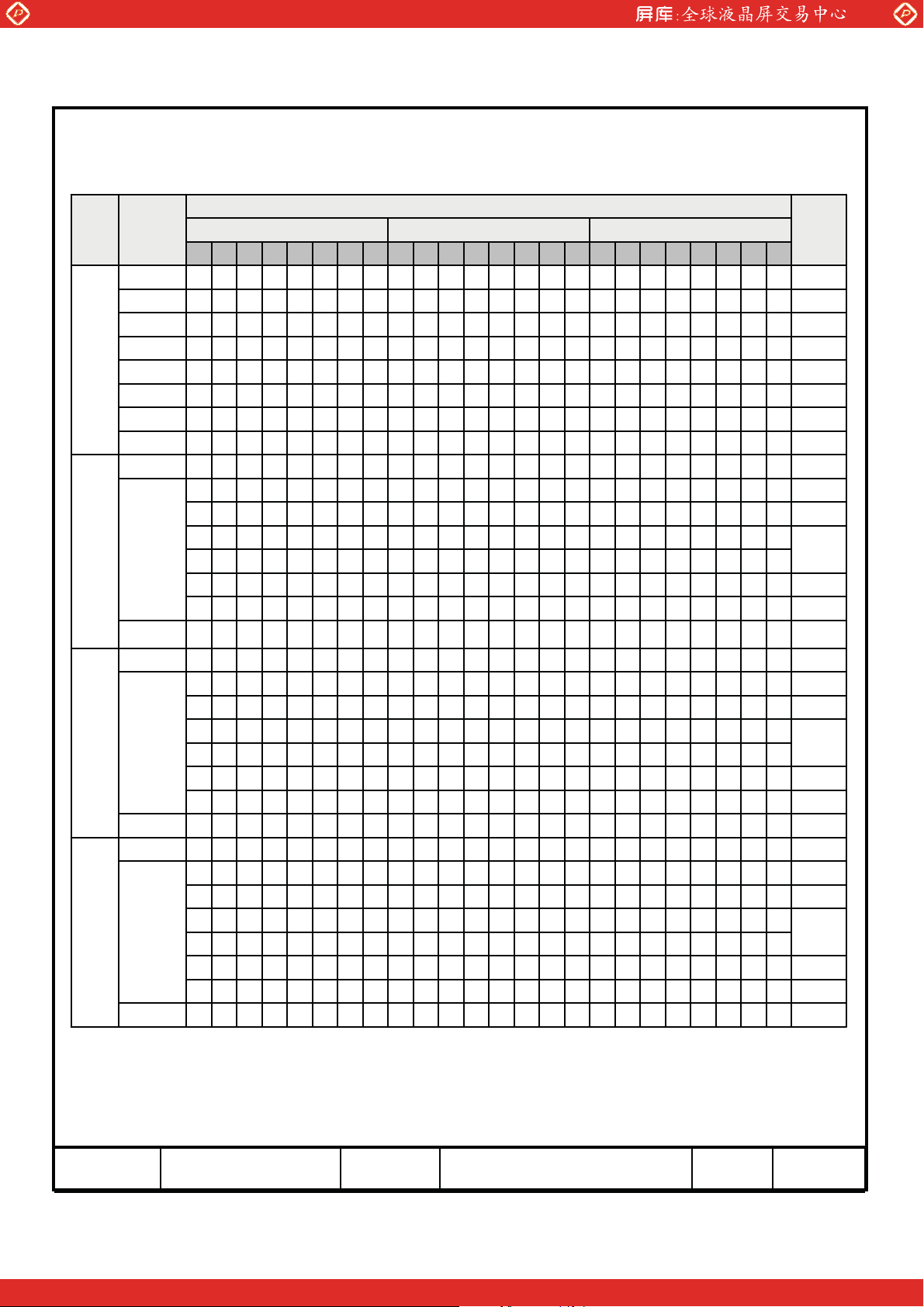

5.5 Input Signals, Basic Display Colors and Gray Scale of Each Color

COLOR

BASIC

COLOR

GRAY

SCALE

OF

RED

GRAY

SCALE

OF

GREEN

GRAY

SCALE

OF

BLUE

DISPLAY

(8bit)

BLACK

EN

ITE

DA

RK

••

••

LIGHT

D

RK

DA

••

••

LIGHT

EN

RK

DA

••

••

LIGHT

DATA SIGNAL

:::::::::

:::::::::::

BLUEGREENRED

1111111111111100000000CYAN

111111111111111111WH

:::::::::

::::::::::::::::::

00000000000011111111RE

:::::::

::::::::::::::::::

0000001111111100000000GRE

:::::::::::::

:::::

::::::::::::::::::

GRAY

SCALE

LEVEL

B7B6B5B4B3B2B1B0G7G6G5G4G3G2G1G0R7R6R5R4R3R2R1R0

-000000000000000000000000

-111111110000000000000000BLUE

-000000001111111100000000GRE

-11

-000000000000000011111111RED

-111111110000000011111111MAGENTA

-000000001111111111111111YELLOW

-111111

R0000000000000000000000000BLACK

R1000000000000000000000001

R2000000000000000000000010

R3~

R252

R252000000000000000011111101

R252000000000000000011111110

R2520000

G0000000000000000000000000BLACK

G1000000000000000100000000

G2000000000000001000000000

G3~

G252

G252000000001111110100000000

G252000000001111111000000000

G25200

B0000000000000000000000000BLACK

B1000000010000000000000000

B2000000100000000000000000

B3~

B252

B252111111010000000000000000

B252111111100000000000000000

B252111111110000000000000000BLUE

Note) Definition of Gray :

Rn : Red Gray, Gn : Green Gray, Bn : Blue Gray (n = Gray level)

Input Signal : 0 = Low level voltage, 1 = High level voltage

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 19

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

6. Interface Timing

6.1 Timing Parameters ( DE only mode )

www.panelook.com

NOTEUnitMAX.TYP.MIN.SYMBOLITEMSIGNAL

Clock

Hsync

Vsync

Frequency

C

H

V

Active

Vertical

Display

Period

VD

Display Term

Vertical

Total

VB

Active

Horizontal

Display

Period

HD

Display Term

Horizontal

Total

H

Note) This product is DE only mode. The input of Hsync & Vsync signal does

not have an effect on normal operation.

(1) Test Point : TTL control signal and CLK at LVDS Tx input terminal in system

(2) Internal VDD = 3.3V

-MHz8475651/T

-KHz534844F

-Hz-60-F

-lines-768-T

-Lines1000806773T

-clocks-1366-T

-clocks175016881420T

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 20

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

6.2 Timing diagrams of interface signal ( DE only mode )

www.panelook.com

TV

DE

DE

DCLK

DATA

SIGNALS

TVD

TVB

TH

THD

TC

DCLK

DISPLAY

DATA

DE

TC

TCH

TDS TDH

TES

TCL

0.5

V

0.5

V

CC

0.5

V

CC

CC

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 21

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

• •• •• • • • • •

6.3 Power ON/OFF Sequence

To prevent a latch-up or DC operation of the LCD Module, the power on/off

sequence should be as the diagram below.

0<T1• •10msec

0<T2• •50msec

0<T3• •50msec

1000msec• •T4

www.panelook.com

1000msec• •T5

(Recommend Value)

100msec• •T6

(Recommend Value)

T1 : VDDrising time from 10% to 90%

T2 : The time from V

T3 : The time from valid data off to V

T4 : V

off time for Windows restart

DD

to valid data at power ON.

DD

off at power Off.

DD

T5 : The time from valid data to B/L enable at power ON.

T6 : The time from valid data off to B/L disable at power Off.

The supply voltage of the external system for the Module input should be the same

as the definition of V

DD

.

Apply the lamp voltage within the LCD operation range. When the back light turns on

before the LCD operation or the LCD turns off before the back light turns off,

the display may momentarily show abnormal screen.

In case of V

= off level,

DD

please keep the level of input signals low or keep a high impedance.

T4 should be measured after the Module has been fully discharged between power off

and on period.

Interface signal should not be kept at high impedance when the power is on.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 22

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 23

Global LCD Panel Exchange Center

www.panelook.com

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 24

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

8. PACKING

8.1 CARTON (Internal Package)

(1) Packing Form

Corrugated fiberboard box and corrugated cardboard as shock absorber

(2) Packing Method

Packing Pallet Box

www.panelook.com

Cushion Set

8.2 Packing Specification

LCD Packing

Pallet

30 ea / (Packing-

Pallet Box)

122.3 kgTotal Pallet Weight

Module (15EA)

RemarkSpecificationItem

1. 90.0kg/LCD(30ea)

2. 14.8kg/Cushion Set(4ea)

4. 8.7kg/Packing-Pallet Box(1ea)

5. Cushion Material : EPS

6. Packing Pallet Box Material : DW4

Pallet weight : 8.8kg1 Box / PalletPallet

-VerticalPacking Direction

1265mm(H) x 1145mm(V) x 928mm(Height)H x V x heightTotal Pallet Size

Pallet(8.8kg) + Module(3*30=90kg) +

Cushion(14.8kg) + Pallet-BOX(8.7kg)

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 25

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

9. MARKING & OTHERS

A nameplate bearing followed by is affixed to a shipped product at the specified

location on each product.

(1) Parts number : LTA230W2-L01-XXXX

(2) Revision: One letters

(3) Lot number : X X X X XXX XX X

(4) Nameplate Indication

www.panelook.com

Cell Position No. (In the Glass)

Glass No. (In the one Lot)

Lot No. (Glass)

Month

Year (Note1)

Product code

Line

LTA230W2-L01

••••••••••••••••••••••••••

(5) Packing box attach

••••••• •••••••••••••••••

80mm

••••••••

••••

Week code : 05 29

week

year

40mm

Revision code

Lot number

100mm

Part number

Revision code

Box serial number

165mm

(6) Others

1. After service part

Lamps cannot be replaced because of the narrow bezel structure.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 26

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

10. Inspection Criteria

When products are shipped, incoming inspection should be carried out with a

sampling inspection based on MIL-STD-105E level II by AQL 1.0%.

CHANGE CONTROL

Design of the product may be changed regarding the specifications, appearance, parts

used, circuits, etc. for product improvement. If a design change is judged to affect the

specifications of this product, supplier should inform customer of the change in advance.

QUALITY CONTROL

www.panelook.com

In the event of a product failure under normal operating conditions, a product trouble

or a functional disorder that can be deemed to be the responsibility of supplier, supplier

should repair the fault or replace the product free of charge within one year from

the product delivery date. However, supplier does not take responsibility for the product

quality in the case of modifications not specified by supplier.

MAINTENANCE

The specifications of the functions of maintenance parts may be partially changed

within the range which provides equivalent or better quality.

In principle, maintenance parts should be product units.

When stopping manufacturing this product, supplier should notify customer in advance.

HANDLING OF DOUBTFUL POINTS

Any doubt not stipulated in this specification is to be resolved by mutual agreement

between customer and supplier, and supplier should make efforts for improvement

in good faith.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 27

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

11. General Precautions

11.1 Handling

(a) When the Module is assembled, it should be attached to the system firmly

using all mounting holes. Be careful not to twist and bend the Module.

(b) Because the inverter use high voltage, it should be disconnected from power

before it is assembled or disassembled.

(c) Refrain from strong mechanical shock and / or any force to the Module.

In addition to damage, this may cause improper operation or damage to the Module

and CCFT back light.

(d) Note that polarizers are very fragile and could be damage easily.

Do not press or scratch the surface harder than a HB pencil lead.

www.panelook.com

(e) Wipe off water droplets or oil immediately. If you leave the droplets for a long

time, staining or discoloration may occur.

(f) If the surface of the polarizer is dirty, clean it using absorbent cotton or soft cloth.

(g) Desirable cleaners are water, IPA(Isopropyl Alcohol) or Hexane.

Do not use Ketone type materials(ex. Acetone), Ethyl alcohol, Toluene, Ethyl acid

or Methyl chloride. It might permanent damage to the polarizer due to chemical

reaction.

(h) If the liquid crystal material leaks from the panel, it should be kept away

from the eyes or mouth . In case of contact with hands, legs or clothes, it must

be washed away with soap thoroughly.

(i) Protect the Module from static, or the CMOS Gate Array IC would be damaged.

(j) Use finger-stalls with soft gloves in order to keep display clean during the

incoming inspection and assembly process.

(k) Do not disassemble the Module.

(l) Do not pull or fold the lamp wire.

(m) Do not adjust the variable resistor located on the Module.

(n) Protection film for polarizer on the Module should be slowly peeled off just before use

so that the electrostatic charge can be minimized.

(o) Pins of I/F connector should not be touched directly with bare hands.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 28

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

11.2 Storage

(a) Do not leave the Module in high temperature, and high humidity for a long time.

It is highly recommended to store the Module with temperature from 0 to 35• •

and relative humidity of less than 70%.

(b) Do not store the TFT-LCD Module in direct sunlight.

(c) The Module should be stored in a dark place. It is prohibited to apply sunlight or

fluorescent light in storing.

11.3 Operation

www.panelook.com

(a) No Connection or disconnect the Module in the "Power On" condition.

(b) Power supply should always be turned on/off by the "Power on/off sequence"

(c) Module has high frequency circuits. Sufficient suppression to the electromagnetic

interference should be done by system manufacturers. Grounding and shielding methods

may be important to minimize the interference.

(d) The cable between the back light connector and its inverter power supply should

be connected directly with a minimized length. A longer cable between

the back light and the inverter may cause lower luminance of lamp(CCFT) and

may require higher startup voltage(Vs).

11.4 Operation Condition Guide

(a) The LCD product should be operated under normal conditions.

Normal condition is defined as below;

- Temperature : 20• •15• •

- Humidity : 55• •20%

- Display pattern : continually changing pattern (Not stationary)

(b) If the product will be used in extreme conditions such as high temperature,

humidity, display patterns or operation time etc.., It is strongly recommended

to contact SEC for Application engineering advice. Otherwise, its reliability and

function may not be guaranteed. Extreme conditions are commonly found at

Airports, Transit Stations, Banks, Stock market, and Controlling systems.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Page 29

Global LCD Panel Exchange Center

• • ••• • • • • • • •• • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • • • • • • • •• • • ••• • • • • • • • •• • • • • • • • • • • • • • • • • • • • • • • •• • • • • • • • • •

11.5 Others

(a) Ultra-violet ray filter is necessary for outdoor operation.

(b) Avoid condensation of water. It may result in improper operation or disconnection

of electrode.

(c) Do not exceed the absolute maximum rating value. ( supply voltage variation,

input voltage variation, variation in part contents and environmental temperature,

and so on)

Otherwise the Module may be damaged.

(d) If the Module keeps displaying the same pattern for a long period of time,

the image may be "sticked" to the screen.

To avoid image sticking, it is recommended to use a screen saver.

www.panelook.com

(e) This Module has its circuitry PCB's on the rear side and should be handled

carefully in order not to be stressed.

(f) Please contact SEC in advance when you display the same pattern for a long time.

One step solution for LCD / PDP / OLED panel application: Datasheet, inventory and accessory!

www.panelook.com

Loading...

Loading...