Page 1

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

1 / 28

SAMSUNG TFT-LCD

MODEL: LSC400HJ01-W

The Information described in this specification is for the first draft and can be changed without prior notice

Samsung Display Co., LTD

Page 2

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

2 / 28

General Description

Description

This model uses a liquid crystal display (LCD) of amorphous silicon TFT as switching components. This

model is composed of a TFT LCD panel, a driver circuit, and an ass’y KIT of source PBA. This 40.0”

model has a resolution of a 1920 x 1080 and can display up to 16.7 million colors(Dithered 1.07B) with

the wide viewing angle of 89° or a higher degree in all directions. This panel is designed to support

applications by providing a excellent performance function of the flat panel display such as home-alone

multimedia TFT-LCD TV and a high definition TV.

General Information

Features

High contrast ratio & aperture ratio with the wide color gamut

SPVA(Super Vertical Align) mode

Wide viewing angle (±178°)

High speed response

FHD resolution (16:9)

RoHS compliance (Pb-free)

Low power consumption

DE (Data enable) mode

The interface (1pixel/clock) of LVDS serial interface

Items

Specification

Unit

Note

Active Display Area

885.6(H) x 498.15(V)

㎜

Switching Components

a-Si TFT Active matrix

Glass Size

TFT : 902.6(H) x 517.1(V)

CF : 902.6(H) x 514.4(V)

㎜

±0.1mm

Panel Size

902.6(H) x 517.1(V)

㎜

±0.1mm

1.80(D)

㎜

±0.2mm

Weight

1,800

g

±10%

Display Colors

16.7M (True Display)

1.07B (Dithered 10bit)

color

Number of Pixels

1,920 × 1,080

pixel

16 : 9

Pixel Arrangement

RGB vertical Stripe

Display Mode

Normally Black

Surface Treatment

Anti Glare

Haze

Haze 2.3%

±2.1%

Hardness

Hard coating 2H

Page 3

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

3 / 28

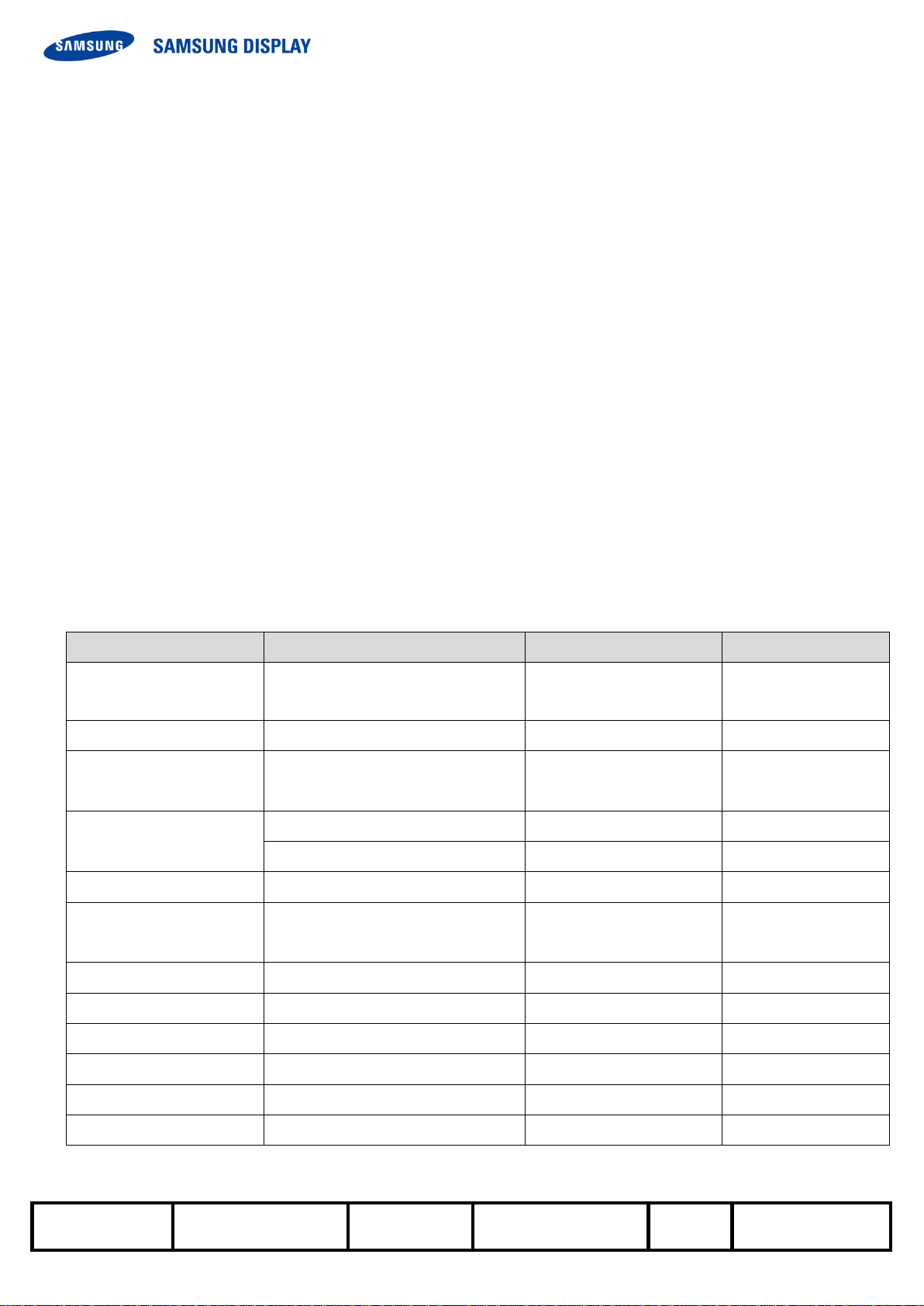

1. Absolute Maximum Ratings

If the figures on measuring instruments exceed maximum ratings, it can cause the malfunction or the

unrecoverable damage on the device.

Item

Symbol

Min.

Max.

Unit

Note

Power supply voltage

V

DD

10.8

13.2

V

(1)

Temperature for storage

(Temperature of glass surface)

T

STG

-20

65

℃

(2),(4)

Operating temperature

T

OPR

0

50

℃

(2),(5)

Humidity for storage

H

STG

5

90

%RH

(2),(4)

Operating humidity

H

STG

20

90

%RG

(2),(5)

Endurance on static electricity

150

V

(3)

Note (1) The power supply voltage at Ta= 25 ± 2 °C

(2) Temperature and the range of relative humidity are shown in the figure below.

a. 90 % RH Max. (Ta ≤ 39 °C)

b. The relative humidity is 90% or less. (Ta >39 °C)

c. No condensation

(3) Keep the static electricity under 150V in Polarizer attaching process.

(4) Operating condition with source PCB

(5) Storage temperature condition including glass

(6) Condition without packing. (Unpacking condition)

Fig. Range for temperature and relative humidity

Page 4

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

4 / 28

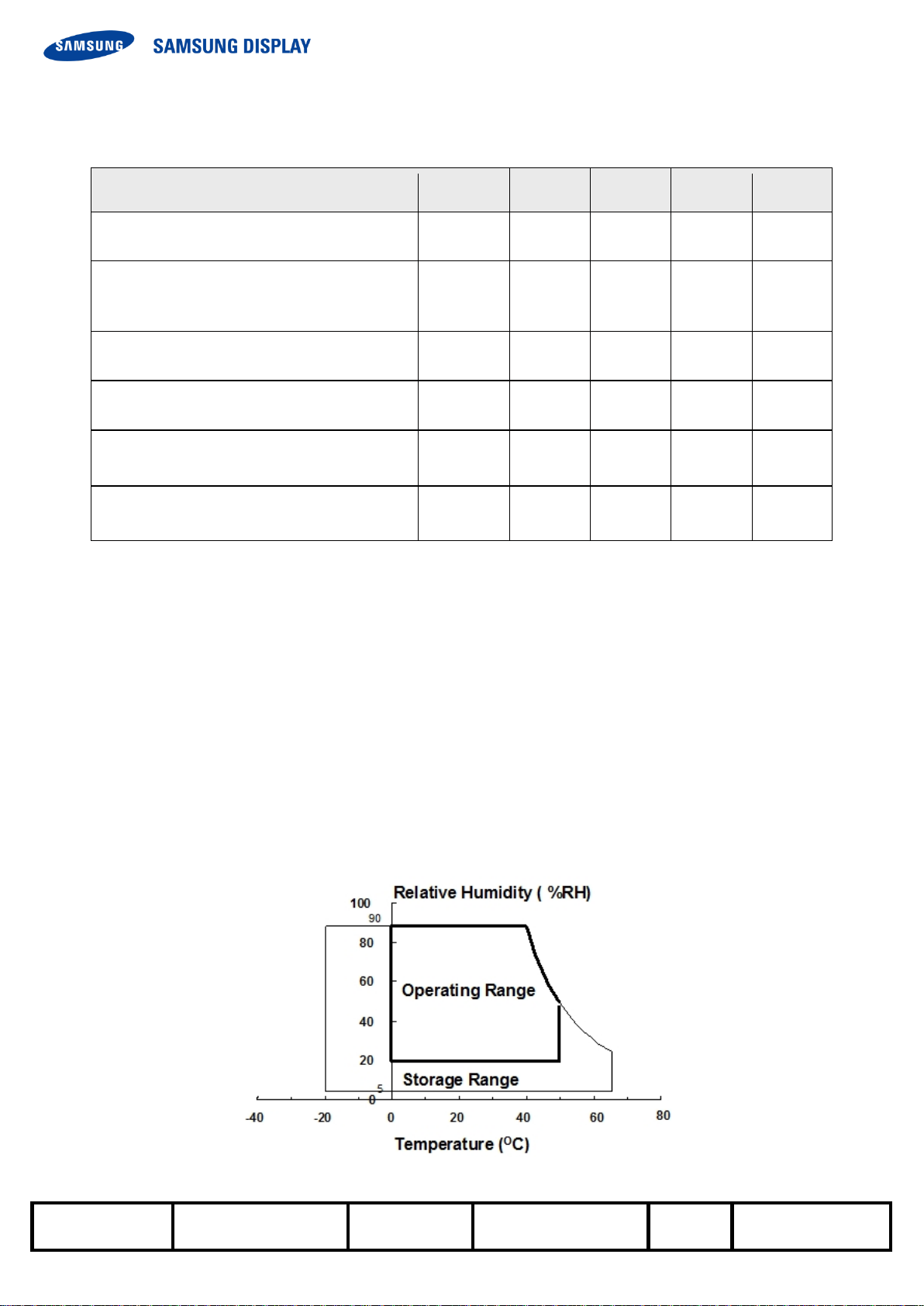

2. Optical characteristics

The optical characteristics should be measured in the dark room or the space surrounded by the similar setting.

Measuring equipment : TOPCON RD-80S, TOPCON SR-3 ,ELDIM EZ-Contrast

(Ta = 25 ± 2°C, VDD=12.0V, fv=60Hz, f

DCLK

=148.5MHz, Light source: D65 Standard light)

Item

Symbol

Condition

Min.

Typ.

Max.

Unit

Note

Contrast ratio

C/R

3000

5000

-

(1)

(At the center of screen)

SR-3

Response

time

G-to-G

Tg

TPAN,SUR

=29.9℃

- 8 16

msec

(3)

RD-80S

Luminance of white

YL

370

450

-

cd/m2

(4)

(At the center of screen)

SR-3

Chromaticity

(CIE 1931)

Red

Rx

0.660

(5),(6)

Ry

Normal

0.328

SR-3

Green

Gx

qL,R=0

0.267

Gy

qU,D=0

TYP.

0.585

TYP.

Blue

Bx

Viewing

-0.03

0.134

+0.03

By

Angle

0.123

White

Wx

0.286

Wy

0.358

Color gamut

-

-

68 - %

(5)

Color

-

7000

K

SR-3

Viewing

Hor.

qL

C/R≥10

75

89

-

Degree

(6)

Angle

qR

75

89

-

SR-3

Ver.

qU

75

89

-

EZ-

Contrast

qD

75

89

-

Brightness uniformity

B

uni

25

%

(2)

(9 Points)

SR-3

transmissivity

T

5.0%

5.3%

%

(7)

D65/SR3

Notice

(a) Setup for test equipment

The measurement should be executed in a stable, windless, and dark room for 40min and 60min after

operating the panel at the given temperature for stabilization of the standard light. (SDC uses the standard

luminance of the D65 media).

This measurement should be measured at the center of screen.

The environment condition: Ta = 25 ± 2 °C

(b) D65 media has the general light source.

The temperature of color is 6487K. The coordinate of color is Wx 0.313, Wy 0.329

The luminance of this product is 7217cd/㎡.

Page 5

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

5 / 28

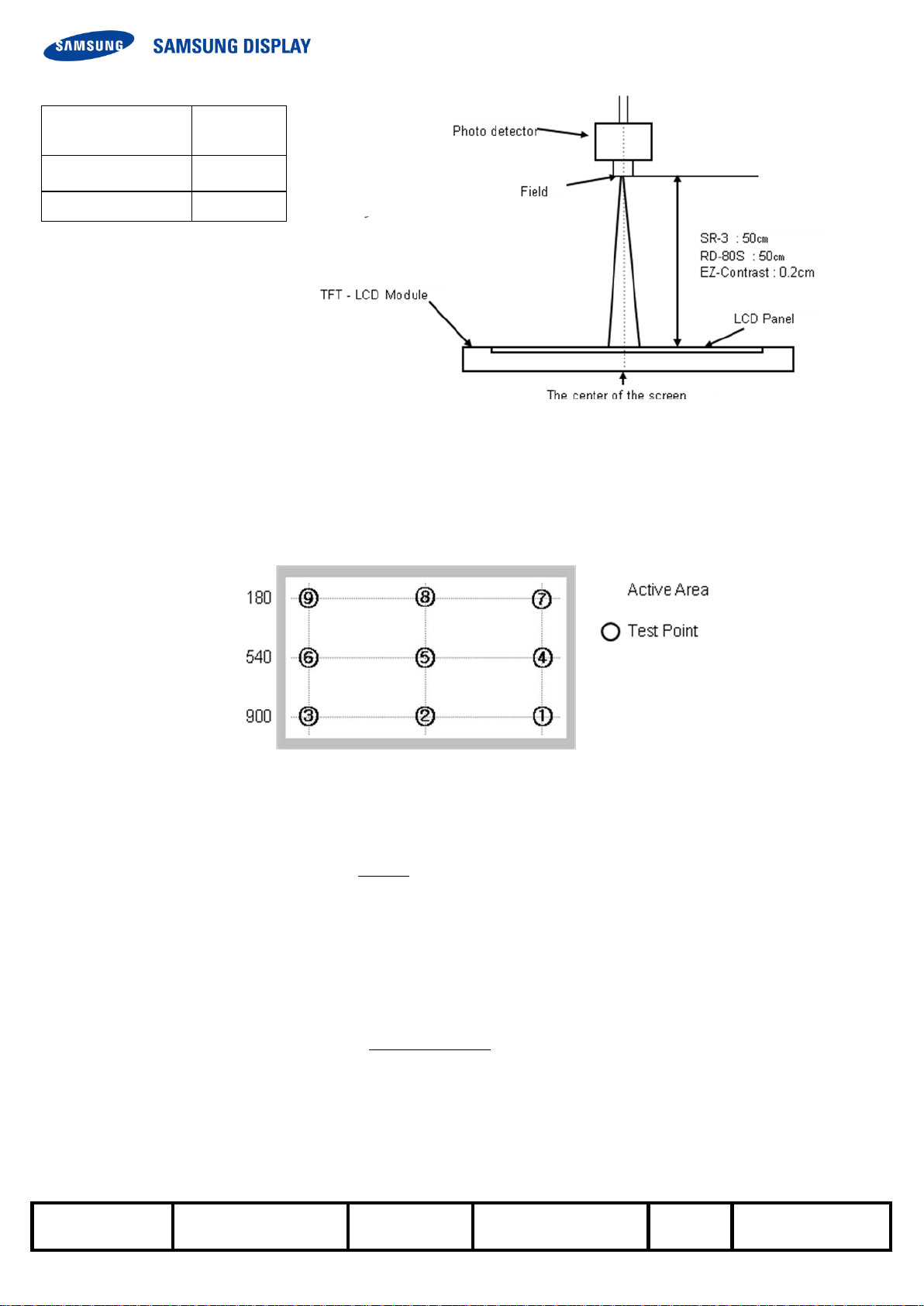

Photo detector

Field

SR-3

2°/1°

RD-80S

1°

(c) The CIE positions D65 as the standard daylight illuminant:

[D65] is intended to represent average daylight and has a correlated color temperature of

approximately 6487 K. CIE standard illuminant D65 should be used in all colorimetric calculations

requiring representative daylight, unless there are specific reasons for using a different illuminant.

- Definition of the test point

Note (1) Definition of contrast ratio (C/R)

: The ratio of gray max (Gmax) & gray min (Gmin) at the center point ⑤ of the panel

The measurement goes in D65 Standard light source

Gmax : The luminance with all white pixels

Gmin : The luminance with all black pixels

Note (2) Definition of the brightness uniformity of 9 points (Test pattern : The full white)

The measurement shall be executed with the standard light source of D65 .

Bmax : The maximum brightness

Bmin : The minimum brightness

C R

G

G

/

max

min

Buni

B B

B

100

( max min)

max

Page 6

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

6 / 28

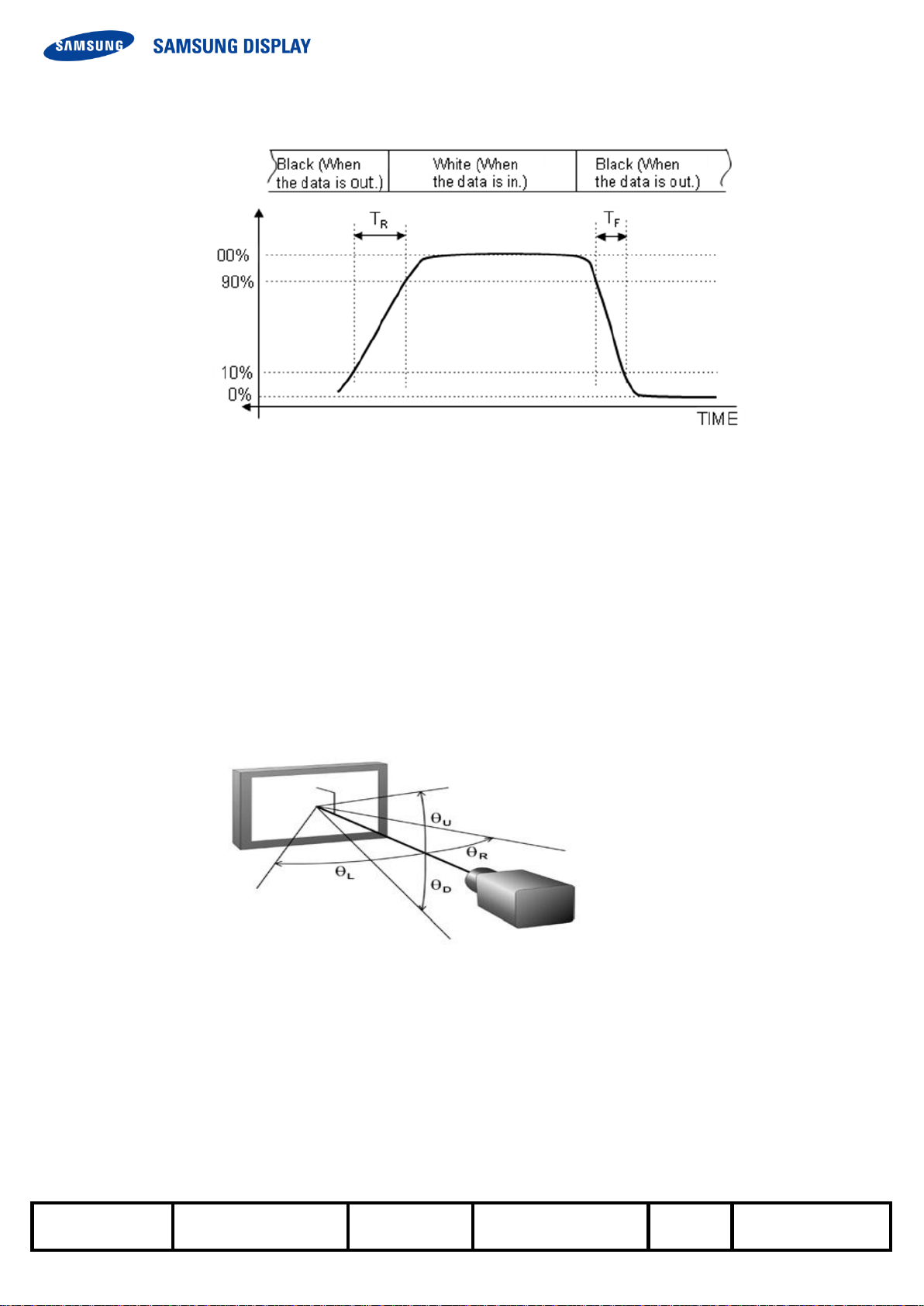

Note (3) Definition of the response time : Sum of Tr, Tf

※ G-to-G : Average response time between whole gray scale to whole gray scale.

The response time is the value that was measured after it was operated in Samsung's standard BLU for

one hour.( at room temperature)

Note (4) The definition of luminance of white: The luminance of white at the center point ⑤

The measurement shall be executed with the standard light source of D65.

Note (5) The definition of chromaticity (CIE 1931)

The color coordinate of red, green, blue and white at the center point ⑤

The measurement shall be executed with the standard light source of D65.

Note (6) Definition of viewing angle

: The range of viewing angle (C/R ≥10)

The measurement shall be executed with the standard light source of D65.

Note (7) Definition of transmissivity

The measurement shall be executed with the standard light source of D65.

Note (8) Definition of Gamma

The response

Of optical instruments

Display data

Gamma X Y

X Z B B B

lum

lum

log( / )/log( / )

( ) / ( )

min max min

100 100

100

Y: Measurement Level / Z: Measurement Brightness

B

max

: Maximum Brightness / B

min

: Minimum Brightness

Page 7

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

7 / 28

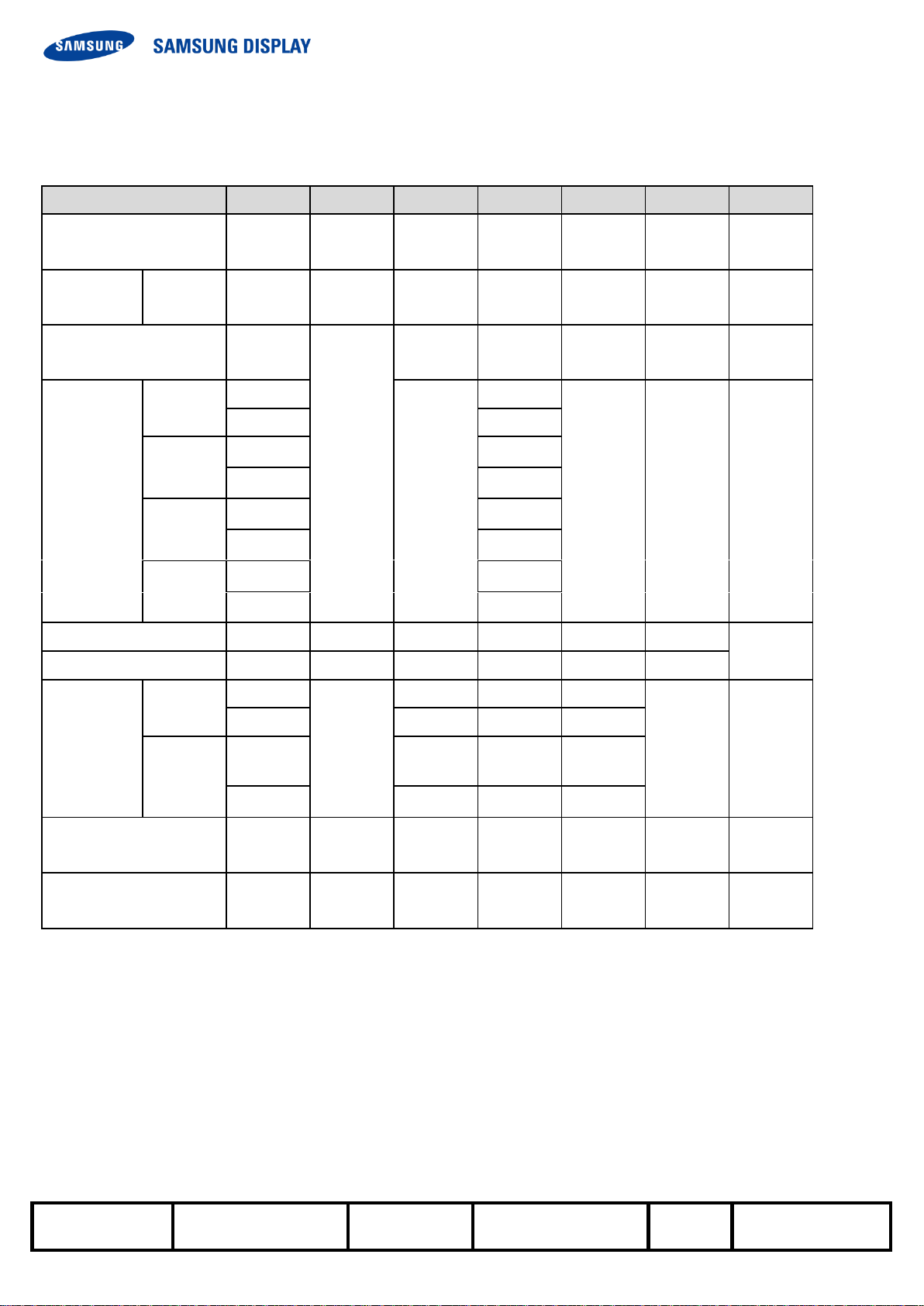

3. Electrical characteristics

3.1 TFT LCD Module

The connector for the display data & timing signal should be connected.

Ta = 25°C ± 2 °C

Item

Symbol

Min.

Typ.

Max.

Unit

Note

Voltage of power supply

V

DD

10.8

12.0

13.2

V

(1)

Current

of power

supply

(a) Black

I

DD

-

660

720

mA

(2),(3)

(b) White

-

730

800

mA

(c) Sub V-Stripe

-

800

1000

mA

Vsync frequency

f

V

47

60

62

Hz

Hsync frequency

f

H

50

67.5

73

kHz

Main frequency

Fdclk

130

148.5

155

MHz Rush current

I

RUSH

- - 5

A

(4)

Note (1) The ripple voltage should be controlled fewer than 10% of V

DD

(Typ.) voltage.

(2) fV=60Hz, fDCLK =148.5MHz, VDD = 12.0V, DC Current.

(3) Power dissipation check pattern (LCD Module only)

(4) Conditions for measurement

a) Black pattern b) White pattern c) Sub V-stripe

The rush current, I

RUSH

can be measured during T

RUSH

is 470us

Page 8

MODEL

LSC400HJ01-W

Doc. No

Page

8 / 28

4. Block diagram

SAMSUNG Confidential

Page 9

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

9 / 28

Page 10

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

10 / 28

Page 11

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

11 / 28

5. The Pin assignment in the input terminal

5.1. Input signal & power Connector : FI-RE51S-HF(JAE/UJU)

Pin

Symbol

Description

Pin

Symbol

Description

1

TCON_WP

Bus release

26

3D_EN

3D Enable PIN

2

SCL_I

I2C SCL

27

3D_SYNC_I

3D SYNC INPUT

3

SDA_I

I2C SDA

28

R2A_N

2nd, LVDS Signal-

4

NC

Not Connect

29

R2A_P

2nd, LVDS Signal+

5

3D_SYNC_O

3D SYNC OUT Signal

30

R2B_N

2nd, LVDS Signal-

6

NC

Not Connect

31

R2B_P

2nd, LVDS Signal+

7

LVDS Option

LVDS Option pin

32

R2C_N

2nd, LVDS Signal-

8

TEMP_SEL0

Not Connect

33

R2C_P

2nd, LVDS Signal+

9

TEMP_SEL1

Not Connect

34

GND

Ground

10

NC

Not Connect

35

R2CLK_N

2nd, LVDS Clock-

11

GND

Ground

36

R2CLK_P

2nd, LVDS Clock+

12

R1A_N

1st, LVDS Signal-

37

GND

Ground

13

R1A_P

1st, LVDS Signal+

38

R2D_N

2nd, LVDS Signal-

14

R1B_N

1st, LVDS Signal-

39

R2D_P

2nd, LVDS Signal+

15

R1B_P

1st, LVDS Signal+

40

R2E_N

2nd, LVDS Signal-

16

R1C_N

1st, LVDS Signal-

41

R2E_P

2nd, LVDS Signal+

17

R1C_P

1st, LVDS Signal+

42

NC

Not Connect

18

GND

Ground

43

NC

Not Connect

19

R1CLK_N

1st, LVDS Clock-

44

GND

Ground

20

R1CLK_P

1st, LVDS Clock+

45

GND

Ground

21

GND

Ground

46

GND

Ground

22

R1D_N

1st, LVDS Signal-

47

NC

Not Connect

23

R1D_P

1st, LVDS Signal+

48

Vin (12V)

DC power supply

24

R1E_N

1st, LVDS Signal-

49

Vin (12V)

DC power supply

25

R1E_P

1st, LVDS Signal+

50

Vin (12V)

DC power supply

51

Vin (12V)

DC power supply

Page 12

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

12 / 28

Note(1) :

- Input Mode 8bit Setting & 8bit input, -> E_Chanel : Floating

- Input Mode 10bit Setting & 8bit input, -> E_Chanel : Keep Level ‘0’

No. 24 / No. 40. : Pull Up

No. 25 / No. 41. : Pull Down

Note (2) Not Connected : This PINS are only used for SDC internal Operations

Sequence: On = Vdd (T1) ≥LVDS Option ≥Interface Signal (T2) / Off = interface Signal (T3) ≥ LVDS Option ≥ Vdd

Notice TCON_WP, SCL_I, SDA_I shouldn't be communicated with I2C device whose output level is 5V'

Notice: Pin number, which starts from the left side.

Note (3) Pin number which starts form the left side

a. Pin for Power GND pins shall be connected to the LCD’s metal chassis.

b. All power input pins should be connected together.

c. All NC pins should be separated from other signal or power.

Fig . The diagram of connector

Page 13

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

13 / 28

5.2 LVDS Interface( LVDS receiver : T-CON (merged), Data format(JEIDA Only)

LVDS pin

JEIDA -DATA

TxOUT/RxIN0

TxIN/RxOUT0

R4

TxIN/RxOUT1

R5

TxIN/RxOUT2

R6

TxIN/RxOUT3

R7

TxIN/RxOUT4

R8

TxIN/RxOUT6

R9

TxIN/RxOUT7

G4

TxOUT/RxIN1

TxIN/RxOUT8

G5

TxIN/RxOUT9

G6

TxIN/RxOUT12

G7

TxIN/RxOUT13

G8

TxIN/RxOUT14

G9

TxIN/RxOUT15

B4

TxIN/RxOUT18

B5

TxOUT/RxIN2

TxIN/RxOUT19

B6

TxIN/RxOUT20

B7

TxIN/RxOUT21

B8

TxIN/RxOUT22

B9

TxIN/RxOUT24

HSYNC

TxIN/RxOUT25

VSYNC

TxIN/RxOUT26

DEN

TxOUT/RxIN3

TxIN/RxOUT27

R2

TxIN/RxOUT5

R3

TxIN/RxOUT10

G2

TxIN/RxOUT11

G3

TxIN/RxOUT16

B2

TxIN/RxOUT17

B3

TxIN/RxOUT23

RESERVED

TxOUT/RxIN4

(dithered 10bit)

TxIN/RxOUT28

R0

TxIN/RxOUT29

R1

TxIN/RxOUT30

G0

TxIN/RxOUT31

G1

TxIN/RxOUT32

B0

TxIN/RxOUT33

B1

TxIN/RxOUT34

RESERVED

Page 14

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

14 / 28

5.3 Input signals, basic display colors and the gray scale of each color.

COLOR

DISPLAY

DATA SIGNAL

GRAY

SCALE

LEVEL

RED

GREEN

BLUE

R0

R1

R2

R3

R4

R5

R6

R7

G0

G1

G2

G3

G4

G5

G6

G7

B0

B1

B2

B3

B4

B5

B6

B7

BASIC

COLOR

BLACK

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 -

BLUE

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 -

GREEN

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 -

CYAN

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 -

RED

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 -

MAGENTA

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 -

YELLOW

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 -

WHITE

1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 -

GRAY

SCALE

OF RED

BLACK

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R0

DARK

↑

↓

LIGHT

1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R1 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

R2

: : : : : : : : : : : : : : : : : : : : : : :

:

R3~

R1020

: : : : : : : : : : : : : : : : : : : : : : :

:

1 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R1021

0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R1022

RED

1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R1023

GRAY

SCALE

OF

GREEN

BLACK

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 G0

DARK

↑

↓

LIGHT

0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 G1

0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 G2

: : : : : : : : : : : : : : : : : : : : : : :

:

G3~

G1020

: : : : : : : : : : : : : : : : : : : : : : :

:

0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 0 0 0 0 0 0 0 0 G1021

0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 G1022

GREEN

0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 G1023

GRAY

SCALE

OF

BLUE

BLACK

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 B0

DARK

↑

↓

LIGHT

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 B1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0

B2 : : : : : : : : : : : : : : : : : : : : : : : :

B3~

B1020

: : : : : : : : : : : : : : : : : : : : : : :

:

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 B1021

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 B1022

BLUE

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 B1023

Page 15

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

15 / 28

Note) The definition of gray :

Rn : Red gray, Gn : Green gray, Bn : Blue gray (n = Gray level)

Input signal : 0 = Low level voltage, 1 = High level voltage

Page 16

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

16 / 28

6. Interface timing

6.1 The parameters of timing ( Only DE mode )

SIGNAL

ITEM

SMBOL

MIN.

TYP.

MAX.

Unit

NOTE

Clock

Frequency

1/T

C

130

148.5

155

MHz

-

Hsync

F

H

50

67.5

73

KHz

-

Vsync

F

V

47

60

63

Hz

-

Term for the

vertical

display

Active

display

period

T

VD

-

1080

-

Lines

-

Total vertical

T

V

1100

1125

1480

Lines

-

Term for the

horizontal

display

Active

display

period

T

HD

-

1920

-

Clocks

-

Total

Horizontal

T

H

2145

2200

2350

clocks

-

Note) These products don’t have to receive the signal of Hsync & Vsync from the input device.

(1) Key points when testing: TTL controls the signal and the CLK at the input terminal of LVDS Tx of the

system.

(2) Internal VDD = 3.3V

(3) Spread spectrum

- The limit of spread spectrum's range of SET in which the LCD module is assembled should be within ± 3 %.

Page 17

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

17 / 28

6.2 Timing diagrams of interface signal (Only DE mode )

Page 18

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

18 / 28

6.3 LVDS CHARACTERISTICS (S100FAP)

(1) LVDS AC electrical characteristics

Characteristics

Symbol

Min

Typ

Max

Unit

Remarks

Skew (Strobe) right margin

TRSRM

200

ps

@RINCLKP=135MHz

400

ps

@RINCLKP=85MHz

450

ps

@RINCLKP=80MHz

510

ps

@RINCLKP=74.25MHz

510

ps

@RINCLKP=72MHz

Skew (Strobe) left margin

TRSLM

200

ps

@RINCLKP=135MHz

400

ps

@RINCLKP=85MHz

450

ps

@RINCLKP=80MHz

510

ps

@RINCLKP=74.25MHz

510

ps

@RINCLKP=72MHz

Receiver DLL lock time

TLT

100

us

Page 19

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

19 / 28

Page 20

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

20 / 28

6.4 The sequence of power on and off – Sony Model attached Reference file

To prevent a latch-up phenomena or the DC operation of the LCD Module, the power on/off sequence should

be accorded with the settings described in the diagram below.

T1 : The VDD rising time from 10% to 90%

T2 : The time from the point which V

DD

reach to 90% of voltage to the point which the valid data is out when

the power is on.

T3: The time from the point which the valid data is out to the point which VDD reach to the 90% of voltage

when the power is off.

T4: the time from the point which the Vdd decrease to the point which the Vdd increase again for windows to

restart.

※ The recommended operating condition of the back light system

T5: The time which takes for B/L to be turned on after the signal is entered when the time is on.

T6 : The time which takes until the signal is out after BL is turned off

The condition of supply voltage to enter in the module from the external system should have

the same condition as the definition of VDD.

Apply the voltage for the lamp within the range which the LCD operates. when the back light is turned on

before the LCD is operated or when the LCD is turned off before the back light is turned off, the display may

show the abnormal screen momentarily.

While the V

DD

is off level, please keep the level of input signals low or keep a high impedance condition.

The figure of T4 should be measured after the module has been fully discharged between the periods

when the power is on and off.

The interface signal must not keep the high impedance condition when the power is on.

Page 21

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

21 / 28

7. Outline dimension

7.1 The adhesive size of POL

The next figure shows the size of POL on the drawing sheet attached to the panel for BLU design.

The POL size of CF : 896.6 X 510.8 (L/R) ± 0.6㎜, ± (U/D) 0.5㎜

The POL size of TFT : 896.6 X 510.8 (L/R) ± 0.6㎜, ± (U/D) 0.5㎜

The total adhesion allowance of POL is is (L/R) ± 1.15㎜, (U/D) ± 1.05㎜

Page 22

MODEL

LSC400HJ01-W

Doc. No

Page

22 / 28

8. Reliability test

8.1 Panel

Item

Test Condition

Quantity

Note

HTOL

60 ℃ (Panel change 500hr / circuit change 250hr)

8

LTOL

-5 ℃ (Panel change 500hr / circuit change 250hr)

4

THB

50 ℃ / 90 %RH(Panel change 500hr / circuit change 250hr)

10

ASG

Low

temperature

Max. frequency 25℃~-40℃

Each

Cell

ASG Product Only

ASG

High

Temperature

Min. frequency 60℃operation 96hr

Each

Cell

ASG Product Only

Image sticking

25 ℃ / Mosaic pattern(9*10) 12hrs

8

Rolling pattern 12hrs / 3cycles

Decompressio

n

-40~50℃, 0m(0ft) ~ 13,700m(45,000ft), 72.5Hr

4

HTS

70 ℃, Storage (Panel change 500hr / circuit change 250hr)

4

LTS

-25 ℃, Storage(Panel change 500hr / circuit change 250hr)

4

Transportation

condition

drop(20cm) → temperature/humidity(-30~60℃ / 40℃ 90%RH)

→ pressure → vibration(5~200Hz 1.05Grms, 2hr) → drop(20cm)

1pallet

WHTS

60 ℃ / 75 %RH , Storage

4

Noise

Electromagnetic noise: Overall 23dB 이하

2

Complex

stress

-20℃~60℃, 0~90%RH, 2cycle

4

ESD

S-IC Input ±7KV, Output ±4KV

3

EOS (optional)

Item

Test condition

Vin Input

step

Surge combination (High impedance)

Pass Condition: 5kV under

Signal Input

step

Surge combination (High impedance)

Pass Condition: 120V under

2

[ Criteria on evaluation]

There should be no change of the product, which may affect to the practical display functions, when the

display quality test is executed under the normal operation setting.

* HTOL/ LTOL : The operating cycle on the high and low temperature

* THB : Temperature humidity slant

* HTS/LTS : The storage at the high and low temperature

* WHTS : The storage in the high temperature with the high humidity

SAMSUNG Confidential

Page 23

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

23 / 28

9. General precautions

9.1 Handling

(a) When the panel kit and BLU kit are assembled, the panel kit and BLU kit should be attached to the

set system firmly by combining each mounted holes. Be careful not to give the mechanical stress.

(b) Be careful not to give any extra mechanical stress to the panel when designing the set, and BLU kit.

(c) Be cautious not to give any strong mechanical shock and / or any forces to the panel kit.

Applying the any forces to the panel may cause the abnormal operation or the damage to the panel

kit and the back light unit kit.

(d) Refrain from applying any forces to the source PBA and the drive IC in the process of the handling

or installing to the set. If any forces are applied to the products, it may cause damage or a

malfunction in the panel kit.

(e) Refrain from applying any forces which cause a constant shock to the back side of panel kit, the set

design and BLU kit. If any forces are applied to the products, it may cause an abnormal display, a

functional failure and etc.

(f) Note that polarizer could be damaged easily.

Do not press or scratch the bare surface with the material which is harder than a HB pencil lead.

(g) Wipe off water droplets or oil immediately. If you leave the droplets for a long time on the product, a

staining or the discoloration may occur.

(h) If the surface of the polarizer is dirty, clean it using the absorbent cotton or the soft cloth.

(i) Desirable cleaners are water or IPA (Isopropyl Alcohol).

Do not use Kenton type materials (ex. Acetone), Ethyl alcohol, Toluene, Ethyl acid or Methyl chloride.

These might cause the permanent damage to the polarizer due to chemical reaction.

(j) If the liquid crystal material leaks from the panel, this should be kept away from the eyes or mouth.

If this contacts to hands, legs, or clothes, you must washed it away with soap thoroughly and see a

doctor for the medical examination.

(k) Protect the panel kit and BLU Kit out of the static electricity. Otherwise the circuit IC could be

damaged.

- Reference : Process control standard of SDC

No.

Item

Control standard

1

Ionizer

All Equipment should be controlled under 150V.(Typ. 100V)

2

Carrying Roller

Carrying Roller should be controlled under 200V.

3

Equipment Ground

Resistance

All Equipment Ground Should be less than 1ohm.

Page 24

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

24 / 28

(l) Remove the stains with finger-stalls wearing soft gloves in order to keep the display clean in the

process of the incoming inspection and the assembly process.

(m) Do not pull or fold the source drive IC which connects to the source PBA and the panel or the gate

drive IC.

(n) Do not pull, fold or bend the source drive IC and the gate drive IC in any processes.

If not, the source drive IC could be bent one time in the process of assembling the panel Kit and the

BLU Kit.

(o) Do not adjust the variable resistor located on the panel kit and BLU kit except when adjusting the

flicker.

(p) Do not touch the pins of the interface connector directly with bare hands.

(q) Be cautious not to be peeled off the protection film.

(r) The protection film for the polarizer on the panel kit should be slowly peeled off just before using so

that the electrostatic charge can be minimized.

(s) The panel kit and BLU kit have high frequency circuits. The sufficient suppression to the EMI should

be done by the set manufacturers.

(t) The set of which the panel is assembled shall not be twisted. If the product is twisted, it may cause

the damage on the product.

(u) Surface Temp. of IC should be controlled less than 100℃, operating over the Temp. can cause the

damage or decrease of lifetime.

- Make sure to peel off slowly

(It is recommended to peel it off at the speed of more than 8sec.

constantly.)

- The peeling direction is shown at the Fig

- Instruct the ground worker to work with the adequate methods

such as the antistatic wrist band.

- Maker sure to be grounded the source PBA while peeling of the

protection film.

- Ionized air should be blown over during the peeling

- The protection film should not t be contacted to the source drive

IC.

- If the adhesive stains remain on the polarizer after the

protection film is peeled off, please move stains with isopropylalcohol liquid.

Page 25

MODEL

LSC400HJ01-W

Doc. No

Page

25 / 28

9.2 Storage

The storage condition for packing

ITEM

Unit

Min.

Max.

Storage

Temperature

(℃)

5

40

Storage

Humidity

(%rH)

35

75

Storage life

6 months

Storage

Condition

(1) The storage room should provide good ventilation and temperature control.

(2) Products should not be placed on the floor, but on the Pallet away from a wall.

(3) Prevent products from direct sunlight, moisture nor water; Be cautious of a buildup

of condensation.

(4) Avoid other hazardous environment while storing goods.

(5) If products delivered or kept in conditions of the recommended temperature or

humidity, we recommend you leave them at a circumstance which is shown in the

following table.

period

1 month

2 months

3 months

4 months

5 months

6 months

Baking

Condition

No Baking

50℃, 10%

24Hr

50℃, 10%, 48Hr

9.3 Operation

(a) Do not connect or disconnect the FFC cable during the "Power On" condition.

(b) Power supply should be always turned on and off by the "Power on/off sequence"

(c) The module has high frequency circuits. The sufficient suppression to the electromagnetic interference

should be done by the system manufacturers. The grounding and shielding methods is important to

minimize the interference.

(d) The cables between TV SET connector and Control PBA interface cable should be connected directly

to have a minimized length. A longer cable between TV SET connector and Control PBA interface

cable maybe operate abnormal display

(e) Recommend to age for over 1 hour at least in the state, which the product is driving initially to stabilize

the characteristic of the initial TFT.

(f) Response time depends on the temperature.( In Lower temperature, it becomes longer)

SAMSUNG Confidential

Page 26

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

26 / 28

9.4 Operation condition guide

(a) The LCD product shall be operated under normal conditions.

The normal condition is defined as below;

- Temperature : 20±15℃

- Humidity : 55±20%

- Display pattern : continually changing pattern (Not stationary)

(b) If the product will be used under extreme conditions such as under the high temperature, humidity,

display patterns or the operation time etc.., it is strongly recommended to contact SDC for the

advice about the application of engineering . Otherwise, its reliability and the function may not be

guaranteed. Extreme conditions are commonly found at airports, transit stations, banks, stock

markets, and controlling systems.

9.5 Others

(a) The ultra-violet ray filter is necessary for the outdoor operation.

(b) Avoid the condensation of water which may result in the improper operation of product or the

disconnection of electrode.

(c) Do not exceed the limit on the absolute maximum rating. (For example, the supply voltage

variation, the input voltage variation, the variation in content of parts and environmental

temperature, and so on) If not, panel may be damaged.

(d) If the module keeps displaying the same pattern for a long period of time, the image may be

remained to the screen. To avoid the image sticking, it is recommended to use a screen saver.

(e) This Panel has its circuitry of PCB's on the rear side, so it should be handled carefully in order for a

force not to be applied.

(f) Please contact the SDC in advance when the same pattern is displayed for a long time

Page 27

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

27 / 28

10. Special precautions

10.1 Lists to be cautious when executing the design process

No.

Component

Expected cause

1

Upholding part for

panel

Prevent the panel from breaking by assigning gaps between the panel and the upholding part for panel on the drawing

for the upholding part for panel.

Refer to the (a), (b), (c) of 3-1 for the design of BLU.

2

The shape of the

upholding part for

panel

Design the upholding part for panel to fit to the panel appropriately when designing the BLU since the shape of the

upholding part for panel may damage the panel.

Refer to the (a), (b), (c) of 3-1 for the design of BLU.

3

The edge of

upholding part for

panel

Design the edge of panel to have a sufficient space with the upholding part for panel when designing the BLU since the

edge of the upholding part for panel may damage the panel when assembling the panel and BLU.

Refer to the (a), (b), (c) of 3-1 for the design of BLU.

4

Upholding part for

panel

Place the upholding part for the panel in order for the shape of mold, which contacts with the panel not to interfere with

the area of panel.

Refer to the (a), (b), (c) of 3-1 for the design of BLU.

5

Drive IC

Design the BLU in order for the COF not to contain the lead crack resulted from the tensioned COF created when the

product is twisted if the space between the D-IC COF and the middle mold isn't sufficient.

Refer to the (a), (b), (c),(d),(e),(f), and (g)of 3-2 for the design of BLU.

6

Drive IC

Design the BLU in order for the product not to contain the lead crack resulted from the tensioned COF caused under the

condition, which the product is twisted by fixing the source PCB.

Refer to the (a), (b), (c),(d),(e),(f), and (g)of 3-2 for the design of BLU.

7

IC

component

1) The temperature of each part of product suggested by our company and the second vendor shall meet the standard

of temperature, which is recommended not to be exceeded by our company when the product is affected under the

various temperature ranges.

Apply over 1mm long separation distance stated in the safety standard between the electric part and each conductor.

(Apply the rated separation distance when insulating.)

8

Thermal pad

Apply the thermal pad in a designated size to the product as a measure to lower the temperature of heat in order for

each part to use the rated temperature.

9

POL

The surrounding area of the POL shall be treated with an electrification treatment since the external ESD may cause a

phenomenon, which the POL is coming off.

In addition, the GND portion of source PBA shall be grounded.

10

PBA

The GND portion of each PBA shall be contacted with the GND portion of BLU.

Refer to the (a) and (b) of 3-3 for the design of BLU.

11

Circuit

The standardized approval from the client is required since the EMI is executed by a client.

Our company can only measure the reference since the client measures the BLU.

12

The height of

component

Design the BLU with considering the maximum height of parts, which our company suggests.

13

Between the FFC

and the C-PBA

Design the instrument with considering the length between the FFC and the control PBA.

(The marginal minimum length of 5mm or 8mm is required.)

14

Panel

The surface temperature of panel shall be maintained within 0℃ and 45℃ when the external ambient temperature is at

25℃. (Design the BLU with considering the increase of the temperature in the panel by the LED, CCFL, and etc.)

15

Aging

Recommend to age for over 1 hour at least in the state, which the product is driving initially to stabilize the characteristic

of the initial TFT.

16

The attachment of

gasket

The additional confirmation by our company is required If the attachment of gasket to the S-PBA of our company is

required.(To fix the S-PBA or the EMI)

17

Drive IC

Design the top chassis and the driver IC to be contacted by placing the shape of emboss inside the top chassis as a

measure to prevent the driver IC from heating. The size of emboss shall be designed in larger size than the size of IC

inside the film of the driver IC.

Refer to the (a), (b), (c),(d),(e),(f), and (g)of 3-2 for the design of BLU.

18

The prohibited

bandwidth

Design the BLU in order for the BLU not to interfere with the area, where the control PBA and the source PBA are

located densely according to the drawing for the BLU from our company.

19

S-PBA

The material, which contacts with the bottom side of S-PBA which has a pattern shall be non-conducting material or

shall be insulated.

Page 28

SAMSUNG Confidential

MODEL

LSC400HJ01-W

Doc. No

Page

28 / 28

Loading...

Loading...