LCD-TV

Chassis : N45A

Model : LN26A330J1D

LN32A330J1D

LN37A330J1D

LN40A330J1D

Manual

SERVICE

TFT-LCD TV Contents

1. Precautions

2. Product specications

3. Disassembly and

4. Troubleshootin

5. Exploded View & Part Lis

6. Wiring Diagra

7. Schematic Diagra

Reassembly

g

t

m

m

LN26A330J1D/LN32A330J1D/

LN37A330J1D/LN40A330J1D

Refer to the service manual in the GSPN (see the rear cover) for the more information.

Contents

1. Precautions .............................................................................................................. 1-1

1-1. Safety Precautions ......................................................................................................... 1-1

1-2. Servicing Precautions .....................................................................................................1-2

1-3. Electrostatically Sensitive Devices (ESD) Precautions .................................................. 1-2

1-4. Installation Precautions .................................................................................................. 1-3

2. Product specications ............................................................................................ 2-1

2-1. Feature & Specications ................................................................................................. 2-1

2-3. Spec Comparison to the Old Models .............................................................................. 2-7

2-4. Accessories .................................................................................................................... 2-8

3. Disassembly and Reassemble ............................................................................... 3-1

3-1. Disassembly ................................................................................................................... 3-1

4. Troubleshooting ...................................................................................................... 4-1

4-1. Troubleshooting .............................................................................................................. 4-1

4-2. Alignments and Adjustments ........................................................................................ 4-19

4-3. Factory Mode Adjustments ........................................................................................... 4-20

4-4. White Balance - Calibration .......................................................................................... 4-28

4-5. White Ratio (Balance) Adjustment ................................................................................ 4-30

4-6. Servicing Information .................................................................................................... 4-31

5. Exploded View & Part List ...................................................................................... 5-1

5-1. LN26A330J1D Exploded View ........................................................................................ 5-1

5-2. LN32A330J1D Exploded View ........................................................................................ 5-3

5-3. LN37A330J1D Exploded View ........................................................................................ 5-5

5-4. LN40A330J1D Exploded View ........................................................................................ 5-7

5-5. LN26A330J1D Parts List ................................................................................................ 5-9

5-6. LN32A330J1D Parts List .............................................................................................. 5-32

5-7. LN37A330J1D Parts List .............................................................................................. 5-55

5-8. LN40A330J1D Parts List .............................................................................................. 5-80

6. Wiring Diagram ........................................................................................................ 6-1

6-1. 26” Wiring Diagram ......................................................................................................... 6-1

6-2. 40” Wiring Diagram ......................................................................................................... 6-2

6-3. Cables ............................................................................................................................ 6-4

7. Schematic Diagram ................................................................................................. 7-1

7-1. Internal Block Diagram of Scaler(MSD2248AL) ............................................................. 7-1

7-2. SCHEMATIC Block Diagram ......................................................................................... 7-2

7-3. SlimHalf Tuner Diagram ................................................................................................ 7-3

7-2. Schematic Diagrams ...................................................................................................... 7-4

GSPN (Global Service Partner Network)

Area Web Site

North America

Latin America

CIS http://cis.samsungportal.com

Europe http://europe.samsungportal.com

China http://china.samsungportal.com

Asia http://asia.samsungportal.com

Mideast & Africa

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

http://service.samsungportal.com

http://latin.samsungportal.com

http://mea.samsungportal.com

© 2008 Samsung Electronics Co.,Ltd.

All rights reserved.

Printed in Korea

P/N: BN82-00362A-00

1. Precautions

1. Precautions

1-1. Safety Precautions

Follow these safety, servicing and ESD precautions to prevent damage and to protect against potential hazards such as

electrical shock.

1-1-1. Warnings

1.

For continued safety, do not attempt to modify the circuit board.

2.

Disconnect the AC power and DC power jack before servicing.

1-1-2. Servicing the LCD TV

1.

When servicing the LCD TV, Disconnect the AC line cord from the AC outlet.

2.

It is essential that service technicians have an accurate voltage meter available at all times. Check the calibration of

this meter periodically.

1-1-3. Fire and Shock Hazard

Before returning the LCD TV to the user, perform the following safety checks:

1.

Inspect each lead dress to make certain that the leads are not pinched or that hardware is not lodged between the

chassis and other metal parts in the LCD TV.

2.

Inspect all protective devices such as nonmetallic control knobs, insulating materials, cabinet backs, adjustment and

compartment covers or shields, isolation resistorcapacitor networks, mechanical insulators, etc.

3.

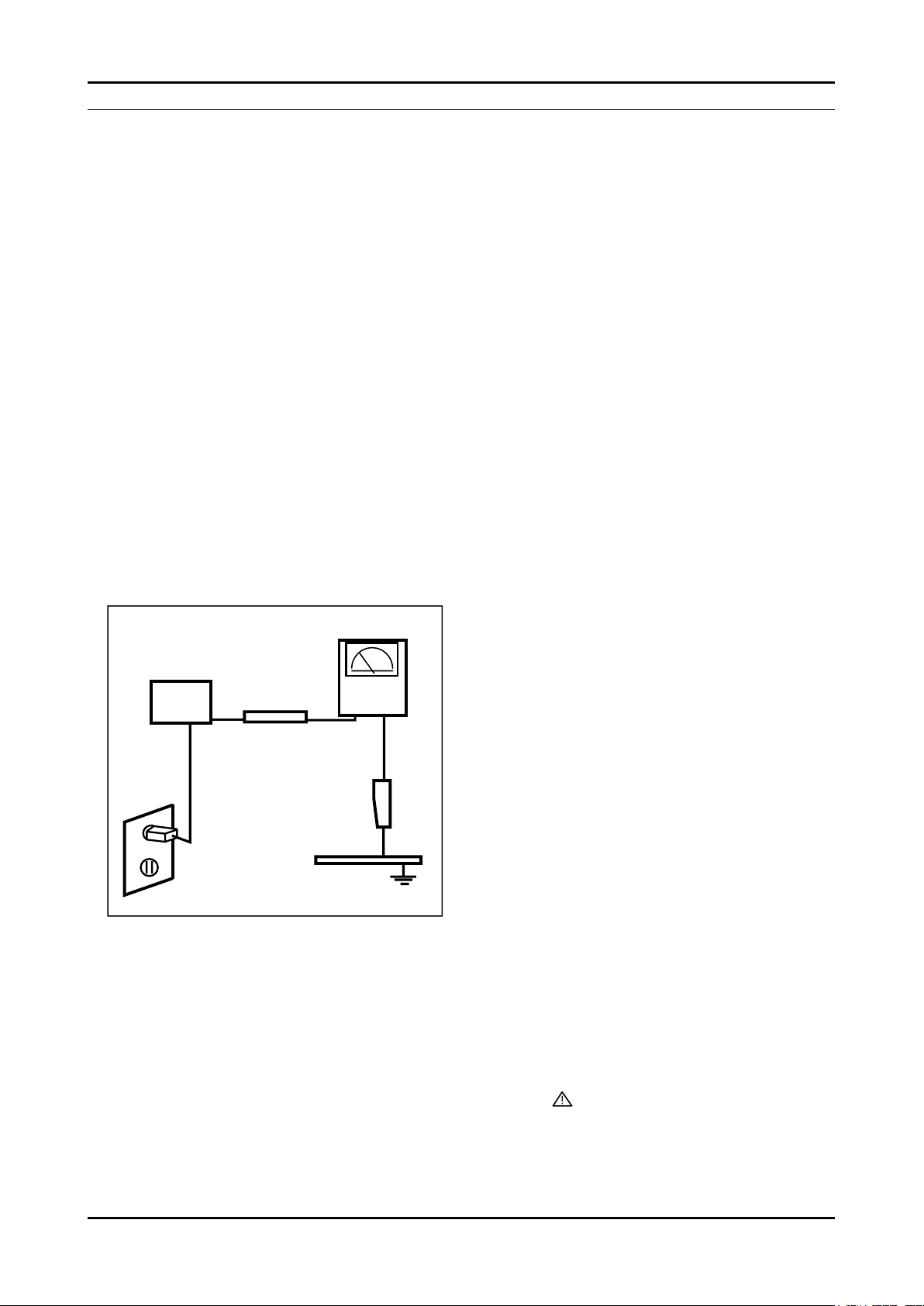

Leakage Current Hot Check (Figure 1-1):

WARNING : Do not use an isolation transformer during this test.

Use a leakage current tester or a metering system that complies with American National Standards Institute (ANSI

C101.1, Leakage Current for Appliances), and Underwriters Laboratories (UL Publication UL1410, 59.7).

(READING SHOULD)

NOT BE ABOVE 0.5mA

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

2-WIRE CORD

*ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

4.

With the unit completely reassembled, plug the AC line cord directly into a 120V AC outlet. With the unit’s AC switch

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

Figure 1-1. Leakage Current Test Circuit

rst in the ON position and then OFF, measure the current between a known earth ground (metal water pipe, conduit,

etc.) and all exposed metal parts, including: metal cabinets, screwheads and control shafts.

The current measured should not exceed 0.5 milliamp.

Reverse the power-plug prongs in the AC outlet and repeat the test.

1-1-4. Product Safety Notices

Some electrical and mechanical parts have special safetyrelated characteristics which are often not evident from visual

inspection. The protection they give may not be obtained by replacing them with components rated for higher voltage,

wattage, etc. Parts that have special safety characteristics are identied by on schematics and parts lists. A substitute

replacement that does not have the same safety characteristics as the recommended replacement part might create

shock, re and/or other hazards. Product safety is under review continuously and new instructions are issued whenever

appropriate.

1-1

1-2

1. Precautions

1-2. Servicing Precautions

WARNING: An electrolytic capacitor installed with the wrong polarity might explode.

Caution: Before servicing units covered by this service manual, read and follow the Safety Precautions section of

this manual.

Note:

1-2-1 General Servicing Precautions

1.

Always unplug the unit’s AC power cord from the AC power source and disconnect the DC Power Jack before

attempting to:

(a) remove or reinstall any component or assembly, (b) disconnect PCB plugs or connectors, (c) connect a test

component in parallel with an electrolytic capacitor.

2.

Some components are raised above the printed circuit board for safety. An insulation tube or tape is sometimes

used. The internal wiring is sometimes clamped to prevent contact with thermally hot components. Reinstall all such

elements to their original position.

3.

After servicing, always check that the screws, components and wiring have been correctly reinstalled. Make sure that

the area around the serviced part has not been damaged.

4.

Check the insulation between the blades of the AC plug and accessible conductive parts (examples: metal panels,

input terminals and earphone jacks).

5.

Insulation Checking Procedure: Disconnect the power cord from the AC source and turn the power switch ON.

Connect an insulation resistance meter (500 V) to theblades of the AC plug.

The insulation resistance between each blade of the AC plug and accessible conductive parts (see above) should be

greater than 1 megohm.

6.

Always connect a test instrument’s ground lead to the instrument chassis ground before connecting the positive lead;

always remove the instrument’s ground lead last.

If unforeseen circumstances create conict between the following servicing precautions and any of the

safety precautions, always follow the safety precautions.

1-3. Electrostatically Sensitive Devices (ESD) Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD are integrated circuits and some eld-effect

transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

1.

Immediately before handling any semiconductor components or assemblies, drain the electrostatic charge from your

body by touching a known earth ground. Alternatively, wear a discharging wrist-strap device. To avoid a shock hazard,

be sure to remove the wrist strap before applying power to the LCD TV.

2.

After removing an ESD-equipped assembly, place it on a conductive surface such as aluminum foil to prevent

accumulation of an electrostatic charge.

3.

Do not use freon-propelled chemicals. These can generate electrical charges sufcient to damage ESDs.

4.

Use only a grounded-tip soldering iron to solder or desolder ESDs.

5.

Use only an anti-static solder removal device. Some solder removal devices not classied as “anti-static” can generate

electrical charges sufcient to damage ESDs.

6.

Do not remove a replacement ESD from its protective package until you are ready to install it. Most replacement ESDs

are packaged with leads that are electrically shorted together by conductive foam, aluminum foil or other conductive

materials.

7.

Immediately before removing the protective material from the leads of a replacement ESD, touch the protective

material to the chassis or circuit assembly into which the device will be installed.

Caution: Be sure no power is applied to the chassis or circuit and observe all other safety precautions.

8.

Minimize body motions when handling unpackaged replacement ESDs. Motions such as brushing clothes together,

or lifting your foot from a carpeted oor can generate enough static electricity to damage an ESD.

1. Precautions

1-4. Installation Precautions

For safety reasons, more than two people are required for carrying the product.

1.

Keep the power cord away from any heat emitting devices, as a melted covering may cause re or electric shock.

2.

Do not place the product in areas with poor ventilation such as a bookshelf or closet. The increased internal

3.

temperature may cause re.

Bend the external antenna cable when connecting it to the product. This is a measure to protect it from being exposed

4.

to moisture. Otherwise, it may cause a re or electric shock.

Make sure to turn the power off and unplug the power cord from the outlet before repositioning the product. Also check

5.

the antenna cable or the external connectors if they are fully unplugged. Damage to the cord may cause re or electric

shock.

Keep the antenna far away from any high-voltage cables and install it rmly. Contact with the highvoltage cable or the

6.

antenna falling over may cause re or electric shock.

When installing the product, leave enough space (10cm) between the product and the wall for ventilation purposes.

7.

A rise in temperature within the product may cause re.

1-3

1. Precautions

Memo

1-4

2. Product specications

2-1. Feature & Specications

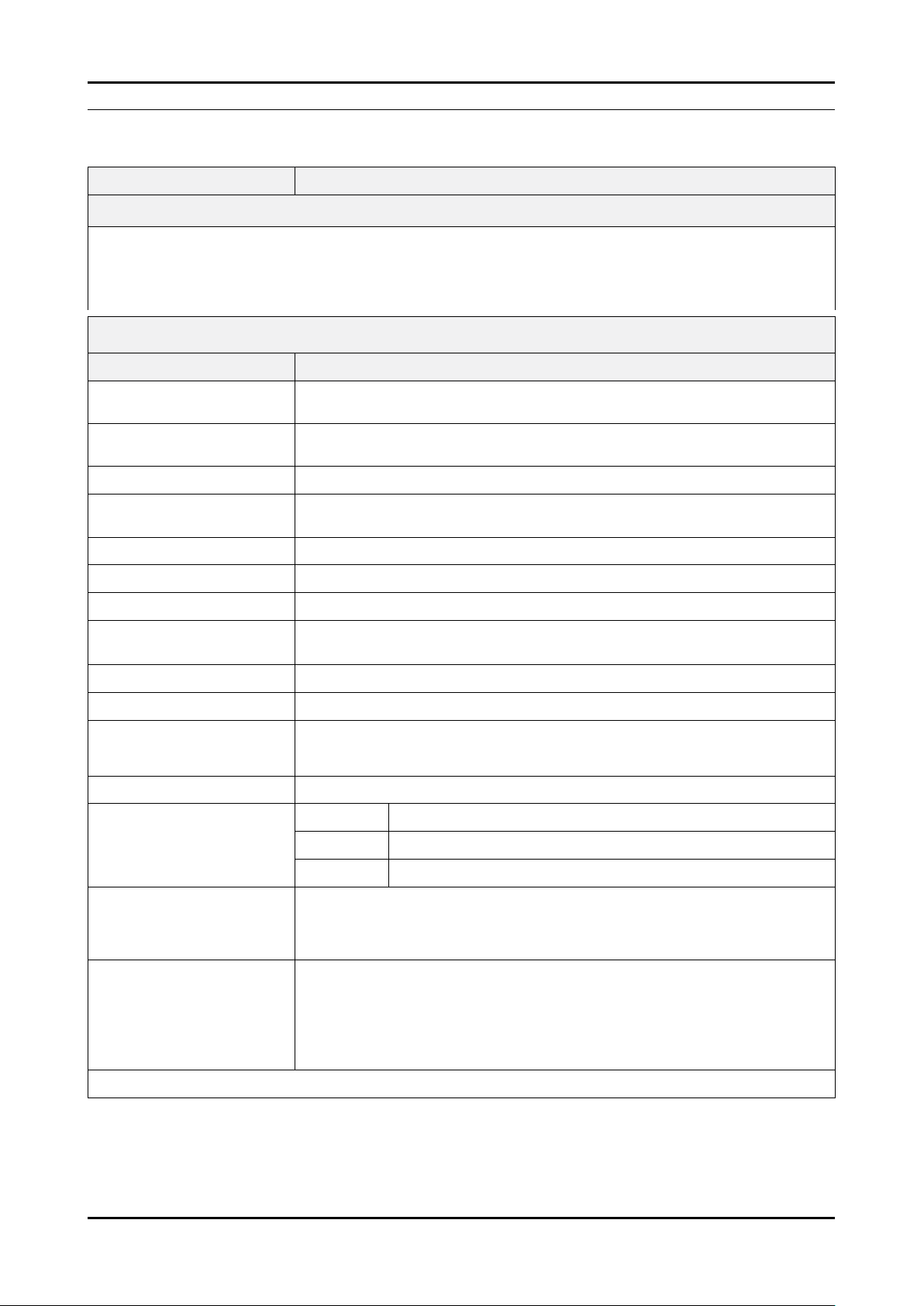

Model LN26A330J1D

Feature

Digital-TV, RF, 3-HDMI, 2-Component, 1-A/V, 1-S-Video, D-DUB

�

Brightness : 500cd/m

�

Contrast Ratio : 800:1

�

Response time : 8ms

�

Item Description

2

Specications

2. Product specications

LCD Panel TFT-LCD panel, RGB vertical stripe, Transmassive mode, Normally white, 26-inch

Scanning Frequency Horizontal : 30 kHz ~ 80 kHz (Automatic)

Display Colors 16.2 million colors

Maximum resolution Horizontal : 1366 Pixels

Input Signal Analog 0.7 Vp-p ± 5% positive at 75Ω , internally terminated

Input Sync Signal H/V Separate, TTL, P. or N.

Maximum Pixel Clock rate 310MHz

Active Display

Horizontal/Vertical

AC power voltage & Frequency AC 110V ~ 220V, 60 Hz

Power Consumption <245 W ( < 1W, stand by )

Dimensions

Set (W x D x H)

Weight (Set) 21.38 lbs (9.7kg)

TV System Tuning Frequency Synthesize (Refer to detailed Frequency Table)

viewable, 0.1405(H)x 0.4215(V)x 3mm pixel pitch

Vertical : 56 Hz ~ 75 Hz (Automatic)

Vertical : 768 Pixels

22.67 x 12.74 inches(575.769(H) x 323.712(V) mm)

26.37 x 8.5 x 19.7 inches(669.7 x 216 x 500.4 mm)_with stand

26.37 x 2.96 x 19.7 inches(669.7 x 75.1 x 446.1 mm)_without stand

System ATSC, NTSC5.38

Sound NTSC-M, AC-3 Digital

Environmental Considerations Operating Temperature : 50˚F ~ 104˚F (10˚C ~ 40˚C)

Operating Humidity : 10% ~ 80%, non-condensing

Storage temperature : -13˚F ~ 113˚F (-25˚C ~ 45˚C)

Storage Humidity : 5% ~ 95%, non-condensing

Environmental Considerations - MAX Internal speaker Out : Right => 10W, Left => 10W

- BASS Control Range : -8 dB ~ + 8dB

- TREBLE Control Range : -8 dB ~ +8 dB

- Headphone Out : 10 mW MAX

- Output Frequency : RF : 80 Hz ~ 15 kHz

A/V : 80 Hz ~ 20 kHz

Note: Anynet+

2-1

2. Product specications

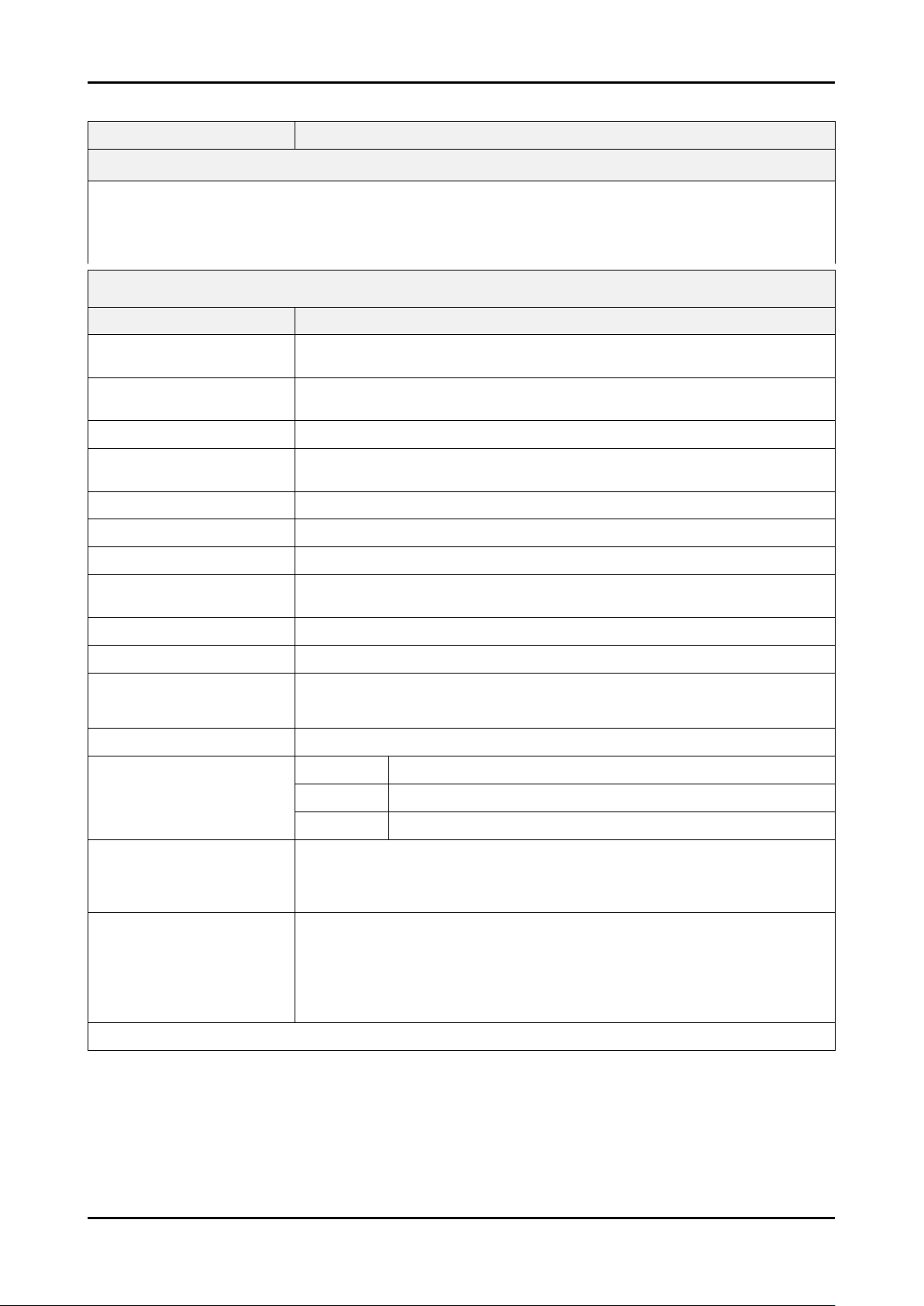

Model LN32A330J1D

Feature

Digital-TV, RF, 3-HDMI, 2-Component, 1-A/V, 1-S-Video, D-DUB

�

Brightness : 500cd/m

�

Contrast Ratio : 800:1

�

Response time : 8ms

�

2

Specications

Item Description

LCD Panel TFT-LCD panel, RGB vertical stripe, Transmassive mode, Normally white, 32-inch

viewable, 0.51075(H)x 0.51075(V)x 3mm pixel pitch

Scanning Frequency Horizontal : 30 kHz ~ 80 kHz (Automatic)

Vertical : 56 Hz ~ 75 Hz (Automatic)

Display Colors 16.7 million colors

Maximum resolution Horizontal : 1366 Pixels

Vertical : 768 Pixels

Input Signal Analog 0.7 Vp-p ± 5% positive at 75Ω , internally terminated

Input Sync Signal H/V Separate, TTL, P. or N.

Maximum Pixel Clock rate 310MHz

Active Display

Horizontal/Vertical

27.47 x 15.44 inches (697.6845(H) x 392.256(V)mm)

AC power voltage & Frequency AC 110V ~ 220V, 60 Hz

Power Consumption <245 W ( < 1W, stand by )

Dimensions

Set (W x D x H)

31.48 x 9.92 x 22.7 inches (799.6 x 252 x 576.5 mm)_with stand

31.48 x 3.11 x 20.56 inches (799.6 x 79 x 522.3 mm)_without stand

Weight (Set) 28.88 lbs (13.1kg)

TV System Tuning Frequency Synthesize (Refer to detailed Frequency Table)

System ATSC, NTSC5.38

Sound NTSC-M, AC-3 Digital

Environmental Considerations Operating Temperature : 50˚F ~ 104˚F (10˚C ~ 40˚C)

Operating Humidity : 10% ~ 80%, non-condensing

Storage temperature : -13˚F ~ 113˚F (-25˚C ~ 45˚C)

Storage Humidity : 5% ~ 95%, non-condensing

Environmental Considerations - MAX Internal speaker Out : Right => 10W, Left => 10W

- BASS Control Range : -8 dB ~ + 8dB

- TREBLE Control Range : -8 dB ~ +8 dB

- Headphone Out : 10 mW MAX

- Output Frequency : RF : 80 Hz ~ 15 kHz

A/V : 80 Hz ~ 20 kHz

Note: Anynet+

2-2

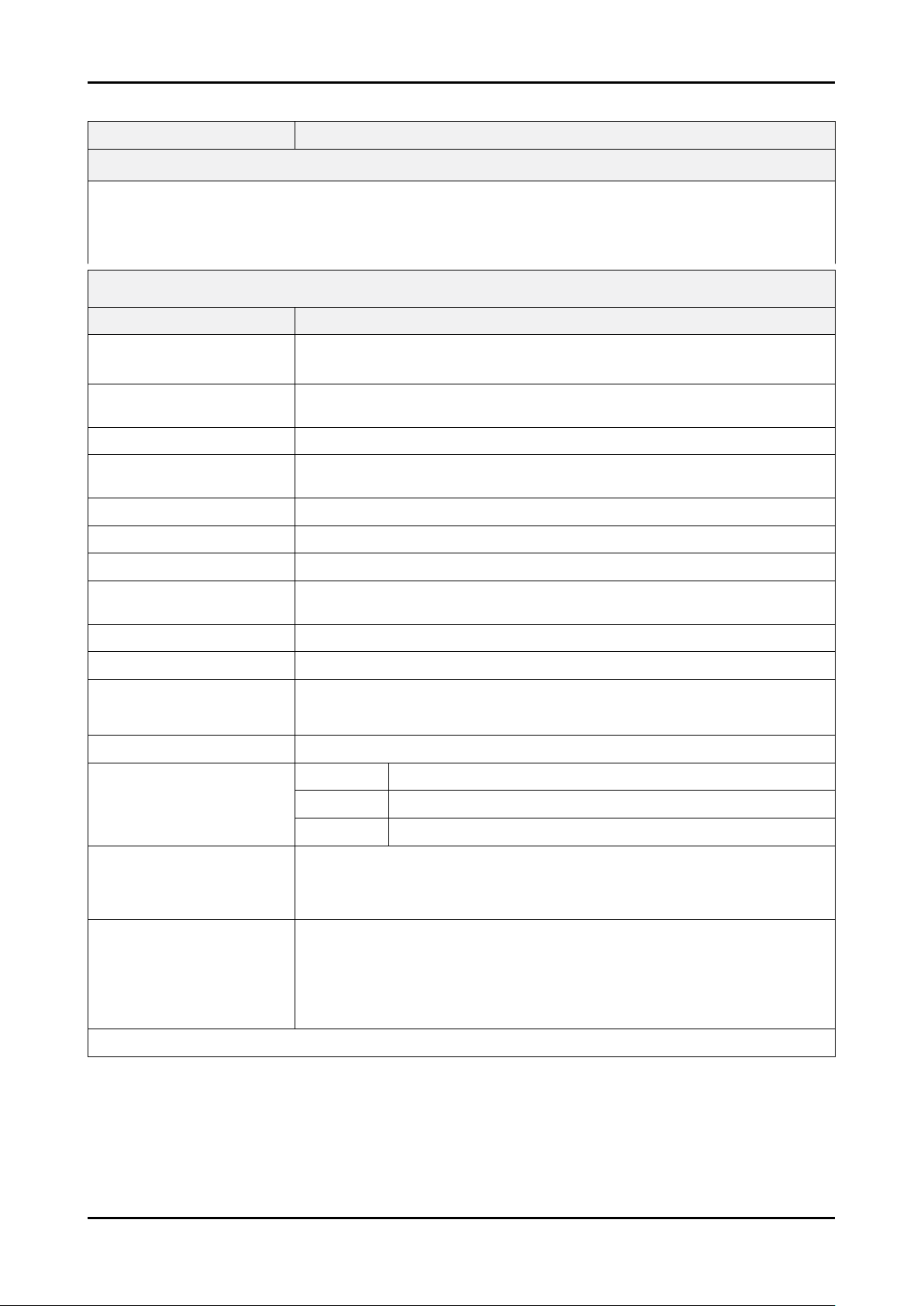

Model LN37A330J1D

Feature

Digital-TV, RF, 3-HDMI, 2-Component, 1-A/V, 1-S-Video, D-DUB

�

Brightness : 500cd/m

�

Contrast Ratio : 800:1

�

Response time : 8ms

�

2

Specications

Item Description

2. Product specications

LCD Panel TFT-LCD panel, RGB vertical stripe, Transmassive mode, Normally white, 40-inch

viewable, 0.648(H)x 0.648(V)x 3mm pixel pitch

Scanning Frequency Horizontal : 30 kHz ~ 80 kHz (Automatic)

Vertical : 56 Hz ~ 75 Hz (Automatic)

Display Colors 16.7 million colors

Maximum resolution Horizontal : 1366 Pixels

Vertical : 768 Pixels

Input Signal Analog 0.7 Vp-p ± 5% positive at 75Ω , internally terminated

Input Sync Signal H/V Separate, TTL, P. or N.

Maximum Pixel Clock rate 310MHz

Active Display

Horizontal/Vertical

32.27 x 18.14 inches(819.6(H) x 460.8(V)mm)

AC power voltage & Frequency AC 110V ~ 220V, 60 Hz

Power Consumption <265 W ( < 1W, stand by )

Dimensions

Set (W x D x H)

36.08 x 11.81 x 25.91 inches (916.4 x 300 x 658.1 mm)_with stand

36.08 x 3.22 x 23.53 inches (916.4 x 81.7 x 597.7 mm)_without stand

Weight (Set) 40.34 lbs (18.3kg)

TV System Tuning Frequency Synthesize (Refer to detailed Frequency Table)

System ATSC, NTSC5.38

Sound NTSC-M, AC-3 Digital

Environmental Considerations Operating Temperature : 50˚F ~ 104˚F (10˚C ~ 40˚C)

Operating Humidity : 10% ~ 80%, non-condensing

Storage temperature : -13˚F ~ 113˚F (-25˚C ~ 45˚C)

Storage Humidity : 5% ~ 95%, non-condensing

Environmental Considerations - MAX Internal speaker Out : Right => 10W, Left => 10W

- BASS Control Range : -8 dB ~ + 8dB

- TREBLE Control Range : -8 dB ~ +8 dB

- Headphone Out : 10 mW MAX

- Output Frequency : RF : 80 Hz ~ 15 kHz

A/V : 80 Hz ~ 20 kHz

Note: Anynet+, WISELINK

2-3

2. Product specications

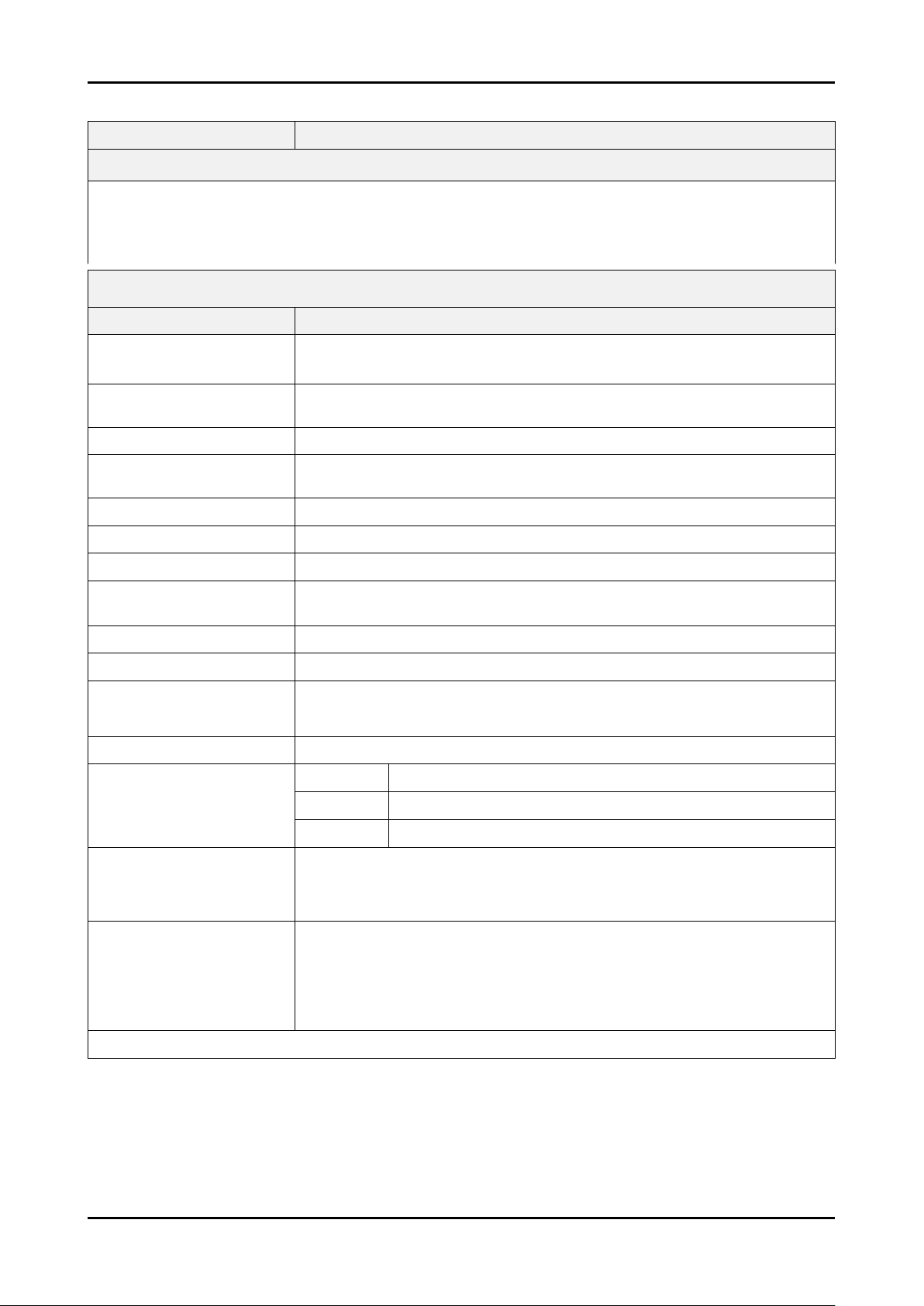

Model LN40A330J1D

Feature

Digital-TV, RF, 3-HDMI, 2-Component, 1-A/V, 1-S-Video, D-DUB

�

Brightness : 500cd/m

�

Contrast Ratio : 800:1

�

Response time : 8ms

�

2

Specications

Item Description

LCD Panel TFT-LCD panel, RGB vertical stripe, Transmassive mode, Normally white, 40-inch

viewable, 0.648(H)x 0.648(V)x 3mm pixel pitch

Scanning Frequency Horizontal : 30 kHz ~ 80 kHz (Automatic)

Vertical : 56 Hz ~ 75 Hz (Automatic)

Display Colors 16.7 million colors

Maximum resolution Horizontal : 1366 Pixels

Vertical : 768 Pixels

Input Signal Analog 0.7 Vp-p ± 5% positive at 75Ω , internally terminated

Input Sync Signal H/V Separate, TTL, P. or N.

Maximum Pixel Clock rate 310MHz

Active Display

Horizontal/Vertical

37.48 x 21.69 inches(952.0(H) x 551.0(V) mm)

AC power voltage & Frequency AC 110V ~ 220V, 60 Hz

Power Consumption <265 W ( < 1W, stand by )

Dimensions

Set (W x D x H)

38.97 x 11.81 x 27.33 inches (989.8 x 300 x 694.3 mm)_with stand

38.97 x 3.22 x 25.03 inches (989.8 x 81.7 x 635.7 mm)_without stand

Weight (Set) 41 lbs (18.6kg)

TV System Tuning Frequency Synthesize (Refer to detailed Frequency Table)

System ATSC, NTSC5.38

Sound NTSC-M, AC-3 Digital

Environmental Considerations Operating Temperature : 50˚F ~ 104˚F (10˚C ~ 40˚C)

Operating Humidity : 10% ~ 80%, non-condensing

Storage temperature : -13˚F ~ 113˚F (-25˚C ~ 45˚C)

Storage Humidity : 5% ~ 95%, non-condensing

Environmental Considerations - MAX Internal speaker Out : Right => 10W, Left => 10W

- BASS Control Range : -8 dB ~ + 8dB

- TREBLE Control Range : -8 dB ~ +8 dB

- Headphone Out : 10 mW MAX

- Output Frequency : RF : 80 Hz ~ 15 kHz

A/V : 80 Hz ~ 20 kHz

Note: Anynet+, WISELINK

2-4

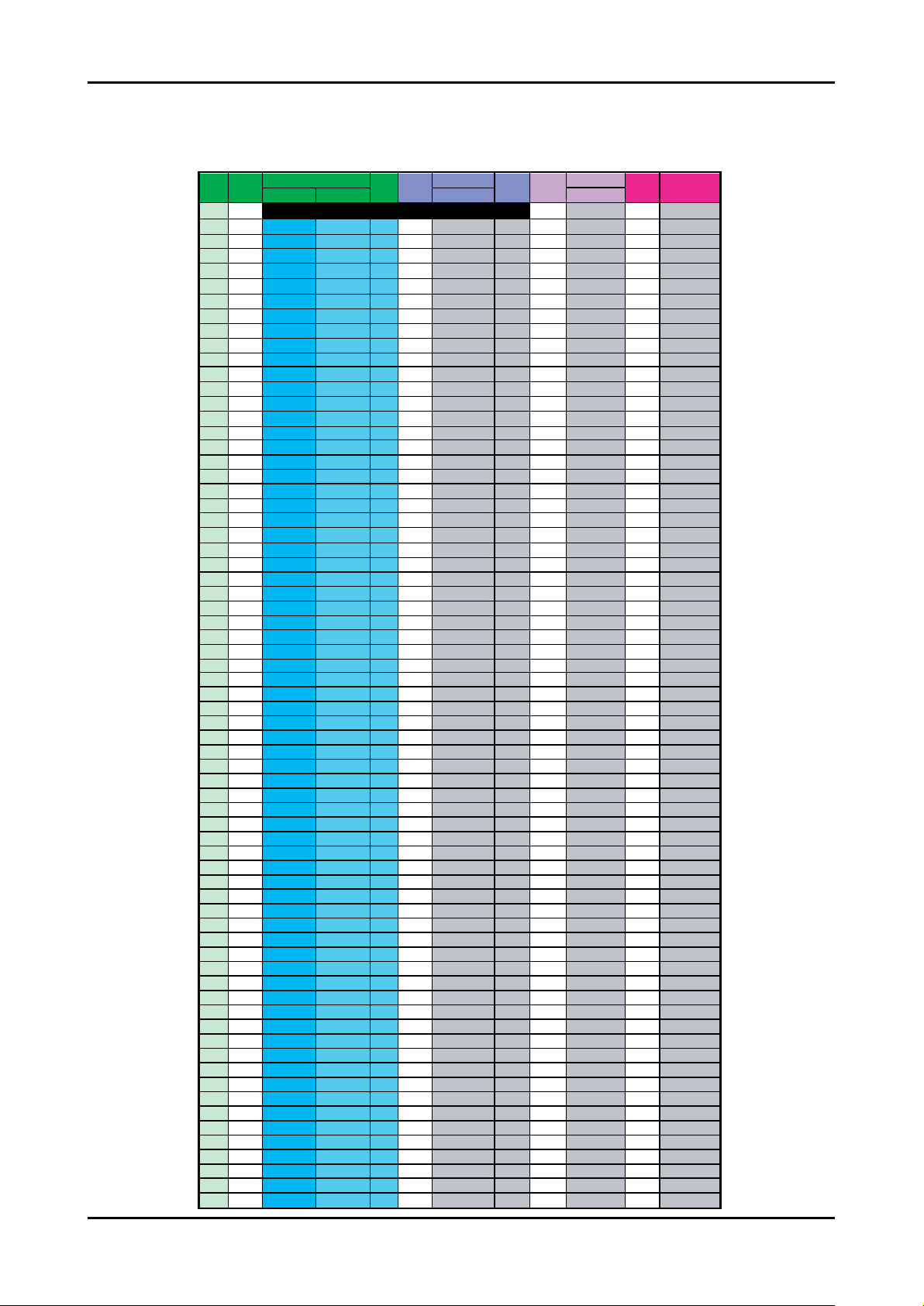

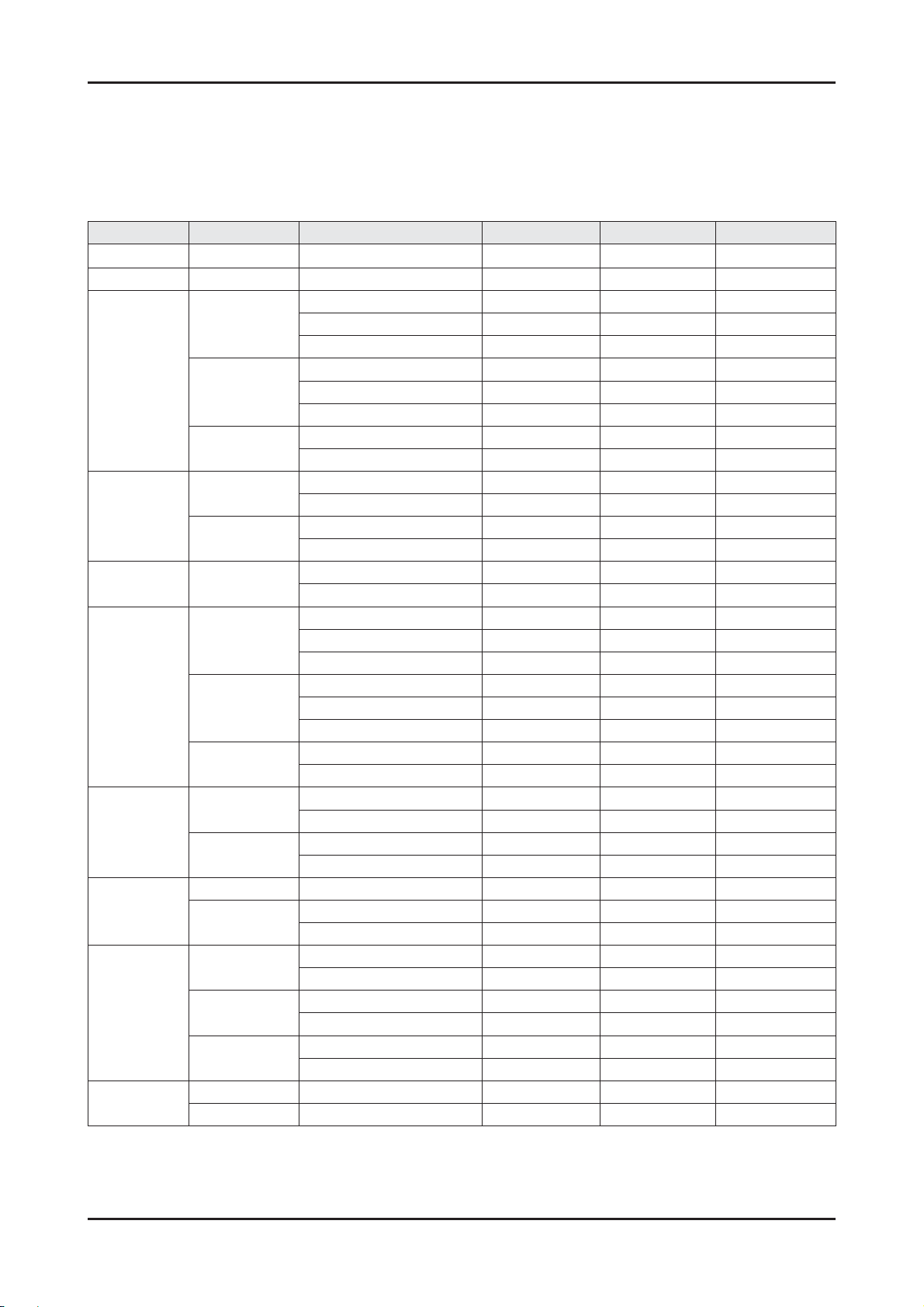

CHANNEL FREQUENCY TABLE

OSD CH NO AIR CH NO CH NO CH NO

Air-DTV Air-NTSC BAND Cable STD BAND Cable HRC Cable IRC

1 1 A-8 72. 00 A-8 73. 25

2 2 57 55. 25 V-L 2 55. 25 V-L 2 54. 00 2 55. 25

3 3 63 61.25 V-L 3 61.25 V-L 3 60.00 3 61.25

4 4 69 67.25 V-L 4 67.25 V-L 4 66.00 4 67.25

5 5 79 77. 25 V-L 5 77. 25 V-L A-7 78. 00 A-7 79. 25

6 6 85 83.25 V-L 6 83.25 V-L A-6 84.00 A-6 85.25

7 7 177 175. 25 V-H 7 175. 25 V-H 7 174. 00 7 175. 25

8 8 183 181.25 V-H 8 181.25 V-H 8 180.00 8 181.25

9 9 189 187.25 V-H 9 187.25 V-H 9 186.00 9 187.25

10 10 195 193.25 V-H 10 193.25 V-H 10 192.00 10 193.25

11 11 201 199.25 V-H 11 199.25 V-H 11 198.00 11 199.25

12 12 207 205.25 V-H 12 205.25 V-H 12 204.00 12 205.25

13 13 213 211.25 V-H 13 211.25 V-H 13 210.00 13 211.25

14 14 473 471. 25 UHF A 121. 25 MID A 120. 00 A 121. 25

15 15 479 477.25 UHF B 127.25 MID B 126.00 B 127.25

16 16 485 483.25 UHF C 133.25 MID C 132.00 C 133.25

17 17 491 489.25 UHF D 139.25 MID D 138.00 D 139.25

18 18 497 495.25 UHF E 145.25 MID E 144.00 E 145.25

19 19 503 501.25 UHF F 151.25 MID F 150.00 F 151.25

20 20 509 507.25 UHF G 157.25 MID G 156.00 G 157.25

21 21 515 513.25 UHF H 163.25 MID H 162.00 H 163.25

22 22 521 519.25 UHF I 169.25 MID I 168.00 I 169.25

23 23 527 525.25 UHF J 217. 25 SUPER J 216. 00 J 217. 25

24 24 533 531.25 UHF K 223.25 SUPER K 222.00 K 223.25

25 25 539 537.25 UHF L 229.25 SUPER L 228.00 L 229.25

26 26 545 543.25 UHF M 235.25 SUPER M 234.00 M 235.25

27 27 551 549.25 UHF N 241.25 SUPER N 240.00 N 241.25

28 28 557 555.25 UHF O 247.25 SUPER O 246.00 O 247.25

29 29 563 561.25 UHF P 253.25 SUPER P 252.00 P 253.25

30 30 569 567.25 UHF Q 259.25 SUPER Q 258.00 Q 259.25

31 31 575 573.25 UHF R 265.25 SUPER R 264.00 R 265.25

32 32 581 579.25 UHF S 271.25 SUPER S 270.00 S 271.25

33 33 587 585.25 UHF T 277.25 SUPER T 276.00 T 277.25

34 34 593 591.25 UHF U 283.25 SUPER U 282.00 U 283.25

35 35 599 597.25 UHF V 289.25 SUPER V 288.00 V 289.25

36 36 605 603.25 UHF W 295.25 SUPER W 294.00 W 295.25

37 37 611 609.25 UHF AA 301.25 HYPER AA 300.00 AA 301.25

38 38 617 615.25 UHF BB 307.25 HYPER BB 306.00 BB 307.25

39 39 623 621.25 UHF CC 313.25 HYPER CC 312.00 CC 313.25

40 40 629 627.25 UHF DD 319.25 HYPER DD 318.00 DD 319.25

41 41 635 633.25 UHF EE 325.25 HYPER EE 324.00 EE 325.25

42 42 641 639.25 UHF FF 331.25 HYPER FF 330.00 FF 331.25

43 43 647 645.25 UHF GG 337.25 HYPER GG 336.00 GG 337.25

44 44 653 651.25 UHF HH 343.25 HYPER HH 342.00 HH 343.25

45 45 659 657.25 UHF II 349.25 HYPER II 348.00 II 349.25

46 46 665 663.25 UHF JJ 355.25 HYPER JJ 354.00 JJ 355.25

47 47 671 669.25 UHF KK 361.25 HYPER KK 360.00 KK 361.25

48 48 677 675.25 UHF LL 367.25 HYPER LL 366.00 LL 367.25

49 49 683 681.25 UHF MM 373.25 HYPER MM 372.00 MM 373.25

50 50 689 687.25 UHF NN 379.25 HYPER NN 378.00 NN 379.25

51 51 695 693.25 UHF OO 385.25 HYPER OO 384.00 OO 385.25

52 52 701 699.25 UHF PP 391.25 HYPER PP 390.00 PP 391.25

53 53 707 705.25 UHF QQ 397.25 HYPER QQ 396.00 QQ 397.25

54 54 713 711.25 UHF RR 403.25 HYPER RR 402.00 RR 403.25

55 55 719 717.25 UHF SS 409.25 HYPER SS 408.00 SS 409.25

56 56 725 723.25 UHF TT 415.25 HYPER TT 414.00 TT 415.25

57 57 731 729.25 UHF UU 421.25 HYPER UU 420.00 UU 421.25

58 58 737 735.25 UHF VV 427.25 HYPER VV 426.00 VV 427.25

59 59 743 741.25 UHF WW 433.25 HYPER WW 432.00 WW 433.25

60 60 749 747.25 UHF XX 439.25 HYPER XX 438.00 XX 439.25

61 61 755 753.25 UHF YY 445.25 HYPER YY 444.00 YY 445.25

62 62 761 759.25 UHF ZZ 451.25 HYPER ZZ 450.00 ZZ 451.25

63 63 767 765.25 UHF AAA 457.25 HYPER AAA 456.00 AAA 457.25

64 64 773 771.25 UHF BBB 463.25 HYPER BBB 462.00 BBB 463.25

65 65 779 777.25 UHF CCC 469.25 ULTRA CCC 468.00 CCC 469.25

66 66 785 783.25 UHF DDD 475.25 ULTRA DDD 474.00 DDD 475.25

67 67 791 789.25 UHF EEE 481.25 ULTRA EEE 480.00 EEE 481.25

68 68 797 795.25 UHF FFF 487.25 ULTRA FFF 486.00 FFF 487.25

69 69 803 801.25 UHF GGG 493.25 ULTRA GGG 492.00 GGG 493.25

OUTPUT FREQUENCY : ANALOG fv:45.75MHz, fs:41.25MHz DIGITAL Fc:44MHz

1.

2.

TUNING STEP SIZE : FIRST PLL 250KHz SECOND PLL 62.5KHz

2. Product specications

2-5

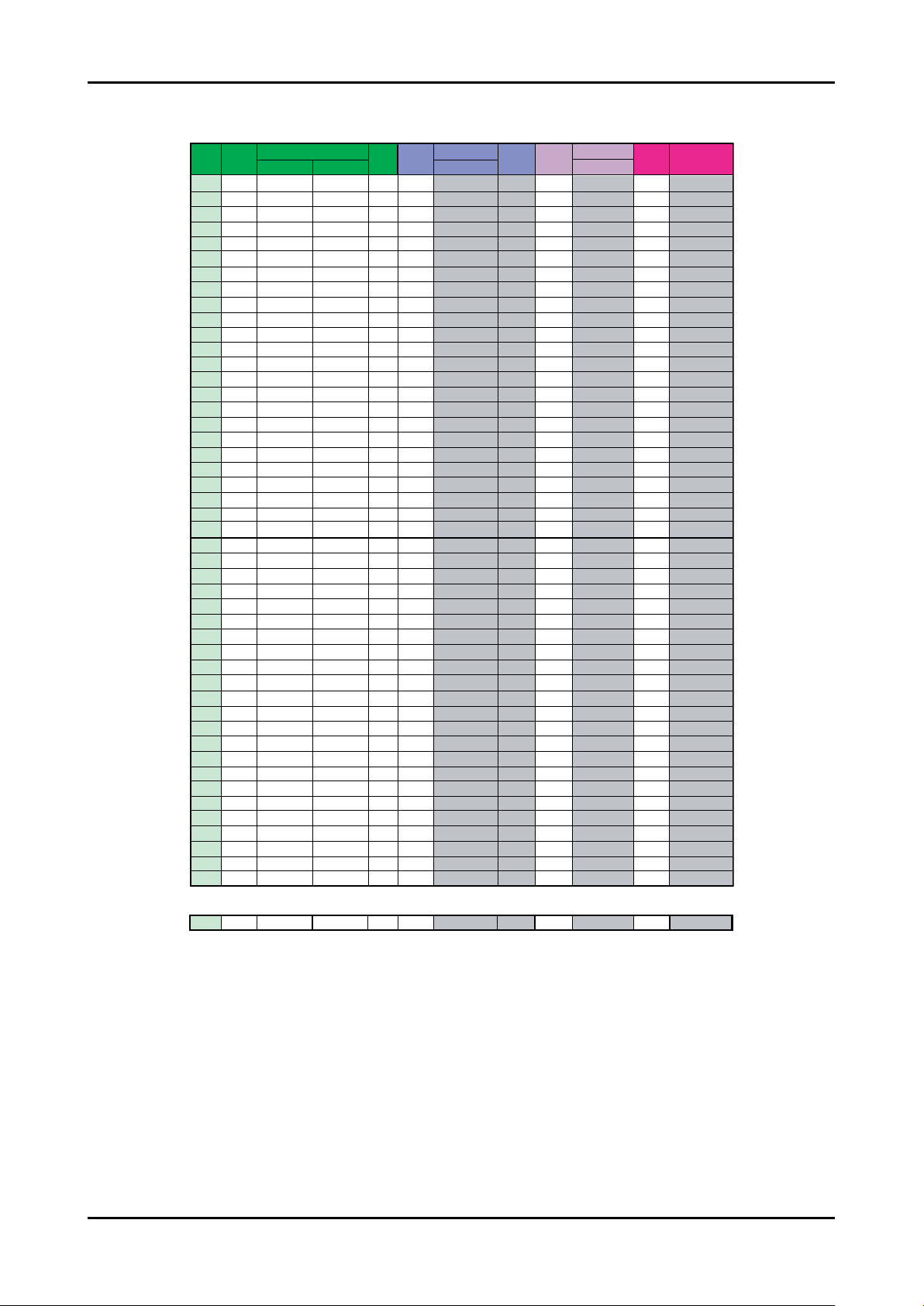

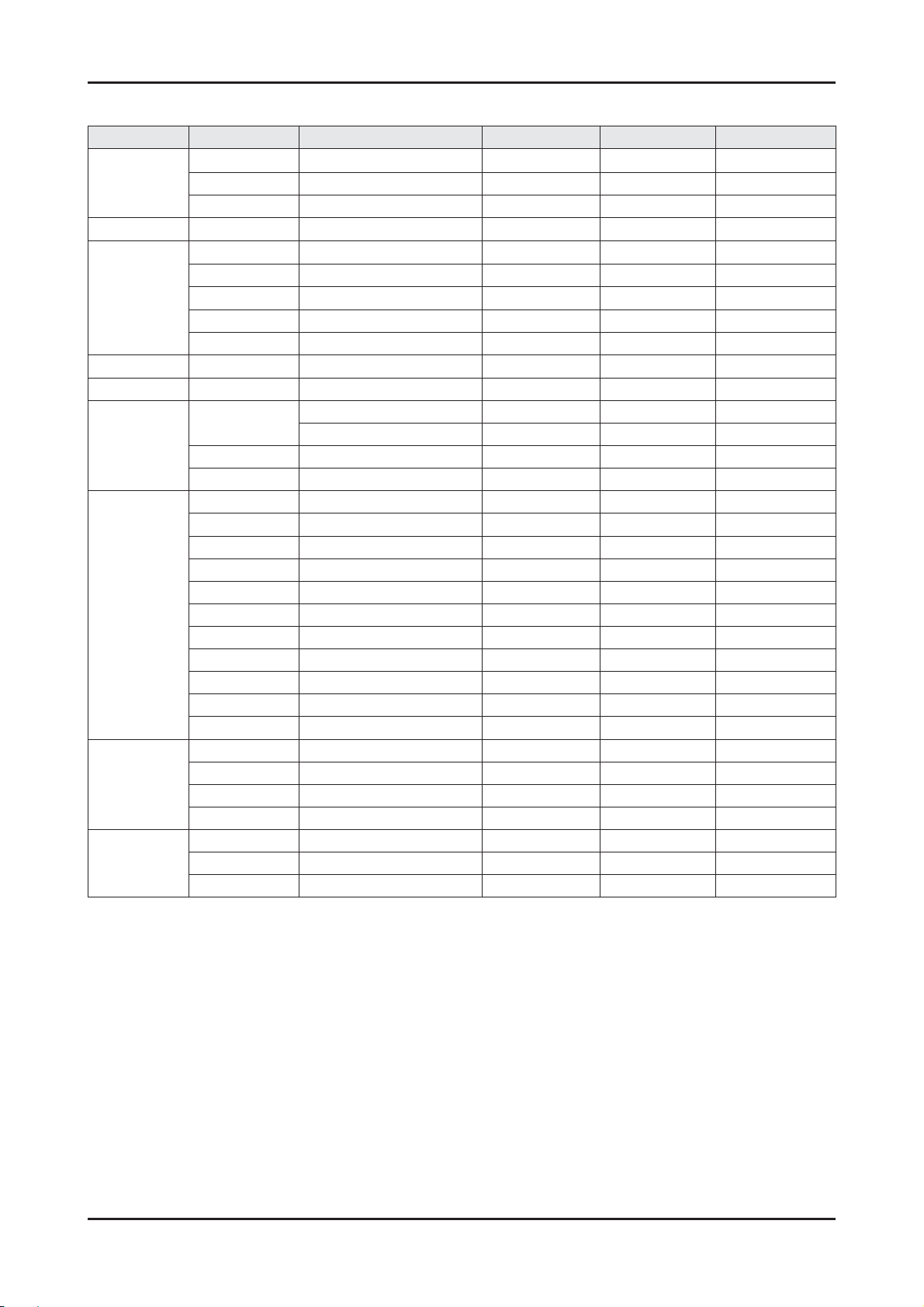

2. Product specications

OSD CH NO AIR CH NO CH NO CH NO

Air-DTV Air-NTSC BAND Cable STD BAND Cable HRC Cable IRC

70 70 HHH 499.25 ULTRA HHH 498.00 HHH 499.25

71 71 III 505.25 ULTRA III 504.00 III 505.25

72 72 JJJ 511.25 ULTRA JJJ 510.00 JJJ 511.25

73 73 KKK 517.25 ULTRA KKK 516.00 KKK 517.25

74 74 LLL 523.25 ULTRA LLL 522.00 LLL 523.25

75 75 MMM 529.25 ULTRA MMM 528.00 MMM 529.25

76 76 NNN 535.25 ULTRA NNN 534.00 NNN 535.25

77 77 OOO 541.25 ULTRA OOO 540.00 OOO 541.25

78 78 PPP 547.25 ULTRA PPP 546.00 PPP 547.25

79 79 79 553.25 ULTRA 79 552.00 79 553.25

80 80 80 559.25 ULTRA 80 558.00 80 559.25

81 81 81 565.25 ULTRA 81 564.00 81 565.25

82 82 82 571.25 ULTRA 82 570.00 82 571.25

83 83 83 577.25 ULTRA 83 576.00 83 577.25

84 84 84 583.25 ULTRA 84 582.00 84 583.25

85 85 85 589.25 ULTRA 85 588.00 85 589.25

86 86 86 595.25 ULTRA 86 594.00 86 595.25

87 87 87 601.25 ULTRA 87 600.00 87 601.25

88 88 88 607.25 ULTRA 88 606.00 88 607.25

89 89 89 613.25 ULTRA 89 612.00 89 613.25

90 90 90 619.25 ULTRA 90 618.00 90 619.25

91 91 91 625.25 ULTRA 91 624.00 91 625.25

92 92 92 631.25 ULTRA 92 630.00 92 631.25

93 93 93 637.25 ULTRA 93 636.00 93 637.25

94 94 94 643.25 ULTRA 94 642.00 94 643.25

95 95 A-5 91. 25 FM A-5 90. 00 A-5 91. 25

96 96 A-4 97.25 FM A-4 96.00 A-4 97.25

97 97 A-3 103.25 FM A-3 102.00 A-3 103.25

98 98 A-2 109.25 MID A-2 108.00 A-2 109.25

99 99 A-1 115.25 MID A-1 114.00 A-1 115.25

100 100 100 649. 25 ULTRA 100 648. 00 100 649. 25

101 101 101 655.25 ULTRA 101 654.00 101 655.25

102 102 102 661.25 ULTRA 102 660.00 102 661.25

103 103 103 667.25 ULTRA 103 666.00 103 667.25

104 104 104 673.25 ULTRA 104 672.00 104 673.25

105 105 105 679.25 ULTRA 105 678.00 105 679.25

106 106 106 685.25 ULTRA 106 684.00 106 685.25

107 107 107 691.25 ULTRA 107 690.00 107 691.25

108 108 108 697.25 ULTRA 108 696.00 108 697.25

109 109 109 703.25 ULTRA 109 702.00 109 703.25

110 110 110 709.25 ULTRA 110 708.00 110 709.25

111 111 111 715.25 ULTRA 111 714.00 111 715.25

112 112 112 721.25 ULTRA 112 720.00 112 721.25

113 113 113 727.25 ULTRA 113 726.00 113 727.25

114 114 114 733.25 ULTRA 114 732.00 114 733.25

115 115 115 739.25 ULTRA 115 738.00 115 739.25

116 116 116 745.25 ULTRA 116 744.00 116 745.25

. .

. . .

. . . .

. .

. . .

. . . .

125 125 125 799.25 ULTRA 125 798.00 125 799.25

. . . . . . . . .

2-6

2. Product specications

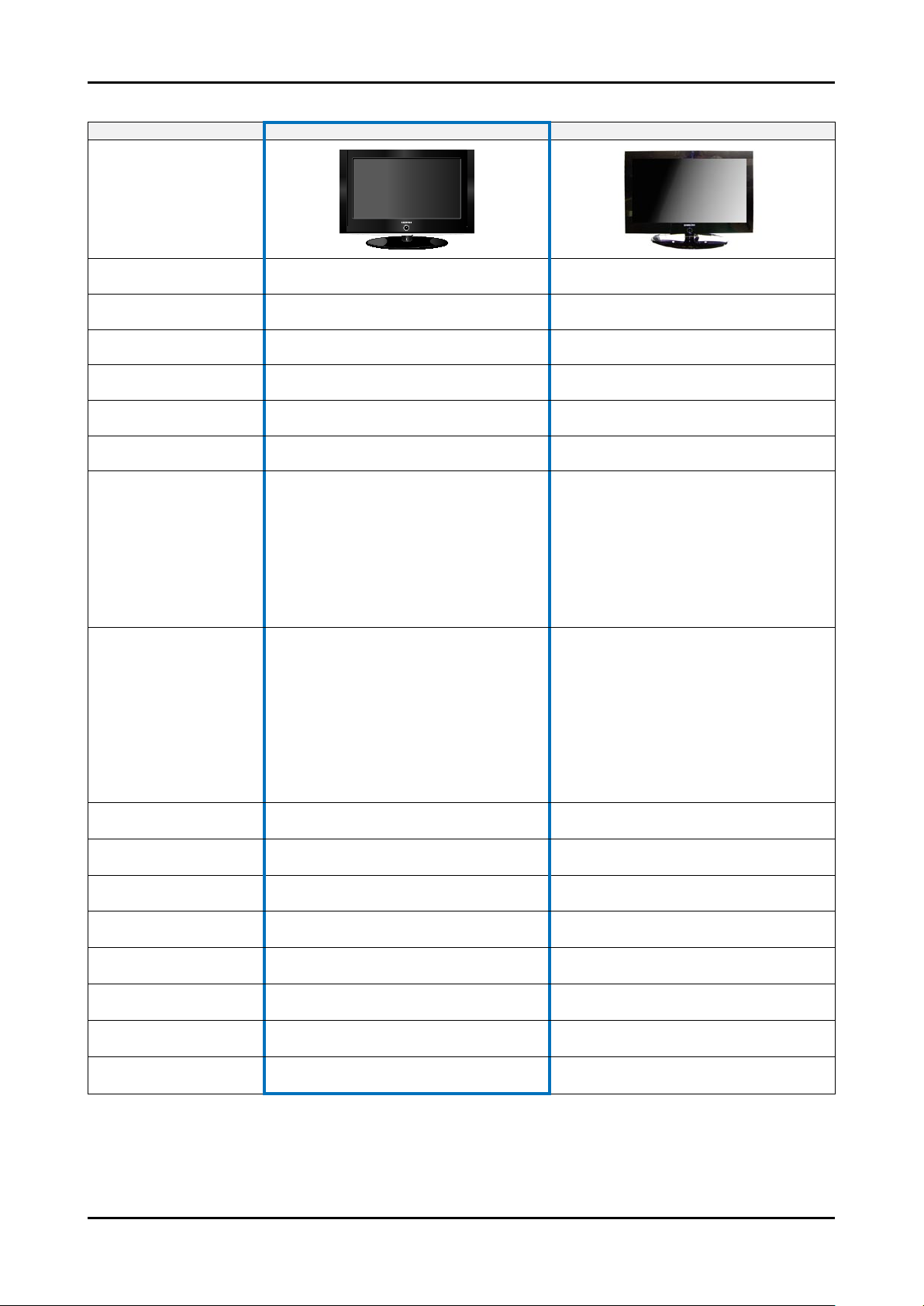

2-3. Spec Comparison to the Old Models

Model LN**A330J1D (19”/26”/32”/37”/40”) LNT**42H (23”/26”/32”/40”/46”)

Design

Display Type LCD TV LCD TV

Built-in Tuner O O

Resolution

LCD Panel TFT LCD Panel 60Hz TFT LCD Panel 60Hz

Screen Size 19”/26”/32”/37”/40” 23” / 26” / 32” / 40” / 46”

Picture ratio 16 : 9 16 : 9

18.78 x 7.09 x 15.24 inches_with stand

19

26

Dimensions (W x H x D)

31.48 x 11.81 x 25.91 inches_with stand

32

36.08 x 11.81 x 25.91 inches_with stand

37

38.97 x 11.81 x 27.33 inches_with stand

40

19

26

Weight

32

37

40

19”=>1440 x 900

26”/32”/37”/40”=>1366 x 768

26.37 x 8.5 x 19.7 inches_with stand

11.24 lbs(set)

21.38 lbs(set)

28.88 lbs(set)

40.34 lbs(set)

41 lbs(set)

1366 x 768

26.29 x 9.13 x 17.53 inches_with stand

23

29.28 x 9.15 x 19.94 inches_with stand

26

34.42 x 11.47 x 22.72 inches_with stand

32

42.67 x 11.81 x 27.17 inches_with stand

40

48.04 x 12.83 x 30.55 inches_with stand

46

23

26

32

40

46

24.25 lbs (set)

31.97 lbs (set)

41.89 lbs (set)

60.63 lbs (set)

80.91 lbs (set)

Brightness 500nit(19”=>300nit) 500 nit

Contrast Ratio 8000:1(19”=>1000:1) 8000:1

Picture Enhacer DNIe(FBE3) DNIe (FBE2)

Equalizer 5 band 5 band

Auto Motion Plus 120Hz Not available Not available

Surround Sound 2 Way SRS TruSurround Dolby Digital 2 Way SRS TruSurround Dolby Digital

Speaker Output 5W x 2 5W x 2

Antenna 1 (Cable/Air) 2 (Cable/Air)

2-7

2. Product specications

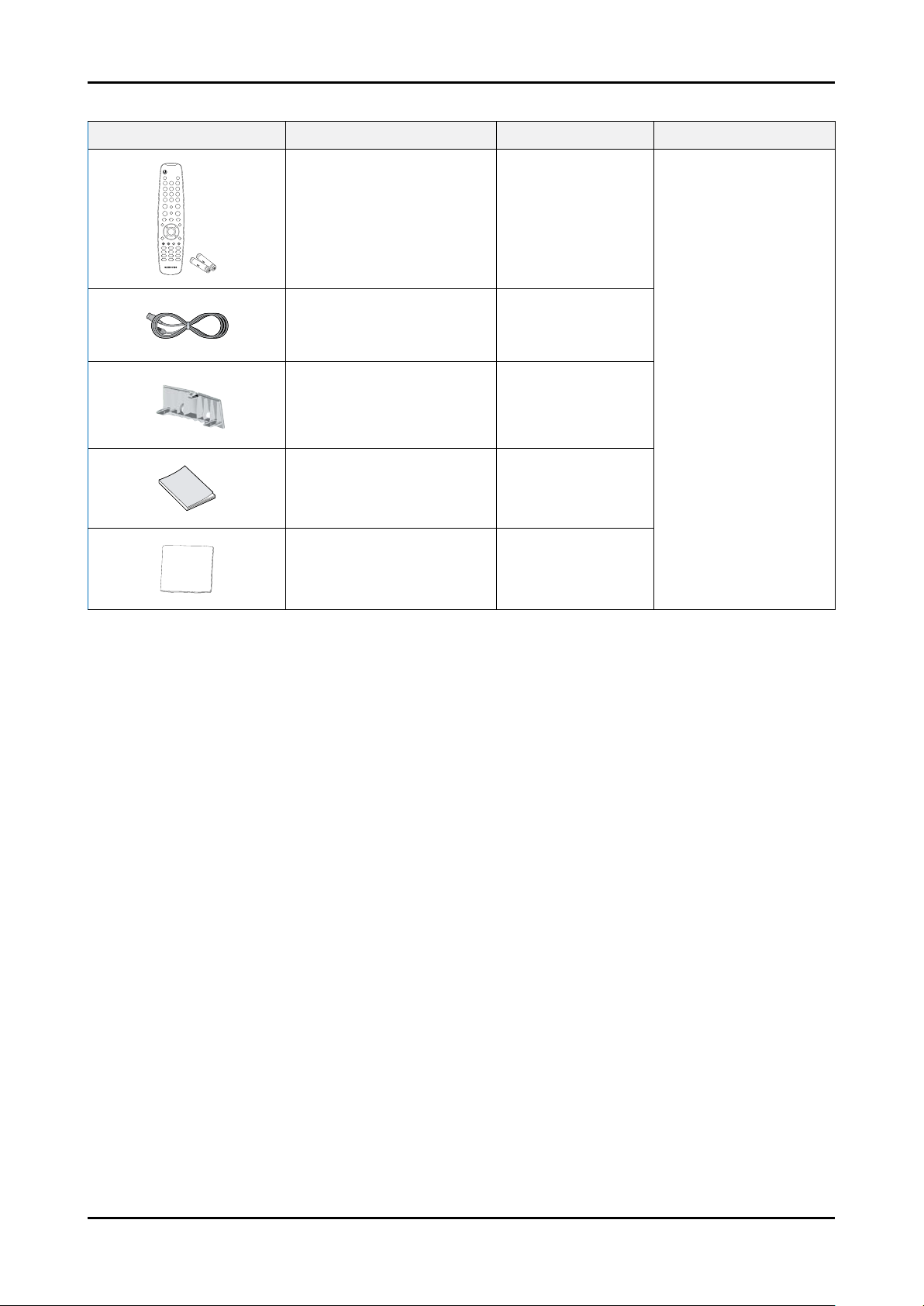

2-4. Accessories

Product Description Code. No Remark

Remote Control & Batteries

(AAA x 2)

Power Cord 3903-000144

Cover-Bottom

Owner’s Instructions BN63-01395A

Cleaning Cloth BN63-01798A

BN59-00687A

26”:BN63-04269A

32”:BN63-04269A

37”:BN63-04243A

40”:BN63-04243A

Samsung Electronics

Service center

2-8

3. Disassembly and Reassemble

3. Disassembly and Reassemble

This section of the service manual describes the disassembly and reassembly procedures for the TFT-LCD TV.

WARNING: This monitor contains electrostatically sensitive devices. Use caution when handling these components.

3-1. Disassembly

Cautions: 1. Disconnect the monitor from the power source before disassembly.

2. Follow these directions carefully; never use metal instruments to pry apart the cabinet.

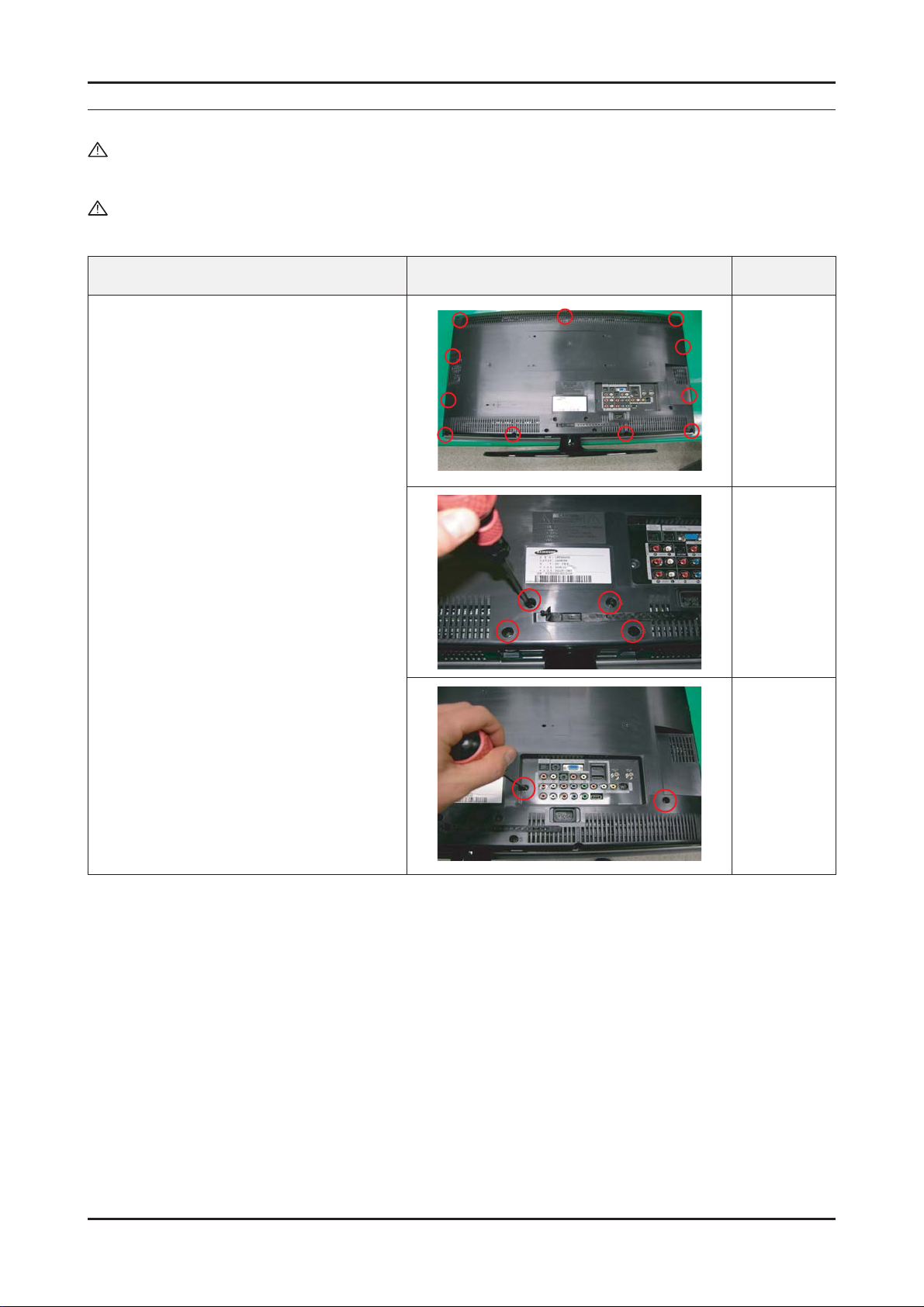

Description Picture Description Screws

1. Place monitor face down on cushioned table.

Remove screws from the rear cover and

remove screws from the stand.

3-1

3. Disassembly and Reassemble

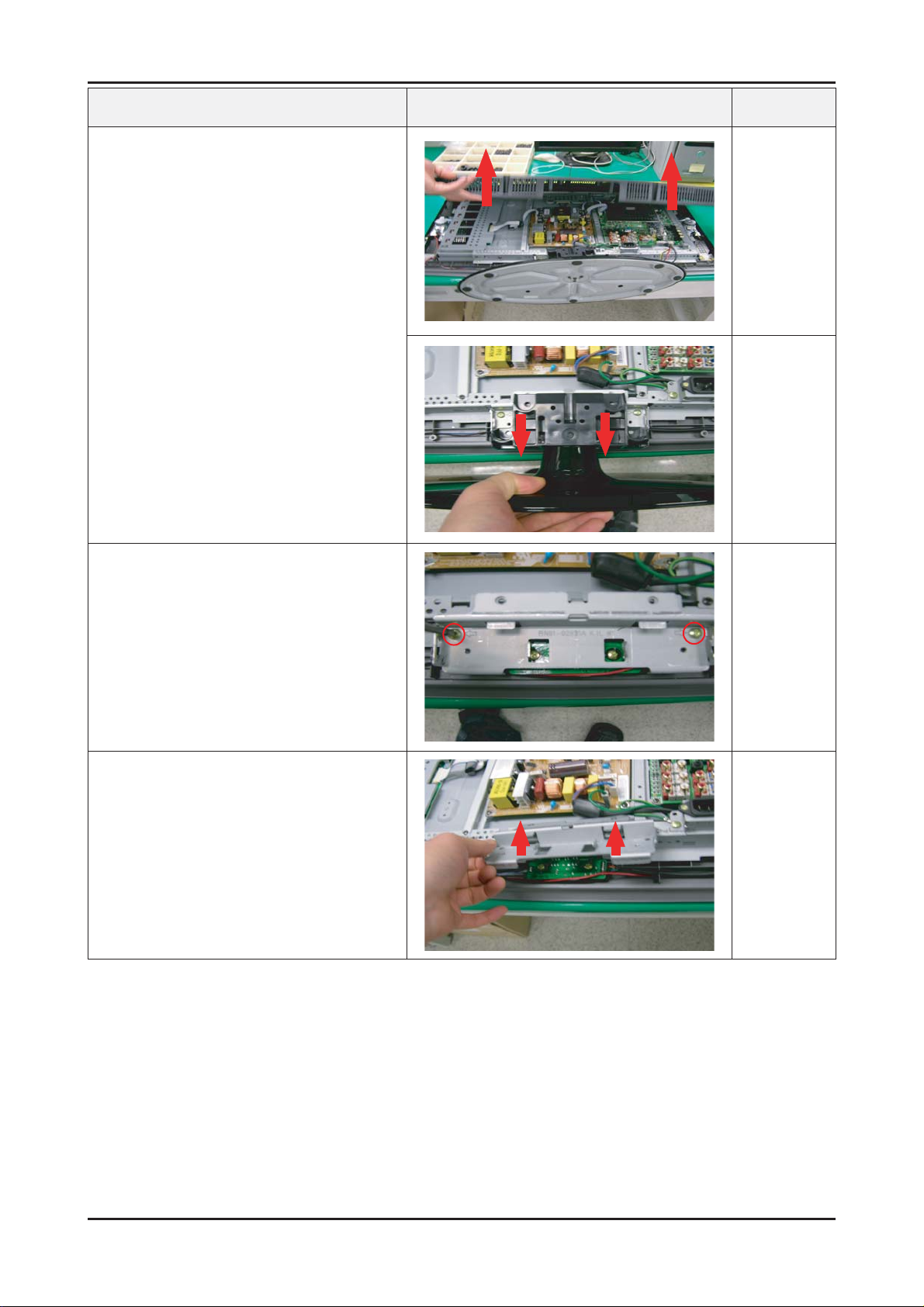

Description Picture Description Screws

2. Lift up the rear cover and remove the stand.

3. Remove Screws from the stand BRKT and lift

up the stand BRKT.

3-2

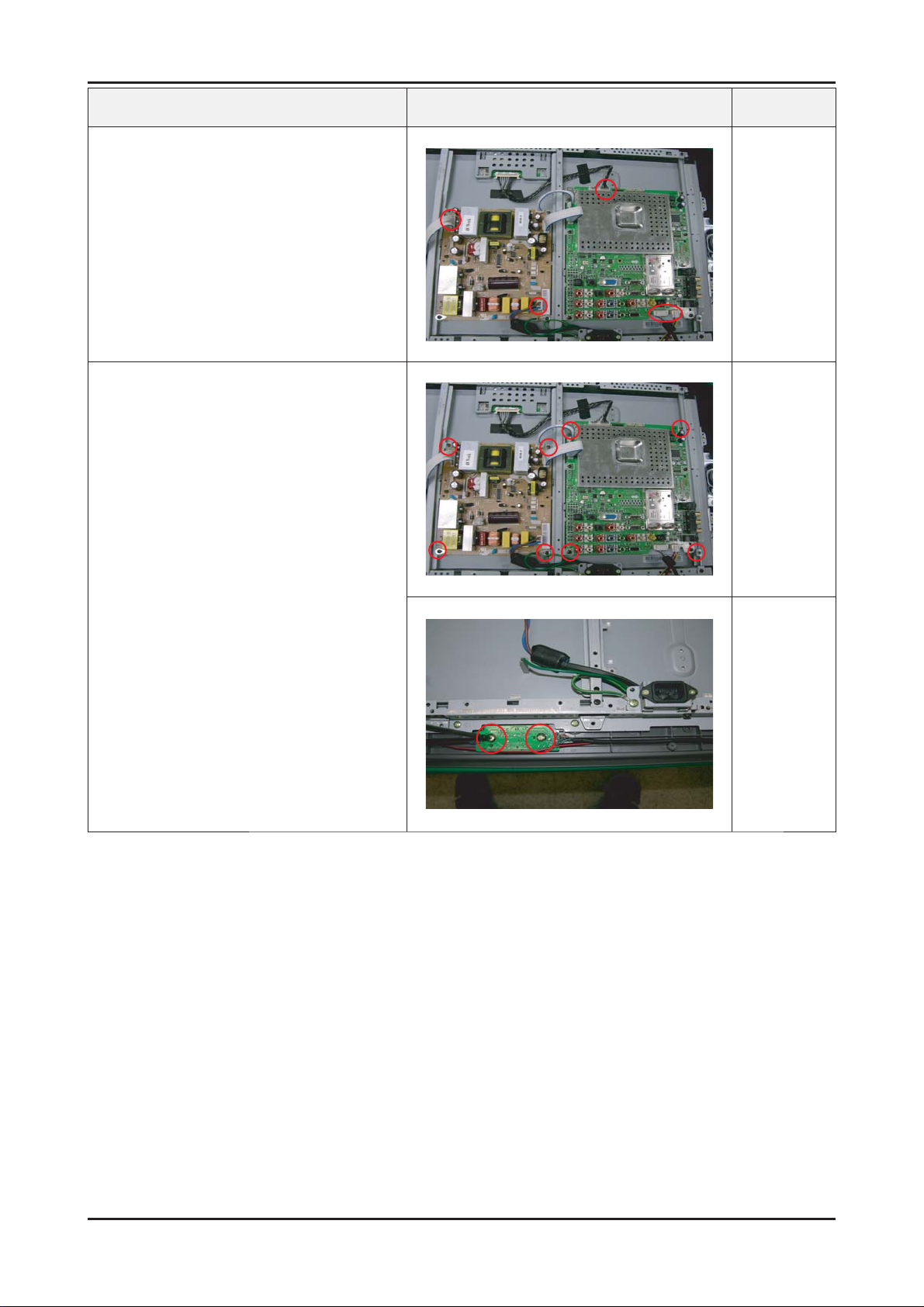

Description Picture Description Screws

4. Remove screws from the shield and

disconnect cable.

5. Remove screws from the boards and remove

screw from the side connector.

3. Disassembly and Reassemble

3-3

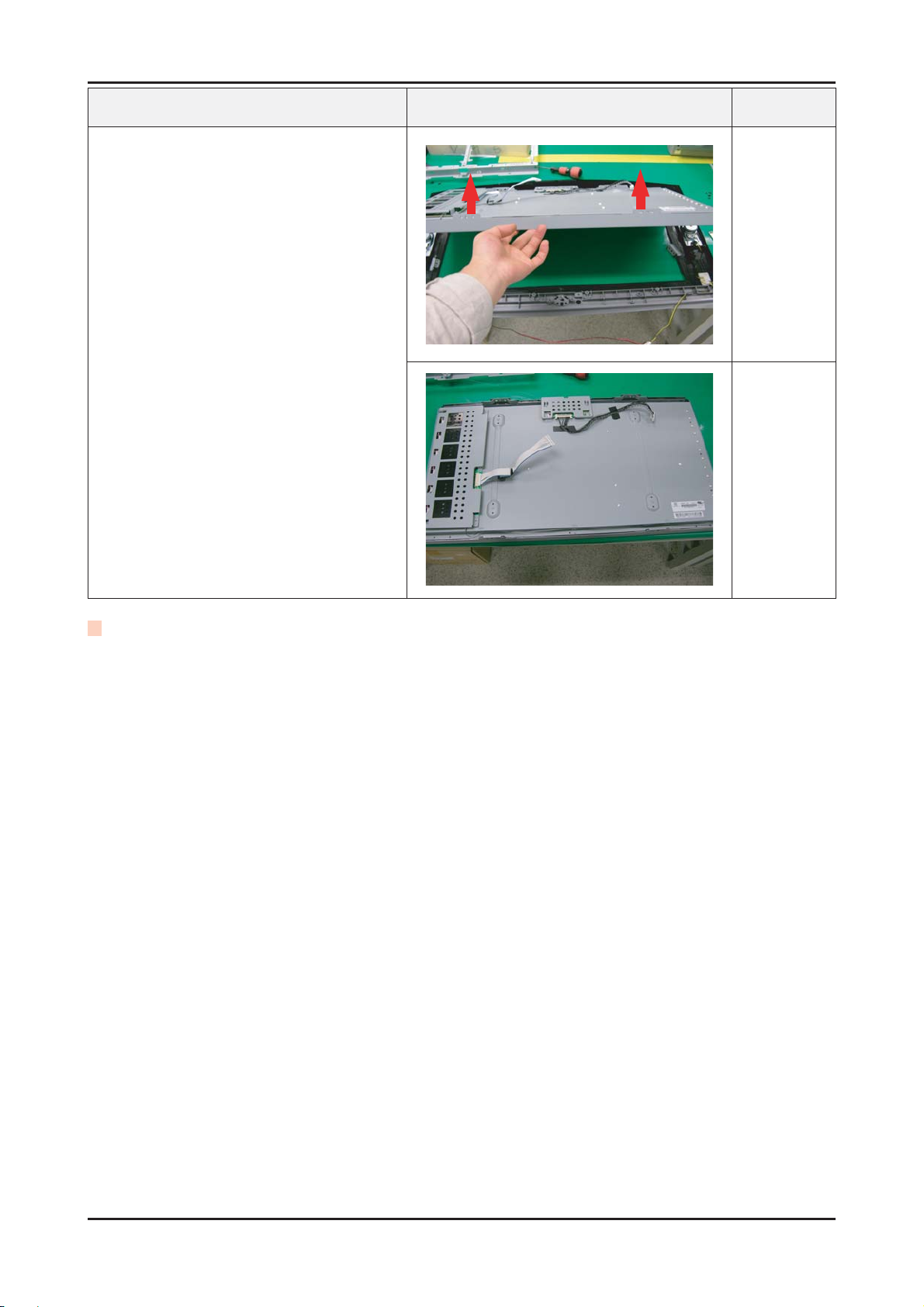

3. Disassembly and Reassemble

Description Picture Description Screws

6. Lift up the speakers and remove screws from

the panel BRKT.

7. Remove screws and lift up the BRKT.

3-4

Description Picture Description Screws

8. Lift up the panel.

3. Disassembly and Reassemble

Reassembly procedures are in the reverse order of disassembly procedures.※

3-5

3. Disassembly and Reassemble

3-2. LCD TV SVC Guide for each symptom

3-2-1 T-Con Board Problem

-. Symptom 1 : Abnormal Picture

-. Symptom 2 : No Picture [No Display but the BLU(Back Light Unit) is on]

If you can see the light as above picture when you push the screen, the BLU is on.

-. How to replace the T-Con Board

1. Remove 4 screws 2. Bend back the shield case

It is easy to check if the BLU is on or off.

and remove the LVDS cable

3-6

3. Remove 2 Cables from T-Con 4. Replace the defective Board

with new one

3. Disassembly and Reassemble

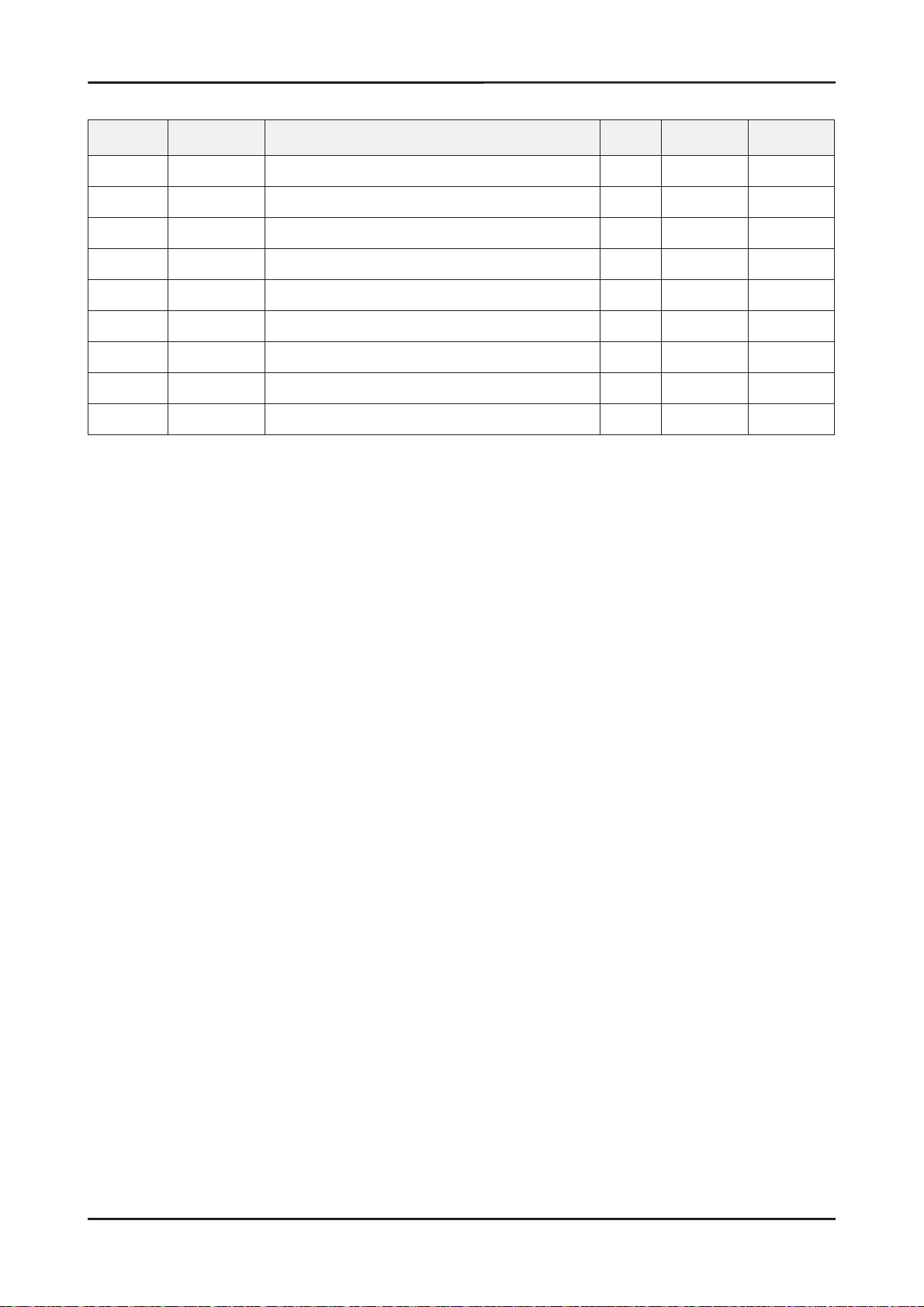

3-2-2 T-Con Board SVC Parts Code for each Model

From now, it is possible to service T-Con Board regarding some models used the Samsung panel

Exel Sheet “Part Code” : T-Con Board Part Code for each Model

Exel Sheet “SVC Guide” : T-Con Board defect list

Exel Sheet “GSPN” : How to order T-Con Board on GSPN system

Project Model Code Side Label Panel Code T-Con code Remark

Bordeaux LNS3251DX SG05 BN07-00368A BN81-01301A 2006 Product

Milano3 LNS4692DX SP01 BN07-00282A BN81-01286A 2006 Product

SP01, SP02 BN07-00385A BN81-01299A 2007 Product

LNT3253HX

Bordeaux-Plus

Bordeaux2

Sonoma2 LNT3232HX

Jasmine

Tulip-Bottom

Tulip-Side

Peony

Peony2

LNT4053HX

LNT4066FX

LNT325HAX

LNT405HAX

LNT3242HX

LNT4042HX

LNT4642HX

LNT4061FX

LNT4661FX

LNT4065FX SX05, SX06, SX07, SX08 BN07-00483A BN81-01304A 2007 Product

LNT4665FX

LNT4071FX

LNT4671FX

LNT5271FX

LNT4096FX SQ01, SQ02 BN07-00477A BN81-01324A 2007 Product

LNT4696FX SQ01, SQ02 BN07-00478A BN81-01283A 2007 Product

SN03, SN04 BN07-00453A BN81-01298A 2007 Product

SQ05, SQ06 BN07-00482A BN81-01300A 2007 Product

SQ01, SQ02 BN07-00387A BN81-01306A 2007 Product

SN03, SN04 BN07-00451A BN81-01325A 2007 Product

SS05, SS06 BN07-00489A BN81-01307A 2007 Product

SQ01, SQ02 BN07-00383A BN81-01305A 2007 Product

SX05, SX06 BN07-00483A BN81-01304A 2007 Product

SH04 BN07-00453A BN81-01298A 2007 Product

SQ05, SQ06 BN07-00482A BN81-01300A 2007 Product

SN03, SN04 BN07-00451A BN81-01325A 2007 Product

SQ07, SQ08 BN07-00489A BN81-01307A 2007 Product

SH05, SH06 BN07-00453A BN81-01298A 2007 Product

SQ07, SQ08 BN07-00482A BN81-01300A 2007 Product

SP07, SP08 BN07-00385A BN81-01299A 2007 Product

SH10, SH11, SH12 BN07-00453A BN81-01298A 2007 Product

SQ14, SQ15, SQ16 BN07-00482A BN81-01300A 2007 Product

SP01, SP02, SP05 BN07-00387A BN81-01306A 2007 Product

SH06, SH07 BN07-00451A BN81-01325A 2007 Product

SQ10, SQ11 BN07-00489A BN81-01307A 2007 Product

SP01, SP03 BN07-00389A BN81-01319A 2007 Product

SN04, SN05 BN07-00452A BN81-01320A 2007 Product

SSO3, SS04 BN07-00409A BN81-01302A 2007 Product

SX07, SX08 BN07-00485A BN81-01303A 2007 Product

SS03, SS04 BN07-00410A BN81-01312A 2007 Product

SX07, SX08 BN07-00506A BN81-01308A 2007 Product

SS03, SS04 BN07-00457A BN81-01315A 2007 Product

SX05, SX06 BN07-00481A BN81-01314A 2007 Product

SQ01 BN07-00286A BN81-01281A 2007 Product

SS02, SS03 BN07-00475A BN81-01281A 2007 Product

SQ01 BN07-00441A BN81-01282A 2007 Product

SS02, SS03 BN07-00476A BN81-01282A 2007 Product

SQ01 BN07-00447A BN81-01284A 2007 Product

SS02, SS03 BN07-00484A BN81-01285A 2007 Product

3-7

3. Disassembly and Reassemble

Project Model Code Side Label Panel Code T-Con code Remark

LNS2651DX SG03, SG04 BN07-00367A BN81-01686A 2006 Product

Bordeaux

Firenze LNS5797DX SP01 BN07-00196A BN81-01703A 2006 Product

Rose

Tulip LNT5265FX SS03, SS05 BN07-00466A BN81-01699A 2007 Product

Jade LN40A330J1D SQ01 BN07-00523A BN81-01692A 2008 Product

Coral

Pearl

Amber

Ruby

LNS2651HDX SG03 BN07-00367A BN81-01686A 2006 Product

LNS2652DX SG03, SG04 BN07-00367A BN81-01686A 2006 Product

LNT4081FX SN01 BN07-00442A BN81-01691A 2007 Product

LNT4681FX SN01 BN07-00443A BN81-01695A 2007 Product

LNT5281FX SN01 BN07-00444A BN81-01698A 2007 Product

LNT5781FX SQ01 BN07-00450A BN81-01706A 2007 Product

LNT7081FX SQ01 BN07-00356A BN81-01704A 2007 Product

LN32A450C1D

LN32A450C1H SQ01 BN07-00521A BN81-01688A 2008 Product

LN40A450C1H SQ01 BN07-00523A BN81-01692A 2008 Product

LN32A550P1F SQ01 BN07-00520A BN81-01689A 2008 Product

LN32A550P3F SQ01 BN07-00520A BN81-01689A 2008 Product

LN40A530P1F SQ01 BN07-00525A BN81-01693A 2008 Product

LN40A550P3F SQ01, SQ02 BN07-00525A BN81-01693A 2008 Product

LN40A550P1F SQ01 BN07-00525A BN81-01693A 2008 Product

LN46A530P1F SQ01 BN07-00518A BN81-01696A 2008 Product

LN46A550P1F SQ01 BN07-00518A BN81-01696A 2008 Product

LN46A550P3F SQ01 BN07-00518A BN81-01696A 2008 Product

LN52A530P1F SQ01 BN07-00522A BN81-01701A 2008 Product

LN52A550P1F SQ01 BN07-00522A BN81-01701A 2008 Product

LN52A550P3F SQ01, SQ02 BN07-00522A BN81-01701A 2008 Product

LN32A650A1F SQ01 BN07-00537A BN81-01690A 2008 Product

LN40A650A1F SQ01 BN07-00529A BN81-01694A 2008 Product

LN46A650A1F SQ01 BN07-00530A BN81-01697A 2008 Product

LN52A650A1F SQ01 BN07-00531A BN81-01702A 2008 Product

LN40A750R1F SQ01 BN07-00529A BN81-01694A 2008 Product

LN46A750R1F SQ01 BN07-00530A BN81-01697A 2008 Product

LN52A750R1F SQ01 BN07-00531A BN81-01702A 2008 Product

SQ01 BN07-00453A BN81-01688A 2008 Product

SS02 BN07-00482A BN81-01692A 2008 Product

3-8

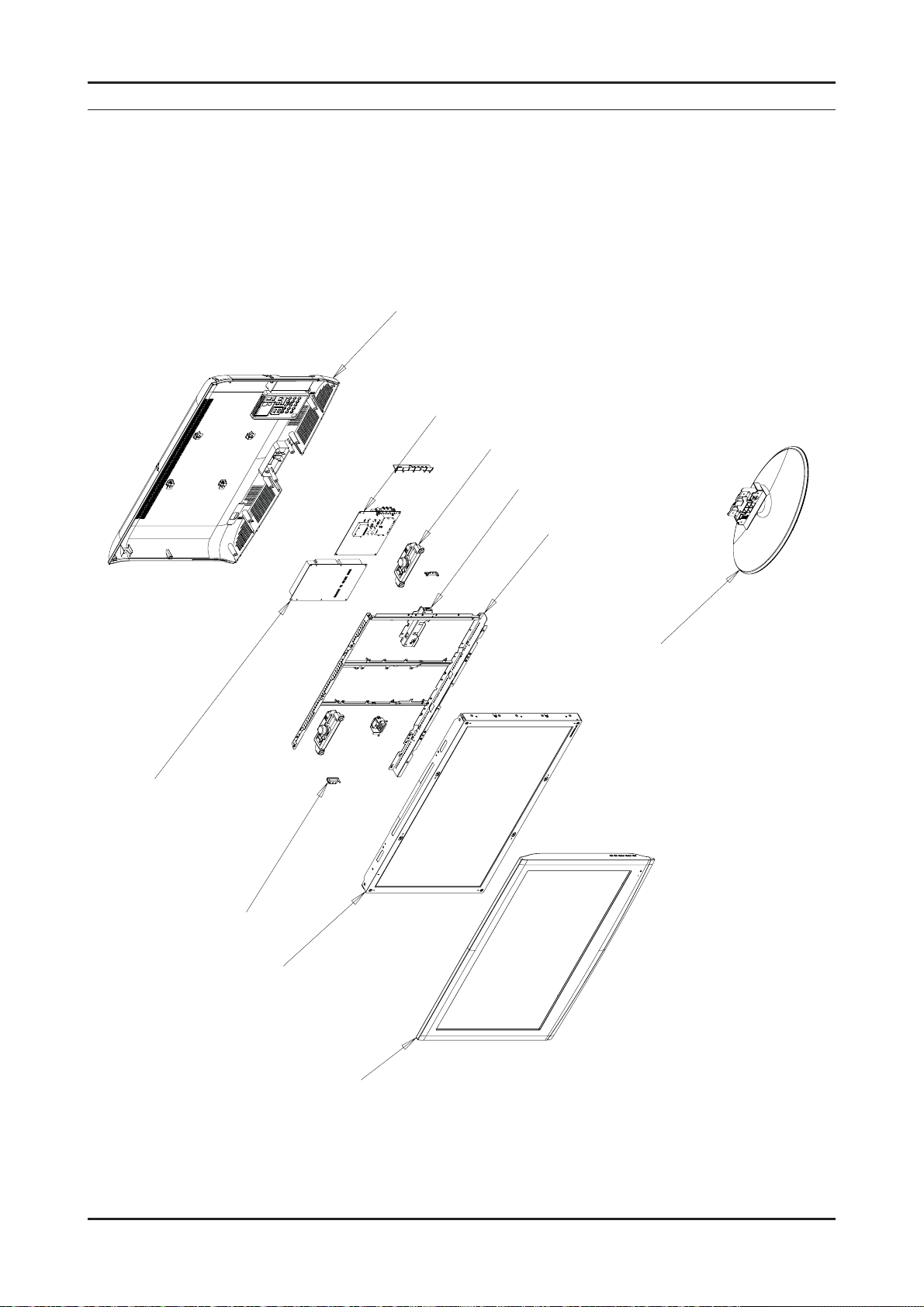

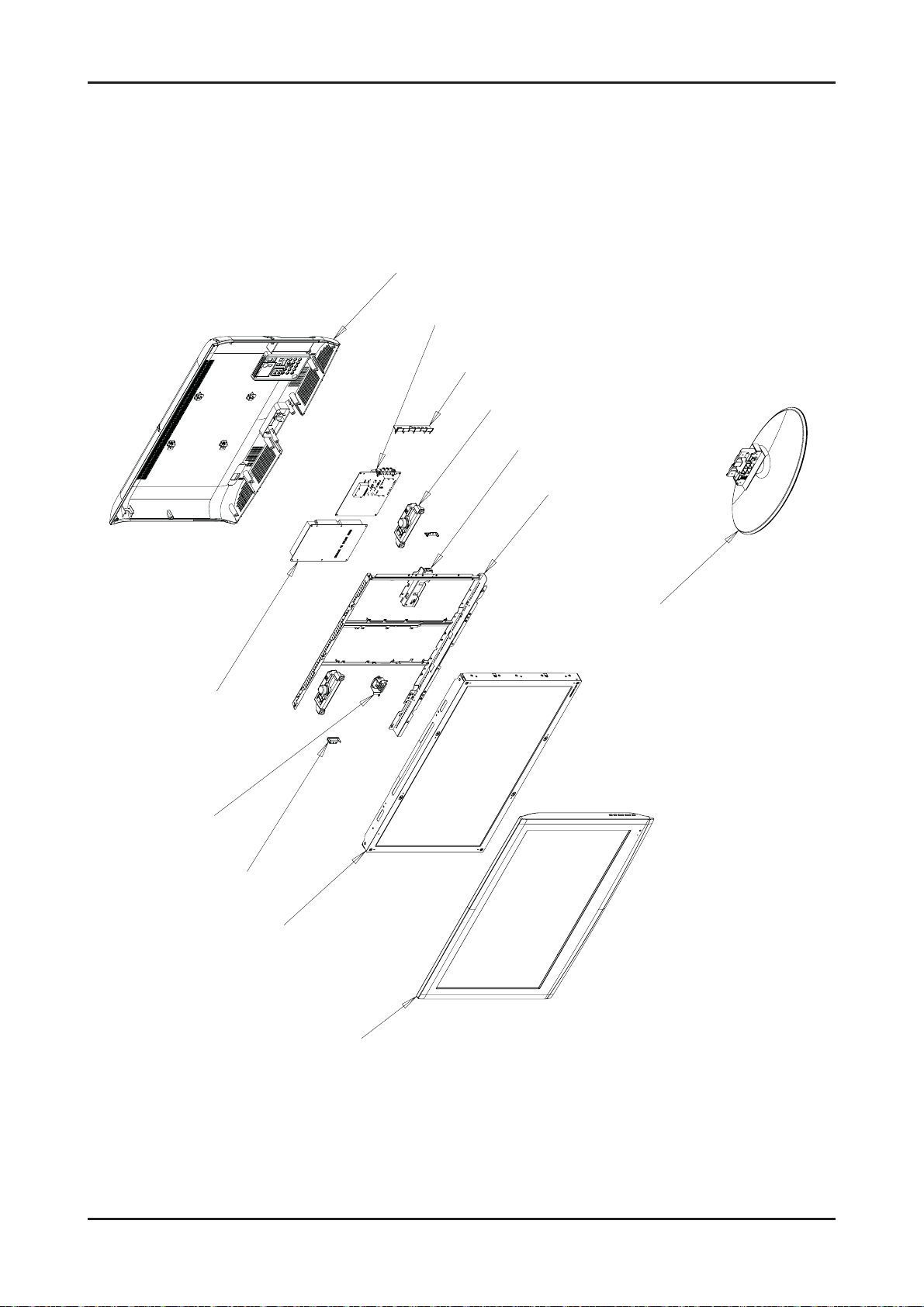

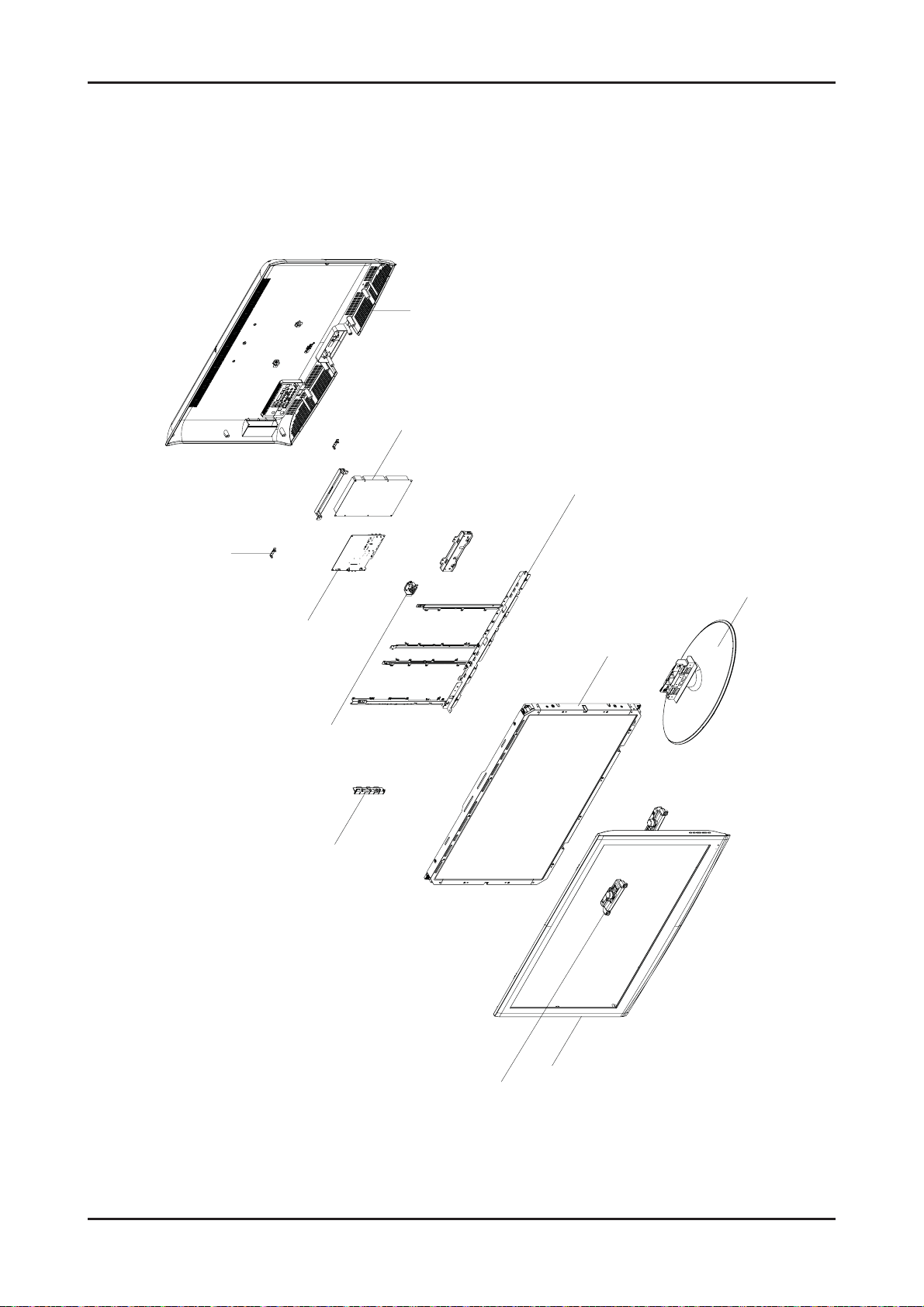

5. Exploded View & Part List

5-1. LN26A330J1D Exploded View

M0013

5. Exploded View & Part List

M0014

T0175

M0107

T0764

T0447

M0027

M0146

M0215

T0003

5-1

5. Exploded View & Part List

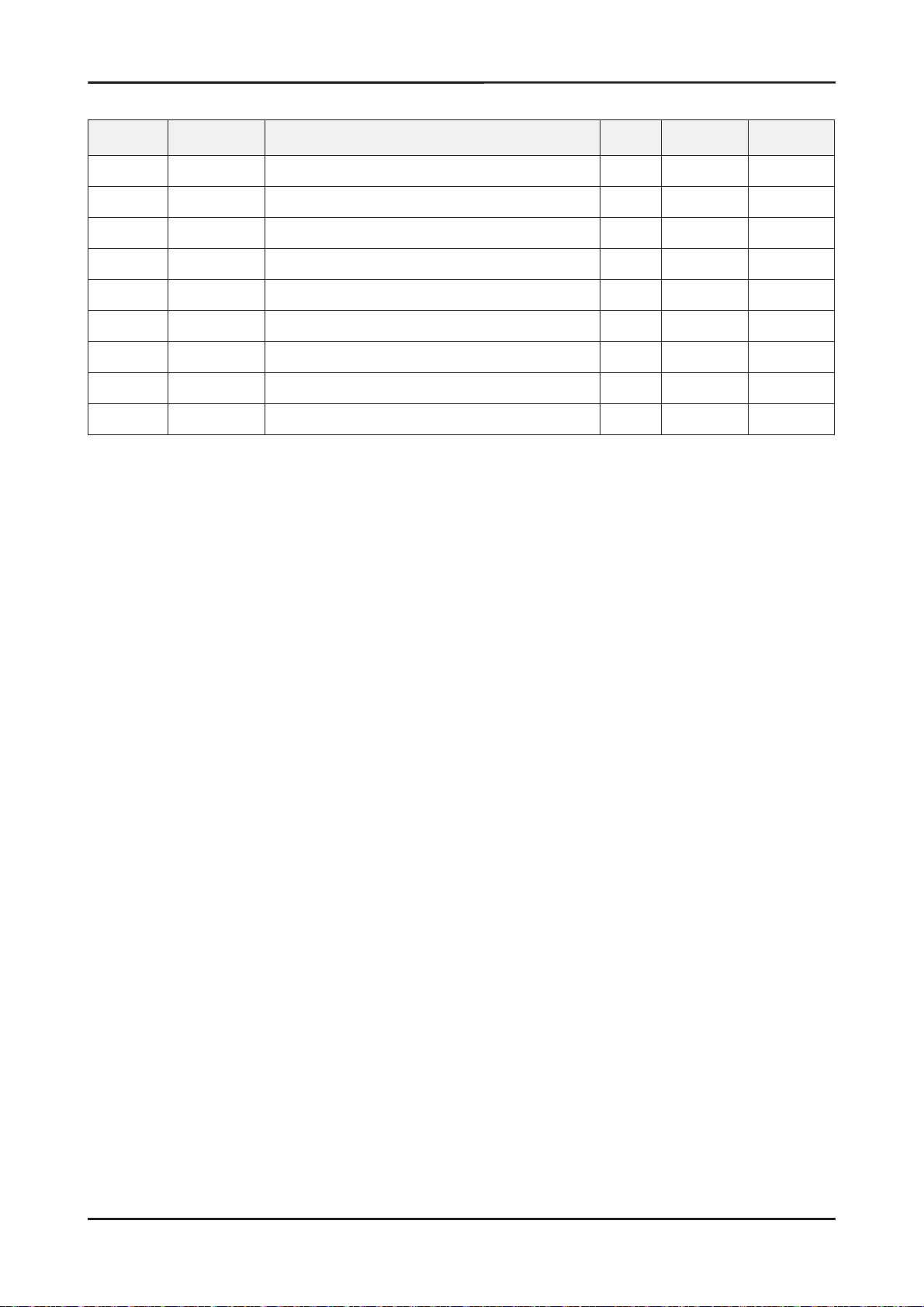

5-1-1. LN26A330J1D Parts List

Location No. Code No. Description & Specifi cation Q’ty S.A/S.N.A Remark

T0003 BN96-04750G ASSY COVER P-FRONT;26L330,UO,PC+ABS,V0,B 1 S.A

M0215 BN07-00364A LCD-PANEL;V260B1-L04 1 S.A

M0146 BN61-02207A BRACKET-PANEL SIDE;Bordeaux 26,SECC,T1.2 4 S.N.A

M0027 BN96-04745A ASSY STAND P-BASE;-,22,23,26S81,-,ABS+PM 1 S.A

M0014 BN94-01724B ASSY PCB MAIN;LN26A330J1DXZA 1 S.A

M0115 BN61-02931A BRACKET-STAND LINK;JASMINE 26,SECC,T1.6 1 S.A

T0175 BN96-04769A ASSY SPEAKER P;16ohm,4pin,5W,Jasmine 23” 1 S.A

T0764 BN44-00192B SMPS-LCDTV;MK32P3,DYREL,AC/DC,180W,AC100 1 S.A

M0013 BN96-04755C ASSY COVER P-REAR;26L330,UO,HIPS,V0,BK50 1 S.A

5-2

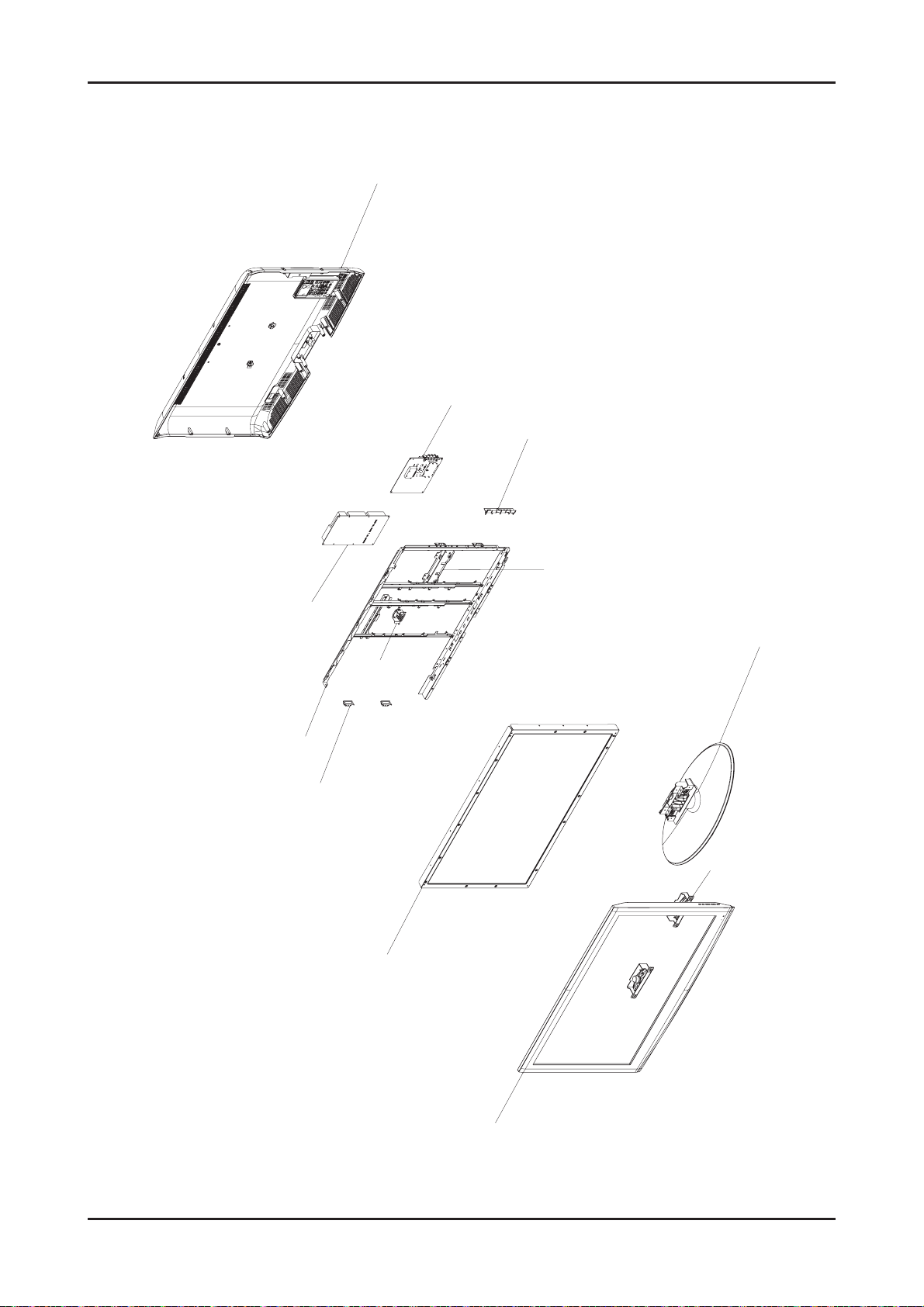

5-2. LN32A330J1D Exploded View

M0013

5. Exploded View & Part List

M0014

M0254

T0175

M0115

T0764

M0258

T0447

M0027

M0146

M0215

T0003

5-3

5. Exploded View & Part List

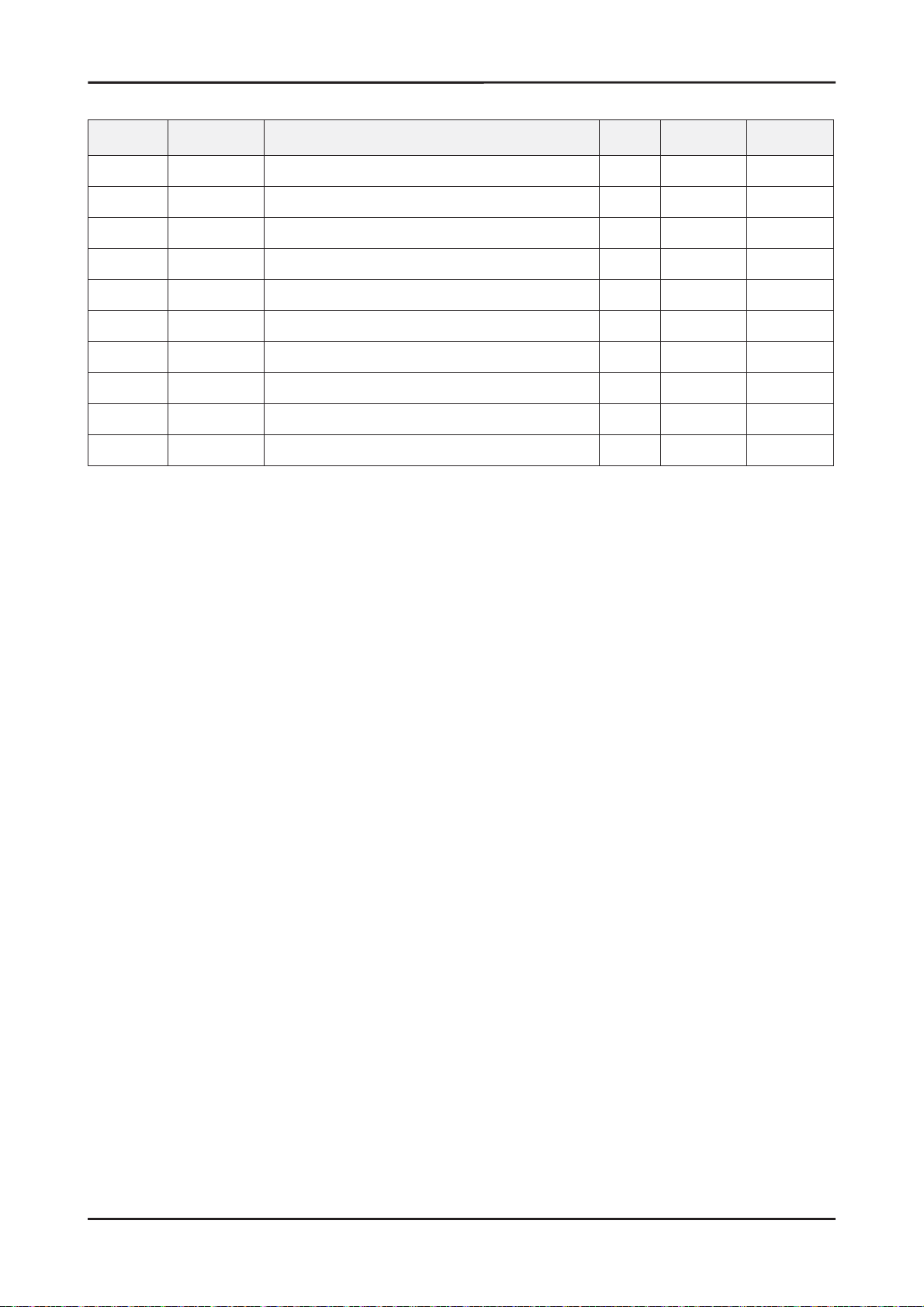

5-2-1. LN32A330J1D Parts List

Location No. Code No. Description & Specifi cation Q’ty S.A/S.N.A Remark

T0003 BN96-04694P ASSY COVER P-FRONT;32L330,UO,PC+ABS,V0,B 1 S.A

M0215 BN07-00348A LCD-PANEL;V315B1-L01 1 S.A

M0146 BN61-02419A BRACKET-PANEL SIDE;SONOMA 32,SECC,T1.2,A 4 S.N.A

M0115 BN61-02947A BRACKET-STAND LINK;JASMINE 32”,SECC,T1.6 1 S.A

T0175 BN96-04770A ASSY SPEAKER P;8ohm,4pin,10W,Jasmine 32” 1 S.A

M0254 BN61-03972A HOLDER-SIDE AV;L330,HIPS,V0,-,-,-,BK500, 1 S.N.A

M0014 BN96-07892B ASSY PCB P-MAIN;BN94-01724R,LN32A330J1DX 1 S.A

M0013 BN96-04696L ASSY COVER P-REAR;32L330,UO,HIPS,V0,BK50 1 S.A

M0027 BN96-07542A ASSY STAND P-BASE;32L330,ABS+PMMA,HB,BK2 1 S.A

5-4

5-3. LN37A330J1D Exploded View

M0013

5. Exploded View & Part List

M0014

M0254

T0764

T0047

M0146

M0115

M0027

M0258

T0175

M0215

T0003

5-5

5. Exploded View & Part List

5-3-1. LN37A330J1D Parts List

Location No. Code No. Description & Specifi cation Q’ty S.A/S.N.A Remark

T0003 BN96-04752M ASSY COVER P-FRONT;37L330,UO,PC+ABS,V0,B 1 S.A

T0175 BN96-04770B ASSY SPEAKER P;8ohm,4pin,10W,600/1250mm, 1 S.A

M0215 BN07-00446A LCD-PANEL;CLAA370WA03SC 1 S.A

M0146 BN61-02971A BRACKET-PANEL TOP;37 BORDEAUX PLUS,SECC, 1 S.N.A

M0115 BN61-02882A BRACKET-STAND LINK;TULIP,40,SECC,T1.6,-, 1 S.A

M0254 BN61-03972A HOLDER-SIDE AV;L330,HIPS,V0,-,-,-,BK500, 1 S.N.A

T0764 BN44-00220A SMPS-LCDTV;MK37P5T,DYREL,AC/DC,171W,AC10 1 S.A

M0014 BN94-01724D ASSY PCB MAIN;LN37A330J1DXZA 1 S.A

M0013 BN96-04756J ASSY COVER P-REAR;37L330,UO,HIPS,V0,BK50 1 S.A

M0027 BN96-07541A ASSY STAND P-BASE;40L330,ABS+PMMA,HB,BK2 1 S.A

5-6

5-4. LN40A330J1D Exploded View

M0013

M0174

5. Exploded View & Part List

T0447

M0146

M0014

M0125

M0254

M0027

M0215

T0175

T0003

5-7

Loading...

Loading...