Samsung LED Display Installation Manual

Samsung Electronics

LED Display Installation Manual

IER / IFR Series

LH0**IER*LS

LH0**IER*FS

LH0**IFR*LS

LH0**IFR*FS

Samsung Electronics

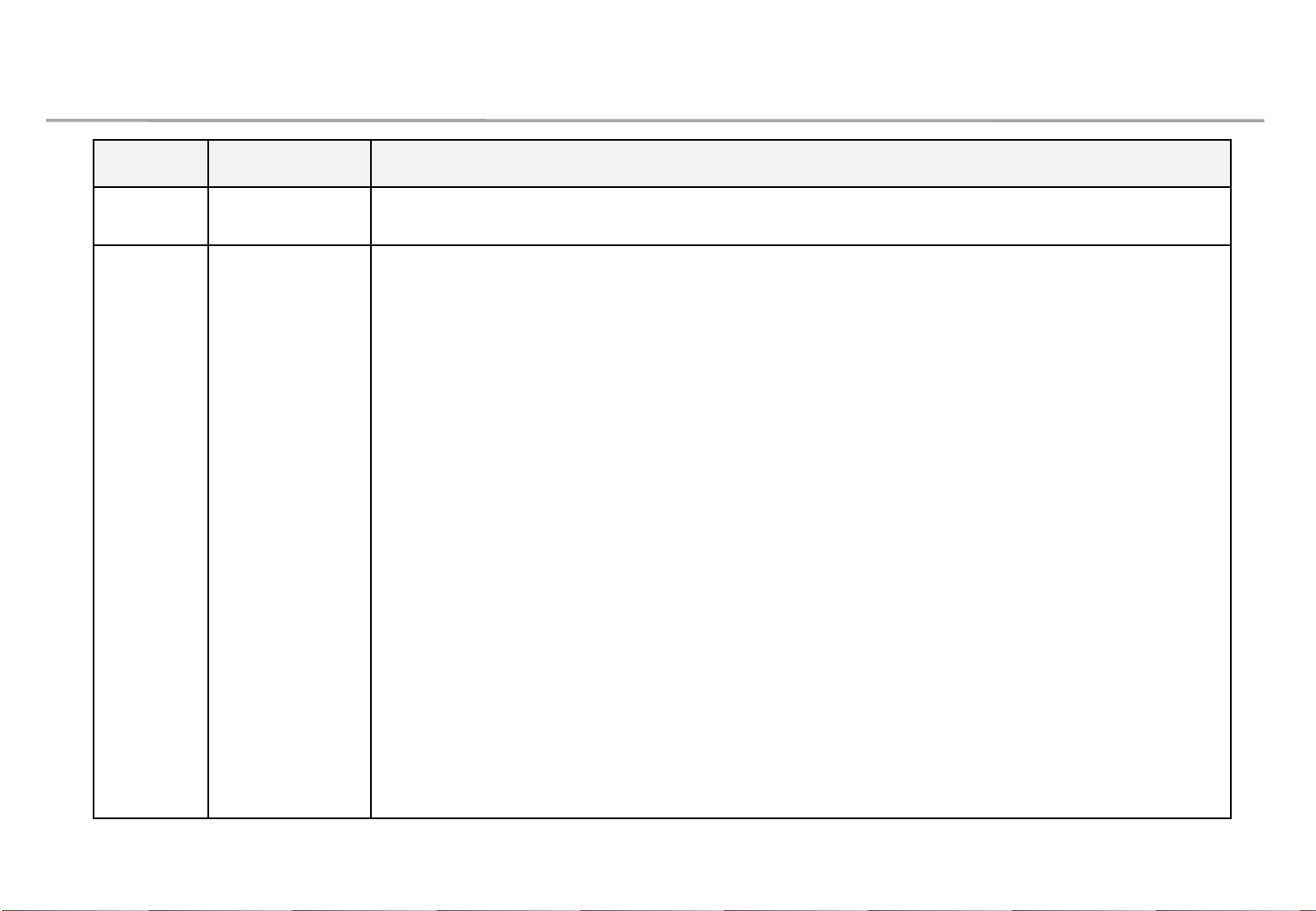

Revision History

1

Version Date (Y/M/D)

Description

2.0 2020/03/20

New

Release

Samsung Electronics

When humidity get into LED package because of high humidity, it is

possible to cause ‘Line defect’ by electrical short in side of LED

Package.

For keeping quality of products during installation, please refer below

cautions.

- If one of below case meet before installation, MUST do dehumidification process.

∙ Case when vacuum packaging is broken before unpacking.

∙ Case when environment condition is exceed Samsung recommended operation condition.

(Please refer Operation condition from User manual)

∙ Case when period between unpacking and turning on the power of products is spent

more than 7days, even though it is under Samsung recommended storage condition.

∙ Case when production date on the label is exceed more than 6 months, even though

vacuum packaging is no problem.

- When Volatile chemicals such as oil paint, solvent are used or operation condition

is exceed around of products installed place, MUST play video more than 2 hours

everyday.

- If it is not meet with upper cases, it is helpful to play video more than 2 hours

everyday for protection for humidity getting into LED Package.

Dehumidification guidance – during installation

Samsung Electronics

Electrical short in package is possible to happen during products are

working.

For keeping quality of products during installation, please refer below

cautions.

- If one of below case meet during operation, MUST do dehumidification process.

∙ Case when environment condition is exceed operation condition.

∙ Case when products are not working more than 1 month, even though environment

condition is under operation condition.

- When environment condition is exceed operation condition, products are out of

warranty. Please check environment condition.

- Even products are operating, if the installed place have extra construction such as

interior modification, MUST do dehumidification following installation condition.

- It is possible to happen dew condensation on surface of products, even though

working on operating condition. When happening dew condensation, MUST

operate after cleaning the dew condensation & dehumidification.

Dehumidification guidance – during operation

Samsung Electronics

Dew condensation due to overcooling

Even though meet with Samsung recommended operation

condition, dew condensation is possible to happen when

surface of products is colder than environment temperature or

hot & humid air blow to cooled surface of products.

(cf : Principle of happening dew on surface of glass which have ice)

Case when dew condensation is happen on products, it is

possible to be the root of defect. In this case, it is possible to

be out of warranty.

Samsung Electronics

When install products, please update latest firmware on online

- You can download latest firmware from SLM site.

∙ URL of SLM Page : https://www.secslm.com

∙ After login Help Download Center에서 Download

∙ Before you download firmware, you MUST check same firmware of model (marked red

letter in below) & upper number of version (marked blue in below).

- You can update firmware through LSM.

∙ Please refer ‘7-1 PC control program’ for the way to update firmware.

5

Guidance of latest firmware

Cabinet : Main - L-xxxMWWAC-nnnn.n xxx = Pan name, nnnn.n = version

FPGA - aabbb_ddddd aa = pixel pitch, bbb = LED package type, ddddd= version

Example : IER P2.5 Cabinet : L-IERMWWAC-1003.1, FPGA : 25252-31046

S-box : TB-KTM2SBMDWWC_100x.x

Samsung Electronics

Table of Contents

1. Product Information and Installation Precautions (P.2)

2. Preparation for Cabinet Installation (P.12)

3. Frame Kit (P.16)

4. Frame Installation (P.17)

5. Cabinet + Frame Installation (P.25)

6. S-Box Connection (P.29)

7. Settings / How to Use (P.47)

8. Power and Cable Connection (P.63)

9. Seam Adjustment (P.72)

Appendix. IER-F/IFR-F series Installation Manual (72 page)

6

Samsung Electronics

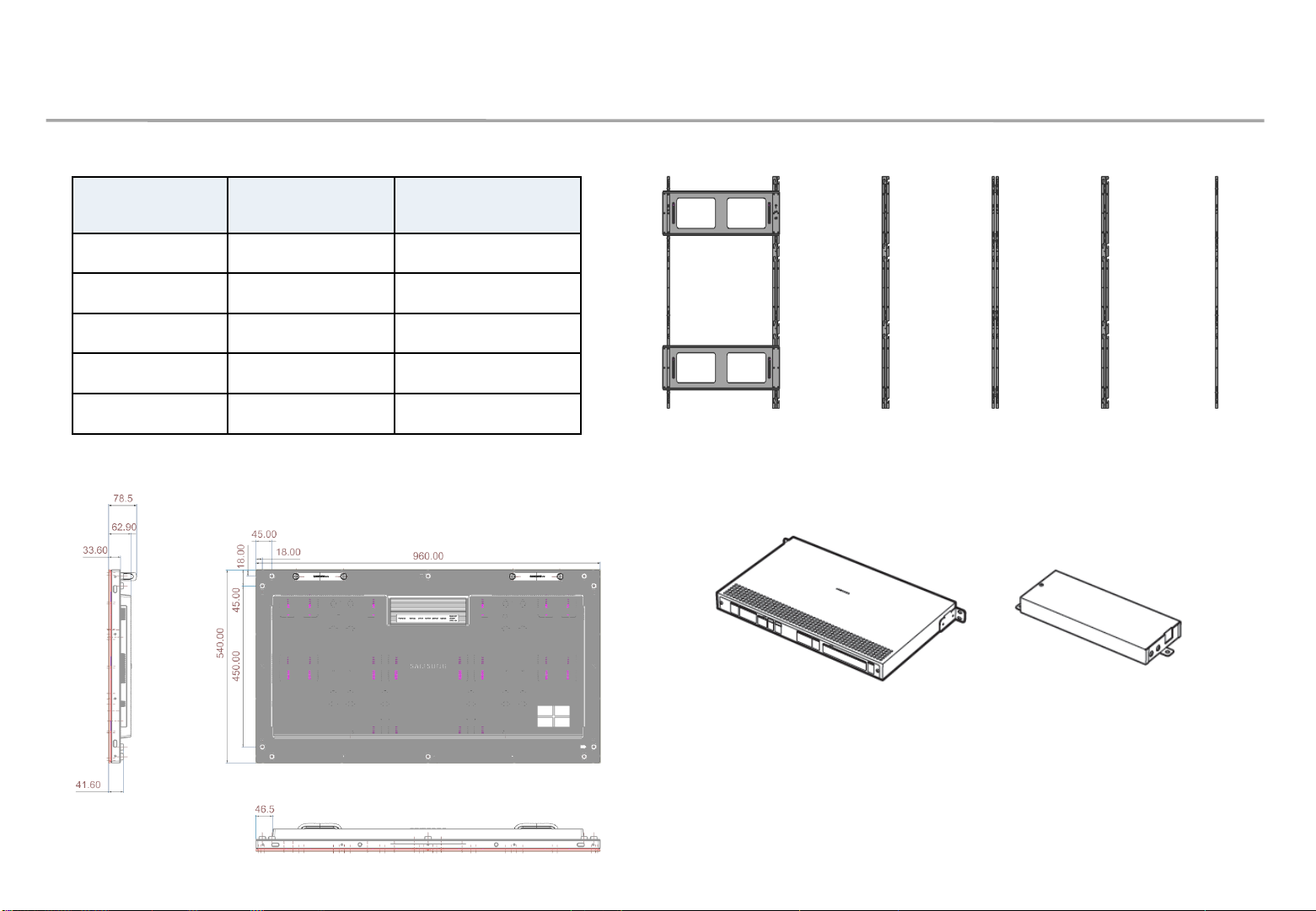

Cabinet Size IER (P2.0, P2.5, P4.0) IFR (P2.5, P4.0)

960x540

(module

4x3)

LH020IER*LS

LH025IER*LS

LH040IER*LS

LH025IFR*LS

LH040IFR*LS

Refer to Manual

(P2~P72)

240x540

(module 1

x3)

IER

-F

(P2.0, P2.5, P4.0)

IFR

-F

(P2.5, P4.0)

LH020IER*FS

LH025IER*FS

LH040IER*FS

LH025IFR*FS

LH040IFR*FS

Refer to

Appendix

(P73~P96)

1. Product Information and Installation Precautions

7

◇ Model Line-up

- IER : Models for Mid-brightness(500~1000nit) with Cupper wire LED

- IFR : Models for High-brightness(1000nit↑) with Gold wire LED

※ IER-F, IFR-F series : Models for Non-Standard Screen (ex. Extend, L-shaped screen). Installation with IER/IFR of same

pitch is recommended.

- This Manual is an Installation Manual for IER/IFR(Appendix. IER-F/IFR-F), which contains information of

models below (Installation process is same for each pitch model)

Samsung Electronics

8

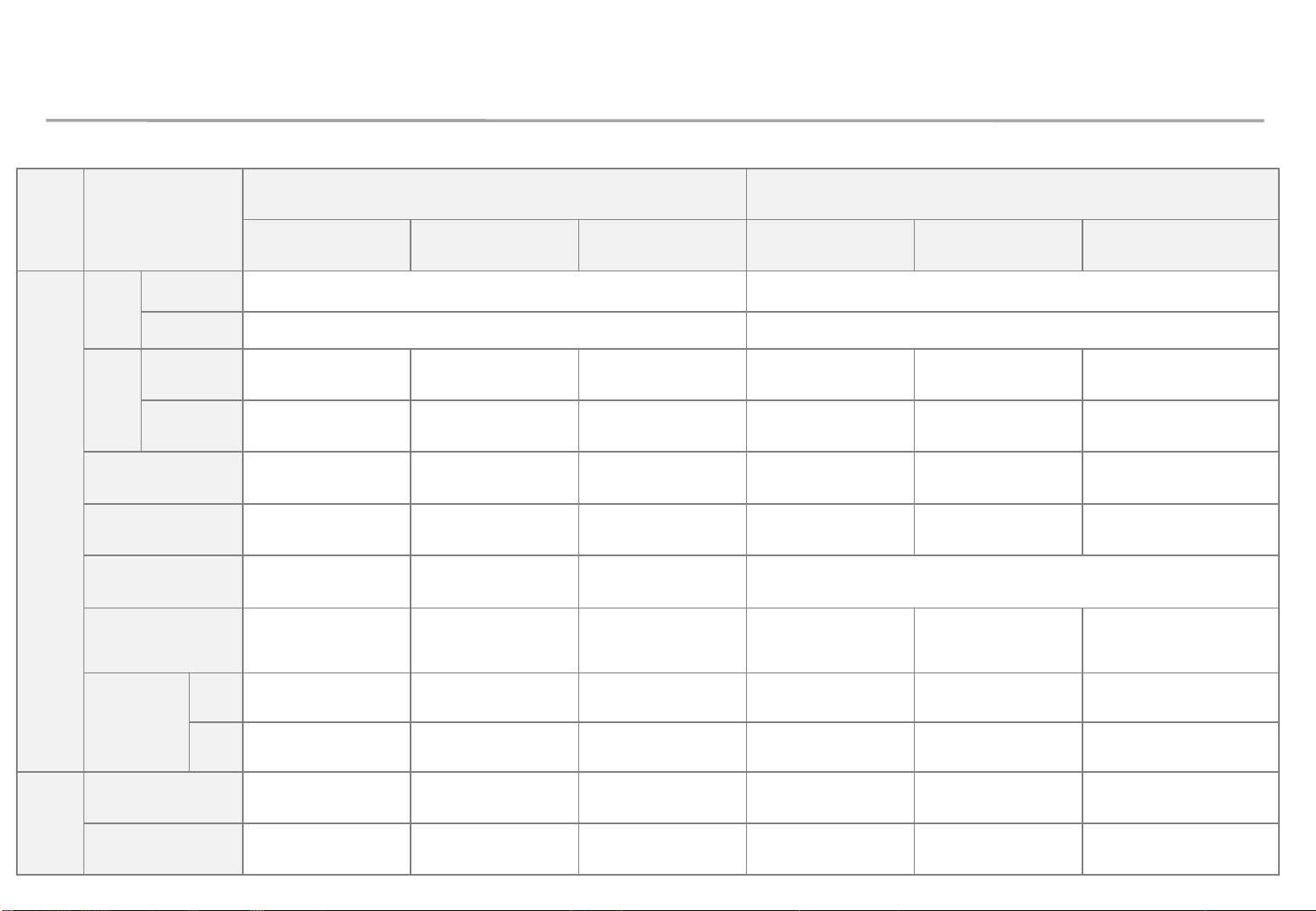

◇ Model specification

Spec

IER / IFR IER-F / IFR-F

P2.0 P2.5 P4.0 P2.0 P2.5 P4.0

Cabinet

Size

Width

960 240

Height

540 540

Resol

ution

Vertical

480 384 240 120 96 60

Horizontal

270 216 135 270 216 135

LED / Cabinet

(Pixel)

64,800 82,944 32,400 16,200 20,736 8,100

Module / Cabinet

12 12 12 3 3 3

Weight(Cabinet)

IER : 12.4kg

IFR : 12.4kg

IER : 10.8kg

IFR : 12.4kg

IER : 10.8kg

IFR : 12.4kg

3.2kg

Power

consumption

(W)

IER : 180W

IFR : TBD

IER : 150W

IFR : 260W

IER : 150W

IFR : 260W

IER : 60W

IFR : TBD

IER : 50W

IFR : 80W

IER : 50W

IFR : 80W

Max

number of

connection

(Set)

110V

IER : 3

IFR : TBD

IER : 4

IFR : 2

IER : 4

IFR : 2

IER : 10

IFR : TBD

IER : 10

IFR : 7

IER : 10

IFR : 7

220V

IER : 6

IFR : TBD

IER : 7

IFR : 4

IER : 7

IFR : 4

IER : 20

IFR : TBD

IER : 20

IFR : 15

IER : 20

IFR : 15

FHD

Screen

FHD

4x4, 16EA 5x5, 25EA 8x8, 64EA 16x4, 64EA 20x5, 100EA 32x8, 256EA

UHD

8x8, 64EA 10x10, 100EA 16x16, 256EA 32x8, 256EA 40x10, 400EA 64x16, 1024EA

※ Installation with IER/IFR of same pitch is recommended.

1. Product Information and Installation Precautions

Samsung Electronics

◇ Frame Kits configuration (See page 14.)

1. Product Information and Installation Precautions

Frame kit Configuration

for installation

Remarks

VG-LFR84FWL

8*4 (32 sets)

VG-LFR53FWL

5*3 (15 sets)

VG-LFR52SWL

5*2 (10 sets)

VG-LFR51PWL

5*1 P (15 sets) PIVOT installation

VG-LFR11SWL

1*1 (1 set)

Narrow

<5*3 Frame>

◇ Cabinet information

9

<S-Box> <I/G>

(Interface Gender)

◇ SNOW-1810U (S-Box, I/G)

※ Please refer to Appendix for information of IER-F / IFR-F Frame Kit

Samsung Electronics

1. Product Information and Installation Precautions

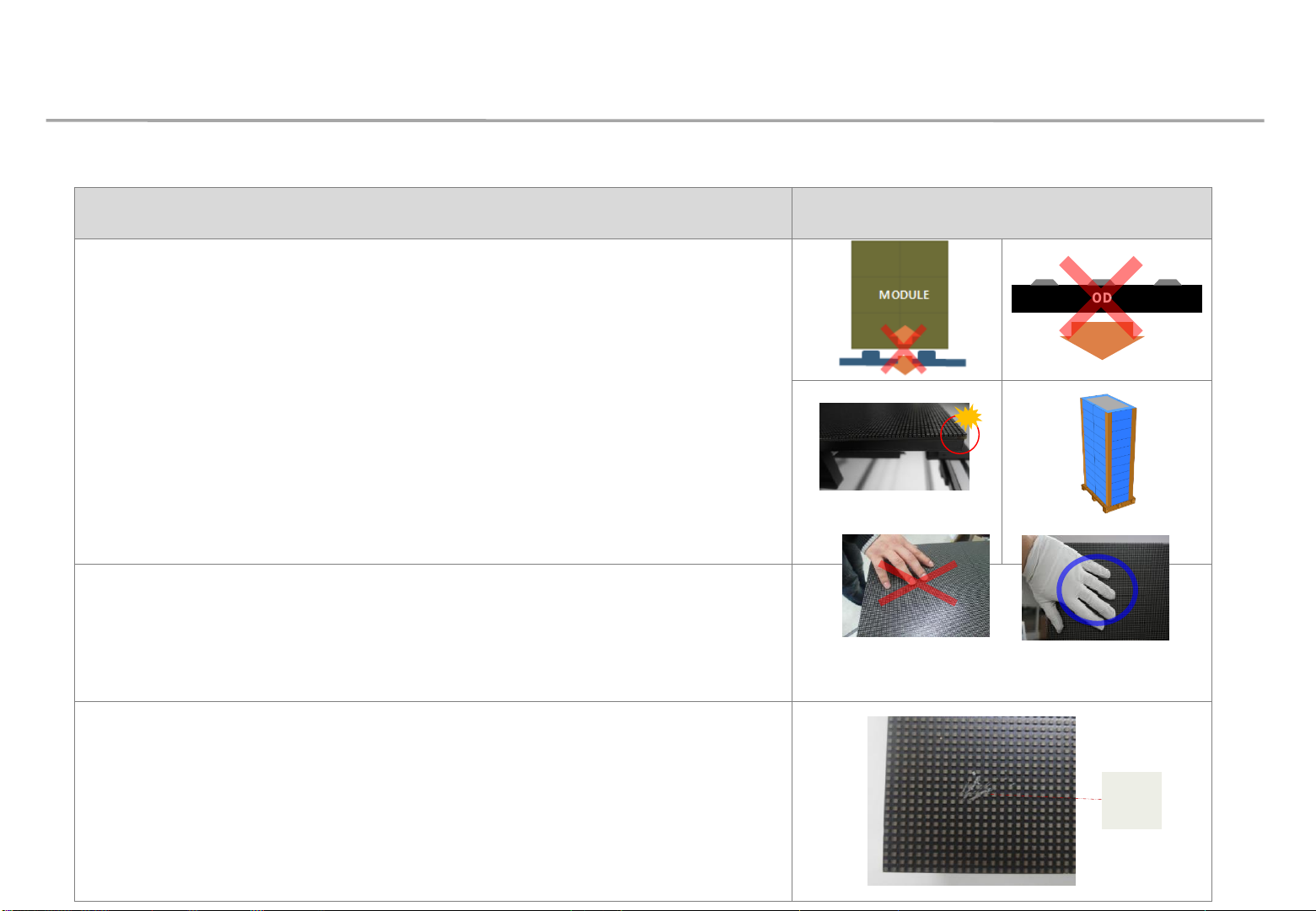

◇ Installation precautions (LED damage)

Precautions Images

[Be careful of external impact or dropping]

①

After removing the Cover-Corner from the product prior to installation,

exercise caution to ensure that the LED surface is not exposed to physical

impact and the product is not dropped onto the floor.

②

Do not place the product on a vibrating object. Make sure the LED surface

does not face down onto the floor.

③

Exercise caution to ensure that the corners of the LED module are not

damaged due to contact with external factors.

④

Make sure the number of loaded rows does not exceed 12.

①

②

③

④

[Be careful of LED damage due to static electricity]

▶

Do not touch the LED surface with bare hands without anti-static gloves.

[Be careful of LED damage due to metallic foreign material]

▶

Exercise caution to ensure that metallic foreign material is not attached to

the LED front.

▶

If metallic foreign material is attached, remove the module and use a

magnet to remove the foreign material.

MODULE

Front

Metallic

foreign

material

10

Samsung Electronics

1. Product Information and Installation Precautions

11

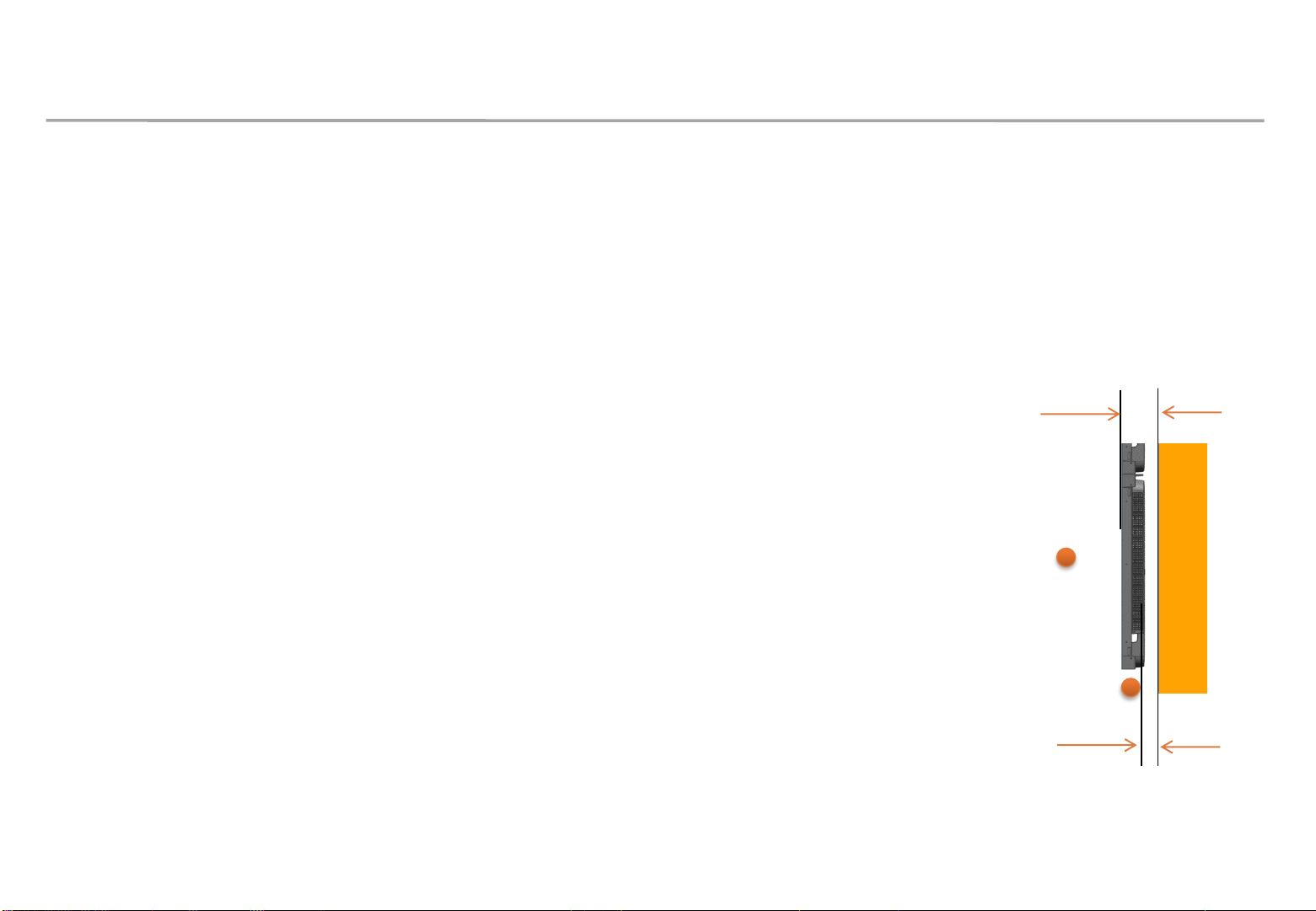

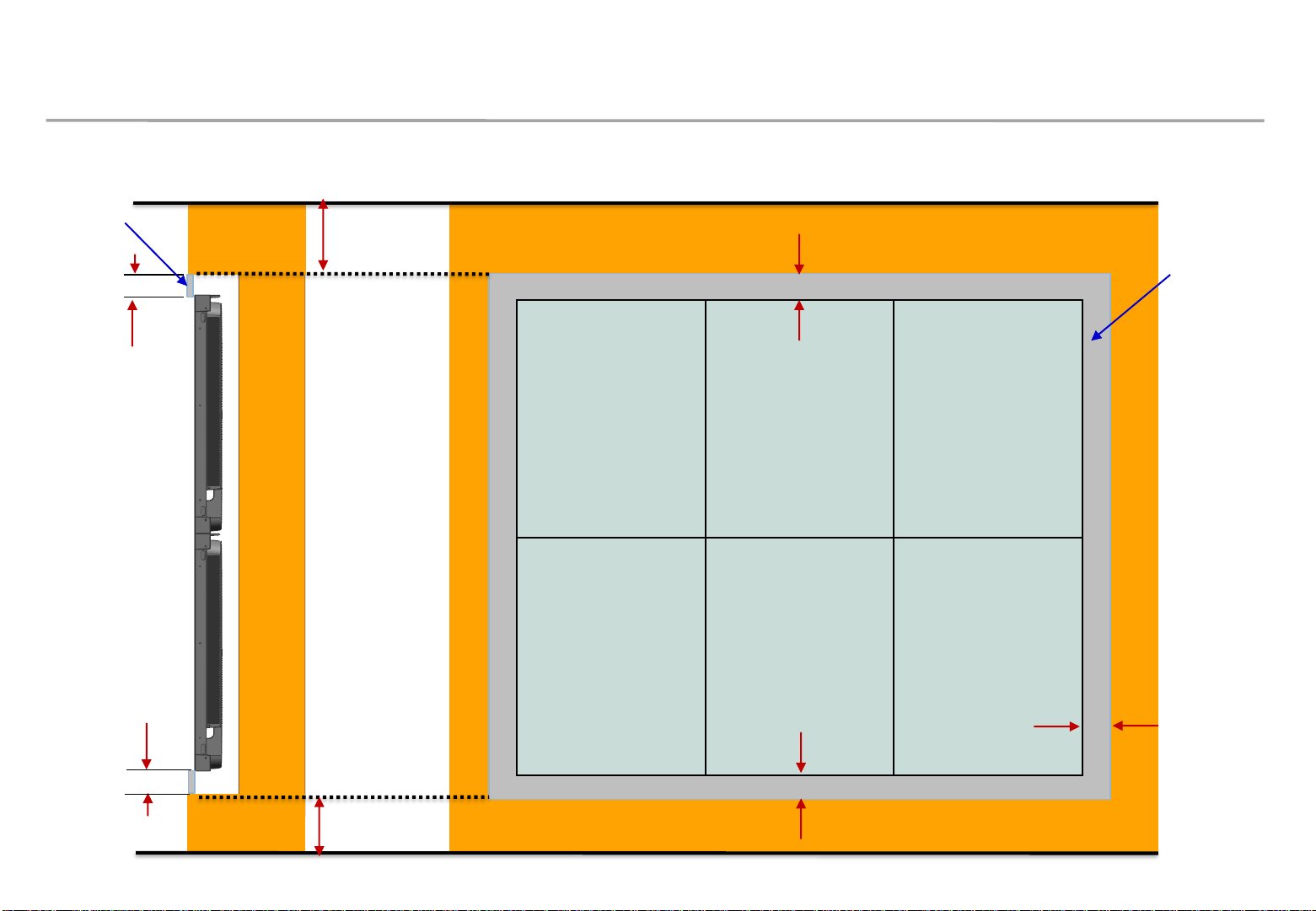

◇ Heat protection guide

Requirements for indoor installation

- Applicable to use of SAMSUNG wall mount (compliant with ADA)

∙ Gap between the product front and the wall: 99.5 mm

∙ Gap between the product rear and the wall: 35.5 mm

- Entry of sunlight

∙ If sunlight enters through glass windows or outer walls of the building,

contact Company HQ for assistance.

- Cold/warm air from HVAC system

∙ Make sure cold or warm air (especially warm air) from an HVAC system

does not reach the product.

- Outdoor temperature measurement position

∙ Center of the product or the inlet area

※ ADA: Americans with Disabilities Act

99.5 mm

35.5 mm

wall

Outdoor temperature

measurement position

Outdoor temperature

measurement position

※ This page is written based on the Full white,

650 nit (back light 7) version

Samsung Electronics

1. Product Information and Installation Precautions

12

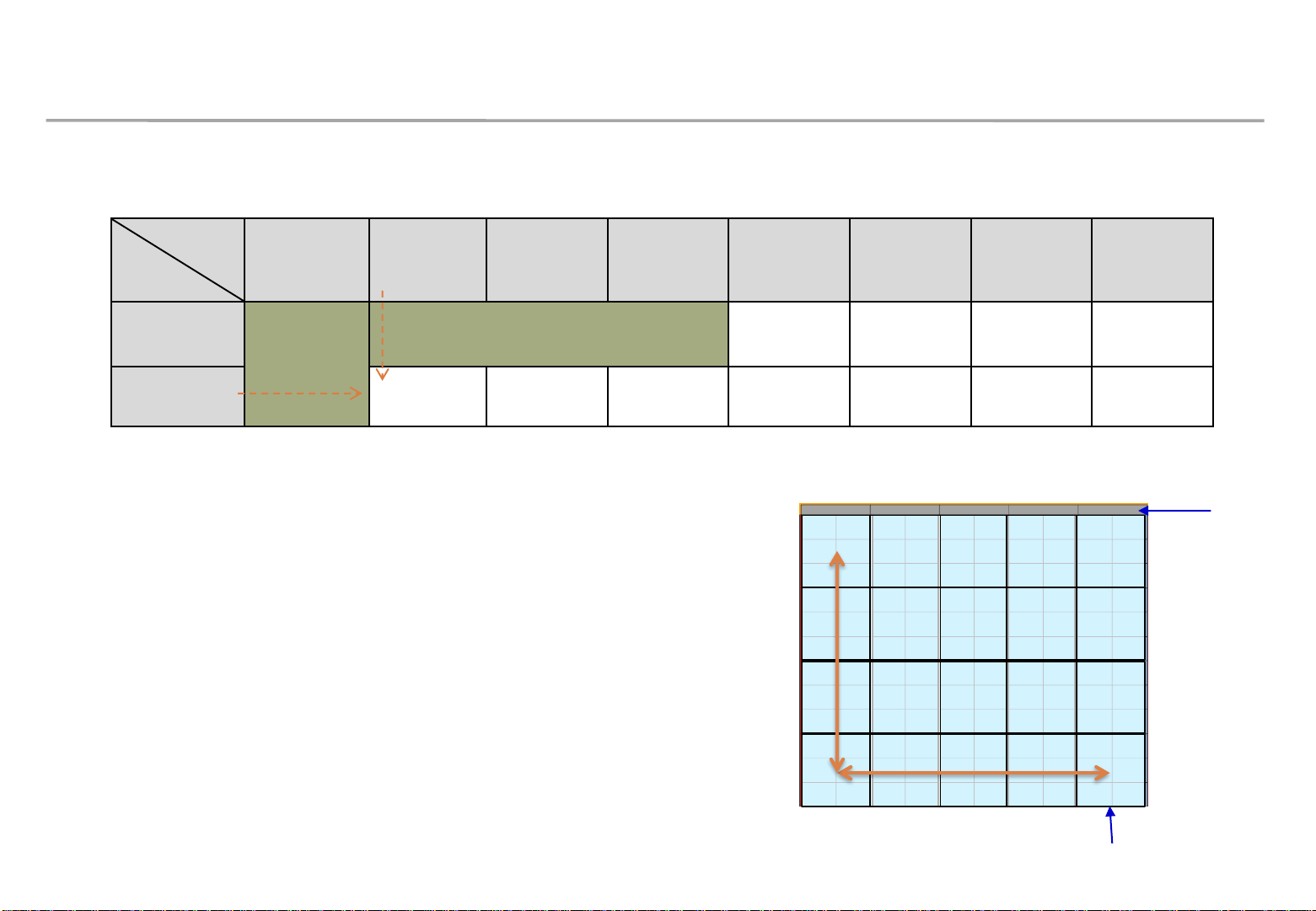

Fan flow rate depending on the number of installed cabinet rows

No. of rows

Outdoor

air temp.

1 to 3

Rows

4 Rows 5 Rows 6 Rows 7 Rows 8 Rows 9 Rows 10 Rows

Below 25℃

Fan

is not

necessary

Fan is not necessary

70 80 90 100

25℃ to 30℃

70 80 100 110 130 145 160

※ CFM = cubic feet per minute

※ Example) If outdoor air temperature is 30℃ and cabinets are

arranged in a 5x4 (horizontal x vertical) configuration,

what is the total CFM ?

→ 70 [CFM/column] x 5 [column]=350 [CFM]

5 Columns

4 Rows

Total minimum flow rate 350 CFM

70 CFM 70 CFM 70 CFM 70 CFM70 CFM

※ For installation under other conditions not covered in this guide, contact the Development Team.

Air vent area

FAN

※ Measurement based on one column

Outdoor air

temperature is

30℃

Samsung Electronics

1. Product Information and Installation Precautions

13

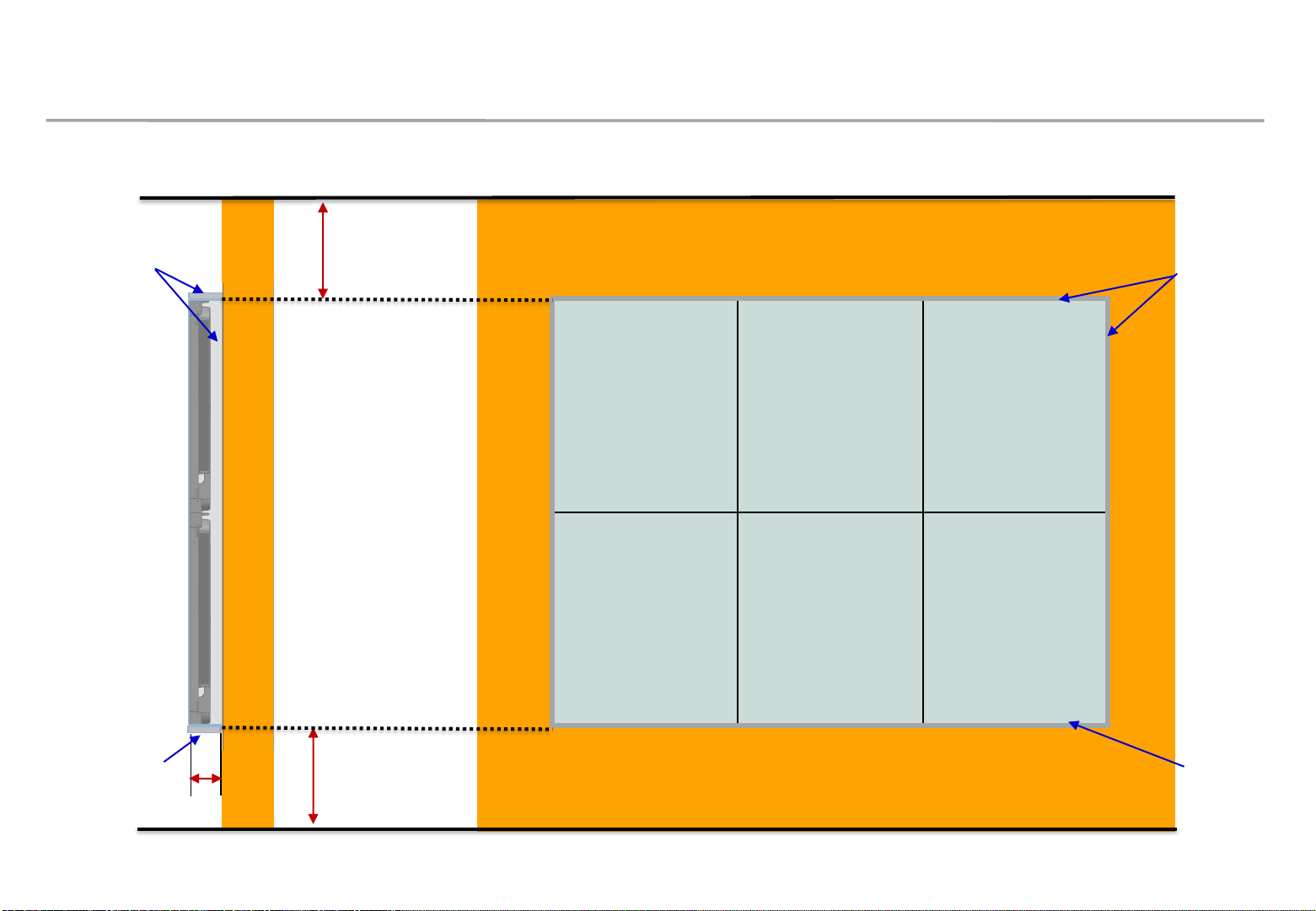

Requirements for using FAN

- Air vent: Should only be installed on the bottom

- Upper portion: Seal the entirety,

except the fan outlets

Shape of FAN unit

WALL

Location of FAN

Air vent area

Seal the left and

right sides

A

B

d

c

Vent requirements

- Use vents with an opening rate of at least 70%

- Opening rate (%) =

𝑐 𝑋 𝑑 𝑋 𝑁𝑜. 𝑜𝑓 𝑣𝑒𝑛𝑡 ℎ𝑜𝑙𝑒

𝐴 𝑋 𝐵

Seal the left and right sides

Samsung Electronics

1. Product Information and Installation Precautions

14

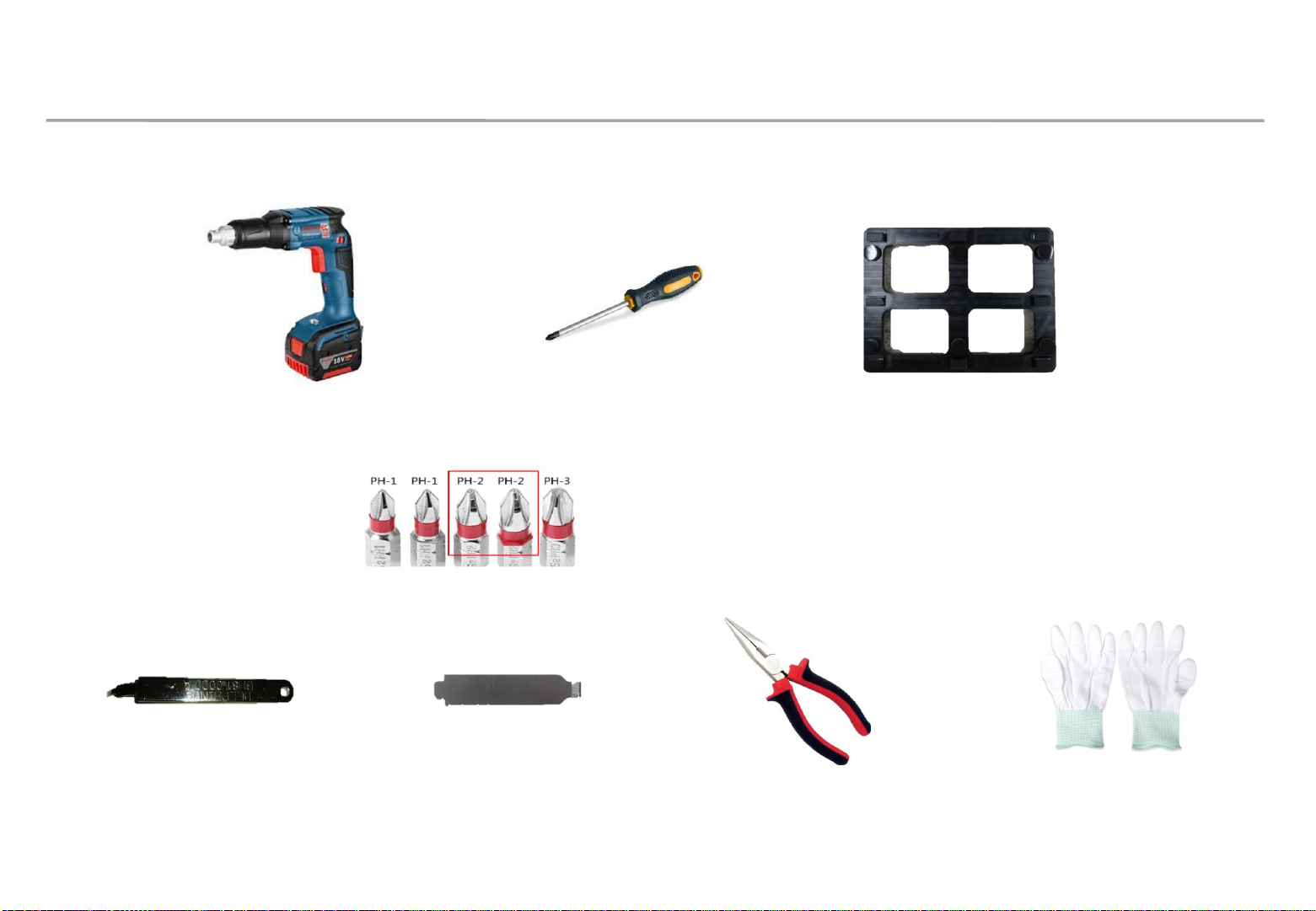

Minimum gap for embedded installation (Applicable when a fan is not used)

Min. 60 mm

WALL

Min. 60 mm

Air vent area

Min. 60 mm

Min. 60 mm

Min. 60 mm

Air vent area

Min. 300 mm (floor)

Min. 500 mm (ceiling)

Samsung Electronics

1. Product Information and Installation Precautions

15

Minimum gap for installation on wall(Applicable when a fan is not used)

WALL

Min. 90 mm

Min. 300 mm (floor)

Min. 500 mm (ceiling)

Air vent area

Air vent area

Air vent area

Air vent area

Samsung Electronics

1. Product Information and Installation Precautions

16

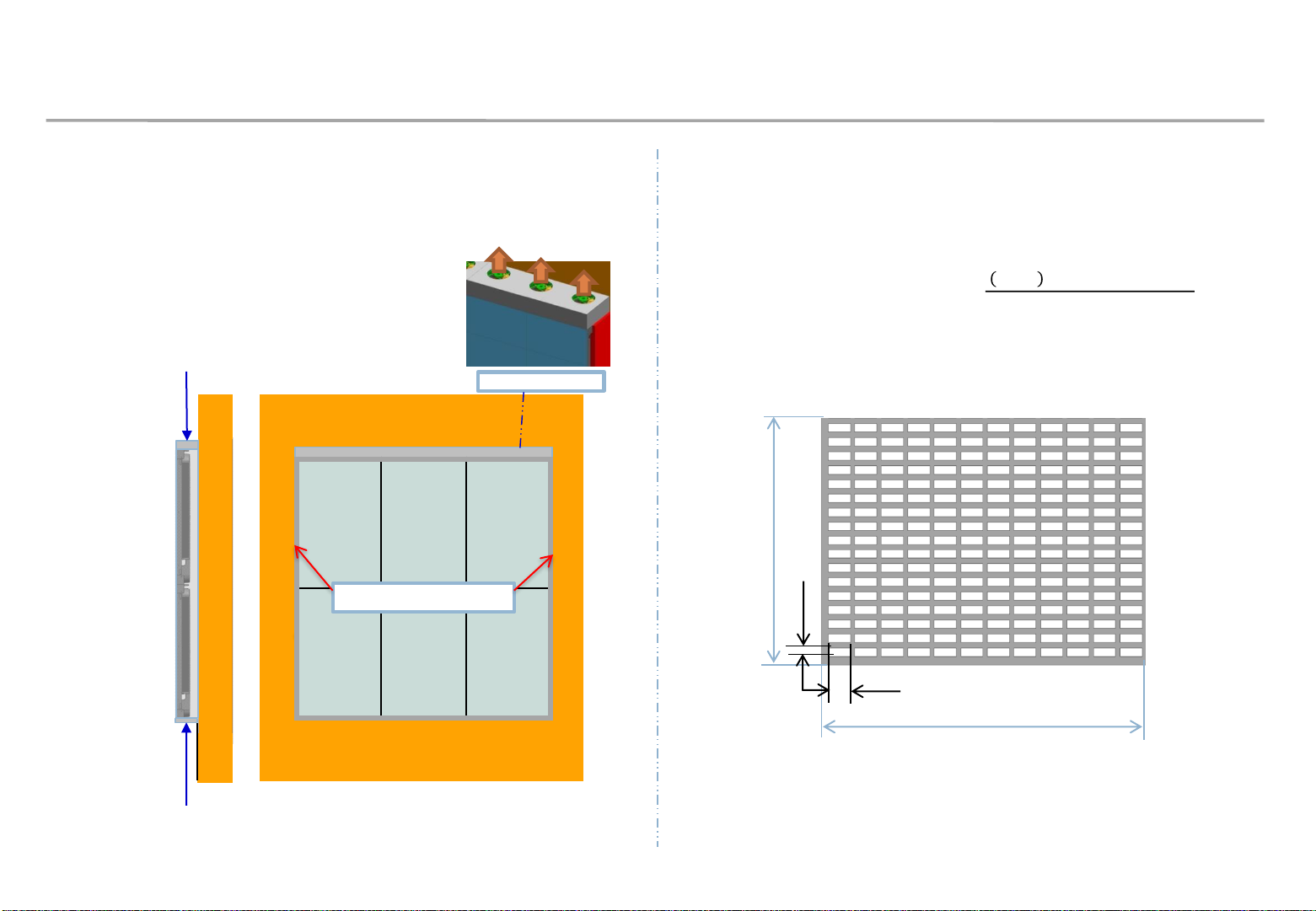

◇ Preparation for installation

LED MODULE JIG

(model name: CY-LJRNLS)

Electric screwdriver

Phillips (+)

screwdriver

Pliers

Service JIG

(BH81-00001A)

Holder Magnet Tool

Anti-static

gloves

※

Recommende

d sizes

Samsung Electronics

2. Preparation for Cabinet Installation

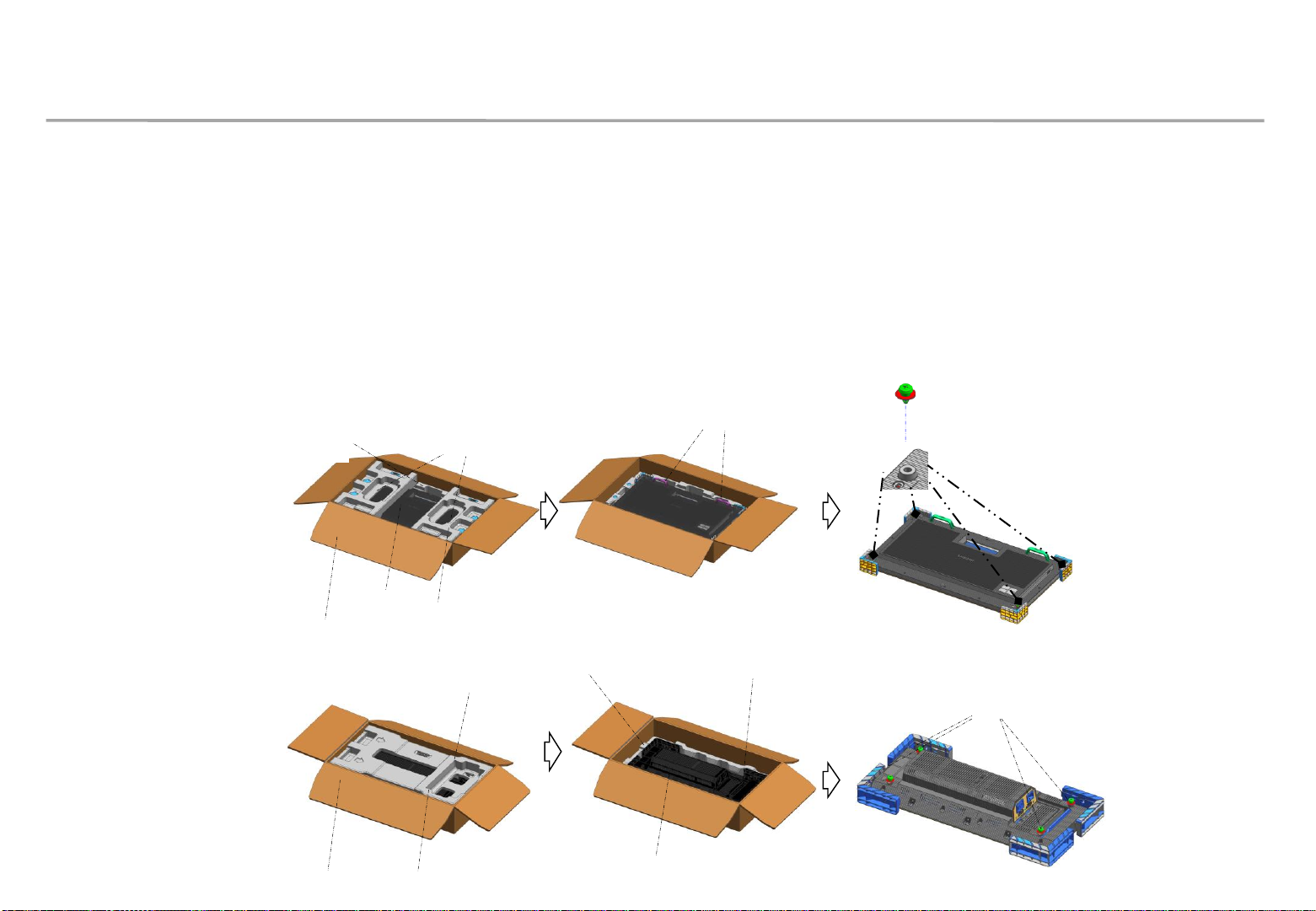

◇ Preparation prior to installation

① Remove the tape on top of the package box and open the box. (See Fig.1.)

② Remove the Top–Cushion and open the shielding bag. Hold the handles inside, take out the set, and then remove the PE bag.

(See Fig.2.)

③ Check that the sliding bolts are properly fastened. (See Fig.3.)

Fig.1 Contents of the

package

Fig. 2 Opening the

package

Fig.3 Checking the bolts

handl

e

TopCushio

n

IB &

cable

BottomCushion

LED

set

Box

SLIDING BOLT

Handle Shape

Top-Cushion

IB & cable

Bottom-Cushion

LED set

Box

SLIDING

BOLT

■ IER

■ IER- F

Samsung Electronics

2. Preparation for Cabinet Installation

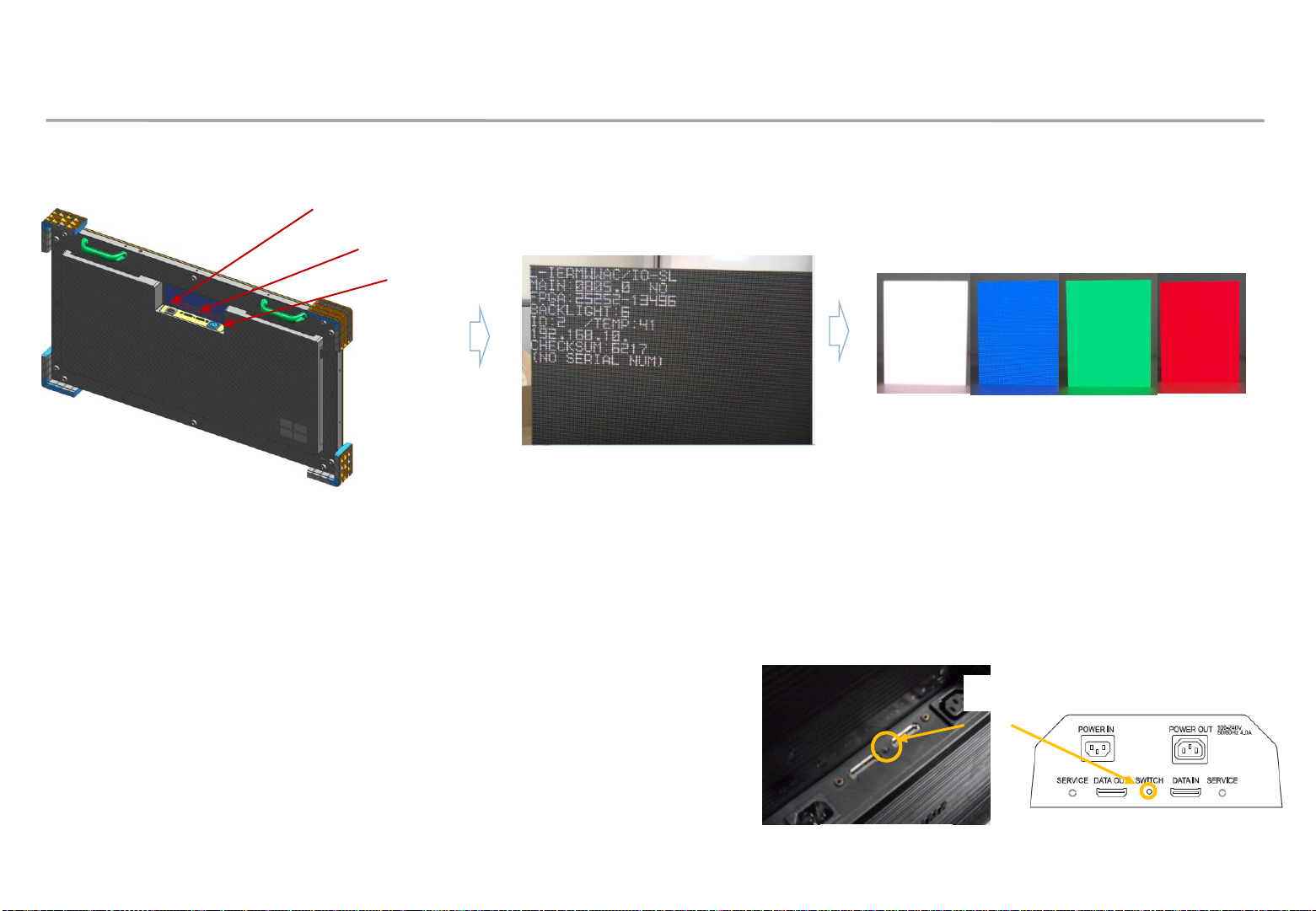

④ Connect the power and check for a problem with the screen. (See Fig.4.)

※ See page 12 for details on how to check for a screen problem.

⑤ Unfasten the screws (four screws in total) and remove the corner covers. (See Fig.5.)

Fig.4 Checking the screen

Fig.5 Removing the corner covers

18

Switch Button

S

C

R

E

W

Guide

Pin

Switch Button

SC

RE

W

■ IER

■ IER- F

Samsung Electronics

◇ Connect the power cord that came with the product and turn on the product.

Check that there is no LED damage and no problem is found on the screen.

※ Steps to perform in the event of White Pattern

- Apply power and press and hold the Switch for 5 seconds.

- When the factory info window appears, press the Switch once again.

- When the color screen appears, press the Switch repeatedly to check for malfunctioning LEDs.

(Each time the Switch is pressed, the LED color is switched in the following order:

white → blue → red → green.)

- To turn off the mode, press and hold the Switch for 5 seconds again.

Switch Button

Power In

Power Out

2. Preparation for Cabinet Installation

7

◈ Note: Checking for a screen problem

Switch

IER IER-F

Samsung Electronics

2. Preparation for Cabinet Installation

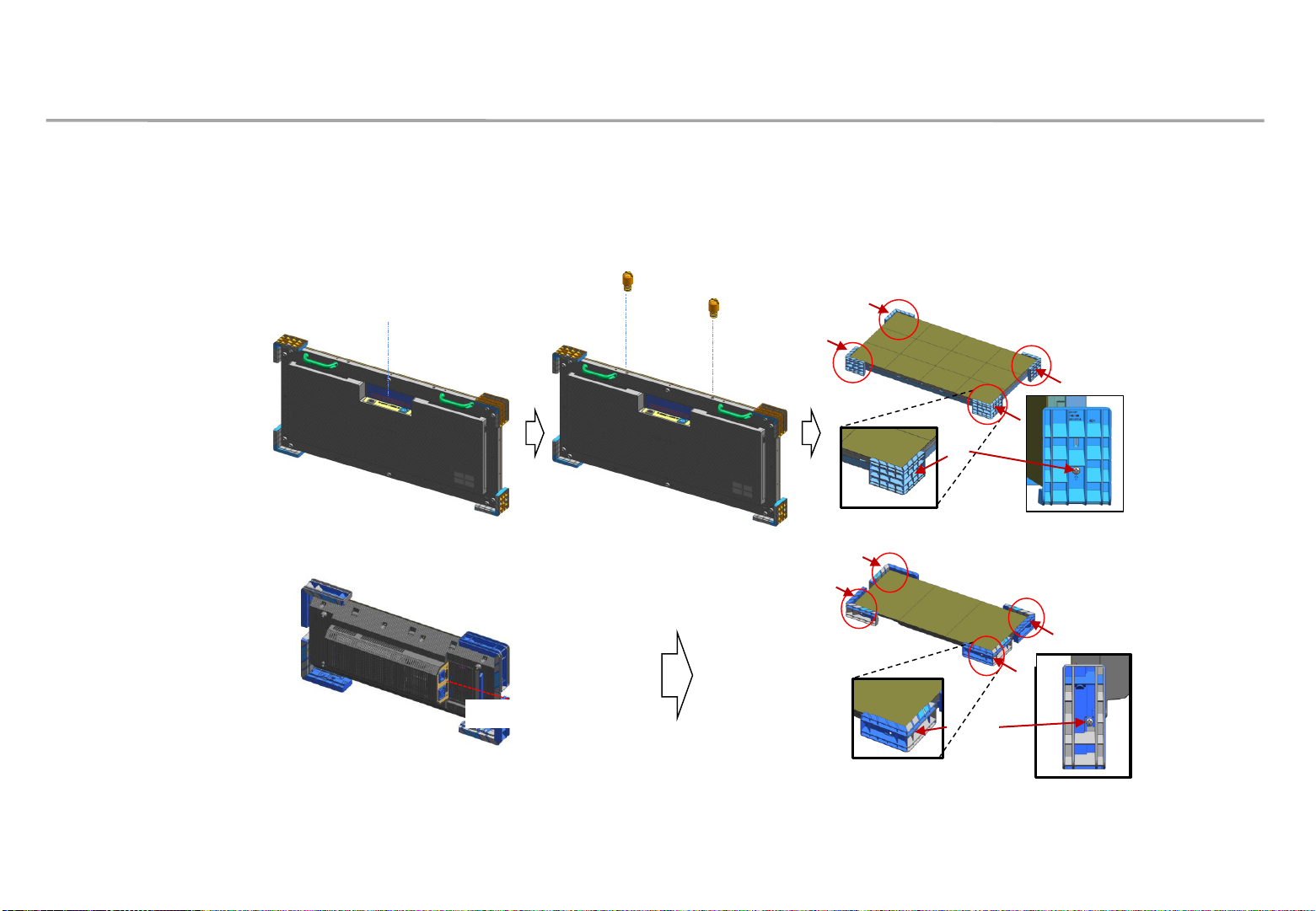

⑧ For cabinets placed on the edge, attach PET sheet before attaching PCB covers.

※ Attach PET sheet to all borders of the LED module (Fig.1), and attach PCB covers to the same outer sides where the

PET sheet has been attached (horizontally 5 points and vertically 4 points, as shown by the blue borders in Fig.2).

※ Attach PET sheet as shown in Fig.3. Make sure the area with no tape guides the LED module.

※ Attach PCB covers as shown in Fig.4.

Fig.2 Borders requiring PET sheet and PCB covers

* Numeric figure: Quantity of PCB covers to attach

Fig.3

Fig.4

PET sheet

No tape

0 to 0.5 mm

20

Fig.1 Attach PET sheet here

Fig.1 Attach PET sheet here

Samsung Electronics

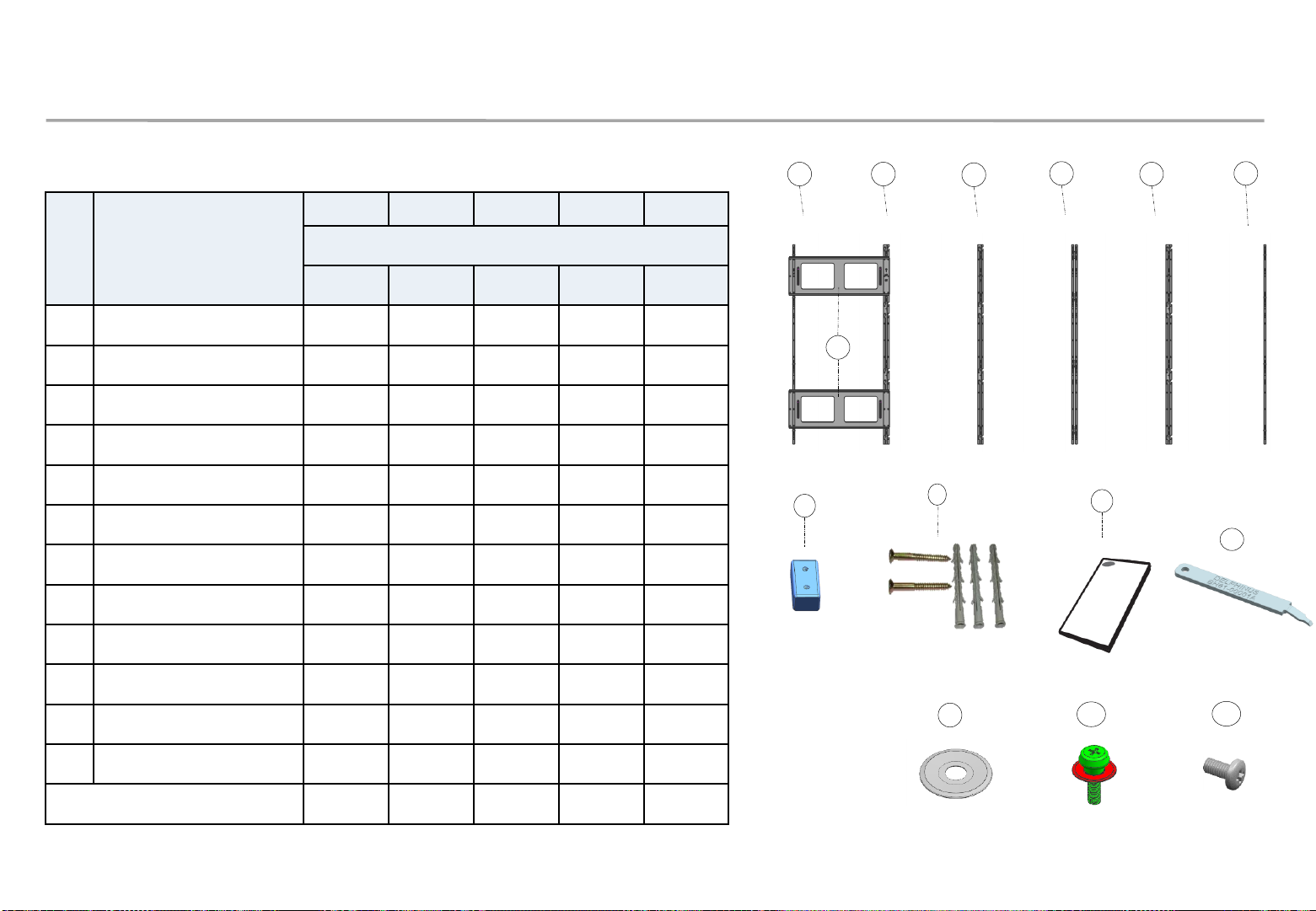

3. Frame Installation

21

a

a

b

b

c

b

d

No. Item

VG-LFR84FWL VG-LFR53FWL VG-LFR52SWL VG-LFR11SWL VG-LFR51PWL

Qty (+spares)

8X4 5X3 5X2 1X1 PIVOT

ⓐ

ASSY BRACKET SIDE

2 2 2 2 2

ⓑ

ASSY BRACKET MIDDLE

6 3 3 - 3

ⓒ

ASSY BRACKET CENTER

1 (+1) 1 (+1) 1 (+1) - 1 (+1)

ⓓ

ASSY BRACKET JIG

2 2 2 - 1

ⓔ

JOINT V

10 7 7 2 7

ⓕ

ASSY ANCHOR SCREW

50 28 21 4 14

ⓖ

QUICK INSTALL GUIDE

1 1 1 1 1

ⓗ

Service JIG 1 1 1

- -

ⓘ

Wrench 1 1 1

1 1

ⓙ

WASHER (SLIDING BOLT) 10 5 5

- -

ⓚ

BOLT – ETC - - -

- 12

ⓛ

SCREW (M4) 20 14 14

4 14

Screen size for installation (mm)

7680X2160 4800X1620 4800X1080 960X540 2700X2880

① Make sure none of the following Frame Kit contents are missing.

g

f

M5, L65, Anchor Screw

h

Service JIG

e

JOINT V

j

WASHER

k

BOLT-ETC

QSG

l

SCREW (M4)

※ Refer to attachment at last page for IER-F installation

Samsung Electronics

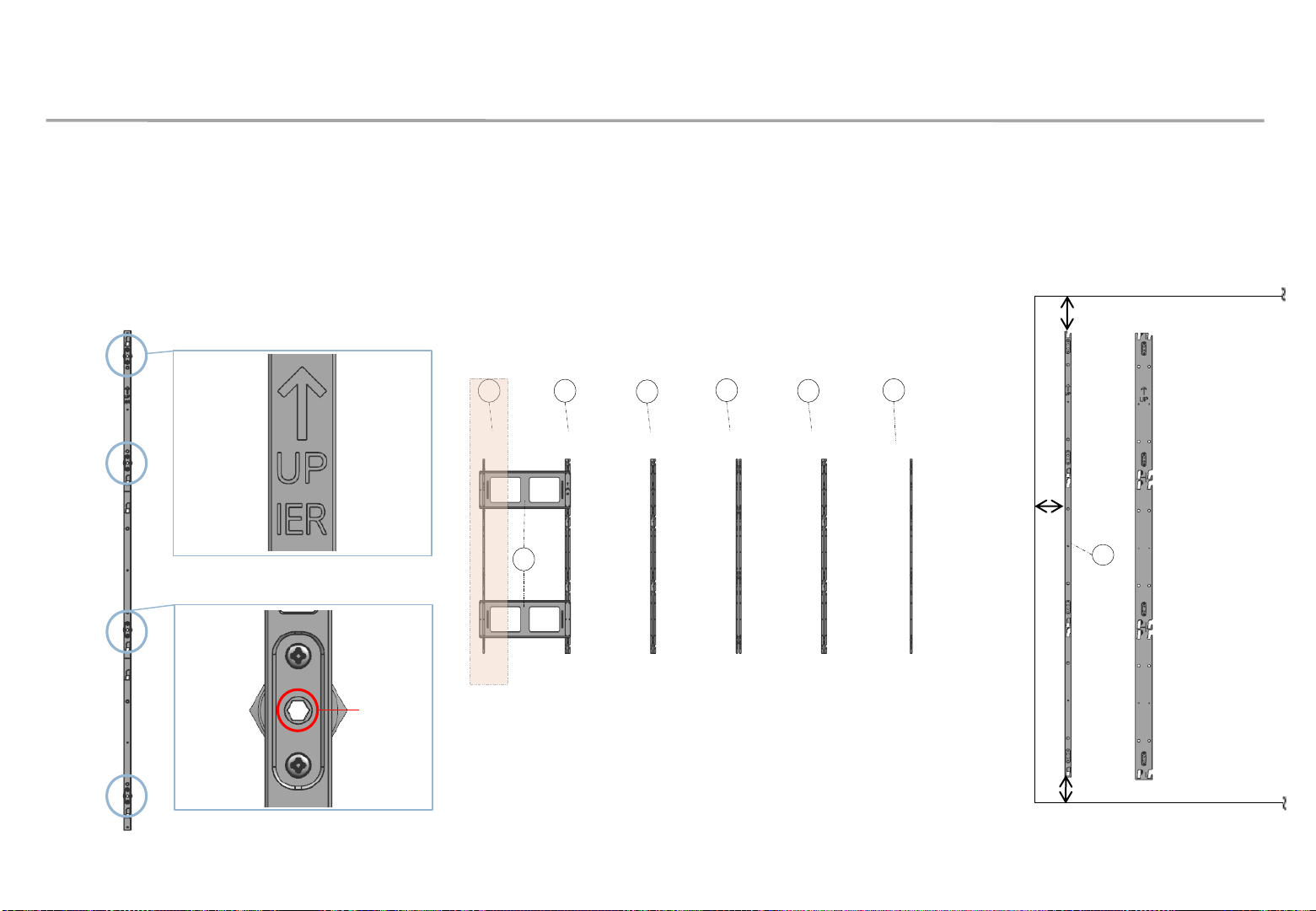

a

a

b

b

c

b

d

3. Frame Installation

② On the left end, place the ⓐBracket Side and fasten the screws to install the Bracket (Fig.3).

※ Fasten one screw first, and use a clinometer to vertically align the right edges and fasten screws into the other holes.

(See the next page for precautions when fastening screws.)

Fasten the screws in the order of screw 1 → screw 2 → screw 3. Fig.1

ⓐ Fix the Bracket Side, following the measurements shown in Fig.4.

Fig.1 Order of fastening the screws

Fig.3 Positions of

components to attach

22

Fig.4 Screw fastening position

based on screen

12 mm or above

25 mm or above

12 mm or above

a

Fig.2 Screwing hole

Screwing

hole

①

③

③

②

Samsung Electronics

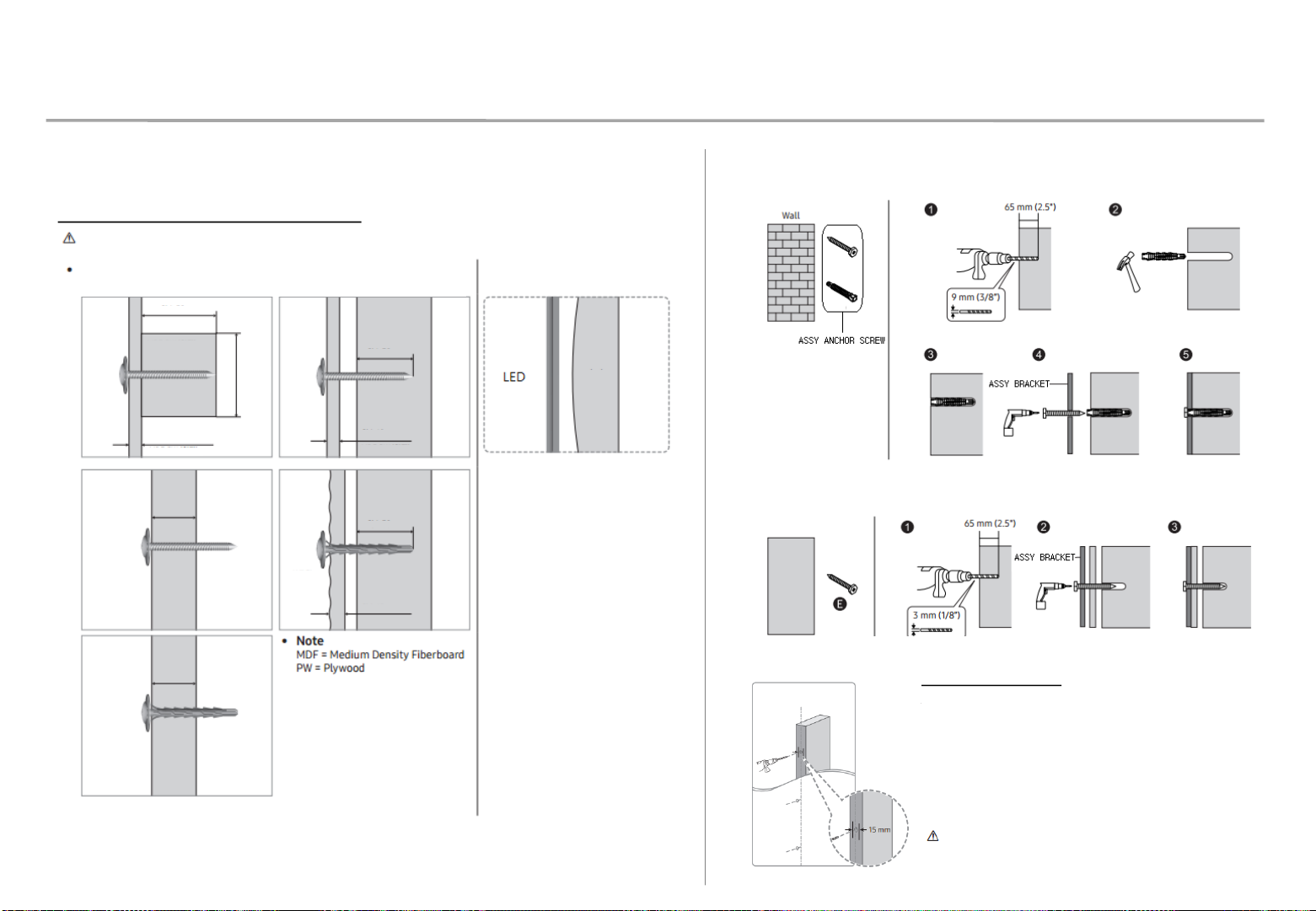

3. Frame Installation

※ Precautions when tightening screws

23

Frames can be installed on a sufficiently thick concrete or interior wall.

Refer to the following figures.

If installing frames on a wall that is

not flat, irregular openings may

develop and affect the exterior

appearance.

• Make sure you check the location of the wood stud inside the

wall before screwing screws into the wall.

• Minimum wood stud size: 51 x 102 mm (2 x 4 inches)

Drill holes (3 mm) before screwing screws into the wall.

• Make sure you drill screw holes in the middle of the wood stud.

• If you screw a screw directly into the wood stud without drilling

a hole, the wood may crack.

• Standard wood stud interval of 16” is supported. (24” is not

supported.)

Samsung Electronics is not responsible for problems

caused as a result of failure to follow the requirements

specified in the installation guide.

Installation requirements

Standard installation requirements by wall type

Check the wall type before installation.

• First check the wall specifications (e.g.

type, thickness, floor plan).

① Sufficiently thick concrete or design wall

② Wood stud inside a plaster board, or MDF wall

Wall

Equipped with

stiffeners, e.g. MDF

or PW (plywood)

MDF, PW (plywood)

MDF, PW (plywood)

MDF, PW (plywood)

At least 10 mm

At least 50 mm

At least 30 mm

At least 10 mm

At least 30 mm

At least 10 mm

MDF, PW (plywood)

At least 25

mm

At least 25

mm

MDF, PW (plywood)

(except the plaster

board thickness)

Concrete composite wall

(except the plaster board

thickness)

At least 50

mm

Art Wall

Concrete

Samsung Electronics

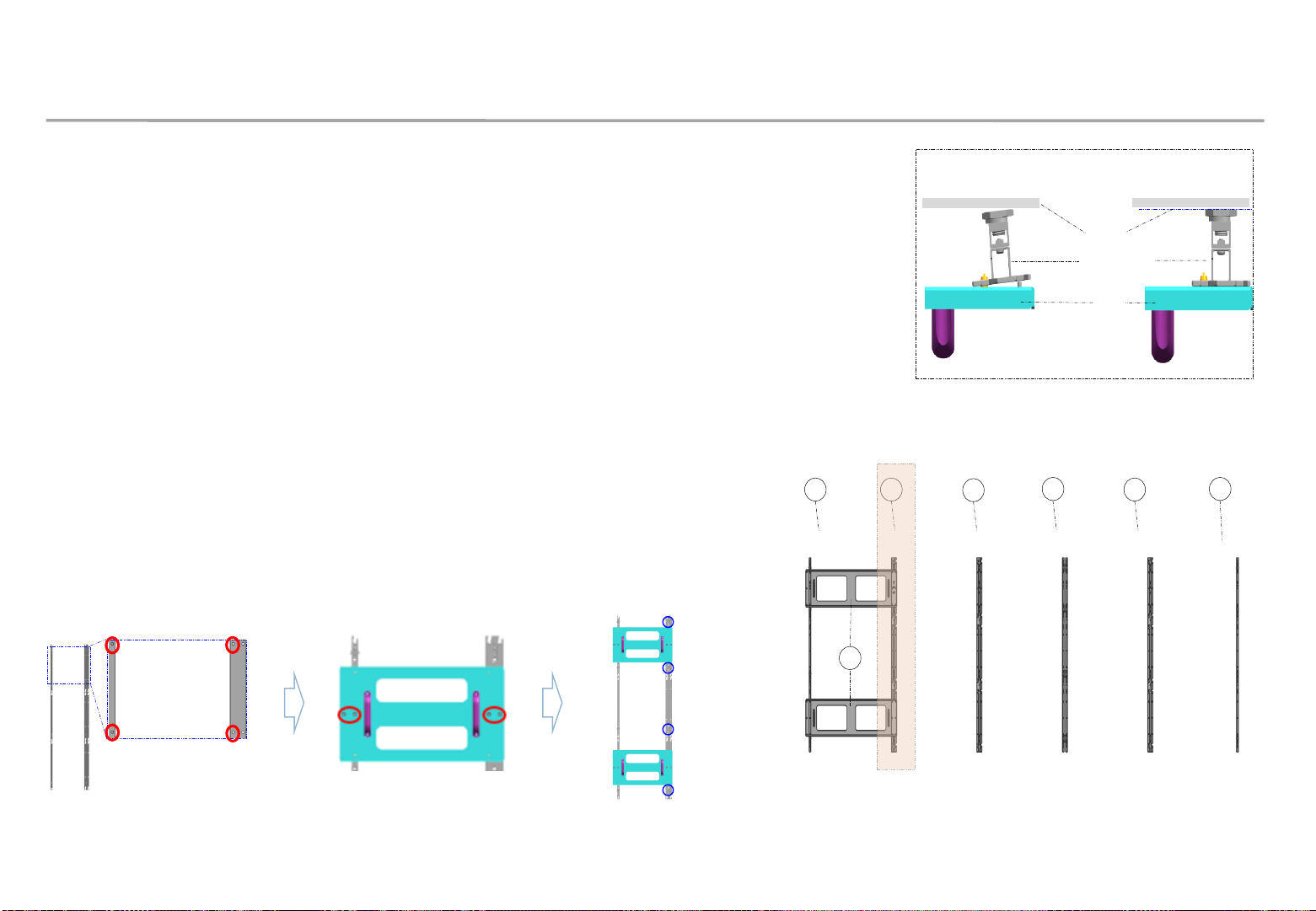

3. Frame Installation

③ Install the ⓑ Bracket Middle.

※ First, check the holes into which to fix the ⓓ JIGs. (See Fig.1.)

※ Next, align the ⓓ JIG with the bracket holes and fasten the four screws. (See Fig.2.)

※ Lastly, fasten the screws to fix the ⓑ Bracket Middle to the wall. (See Fig.3.)

※ Caution: The surface ⓓ should be attached to ⓐ and ⓑ. The three surfaces (the wall,

ⓐ and ⓑ, and ⓓ) should be in parallel. (See Fig.4.)

④ Use the same steps above to install all ⓑBracket Middle,

in the left-to-right order.

※ Install the Bracket Center in the middle of the Frame Kit.

Fig1. Checking the holes

Fig2. Fixing the Jigs

(with screws)

Fig4. Keeping frames parallel

Fig3. Fastening the screws

Fig.5 Positions of components to attach

24

ⓐ,ⓑ,ⓒ

Wall

Incorrect

installation

Correct

installation

ⓓ

a

a

b

b

c

b

d

Samsung Electronics

3. Frame Installation

25

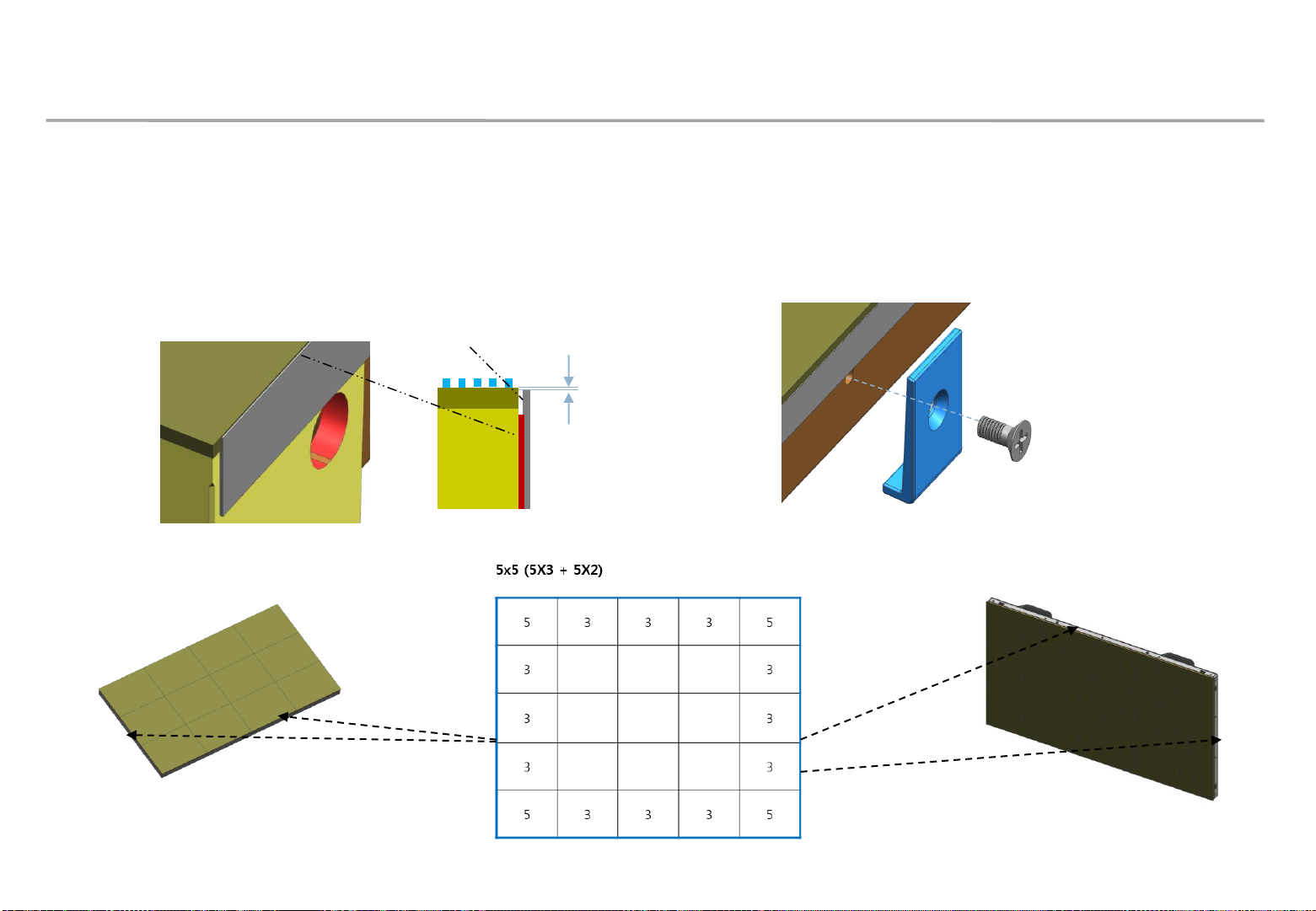

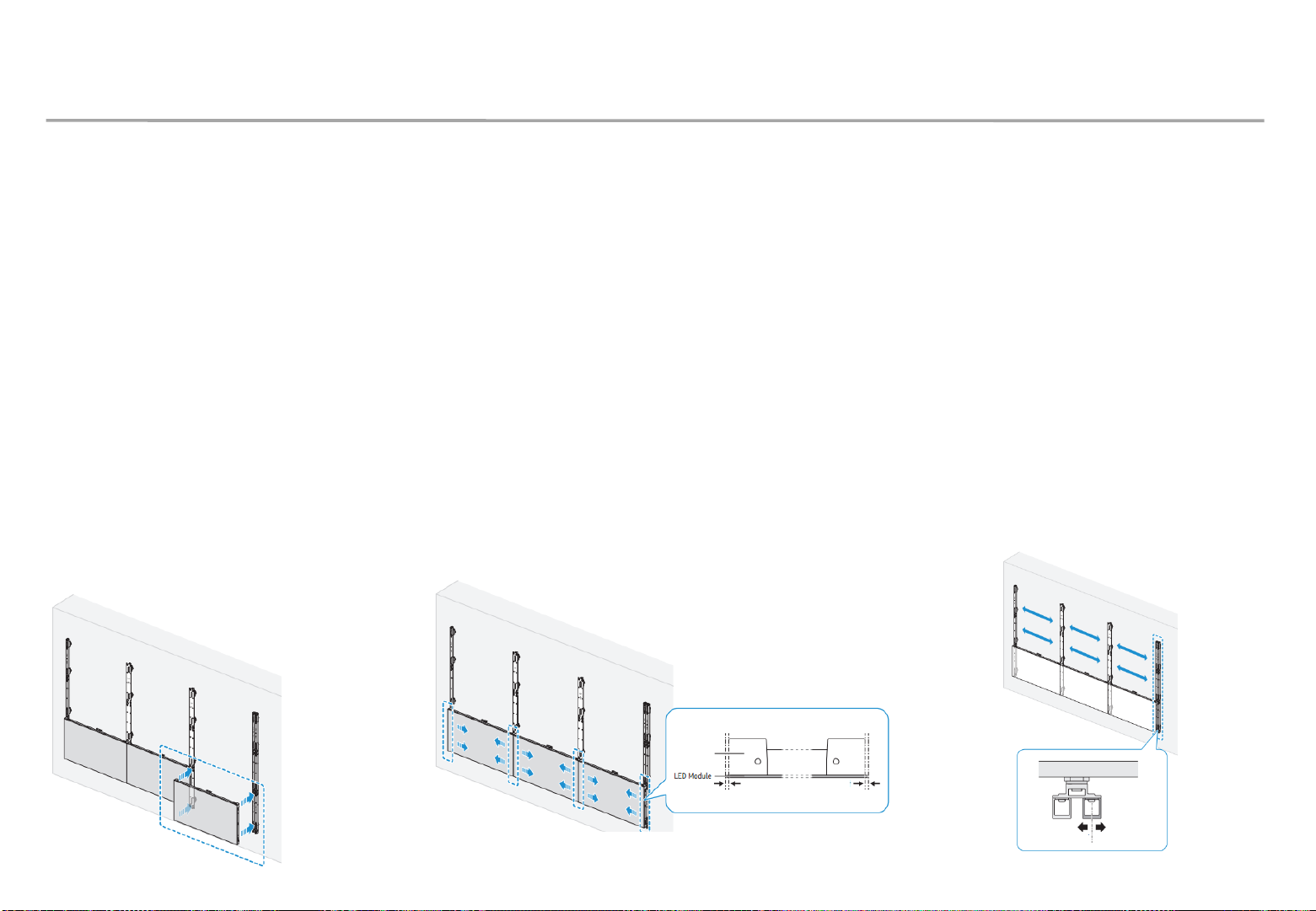

⑤ After installing the Bracket Center, install the lowest row cabinets. (See Fig.6.)

⑥ After installing the cabinets, push the LED modules toward the middle and check the height

difference between the cabinets on both ends and the LED modules. (See Fig.7.)

⑦ Roughly adjust the height difference between the left and right sides, and make fine adjustment

as shown below. (See Fig.8.)

• If the height difference is greater than 0.5 mm, move the frame outwardly.

• If the height difference is smaller than 0.0 mm, move the frame inwardly.

• Adjust height difference each time an additional cabinet is installed.

It is not necessary to adjust a height difference in the 0.0 to 0.5 mm range.

⑧ After adjustment is completed, install the ⓑBracket Middle.

(See step ② for details on how to install.)

⑨ Lastly, install the ⓐBracket Side.

Fig.7 Checking height difference

Fig.8 Adjusting height difference

Fig.6 Installing cabinets

Height difference

greater than 0.5 mm

Height difference

smaller than 0.0 mm

Height

difference

Height

difference

Cabinet

Samsung Electronics

4. Frame Installation – Adjusting the Frame

Center (Important)

26

Fig.7 (check the gap) Fig.8 (adjust the gap)

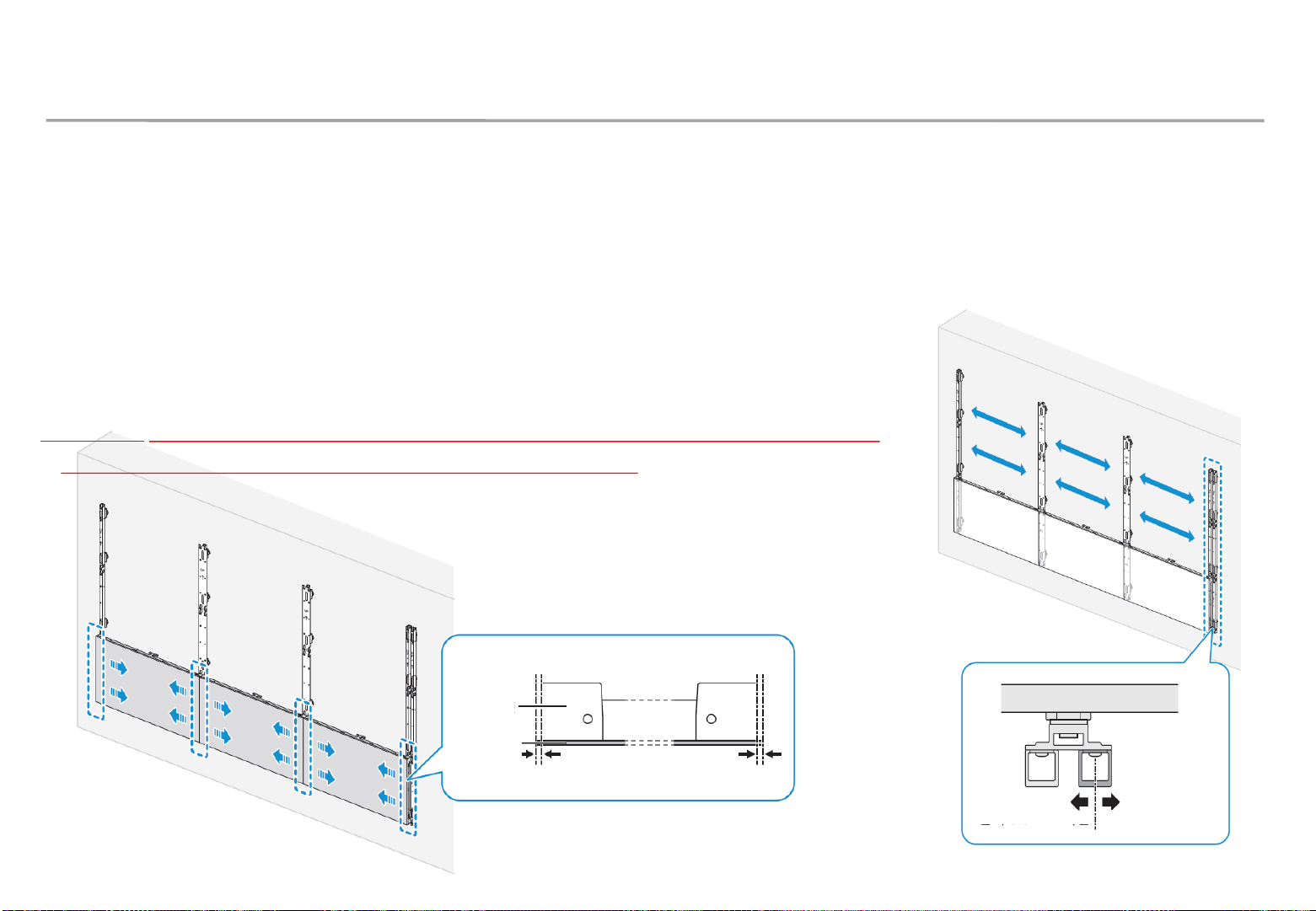

• Install the Frame Center after a Frame Side and two Frame Middles are installed based on the VG-LFR53FWL.

• Before installing Frame Middle next to the Frame Center, be sure to hang the IER Cabinet on the bottom line.

• Push the modules to the center and check the Frame Center so that there is no gap between cabinets and

between modules.

• When the module’s end is protruded more than 0.5 mm to the right based on the Frame Center, adjust the right

side of Frame Center outward.

• When the module’s end is protruded within 0.0 mm to the right based on the Frame Center, adjust the right side

of Frame Center inward.

• When installed long left to right, repeat the above procedure whenever a Frame Center is installed.

※ Otherwise, it may cause maintenance issues due to difficulty in attachment and detachment of a module.

Excessive attachment may cause the module’s dislocation. (see page 26)

◆Bracket Center’s usable section,

VG-LFR53FWL: Every 3 rows

VG-LFR52SWL: Every 3 rows

VG-LFR84FWL: Every 4 rows

LED Module

Gap is within 0.0 mm

Gap is over 0.5 mm

Cabinet

Gap

Gap

Samsung Electronics

3. Frame Installation

27

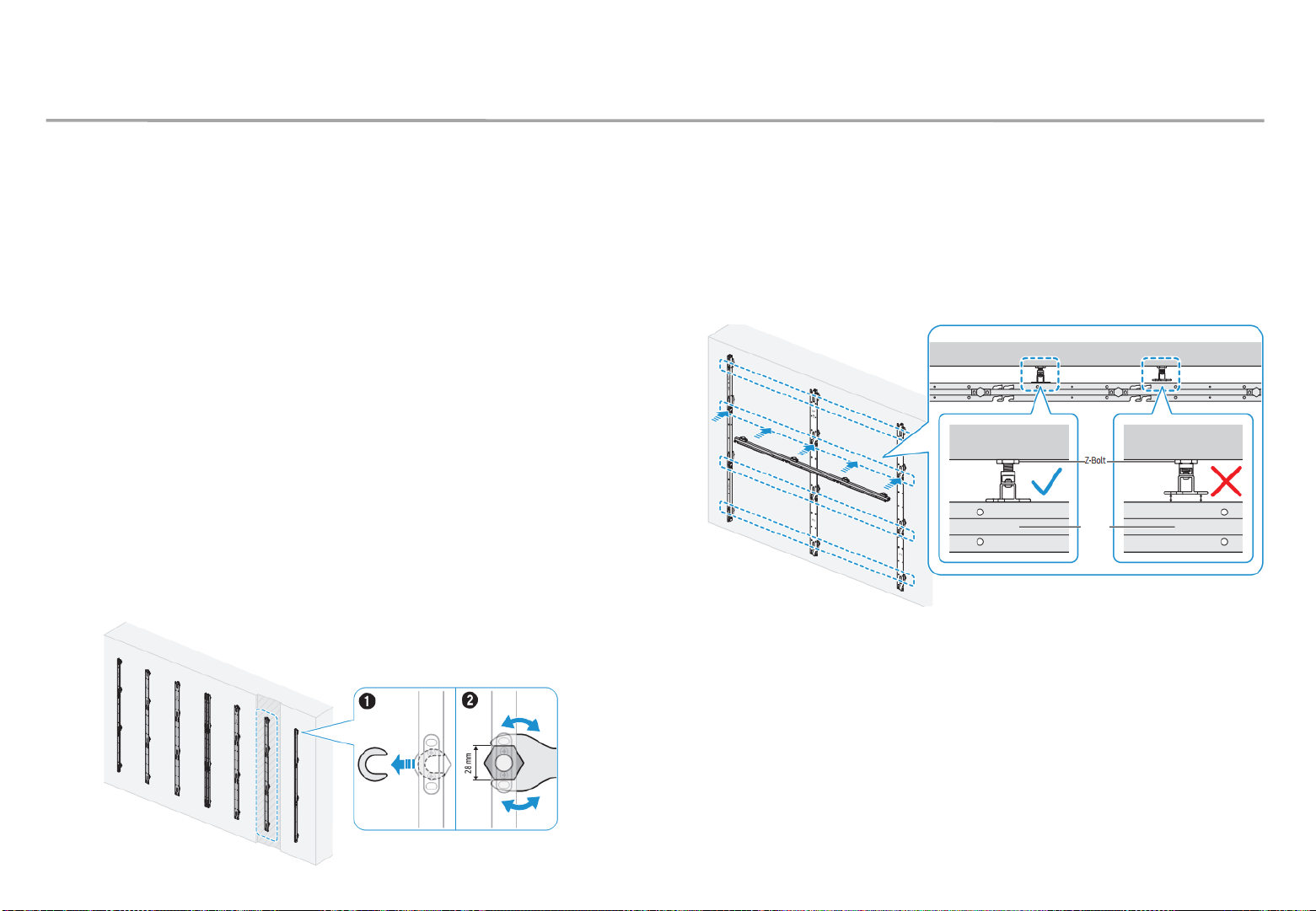

※ If installing three or more ASSY BRACKETs, adjust the flatness, because the wall or a

structure may cause warping.

– After installing three or more ASSY BRACKETs, put a spare ASSY

BRACKET horizontally and measure the height difference.

If a height difference is found, adjust the Z-Bolts of the ASSY

BRACKETs to adjust the flatness.

– How to adjust height

1. To adjust the height of a Z-Bolt of a frame, first remove the washer.

2. Use a 28 mm wrench to adjust the Z-Bolt height.

Flatness measurement positions:

Around areas where screws are fastened

Wall

Spare

frame

Wall

Wall

Samsung Electronics

※ The Frame Kit product can be installed by extending the size as required.

- Components can be extended horizontally or vertically for installation.

- When installing ASSY BRACKET JIGs for fixing the joints between ASSY BRACKETs, make sure two persons work together so that the

ASSY BRACKET JIGs can be fixed properly.

(While one person holds an ASSY BRACKET JIG on the position to fix the JIG, the other person can fasten screws on the ASSY BRACKET JIG.)

- When performing extended installation, an ASSY BRACKET CENTER should be installed between the ASSY BRACKET MIDDLEs.

(It is recommended that one ASSY BRACKET CENTER be installed for three to four ASSY BRACKET MIDDLEs.)

28

3. Frame Installation

Samsung Electronics

3. Frame Installation

29

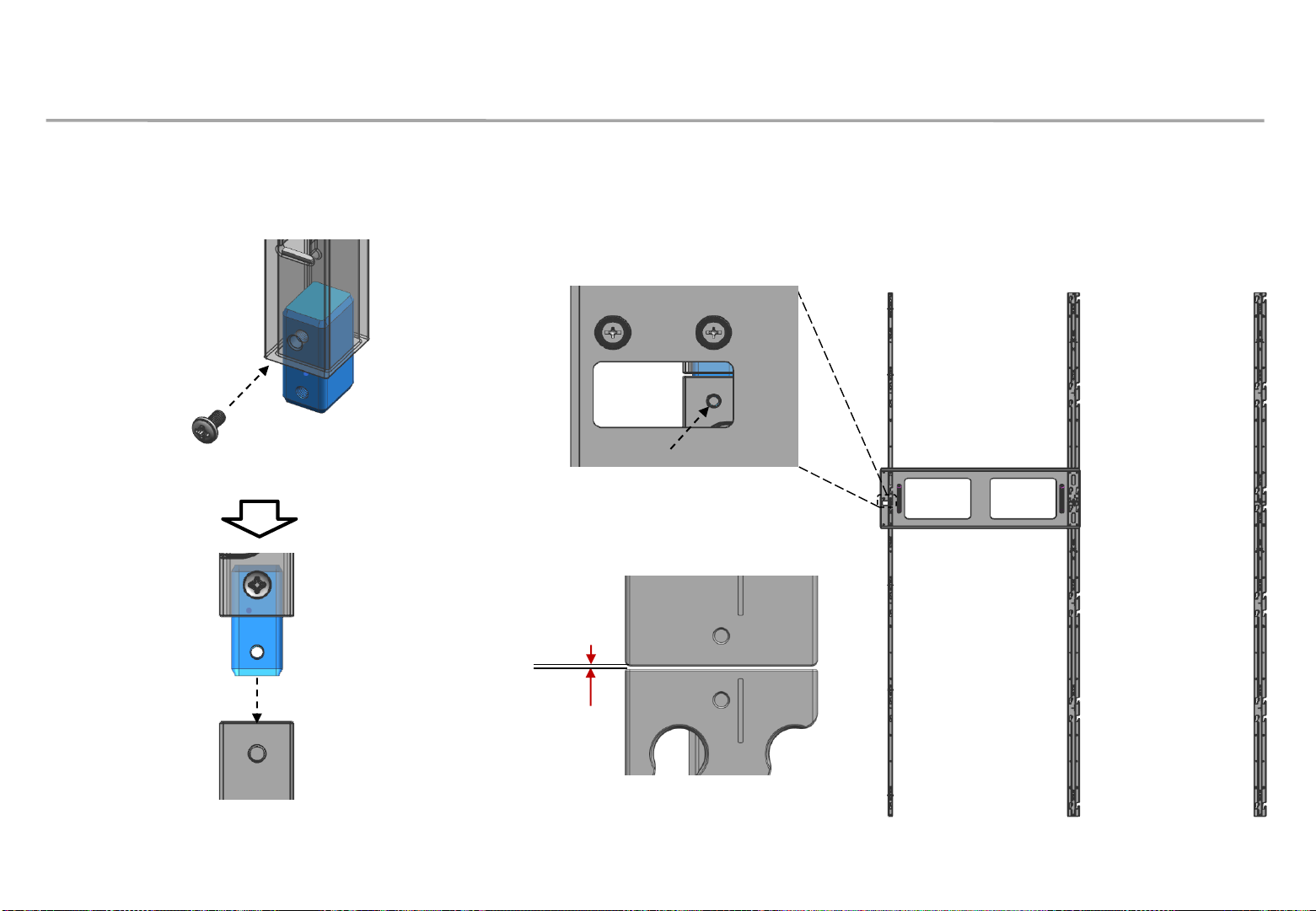

※ Vertical frame extension

-Attach the Joint V (vertical) to the target frame for extension

Fasten M4

<Vertical extension>

M4 screw

- Insert the joints of the additional frame into the existing frame. Insert jigs

to place the frames into position.

- After attaching the jigs, fasten screws between the frames.

- Distance between connected frames for extension is 1 mm.

1 mm

* FRAME 연장시 수직, 수평이 틀어지기 쉽다. 연장하면서 수평 수직 CHECK 를 반드시 해야한다. ( 레이저 수평계 / 실 등)

Loading...

Loading...