Samsung LE17LS, LE17LT, LE17KS, LE17KT, LE17JS Service Manual

...

COLOR MONITOR

LE15V*/

LE17LS/LE17LT/LE17KS/

LE17KT/LE17JS/LE17JT

SERVICE

Manual

COLOR MONITOR CONTENTS

1. Precautions

2. Product Specifications

3. Disassembly & Reassembly

4. Alignment & Adjustments

5. Troubleshooting

6. Exploded View & Parts List

7. Electrical Parts List

8. Block Diagram

9. Wiring Diagram

10. PCB Layout

11. Schematic Diagrams

❈ This Service Manual is a property of Samsung

Electronics Co., Ltd.

Any unauthorized use of Manual can be punished

under applicable International and/or domestic law.

Samsung Electronics Co.,Ltd.

416, Maetan-3Dong, Yeongtong-Gu, Suwon City, Kyungki-Do, Korea, 443-742

Printed in Korea

P/N : BH82-00015J-00

URL : http://itself.sec.samsung.co.kr/

1 Precautions

!

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

(READING SHOULD

NOT BE ABOVE 0.5mA)

LEAKAGE

CURRENT

TESTER

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

1-1 Safety Precautions

WARNINGS

1. For continued safety, do not attempt to modify the

circuit board.

2. Disconnect the AC power before servicing.

3. When the chassis is operating, semiconductor

heatsinks are potential shock hazards.

1-1-1 Servicing the High Voltage circuit

and CRT :

1. When servicing the high voltage circuit, remove the

static charge by connecting a 10 kohm resistor in

series with an insulated wire (such as a test probe)

between the chassis and the anode lead.

2. When troubleshooting a monitor with excessively

HV, avoid being unnecessarily close to the monitor.

Do not operate the monitor for longer than is

necessary to locate the cause of excessive voltage.

3. High voltage should always be kept at the rated

value, no higher. Only when high voltage is

excessive are X-rays capable of penetrating the shell

of the CRT, including the lead in glass material.

Operation at high voltages may also cause failure of

the CRT or high voltage circuitry.

4. When the HV regulator is operating properly, there

is no possibility of an X-ray problem. Make sure the

HV does not exceed its specified value and that it is

regulating correctly.

5. The CRT is especially designed to prohibit

X-ray emissions. To ensure continued X-ray

protection, replace the CRT only with one that is

the same or equivalent type as the original.

6. Handle the CRT only when wearing shatterproof

goggles and after completely discharging the high

voltage anode.

7. Do not lift the CRT by the neck.

2. Inspect all protective devices such as nonmetallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

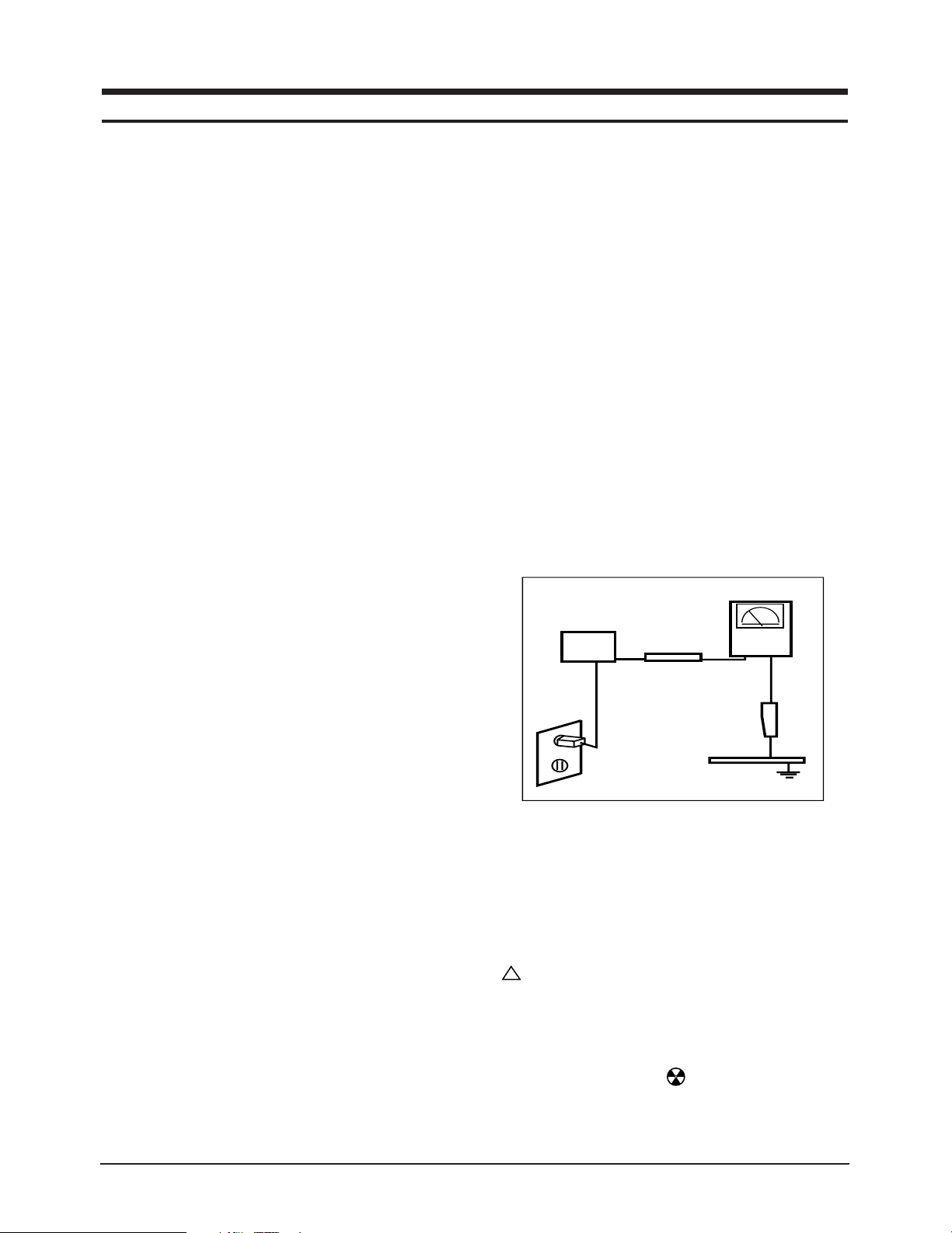

3. Leakage Current Hot Check (Figure 1-1):

WARNING: Do not use an isolation transformer during

this test.

Use a leakage current tester or a metering system

that complies with American National Standards

Institute (ANSI C101.1, Leakage Current for

Appliances), and Underwriters Laboratories (UL

Publication UL1410, 59.7).

4. With the unit completely reassembled, plug the AC

line cord directly into a 120V AC outlet. With the

unit’s AC switch first in the ON position and then

OFF, measure the current between a known earth

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including: metal cabinets,

screwheads and control shafts. The current

measured should not exceed 0.5 milliamp. Reverse

the power-plug prongs in the AC outlet and repeat

the test.

1-1-2 Fire and Shock Hazard :

Before returning the monitor to the user, perform the

following safety checks:

1. Inspect each lead dress to make certain that the

leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in

the monitor.

1-1-3 Product Safety Notices

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection. The protection they give

may not be obtained by replacing them with

components rated for higher voltage, wattage, etc. Parts

Figure 1-1. Leakage Current Test Circuit

that have special safety characteristics are identified by

on schematics and parts lists. A substitute

replacement that does not have the same safety

characteristics as the recommended replacement part

might create shock, fire and / or other hazards. Product

safety is under review continuously and new

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

instructions are issued whenever appropriate.

Components identified by on schematics and parts

lists must be sealed by a soldering iron after

replacement and adjustment.

1-1

1 Precautions

1-2 Servicing Precautions

WARNING1: First read the “Safety Precautions” section of this manual. If unforeseen circumstances

create conflict between the servicing precautions and safety precautions, always

follow the safety precautions.

WARNING2: A high voltage VR replaced in the wrong direction may cause excessive X-ray

emissions.

WARNING3: An electrolytic capacitor installed with the wrong polarity might explode.

1. Servicing precautions are printed on the cabinet,

and should be followed closely.

2. Always unplug the unit’s AC power cord from the

AC power source before attempting to: (a) remove

or reinstall any component or assembly, (b)

disconnect PCB plugs or connectors, (c) connect all

test components in parallel with an electrolytic

capacitor.

3. Some components are raised above the printed

circuit board for safety. An insulation tube or tape

is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the area around the

serviced part has not been damaged.

5. Check the insulation between the blades of the AC

plug and accessible conductive parts (examples:

metal panels, input terminals and earphone jacks).

6. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the power

switch ON. Connect an insulation resistance meter

(500 V) to the blades of the AC plug.

The insulation resistance between each blade of the

AC plug and accessible conductive parts (see

above) should be greater than 1 megohm.

7. Never defeat any of the +B voltage interlocks. Do

not apply AC power to the unit (or any of its

assemblies) unless all solid-state heat sinks are

correctly installed.

8. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrument’s

ground lead last.

1-3 Electrostatically Sensitive Devices (ESD) Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD are integrated circuits and some field-effect

transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known earth

ground. Alternatively, wear a discharging wriststrap device. To avoid a shock hazard, be sure to

remove the wrist strap before applying power to

the monitor.

2. After removing an ESD-equipped assembly, place it

on a conductive surface such as aluminum foil to

prevent accumulation of an electrostatic charge.

3. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESDs.

4. Use only a grounded-tip soldering iron to solder or

desolder ESDs.

5. Use only an anti-static solder removal device. Some

solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage

ESDs.

6. Do not remove a replacement ESD from its

protective package until you are ready to install it.

Most replacement ESDs are packaged with leads

that are electrically shorted together by conductive

foam, aluminum foil or other conductive materials.

7. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

Caution: Be sure no power is applied to the

chassis or circuit and observe all

other safety precautions.

8. Minimize body motions when handling

unpackaged replacement ESDs. Motions such as

brushing clothes together, or lifting your foot from

a carpeted floor can generate enough static

electricity to damage an ESD.

9. Indicates ESDs on the Schematic Diagram in

this manual.

1-2 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

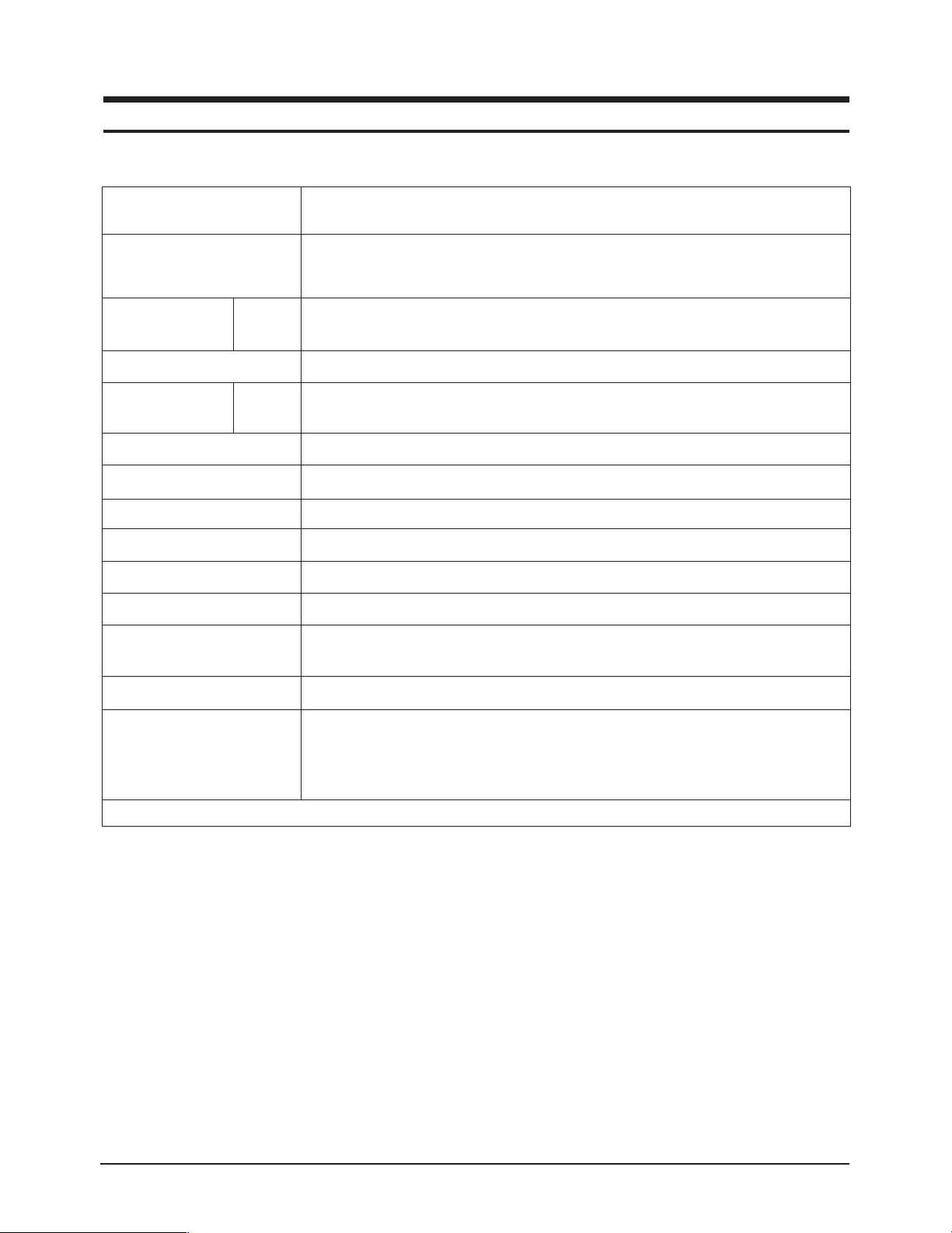

2 Product Specifications

2-1 LE15V* Specifications

2 Product Specifications

Item

Picture Tube: 15-Inch (38 cm): 13.8-inch (35 cm) viewable,

Full-square flat-face tube, 90˚ Deflection, Semi- tint, Non-glare, Invar shadow mask,

Anti-static silica coating, 0.28 mm Dot pitch

Scanning Frequency Horizontal 30 KHz ~ 55 KHz (Automatic)

Vertical 50 Hz ~ 120 Hz (Automatic)

Display Colors Unlimited colors

Maximum Resolution Horizontal 1024 Dots

Vertical 768 Lines

Input Video Signal Analog, 0.7 Vp-p positive at 75 Ω, internally terminated

Input Sync Signal Separate Sync : TTL level positive/negative

Maximum Pixel Clock rate 65 MHz

Active Display Horizontal : 267 mm ± 4 mm, Vertical : 200 mm ± 4 mm

Input Voltage AC 90 ~ 264 Volts, 60 Hz / 50 Hz ± 3 Hz

Power Consumption 70 Watt (Max)

Dimensions Set (W x D x H) 14.2 x 14.8 x 11.5 Inches (361 x 376 x 292 mm) Stand of stand installed

Package 17.3 x 18.3 x 14.8 Inches (439 x 464 x 376 mm)

Description

Weight (Set/Package) 11.0 kg (24.3 lbs) Stan of stand installed / 12.5 kg (27.6 lbs)

Environmental Considerations Operating Temperature : 32°F ~ 104°F (0°C ~ 40°C)

Humidity : 10 % ~ 80 %

Storage Temperature : –4°F ~ 113°F (–20°C ~ 45°C)

Humidity : 5 % ~ 95 %

• Designs and specifications are subject to change without prior notice.

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

2-1

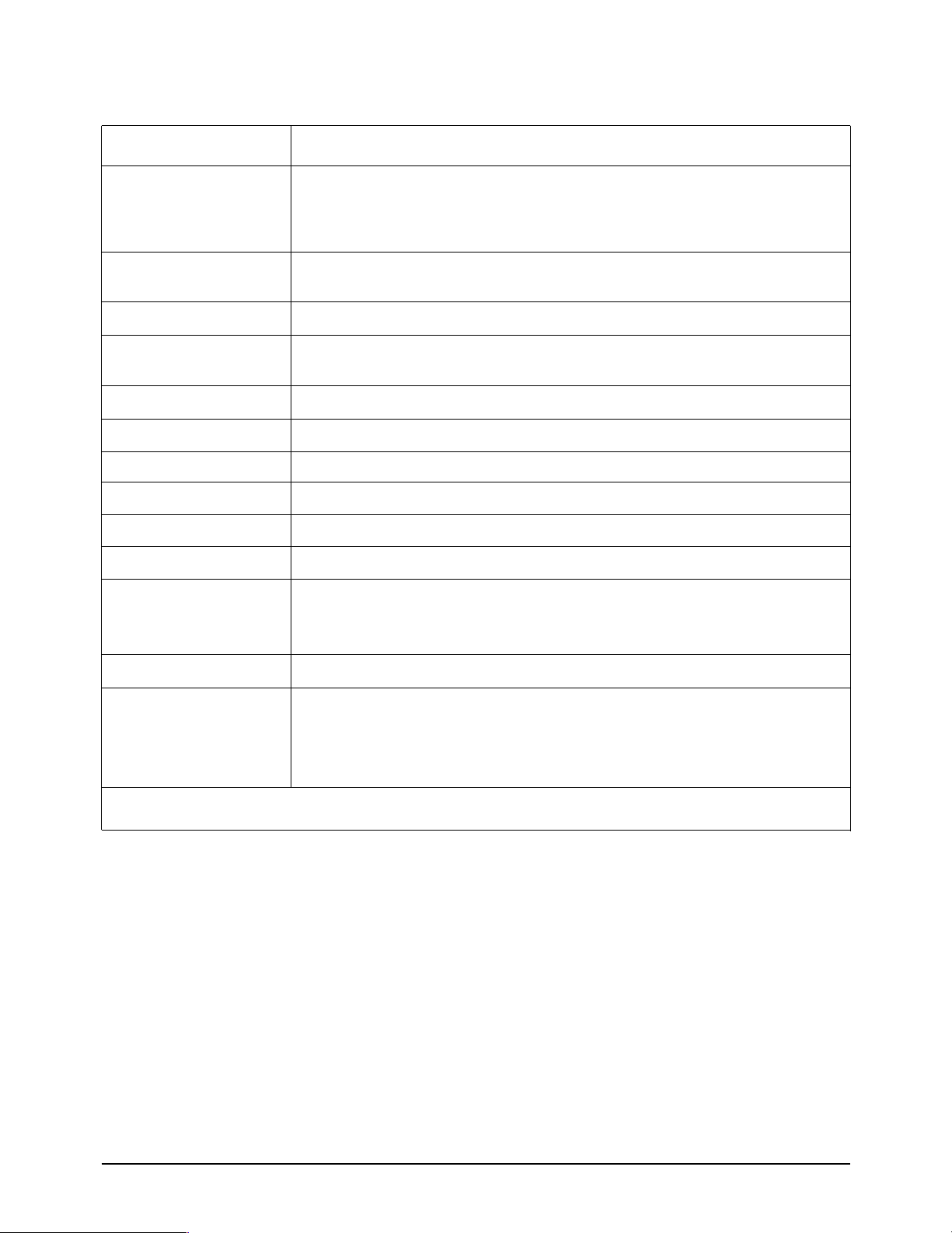

2-2 LE17LS/LE17LT/LE17KS/LE17KT/LE17JS/LE17JT Specifications

Item

Picture Tube 17-Inch (43 cm): 16-inch (40.6 cm) viewable,

Flat-face, 90˚ Deflection, 0.20 mm (Horizontal) Dot pitch,

Silica coated with anti-electrostatic properties (TCO: Multilayer coating),

Medium-short persistence phosphor

Scanning Frequency Horizontal : 30 kHz ~ 70 kHz , 30kHz ~ 85 kHz

Vertical : 50 Hz ~ 160 Hz

Display Colors Unlimited colors

Maximum Resolution Horizontal : 1280 Dots, 70K / 1600 Dots, 85K

Vertical : 1024 Lines, 70K / 1200 Dots, 85K

Input Video Signal Analog, 0.7 Vp-p positive at 75 Ω, internally terminated

Input Sync Signal Separate Sync: TTL level, positive/negative

Maximum Pixel Clock rate 110 MHz

Active Display Horizontal : 312 mm ± 4 mm, Vertical : 234 mm ± 4 mm

Input Voltage AC 100 - 240C, 60 / 50 Hz 1.2A

Power Consumption 90 Watt (Max) 85K, 80Watt (Max) 70K

Description

Dimensions

Set (W x D x H) 15.8 x 16.1 x 12.7 Inches (401 x 410 x 323 mm) Stand of stand installed

Package 18.3 x 20.4 x 18.1 Inches (464 x 518 x 459 mm)

Weight (Set/Package) 14.3 kg (31.5 lbs) Stand of stand installed / 16.2 kg (35.7 lbs)

Environmental Considerations Operating Temperature : 32°F ~ 104°F (0°C ~ 40°C)

Humidity : 10 % ~ 80 %

Storage Temperature : -4°F ~ 113°F (-20°C ~ 45°C)

Humidity : 5 % ~ 95 %

• Designs and specifications are subject to change without prior notice.

2-2 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

2-3 Pin Assignments

5

15

Sync

Type

Pin No.

Separate

2 Product Specifications

Macintosh

10

11

12

13

14

15

1

2

3

4

5

6

7

8

9

Red

Green

Blue

GND

DDC Return

GND-R

GND-G

GND-B

DC 5V

GND-Sync/Self-raster

GND

DDC Data

H-Sync

V-Sync

DDC Clock

GND-R

Red

H/V Sync

Sense 0

Green

GND-G

Sense 1

Reserved

Blue

Sense 2

GND

V-Sync

GND-B

GND

H-Sync

Figure 2-1. Male Type Figure 2-2. Male Type

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

2-3

2 Product Specifications

QRS

P

O

Video

Sync

Sync

Horizontal

Vertical

CDE

P

O

B

A

Video

Sync

Sync

2-4 Timing Chart

This section of the service manual describes the timing that the computer industry recognizes as standard

for computer-generated video signals.

2-4-1 LE15V*

Table 2-1 Timing Chart

Timing

fH (kHz)

A µsec

B µsec

C µsec

D µsec

E µsec

fV (Hz)

O msec

P msec

Q msec

R msec

S msec

Clock

Frequency

(MHz)

Mode

640/75 Hz

640 x 480

37.500

26.667

2.032

3.810

20.317

0.508

75.000

13.333

0.080

0.427

12.800

0.027

31.500

VESA (LE15V* Only)

640/85 Hz

640 x 480

43.269

23.111

1.556

2.222

17.778

1.556

85.008

11.764

0.671

0.578

11.093

0.023

36.000

800/85 Hz

800 x 600

53.674

18.631

1.138

2.702

14.222

0.569

85.061

11.756

0.056

0.503

11.179

0.019

56.250

A : Line time total B : Horizontal sync width O : Frame time total P : Vertical sync width

C : Back porch D : Active time Q : Back porch R : Active time

E : Front porch S : Front porch

2-4 LE15V*/LE17LS/LE17LT/

Polarity

H.Sync

V.Sync

Remark

Video

C D

Sync

Negative

Negative

Separate

Negative

Negative

Separate

Positive

Positive

Separate

Separate Sync

Video

E

B

A

Q R S

Sync

P

O

LE17KS/LE17KT/LE17JS/LE17JT

QRS

P

O

Video

Sync

Sync

Horizontal

Vertical

CDE

P

O

B

A

Video

Sync

Sync

2-4-2 LE17LS/LE17LT/LE17KS/LE17KT

Table 2-2 Timing Chart

2 Product Specifications

Timing

fH (kHz)

A µsec

B µsec

C µsec

D µsec

E µsec

fV (Hz)

O msec

P msec

Q msec

R msec

S msec

Clock

Frequency

(MHz)

Mode

640/75 Hz

640 x 480

37.500

26.667

2.032

3.810

20.317

0.508

75.000

13.333

0.080

0.427

12.800

0.027

31.500

VESA

800/85 Hz

800 x 600

53.674

18.631

1.138

2.702

14.222

0.569

85.061

11.756

0.056

0.503

11.179

0.019

56.250

1024/85 Hz

1024 x 768

68.677

14.561

1.016

2.201

10.836

0.508

84.997

11.765

0.044

0.524

11.183

0.015

94.500

A : Line time total B : Horizontal sync width O : Frame time total P : Vertical sync width

C : Back porch D : Active time Q : Back porch R : Active time

E : Front porch S : Front porch

Polarity

H.Sync

V.Sync

Remark

Video

C D

Sync

Negative

Negative

Separate

Positive

Positive

Separate

Positive

Positive

Separate

Separate Sync

Video

E

B

A

Q R S

Sync

P

O

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

2-5

2 Product Specifications

QRS

P

O

Video

Sync

Sync

Horizontal

Vertical

CDE

P

O

B

A

Video

Sync

Sync

2-4-3 LE17JS/LE17JT

Table 2-3 Timing Chart

Timing

fH (kHz)

A µsec

B µsec

C µsec

D µsec

E µsec

fV (Hz)

O msec

P msec

Q msec

R msec

S msec

Clock

Frequency

(MHz)

Mode

640/75 Hz

640 x 480

37.500

26.667

2.032

3.810

20.317

0.508

75.000

13.333

0.080

0.427

12.800

0.027

31.500

VESA

1024/85 Hz

1024 x 768

68.677

14.561

1.016

2.201

10.836

0.508

84.997

11.765

0.044

0.524

11.183

0.015

94.500

1280/75 Hz

1280 x 1024

79.976

12.504

1.067

1.837

9.481

0.119

75.025

13.329

0.038

0.475

12.804

0.013

135.000

A : Line time total B : Horizontal sync width O : Frame time total P : Vertical sync width

C : Back porch D : Active time Q : Back porch R : Active time

E : Front porch S : Front porch

Polarity

H.Sync

V.Sync

Remark

Video

C D

Sync

Negative

Negative

Separate

Positive

Positive

Separate

Positive

Positive

Separate

Separate Sync

Video

E

B

A

Q R S

Sync

P

O

2-6 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

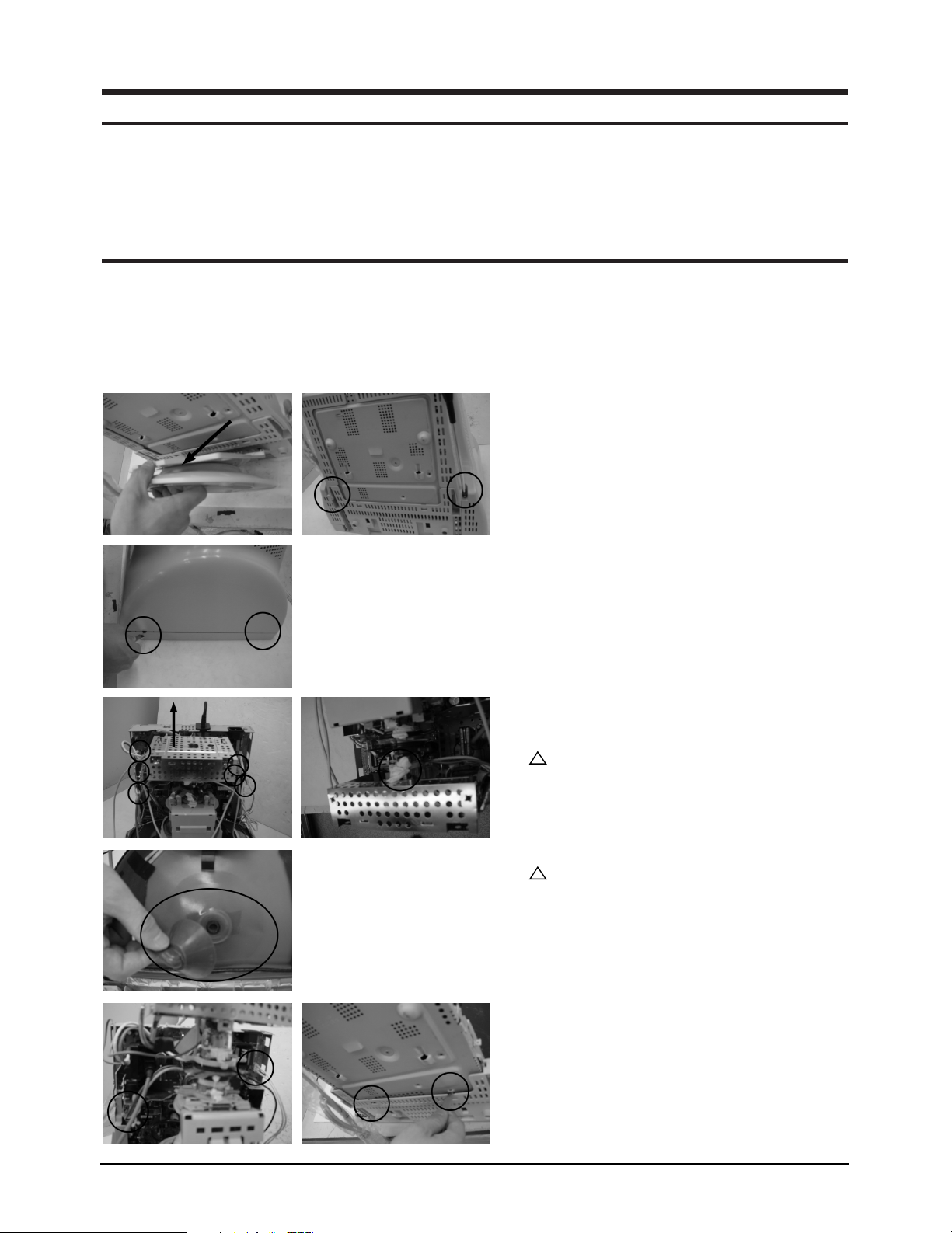

3 Disassembly and Reassembly

!

!

This section of the service manual describes the disassembly and reassembly procedures for the

LE15V*/LE17LS/LE17LT/LE17KS/LE17KT/LE17JS/LE17JT TFT-LCD monitors.

WARNING: This monitor contains electrostatically sensitive devices. Use caution when handling

these components.

3-1-1 LE15V*

Cautions:1. Disconnect the monitor from the power source before disassembly.

2. Follow these directions carefully; never use any metal instrument except provided jig to

separate the cabinet.

3. R/Cover opening jig : BH81-00001A

1. Release the snaps on the rear stand and pull

the stand backwards from the monitor and

remove 2 screws from the rear top shield.

2. Insert the openning jig into the grooves at

each side and press until it cilcks and lift up

the rear cover.

3. Disconnect 6 ground from the shield video

and carefully remove the silicon glue on the

CDT socket with a razor.

Caution : CDT socket may be easily

damaged. Please use caution when removing

the silicon glue.

4. High voltage may be present.

Caution : Remove the high voltage cap

from the CDT.

5. Disconnect DY cable, D-COIL cable from the

CDT socket. Using the jig, release the snaps

connecting the front cover and the PCB. Lift

up the bottom to separate the two shields.

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

3-1

3 Disassembly and Reassembly

!

3-1-2 LE17KS/LE17KT/LE17JS/LE17JT

6. Disconnect function wire connecter from the

MAIN board. Remove 4 screws from the front

cover.

7. Remove CDT from the front cover.

1. Release the snaps on the rear stand and pull

the stand backwards from the monitor and

remove 2 screws from the rear top shield.

2. Insert the opining jig into the grooves at each

side and press until it cilcks and lift up the

rear cover.

3. Remove 2 screws from the shield and lift up

the shield.

4. Disconnect 3 ground from the shield video

and carefully remove the silicon glue on the

CDT socket with a razor.

Caution : CDT socket may be easily

damaged. Please use caution when remoning

the silicon glue.

3-2 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

3 Disassembly and Reassembly

!

5. High voltage may be present.

Caution : Remove the high voltage cap

from the CDT.

6. Disconnect DY cable, D-COIL cable from the

CDT socket. Using the jig, release the snaps

connecting the front cover and the PCB. Lift

up the bottom to separate the two shields.

7. Disconnect function wire connecter from the

MAIN board. Remove 4 screws from the front

cover.

3-1-3 LE17LS/LE17LT

8. Remove CDT from the front cover.

1. Release the snaps on the rear stand and pull

the stand backwards from the monitor and

remove 2 screws from the rear top shield.

2. Insert the opining jig into the grooves at each

side and press until it cilcks and lift up the

rear cover.

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

3-3

3 Disassembly and Reassembly

!

!

3. Disconnect 3 ground from the shield video

and carefully remove the silicon glue on the

CDT socket with a razor.

Caution : CDT socket may be easily

damaged. Please use caution when remoning

the silicon glue.

4. High voltage may be present.

Caution : Remove the high voltage cap

from the CDT.

5. Disconnect DY cable, D-COIL cable from the

CDT socket. Using the jig, release the snaps

connecting the front cover and the PCB. Lift

up the bottom to separate the two shields.

6. Disconnect function wire connecter from the

MAIN board. Remove 4 screws from the front

cover.

7. Remove CDT from the front cover.

3-2 Reassembly

Reassembly procedures are in the reverse order of disassembly procedures.

3-4 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

4 Alignment and Adjustments

This section of the service manual explains how to make permanent adjustments to the monitor. Directions

are given for adjustments using the monitor Interface Board Ver. 2.0 and software (Softjig).

4-1 Adjustment Conditions

Caution: Changes made without the Softjig are saved only to the user mode settings. As such, the

settings are not permanently stored and may be inadvertently deleted by the user.

4-1-1 Before Making Adjustments

4-1-1 (a) ORIENTATION

When servicing, always face the monitor to the

east.

4-1-1 (b) WARM-UP TIME

The monitor must be on for 30 minutes before

starting alignment. Warm-up time is especially

critical in color temperature and white balance

adjustments.

4-1-1 (c) SIGNAL

Analog, 0.7 Vp-p positive at 75 ohm, internal

termination

Sync: Separate

(TTL level negative/positive)

4-1-1 (d) SCANNING FREQUENCY

Horizontal :

Horizontal :

Horizontal :

Vertical : 50 Hz to 120 Hz (15” Automatic)

Vertical : 50 Hz to 160 Hz (17” Automatic)

Unless otherwise specified, adjust at the

800 x 600 mode (15” 54 kHz/85 Hz),

1024 x 768 mode (17” 68 kHz/85 Hz),

Refer to Table 2-1 on page 2-3.

30 kHz to 54 kHz (15” Automatic)

30 kHz to 70 kHz (17” 70kHz Automatic)

30 kHz to 85 kHz (17” 85kHz Automatic)

4-1-2 Required Equipment

The following equipment may be necessary for

adjustment procedures:

4-1-2 (a) DISPLAY CONTROL ADJUSTMENT

1. Non-metallic (–) screwdriver:

1.5, 2.5, 3 mm

2. Non-metallic (+) screwdriver:

1.5, 2.5, 3 mm

3. Digital Multimeter (DMM), or

Digital Voltmeter

4. Signal generator, or

DM200 software

5. Personal computer

4-1-2 (b) COLOR ADJUSTMENTS

1. All equipment listed in 4-1-2 (a), above

2. Color analyzer, or any luminance

measurement equipment.

4-1-3 After Making Adjustments

After finishing all adjustments, test the monitor in

all directions. If, for example, the monitor does not

meet adjustment specifications when facing north,

reposition the monitor to face east and readjust.

This time, try for an adjustment closer to the ideal

setting within the tolerance range. Test the unit

again in all directions. If the monitor again fails to

meet specifications in every direction, contact

your Regional After Service Center for possible

CRT replacement.

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

4-1

4 Alignment and Adjustments

4-2 Display Control Adjustments

4-2-1 HIGH VOLTAGE

Signal: 800 x 600 (15” 54 kHz/85 Hz)

1024 x 768 (17” 68 kHz/85 Hz)

Display image: Don’t care

Contrast: Minimum

Brightness: Minimum

Limit: 25.0 kV ± 0.3 kV (15”)

26.0 kV ± 0.3 kV (17”)

Measure the high voltage level at the anode cap.

High voltage should be within the limit as above.

4-2-2 CENTER RASTER (17” 85kHz only)

Adjust SW401 so that the back raster comes to the

center when you apply basic mode for 17”.

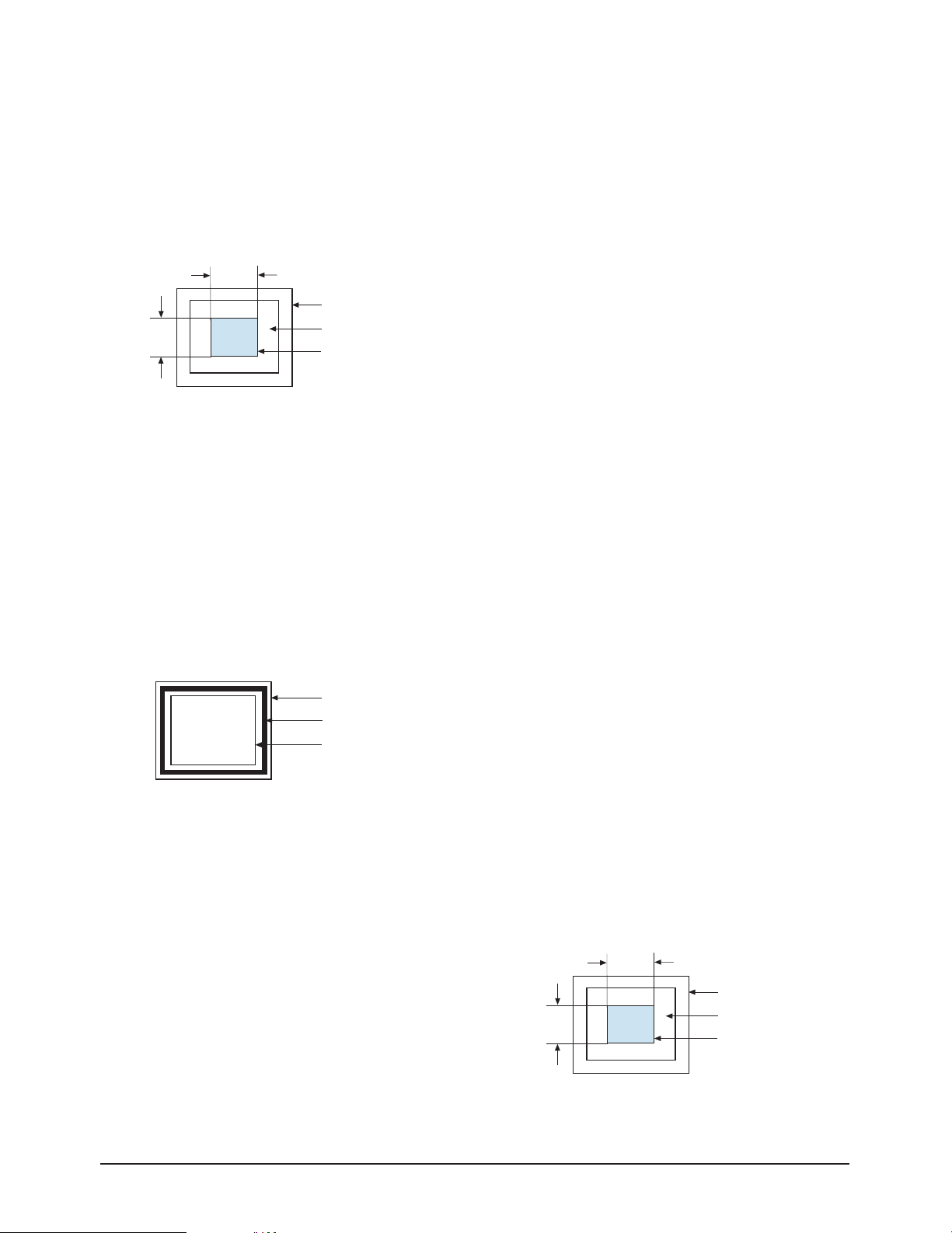

4-2-3 Centering

Centering means to position the center point of

the display in the middle of the display area.

Horizontal size and position and vertical size and

position control the centering of the display.

Adjust the horizontal size and vertical size to their

optimal settings: 267 mm (H) x 200 mm (V) : (15”)

312 mm (H) x 234 mm (V) : (17”).

Adjust the horizontal position and vertical

position to ≤ 5.0 mm of the center point of the

screen.

|A-B| ≤ 5.0 mm. |C-D| ≤ 5.0 mm.

A

* In Softjig window, “Geometry” has to be

selected for GD adjustment.

4-2-3 (a) HORIZONTAL SIZE ADJUSTMENT

C

DISPLAY AREA

B

EDGE OF BEZEL

D

Figure 4-1. Centering

Use control bar after selecting size B+ in the left

Menu to adjust the horizontal size of the display,

Pattern to 267mm(Tolerance : ±4mm.)(15”)

Pattern to 312mm(Tolerance : ±4mm.)(17”)

Run the All Mode save in the Right Menu.

Caution :

scannig times except for 800 x 600 (54 kHz/85 Hz) ->

15” 1024x768 (68kHz/85Hz) -> 17”.

4-2-3 (b) VERTICAL SIZE ADJUSTMENT

CONDITIONS

Scanning frequency: 54 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Use control bar after selecting “V-SIZE” in left

menu to adjust the vertical size of the display

pattern to 200 mm.(Tolerance: ± 4 mm.) : 15”,

4-2-3 (c) HORIZONTAL POSITION ADJUSTMENT

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

Display image: Crosshatch pattern

Use control bar after selecting “H-POSITION” in

left menu to center the horizontal image on the

raster.

4-2-3 (d) VERTICAL POSITION ADJUSTMENT

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

Display image: Crosshatch pattern

Use control bar after selecting “V-POSITION” in

left menu to center the vertical image on the

raster.

Do not Run the All mode Save at the other

68 kHz/85 Hz

234 mm.(Tolerance: ± 4 mm.) : 17”

68 kHz/85 Hz : 17”

68 kHz/85 Hz : 17”

CONDITIONS

Scanning frequency: 54 kHz/85 Hz (15”)

68 kHz/85 Hz (17”)

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Click Standard Dump on the right Menu in the

general field.

4-2 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

4 Alignment and Adjustments

4-2-4 Linearity

Linearity affects the symmetry of images as they

appear on the screen. Unless each row or column

of blocks in a crosshatch pattern is of equal size,

or within the tolerances shown in Tables 4-2 and

4-3, an image appears distorted, elongated or

squashed.

Table 4-1. Standard Modes Linearity:

800 x 600 / 85Hz (15”)

Adjacent Linearity

Preset mode ≤ 4% ≤ 8%

Pre-load mode (48kHz~) ≤ 5% ≤ 14%

❈ Preset Mode : 54KHz / 85Hz

Pre-load Mode : Refer to Timing Chart

Table 4-2. Standard Modes Linearity:

1024 x 768 / 85Hz (17”)

Standard Modes Linearity

Each block (10 %)

4 : 3

Horizontal: 20.9~23.1

Vertical : 20.9~23.1

Horizontal: Less than 0.88 mm

Vertical : Less than 0.88 mm

Entire Linearity

Difference between

adjacent blocks (4 %)

68 kHz/85 Hz : 17”

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Use control bar after selecting “TRAPEZOID” in

left menu to make the image area rectangular.

| A - B | < 4 mm

A

B

A

B

Figure 4-2. Trapezoid

4-2-6 Pinbalance Adjustment

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Table 4-3. Other Modes Linearity:

above 40 KHz(Hf) : 17”

Supported Timing Mode

Difference between

adjacent blocks (5 %)

Horizontal: Less than 1.10 mm

Vertical : Less than 1.10 mm

4 : 3

Each block (14 %)

Horizontal: 20.5~23.5

Vertical : 20.5~23.5

Off Spec : Under 40 KHz (Hf)

4-2-4 (a) VERTICAL LINEARITY ADJUSTMENT

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

To adjust the Vertical Linearity, refer to Tables 4-2

and 4-3 for the tolerance range.

Use control bar after selecting “V-LINEARITY

BAL” in left menu to optimize the image.

4-2-5 Trapezoid Adjustment

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

D1 D2 D1

Figure 4-3. Pinbalance

Use control bar after selecting “PINBALANCE” in

left menu to optimize the image.

4-2-7 Parallelogram Adjustment

CONDITIONS

Scanning Frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Use control bar after selecting “PARALLEL” in

left menu to make the image area rectangular.

4 mm

Figure 4-4. Parallelogram

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

4-3

4 Alignment and Adjustments

4-2-8 Side Pincushion Adjustment

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: Crosshatch pattern

Use control bar after selecting “PINCUSHION” in

left menu to straighten the sides of the image area.

| C1 |, | C2 | ≤ 2.0 mm, | D1 |, | D2 | ≤ 2.0 mm.

C2

D1 D2

C1

Figure 4-5. Pincushion

4-3 Color Adjustments

4-2-9 Degauss

No adjustments are available for the degaussing

circuit. The degaussing circuit can effectively

function only once every 30 minutes.

4-2-10 To Delete the User Mode Data

To delete the adjustment data from the user

modes, click “@4: USER DELETE” in right menu.

4-2-11 Save the Data

To save the adjustment data for a mode, press

“@3: ALL MODE SAVE” in right menu.

CAUTION:Check below condition before color

adjustment

Video signal : Analog 0.7 Vp-p (at 75 Ω)

Sync : TTL level (H, V seperate signal)

* Select “Color” in Softjig menu for color adjustment.

4-3-1 Color Coordinates (Temperature)

Color temperature is a measurement of the

radiant energy transmitted by a color. For

computer monitors, the color temperature refers

to the radiant energy transmitted by white. Color

coordinates are the X and Y coordinates on the

chromaticity diagram of wavelengths for the

visible spectrum.

CONDITIONS

Measurement instrument: Color analyzer

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: White flat field at

center of display area

Luminance: Maximum

PROCEDURE

Use the directions in sections 4-3-2 through 4-3-3

to adjust the color coordinates for:

9300K to x = 0.283 ± 0.02, y = 0.298 ± 0.02

6500K to x = 0.313 ± 0.02, y = 0.329 ± 0.02

4-3-2 Color Adjustments for 9300K

4-3-2 (a) BACK RASTER COLOR ADJUSTMENT

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: Back raster pattern

Brightness: Maximum

Contrast: Maximum

1. Select “@1: CHANNEL 1” in right menu to

control the color for 9300K.

2. Adjust the luminance of the back raster to

between 0.5 to 0.7 ft-L using control bar after

selecting “GREEN CUTOFF” in the menu.

3. Use control bar after selecting “BLUE

CUTOFF” in left menu to set the “y”

coordinate to 0.298 ± 0.02.

4. Use control bar after selecting “RED

CUTOFF” in left menu to 0.283 ± 0.02.

* If color values can not be matched to desirable

values, repeat sequences 3 and 4 after

readjusting “GREEN CUTOFF” control.

4-4 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

4 Alignment and Adjustments

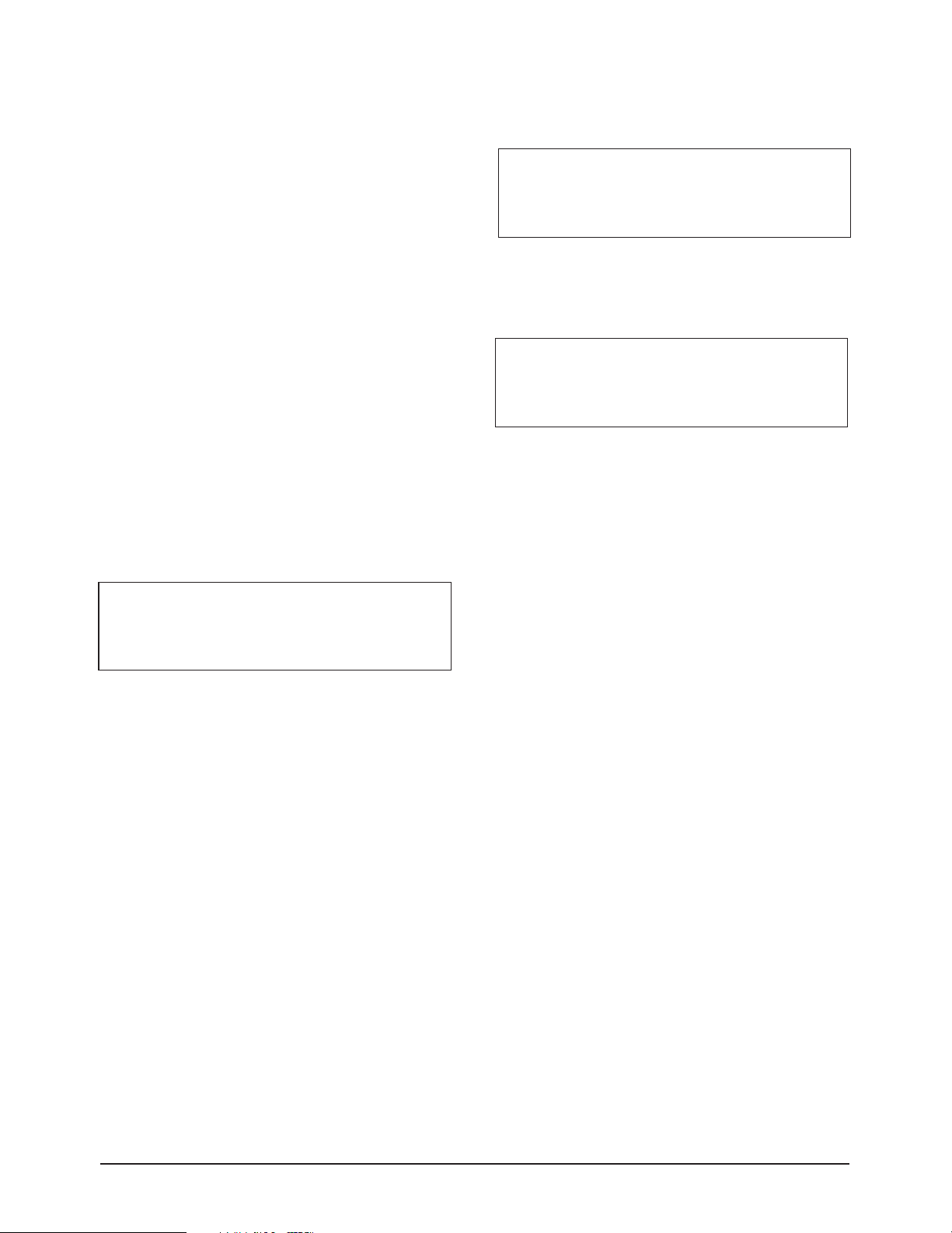

4-3-2 (b) WHITE BALANCE ADJUSTMENT

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: White box pattern

Brightness: 0.06ft-L at Back Raster

Pattern Display

Contrast: Maximum

1/3H-1/2H

FRONT BEZEL OPENING

1/3V-1/2V

BACK RASTER

WHITE WINDOW

Figure 4-6. White Box Pattern

1. Use control bar after selecting “RED GAIN”,

“GREEN GAIN” and “BLUE GAIN” to adjust

the luminance 47 ± 1 ft-L(15”), 42 ± 1 ft-L(17”)

with the color coordinates ranged for 9300K to

x = 0.283 ± 0.02, y = 0.298 ± 0.02.

4-3-2 (c) ABL ADJUSTMENT

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: Full white pattern

Brightness: Maximum

Contrast: Maximum

FRONT BEZEL OPENING

BACK RASTER

WHITE WINDOW

4-3-2 (d) WHITE BALANCE ADJUSTMENT VERIFICATION

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: Back raster pattern

Full White Pattern

X-Y Coordinates: x = 0.283 ± 0.02,

y = 0.298 ± 0.02

ABL Luminance Refer to 4-3-2(c)

Brightness: Maximum

Contrast: 5 ft-L, 24 ft-L

1. Check whether the color coordinates of the

back raster satisfy the above spec.

If they do not, return to 4-3-2 (a) and readjust

all settings.

2. Display a full white pattern.

3. Select “Geometry” in softjig menu.

4. Select “@7: 5-ft “ in right menu.

5. Check whether the white coordinates of the

video meet the above coordinates spec.

6. Select “@8: 24-ft “ in right menu.

7. Check whether the white coordinates of the

video satisfies the above spec.

If they do not, return to 4-3-2 (a) and readjust

all settings.

Select “Color” and click “@2: CHANNEL 2”

for color ajdustment for 6500K

Repeat the sequence for 9300K adjustment.

luminance values are the same as 9300K, but

the color coordinats of back raster and white

box are : x = 0.313 ± 0.02 y = 0.329 ± 0.02

Figure 4-7. Full White Pattern

1. Check the ABL. If it is not within

specifications, use the ABL controls to adjust.

31 ± 1 ft-L

2. Select “@4: COLOR SAVE” to save the data.

3. Select “@6: ALL COLOR SAVE” to save CH2.

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

4-3-3 MAGIC BRIGHT ADJUSTMENT (MB MODEL ONLY)

CONDITIONS

Scanning frequency: 68 kHz/85 Hz : 17”

Display image: White box pattern

Brightness: 0.06ft-L at Back Raster

Pattern Display

Contrast: Maximum

1/3H-1/2H

FRONT BEZEL OPENING

1/3V-1/2V

Figure 4-8. White Box Pattern

BACK RASTER

WHITE WINDOW

4-5

4 Alignment and Adjustments

1. Use control bar after selecting “RED GAIN”,

“GREEN GAIN” and “BLUE GAIN” to adjust

the luminance 115 ± 1 ft-L (17”) with the color

coordinates ranged for 9300K to x = 0.283 ±

0.02, y = 0.298 ± 0.02.

4-3-4 Color Adjustments for sRGB

4-3-4 (a) BACK RASTER COLOR ADJUSTMENT

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Screen: Back raster pattern

Bright: MAX

Contraster: MAX

1. Select COLOR CHANNEL 4 to control the

color for sRGB.

2. Adjust the luminance of the back raster to

between 0.5 to 0.7 ft-L using the G_CUT

controls.

3. Click on the << or >> boxes next to R_CUT

and B_CUT to adjust the R-Bias to x = 0.312 ±

0.02 and the B-Bias to y = 0.329 ± 0.02.

Luminance Table 4-4.

Without ABL 28 ft-L

4-3-5 Luminance Uniformity Check

Luminance is considered uniform only if the ratio

of lowest to highest brightness areas on the screen

is not less than 7.5:10.

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: White flat field

Brightness: Cut off point at 24 ft-L

Contrast: Maximum

PROCEDURE

Measure luminance at nine points on the display

screen (see figure below).

4-3-4 (b) GAIN (WITHOUT ABL) ADJUSTMENT

1. Bright should be cut off.

2. Save after adjusting : (Color coordinates

x=0.312 ± 0.015, y=0.329 ± 0.015

Brightness : 28 ± 1 F/L) with R, G, B gain key.

Notice : The condition for adjusting is the same as

9300K.

Don't adjust ABL to SRGB Mode

Modify with ABL.

Delete all contents and add the contents

below.

4-3-4 (c) WHITE BALANCE ADJUSTMENT

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: Full white pattern

Brightness: Cut-off

Contrast: Maximum

1. Click on the << or >> boxes next to R_GAIN

and B_GAIN to make the video white.

(For sRGB color adjustment:

x = 0.312 ± 0.02, y = 0.329 ± 0.02.)

2. Select COLOR FACTORY SAVE to save the

data.

Figure 4-9. Luminance Uniformity Check Locations

4-3-6 Focus Adjustment

CONDITIONS

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: “H” character pattern

Brightness: Cut off point

Contrast: MaximumPROCEDURE

1. Adjust the Focus VR on the FBT to display the

sharpest image possible. (17” only)

2.

Use Locktite to seal the Focus VR in position. (17” only)

4-3-7 Color Purity Adjustment

Color purity is the absence of undesired color.

Conspicuous mislanding (unexpected color in a

uniform field) within the display area shall not be

visible at a distance of 50 cm from the CRT

surface.

4-6 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

CONDITIONS

Orientation: Monitor facing east

Scanning frequency: 54 kHz/85 Hz : 15”

68 kHz/85 Hz : 17”

Display image: White flat field

Luminance: Cut off point at the center

of the display area

Note: Color purity adjustments should only be

attempted by qualified personnel.

PROCEDURE

Use the following procedure to correct minor

color purity problems : 15”

4 Alignment and Adjustments

Table 4-6. Color Purity Tolerances

Red: x = 0.645 ± 0.015 y = 0.321 ± 0.015

Green: x = 0.285 ± 0.015 y = 0.600 ± 0.015

Blue: x = 0.142 ± 0.015 y = 0.057 ± 0.015

(LE17KS/KT Model)

(For 9300K color adjustment: x = 0.283 ± 0.02, y = 0.298 ± 0.02)

Table 4-7. Color Purity Tolerances

1. Make sure the display is not affected by

external magnetic fields.

2. Make sure the spacing between the PCM

assembly and the CRT stem is 29 mm ± 1 mm.

3. Display a green pattern over the entire display

area.

4. Adjust the purity magnet rings on the PCM

assembly to display a pure green pattern.

(Optimum setting: x = 0.295 ± 0.015, y = 0.594 ± 0.015)

Table 4-5. Color Purity Tolerances

Red: x = 0.640 ± 0.015 y = 0.323 ± 0.015

Green: x = 0.295 ± 0.015 y = 0.594 ± 0.015

Blue: x = 0.142 ± 0.015 y = 0.066 ± 0.015

(For 9300K color adjustment: x = 0.283 ± 0.015, y = 0.298 ± 0.015)

5. When you have the PCMs properly adjusted,

carefully glue them together to prevent their

movement during shipping.

Use the following procedure to correct minor

color purity problems : 17”

Red: x = 0.645 ± 0.015 y = 0.318 ± 0.015

Green: x = 0.276 ± 0.015 y = 0.596 ± 0.015

Blue: x = 0.145 ± 0.015 y = 0.060 ± 0.015

(LE17LS/LT Model)

(For 9300K color adjustment: x = 0.283 ± 0.02, y = 0.298 ± 0.02)

6. When you have the PCMs properly adjusted,

carefully glue them together to prevent

movement during shipping.

1. Make sure the display is not affected by

external magnetic fields.

2. Make sure the spacing between the PCM

assembly and the CRT stem is 29 mm ± 1 mm.

3. Display a green pattern over the entire display

area.

4. Adjust the purity magnet rings on the PCM

assembly to display a pure green pattern.

Optimum setting: x = 0.285 ± 0.015,

y = 0.600 ± 0.015

5. Repeat steps 4 and 5 using a red pattern and

then again, using a blue pattern.

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

4-7

4 Alignment and Adjustments

Memo

4-8 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

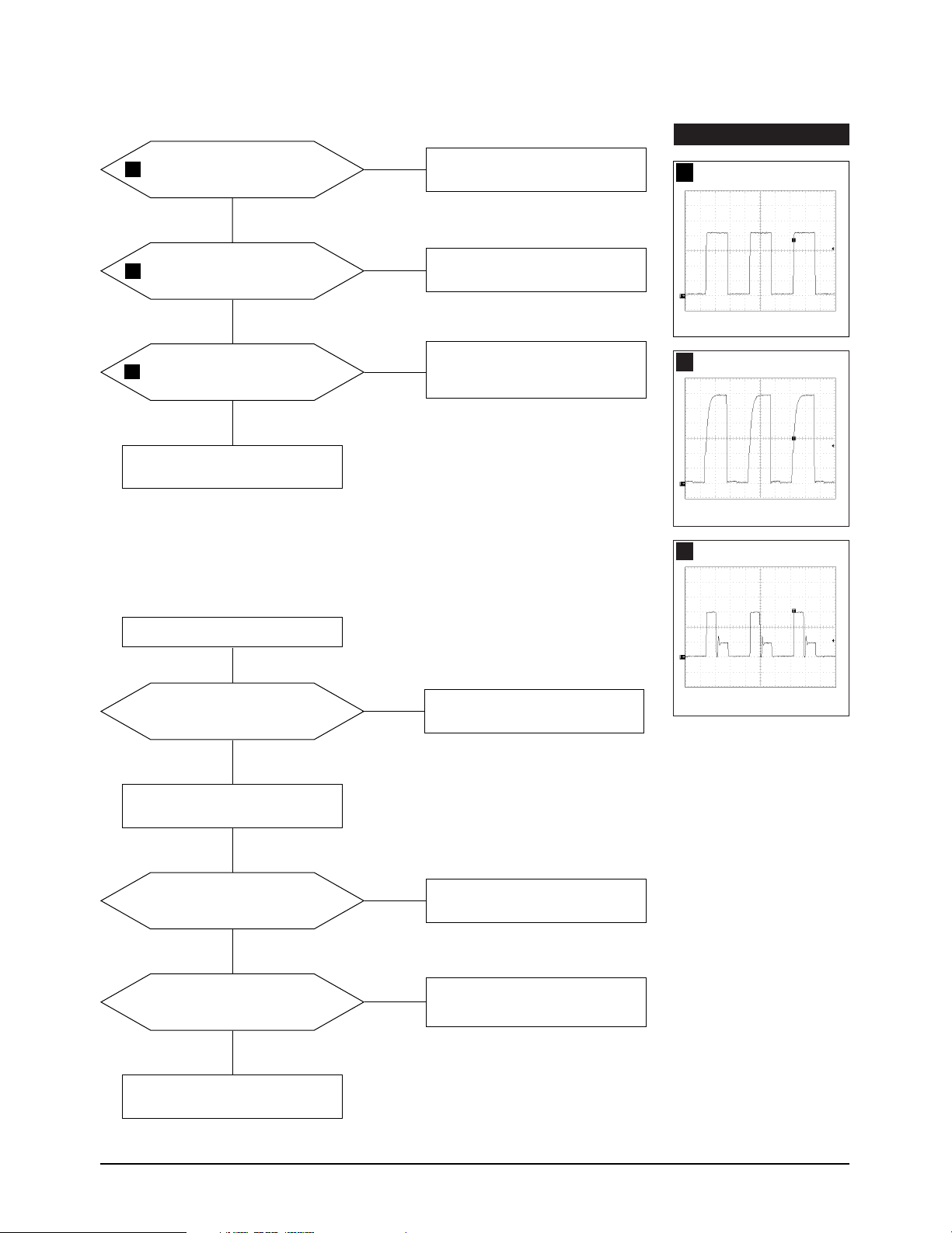

5 Troubleshooting

5-1 Parts Level Troubleshooting

Notes: Check the following circuits.

• No raster appears: Power circuit, Horizontal output circuit.

• High voltage develops but no raster appears: Video output circuits.

• High voltage does not develop: Horizontal output circuits.

5-1-1 No Power Supply

Check and replace D601 and FH1

Chirping noise exists?

No

Repeating start?

No

1

IC601 Pin 1 waveform is right?

Yes

C627 Voltage is 13 V ± 0.5V?

Yes

Yes

No

No

Check and replace IC601.

Check and replace D606.

Check and replace IC601.

Check and replace IC201,

IC301, IC401, Q590, Q490,

and 12V regulator circuit.

WAVEFORMS

332 Vpp (IC601, #1)

1

Yes

Normal operation?

Yes

Verify voltages.

Done

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

No

Replace main board.

5-1

5 Troubleshooting

5-1-2 DPMS Failure

Check signal source

H/V sync. video level.

Make no H/V Sync. (power off mode)

LED blinks?

Yes

+12 V line off?

Yes

2

IC601 Pin 1 output

voltage exists?

Yes

No

No

No

Check IC201 Pin 40.

Check IC201 Pin 5/Pin 6 and

Q624, Q625 operation.

Refer to 5-1-1 no power supply.

WAVEFORMS

332Vpp (IC601, #1)

2

Done

5-2 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

5-1-3 H_Deflection Failure

5 Troubleshooting

Does PWM output signal appear

3

at Pin 28 (B_DRV) of IC401?

Yes

Does horizontal pluse signal

4

appear at Pin 26 of IC401?

Yes

Does 110 Vp-p signal appear

5

at Collector of Q401?

Yes

Check Q590, Q490 and T401.

No

No

No

Does DC 12V appear at

Pin 29 of IC401?

Yes

Check IC401.

Check IC401.

Check Q401.

No

Check 12 V line.

WAVEFORMS

12 Vpp (IC401, #28)

3

2.00V (IC401, #26)

4

5-1-4 S Correction Failure

Check S1 ~ S3 signal.

S1~S3 signals are correct at each

frequency block?

Yes

Check and replace Q451, Q452,

Q453, Q454, Q458, Q457, Q456,

Q455, D451, D452, D453, D454.

No

Check and replace IC201.

78 Vpp (Q401, Collector)

5

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

5-3

5 Troubleshooting

5-1-5 H_Lin. Failure Check and Replace L441 (Fix Type)

5-1-6 Invariable H_Size

IC401 Pin 28 voltage varies with

different B_DRV DAC values?

Yes

Q590 gate output duty varies with

different B_DRV DAC values?

5-1-7 Abnormal H_Size

IC401 Pin 24 output duty

varies with different B+ offset

DAC values?

Yes

6

Q490 collector

waveform is right?

No

No

No

No

Check and replace IC401.

Check some parts around Q590,

Pin 14~16 of IC401.

Check and replace IC201, IC401.

Check and replace Q411,

Q412, Q413, and Q414.

WAVEFORMS

1300 Vpp (Q490, Collector)

6

Yes

Check components

around D405 and L411.

5-4 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

5-1-8 Side Pin or Trap Failure

5 Troubleshooting

7

IC401 Pin 24 output exists?

Yes

Refer to 5-1-7

abnormal H_Size

.

5-1-9 Para. or Pin Balance Failure

IC401 Pin 24 output varies with

different DAC values?

No

Replace IC401.

No

Yes

Check and replace IC401.

Refer to 5-1-7

abnormal H_Size

WAVEFORMS

0.44 Vpp (IC401, #24)

7

.

5-1-10 Tilt Failure ( Only 17” Function)

Check tilt connector connection

IC201 Pin 20 output duty varies

with different DAC values?

Yes

Q323 Base output varies with

different DAC values?

Yes

Check and replace Q321 and Q322.

No

Check and replace IC201.

No

Check and replace Q323.

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

5-5

5 Troubleshooting

5-1-11 V Deflection Failure

13V and –10V lines are on?

Yes

No

Refer to 5-1-1 no power supply

WAVEFORMS

2.5 Vpp (IC401, #23)

8

IC401 Pin 23 output exists?

8

Yes

9

IC301 Pin 6 output exists?

Yes

Check DY connector connection.

No

No

5-1-12 V Size or Position Variation Failure

IC401 Pin 23 output varies with

different DAC values?

No

Check and replace IC401.

Check and replace

components around IC301.

Check and replace IC201 and IC401.

50 Vpp (IC301, #6)

9

Yes

Check and replace IC301.

5-6 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

5-1-13 High Voltage Failure

IC401 Pin 28 OSC pulse exists?

3

Yes

No

Check and replace IC401

and +12 V line.

5 Troubleshooting

WAVEFORMS

12 Vpp (IC401, #28)

3

Q590 gate driving pulse exists?

10

Yes

Q590 drain pulse exists?

11

Yes

Done

5-1-14 ABL Failure

Input full white pattern to monitor.

IC102 Pin 22 input exists and

varies with different patterns?

No

No

No

Check and replace Q501 and Q502.

Check and replace

Q590, L501 and D501.

Check 50V Line.

Check and replace IC102.

12 Vpp (Q590, Gate)

10

150 Vpp (Q590, Drain)

11

Yes

Check CN201.

T501 Pin 8 output exists?

Yes

IC201 Pin 26 output exists and

varies with different patterns?

Yes

Done

LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

No

Check and replace T501.

No

Check and replace IC201.

5-7

5 Troubleshooting

5-1-15 Dynamic Focus Failure ( Only 17” Function)

12

IC401 Pin 32 output is right?

Yes

Some parts around Q551 are right?

Yes

T561 Pin 6 input is right?

13

Yes

T561 Pin 1 output is right?

14

Yes

Check the connection between FBT

focus pin and CRT socket PCB.

No

No

No

No

Replace the IC401.

Replace failed part.

Check and replace C443.

Replace the T561.

WAVEFORMS

0.58 Vpp (IC401, #32)

12

50.0 V (T561, #6)

13

380 Vpp (T561, #1)

14

5-8 LE15V*/LE17LS/LE17LT/

LE17KS/LE17KT/LE17JS/LE17JT

Loading...

Loading...