Page 1

LCD-TV

Chassis : N65E

Model : LE32B53*P7N

Manual

SERVICE

TFT-LCD TV contents

1. Precautions

2. Product specications

3. Disassembly and

4. Troubleshootin

5. Exploded View & Part Lis

6. Wiring Diagra

Reassembly

g

t

m

LE32B53*P7N

Refer to the service manual in the GSPN (see the rear cover) for the more information.

Page 2

Contents

1. Precautions .............................................................................................................. 1-1

1-1. Safety Precautions ......................................................................................................... 1-1

1-2. Servicing Precautions .....................................................................................................1-2

1-3. Electrostatically Sensitive Devices (ESD) Precautions .................................................. 1-2

1-4. Installation Precautions .................................................................................................. 1-3

2. Product specications ............................................................................................ 2-1

2-1. Feature & Specications ................................................................................................. 2-1

2-2. New Features explanation .............................................................................................. 2-5

2-3. Specication Comparison to Old Models ........................................................................ 2-6

2-4. Accessories .................................................................................................................... 2-7

3. Disassembly and Reassembly ............................................................................... 3-1

3-1. Disassembly and Reassembly ....................................................................................... 3-1

4. Troubleshooting ...................................................................................................... 4-1

4-1. Troubleshooting .............................................................................................................. 4-1

4-2. Alignments and Adjustments ........................................................................................ 4-25

4-3. Factory Mode Adjustments ........................................................................................... 4-26

4-4. White Balance - Calibration .......................................................................................... 4-37

4-5. White Ratio (Balance) Adjustment ................................................................................ 4-37

4-6. Servicing Information .................................................................................................... 4-38

4-7. S/W UPDATE MANUAL (use ISP TOOL & JIG) ........................................................... 4-39

4-8. Mechanical diagram ..................................................................................................... 4-42

5. Exploded View & Part List ...................................................................................... 5-1

5-1. LE32B53*P7N Exploded View ........................................................................................ 5-1

5-2. LE32B53*P7N Parts List ................................................................................................ 5-3

6. Wiring Diagram ........................................................................................................ 6-1

6-1. Wiring Diagram 32” ......................................................................................................... 6-1

6-2. Connector Functions ...................................................................................................... 6-5

6-3. Cables ............................................................................................................................ 6-5

Page 3

GSPN (Global Service Partner Network)

Area Web Site

North America

Latin America

CIS http://cis.samsungportal.com

Europe http://europe.samsungportal.com

China http://china.samsungportal.com

Asia http://asia.samsungportal.com

Mideast & Africa

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

http://service.samsungportal.com

http://latin.samsungportal.com

http://mea.samsungportal.com

© 2009 Samsung Electronics Co.,Ltd.

All rights reserved.

Printed in Korea

P/N: BN82-00658A-00

Page 4

1. Precautions

1. Precautions

1-1. Safety Precautions

Follow these safety, servicing and ESD precautions to prevent damage and to protect against potential hazards such as

electrical shock.

1-1-1. Warnings

1.

For continued safety, do not attempt to modify the circuit board.

2.

Disconnect the AC power and DC power jack before servicing.

1-1-2. Servicing the LCD TV

1.

When servicing the LCD TV, Disconnect the AC line cord from the AC outlet.

2.

It is essential that service technicians have an accurate voltage meter available at all times.

Check the calibration of this meter periodically.

1-1-3. Fire and Shock Hazard

Before returning the LCD TV to the user, perform the following safety checks:

1.

Inspect each lead dress to make certain that the leads are not pinched or that hardware is not lodged between the

chassis and other metal parts in the LCD TV.

2.

Inspect all protective devices such as nonmetallic control knobs, insulating materials, cabinet backs, adjustment and

compartment covers or shields, isolation resistorcapacitor networks, mechanical insulators, etc.

3.

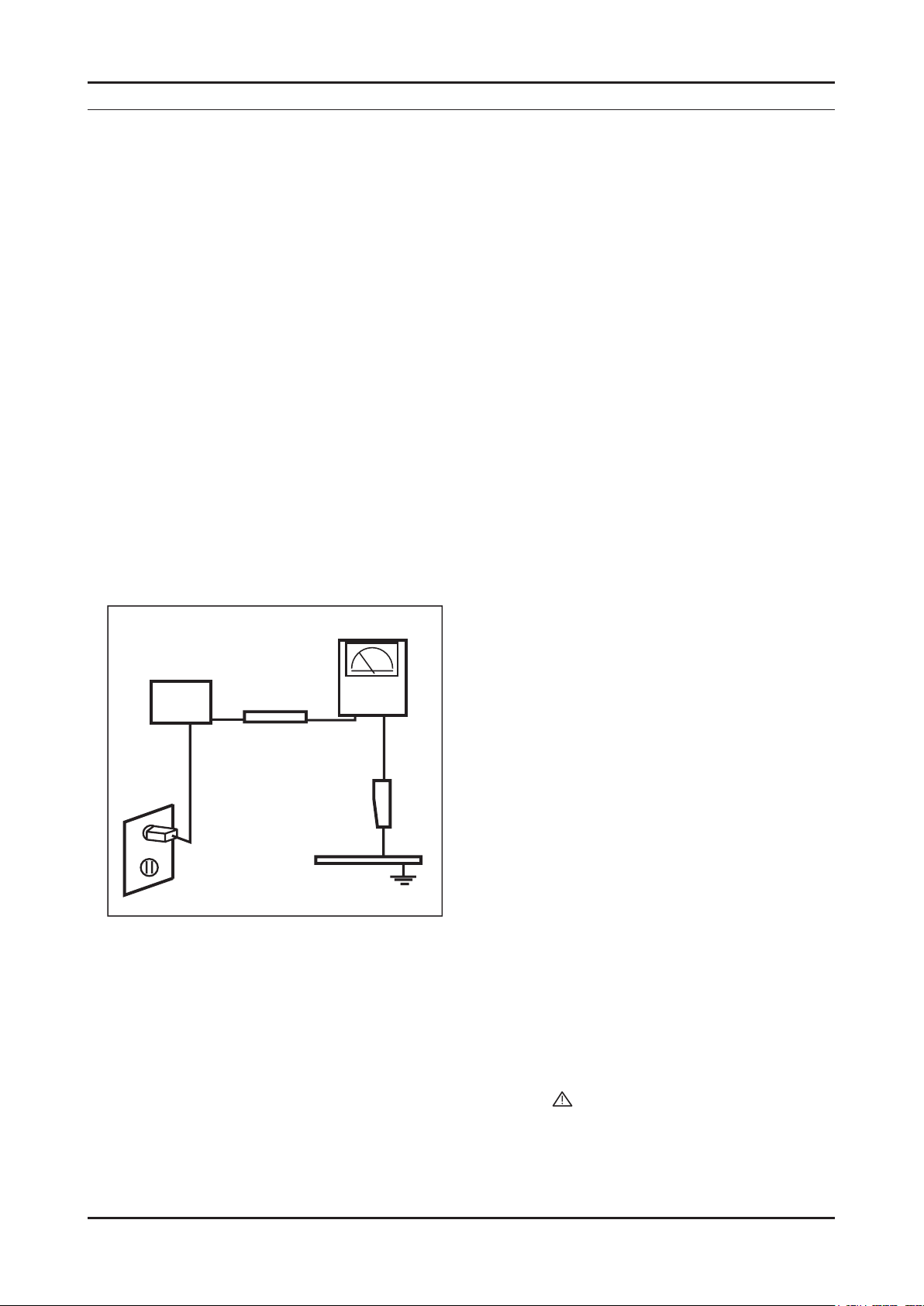

Leakage Current Hot Check (Figure 1-1):

WARNING : Do not use an isolation transformer during this test.

Use a leakage current tester or a metering system that complies with American National Standards Institute (ANSI

C101.1, Leakage Current for Appliances), and Underwriters Laboratories (UL Publication UL1410, 59.7).

(READING SHOULD)

NOT BE ABOVE 0.5mA

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

2-WIRE CORD

*ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

4.

With the unit completely reassembled, plug the AC line cord directly into a 120V AC outlet. With the unit’s AC switch

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

Figure 1-1. Leakage Current Test Circuit

rst in the ON position and then OFF, measure the current between a known earth ground (metal water pipe, conduit,

etc.) and all exposed metal parts, including: metal cabinets, screwheads and control shafts.

The current measured should not exceed 0.5 milliamp.

Reverse the power-plug prongs in the AC outlet and repeat the test.

1-1-4. Product Safety Notices

Some electrical and mechanical parts have special safetyrelated characteristics which are often not evident from visual

inspection. The protection they give may not be obtained by replacing them with components rated for higher voltage,

wattage, etc. Parts that have special safety characteristics are identied by on schematics and parts lists. A substitute

replacement that does not have the same safety characteristics as the recommended replacement part might create

shock, re and/or other hazards. Product safety is under review continuously and new instructions are issued whenever

appropriate.

1-1

Page 5

1-2

1. Precautions

1-2. Servicing Precautions

WARNING: An electrolytic capacitor installed with the wrong polarity might explode.

Caution: Before servicing units covered by this service manual, read and follow the Safety Precautions section of

this manual.

Note:

1-2-1 General Servicing Precautions

1.

Always unplug the unit’s AC power cord from the AC power source and disconnect the DC Power Jack before

attempting to:

(a) remove or reinstall any component or assembly, (b) disconnect PCB plugs or connectors, (c) connect a test

component in parallel with an electrolytic capacitor.

2.

Some components are raised above the printed circuit board for safety. An insulation tube or tape is sometimes

used. The internal wiring is sometimes clamped to prevent contact with thermally hot components. Reinstall all such

elements to their original position.

3.

After servicing, always check that the screws, components and wiring have been correctly reinstalled. Make sure that

the area around the serviced part has not been damaged.

4.

Check the insulation between the blades of the AC plug and accessible conductive parts (examples: metal panels,

input terminals and earphone jacks).

5.

Insulation Checking Procedure: Disconnect the power cord from the AC source and turn the power switch ON.

Connect an insulation resistance meter (500 V) to theblades of the AC plug.

The insulation resistance between each blade of the AC plug and accessible conductive parts (see above) should be

greater than 1 megohm.

6.

Always connect a test instrument’s ground lead to the instrument chassis ground before connecting the positive lead;

always remove the instrument’s ground lead last.

If unforeseen circumstances create conict between the following servicing precautions and any of the

safety precautions, always follow the safety precautions.

1-3. Electrostatically Sensitive Devices (ESD) Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD are integrated circuits and some eld-effect

transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

1.

Immediately before handling any semiconductor components or assemblies, drain the electrostatic charge from your

body by touching a known earth ground. Alternatively, wear a discharging wrist-strap device. To avoid a shock hazard,

be sure to remove the wrist strap before applying power to the LCD TV.

2.

After removing an ESD-equipped assembly, place it on a conductive surface such as aluminum foil to prevent

accumulation of an electrostatic charge.

3.

Do not use freon-propelled chemicals. These can generate electrical charges sufcient to damage ESDs.

4.

Use only a grounded-tip soldering iron to solder or desolder ESDs.

5.

Use only an anti-static solder removal device. Some solder removal devices not classied as “anti-static” can generate

electrical charges sufcient to damage ESDs.

6.

Do not remove a replacement ESD from its protective package until you are ready to install it. Most replacement ESDs

are packaged with leads that are electrically shorted together by conductive foam, aluminum foil or other conductive

materials.

7.

Immediately before removing the protective material from the leads of a replacement ESD, touch the protective

material to the chassis or circuit assembly into which the device will be installed.

Caution: Be sure no power is applied to the chassis or circuit and observe all other safety precautions.

8.

Minimize body motions when handling unpackaged replacement ESDs. Motions such as brushing clothes together,

or lifting your foot from a carpeted oor can generate enough static electricity to damage an ESD.

Page 6

1. Precautions

1-4. Installation Precautions

For safety reasons, more than a people are required for carrying the product.

1.

Keep the power cord away from any heat emitting devices, as a melted covering may cause re or electric shock.

2.

Do not place the product in areas with poor ventilation such as a bookshelf or closet. The increased internal

3.

temperature may cause re.

Bend the external antenna cable when connecting it to the product. This is a measure to protect it from being exposed

4.

to moisture. Otherwise, it may cause a re or electric shock.

Make sure to turn the power off and unplug the power cord from the outlet before repositioning the product. Also check

5.

the antenna cable or the external connectors if they are fully unplugged. Damage to the cord may cause re or electric

shock.

Keep the antenna far away from any high-voltage cables and install it rmly. Contact with the highvoltage cable or the

6.

antenna falling over may cause re or electric shock.

When installing the product, leave enough space (0.4m) between the product and the wall for ventilation purposes.

7.

A rise in temperature within the product may cause re.

1-3

Page 7

1. Precautions

Memo

1-4

Page 8

2. Product specications

2-1. Feature & Specications

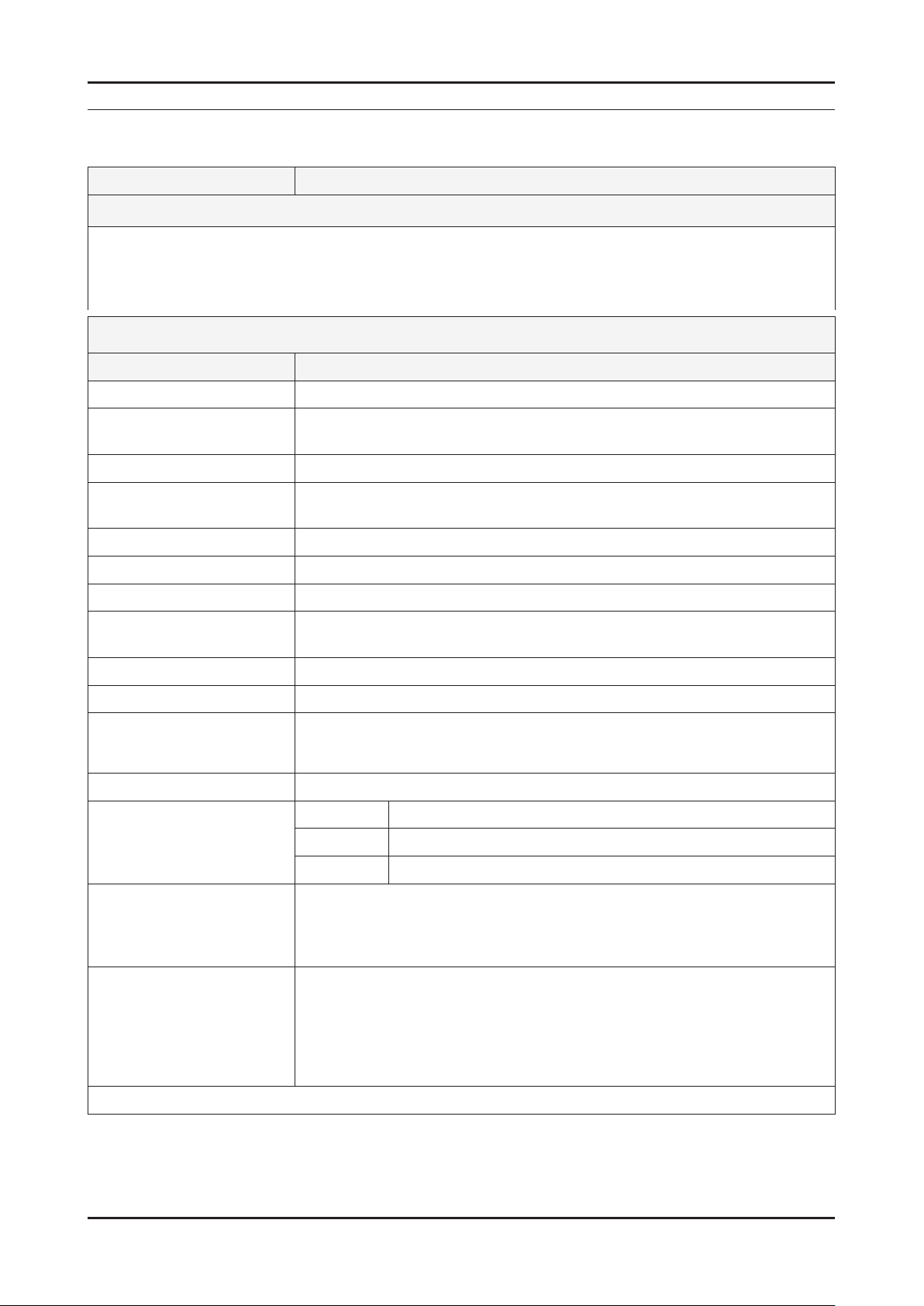

Model LE32B53*P7N

Feature

DTV/ATV, 3-HDMI, 1-Component, 1-A/V, D-SUB, 1-SCART

�

Brightness : 500cd/m

�

High Contrast Ratio : 50,000:1

�

Response Time : 6.5ms

�

Item Description

LCD Panel DTV/ATV, 3-HDMI, 1-Component, 1-A/V, D-SUB, 1-SCART

Scanning Frequency Horizontal : 30 kHz ~ 80 kHz (Automatic)

Display Colors 16.7 million colors

Maximum resolution Horizontal : 1920 Pixels

2

Specications

Vertical : 47 Hz ~ 75 Hz (Automatic)

Vertical : 1080 pixels

2. Product specications

Input Signal Analog 0.7 Vp-p ± 5% positive at 75Ω , internally terminated

Input Sync Signal H/V Separate, TTL, P. or N.

Maximum Pixel Clock rate 310MHz

Active Display

Horizontal/Vertical

AC power voltage & Frequency AC 110V ~ 220V, 60 Hz

Power Consumption <130W (<1W, stand by )

Dimensions

Set (W x D x H)

Weight 12.9 kg

TV System Tunning Frequency Synthesize (Refer to detailed Frequency Table)

Environmental Considerations Operating Temperature : 50˚F ~ 104˚F (10˚C ~ 40˚C)

Audio Spec. - MAX Internal speaker Out : Right => 10W, Left => 10W

27.47 x 15.44 inches (697.68(H) x 392.26(V)mm)

801 x 87.7 x 158.1 mm_with stand

801 x 220.2 x 562.5 mm_without stand

System DVB-T/C, PAL, SECAM, NT4.43

Sound BG, DK, L/L’, NICAM, MPEG1, DD, DD+, HE-AAC

Operating Humidity : 10% ~ 80%, non-condensing

Storage temperature : -13˚F ~ 113˚F (-25˚C ~ 45˚C)

Storage Humidity : 5% ~ 95%, non-condensing

- BASS Control Range : -8 dB ~ + 8dB

- TREBLE Control Range : -8 dB ~ +8 dB

- Headphone Out : 10 mW MAX

- Output Frequency : RF : 80 Hz ~ 15 kHz

A/V : 80 Hz ~ 20 kHz

Note: TruSurround HD, Film Mode, Energy Saving, Anynet+

2-1

Page 9

2. Product specications

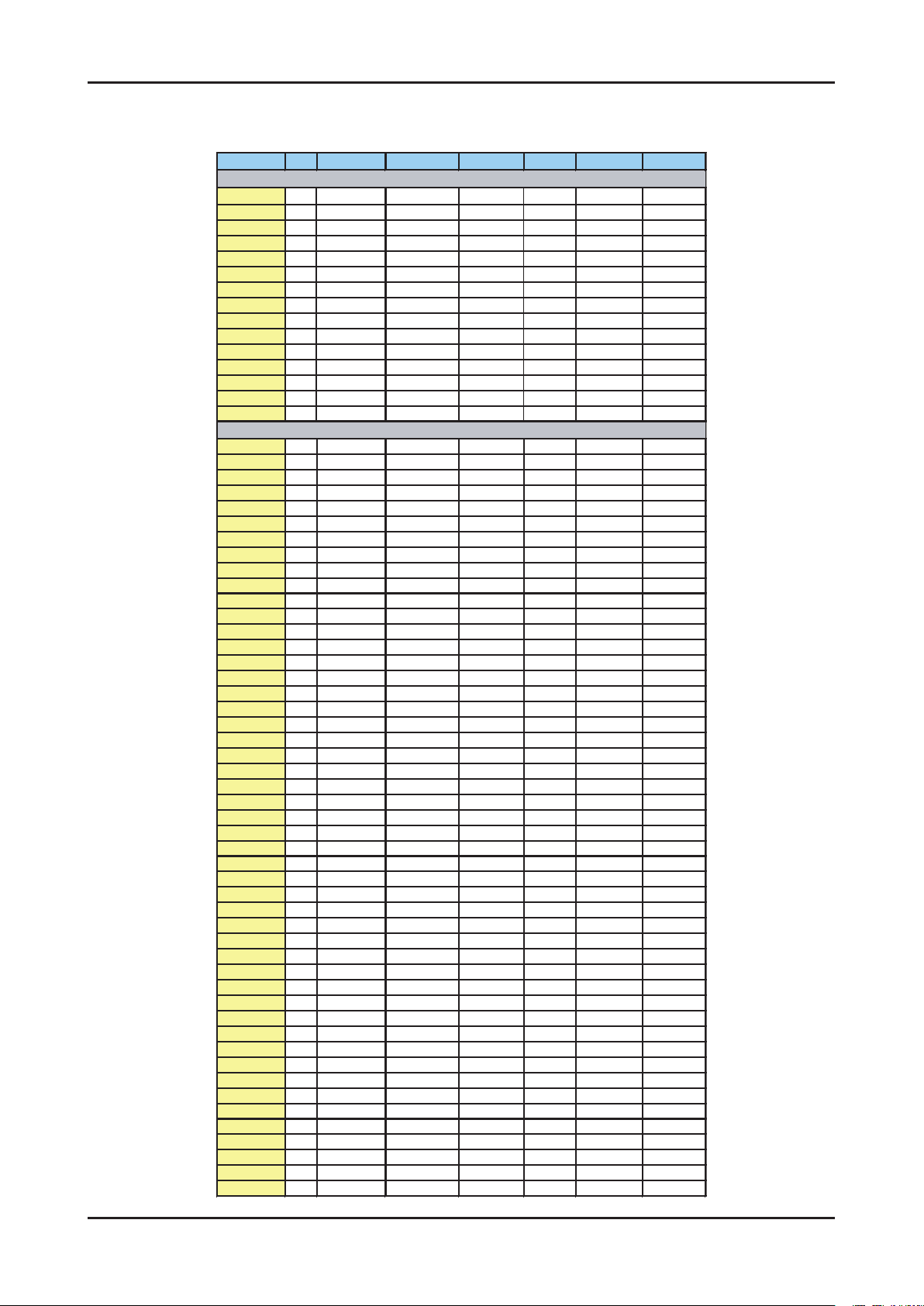

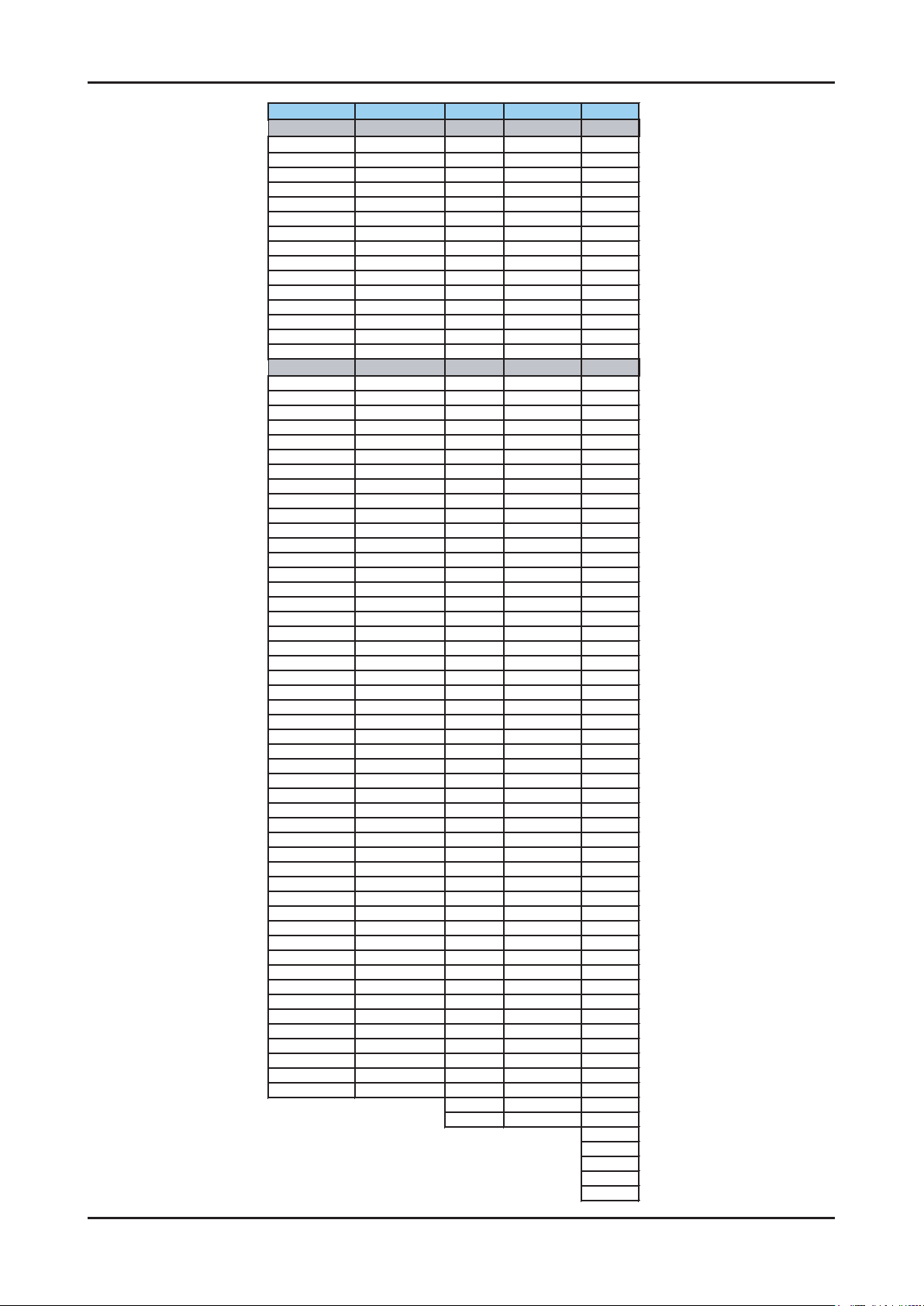

Channel UK France Germany Italy Spain Sweden Finland

VHF

[A] 56

[B] 64.5

[C] 84.5

[D] 177.5

[5] 178.75 [5] 177.5 [E] 186 [5] 177.5 [5] 177.5

[6] 186.75 [6] 184.5 [F] 194.5 [6] 184.5 [6] 184.5

[7] 194.75 [7] 191.5 [G] 203.5 [7] 191.5 [7] 191.5

[8] 202.75 [8] 198.5 [H] 212.5 [8] 198.5 [8] 198.5

[9] 210.75 [9] 205.5 [H1] 219.5 [9] 205.5 [9] 205.5

[10] 218.75

[10] 212.5 [H2] 226.5 [10] 212.5

[10] 212.5

[11] 219.5 [11] 219.5

[11] 219.5

[12] 226.5 [12] 226.5

[12] 226.5

UHF

21 474 474 474 474 474 474 474

22 482 482 482 482 482 482 482

23 490 490 490 490 490 490 490

24 498 498 498 498 498 498 498

25 506 506 506 506 506 506 506

26 514 514 514 514 514 514 514

27 522 522 522 522 522 522 522

28 530 530 530 530 530 530 530

29 538 538 538 538 538 538 538

30 546 546 546 546 546 546 546

31 554 554 554 554 554 554 554

32 562 562 562 562 562 562 562

33 570 570 570 570 570 570 570

34 578 578 578 578 578 578 578

35 586 586 586 586 586 586 586

36 594 594 594 594 594 594 594

37 602 602 602 602 602 602 602

38 610 610 610 610 610 610 610

39 618 618 618 618 618 618 618

40 626 626 626 626 626 626 626

41 634 634 634 634 634 634 634

42 642 642 642 642 642 642 642

43 650 650 650 650 650 650 650

44 658 658 658 658 658 658 658

45 666 666 666 666 666 666 666

46 674 674 674 674 674 674 674

47 682 682 682 682 682 682 682

48 690 690 690 690 690 690 690

49 698 698 698 698 698 698 698

50 706 706 706 706 706 706 706

51 714 714 714 714 714 714 714

52 722 722 722 722 722 722 722

53 730 730 730 730 730 730 730

54 738 738 738 738 738 738 738

55 746 746 746 746 746 746 746

56 754 754 754 754 754 754 754

57 762 762 762 762 762 762 762

58 770 770 770 770 770 770 770

59 778 778 778 778 778 778 778

60 786 786 786 786 786 786 786

61 794 794 794 794 794 794 794

62 802 802 802 802 802 802 802

63 810 810 810 810 810 810 810

64 818 818 818 818 818 818 818

65 826 826 826 826 826 826 826

66 834 834 834 834 834 834 834

67 842 842 842 842 842 842 842

68 850 850 850 850 850 850 850

69 858 858 858 858 858 858

Frequency (DTV)

2-2

Page 10

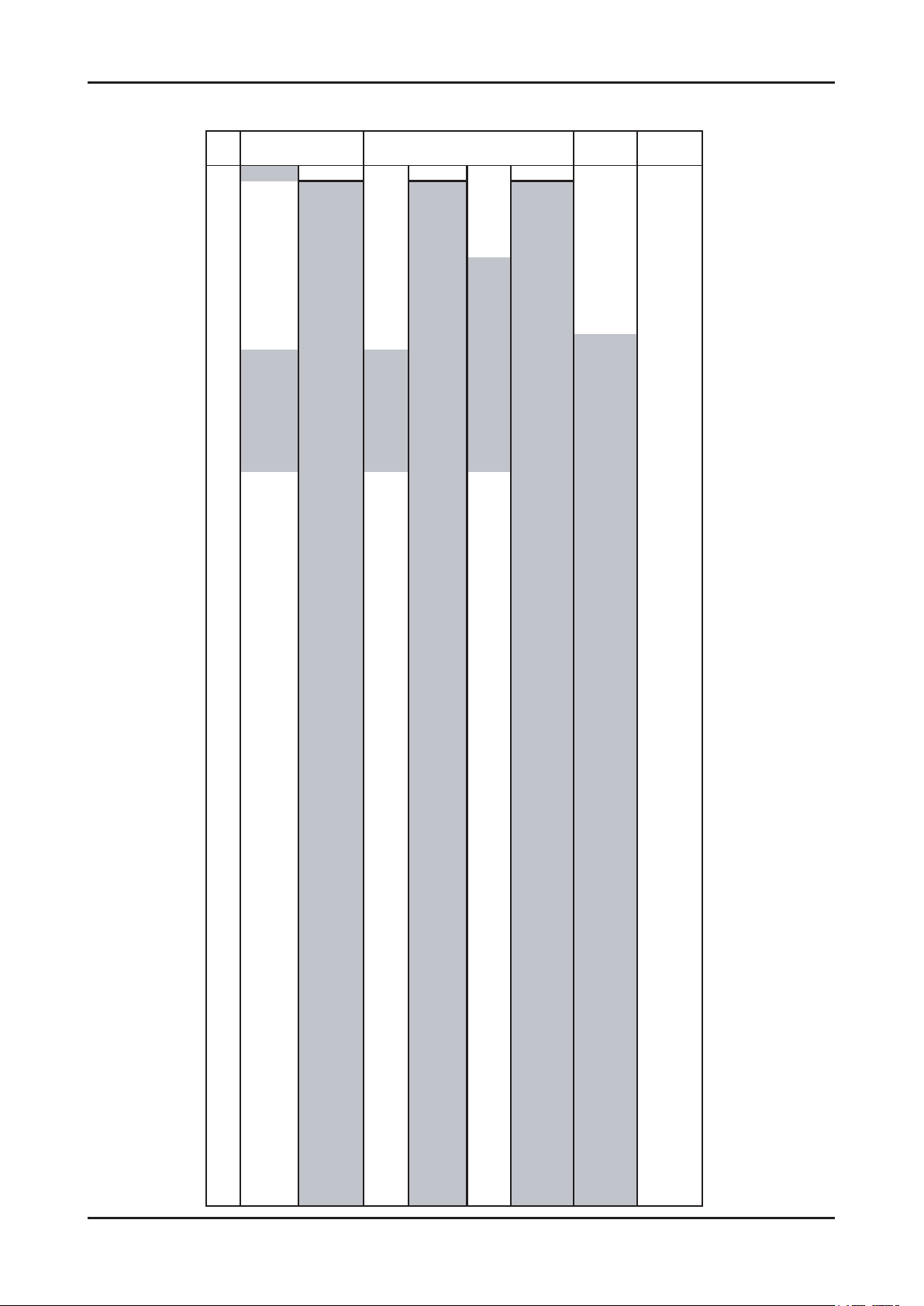

Australia Netherlands China Hongkong Taiwan

[0] 48.5 [1]52. 5

[1] 59.5

[2]60.5

[2] 66.5

[3]68.5

[3] 88.5

[4]80

[4] 97.5 [5] 174.5

[5]88

[5] 104.5 [6] 181.5

[6]171

[5A] 140.5 [7] 188.5

[7]179

[6] 177.5 [8] 195.5

[8]187

[7] 184.5 [9] 202.5

[9]195

[8] 191.5 [10] 209.5

[10]203

[9] 198.5 [11] 216.5

[11]211

[9A] 205.5 [12] 223.5

[12]219

[10] 212.5

[11] 219.5

[12] 226.5

474 [13]474 [21]474 [14]473

482 [14]482 [22]482 [15]479

490 [15]490 [23]490 [16]485

498 [16]498 [24]498 [17]491

506 [17]506 [25]506 [18]497

514 [18]514 [26]514 [19]503

520~526, 6MHz

522 [19]522 [27]522 [20]509

529.5 530 [20]530 [28]530 [21]515

536.5 538 [21]538 [29]538 [22]521

543.5 546 [22]546 [30]546 [23]527

550.5 554 [23]554 [31]554 [24]533

557.5 562 [24]562 [32]562 [25]539

564.5 570 [25]610 [33]570 [26]545

571.5 578 [26]618 [34]578 [27]551

578.5 586 [27]626 [35]586 [28]557

585.5 594 [28]634 [36]594 [29]563

592.5 602 [29]642 [37]602 [30]569

599.5 610 [30]650 [38]610 [31]575

606.5 618 [31]658 [39]618 [32]581

613.5 626 [32]666 [40]626 [33]587

620.5 634 [33]674 [41]634 [34]593

627.5 642 [34]682 [42]642 [35]599

634.5 650 [35]690 [43]650 [36]605

641.5 658 [36]698 [44]658 [37]611

648.5 666 [37]706 [45]666 [38]617

655.5 674 [38]714 [46]674 [39]623

662.5 682 [39]722 [47]682 [40]629

669.5 690 [40]730 [48]690 [41]635

676.5 698 [41]738 [49]698 [42]641

683.5 706 [42]746 [50]706 [43]647

690.5 714 [43]754 [51]714 [44]653

697.5 722 [44]762 [52]722 [45]659

704.5 730 [45]770 [53]730 [46]665

711.5 738 [46]778 [54]738 [47]671

718.5 746 [47]786 [55]746 [48]677

725.5 754 [48]794 [56]754 [49]683

732.5 762 [49]802 [57]762 [50]689

739.5 770 [50]810 [58]770 [51]695

746.5 778 [51]818 [59]778 [52]701

753.5 786 [52]826 [60]786 [53]707

760.5 794 [53]834 [61]794 [54]713

767.5 802 [54]842 [62]802 [55]719

774.5 810 [55]850 [63]810 [56]725

781.5 818 [56]858 [64]818 [57]731

788.5 826 [57]866 [65]826 [58]737

795.5 834 [58]874 [66]834 [59]743

802.5 842 [59]882 [67]842 [60]749

809.5 850 [60]890 [68]850 [61]755

816.5 858 [61]898 [69]858 [62]761

[62]906 [63]767

[63]914 [64]773

[65]779

[66]785

[67]791

[68]797

[69]803

2. Product specications

2-3

Page 11

2. Product specications

CH

NEWZEAL CHINA

(PAL D/K)

1 69-855.25 49.25

69-855.25

176.00 69-855.25 45.25 49.25

2 48.25 E2-48.25 59.25 184.00 FA-47.75 55.25 57.25

3 55.25 E3-55.25 77.25 192.00 FB-55.75 62.25 65.25

4 62.25 E4-62.25 85.25 200.00

FC1-60.50

175.25 77.25

5 175.25 X -69.25 93.25 208.00 FC-53.75 182.25 85.25

6 182.25 Y -76.25 175.25 216.00 B-116.75 189.25 168.25

7 189.25 Z -83.25 183.25 C-128.25 196.25 176.25

8 196.25 Z1-90.25 191.25 D-140.75 203.25 184.25

9 203.25 Z2-97.25 199.25 E-152.75 210.25 192.25

10 210.25 S1-105.25 207.25 F-164.75 217.25 200.25

11 217.25 S2-112.25 215.25 F1-176.00 224.25 208.25

12 224.25 S3-119.25 223.25 G -176.75 216.25

13 S4-126.25 F2-184.00 471.25

14 S5-133.25 H -188.75 479.25

15 S6-140.25 F3-192.00 487.25

16 S7-147.25 F4-200.00 495.25

17 S8-154.25 I -200.75 503.25

18 S9-161.25 F5-208.00 511.25

19 S10-168.25 J -212.75 519.25

20 E5-175.25 F6-216.00 527.25

21 471.25 E6-182.25 471.25 471.25 K -224.75 535.25

22 479.25 E7-189.25 479.25 479.25 L -236.75 543.25

23 487.25 E8-196.25 487.25 487.25 M -248.75 551.25

24 495.25 E9-203.25 495.25 495.25 N -260.75 559.25

25 503.25

E10-210.25

503.25 503.25 O -272.75 607.25

26 511.25

E11-217.25

511.25 511.25 P -284.75 615.25

27 519.25

E12-224.25

519.25 519.25 Q -296.75 623.25

28 527.25

S11-231.25

527.25 527.25 631.25

29 535.25

S12-238.25

535.25 535.25 639.25

30 543.25

S13-245.25

543.25 543.25 647.25

31 551.25

S14-252.25

551.25 551.25 655.25

32 559.25

S15-259.25

559.25 559.25 663.25

33 567.25

S16-266.25

567.25 567.25 671.25

34 575.25

S17-273.25

575.25 575.25 679.25

35 583.25

S18-280.25

583.25 583.25 687.25

36 591.25

S19-287.25

591.25 591.25 695.25

37 599.25

S20-294.25

599.25 599.25 703.25

38 607.25

S21-303.25

607.25 607.25 711.25

39 615.25

S22-311.25

615.25 615.25 719.25

40 623.25

S23-319.25

623.25 623.25 727.25

41 631.25

S24-327.25

631.25 631.25 735.25

42 639.25

S25-335.25

639.25 639.25 743.25

43 647.25

S26-343.25

647.25 647.25 751.25

44 655.25

S27-351.25

655.25 655.25 759.25

45 663.25

S28-359.25

663.25 663.25 767.25

46 671.25

S29-367.25

671.25 671.25 775.25

47 679.25

S30-375.25

679.25 679.25 783.25

48 687.25

S31-383.25

687.25 687.25 791.25

49 695.25

S32-391.25

695.25 695.25 799.25

50 703.25

S33-399.25

703.25 703.25 807.25

51 711.25

S34-407.25

711.25 711.25 815.25

52 719.25

S35-415.25

719.25 719.25 823.25

53 727.25

S36-423.25

727.25 727.25 831.25

54 735.25

S37-431.25

735.25 735.25 839.25

55 743.25

S38-439.25

743.25 743.25 847.25

56 751.25

S39-447.25

751.25 751.25 855.25

57 759.25

S40-455.25

759.25 759.25 863.25

58 767.25

S41-463.25

767.25 767.25 871.25

59 775.25 775.25 775.25 879.25

60 783.25 783.25 783.25 887.25

61 791.25 791.25 791.25 895.25

62 799.25 799.25 799.25 903.25

63 807.25 807.25 807.25 911.25

64 815.25 815.25 815.25 919.25

65 823.25 823.25 823.25 927.25

66 831.25 831.25 831.25 935.25

67 839.25 839.25 839.25 943.25

68 847.25 847.25 847.25 951.25

FRANCE

(SECAM-L)

CCIR

(PAL B/G)

OIRT

(SECAM D/K)

Frequency (ATV)

2-4

Page 12

2. Product specications

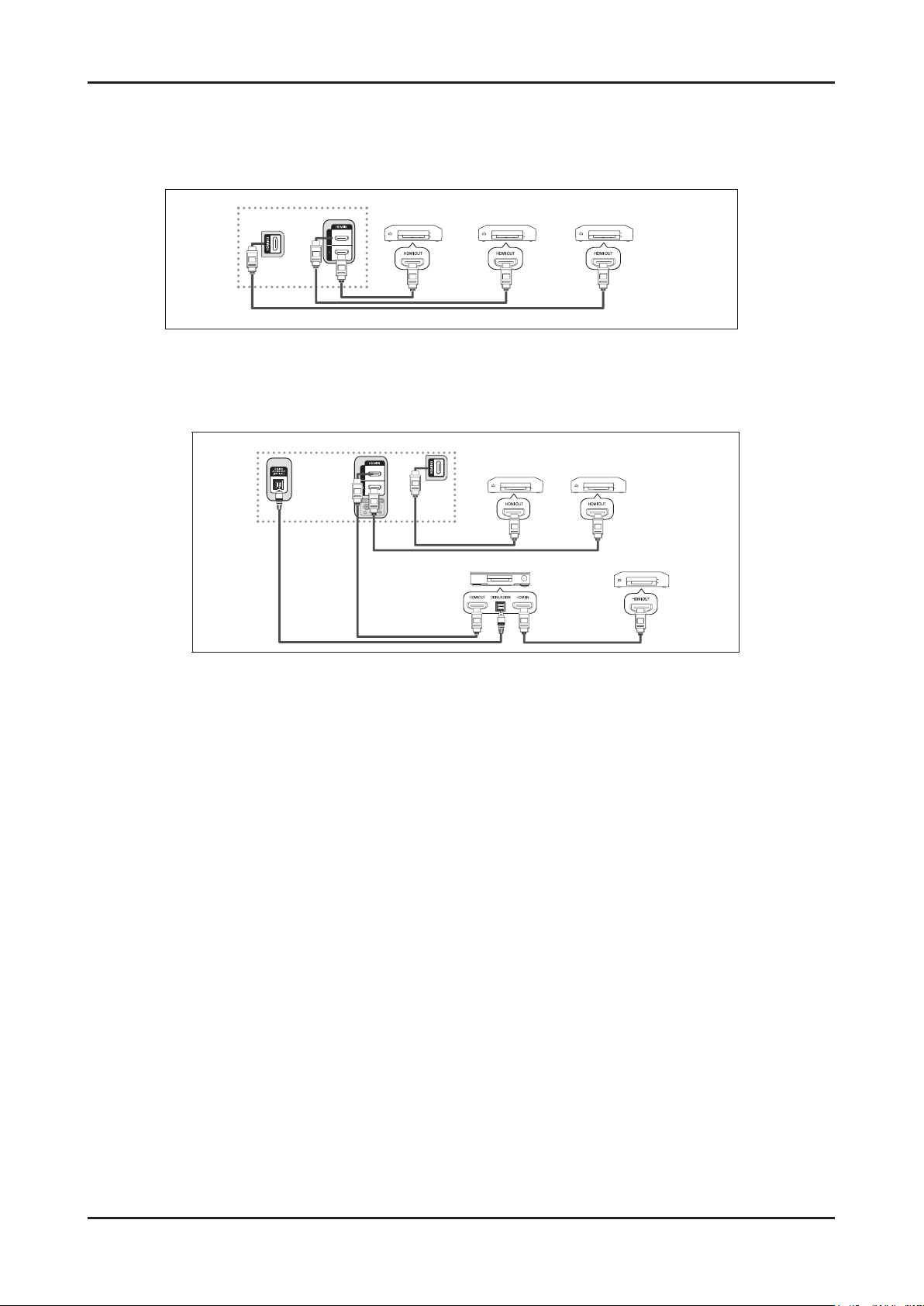

TV

Anynet+ Device 1

Anynet+ Device 2 Anynet+ Device 3

HDMI 1.3 Cable

HDMI 1.3 Cable

HDMI 1.3 Cable

TV

Anynet+ Device 1

Anynet+ Device 2

Anynet+ Device 3

HDMI 1.3 Cable

HDMI 1.3 Cable

HDMI 1.3 Cable

Optical Cable

Home Theater

HDMI 1.3 Cable

2-2. New Features explanation

Anynet+: Anynet+ is an AV network system that enables you to control all connected Samsung AV devices

�

with the TV’s remote.

To directly connect to TV

Connect the [HDMI 1], [HDMI 2] or [HDMI ] jack on the TV and the HDMI OUT jack of the corresponding

Anynet+ device using an HDMI cable.

To connect to Home Theater

Connect the [HDMI 1], [HDMI 2] or [HDMI ] jack on the TV and the HDMI OUT jack of the corresponding Anynet+

1.

device using an HDMI cable.

Connect the HDMI IN jack of the home theater and the HDMI OUT jack of the corresponding Anynet+

2.

device using the HDMI cable.

- Connect the Optical cable between [Digital Audio Out (Optical)] on your TV and Digital Audio Input on the

Home Theater.

- When following the connection above, the Optical jack only outputs 2 channel audio. You will only hear sound from

the Home Theater’s Front Left and Right speakers and the subwoofer. If you want to hear 5.1 channel audi

connect the DIGITAL AUDIO OUT (OPTICAL) jack on the DVD / Satellite Box (ie Anynet Device 1 or 2) directly

to the Ampli er or Home Theater, not the TV.

- Connect only one Home Theater.

- You can connect an Anynet+ device using the HDMI 1.3 cable. Some HDMI cables may not support Anynet+

functions.

- Anynet+ works when the AV device supporting Anynet+ is in the Standby or On status.

- Anynet+ supports up to 12 AV devices in total. Note that you can connect up to 3 devices of the same type.

2-5

Page 13

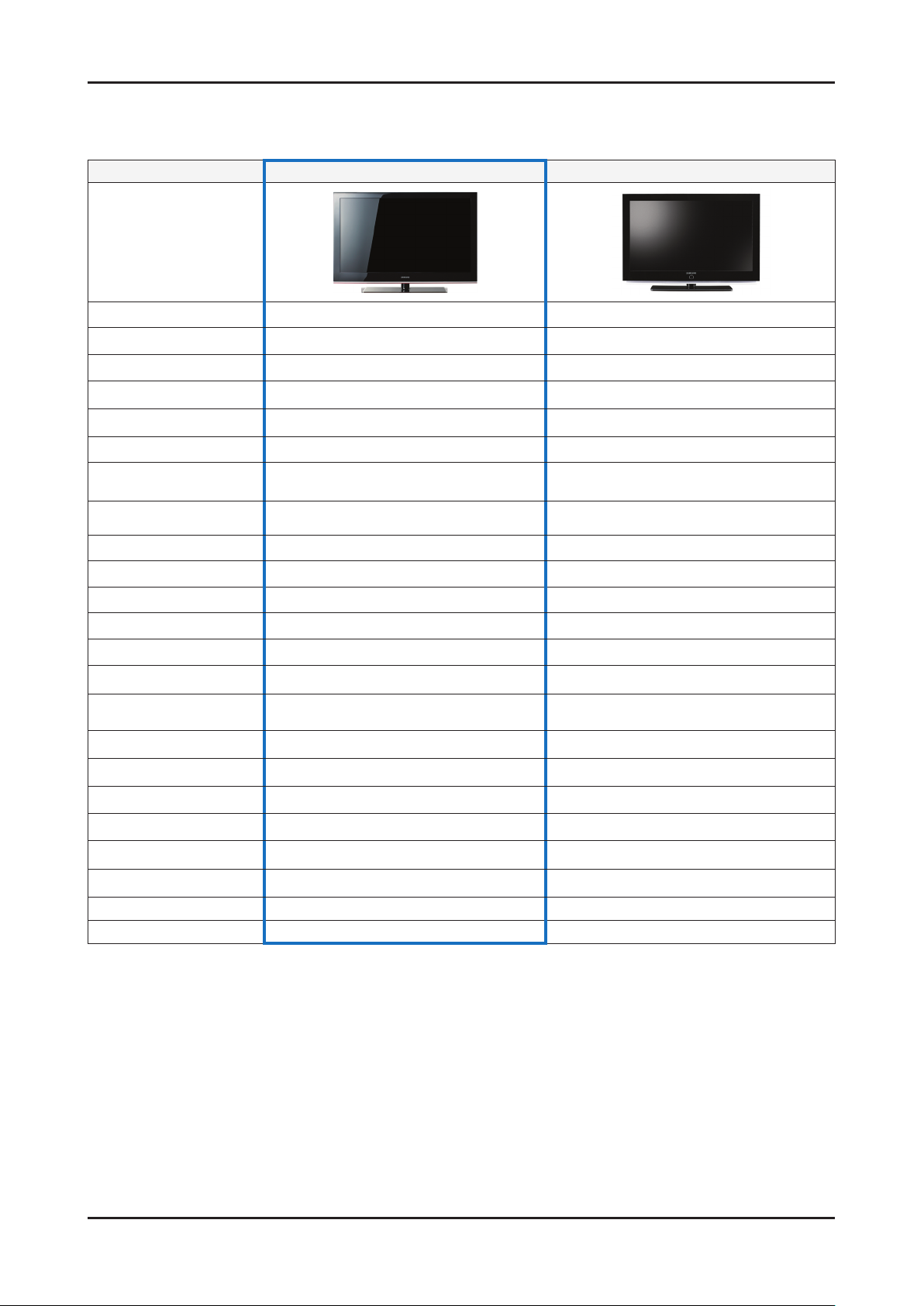

2. Product specications

2-3. Specication Comparison to Old Models

O : application, X : non-application

※

Model B530(LE32B53*P7N) A530(LE32A53***)

Design

Display Type LCD TV LCD TV

Built-in Tuner O O

Resolution 1920 x 1080 1920 x 1080

LCD Panel TFT LCD Panel TFT LCD Panel

Screen Size 32” 32”

Picture ratio 16 : 9 16 : 9

Dimensions (W x H x D) 31.9 x 22.1 x 8.7 inchs_with stand 34.1 x 22.1 x 8.7 inchs_with stand

Weight 27.96 lbs_with stand 30.20 lbs_with stand

Brightness 500 cd

Contrast Ratio 50,000:1 50,000:1

Picture Enhacer DNIe (SEMS12) DNIe (FBE3)

Equalizer 5 Band 5 Band

Auto Volume Control O O

Surround Sound SRS TruSurround HD SRS TruSurround XT

Speaker Output 10W + 10W 10W + 10W

PIP X O

Double Window X O

TTX O O

Entertainment Mode X O

Game Mode O X

Energy Saving O O

Anynet+ O O

Antenna 1(Cable/Air) 1(Cable/Air)

2

500 cd

2

2-6

Page 14

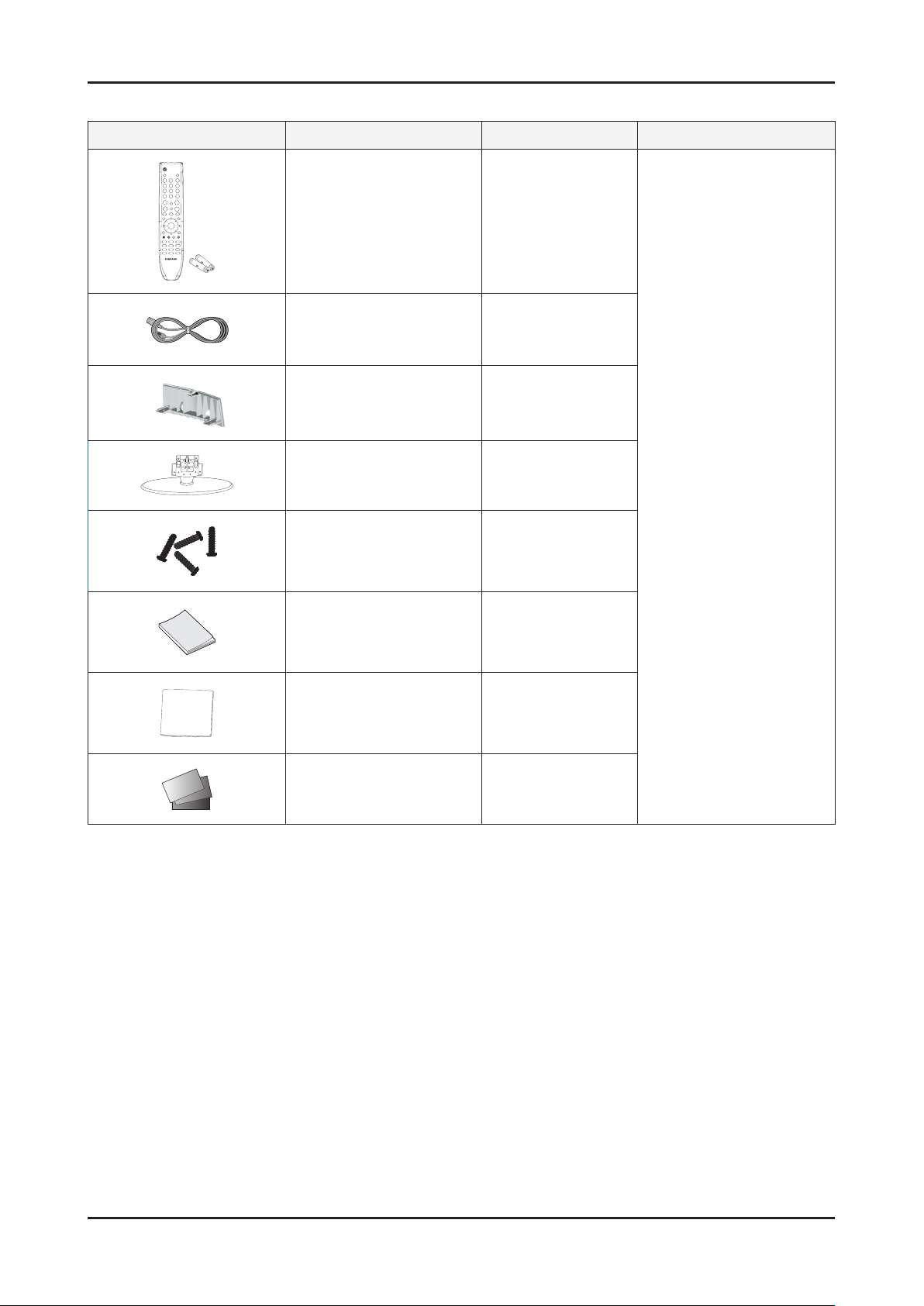

2-4. Accessories

Product Description Code. No Remark

2. Product specications

Remote Control & Batteries

(AAA x 2)

Power Cord 3903-000144

Cover-Bottom BN63-05356A

Stand BN96-09131A

Screw

(for the stand - M4, L6)

Owner’s Instructions BN68-02274A

BN59-00856A

6002-001294

Samsung Electronics

Service center

Cleaning Cloth BN-63-01798B

Warranty Card / Registration

Card / Safety Guide Manual

(Not available in all locations)

AA68-03242L

2-7

Page 15

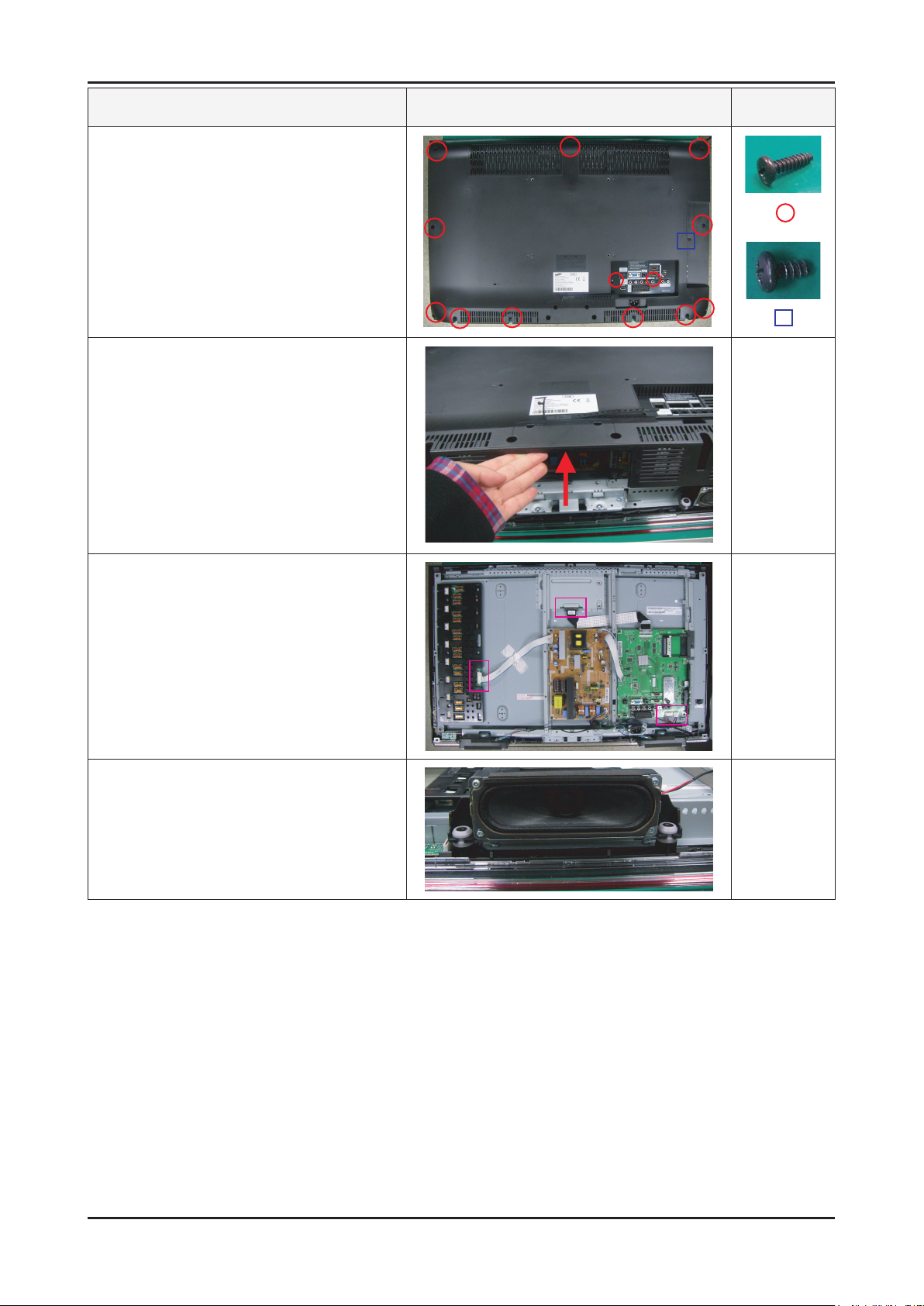

3. Disassembly and Reassembly

3. Disassembly and Reassembly

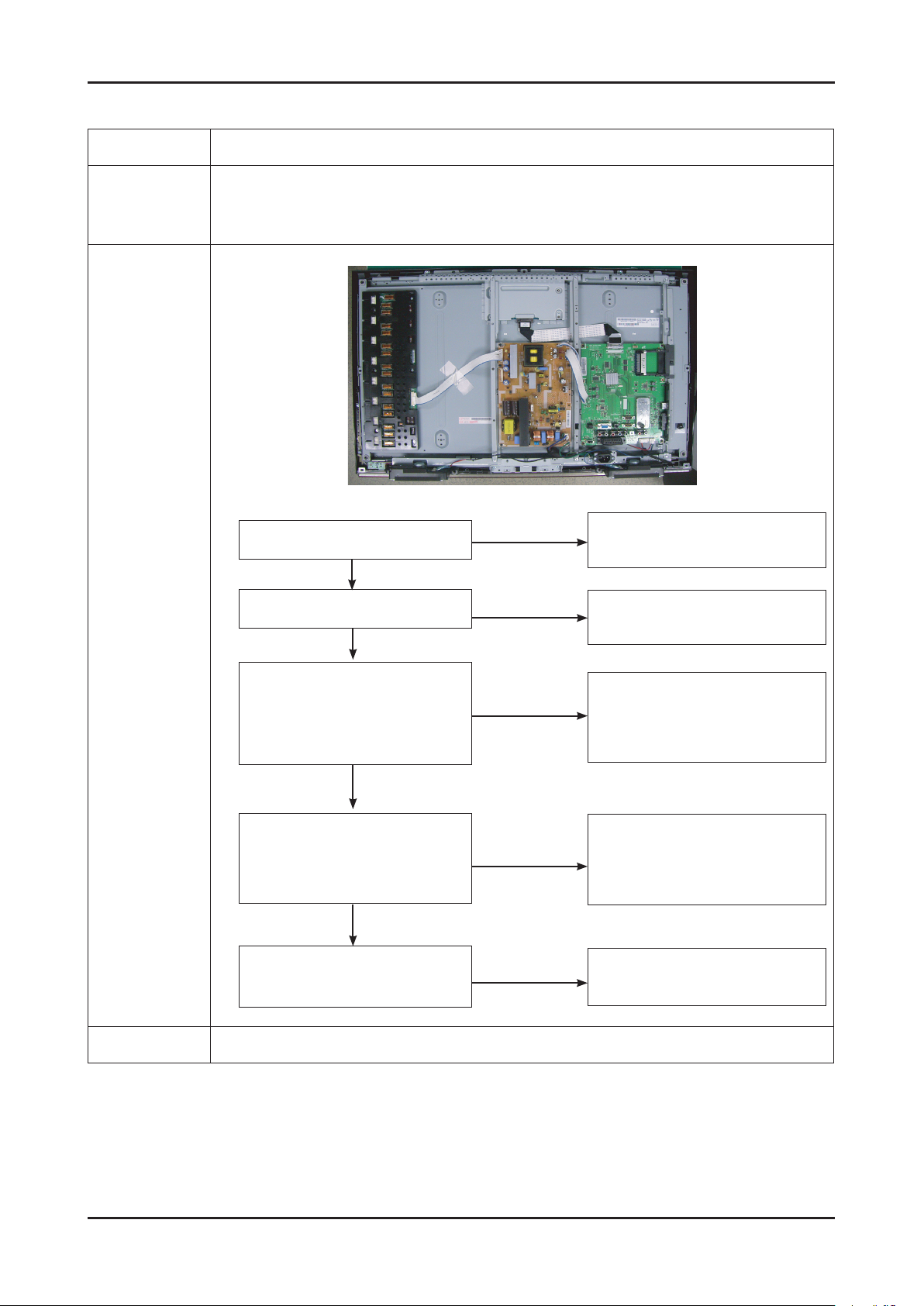

This section of the service manual describes the disassembly and reassembly procedures for the B530(LE32B53*P7N)

LCD TV.

WARNING: This LCD TV contains electrostatically sensitive devices. Use caution when handling these components.

3-1. Disassembly and Reassembly

Cautions: 1. Disconnect the LCD TV from the power source before disassembly.

2. Follow these directions carefully; never use metal instruments to pry apart the cabinet.

3. For Disassembly and Reassembly, (+) screw driver is used.

Description Picture Description Screws

1. Place the TV face down on cushioned table.

Remove 4 screws from the Stand.

Remove stand.

3-1

Page 16

3. Disassembly and Reassembly

Description Picture Description Screws

2. Remove the 14 screws of rear-cover.

3. Lift up the rear-cover.

4. Disconnect the cable.

5. Remove the left and right speaker.

3-2

Page 17

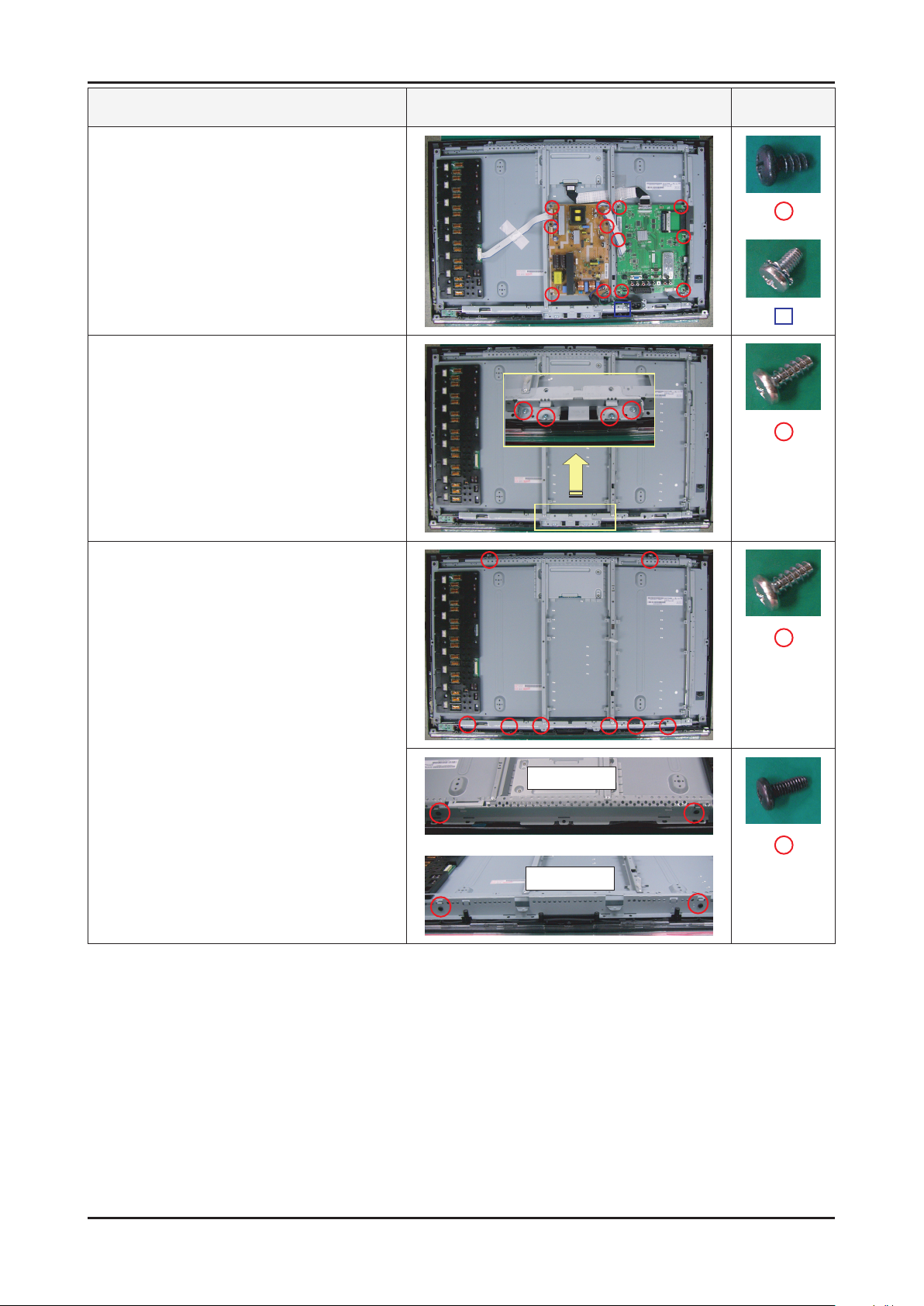

Description Picture Description Screws

TOP

BOTTOM

6. Remove the 6 screws of main board and

6 screws of IP board and 1 screw of inlet

socket.

7. Remove the 4 screws of bracket stand link.

3. Disassembly and Reassembly

8. Remove the 12 screws of bracket. Lift up the

bracket.

3-3

Page 18

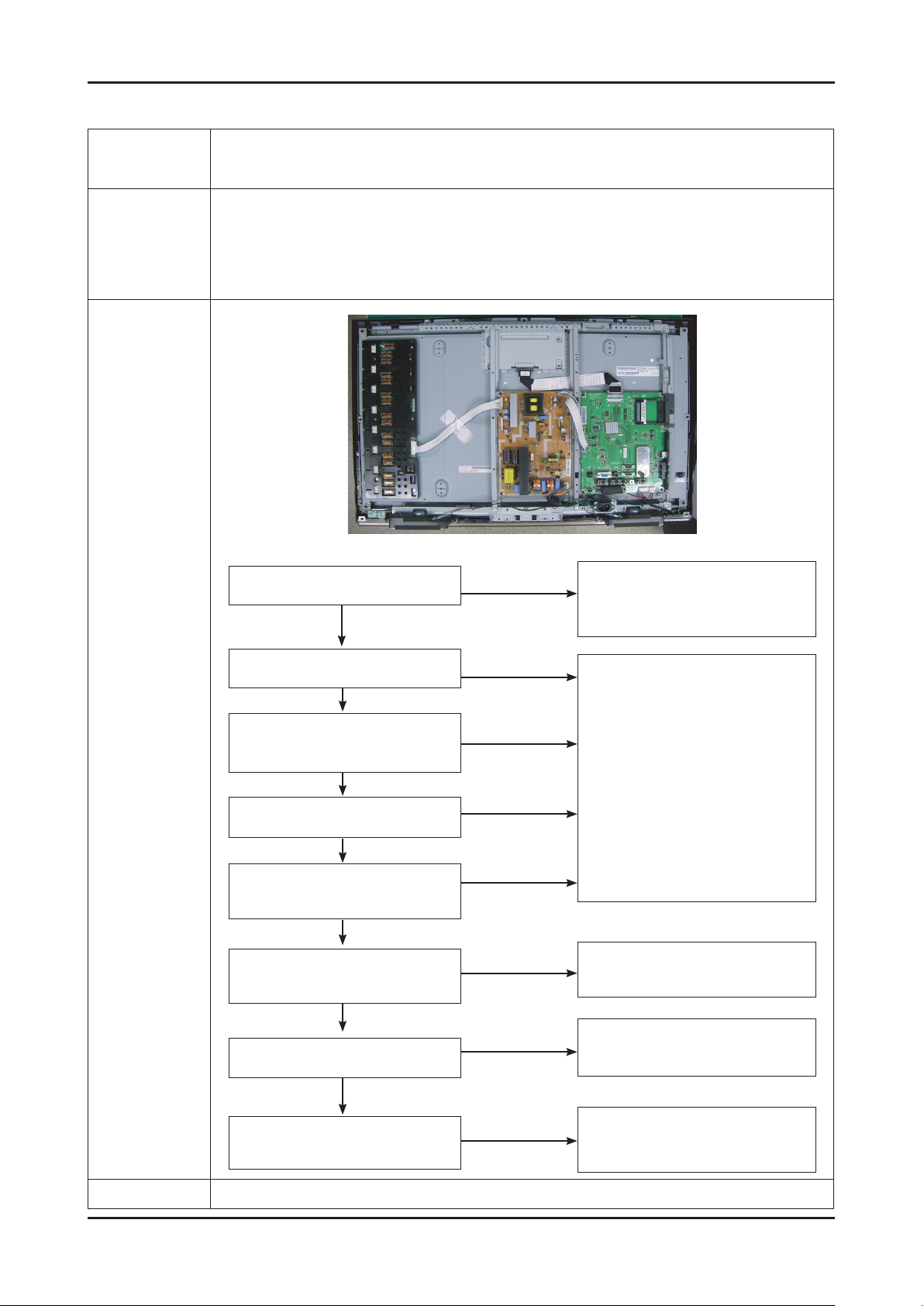

3. Disassembly and Reassembly

Description Picture Description Screws

9. Lift up the panel.

Reassembly procedures are in the reverse order of disassembly procedures.

※

3-4

Page 19

4. Troubleshooting

4-1. Troubleshooting

4-1-1. Previous check

Check the various cable connections rst.

1.

• Check to see if there is a burnt or damaged cable.

• Check to see if there is a disconnected or loose cable connection.

• Check to see if the cables are connected according to the connection diagram.

Check the power input to the Main Board.

2.

4. Troubleshooting

4-1

Page 20

4. Troubleshooting

4-1-2. No Power

-

Symptom

Major

checkpoints

-

-

The IP relay or the LEDs on the front panel does not work when connecting the power cord if the cables are

improperly connected or the Main Board or SMPS is not functioning. In this case, check the following:

-

-

-

-

The LEDs on the front panel do not work when connecting the power cord.

The SMPS relay does not work when connecting the power cord.

The units appears to be dead.

Check the internal cable connection status inside the unit.

Check the fuses of each part.

Check the output voltage of SMPS.

Replace the Main Board.

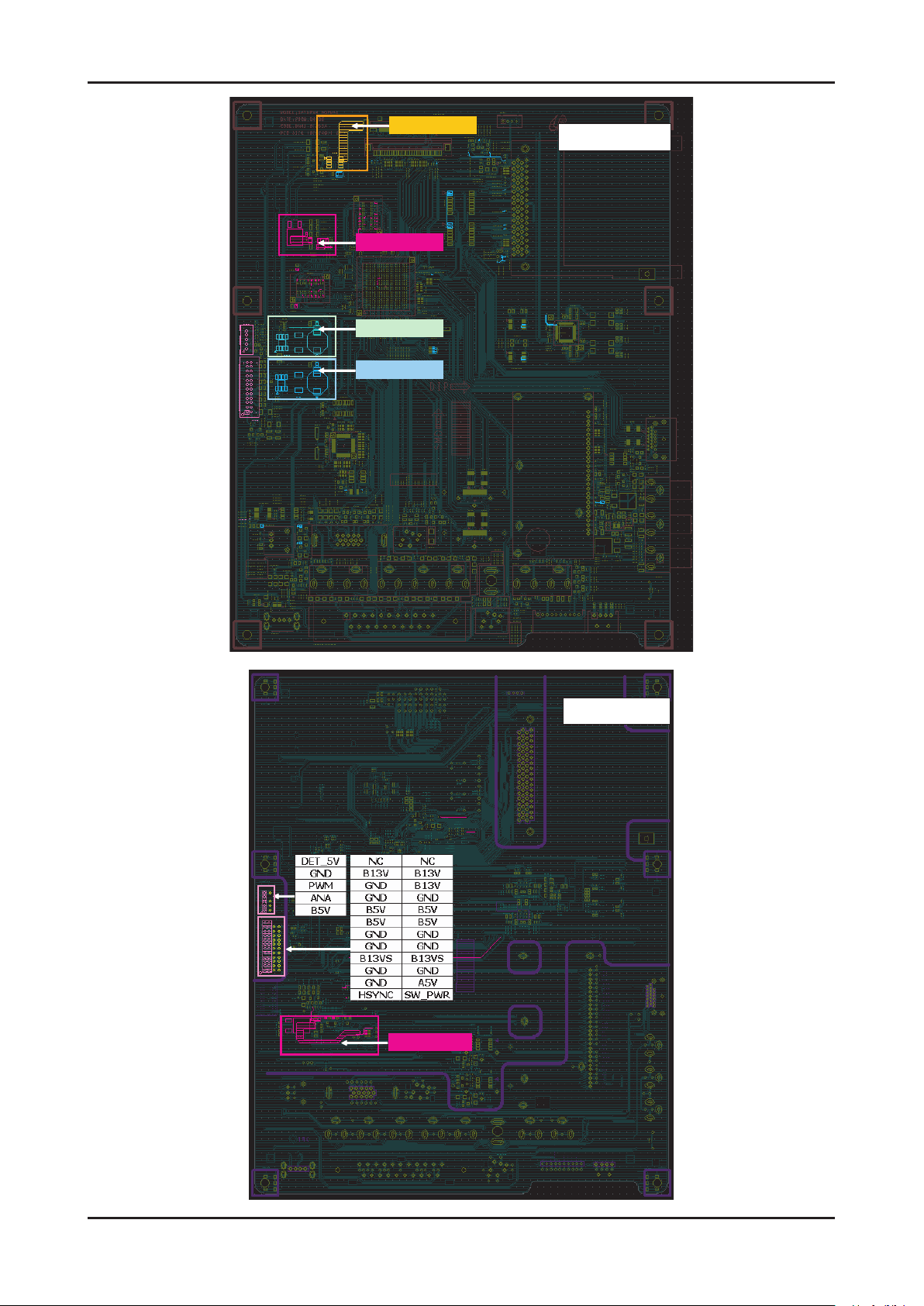

Diagnostics

Lamp(Backlight) Off,

power indicator LED on?

Yes

Does proper Stand-By DC

A5V_PW appear at TP2004?

Yes

Does proper Main B12VS_PW,

B13V_PW, B5V_PW appear at

TP2007~8, TP2020~2, TP2013~6?

Yes

Does proper A3.3V_PW

appear at R2028?

Yes

Does proper B3.3V_PW, B1.9V_PW,

B1.25V_PW appear at

C2607, C2590, C2105?

Yes

Does proper PANEL_VCC_PW

appear at LVDS connector Pin #1~5

of T-con b’d?

Yes

No

No

No

No

No

No

Change the 30P power cable

or IP board

Change the Main Assy

Change the LVDS cable

4-2

Caution

Does proper DC B12V

appear at F1 of T-con b’d?

Yes

A power is supplied to set?

Make sure to disconnect the power before working on the IP board.

No

No

Change the T-con b’d

Check a other function

(No picture part)

Replace a LCD Panel

Page 21

4. Troubleshooting

TOP

B3.3V_PW

B1.25V_PW

B1.25V_PW

PANEL_PW

BOTTOM

A3.3V_PW

4-3

Page 22

4. Troubleshooting

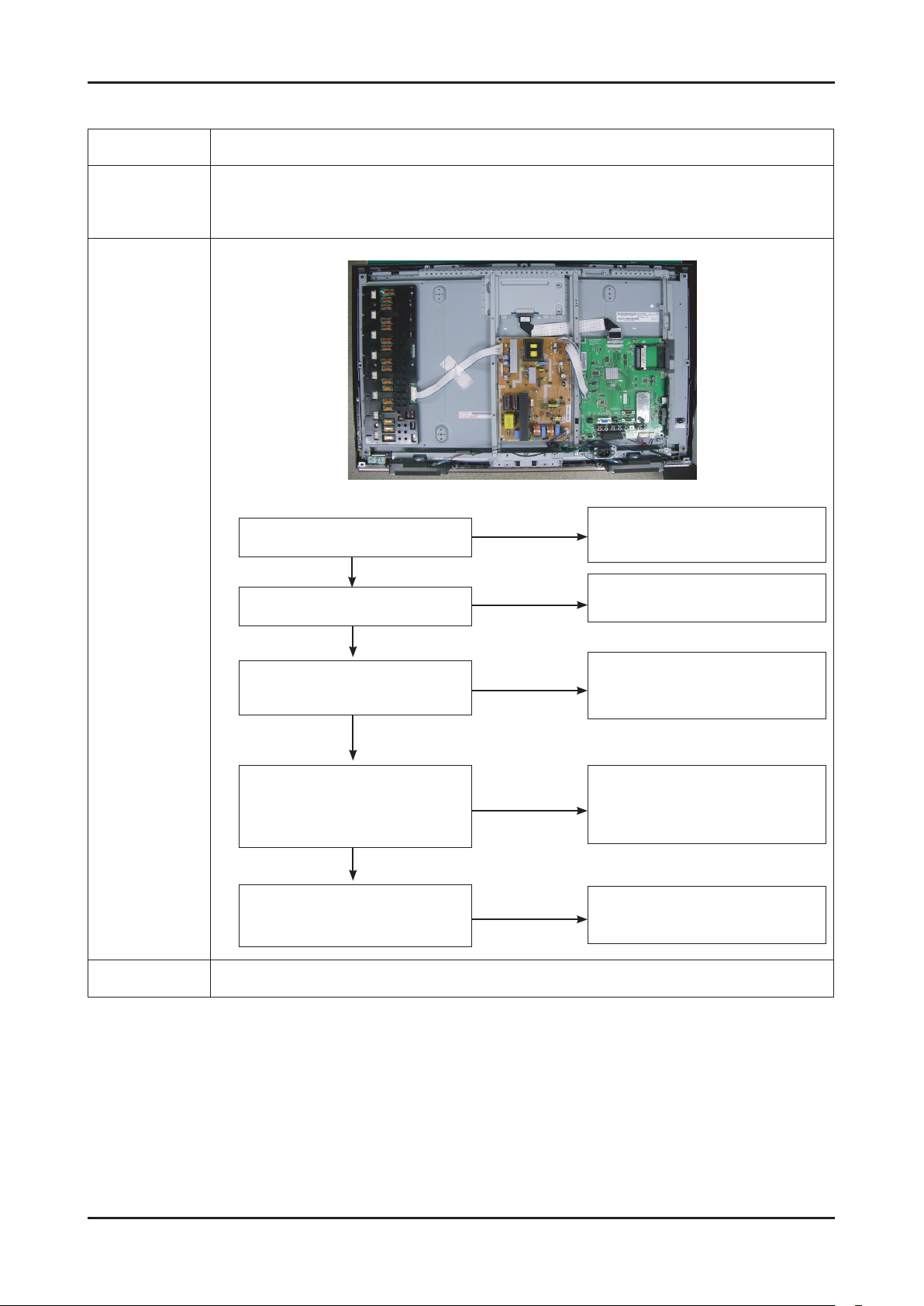

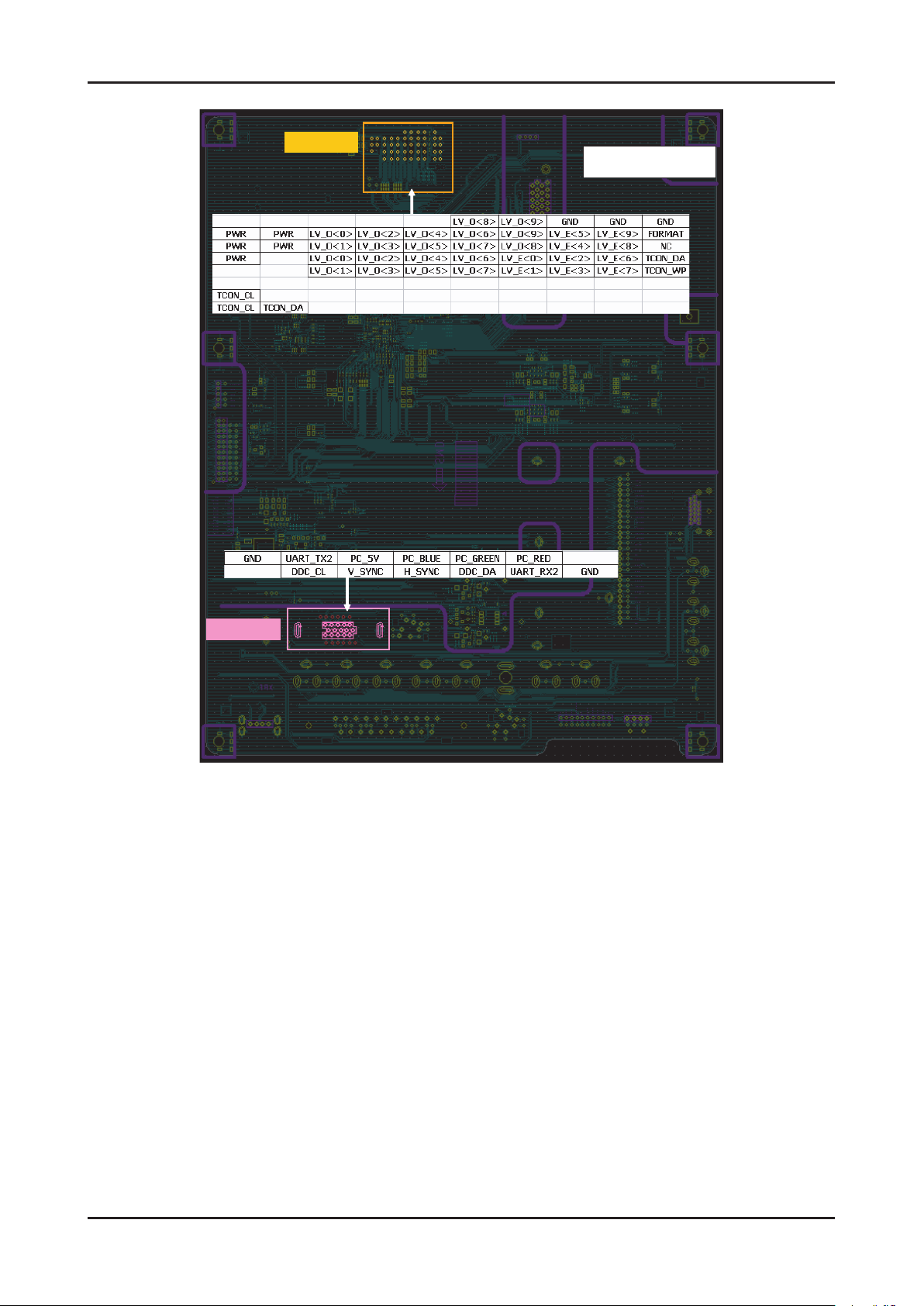

4-1-3. No Video (Analog PC signal)

Symptom Audio is normal but no picture is displayed on the screen.-

Check the PC source

Major

checkpoints

-

Check the Arsenal, Check the Chelsea.

-

This may happen when the LVDS cable connecting the Main Board and the Panel is disconnected.

-

Diagnostics

Power indicator LED is off.

Lamp(Backlight) on, no video

Yes

Check the PC source and

check the connection of D-SUB

Yes

Does the signal appear at TP5002,

1

2

5003, 5004, 5006, 5008?

Yes

Does the digital data appear at

Pin #19,20,34,35 (LVDS Data clk)

of LVDS connector?

Yes

Check the LVDS cable?

Check the T-Con B’d?

Replace the LCD panel?

No

No

No

No

No

Check a set

in the ‘Stand-by mode’ or

‘DPMS mode’

Input the analog

PC signal properly.

Check CN5001, PC cable.

Change the Main Assy

Check IC4010 (Saturn4)

Change the Main Assy

Please, Contact Tech support.

Caution Make sure to disconnect the power before working on the IP board.

4-4

Page 23

4. Troubleshooting

BOTTOM

LVDS

D-SUB

4-5

Page 24

4. Troubleshooting

WAVEFORMS

1

2

PC input (V-sink , H-sink , R/G/B)

LVDS output

4-6

Page 25

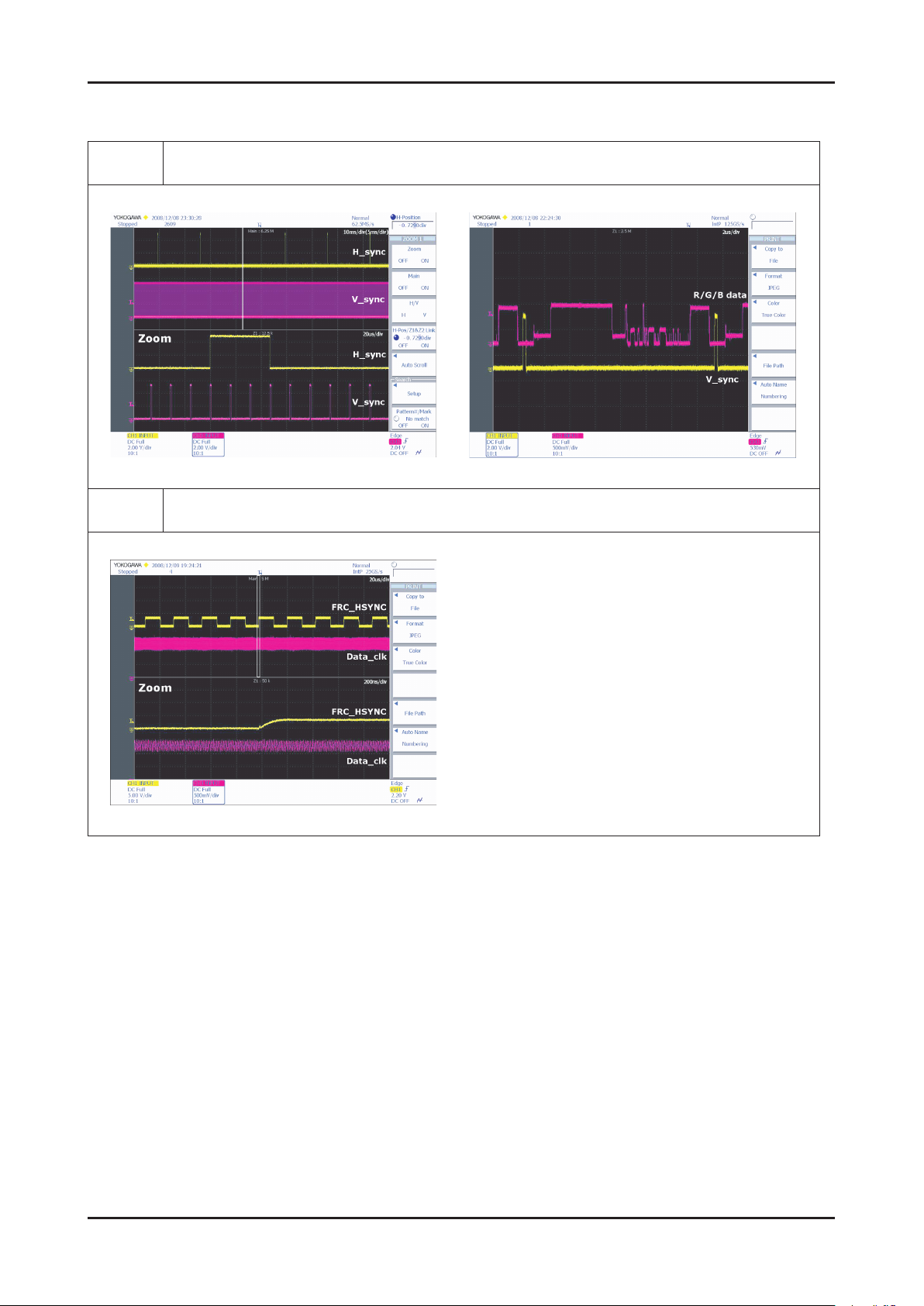

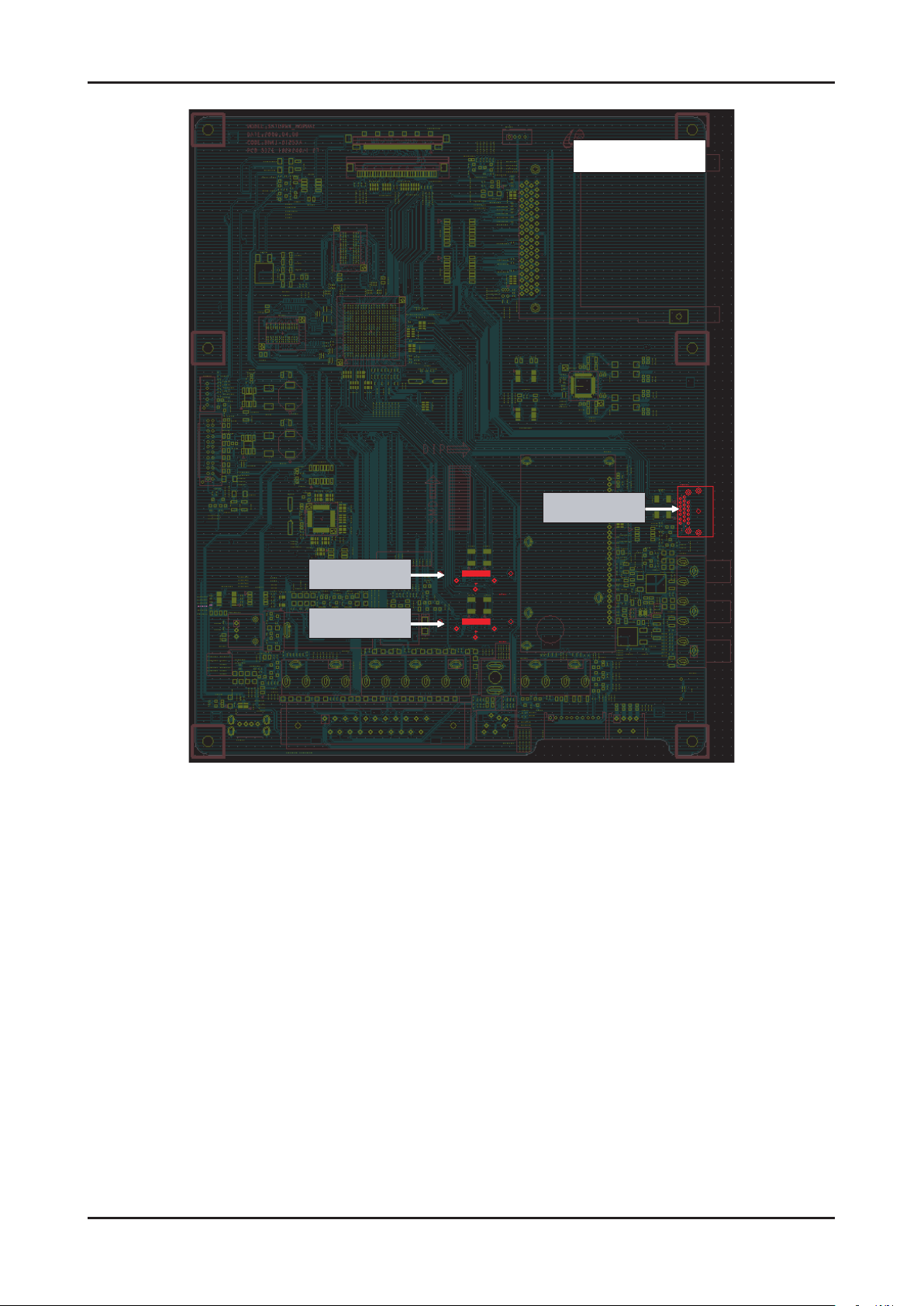

4-1-4. No Video (HDMI 1, 2, 3 - Digital Signal)

Symptom Audio is normal but no picture is displayed on the screen.-

Check the HDMI source.

Major

checkpoints

-

Check the HDMI switch, Check the Chelsea.

-

This may happen when the LVDS cable connecting the Main Board and the Panel is disconnected.

-

4. Troubleshooting

Diagnostics

Power Indicator is off.

Lamp(Backlight) Off, no video?

Yes

Check the HDMI source and check

the connection of HDMI cable?

Yes

Does the signal appear at

3

2

CN6009 (Pin#12 , #7 )(HDMI1)

CN6002 (Pin#12 , #7 )(HDMI2)

CN6004 (Pin#12 , #7 )(HDMI3)

(HDMI RX_Clk , RX_Data)?

Yes

Does the digital data appear at

Pin #19,20,34,35 (LVDS Data clk)

of LVDS connector?

Yes

Check the LVDS cable?

Check the T-Con B’d?

Replace the LCD panel?

No

No

No

No

No

Check a set

in the ‘Stand-by mode’.

Input the HDMI signal properly

Check CN6009, CN6002, CN6004

Check HDMI cable

Change the Main Assy

Check IC4010 (Saturn4)

Change the Main Assy

Please, Contact Tech support

Caution Make sure to disconnect the power before working on the IP board.

4-7

Page 26

4. Troubleshooting

HDMI1

HDMI2

HDMI3

TOP

4-8

Page 27

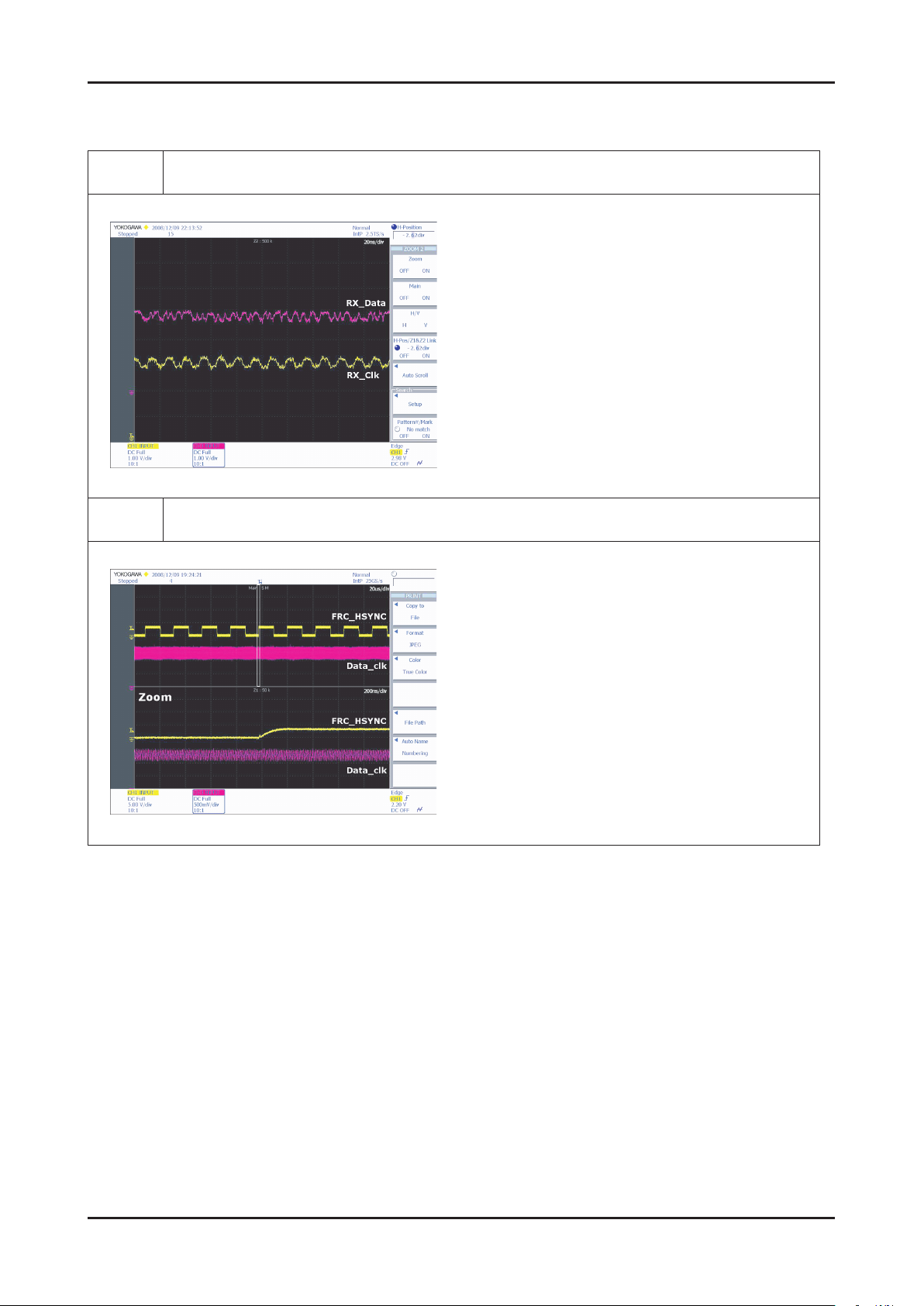

WAVEFORMS

4. Troubleshooting

3

2

HDMI input (RX_Data, RX_Clk)

LVDS output

4-9

Page 28

4. Troubleshooting

4-1-5. No Video (Tuner_CVBS)

Symptom Audio is normal but no picture is displayed on the screen.-

Check the Tuner CVBS source.

Major

checkpoints

-

Check the Tuner, Check the Chelsea.

-

This may happen when the LVDS cable connecting the Main Board and the Panel is disconnected.

-

Diagnostics

Power indicator LED is off.

Lamp(Backlight) on, no video?

Yes

Check the RF source and

check the connection of RF cable?

Yes

Does the DC TU5V_PW, TU33V_PW

appear at #3, #5 Pin of Tuner?

Yes

4

2

Does the CVBS data appear at

#9 pin of Tuner?

Yes

Does the digital data appear at

Pin #19,20,34,35 (LVDS Data clk)

of LVDS connector?

Yes

No

No

No

No

No

Check a set

in the ‘Stand-by mode’.

Input the RF source properly.

Change the Main Assy

Check Tuner

Change the Main Assy

Check IC4010 (Saturn4)

Change the Main Assy

Check the LVDS cable?

Check the T-Con B’d?

Replace the LCD panel?

Caution Make sure to disconnect the power before working on the IP board.

No

4-10

Please, Contact Tech support

Page 29

4. Troubleshooting

TUNER

TOP

4-11

Page 30

4. Troubleshooting

WAVEFORMS

CVBS OUT (Grey Bar)

4

LVDS output

2

4-12

Page 31

4-1-6. No Video (Tuner DTV)

Symptom Audio is normal but no picture is displayed on the screen.-

Check the DTV source.

Major

checkpoints

-

Check the Tuner, Check the Chelsea.

-

This may happen when the LVDS cable connecting the Main Board and the Panel is disconnected.

-

4. Troubleshooting

Diagnostics

Power indicator LED is off.

Lamp(Backlight) on, no video

Yes

Check the connection of RF cable

Yes

Check the ‘signal strength’

in Self Diagnosis menu

Strength is enough?

Yes

Does the DC B5V_VCCT_PW,

B1.25VT_PW, B3.3V_PW

appear at #3, #15, #12 Pin of Tuner?

Yes

Does the digital data appear at

Pin #19,20,34,35 (LVDS Data clk)

2

of LVDS connector?

Yes

No

No

No

No

No

Check a set

in the ‘Stand-by mode’.

Input the RF cable properly.

Check the D-TV source.

Change the Main Assy

Check IC4010 (Saturn4)

Change the Main Assy

Check the LVDS cable?

Check the T-Con B’d?

Replace the LCD panel?

Caution Make sure to disconnect the power before working on the IP board.

No

Please, Contact Tech support

4-13

Page 32

4. Troubleshooting

TUNER

TOP

4-14

Page 33

WAVEFORMS

4. Troubleshooting

2

LVDS output

4-15

Page 34

4. Troubleshooting

4-1-7. No Video (Video CVBS)

Symptom Audio is normal but no picture is displayed on the screen.-

Check the Video CVBS source

Major

checkpoints

-

Check the Chelsea.

-

This may happen when the LVDS cable connecting the Main Board and the Panel is disconnected.

-

Power indicator LED is off.

Lamp(Backlight) on, no video?

Yes

Diagnostics

4

2

Caution Make sure to disconnect the power before working on the IP board.

Check the video source and

check the connection of video cable?

Yes

Does the CVBS data appear at

TP - 7045?

Yes

Does the digital data appear at

Pin #19,20,34,35 (LVDS Data clk)

of LVDS connector?

Yes

Check the LVDS cable?

Check the T-Con B’d?

Replace the LCD panel?

No

No

No

No

No

Check a set

in the ‘Stand-by mode’.

Input the video source properly.

Check CN7005

Change the Main Assy

Check IC4010 (Saturn4)

Change the Main Assy

Please, Contact Tech support

4-16

Page 35

4. Troubleshooting

Side-AV

AV2_CVBS

BOTTOM

4-17

Page 36

4. Troubleshooting

WAVEFORMS

CVBS OUT (Grey Bar)

4

LVDS output

2

4-18

Page 37

4-1-8. No Video (Component)

Symptom Audio is normal but no picture is displayed on the screen.-

Check the Component source

Major

checkpoints

-

Check the chelsea.

-

This may happen when the LVDS cable connecting the Main Board and the Panel is disconnected.

-

4. Troubleshooting

Diagnostics

Power indicator LED is off.

Lamp(Backlight) on, no video?

Yes

Check the component source and

check the connection of

component cables(Y,Pb,Pr)?

Yes

Does the component data appear at

5

2

TP - 5100, 5024, 5025

(Comp1 / Y, Pb, Pr)?

Yes

Does the digital data appear at

Pin #19,20,34,35 (LVDS Data clk)

of LVDS connector?

Yes

Check the LVDS cable?

Check the T-Con B’d?

Replace the LCD panel?

No

No

No

No

No

Check a set

in the ‘Stand-by mode’.

Input the component

source properly.

Check CN5003

Change the Main Assy

Check IC4010 (Saturn4)

Change the Main Assy

Please, Contact Tech support

Caution Make sure to disconnect the power before working on the IP board.

4-19

Page 38

4. Troubleshooting

COMPONEN T

YPbPr

BOTTOM

4-20

Page 39

WAVEFORMS

4. Troubleshooting

5

2

Compnent_Y (Gray scale) / Pb / Pr (Color bar)

LVDS output

4-21

Page 40

4. Troubleshooting

4-1-9. No Sound

Symptom Video is normal but there is no sound..-

Major

checkpoints

-

-

-

When the speaker connectors are disconnected or damaged.

When the sound processing part of the Main Board is not functioning.

Speaker defect..

Check the source and

check the connection of sound cable

(Comp/PC/DVI to HDMI).

Yes

No

Input the sound source properly.

Diagnostics

7

Caution Make sure to disconnect the power before working on the IP board.

Does the sound data appear at

CN5002(COMP), CN5011(PC, DVI),

CN7005(AV), JA3201_EU(SCART)?

Yes

Does the B12VS_PW

appear at TP2007~8?

Yes

Does the sound data appear at

TP - L-, L+, R-, R+?

Yes

Replace speaker

No

No

No

No

Check CN5002(COMP), CN5011

(PC, DVI), CN7005(AV), JA3201_

EU(SCART) Change the Main Assy

Change the Main Assy

Check IC4010 (Saturn4)

Check IC9002 (Sound AMP)

Change the Main Assy

Please, Contact Tech support

4-22

Page 41

4. Troubleshooting

Side-AV

SCART

PC audio

COMPONENT

BOTTOM

TOP

Sound AMP

Speaker out

4-23

Page 42

4. Troubleshooting

WAVEFORMS

I2C Data

6

Speaker out

7

4-24

Page 43

4-2. Alignments and Adjustments

4-2-1. General Alignment Instuction

Usually, a color LCD-TV needs only slight touch-up adjustment upon installation.

1.

Check the basic characteristics such as height, horizontal and vertical sync.

Use the specied test equipment or its equivalent.

2.

Correct impedance matching is essential.

3.

Avoid overload. Excessive signal from a sweep generator might overload the front-end

4.

of the TV. When inserting signal markers, do not allow the marker generator to distort test result.

Connect the TV only to an AC power source with voltage and frequency as specied on

5.

the backcover nameplate.

Do not attempt to connect or disconnect any wire while the TV is turned on. Make sure

6.

that the power cord is disconnected before replacing any parts.

To protect against shock hazard, use an isolation transformer.

7.

4. Troubleshooting

4-25

Page 44

4. Troubleshooting

4-3. Factory Mode Adjustments

4-3-1 Entering Factory Mode

To enter ‘Service Mode’ Press the remote -control keys in this sequence :

- If you do not have Factory remote - control

INFOPower OFF MENU MUTE

4-3-2 How to Access Service Mode

Using the Customer Remote

Turn the power off and set to stand-by mode

1.

Press the remote buttons in this order; POWER OFF- INFO - MENU - MUTE to turn the set on.

2.

The set turns on and enters service mode. This may take approximately 20 seconds.

3.

Press the Power button to exit and store data in memory.

4.

- If you fail to enter service mode, repeat steps 1 and 2 above.

Initial SERVICE MODE DISPLAY State

5.

OPTION

ADC/WB

Control

Advanced

Expert

T-CRLPEUC-XXXX

T-CRLPEUFC-XXXX

T-CRLPEUS-XXXX

DTP-LP-XXXX-XX

DTP-LP-App-XXXX-XX

OPTION : F100 00

ADC : HDMI X COMP X PC X AV X

EDID : SUCCESS

HDCP : SUCCESS

Current Flash : Flash X

Build Date : XX-XX-XXXX

Date Of Purchase : XX/XX/XX

* How to enter the hidden factory mode.

a. into the factory mode

b. move the tap to Advanced

c. key input : 0 + 0 + 0 + 0

** hidden menu : Advanced

6. Buttons operations withn Service Mode

Menu Full Menu Display/Move to Parent Menu

Direction Keys /

Direction Keys /

Source

Item Selection by Moving the Cursor

Data Increase / Decrease for the Selected Item

Cycles through the active input source that are connected to the unit

4-26

Page 45

4-3-3 Factory Data

4. Troubleshooting

OPTION

ADC/WB

Factory Name Data Range

Factory Reset

Type 32L6AF1C 19D6THOC, 19I6THOC… (PANEL, INCH)

Model LB530 LB530 / LB540 / LB550 / LB460 / LB360 / LB650 / LB530S

TUNER Auto Auto/Sem_SL/Alps_SL/Sem_TC

Region EU EU/ND/ASIA/CHN

DDR SAMSUNG SAMSUNG / Etron

Light Effect Off On / Off

CH Table SUWON SUWON, SESK…(Factory Channel Type)

Medialink Type

Local Set Others Others/Russia

PDP GROUP

Factory Name

ADC

ADC Tarhet

ADC RESULT

WB

ADC

ADC Target

Factory Name Data Range

AV Calibration

Comp Calibration

PC Calibration

HDMI Calibration

Factory Name Data Range

1st_AV_Low

1st_AV_High

1st_AV_Delta

1st_COMP_Low

1st_COMP_High

1st_COMP_Delta

1st_PC_Low

1st_PC_High

1st_PC_Delta

2nd_Low

2nd_High

2nd_Delta

Success

Success

Success

Success

18

220

1

16

235

1

2

235

1

1

235

1

Success / Failure

Success / Failure

Success / Failure

Success / Failure

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

4-27

Page 46

4. Troubleshooting

ADC RESULT

Factory Name

1st_AV_Gain

1st_AV_Offset

1st_Comp_Gain

1st_Comp_Gain_Cb

1st_Comp_Gain_Cr

1st_Comp_Offset

1st_Comp_Offset_Cb

1st_Comp_Offset_Cr

1st_PC_R_Gain

1st_PC_G_Gain

1st_PC_B_Gain

1st_PC_R_Offset

1st_PC_G_Offset

1st_PC_B_Offset

2nd_R_Offset

2nd_G_Offset

2nd_B_Offset

2nd_R_Gain

2nd_G_Gain

2nd_B_Gain

AV / RF Component

136

136

136

107

107

107

136

136

136

107

136

136

136

107

107

107

136

136

136

107

134

134

134

67

67

67

134

134

134

67

134

134

134

67

67

67

134

134

134

67

Mode

HDMI / DTV /

HDMI-PC

136

136

136

100

100

100

136

136

136

100

136

136

136

100

100

100

136

136

136

100

PC

192

192

192

32

32

32

192

192

192

32

192

192

192

32

32

32

192

192

192

32

Range

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

WB

Factory Name

Sub Brightness

R_Offset

G_Offset

B_Offset

Sub Contrast

R_Gain

G_Gain

B_Gain

Movie R Offset

Movie B Offset

Movie R Gain

Movie B Gain

Mode

AV Component HDMI / DTV PC

128

512

512

512

128

512

512

512

128

512

512

512

128

512

512

512

128

512

512

512

128

512

512

512

128

512

512

512

128

512

512

512

128

512

512

512

128

512

512

512

128

512

512

512

128

512

512

512

4-28

Page 47

4. Troubleshooting

Control

EDID

Factory Name

EDID

Sub Option

PDP Option

Hotel Option

Shop Option

Sound

Cong Option

Factory Name Data Range

EDID ON/OFF

EDID WRITE ALL

EDID WRITE PC

EDID WRITE DVI

EDID WRITE HDMI1

EDID WRITE HDMI2

EDID WRITE HDMI3

EDID WRITE HDMI4

EDID VERSION

Off

Success

Success

Success

Success

Success

Success

Failure

HDMI 1.3

Success / Failure

Success / Failure

Success / Failure

Success / Failure

Success / Failure

Success / Failure

Success / Failure

HDMI 1.2 / HDMI 1.3

On / Off

4-29

Page 48

4. Troubleshooting

Sub

Option

Factory Name Data Range

Mute Time(VIDEO)

ready

TTX LIST

TTX

TTX Group

Hotplug

Hotplugcontrol

Spread Spectrum

Auto Power

Arab

NT Conversion

Mirror

HDMI EQ1

HDMI EQ2

HDMI EQ3

HDMI EQ4

EER Count

WM Calib

Panel Enter Key

Panel Display Time

CHECKSUM

View Log

Font Data Viewer

Dimm Type

Gamma

Carrier Mute

Anynet+

HPD Polarity

High Devi

Volum Curve

HotPlug Delay

HP Ident

PC Ident

Info Live

Watchdog

LVDS Format

OSD Resolution

Bus Stop

OTA Code

Panel Auto Setting

OTA Duration Test

Alternate Del

4

Failure

FLOF

On

Lang OSD

On

On

On

Off

Off

Off

Middle

Middle

Middle

Middle

XHr

0x0000

INT_NEG

0.95

Off

On

Off

EU

9

Low

On

On

JEIDA

1920*1080

0 ~ 10

Success / Failure

FLOF / LIST

On / Off

Lang OSD/ W Europe/E Europe/Russia/Greek/Turkey/Arab/Farsi/ArabHbrw

On / Off

On / Off

On / Off

On / Off

On / Off

On / Off

Low / Middle / High / Strong

Low / Middle / High / Strong

Low / Middle / High / Strong

Low / Middle / High / Strong

INT / EXT / INT_NEG / INT_POS / EXT_NEG

Off / 0.85 / 0.88 / 0.90 / 0.93 / 0.95 / 0.98

On / Off

On / Off

On / Off

NT / EU / EA

0 ~ 63

Low / High

On / Off

On / Off

JEDIA / VESA

4-30

Page 49

Spread Spectrum

Factory Name Data Range

Spread Spectrum

Step1

Step2

Range1

Range2

DDR Spread

On

149

0

215

0

2% Spread

On / Off

0~255

0~3

0~255

0~4

Off / 1% Spread / 2% Spread

4. Troubleshooting

PDP Option

Hotel Option

Factory Name Data Range

PIXEL SHIFT TEST

LOGIC CONNECT

PATTERN SELECT

PANEL VERSION

PANEL INCH

PANEL TYPE

PANEL TEMPERATURE

LOGIC SW VERSION

LOGIC SW CHECKSUM

SAPC_Timer

APC_Speed

LOGIC USB D/L

Factory Name Data Range

Hotel Mode

Power On Channel

Power On Source

Power On Volume

Min Volume

Max Volume

Panel Button Lock

Pic Menu Lock

Music Mode (AV)

Music Mode (PC)

Music Mode (Comp)

Music Mode Backlight

Menu Display

Power On Option

Ch Remap On/Off

Program Ch

Original Ch/Src

Auto PC

Energy Saving

Cloning : TV to USB

Cloning : USB to TV

Welcome Message

Off

Off

0

On

Slow

Failure

Off

3

TV

10

0

100

Off

Off

Off

Off

Off

Off

On

Last Option

Off

Off

On / off

On / off

0 ~ 31

On / off

Slow / Fast

Not Match / Match / Failure

TV / S-Video / Comp1 / PC / HDMI1 / HDMI2 / HDMI4

Standby / Power On / Last Option

Off / Low / Mid / High / Auto

On / Off

On / Off

On / Off

On / Off

On / Off

On / Off

On / Off

On / Off

On / Off

4-31

Page 50

4. Troubleshooting

Shop Option

Sound

Factory Name Data Range

Shop Mode

USB DEMO ON (SEC)

USB DEMO OFF (SEC)

Factory Name Data Range

FM Prescale

AM Prescale

Nicam Prescale

A2 M2S Threshold

A2 S2M Threshold

A2 PilotPhaseOn

A2 PilotPhaseOff

A2 Identon

A2 Identoff

A2 Carr1AmpOnThr

A2 Carr1AmpOffThr

A2 Carrier1SNRonThr

A2 Carrier1SNRoffThr

A2 Carr2AmpOnThr

A2 Carr2AmpOffThr

A2 Carrier2SNRonThr

A2 Carrier2SNRoffThr

Nicam Sig Error On

Nicam Sig Error Off

Compression mode

Dolby Test Mode

DTV Level

Master Vol

PWM Modulation

DRC1 Threshold

DRC2 Threshold

Speaker EQ

SC1 Vol

SC2 Vol

Audio Delay

SUB AMP Master Vol

SUB AMP PWM Mod

SUB DRC Thresh

SUB Speaker EQ

Off On / Off

68

49

72

0x02

0x01

0x10

0x1E

0x02

0x00

0x04

0x02

0x15

0x7F

0x08

0x03

0x10

0x18

0x23

0x3F

RF

off

-12dB

32

254

0x35

0x23

On

16

16

60

Cong Option

4-32

Factory Name Data Range

Number of AV

Number of SVIDEO

Number of COMP

Number of HDMI

Number of SCART

DVI Sound

Headphone

Number of USB PORT

LNA SUPPORT

MFT OFFSET

1

0

1

3

1

0

0

off

0 ~ 2

0 ~ 1

0 ~ 2

0 ~ 4

0 ~ 2

0 ~ 1

0 ~ 1

On / Off

Page 51

4. Troubleshooting

Advanced

WB

Movie

Factory Name

FBE

WB Movie

EPA Standard

ADJUST

YC_Delay

SHARPNESS

PE

PQ Others

Color Space

EEPROM RESET

Factory Name Data Range

WB Movie

Color Mode

Color Tone

Msub Brigh

Msub Contr

W1_RGAIN

W1_BGAIN

W1_ROFFS

W1_BOFFS

W2_RGAIN

W2_BGAIN

W2_ROFFS

W2_BOFFS

N_RGAIN

N_BGAIN

N_ROFFS

N_BOFFS

Movie Contr

Movie Brigh

Movie Color

Movie Sharp

Movie Tint

Movie BkLight

M.Gamma

M_Sub Gamma

Off

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

---

On / Off

Dynamic / Standard / Movie

Cool / Normal / Warm1 / Warm2

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

3 ~ 100

2 ~ 100

1 ~ 100

0 ~ 100

0 ~ 50

0 ~ 10

Off / 0.85 / 0.88 / 0.90 / 0.93 / 0.95 / 0.98 / M1 / M2 / M3 / M4

-3 ~ +3

4-33

Page 52

4. Troubleshooting

EPA Standard

ADJUST

Factory Name Data Range

Std Contr

Std Bright

Std Sharp

Std Color

Std Tint

Std Backlight

Factory Name Data Range

Dynamic Dimming

LNA Plus

Power Key Protect

Uart Select

Debug Mode

Back End Mute

PDP FRC

Visual Test

Standby Mode Time

Delete alt.ver

OTA conrm Time

OTA limit Time

Dynamic CE

FWC

1080p 48Hz

PWM Max

Quick Start

DTV LNA

HDCP Download

Test Pattern

Off

Off

Auto Wall

Debug Off

Disable

45 Min

2 Flash

90 Min

3 Hour

Off

Off

On

100

Auto

On

Off

95

45

50

50

50

8

Debug Off / Debug Smart / Debug RunTime

0 ~ 100

0 ~ 100

0 ~ 100

0 ~ 100

0 ~ 100

0 ~ 10

On / Off

On / Off

Auto Wall / Debug / MDC / On1 / On2

Disable / Enable

2 Min / 45 Min

2 Min / 90 Min

3 Min / 3 Hour

On / Off

On / Off

On / Off

1 ~ 100

Auto / On / Off

On / Off

Off / 1 ~ 13

LNA Plus

YC_Delay

Factory Name Data Range

RF dB1 Level

RF dB2 Level

RF dB3 Level

RF dB4 Level

Factory Name Data Range

PAL BG

PAL DK

PAL I

SECAM BG

SECAM DK

SECAM L

NTSC 358

NTSC 443

AV PAL

AV SECAM

AV NT358

AV NT443

AV PAL60

1

1

1

4

4

5

1

1

1

5

1

1

1

4

6

8

14

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 255

0 ~ 3

0 ~ 3

0 ~ 3

0 ~ 7

0 ~ 7

0 ~ 7

0 ~ 3

0 ~ 3

0 ~ 3

0 ~ 7

0 ~ 3

0 ~ 3

0 ~ 3

4-34

Page 53

4. Troubleshooting

SHARPNESS

SHARPNESS

Factory

Name

H1 Gain

H2 Gain

H3 Gain

H4 Gain

V1 Gain

V2 Gain

H overshoot

V overshoot

H undershoot

V undershoot

Coring TH2

Coring TH1

Comp/HDMI/

DTV 720p

20

8

8

8

20

8

FF

20

FF

20

1

1

Data

Data Range component HDMI DTV

RF CVBS SD

25

12

10

8

20

12

20

20

20

20

1

1

Data

25

12

10

8

20

12

20

20

20

20

1

1

PC / HDMI

PC

8

8

8

8

8

8

0

0

0

0

0

0

25

12

C

20

12

20

20

20

20

8

1

1

HD

(720p)

20

8

8

8

20

8

FF

20

FF

20

1

1

Range

0 ~ 3F

0 ~ 3F

0 ~ 3F

0 ~ 3F

0 ~ 3F

0 ~ 3F

0 ~ FF

0 ~ FF

0 ~ FF

0 ~ FF

0 ~ F

0 ~ F

SD

25

12

8

8

20

12

20

20

20

20

1

1

HD

(720p)

20

8

8

8

20

8

FF

20

FF

20

1

1

SD

25

12

C

8

20

12

20

20

20

20

1

1

HD

(720p)

20

8

8

8

20

8

FF

20

FF

20

1

1

PE

Factory Name

Skin x

Skin y

B_slope

DLC_ML

DLC_MH

DLC_H

Skin_SAT

Skin_HUE

M_Skin_HUE

M_Skin_x

M_Skin_y

Mid_color_level

M_Mid_color_level

RF CVBS

0

0

A0

60

70

EB

0

40

40

0

0

180

180

0

0

A0

60

70

EB

0

40

40

0

0

180

180

Data

component

SD HD

0

0

A0

60

70

EB

0

40

40

0

0

180

180

0

0

A0

60

70

EB

0

40

40

0

0

180

180

HDMI DTV

0

0

A0

60

70

EB

0

40

40

0

0

180

180

0

0

A0

60

70

EB

0

40

40

0

0

180

180

PC /

HDMI PC

0

0

80

60

70

EB

0

0

0

0

0

180

180

Range

0 ~ 11

0 ~ 11

80~FF

0~FF

0~FF

0~FF

0~F

0~7F

0~7F

0 ~ 11

0 ~ 11

0 ~ 255

0 ~ 255

4-35

Page 54

4. Troubleshooting

PQ Others

Color

Space

Factory

Name

Red Sat

Red Hue

Green Sat

Green Hue

Blue Sat

Blue Hue

Cyan Sat

Cyan Hue

Magenta Sat

Magenta Hue

Yellow Sat

Yellow Hue

FWC CB

FWC CR

Factory Name Data Range

7.5 IRE NTSC

7.5 IRE

4

7

A

A

4

2

Comp SD

HDMI SD

DTV SD

4

40

7

7F

A

50

A

50

4

40

2

40

15

15

RF

AV

Native Native Native Auto Auto Auto -

40

7F

50

50

40

40

15

15

Off

16

COMP HD

HDMI HD

DTV HD

4

40

7

7F

A

50

A

50

4

40

2

40

15

15

RF

AV

0

40

0

40

0

40

0

40

0

40

0

40

15

15

On / Off

0 ~ 60

Comp SD

HDMI SD

DTV SD

0

40

0

40

0

40

0

40

0

40

0

40

15

15

COMP HD

HDMI HD

DTV HD

0

40

0

40

0

40

0

40

0

40

0

40

15

15

PC/

HDMI PCRange

Color

Space

0

40

0

40

0

40

0

40

0

40

0

40

15

15

0~F

0~7F

0~F

0~7F

0~F

0~7F

0~F

0~7F

0~F

0~7F

0~F

0~7F

0~30

0~30

EEPROM RESET Factory Name Data

EEPROM RESET Enter - Set off

NVR All Clear Off/On

Tuner Status

(Read Only)

SNR

BER

Signal Strength

Frequency

LNA Status

BandWidth

FFT

Modulation

Code Rate

Gl

Hier Modulation

Frequency Offset

Timing Offset

AGC

UCB

PLL Type

DEMOD Type

TPS Lock

RS Lock

4-36

Page 55

4-4. White Balance - Calibration

4-4-1 White Balance -Calibration

4. Troubleshooting

1. Calibration

AV Calibration

Comp Calibration

PC Calibration

HDMI Calibration

4-4-2 White Balance - Adjustment

(low light) (hight light)

3. W/B

Sub Bright

R offset

G offset

B offset

Sub Contrast

R gain

G gain

B gain

(W/B adjustment Condition refer next page)

4-5. White Ratio (Balance) Adjustment

You can adjust the white ratio in factory mode (1:Calibration, 3:White-Balance).

1.

Since the adjustment value and the data value vary depending on the input source, you have to

2.

adjust these in CVBS, Component 1 and HDMI 1 modes.

The optimal values for each mode are congured by default. (Refer to Table 1, 2)

3.

It varies with Panel’s size and Specication.

- Equipment : CS-210

- Pattern: MIK K-7256 #92 “Flat W/B Pattern” as standard

- Use other equipment only after comparing the result with

that of the Master equipment.

- Set Aging time : 60min

- Calibration and Manual setting for WB adjustment.

HDMI : Calibration at #24 Chessboard Pattern Manual adjustment #92 pattern (720p)

COMP: Calibration at #24 Chessboard Pattern Manual adjustment at #92 pattern (720p)

CVBS: Calibration at #24 Chessboard Pattern Manual adjustment at #92 pattern (PAL)

- If nishing in HDMI mode, adjustment coordinate is almost same in AV/COMP mode.

- White Balance Manual Adjustment

4-37

Page 56

4. Troubleshooting

P-Mode

CVBS

(PAL)

COMP

(720P)

HDMI

(720P)

x y Y (Luminance) T(K) + MPCD

H/L 272 278

L/L 272 278

H/L 272 278

L/L 272 278

H/L 272 278

L/L 272 278

Adjustment Coordinate

-

(Sub_CT:130)

12.6cd/m

(Sub_CT:130)

13.0cd/m

(Sub_CT:130)

13.0cd/m

2

(3.7 Ft)

-

2

(3.8 Ft)

-

2

(3.8 Ft)

12,000 (±0)

12,000 (±0)

12,000 (±0)

12,000 (±0)

12,000 (±0)

12,000 (±0)

- Adjustment Specication

White Balance : High light (±1), Low light (±3)

Luminance : High light (Don’t care), Low light (±0.2 Ft/L)

4-6. Servicing Information

4-6-1 USB Download Method

Samsung may offer upgrades for TV’s rmware in the future. Please contact the Samsung call center at 1-800-

SAMSUNG (726-7864) to receive information about downloading upgrades and using a USB drive. Upgrades will be

possible by connecting a USB drive to the USB port located on your TV.

Insert a USB drive containing the rmware upgrade into the

1.

USB port on the rear of the TV.

Press the MENU button to display the menu.

2.

Press the or button to select “Support”, then press the

ENTER button.

Press the or button to select “SW Upgrade”, then press

3.

the ENTER button.

The message “Scanning for USB. It may take up to 30

seconds.” is displayed.

The message “Upgrade version XXXX to version XXXX?

4.

The system will be reset after upgrade.” is displayed.

Press the or to select the “OK”, then press the ENTER

button.

Please be careful to not disconnect the power or remove the

USB drive while upgrades are being applied. The TV will turn off

and turn on automatically after completing the rmware upgrade.

Please check the rmware version after the upgrades are

complete. When software is upgraded, video and audio settings

you have made will return to their default (factory) settings.

We recommend you write down your settings so that you can

easily reset them after the upgrade.

4-38

Page 57

4-7. S/W UPDATE MANUAL (use ISP TOOL & JIG)

Order Description

Connect Mstar JIG to the TV Set with

1

D-SUB cable.

Enter the factory mode and Check the

2

Flash of current S/W.

4. Troubleshooting

Open the Flash Downloader.

3

(ISP TOOL)

Select the ‘Read’ Tab and Choose the

4

S/W. (merge.bin)

4-39

Page 58

4. Troubleshooting

Order Description

Select the ‘Connect’ Tab and Check

5

the Device Type Message.

Select the ‘Device’ Tab and

6

Check ‘WP Pin pull to high during

ISP’.

Select the ‘Auto’ Tab and Check

‘Multi Flashes’. After you can see the

7

“SpiFlash_X” menu. Check the same

Flash no. that Current Flash

on factory menu.

8 Check all process and push ‘Run’.

4-40

Page 59

Order Description

Check the Verify OK,

9

and ‘PASS’ message.

4. Troubleshooting

10

Select the ‘Dis Con’ Tab

And disconnect the JIG.

4-41

Page 60

4. Troubleshooting

4-8. Mechanical diagram

Set Size

(With stand)

Set Size

(W/O stand)

Opening Size 699 x 393.8

USA

Packing Size

ETC

Net(Set) Weight

(With Stand)

Net(Set) Weight

(W/O Stand)

Gross Weight

(After Packing)

USA -

EUR 12.86

USA -

EUR 10.88

USA -

EUR 16.7

KOR -

801.0*220.2*562.5

801.0*87.7*518.1

905*615*200KOR

4-42

Page 61

5. Exploded View & Part List

T0003

M0027

M0013

M0115

T0764

T0522

M0014

M0254

M0107

M0215

T0447

5-1. LE32B53*P7N Exploded View

5. Exploded View & Part List

5-1

Page 62

5. Exploded View & Part List

5-1-1. LE32B53*P7N Parts List

Location No. Code No. Description & Specication Q’ty S.A/S.N.A Remark

T0003 BN96-09658R ASSY COVER P-FRONT;LB530 32,EO(08),ABS+P 1 S.A

M0013 BN96-06947G ASSY COVER P-REAR;LB530 32,EO(08),HIPS,H 1 S.A

M0215

T0447 BN96-04681G ASSY BRACKET P-PANEL;-,32R81,-,-,-,-,CMO 1 S.N.A

M0014 BN94-02665A ASSY PCB MAIN;PN58B850Y1FXZA 1 S.A

M0107 BN63-03039A SHIELD-COVER;MURANO40,PCM,T0.5,IDTV 1 S.A

T0764

M0254 BN61-05651A HOLDER-SIDE AV;08’ PANEL,HIPS,BK500,HB, 1 S.N.A

T0522 BN96-06818B ASSY SPEAKER P-ASSY SPEAKER P;8ohm,CORAL 1 S.A

M0115 BN61-03706A BRACKET-STAND LINK;BRACKET-STAND-LINK 32 1 S.N.A

M0027 BN96-09131A ASSY STAND P-BASE;LB530 32,ABS+PMMA,HB,B 1 S.A

BN07-00512A

BN07-00574A

BN44-00216A

BN44-00234A

LCD-PANEL;T315HW01 V0

LCD-PANEL; LTF320HA03

SMPS-LCDTV;MK37P5T,SEM,AC/DC,171W,AC100~

SMPS-LCD TV;MK37P6,DYREL

1 S.A

1 S.A

5-2

Page 63

5. Exploded View & Part List

5-2. LE32B53*P7N Parts List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

LE32B530P7NXXC LE32B530P7N,N65E/32AP7-G5P,32,LCD-TV,SPA

0.1 M0002 BN90-01550H ASSY COVER REAR;LB530 32(08) 1 S.N.A

..2 T0081 6002-001294 SCREW-TAPPING;BH,+,,M4,L16,ZPC(BLK) 1 S.N.A

..2 T0081 6002-001294 SCREW-TAPPING;BH,+,,M4,L16,ZPC(BLK) 11 S.N.A

..2 T0081 6002-001294 SCREW-TAPPING;BH,+,,M4,L16,ZPC(BLK) 1 S.N.A

..2 M0013 BN96-06947G ASSY COVER P-REAR;LB530 32,EO(08),HIPS,H 1 S.A

...3 BR/WALL+C/ 6003-001188 SCREW-TAPTYPE;BH,+,-,B,M4,L10,ZPC(WHT),S 4 S.N.A

...3 T0101 BN61-03348A BRACKET-WALL;LCD TV 32,SECC T1.2 4 S.N.A

...3 M0006 BN63-04366F COVER-REAR;L530 32,EO,HIPS,HB,BK500 1 S.N.A

...3 T0071 BN64-01134A INLAY-TERMINAL;LA530,EO,PS SHEET,T0.5,BL 1 S.N.A

0.1 M0001 BN90-01949K ASSY COVER FRONT;LB530 32 1 S.N.A

..2 T0522 BN96-06818B ASSY SPEAKER P-ASSY SPEAKER P;8ohm,CORAL 1 S.A

..2 T0003 BN96-09658R ASSY COVER P-FRONT;LB530 32,EO(08),ABS+P 1 S.A

...3 IR-PCB+H/B 6003-001188 SCREW-TAPTYPE;BH,+,-,B,M4,L10,ZPC(WHT),S 1 S.N.A

...3 K/C+C/F 6003-001188 SCREW-TAPTYPE;BH,+,-,B,M4,L10,ZPC(WHT),S 2 S.N.A

...3 T0069 AA60-00091J SPACER-FELT;FELT,330X10,BLK,T0.5 2 S.N.A

...3 T0069 AA60-00091N SPACER-FELT;FELT,70X10,BLK,T1.0 1 S.N.A

...3 T0069 AA60-00171Q SPACER-FELT;56L3,FELT,690,T0.35,8 2 S.N.A

...3 BN61-04692A BOSS-PRIMER;#94,clear,35cps 0.58 S.N.A

...3 BN63-01925A FELT-VIBRATION;42D5,FELT,T0.35,10,370 2 S.N.A

...3 CCM1 BN63-02183F COVER-SHEET;Rhcm,PE Vinyl,T0.05,900mm,20 2.1 S.N.A

...3 M0112 BN63-04364H COVER-FRONT;LB530 32,EO,ABS+PMMA,HB,BK23 1 S.N.A

...3 CCM1 BN63-04755A COVER-SHEET;AMBER,PE,T0.05,W150mm,200M,6 3 S.N.A

...3 T0059 BN64-00379A INDICATOR LED;ROME-II,23,PC,CLEAR 1 S.N.A

...3 T0061 BN64-00453A WINDOW-REMOCON;32R71,PC,VIOLET 1 S.N.A

...3 T0022 BN64-00755A KNOB-CONTROL;32L450,ABS,V0,BK07 1 S.N.A

...3 BN64-00991B DECORATION-BOTTOM;32,LB530,PC CLEAR,RED 1 S.N.A

...3 BN96-06930B ASSY HOLDER P-BOSS;32L530,HIPS,HB,BK500 1 S.N.A

....4 BN61-03261J BOSS-TAPE;Tulip,ACRYL,T1.1,W16.0mm,GRAY, 0.62 S.N.A

....4 BN61-03885B HOLDER-BOSS BOTTOM;32L530,HIPS,HB,BK500 1 S.N.A

....4 BN61-04692A BOSS-PRIMER;#94,clear,35cps 0.001 S.N.A

...3 M0145 BN96-07269A ASSY BOARD P-FUNCTION;LN40A450C1D,CT5000 1 S.A

...3 M0146 BN96-07270R ASSY BOARD P-POWER & IR;LE32A466C2MXZF,C 1 S.N.A

0.1 M0216 BN90-02228A ASSY STAND;LB530 32,UO(08) 1 S.N.A

..2 BN61-05213A GUIDE-STAND NECK;32,LB530,ABS+PMMA,HB 1 S.N.A

..2 M0027 BN96-09131A ASSY STAND P-BASE;LB530 32,ABS+PMMA,HB,B 1 S.A

...3 T0081 6002-001294 SCREW-TAPPING;BH,+,,M4,L16,ZPC(BLK) 4 S.N.A

...3 C/STANDBOT 6003-001239 SCREW-TAPTYPE;FH,+,B,M4,L10,ZPC(WHT),SWR 6 S.N.A

...3 BN61-02232A HOLDER-SWIVEL RING;32R71,ACETAL NATUAL,N 1 S.N.A

...3 BN61-02233A HOLDER-SWIVEL RING;32R71,ACETAL NATUAL,N 1 S.N.A

...3 BN61-02236A BRACKET-HINGE SWIVEL;BORDEAUX 32,SECC,T1 1 S.N.A

...3 BN61-03707A BRACKET-STAND BOTTOM;PEARL 32,SECC,T2.0 1 S.N.A

...3 BN61-03872A GUIDE-STAND BOTTOM;L450 32INCH,PC+GF(20% 1 S.N.A

....4 BN61-02932B BRACKET-STOPPER NUT;L450,M4,OD8,L24,MOLD 3 S.N.A

...3 CCM1 BN63-02183D COVER-SHEET;Rhcm,PE Vinyl,T0.05,680mm,20 0.4 S.N.A

5-3

Page 64

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

...3 T0004 BN63-05520A COVER-STAND BASE;32,LB530,ABS+PMMA,HB 1 S.N.A

...3 M0126 BN73-00052C RUBBER-FOOT;LCD TV,CR RUBBER,T2.0 DIA19, 6 S.N.A

..2 BN96-11175A ASSY COVER P-GUIDE STAND;LB530 32,UO(08) 1 S.N.A

...3 T0920 BN61-04993A GUIDE-STAND;32,LB530,PC+GF(20%) V0,BLK 1 S.N.A

0.1 BN91-01964R ASSY LCD-AUO;LE32A556P1CXXE,AUO 1 S.N.A

..2 M0215 BN07-00512A LCD-PANEL;T315HW01 V0 1 S.A

0.1 M0017 BN91-04302A ASSY CHASSIS;LE32B530P7NXXC 1 S.N.A

..2 M0014 BN94-02665A ASSY PCB MAIN;PN58B850Y1FXZA 1 S.N.A

...3 0202-001557 SOLDER-CREAM;LST57-A,D38-63,42SN/57BI/1A 11 S.N.A

...3 CN6004 3701-001388 CONNECTOR-HDMI;20P,Phosphor Bronze,ANGLE 1 S.A

...3 CN5001 3701-001480 CONNECTOR-DSUB;15P,3R,FEMAIL,STAMPED PIN 1 S.A

...3 CN906 3707-001081 CONNECTOR-OPTICAL;STRAIGHT,SPDIF 1 S.A

...3 CN1001_EU 3709-001551 CONNECTOR-CARD SLOT;68P,1.27mm,DIP,AU50U 1 S.A

...3 CN330 3711-004379 HEADER-BOARD TO CABLE;BOX,4P,1R,2mm,STRA 1 S.A

...3 CN330 3711-004531 HEADER-BOARD TO CABLE;BOX,10P,1R,2mm,ANG 1 S.A

...3 CN330 3711-006715 HEADER-BOARD TO CABLE;BOX,4P,1R,2.5mm,AN 1 S.N.A

...3 CN330 3711-006765 HEADER-BOARD TO CABLE;BOX,5P,1R,2mm,STRA 1 S.N.A

...3 CN330 3711-006766 HEADER-BOARD TO CABLE;BOX,24P,2R,2mm,STR 1 S.A

...3 JA3201_EU 3722-000498 JACK-SCART;21P,SN,BLK 1 S.A

...3 JA330 3722-001061 JACK-PHONE;1P,3.6PI,AG,BLK,N 1 S.A

...3 CN6001 3722-002516 JACK-USB;4P/1C,AU30U,BLK,STRAIGHT,A TYPE 1 S.A

...3 JA333 3722-002690 JACK-PIN;3P,Ni,RED/WHT/YEL,ANGLE 1 S.A

...3 JA333 3722-002691 JACK-PIN;2P,Ni,WHT/RED,STRAIGHT 1 S.A

...3 JA333 3722-002691 JACK-PIN;2P,Ni,WHT/RED,STRAIGHT 1 S.A

...3 JA333 3722-002703 JACK-PIN;3P,Ni,GRN/BLU/RED,STRAIGHT 1 S.A

...3 CIS3 BN40-00137A TUNER;DNOQ403SH151A(S),DNOQ403SH151A(S), 1 S.A

...3 X1005 BN61-04928A BRACKET-SUPPORT PCB;SPCC,T 0.8,SCREW-M4 1 S.N.A

...3 HDCP BN97-00688A ASSY HDCP;BN46-00018A,PS-42V6S,D73A,GENE 1 S.N.A

....4 BN46-00018A KEY CODE-CERTIFICATE;(HDCP KEY)PPM42M5S, 1 S.N.A

...3 T0174 BN97-03599A ASSY SMD;LE32B530P7NXXC 1 S.N.A

....4 SUB05 0202-001477 SOLDER-CREAM;LST309-M,D20~45um,96.5Sn/3A 1 S.N.A

....4 D2101 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3003_530 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D5002 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D5005 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D5010 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D6003 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D6009 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D6011 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D6025 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D6027 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D6630 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D7028 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D7030 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D7031 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D7032 0401-001056 DIODE-SWITCHING;MMBD4148SE,100V,200mA,SO 1 S.A

....4 D3100_530 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

....4 D6100 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

....4 D9001 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

5-4

Page 65

5. Exploded View & Part List

Level Location No. Code No. Description & Specication Q’ty SA/SNA Remark

....4 D9002 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

....4 D9004 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

....4 D9005 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

....4 D9006 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

....4 D9015 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

....4 D9016 0401-001099 DIODE-SWITCHING;1N4148WS,75V,150mA,SOD-3 1 S.N.A

....4 D2008 0402-001098 DIODE-RECTIFIER;SK34,40V,3A,SMC,TP 1 S.N.A