SAMSUNG FAXF700ATGXIL Service Manual

FACSIMILE

SF700AT

CONTENTS

1. Precautions

2. Specification

3. Operating Instructions

4. Disassembly and Reassembly

5. Circuit Description

6. Troubleshooting

7. Electrical Parts List

8. Exploded Views and Parts List

9. PCB Diagrams

10. Block Diagram

11. Wiring Diagram

12. Schematic Diagrams

FACSIMILE

SERVICE

Manual

Samsung Electronics Co.,Ltd. APR. 1998.

Printed in Korea.

JF68-60A

ELECTRONICS

7. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

provide could be lost if a replacement

component differs from the original. This

holds true, even though the replacement may

be rated for higher voltage, wattage, etc.

Components critical for safety are indicated in

the parts list with symbols . Use only

replacement components that have the same

ratings, especially for flame resistance and

dielectric specifications. A replacement part

that does not have the same safety

characteristics as the original may create

shock, fire, or other safety hazards.

SF700AT 1-1

1. Be sure that all built-in protective devices are

in place. Restore any missing protective

shields.

2. Make sure there are no cabinet openings

through which people- particularly childrenmight insert fingers or objects and contact

dangerous voltages.

3. When re-installing chassis and assemblies, be

sure to restore all protective devices, including

control knobs and compartment covers.

4. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of this equipment, such as

auxiliary connectors, etc. Such alterations and

modifications will void the manufacturer's

warranty.

5. Components, parts, and wiring that appear to

have overheated or are otherwise damaged

should be replaced with parts which meet the

original specifications. Always determine the

cause of damage or overheating, and correct

any potential hazards.

6. Observe the original lead dress, especially near

sharp edges, AC, and high voltage power

supplies. Always inspect for pinched, out-ofplace, or frayed wiring. Do not change the

spacing between components and the printed

circuit board.

1. Precautions

Follow these safety, ESD, and servicing precautions to prevent personal injury and equipment damage.

1-1 Safety Precautions

1-2 ESD Precautions

Certain semiconductor devices can be easily damaged by static electricity. Such components are commonly

called "Electrostatically Sensitive (ES) Devices", or ESDs. Examples of typical ESDs are: integrated circuits,

some field effect transistors, and semiconductor "chip" components.

The techniques outlined below should be followed to help reduce the incidence of component damage

caused by static electricity.

Precautions

1-2 SF700AT

CAUTION: Be sure no power is applied to the

chassis or circuit, and observe all other safety

precautions.

1. Immediately before handling a semiconductor

component or semiconductor-equipped

assembly, drain off any electrostatic charge on

your body by touching a known earth ground.

Alternatively, employ a commercially

available wrist strap device, which should be

removed for your personal safety reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly

equipped with ESDs, place the assembly on a

conductive surface, such as aluminum or

copper foil, or conductive foam, to prevent

electrostatic charge buildup in the vicinity of

the assembly.

3. Use only a grounded tip soldering iron to

solder or desolder ESDs.

4. Use only an "anti-static" solder removal device.

Some solder removal devices not classified as

"anti-static" can generate electrical charges

sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When

sprayed, these can generate electrical charges

sufficient to damage ESDs.

6. Do not remove a replacement ESD from its

protective packaging until immediately before

installing it. Most replacement ESDs are

packaged with all leads shorted together by

conductive foam, aluminum foil, or a

comparable conductive material.

7. Immediately before removing the protective

shorting material from the leads of a

replacement ESD, touch the protective material

to the chassis or circuit assembly into which

the device will be installed.

8. Maintain continuous electrical contact between

the ESD and the assembly into which it will be

installed, until completely plugged or soldered

into the circuit.

9. Minimize bodily motions when handling

unpackaged replacement ESDs. Normal

motions, such as the brushing together of

clothing fabric and lifting one's foot from a

carpeted floor, can generate static electricity

sufficient to damage an ESD.

1. Exercise caution when replacing a Lithium

battery. There could be a danger of explosion

and subsequent operator injury and/or

equipment damage if incorrectly installed.

2. Be sure to replace the battery with the same or

equivalent type recommended by the

manufacturer.

3. Lithium batteries contain toxic substances and

should not be opened, crushed, or burned for

disposal.

1-3 Lithium Battery Precautions

2. Specification

2-1 Transmitter

210 x 297 mm

257 x 1500 mm

148 x 180 mm

0.085 x 0.115 mm

B4 paper,2056 scan elements along 257 line length

A4 : 208 mm, B4 : 252 mm

Flat-bed scanning using CIS

Intermittent scanning by stepping motor

203 pels/in (8 dots/mm)

Super Fine 3.85 lines/mm

Fine 7.7 lines/mm

Standard 15.4 lines/mm

SF700AT 2-1

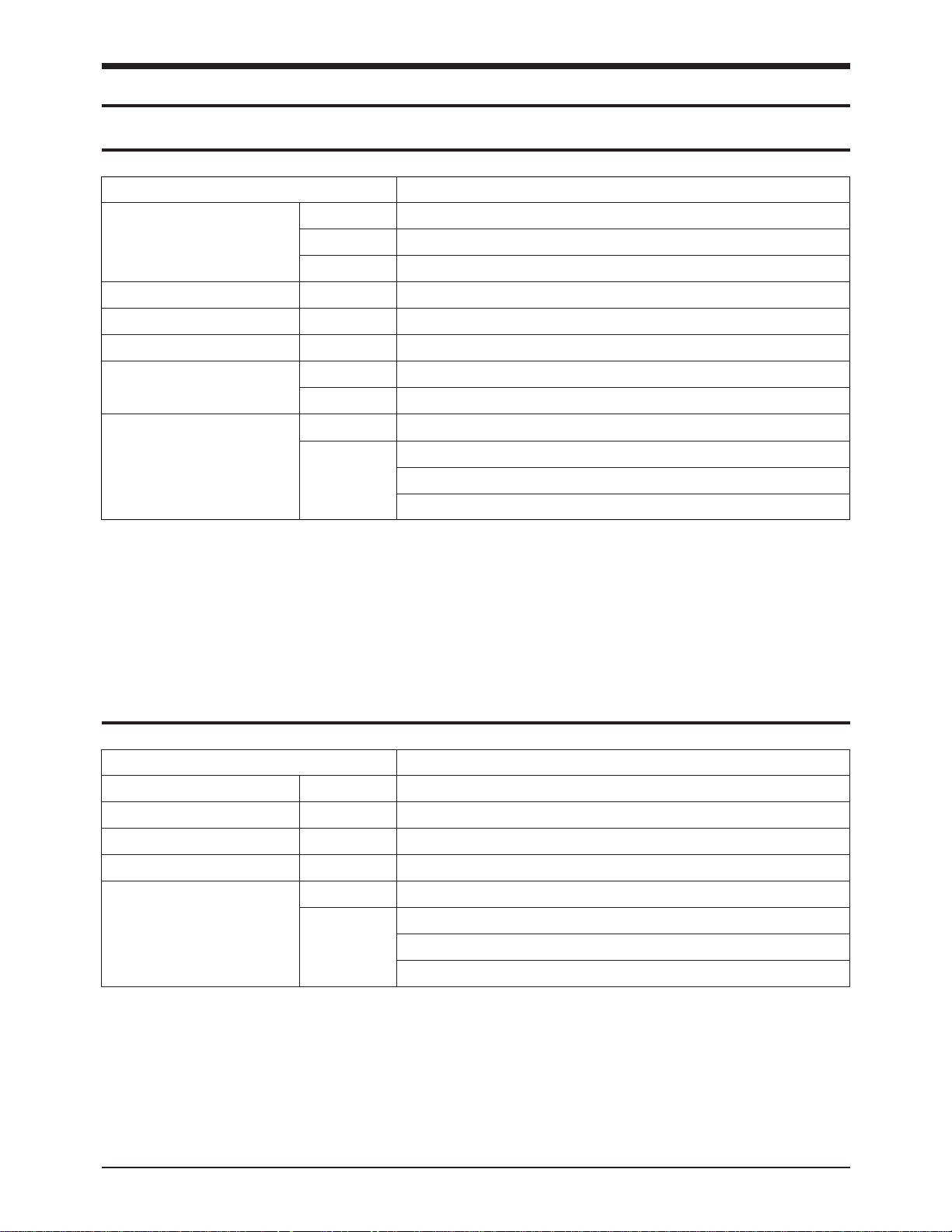

Parameter Specification

Normal

Max.

Min.

Horizontal

Vertical

Horizontal

Vertical

Document Size

Document Thickness

Scan Line Length

Effective Scanning Width

Scanning Method

Resolution

MH (Modified Huffman)

B4/A4 x 30 m, core 12.7 mm diametre

252 mm

Thermal recording with solid state Thermal Printing Head

203 pels/in (8 dots/mm)

Super Fine 3.85 lines/mm

Fine 7.7 lines/mm

Standard 15.4 lines/mm

Parameter Specification

Horizontal

Vertical

Coding Scheme

Recording Paper Size

Effective Recording Width

Recording Method

Resolution

2-2 Receiver

Specifications

2-2 SF700AT

Public Switched Telephone Network (PSTN)

Direct coupling

9600, 7200, 4800, 2400 bps

QAM, DPSK and FSK

(V.29, V.27ter with fall back function and V.21)

1700 Hz (9600/7200 bps)

1800 Hz (4800/2400 bps)

1100 Hz (CNG)

2100 Hz (CED)

300 bps (FSK)

0 dBm to -15 dBm +0.0/-3 dBm, adjustable 1 dB steps

0 dBm to -43 dBm

600 ohm +/- 30%

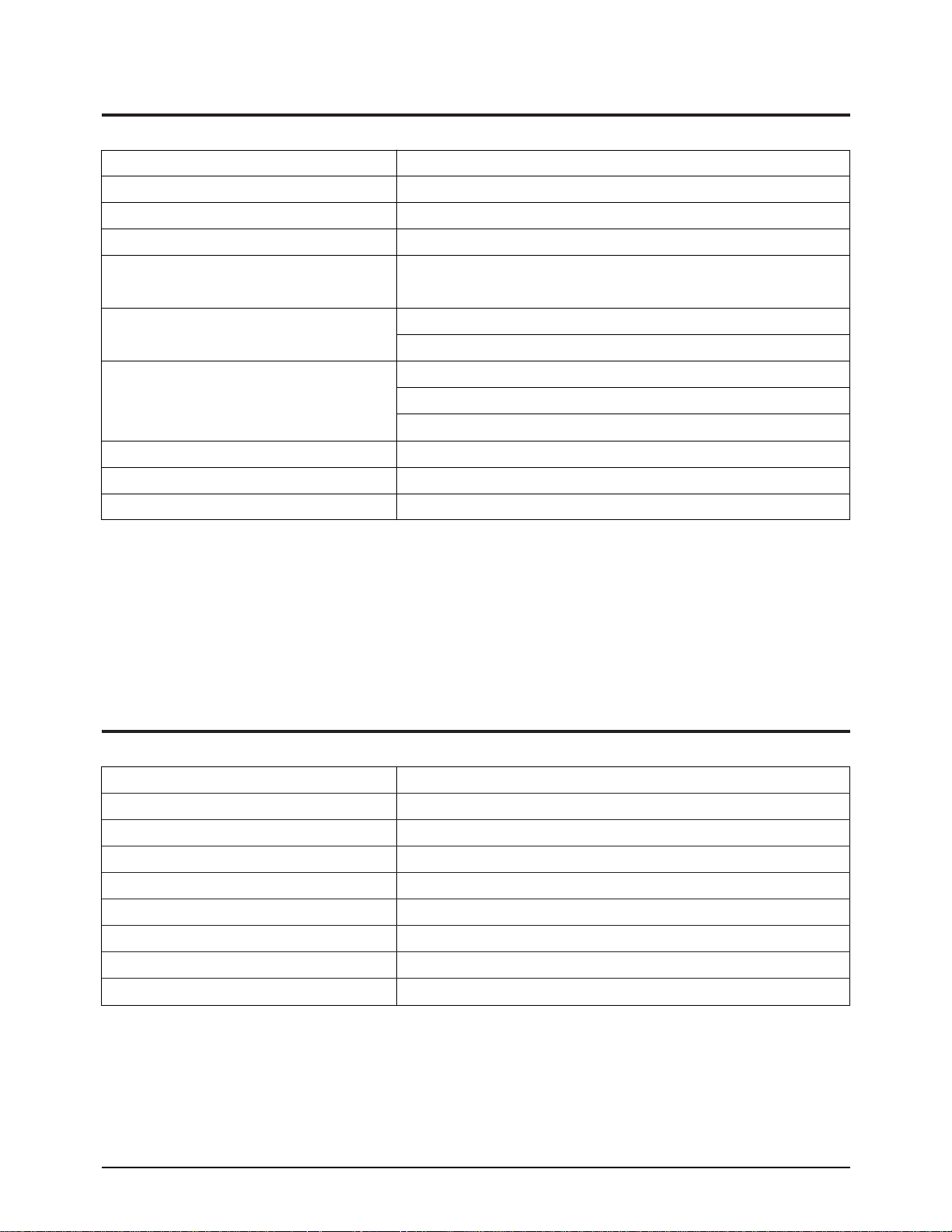

Parameter Specification

Communication Facility

Line Coupling

Transmission Speed

Modem

Carrier Frequency

Control Signal

Output Level

Input Sensitivity

Input & Output Impedance

2-3 Line Control Block

DP/DTMF

Direct dialing, Memory dialing, Redialing

10 memory dial (power on)

Check Power Label attached near the power outlet

50 to 95 °F (10 °C to 35 °C)

20 to 80 % RH (Non-Condensing)

305 X 116 X 243 mm

3.9 Kg

Parameter Specification

Dialling Signal

Dialling Method

Memory Capacity

Power Requirement

Temperature

Relative Humidity

Dimension

Weight

2-4 Others

SF700AT 3-1

3. Operating Instructions

3-1 How To Enter Service Mode

In service (Tech) mode, the technician can check the machine and perform various test to isolate the cause of

a malfunction.

To enter service mode, press MENU, #, 1, 9, 3, 4 in sequence, and 'TECH' will be displayed in the LCD to

confirm that the machine has entered service (tech) mode. While in service mode, the machine still performs

all normal operations. To return to normal user mode, press 'MENU, #, 1, 9, 3, 4' in sequence again, or turn

the power switch off, then on by plugging the power cord out, then in.

Options changed while in service mode do not remain changed, unless you first clear machine memory.

3-2 Changing Options

3-2-1 Selectable Options

GRAY SCALE LEVEL

Choose either 16 or 64 gray scale levels. The

selected level is also used in the photo sending

mode. If you select 64 levels, transmission time is

longer, however the result at the receiving end

will be superior. This mode works only when the

remote machine is capable of super-fine mode.

CONFIRMATION REPORT PRINTOUT

Select whether a confirmation report prints each

time a user sends a fax.

YES: The machine prints out the report

automatically after each fax sent.

ERROR : The machine prints a report only when

there is an error.

NO: The machine does not print the report

automatically. User can print the list on

demand.

RING BEFORE ANSWER

Select the number of rings the machine allows

before it answers a call in automatic receiving

mode.

PAPER CUTTING

Choose cutting or non-cutting mode.

Choose YES to cut the paper automatically after

each document received or copied.

Choose NO to print a tear line and not to cut the

paper.

FAX FORWARD

With this feature activated, the machine

automatically transfers incoming fax received in

the automatic receiveing mode to a specified

remote fax machine.

Choose YES to turn on this feature and enter the

remote fax number you want to be forwarded.

Choose NO to turn off the feature.

CALL TRANSFERRING

This feature allows the fax machine to transfer

incoming caller's message to a specified remote

location.

Choose YES to turn on this feature. The LCD

display asks to enter the telephone number you

want to be transferred.

Choose NO to turn off the feature.

Operating Instructions

3-2 SF700AT

CALL MONITORING

This feature enables you to hear callers leaving

messages on the machine.

Choose YES to turn on this feature.

Choose NO to turn off this feature.

TOLL SAVER

This feature lets the user dial into this machine

from a remote phone and check whether anyone

has left a message without being charged for a

charge call. When toll saver is on and there are

messages waiting to be heard, the machine

answers on the number of rings you specify in the

ring count option. If there are no messages, the

machine answers on the second ring after the

number specified. This gives the user time to hang

up the phone before the machine answers - and

saves the price of the call.

Choose YES to turn on this feature.

Choose NO to turn off this feature.

MESSAGE RECORDING TIME

You can select the maximum time allowed for

caller messages and memos.

If you choose YES, the LCD display shows you the

time limits available. Choose the proper time. If

you choose 0, it allows callers to hear the greeting

message but doesn't permit them to leave

messages.

REMOTE PASSWORD CODE

You can change the two-character password used

to access your machine from a remote phone. The

password is preset to "#19#" (pound one nine

pound) at the factory. The first and the last #'s are

fixed, but you can change the middle numbers

from 01 to 98. The machine doesn't accept double

character codes (11, 22, etc.) as passwords, because

line conditions can occasionally make the machine

fail to recognize a double digit code.

Enter the characters you want to use, then press

START.

BATTERY ALARM

You can turn on the battery alarm feature. With

this feature on, the machine displays the low

battery message in the LCD and sounds beeps to

alert you low battery condition.

Choose YES to turn on the battery alarm feature.

Choose NO to turn off the battery alarm feature.

SILENCE CHECK

In TAD mode, The machine decides the next

action when detected a silence of 10 seconds.

The actions are:

RCV: Swiches to receive mode.

RECORD: Keeps the recording the silence.

CUT: Disconnect the line and returns to standby

mode.

MODEM SPEED

Select baud rate of 9600, 7200, 4800, or 2400 bps.

The lower the baud rate, the larger the acceptable

error rate. T30 protocol has a fixed speed of 300

bps in the protocol mode. When the TX speed is

set to 9600 or 7200 bps, the RX speed will be either

V.29 or V.27 ter. When the TX speed is set to 4800

or 2400 bps, the RX speed will be V.27 ter.

MONITOR LINE

You can hear line signals through a tone speaker.

The volume is adjustable.

Choose YES to monitor the line signal.

Choose NO to turn off this feature. Speaker will be

active only for dialing, the starting part of the

phase B of CCITT, and key tones.

TRANSMISSION LEVEL

You can set the transmission level to between

0 and -15 dBm in 1 dB steps using the control

panel keypad.

Accuracy is + 0 /-3 dBm.

Operating Instructions

SF700AT 3-3

RECEPTION LEVEL

Reception level may be too low due to cable losses.

If set to -43 dBm, reception sensitivity will be

between 0 and -43 dBm.

If set to -48 dBm, reception sensitivity will be

between 5 and -48 dBm.

CABLE EQUALISER

Copper telephone wire attenuates low frequencies

less than high frequencies. The longer a cable is,

the more pronounced the effect. To compensate for

this attenuation you may need to set the machine

to match the cable length currently used. Select

short or long.

BUSY ON DROP OUT TIME

While checking busy on time, if any signal noise is

detected, the machine will ignore the signal noise

unless it is greater than a specified time.

BUSY OFF DROP OUT TIME

While checking busy off time, if any signal noise is

detected, the machine will ignore the signal noise

unless it is greater than a specified time.

FLASH TIME

This feature allows you to change the recall time.

BUSY TONE DETECTION LEVEL

While checking tone in ANS/FAX mode, If any

signal which is great than set level is detected for a

few seconds the machine will disconnect the line.

3-2-2 Changing Options

ress MENU, 3, START/COPY in sequence.

Press < or > to select the desired option item.

When the desired option item appears, press

START and use > or < to change the status of a

selected function.

3-4 SF700AT

3-3 Test Mode

Test mode is used to test machine functions. To enter test mode, press MENU, 0, START/COPY buttons in

sequence.

Operating Instructions

TPH TEST

You can print a TPH test pattern and check the

heating element of TPH with this test pattern.

MODEM TEST

The modem will send various transmit signals on

the telephone line. You can check the following:

¥ FSK test

¥ tones: 1100 Hz, 1650 Hz, 1850 Hz, 2100 Hz

¥ G3 training: 9600, 7200, 4800, 2400 bps

DTMF TEST

The machine tests its DTMF (Dual Tone Multi

Frequency). When you press any key on the

keypad, including and #, you will hear the

corresponding key tone.

LINE PATH TEST

Tests the telephone line loop.

ROM TEST

Tests machine ROM (Read Only Memory). The

result and the software version appear in the LCD

in the following format:

CHKSUM= XX, VXX, OK

MEMORY CLEAR

Erases contents of RAM. When memory is cleared,

the machine returns to default settings.

Operating Instructions

SF700AT 3-5

3-4 Report Printout

A number of useful reports can be printed in service mode. One of these lists is the protocol list, which

contains detailed information which may be required when contacting technical support. To print this list,

press MENU, 4, START/COPY in sequence.

When a report name appears in the display, scroll through the list of reports by pressing < or >. When a

desired report is selected, press START/COPY.

CONFIRMATION REPORT

Shows the last transmission result .

MEMORY INFORMATION REPORT

Shows a specific information on memory

transmission currently registered in memory.

VOICE STATUS REPORT

Shows the status of the recorded voice messages.

TRANSMISSION JOURNAL

Shows information about faxes sent.

RECEPTION JOURNAL

Shows information about faxes received.

TELEPHONE NUMBER LIST

Lists all numbers stored in the machine's onetouch and speed dialling memory.

SYSTEM DATA LIST

Shows all options that were set in user mode and

service mode.

PROTOCOL LIST

This list is available in the service mode only, and

shows the sequence of the CCITT group 3 T.30

protocol during the most recent TX or RX

operation. You can check for send and receive

errors with this list.

If a communication error occurs while the machine

is in service mode, the protocol list will print

automatically.

HELP LIST

This report illustrates the machine's basic

functions and commands. Use as a quick reference

guide.

Operating Instructions

3-6 SF700AT

3-5 LCD Display

3-5-1 During communication

In user mode, the LCD shows the remote

machine's TTI number, communication type,

(send or receive), and page number.

In service mode, the display shows the

communication type, abbreviations for the CCITT

Group 3 T.30 protocol as they occur, the protocol

type (G3), coding type (MH), baud rate in kbps,

and line time.

3-5-2 If a communication problem

occurs:

In user mode, the display shows one of the

following reasons: PAPER JAM, CUTTER JAM,

SEND ERROR, or RECEIVE ERROR.

In service mode, the display shows all error

messages available in user mode, as well as

additional error messages not available in user

mode.

Error messages shown in service mode only are as

follows:

PRE-MESSAGE ERROR:

problem occurred during phase B of session

MESSAGE ERROR:

problem occurred during phase C of session

POST-MESSAGE ERROR:

problem occurred during phase D of session

LINE ERROR:

machine cannot connect or has lost connection

with the remote machine

Additional messages, not shown above, will

appear in the transmission and reception journals

printed in service mode.

SF700AT 4-1

4. Disassembly and Reassembly

Note: Make sure power is OFF, and unplug the power cord from the wall outlet.

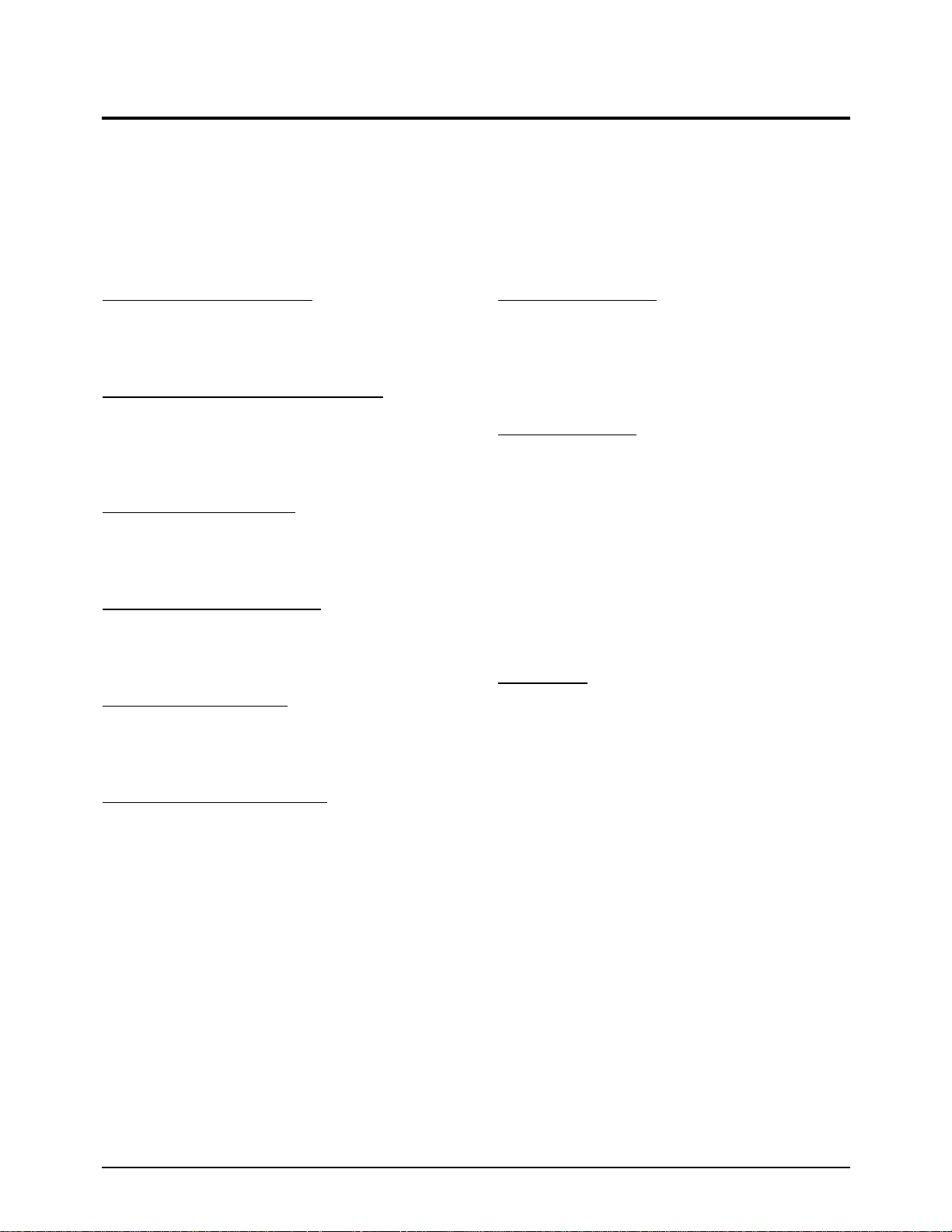

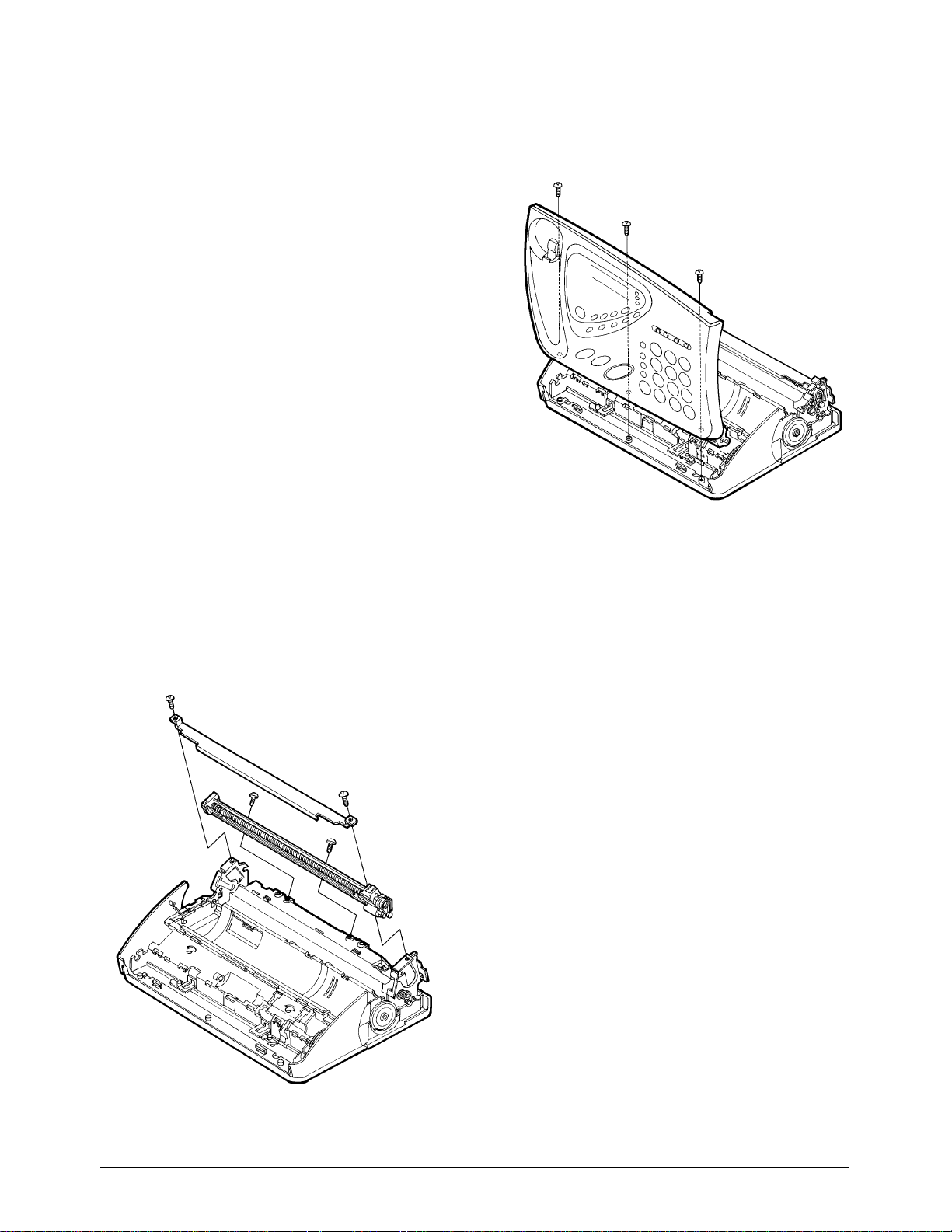

4-1 Main Chassis

4-2 Main PBA and LIU PBA

Figure 4-2

1. Disconnect the handset cord modular plug

from the machine.

2. Remove the the six screws.

3. Remove the Main Chassis.

1. Loosen the six screws fastening the base.

2. Unplug the connector from the PBAs

3. Remove the MAIN PBA and LIU PBA.

Figure 4-1

Disassembly and Reassembly

4-2 SF700AT

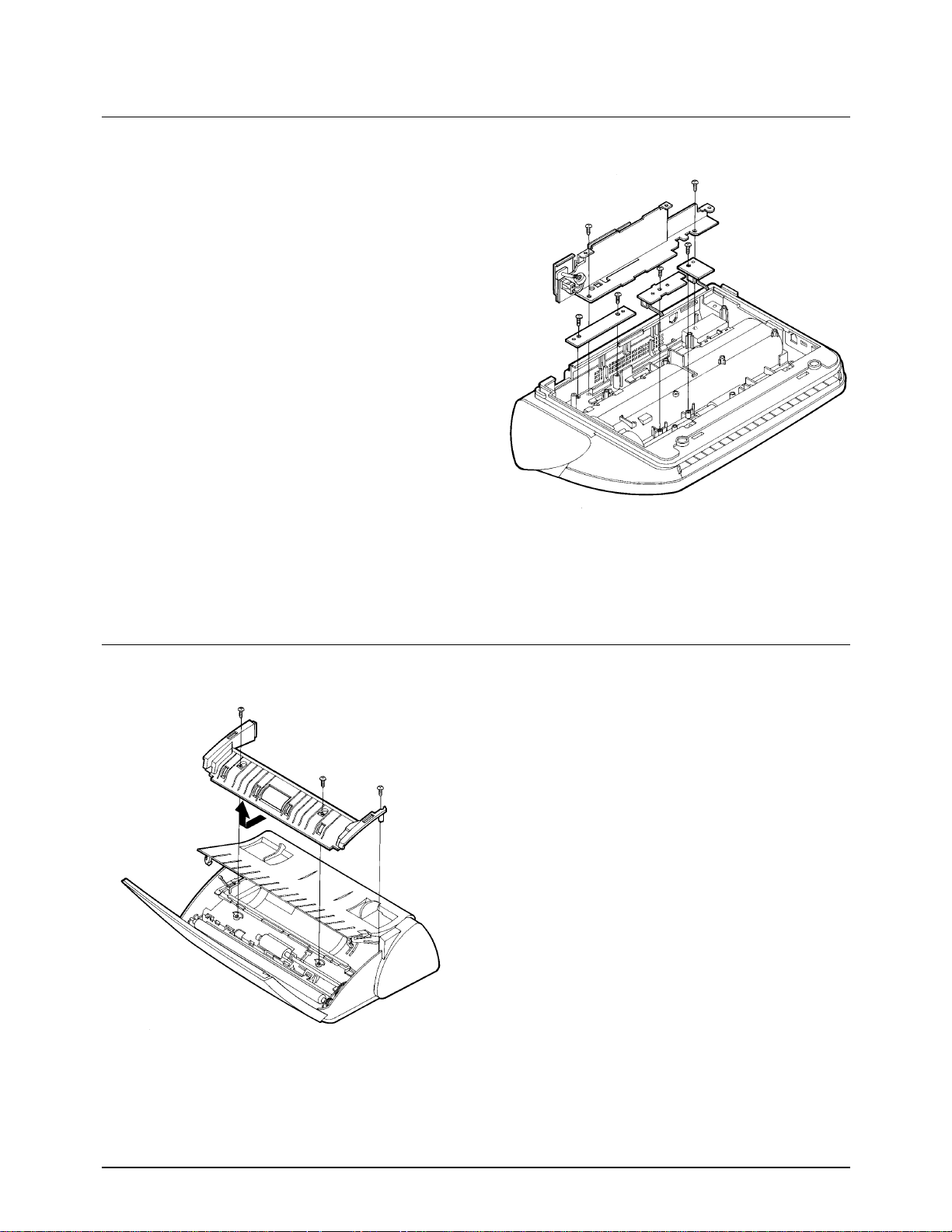

4-3 Sensor PBA & Power

4-4 Top Cover

Figure 4-4

1. Loosen the six screws fastening the base.

2. Remove the Sensor PBA and Power.

1. Open the operation panel and RX-Cover.

2. Loosen the three screws fastening the top

cover.

3. Lift the top cover carefully.

Figure 4-3

Disassembly and Reassembly

SF700AT 4-3

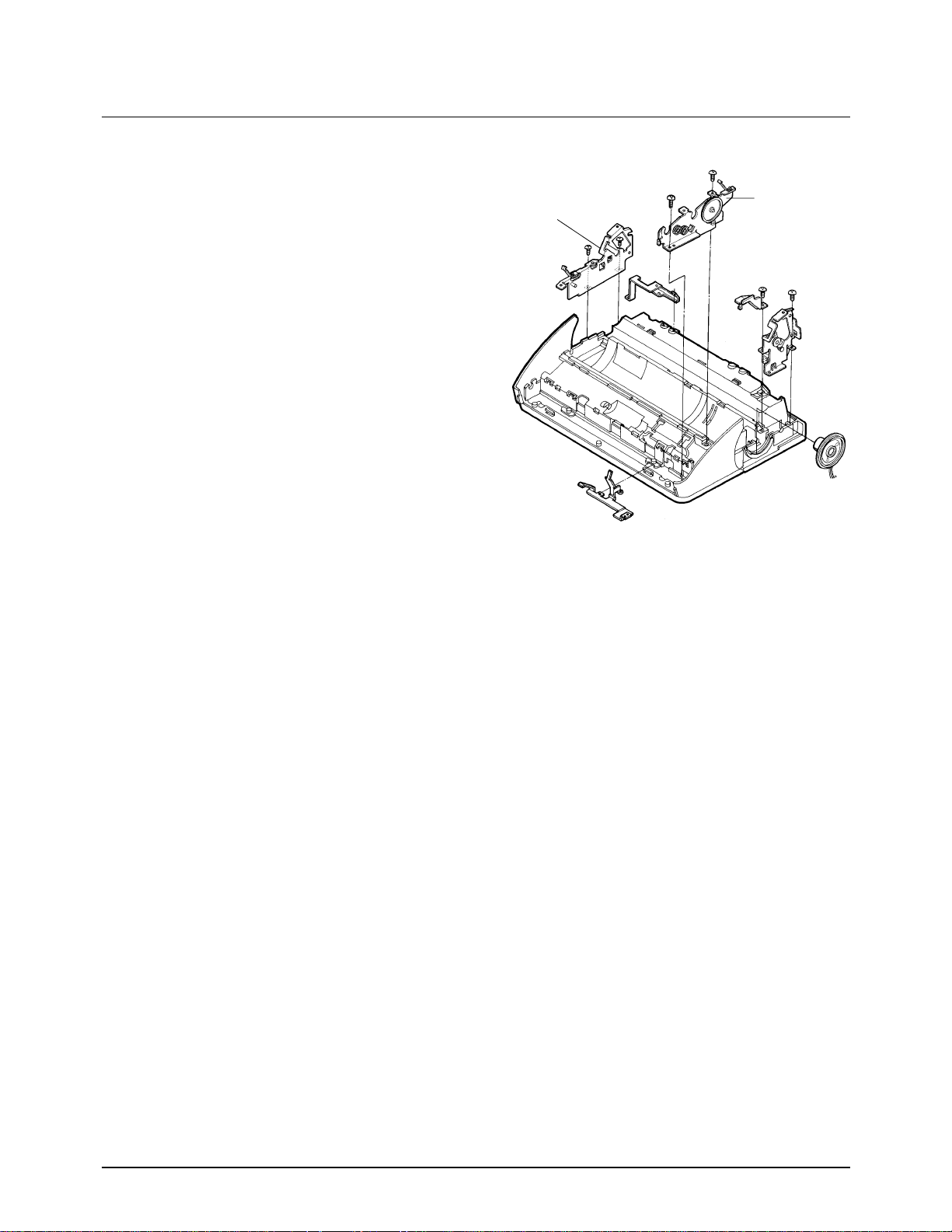

4-5 Rear Cover

4-6 RX Cover

Figure 4-6

1. Loosen the four screws fastening the rear cover.

2. Remove the Rear Cover.

1. Hold the wire spring as shown in figure 4-6.

1. Remove the bushing.

3. Lift RX cover assembly, while pulling in the

direction of arrow.

Figure 4-5

Disassembly and Reassembly

4-4 SF700AT

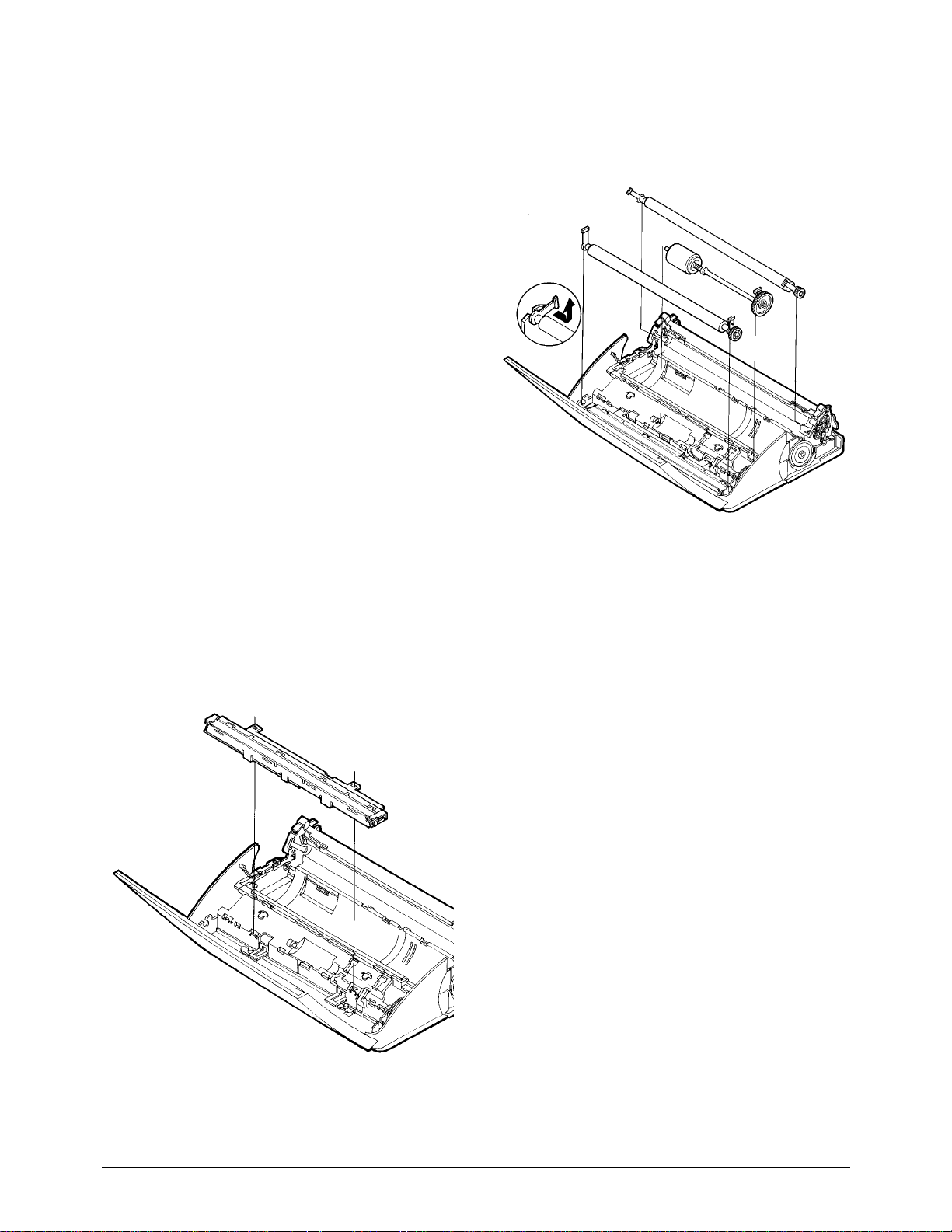

4-7 Rollers

4-8 CIS

Figure 4-8

1. Hold the bushing as shown in figure 4-7.

Remove the roller assembly from the bushing

with screwdriver.

2. Lift roller assembly, while pulling in the

direction of arrow.

1. Lift the CIS assembly.

2. Unplug the connector.

Figure 4-7

Disassembly and Reassembly

SF700AT 4-5

4-9 OPE Assembly

Figure 4-10

1. Loosen the three screws.

2. Lift the OPE assembly.

Figure 4-9

4-10 Cutter Assembly

1. Loosen the two screws fastening the Base.

2. Remove the cover cutter.

3. Loosen the two screws fastening the Base.

4. Lift the cutter.

Disassembly and Reassembly

4-6 SF700AT

Figure 4-11

4-11 TX, RX Motor

1. Loosen the two screws fastening the Base.

(Rx motor assÕy)

2. Loosen the two screws fastening the Base.

(Tx motor assÕy)

TX Motor assÕy

RX Motor assÕy

SF700AT 5-1

5. Circuit Description

5-1 General

The main circuit board consists of memory, MODEM, TX- and RX-related circuitry, Speakerphone, TAD,

and the Integrated Facsimile Controller (IFC), which includes the CPU and I/O device drivers and controls

the system.

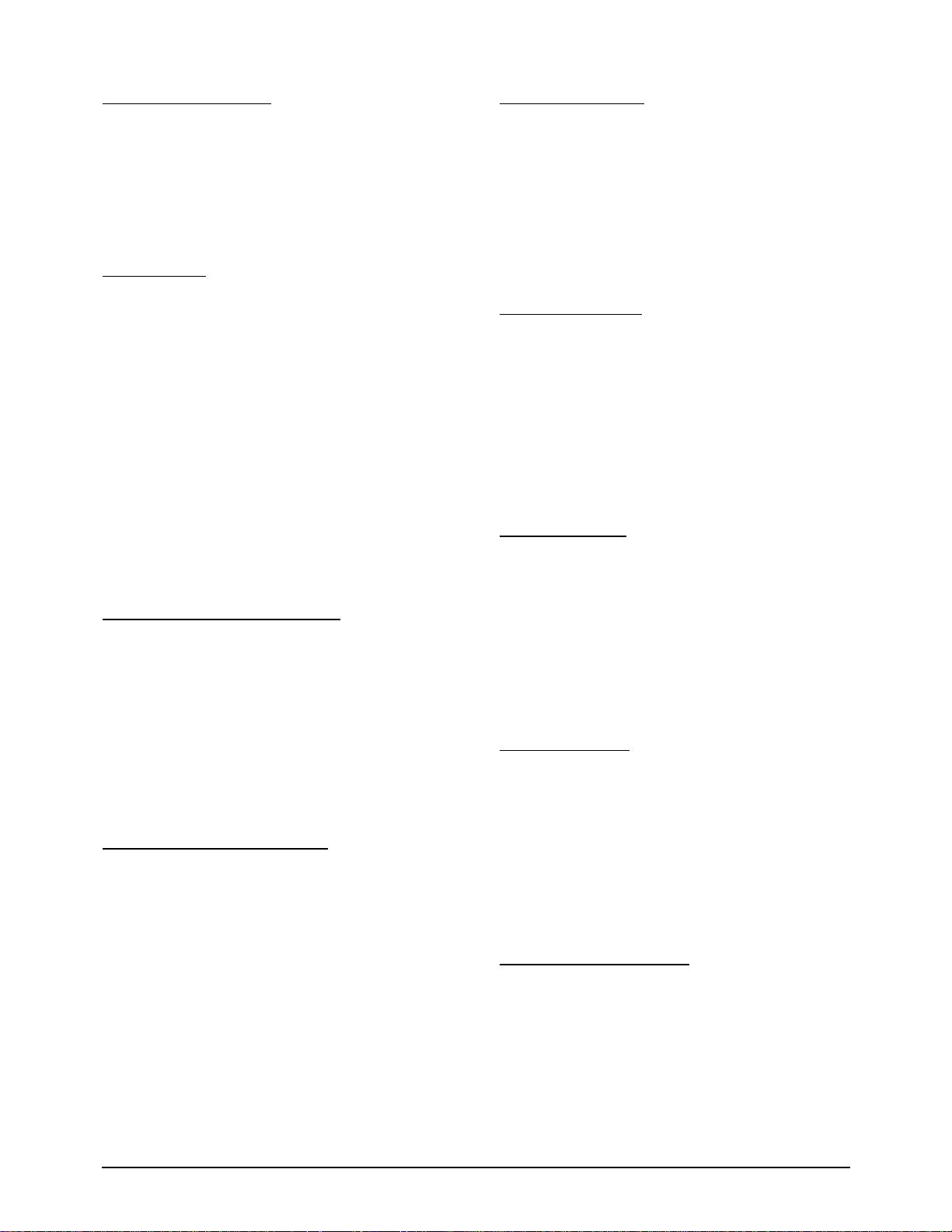

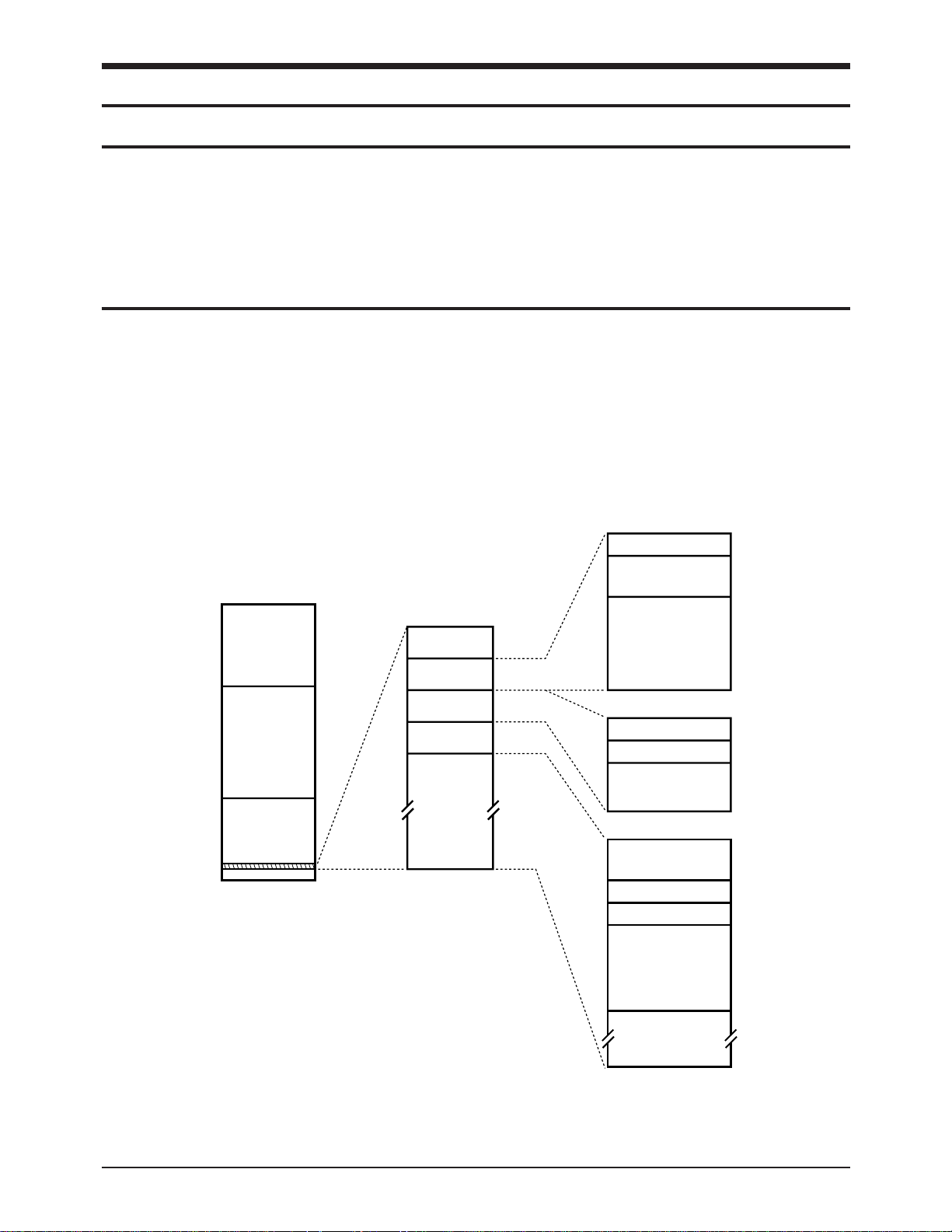

5-2 IFC

This circuit consists of the data and address bus, real time clock (RTC), image sensor, motor driver

controller, Thermal Print head controller, IFC including I/O port, and system reset circuit.

Figure 5-1: XFC-B Memory Map

CPU (Logical) Address Space

FFFFFF

F00000

0FFFFF

000000

MCSn

ROMCSn

CS0n

Not

Available

Internal

Registers

CS2n CS4n

CS1n

Internal

Memory

00FFFF

00FF00

00FE00

00FD00

00FC00

00E000

Reserved

Setup

Registers

Operational

Registers

CS4n

CS3n

CS2n

Reserved

Shading Inversion

DBCMC Buffer

Dither Table

Reserved

00FEFF

00FEE0

00FE80

00FE00

00FDFF

00FDC0

00FD80

00FD00

00FBFF

00FBE0

00FBD0

00FBC0

00FB80

00E000

5-2-1 Memory Map

The external memory of the CPU is divided into

32kB RAM (0000H through 8000H) and 64kB ROM

(FF0000H through FFFFFFH).

Circuit Description

5-2 SF700AT

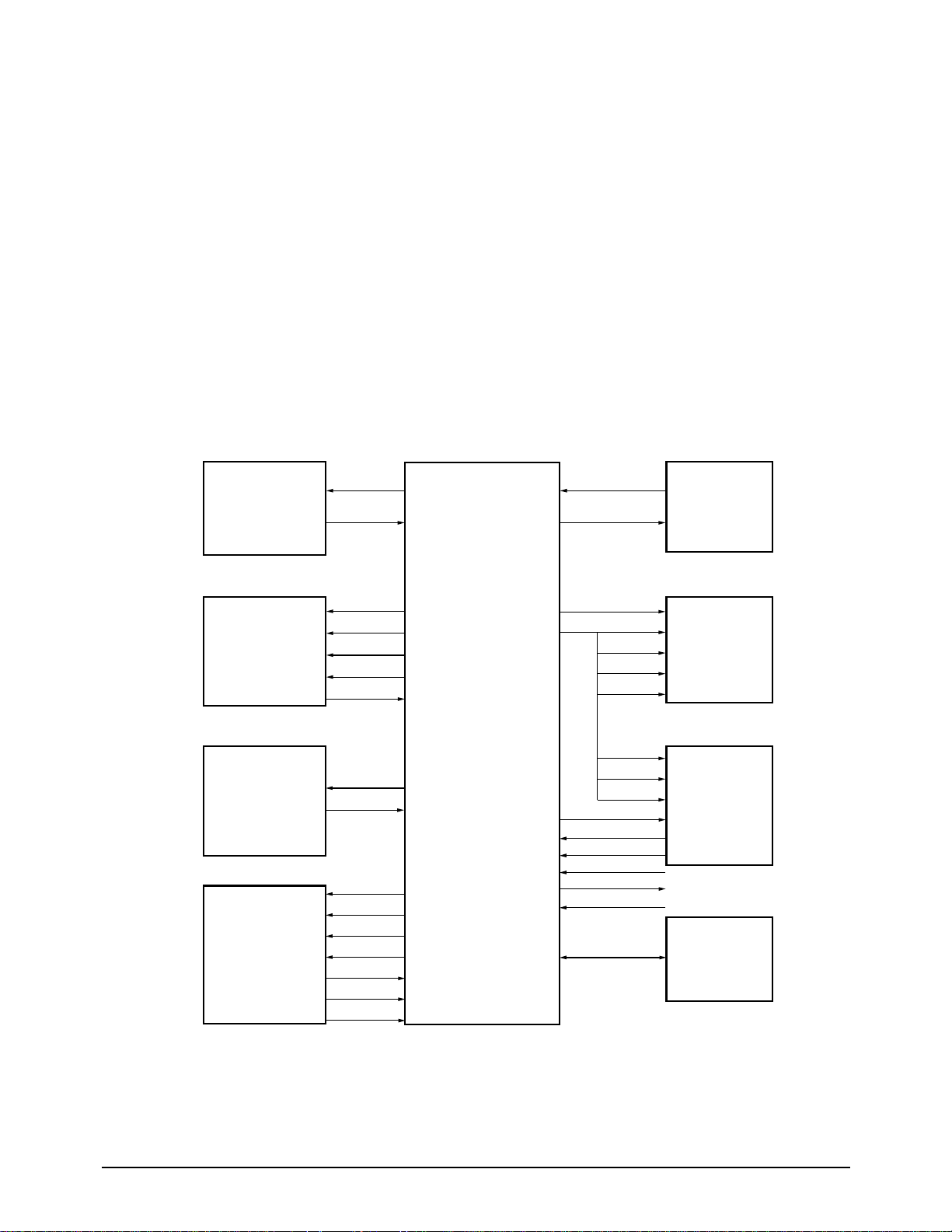

Figure 5-2: XFC-B Hardware Interface Signals

5-2-2 Data & Address Bus Control

/RD and /WR signals are active in the low state,

with the PH2 clock in a high state, and an internal

wait state occurs in the TSTCLK (6 MHz). These

signals are sent to the /RD and /WR ports of

RAM , ROM, and the MODEM in order to read or

write data when a chip select line is active.

/CS0: RAM chip select active (low)

/ROMCS: ROM chip select active (low)

/MCS: MODEM chip select active (low)

D0 - D7: 8 bit data bus

A0 - A16: address bus

5-2-3 System Clock

The 6 MHz internal clock frequency is generated

by dividing the 12 MHz system clock from

MODEM by two inside the MODEM.

OPERATOR

PANEL

SERIAL

COMMUNICATION

PRINTER

DATA

CONTROL

AND

SENSORS

MOTOR

DRIVER

(MOTOR)

SCANNER

CONTROL

AND

PROCESSING

RTC

CRYSTAL

EXTERNAL

BUS

MODEM

GENERAL

PURPOSE

I/ 0

TXD

RXD

STB 0~3

PDAT

PCLK

PLAT

THADI

SM 0~3

MOTOR POS

START

SCLK

VIDCTL1

H/B

Vin

+Vref

-Vref

XIN

XOUT

/ROMCS

/RAMCS

/RD/WR

D0~D7

A0~A16

/RD/WR

D0~D7

A0~A4

/MCS

/MIRQ

SYSCLK

/PWRDWN

/RESET

/BATRST

IFC(XFC-B)

Loading...

Loading...