Page 1

SF-4500/4500C

Msys4700/4800

MJ-4500C

M a n u a l

S E R V I C E

INKJET PRINTER COMPOUND CONTENTS

1. Precaution

2. Specifications

3. Installations

4. Disassembly & Assembly

5. List of Abbreviations

6. Special Circuit Descriptions

7. Theory of Mechanism

8. Troubleshooting

9. Exploded Views and Parts List

10. Packing Diagram and Parts List

11. Electrical Parts List

12. Block Diagrams

13. PCB Diagrams

14. Schematic Diagrams

Page 2

Page 3

1-1Samsung Electronics

1-1 Safety Precautions

1. Be sure that all built-in protective devices are in

place. Restore any missing protective shields.

2. Make sure there are no cabinet openings through

which people- particularly children- might insert

fingers or objects and contact dangerous

voltages.

3. When re-installing chassis and assemblies, be

sure to restore all protective devices, including

control knobs and compartment covers.

4. Design Alteration Warning:

Never alter or add to the mechanical or electrical

design of this equipment, such as auxiliary

connectors, etc. Such alterations and

modifications will void the manufacturer’s

warranty.

5. Components, parts, and wiring that appear to

have overheated or are otherwise damaged

should be replaced with parts which meet the

original specifications. Always determine the

cause of damage or overheating, and correct any

potential hazards.

6. Observe the original lead dress, especially

near sharp edges, AC, and high voltage power

supplies. Always inspect for pinched,

out-of-place, or frayed wiring. Do not change

the spacing between components and the

printed circuit board.

7. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which might

not be obvious from visual inspection. These safety features and the protection they provide could

be lost if a replacement component differs from

the original. This holds true, even though the

replacement may be rated for higher voltage,

wattage, etc.

Components critical for safety are indicated in the

parts list with symbols . Use only replace-

ment components that have the same

ratings, especially for flame resistance and dielectric specifications. Areplacement part that does

not have the same safety characteristics as the

original may create shock, fire, or other

safety hazards.

Follow these safety, ESD, and servicing precautions to prevent personal injury and equipment damage.

1. Precautions

Page 4

1-2 Samsung Electronics

1-2 ESD Precautions

Certain semiconductor devices can be easily

damaged by static electricity. Such components are

commonly called “Electrostatically Sensitive (ES)

Devices”, or ESDs. Examples of typical ESDs are:

integrated circuits, some field effect transistors, and

semiconductor “chip” components.

The techniques outlined below should be followed to

help reduce the incidence of component damage

caused by static electricity.

CAUTION: Be sure no power is applied to the

chassis or circuit, and observe all

other safety precautions.

1. Immediately before handling a semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic charge on your body by

touching a known earth ground. Alternatively,

employ a commercially available wrist strap

device, which should be removed for your personal safety reasons prior to applying power to

the unit under test.

2. After removing an electrical assembly equipped

with ESDs, place the assembly on a conductive

surface, such as aluminum or copper foil, or

conductive foam, to prevent electrostatic charge

buildup in the vicinity of the assembly.

3. Use only a grounded tip soldering iron to solder

or desolder ESDs.

4. Use only an “anti-static” solder removal device

Some solder removal devices not classified as

“anti-static” can generate electrical charges

sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When

sprayed, these can generate electrical charges sufficient to damage ESDs.

6. Do not remove a replacement ESD from its

protective packaging until immediately before

installing it. Most replacement ESDs are

packaged with all leads shorted together by

conductive foam, aluminum foil, or a

comparable conductive material.

7. Immediately before removing the protective

shorting material from the leads of a

replacement ESD, touch the protective material to

the chassis or circuit assembly into which the

device will be installed.

8. Maintain continuous electrical contact between

the ESD and the assembly into which it will be

installed, until completely plugged or soldered

into the circuit.

9. Minimize bodily motions when handling unpackaged replacement ESDs. Normal motions, such as

the brushing together of

clothing fabric and lifting one’s foot from a

carpeted floor, can generate static electricity

sufficient to damage an ESD.

1-3 Lithium Battery Precautions

1. Exercise caution when replacing a Lithium

battery. There could be a danger of explosion and

subsequent operator injury and/or

equipment damage if incorrectly installed.

2. Be sure to replace the battery with the same or

equivalent type recommended by the

manufacturer.

3. Lithium batteries contain toxic substances and

should not be opened, crushed, or burned for disposal.

Precautions

Page 5

Specification

Samsung Electronics 2-1

2. Specification

2-1 Printer Engine

2-2 Head

Te c h n o l o g y

Speed Color (*1)

Mono (*2)

Resolution

C o l o r

M o n o

Printing Wi d t h

Feeding Method

A u t o m a t i c

Manual Tr a y

E m u l a t i o n

Printer Driver

I n t e r f a c e

Thermal Inkjet

1-pen & Print Head Swapping Ty p e

3ppm at Draft Mode

8ppm at Draft Mode

600 x 600 dpi (1200 x 1200 dpi A d d r e s s a b l e )

600 x 600 dpi (1200 x 1200 dpi A d d r e s s a b l e )

2 0 3 m m

130 Sheets of 20lb cut sheets

N o

Host Based Printing (GDI)

Windows 3.1/3.11, Windows 95/98 driver

IEEE 1284 Compatible Parallel Interface (ECP)

Ink M-3 Ink C-3

Print Head 208 nozzles 192 nozzles

Ink type Pigment D y e

Ink Color Black C o l o r

Ink Yield about 600 sh. about 200 sh.

(*1) The average printing time with 15%/A4 test image of Samsung.

(*2) The average printing time with 4%/A4 test image of Samsung.

Page 6

Specification

2-2 Samsung Electronics

2-3 Facsimile

C o m p a t i b i l i t y

Scan method

Scan width

Scan Resolution

Scan Speed

Feeding method

A D F

G u i d e

S t a c k e r

Paper Tray

Modem Speed

Coding Method

L C D

R e s o l u t i o n

Gray Scale & Contrast

Capacity (*3)

Back-up Time

C o n f i d e n t i a l

D e l a y e d

Group Dial

Forced Memory Tx.

Priority Tx.

Memory Rx.

I T U - G 3

CIS

Max. 216mm, Effective: 210mm

300 x 300 dpi

3 sec

S h e e t - f e d

30 sheets

Document Input Guide

Document Output Stacker (No Paper Stacker)

BIN Type (No Manual Tray)

14.4 Kbps

MH, MR, MMR, Error Correction Mode

2 Lines Each of 16 Characters

Selectable by 1-Key, 2-LEDs

- Standard : 200 x 100 dpi

- Fine : 200 x 200 dpi (Default)

- Superfine : 300 x 300 dpi

Selectable by 1-Key, 2-LEDs

- D a r k e n

- Lighten

- Photo : Error diffusion

SF-4500/Msys4700 : 1.0 Mbyte (Factory Option : 3M)

SF-4500C/Msys4800/MJ-4500C : 0.5 Mbyte (Factory Option : 2.5M)

30 Minutes (Continuous Power Failare)

N o

Upto 30 Locations

5 Number Programmable

Y e s

Y e s

Automatic reception when paper empty.

G E N E R A L

S C A N N I N G

M E M O R Y

(*3) Monochromatic CCITT NO. 1 CHART can be saved by 80 sheets per 1.0M Byte.

Page 7

Specification

Samsung Electronics 2-3

2-3 Facsimile (continued)

One-touch Dial

Speed Dial

Chain Dial

Handset & Cradle

On-hook Dial

Last Number Redial

Auto Busy Redial

No Power Operation

Hold & Mute

P a u s e

Ringer Vo l u m e

Tone/pulse Select

F l a s h

M e r c u r y

D R P D

TX/RX Journal

Image T C R

Delayed Dial List

System Data

Tel Number List

Help List

Multipage Copy

Gray Scale

Reduction &

E n l a r g e m e n t

Answering I/F

Ext. Phone

P o l l i n g

S e n s o r s

Error Indicator

Voice Request

Real Time Clock

RT I

20 Locations

50 Locations

Ye s

Option

Yes, 1-Key

Yes, 1-Key

Y e s

UK : CALLING only, Other Country : No

N o

Yes, Use Redial Key

S/W Option Setting (4Steps)

S/W Option setting (Pulse for NPO)

UK : Yes, Other Country : No

N o

US : Yes, Other Country : No

Ye s

Yes, Reduction of First Page Sent by Memory T x

Ye s

Ye s

Ye s

Ye s

Upto 99 Pages

256 Levels

2 5 % ~ 2 0 0 %

(Reference is the top center of Document)

Ye s

1-jack, Extension Phone T r a n s f e r

Ye s

No Paper, Paper Jam

1 - L E D

Yes, On-hook Dial

Ye s

Ye s

T E L E P H O N E

R E P O RT &

L I S T

C O P Y

T E L I / F

O T H E R S

Page 8

Specification

2-4 Samsung Electronics

2-4 Scanner

Compatibility T WA I N

Technology Platen CIS

Light Source for Color CIS RGB LEDs (Line Order Control)

2-5 Power & Size

2-6 Accessaries

Power Source U S A : 110V 60 Hz, UK/GER : 220V 50 HZ

Dimensions (W x D x H) 360 x 325 x 190 mm (Without Handset)

Weight 5 . 7 K g

Tel

Handset / curlcord

Tel Line

Power Cord

Parrallel Cable

FAX Driver

Ink Cartridge

M a n u a l

Carrier Sheet

Bundle S/W

Contents (*5)

(one CD-ROM)

S u p p l y

1 E A / 1EA

1 E A

1 E A

N o

2 Diskettes

INK-M3 (MONO) 1EA (*4), INK-C3 (COLOR) 1EA ( * 4 ’ )

Ye s

Yes (*4)

Electronic Manual, Prt Driver, Presto page manager, Smart_Fax,

Photo Album, Twain Driver

D e f a u l t

(*4) SF-4500/SF-4500C/Msys4700/Msys4800 only

(*4’) SF-4500C/MJ-4500C only

(*5) The smart_fax allows a on-screen remote contro l .

Page 9

Samsung Electronics 3-1

3. Installation

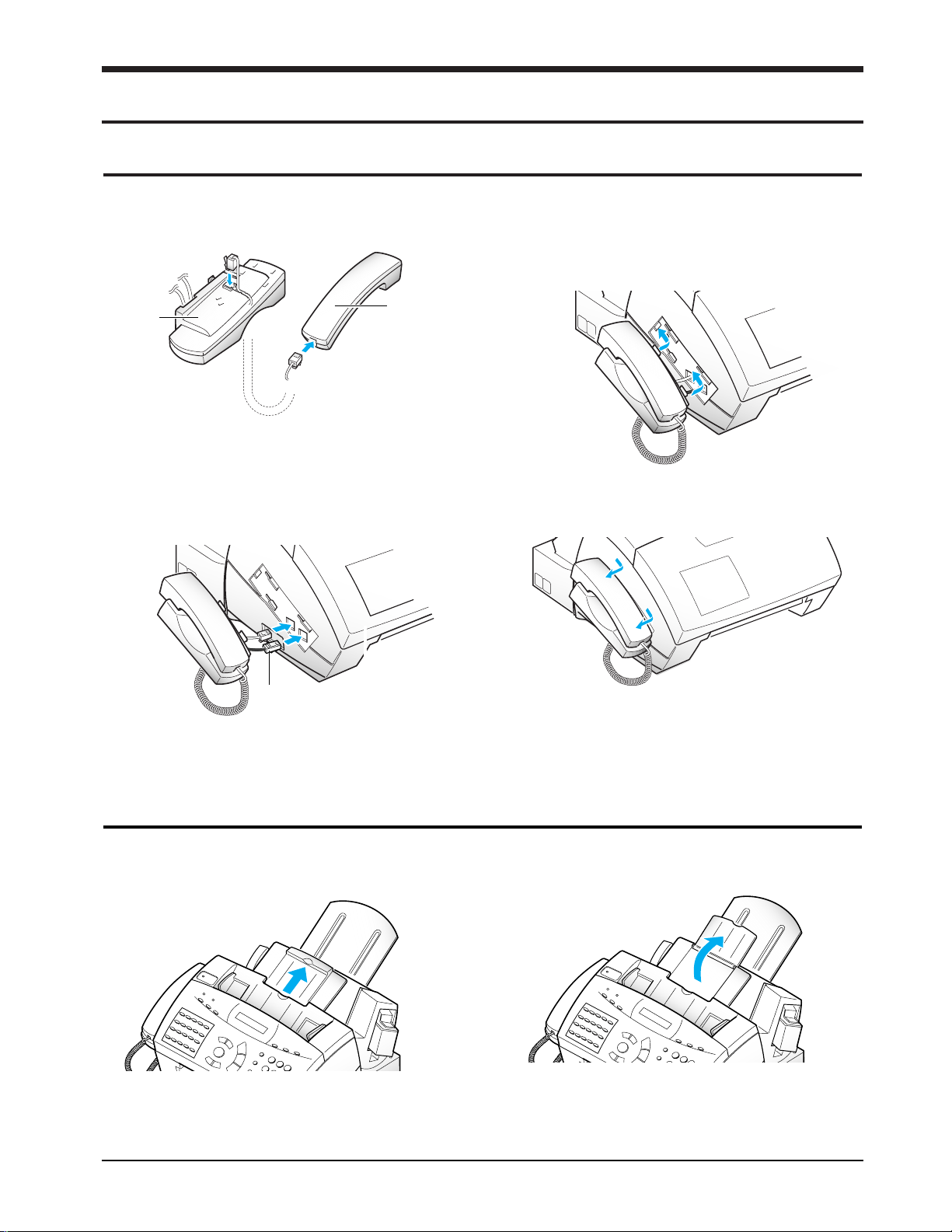

3-1 Handset and Handset Cradle

1. Plug one end of the coiled cord into the jack on

the handset.

2. Plug the cradle’s modular cords into the modular

jacks on the left side of your machine.

3. Attach the handset cradle to the main body. Insert

the two tabs of the cradle into the slots on the left

side of the main body as shown, and push it up.

Note: If you want to remove the handset, slide it

down, then take it out.

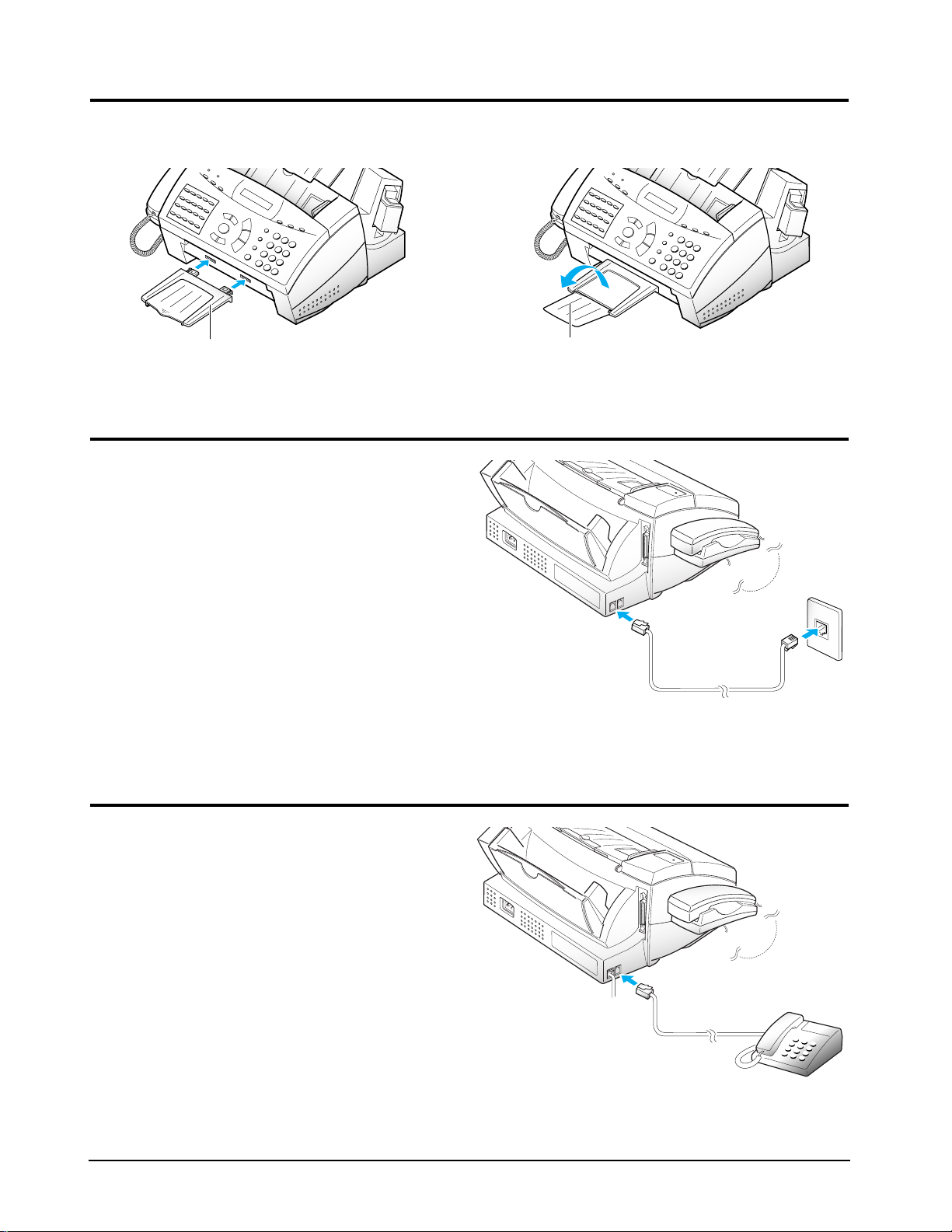

1. Pull the document tray upward. 2. Fold out the extender on the document tray.

0000000000

00000000000000000000000000

Cradle

Handset

Be sure to insert white

cord into the front hole

3-2 Document Tray

Page 10

3-2

Samsung Electronics

3-3 Document Exit Tray

1. Insert the two tabs on the document exit tray into

the slots on the front of your machine.

2. Fold out the extender, if necessary.

3-4 Telephone Line

Plug one end of the telephone line cord into the TEL

LINE jack and the other end into a standard phone

wall jack.

Document exit tray

Extender

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

3-5 Extension Phone (Optional)

Plug one end of the modular cord into the EXT.TEL

jack on the back of your machine.

Plug the other end of the cord into a modular

jack on a telephone answering device or a regular

telephone to use as an extension.

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Page 11

Samsung Electronics 3-3

3-6 AC Power Cord

Plug one end of the cord into the back of the

machine and the other end into a standard,

grounded 3-prong AC power outlet.

The machine turns on. All lamps on the control

panel light up and the LCD displays ‘SYSTEM

INITIAL’ then ‘PAPER OUT’. Load the paper as

described on page 3-4.

If you want to turn it off, unplug the power cord.

Note : If documents are deleted from memory due

to a power failure, the machine automatically

prints out a Power failure report after power is

supplied.

1. Connect a bi-directional parallel printer cable to

the 36 pin printer jack on your machine.

It is recommended to use the parallel cable that

supports IEEE-1284 bi-directional communications.

2. Fasten the metal clips to the parallel cable.

3. Connect the other end of the parallel cable to

your computer.

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

3-7 Connecting Printer Cable

Printer cable

Page 12

3-4

Samsung Electronics

3-8 Loading Paper

1. Pull the paper support on the paper bin all the

way up.

2. Fan the paper and insert the paper with the print

side facing you.

3. Hold the left paper guide and move it to the right

to match the width of the paper.

The LCD displays ‘PAPER OUT’ when paper is not loaded. You can load approximately 130 sheets of paper.

3-9 Loading an Envelope

You can load a standard or non-standard sized envelope.

Paper support

Paper Guide

1. Turn the envelope guide upright.

2. Load the envelope and move it to the far right 1.

Then push it slightly down 2. The right edge of

the envelope must align with the raised edge of

the envelope guide.

3. Slide the left paper guide to the right to match the

width of the envelope.

Notes :

•If you remove the envelope after it is loaded, you

must press the Form Feed button to load the envelope again.

•The acceptable width of the envelope is in the

range of 98.5mm ~ 215.9mm.

•The envelope should be made of 20-24lb paper.

Envelope Guide

Paper Guide

1

2

Page 13

Samsung Electronics 3-5

3-10 Installing Print Cartridge

3-10-1 Print Cartridge

1. When you install a new print cartridge, press the

Cartridge button on the control panel. The LCD

displays ‘CHECK CARTRIDGE! PLEASE

INSTALL’, and the print cartridge moves to the

load position.

If you install a color cartridge, use ‘Install

Cartridge’ tab in the SF4400 Control Program on

your PC.

2. Lift the control panel 1 with your hand and open

the cartridge compartment cover 2.

3. If you are replacing a used cartridge, remove the

old cartridge.

Pull the print cartridge handle toward you until

you hear a click, then remove the print cartridge.

4. Remove the new print cartridge from its packaging. Hold the print cartridge by the black areas or

colored top only. Do not touch the copper area.

5. Carefully remove the tape covering the printhead.

Be sure to remove all the tape.

Control panel

Cartridge compartment cover

1

2

Cartridge

handle

Page 14

3-6

Samsung Electronics

6. Insert the print cartridge in the carrier.

7. Push the cartridge firmly in the direction of the

arrow until it clicks into place.

8. After installing the print cartridge, close the cover

and replace the control panel.

9. Use ‘Install Cartridge’ tab on your PC for a color

cartridge.

The LCD displays ‘THE CARTRIDGE IS 1:NEW

2:USED’.

10. Choose ‘1:NEW’ by using the F or E button, or by

pressing the 1 button.

11. Press the Cartridge button. The LCD displays

briefly ‘MONO INSTALLED’ (or ‘COLOR

INSTALLED’ for color print cartridge).

Use ‘Install Cartridge’ tab on your PC for a color

cartridge.

If the cartridge is not installed properly, the LCD

displays ‘CHECK CARTRIDGE! PLEASE

INSTALL’. Remove the cartridge and re-insert it.

Notes :

• When you install a new cartridge, you must choose

‘1:NEW.’ When you install a used cartridge, select

‘2:USED’, which helps you check the amount of ink

remaining. If you mix up several used cartridges, it

will be difficult to check the amount of ink remaining. Once a new print

cartridge is installed, use it until it has completely

run out of.

• If you want to install a color cartridge to print a file

from your PC, you should use ‘Install Cartridge’

tab in the SF4500 Control Program on your PC. If

you use the Cartridge button on this machine, the

machine beeps a warning tone and briefly displays

‘RE-INSTALL COLOR USING

PC-DRIVER’. Press ‘Install Cartridge’ tab on your

PC, or the file may print using composite black.

Page 15

Samsung Electronics 3-7

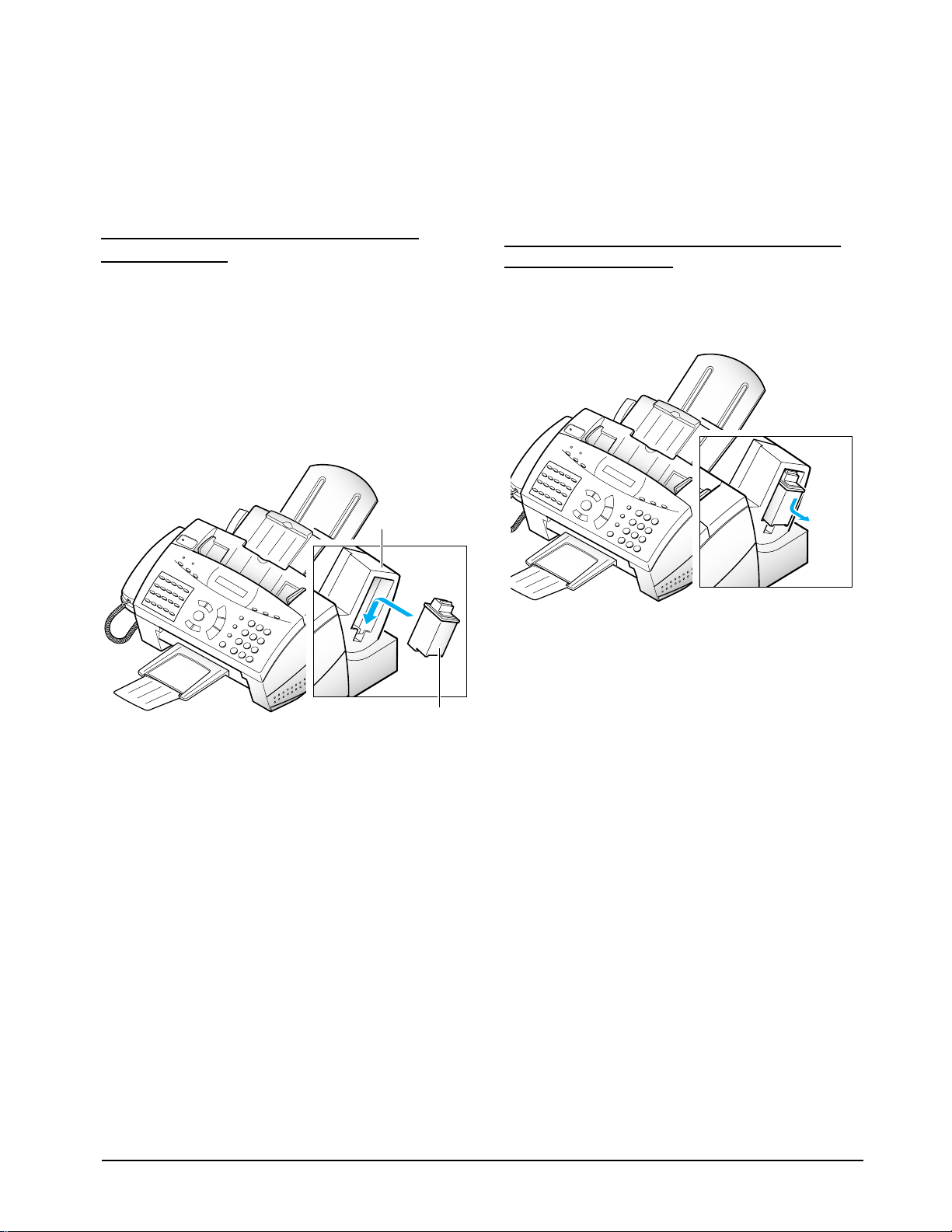

3-10-2 Print Cartridge Storage Unit

The print cartridge storage unit provides a

convenient place to store an extra black or color print

cartridge, and prevents an opened cartridge from

drying out.

TO STORE A PRINT CARTRIDGE IN THE

STORAGE UNIT

Insert the print cartridge into the storage unit and

slightly push it down.

When switching between the color and black print

cartridges, keep the unused one in the print

cartridge storage unit. The storage unit prevents the

print cartridge from drying out while providing easy

access to it.

TO REMOVE A PRINT CARTRIDGE FROM

THE STORAGE UNIT

Push the cartridge slightly down and pull it toward

you.

Storage unit

Cartridge

Page 16

Samsung Electronics 4-1

4. Disassembly and Reassembly

4-1 General Precautions on Disassembly

When you disassemble and reassemble components, you must use extreme caution. The close proximity of cables

to moving parts makes proper routing a must. If components are removed or replaced, any cables

disturbed by the procedure must be replaced as close as possible to their original positions. Before removing any

component from the machine, note the cable routing that will be affected.

Whenever servicing the machine, you must perform as follows:

1. Check to verify that documents are not stored in memory.

2. Move the printer cartridge to far right to cap the nozzle.

3. Unplug the power cord.

4. Use a flat and clean surface.

5. Replace only with authorized components.

6. Do not force plastic-material components.

7. Make sure all components are in their proper position.

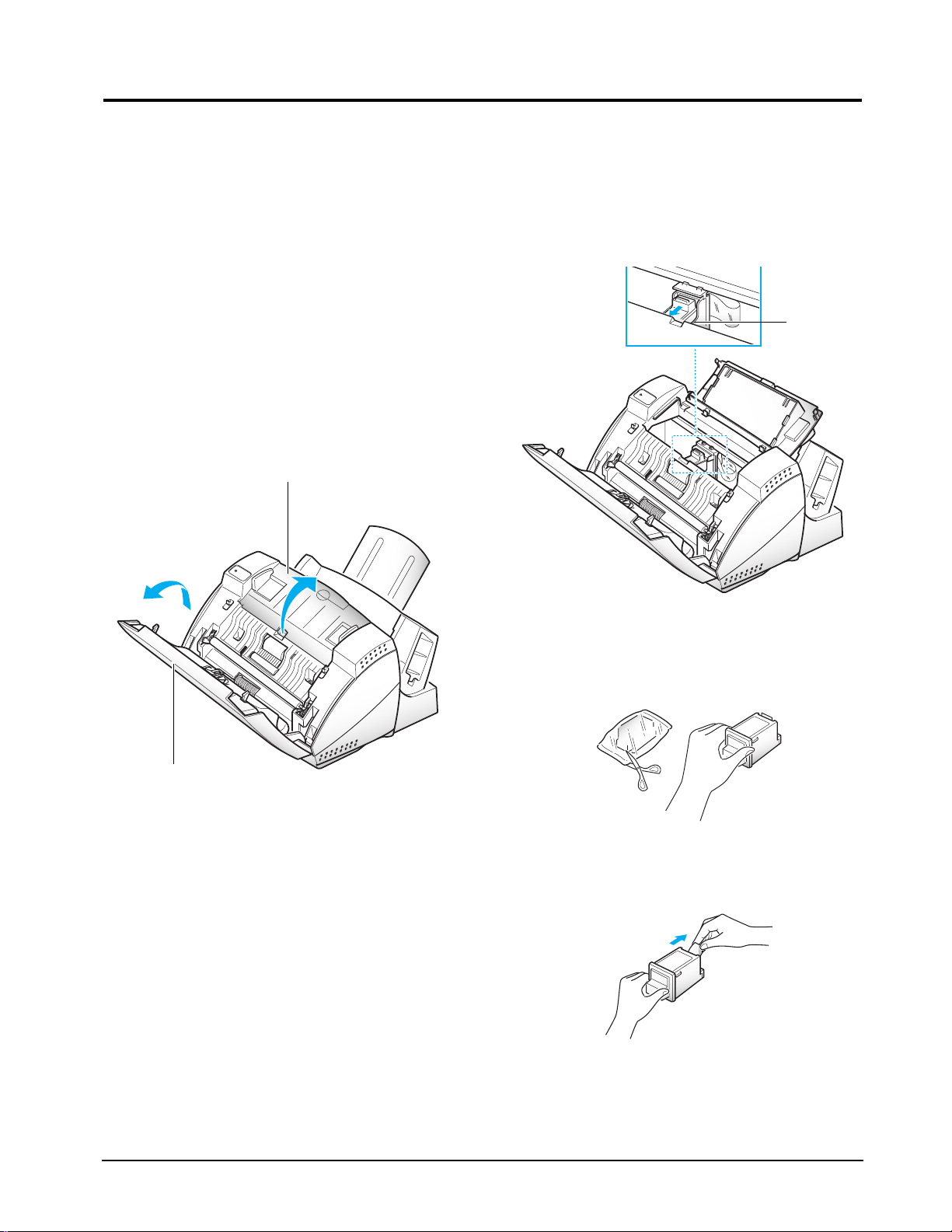

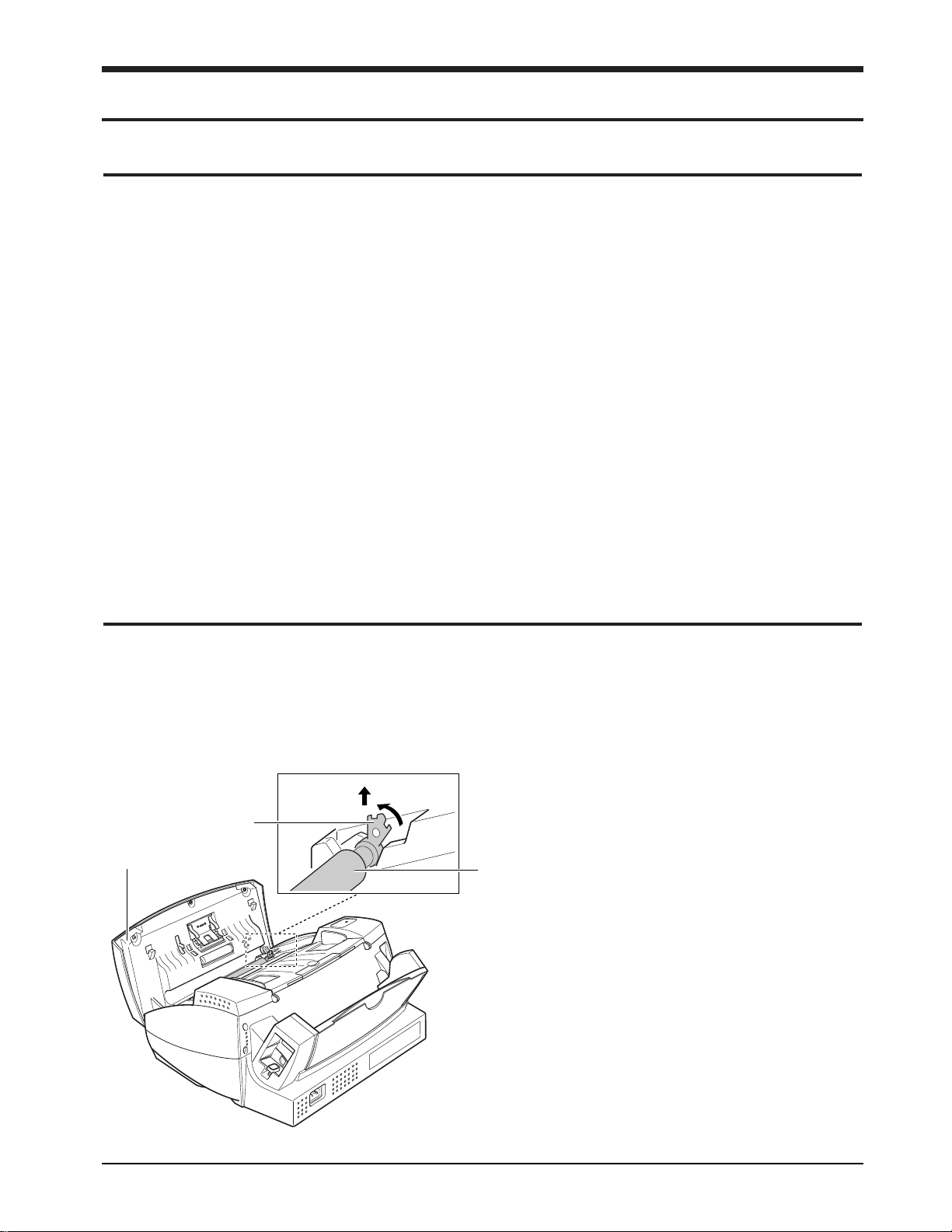

1. Lift the control panel using hand.

2. Push the bushing on both ends of the roller slightly inward, then rotate it until it reaches the slot as

shown below. Then lift the roller out.

Note : Check the roller for any dirt. If dirty, wipe it

off with soft cloth dampened with water. If

the roller is heavily worn, replace it with a

new one.

4-2 White Roller Ass’y

Bushing

White roller

Control panel

B

A

Page 17

4-2 Samsung Electronics

Disassembly

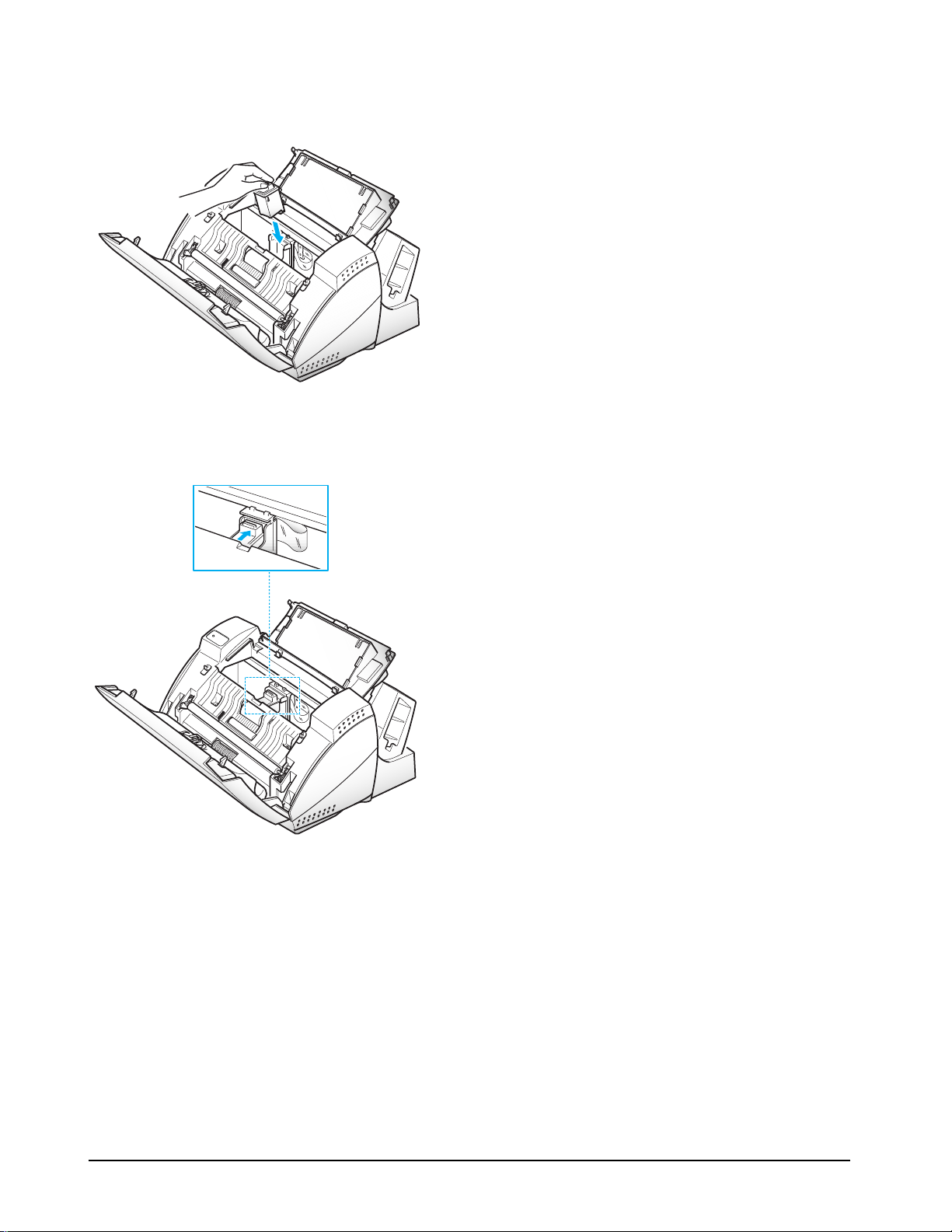

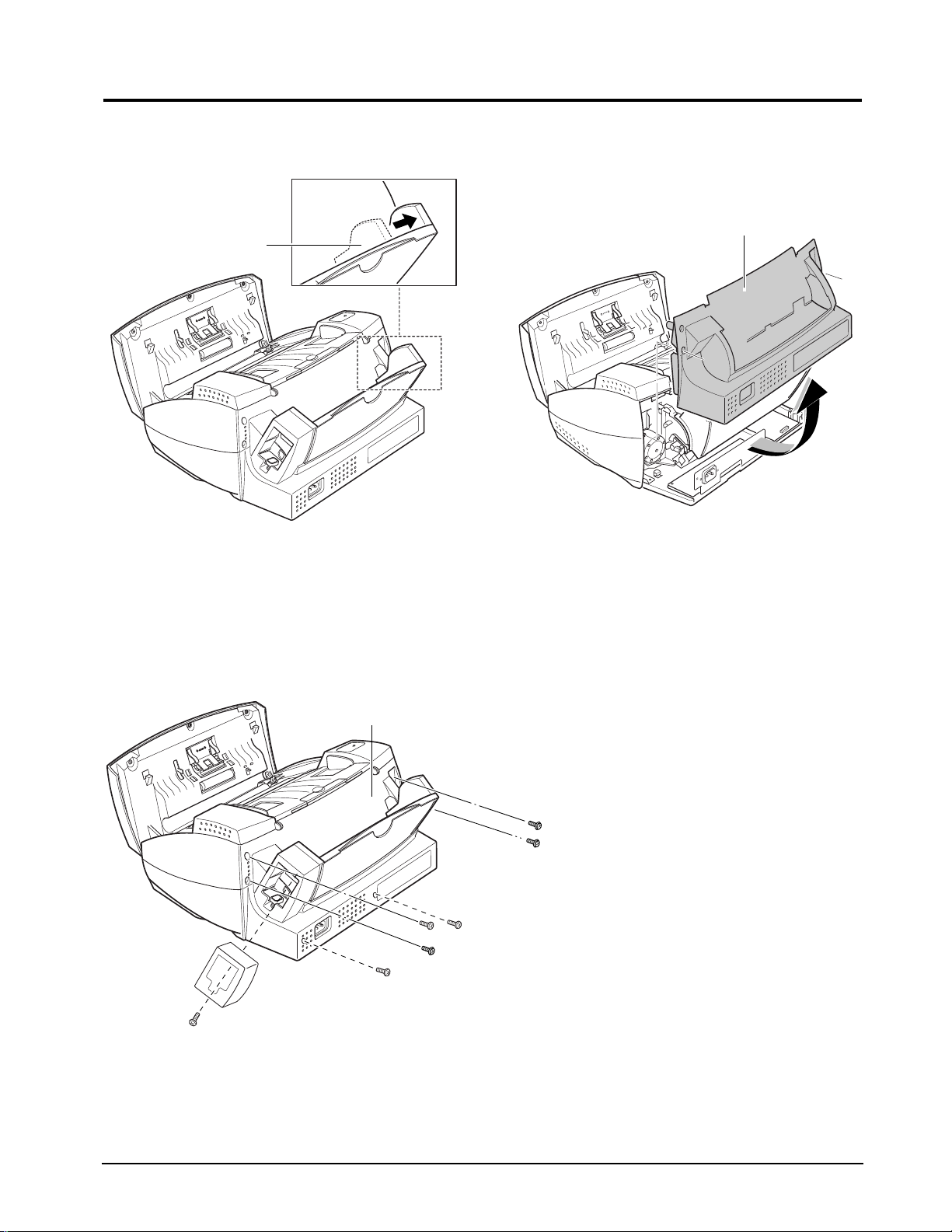

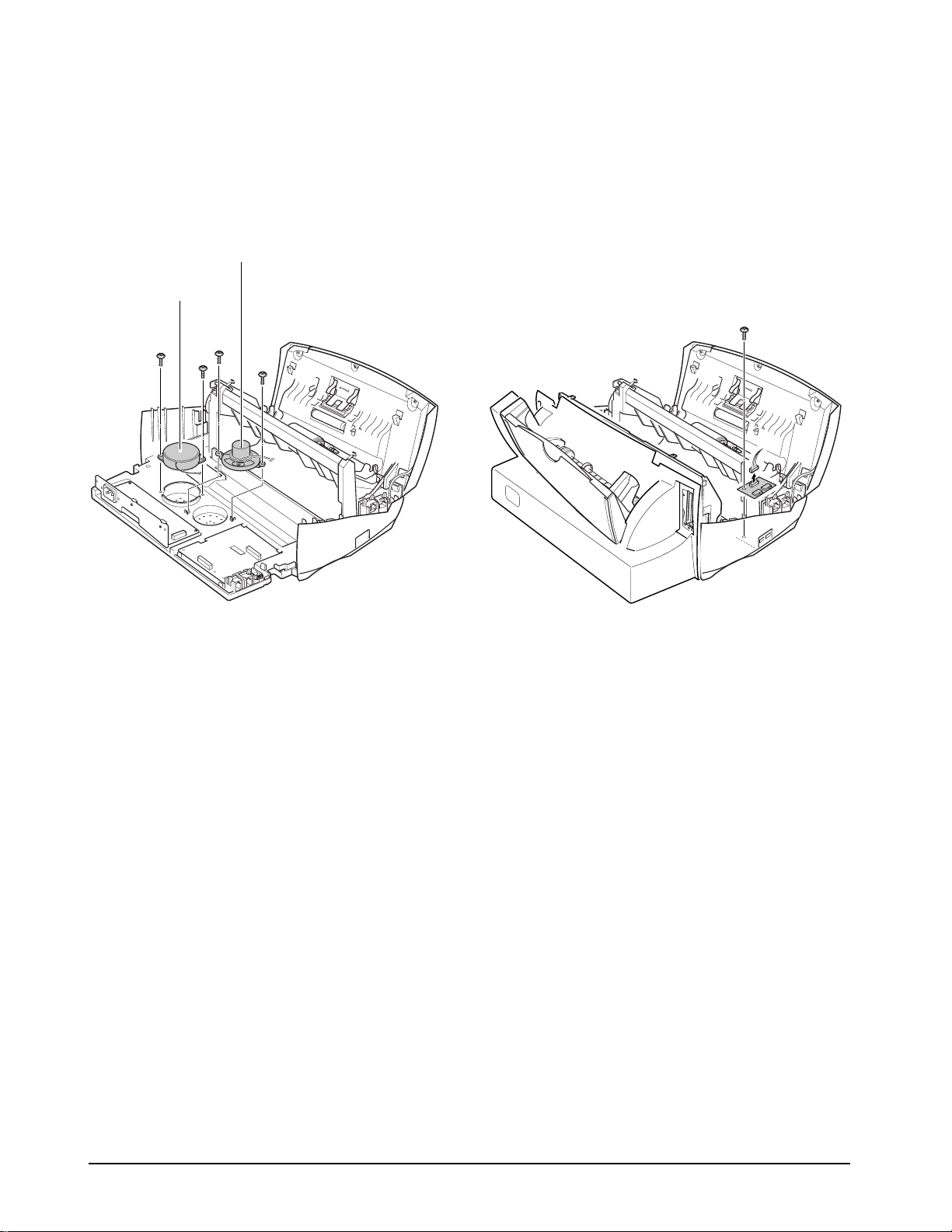

4-3 Top Cover Ass’y

1. Lift the control panel and open the print

cartridge compartment cover. Remove the white

roller ass’y. Remove the six screws shown below.

2. Remove the print cartridge. Remove the two

screws shown below and take out the top cover

ass’y.

Note: When you reassemble the top cover ass’y,

make sure the tabs in the bottom of the ass’y fit

into the slots in the base ass’y.

Control panel

Cartridge compartment

cover

Top cover ass’y

Base ass’y

Page 18

Samsung Electronics 4-3

Disassembly

4-4 Rear Cover Ass’y

1. Holding the paper guide, move it in the direction

of arrow.

2. Remove the storage Unit, and remove the six

screws shown below.

3. Holding the rear cover ass’y, take it out by

rotating it to be released properly.

Paper guide

Rear cover ass’y

Rear cover ass’y

Page 19

4-4 Samsung Electronics

Disassembly

4-5 Base Ass’y

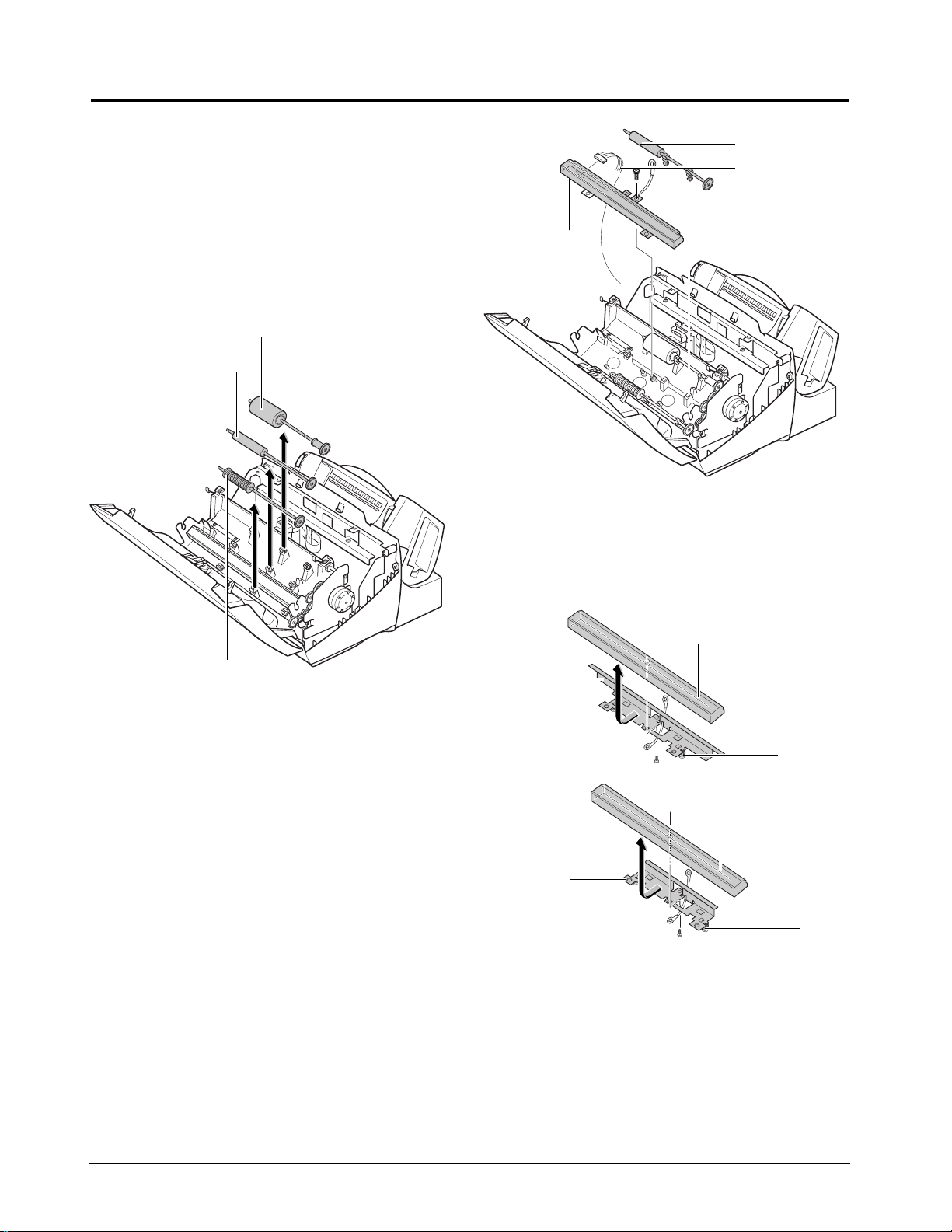

4-5-1 Rollers (ADF Roller, Drive Roller,

Exit Shaft)

1. Before you disassemble the rollers, you should

remove:

– Top Cover Ass’y (see page 4-2)

2. Take out the rollers from the base ass’y.

Note : Clean the surface of the rollers with ethyl alco-

hol. After wiping them, you must dry them

completely.

4-5-2 CIS (Contact Image Sensor)

1. Before you disassemble the CIS, you should

remove:

– Top Cover Ass’y (see page 4-2)

2. Remove the drive roller as described in ‘4-5-1

Rollers’.

3. Remove the one screw securing the CIS ass’y and

unplug the CIS harness. Take out the CIS ass’y.

4. Turn the CIS ass’y over. Remove the one screw to

release the CIS from the bracket.

Note: Be careful not to lose the springs.

Note : Check the glassy surface of the CIS for any

stain or scratch. If stained, wipe off with ethyl

alcohol. If it is heavily stained or scratched,

replace it with a new one.

Note : There is a little difference mono bracket and

color bracket.

ADF roller

Drive roller

Exit shaft

CIS ass’y

Drive roller

CIS harness

Spring

Mono

Bracket

CIS

Spring

Color

Bracket

CIS

Page 20

Samsung Electronics 4-5

Disassembly

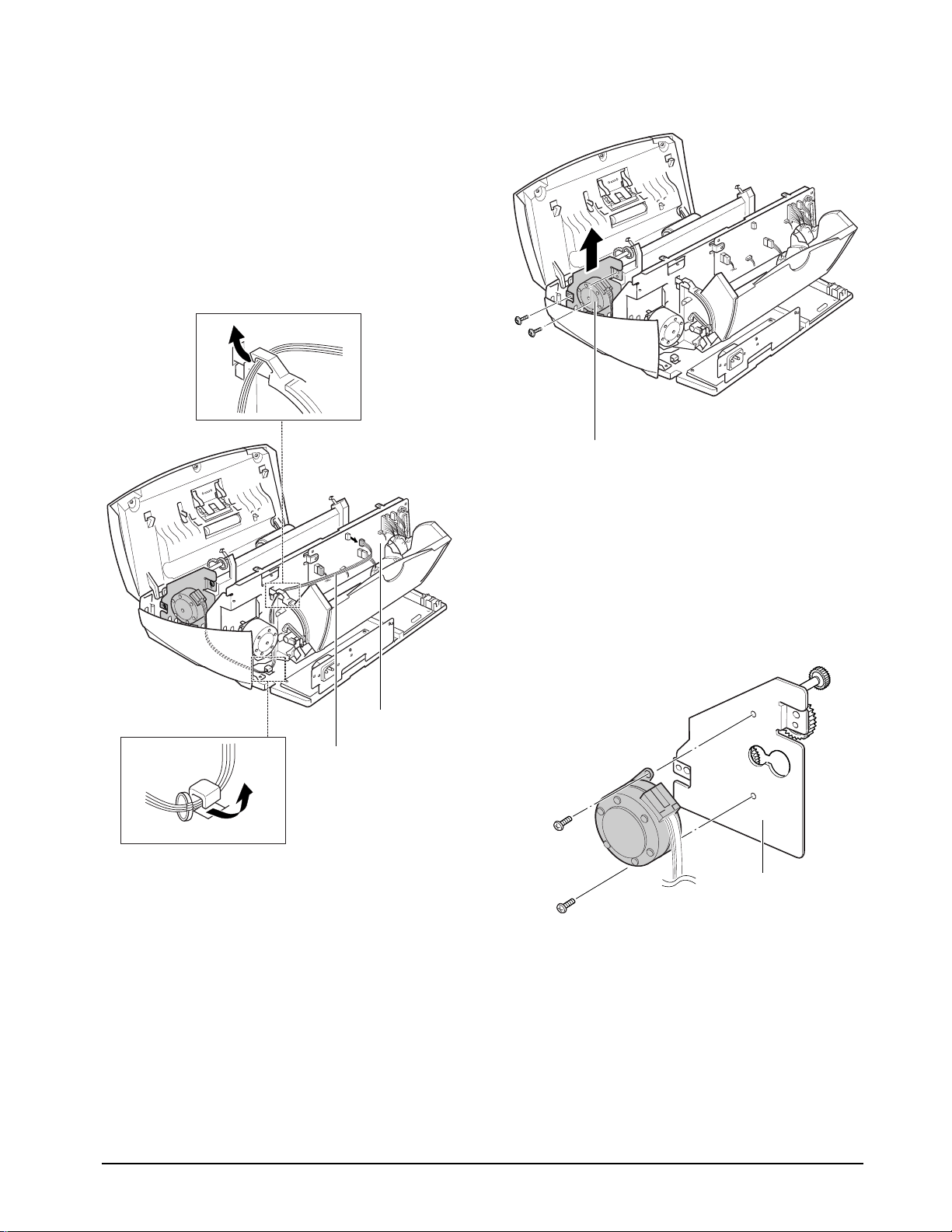

4-5-3 Scan Motor

1. Before you disassemble the CIS, you should

remove:

– Top Cover Ass’y (see page 4-2)

– Rear Cover Ass’y (see page 4-3)

2. Unplug the motor connector from the main PBA.

Make sure the harness is released from two hooks

securing the harness as shown below.

3. Remove the two screws as shown below and take

out the scan motor ass’y.

4. Remove the two screws securing the motor to the

motor bracket.

Main PBA

Motor harness

Hook1

Hook2

Scan motor ass’y

Motor bracket

Page 21

4-6 Samsung Electronics

Disassembly

4-5-4 SMPS

1. Before you disassemble the SMPS, you should

remove:

– Rear Cover Ass’y (see page 4-3)

2. Unplug the SMPS connector from the Main PBA.

Make sure the harness is released from the hook

as shown below.

3. Remove the one screw securing the ground wires

to the bracket as shown.

4. Remove the one screw securing the ground wire

to the main frame as shown. Make sure the

harness is released from the hook securing as

shown below.

5. Pushing down the hooks on both ends, pull out

the SMPS.

Hook

Bracket-LF

SMPS connector

LIU ground wire

Ground

wire 2

SMPS

Main frame

Hook

SMPS

Page 22

Samsung Electronics 4-7

Disassembly

4-5-5 LIU PBA

1. Before you disassemble the LIU PBA, you should

remove:

– Rear Cover Ass’y (see page 4-3)

2. Remove the one screw securing the ground wires

to the bracket.

3. Pulling the snap fits locking the PBA outward,

push up the LIU PBA.

4. Unplug all the connectors from the LIU PBA.

Bracket-LF

LIU ground wire

SMPS ground wire

LIU PBA

Page 23

4-8 Samsung Electronics

Disassembly

4-5-6 Speaker and Buzzer*

1. Before you disassemble the speaker and buzzer,

you should remove:

– Printer Unit (see page 4-11)

2. Remove the four screws securing the speaker and

buzzer.

4-5-7 Volume PBA

1. Before you disassemble the Volume PBA, you

should remove:

– Top Cover Ass’y (see page 4-2)

2. Unplug the one connector and remove the one

screw shown below, and take out the PBA.

Speaker

Buzzer*

*Optional

Page 24

Samsung Electronics 4-9

Disassembly

4-6-1 ADF Rubber Pad

1. Open the OPE unit.

2. Insert a flat blade screw driver into the slot as

shown below, and release the latches. Take out the

rubber holder, sheet ADF and the rubber pad.

Notes:

• When you reassemble the rubber pad, be sure that

the rubber pad, sheet ADF and holder fit into the

guide boss and the holder latches fit into the

corresponding hole. Then push firmly until it

clicks.

• Clean the surface of the rubber pad with ethyl alcohol. After wiping it, be sure to dry it.

Check the rubber wear. If the wear reaches 1/2

its original thickness, replace it with a new one.

OPE unit

Rubber pad

Rubber holder

Guide boss

4-6 OPE Ass’y

Page 25

4-10 Samsung Electronics

Disassembly

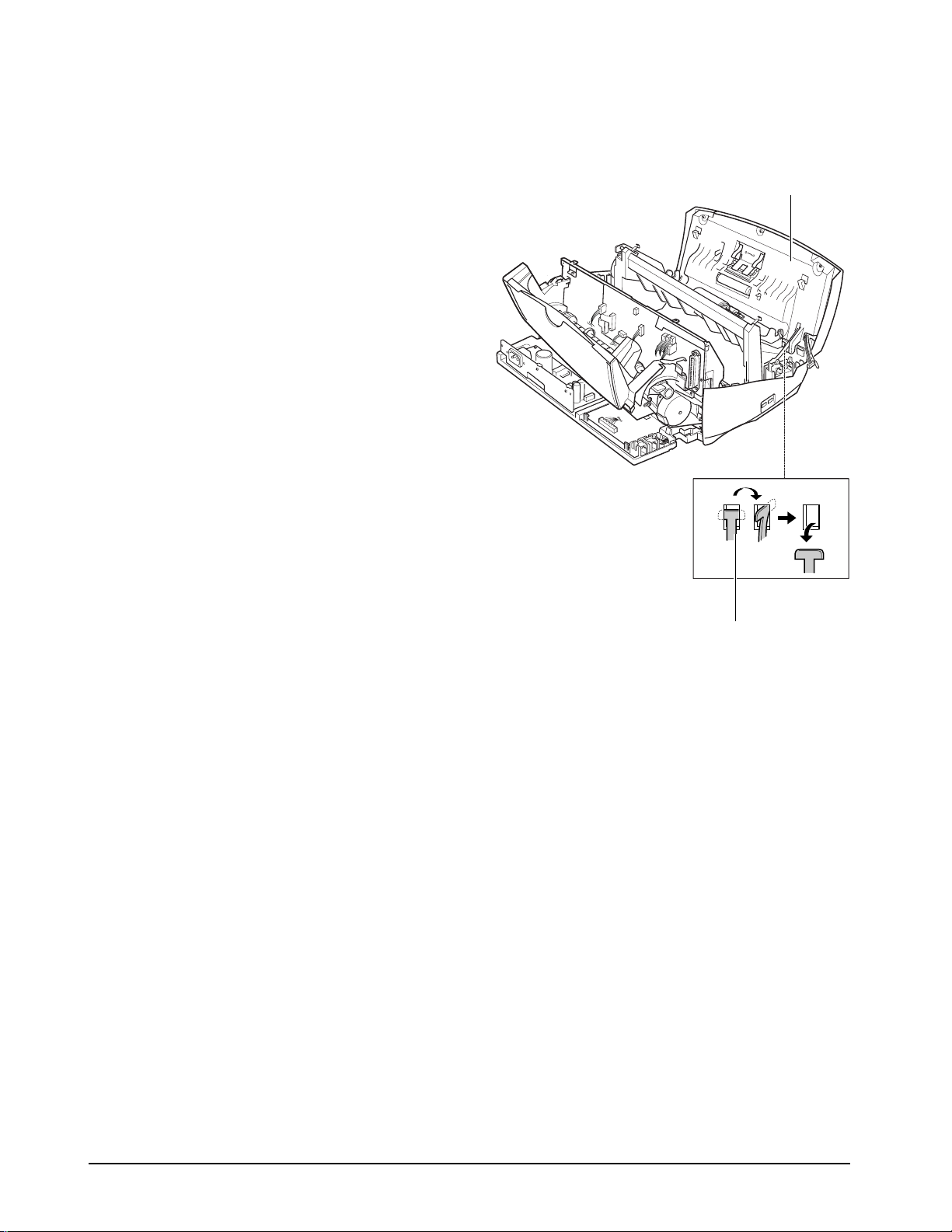

4-6-2 OPE Unit

1. Before you disassemble the OPE unit, you should

remove:

– Top Cover Ass’y (see page 4-2)

– Rear Cover Ass’y (see page 4-4)

2. Unplug the OPE (NPO) connector from the LIU

PBA.

3. Turn the tie stopper 90 degrees as shown below

and take out the OPE unit.

OPE unit

Tie stopper

Page 26

Samsung Electronics 4-11

Disassembly

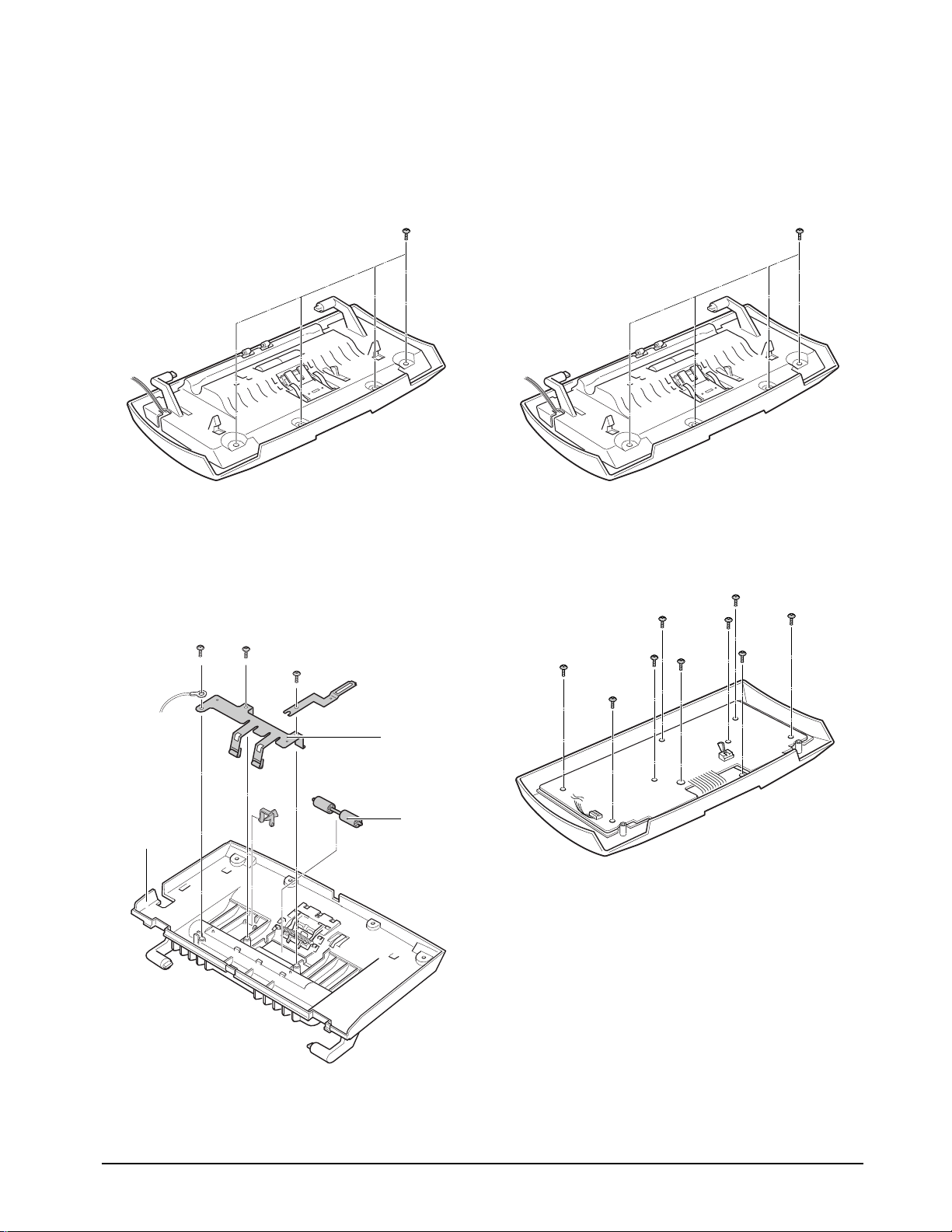

4-6-3 Roll Pinch

1. Before you disassemble the roll pinch, you

should remove:

– OPE Unit (see page 4-9)

2. Remove the four screws securing the OPE unit.

3. Turn the upper scan frame of the OPE unit over.

4. Remove the three screws and take out the spring

pinch. Then take out the roll pinch.

4-6-4 OPE PBA

1. Before you disassemble the OPE PBA, you

should remove:

– OPE Unit (see page 4-9)

2. Remove the four screws securing the OPE unit.

3. Remove the nine screws and take out the PBA

and LCD.

Notes:

• Do not turn the OPE unit upside down after you

remove the screws securing the PBA. Keys and

rubber contacts may be separated and easily lost.

• When you reassemble the OPE unit, make sure

the keys are in correct position.

• When you reassemble the PBA, secure the screws

according in the order of the number printed on

the PBA.

• After reassembling, operate the machine to make

sure it works properly.

• After reassembling, make sure the LCD is not

blocked.

Upper scan

frame

Spring pinch

Roll pinch

Page 27

4-12 Samsung Electronics

Disassembly

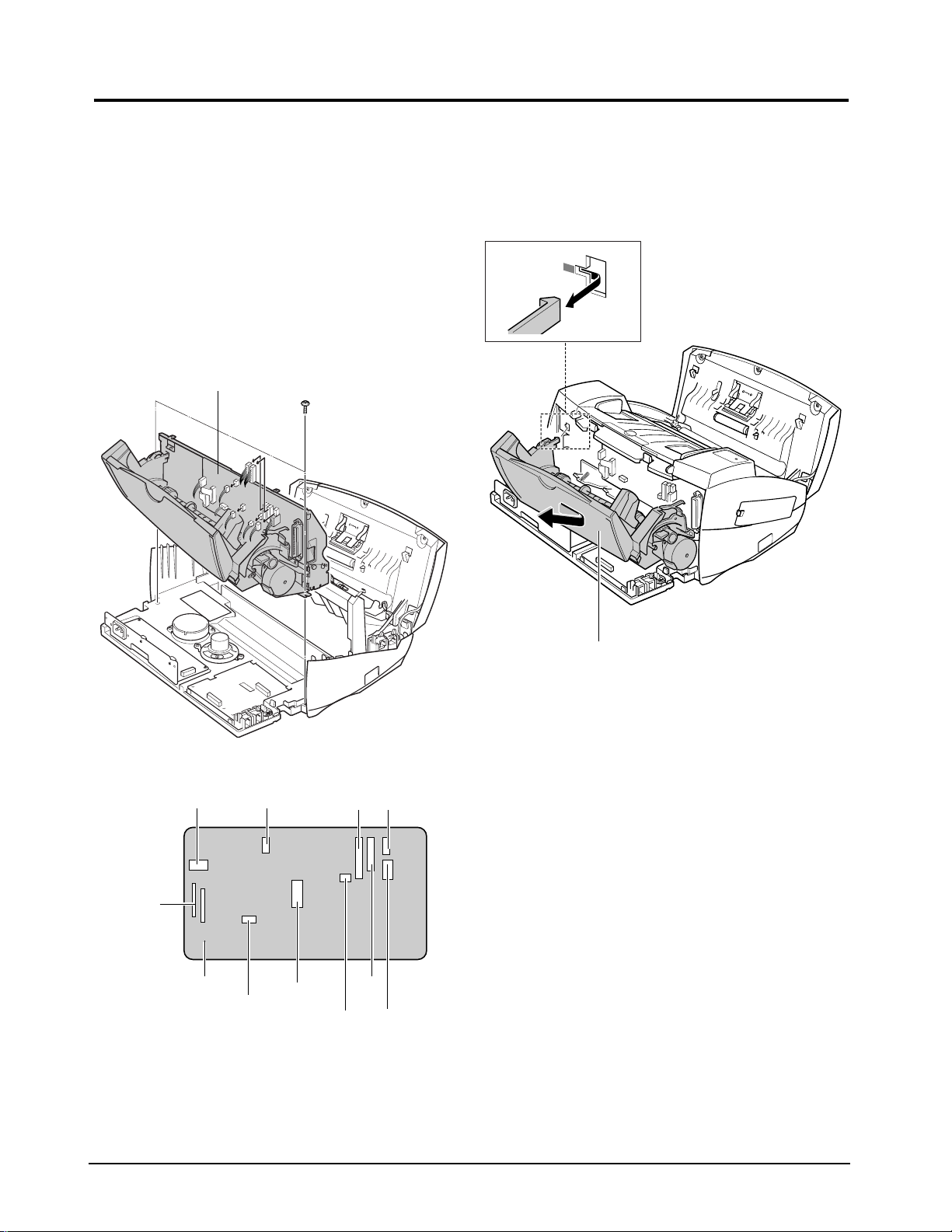

4-7 Printer Ass’y

4-7-1 Printer Unit

1. Before you disassemble the printer unit, you

should remove:

– Top Cover Ass’y (see page 4-2)

– Rear Cover Ass’y (see page 4-3)

2. Remove the two screws securing the printer unit,

and unplug the six connectors from the Main

PBA. Take out the printer unit.

Note: When you reassemble the unit, do not pinch or

short the wire harness.

3. Remove the ASF feeder ass’y from the printer unit

by pushing the tab inward and take the ass’y out

in the direction of arrow.

Main PBA

Print Head

Main PBA

Speaker

SMPS

Senser

LIU OPE

CIS

LF motor

TX motorCR motor

ASF feeder ass’y

Page 28

Samsung Electronics 4-13

Disassembly

4-7-2 ASF Feeder Ass’y

1. Before you disassemble the ASF feeder ass’y, you

should remove:

– Rear Cover Ass’y (see page 4-3)

2. Unplug all connectors from the Main PBA and

remove the two screws shown below.

4. Remove the one screw, then remove pick up shaft

from the ASF frame while pushing it to the right

to disengage the gear.

Note : When you reassemble the ASF feeder ass’y,

insure the harness in the line feed motor is not

pinched or shorted.

Pick up shaft

Page 29

4-14 Samsung Electronics

Disassembly

4-7-3 Home Ass’y

1. Before you disassemble the home ass’y, you

should remove:

– Printer Unit (see page 4-11)

2. Pushing the both ends of the home ass’y, take out

the ass’y in the direction of arrow.

4-7-5 Base Frame Ass’y

1. Before you disassemble the base frame ass’y, you

should remove:

– Printer Unit (see page 4-11)

– Carrier Ass’y

2. Remove the friction ass’y, then take out the

actuator feed.

3. Pull out the base frame ass’y.

Home ass’y

Roller friction ass’y

Actuator feed

Base frame ass’y

Page 30

Samsung Electronics 4-15

Disassembly

4-7-4 Carrier Ass’y

1. Before you disassemble the carrier ass’y, you

should remove:

– Printer Unit (see page 4-11)

2. Remove the cable holder. Remove the one screw

on the right side of the main frame, and remove

the spring. Then take out the carrier shaft.

4-7-6 Feed Roller Ass’y

1. Before you disassemble the feeder roller ass’y, you

should remove:

– Printer Unit (see page 4-11)

– Carrier Ass’y

– Base Frame Ass’y

2. Remove the bearing feed from the main frame.

Pull the feeder roller in the direction of arrow and

take it out.

Carrier shaft

Head cable

Cable holder

Feed roller

Bearing feed

Page 31

4-16 Samsung Electronics

Disassembly

4-7-7 Line Feeder Bracket Ass’y

1. Before you disassemble the line feeder bracket

ass’y, you should remove:

– Printer Unit (see page 4-11)

– Feeder Roller Ass’y (see page 4-12)

2. Remove the two screws and take out the LF

bracket ass’y.

4-7-8 Main PBA

1. Before you disassemble the Main PBA, you

should remove:

– Top Cover Ass’y (see page 4-2)

– Rear Cover Ass’y (see page 4-3)

2. Remove the three screws securing the Main PBA.

When you remove the one screw at the bottom,

pull the timing belt.

3. Unplug all connectors from the Main PBA.

4. Pull the sensor lever towards you and take out

the Main PBA.

LF bracket ass’y

Main PBA

Sensor lever

Timing belt

Page 32

6. Circuit

6-1 Main PBA

6-1-1 Summary

The main circuit that consists of CPU, MFP

c o n t roller (built-in 32bit RISC processor core :

ARM7TDMI) including various I/O device

drivers, system memory, scanner, printer, motor

d r i v e r, PC I/F, and FAX transceiver controls the

whole system. The entire stru c t u re of the main

c i rcuit is as follows:

Fig.6-1-1. Entire Structure of Main Circuit for Each Key Signal

Samsung Electronics 6-1

Page 33

6-1-2 MFP Controller (KS32C6200 : U16)

M F P C o n t roller consists of CPU(ARM7TDMI RISC

p rocessor), 2K-byte cache, data and address buses,

serial communication part with LIU(Line Interface

Unit), OPE(OPERATION PANEL) print head cont ro l l e r, parallel port interface, external DMApart to

receive data from external color image pro c e s s o r

(SCANIP:U18), LF/CR motor diver

c o n t roller and I/O contr o l l e r.

6-1-2-1. SYSTEM CLOCK

The internal clock frequency is 30MHz. 30MHz

system clock (MCLK) supplied from the outside is

used without being divided inside.

6-1-2-2. DATA& ADDRESS BUS CONTROL

• /RD & /WR

/RD & /WR signals are synchronized with

MCLK(30MHz) and become LOW ACTIVE.

These signals are strobe signals used to read and

write data when each CHIP SELECT is connected

with /RD and /WR pin of RAM, ROM, MODEM

and the outside devices and becomes active.

• C H I P SELECT (/IP_CS, /ROMCS, /MCS /

R A M C S )

- /IP-CS : SCANIP(U18) CHIP SELECT (LOW

A C T I V E )

- /ROMCS : ROM/FLASH MEMORY(U5) CHIP

SELECT (LOW A C T I V E )

- /MCS : MODEM(U15) CHIP SELECT (LOW

A C T I V E )

- /RAMCS : SRAM (U14) CHIP SELECT (LOW

A C T I V E )

When each CHIP SELECT is low, data can be read or

w r i t t e n .

• D0 - D15

- 16bit data bus

• A0 - A 1 7

- ADDRESS BUS (A18 - A21 are re s e r v e d . )

6-2 Samsung Electronics

Page 34

6-1-2-3, LIU(Line Interface Unit) Serial

Communication Part

U A RT (Universal A s y n c h ro n o u s

R e c e i v e r / Transmitter) at KS32C6200 enables the

main and LIU, main and OPE to transmit serial

Fig.6-1-2. UART BLOCK DIAGRAM

data. The block diagram of UART is as follows:

(Fig.6-1-2) KS32C6200 has 2 UART channels. The

baud rate is 9600bps.

Fig.6-1-3 UART DATAFORMAT

Samsung Electronics 6-3

Page 35

6-1-2-4 EXTERNAL D M A

It brings data from an external device (SCANIP:U18)

using DMAchannel 0. DMAREQUEST sent from an

external device to KS32C6200 activates DMA

ACKNOWLEDGE signal and drives DMAchannel 0

to produce CHIP SELECT and READ STROBE (/RD)

at the external

device and bring data from it. It generates address of

destination memory, CHIP SELECT and WRITE

STROBE (/WR) in order to move this data into

destination memory, and then stores the data.

Fig.6-1-4 EXTERNAL DMA TIMING DIAGRAM

6-4 Samsung Electronics

Page 36

6-1-2-5. DRAM CONTROLLER

6-1-2-6. PARALLEL PORT INTERFACE

As KS32C6200 has DRAM controller in it, DRAM can

be connected with external memory.

The control mode of DRAM controller enabling

E A R LY WRITE, NORMALREAD, PAGE MODE,

and BYTE/HALF WORD ACCESS supports EDO

DRAM as well as normal DRAM. DRAM

READ/WRITE signals are /R D and /W Rs i g n a l s

used to control system buses. It supports CAS

BEFORE RAS for DRAM REFRESH and self-re f re s h

mode for DRAM backup. Connected with common

/L C A S , /U C A Sand RAS [1:0], it consists of 2 banks.

Though each may be connected with up to 1M - 4M

h a l f w o rd, two (2) of 512 Kbytes are

connected for this pro d u c t .

This part connected with the computer through the

c e n t ronics connector makes possible parallel

interface with the computer. Data is transmitted

a c c o rding to the standard of IEEE P1284. This MFP

c o n t roller supports compatibility mode the

traditional way to transmit print data, nibble mode

(4bit data) to upload data to the computer, and

duplex high-speed transmission with the computer

E C P (Extended Capabilities Port: 8bit data

transmission) all together.

It enables PC data to be printed and scanned data to

be uploaded quickly to the computer. Besides,

various data transmission and reception with the

computer such as uploading received fax data,

downloading fax data to be sent, and monitoring system control signals and system conditions are carried

out here .

Fig.6-1-5 Compatibility Hardware handshaking Timing

Samsung Electronics 6-5

Page 37

Fig.6-1-6 ECP Hardware Handshaking Timing (forward)

Fig.6-1-7 ECP Hardware Handshaking Timing (reverse)

6-6 Samsung Electronics

Page 38

6-1-2-7. INKJET HEAD CONTROLLER

This part produces major control signals used to

drive INKJET head. It consists of signals to drive

head nozzles, /HGA[13:1], HOE[16:1], /F A U LTT E S T, /HEAD-EN, and BIASOFF, and consists of signals to check the status of the head, HEAD-DATA .

It has double height print head, system 208 nozzles

for mono and 192 nozzles for color, and uses

/HGA[13:1], HOE[16:1] signals and /HEAD-EN to

drive these nozzles. Fig.5-1-8 is timing diagram of

each signal.

Fig.6-1-8 Timing Diagram to Drive Head

Samsung Electronics 6-7

Page 39

Fig.6-1-9. Timing Diagram for Each Nozzle

The above control signals are sent to head driver and

the head driver converts these signals to the level

( + 11.75V) to drive head nozzles.

5-1-2-8. PRINTER MOTOR CONTROLLER

(CRPHA, CRPHB, CRIA0, 1, CRIB0, 1,

LFPHA, LFPHB, LFIA0, 1, LFIB0, 1)

M F P C o n t roller (KS32C6200:U16) supports 2

stepper motors. It controls CR (Carriage Return)

motor used to print documents and LF (Line Feed)

motor used to feed and eject paper.

CR motor controller can support 75, 150, 200, 300,

600, or 1200dpi according to resolution, while LF

motor controller supports uni-polar and bi-polar

a c c o rding to the kind of motors. Though full step,

half step and software control are possible for both,

bi-polar CR motor is controlled half step and LF

motor is controlled half step and quarter step here .

6-8 Samsung Electronics

Page 40

5-1-2-9. I/O PORT FOR KS32C6200

PIN NAME

G O P 0 / T X D 0

G O P 1 / T X D 1

G O P 2 / n E D A C K

G O P 3 / TO N E

G O P 4 / n R S T 0

G O P 5 / n I O W R 1

G O P 6 / n I O W R 2

G O P 7 / n I O R D 1

G O P 8 / n I O R D 2

G O P 9 / C L K O U T

G O P 1 0 / F I R E P S

G O P 11 / n H S C

PIN NO

1 2 2

1 2 4

1 3 9

1 4 9

1 5 0

1 3 4

1 5 5

1 5 6

1 5 1

1 5 2

1 5 3

1 5 4

I/O PORT NAME

p

p

p

p

p

p

p

p

p

p

p

p

L I T _ T X D

O P E _ T X D

n X D A C K

K E Y C L I C K

n R S T 0

n FA U LT _ T E S T

R X _ C T L

n H E A D _ E N

TO N E _ C T L

I P _ C L K

n R S T _ O U T

B I A S O F F

DESCRIPTION FOR STATE

H L

Serial Data Output to ILIU

Serial Data Output to OPE

D M AAcknowledge to

–

S c a n _ I P

Keyclick To n e

Watchdog Reset Signal Output

– Head Fault Test Enable

Line for RX. Line for TX. or Remote

– Head Enable

Line Monitoring K e y c l i c k

Clock Output for Scan_IP

External Reset Output

– Head Data Read

G O P 1 2 / n H S M

G I P 0 / n R X D 1

G I P 1 / n R X D 2

G I P 2 / n E I N T 1

G I P 3 / n E I N T 2

G I P 4 / n E D R E Q

G I P 5 / U C L K

G I O P 0 / T C K

G I O P 1 / T M S

G I O P 2 / T D I

G I O P 3 / n T R S T

G I O P 4 / T D O

3 0

1 2 3

1 2 5

1 3 6

1 3 7

1 3 8

1 2 8

3 7

3 8

3 9

4 0

4 1

p

I

I

I

I

I

I

B

B

B

B

B

C R _ R E F

L I U _ R X D

O P E _ R X D

n M I R Q

n T X _ I N T

n X D R E Q

H E A D _ D ATA

T C K

T M S

T D I

n T R S T

T D O

LQ Mode Printing Draft Mode Printing

Serial Data Input from ILIU

Serial Data Input from OPE

– Modem Interrupt request

SCAN motor Interrupt

–

–

Serial Head Data from Head

Test Clock for ICE

TA P Controller Enable –

Serial Data Input from Emulator

– TA P Controller Reset

Serial Data Output to Emulator

D M ARequest from Scan_IP

r e q u e s t

Samsung Electronics 6-9

Page 41

6-1-2-10. RESET CIRCUIT

As for this product, there are 2 power resets of primary reset(/F-POR) and secondary reset(/POR) and

also reset by watchdog timer (/RSTO). Primary re s e t

is used to initialize flash memory when the system is

turned on, while secondary reset is used to initialize

the whole system by initializing MFP c o n t ro l l e r

(KS32C6200) after primary

reset. Primary reset makes flash memory wait in

READ mode to fetch program

codes, and secondary reset makes the main

c o n t roller (KS32C6200) wake up and initialize

external peripherals to operate the system.

Fig.5-1-10 is Power Reset Timing Diagram.

Fig.6-1-10 POWER RESET TIMING DIAGRAM

• POWER MONITOR (U103: KIA7045F)

If +5V supplied to KIA7045F is so unstable as to

reach +4.65V - +4.35V (typically 4.5V), it will

recognize it as power failure. Then KIA7045F

output terminal becomes low (0V) and the voltage

is impressed to flash memory and KS32C6200, ru n-

KS32C6200 are reset first. Thereafter modem, print

c o n t rol parts and SCANIP(Color Image Pr o c e s s o r )

linked to /RSTOUT terminal of KS32C6200 are

reset as well. KIA7045F output

terminal of open drain stru c t u re is pulled up 5.1k Ω

and put out.

ning RESET (LOW ACTIVE). Flash memory and

6-10 Samsung Electronics

Page 42

6-1-3 System Memory

6-1-4-2. SCAN RESOLUTION

System memory consists of 512KB flash memory,

2MB DRAM, and 32KB SRAM. Flash memory,

DRAM and SRAM are selected by each CHIP

SELECT (/ROMCS, /RAS0, /RAS1, /LCAS, /UCAS,

/RAMCS), and data is accessed half word (16bits) by

half word and one byte (8bits) by one byte.

DRAM is designed to be able to add 2MB to the basic

2MB so that buyers can make their options.

In addition, the backup circuit built in for DRAM

keeps data in user memory during at least

30-miniute power failure. Super capacitor

(1F) is used as a backup element. SRAM holds

telephone numbers and journal information and can

keep minimum information using backup battery

( L i t h i u m ) .

6-1-4. Scanner

6-1-4-1. SUMMARY

This sheet-fed type device to read manuscripts has

300dpi CIS as an image sensor. The design is focused

on 30-sheet ADF and 3-second quick scan functions.

– Normal(Quick) : 1/3.85mm, 1/8mm (98×2 0 3 d p i )

– Fine : minor scanning 1/7/7mm, main

scanning 1/8mm (196×2 0 3 d p i )

– Super Fine : minor scanning 1/300inch, main

scanning 1/300inch(300×3 0 0 0 d p i )

6-1-4-3. CIS : Contact Image Sensor improves

p roductivity and is designed to be replaced easily.

Color models have color CIS.

➀ SF-4500/Msys4700/MJ-4500 : BN-30216D, 10Pin

C o n n e c t o r

– Minimum Scan Line Time: 1.8mS

– Light Source Power : 12V

– Maximum Pixel frequency : 2MHz

– Effective Sensor Element : 2552

– Clamp Level : 1.2 - 1.6V

– Bright Output : MIN 0.8V

➁ SF-4500C/Msys4800/MJ-4500C : CXB-30216G, 12

Pin Connector

– Minimum Scan Line Time for one color : 1.5mS

– Color Separation : RGB LED transfer mode

– Light Source Power : 12V

– Maximum Pixel frequency : 2MHz

– Effective Sensor Element : 2552

– Clamp Level : 1.2 - 1.6V

– Bright Output : MIN 0.8V

C I S

S C A N I P

CIS Control

Fig.6-1-11 CIP1A Block Diagram

Samsung Electronics 6-11

Page 43

6-1-4-4. IMAGE PROCESSING

1) Image signal input: CIS output signals are offset at

1-4V with about 2.8V white level. Optimum input

level of SCANIP is 1.5V offset and 3.5V white

level. So OPA M P is used to design

interface circuit of SCANIP.

2) Image processing : The scanner reads pixel data

value of image sensor CIS(Contact Image Sensor)

300dpi lines by 300dpi lines, and stores it in scan

b u ffer through TIP algorithm if Normal is

selected for Image Processor SCANIP, thro u g h

E r ror Diffusion algorithm if medium, or thr o u g h

D M A without algorithm if PC Scan mode.

Commonly for all the three modes, it is pro c e s s e d

after shading correction and gamma corre c t i o n .

5×5 Window Processing begins after data is store d

in 32K Byte external SRAM.

Image Processor SCANIPhas the following

s p e c i f i c a t i o n s :

➀ Package: 128 Pin QFP

➁ Operating Frequency: 25 - 40MHz

➂ Minimum Scan Line Time: 1.5mS

➃ Scan Resolution: Max. 300DPI

➄ Scan Width: B4

➅ Major functions

– Internal 8bit A D C

– Black/White shading correction for each color

R . G . B

– Gamma correction for each color R.G.B

– Mono CIS (Canon, Dyna) interface

– Color CIS (Canon, Dyna, Toshiba) interface

– Automatic Motor Contro l

– Image Processing Mode : TIP, Ord e red dither,

E r ror diff u s i o n

– 256 Gray Scale

– AGC function

– PC Gray Scan function

➆ External SRAM: 32Kbyte, 15Ns Access Ti m e

3) CIS LED Driver: LED in CIS is on with 11 . 7 5 V. TR

c i rcuit is built in to drive this LED.

– Maximum LED current: 300mA

4) PC Scan function

– Resolution(V×H) : 3 0 0×3 0 0 / 7 5×75dpi

( P re-scanning mode)

1 9 6×2 0 3 / 9 8×2 0 3 d p i

– Mono Bit Depth : 8bits Gray Scan/1bit Te x t

Scan/1bit Halftone Scan

– Color Bit Depth : 24bits (8bits/R.G.B.)

– PC Interface: IEEE 1284 NIBBLE, BYTE, ECP

– T WAIN Driver: 1CD-ROM title provided along

with Bundle S/W.

5) Additional Spec.

– Scan Line Time : 2.5mS/line

– Contrast Control : 3 Step

( N o r m a l / D a r k e n / L i g h t e n )

– Enlargement & Reduction : 25 ~ 200%

6-12 Samsung Electronics

Page 44

6-1-4-5 I/O PORT FOR SCANIP

R E G I S T E R

N A M E

G P I

G P O

PIN NAME

for A S I C

G P I 0

G P I 1

G P I 2

G P I 3

G P I 4

G P I 5

G P I 6

G P I 7

G P O 0

G P O 1

G P O 2

G P O 3

G P O 4

G P O 5

I / O P O RT N A M E

I

I

I

I

I

I

I

I

p

p

p

p

p

p

O K 2 P R I N T

H O M E _ S E N

r e s e r v e d

n P _ E X I T

P _ E M P T Y

n R I N G _ D E T

n H O O K _ O F F

RY / n B Y

r e s e r v e d

n O P E _ R S T

B L E D ( C / – )

R L E D ( C / – )

G L E D ( C / M )

RT C _ E N

DESCRIPTION FOR STA T E

H L

Head OK Head NG

Head parking –

– Paper Detected

Paper empty –

– Ring Detected

– H/S hook off

Flash Ready Flash Busy

OPE reset off OPE seset on

1

1

2

BLED On BLED Off

RLED On RLED Off

GLED On GLED Off

RTC Enable RTC disable

G P I O 1

G P I O 2

G P O 6

G P O 7

G P I O 0

G P I O 1

G P I O 2

G P I O 3

G P I O 4

G P I O 5

G P I O 6

G P I O 7

G P I O 8

G P I O 9

G P I O 1 0

G P I O 11

G P I O 1 2

G P I O 1 3

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

p

P R E _ H E AT

C L K _ S E L

r e s e r v e d

r e s e r v e d

r e s e r v e d

r e s e r v e d

r e s e r v e d

r e s e r v e d

r e s e r v e d

r e s e r v e d

C M L O N

V O L 2

V O L 1

V O L 0

r e s e r v e d

n S P K _ C T L

Head Preheat On –

Jupiter idle mode Jupiter ?? mode

Fax or Tel Line Ext Phone Connection

C o n n e c t i o n

Bell (3 level) Volume (4 level)

Bell or Volume control

–

Audio amp. off Audio amp. on

G P I O 1 4

G P I O 1 5

p

B

T H M _ C L K

T H M _ D ATA

Clock IN for T h e r m o m e t e r

Serial Data from/to T h e r m o m e t e r

1 C/– : Color Only

2 C/M : Color/Mono

Samsung Electronics 6-13

Page 45

6-1-5 Printer

6-1-5-1. GENERAL

It drives inkjet head to print printing data re c e i v e d

f rom the computer or fax data coming through the

line. It roughly consists of head driver, head

c o n t ro l l e r, and the ambient temperature sensor. Fig.61 - 11. Block Diagram of Printer shows the entire stru ct u re .

6-1-5-2. HEAD DRIVER (U26, U27, U32, U22)

This part drives and inks inkjet head. Color inkjet

head drives 192 nozzles, while mono inkjet head drives 208 nozzles. Mono inkjet head is composed of 16

g roups of 13 nozzles. As to the driver that composes

each nozzle, 13 row 7-bit driver (U26, U27) selects

head address and 16 column 8-bit

driver (U32, U33) sends head data. Head driver

converts control signals from MFP c o n t roller to

+ 11 . 7 5 V, the level to be able to drive the head, and

p rovides them for the inkjet head.

• Row Driver Circuit (HD7:U26:U27)

This is a 13-line signal impressed to row drive IC

t h rough the output port of MFPc o n t ro l l e r ( / H G A 1

- /HGA13), used as an address to drive the head in

ink cartridge. Pulse period differs according to

head driving

f re q u e n c y. In 1200dpi (in case of Head: 12KHz)

mode, timing period is 2.6usec (1/1200÷16 gro u p s ) .

The signal put in each driver(window time) is

active “L”, with the biggest driver current max

1 0 0 m Aand output voltage +1 1 . 7 5 V .

• Column Driver Circuit (HD8:U32,U33)

It is the fire enable pulse of real head. 16 lines are

put out as head driving data lines through the output port of MFP c o n t roller (HOE1 - HOE16).

Enable pulse impressed to the head is put out within window time (Low). It has the function to move

it forward or backward by the register in MFP c o nt ro l l e r. Besides the output signal may

d i ffer in accordance with the type of head (mono or

color). If there is data, printing image is put out at

“H”. If not, it is put out at “L”. In case of Babbage

head, pulse width is always 1.3use re g a rdless of

the type of the head, with the

maximum driving current 400mAand output voltage +11 . 7 5 V.

6-14 Samsung Electronics

Page 46

6-1-5-3. HEAD CONTROLLER

This part consists of +22V Power Controller to

c o n t rol head driver, Fault Test, Head Detection,

Substrate Heating and ambient Te m p e r a t u re

S e n s o r. It checks and controls head driver and ink

c a r t r i d g e .

Fig.6-1-12 Block Diagram of Printer

Samsung Electronics 6-15

Page 47

• +22V Power Contro l l e r

If you insert power cords, the main board will be

supplied with power. /POR signal put out thro u g h

reset circuit activates MFP c o n t ro l l e r

(K32C6200:U16) and MFP c o n t roller puts out external circuit reset signal /RST - O U T. This /

R S T-OUT signal and Vrefx (+2.5V) divided thro u g h

+30V are impressed to the input

terminal of the comparator, putting out +22V if the

output of the comparator is “high” or getting

turned off if “low”.(in case of /FA U LT-TEST

signal: HIGH) While +22V is being impressed after

/ R S T-OUT is “High”, comparator output gets

“low” and turns off +22V driving TR(TIP112) if

/ FA U LT-TEST signal is put out at “low” when you

check a short of the head driver and the ink cartridge (head).

• FA U LT TEST CIRCUIT

This is a signal to detect whether the head

receiving the output of head column driver is in a

short. After /F A U LT-TEST signal is put out at

“low” and +22V is turned “off”, “OK2PRINT”

signal is entered. The port of KS32C6200(U16)

shows normal condition if “H” and a short if “L”.

If you make FA U LT-TEST output “L” to detect

fault of the head, +22V gets off. If the head is in a

short (LOW), when the level of “/FA U LT- T E S T ”

signal goes “L” and final “OK2PRINT” output

goes “L”. KS32C6200(U16) reads this signal and

checks whether the head input receiving the

driver output is in a short. Diode cathode is

attached to each output transistor collector in the

column driver. 8 anode terminals of diode become

common as one and put out /FA U LT signal, which

is pulled up by bias circuit controlled by /F A U LTTEST and shows the condition by OK2PRINT

t h rough the comparator.

• S U B S T R ATE HEAT CIRCUIT

Mono ink cartridge of Babbage head is 600dpi head

that uses pigment ink. It is very sensitive to the

t e m p e r a t u re in and around the cartridge. In

p a r t i c u l a r, the viscosity of ink affects print quality

as it is inversely proportional to temperature by an

exponential function. This signal used to

compensate it helps you get equal inking quality

by warming the ink chamber in the cartridge with

aluminum pattern heater before starting to print if

the surrounding temperature is lower than

s t a n d a rd (below 35°…).(Refer to Timing Chart.) It

sends PRE-HEAT signal through I/O port of

SCANIP(Color Image Processor:U18) and supplies

+ 11 . 7 5 V.

Mono Head

7 0 ° C

3 5 ° C

Pre-Heat if below 35°c

Fig.6-1-13. Temperature around Mono Head

6-16 Samsung Electronics

Page 48

Color Head

7 0 ° C

Fig.6-1-14. Temperature around Color Head

• HEAD DETECTION CIRCUIT

Babbage ink cartridge has 8-bit mask ROM I.D. to

check the type of cartridge. In order to detect the

head, HSM signal is used as ENABLE signal and

BA3 signal as STA RT & STO P B I T, and BA1 and

BA2 as clock signal of each bit, and ID signal in the

cartridge is put in HEAD-DATAport of KS32C6200

t h rough BSF line. With each bit

c o n t rolled, 8bit I.D data is read and ST O Pbit is put

out of BA3(LOAD) port. Then it finishes.

If data is mono, it is 07H. If color, 08H.

Fig.6-1-15. HEAD DETECTION TIMING DIAGRAM

Samsung Electronics 6-17

Page 49

• SURROUNDING TEMPERATURE SENSOR

DS1621S(DALLAS SEMI.) is applied to read the

t e m p e r a t u re around ink cartridge. It is used to get

optimum inking quality by keeping the viscosity of

ink in the cartridge in the specified lerel. The way

to read temperature is similar to EEPROM, cont rolled by THM-CLK, THM-DATALINE. Digital

thermometer to check the surrounding temperature

is assembled along with home sensor in the frame

of assembly CR. After each line is inked, it re a d s

the surrounding temperature and heats substrate

heater in the ink cartridge during the accelerating

time of CR to keep the viscosity of ink in the specified lere l .

6-1-5-4. HEAD DRIVING TIMING

C o n t rol signal from MFPc o n t roller (KS32C6200:U16)

enters the head driver (U26, U27, U32, U33) and it

becomes the level to be able to drive the head nozzles

( + 11.75V). It is depicted in the following diagram.

Fig.6-1-16. HEAD DRIVING TIMING DIAGRAM

6-18 Samsung Electronics

Page 50

Fig.6-1-17. TIMING DIAGRAM FOR EACH NOZZLE

Samsung Electronics 6-19

Page 51

6-1-5-5. INK CARTRIDGE

• PIN A R R AY OF MONO INK CART R I D G E

T h e re are 208 heater chips in mono ink cartridge.

C o l u m n

D a t a ( B P x )

1 1 2 1 1 5 9 3 2 3 1 7 11 5 2 5 1 9 1 3 7

2 2 0 1 4 8 2 2 2 1 6 1 0 4 2 4 1 8 1 2 6 2 6

3 2 7 4 7 4 1 3 5 2 9 4 9 4 3 3 7 3 1 5 2 4 5 3 9 3 3

4 4 6 4 0 3 4 2 8 4 9 4 2 3 6 3 0 5 0 4 4 3 8 3 2 5 2

5 5 3 7 3 6 7 6 1 5 5 7 5 6 9 6 3 5 7 7 7 7 1 6 5 5 9

6 7 2 6 6 6 0 5 4 7 4 6 8 6 2 5 6 7 6 7 0 6 4 5 8 7 8

7 7 9 9 9 9 3 8 7 8 1 1 0 1 9 5 8 9 8 3 1 0 3 9 7 9 1 8 5

8 9 8 9 2 8 6 8 0 1 0 0 9 4 8 8 8 2 1 0 2 9 6 9 0 8 4 1 0 4

9 1 0 5 1 2 5 11 9 11 3 1 0 7 1 2 7 1 2 1 11 5 1 0 9 1 2 9 1 2 3 11 7 111

1 0 1 2 4 11 8 11 2 1 0 6 1 2 6 1 2 0 11 4 1 0 8 1 2 8 1 2 2 11 6 11 0 1 3 0

11 1 3 1 1 5 1 1 4 5 1 3 9 1 3 3 1 5 3 1 4 7 1 4 1 1 3 5 1 5 5 1 4 9 1 4 3 1 3 7

1 2 3 4 5 6 7 8 9 1 0 11 1 2 1 3

Address (BA1_ ~ BA13_)

1 2 1 5 0 1 4 4 1 3 8 1 3 2 1 5 2 1 4 6 1 4 0 1 3 4 1 5 4 1 4 8 1 4 2 1 3 6 1 5 6

1 3 1 5 7 1 7 7 1 7 1 1 6 5 1 5 9 1 7 9 1 7 3 1 6 7 1 6 1 1 8 1 1 7 5 1 6 9 1 6 3

1 4 1 7 6 1 7 0 1 6 4 1 5 8 1 7 8 1 7 2 1 6 6 1 6 0 1 8 0 1 7 4 1 6 8 1 6 2 1 8 2

1 5 1 8 3 2 0 3 1 9 7 1 9 1 1 8 5 2 0 5 1 9 9 1 9 3 1 8 7 2 0 7 2 0 1 1 9 5 1 8 9

1 6 2 0 2 1 9 6 1 9 0 1 8 4 2 0 4 1 9 8 1 9 2 1 8 6 2 0 6 2 0 0 1 9 4 1 8 8 2 0 8

6-20 Samsung Electronics

Page 52

• PIN A R R AY OF COLOR INK CART R I D G E

T h e re are 192 heater chips in mono ink cartridge. One cartridge has 64 Cyan, 64 Magenta, 64 Yellow heaters

and (64 x 3 colors) 192 nozzles.

C o l u m n

D a t a ( B P x )

1 - 1 9 1 3 7 11 2 1 1 5 9 3 2 3 1 7 11 5

2 1 5 1 2 6 - 2 0 1 4 8 2 2 2 1 6 1 0 4 2 4

3 2 5 4 5 3 9 3 3 2 7 4 7 4 1 3 5 2 9 4 9 4 3 3 7 3 1

4 4 4 3 8 3 2 2 6 4 6 4 0 3 4 2 8 4 8 4 2 3 6 3 0 5 0

5 5 1 7 1 6 5 5 9 5 3 7 3 6 7 6 1 5 5 7 5 6 9 6 3 5 7

6 7 0 6 4 5 8 5 2 7 2 6 6 6 0 5 4 7 4 6 8 6 2 5 6 7 6

7 7 7 9 7 9 1 8 5 7 9 9 9 9 3 8 7 8 1 1 0 1 9 5 8 9 8 3

8 9 6 9 0 8 4 7 8 9 8 9 2 8 6 8 0 1 0 0 9 4 8 8 8 2 1 0 2

9 1 0 3 1 2 3 11 7 111 1 0 5 1 2 5 11 9 11 3 1 0 7 1 2 7 1 2 1 11 5 1 0 9

1 0 1 2 2 1 6 6 11 0 1 0 4 1 2 4 11 8 11 2 1 0 6 1 2 6 1 2 0 11 4 1 0 8 1 2 8

11 1 2 9 1 4 9 1 4 3 1 3 7 1 3 1 1 5 1 1 4 5 1 3 9 1 3 3 1 5 3 1 4 7 1 4 1 1 3 5

1 2 3 4 5 6 7 8 9 1 0 11 1 2 1 3

Address (BA1_ ~ BA13_)

1 2 1 4 8 1 4 2 1 3 6 1 3 0 1 5 0 1 4 4 1 3 8 1 3 2 1 5 2 1 4 6 1 4 0 1 3 4 1 5 4

1 3 1 5 5 1 7 5 1 6 9 1 6 3 1 5 7 1 7 7 1 7 1 1 6 5 1 5 9 1 7 9 1 7 3 1 6 7 1 6 1

1 4 1 7 4 1 6 8 1 6 2 1 5 6 1 7 6 1 7 0 1 6 4 1 5 8 1 7 8 1 7 2 1 6 6 1 6 0 1 8 0

1 5 1 8 1 - - 1 8 9 1 8 3 - - 1 9 1 1 8 5 - - - 1 8 7

1 6 - - 1 8 8 1 8 2 - - 1 9 0 1 8 4 - - 1 9 2 1 8 6 -

Samsung Electronics 6-21

Page 53

6-1-6 Motor Driver

6-1-6-1. GENERAL

This product use 3 stepper motors, i.e. CR(Cartridge

Return) motor and LF(Line Feed) motor, TX

( Transmission) motor.

CR motor moves left and right all-in-one carriage of

inkjet head and shuttle scanner. It helps the printer

print accurately on the paper. LF motor is driven to

feed and eject paper for printing and to feed and eject

documents to read for scanning. Bi-polar CR motor is

c o n t rolled half step with maximum 24ips(inch/sec),

while LF motor half step and

quarter step at maximum 6ips.

C R _ R E F

H L L 4 9 0 Mono LQ is being driven

C R I A 1 C R I A 0

( C R I B 1 ) ( C R I B 0 )

C U R R E N T ( m A ) O P E R AT I O N R E M A R K

6-1-6-2. CR (CARRIAGE RETURN) MOTOR

DRIVING CIRCUIT

CR motor moves the carriage left and right when ink

cartridge prints something on paper.

- Motor Type : Stepper motor, bi-polar

- Driving Voltage : +30V

- Winding Resistance : 6Ω ± 10%

- Driving IC : TEA3718DP × 2

L L L 6 7 0 Color draft is being driven

L L L 6 7 0 Mono draft is being driven

X H H 0 No current

As shown in the above table, current in each mode is

adjusted by voltage of driver(U25, U28) CRV R E F

input. If the output of CR_REF signal controlled by

M F P c o n t roller(U16) is “low”, TR(Q12) will be turned

o ff and the voltage put in to CRVREF of

driver (U25, U28) with +5V divided will go up

(+4.5V).

It becomes the standard of the driver, resulting in

high current. If CR_REF output is “high”, TR(Q12)

will be turned on and the voltage put in to CRV R E F

will go down (+3.0V), resulting in low current in the

m o t o r.

6-22 Samsung Electronics

Page 54

6-1-6-3. LF (LINE FEED) MOTOR DRIVING CIRCUIT

LF motor is driven to feed and eject documents and paper.

- Motor Type: stepper motor, bi-polar

- Driving Voltage : +30V

- Winding Resistance : 12Ω ± 10%

- Driving IC : PBL3717A × 2

L F I A 1 L F I A 0 C U R R E N T ( m A ) O P E R AT I O N R E M A R K

L L 6 7 0 When feeding document/paper

L H 4 0 0 When ejecting document/paper

X H 0 No current

6-1-6-4. TX(TRANSMISSION) MOTOR DRIVING CIRCUIT

TX Motor is driven at maximum 1200pps when feeding or ejecting sheets.

- Motor Type: stepper motor

- Driving Voltage : +30V

- Winding Resistance : 4.6Ω ± 10%

- Step Degree : 7.5 deg/step

- Driving IC : PBL3717A× 2

T X I A 1 T X I A 0 C U R R E N T ( m A ) O P E R AT I O N R E M A R K

L L 6 7 0 Quick Scan/Fine/Super Fine

H L 2 2 1 S t a n d b y

H H 0 I d l e

Driving speed for each mode

MODE PHASE S P E E D R E M A R K

Quick Scan 2–2 phase 1 2 0 0 p p s

F i n e 1–2 phase 4 0 0 p p s

Super Fine 2–2 phase 4 0 0 p p s

Samsung Electronics 6-23

Page 55

6-1-7 FAX Transceiver

6-1-7-1. GENERAL

This circuit processes transmission signals of modem

and between LIU and modem.

This circuit is added only to SmartJet 2000,

S F - 4 3 0 0 C .

6-1-7-2. MODEM (U15)

K S 1 6 117 is a single chip fax modem. It has functions

of DTMF detection and DTMF signal production

as well as functions of modem. TX OUT is

transmission output port and RX IN is received data

input port. /POR signal controlled by MFP

c o n t roller (U16:KS32C6200) can initialize

modem(/RST_OUT) without turning off the system.

D0 - D7 are 8-bit data buses. RS0 - RS4 signals to

select the register in modem decide the mode. /CS is

a

signal to select modem chips. /RD and /WR signals

c o n t rol READ and WRITE re s p e c t i v e l y. /IRQ is a signal for modem interrupt.

Transmission speed of KS16117 is supported up to

1 4 . 4 k .

6-1-7-3. TRANSMITTER

This circuit processes transmission output, analog

signal of modem(KS16117).

Output signal in each mode goes out of modem

( T X O U T:U15-44). After D/Asignals are smoothed

and filtered through active filter (U12-2), they are

b u ff e red under OPAMP(U12-6) and put out to LINE

t h rough LIU boar d .

6-1-7-4. RECEIVER

In the receiving mode, analog signals coming in

t h rough LIU board are amplified at OPA M P

(U13-6), and then transmitted to input terminal of

modem (RXIN:U15-45) through smoothing filter

( U 1 3 - 2 ) .

M O D E M

K S 1 6 11 7

( U 1 5 )

U 1 2

U 1 3

Fig.6-1-18. FAX TRANSCEIVER

FAX T R A N S M I S S I O N

LIU

FAX RECEPTION

6-24 Samsung Electronics

Page 56

6-2. OPE PBA

6-2-1. SUMMARY

OPE Board is separated functionally from the main

b o a rd and operated by the micom(Z8601) in the

b o a rd. OPE and the main use UART (universal async h ronous receiver/transmitter) channel to exchange

information. OPE reset can be controlled by the main.

OPE micom controls key-scanning and LCD and

LED display, detects documents and

senses SCAN position. If there occurs an event in

OPE (such as key touch and sensor level change), it

sends specific codes to the main to respond to the situation and the main analyzes these codes and operates the system. For example, if the main is to display

messages in OPE, the main transmits data thro u g h

U A RT line to OPE according to the

designated format and OPE displays this on LCD,

LED. OPE’s sensing is also transmitted to the main

t h rough UART line and then the main drives

necessary operation.

6-2-2 OPE Circuit

OPE PBAconsists of U1 (MICOM, Z8601), LCD, key

matrix, LED indicators, SCAN position sensor and

the document detect sensor. Refer to OPE Schematic

Diagram and Wiring Diagram sections of this manua l .

• Signals from the key matrix are delivered to

U 1 X / Y input pin group (P1-x).

• U1 pin 4 (TXD ATA) is the UART code sent to

MAIN PBA.

• Display from the controller is received at U1 pin 5

(RX DAT A ) .

• LCD drive signals are sent from U1 P2-x pin gro u p ,

P3-4~P3-6 pins.

• Machine status LED drive signals are sent from U1

P0-x pin gro u p .

• Document detect sensor output is received at U1

pin 33 (P3-3).

• Scan position sensor output is received at U1 pin 43

( P 3 - 1 ) .

Fig.6-2-1. OPE BLOCK DIAGRAM

Samsung Electronics 6-25

Page 57

6-3 LIU PBA

6-3-1 Summary

LIU(Line Interface Unit) circuit added only to

SF-4500, SF-4500C is controlled by the main circuit.

It monitors telephone line and helps interface

between the system and the telephone line. It uses

1-LIU(STI9510) to control the whole LIU,

MODEM/LINE INTERFACE, RING SIGNAL

D E T E C TOR, DIALER, LINE CURRENT

D E T E C TOR, and SERIALI N T E R FA C E .

6-3-2 Modem/Line Interface

This is the path through which transmitted and

received data of modem is put in and out.

• CML1 Relay: It divides telephone line into

external telephone and fax.

• U3-3 TIT(Transformer Input from T r a n s f o r m e r ) :

This single ended input receives image signals

f rom modem through transformer T2 and

transmits them on telephone line.

• U3-40 ROT(Receive Output Transformer): This output transformer receives signals on telephone line

and delivers them to modem through

transformer T1. It has AC impedance of 10Kohm or

o v e r.

• AC impedance: Normal operation range of

U3(STI9510) is from 15mAto 100mA. DC

characteristics depend on the voltage of U3-37

LI(Line Input) terminal and the voltage of

resistance R48 between U3-37 LI(Line Input)

terminal and U3-39 LS terminal.

6-3-3 Ring Signal Detector

• U3-28(MO) terminals are ring signal output

terminals. Q4 and Q5 put out ring signals and

drive Piezzo. It has only the functions related to

ring detection such as driving the photocoupler of

U4 and delivering ring signals to MFP

c o n t roller of the main.

6-3-4 Dialer

6-3-4-1. MF DIAL

• Default mode it is set in DP. You can change it to

MF mode by control of MFP c o n t ro l l e r.

• MF signal can be measured at (tone level of low

g roup: typical - 14dBm) U3-4 MFO(DTMF

Generator Output). The signal is adjustable by R40,

R41 and C29. The adjusted signal enters U3-9 MFI

(DTMF Amplifier Input) and is amplified to be

transmitted on telephone line.

• U3-39 LS(Line Current Sense Input) terminals

show the final signals transmitted to telephone

l i n e .

6-3-4-2. DP DIAL

• If U3-2(DMS) is made Vcc by R42, it is set at 33:67

D P signal. If it is made Vss by R43, it is set at DP

signal. This product is set at DP s i g n a l .

• D P signal is made by U3-27(DPn) terminals. This

signal turns on/off Q1. The signal made at that

time turns on/off Q2, which interrupts DC

c u r rent on telephone line and puts out pulse

signal on telephone line.

• U3-35 CS terminals : It makes Make Resistance by

shorting telephone line with Vss during Make period of DPd i a l .

6-3-5 Line Current Detector

• When CML1 relay connects telephone line, U3

(STI9510) of LIU board and MFP c o n t roller of the

main board (U16) start communication thro u g h

U A RT. U3 of LIU board sends signal that includes

information of line current value, whenever it

receives orders or data from U16 of the main board .

6-26 Samsung Electronics

Page 58

6-3-6 Serial Interface

• This part does serial communication with MFP

c o n t roller of the main board (MAIN PBA:U16) that

c o n t rols the whole system. It controls LIU by giving and taking all control orders and line

s t a t u s .

• U 3 - 11 RxD : Schmitt Trigger input, Receiving

t e r m i n a l .

• U3-29 TxD : Open Drain output terminal

• S t a n d a rd UART communication

- Baud Rate : 9600bps

- Start, Stop bit : 1bit each

- Data bits : 8 bit

- Parity bit : none

6-3-7 MAJOR FUNCTIONS OF PARTS

1) U3 : S T I 9 5 1 0

- Key part of LIU board. Speech Network,

D i a l e r, Ringer and UART are built in one IC

p a c k a g e .

2) U5 : PC817

- Photo coupler. It enables UART of

U3(STI9510) to receive control signal or

dialing information from MFP c o n t roller of

the main board (U15).

- Insulation Detween prinary and secondany

c i rcuit part.

3) U6 : PC817

- Photo coupler. It enables UART ( U 3 - 2 9 : T x D )

of U3(STI9510) to deliver telephone line

status or response signal about control

signal or dialing information from LIU MFP

c o n t roller of the main board (U15).

- Insulation Detween prinary and secondany

c i rcuit part.

4) U4 : PC817

- It senses and delivers ring signal to the main

b o a rd .

- Insulation Detween prinary and secondany

c i rcuit part.

5) U2 : PC814

- It senses hook-off (Line connection) of the

external telephone and delivers it to the

main board .

- Insulation Detween prinary and secondany

c i rcuit part.

6) BD1 : BRIDGE DIODE

- R e g a rdless of the polarity of DC power

f rom telephone line, the voltage put out on

Pin.1 has always + polarity against pin

Pin.2. So DC loop forms always in the same

d i rection re g a rdless of the polarity of the

telephone line.

7) T2,T3 : T R A N S F O R M E R

- It delivers signals from the telephone line

to modem or signals from modem to the

t e l e p h o n e

l i n e .

- Insulation Detween prinary and

secondany circuit part.

Samsung Electronics 6-27

Page 59

6-4 SMPS

6-4-1 Block Diagram of Power Circuit

Refer to the following block diagram.

POWER SUPPLY

6-4-2. Specifications of Power Circuit

6-4-2-1. INPUT CONDITIONS

120V 220V Free Voltage

1 Input Rated Voltage A C 1 2 0 Vac (a) A C 2 2 0 – 2 4 0 Vac (a) A C 11 0 – 2 4 0 Vac (a)

2 Input Voltage Turning Range A C 8 5 – 1 3 5 Vac (b) A C 1 8 0 – 2 7 0 Vac (b) A C 8 5 – 2 7 0 Vac (b)

3 Rated Grequency 60Hz 50–60Hz 5 0 – 6 0 H z

4 Frequency Range 57–63Hz 47–63Hz 47–63Hz

5 Input Current 0.5Arms 0.3Arms 0 . 5 A r m s

6-28 Samsung Electronics

Page 60

6-4-2-2. OUTPUT CONDITIONS

NO ITEM CH1 CH2 CH3

1 RATED OUTPUT VOLTAGE +5.0V +11.75V +30V

2 RATED OUTPUTCURRENT 0.5A 0.8A 0.5A

3 MAXIMUM LOAD CURRENT 0.8A 1.3A 0.76A

4 LOAD CHANGE RANGE 0.1 ~ 0.8A 0.03 ~ 1.3A 0.05 ~ 0.76A

6-4-3. Power Circuit

6-4-3-1 INPUT

This product is equipped with a thre e - w i re

g rounding-type power inlet. Insulation is class 1.

When a power device part breaks down or some

t rouble in this circuit causes a short, excess curr e n t

runs through a fuse and blows it to protect power

devices and the system from excess current and

p revent a fire .

Input filter of power input terminal removes line

noise flown in from outside and reduces noise which

is made in power circuit and logic part and conducted or radiated through power cord s .

AC input voltage is rectified by bridge diode of full

wave re c t i f i e r, is converted to DC voltage by smoothing circuit, and switches the power device of this

voltage.

As switching is in RCC(Ringing Choke Converter)

mode, switching frequency changes from about

50KHz to 100KHz.

PWM(Pulse Width Modulation) Control Circ u i t

adjusts the duty of the switching device by sensing

the change of output voltage, and protects this

p roduct from excess current by receiving signals

f rom excess current detecting circ u i t .

6-4-3-2 DRIVING CIRCUIT (START-UP CIRCUIT)

If you insert a power plug into AC outlet, full-wave

rectified DC output voltage is generated at input

e l e c t rolysis condenser and supplied to the gate of a

switching device through driving resistance. This

voltage drives the switching device. Once it is

driven, it continues to switch via PWM control

c i rcuit with power supplied by auxiliary coil Nb.

6-4-3-3 SWITCHING CIRCUIT

(VOLTAGE STABILIZATION)

11.75V of 2nd voltage is detected by voltage detector

and feeds back through photo coupler to 1st PWM

C o n t rol Circuit signals compared by error amplifier.

PWM Control Circuit controls the gate of power transistor according to the feedback voltage so as to supply load with stable output voltage.

Samsung Electronics 6-29

Page 61

6-4-3-4 OCP CIRCUIT

(OVER CURRENT PROTECTIVE CIRCUIT)

If a short in secondary load terminal or a short inside

power device causes excess current, power consump-

tion increases. Then it increases current of power

t r a n s i s t o r.

The current of power transistor increases linearly

when it is on. This current is detected by sensing

resistance and is impressed to excess voltage

p rotective circuit of PWM control circuit through RC

integration circuit where over current protection is

built in.

If this voltage becomes bigger than Vbe of excess

c u r rent control transistor, the potential of power tran-

sistor gate falls immediately and it stops driving

power transistor to protect it from excess current.

6-4-3-5 O V P CIRCUIT

(OVER VOLTAGE PROTECTIVE CIRCUIT)

If the main power of power device 11.75V incre a s e s

a b n o r m a l l y, this excess voltage is detected by OVP

detecting circuit and 11.75V output terminal shifts to

a state similar to

a short.

If 11.75V output terminal shorts, over current runs on

over current detecting terminal and OCP c i rc u i t

operates to prevent a fire in power device.

6-4-3-6 +5V OUTPUT TERMINAL

S q u a re wave voltage generated by Ns1 produces DC

voltage rectified and smoothed by half-wave re c t i f i e r.

This voltage put in to a thre e - w i re regulator generates stable DC power of +5V.

6-4-3-7 +30V OUTPUT TERMINAL

S q u a re wave voltage generated by Ns2 is r e c t i f i e d

and smoothed by half-wave rectifier and supplies

load with output voltage without separate

regulation.

6-4-3-8 +11.75V OUTPUT TERMINAL

S q u a re wave voltage generated by Ns3 is r e c t i f i e d

and smoothed by half-wave re c t i f i e r, and then detected by voltage detector. Signals compared by erro r

amplifier are fed back to primary PWM

c o n t rol circuit through photo coupler.

PWM control circuit controls the voltage of power

transistor gate driver according to the voltage to supply load with stable output voltage.

6-5. Others

6-5-1. Paper Sensing Circuit

This circuit senses whether there is paper or not,

using photo interru p t e r. If there is no paper, the lever

will cover its sensor and output “/P_EXIT”

will become “High”. If there is paper, the lever will

be lifted and output “/P_EXIT” will become “Low”.

6-30 Samsung Electronics

Page 62

6-5-2. Home Sensing Circuit

This circuit senses whether carriage is at home or

not. This function is carried out when the system is

turned on or when the head is capped. Photo

i n t e r rupter is used as a home detecting sensor,

attached to the back of the carriage. When the

carriage moves left and right, output is “high” if the

frame rib covers the center of the sensor and “low” if

it is out of home.

6-5-3 Temp IC Driving Circuit

T E M P IC(DC1621S, Thermometer) mounted on the

sensor card on the back of the carriage is used to re a d

the temperature around ink cartridge.

This IC converts the temperature around IC

package into digital and sends the temperature data

to serial to make it sense the temperature

a round the head. It senses temperature so that the

t e m p e r a t u re of the head can be the optimum when

you print something. The above IC sends data serially using signal lines(THM_DATA, THM_CLK).

Samsung Electronics 6-31

Page 63

Samsung Electronics 8-1

8. Troubleshooting