SAMSUNG FAXF3000I Service Manual

SERVICE

SAMSUNG FACSIMILE

SF3000/SF3000T

Manual

FACSIMILE CONTENTS

1. Precautions

2. Specifications

3. Installation

4. Service Mode

5. Circuit Description

6. Disassembly and Reassembly

7. Troubleshooting

8. Packing Assembly

9. Electrical Parts List

10. Block Diagram,

11. Connection Diagram

12. Schematic Diagrams

©Samsung Electronics Co., Ltd. Jul. 1998

Printed in Korea

P/N. JB68-60988A

ELECTRONICS

1. Precautions

Follow these safety, ESD, and servicing precautions to prevent personal injury and equipment damage.

1-1. Safety Precautions

1. Be sure that all built-in protective devices are in

place. Restore any missing protective shields.

2. Make sure there are no cabinet openings through

which people- particularly children- might insert

fingers or objects and contact dangerous voltages.

3. When re-installing chassis and assemblies, be

sure to restore all protective devices, including

control knobs and compartment covers.

4. Design Alteration Warning:

Never alter or add to the mechanical or electrical

design of this equipment, such as auxiliary

connectors, etc. Such alterations and

modifications will void the manufacturerÕs

warranty.

5. Components, parts, and wiring that appear to

have overheated or are otherwise damaged

should be replaced with parts which meet the

original specifications. Always determine the

cause of damage or overheating, and correct any

potential hazards.

6. Observe the original lead dress, especially near

sharp edges, AC, and high voltage power

supplies. Always inspect for pinched, out-ofplace, or frayed wiring. Do not change the

spacing between components and the printed

circuit board.

7. Product Safety Notice:

Some electrical and mechanical parts have special

safety-related characteristics which might not be

obvious from visual inspection. These safety

features and the protection they provide could be

lost if a replacement component differs from the

original. This holds true, even though the

replacement may be rated for higher voltage,

wattage, etc.

Components critical for safety are indicated in

the parts list with symbols . Use only

replacement components that have the same

ratings, especially for flame resistance and

dielectric specifications. A replacement part that

does not have the same safety characteristics as

the original may create shock, fire, or other safety

hazards.

Samsung Electronics 1-1

1-2 Samsung Electronics

Precautions

1-2. ESD Precautions

Certain semiconductor devices can be easily

damaged by static electricity. Such components are

commonly called ÒElectrostatically Sensitive (ES)

DevicesÓ, or ESDs. Examples of typical ESDs are:

integrated circuits, some field effect transistors, and

semiconductor ÒchipÓ components.

The techniques outlined below should be followed

to help reduce the incidence of component damage

caused by static electricity.

CAUTION: Be sure no power is applied to the

chassis or circuit, and observe all other safety

precautions.

1. Immediately before handling a semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic charge on your body

by touching a known earth ground. Alternatively,

employ a commercially available wrist strap

device, which should be removed for your personal

safety reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped

with ESDs, place the assembly on a conductive

surface, such as aluminum or copper foil, or

conductive foam, to prevent electrostatic charge

buildup in the vicinity of the assembly.

3. Use only a grounded tip soldering iron to solder

or desolder ESDs.

4. Use only an Òanti-staticÓ solder removal device.

Some solder removal devices not classified as

Òanti-staticÓ can generate electrical charges

sufficient to damage ESDs.

5. Do not use Freon-propelled chemicals. When

sprayed, these can generate electrical charges

sufficient to damage ESDs.

6. Do not remove a replacement ESD from its

protective packaging until immediately before

installing it. Most replacement ESDs are

packaged with all leads shorted together by

conductive foam, aluminum foil, or a comparable

conductive material.

7. Immediately before removing the protective

shorting material from the leads of a replacement

ESD, touch the protective material to the chassis

or circuit assembly into which the device will be

installed.

8. Maintain continuous electrical contact between

the ESD and the assembly into which it will be

installed, until completely plugged or soldered

into the circuit.

9. Minimize bodily motions when handling

unpackaged replacement ESDs. Normal motions,

such as the brushing together of clothing fabric

and lifting oneÕs foot from a carpeted floor, can

generate static electricity sufficient to damage an

ESD.

1-3. Lithium Battery Precautions

1. Exercise caution when replacing a Lithium

battery. There could be a danger of explosion and

subsequent operator injury and/or equipment

damage if incorrectly installed.

2. Be sure to replace the battery with the same or

equivalent type recommended by the

manufacturer.

3. Lithium batteries contain toxic substances and

should not be opened, crushed, or burned for

disposal.

2. Specification

GENERAL

Application Circuit : PSTN or behind PABX

Mode of Operation : Half-Duplex

Communication Mode : ITU Group 3

Effective Scanning Width : A4 (210 mm)

Scanning Method : CIS

Recording Paper Size : A4, Letter, Legal

Effective Recording Width : 8 inch (203.2 mm)

Recording Method : Thermal Ink-Jet

ADF : 15 sheets (based on A4 /20 lbs)

Paper Capacity : 100 sheets (based on A4, 10mm)

Resolution : Standard/Fine/Super Fine/Photo

Gray Scale : 64 levels

Contrast : Light/Auto/Dark

Memory : 512 kbyte for EPROM, 32 kbyte for SRAM

Modem Speed : Max. 14,400 bps

Coding Method : MH/MR/MMR

Transmission Speed : 10 seconds (Phase C by ITU 4% Chart/Memory TX)

Back Up Battery : 3 V Lithum / non-rechargeable

Power Supply : Check power label attached near the power cord connection.

Insulation Resistance : 50 Mohm or more (typ. 3 G at 500 V)

Dimension (W x D x H mm) : 384 x 330 x 183 mm (including ASF)

Samsung Electronics 2-1

2-2 Samsung Electronics

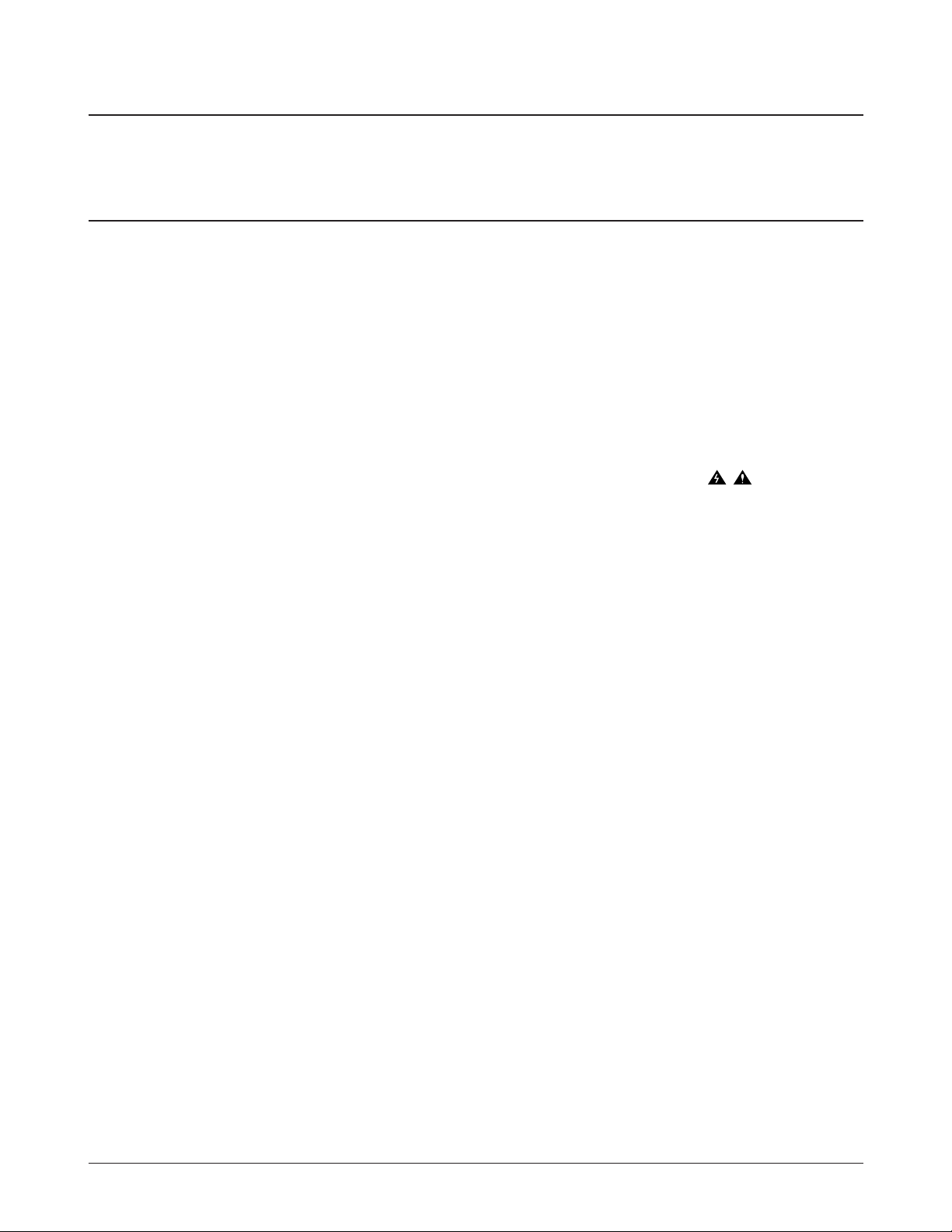

LIU

Out Band Signal Level :

0 - 4 kHz P-20 dBm or less

4 - 12 kHz P-40 dBm or less

2 kHz or more P-60 dBm or less

Input Level Range : -5 ~ -48 dBm

Coding Format

H

1209 Hz 1336 Hz 1477 Hz

L

697 Hz 1 2 3

770 Hz 4 5 6

852 Hz 7 8 9

941 Hz * 0 #

Frequency Tolerance : ± 1.5%

Specification

3. Installation

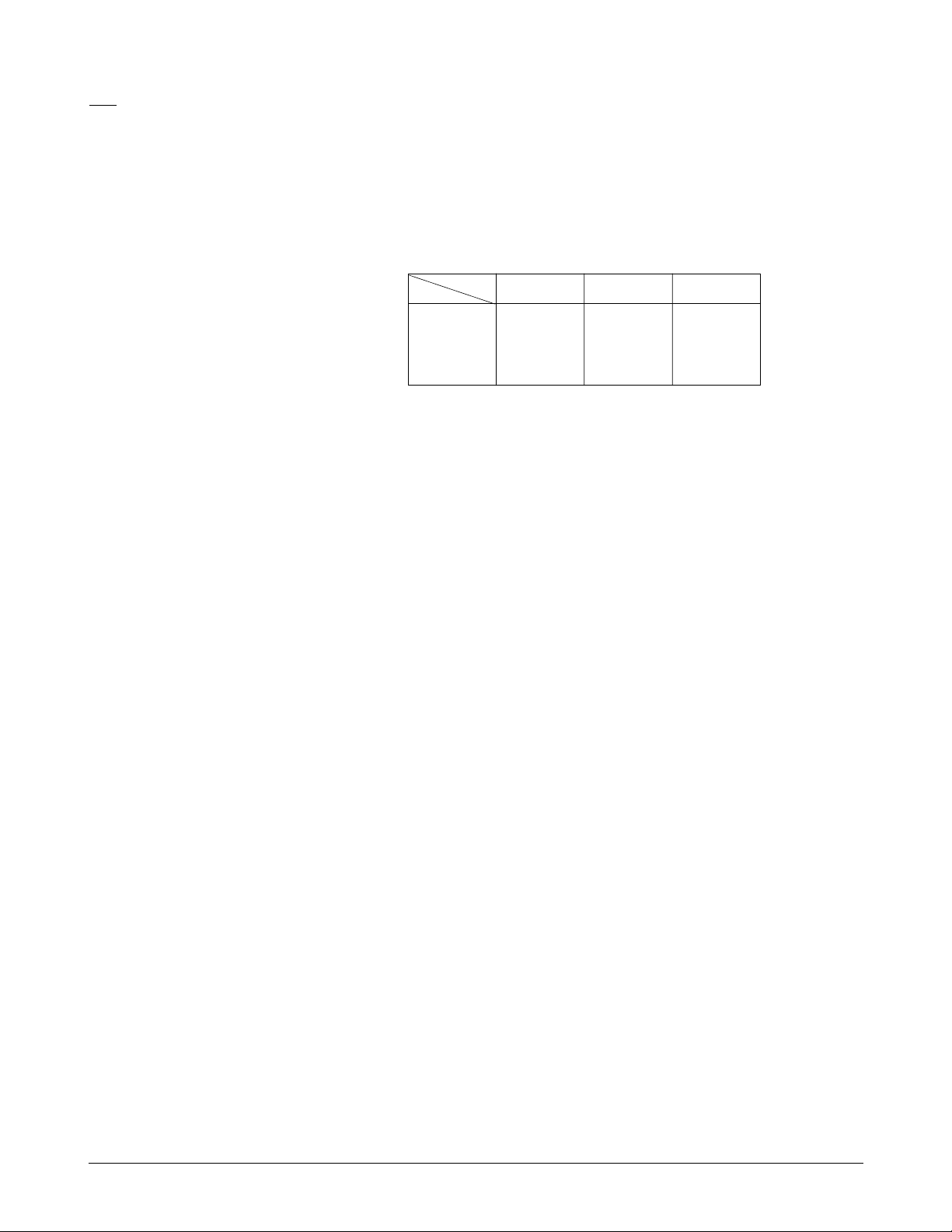

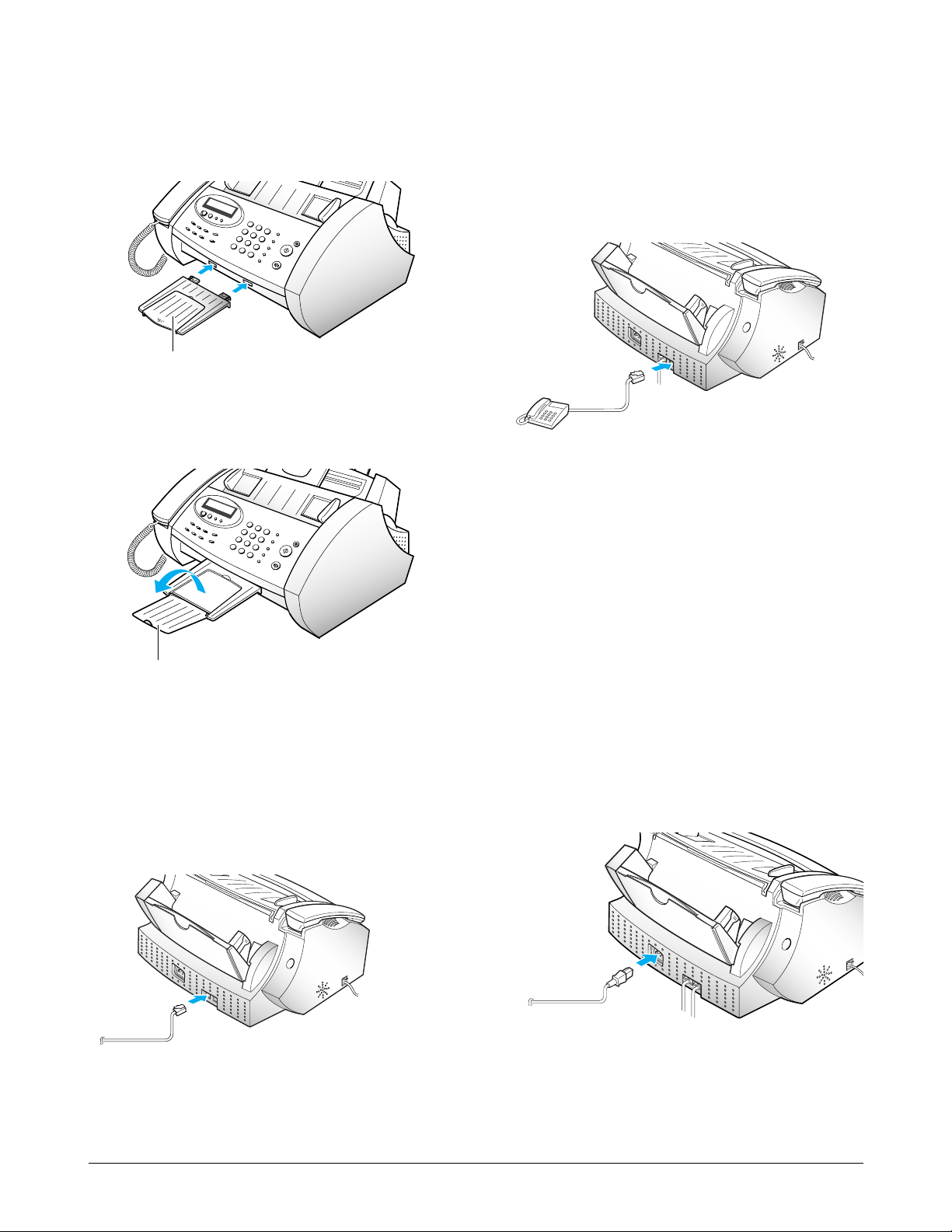

3-1. Connections

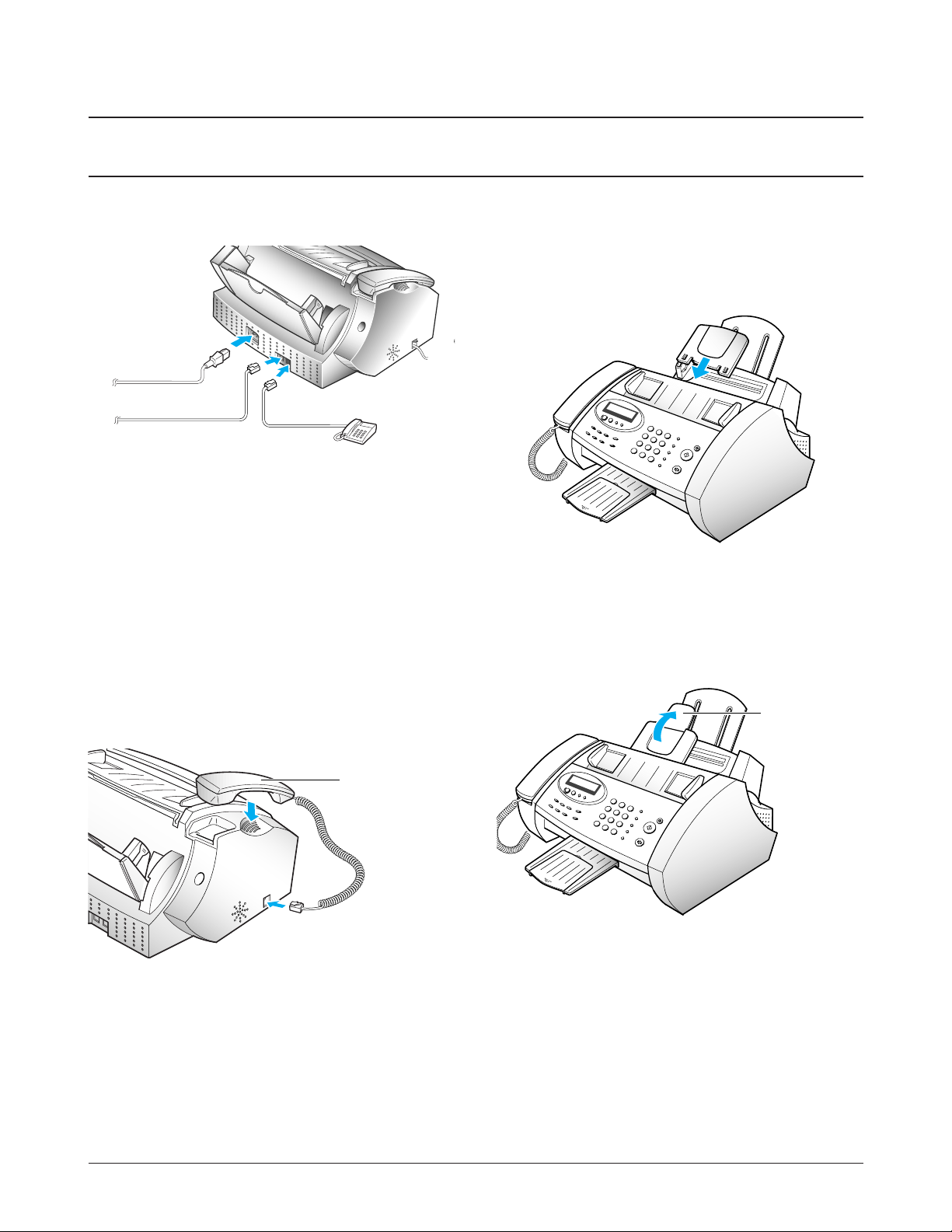

3-1-1. Connection Diagram 3-1-3. Document Tray

1. Insert the two tabs on the document tray into the

slot on top of your machine.

2. Fold out the extender on the document tray, if

necessary.

3-1-2. Handset

Plug one end of the coiled cord into the jack on the

handset, the other end into the modular jack on the

left side of the machine.

Samsung Electronics 3-1

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Extension phone (option)

(for SF3000 only)

Phone line cord

AC power

cord

Handset

Extender

3-2 Samsung Electronics

Installation

3-1-4 Document Exit Tray

1. Insert the two tabs on the document exit tray into

the slots on the front of your machine.

2. Fold out the extender, if necessary.

3-1-5. Telephone Line

Plug one end of the telephone line cord into the

TEL. LINE jack,the other end into a standard phone

wall jack.

3-1-6. Extension Phone (Optional)

(SF3000 only)

Plug one end of the cord of your extension phone

into the TAM lead and the plug of the TAM lead

into the socket marked EXT. LINE on the back of the

machine.

3-1-7. AC Power Cord

Plug one end of the cord into the back of the

machine, and the other into a standard, grounded 3pin AC socket (220 - 240 V, 50 - 60 Hz).

The machine turns on and the LCD displays

ÔSYSTEM INITIAL..Õ. If there is no cartrige installed,

or no paper, the display shows ÔNO CARTRIDGEÕ

or ÔPAPER EMPTYÕ.

To turn the machine off, unplug the power cord.

Note: If documents are deleted from memory due to

a power failure, the machine automatically prints

out a Power Failure report when power is reapplied.

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Extender

Document exit tray

Samsung Electronics 3-3

Installation

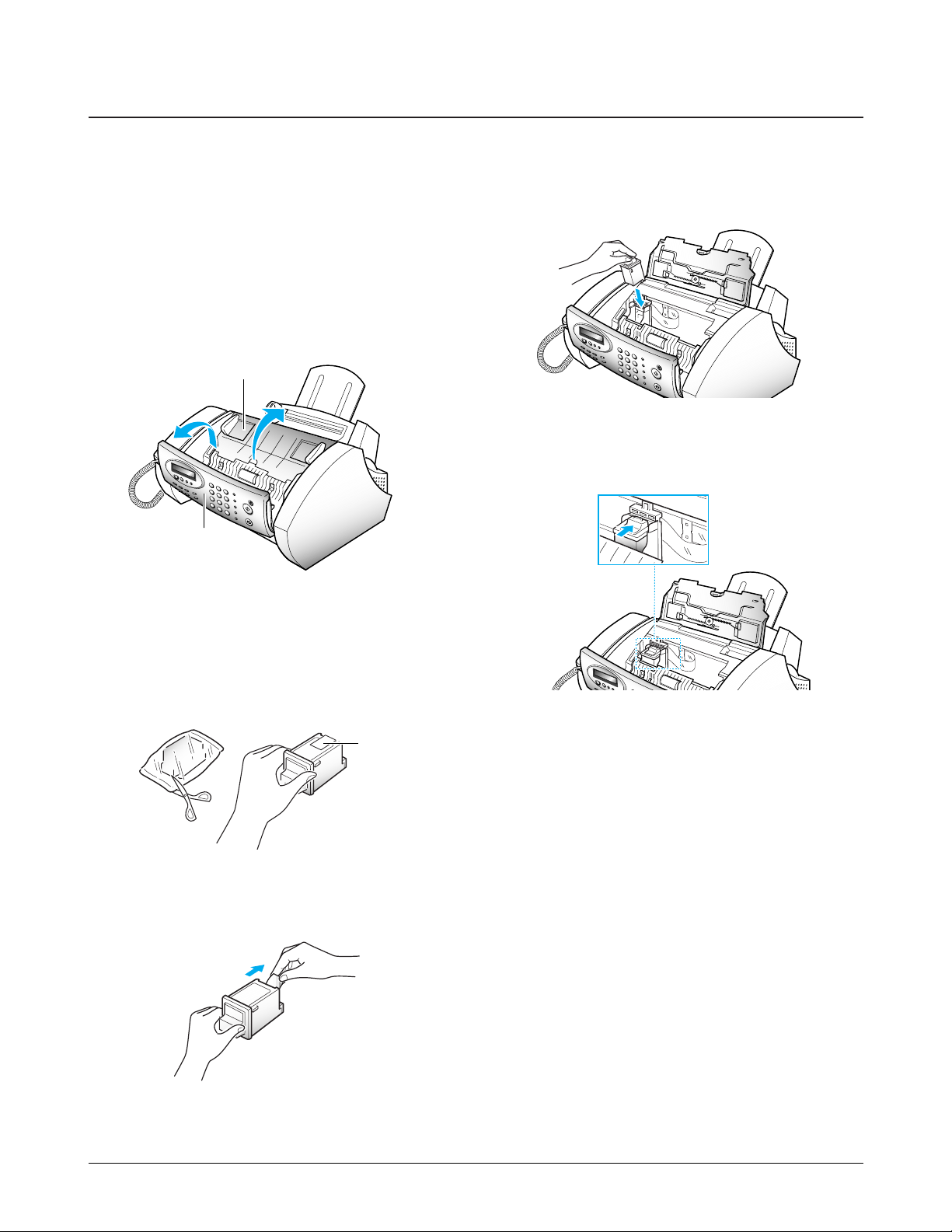

3-1-8. Backup Battery (SF3000T only)

1. Lift the control panel ➀ and open the cartridge

compartment cover ➁.

2. Remove the old battery, if necessary.

Connect the new battery to the clips.

3. Insert the battery into the battery slot.

The battery maintains setup configuration and

messages when a power failure occurs or when

power is accidentally disconnected.

We recommend you use an alkaline battery

because it lasts longer than a conventional

battery.

4. Close the cartridge compartment cover, and close

the control panel.

The battery can maintain the internal memory for

about 20 hours. If the backup battery is weak or

missing, the LCD displays a warning message.

➀

➁

1. Pull the paper support on the paper bin all the

way up.

2. Fan and insert the paper, with the printing side

facing you.

3. Squeeze the left paper guide and move it to the

right to match the width of the paper.

Note: The machine is preset to load A4-size paper.

To load letter or legal-size paper, you have to

set ÔPAPER SIZEÕ option to the desired size.

3-4 Samsung Electronics

Installation

3-2. Loading Paper

The display shows ÔPAPER EMPTYÕ when paper is not loaded. You can load approximately 100 sheets of paper.

Paper Guide

Paper support

Samsung Electronics 3-5

Installation

1. Press Menu.

2. Press ¹ or until Ô1.CHANGE CART.Õ is

displayed, then press Start/Copy.

3. Lift the control panel ➀, and open the cartridge

compartment cover ➁.

4. Remove the new print cartridge from its

packaging. Hold by the black areas or colored

top only. Do not touch the copper area.

5. Carefully remove the tape covering the

printhead. Be sure to remove all the tape.

6. Insert the print cartridge in the carrier.

7. Push the cartridge firmly in the direction of the

arrow until it clicks into place.

8. After installing the print cartridge, close the

cover and replace the control panel.

9. The display shows Ô:NEW :USED.Õ Press

Start/Copy to confirm ÔNEWÕ. (For used

cartridge, press ¹ or then press Start/Copy.)

The display briefly shows ÔMONO INSTALLED.Õ

If the cartridge is not installed properly, ÔNO

CARTRIDGEÕ is displayed. Remove the cartridge

and re-insert it.

10. The display asks if you want to run a SELF

TEST. Press Start/Copy to run the printer self

test.

If you press Stop, the machine returns to

Standby mode.

11. The machine prints out a test pattern of the

printer.

3-3. Installing Print Cartridge

When the machine is powered up without the print cartridge installed, the LCD displays ÔNO CARTRIDGE Õ.

Cartridge compartment cover

➀

➁

copper area

Control panel

3-6 Samsung Electronics

Memo

Installation

6. Disassembly and Reassembly

6-1. General Precautions on Disassembly

Samsung Electronics 6-1

When disassemble and reassembling components, use extreme caution. The close proximity of cables to moving

parts makes proper routing a must. If components are removed or replaced, any cables

disturbed by the procedure must be replaced as close as possible to their original positions. Before removing

any component from the machine, note the cable routing that will be affected.

Whenever servicing the machine, you must perform the following:

1. Check that documents are not stored in memory.

2. Remove the print cartridge.

3. Unplug the power cord.

4. Work on a flat and clean surface.

5. Replace only with authorized components.

6. Do not force plastic components.

7. Make sure all components are in their proper position.

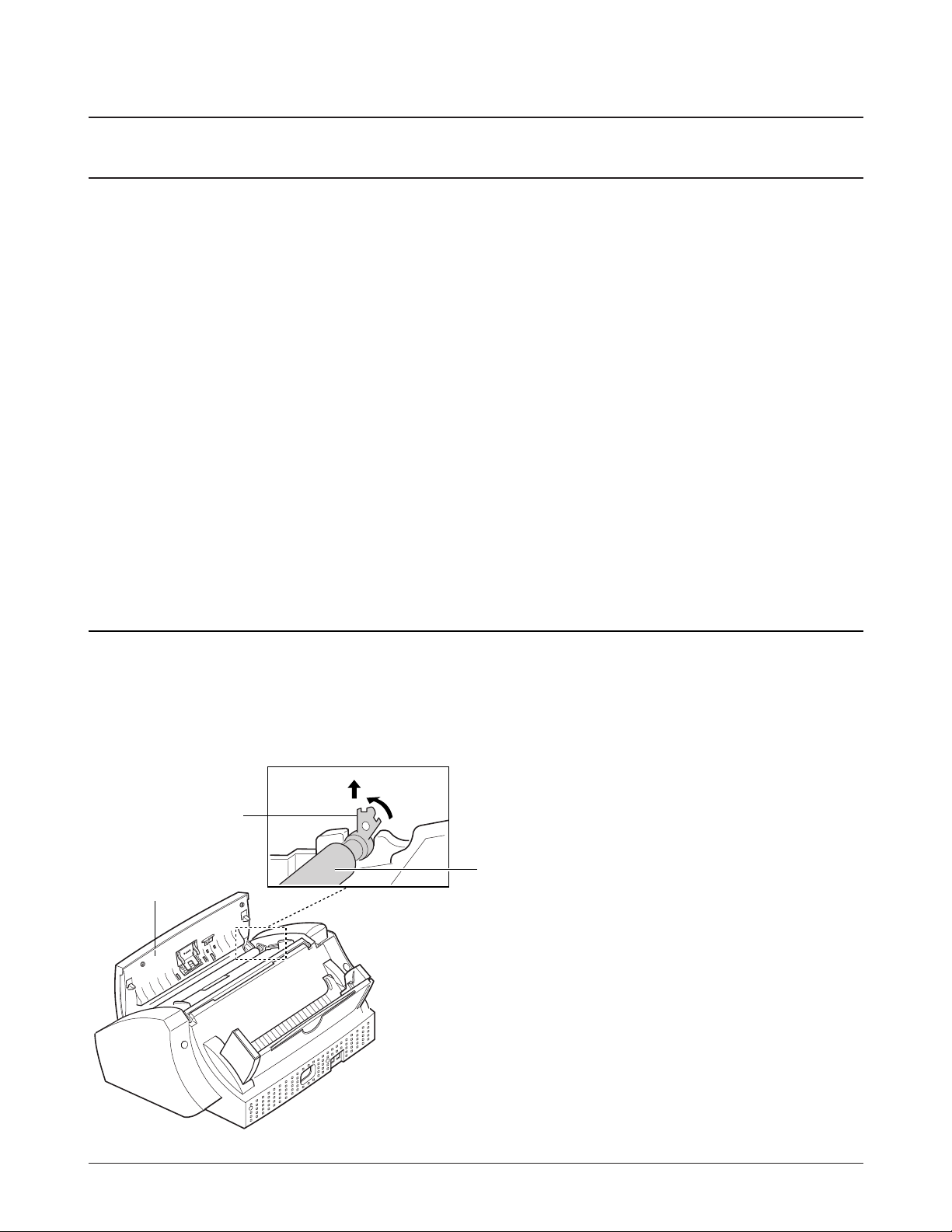

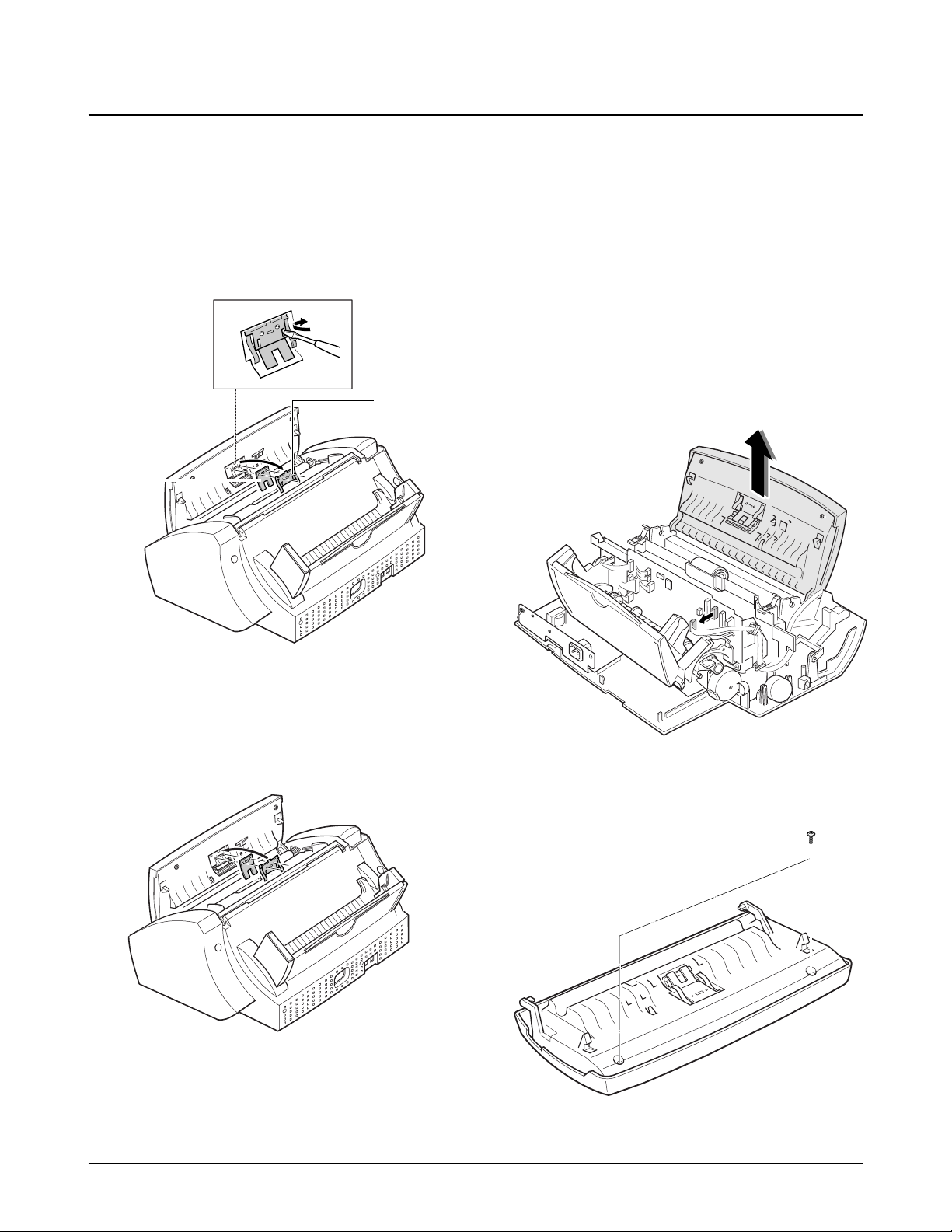

1. Lift the control panel.

2. Push the white clip on each end of the roller

slightly inward, then rotate it until it reaches the

slot, as shown below. Then lift the roller out.

Note : Check the roller for dirt. If dirty, wipe it off

with soft cloth dampened with water. If the

roller is heavily worn, replace it with a new

one.

6-2. White Roller

white clip

Control panel

White roller

B

A

6-2 Samsung Electronics

Disassembly and Reassembly

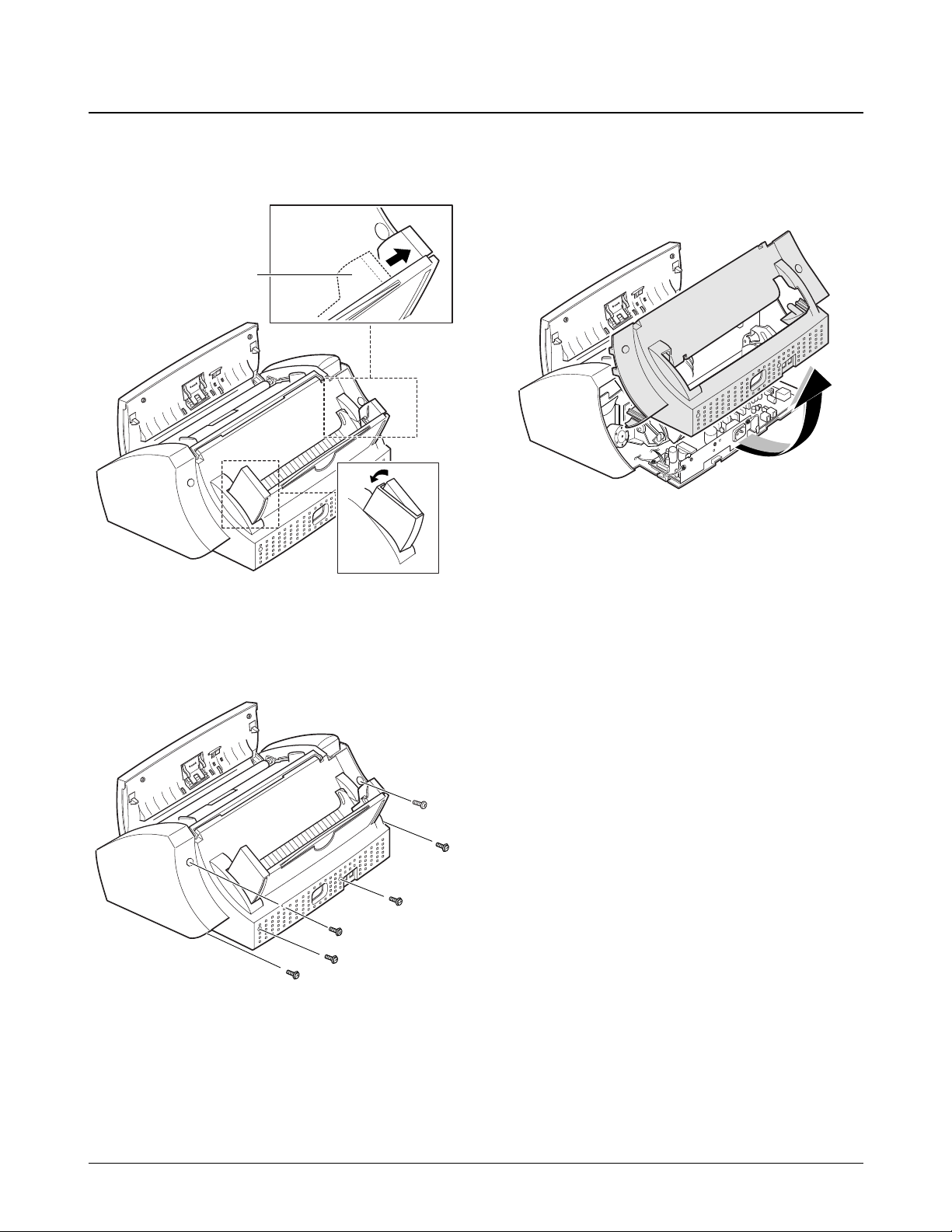

6-3. Rear Cover

1. Holding the paper guide, move it in the direction

of arrow.

2. Remove the six screws, as shown below.

3. Holding the rear cover assÕy, take it out by

rotating it to release properly.

Paper guide

1. Before you disassemble the top cover, you should

remove:

Ð Rear Cover (see page 6-2)

2. Remove the handset, and unplug the connector

from the main board.

3. Release the tie stopper supporting the control

panel.

4. Remove the four screws securing the cover.

5. If you want to remove the speaker, turn the top

cover over, and remove the two screws securing

it.

6-3Samsung Electronics

Disassembly and Reassembly

6-4. Top Cover and Speaker

Tie stopper

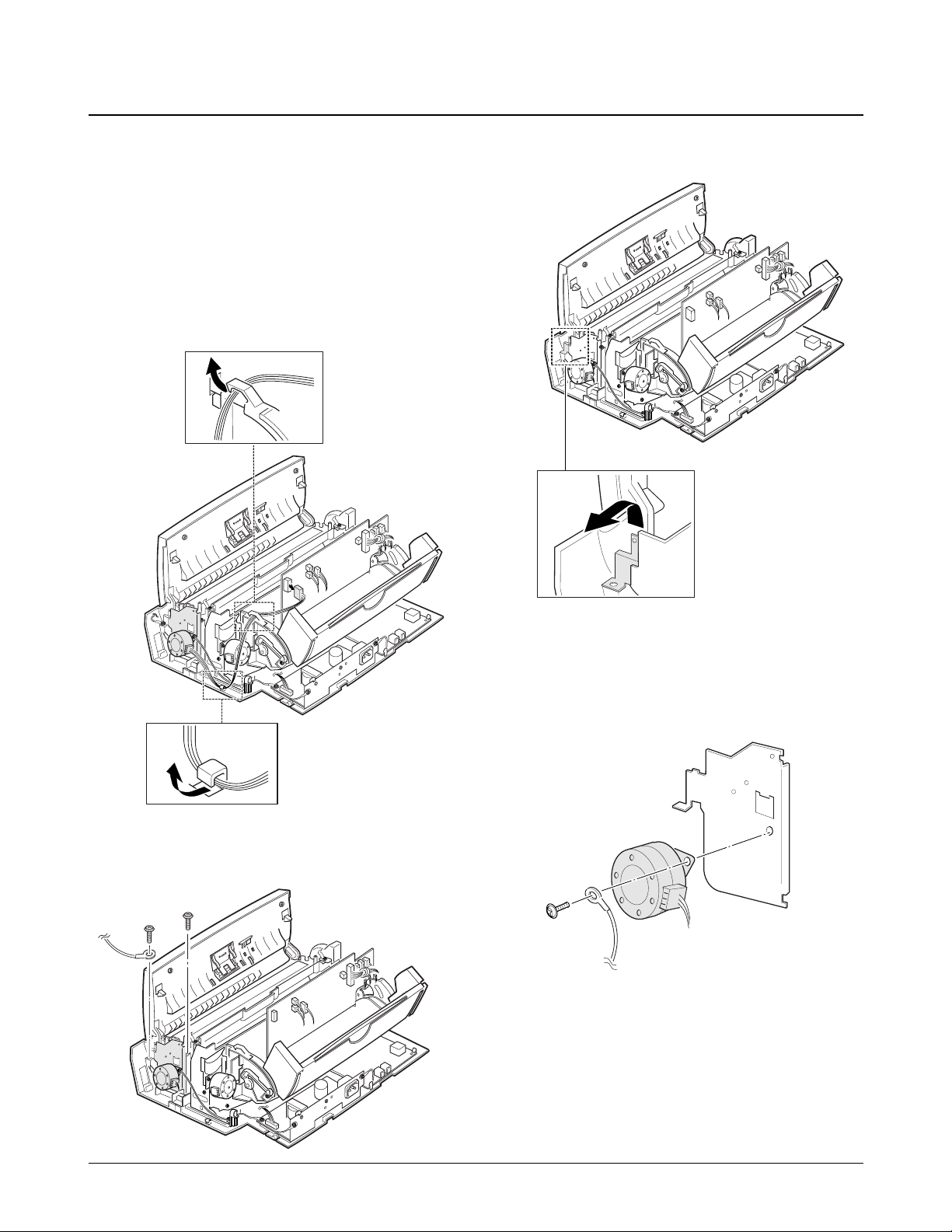

1. Before disassembling the scan motor, you should

remove:

Ð Rear Cover (see page 6-2)

Ð Top Cover (see page 6-3)

2. Unplug the motor connector from the main

board. Make sure the harness is released from the

two hooks, as shown below.

3. Remove the two screws as shown below.

4. Remove the ground plate.

5. Remove the ground screw securing the motor to

the motor bracket.

6-4 Samsung Electronics

Disassembly and Reassembly

6-5. Scan Motor

Ground plate

Samsung Electronics 6-5

Disassembly and Reassembly

6-6. ADF Roller and Contact Image Sensor (CIS)

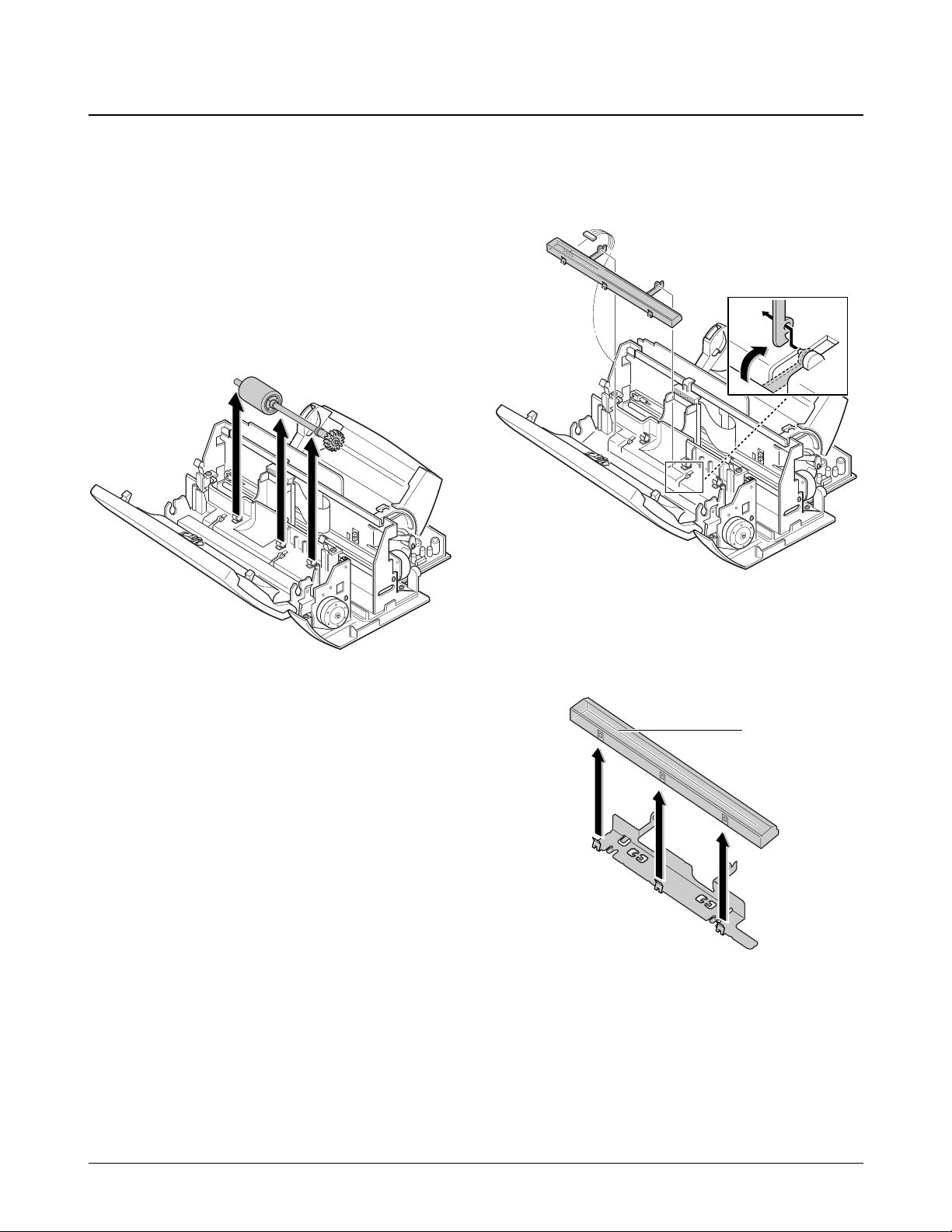

1. Before disassembling the roller and CIS, you

should remove:

Ð Rear Cover (see page 6-2)

Ð Top Cover (see page 6-3)

2. Remove the ADF roller. When you assemble the

roller, make sure it is properly hooked.

Note : Clean the surface of the roller with ethyl

alcohol. After wiping it, you must dry it

completely.

3. Unplug the CIS harness, then remove the CIS

assÕy. To remove the CIS assÕy, turn it up and

slide the two legs far left, and pull it up.

4. Remove the CIS from the bracket.

Note: Check the glassy surface of the CIS for stains

or scratches. If stained, wipe off with ethyl

alcohol. If it is heavily scratched, replace it

with a new one.

CIS

6-6 Samsung Electronics

Disassembly and Reassembly

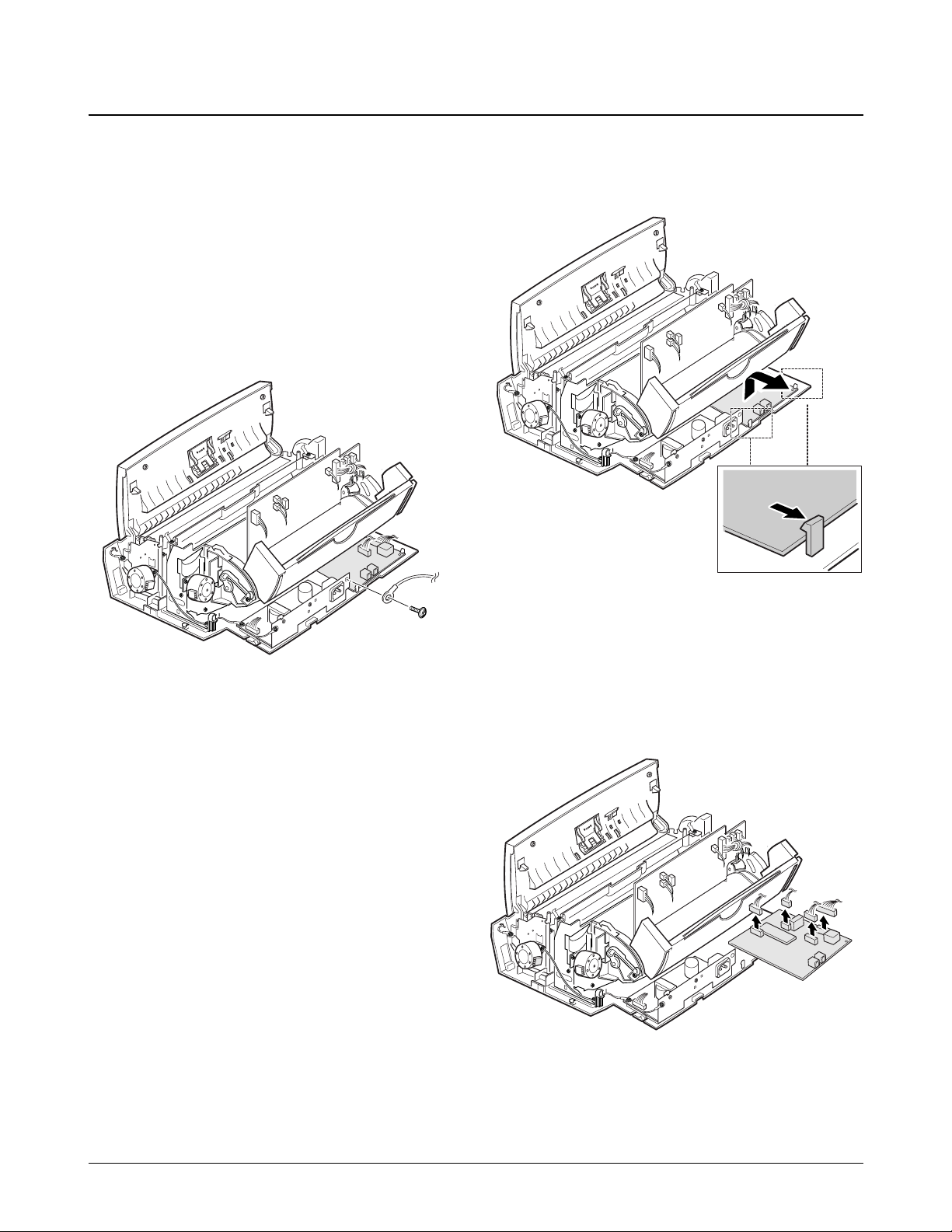

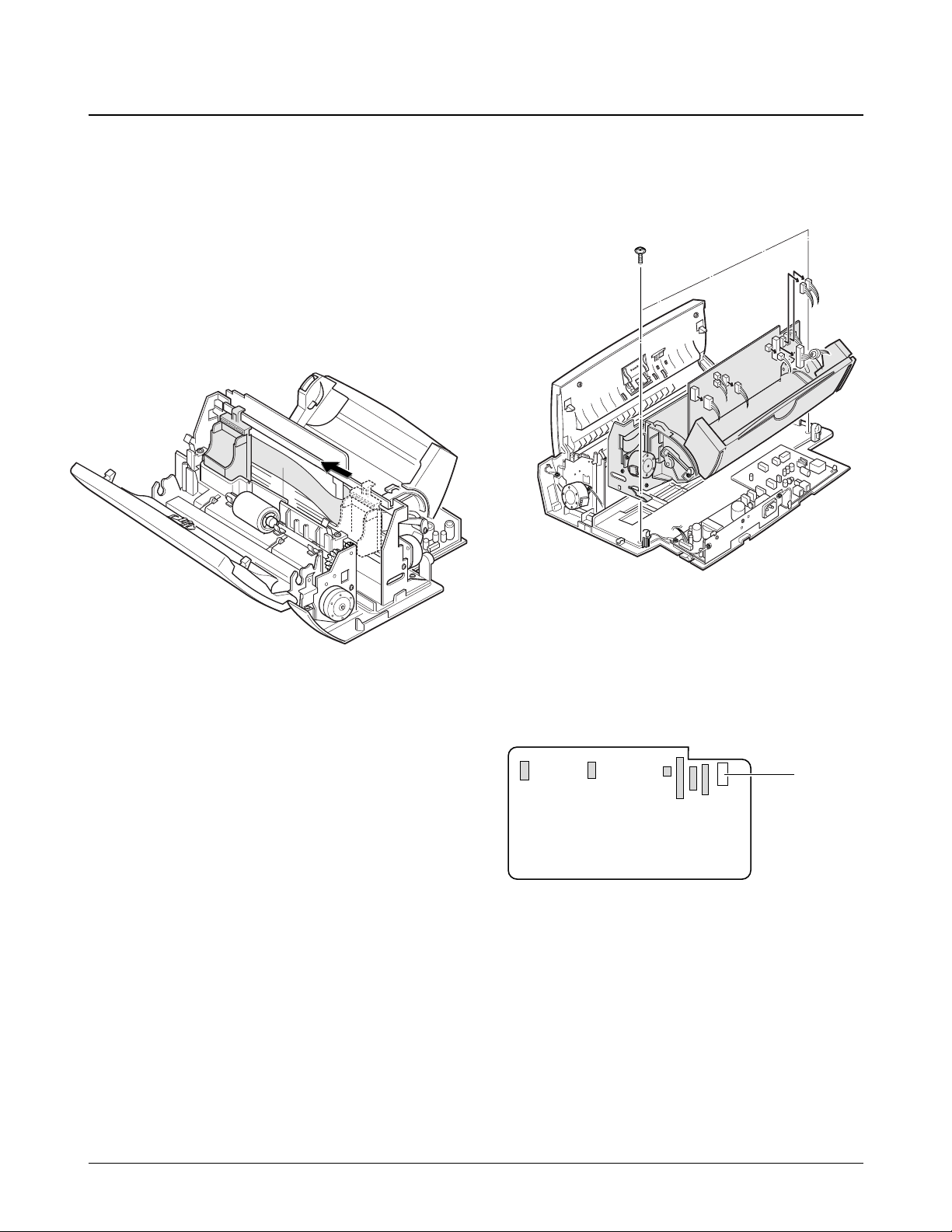

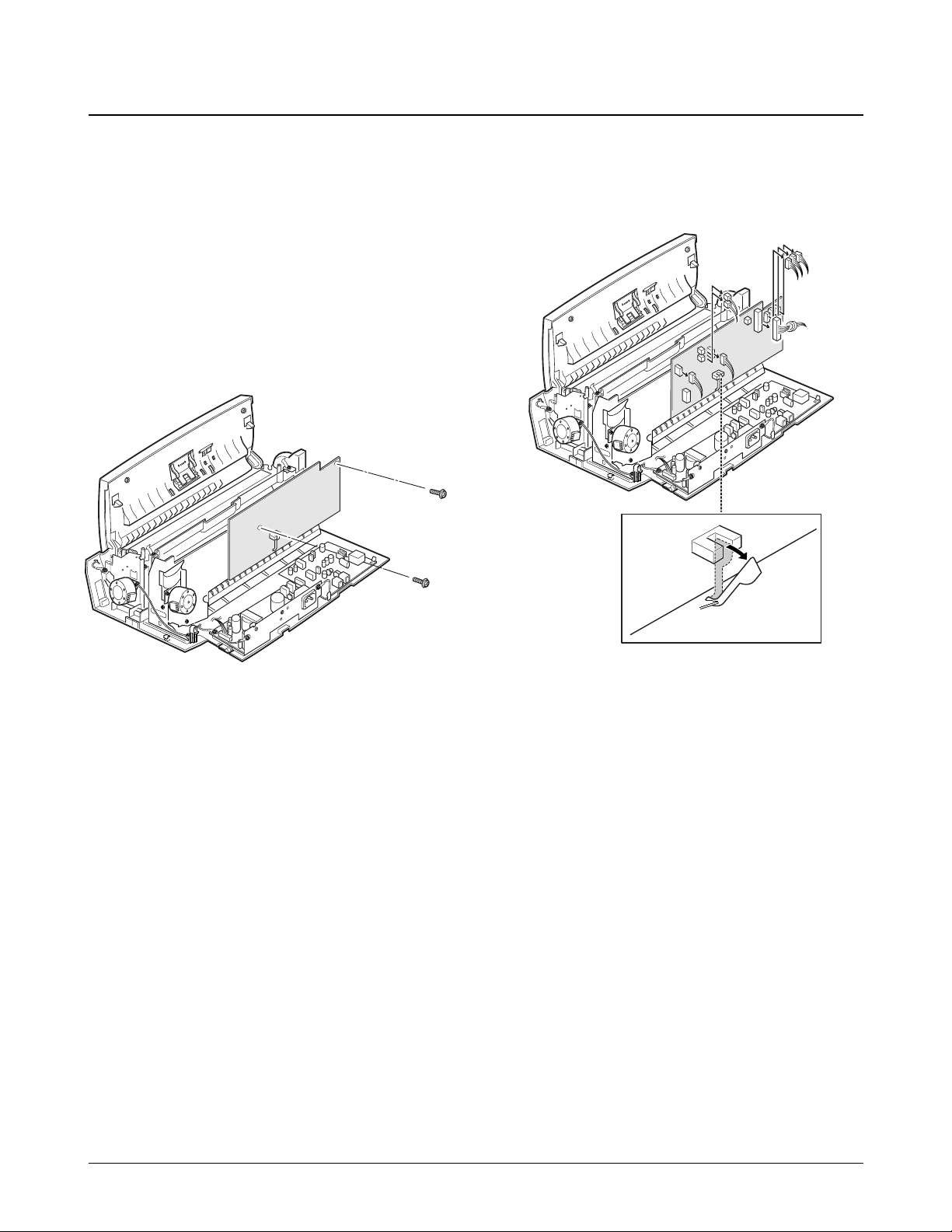

1. Before disassembling the SMPS, you should

remove:

Ð Rear Cover (see page 6-2)

2. Unplug the SMPS connector from the main

board. Make sure the harness is released from the

hook.

3. Remove the two ground screws from the bracket,

as shown.

4. Pushing down the hook, as shown in the inset,

remove the SMPS.

6-7. SMPS

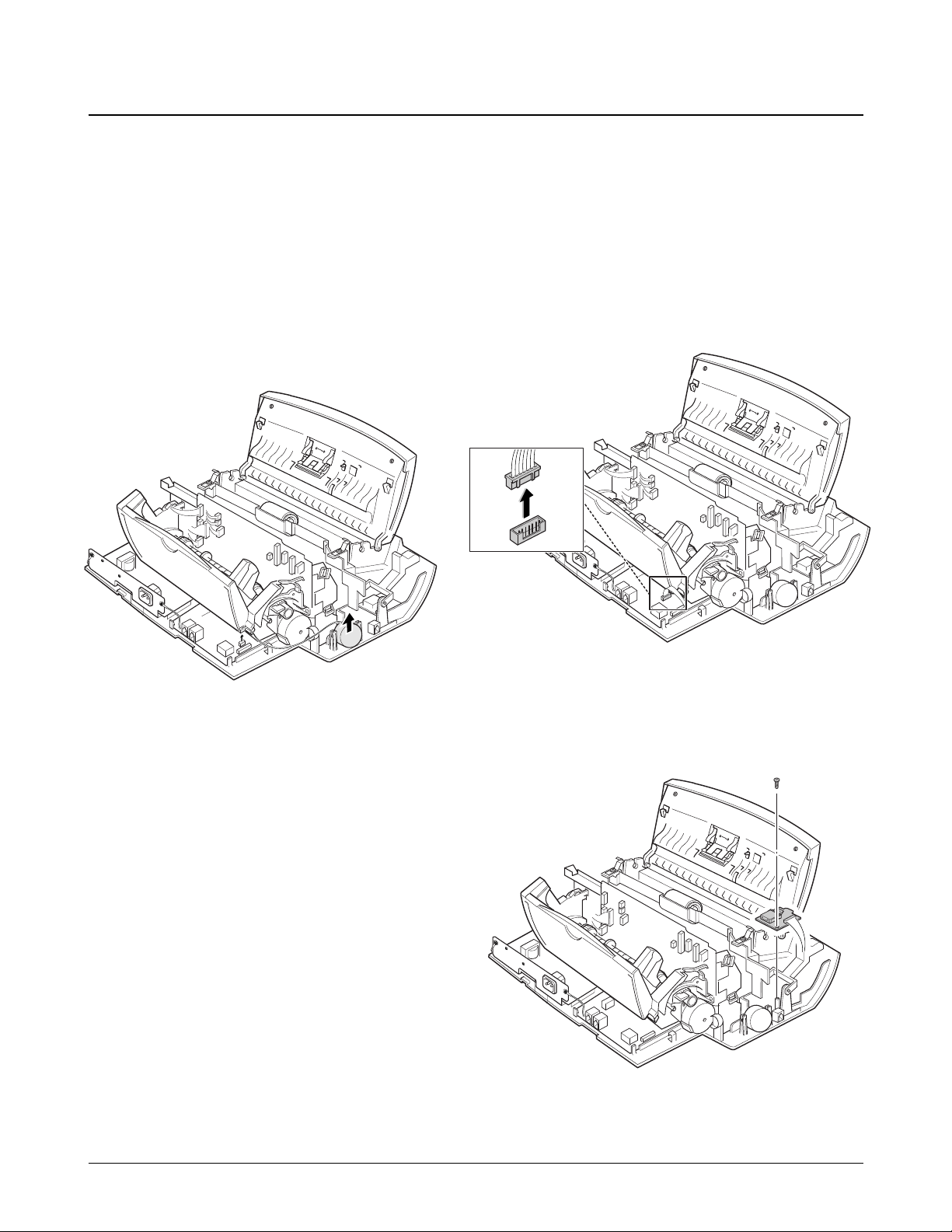

1. Before disassembling the board, you should

remove:

Ð Rear Cover (see page 6-2)

Ð Top Cover (see page 6-3)

2. Remove the screw securing the ground wires to

the SMPS bracket.

3. Pulling the snaps locking the board outward,

remove the board.

4. Unplug all the connectors from the board.

Samsung Electronics 6-7

Disassembly and Reassembly

6-8. LIU Board

Snap fit

6-8 Samsung Electronics

Disassembly and Reassembly

6-9-1. Buzzer

1. Before disassembling the buzzer, you should

remove:

Ð Rear Cover (see page 6-2)

Ð Top Cover (see page 6-3)

2. Unplug the connector from the LIU board, and

remove the buzzer.

6-9-2. Hook Board

1. Before disassembling the board, you should

remove:

Ð Rear Cover (see page 6-2)

Ð Top Cover (see page 6-3)

2. Unplug the connector from the LIU board.

3. Remove the screw, then remove the board.

6-9. Buzzer and Hook Board

6-10-1. ADF Rubber Pad

1. Open the control panel.

2. Insert a flat blade screw driver into the slot as

shown below, and remove the rubber holder and

the rubber pad.

Notes:

¥ When reassembling the rubber pad, be sure that it

and the holder fit into the guide boss and the

holder latches fit into the corresponding hole.

Then push firmly until it clicks.

¥ Clean the surface of the rubber pad with ethyl

alcohol. After wiping, be sure to dry it. Check for

rubber wear. If the wear reaches 1/2 its original

thickness, replace it with a new one.

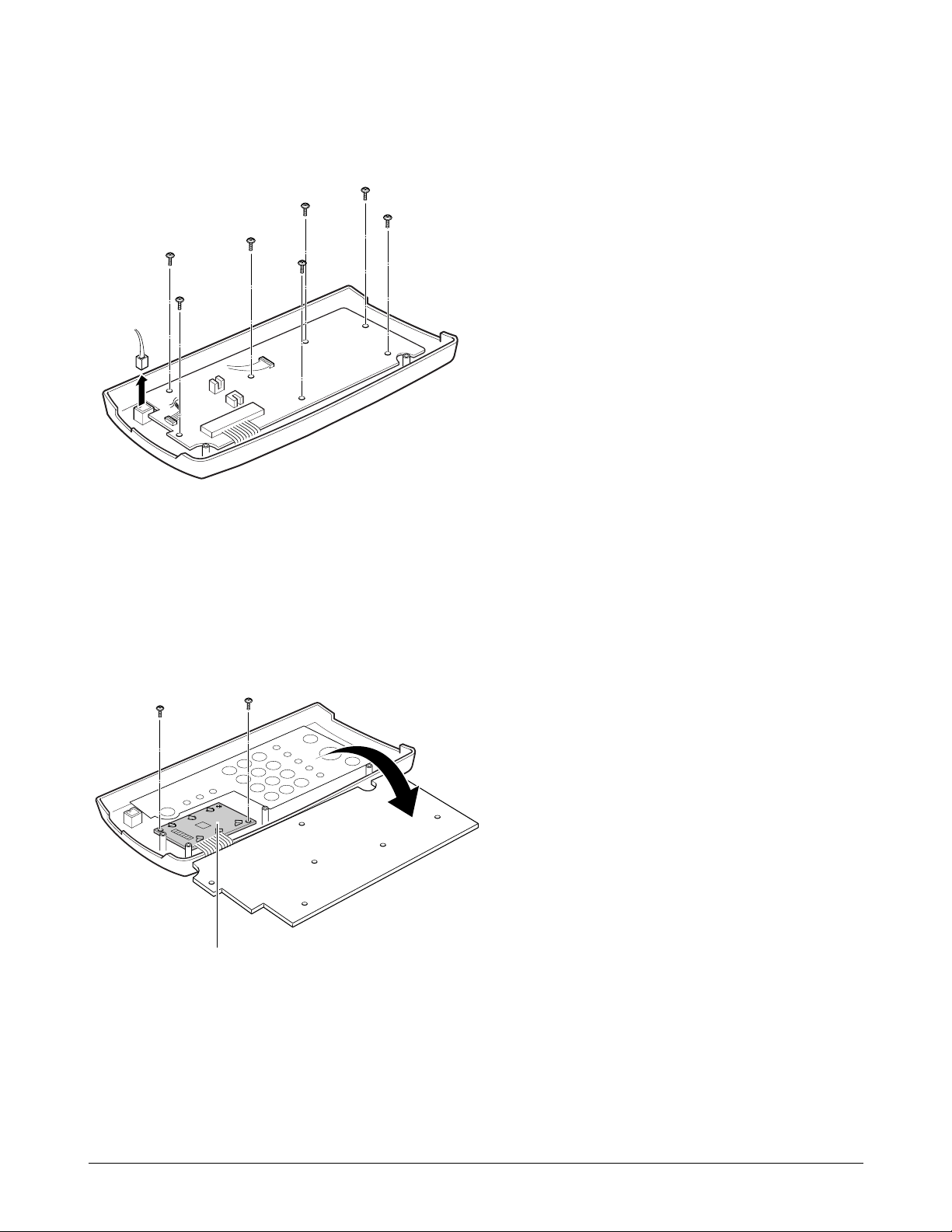

6-10-2. OPE Unit

1. Before disassembling the OPE unit, you should

remove:

Ð Dummy ASF (see page 6-2)

Ð Rear Cover (see page 6-2)

Ð Top Cover (see page 6-3)

Ð LIU Board (see page 6-7)

2. Unplug the connector from the main board, and

pull up the OPE unit.

3. Remove the two screws and remove the cover.

Samsung Electronics 6-9

Disassembly and Reassembly

6-10. OPE Unit

Rubber pad

Rubber holder

6-10 Samsung Electronics

Disassembly and Reassembly

4. Remove the microphone (SF3000T only) and the

seven screws.

5. Remove the OPE board. Then remove the two

screws from the LCD and remove the LCD.

Notes:

¥ Do not turn the OPE unit upside down after you

remove the screws securing the board. Keys and

rubber contacts may be separated and easily lost.

¥ When reassembling the OPE unit, make sure the

keys are in correct position.

¥ When reassembling the board, secure the screws

according to the order printed on the PBA.

¥ After reassembling, operate the machine to make

sure it works properly.

¥ After reassembling, make sure the LCD is not

blocked.

LCD

Microphone

(SF3000T only)

1. Before disassembling the printer unit, you should

remove:

Ð Dummy ASF (see page 6-2)

Ð Rear Cover (see page 6-2)

Ð Top Cover (see page 6-3)

2. Slide the cartridge carrier, as shown below.

3. Remove the two screws securing the printer unit,

and unplug the six connectors from the main

board.

The connectors are located as shown below. It is

not necessary to unplug the LF motor connector

to remove the printer unit.

4. Remove the printer unit. When you pull up

printer unit, be careful to properly release the

harnesses.

Samsung Electronics 6-11

Disassembly and Reassembly

6-11. Printer Unit

LF motor

6-12 Samsung Electronics

Disassembly and Reassembly

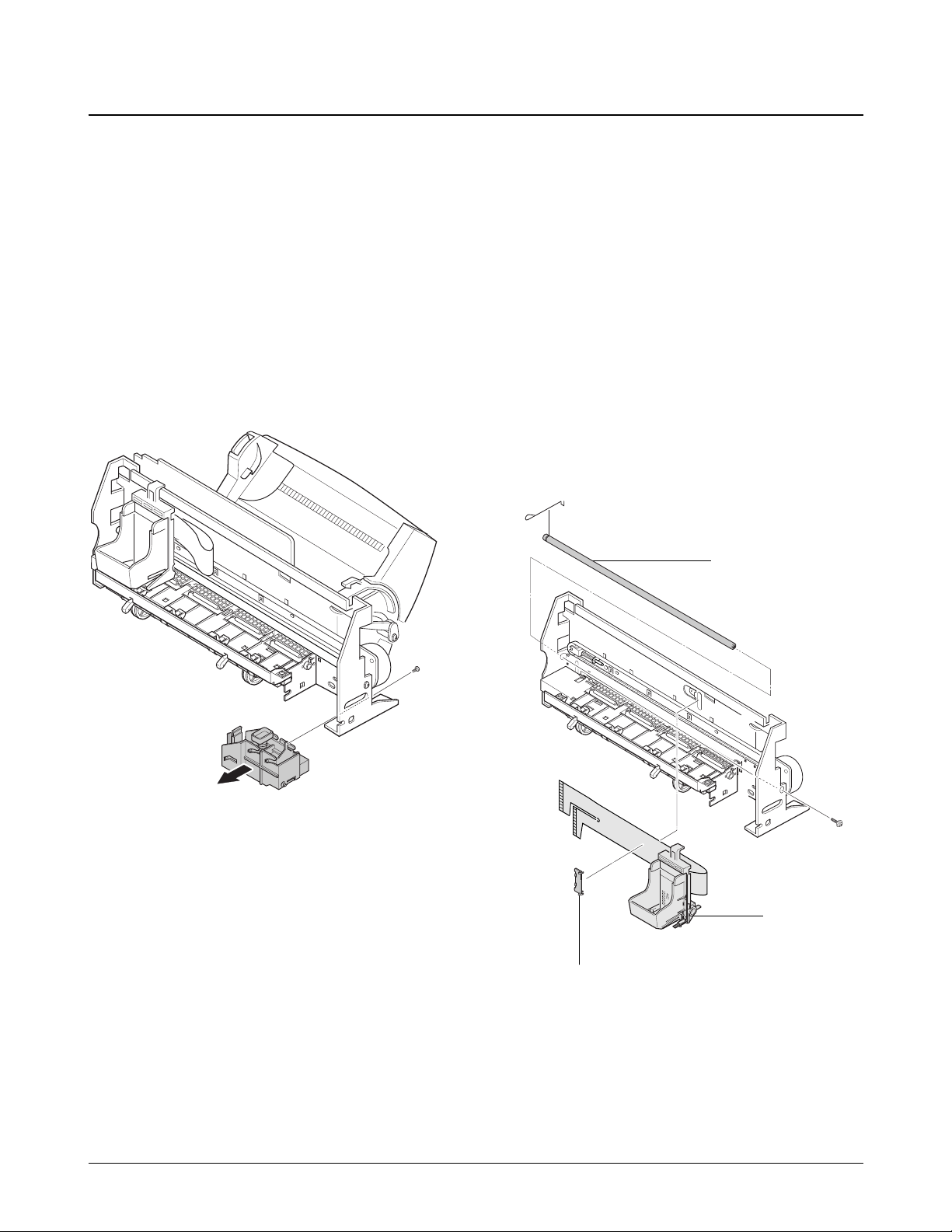

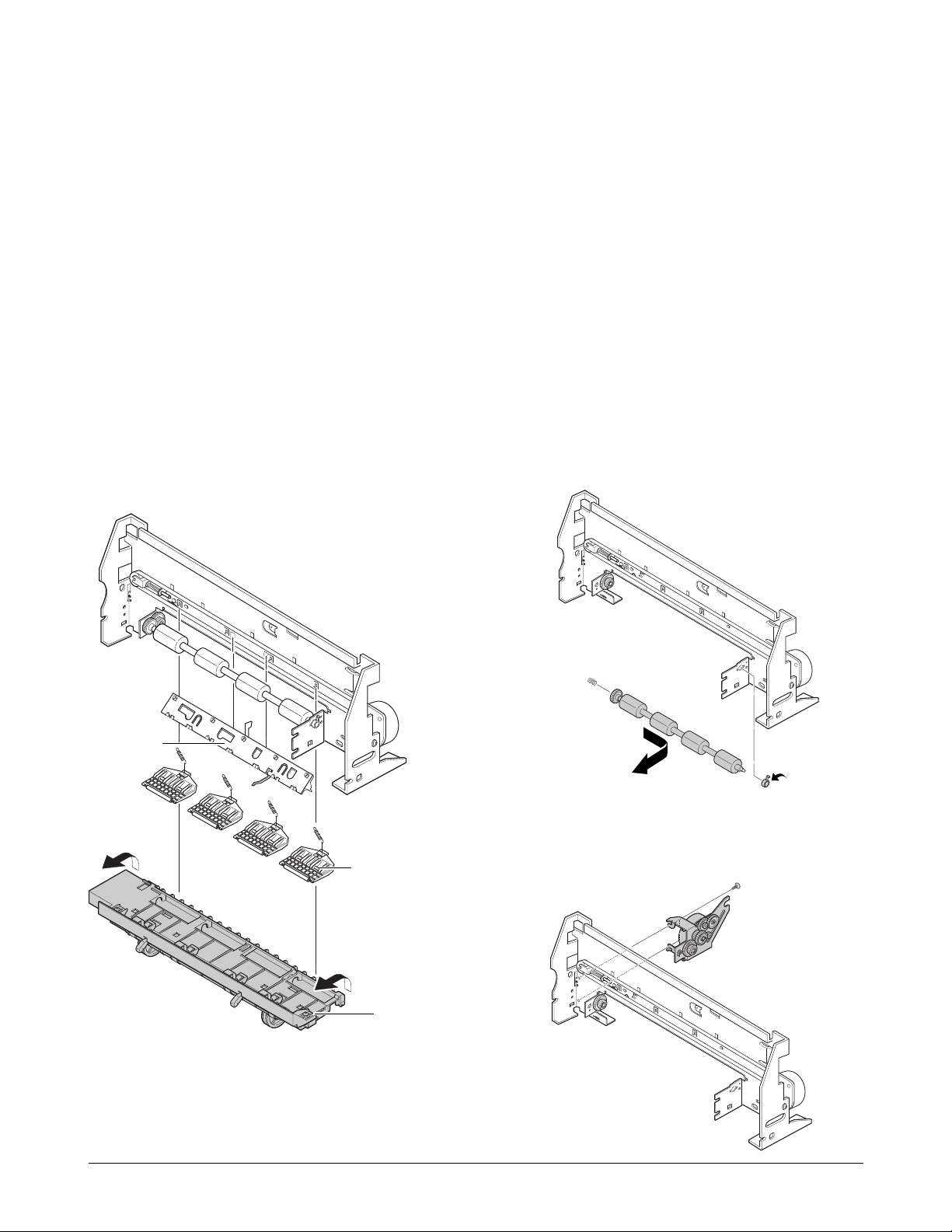

1. Before disassembling the ASF feeder assÕy, you

should remove:

Ð Dummy ASF (see page 6-2)

Ð Rear Cover (see page 6-2)

2. Remove the two screws securing the ASF feeder.

3. Unlock the ASF feeder assembly, and remove it.

4. Remove the screw securing the pickup shaft. To

remove the pickup shaft, pull it to the far right

and take it out.

Note : When reassembling the ASF feeder assÕy,

insure the harness for the line feed motor is

not pinched or shorted.

6-12. ASF Feeder

Pickup shaft

6-13-1. Cartridge Carrier Home Assembly

1. Before disassembling the cartridge carrier home,

you should remove:

Ð Dummy ASF (see page 6-2)

Ð Rear Cover (see page 6-2)

Ð Top Cover (see page 6-3)

Ð Printer Unit (see page 6-11)

2. Remove the screw securing the cartridge carrier

home, and take it out.

6-13-2. Cartridge Carrier Assembly

1. Before disassembling the cartridge carrier

assembly, you should remove:

Ð Dummy ASF (see page 6-2)

Ð Rear Cover (see page 6-2)

Ð Top Cover (see page 6-3)

Ð Printer Unit (see page 6-11)

Ð Cartridge Carrier Home Assembly

(see page left)

Ð ASF Feeder (see page 6-12)

Ð Main Board (see page 6-15)

2. Remove the cable holder, and remove the screw

on the right side of the frame.

Samsung Electronics 6-13

Disassembly and Reassembly

6-13. Printer Unit Miscellaneous

Carrier shaft

Carrier

Holder

6-13-3. Base Frame Assembly

1. Before disassembling the base frame assembly,

you should remove:

Ð Dummy ASF (see page 6-2)

Ð Rear Cover (see page 6-2)

Ð Top Cover (see page 6-3)

Ð Printer Unit (see page 6-11)

Ð Cartridge Carrier Home Assembly

(see page 6-13)

Ð Cartridge Carrier Assembly (see page 6-13)

Ð ASF Feeder (see page 6-12)

Ð Main Board (see page 6-15)

2. Remove the roller friction assemblies, then the

actuator feed.

3. Remove the base frame assembly.

6-13-4. Feed Roller Assembly and Line

Feeder Bracket Assembly

1. Before disassembling the feeder roller assÕy,

and/or the line feed bracket assÕy, you should

remove:

Ð Dummy ASF (see page 6-2)

Ð Rear Cover (see page 6-2)

Ð Top Cover (see page 6-3)

Ð Printer Unit (see page 6-11)

Ð Cartridge Carrier Home Assembly

(see page 6-13)

Ð Cartridge Carrier Assembly (see page 6-13)

Ð Base Frame Assembly (see page left)

2. Remove the feed bearing from the main frame.

Pull the feeder roller in the direction of arrow,

and take it out.

3. Remove the two screws, then remove the feeder

bracket assembly.

6-14 Samsung Electronics

Disassembly and Reassembly

Holdr Roller

Roller friction assÕy

Base frame assÕy

Samsung Electronics 6-15

Disassembly and Reassembly

1. Before disassembling the main board, you should

remove:

Ð Dummy ASF (see page 6-2)

Ð Rear Cover (see page 6-2)

Ð Top Cover (see page 6-3)

Ð ASF Feeder (see page 6-12)

2. Remove the two screws securing the main board.

3. Unplug all connectors from the main board.

Then, pull the sensor lever towards you and

remove the main board.

6-14. Main Board

Sensor lever

6-16 Samsung Electronics

Disassembly and Reassembly

Memo

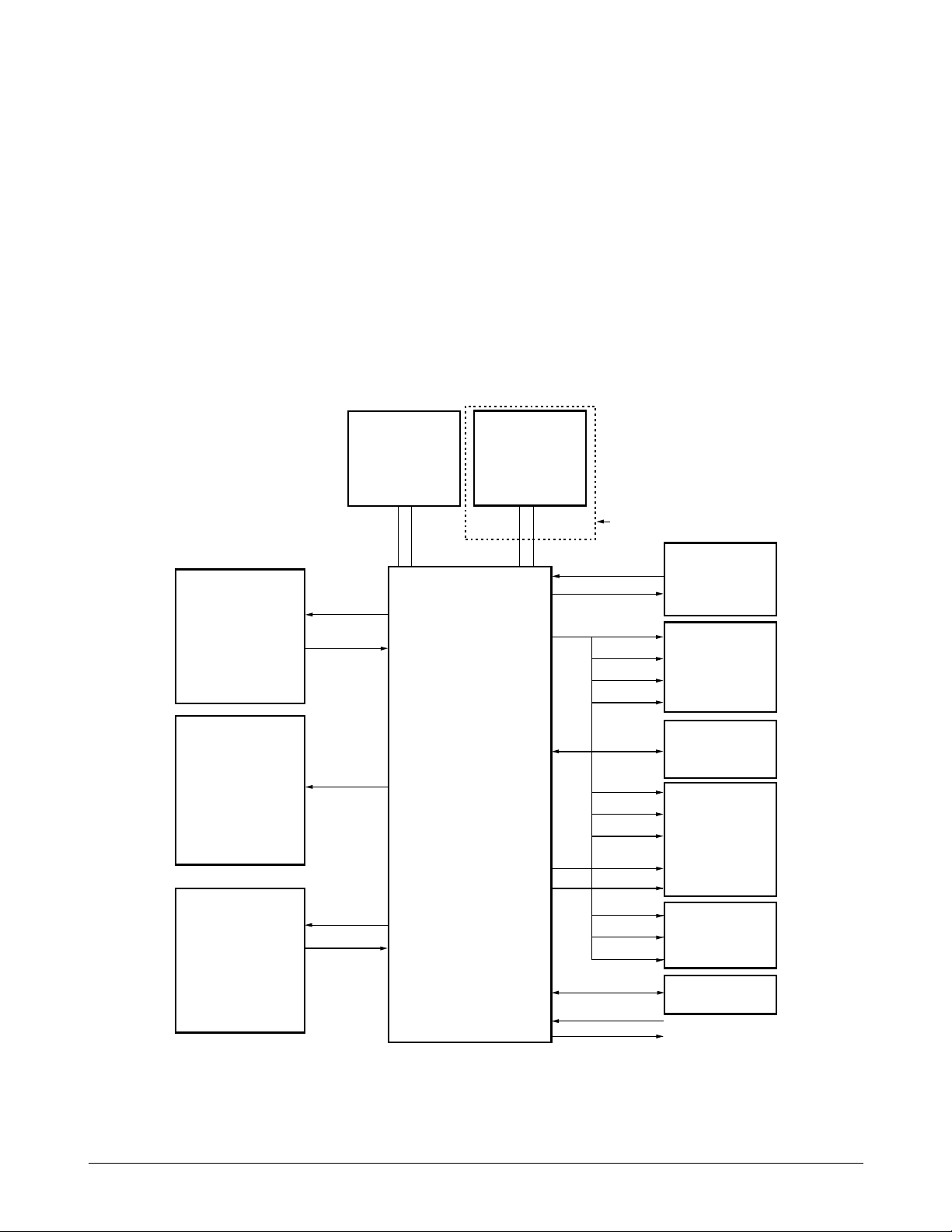

5. Circuit Description

5-1. General

The main circuit board consists of a Jupiter-2 Chip (KS32C6500), memory, TX- and RX-related circuitry, and

some portions of the Line interface Unit, and controls the system.

5-2. System Control Part

This circuit consists of the EP-ROM and SRAM, External Real Time Clock crystal, RTC and memory back-up,

and the Jupiter-2 Chip (KS32C6500). The Jupiter-2 Chip is an integrated 14400bps modem, image processor, 16bit MPU, peripheral control, and analog front end circuit on a single-chip.

The modem is 14400 bps half duplex. It is a monolithic device incorporating an over sampling Σ∆ AFE, digital

filters, a digital signal processor (SDIP4) and CPU-Interface logic.

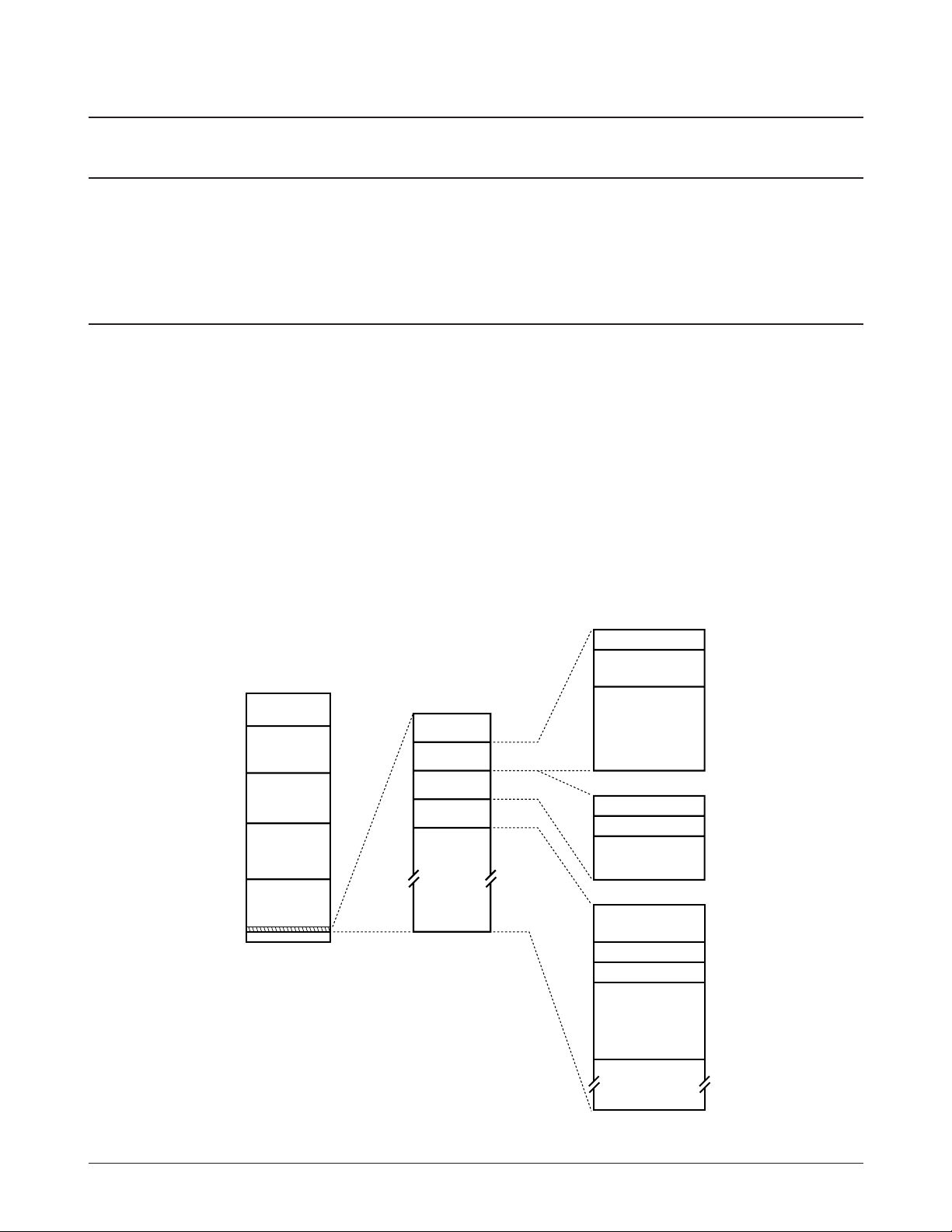

5-2-1. Memory Map

The external memory of the CPU is divided into 32kB RAM (0000H through 7FFFH), 512kB ROM (FC0000H

through FFFFFFH) and 1024kB DRAM (010000H through 07FFFFH).

Samsung Electronics 5-1

Figure 5-1 KS32C6500 External Memory Map

CPU (Logical) Address Space

FFFFFF

FC0000

ROMCSn

CAS0

CAS1

CAS2

C00000

400000

800000

000000

MCSn

Internal

Registers

CS2n CS4n

CS1n

Internal

Memory

00FFFF

00FF00

00FE00

00FD00

00FC00

00E000

Reserved

Setup

Registers

Operational

Registers

CS4n

CS3n

CS2n

Reserved

Shading Inversion

DBCMC Buffer

Dither Table

Reserved

00FEFF

00FEE0

00FE80

00FE00

00FDFF

00FDC0

00FD80

00FD00

00FBFF

00FBE0

00FBD0

00FBC0

00FB80

00E000

5-2-2. Jupiter-2 Chip

KS32C6500 internal logic generates chip select

signals for both memory chips and peripherals. To

support external access, from one to three wait

cycles can be inserted under program control during

external accesses. A chip select signal line goes

active (low) whenever its corresponding device is

accessed over the external interface. The peripheral

addresses are located in data memory.

/SRAMCS : SRAM chip select active (low)

/ ROMCS : EP-ROM chip select active (low)

D0ÐD15 : 16 bit data bus

A0ÐA17 : address bus

5-2-3. System Clock

The 30 MHz internal system clock frequency is

supplied by an external clock generator.

5-2 Samsung Electronics

Circuit Description

Figure 5-2 Hardware Interface Signals

OPERATING

PANEL

SERIAL

COMMUNICATION

HEAD

DRIVER

RTC

CRYSTAL

(32, 768KHZ)

SDIP4 TAD PART

KS32C6500

MOTOR

DRIVER

(CR, LF

MOTOR)

DATA

MEMORY

(SRAM)

PROGRAM

MEMORY

(EPROM)

DRAM.

(USER MEMORY)

GENERAL

PURPOSE I/ 0

TXD

A0~A5

D0~D15 D0~D7

CONTROL

RXD

PHINA~D

CONTROL

+24

XIN

ONLY SF3000T

XOUT

/DMS

/RD/WR

D0~D7

A0~A14

/RD

/LCAS

/RASO~

/UCAS

D0~D15

A0~A17

/A16

/PMS

/RD/WR

D0~D7

A0~A4

/RESET

/RESTO

MODEM

Loading...

Loading...