Page 1

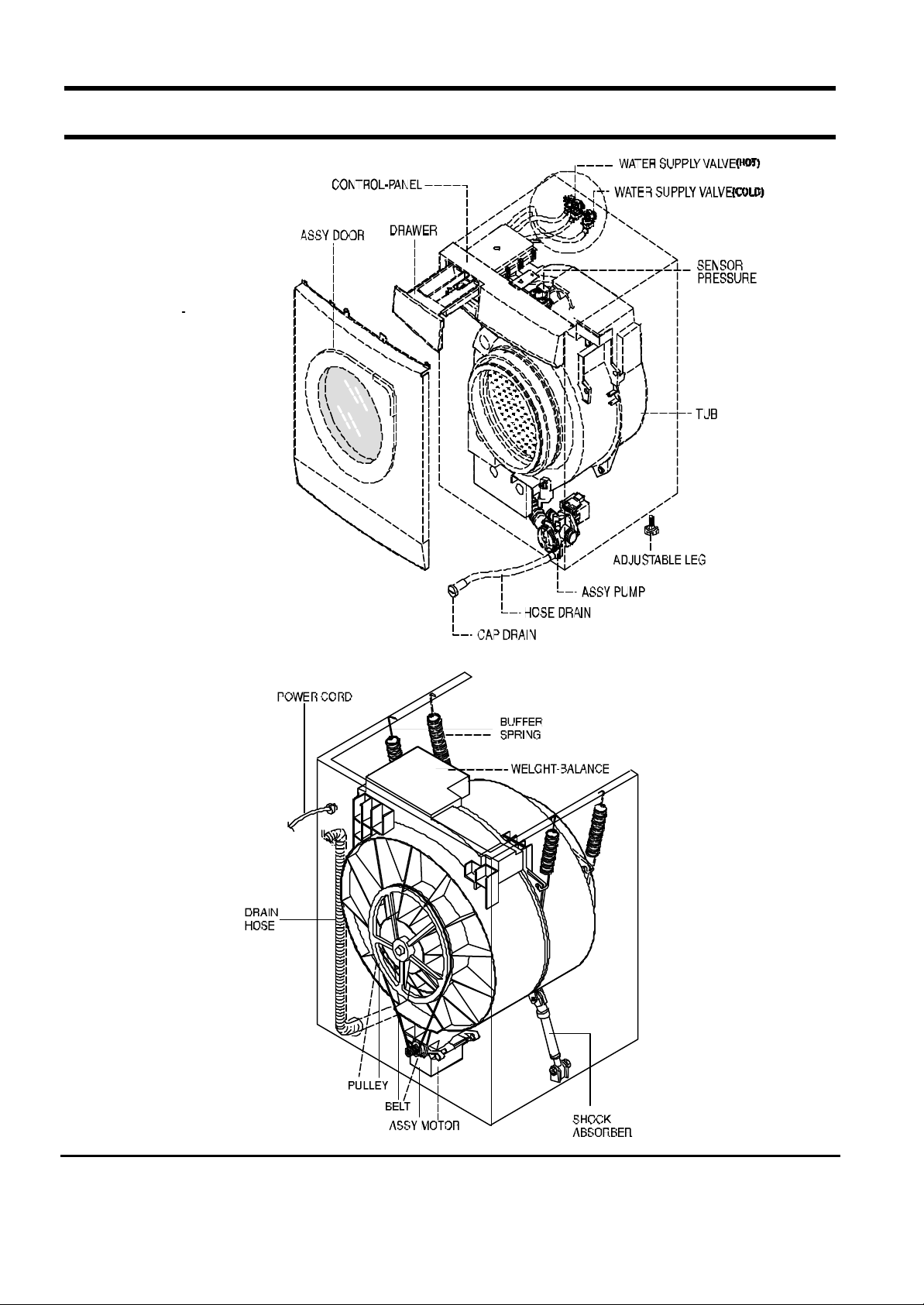

3. Overview of the Washing Machine

OPTION

OPTION

OPTION

4

Page 2

4. Overview of the control panel

F1215J/F1213J/F1015J/F1013J

F1215J/F1015J

5

Page 3

4. Overview of the control panel

any buttons being touched,

F815J

F813J

1 2 3 4 5 6

8

7

10 11

9

1. Detergent dispenser

2. Display panel

Displays the remaining wash cycle time and error messages.

3. Baby Clothes button

Press the button to select one of the three available Baby Clothes programs.

Cotton(Underwear) ‘ Coloreds ‘ Delicates

4. Option button

Press the button repeatedly to cycle through the available partial wash options

{ Rinse+ ‘ Prewash ‘ (Rinse++ Prewash) ‘ Cancel ‘ Rinse+}.

Note : Prewash/Eco+ is available only with Baby Clothes,Cotton, Coloureds,

Synthetics or Delicate programs.

5. Spin selection button

Press the button repeatedly to cycle through the available spin speed options.

When pressing this button during operation, you can see the selected spin

speed in the display panel.

F815J no, rh, 4, 6, 8,(×100rpm)

6.Temperature selection button

Press the button repeatedly to cycle through the available water temperature options

(cold water, 30 °C, 40 °C , 60 °C and 95 °C).

When pressing this button during washing, you can see the selected temperature in the display panel.

7. Delay (Start) button

Press the button repeatedly to cycle through the available delayed start options

(from 1 hour to 24 hours in one hour increments).

8. Door (Open) button (S815J)

F813J

Press to open the washing machine door.

Note: You cannot open the door until you press (On/Off).

9. Fuzzy Control dial

Cotton, Coloureds, Synthetics, Delicates, Wool, Quick, Rinse+Spin, Spin, Drain

Turn the dial to select one of the nine available wash programs.

10. Start/Pause button

Press to pause and restart programs.

11. (On/Off) button

Press once to turn the washing machine on, press again to turn the washing machine off.

If the washing machine power is left on for longer than 10 minutes without

6

the power automatically turns off.

Page 4

5. Main function

1) Auto power S/W off function

●

After power on, the auto power S/W off function automatically switches power off for you if you do not press

selection button for 10 minutes

●

After selecting the function, the auto power S/W off function automatically switches power off for you if you do

not press start/pause button for 10 minutes

●

until 5 minutes past, After finishing the last function, the auto power S/W off function automatically switches

power off for you if you do not re-select the course button or manual button

2) Door open function

●

Door just can be opened at water level 23.80 KHz over, water temperature 55

off door is not opened (F1215J,F1015,F815)

●

If door is open during the operating, all operating is halted, and door error message will be displayed (2-digit

panel displays "Ed" 4-digit panel displays "door") and error melody will coming out

●

Door open error can be cleared by closing the door. the operating keeps going on

3) Rinse hold function

●

If rinse hold function selected, the operating is finished , the machine do not drain the water after last rinse

℃

below, motro off, if power is

4) No spin function

●

If no spin function selected, the operating is finished after last rinse

5) Drain function

●

Drain function is over, after pumping out the water for 2 minutes , without motor rotating

6) Pre-washing function

●

Pre-washing function can be selected ,when you choice the following mode; cotton, coloreds, sythetics, delicates,

baby cotton

●

Water level/reverse time is the same with the selected course

●

Pre-washing takes about 15 minutes

7) Rinse+ function

●

This function practises rinse process once more

7

Page 5

5. Main function

8) Power-out compensation function

●

If power is out on selected process, the process before power out is stored to EEPROM, once power is back

the process before power out continues.

●

When power is back, washing process starts from the process at the point of the power out, rinse/drain process

starts from the initial process.

POWER-OUT COMPENSATION FUNCTION PROCESS

WASHINGSTART

POWER OUT

SAVE DATA

to EEPROM

READ DATA

(PROCESS+TIME)

9) Water heater Error function

①

This function starts working, when the heater works abnormally.

(this function begins sensing the heater 2 minutes later, after the heater operating)

②

The value of the initial thermistor(A1) is compared with that of the thermistor(A2) in 2 minutes (Y=A2-A1)

- For 10 minute the variance of temperature(Y) is less than 2℃"E5"message is displayed on the panel.

③

The value of the initial thermistor(A1) is compared with that of the thermistor(A2) in 11 minutes (Y=A2-A1)

- For 1 minute the variance of temperature(Y) increases more than 7℃(0.3V) "E6"message is displayed on the

panel.

④

At this time heater, Error "E5 (heater do not work), E6(overheated)" is displayed and all working process off

⑤

The heater operating continues during heating hours, if washing hour is left over, the residual washing process

keeps going without heating.

POWER BACK

MICOM RESTORE

RESTART

PROCESS

RINSE/DRAIN

START

SAVE DATA

to EEPROM

RINSE/DRAIN

PROCESS

POWER OUT

POWER BACK

MICOM RESTORE

FINISH

8

Page 6

5. Main function

10) Fuzzy washing function ( weight-sensing)

☞

After finishing initial water supply, when the fall of the water level needs supplementary water supply,

Sensing function perceives the weight with the supplementary water supply numbers and starts to work.

Under the course of Cotton, or Coloureds, if the supplementary water supply numbers become 3 - 4 times the

function is going at default condition ( high water level ), if 1-2 below that is going at middle level, if 0 below

low water level, heating hours and rinse hours depend on the above data.

ECO PRE mode is selected, the process going on at default condition.

Washing hours

Cotton Coloureds

High Default Default Default

Middle Default-12 min Default-7min 23.30KHZ

Low Default-25 min Default-15min 23.70KHZ

※

After sensing weight, above hours is decreased from above default hours

11) Bubble -detecting function

At the each condition of washing&dehydrating , rinse&dehydrating , hydrating, bubble -detecting function works,

this function works 5times normally, if the function detects bubbles at 6 times , the bubble-detecting function

stops and go on to the next process.

●

The bubble-detecting function during washing & dehydrating to rinse & dehydrating

after 2 times instant dehydrating and before main dehydrating, if the water level is under 25.45KHZ, Bubble

→

Detecting function thinks there are bubbles and add the bubbles-removing rinse, needing hours are above

hours and 8 min 40 sec.

→

The bubble-detecting function during single hydrating process

after 2 times instant dehydrating and before main dehydrating , if the water level is 25.45KHZ below or

during main dehydrating, water level data is 23.80KHZ below Bubble-detecting function thinks there are

bubbles and add the bubbles-removing rinse 1 times, needing hours are above hours and 5 min 55 sec.

Rinse water level

Bubble-detecting function operating process

20 sec

laundry scattering

draining &reverse

1 min

unb alance

detecting range

500rpm

200rpm

bubble de tection

9

Page 7

5. Main function

12) Unbalance detecting & laundry balance positioning system

①

Just before the hydrating process and just after reversal rotation for balancing laundry position, this function is

carried out

②

The initial 6 sec is the period of reversal rotation for balancing laundry position , Drum rotates 50rpm for

initial 6 sec

③

Next 10 sec, the rotation increases the speed from 50 rpm to 90 rpm slowly

④

During the next 18 sec, drum rotates at the speed of 90 rpm, the sensor decides the degree of laundry

unbalance with TACHO data which is attached to motor

⑤

If the degree of unbalanced laundry is over 6 times to default value, laundry balancing system carries out

feed back process 6 times

Unbalance detecting & laundry balance positioning system

500rpm

600rpm

200rpm

500rpm

20 sec

laundry scattering

unb alance

detecting range

90rpm

13) R.P.M control

The rotating motor enables the magnetics( i.e generator) to generate magnetic flux in proportion to r.p.m,

magnetic flux induced by coil sensor in the opposite side produces the wave like the figure below to dΦ/dt and

via rectangual wave generating citcuit, the waves reaches MICOM and micom controls r.p.m with the pulse,

count and cycle inputted by program.

<COIL electrical wave at both ends>

V (VOLT)

Vp

T (HOUR)

10

Page 8

6. Technical point

1) Motor on/off time at each course

Washing Rinse

Course

Cw Off Ccw Off Cw Off Ccw Off

Cotton 13 3 13 3 10 5 10 5 50

Coloureds 11 4 11 4 10 5 10 5 50

Synthetics 7 8 7 8 7 8 7 8 40

Delicates 5 10 5 10 5 10 5 10 30

Wools 2 58 2 58 2 28 2 28 25

Quick 12 3 12 3 10 5 10 5 45

※

Motor on/off time is measured in cold water, in heating time motor on/off time is 10 sec on and 5sec off in

the cotton course, beside cotton course, in the other course motor on/off time is the same with that of cold

water use.

2) Final dehydrating r.p.m at each course

unit:sec

Motor r.p.m

unit:rpm

Model

Course

Cotton 1200 1000 800

Coloureds 1200 1000 800

Synthetics 800 800 800

Delicates 600 600 600

Wools 400 400 400

Quick 1000 1000 800

※

You can change the r.p.m to the above a table by use spin button under no spin situation.

F1215J

F1213J

F1015J

F1013J

3) The water supply control at each process cycle

Model

Process cycle

Washing Cold water 5L/min / cold 10L/min

Rinse Cold 10L/min

F813J

F815J

F813J

Final rinse Cold water 5L/min + cold 10L/min

11

Loading...

Loading...