DVD- RECORDER

SERVICE

ΠMulti format recording

DVD-RW/ DVD-R

´ Multi format playback

DVD / DVD-RW / DVD-R

CD / CD-R / CD-RW / MP3 / JPEG / DIVX

ˇ Recording mode

XP(1Hour) / SP(2Hour) / LP(4Hour) /

EP(6~8Hour)

¨ Progressive scan

ˆ Automatic Chapter product on

Ø 59mm Slim Design

Manual

DVD-RECORDER

Merit & Character regarding Product

SERVICE MANUAL

DVD-HR730 / HR732 / HR734

DVD-HR730 / DVD-HR732

DVD-HR734

© Samsung Electronics Co., Ltd. MAR. 2006

Printed in Korea

AK82-01022A

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

international and/or domestic law.

Chassis : Andes (3rd Generation)

/

VD-HR730

D

D

VD-HR732 /AND, SAM, XFA, XSA, XSG, XSH, XSS,

XST

COM, EUR, SED, SEO, SMR, XEB, XEC, XEE,

XEF, XEG, XEH, XEN, XEO

XFA, XSA, XSG, XSH, XSS, XST

, XET, XEU, XEV,

ELECTRONICS

DVD-HR734

/COM, EUR, SED, SEO, XEB, XEC, XEE, XEF,

XEG, XEH, XEN, XEO, XET,

XEU, XEV

CONTENTS

1. Precautions (1-1 ~ 1-6)

1-1 Safety Precaution (1-1)

1-2 Servicing Precautions (1-3)

1-3 ESD Precautions (1-4)

1-4 Handling the optical pick-up (1-5)

2. Product Specification (2-1 ~ 2-4)

2-1 Product Specification (DVD-HR730, DVD-HR734 Europe) (2-1)

2-2 Product Specification (DVD-HR730, DVD-HR732, DVD-HR734 Asia) (2-2)

2-3 Chassis Product Specification (2-3)

2-4 Option Product Specification (2-4)

3. Software Update (3-1 ~ 3-4)

3-1 Drive Firmware Update (3-1)

3-2 Flash Update (3-3)

4. Disassembly and Reassembly (4-1 ~ 4-8)

4-1 Cabinet and PCB (4-1)

4-2 PCB Location (4-8)

5. Trouble Shooting (5-1 ~ 5-14)

6. Exploded View and Parts List (6-1 ~ 6-6)

6-1 Cabinet Assembly (DVD-HR730, DVD-HR732) (6-2)

6-2 Cabinet Assembly (DVD-HR734) (6-4)

7. Electrical Parts List (7-1 ~ 7-14)

8. Block Diagram (8-1 ~ 8-8)

8-1 All Block Diagram (8-2)

8-2 DIC1 (DMN8602) Block Diagram (8-3)

8-3 AIC1 (PCM1743A) Block Diagram (8-4)

8-4 AIC3 (PCM1803A) Block Diagram (8-5)

8-5 PIC1 (TSB4AB1) Block Diagram (8-6)

8-6 TIC1 (TVP5146) Block Diagram (8-7)

9. Wiring Diagram (9-1 ~ 9-2)

10. PCB Diagrams (10-1 ~ 10-10)

10-1 S.M.P.S. PCB (10-2)

10-2 Main PCB (10-4)

10-3 Jack PCB (10-6)

10-4 Function PCB (DVD-HR730, DVD-HR732) (10-8)

10-5 Function PCB (DVD-HR734) (10-9)

11. Schematic Diagrams (11-1 ~ 11-20)

11-1 S.M.P.S. (SMPS PCB) (11-3)

11-2 Main Connector (Main PCB) (11-4)

11-3 DDR (Main PCB) (11-5)

11-4 IEEE1394 (Main PCB) (11-6)

11-5 Video Decorder (Main PCB) (11-7)

11-6 Domino (Main PCB) (11-8)

11-7 Audio AD/DA (Main PCB) (11-9)

11-8 VPS / PDC (Jack PCB) (11-10)

11-9 System Control (Jack PCB) (11-11)

11-10 TM Block (Jack PCB) (11-12)

11-11 A2/ NICAM (Jack PCB) (11-13)

11-12 Power (Jack PCB) (11-14)

11-13 Connection (Jack PCB) (11-15)

11-14 I/O (Jack PCB) (11-16)

11-15 I/O Switching (Jack PCB) (11-17)

11-16 Display Key (Jack PCB) (11-18)

11-17 Function (Function PCB) (11-19)

CONTENTS

12. Operating Instructions (12-1 ~ 12-10)

13. Circuit Operating Descriptions (13-1 ~ 13-14)

13-1 Power (13-1)

13-2 AV Codec (13-4)

13-3 SERVO (DVP Multi Drive) (13-7)

13-4 Video In/Out block (13-9)

13-5 Audio (13-12)

13-6 Tuner (13-13)

13-7 IF (13-14)

14. Reference Information (14-1 ~ 14-12)

14-1 Introduction to DVD (14-1)

14-2 DVD-Video Fromat (14-3)

14-3 About IEEE1394 (14-9)

CONTENTS

Samsung Electronics 1-1

1. Precautions

1-1 Safety Precautions

1) Before returning an instrument to the customer,

always make a safety check of the entire instrument,

including, but not limited to, the following items:

(1) Be sure that no built-in protective devices are

defective or have been defeated during servicing.

(1)Protective shields are provided to protect both

the technician and the customer. Correctly replace

all missing protective shields, including any

removed for servicing convenience.

(2)When reinstalling the chassis and/or other assembly in the cabinet, be sure to put back in place

all protective devices, including, but not limited to,

nonmetallic control knobs, insulating fish papers,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not operate this instrument or permit it to be operated without all protective devices correctly installed and

functioning.

(2) Be sure that there are no cabinet openings through

which adults or children might be able to insert

their fingers and contact a hazardous voltage. Such

openings include, but are not limited to, excessively wide cabinet ventilation slots, and an improperly fitted and/or incorrectly secured cabinet back

cover.

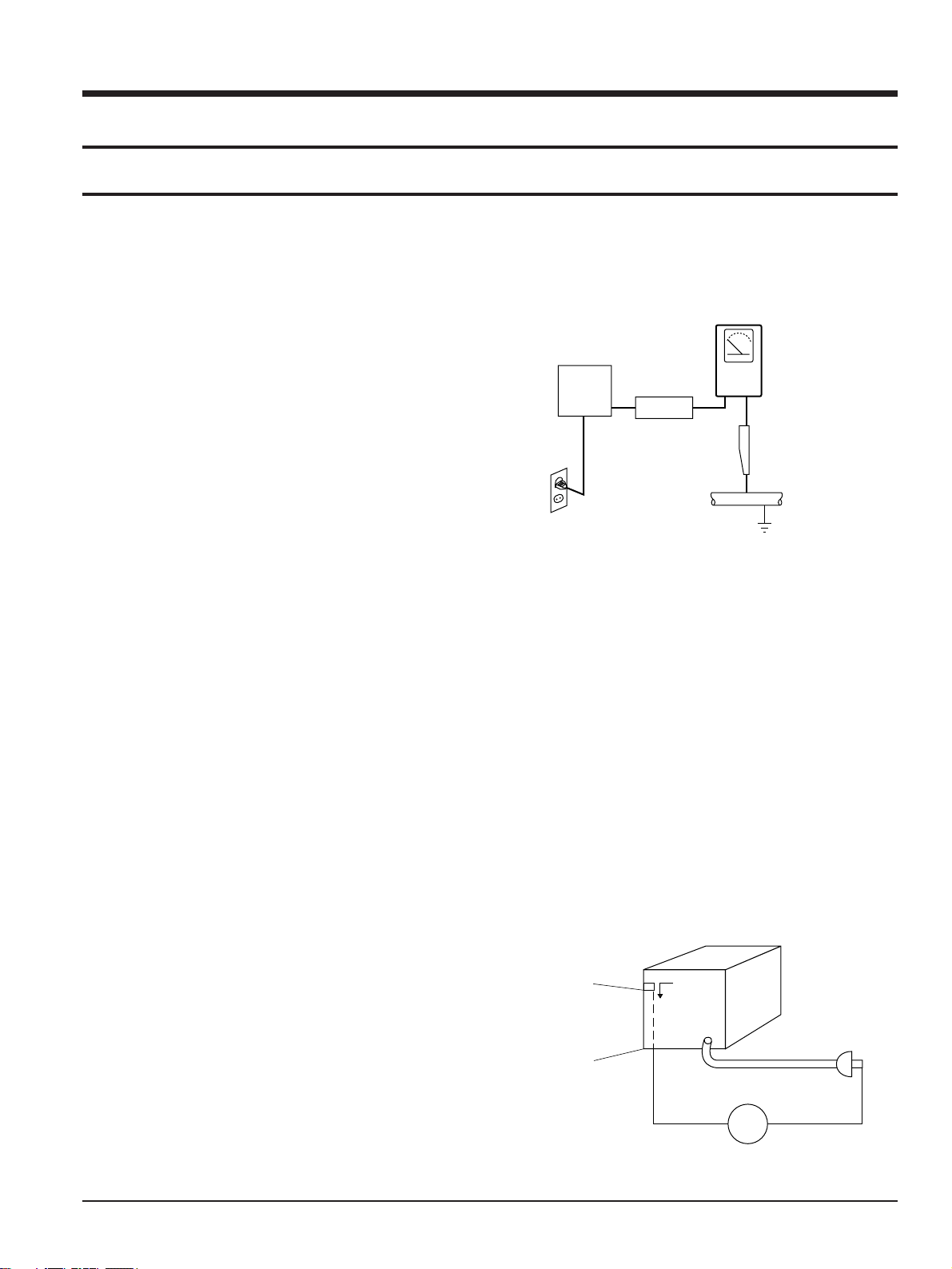

(3) Leakage Current Hot Check-With the instrument

completely reassembled, plug the AC line cord

directly into a 230V(220V ~ 240V) AC outlet. (Do

not use an isolation transformer during this test.)

Use a leakage current tester or a metering system

that complies with American National Standards

institute (ANSI) C101.1 Leakage Current for

Appliances and Underwriters Laboratories (UL)

1270 (40.7). With the instrument’s AC switch first in

the ON position and then in the OFF position, measure from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the

instrument (antennas, handle brackets, metal cabinets, screwheads, metallic overlays, control shafts,

etc.), especially any exposed metal parts that offer

an electrical return path to the chassis.

Any current measured must not exceed 0.5mA.

Reverse the instrument power cord plug in the outlet and repeat the test. See Fig. 1-1.

Any measurements not within the limits specified

herein indicate a potential shock hazard that must

be eliminated before returning the instrument to

the customer.

Fig. 1-1 AC Leakage Test

(4) Insulation Resistance Test Cold Check-(1) Unplug

the power supply cord and connect a jumper wire

between the two prongs of the plug. (2) Turn on the

power switch of the instrument. (3) Measure the

resistance with an ohmmeter between the

jumpered AC plug and all exposed metallic cabinet

parts on the instrument, such as screwheads,

antenna, control shafts, handle brackets, etc. When

an exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2

megohm. When there is no return path to the chassis, the reading must be infinite. If the reading is

not within the limits specified, there is the possibility of a shock hazard, and the instrument must be

repaired and rechecked before it is returned to the

customer. See Fig. 1-2.

Fig. 1-2 Insulation Resistance Test

(READING SHOULD

NOT BE ABOVE

0.5mA)

EARTH

GROUND

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METER

SURFACES

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

LEAKAGE

CURRENT

TESTER

Antenna

Terminal

Exposed

Metal Part

ohm

ohmmeter

Precautions

1-2 Samsung Electronics

2) Read and comply with all caution and safety related notes on or inside the cabinet, or on the chassis.

3) Design Alteration Warning-Do not alter or add to

the mechanical or electrical design of this instrument. Design alterations and additions, including

but not limited to, circuit modifications and the

addition of items such as auxiliary audio output

connections, might alter the safety characteristics of

this instrument and create a hazard to the user. Any

design alterations or additions will make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

4) Observe original lead dress. Take extra care to

assure correct lead dress in the following areas:

(1) near sharp edges, (2) near thermally hot parts (be

sure that leads and components do not touch thermally hot parts), (3) the AC supply, (4) high voltage,

and (5) antenna wiring. Always inspect in all areas

for pinched, out-of-place, or frayed wiring, Do not

change spacing between a component and the

printed-circuit board. Check the AC power cord for

damage.

5) Components, parts, and/or wiring that appear to

have overheated or that are otherwise damaged

should be replaced with components, parts and/ or

wiring that meet original specifications.

Additionally, determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

6) Product Safety Notice-Some electrical and mechanical parts have special safety-related characteristics

which are often not evident from visual inspection,

nor can the protection they give necessarily be

obtained by replacing them with components rated

for higher voltage, wattage, etc. Parts that have special safety characteristics are identified by shading,

an ( )or a ( )on schematics and parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire and/or

other hazards. Product safety is under review continuously and new instructions are issued whenever appropriate.

Precautions

Samsung Electronics 1-3

1-2 Servicing Precautions

CAUTION : Before servicing units covered by this

service manual and its supplements, read and follow

the Safety Precautions section of this manual.

Note : If unforseen circumstances create conflict

between the following servicing precautions and any

of the safety precautions, always follow the safety precautions. Remember: Safety First.

1-2-1 General Servicing Precautions

(1) a. Always unplug the instrument’s AC power cord

from the AC power source before (1) re-moving

or reinstalling any component, circuit board,

module or any other instrument assembly, (2)

disconnecting any instrument electrical plug or

other electrical connection, (3) connecting a test

substitute in parallel with an electrolytic capacitor in the instrument.

b. Do not defeat any plug/socket B+ voltage inter-

locks with which instruments covered by this

service manual might be equipped.

c. Do not apply AC power to this instrument and

/or any of its electrical assemblies unless all

solid-state device heat sinks are correctly installed.

d. Always connect a test instrument’s ground lead

to the instrument chassis ground before connecting the test instrument positive lead. Always

remove the test instrument ground lead last.

Note : Refer to the Safety Precautions section ground

lead last.

(2) The service precautions are indicated or printed on

the cabinet, chassis or components. When servicing, follow the printed or indicated service precautions and service materials.

(3) The components used in the unit have a specified

flame resistance and dielectric strength.

When replacing components, use components

which have the same ratings. Components identified by shading, by( ) or by ( ) in the circuit diagram are important for safety or for the characteristics of the unit. Always replace them with the exact

replacement components.

(4) An insulation tube or tape is sometimes used and

some components are raised above the printed

wiring board for safety. The internal wiring is

sometimes clamped to prevent contact with heating components. Install such elements as they

were.

(5) After servicing, always check that the removed

screws, components, and wiring have been installed correctly and that the portion around the

serviced part has not been damaged and so on.

Further, check the insulation between the blades of

the attachment plug and accessible conductive

parts.

1-2-2 Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet

and turn the power ON. Connect the insulation resistance meter (500V) to the blades of the attachment

plug. The insulation resistance between each blade of

the attachment plug and accessible conductive

parts(see note) should be more than 1 Megohm.

Note : Accessible conductive parts include metal panels, input terminals, earphone jacks, etc.

Precautions

1-4 Samsung Electronics

1-3 ESD Precautions

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive Devices(ESD). Examples of typical ESD

devices are integrated circuits and some field-effect

transistors and semiconductor chip components. The

following techniques should be used to help reduce

the incidence of component damage caused by static

electricity.

(1) Immediately before handling any semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic charge on your body by

touching a known earth ground. Alternatively,

obtain and wear a commercially available discharging wrist strap device, which should be

removed for potential shock reasons prior to applying power to the unit under test.

(2) After removing an electrical assembly equipped

with ESD devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

(3) Use only a grounded-tip soldering iron to solder or

unsolder ESD devices.

(4) Use only an anti-static solder removal devices.

Some solder removal devices not classified as

“anti-static” can generate electrical charges sufficient to damage ESD devices.

(5) Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESD devices.

(6) Do not remove a replacement ESD device from its

protective package until immediately before your

are ready to install it.(Most replacement ESD

devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive materials).

(7) Immediately before removing the protective ma-

terials from the leads of a replacement ESD device,

touch the protective material to the chassis or circuit assembly into which the device will be

installed.

CAUTION : Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

(8) Minimize bodily motions when handling unpack-

aged replacement ESD devices. (Otherwise harmless motion such as the brushing together of your

clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient

to damage an ESD device).

Precautions

Samsung Electronics 1-5

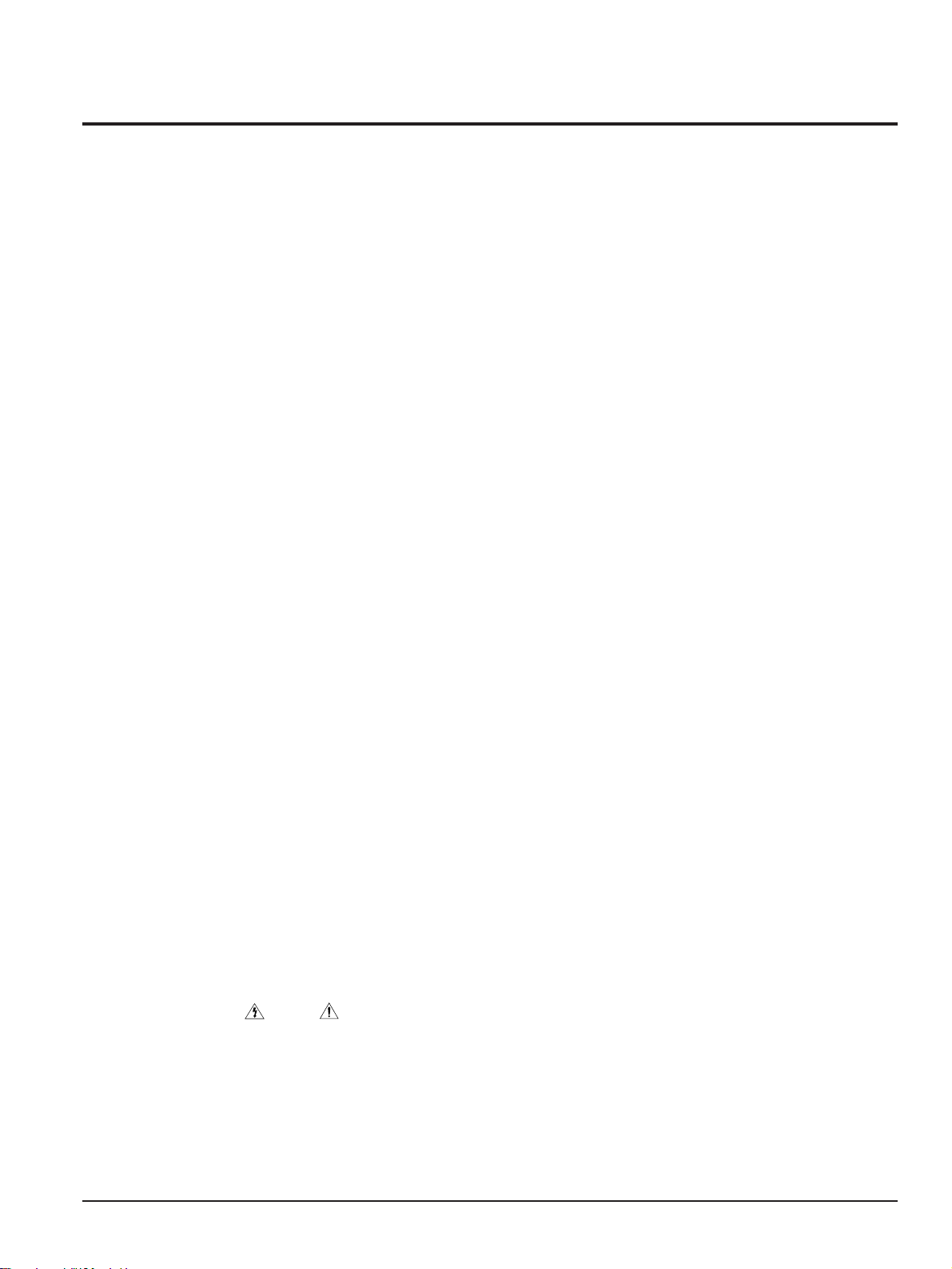

1-4 Handling the optical pick-up

The laser diode in the optical pick up may suffer electrostatic breakdown because of potential static electricity from clothing and your body.

The following method is recommended.

(1) Place a conductive sheet on the work bench (The

black sheet used for wrapping repair parts.)

(2) Place the set on the conductive sheet so that the

chassis is grounded to the sheet.

(3) Place your hands on the conductive sheet(This

gives them the same ground as the sheet.)

(4) Remove the optical pick up block

(5) Perform work on top of the conductive sheet. Be

careful not to let your clothes or any other static

sources to touch the unit.

◆ Be sure to put on a wrist strap grounded to the

sheet.

◆ Be sure to lay a conductive sheet made of copper

etc. Which is grounded to the table.

Fig.1-3

(6) Short the short terminal on the PCB, which is in-

side the Pick-Up ASS’Y, before replacing the PickUp. (The short terminal is shorted when the PickUp Ass’y is being lifted or moved.)

(7) After replacing the Pick-up, open the short termi-

nal on the PCB.

WRIST-STRAP

FOR GROUNDING

1M

THE UNIT

1M

CONDUCTIVE SHEET

Precautions

1-6 Samsung Electronics

MEMO

Samsung Electronics 2-1

Power requirements AC 220~240V ,50Hz

Power consumption 2.7Watts (Tandby Power), 35Watts (Recording & Playback Simultaneously)

General

Weight 3.9 Kg

Dimensions 430mm(W) x 300mm(D) x 59mm(H)

Operating temp +5°C to +35°C

Other conditions Keep level when operating. Less than 75% operating humidity

Video Composite Video : 1.0 V p-p at 75ohm load, sync negative

Audio Max. Audio input level : 2Vrms

DV Input IEEE 1394(4p) compatible jack

Input Receivable Channels PAL B/G, DK, I

Scart Jack

AV1 (Scart TV) Video : Composite, Audio : analogue

AV2 (Scart Ext) Video : Composite, RGB Audio : analogue

Audio

Analogue output jacks X 2

Optical/coaxial digital audio output

Composite Video : Video output jack X 1

Output

Video S-Video output X 1 (Y: 1.0Vp-p, C:0.286Vp-p at 75 ohm load)

Component output X 1 (Y: 1.0Vp-p ,Pb:0.70Vp-p, Pr:0.70Vp-p at 75ohm load)

Scart Jack AV1 (Scart TV) Video : Composite, RGB Audio : analogue

Picture compression format MPEG-II

Audio compression format Dolby digital 2ch/256kbps, MPEG-II

Recording

Recording Quality

XP (about 8.5 Mbps), SP (about 4.5 Mbps), LP (about 2.5 Mbps),

EP (about 1.6 Mbps or about 1.2 Mbps), FR (about 1.2 Mbps to 8Mbps)

Audio frequency characteristics 20 Hz ~ 20 KHz

2. Product Specification

2-1 Product Specification (DVD-HR730, DVD-HR734 Europe)

Product Specification

2-2 Samsung Electronics

Power requirements AC 220~240V ,50Hz

Power consumption 2.7Watts (Tandby Power), 35Watts (Recording & Playback Simultaneously)

General

Weight 3.9 Kg

Dimensions 430mm(W) x 300mm(D) x 59mm(H)

Operating temp +5°C to +35°C

Other conditions Keep level when operating. Less than 75% operating humidity

Video Composite Video : 1.0 V p-p at 75ohm load, sync negative

Audio Max. Audio input level : 2Vrms

DV Input IEEE 1394(4p) compatible jack

Input Receivable Channels PAL B/G, B/B

AV1 (Rear) Video : Composite, S-Video Audio : analogue

AV2 (Front) Video : Composite Audio : analogue

Audio

Analogue output jacks X 2

Optical/coaxial digital audio output

Output

Composite Video : Video output jack X 1

Video S-Video output X 1 (Y: 1.0Vp-p, C:0.286Vp-p at 75 ohm load)

Component output X 1 (Y: 1.0Vp-p ,Pb:0.70Vp-p, Pr:0.70Vp-p at 75ohm load)

Picture compression format MPEG-II

Audio compression format Dolby digital 2ch/256kbps, MPEG-II

Recording

Recording Quality

XP (about 8.5 Mbps), SP (about 4.5 Mbps), LP (about 2.5 Mbps),

EP (about 1.6 Mbps or about 1.2 Mbps), FR (about 1.2 Mbps to 8Mbps)

Audio frequency characteristics 20 Hz ~ 20 KHz

2-2 Product Specification (DVD-HR730, DVD-HR732, DVD-HR734 Asia)

Product Specification

Samsung Electronics 2-3

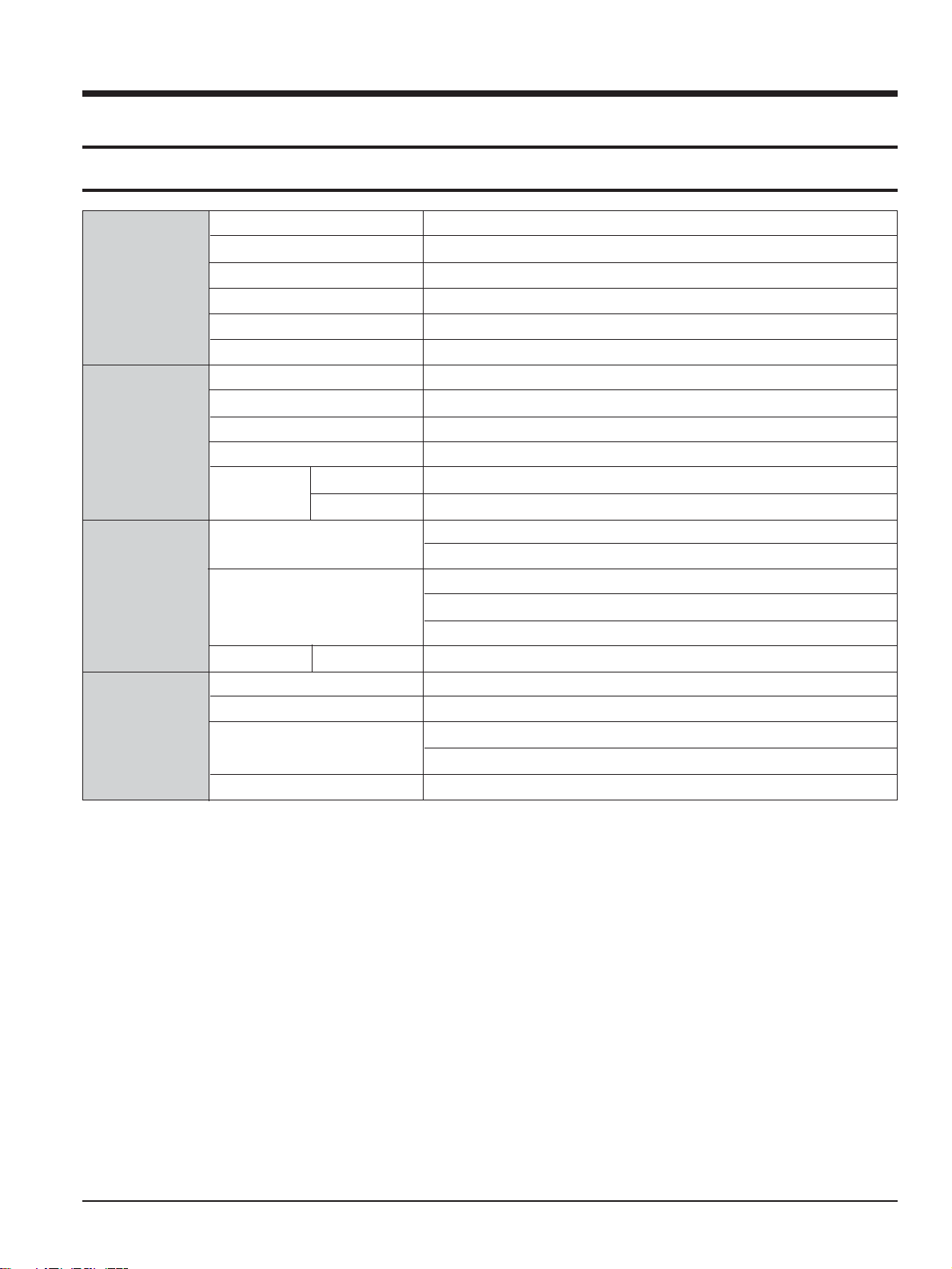

General Model Name DVD-HR720

DVD-HR730/HR734(Europe)

DVD-HR730/HR732/HR734(Asia)

Info Function Standard Standard Standard

COLOR SYSTEM PAL PAL PAL

SYSTEM BROADCAST - I, B/G, D/K, L/L’ I, B/G, D/K, L/L’ B/B, B/G

AUTO CLOCK O O DVD-RAM O - DVD-R O O O

DVD-RW O O O

VIDEO MPEG-2 MPEG-2 MPEG-2

AUDIO 2ch 2ch 2ch

RECORDER DVD-RAM/-R(4.7GB) O - FUNCTION HDD 80GB 80GB 80GB

Flexible Recording O O O

OTR O O O

Time Slip O - O

Video Plus+/Show View/G-Code Video Plus+/Show View - -

Quick Dubbing O O O

EPG(Gemstar) - - -

IR Blaster - - -

Play List O O O

SUB Auto Chaptering O O O

FUNCTION JPEG Browser with BG music O O O

DV Input O O O

10in2 Memory Slot - - -

DVD-RAM/-R/-RW O/O/(O) -/O/(O) O/O/(O)

DVD-Video/VCD/CD-DA O/-/O O/O/- O/O/-

CD-R/RW O/O O/O O/O

PLAYBACK Music CD O O O

FUNCTION MPEG4/Divx O O O

Multi Memory Card - - -

Progressive Scan Output O O O

Upscaling(720P/1080i) O O O

Video / Audio 21pin (on the rear) Yes (AV1) Yes (AV1) -

Sat. 21 pin (on the rear) with RGB Yes (AV2) Yes (AV2) -

Video/Audio in RCA Jack (on the front ) Yes (AV3) Yes (AV3) Yes (AV2)

Video/Audio in RCA Jack (on the rear) - - Yes (AV1)

Video/Audio out RCA Jack (on the rear) Yes x 1 Yes x 1 Yes

Additional Audio output (on the rear) Yes x 1 Yes x 1 Yes

Aerial In / Ant.- out (on the rear) Yes Yes Yes

IN/OUT RGB Output 21 pin Yes (SCART-1) X 1 Yes (SCART-1) X 1 -

Coaxial Digital Audio output Yes x 1 Yes x 1 Yes x 1

Optical Digital Audio output Yes x 1 Yes x 1 Yes x 1

S-Video output (on the rear) Yes x 1 Yes x 1 Yes x 1

S-Video input (on the front) - - -

S-Video input (on the rear) - - Yes

DV input (on the front) Yes Yes Yes

Component VIdeo Output Yes Yes Yes

2-3 Chassis Product Specification

Product Specification

2-4 Samsung Electronics

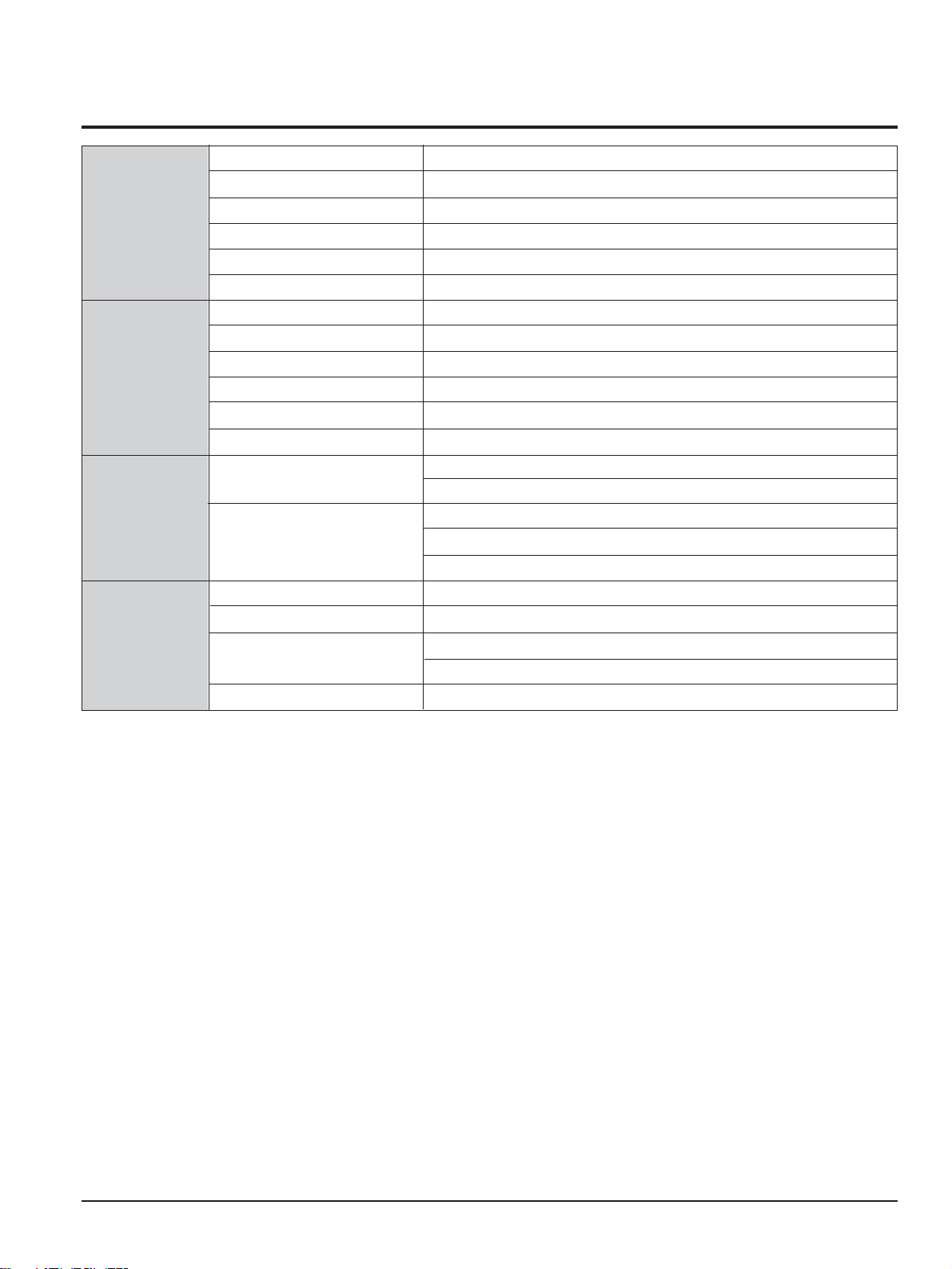

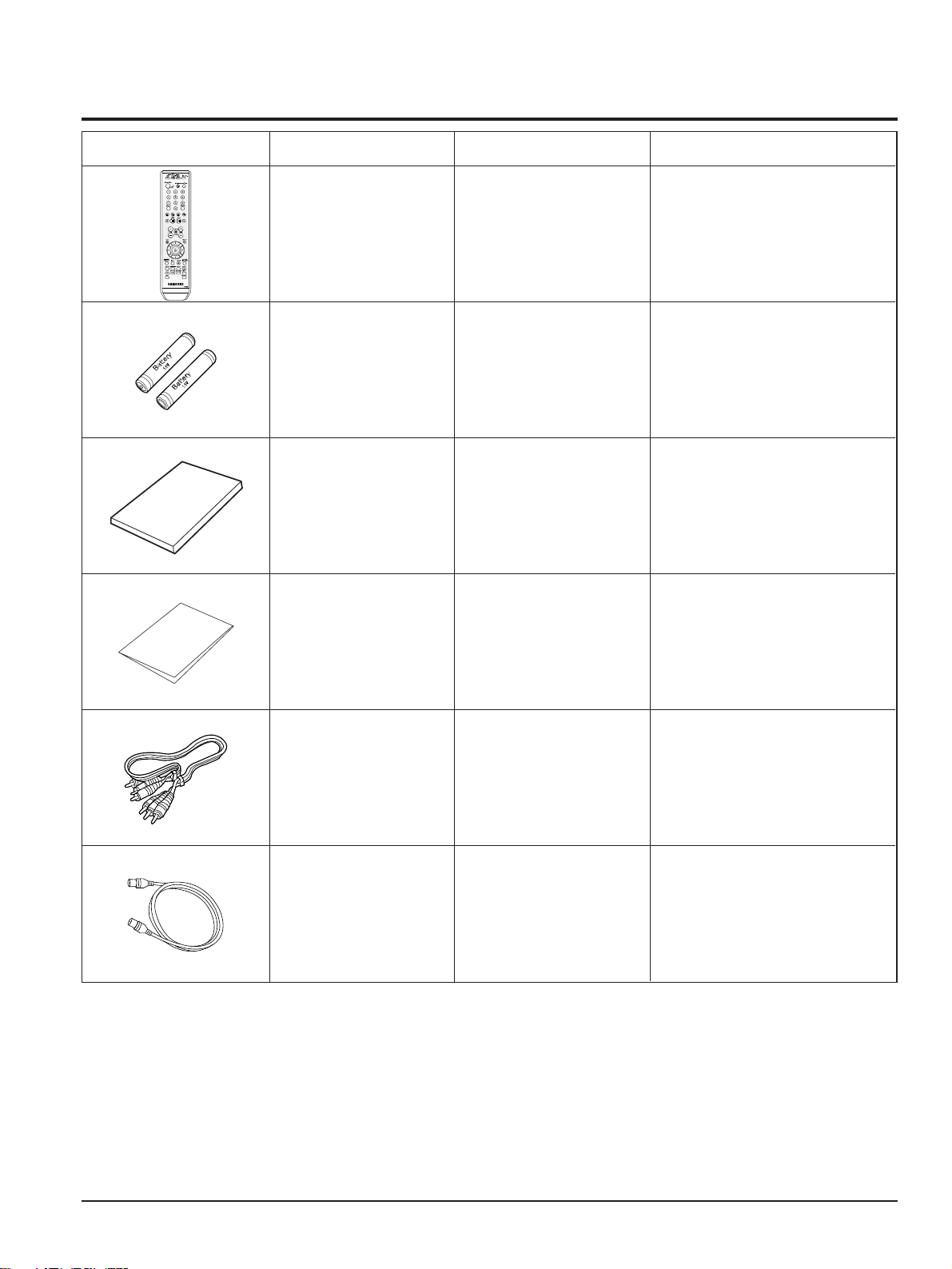

2-4 Option Product Specification

Description Fig Description Parts No Remark

Remote

Control

Batteries for

Remote Control

AK59-00053H

4301-001035

Model Standard of

DVD-VR730/XEU

Model Standard of

DVD-VR730/XEU

S.N.A

Model Standard of

DVD-VR730/XEU

Model Standard of

DVD-VR730/XEU

S.N.A

Model Standard of

DVD-VR730/XEU

Model Standard of

DVD-VR730/XEU

AK68-01025A

AK68-01023A

AC39-42001R

AC39-00018A

User’s Manual

Quick Guide

Video/Audio

Cable

RF Cable

Samsung Electronics

3-1

3. Software Update

3-1 Drive Firmware Update

3-1-1 Introduction

When you can not record and play on specific recording media (especially on newly available DVD-RW or DVD-R).

3-1-2 How to make an update disc

• Write the downloaded file onto a blank CD-R or CD-RW disc, using the following settings :

1) Download the software update file from the samsung internet site. (http://europe.samsungportal.com)

2) Write the file to disc using the CD-RW of your computer.

• Recommended Application Program

- Nero Burning / Easy CD Creator ..etc

• Option

- Extension name : “*.SMD”

- Multisession : No Multisession

- File name lenght : Max. of 11 = 8 + 3

- Format : Mode 1

- Character set : ISO 9660 or Joliet Format

- CD Close & Dise at once

N O T E

Very important : please read the notice below before updating your unit.

The following events may interrupt the update process and MAY RESULT IN PERMANENT DAMAGE TO THE UNIT WHILE UPDATING

! Unplugging the power cord.

@ Power Outage.

# Dirt or Scratches on the disc.

$ Opening a disc tray during processing.

WARNING

3-2

Software Update

Samsung Electronics

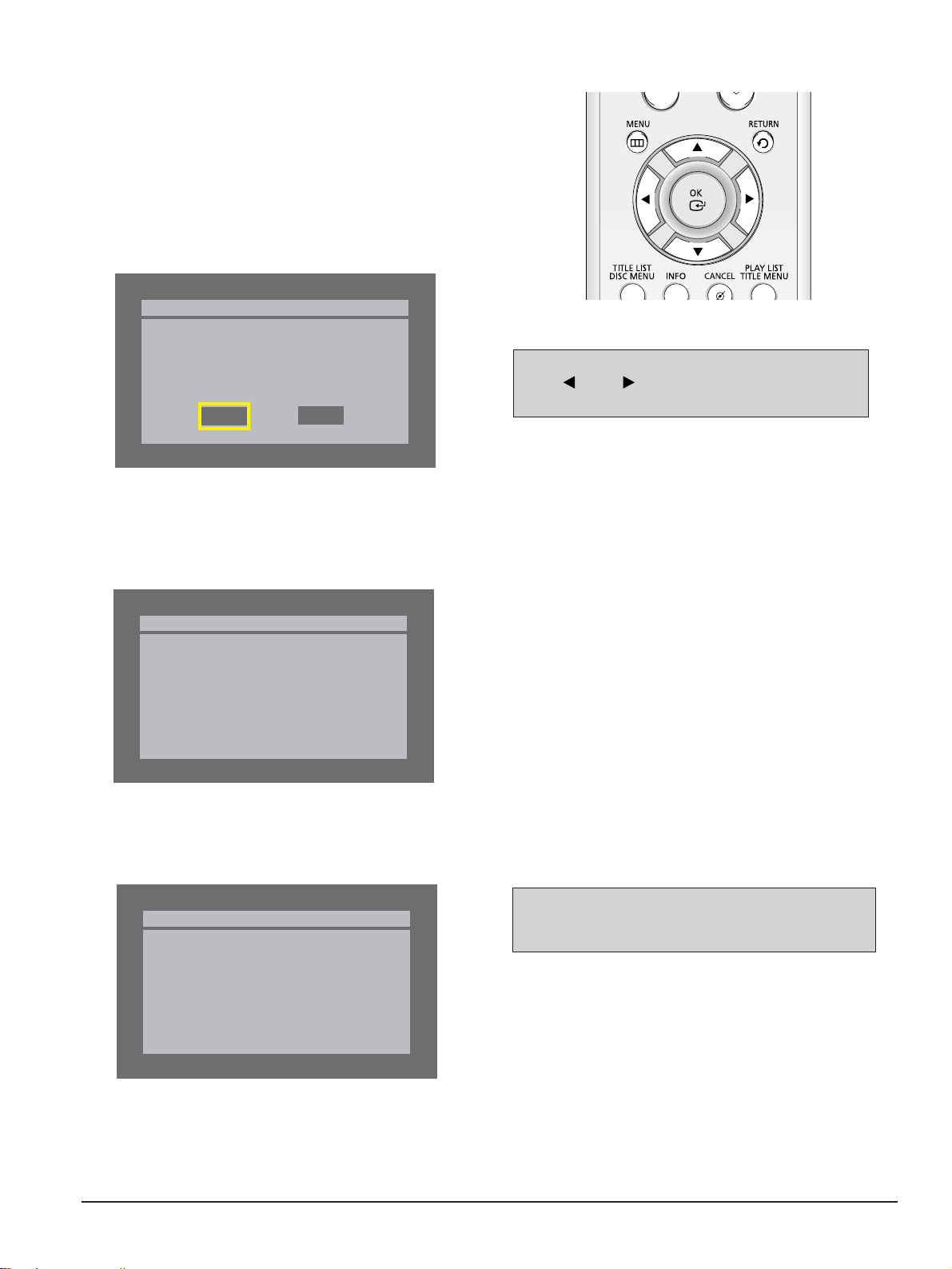

Fig. 3-2

* If you don’t see the message above, try another disc. Generally, this is caused by disc quality and by disc creating problem.

4) Press the OK button on the remote control (Fig. 3-1).

Fig.3-3

5) It takes about 1~2 minutes to complete the update.

The message below will be displayed in the screen after update is completed and the tray will open automatically.

Fig. 3-4

6) After removing the update disc, turn off the unit with power button.

Turn on the power again the tray will then close.

The drive firmware is now complete.

Drive Update

Do you want to update drive-firmware?

Version: Xx.X.HR730 -> XX.X.HR730

No

Yes

Atfer checking old and new version, select “Yes” or “No”

with “ ” or “ ” on the remote control.

* The Version is indicated by “XX.X modelname”

You will see “LOAD” on FLT Display.

Drive Update

Now, processing...

please, do not turn off the power.

Drive Update

Drive firmware is successfully

updated.

Fig. 3-5

1) Press OPEN/CLOSE to open the disc tray.

2) Insert the update CD-R disc with the software update, label

facing up.

3) Press OPEN/CLOSE to close the disc tray.

* It takes about 1~2 minites before the mesage below appears.

Fig. 3-1 Remote Control

Software Update

3-3

Samsung Electronics

3-2 Flash Update

3-2-1 Introduction

When you encounter the problem which is not related in drive firmware necessity.

3-2-2 How to make an update disc

Write the downloaded file onto a blank CD-R or CD-RW disc, using the following settings :

1) Download the software update file from the samsung internet site. (http://europe.samsungportal.com)

2) Write the file to disc using the CD-RW of your computer.

• Recommended Application Program

- Nero Burning / Easy CD Creator ..etc

• Option

- Multisession : No Multisession

- CD close & disc at once

- ISO 9660 or joliet format

- Extension name : “*.RUF”

• In order to increase disc playability, add a dummy file (over 100MB) together with the latest program.

(The dummy file can be any kind of file except MP3 file etc which can be played in the unit and we recommend to use a file whose

extension name as “*.dmy”, which can be changed from original one.)

N O T E

Very important : please read the notice below before updating your unit.

The followong events may interrupt the update process and MAY RESULT IN PERMANENT DAMAGE TO THE UNIT WHILE UPDATING

! Unplugging the power cord.

@ Power Outage.

# Dirt or Scratches on the disc.

$ Opening a disc tray during processing.

WARNING

3-4

Software Update

Samsung Electronics

Fig. 3-7

* If you don’t see the message above, try another disc.

Generally, this is caused by disc quality and by disc creating problem.

4) Press the OK button on the remote control (Fig. 3-6).

Fig. 3-8

5) It takes about 5 minutes to complete the update.

The message below will be displayed in the screen after update is completed and the tray will open automatically.

Fig. 3-9

6) After removing the update disc, turn off the unit with power button.

Turn on the power again and the tray will then close.

The Flash update is now complete.

* If the message to the left isn’t displayed after 10minutes

and the unit is no longer functioning properly, contact a

samsung authorized service center.

Atfer checking old and new version, select “Yes” or “No”

with “ ” or “ ” on the remote control.

* The Version is indicated by “YYMMDD.xx modelname”

Flash Update

Do you want to update flash memory?

Version : YYMMDD.xx.HR730

-> YYMMDD.xx.HR730

No

Yes

Flash Update

Now, Processing...

Plase. do not turn off the power.

Flash Update

Flash memory is successfully

updated.

1) Press OPEN/CLOSE to open the disc tray.

2) Insert the update CD-R disc with the software update, label

facing up.

3) Press OPEN/CLOSE to close the disc tray.

Fig. 3-6 Remote Control

Samsung Electronics

4-1

4. Disassembly and Reassembly

4-1 Cabinet and PCB

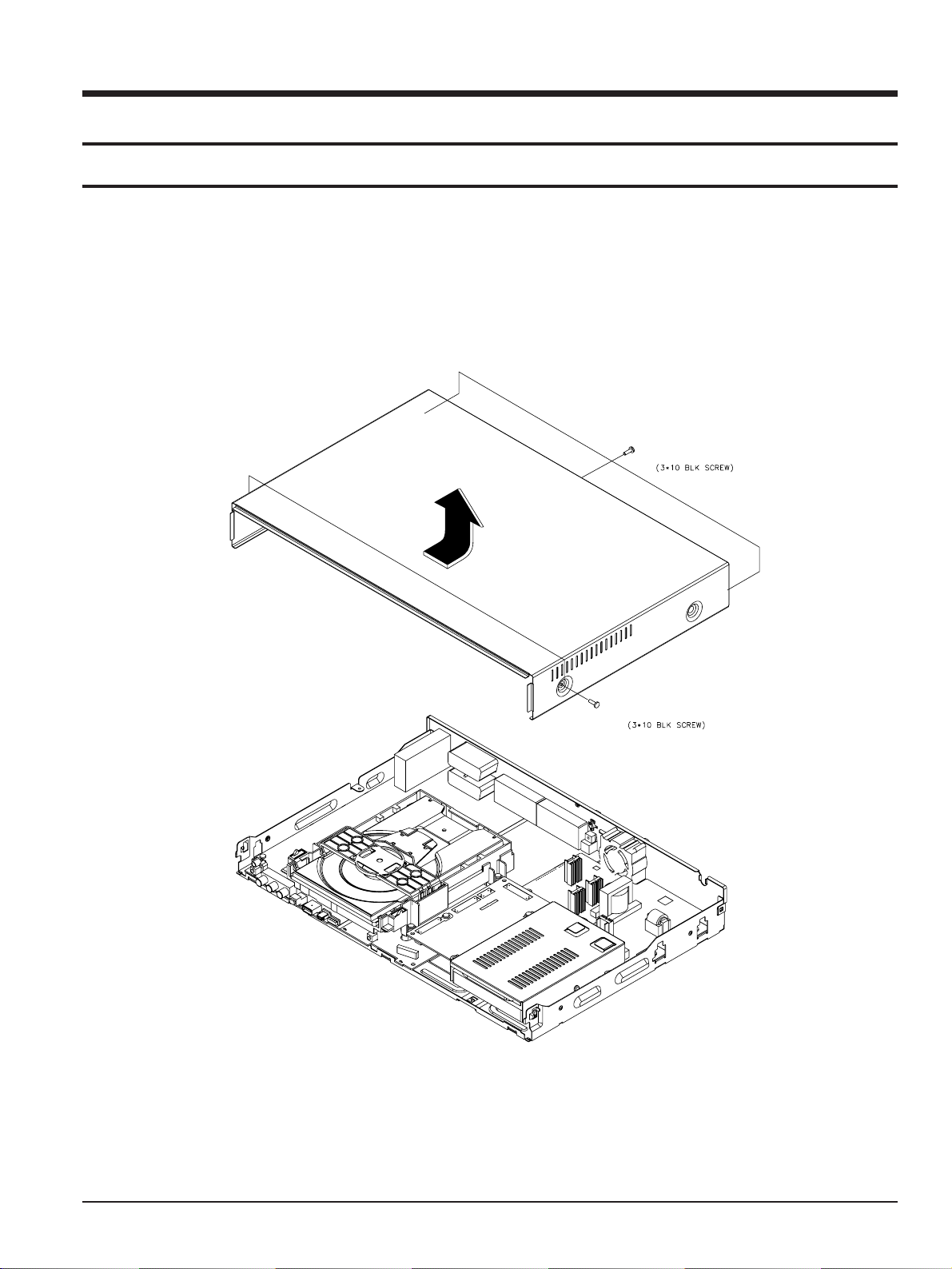

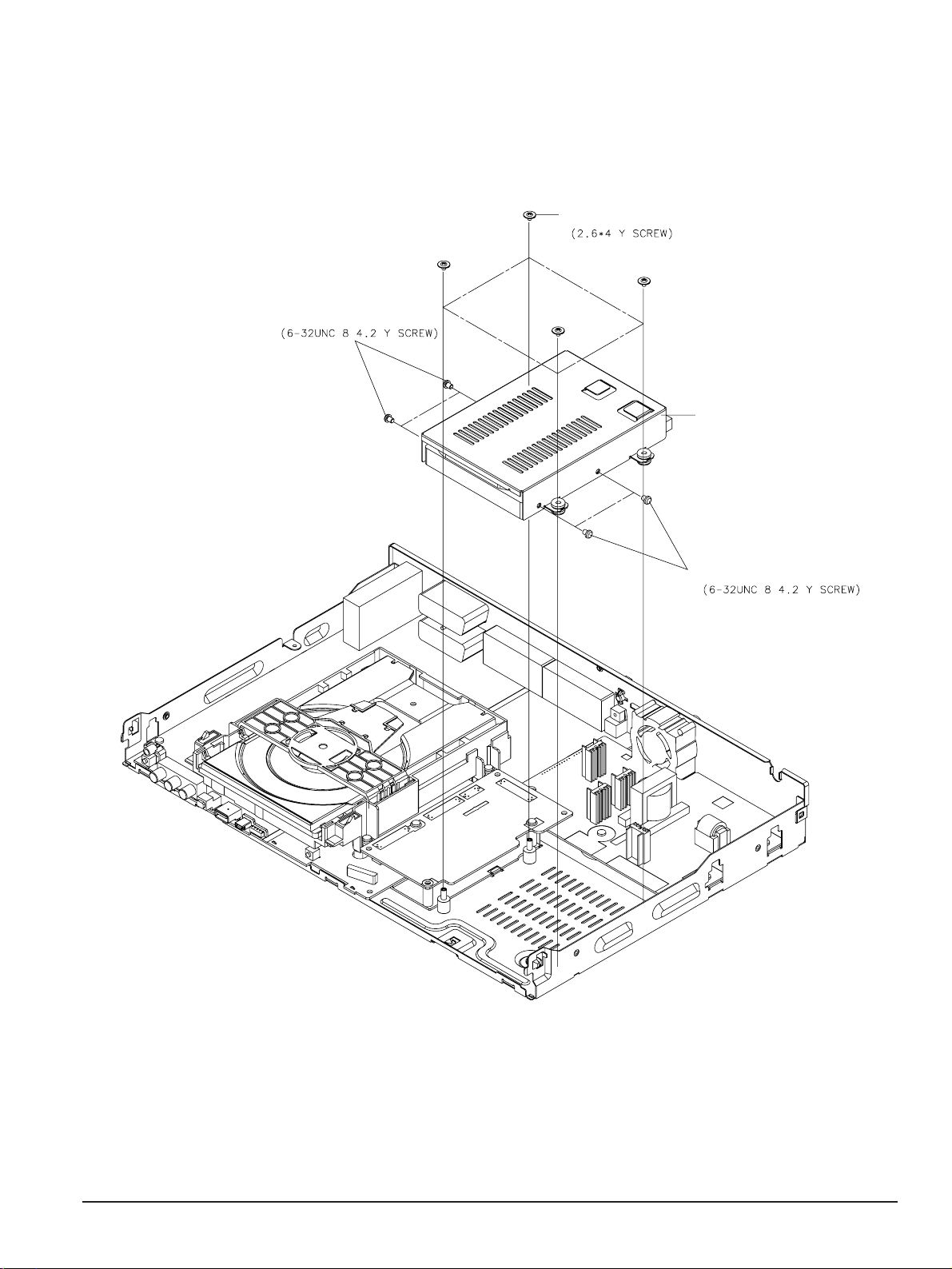

4-1-1 Top Cabinet Removal

1) Remove 5 Screws Œ, ´.

2) Lift up the Top Cabinet in direction of arrow.

Fig. 4-1 Top Cabinet Removal

Note : Reassembly in reverse order.

Π3 SCREWS

´ 2 SCREWS

4-2

Samsung Electronics

Disassembly and Reaasembly

Fig. 4-2 Ass’y Front-Cabinet Removal

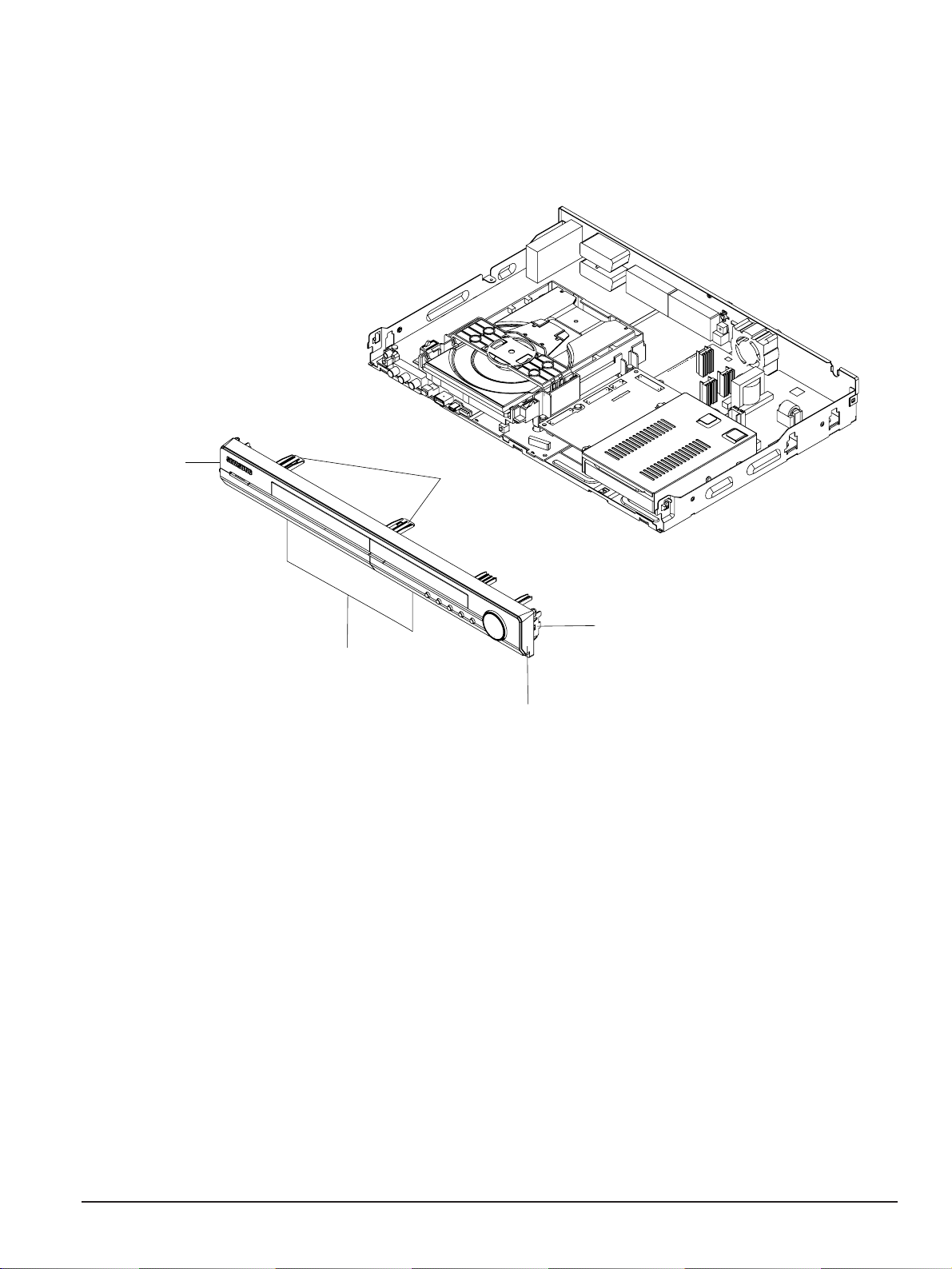

4-1-2 Ass’y Front-Cabinet Removal

1) Release 6 Hooks Œ, ´, ˇ, ¨ and Ass’y Front-Cabinet ˆ.

Π1 HOOK

¨ 2 HOOKS

´ 1 HOOK

ˇ 2 HOOKS

ˆ ASS'Y FRONT-CABINET

Disassembly and Reaasembly

Samsung Electronics

4-3

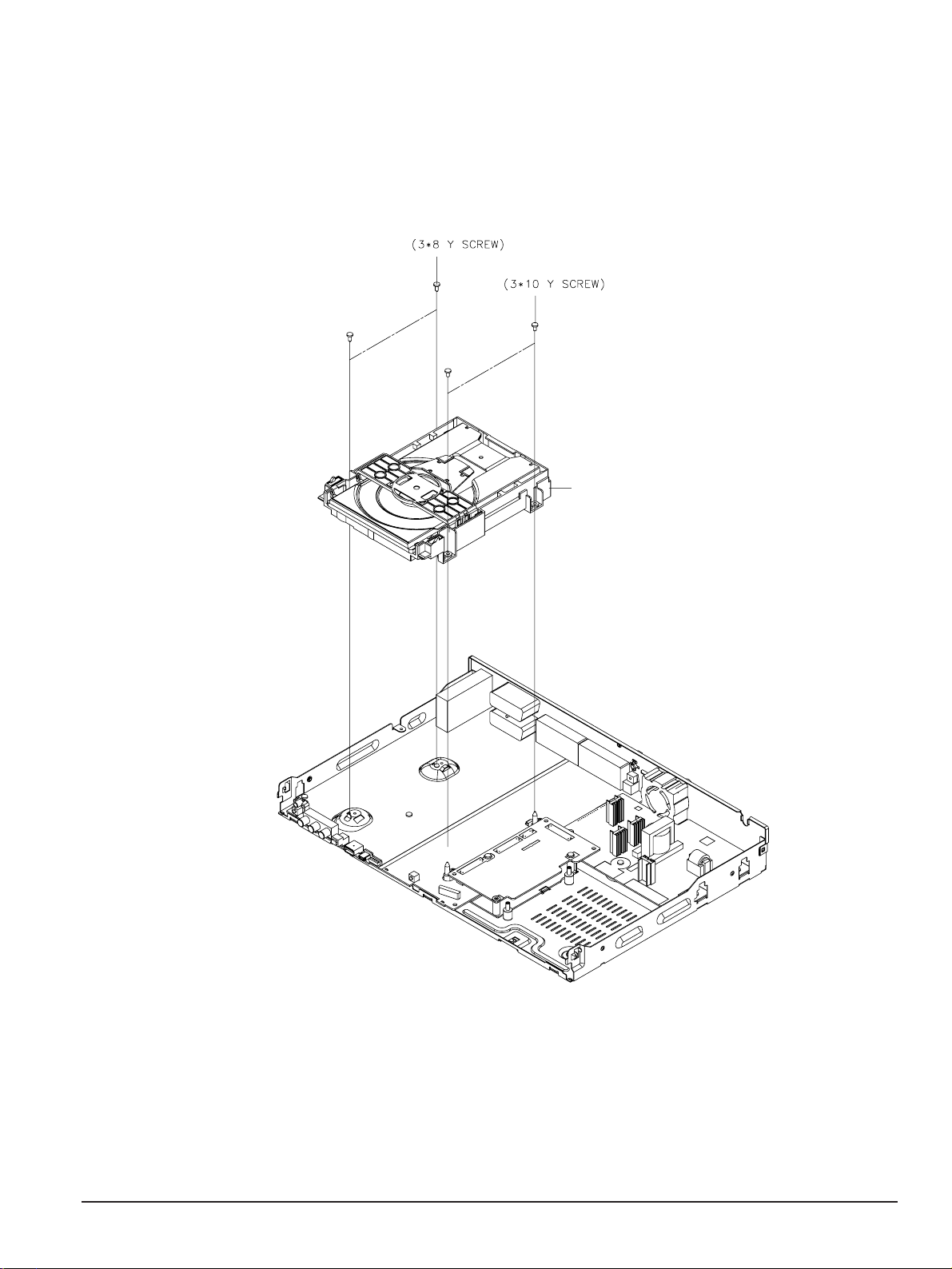

4-1-3 Hard Disk Removal

1) Remove 8 Screws Œ, ´, ˇ from the Hard Disk and lift it up.

Fig. 4-3 Hard Disk Removal

´ 2 SCREWS

Π4 SCREWS

HARD DISK

ˇ 2 SCREWS

4-4

Samsung Electronics

Disassembly and Reaasembly

Fig. 4-4 Ass’y Deck Removal

4-1-4 Ass’y Deck Removal

1) Remove 4 Screws Œ, ´ from the Ass’y Deck and lift it up.

Π2 SCREWS

´ 2 SCREWS

Assy Deck

Disassembly and Reaasembly

Samsung Electronics

4-5

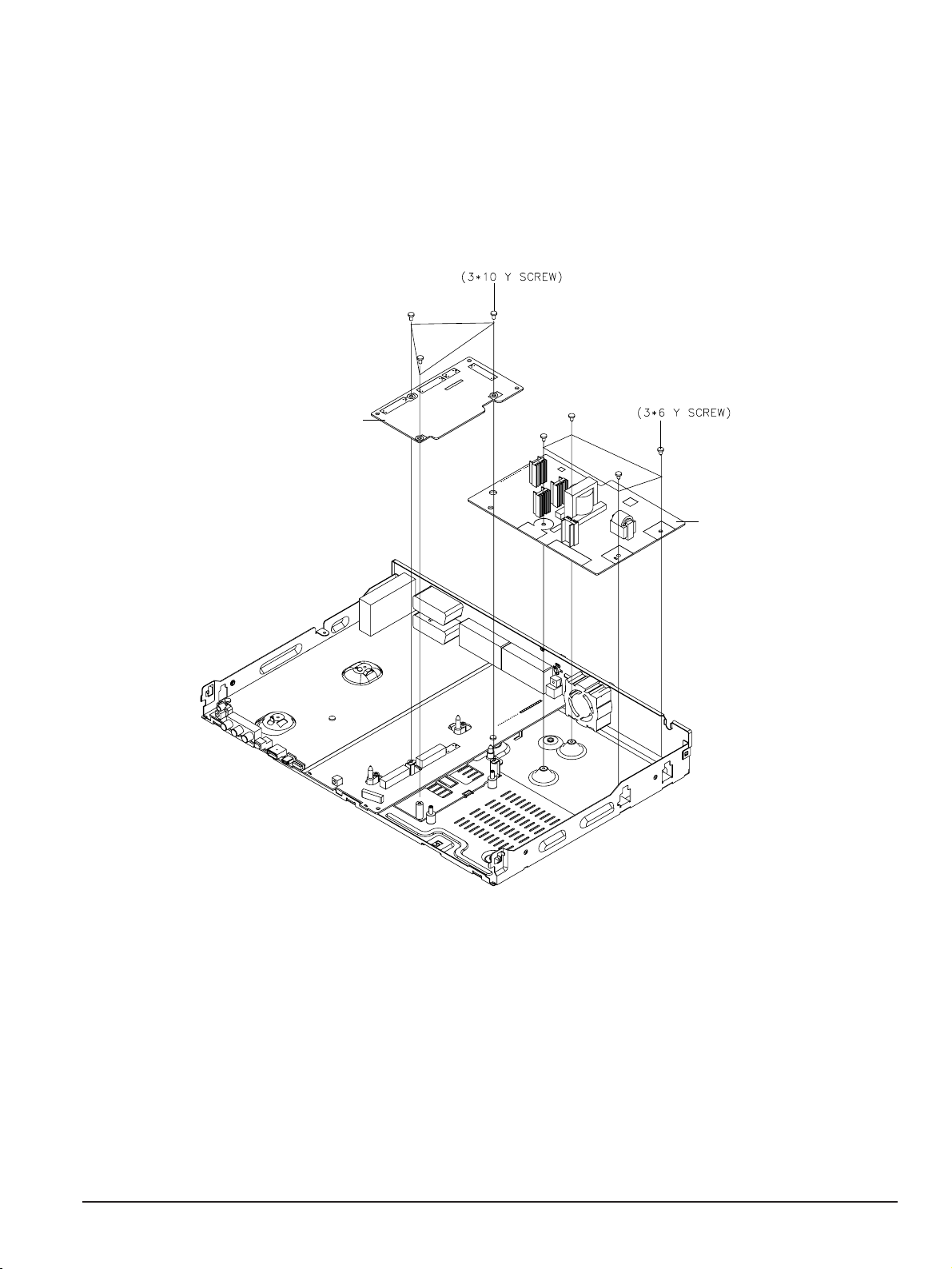

Fig. 4-5 Main PCB and S.M.P.S. PCB Removal

4-1-5 Main PCB and S.M.P.S. PCB Removal

1) Remove 3 Screws Œfrom the Main PCB ´ and lift it up.

2) Remove 4 Screws ˇ from the S.M.P.S. PCB ¨ and lift it up.

Π3 SCREWS

´ MAIN PCB

ˇ 4 SCREWS

¨ SMPS PCB

4-6

Samsung Electronics

Disassembly and Reaasembly

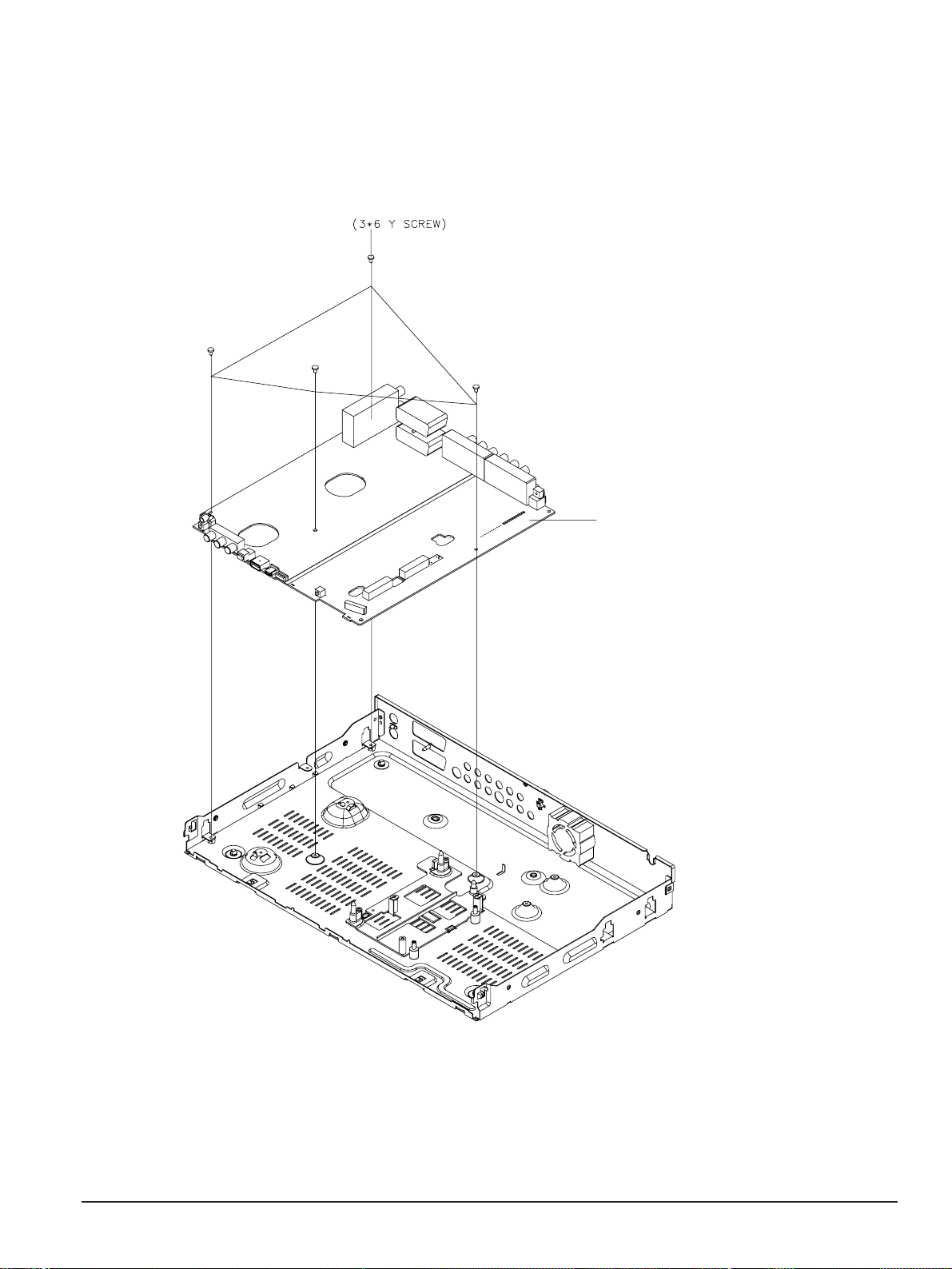

4-1-5 Jack PCB Removal

1) Remove 4 Screws Œ from the Jack PCB ´ and lift it up.

Fig. 4-5 Jack PCB Removal

Π4 SCREWS

´ JACK PCB

Disassembly and Reaasembly

Samsung Electronics

4-7

4-1-6 DC FAN Removal

1) Remove 2 Screws Œ, from the DC Fan ´ and lift it up.

Fig. 4-6 DC FAN Removal

´ DC FAN

Π2 SCREWS

4-8

Samsung Electronics

Disassembly and Reaasembly

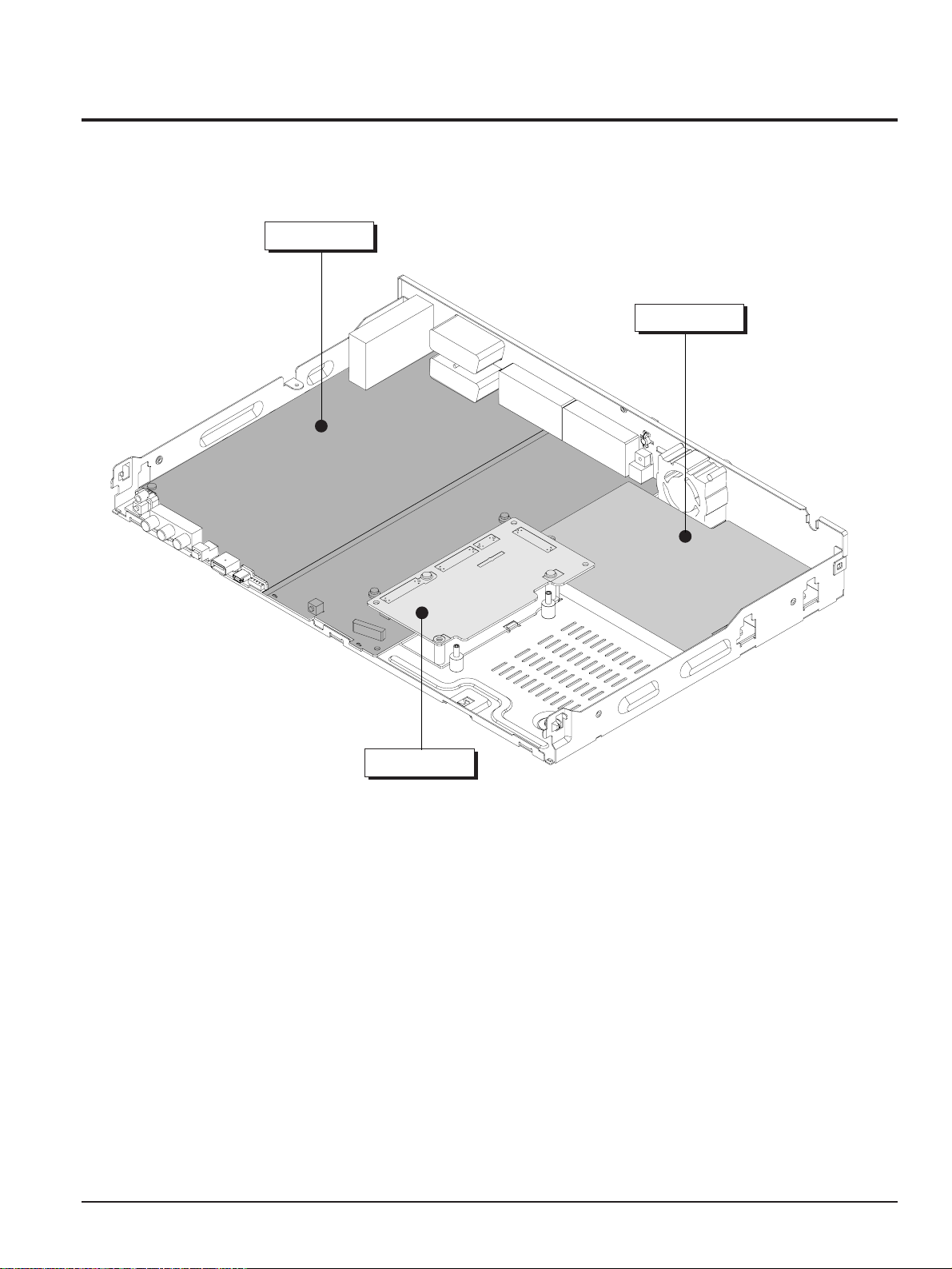

4-2 PCB Location

Fig. 4-7 PCB Location

JACK PCB

S.M.P.S. PCB

MAIN PCB

Samsung Electronics 5-1

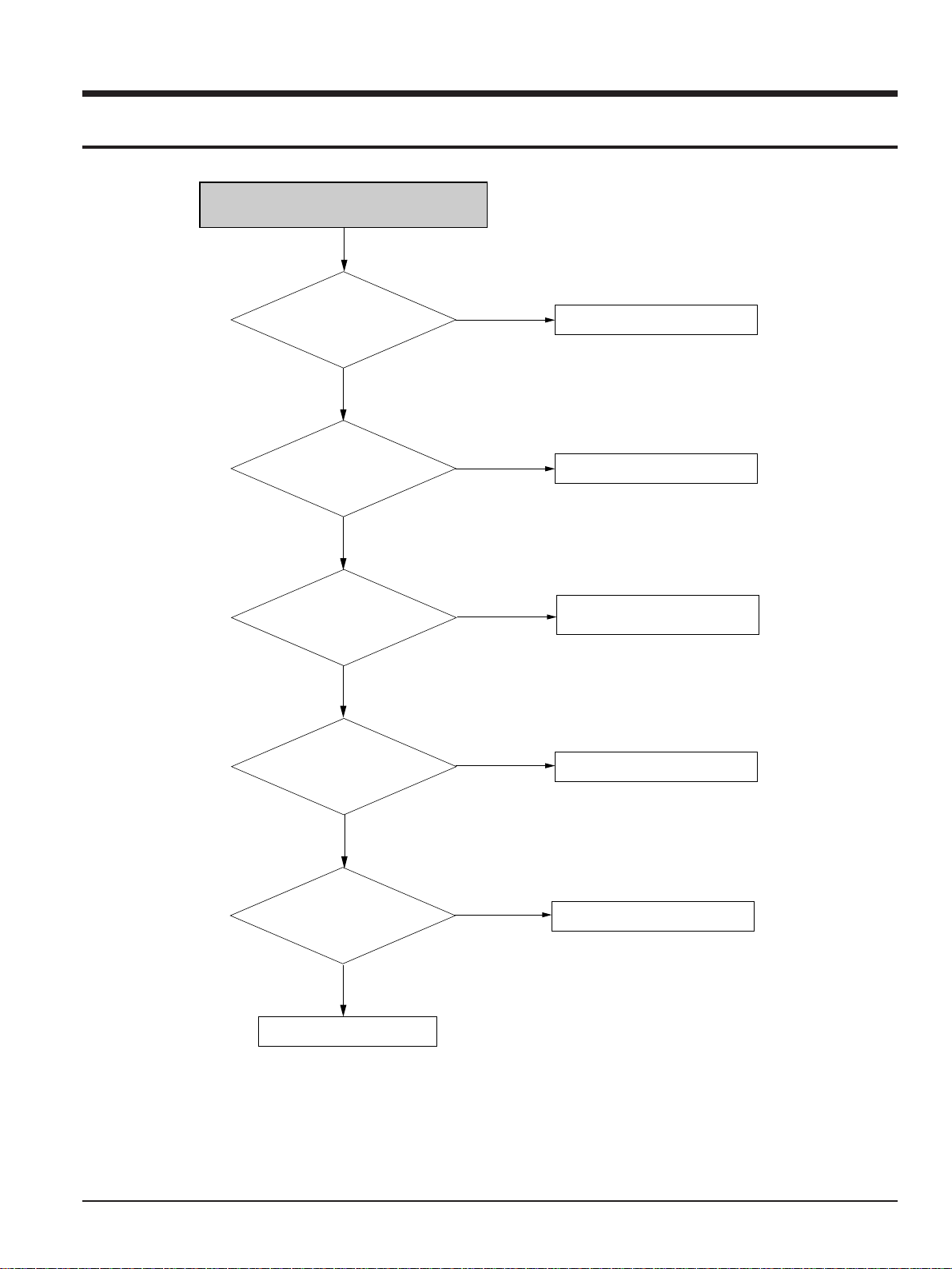

5. Troubleshooting

NO Power Detected

(Stand by LED OFF)

PAFT1 is normal?

Yes

6pin of AIC1 in the

function key is normal?

No

PVDLL1, PSDZ1

PFZZ1, PVZL1

SHOR and OPEN

Are normal?

Yes

Is there voitage at

Collector of

QISO1

No

Yes

No

No

Change fuse

Change AVFP1 LED Module

Change short circuited or

opened parts

Check 2st voltage

Yes

Operation of QISO1 is

Normal?

Yes

Check feed back ICISO1

No

Replace QISO1

Troubleshooting

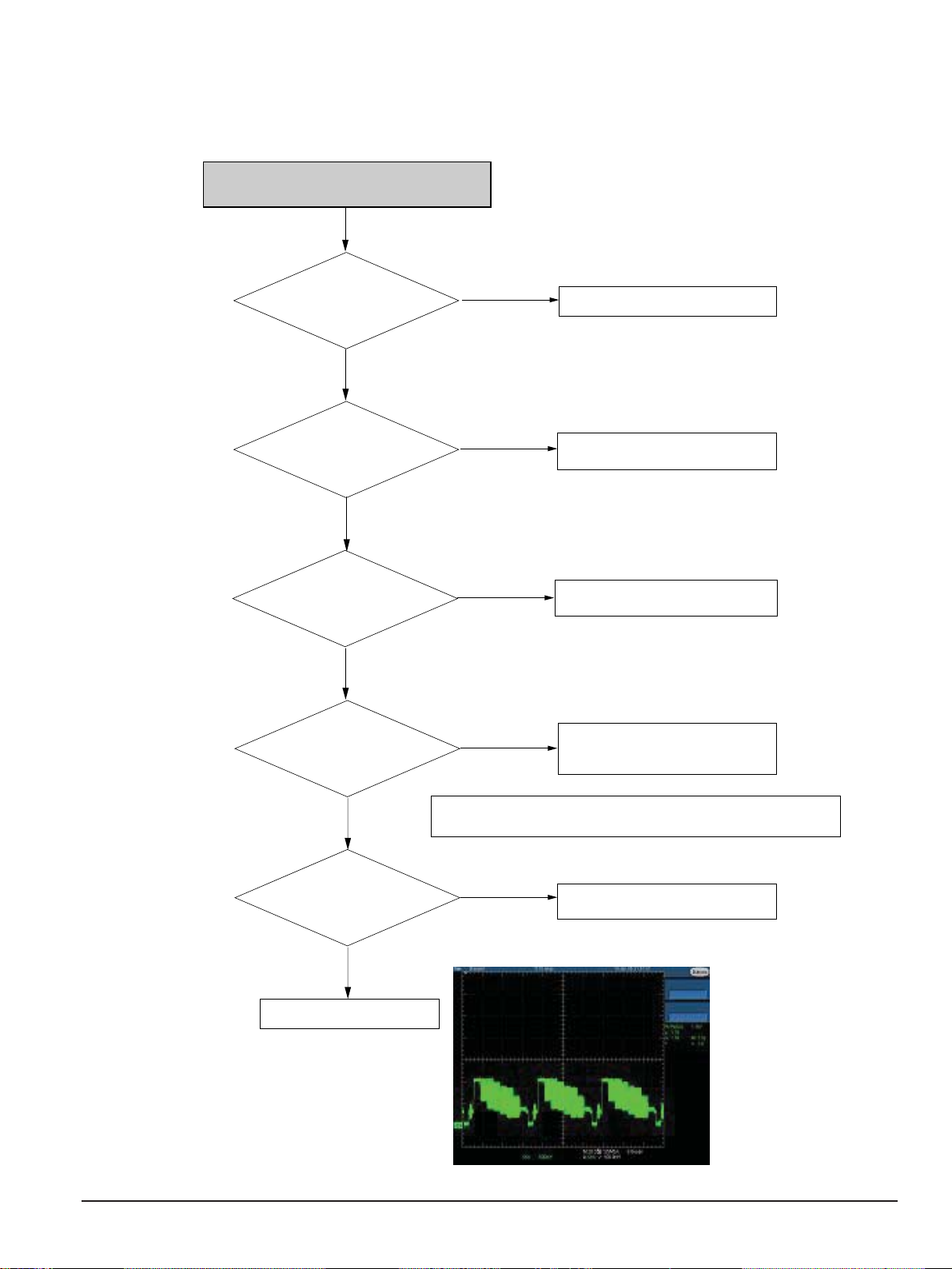

5-2 Samsung Electronics

CVBS Video (AV1, RCA)

11pin in MCN2 of jack PCB or

CON2 of Main PCB has

normal level?

Yes

Analog signals are

inputed normally

IC216(pin 31,33)

Yes

Power is

normal(5V) at IC216(pin 30, 34)

Yes

I2C singles in

IC216(pin16, 18) are

swinged between 0~5V?

No

No

No

No

Check the DIC1 on Main PCB

Check the connection between

11pin MCN2 of Jack PCB and IC216

Check the connection between

IC216 nad BCN2A(pin 5, 6)

Check the connection between

IC216(pin16, 18) and

FIC1(pin 27,28)

Yes

Video signal of

About P-P1V appears at

Output jack?

Yes

Check the RCA cable

# IF Recorder is under PSO(progressive scan output) MODE, it does not

output the CVBS& S-Video, RGB signal.

No

CVBS(Color-bar)

Check the connection between

IC216 and output jack

Troubleshooting

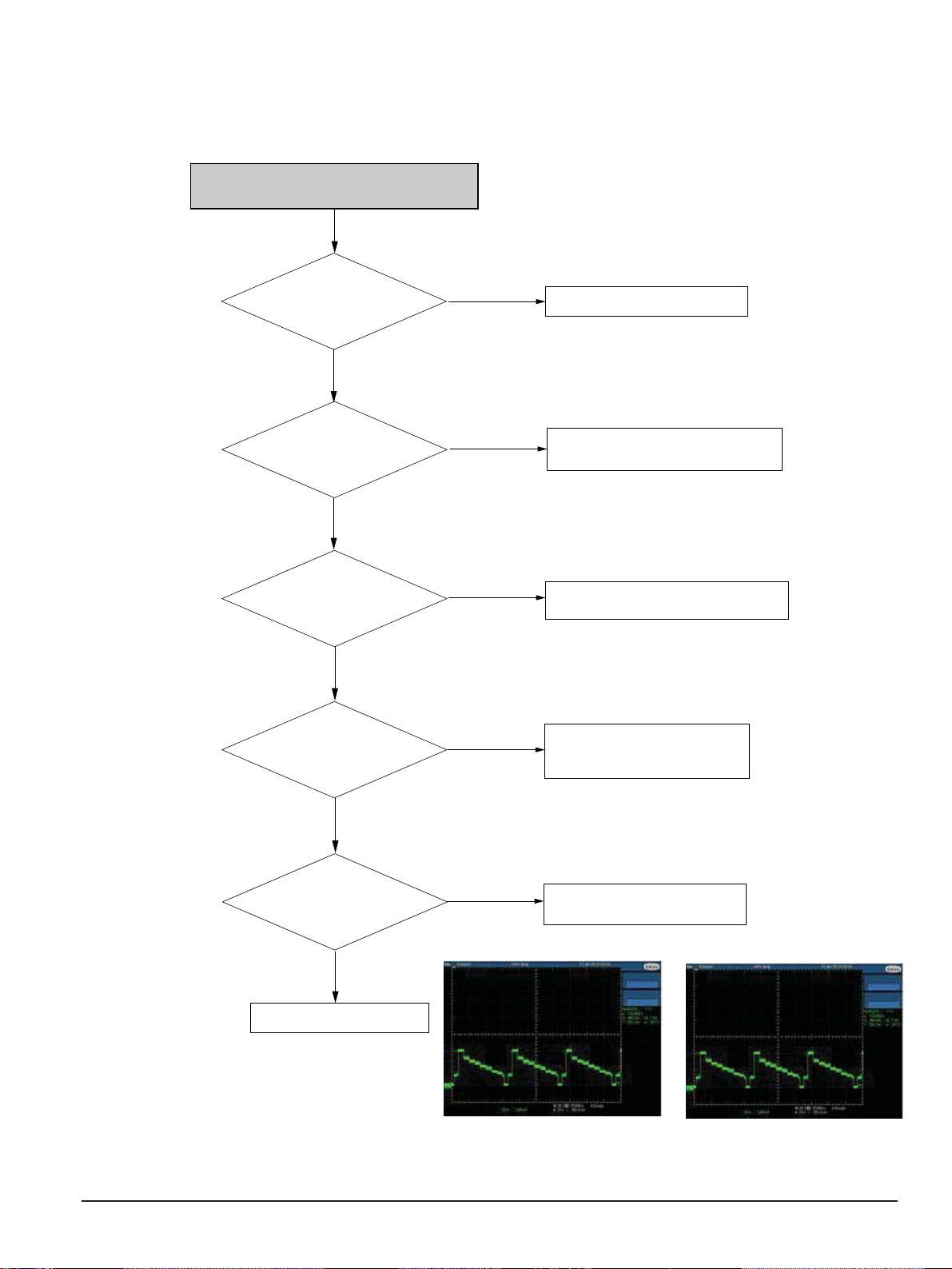

Samsung Electronics 5-3

Component (Y, Cb, Cr) output error

2/4/6 Pin in MCN2 of

Jack PCB or CON2 of Main PCB

has normal level?

Yes

Analong signals are

inputted normally

IC216(pin 27,28,29)

Yes

Power is normal (5V) at

IC216(pin 30,34)

Yes

I2C singnal in

IC216(pin16, 18) are swinged

between 0~5V?

No

No

No

No

Check the DIC1 on MAIN PCB

Check the connection between pin 2, 4, 6

in MCN2 of Jack PCB and IC216

Y(Color-bar)

Check the connection between

IC216 and BCN2A(pin5, 6)

Pb(Color-bar)

Check the connection between

IC216 (pin16,18) and

FIC1 (pin27, 28)

Yes

Pr(Color-bar)

Video signal of

About P-P1V appears at

Output Jack?

Yes

Check the RCA cable

# IF Recorder is under PSO(progressive scan output) MODE, or it does not

No

output the CVBS& S-Video signal.

Check the connection between IC216

and output jack

Troubleshooting

5-4 Samsung Electronics

S-Video output error

10pin and 8pin in

MCN2 of Jack PCB or CON2 of

Main PCB has normal

level?

Yes

Analog signals are

inputted normally

IC216(pin331, 33)

Yes

Power is normal (5V)

at IC216(pin30, 34)

Yes

I2C signal in

IC216(pin16, 18) are swinged

between 0~5V

Yes

No

No

No

No

Check the DIC1 on Main PCB

Check the connection between 10pin and

8pin in MCN2 of Jack PCB and IC216

Check the connection between

IC216 and BCN2A pin5, 6)

Check the connection between

IC216(pin16, 18) and

FIC1(pin27, 28)

Video signals of

about P-P1V appears at

output jack?

Yes

Check the S-Video cable

No

Y(Color-bar)

Check the connection between

IC216 and output jack

C(Color-bar)

Loading...

Loading...