SAMSUNG DVD_907-927 Service Manual Cover

DIGITAL VERSATILE DISC PLAYER

DVD-907/927

SERVICE

1. Precautions

2. Reference Information

3. Product Specification

4. Operating Instructions

5. Disassembly and Reassembly

6. IC Descriptions

7. Circuit Descriptions

8. Troubleshooting

9. Exploded Views and Parts List

10. Packing Diagram

11. Electrical Parts List

12. Block Diagram

13. PCB Diagrams

14. Wiring Diagram

15. Schematic Diagrams

Manual

DIGITAL VERSATILE DISC PLAYER CONTENTS

DVD-907

DVD-927

ELECTRONICS

© Samsung Electronics Co., Ltd. May. 1998

Printed in Korea

AH68-20198A

Samsung Electronics 1-1

1. Before returning an instrument to the customer,

always make a safety check of the entire instrument, including, but not limited to, the following

items:

(1) Be sure that no built-in protective devices are

defective or have been defeated during servicing.

(1)Protective shields are provided to protect both

the technician and the customer. Correctly replace

all missing protective shields, including any remove

for servicing convenience. (2) When reinstalling the

chassis and/or other assembly in the cabinet, be

sure to put back in place all protective devices,

including, but not limited to, nonmetallic control

knobs, insulating fishpapers, adjustment and

compartment covers/shields, and isolation resistor/capacitor networks. Do not operate this instrument or permit it to be operated without all protective devices correctly installed and functioning.

(2) Be sure that there are no cabinet openings

throught which adults or children might be able to

insert their fingers and contact a hazardous voltage. Such openings include, but are not limited to,

excessively wide cabinet ventilation slots, and an

improperly fitted and/or incorrectly secured cabinet

back cover.

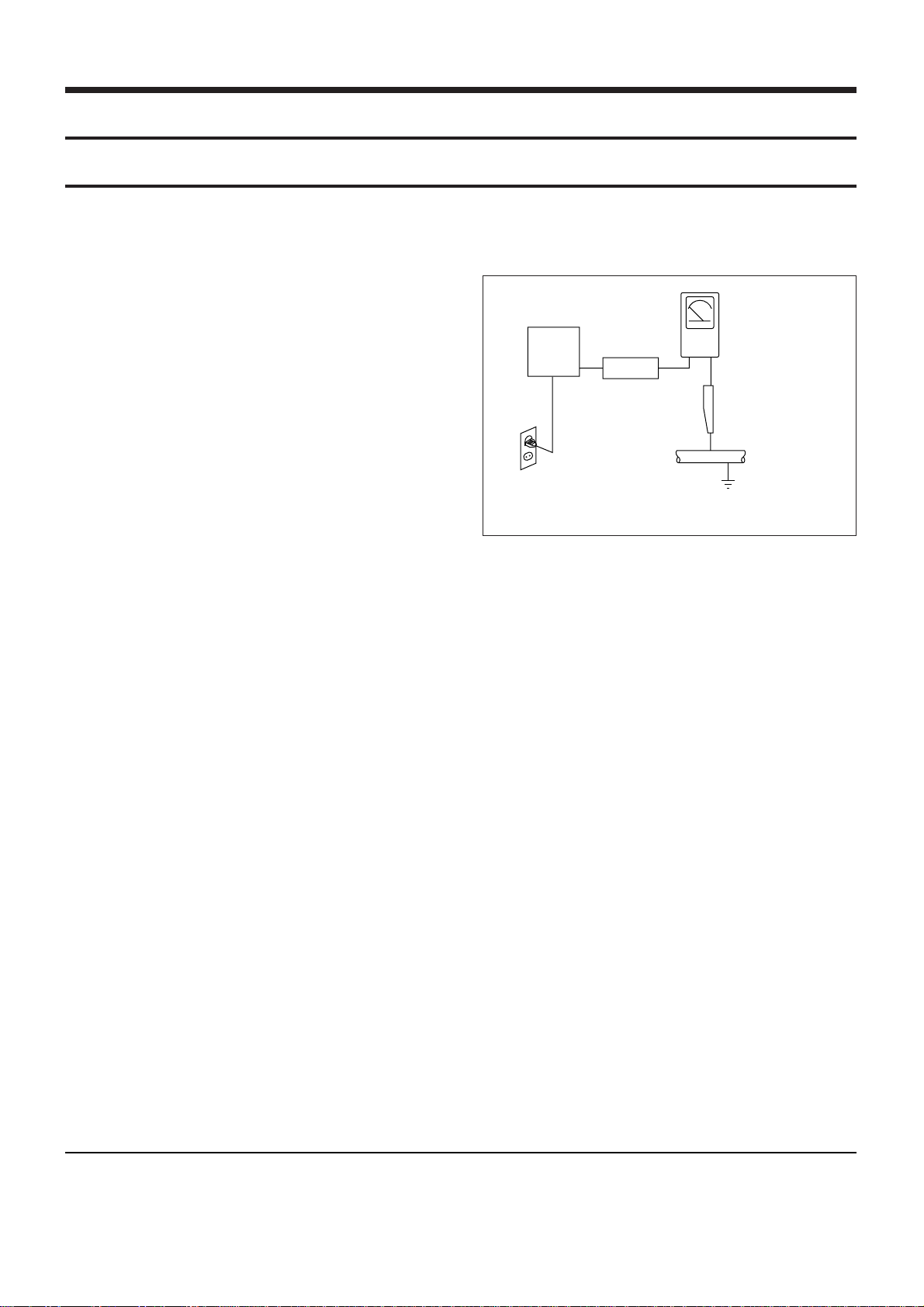

(3) Leakage Current Hot Check-With the instrument

completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use a isolation transformer during this test.) Use a leakage

current tester or a metering system that complies

with American National Standards institute(ANSI)

C101.1 Leakage Current for Appliances and

Underwriters Laboratories (UL) 1270 (40.7). With

the instrument’s AC switch first in the ON position

and then in the OFF position, measure from a

known earth ground (metal waterpipe, conduit, etc.)

to all exposed metal parts of the instrument (antennas, handle brackets, metal cabinets, screwheads,

metallic overlays, control shafts, etc.), especially

any exposed metal parts that offer an electrical

return path to the chassis.

Any current measured must not exceed 0.5 millamp. Reverse the instrument power cord plug in

the outlet and repeat the test. See Figure 1-1.

Fig. 1-1 AC Leakage Test

Any measurements not within the limits specified

herein indicate a potential shock hazard that must

be ellminated before returning the instrument to the

customer.

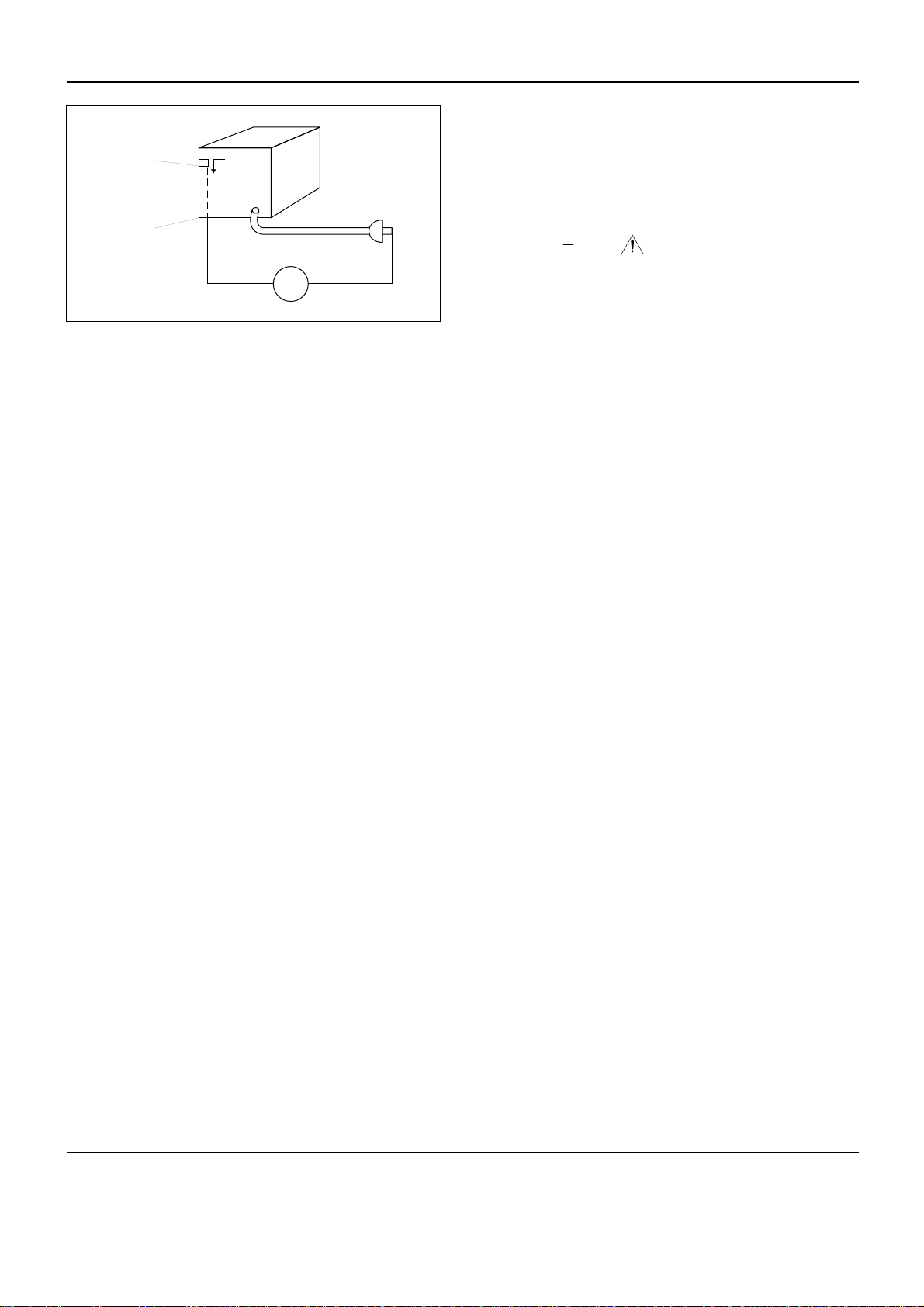

(4) Insulation Resistance Test Cold Check-(1) Unplug

the power supply cord and connect a jumper wire

between the two prongs of the plug. (2) Turn on

the power switch of the instrument. (3) Measure

the resistance with an ohmmeter between the

jumpered AC plug and all exposed metallic cabinet

parts on the instrument, such as screwheads,

antenna, control shafts, handle brackets, etc. When

an exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2

megohm. When there is no return path to the chassis, the reading must be infinite. If the reading is not

within the limits specified, there is the possibility of

a shock hazard, and the instrument must be

repared and rechecked before it is returned to the

customer. See figure 1-2.

Device

Under

Test

(Reading should

not be above

0.5mA)

Leakage

Current

Tester

Earth

Ground

Test all

exposed metal

surfaces

Also test with

plug reversed

(using AC adapter

plug as required)

2-Wire Cord

1. Pre cautions

1-1 Safety Precautions

Precautions

1-2 Samsung Electronics

Fig.1-2 Insulation Resistance Test

2. Read and comply with all caution and safety related

notes non or inside the cabinet, or on the chassis.

3. Design Afteration Warning-Do not alter of add to the

mechanical or electrical design of this instrument.

Design alterations and additions, including but not

limited to, circuit modifications and the addition of

items such as auxiliary audio output connections,

might alter the safety characteristics of this instrument and create a hazard to the user. Any design

alterations or additions will make you, the servicer,

responsible for personal injury or property damage

resulting therefrom.

4. Observe original lead dress. Take extra care to

assure correct lead dress in the following areas:(1)

near sharp edges, (2) near thermally hot parts (be

sure that leads and components do not touch thermally hot parts), (3) the AC supply, (4) high voltage,

and (5) antenna wiring. Always inspect in all areas

for pinched, out-of-place, or frayed wiring, Do not

change spacing between a componect and the

printed-circuit board. Check the AC power cord for

damage.

5. Components, parts, and/or wiring that appear to

have overheated or that are otherwise damaged

should be replaced with components, parts and/or

wiring that meet original specifications. Additionally,

determine the cause of overheating and/or damage

and, if necessary, take corrective action to remove

any potential safety hazard.

6. Product Safety Notice-Some electrical and mechanical parts have special safety-related characteristics

which are often not evident from visual inspection,

nor can the protection they give necessarily be

obtained by replacing them with components rated

for higher voltage, wattage, etc. Parts that have

special safety characteristics are identified by shading, an ( x )or a ( )on schematisc and parts lists.

Use of a substitute replacement that does not have

the same safety characteristics as the recommended replacement part might created shock, fire

and/or other hazards. Product safety is under

review continuously and new instructions are

issued whenever appropriate.

Antenna

Terminal

Exposed

Melal Part

ohm

ohmmeter

Samsung Electronics 1-3

CAUTION: Before servicing Instruments covered by

this service manual and its supplements, read and follow the Safety Precautions section of this manual.

Note: If unforseen circument create conflict between

the following servicing precautions and any of the

safety precautions, always follow the safety precautions. Remember: Safety First.

1-2-1 General Servicing Precautions

(1) a. Always unplug the instrument’s AC power cord

from the AC power source before (1) removing

or reinstalling any component, circuit board,

module or any other instrument assembly, (2)

disconnecting any instrument electrical plug or

other electrical connection, (3) connecting a test

substitute in parallel with an electrolytic capacitor in the instrument.

b. Do not defeat any plug/socker B+ voltage inter-

locks with which instruments covered by this

service manual might be equipped.

c. Do not apply AC power to this instrument and/or

any of its electrical assemblies unless all solidstate device heat sinks are correctly installed.

d. Always connect a test instrument’s ground lead

to the instrument chassis ground before connecting the test instrument positive lead. Always

remove the test instrument ground lead last.

Note: Refer to the Safety Precautions section ground

lead last.

(2) The service precautions are indicated or printed on

the cabinet, chassis or components. When servicing, follow the printed or indicated service precautions and service materials.

(3) The components used in the unit have a specified

flame resistance and dielectric strength. When

replacing components, use components which

have the same retings. Components identified by

shading, by( x ) or by ( ) in the circuit diagram

are important for safety or for the characteristics of

the unit. Always replace them with the exact

replacement components.

(4) An insulation tube or tape is sometimes used and

some components are raised above the printed wiling board for safety. The internal wiring is sometimes clamped to prevent contact with heating components. Install such elements as they were.

(5) After servicing, always check that the removed

screws, corponents, and wiring have been installed

correctly and that the portion around the serviced

part has not been damaged and so on. Further,

check the insulation between the blades of the

attachment plug and accessible conductive parts.

1-2-2 Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and

turn the power ON. Connect the insulation resistance

meter (500V) to the blades of the attachment plug. The

insulation resistance between each blade of the

attachment plug and accessible conductive parts(see

note) should be more than 1 Megohm.

Note: Accesible conductive parts include metal panels, input terminals, earphone jacks, etc.

1-2 Servicing Precautions

1-4 Samsung Electronics

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be

damaged easily by static electricity.

Such components commonly are called Electro statically Sensitive Devices(ESD). Examples of typical

ESD devices are integrated circuits and some fieldeffect transistors and semiconductor chip components.

The following techniques should be used to help

reduce the incidence of component damage caused

by static electricity.

(1) Immediately before handling any semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic aharge on your body by

touching a known earth ground. Alternatively,

obtain and wear a commercially available discharging wrist strap device, which should be

removed for potential shock reasons prior to applying power to the unit under test.

(2) After removing an electrical assembly equipped

with ESD devices, place the assembly on a conductive surface such as aluminum foil, to prevent

electrostatic charge buildup or exposure of the

assembly.

(3) Use only a grounded-tip soldering iron to solder or

unsolder ESD devices.

(4) Use ouly an anti-static solder removal devices.

Some solder removal devices not classified as

“anti-static” can generate electrical charges sufficient to damage ESD devices.

(5) Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damge

ESD devices.

(6) Do not remove a replacement ESD device from its

protective package until immediately before your

are ready to install it.(Most replacement ESD

devices are packaged with leads electrically shorted together by condutive foam, aluminum foil or

comparable conductive materials).

(7) Immediately before removing the protective mate-

rials from the leads of a replacement ESD device,

touch the protective material to the chassis or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis

or circuit, and observe all other safety precautions.

(8) Minimize bodily motions when handling unpack-

aged replacement ESD devices. (Otherwise harmless motion such as the brushing together of your

clothes fabric or the lifting of your foot from a carpeted floor can generate static electrictity suffcient

to damage an ESD device).

1-3 ESD Precautions

Samsung Electronics 1-5

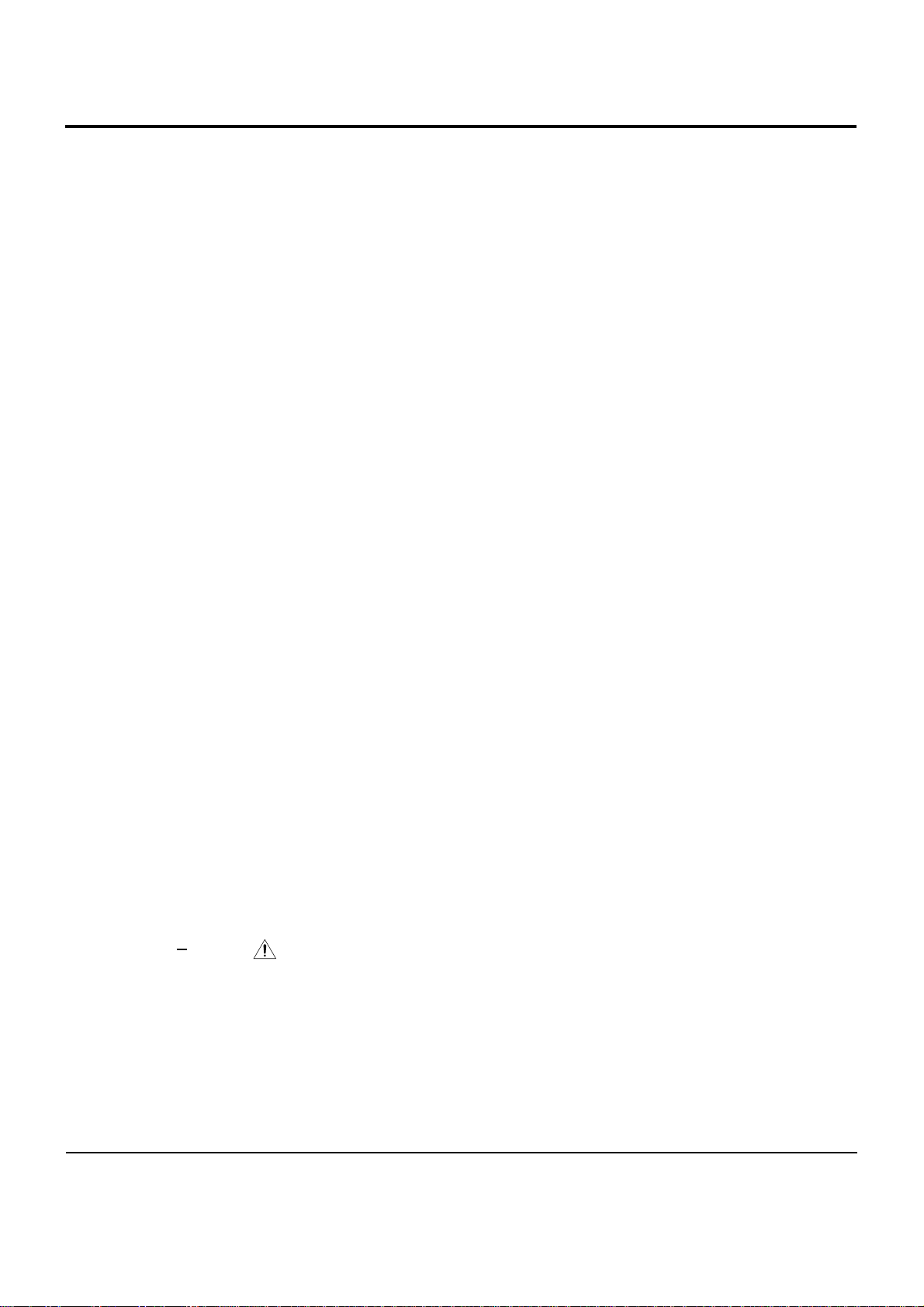

* The laser diode in the optical pick up may suffer elec-

trostatic breakdown because of potential static electricity from clothing and your body.

The following method is recommended.

(1) Place a conductive sheet on the work bench (The

black sheet used for wrapping repair parts.)

(2) Place the set on the conductive sheet so that the

chassis is grounded to the sheet.

(3) Place your hands on the conductive sheet(This

gives them the same ground as the sheet.)

(4) Romove the optical pick up block

(5) Perform work on top of the conductive sheet. Be

careful not to let your clothes or any other static

sources to touch the unit.

* Be sure to put on a wrist strap grounded to the

sheet.

* Be sure to lay a conductive sheet made of copper

etc. Which is grounded to the table.

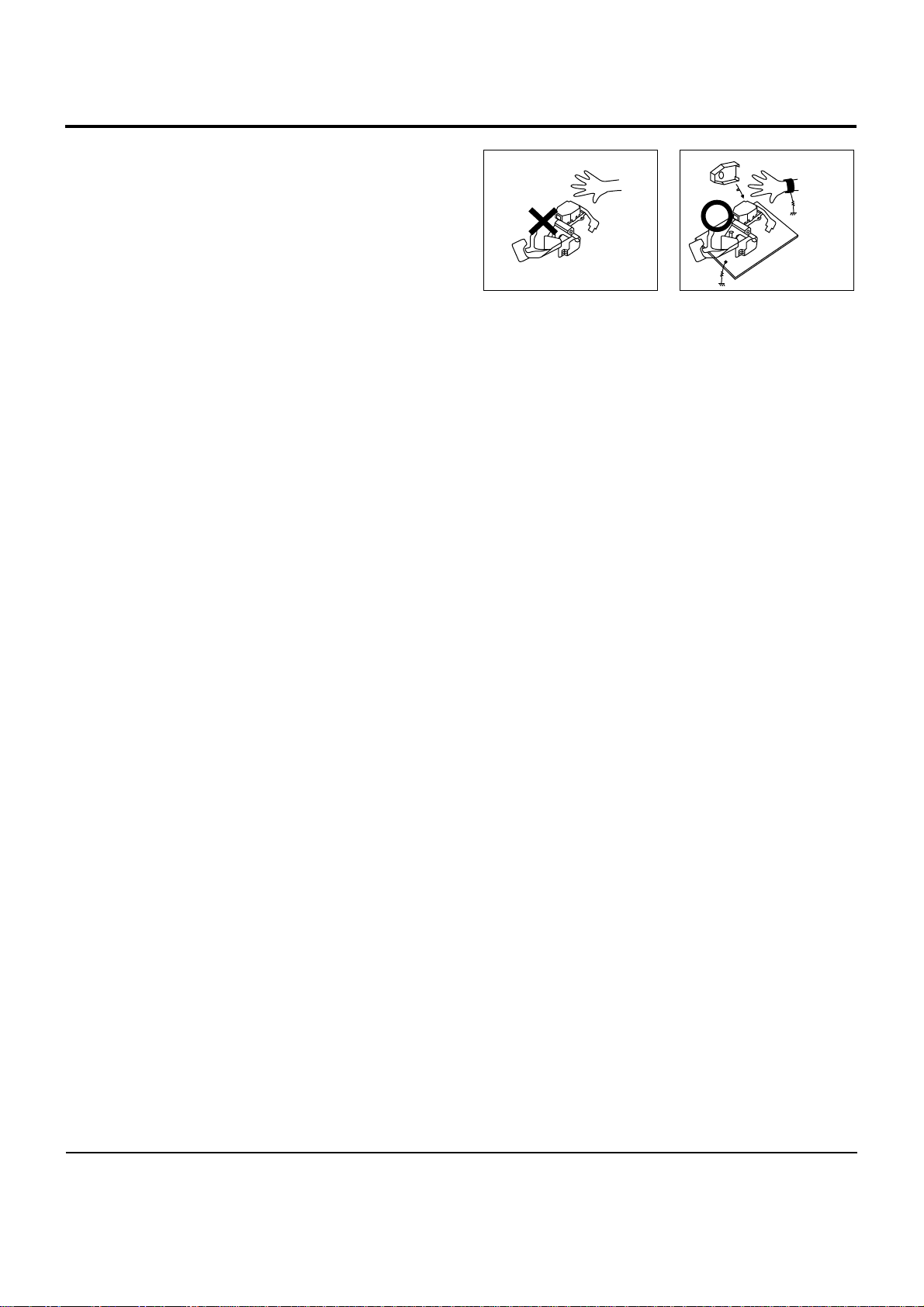

Fig.1-3

(6) Short the short terminal on the PCB, which is inside

the Pick-Up ASS’Y, before replacing the Pick-Up.

(The short terminal is shorted when the Pick-Up

Ass’y is being lifted or moved.)

(7) After replacing the Pick-up, open the short terminal

on the PCB.

1-4 Handling the optical pick-up

THE UNIT

WRIST-STRAP

FOR GROUNDING

1M

1M

CONDUCTIVE SHEET

1-6 Samsung Electronics

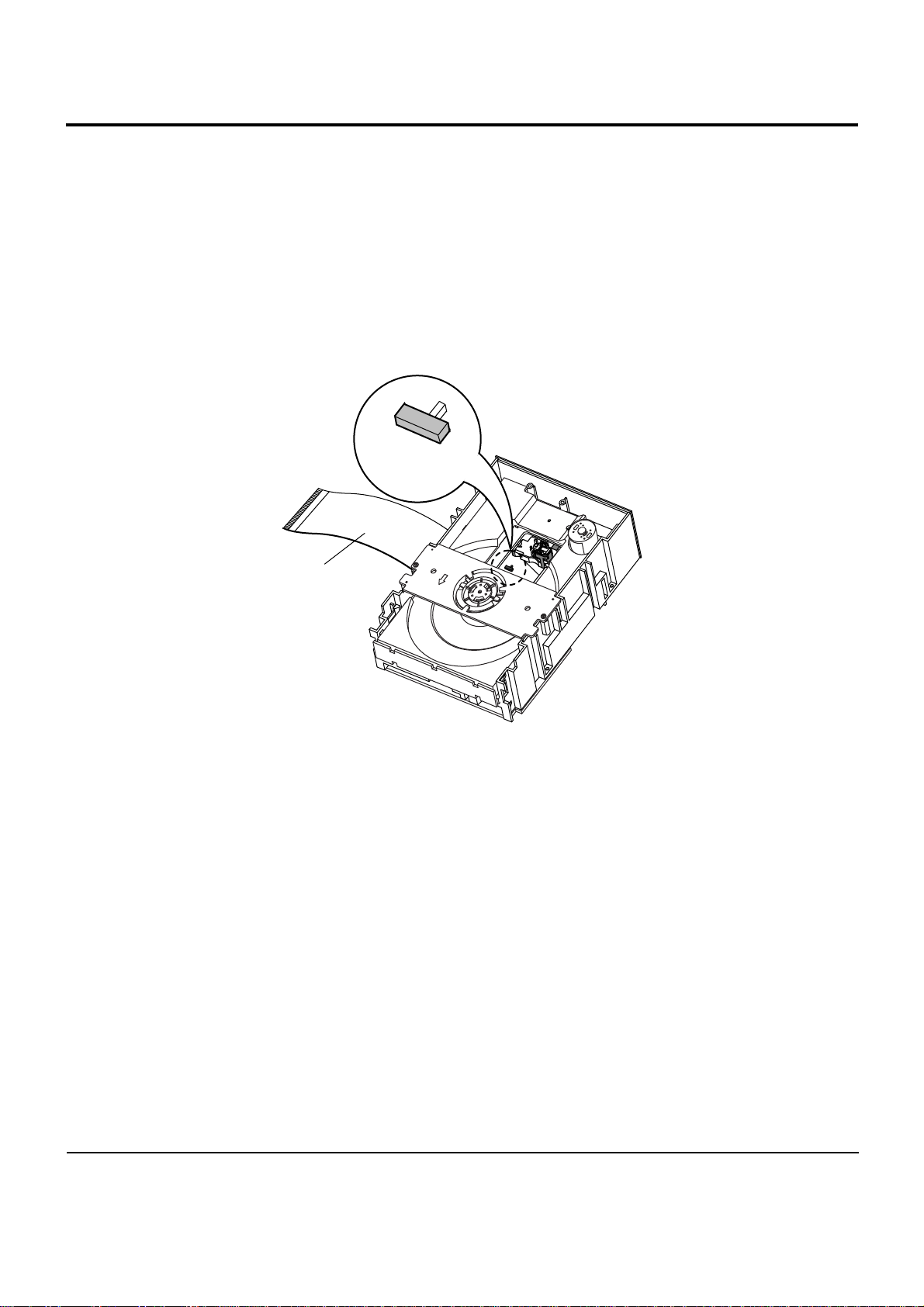

1-5-1 Disassembly

1) Remove the power cable.

2) Switch LD SW3 on deck PCB to ‘S’ before removing the FPC

( inserted into Main PCB CN1. See Fig 1-4.)

3) Disassemble the deck.

4) Disassemble the deck PCB.

5) Replace the Pick-up.

1-5-2 Assembly

1) Replace the Pick-up.

2) Assemble the deck PCB.

3) Reassemble the deck.

4) Switch LD SW3 on deck PCB to ‘O’ and insert

FPC into Main PCB CN1 (See Fig 1-4).

O

S

LD

SW3

FPC

1-5 Pick-up disassembly and ressembly

Note : If the assembly and disassembly are not done in correct sequence, the Pick-up may be damaged.

Fig. 1-4

Samsung Electronics 2-1

2. Reference Information

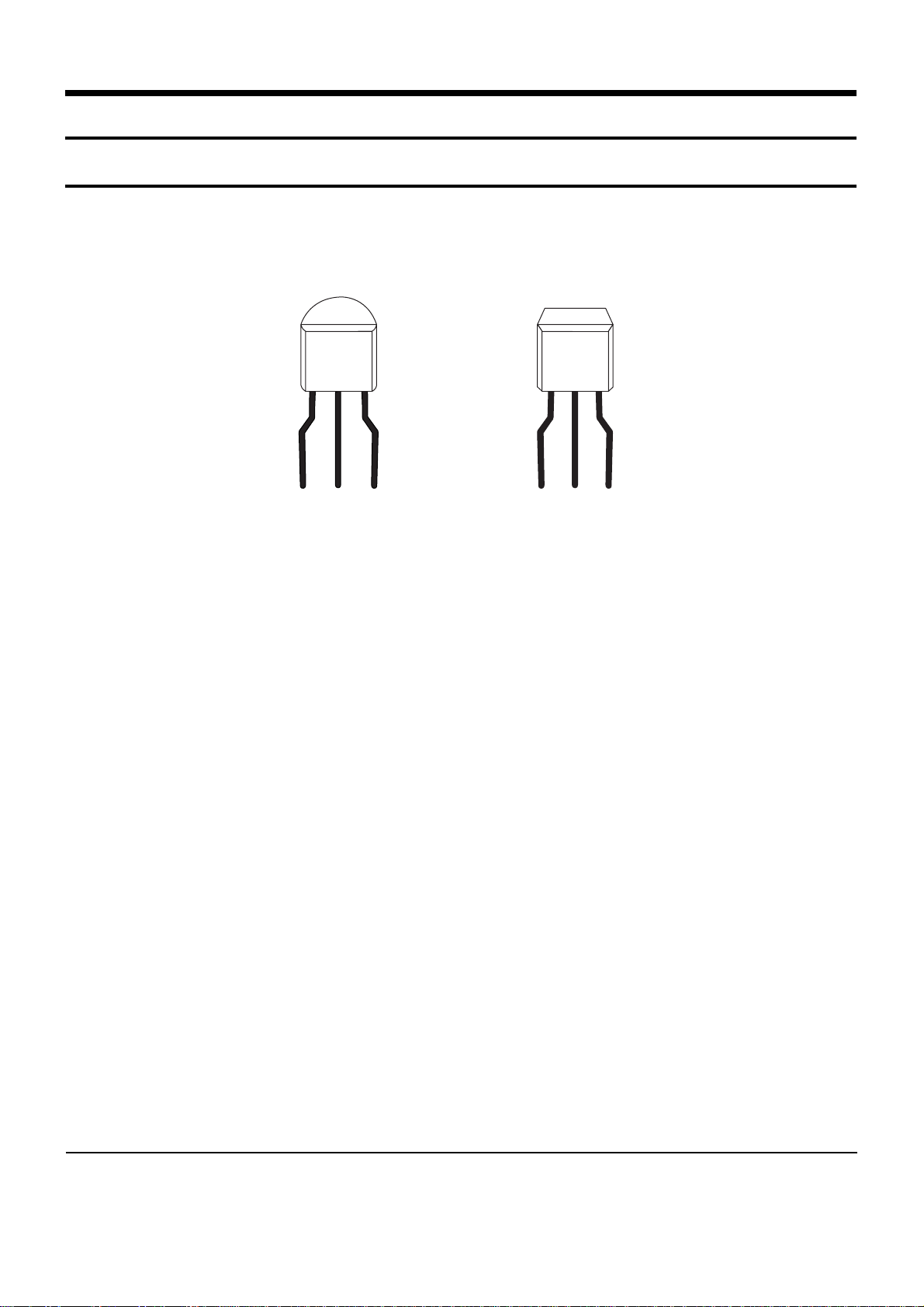

2-1 Semiconductor Base Diagram

Fig. 2-1

RQ1

SS9012

S9012

G-634

E B C

D G S

K184

Y 6A

SQ1

K184

2-2 Samsung Electronics

2-2 Chip Replacement

1) Do not touch the part body directly with the soldering iron. ICs, especially TSOP, are easily damaged by heat.

2) Use care regarding soldering iron tip and avoid

repidly heating parts. Some parts can be damaged

by sudden heating. Preheat the part at about

100°… for several minutes before installing it.

3) Use soldering tip temperature of about 240°… or

larger parts, use a slightly higher temperature

(about 280°…).

4) The thin(0.3mm)solder for miniature parts does

not contain adequate flux. Supplementary flux is

thus needed in most cases.

5) Use care not to damage the circuit pattern, especially when removing.

6) Because of the many pins, cleanliness of the pattern is extremely important after removing the IC.

7) Use care to avoid solder bridges. Remove any that

occurs.

8) Position the part carefully. They will also affect the

soldering operation. Be very precise in positioning

the IC. Soldering opposite pins first holds the IC in

place and makes soldering the other pins easier.

9) Do not reuse removed parts.

10) Check for solder joints, especially miniature parts

with small lead.

11) A defective trimming resistor cannot be adjusted

externally. Replace with an ordjnary variable resistor.

12) It is important to inspect the work with a magnifier.

Check after installing (cold solder joints, etc.).

2-2-1 Precaution for the chip Replacement

The tools for the chip replacement are as follows:

1) Thin tip type soldering iron

2) Small flat-blade tip-type soldering iron

3) Special desoldering tip iron

4) Airblower unit

5) Flat Package Pick-up

6) Flux can be cleaned by water

7) 0.3mm thin solder can be cleaned by water

8) Desoldering wire

9) Tweezers

2-2-2 Tools for the Chip Replacement

2-2-3 Chip Resistors and Chip Capacitors

-- Kind of the Part

The kind of chip resistors and chip capacitors as follows:d

1) Think Film Chip Resistors

2) Carbon Film Chip Resistors

3) Metal Film Chip Resistors

4) Chip Ceramic Capacitors

5) Chip Trimming Resistors

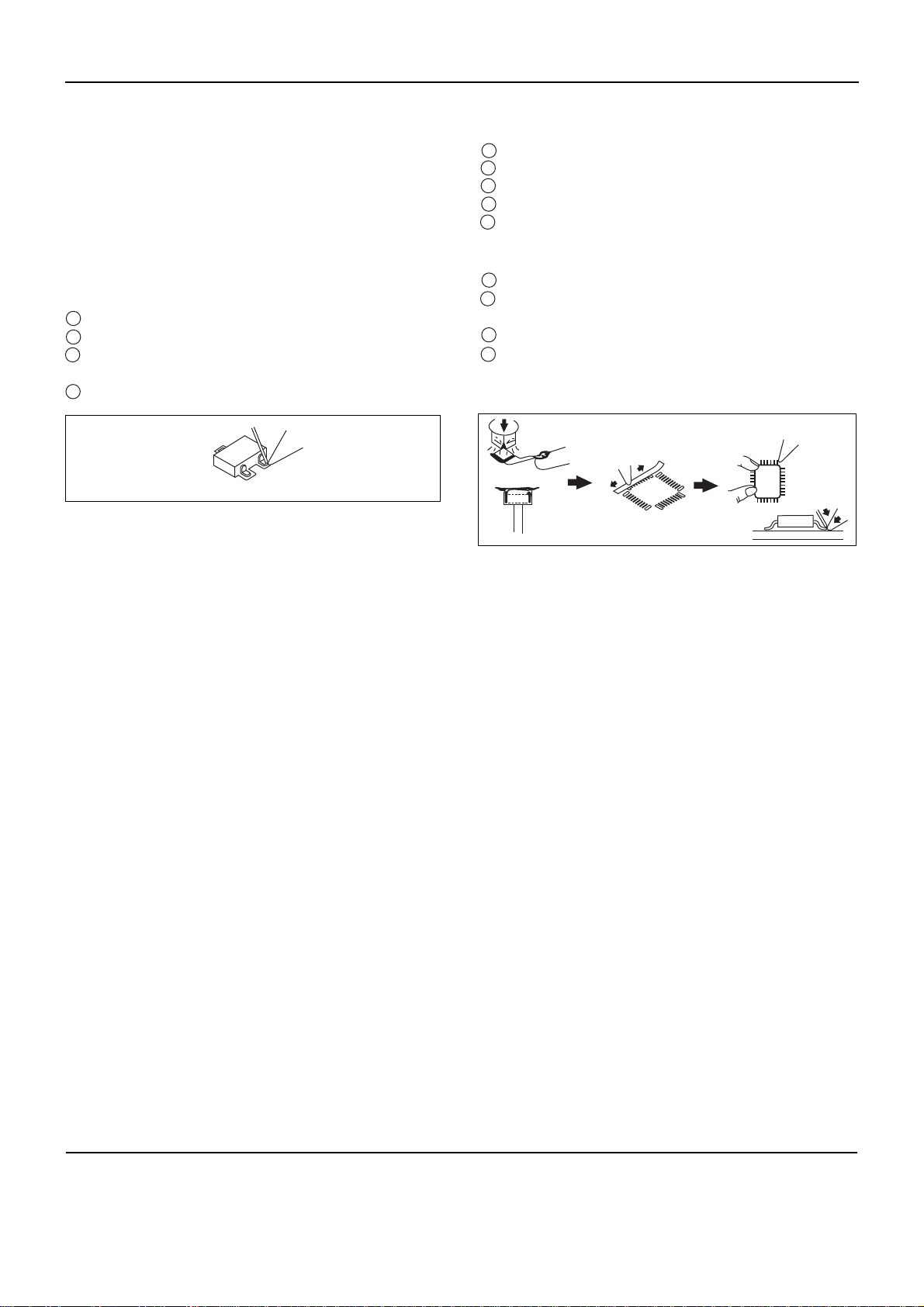

-- Removing the Part

1) Using two soldering irons:

Use thin tip soldering irons.

Use soldering tip temperature of about 280°….

Simultaneously heat both ends of the part.

While heating, grasp the part with the tips of the

soldering irons and remove it.

Use desoldering wire to completely remove the old

solder from the part location of the board.

A clean pattern for installing the new part is very

important.

Fig 2-2

-- Installing the Part

1) Use desoldering wire to remove the previous solder.

2) Clean the location.

3) Apply flux.

4) Position the IC and solder two pins at opposite sides.

5) Use a sharp tipped soldering iron and carefully

solder each Pin.(After gaining experience, a thicker

tip can be used for better work efficiency.)

6) Remove any solder bridges with desoldering wire.

7) Inspect the work with a magnifier.

1

2

3

4

5

6

Precautions

Samsung Electronics 2-3

-- Kind of the Part

The kind of the part is as follows:

1) Chip VRs.

2) Chip Trimmer Capacitors

3) Diode

4) Transistors

-- Removing the Part

1) Using two soldering irons:

Use small flat-blade tips.

Heat the leads of the part simultaneously.

When the solder melts, grasp and remove the part

with the soldering iron tips.

Remove the old solder with desoldering wire.

2-2-4 Diodes and Tr.

-- The kind of the Chip ICs

The kind of the chip ICs are as follows:

1) SOP(Small Outline Package)IC

2) SSOP(Shrink Small Outline Package)IC

3) VSOP(Very Small Outline Package)IC

4) QFP(Quad Flat Package)IC

5) VQFP(Very Quad Flat Package)IC

6) PLCC(Plastic Leaded Chip Carrier)IC

7) TSOP(Thin Small Outline Package)IC

2-2-5 Chip ICs

-- Removing the Part

1) Using special desoldering iron:

Selet the tip according to the size and shape of the IC.

“Tin” the tip with a small amount of the IC leads.

Set the tip squarely over the IC leads.

When the solder melts, carefully twist the iron.

Raise and remove the IC.

2) Using shaped airblower unit:

Select the correct nozzle.

Select the temperature and airblow(suggested:

temperature:7, airblow:4)

Engage the IC removing tool.

Use the airblow to preheat the IC for about 5

seconds, then heat with the nozzle until the IC

remover lifts the part from the board.

IC

Fig 2-4

-- Installing the Part

1) Use desoldering wire to remove the previous solder.

2) Clean the location.

3) Apply flux.

4) Position the IC and solder two pins at opposite sides.

5) Use a sharp tipped soldering iron and carefully sol

der each Pin.(After gaining experience, a thicker tip

can be used for better work efficiency.)

6) Remove any solder bridges with desoldering wire.

7) Inspect the work with a magnifier.

Fig 2-3

-- Installing the Part

1) Clean the area where the new part is to be mounted.

2) Apply flux.

3) Set part correctly into position, prevent it from shifting.

4) Use sharp soldering iron tip. Bring close to the

part contact without actually touching it. Melt thin

solder between the tip and part si that it flows into

the part contact.

1

234

123

45123

4

Precautions

2-4 Samsung Electronics

MEMO

6-1Samsung Electronics

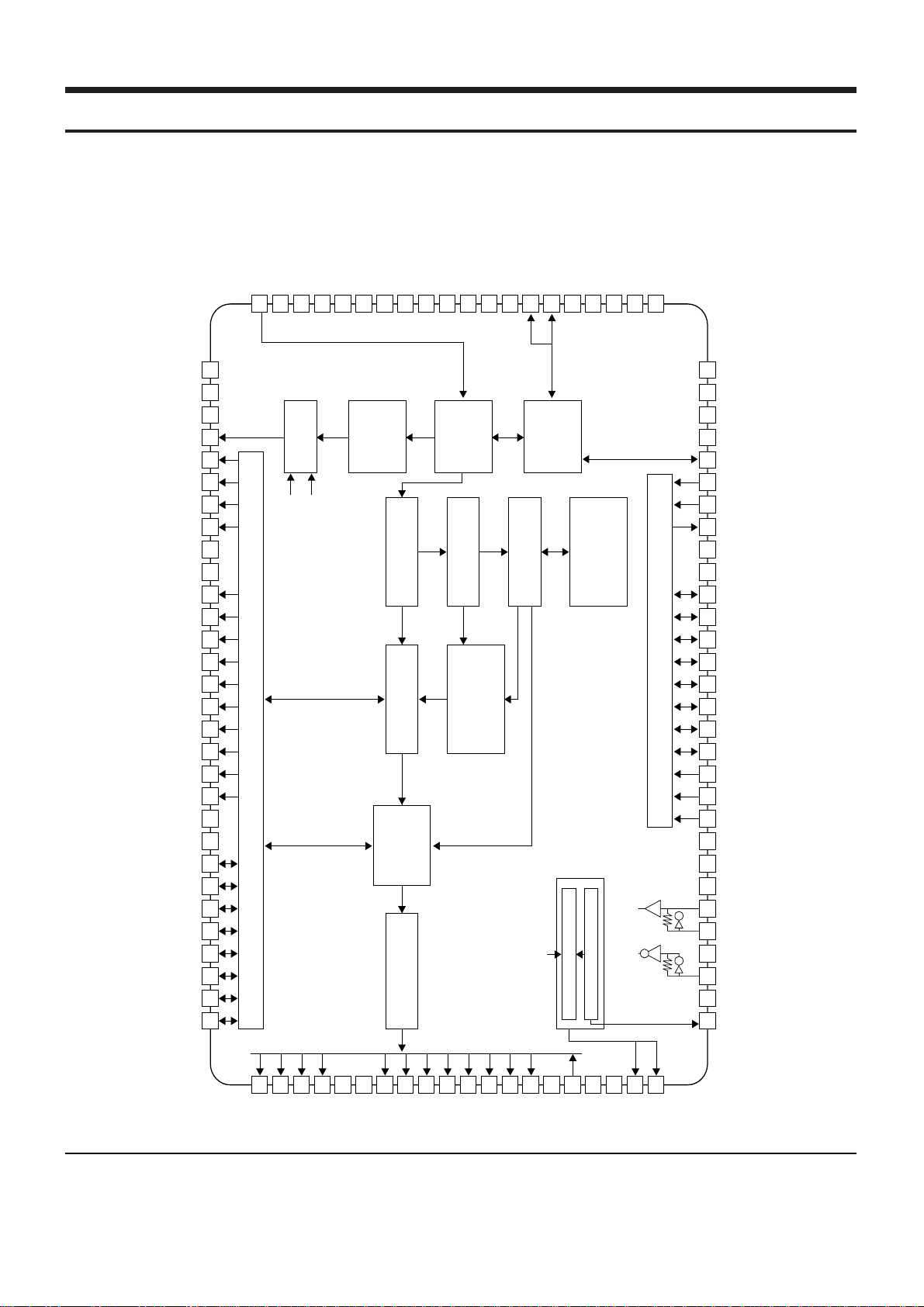

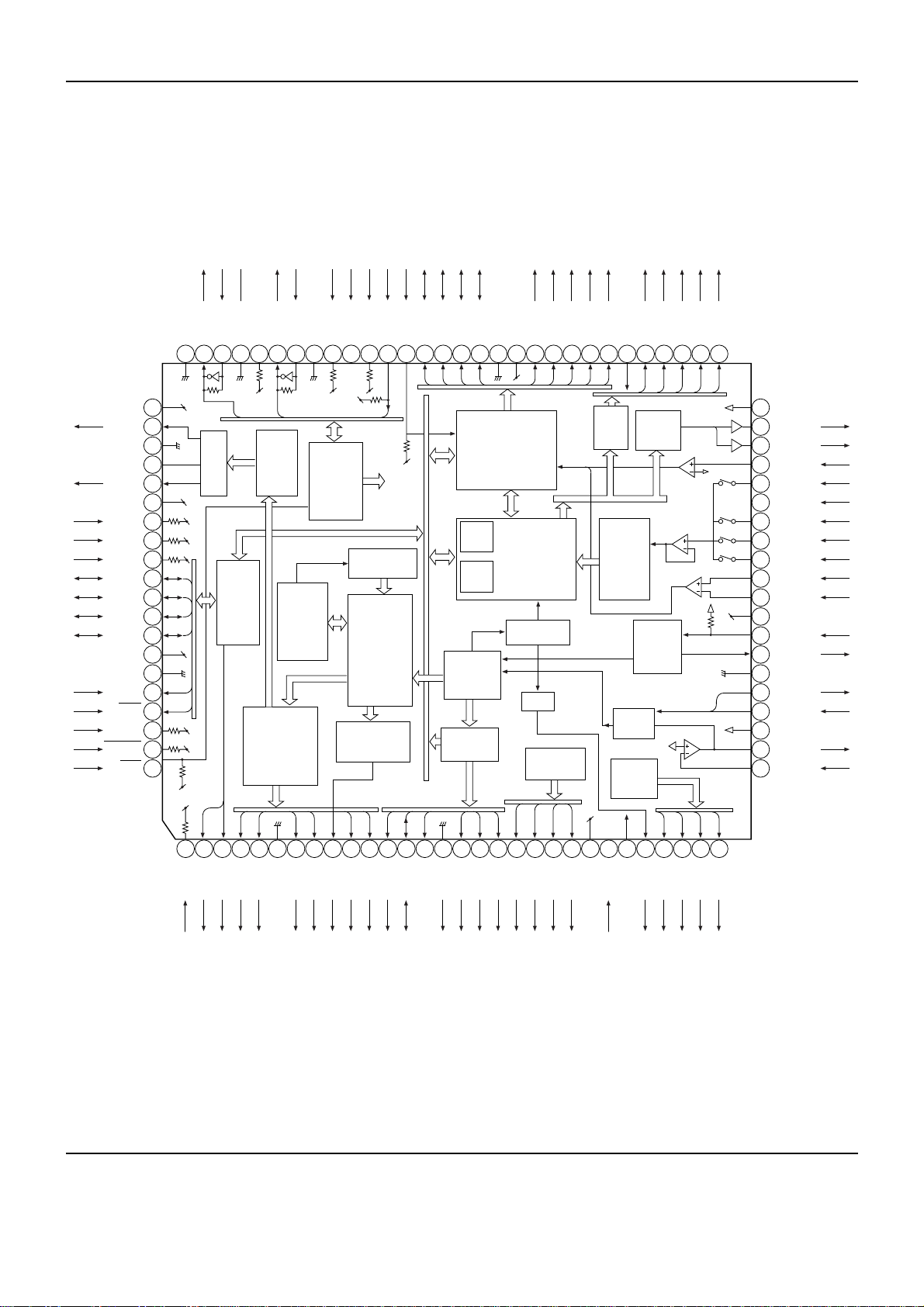

6-1 DVD DATA PROCESSOR

TC90A19F

DIC1

80 79 78 77 76 75 74 73 72 71 70 69 68 67 66 65 64 63 62 61 60 59 58 57 56 55 54 53 52 51

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30

81828384858687888990919293949596979899

100

81828384858687888990919293949596979899

100

R

VSS

RVR

I

DVR

D

M

O

R

A

S

N

C

A

S

N

M

O

E

N

M

W

E

N

D

VSS

DVD

D

3

M

A

9

M

A

8

M

A

7

M

A

6

M

A

5

M

A

4

M

A

3

M

A

2

M

A

1

M

A

0

D

VSS

DVD

D

5

M

D

7

M

D

6

M

D

5

M

D

4

M

D

3

M

D

2

M

D

1

M

D

0

Memory I/F

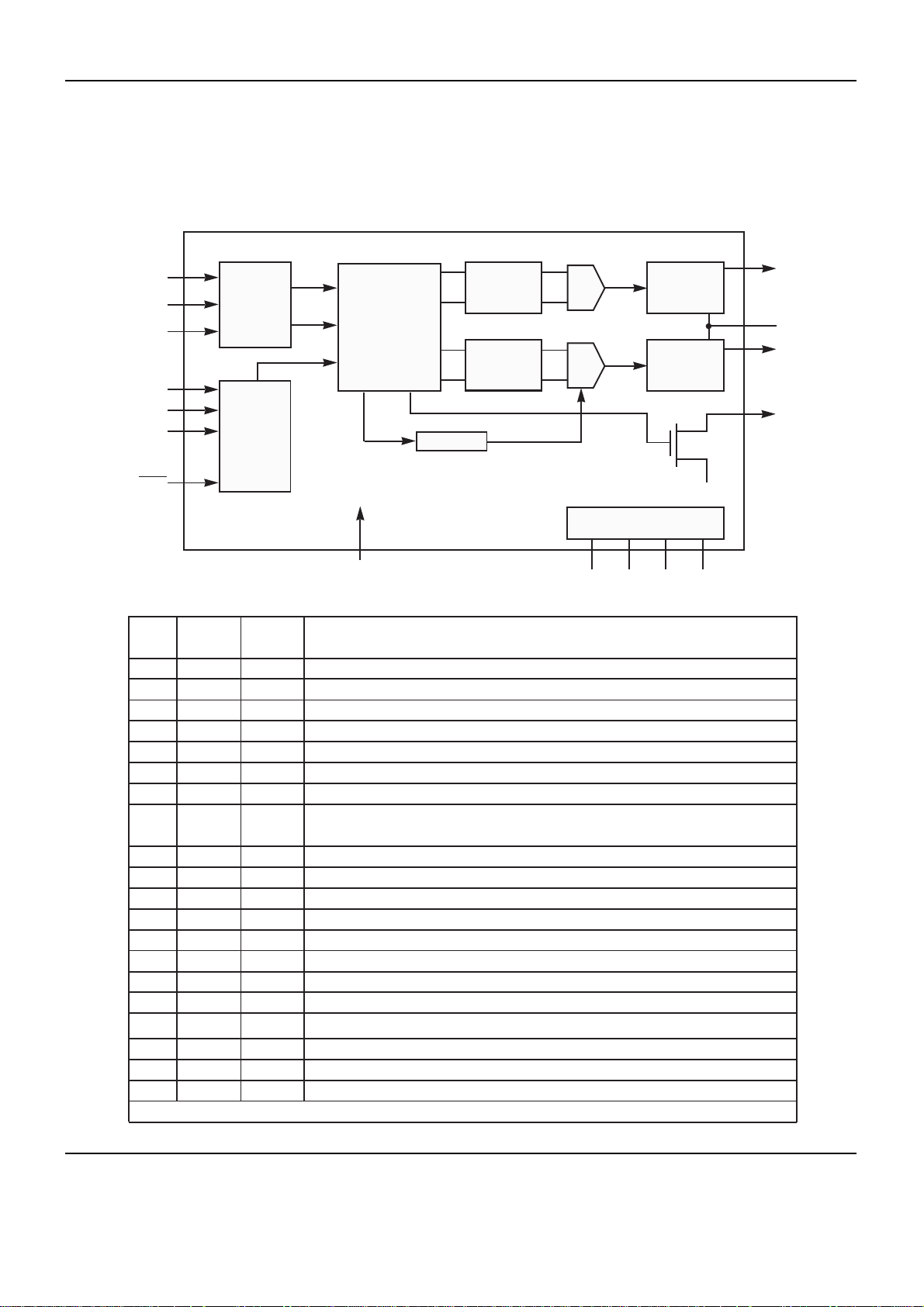

De-Scrambler ECC 8/16 DEM Sync Det.

Control

Circuit

Frame Sync

Sector Sync

Frame Number

Correction

PWM

CLV

Contol

RF Signal

Process

PLL

(SVCK)

(PFCK)

HOST INTERFACE

(ECC)

STATUS OUT

UNIVERSAL PWM

(DPCK) (SVCK)

E

D

3

E

D

2

E

D

1

E

D

0

P

L

C

K

H

A

I

H

A

0

HIN

T

DVD

D

5

D

VSS

H

D

7

H

D

6

H

D

5

H

D

4

H

D

3

H

D

2

H

D

1

H

D

0

H

CEN

HDR

D

H

D

W

T

N

C

DVD

D

3

D

VSS

S

VCK

0

DVC

K

1

DVD

D

3

DPC

K

1

D

VSS

D

P

W

M

RFIN

RVDD

RVR2

AVDD

PVR

VRC

AVR

AVSS

SCLO

VCOF

LPFO

LPFN

RLLD

PDOP

PDON

TEST

ED7

ED6

ED5

ED4

SD7

SD6

SD5

SD4

DVSS

DVDD3

SD3

SD2

SD1

SD0

SERR

SBGN

SENB

SDCK

DVSS

SREQ

RSTN

DVDD3

STDA

STCK

6. IC Descriptions

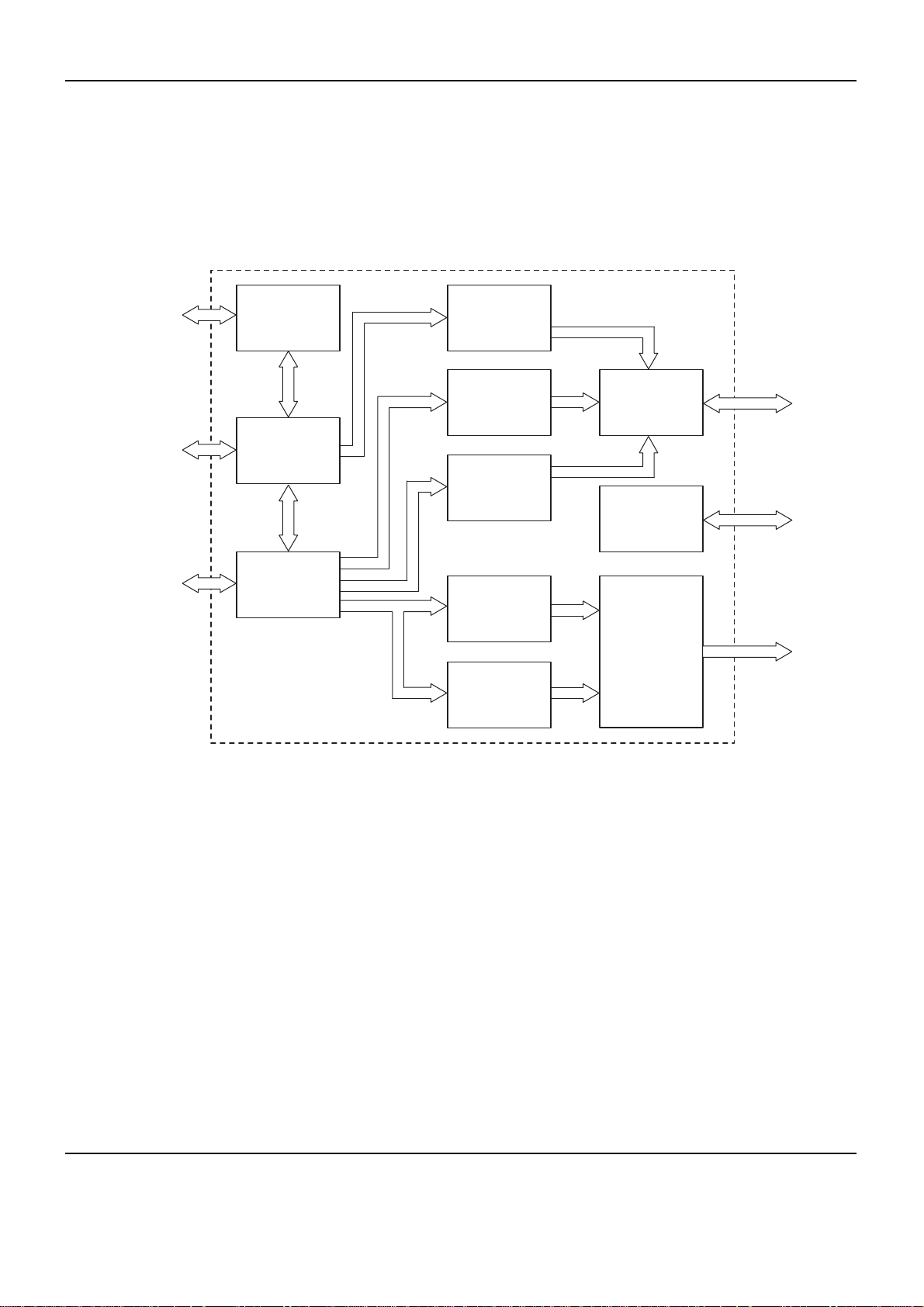

BLOCK DIAGRAM

IC Descriptions

6-2 Samsung Electronics

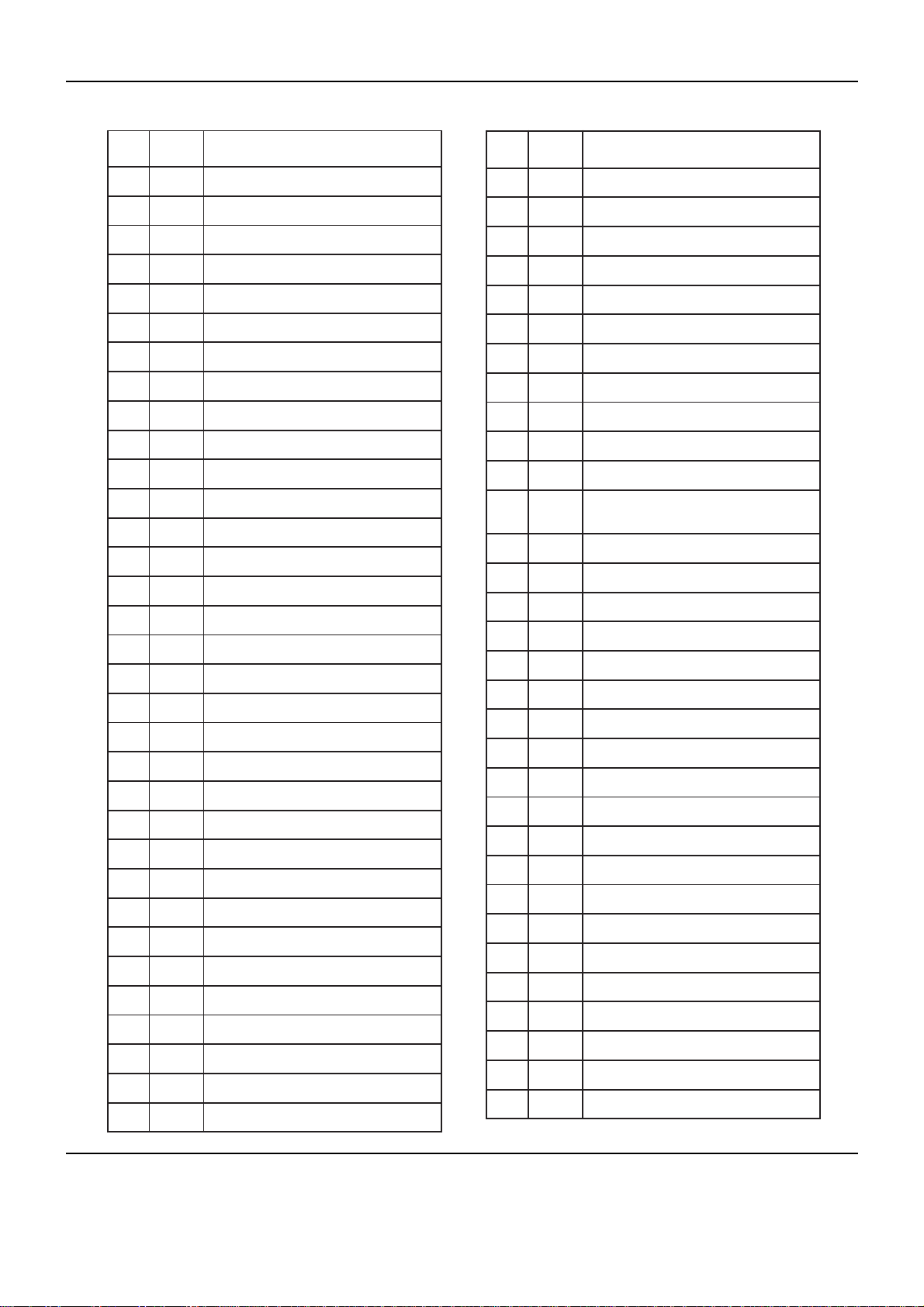

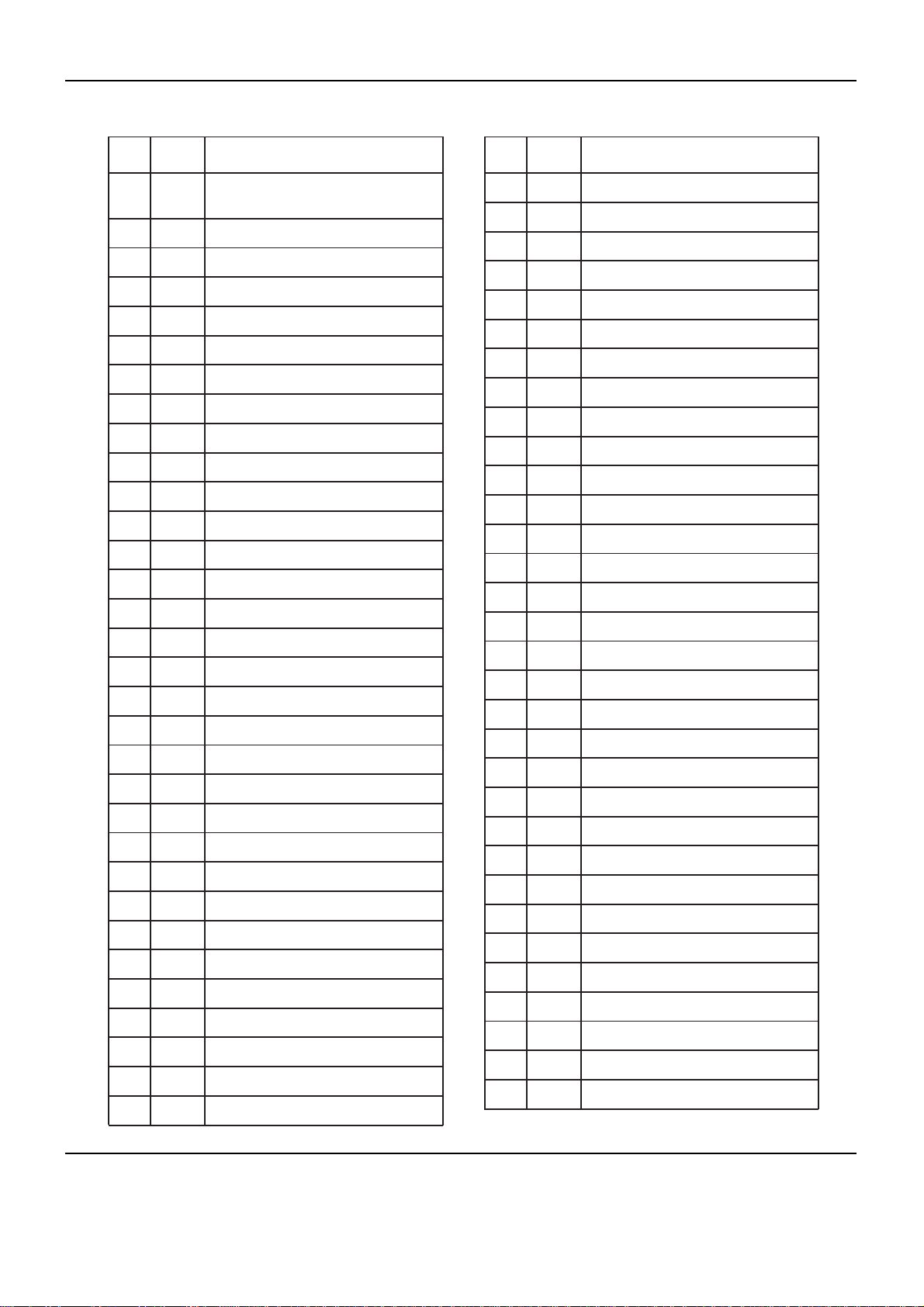

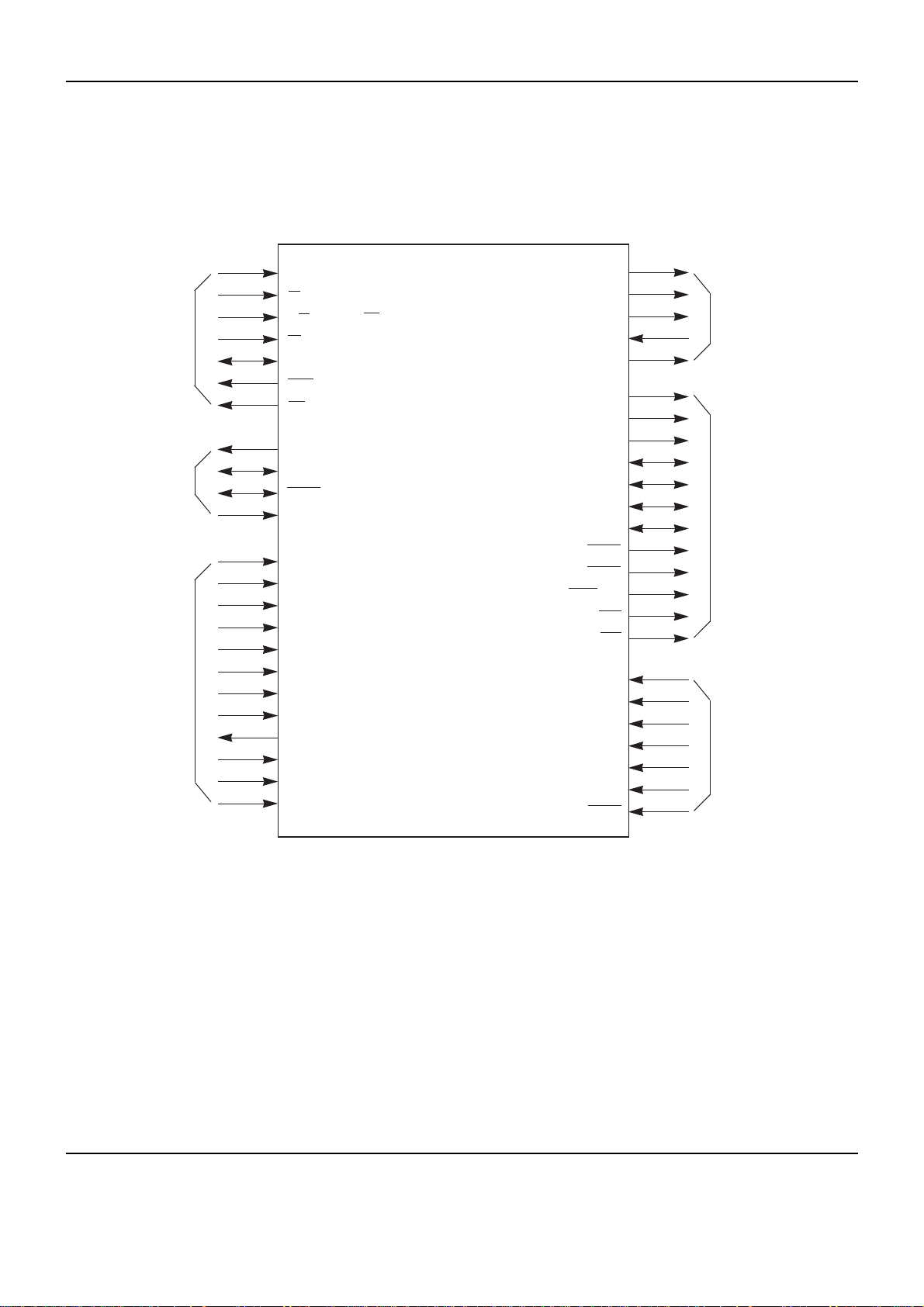

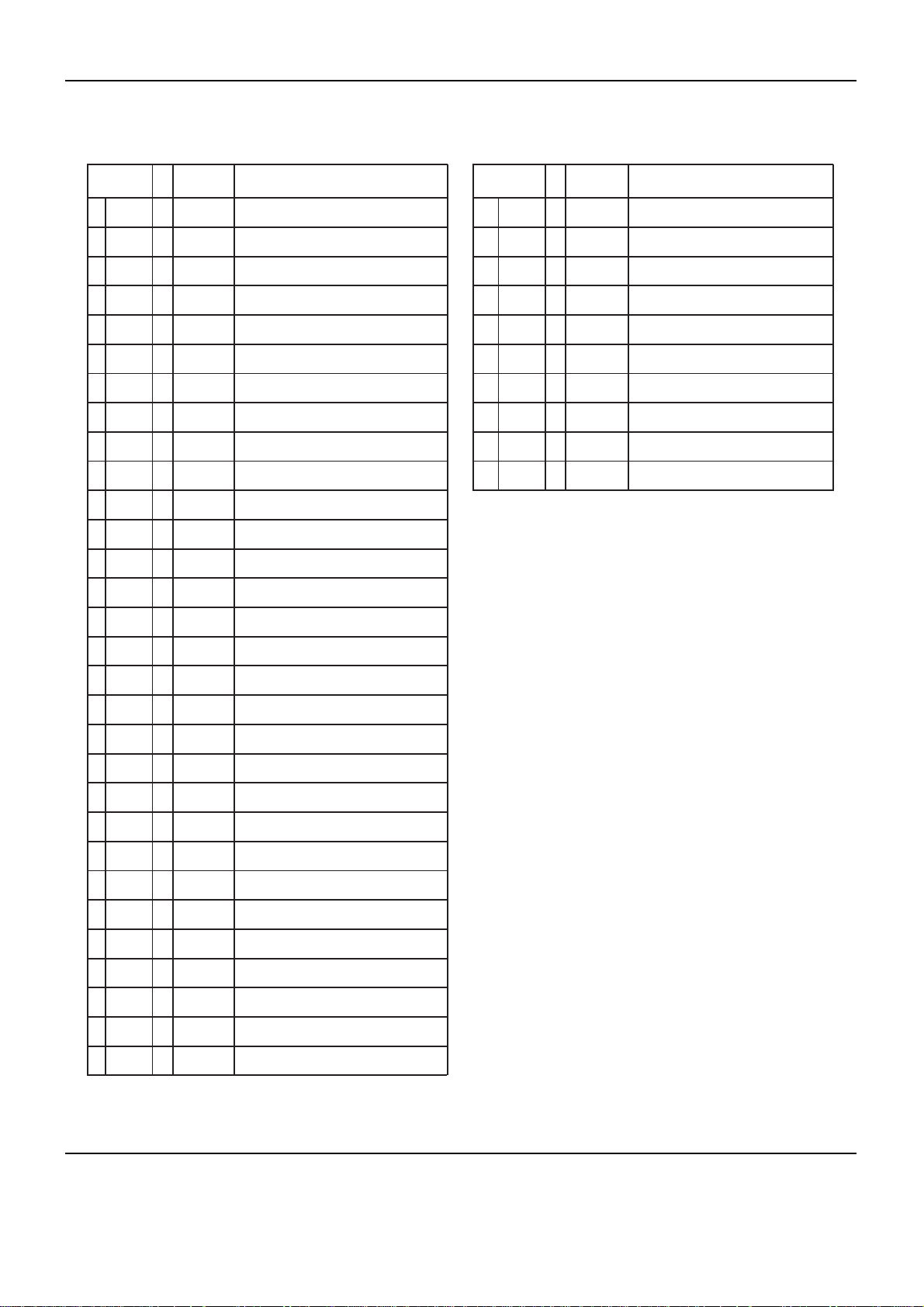

PIN ASSIGNMENT

Extension data bus I/O

UPWM

DV

SS1

DPCKI

DVDD1

SVCKI

SVCKO

DV

SS1

DV

DD1

WAIT

HDWT

HDRD

HCEN

HD0

HD1

HD2

HD3

HD4

HD5

HD6

HD7

DV

SS2

DV

DD2

HINT

HA0

HA1

PLCK

ED0

ED1

ED2

ED3

ED4

ED5

ED6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

NAME FUNCTION

Wide use PWM output

Digital ground

Signal process reference clock input

(27 to 34MHz)

Digital power supply (3.3V)

Servo reference clock input

(oscillation circuit input)

Servo reference clock output

(oscillation circuit input)

Digital ground

Digital power supply (3.3V)

Waiting

MPU WRITE signal input

MPU READ signal input

MPU chip selection

MPU data bus I/O

MPU data bus I/O

MPU data bus I/O

MPU data bus I/O

MPU data bus I/O

MPU data bus I/O

MPU data bus I/O

MPU data bus I/O

Digital ground

Digital power supply

MPU interruption signal output

(interruption:L)

MPU address bus input

MPU address bus input

VCO oscillation clock I/O

Extension data bus I/O

Extension data bus I/O

Extension data bus I/O

Extension data bus I/O

Extension data bus I/O

Extension data bus I/O

PIN

NAME FUNCTION

PIN

External RAM address bus output

ED7

TEST

PDON

PDOP

TMAX

LPFN

LPFO

VCOF

SLCO

AV

SS

AVR

VRC

PVR

AVDD

RVR2

RV

DD

RFIN

RV

SS

RVR1

DVR

DMO

RASN

CASN

MOEN

MWEN

DV

SS1

DV

DD1

MA9

MA8

MA7

MA6

MA5

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

Extension data bus I/O

Test mode input

Phase error signal output(- polarity)

Phase error signal output(+polarity)

RLL detecting result output

Inverting input for PLL loop filter amplifier

Output for PLL loop filter amplifier

VCO filter output

DAC output for making data slice level

Analog ground

Non PLL system analog reference voltage

(1.65V)

Resistor dividing point electrical potential

output(for analog reference electrical potential

generation)

PLL system analog reference voltage

output(1.65V)

Analog power supply (3.3V)

Second reference voltage(for connecting

capacitor)

For power supply

RF signal input

For ground

First reference voltage

(for connecting capacitor)

DMO reference voltage input (2.1V)

Disc equalizer output

(3 value PWM +Hiz) for DVD

External RAM row address selection (negative

logic)

External RAM column address selection

(negative logic)

External RAM output acknowledgement signal

output

External RAM READ/WRITE selection

Digital ground

Digital power supply

External RAM address bus output

External RAM address bus output

External RAM address bus output

External RAM address bus output

IC Descriptions

6-3Samsung Electronics

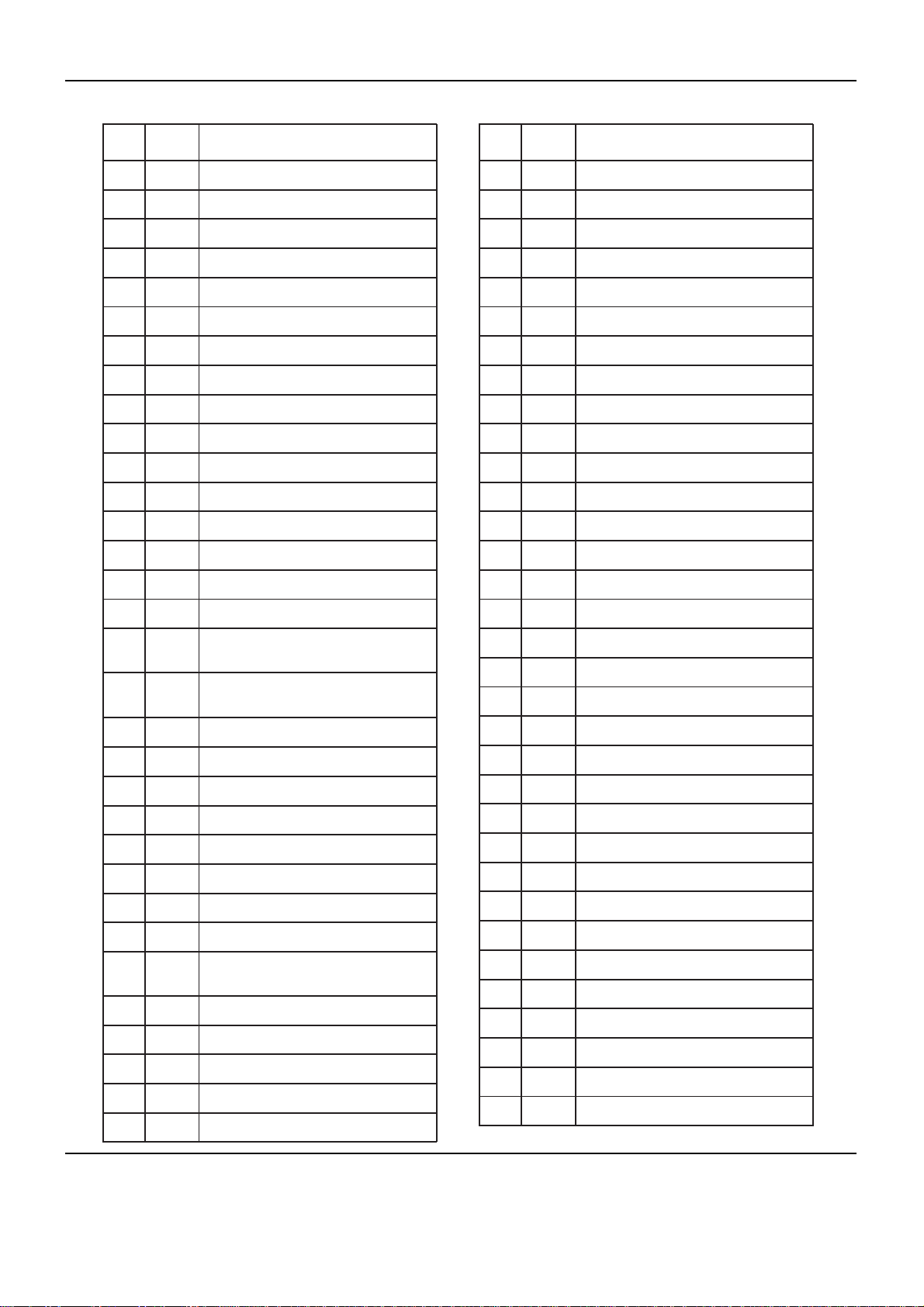

PIN ASSIGNMENT

MA4

MA3

MA2

MA1

MA0

DV

SS2

DV

DD2

MD7

MD6

MD5

MD4

MD3

MD2

MD1

MD0

SD7

SD6

SD5

SD4

DV

SS1

DV

DD1

SD3

SD2

SD1

SD0

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

External RAM address bus output

External RAM address bus output

External RAM address bus output

External RAM address bus output

External RAM address bus output

Digital ground

Digital power supply

External RAM data bus I/O

External RAM data bus I/O

External RAM data bus I/O

External RAM data bus I/O

External RAM data bus I/O

External RAM data bus I/O

External RAM data bus I/O

External RAM data bus I/O

MPEG data output

MPEG data output

MPEG data output

MPEG data output

Digital ground

Digital power supply

MPEG data output

MPEG data output

MPEG data output

MPEG data output

SERR

SBGN

SENB

SDCK

DV

SS1

SREQ

RSTN

DV

DD1

STDA

STCK

Digital power supply

MPEG data reliability flag output

(data error:L)

MPEG output secter synchronous signal output

(secter top:L)

MPEG data effective flag output (effective:L)

MPEG data transfer clock output

Digital ground

MPEG data request flag input(request:L)

Hard reset input (reset:L)

Operation monitor data output

(Output is carried out in synchronization

with the falling edge of SDCK)

Operation monitor synchronous signal

output (data top bit:L)

91

92

93

94

95

96

97

98

99

100

NAME FUNCTION

PIN

NAME FUNCTION

PIN

IC Descriptions

6-4 Samsung Electronics

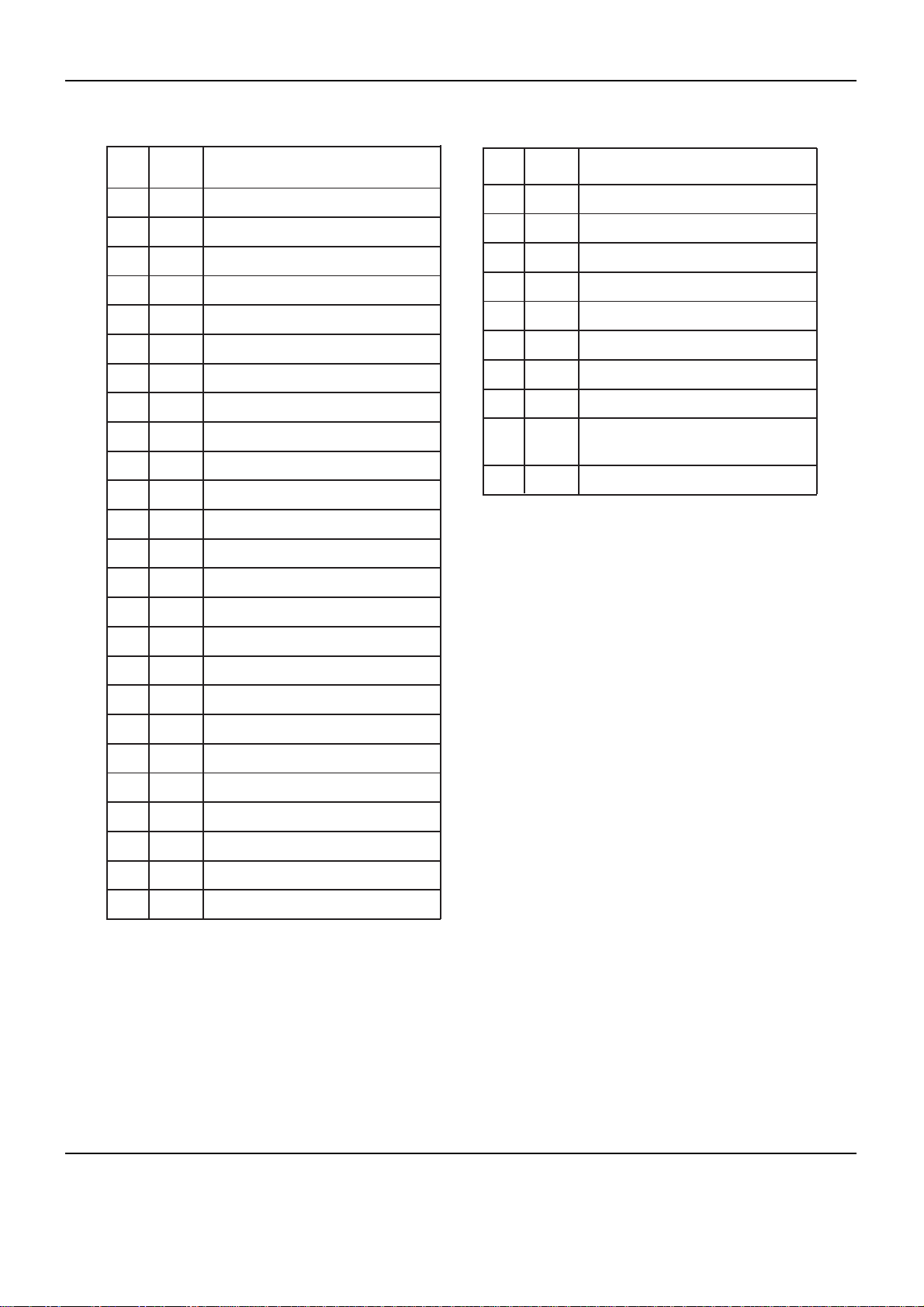

6-2 RF IC

TA1236F

RIC1

48 47 46 45 44 43 42 41 40 39 38 37 36 35 34 33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

LPF

LPF

LPF

SEL

Vref

Focus

Error

Detector

LD-APC

LD-Po Sel.

ATT

CD-EQ

DVD-EQ

VCA

DVD-EQ

SEL

Peak &

Bottom

Detector

SEL

Ripple

Detector

VREF & 2VR

GEN.

TIME-CON.

LPF

Fullwave

RECT.

GND3

RFR FIL

RFRP

OUT

RFcen

FWR FIL

FE

OUT

FE

IN

DVDGD

NC

PRE FIL

NC

TE

OUT

V

ref

V

ref

FIL

2V

ref

2V

ref

FIL

GND2

MCK

ADJ. FIL

Vcc2

RPD etP

DetSR

RPDetB

GND1

DPD

TE

NC

3B

OUT

3B

IN

3BTE

SB

OUT

SB

IN

TE BAL

S/D sel

F

IN

E

IN

V

refIN

D

IN

C

IN

B

IN

A

IN

Vcc1

RFN

IN

RFP

IN

LDP

sel

OUT

LDC

Vcc3

MD

IN

RF

Gain

DVD

sel

EQ

OUTEQINSQsel

DVD EQ

CDEQ

DVD

Time

CD

Time

RF CD

OUT

DPD/3B sel

Vcc4

RF

cen

P

RF

cen

B

RF DVD

OUT

RP

sel

BLOCK DIAGRAM

IC Descriptions

6-5Samsung Electronics

RF system ground

TEB

SBI

SBAD

3BTE

3BIN

3BO

N.C.

TE1B

GNDSV

RFB

DETR

RFP

V

CCD

ADJF

MCK

GNDD2

2CVR

2VR

CVR

V

REF

TEO

N.C.

RFDEQ

N.C.

EQGD

FEI

FEO

3TF

RFZC

RFRP

RPF

GNDRF

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Control input to change sub beam

subtraction ratio at-3beam system tracking

error(TE)generation

Inverting input for sub-beam summing

amplifier

Sub-beam summing amplifier output

3 beam TE signal intermediate output

Amplifier inverting input for 3 beam TE

level adjustment

Amplifier output for 3 beam TE level adjustment

No connection

DPD system TE signal input

Servo system ground

RF ripple datector

RF ripple datector

RF ripple datector

Power supply

Filter external capacitor for DVD-EQ time

constant compensation

Clock input for DVD-EQ time constant

compensation

Ground

Reference voltage smoothing external capacitor

Reference voltage twice output

Reference voltage smoothing external capacitor

Reference voltage output

TE output after switching DPD/3B

No connection

Pre filter output for RF

No connection

Group delay characteristic control input for

DVD-EQ

Inverting input for focus error(FE) signal output

amplifier

FE output

Filter external capacitor to DVD-WV

detecting signal

Amplitude center voltage output of RF ripple

signal

RF ripple signal output

Filter external capacitor for RFRP signal

Control input when selecting DVD-WV

detecting signal for RFRP

RPS

SFSD

RFZB

RFZP

V

CC3

1B3B

RFCD

CD

TIME

CDF

FREQ

HSB

EQI

EQO

CD/SD

RFG

V

CCRF

MDI

LDC

LDO

LDP

RFP

RFN

V

CC5V

AI

BI

CI

DI

V

IRF

TNI

TPI

DBL

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

EQ output for DVD

RFRP center level detection

RFRP center level detection

Power supply for reference voltage

Control input to select DPD or 3B for TE

Signal

EQ output for CD

Frequency adjustment input for CD-EQ

curve

Frequency adjustment input for DVD-EQ

curve

Peak gain adjustment input for CD-EQ curve

DVD-EQ curve peak gain adjustment Input

Normal/four times linear speed selecting input

for CD-EQ

DVD/CD-EQ input

VCA passing Output for RFN and RFP

Selection control input for DVD-CD

Control input for RF signal VCA

RF system power supply

Monitoring input for laser diode APC

ON/OFF control input for LD

External current driver control output

for LD

Selection input for APC control polarity

RF signal non-inverting input from PU

RF signal inverting input from PU

Servo system power supply

Main beam four divisions detector A input for

making focus error (FE)

Main beam four divisions detector B input for

making FE

Main beam four divisions detector C input for

making FE

Main beam four divisions detector D input for

making FE

2.1V reference voltage input

Sub-beam E input

Sub-beam F input

Single/double layer system

selection input

NAME FUNCTION

PIN

NAME FUNCTION

PIN

PIN ASSIGNMENT

IC Descriptions

6-6 Samsung Electronics

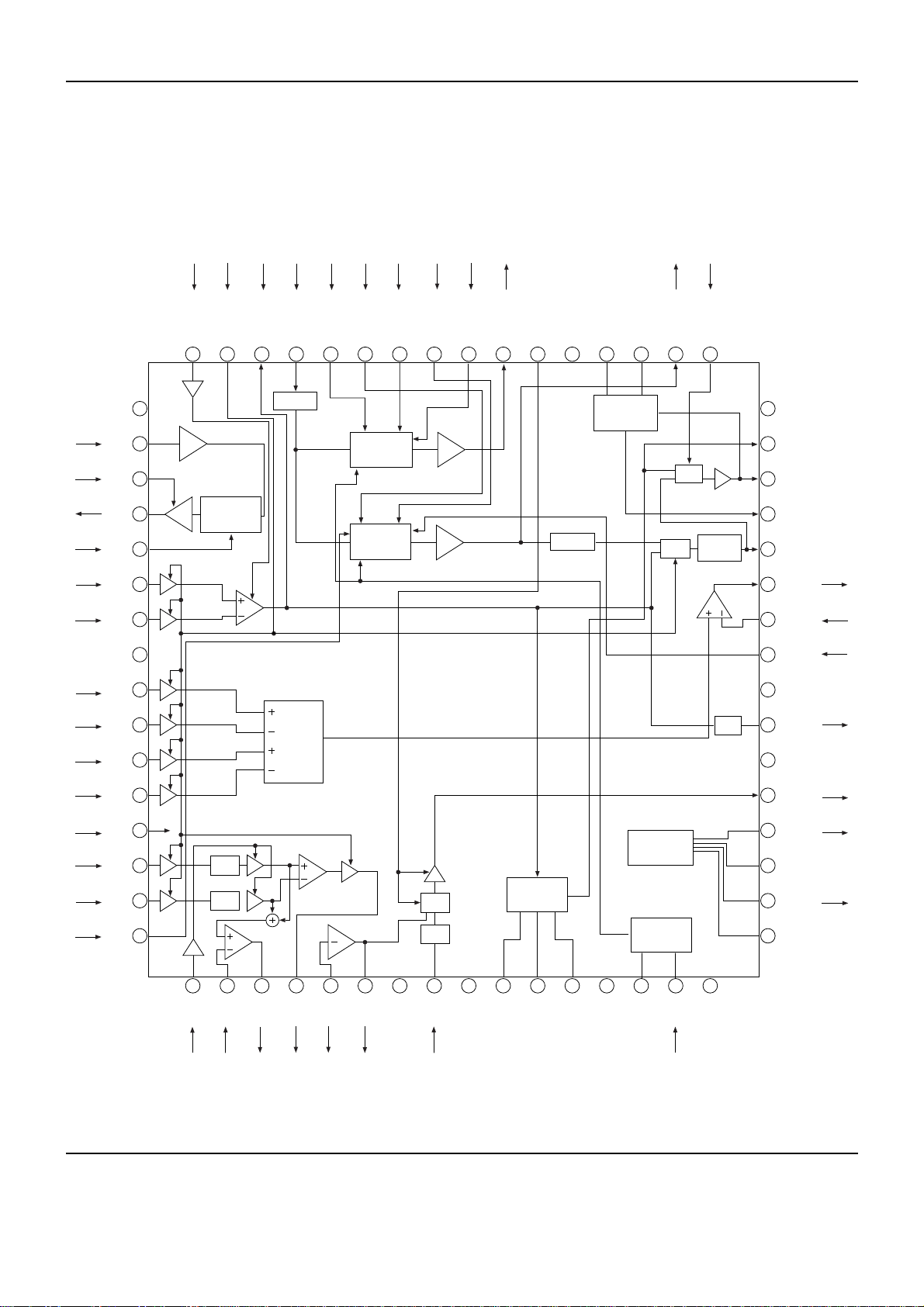

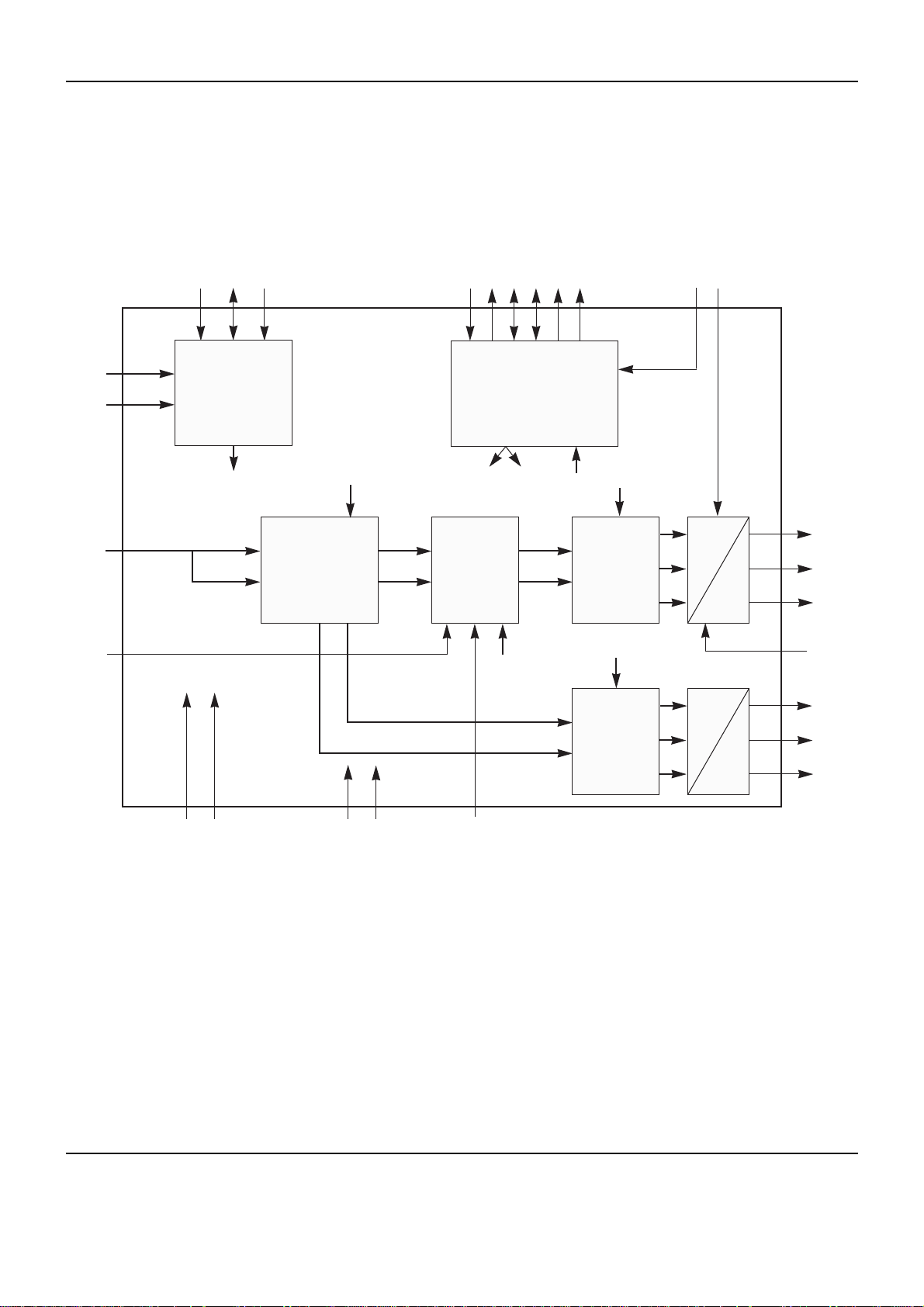

6-3 SERVO & CD DATA PROCESSOR

TC9420F

SIC7

1234567

8

9

101112131415161718192021222324252627282930

8079787776757473727170696867666564636261605958575655545352

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

VREE

TRO

FOO

TEZI

TEI

TSIN

SBAD

FEI

RFRP

RFZI

RFCT

AVDD

RFI

SLCO

AVSS

VCOF

VCOREF

PVREF

LPFO

LPFN

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

DVDD

RO

DVSS

DVR

LO

DVDD

TEST1

TEST2

TEST3

BUS0

BUS1

BUS2

BUS3

VDD

VSS

BUCK

CCE

TEST4

TSMOD

RST

XVDDXOXI

XVSS

VDD

PXO

PXI

VSS

TESIO1

TESIN

DACT

CKSE

DMOUT

IO3

IO2

IO1

IO0

VSS

VDD

FLGD

FLGC

FLGB

FLGA

SEL

2VREF

DMO

FVO

FMO

TEBC

RFGC

TEST0

HSO

UHSO

EMPH

LRCK

VSS

BCK

AOUT

DOUT

MBOV

IPF

SBOK

CLCK

VDD

VSS

DATA

SFSY

SBSY

SPCK

SPDA

COFS

MONIT

VDD

TESIO0

P2VREF

SPDO

PDOS

PDO

TMAXS

TMAX

LPF

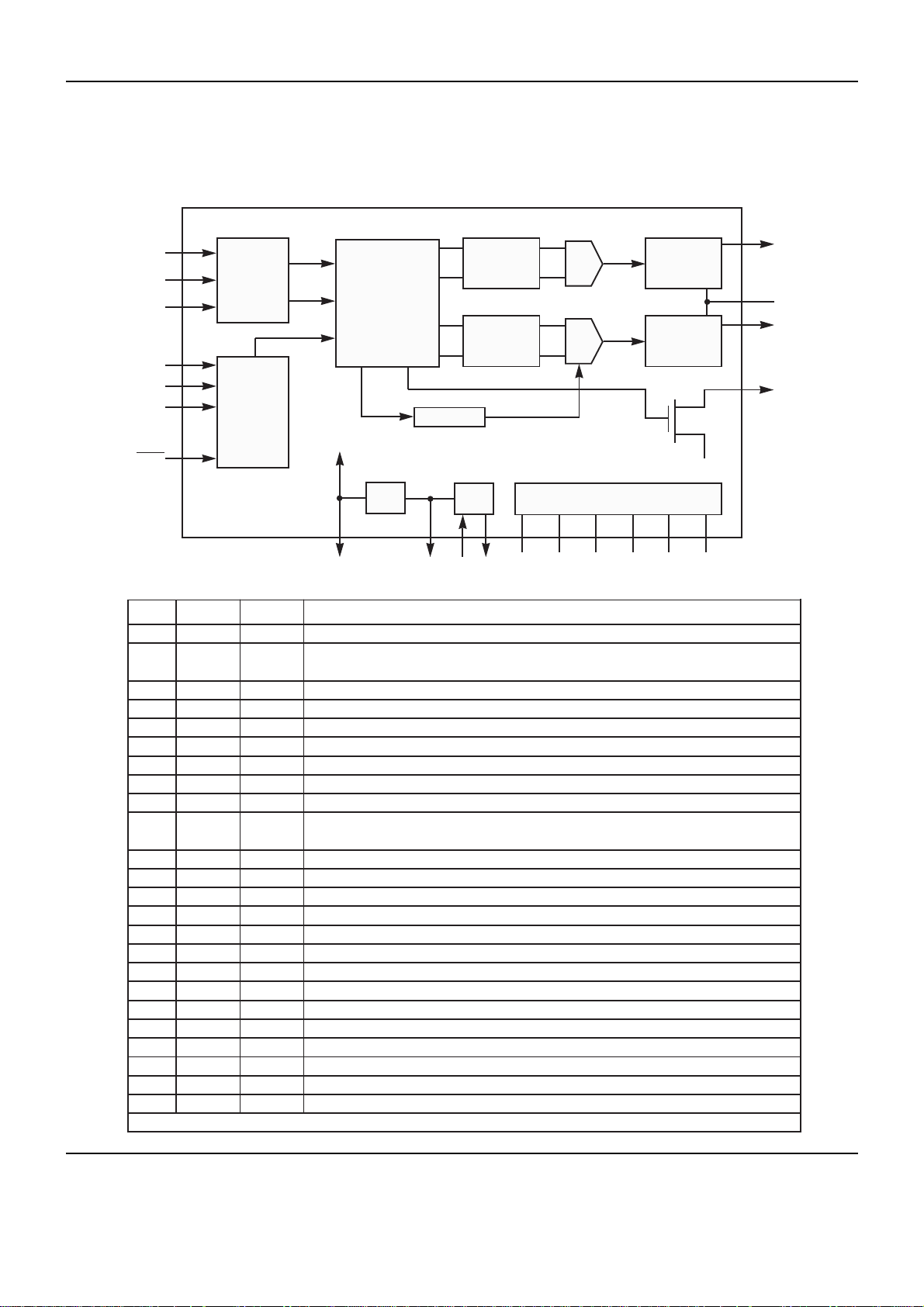

1bit

DAC

clock

Generatev

micom

interface

Audio

out

Digital out

status

PLL

TMAX

VCO

PWM

Data

slia

A/D

D/A

PWM

Servo

control

ROM

RAM

16k RAM

Address

Circuit

CLV SERVO

EFM

Digital

EQ

Demod.

Compen-

sating

Circuit

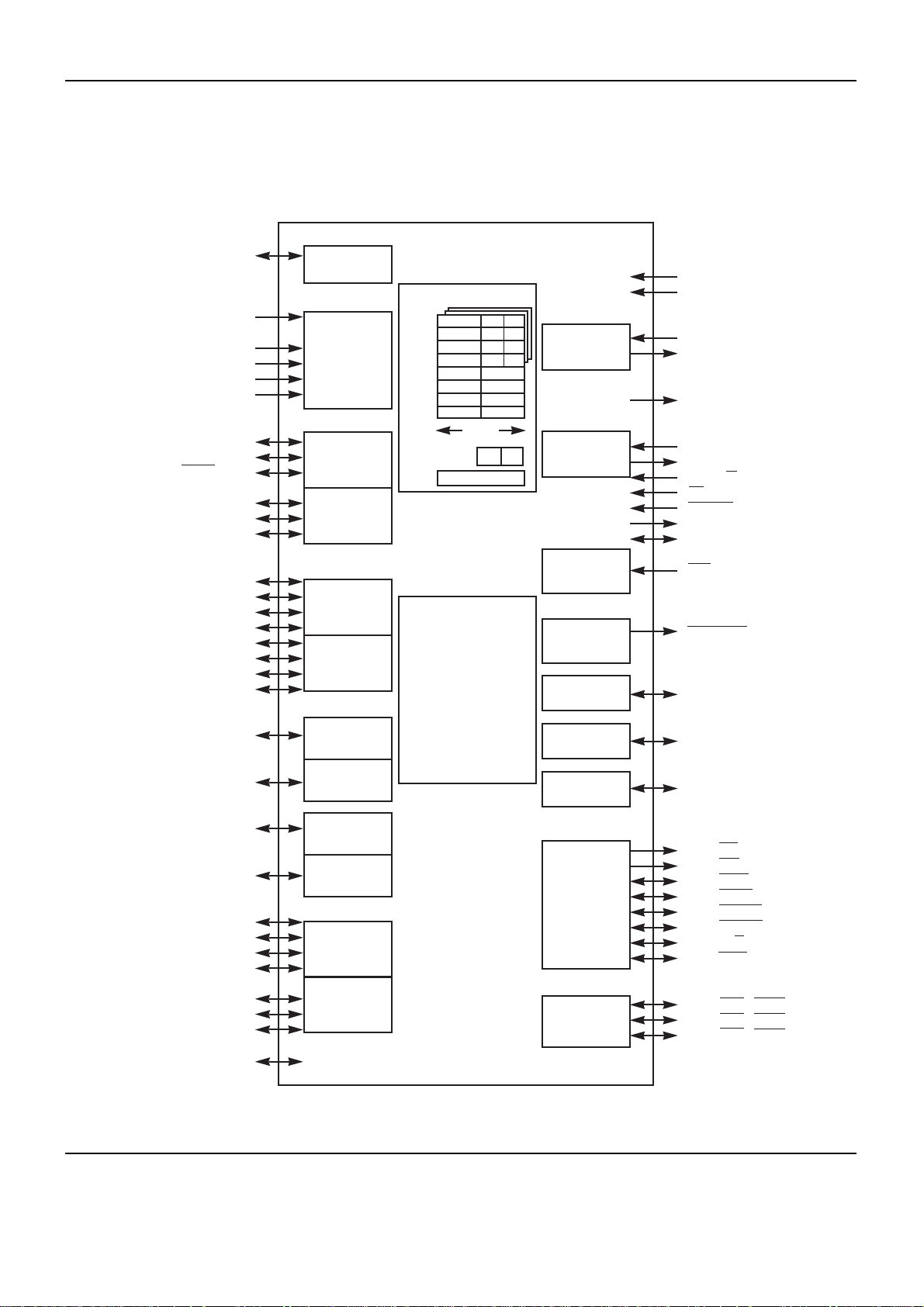

BLOCK DIAGRAM

IC Descriptions

6-7Samsung Electronics

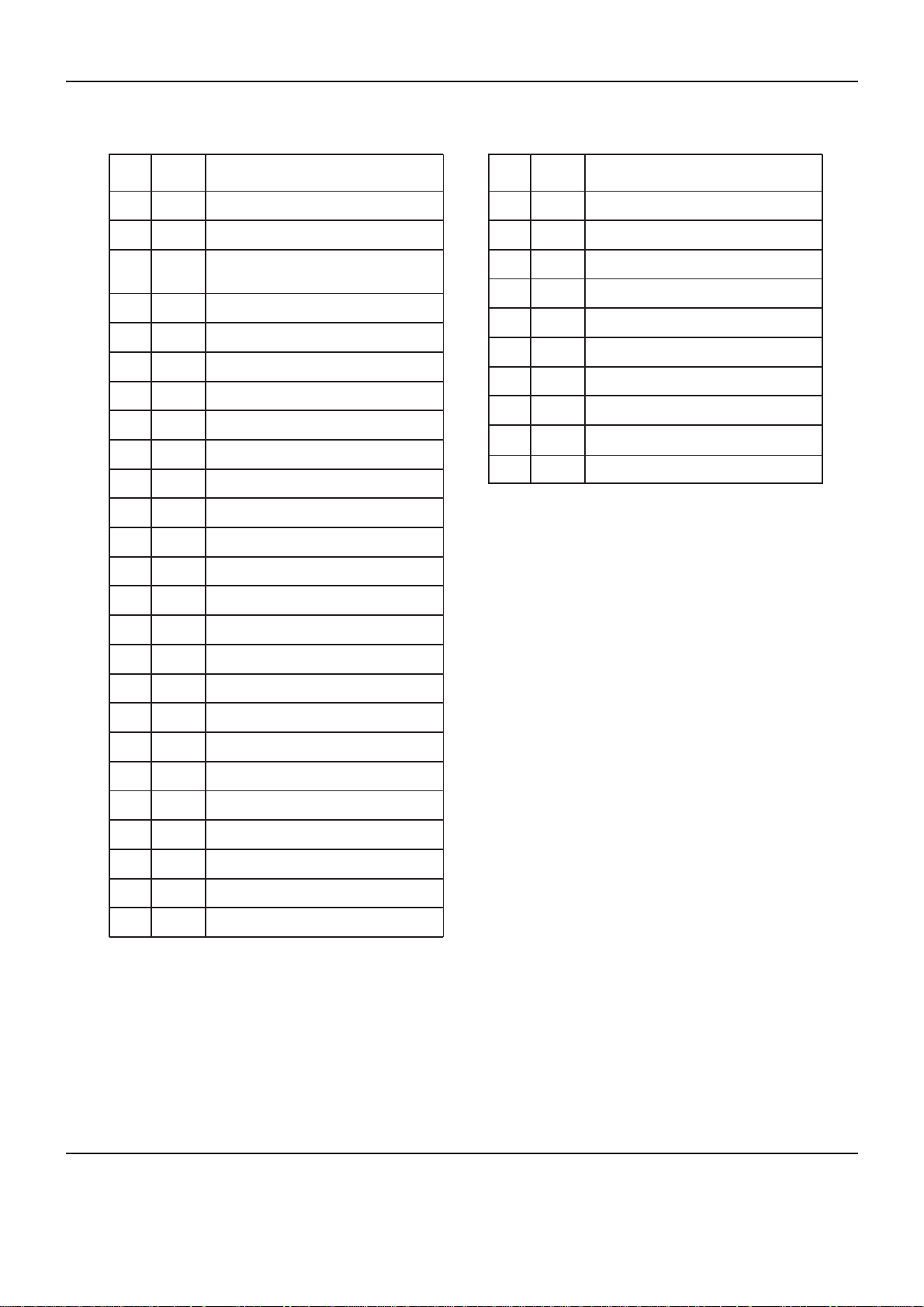

Amplifier (for low pass filter)output

TEST0

/HSO

/UHSO

EMPH

LRCK

V

SS

BCK

AOUT

DOUT

MBOV

IPF

SBOK

CLCK

V

DD

V

SS

DATA

SFSY

SBSY

SPCK

SPDA

COFS

MONIT

VDD

TESIO0

P2V

REF

SPDO

POOS

PDO

TMAXS

TMAX

LPFN

LPFO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

For test mode

Playback speed mode flag ouput

Playback speed mode flag output

Emphasis flag output of sub-code Q

data(H:emphasis ON,L:emphasis OFF)

Channel clock(44.1kHz)output

Digital ground

Bit clock(1.4122MHz) output

Audio data output

Digital Out output

Buffer memory over signal output

Compensation flag output

CRCC judging result output of sub-code Q

data(result OK:H)

Clock I/O

(for sub-code P to W data reading)

Digital + power supply

Digital ground

Sub-code P to W data output

Playback system frame synchronous signal

output or Servo system internal register data

Read clock output

Sub-code block synchronous output or

Servo system internal register data latch pulse

output

Processor status signal Read clock

(176.4kHz)output

Processor status signal output

Correction system frame clock(7.35khz) output

LSI internal signal monitor output

Digital + power supply

Test I/O

2VREF terminal for PLL system

VCO center frequency shift output

Phase difference signal output between

EFM signal and PLCK signal

(at 8 times speed operation)

Phase difference signal output between EFM

signal and PLCK signal

TMAX detection result output

TMAX detection result output

Amplifier (for low pass filter)

inverting input

Wide use I/O port

PV

REF

VCO

REF

VCOF

AV

SS

SLCO

RFI

AV

DD

RFCT

RFZI

RFRP

FEI

SBAD

TSIN

TEI

TEZI

FOO

TRO

V

REF

RFGC

TEBC

FMO

FVO

DMO

2V

REF

SEL

FLGA

FLGB

FLGC

FLGD

V

DD

V

SS

IO0(FMOP)

I

O1(FMON

)

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

VREF terminal for PLL system

VCO center frequency reference level

Filter terminal for VCO

Analog system ground

Data slice level making DAC output

RF signal input

Analog system power supply

RFRT signal center level input

RFRT zero cross input

RF ripply signal input

Focus error signal input

Sub-beam addition signal input

Input terminal

(in case of tracking of mode)

Tracking error input

Input for tracking error, zero cross

Focus equalizer output

Tracking equalizer output

Analog reference power supply

RF amplitude adjustment control signal output

Tracking balance control signal output

Feed equalizer output

Speed error signal of feed search EQ output

Disc equalizer output

Analog reference power sypply (2x V

REF

)

APC circuit ON/OFF signal output

External floag output

(for monitoring internal signal)

External floag output

(for monitoring internal signal)

External floag output

(for monitoring internal signal)

External floag output

(for monitoring internal signal)

Digital + power supply

Digital ground

Wide use I/O port

NAME FUNCTION

PIN

NAME FUNCTION

PIN

PIN ASSIGNMENT

IC Descriptions

6-8 Samsung Electronics

IO2(DMOP)

IO2(DMON)

/DMOUT

/CKSE

/DACT

TESIN

TESIO1

V

SS

PXI

PXO

V

DD

XVSS

XI

XO

XV

DD

DVDO

RO

DV

SS

DVR

LO

DV

DD

TEST1

TEST2

TEST3

BUS0

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

Wide use I/O port

Wide use I/O port

Mode setting to output binary PWM signals of field

equalizer from IO0 and IO1 terminals and of disc

equalizer from IO2 and IO3 terminals

X¡fltal selection

DAC test mode

Test input (external VCO clock input)

Test I/O

Digital ground

DPS system clock oscillation circuit input

DPS system clock oscillation circuit output

Digital + power supply

Ground for system clock oscillation circuit

System clock oscillation circuit input

System clock oscillation circuit output

+ power supply for system clock oscillation

circuit

D/A converting section power supply

R channel data forward rotation output

D/A converting section ground

D/A converting section reference voltage

L channel data forward rotation output

D/A converting section power supply

Test mode terminal

Test mode terminal

Test mode terminal

Data I/O (for microcomputer interface)

BUS1

BUS2

BUS3

V

DD

VSS

BUCK

/CCE

TEST4

/TSMOD

/RST

91

92

93

94

95

96

97

98

99

100

Chip enable signal input for microcomputer

interface

Data I/O (for microcomputer interface)

Data I/O (for microcomputer interface)

Data I/O (for microcomputer interface)

Digital + power supply

Digital ground

Clock input for microcomputer interface

Test mode terminal

Local test mode selection

Reset signal input

NAME FUNCTION

PIN

NAME FUNCTION

PIN

PIN ASSIGNMENT

IC Descriptions

6-9Samsung Electronics

6-4 AUDIO/VIDEO DECODER

ZiVA D6-L

BIC1

Memory

Controller

OSD

Decoder

Video

Mixer

Video

Interface

Audio

Interface

Sync

Generator

Subpicture

Decoder

MPEG

Video

Decoder

Dolby Digital

Audio

Decoder

MPEG

Audio

Decoder

Host

Interface

Control Logic

Program

Stream

Decoder

DRAM/

ROM

Interface

Host

Interface

DVD/CD

Interface

ZZiiVVAA DD eecc oodd eerr

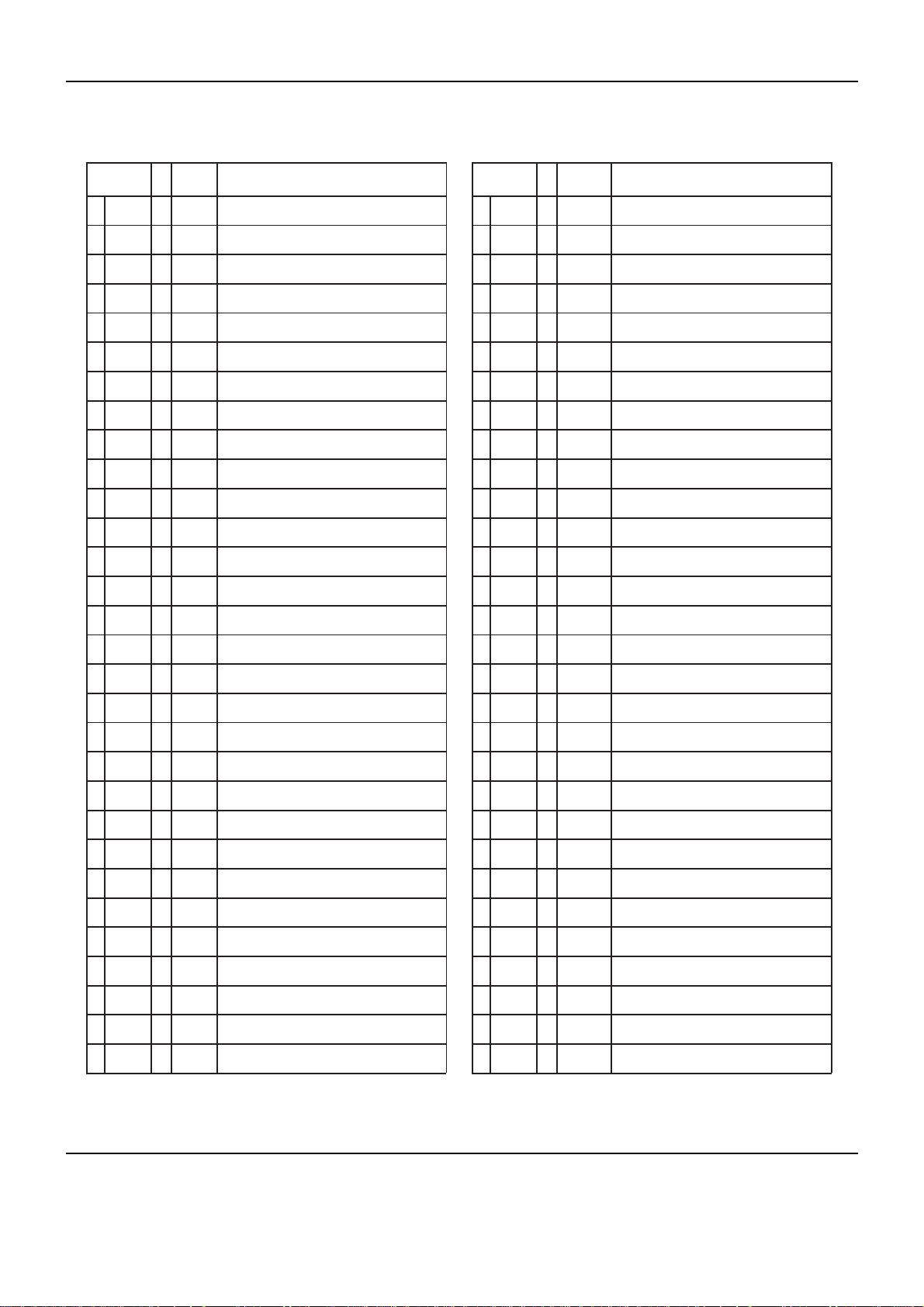

BLOCK DIAGRAM

Digital Audio

and

IEC-958

Interface

IC Descriptions

6-10 Samsung Electronics

LOGIC DIAGRAM

HADDR[2:0]

CS

R/W (M Mode)/WR (I Mode)

RD (I Mode)

HDATA[7:0]

WAIT

INT

Host

Interface

Signals

Video

Interface

Signals

DVD/CD

Interface

Signals

Audio

Interface

Signals

DRAM/ROM

Interface

Signals

Global

Interface

Signals

DA-DATA[2:0]

*

DA-LRCK

DA-BCK

DA-XCK

IEC958

MADDR[8:0]/MROMA[8:0]

MADDRH4

MADDRH1

MDATA[31:0]

MDATA[47:32]/MROMDATA[15:0]

MDATA[60:48]/MROMA[21:9]

MDATA[63:61]

MRAS1

MRAS0

MCAS[1:0]

MWE

MCE

SYSCLK

VDD

VSS

A_VSS

A_VDD

VDD5MAX

RESET

VDATA[7:0]

HSYNC

VSYNC

VCK

DVD-DATA[0]/CD-DATA

DVD-DATA[1]/CD-LRCK

DVD-DATA[2]/CD-BCK

DVD-DATA[3]/CD-C2PO

DVD-DATA[4]

DVD-DATA[5]

DVD-DATA[6]

DVD-DATA[7]

REQUEST

CSTROBE

ERROR

DACK

IC Descriptions

6-11Samsung Electronics

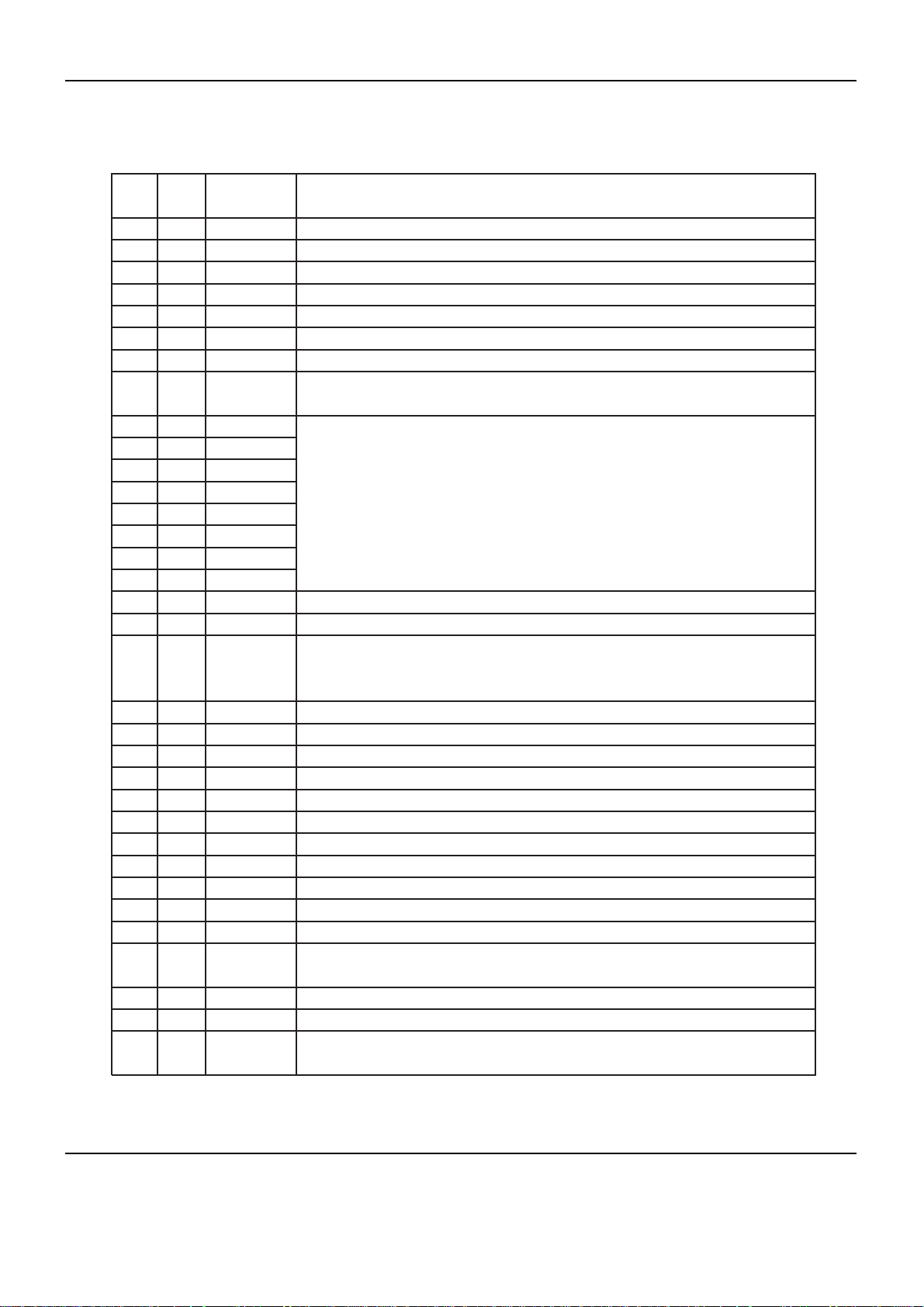

6-5 MAIN MICOM

TMP93CS41

MIC1

PAO~PA6

PA7(SCOUT)

P50 to P57

(ANO to AN7)

AVCC

AVSS

VREFH

VREFL

(TXD0)P90

(RXD0)P91

(SCLK0/CTS0)P92

(TXD1)P93

(RXD1)P94

(SCLK1)P95

(PG 00)P60

(PG 01)P61

(PG 02)P62

(PG 03)P63

(PG 10)P64

(PG 11)P65

(PG 12)P66

(PG 13)P67

(T10)P70

(T01)P71

(T02)P72

(T03)P73

(INT4/T14)P80

(INT5/T15)P81

(T04)P82

(T05)P83

(INT6/T16)P84

(INT7/T17)P85

(T06)P86

(INTO)P87

VCC[3]

VSS[3]

X1

X2

CLK

XT1

XT2

AM8/16

EA

RESET

ALE

TEST2,1

NMI

WDTOUT

P00 to P07

(AD0 to AC7)

P10 to P17

(AD8 to AD15/A8 toA15

P20 to P27

(A0 to A7/A16 to A23)

P30(RD)

P31(WR)

P32(HWR)

P33(WAIT)

P34(BUSRQ)

P35(BUSAK)

P36(R/W)

P37(RAS)

P40(CS0/CAS0)

P41(CS1/CAS1)

P42(CX2/CAS2)

cPORT A

High

Frequency

OSC

Low

Frequency

OSC

INTERRUPT

CONTROLLER

WATCH-DOG

TIMER

PORT 0

PORT 2

PORT 3

CS/WAIT

CONTROLLER

(3-BLOCK)

PORT 1

10-BIT 8CH

A/D

CONVERTER

SERIAL I/O

(CH,0)

SERIAL I/O

(CH,1)

PATTERN

GENERATOR

(CH,0)

PATTERN

GENERATOR

(CH,1)

16BIT TIMER

(TIMER 4)

16BIT TIMER

(TIMER 5)

8BIT TIMER

(TIMER 0)

8BIT TIMER

(TIMER 1)

8BIT PWM

(TIMER 2)

8BIT PWM

(TIMER 3)

900L-CPU

2KB RAM

XWA

XBC

ADE

XHL

XIX

XIY

XIZ

XSP

W

B

D

H

IX

IY

IZ

SP

A

C

E

L

32bit

FSR

P C

BLOCK DIAGRAM

IC Descriptions

6-12 Samsung Electronics

/CCE

BUCK

TEST1

TEST2

BUS0

BUS1

BUS2

BUS3

RPSEL

DFS

ALE

VCC

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

AD8

AD9

AD10

AD11

AD12

AD13

AD14

AD15

P96

P97

Test1

Test2

PA0

PA1

PA2

PA3

PA4

PA5

PA6

PA7

ALE

VCC

P00

P01

P02

P03

P04

P05

P06

P07

P10

P11

P12

P13

P14

P15

P16

P17

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

O

O

O

I

I/O

I/O

I/O

I/O

O

O

O

O

O

O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

Digital Servo Chip Enable

Digital Servo I/F Clock

Digital Servo I/F Data 0

Digital Servo I/F Data 1

Digital Servo I/F Data 2

Digital Servo I/F Data 3

Ripple Detect Output S/W

“H”=96KHz

Address Chip Enable

+5V

Address/Data Bus0

Address/Data Bus1

Address/Data Bus2

Address/Data Bus3

Address/Data Bus4

Address/Data Bus5

Address/Data Bus6

Address/Data Bus7

Address/Data Bus8

Address/Data Bus9

Address/Data Bus10

Address/Data Bus11

Address/Data Bus12

Address/Data Bus13

Address/Data Bus14

Address/Data Bus15

VREFL

AVSS

AVCC

SRQ

RRQ

LDON

SLEDOUT

SLEDIN

SLEDFG

DSPLT

DIF2

ML1

SBSY

DVDINT

MRST

DPINT

TXD

RXD

SCLK

MD

ML2

MC

AM8/16

CLK

V

CC

Vss

X1

X2

EA

RESET

NMI

P70

P71

P72

P73

P80

P81

P82

P83

P84

P85

P86

P87

P90

P91

P92

P93

P94

P95

AM8/16

CLK

V

CC

VSS

X1

X2

EA

Reset

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

I

I

I

I

O

O

O

O

I

O

O

O

I

O

O

I

O

I

I

O

O

O

I

O

I

I

I

O

I

I

FUNCTION

PIN I/O NAME

Reference Voltage Input to A/DC(¡ L¡–)

GND pin for A/D Converter(0V)

Power supply pin for A/D Converter

Fromt Micom - -> Main Micom Request

Fromt Micom <- - Main Micom Request

Laser On (“H”=on)

Forward Slide Move

Reverse Slide Move

Hall Count Input

Sony DSP Data Latch

AKM4324 Control(“L”=16/20bit, “H”=24bit)

Audio DAC Data Latch 1

SUBQ Block Sync. Signal INT.

A/V Decoder INT.

LSI Reset

Data Processor INT.

Front Micom Trans. Data

Front Micom Receive Data

Front Micom Communication Clock

Audio DAC Trans. Data

Audio DAC Data Latch 2

Audio DAC Trans. Clock

8bit External Data Bus Width(¡ H¡–)

Clock Output(System Clock/2)

Power Supply Pin(+5V)

GND Pin(0V)

20MHz

20MHz

TMP93CS41F:¡–L¡–

Micom Rest Input

FUNCTION

PIN I/O NAME

PIN ASSIGNMENT

IC Descriptions

6-13Samsung Electronics

VSS

VCC

A16

A17

A18

A19

A20

A21

A22

A23

/RD

/WR

ML0/DIF0

WAIT

/BUSRQ

/BUSAK

ED_K

ED_T

/CS0

/CS1

/CS2

DVD_SEL

OPEN

CLOSE

S/D_SEL

SDA

SCL

BASS

SLEDGS

WDTO

V

SS

V

CC

A16

A17

A18

A19

A20

A21

A22

A23

P30

P31

P32

P33

P34

P35

P36

P37

P40

P41

P42

P60

P61

P62

P63

P64

P65

P66

P67

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

I/O

O

O

O

O

O

O

O

O

O

O

O

I

I

O

O

O

O

O

O

O

O

O

O

O

O

O

O

GND(0V)

+5V

Address Bus 16

Address Bus 17

Address Bus 18

Address Bus 20

Address Bus 21

Address Bus 22

Address Bus 23

Strobe for Reading External Momory

Strobe for Writing Data AD0 to AD7

Audio DAC Data Latch 0

/AKM4324 Control(“L”=16/24bit, “H”=20bit)

Address Bus 19

Request CPU Bus Wait

Bus Request

Bus Acknowledge

EEPROM Trans. Clock(I2S)

EEPROM Trans. Data(I2S)

Chip Select 0

Chip Select 1

Chip Select 2

DVD/CD Mode Control(DVD=”Low”)

Door Open Motor Control

Door Close Motor Control

Single/Dual Disc Select(Single=”Low”)

Video Encoder Trans. Data(l

2

C)

Video Encoder Trans. Clock(l

2

C)

Bass Redirection Control(“L”=SW On, “H”=SW Off)

Sled Gain Select

FUNCTION

PIN I/O NAME

FUNCTION

PIN I/O NAME

VSS

FEI

SPFG

/SECAM

/PAL

/NTSC

OP-SW

CL-SW

VREFH

V

SS

P50

P51

P52

P53

P54

P55

P56

P57

VREFH

91

92

93

94

95

96

97

98

99

100

I

I

I

I

I

I

I

I

I

GND

Focus Error Input

Spindle FG Input

SECAM=”H”

PAL =”H”

NTSC=”H”

Door Open SW

Door Close SW

Reference Voltage Input to A/DC(¡ H¡–)

PIN ASSIGNMENT

IC Descriptions

6-14 Samsung Electronics

6-6 DIGITAL VIDEO ENCODER

SAA7128

VIC1

I'C-

INTERFACE

SYNC/

CLOCK

MP

MP

9..16

44

20

21

I'C-Control

I'C-Control

I'C-Control

I'C-Control

I'C-Control

Clock&Timing

RESN

40

42

41

35

34

7

8

43

37

4

25,28,31,36

SDA

SCL

XTALI

XTAL

RCV1

RCV2

TTXRQ

XCLK

LLC1

VDDA

VDD I2C

SA

MP(7:0)

TTX

FADER

ENCODER

OUTPUT-

INTERFACE

D

A

RGB-

PROCESSOR

D

22,32,33

23

26

29

30

27

Y

C

Y

5,18,38

6,17,39

2

3

VSS

VDD

SP

AP

19

RTC1

CbCr

Y

CbCr

24

R(Cr)

VSSA

G(Y)

B(Cb)

CVBS

(CSYNC)

VBS

(CVBS)

C

(CVBS)

A

BLOCK DIAGRAM

IC Descriptions

6-15Samsung Electronics

NAME

res.

SP

AP

LLC1

V

SS1

VDD1

RCV1

RCV2

MP7

MP6

MP5

MP4

MP3

MP2

MP1

MP0

V

DD2

VSS2

RTCI

VDD

12C

SA

V

SSA1

R(Cr)

C

V

DDA1

G(Y)

VBS

V

DDA2

B(Cb)

CVBS

V

DDA3

VSSA2

VSSA3

XTAL

XTAL1

I/O

I

I

I

I

I

I/O

I/O

I

I

I

I

I

I

I

I

I

I

I

I

I

I

O

O

I

O

O

I

O

O

I

I

I

O

I

PIN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

FUNCTION

reserved pin, do not connect

Test Pin;connected to digital ground for normal operation

Test Pin;connected to digital ground for normal operation

Line-Locked Clock input;this is the 27 MHz master clock

digital supply ground 1

digital supply 1

digital supply voltage 2

digital ground 2

Real Time Control input. If the LLC1 clock is provided by an SAA7111 or SAA7151B,

RTCI should be connected to the RTCO pin of the respective decoder to improve the

signal quality.

Sense input for 12C bus voltage;connect to 12C bus supply

Select 12C address; low selects slave address 88h, high selects slave address 8Ch.

Analog ground 1 for Red (Cr), C(CVBS), Green(Y) outputs

Analog ground 3 for the DAC reference ladder and the oscillator

Crystal oscillator output

Crystal oscillator input; if the oscillator is not used, this pin should be connected to

ground.

Analog output of Red (Cr)signal

Analog output of Chrominance (CVBS) signal

Analog supply voltage 1 for R(Cr), C(CVBS) outputs

Analog output of Green(Y) signal

Analog output of VBS (CVBS) signal

Analog supply voltage 2 for VBS(CVBS), Green(Y) outputs

Analog output of Blue(Cb) signal

Analog output of CVBS(CSYNC) signal

Analog supply voltage 3 for Blue(Cb)and CVBS(CSYNC), outputs

Analog ground 2 for VBS (CVBS), Blue(Cb), CVBS(CSYNC)outputs

Raster Contral 1 for video port. This pin receives/provides a VS/FS/FSEQ signal.

Raster Contral 2 for video port. This pin provides an HS pulse of programmable length

or receives an HS pulse.

Double speed 54 MHzMPEG port. It is an input for ¡

CCIR 656

¡–style multiplexed Cb, Y,

Cr data. Data are sampled on the rising and falling clock edge;data sampled on the

risting edge then are sent to the encoding part of the device, data sampled on the

falling edge are sent to the RGB part of the device.(or vice verse, depending on

programming)

PIN ASSIGNMENT

IC Descriptions

6-16 Samsung Electronics

NAME

V

DDA4

XCLK

V

SS3

VDD3

RESN

SCL

SDA

TTXRQ

TTX

PIN ASSIGNMENT

I/O

I

O

I

I

I

I

I/O

O

I

PIN

36

37

38

39

40

41

42

43

44

FUNCTION

Analog supply voltage 4 for the DAC reference ladder and the oscillator

Clock output of the crystal oscillator

digital supply ground 3

digital supply 3

12C serial clock input

12C serial data input/output

Teletext Request output, indicating when text bits are requested

Teletext bit stream input

Reset input, active LOW. After reset is applied, all digital I/Os are in input mode; PALBlackburst on CVBS, VBS and C;RGB outputs set to lowest voltage.

The 12C-bus receiver waits for the START condition.

IC Descriptions

6-17Samsung Electronics

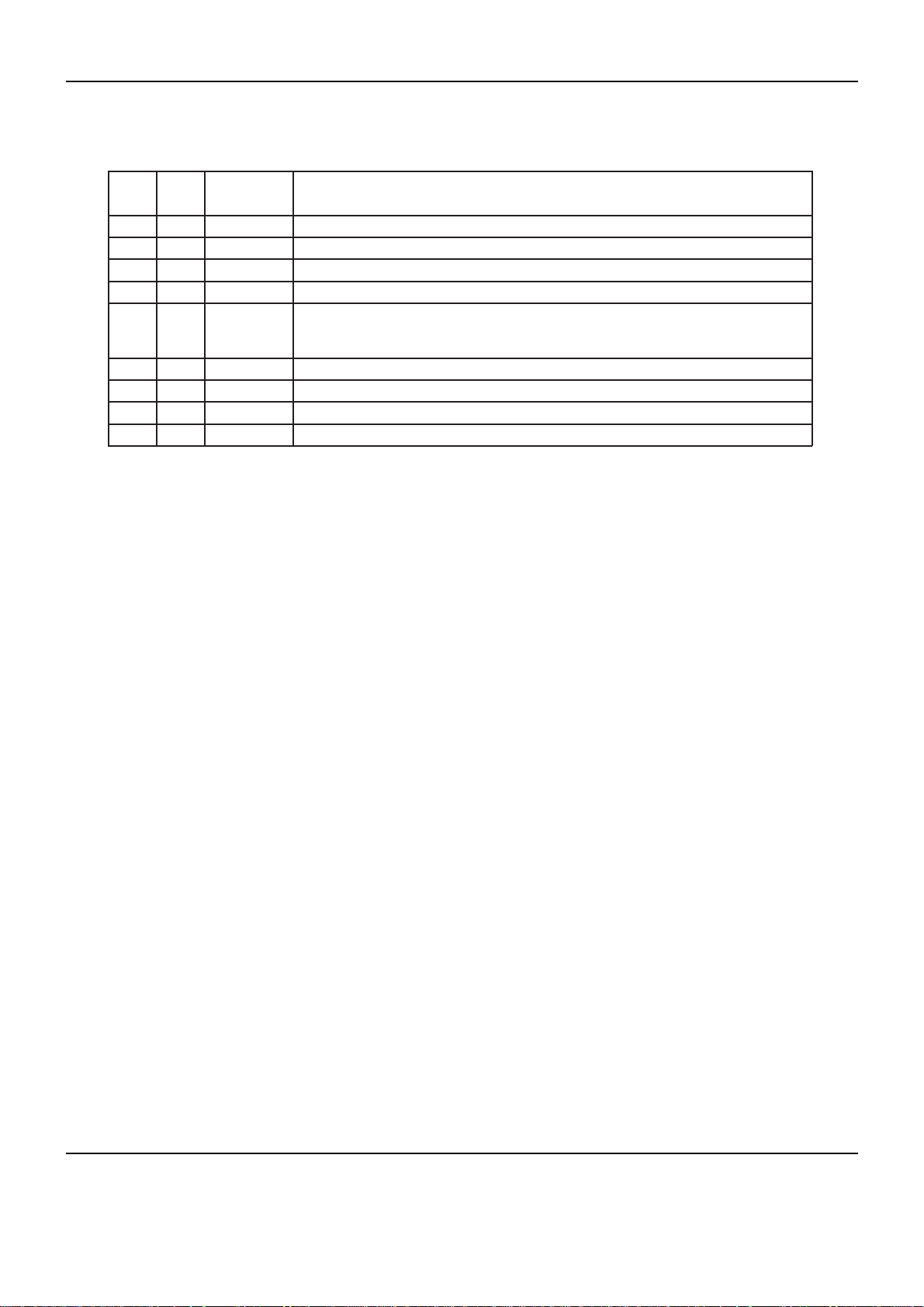

6-7 DIGITAL-TO-ANALOG CONVERTER

PCM 1720

AIC1(Rev.1), AIC2

1

2

3

4

¡

5

¡

6

¡

7

¡

8

9

10

11

12

13

14

¡

15

¡

16

¡

17

18

19

20

NC

SCKI

TEST

ML

MC

MD

RSTB

ZERO

V

OUT

R

AGHD

V

CC

V

OUT

L

CAP

BCKIN

DIN

LRCIN

NC

NC

V

DD

DGND

NAME

Low-pass

Filter

V

OUT

L

CAP

V

OUT

R

ZERO

Multi-level

Dalta-Sigma

Modulator

BPZ-Cont.

SCKI

256fs/384f

s

Low-pass

Filter

DAC

BLOCK DIAGRAM

PIN ASSIGNMENT

8X Oversampling

Digital Filter

with Function

Controller

Multi-level

Dalta-Sigma

Modulator

Serial

Input

I/F

Mode

Control

I/F

Power Supply

Open Drain

BCKIN

LRCIN

DIN

ML

MC

MD

RSTB

DAC

VCCAGND VDDDGND

PIN

I/O

-

IN

OUT

IN

IN

IN

IN

OUT

OUT

PWR

PWR

OUT

-

IN

IN

IN

-

-

PWR

PWR

FUNCTION

No Connection.

System Clock input: 256fsor 384fs.

Reserved for Factory Use.

Latch Enable for Serial Control Data.

Clock for Serial Control Data.

Data Input for Serial Control.

Reset Input. When this pin is low, the digital filters and modulators are held in reset.

Zero Data Flag. This pin is low when the data is continuously zero for more than

65,535 cycles ro BCKIN.

Right Channel Analog Output.

Analog Ground.

Analog Power Supply (+5V).

Left Channel Analog Output.

Common Pin for Analog Output Amplifiers.

Bit Clock for Clocking in the Audio Data.

Serial Audio Data input.

Left/Right Word Clock. Frequency is equal to fs.

No Connection.

No Connection.

Digital Power supply(+5V). Recommended connection is to the analog power supply.

Digital Ground. Recommended connection is to the digital ground plane.

¡

These pins include internal pull-up resistors.

IC Descriptions

6-18 Samsung Electronics

6-8 DIGITAL-TO-ANALOG CONVERTER WITH PLL

PCM 1723

AIC3

Low-pass

Filter

V

OUTL

CAP

V

OUTR

ZERO

Multi-level

Dalta-Sigma

Modulator

BPZ-Cont.

OSCPLL

SCKO

MCKO XTI XTO

256fs/384f

s

Low-pass

Filter

DAC

BLOCK DIAGRAM

8X Oversampling

Digital Filter

with Function

Controller

Multi-level

Dalta-Sigma

Modulator

Serial

Input

I/F

Mode

Control

I/F

Power Supply

BCKIN

LRCIN

DIN

ML

MC

MD

RSTB

DAC

VCP PGND VCC AGND VDD DGND

PIN ASSIGNMENT

PIN

NAME

I/O

1

2

3

4

5

6

'

7

'

8

'

9

'

10

11

12

13

14

15

16

'Ł

17

'Ł

18

'Ł

19

20

21

22

23

24

XTI

SCKO

V

CP

NC

MCKO

ML

MC

MD

RSTB

ZERO

V

OUT

B

AGND

V

CC

V

OUT

L

CAP

BCKIN

DIN

LRCIN

NC

RES

V

DD

DGND

PGND

XTO

IN

OUT

PWR

N/A

OUT

IN

IN

IN

IN

OUT

OUT

GND

PWR

OUT

IN

IN

IN

N/A

N/A

PWR

GND

GND

Out

FUNCTION

Master Clock Input.

System Clock Out. This output is 256fsor 384fs.

system clock generated by the internal PLL.

PLL Power Supply (+5V).

No Connection.

Buffered clock output of crystal oscillator.

Latch for serial control data.

Clock for serial control data.

Data for serial control.

Reset Input. When this pin is low, the digital filters and modulators are held in reset.

Zero Data Flag. This pin is low when the input data is continuously zero for more than

65,535 cycles ro BCKIN.

Right Channel Analog Output.

Analog Ground.

Analog Power Supply (+5V).

Left Channel Analog Output.

Common Pin for analog output amplifiers.

Bit Cclock for clocking in the audio data.

Serial audio data input.

Left/Right Word Clock. Frequency is equal to fs.

No Connection.

Reserved for factory use, do not connect.

Analog Power Supply (+5V).

Digital Ground.

PLL Ground.

Crystal oscillator output.

Note:(1)Schmitt triger input with intermal pull-up resistors. (2) Schmitt triger input.

Loading...

Loading...