Samsung DMR78AHS/XAA, DMR78AHS/XAC, DMR78AHB/XAA, DMR78AHB/XAC, DMR78AHW/XAA Service Manual

...

DISHWASHER

Model Name :DMR78 Series

DMR77 Series

DMR57 Series

Model Code :

DMR78AHS/XAA DMR78AHS/XAC

DMR78AHB/XAA DMR78AHB/XAC

DMR78AHW/XAA DMR78AHW/XAC

DMR77LHS/XAA DMR77LHS/XAC

DMR77LHB/XAA DMR77LHB/XAC

DMR77LHW/XAA DMR77LHW/XAC

DMR57LFS/XAA DMR57LFS/XAC

DMR57LFB/XAA DMR57LFB/XAC

DMR57LFW/XAA DMR57LFW/XAC

SERVICE

DISHWASHER CONTENTS

Manual

Safety Instructions1.

Features and Specications2.

Disassembly and 3.

Reassembly

Troubleshooting4.

Exploded Views and 5.

Parts List

PCB Diagram6.

Wiring Diagram7.

Schematic Diagram8.

Reference9.

Refer to the service manual in the GSPN (see the rear cover) for the more information.

Contents

The issues of changing.................................................................................................................4

1. Safety Instructions .................................................................................................................1-1

1-1. Safety Instructions for Service Engineers .......................................................................................................1-1

2. Features and Specications ..................................................................................................2-1

2-1. Features .........................................................................................................................................................2-1

2-2. Specications .................................................................................................................................................2-2

2-3. Comparing Specications with Existing Models .............................................................................................2-3

2-4. Options Specications ....................................................................................................................................2-5

3. Disassembly and Reassembly ..............................................................................................3-1

3-1. Tools for Removal and Reassembly ...............................................................................................................3-1

3-2. Standard Disassembly Drawings ....................................................................................................................3-2

3-3. Checkpoints after Finishing a Service ..........................................................................................................3-23

4. Troubleshooting .....................................................................................................................4-1

4-1. Changed Components ....................................................................................................................................4-1

4-2. Service Inspection Mode ................................................................................................................................4-2

5. Exploded Views and Parts List ..............................................................................................5-1

5-1. MAIN (DMR77, DMR78) .................................................................................................................................5-2

5-2. ASSY-DOOR (DMR77, DMR78) .....................................................................................................................5-4

5-3. ASSY-TUB (DMR77, DMR78) ........................................................................................................................5-6

5-4. ASSY-BASE (DMR77, DMR78) ......................................................................................................................5-8

5-5. ASSY-SUMP (DMR77, DMR78) ...................................................................................................................5-10

5-6. ASSY-CASE (DMR77, DMR78) ....................................................................................................................5-12

5-7. MAIN (DMR57) .............................................................................................................................................5-14

5-8. ASSY-DOOR (DMR57) .................................................................................................................................5-16

5-9. ASSY-TUB (DMR57) .....................................................................................................................................5-18

5-10. ASSY-BASE (DMR57) ................................................................................................................................5-20

5-11. ASSY-SUMP (DMR57) ................................................................................................................................5-22

5-12. ASSY-CASE (DMR57) ................................................................................................................................5-24

6. PCB Diagram.........................................................................................................................6-1

6-1. Old PBA - Main PCB .......................................................................................................................................6-1

6-2. New PBA- Main PCB ......................................................................................................................................6-2

6-3.Old PBA - Detailed Specications and Descriptions for Connectors and Relay Terminals (MAIN PBA) .........6-3

6-4. New PBA- Detailed Specications and Descriptions for Connectors and Relay Terminals (MAIN PBA) ......6-4

6-5. Detailed Specications and Descriptions for Connectors (TOUCH 7KEY - DMR77, DMR78) .......................6-5

6-6. Detailed Specications and Descriptions for Connectors (TOUCH 7KEY - DMR57) .....................................6-6

6-7. Detailed Specications and Descriptions for Connectors (TOUCH 3KEY - DMR77,DMR78) ........................6-7

6-8. Detailed Specications and Descriptions for Connectors (DISPLAY LED - TOP - DMR77, DMR78 (DD07-00008A,

8B)) .......................................................................................................................................................................6-8

6-9. Detailed Specications and Descriptions for Connectors (DISPLAY LED - FRONT - DMR77, DMR78 (DD07-

00009A, 9B)) ..........................................................................................................................................................6-8

6-10. Detailed Specications and Descriptions for Connectors (DISPLAY LED - FRONT - DMR57) ....................6-9

7. Wiring Diagram ......................................................................................................................7-1

7-1. Old Wiring Diagram (DMR77/78) ....................................................................................................................7-1

7-2. Old Wiring Diagram (DMR57) .........................................................................................................................7-2

7-3. New PBA - Wiring Diagram (DMR78, DMR77 , DMR57) ...............................................................................7-3

8. Schematic Diagram ...............................................................................................................8-1

8-1. MAIN CONTROL (DMR78, DMR77 , DMR57) ...............................................................................................8-1

8-3. TOUCH KEY (7KEY - DMR77, DMR78) .........................................................................................................8-2

8-4. TOUCH KEY (3KEY - DMR77, DMR78) .........................................................................................................8-3

8-5. TOUCH KEY (7KEY - DMR57) .......................................................................................................................8-4

9. Reference ..............................................................................................................................9-1

9-1. Model Number Naming Rules ........................................................................................................................9-1

9-2. Terminology ....................................................................................................................................................9-2

The issues of changing

Date Contents

Add the Model(DMR78) ሪ

2008. 12. 01

Change the Service inspection mode entry method. (Page 4-1)

Add the Assy-install kit for SVC parts (Page 2-5) ሪ

1. Safety Instructions

1-1. Safety Instructions for Service Engineers

Make sure to observe the following instructions to operate the product correctly and safely and prevent possible ሪ

accidents and hazards while servicing.

Two types of safety symbols, Warning and Caution, are used in the safety instructions. ሪ

1. Safety Instructions

Warning

Caution

Hazards or unsafe practices that may result in severe personal injury or death.

Hazards or unsafe practices that may result in minor personal injury or property damage.

Warning

Before Servicing

(When servicing electrical parts or harnesses) Make sure to disconnect the circuit ࣃ

breaker or power cable before servicing.

Failing to do so may result in a risk of electric shock. ➢

Do not allow consumers to connect several appliances to a single power outlet at the

ࣃ

same time.

There is a risk of re due to overheating. ➢

When removing the power cord, make sure to hold the power plug when pulling the plug ࣃ

from the outlet.

Failing to do so may damage the plug and result in re or electric shock. ➢

When the dishwasher is not being used, make sure to disconnect the circuit breaker or ࣃ

power cable from the power outlet.

Failing to do so may result in electric shock or re due to lightning. ➢

Do not place or use gasoline, thinners, alcohol, or other ammable or explosive ࣃ

substances near the dishwasher.

There is a risk of explosion and re caused from electric sparks. ➢

1-1

1-2

1. Safety Instructions

While Servicing

Check if the power cable is damaged, attened, cut or otherwise degraded. ࣃ

If faulty, replace it immediately. ➢

Failing to do so may result in electric shock or re.

ࣃ

Completely remove any dust or foreign material from the housing, wiring and connection

parts.

This will prevent a risk of re due to tracking and shorts in advance. ➢

ࣃ

When connecting wires, make sure to connect them using the relevant connectors and

check that they are completely connected.

If tape is used instead of the connectors, it may cause re due to tracking. ➢

ࣃ

Make sure to discharge the PBA power terminals before starting the service.

Failing to do so may result in a high voltage electric shock. ➢

ࣃ

When replacing the heater, make sure to fasten the holder heater after ensuring that it is

inserted into the bracket-heater.

If not inserted into the bracket-heater, it touches the tub and causes noise and ➢

electric leakage.

After Servicing

Check for any water leakage. ࣃ

Perform a test run for the dishwasher using the standard(normal) cycle and check ➢

whether there is any water leakage through the oor section or the pipes.

Do not allow consumers to repair or service any part of the dishwasher themselves.

ࣃ

This may result in personal injury and shorten the product lifetime. ➢

If it seems that grounding is needed due to water or moisture, make sure to run ࣃ

grounding wires.

(Check the grounding of the power outlet, and additionally ground it to a metallic water

pipe.)

Failing to do so may result in electric shock due to electric leakage. ➢

[Running a grounding wire]

- Twist a grounding wire (copper wire) two or three times around the tap.

- If you connect the grounding wire to a copperplate, bury it 75 cm under the earth in a

place with a lot of moisture.

Do not connect the grounding wire to a gas pipe, plastic water pipe or telephone

wire. There is a risk of electric shock or explosion.

1-3

1. Safety Instructions

Caution

Before Servicing

Do not sprinkle water onto the dishwasher directly when cleaning it. ࣃ

This may result in electric shock or re, and may shorten the product lifetime. ➢

ࣃ

Do not place any containers with water on the dishwasher.

If the water is spilled, it may result in electric shock or re. This will also shorten the ➢

product lifetime.

Do not install the dishwasher in a location exposed to snow or rain. ࣃ

This may result in electric shock or re, and shorten the product lifetime. ➢

Do not press a control button using a sharp tool or object. ࣃ

This may result in electric shock or damage to the product. ➢

During Servicing

When wiring a harness, make sure to seal it completely so no liquid can enter. ࣃ

Make sure that they do not break when force is exerted. ➢

Check if there is any residue that shows that liquid entered the electric parts or

ࣃ

harnesses.

If any liquid has entered into a part, replace it or completely remove any remaining ➢

moisture from it.

If you need to place the dishwasher on its back for servicing purposes, place a support(s)

ࣃ

on the oor and lay it down carefully so the back is on the oor.

Do not lay it down on its front or side. This may result in scratches to the surface or ➢

damage to the parts.

1. Safety Instructions

After Servicing

Check the assembled status of the parts. ࣃ

They must be the same as before servicing. ➢

ࣃ

Check the insulation resistance.

Disconnect the circuit breaker or power cable from the power outlet and measure ➢

the insulation resistance between the power wires and the grounding wire of the

dishwasher. The value must be greater than 10MΩ when measured with a 500V DC

Megger.

Check whether the product is level with the oor. Check if there are any deformations in

ࣃ

the sink. Check that the dishwasher is rmly installed to the sink.

Vibrations can shorten the lifetime of the product. ➢

1-4

2. Features and Specications

2-1. Features

Features Description Remarks

The upper rack is slanted for larger dishes. The space ሪ

Extra large capacity

has been maximized to accommodate a variety of dish

sizes.

2. Features and Specications

Elegant design with

digital touch sensors

Increased convenience

Extremely quiet operation

Self-cleaning lter

Digital touch sensors are used in the control panel for more ሪ

simple operation, with a touch of elegance.

The smart auto cycle determines the level of soil on the ሪ

dishes and initiates the optimal cycle using this feature

saving water, energy and time. (DMR77 and DMR78 only)

Efcient noise control technology is used for the quietest ሪ

possible operation. Your new Samsung dishwasher will be

quieter than ever.

Cleaning the lter yourself is a thing of the past! This product ሪ

keeps food waste internally while operating, then drains it

automatically with the water.

Applicable to all of the

DMR77, DMR78 and

DMR57 models

2-1

2-2

2. Features and Specications

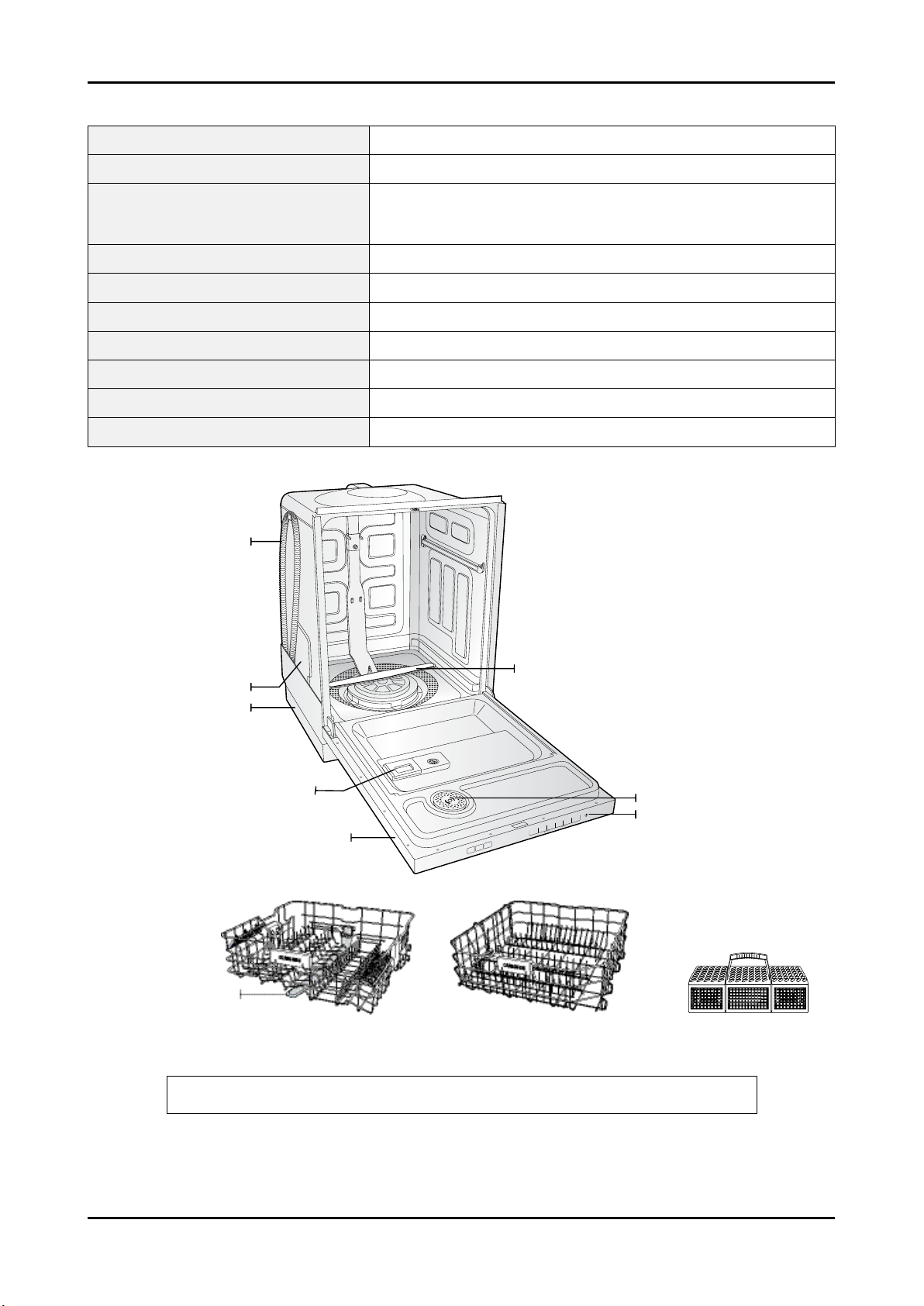

2-2. Specications

Wash capacity

Type

Model

Power

Used water pressure

Wash type

Dry type

Power usage

Standard amount of used water

Size (W×D×H)

Drain hose

14 place settings

Dishwasher

DMR78AHS, DMR78AHB, DMR78AHW

DMR 77LHS, DMR 77LHB, DMR 77LHW

DMR 57LFS, DMR 57LFB, DMR 57LFW

Single-phased alternating current of 60Hz, 15A at 120V

20 ~ 120 psi (140 ~ 830 kPa)

Rotating nozzle spray

Condensed dry system

Main Motor : 165W / Heater : 1100W

3.9~7.7 gallon(14.8~29ℓ), Normal Cycle

23 ⅞” x 24 ¾” x 33 ⅞” inch (605 x 622 x 860 mm )

Air brake

Middle nozzle

Base

Lower nozzle

Dispenser

Door

Upper rack Lower rack Cutlery basket

Above images might differ in the dishwasher models.

Vapor vent cover

Control panel

2-3

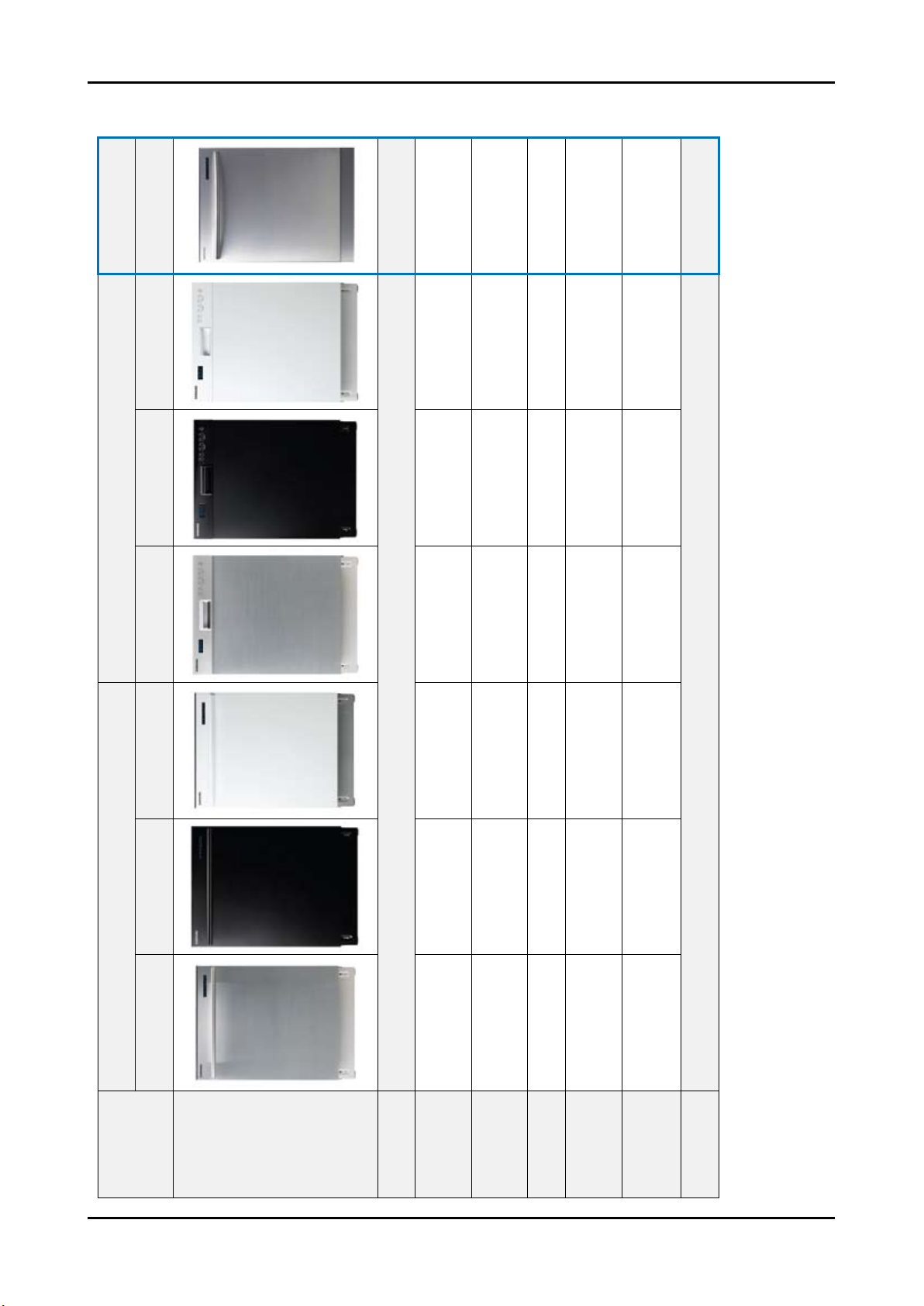

2. Features and Specications

2-3. Comparing Specications with Existing Models

BEST MODEL BETTER MODEL GGH DESIGN

DMR 77LHS DMR 77LHB DMR 77LHW DMR 57LFS DMR 57LFB DMR 57LFW DMR78AHS

Model

Photo

Design Specications

Frame

Control

STS Black White STS Black White STS

Front

Black Black Black Silver Black White Black

Panel

Aluminum Black White X X X STS

Cover

Handle

X X X Cr Black Cr X

Handle

Silver Black White Silver Black White Silver

Cover

Front L

Functional Specications

2. Features and Specications

Functional Specications

BEST MODEL BETTER MODEL GGH DESIGN

DMR 77LHS DMR 77LHB DMR 77LHW DMR 57LFS DMR 57LFB DMR 57LFW DMR78AHS

Model

O O O O O O O

Soil

Sensors

Detection

One-touch One-touch One-touch 2-stage 2-stage 2-stage One-touch

Height

Basket

Adjustment

O O O X X X O

O O O O O O O

Half Load

Child Lock

O O O X X X O

Smart Auto

O O O O O O O

Sanitize

Leakage

O O O O O O O

Sensor

O O O O O O O

O O O O O O O

Fan Motor

Delay start

O O O X X X O

Quick cycle

2-4

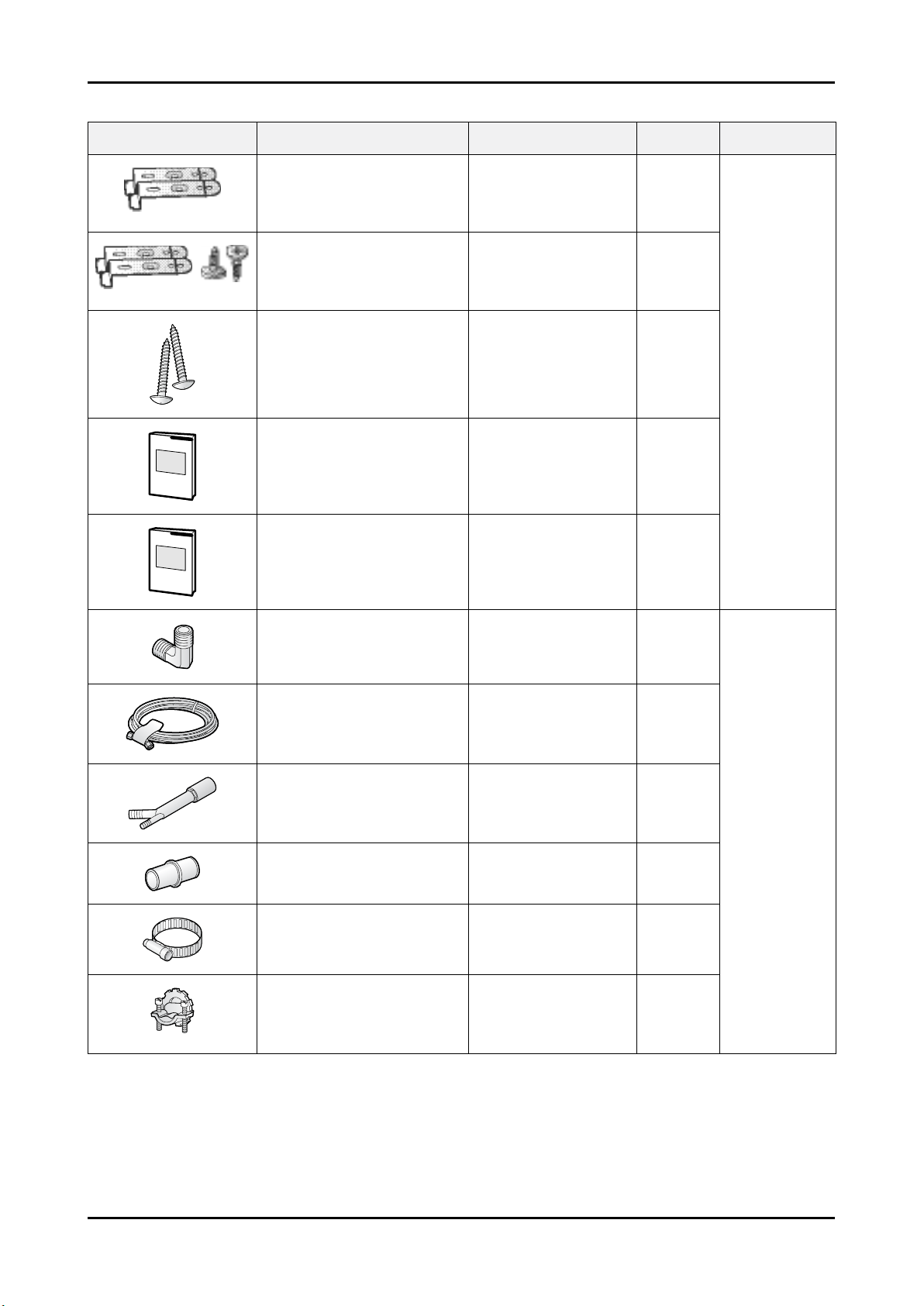

2-4. Options Specications

Photo Item Code Quantity Remarks

Assy-install kit for Top

(Bracket-install + Screw)

2. Features and Specications

Bracket-install DD61-00176A 2

mounting

DD94-01002A 2+2

Screw for side mounting DD81-01266A 2

DD68-00036A(DMR78)

User Manual

Installation Guide DD68-00027A 1

Elbow - 1

Water Supply Line

(Flexible STS supply line is

recommend)

Air Gap - 1

DD68-00018A(DMR77)

DD68-00026A (DMR57)

- 1

Provided with

the dishwasher

1

Rubber Connector - 1

Hose Clamp - 1

Strain Relief - 1

Sold separately

2-5

2. Features and Specications

Memo

2-6

3. Disassembly and Reassembly

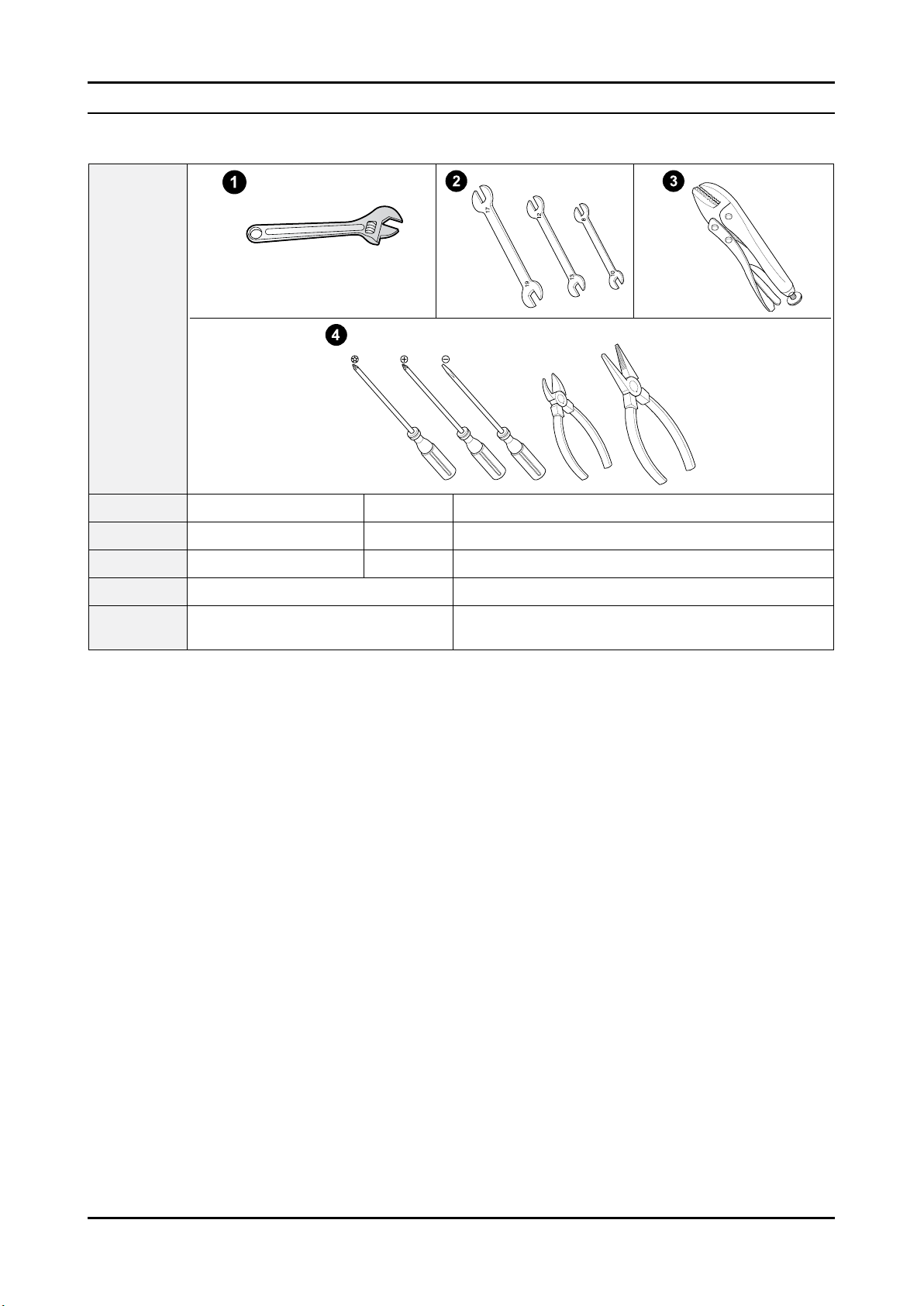

3-1. Tools for Removal and Reassembly

Tool image

No. Tool Type Remarks

3. Disassembly and Reassembly

➊

➋

➌

➍

Adjustable Wrench

Open-end Wrench 1-7/16” Leg

Vice pliers

Others

(screwdriver, nipper, long nose pliers)

* Preparation for parts replacement

1. Take out the residual water inside the product.

(Drain the water by operating the drain pump)

2. Close the water supply valve.

3. Turn off the power & disconnect power cable.

You must turn off the circuit breaker connected to the product.

4. Pull out the unit from the sink and lay it on the oor.

Be careful of the drain hose when pulling out the unit.

Common tools for servicing

Screwdriver - Philips, at, Torx T20

3-1

3-2

3. Disassembly and Reassembly

3-2. Standard Disassembly Drawings

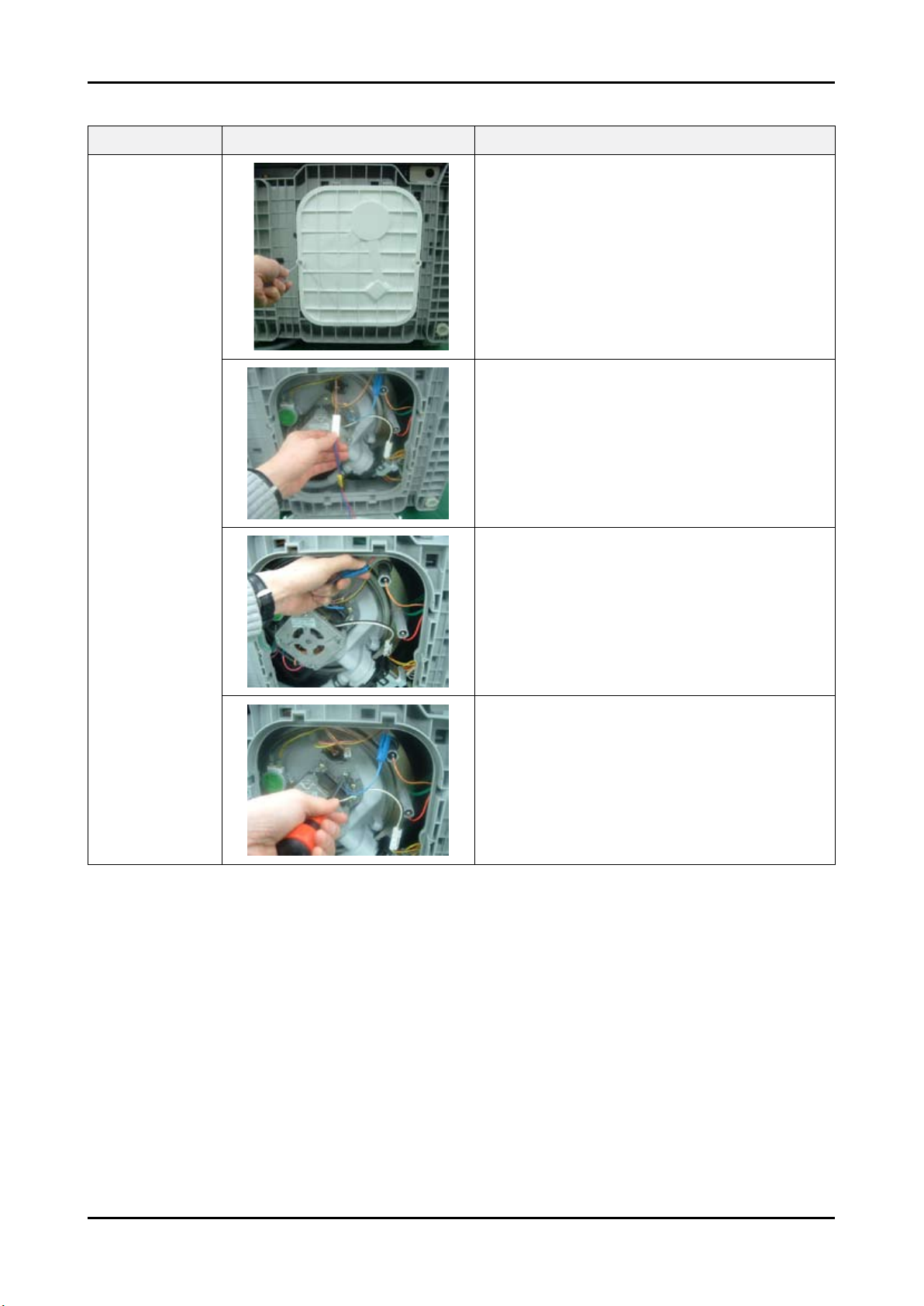

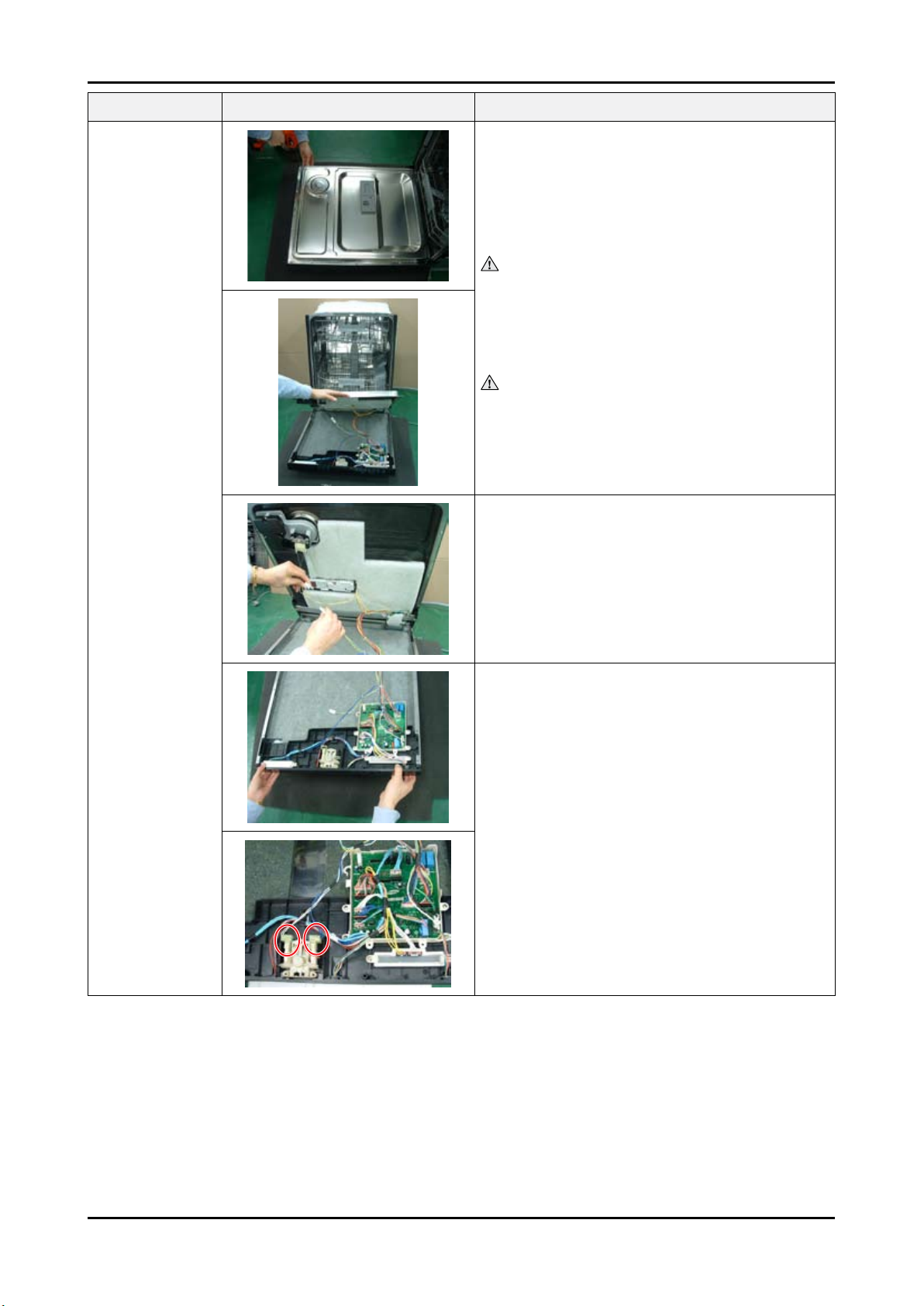

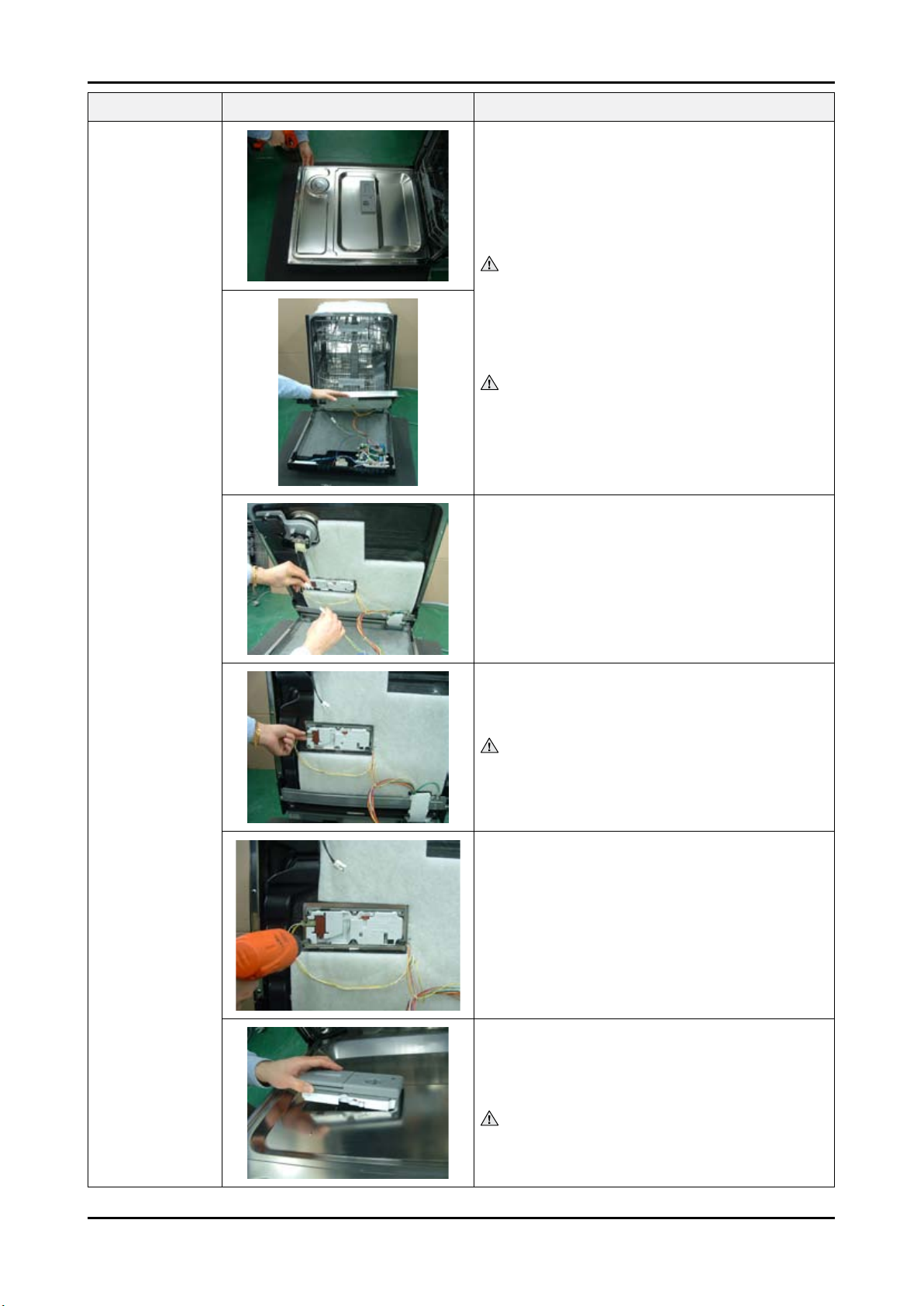

Part Photo Description

Thermistor

1. Place the dishwasher on its back so that you can

see the base. Remove the two (2) screws that hold

the base and the shutter in place.

2. Remove the leakage sensor connector (white) inside

the shutter.

3. Disconnect the wire terminal (blue) connected to the

thermistor.

4. Check the location of the thermistor and remove the

two (2) screws that hold the thermistor to the case

sump.

3-3

3. Disassembly and Reassembly

Part Photo Description

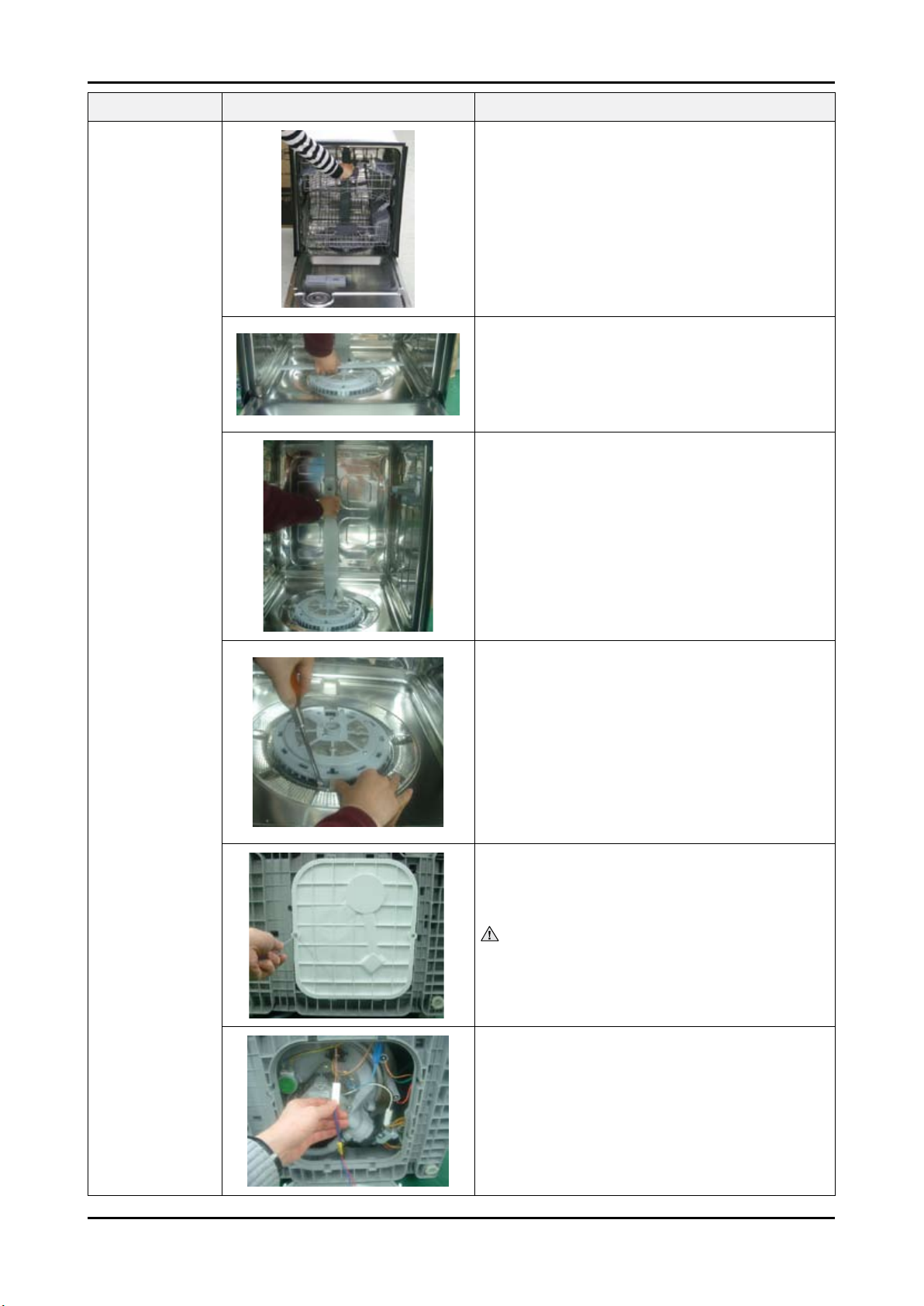

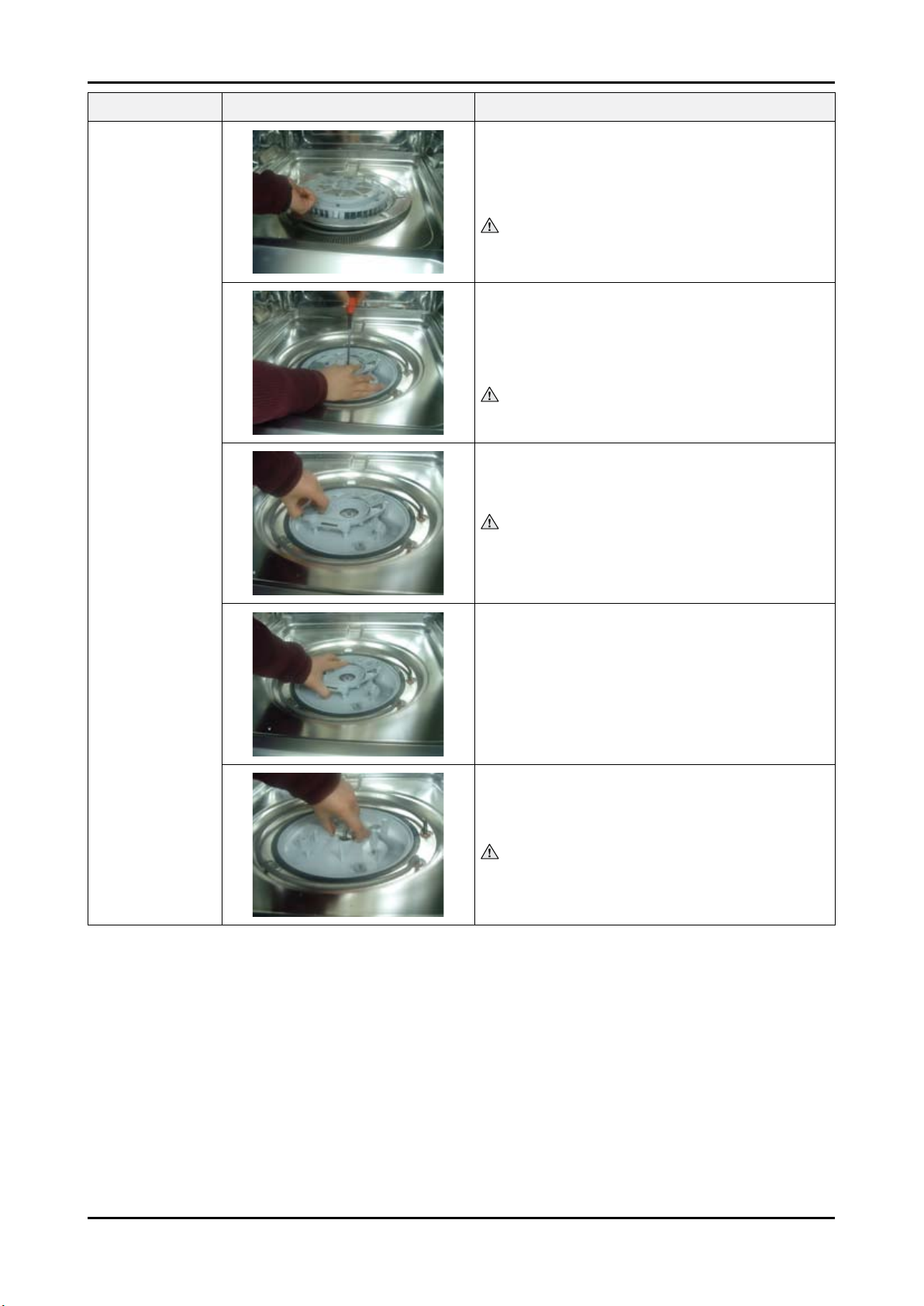

1. Open the door completely.

Remove the upper and lower baskets.

Place the baskets you’ve just removed in a safe

location so that they do not interfere with the

service operations and to prevent them from being

damaged.

2. Use your hand to hold the lower nozzle and remove

it.

Place the removed lower nozzle in a safe location

along with the bask ets.

3. Hold the nozzle duct, and rotate and remove it.

To remove it smoothly, remove the hooks clamping

the bracket duct (U) using a at screwdriver and

remove the hooks clamping the bracket duct (M).

Pull them out while rotating them to the left.

Heater

4. Remove the cover heater from the sump assy.

You will need a at screwdriver for the removal.

To remove a hook from the cover heater, insert the

end of the screwdriver into the gap between cover

heater and cover sump, and push the handle of

screwdriver and the hook.

Remove remain four(4) hooks using same way.

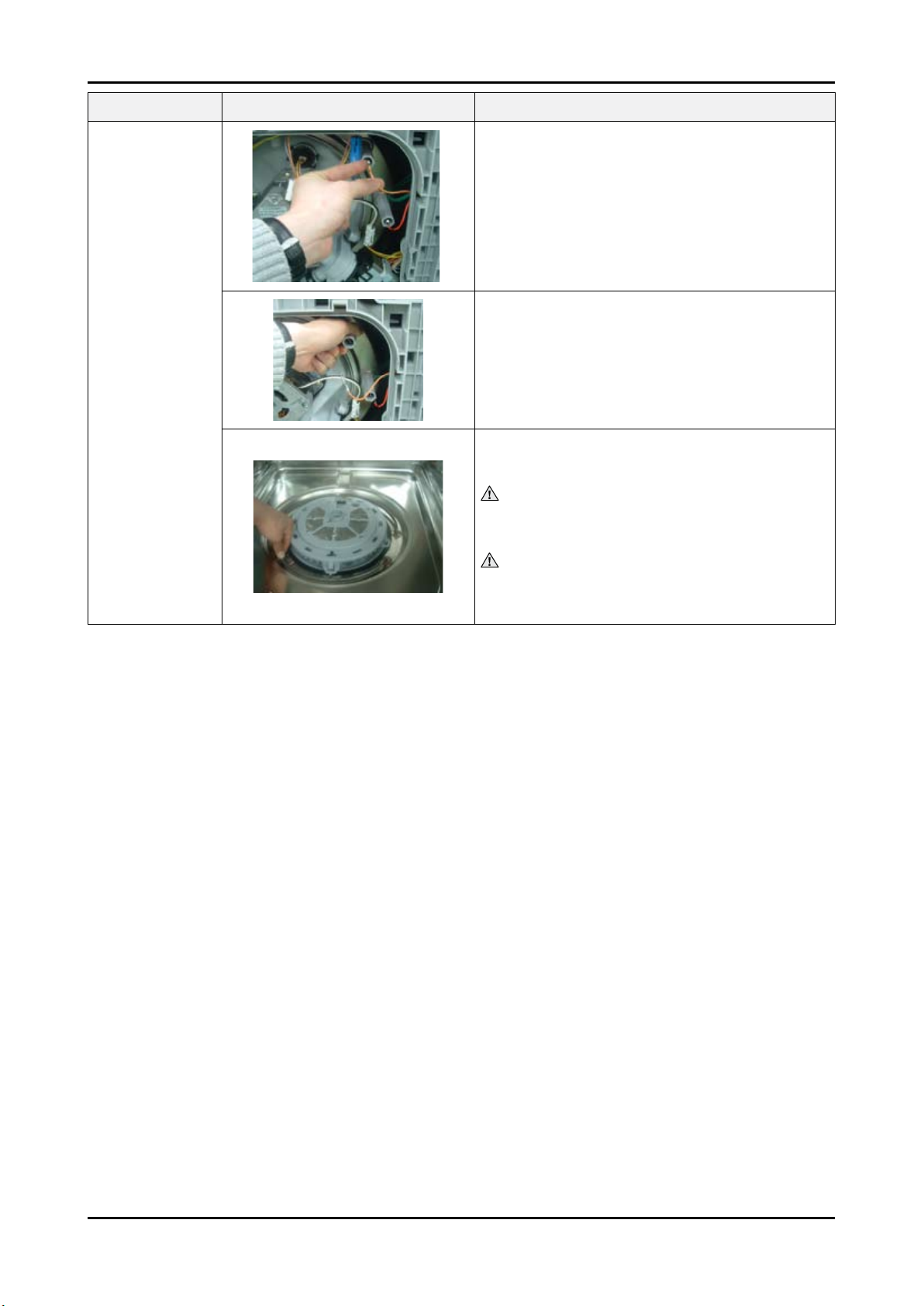

5. Place the dishwasher on its back so that you can

see the base. Remove the two (2) screws that hold

the base and the shutter in place.

Caution

Before placing the dishwasher on its back, make

sure to check whether any water is left. Remove

any remaining water. (There is a risk of re due to a

water leakage while servicing).

6. Remove the leakage sensor connector (white) in the

shutter.

3-4

3. Disassembly and Reassembly

Part Photo Description

Heater

7. Remove the two (2) terminals which are inserted into

the heater.

Do not pull the wire. Remove it by holding the

metallic part at the end of the wire.

8. Remove the two (2) holder heaters which

are connected to the heater by rotating them

counterclockwise.

9. Place the dishwasher the right way up again.

Open the door and hold and remove the heater.

Caution

The heater may be very hot. Make sure to check it

before touching the heater.

Caution

Make sure to check whether any water is left.

Remove any remaining water, to prevent water

leakages while servicing.

3-5

3. Disassembly and Reassembly

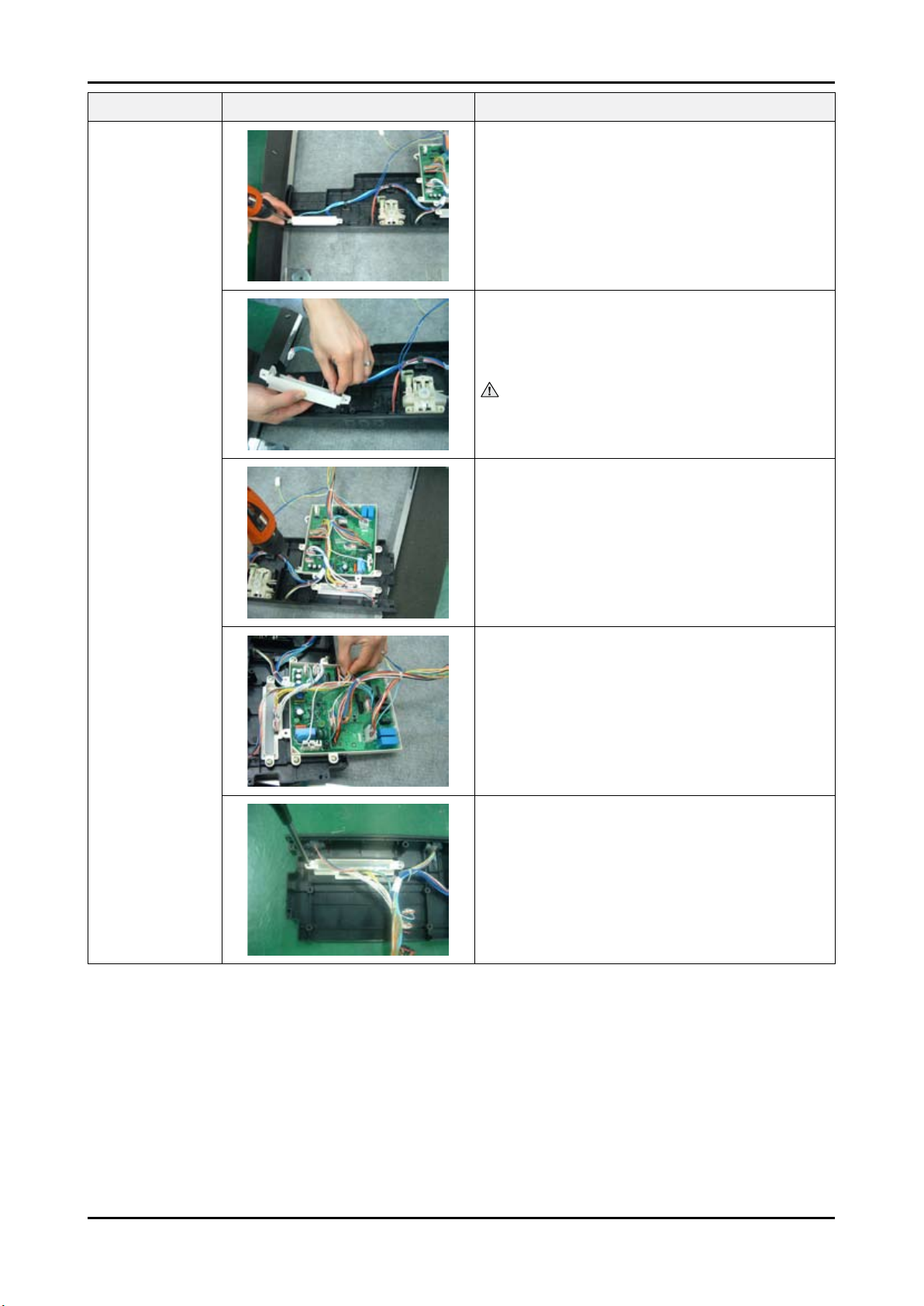

Part Photo Description

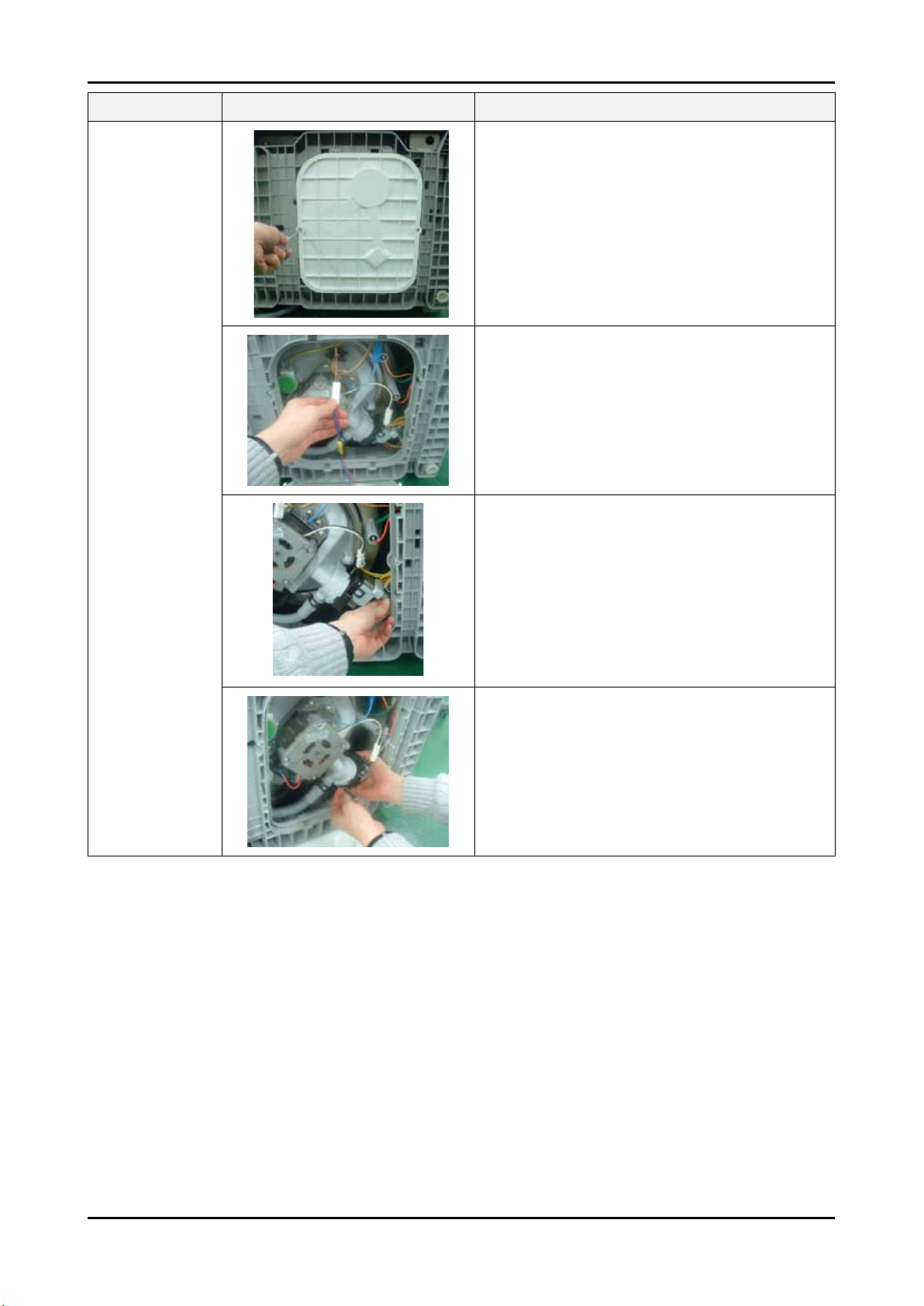

1. Place the dishwasher on its back so that you can

see the base. Remove the two (2) screws that hold

the base and the shutter in place.

2. Remove the leakage sensor connector (white) in the

shutter.

Drain Pump

3. Disconnect the two (2) drain pump connectors.

4. Remove the drain pump by rotating it

counterclockwise.

When removing the drain pump, lift up the hook

holding it in place slightly and then rotate it so that

the hook is not damaged.

3-6

3. Disassembly and Reassembly

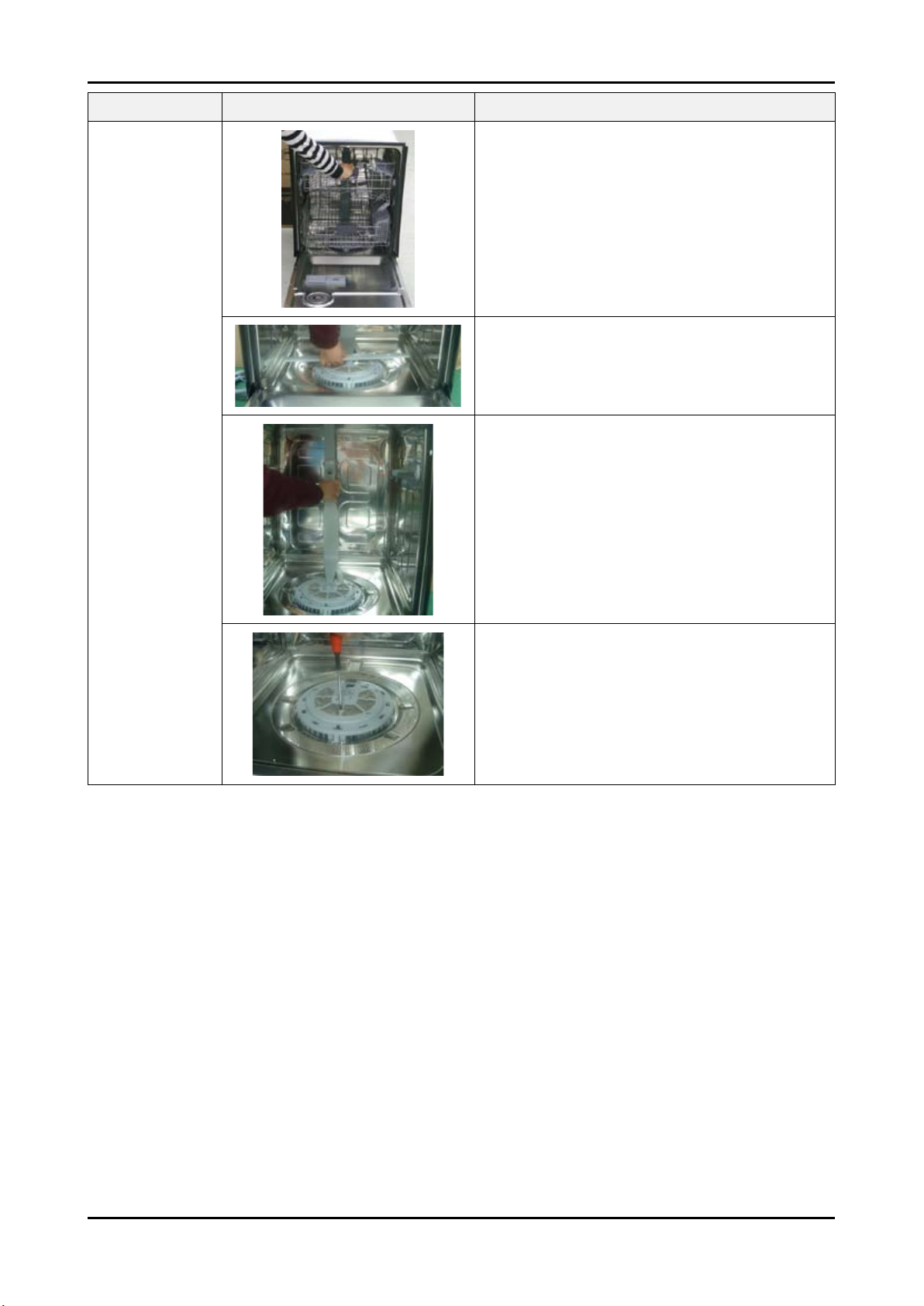

Part Photo Description

Circulation Motor

1. Open the door completely.

Remove the upper and lower baskets.

Place the baskets you’ve just removed in a safe

location so that they do not interfere with the

service operations and to prevent them from being

damaged.

2. Use your hand to hold the lower nozzle and remove

it.

Place the removed lower nozzle in a safe location

along with the baskets.

3. Hold the nozzle duct, and rotate and remove it.

To remove it smoothly, remove the hooks clamping

the bracket duc t (U) using a at screwdriver and

remove the hooks clamping the bracket duct (M).

Pull them out while rotating them to the left.

4. Remove the sump assy.

Remove the ten (10) screws on the assy lter mesh.

(Except the two (2) screws holding the holder nozzle

L in place)

3-7

3. Disassembly and Reassembly

Part Photo Description

5. Remove the screws and lift up and remove the

cover sump. The cover sump, cover scroll, assy

lter mesh, holder nozzle L, and cover heater will be

removed together.

Caution

Place the removed parts in a safe location to prevent

them from being damaged.

6. Remove the Impeller circulation.

Remove the screw (1) that is holding the circulation

motor to the shaft. Use your hand to hold the

impeller circulation and turn the screw.

Caution

Turn the screw clockwise to remove it.

7. Remove the valve distributor.

Remove the seal distributor.

Circulation Motor

Caution

Make sure to check whether any water is left.

Remove any remaining water to prevent water

leakages while servicing.

8. Remove the case scroll.

Check if the seal rubber scroll is normal. If it is

damaged or hardened, replace it.

9. Remove the cutter disposer.

Caution

Both sides are sharp. Be careful when removing it.

3-8

3. Disassembly and Reassembly

Part Photo Description

Circulation Motor

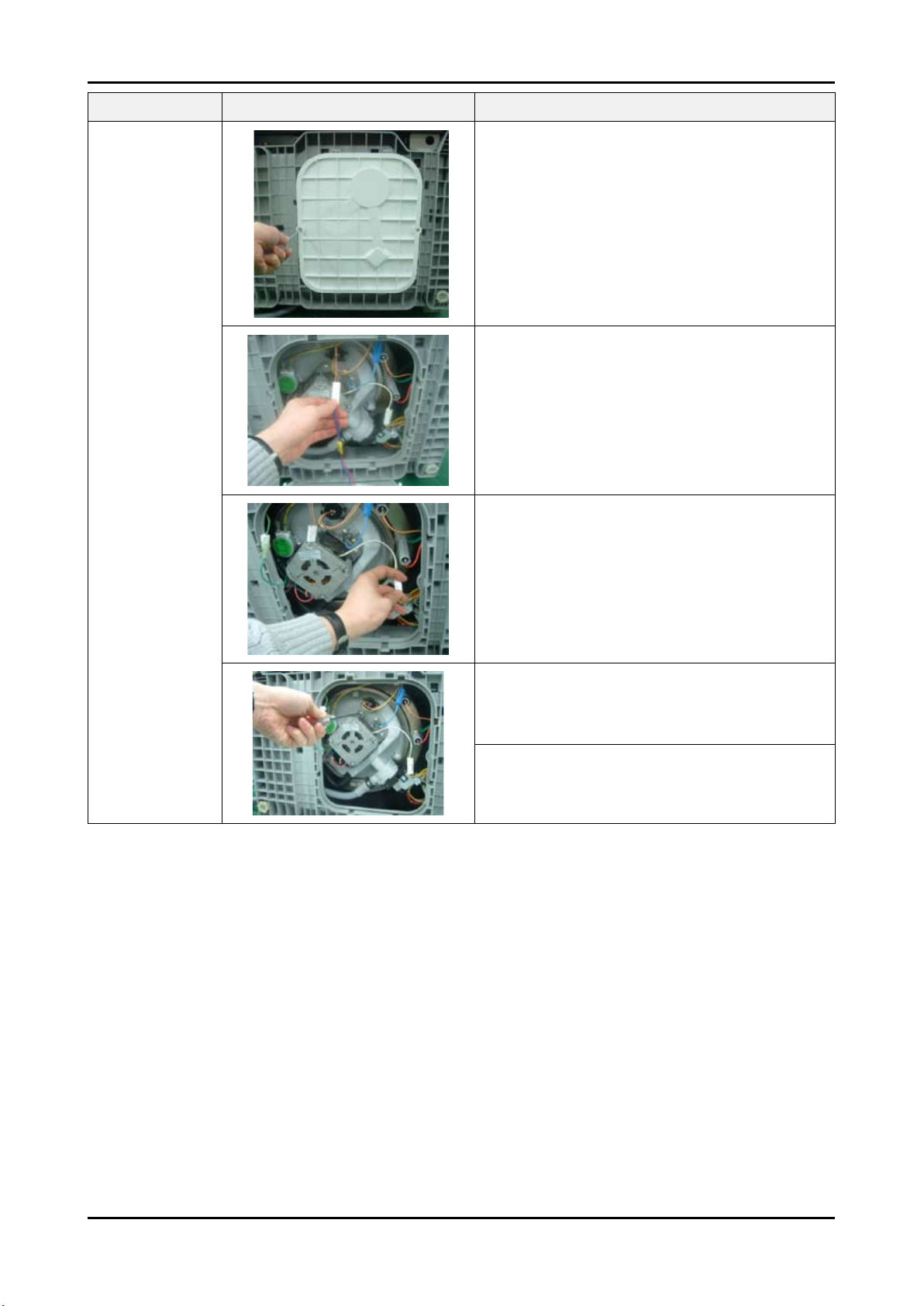

10. Place the dishwasher on its back so that you can

see the base. Remove the two (2) screws that hold

the base and the shutter in place.

11. Remove the leakage sensor connector (white) inside

the shutter.

12. Remove the circulation motor connector (white).

13. Remove the ve (5) screws holding the circulation

motor and the sump in place.

14. Hold and pull the circulation motor to remove it from

the sump.

3-9

3. Disassembly and Reassembly

Part Photo Description

1. Place the dishwasher on its back so that you can

see the base. Remove the two (2) screws that hold

the base and the shutter in place.

2. Remove the leakage sensor connector (white) inside

the shutter.

Distributor Motor

3. Remove the two (2) distributor motor connectors.

4. Remove the two (2) screws that hold the distributor

motor in place.

(You can remove one of the two screws through the

hole in the base.)

Pull the distributor motor out.

Caution

Be careful removing because it is combine with

rubber seal and distributor valve.

3-10

3. Disassembly and Reassembly

Part Photo Description

Leakage

Sensor

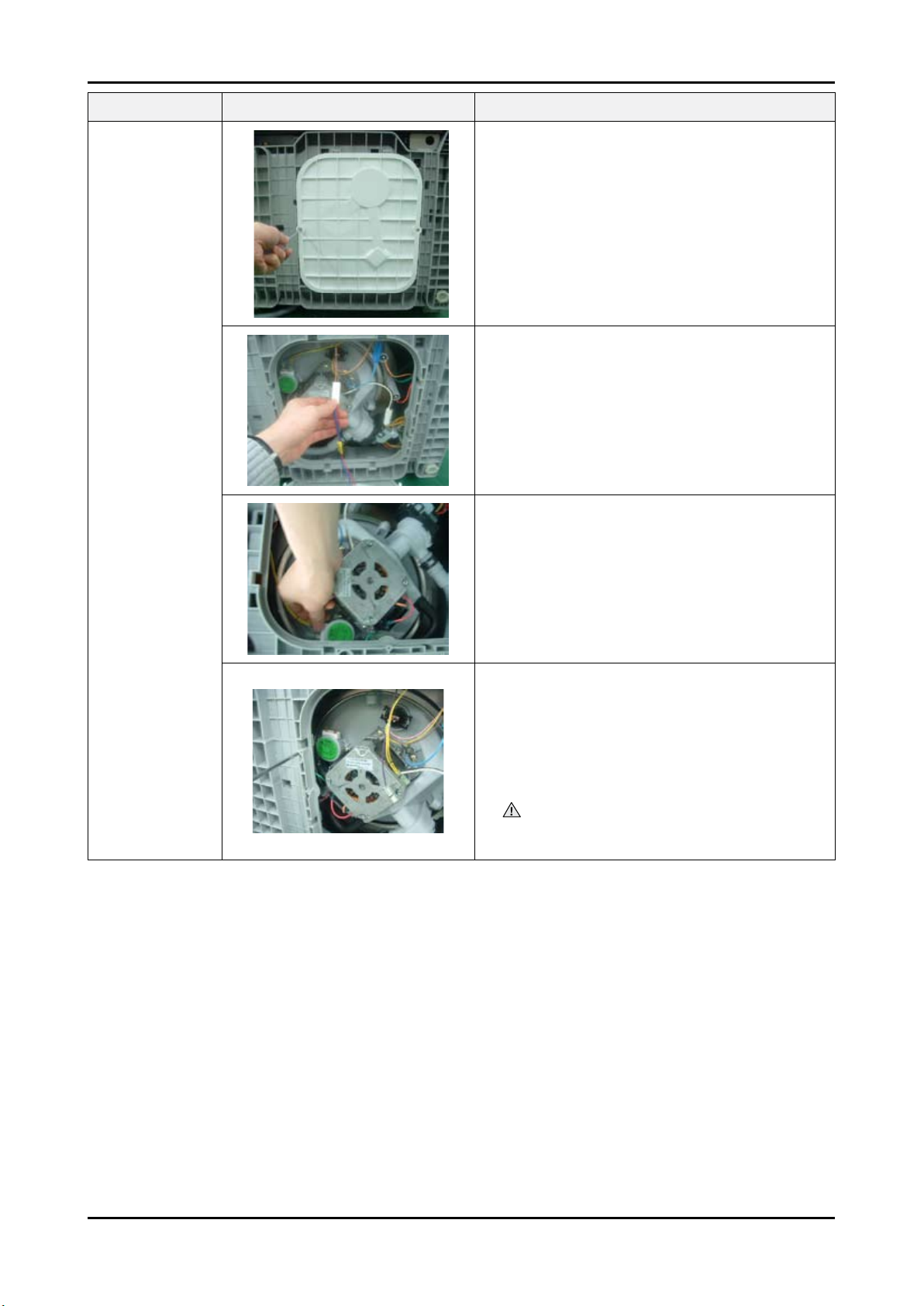

1. Place the dishwasher on its back so that you can

see the base. Remove the two (2) screws that hold

the base and the shutter in place.

2. Remove the leakage sensor connector (white) inside

the shutter.

3. Remove the leakage sensor from the shutter by

unfastening the two (2) screws holding it in place.

3-11

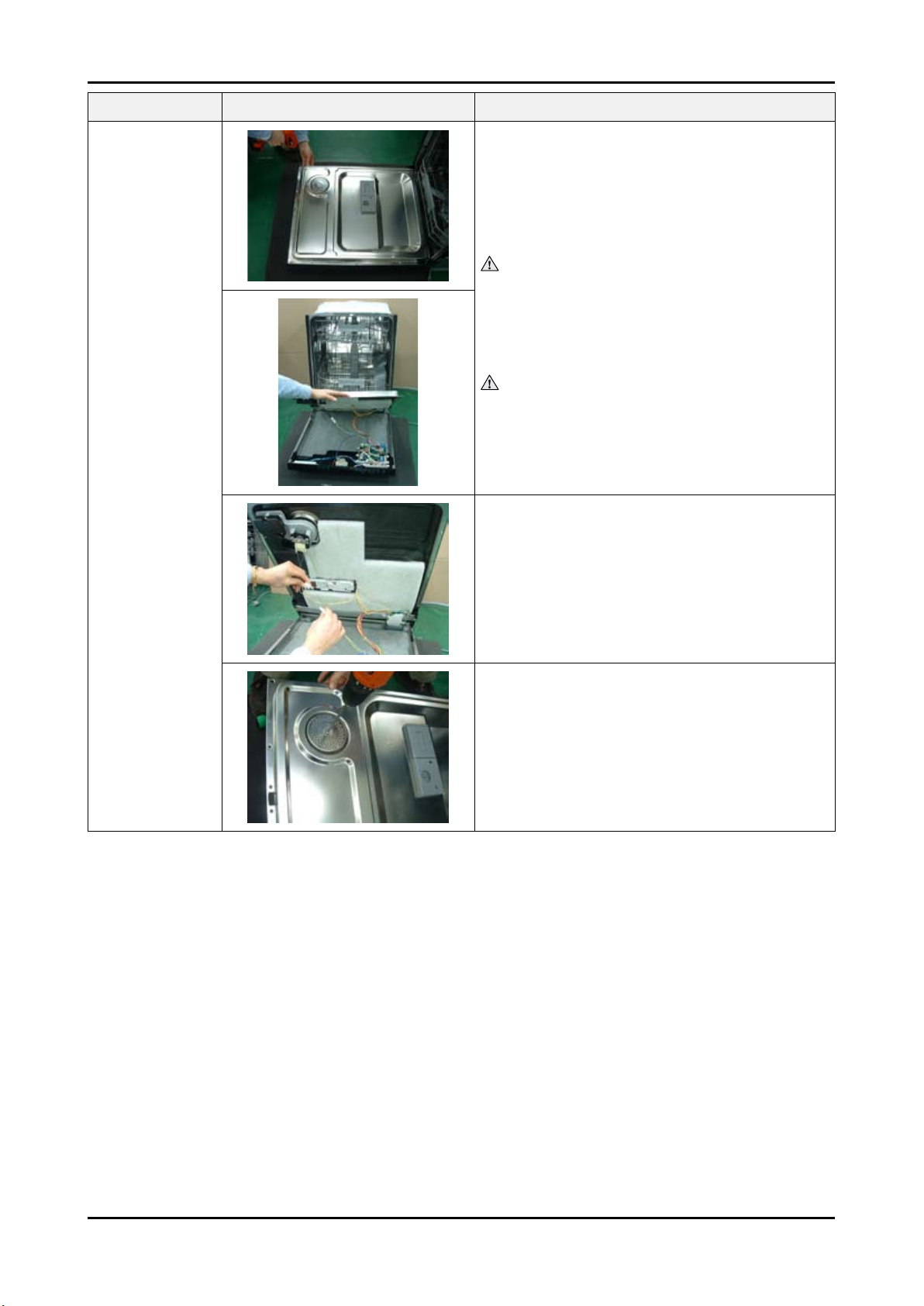

3. Disassembly and Reassembly

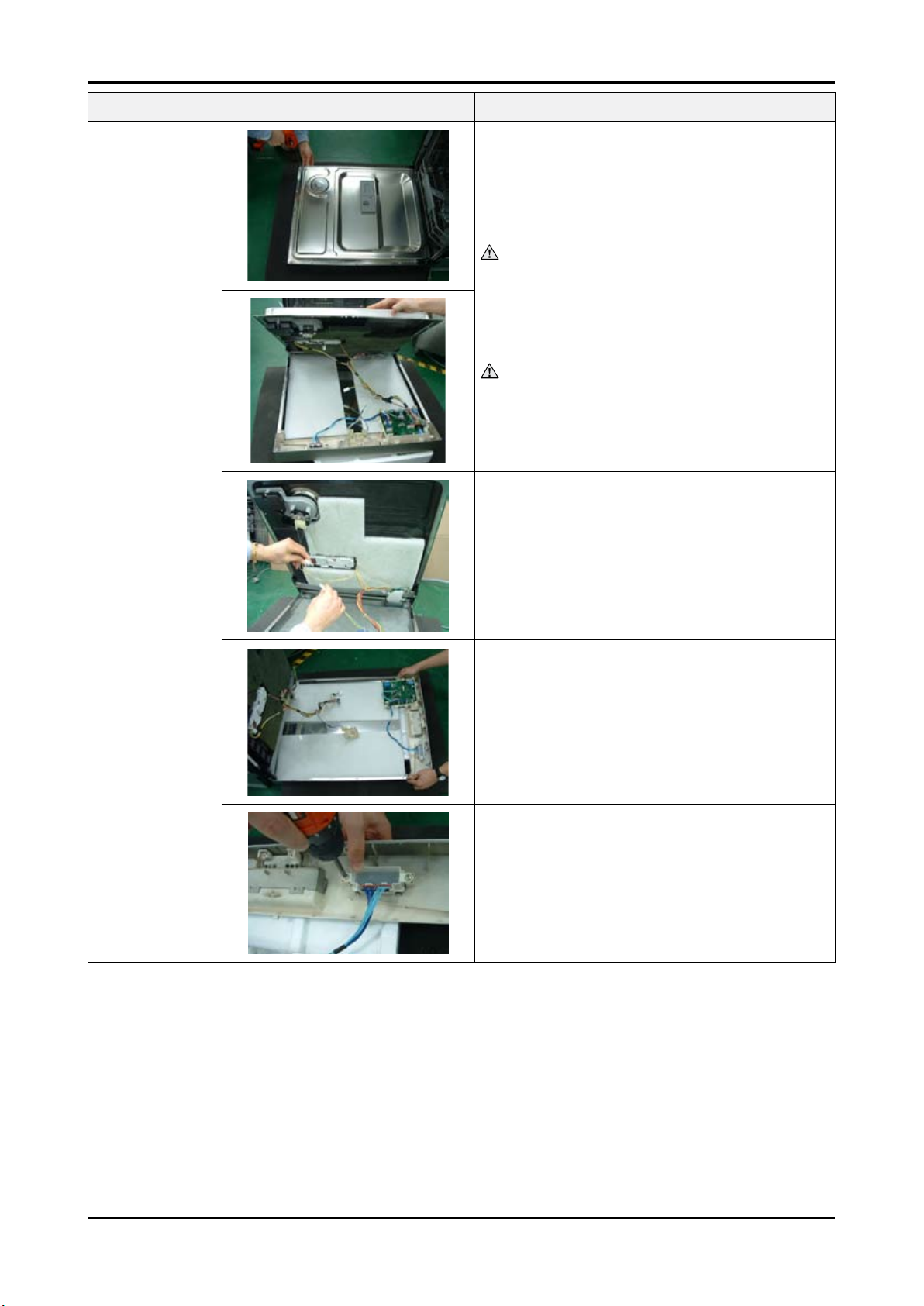

Part Photo Description

1. Open the door completely.

Remove the twelve (12) screws holding the tub front,

fame front, and panel front in place.

Caution

Before removing the screws, place a cushioned mat

on the oor to prevent the handle and frame front

from being scratched. After removing them, make

sure to hold the tub front with your hand while you

are working as the tub may close and harm you.

Caution

Do not place the removed screws on the tub front.

They may fall into the sump assy.

Panel Control

(DMR78/77 series)

2. Remove the fan motor connector.

3. Now remove the frame front and the panel control

assy. Place it on the oor and perform the following:

Remove the panel control from the frame front.

You can remove the panel control by holding and

pulling it.

And, you can remove and replace the door lock

switch in this step. (Remove both connectors of door

lock switch.)

3-12

3. Disassembly and Reassembly

Part Photo Description

4. Remove the two (2) screws holding the panel control

and the display LED in place.

5. Remove the two (2) display LED connectors.

Now, you can remove the seal guide LED and the

display LED.

Caution

When reassemble the display LED, ensure to place

the seal guide LED on original location.

Panel Control

(DMR78/77 series)

6. Remove the four (4) screws holding the PCB assy

and panel control in place.

7. Remove all the connectors connected to the PCB

assy.

8. Remove the two (2) screws holding the display LED

(F) and the panel control in place.

Remove the two (2) display LED (F) connectors.

Now remove the seal guide LED (F) and the display

LED (F).

3-13

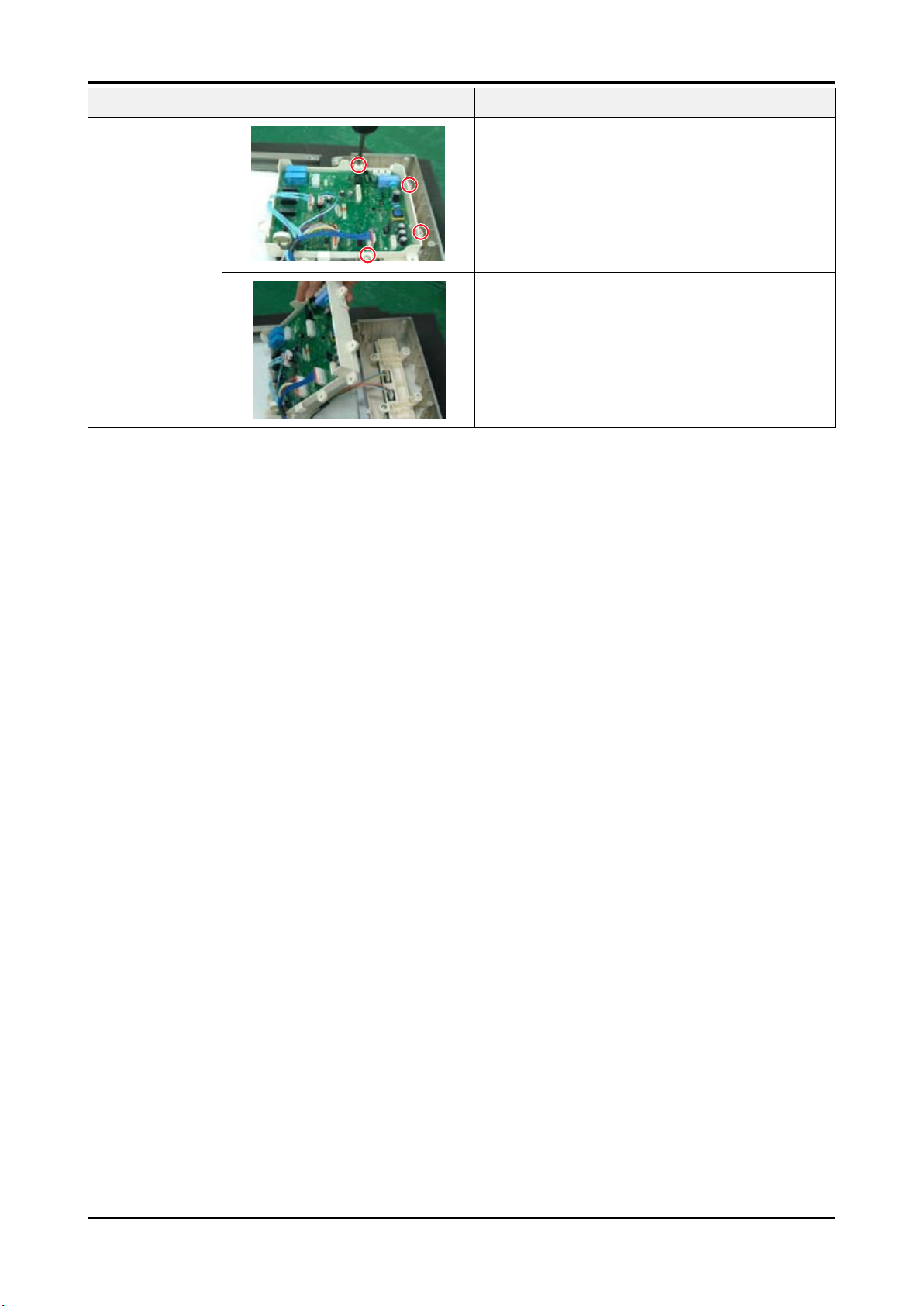

3. Disassembly and Reassembly

Part Photo Description

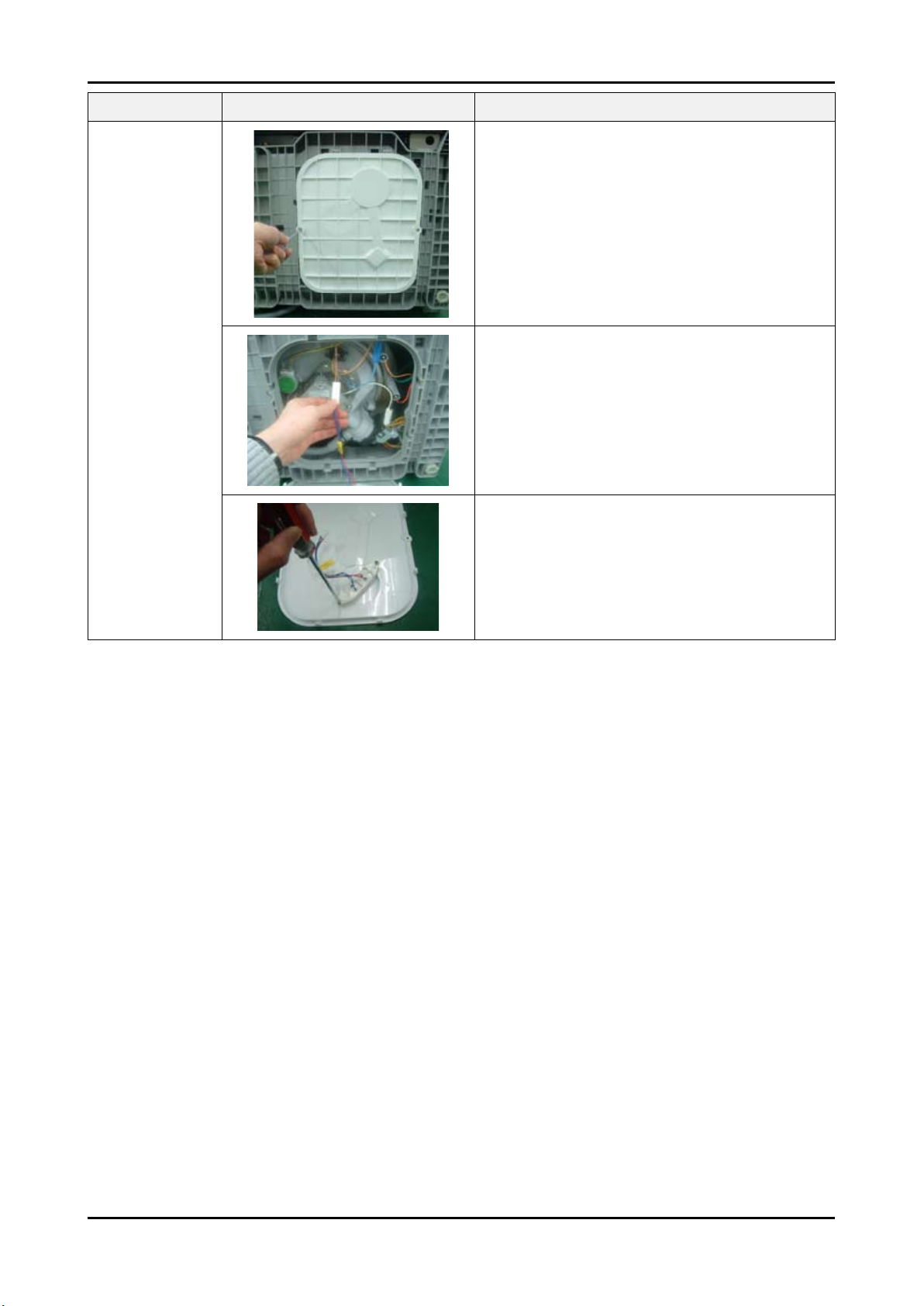

1. Open the door completely.

Remove the twelve (12) screws holding the tub front,

fame front, and panel front in place.

Caution

Before removing the screws, place a cushioned mat

on the oor to prevent the handle and frame front

from being scratched. After removing them, make

sure to hold the tub front with your hand while you

are working as the tub may close and harm you.

Caution

Do not place the removed screws on the tub front.

They may fall into the sump assy.

Panel Control

(DMR57 series)

2. Remove the fan motor connector.

3. Now remove the frame front and the panel control

assy. Place it on the oor and perform the following:

Remove the panel control from the frame front.

You can remove the panel control by holding and

pulling it.

And, you can remove and replace the door lock

switch in this step. (Remove both connectors of door

lock switch.)

4. Remove the two (2) screws holding the panel control

and the display LED in place. Remove the two (2)

display LED connectors.

Now, you can remov e the seal guide LED and the

display LED.

3-14

3. Disassembly and Reassembly

Part Photo Description

Panel Control

(DMR57 series)

5. Remove the four (4) screws holding the PCB assy

and panel control in place.

Remove all the connectors connected to the PCB

assy.

6. You can remove the PCB assy.

3-15

3. Disassembly and Reassembly

Part Photo Description

1. Open the door completely.

Remove the twelve (12) screws holding the tub front,

fame front, and panel front in place.

Caution

Before removing the screws, place a cushioned mat

on the oor to prevent the handle and frame front

from being scratched. After removing them, make

sure to hold the tub front with your hand while you

are working as the tub may close and harm you.

Caution

Do not place the removed screws on the tub front.

They may fall into the sump assy.

Dispenser

2. Remove the fan motor connector.

3. Remove the four (4) connectors on both sides of the

Dispenser.

Caution

The connectors are of the locking type and are

hard to remove. Be careful not to break them when

removing them.

4. Remove the six (6) screws holding the tub front and

the two (2) racket dispensers in place.

5. The dispenser is xed to the tub front with a hook.

Use a at screwdriver to remove it from the tub front.

Caution

Be careful as the tub front is sharp.

3-16

3. Disassembly and Reassembly

Part Photo Description

Fan Motor

1. Open the door completely.

Remove the twelve (12) screws holding the tub front,

fame front, and panel front in place.

Caution

Before removing the screws, place a cushioned mat

on the oor to prevent the handle and frame front

from being scratched. After removing them, make

sure to hold the tub front with your hand while you

are working as the tub may close and harm you.

Caution

Do not place the removed screws on the tub front.

They may fall into the sump assy.

2. Remove the fan motor connector.

3. Remove the single (1) screw holding the bracket

cover fan in place.

Loading...

Loading...