Page 1

DLP Training

(Atlantis Chassis)

March 2004

Page 2

Agenda

1. Power Supply

2. Digital Board

3. Analog Board

4. DMD Board

5. Troubleshooting

6. Initialization Process

7. LED Indicators

8. Optical Section

9. Service Hints

10. Parts Information

11. Dimensions

12. Review

Page 3

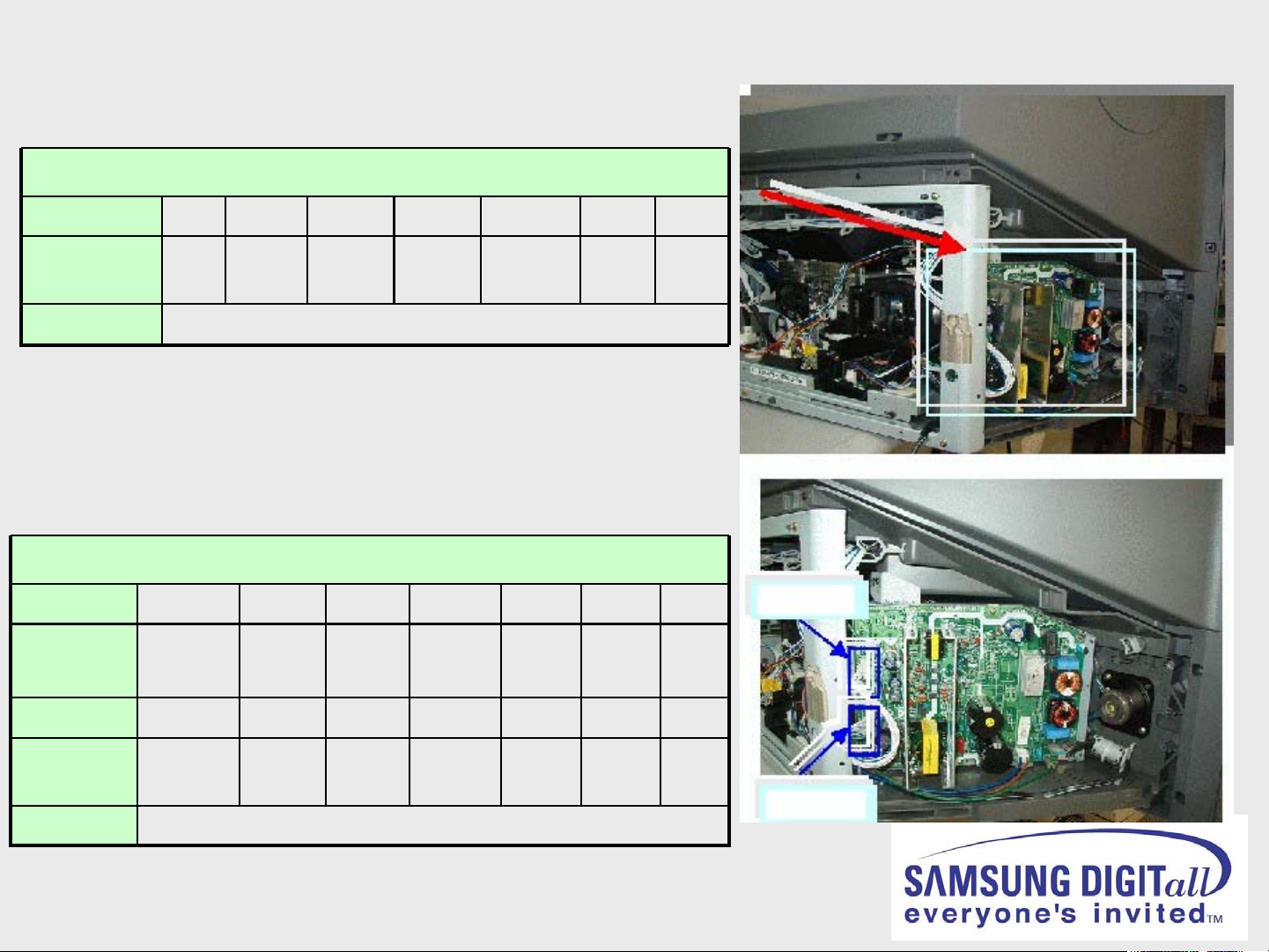

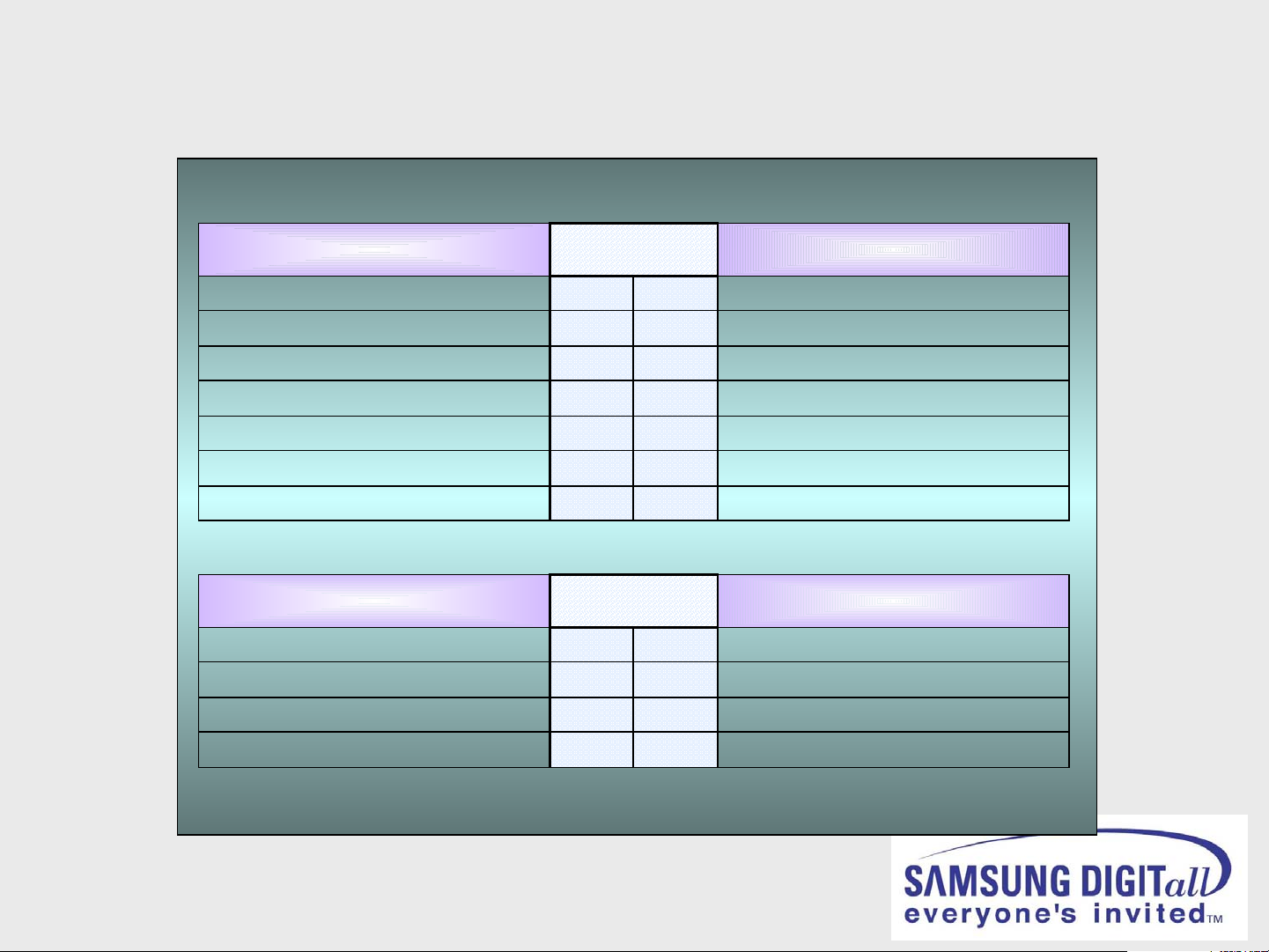

Power Supply Board

CN803

Pin #

Spec

Used

Pin #

Spec

Pin #

A

Power

-Mute

GND33VBGND5V

-S/W

Supplies DC voltage to the PCB ANALOG

CN802

S14.

5VB

S-

GND

S14.

5VB

S-

GND

12 13109118

5.7

VB

7654321

N.CN.C.Power

GN

D

7654321

CN 803

Spec

Used

GND12VB

B

Supplies DC voltage to the PCB ANALOG

70VBGNDGND12V

CN 802

Page 4

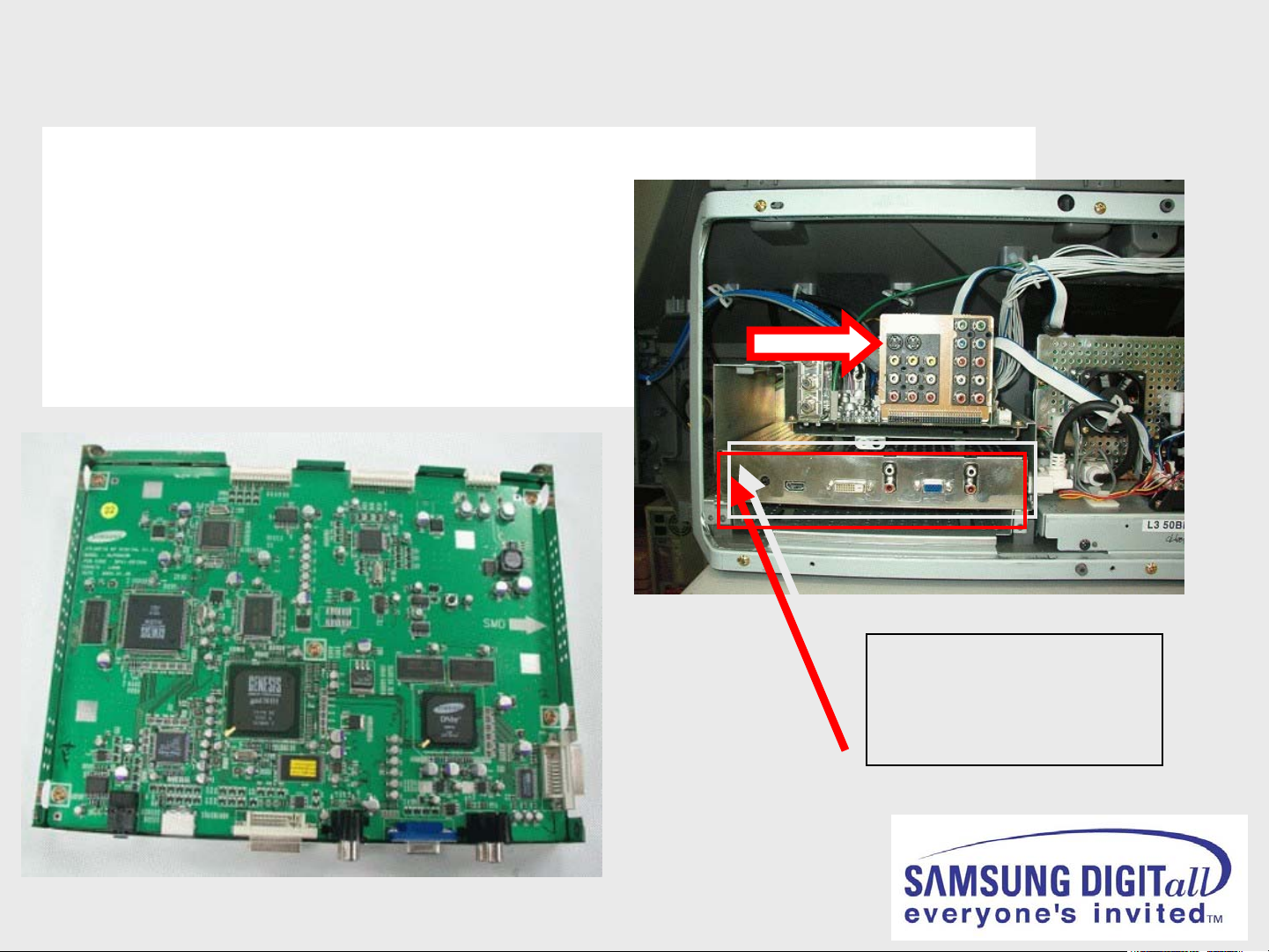

Digital Board

• Microprocessor (Generates turn on signal to power board)

• Monitor LED’s

• All Digital Video Processing

• Sensor / Switch Controls

• OSD / Menu

RS232- Factory Use Only

HDMI- A/V Input

RGB-PC Input

DVI – Digital Visual Interface

Page 5

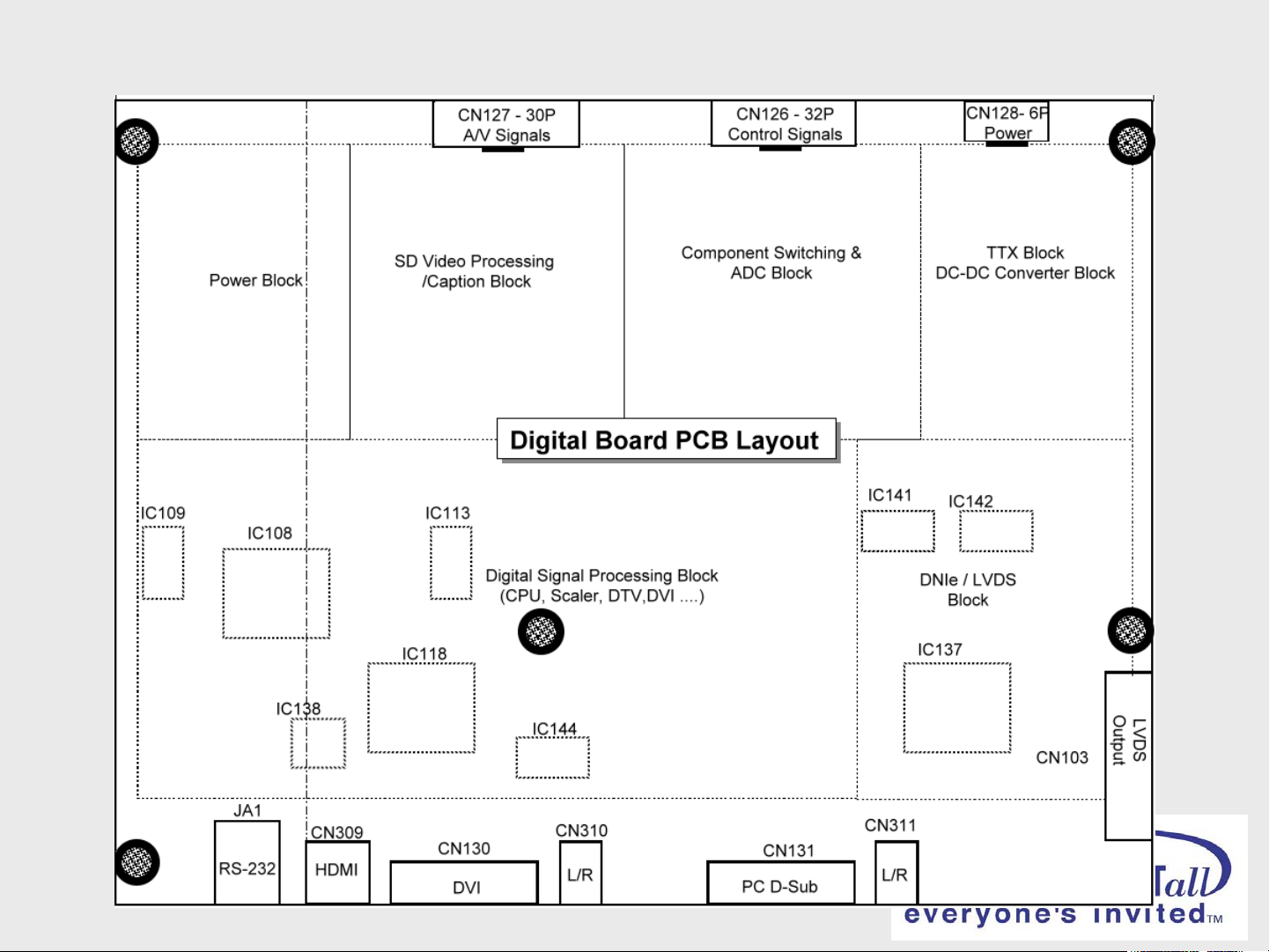

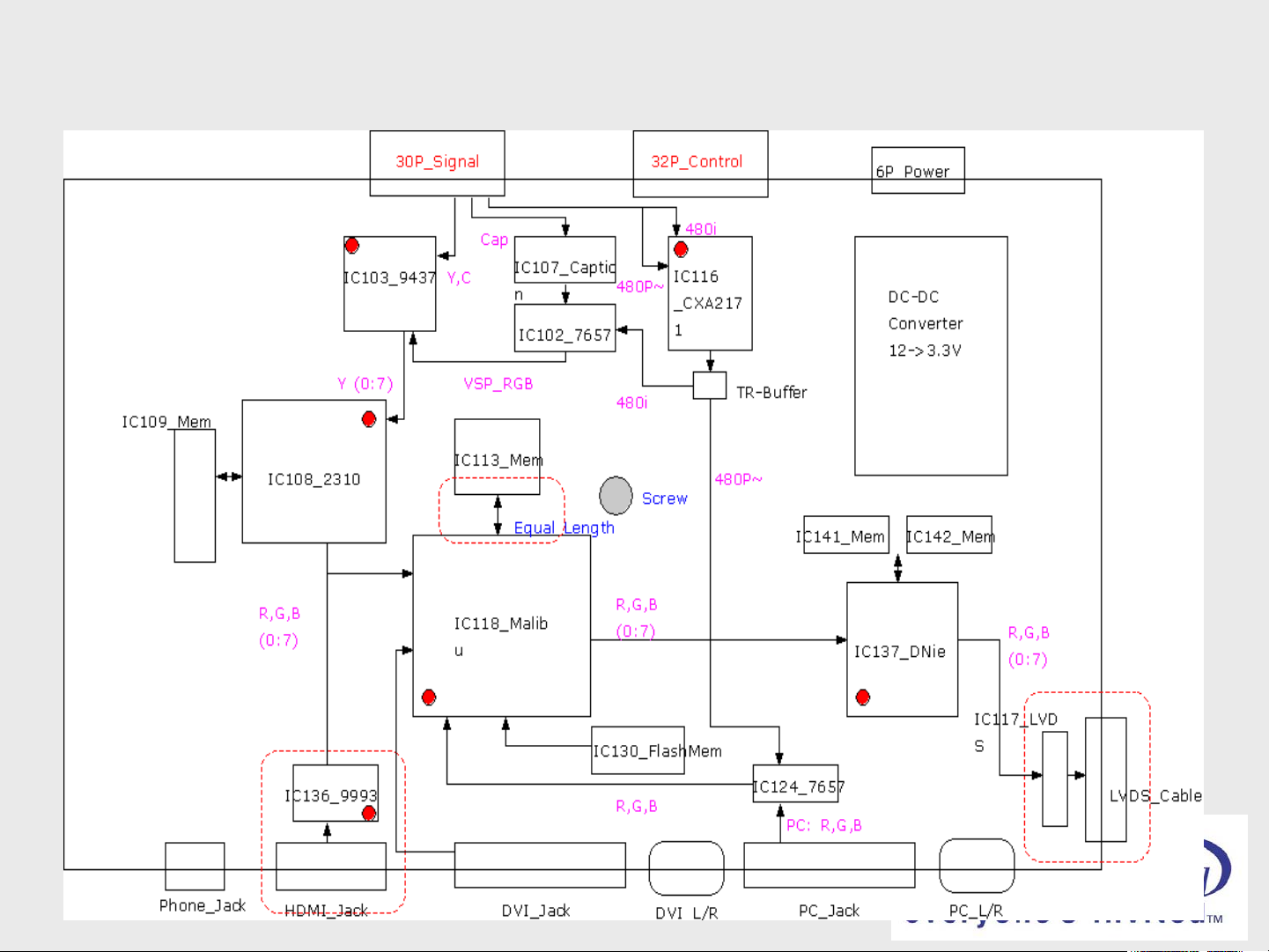

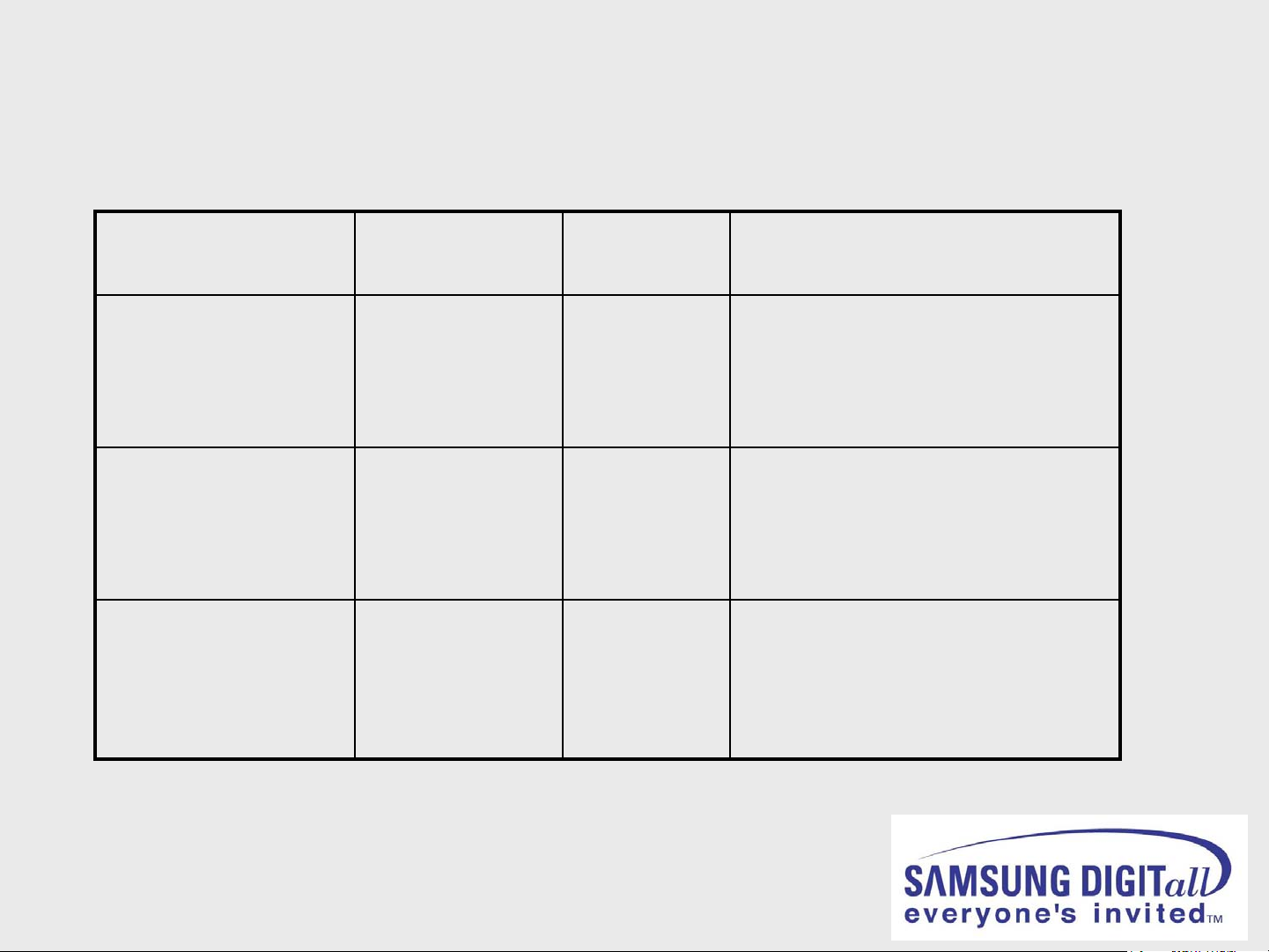

Digital Board Layout

Page 6

Digital Board Characteristics

Page 7

Analog Board

• Distributes supply voltage from the Power Board to Digital Board

• Transfers Turn-On Command from Digital Board to Power Board.

• Encompasses the majority of the Audio Circuit

• Analog Video Switching / Processing

Page 8

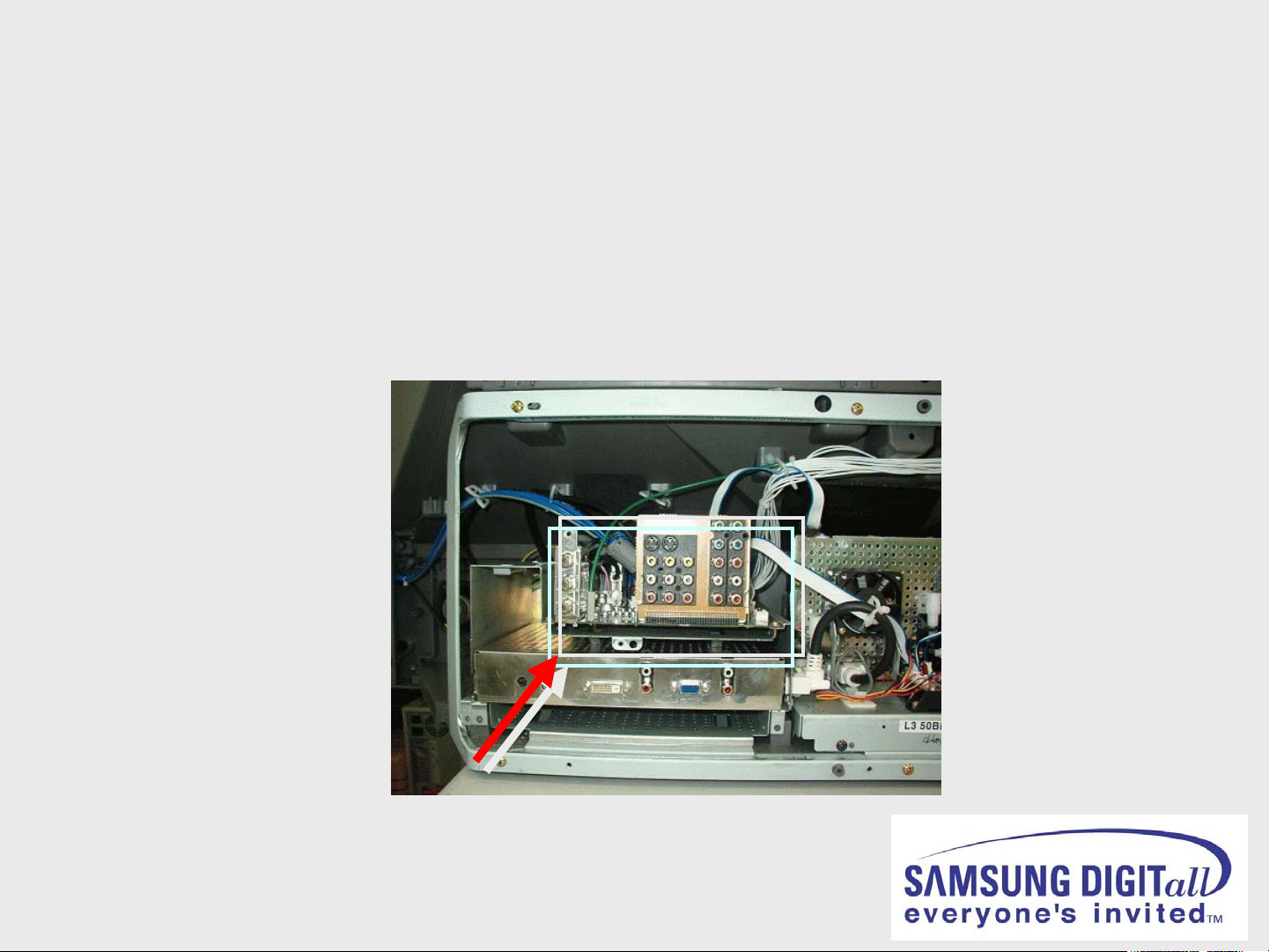

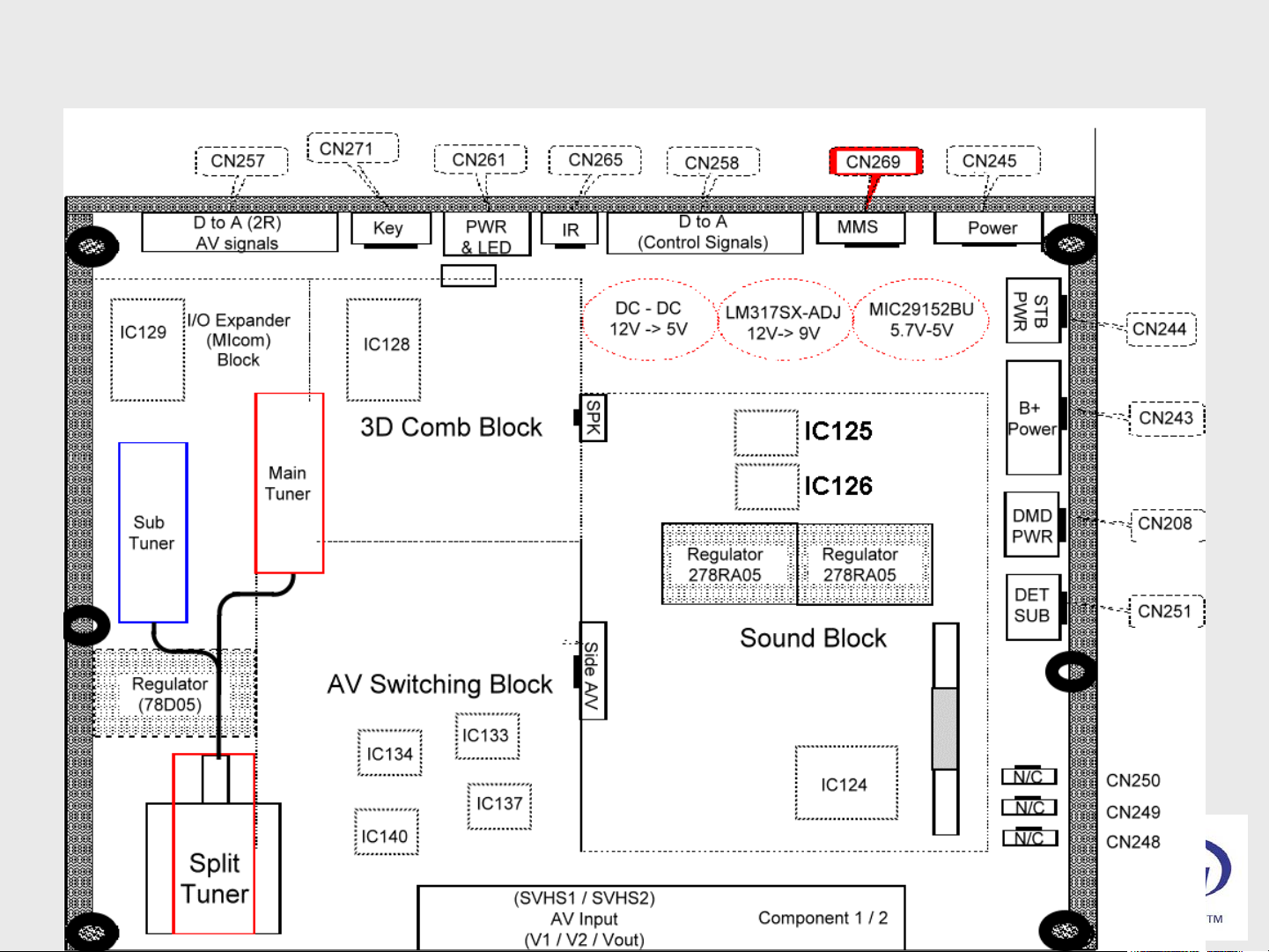

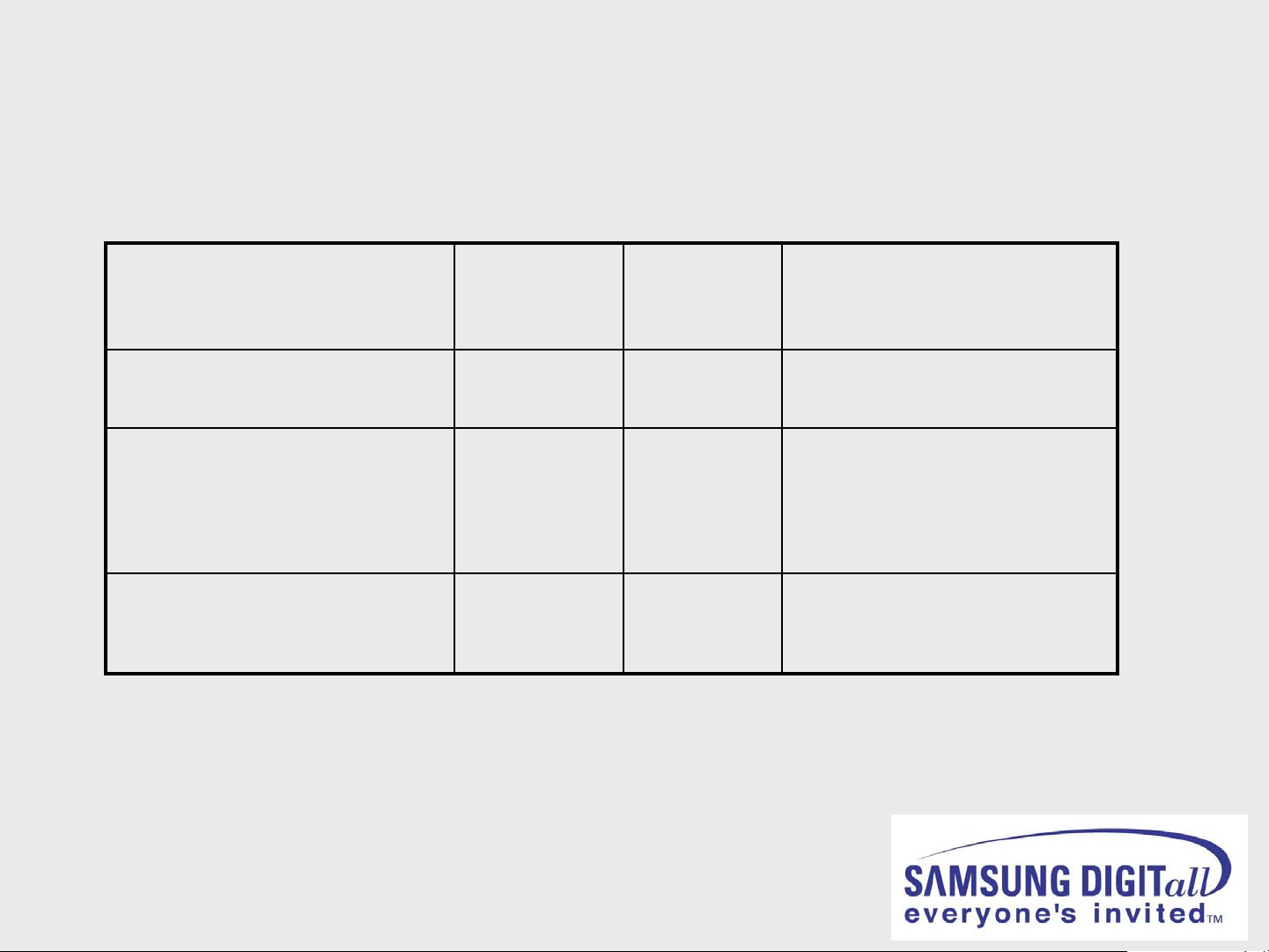

Analog PCB Layout

Page 9

Analog Board Block Diagram

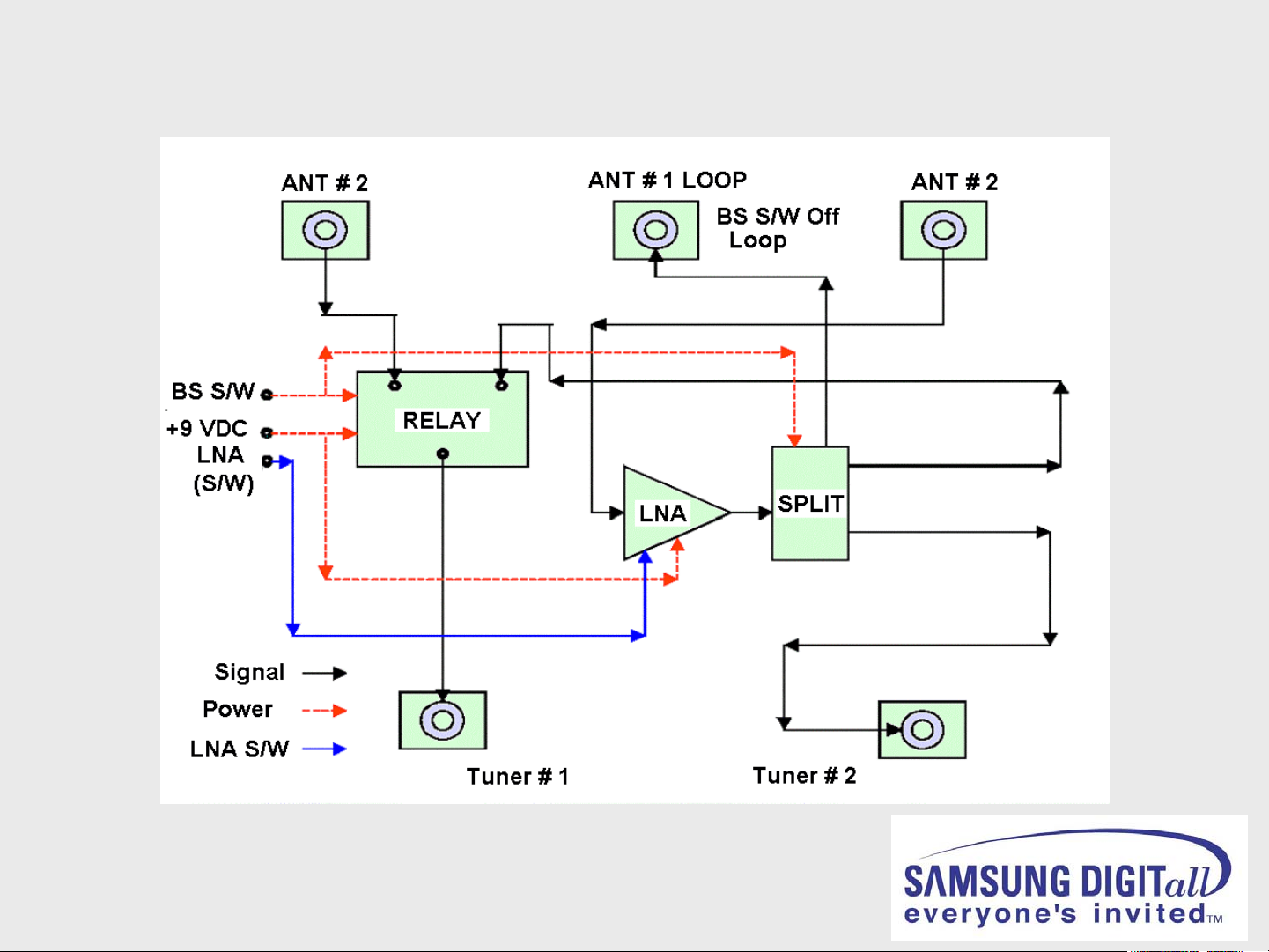

RF SWITCH (LNA) BLOCK

Page 10

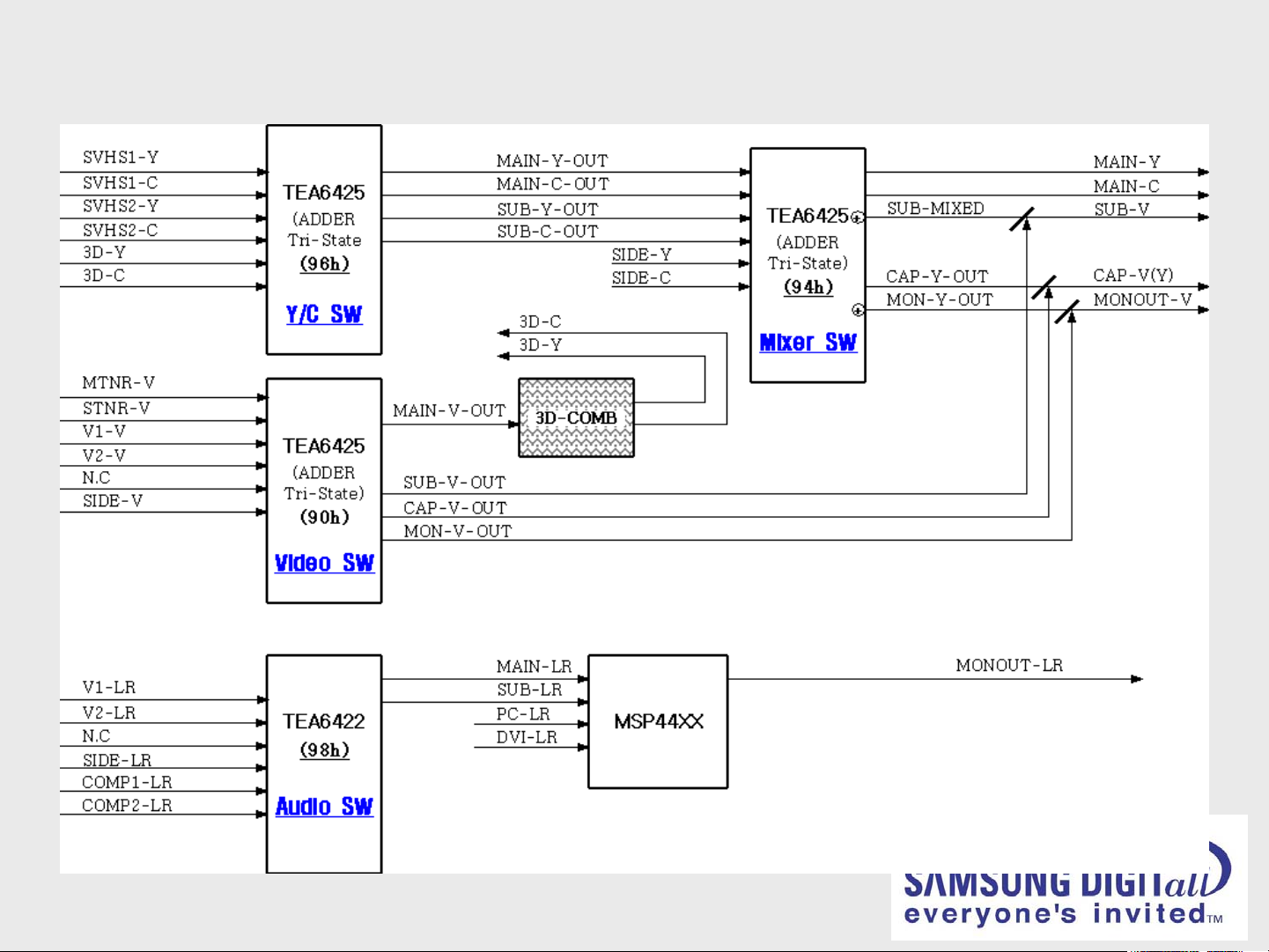

AV Switching (TEA64XX) Block

Page 11

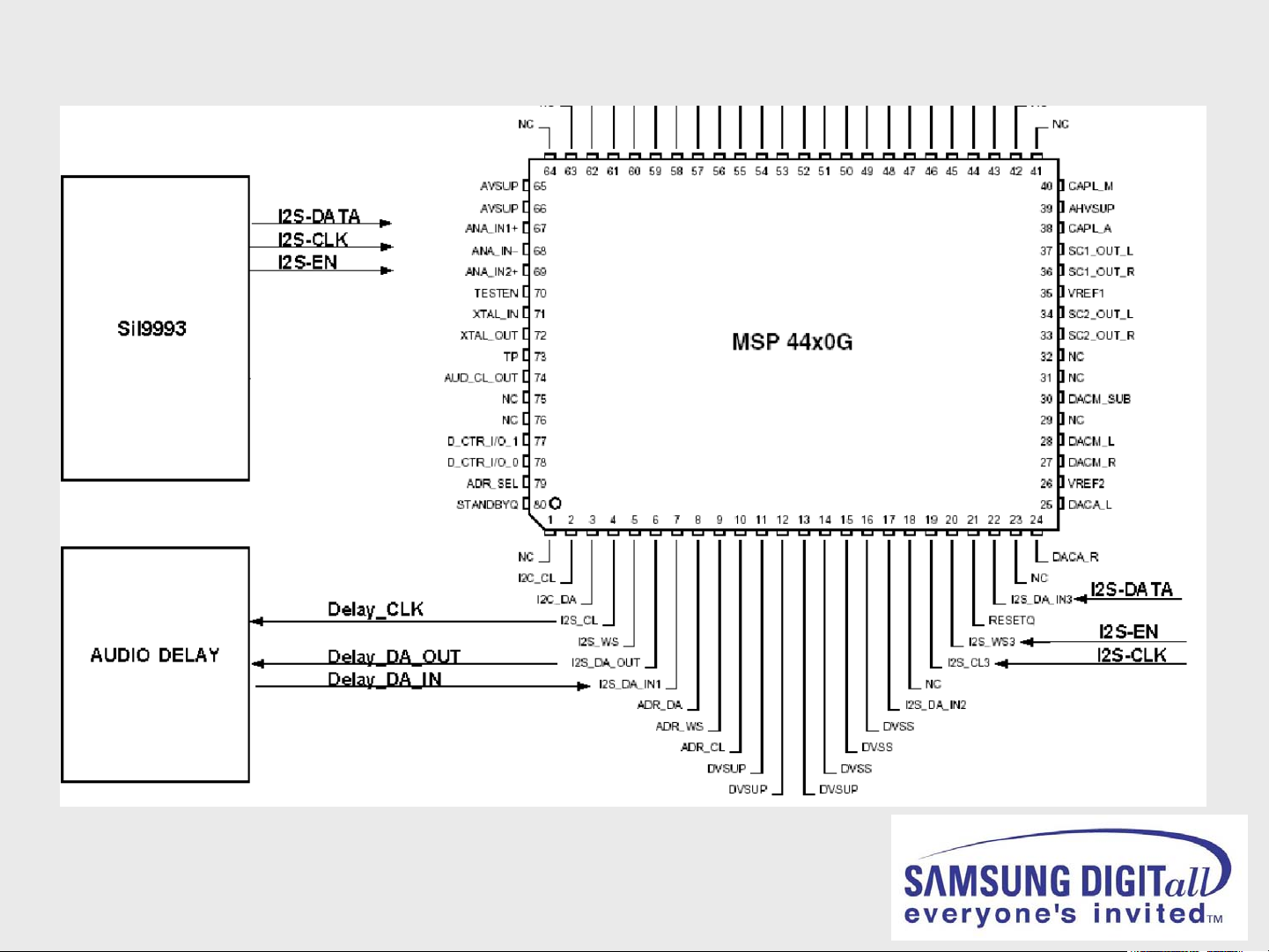

Audio Delay and HDMI Audio

Page 12

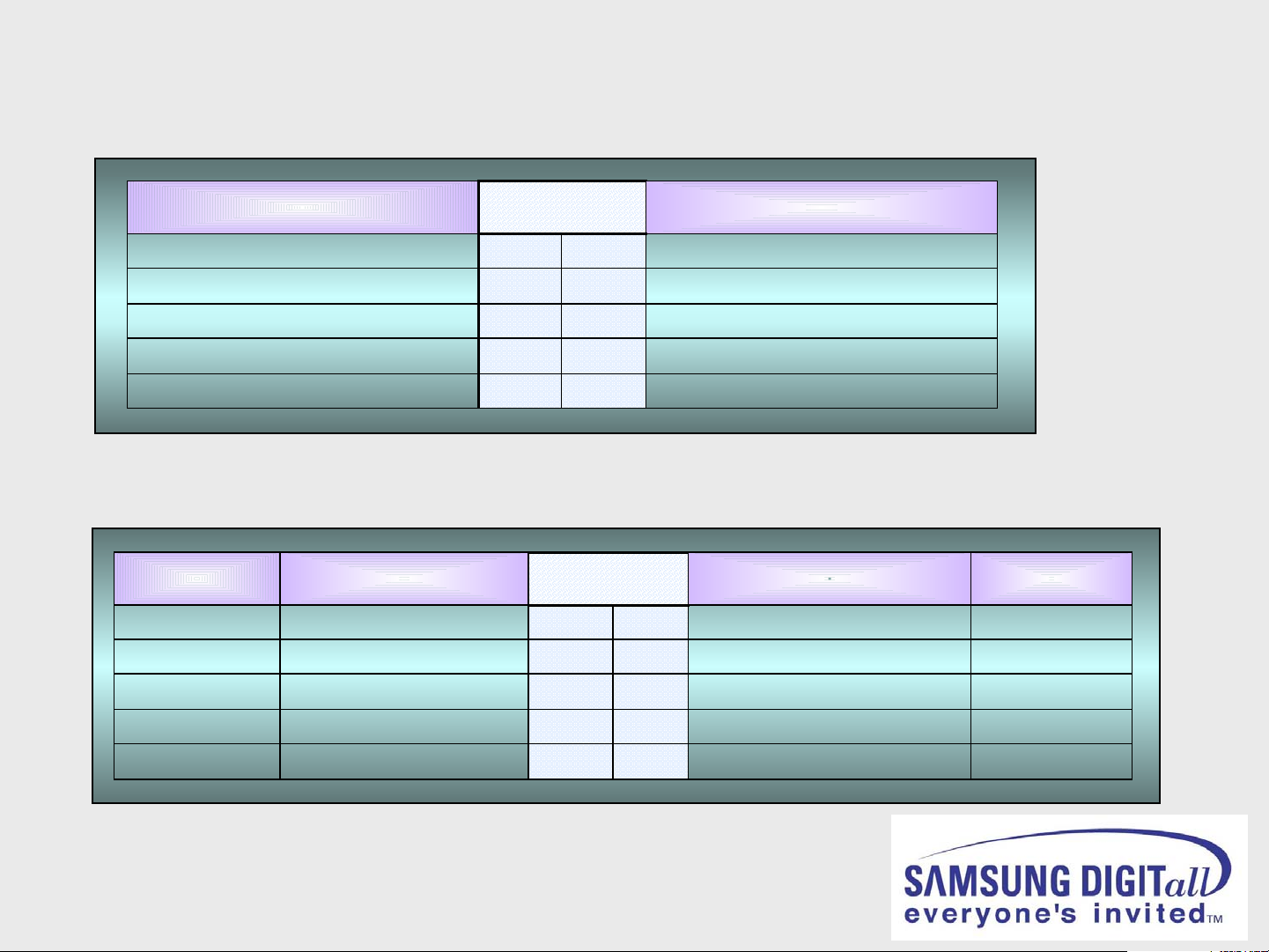

CN 257 Pin Assignment

CN257- Supplies AV Signals to PCB DIGITAL

Pin Name I/O PIN No. I/O Pin Name

Comp1-Y

Comp1-Pb

Comp1-Pr

Comp2-Y

Comp2-Pr

Comp2-Pb

N.C.

N.C.

N.C.

Main-Y/V

Main-C

Sub-Y/V

Sub-C

Caption-CVBS

IR

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

1 2 GND

3 4 GND

5 6 GND

7 8 GND

9 10 GND

11 12 GND

13 14 GND

15 16 GND

17 18 GND

19 20 GND

21 22 GND

23 24 GND

25 26 GND

27 28 GND

29 30 GND

Page 13

CN258 Pin Assignment

CN258- Connects Control Signals between PCB Analog and PCB Digital

Pin Name I/O PIN No. I/O Pin Name

LED1

LED2

LED3 5 6 GND

Key1

Key2 9 10

Reset-D

I2C-ST OP

Power-SW

N.C. 17 18

N.C.

GND

MCLK_AUDIO

S-MUTE

PC-L

PC-R 29 30 DVI-R

↔

→

←

←

←

←

←

←

→

→

→

1 2

3 4

7 8

11 12 GND

13 14

15 16 SCL-Digital

19 20

21 22 I2S-E N -H DMI

23 24 I2S-DATA-HDMI

25 26

27 28

↔

←

↔

←

←

←

←

←

←

SDA-Micom

SCL-Micom

SDA-Analog

SCL-Analog

SDA-Digital

GND

I2S-CLK-HDMI

GND

DVI-L

GND

←

31 32

←

GND

Page 14

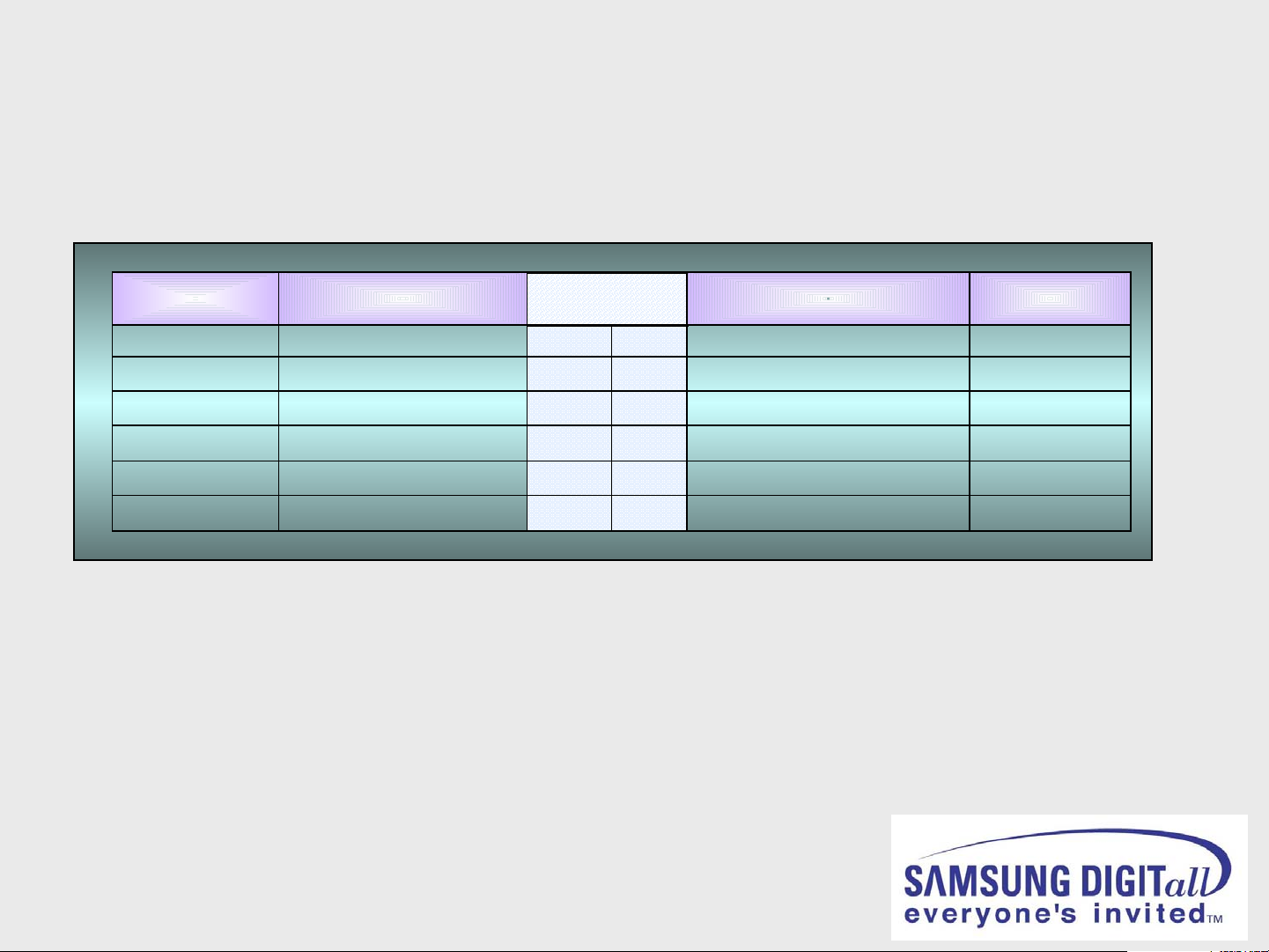

CN243/CN244 Pin Assignment

CN243 / 244 Receives Power Signals from PCB POWER

Pin Name PIN No. Pin Name

Power-Mute 1 2 S14.5VB

S-GND 3 4 S14.5VB

S-GND 5 6 5.7VB

GND 7 8 12VB

GND 9 10 12VB

GND 11 12 70VB

GND 13 -

Pin Name PIN No. Pin Name

5VA 1 2 GND

33VB 3 4 GND

Power-SW 5 6 N.C.

N.C. 7 -

Page 15

CN208 / CN251 Pin Assignment

CN208 Supplies Power Signals to PCB DMD

Pin Name PIN No. Pin Name

5VB 1 2 5VB

GND 3 4 GND

12VB 5 6 12VB

GND 7 8 GND

GND 9 - -

CN251 supplies power to Actuator / Protection Board

Pin Name SUB Detector/Actuator PIN No. SUB Detector/Actuator Pin Name

GND Ground 1 2 Fan-VCC 12VB

GND Ground 3 4 SDA-Memory SDA-M

SCL-M SCL-Memory 5 6 Ground GND

5VA 5VA 7 8 Ground GND

70VB 70VB 9 10 Ground GND

Page 16

CN223 Pin Assignment

CN223 Receives AV Signals from PCB SIDE-AV

Pin Name Side AV PIN No. Side AV Pin Name

Side-Y SVHS Y (Luma) 1 2 SVHS C (Chroma) Side-C

GND Ground 3 4 Video (CVBS) Side-V

GND Ground 5 6 Side Sound L Side-L

GND Ground 7 8 Side Sound R Side-R

GND Ground 9 10 SVHS Jack Detect Side-SDET

Side-VDET Video Jack Detect 11 -

Page 17

I/O Expander Pin Assignment

DES NAME PIN PIN NAME DES

GND VSS 1

XIN 2 31 P0.2 I/O S1-DET

XOUT 3 30 P0.3 I/O S2-DET

GND TEST 4 29 P0.4 I/O,ADC Side-SDET

Comp2-DET I/O P0.1 5 28 P0.5 I/O,ADC V1-DET

Comp1-DET I/O P0.0 6 27 P0.6 I/O,A D C V2-DET

RESET-D RESET 7 26 P0.7 I/O,A DC Side-VDET

S

3

P

9

4

32 VDD

2

RF-SEL O P3.0 8 25 P3.1 O SOUND-RESET

8

LNA-SW O P3.2 9 24 P3.3 O DEFAULT

MTNR-AFT I/O,A D C P2.0 10 23 P1.0 I/O DELAY1

STNR-AFT I/O,A D C P2.1 11 22 P1.1 I/O DELAY2

N.C I/O,A DC P2.2 12 21 P1.2 I/O GAIN0

N.C I/O,A DC P2.3 13 20 P1.3 I/O GAIN1

RF-AGC I/O,A DC P2.4 14 19 P2.7 SCL SCL-A

/

3

2

S

O

P

GND ADDRESS P2.5 15 18 P2.6 SDA SDA-A

GND AVSS 16 17 AVREF

Page 18

DMD Board

• Controls Lamp Turn-On

• Powers Color Wheel

Motor

• Drives DMD Panel

• Sensor Controls

• Attached to Light Engine

Page 19

DMD Block Diagram

Page 20

Troubleshooting

Page 21

OP101

OP101

Dead Set

Check power

to analog

board CN245

OK

Unplug

connector

CN245 if LED

(OP103)

turns on

replace the

digital board

Is 5V standby

LED(OP103) lit

on analog board?

Yes

Make sure CN103

on digital board

is connected

OK

Replace keypad

No

NG

NG

Reconnect CN103

Unplug the

Actuator

Board

OK

CN103

Replace the

Actuator

CN103

NG

Replace the

Power

board

Page 22

CN106

CN106

Blinking Temp LED

Check Temp Sensor

connector CN106

on Actuator Board

OK

NG

Re-insert

connector

Install jumper across

Temp Sensor Terminals.

Does it work?

Yes

Replace Temp Sensor.

No

Temp Sensor

Temp Sensor

Replace

the Actuator board

Page 23

Blinking Temp and Timer LED

Yes

Are fans running?

Replace Actuator board

No

Check for 8VDC

voltage(s) at CN103,104

on Actuator Board

NG

Check CN802 pin 8,10

on Power board for 12VB

OK

Replace

NG

OK

Replace fan(s)

NG

Remove power and

check the DMD,

Actuator and Digital

boards for short

circuit on the 12V

line to ground.

the Actuator

board

Page 24

All Front Panel LEDs Blinking

All three LEDs blinking is the most common failure indication. It can be caused by

defective lamp, defective color wheel, fan failure or other defective components.

wheel assembly

Replace

NO

Replace color

NG

OK

OK

Does color

wheel run?

YES

If Lamp is on

with no Video,

Check

Is lamp on?

YES

NO

See next page

DMD BOARD

connector

CN103 on the

Digital board

Page 25

All Front Panel LEDs Blinking Continued

NO

Does lamp

come on, then

shut off?

Check 220-280V dc to lamp ballast (CN1)

Replace Power Board

OK

Replace lamp

assembly

Check pin 2 on CN504 (lamp enable)

Measure with DC meter

NG

Re-install

lamp assembly

NG

OK

on DMD Board for 5V p-p (90Hz).

NG

Replace

OK

YES

Check 0V dc at

CN504

(lamplitz) pin 5

on DMD Board

OK

Replace

ballast or

assembly

NG

lamp

or ballast

DMD Board

Page 26

Blinking Lamp and Temp. LED’s

Is lamp

cover installed?

Yes

Make sure lamp cover

switch is activating

OK

Short CN107

Check boss

NG

No

Install lamp cover

CN107

CN107

on Actuator Board

Replace the Actuator board

on Lamp Cover

NG

Page 27

Initialization Process

Standby LED

1. Standby LED on Analog PCB ON (5V)

2. Power ON signal from Sub Front PCB or IR sensor

to Digital PCB.

3. Power ON signal generated by Digital PCB->

Analog PCB-> POWER PCB.

4. All other voltages turn on (3 status LED’s on

analog board lit) .

5. Fans turn on.

6. Fan protection circuit verifies Fan Operation.

7. Digital PCB tells DMD PCB to turn color wheel and

lamp on.

8. DMD / digital PCB’s check feedback (LampLitz –

low, DDP ready – High) signals from lamp and DMD

Controller (DDP1011).

9. If OK, Digital PCB tells DMD to remove video mute.

Page 28

Front Panel LED Indicators

Legend

¦ = LED On

|= LED Off

= LED Blinking

Timer Lamp Standby/

Temp

| | ¦ Standby State

¦ | | Auto Timer On/Off has been set

| | | Set is operating Normally

| | Turn on state, picture will appear in about 15 seconds

| Auto Timer On/Off has been set, picture will appear in ~ 25

| A cooling fan inside the set is not operating properly

| The Lamp cover on the rear of the set is not installed properly.

| | Excessive Temperature error, check for proper ventilation

Indication

seconds

Lamp does not light, replace with a new lamp

Page 29

Optical Section

Page 30

Background

Samsung introduced their new DLP technology projection televisions in

2002. DLP stands for

Digital Light Processing

DLP is quite different than conventional projection television, which uses

three separate color CRT’s. These separate video signals are projected

and combined on the screen. DLP, on the other hand, has no CRT’s.

Instead, one high intensity lamp is used to project one image on the

screen.

DLP technology was first developed by Texas Instruments.

The heart of this technology is the DMD, or

Digital Micromirror Device.

Page 31

L2 and L3 Design Comparison

DMD PANEL

Incident light

1280 X 720

(921600 pixels)

Incident light

L2 Design : HD2 Panel

0.79

* Unit = Inch

L3 Design : HD3 Panel

Diamond Pixel Pattern

640 x 720

(460800 pixels)

* Unit = Inch

Page 32

Incident light

DMD Differences

1280 X 720

(921600 pixels)

Incident light

640 x 720

(460800 pixels)

0.79

Focus

Adjust

Focus

Adjust

Page 33

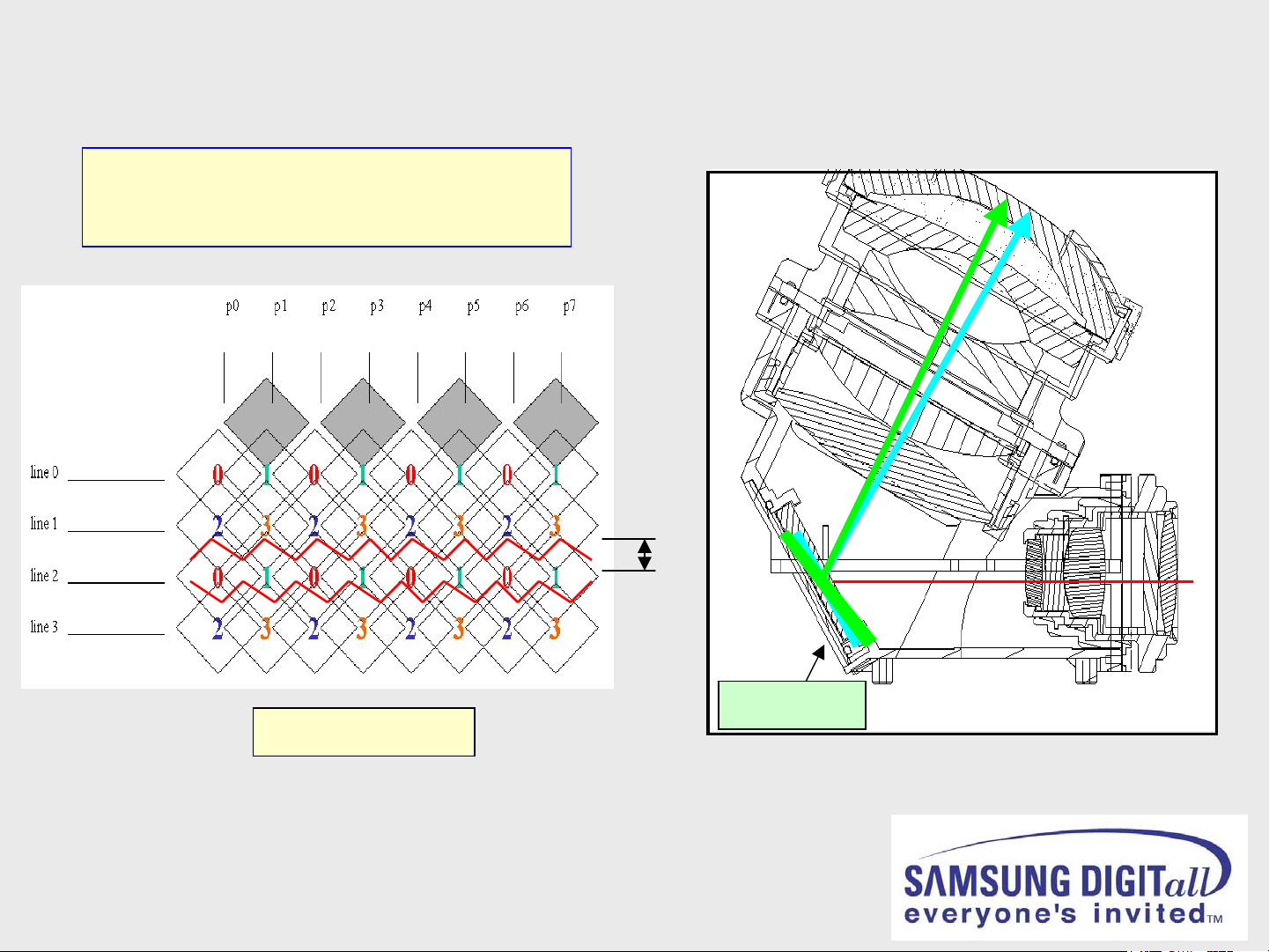

1. Display Resolution

p0 p1 p2 p3 p4 p5 p6 p7

p0 p1 p2 p3 p4 p5 p6 p7

1

1

1

line 0

line 0

line 1

line 1

line 2

line 2

line 3

line 3

1

1

2

2

2

1 1 1 1

1 1 1 1

2 2 2 2

2 2 2 2

2

2

2

Low Resolution

1

1

1

2

2

Design Concept

Frame 1 Frame 2

p0 p1 p2 p3 p4 p5 p6 p7

p0 p1 p2 p3 p4 p5 p6 p7

line 0

line 0

line 1

line 1

line 2

line 2

line 3

line 3

Driving Actuator

=

1

1

1

2

2

2

2

1 1 1 1

1 1 1 1

2 2 2 2

2 2 2 2

1

1

1

2

2

line 0

line 0

line 1

line 1

line 2

line 2

line 3

line 3

1

1

2

2

2

2

0 0 0 0

0 0 0 0

2 2 2 2

2 2 2 2

p0 p1 p2 p3 p4 p5 p6 p7

p0 p1 p2 p3 p4 p5 p6 p7

0 0 0 0

0 0 0 0

3 3 3 3

+

p0 p1 p2 p3 p4 p5 p6 p7

p0 p1 p2 p3 p4 p5 p6 p7

1

1

2

3

2

3

1 1 1 1

1 1 1 1

3 3 3 3

3 3 3 3

3 3 3 3

0 0 0 0

0 0 0 0

3 3 3 3

3 3 3 3

1

1

3 3 3

3 3 3

1

1

2

2

10 0 0 0

10 0 0 0

2

2

( dr iven to bla ck)

( dr iven to bla ck)

High Resolution

X2 RESOLUTIONX1 RESOLUTION

Page 34

Realizing Method

Mirror movement by vibration of

Mirror movement by vibration of

Piezoelectric material.

Piezoelectric material.

Vibration Distance = ½ Pixel

X2 Resolution

460800 pixels -> 921600 pixels

Effect = Jagged line to Smooth line

Actuator

Folding Mirror VibrationFolding Mirror Vibration

Page 35

Light Engine Breakdown

LAMP MODULE

OPTICAL MODULE

DMD MODULE

Page 36

Optical Module

PROJECTION LENS

COLOR WHEEL

LOCATION OF DMD

LIGHT TUNNEL

Page 37

NDF

Color Wheel

<Air Bearing Type Motor>

<Air Bearing Type Motor>

Life time : over 30,000 hrs (max 50,000 hrs)

Life time : over 30,000 hrs (max 50,000 hrs)

On/off : over 50,000 times (max 300,000 times)

On/off : over 50,000 times (max 300,000 times)

Less Vibration & Noise

Less Vibration & Noise

7

*Addition = Neutral Density Filter

NDF Purpose: Decrease Dither noise.

10,800

Page 38

60Hz

Actuator

SpecificationItemsNo.

79gMass1

0~0.015deg.Mirror tilt angle range2

Purpose: Smooth Picture

by ½ Pixel movement

using 60Hz mirror

vibration.

<1.0 mSecState transition time3

+/-0.025deg.Initial static angle4

Page 39

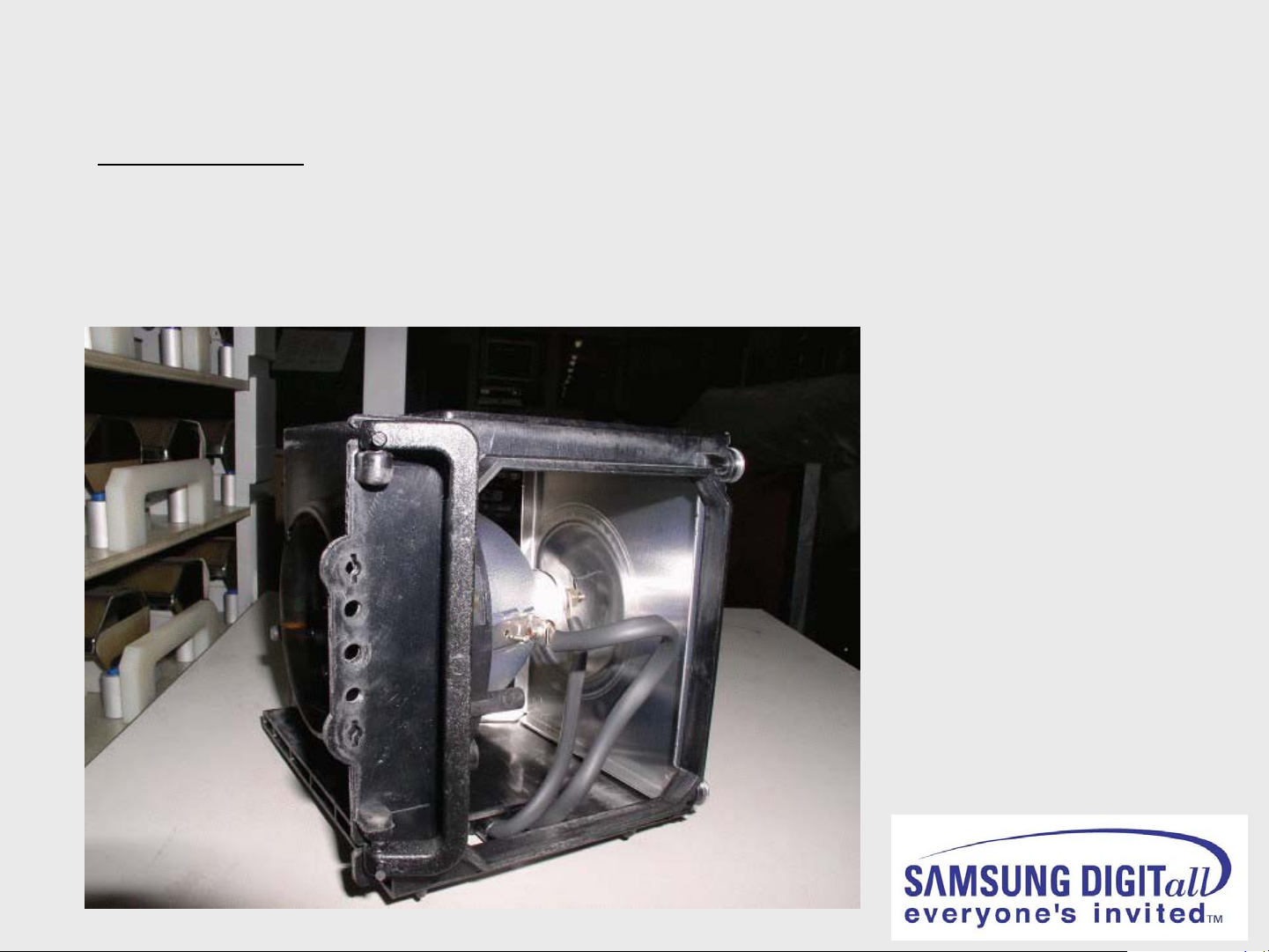

Lamp

Full name : High Pressure Mercury Lamp

Full name : High Pressure Mercury Lamp

Maker : Philips

Maker : Philips

Specification

Specification

Arc gap : 1.0 mm

Arc gap : 1.0 mm

Wattage : 100W or 120W

Wattage : 100W or 120W

Life time : about 8000 – 6000hrs

Life time : about 8000 – 6000hrs

Optical Specification

Optical Specification

Reflector type : E23

Reflector type : E23

Size : 95.25 +/-0.5mm

Size : 95.25 +/-0.5mm

Mount to focal point : 52mm

Mount to focal point : 52mm

(Reflector)

Bulb

Mount to Focal Point

Cover Glass

Page 40

Maker : Philips

Maker : Philips

Type no. : EUC 120PH/11

Type no. : EUC 120PH/11

Ignition : 20KV(Max 25KV)

Ignition : 20KV(Max 25KV)

Size : 150 x 60 x 32mm

Size : 150 x 60 x 32mm

Ambient temp. : under 65deg C.

Ambient temp. : under 65deg C.

Ballast

Page 41

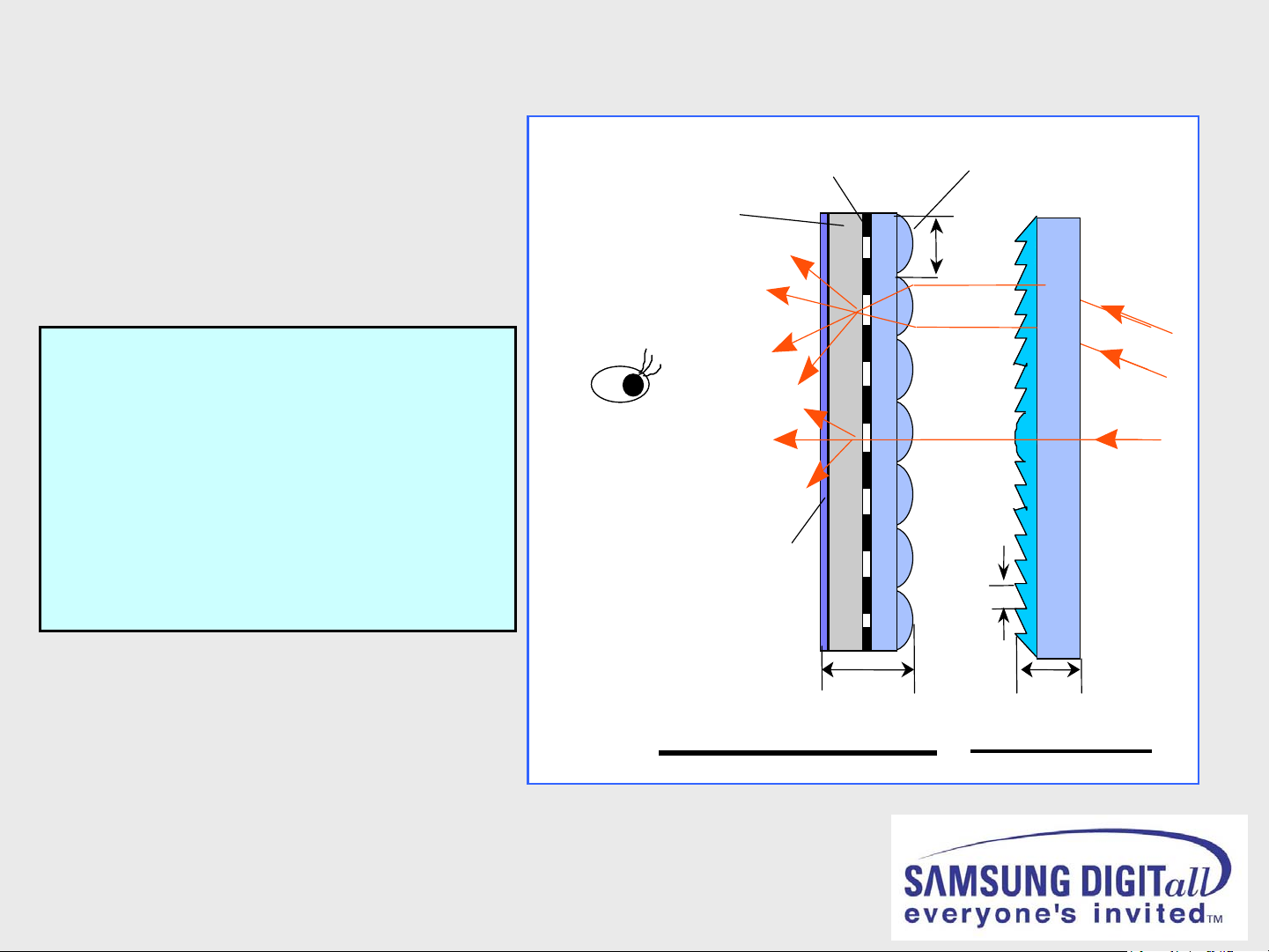

Good Point :

Good Point :

1. Good Contrast

1. Good Contrast

2. No reflection of out-light.

2. No reflection of out-light.

3. Good View Angle (140 deg)

3. Good View Angle (140 deg)

4. Reduced Moire

4. Reduced Moire

5. Increased Screen Gain

5. Increased Screen Gain

Screen

Diffusion Plate

Diffusion Plate

High Brightness,

High Brightness,

High Contrast

High Contrast

Hard Coat

Hard Coat

Anti-static

Anti-static

function

function

Black Stripe(BS)

Black Stripe(BS)

Lenticular Lens

Lenticular Lens

155um

um

98

98um

61.9um

2.1mm

2.1mm

Lenticular Screen

Lenticular Screen

2.0mm

2.0mm

Fresnel Lens

Fresnel Lens

Page 42

Optical Specification

Parameter

Nominal

value

Commentunit

7-segment color wheel, TI

nits460Brightness

development board, no spoke

light recapture, reference lamp

Uniformity (ANSI)

-Typical

- Minimal

Contrast full on/off

–Typical

+/- 15

+/- 25

n.a.1500:1

%

%

+: brightest of 13 ANSI

points/average of 9 points

-: darkest of 13 ANSI

points/average of 9 points

7 segment color wheel,

TI development board, no

spoke light recapture

Page 43

Optical Specification Continued

Nominal

Parameter

value

Commentunit

Color Temperature

Projection distance

at 50” screen size

7,500 K

(Warm 1)

measured in image centern.a.

design valuen.a.≥ 2.6F-number

projection distance: distance from

mm585

mm30.98 mmExit pupil position

vertex of front lens to projection

screen

design value, distance to vertex of

front lens

design valuedeg.94F.O.V (Field of View)

Diamond Pixel Configurationmm12.451 x 7.008Panel size

Page 44

Optical Specification Continued

Nominal

Parameter

value

Commentunit

Lateral color aberration

@ 50” (R-G; B-G)

TV distortion

- in horizontal direction

- in vertical direction

≤ 7

≤ 8.5

≤ |0.3|

≤ |0.3|

µm

µm

%

%

Design value

440/546/640 nm

Pin Cushion or Barrel

condition

mechanical design valuedeg.66folding angle

Page 45

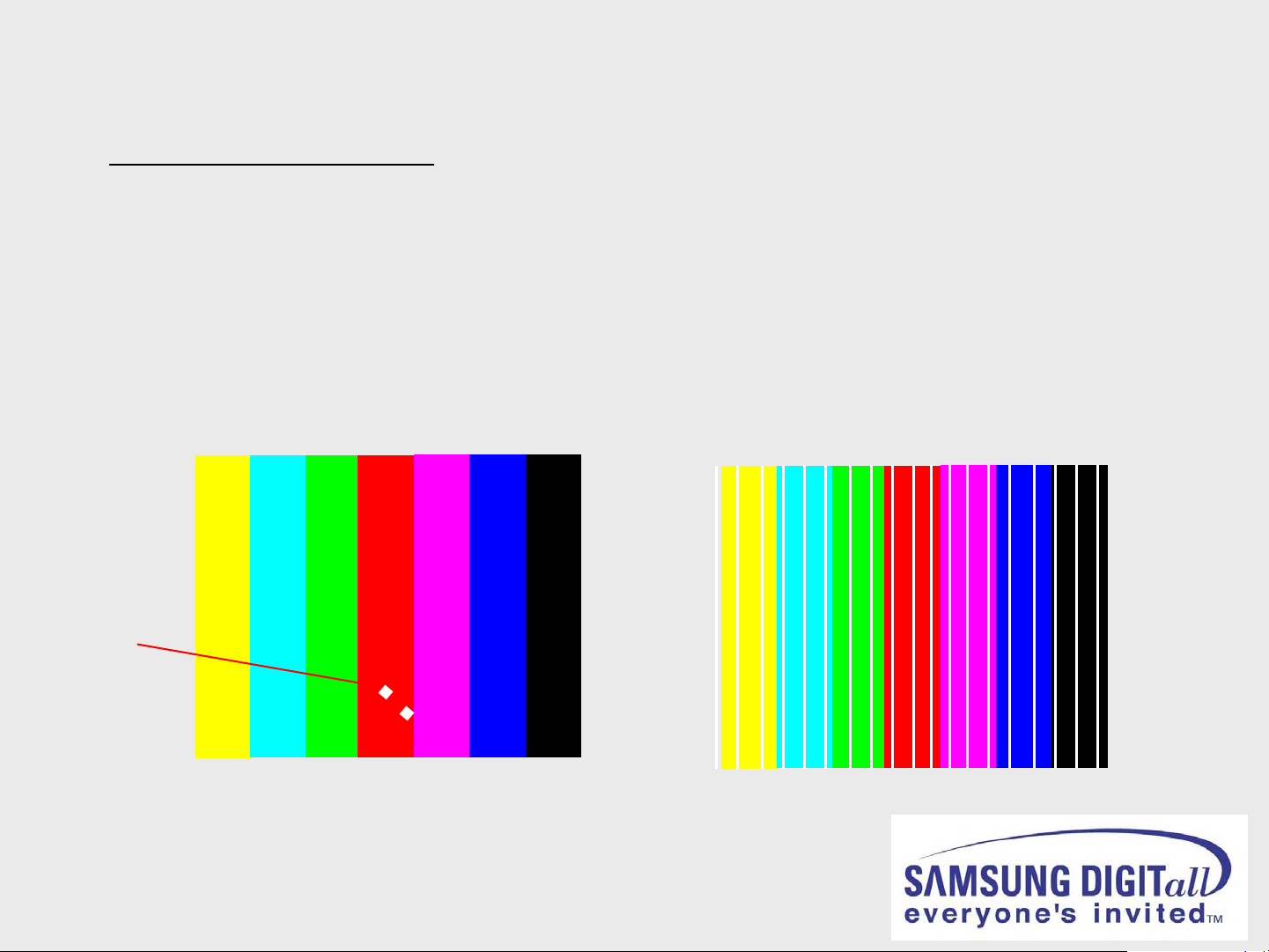

Service Hint #1

DMD BOARD ASSY

Problem : PIXEL DEFECT, VERTICAL LINE

Solution : Change the DMD Board assembly.

Vertical Line Problem (Jail Bar effect)

Pixel

Defect

Page 46

Service Hint #2

Color Wheel Assembly

13. Service Module

Problem : INCREASED NOISE

Solution : Change the Color wheel module.

Page 47

Service Hint #3

LAMP ASSY

Problem : LOW BRIGHTNESS or No Power

Solution : Change the Lamp module

Page 48

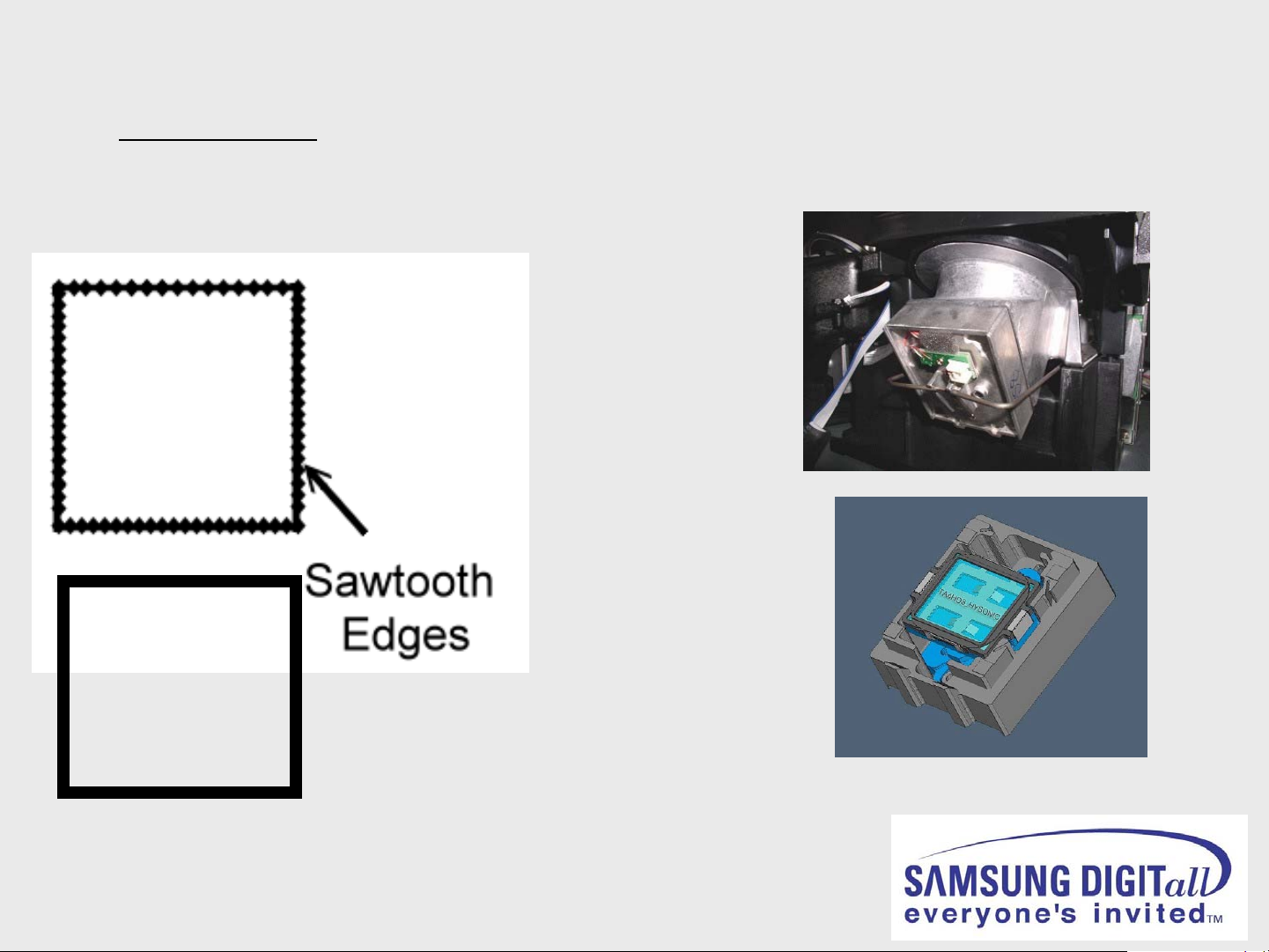

Service Hint #4

ACTUATOR

Problem : High Frequency Noise(1200Hz), Distorted edges in Picture

Solution : Change the Actuator

Actual

Page 49

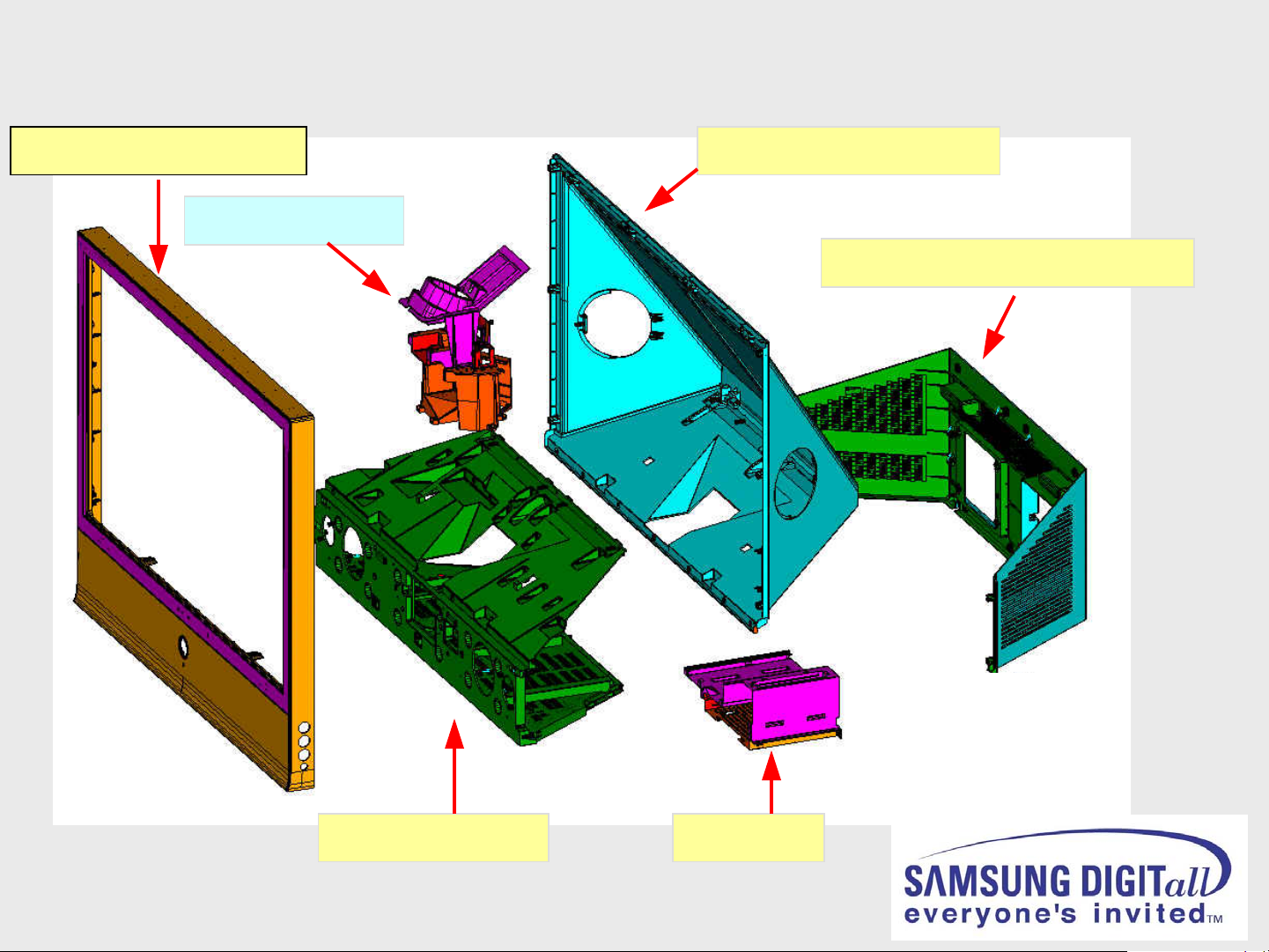

Mechanic

Page 50

L3 DLP Main Parts

CABINET-FRONT

ENGINE ASSY

CABINET-BACK TOP

CABINET-BACK, BOTTOM

CABINET-MAIN

CHASSIS

Page 51

Set Dimensions

MODEL

46L3

50L3

56L3

61L3

MODEL

46L3

W x D x H

( mm Unit )

1094 x 339 x 814

1182 x 359 x 870

1330 x 396 x 963

1446 x 425 x 1035

Mirror Size

SIZE (W1 x W2 x H)

1035 x 530 x 523

Weight

(Kg)

31.5

35

41.5

45

W x D x H

( mm Box)

1205 x 455 x 950

1300 x 480 x 1010

1450 x 520 x 1105

1580 x 565 x 1170

Screen Size

MODEL

46L3

Weight

(Kg)

39

43

53

57

SIZE (W x H)

1021 x 580.5

50L3

56L3

61L3

1030 x 580 x 570

1279 x 650 x 645

1395 x 692 x 700

* Dimensions in mm

50L3

56L3

61L3

1126 x 646

1257 x 713.5

1381 x 790

Page 52

The End

Thank You!

Thank You!

Loading...

Loading...