Page 1

DIGITAL CABLE RECEIVER

STANDBY

BASIC : DCB

-H380R

Application Models:

DCB-H380R

Application Area:

BAS, XEN

SERVICE MANUAL DCB-H380R

Manual

If you want to know additional information which is not included on this Service

Manual, Please refer to the SKP(Samsung Knowledge Portal) web site.

Area Web Site

North America URL ; http://service.samsungportal.com

Latin America URL ; http://latin.samsungportal.com

CIS URL ; http://cis.samsungportal.com

Europe URL ; http://europe.samsungportal.com

China URL ; http://china.samsungportal.com

Asia URL ; http://asia.samsungportal.com

Mideast & Africa URL ; http://mea.samsungportal.com

SERVICE

DIGITAL CABLE RECEIVER Contents

1. Precautions

2. Product Specification

3. Disassembly and Reassembly

4. Trouble Shooting

5. Exploded View and Parts List

6. PCB Diagrams

7. Schematic Diagrams

This Service Manual is a property of Samsung Electronics Co .,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

© Samsung Electronics Co., Ltd. NOV. 2008

Printed in Korea

Page 2

CONTENTS CONTENTS

1. Precautions 1-1 ~ 1-4

1-1 Safety Precautions (1-1)

1-2 Servicing Precautions (1-3)

1-3 ESD Precautions (1-4

2. Product Specication 2-1 ~ 2-4

2-1 Product Specication (2-1)

2-2 Chassis Product Specication (2-2)

2-3 Option Product Specication (2-3)

3. Disassembly and Reassembly 3-1 ~ 3-4

3-1 Cabinet Disassembly (3-1)

4. Troubleshooting 4-1 ~ 4-18

4-1 Troubleshooting (4-2)

4-2 Software Upgrade (4-17)

5. Exploded View and Parts List 5-1 ~ 5-14

5-1 Ass'y Chassis (5-2)

7-7 Decoupling (Main PCB) (7-9)

7-8 Flash / Reset / DCU (Main PCB) (7-10)

7-9 SDRAM(System) (Main PCB) (7-11)

)

7-10 SDRAM(Video) (Main PCB) (7-12)

7-11 SCART (Main PCB) (7-13)

7-12 SCART Wave Form (Main PCB) (7-14)

7-13 Audio / HDMI / SPDIF (Main PCB) (7-15)

7-14 Modem (Main PCB) (7-16)

7-15 GPIO/Front/SmartCard/NV (Main PCB) (7-17)

7-16 STv0362 (Main PCB) (7-18)

7-17 Front (Front PCB) (7-19)

5-2 Electrical Parts List (5-4)

6. PCB Diagrams 6-1 ~ 6-8

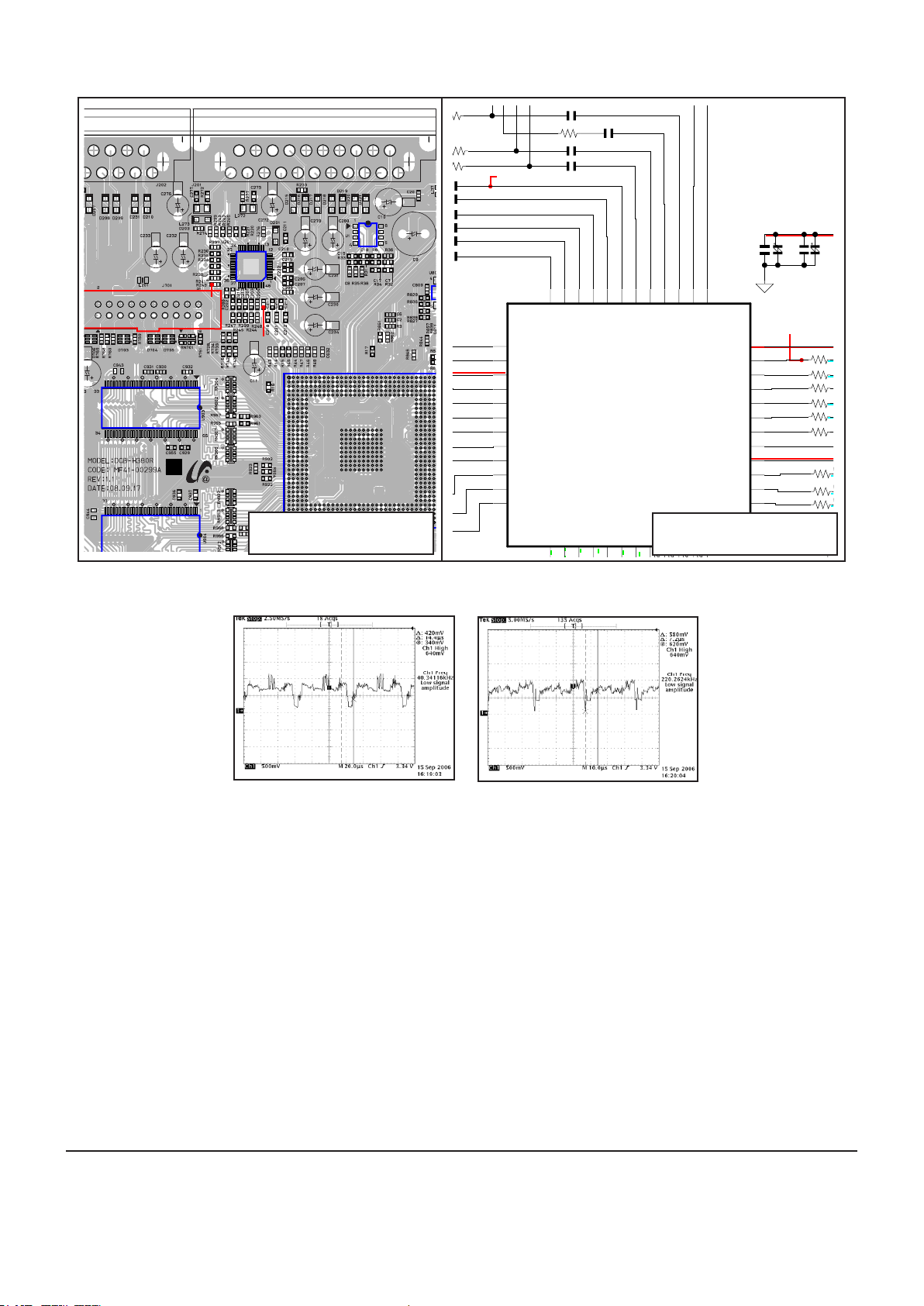

6-1 Wiring Diagram (6-2)

6-2 Main PCB (6-3)

6-3 Main PCB Wave Form (6-4)

6-3 Front PCB (6-7)

7. Schematic Diagrams 7-1 ~ 7-20

7-1 All block Diagram (7-2)

7-2 Power Supply Circuit Operating Descriptions (7-3)

7-3 SMPS (Main PCB) (7-5)

7-4 Tuner (Main PCB) (7-6)

7-5 DEMOD (Main PCB) (7-7)

7-6 Power (Main PCB) (7-8)

Page 3

1. Precautions

1-1 Safety Precautions

1) Before returning an instrument to the customer,

always make a safety check of the entire instrument,

including, but not limited to, the following items:

(1) Be sure that no built-in protective devices are

defective or have been defeated during servicing.

(1)Protective shields are provided to protect both

the technician and the customer. Correctly replace

all missing protective shields, including any

removed for servicing convenience.

(2)When reinstalling the chassis and/or other

assembly in the cabinet, be sure to put back in place

all protective devices, including, but not limited to,

nonmetallic control knobs, insulating fish papers,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not operate

this instrument or permit it to be operated without

all protective devices correctly installed and

functioning.

(2) Be sure that there are no cabinet openings through

which adults or children might be able to insert

their fingers and contact a hazardous voltage. Such

openings include, but are not limited to, excessively

wide cabinet ventilation slots, and an improperly

fitted and/or incorrectly secured cabinet back

cover.

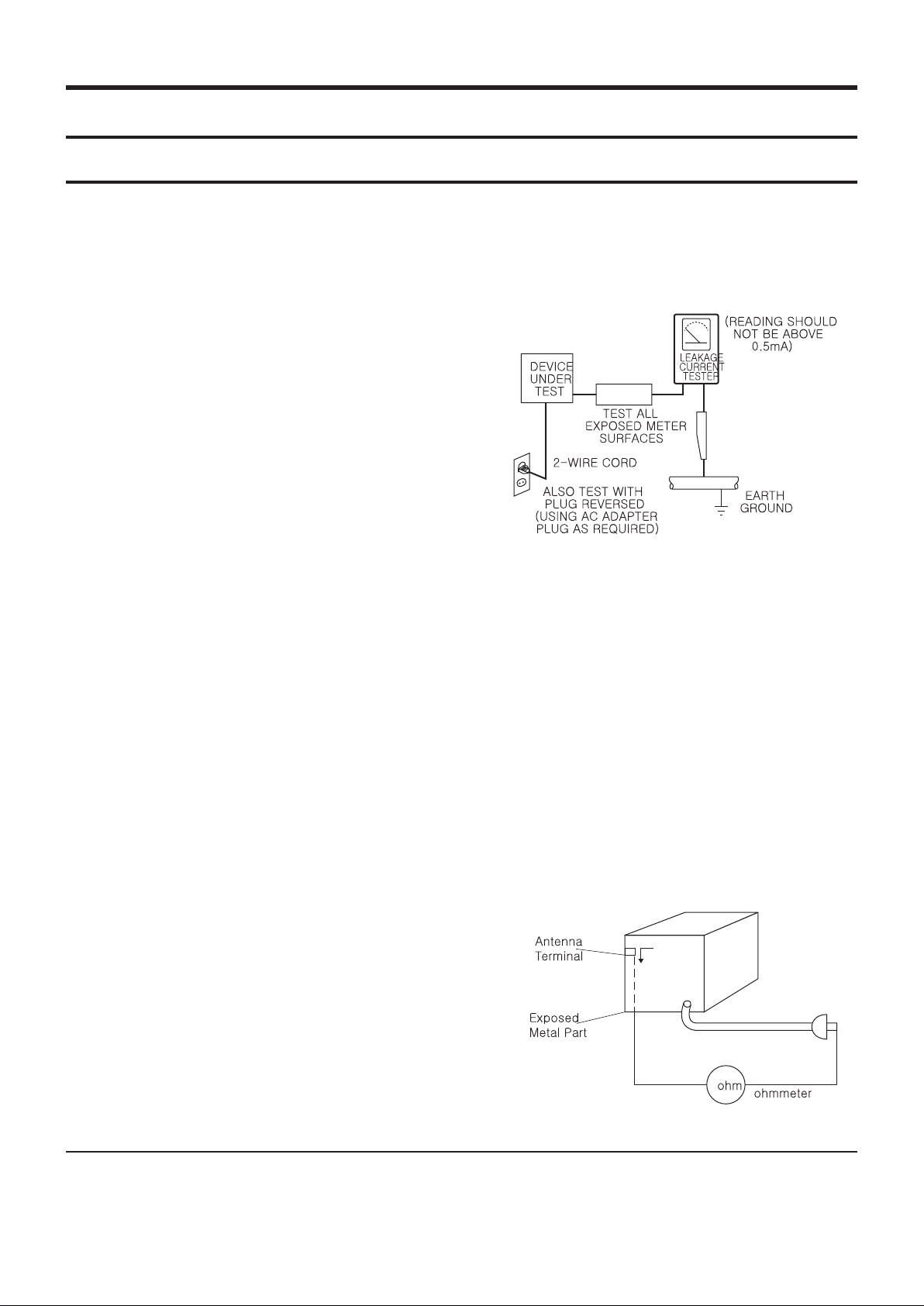

(3) Leakage Current Hot Check-With the instrument

completely reassembled, plug the AC line cord

directly into a 230V(220V ~ 240V) AC outlet. (Do

not use an isolation transformer during this test.)

Use a leakage current tester or a metering system

that complies with American National Standardsp

institute (ANSI) C101.1 Leakage Current for

Appliances and Underwriters Laboratories (UL)

1270 (40.7). With the instrument’s AC switch first in

the ON position and then in the OFF position,

measure from a known earth ground

(metal water pipe,

conduit, etc.) to all exposed metal parts of the

instrument (antennas, handle brackets, metal

cabinets,

screwheads, metallic overlays, control shafts,

etc.), especially any exposed metal parts that offer

an electrical return path to the chassis.

Any current measured must not exceed 0.5mA.

Reverse the instrument power cord plug in the outlet

and repeat the test. See Fig. 1-1.

Any measurements not within the limits specified

herein indicate a potential shock hazard that must

be eliminated before returning the instrument to

the customer.

Fig. 1-1 AC Leakage Test

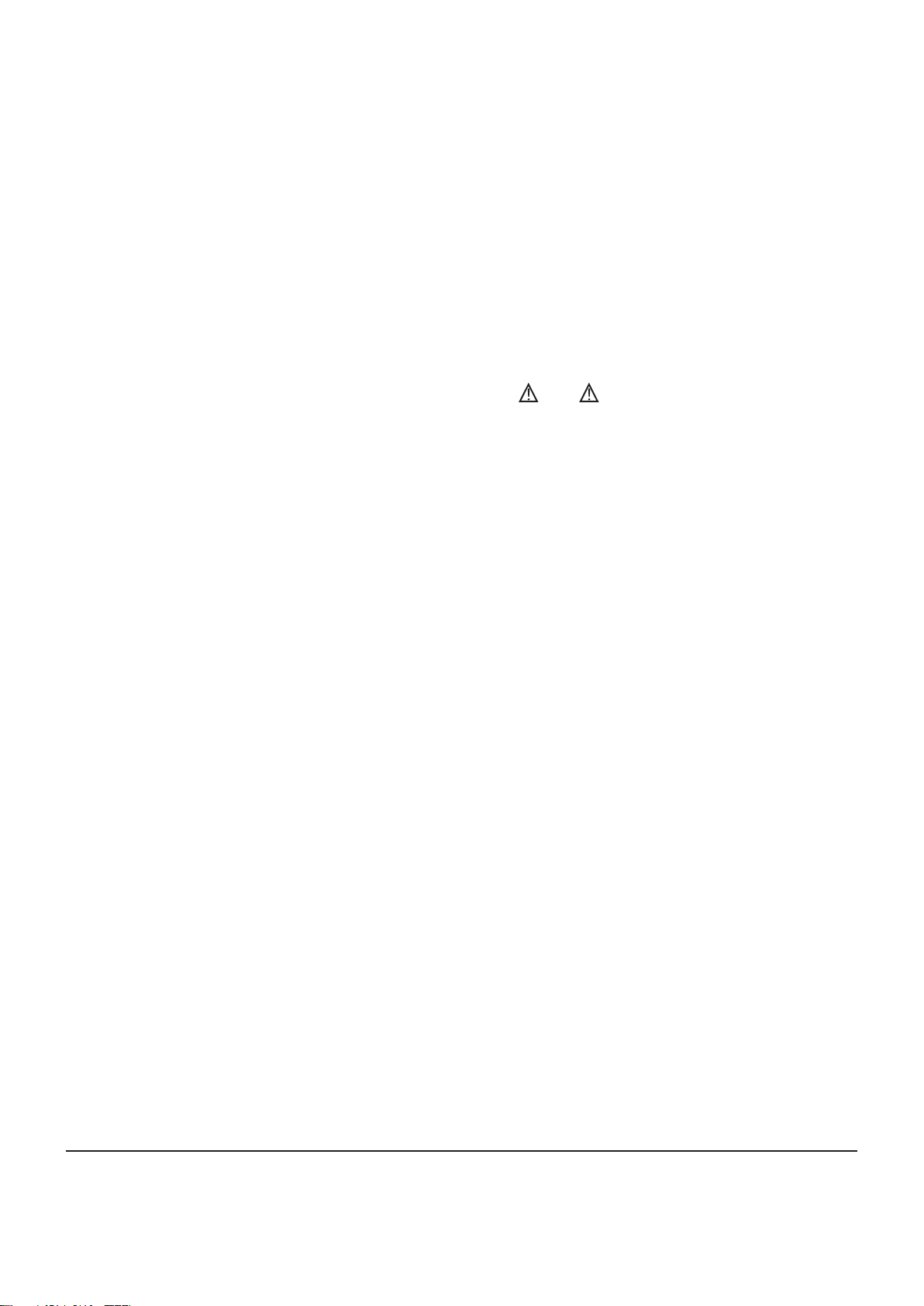

(4) Insulation Resistance Test Cold Check-(1) Unplug

the power supply cord and connect a jumper wire

between the two prongs of the plug. (2) Turn on the

power switch of the instrument. (3) Measure the

resistance with an ohmmeter between the

jumpered AC plug and all exposed metallic cabinet

parts on the instrument, such as screwheads,

antenna, control shafts, handle brackets, etc. When

an exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2

megohm. When there is no return path to the chassis,

the reading must be infinite. If the reading is

not within the limits specified, there is the possibility

of a shock hazard, and the instrument must be

repaired and rechecked before it is returned to the

customer. See Fig. 1-2.

Fig. 1-2 Insulation Resistance Test

Samsung electronics 1-1

Page 4

Precautions

1-2 Samsung Electronics

2) Read and comply with all caution and safety related

notes on or inside the cabinet, or on the chassis.

3) Design Alteration Warning-Do not alter or add to

the mechanical or electrical design of this

instrument.

Design alterations and additions, including

butnotlimitedto,circuitmodicationsandthe

addition of items such as auxiliary audio output

connections, might alter the safety characteristics of

this instrument and create a hazard to the user. Any

design alterations or additions will make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

4) Observe original lead dress. Take extra care to

assure correct lead dress in the following areas:

(1) near sharp edges, (2) near thermally hot parts (be

sure that leads and components do not touch

thermally

hot parts), (3) the AC supply, (4) high voltage,

and (5) antenna wiring. Always inspect in all areas

for pinched, out-of-place, or frayed wiring, Do not

change spacing between a component and the

printed-circuit board. Check the AC power cord for

damage.

5) Components, parts, and/or wiring that appear to

have overheated or that are otherwise damaged

should be replaced with components, parts and/ or

wiringthatmeetoriginalspecications.

Additionally, determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

6) Product Safety Notice-Some electrical and mechanical

parts have special safety-related characteristics

which are often not evident from visual inspection,

nor can the protection they give necessarily be

obtained by replacing them with components rated

for higher voltage, wattage, etc. Parts that have

specialsafetycharacteristicsareidentiedby

shading,

an ( )or a ( )on schematics and parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacementpartmightcreateshock,reand/or

other hazards. Product safety is under review

continuously and new instructions are issued

whenever appropriate.

Page 5

Samsung Electronics 1-3

Precautions

1-2 Servicing Precautions

CAUTION : Before servicing units covered by this

service manual and its supplements, read and follow

the Safety Precautions section of this manual.

Note:Ifunforseencircumstancescreateconict

between the following servicing precautions and any

of the safety precautions, always follow the safety precautions.

Remember: Safety First.

1-2-1 General Servicing Precautions

(1) a. Always unplug the instrument’s AC powercord

from the AC power source before (1) re-moving

or reinstalling any component, circuit board,

module or any other instrument assembly, (2)

disconnecting any instrument electrical plug or

other electrical connection, (3) connecting a test

substitute in parallel with an electrolytic ca

pacitor in the instrument.

b. Do not defeat any plug/socket B+ voltage

interlocks with which instruments covered by

this service manual might be equipped.

c. Do not apply AC power to this instrument and

/or any of its electrical assemblies unless all

solid-state device heat sinks are correctly installed.

d. Always connect a test instrument’s ground lead

to the instrument chassis ground before connecting

the test instrument positive lead. Always

remove the test instrument ground lead last.

(4) An insulation tube or tape is sometimes used and

some components are raised above the printed

wiring board for safety. The internal wiring is

sometimes clamped to prevent contact with heating

components. Install such elements as they

were.

(5) After servicing, always check that the removed

screws, components, and wiring have been installed

correctly and that the portion around the

serviced part has not been damaged and so on.

Further, check the insulation between the blades of

the attachment plug and accessible conductive

parts.

1-2-2 Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet

and turn the power ON. Connect the insulation resistance meter (500V) to the blades of the attachment

plug. The insulation resistance between each blade of

the attachment plug and accessible conductive

parts(see note) should be more than 1 Megohm.

Note : Accessible conductive parts include metal panels,

input terminals, earphone jacks, etc.

Note : Refer to the Safety Precautions section ground

lead last.

(2) The service precautions are indicated or printed on

the cabinet, chassis or components. When servicing,

follow the printed or indicated service precautions

and service materials.

(3)Thecomponentsusedintheunithaveaspecied

ameresistanceanddielectricstrength.

When replacing components, use components

whichhavethesameratings.Componentsidentied

by shading, by( ) or by ( ) in the circuit diagram

are important for safety or for the characteristics

of the unit. Always replace them with the exact

replacement components.

Page 6

Precautions

1-3 ESD Precautions

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damagedeasily by static electricity.

Such components commonly are called Electrostatically Sensitive Devices(ESD). Examples of typical ESD

devicesareintegratedcircuitsandsomeeld-effect

transistors and semiconductor chip components. The

following techniques should be used to help reduce

the incidence of component damage caused by static

electricity.

(1) Immediately before handling any semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic charge on your body by

touching a known earth ground. Alternatively,

obtain and wear a commercially available

discharging wrist strap device, which should be

removed for potential shock reasons prior to

applying power to the unit under test.

CAUTION : Be sure no power is applied to the chassis

or circuit, and observe all other safety precautions.

(8) Minimize bodily motions when handling

unpackaged replacement ESD devices.

(Otherwise harmless

motion such as the brushing together of your

clothes fabric or the lifting of your foot from a

carpetedoorcangeneratestaticelectricity

sufcienttodamageanESDdevice).

(2) After removing an electrical assembly equipped

with ESD devices, place the assembly on a

conductive surface such as aluminum foil, to

prevent electrostatic

charge buildup or exposure of the assembly.

(3) Use only a grounded-tip soldering iron to solder or

unsolder ESD devices.

(4) Use only an anti-static solder removal devices.

Somesolderremovaldevicesnotclassiedas

“anti-static”cangenerateelectricalchargessufcient

to damage ESD devices.

(5) Do not use freon-propelled chemicals. These can

generateelectricalchargessufcienttodamage

ESD devices.

(6) Do not remove a replacement ESD device from its

protective package until immediately before your

are ready to install it.(Most replacement ESD

devices are packaged with leads electrically shorted

together by conductive foam, aluminum foil or

comparable conductive materials).

(7) Immediately before removing the protective

materials from the leads of a replacement ESD

device, touch the protective material to the

chassis or circuit assembly into which the device

will be installed.

1-4 Samsung Electronics

Page 7

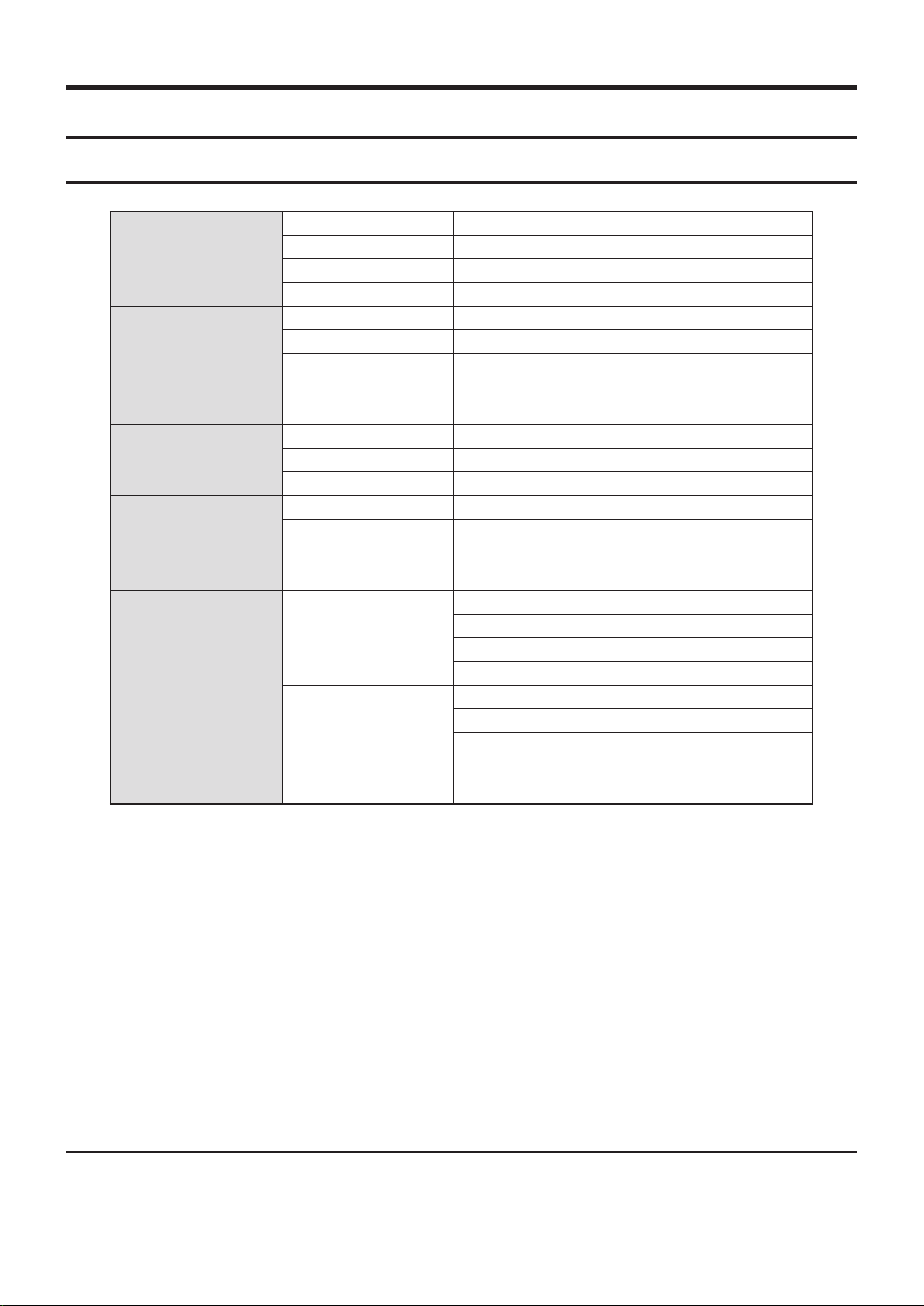

2. Product Specication

2-1 Product Specication

Power Supply

Tuner

Video Decoder

Audio Decoder

A/V Out

Physical Specication

Input Voltage 230 +/- 15% VAC, 50Hz

Power Consumtion Max 20W,

Digital Broadcasting DVB-C (16QAM ~ 256QAM)

Input Signal Level -75dBm~-25dBm

Input Impedance 75 ohm Unbalanced

Connector Type IEC female in accordance with IEC 60169-2

Video Format 4:3(Normal) & 16:9(Wide)

Sample Frequency 32, 44.1, 48 kHz

Type SMPS

Fuse Rating 250V/T1.6A

Freq. Range 109MHz - 862MHz

Prole MPEG 2 MP@ML, MPEG 4 H.264

Resolution HD:576P, 720P, 1080i, SD:576i

Output Dolby Digital / PCM

Audio Mode Mono / Stereo

Interface RCA(L/R), S/PDIF(Optical), HDMI

TV SCART(CVBS,RGB)

Video Out

Audio Out

Size 270 × 200 × 40

Weight 1.2 Kg

VCR SCART(CVBS)

RCA(Component) x 1

HDMI

RCA(L/R)×1

S/PDIF×1

HDMI x 1

Samsung Electronics 2-1

Page 8

Product Specication

2-2 Samsung Electronics

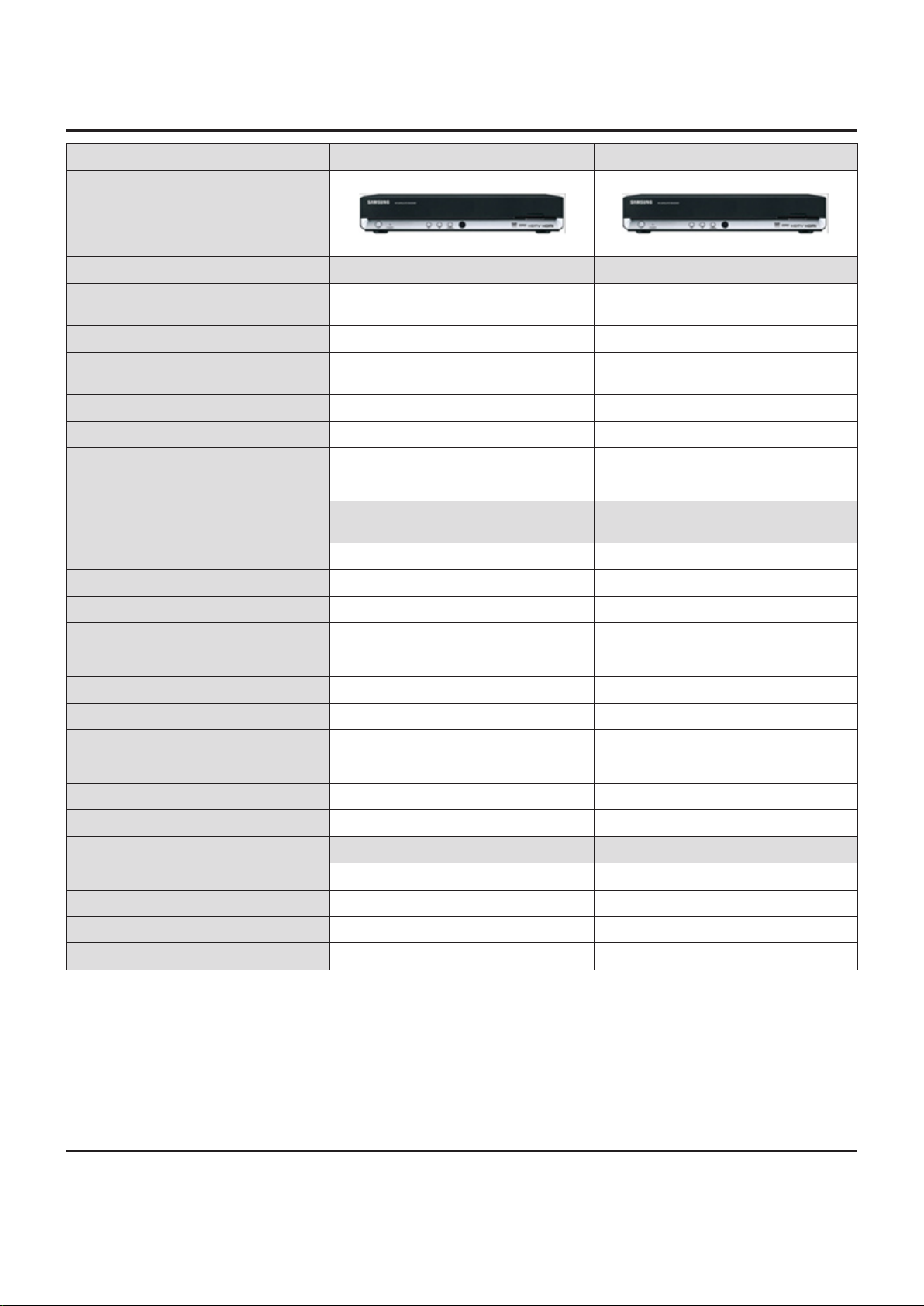

2-2 Chassis Product Specication

Model Name DTB-H380Z DCB-H380R

Chassis

Modulation Format DVB-T DVB-C

Decoding Format

Denition

Resolution

Dolby Decoding

MPEG 2 MP@ML,

MPEG 4 H.264

HD/SD HD/SD

HD : 576p,720p,1080i

SD : 576i

O O

MPEG 2 MP@ML,

MPEG 4 H.264

HD : 576p,720p,1080i

SD : 576i

Loop Through

Down Mixed 2ch supported

SPDIF Supported

OSD Language

Subtitle(Caption)

EPG

Channel List

Favorite Channel List

Audio Volume control

Factory Default

S/W Update

SCART(CVBS)

SCART(S-Video)

SCART(RGB)

SCART(YUV)

Component(YPbPr) : RCA X O

HDMI

(English, Norway, Sweden)

O O

O O

O O

3 Languages

(English, Nederland, France)

O O

O O

O O

O O

O O

O O

O O

O O

X X

O O

X X

O O

3 Languages

Digital Audio(Optical)

L/R Ch : RCA

Power LED indicator

O O

O O

O O

Page 9

Samsung Electronics 2-3

Product Specication

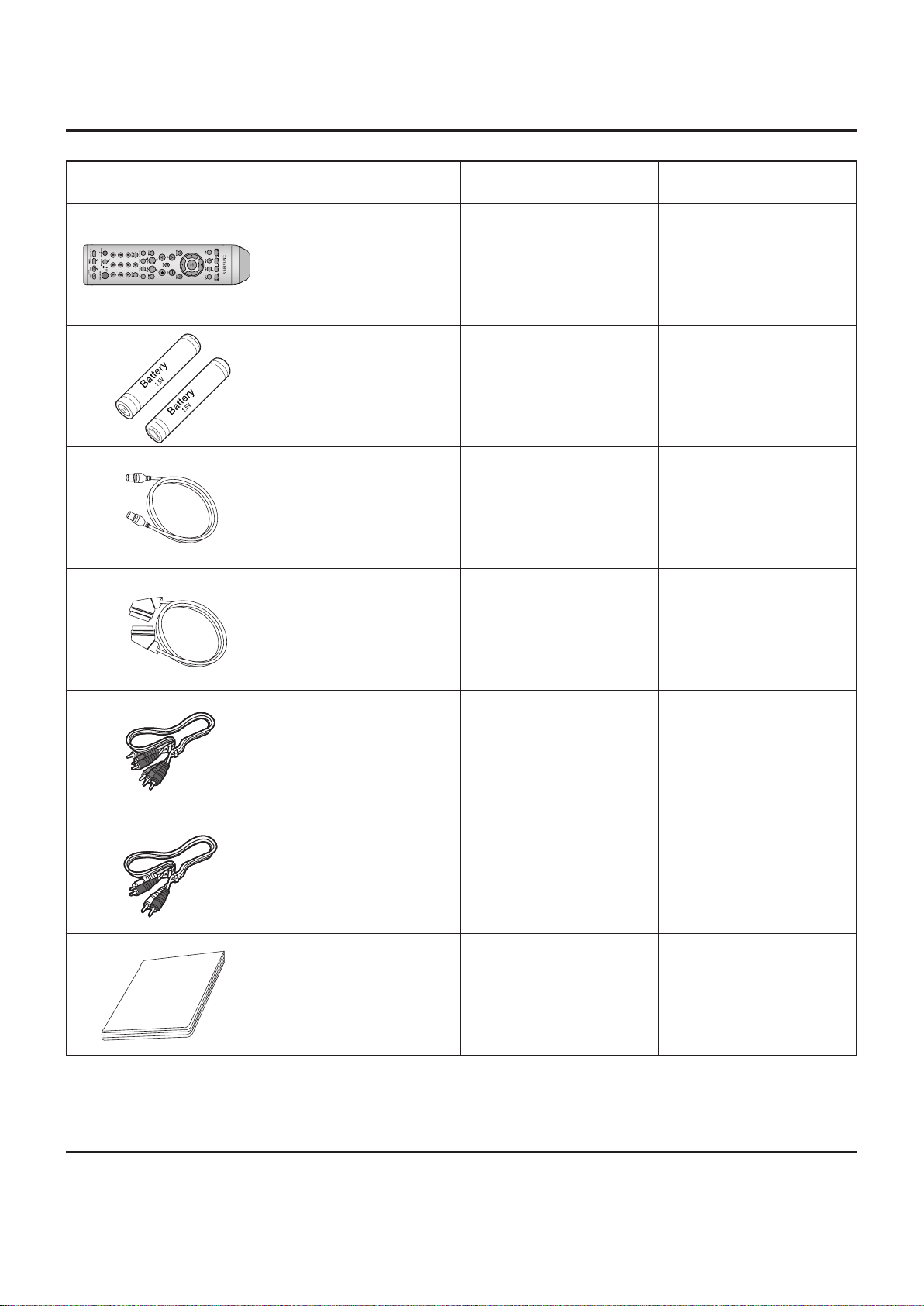

2-3 Option Product Specication

Description Fig Description Parts No Remark

Remote Control MF59-00286A

Batteries for

Remote Controller

(AAA Type)

RF Cable

(1.2M)

SCART Cable

(1.2M)

4301-000115

AC39-00017A

AC39-00015A

Model Standard of

DCB-H380N/XEN

Model Standard of

DCB-H380N/XEN

S.N.A

Model Standard of

DCB-H380N/XEN

Model Standard of

DCB-H380N/XEN

RCA Cable

(Component)

RCA Cable

(Audio L/R)

User's Manual MF68-00473A

MF39-00284A

MF39-00286A

Model Standard of

DCB-H380N/XEN

Model Standard of

DCB-H380N/XEN

Model Standard of

DCB-H380N/XEN

Page 10

Product Specication

M E M O

2-4 Samsung Electronics

Page 11

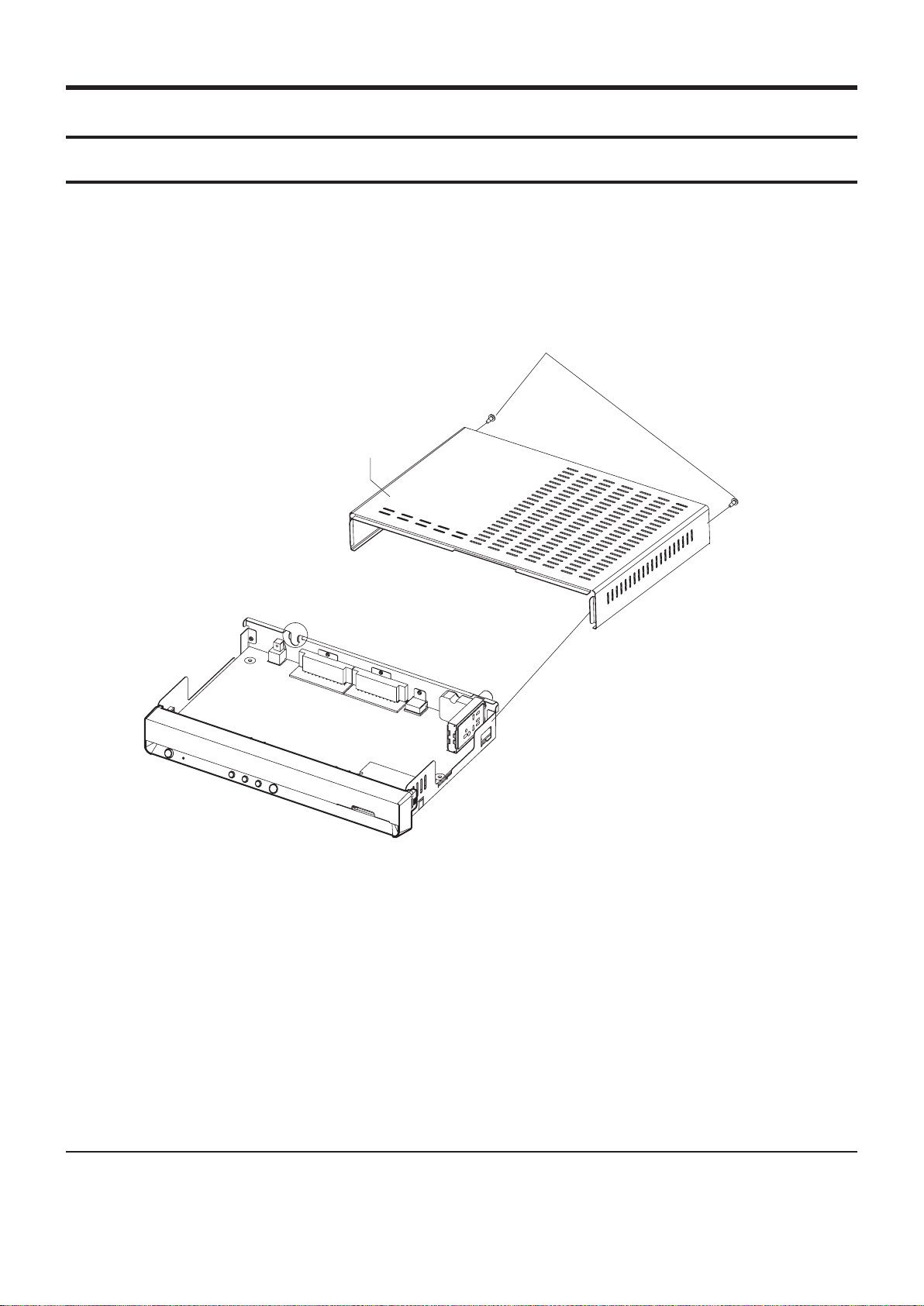

3. Disassembly and Reassembly

3-1 Cabinet and PCB

Samsung Electronics 3-1

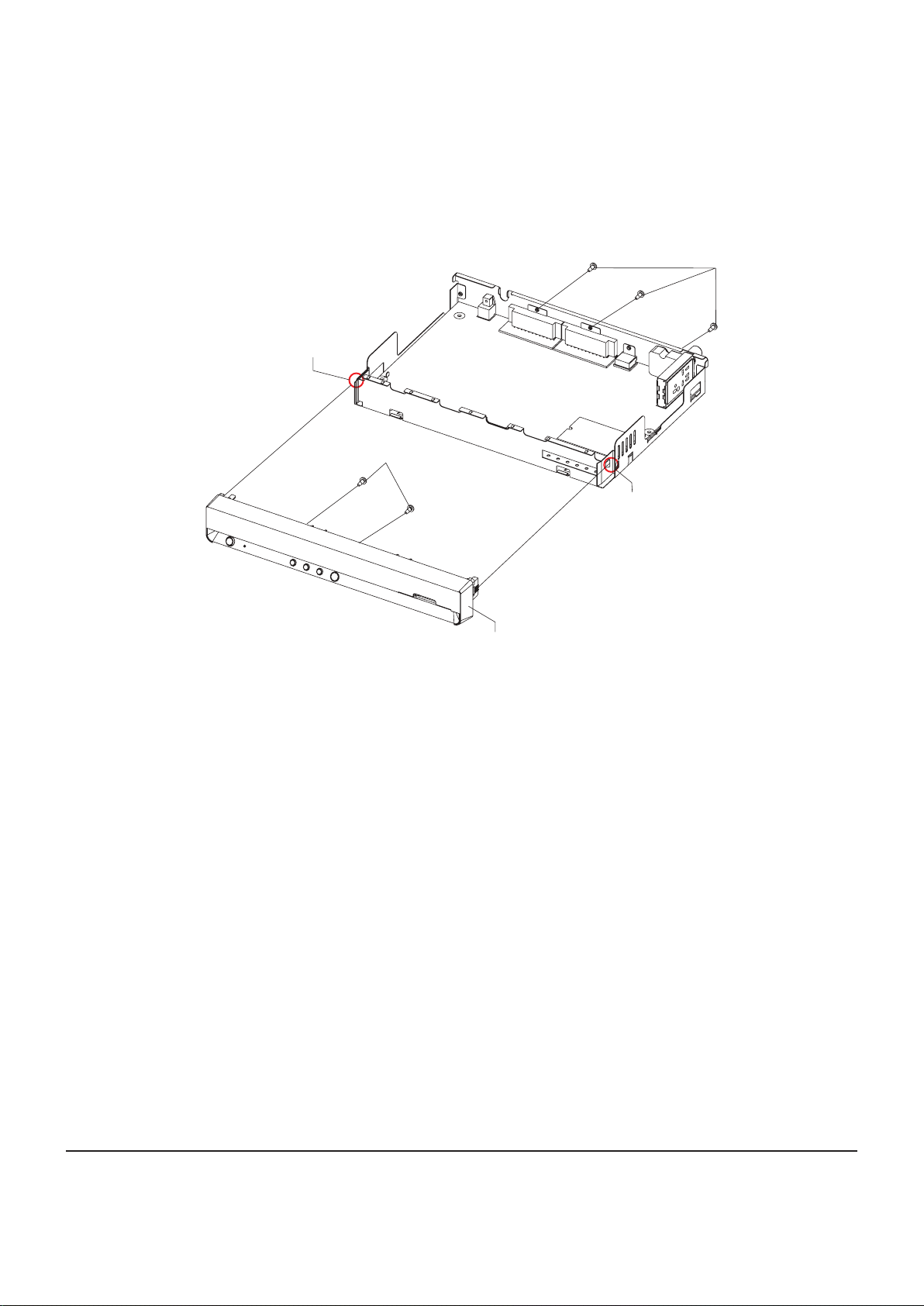

3-1-1 Cover-Top Removal

1) Remove 2 Screws q.

2) Remove Cover-Top w.

.

Fig. 3-1 Cover-Top Removal

q 2 SCREWS

(T 3 X 8 B)

w COVER-TOP

Page 12

Disassembly and Reassembly

3-2 Samsung Electronics

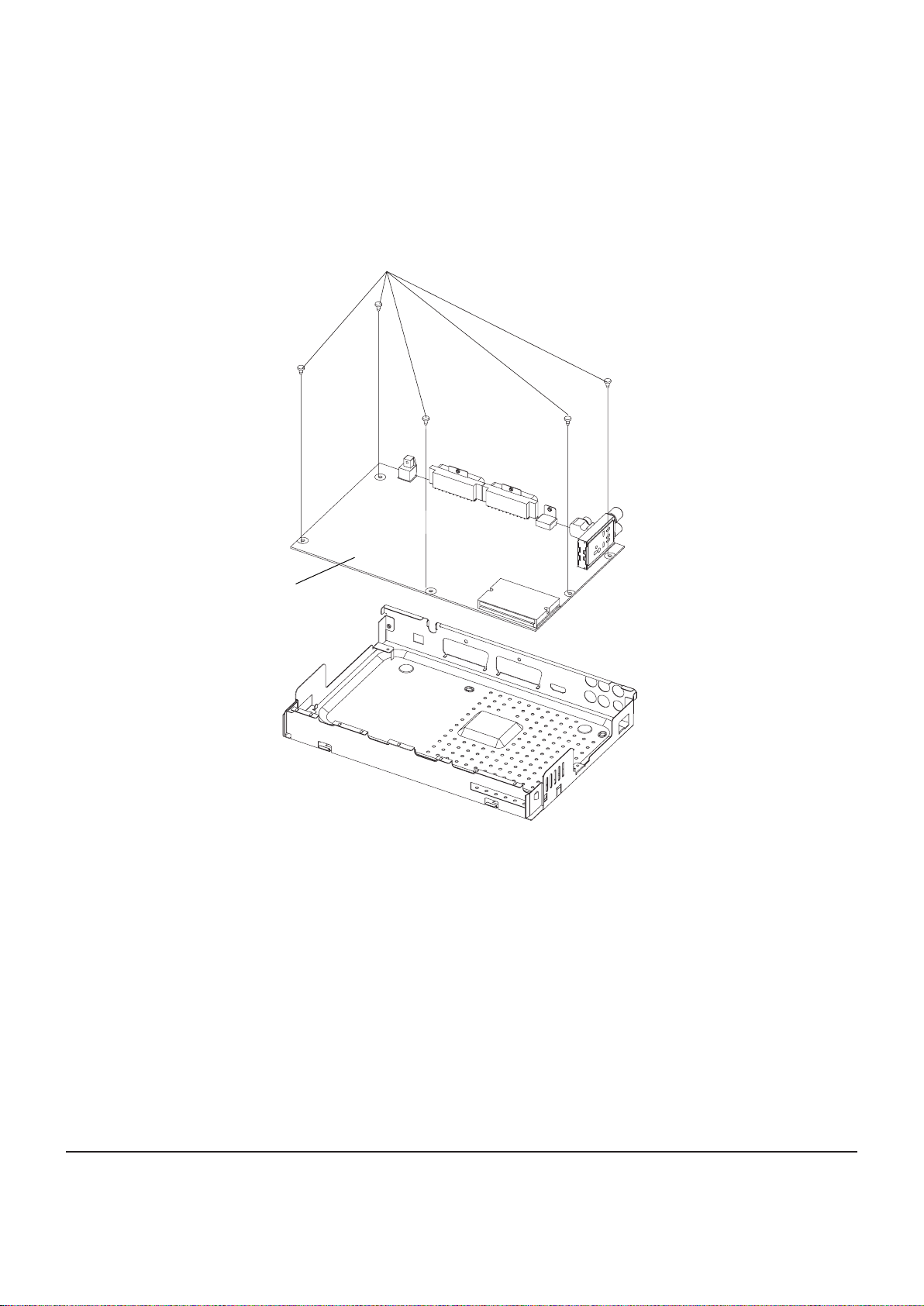

3-1-2 Ass'y Front Removal

1) Remove 2 Hooks q, w.

2) Remove 5 Screws e, r.

3) Remove Ass'y Front t.

Fig. 3-2 Ass'y Front Removal

q 1 HOOK

w 1 HOOK

t ASS'Y FORNT

e 2 SCREWS

(T 3 X 8 B)

r 3 SCREWS

(T 3 X 8 W)

Page 13

Samsung Electronics 3-3

Disassembly and Reassembly

3-1-3 Main board Removal

1) Remove 5 Screws q.

2) Remove Main board w.

Fig. 3-3 Main board Removal

w MAIN BOARD

q 5 SCREWS

(T 3 X 6W)

Page 14

Disassembly and Reassembly

3-4 Samsung Electronics

M E M O

Page 15

4. Troubleshooting

4-1 Troubleshooting ---------------------------------------------------------------------------------- 4-2

4-2 Software Upgrade ----------------------------------------------------------------------------- 4-17

Samsung Electronics 4-1

Page 16

Troubleshooting

4-2 Samsung Electronics

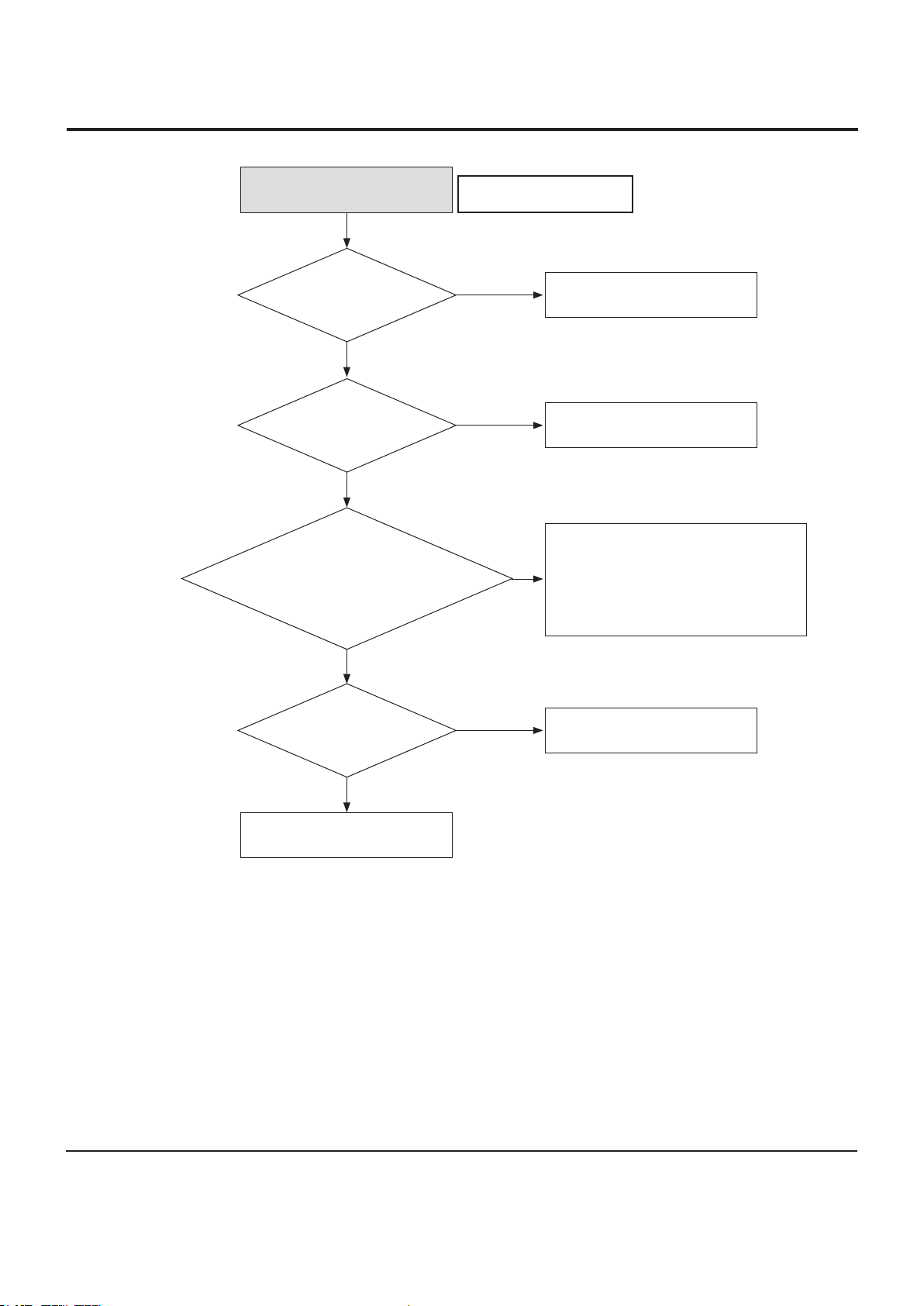

4-1 Troubleshooting

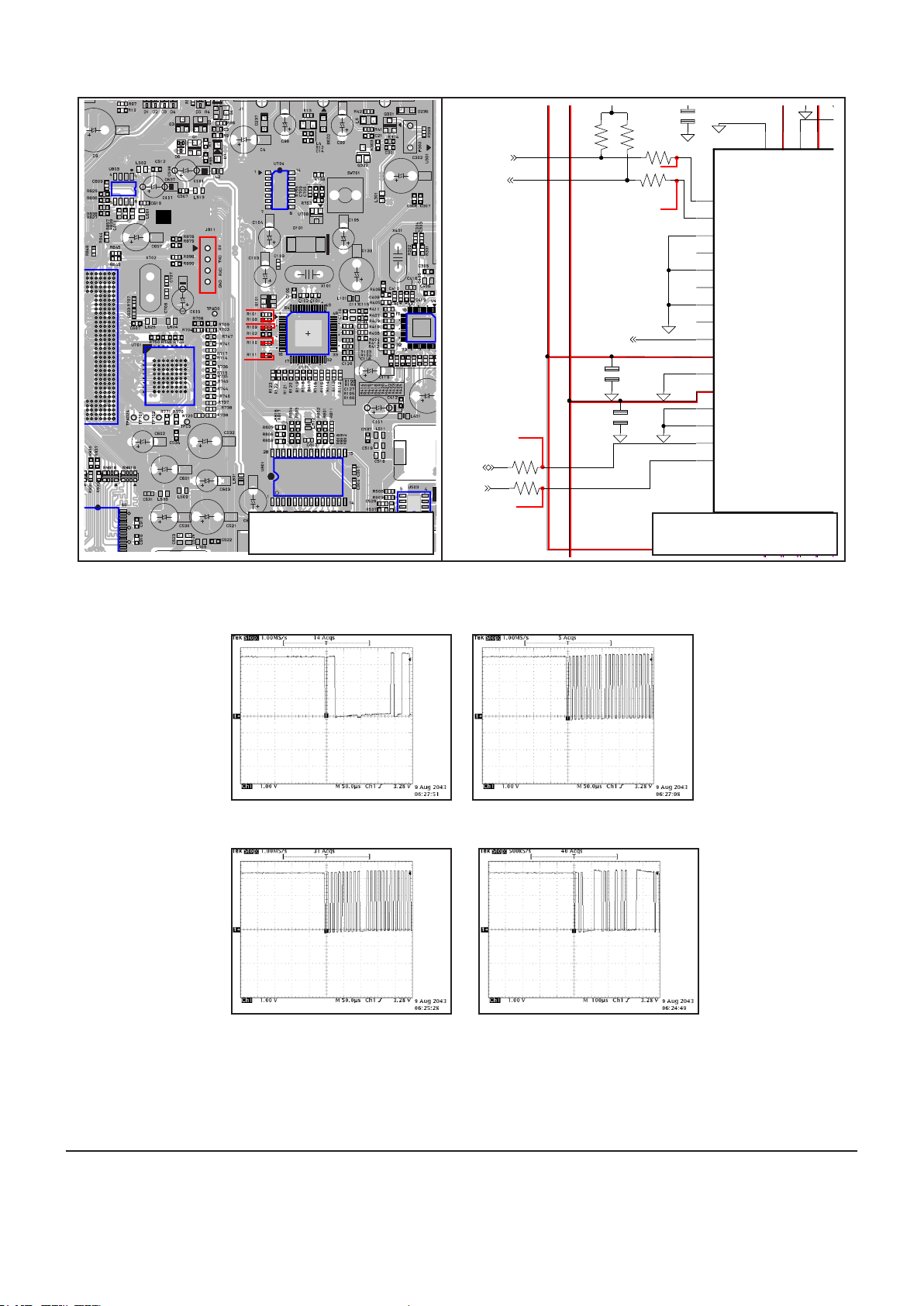

No Power(LED Off)

Cable connection

is right?

Yes

Input

Voltage from SMPS is

OK? (5V(L512, 14V

(PPIJ1 #1))

Yes

Regulated

Voltage is OK?

((12V(PPIJ #2), 1.1V(L505),1.3(U502 #4)

2.6V(L508,L509,L511) 3.3V(U504 #2,

U506 #2)) 1.0V(L515)

♦ No display even OSDA

No

No

No

Connect power plug pin

Check Power Adaptor

No 1.1V : U501 check

No 1.3V : U502 check

No 2.6V : U503 check

No 3.3V : U504,U506 check

No 12V : PPIJ1 checkNo

Yes

27MHz(X101)

is ok? 27MHz(X701 #3)

is ok? 30MHz(X702) is ok?

Yes

Check U100

No

No 27MHz : X101,X701 check

No 30MHZ : X702 check

Page 17

Samsung Electronics 4-3

Troubleshooting

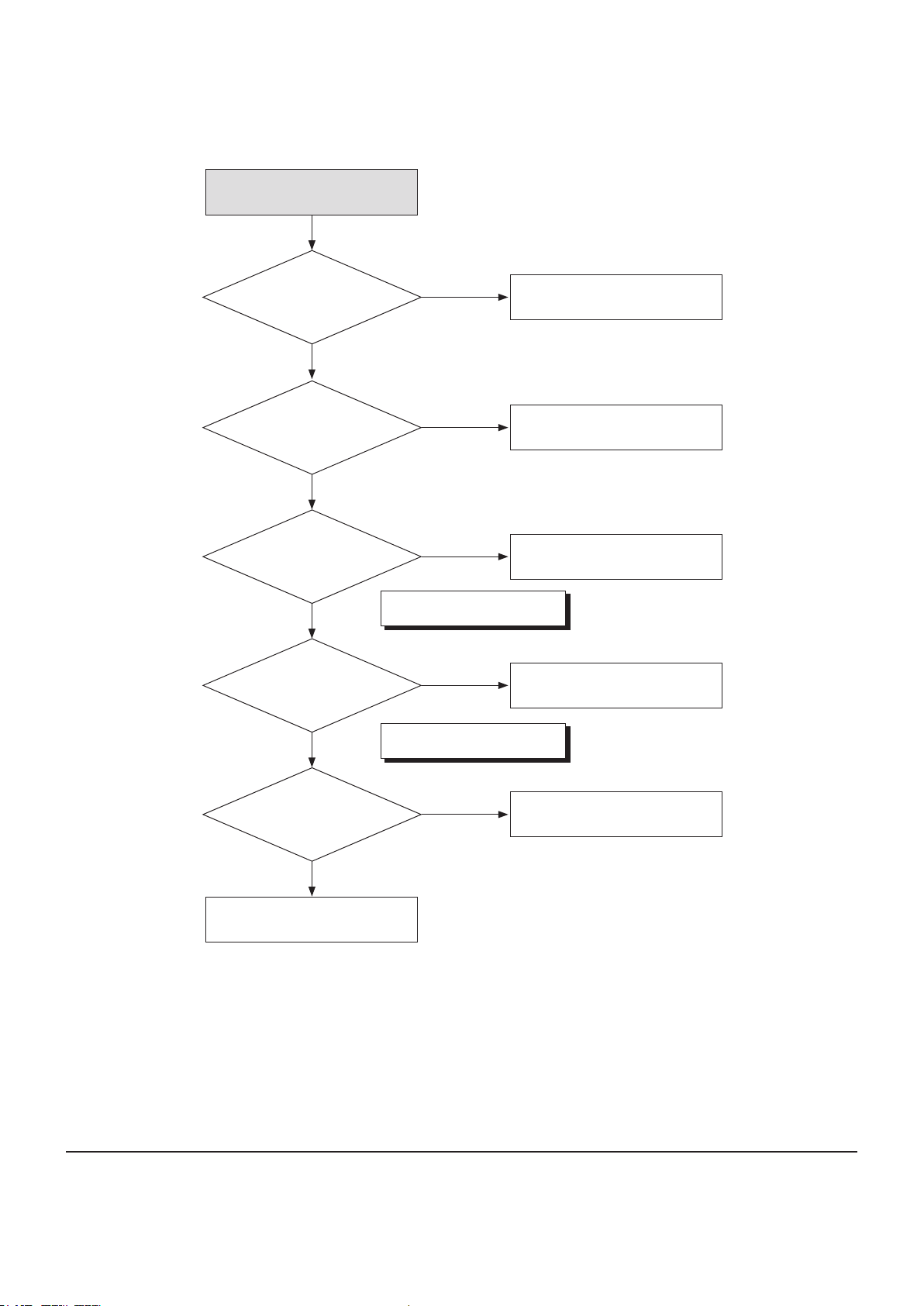

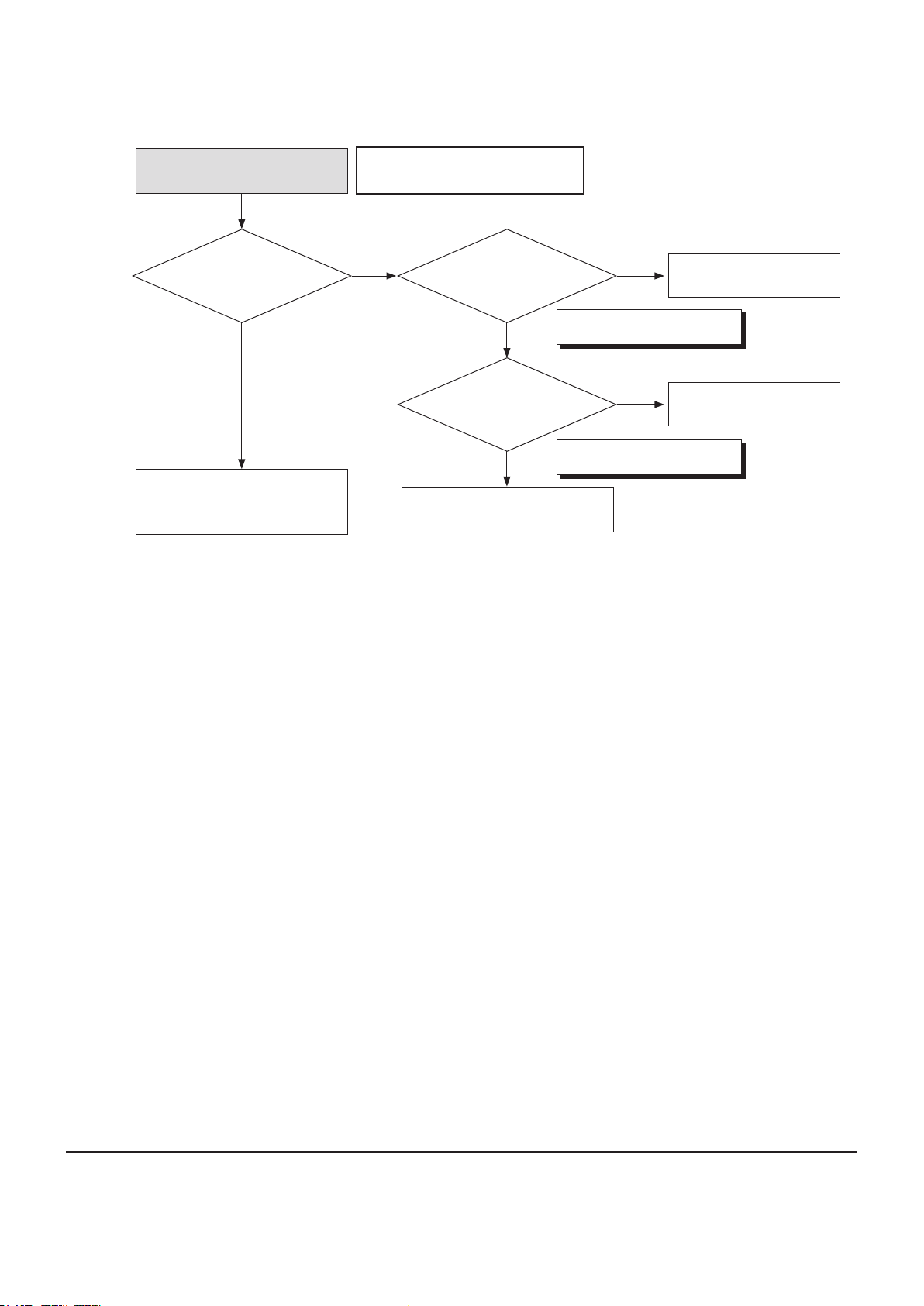

No Locking

RF Cable connection

are right?

Yes

Check

Demodulator

input Voltage(1.0V(Q101#2),

3.3V(U506 #2))

Yes

Check

I2C Line

(R110, R111) while

Channel Up/Down

Yes

Check

I2C line

(R108,R109) while

Channel Up/Down

Yes

No

No

No

Refer to a pattern

image of Table 4-1

No

Refer to a pattern

image of Table 4-1

Connect RF Cable to Antenna

properly

Check Q101, D101

Check U101

Check Tuner

Check Tuner(U301)

(5V(L301))

Yes

Check U100

No

Check SMPS

Page 18

Troubleshooting

4-4 Samsung Electronics

U401

U101

U704

J811

U701

U801

U503

U803

C111

100nF

0

R111

C116

100nF

Q101

MMBT3904

1

2

3

R101

4.7K

SDAT

SCLT

R105

1K

C114

100nF

C110

103

T3.3V

C113

100nF

R102

4.7K

0

R109

C124

103

C123

103

R104

470

C106

100nF

SDA0

C120

103

C125

103

T3.3V

R108

0

C126

103

C127

103

/RST_TM

C118

100nF

0

R110

C109

100nF

R103

470

C112

100nF

C108

100nF

C117

106

SCL0

C107

100nF

X101

27MHz

1

2

IF_AGC_EXT

IM

IP

R106

10K

R199

47

R198

47

150

R197

1K

R196

C103

10uF/16V

C104

10uF/16V

C105

10uF/16V

C119

10uF/16V

C128

100nF

C115

1uF

C134

1uF

U101

STV0297E

1

GPIO9

2

GPIO8

3

TDI

4

TDO

5

TRST

6

TCK

7

TMS

8

GPIO7

9

N_RESET

10

VDD10

11

GND11

12

VDD_IO_3V312

13

GPIO6/CS0

14

GPIO5/CS1

15

SDA

16

SCL

17

M_CK OUT18M_SY NC19M_VA LID20M_ER R21TS_D ATA_022TS_D ATA_123TS_D ATA_224TS_D ATA_325VDD2 526GND2 627VDD_ IO_3V 32728TS_D ATA_429TS_D ATA_530TS_D ATA_631TS_D ATA_732GPIO 4/SDA T

33

GPIO3

34

GPIO2

35

GPIO1

36

GPIO0

37

VDD37

38

GND38

39

VDD_IO_3V339

40

GNDAS

41

INM

42

INP

43

VCCAISO

44

INCM

45

REFM

46

REFP

47

GNDA

48

VCCA

49

GNDD50VDDD

51

GNDA _PLL52VCCA _PLL53GNDD _PLL54VCCD _PLL

55ZO56

VCCA _OSC

57A58

GNDA _OSC

59

VBAS E

60

VDD1 0REG

61

VDD6 162GND6 2

63

VDD_ IO_3V 363

64

CLK_ TST

D101

S3J

1

2

C102

0.024NF

C101

0.024NF

I2C Address = 0x38

Refer to a pattern

image of Main PCB page 6-5

Refer to a pattern

image of DEMOD page 7-7

Fig. 4-1

q

R110

e

R108

w

R111

r

R109

Page 19

Samsung Electronics 4-5

Troubleshooting

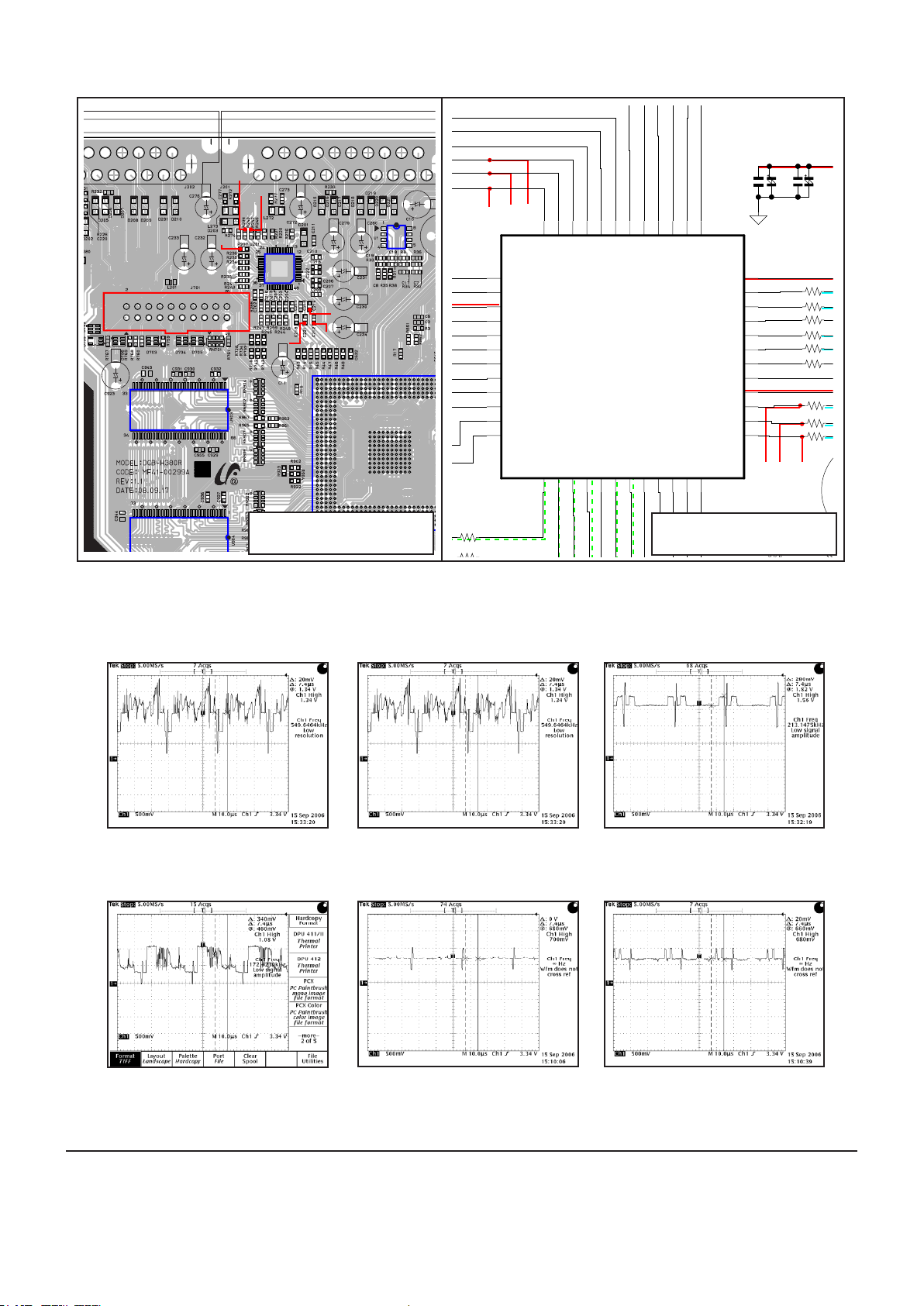

No Video (YPbPr)

Cable

connection

and Video output mode

is right?

No

Reconnect/Change

Video signal Type

(HDTV->Component)

- Other Video Output is OK.

- YPbPr mode must be selected.

Yes

Filtered

YPbPr signal is OK?

(R239,R240

R237)

No

Unltered

YPbPr signal is OK?

(C214,C212,C221)

No

Check U100

Yes

Refer to a pattern

image of Table 4-2

Yes

Refer to a pattern

image of Table 4-2

Check Jack(J1)

Check U201

Page 20

Troubleshooting

4-6 Samsung Electronics

U401

U101

U704

J811

U701

U100

U904

U903

J701

U201

U1

U803

C209

472

220

D217 RLZ15B

12

ROUTTV_P15

YCVBSOUTVCR

D209 RLZ15B

12

75

R235

D210 RLZ15B

12

SLBTV_P8

D219 RLZ15B

12

C216

1uF

75

R238

C219

1uF

LINVCR_P6

220

R299

YCVBSOUTTV

12K

R233

BVCR_P7

GVCR_P11

D206 RLZ15B

12

12K

R232

CVBSINVCR_P20

75

CVBSINTV_P20

75

D205 RLZ15B

12

C214

1uF

C204

220nF

ROUTVCR_P1

75

R239

D207 RLZ15B

12

BOUTTV_P7

21P_SCART

J201

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

75

R237

GVCR_P11

D218 RLZ15B

12

620

R220

BVCR_P7

75

C212

1uF

75

R241

GOUTTV_P11

YCVBSOUTVCR

D220 RLZ15B

12

LOUTVCR_P3

21P_SCART

J202

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

75

R234

75

R243

D216 RLZ15B

12

75

R240

FBINVCR_P16

C201

220nF

C221

1uF

BOUTTV_P7

RINVCR_P2

D221 RLZ15B

12

GOUTTV_P11

220

R288

ROUTTV_P1

YCVBSOUTTV

CVBSINTV_P20

D215 RLZ15B

12

LOUTTV_P3

CVBSINVCR_P20

C217

1uF

5.0VSC

RVCR_P15

ROUTTV_P15

D231 RLZ15B

12

220

C218

1uF

FBINTV_P16

C202

220nF

RVCR_P15

C213

1uF

D208 RLZ15B

12

C205

472

75

SLBVCR_P8

75

R236

C203

220nF

47uF

C233

47uF

C232

HDOUT_Pb

HDOUT_Pr

HDOUT_Y

U201

STV6418AH

1 VCCA

2

DECAV

3

VCC12

4

GNDref

5

ALIN_TV

6

ARIN_TV

7

ALIN_VCR

8

ARIN_VCR

9

ALIN+_ENC

10

ALIN-_ENC

11

ARIN+_ENC

12

ARIN-_ENC

13

ALOU T_VCR14AROU T_VCR15ALOU T_TV16AROU T_TV17GNDD18SDA19SCL20IT_O UT21SLB_ VCR22SLB_ TV23FBIN _VCR24FBOU T_TV

25

B/PbOUT_HD

26

G/YOUT_HD

27

R/PrOUT_HD

28

VCCHD

29

GNDV

30

BOUT_TV

31

GOUT_TV

32

R/COUT_TV

33

COUT_VCR

34

Y/CVBSOUT_VCR

35

Y/CVBSOUT_TV

36

VCC

37

CIN_ TV

38

Y/CV BSIN_T V

39

Y/CV BSIN_V CR40R/C/ PrIN_V CR

41

G/YI N_VCR

42

B/Pb IN_VCR

43

Y/CV BSIN_E NC

44

YIN_ ENC45CIN_ ENC

46

R/Y/ C/PrIN _ENC

47

G/Y/ CIN_EN C

48

B/Pb IN_ENC

D236

RLZ15B

1 2

D237

RLZ15B

1 2

D238

RLZ15B

1 2

TV

AUX

NEAR RCA JACK

Refer to a pattern

image of Main PCB page 6-5

Refer to a pattern

image of page 7-13

Fig. 4-2

q

R239

w

R240

e

R237

r

C214

t

C212

y

C221

Page 21

Samsung Electronics 4-7

Troubleshooting

No Video (SCART(CVBS))

Cable

Connection

and Video Output type

are right?

Yes

CVBS

output is OK?

(R243)

No

DC input

is OK? (5V:L201,

12V:C231+)

Yes

Refer to a pattern

image of Table 4-3

- Other Video Output is OK.

- OSD is not displayed on CVBS output

♦ It need to check whether TV supports RGB/S-Video input.

No

Yes

No

Reconnect/change

Video output mode

Check Jack(J201)

Check SMPS

Trouble shooting

CVBS

signal from U100

is OK? (C217)

No

Check U100

Yes

Refer to a pattern

image of Table 4-3

Check U201

Page 22

Troubleshooting

4-8 Samsung Electronics

U401

U101

U704

J811

U701

U100

U904

U903

J701

U201

U1

U803

C209

472

D217 RLZ15B

12

ROUTTV_P15

YCVBSOUTVCR

D209 RLZ15B

12

75

R235

D210 RLZ15B

12

SLBTV_P8

D219 RLZ15B

12

C216

1uF

75

R238

C219

1uF

LINVCR_P6

220

R299

YCVBSOUTTV

12K

R233

BVCR_P7

GVCR_P11

D206 RLZ15B

12

12K

R232

CVBSINVCR_P20

75

CVBSINTV_P20

75

D205 RLZ15B

12

C214

1uF

C204

220nF

ROUTVCR_P1

75

R239

D207 RLZ15B

12

BOUTTV_P7

J201

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

75

R237

GVCR_P11

D218 RLZ15B

12

BVCR_P7

75

C212

1uF

75

R241

GOUTTV_P11

YCVBSOUTVCR

LOUTVCR_P3

21P_SCART

J202

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

75

R234

75

R243

D216 RLZ15B

12

75

R240

FBINVCR_P16

C201

220nF

C221

1uF

BOUTTV_P7

RINVCR_P2

GOUTTV_P11

220

R288

ROUTTV_P1

YCVBSOUTTV

D215 RLZ15B

12

LOUTTV_P3

CVBSINVCR_P20

C217

1uF

5.0VSC

RVCR_P15

ROUTTV_P15

D231 RLZ15B

12

C218

1uF

FBINTV_P16

C202

220nF

RVCR_P15

C213

1uF

D208 RLZ15B

12

C205

472

75

SLBVCR_P8

75

R236

C203

220nF

47uF

C233

47uF

C232

HDOUT_Pb

HDOUT_Pr

HDOUT_Y

U201

STV6418AH

1 VCCA

2

DECAV

3

VCC12

4

GNDref

5

ALIN_TV

6

ARIN_TV

7

ALIN_VCR

8

ARIN_VCR

9

ALIN+_ENC

10

ALIN-_ENC

11

ARIN+_ENC

12

ARIN-_ENC

ALOU T_VCR

AROU T_VCR

ALOU T_TV

AROU T_TV

GNDD

SDA

SCL

IT_O UT

SLB_ VCR

SLB_ TV

FBIN _VCR

FBOU T_TV

25

B/PbOUT_HD

26

G/YOUT_HD

27

R/PrOUT_HD

28

VCCHD

29

GNDV

30

BOUT_TV

31

GOUT_TV

32

R/COUT_TV

33

COUT_VCR

34

Y/CVBSOUT_VCR

35

Y/CVBSOUT_TV

36

VCC

37

CIN_ TV

38

Y/CV BSIN_T V

39

Y/CV BSIN_V CR40R/C/ PrIN_V CR

41

G/YI N_VCR

42

B/Pb IN_VCR

43

Y/CV BSIN_E NC

44

YIN_ ENC45CIN_ ENC

46

R/Y/ C/PrIN _ENC

47

G/Y/ CIN_EN C

48

B/Pb IN_ENC

1 2

1 2

1 2

TV

AUX

NEAR RCA JACK

Refer to a pattern

image of Main PCB page 6-5

Refer to a pattern

image of page 7-13

Fig. 4-3

q

R243

w

C217

Page 23

Samsung Electronics 4-9

Troubleshooting

No Video (HDMI)

Check

HDMI Cable

Connection between TV

& Settop Box

Yes

TMDS

Clock

is OK? Check the

frequency with Frequency counter

576p:27MHz 720p,1080i:

74.25MHz (D4)

No

Check U100

No

- Other Video Output is OK.

- HDMI Connector must be connected to display device (e.g.TV).

- Check input mode of TV (HDMI)

Connect Cable Properly

Yes

Check Jack(J5)

Page 24

Troubleshooting

4-10 Samsung Electronics

No Analog Audio (L/R)

Audio

Mode is Mute?

Volume is OK?

Yes

SCART Audio is OK?

No

Audio

signal from U1 is OK?

(1 pin, 7 pin of U1)

Yes

- Digital Audio HDMI/SPDIF Output is OK

No

No

No

Refer to a pattern

image of Table 4-5

Check Audio setting

Audio

output from U201 is

OK? (R274,R276)

Check U1

Yes

Refer to a pattern

image of Table 4-4

Check J201

Audio

signal from U100

is OK (R34,R35,R36,R38)

No

Check U100

Yes

Check U201

Page 25

Samsung Electronics 4-11

Troubleshooting

U401

U101

U704

J811

U701

U100

U903

J701

U201

U1

U803

C209

472

220

R279

D217 RLZ15B

12

C277

4.7nF

ROUTTV_P15

YCVBSOUTVCR

D209 RLZ15B

12

75

R235

D210 RLZ15B

12

SLBTV_P8

D219 RLZ15B

12

C216

1uF

VDAC0_Y

75

R238

C219

1uF

LINVCR_P6

6.8uH

L271

220

R299

YCVBSOUTTV

12K

R233

BVCR_P7

GVCR_P11

D206 RLZ15B

12

12K

R232

CVBSINVCR_P20

VDAC0_CV

75

R246

75

R245

CVBSINTV_P20

75

R247

SLBVCR_P8

D205 RLZ15B

12

C214

1uF

C204

220nF

ROUTVCR_P1

CIC21J601NE

L201

C271

4.7nF

75

R239

D207 RLZ15B

12

C215

1uF

VDAC1_Y

6.8uH

L272

BOUTTV_P7

C210

100nF

75

R237

620

R221

GVCR_P11

D218 RLZ15B

12

620

R220

BVCR_P7

75

R244

75

R242

C222

1uF

C212

1uF

75

R241

SCART_INT

C273

4.7nF

GOUTTV_P11

FBINVCR_P16

100

R271

C275

4.7nF

YCVBSOUTVCR

D204

RLZ15B

12

C220

1uF

D220 RLZ15B

12

D5.0V

LOUTVCR_P3

VDAC1_Pr

VDAC0_C

75

R234

75

R243

D216 RLZ15B

12

220

R274

C208

472

VDAC1_Pb

75

R240

6.8uH

L274

FBINVCR_P16

C201

220nF

C221

1uF

BOUTTV_P7

RINVCR_P2

D221 RLZ15B

12

GOUTTV_P11

220

R288

ROUTTV_P1

YCVBSOUTTV

CVBSINTV_P20

C223

1uF

D215 RLZ15B

12

LOUTTV_P3

CVBSINVCR_P20

C217

1uF

5.0VSC

RVCR_P15

ROUTTV_P15

100

R275

C211

100nF

SLBTV_P8

D231 RLZ15B

12

220

R276

220

R280

C218

1uF

6.8uH

L273

FBINTV_P16

D202

RLZ15B

12

C202

220nF

RVCR_P15

C213

1uF

D208 RLZ15B

12

C207

472

FBINTV_P16

C205

472

75

R248

SLBVCR_P8

75

R236

C203

220nF

10uF/50V

C272

10uF/50V

C274

10uF/50V

C276

10uF/50V

C278

10uF/50V

C279

10uF/50V

C280

D211

RLZ15B

1 2

D213

RLZ15B

1 2

D203

RLZ15B

1 2

D201

RLZ15B

1 2

47uF

C234

47uF

C233

47uF

C232

47uF

C230

HDOUT_Pb

HDOUT_Pr

HDOUT_Y

U201

STV6418AH

1 VCCA

2

DECAV

3

VCC12

4

GNDref

5

ALIN_TV

6

ARIN_TV

7

ALIN_VCR

8

ARIN_VCR

9

ALIN+_ENC

10

ALIN-_ENC

11

ARIN+_ENC

12

ARIN-_ENC

13

ALOU T_VCR14AROU T_VCR15ALOU T_TV16AROU T_TV17GNDD18SDA19SCL20IT_O UT21SLB_ VCR22SLB_ TV23FBIN _VCR24FBOU T_TV

25

B/PbOUT_HD

26

G/YOUT_HD

27

R/PrOUT_HD

28

VCCHD

29

GNDV

30

BOUT_TV

31

GOUT_TV

32

R/COUT_TV

33

COUT_VCR

34

Y/CVBSOUT_VCR

35

Y/CVBSOUT_TV

36

VCC

37

CIN_ TV

38

Y/CV BSIN_T V

39

Y/CV BSIN_V CR40R/C/ PrIN_V CR

41

G/YI N_VCR

42

B/Pb IN_VCR

43

Y/CV BSIN_E NC

44

YIN_ ENC45CIN_ ENC

46

R/Y/ C/PrIN _ENC

47

G/Y/ CIN_EN C

48

B/Pb IN_ENC

D236

RLZ15B

1 2

D237

RLZ15B

1 2

D238

RLZ15B

1 2

TV

AUX

NEAR RCA JACK

Refer to a pattern

image of Main PCB page 6-5

Fig. 4-4

q

R274

w

R276

Fig. 4-3

Refer to a pattern

image of page 7-13

Page 26

Troubleshooting

4-12 Samsung Electronics

U401

U101

U704

J811

U100

U201

U1

U803

A

A

VCC

GND

A

RR

WB

G

AA

VIDEO-AUDIO

Peripherals

TX2+

TX2-

TXC-

TXC+TX1+

TX0+

TX0-

TX1-

TX0+

TX1-

TXC+

TX0-

TXC-

TX0-

HDMI_HTPLG

TXC+

PCMOUT2

PCMOUT4

AUD_RN

TXC-

TX1-

HDMI_CEC

TX1+

TX2-

AUD_RP

TX0+

PCMOUT3

TXC+

CEC

TX1+

AUD0_SPDIF

TX1+

CEC

TX0-

TX2+

AUD_LN

TX2-

AUD_LP

TX2+

TX2-

TX2+

TX0+

TX1-

TXC-

D5.0V

D5.0V

5V_HDMI

12VA

D5.0V

140/F

7.5K/F

560/F

R31

7.5K/F

140/F

100

R36

140/F

560/F

R33

47

R17

560/F

R8

140/F

100

R34

560/F

R32

140/F

100

100K

R7

560/F

R16

100

R38

140/F

C17

6.8n

C18

6.8n

C19

6.8n

C7

6.8n

D3.3V

RClamp0502B

D3

1

2

3

RClamp0502B

D6

1

2

3

RClamp0502B

D2

1

2

3

RClamp0502B

D1

1

2

3

RClamp0502B

D5

1

2

3

RClamp0502B

D4

1

2

3

AUD_L0

AUD_R0

FHP3230

U1

1234

5 6 7 8

Q2

2N7002

D

G

S

Q3

2N7002

D

G

S

D3. 3V

SCL2

SDA2

10uF/50V

C98

6.8uH

6.8uH

10uF/50V

C99

C21

4.7nF

220K

R42

C14

4.7nF

AUD_R1

220K

R13

AUD_L1

1uF

C11

1.5K

R4

1.5K

R5

RCA_JACK

J1

GND

1

GND

4

GND

7

Green

8

Audio_Red

3

Video_Red

2

Blue

5

White

6

HDOUT_Pr

HDOUT_Pb

HDOUT_Y

220

R12

220

R41

C2

120

D3.3V

27K

R3

Q1

2N7002

D

G

S

D5.0V

1K

R96

KSR1104

Q4

3

C

2

B

1

E

2.2K

R95

D8

RLZ5.6B

1 2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

U100

STi7101CWD

VIDOUTYC9

T31

VIDANACVOUT1

C34

AUDANAVBGIN

C28

AUDPCMOUT0

A25

VIDANAGOUT0

F34

AUDSCLKOUT

E24

AUDPCMOUT1

B25

AUDANAOUTPR

A28

AUDPCMOUT2

C25

AUDPCMOUT3

D25

AUDDATAIN

D29

AUDPCMOUT4

E25

VIDANAROUT0

D34

AUDLRCLKIN

E28

AUDANAIREFOUT

C27

AUDANAOUTMR

B28

VIDANACOUT1

A34

VIDANADUMPR0

D33

AUDANAOUTML

B27

VIDOUTHSYNC

M33

AUDPCMCLKOUT

D26

VIDANADUMPY1

B33

VIDANADUMPB0

E33

VIDANAYOUT1

B34

AUDLRCLKOUT

E26

AUDSTRBIN

D28

VIDANAREXT0

A31

VIDANAREXT1

A32

VIDANAGNDREXT0

B31

VIDANADUMPC1

A33

VIDANAGNDREXT1

B32

AUDSPDIFOUT

D24

VIDOUTYC0

L34

VIDOUTVSYNC

M34

VIDOUTYC1

L33

VIDANABOUT0

E34

VIDOUTYC2

K34

VIDANADUMPCV1

C33

VIDOUTYC10

T30

VIDOUTYC3

K33

VIDANADUMPG0

F33

VIDOUTYC11

R31

VIDOUTYC4

J34

VIDOUTYC12

R30

VIDOUTYC5

J33

VIDOUTYC13

P31

VIDOUTYC6

H34

AUDANAOUTPL

A27

VIDOUTYC14

P30

VIDOUTYC7

H33

VIDOUTYC15

N31

VIDOUTYC8

U30

U100

STi7101CWD

SATA_RXN

AP31

TMDSTX2P

P33

TMDSTX1N

R34

SATA_TXP

AN30

DAA_C2A

AP5

TMDSTXOP

T33

USB_DN

AP25

DAA_C1A

AN5

TMDSTXCN

U34

SATA_RXP

AN31

USB_DP

AN25

TMDSTXON

T34

SATA_REF

AM30

TMDSTX2N

P34

TMDSTXCP

U33

SATA_TXN

AP30

TMDSREF

T32

USB_REF

AM25

TMDSTX1P

R33

NC1

A29

NC2

C30

NC3

G5

NC4

L31

NC5

AL6

NC6

AM5

NC7

AN9

NC8

AP9

NC9

AM31

C6

680

1

2

( Sheet Pattern 55 B|0m )

Place these diode as close as possible to Jack

HDMI

VDAC_AVDD33 needs to be very clean. If you use switching supplies, consider using a small linear regulator for this supply. (250 mA worst case)

JACK ?! 1YA"9hD!

Treat each of these as 100 ohm diff pairs and spaced greater than 0.05" from adjacent pairs

NEAR STI710X

r

7 Pin of U1

Refer to a pattern

image of Main PCB page 6-5

e

1 Pin of U1

Fig. 4-5

Refer to a pattern

image of page 7-15

Page 27

Samsung Electronics 4-13

Troubleshooting

No Digital Audio (Optical)

Check

Dolby digital

Mode and TV supports

Selected mode And

connection

Yes

Digital

Audio Signals are OK?

(R2)

No

image of Table 4-6

- Analog Audio Output is OK

No

Yes

Refer to a pattern

Connect cable or change

“Dolby digital auto selection” to ‘off’

5V (L1) is Ok?

Check SMPS

No

Yes

Check JP2

Check U100

Page 28

Troubleshooting

4-14 Samsung Electronics

U101

U704

J811

U701

U100

U903

J701

U201

U1

U803

U1102

U1101

A

A

TXC-

TXC+

22

R2

Optical_JACK

JP2

VIN

1

VCC

2

GND

3

C1

100nF

D5.0V

CIC21J601NE

L1

AUD0_SPDIF

( Sheet Pattern 55 B|0m )

1

* Hole @LA_<30h

3

Place these diode as close as possible to Jack

C

SPDIF

AC

A

BAV99

JACK ?! 1YA"9hD!

2

Refer to a pattern

image of Main PCB page 6-5

Fig. 4-6

q

Refer to a pattern

image of page 7-5

R2

Page 29

Samsung Electronics 4-15

Troubleshooting

No Digital Audio (HDMI)

Does the TV support

DVI input only?

Yes

Connect Analog Audio L/R

- Analog Audio Output is OK

- HDMI Video is OK.

No

Check U100

Page 30

Troubleshooting

4-16 Samsung Electronics

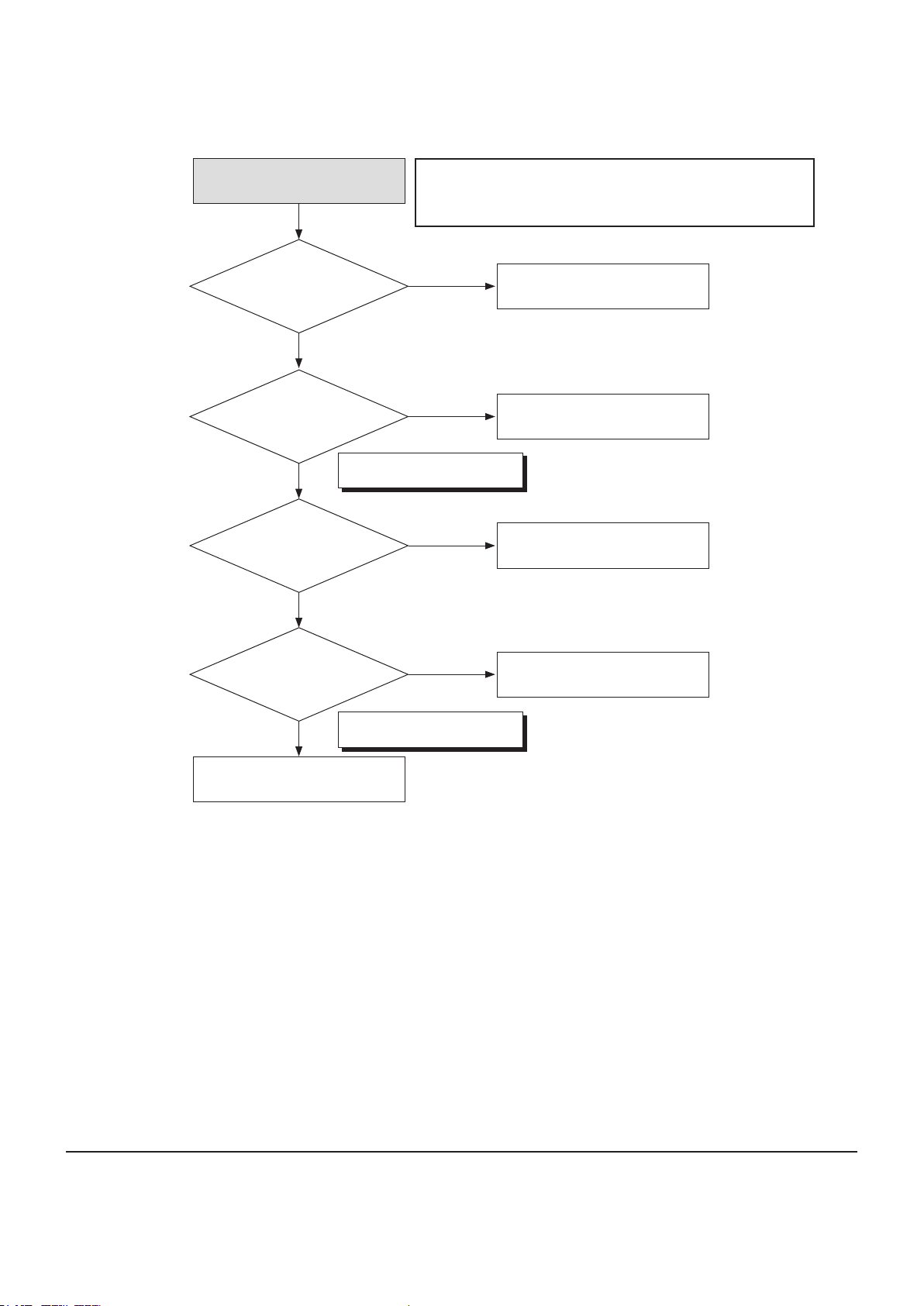

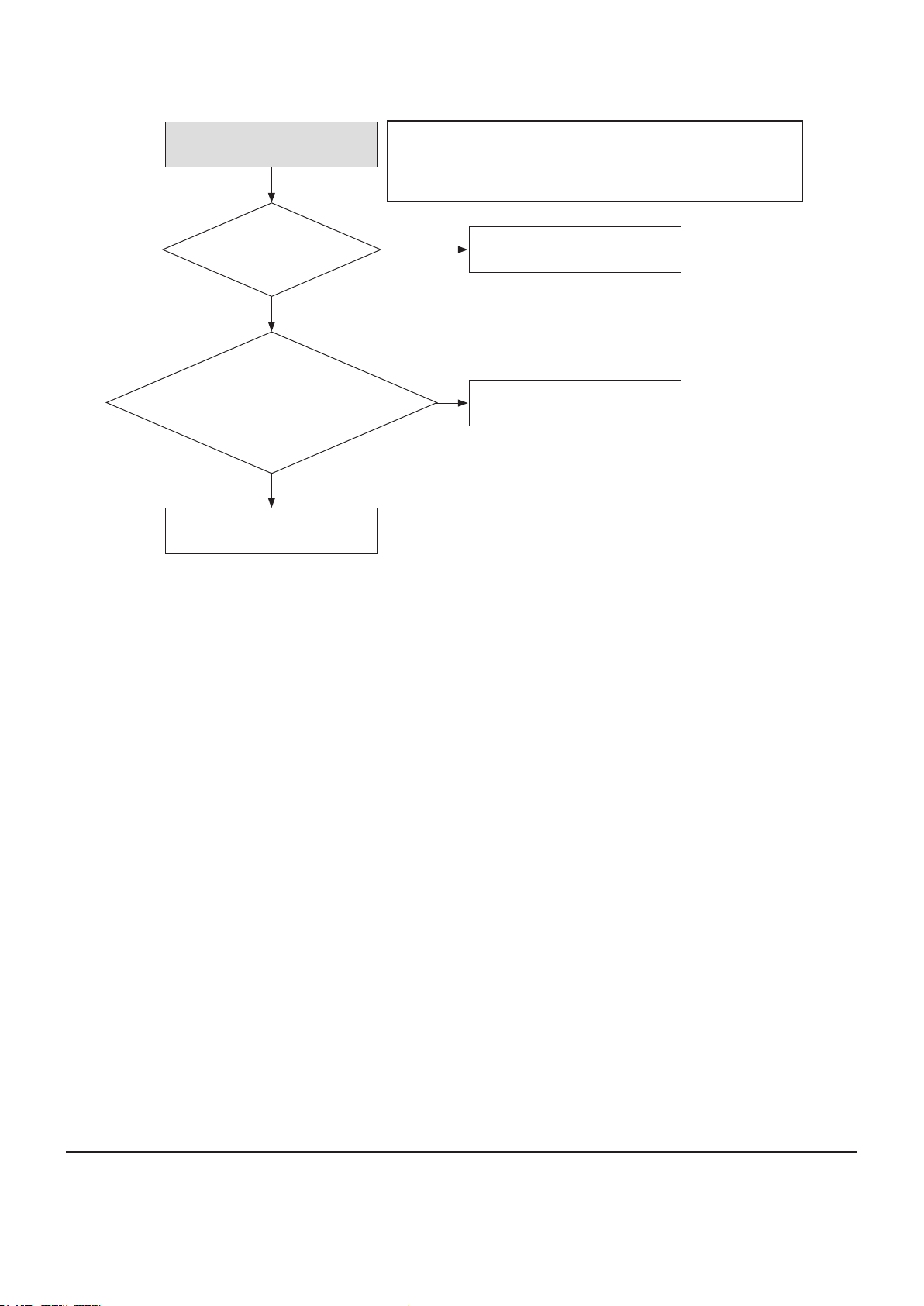

● SMPS Trouble shooting

No Power Detected

Check the Power

Plug connection

Yes

Check

the Voltage at

PACT1's both ends of

AC input voltage

Yes

Meas-

ure voltage of

PRCU1. (voltage of this point

≒ RMS voltage x

1.4)

Yes

Check the

voltage

of PQIZ1's Vcc for

SMPS

No

No

No

No

Connect Power Plug

Check PAFT1(Fuse) and

if it is broken, replace with new one

Check the PLRU1

Check the opening of PADT1~4

If the S/W IC is operating unstable

or no operation, so PQIZ1

should be replaced with new one.

Yes

Check the shorting at

several main power

Page 31

Samsung Electronics 4-17

Troubleshooting

4-2 Software Upgrade

You can download and upgrade the software of this STB through OTA, when the new software is released.

If there is a new version of software to download, the Software upgrade banner will be activated. You can navigate

to the Software upgrade with RCU and Press the OK button.

Fig. 4-7

Then you can see the below S/W upgrade screen.

During downloading don't turn off the STB. After downloading, STB will reboot automatically.

Fig. 4-8

Page 32

Troubleshooting

M E M O

4-18 Samsung Electronics

Page 33

5. Exploded View and Parts List

삼성전자

5-1

5-1 Ass'y Chassis -------------------------------------------------------------------------------------- 5-2

5-2 Electrical Parts List ----------------------------------------------------------------------------5-4

Page 34

Exploded Views and Parts List

5-2 This Document can not be used without Samsung's authorization Samsung Electronics

5-1 Ass'y Chassis

P001

A001

W004

(T 3 X 6W)

S.N.A : Service Not Available

S.N.A

C001

P005

W002

(T 3 X 8 W)

W001

(T 3 X 8 B)

W001

(T 3 X 8 B)

W003

(T 3 X 8 B)

C015

Page 35

Samsung Electronics This Document can not be used without Samsung's authorization 5-3

Exploded Views and Parts List

Loc. No Parts No. Description ; Specication Q ty SNA Remark

A001 MF59-00286A REMOCON-ASSY;DCB-H360R,SEC,196.4 1 SA

C001 MF97-00287E ASSY CABINET-TOP;SECC t0.5 TM652

1 SA

C015

MF97-00389E ASSY PANEL-FRONT;DCB-H380R,DCB-H 1 SA

P001 MF92-00276A

ASSY PCB MAIN;ZIGGO,DCB-H380R,-, 1 SA

P005 MF92-00258A ASSY PCB FRONT;-,DTB-H380Z,FRONT 1 SA

W001 6003-000282

SCREW-TAPTITE;BH,+,-,B,M3,L8,ZPC 4 SA

W002 6003-001547

SCREW-TAPTITE;BH,+,-,B-TITE,M3,L 3 SA

W003 6003-001547 SCREW-TAPTITE;BH,+,-,B-TITE,M3,L 2 SA

W004 6003-001561 SCREW-TAPTITE;BH,+,-,B,M3,L6,ZPC 5 SA

Page 36

Exploded Views and Parts List

5-4 This Document can not be used without Samsung's authorization Samsung Electronics

Exploded Views and Parts List

5-4 This Document can not be used without Samsung's authorization Samsung Electronics

MAIN PCB

P001 MF92-00276A ASSY PCB MAIN;ZIGGO,DCB-H380R,-, 1 SA

BD5 3301-001202 BEAD-SMD;120ohm,4532,TP,167ohm/260MHz,2 1 SA

BD6 3301-001202 BEAD-SMD;120ohm,4532,TP,167ohm/260MHz,2 1 SA

C1 2203-005461 C-CER,CHIP;0.033nF,10%,3kV,NP0,TP,4520 1 SA

C10 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C1000 2401-004333 C-AL;470uF,20%,10V,LZ,TP,8x11.5,5mm 1 SA

C1008 2203-005565 C-CER,CHIP;1nF,5%,50V,NP0,TP,1608 1 SA

C1009 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C1010 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C1011 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 SA

C1012 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C104 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C106 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C1067 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C107 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C1079 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 SA

C108 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C1080 2401-003034 C-AL;220uF,20%,16V,WT,TP,8x11.5,5 1 SA

C1083 2203-005571 C-CER,CHIP;10000nF,+80-20%,6.3V,Y5V,2012 1 SA

C1085 2203-005571 C-CER,CHIP;10000nF,+80-20%,6.3V,Y5V,2012 1 SA

C1086 2203-005929 C-CER,CHIP;10000nF,10%,16V,X7R,3225 1 SA

C1088 2203-005929 C-CER,CHIP;10000nF,10%,16V,X7R,3225 1 SA

C1089 2203-001103 C-CER,CHIP;6.8nF,10%,50V,X7R,1608 1 SA

C1091 2203-001554 C-CER,CHIP;1.8nF,10%,50V,X7R,1608 1 SA

C1092 2203-001652 C-CER,CHIP;470nF,+80-20%,16V,Y5V,1608 1 SA

C1093 2203-006818 C-CER,CHIP;47000nF,20%,6.3V,X5R,3216 1 SA

C1096 2203-001652 C-CER,CHIP;470nF,+80-20%,16V,Y5V,1608 1 SA

C1097 2203-006818 C-CER,CHIP;47000nF,20%,6.3V,X5R,3216 1 SA

C1099 2203-005571 C-CER,CHIP;10000nF,+80-20%,6.3V,Y5V,2012 1 SA

C11 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C110 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C1100 2203-005571 C-CER,CHIP;10000nF,+80-20%,6.3V,Y5V,2012 1 SA

C1102 2203-005929 C-CER,CHIP;10000nF,10%,16V,X7R,3225 1 SA

C1103 2203-005929 C-CER,CHIP;10000nF,10%,16V,X7R,3225 1 SA

C1106 2203-001103 C-CER,CHIP;6.8nF,10%,50V,X7R,1608 1 SA

C1108 2203-000715 C-CER,CHIP;3.3nF,10%,50V,X7R,1608 1 SA

C111 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C1110 2203-001652 C-CER,CHIP;470nF,+80-20%,16V,Y5V,1608 1 SA

C1111 2203-006818 C-CER,CHIP;47000nF,20%,6.3V,X5R,3216 1 SA

C1112 2203-001652 C-CER,CHIP;470nF,+80-20%,16V,Y5V,1608 1 SA

C1114 2203-006818 C-CER,CHIP;47000nF,20%,6.3V,X5R,3216 1 SA

C1115 2401-004280 C-AL;100uF,20%,35V,LZ,TP,8X11.5,5mm 1 SA

C1116 2401-004280 C-AL;100uF,20%,35V,LZ,TP,8X11.5,5mm 1 SA

C1117 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 SA

C1118 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 SA

C112 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C114 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C1140 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C1141 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C1142 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C1143 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C1144 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C1145 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1146 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C1147 2203-000292 C-CER,CHIP;0.01nF,5%,50V,C0G,1608 1 SA

C1148 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C1149 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C1150 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C1151 2203-000405 C-CER,CHIP;0.18nF,5%,50V,C0G,1608 1 SA

C1152 2203-000783 C-CER,CHIP;0.33nF,5%,50V,C0G,1608 1 SA

C1153 2203-000838 C-CER,CHIP;0.39NF,5%,50V,C0G,TP,1608 1 SA

C1154 2203-001052 C-CER,CHIP;0.56nF,10%,50V,X7R,TP,1608 1 SA

C1155 2203-001126 C-CER,CHIP;0.68nF,10%,50V,X7R,1608 1 SA

C1156 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C1157 2203-000783 C-CER,CHIP;0.33nF,5%,50V,C0G,1608 1 SA

C1158 2203-000838 C-CER,CHIP;0.39NF,5%,50V,C0G,TP,1608 1 SA

C1159 2203-001656 C-CER,CHIP;0.47nF,5%,50V,NP0,1608 1 SA

C116 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C1160 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C1161 2203-000140 C-CER,CHIP;1.5nF,10%,50V,X7R,1608 1 SA

C1162 2203-001126 C-CER,CHIP;0.68nF,10%,50V,X7R,1608 1 SA

C1163 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

C1165 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C117 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C120 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C121 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C124 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C125 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C126 2401-001374 C-AL;470uF,20%,16V,WT,TP,10x12.5mm, 1 SA

C127 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C128 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C129 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C130 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C131 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C132 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C134 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C135 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C136 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C137 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C138 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C139 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C140 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C141 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C142 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C143 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C144 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C146 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C147 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C2 2203-005461 C-CER,CHIP;0.033nF,10%,3kV,NP0,TP,4520 1 SA

C211 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 SA

C212 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C213 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C215 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C218 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C219 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C225 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C226 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C228 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C229 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C230 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

5-2 Electrical Parts List

Loc.No Part No Description ; Specification Q'ty S.N.A Remark Loc.No Part No Description ; Specification Q'ty S.N.A Remark

Page 37

Exploded Views and Parts List

Samsung Electronics This Document can not be used without Samsung's authorization 5-5

Loc.No Part No Description ; Specification Q'ty S.N.A Remark Loc.No Part No Description ; Specification Q'ty S.N.A Remark

C231 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C232 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C233 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C234 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C240 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C242 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C243 2203-006069 C-CER,CHIP;4700nF,10%,6.3V,X7R,2012 1 SA

C244 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C245 2203-006069 C-CER,CHIP;4700nF,10%,6.3V,X7R,2012 1 SA

C246 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C247 2203-006069 C-CER,CHIP;4700nF,10%,6.3V,X7R,2012 1 SA

C248 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C249 2203-006069 C-CER,CHIP;4700nF,10%,6.3V,X7R,2012 1 SA

C250 2203-006069 C-CER,CHIP;4700nF,10%,6.3V,X7R,2012 1 SA

C251 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C252 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C255 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C256 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C257 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C258 2203-000189 C-CER,CHIP;100nF,+80-20%,25V,Y5V,1608 1 SA

C262 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C265 2203-005834 C-CER,CHIP;22000nF,+80-20%,10V,Y5V,3216 1 SA

C266 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C268 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C269 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C270 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C272 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C273 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C276 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C277 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C278 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C281 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C282 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C283 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C284 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C285 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C286 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C287 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C293 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C294 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C295 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C296 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C297 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C298 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C299 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C3 2203-006468 C-CER,CHIP;10nF,10%,250V,X7R,-,2012 1 SA

C300 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C301 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C302 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C303 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C304 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C305 2203-005834 C-CER,CHIP;22000nF,+80-20%,10V,Y5V,3216 1 SA

C306 2203-005834 C-CER,CHIP;22000nF,+80-20%,10V,Y5V,3216 1 SA

C310 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C311 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C312 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C313 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C314 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C315 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C317 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C318 2203-006069 C-CER,CHIP;4700nF,10%,6.3V,X7R,2012 1 SA

C319 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C322 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C324 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C325 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C326 2203-006069 C-CER,CHIP;4700nF,10%,6.3V,X7R,2012 1 SA

C327 2401-003378 C-AL;1000μF,20%,10V,WT,-,10x12.5,5 1 SA

C328 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C329 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C330 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C379 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C380 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C381 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C382 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C383 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C384 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C385 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C386 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C387 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C388 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C389 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C390 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C391 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C392 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C393 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C394 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C395 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C4 2401-003645 C-AL;1UF,20%,50V,WT,TP,4X5MM,5 1 SA

C404 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C407 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C408 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C409 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 SA

C410 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C411 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C412 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C413 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C414 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C415 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C416 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C417 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C418 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C419 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C420 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C421 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C422 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C423 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C424 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C425 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C426 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C427 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C428 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C429 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C430 2203-005834 C-CER,CHIP;22000nF,+80-20%,10V,Y5V,3216 1 SA

C431 2203-000531 C-CER,CHIP;2.7nF,10%,50V,X7R,1608 1 SA

C432 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C433 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C434 2203-005834 C-CER,CHIP;22000nF,+80-20%,10V,Y5V,3216 1 SA

C437 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C439 2203-000531 C-CER,CHIP;2.7nF,10%,50V,X7R,1608 1 SA

Page 38

Loc.No Part No Description ; Specification Q'ty S.N.A Remark

Exploded Views and Parts List

5-6 This Document can not be used without Samsung's authorization Samsung Electronics

Loc.No Part No Description ; Specification Q'ty S.N.A Remark

C440 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C442 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C461 2203-001222 C-CER,CHIP;0.82nF,10%,50V,X7R,1608 1 SA

C462 2203-001222 C-CER,CHIP;0.82nF,10%,50V,X7R,1608 1 SA

C463 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C464 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C465 2203-002233 C-CER,CHIP;0.0005nF,0.1pF,50V,NP0,TP,160 1 SA

C466 2203-002233 C-CER,CHIP;0.0005nF,0.1pF,50V,NP0,TP,160 1 SA

C467 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,1608 1 SA

C470 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C471 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C472 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,1608 1 SA

C473 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,1608 1 SA

C474 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,1608 1 SA

C475 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,1608 1 SA

C476 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,1608 1 SA

C493 2401-004280 C-AL;100uF,20%,35V,LZ,TP,8X11.5,5mm 1 SA

C495 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C496 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C497 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C498 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C499 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C5 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C50 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C500 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C501 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C502 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 SA

C503 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C504 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C505 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C506 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 SA

C507 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C508 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C509 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C51 2203-000560 C-CER,CHIP;220nF,+80-20%,25V,Y5V,1608 1 SA

C510 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 SA

C511 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C512 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C513 2203-005571 C-CER,CHIP;10000nF,+80-20%,6.3V,Y5V,2012 1 SA

C514 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 SA

C515 2203-005571 C-CER,CHIP;10000nF,+80-20%,6.3V,Y5V,2012 1 SA

C516 2203-000140 C-CER,CHIP;1.5nF,10%,50V,X7R,1608 1 SA

C517 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C518 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C519 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C520 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C521 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C522 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C523 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C524 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 SA

C526 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C527 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 SA

C529 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C530 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C531 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C532 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C535 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C536 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C537 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C539 2203-005565 C-CER,CHIP;1nF,5%,50V,NP0,TP,1608 1 SA

C54 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C540 2203-007133 C-CER,CHIP;10000nF,10%,16V,X5R,TP,2012 1 SA

C541 2203-000405 C-CER,CHIP;0.18nF,5%,50V,C0G,1608 1 SA

C542 2203-000405 C-CER,CHIP;0.18nF,5%,50V,C0G,1608 1 SA

C543 2401-001548 C-AL;47uF,20%,25V,WT,TP,5x11,5 1 SA

C544 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C545 2203-005571 C-CER,CHIP;10000nF,+80-20%,6.3V,Y5V,2012 1 SA

C546 2203-005571 C-CER,CHIP;10000nF,+80-20%,6.3V,Y5V,2012 1 SA

C547 2203-000140 C-CER,CHIP;1.5nF,10%,50V,X7R,1608 1 SA

C548 2203-007133 C-CER,CHIP;10000nF,10%,16V,X5R,TP,2012 1 SA

C550 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C561 2203-005571 C-CER,CHIP;10000nF,+80-20%,6.3V,Y5V,2012 1 SA

C564 2401-004280 C-AL;100uF,20%,35V,LZ,TP,8X11.5,5mm 1 SA

C565 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C566 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C567 2401-001548 C-AL;47uF,20%,25V,WT,TP,5x11,5 1 SA

C568 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C569 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C570 2401-004280 C-AL;100uF,20%,35V,LZ,TP,8X11.5,5mm 1 SA

C571 2203-000925 C-CER,CHIP;470nF,+80-20%,50V,Y5V,2012 1 SA

C573 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C574 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C575 2203-005083 C-CER,CHIP;220nF,10%,50V,X7R,TP,1608,- 1 SA

C576 2401-004280 C-AL;100uF,20%,35V,LZ,TP,8X11.5,5mm 1 SA

C577 2203-000925 C-CER,CHIP;470nF,+80-20%,50V,Y5V,2012 1 SA

C578 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C579 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C58 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C581 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C582 2203-005083 C-CER,CHIP;220nF,10%,50V,X7R,TP,1608,- 1 SA

C583 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C59 2203-001408 C-CER,CHIP;0.27nF,5%,50V,NP0,1608 1 SA

C598 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C6 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C60 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C600 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C602 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C603 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 SA

C604 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C607 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C608 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 SA

C609 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C61 2203-006170 C-CER,CHIP;220nF,10%,16V,X7R,1608 1 SA

C610 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C611 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 SA

C612 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C613 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,TP,1608 1 SA

C614 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C615 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C616 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C617 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 SA

C618 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C619 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C62 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 SA

C629 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C630 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C631 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C632 2203-000925 C-CER,CHIP;470nF,+80-20%,50V,Y5V,2012 1 SA

Page 39

Exploded Views and Parts List

Samsung Electronics This Document can not be used without Samsung's authorization 5-7

Loc.No Part No Description ; Specification Q'ty S.N.A Remark Loc.No Part No Description ; Specification Q'ty S.N.A Remark

C633 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 SA

C634 2203-005565 C-CER,CHIP;1nF,5%,50V,NP0,TP,1608 1 SA

C635 2203-000405 C-CER,CHIP;0.18nF,5%,50V,C0G,1608 1 SA

C636 2203-000405 C-CER,CHIP;0.18nF,5%,50V,C0G,1608 1 SA

C638 2401-004280 C-AL;100uF,20%,35V,LZ,TP,8X11.5,5mm 1 SA

C639 2203-005083 C-CER,CHIP;220nF,10%,50V,X7R,TP,1608,- 1 SA

C64 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C642 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C643 2203-000925 C-CER,CHIP;470nF,+80-20%,50V,Y5V,2012 1 SA

C644 2401-004280 C-AL;100uF,20%,35V,LZ,TP,8X11.5,5mm 1 SA

C646 2203-005083 C-CER,CHIP;220nF,10%,50V,X7R,TP,1608,- 1 SA

C649 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C65 2203-000384 C-CER,CHIP;0.015nF,5%,50V,C0G,1608 1 SA

C651 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C653 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 SA

C654 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C655 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 SA

C656 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 SA

C657 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 SA

C658 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 SA

C659 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 SA

C66 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C660 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 SA

C661 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 SA

C662 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 SA

C67 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C69 2203-000332 C-CER,CHIP;0.012nF,5%,50V,C0G,1608 1 SA

C7 2203-000531 C-CER,CHIP;2.7nF,10%,50V,X7R,1608 1 SA

C70 2203-000332 C-CER,CHIP;0.012nF,5%,50V,C0G,1608 1 SA

C73 2203-000384 C-CER,CHIP;0.015nF,5%,50V,C0G,1608 1 SA

C76 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,1608 1 SA

C77 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C78 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C783 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C784 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C79 2203-000384 C-CER,CHIP;0.015nF,5%,50V,C0G,1608 1 SA

C790 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C795 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C796 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C797 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C798 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C8 2203-006467 C-CER,CHIP;0.68nF,10%,3000V,X7R,4520 1 SA

C800 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C801 2203-000384 C-CER,CHIP;0.015nF,5%,50V,C0G,1608 1 SA

C802 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C803 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C806 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C808 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C809 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C81 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C810 2203-000384 C-CER,CHIP;0.015nF,5%,50V,C0G,1608 1 SA

C811 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C812 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C821 2203-000646 C-CER,CHIP;0.024NF,5%,50V,C0G,TP,1608 1 SA

C822 2203-000646 C-CER,CHIP;0.024NF,5%,50V,C0G,TP,1608 1 SA

C823 2203-001656 C-CER,CHIP;0.47nF,5%,50V,NP0,1608 1 SA

C831 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C832 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C833 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C834 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C84 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C85 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C86 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C88 2203-000626 C-CER,CHIP;0.022nF,5%,50V,C0G,1608 1 SA

C9 2203-006467 C-CER,CHIP;0.68nF,10%,3000V,X7R,4520 1 SA

C904 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C907 2401-004333 C-AL;470uF,20%,10V,LZ,TP,8x11.5,5mm 1 SA

C91 2203-000626 C-CER,CHIP;0.022nF,5%,50V,C0G,1608 1 SA

C910 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C911 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C912 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C913 2203-005565 C-CER,CHIP;1nF,5%,50V,NP0,TP,1608 1 SA

C914 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C915 2203-005565 C-CER,CHIP;1nF,5%,50V,NP0,TP,1608 1 SA

C916 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C918 2203-005565 C-CER,CHIP;1nF,5%,50V,NP0,TP,1608 1 SA

C919 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C92 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C920 2203-005565 C-CER,CHIP;1nF,5%,50V,NP0,TP,1608 1 SA

C921 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C922 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C924 2203-005834 C-CER,CHIP;22000nF,+80-20%,10V,Y5V,3216 1 SA

C925 2203-005565 C-CER,CHIP;1nF,5%,50V,NP0,TP,1608 1 SA

C926 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C927 2203-005565 C-CER,CHIP;1nF,5%,50V,NP0,TP,1608 1 SA

C928 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C936 2203-005565 C-CER,CHIP;1nF,5%,50V,NP0,TP,1608 1 SA

C937 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C938 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C939 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C94 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C940 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 SA

C941 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C942 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C943 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 SA

C944 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C945 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C946 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 SA

C947 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C948 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C949 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 SA

C951 2401-004402 C-AL;47uF,20%,16V,WT,TP,6.3x5mm,5mm 1 SA

C952 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C953 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C954 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C956 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C957 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 SA

C958 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C959 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C96 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5V,-,1608 1 SA

C960 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C961 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,TP,1608 1 SA

C962 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C963 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C968 2203-005565 C-CER,CHIP;1nF,5%,50V,NP0,TP,1608 1 SA

C969 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

C97 2401-004227 C-AL;100μF,20%,10V,NXB,TP,6.3x7mm, 1 SA

C971 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,1608 1 SA

Page 40

Loc.No Part No Description ; Specification Q'ty S.N.A Remark