Page 1

DIGITAL CABLE RECEIVER

SERVICE

ΠDigital Cable HD Receiver for DVB-C

´ MPEG2 and H.264 Decoding

ˇ HDMI(HDCP)

¨ Teletext and subtitle

ˆ EPG (Now and Next)

Manual

DIGITAL CABLE RECEIVER Merit & Character regarding Product

SERVICE MANUAL

DCB-H360R/DCB-H360RS/DCB-H360RA

© Samsung Electronics Co., Ltd. JAN. 2007

Printed in Korea

MF82-00244A

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

international and/or domestic law.

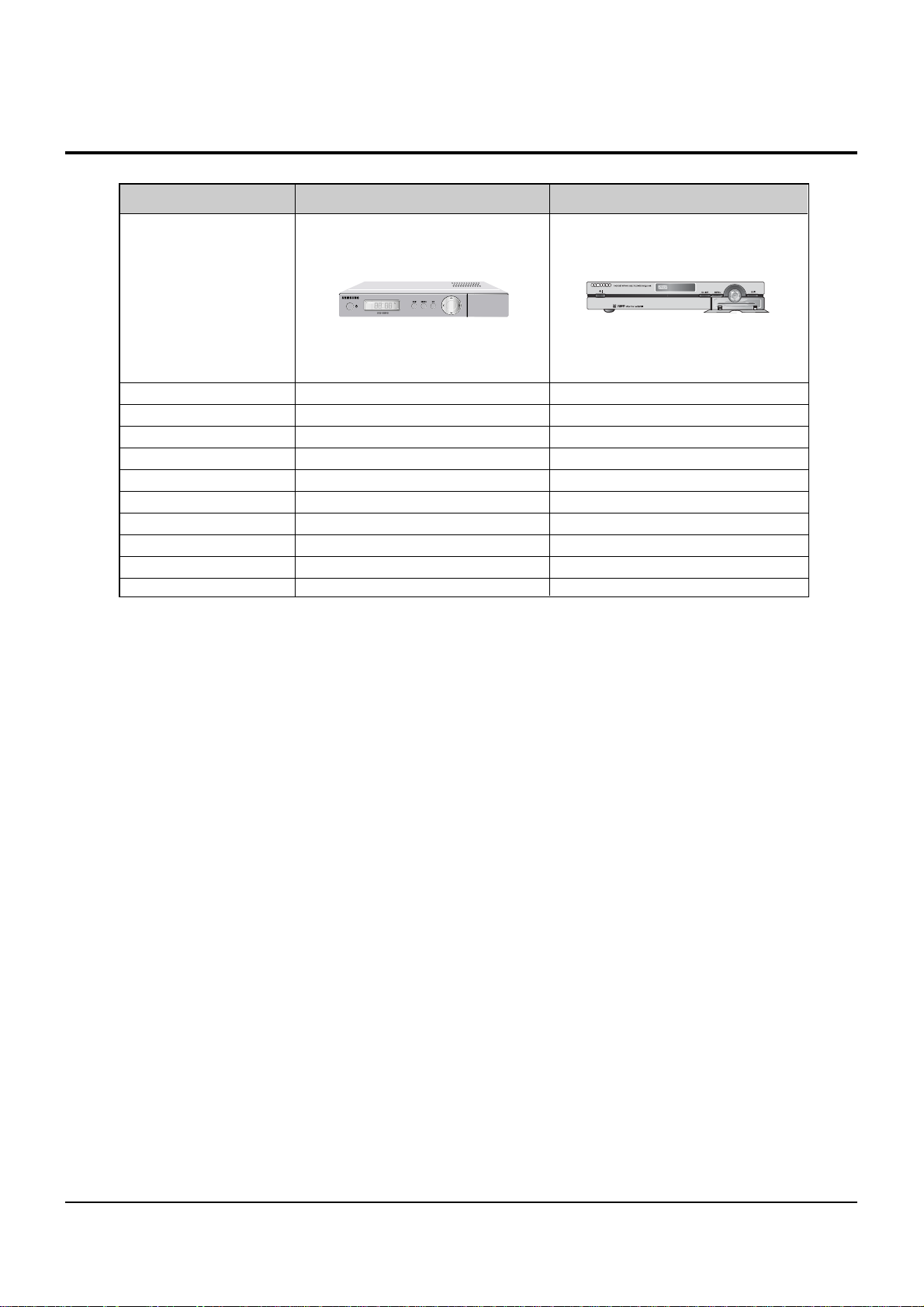

• This Service Manual is for DCB-H360RA(S).

In appearance, there is no difference between DCB-H360R(S) and DCB-H360RA(S) because two models have the same Ass’y

Front Cabinet.

We can identify DCB-H360RA from DCB-H360R by the model name of Label-Rating on Chassis-Rear.

and the existence of HDMI Transmitter(U1101) on Assy Main.

• How to identify them by Label-Rating ; See next page.

When servicing, be sure to confirm the model name on Label-Rating of Chassis-Rear.

BASIC :

DCB-H360R

Application Models :

XEE, XEN

ELECTRONICS

DCB-H360R / DCB-H360RS /

DCB-H360RSA

Application Areas :

Page 2

CONTENTS

1. Precautions 1-1 ~ 1-4

1-1 Safety Precaution (1-1)

1-2 Servicing Precautions (1-3)

1-3 ESD Precautions (1-4)

2. Product Specification 2-1 ~ 2-4

2-1 Product Specification (2-1)

2-2 Chassis Product Specification) (2-2)

2-3 Option Product Specification (2-3)

3. Software Update 3-1 ~ 3-2

3-1 To Upgrade the Software (3-1)

4. Disassembly and Reassembly 4-1 ~ 4-4

4-1 Cabinet and PCB (4-1)

5. Trouble Shooting 5-1 ~ 5-12

6. Exploded View and Parts List 6-1 ~ 6-2

7. Electrical Parts List 7-1 ~ 7-14

8. Block Diagrams 8-1 ~ 8-6

8-1 All Block Diagram (8-2)

8-2 U301, U302(K4D261638I) Block Diagram (8-3)

8-3 U2001(LV5045) Block Diagram (8-4)

8-4 U210(S5H2600X) Block Diagram (8-5)

9. Wiring Diagram 9-1 ~ 9-2

Page 3

10. PCB Diagrams 10-1 ~ 10-8

10-1 Main PCB (10-2)

10-2 S.M.P.S PCB (10-5)

10-3 Front PCB (10-7)

11. Schematic Diagrams 11-1 ~ 11-22

11-1 Tuner (Main PCB) (11-2)

11-2 S5H2600_H.264_Main (Main PCB) (11-3)

11-3 S5H2600_H.264_DDR I/F (Main PCB) (11-4)

11-4 S5H2600_H.264_Power & GND (Main PCB) (11-5)

11-5 TS_IO/CAP_IO (Main PCB) (11-6)

11-6 DDR_DDR-CTL (Main PCB) (11-7)

11-7 Flash_LAN I/F (Main PCB) (11-8)

11-8 PCI_PCI I/F (Main PCB) (11-9)

11-9 System_GPIO_IIC_SC I/F (Main PCB) (11-10)

11-10 Audio Out (Main PCB) (11-11)

11-11 HDMI (Main PCB) (11-12)

11-12 VCXO_System Clock (Main PCB) (11-13)

11-13 Dual Scart I/F (Main PCB) (11-14)

11-14 Dual Scart Connector (Main PCB) (11-15)

11-15 Smart Card (Main PCB) (11-16)

11-16 GPIO-Expander_CS (Main PCB) (11-17)

11-17 Reset_JTAG_Front IF_RS232C_EEPROM (Main PCB) (11-18)

11-18 S5H2100_Power_GND (Main PCB) (11-19)

11-19 Main_DC Core Power (Main PCB) (11-20)

11-20 S.M.P.S (S.M.P.S PCB) (11-21)

11-21 Front (Front PCB) (11-22)

12. Operating Instructions and Installation 12-1 ~ 12-32

CONTENTS

Page 4

13. Circuit Operating Descriptions 13-1 ~ 13-10

13-1 Main Processor (13-1)

13-2 Memory Interface (13-4)

13-3 Video Out (13-6)

13-5 Audio Out (13-8)

14. Reference Information 14-1 ~ 14-4

14-1 Terhnical Overview (14-1)

14-2 MPEG2 + H.264 SOC Solution - Main chip set (14-3)

14-3 Model Declaration (14-4)

CONTENTS

Page 5

Samsung Electronics 1-1

1. Precautions

1-1 Safety Precautions

1) Before returning an instrument to the customer,

always make a safety check of the entire instrument,

including, but not limited to, the following items:

(1) Be sure that no built-in protective devices are

defective or have been defeated during servicing.

(1)Protective shields are provided to protect both

the technician and the customer. Correctly replace

all missing protective shields, including any

removed for servicing convenience.

(2)When reinstalling the chassis and/or other assembly in the cabinet, be sure to put back in place

all protective devices, including, but not limited to,

nonmetallic control knobs, insulating fish papers,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not operate this instrument or permit it to be operated without all protective devices correctly installed and

functioning.

(2) Be sure that there are no cabinet openings through

which adults or children might be able to insert

their fingers and contact a hazardous voltage. Such

openings include, but are not limited to, excessively wide cabinet ventilation slots, and an improperly fitted and/or incorrectly secured cabinet back

cover.

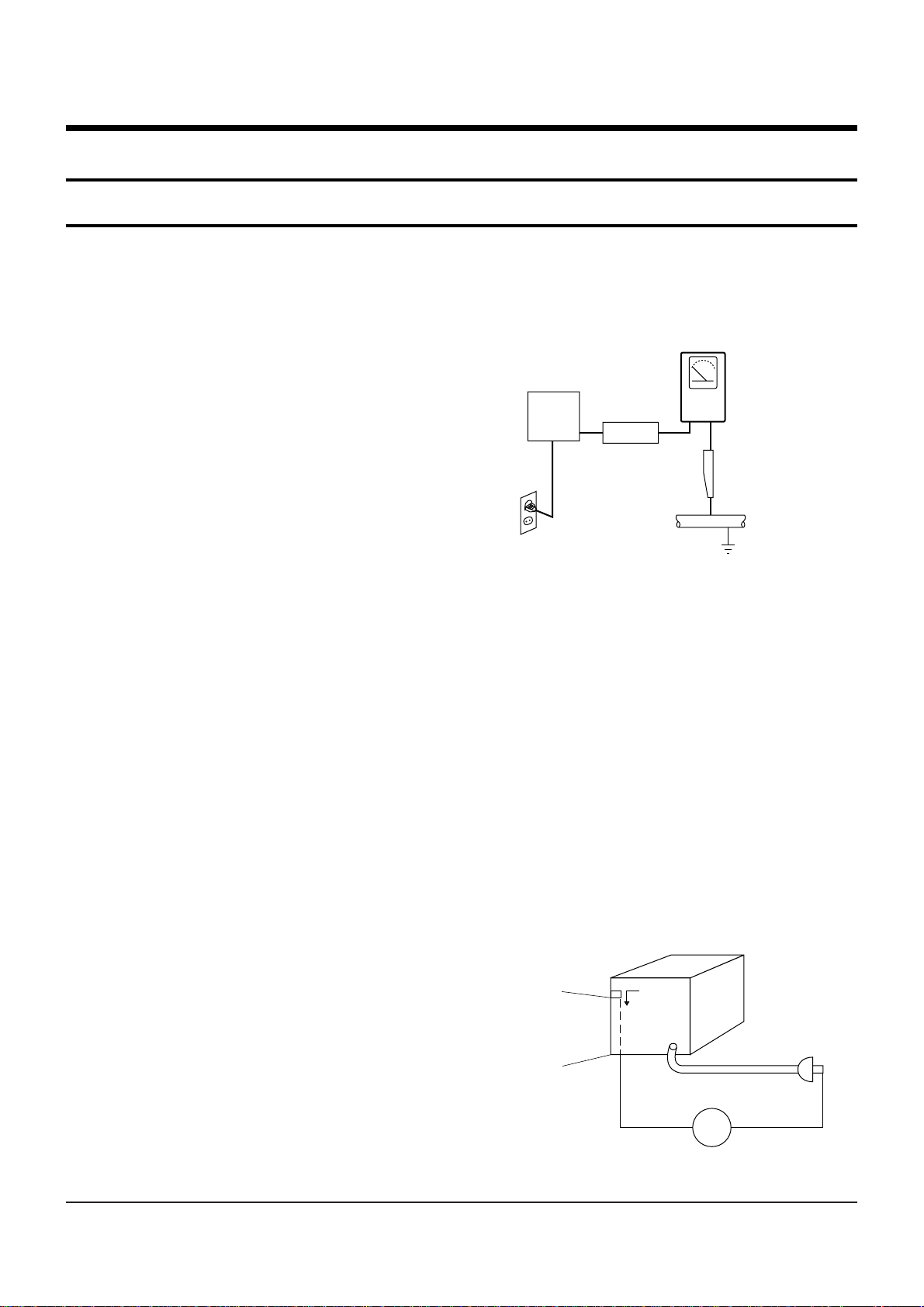

(3) Leakage Current Hot Check-With the instrument

completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a leakage

current tester or a metering system that complies

with American National Standards institute (ANSI)

C101.1 Leakage Current for Appliances and

Underwriters Laboratories (UL) 1270 (40.7). With

the instrument’s AC switch first in the ON position

and then in the OFF position, measure from a

known earth ground (metal water pipe, conduit,

etc.) to all exposed metal parts of the instrument

(antennas, handle brackets, metal cabinets, screwheads, metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5mA.

Reverse the instrument power cord plug in the outlet and repeat the test. See Fig. 1-1.

Any measurements not within the limits specified

herein indicate a potential shock hazard that must

be eliminated before returning the instrument to

the customer.

Fig. 1-1 AC Leakage Test

(4) Insulation Resistance Test Cold Check-(1) Unplug

the power supply cord and connect a jumper wire

between the two prongs of the plug. (2) Turn on the

power switch of the instrument. (3) Measure the

resistance with an ohmmeter between the

jumpered AC plug and all exposed metallic cabinet

parts on the instrument, such as screwheads,

antenna, control shafts, handle brackets, etc. When

an exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2

megohm. When there is no return path to the chassis, the reading must be infinite. If the reading is

not within the limits specified, there is the possibility of a shock hazard, and the instrument must be

repaired and rechecked before it is returned to the

customer. See Fig. 1-2.

Fig. 1-2 Insulation Resistance Test

(READING SHOULD

NOT BE ABOVE

0.5mA)

EARTH

GROUND

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METER

SURFACES

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

LEAKAGE

CURRENT

TESTER

Antenna

Terminal

Exposed

Metal Part

ohm

ohmmeter

Page 6

Precautions

1-2 Samsung Electronics

2) Read and comply with all caution and safety related notes on or inside the cabinet, or on the chassis.

3) Design Alteration Warning-Do not alter or add to

the mechanical or electrical design of this instrument. Design alterations and additions, including

but not limited to, circuit modifications and the

addition of items such as auxiliary audio output

connections, might alter the safety characteristics of

this instrument and create a hazard to the user. Any

design alterations or additions will make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

4) Observe original lead dress. Take extra care to

assure correct lead dress in the following areas:

(1) near sharp edges, (2) near thermally hot parts (be

sure that leads and components do not touch thermally hot parts), (3) the AC supply, (4) high voltage,

and (5) antenna wiring. Always inspect in all areas

for pinched, out-of-place, or frayed wiring, Do not

change spacing between a component and the

printed-circuit board. Check the AC power cord for

damage.

5) Components, parts, and/or wiring that appear to

have overheated or that are otherwise damaged

should be replaced with components, parts and/ or

wiring that meet original specifications.

Additionally, determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

6) Product Safety Notice-Some electrical and mechanical parts have special safety-related characteristics

which are often not evident from visual inspection,

nor can the protection they give necessarily be

obtained by replacing them with components rated

for higher voltage, wattage, etc. Parts that have special safety characteristics are identified by shading,

an ( )or a ( )on schematics and parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire and/or

other hazards. Product safety is under review continuously and new instructions are issued whenever appropriate.

Page 7

Precautions

Samsung Electronics 1-3

1-2 Servicing Precautions

CAUTION : Before servicing units covered by this

service manual and its supplements, read and follow

the Safety Precautions section of this manual.

Note : If unforseen circumstances create conflict

between the following servicing precautions and any

of the safety precautions, always follow the safety precautions. Remember: Safety First.

1-2-1 General Servicing Precautions

(1) a. Always unplug the instrument’s AC power cord

from the AC power source before (1) re-moving

or reinstalling any component, circuit board,

module or any other instrument assembly, (2)

disconnecting any instrument electrical plug or

other electrical connection, (3) connecting a test

substitute in parallel with an electrolytic capacitor in the instrument.

b. Do not defeat any plug/socket B+ voltage inter-

locks with which instruments covered by this

service manual might be equipped.

c. Do not apply AC power to this instrument and

/or any of its electrical assemblies unless all

solid-state device heat sinks are correctly installed.

d. Always connect a test instrument’s ground lead

to the instrument chassis ground before connecting the test instrument positive lead. Always

remove the test instrument ground lead last.

Note : Refer to the Safety Precautions section ground

lead last.

(2) The service precautions are indicated or printed on

the cabinet, chassis or components. When servicing, follow the printed or indicated service precautions and service materials.

(3) The components used in the unit have a specified

flame resistance and dielectric strength.

When replacing components, use components

which have the same ratings. Components identified by shading, by( ) or by ( ) in the circuit diagram are important for safety or for the characteristics of the unit. Always replace them with the exact

replacement components.

(4) An insulation tube or tape is sometimes used and

some components are raised above the printed

wiring board for safety. The internal wiring is

sometimes clamped to prevent contact with heating components. Install such elements as they

were.

(5) After servicing, always check that the removed

screws, components, and wiring have been installed correctly and that the portion around the

serviced part has not been damaged and so on.

Further, check the insulation between the blades of

the attachment plug and accessible conductive

parts.

1-2-2 Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet

and turn the power ON. Connect the insulation resistance meter (500V) to the blades of the attachment

plug. The insulation resistance between each blade of

the attachment plug and accessible conductive

parts(see note) should be more than 1 Megohm.

Note : Accessible conductive parts include metal panels, input terminals, earphone jacks, etc.

Page 8

Precautions

1-4 Samsung Electronics

1-3 ESD Precautions

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive Devices(ESD). Examples of typical ESD

devices are integrated circuits and some field-effect

transistors and semiconductor chip components. The

following techniques should be used to help reduce

the incidence of component damage caused by static

electricity.

(1) Immediately before handling any semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic charge on your body by

touching a known earth ground. Alternatively,

obtain and wear a commercially available discharging wrist strap device, which should be

removed for potential shock reasons prior to applying power to the unit under test.

(2) After removing an electrical assembly equipped

with ESD devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

(3) Use only a grounded-tip soldering iron to solder or

unsolder ESD devices.

(4) Use only an anti-static solder removal devices.

Some solder removal devices not classified as

“anti-static” can generate electrical charges sufficient to damage ESD devices.

(5) Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESD devices.

(6) Do not remove a replacement ESD device from its

protective package until immediately before your

are ready to install it.(Most replacement ESD

devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive materials).

(7) Immediately before removing the protective ma-

terials from the leads of a replacement ESD device,

touch the protective material to the chassis or circuit assembly into which the device will be

installed.

CAUTION : Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

(8) Minimize bodily motions when handling unpack-

aged replacement ESD devices. (Otherwise harmless motion such as the brushing together of your

clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient

to damage an ESD device).

Page 9

Samsung Electronics

2-1

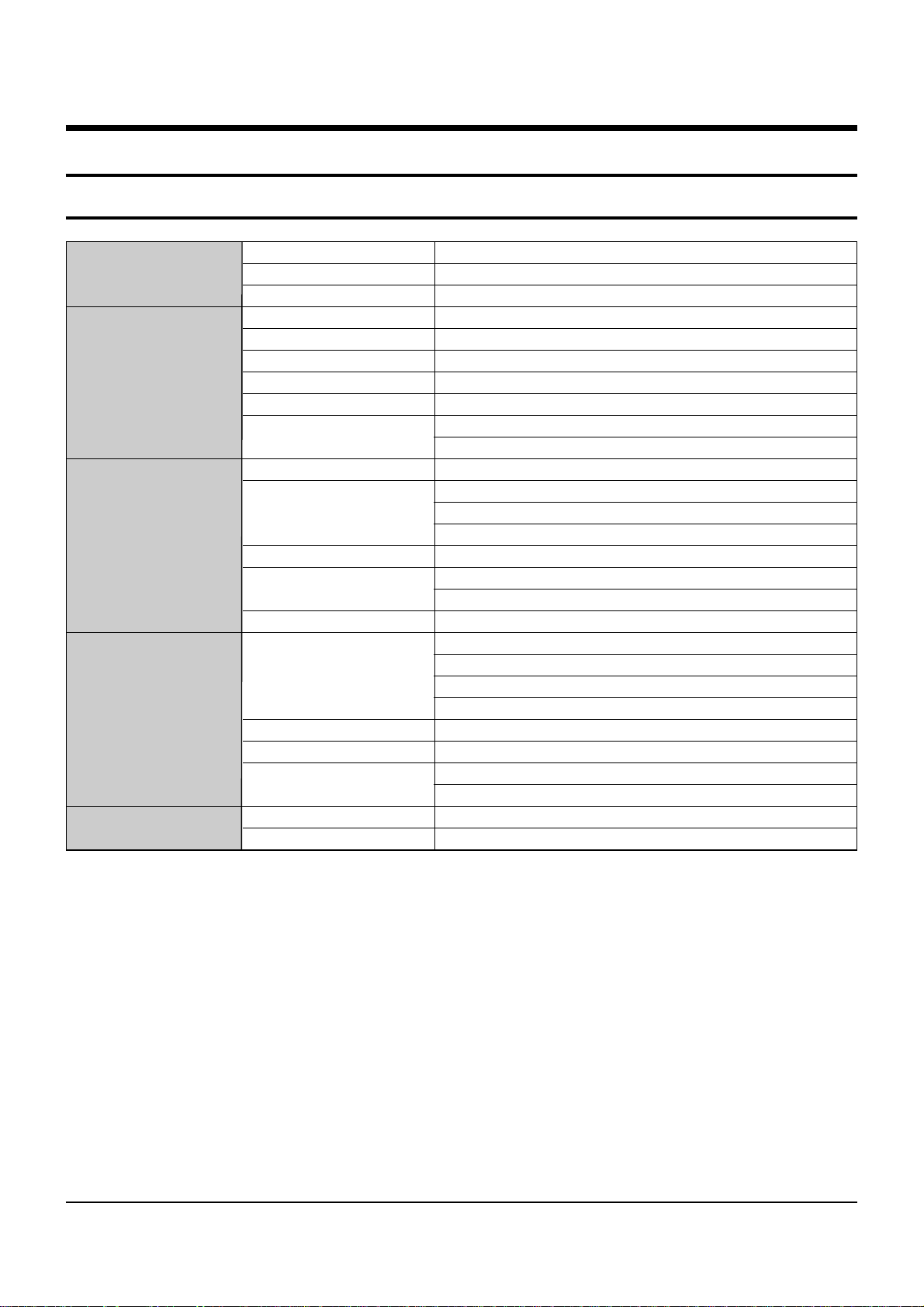

Type SMPS

Input voltage AC 100-240V~, 50/60 Hz

Fuse rating 250 V/T1.6AH

Input Frequency 50.5~858 MHz

Channel Bandwith 8 MHz

DEMODULATION QAM DVB-C

SYMBOL RATE MAX 7.252 Msps

Constellation 16, 32, 64, 128, 256 QAM

CABLE OUT RF LOOP-THROUGH OUTPUT for other

receiver or TV

System decoding MPEG-2 ISO/IEC 13818-2

Profile@Level (MP@HL(HD), MP@ML(SD))

H.264 ISO/IEC 14496-10

(MP@L3, MP@L4, HP@L4 up to 30 Mbps)

Resolution 1080i, 720p, 576p, (576i)

Video Output SD output (2 SCART (AV1,AV2), Composite RCA)

HD output (Component (YPBPR), HDMI)

Video Format 4:3(Normal) & 16:9 (Widescreen)

System decoding MPEG Audio-1 ISO/IEC 11172-3

(Layer1, Layer2)

MPEG Audio-2 ISO/IEC 13818-3

Dolby Digital (AC-3)

Audio mode Mono, Dual stereo, Joint stereo

Sampling Rate 32kHz, 44.1kHz, 48kHz, 96kHz

Audio output Analog output (L/R (RCA) 1 CH)

Digital output (S/PDIF(Optical))

Size (W x D x H) 351 x 227 x 60 mm

Weight (Net) 2.47Kg

Power Supply

Tuner

&

Demoduator

Video Decoder

Audio Decoder

Phisical Specifcation

2. Product Specification

2-1 Product Specification

Page 10

Product Specification

2-2

Samsung Electronics

Model DCB-S300G DCB-H360R

Input Voltage AC 100-240V~,50/60Hz AC 100-240V~, 50/60 Hz

Size 270 X 200 X 45mm 351 X 227 X 60mm

Weight 1.195Kg 2.475Kg

Decoding Format Mpeg-2(ISO/IEC-13812-1) Mpeg-2(ISO/IEC-13818-3)

Video Format PAL PAL

Resolution 720p 1080i, 720p, 576p, (576i)

Audio Mode Dolby Decoding AC-3 Dolby Decoding AC-3

MPEG Audio Decoding MPEG 1 ISO/IEC 11172-1 layer 1 & 11 MPEG 1 ISO/IEC 11172-3

Down Mixed Chanel 2CH Chanel 2CH

Sampling Rates Supported 32, 44.1, 48 KHz 32kHz, 44.1kHz, 48kHz, 96kHz

Chassis

2-2 Chassis Product Specification

Page 11

Product Specification

2-3

Samsung Electronics

2-3 Option Product Specification

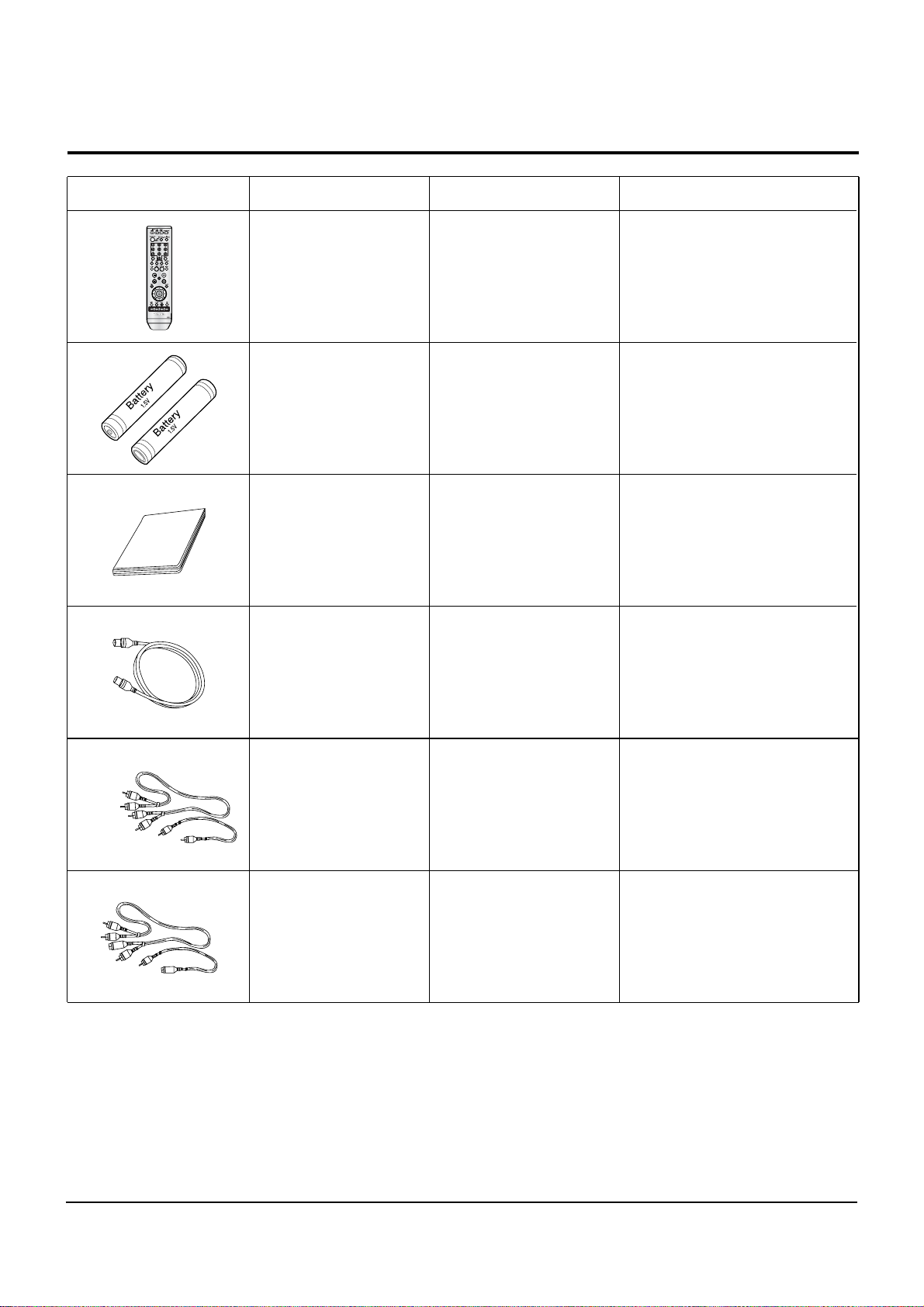

Description Fig Description Parts No Remark

Remote

Control

Batteries for

Remote Control

MF59-00286A

4301-001035

Model Standard

of DCB-H360R/XEN

S.N.A

Model Standard

of DCB-H360R/XEN

Model Standard

of DCB-H360R/XEN

Model Standard

of DCB-H360R/XEN

MF68-00397A

AC39-00017A

User’s Manual

RF Cable

Model Standard

of DCB-H360R/XEN

AC39-42001R

AV Cable

Model Standard

of DCB-H360R/XEN

MD39-00107A

RCA Cable

Page 12

Product Specification

2-4

Samsung Electronics

MEMO

Page 13

Samsung Electronics

3-1

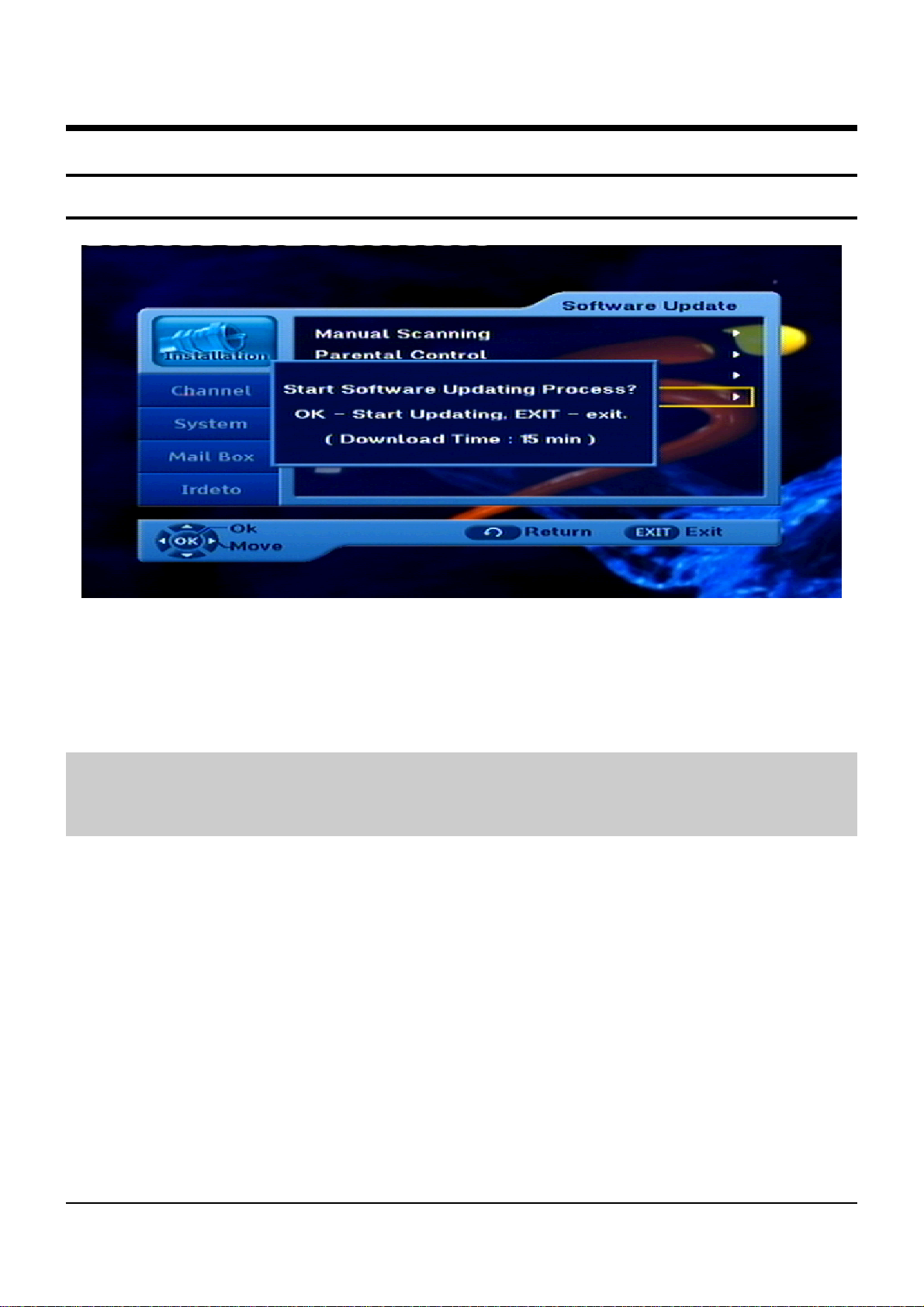

3. Software Update

3-1 To Upgrade the Software

Fig. 3-1

To upgrade the software, place the cursor on Installation Software Update menu and press the OK key.

If new software is available, banner “Start Software Updating Process ?”

will be displayed. There is also information about estimated time of software download.

Press the OK key to confirm and start Software Updating process.

If there is the newest software on your STB “You don’t need to update software!” will be displayed.

Note : STB automatically reboots for software upgrading process. During the upgrading process, TV screen will remain

blank for approximately 10 minutes.

Window display at the STB front panel will show the progress. Service will be resumed automatically after

the upgrade is completed.

Page 14

3-2

Software Update

Samsung Electronics

MEMO

Page 15

Samsung Electronics 4-1

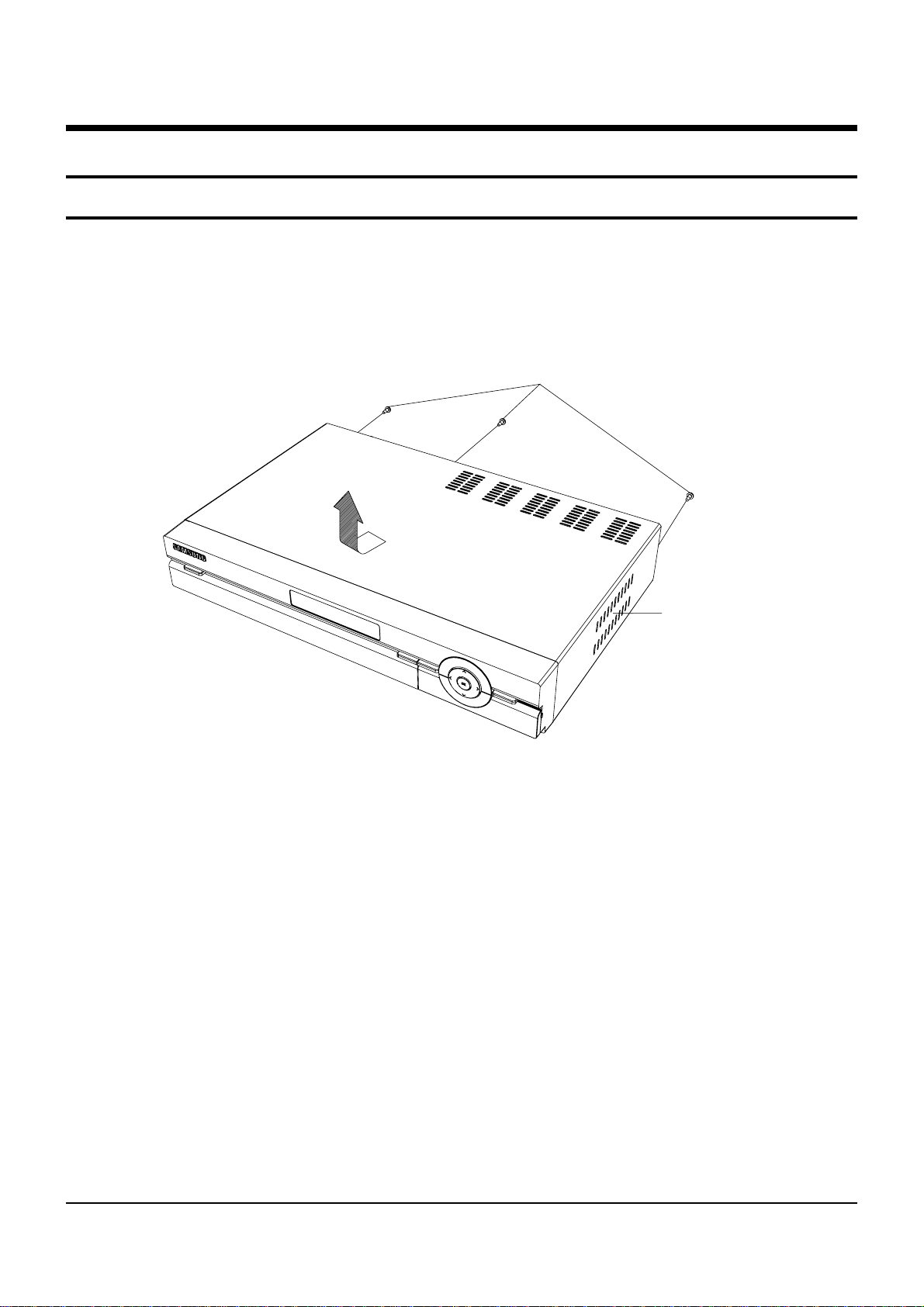

4. Disassembly and Reassembly

4-1 Cabinet and PCB

4-1-1 Top Cabinet Removal

1) Remove 3 Screws Œ the back Top Cabinet ´.

2) Lift up the Top Cabinet ´ in direction of arrow.

Fig. 4-1 Top Cabinet Removal

Π3 SCREWS

(3 X 8 B)

´ TOP CABINET

Page 16

4-2

Disassembly and Reassembly

Samsung Electronics

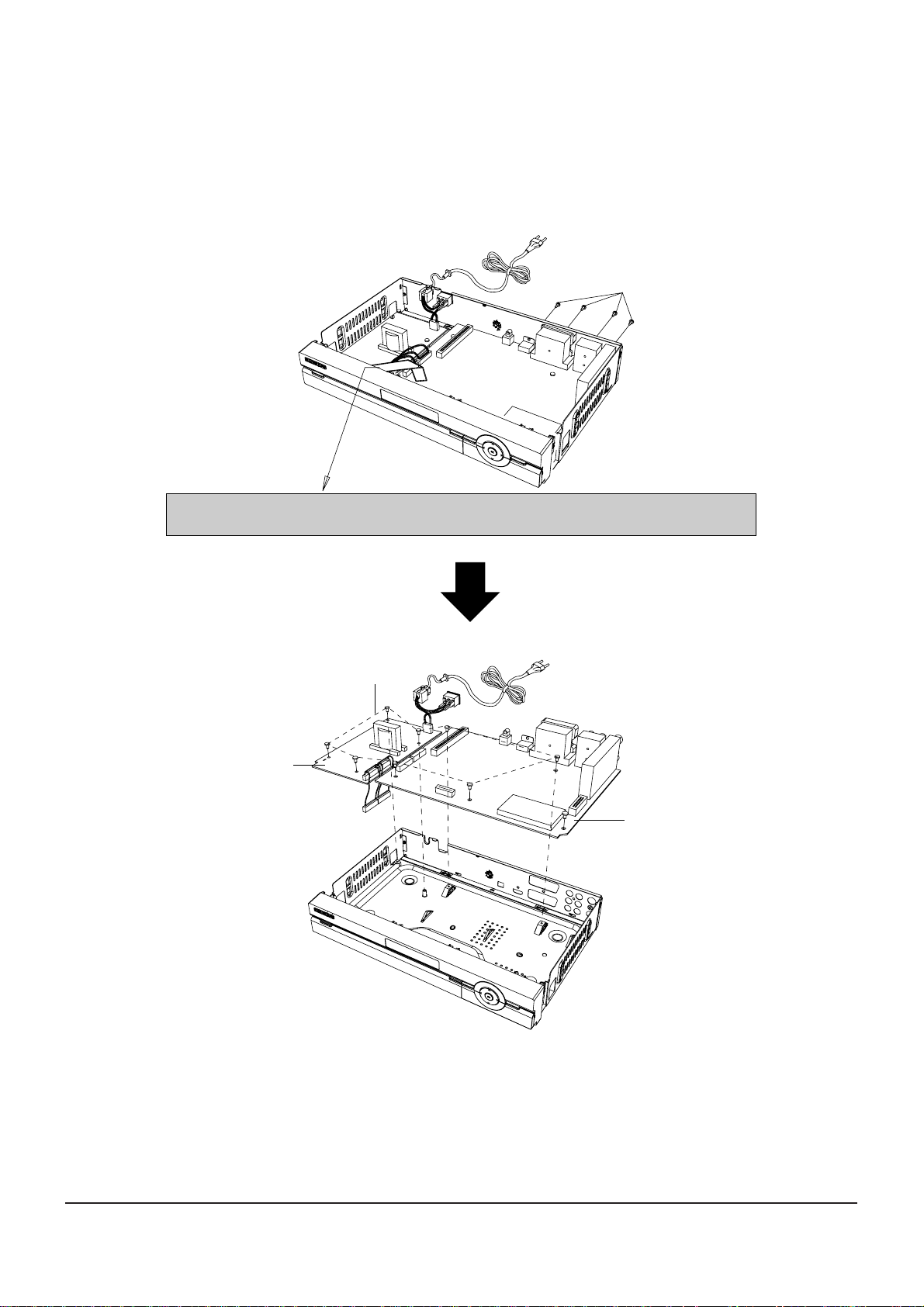

4 -1-2 Main PCB, S.M.P.S PCB Removal

1) Remove 12 Screws Œ, ´.

2) Lift up the Main PCB ˇ, S.M.P.S PCB ¨.

Fig. 4-2 Main PCB, S.M.P.S PCB Removal

CAUTION : After assemble Ass’y panel Front at Ass’y cabinet front assembly

That assemble cable-flat. (dissolution in reverse order)

Π4 SCREWS

(3 X 8 B)

¨ S.M.P.S PCB

´

8 SCREWS

(3 X 8 Y)

ˇ MAIN PCB

Page 17

Disassembly and Reassembly

4-3Samsung Electronics

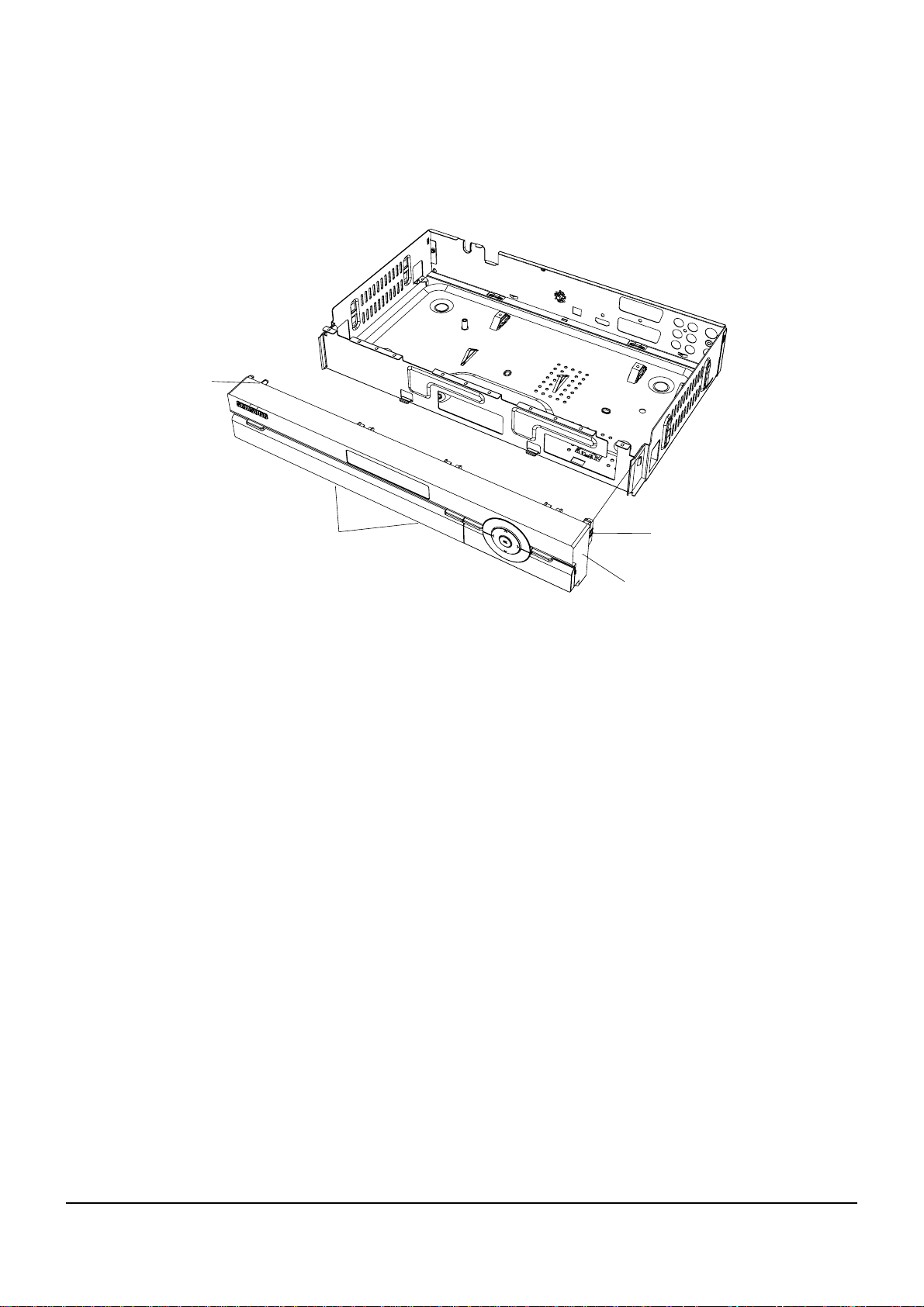

4-1-3 Ass’y Front-Cabinet Removal

1) Release 4 Hooks Œ, ´, ˇ and remove the Ass’y Front-Cabinet ¨.

Fig. 4-3 Ass’y Front-Cabinet Removal

Π1 HOOK

ˇ 2 HOOKS

´ 1 HOOK

¨ ASS'Y FRONT-CABINET

Page 18

4-4

Disassembly and Reassembly

Samsung Electronics

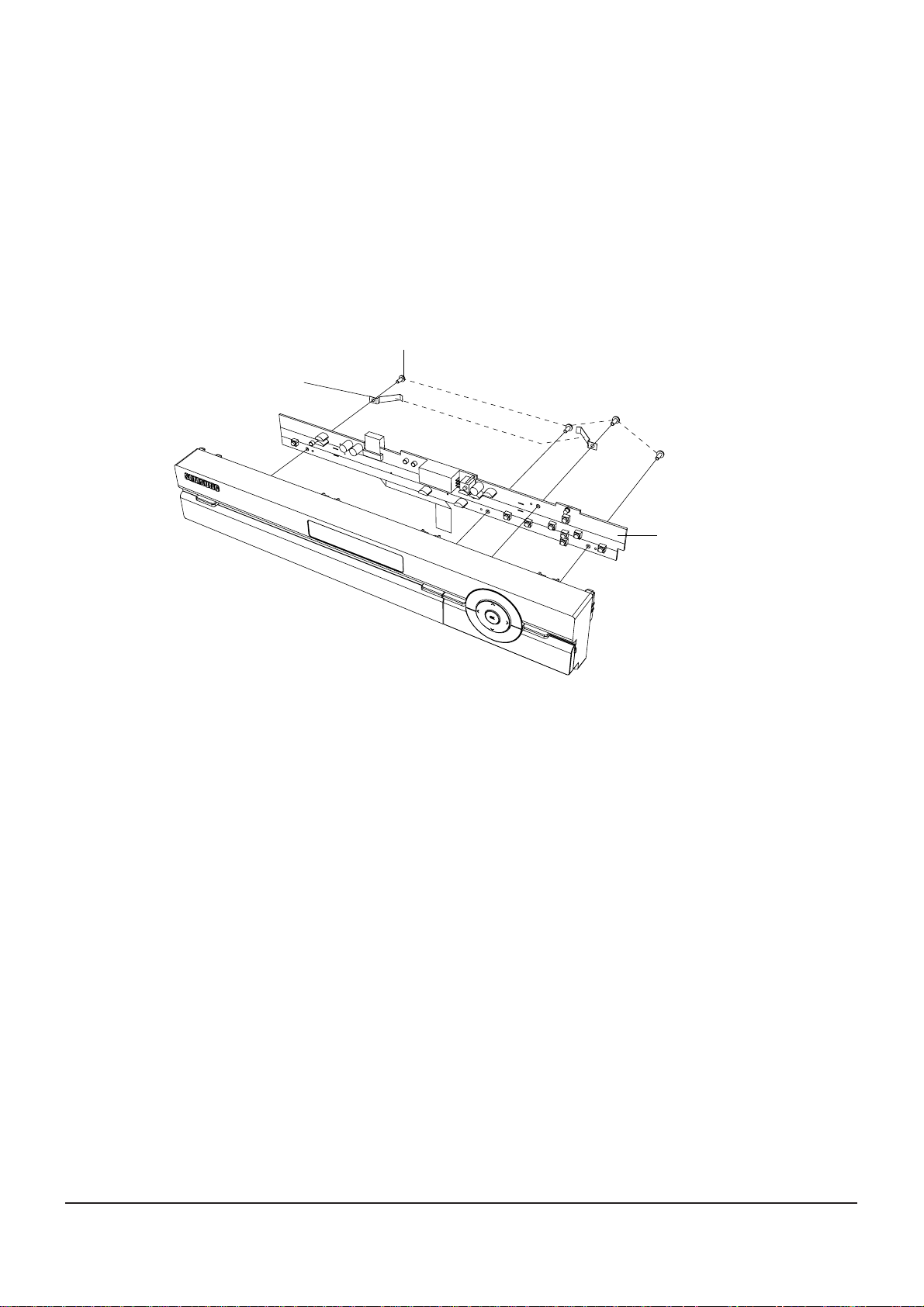

4-1-4 Front PCB Removal

1) Remove 4 Screws Œ.

1) Remove 2 PCB BRACKETS ´.

1) Remove FRONT PCB ˇ.

Fig. 4-4 Front PCB Removal

´ 2 PCB BRACKETS

Π4 SCREWS

(3 X 8 Y)

ˇ FRONT PCB

Page 19

Samsung Electronics

5-1

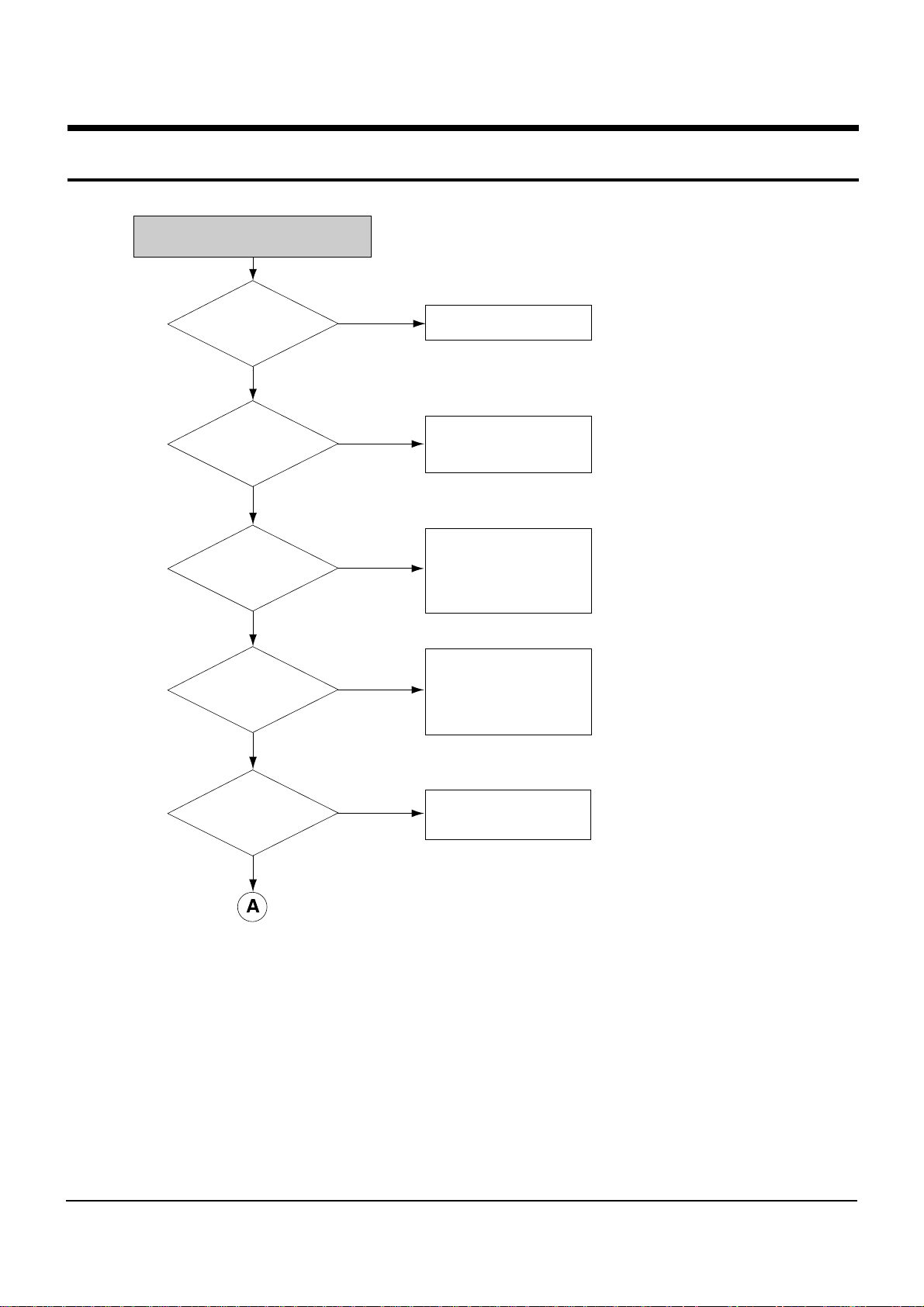

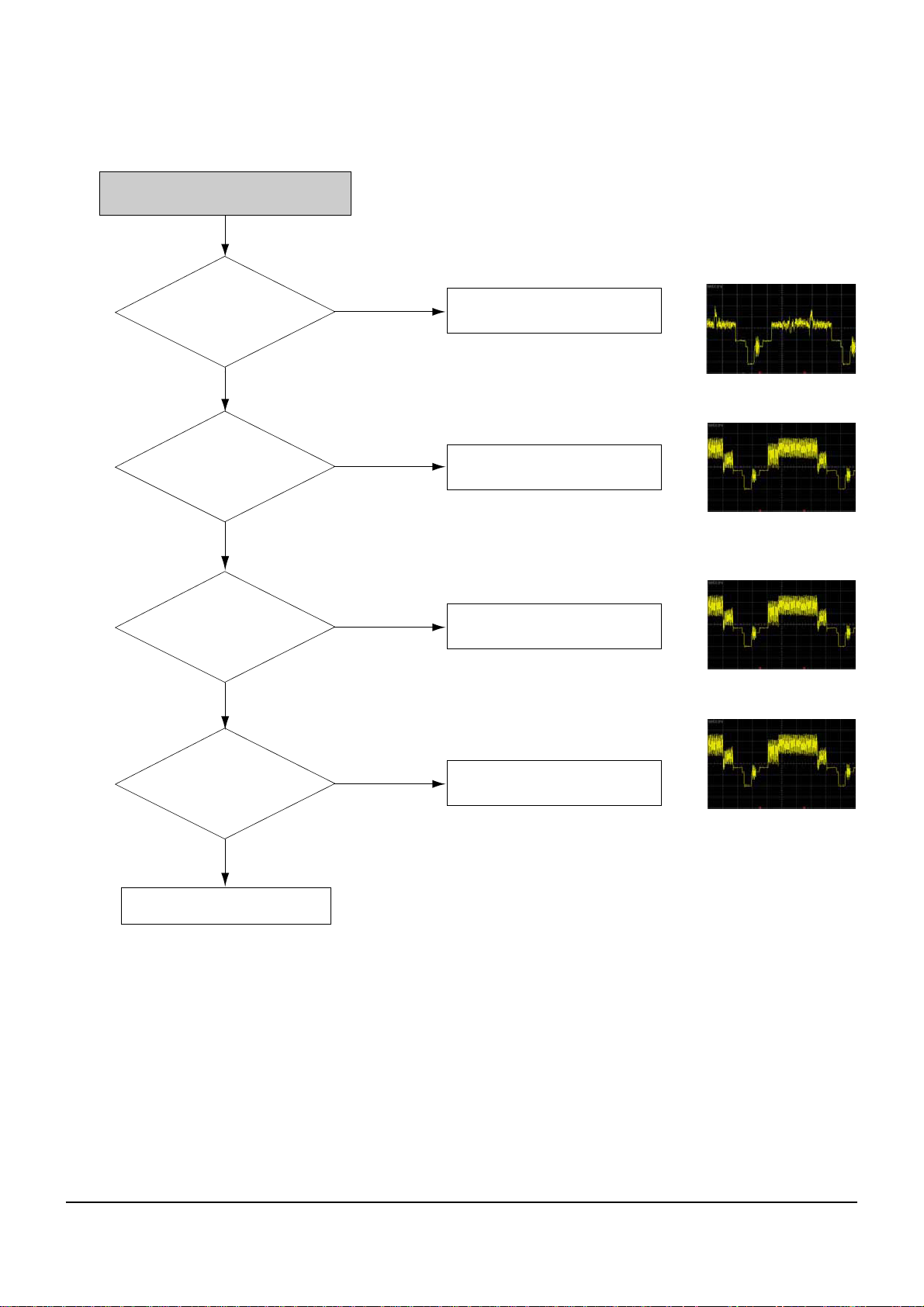

5. Troubleshooting

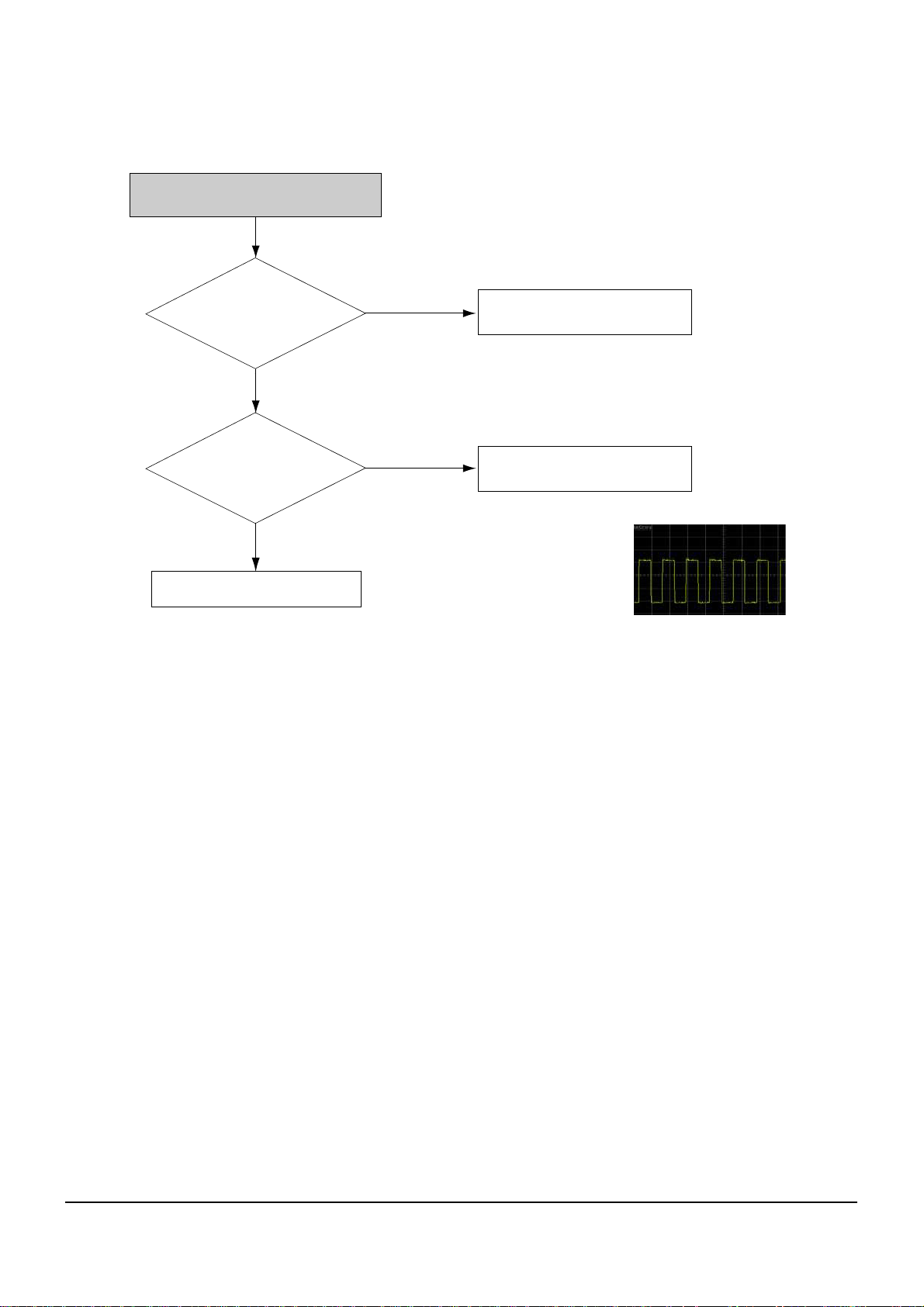

No Power Detected

Check the Power

Plug connection

Check the Voltage

at C2's both ends of AC

input voltage

Measure the

voltage of C39 1.4times

of input

Check the

voltage of Vcc for SMPS

controller

Check the

connection at several main

power

Check the shorting at

several main power

Connect Power Plug

Check F1(Fuse) "REMOVE"

and Change

• Check the Ri

(R1 : 2W 2.7Ω)

• Check the shoting of Q1

If the controller is

operating unstably or no

operation,change the U1

No

Yes

Yes

Yes

Yes

No

No

No

Yes

No

Page 20

Troubleshooting

5-2

Samsung Electronics

Check the existing

of pulse at pin10 of U5

• U5 pin8 voltage

• U5 pin12 PULSE

• Q3 EMITTER PUSE

Check the gate

pulse(pin1) of

Q13/Q14

Q17/Q18/Q10/Q16/Q12

PULSE

Connect between SMPS and

Main Power

No

Yes

Yes

No

Page 21

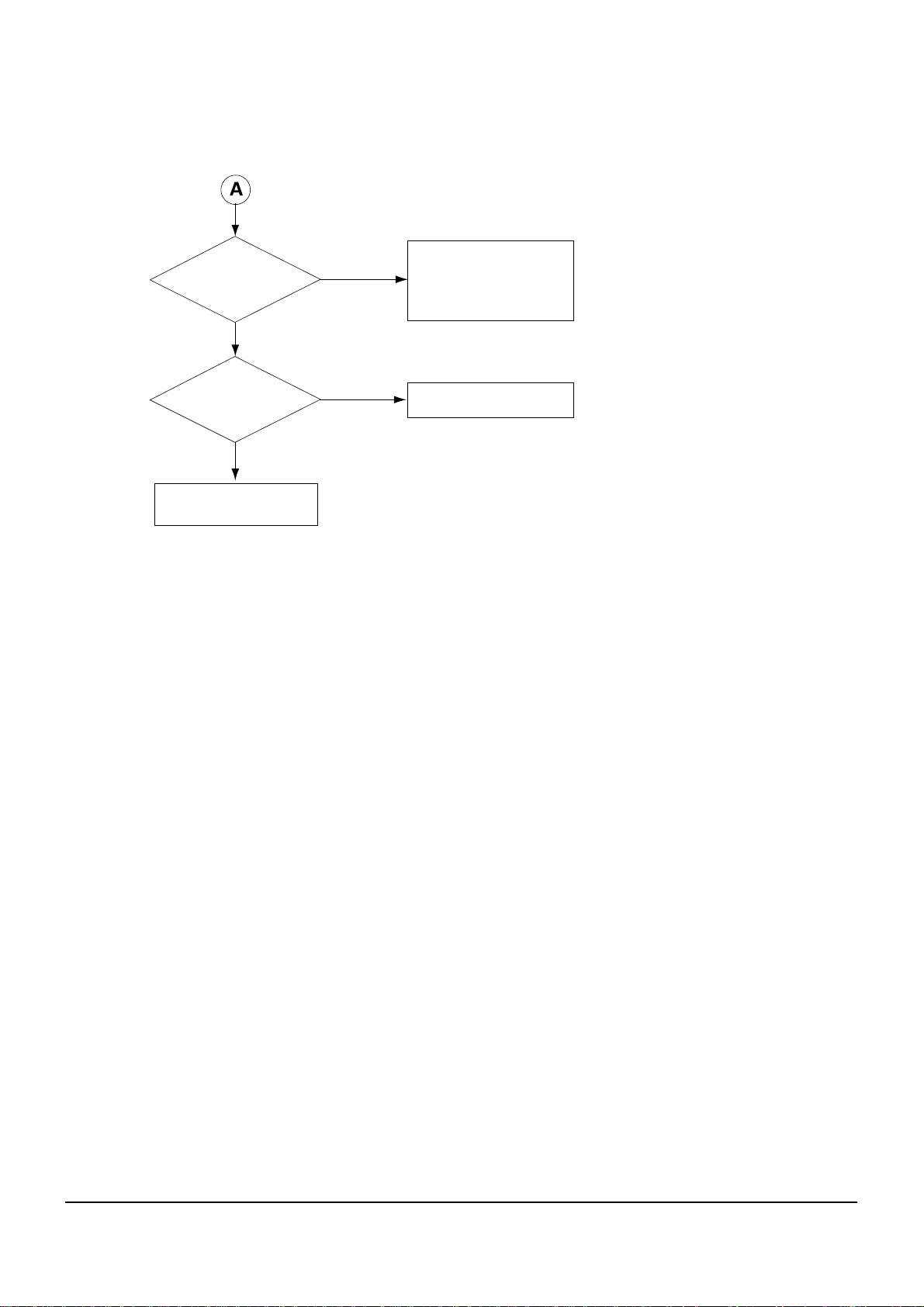

Troubleshooting

5-3

Samsung Electronics

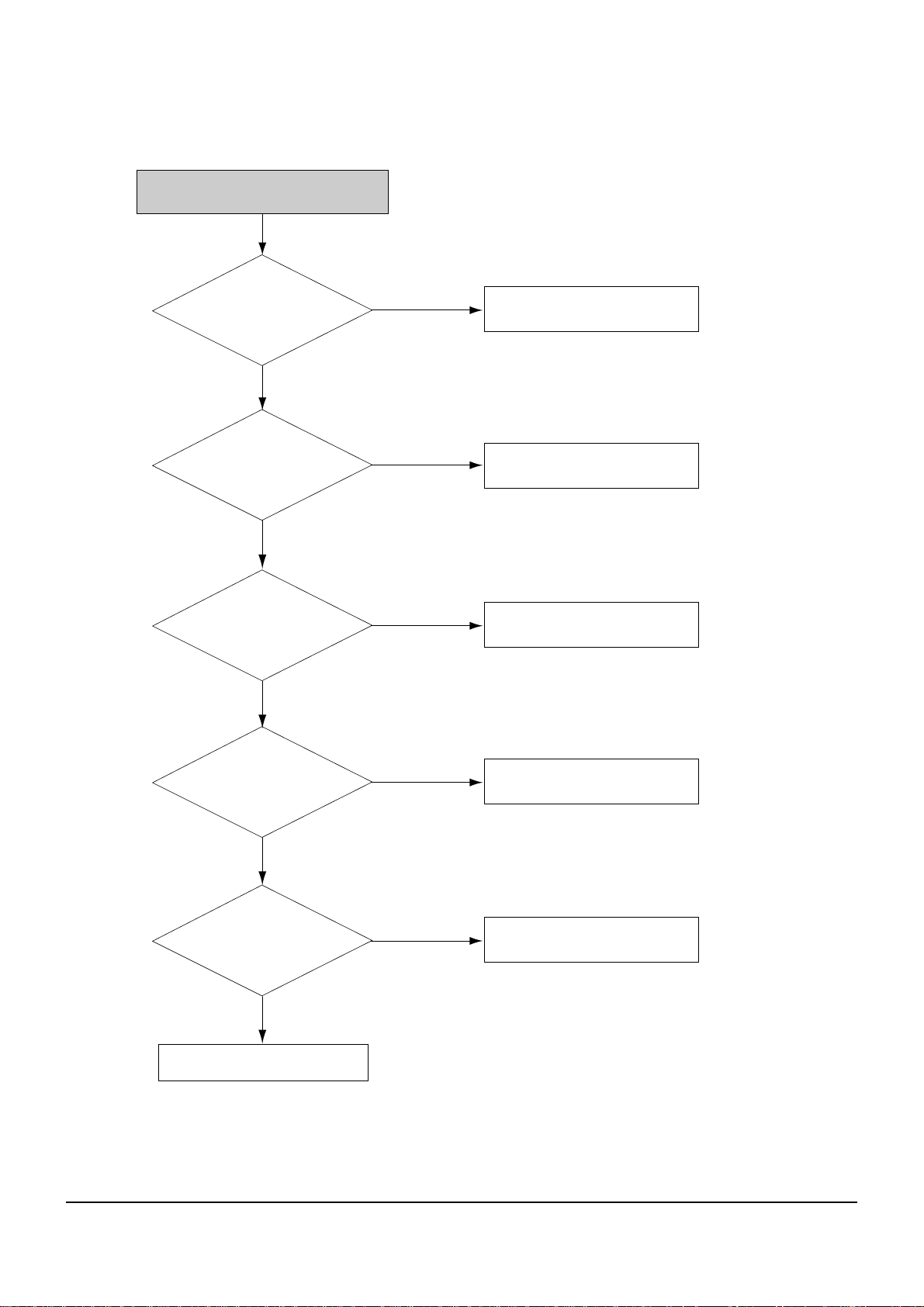

TV channel Missing

Antenna Cable is

connected well ?

Check I2C data bus of

Tuner 29,30 pin.

Data/clock signal OK?

Check TS & Clock pins

from 20pin to 28pin.

Data & clock OK?

Check serial registers'

condition of TS & control pins.

No problem ?

Connect Antenna cable.

Check tuner's(TM101) voltages.

5,11,12pin=5V,6pin=32V,14,15pin=3.3V

and 16pin(Reset)="High"

Check Voltage drive

circuit and repair trouble.

Check I2C bus line

between tuner and CPU.

Change for same spec tuner.

Correct resistors of

location(R107~R121).

Check HD Decoder "U25".

Tuner 29pin

Tuner 30pin

TS & Clock 20pin

TS & Clock 21~28pin

No

Yes

Yes

Yes

No

No

No

Yes

Yes

No

Page 22

Troubleshooting

5-4

5-4

Samsung Electronics

Composite Video signal Missing

(RCA Connector)

Check CVBS input

at 4pin of U1003 (HD Filter).

Check Failure mode of U25(S5H2110).

Check CVBS output

1,2 pin of U1003 (HD Filter).

Check Failure mode of

U1003(LA73060V)

Check Failure mode

of J1002(RCA Connector)

4pin of U1003

1,2 pin of U1003

No

Yes

Yes

No

Page 23

Troubleshooting

5-5

Samsung Electronics

Check Failure mode

of J1401 SCARTConnector)

Composite Video signal Missing

(SCART Connector)

Check CVBS input

at 4pin of U1003

(HD Filter).

Check Failure mode

of U25(S5H2110).

Check CVBS output

1,2 pin of U1003

(HD Filter).

Check Failure mode

of U1003(LA73060V)

Check CVBS input

43 pin of U1301

(AV Switch).

Check R1306,C1318,R1056

R1035,C1056,C1009

Check CVBS output

30,34 pin of U1301

(AV Switch).

Check Failure mode

of U1301(MAX4397S)

4pin of U1003

1,2 pin of U1003

43 pin of U1301]

30,34 pin of U1301

Yes

Yes

No

No

Yes

Yes

No

No

Page 24

Troubleshooting

5-6

Samsung Electronics

Check Failure mode

of J1002(RCA Connector)

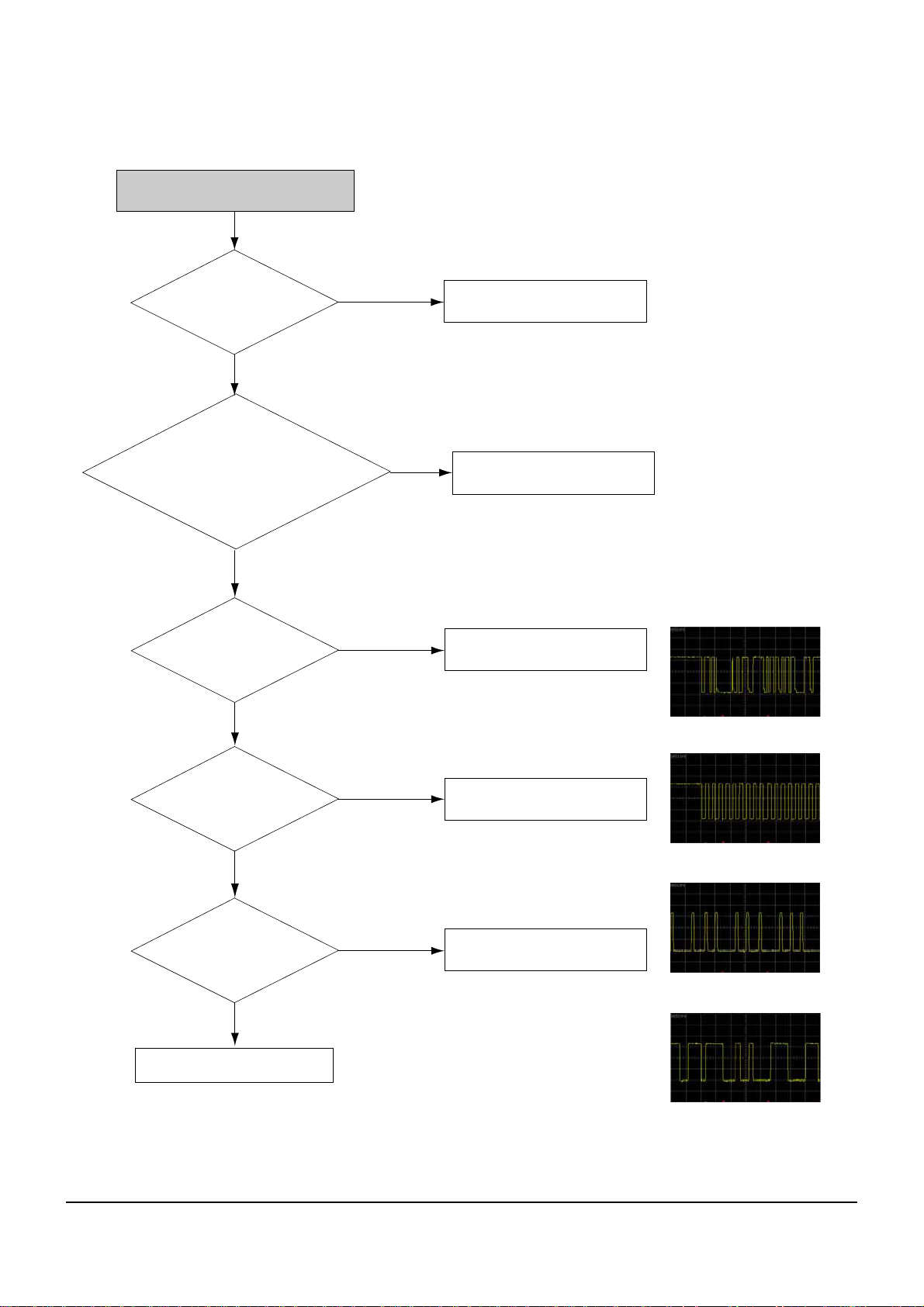

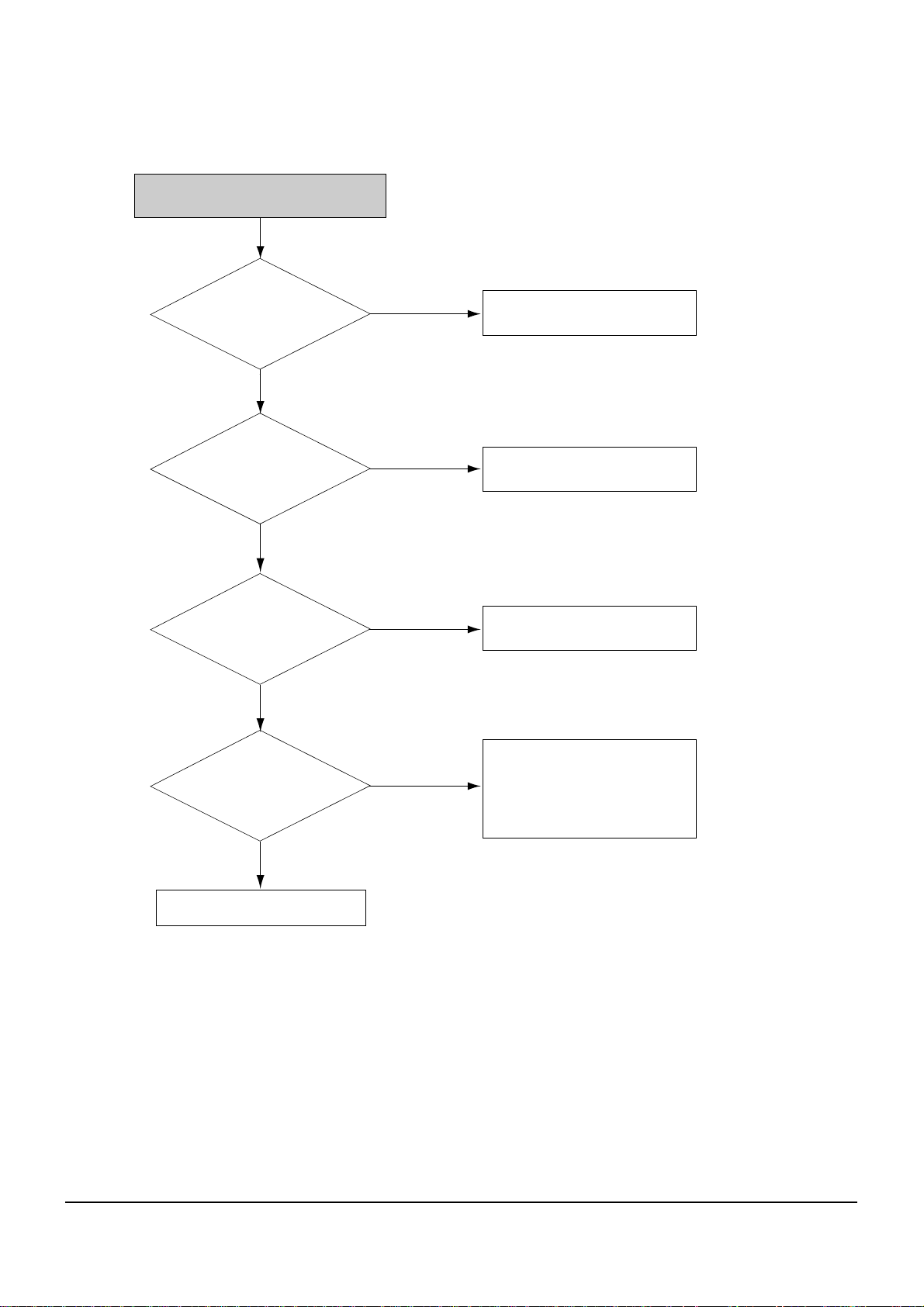

Component Signal Missing

Check Y/Pb/Pr mode or not.

Change to YPbPr mode.

Check Y/Pb/Pr signal at

C1024,C1025,C1026.

Check Failure mode of U25(S5H2110).

Check Y/Pb/Pr signal at

C1027,C1029,C1030.

Check Failure mode

of U1003(LA73060V).

Check Y/Pb/Pr signal at

R1006, L1008, R1010,

L1009, R1005, L1007

Check

Y: R1006, L1008

Pb: R1010, L1009

Pr: R1005, L1007

Refer to Wave pattern image

of Table 5-1

Refer to Wave pattern image

of Table 5-1

Refer to Wave pattern image

of Table 5-1

No

Yes

Yes

Yes

Yes

No

No

No

Page 25

Troubleshooting

5-7

Samsung Electronics

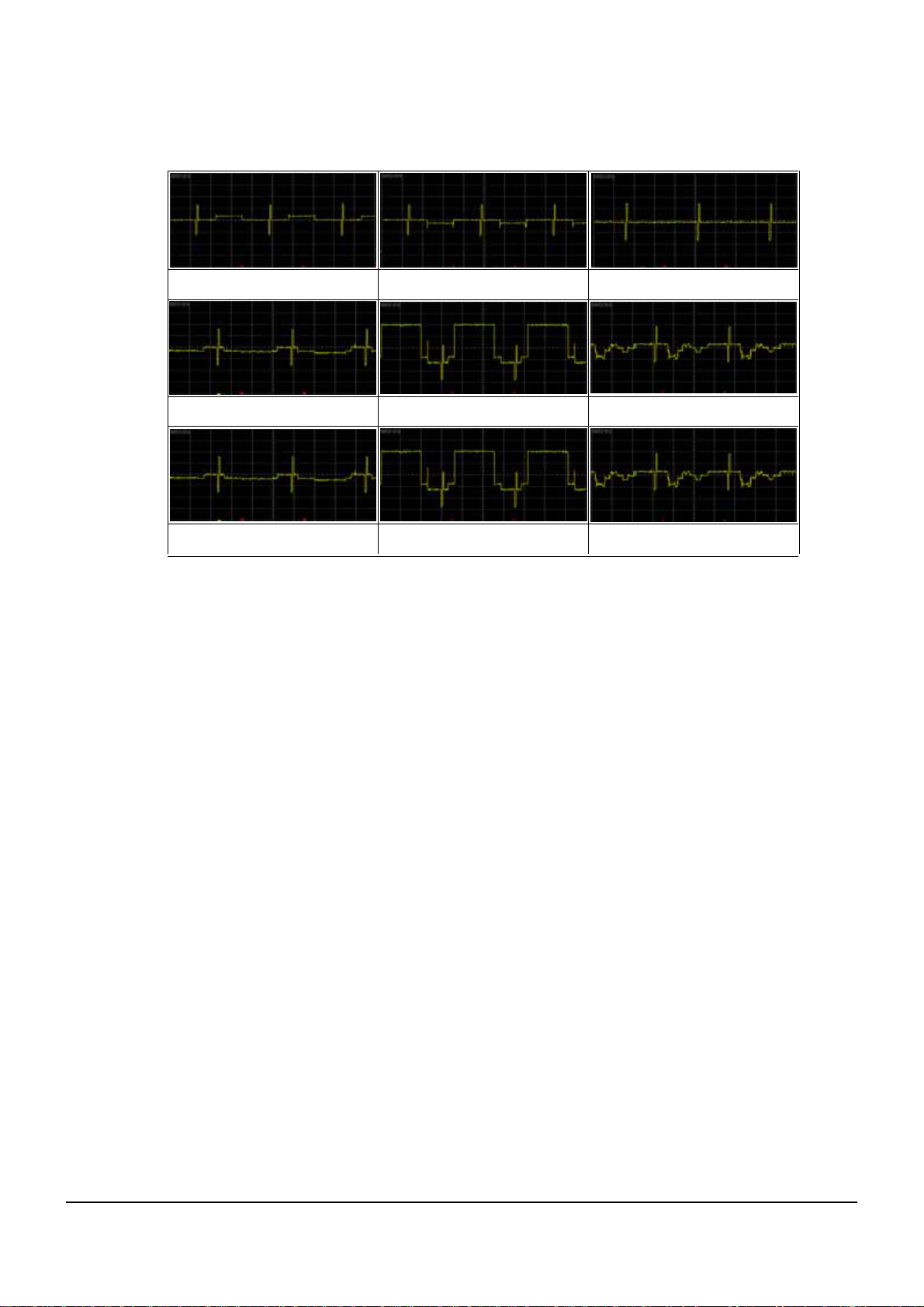

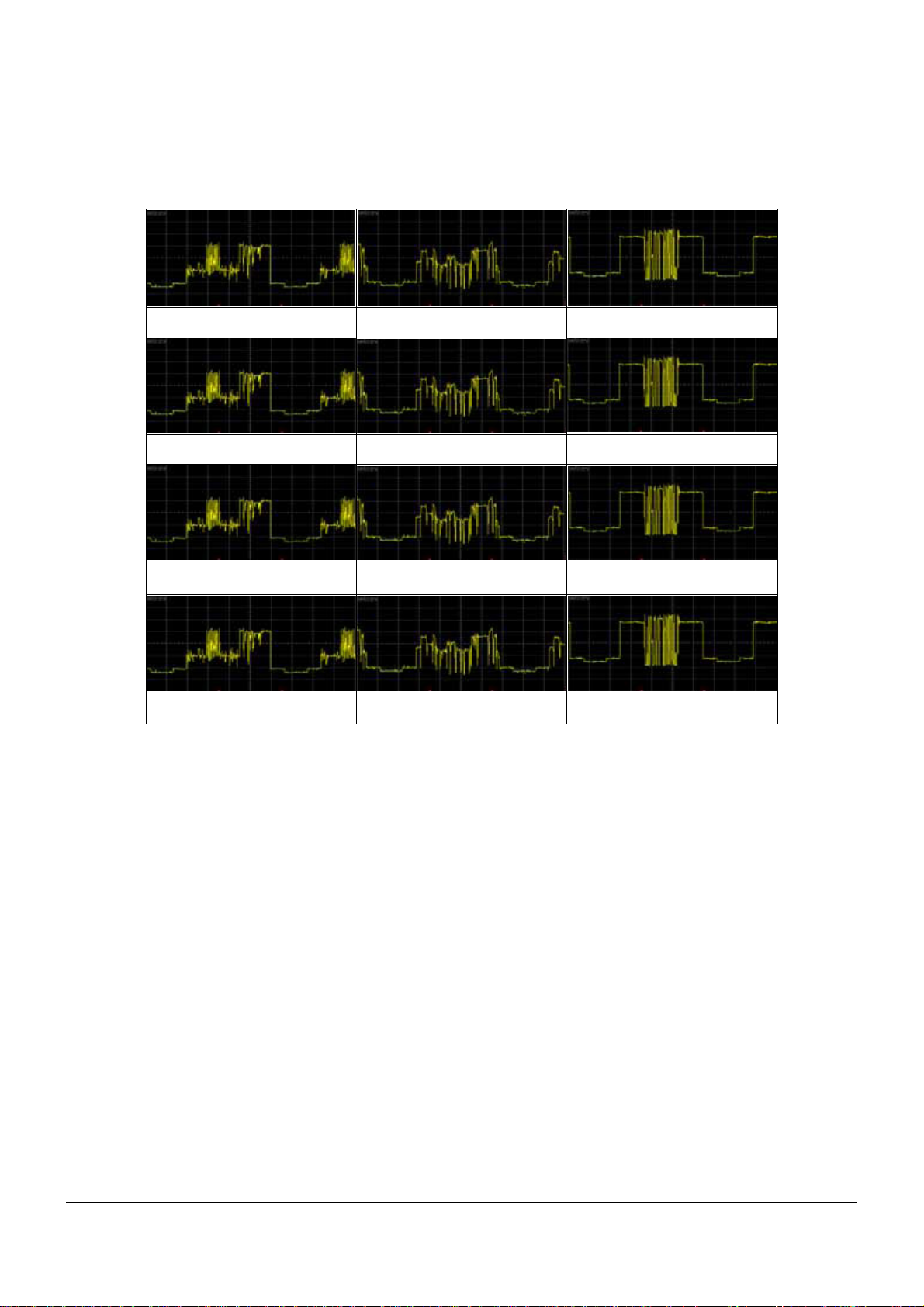

<Table 5-1>

Y/Pb/Pr Signal at C1024

Y/Pb/Pr Signal at C1027

Y/Pb/Pr Signal at L1008

Y/Pb/Pr Signal at C1025

Y/Pb/Pr Signal at C1029

Y/Pb/Pr Signal at L1009

Y/Pb/Pr Signal at C1026

Y/Pb/Pr Signal at C1030

Y/Pb/Pr Signal at L1007

Page 26

Troubleshooting

5-8

Samsung Electronics

Check RGB-Jack Connection

(STB<->TV).

RGB Signal Missing (SCART Jack)

Check DTV Output Select

switch RGB mode or not.

Change to RGB mode.

Check R/G/B signal

at C1024,C1025,C1026.

Check Failure mode of U25(S5H2110).

Check R/G/B signal

at R1012, R1014, R1016

Check Failure mode

of U1003(LA73060V).

Check R/G/B signal

at Pin31,32,33 of U1301

Check Failure mode

of U1301(MAX4397S)

Check R/G/B signal at

Pin7,11,15 of SCART Jack

Check R1403,R1404,R1405,

R1409,R1410,R1411

C1405,C1406,C1407

Refer to Wave pattern image

of Table 5-2

Refer to Wave pattern image

of Table 5-2

Refer to Wave pattern image

of Table 5-2

Refer to Wave pattern image

of Table 5-2

No

Yes

Yes

Yes

No

No

No

Yes

Yes

No

Page 27

Troubleshooting

5-9

Samsung Electronics

R/G/B Signal C1024 R/G/B Signal C1025

R/G/B Signal C1026

R/G/B Signal R1012-R R/G/B Signal R1014-G

R/G/B Signal R1016-B

R/G/B Signal U1301-31_R R/G/B Signal U1301-32_G

R/G/B Signal U1301-33_B

R/G/B Signal SCRAT-15_R R/G/B Signal SCRAT-11_G

R/G/B Signal SCRAT-7_B

<Table 5-2>

Page 28

Troubleshooting

5-10

Samsung Electronics

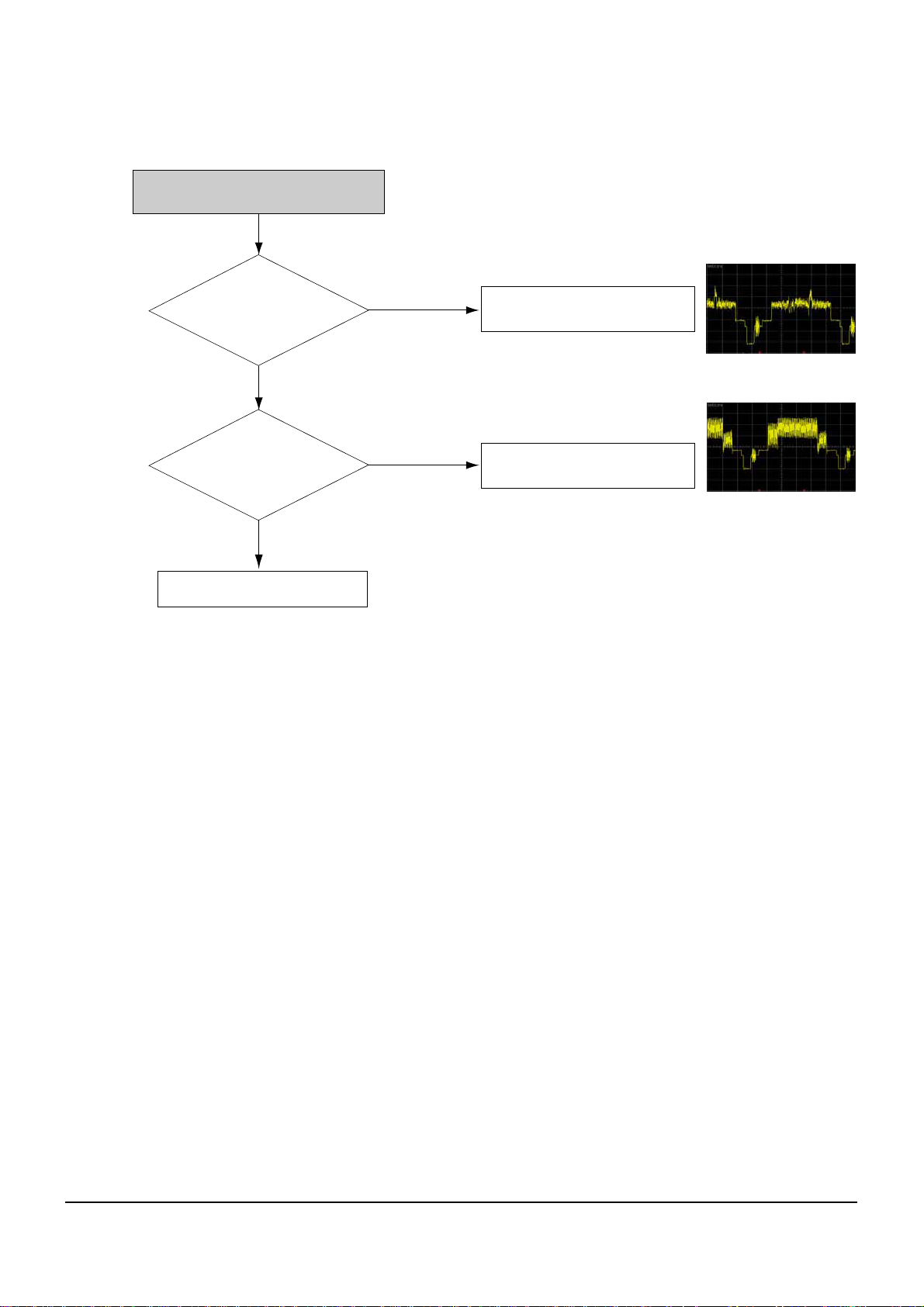

SPDIF Output Missing (Optical)

Check +5V

at Pin2 of J1001 ?

Check +5V Drive

Check Digital Audio signal

at R1019

Check Failure mode

of U25(S5H2110).

Check J1001 Optical Jack

Failure mode

Digital Audio signal at R1019

No

Yes

Yes

No

Page 29

Troubleshooting

5-11

Samsung Electronics

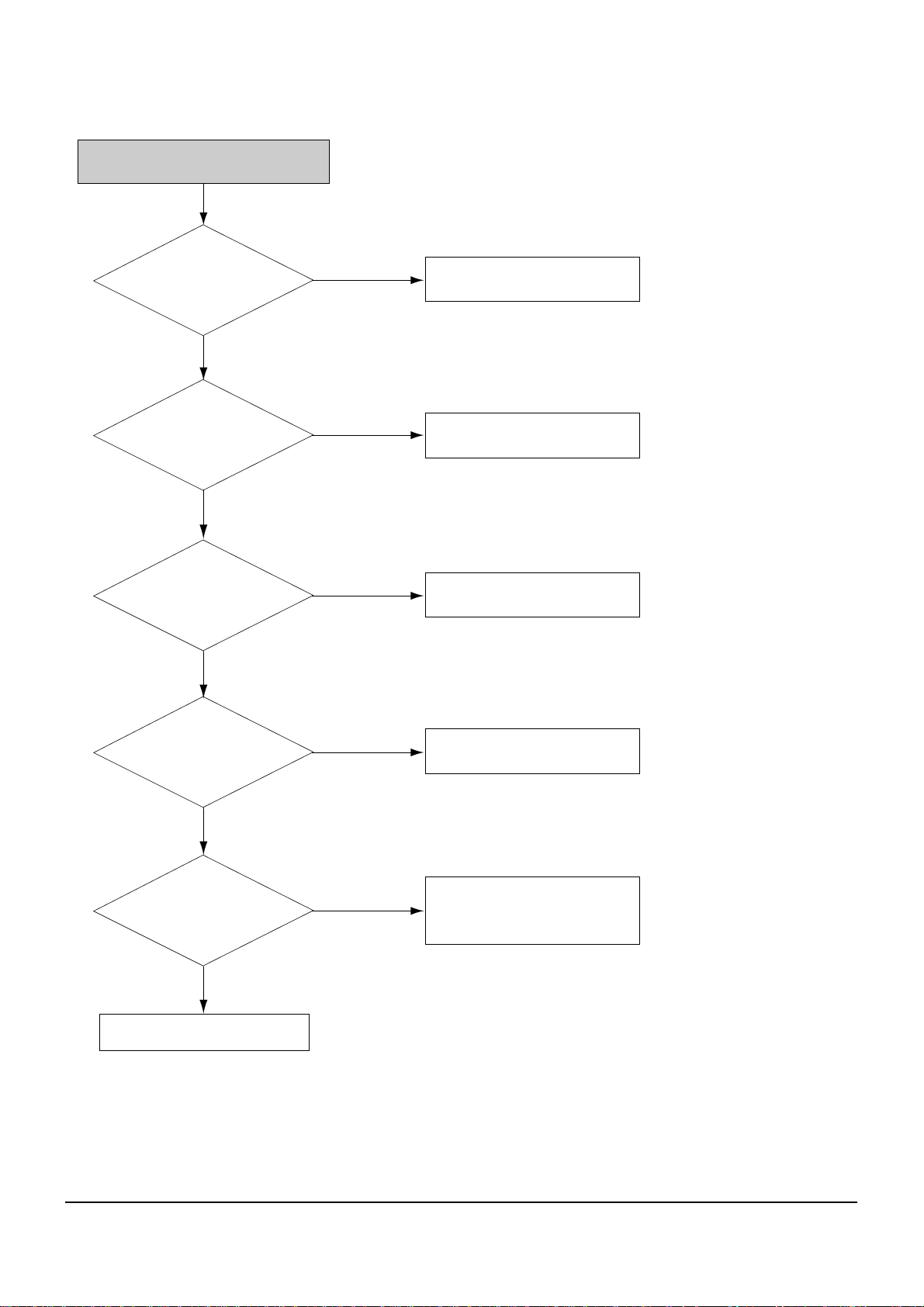

RCA Sound Output Missing

Check Digital Audio Data at

R1159, R1160, R1161, R1162

Check Failure mode

of U25(S5H2110).

Check +5V at Pin6

of U1002

Check +5V Drive

Check Analog Audio

output at Pin7,8pins of

U1002,

Check U1002

Failure mode.

Check Audio signal at

1,7pins of U1001

Check U1001 Failure mode and

application circuit

Check Audio signal at

C1011, C1017

Check Q1040, 1041 of Audio mute

Check Failure mode

of J1002(RCA Connector)

Refer to Wave pattern image

of Table 5-3

Refer to Wave pattern image

of Table 5-3

Refer to Wave pattern image

of Table 5-3

Refer to Wave pattern image

of Table 5-3

No

Yes

Yes

Yes

No

No

No

Yes

Yes

No

Page 30

Troubleshooting

5-12

Samsung Electronics

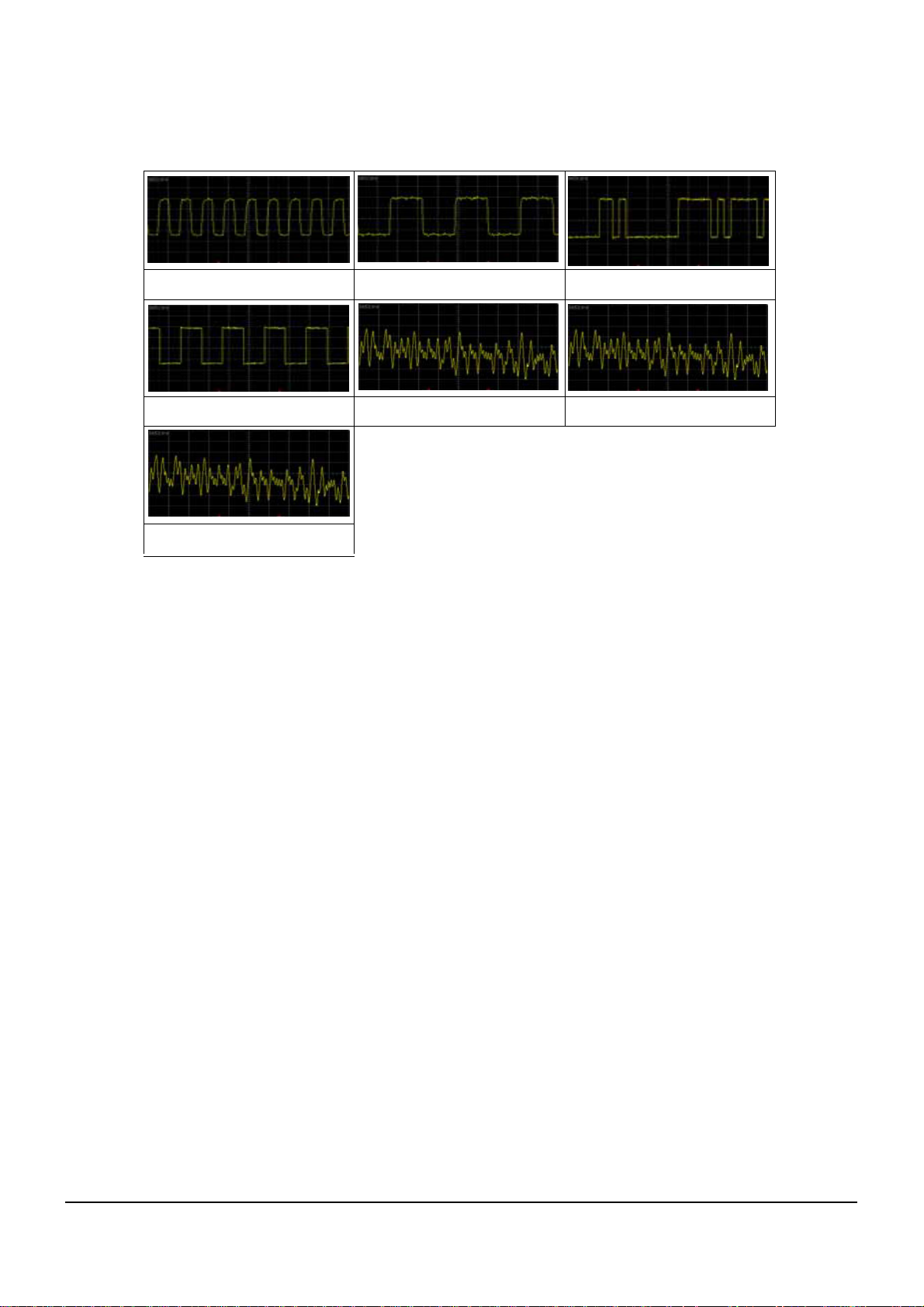

<Table 5-3>

Digital Audio Data at R1159 Digital Audio Data at R1160

Digital Audio Data at R1161

Digital Audio Data at R1162 Analog Audio output at Pin7,8pins

Audio signal at 1,7pins

Audio signal at C1011, C1017

Page 31

Samsung Electronics 6-1

6. Exploded View and Parts List

6-1 Cabinet Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6-2

Page 32

Exploded View and Parts List

6-2 Samsung Electronics

S.N.A : Service Not Available

6-1 Cabinet Assembly

W275

P025

P003

P005

FL619

P001

W260

W004

C015

A001

W004

ST025

C001

C022

Page 33

Exploded View and Parts List

6-3Samsung Electronics

Loc. No Parts No. Description ; Specification Q’ty S.N.A Remark

A001 MF59-00286A REMOCON-ASSY;DCB-H360R,SEC,196.4*48*31.1 1 SA

C001 MF97-00365B ASSY-CABINET FRONT;HIPS,DCB-H360R/XEN,BL 1 SA

C015 MF63-00060D COVER-TOP;DCB-H360RS,PCM,T0.625,W351,L20 1 SA

C022 MF64-00386A DOOR-FRONT;DCB-H360R,ABS,T2,H13.2,W99,L2 1 SNA

FL619 3809-001467 CABLE-FLAT;30V,80C,150MM,15P,1MM,UL2896 1 SA

P001 MF92-00210A ASSY PCB-MAIN;DCB-H365R,ASSY 1 SA

P003 MF92-00164A ASSY PCB-SMPS;DCB-H360R,SMPS 1 SA

P005 MF92-00165A ASSY PCB-FRONT;DCB-H360R,FRONT 1 SA

P025 3903-000281 CBF-POWER CORD;AT,EU,CP2,HOUSING(2P),250 1 SA

ST025 MF64-00133A DOOR-LOCK;SIR-S4120TR,SUS304,T0.2,H3.9,W 1 SNA

W004 6003-000283 SCREW-TAPTITE;BH,+,-,B,M3,L8,ZPC(WHT),SW 5 SA

W260 6003-001547 SCREW-TAPTITE;BH,+,-,B-TITE,M3,L8,ZPC(WH 3 SA

W275 6003-001561 SCREW-TAPTITE;BH,+,-,B,M3,L6,ZPC(WHT),SW 8 SA

Page 34

Exploded View and Parts List

6-4 Samsung Electronics

MEMO

Page 35

This Document can not be used without Samsung’s authorization

Loc.No Part No Description ; Specification Q’ty S.N.A Remark Loc.No Part No Description ; Specification Q’ty S.N.A Remark

Samsung Electronics

7-1

P001 MF92-00210A ASSY PCB-MAIN;DCB-H365R,ASSY 1 SA

C1001 2402-001083 C-AL,SMD;100uF,20%,50V,GP,TP,10x 1 SA

C1002 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1003 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1004 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1005 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1006 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1007 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1008 2203-000715 C-CER,CHIP;3.3nF,10%,50V,X7R,160 1 SA

C1009 2402-000135 C-AL,SMD;22uF,20%,16V,GP,TP,5.3x 1 SA

C1010 2203-000405 C-CER,CHIP;0.18nF,5%,50V,C0G,160 1 SA

C1011 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1012 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1013 2203-000491 C-CER,CHIP;2.2nF,10%,50V,X7R,160 1 SA

C1014 2203-000405 C-CER,CHIP;0.18nF,5%,50V,C0G,160 1 SA

C1015 2203-000715 C-CER,CHIP;3.3nF,10%,50V,X7R,160 1 SA

C1016 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1017 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1018 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1019 2203-000491 C-CER,CHIP;2.2nF,10%,50V,X7R,160 1 SA

C1020 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C1021 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1022 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1023 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1024 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1025 2402-000173 C-AL,SMD;4.7uF,20%,35V,GP,TP,4.3 1 SA

C1026 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1027 2402-001136 C-AL,SMD;330UF,20,16V,GP,TP,8X10 1 SA

C1028 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C1029 2402-000135 C-AL,SMD;22uF,20%,16V,GP,TP,5.3x 1 SA

C1030 2402-001136 C-AL,SMD;330UF,20,16V,GP,TP,8X10 1 SA

C1031 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1032 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1033 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1034 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1035 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1036 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1037 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,16 1 SA

C1038 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,16 1 SA

C1039 2203-000815 C-CER,CHIP;0.033nF,5%,50V,C0G,16 1 SA

C104 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1040 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1041 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C1042 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1043 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1046 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C105 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1056 2402-001096 C-AL,SMD;220UF,20%,16V,GP,TP,6.6 1 SA

C1057 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,1608 1 SA

C106 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C1067 2203-000125 C-CER,CHIP;1.2nF,10%,50V,X7R,TP, 1 SA

C107 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C108 2203-005249 C-CER,CHIP;100nF,10%,50V,X7R,160 1 SA

C109 2402-001083 C-AL,SMD;100uF,20%,50V,GP,TP,10x 1 SA

C110 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1101 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1102 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1103 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1104 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1105 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 SA

C1106 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1107 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1108 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1109 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C111 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1110 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1111 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1112 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1113 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1114 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1115 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1116 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1117 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1118 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1119 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C112 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C1120 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1121 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C1122 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1123 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1124 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1125 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1126 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1127 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1128 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1129 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C113 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1130 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C1131 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1132 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1135 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1201 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1202 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1203 2203-001020 C-CER,CHIP;0.004NF,0.25PF,50V,C0 1 SA

C1204 2203-001020 C-CER,CHIP;0.004NF,0.25PF,50V,C0 1 SA

C1205 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1206 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1207 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C1208 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1209 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1222 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1223 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1224 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1225 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1301 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C1302 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1303 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

7. Electrical Parts List

Page 36

This Document can not be used without Samsung’s authorization

Loc.No Part No Description ; Specification Q’ty S.N.A RemarkLoc.No Part No Description ; Specification Q’ty S.N.A Remark

7-2

Samsung Electronics

Electrical Parts List

C1304 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1305 2402-000117 C-AL,SMD;10uF,20%,35V,GP,TP,5.3x 1 SA

C1307 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1309 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C1310 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1311 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1312 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1313 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1314 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C1315 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1316 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1317 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1318 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1321 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1322 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1401 2402-000117 C-AL,SMD;10uF,20%,35V,GP,TP,5.3x 1 SA

C1402 2402-000117 C-AL,SMD;10uF,20%,35V,GP,TP,5.3x 1 SA

C1403 2402-000117 C-AL,SMD;10uF,20%,35V,GP,TP,5.3x 1 SA

C1404 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,160 1 SA

C1405 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1406 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1407 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1408 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1409 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1410 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1411 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1412 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1413 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,160 1 SA

C1414 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,160 1 SA

C1415 2402-000117 C-AL,SMD;10uF,20%,35V,GP,TP,5.3x 1 SA

C1416 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,160 1 SA

C1417 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,160 1 SA

C1418 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,160 1 SA

C1419 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1420 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1421 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1422 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1423 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1424 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1425 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1426 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1427 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1428 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1429 2203-000236 C-CER,CHIP;0.1nF,5%,50V,C0G,1608 1 SA

C1430 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,160 1 SA

C1431 2203-000888 C-CER,CHIP;4.7nF,10%,50V,X7R,160 1 SA

C1501 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1502 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1503 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1504 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1505 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,160 1 SA

C1506 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1507 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1508 2203-001607 C-CER,CHIP;0.22nF,5%,50V,NP0,160 1 SA

C1509 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1510 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1511 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1512 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1513 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C1514 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1515 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1702 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1806 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C1807 2203-001052 C-CER,CHIP;0.56nF,10%,50V,X7R,TP 1 SA

C1808 2402-000117 C-AL,SMD;10uF,20%,35V,GP,TP,5.3x 1 SA

C1811 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1812 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1813 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1814 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C1815 2203-000783 C-CER,CHIP;0.33nF,5%,50V,C0G,160 1 SA

C1816 2203-000783 C-CER,CHIP;0.33nF,5%,50V,C0G,160 1 SA

C1866 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1867 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1868 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1869 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1870 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1871 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1872 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1873 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1874 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C1875 2203-000998 C-CER,CHIP;0.047nF,5%,50V,C0G,16 1 SA

C2001 2402-001096 C-AL,SMD;220UF,20%,16V,GP,TP,6.6 1 SA

C2002 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C2003 2203-002398 C-CER,CHIP;22nF,10%,50V,X7R,1608 1 SA

C2004 2402-001100 C-AL,SMD;0.1uF,20%,50V,GP,TP,4.3 1 SA

C2005 2203-002398 C-CER,CHIP;22nF,10%,50V,X7R,1608 1 SA

C2006 2203-001656 C-CER,CHIP;0.47nF,5%,50V,NP0,160 1 SA

C2007 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C2008 2203-001656 C-CER,CHIP;0.47nF,5%,50V,NP0,160 1 SA

C2009 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C201 2203-000491 C-CER,CHIP;2.2nF,10%,50V,X7R,160 1 SA

C2010 2203-000541 C-CER,CHIP;0.2nF,5%,50V,C0G,1608 1 SA

C2011 2203-002398 C-CER,CHIP;22nF,10%,50V,X7R,1608 1 SA

C2012 2203-002398 C-CER,CHIP;22nF,10%,50V,X7R,1608 1 SA

C2013 2203-000560 C-CER,CHIP;220nF,+80-20%,25V,Y5V 1 SA

C2014 2402-001173 C-AL,SMD;1000UF,20%,6.3V,WT,TP,1 1 SA

C2015 2402-001173 C-AL,SMD;1000UF,20%,6.3V,WT,TP,1 1 SA

C2016 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C2017 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C2018 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C2019 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C202 2203-000140 C-CER,CHIP;1.5nF,10%,50V,X7R,160 1 SA

C2020 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C2021 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C2022 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C2023 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C2024 2203-000257 C-CER,CHIP;10nF,10%,50V,X7R,1608 1 SA

C2033 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C2034 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C301 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C302 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C303 2402-001019 C-AL,SMD;2.2uF,20%,35V,GP,TP,3.3 1 SA

C304 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

Page 37

This Document can not be used without Samsung’s authorization

Loc.No Part No Description ; Specification Q’ty S.N.A Remark Loc.No Part No Description ; Specification Q’ty S.N.A Remark

Electrical Parts List

Samsung Electronics

7-3

C305 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C306 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C307 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C308 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C309 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C310 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C311 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C312 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C313 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C314 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C315 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C316 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C317 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C318 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C319 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C320 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C321 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C322 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C323 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C401 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C402 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C403 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C404 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C405 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C406 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C407 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C408 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C409 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C410 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C411 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C412 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C413 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C414 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C415 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C416 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C417 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C418 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C419 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C420 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C421 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C422 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C423 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C424 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C425 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C426 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C427 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C428 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C429 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C430 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C431 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C432 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C433 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C434 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C435 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C436 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C437 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C438 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C439 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C450 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C451 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C452 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C453 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C454 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C455 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C456 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C457 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C458 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C459 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C460 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C461 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C462 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C463 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C464 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C465 2402-001178 C-AL,SMD;10uF,20%,16V,WT,TP,4.3x 1 SA

C466 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C467 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C468 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C469 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C470 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C471 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C472 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C473 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C474 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C475 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C476 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C477 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C478 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C479 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C480 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C481 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C482 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C483 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C484 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C485 2402-001238 C-AL,SMD;1uF,20%,50V,HR,TP,4.3x4 1 SA

C486 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C487 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

C488 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C489 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

C490 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C491 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C499 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C500 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C501 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C502 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C503 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C504 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C505 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C601 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C602 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C603 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C604 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C605 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C606 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C607 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

Page 38

C608 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C609 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C610 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C611 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C612 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C613 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C614 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C615 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C616 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C617 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C618 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C619 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C620 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C621 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C622 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C623 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C624 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C625 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C626 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C627 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C628 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C629 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C630 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C631 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C632 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C633 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C634 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C635 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C636 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C637 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C638 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C639 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C640 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C641 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C642 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C643 2402-001096 C-AL,SMD;220UF,20%,16V,GP,TP,6.6 1 SA

C644 2402-001096 C-AL,SMD;220UF,20%,16V,GP,TP,6.6 1 SA

C646 2402-001019 C-AL,SMD;2.2uF,20%,35V,GP,TP,3.3 1 SA

C647 2402-001019 C-AL,SMD;2.2uF,20%,35V,GP,TP,3.3 1 SA

C650 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C652 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C653 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C654 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

C655 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C656 2402-001096 C-AL,SMD;220UF,20%,16V,GP,TP,6.6 1 SA

C657 2402-001096 C-AL,SMD;220UF,20%,16V,GP,TP,6.6 1 SA

C701 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C702 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C703 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C707 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C708 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C709 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C711 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C801 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C802 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C803 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

C811 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

C901 2203-000681 C-CER,CHIP;0.027nF,5%,50V,C0G,16 1 SA

C902 2203-000681 C-CER,CHIP;0.027nF,5%,50V,C0G,16 1 SA

C903 2203-001554 C-CER,CHIP;1.8nF,10%,50V,X7R,160 1 SA

C904 2203-001052 C-CER,CHIP;0.56nF,10%,50V,X7R,TP 1 SA

C905 2203-000541 C-CER,CHIP;0.2nF,5%,50V,C0G,1608 1 SA

C906 2203-000140 C-CER,CHIP;1.5nF,10%,50V,X7R,160 1 SA

C907 2203-000440 C-CER,CHIP;1nF,10%,50V,X7R,1608 1 SA

CA10 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA100 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA101 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA102 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA103 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA104 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA105 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA106 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA107 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA108 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA109 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA11 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA110 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA111 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA112 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA113 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA114 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA115 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA116 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA117 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA118 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA119 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA12 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA120 2402-001181 C-AL,SMD;100uF,20%,16V,HR,TP,6.6 1 SA

CA121 2402-001155 C-AL,SMD;47UF,20%,16V,WT,TP,6.3X 1 SA

CA122 2203-005819 C-CER,CHIP;1000nF,+80-20%,16V,Y5 1 SA

CA123 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

CA124 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA125 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

CA126 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

CA127 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA13 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA14 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA143 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA144 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA145 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA146 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA147 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA148 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA149 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA15 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA150 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA151 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA152 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA153 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA154 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA155 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA156 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA157 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

Loc.No Part No Description ; Specification Q’ty S.N.A Remark

7-4

Samsung Electronics

Electrical Parts List

Loc.No Part No Description ; Specification Q’ty S.N.A Remark

This Document can not be used without Samsung’s authorization

Page 39

CA158 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA159 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA16 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA160 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA161 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA162 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA163 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA164 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA165 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA166 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA17 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA172 2402-001178 C-AL,SMD;10uF,20%,16V,WT,TP,4.3x 1 SA

CA173 2402-001181 C-AL,SMD;100uF,20%,16V,HR,TP,6.6 1 SA

CA174 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

CA175 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA176 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA177 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA178 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA18 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA194 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA30 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA31 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA32 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA33 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA34 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA38 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA39 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA40 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA41 2402-001178 C-AL,SMD;10uF,20%,16V,WT,TP,4.3x 1 SA

CA42 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA43 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA44 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA45 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA46 2402-000176 C-AL,SMD;10uF,20%,16V,GP,TP,4.3x 1 SA

CA56 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA57 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA58 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA59 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA60 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA61 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA62 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA63 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA64 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA65 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA66 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA67 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA68 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA69 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA70 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA71 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA72 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA73 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA74 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA75 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA76 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA77 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA78 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA79 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA80 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA81 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA82 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA83 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA84 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA85 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA86 2402-001178 C-AL,SMD;10uF,20%,16V,WT,TP,4.3x 1 SA

CA87 2402-001042 C-AL,SMD;100uF,20%,16V,GP,TP,6.6 1 SA

CA88 2402-000008 C-AL,SMD;47uF,20%,16V,GP,TP,6.6x 1 SA

CA89 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA9 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA90 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA91 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA92 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA93 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA94 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA95 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA96 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA97 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA98 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CA99 2203-005148 C-CER,CHIP;100nF,10%,16V,X7R,160 1 SA

CN1101 3701-001351 CONNECTOR-HDMI;19P,2R,HDMI,ANGLE 1 SA

CN1503 3709-001259 CONNECTOR-CARD SLOT;8P,2.54mm,ST 1 SA

CN1801 3708-001755 CONNECTOR-FPC/FFC/PIC;15P,1mm,ST 1 SA

CN2001 3711-000577 HEADER-BOARD TO CABLE;BOX,10P,1R 1 SA

CN2002 3711-000577 HEADER-BOARD TO CABLE;BOX,10P,1R 1 SA

D1103 0406-001239 DIODE-TVS;RClamp0502B,6V,125W,SO 1 SA

D1104 0406-001239 DIODE-TVS;RClamp0502B,6V,125W,SO 1 SA

D1105 0406-001239 DIODE-TVS;RClamp0502B,6V,125W,SO 1 SA

D1106 0406-001239 DIODE-TVS;RClamp0502B,6V,125W,SO 1 SA

D1401 0401-001116 DIODE-SWITCHING;BAV99DW,75V,150M 1 SA

D1402 0401-001116 DIODE-SWITCHING;BAV99DW,75V,150M 1 SA

D1403 0401-001116 DIODE-SWITCHING;BAV99DW,75V,150M 1 SA

D1404 0401-001116 DIODE-SWITCHING;BAV99DW,75V,150M 1 SA

D1405 0401-001116 DIODE-SWITCHING;BAV99DW,75V,150M 1 SA

D1406 0401-001116 DIODE-SWITCHING;BAV99DW,75V,150M 1 SA

D1407 0401-001116 DIODE-SWITCHING;BAV99DW,75V,150M 1 SA

D1408 0401-001116 DIODE-SWITCHING;BAV99DW,75V,150M 1 SA

D1409 0401-001116 DIODE-SWITCHING;BAV99DW,75V,150M 1 SA

D1410 0401-001116 DIODE-SWITCHING;BAV99DW,75V,150M 1 SA

D2001 0402-001192 DIODE-RECTIFIER;ES2D,200V,2A,DO- 1 SA

J1001 3707-001070 CONNECTOR-OPTICAL;PLUG,GP1FA550T 1 SA

J1002 3722-002027 JACK-PIN;6P/6C,SN,YEL/GN/WH/BL/R 1 SA

J1401 3722-001345 JACK-SCART;42P/2R,SN,BLK 1 SA

L1001 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

L1002 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

L1003 2703-000367 INDUCTOR-SMD;33uH,5%,2520 1 SA

L1004 2703-000367 INDUCTOR-SMD;33uH,5%,2520 1 SA

L1005 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

L1006 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

L1007 3301-001234 BEAD-SMD;80ohm,1608,280mA,,,,0.2 1 SA

L1008 3301-001234 BEAD-SMD;80ohm,1608,280mA,,,,0.2 1 SA

L1009 3301-001234 BEAD-SMD;80ohm,1608,280mA,,,,0.2 1 SA

L101 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

L102 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

Electrical Parts List

Samsung Electronics

7-5

Loc.No Part No Description ; Specification Q’ty S.N.A Remark Loc.No Part No Description ; Specification Q’ty S.N.A Remark

This Document can not be used without Samsung’s authorization

Page 40

L103 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

L104 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

L1052 2703-000158 INDUCTOR-SMD;1uH,10%,2012 1 SA

L1101 2703-000158 INDUCTOR-SMD;1uH,10%,2012 1 SA

L1102 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

L1103 2703-000403 INDUCTOR-SMD;22uH,10%,3225 1 SA

L1104 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

L1105 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

L1201 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

L1301 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

L1401 2703-000229 INDUCTOR-SMD;6.8UH,20%,2012 1 SA

L1402 2703-000229 INDUCTOR-SMD;6.8UH,20%,2012 1 SA

L1403 2703-000229 INDUCTOR-SMD;6.8UH,20%,2012 1 SA

L1404 2703-000229 INDUCTOR-SMD;6.8UH,20%,2012 1 SA

L1405 2703-000229 INDUCTOR-SMD;6.8UH,20%,2012 1 SA

L1406 2703-000229 INDUCTOR-SMD;6.8UH,20%,2012 1 SA

L1407 2703-000229 INDUCTOR-SMD;6.8UH,20%,2012 1 SA

L1408 2703-000229 INDUCTOR-SMD;6.8UH,20%,2012 1 SA

L1409 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

L1501 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

L1502 3301-000314 BEAD-SMD;120ohm,1.6x0.8x0.8mm,-, 1 SA

L2001 3301-001684 BEAD-SMD;120ohm,4532,TP,-,- 1 SA

L2002 3301-001684 BEAD-SMD;120ohm,4532,TP,-,- 1 SA

L2004 3301-001684 BEAD-SMD;120ohm,4532,TP,-,- 1 SA

L2005 3301-001684 BEAD-SMD;120ohm,4532,TP,-,- 1 SA

L2006 3301-001484 BEAD-SMD;220ohm,2012,TP,210ohm/9 1 SA

L2008 2702-001133 INDUCTOR-RADIAL;68uH,10%,8.5x8.3 1 SA

L2009 2702-001133 INDUCTOR-RADIAL;68uH,10%,8.5x8.3 1 SA

L2010 3301-001484 BEAD-SMD;220ohm,2012,TP,210ohm/9 1 SA

L2011 3301-001145 BEAD-SMD;60ohm,4516,TP,70ohm/45M 1 SA

L2012 3301-001484 BEAD-SMD;220ohm,2012,TP,210ohm/9 1 SA

L301 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

L401 3301-001684 BEAD-SMD;120ohm,4532,TP,-,- 1 SA

L403 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

L404 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

L405 3301-001684 BEAD-SMD;120ohm,4532,TP,-,- 1 SA

L406 3301-001684 BEAD-SMD;120ohm,4532,TP,-,- 1 SA

L408 3301-001684 BEAD-SMD;120ohm,4532,TP,-,- 1 SA

L410 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

L601 3301-001484 BEAD-SMD;220ohm,2012,TP,210ohm/9 1 SA

L602 3301-001484 BEAD-SMD;220ohm,2012,TP,210ohm/9 1 SA

LA11 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

LA12 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

LA13 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

LA16 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

LA2 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

LA3 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

LA6 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

LA7 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

LA9 3301-001495 BEAD-SMD;120ohm,2012,2500mA,TP,1 1 SA

PCB MF41-00222A PCB-MAIN;DCB-H360R,FR-4,4LAYER,- 1 SNA

Q1040 0501-000457 TR-SMALL SIGNAL;MMBT2222A,NPN,35 1 SA

Q1041 0501-000457 TR-SMALL SIGNAL;MMBT2222A,NPN,35 1 SA

Q1042 0501-000462 TR-SMALL SIGNAL;MMBT2907A,PNP,35 1 SA

Q1043 0501-000462 TR-SMALL SIGNAL;MMBT2907A,PNP,35 1 SA

Q1101 0505-000110 FET-SILICON;2N7002,N,60V,115mA,7 1 SA

Q1102 0505-000110 FET-SILICON;2N7002,N,60V,115mA,7 1 SA

Q1807 1203-003814 IC-RESET;ASM809REURF-T,SOT-23,3P 1 SA

Q1808 0504-000129 TR-DIGITAL;KSR1104,NPN,200mW,47K 1 SA

Q2001 0505-002093 FET-SILICON;MCH6305,P,-20V,-4A,0 1 SA

Q2003 0502-001279 TR-POWER;2SC5565,NPN,1300mW,SC-6 1 SA

Q2004 0505-002093 FET-SILICON;MCH6305,P,-20V,-4A,0 1 SA

Q701 0504-000129 TR-DIGITAL;KSR1104,NPN,200mW,47K 1 SA

R1001 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 SA

R1002 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 SA

R1003 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R1004 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R1005 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 SA

R1006 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 SA

R1007 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R1009 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R1010 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 SA

R1012 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1013 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1014 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1015 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1016 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1017 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1019 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R1020 2007-000125 R-CHIP;3.9Kohm,5%,1/10W,TP,1608 1 SA

R1021 2007-001179 R-CHIP;8.2Kohm,5%,1/10W,TP,1608 1 SA

R1022 2007-000329 R-CHIP;11Kohm,5%,1/10W,TP,1608 1 SA

R1023 2007-001179 R-CHIP;8.2Kohm,5%,1/10W,TP,1608 1 SA

R1024 2007-000329 R-CHIP;11Kohm,5%,1/10W,TP,1608 1 SA

R1025 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 SA

R1026 2007-000120 R-CHIP;680ohm,5%,1/10W,TP,1608 1 SA

R1028 2007-000125 R-CHIP;3.9Kohm,5%,1/10W,TP,1608 1 SA

R1029 2007-000120 R-CHIP;680ohm,5%,1/10W,TP,1608 1 SA

R1032 2007-000125 R-CHIP;3.9Kohm,5%,1/10W,TP,1608 1 SA

R1033 2007-000125 R-CHIP;3.9Kohm,5%,1/10W,TP,1608 1 SA

R1034 2007-000322 R-CHIP;110ohm,5%,1/10W,TP,1608 1 SA

R1035 2007-000287 R-CHIP;100OHM,1%,1/10W,TP,1608 1 SA

R1037 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 SA

R1040 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 SA

R1041 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 SA

R1042 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 SA

R1043 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 SA

R1056 2007-000971 R-CHIP;5.1ohm,5%,1/10W,TP,1608 1 SA

R1057 2007-000744 R-CHIP;30ohm,5%,1/10W,TP,1608 1 SA

R107 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R108 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R109 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R110 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1101 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R1102 2007-001044 R-CHIP;56ohm,5%,1/10W,TP,1608 1 SA

R1103 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 SA

R1105 2007-000683 R-CHIP;3.3Kohm,1%,1/10W,TP,1608 1 SA

R1106 2007-000119 R-CHIP;560ohm,5%,1/10W,TP,1608 1 SA

R1107 2007-000683 R-CHIP;3.3Kohm,1%,1/10W,TP,1608 1 SA

R1108 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1109 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R111 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1110 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R1111 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

Loc.No Part No Description ; Specification Q’ty S.N.A Remark

7-6

Samsung Electronics

Electrical Parts List

Loc.No Part No Description ; Specification Q’ty S.N.A Remark

This Document can not be used without Samsung’s authorization

Page 41

R1113 2007-000073 R-CHIP;91ohm,5%,1/10W,TP,1608 1 SA

R1114 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 SA

R1118 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1119 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R112 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1120 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1121 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1122 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1123 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1124 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1125 2007-000903 R-CHIP;430ohm,1%,1/10W,TP,1608 1 SA

R1126 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1127 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1128 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R1129 2007-001164 R-CHIP;75ohm,1%,1/10W,TP,1608 1 SA

R113 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1130 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 SA

R1131 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 SA

R1132 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R1133 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R1134 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R1135 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1136 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1137 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 SA

R1138 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 SA

R1139 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R114 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1140 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R1141 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R1143 2007-000097 R-CHIP;47Kohm,5%,1/10W,TP,1608 1 SA

R1144 2007-000116 R-CHIP;120ohm,5%,1/10W,TP,1608 1 SA

R1145 2007-000116 R-CHIP;120ohm,5%,1/10W,TP,1608 1 SA

R1146 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 SA

R1147 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 SA

R1148 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R115 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1155 2007-001044 R-CHIP;56ohm,5%,1/10W,TP,1608 1 SA

R1156 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R1159 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R116 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1160 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R1161 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R1162 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R1164 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1165 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1166 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1167 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1168 2007-000084 R-CHIP;4.7Kohm,5%,1/10W,TP,1608 1 SA

R1169 2007-000962 R-CHIP;5.1Kohm,1%,1/10W,TP,1608 1 SA

R117 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1170 2007-000929 R-CHIP;470ohm,1%,1/10W,TP,1608 1 SA

R1171 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1172 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1173 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1174 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1175 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1176 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1177 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1178 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1179 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R118 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1180 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1181 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1182 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1190 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1201 2007-000962 R-CHIP;5.1Kohm,1%,1/10W,TP,1608 1 SA

R1202 2007-000962 R-CHIP;5.1Kohm,1%,1/10W,TP,1608 1 SA

R1203 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 SA

R1204 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 SA

R1205 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 SA

R1207 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 SA

R1208 2007-000071 R-CHIP;22ohm,5%,1/10W,TP,1608 1 SA

R1209 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 SA

R121 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1210 2007-000078 R-CHIP;1Kohm,5%,1/10W,TP,1608 1 SA

R1212 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R122 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R123 2007-000113 R-CHIP;33ohm,5%,1/10W,TP,1608 1 SA

R1301 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 SA

R1302 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 SA

R1304 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R1305 2007-000074 R-CHIP;100ohm,5%,1/10W,TP,1608 1 SA

R1306 2007-000070 R-CHIP;0ohm,5%,1/10W,TP,1608 1 SA

R1311 2007-000102 R-CHIP;100Kohm,5%,1/10W,TP,1608 1 SA

R1317 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 SA

R1318 2007-000962 R-CHIP;5.1Kohm,1%,1/10W,TP,1608 1 SA

R1319 2007-000962 R-CHIP;5.1Kohm,1%,1/10W,TP,1608 1 SA

R1401 2007-000077 R-CHIP;470ohm,5%,1/10W,TP,1608 1 SA

R1402 2007-000077 R-CHIP;470ohm,5%,1/10W,TP,1608 1 SA

R1403 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 SA

R1404 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 SA

R1405 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 SA

R1406 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 SA

R1407 2007-000106 R-CHIP;220Kohm,5%,1/10W,TP,1608 1 SA

R1408 2007-000106 R-CHIP;220Kohm,5%,1/10W,TP,1608 1 SA

R1409 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 SA

R1410 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 SA

R1411 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 SA

R1412 2007-000090 R-CHIP;10Kohm,5%,1/10W,TP,1608 1 SA

R1413 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 SA

R1414 2007-000106 R-CHIP;220Kohm,5%,1/10W,TP,1608 1 SA

R1415 2007-000106 R-CHIP;220Kohm,5%,1/10W,TP,1608 1 SA

R1420 2007-000077 R-CHIP;470ohm,5%,1/10W,TP,1608 1 SA

R1421 2007-000102 R-CHIP;100Kohm,5%,1/10W,TP,1608 1 SA

R1422 2007-000102 R-CHIP;100Kohm,5%,1/10W,TP,1608 1 SA

R1423 2007-001167 R-CHIP;75ohm,5%,1/10W,TP,1608 1 SA