Page 1

INSTALLATION

HSILGNE

MANUA

DH60T Series

DH48T Series

DC60T Series

DC48T Series

DC60TV Series

DC48TV Series

L

LOÑAPSE

SI

AÇ

N

ARF

System Air Conditioner(Cooling and Heating)

This product is not manufactured for Iran.

SVC Warranty will not be applicable and the user will be responsible

for service expenses when the product is used in Iran.

E

S F A

DB98-23539A(7)

Page 2

Safety Precautions

The following safety precautions must be taken when using your air conditioner.

◆ The unit should not be installed by the user. Ask the dealer or authorized

company to install the units except room air conditioners for the U.S.A and

Canada area.

◆ If the unit is installed improperly, water leakage, electric shock or fire may

result.

◆ Mount with the lowest moving parts at least 2.5 m above the floor or grade

level. (If applicable)

◆ The manufacturer does not assume responsibility for accidents or injury

caused by an incorrectly installed air conditioner. If you are unsure about

installation, contact an installation specialist.

◆ When installing the built-in type air conditioner, keep all electrical cables

such as the power cable and the connection cord in pipe, ducts, cable

channels e.t.c to protect them against liquids, outside impacts and so on.

◆ This appliance is not accessible to the general public. This appliance

should be installed according to the provided installation

instruction.

WARNING

INSTALLING THE UNIT

◆ If the power cord of this air conditioner is damaged, it must be replaced by

the manufacturer, its service agent or similarly qualified persons in order to

avoid a hazard.

◆ The unit must be plugged into an independent circuit if applicable or

connect the power cable to the auxiliary circuit breaker. An all pole

disconnection from the power supply must be incorporated in the fixed

wiring with a contact opening of >3mm.

◆ Do not use an extension cord with this product.

◆ If the unit is equipped with a power supply cord and a plug, the plug must

be accessible after installation.

◆ The air conditioner must be installed in accordance with national wiring

regulations and safety regulations wherever applicable.

POWER SUPPL Y LINE,

FUSE OR CIRCUIT

BREAKER

Risk of electric shock. • Can cause injury or death. • Disconnect all

remote electric power supplies before servicing, installing or cleaning.

• This must be done by the manufacturer or its service agent or a similar

qualified person in order to avoid a hazard.

E-2

Page 3

E-3

H

SILGN

E

Preparation for Installation ............................................................................ 4

Deciding on Where to Install the Air Conditioner ........................................ 5

Indoor Unit Installation ................................................................................ 10

Purging the Unit .......................................................................................... 11

Connecting the Connection Cord ................................................................ 11

Connecting the Cables to the Outdoor Unit ................................................ 16

Drain Hose Installation ................................................................................ 17

Connecting the Indoor Unit Assembly Piping .............................................. 19

Cutting/Flaring the Pipes ............................................................................. 20

Checking Correct Grounding ....................................................................... 21

Fixing the Unit in Position ........................................................................... 22

Connecting Up and Removing Air In the Circuit ......................................... 23

Performing Leak Tests ................................................................................ 24

Insulation ..................................................................................................... 25

Adjusting Air Flow ........................................................................................ 26

Setting Up the Model Option ....................................................................... 27

Assigning Address to Indoor Unit ................................................................ 30

Additional Functions .................................................................................... 31

Drain Pump Installation (Optional) .............................................................. 33

Setting Up Option Switches (Outdoor unit) ................................................. 35

Testing Operations ...................................................................................... 37

Troubleshooting .......................................................................................... 38

Parts List ................................................................................................... 42

Contents

................................ 25

Pump Down Procedure (When removing the product)

Page 4

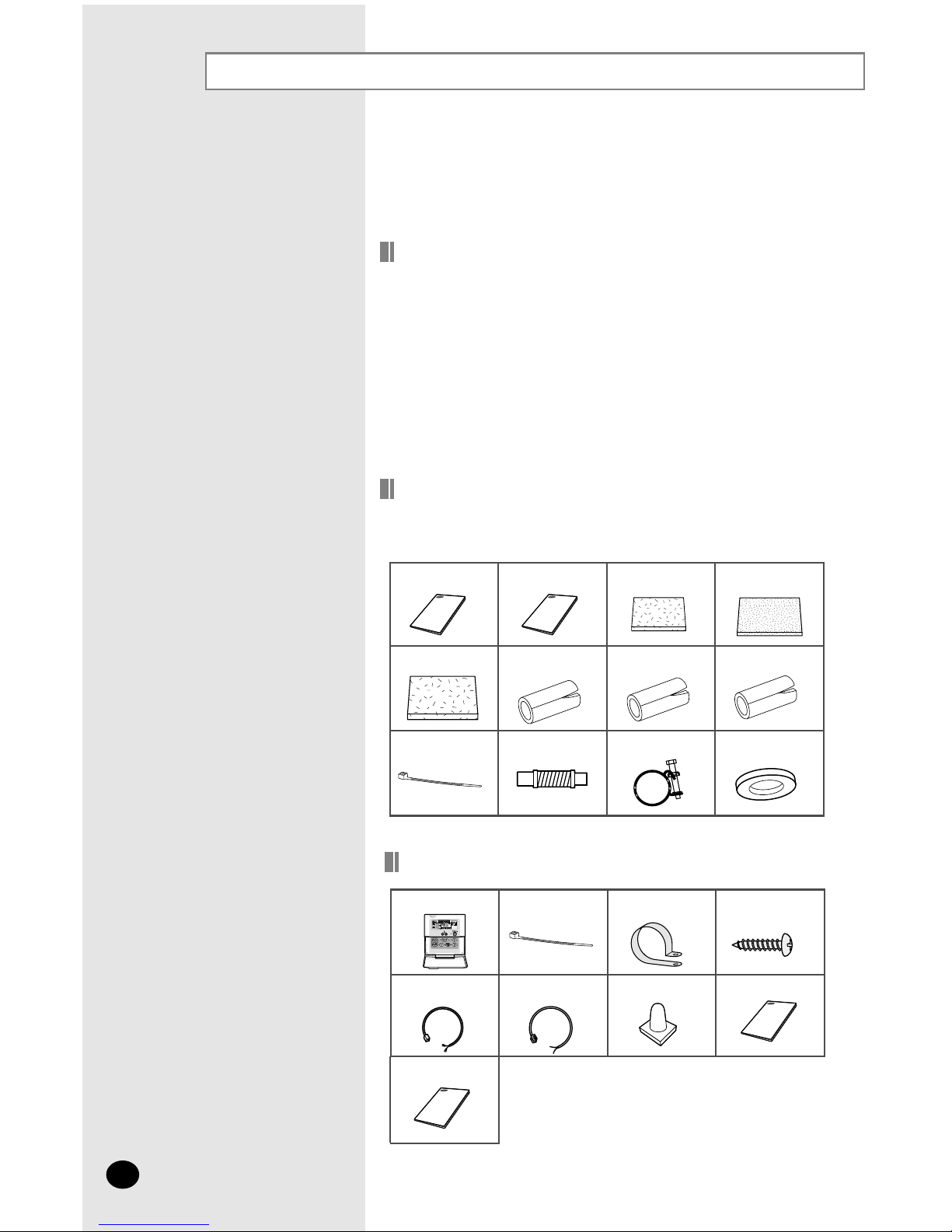

E-4

Preparation for Installation

When deciding on the location of the air conditioner with the owner,

the following restrictions must be taken into account.

Do NOT install the air conditioner in a location where it will come into

contact with

the following elements:

◆

Combustible gases

◆

Saline air

◆

Machine oil

◆

Sulphide gas

◆

Special environmental conditions

If you must install the unit in such conditions, first consult your dealer

Cable-Tie Cable

Clamp M4 x 16 Tapped

Screws

Indoor unit power

drawing cable

Communication cable of

the wired remote

controller

Wire joint

Owner’s Instruction

Installation Manual

Wired remote controller

Owner’s

Instructions(1)

Installation

Manual(1)

Insulation Cover

Pipe

in

(1)

Insulation Cover

Pipe out(1)

Insulation Pipe in(1)

Insulation Cover

Drain(1)

Insulation Pipe out(1)

Clamp hose(2)

Cable-Tie(8)

Flexible hose(1)

Accessories

General

Wired Remote Controller Accessories

◆ The following accessories are supplied with the indoor unit.

The type and quantity may differ depending on the specifications.

Insulation Drain (1)

Rubber(8)

Page 5

E-5

Deciding on Where to Install the Air Conditioner

Indoor Unit

There must be no obstacles near the air inlet and outlet.

Install the indoor unit on a ceiling that can support its weight.

Maintain sufficient clearance around the indoor unit.

Make sure that the water dripping from the drain hose runs away cor-

rectly and safely.

The indoor unit must be installed in this way, that they are out of public

access. (Not touchable by the users)

After connecting a chamber, insulate the connection part between the

indoor unit and the chamber with t10 or thicker insulation. Otherwise,

there can be air leak or dew from the connection part.

20mm or more

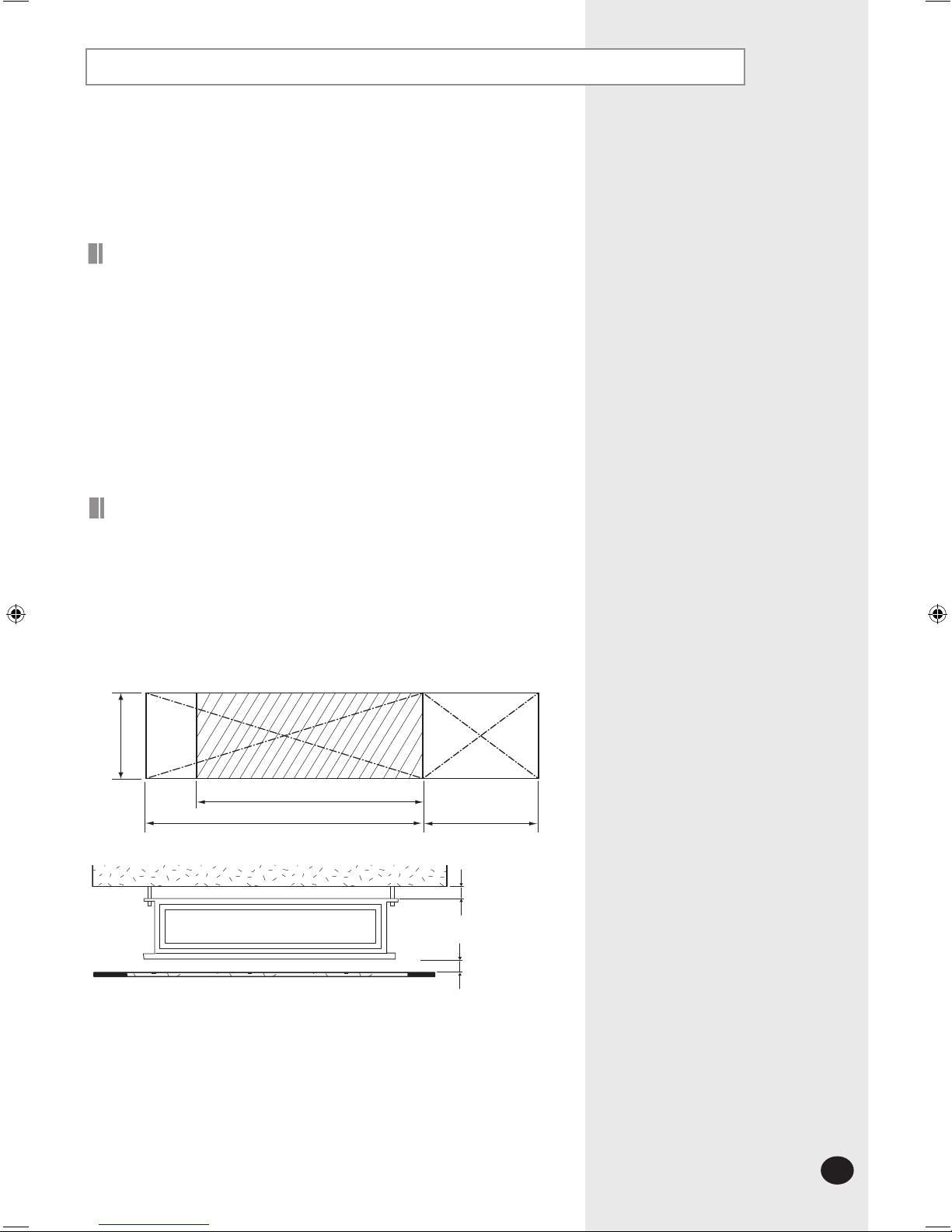

Space Requirements for Installation& Service

Construction Standard for Inspection Hole

1)

In case, the ceiling is tex tile, Inspection hole dose not need.

2)

In case, the ceiling is plaster board, Inspection hole depends on Inside

height of the ceiling.

a.

Height is more than 1m : Only "B" [Inspection for PBA] is applied.

b.

Height is less than 1m : Both "A"&"B" are applied.

c. "A"&"B" are inspection holes .

Unit Width(W)

"A"=W+100mm

Unit Depth(D)+50mm

"B"=500mm

20mm or more

You must have 20mm or more space between the ceiling and the bottom of

indoor unit. Otherwise, the noise from the vibration of indoor unit may bother

the user.When the ceiling is under construction, the hole for check-up must be

made to take service, clean and repair the unit.

It is possible to install the unit at an height of between 2.2~2.5m from the

ground, if the unit has a duct with a well defined lenght (300mm or more), to

avoid fan motor blower contact.

Page 6

Deciding on where to install the Air Conditioner (Continued)

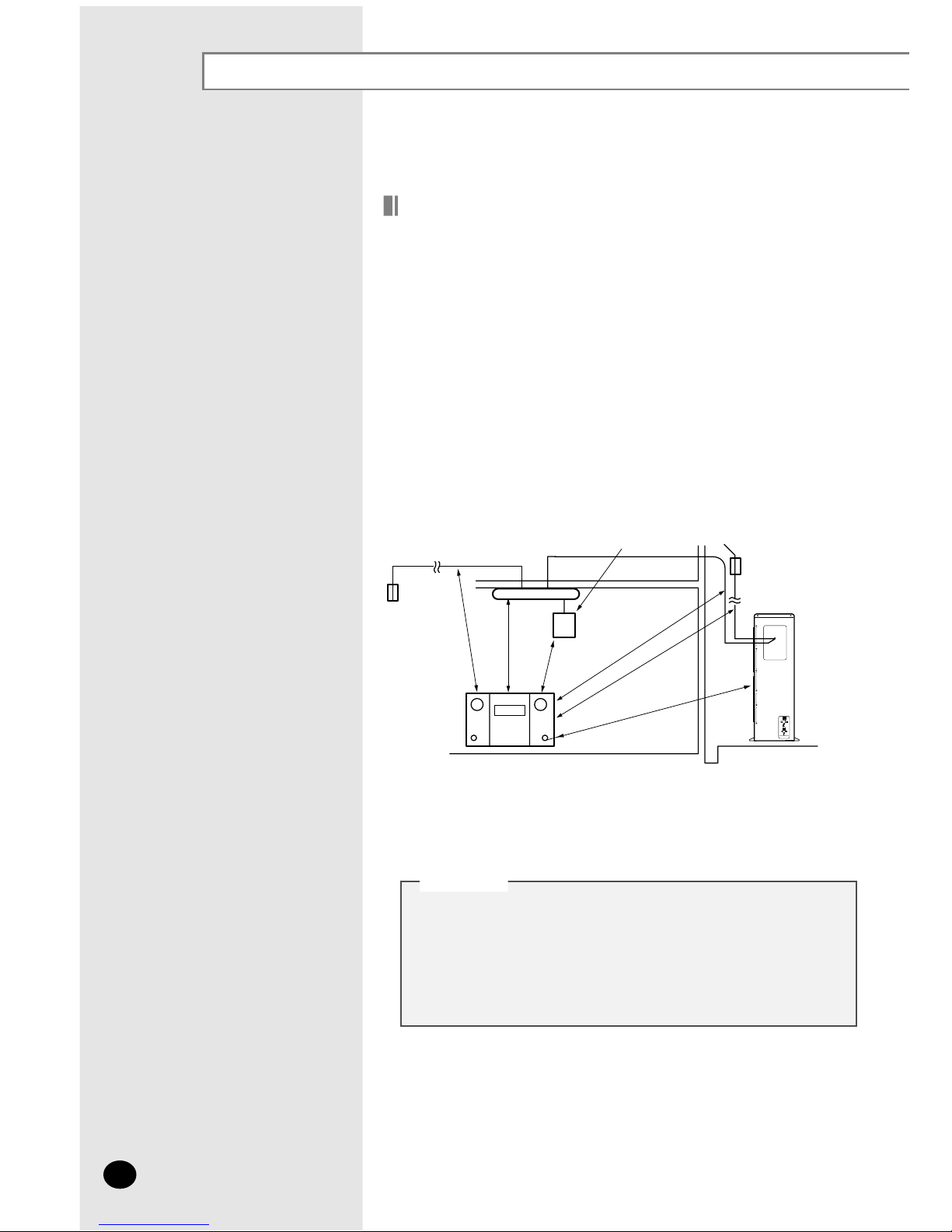

Outdoor Unit

◆ The outdoor unit must not be placed on its side or upside down, as the

compressor

lubrication oil will run into the cooling circuit and seriously

damage

the unit.

◆ Choose a location that is dry and sunny, but not exposed to direct sunlight or

strong

winds.

◆ Do not block any passageways or thoroughfares.

◆ Choose a location where the noise of the air conditioner when running and

the

discharged air do not disturb any neighbours.

◆ Choose a position that enables the pipes and cables to be easily connected

to

the indoor unit.

◆ Install the outdoor unit on a flat, stable surface that can support its weight

and

does not generate any unnecessary noise and vibration.

◆ Position the outdoor unit so that the air flow is directed towards the open

area

.

◆ Maintain sufficient clearance around the outdoor unit, especially from a radio,

compute

r, stereo system, etc.

◆ If the outdoor unit is installed at a height, ensure that its base is firmly fixed in

position

.

◆ Make sure that the water dripping from the drain hose runs away correctly

and

safely.

e

r

o

m

r

o

m

5

.

1

Indoor Unit

Circuit

Breaker

Outdoo

r

Unit

Remote

Controller

e

r

o

m

r

o

m

1

e

r

o

m

r

o

m

1

e

r

o

m

r

o

m

5

.

1

e

r

o

m

r

o

m

5

.

1

m

5

.

1

m

r

o

e

r

o

Circuit Breaker

Stere

o

◆ You have just purchased a system air conditioner and it

has been installed by your installation specialist.

◆ This device must be installed according to the national

electrical rules.

CCCCAAAAUUUUTTTTIIIIOOOONN

NN

E-6

◆ When installing the model DC48FTVX/DC60GTVX/

DC60FTVX get rid of the cushion on the top of compressor.

Page 7

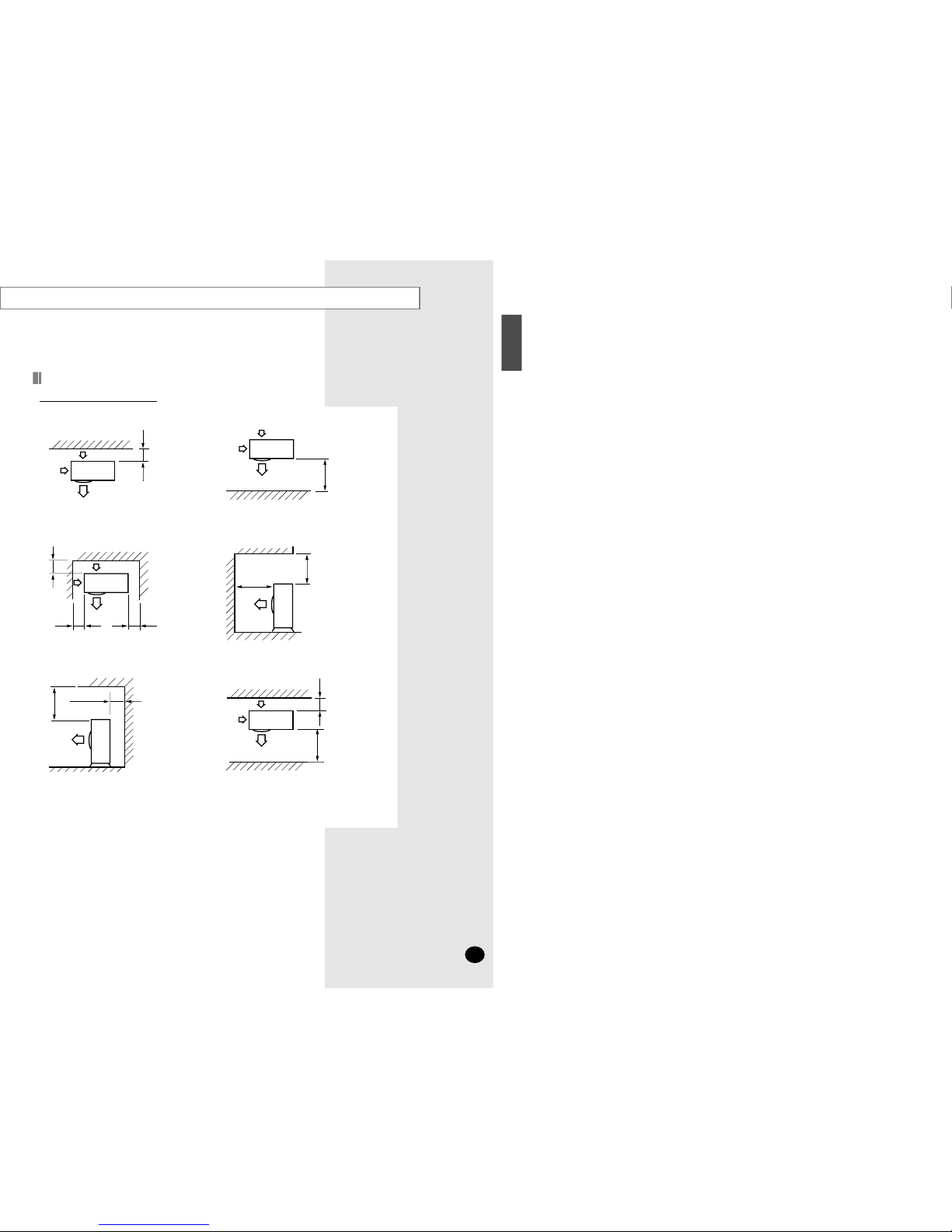

ero

m

r

o

300

❋ When the air outlet is opposite the wall

erom

r

o

2000

❋ When the air outlet is towards the wall

e

rom

ro

300

300 or more

600

or more

❋ When 3 sides of the outdoor unit are

blocked

by the wall

erom

ro

0

051

2000 or more

❋ The upper part of the outdoor unit and

the

air outlet is towards the wall

e

rom

ro

005

300 or more

❋ The upper part of the outdoor unit

and

the air outlet is opposite the wall

e

r

o

m

ro

00

3

ero

m

r

o

2000

❋ When front and rear side of the outdoor

unit

is towards the wall

Unit : mm

Space Requirements for Outdoor Unit

When installing 1 outdoor unit

H

SILGN

E

E-7

Page 8

E-8

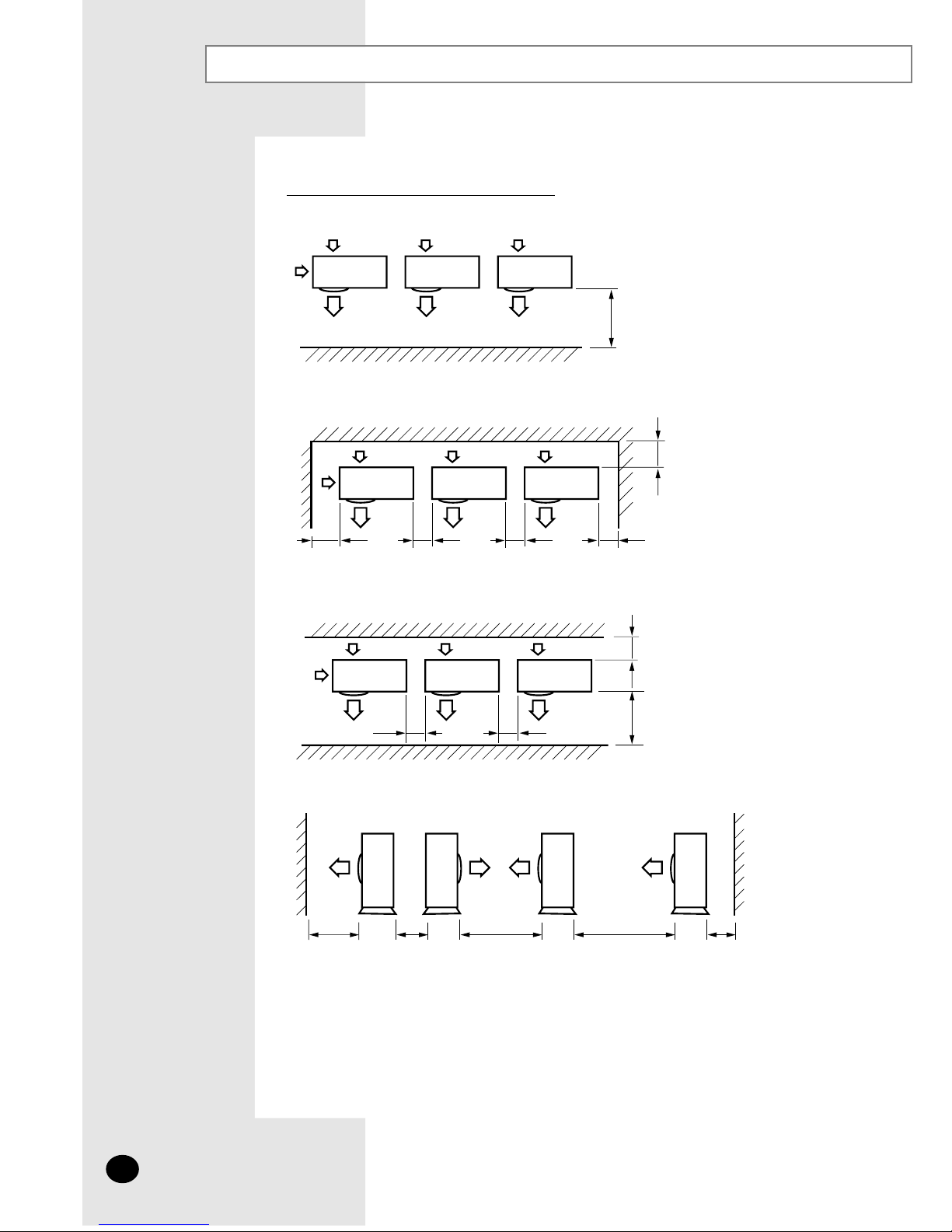

Deciding on where to install the Air Conditioner (Continued)

Unit : mm

e

rom r

o

0

0

02

✽

When the air outlet is towards the wall

erom

ro

003

300 or more

200

0

or more 1000 or more 5000 or more 200 or more4000 or more

60

0

or more 600 or more

e

ro

m

r

o

0

03

e

rom ro

000

2

600 or more 600 or more

60

0 or more

✽

When 3 sides of the outdoor unit are blocked by the wall

✽

When front and rear side of the outdoor unit is towards the wall

✽✽

When front and rear side of the outdoor unit is towards the wall

When installing more than 1 outdoor unit

Page 9

ENGLISH

102

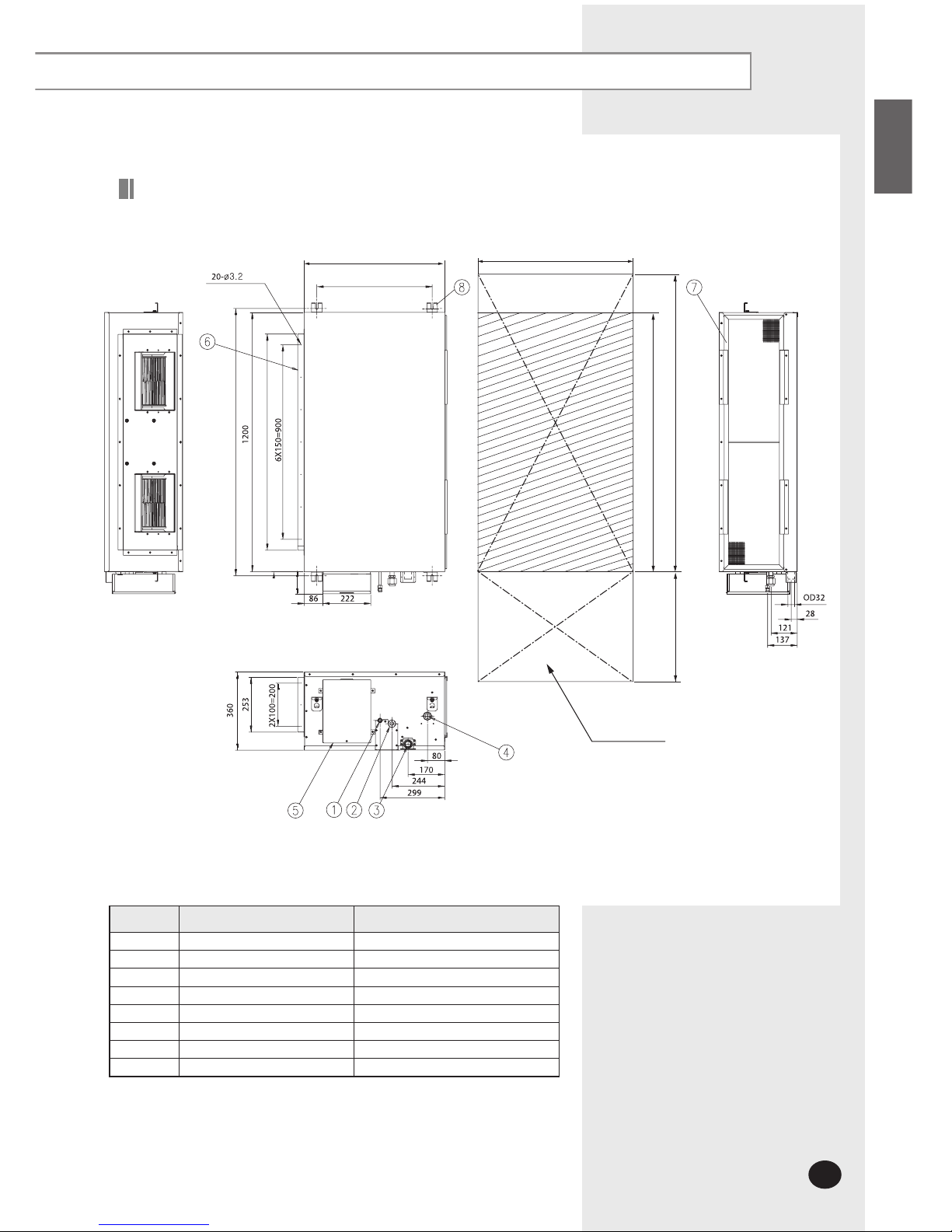

No. Name Description

1 Liquid pipe connection ø9.52

2 Gas pipe connection ø19.05

3 Drain pipe connection OD32 ID26

4 Drain pipe connection Using drain pump (Optional)

5 Power supply connection

6 Air discharge flange

7 Air filter

8 Hook M8~M10

Unit : mm

Drawing of the indoor unit

E-9

Page 10

Indoor Unit Installation

E-10

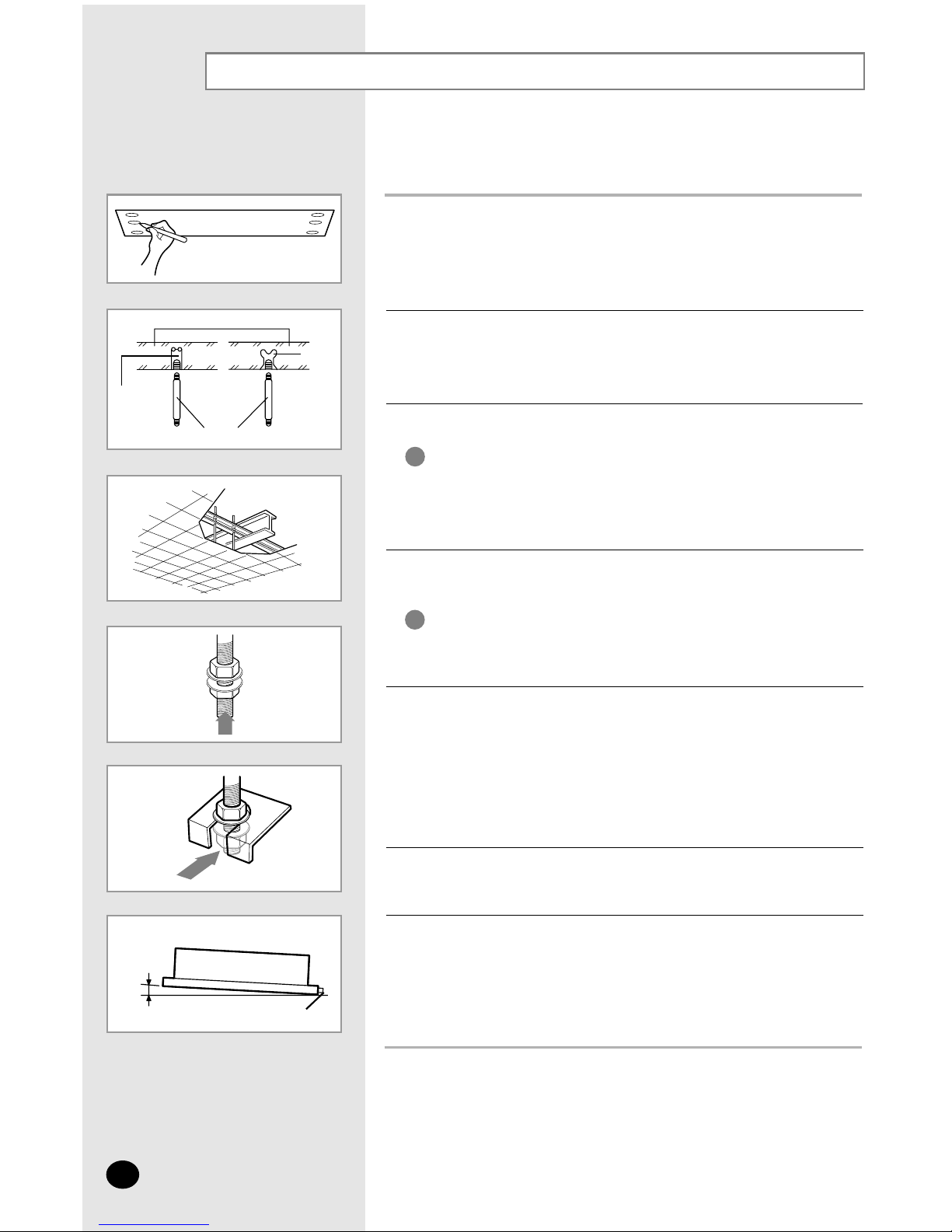

1

Mark the place to insert the suspension bolt where you want to install the

indoor unit.

2

Insert bolt anchors. Use existing ceiling supports or construct a suitable

support as shown in figure.

3

Install the suspension bolts depending on the ceiling type.

4

Screw eight nuts to the suspension bolts making space for hanging

the indoor unit.

5

Hang the indoor unit to the suspension bolts between two nuts.

6

Screw the nuts to suspend the unit.

7

Adjust level of the unit by using measurement plate for all 4 sides.

Ensure that the ceiling is strong enough to support

the weight of the indoor unit.

Before hanging the unit, test the strength of each

attached suspension bolt.

IMPORTANT

You must install the suspension bolts more than 4

when installing the indoor unit.

IMPORTANT

◆ Tubing must be laid and connected inside the ceiling when

suspending the unit. If the ceiling is already constructed,

lay the tubing into position for connection to the unit before

placing the unit inside the ceiling.

NNNNoooottttee

ee

◆ Refer to page 9 for the dimension.

NNNNoooottttee

ee

◆ For proper drainage of condensate, give a 10mm slant to the

left or right side of the unit which will be connected with the drain

hose, as shown in the figure. Make a tilt when you wish to install

the drain pump, too.

NNNNoooottttee

ee

Concrete

Suspension bolt(M8)-field supply

Hole in anchor

Hole in plug

Insert

Ceiling support

Drain hose connection port

10mm

Page 11

ENGLISH

E-11

Purging the Unit

On delivery, the indoor unit is loaded with an inert nitrogen gas.

All this gas must therefore be purged before connecting the assembly

piping. To purge the inert gas, proceed as follows.

Unscrew the caps at the end of each pipe.

Result:

All inert gas escapes from the indoor unit.

◆ To prevent dirt or foreign objects from getting into the pipes

during installation, do NOT remove the caps completely until

you are ready to connect the piping.

NNNNoooottttee

ee

Connecting the Connection Cord

The indoor unit is powered from the outdoor unit via the connection cord.

◆ When connecting the cables, you must pass them through

the cable clamp to fix them securely.

NNNNoooottttee

ee

Remove the screw on the electrical component box and remove the cover

plate.

1

Route the connection cord through the side of the indoor unit and connect

the cable to terminals as shown in pages 12 and 15.

2

Route the other end of the cable to the outdoor unit through the ceiling &

the hole on the wall.

3

Reassemble the electrical component box cover, carefully tightening the

screw.

4

Page 12

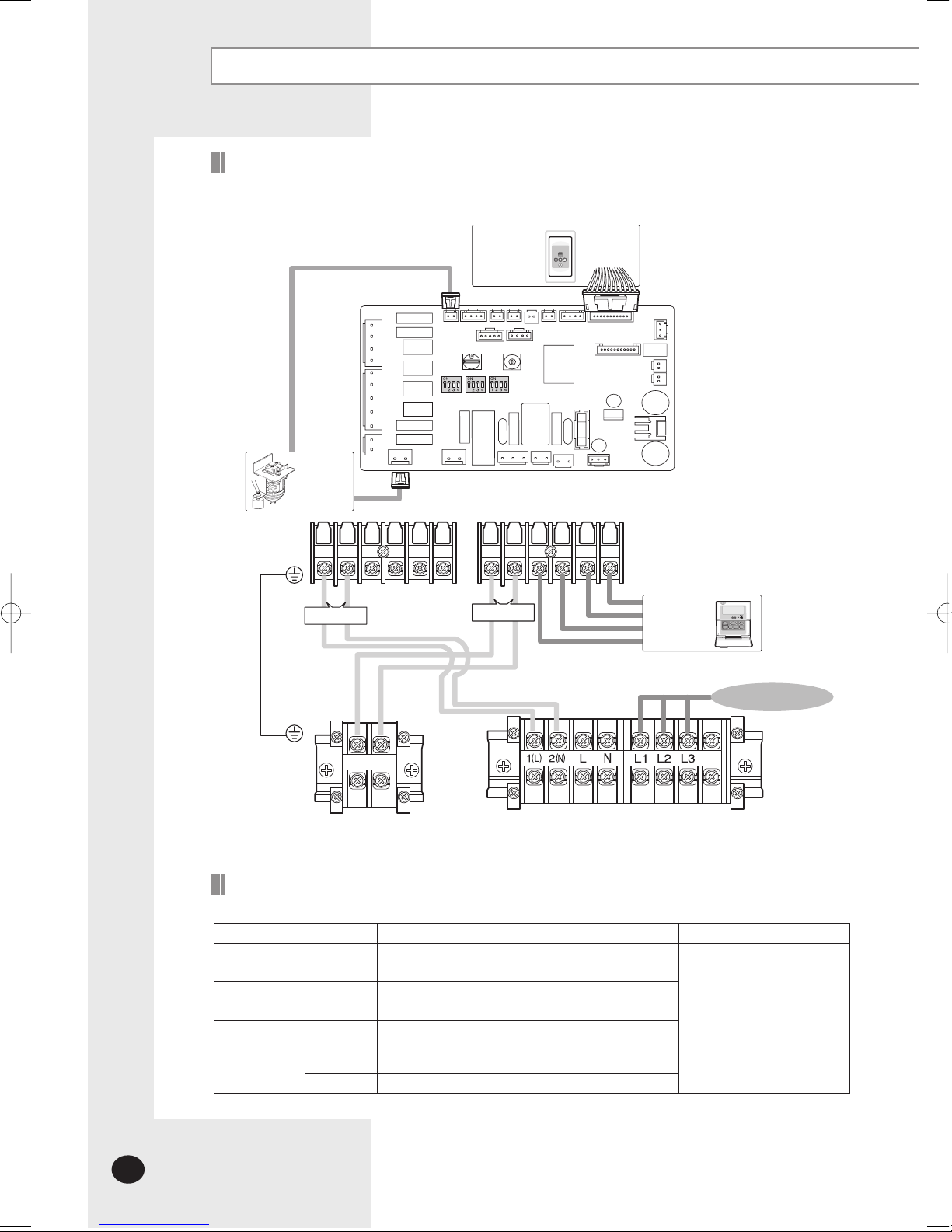

E-12

Connecting the Connection Cord (Continued)

1(L)

2(N)

Vc Vc Vw Vw F1 F2 V1 V2 F3 F4

F1 F2

Receiver &

Display Unit

(Optional)

Float Switch

Drain Pump

(Optional)

Wired

Remote

Controller

MAIN PCB

3ø220V~, 60H

z

Communication

Power

The following electrical characteristics must be respected.

MODEL

Power

Circuit breaker

Indoor unit power cable

Communication cable

Wired remote controller power

& communication cable

Power cable

20m or less

50m or less

DH48FTA(X), DH60FTA(X), DC48FTA(X), DC60FTA(X)

3ø 220V~, 60Hz

30A

1.25mm

2

(CV, 3 wire)

0.75~1.0mm2(CV, 2 wire)

The power cables are not

supplied with the air

conditioner.

The user should purchase

them separately.

0.5~0.75mm

2

(CV, 2 wire)

5.5mm

2

(CV, 4 wire)

8.0mm2(CV, 4 wire)

Note

MAIN POWER

Indoor Unit

Outdoor Unit

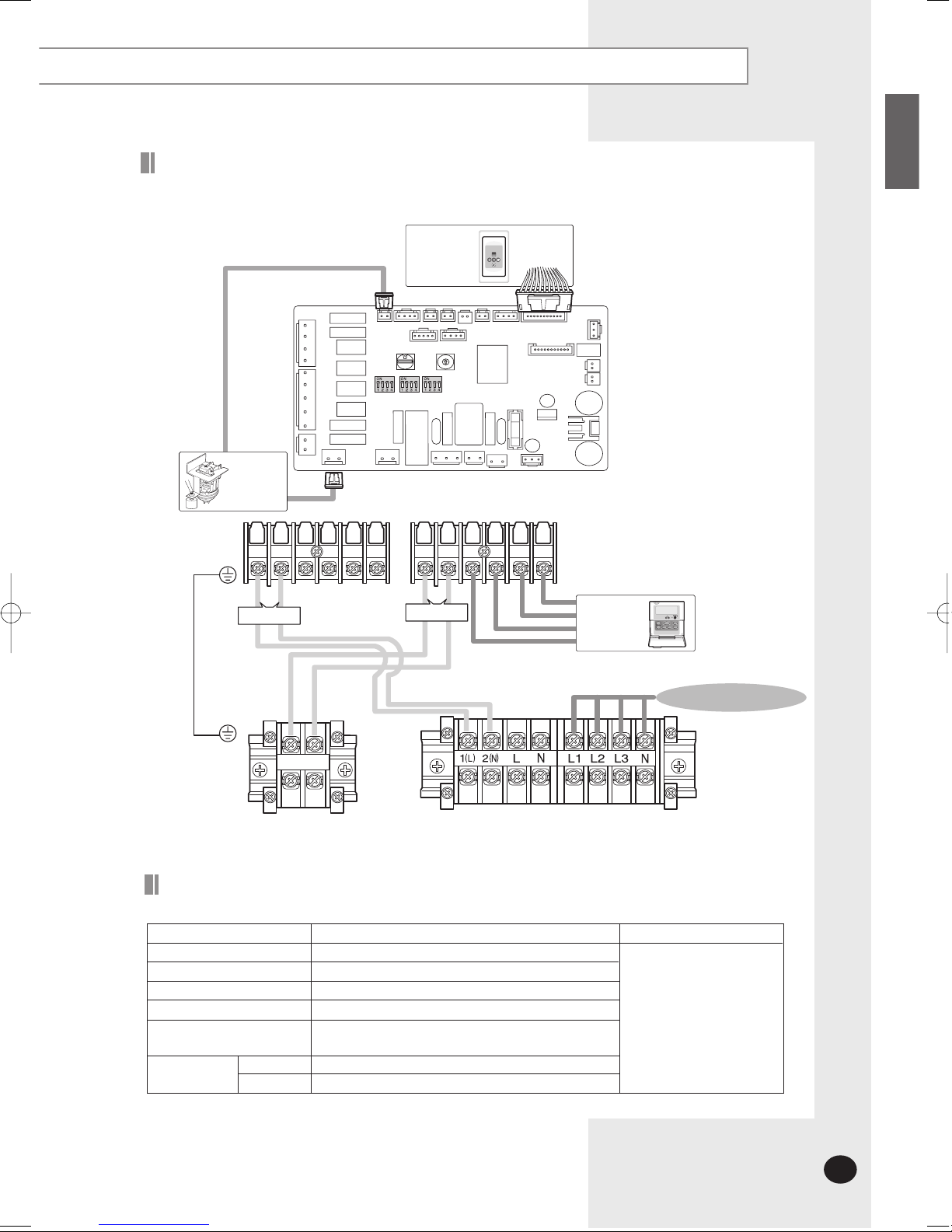

Wiring Diagram (DH48FTA, DH60FTA, DC48FTA, DC60FTA )

Cable Specifications

Page 13

ENGLISH

E-13

1(L)

2(N)

Vc Vc Vw Vw F1 F2 V1 V2 F3 F4

F1 F2

Receiver &

Display Unit

(Optional)

Float Switch

Drain Pump

(Optional)

Wired

Remote

Controller

MAIN PCB

3ø380 - 415V~, 50H

z

Communication

Power

MAIN POWER

Indoor Unit

Outdoor Unit

The following electrical characteristics must be respected.

MODEL

Power

Circuit breaker

Indoor unit power cable

Communication cable

Wired remote controller power

& communication cable

Power cable

20m or less

50m or less

DH48GTA(X), DH60GTA(X), DC48GTA(X), DC60GTA(X)

3ø 380-415V~, 50Hz

20A

1.25mm

2

(CV, 3 wire)

0.75~1.0mm2(CV, 2 wire)

The power cables are not

supplied with the air

conditioner.

The user should purchase

them separately.

0.5~0.75mm

2

(CV, 2 wire)

2.0mm

2

(CV, 5 wire)

2.5mm2(CV, 5 wire)

Note

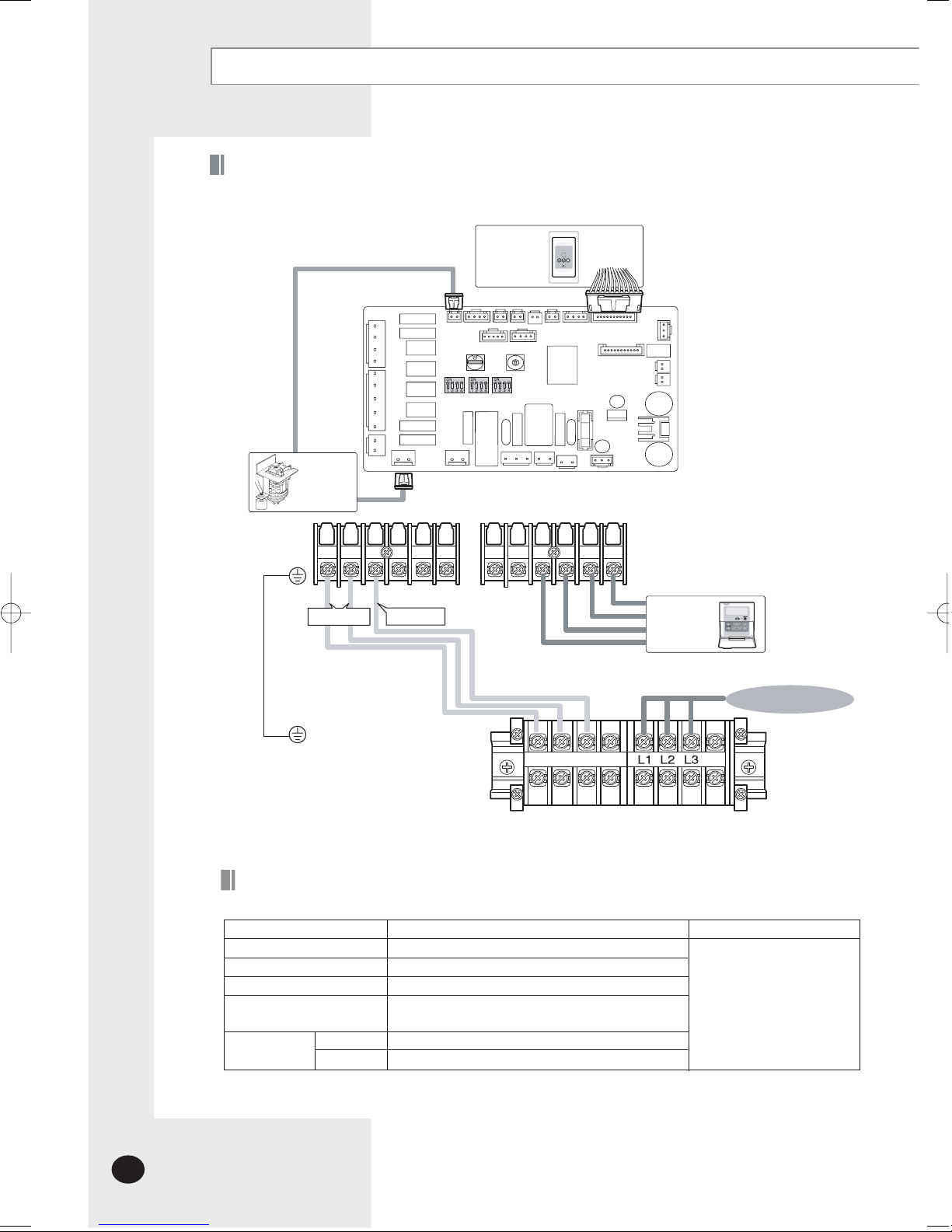

Cable Specifications

Wiring Diagram (DH48GTA, DH60GTA, DC48GTA, DC60GTA)

Page 14

E-14

Connecting the Connection Cord (Continued)

1(L)

2(N)

3(C)

Vc Vc

F1 F2 V1 V2 F3 F4

3(C)2(N)1(L)

Receiver &

Displ

ay Unit

(Option

al)

Float Switch

Dra

in Pump

(Option

al)

Wired

Remo

te

Controller

MAIN PCB

Power

3ø 220V~, 60H

z

MAIN POWER

Indo

or

Unit

Outdo

or Unit

Wiring Diagram (DC48FTVA,DC60FTVA)

Signal

The following electrical characteristics must be respected.

MODEL

Po

we

r

Circu

it breaker

Indo

or

unit power cable

Wired remote controller power

& communication cable

Power cable

20m or less

50m or less

DC48FTVA(X),DC60FTVA(X)

3ø 220V~, 60Hz

30

A

1.2

5mm2(CV, 4 wire)

The power cables are not

suppli

ed with the air

conditio

ner.

The

user should purchase

th

em separately.

0.5~0.7

5mm

2

(CV, 2 wire)

5.5

mm

2

(CV, 4 wire)

8.0

mm2(CV, 4 wire)

Note

Cable Specifications

Page 15

HSILGNE

E-15

1(L)

2(N)

3(C)

Vc Vc

F1 F2 V1 V2 F3 F4

3(C)2(N)1(L)

Receiver &

Displ

ay Unit

(Option

al)

Float Switch

Dra

in Pump

(Option

al)

Wired

Remote

Control

ler

MAIN PCB

Power

3ø 380 - 415V~, 50H

z

MAIN POWER

Indo

or

Unit

Outdo

or Unit

Wiring Diagram (DC48GTVA,DC60GTVA)

Signal

The following electrical characteristics must be respected.

MODEL

Pow

e

r

Circui

t breaker

Indoo

r

unit power cable

Wired remote controller power

& communication cable

Power cable

20m or less

50

m or less

DC48GTVA(X),DC60GTVA(X)

3ø 380-415V~, 50Hz

20

A

1.25

mm2(CV, 4 wire)

Th

e power cables are not

supplie

d with the air

condition

er.

Th

e

user should purchase

the

m separately.

0.5~0.75

mm

2

(CV, 2 wire)

2.0

mm

2

(CV, 5 wire)

2.5

mm2(CV, 5 wire)

No

te

Cable Specifications

Page 16

E-16

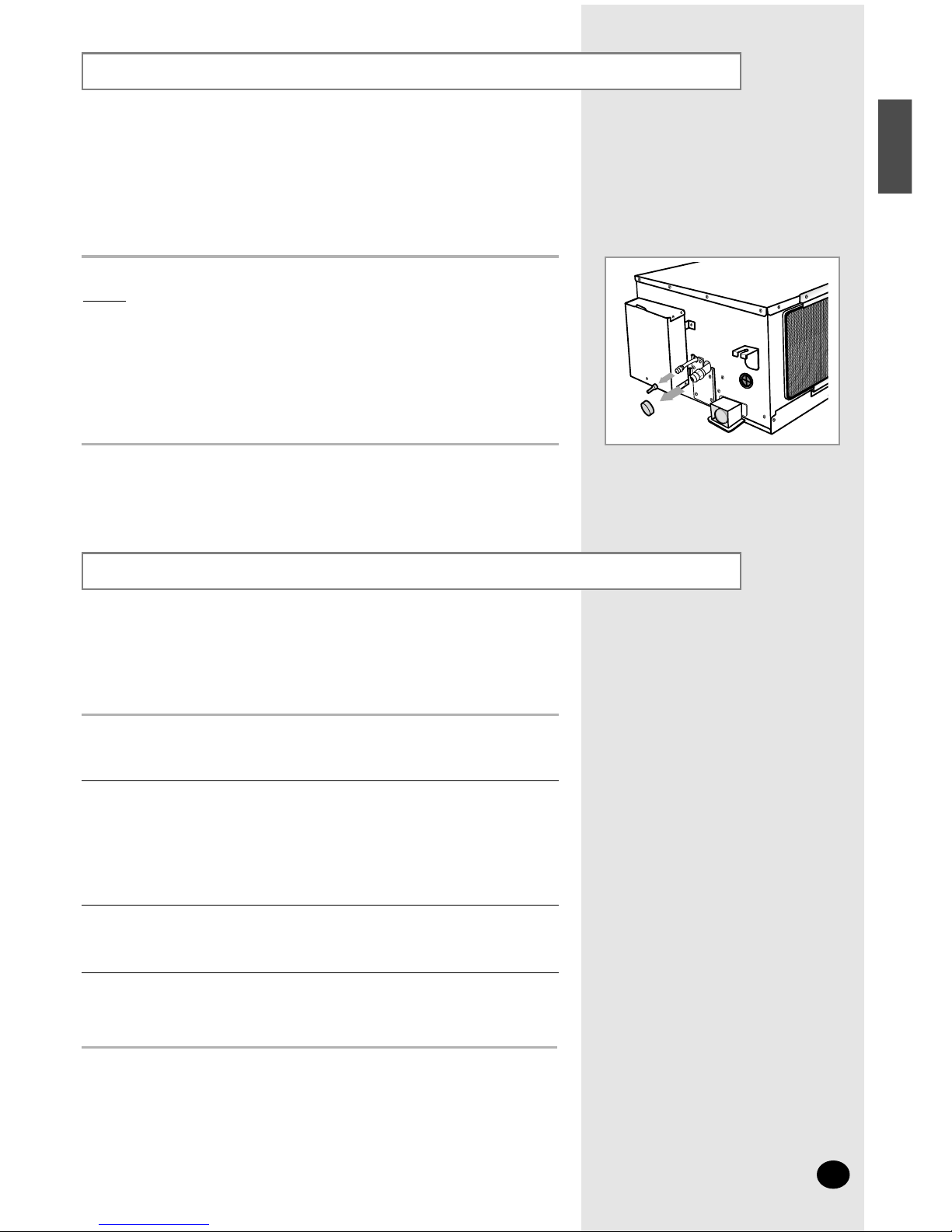

Connecting the Cables to the Outdoor Unit

Two electric cables must be connected to the outdoor unit.

◆ The connection cord connecting the indoor unit to the outdoor unit

◆ The power cable connecting the auxiliary circuit breaker to the

outdoor unit

Remove the terminal board cover on the side of the outdoor unit.

Connect the connection cord and power cable to terminals as shown in the

diagram.

1

2

Connect the power cable to the auxiliary circuit breaker.

3

Replace the terminal board cover, carefully tightening the screw.

4

◆

CCCCAAAAUUUUTTTTIIIIOOOONN

NN

Keep the power cable and the connection cord in a

steel pipe to protect them against liquids, outside

impacts and so on.

Page 17

ENGLISH

E-17

Drain Hose Installation

Care must be taken when installing the drain hose for the indoor unit

to ensure that any condensate water is correctly drained outside. The

drain hose can be installed to the right of the base pan.

Unscrew the 4 tapped screws to remove the cover of the drain hose

connection port.

1

Insert the flexible hose to the drain hose port.2

CCCCAAAAUUUUTTTTIIIIOOOONN

NN

When not installing the drain pump

Do not give the hose and upward gradient

after the connection port.

This will cause water to flow backwards when

the unit is stopped, resulting in water leaks.

Do not apply force to the piping on the unit side

when connecting the drain hose. The hose should

not be allowed to hang loose from its connection to

the unit. Fasten the hose to a wall, frame or other

support as close to the unit as possible.

Upward gradient

Support pieces

Ceiling

Ceiling

75cm or less

Ceiling

When installing the drain pump

If it is necessary to increase the height of the

drain hose somewhat, the portion directly after

75cm. If it is raised higher than 75cm, there can

be water leaks.

◆ Fix the flexible hose to the indoor unit with the supplied cable

clamp securely.

(Use the screwdriver to fix the flexible hose securely.)

NNNNoooottttee

ee

Install the drain hose so that its length can be as short as possible.

Internal diameter of the drain hose should be the same or slightly bigger

than the external diameter of the drain hose port.

◆

Inner diameter of the drain hose

3

Wrap the drain hose with the insulation drain as shown in figure and secure it.

4

◆ Give a slightly slant to the drain hose for proper drainage of

condensate.

◆ Fix the flexible hose to the PVC with the supplied cable tie

securely.

NNNNoooottttee

ee

32mm(Inner diameter)

CCCCAAAAUUUUTTTTIIIIOOOONN

NN

Must fit tightly against

body without any gap.

Insulation cover drain

No gap

Insulation drain hose

Cable-Tie

Indoor

Unit

Drain hose connection port

Cable

Clamp

Page 18

Drain Hose Installation (Continued)

E-18

Prepare a little water about 5 liters.

Pour water into the base pan in the indoor unit as shown in figure.1

Confirm that the water flows out through the drain hose.

2

Testing the drainage

Page 19

Connecting the Indoor Unit Assembly Piping

ENGLISH

E-19

There are two refrigerant pipes of differing diameters:

◆ A smaller one(9.52mm, 3/8

"

) for the liquid refrigerant

◆ A larger one(19.05mm, 3/4

"

) for the gas refrigerant

◆ The thickness of tube should not less than 1.0mm.

◆ The inside of copper tube must be clean & has no dust.

The connection procedure for the refrigerant pipes varies according to

the exit position of the pipes from the indoor unit, as seen when facing

the indoor in the “A” side.

◆ Liquid refrigerant port

◆ Gas refrigerant port

◆ Drain hose connection port

Remove the pinch pipe on the pipes and connect the assembly pipes to

each pipe, tightening the nuts, first manually and then with a torque

wrench, a spanner applying the following torque.

Must use insulator which is thick enough to cover the refrigerant tube to

protect the condensate water on the outside of pipe falling onto the floor

and the efficiency of the unit will be better.

1

2

Cut off any excess foam insulation.

3

Be sure that there must be no crack or wave on the bended area.

4

It would be necessary to double the insulation thickness (10mm or more)

to prevent condensation even on the insulator when if the installed area is

warm and humid.

5

Shape an oil trap as shown in figure the oil trap must be formed every

level difference of 10m.

6

◆ If the pipes must be shortened refer to page 18.

NNNNoooottttee

ee

Outer Diameter Torque

9.52 mm (3/8") 250~280 kgf•cm

19.05 mm (3/4") 990~1210 kgf•cm

Indoor unit

Outdoor unit

Oil trap (Must be install

every 10m)

a. When the indoor unit is above the outdoor

unit

Radius

5cm

Oil trap

(suction tube)

Outdoor unit

Indoor unit

b. When the outdoor unit is above the indoor

unit

Oil trap(Must be installed

every 10m)

Drain hose connection port

Liquid

refrigerant port

A

Gas refrigerant port

Page 20

E-20

Cutting/Flaring the Pipes

Connect the pipe within 50m and cutting pieces will not be gone

into the pipe as being clean to pipe section.

Make sure that you have the required tools available (pipe cutter, reamer,

flaring tool and pipe holder).

If you wish to shorten the pipes, cut it with a pipe cutter, taking care to

ensure that the cut edge remains at a 90° angle with the side of the pipe.

Refer to the illustrations below for examples of edges cut correctly and

incorrectly.

1

2

To prevent any gas from leaking out, remove all burrs at the cut edge of the

pipe, using a reamer.

3

Slide a flare nut on to the pipe and modify the flare.

Outer Diameter(D) Depth (A)

9.52 mm (3/8") 1.8 mm

19.05 mm (3/4") 2.2 mm

4

Align the pipes and tighten the flare nuts first manually and then with

a torque wrench, applying the following torque.

Outer Diameter Torque

9.52 mm (3/8") 250~280 kgf•cm

19.05 mm (3/4") 990~1210 kgf•cm

6

Check that the flaring is correct, referring to the illustrations below for

examples of incorrect flaring.

5

90

O

Oblique Rough Burr

Inclined Damaged Surface Cracked Uneven Thickness

◆

CCCCAAAAUUUUTTTTIIIIOOOONN

NN

In case of welding the pipe, you must weld with nitrogen

gas blowing.

Page 21

ENGLISH

E-21

Checking Correct Grounding

If the power distribution circuit does not have an earth or the ground does

not comply with specifications, an grounding electrode must be installed.

The corresponding accessories are NOT supplied with the air conditioner.

Select an grounding electrode that complies with the specifications given

in the illustration.

1

Determine a suitable location for the grounding electrode:

◆ In damp hard soil rather than loose sandy or gravel soil that has a

higher grounding resistance

◆ Away from underground structures or facilities, such as gas pipes,

water pipes, telephone lines and underground cables

◆ At least two metres away from a lightening conductor grounding

electrode and its cable

2

Install a green/yellow coloured grounding wire (Ø1.6 mm, section 2 mm

2

or greater):

◆ If the grounding wire is too short, connect an extension lead, in a

mechanical way and wrapping it with insulating tape (do not bury the

connection)

◆ Secure the grounding wire in position with staples

4

Finish wrapping insulating tape around the rest of the pipes leading to the

outdoor unit.

3

Carefully check the installation, by measuring the grounding resistance

with a ground resistance tester. If the resistance is above required level,

drive the electrode deeper into the ground or increase the number of

grounding electrodes.

5

Connect the grounding wire to the electrical component box inside of the

outdoor unit.

6

◆ The grounding wire for the telephone line cannot be used to

ground the air conditioner.

NNNNoooottttee

ee

◆

If the grounding electrode is installed in an area of

heavy traffic, its wire must be connected securely.

NNNNoooottttee

ee

Terminal M4

PVC-insulated green/

yellow wire, 2mm

2

x 3.5 mTogrounding

screw

Steel

core

Carbon

plastic

30cm

50cm

Page 22

Fixing the Unit in Position

E-22

The outdoor unit must be installed on a rigid and stable base to avoid any

increase in the noise level and vibration, particularly if the outdoor unit is to

be installed close to a neighbour. If it is to be installed in a location exposed to

strong winds or at a height, the unit must be fixed to an appropriate support

(wall or ground).

Position the outdoor unit so that the air flow is directed towards the

outside.

1

Attach the outdoor unit to the appropriate support using anchor bolts.

2

If the outdoor unit is exposed to strong winds, install shield plates around

the outdoor unit, so that the fan can operate correctly.

3

670mm

403mm

Page 23

Connecting Up and Removing Air In the Circuit

H

SILGN

E

E-23

If you have used...

More than 5 metres

of the pipes

“A”g of refrigerant (R22)

must be added for each

extra metre.

Less than 5 metres

of piping

The purge time is normal

Then...

The outdoor unit is loaded with sufficient R22 refrigerant for 5 metres of piping.

The air in the indoor unit and in the pipe must be purged. If air remains in the

refrigeration pipes, it will affect the compressor, reduce to cooling capacity and

could lead to a malfunction. Refrigerant for air purging is not charged in the

outdoor unit. Use Vacuum Pump as shown at the figure.

Adding Refrigerant

Refrigerant must be added if the piping measures more than 5 metres in

length (maximum of 50 metres). This operation can only be performed by

a qualified refrigeration specialist.

Connect each assembly pipe to the appropriate valve on the outdoor unit

and tighten the flare nut.

1

Referring to the illustration opposite, tighten the flare nut on section B first

manually and then with a wrench, applying the following torque.

Outer Diameter Torque

9.52 mm (3/ 8") 250~280 kgf•cm

19.05 mm (3/ 4")

990~1210

kgf•cm

2

Connect the charging hose of low pressure side of manifold gauge to the

packed valve having a service port as shown at the figure.

3

Open the valve of the low pressure side of manifold gauge counterclockwise.

4

Purge the air from the system using vacuum pump for about 10 minutes.

Close the valve of the low pressure side of manifold gauge clockwise.

Make sure that pressure gauge show -0.1MPa(-76cmHg) after about

10 minutes.

This procedure is very important in order to avoid gas leak.

Turn off the vacuum pump.

Remove the hose of the low pressure side of manifold gauge.

5

Set valve cork of both liquid side and gas side of packed valve to the

open position.

6

Mount the valve stem nuts and the service port cap to the valve, and

tighten them at the torque of 183kgf•cm with a torque wrench.

7

Check for gas leakage.

At this time, especially check for gas leakage from the 3-way valve’s

stem nuts(A port), and from the service port cap.

8

A

B

C

D

Outdoor unit Indoor unit

Gas

pipe side

Liquid

pipe side

Valve stem

A(gas)

B(liquid)

Stem

cap

Vacuum

pump

Outdoor Unit

DH48FTX

DH48GTX

DH60FTX

DH60G

TX

DC48FTX

DC48GTX

DC60FTX

DC60GTX

“A”

40

40

50

50

40

40

50

50

When installing, make sure there is no leakage.

When recovering the refrigerant, ground the compressor first before removing

the connection pipe.

If the refrigerant pipe is not properly connected and the compressor works with

the service valve open, the pipe inhales the air and it makes the pressure inside

of the refrigerant cycle abnormally high, It may cause explosion and injury.

Page 24

E-24

Performing Leak Tests

Before completing the installation (insulation of the hose and piping),

you must check that there are no gas leaks.

To check for gas leaks on the... Then, using a leak detector,

check the...

Indoor unit Flare nuts at the end of sections

A and B.

Outdoor unit Valves on sections C and D.

D

C

AB

Page 25

ENGLISH

E-25

Insulation

Once you have checked that there are no leaks in the system, you can

insulate the piping and hose.

To avoid condensation problems, place heat-resistant polyethylene

foam separately around each refrigerant pipe.

1

Wind insulating tape around the pipes.

2

Finish wrapping insulating tape around the rest of the pipes leading to the

outdoor unit.

3

No gap

Heat resistant polyethylene

foam

Insulation

cover pipe

Insulation

pipe

Be sure to overlap

the insulation

Body

CCCCAAAAUUUUTTTTIIIIOOOONN

NN

Must fit tightly against

body without any gap.

◆ Always make the seam of pipes face upwards.

NNNNoooottttee

ee

Pump Down Procedure (When removing the product)

1) Turn on the air conditioner and select Cool mode to run the compressor for 3 minutes.

2) Release the valve caps on High and Low pressure side.

3) Use L wrench to close the valve on the high pressure side.

4) Approximately 2 minutes after, close the valve on the low pressure side.

5) Stop operation of the air conditioner.

6) Disconnect the pipes.

Page 26

E-26

Adjusting Air Flow

E. S. P(External Static Pressure) Setting for Phase Control Motor

With its phase control motor, you can adjust the indoor unit fan speed depending on the installation

conditi

on.

If the external static pressure is high so that the duct becomes longer or if the external static

press

ure is low so that the duct becomes shorter, adjust the fan speed by referring the following table.

Re

fer to the page 25 to set the option code.

Range of static pressure (Factory preset)

Static Pressure(mmAq)

Mode

l

CMM

(CFM

)

Step

Option Code for Indoor Unit

1086420

DH48FTA

DH48G

TA

DH60F

TA

DH60G

TA

DC48F

TA

DC48G

TA

DC60FTA

DC60G

TA

represents E. S. P(External Static Pressure) range of factory setting.

You don't have to adjust the fan speed separately if the external static pressure of the installation

pl

ace is in . When it is out of , input the appropriate option code.

If you input the inappropriate option code, error may occur or the air conditioner is out

of

order. The option code must be inputted correctly by the installation specialist or

serv

ice agent.

NNNNoooottttee

ee

Hi

Mid

Low

Hi

Mid

Low

Hi

Mid

Low

Hi

Mid

Low

Hi

Mid

Low

Hi

Mid

Low

Hi

Mid

Low

Hi

Mid

Low

40(1412)

35(1236)

30(1059)

40(1412)

35(1236)

30(1059)

50(1765)

45(1589)

40(1412)

50(1765)

45(1589)

40(1412)

40(1412)

35(1236)

30(1059)

40(1412)

35(1236)

30(1059)

50(1765)

45(1589)

40(1412)

50(1765)

45(1589)

40(1412)

Model

Exter

nal static pressue(mmAq)

DH48FTA

DC48FTA

DH60FTA

DC60FTA

DH48GTA

DC48GTA

DH60GTA

DC60GTA

Min.

0

No

rm

al

2

Ma

x.

4

6 8 10

015811

-1303C2

011801

-1303F3

0158

11

-13023D

011803

-1401EC

0158

11

-14029F

011803

-130137

0158

11

-13025E

011803

-14032F

0158

11

-1403A0

011803

-130159

0158

11

-13027F

011804

-140252

0158

11

-1403D2

011803

-13018C

0158

11

-130390

011804

-140285

015813

-140

113

011804

-1300F4

015813

-130104

011804

-1402CC

015813

-140328

011803

-1301BF

011804

-1402CA

015813

-140175

010801

-1303F3

010803

-130137

010803

-130159

010803

-13018C

010804

-1300F4

010803

-1301BF

0108

11

-13023D

010811

-13025E

0108

11

-13027F

010811

-130390

010813

-130104

010811

-1303C2

010803

-1401EC

010803

-14032F

010804

-140252

010804

-140285

010804

-1402CC

010804

-1402CA

0108

11

-14029F

010811

-1403A0

0108

11

-1403D2

010813

-140

113

010813

-140328

15

-

015813

-1303FB

-

015814

-140223

-

010813

-1303FB

-

010814

-140223

010813

-140175

DC48FTVA

DC48G

TVA

DC60F

TVA

DC60G

TV

A

Hi

Mid

Low

Hi

Mid

Low

Hi

Mid

Low

Hi

Mid

Low

010814

-1300A1

010814

-1300E5

010814

-130208

010814

-13024B

010814

-1303A1

010814

-13027E

0108

13

-13018E

010814

-1300A0

0108

14

-1300C2

010814

-1300E5

010814

-130249

010814

-130217

010814

-1402AF

010814

-1403C2

010814

-1403E4

010814

-1403F6

010814

-1403FB

010814

-1403F8

010814

-1400D7

010814

-14020A

0108

14

-14023C

010814

-14025E

010814

-1403F6

0108

14

-1303E1

-

010814

-1303F9

010814

-1403A2

010814

-1403FD

DC48FTVA

DC60FTVA

DC48GTVA

DC60GTVA

34(870)

30(813)

38(984)

34(904)

30(823)

46(1042)

42(970)

37(893)

41(1226)

38(1192)

35(1143)

38(920)

Page 27

Setting Up the Mode Option

ENGLISH

E-27

Setting Option Setup Method

Prepare of the Option Setup mode.

1

For example) Option Code :

Enter the Option Setup mode and select your option according to the

following procedure.

2

a. Take out the batteries of remote control.

b. Press the button simultaneously and insert the battery again.

c. Make sure the remote control display shows as .

The default value is . Otherwise, push the button to .

◆

Every time you press the button, the display panel reads or

repeatedly.

1

2

3

4

5

6

1

2

3

4

5

6

Press the button to set the display panel to .

◆

Every time you press the button, the display panel reads

repeatedly.

...

Press the button to set the display panel to .

◆

Every time you press the button, the display panel reads

repeatedly.

...

Press the button to set the display panel to .

◆

Every time you press the button, the display panel reads

repeatedly.

...

Press the button to set the display panel to .

◆

Every time you press the button, the display panel reads

repeatedly.

...

Press the button to set the display panel to .

◆

Every time you press the button, the display panel reads

repeatedly.

...

❊ Setting is not required if you want to input

. is displayed by default.

Page 28

E-28

Setting Up the Mode Option (Continued)

7

8

9

10

11

12

Press the button, then the default value is .

Press the button to set the display panel to .

◆

Every time you press the button, the display panel reads

repeatedly.

...

Press the button to set the display panel to .

◆

Every time you press the button, the display panel reads

repeatedly.

...

Press the button to set the display panel to .

◆

Every time you press the button, the display panel reads

repeatedly.

...

Press the button to set the display panel to .

◆

Every time you press the button, the display panel reads

repeatedly.

...

Press the button to set the display panel to .

◆

Every time you press the button, the display panel reads

repeatedly.

...

Check you made right selections upon completion of the selection.

3

a. Press the button once to check the former part of option code

you inputted.

◆

The display part shows .

b. Press the button once more to check the latter part of option

code you inputted

◆

The display part shows .

❊ Setting is not required if you want to input

. is displayed by default.

7

8

9

10

11

12

Page 29

Press the button.

4

When you press the button towards the indoor unit,

the sound 'Ding' or 'Diriring' is heard and the power indicator of the

display flashes at the same time. Then the option code setting is

completed.

(If the sound is not heard, press the button again.)

Check the air conditioner operates normally.

5

a. Remove the battery from the remote control.

b. Insert the battery into the remote control again.

c. Press the towards the indoor unit.

If all indicators of the indoor unit are flashing, plug out the power plug

an

d plug it in again. Then press the button.

If the air conditioner does not operate normally or all lamps indicators

flash

, check that the correct option code is set up.

NNNNoooottttee

ee

Option items

Model

SEG1 SEG2 SEG3 SEG4 SEG5 SEG6 SEG7 SEG8 SEG9 SEG10 SEG11 SEG12

DH48FTA

DH48GTA

DH60FTA

DH60GTA

DC48FTA

DC48GTA

DC60FTA

DC60GTA

Remote

Cont

r

ol

DC48FTVA

DC48GTVA

DC60FTVA

DC60GTVA

HS

ILGNE

E-29

❋

Page 30

E-30

Assigning Address to Indoor Unit

Before installing the indoor unit, assign an address to the indoor unit

according to the air conditioning system plan.

1

The address of the indoor unit is assigned by adjusting MAIN(SW02) and

RMC(SW04) rotary switches.

2

It is required to set the RMC address if you install the wired remote controller

and/or the centralized controller.

3

If you install optional accessories such as the wired remote controller, centralized

controller, etc. see an appropriate installation manual.

4

If an optional accessory is not installed, you do not have to set the RMC

address. However, adjust K1 and K2 switches of the SW05 DIP switch to "ON"

position in this case.

5

SW05

SW02 SW04

SW07SW06

K1 K2 K3 K4

SW05

SW06

K5 K6 K7 K8

SW07

K9

K10

K11

K12

SW02

SW04

Page 31

ENGLISH

E-31

Additional Functions

Compensation for lost temperature in heating operation

◆ Reduces the difference between an actual room temperature and a sensed

temperature by the air conditioner when heating.

Adjusting filter cleaning cycle

◆ You can adjust the cycle for filter sign indicator.

K5 2°C compensation 5°C compensation

Switch No.

Switch ON Switch OFF

K6 1000 hours 2000 hours

Switch No.

Switch ON Switch OFF

Hot water heater

◆ You must adjust the K7 when you install the hot water heater.

K7 No use of hot water heater Use of hot water heater

Switch No.

Switch ON Switch OFF

SW06

K5 K6 K7 K8

SW06

K5 K6 K7 K8

SW06

K5 K6 K7 K8

Page 32

E-32

Additional Functions (Continued)

External Control

You must adjust the K11 when you use external control.

K11

No use of

external control

Use of

external control

Switch No.

Switch ON Switch OFF

You can use external control when the K11 switch is turned off.

Operatio

n ON/OFF Function

CN83(RED) Operation ON Operation OFF

Connector No.

SH

O

RT OPEN

Operation State Display

PIN #1 and #2 of CN81(RED)

PI

N #3 and #4 of CN81(RED)

+12

V Out if any error occurs

+12

V Out when the compressor is operating

Connector No.

Functi

o

n

CN83(RED)

SW07

K 9

K 1

0

K 1

1

K 12

ON/OFF Switch

Comp. Status Display

Erro

r Display

AC

22

0

V

Sub. PCB

CN81(RE

D)

❋

❋

Page 33

ENGLISH

E-33

Drain Pump Installation (Optional)

Accessories

Drain Pump and Float

Switch(1)

M4 X 12 Tapped

Screw (4)

Cable-Tie (3) Insulation Drain (2) Drain Hose (1)

Remove the air filter.

Assemble the drain socket as seen in the picture after removing the rubber

cap.

1

2

Assemble the float switch with the drain pump.

3

Connect the drain hose.

4

Attach the drain hose tightly with the cable tie or a bonding

agent so that it does not get removed or water does not drain.

NNNNoooottttee

ee

Drain socket

Drain pump and

float switch

Drain hose

Page 34

E-34

Drain Pump Installation (optional) (Continued)

Insert the flexible hose into the drain socket until it clicks.

5

Connect the cable to the electrical component box as shown at the figure.

6

Adjust K4 DIP switch(SW05) to the "OFF" position.

7

◆

Wrap the drain tube outlet on the right and left side of

the indoor unit with an insulating materials.

NNNNoooottttee

ee

◆

Connect the drain pump cable to yellow terminal(CN74)

and the float switch to black terminal(CN51).

NNNNoooottttee

ee

◆

Check if water does not drain.

◆

Insulate the drain hose so that frost does not form.

NNNNoooottttee

ee

Switch No.K4Switch Position

ON

OFF

Using Drain Pump

X

O

K1 K2 K3 K4

SW05

Cable-tie

Indoor unit

Drain hose

Insulation

Must fit tightly against body without any gap.

Float switch

Drain pump

Page 35

Setting Up Option Switches (Outdoor unit)

You should display that how many indoor units are connected to

the outdoor unit. Refer to the table below, then turn the arrow to

appropriate position.

Rotary Switch

0 or 1

2

3

4

5

6

7

8

One

Two

Thre

e

Four

Five

Six

Seven

Eight

9

A

B

C

D

E

F

-

Nine

Ten

Eleven

Twelve

Thirteen

Fourteen

Fifteen

-

Switch No.

Number

of

indoor

unit(s)

Switch No.

Number

of

indoor

unit(s)

Rotary switch

Displa

y

PCB

KEY

Function

Number of

press times

1

2

3

4

K1 K3K2

CHECK

MODE

Use the K1 only for heat pump models.

Except for cooling only models

(The outdoor unit PCB is not applied to the cooling only value models :

DC48FTV,DC48GTV,DC60FTV,DC60GTV)

DISPLAY

MODE

RESET

K4

DIS 1 DIS 2

K1

(Displayed on SEG 3, 4)

Adding refrigerant at

heating mode

Test operation at

heating mode

End

-

K2

(Displayed on SEG 3, 4)

Adding refrigerant at

cooling mode

Test operation at

cooling mode

Pump Down for recovery

of refrigerant

End

K3

(Displayed on SEG 3, 4)

Reset

-

-

-

K4

(Displayed on SEG 3, 4)

Displays data

-

-

-

Summary of KEY functions

DisplayKEY

ITEM NO. CURRENT DATA DISPLAY

E-35

H

SILGN

E

❋

❋

Page 36

Setting up Option Switches (Outdoor unit) (Continued)

K1

K2

K3

K4

1

2

3

1

2

3

4

1

2

3

4

5

6

7

Adding refrigerant for heat pump models

Test operation for heat pump models

End

Adding refrigerant for cooling only models

Test operation for cooling only models

Pump Down for recovery of refrigerant

End

Reset

Discharge temperature of compressor

Temperature of outdoor heat exchanger

Outdoor temperature

Step of electronic expansion valve

(0 step : all closed, 480 step : all open)

Temperature of evaporator

Indoor temperature

Stopping view mode & display communication data

120STEP

(12 x 10)

-2

°C

12

°C

22

°C

-2

°C

12

°C

22

°C

110

°C

38

°C

34

°C

Reading data indicated on the display

KEY

Number of

press

Item

Example

Display Meaning

E-36

Page 37

Testing Operations

Check the power supply between the outdoor unit and the auxiliary circuit

breaker.

◆

Single phase power supply: L, N

◆

Three phase power supply: L1, L2, L3

1

Check the indoor unit.

◆

Check that you have connected the power and communication

cables correctly. (If the power cable and communication cables

one mixed up or connected incorrectly, the PCB will be damaged.)

2

If the outdoor unit is powered on, it will start tracking to check user's

option(s) and number of indoor unit.

- At this time, the SEG 1 and SEG 2 on outdoor unit PCB display the

number of indoor unit registered and the SEG 3 and SEG 4 display

the number of indoor units which responded.

- If an error mode is displayed, fix the error according to the service

manual.

- If you press K2, the compressor starts operation.

Operate the compressor for 20 minutes, then add refrigerant according

to the pipe length.

- If you press K2 again, test operation is started.

- If you don't stop the operation of adding refrigerant, it will be stopped

automatically after 1 hour.

- If you don't stop test operation, it will be stopped automatically

after 1 hour.

- If K2 is pressed during the operation of adding refrigerant, test operation

is started without compressor stopping. Therefore, start test operation

after the operation of adding refrigerant.

- The compressor can be operated after completely 3-minute preparation

and tracking.

- When testing operations at Heating Mode, press K1 instead of K2.

3

Press K2 on the outdoor unit PCB.

4

- You should test operations for more than 30 minutes.

- Check that the water dripping from the drain hose runs away correctly

and safely.

Check that indoor and outdoor temperatures, step of electronic expansion

valve and operation of compressor by using the display mode(K4).

5

Check that there is any error mode in the outdoor unit PCB during the test.

6

To complete the test, press the test operation KEY(K2) again.

7

ENGLISH

E-37

Page 38

Troubleshooting

Detection of errors

◆ If an error occurs during the operation, one or more LED flickers and the operation is stopped except the LED.

◆ If you re-operate the air conditioner, it operates normally at first, then detect an error again.

LED Display

LED Display on the receiver & display unit

1. Indoor unit error

(Display is unrelated

with operation)

2. Outdoor unit error

(Display is unrelated

with operation)

Error of temperature sensor

in the indoor unitt (Open/Short)

Error of heat exchanger sensor

in the indoor unit

Error of the outdoor temperature sensor

Error of the condensor temperature sensor

Error of the discharge temperature sensor

1. No communication for 2 minutes

between indoor units

(Communication error for more than 2 minutes)

2. Indoor unit receiving the communication

error from outdoor unit

3. Outdoor unit tracking 3 minutes error

4. When sending the communication error

from the outdoor unit, the mismatching

of the communication numbers and

installed numbers after completion of

tracking

(Communication error for more than 2 minutes)

Power reset

XXX

XXX

XXXX

X

X

X

X

X

X

X

● On Flickering X Off

◆

If you turn off the air conditioner when the LED is flickering, the LED is also turned off.

RemarksAbnormal conditions

Indicators

Blue Red

Concealed Type

Standard Type

E-38

Page 39

Error of setting option switches for optional

accessories

1. Error of electronic expansion valve close

2. Error of electronic expansion valve open

3. 2’nd detection of high temperature cond

4. 2’nd detection of high temperature

discharge

5. Error of reverse phase

6. Compressor down due to 6’th detection

of freezing

Communication error between indoor units

XXX

XXX

XX

● On Flickering X Off

◆

If you turn off the air conditioner when the LED is flickering, the LED is also turned off.

LED Display

Detection of the float switch

XX

EEPROM error

XX

EEPROM option error

RemarksAbnormal conditions

Indicators

Blue Red

Concealed Type

Standard Type

ENGLISH

E-39

Page 40

Troubleshooting (Continued)

Explanation

Display

Compressor down due to protection control of the discharge

temperature sensor

Control due to the condenser temperature sensor when cooling

mode

Error about protection

control of the outdoor unit

Communication and the

indoor unit errors

Self-diagnosis of the

indoor and outdoor unit

Wired remote controller

errors

Error about the outdoor unit

sensor (Open/Short)

Detection during the

operation of the indoor unit

(sensing and sending errors

into the communication data)

Remark

Error of the low pressure switch (Protection control)

Reverse phase error (Protection control)

In removing frost

Error of the outdoor temperature sensor (Open/Short)

Error of condensor temperature sensor (Open/Short)

Master wired remote controller ↔Slave wired remote controller

COM1/COM2 Cross-installed error

Error of setting option for wired remote controller COM2

Error of discharge temperature sensor (Open/Short)

- System down caused by communication error after completion

of tracking

- Mismatching of the indoor unit numbers set with those

communication after completion of 5 times tracking

Error of electronic expansion valve close in the outdoor unit

(when it is detected more than once)

Error of communication between the indoor unit and the wired

remote controller

Error of temperature sensor in the indoor unit (Open/Short)

Error of the heat exchanger sensor in the indoor unit (Open/Short)

Error of electronic expansion valve open in the outdoor unit

(when it is detected more than once)

Wired remote controller

◆ If an error occurs, is displayed on the wired remote controller.

◆ If you would like to see an error code, press the Test button.

E-40

Page 41

High temperature of Discharge (Protection control)

High temperature of outdoor heat exchanger (Protection control)

Rev

ers

e phase error (Protection control)

COMP DOWN to protect being frozen

In removing frost

Error of OUTTEMP sensor (OPEN/SHORT)

Error of temperature sensor in outdoor heat exchanger (OPEN/SHORT)

Error of Discharge TEMPsensor (OPEN/SHORT)

Sys

tem

Down caused by communication error after

completio

n of tracking

Mismatc

hing of the indoor unit numbers set with those

communicated after completion of tracking

Er

ror of float switch in indoor unit

Er

ror of setting option switches for optional accessories

OPEN/

SHORT error of room sensor in indoor unit

OPEN/

SHORT error of eva in sensor in indoor unit

EEP

ROM option error

Er

ror of fan starting

Open error of electronic expansion valve in outdoor unit

(Detected once or more times)

Clos

e error of electronic expansion valve in outdoor unit

(Detected once or more times)

Belo

w -5°C when cooling (Outdoor temperature)

Over 30°C when heating (Outdoor temperature)

If an error occurs during the operation, it is displayed on the outdoor unit PCB .

Outdoor unit

x

x

Explanation

Display

Error about protection

control

of outdoor unit

Errors about outdoor unit

sensor (OPEN/SHORT)

Detec

tion during the

opera

tion of indoor unit

(Sensing and sending errors

into

the communication data)

Communication and indoor

unit errors

Self-diagnosi

s of indoor

and outdoor unit (x:indoor

unit

address)

Display

s of operating status

Remark

Flicker

Flicker

K1, K2, K3, K4,

K5

Flicker

x

x

The order of priority : E1 → E2 → E5 → P0 → P1 → P4 → P5 → P9 → t1 → t2 → t3 → tu → to →

G4 → G5 → E3 → qx → rx → vx → K1, K2, K3, K4, K5

- In case that the same error displays from multi-indoor units, the one having the faster

address has the priority.

HNGLIS

E

Except for cooling only value models

(The outdoor unit PCB is not applied to the cooling only value models : DC48FTV,DC48GTV,DC60FTV,DC60

GTV)

*

E-41

Page 42

Parts List

E-42

Receiver & Display Unit Accessories

STS 2S-2x10

tapped screw

4

2S-4x12

tapped screw

2

Concealed T

ype

Standard Type

M4x16 tapped

screw

7

Cable-tie2Cable clamp

5

Battery

2

Remote control

holder

1

STS 2S-2x10

tapped screw

2

Owner’s

instructions

1

Installation

manual

1

Owner’s

instructions

1

Installation

manual

1

Owner’s

instructions

1

Installation

manual

1

Wireless Remote Controller Accessories

Wire kit

1

Wire kit

1

◆ Receiver & display unit ◆ Wire kit

◆ Wire kit

◆ Receiver & display unit

Receiver &

display unit

1

Receiver &

display unit

1

Wireless

remote controller

1

E-40

Page 43

ENGLISH

E-43

Centralized Controller Accessories

Cable-tie2Cable clamp

5

M4x16 tapped

screw

7

Owner’s

instructions

1

Installation

manual

1

Centralized

controller

1

T ransmitter Accessories

Function Controller Accessories

Cable-tie2Cable clamp

6

M4x16 tapped

screw

7

Owner’s

instructions

1

Installation

manual

1

Function

controller

1

7-day Scheduler Accessories

Cable-tie2Cable clamp

2

M4x16 tapped

screw

4

Owner’s

instructions

1

Installation

manual

1

7-day

Scheduler

1

Transmitter

power cable

1

Transmitter

communication cable

1

Installation

manual

1

Transmitter

1

◆

If you would like to install the centralized controller,

you must install the transmitter in the outdoor unit.

NNNNoooottttee

ee

Page 44

Loading...

Loading...