Page 1

6-1-1 Before Making Adjustments

6-1-1 (a) ORIENTATION

When servicing, always face the monitor to the

east.

6-1-1 (b) MAGNETIC FIELDS

Whenever possible, use magnetic field isolation

equipment such as a Helmholtz field to surround

the monitor. If a Helmholtz field is not available,

frequently degauss the unit under test.

Caution: Other electrical equipment may cause

external magnetic fields which may

interfere with monitor performance.

Use an external degaussing coil to limit magnetic

build up on the monitor. If an external degaussing

coil is not available, use the internal degaussing

circuit. However, do not use the internal

degaussing circuit more than once per 30 minutes.

6-1-1 (c) WARM-UP TIME

The monitor must be on for 30 minutes before

starting alignment. Warm-up time is especially

critical in color temperature and white balance

adjustments.

6-1-1 (d) SIGNAL

Analog, 0.714 Vp-p positive at 75 ohm, internal

termination

Sync: Separate/Composite

(TTL level negative/positive)

Sync-on-Green:

Composite sync 0.286 Vp-p negative

(Video 0.714 Vp-p positive)

6-1-1 (e) SCANNING FREQUENCY

Horizontal: 30 kHz to 96 kHz (Automatic)

Vertical: 50 Hz to 160 Hz (Automatic)

Unless otherwise specified, adjust at the

1024 x 768 mode (H: 68 kHz, V: 85 Hz) signals.

Refer to Table 3-1 on page 3-3.

6-1-1 (f) +B 220 V LINE ADJUSTMENT

Signal: 1024 x 768 mode (68 kHz/85 Hz)

Display image: Full white

Contrast: Maximum

Brightness: Maximum

6-1-1 (g) HIGH VOLTAGE ADJUSTMENT

Signal: 1024 x 768 mode (68 kHz/85 Hz)

Display image: Full white

Contrast: Maximum

Brightness: Maximum

Limit: 27 kV ± 0.5 kV (19”)

26 kV ± 0.5 kV (17”)

Measure the hight voltage level at the anode cap.

High voltage should be within the limit as above.

If the high voltage needs adjustment use the

following procedure.

PROCEDURE

1. Turn the power off and disconnect the AC line

cord from the power source.

2. Unsolder and remove VR501 on the Main

PCB.

3. Replace VR501 and adjust the high voltage to

the specification.

4. Using a soldering iron, melt the adjustment

cap on VR501 to prevent any movement.

6-1-1 (h) G2 (SCREEN) VOLTAGE ADJUSTMENT

Signal: 1024 x 768 mode (68 kHz/85 Hz)

Display image: Full white

Contrast: Maximum

Brightness: Maximum

Adjust the Screen VR of the FBT so that the G2

(Screen) Voltage for SDD is 600 V ± 10 V, for

Hitachi it is 600 V ± 10 V and for Toshiba it is

700 V ± 10 V.

6-1-1 (i) CENTER RASTER

Adjust VR401 so that the back raster comes to the

center when you apply a signal of 93 kHz/85 Hz.

CSH7839L/CSH9839L 6-1

6 Alignment and Adjustments

This section of the service manual explains how to make permanent adjustments to the monitor. Direction

is given for adjustment using the monitor Interface Board Ver. 2.0 and software (SoftJig).

6-1 Adjustment Conditions

Caution: Changes made without the SoftJig are saved only to the user mode settings. As such, the

settings are not permanently stored and may be inadvertently deleted by the user.

Page 2

6-1-1 (j) BRIGHTNESS AND CONTRAST

Unless otherwise specified, adjust control

volumes:

Brightness: Maximum

Contrast: Maximum

6-1-2 Required Equipment

The following equipment may be necessary for

adjustment procedures:

6-1-2 (a) DISPLAY CONTROL ADJUSTMENT

1. Non-metallic (–) screwdriver: 1.5 mm

Non-metallic (–) screwdriver: 3 mm

2. Philips (+) screwdriver: 1.5 mm

3. Non-metallic hexkey: 2.5 mm

4. Digital Multimeter (DMM), or

Digital Voltmeter (DVM)

5. Signal generator, or

Computer with a video board that uses the

ET-4000 chipset (strongly recommended if

using Samsung DM 200 software) and that

displays: 1280 x 1024 @ 85 Hz, or 1600 x 1200

@ 85 Hz (maximum).

6. Personal computer

7. Required software: Softjig.exe from Samsung

which includes the cg17p.c data file

Samsung DM200, or DisplayMate for

Windows from Sonera Technologies

8. Interface Board Ver. 2.0 Code No.

BH81-90001K

9. Parallel communications cable (25-pin to

25-pin); Code No. BH81-90001H

10. Signal cable (15-pin to 15-pin cable with

additional 3-pin connector); Code No.

BH81-90001J

11. 5 V DC adapter, not supplied

Note: SoftJig Ass’y (includes items 8, 9 and 10)

Code No. BH81-90001L

6-1-2 (b) COLOR ADJUSTMENTS

1. All equipment listed in 6-1-2 (a), above

2. Color analyzer, or any luminance

measurement equipment

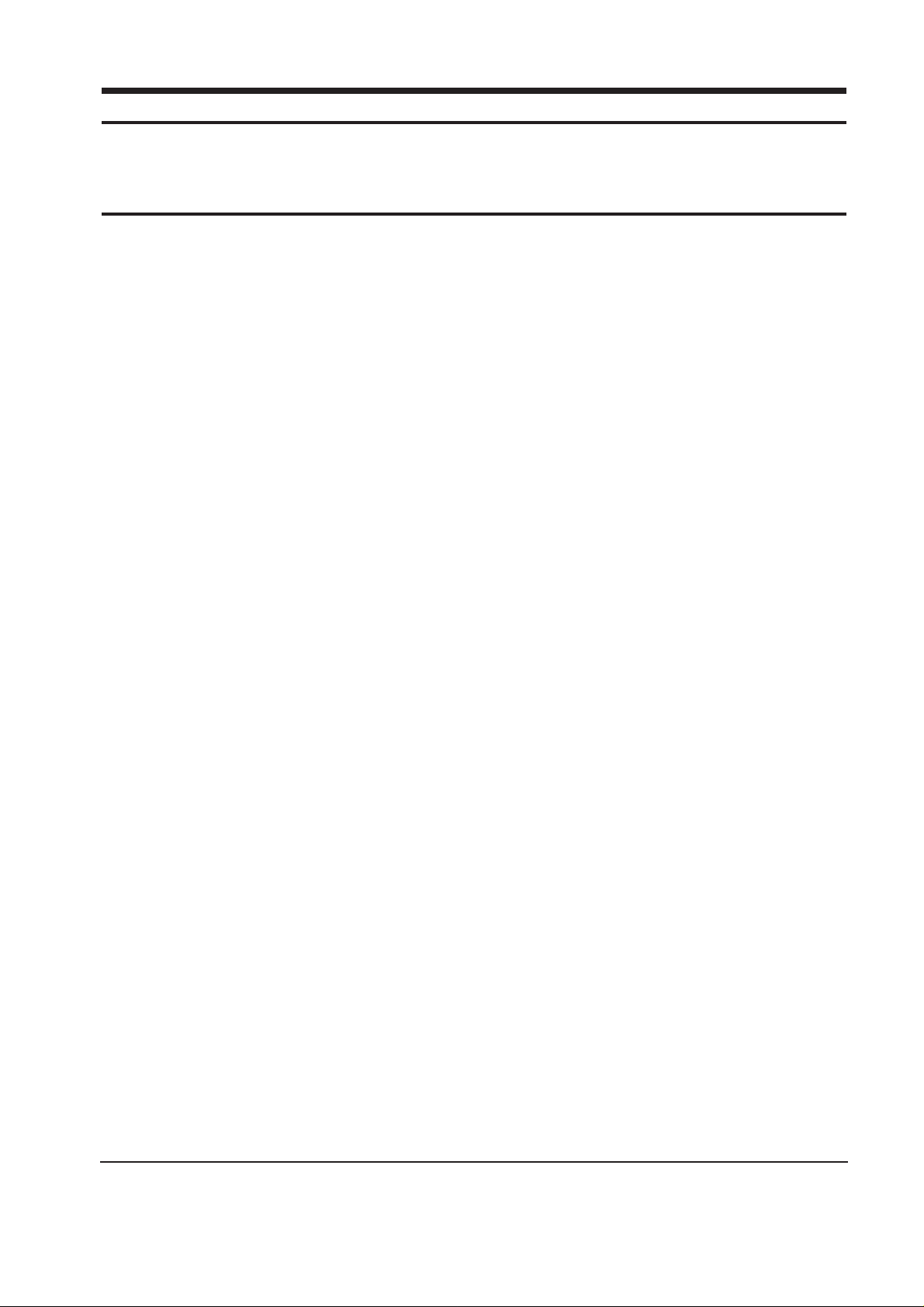

6-1-3 Connecting the SoftJig

Connect the monitor to the signal generator and/

or PC as illustrated in Figures 6-1 and 6-2.

Note: The signal cable connector which includes

the 3-wire cable must connect to the

monitor. If you use Setup 2 (PC only, no

signal generator) you can only make

adjustments to the signal timing available

on that computer system. To make

corrections to all factory timings requires

the use of an additional signal generator.

6-1-4 After Making Adjustments

After finishing all adjustments, test the monitor in

all directions. If, for example, the monitor does not

meet adjustment specifications when facing north,

reposition the monitor to face east and readjust.

This time, try for an adjustment closer to the ideal

setting within the tolerance range. Test the unit

again in all directions. If the monitor again fails to

meet specifications in every direction, contact

your Regional After Service Center for possible

CRT replacement.

6 Alignment and Adjustments

6-2 CSH7839L/CSH9839L

MONITOR

INTERFACE

BOARD VER. 2.0

PC

SIGNAL

GENERATOR

3-WIRE

CABLE

SIGNAL CABLE

5V DC

ADAPTOR

PARALLEL CABLE

Figure 6-1. Setup 1, With Signal Generator

MONITOR

INTERFACE

BOARD VER. 2.0

PC

3-WIRE CABLE

SIGNAL CABLE

PARALLEL CABLE

D-SUB

CONNECTOR

5V DC

ADAPTOR

Figure 6-2. Setup 2, Without Signal Generator

Page 3

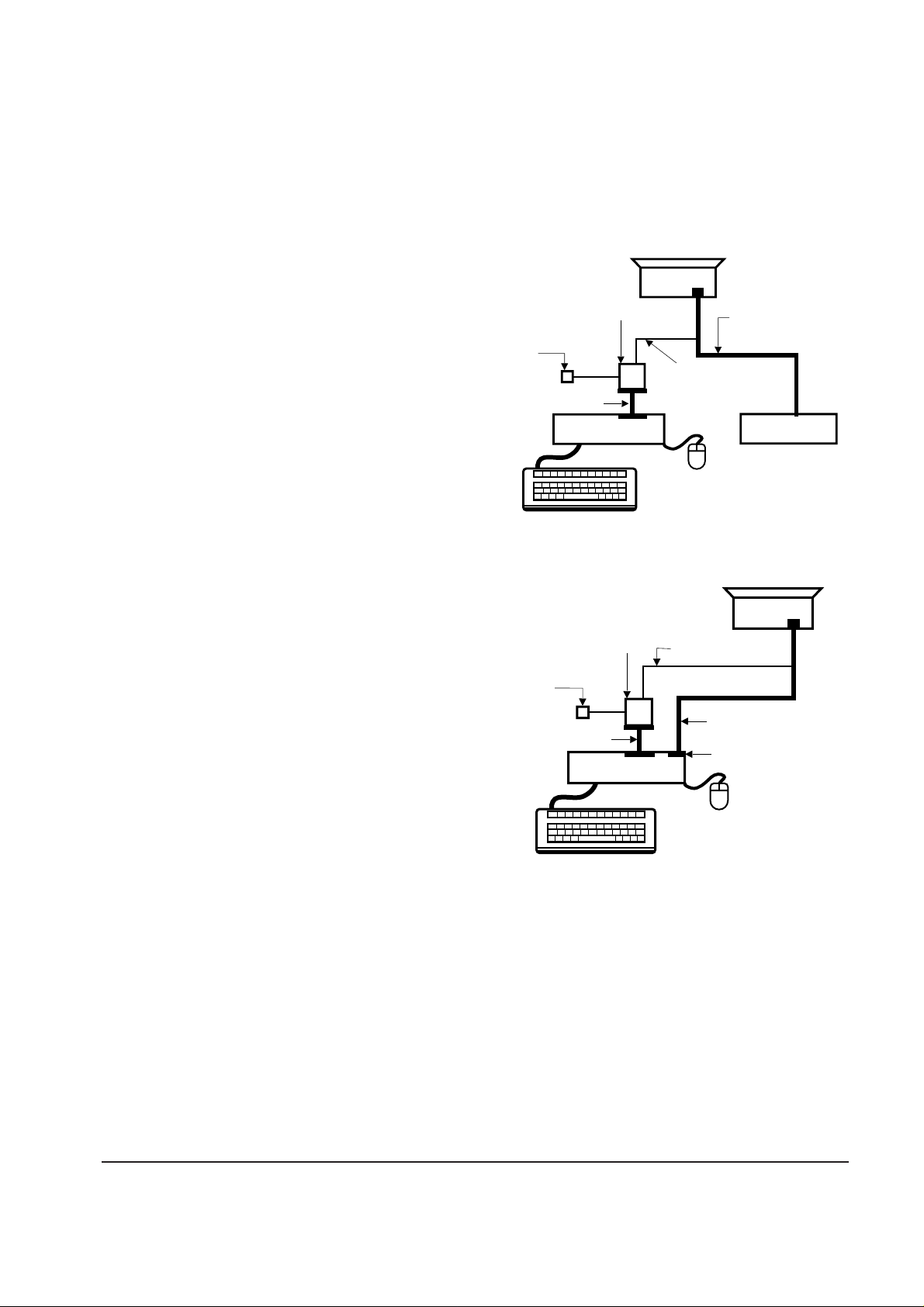

6-2-1 Centering

Centering means to position the center point of

the display in the middle of the display area.

Horizontal size and position and vertical size and

position control the centering of the display.

Adjust the horizontal size and vertical size to their

optimal settings: 352 mm (H) x 264 mm (V) - 19”,

306 mm (H) x 230 mm (V) - 17”.

1024 x 768 mode (68 kHz/85Hz)

Adjust the horizontal position and vertical

position to ≤ 4.0 mm of the center point of the

screen.

|A-B| ≤ 4.0 mm. |C-D| ≤ 4.0 mm.

Figure 6-3. Centering

6-2-1 (a) HORIZONTAL SIZE ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Cut-off

Contrast: Maximum

Click on the << or >> box next to H_SIZE to

adjust the horizontal size of the display pattern to

352 mm (19”), 306 mm (17”). (Tolerance: ± 3 mm.)

6-2-1 (b) VERTICAL SIZE ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Cut-off

Contrast: Maximum

Click on the << or >> box next to V_SIZE to

adjust the vertical size of the display pattern to

264 mm (19”), 230 mm (17”). (Tolerance: ± 3 mm.)

6-2-1 (c) HORIZONTAL POSITION ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Cut-off

Contrast: Maximum

Click on the << or >> box next to H_POSI to

center the horizontal image on the raster.

6-2-1 (d) VERTICAL POSITION ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Cut-off

Contrast: Maximum

Click on the << or >> box next to V_POSI to

center the vertical image on the raster.

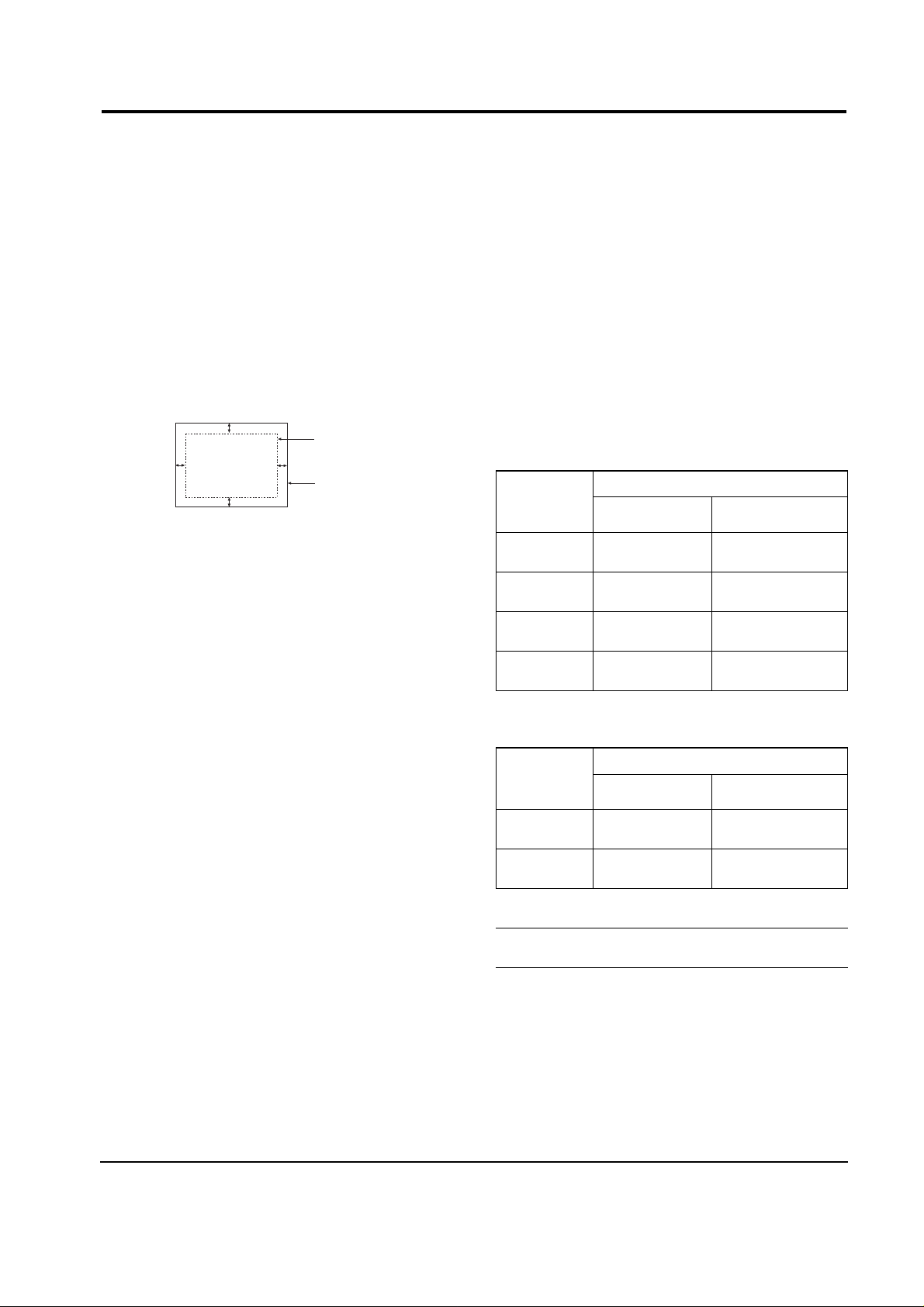

6-2-2 Linearity

Linearity affects the symmetry of images as they

appear on the screen. Unless each row or column

of blocks in a crosshatch pattern is of equal size,

or within the tolerances shown in Tables 6-1 and

6-2, an image appears distorted, elongated or

squashed.

Table 6-1. Factory Preset Modes Linearity

Table 6-2. Other Modes Linearity: VGA, SVGA, XGA,

MAC, etc.

6-2-2 (a) HORIZONTAL LINEARITY ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Cut-off

Contrast: Maximum

6 Alignment and Adjustments

CSH7839L/CSH9839L 6-3

6-2 Display Control Adjustments

C

A

DISPLAY AREA

EDGE OF BEZEL

B

D

4 : 3 (19”)

4 : 3 (17”)

5 : 4 (19”)

5 : 4 (17”)

Horizontal: 20.5~23.5

Vertical : 20.5~23.5

Horizontal: 17.8~20.5

Vertical : 17.8~20.5

Horizontal: 19.18~22.07

Vertical : 20.5~23.5

Horizontal: 16.7~19.2

Vertical : 17.8~20.5

Supported Timing Mode

Each block (14 %)

Difference between

adjacent blocks (5 %)

Horizontal: Less than 1.10 mm

Vertical : Less than 1.10 mm

Horizontal: Less than 0.96 mm

Vertical : Less than 0.96 mm

Horizontal: Less than 1.03 mm

Vertical : Less than 1.10 mm

Horizontal: Less than 0.90 mm

Vertical : Less than 0.96 mm

4 : 3 (19”)

4 : 3 (17”)

5 : 4 (19”)

5 : 4 (17”)

Horizontal: 20.9~23.1

Vertical : 20.9~23.1

Horizontal: 18.2~20.1

Vertical : 18.2~20.1

Horizontal: 19.60~21.65

Vertical : 20.9~23.1

Horizontal: 17.1~18.9

Vertical : 18.2~20.1

Standard Modes Linearity

Each block (10 %)

Difference between

adjacent blocks (4 %)

Horizontal: Less than 0.88 mm

Vertical : Less than 0.88 mm

Horizontal: Less than 0.77 mm

Vertical : Less than 0.77 mm

Horizontal: Less than 0.82 mm

Vertical : Less than 0.88 mm

Horizontal: Less than 0.72 mm

Vertical : Less than 0.77 mm

Page 4

To adjust the Horizontal Linearity, refer to Tables

6-1 and 6-2 for the tolerance range.

Click on the << or >> box next to H_LIN to

optimize the image.

6-2-2 (b) VERTICAL LINEARITY ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Cut-off

Contrast: Maximum

To adjust the Vertical Linearity, refer to Tables 6-1

and 6-2 for the tolerance range.

Click on the << or >> box next to V_LIN to

optimize the image.

6-2-3 Trapezoid Adjustment

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Cut-off

Contrast: Maximum

Click on the << or >> box next to TRAPE to make

the image area rectangular.

Figure 6-4. Trapezoid

6-2-4 Pinbalance Adjustment

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Cut-off

Contrast: Maximum

Click on the << or >> box next to PIN_BAL to

optimize the image.

6-2-5 Parallelogram Adjustment

CONDITIONS

Scanning Frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Cut-off

Contrast: Maximum

Click on the << or >> box next to PARALL to

make the image are rectangular.

Figure 6-6. Parallelogram

6-2-6 Side Pincushion Adjustment

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Cut-off

Contrast: Maximum

Click on the << or >> box next to BARREL to

straighten the sides of the image area.

6-2-7 Tilt Adjustment

CONDITIONS

Scanning Frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Cut-off

Contrast: Maximum

Click on the << or >> box next to ROTATE to

correct the tilt of the display.

6-2-8 Degauss

No adjustments are available for the degaussing

circuit. The degaussing circuit can effectively

function only once per 30 minutes.

6-2-9 To Delete the User Mode Data

To delete the adjustment data from the user

modes, click USER DELETE.

6-2-10 Save the Data

To save the adjustment data for a mode, press

FACTORY SAVE.

6 Alignment and Adjustments

6-4 CSH7839L/CSH9839L

| C1 |, | C2 | ≤ 2.0 mm, | D1 |, | D2 | ≤2.0 mm.

Figure 6-7. Pincushion

A

5 mm

B

A

B

| D1 |, | D2 | ≤ 2.0 mm

Figure 6-5. Pinbalance

D1 D2 D1

C2

D2D1

C1

| A - B | < 5 mm

Page 5

6-3-1 Color Coordinates (Temperature)

Color temperature is a measurement of the

radiant energy transmitted by a color. For

computer monitors, the color temperature refers

to the radiant energy transmitted by white. Color

coordinates are the X and Y coordinates on the

chromaticity diagram of wavelengths for the

visible spectrum.

CONDITIONS

Measurement instrument: Color analyzer

Scanning frequency: 68 kHz/85 Hz

Display Size : 352 (H) x 264 (V) - 19”

306 (H) x 230 (V) - 17”

Display image: White flat field at

center of display area

Brightness: Cut-off

Contrast: Maximum

PROCEDURE

Use the directions in sections 6-3-2 through 6-3-4

to adjust the color coordinates for:

9300K to x = 0.283 ± 0.02, y = 0.298 ± 0.02

6500K to x = 0.313 ± 0.02, y = 0.329 ± 0.02

5000K to x = 0.346 ± 0.02, y = 0.359 ± 0.02

6-3-2 Color Adjustments for 9300K

6-4-2 (a) BACK RASTER COLOR ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Back raster pattern

Brightness: Cut-off

Contrast: Maximum

1. Select COLOR CHANNEL 1 to control the

color for 9300K.

2. Adjust the luminance of the back raster to

between 0.3 to 1ft-L using the G_CUT

controls.

3. Click on the << or >> box next to B_CUT to

set the “y” coordinate to 0.298 ± 0.02.

4. Click on the << or >> box next to R_CUT to

set the “x” coordinate to 0.283 ± 0.02.

Note: If the above adjustments cannot be

done to each coordinate, click on the

<< or >> box next to G_CUT to decrease

or increase the green cutoff (bias) and

repeat procedures 2 and 3.

6-3-2 (b) G-GAIN ADJUSTMENT

Figure 6-8. Green Box Pattern

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Green box pattern

Brightness: Cut-off

Contrast: Maximum

1. Click on the << or >> box next to G_GAIN to

adjust the brightness of the Green Gain to

25 ± 1 ft-L (19”), 30 ± 1 ft-L (17”).

Note: If you can’t increase the Green Gain to

the appropriate value, click on the >>

box next to increase the ABL point.

6-3-2 (c) WHITE BALANCE ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Full white pattern

Brightness: Cut-off

Contrast: Maximum

Figure 6-9. Full White Pattern

1. Click on the << or >> boxes next to R_GAIN

and B_GAIN to make the video white.

(For 9300K color adjustment:

x = 0.283 ± 0.02, y = 0.298 ± 0.02.)

Note: Do not touch the G_GAIN controls.

2. Check the ABL. If it is not within the

specifications (30 ± 1 ft-L), use the ABL

controls to adjust it.

3. Select COLOR FACTORY SAVE to save the

data.

6 Alignment and Adjustments

CSH7839L/CSH9839L 6-5

6-3 Color Adjustments

1/3H-1/2H

1/3V-1/2V

FRONT BEZEL OPENING

BACK RASTER

GREEN WINDOW

FRONT BEZEL OPENING

BACK RASTER

WHITE WINDOW

Page 6

6-4-2 (d) WHITE BALANCE ADJUSTMENT VERIFICATION

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Back raster pattern

X-Y Coordinates: x = 0.283 ± 0.02,

y = 0.298 ± 0.02

Raster Luminance 0.3 ~ 1ft-L

ABL Luminance 30 ± 1 ft-L

Brightness: Cut-off

Contrast: Maximum

1. Check whether the color coordinates of the

back raster satisfy the above spec.

If they do not, return to 6-3-2 (a) and readjust

all settings.

2. Display a full white pattern.

Note: Do not touch the G_GAIN controls.

3. Adjust the Contrast Control on the monitor so

that the luminance of the video is about 5 ft-L.

4. Check whether the white coordinates of the

video meet the above coordinates spec.

5. Adjust the Contrast Control again so that the

luminance of the video is about 20 ft-L.

6. Check whether the white coordinates of the

video satisfies the above spec.

If they do not, return to 6-3-2 (a) and readjust

all settings.

6-4-3 Color Adjustments for 6500K

6-4-3 (a) BACK RASTER COLOR ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Back raster pattern

Brightness: Cut-off

Contrast: Maximum

1. Select COLOR CHANNEL 2 to control the

color for 6500K.

2. Adjust the luminance of the back raster to

between 0.3 to 1.0 ft-L using the G_CUT

controls.

3. Click on the << or >> boxes next to R_CUT

and B_CUT to adjust the R-Bias to x = 0.313 ±

0.02 and the B-Bias to y = 0.329 ± 0.02.

6-4-3 (b) G-GAIN ADJUSTMENT

This procedure is the same as that for 9300K, refer

to the procedure on page 6-5.

6-4-3 (c) WHITE BALANCE ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Full white pattern

Brightness: Cut-off

Contrast: Maximum

1. Click on the << or >> boxes next to R_GAIN

and B_GAIN to make the video white.

(For 6500K color adjustment:

x = 0.313 ± 0.02, y = 0.329 ± 0.02.)

2. Refer to the procedure for 9300K, section

6-3-2 (c) steps 2 and 3.

6-3-3 (d) WHITE BALANCE ADJUSTMENT VERIFICATION

Refer to the procedure for 9300K, section 6-3-2 (d).

6-3-4 Color Adjustments for 5000K

6-4-4 (a) BACK RASTER COLOR ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Back raster pattern

Brightness: Cut-off

Contrast: Maximum

1. Select COLOR CHANNEL 3 to control the

color for 5000K.

2. Adjust the luminance of the back raster to

between 0.3 to 1.0 ft-L using the G_CUT

controls.

3. Click on the << or >> boxes next to R_CUT

and B_CUT to adjust the R-Bias to x = 0.346 ±

0.02 and the B-Bias to y = 0.359 ± 0.02.

6-3-4 (b) G-GAIN ADJUSTMENT

This procedure is the same as that for 9300K, refer

to the procedure on page 6-5.

Adjust the brightness of the G_GAIN less 5 ft-L

than brightness of procedure for 9300K.

6-3-4 (c) WHITE BALANCE ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Full white pattern

Brightness: Cut-off

Contrast: Maximum

1. Click on the << or >> boxes next to R_GAIN

and B_GAIN to make the video white.

(For 5000K color adjustment:

x = 0.346 ± 0.02, y = 0.359 ± 0.02.)

2. Refer to the procedure for 9300K, section

6-3-2 (c) steps 2 and 3.

6 Alignment and Adjustments

6-6 CSH7839L/CSH9839L

Page 7

6-3-4 (d) WHITE BALANCE ADJUSTMENT VERIFICATION

Refer to the procedure for 9300K, section 6-4-2 (d).

6-3-5 Luminance Uniformity Check

Luminance is considered uniform only if the ratio

of lowest to highest brightness areas on the screen

is not less than 7.5:10.

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

(1024 x 768)

Display image: White flat field

Display size 352 (H) x 264 (V) - 19”

306 (H) x 230 (V) - 17”

Brightness: Cut off point

Contrast: Maximum

PROCEDURE

Measure luminance at nine points on the display

screen (see figure below).

6-3-6 Focus Adjustment

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: “H” character pattern

Brightness: Cut off point

Contrast: Maximum

PROCEDURE

1. Adjust the Focus VR on the FBT to display the

sharpest image possible.

2. Use Locktite to seal the Focus VR in position.

6-3-7 Color Purity Adjustment

Color purity is the absence of undesired color.

Conspicuous mislanding (unexpected color in a

uniform field) within the display area shall not be

visible at a distance of 50 cm from the CRT

surface.

CONDITIONS

Orientation: Monitor facing east

Scanning frequency: 68 kHz/85 Hz

Display image: White flat field

Luminance: Cut off point at the center

of the display area

Note: Color purity adjustments should only be

attempted by qualified personnel.

PROCEDURE

For trained and experienced service technicians

only.

Use the following procedure to correct minor

color purity problems:

1. Make sure the display is not affected by

external magnetic fields.

2. Very carefully break the glue seal between the

2-pole purity convergence magnets (PCM), the

band and the spacer (see Figure 6-11 and

6-12).

3. Make sure the spacing between the PCM

assembly and the CRT stem is 29 mm ± 1 mm.

4. Display a green pattern over the entire display

area.

5. Adjust the purity magnet rings on the PCM

assembly to display a pure green pattern.

(Optimum setting: x = 0.295 ± 0.015,

y = 0.594 ± 0.015)

6. Repeat steps 4 and 5 using a red pattern and

then again, using a blue pattern.

Table 6-3. Color Purity Tolerances

(For 9300K color adjustment: x = 0.283 ± 0.02, y = 0.298 ± 0.02)

7. When you have the PCMs properly adjusted,

carefully glue them together to prevent their

movement during shipping.

6 Alignment and Adjustments

CSH7839L/CSH9839L 6-7

Red: x = 0.640 ± 0.015 y = 0.323 ± 0.015

Green: x = 0.295 ± 0.015 y = 0.594 ± 0.015

Blue: x = 0.142 ± 0.015 y = 0.066 ± 0.015

Figure 6-10 Luminance Uniformity Check Locations

Page 8

Table 6-4. Misconvergence Tolerances

Figure 6-11. Magnet Configuration

Figure 6-12. Toshiba Magnet Configuration

Figure 6-13. Convergence Measurement Areas

6-4-1 Static (Center) Convergence

Static convergence involves alignment of the red,

blue and green lines in the center area of the

display. See “Dynamic Convergence” for

alignment of the color fields around the edges of

the display.

CONDITIONS

Direction: Monitor facing east

Warm-up: 30 minutes

Display image: Crosshatch pattern

Tolerances: See Table 6-5

PROCEDURE

As shown in Figure 6-11 and 6-12, the CRT used

in these monitors has the same magnet

configuration as shown in Table 6-6 below.

Table 6-5. Magnet Order

Use the following steps to correct any static

misconvergence:

1. Make sure the display is not affected by

external magnetic fields.

2. Locate the pair of 4-pole magnet rings.

3. Unlock the rings and rotate the individual

rings (change the spacing between tabs) to

converge the vertical red and blue lines.

4. Rotate the pair of rings (maintaining the

spacing between tabs) to converge the

horizontal red and blue lines.

6 Alignment and Adjustments

6-8 CSH7839L/CSH9839L

6-4 Convergence Adjustments

Misconvergence occurs when one or more of the electron beams in a multibeam CRT fail to meet the

other beams at a specified point.

CRT

FRONT

1

2

3

4

8

5

9

6

7

10

11

Samsung SDD and Hitachi CRT

1 Setup Bolt 2 Bow Magnet 3 Band 4 2-Pole Magnet

5 Spacer 6 4-Pole Magnet 7 Spacer 8 6-Pole Magnet

9 Holder 10 Band 11 Tabs

CRT

FRONT

P

1

2

3

4

8

5

9

6

7

10

11

Toshiba CRT

1 Setup Bolt 2 Bow Magnet 3 Spacer 4 2-Pole Magnet

5 Band 6 6-Pole Magnet 7 Spacer 8 4-Pole Magnet

9 Holder 10 Band 11 Tabs

A

B

230 MM

306 MM

CRT Manufacturer Magnet Order from Front of CRT

SDD and Hitachi Convergence bow, 2-pole,

4-pole, 6-pole

Toshiba Convergence bow, 2-pole,

6-pole, 4-pole

Position Error in mm CRT Dot Pitch REMARK

Center (A) 0.30 0.26 —

Edge (B) 0.50 0.26 < 1024 X 768

0.4 ≥ 1024 X 768

Page 9

5. After completing the red and blue center

convergence adjustment, locate the pair of

6-pole magnet rings.

6. Rotate the individual rings (change the

spacing between tabs) to converge the vertical

red and blue (magenta) and green lines.

7. Rotate the pair of rings (maintaining the

spacing between tabs) to converge the

horizontal red and blue (magenta) and green

lines. Don’t rotate the 2-pole magnets as they

adjust for color purity.

8. Mark the correct position for the magnets and

apply a small line of glue to hold the magnets

in place. Lock the rings in place.

6-4-2 Dynamic (Edge) Convergence

Use the following procedure to correct minor

dynamic (edge) misconvergence. If, after using

this procedure, dynamic misconvergence around

the periphery of the display area is still greater

than the tolerance, contact the Regional After

Service Center for possible CRT replacement.

1. Make sure the display is not affected by

external magnetic fields.

2. Make sure the static convergence is properly

adjusted.

3. Strategically place small rubber magnets on

the back of the CRT to correct the

misconvergence. Be careful not to remove the

paper protecting the adhesive on the magnets

until you are satisfied with their placement

and the dynamic convergence.

4. When you are satisfied with the convergence

around the edge of the CRT, permanently glue

the magnets to the back of the CRT.

WARNING: Do not remove or change the

position of the factory installed

wedges. These wedges were

installed by the CRT manufacturer

and are properly placed for this

CRT; their removal may result in

damage to the CRT.

6 Alignment and Adjustments

CSH7839L/CSH9839L 6-9

!

Red and Blue Alignment

(4-pole magnet movement)

Red, Blue and Green Alignment

(6-pole magnet movement)

R

B

B

R

O-Magnetic

Field

Motion (1)

Motion (2)

(1) SPREAD

TAB

MAGNET

VERTICAL

MISALIGNMENT

HORIZONTAL

MISALIGNMENT

SHIFT DIRECTION OF

CROSSHATCH PATTERN

SHIFT DIRECTION OF

CROSSHATCH PATTERN

OR

MOVE

TOGETHER

Figure 6-14. Magnet Movements

B

R

B

R

B

R

B

R

M

G

G

R

G

M

G

R

B

G

M

G

M

B

Page 10

6-4-3 Bow Convergence Adjustments

CONDITIONS

Orientation: Monitor facing east.

Display Image: Crosshatch pattern with mixed

RGB colors.

Required tools: Flat-head (–) screwdriver, 1.5 mm

Philips (+) screwdriver, 1.5 mm

Hexkey, 2.5 mm

PROCEDURE

Bow convergence adjustments are not available

for the CRTs used in the CSH7839L/CSH9839L

monitors. While all CRTs have bow convergence

magnets, they are sealed in the CRT factory and

are not user or service technician adjustable. Do

not touch these magnets (see Figures 6-11 and 6-

12). If bow convergence adjustment is out of

alignment, replace the CRT.

Bow misconvergence should not exceed the values

listed in Table 6-5: Misconvergence Tolerances.

6-4-4 Balance Convergence Adjustments

Balance Convergence involves alignment of red

and blue lines when they are misaligned at one

end more so than at the other end. The Deflection

Yoke holds the balance coils which can correct

balance misconvergences.

Figure 6-15. SDD and Hitachi Deflection Yoke

Figure 6-16. Toshiba Deflection Yoke

6-4-4 (a) HORIZONTAL LINE RED AND BLUE

BALANCE CONVERGENCE

Figure 6-17. Horizontal Line Balance Misconvergence

Use a 2.5 mm hexkey at the Horizontal Balance

Coil (XV). Turning it right raises the right end of

the blue line and lowers the left end. Turning the

VR to the left lowers the right end of the blue line

and raises the left end.

6-4-4 (b) VERTICAL RED AND BLUE BALANCE

CONVERGENCE

Figure 6-18. Vertical Line Balance Misconvergence

Use a 1.5 mm screwdriver (flat-head [–] for SDD

DYs and phillips type [+] for Toshiba DYs) at the

YH variable register. Turning the VR left tilts the

blue line to the right. Turning it right tilts the blue

line to the left.

6-4-4 (c) UPPER AND LOWER HORIZONTAL LINE

CONVERGENCE

Figure 6-19. Upper and Lower Balance Misconvergence

Use a 1.5 mm screwdriver (flat-head [–] for SDD

DYs and phillips type [+] for Toshiba DYs) at the

Yv variable register. Turning the VR to the left

moves the blue line at the top upward and at the

bottom, the line moves downward. Turning it

right moves the blue line at the top downward

and at the bottom, the line moves upward.

6 Alignment and Adjustments

6-10 CSH7839L/CSH9839L

BLUE

RED

REDBLUE

RED

BLUE

RED

BLUE

YH

Xv

Y

v

HORIZONTAL

BALANCE COIL

YV

XV

YH

Loading...

Loading...