Samsung CLX-FIN40S, CLX-FIN40L Service Manual

Service Manual

Finisher Service Manual

CLX-FIN40S / CLX-FIN40L

1. Application Model

• CLX-925x/935x series

• SCX-8x30/8x40 series

2. Stack Capacity (A4/LT 80gsm)

• CLX-FIN40S : 1,000 sheets (Main) / 250 sheets (Top)

• CLX-FIN40L : 3,000 sheets (Main) / 250 sheets (Top)

3. Staple (Finisher)

• Capacity : 50 sheets (90gsm)

• Cartridge Capacity : 5,000 clinching/cartridge

4. Staple (Booklet maker)

• Staple/Fold capacity : 15 sheets

• Cartridge Capacity : 1,000 clinching/cartridge)

The keynote of Product

ⓒ

Samsung Electronics Co.,Ltd. April. 2010

Printed in Korea.

VERSION NO. : 1.00 CODE : FIN4-00000E

GSPN (Global Service Partner Network)

North America : service.samsungportal.com

Latin America : latin.samsungportal.com

CIS : cis.samsungportal.com

Europe : europe.samsungportal.com

China : china.samsungportal.com

Asia : asia.samsungportal.com

Mideast & Africa : mea.samsungportal.com

1.1 General Specif cations …………………………………………… 1-1

1.2 Finisher Specif cations …………………………………………… 1-2

1.3 Booklet Maker Specif cations …………………………………… 1-3

1.4 Media Specif cations …………………………………………… 1-4

1.5 Tray Capacity Specif cations …………………………………… 1-9

1.6 Mode Feature …………………………………………………… 1-10

1.7 Staple Set Specif cations ………………………………………… 1-11

1.8 Hole Punch Specif cations ……………………………………… 1-14

1.9 Booklet Maker Specif cations …………………………………… 1-16

2.1 Front sectional view ……………………………………………… 2-1

a) CLX-FIN40S ……………………………………………………… 2-1

b) CLX-FIN40L ……………………………………………………… 2-2

2.2 Paper path ………………………………………………………… 2-4

a) CLX-FIN40S ……………………………………………………… 2-4

b) CLX-FIN40L ……………………………………………………… 2-5

2.3 Layout of electrical parts ………………………………………… 2-6

a) CLX-FIN40S ……………………………………………………… 2-6

b) CLX-FIN40L ……………………………………………………… 2-8

c) CLX-BRG200 …………………………………………………… 2-12

2.4 Function of units …………………………………………………… 2-13

a) CLX-FIN40S …………………………………………………… 2-13

b) CLX-FIN40L …………………………………………………… 2-14

2.5 Block diagram …………………………………………………… 2-15

2.6 Plug and jack location list ……………………………………… 2-16

chapter 1 Specifi cation

chapter 2 System Confi guration

Contents

3.1 General precautions on disassembly …………………………… 3-1

3.2 CLX-FIN40S disassembly ……………………………………… 3-2

3.2.1 AS-FRAME UNIT …………………………………………… 3-2

3.2.2 AS-COMPILER EJECTOR ………………………………… 3-17

3.2.3 AS-STAPLER ENDFENCE ………………………………… 3-28

3.2.4 ENDFENCE UNIT …………………………………………… 3-34

3.2.5 Finisher exit sensor ………………………………………… 3-35

3.2.6 AS-BELT ……………………………………………………… 3-37

3.3 CLX-FIN40L disassembly ………………………………………… 3-38

3.3.1 AS-FRAME UNIT …………………………………………… 3-38

3.3.2 Booklet unit ………………………………………………… 3-45

3.3.2.1 Feed Pulley …………………………………………… 3-45

3.3.2.2 AS-MAGNET …………………………………………… 3-46

3.3.2.3 Entrance guide sub assy ……………………………… 3-47

3.3.2.4 Pulley, Gear, Belt. ……………………………………… 3-50

3.3.2.5 AS-SADDLE stapler:EH-280 ………………………… 3-51

3.3.2.6 AS-MAIN-PADDLE …………………………………… 3-52

3.3.2.7 JOG UNIT ……………………………………………… 3-52

3.3.2.8 BM paper present sensor ……………………………… 3-54

3.3.2.9 Blade home sensor …………………………………… 3-55

3.3.2.10 CSP- GEAR …………………………………………… 3-56

3.3.2.11 Folding exit sensor …………………………………… 3-57

3.3.2.12 BM entrance sensor & Moving guide home sensor 3-59

3.3.2.13 Stopper guide upper magnet ………………………… 3-60

4.1 Error code and error message ………………………………… 4-1

4.2 Troubleshooting for error code ………………………………… 4-3

4.3 Finisher Self-Test Mode ………………………………………… 4-37

4.4 Adjusting the staple position (CLX-FIN40L) …………………… 4-40

4.5 Adjusting the Paper Skew ……………………………………… 4-43

chapter 4 Troubleshooting

Contents

chapter 3 Replacement procedure

General Precautions

The service should be done by a qualified service technician.

1. Before servicing or maintenance work, be sure to turn off and unplug the equipment first.

2. Be sure to fix and plug in the power cord securely after the service so that no one trips over it.

3. When servicing the machines with the power turned ON, be sure that the touch screen and

rotating/operating sections are working normally.

4. When servicing or maintaining the finisher / punch unit / bridge unit, be careful about the rotating or

operation sections such as gears, pulleys, sprockets, cams, belts, etc.

5. When parts are disassembled, reassembly is basically the reverse of disassembly unless otherwise

noted in this manual or other related materials. Be careful not to reassemble small parts such as screws,

washers, pins, E-rings to the wrong places.

6. Basically, the machine should not be operated with any parts removed or disassembled.

7. Delicate parts for preventing safety hazard problems (such as breakers, door switches, sensors, etc. if

any) should be handled/installed/adjusted correctly.

8. Use suitable measuring instruments and tools.

9. After completing servicing and maintenance of the finisher / bridge unit / punch unit, check operation.

1. Specification

1-1

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

1. Specifications

- Color Model : 94.8 Kg

- Mono Model : 92.7 Kg

- Color Model : 70.2 Kg

- Mono Model : 68 Kg

- Color Model

876 x 610 x 1074 mm

- Mono Model

876 x 610 x 1018 mm

30.5 KgPacked Weight

25.7 KgModule Weight

Weight

696 x 610 x 536 mm

W x D x HSize

[Finisher]

- Paper feeding / paddling parts : 2,000K

- Finishing parts (Tamping / ejecting / stacking) : 2,000K / 5 sheets job

= 400K

- Finisher Stapler : 300K (maker guaranteed cycle)

90 gsm 2 sheets 5,000 stapling

10 sheets 30,000 stapling

50 sheets 5,000 stapling

: 500K (maker guaranteed cycle)

80 gsm 2 sheets 5,000 stapling

10 sheets 30,000 stapling

50 sheets 5,000 stapling

[Booklet Maker]

- Paper feeding / paddling parts : 2,000K

- parts related folding : 2,000K / 5 sheets job = 400K

- Booklet Stapler : 200K (maker guaranteed cycle)

80 gsm 2 sheets 5,000 stapling

10 sheets 32,000 sheets

25 sheets 3,000 stapling

[Hole punch]

: 1,000K/5 years (maker guaranteed cycle)

SET Life Cycle

150K

Max Monthly

Duty

11KAMPV

Reliability @

Service

Any operation : Non-staple : Non-punch mode

: 56dB(A) run continuous

IOT+Booklet

Finisher

Any operation : Non-staple : Non-punch mode

: 54dB(A) run continuous

Booklet

Finisher only

Acoustic

Noise Level*

10 ~ 90% RHStorage

20 ~ 80% RHOperating

Humidity

-20 ~ 40 ℃Storage

10 ~ 32 ℃Operating

Temperature

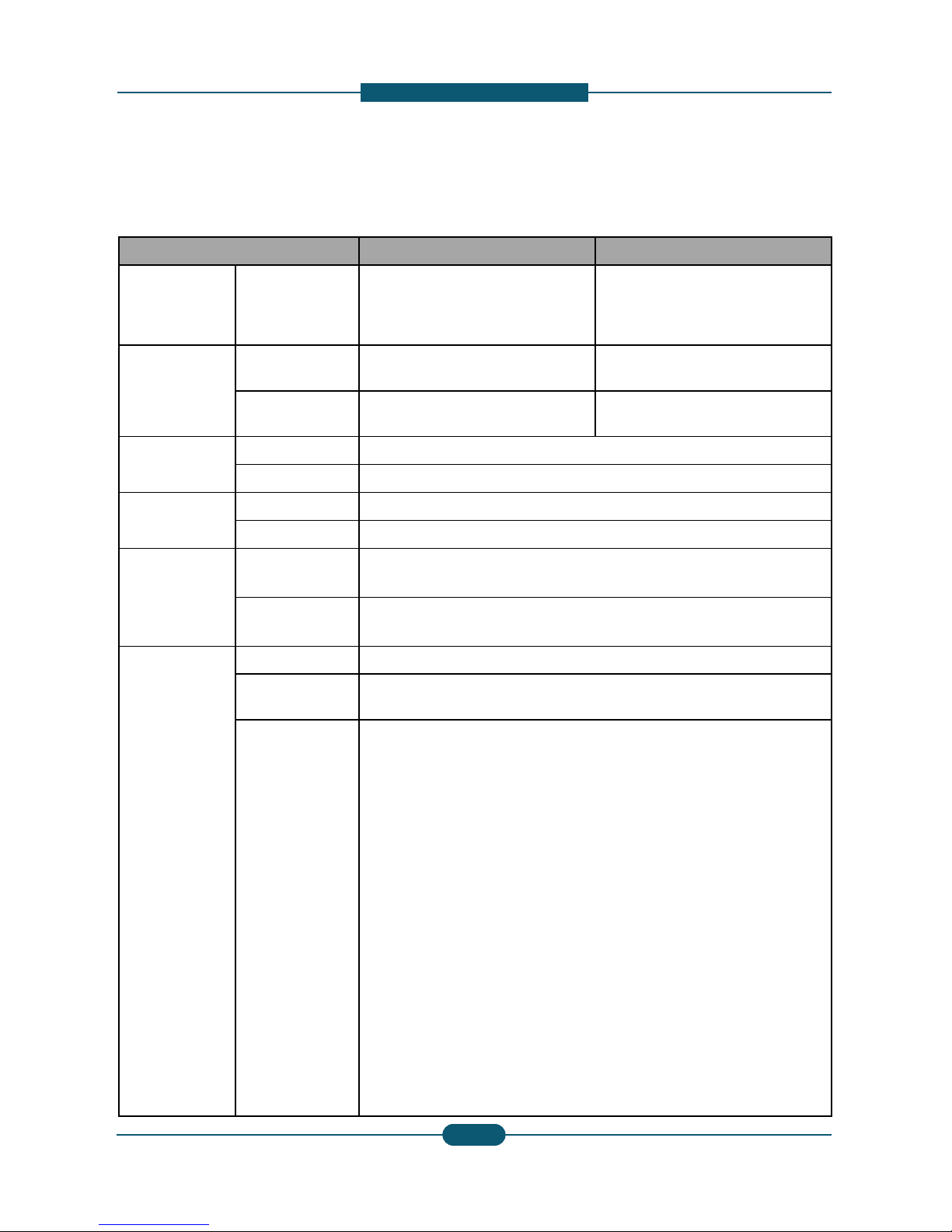

CLX-FIN40LCLX-FIN40SItem

1.1 General Specifications

1. Specification

1-2

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

NA2/3, EU2/4NA2/3, EU2/4available unit

60 ~ 216 gsm60 ~ 216 gsmPaper weight

Hole Punch

YesYesOffline

5,000 clinching/cartridge5,000 clinching/cartridgeCartridge Capacity

50 sheets (90gsm)50 sheets (90gsm)Capacity

60 ~ 216 gsm60 ~ 216 gsmPaper weight

-Front/Rear Corner(45°,Flat)

-Dual

-Front/Rear Corner(45°,Flat)

-Dual

Clinching position

Staple

30mm30mmOffset (Staple/Non Staple)

56 ~ 253 gsm56 ~ 253 gsmTop

60 ~ 216 gsm60 ~ 216 gsmMain

Paper Weight

89 x 148 ~ 12.6 x 18"89 x 148 ~ 12.6 x 18"Top

Statement SEF ~ 12 x 18"Statement SEF ~ 12 x 18"Main

Paper Size

250 sheets250 sheetsTop

3,000 sheets1,000 sheetsMain

Stack Capacity

(A4/LT 80gsm)

Minimized skipMinimized skipStaple

0 Skip0 SkipNon Staple

Skips Pitch

Stand aloneHanging typeConfiguration

CenterCenterPaper alignment

112.5~245 mm/sec112.5~245 mm/secFeed Velocity

25~5025~50PPM

Speed

CLX-FIN40LCLX-FIN40SItem

1.2 Finisher Specifications

1. Specification

1-3

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

1.3 Booklet Maker Specifications

1,000 clinching/cartridgeStaple Cartridge Capacity

20 sets / 15 sheetsTray Capacity

Max. 216 gsmV folding1 sheet folding mode

15 sheetsStaple/Fold Capacity

Cover sheet = Max. 216 gsm60 ~ 120 gsmPaper Weight

B5 SEF ~ 12 x 18"Paper Size

CenterPaper alignment

112.5~245 mm/secFeed Velocity

Minimized skip25~50PPM

Speed

RemarkCLX-FIN40LItem

1. Specification

1-4

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

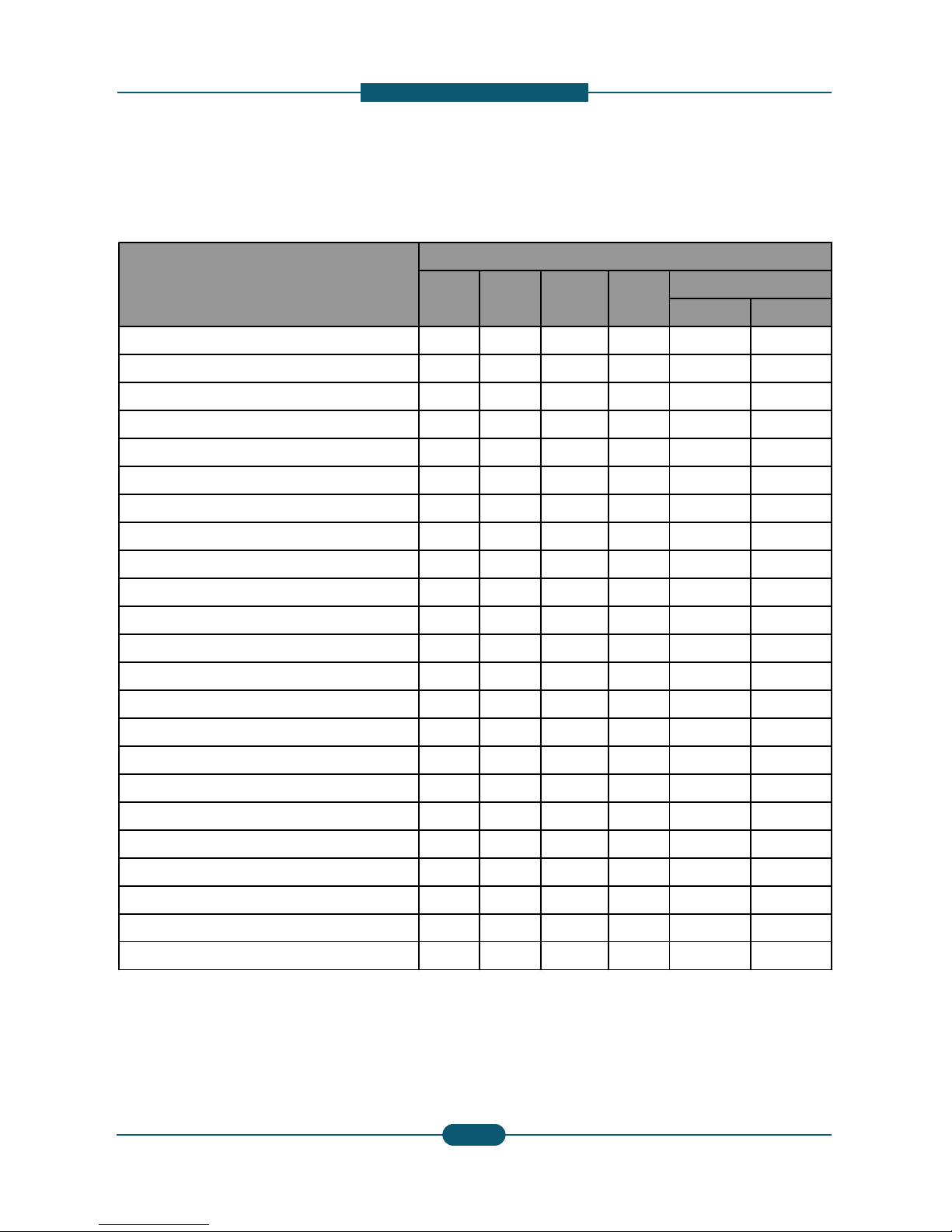

1.4 Media Specifications

OOXOOSEF8.5×13.5215.9×342.9Oficio

OOXOOSEF8.5X13216X330Folio

OOXOOSEF8.5X11216X279Letter

OOXOOSEF8.5X14216X356Legal

OOXOOSEF8.3X11.7210X297A4

OOXOOSEF7.7X10.6195X27016k

OOXOOSEF7.3X10.5184X267Executive

OOXOOSEF6.9X9.8 182X257B5(JIS)

OOXOOSEF6.9×9.8176×250 B5(ISO)

XXXOXSEF6.4×9.0162×229C5 Env

XXXOOSEF5.8X8.3148X210A5

XXXOOSEF5.5X8.5140X216Statement

XXXOXSEF4.5×6.4114×162C6 Env

XXXOXSEF4.3×8.7110×220DL Env

XXXOXSEF4.1×9.5105×241No 10 Env

XXXOXSEF4.1X5.8 105X148A6

XXXOXSEF4.0×6.0101.6×152.4

PostCard

4x6

XXXOXSEF3.9×7.598.4×190.5

Monarch

Env

XXXOXSEF3.9X8.998X225No 9 Env

OXOOOLEF8.3X11.7297X210A4

OXOOOLEF11X8.5279X216Lt

OXOOOLEF10.5X7.3267X184Executive

OXOOOLEF10.1×7.2257X182B5(JIS)

OOXOOLEF8.5X5.5216X140Statement

OOXOOLEF8.3X5.8210X148A5

Flat45°

60-

256 g

60-

216 g

DUAL

Corner

Top

tray

Main

tray

DirectionInchesmm

Staple position OutputOrientationPaper size

Name

a) Output and Staple position

1.4.1 Media Size & mechanism Constraint

1. Specification

1-5

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

OXOOOSEF10 X14.7254X374Tabloid

OOXOOSEF9.1X12.8229×324C4

OXOOOSEF10.6X15.4270X3908K

OXOOOSEF10X14.3257X364B4

NANANAONA-

W3.5-12.3 ~

L 5.5-18

W 89-312 ~

L 140-457.2

Custom

XXXOXSEF12.6×17.7320×450SRA3

OXOOOSEF12×18304.8×457.2

Tabloid

Extra

OXOOOSEF11.7X16.5297X420A3

OXOOOSEF11X17279X432Ledger

Flat45°

60-

256 g

60-

216 g

DUAL

Corner

Top

tray

Main

tray

DirectionInchesmm

Staple position OutputOrientationPaper size

Name

b) Punch and Booklet Maker

XOXOXXSEF5.8X8.3148X210A5

XOXOXXSEF5.5X8.5140X216Statement

XXXXXXSEF4.5×6.4114×162C6 Env

XXXXXXSEF4.3×8.7110×220DL Env

XXXXXXSEF4.1×9.5105×241No 10 Env

XXXXXXSEF4.1X5.8 105X148A6

XXXXXXSEF4.0×6.0101.6×152.4

PostCard

4x6

XXXXXXSEF3.9×7.598.4×190.5

Monarch

Env

XXXXXXSEF3.9X8.998X225No 9 Env

XOOOOOLEF8.3X11.7297X210A4

XOOOOOLEF11X8.5279X216Lt

XOOOOOLEF10.5X7.3267X184Executive

XOOOOOLEF10.1×7.2257X182B5(JIS)

XOXOXOLEF8.5X5.5216X140Statement

XOXOXOLEF8.3X5.8210X148A5

4H2H3H2H

Scan

4H

EU 2/4HNA 2/3

DirectionInchesmm

Booklet

Maker

PunchOrientationPaper size

Name

1. Specification

1-6

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

NANANANANANA-

W3.5-12.3 ~

L 5.5-18

W 89-312 ~

L 140-457.2

Custom

XXXXXXSEF12.6×17.7320×450SRA3

OOOOOOSEF12×18304.8×457.2

Tabloid

Extra

OOOOOOSEF11.7X16.5297X420A3

OOOOOOSEF11X17279X432Ledger

OOOOOOSEF10.6X15.4270X3908K

OOOOOOSEF10X14.3257X364B4

OOXOOOSEF10 X14.7254X374Tabloid

OOXOXOSEF9.1X12.8229×324C4

OOXOXOSEF8.5×13.5215.9×342.9Oficio

OOXOXOSEF8.5X13216X330Folio

OOXOXOSEF8.5X11216X279Letter

OOXOXOSEF8.5X14216X356Legal

OOXOXOSEF8.3X11.7210X297A4

OOXOXOSEF7.7X10.6195X27016k

OOXOXOSEF7.3X10.5184X267Executive

OOXOXOSEF6.9X9.8 182X257B5(JIS)

OOXOXOSEF6.9×9.8176×250 B5(ISO)

XXXXXXSEF6.4×9.0162×229C5 Env

4H2H3H2H

Scan

4H

EU 2/4HNA 2/3

DirectionInchesmm

Booklet

Maker

PunchOrientationPaper size

Name

1. Specification

1-7

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

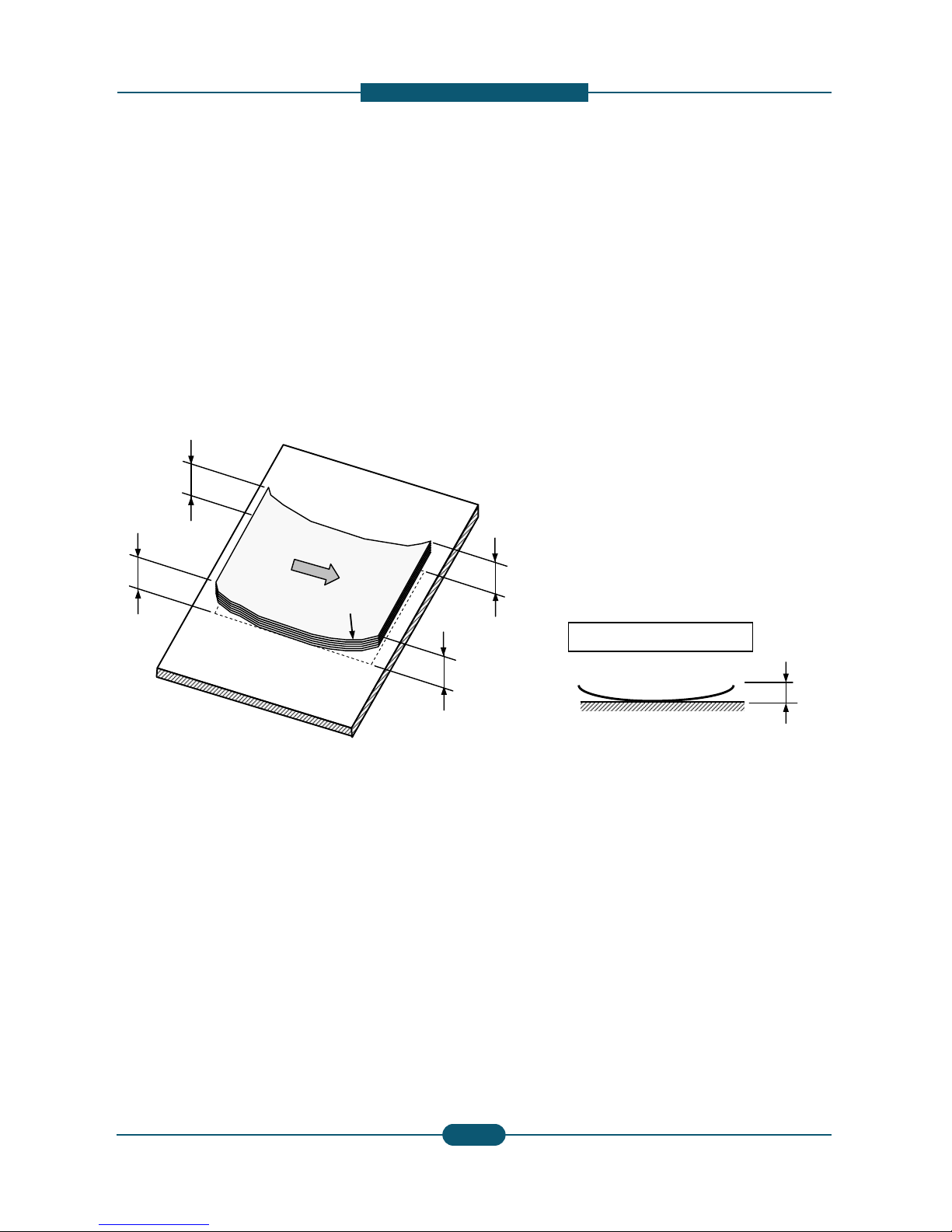

1.4.2 Media Type & Condition

¾ Special Paper: Finisher must be able to handle special types of papers such as Tab, Archive,

Transparencies, etc (See 1.4.3). A slight underperformance is tolerable for special

papers, however it must not damage the paper in any case.

¾ Static : All static must be controlled so that it would not harm the quality of the stack. Users must never

be shocked by static from the finisher body or finisher’s any module.

¾ Curl : Finisher shall handle ±1/2” curled output as delivered from the IOT.

A1(mm)

A2(mm)

A4(mm)

A3(mm)

Feeding Direction

Radius(R)

10 sheets

Glass

A

A = MAX (A1,A2,A3,A4)

[‘Curl’ measuring method]

¾ Skew : Finisher must be able to control ‘skew’ of the sheet received from the IOT. The skew must be

less than 1% of the length of the paper received from IOT main body (feeding direction).

1. Specification

1-8

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

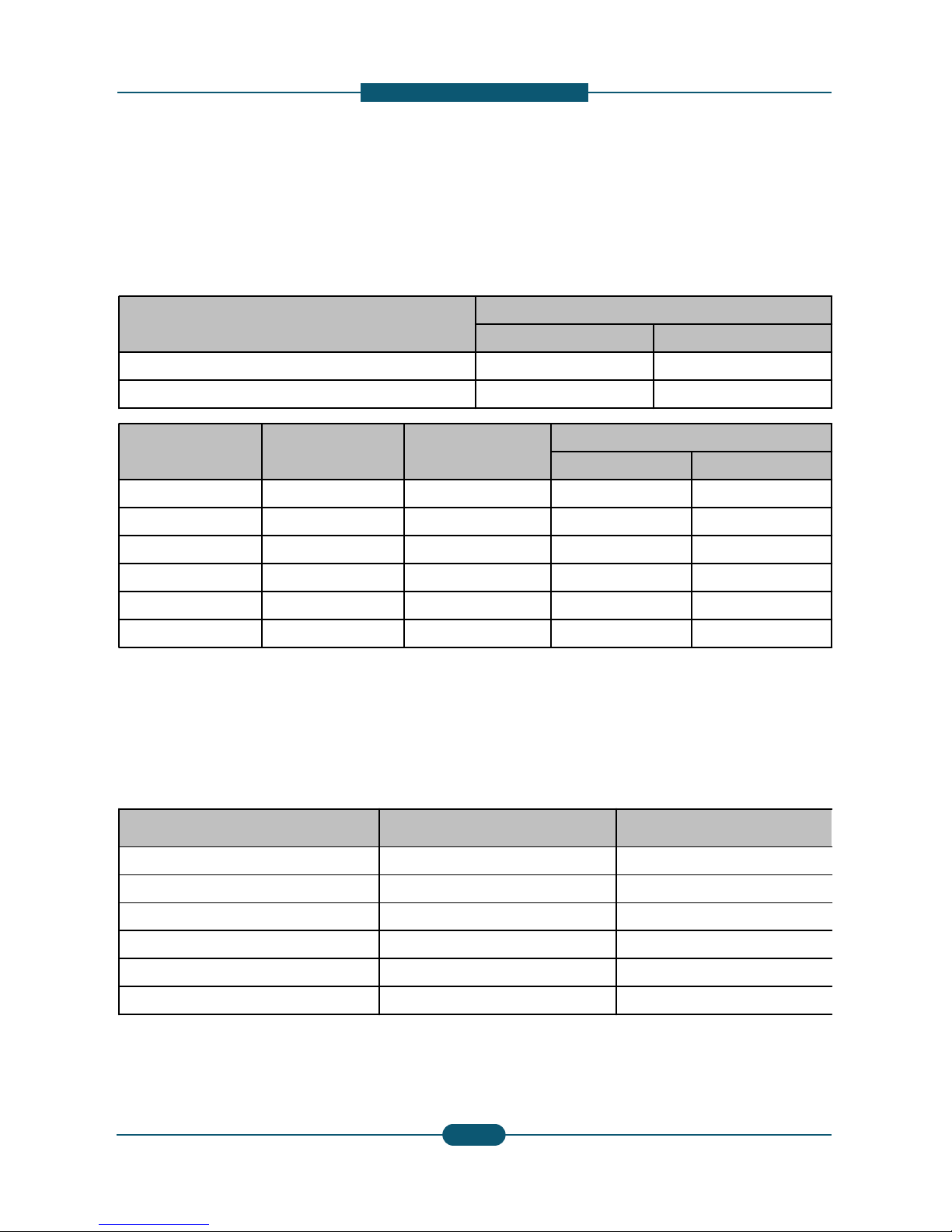

1.4.3 Media Performance

The Finisher must be able to control all following types of media.

XXOXOOTab*

XXXXOOLabels (120~150 g/㎡)

XXXXOOTransparency (138~146 g/㎡)

XXXXOXEnvelope(75~90 g/㎡)

XOXOOOThick Glossy (170~216 g/㎡)

XOOOOOThin Glossy (106~169 g/㎡)

XXXOOOThick Cardstock (170~216 g/㎡)

XXOOOOThin Cardstock (105~163 g/㎡)

XXXOOOPre-Punched

OOOOOOLetterHead

OOOOOOArchive

OOOOOOBond

OOOOOORecycled (60~90 g/㎡)

OOOOOOPre-Printed (75~90 g/㎡)

OOOOOOColored (75~90 g/㎡)

OOOOOOCotton (75~90 g/㎡)

OOOOOOThin (60~70 g/㎡)

XXXXOXExtra Heavy weight 2 (217~253 g/㎡)

XOOOOOExtra Heavy weight 1 (176~216 g/㎡)

XOOOOOHeavy weight 2 (121~175 g/㎡)

OOOOOOHeavy weight 1 (106~120 g/㎡)

OOOOOOThick (91~105 g/㎡)

OOOOOOPlain(60~90 g/㎡)

ContentCover

BM

HPStaple

Top

Tray

Main

Tray

Function

Paper Type

*The tab must be positioned on the lead edge as it enters the finisher.

1. Specification

1-9

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

1.5 Tray Capacity Specifications

1.5.1 Main Tray

The Main Tray must accommodate following capacities. Slight diminishing of the capacity due to buildup

staples can be tolerated, however jamming caused by the buildup blocking the path of ejecting papers must

be prevented.

2,100700Over 70,000 mm

2

3,0001,000Under 70,000 mm

2

CLX-FIN40LCLX-FIN40S

Stack Capacity

Paper Dimension (80gsm)

2,100 700 124,740 297X420A3

2,100 700

120,528 279X432Ledger

2,100 700

76,896 216X356Legal

3,000 1,000

62,370 297X210A4

3,000 1,000

60,264 216X279Letter

3,000 1,000

31,080 210X148A5

CLX-FIN40LCLX-FIN40S

Stack capacity

DimensionSizePaper

¾ The Main Tray may suffer slight degradation of stack quality when it accommodates various types of

papers. (ex. when trying to stack a long paper while the main tray is already stacked with short papers)

1.5.2 Top Tray

The Top Tray must accommodate up to 250 sheets (80gsm Plain Paper) of various types that fits the paper

path. However, the capacity may lessen slightly depending on the condition of the paper received from IOT.

25 sheetsEnvelope

~ 90 sheets200gsm

100 sheets~200 gsm

120 sheets~160 gsm

160 sheets~120 gsm

250 sheets~80 gsm

RemarkStack CapacityPaper Weight

1.5.3 Booklet Maker Tray

The Booklet Maker Tray must be able to accommodate 20 sets of staple folded sheets (Maximum size of a

set = one 216gsm cover page + 80gsm 14 sheets). However, the capacity may lessen slightly depending

on the condition of the paper received from IOT.

1. Specification

1-10

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

1.6 Mode Feature

¾ Main Stack Mode : Must be able to receive faced-down images from the IOT and stack as much as

3,000 sheets (A4/LT 80gsm) onto the main stacker tray. The Stacker tray must be able to

accommodate various types and sizes of sheets.

¾ Offset Mode : Shifts the space between sets to 30mm in order to distinguish sets that have been

post-processed during Main Stack Mode.

¾ Top Stack Mode : The finisher must be able to assort and discharge papers to the top tray, and

stack as much as 250 sheets(80gsm). Sheets that have been collected to the Top tray cannot access

post-processing functions such as offset, stapling, punching, etc.

¾ Staple Mode : When the user selects this mode, it staples designated corner of the papers that have

to compiled (more than 2 pages).

. Corner staple(Front, Rear): Clinches at 45 degrees from the paper path.

. Dual staple: Clinches at 90 degree from the paper path designated according to the type of paper

¾ In case of simplex copy, the clincher leg must face the back side of the image. The stapler must be

able to clinch as much as 50 sheets (90gsm).

¾ Hole Punch : The punch module should accommodate NA2/3, EU2/4, or Scandinavia 4 hole

module(TBD) depending on the target market. There must be a waste hopper that collects wastes

produced during hole punching. The waste hopper must be big enough to allow at least 5,000

punches before it becomes full.

¾ Booklet Maker Mode : A Dual Stapling must be possible at V-folding line of the paper (that can

cover 15 sheets, or a 216gsm cover + fourteen 80gsm sheets, etc) that goes through the Booklet

maker. The folding is positioned at the centerline of the paper path.

1. Specification

1-11

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

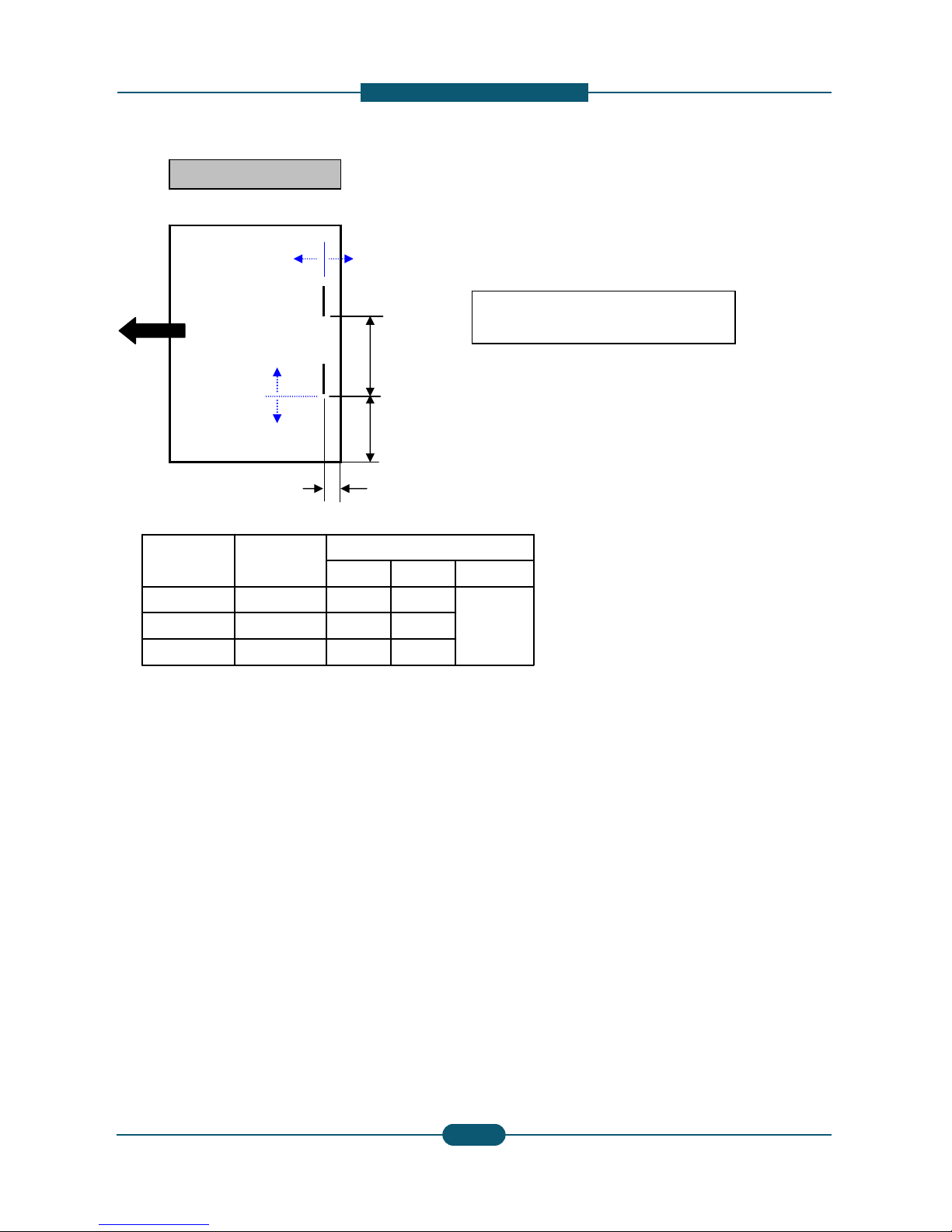

1.7 Staple Set Specifications

1.7.1 Staple Clinching Position & Accuracy

• Staple Clinching Position changes according to papers types and path directions.

• In Staple mode, papers are passed to the Main Tray. Minimum 2 sheets /set Job is needed in order

to select Staple mode.

45° Rear Corner

B±2 mm

Direction

of Feed

-

+

B±2 mm

Direction

of Feed

(+)

(-)

(+)

(-)

D±2 mm

A±2 mm

Direction

of Feed

45° Front Corner

(+)

(-)

1.0mm1.0mm6.0mmB

Service

Mode

5.0mm5.0mm6.0mmA

Remark(-)(+)

Adjustable amount

NominalDimension

NANA6.0mmD

Service

Mode

5.0mm5.0mm6.0mmA

Remark(-)(+)

Adjustable amount

NominalDimension

Flat Front Corner

D±2 mm

Direction

of Feed

(+)

(-)

Flat Rear Corner

D±2 mm

A±2 mm

Direction

of Feed

(+)

(-)

NANA

6.0mmD

Service

Mode

5.0mm5.0mm6.0mmA

Remark(-)(+)

Adjustable amount

NominalDimension

NANA6.0mmD

Service

Mode

5.0mm5.0mm6.0mmA

Remark(-)(+)

Adjustable amount

NominalDimension

1. Specification

1-12

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

A = (Paper size_STS/2)-79.5

Depend on paper size

+

+

Dual

D±2 mm

B±2 mm

A±2 mm

Direction

of Feed

(+) (-)

(+)

(-)

NANA148mmD

1.0mm1.0mm6.0mmB

Service

Mode

5mm5.0mmSee blockA

Remark(-)(+)

Adjustable amount

NominalDimension

1. Specification

1-13

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

1.7.2 Staple Leg quality

The following is Stapler leg quality.

0.8 mm Max

0.9mm Max Flatness0.4mm M 0.6mm Max Burr

1.7.3 Staple Capability

• The Finisher stapler can clinch as much as 50 sheets (90gsm each) and Booklet stapler can clinch as

much as 15 sheets (216gsm 1 cover + 80gsm 14 contents)

• Table of Staple Capacity for each weight-type of papers.

8~120 gsm

12~90 gsm

14~80 gsm

Covers Mode

(1 cover sheet of 216gsm)

10~120 gsm

15~90 gsm

15~80 gsm

No Covers Mode

Booklet

30~120 gsm

40~90 gsm

46~80 gsm

49~75 gsm

50~60 gsm

Covers Mode

(Two cover sheets of 160 gsm)

20~200 gsm

25~160 gsm

33~120 gsm

50~80 gsm

No Covers Mode

Finisher

Number of SheetsPaper WeightModeStaple

The controller controls the maximum number of papers per clinch; however, the user must be aware of the

thickness and the size of the papers that would be clinched. When the user puts in more than the number of

papers that can clinched together, the clinching will not take place. Instead, the user will be required to

select ‘sub-set mode’ or ‘divide clinching’ on the GUI.

1. Specification

1-14

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

1.8 Hole Punch Specifications

EU 2/4 Hole

Direction

of Feed

a1

Center Line

c

c

c

Ф

b

a2

Z

(+)

(-)

Available Punch Hole

STS Position adjustment

(-)

Available Punch Hole

DOF Position adjustment

X

(+)

NA 3 Hole

Direction

of Feed

Center Line

d

d

Ф

a1

d’

X

a2

Z

(+)

(-)

Available Punch Hole

STS Position adjustment

(-)

Available Punch Hole

DOF Position adjustment

X

(+)

±5.0mm(0.1mm/step)Z±5.0mm(0.1mm/step)Z

±5.0mm(0.1mm/step)X±5.0mm(0.1mm/step)X

8± 0.5 mm8± 0.5 mm

Ф

6.5 ±0.5

mm

6.5 ±0.5

mm

Ф

108±0.5

mm

108±0.5

mm

d 80 ±0.5 mm80 ±0.5 mmc

β±3 mmβ±2 mmd’α±3 mmα±2 mmb

10.5± 3 mm

10.5 ± 2

mm

a1, a2

10. 5 ±3

mm

10. 5 ± 2

mm

a1, a2

99.97%95%99.97%95%

3 Position2 & 4 Position

α = (Paper Size_STS – 3C) ÷ 2 β = (Paper Size_STS - 2d) ÷ 2

1. Specification

1-15

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

Scandinavia 4 Hole

Direction

of Feed

Center Line

c

d

d

a1

Ф

b

a2

NA 2 Hole

Direction

of Feed

a1

c

Ф

Center Line

b

a2

Z

(+)

(-)

Available Punch Hole

STS Position adjustment

(-)

Available Punch Hole

DOF Position adjustment

X

(+)

Z

(+)

(-)

Available Punch Hole

STS Position adjustment

(-)

Available Punch Hole

DOF Position adjustment

X

(+)

±5.0mm(0.1mm/step)Z

±5.0mm(0.1mm/step)Z±5.0mm(0.1mm/step)X

±5.0mm(0.1mm/step)X6 ± 0.5 mm6 ± 0.5 mm

Ф

8 ± 0.5 mm8 ± 0.5 mm

Ф

21 ± 0.5 mm21 ± 0.5 mmd

70 ± 0.5 mm70 ± 0.5 mmc70 ± 0.5 mm70 ± 0.5 mmc

Ω±3 mmΩ±2 mmbγ± 3 mmγ±2 mmb

10.5 ± 3 mm10.5 ± 2 mma1, a210.5 ± 3 mm10.5 ± 2 mma1, a2

99.97%95%99.97%95%

2 Position (NA)4 Position (Scandinavia)

γ = (Paper Size_STS - c - 2d) ÷ 2 Ω = (Paper Size_STS - c) ÷ 2

* The “X” dimension can be adjust under both service mode and user mode, but the “Z” dimension can be

adjust only service mode.

1. Specification

1-16

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

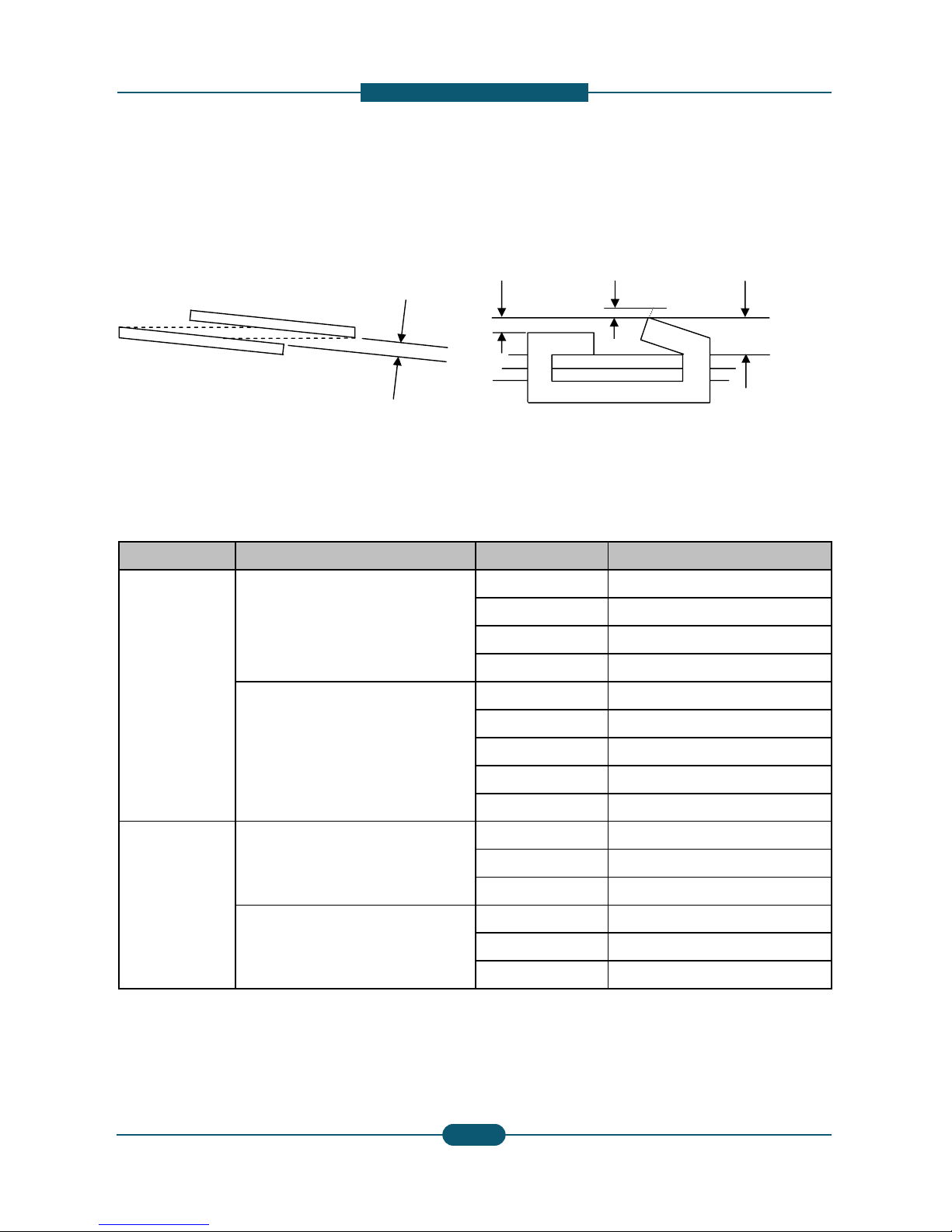

1.9 Booklet Maker Specifications

1.9.1 Booklet Staple & Fold Position and Within Set Registration

A

B

120±2mm

Lead

Edge

Center line

Folding Line

Y

X

0 ± 1.5

mm

(Available Folding Line Position Adjustment)

C

(+)

(-)

87.5 ± 2mm228.5 ± 1.5mm304.8 x 457.212 x 18

83.5 ± 2mm210 ± 1.5 mm297 x 420A3

74.7 ± 2mm216.0 ± 1.5mm279 x 432Ledger

43 ± 2mm165.1 ± 1.5 mm216 x 3308.5 x 13

43 ± 2mm178.0 ± 1.5mm216 x 3568.5 x 14

43 ± 2mm139.5 ± 1.5mm216 x 279LT

40 ± 2mm148.5 ± 1.5 mm210 x 297A4

‘B’ Dimension‘A’ DimensionPaper Size

4.0mm2.0mmY

4.0mm2.0mmX

99.97%95%

A4, LT, 8.5x14, 8.5x13, Ledger, A3, 12x18

± 5.0mm (0.1mm/step)426.0mm ≤ L

± 5.0mm (0.1mm/step)358.5mm ≤ L < 426.0mm

± 5.0mm (0.1mm/step)288mm ≤ L < 358.5mm

± 5.0mm (0.1mm/step)L < 288.0mm

‘C’ DimensionPaper Size of DOF (L=Sheet Length)

* The “C” dimension can be adjust under both service mode and user mode. And the staple position follow

that value of “C”.

1. Specification

1-17

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

1.9.2 Booklet Folding Quality

Folding Line

Z1 Z2

X

Y = Z1 – Z2

3.6mm2.1mm3.0mm1.5mm

Y (as measured on the inside of

the booklet) AZAP

3.1mm1.4mm2.5mm1.0mm

Y (as measured on the inside

sheet of the booklet) B zone,

80gsm (20lbs) paper

25mm22mm35mm30mm

X (measured at any point along

the book) 80gsm (20lbs) or

equivalent papers, ambient

conditions) AZAP

99.97%

Samples

95%

Samples

99.97%

Samples

95%

Samples

Input paper A3 / Ledger / 12x18Input paper A4 / LT / 8.5x13 /

8.5x14

1.9.3 Booklet Staple Leg Quality

A

B C

D

z B < 1.2 mm

z A < B

z A and C < 0.4 mm

z D < 0.4 mm

2. System Configuration

2-1

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

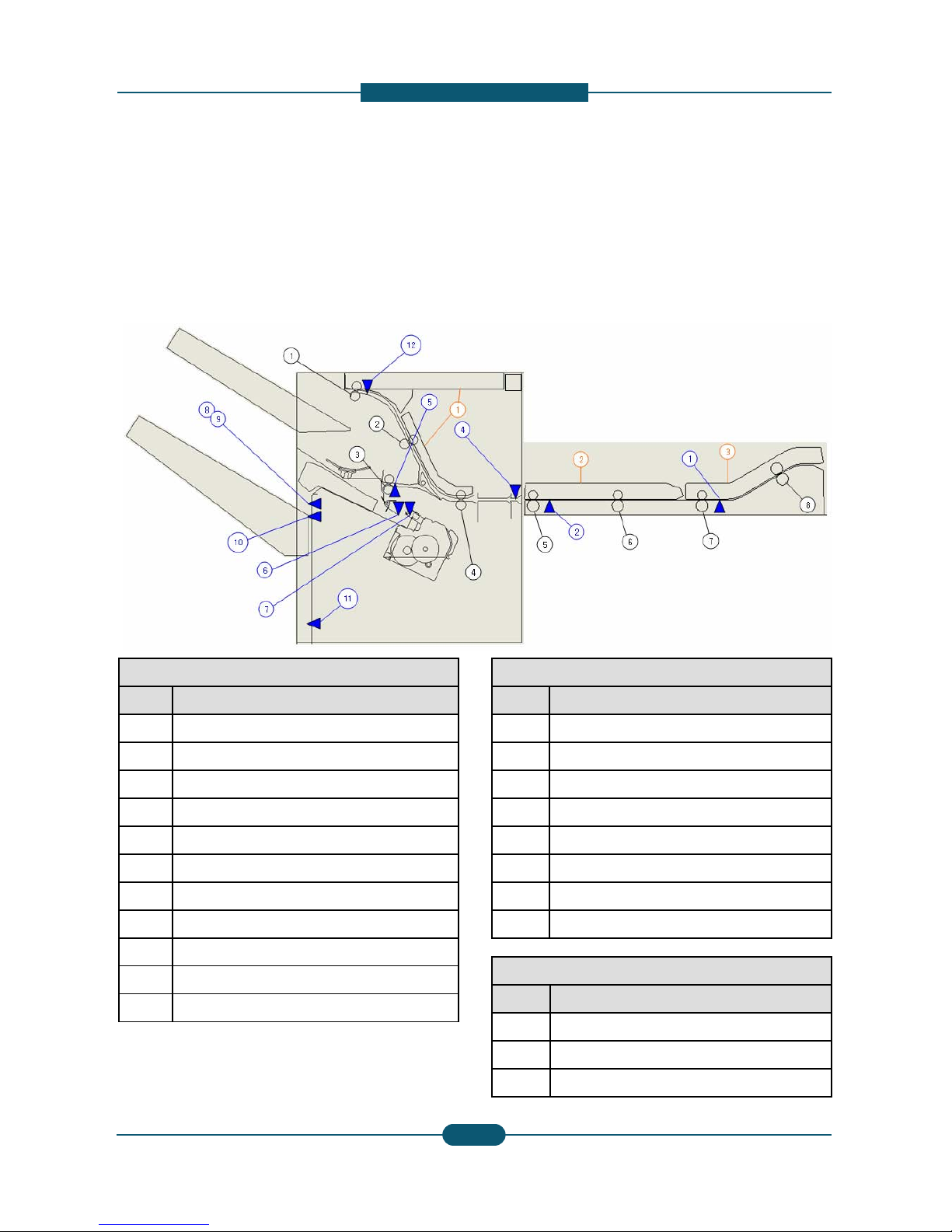

2. System Configuration

a) CLX-FIN40S

2.1 Front sectional view

Sensor

No. Name

1 Trans Bridge Input Sensor

2 Trans Bridge Exit Sensor

4 Finisher Input Sensor

5 Finisher Compile Exit Sensor

6 Paper Present Sensor

7 Paper Height Sensor

8 Stacker Upper Limit Emitting Sensor

9 Stacker Upper Limit Receiving Sensor

10 Stack Level Sensor

11 Stacker Bin Full Sensor

12 Finisher Top Exit Sensor

Jam Removal Guide

No. Name

1 Top door guide

2 TB left cover

3 TB right cover

Feed Roller

No. Name

1 Top exit roller

2 Top middle roller

3 Finisher Compile Exit roller

4 Entrance roller

5 TB exit roller

6 TB middle-2 roller

7 TB middle-1 roller

8 TB entrance roller

2. System Configuration

2-2

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

12

98

10

1

5

6

7

4

3

2 1

11

13

14

16

15

2

3

4

5 6

7 8

9

10

11

12

1

2 3

4

5

6

7

8

9

10

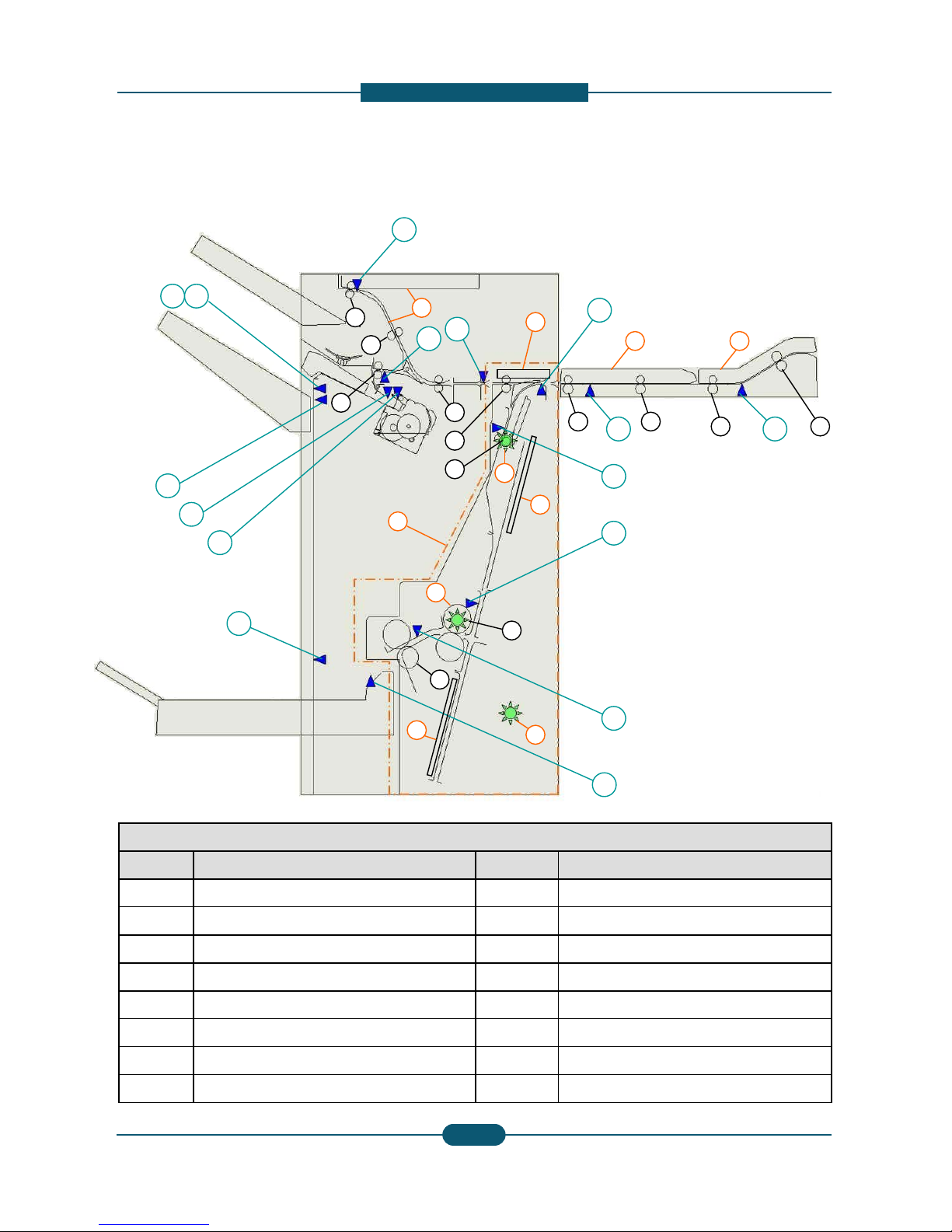

b) CLX-FIN40L

Stacker Upper Limit Emitting Sensor

Paper Height Sensor

Paper Present Sensor

Finisher Compile Exit Sensor

Finisher Input Sensor

Booklet Input Sensor

Trans Bridge Exit Sensor

Trans Bridge Input Sensor

Name

8

7

6

5

4

3

2

1

No.

BM Set Detect Sensor16

Booklet Folding Exit Sensor15

Booklet Compile Present Sensor14

Booklet Compile Exit Sensor13

Finisher Top Exit Sensor12

Stacker Bin Full Sensor11

Stack Level Sensor10

Stacker Upper Limit Receiving Sensor9

NameNo.

Sensor

2. System Configuration

2-3

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

BM Conveyor Exit Roller12

BM Folding Roller11

BM Compile Exit Roller10

Finisher Trans Roller9

TB Entrance Roller8

TB Middle-1 Roller7

TB Middle-2 Roller6

TB Exit Roller5

Entrance Roller4

Finisher Compile Exit Roller3

Top Middle Roller2

Top Exit Roller1

NameNo.

Feed Roller

BM Knife Knob10

BM Folding Roller Knob9

BM Roller Knob8

BM Stopper Cover7

BM Compile Cover6

Finisher Trans Guide5

Booklet Module4

TB Right Cover3

TB Left Cover2

Top Door Guide1

NameNo.

Jam Removal Guide

2. System Configuration

2-4

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

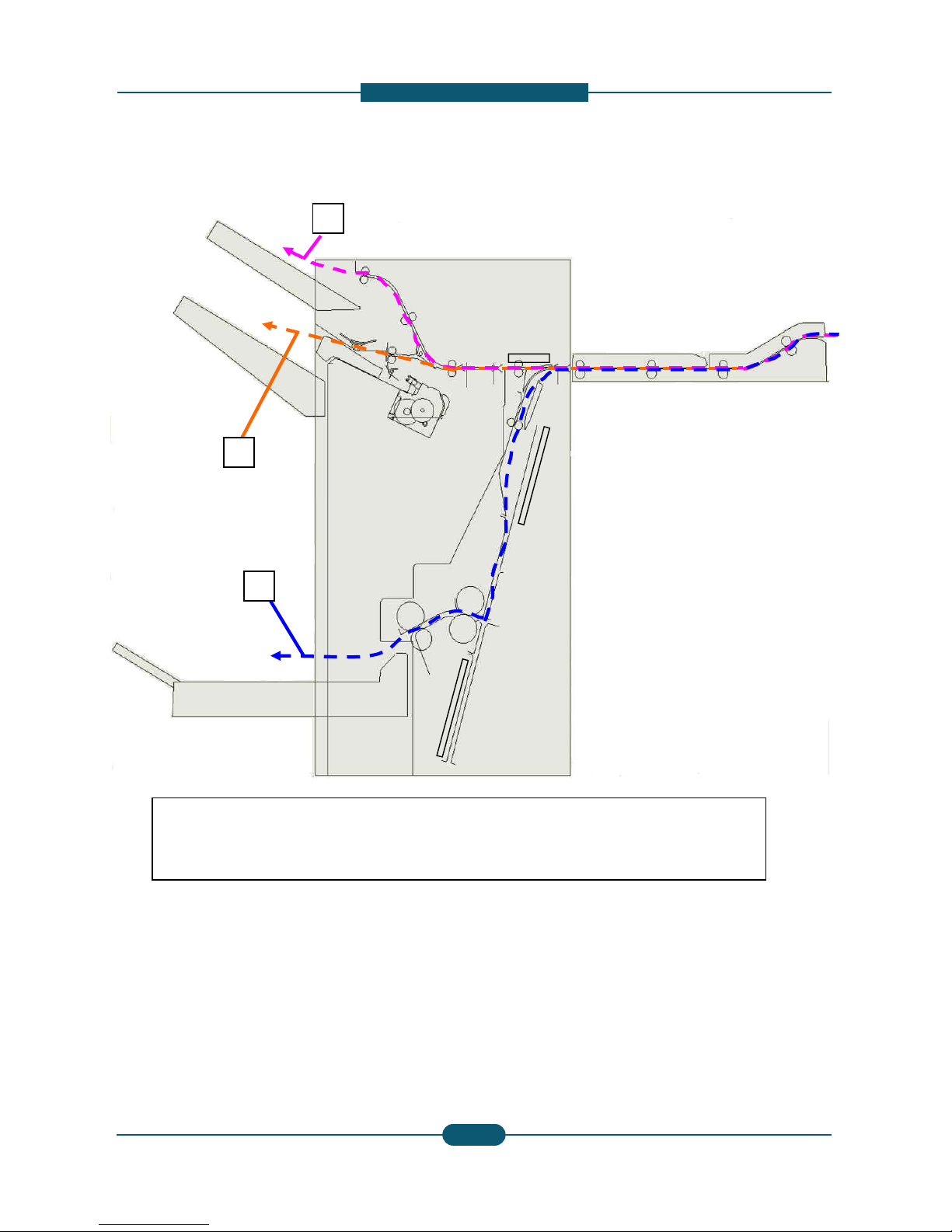

2.2 Paper path

a) CLX-FIN40S

1. Finisher Main Tray - Staple & Punch (Optional)

2. Finisher Top Tray - Punch (Optional)

1

2

2. System Configuration

2-5

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

1. Finisher Main Tray - Staple & Punch (Optional)

2. Finisher Top Tray - Punch (Optional)

3. Booklet Conveyor Tray – Folding & Staple

b) CLX-FIN40L

2

1

3

2. System Configuration

2-6

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

2.3 Layout of electrical parts

a) CLX-FIN40S

M2

M1

M3

M5

M4

M6

M7 M8

M9

M10

M11

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

S24

S26

P1

P2

P3

P4

S25

S23

FunctionDescription

Part Code

Symbol

Diverter Home SensorAS-SENSOR:KIT5011C

JC81-07420A

S5

Feed Entrance SensorPHOTO SENSOR:PS119ED1JC81-03480AS4

Feed Top Exit SensorAS-SENSOR:KIT5011C

JC81-07420A

S3

Feed Compile Exit SensorAS-SENSOR:KIT5011C

JC81-07420A

S2

Offline Stapler SensorAS-SENSOR:KIT5011C

JC81-07420A

S1

2. System Configuration

2-7

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

Front Cover I/L SwitchAS-MICRO SWITCH:VP333A-0D:LEVERJC81-07404AS26

Top Cover I/L SwitchAS-MICRO SWITCH:VP333A-0D:LEVERJC81-07404AS25

Stacker Upper Limit SwitchMICRO SWITCH:VP333A-0DJC81-03469AS24

SCU Home SensorAS-SENSOR:KIT5011C

JC81-07420A

S23

Stacker Encoder SensorAS-SENSOR:KIT5011C

JC81-07420A

S22

Stacker Bottom Limit SensorAS-SENSOR:KIT5011C

JC81-07420A

S21

Stacker Upper Limit SensorAS-SENSOR:LIS9008HJC81-07403AS20

Stacker Upper Limit SensorAS-SENSOR:KIT5011C

JC81-07420A

S19

Stacker Upper Limit SensorAS-SENSOR:KIS9009HJC81-07396AS18

Stapler Home SensorAS-SENSOR:KIT5011C

JC81-07420A

S17

Stapler Sub SensorAS-SENSOR:KIT5011C

JC81-07420A

S16

Staple Safety SensorAS-SENSOR:KIT5011C

JC81-07420A

S15

Staple Clinching Home SensorAS-SENSOR:KIT5011C

JC81-07420A

S14

Extension Tray Home SensorAS-SENSOR:KIT5011C

JC81-07420A

S13

Ejector Encoder SensorAS-SENSOR:KIT5011C

JC81-07420A

S12

Symbol

Part Code

Description Function

S6

JC81-07420A

AS-SENSOR:KIT5011C Rear Tamper Home Sensor

S7

JC81-07420A

AS-SENSOR:KIT5011C Front Tamper Home Sensor

S8

JC81-07420A

AS-SENSOR:KIT5011C Main Paddle Home Sensor

S9

JC81-07420A

AS-SENSOR:KIT5011C Compile Paper Sensor

S10

JC81-07420A

AS-SENSOR:KIT5011C Eject Limit Sensor

S11

JC81-07420A

AS-SENSOR:KIT5011C Ejector Home Sensor

P1 JC81-07393A AS-PCB MAIN Finisher Main PCB

P2 JC81-07406A AS-PCB OP Offline Staple OP PCB

P3 JC81-07407A AS-PCB STAPLER RELAY Stapler Relay Moving PCB

P4 CF10 8275B

PCB ASSY:STAPLER RELAY FIXED:CFIN

Stapler Relay PCB

M1

JC81-03479A

ASSY:HB MOTOR:S2M19T Feed Entrance Motor

M2

JC81-03479A

ASSY:HB MOTOR:S2M19T Feed Exit Motor

M3 JC81-03486A ASSY:PM MOTOR:S2M12T Front Tamper Motor

M4 JC81-03486A ASSY:PM MOTOR:S2M12T Rear Tamper Motor

M5 JC81-03478A ASSY:PM MOTOR:S2M20T Main Paddle Motor

M6 JC81-07388A AS-MOTOR DC EJECTOR Ejector Motor

M7 JC81-07387A AS-MOTOR PM:Z18:HELICAL Extension Tray Motor

M8 JC81-07389A AS-MOTOR PM:STAPLER Stapler Sub Moving Motor

M9 JC81-07389A AS-MOTOR PM:STAPLER Stapler Main Moving Motor

M10 JC81-03473A ASSY:PM MOTOR:Z18 SCU Motor

M11 CF10 6802A ASSY:3657 DC MOTOR:S2M14T Stacker Moving Motor

2. System Configuration

2-8

SAMSUNG ELECTRONICS

Service Manual

CLX-FIN40S/CLX-FIN40L

S4

M1

M2

M3

M4

M5

M6

M7

M8

M9

M10

M11

S1

M21

S2

S3

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

S23

SW1

SW2

SW3

S35

P1

P2

P3

P4

b) CLX-FIN40L

Booklet Module

See the next page.

Loading...

Loading...