SAMSUNG CL21M6WKX-RCL, CL21M6WKX-XAX, CT29M6WKX-MAM Service Manual

COLOR TELEVISION RECEIVER

Chassis : K57A(N)

Model : CL21M6WKX/RCL

CL21M6WKX/XAX

CT29M6WKX/MAM

COLOR TELEVISION RECEIVER CONTENTS

Precautions

Specifications and IC Data

Disassembly and Reassembly

Alignment and Adjustment

Troubleshooting

Exploded View and Parts List

Electrical Parts List

Block Diagram

Wiring Diagram

Schematic Diagrams

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

ELECTRONICS

© Samsung Electronics Co., Ltd. OCT. 2002

Printed in Korea

AA82- 00170A

1. Precautions

1-1 Safety Precautions

1. Be sure that all of the built-in protective

devices are replaced. Restore any missing

protective shields.

2. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including: nonmetallic control knobs

and compartment covers.

3. Make sure that there are no cabinet openings

through which people—particularly

children—might insert fingers and contact

dangerous voltages. Such openings include

the spacing between the picture tube and the

cabinet mask, excessively wide cabinet

ventilation slots, and improperly fitted back

covers.

If the measured resistance is less than 1.0

megohm or greater than 5.2 megohms, an

abnormality exists that must be corrected

before the unit is returned to the customer.

4. Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANIS C101.1, Leakage Current for

Appliances), and Underwriters Laboratories

(UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug

the AC line cord directly into the power

outlet. With the unit’s AC switch first in the

ON position and then OFF, measure the

current between a known earth ground (metal

water pipe, conduit, etc.) and all exposed

metal parts, including: antennas, handle

brackets, metal cabinets, screwheads and

control shafts. The current measured should

not exceed 0.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat the

test.

Fig. 1-1 AC Leakage Test

6. Antenna Cold Check:

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across

the two AC prongs. Connect one lead of the

ohmmeter to an AC prong. Connect the other

lead to the coaxial connector.

7. X-ray Limits:

The picture tube is especially designed to prohibit X-ray emissions. To ensure continued

X-ray protection, replace the picture tube only

with one that is the same type as the original.

Carefully reinstall the picture tube shields and

mounting hardware; these also provide X-ray

protection.

8. High Voltage Limits:

High voltage must be measured each time servicing is done on the B+, horizontal deflection

or high voltage circuits. Correct operation of

the X-ray protection circuits must be

reconfirmed whenever they are serviced.

(X-ray protection circuits also may be called

“horizontal disable” or “hold-down”.)

Heed the high voltage limits. These include

the X–ray Protection Specifications Label, and

the Product Safety and X-ray Warning Note on

the service data schematic.

Precautions

1-1

LEAKAGE

CURRENT

TESTER

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

(READING SHOULD

NOT BE ABOVE

0.5mA)

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential

hazards such as electrical shock and X-rays.

1-1 Safety Precautions (Continued)

9. High voltage is maintained within specified

limits by close-tolerance, safety-related

components and adjustments. If the high

voltage exceeds the specified limits, check

each of the special components.

10. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of this unit. Example: Do not

add auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also,

any design changes or additions will void the

manufacturer’s warranty.

11. Hot Chassis Warning:

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only

if the AC power plug is inserted so that the

chassis is connected to the ground side of the

AC source.

To confirm that the AC power plug is inserted

correctly, do the following: Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the

reading is greater than 1.0V, remove the AC

power plug, reverse its polarity and reinsert.

Re-measure the voltage between the chassis

and ground.

12. Some TV chassis are designed to operate with

85 volts AC between chassis and ground,

regardless of the AC plug polarity. These units

can be safely serviced only if an isolation

transformer inserted between the receiver and

the power source.

13. Some TV chassis have a secondary ground

system in addition to the main chassis ground.

This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulating material that must not be defeated

or altered.

14. Components, parts and wiring that appear to

have overheated or that are otherwise

damaged should be replaced with parts that

meet the original specifications. Always

determine the cause of damage or overheating, and correct any potential hazards.

15. Observe the original lead dress, especially

near the following areas: Antenna wiring,

sharp edges, and especially the AC and high

voltage power supplies. Always inspect for

pinched, out-of-place, or frayed wiring. Do

not change the spacing between components

and the printed circuit board. Check the AC

power cord for damage. Make sure that leads

and components do not touch thermally hot

parts.

16. Picture Tube Implosion Warning:

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure

that the replacement picture tube is the same

as the original.

17. Do not remove, install or handle the picture

tube without first putting on shatterproof

goggles equipped with side shields. Never

handle the picture tube by its neck. Some

“in-line” picture tubes are equipped with a

permanently attached deflection yoke; do not

try to remove such “permanently attached”

yokes from the picture tube.

18. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

give might be lost if the replacement component differs from the original—even if the

replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( ) or ( ).

Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications.

A replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

Precautions

1-2 Samsung Electronics

1-2 Servicing Precautions

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit’s AC power cord from

the AC power source before attempting to: (a)

Remove or reinstall any component or

assembly, (b) Disconnect an electrical plug or

connector, (c) Connect a test component in

parallel with an electrolytic capacitor.

3. Some components are raised above the printed

circuit board for safety. An insulation tube or

tape is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the portion around

the serviced part has not been damaged.

5. Check the insulation between the blades of the

AC plug and accessible conductive parts

(examples: metal panels, input terminals and

earphone jacks).

6. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the

power switch ON. Connect an insulation

resistance meter (500V) to the blades of the AC

plug.

The insulation resistance between each blade

of the AC plug and accessible conductive parts

(see above) should be greater than 1 megohm.

7. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of

its assemblies) unless all solid-state heat sinks

are correctly installed.

8. Always connect a test instrument’s ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument’s ground lead last.

Precautions

1-3

Warning1: First read the “Safety Precautions” section of this manual. If some unforeseen circumstance creates a conflict between

the servicing and safety precautions, always follow the safety precautions.

Warning2: An electrolytic capacitor installed with the wrong polarity might explode.

1. Some semiconductor (“solid state”) devices

are easily damaged by static electricity. Such

components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component damage

caused by static electricity.

2. Immediately before handling any semicon

ductor components or assemblies, drain the

electrostatic charge from your body by

touching a known earth ground. Alternatively,

wear a discharging wrist-strap device. (Be

sure to remove it prior to applying power—

this is an electric shock precaution.)

3. After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4. Do not use freon-propelled chemicals. These

can generate electrical charges that damage

ESDs.

5. Use only a grounded-tip soldering iron when

soldering or unsoldering ESDs.

6. Use only an anti-static solder removal device.

Many solder removal devices are not rated as

“anti-static”; these can accumulate sufficient

electrical charge to damage ESDs.

7. Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive materials.

8. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

9. Minimize body motions when handling

unpackaged replacement ESDs. Motions such

as brushing clothes together, or lifting a foot

from a carpeted floor can generate enough

static electricity to damage an ESD.

Precautions

1-4 Samsung Electronics

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

CAUTION

These servicing instructions are for use by

qualified service personnel only.

To reduce the risk of electric shock do not

perform any servicing other than that contained

in the operating instructions unless you are

qualified to do so.

Samsung Electronics 2-1

Specifications and IC Data

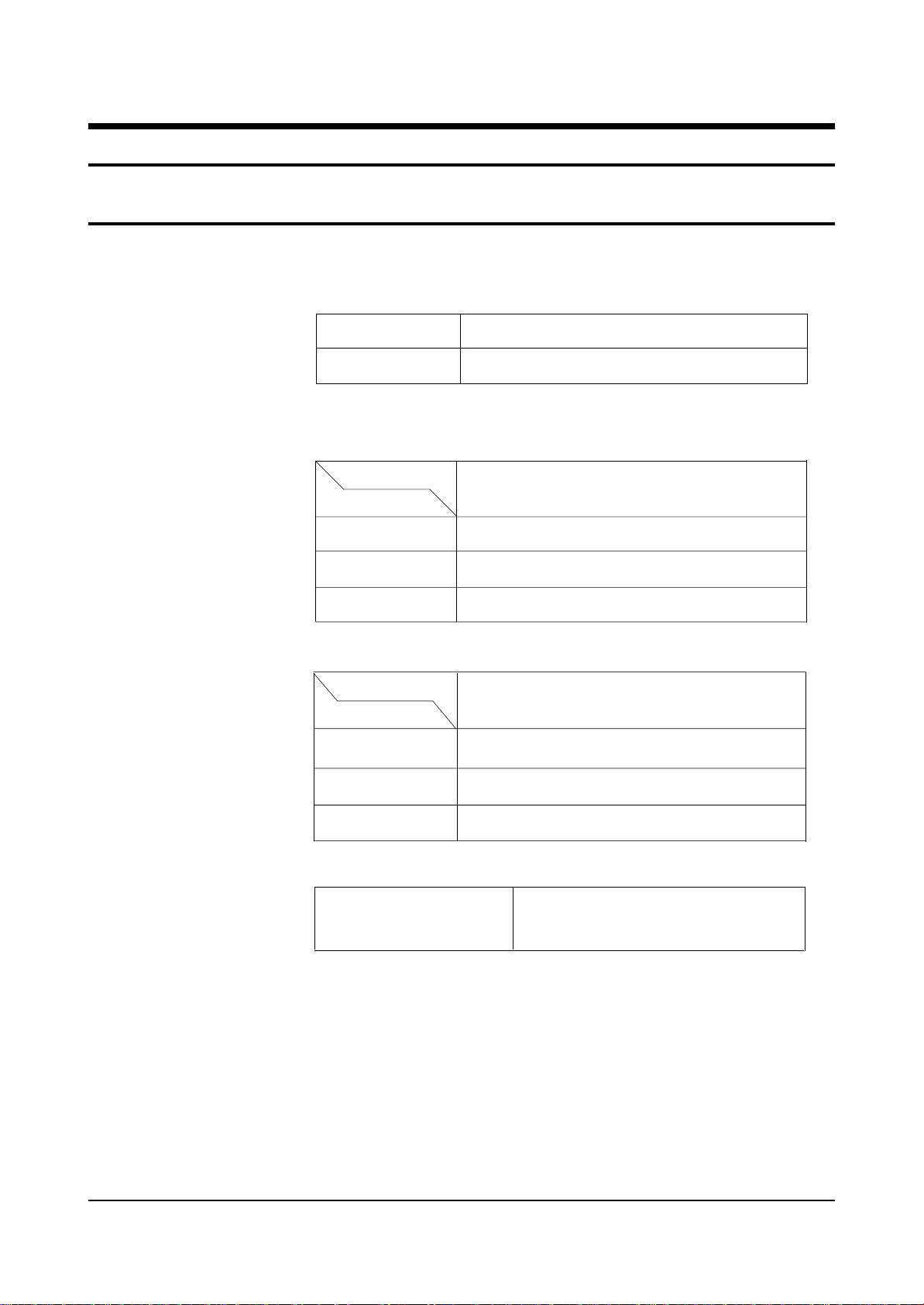

2. Specifications and IC Data

2-1 Specifications

Television System:

Channels:

Intermediate Frequencies (MHz) :

MODEL

TXM2792FX

System

Band

VHF

UHF

CABLE

SYSTEM

IF Carrier Frequency

Picture IF Carrier

SYSTEM

NTSC ONLY

NTSC

2 - 13

14 - 69

1 - 125

NTSC

45.75

Picture Tube:

Power Requirements:

Antenna Input Impedance:

Speaker Impedance

Sound IF Carrier

Color Sub Carrier

29 Inch

AC 120V, 60Hz

VHF, UHF : Telescopic dipole antenna (75 ohm unbalanced type )

8 ohm, 15W+15W (Dual Type)

A68QCP891X100

29Inch Flat, +380MG

41.25

42.18

2-2 Samsung Electronics

2-2 IC Line Up

Specifications and IC Data

Table 2-1 IC Line-Up

Loc. No

IC201S

IC301

IC501

IC602

IC801S

IC802 KA7632

IC202

PC801S

PC802S

IC101

IC601

ICP01

Specification

SPM-464A

LA7845

TDA6108QJF

TDA7297

KA5Q1265R

M24C08

TCET1108 / LTV817B

LA7510

MSP-3425G-B8

VIPER12AD1P

Description

TDA9592 PS/NI, SPM-464A,64P

VERTICAL OUTPUT

RGB DRIVE AMP

SOUND-AMP (15W x 2CH)

POWER IC (STR)

CUSTOM REGULATOR (5V, 8V, 3.3V)

EEPROM

PHOTO COUPLER

IF DETECTOR-IC

Sound Processor

PWM CONTROCER-IC

Remark

Philips

Sanyo

Philips

Philips

FIAIR CHILD

FIAIR CHILD

TEMIC

Micronas

ICW01

ICG01

NJM2235D

4558

VIDEO Swiching-IC

OP AMP-IC

2-3 Semiconductor Base Diagrams

Specifications and IC Data

Samsung Electronics 2-3

Fig. 2-1 Semiconductor Base Diagrams

ELECTROLYTICCONDENSER

TRANSISTOR

KSD5703

KSA614

DIODE

TRANSISTOR

KSC815-Y

KSA539-Y

IC

SPM464A(Pin 64)

MSP3425G(Pin 52)

LM393(Pin 8)

VIPER12ADIP(Pin 8)

M24C08(Pin 8)

4558(Pin 8)

NJM2235D(Pin 8)

SAW-FILTER

M3953M

1

1

1

M9370M

B

C

E

IC

LA7845(Pin 7)

TDA6108Q(Pin 9)

KA7632(Pin 10)

E B C

TRANSISTOR

KSC2331-Y

E C B

2-4

MEMO

Disassembly and reassembly

Samsung Electronics 3-1

3. Disassembly and Reassembly

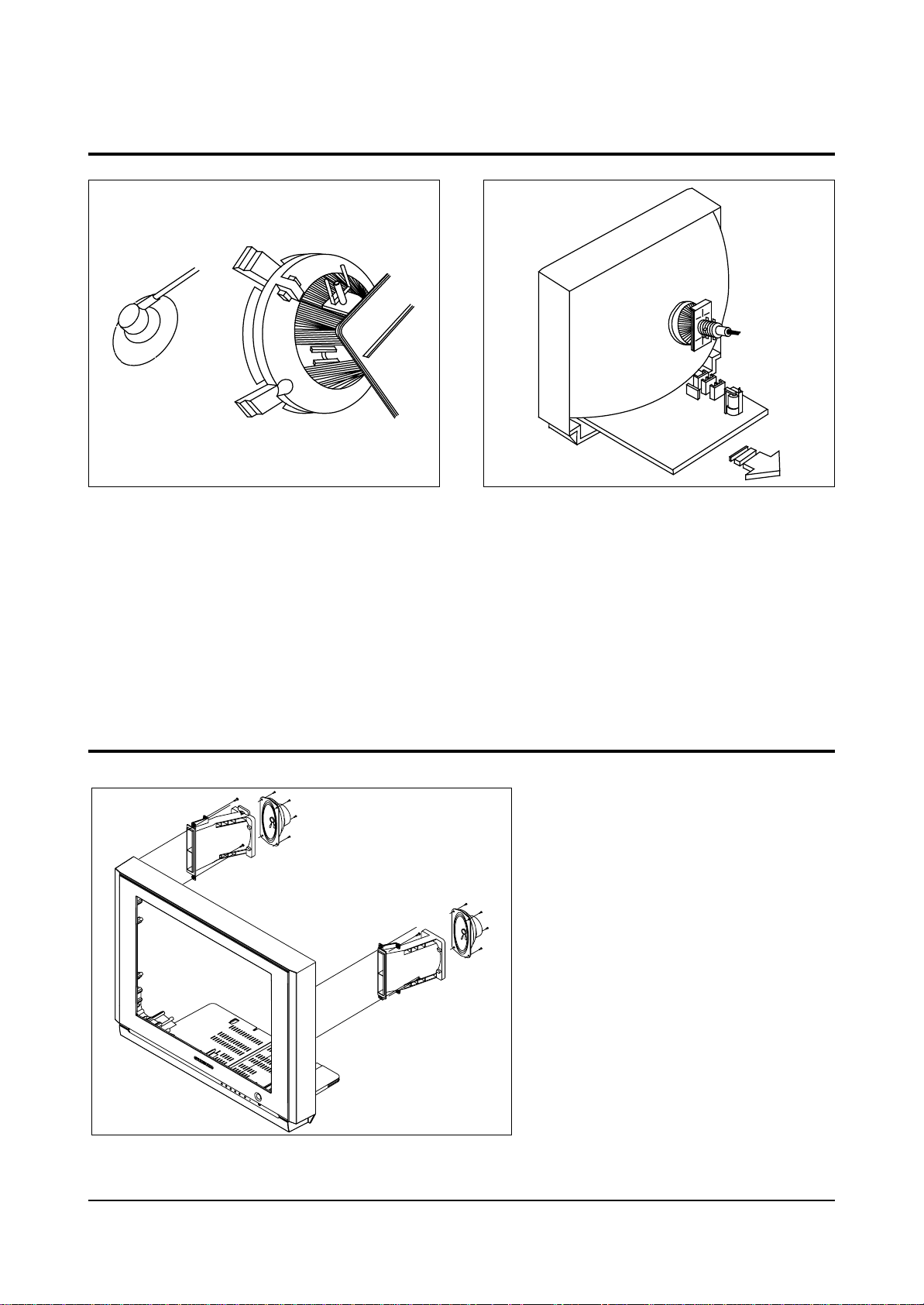

3-1 Back Cover Removal

1. After removing the screws, press the tension rib and pull the cabinet backwards.

2. To reassemble, press the tension rib (see diagram).

Disassembly and reassembly

3-2 Samsung Electronics

3-2 Main Board Removal

3-3 Speaker Removal

1. Separate the socket board from the CRT neck.

2. Remove the Anode Cap from the CRT.

3. Remove the main board by pulling it with both hands.

Warning: The FBT is charged with high voltage.

Before removing the Anode Cap, discharge the voltage

through one of the heat sinks on the main board.

1. Remove the speaker by

pressing the tension rib.

Disassembly and reassembly

Samsung Electronics 3-3

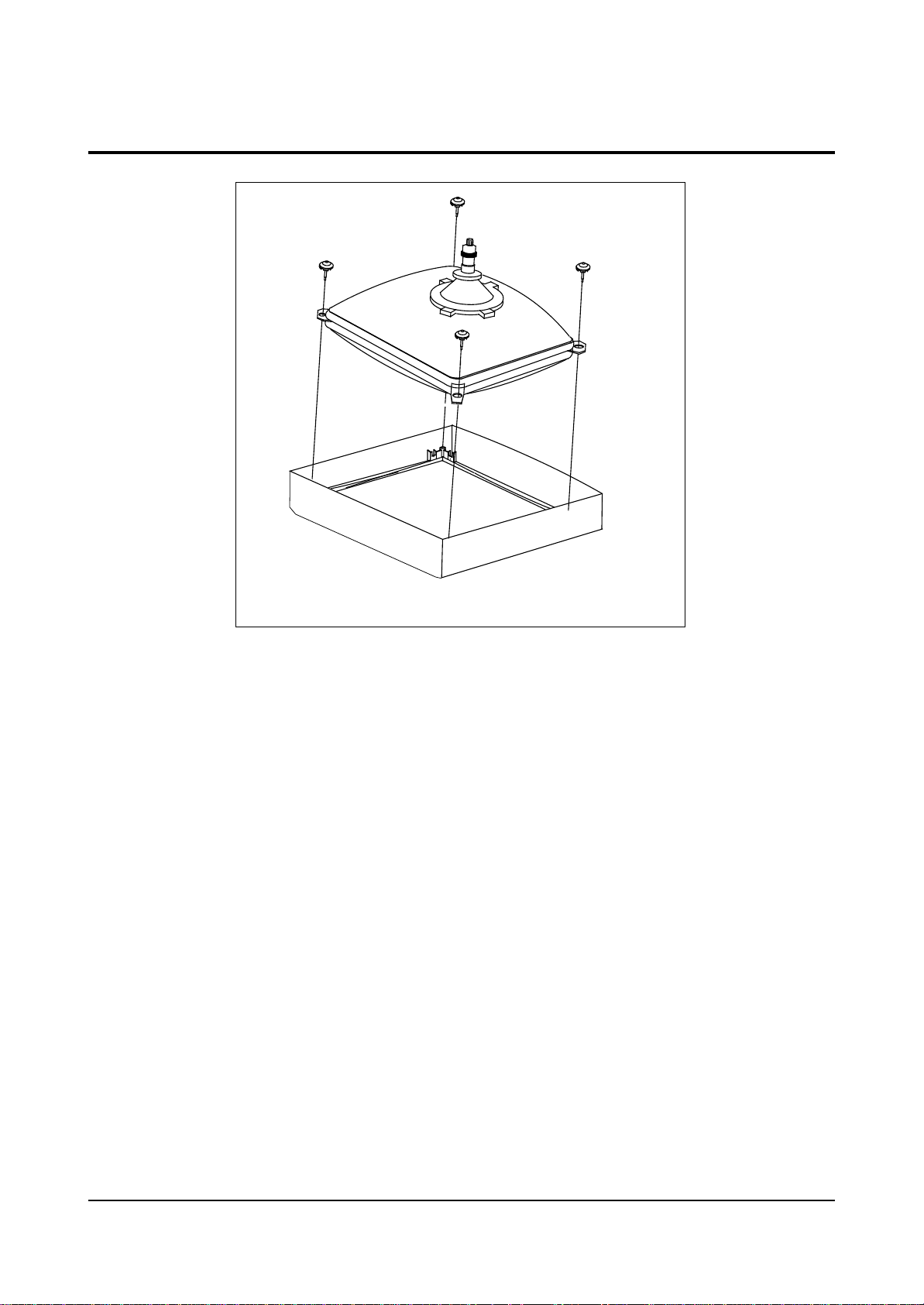

3-4 CRT Removal

1. Spread a soft mat on the floor. Place the TV set face

down.

2. Remove the 4 nuts mounting the CRT to the front cabinet. Lift the CRT.

3. Caution: Because of the high vacuum and large surface

area of the picture tube, be careful while handling it: (1)

Always lift the picture tube by grasping it firmly around

the faceplate, (2) Never lift the tube by its neck. (3) Do

not scratch the picture tube or apply excessive pressure.

Fractures of the glass may cause an implosion.

3-4 Samsung Electronics

MEMO

Samsung Electronics

Troubleshooting

5-1

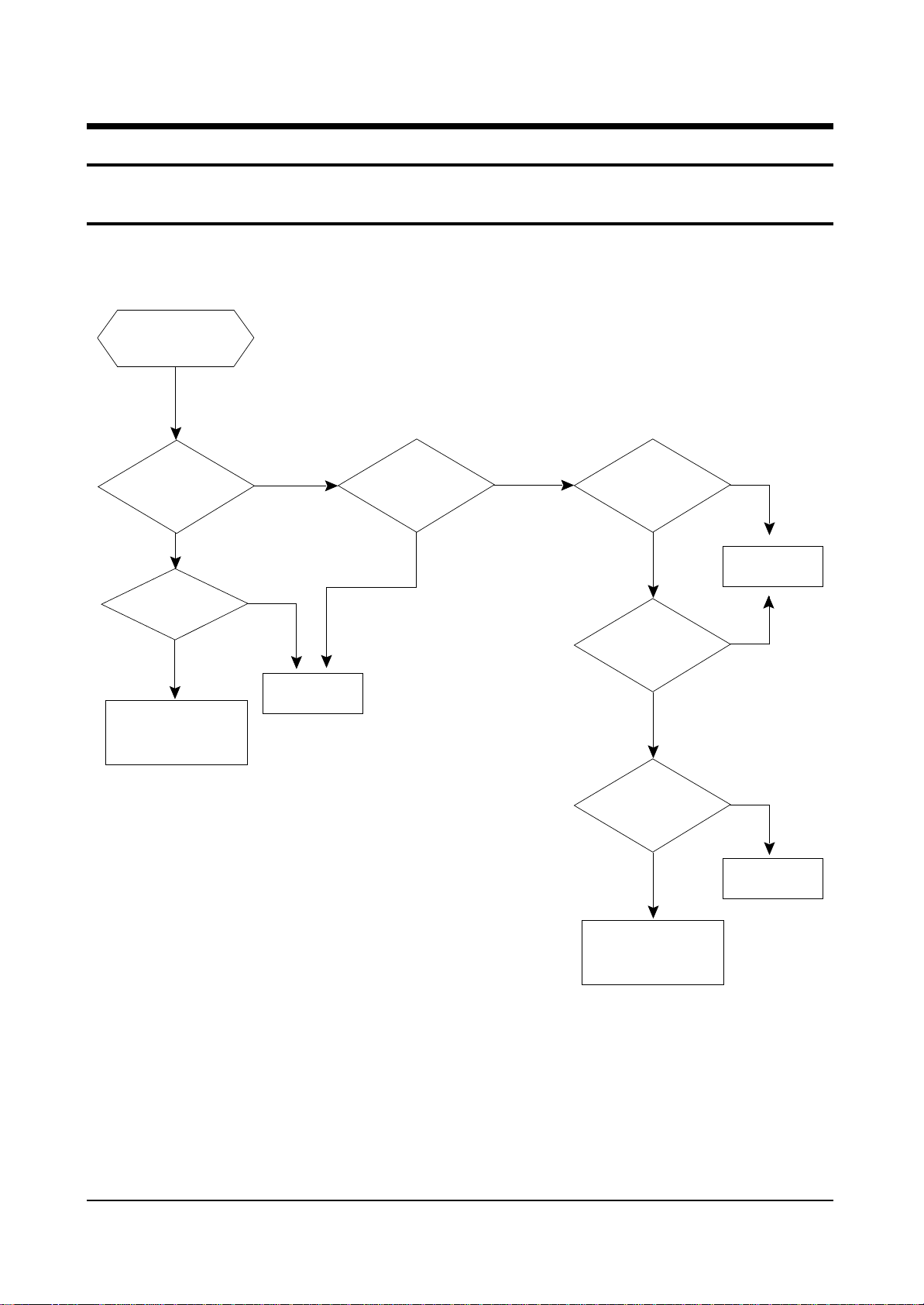

5. Troubleshooting

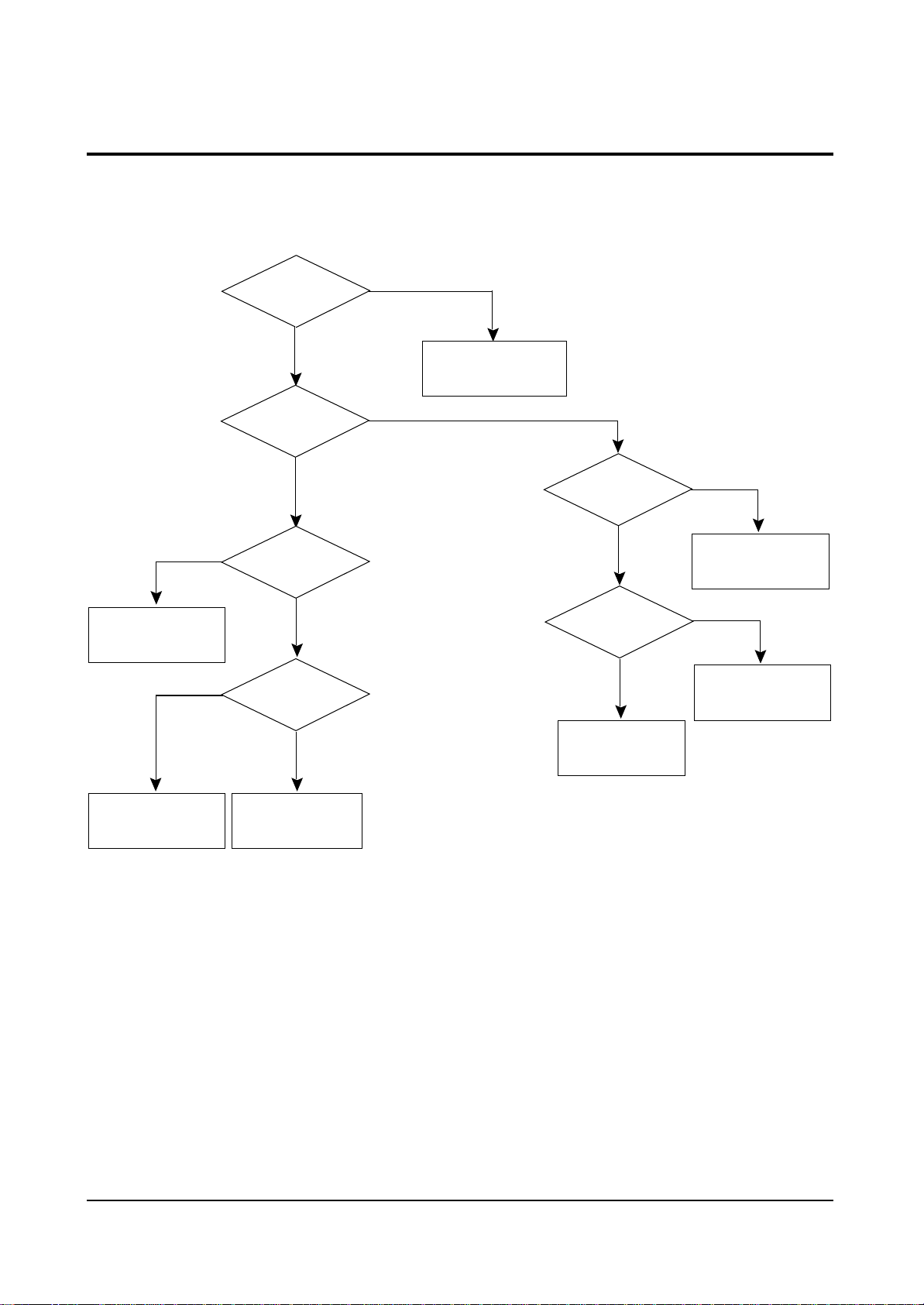

5-1 No Power

Counect

the Power code

Power LED

LED Off

Check the

12.5V-A Line

Abnormal

Check the

FD802S, IC801S

or AC-Fuse

Check

the

LED On

Normal

Check/Replace

IC802

Abnormal

Check the

3.3V-A,8V-A Line

of IC201S

Normal

Check the

X-tal,SDA,SCL port

of IC201S

Normal

Check the

(33)Pin (H-Drive)

of IC201S

Normal

Check the

130V- A Line

Normal

Abnormal

Replace

IC201 S

Abnormal

Abnormal

Check the

FBT,D808

Check / Replace

Q401

5-2 Samsung Electronics

5-2 No Video (Sound OK)

Troubleshooting

Check RK,GK,BK

Signal

Nornal

Check the

Voltage of heater

Nornal

Check

CRT and FBT

Abnormal

Abnormal

Check/Replace

R418,R522,R523

Abnormal

Check/Replace

IC201S

Abnormal

Check R,G,B

Signal into CRT

PCB

Abnormal

Check IC201S

Pin 51,52,53

(R.G.B)

Nornal

Check IC201S

Pin50(IK,V-GUARD)

Nornal

Check IC501

B+(180V-B)

Abnormal

Check the

resistance of R519

Nornal

Check/Replace

D407,FBT

Nornal

Check IC301

+

B Volt

-

Abnormal

Abnormal

Replace

Nornal

IC301 Check/Replace

D406,R414,D405,R413

Check/Replace

R519

Nornal

Check

CRT and FBT

5-3 No Sound (Video OK)

Troubleshooting

Samsung Electronics 5-3

Abnormal

Check

IC101,TUNER

Abnormal

Checkthe signal

Output from CN602

CN603

Abnormal

Check IC602

Pin4,12

Abnormal

Check IC601

Pin47(SIF)

Normal

Check IC601

B+

Normal

Check

Speaker and Wire

Check IC602

Abnormal

Check FD801S

Normal

Normal

Normal

B+

Replace

IC602

Abnormal

D805

Replace

FD801S,D805

Check

B+ Line

5V-B, 8V-B

Normal

Check/Replace

IC601

See

No Power

5-4 Samsung Electronics

Troubleshooting

5-4 Horizontal Lines Appear or Screen

Check IC301 B+

16V-C,-13.5V-C

Normal

Check IC201S

Pin 21,22

(VDN,VDP)

Normal

Check / Replace

IC301

Abnormal

Abnormal

Check

R413,R414

D405,D406

Check

IC201S

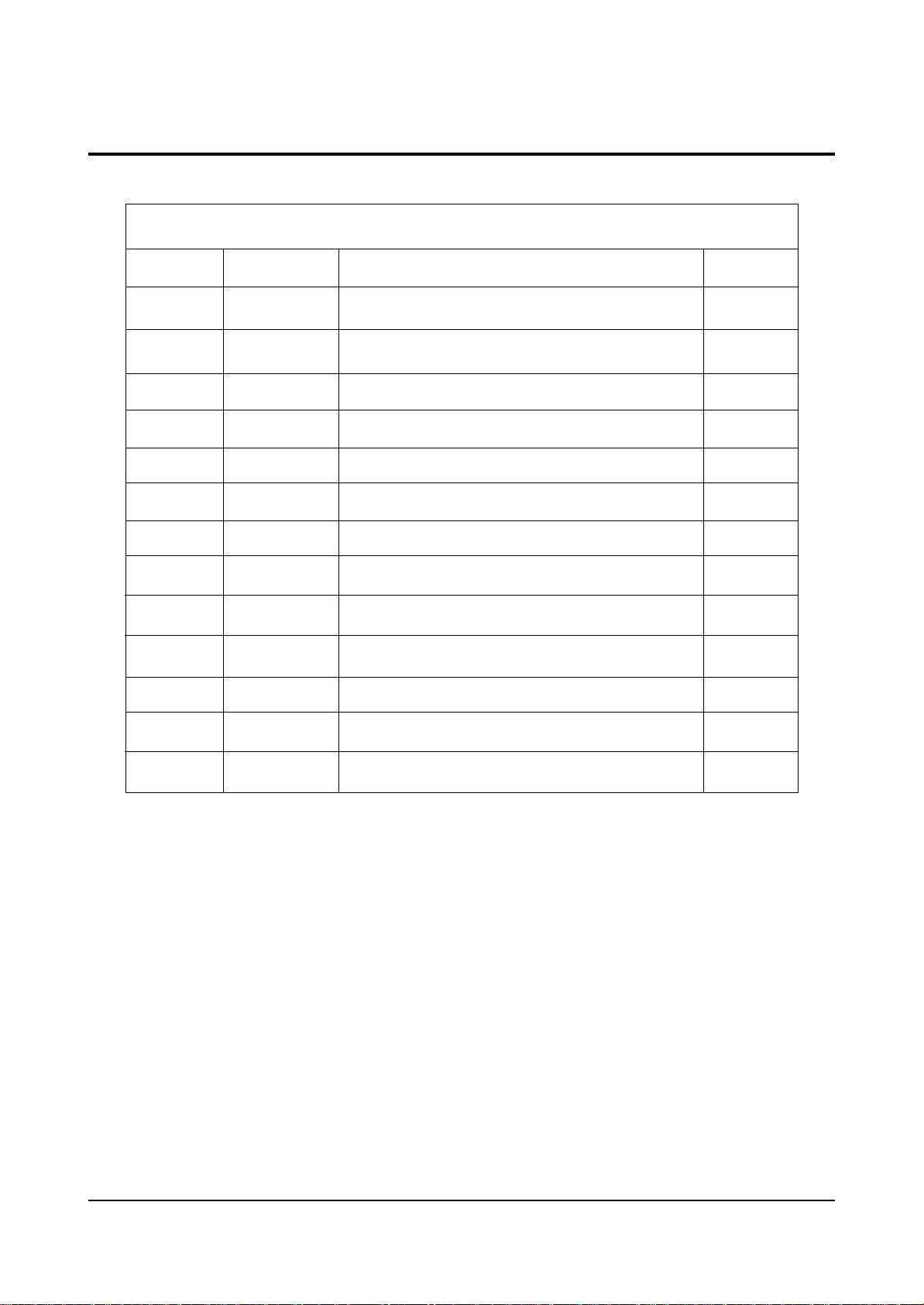

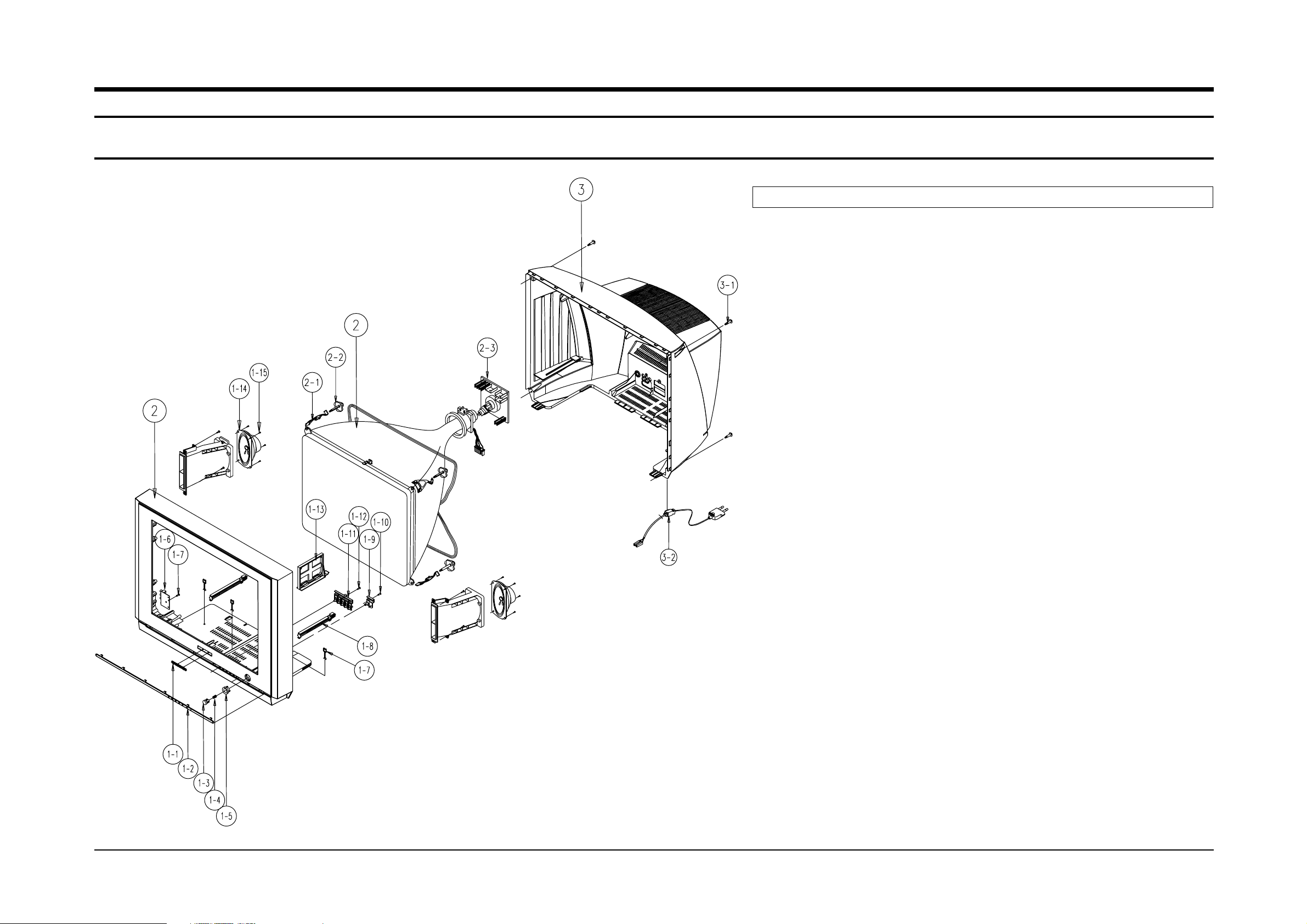

6. Exploded View & Parts List

6-1 CL21M6WKX/RCL

Exploded View & Parts List

Samsung Electronics 6-1

No Code No Description;Specification Q’ty Remark

AA64-02330P CABINET-FRONT;21M6 K57A NT-AMER,HIPS,HB, 1 F/C

1-1 AA64-70123A BADGE-BRAND;NEW,AL,-,-,L=50,FLAT,SILVER, 1

1-2 AA63-00613A COVER-CONTROL;DP,21M6,AA63-00540A 1 CC

1-3 AA64-02100B KNOB POWER;25M6,29M6,ABS,HB,G3676,IVN-11 1 KP

1-4 AA61-60003J SPRING-CS;-,SUS304,-,-,OD6,N7,OD6,-,-,-, 1

1-5 AA64-02104B DECORATION-POWER;25M6,29M6,ABS,HB,WHT,SV 1 DP

1-6 AA96-01180A ASSY PCB P-A/V SIDE;CL21M6WK,K57A 1 APAVS

1-7 6003-001268 SCREW-TAPTITE;TH,+,B,M4.0,L12.0,ZPC(YEL) 1 AV+CF

1-8 AA61-00711B HOLDER-PCB;29U1,U2,HIPS FV2,BK502(HB-PRO 2 HP

1-9 AA64-02103B WINDOW-RMC,LED;25M6,29M6,ACRYL,HB,CLEAR 1 WR

1-10 6003-001026 SCREW-TAPTITE;RH,+,B,M4,L15,ZPC(BLK),SWR 1 WR+CF

1-11 AA64-02102B KNOB CONTROL;25M6,29M6,ABS,HB,G3676,SV10 1 KC

1-12 6003-001026 SCREW-TAPTITE;RH,+,B,M4,L15,ZPC(BLK),SWR 1 KC+CF

1-13 SUPPORT-CRT 1

1-14 AA91-00427A ASSY HOLDER SPK;-,PP,8OHM/15W,BLK,SEMI-D 1 AHS

1-15 6006-001095 SCREW-ASS’Y TAPT;WP,BH,+,M4,L12,ZPC(YEL) 4 SPK+CF

2 AA03-00317A CRT COLOR;A51QDX992X,0MG,1.85MH,18.0MH,2 1 CRT

2-1 AA65-00009B CLAMP-D,COIL;NYLON 66,V0,-,-,21A8,- 4 CDCOIL

2-2 AA60-10050R SCREW-ASSY;WC,HH,+M5,L31.5,SWR 4 CRT+CF

2-3 3704-001105 SOCKET-CRT;11P,20PI,26.5PI,NI,- 1 V999S

3 AA64-02841A CABINET BACK;DP,21M6,HB,AA64-02331B 1 C/B

3-1 6003-001026 SCREW-TAPTITE;RH,+,B,M4,L15,ZPC(BLK),SWR 4 CB+CF

3-2 AA96-20109C ASSY PWR-CORD;CP2/NO(4.0)H/C300,KKP419C, 1 PWR/AC

Loading...

Loading...