Page 1

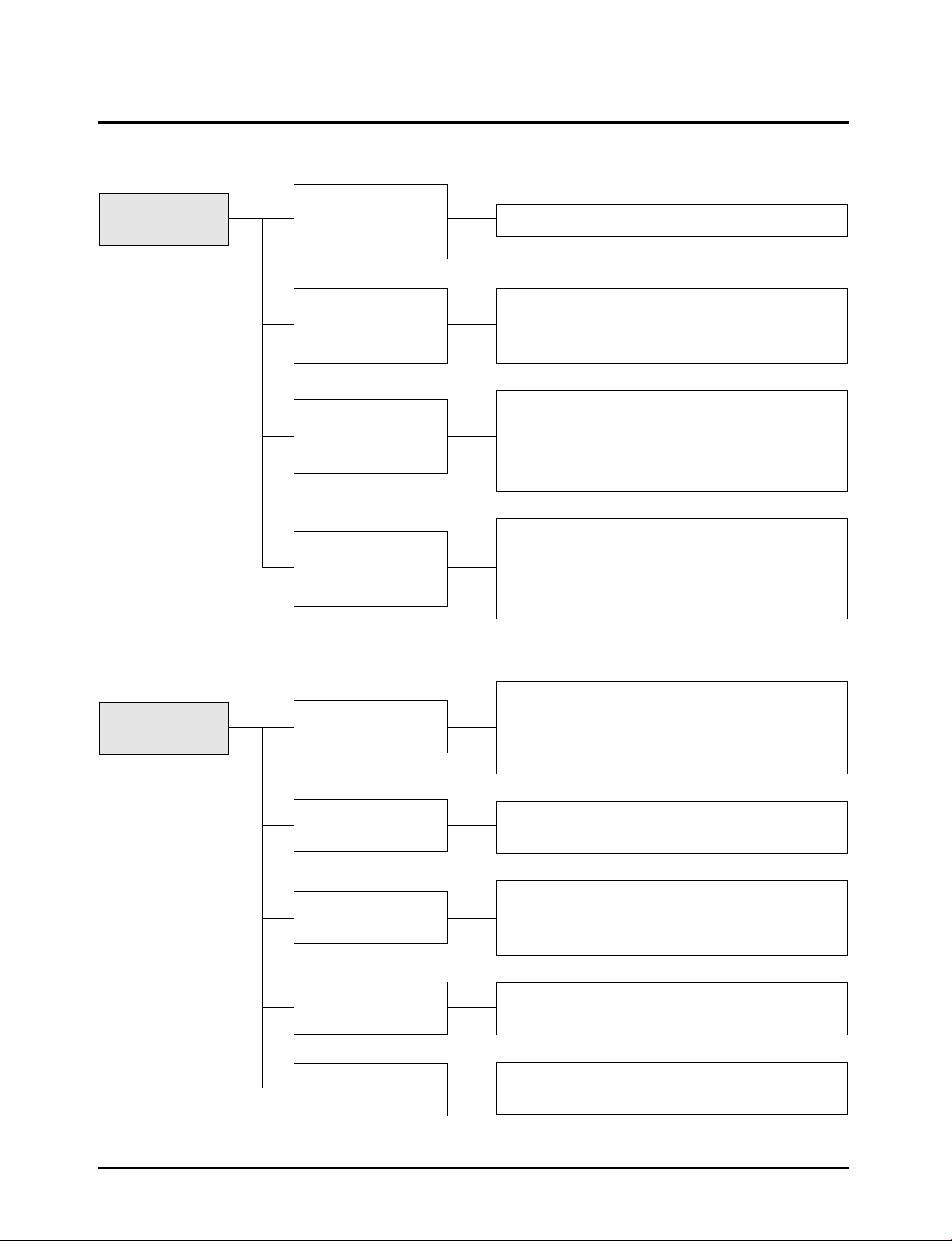

CASSETTE TYPE AIR CONDITIONER

(Cool and Heat)

Type

ACH1800E(1)

ACH2400E(1)

ACH3600G(1)

ACH4400G(1)

CH18ZA

CH24ZA

CH36ZA

CH44ZA

CH18CA

CH24CA

CH36CA

CH44CA

SERVICE

Indoor Unit

ICH1800E

ICH2400E

ICH3600G

ICH4400G

CH18ZA

CH24ZA

CH36ZA

CH44ZA

CH18CA

CH24CA

CH36CA

CH44CA

Outdoor Unit

UBH1800E

UBH2400E

UCH3600G

UCH4400G

CH18ZAX

CH24ZAX

CH36ZAX

CH44ZAX

CH18CAX

CH24CAX

CH36CAX

CH44CAX

Manual

Panel

IFS095G00/01

IFS095G00/01

IFS095G00/01

IFS095G00/01

CH01(02)ZAP

CH01(02)ZAP

CH01(02)ZAP

CH01(02)ZAP

CH01(02)ZAP

CH01(02)ZAP

CH01(02)ZAP

CH01(02)ZAP

AIR CONDITIONER CONTENTS

1. Precautions

2. Product Specifications

3. Operating Instructions

4. Installation

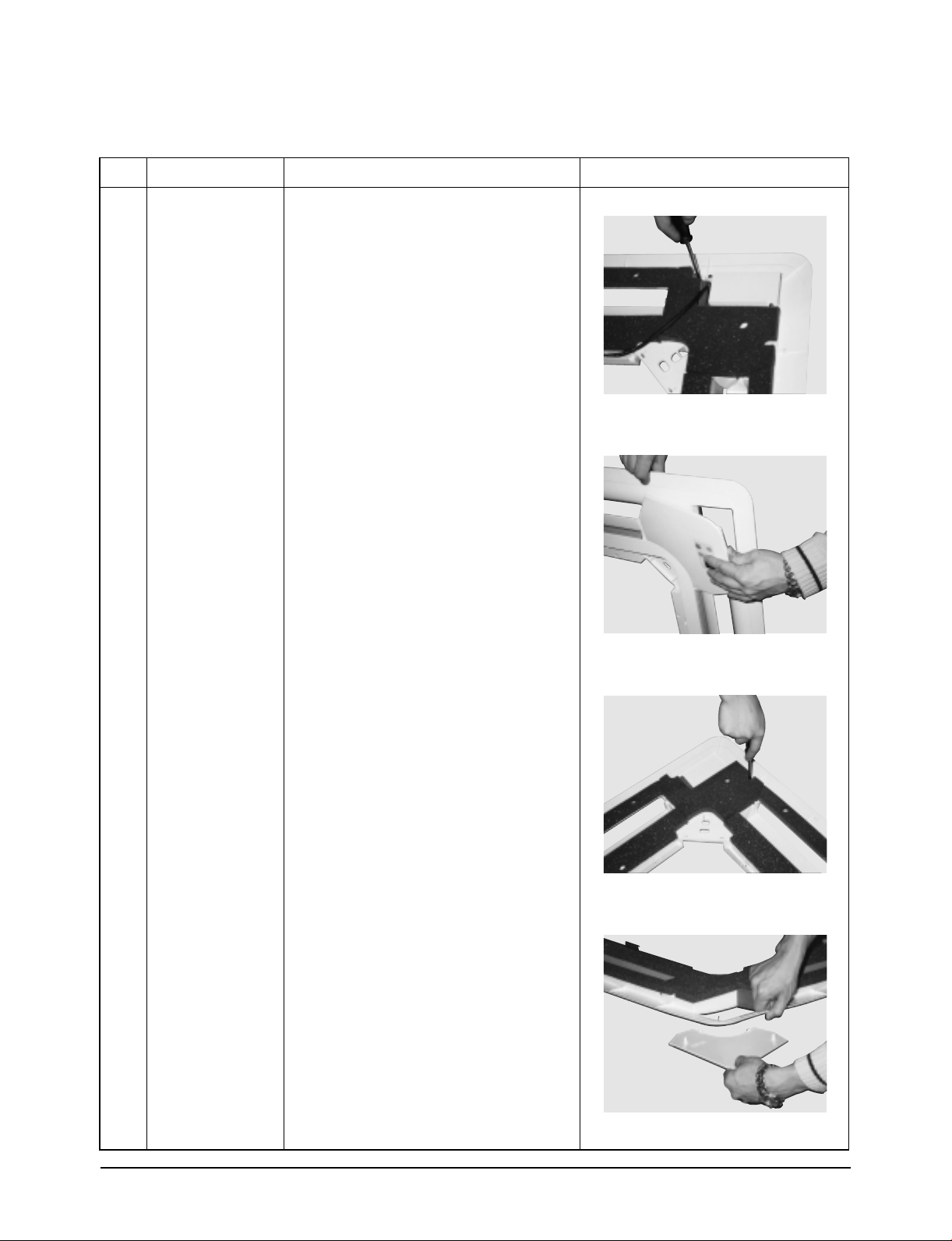

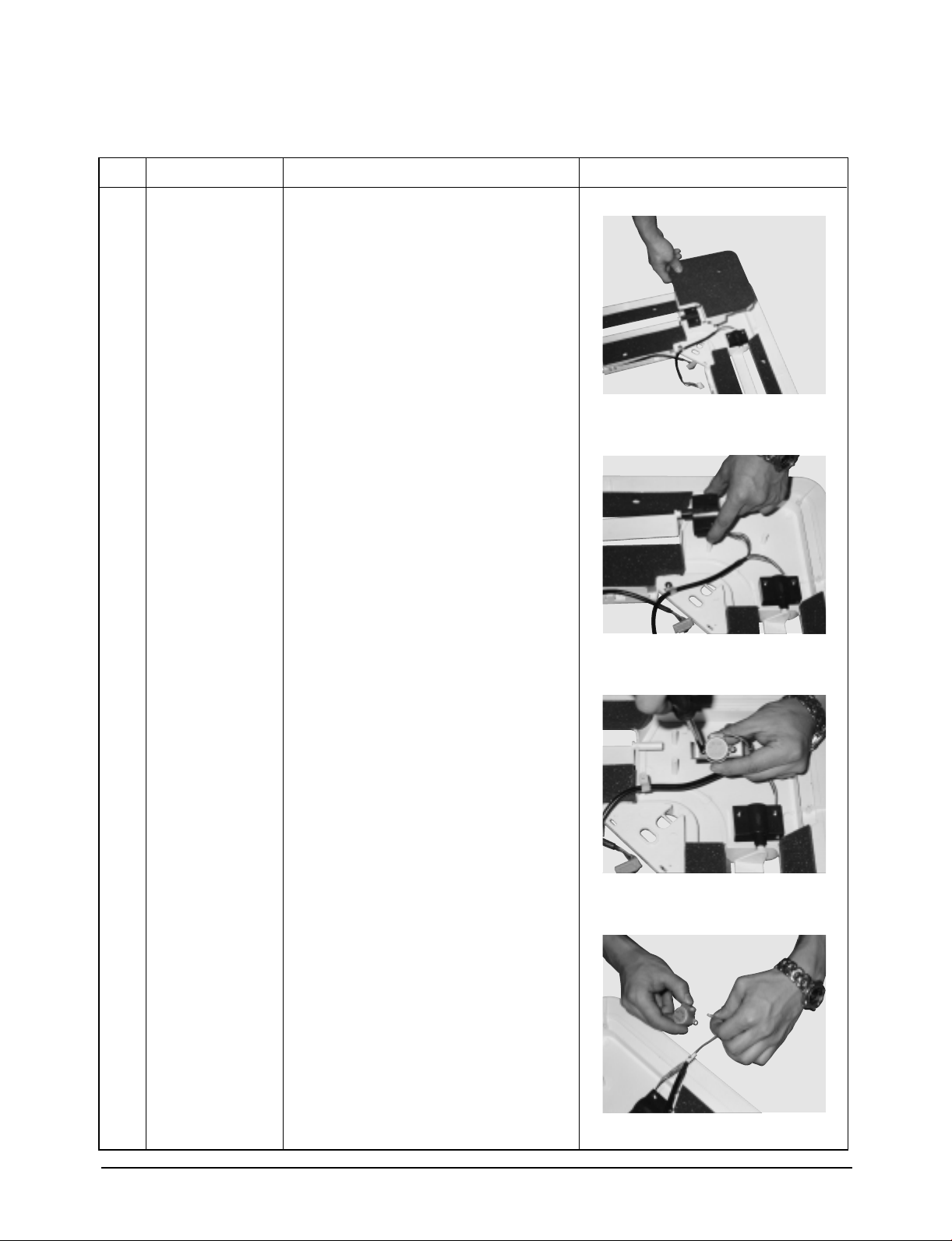

5. Disassembly and Reassembly

6. Troubleshooting

7. Exploded Views and Parts List

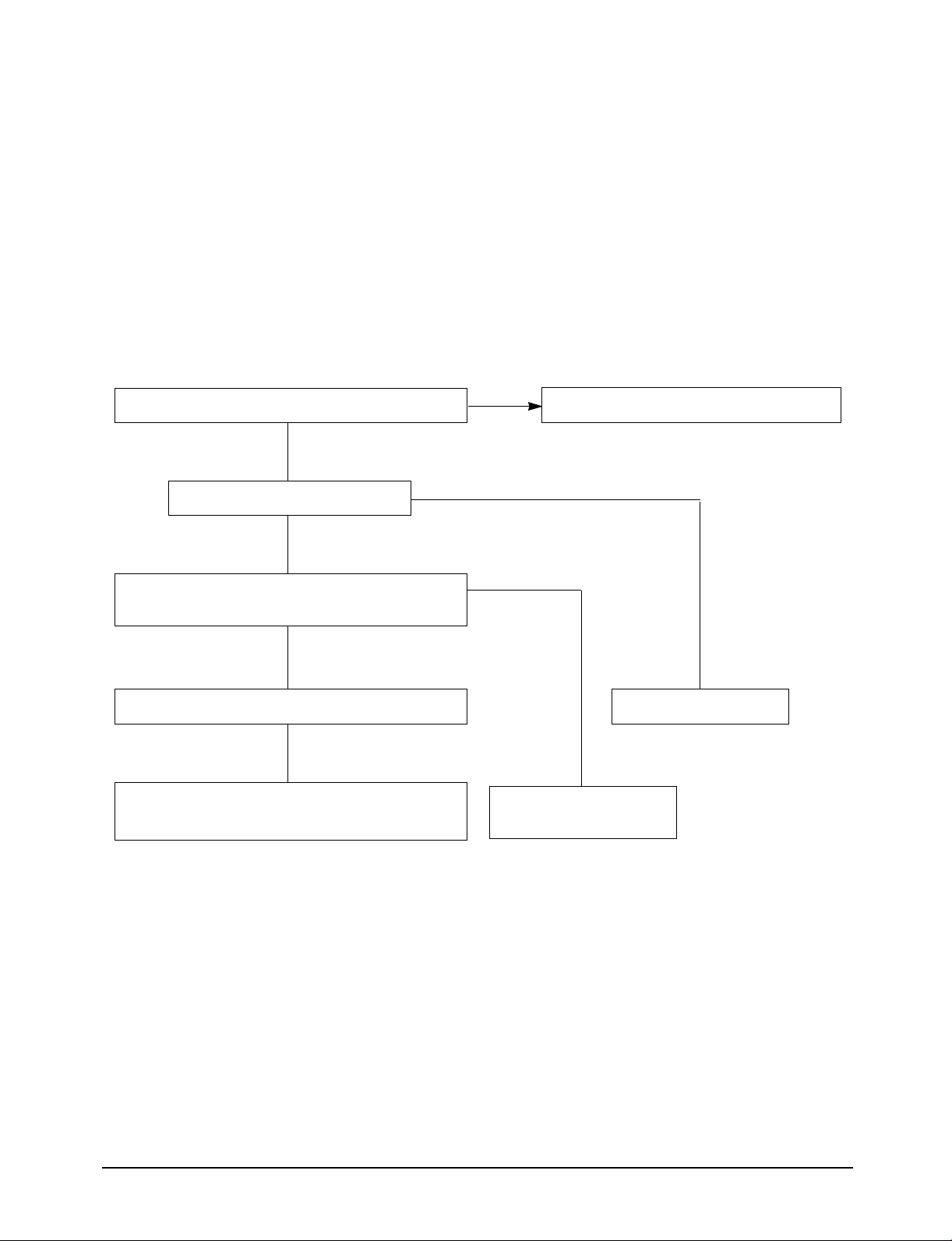

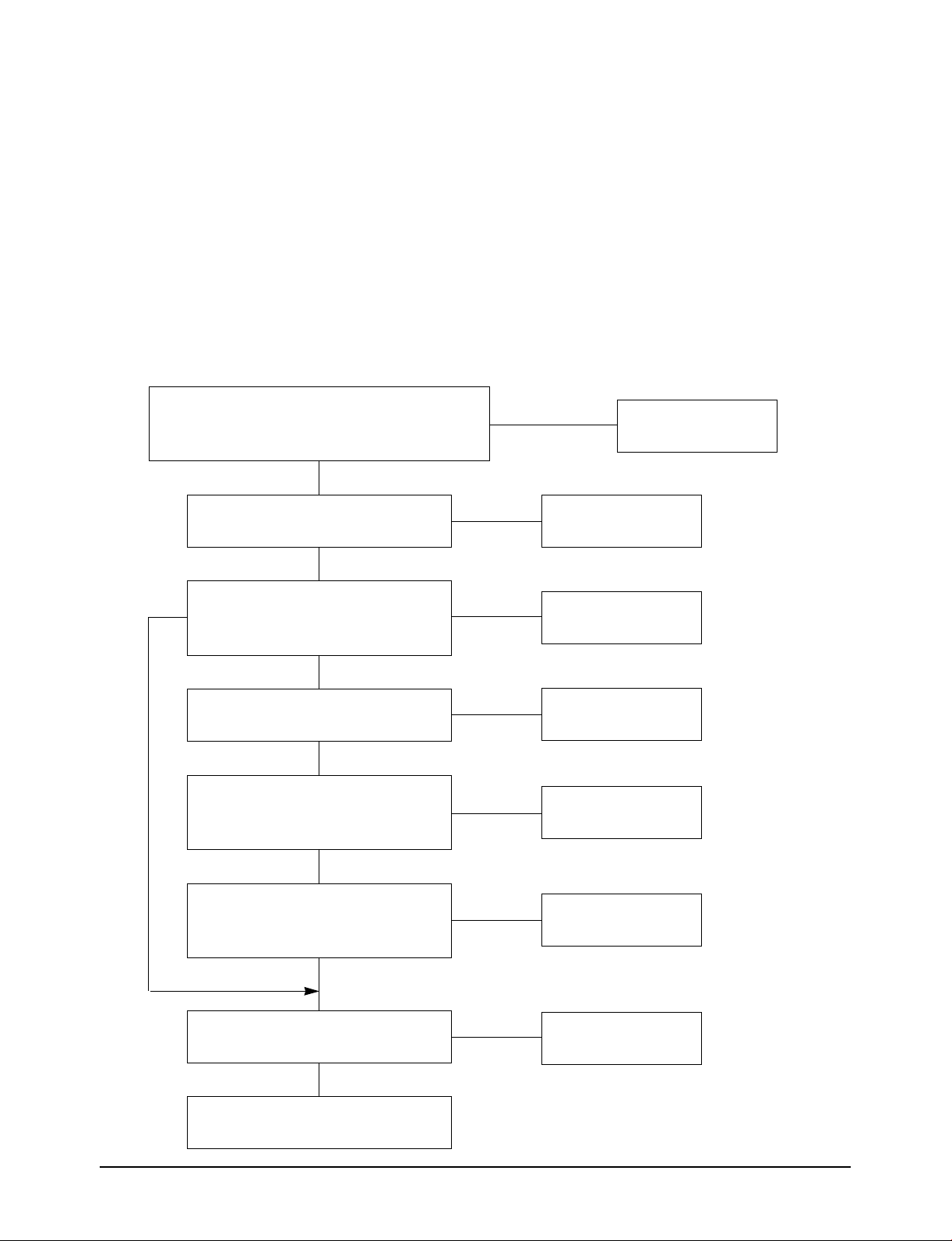

8. Block Diagrams

9. PCB Diagrams

10. Schematic Diagrams

11. Wiring Diagrams

Page 2

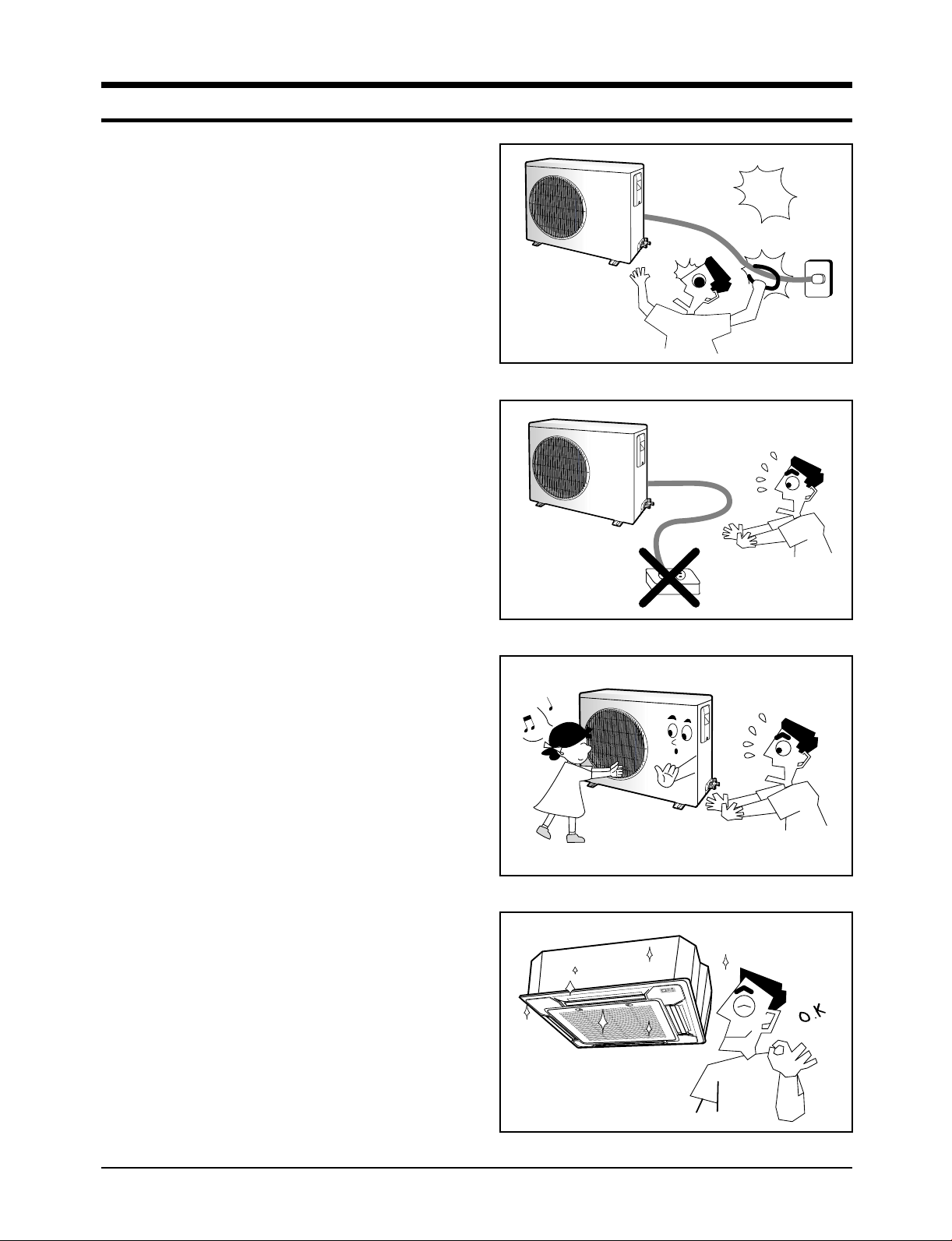

1. Precautions

dangerous

1. Warning: Prior to repair, disconnect the

power cord from the circuit breaker.

2. Use proper parts: Use only exact replacement

parts. (Also, we recommend replacing parts

rather than repairing them.)

3. Use the proper tools: Use the proper tools

and test equipment, and know how to use

them. Using defective tools or test equipment may cause problems later-intermittent

contact, for example.

4. Power Cord: Prior to repair, check the power

cord and replace it if necessary.

5. Avoid using an extension cord, and avoid

tapping into a power cord. This practice

may result in malfunction or fire.

Fig. 1-1 Avoid Dangerous Contact

6. After completing repairs and reassembly,

check the insulation resistance. Procedure:

Prior to applying power, measure the resistance between the power cord and the

ground terminal. The resistance must be

greater than 30 megohms.

7. Make sure that the grounds are adequate.

8. Make sure that the installation conditions

are satisfactory. Relocate the unit if necessary.

9. Keep children away from the unit while it is

being repaired.

10. Be sure to clean the unit and its surrounding

area.

11. Be sure that the installed conditions are

satisfactory and correct according to the

specifications.

Fig. 1-2 No Tapping and No Extension Cords

Fig. 1-3 No Kids Nearby!

Samsung Electronics

Fig. 1-4 Clean the Unit

1-1

Page 3

MEMO

1-2 Samsung Electronics

Page 4

2. Product Specifications

2-1 Table of Specifications

MODEL

Capacity

Power supply

Power input

Running

current

EER

Indoor

Fan speed

unit

Air

circulation

Noise Level

(Sound

pressure)

Heat

exchanger

Fan

Dimensions

Weight

Panel

Dimensions

Weight

Outdoor

Fan speed

unit

INDOOR UNIT

OUTDOOR UNIT

Cooling

Btu/h

W

Heating

Btu/h

W

Cooling

Heating

Cooling

Heating

Cooling

Heating

H.H

Hi

Med

Low

H.H

Hi

Med

Low

Hi

Med

Low

kW

kW

A

A

W/W

W/W

r.p.m.

r.p.m.

r.p.m.

r.p.m.

3

/min

m

3

/min

m

3

/min

m

3

/min

m

dB(A)

dB(A)

dB(A)

type

row x stages x fin pitch

type

motor output

H

W

D

kg

H

W

D

kg

Hi

Low

W

mm

mm

mm

Net/Gross

mm

mm

mm

Net/Gross

r.p.m.

r.p.m.

ICH1800E/CH18ZA

UBH1800E/CH18ZAX

17,400

18,400

ICH2400E/CH24ZA

UBH2400E/CH24ZAX

5,100

5,400

23,000

6,700

24,500

7,200

ICH3600G/CH36ZA

UCH3600G/CH36ZAX

34,500

10,100

38,600

11,300

ICH4400G/CH44ZA

UCH4400G/CH44ZAX

43,000

12,600

46,000

13,500

CH18CA

CH18CAX

17,400

5,100

19,400

5,700

CH24CA

CH24CAX

22,100

6,500

25,500

7,500

CH36CA

CH36CAX

32,400

9,500

42,000

12,300

220-240~ 50Hz 380-415V 3~ 50Hz 220-240~ 50Hz 380-415V 3 ~ 50Hz

1.75

1.80

8.0

8.2

2.8

2.9

(410)

370

330

290

16

14

12

10

39

37

35

slit fin coil

2x8x1.4(890/980)

Turbo

35

230

840

840

29/34

42

950

950

5/10

950

500

2.30

2.65

10.5

12.3

2.7

2.8

(480)

440

400

360

18

16

14

12

41

39

37

slit fin coil

2x8x1.4(890/980)

3x10x1.5(890/980)

Turbo

35

230

840

840

29/34

42

950

950

5/10

750

400

3.40

3.90

6.0

6.7

2.8

2.9

(710)

630

550

470

29

25

21

17

50

47

45

slit fin coil

Turbo

70

288

840

840

34/40

42

950

950

5/10

750

400

4.30

4.90

7.7

8.8

2.7

2.8

(740)

660

580

500

31

27

23

19

52

49

47

slit fin coil

3x10x1.5(890/980)

2x8x1.4(890/980)

Turbo

80

288

840

840

34/40

42

950

950

5/10

900

450

1.85

1.90

8.6

8.7

2.7

3.0

(410)

370

340

290

14

12

10

8

41

39

37

slit fin coil

Turbo

35

230

840

840

29/34

42

950

950

5/10

930

480

2.45

2.6

11.5

12.5

2.5

2.8

(480)

440

400

360

18

16

14

12

43

41

39

slit fin coil

2x8x1.4(890/980)

3x10x1.5(890/980)

Turbo

35

230

840

840

29/34

42

950

950

5/10

750

400

3.4

4.0

5.9

6.7

2.6

3.0

710

630

550

470

29

25

21

17

50

48

46

slit fin coil

Turbo

70

288

840

840

34/40

42

950

950

5/10

750

450

CH44CA

CH44CAX

38,500

11,300

47,500

14,000

4.45

5.4

8.2

9.5

2.5

2.6

740

660

580

500

31

27

23

19

52

50

48

slit fin coil

3x10x1.5(890/980)

Turbo

80

288

840

840

34/40

42

950

950

5/10

900

450

Samsung Electronics

2-1

Page 5

Product Specifications

MODEL

Outdoor

unit

Condition

Piping

INDOOR UNIT

OUTDOOR UNIT

Air circulation (Hi)

Sound pressure level

Fan

type

motor output

Compressor

type

model

motor output

protection

Heat

exchanger

type

row x stages x fin pitch

face area

Refrigerant

control

(R22)charge

Dimensions

Weight

Indoor unit

(HXWXD)

kg

Cool(DB/WB)

Heat(DB/WB)

Outdoor unit

Cool(DB/WB)

Heat(DB/WB)

Pipe O.D.

size

Liquid

Gas

Connection method

Between

Height

Pipe length

ICH1800E/CH18ZA

UBH1800E/CH18ZAX

m3/min

dB(A)

W

kW

2x24x1.7(824)

2

m

g

mm

Net/Gross

˚C

˚C

˚C

˚C

mm(inch)

mm(inch)

m

m

35

55

propeller

35

scroll

ZR22K3-PFJ

1.37

Internal

wave fin coil

0.494

Capillary

2,000

620x787x320

63/68

27/19

20/15

35/24

7/6

9.52(3/8")

15.88(5/8")

Flare

Max. 15

Max. 30

ICH2400E/CH18ZA

UBH2400E/CH24ZAX

propeller

ZR28K3-PFJ

Internal

D fin coil

2x24x1.7(896)

Capillary

638x880x310

9.52(3/8")

15.88(5/8")

Max. 15

Max. 30

45

56

60

scroll

1.74

0.538

2,400

67/72

27/19

20/15

35/24

7/6

Flare

ICH3600G/CH36ZA

UCH3600G/CH36ZAX

80

62

propeller

73

scroll

ZR47KC-TFD

2.92

Internal

wave fin coil

2x48x1.7(935/915)

1.122

Capillary

2,700

1240x930x385

120/130

27/19

20/15

35/24

7/6

9.52(3/8")

19.05(3/4")

Flare

Max. 25

Max. 50

ICH4400G/CH44ZA

UCH4400G/CH44ZAX

90

63

propeller

114

scroll

ZR61KC-TFD

3.79

Internal

wave fin coil

2x48x1.7(935/915)

1.122

Capillary

3,300

1240x930x385

123/133

27/19

20/15

35/24

7/6

9.52(3/8")

19.05(3/4")

Flare

Max. 25

Max. 50

CH18CA

CH18CAX

35

54

propeller

35

scroll

ZR22K3E-PFJ

1.37

Internal

wave fin coil

2x24x1.7(824)

0.494

Capillary

1,800(R407C)

620x787x320

63/68

27/19

20/15

35/24

7/6

9.52(3/8")

15.88(5/8")

Flare

Max. 15

Max. 30

CH24CA

CH24CAX

45

55

propeller

60

scroll

ZR28K3E-PFJ

1.74

Internal

D fin coil

2x24x1.7(896)

0.538

Capillary

2,000(R407C)

638x880x310

67/72

27/19

20/15

35/24

7/6

9.52(3/8")

15.88(5/8")

Flare

Max. 15

Max. 30

CH36CA

CH36CAX

CH44CAX

80

61

propeller

73

scroll

ZR47KCE-TFD

ZR61KCE-TFD

2.92

Internal

wave fin coil

2x48x1.7(935/915)

wave fin coil

2x48x1.7(935/915)

1.122

Capillary

2,250(R407C)

1,240x930x305

2,800(R407C)

1,240x930x385

120/130

27/19

20/15

35/24

7/6

9.52(3/8")

19.05(3/4")

19.05(3/4")

Flare

Max. 25

Max. 50

CH44CA

90

62

propeller

114

scroll

3.79

Internal

1.122

Capillary

123/133

27/19

20/15

35/24

7/6

9.52(3/8")

Flare

Max. 25

Max. 50

* Wind flow : It is data of heating standard opertion.

2-2

Samsung Electronics

Page 6

2-2 Dimensions

2-2-1 Indoor unit

• Indoor Unit Dimensions (ICH1800E/ICH2400E/CH18ZA/CH24ZA/CH18CA/CH24CA)

Unit : mm

200

Drain tube outlet

145

Water Supply Intake

950 (Dimensions of Front Panel)

880 (Cutting Dimensions of Ceiling)

766 (Space of Suspension Bolts)

Liquid refrigerant port

Gas refrigerant port

Fixing bracket

146

126

699 (Space of Suspension Bolts)

156

840 (Outer Dimensions)

880 (Cutting Dimension of Ceiling)

246

25

290

260

90

110

Samsung Electronics

840 (Outer Dimensions)

230

2-3

Page 7

• Indoor Unit Dimensions (ICH3600G/ICH4400G/CH36ZA/CH44ZA/CH36CA/CH44CA)

Unit : mm

258

Drain tube outlet

145

Water Supply Intake

950 (Dimensions of Front Panel)

880 (Cutting Dimensions of Ceiling)

766 (Space of Suspension Bolts)

Liquid refrigerant port

Gas refrigerant port

Fixing bracket

146

126

699 (Space of Suspension Bolts)

156

840 (Outer Dimensions)

880 (Cutting Dimension of Ceiling)

262

148

168

25

260

290

2-4

840 (Outer Dimensions)

288

Samsung Electronics

Page 8

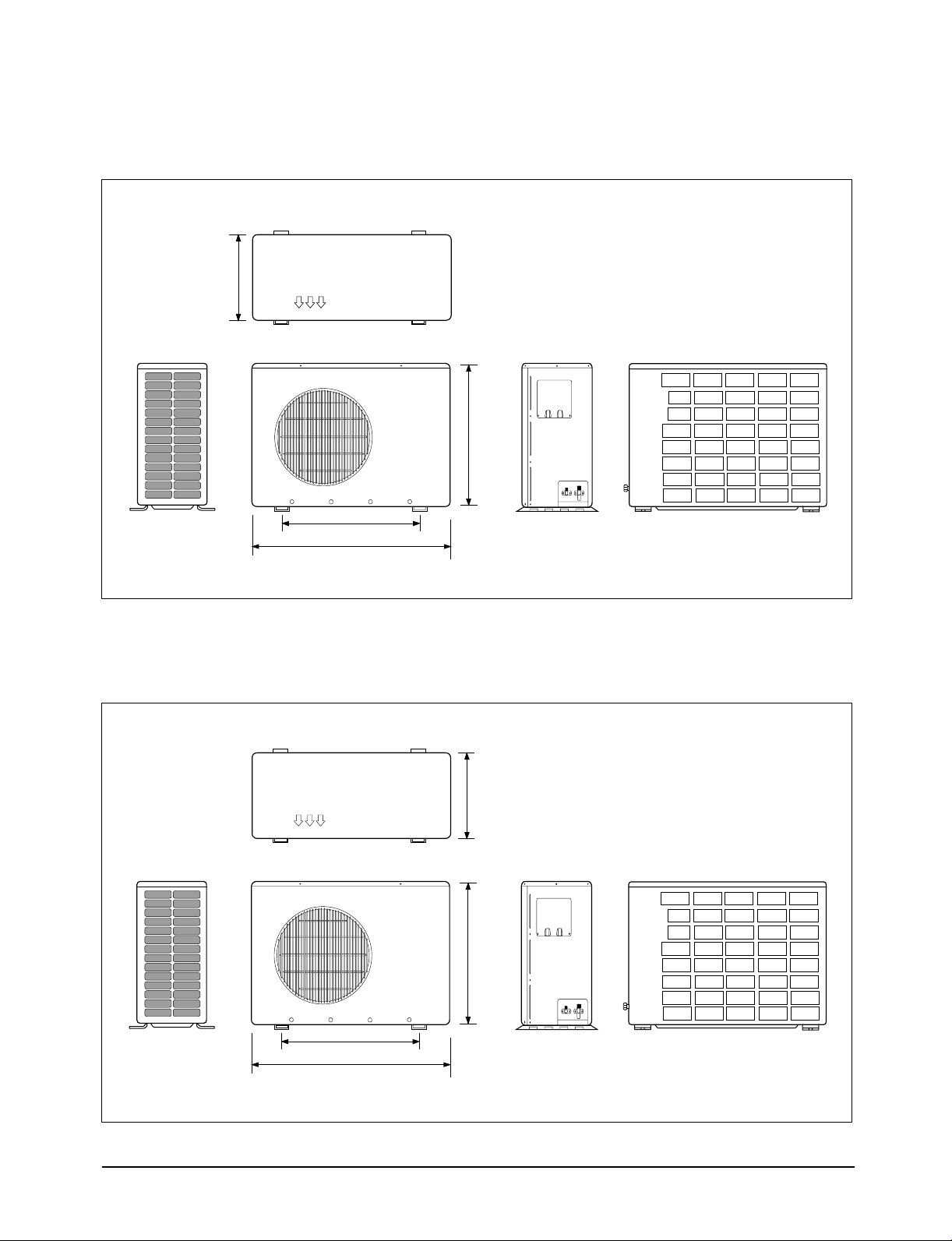

2-2-2 Outdoor Unit

• Outdoor Unit Dimensions (UBH1800E/CH18ZAX/CH18CAX)

320

(Front view) (Rear view)

638

582

787

• Outdoor Unit Dimensions (UBH2400E/CH24ZAX/CH24CAX)

310

(Front view) (Rear view)

638

660

880

Samsung Electronics

2-5

Page 9

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

Product Specifications

• Outdoor Unit Dimensions

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

;;;;;

(UCH3600G/CH36ZAX/UCH4400G/CH44ZAX/CH36CAX/CH44CAX)

930

1420

385

Input bolt fixing dimension

A

840mm

2-6

B

415mm

A

B

Samsung Electronics

Page 10

2-2-3 Remote control

• Wired Remote Controller-Buttons and Display

• Wireless Remote Controller-Buttons and Display

Samsung Electronics

2-7

Page 11

Product Specifications

• Centralized Controller

2-8

Samsung Electronics

Page 12

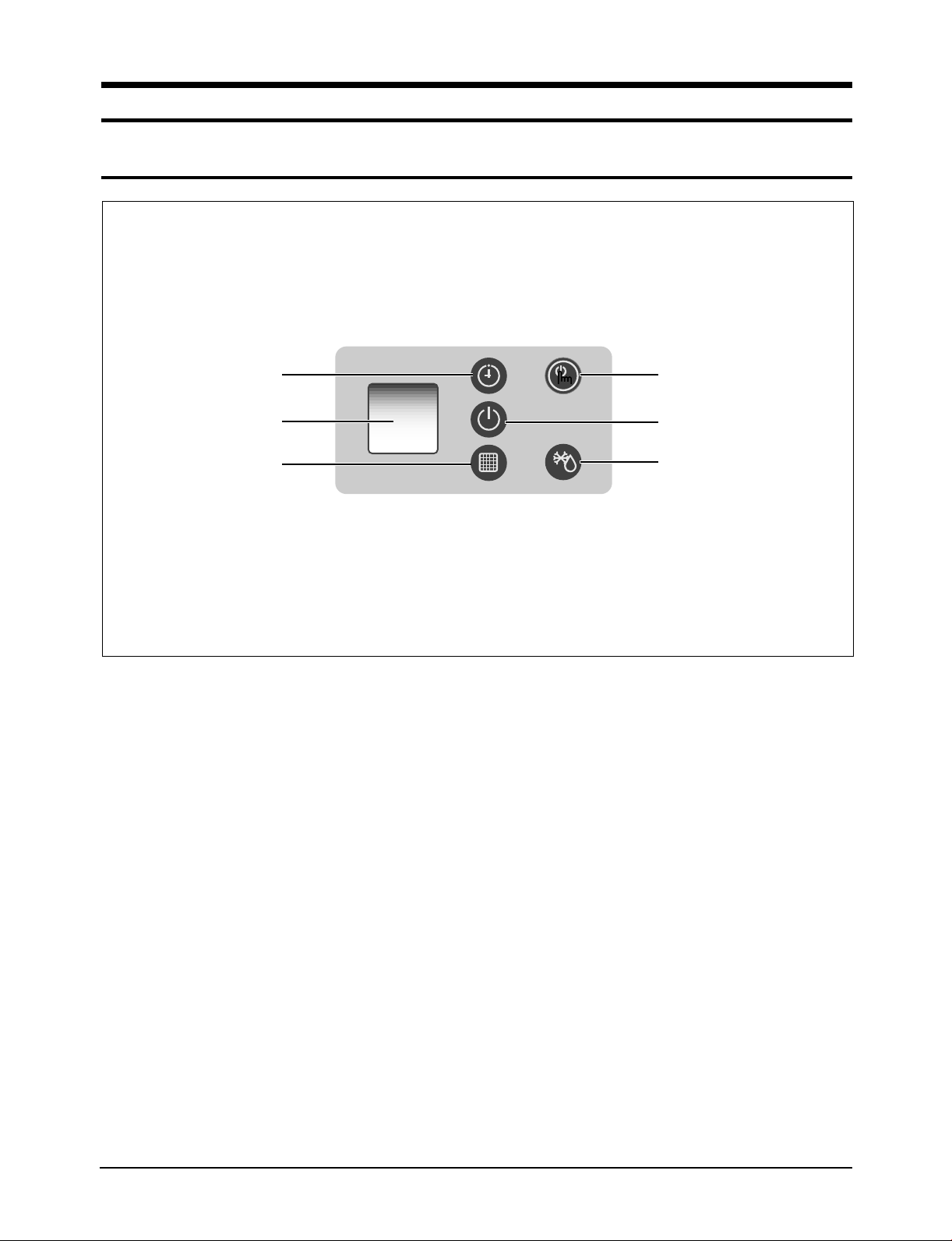

3. Operating Instructions

Timer indicator On/Off button

On/Off indicator

Removing frost indicator

Remote control sensor

Filter Sign indicator

3-1 Display on Indoor unit

Samsung Electronics

3-1

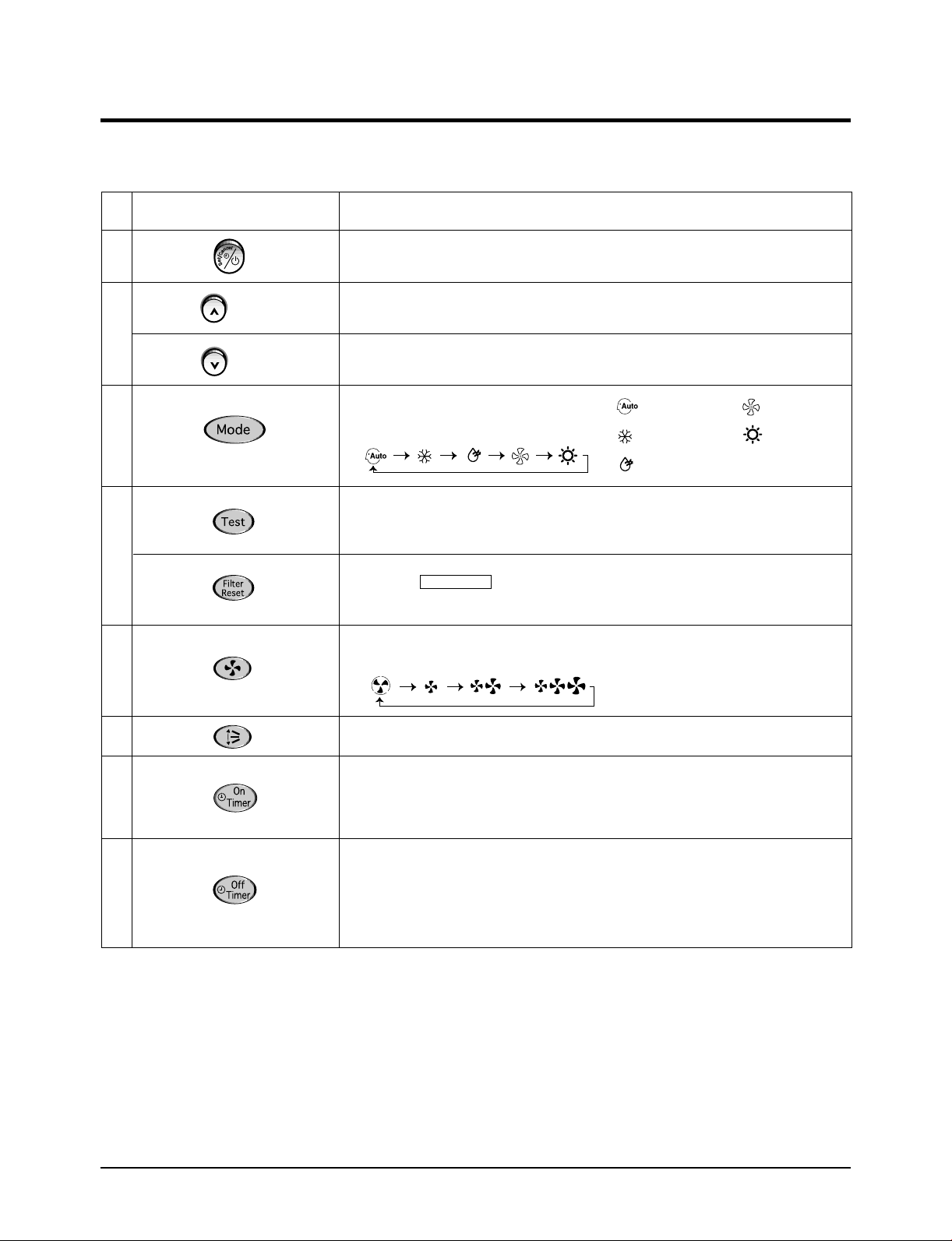

Page 13

3-2 Name & Functions in Remote Control

3-2-1 Wired Remote Controller-Buttons

NO

1

2

3

4

5

NAMED OF KEY

(UP)

(DOWN)

FUNCTION OF KEY

Power On/Off button to start and stop airconditioner or timer set up

Temp. up button. To increase the temperature by the pressing

the temperature button

Temp. down button. To decrease the temperature by the pressing

the temperature button

Each time you press this button

Mode is changed in the following order

To complete the installation, checks and tests to ensure that the air conditioner is

operating correctly.

When the indicator appeard on the remocon screen, cleaning the air

conditioner filter. After that, press this button.

Each time you press this button,

FAN SPEED is changed in the following order.

FILTER SIGN

: Auto Mode : Blowing

: Cooling Mode : Heat Mode

: Dehumidifying Mode

3-2

6

7

8

Adjust air flow vertically.

The ON Timer enables you to switch onthe air conditioner automatically

after a given period of time that is from 30 minutes to 24 hours.

To cancel the On Time, press the (Set/Cancel) button.

The Off Timer enables you to switch off the air conditioner automatically

after a given period of time that is from 30 minutes to 24 hours.

To cancel the On Time, press the (Set/Cancel) button.

Samsung Electronics

Page 14

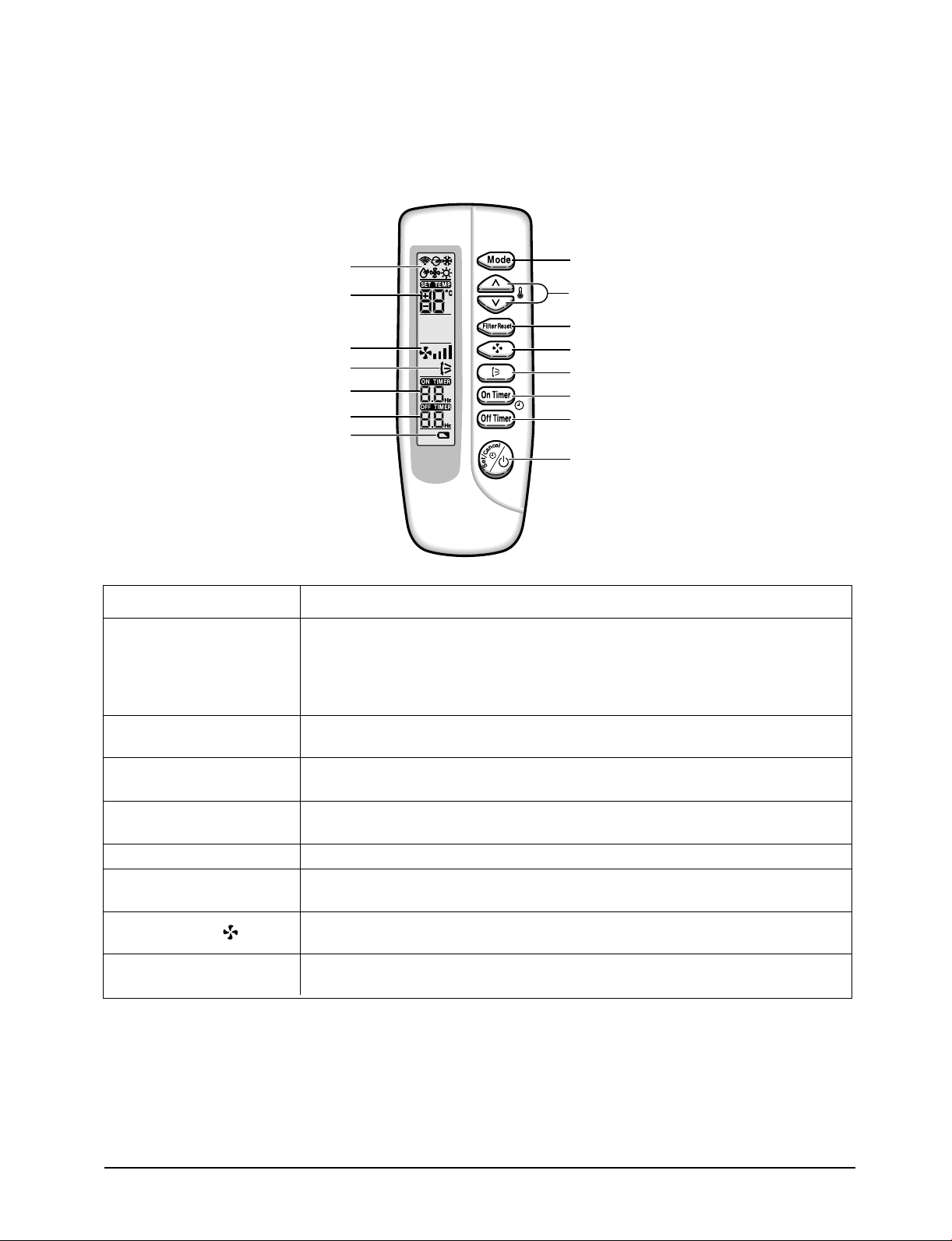

3-2-2 Wireless Remote Controller

Operating Instructions and Installation

NO

1

2

3

4

5

NAMED OF KEY

(UP)

(DOWN)

FUNCTION OF KEY

Power On/Off button to start and stop airconditioner or timer set up

Temp. up button. To increase the temperatute by the pressing

the temperature button

Temp. down button. To decrease the temperature by the pressing

the temperature button

Each time you press this button

Mode is changed in the following order

When the indicator appeard on the remoconscreen, cleaning the air

conditioner filter. After that, press the this button.

Each time you press this button,

FAN SPEED is changed in the following order.

FILTER SIGN

: Auto Mode : Blowing

: Cooling Mode : Heat Mode

: Dehumidifying Mode

6

7

8

Adjust air flow vertically.

The ON Timer enables you to switch onthe air conditioner automatically

after a given period of time that is from 30 minutes to 24 hours.

To cancel the On Time, press the (Set/Cancel) button.

The Off Timer enables you to switch off the air conditioner automatically

after a given period of time that is from 30 minutes to 24 hours.

To cancel the On Time, press the (Set/Cancel) button.

Samsung Electronics

3-3

Page 15

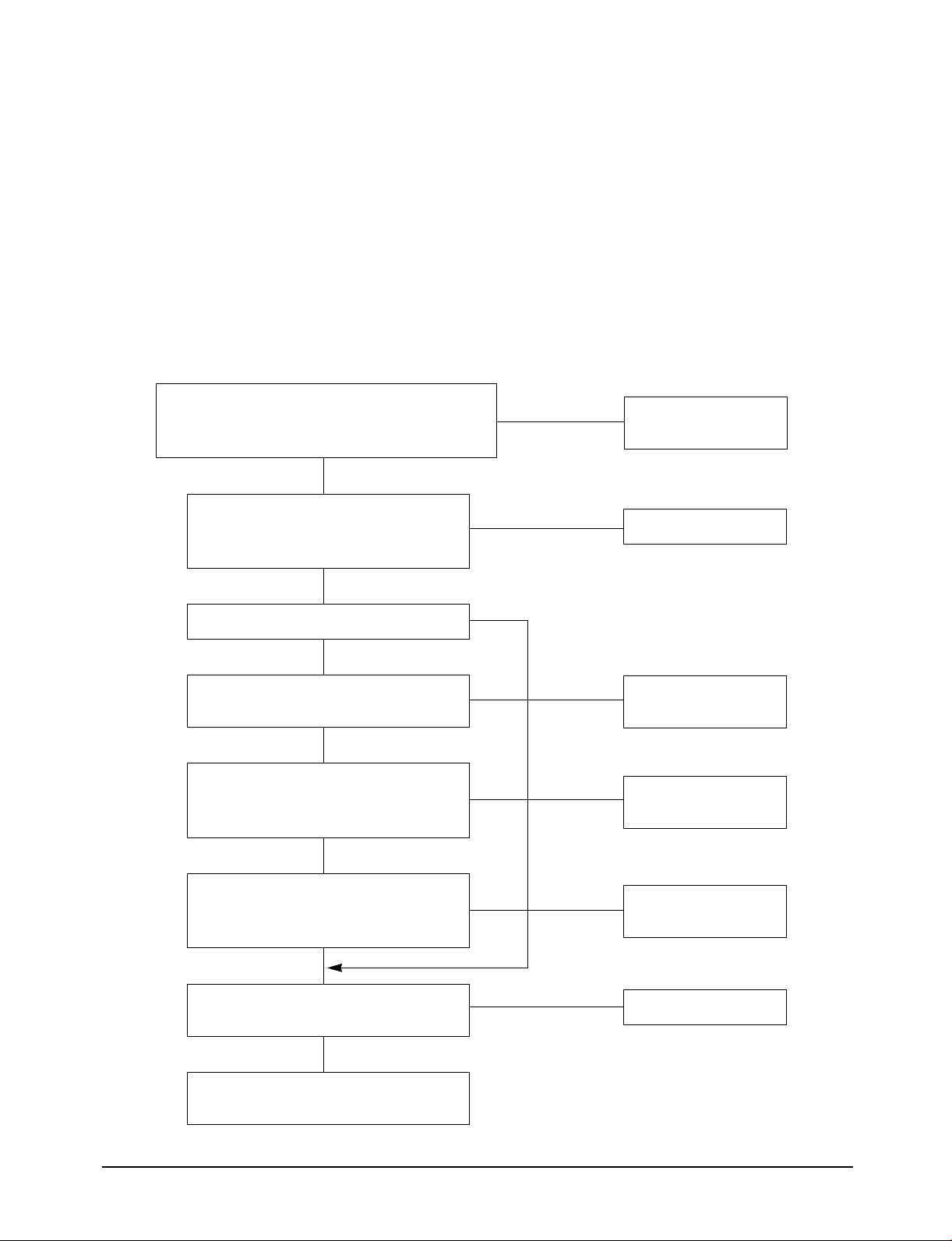

3-3 Control system diagram

Operation

mode

RECEIVE &

DISPLAYUNIT

ON/OFF KEY

WIRELESS

REMOTE

CONTROLLER

WIRED

REMOTE

CONTROLLER

CENTRALIZED

CONTROLLER

* Automatic operation

* Start/Stop, operation mode select, wind volume select,

temperature control, filter reset, reserved operation, up

and down operation(cassette), timer cancel

* Start/Stop, operation mode select, wind volume select,

temperature control, filter reset, reserved operation, up

and down operation(cassette), timer cancel, startup,

group control setting and disassembly

* Centralized control

→ 16 chamber set all on, 16 chamber set all off

→ Each chamber set on/off

→ Centralized control level setting

Operating

selection mode

Automatic

operation

Cooling

operation

Dehumidifying

operation

Blowing

operation

Heating

operation

Automatic change over according to the desired

temperature 18˚C ~ 30˚C.

Automatic wind volume control according to the difference between the desired temperature and room temperature

Room temperature control according to the desired

temperature (18˚C ~ 30˚C)

Humidity control depending upon the difference

between the desired temperature and the room

temperature (18˚C ~ 30˚C)

Indoor fan motor operation only (breeze, weak, strong

wind or weak, strong, turbo)

Room temperature control according to the desired

temperature (16˚C ~ 30˚C)

3-4

Samsung Electronics

Page 16

Operating Instructions and Installation

Wind volume

select mode

Wind flow select

mode

Reserved

operation mode

Manual 3 steps

Wind

volume auto

Up and down

rotation

Timer operation

for

30min ~ 24 hours

Breeze, weak, strong (available at cooling, heating,

blowing)

Auto wind volume control depending on the difference

between the desired temperature and room temperature

Available by wire and wireless remote controller and

operated only for rotation/stop (cassette type model

dedicated)

Selectable by wired & wireless remote controller and

available for start, stop, start/stop reservation

Samsung Electronics

3-5

Page 17

3-4 Micro Computer Block Diagram (Cassette) - Indoor

3-6

Samsung Electronics

Page 18

3-5 Micro Computer Block Diagram - Outdoor

Samsung Electronics

3-7

Page 19

MEMO

3-8 Samsung Electronics

Page 20

4. Installation

4-1 Operation of the Remote Controller (Wired/Wireless receiving board)

4-1-1 Name and function of each part for the wired remote controller

Communication error indicator

On Timer setting

Off Timer setting

Test indicator

Temperature adjustment

buttons

On Timer button

Off Timer button

Test button

Removing frost indicator

Operating mode

Mode selection button

Centralized controller indicator

(In case of installing the Centralized controller)

Temperature setting

Fan speed

Air flow direction

Filter Sign indicator

On/Off & Timer

Set/Cancel button

On/Off indicator

Fan speed

adjustment button

Swing button

Filter Reset button

BUTTON NAME FUNCTION

• Start and stop of operation

On/OFF & Timer

Set/Cancle

Temperature adujustment

(…, †)

On Timer

Off Timer

Test

Mode Selection

Filter Reset

Fan Speed

Flow Direction

- To toggle the operation On and Off.

• When making the reservation

- The reservation time can be set or canceled when pushing the Timer Set/ Cancel button

after adjusting the reservation time with On Timer or Off Timer.

• To increase (

…) or decrease (†) the desired temperature.

• One cycle or continuous operation is available.

• To increase the On reservation time

• One cycle or continuous operation is available.

• To increase the Off reservation time

• One cycle or continuous operation is available.

• Pressing the key for more than 3 seconds with the SET off starts the initial operation (forced

cooling operation for 3 minutes).

• To rotate in the order of AUTO → Cooling → Dehumidifying → Blowing → heating.

• When the filter sign display starts to show the replacement time of filter of indoor unit,

pressing the key after cleaning the filter resets the filter sign.

• The wind mode to rotate in the order of wind select button, Breeze → Weak → Strong →

Wind auto → Breeze.

• The blades ard moving between up and down.

Samsung Electronics

4-1

Page 21

Installation

4-1-2 Name and function of each part for the wireless remote controller

Operating mode

Temperature setting

Fan speed

Air flow direction

On Timer setting

Off Timer setting

Battery discharge indicator

Mode selection button

Temperature adjustment

buttons

Filter Reset button

Fan speed adjustment button

Swing button

On Timer button

Off Timer button

On/Off & Timer Set/Cancel

button

BUTTON NAME FUNCTION

• Start and stop of operation

On/OFF & Timer

Set/Cancle

Temperature adjustment

(…, †)

On Timer

Off Timer

Mode

Filter Reset

Fan Speed( )

Swing button

(Timer Cancel)

- To toggle the operation On and Off.

• When making the reservation

- The reservation time can be set or canceled when pushing the Timer Set/ Cancel button

after adjusting the reservation time with On Timer or Off Timer.

• To increase (…) or decrease (†) the desired temperature.

• One cycle or continuous operation is available.

• To increase the On reservation time

• One cycle or continuous operation is available.

• To increase the Off reservation time

• One cycle or continuous operation is available.

• To rotate in the order of Auto → Cooling → Dehumidifying → Blowing → Heating

• When the filter sign display starts to show the replacement time of filter of indoor unit,

pressing the key after cleaning the filter resets the filter sign.

• The wind mode to rotate in the order of wind select button, Breeze → Weak → Strong →

Wind auto → Breeze.

• The blades are moving between up and down. (In case of Cassette model)

• To cancel the reservation setting (In case of Duct model).

There is no test key separately assigned to the

wireless remote controller.

<When doing the test operation with wireless remote

controller...>

1. Remove both batteries from the wireless remote

controller.

4-2

2. At the state of simultaneous pressing of On Timer key

and Off Timer key, insert the batteries in the wireless

remote controller.

3. When the wireless remote controller is on the TEST

MODE, press On/Off key to make the SET for the Test

operation.

Samsung Electronics

Page 22

4-1-3 Appearance and function wireless receiving board

Installation

Timer indicator

Remote control sensor

Filter Sign

indicator

On/Off button

On/Off indicator

Removing frost

indicator

4-1-4 Opeartion specification of wireless receiving board

PART NAME

DEFROST LAMP

FILTER SIGN LAMP

TIMER LAMP

ON-OFF LAMP

ON-OFF BUTTON

Wireless receiving board and outdoor unit PCB display specification when error occurs

4-1-5

SOURCE & OPERATION SPEC.

RED, lamp on during defrost operation

Green, display during filter cleaning

Green, lamp when setting the reserve operation

Red, lamp during operation on

On/Off toggle operation

REMARK

in ERROR DISPLAY : flickering

in ERROR DISPLAY : filickering

in ERROR DISPLAY : flickering

in ERRO DISPLAY :flickerning

Operated only for automatic mode operation

ERROR MODE

(OUTDOOR DISPLAY)

E1

E5

E6

E9

EA

EC

Ed

Samsung Electronics

CONTENTS OF ERROR

Abnormal on indoor temperature sensor

(4.9[V] and higher, 0.5[V] and lower

Abnormal on indoor pipe temperature sensor

(4.9[V] and higher, 0.5[V] and lower

Abnormal on outdoor temperature sensor

(4.9[V] and higher, 0.5[V] and lower

Float switch detection

Indoor ↔ outdoor communication defect

Indoor unit ↔ wired remote controller

communication defect

Abnormal on outdoor pipe temperature sensor

(4.9[V] and higher, 0.5[V] and lower

WIRELESS RECEIVING BOARD

DISPLAY (INDOOR UNIT)

Reservation LED flickering

(1Hz period)

Operation LED and reservation

LED flickering (1Hz period)

Operation LED and filter LED

flickering (1Hz period)

Reservation LED and filter LED

alternating flickering (1Hz period)

Reservation LED and filter LED

flickering (1Hz period)

Operation LED and reservation

LED alternating flickering (1Hz

period)

Filter LED flickering (1Hz period)

REMARK

Restored when the indoor

temperature sensor is normal

Restored when the indoor pipe

temperature sensor is normal

Restored when the outdoor

temperature sensor is normal

Float switch detection

Re-detecting by operating off

signal after restoring

Restored when outdoor pipe

temperature sensor is normal

4-3

4-3

Page 23

Installation

Indoor unit

Wireless

receiving

board

Wireless

remote

controller

Outdoor unit

Indoor unit

Wireless

receiving

board

Wireless

remote

controller

Wired remote

controller

Outdoor unit

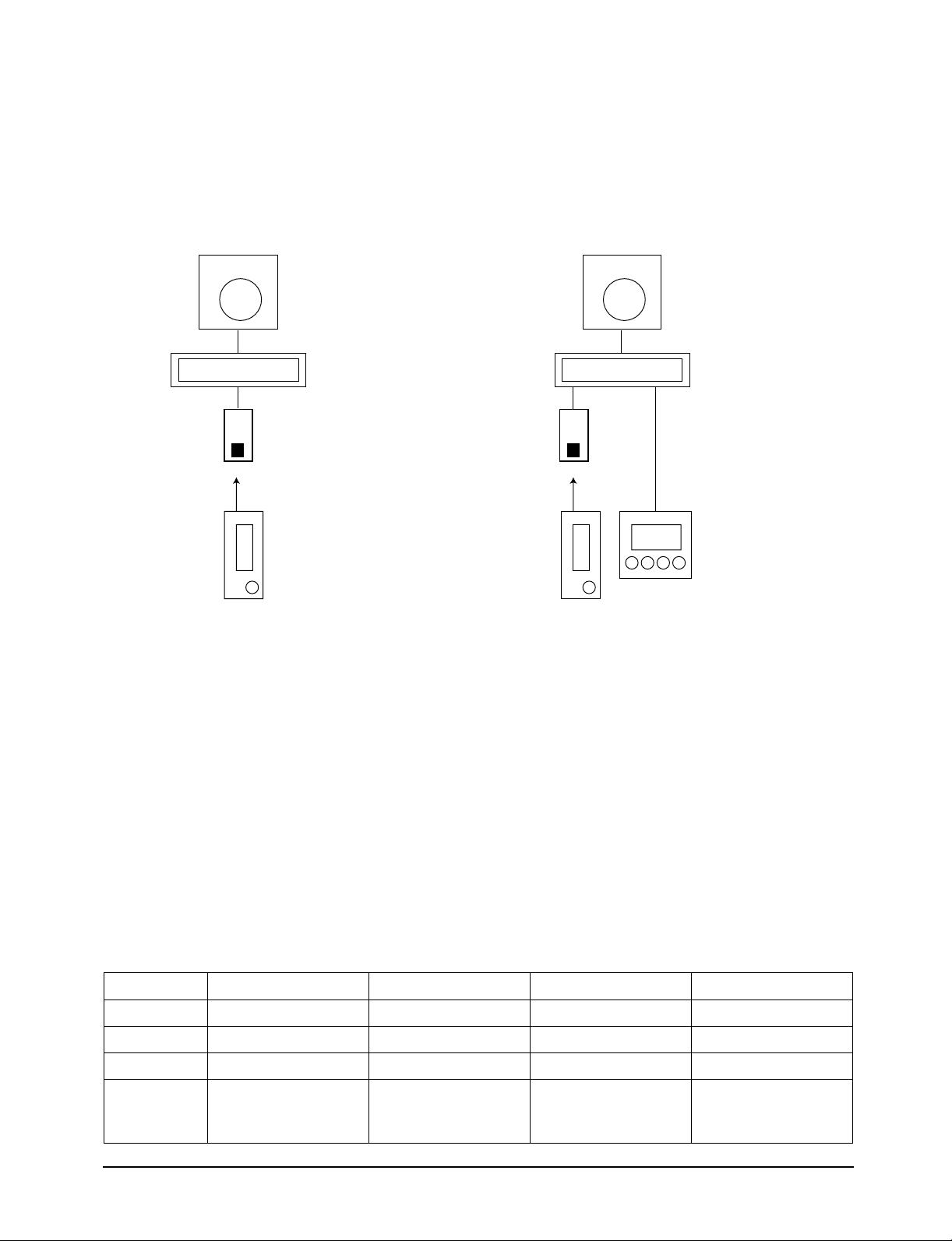

4-1-6 Example of remote controller control

1 chamber wireless remote controller single operation and 1 chamber wireless remote controller + wired

remote controller combination control

Example of 1 chamber single operation

(wireless remote controller)

* In case of 1 chamber single operation (wireless remote controller+wired remote controller), both setting of wired remote controller

to MASTER/SLAVE is available.

Example of 1 chamber single operation

(wireless + wired remote controller)

<Setting of wired remote controller to MASTER MODE >

1. Put off the power.

2. For the combined use of wired remote controller

and wireless remote controller, put on the option

switch(DS01)4 of wired remote controller.

✽ After resetting the option in the wired remote

controller, be sure to put the power on again so

that the set option can be applied.

3. Putting off the option switch 4 of wired remote

controller disables the control by wireless remote

controller.

4. Put on the power.

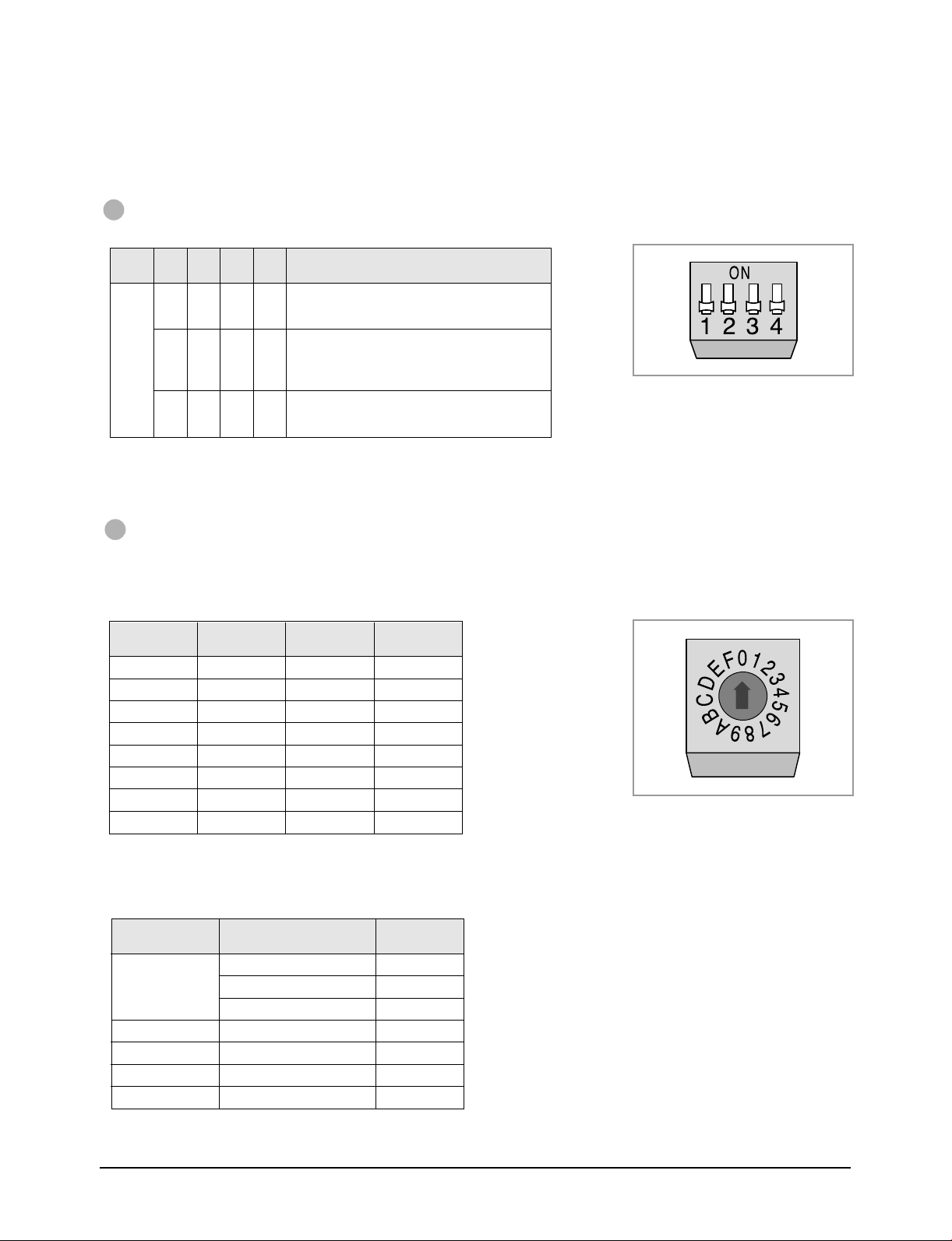

4-1-7 PCB option and switch(DS01) setting of wired remote controller

DIP SWITCH NO

1

2

3

OPTION ITEM

Basic specification

Indoor unit control

Basic specification

SW ON

Group control

SW OFF

-

-

Indoor unit 1 chamber control

-

-

DEFAULT

Fixed to OFF

OFF

Fixed to OFF

4-4

4

Combined use of

wireless remote

controller

Able to operate of wired

remote controller

(SLAVE MODE)

Disable to operate the

wireless remote controller

(MASTER MODE)

OFF

Samsung Electronics

Page 24

4-1-8 Function comparison of wired remote controller vs wireless remote controller

Installation

In case of control for the wired remote controller

and wireless remote controller installed

individually, almost similar functions are

performed, and in case of combined use of wired

and wireless remote controllers, Enalbe/Disable

PART NAME

Operation ON/OFF

Wind flow setting

Wind volume setting

Group operation

Test operation

Operation mode setting

Reservation function

Timer cancel

Temperature setting

WIRED REMOTE CONTROLLER

ON/OFF available

Up and down control available (Cassette model)

Breeze/Weak/Strong/Wind auto adjustment available

16 chamber group operation available

Test operation by test button

Settable of auto/cooling/

dehumidifying/blowing/heating

Start/stop/start-stop reservation available

Timer cancel button provided (Duct model)

Cooling : 18˚C ~ 30˚C

Heating : 16˚C ~ 30 ˚C settable

can be set at the wired remote controller for the

wireless remote controller but the 16 chambers

operation can be done only from wired remote

controller.

WIRELESS REMOTE CONTROLLER

ON/OFF available

Up and down control available (Cassette model)

Breeze/Weak/Strong/Wind auto adjustment available

16 chamber group function not available

Available by combination of button during the power

reset without test button

Settable of auto/cooling/

dehumidifying/blowing/heating

Start/stop/start-stop reservation available

No timer cancel button

Cooling : 18°C ~30°C

Heating : 16°C ~30°C settable

Filter reset

Centralized control display

Self-diagnosis among the

group control

Error display

Master/slave setting

Filter reset button provided

Displayed as centralized control

To display while scanning the installed set

during reset

Displayed as 2 digit segment

Master/slave settable by PCB option switch

Filter reset button provided

No function

No function

No function

No function

4-1-9 Option and dip switch setting(SW2) of ass'y main in PCB

DIP SWITCH

1

2

3

4

5

OPTION ITEM

VENTILATOR FAN

DRAIN PUMP

FLOAT SWITCH

FILTER CLEANING PERIOD

INDOOR FAN MOTOR SPEED

SW ON

Not installed

Installed

Installed

1000 Hr

NORMAL SPEED

SW OFF

Installed

Not installed

Not installed

2000 Hr

HIGH SPEED

DEFAULT

-

-

-

-

-

Samsung Electronics

4-5

Page 25

4-2 Control of the Remote Controller

Indoor unit

"A" chamber

Wireless

receiving board

Wireless

remote

controller

Outdoor unit

Wired remote

controller

Indoor unit

"B" chamber

"C" ~"N" chamber

Wireless

receiving board

Wireless

remote

controller

Outdoor unit

Wired remote

controller

"O" chamber

Wireless

receiving board

Wireless

remote

controller

Wired remote

controller

"P" chamber

Wireless

receiving board

Wireless

remote

controller

Wired remote

controller

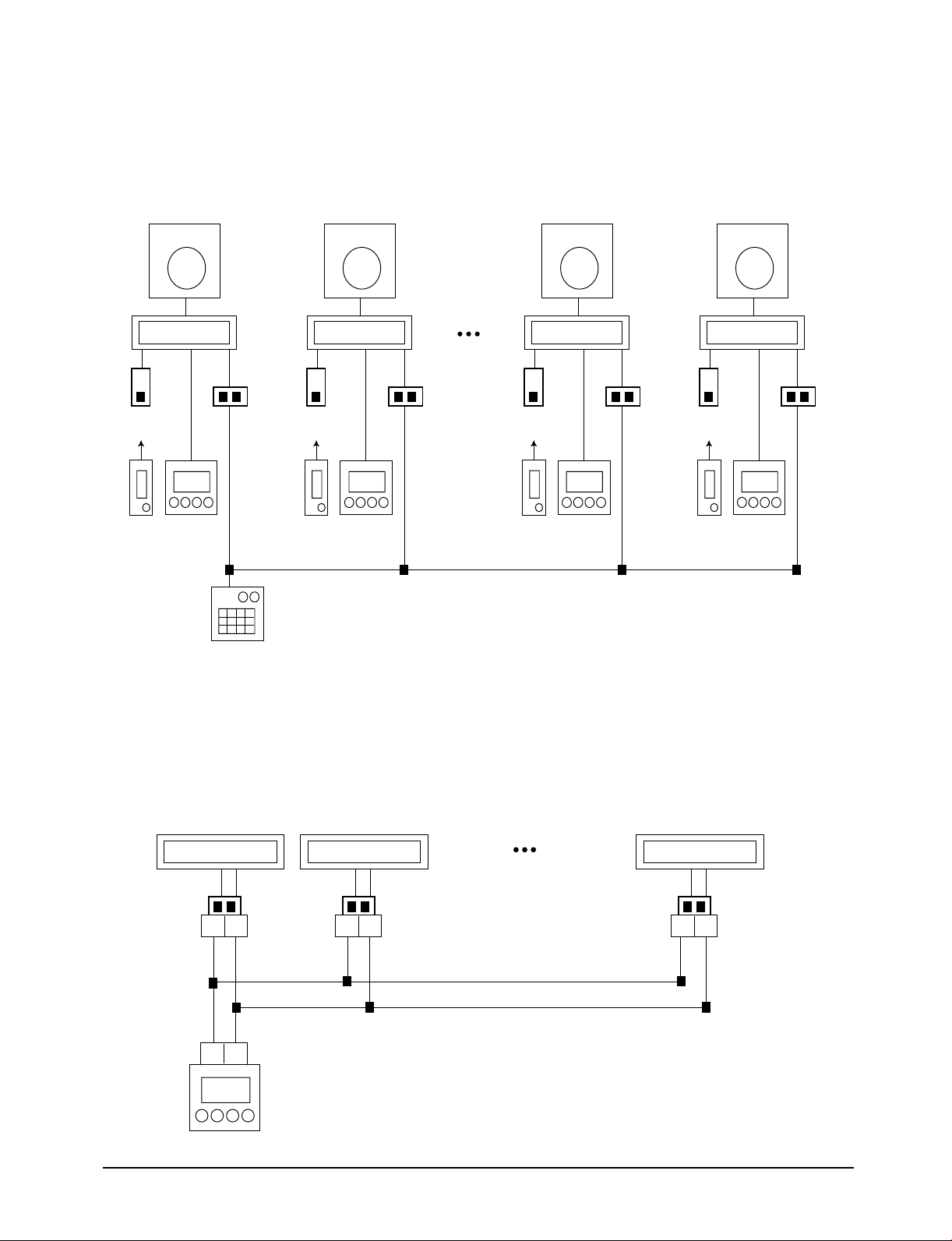

4-2-1

Chamber Group Control(Wireless remote controller + Wired remote controller system)

• The 16 chamber remote controller operation by wired remote controller can be simultaneously performed

all for 16 chambers through setting the 16 chambers to one group through one wired remote controller.

• While operated in Group, the control by wireless remote controller installed in all chambers (“A” ~ “F”)

is disabled except the wired remote controller installed in the “A” chamber and the simultaneous use

with the option item, the centralized controller is also disabled.

4-2-2

1. Setting of indoor unit Main PCB

The group operation of 16 chambers and operation method by wired remote controller

• Put off all of set power installed in each room.

• Remove the centralized controller if any is used already.

• Remove CN20 connector and wire of main PCB of Indoor unit except the one installed in “A” with

reference of the figure.

• Connect the communicating line from “A” chamber to “F” chamber.(R1<->R1, R3<->R3)

• Connect the “R1”, “R2” and “R3” of indoor terminal board installed to the “R1”,”R2”,”R3” of wired

remote controller, respectively.

• Adjust the address of digital switch of indoor unit PCB in “A” chamber to “0”.

Adjust the address of digital switch of indoor unit PCB in “B” chamber to “1”. In such a way, adjust the

address of digital switch up to chamber “F”.

4-6

Samsung Electronics

Page 26

• Put on the set power installed in each chamber.

Caution :

• During the connection, connect the “R1” of indoor unit terminal board installed in each chamber with “R1”.

• During the connection, connect the “R3” of indoor unit terminal board installed in each chamber with “R3”.

• Do not connect the terminal R2 of indoor unit terminal board from “B” to “F” chamber except A” chamber.

• The option item, centralized controller shall be removed since the simultaneous use with wired remote controller is disable

during the group control.

• Adjust the address of indoor unit digital switch installed in each chamber so that it might not be duplicated.

2. Setting of wired remote controller

• Put off the set power where the wired remote controller is installed.

• Put on the option switch SW2(DS01) of wired remote controller.

• Put on the set power where the wired remote controller is installed.

Installation

Caution :

• The option can be applied when the power is put again after resetting the option of wired remote controller. Be sure to keep the

set power on/off after option setting.

Samsung Electronics

4-7

4-7

Page 27

R1 R2 R3

R1 R2 R3

Indoor unit

"A" chamber

R1 R2 R3

Indoor unit

"B" chamber "C" ~ "N" chamber

R1 R2 R3

Indoor unit

"O" chamber

R1 R2 R3

Indoor unit

"P" chamber

Wired remote

controller

Installation

4-2-3 Operation method of wired remote controller

Figure. 16 Chamber Group Control Connection Diagram

• Press the ON/OFF button of wired remote controller to be on.

At the time, the set installed from A chamber to F chamber is getting on in order with the interval of 2

seconds.

• Select the operation of auto/cooling/dehumidi-fying/blowing/heating by pressing MODE BUTTON.

• Select breeze/weak/strong/wind auto by pressing the wind volume button.

• Adjust the temperature set button to set the desired temperature.

✽ For reference

• The communication between wired remote

controller and indoor unit is made through the

synchronization with the output signal of zero

cross detect circuit, and when 50Hz power is

used, it has the 50bps transmission speed and

Indoor unit

RECEIVE MODE

SEND MODE

Wired remote

controller

when it has 60Hz power it has 60bps transmission

speed. The transmission data between the wired

remote controller and indoor unit is shown as in

the figure.

Since the communication data between wired remote

controller and indoor unit is consisting of total

10Byte, 2 seconds are required when using 50Hz

power.

• For the communicating time with 16 chambers

during the normal operation, 32 seconds are

required and for the time with 16 chamber during

the reservation operation, 64 seconds are required

Caution :

• The power of each chamber shall be used with the one

having the same frequency during the group operation by use

of wired remote controller.

• The communicating line between the wired remote controller

and indoor unit shall be of 100 m at maximum.

due to the increase of communicating data.

4-8

Samsung Electronics

Page 28

4-2-4 Startup method by wired remote controller

Installation

Startup in case of the “A” chamber single

operation

• Put on the set power.

• Adjust the address of digital switch of indoor

unit PCB to “0”.

• Put ON the option switch(DS01) N02 of wired

remote controller PCB.

• Put on the set power.

• Press the test button of wired remote controller

Error Code

01

05

06

09

Indoor unit room thermistor error

Indoor unit pipe thermistor error

Outdoor unit thermistor error

Float switch open error

Meaning

for more than 3 seconds.

• The set is operated for 3 minutes by the forced

cooling operation and the set is off after 3

minutes.

• The error occurring during the test operation is

displayed on the wired remote controller

windows and it shall be referred to the

following table.

Checking Area

• Indoor unit thermistor available or not and

disconnected

• Indoor unit PCB

• Indoor unit pipe thermistor

• Indoor unit PCB

• Outdoor unit thermistor

• Outdoor unit PCB

• Drain pump, float switch

• Drain system

• Dip SW2 of indoor unit main PCB

(If the drain pump is not installed, SW2 and

SW4 shall be at the Off position.)

0A

0C

0D

Indoor unit ↔ outdoor unit communicating error

Wired remote controller ↔ indoor unit

communication error

Outdoor unit pipe thermistor error

• Indoor unit ↔ outdoor unit communicating

error

• Indoor unit ↔ outdoor unit communicating

cable

• Indoor unit PCB, Outdoor unit PCB

• Wired remote controller ↔ indoor unit

communication cable

• Indoor unit main PCB

• Outdoor unit pipe thermistor

• Outdoor unit PCB

Caution :

• Unless the address of digital switch of indoor unit PCB is set to “0” in case of “A” chamber single operation, the control by the wired

remote controller is disabled.

• The power of SET shall be put on again after the resetting of wired remote controller option so that the the set option can be applied.

Be sure to keep the power on/off of SET before and after the setting.

• The first digit of error code displayed during the single operation and group operation may be different. The first digit(MSB) stands for

the address of the set where the error occurs. Since it is the single operation, the address of SET is “0”.

Samsung Electronics

4-9

4-9

Page 29

Installation

Startup of group operation

• Put off the power of SET.

• Adjust the addresses of digital switch of indoor

unit PCB to “0”~”15”, respectively.

• Put on the option switch SW2 of wired remote

controller PCB.

• Put on the power of SET.

• On the wired remote controller display, the digits

“00” → “11” → “22” → are displayed up to “FF”.

After “FF” display, the wired remote controller is

automatically set to the preserved operation

status of indoor unit of chamber “A”.

Error Code

*1

*5

*6

Indoor unit room thermistor error

Indoor pipe thermistor error

Outdoor unit thermistor error

Meaning

• If the current SET of chamber “A” is ON, put the

set off by pressing the ON/OFF button.

Only at the SET off of chamber “A”, the TEST mode

is enabled.

• Press the TEST BUTTON of wired remote

controller for more than 3 seconds.

• If the SET is operating for 3 minutes through

forced cooling operation, the SET is off after 2

minutes.

• The Error occurring in the TEST operation

displays in the wired remote controller display

window and is referred to the following table.

Checking Area

• Indoor unit thermistor exist or not disconnected

• Indoor unit PCB

• Indoor unit pipe thermistor

• Indoor unit PCB

• Outdoor unit thermistor

• Outdoor unit PCB

*9

*A

*C

*D

Float switch open error

Indoor unit ↔ outdoor unit communication error

Wired remote controller ↔ indoor unit

communication error

Outdoor unit pipe thermistor error

• Drain pump, float switch

• Drain system

• Dip SW2 of indoor unit main PCB

(If drain pump is not installed, SW2 and SW4

shall be at OFF position.)

• Indoor unit ↔ Outdoor unit communication cable

• Indoor unit PCB, outdoor unit PCB

• Wired remote controller ↔ indoor unit

communication cable

• Indoor unit main PCB

• Outdoor unit pipe thermistor

• Outdoor unit PCB

Caution :

• Test operation is disabled when the chamber “A” is on after initialization of wired remote controller.

• The communication time between wired remote controller and indoor unit is required for 2 seconds. If any one of set is ON, be sure to

put it off by pressing the ON/OFF button and start the TEST operation after 35 seconds at minimum.(The communication time with all

chambers : 16 x 2 seconds = 32seconds)

• For the reservation operation, the communication time between all 16 chambers is required for 64 seconds due to the increase of

communication data.

• The first digit (MSB) of error code displayed during the group operation stands for the address of SET where the error occurs.

4-10

Samsung Electronics

Page 30

4-3 Controller

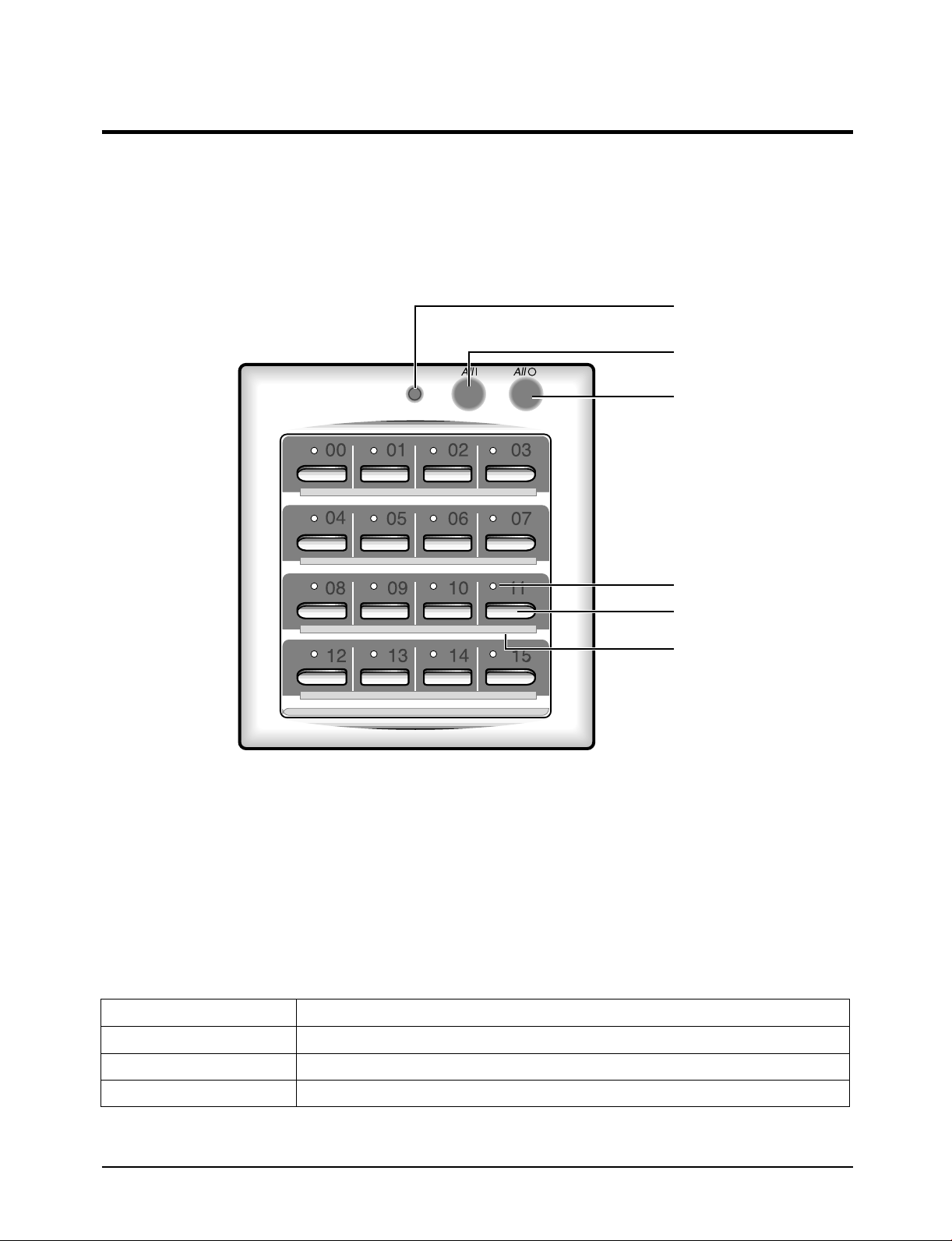

4-3-1 Appearance and characteristics of Centralized Controller

The centralized controller is installed on the wall.

The centralized controller is an optional accessory.

Operating lamp

All On button

All Off button

NOTE : Operating lamp comes on when at least one air conditioner

connected to the centralized controller is operating.

• Since the centralized controller has the relay

equipment, the option mounted on the indoor

unit, the On/Off can be set for 16 chambers

through the modem communication.

• Linkage of wired remote controller to wired

remote controller is available by 3 kinds of level.

BUTTON NAME

On/Off indicators

On/Off buttons

Index

• The maximum extended distance of 1 Km is

possible through modem communication. (the

relay equipment is installed at the option item,

indoor unit)

• The connection by non-polarity method is easy.

FUNCTION

ALL1

ALL0

"01" ~ "16"

Samsung Electronics

• To put on all 16 chambers' set.

• To put off all 16 chambers' set.

• To put on/off set assigned with the number.

4-11

Page 31

Installation

Indoor unit

"A"

chamber

Transmitter

Wireless

receiving board

Wireless

remote

controller

Outdoor unit

Wired remote

controller

Centralized controller

"C" ~"N" chamber

16

chamber

Indoor unit

"B"

chamber

Transmitter

Wireless

receiving board

Wireless

remote

controller

Outdoor unit

Wired remote

controller

Indoor unit

"O"

chamber

Transmitter

Wireless

receiving board

Wireless

remote

controller

Outdoor unit

Wired remote

controller

Indoor unit

"P"

chamber

Transmitter

Wireless

receiving board

Wireless

remote

controller

Outdoor unit

Wired remote

controller

01 02

Indoor unit

"A" chamber "B" chamber "P" chamber

"C" ~ "O" chamber

Transmitter Transmitter Transmitter

01 02 01 02

Indoor unit

01 02

Indoor unit

4-3-2 Example of the centralized control system configuration

Figure. 16 Chambers Centralized Control (wireless remote controller + wired

remote controller + centralized controller) System

4-3-3 Chambers Cnetralized Control System Connection Diagram

4-12

Samsung Electronics

Page 32

Installation

4-3-4 Centralized control operation method

1. Setting of indoor unit

• Put off the set to be installed.

• Put off the power of the centralized controller.

• Mount the Transmitter, the option item on the indoor unit set terminal board.

• Adjust the address of digital switch of Transmitter mounted. (Adjust the address of Transmitter

mounted in chamber “A” to “0” and “B” to “1”... continue the adjustment up to “F” to “F”)

• Connect the terminals O1 and O2 of the terminal board mounted on the centralized controller to the O1

and O2 of the terminal board installed in chamber “A”.

• If the wired remote controller is installed, be sure to put off the SW2(DS01) of PCB option switch.

• Remove the centralized controllers installed at chamber “B” to chamber “F” if any except the A

chamber.

• Adjust the address of digital switch of indoor unit PCB to “0”.

• Connect O1 and O2 of terminal board installed in chamber A to O1 and O2 of terminal board installed

in chamber B.

• Continue to connect O1 and O2 of terminal board mounted on indoor unit in chamber B ~ F to O1 and

O2 of terminal board of centralized controller(recommended).

2. Setting at centralized control side

• Adjust the applicable level of centralized controller with the reference of the table.

3. When the setting is finished at indoor unit and centralized controller,

• Put on the power of installation completed set of each chamber.

• Put on the power of centralized controller.

DIP SWITCH

LEVEL 0

LEVEL 1

LEVEL 2

Error Code

LED flickering

SW1

OFF

OFF

OFF

SW2

OFF

OFF

OFF

Communication error between indoor unit and

centralized controller

SW3

OFF

OFF

ON

Meaning

SW4

OFF

ON

OFF

Set operation according to the final controlled one among the

centralized controller, wire, and wireless

When centralized controller OFF : disable to control wired and

wireless

When centralized controller ON : enable to control wired and

wireless

Enable to control only in the centralized controller

Disable to control the wired and wireless remote controller

Transmitter, indoor unit, centralized controller

REMARK

Checking Area

Caution :

• The communication between centralized controller and Transmitter is modem method and there is no polarity but connect “O1”

terminal to “O1” terminal and “O2” terminal to “O2”terminal.

• The address of Transmitter mounted on each indoor unit shall not be duplicated.

• After the resetting of operation level of centralized controller, it is not necessary to reset the power differently from that of wired

remote controller. In other words, the operation level can be reset even during the operation if required.

Samsung Electronics

4-13

Page 33

Installation

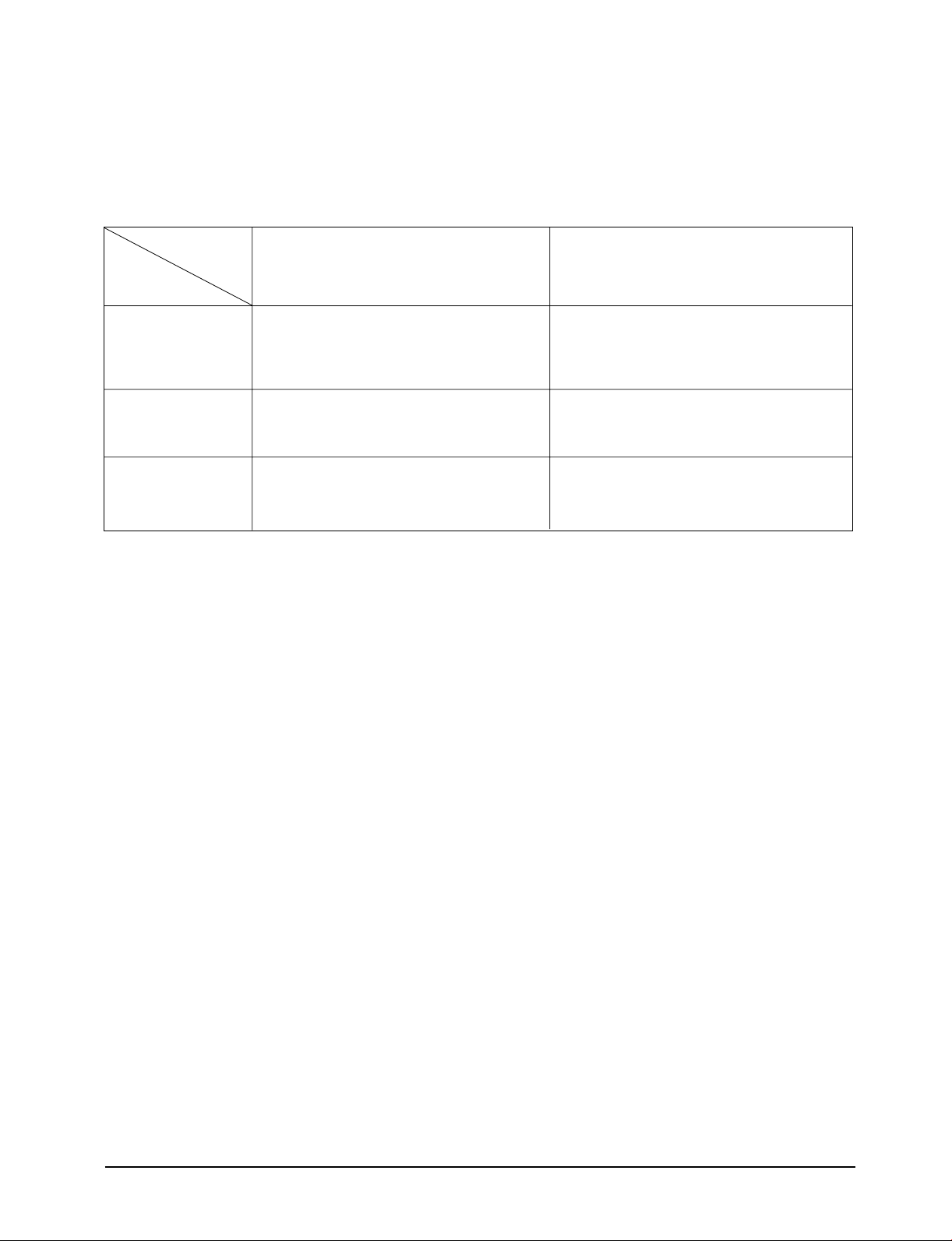

4-3-5 Operation specification of wireless and wired remote controller while using the

centralized controller.

Centralized

controller

LEVEL 0

LEVEL 1

LEVEL 2

Wired remote

controller

MASTER

Wired remote controller has the priority of control

over the wireless.

A area : to be operated be the final input of

centralized controller and wired remote controller,

and the wireless remote controller does not work

even through installed.

B area : The wired remote controller operates only

when the centralized controller is on but the wireless

remote.

C area : only the centralized controller operates but

the wired and wireless remote controller do not

work.

SLAVE

Wired remote controller has not the priority of control

over the wireless.

D area : to be operated by the final input of

centralized controller, wired remote controller and

wireless remote controller.

E area : the wired and wireless remote controller

operate only when the centralized controller in on.

F area : only the centralized controller operates but

the wired and wireless remote controller do not

work.

4-14

Samsung Electronics

Page 34

4-4 Selecting Area for Installation

Select an area for installation that is suitable to

the customer’s needs.

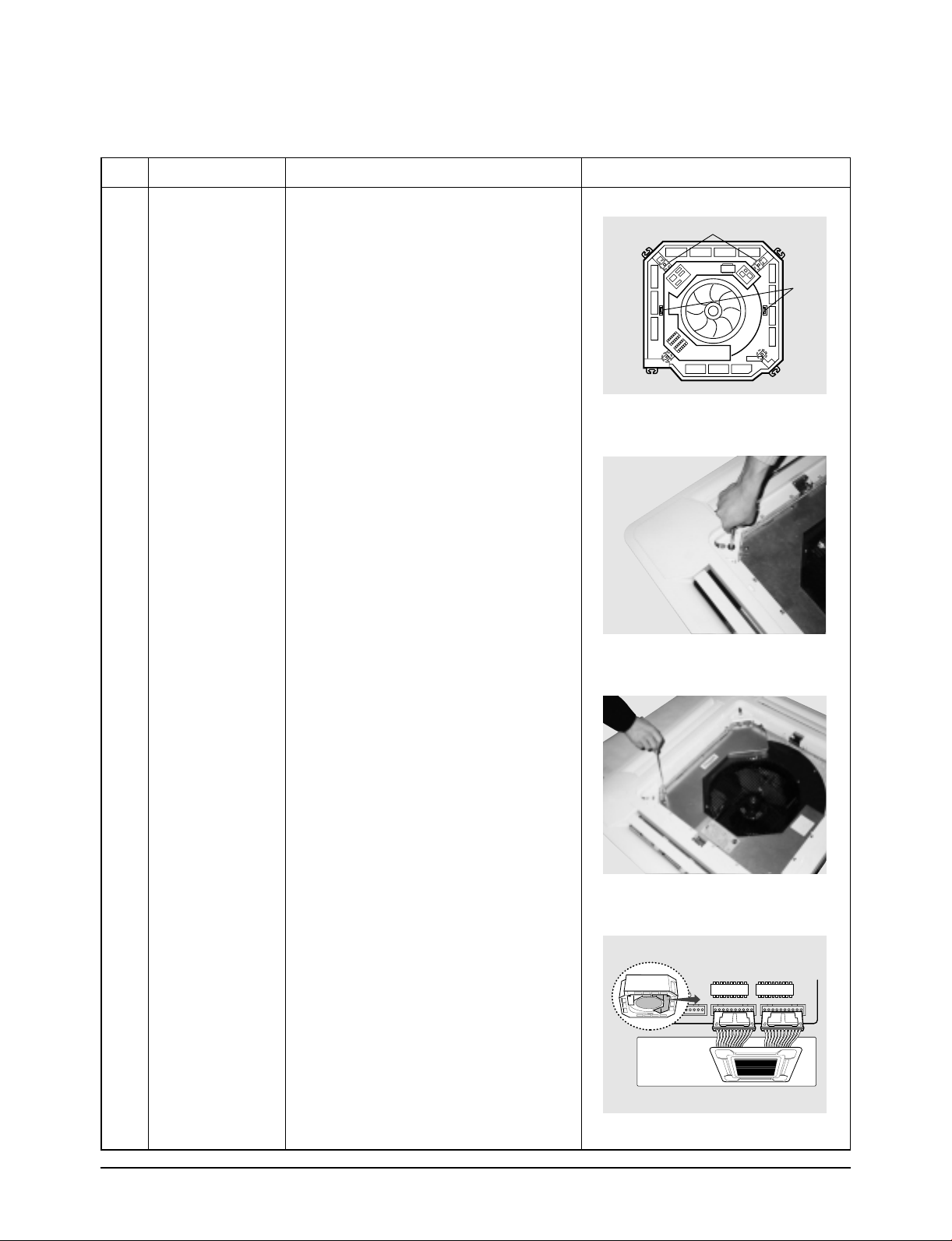

4-4-1 Indoor Unit

1. Make sure that you install the indoor unit in an

area providing good ventilation. It must not be

blocked by an obstacle affecting the airflow near

the air inlet or the air outlet.

2. Make sure that you install the indoor unit in an

area allowing good air handling and endurance

of vibration of the indoor unit.

3. Make sure that you install the indoor unit in an

area where there is no source of heat or vapor

nearby or direct sunlight.

4. Make sure that you install the indoor unit in an

area from which hot or cool air will spread

evenly in the room.

10. Please use the given accessories to install the

indoor unit. (set of slings)

• Check that the installed location is strong

enough to hang the indoor unit on.

• The distances of the following should be

limited:

The lengths of refrigerant tube 30 m.

The height difference between indoor and

outdoor unit should be less than 15 m.

5. Make sure that you install the indoor unit in an

area that provides easy pipe connection with

the outdoor unit, and easy drainage for

condensed water.

6. The ceiling should not be inclined by more than

2 degrees.

7. The distance between the indoor unit and the

outdoor unit should not be longer than A.

(recommended distance between two units is 5m.).

and the height difference between the indoor unit

and the outdoor unit should be less than B.

Model

A

B

30m ✳✳18/24✳✳

50m ✳✳36/44✳✳

15m ✳✳18/24✳✳

25m ✳✳36/44✳✳

8. There should be enough space around the indoor

unit to provide easy installation and service.

★

150cm

★

Air flow out

Air flow out

150cm

20 cm

20cm

Air flow in

100cm

Air flow in

20cm

Air flow out

20cm

Air flow out

★

★

150cm

150cm

9. There are 4 ways to select the number of air outlets

(see the figure). The selection depends on the

shape of the room and installation location of

indoor units.

Samsung Electronics

Remark : The distance of “★” sign will equal 20 cm ,

if you close the air outlet on that side.

4-15

Page 35

0.15 m.

1.5 m.

Building

Wall

Installation

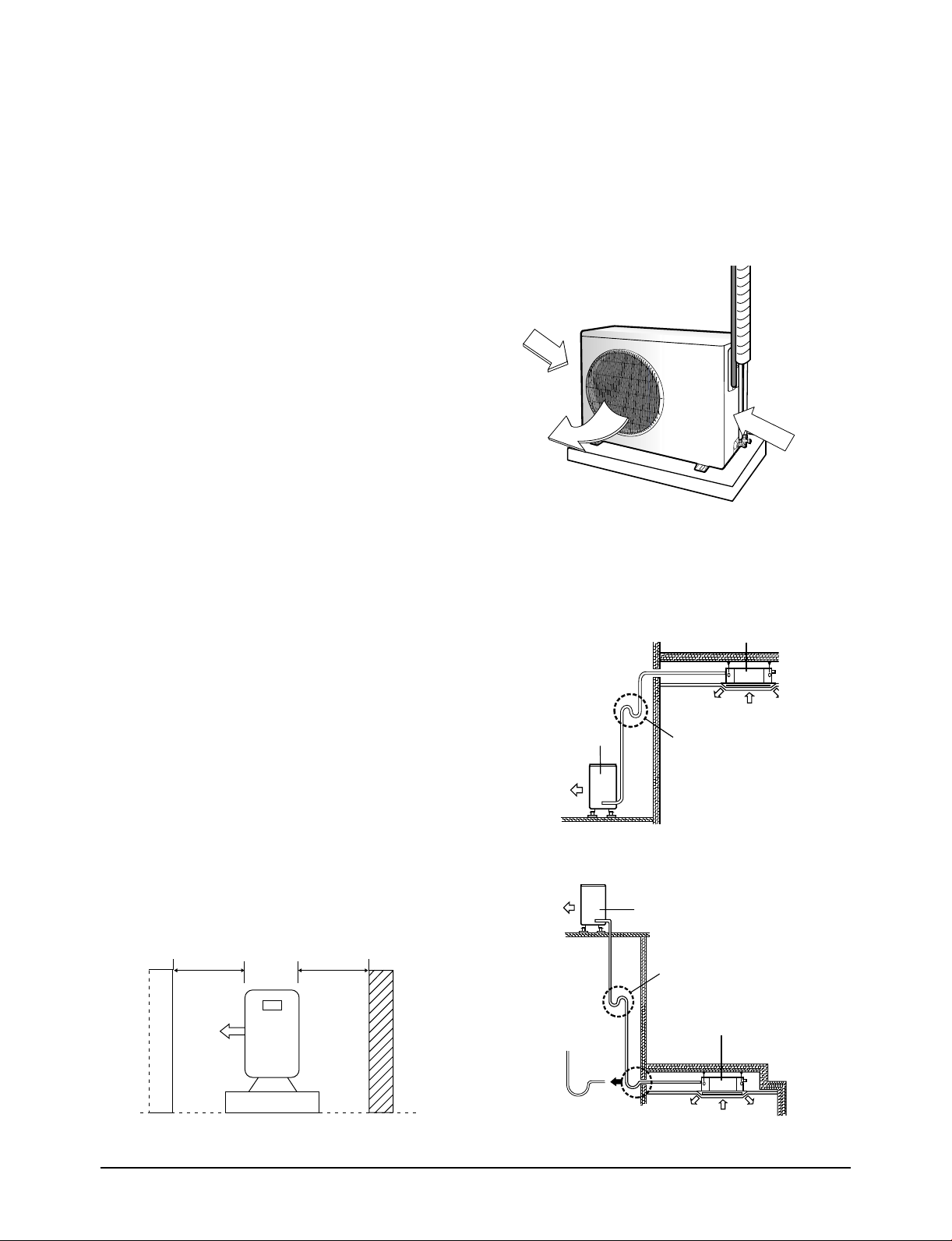

4-4-2 Outdoor unit

1. Make sure that you install the outdoor unit in

an area not exposed to the rain or direct

sunlight. (Install a separate sunblind if exposed

to direct sunlight.)

2. Make sure that you install the outdoor unit in

an area, not amplifying noise or vibration,

especially to avoid disturbing neighbours. (Fix

the unit firmly if it is mounted on a high place.)

3. Make sure that you install the outdoor unit in

an area providing good ventilation and which is

not dusty. It must not be blocked by any

obstacle affecting the airflow near the air inlet

and the air outlet.

4. Make sure that you install the outdoor unit in

an area free from animals or plants.

5. Make sure that you install the outdoor unit in

an area not blocking the traffic.

6. Make sure that you install the outdoor unit in

area easy to drain condensed water.

10. If you install the outdoor unit in a location that

has open airflow, you should install the outdoor

unit in a direction that airflow out from the

outdoor unit is perpendicular to the open air

flow direction.

Open Air

Air flow out

Open Air

11. Install the oil trap according to the installation

condition. (see the figure)

a. When the indoor unit is above the outdoor unit

Indoor unit

7. If installed on a desk, it should not be installed

in a direction that puts open airflow is against

airflow from the outdoor unit. It will make the

air conditioner malfunction.

8. Do not let hot air flow into the outdoor unit

because the air conditioner will malfunction.

The hot air may come from other near-by the

outdoor unit or heating equipment or itself.

9. If install the outdoor unit directly against the

wall, the minimum distance between the

outdoor unit and the wall should be 1.5 m.

Outdoor unit

b. When the outdoor unit is above the indoor unit

Radius

5cm

Oil trap

(suction tube)

Oil trap

(Must be installed every 6m)

Outdoor unit

Oil trap

(Must be installed every 6m)

Indoor unit

4-16

Samsung Electronics

Page 36

Installation

12. You should leave spacing around the outdoor

unit at least according to the figure for easy

installation, service and ventilation.

0.1 m.

0.1 m.

0.35 m.

13. Install the outdoor unit on a rigid base.

14. Fasten the outdoor unit to the base by using

bolts or nuts.

15. In case of hanging the outdoor unit, you should

hang it on a rigid wall area and use right angle

steel thickness of 4 mm. as a holder.

Rigid wall

Fasten right angle steel by using screws

Right angle steel thickness of 4 mm.

Caution :

It is harmful to the air conditioner if it is used in the following

environments: greasy areas (including near machines), salty

areas such as coast areas, areas where sulfuric gas is present

such as hot spring areas, large variance in electricity voltage

such as in a factory. Contact your dealer for advice.

Samsung Electronics

4-17

Page 37

Installation

O

WNER'S

INSTRUCTIONS

SPLIT-TYPE

R

OOM AIR CON

D

I

T

I

O

NE

R

OWNE

R

'S

I

NSTRUC

T

IONS

MAN

UA

L DE I

NS

TRUC

CIO

N

ES

IS

TRU

Z

I

ONI PER L'USO

M

ANUAL D

E

INSTR

UÇ

Õ

ES

MANUEL D'UTILISATIO

N

GEB

RA

UCHSA

NWEISUNG

Splut-type Room Air

Co

ndi

t

ioner

Aire

acon

dicionado do

m

é

st

ico sist

ema Split

Con

d

izionator

e d'

aria p

er

ambienti ad unità Separate

Aparelho de ar cond

i

c

i

onado

ti

po S

pl

it

Cl

i

matiseur de

type séparé

Get

e

ilte raumklim

aa

nlage

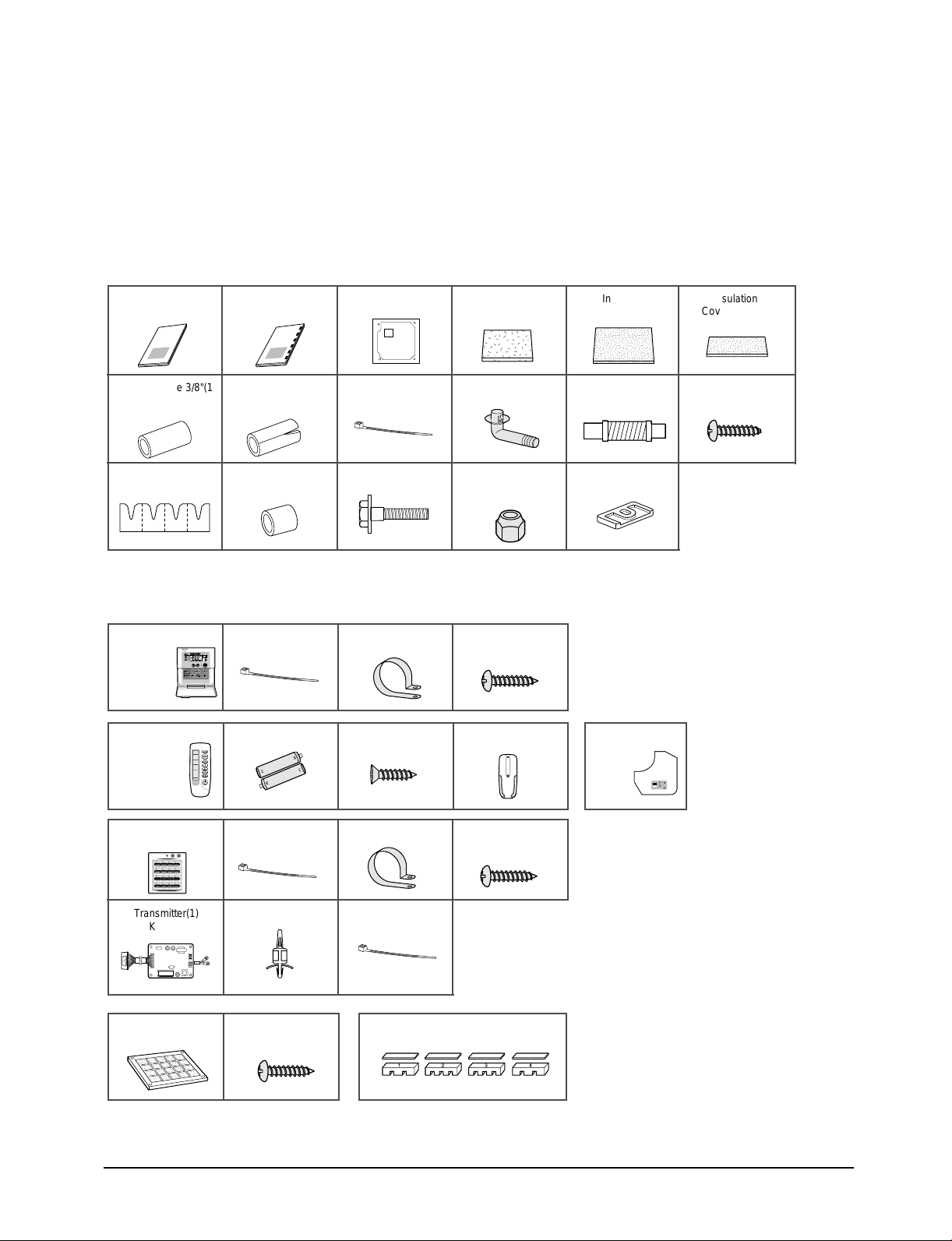

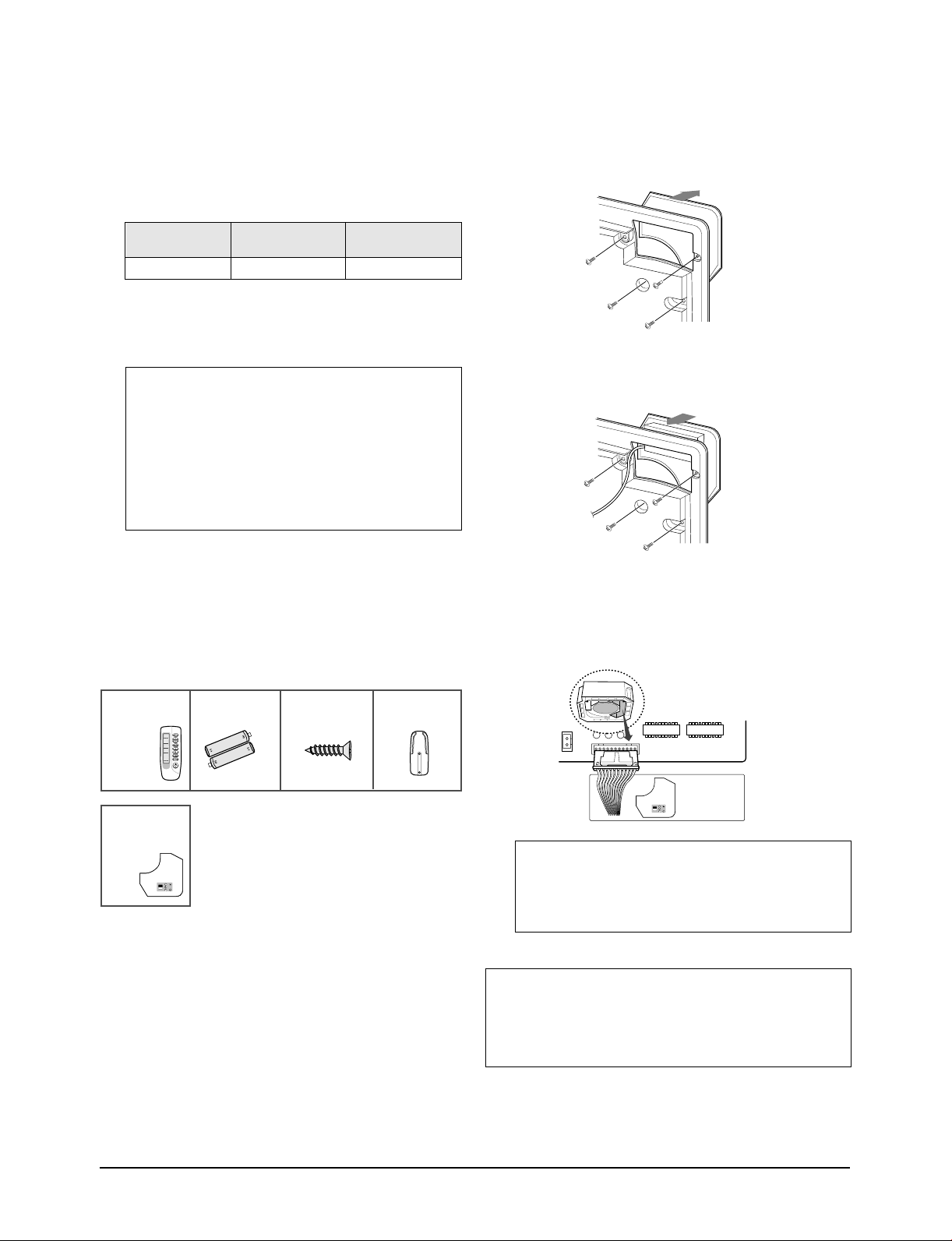

4-4-3. Air Conditioner and Accessories

The following accessories are supplied with the air conditioner. The quantities are indicated in parantheses.

Basic Accessories

Owner’s

Instructions(1)

Insulation Pipe 3/8"(1)

Insulation Pipe 5/8"(1)

Insulation Pipe 3/4"(1)

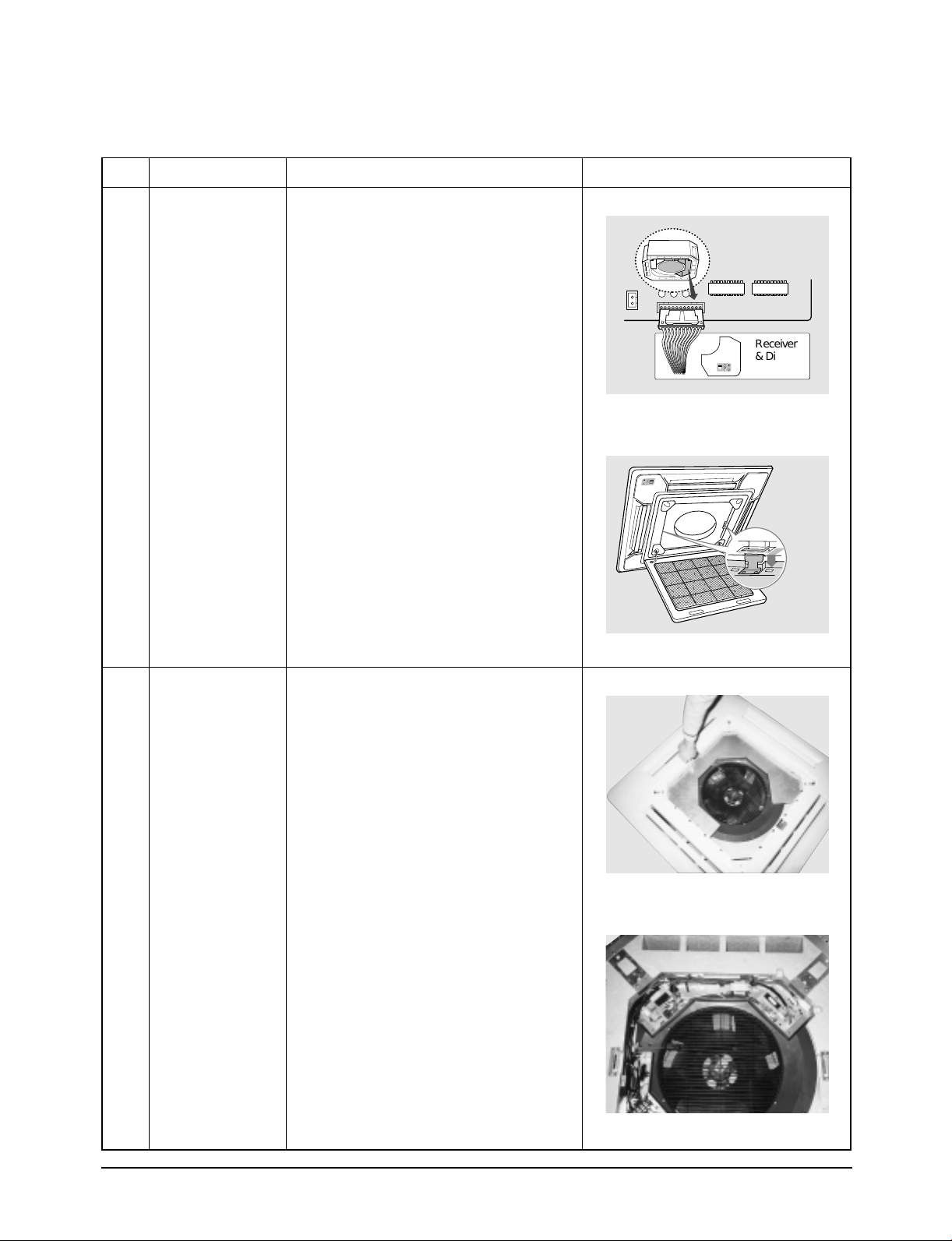

Pad Stopper(1) Insulation Drain Sub

Installation

Manual(1)

Insulation Drain

Pipe(1)

(1)

Optional Accessories

Wired Remote

Controller(1)

KR-H50210

Wireless Remote

Controller(1)

KR-H40200

Cable-Tie(2) Cable Clamp(5) M4 X 16 Tapped

Battery(2) M4 X 16 Tapped

Pattern Sheet(1) Insulation

Cover Drain(1)

Insulation

Cover Pipe(2)

Insulation

Cover Band(1)

Cable-Tie(5) Drain Plug(1) Flexible Hose(1) M4 X 12 Tapped

Screw(4)

Bolt(4)

Flare Nut 3/8"(1)

Flare Nut 5/8"(1)

Flare Nut 3/4"(1)

Rubber Leg (4)

Screw(7)

Screw(2)

Remote Controller

Holder(1)

Receiver & Display

Unit(1)

(KRE-H1000)

Centralized Controller(1)

KR-H60110

Transmitter(1)

Cable-Tie(2) Cable Clamp(5) M4 X 16 Tapped

Screw(7)

Spacer Support(4) Cable-Tie(2)

KT-A00

Bio-Pure Filter(1)

KF-C1B0

M4 X 10 Tapped

Screw(4)

Air blocking Kit(1) KAB-A00

NOTE : Refrigeration pipes and their insulating materials, power cables are not supplied.

4-18

Samsung Electronics

Page 38

4-5 Installation Diagram of Indoor Unit and Outdoor Unit

4-5-1 Piping, Drain Hose Direction

Respect the clearances and maximum lengths indicated in the diagram below when installing the unit.

Liquid Refrigerant tube

Gas Refrigerant tube

“H”metres

maximum

10cm

✴ The appearance of the outdoor unit

may be different from the diagram

depending on the model.

Space requirement when installing the indoor unit

255mm

1000mm or more

230mm

17mm

Drain hose

15cm

1500mm or more

20mm

10cm

35cm

Model

✴✴18✴✴

✴✴

24

✴✴

L30H

15

Samsung Electronics

4-19

Page 39

Installation

4-5-1 Piping, Drain Hose Direction

Respect the clearances and maximum lengths indicated in the diagram below when installing the unit.

Liquid Refrigerant tube

Gas Refrigerant tube

Drain hose

“H”metres

maximum

Model

✴✴36✴✴

✴✴

44

✴✴

L50H

25

10cm

10cm

✴

The appearance of the outdoor unit

may be different from the diagram

15cm

depending on the model.

Space requirement when installing the indoor unit (In case of✴✴36✴✴/✴✴44✴✴)

1500mm or more

305mm

1000mm or more

288mm

17mm

20mm

35cm

4-20

Obstacle

Samsung Electronics

Page 40

Installation

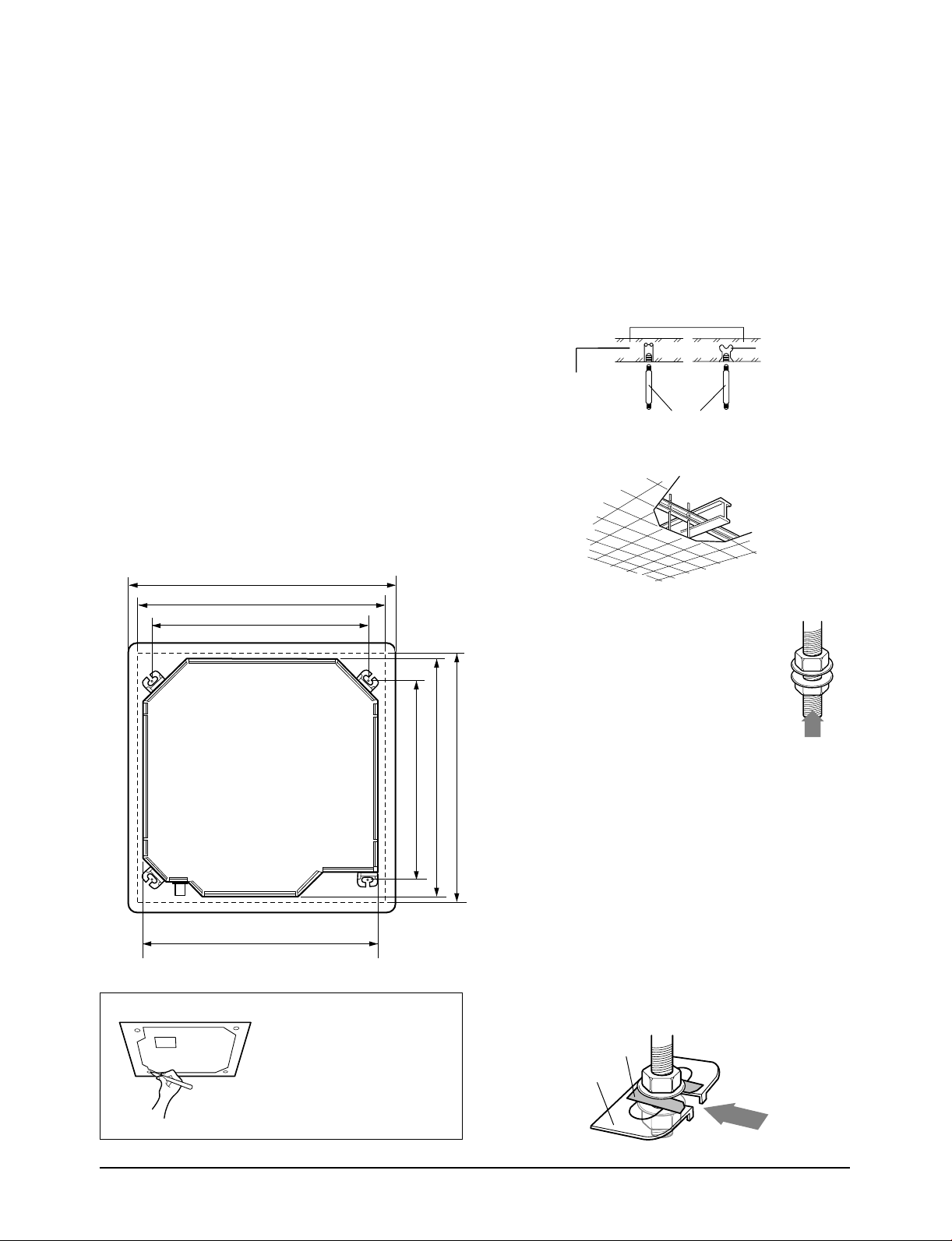

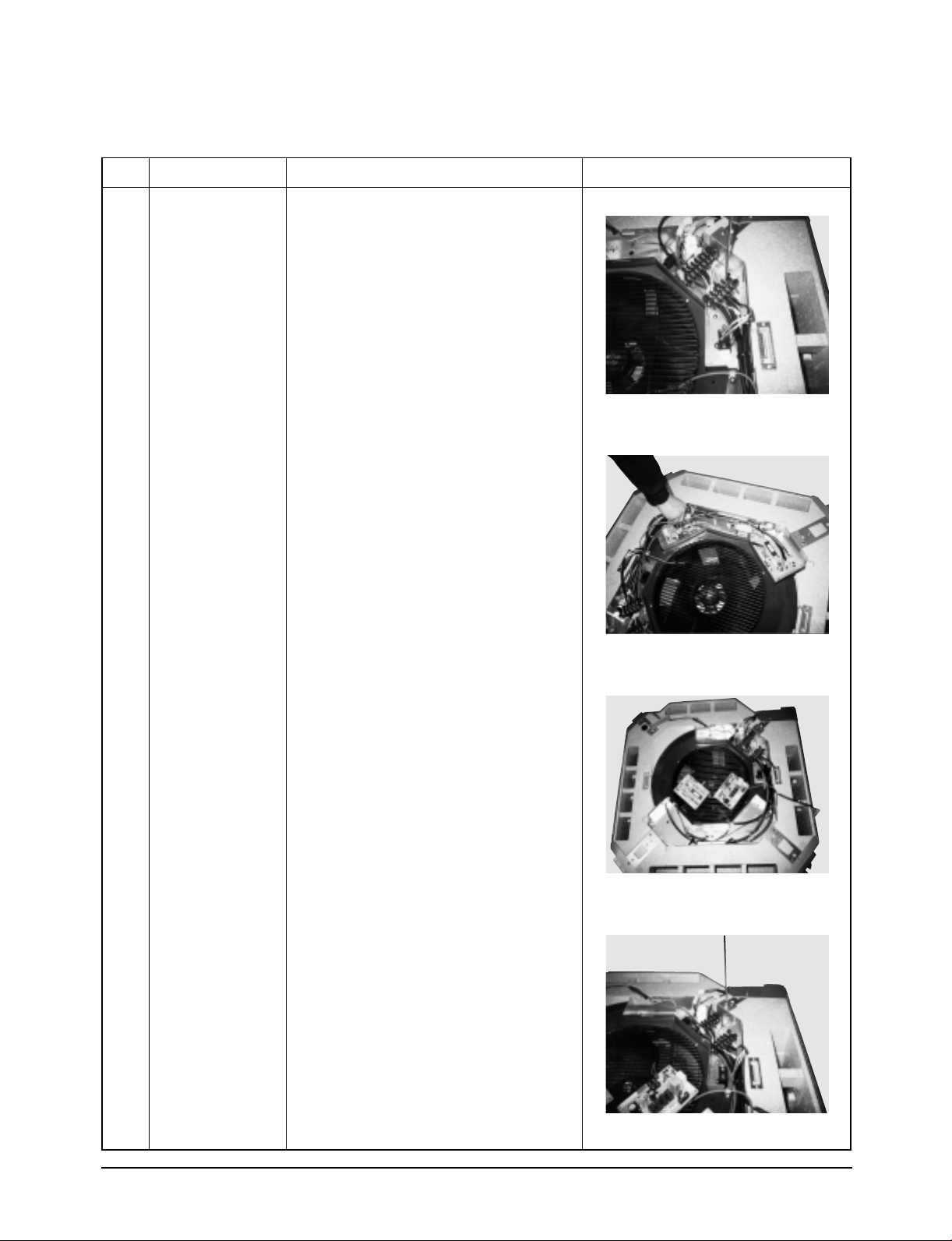

4-5-2 Preparing the Area for Installation

Preparing the Area for Installation of Indoor Unit

1. Measure the distance between ceiling and

ceiling wall.

2. Place the pattern sheet on the ceiling.

3. Cut the ceiling to install the indoor unit by

attaching the pattern sheet onto the ceiling.

Then cut the pattern sheet and ceiling in section

A and make a hole in the ceiling at the position

of the hook. Use the plummet to mark the

position on the ceiling wall, which is vertically

in line with the hole in the ceiling, and make

these 4 holes in the ceiling wall.

4. Insert bolt anchors, use existing ceiling supports

or construct a suitable support as shown in

figure.

950 (Dimensions of Front Panel)

880 (Cutting Dimensions of Ceiling)

766 (Space of Suspension Bolts)

5. Install the suspension bolts depending on the

ceiling type.

IMPORTANT : Ensure that the ceiling is strong enough

to support the weight of the indoor unit.

Before hanging the unit, test the strength

of each attached suspension bolt.

Concrete

Insert

Hole in anchor

Hole in plug

Suspension bolt(M8)-field supply

Ceiling support

6. Screw eight nuts to the suspension

bolts making space for hanging the

indoor unit.

840 (Outer Dimensions)

Samsung Electronics

840 (Outer Dimensions)

699 (Space of Suspension Bolts)

NOTE :

◆ Since the diagram is made of

paper, it may shrink or stretch

slightly due to temperature or

humidity. For this reason, before

drilling the holes maintain the

correct dimensions between the

markings; refer to page 2-3.

IMPORTANT : You must install the suspension bolts

more than four when installing the indoor

unit.

7. Hang the indoor unit to the suspension bolts

880 (Cutting Dimension of Ceiling)

between two nuts.

NOTE: ◆ Tubing must be laid and connected inside the

ceiling when suspending the unit. If the ceiling

is already constructed, lay the tubing into

position for connection to the unit before

placing the unit inside the ceiling.

8. Screw the nuts to suspend the unit. Cut a pad

stopper and place it on the bracket at this time.

Pad stopper

Bracket

4-21

Page 41

Installation

9. Adjust the unit to the appropriate position

considering the installation area for the front

panel.

9-1 Place the pattern sheet on the indoor unit.

9-2 Adjust a space between the ceiling and the

indoor unit by using the gauge of

dimensions.

9-3 Fix the indoor unit securely after adjusting

level of the unit by using a leveler.

9-4 Remove the pattern sheet, connect the other

cables and install the front panel.

Indoor Unit

17mm

Gauge of

Dimensions

20mm

Ceiling

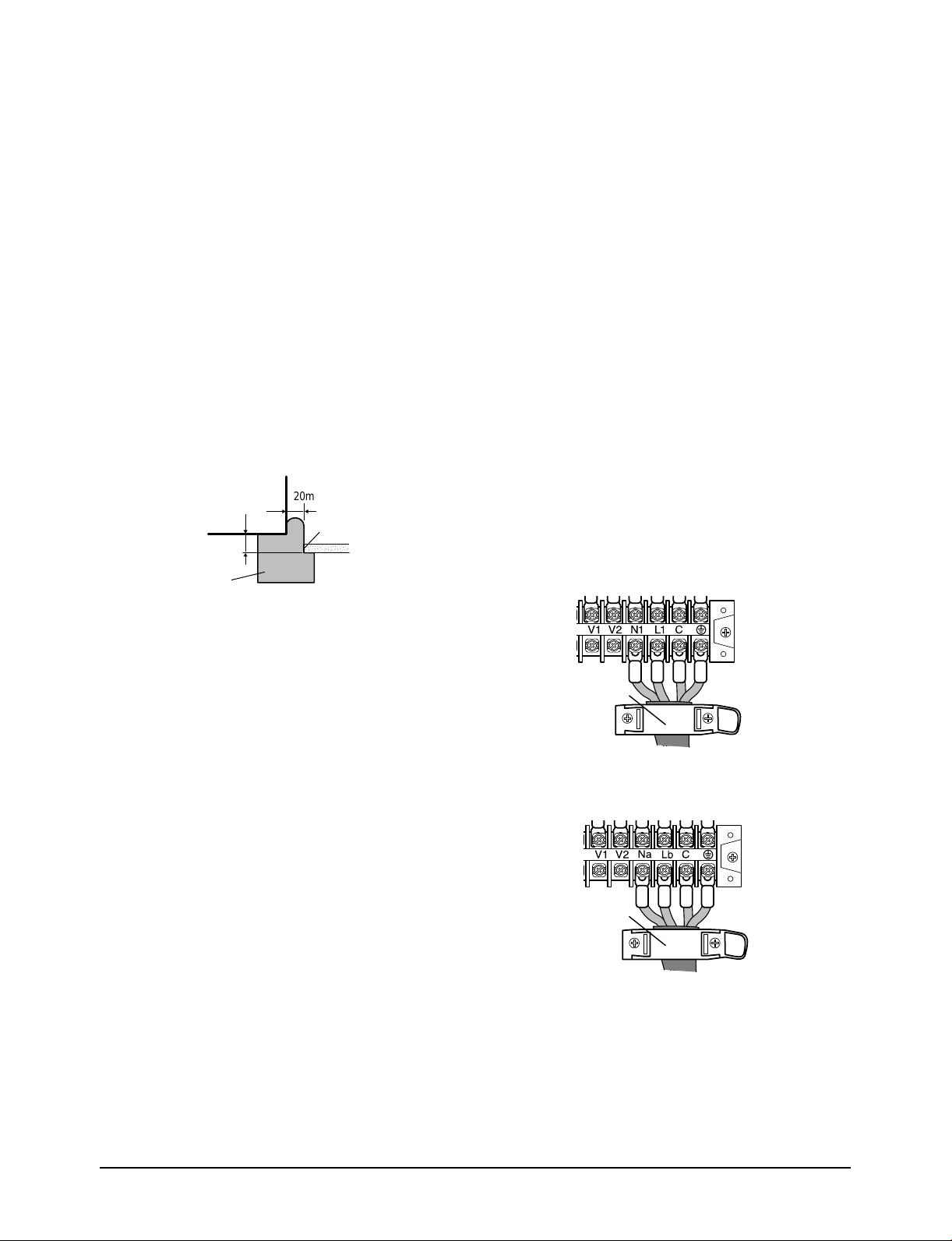

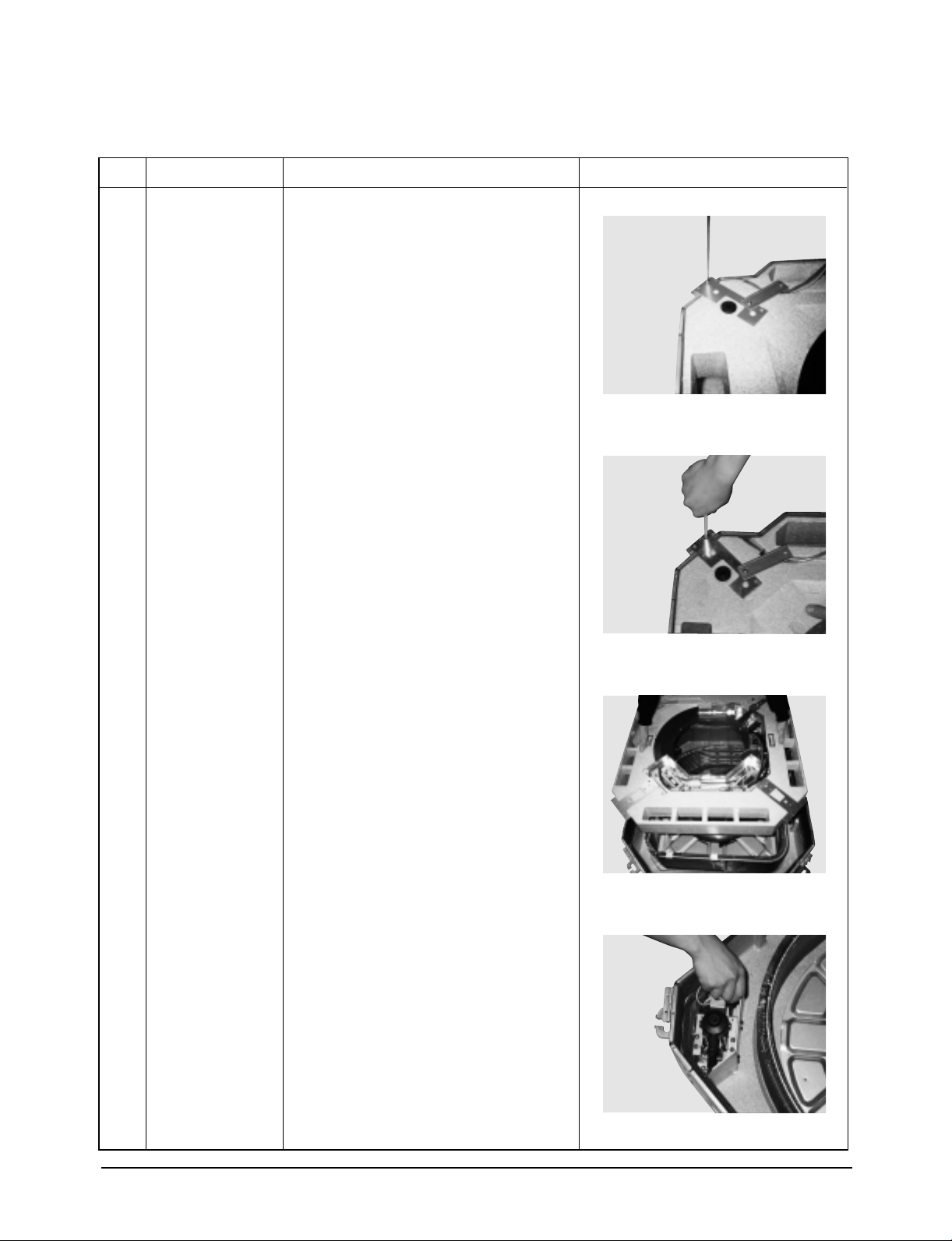

4-5-3 Connecting the connection cord

The indoor unit is powered from the outdoor unit via the

connection cord.

1. Remove the screws on the electrical component

box and remove the cover plates.

2. Route the connection cord through the side of

the indoor unit and connect the cable to

terminals as shown in page 4-23, 4-24.

3. Route the other end of the cable to the outdoor

unit through the ceiling & the hole on the wall.

4. Reassemble the electrical component box cover,

carefully tightening the screws.

5. For further details on how to plug the other end

of the connection cord into the outdoor unit,

refer to page 4-25, 4-26.

Cable Clamp

(1ø, 220V-240V~, 50Hz)

Cable Clamp

(3ø, 380V-415V~, 50Hz)

4-22

Samsung Electronics

Page 42

Installation

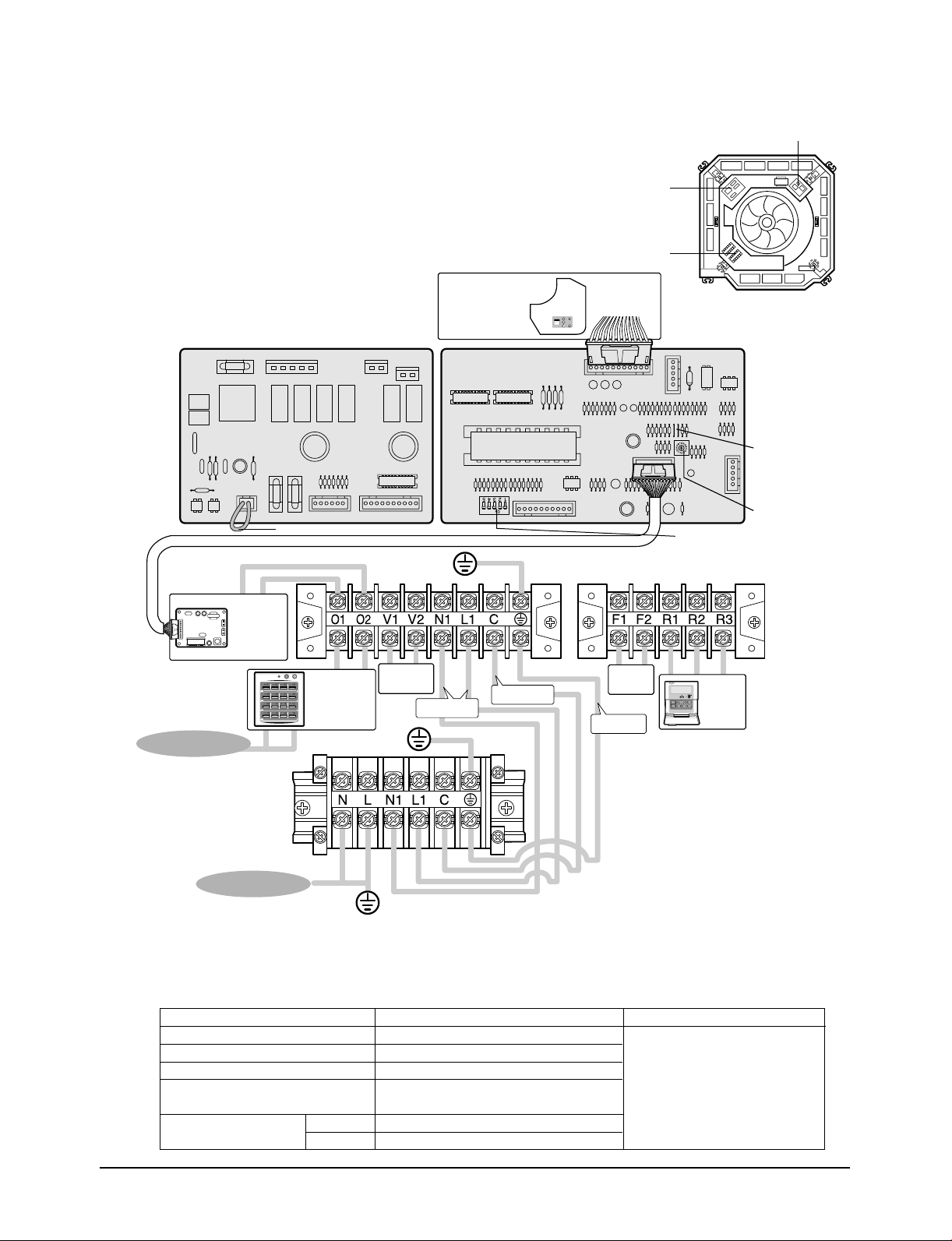

Wiring Diagram

SUB PCB MAIN PCB

CN20 Connector

Receiver & Display

Unit(Optional)

SW2

Sub PCB

Terminal block

CN9

CN7

SW1

DIP Switch

Indoor Unit

Main PCB

Jumper

Wire

Rotary

Digital

Switch

Transmitter

(Optional)

Centralized

Controller

(Optional)

Ventilator

Motor

Power

Communication

MAIN POWER

Outdoor Unit

MAIN POWER

Cable Specifications

The following electrical characteristics must be respected.

MODEL

Power

Sub switch

Fuse

Min. size of electric Wires

from/to the indoor/outdoor unit

Size of electric input wires

20m or less

50m or less

ACH1800E/2400E, CH18ZA/24ZA, CH18CA/24CA

1Ø - 220V-240V~, 50Hz

30A

30A

H07RN-F, 4G, 1.0mm

H07RN-F, 3G, 2.5mm

H07RN-F, 3G, 4.0mm

Float

Switch

EARTH

Wired

Remote

Controller

(Optional)

Note

The power cables are not

supplied with the air conditioner.

The user should purchase them

2

2

2

separately.

Samsung Electronics

4-23

Page 43

Installation

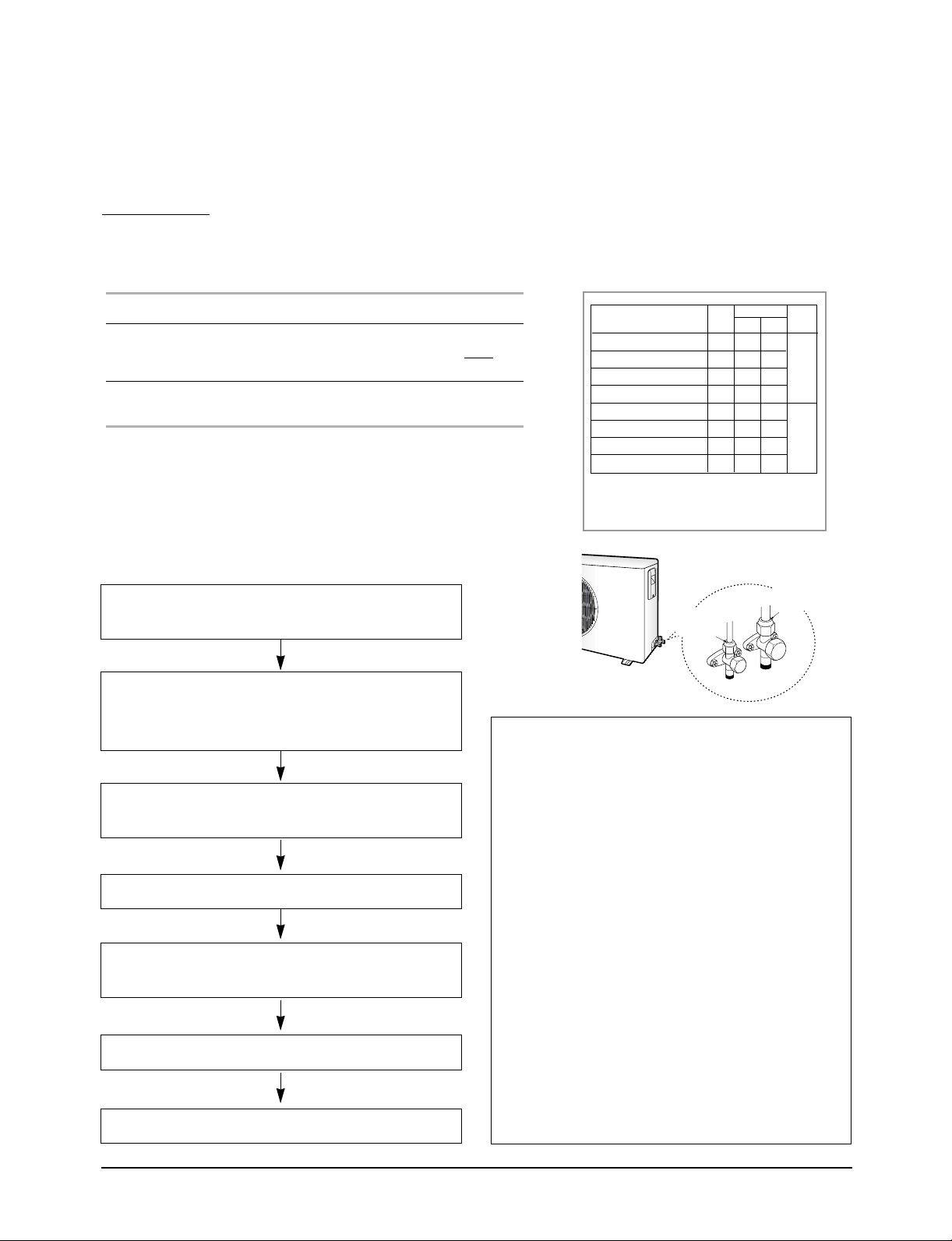

Wiring Diagram

Sub PCB

Terminal block

Receiver & Display

Unit(Optional)

SUB PCB MAIN PCB

CN9

CN7

SW1

Main PCB

Jumper

Wire

Transmitter

(Optional)

MAIN POWER

220-240V~, 50Hz

Cable Specifications

CN20 Connector

Centralized

Controller

(Optional)

Ventilator

Motor

SW2

Power

Communication

Outdoor Unit

Float

Switch

DIP Switch

Indoor Unit

Wired

Remote

Controller

(Optional)

Rotary

Digital

Switch

MAIN POWER

3Ø, 380-415V~, 50Hz

4-24

The following electrical characteristics must be respected.

MODEL

Power

Sub switch

Fuse

Min. size of electric Wires

from/to the indoor/outdoor unit

Size of electric input wires

20m or less

50m or less

ACH3600G/4400G, CH36ZA/44ZA, CH36CA/44CA

3Ø, 380V-415V~, 50Hz

30A

30A

H07RN-F, 4G, 1.0mm

H07RN-F, 3G, 2.5mm

H07RN-F, 3G, 4.0mm

2

2

2

Note

◆ The power cables are not

supplied with the air conditioner.

The user should purchase them

separately.

◆ When connecting the cables to

the main power, you should

connect each cable(L1, L2 &

L3) properly.

Samsung Electronics

Page 44

Installation

4-5-4 Connecting the Cables to the Outdoor

Unit

Two electric cables must be connected to the outdoor

unit.

• The connection cord connecting the indoor unit to

the outdoor unit

• The power cable connecting the auxiliary circuit

breaker to the outdoor unit

1. Remove the terminal board cover on the side of

the outdoor unit.

2. Connect the connection cord(L1, N1, C1, )

and power cable(N, L) to terminals as shown in

the diagram.

3. Connect the power cable to the auxiliary circuit

breaker.

An all pole disconnection from the power

supply must be incorporated in the fixed

wiring(≥3mm).

4. Replace the terminal board cover, carefully

tightening the screw.

Indoor Unit

EARTH

Power

Outdoor Unit

Communication

Power Cable

Auxiliary circuit

breaker

Wiring Diagram

Caution :

Keep the power cable and the connection cord in a steel pipe to

protect them against liquids, outside impacts and so on.

4-25Samsung Electronics

Page 45

Installation

Two electric cables must be connected to the outdoor

unit.

• The connection cord connecting the indoor unit to

the outdoor unit

• The power cable connecting the auxiliary circuit

breaker to the outdoor unit

1. Remove the terminal board cover on the side of

the outdoor unit.

2. Connect the connection cord (Na, Lb, C, )

and power cable(L1, L2, L3, N, ) to

terminals as shown in the diagram.

3. Connect the power cable to the auxiliary circuit

breaker.

An all pole disconnection from the power

supply must be incorporated in the fixed

wiring(≥3mm).

4. Replace the terminal board cover, carefully

tightening the screw.

Indoor Unit

Power

Wiring Diagram

Communication

EARTH

Outdoor Unit

Power Cable

Auxiliary circuit

breaker

Caution :

Keep the power cable and the connection cord in a steel pipe to

protect them against liquids, outside impacts

and so on.

Samsung Electronics4-26

Page 46

Installation

4-5-5 Checking Correct Grounding

If the power distribution circuit does not have an earth

or the ground does not comply with specifications, an

grounding electrode must be installed.

The corresponding accessories are not supplied with

the air conditioner.

1. Select an grounding electrode that complies

with the specifications given in the illustration.

Carbon

plastic

yellow wire, 2mm

2. Determine a suitable location for the grounding

electrode:

• In damp hard soil rather than loose sandy or

gravel soil that has a higher grounding

resistance

• Away from underground structures or

facilities, such as gas pipes, water pipes,

telephone lines and underground cables

• At least two metres away from a lightening

concassetteor grounding electrode and its

cable

Steel

core

PVC-insulated green/

2

x 3.5 m

Terminal M4

grounding

screw

To

3. Finish wrapping insulating tape around the rest

of the pipes leading to the outdoor unit.

4. Install a green/yellow coloured grounding wire

2

(Ø1.6 mm, section 2 mm

or greater):

• If the grounding wire is too short, connect an

extension lead, in a mechanical way and

wrapping it with insulating tape (do not bury

the connection)

• Secure the grounding wire in position with

staples

NOTE : ◆ If the grounding electrode is installed in an

area of heavy traffic, its wire must be

connected securely.

5. Carefully check the installation, by measuring

the grounding resistance with an ground

resistance tester. If the resistance is above

required level, drive the electrode deeper into

the ground or increase the number of grounding

electrodes.

6. Connect the grounding wire to the electrical

component box inside of the outdoor unit.

4-5-6 Drain Hose Installation

NOTE : ◆ The grounding wire for the telephone line

cannot be used to ground the air conditioner.

50cm

30cm

Samsung Electronics

Care must be taken when installing the drain hose for

the indoor unit to ensure that any condensate water is

correctly drained outside.

1. Insert the flexible hose

to the drain tube

outlet, if necessary.

NOTE : ◆ Attach the drain hose to the drain tube outlet

with the adhesives to prevent water leaks,

then secure the hose with a band etc..(The

band is not supplied with the air conditioner.)

Drain tube

outlet

4-27

Page 47

Installation

CCCCAAAAUUUUTTTTIIIIOOOONN

NN

Do not install air bleeding tubes, as this may

cause water to spray from the drain tube outlet.

Check that the indoor unit is level with the

ceiling by using the leveler.

If it is necessary to increase the height of the drain hose

somewhat, the portion directly after 30cm. If it is raised

higher than 50cm, there can be water leaks.

Air bleeder

Ceiling

300mm or less

1~1.5m

C

B

A

Do not give the hose and upward gradient after the

connection port.

This will cause water to flow backwards when

the unit is stopped, resulting in water leaks.

Do not apply force to the piping on the unit side when

connecting the drain hose. The hose should not be

allowed to hang loose from its connection to the unit.

Fasten the hose to a wall, frame or other support as

close to the unit as possible.

Upward gradient

Support pieces

1~1.5m

1/100 or more

Flexible hose

Band joint

Ceiling

Ceiling

Ceiling

✳✳18/✳✳24 ✳✳36/✳✳44

A

750 mm 750 mm

B 200 mm 258 mm

C 550 mm 482 mm

2. Install the drain hose so that its length can be as

short as possible. Internal diameter of the drain

hose should be the same or slightly bigger than

the external diameter.

• Inner diameter of the drain hose

Flexible hose is connected

32mm(Outer diameter)

Flexible hose is not connected

27mm(Outer diameter)

NOTE : ◆ Give a slightly slant to the drain hose for proper

drainage of condensate.

NOTE : ◆ Secure the drain hose with the band joint and the

cable-tie not to be separated from the unit.

Insulation drain sub

Indoor

Unit

Adhesives

Band(Not supplied)

Insulation drain pipe

Insulation cover drain

Caution :

Must fit tightly against body without any gap.

No gap

3. Wrap the drain hose with the insulation drain as

shown in figure and secure it.

NOTE : ◆ When connecting the drain hose without the

flexible hose, you should attach it to the drain

tube outlet with adhesives and tapes to

prevent water leaks.

Caution :

Samsung Electronics4-28

Page 48

Installation

Testing the drainage

You should test the drainage after completing the

installation.

Prepare a little water about 2.0 liter.

1. Remove two screws on the cover drain pump

and pull out the cover.

Cover drain pump

2. Pour water into the indoor unit as shown in

figure.

4-5-7 Connecting the Indoor Unit Assembly

Piping

There are two refrigerant pipes of differing diameters:

• Asmaller one(9.52mm, 3/8") for the liquid refrigerant

• Alarger one(15.88mm, 5/8") for the gas refrigerant

• The thickness of tube should not less than 1.0mm.

• The inside of copper tube must be clean & has no

dust.

The connection procedure for the refrigerant pipes

varies according to the exit position of the pipes from

the indoor unit, as seen when facing the indoor in the

"A" side.

• Liquid refrigerant port

• Gas refrigerant port

Liquid refrigerant port

A

Gas refrigerant

port

NOTE : ◆ If you do not pour water inside the water

supply intake, water may spill from the indoor

unit.

3. Confirm that the water flows out through the

drain hose.

NOTE : ◆ You can check the drainage only when the air

conditioner is turned on.

4. Reassemble the cover drain pump and the

screws.

1. Remove the protection caps

on the pipes and connect

the assembly pipes to each

pipe, tightening the nuts,

first manually and then

with a wrench, a spanner

applying the following

torque.

Outer Diameter Torque (kgf•cm)

19.52 mm (3/8") 300

15.88 mm (5/8") 750

Samsung Electronics

4-29

Page 49

Installation

90

O

2. Must use insulator which is thick enough to

cover more than 10mm the refrigerant tube to

protect the condensate water on the outside of

pipe falling onto the floor and the efficiency of

the unit will be better.

a. When the indoor unit is above the outdoor unit

Indoor unit

Outdoor unit

b. When the outdoor unit is above the indoor unit

Oil trap

(Must be installed every 6m)

Outdoor unit

7. For further details on connecting up to the

outdoor unit and purging the refrigerant circuit.

NOTE : ◆ For further details on connecting up to the

outdoor unit and purging the refrigerant circuit.

4-5-8 Cutting/Flaring the Pipes

Connect the pipe within 30m and cutting pieces will not

be gone into the pipe as being clean to pipe section

1. Make sure that you have the required tools

available (pipe cutter, reamer, flaring tool and pipe

holder).

Oil trap

(Must be installed every 6m)

Indoor unit

Radius

5cm

Oil trap

(suction tube)

3. Cut off any excess foam insulation.

4. Be sure that there must be no crack or wave on

the bended area.

5. It would be necessary to double the insulation

thickness to prevent condensation even on the

insulator when if the installed area is warm and

humid.

6. Shape an oil trap as shown in figure. The oil

trap must be formed every level difference of

6m.

2. If you wish to shorten the pipes, cut it with a

pipe cutter, taking care to ensure that the cut

edge remains at a 90° angle with the side of the

pipe. Refer to the illustrations below for