Samsung AS09HPBN, AS12HPBN, AS09HPA, AS12HPA Training Manual

AS09HPBN

AS12HPBN

CONTENTS

Precautions 1

Product Specifications 2

Operating Instructions & Installation 3

Disassembly and Reassembly 10

Refrigerating Cycle Diagram 16

Feature & Operation 27

Set Up the Model Option 46

Troubleshooting 49

Exploded Views and Parts List 62

Block Diagram 67

PCB Diagram 68

Wiring Diagram 77

Schematic Diagram 79

1. Precautions

11) Cut off the power.

● Make sure to cut off the power before repair. If not, you may

be damaged by an electric shock.

12) Do not install an outdoor unit on the apartment outside

wall(or equivalent) for safety.

● Installing an outdoor unit on the apartment outside wall(or

equivalent) is prohibited for the safety purpose. Service will

not be available for the outdoor unit where our servicemen

can not access and the cost of moving the outdoor unit to

the service area will be borne by the customer.

● If requested by the customer, you shall discourage him to

install an outdoor unit on the apartment outside wall(or

equivalent).

13) The air conditioner outdoor unit shall be installed 2m

above ground and kept away from pedestrians to prevent

direct exposure to hot wind. (according to the Building

Facility Standard Regulations)

14) Keep the drain hose outlet free.

● Otherwise, air flow will get slow, which may hinder cooling

capacity.

● Also, dew may be laden on the service valve.

15) Use of Certified Parts

● Use certified parts only. (An electric contact part, if broken

down, shall not be repaired but replaced with a new one.

Remodeling shall be prohibited. In no case, the customer

shall repair the product on his own because this is dangerous enough to bring about breakdown or fire.)

16) Ban on Middle Connection of Power Cord

● Do not cut the power cord in the middle to be connected to

other power cord nor use a middle socket between two

power cords. This is dangerous enough to bring about

breakdown or fire.

17) Check Insulation

● After assembly, be sure to check insulation resistance.

(Use an insulation ohmmeter to measure the insulation

resistance between the power cord and the earthing wire.

Do not supply power until it reads 30MΩ.)

18) Be sure to keep the symmetry of the product.

● Otherwise, you may hear vibration noise.

19) Caution for Children

● Do not keep children off the product while it is in repair.

Otherwise, they might be endangered.

10) Be sure to put the indoor or outdoor unit free of corrosive

gases such as sulfuric water, ammonium, and sulfuric

gas.

● Otherwise, copper tubes or soldered parts could be

corroded causing refrigerant leak.

11) Arrangement of surroundings

● After repair finishes, clean the air conditioner and its

surroundings and inform the customer of what it is like.

1Samsung Electronics

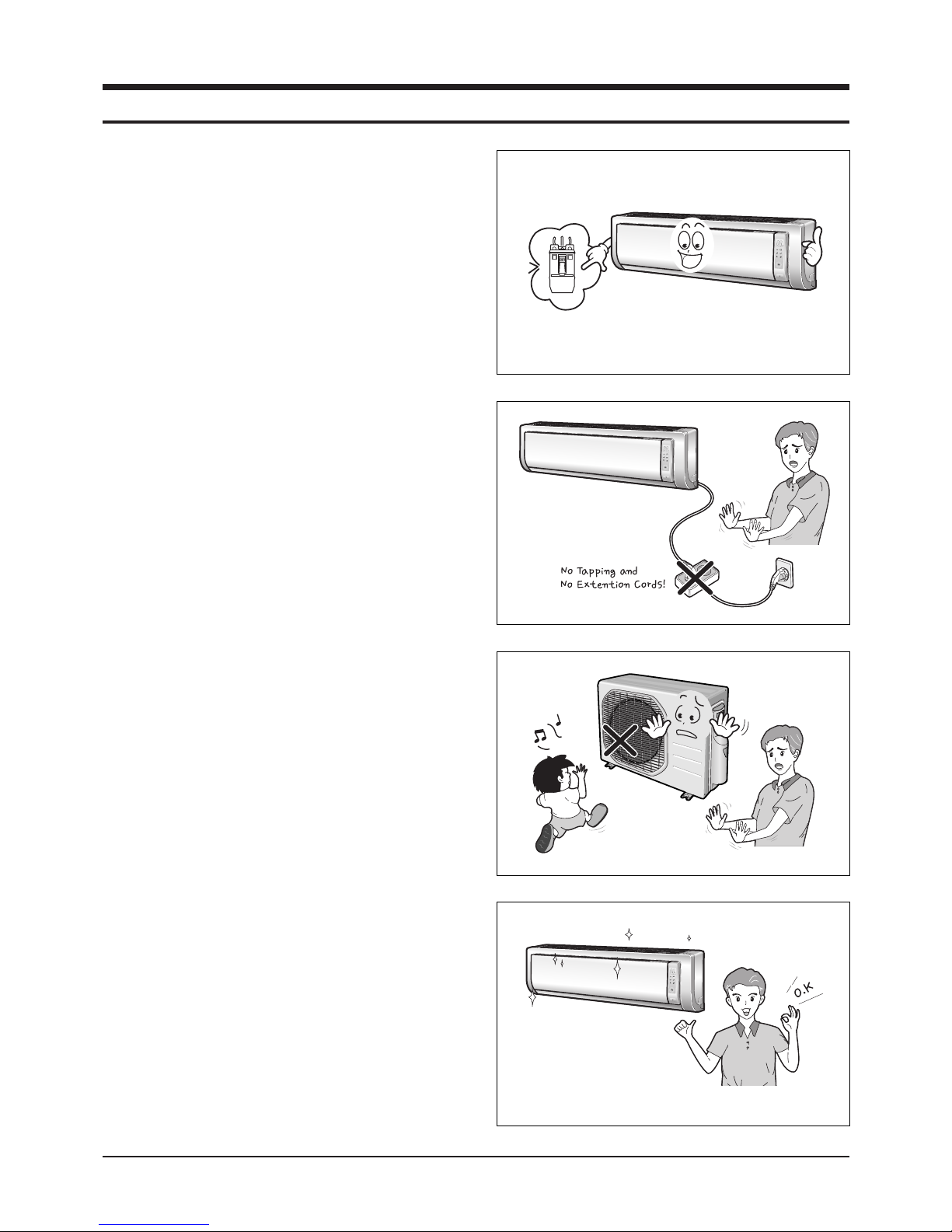

2. Product Specifications

2-1 Table

Item

Type

Cooling kW

Heating kW

Dehumidifying |/h

Air Volume

Performance

Noise

Energy Efficiency Ratio

Power ph-V-Hz

Power Consumption

Operating Current

Powe r

Power Factor

Starting Current A

Power Cord Number of Core Wire

Outer Dimension

Weight(Net) kg

Refrigerant Pipe

Drain Hose D x L(mm)

Size

Compressor Motor Type

Oil Type

Blower Motor Type

Heat Exchanger

Refrigerant Control Unit

Freezer Oil Capacity cc

Refrigerant to Change(R410A) g

Protection Device(OLP)

Cooling Test Condition

Maximum Operation Condition

Type

Type

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Cooling

Heating

Length m

Capacity A

Width x Height

x Depth

Liquid mm x L(m)

Gas mm x L(m)

Rated Output

Rated Output W

Model

3

m

/min

(H/M/L)

dB

(H/M/L)

W/W

W

A

%

mm

inch

AS09HPBN AS12HPBN

Indoor unit Outdoor unit

Wall-mounted

2.70

2.90

1.0

7.5/6.9/6.3 25

8.0/7.4/6.8 25

40/36/32 51/51

40/36/32 51/51

3.21

3.41

1-220/240-50

840

850

3.9

3.7

93.6

99.9

21

2.1

5G

250V-10A

950 x 268 x 165 790 x 548x 285

37.4 x 10.6 x 6.5 31.1 x 21.6 x 11.2

9.0 33.8

ø6.35 x 7.5

ø9.52 x 7.5

ø18 x 550

Rotary, G4A091JU

Induction Motor(PSC)

930

DAPHNE FV68S(PVE)

Cross-flow Propeller

Resin / steel steel

15 50

2ROW 12STEP 1ROW 24STEP

CAPILLARY TUBE

280

730

RBC12054-12500

INDOOR UNIT : DB27˚C WB19˚C OUTDOOR UNIT : DB35˚C WB24˚C

INDOOR UNIT : DB32˚C WB23˚C OUTDOOR UNIT : DB43˚C WB26˚C

Indoor unit Outdoor unit

Wall-mounted

3.50

3.80

1.4

8.3/7.0/5.7 25

9.5/8.9/8.3 25

43/38/34 53/53

43/38/34 53/53

3.21

3.22

1-220/240-50

1,090

1,180

5.0

5.4

94.8

95.0

28

2.1

5G

250V-10A

950 x 268 x 165 790 x 548x 285

37.4 x 10.6 x 6.5 31.1 x 21.6 x 11.2

9.0 36.0

ø6.35 x 7.5

ø9.52 x 7.5

ø18 x 550

Rotary, G8C124JU

Induction Motor(PSC)

1,267

DAPHNE FV68S(PVE)

Cross-flow Propeller

Resin / steel steel

15 50

2ROW 12STEP 2ROW 24STEP

CAPILLARY TUBE

500

950

RBC12128-12500

Samsung Electronics2

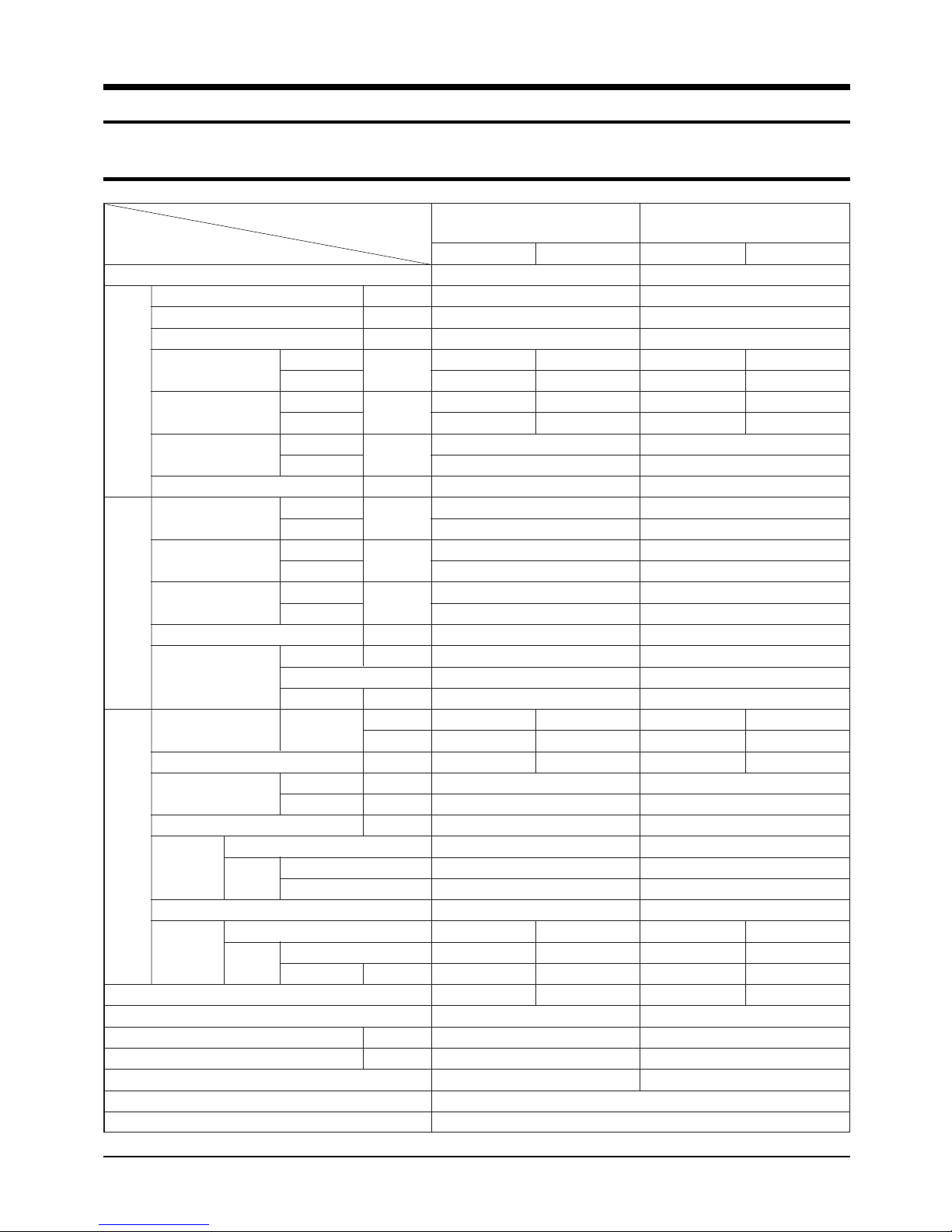

3. Operating Instructions & Installation

3-1 View of the Unit

3-1-1 Indoor Unit

Air Inlet

Room Temperature sensor

Power(On/Off) button

Air filter

(under the grille)

Operation indicator

(Auto-Cool, Cool, Dry, Fan : Blue

Auto-Heat, Heat : Orange)

Turbo function indicator

Fan speed indicator

Remote control sensor

Airflow blades

(outlet)

Set temperature &

room temperature

(Blue)

Timer indicator

(Orange)

(Blue)

Auto cleaning indicator

(Blue)

Energy saving indicator

(Blue)

Anion indicator

(Blue)

3Samsung Electronics

Operating Instructions & Installation

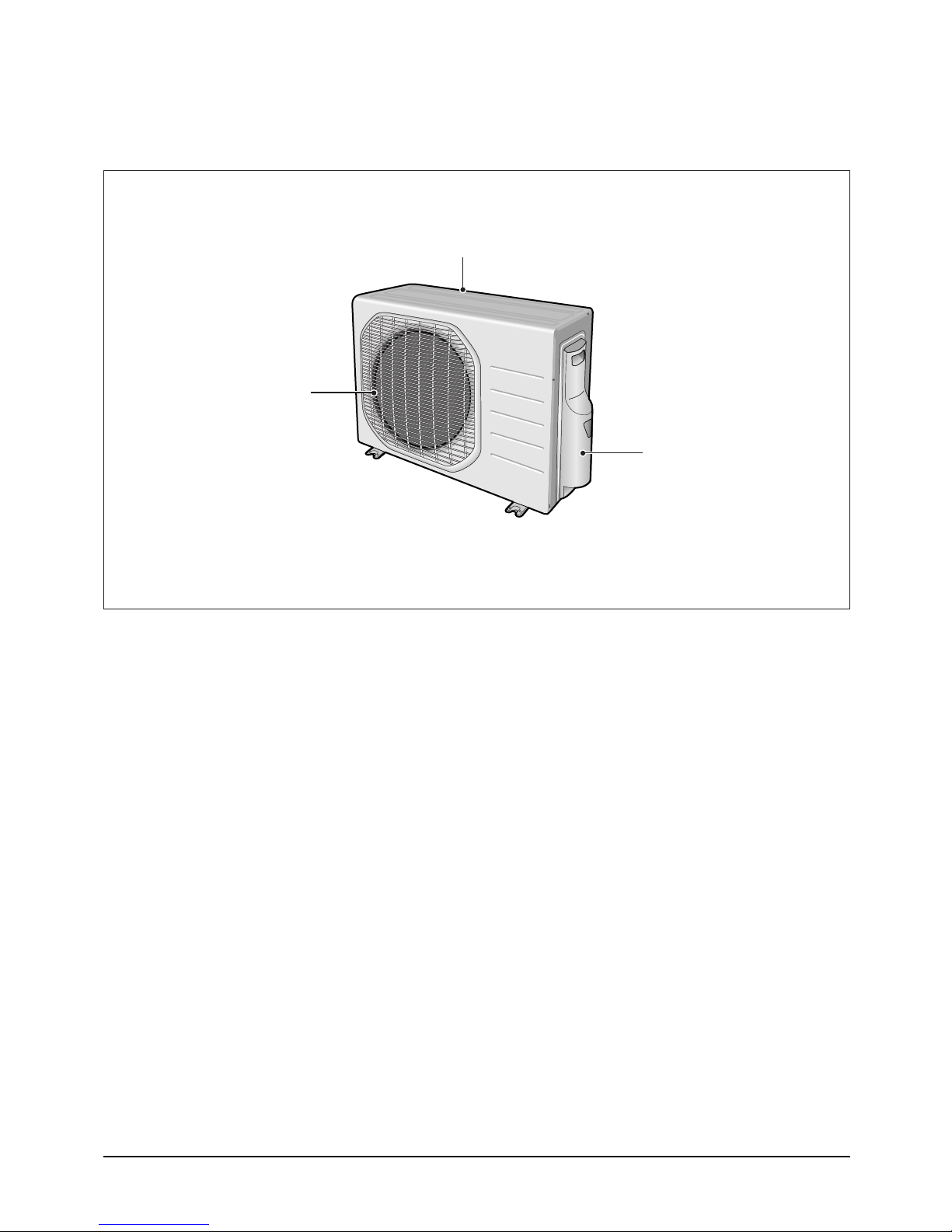

3-1-2 Outdoor Unit

Air Outlet

Air Inlet(Rear)

Connection Valve

(inside)

Samsung Electronics4

3-2 Air Conditioner and Accessories

O

W

N

E

R

’

S

I

N

S

T

R

U

C

T

I

O

N

S

M

A

N

U

A

L

D

E

I

N

S

T

R

U

C

C

I

O

N

E

S

I

S

T

R

U

Z

I

O

N

I

P

E

R

L

’

U

S

O

M

A

N

U

A

L

D

E

I

N

S

T

R

U

˝

E

S

M

A

N

U

E

L

D

’

U

T

I

L

I

S

A

T

I

O

N

G

E

B

R

A

U

C

H

S

A

N

W

E

I

S

U

N

G

S

p

l

u

t

-

t

y

p

e

R

o

o

m

A

i

r

C

o

n

d

i

t

i

o

n

e

r

A

i

r

e

a

c

o

n

d

i

c

i

o

n

a

d

o

d

o

m

s

t

i

c

o

s

i

s

t

e

m

a

S

p

l

i

t

C

o

n

d

i

z

i

o

n

a

t

o

r

e

d

’

a

r

i

a

p

e

r

a

m

b

i

e

n

t

i

a

d

u

n

i

t

S

e

p

a

r

a

t

e

A

p

a

r

e

l

h

o

d

e

a

r

c

o

n

d

i

c

i

o

n

a

d

o

t

i

p

o

S

p

l

i

t

C

l

i

m

a

t

i

s

e

u

r

d

e

t

y

p

e

s

p

a

r

G

e

t

e

i

l

t

e

r

a

u

m

k

l

i

m

a

a

n

l

a

g

e

O

W

N

E

R

’

S

I

N

S

T

R

U

C

T

I

O

N

S

M

A

N

U

A

L

D

E

I

N

S

T

R

U

C

C

I

O

N

E

S

I

S

T

R

U

Z

I

O

N

I

P

E

R

L

’

U

S

O

M

A

N

U

A

L

D

E

I

N

S

T

R

U

˝

E

S

M

A

N

U

E

L

D

’

U

T

I

L

I

S

A

T

I

O

N

G

E

B

R

A

U

C

H

S

A

N

W

E

I

S

U

N

G

S

p

l

u

t

-

t

y

p

e

R

o

o

m

A

i

r

C

o

n

d

i

t

i

o

n

e

r

A

i

r

e

a

c

o

n

d

i

c

i

o

n

a

d

o

d

o

m

s

t

i

c

o

s

i

s

t

e

m

a

S

p

l

i

t

C

o

n

d

i

z

i

o

n

a

t

o

r

e

d

’

a

r

i

a

p

e

r

a

m

b

i

e

n

t

i

a

d

u

n

i

t

S

e

p

a

r

a

t

e

A

p

a

r

e

l

h

o

d

e

a

r

c

o

n

d

i

c

i

o

n

a

d

o

t

i

p

o

S

p

l

i

t

C

l

i

m

a

t

i

s

e

u

r

d

e

t

y

p

e

s

p

a

r

G

e

t

e

i

l

t

e

r

a

u

m

k

l

i

m

a

a

n

l

a

g

e

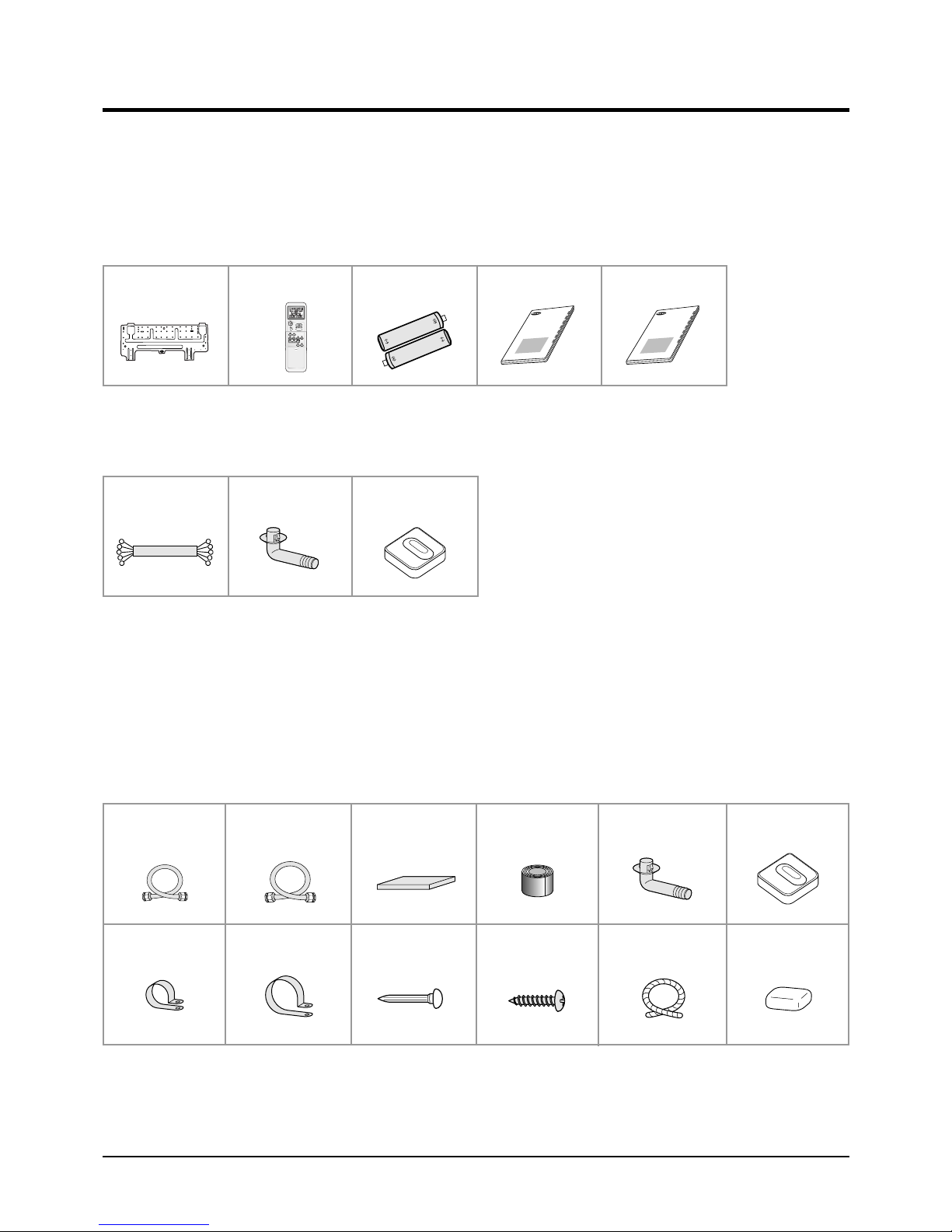

The following accessories are supplied with the air conditioner.

- The number of each accessory is indicated in parentheses.

3-2-1 Accessories in the Indoor Unit Case

Installation Plate (1) Remote Control (1) Batteries for

Remote Control (2)

User’s Manual (1) Installation Manual (1)

3-2-2 Accessories in the Outdoor Unit Case

5-wire

Assembly Cable (1)

- The flare nuts are attached to the end of each pipe of an evaporator or a service port.

Use the nuts when connecting the pipes.

- The 5-wire assembly cable is optional. If it is not supplied, use the standard cable.

- The drain plug and rubber leg are only included when the air conditioner is supplied without the assembly pipe as seen in the

picture below.

Drain Plug (1) Rubber Leg (4)

The following connection accessories are optional.

If they are not supplied, you should prepare them before installing the air conditioner.

Assembly Pipe, ø6.35mm

by 7.5m (1)

Pipe Clamps A (3) Pipe Clamps B (3) Cement Nail (6) M4 x 16 Tapping

Assembly Pipe, ø9.52mm

by 7.5m (1)

PE T3 Foam Tube

Insulation (1)

Vinyl Tape,

Width 50mm (1)

Screws (10)

Drain Plug (1) Rubber Leg (4)

Drain Hose,

length 2m (1)

Putty 100g (1)

- If these accessories are supplied, you can find them in the accessory box.

5Samsung Electronics

3-3 Installation

D

A

3-3-1 Before Installation

Keep the air conditioner outlet and inlet free from its surroundings.

In case of installation, keep the symmetry and fix it to prevent vibration.

The pipe length shall meet the standard as far as possible.

3-3-2 Installation Procedure

■ Location

Install the product in an area to guarantee the best cooling effect, convenience of piping and electric work, and inexistence of

vibration or wind.

■ Wall Drilling

Drill the wall downward in a diameter of 60 to 65mm.

■ Fixing Indoor Unit & Outdoor Unit

Fix the air conditioner indoor unit securely to the wall. Secure the outdoor unit in a suitable position.

■ Pipe Spooling & Connecting

You shall cut the pipe with a pipe cutter and grind all the burrs of the cut surface.

Pipe expansion may continue until the pipe surface becomes uneven or torn apart.

Be sure to use a torque wrench to tighten pipes or flare nuts.

<Torque & Depth>

Outer Diameter(D)

6.35mm(1/4")

9.52mm(3/8")

Torque

140~170

250~280

(kgf.cm)

Depth

1.3mm

1.8mm

(A)

■ Leak Test

Put an inert gas like nitrogen in the outdoor unit pipe and put soap bubbles or other test liquids on the pipe surface for the leak test.

■ Drain Hose Connecting

Install the drain hose downward to drain water naturally. Be sure to pour water into the hose to check if it drains well.

■ Electric & Earth Work

Electric and earth work shall meet the "Electric Facility Technology Standard" and the "Internal Wire Regulation" of the Electric

Business Laws.

■ Inspection & Trial Run

Upon completion of the tests, you shall make a trial run while you explain the main functions of the air conditioner to finish the

installation.

Samsung Electronics6

3-4 Installation Diagram of Indoor Unit and Outdoor Unit

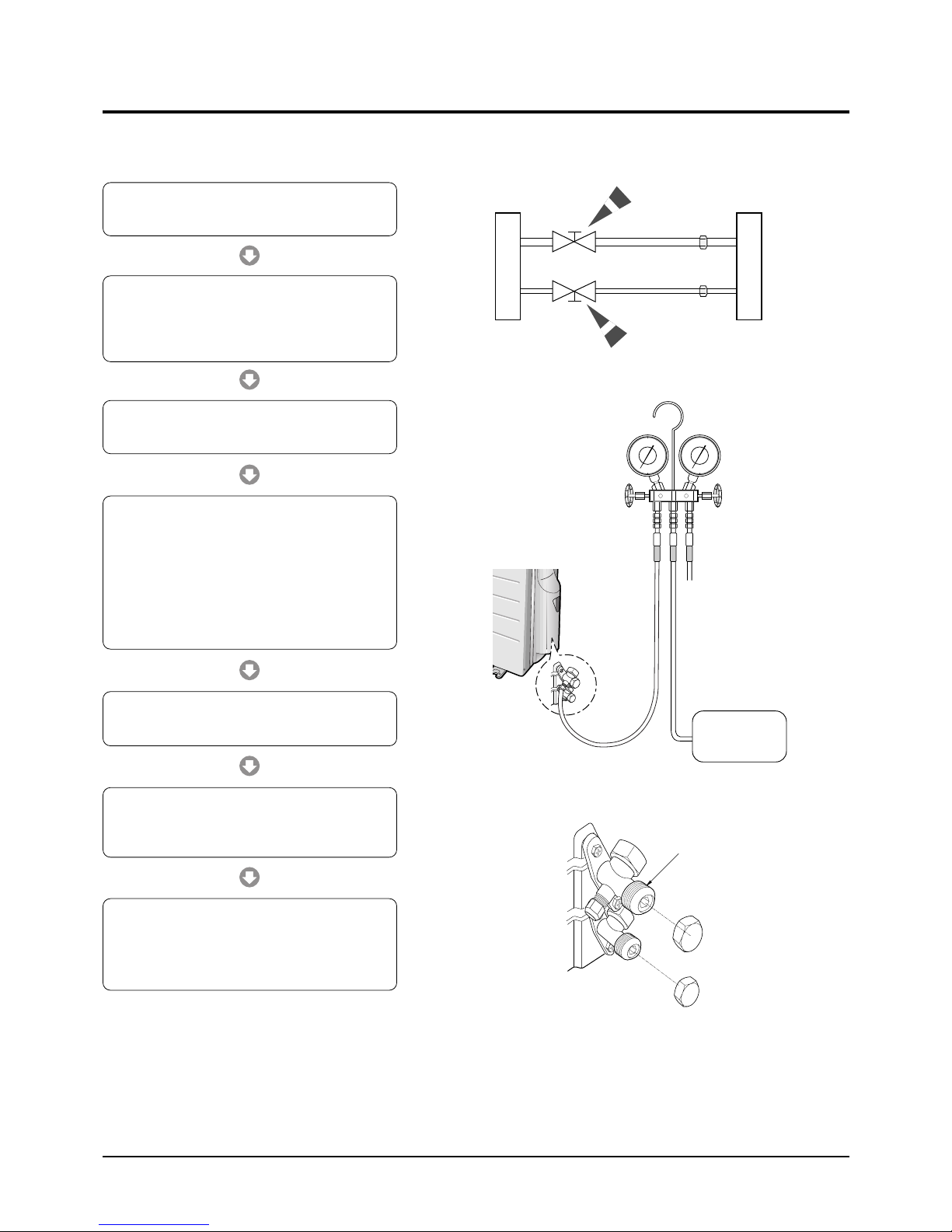

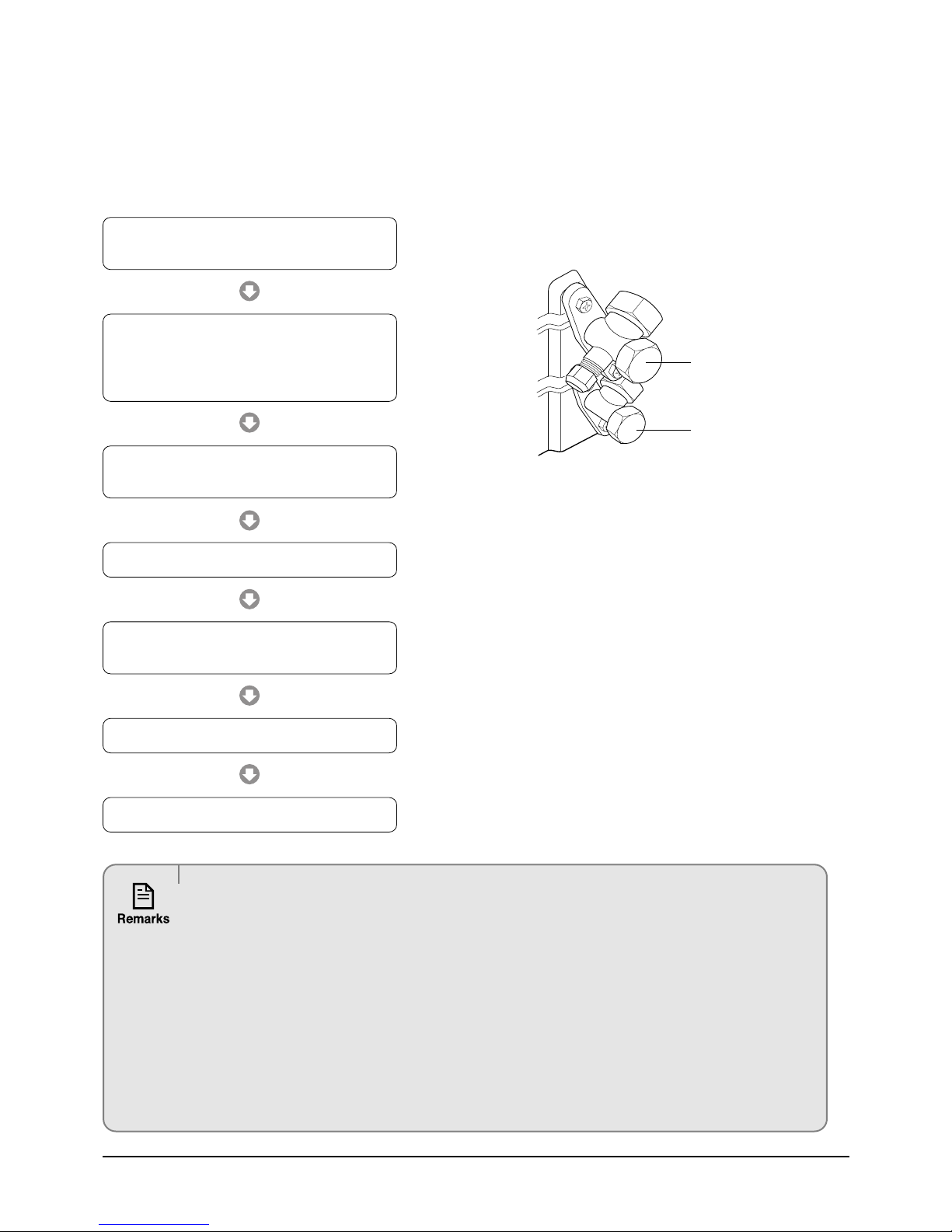

3-4-1 Air-Purge Procedure

1) Connect each assembly pipe to the appropriate

valve on the outdoor unit and tighten the flare nut.

2) Connect the charging hose of low pressure side

of manifold gauge to the packed valve having a

service port (3/8" Packed valve) as shown at the

figure.

3) Open the valve of the low pressure side of

manifold gauge counter-clockwise.

4) Purge the air from the system using vacuum

pump for about 30 minutes.

- After that, please recheck that pressure is

stabilized.

- Close the valve of the low pressure side of

manifold gauge clockwise.

- Remove the hose of the low pressure side

of manifold gauge.

Outdoor unit

Indoor unit

A

B

Gas pipe side

Liquid pipe side

C

D

5) Set valve cork of both liquid side and gas side of

packed valve to the open position.

6) Mount the valve stem nuts to the 2-Way and

3-Way valve. And mount the service port cap to

3-Way valve.

7) Check for gas leakage.

- At this time, especially check for gas

leakage from the 3-Way valve’s stem nuts,

and from the service port cap.

Valve stem

Stem cap

Vacuum Pump

A

(gas)

B

(liquid)

7Samsung Electronics

Operating Instructions & Installation

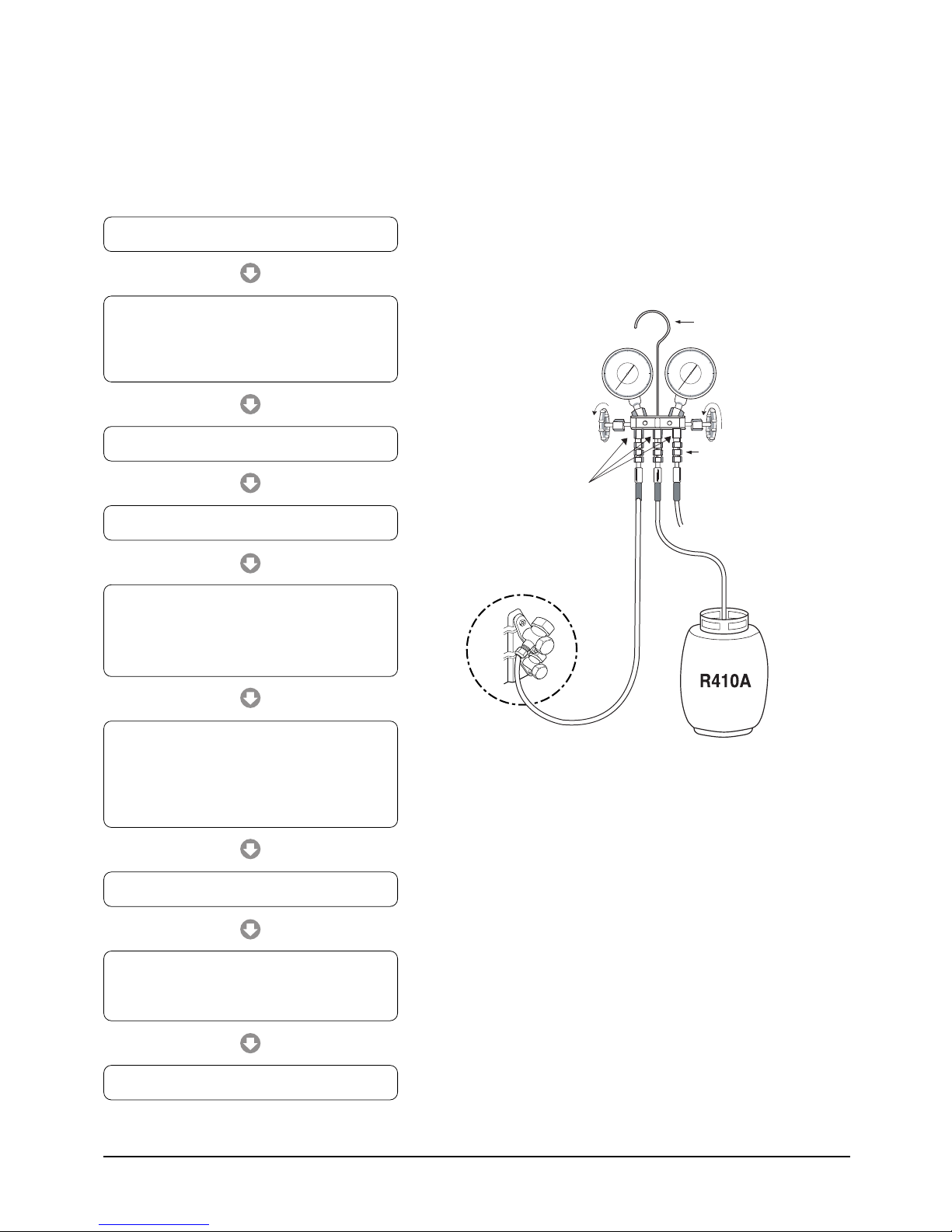

3-4-2 Refrigerant Refill(R410A)

Refill an air conditioner with refrigerant when refrigerant has been leaked at installing or using.

1) Purge air(for new installation only).

2) Turn the 3-Way valve clockwise to close,

connect the pressure gauge (low pressure side) to

the service valve, and open the 3-Way valve

again.

3) Connect the tank to refill with refrigerant.

4) Set the unit to cool operation mode.

5) Check the pressure indicated by the pressure

gauge(low pressure side).

* Standard pressure is should be 9.0~10.0kg/cm

in a regular, high operation mode.

6) Open the refrigerant tank and fill with refrigerant

until the rated pressure is reached.

* It is recommended not to pour the refrigerant

in too quickly, but gradually while operating a

pressure valve.

Suspension hook

Compound

gauge

For mounting

other and of

hose when

not in use

2

High

pressure

gauge

Hand

wheel

Finger tight

fittings

Connected to

high pressure

side

Charging line

7) Stop operation of the air conditioner.

8) Close the 3-Way valve, disconnect the

pressure gauge, and open the 3-Way valve

again.

9) Close the cap of each valve.

Samsung Electronics8

Operating Instructions & Installation

3-4-3 "Pump down" Procedure

Pump down will be carried out when an evaporator is replaced or when the unit is relocated in another area.

1) Remove the caps from the 3-Way valve and the

3-Way valve.

2) Turn the 3-Way valve clockwise to close and

connect a pressure gauge (low pressure side)

to the service valve, and open the 3-Way valve

again.

3) Set the unit to cool operation mode.

(Check if the compressor is operating.)

3-Way Valve

2-Way Valve

4) Turn the 3-Way valve clockwise to close.

5) When the pressure gauge indicates "0" turn the

3-Way valve clockwise to close.

6) Stop operation of the air conditioner.

7) Close the cap of each valve.

Relocation of the air conditioner

• Refer to this procedure when the unit is relocated.

• Carry out the pump down procedure (refer to the details of 'pump down').

• Remove the power cord.

• Disconnect the assembly cable from the indoor and outdoor units.

• Remove the flare nut connecting the indoor unit and the pipe.

• At this time, cover the pipe of the indoor unit and the other pipe using a cap or vinyl plug to avoid foreign

material entering.

• Disconnect the pipe connected to the outdoor unit.

At this time, cover the valve of the outdoor unit and the other pipe using a cap or vinyl plug to avoid foreign

material entering.

• Make sure you do not bend the connection pipes in the middle and store together with the cables.

• Move the indoor and outdoor units to a new location.

• Remove the mounting plate for the indoor unit and move it to a new location.

9Samsung Electronics

4. Disassembly and Reassembly

Stop operation of the air conditioner and electrically isolate before repairing the unit.

4-1 Indoor Unit

No Parts Procedure Remark

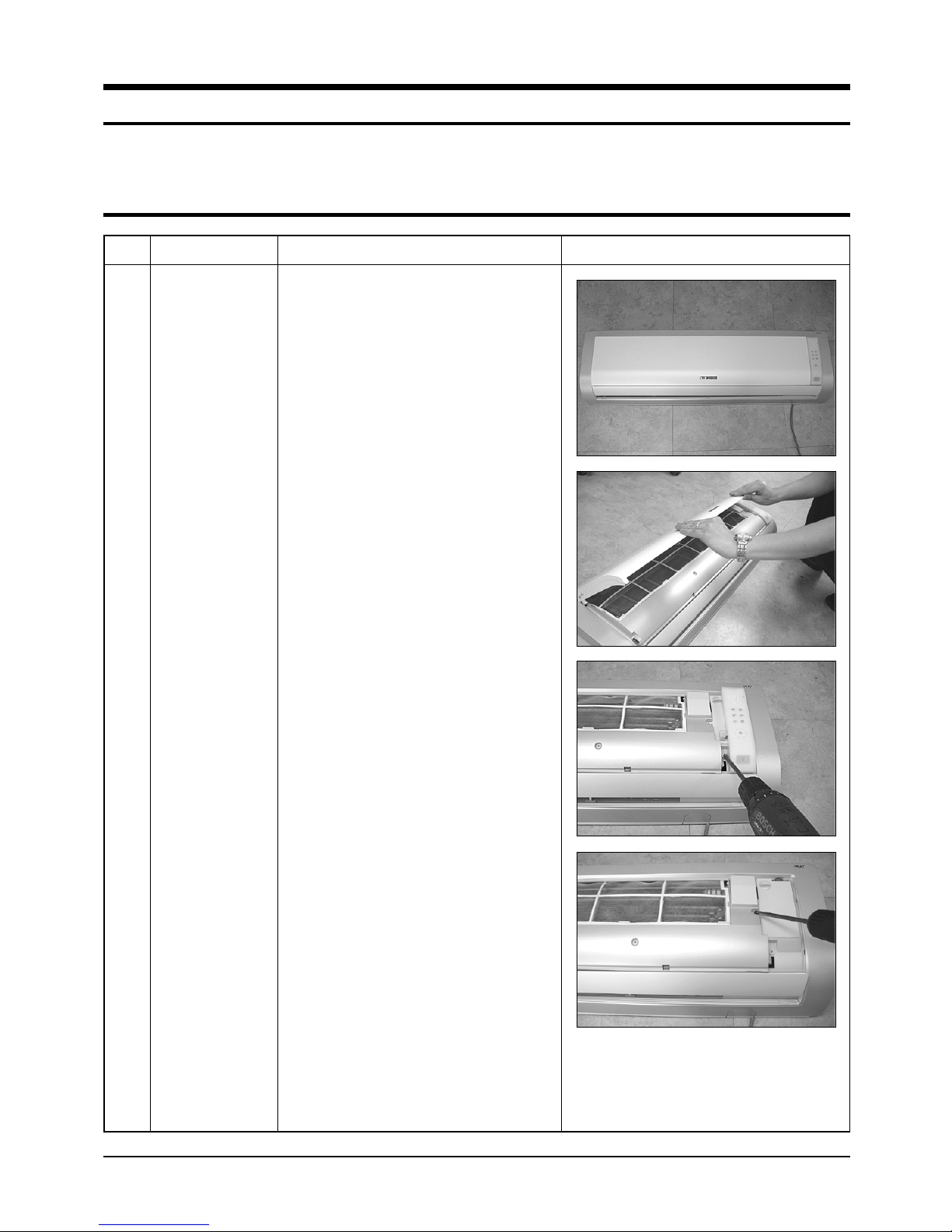

1 Panel Front

1) Stop the air conditioner operation and

shut off the main power.

2) Detach the Front Grille after pushing out it.

3) Loosen 1 of the right screw and detach

the Ass'y display.

4) Loosen 1 of the right screw and detach the

Terminal Cover.

5) Detach the cover PCB-DVM and thermistor

from the Panel Front.

Samsung Electronics10

Disassembly and Reassembly

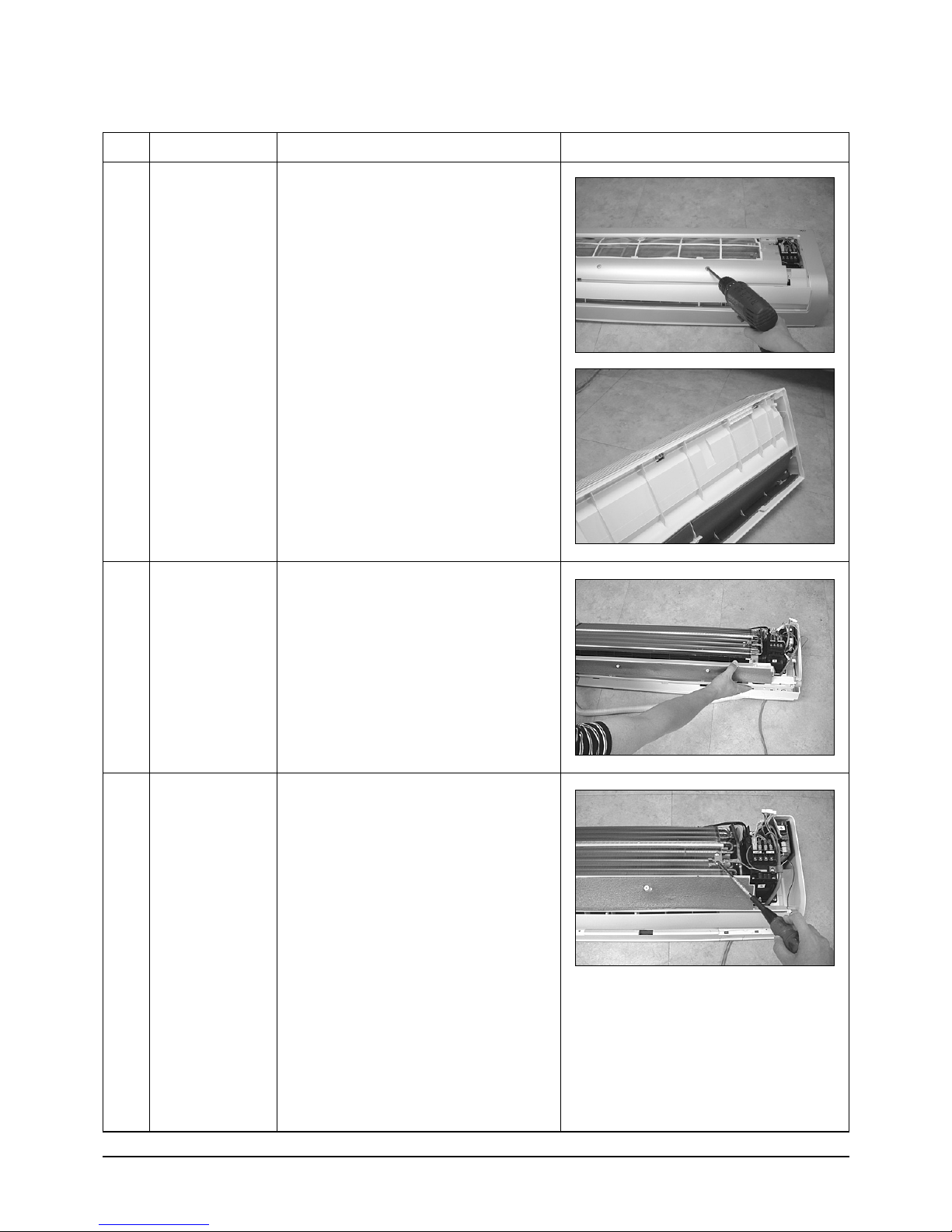

No Parts Procedure Remark

6) Loosen 5 fixing screws of Panel Front.

7) Unlock 2 hooks to fix Panel Front and

Tray Drain.

8) Unlock 2 hooks to fix Panel Front and

Back Body.

2

3

Tray Drain

Heat Exchanger

1) Detach the connected wire of Stepping

Motor.

2) Pull Tray Drain out from the Back Body.

1) Loosen 1 fixing earth screw of right side.

11Samsung Electronics

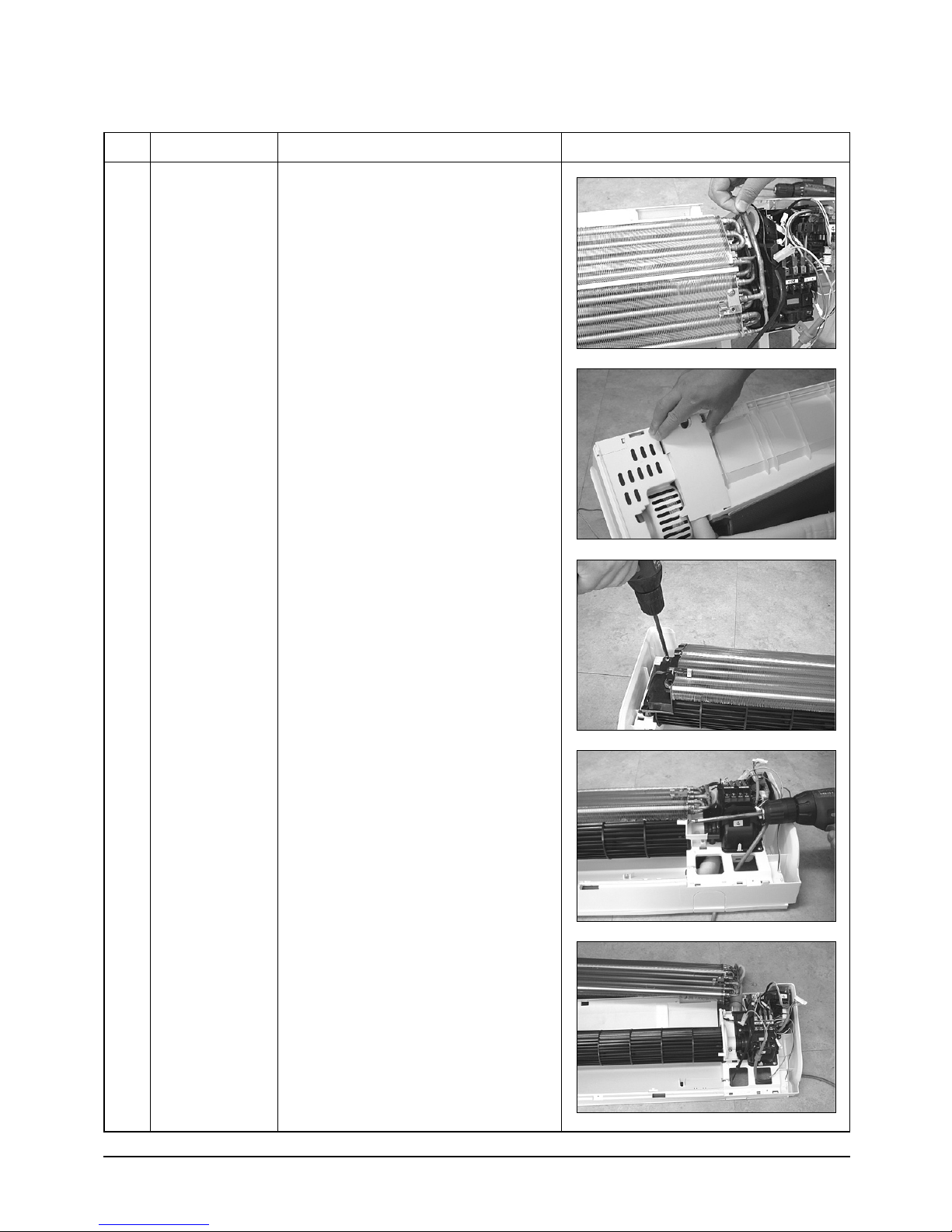

Disassembly and Reassembly

No Parts Procedure Remark

2) Detach the Room Sensor.

3) Detach the Holder Pipe at the rear side

of the unit.

4) Loosen 3 fixing screws of left Holder Evap.

5) Loosen 1 fixing screw of right Holder

Motor.

6) Detach the Heat Exchanger from the

indoor unit.

Samsung Electronics12

Disassembly and Reassembly

No Parts Procedure Remark

4

Electrical Parts

(Main PCB)

1) Loosen 4 fixing screws of right Holder

control.

2) Take all the connector of PCB upper side

out.(Including Power Cord)

3) Detach the outdoor unit connection wire

from the Terminal Block.

4) Pull the PCB up to detach.

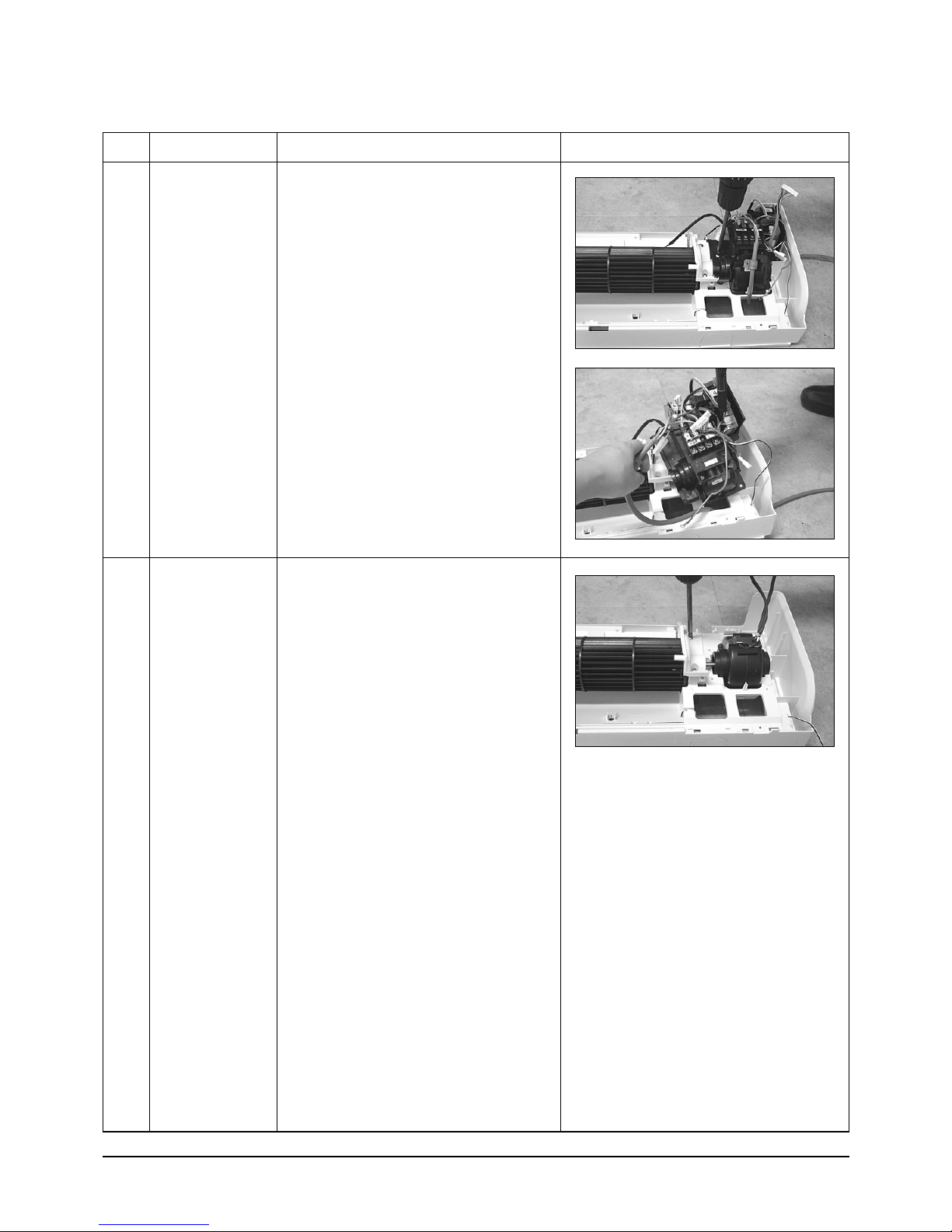

5

Fan Motor

&

Cross Fan

1) Loosen 2 fixing screws and detach the

Motor Holder.

2) Loosen 1 fixing screw of Fan Motor.

3) Detach the Fan Motor from the Fan.

4) Detach the Fan from the left Holder

Bearing.

13Samsung Electronics

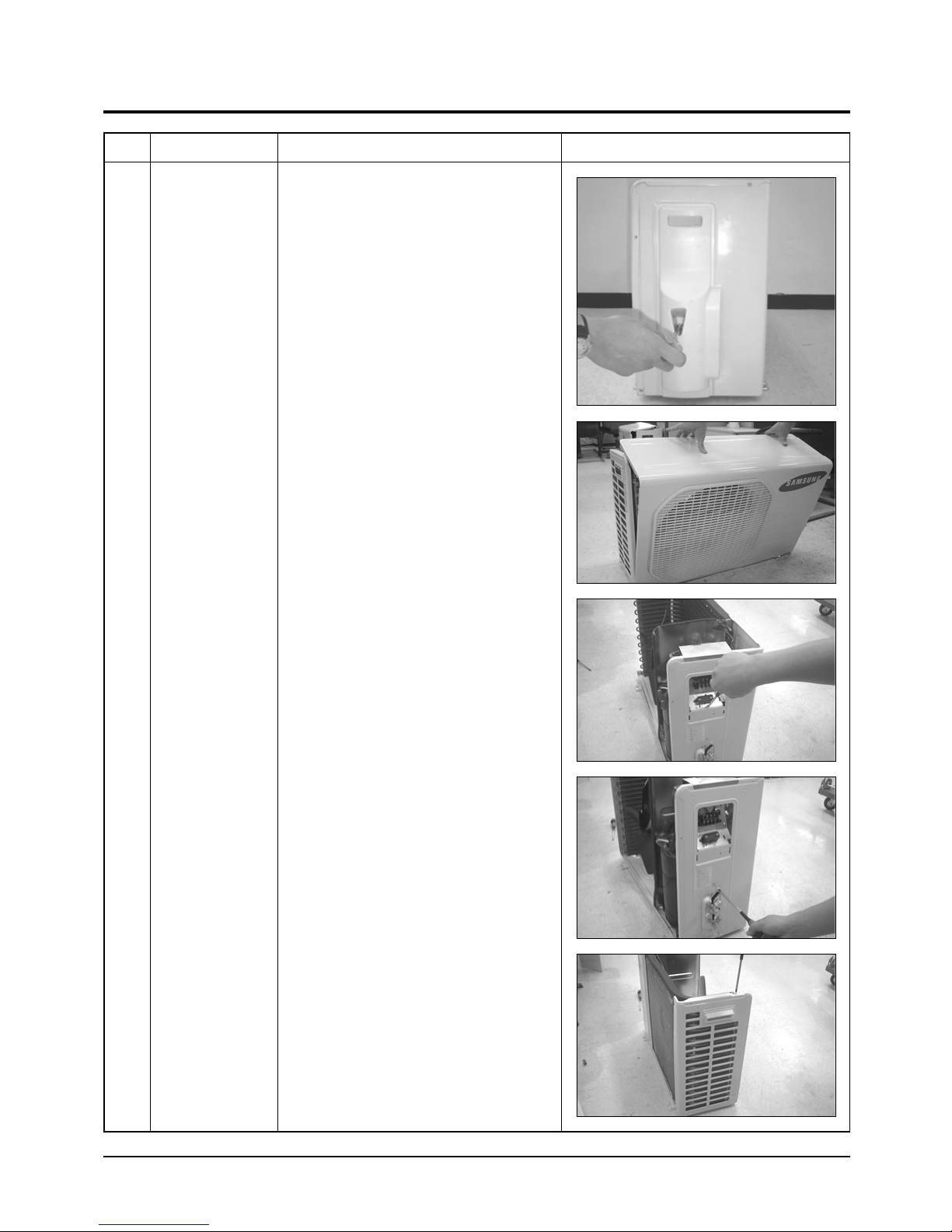

4-2 Outdoor Unit

No Parts Procedure Remark

1 Common Work

1) Loosen 1 fixing screw of the Cover-Side.

2) Loosen each 3 fixing screws on both right

and left Cabinet-Side edge and a fixing

screw on the Cabinet-Front lower to detach

the Cabinet-Front.

3) Loosen 6 fixing screws of the Cabinet-Side

RH.

4) Loosen 2 fixing screws of the Cabinet-Side

LF.

Samsung Electronics14

Disassembly and Reassembly

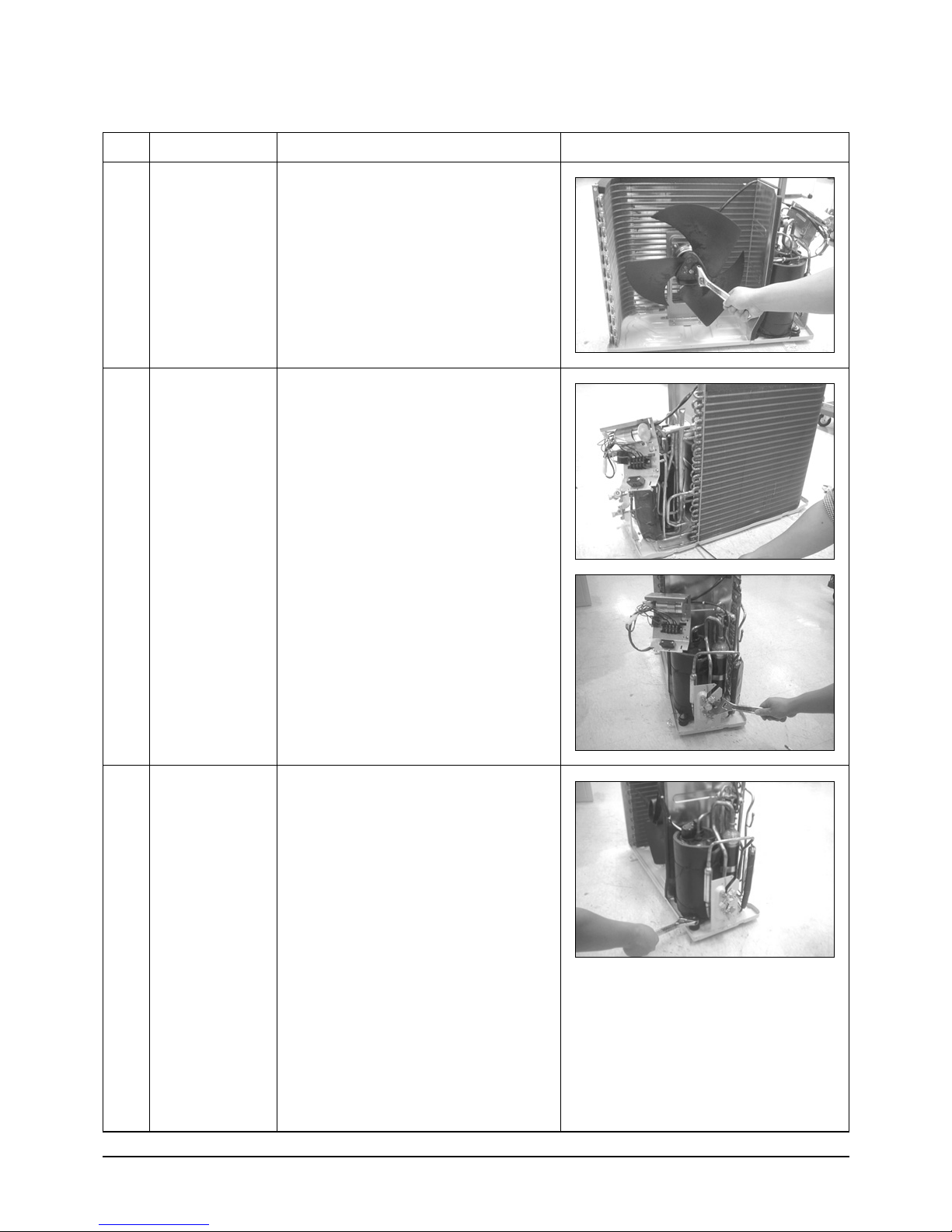

No Parts Procedure Remark

2

3

Fan & Motor

Heat Exchanger

1) Detach the Nut Flange.(Turn counterclockwise because the screw is right-handed)

2) Detach the Fan.

3) Loosen 4 fixing screws to detach

the Motor.

1) Loosen 2 fixing screws on both sides.

2) Disassemble the pipe in both inlet and

outlet with welding torch.

3) Detach the Heat Exchanger.

4

Compressor

1) Loosen the Terminal Cover nut to open the

Terminal Cover.

2) Disassemble the cloth sound felt.

3) Disassemble the pipe in both inlet and

outlet of the Compressor with welding

torch.

4) Disassemble the pipe in both inlet and

outlet of the Condenser with welding torch.

5) Loosen the 3 bolts at the bottom.

6) Detach the Compressor.

15Samsung Electronics

Cooling

Heating

Gas Leak Check Polnt

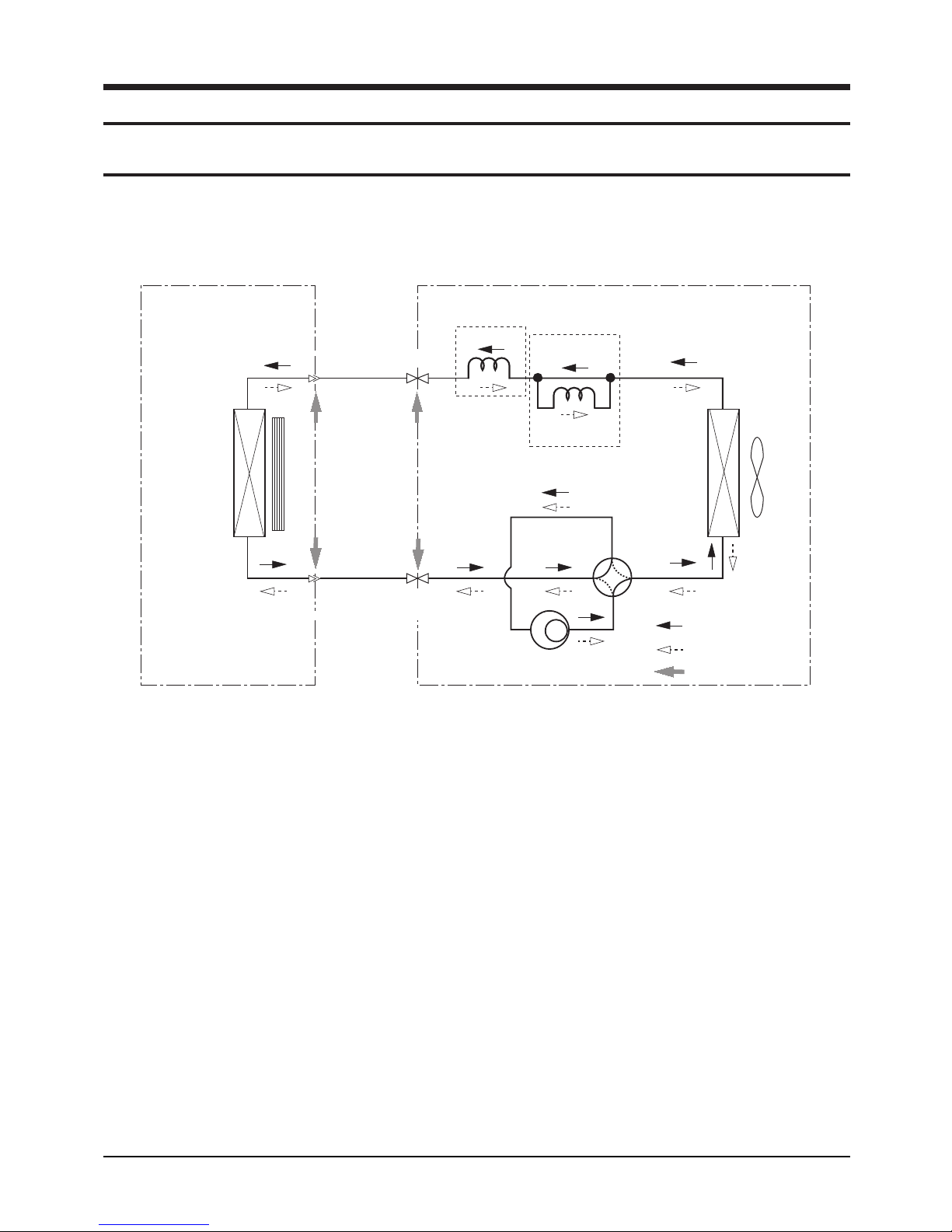

5. Refrigerating Cycle Diagram

5-1 Refrigerating Cycle Diagram

Indoor Unit

Heat

Exchanger

(Evaporator)

Outdoor Unit

T

1

Liquid side

Cross fan

T

2

Gas side

2-Way valve

3-Way valve

Capillary tube

✳Note

Check valve

Capillary tube

Heat

Exchanger

(Condenser)

Propeller fan

4-Way valve

Compressor

Samsung Electronics16

5-2 Refrigerant Cycle Characteristic

DB32.4/WB24.0

DB30.6/WB22.5

DB27.0/WB19.0

DB24.0/WB17.0

DB21.0/WB15.0

Cooling Capacity(kW)

Cooling Capacity Distribution

6.0

5.0

4.0

3.0

2.0

1.0

0.0

25 35 45

Outdoor Temp.(DB C)

Indoor Temp.( C)

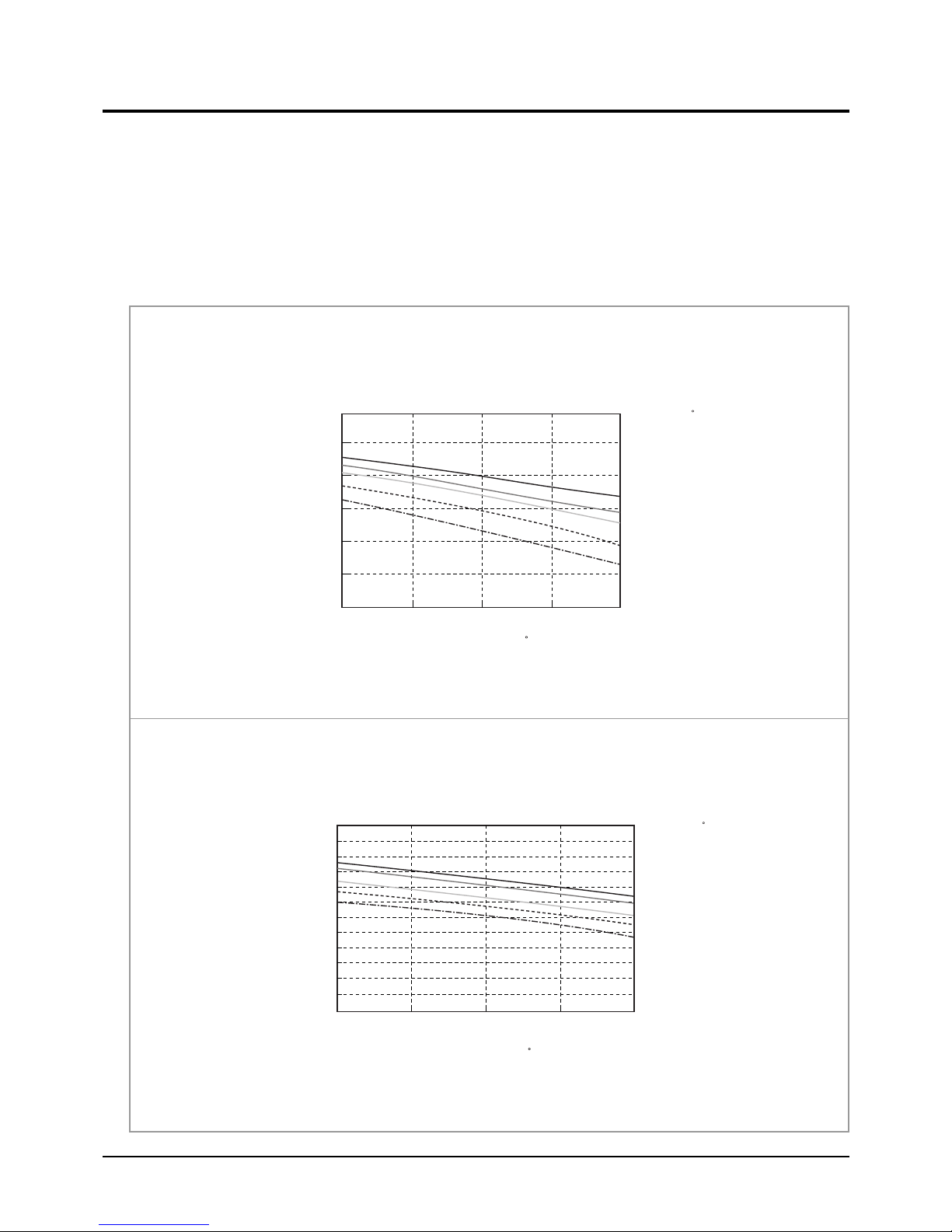

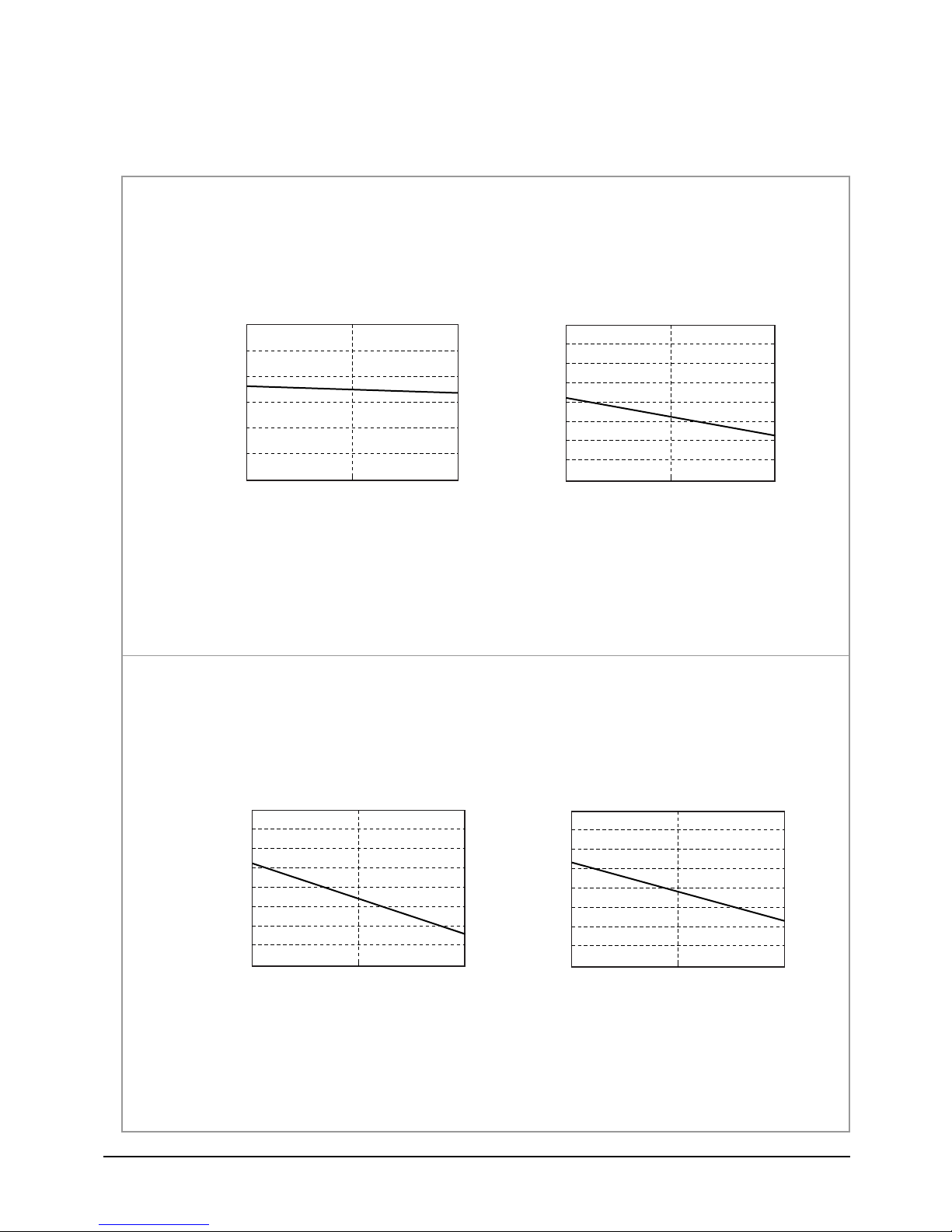

5-2-1 Capacity Distributions

Capacity Distributions according to indoor and outdoor temperature variation.

■ COOLING MODE

- Indoor Temp. Variation : 21.0˚C ~ 32.4˚C

- Outdoor Temp. Variation : 25.0˚C ~ 45.0˚C

■ AS09HPBN

Cooling Capacity Distribution

■ AS12HPBN

4.0

3.0

2.0

Cooling Capacity(kW)

1.0

25.0 35.0 45.0

Outdoor Temp.(DB C)

Indoor Temp.( C)

DB32.4 / WB24.0

DB30.6 / WB22.5

DB27.0 / WB19.0

DB24.0 / WB17.0

DB21.0 / WB15.0

17Samsung Electronics

Refrigerating Cycle Diagram

DB15.0

DB20.0

DB25.0

Heating Capacity

Heating Capacity Distribution

6.00

5.00

4.00

3.00

2.00

1.00

0.00

1.0/0.0 7.0/6.0 20.0/15.0

Indoor Temp.( C)

Outdoor Temp.(DB/WB C)

■ HEATING MODE

- Indoor Temp. Variation : 15.0˚C ~ 25.0˚C

- Outdoor Temp. Variation : 1.0˚C ~ 20.0˚C

■ AS09HPBN

Heating Capacity Distribution

■ AS12HPBN

4.00

3.00

2.00

Heating Capacity(kW)

1.00

1.0/0.0 7.0/6.0 20.0/15.0

Outdoor Temp.(DB/WB C)

Indoor Temp.( C)

DB15.0

DB20.0

DB25.0

Samsung Electronics18

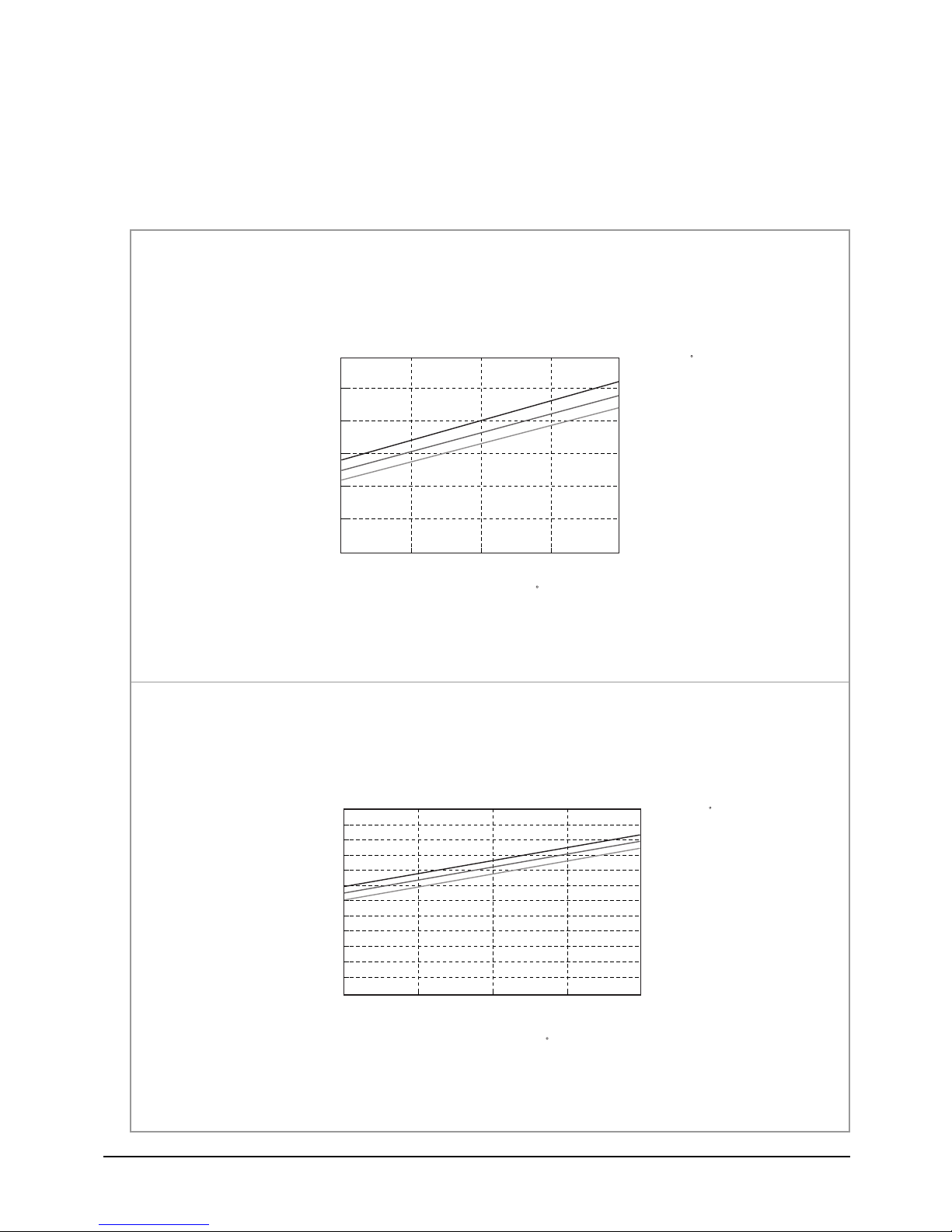

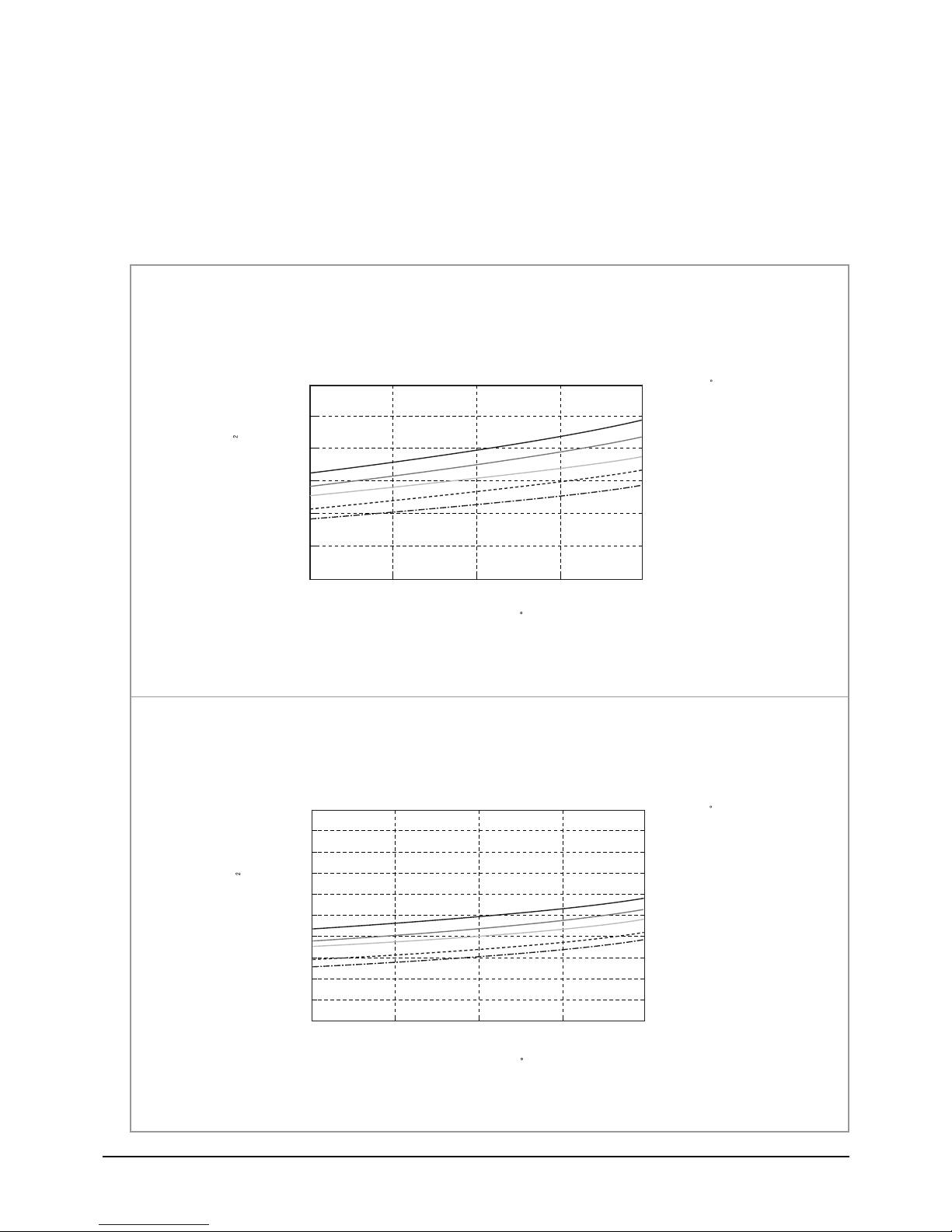

5-2-2 Power Consumption Distributions

Power consumption(W)

Power consumption Distribution(Cooling mode)

1,400

1,300

1,200

1,100

1,000

900

800

25 35 45

DB32.4 / WB24.0

DB30.6 / WB22.5

DB27.0 / WB19.0

DB24.0 / WB19.0

DB21.5 / WB15.0

Indoor Temp.( C)

Outdoor Temp.(DB C)

Power Consumption Distributions according to indoor and outdoor temperature variation.

■ COOLING MODE

- Indoor Temp. Variation : 21.0˚C ~ 32.4˚C

- Outdoor Temp. Variation : 25.0˚C ~ 45.0˚C

■ AS09HPBN

Power consumption Distribution(Cooling mode)

Refrigerating Cycle Diagram

■ AS12HPBN

1,100

1,000

900

800

700

Power consumption(W)

600

500

25 35 45

Outdoor Temp.(DB C)

Indoor Temp.( C)

DB32.4 / WB24.0

DB30.6 / WB22.5

DB27.0 / WB19.0

DB24.0 / WB19.0

DB21.5 / WB15.0

19Samsung Electronics

Refrigerating Cycle Diagram

Power consumption(W)

Power consumption Distribution(Heating mode)

1,500

1,400

1,300

1,200

1,100

1,000

900

25 35 45

DB25.0

DB20.0

DB15.0

Indoor Temp.( C)

Outdoor Temp.(DB/WB C)

■ HEATING MODE

- Indoor Temp. Variation : 15.0˚C ~ 25.0˚C

- Outdoor Temp. Variation : 1.0˚C ~ 20.0˚C

■ AS09HPBN

Power consumption Distribution(Heating mode)

■ AS12HPBN

1,050

950

850

750

Power consumption(W)

650

1.0/0.0 7.0/6.0 20.0/15.0

Indoor Temp.( C)

DB25.0

DB20.0

DB15.0

Outdoor Temp.(DB/WB C)

Samsung Electronics20

Refrigerating Cycle Diagram

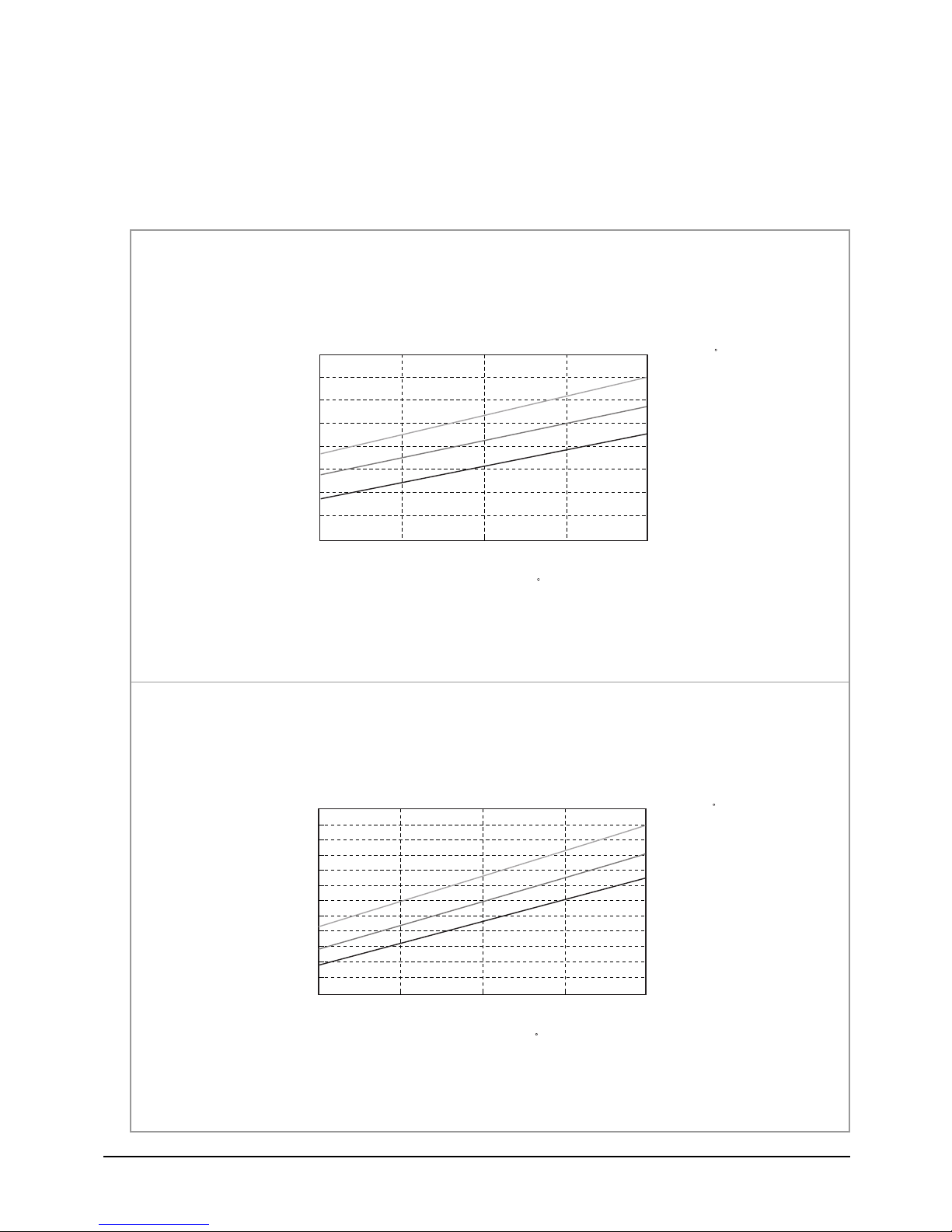

5-2-3 Capacity and Power Consumption Distributions

Capacity and power Consumption distributions according to the length of connecting Pipe between indoor unit and outdoor unit.

■ COOLING MODE

■ AS09HPBN

Coooling Capacity(kW)

■ AS12HPBN

Cooling Capacity

4

3

2

1

7.5 15.0

Length of Connecting Pipe(m)

Cooling Capacity

Power consumption(Cooling)

1,100

1,000

900

800

700

Power consumption(W)

600

500

7.5 15.0

Length of Connecting Pipe(m)

Power consumption(Cooling)

3.70

3.50

3.30

3.10

Cooling Capacity(kW)

2.90

7.5 15.0

Length of Connecting Pipe(m)

1,300

1,200

1,100

1,000

Power consumption(W)

900

7.5 15.0

Length of Connecting Pipe(m)

21Samsung Electronics

Refrigerating Cycle Diagram

■ HEATING MODE

■ AS09HPBN

4.00

3.00

2.00

Heating Capacity(kW)

1.00

■ AS12HPBN

Heating Capacity

7.5 15.0

Length of Connecting Pipe(m)

Power consumption(Heating)

1,050

950

850

750

Power consumption(W)

650

7.5 15.0

Length of Connecting Pipe(m)

Heating Capacity

4.30

4.10

3.90

3.70

Heating Capacity(kW)

3.50

7.5 15.0

Length of Connecting Pipe(m)

Power consumption(Heating)

1,350

1,250

1,150

1,050

Power consumption(W)

950

7.5 15.0

Length of Connecting Pipe(m)

Samsung Electronics22

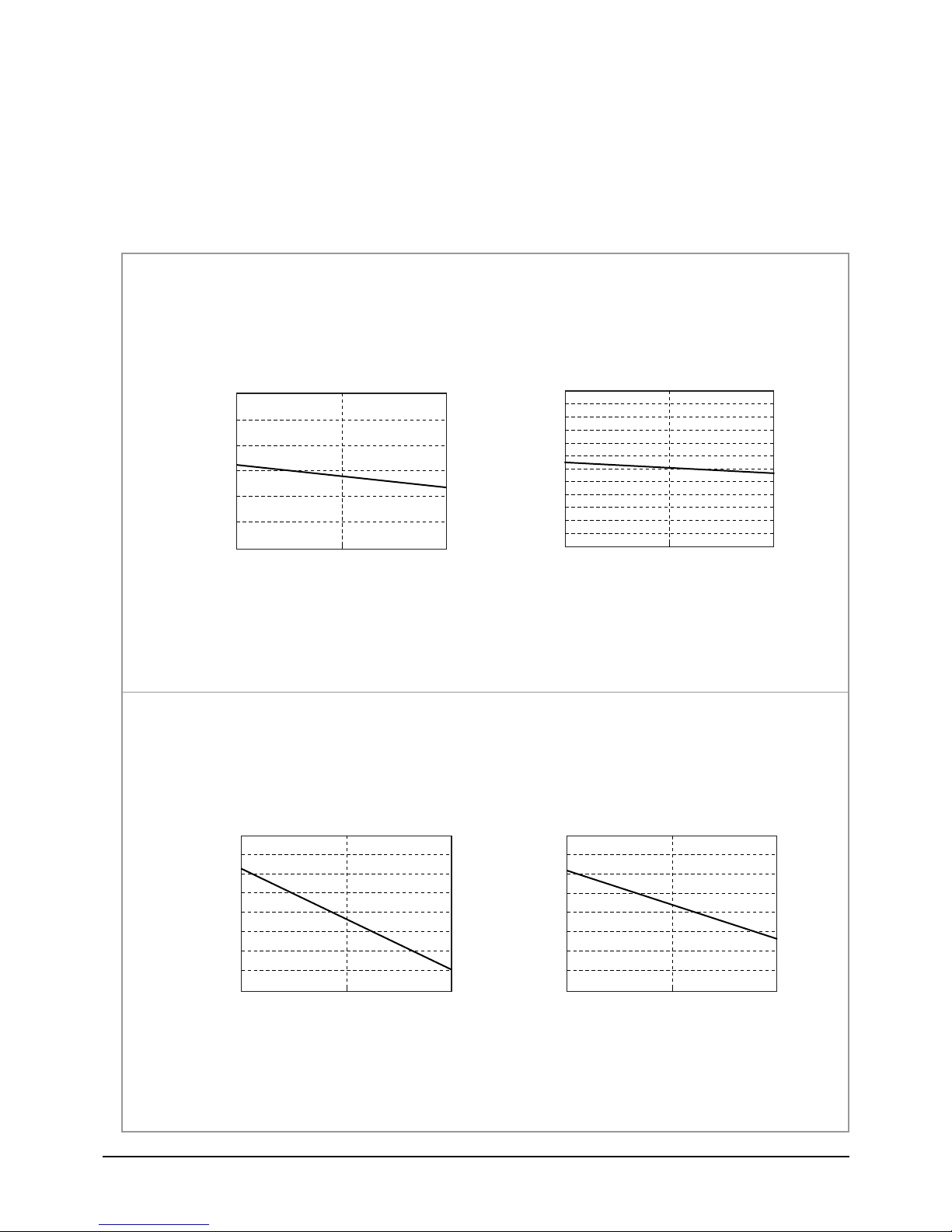

5-2-4 Low Pressure Distributions

DB32.4 / WB24.0

DB30.6 / WB22.5

DB27.0 / WB19.0

DB24.0 / WB19.0

DB21.5 / WB15.0

Low pressure(kg/cm G)

Low Pressure Distribution(Cooling mode)

15.0

13.0

11. 0

9.0

7.0

5.0

25 35 45

Outdoor Temp.(DB C)

Indoor Temp.( C)

■ COOLING MODE

- Indoor Temp. Variation : 21.0˚C ~ 32.4˚C

- Outdoor Temp. Variation : 25.0˚C ~ 45.0˚C

■ AS09HPBN

Refrigerating Cycle Diagram

Low Pressure Distribution(Cooling mode)

■ AS12HPBN

12.0

10.0

8.0

Low pressure(kg/cm G)

6.0

25 35 45

Indoor Temp.( C)

DB32.4 / WB24.0

DB30.6 / WB22.5

DB27.0 / WB19.0

DB24.0 / WB17.0

DB21.0 / WB15.0

Outdoor Temp.(DB C)

23Samsung Electronics

Refrigerating Cycle Diagram

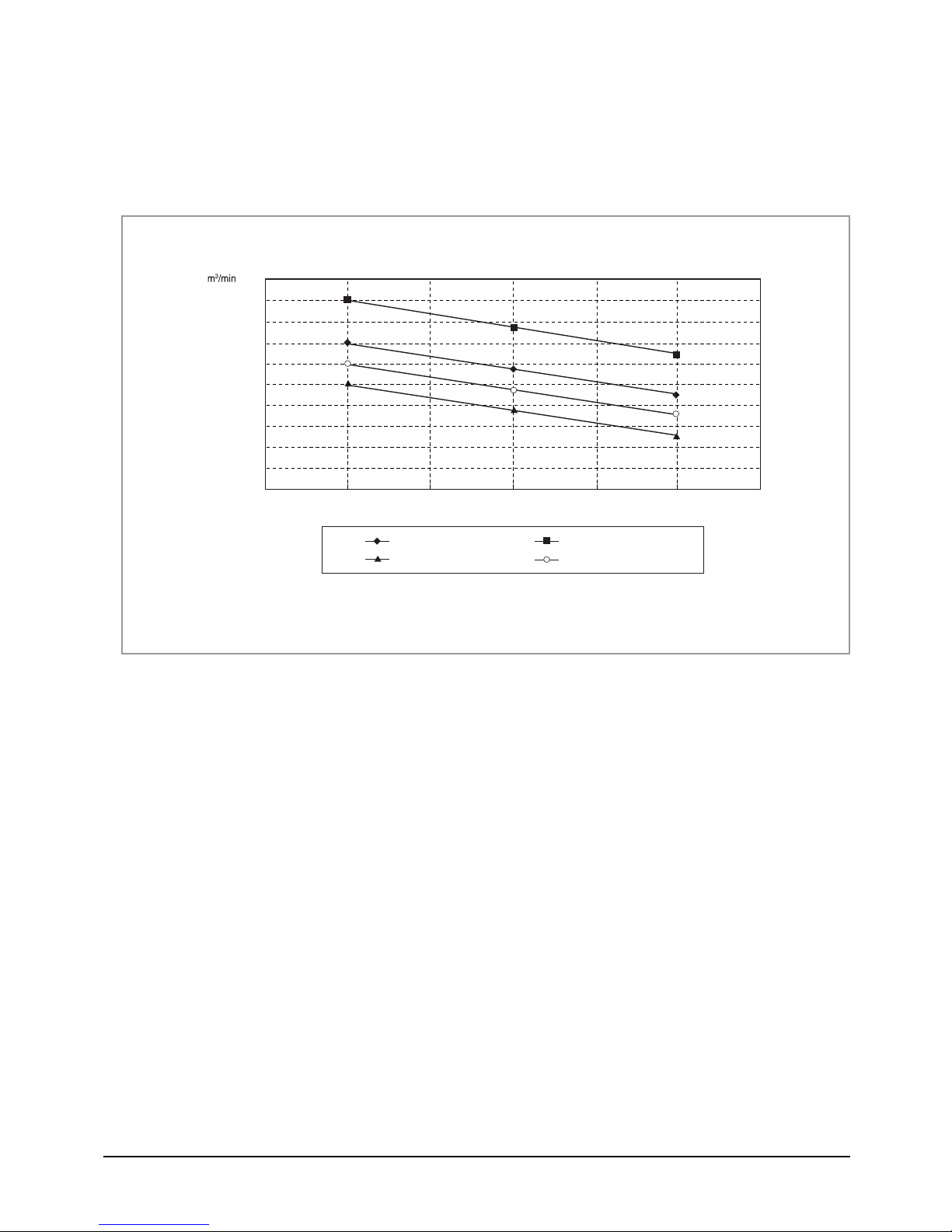

5-2-5 Air Volume according to the RPM variation(High/Mid/Low)

■ Indoor Unit

10

9.5

9

8.5

8

7.5

7

6.5

6

5.5

5

High Mid

Low

RPM

■ Outdoor Unit

The air volume is 25m3/min regardless of model.

12,000BTU-Cooling-Vol.

19,000BTU-Cooling-Vol.

12,000BTU-Heating-Vol.

19,000BTU-Heating-Vol.

Samsung Electronics24

Loading...

Loading...